Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

20-inch Planer

Models 209 and 209HH

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-0260283

Ph.: 800-274-6848 Revision D1 11/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service

Center located throughout the United States can give you quick service. In most cases, any of these WMH Tool Group

Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and

major repair on your POWERMATIC

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with your

local WMH Tool Group distributor, or visit powermatic.com.

WARRANTY

POWERMATIC products carry a limited warranty which varies in duration based upon the product.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

The Five Year Warranty does not cover products used for commercial, industrial or educational purposes. Products with a Five

Year Warranty that are used for commercial, industrial or education purposes revert to a One Year Warranty. This warranty does

not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair or

alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose to have the product returned, you will be responsible for the handling and shipping costs of the

return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information and are

not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

®

tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

2

Page 3

Table of Contents

Warranty and Service.................................................................................................................................... 2

Table of Contents.......................................................................................................................................... 3

Warning.........................................................................................................................................................4

Introduction ...................................................................................................................................................6

Features ........................................................................................................................................................ 6

Specifications ................................................................................................................................................ 7

Unpacking .....................................................................................................................................................8

Assembly....................................................................................................................................................... 9

Knife Gauge (model 209 only)................................................................................................................... 9

Handwheel................................................................................................................................................. 9

Extension Tables .....................................................................................................................................10

Dust Hood................................................................................................................................................ 10

Electrical Connections .............................................................................................................................10

Extension Cords ...................................................................................................................................... 11

Adjustments ................................................................................................................................................11

Belt Tension............................................................................................................................................. 11

Table Rollers ...........................................................................................................................................11

Cutterhead...............................................................................................................................................12

Knife Adjustments (Model 209 only)........................................................................................................12

Replacing and Re-setting Knives (Model 209 only) ................................................................................13

Replacing or Rotating Knife Inserts (Model 209HH only)........................................................................ 14

Work Table Parallel to Cutterhead .......................................................................................................... 15

Know the Transmitting Rollers of Your Planer (Figure 23).....................................................................15

Anti-Kickback Fingers..............................................................................................................................16

Infeed and Outfeed Roller Spring Tension.............................................................................................. 16

Height of Infeed Roller, Chipbreaker, Pressure Bar and Outfeed Roller ................................................16

Infeed Roller Height................................................................................................................................. 17

Chipbreaker Height..................................................................................................................................17

Pressure Bar Height ................................................................................................................................ 18

Chip Deflector.......................................................................................................................................... 18

Feed Speed Control ................................................................................................................................ 18

Changing Accessories for Lowest Feed Speed ......................................................................................18

Return Rollers.......................................................................................................................................... 19

Depth of Cut ............................................................................................................................................19

Maintenance................................................................................................................................................ 20

Lubrication ...............................................................................................................................................20

Troubleshooting: Operating Problems ........................................................................................................ 22

Troubleshooting: Mechanical and Electrical Problems ............................................................................... 23

Optional Accessories ..................................................................................................................................24

Replacement Parts...................................................................................................................................... 24

Cutterhead Assembly .............................................................................................................................. 25

Parts List: Cutterhead Assembly ............................................................................................................. 26

Base Assembly........................................................................................................................................ 28

Parts List: Base Assembly.......................................................................................................................29

Gearbox Assembly .................................................................................................................................. 30

Parts List: Gearbox Assembly ................................................................................................................. 31

Stand Assembly....................................................................................................................................... 32

Parts List: Stand Assembly .....................................................................................................................33

Parts List: Table Assembly...................................................................................................................... 34

Electrical Connections – 3 Phase, 230 Volt only ........................................................................................36

Electrical Connections – 3 Phase, 460 Volt only ........................................................................................37

3

Page 4

Warning

As with all machines, there is a certain amount of hazard involved with the use of this planer. Use the

machine with the respect and caution demanded where safety precautions are concerned. When normal

safety precautions are overlooked or ignored, personal injury to the operator can result.

Read, understand and follow the safety and operating instructions found in this manual. Know the

limitations and hazards associated with this machine.

Electrical grounding. Make certain that the machine frame is electrically grounded and that a ground

lead is included in the incoming electrical service. In cases where a cord and plug are used, make certain

that the grounding plug connects to a suitable ground. Follow the grounding procedure indicated in the

National Electrical Code.

Eye safety. Wear an approved safety shield, goggles, or glasses to protect eyes. (NOTE: Common

eyeglasses are only impact-resistant, they are not safety glasses.)

Personal protection. Before operating the machine, remove tie, rings, watch and other jewelry and roll

up sleeves above the elbows. Remove all loose outer clothing and confine long hair. Protective type

footwear should be used. Where the noise exceeds the level of exposure allowed in Section 1910.95 of

the OSHA Regulations, use hearing protective devices. Do not wear gloves.

Guards. Keep the machine guards in place for every operation for which they can be used. If any guards

are removed for maintenance, DO NOT OPERATE the machine until the guards are reinstalled.

Placement. Place machine so that potential kickback area is not in line with aisles, doorways, wash

stations, or other work areas.

Work area. Keep the floor around the machine clean and free of scrap material, saw dust, oil and other

liquids to minimize the danger of tripping or slipping. Be sure the table is free of all scrap, foreign material

and tools before starting to cut. Make certain the work area is well lighted and that a proper exhaust

system is used to minimize dust. It is recommended that anti-skid floor strips are used on the floor area

where the operator normally stands and that each machine’s work area be marked off. Provide adequate

work space around the machine.

Avoid accidental starting: Make certain motor switch is in off position before connecting power to the

machine.

Operator position. Maintain a balanced stance and keep your body under control at all times. Stand to

one side out of line with the table and make sure no one else is standing in line with the table.

Housekeeping. Before turning on machine, remove all extra equipment such as keys, wrenches, scrap,

and cleaning rags away from the machine

Careless acts. Give the work you are doing your undivided attention. Looking around, carrying on a

conversation, and “horseplay” are careless acts that can result in serious injury.

Disconnect machine before performing any service or maintenance or when changing blades. A

machine under repair should be RED TAGGED to show it should not be used until the maintenance is

complete.

Maintain tools in top condition. Keep tools sharp and clean for safe and best performance. Dull tools

increase noise levels and can cause kickbacks and glazed surfaces. Check the condition and adjustment

of the tools before making any cuts. Follow the sharpening instructions on knife grinding and jointing,

installing and adjustments.

4

Page 5

Hand safety. Keep hands outside the machine. NEVER reach under the guards to try to clear stock that

stops feeding. Do not clear chips and sawdust with hands; use a brush. Do not have any part of the

hands under that part of the board that is over the table when starting a cut; the infeed roll will engage the

board and force it down against the table causing a pinching action. Do not operate machine while the

gear cover is open.

Cutterhead rotation: Be sure cutterhead rotates under power in a counterclockwise direction when

viewed from the main drive motor side.

Material condition: Do not plane boards with loose knots or with nails or any foreign material on its

surface. Knife impact on these objects can cause the knives to be pulled out and cause them to shatter

against the chipbreaker or pressure bar. Twisted, warped, or in wind stock should first be jointed on one

surface before attempting to plane a parallel surface on the planer. Serious stock flaws cannot be

removed by use of a planer alone.

Machine adjustments: Make all machine adjustments with power off except feed rate.

Job completion. If the operator leaves the machine area for any reason, the planer should be turned

"off" and the cutterhead should come to a complete stop before his departure. In addition, if the operation

is complete, he should clean the planer and the work area. Never clean the planer with power "on" and

never use the hands to clear sawdust and debris; use a brush.

Replacement parts. Use only Powermatic or factory authorized replacement parts and accessories;

otherwise the warranty and guarantee is null and void.

Misuse. Do not use this Powermatic planer for other than its intended use. If used for other purposes,

Powermatic disclaims any real or implied warranty and holds itself harmless for any injury or damage

which may result from that use.

If you are not thoroughly familiar with the operation of planers, obtain advice from your supervisor,

instructor or other qualified person.

Drugs, alcohol, medication. Do not operate this machine while under the influence of drugs, alcohol, or

any medication.

Health hazards. Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and other masonry products.

* Arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area, and work with approved safety equipment,

such as those dust masks that are specifically designed to filter out microscopic particles.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

5

Page 6

Introduction

This manual is provided by WMH Tool Group covering the safe operation and maintenance procedures

for a Powermatic Model 209 and 209HH Planer. This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance instructions and parts breakdown. This machine

has been designed and constructed to provide years of trouble free operation if used in accordance with

instructions set forth in this manual. If there are any questions or comments, please contact either your

local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

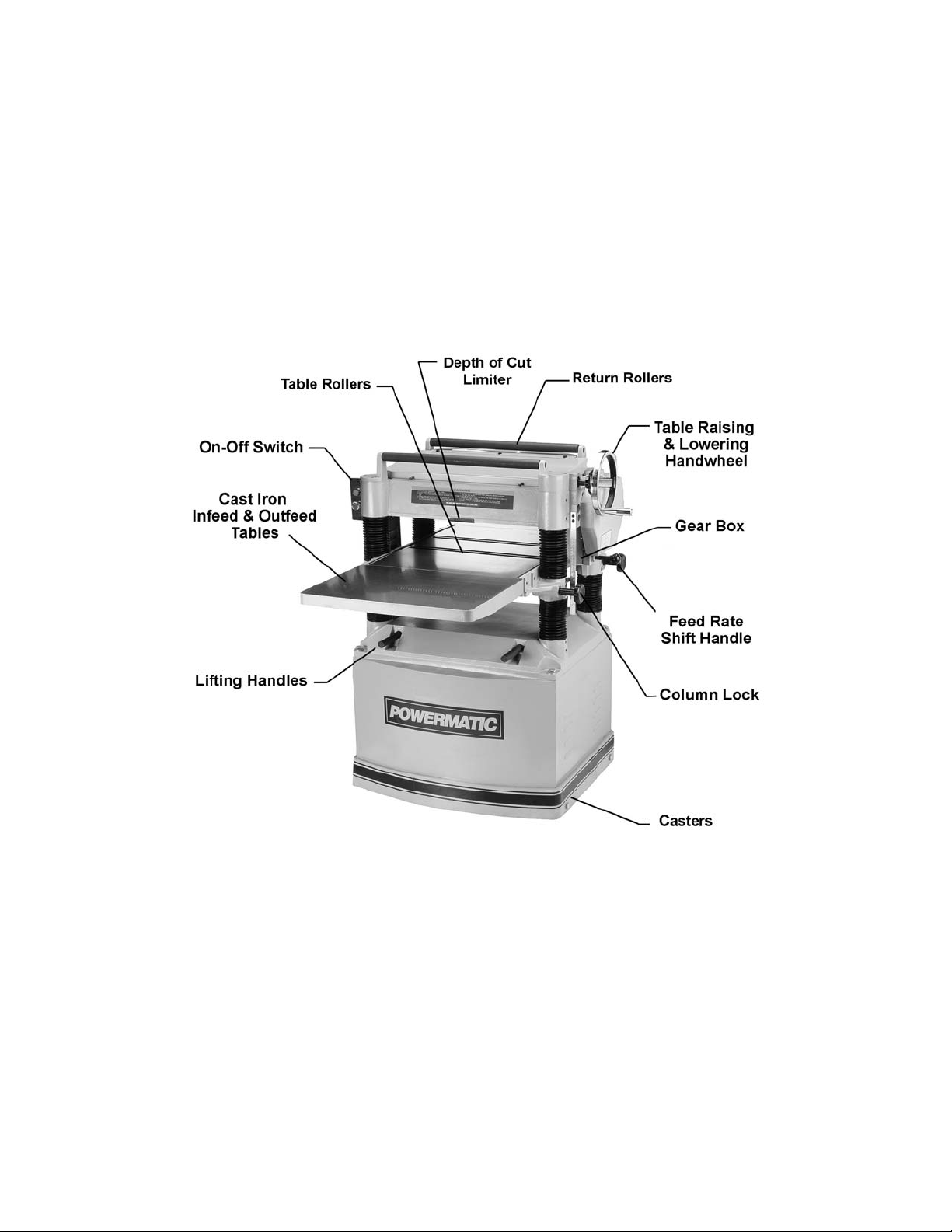

Features

Figure 1

6

Page 7

Specifications

Model Number.......................................................................209-1 .......................................................209-3

Stock Number ..................................................................1791296 .................................................. 1791297

Table Area (in.) ............................................................25-3/4 x 20 .............................................. 25-3/4 x 20

Maximum Planing Width (in.) ..................................................... 20 ............................................................ 20

Maximum Planing Thickness (in.) ................................................ 8 .............................................................. 8

Full Width Cutting Depth (in.).................................................. 3/32 ......................................................... 3/32

Minimum Planing Length (in.) ................................................6-3/4 ........................................................6-3/4

Knives........................................................................................... 4 .............................................................. 4

Blade Size (in.)............................................................ 20 x 1 x 1/8 ............................................. 20 x 1 x 1/8

Cutterhead Speed (RPM)......................................................5,000 ....................................................... 5,000

Cuts per Minute................................................................... 20,000 ..................................................... 20,000

Cutterhead Diameter (in.).....................................................3-3/16 ......................................................3-3/16

Feeding Speed (FPM).................................................... 24 and 31 ................................................ 24 and 31

Motor ........................................................ TEFC, 5HP, 1Ph, 230V .................. TEFC, 5HP, 3Ph, 230/460V*

Dust Chute Diameter (in.) ............................................................5 .............................................................. 5

Overall Dimensions (LxWxH)(in.)...................26 x 36-5/8 x 41-3/8 ................................ 26 x 36-5/8 x 41-3/8

Net Weight (lbs.) ......................................................................770 .......................................................... 770

Shipping Weight (lbs.) ..............................................................880 .......................................................... 880

*pre-wired 230 volt

Model Number................................................................. 209HH-1 ..................................................209HH-3

Stock Number ..................................................................1791315 .................................................. 1791316

Table Area (in.) ............................................................25-3/4 x 20 .............................................. 25-3/4 x 20

Maximum Planing Width (in.) ..................................................... 20 ............................................................ 20

Maximum Planing Thickness (in.) ................................................ 8 .............................................................. 8

Full Width Cutting Depth (in.).................................................. 3/32 ......................................................... 3/32

Minimum Planing Length (in.) ................................................6-3/4 ........................................................6-3/4

Knives.......................................................... 132 four-sided inserts ............................. 132 four-sided inserts

Cutterhead Speed (RPM)......................................................5,000 ....................................................... 5,000

Cuts per Minute................................................................... 20,000 ..................................................... 20,000

Cutterhead Diameter (in.).....................................................3-1/16 ......................................................3-1/16

Feeding Speed (FPM).................................................... 24 and 31 ................................................ 24 and 31

Motor ........................................................ TEFC, 5HP, 1Ph, 230V .................. TEFC, 5HP, 3Ph, 230/460V*

Dust Chute Diameter (in.) ............................................................5 .............................................................. 5

Overall Dimensions (LxWxH)(in.)...................26 x 36-5/8 x 41-3/8 ................................ 26 x 36-5/8 x 41-3/8

Net Weight (lbs.) ......................................................................801 .......................................................... 801

Shipping Weight (lbs.) ..............................................................911 .......................................................... 911

*pre-wired 230 volt

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and

without prior notice, without incurring obligations.

7

Page 8

Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Planer is

assembled and running properly.

