Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

22-inch Planer

Models 201 and 201HH

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-0460224

Ph.: 800-274-6848 Revision J 02/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provid e pr o of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Information

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 4

Introduction ............................................................................................................................................. 6

Specifica tions ................................................................................................................ .......................... 6

Recei ving ................................................................................................................................................ 7

Installation ............................................................................................................................................... 7

Installing Dust Hood ............................................................................................................................. 8

Grounding Inst r uc tions ............................................................................................................................. 8

Inspection ................................................................................................................................................ 9

Adjustments ................................................................................................................... ......................... 9

Depth of Cut......................................................................................................................................... 9

Feed Rate Adjustment ......................................................................................................................... 9

Belt Tension ......................................................................................................................................... 9

Opening Hood .................................................................................................................................... 10

Knife Installation and Adjustment (Straight Cutterhead only) .............................................................. 10

Replacing or Rotating Knife Inserts (Heli c al Cutt er head only) ............................................................. 11

The Planer’s Feed System ..................................................................................................................... 12

Anti-Kickback Fingers ........................................................................................................................ 12

Infeed Roller ...................................................................................................................................... 12

Chipbre aker ....................................................................................................................................... 13

Pressure Bar ...................................................................................................................................... 13

Outfeed Roll er .................................................................................................................................... 14

Table Roller s ...................................................................................................................................... 14

Table Adj ustments ............................................................................................................................. 15

Operating Controls ................................................................................................................................ 16

Test Cutting and T r oubleshooting .......................................................................................................... 16

Maintenance .......................................................................................................................................... 18

Lubrication ......................................................................................................................................... 18

Troubleshooting: Planer Operating Problems ......................................................................................... 19

Troubleshooting: Mechanical and Electrical Problems ............................................................................ 20

Replacement Parts ................................................................................................................................ 21

Parts List: Base Assembly .................................................................................................................. 22

Gearbox Assembly ............................................................................................................................. 24

Parts List: Gearbox Assembly ............................................................................................................ 25

Column Assembly .............................................................................................................................. 26

Parts List: Column Assembly .............................................................................................................. 27

Table Assembly ................................................................................................................................. 28

Parts Lis t: Ta b le Assembly ................................................................................................................. 29

Parts List: Top Cover Assembly ......................................................................................................... 30

Cutterhead Assembly ......................................................................................................................... 31

Parts List: Cutt er head A ssembly ........................................................................................................ 32

Electri c al Connec tions – 1 Phase, 230 Volt ............................................................................................ 34

Electri c al Connec tions – 3 Phase, 230 Volt ............................................................................................ 35

3

Page 4

Warning

1. Read and understand the ent ire owner’s manual befor e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This planer i s designed and intended f or use by properly trai ned and experienced personnel only. If

you are not familiar with the proper and safe operation of a planer, do not use until proper training and

knowledge have been obtained.

5. Do not use this planer for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Al ways wear ap prov ed saf ety glasses/face shields whil e usi ng thi s planer. Ev er yday eyegl asses onl y

have impact resistant lenses; they are not safety glasses.

7. Before operating t his planer, remove tie, rings, watches and other jewelr y, and roll sleeves up past

the elbows. Remove all loose clothing and c onfine long hair. Non-sli p footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during ext ended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

Lead from lead based paint.

Crystalline silica from bricks, c em ent and ot her m asonry pr oducts.

Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machi ne while tired or under the influence of drugs, alcohol or any medication.

11. M ak e c er tain the machine is properl y grounded.

12. W ith the exception of feed rate adjustm ent, make all machine adjustments or maint enance with the

machine disconnec ted from t he power source. A mac hine under repair should be RED T AGGED to

show it should not be used until the maintenance is complet e.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Keep safety guards in place at all times when the machi ne is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately after c om pletion of maintenance.

15. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

16. P r ov ide for adequate space surroundi ng work ar ea and non-glare, ov er head lighting.

17. K eep the floor around the machi ne cl ean and fr ee of scrap material, oil and grease.

18. K eep v isitors a safe distance fr om the work area. K eep chi ldren away.

4

Page 5

19. M ak e y our workshop child proof wit h padloc k s, m aster swit c hes or by r em ov ing starter keys.

20. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

21. M aintain a balanc ed stance at all t imes so that you d o not fall or lean against mov ing parts. Do not

overreach or use excessiv e force to perform any machine operation. Stand to the side out of li ne with

the table and make sure no one el se i s standi ng in line with the table.

22. Use the ri ght t ool at the cor rect speed and feed r ate. Do not for ce a tool or attachment to do a job for

which it was not designed. T he ri ght tool will do the job better and m or e safely.

23. Mai ntain t ools with care. Keep kniv es sharp and clean f or the best and saf est perf ormanc e. Dull tool s

increase noise lev els and can cause ki ckbacks and glazed surf aces. Broken gi bs/kniv es that are not

securely loc ked in the cutterhead c an be thrown out of the planer causing severe or fatal injury as

well as severe damage to the machine. Follow instructions for lubricating machine and changing

accessories. Use recommended accessories; improper accessories may be hazar dous.

