Powermatic 54A Instruction Manual & Parts List

6" JOINTER

Model 54A

Instruction Manual & Parts List

M-0460246

(800) 274-6848

www.powermatic.com

This manual has been prepared for the owner and operators of a Powermatic Model 54A, 6"

Jointer. Its purpose, aside from machine operation, is to promote safety through the use of

accepted correct operating and maintenance procedures. Completely read the safety and maintenance instructions before operating or servicing the machine. To obtain maximum life and

efficiency from your jointer and to aid in using the machine safely, read this manual thoroughly

and follow all instructions carefully .

Warranty & Service

The WMH T ool Group warrants every product it sells. If one of our tools needs service or repair , one of our

Authorized Repair S tations located throughout the United S tates can give you quick service.

In most cases, any one of these WMH Tool Group Repair S tations can authorize warranty repair, assist you in

obtaining parts, or perform routine maintenance and major rep air on your JET , Powermatic, Performax, or

Wilton tools.

For the name of an Authorized Repair S tation in your area, please call 1-800-274-6848.

More Information

Remember, the WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH T ool Group distributor .

WMH T ool Group W arranty

The WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follow: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and-tear, rep air or alterations outside our facilities, or to a lack of maintenance.

THE WMH TOOL GROUP LIMITS ALL IMPLIED W ARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM

THE DATE THE PRODUCT WAS PURCHASED A T RET AIL. EXCEPT AS ST A TED HEREIN, ANY IMPLIED

WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME ST A TES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMIT A TION MA Y

NOT APPL Y TO YOU. THE WMH T OOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEA TH, INJURIES

TO PERSONS OR PROPERTY, OR FOR INCIDENT AL, CONTINGENT , SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME ST A TES DO NOT ALLOW THE EXCLUSION OR LIMITA TION OF INCIDENT A L OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMIT A TION OR

EXCLUSION MA Y NOT APPL Y T O YOU.

T o take advant age of this warranty , the product or part must be returned for examination, postage prep aid, to an

Authorized Repair S tation designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the

product, or refund the purchase price if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept a refund. We will return repaired product or replacement at WMH's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of WMH's warranty ,

then the user must bear the cost of storing and returning the product. This warranty gives you specific legal

rights; you may also have other rights which vary from state to state.

The WMH Tool Group sells through distributors only . Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

2

TABLE OF CONTENTS

Safety:

Instructions .............................................................................................................................................. 4

Decals ..................................................................................................................................................... 6

Specifications .................................................................................................................................................. 6

Receiving the Jointer ........................................................................................................................................ 7

Installation ....................................................................................................................................................... 7

Mounting Jointer to Stand ........................................................................................................................ 7

Installing Belt ........................................................................................................................................... 8

Installing Pulley Cover.............................................................................................................................. 8

Fence Installation & Removal................................................................................................................... 8

Cutterhead Guard Installation & Removal ................................................................................................. 8

Installing Dust Chute................................................................................................................................ 9

Grounding Instructions ............................................................................................................................. 9

Extension Cords .............................................................................................................................10

Rewiring motor for 230 Volts ...........................................................................................................10

Safety Switch .........................................................................................................................................11

Adjustments:

Raising & Lowering Tables...................................................................................................................... 11

Installing New Knives ..............................................................................................................................12

Outfeed Table & Knives...........................................................................................................................13

Depth of Cut............................................................................................................................................14

Jointing Knives........................................................................................................................................14

T able Gibs and Leveling ..........................................................................................................................15

Fence Adjustments: Tilt ..........................................................................................................................15

Fence Adjustments: Stop........................................................................................................................16

Cutterhead Removal................................................................................................................................16

Basic Operations ............................................................................................................................................17

Surfacing ................................................................................................................................................17

Surfacing Long Boards............................................................................................................................18

Jointing (or Edging) .................................................................................................................................19

Beveling ..................................................................................................................................................19

Cross Grain ............................................................................................................................................19

Skewing (Shear Cutting) .........................................................................................................................20

Push Blocks ...................................................................................................................................................20

Optional Accessories ......................................................................................................................................21

Parts List / Exploded Views:

Fence Assembly................................................................................................................................22-23

Base & Table Assembly.....................................................................................................................24-25

Cutterhead Assembly.........................................................................................................................26-27

Stand Assembly.................................................................................................................................28-29

3

!

SAFETY INSTRUCTIONS

As with all machines, there is a certain amount of hazard involved with the use of this jointer . Use the machine with

the respect and caution demanded where safety precautions are concerned. When normal safety precautions are

overlooked or ignored, personal injury to the operator can result.

Read the manual. Read, understand, and follow the safety instructions found in this manual. Know the limitations and hazards in using the model 54A - 6" Jointer. Decals are placed on each machine as reminders of good

safety practice.

Guards. Be sure machine guards are in place and in good working order. Use them at all times on operations

where they can be used. If a guard must be removed for any operation, make sure it is replaced immediately

following completion of that operation.