Compare the contents of your container with the

following parts list to make sure all parts are

intact. Missing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

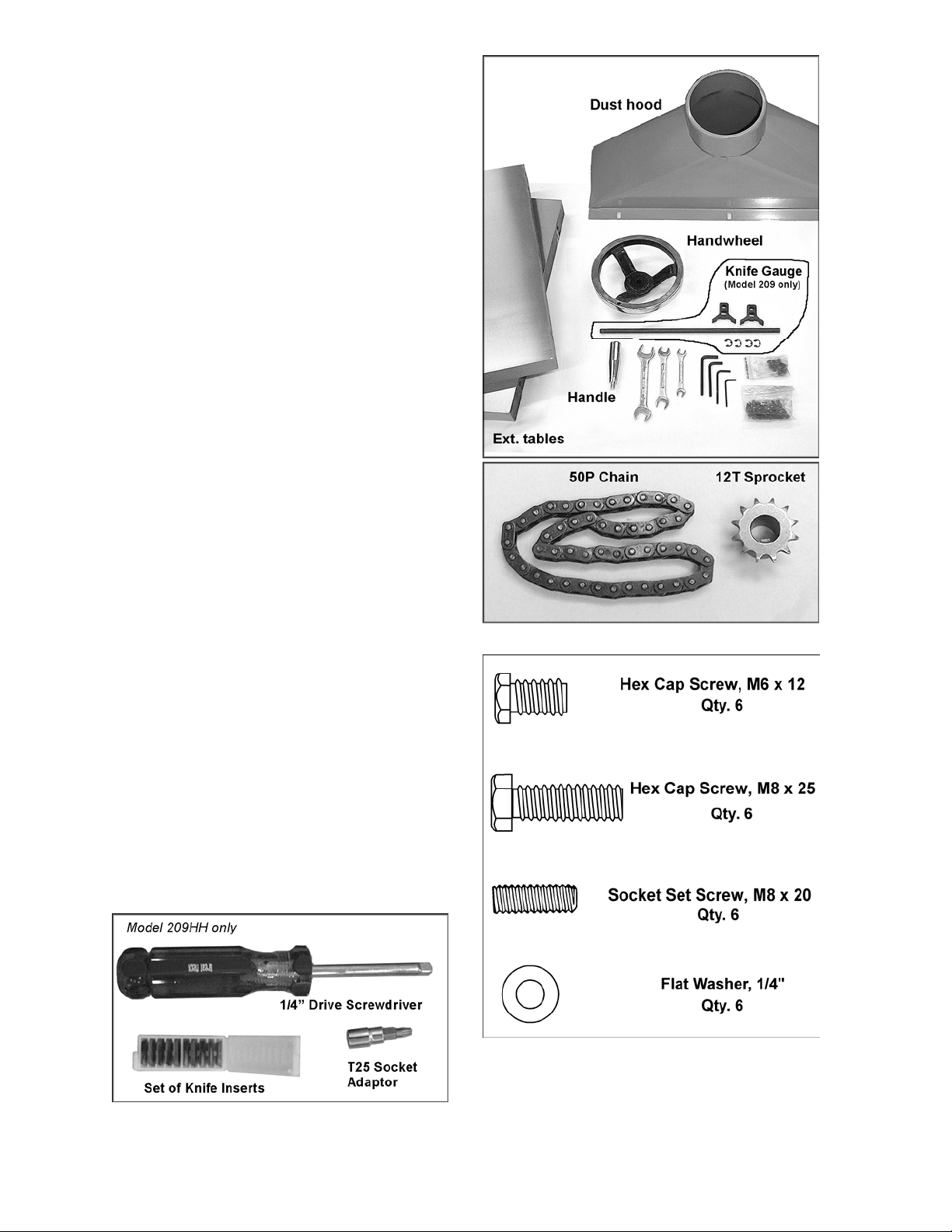

Crate Contents (Figure 2):

Models 209 and 209HH:

1 Planer (not shown)

1 Dust Hood

2 Cast Iron Extension Tables

1 Handwheel

1 Handle

1 Low Speed Gear Kit (#6292822) containing:

1 50P Chain

1 12T Sprocket

3 Open-End Wrenches (8-10,12-14,17-19mm)

4 Hex Wrenches (3,4,5 and 6mm)

2 Hardware Bags*

(*Contents of hardware bags are drawn full

scale in Figure 3.)

1 Owner’s Manual (not shown)

1 Warranty Card (not shown)

Model 209 ONLY:

1 Knife Setting Gauge

Model 209HH ONLY:

1 1/4” Drive Screwdriver

1 T25 Torx Drive Socket Adaptor

1 Set of 10 Knife Inserts

Figure 2

Figure 4

Figure 3

8

Page 9

Assembly

Tools required for assembly:

Forklift or hoist with slings

Pliers

Open-End Wrenches (10,12,19mm) – provided

Hex Wrenches, 4 and 5mm – provided

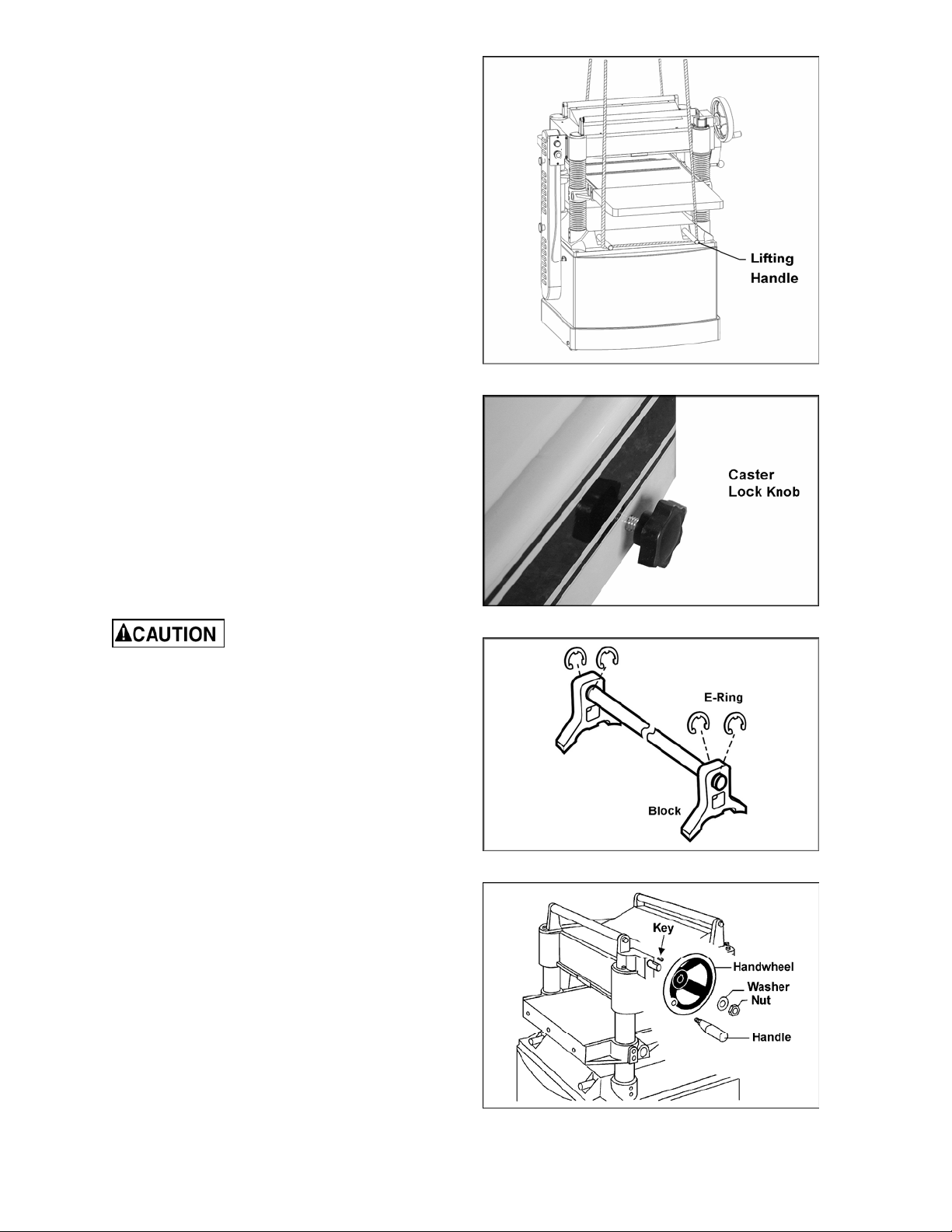

Remove the screws holding the planer to the

pallet and use a forklift or hoist to lift the planer

off the pallet. Forks and straps should always be

placed under the four lifting handles when lifting

this machine (Figure 5). The lifting handles can

be pushed back in when not in use.

The planer should be operated in a well-lit area

with a sturdy floor and good ventilation. It can be

rolled on its casters to the desired location.

Tighten the lock knob (Figure 6) to prevent

movement during operation or adjustments.

Exposed surfaces, such as tables, rollers,

cutterhead, etc., have been given a protective

coating at the factory. This should be removed

with a soft cloth moistened with a good

commercial solvent. Do not use acetone,

gasoline, lacquer thinner, or other solvents with

a low flash point. Do not use an abrasive pad

because it may scratch the polished cast iron

surfaces.

Use care when cleaning

around the cutterhead area – knives are

extremely sharp!

Figure 5

Figure 6

Knife Gauge (model 209 only)

Place the two gauge blocks on the ends of the

shaft (Figure 7) and use a pliers to press the

four e-rings into the grooves on each side of the

blocks.

Handwheel

1. Remove the nut and washer from the

gearbox shaft, and place the handwheel

onto the shaft (Figure 8), making sure it is

oriented so the handwheel slips over the

key.

2. Place flat washer and hex nut on shaft and

tighten with 19mm wrench.

3. Mount the handle into the threaded hole in

the handwheel, and tighten with a 12mm

wrench placed over the flat on the handle.