24. Do not attempt to pl ane boards shorter than 10” (254mm) in length wit hout butting a board of equal

thickness behind i t to help it thr ough the planer . Be sure the last board of a butted sequence i s 10” or

longer.

25. Do not feed stacked boards through a planer; a kickback may occur causing severe or fatal injury.

26. Do not pl ane a board with l oose knots or with nail s or any foreign m aterial on its surface. Twisted,

warped, or wind- in stock should f irst be joint ed on one surface bef ore attempting to pl ane a parallel

surface on the planer . Serious stock flaws cannot be rem ov ed by use of a planer alone.

27. If the board bei ng planed stops feedi ng, disengage or t urn the f eed off and turn the power off . Wait

until the cutt erhead comes to a complete stop before lowering the t able to remove the board. Never

lower the tabl e with t he power on and the stoc k st ill in the machine, as a kickback can occur.

28. Keep hands outside of the machine. Never reach under the guards to try to clear stock that has

stopped feedi ng. When star ti ng a cut , do not hav e any part of the hand s under that par t of t he board

that is over the table; the infeed roller will engage the board and force it down against the table

causing a pinching action.

29. Disconnect machine from power source before cl eaning. Use a brush or compressed air to remov e

chips or debris — do not use your hands.

30. Do not stand on the machine. Seri ous i njury could occur if the machine tips over.

31. Never leave the mac hine r unning unattended. Turn the power off and do not leav e the m ac hine until it

comes to a complete stop.

32. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result i n mi nor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Powermatic Model 201 and 201HH Planer. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordanc e with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or Powermatic. Powermati c can also be reached at our web site: www.powermati c .com.

Specifications

Model Number ....................................................................... 201................................................... 201HH

Stock Number (7.5HP , 1Ph, 230V) ................................ 1791261.................................................1791267

Stock Number (7.5HP , 3Ph, 230V) ...............................................................................................1791268

Working Wid th (in.) .................................................................. 22.......................................................... 22

Maximum Depth of Cut (in.) .................................................. 3/16....................................................... 3/16

Minimu m Thicknes s (in.) ......................................................... 1/8......................................................... 1/8

Maximum Thickness (in.) ..................................................... 9-1/4...................................................... 9-1 /4

Segmented Infeed Roller Diameter (in.) ..................................... 3............................................................ 3

Steel Outfeed Roller Diameter (in.) ............................................ 3 ............................................................ 3

Feed Speeds (FPM) .................................................... 20 and 30............................................... 20 and 30

Bed Rollers, Front Adjustable .................................................... 2............................................................ 2

Minimum Lengt h Work piec e (i n.).............................................. 10.......................................................... 10

Cutterhead Style .............................................................. stra ight.................................................... helical

Cutterhead Diameter (in.) .................................................... 3 -1/4...................................................... 3-1/4

Number of Knives ...................................................................... 4............................. 125 four-sided inserts

Number of Cutterhead Rows................................................... n/a............................................................ 5

Cutterhead Speed (RP M ) .................................................... 4800...................................................... 4800

Cuts per Minute ................................................................ 19,200......................................... not applicable

Table Size (LxW)(in.) ................................................. 32-1/2 x 24............................................. 32- 1/2 x 24

Table Support ............................................................... 2-column................................................ 2-column

Manual Table Height Adjustment (in.) ...................... 1 turn = 1/16.......................................... 1 turn = 1/16

Readout Scale ................................................................... mm/ in..................................................... mm/in

Dust Port Diameter (in.) ............................................................. 5............................................................ 5

Dust Collecti on Minimum CFM Required ................................ 900........................................................ 900

Shipping Weight , approximate (lbs.)..................................... 1430...................................................... 1430

Net Weight, approximate (lbs.) ............................................. 1350...................................................... 1350

Overall Dimensions (LxWxH)(in.) .............................. 42 x 49 x 59........................................... 42 x 49 x 59

The above specifications were current at the tim e this manual was publi shed, but because of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligati ons.

