Page 1

20" THICKNESS PLANER

Model 208

Instruction Manual & Parts List

M-0460217

(800) 274-6848

www .powermatic.com

Page 2

This manual has been prepared for the owner and operators of a Powermatic Model 208 Planer .

Its purpose, aside from machine operation, is to promote safety through the use of accepted

correct operating and maintenance procedures. Completely read the safety and maintenance

instructions before operating or servicing the machine. To obtain maximum life and efficiency

from your planer and to aid in using the machine safely, read this manual thoroughly and follow

all instructions carefully.

Warranty & Service

The WMH T ool Group warrants every product it sells. If one of our tools needs service or repair , one of our

Authorized Repair S tations located throughout the United S tates can give you quick service.

In most cases, any one of these WMH Tool Group Repair S tations can authorize warranty repair, assist you in

obtaining parts, or perform routine maintenance and major rep air on your JET , Powermatic, Performax, or

Wilton tools.

For the name of an Authorized Repair S tation in your area, please call 1-800-274-6848.

More Information

Remember, the WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH T ool Group distributor .

WMH T ool Group W arranty

The WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follow: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and-tear, rep air or alterations outside our facilities, or to a lack of maintenance.

THE WMH TOOL GROUP LIMITS ALL IMPLIED W ARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM

THE DATE THE PRODUCT WAS PURCHASED A T RET AIL. EXCEPT AS ST A TED HEREIN, ANY IMPLIED

WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME ST A TES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMIT A TION MA Y

NOT APPL Y TO YOU. THE WMH T OOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEA TH, INJURIES

TO PERSONS OR PROPERTY, OR FOR INCIDENT AL, CONTINGENT , SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME ST A TES DO NOT ALLOW THE EXCLUSION OR LIMITA TION OF INCIDENT A L OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMIT A TION OR

EXCLUSION MA Y NOT APPL Y T O YOU.

T o take advant age of this warranty , the product or part must be returned for examination, postage prep aid, to an

Authorized Repair S tation designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the

product, or refund the purchase price if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept a refund. We will return repaired product or replacement at WMH's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of WMH's warranty ,

then the user must bear the cost of storing and returning the product. This warranty gives you specific legal

rights; you may also have other rights which vary from state to state.

The WMH Tool Group sells through distributors only . Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

Page 3

TABLE OF CONTENTS

SAFETY

General Rules ................................................................................................................................. 4

Specific Rules ................................................................................................................................. 4

FEATURES & SPECIFICATIONS ......................................................................................................... 5

RECEIVING THE PLANER .................................................................................................................... 6

INSTALLATION & ASSEMBLY

Lifting Handles ................................................................................................................................6

Stand Assembly .............................................................................................................................. 6

Table Extension Rollers .................................................................................................................. 6

Motor, Motor Pulley & Belt .............................................................................................................. 6

ADJUSTMENTS

Table Roller Adjustment .................................................................................................................. 7

Adjusting Table Extension Rollers .................................................................................................. 8

Depth of Cut ................................................................................................................................... 8

Cutterhead Adjustment ................................................................................................................... 9

Knife Adjustment ............................................................................................................................ 9

Replacing & Resetting Knives ...................................................................................................... 10

Checking Working Table Parallel to Cutterhead ........................................................................... 10

Adusting Working Table Parallel to Cutterhead ............................................................................ 11

The Transmitting Rollers of Your Planer ...................................................................................... 11

Adusting Infeed & Outfeed Roller Spring Tension........................................................................ 11

Anti-Kickback Fingers ................................................................................................................... 12

Height of Infeed Roller, Chipbreaker, Pressure Bar & Outfeed Roller ......................................... 12

Feed Speed Control ..................................................................................................................... 13

Changing Accessories for Lowest Feed Speed ........................................................................... 13

Return Rollers ............................................................................................................................... 13

Dust Collector Hood ..................................................................................................................... 13

MAINTENANCE ................................................................................................................................... 14

Changing Gearbox Lubricant........................................................................................................ 14

PARTS LIST & EXPLODED VIEW

Base Assembly ............................................................................................................................. 15

Cutterhead Assembly .............................................................................................................. 16-17

Table Assembly ............................................................................................................................ 18

Column Assembly ......................................................................................................................... 19

Gearbox Assembly .................................................................................................................. 20-21

OPTIONAL ACCESSORIES ................................................................................................................ 22

Page 4

SAFETY : General Rules

scrap material and sawdust to mimimize the danger of slipping.

READ THE MANUAL: Always read the owner's

manual carefully before attempting to use the

machine. Know the limitations and hazards associated with its use.

INST ALLATION: If mounting machine to the floor ,

use high quality anchor bolts through the mounting holes on the base. If using a mobile base, be

sure to lock the wheels.

PROTECTION: Take every precaution to protect

yourself, others around you, and the machine itself, from improper use. Safety is a combination

of using common sense, knowing how to use the

machine, and being alert at all times when using

the machine.

EYES: Always wear approved safety goggles,

glasses, or a face shield when operating this machine. There are no exceptions to this rule.

DRESS CODE: Do not wear loose clothing, neckties, jewelry , or gloves that can get caught in moving parts. Confine long hair . Keep sleeves above

the elbow.

PLACEMENT: Place machine so that potential

kickback area is not in line with aisles, doorways,

wash stations, or other work areas.

POWER ON: On machines equipped with a

manual starter make sure the starter is in "OFF"

position before connecting power to machine.

CHECK DAMAGED PARTS: Check for alignment of moving parts, binding of moving parts,

breakage of parts, mounting, and any other condition that may affect the machine's operation. A

guard or other part that is damaged should be properly repaired or replaced.

TURN POWER OFF: Never leave machine running attended. Do not leave machine until it comes

to a complete stop.

IF YOU ARE NOT thoroughly familiar with the

operation of planers, obtain advice from your supervisor, instructor or other qualified person.

DRUGS, ALCOHOL, MEDICATION: Do not operate tool while under the influence of drugs, alcohol, or any medication.

WARNING: The dust generated by certain woods

and wood products can be dangerous to your

health. Always operate machinery in well ventilated areas and provide for proper dust removal.

Use wood dust collection systems whenever possible.

ELECTRICAL GROUNDING: Y our machine must

be electrically grounded. If a cord and plug are

used, make certain the grounding lug connects to

a suitable ground. Follow the grounding procedure

indicated by the National Electric Code. Keep

power tools in dry areas free from moisture.

GUARDS: Be sure machine guards are in place

and in good working order. Use them at all times

on operations where they can be used. If a guard

must be removed for any operation, make sure it

is replaced immediately following completion of

that operation.

POWER OFF: Make sure the machine is either

unplugged or electrically disconnected and locked

out when performing maintenance or service work.