Figure 7 – Model 209 only

Figure 8

9

Page 10

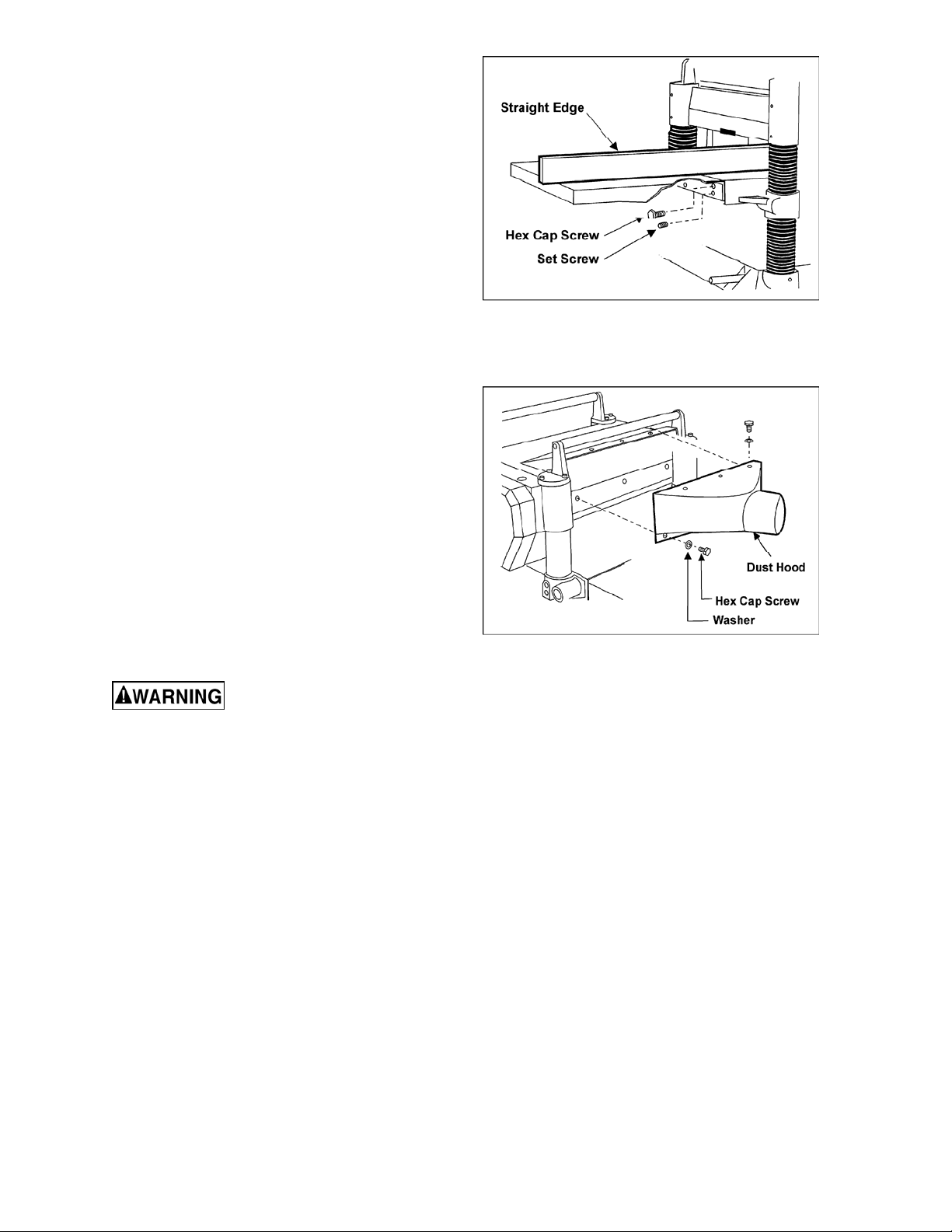

Extension Tables

1. Mount a cast iron table to the edge of the

main table with three M8 x 25 hex cap

screws (Figure 9) using a 12mm wrench. Do

not fully tighten yet.

2. The extension table must be leveled with the

main table. Place a straight edge (such as a

jointed board) across both tables.

3. Insert three socket set screws with a 4mm

hex wrench, and screw them in or out as

needed until tables are level.

4. Securely tighten the hex cap screws.

5. Mount the second extension table to the

opposite side of the planer table, using the

same procedure.

Dust Hood

Mount the hood to the rear of the head casting

with six M6 x 12 hex cap screws and six 1/4" flat

washers (Figure 10), with a 10mm wrench.

It is recommended that you use a dust collection

system with this planer. If you are not using a

dust collection system, do not attach the dust

hood to the planer, as the accumulation of dust

inside the hood may create a safety hazard, or

eventually cause jamming of the rollers.

Figure 9

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. The

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

A power plug is not provided with the 209

planer. You may either connect one or "hardwire" the machine directly to your electrical

panel provided there is a disconnect near the

machine. Consult electrical schematics on

pages 35-37 for further clarification of wiring

setup.

This machine must be grounded. Grounding

provides a path of least resistance to help divert

current away from the operator in case of

electrical malfunction.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the machine.

Figure 10

10

Page 11

Extension Cords

The use of an extension cord is not

recommended for this machine, but if one

proves necessary make sure the cord rating is

suitable for the amperage listed on the

machine's motor plate. An undersize cord will

cause a drop in line voltage resulting in loss of

power and overheating.

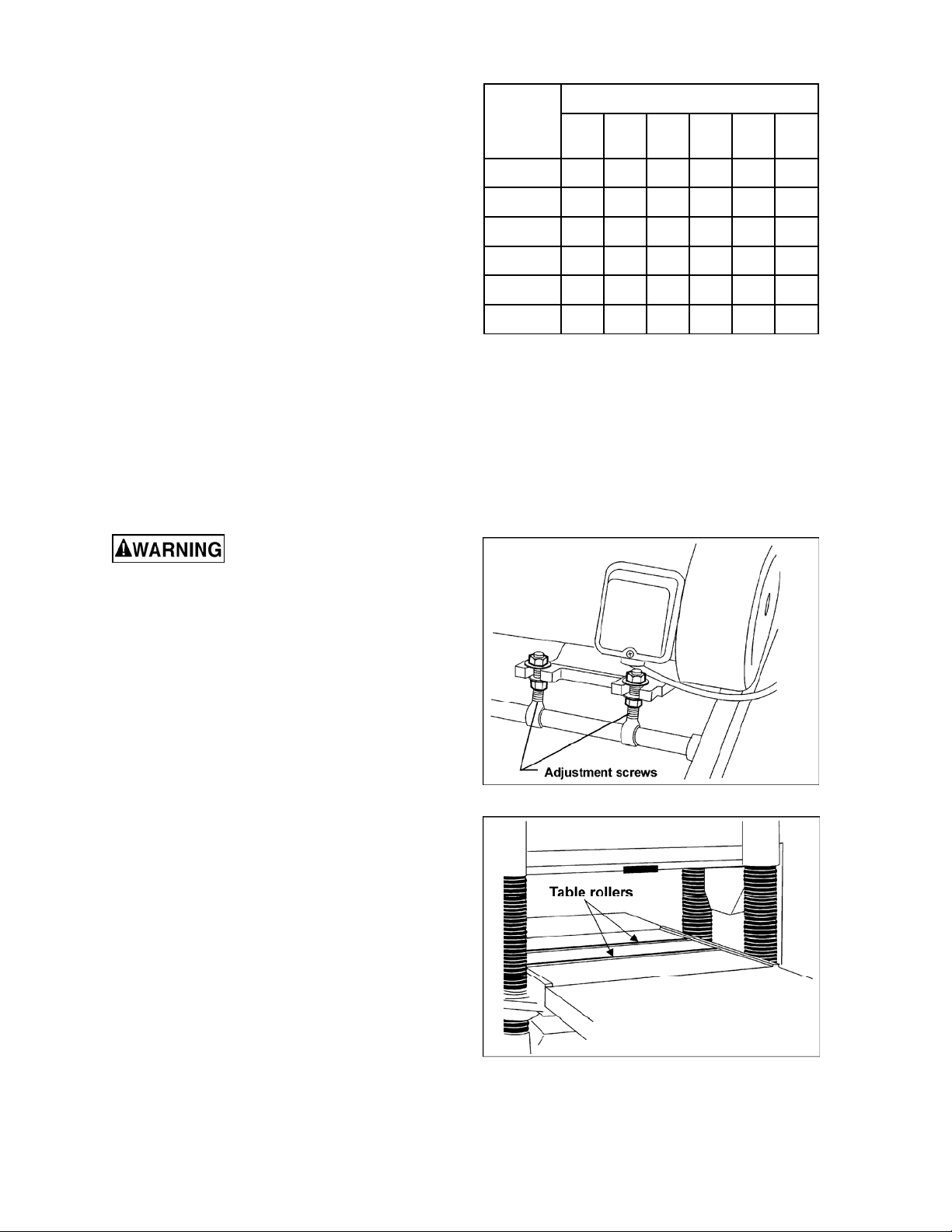

The chart in Figure 11 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. The smaller the gauge number

the heavier the cord.

Adjustments

Tools required for adjustments:

3, 5, 6, and 10mm hex wrenches

12, 14 and 19mm open-end wrenches

Feeler gauges

Straight edge

Gauge block or dial gauge

Cross-point (Phillips) screwdriver

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

feet

feet

feet

feet

feet

200

feet

Figure 11

Disconnect machine from

power source before making any adjustments (except feed rate).

Belt Tension

Inspect the tension of the belts frequently during

the first few times you use the planer. Belts often

stretch during this trial period. If they require

tightening, proceed as follows:

1. Remove the belt guard and the rear panel.

2. Loosen the bottom nuts on the motor

adjustment screws (Figure 12) with a 19mm

wrench.

3. Turn the top nuts to lower the motor plate,

which will increase the belt tension.

4. Proper tension is achieved when there is

slight deflection in the belt midway between

the pulleys, using moderate finger pressure.