Work area. Keep the floor around the machine clean and free of scrap material, saw dust, oil and other liquids to

minimize the danger of tripping or slipping. Be sure the table is free of all scrap, foreign material and tools before

starting to cut. Make certain the work area is well lighted and that a proper exhaust system is used to minimize

dust. Powermatic recommends the use of anti-skid floor strips on the floor area where the operator normally

stands and that each machine's work area be marked off. Provide adequate work space around the machine.

Don't use machine in damp or wet locations, or expose it to rain.

Keep children away . All visitors should be kept a safe distance from the work area.

Make workshop child-proof with padlocks, master switches, or by removing starter keys.

Don't force tool. It will do the job better and safer at the rate for which it was designed.

Personal protection. Before operating the machine, remove tie, rings, watch and other jewelry and roll up sleeves

above the elbows. Remove all loose clothing and confine long hair. Protective type footwear should be used.

Where the noise exceeds the level of exposure allowed in Section 1910.95 of the OSHA Regulations, use hearing

protective devices. Do not wear gloves.

Eye safety. Always wear approved safety goggles, glasses, or a face shield when operating this machine.

Everyday eyeglasses only have impact resistant lenses, they are NOT safety glasses.

Support the workpiece adequately at all times during operation; maintain control of the work at all times.

Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees both hands to

operate tool.

Don't overreach. Keep proper footing and balance at all times.

Maintain tools with care. Keep tools sharp and clean for best and safest performance. Follow instructions

for lubrication and changing accessories.

Disconnect machine before performing any service or maintenance.

Reduce the risk of unintentional starting. Make sure switch is in off position before plugging in.

Use recommended accessories. Consult the owner’s manual for recommended accessories. The use of

improper accessories may cause risk of injury to persons.

Never stand on machine. Serious injury could occur if the machine is tipped or if the cutting tool is uninten-

tionally contacted.

Check damaged parts. Before further use of the tool, a guard or other part that is damaged should be

carefully checked to determine that it will operate properly and perform its intended function - check for

alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that

may affect its operation. A guard or other p art that is damaged should be properly repaired or replaced.

4

Direction of feed. Feed work into a blade or cutter against the direction of rotation of the blade or cutter only .

Never leave machine running unattended. Turn power off. Don’t leave machine until it comes to a complete

stop.

Do not perform jointing operations on material shorter than 8", narrower than 3/4 inch, or less than 1/4 inch

thick.

Do not perform planing operations on material shorter than 8", narrower than 3/4 inch, or wider than 6", or

thinner than 1/2 inch.

Maintain the proper relationships of infeed and outfeed table surfaces and cutter head knife path.

Do not back the work toward the infeed table.

Do not attempt to perform an abnormal or little-used operation without study and the use of adequate hold-

down/push blocks, jigs, fixtures, stops, and the like.