HOUSEKEEPING: Before turning on machine, remove all extra equipment such as keys, wrenches,

scrap, stock, and cleaning rags from the machine.

Keep the area around machine clean and free of

SAFETY: Specific Rules

KEEP CUTTERHEAD SHARP and free of all rust

and pitch.

CHECK MA TERIAL for loose knots, nails and other

defects.

REMOVE SHAVINGS only with the power "off".

CHECK that the switch is in "off" position before

plugging in power cord.

BEFORE MOVING table upward or downward,

loosen locking knobs. After choosing proper position, tighten locking knobs.

BE SURE the knives of cutterhead are correct and

all hex screws are secured tightly before use.

4

Page 5

KEEP HANDS AWAY from the feed rolls and

cutterhead.

REMOVE adjusting tools and loose articles from

machine before operating.

DO NOT OPERA TE machine while the gear cover

is open.

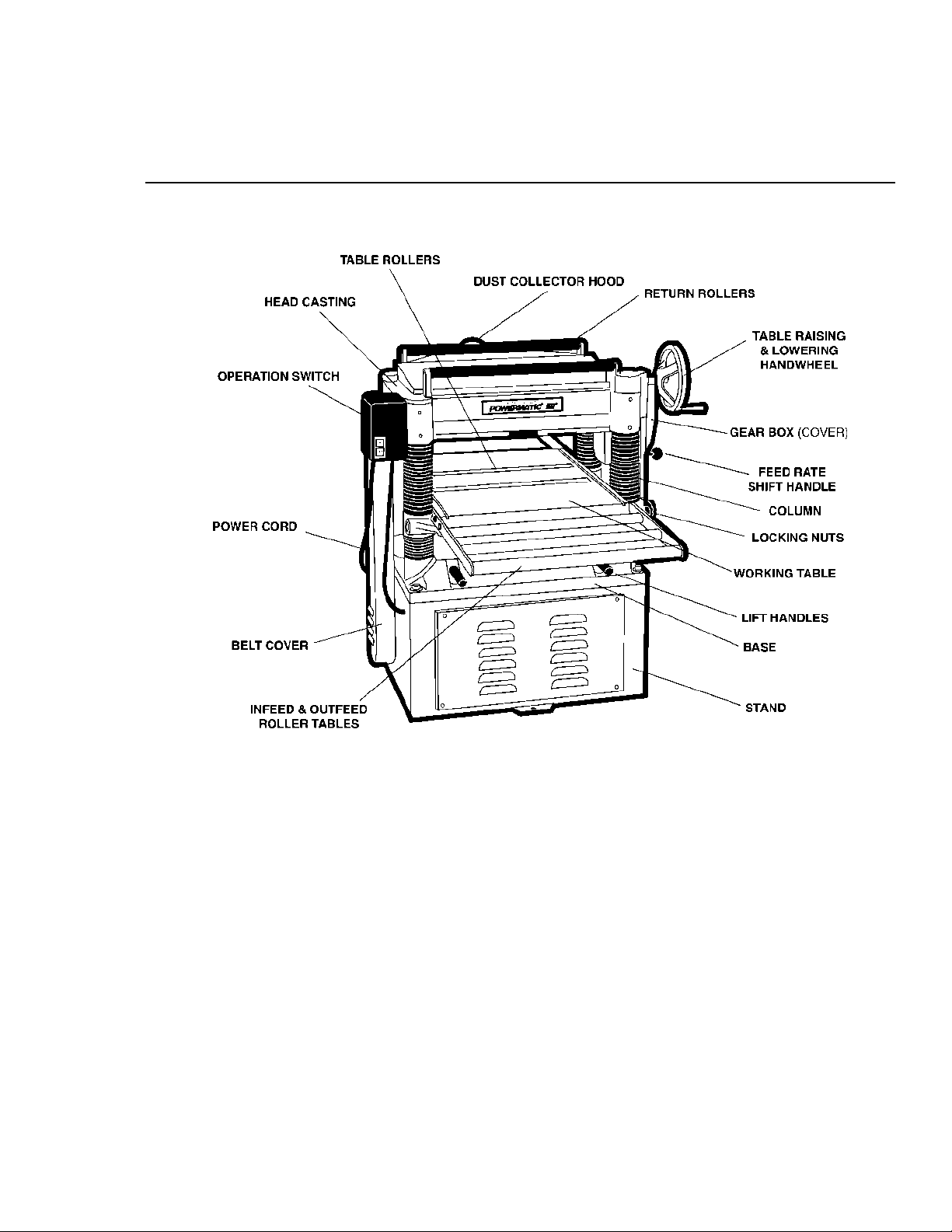

FEATURES & SPECIFICATIONS - Model 208, 20" planer

FIGURE 1

Table Area ................................................................................................ 25-3/4" x 20"

Maximum planing width ........................................................................................... 20"

Maximum planing thickness.......................................................................................8"

Full width cutting depth ......................................................................................... 3/32"

Minmum planing length........................................................................................6-3/4"

Knives ......................................................................................................................... 4

Blade size............................................................................................... 20" x 1" x 1/8"

Cutterhead speed ........................................................................................ 5,000 RPM

Cuts per minute.................................................................................................. 20,000

Cutterhead diameter ..........................................................................................3-3/16"

Feeding speed.......................................................................................... 24 & 31 FPM

Motor ................................................................................................. 3HP, 1Ph, 230V

5HP, 3Ph, 230/460V

Dust chute ...........................................................................................................5" dia.

Overall dimensions ........................................................ 26" L x 36-5/8" W x 41-3/8" H

Net weight ........................................................................................................ 640 lbs.

5

Page 6

RECEIVING THE PLANER

ST AND ASSEMBL Y

Carefully unpack the planer and any loose items

from the wood crate and inspect for damage. Any

damage should be reported to your distributor and

shipping agent immediately. Before proceeding

further, read your manual thoroughly to familiarize yourself with proper assembly, maintenance

and safety procedures.

Remove the screws that hold planer to the shipping crate. Remove the protective coating from

the table, bed rolls, feed rolls, cutterhead and loose

items packed with the machine, including lifting

handles and motor pulley. This coating may be

removed with a soft cloth moistened with Kerosene. DO NOT use acetone, gasoline or lacquer

thinner for this purpose. DO NOT use solvents on

plastic parts.

CAUTION: Use care when cleaning the

cutterhead as knives are very sharp.

INSTALLATION & ASSEMBLY

For best planing performance, locate planer on

solid, level foundation and anchor to the floor with

good quality lag screws:

1. With machine in position, test table surface lengthwise and crosswise with machinist

level. Place metal shims under low corners.

2. Check that all four corners are supported,

then tighten lag screws.