5. Tighten the bottom nuts (Figure 12).

Table Rollers

Your planer is supplied with two table rollers

(Figure 13) which turn as the stock is fed into the

machine, thus reducing friction. It is not possible

to give exact dimensions on the proper height

setting of the table rollers because each type of

wood behaves differently. As a general rule,

however, when planing rough stock the table

rollers should be set at high position.

Figure 12

Figure 13

11

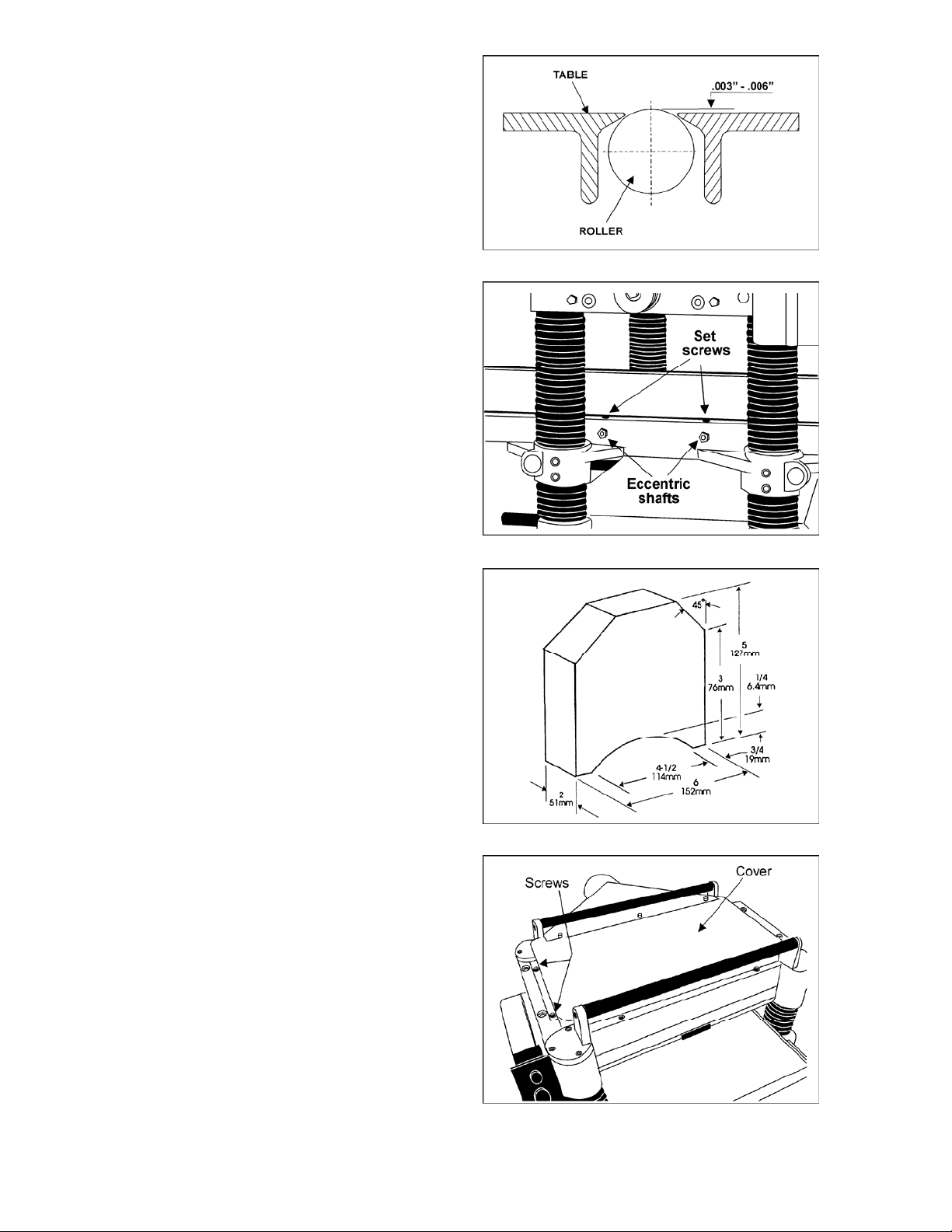

Page 12

When planing smooth stock the rollers should be

set at low position.

NOTE: When raising the roller higher above the

table, the range is from .003" to .006" (Figure

14).

The table rollers are factory set for average

planing and are parallel to the table surface. If

you desire to adjust the table rollers higher or

lower, proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge across both rollers.

3. On one side of the table, loosen the set

screws (Figure 15) with a 3mm hex wrench,

and turn the eccentric shafts to raise or

lower the rollers.

4. When proper height is achieved, tighten set

screws.

5. Adjust the rollers from the opposite side of

the table in the same manner.

IMPORTANT: Be sure that the height of front

and rear rollers are the same. The table rollers

must always be set parallel to the table.

Cutterhead

Figure 14

Figure 15

Although your planer was carefully adjusted at

the factory, it should be checked before being

put into operation. Any inaccuracies due to

rough handling in transit can be corrected by

following the directions in this manual.

To check the adjustments you will need a knifesetting gauge (provided), feeler gauges, and a

dial gauge or home-made gauge block made of

hardwood. This gauge block can be made by

following the dimensions shown in Figure 16.

You will also need to remove the belt guard, so

you can rotate the cutterhead using the pulley.

Knife Adjustments (Model 209 only)

When checking or adjusting cutterhead knives

on the model 209 Planer, proceed as follows:

1. Disconnect machine from power source.

2. Remove the six screws and upper cover

(Figure 17).

3. To check and adjust knives, use the

provided knife setting gauge and check all

four knives. Knives should just contact the

bottom of the center protrusion (D, Figure

18) of the knife gauge. Make sure the feet of

the knife gauge sit solidly upon the

cutterhead, and that its shaft is parallel to

the cutterhead (see Figure 19).

Figure 16

Figure 17

12

Page 13

4. If an adjustment to one or more of the knives

is necessary, slightly loosen the knife gib (E,

Figure 18) by turning the six screws (F,

Figure 18) into the gib (i.e. clockwise, when

facing the screw heads) with a 12mm hex

wrench. Turn the screws just enough to

relieve stress in the cutterhead without

disturbing the setting of the knives. Do this

for all four knives at the same time.

5. With the knife setting gauge (C, Figure 18)

in place over a knife (G, Figure 18), continue

to loosen the screws (F, Figure 18) until the

springs (H, Figure 18) begin raising the

knife. When knife comes in contact with the

center protrusion of the gauge, snug the gib

by lightly backing out the six screws (F,

Figure 18) against the slot (i.e. counterclockwise).

NOTE: At this time, tighten the knife into the

slot just enough to hold knife in position.

6. If additional knives must be reset, repeat

step 5.

7. After all knives are set with screws just

snug, back out and tighten the six screws (F,

Figure 18) against the slot starting with the

end screws first, then the center screws,

until the knife is securely held in the

cutterhead. Tighten the remaining three

knives in the same manner.

After setting or installing

knives, re-check all gib screws. Loose gib

screws can result in knives being thrown out

of the cutterhead, causing severe damage to

the machine and possible serious or fatal

injury to the operator or bystanders.

Replacing and Re-setting Knives (Model 209 only)

If the knives are removed for sharpening, care

must be exercised in replacing and re-setting

them. Proceed as follows:

1. Disconnect machine from power source.

2. Remove six screws and upper cover (see

Figure 17).

3. To remove knife, loosen the gib (E, Figure

18) by turning the six gib screws clockwise.

Remove gib, knife and springs.

4. Remove the remaining three knives in the

same manner.

5. Thoroughly clean the knife slots, gibs,

springs and gib screws. Check the gib

screws; if the threads appear worn or

stripped or if the heads are becoming

rounded, replace them.

Figure 18 – Model 209 only

Figure 19 – Model 209 only

13

Page 14

6. Inspect the cutting edge of the knives for

nicks or wire edge. Hone the knives slightly

using a stone or if the knives are to be

sharpened, maintain a cutting angle of 35

degrees.

7. Insert springs, knife and gib into slot of

cutterhead. Back out screws just enough to

hold the knife in the cutterhead.

8. Place knife setting gauge (Figure 19) over

knife.

9. While holding down the knife gauge, loosen

all six screws by turning them into the gib

until the cutting edge of the knife comes in

contact with the protrusion of the gauge.

Snug up the gib by slightly backing out the

six screws against the slot.

NOTE: At this time, only tighten the knife

into the slot just enough to hold the knife in

position.

10. Replace and re-set the other three knives in

the same manner.

11. After all four knives are set with the screws

just snug, back out and tighten the six

screws against the slot starting with the end

screws first and then the center screws until

the knife is securely held in the cutterhead.

Tighten the remaining three knives in the

same manner.

Figure 19 repeated

After replacing and checking

knives, check again carefully. Make certain

the direction of knives is correct and all 24

gib screws are tightened securely.