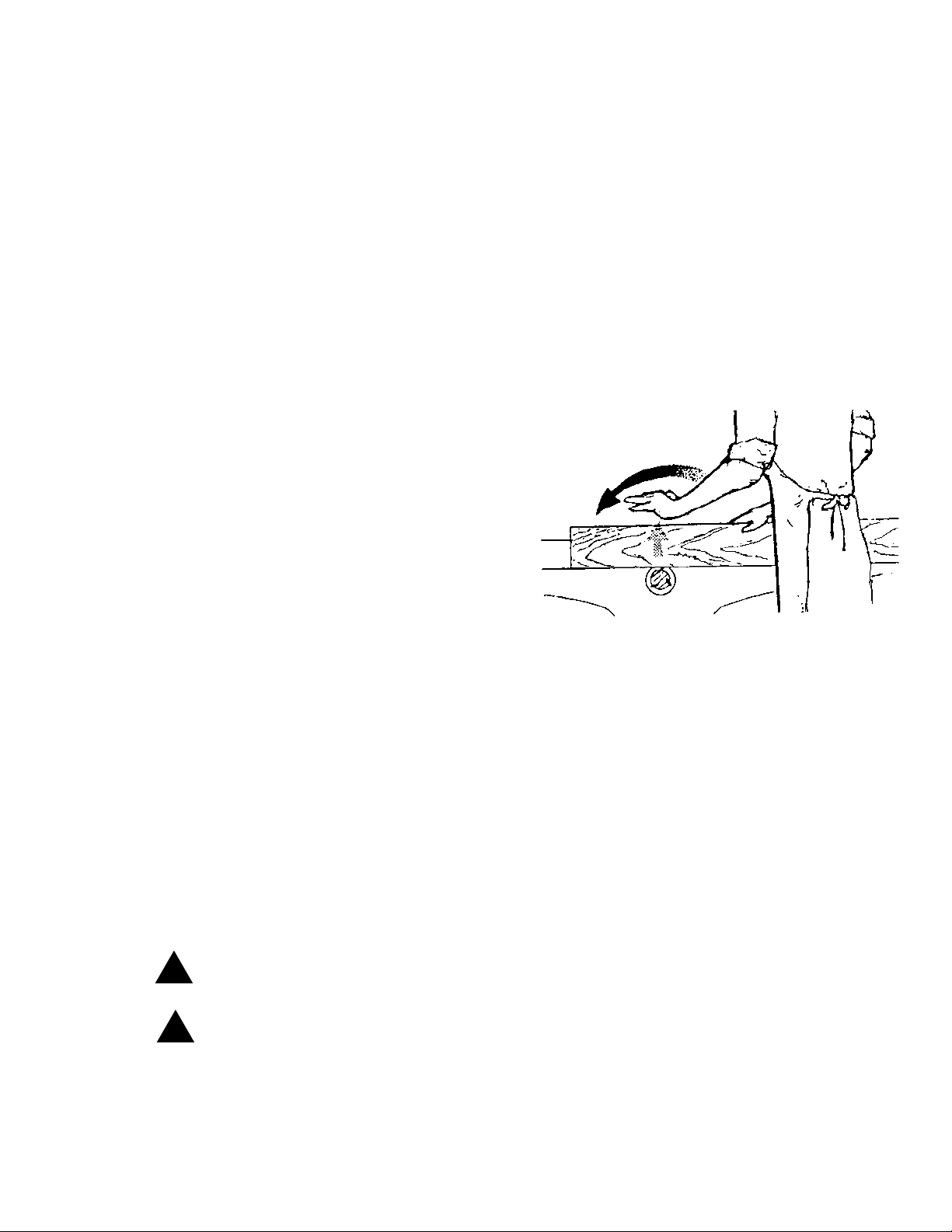

Hand safety . It is good practice to move the hands

in an alternate motion from back to front as the work

continues through the cut. Never pass the hands

directly over the cutter knife. As one hand approaches

the knives remove it from the stock in an arc motion

and place it back on the stock in a position beyond

the cutterknife.

Three inch rule. When working a piece of wood on

the jointer, follow the 3 inch radius rule. The hands

must never be closer than 3 inches to the cutter head.

Health hazards. Some dust created by power

sanding, sawing, grinding, drilling and other construction activities contains chemicals known to cause cancer,

birth defects or other reproductive harm. Some examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and other masonry products.

* Arsenic and chromium from chemically-treated lumber .

Y our risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment, such

as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

CAUTION: (This means that if precautions are not heeded, it may result in minor or moderate injury

!

and/or possible machine damage)

WARNING: (This means that if precautions are not heeded, it could result in serious injury or

!

possibly even death).