3. Re-test level of table surface in both directions, and adjust if necessary.

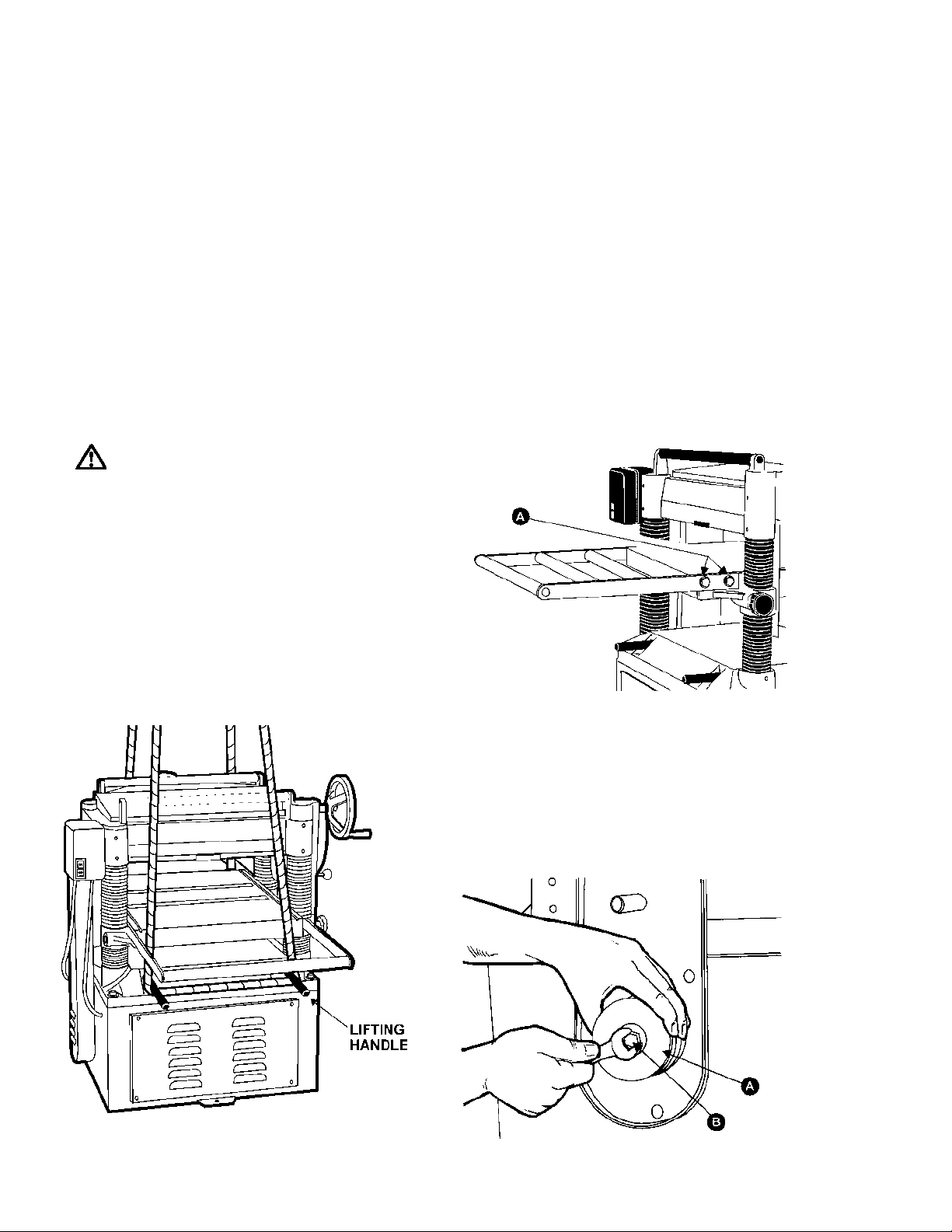

TABLE EXTENSION ROLLERS

Mount the table extension rollers to the table using the provided hex hd. screws (A) and washers,

Figure 3. The rollers should be adjusted before

using the planer, see "Adjusting Table Extension

Rollers" pg. 8.

LIFTING HANDLES

There are four lifting handles, Figure 2, furnished

with the machine. If any type of sling is used to lift

the machine, be sure to attach to lifting handles

only. Make sure machine is kept in level position

while lifting. The lifting handles can be pushed

back in when not in use.