Replacing or Rotating Knife Inserts

(Model 209HH only)

The knife inserts on the model 15HH are foursided. When dull, simply remove each insert,

rotate it 90° for a fresh edge, and re-install it.

Use the provided screwdriver with the socket

adaptor to remove the knife insert screw. See

Figure 20. It is advisable to rotate all inserts at

the same time to maintain consistent cutting.

However, if one or more knife inserts develops a

nick, rotate only those inserts that are affected.

Each knife insert has an etched reference mark

so you can keep track of the rotations.

IMPORTANT: When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform. Dust

accumulation between these elements can

prevent the insert from seating properly, and

may affect the quality of the cut.

Figure 20 – Model 209HH only

Before installing each screw, lightly coat the

screw threads with machine oil and wipe off any

excess.

Securely tighten each screw which holds the

knife inserts before operating the planer!

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propelled at high speed from a

rotating cutterhead, causing injury.

14

Page 15

Work Table Parallel to Cutterhead

The work table is set parallel to the cutterhead at

the factory and no further adjustment should be

necessary. If your machine is planing a taper,

first check to see if the knives are set properly in

the cutterhead. Then check to see if the work

table is set parallel to the cutterhead. Proceed

as follows:

1. Disconnect machine from power source.

2. Place the gauge block (Figure 21) on the

work table directly under the edge of a knife

or knife insert as shown. Make slight contact

with the knife edge by gently raising the

table.

3. Move the gauge block to the opposite end of

the work table. The distance from the work

table to the edge of the knife should be the

same on both ends of the knife.

If the work table is not parallel to the cutterhead,

perform the adjustment procedure as follows:

1. Disconnect machine from power source.

2. Remove bolts holding the planer to the

stand. Tilt planer on its side to expose

underside of base (Figure 22).

Figure 21

3. Remove bolt (A, Figure 22) and loosen bolt

(B-Figure 22) which will allow you to move

the idler sprocket assembly (C, Figure 22)

far enough to release tension on the chain.

4. Remove the chain from the particular

sprocket on the corner of the base that you

need to adjust.

5. Turn the sprocket by hand to bring that

corner into adjustment with the other three

corners. NOTE: Turning sprocket clockwise

will increase the distance between the

working table and the head casting;

counterclockwise will decrease the distance.

This adjustment is very sensitive and it

should not be necessary to turn the sprocket

more than one or two teeth.

6. When adjustments are correct, replace

chain around corner sprocket, slide idler

sprocket (C-Figure 22) back to re-tension

chain, tighten bolt (B, Figure 22) and insert

and tighten bolt (A, Figure 22).

Know the Transmitting Rollers of Your Planer (Figure 23)

Figure 22

A. Anti-Kickback Fingers

B. Infeed Roller

C. Chipbreaker

D. Cutterhead

E. Pressure Bar

F. Outfeed Roller

15

Figure 23

Page 16

Anti-Kickback Fingers

The anti-kickback fingers (A, Figure 23) are an

important safety feature, as they help prevent

kickback of stock. They operate by gravity and

should be inspected frequently to make sure

they re free of gum and pitch, so that they move

independently and operate correctly.

Infeed and Outfeed Roller Spring Tension

The infeed roller (B, Figure 23) and outfeed

roller (F, Figure 23) are those parts of your

planer that feed the stock while it is being

planed. The infeed roller and the outfeed roller

are under spring tension and this tension must

be sufficient to feed the stock uniformly through

the planer without slipping but should not be so

tight that it causes damage to the board. The

tension should be equal at both ends of each

roller.

To adjust the spring tension of the infeed and

outfeed rollers, turn screws (Figure 24) with a

hex wrench. Turn screws on both ends of

infeed/outfeed rollers in the same manner.

Figure 24

Height of Infeed Roller, Chipbreaker, Pressure Bar and Outfeed Roller

The infeed roller, chipbreaker, pressure bar and

outfeed roller are adjusted at the factory. The

height relationship between these items and the

cutterhead is crucial for accurate and safe

planing. The infeed roller, chipbreaker, pressure

bar, and outfeed roller should be set .020"

(0.5mm) below the cutting circle. See Figure 25.

If any adjustments are necessary for the infeed

roller, chipbreaker, pressure bar or outfeed

roller, they should be done carefully. Use the

following steps as an example of procedure.

NOTE: This procedure uses a home-made

gauge block and feeler gauges, which should be

sufficient for most planer operations. If extra

precise measurements are desired, however,

use a dial indicator device. A bed and feed roller

gauge with dial indicator (stock # 2230002) is

available as an accessory for this machine, and

may be purchased from WMH Tool Group.

Figure 25

16

Page 17

Outfeed Roller Height

1. Disconnect machine from power source.

2. Make sure the knives are set properly as

previously explained under "Knife

Adjustment."

3. Place the gauge block (J, Figure 26) on the

table directly beneath the cutterhead (D,

Figure 26).

4. Using a 0.02" (0.5mm) feeler gauge (K,

Figure 26) placed on top of the gauge block,

raise the work table until the knife just

touches the feeler gauge when the knife is

at its lowest point. Do not move the work

table any further until the outfeed roller is

adjusted.

5. Remove the feeler gauge and move the

gauge block (J, Figure 27) under one end of

the outfeed roller (F, Figure 27). The bottom

of the outfeed roller should just touch the top

of the gauge block. If an adjustment to the

outfeed roller is necessary, loosen the lock

nut (L, Figure 27) and turn screw (M, Figure

27) until the outfeed roller just touches the

gauge block. Then tighten lock nut (L, Figure

27).

Figure 26

6. Check and adjust the opposite end of the

outfeed roller in the same manner.

Infeed Roller Height

Use the exact same procedure for checking the

infeed roller as you did for the outfeed roller,

except use a .004" (0.1mm) feeler gauge atop

the gauge block. If adjustment is necessary, use

the lock nut and screw on each end of the infeed

roller.

Chipbreaker Height

The chipbreaker breaks off the larger chips

before the stock reaches the cutterhead. Use

the gauge block and a .004" (0.1mm) feeler

gauge to check the height of the chipbreaker,

following the same procedure as above. If

adjustment is needed:

1. Remove top cover.

2. Loosen the lock nuts (A, Figure 28) at both

ends of the chipbreaker, and turn the set

screws to raise or lower the chipbreaker as

needed. The set screws should be turned

the same amount.

Figure 27

Figure 28

3. When the chipbreaker contacts the gauge

block, tighten both lock nuts (A, Figure 28).

17

Page 18

Pressure Bar Height

The pressure bar prevents the stock from lifting

after it passes under the cutterhead. Check the

height of the pressure bar with your gauge block

and a .008" (0.2mm) feeler gauge. If adjustment

is needed:

1. Remove top cover.

2. Loosen the lock nuts (B, Figure 29) on both

ends of the pressure bar and turn the set

screws as needed.

3. When the pressure bar contacts the top of

the gauge block, tighten the lock nuts (B,

Figure 29).

Chip Deflector

The chip deflector (C, Figure 29) keeps wood

chips from falling into the outfeed roller. The

deflector should be set approximately 1/16" from

the tip of the knives. Make sure the deflector's

front edge is beveled to match the shape of the

cutterhead.

Feed Speed Control

Your machine is equipped with a spiral, serrated

infeed roller and a solid steel outfeed roller.

When the feed rollers are engaged, they turn to

feed the stock. The feed rollers slow

automatically when the machine is under heavy

load for best planing in all conditions. The feed

rollers are driven by chains (A, Figure 30) and

sprockets (B, Figure 30) which take power

directly from the cutterhead through the oil bath

gear box (C, Figure 30).

The gear box has two feed speeds. These are

set by pulling out or pushing in the shift lever (D,

Figure 30) while the machine is running. The

feed speed range is shown in Figure 31.

Figure 29

Figure 30

Do not attempt to change

feed speed while stock is passing through

the machine. Damage to the gearbox may

result.

Changing Accessories for Lowest Feed Speed

The lowest feed speeds for your planer (16.2

fpm and 20.7 fpm) can be obtained by replacing

the lower (gear shaft) sprocket and its chain

(Figure 31).

A low speed gear kit, consisting of a 50P chain

and 12T sprocket, is provided with your planer.

To change the sprocket and chain on your

machine, proceed as follows:

18

Figure 31

Page 19

1. Disconnect machine from power source.

2. Remove the three hex cap screws and

washers (E, Figure 30).

3. Remove the three sprockets (B, Figure 30)

from the infeed roller, outfeed roller and the

gear shaft at the same time.

4. When all sprockets have been removed,

replace the gear shaft sprocket (G, Figure

31) and its chain (F, Figure 31) with those of

a different size.

5. Mount all three sprockets and chains to their

shafts, and tighten all hex cap screws and

washers (E, Figure 30).

Return Rollers

The two return rollers on top of the machine

serve as a convenient rest for stock. They save

time and motion for the operator as the stock is

returned to the infeed side.