5

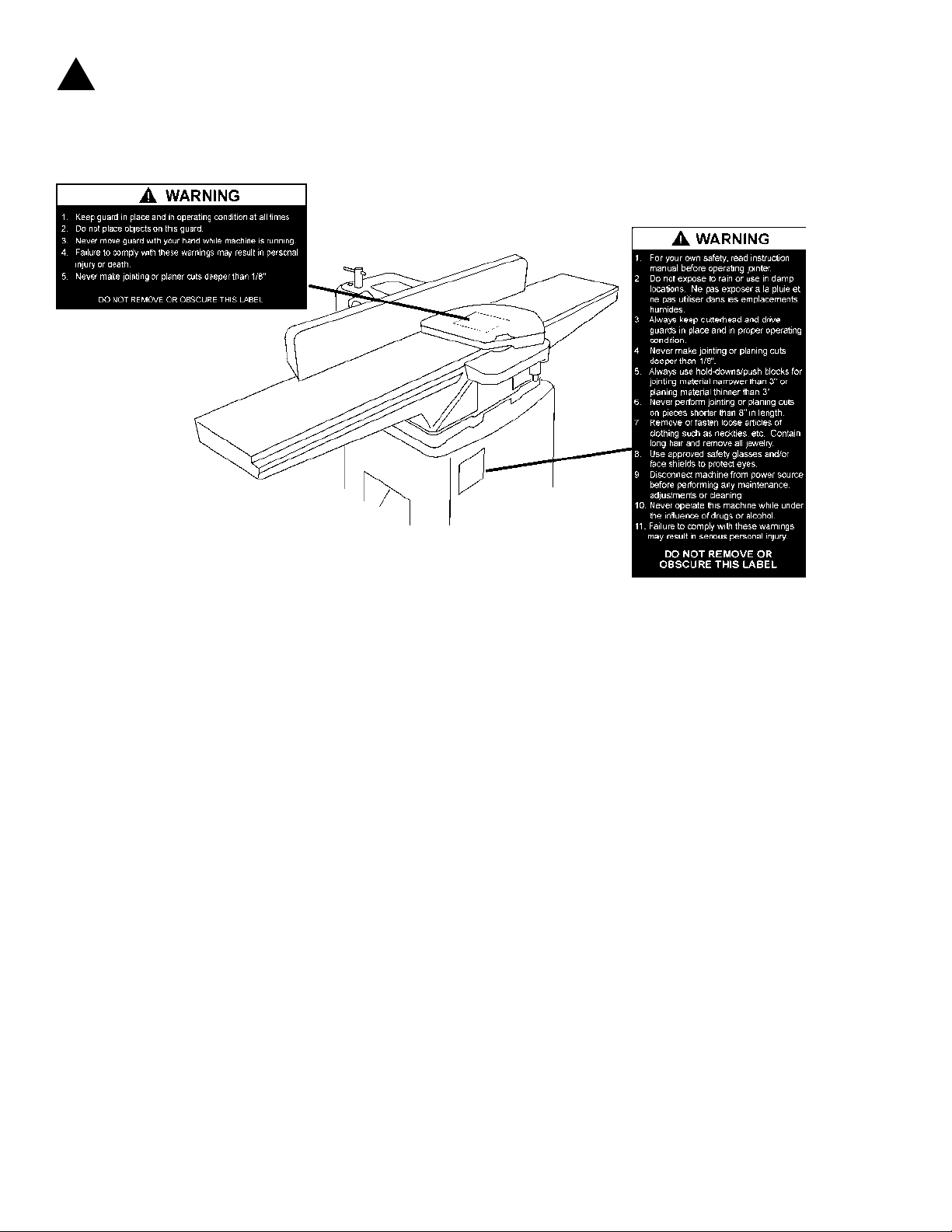

!

SAFETY DECALS

Familiarize yourself with the location of these decals on your jointer.

SPECIFICATIONS - Model 54A Jointer

Table ...................................................................................................................................................... 7" x 66"

T able support ............................................................................................................................dove-tailed ways

Cutterhead ......................................................................................................... 3 knife "controlled chip" design

Cutterhead speed........................................................................................... 6000 RPM (18,000 cuts per min.)

Cutting capacity....................................................................................................................................1/2" x 6"

Knives ..................................................................................................................... (three) 6-1/16" x 5/8" x 1/8"

Fence size overall .................................................................................................................................. 4" x 38"

Fence tilt .....................................................................................................................................+/- 45 degrees

S tops ....................................................................................................- 45 degrees, + 45 degrees, 90 degrees

Height with stand .......................................................................................................................................... 32"

Motor ..............................................................................................1 HP , 1 Ph, 1 15/230v , 60 Hz (prewired 1 15v)

Base weight........................................................................................................................................... 134 lbs.

Stand weight............................................................................................................................................ 64 lbs.

Switch..............................................................................................................................................push button

NOTE: The above specifications were current at the time this manual was published, but because of our policy

of continuous improvement, Powermatic reserves the right to change specifications without notice and without

incurring obligations.

6

RECEIVING THE JOINTER

Upon delivery , open shipping containers and check that

all parts are in good condition. Any damage should be

reported to your distributor and shipping agent immediately. Before proceeding further, read your manual

and familiarize yourself thoroughly with assembly,

maintenance and safety procedures.

Contents of box 1:

1 jointer stand

1 door

1 dust chute

Contents of box 2:

1 jointer assembly

1 fence assembly

1 pulley cover

1 belt

1 cutterhead guard

2 hold-downs

1 hardware bag

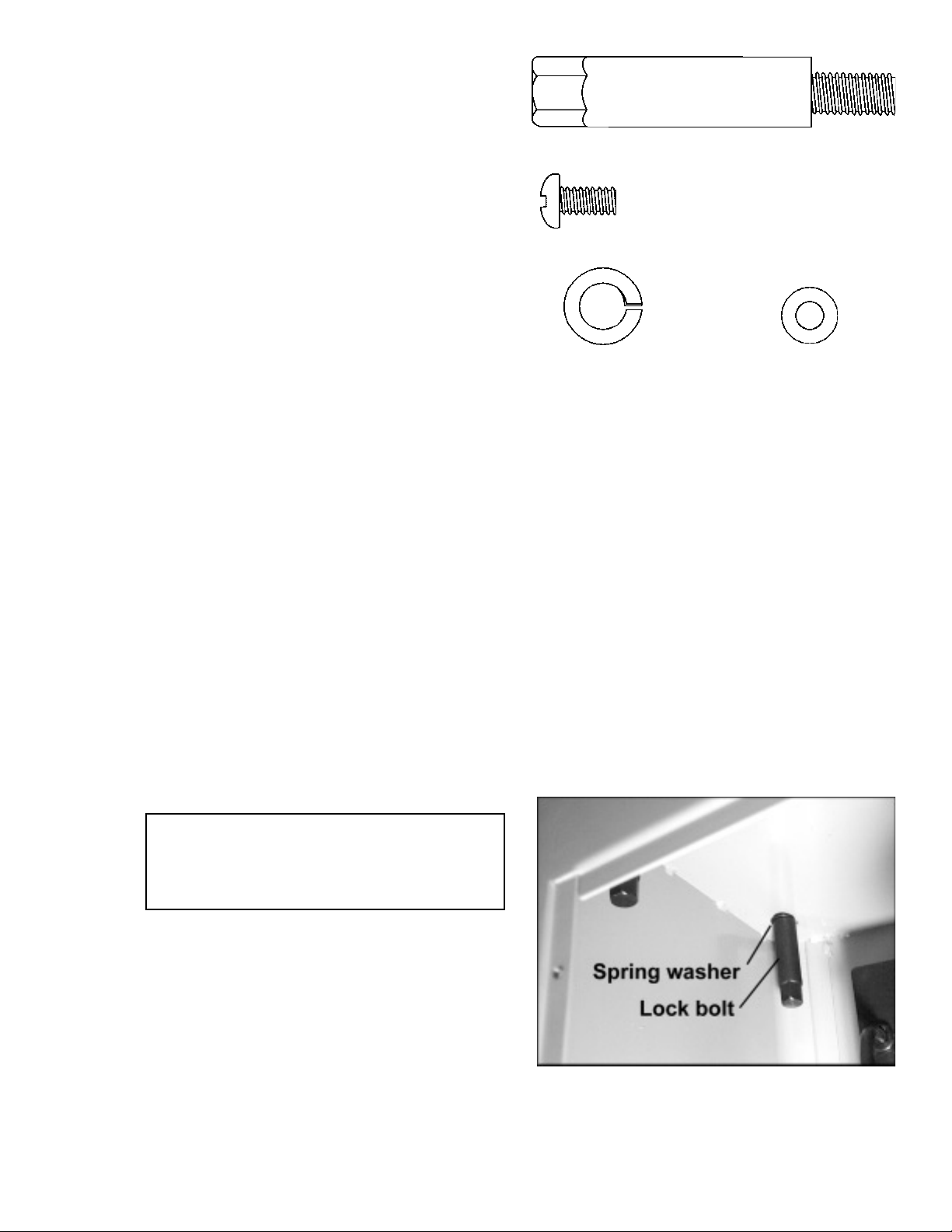

The contents of the hardware bag are drawn full scale

in Figure 1.

Handle screw

1/4-20 x 1/2

Spring washer

10.2 mm x 18.5 mm

Qty. 3

Lock bolts

Qty. 3

Qty. 8

Flat washer

4.3 mm x 10 mm x 1 mm

Qty. 8

FIGURE 1

Moisten a soft cloth with kerosene and remove the

protective coating from all machined surfaces of the

jointer. Do NOT use an abrasive pad. Do not use

gasoline, acetone or lacquer thinner, as this may damage painted surfaces.

Although some users prefer a wax coating for the table

surfaces, white talcum powder rubbed in vigorously

once a week with a blackboard eraser will fill any casting pores and form a moisture barrier. Talcum powder

will not stain wood or mar finishes.

INSTALLATION

Tools required

12mm and 14mm wrenches

screwdriver

Locate the jointer in an area that is level and provides

a solid foundation. Make sure that any potential kickback is not in line with aisles, doorways, wash stations or other work areas.

MOUNTING JOINTER TO STAND

1. Position the jointer on the stand so that the pulley attached to the cutterhead on the jointer is directly

above and on the same side as the motor pulley .

2. Use three lock bolts and spring washers to firmly

fasten the jointer to the stand. The bolts are threaded

up through the holes in the stand into the base of the

jointer. See Figure 2. Use a wrench to tighten.