FIGURE 3

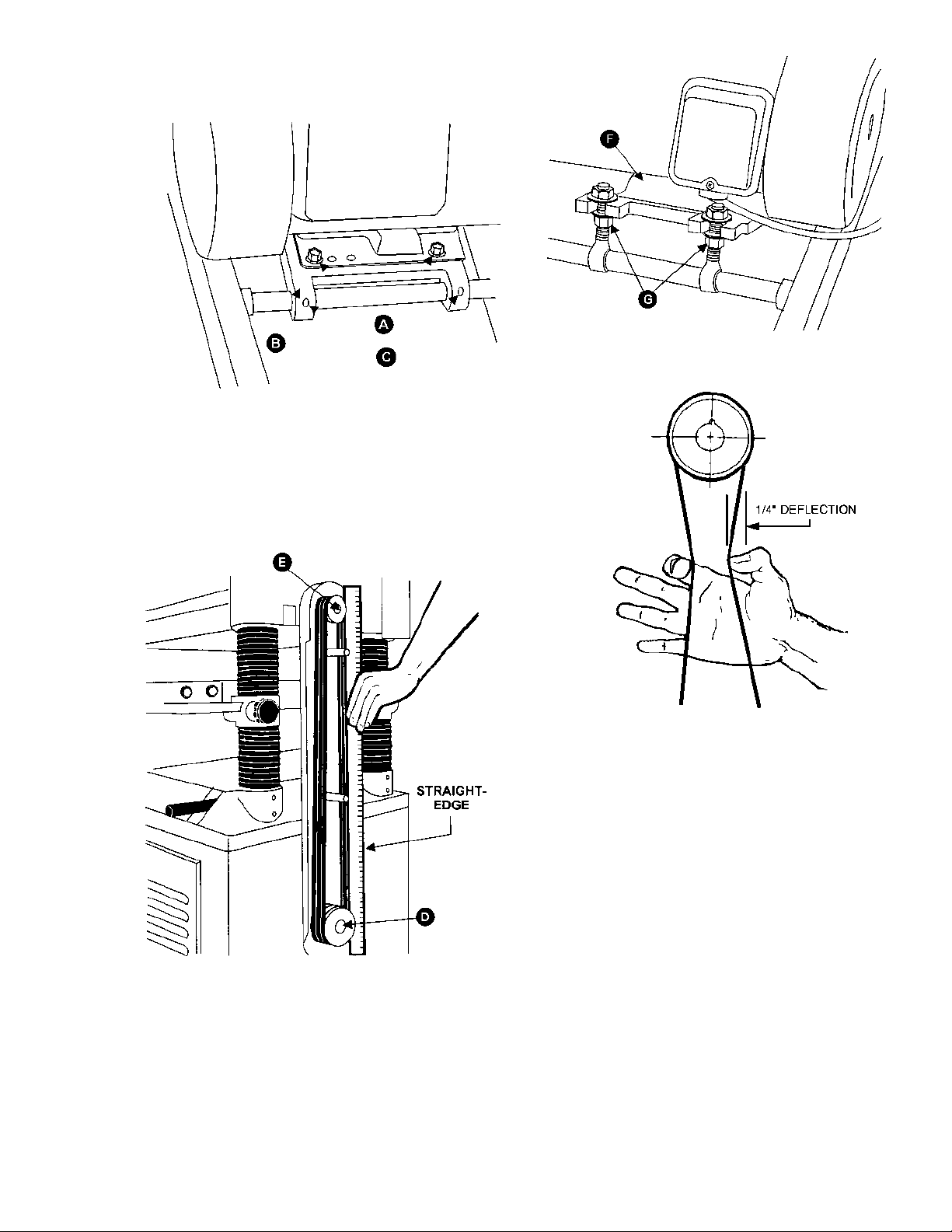

MOTOR, MOTOR PULLEY & BELT

1. Assemble the motor pulley (A) to the motor shaft by aligning it with the key in the shaft,

and tighten the screw (B) in the motor shaft, as

shown in Figure 4.

FIGURE 2

6

FIGURE 4

Page 7

2. Assemble the motor to the motor mounting plate (B), using the provided hardware (A), Figure 5.

FIGURE 5

3. Using a straight edge, align the motor pulley (D) and cutterhead pulley (E) as shown Figure

6. The motor plate can be moved for alignment

by loosening the set screws (C) in the motor plate

(B) as shown in Figure 5.

FIGURE 7

FIGURE 6

4. Assemble the belts to the two pulleys, Figure 6. Adjust for the proper belt tension by raising

or lowering the motor plate (F), Figure 7, then

tighten the nuts (G). Proper tension is obtained

when there is approximately 1/4" deflection of the

center span of the pulleys by using light finger pressure, Figure 8.

FIGURE 8

ADJUSTMENTS

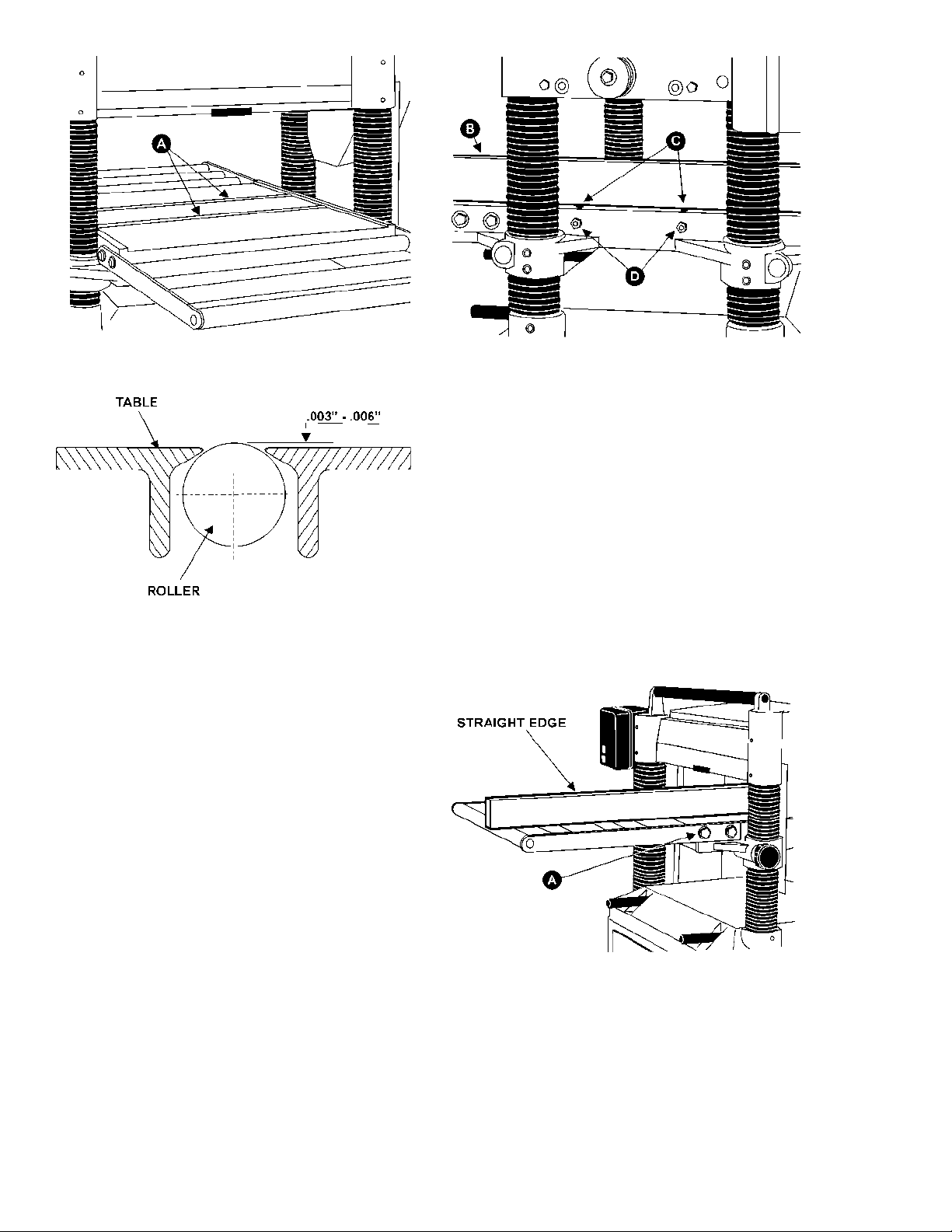

TABLE ROLLER ADJUSTMENT

Your planer is supplied with two table rollers (A),

Figure 9, which turn as the stock is fed into the

planer , thus reducing friction. It is not possible to

give exact dimensions on the proper height setting of the table rollers because each type of wood

behaves differently.

As a general rule, however, when planing rough

stock, the table rollers should be set at high position. When planing smooth stock the rollers should

be set at low position.

NOTE: When raising the roller higher above the

table, the range is from .003" to .006", see Figure

10.

7

Page 8

FIGURE 9

FIGURE 10

The table rollers are factory set for average planing and are parallel to the table surface. If you

desire to adjust the table rollers higher or lower,

proceed as follows:

1. Disconnect machine from power source.

2. Lay a straight edge (B), Figure 11, across

both rollers.

3. On one side of the table, loosen the screws

(C) with an Allen wrench, and turn the eccentric

shafts (D) to raise or lower the rollers.