Depth of Cut

The cutting depth scale is a combination

inch/metric scale (A, Figure 32), with a cutting

range from 0 to 8" (204mm). The distance of

upward or downward movement is controlled by

the handwheel (B, Figure 32). One revolution of

the handwheel is .059" (1.5mm). Before moving

the table up or down, loosen the lock nuts (C,

Figure 32). After obtaining proper table position,

tighten the lock nuts (C, Figure 32).

Maximum depth of cut is 1/8". A limiter (D,

Figure 32) is provided to limit the depth of cut on

full width planing from 3/16" to 1/8".

The depth scale and pointer are adjustable and

should be checked for accuracy. Proceed as

follows:

1. Connect power, and turn on the planer.

2. Take a scrap board and measure its exact

thickness with calipers.

3. Raise or lower the table so the scale reads

the thickness of the board minus 1/16".

Feed the board through the planer.

Figure 32

4. Move the table up another 1/16". Flip the

board over and plane the other side.

5. Measure the board with calipers and

compare with the depth scale on the planer.

If the scale needs adjustment, loosen the

screws and shift the scale up or down as

needed. Tighten screws when finished.

19

Page 20

Maintenance

Disconnect machine from

power source before performing any

maintenance.

Periodic or regular inspections are required to

ensure that the machine is in proper adjustment,

that all screws are tight, that belts are in good

condition, that dust has not accumulated in the

electrical enclosures, and that there are no worn

or loose electrical connections.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but

mandatory for accurate planing.

Close-fitting parts, such as the cutterhead slot

and gibs, should be cleaned with a cloth or

brush and non-flammable solvent, and freed

from clinging foreign matter.

Remove resin and other accumulations from

feed rollers and table with a soft rag and nonflammable solvent.

Lubrication

The bearings on the cutterhead are factory

lubricated and sealed for life – no lubrication is

required.

GEARBOX LUBRICANT

The lubricant in the gear box must be replaced

every 2,500 hours. Multi-purpose gear box

lubricant will be suitable.

To replace the lubricant:

1. Remove the drain plug (A, Figure 33) with a

14mm wrench, and remove filler cap (BFigure 33). Drain dirty oil thoroughly.

2. Tighten the drain plug (A, Figure 33).

3. Fill with clean lubricant through hole (B,

Figure 33).

4. Tighten filler cap (B, Figure 33).

Periodically check all the chains for proper

tension and adjust accordingly if required.

TIP: If a foreign object nicks the knives, instead

of throwing them away or trying to grind out the

deep nick, simply stagger the knives in the head,

moving one knife no more than 1/4" to the right

and another knife no more than 1/4" to the left.

The nick should no longer be noticeable.

The table should be kept clean and free of rust.

Some users prefer a paste wax coating. Another

option is talcum powder applied with a

blackboard eraser rubbed in vigorously once a

week; this will fill casting pores and form a

moisture barrier. This method provides a table

top that is slick and allows rust rings to be easily

wiped from the surface. Important also is the fact

that talcum powder will not stain wood or mar

finishes as wax pickup does.

Figure 33

20

Page 21

The item numbers on this chart are referenced to the surrounding illustrations.

No. Position Interval Suitable Types of Lubricant Figure No.

1 Drive Chain Frequently Grease 33

2 Gear Box When operated more than 2,500

hours

3 Return Rollers Frequently SAE-30 35

4 Worm Gear Frequently Grease 36

5 Lead Screw Frequently Grease 36

6 Column Frequently Clean and SAE-30 36

7 Table Chain Frequently Grease 37

8 Feed Rollers Frequently SAE-30 38

Figure 34

Standard gear oil, 70-90 weight

33

Figure 35

Figure 36

Figure 37

Figure 38

21

Page 22

Troubleshooting: Operating Problems

Trouble Probable Cause Remedy

Table rollers not set properly. Adjust rollers to proper height.

Snipe.

(NOTE: Snipe cannot

be eliminated, but

can be so minimized

as to be negligible.)

Fuzzy grain.

Torn grain.

Inadequate support of long boards.

Uneven feed roller pressure front to

back.

Dull knives or knife inserts.

Lumber not butted properly.

Planing wood with high moisture

content.

Dull knives or knife inserts.

Too heavy a cut. Adjust proper depth of cut.

Knives (or inserts) cutting against the

grain.

Dull knives or knife inserts.

Dull knives or knife inserts.

Support long boards with extension

rollers.

Adjust feed roller pressure.

209: Sharpen or replace knives.

209HH: Rotate or replace inserts.

Butt end to end each piece of stock

as they pass through.

Remove moisture by drying, or use

different stock.

209: Sharpen or replace knives.

209HH: Rotate or replace inserts.

Cut along the grain where possible.

209: Sharpen or replace knives.

209HH: Rotate or replace inserts.

209: Sharpen or replace knives.

209HH: Rotate or replace inserts.

Rough/raised grain.

Rounded, glossy

surface.

Poor feeding of

lumber.

Too heavy a cut. Adjust proper depth of cut.

Planing wood with high moisture

content.

Dull knives or knife inserts.

Feed rate too slow. Increase feed rate.

Cutting depth too shallow. Increase cutting depth.

Inadquate feed roller pressure.

Planer table rough or dirty.

Belt slipping on pulleys. Tighten belt.

Surface of feed rollers too smooth.

Remove moisture by drying, or use

different stock.

209: Sharpen or replace knives.

209HH: Rotate or replace inserts.

Adjust feed roller tension. If proper

tension cannot be achieved, replace

feed rollers.

Clean pitch and residue from table,

and apply paste wax.

Lightly roughen the feed roller surface

with sandpaper.

22

Page 23

Troubleshooting: Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Uneven depth of cut

side to side.

Board thickness does

not match depth of

cut scale.

Chain is jumping.

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

Knife projection from cutterhead is

incorrect (209 only)

Table not parallel to cutterhead. Adjust table/cutterhead parallelism.

Depth of cut scale is incorrect. Adjust depth of cut scale.

Inadequate tension. Adjust chain tension.

Sprockets misaligned. Align sprockets.

Sprockets are worn. Replace sprockets.

No incoming power. Verify power connections to planer.

Overload automatic reset has not

reset.

Planer frequently trips.

Building circuit breaker trips or fuse

blows.

Adjust knife projection.

When planer overloads on the circuit

breaker built into the motor starter, it

takes time for the machine to cool

down before restart. Allow unit to

adequately cool before attempting

restart. If problem persists, check

amp setting on the motor starter

inside the electrical box.

One cause of overloading trips which

is not electrical in nature is too heavy

a cut. The solution is to take a lighter

cut.

If too deep a cut is not the problem,

then check the amp setting on the

overload relay. Match the full load

amps on the motor as noted on the

motor plate.

If amp setting is correct then there is

probably a loose electrical lead.

Check amp setting on motor starter.

Verify that planer is on a circuit of

correct size. If circuit size is correct,

there is probably a loose electrical

lead. Check amp settting on motor

starter.

Loose electrical connections.

23

Go through all the electrical

connections on the planer including

motor connections, verifying the

tightness of each. Look for any signs

of electrical arcing which is a sure

indicator of loose connections or

circuit overload.

Page 24

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

(cont.)

Motor starter failure.

Motor failure.

Examine motor starter for burned or

failed components. If damage is

found, replace motor starter. If motor

starter looks okay but is still suspect,

you have two options: have a

qualified electrician test the motor

starter for function, or purchase a new

starter and establish if that was the

problem on changeout.

If you have access to a voltmeter, you

can separate a starter failure from a

motor failure by first, verifying

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20.

If incoming voltage is incorrect, you

have a power supply problem.

If voltage between starter and motor

is incorrect, you have a starter

problem.

If voltage between starter and motor

is correct, you have a motor problem.

If electric motor is suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it to a

quality electric motor repair shop and

have it tested.

Check to confirm all electrical

Miswiring of the unit.

On/off switch failure.

connections are correct and properly

tight. Make any needed corrections.

If the on/off switch is suspect, you

have two options: Have a qualified

electrician test the switch for function,

or purchase a new on/off switch and

establish if that was the problem on

changeout.