FIGURE 2

7

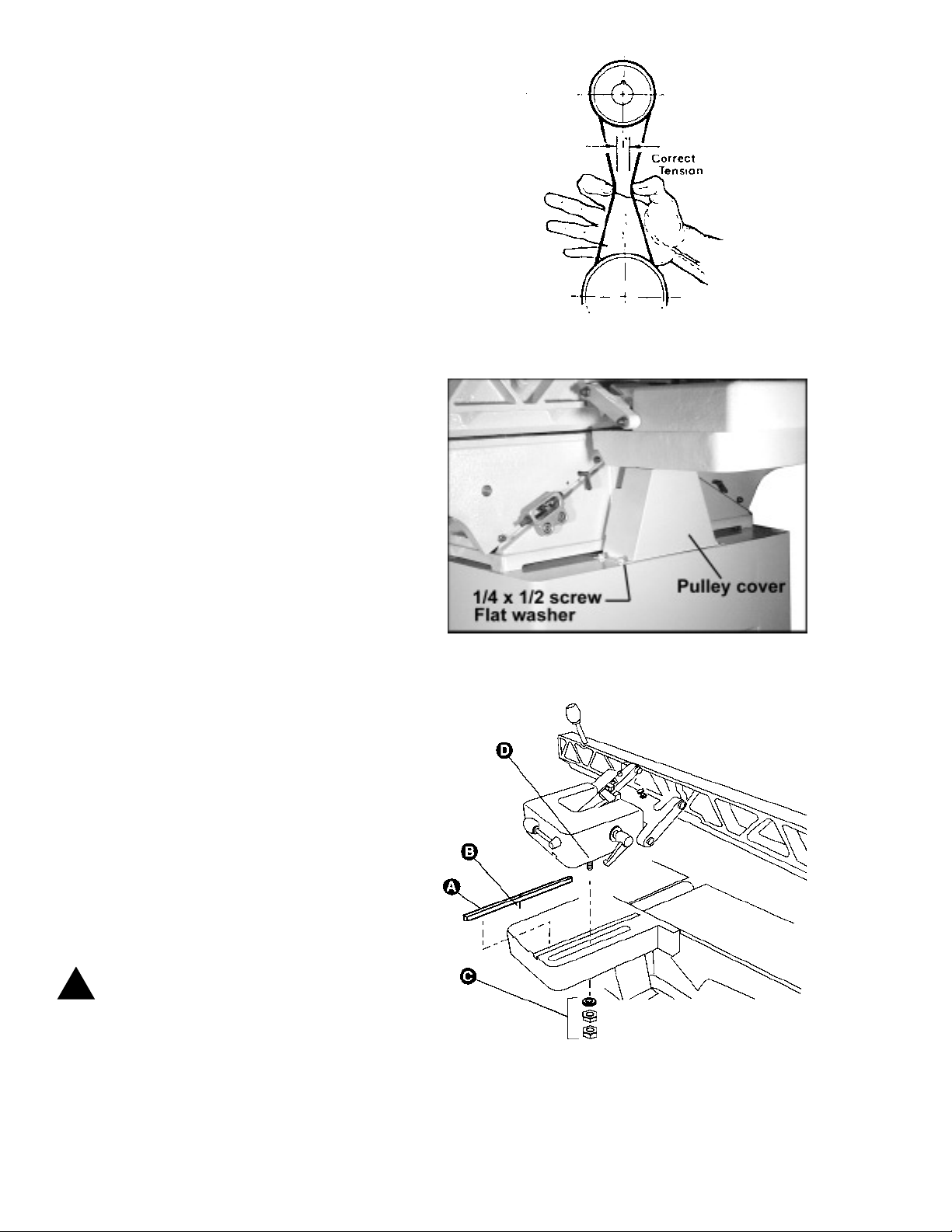

INSTALLING BELT

T o att ach the belt to the cutterhead pulley and motor

pulley, first reach into the dust chute with a wrench

and loosen the four bolts holding the motor to the

mount bracket. Align the pulleys using the slotted

holes on the mounting bracket. Raise the motor as

high as possible and mount the belt on to both pulleys. Allow the motor to drop and create tension on

the belt. Pull down on the motor to achieve the desired belt tension (the correct belt tension is achieved

when the belt can be deflected approximately one inch

at the center belt span using light finger pressure as

shown in Figure 3.) Snug tight the four bolts.

INSTALLING PULLEY COVER

The pulley cover is mounted with four 1/4-20 x 1/2

handle screws and four flat washers to the threaded

holes in the base, as shown in Figure 4.

FIGURE 3

FENCE INSTALLATION & REMOVAL

Place the key (A) into the machined slot of the fence

support as in Figure 5. The spring pin (B) should go

into the hole in the slot. The key should be firmly

seated in the slot. Lightly coat the mating surfaces

of the fence support and the fence slide base with oil.

Place the fence slide base on the fence support, aligning the key with the machined slot in the fence slide

base.

Attach the two hex nuts and flat washer (C) on to the

locking screw (D) and tighten, as shown in Figure 5.

When the locking screw is tightened, the fence should

be secure. Loosen the locking screw to slide the

fence to the desired position on the table and retighten

the locking screw.