4. When the proper height is achieved,

tighten screws (C).

5. Adjust the rollers from the opposite side

of the table in the same manner.

FIGURE 11

ADJUSTING TABLE EXTENSION

ROLLERS

Place a straight edge over the extension rollers

and the table, as shown in Figure 12, to make sure

the extension rollers and the table are at the same

height.

If necessary, adjust the table extension rollers as

follows:

1. Loosen the screws and washers (A) to

move the table extension roller to the proper position, then retighten the screws.

2. Adjust both front and rear extension rollers in the same manner.

IMPORTANT: Be sure that the height of front and

rear rollers are the same. The table rollers must

always be set parallel to the table.

8

FIGURE 12

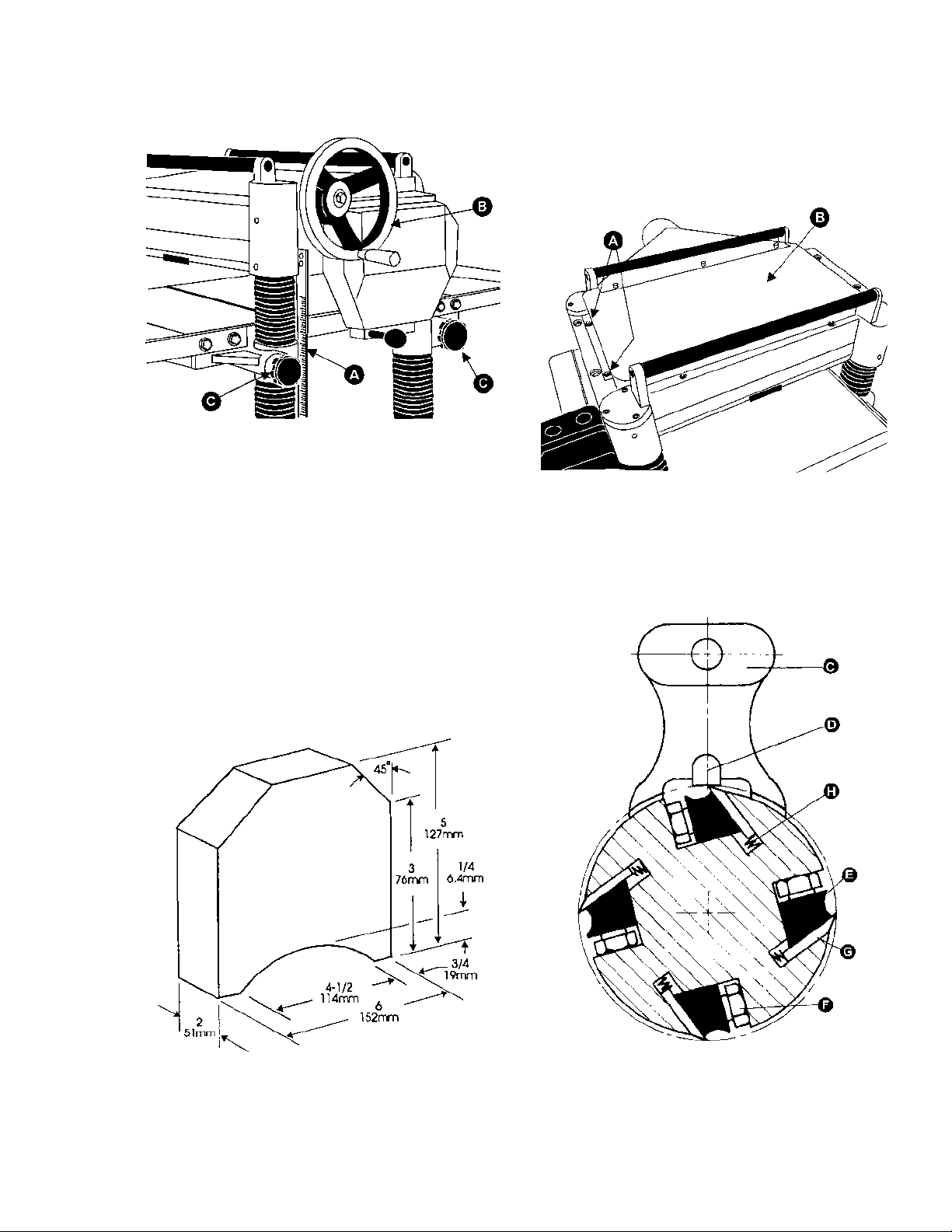

ADJUSTING DEPTH OF CUT

The cutting depth scale is a combination inch/metric scale (A), Figure 13, with a cutting range from

0 to 8" (204mm). The distance of upward or downward movement is controlled by the handwheel

(B). One revolution is .059" (1.5mm). Before

Page 9

moving the table up or down, loosen the lock nuts

(C). After obtaining the proper table position,

tighten the lock nuts (C).

FIGURE 13

KNIFE ADJUSTMENT

When checking or adjusting the cutterhead knives,

proceed as follows:

1. Disconnect machine from power source.

2. Remove the six screws (A) and remove

upper cover (B), Figure 15.

CUTTERHEAD ADJUSTMENT

Although your planer was carefully adjusted at the

factory , it should be checked before being put into

operation. Any inaccuracies due to rough handling in transit can easily be corrected by following these directions.

To check the adjustments you will need a straight

edge, feeler gauge, and a home-made gauge

block made of hardwood. This gauge block can

be made by following the dimensions shown in

Figure 14.

FIGURE 15

3. To check and adjust knives, use the provided knife gauge (C) and check all four knives,

Figure 16. Knives should just contact the bottom

of the center protrusion (D) of the knife gauge.

FIGURE 14

FIGURE 16

4. If an adjustment to one or more of the

knives is necessary, slightly loosen the knife gib

(E), Figure 16, by turning the six locking screws

9

Page 10

(F) into the gib. Turn the screws just enough to

relieve stress in the cutterhead without disturbing

the setting of the knives. Do this for all four knives

at the same time.

5. With the gauge in place over a knife (G),

continue to loosen the locking screws (F) until the

lifter springs (H), begin raising the knife. When

knife comes into contact with the center protrusion (D) of the gauge, snug up the gib by lightly

backing out the six locking screws (F) against the

slot. NOTE: At this time, only tighten the knife

into the slot just enough to hold knife in position.

6. If additional knives must be reset, repeat

step 5.

7. After all four knives are set with screws

just snug, back out and tighten the six locking

screws (F), Figures 16 & 17, against the slot starting with the end screws first, then the center

screws, until the knife is securely held in the

cutterhead. Tighten remaining three knives in the

same manner.

IMPORTANT: Double check all screws for tightness.

same manner.

5. Thoroughly clean the knife slots, gibs,

springs and locking screws. Check the locking

screws; if the threads appear worn or stripped or

if the heads are becoming rounded, replace them.