Optional Accessories

2230002 Bed and Feed Roller Gauge

6292621 Knives, Single-Sided (set of 4) for model 209 only

1791212 Knife Inserts (set of 10) for model 209HH only

708520 DRO Scale Retrofit Kit

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

24

Page 25

Cutterhead Assembly

25

Page 26

Parts List: Cutterhead Assembly

Index No. Part No. Description Size Qty

1 ...............6012204 ...................Nut........................................................................ 5/16-18NC .................. 2

2 ...............6292622 ...................Knife Locking Bar * .............................................. .................................... 4

3 ...............6284811 ...................Belt (model 209)................................................... .................................... 3

.................209HH-1003............. Belt (model 209HH) ............................................. .................................... 3

4 ...............6292696 ...................Bolt ....................................................................... .................................... 2

5 ...............6292639 ...................Hex Head Bolt...................................................... M8 x 1.25P x 20L ........ 2

6 ...............6292631 ...................Washer................................................................. 8 x 30 x 3 ....................1

7 ...............6292660 ...................Hex Head Bolt With Washer ................................ M6 x 1.25P x 20L ...... 16

8 ...............6292621 ...................Knife *................................................................... .................................... 4

9 ...............6292698 ...................Hex Nut ................................................................ 5/16”-18NC ................. 2

10 .............6292630 ...................Machined Pulley................................................... .................................... 1

11 .............6292633 ...................Motor Pulley ......................................................... .................................... 1

12 .............6292672 ...................Collector Tube...................................................... .................................... 1

13 .............6292654 ...................Hex Head Bolt...................................................... M6 x 1.0P x 12L ........ 10

14 .............6292653 ...................Washer................................................................. 1/4 ............................. 12

15 .............TS-1482011 .............Hex Cap Screw .................................................... M6 x 1.0P x 10L..........6

16 .............6292670 ...................Upper Cover......................................................... .................................... 1

17 .............6292814 ...................Flat Washer.......................................................... 8.5 x 23 x2T ................ 4

18 .............7292675 ...................Hex Cap Screw .................................................... M6 x 1.0P x 16L.......... 9

19 .............6292682 ...................Handwheel ........................................................... .................................... 1

20 .............6292684 ...................Handle.................................................................. .................................... 1

21 .............6292620 ...................Spring * ................................................................ ....................................8

22 .............6292663 ...................Chip Deflector ...................................................... .................................... 1

23 .............6292652 ...................Plate Spring.......................................................... .................................... 3

24 .............6292640 ...................Set Screw............................................................. M6 x 1.0P x 16............ 9

25 .............6292662 ...................Plate Spring.......................................................... 0.6 ............................... 1

26 .............6292637 ...................Screw ................................................................... M22 x 1.5P x 20 .......... 4

27 .............6292720 ...................Collar.................................................................... .................................... 1

28 .............6292716 ...................Bracket ................................................................. .................................... 1

29 .............6292717 ...................Shaft..................................................................... .................................... 1

30A ........... 209HH-IPA...............Idle Pulley Assembly – model 209HH (index no. 14,30,31,91,112) ......... 1

30 .............6292715 ...................Idle Pulley............................................................. .................................... 2

31 .............6292714 ...................Shaft..................................................................... .................................... 2

32 .............6292693 ...................Safety Hatch......................................................... .................................... 1

33 .............6292690 ...................Spring Pin............................................................. 6 Dia x20..................... 2

34 .............6292689 ...................Cover.................................................................... .................................... 1

35 .............6292694 ...................Socket Head Cap Screw...................................... M8 x 1.25P x 40L........ 1

36 .............6292719 ...................Spring................................................................... .................................... 1

37 .............6292718 ...................Hanger ................................................................. ....................................1

38 .............6292817 ...................Round Head Screw.............................................. M6 x 1.0P x 12L..........1

39 .............6292818 ...................Hex Head Bolt...................................................... M8 x 1.25P x 18L ........ 4

41 .............6296255 ...................Safety Hatch......................................................... .................................... 1

43 .............6292618 ...................Set Screw............................................................. M10 x 1.5P x 12L........ 8

44 .............TS-1524031 .............Set Screw............................................................. M8 x 1.25P x 12L ........ 5

45 .............6292617 ...................Casting Head ....................................................... .................................... 1

46 .............6292659 ...................Shaft..................................................................... .................................... 2

47 .............6292705 ...................Rivet ..................................................................... .................................... 4

48 .............6292641 ...................Hex Nut ................................................................ M6 x 1.0P.................... 8

49 .............6292661 ...................Set Screw............................................................. M6 x 1.0 x 20L ............ 2

50 .............6292669 ...................Flat Head Machine Screw.................................... M6 x 0.8P x 8L............ 2

51 .............6292668 ...................Cut Limiter Plate .................................................. .................................... 1

52 .............6292687 ...................Cut Limiter Pointer ............................................... .................................... 1

53 .............6292685 ...................Scale .................................................................... .................................... 1

54 .............BB-6206ZZ...............Bearing................................................................. 6206ZZ-2NSE............. 1

55 .............6292629 ...................Key ....................................................................... 8 x 8 x 36 .................... 1

56 .............6292619 ...................Cutterhead *......................................................... .................................... 1

* Index Nos. 2, 8, 21 and 56 are used only on the Model 209 Planer.

26

Page 27

58 .............6292636 ...................Spring................................................................... .................................... 4

59 .............6292635 ...................Bushing ................................................................ .................................... 4

60 .............6292638 ...................Plate ..................................................................... .................................... 4

61 .............6292658 ...................Lock Washer ........................................................ .................................... 2

62 .............6292657 ...................Pressure Plate ..................................................... .................................... 1

63 .............6292646 ...................Outfeed Roller...................................................... .................................... 1

64 .............6292642 ...................Key ....................................................................... 5 x 5 x 23 .................... 2

65 .............6292647 ...................Sprocket ............................................................... .................................... 1

66 .............6292644 ...................Washer................................................................. 6.2 x 20 x 3T ............... 2

67 .............6292645 ...................Hex Head Bolt...................................................... M6 x 1.0P x 16L .......... 2

68 .............6292656 ...................Bracket ................................................................. .................................... 1

69 .............6292655 ...................Shaft..................................................................... .................................... 1

70 .............6292650 ...................Chip Breaker ........................................................ .................................... 1

71 .............6292643 ...................Sprocket ............................................................... 31T .............................. 1

72 .............6292649 ...................Retaining Ring ..................................................... STW-12....................... 2

73 .............6292667 ...................Retaining Ring ..................................................... .................................... 2

74 .............6292665 ...................Collar.................................................................... .................................. 56

75 .............6292664 ...................Anti-kickback Finger............................................. .................................. 55

76 .............6292648 ...................Locking Bolt.......................................................... .................................... 1

77 .............6292666 ...................Shaft..................................................................... .................................... 1

78 .............6292651 ...................Nut........................................................................ M12 x 1.75P................ 2

79 .............6292634 ...................Infeed Roller......................................................... .................................... 1

80 .............6292706 ...................Chain ................................................................... 06B.............................. 1

81 .............6292673 ...................Roller Stand ......................................................... .................................... 3

82 .............6292674 ...................Roller.................................................................... .................................... 2

83 .............6292678 ...................Gear Box Worm ................................................... .................................... 1

84 .............6292677 ...................Hex Socket Cap Screw ........................................ M6 x 1.0P x 50L.......... 3

85 .............6292676 ...................Worm.................................................................... .................................... 1

86 .............6292681 ...................Key ....................................................................... 4 x 4 x 10 .................... 1

87 .............6292679 ...................Bearing................................................................. 6201Z.......................... 1

88 .............6292680 ...................Retaining Ring ..................................................... RTW-32....................... 1

89 .............6292713 ...................Collar.................................................................... .................................... 1

90 ............. 6292683 ...................Washer................................................................. 1/2 .............................. 1

91 .............6292813 ...................Hex Socket Cap Screw ........................................ M6 x 1.0P x 10L.......... 1

92 .............6292821 ...................Hex Socket Cap Screw ........................................ M5 x 0.8P x 10L.......... 3

93 .............6292815 ...................Hex Head Bolt...................................................... M6 x 1.0P x 16L .......... 5

94 .............209-1094 ..................Sponge................................................................. .................................... 2

95 .............209-1095 ..................Pulley Guard ........................................................ .................................... 1

96 .............209-1096 ..................Pulley Cover......................................................... .................................... 1

97 .............209-1097 ..................Strain Relief, Momentary Switch Cord................. .................................... 1

98 .............TS-1540031 .............Hex Nut ................................................................M5 x 0.8P.................... 2

99 .............TS-1550031 .............Flat Washer.......................................................... 5 x 12 x 0.8T ............... 4

100 ...........209-1100 ..................Switch Box ........................................................... .................................... 1

101 ...........209-1101 ..................Switch, Off............................................................ .................................... 1

102 ...........209-1102 ..................Switch, On............................................................ .................................... 1

103 ...........209-1103 ..................Switch Plate ......................................................... .................................... 1

104 ...........TS-1481041 .............Hex Cap Screw .................................................... M5 x 0.8P x 16L.......... 2

105 ...........209-1105 ..................Cord ..................................................................... .................................... 1

106 ...........6012192 ................... Warning Label ...................................................... .................................... 1

107 ...........6292820 ................... Label .................................................................... .................................... 1

108 ...........6292819 ................... Label, Lubrication................................................. .................................... 1

109 ...........1791275 ................... Helical Cutterhead **............................................ .................................... 1

110 ...........1791212 ................... Knife Insert (set of 10) ** ...................................... ........................ total 132

111 ...........15HH-2102...............Knife Insert Screw ** ............................................ ................................ 132