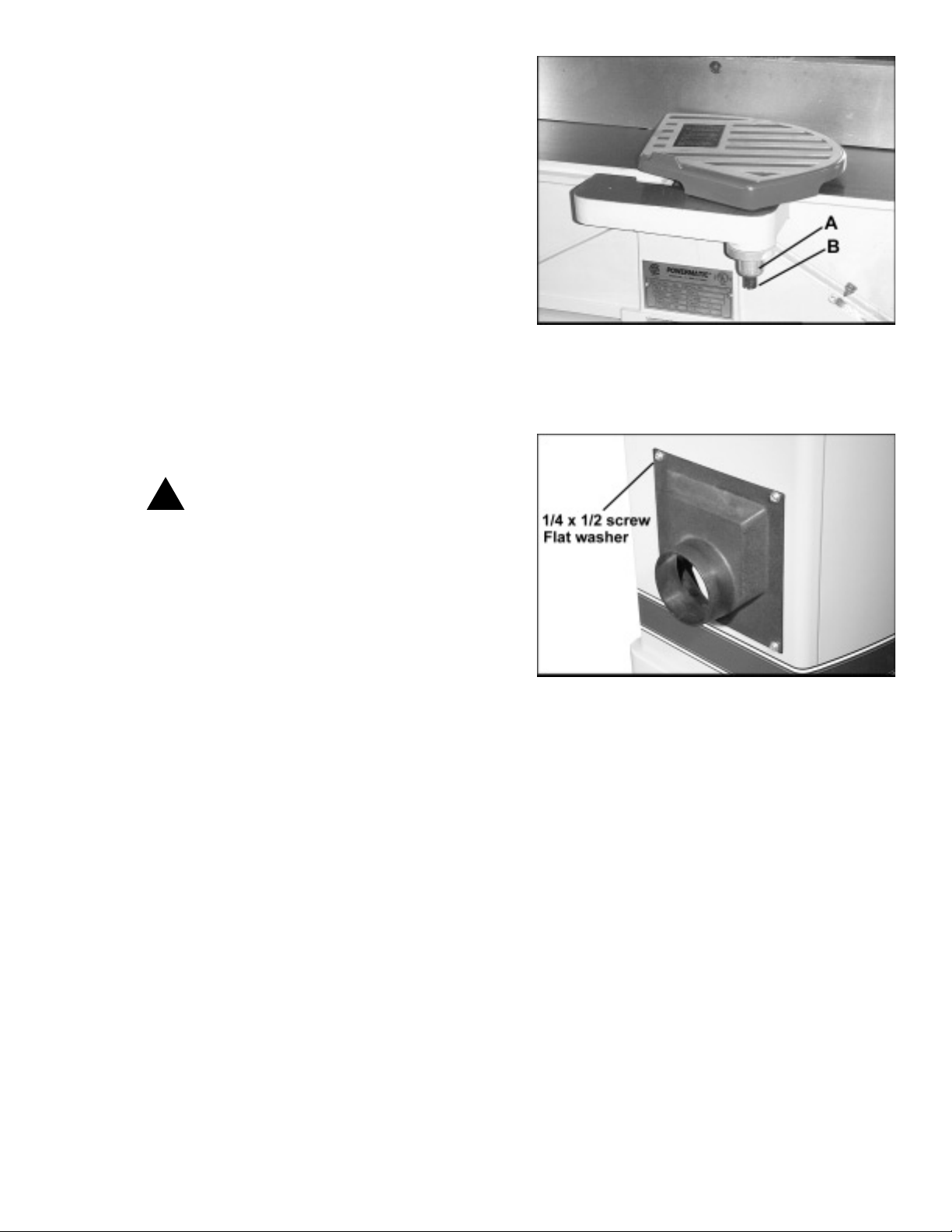

CUTTERHEAD GUARD INSTALLATION &

REMOV AL

WARNING: Use the jointer guard for all

!

operations.

FIGURE 4

1. Disconnect jointer from power source.

2. Turn knob (A) counterclockwise to create tension on spring, and hold it there. See Figure 6

3. Insert guard post (B) down through hole in front

of ledge.

8

FIGURE 5

4. Slightly turn knob (A), if necessary, until the guard

seats itself, and the spring engages the slot at the

end of the guard post.

5. Check the guard for proper tension. If guard does

not spring back into place when pulled back from

cutterhead, remove guard and adjust spring tension

by repeating steps 1-3 until correct tension is

achieved. NEVER run the jointer without the guard

being in place and in perfect working order .

INSTALLING DUST CHUTE

Mount the dust chute to the pre-tapped holes in the

side of the stand with four 1/4-20 x 1/2 handle screws

and four flat washers. See Figure 7.

GROUNDING INSTRUCTIONS

WARNING: If the machine does not come

!

wired to run, the electricals and motor

wiring must be done by a qualified

electrician. The machine must be

properly grounded to help avoid

electrical shock and possible death.

Follow the recommendations made by

the National Electrical Code for

grounding.

1. All grounded, cord connected tools:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current

to reduce the risk of electric shock. This tool is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify the plug

provided - if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The conductor with insulation having an outer surface that is

green, with or without yellow stripes, is the equipment-grounding conductor. If rep air or replacement of

the electric cord or plug is necessary , do not connect

the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool’s plug.

Repair or replace damaged or worn cord immediately .