6. Inspect the cutting edge of the knives for

nicks or wire edge. Hone the knives slightly using

a stone or if the knives are to be sharpened, maintain a cutting angle of 35 degrees as shown in

Figure 16.

7. Insert springs (H), knives (G) and gib (E)

into slot of cutterhead. Back out locking screws

(F) just enough to hold the knife in the cutterhead.

8. Place knife gauge (C) over knife as shown

in Figure 16.

9. While holding down on the knife gauge,

loosen all six locking screws (F) by turning them

into the gib (E) until cutting edge of knife comes

into contact with the protrusion (D) of the gauge.

Snug up the gib by slightly backing out the six locking screws against the slot.

NOTE: At this time, only tighten the knife into the

slot just enough to hold the knife in position.

10. Replace and reset the other three knives

in the same manner.

1 1. After all four knives are set with the screws

just snug, back out and tighten the six screws (F)

against the slot starting with the end screws first

and then the center screws until the knife is securely held in the cutterhead. Tighten the remaining three knives in the same manner.

FIGURE 17

REPLACING & RESETTING KNIVES

If the knives are removed for sharpening, care

must be exercised in replacing and resetting them.

Proceed as follows:

1. Disconnect machine from power source.

2. Remove six screws and upper cover (see

Figure 15).

3. To remove knife, loosen the gib (E), Figure 16, by turning the six locking screws (F) into

the gib. Remove gib (E), knife (G), and springs

(H). NOTE: The inner two springs will pop out

when the knife and gib are removed.

4. Remove the remaining three knives in the

10

WARNING: AFTER REPLACING AND

CHECKING KNIVES,

FULLY. MAKE CERTAIN THE DIRECTION OF

KNIVES IS CORRECT AND ALL 24 LOCKING

SCREWS ARE TIGHTENED SECURELY!

CHECK AGAIN CARE-

CHECKING WORKING T ABLE P ARALLEL

TO CUTTERHEAD

The working table is set parallel to the cutterhead

at the factory and no further adjustment should be

necessary . If your machine is planing a t aper, first

check to see if the knives are set properly in the

cutterhead. Then check to see if the working table

is set parallel to the cutterhead. Proceed as follows:

1. Disconnect machine from power source.

2. Place the gauge block (A), Figure 18, on

the working table directly under front edge of head

casting (B). Make slight contact by gently raising

table.

Page 11

FIGURE 18

ners.

NOTE: Turning sprocket clockwise will increase

the distance between the working table and

headcasting; counter-clockwise will decrease the

distance. This adjustment is very sensitive and it

should not be necessary to turn the sprocket more

than one or two teeth.

6. When adjustments are correct, replace

chain around corner sprocket, slide sprocket (C)

back to re-tension chain, tighten bolt (B) and replace and tighten bolt (A).

KNOW THE TRANSMITTING ROLLERS

OF YOUR PLANER

3. Move the gauge block to opposite end of

the working table. NOTE: Distance from the working table to edge of the head casting should be

the same.

4. Adjust opposite end in the same manner.

ADJUSTING WORKING T ABLE

P ARALLEL TO CUTTERHEAD

If the working table is not parallel to the cutterhead,

perform the adjustment procedures as follows:

1. Disconnect the machine from power

source.

2. Tilt planer on its side to expose underside

of base, as shown in Figure 19.

3. Remove bolt (A) and loosen bolt (B) which

will allow you to move the idler sprocket assembly

(C) far enough to release tension on the chain, as

shown in Figure 19.

A. Anti-Kickback Fingers

B. Infeed Roller

C. Chipbreaker

D. Cutterhead

E. Pressure Bar

F. Outfeed Roller

The infeed roller (B) and outfeed roller (F), Figure

20, are those parts of your planer that feed the

stock while it is being planed. The infeed roller

and the outfeed roller are under spring tension and

this tension must be sufficient to feed the stock

uniformly through the planer without slipping but

should not be so tight that it causes damage to

the board. The tension should be equal at both

ends of each roller.

FIGURE 19

4. Remove chain from the particular sprocket

on corner of base that must be adjusted.

5. Turn the sprocket by hand to bring that

corner into adjustment with the other three cor-

FIGURE 20

ADJUSTING INFEED & OUTFEED

ROLLER SPRING TENSION

To adjust the spring tension of the infeed and

outfeed rollers, turn screws (G & H) with an Allen

wrench, Figure 21. Turn screws on opposite end

of infeed/outfeed rollers in the same manner.

11

Page 12

FIGURE 21

ANTI-KICKBACK FINGERS

The anti-kickback fingers (A), Figure 20, are provided on your planer to prevent kickback of stock.

They operate by gravity and it is necessary to inspect them occasionally to make sure they are free

of gum and pitch, so that they move independently

and operate correctly.

To check and adjust the outfeed roller below the

cutting circle, proceed as follows:

1. Disconnect machine from power source.

2. Make sure the knives are adjusted properly as previously explained under "Checking &

Adjusting of Knives."

3. Place the gauge block (J) on the table directly underneath the cutterhead (D), Figure 23.

Using a 0.02" (0.5mm) feeler gauge (K) placed

on top of the gauge block, raise the working table

until the knife just touches the feeler gauge when

the knife is at its lowest point. Do not move the

working table any further until the outfeed roller is

adjusted.

HEIGHT OF INFEED ROLLER, CHIPBREAKER, PRESSURE BAR & OUTFEED

ROLLER

The infeed roller, chipbreaker, pressure bar and

outfeed roller are adjusted at the factory. The

infeed roller and the chipbreaker should be set at

0.004" (0.1mm) below the cutting circle; the pressure bar should be set at 0.008" (.02mm) below

the cutting circle; and the outfeed roller should be

set at 0.02" (0.5mm) below the cutting circle. See

Figure 22.

If an adjustment to the infeed roller, chipbreaker,

pressure bar or outfeed roller is necessary, use

the following steps as an example of procedure.

FIGURE 22

FIGURE 23

4. Move the gauge block (J) under one end

of the outfeed roller (F), Figure 24. The bottom of

the outfeed roller should just touch the top of the

gauge block. If an adjustment to the outfeed roller

is necessary , loosen the lock nut (L) and turn screw

(M) until the outfeed roller just touches the gauge

block. Then tighten lock nut (L).

5. Check and adjust opposite end of the

outfeed roller in the same manner.

12

Page 13

FIGURE 24

FEED SPEED CONTROL

Your machine is equipped with a spiral, serrated

infeed roller and a solid steel outfeed roller . When

the feed rollers are engaged, they turn to feed the

stock. The feed rollers slow automatically when

the machine is under heavy load for best planing

in all conditions. The feed rollers are driven by

chains (A), Figure 25, and the sprockets (B) which

take power directly from the cutterhead through

the oil bath gear box (C).

The gear box has two feed speeds. These are

set by pulling out or pushing in the shift lever (D)

while the machine is running. The feed speed

range is shown in Figure 26.

change the sprocket and the chain on your machine, proceed as follows:

1. Disconnect machine from power source.

2. Remove the three hex hd screws (E) and

washers, Figure 25.

3. Remove the three sprockets (B) from the

infeed roller, outfeed roller and the gear shaft at

the same time.

4. When sprockets (B) are removed, replace

the lower sprocket which will be assembled on the

gear shaft.

5. Assemble the three sprockets and chains

to the shafts, and tighten the hex hd. screws (E).

FPM

A/C

20/16 50P 12T

31/24 52P 18T

CHAIN

(F)

SPROCKET

(G)

FIGURE 25

CHANGING ACCESSORIES FOR

LOWEST FEED SPEED

The lowest feed speed for your planer (16.2 fpm

& 20.7 fpm) can be obtained by replacing the lower

(gear shaft) sprocket and the chain, Figure 26. To

FIGURE 26

RETURN ROLLERS

The two return rollers on the top of the machine

serve as a convenient rest for stock . They save

time and motion for the operator as the stock is

returned to the infeed side.

DUST COLLECTOR HOOD

The dust collector hood comes standard with the

model 208 planer , and helps maintain a clean and

safe work area. It is assembled to the planer with

hex head screws and washers.

13

Page 14

MAINTENANCE

Lubrication Guide for Model 208, 20" Planer

No. Position Interval Suitable Types of Oil Fig. No.

1 Chain Frequently Grease 29

Gear Box When operated more than 2,500 hours HD-100, Mobil Gear 627, Shell Omala 100,

2

3 Rollers Frequently SAE-30 30

4 Worm Gear Frequently Grease 31

5 Lead Screw Frequently Grease 31

6 Column Frequently Clean and SAE-30 31

7 Chain Frequently Grease 32

8 Bushing Frequently SAE-30 33

FIGURE 28

ESSO Spartan EP-100

29

FIGURE 29

FIGURE 31

CHANGING GEARBOX LUBRICANT

The lubricant in the gear box must be replaced

every 2,500 hours. Multi-purpose gear box lubricant will be suitable.

To replace the gearbox lubricant:

1. Remove the drain plug (A), Figure 29, and

filler cap (B). Drain dirty oil thoroughly.

2. Tighten the drain plug (A).

3. Fill with clean lubricant through hole (B).

4. Tighten filler cap (B).

14

FIGURE 30

FIGURE 32

FIGURE 33

Page 15

PARTS LIST: Base Assembly (208 Planer)

No. Part No. Description

1 6292793 Stand

2 6292794 Cover

3 6292795 Machine Screw, M6 X 1.0P-20

4 6292796 Bar

5 6292797 Motor Mount

6 6292711 Set Screw, M8 X 1.25P-8

7 6292798 Collar

8 6292799 Adjusting Bolt

9 6292651 Nut, M12 X 1.75P

10 6292683 Washer, 1/ 2

1 1 6292800 Hex Head Screw M8 X 1.25P-25

No. Part No. Description

12 6292801 Washer, 5/16

13 6292802 Nut, M8 X 1.25P

14 6292803 Motor, 3HP 1Ph

6292824 Motor, 5HP 3Ph

15 6292804 Key

16 6292805 Hex Head Screw, M12X1.75P-60

17 6292825 Power Supply Wire, 3 Ph

6292806 Power Supply Wire, 1 Ph

18 6292807 Relief Bushing

19 6292801 Washer, 5/16

15

Page 16

PARTS LIST: Cutterhead Assembly (208 Planer)

No. Part No. Description

1 6292617 Head Casting

2 6292618 Set Screw, M10 X 1.5P-12

3 6292619 Cutterhead

4 6292623 Hex Head Screw, M8 X 1.25P-10

5 6292621 Single Sided Knives (Set of 4)