FIGURE 6

FIGURE 7

9

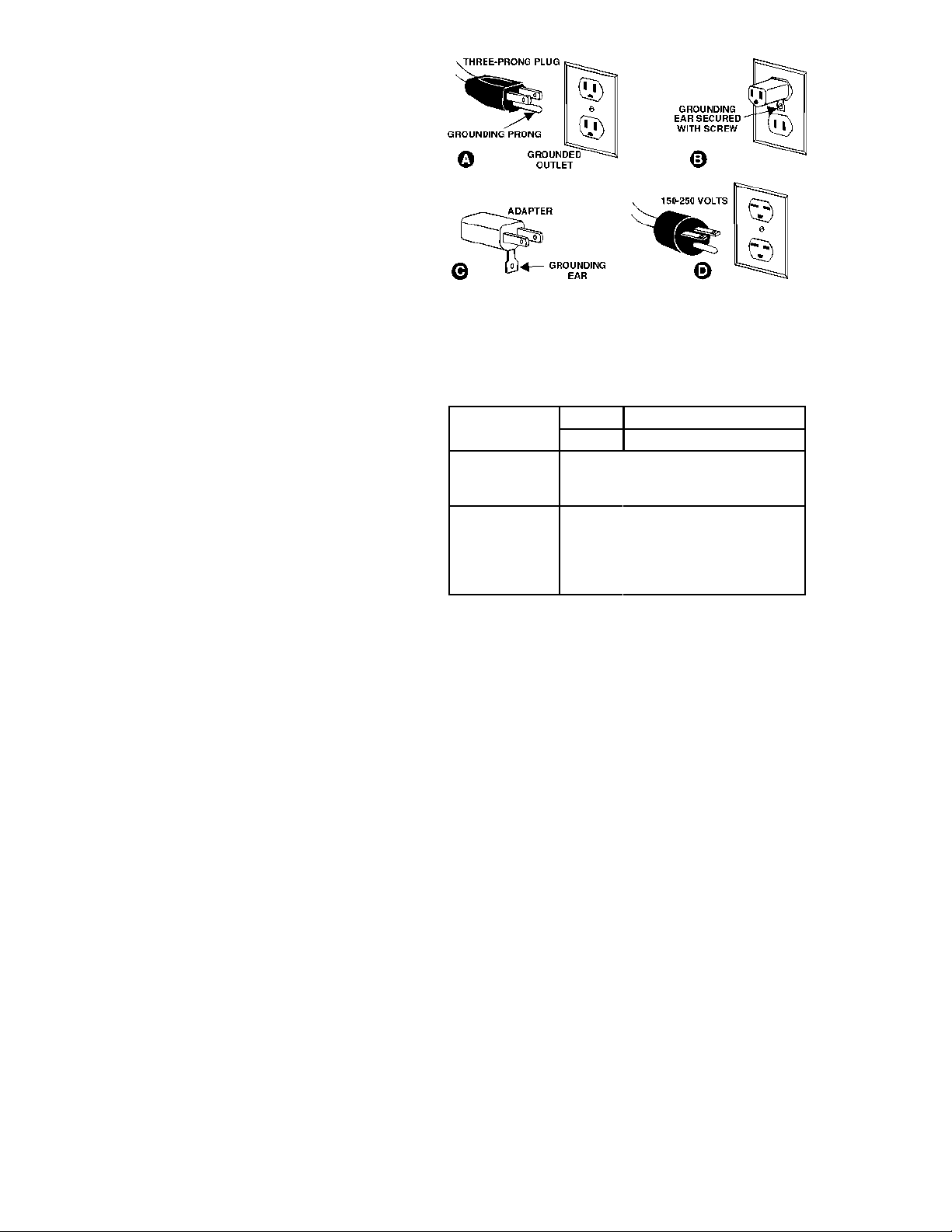

2. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating less than

150 volts:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Sketch A,

Figure 8. The tool has a grounding plug that looks

like the plug illustrated in Sketch A.

A temporary adapter, which looks like the adapter illustrated in Sketches B and C in Figure 8, may be

used to connect this plug to a 2-pole receptacle as

shown in Sketch B if a properly grounded outlet is not

available. The temporary adapter should be used only

until a properly grounded outlet can be installed by a

qualified electrician. The green-colored rigid ear, lug,

and the like, extending from the adapter must be connected to a permanent ground such as a properly

grounded outlet box.

3. Grounded, cord-connected tools intended for use

on a supply circuit having a nominal rating between

150-250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Sketch D

Figure 8. The tool has a grounding plug that looks

like the plug illustrated in Sketch D.

Make sure the tool is connected to an outlet having

the same configuration as the plug. No adapter is

available or should be used with this tool. If the tool

must be reconnected for use on a different type of

electric circuit, the reconnection should be made by

qualified service personnel and after reconnection, the

tool should comply with all local codes and ordinances.

Ampere Rating

More Not

Than More

Than

0 6

6 10

10 12

12 16

FIGURE 8

Volts Total length of cord in feet

115/230 25' 50' 100' 150'

AWG

18 16 16 14

18 16 14 12

15 16 14 12

14 12 Not

recommended

FIGURE 9

EXTENSION CORDS

Use proper extension cord. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating. Figure 9 shows the correct

size to use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier gauge.

The smaller the gauge number, the heavier the cord.

REWIRING MOTOR FOR 230 VOLTS

When rewiring the supplied electric motor for 230 volts,

be sure power cord is unplugged then change the

connections as illustrated in the diagram in the motor

wiring box. Always secure wire nuts with friction t ape.

A new plug will be required for 230 volts as illustrated

in Figure 8, Sketch D.

10

Loading...

Loading...