6 6292622 Knife Locking Bar

7 6292620 Spring

9 6292625 Knife Setting Gauge

11 6292813 Cap Screw, M6 X 1.0P-10

12 6292628 Bearing 6206 ZZ

13 6292629 Key, 8 X 8 X 36

14 6292630 Machine Pulley

15 6292631 Washer, 8 X 30 X 3

16 6292632 Set Screw, M6 X 1.0P-25

17 6292633 Motor Pulley

18 6292634 Infeed Roller

19 6292635 Bushing

20 6292636 Spring

21 6292637 Screw, M22 X 1.5P-20

22 6292638 Plate

23 6292639 Hex Head Screw, M8 X 1.25P-20

24 6292640 Set Screw, M6 X 1.0P-16

25 6292641 Nut, M6 X 1.0P

26 6292642 Key, 5 X 5 X 23

27 6292643 Sprocket 31T

28 6292644 Washer, 6.2 X 22 X 3

29 6292645 Hex Head Screw, M6 X 1.0P-16

30 6292646 Outfeed Roller

31 6292647 Sprocket

32 6292648 Locking Bolt

33 6292649 Retaining Ring STW-12

34 6292650 Chip Breaker

35 6292651 Nut, M12 X 1.75P

36 6292652 Plate Spring

37 6292653 Washer, 1/4

38 6292654 Hex Head Screw, M6 X 1.0P-12

39 6292655 Shaft

40 6292656 Bracket

41 6292657 Pressure Plate

42 6292658 Spring Washer

43 6292659 Shaft

44 6292660 Set Screw, M6 X 1.0P-12

45 6292661 Set Screw, M6 X 1.0P-20

46 6292662 Plate Spring, 0.6

47 6292663 Chip Deflector Plate

48 6292664 Anti-kickback Finger

49 6292665 Collar

50 6292666 Shaft

51 6292667 Retaining Ring

52 6292668 Cut Limiter Plate

53 6292669 Flat Head Machine Screw,

M5 X 0.8P-12

54 6292670 Upper Cover

55 6292671 Gasket

56 6292672 Dust Hood

57 6292673 Roller Stand

No. Part No. Description

58 6292674 Roller

59 6292675 Cap Screw, M6 X 1.0P-16

60 6292678 Gear Box Worm

61 6292677 Cap Screw, M6 X 1.0P-50

62 6292676 Worm

63 6292679 Bearing 6201 Z

64 6292680 Retaining Ring, RTW-32

65 6292681 Key 4 x 4 x 10

66 6292682 Handwheel

67 6292683 Washer, 1/2

68 6292684 Handle

69 6292685 Scale

70 6292686 Machine Screw, M5 X 0.8P X 10

71 6292687 Cut Limit Pointer

72 6292814 Flat Washer

73 6292689 Cover

74 6292690 Spring Pin

75 6292691 Safety Hatch

77 6292693 Safety Hatch

78 6292694 Cap Screw, M8 X 1.25P-40

79 6292695 Pulley Guard

80 6292696 Bolt

81 6292815 Hex Head Screw, M6X1.0P-16

82 6292698 Nut, 5/16-18NC

83 6292699 Belt

84 6292700 Pulley Cover

85 6292710 Knob, 5/16-18NC

86 6292701 Switch Board

87 6816292 Switch, 3 HP, 1 PH

6816295 Switch, 5 HP, 3 PH

6816296 Switch, 5 HP, 3 Ph, 460V

88 6292703 Nut, M5 X 0.8P

89 6292704 Name Plate

90 6292705 Rivet

91 6292706 Chain 06B

92 6292707 Relief Bushing

93 6292708 Power Supply Wire, 1 Ph

6292826 Power Supply Wire, 3 Ph

94 6292709 Tooth Washer, EOW-5

95 6292813 Cap Screw, M6 X 1.0P-10

96 6292711 Cap Screw, M8 X 1.25P-8

97 6292816 Label

98 6292713 Collar

99 6292714 Shaft

100 6292715 Idle Pulley

101 6292716 Bracket

102 6292717 Shaft

103 6292718 Hanger

104 6292719 Spring

105 6292720 Collar

106 6292817 Round Head Screw, M6X1.0P-12

107 6292818 Hex Head Screw, M8X1.25P-18

108 6292819 Label

109 6292820 Label

1 1 0 6292821 Cap Screw, M5X0.8P-10

16

Page 17

EXPLODED VIEW: Cutterhead Assembly (208 Planer)

17

Page 18

PARTS LIST: Table Assembly (208 Planer)

No. Part No. Description

1 6292721 Middle Table

2 6292722 Roll

3 6292679 Bearing 6201 Z

4 6292724 Eccentric Shaft

5 6292660 Set Screw, M6 X 1.0P-12

6 6292725 Lock Bar

7 6292726 Locking Bolt

8 6292727 Locksmith

9 6292728 Knob

10 6292729 Cap Screw M8 X 1.25P-20

No. Part No. Description

11 6292730 Roller Frame

12 6292731 Roller

13 6292732 Hex Head Screw, M10 X 1.5P-25

14 6292626 Washer, 3/ 8

15 6292808 Shaft

16 6292809 Bushing

17 6292811 Washer

18 6292810 Hex Head Screw, M6X1.0P-12

18

Page 19

PARTS LIST: Table Base Assembly (208 Planer)

NO. PART NO. DESCRIPTION

1 6292733 BASE

2 6292618 SCREW, SET M10 X 1.5P-12

3 6292734 COLUMN

4 6292735 COLUMN

5 6292736 SCREW, LEAD

6 6292737 SCREW, LEAD

7 6292738 NUT

8 6292739 BUSHING

9 6292740 RING, RETAINING RTW-38

10 6292741 KEY 4 X 4 X 10

11 6292742 GEAR , 24T

12 6292649 RING, RETAINING STW-12

13 6285855 BEARING 6202 ZZ

14 6292744 RING, RETAINING RTW-35

16 6292746 SPROCKET 10T

NO. P ART NO. DESCRIPTION

17 6292626 WASHER, 3/8 X 20 X 2

18 6292627 NUT, M10 X 1.25P

19 6292747 WASHER 8.2 X 22 X 3

20 6292748 SCREW, HEX. HD. M18 X

1.25P-25

21 6292749 BRACKET

22 6292750 SHAFT

23 6292751 SPROCKET 10T

24 6292752 RING, RETAINING STW-15

25 6292753 CHAIN #40

26 6292754 POST, CRANE

27 6292755 RING, RETAINING ETW-19

28 6292756 BAND, PIPE

29 6292757 SCREW, MACHINE M5 X 0.8P-8

30 6292758 BEND, EXPANSION

19

Page 20

PARTS LIST: Gearbox Assembly (208 Planer)

NO. P ART NO. DESCRIPTION

1 6292759 Gear Box

2 6292760 Oil Seal

3 6292761 Bearing, 6204ZZ

4 6292762 Gear 16T

5 6292763 Cap Screw, M6 X 1.0P-20

6 6292764 Washer

7 6292675 Cap Screw, M6 X 1.0-16

8 6292765 Bearing 6201

9 6292766 Gear 47T

10 6292767 Shaft 18T

1 1 6292768 Key 5 X 5 X 12

12 6292769 Gear 71T

13 6292770 Key 5 X 5 X 10

14 6292771 Shaft 18T

17 6292772 Gear Assembly

19 6292813 Cap Screw, M6 X 1.0-10

20 6292774 Key 6 X 6 X 40

21 6292775 Ball, 6 Diameter

22 6292776 Spring

NO. P ART NO. DESCRIPTION

23 6292777 Shaft

24 6292778 Oil Seal SC25 X 47 X 6

25 6292791 Sprocket 18T

6292779 Sprocket 12T

27 6292792 Chain 06B X 52P

6292780 Chain 06B X 50P

28 6292654 Hex Head Screw, M6 X 1.0P-12

29 6292781 Clutch

30 6292782 Handle

31 6292653 Washer, 1/4

32 6292654 Hex Head Screw, M6 X 1.0P-12

33 6292783 Oil Ring P-12

34 6292784 Knob

35 6292785 Pin

36 6292786 Packing Piece

37 6292787 Cover

38 6292788 Cap Screw, M6 X 1.0P-25

39 6292789 Oil Plug, PT1/4-19

40 6292790 Cap Screw, M8 X 1.25P-50

20

Page 21

EXPLODED VIEW: Gear Box Assembly (208 Planer)

21

Page 22

Electrical Schematic: Model 208-1 (Single Phase)

22

Page 23

Electrical Schematic: Model 208-3 (Three Phase)

23

Page 24

OPTIONAL ACCESSORIES (208 Planer)

6292621 Knives (set of 4)

6292822 Low speed gear kit.

6292773 Hardware Kit.

24

Page 25

252627

Page 26

Page 27

T o order parts or reach our service dep artment, please call our toll-free number between 8:00 a.m. and 4:30 p.m.

(CST), Monday through Friday . Having the Model Number and Serial Number of your machine available when

you call will allow us to serve you quickly and accurately . Locating the EDP number of the part(s) required from

your parts manual will also expedite your order.

Phone No.: (800) 274-6848

Fax No. (800) 274-6840

If you are calling from Canada, please call 800-238-4746

E-mail: powermatic@powermatic.com

Website: www.powermatic.com

Page 28

04/01

P.O. Box 1349

Auburn, WA 98071-1349

Phone: (800) 274-6848

Fax: (800) 274-6840

E-mail: powermatic@powermatic.com

Website: www .powermatic.com

C

POWERMA TIC ALL RIGHTS RESERVED

Loading...

Loading...