6

Page 7

Receiving

Open shipping crate and check for shipping

damage. Report any damage immediately to

your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of crate:

1 planer

1 dust chute w/ fasteners

4 screws w/ hex nuts (for leveling feet)

4 leveling feet

1 knife-setting gauge (201 only)

2 star point screwdriv er s (201HH only)

1 set of 10 knife inserts (201HH only)

10 knife insert screws (201HH only)

1 6mm hex wrench

1 8mm hex wrench

1 10mm hex wrench

1 12mm & 14mm wrench

1 22mm & 24mm wrench

1 Operating Instruct ions and Parts Manual

1 Warranty Card

Installati on

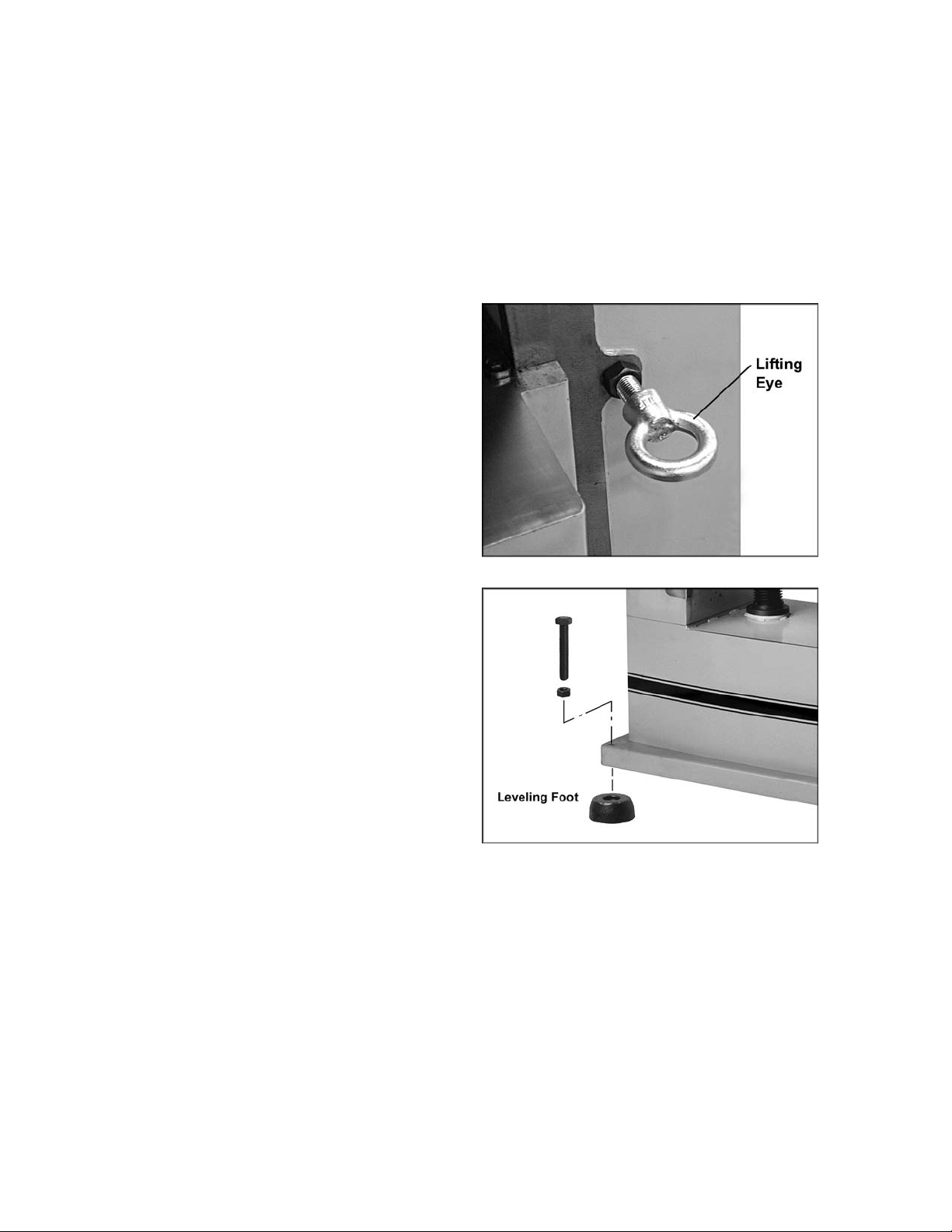

Remove the screws holding the base of the

machine to the ski d. Use the lif ting eyes on fr ont

and back of the pl aner f or hoisti ng it off the ski d.

See Figure 1. Make sure the hex nuts are

tightened bef ore lifting. The lifting eyes can be

removed once the planer is situated.

Place the planer on a solid foundation,

preferably a concrete floor. The four leveling feet

should be placed beneat h the corners, and the

screws and hex nuts used for leveling

adjustments. See Figure 2. Alternatively, you

can secure the mac hine t o the fl oor by usi ng l ag

screws through the holes in the base.

The machine area should be clean, dry, well

ventilated, and well lighted. Since planers can

create noise probl ems, the site selecti on should

be one which mi nim izes rev erberant sound f rom

walls, ceilings and other equipment. Electricals

should be installed so that they are protected

from damage and exposure.

Exposed metal parts have been given a

protectiv e coating at the fact ory. This should be

removed wit h a soft rag and k erosene or a good

commercial solvent. Do not use an abrasive

pad, as it may scratch polished metal surfaces.

Figure 1

Figure 2

IMPORTANT: All knives or knife inserts on

the cutterhead should be checked for

tightness before operating the planer.

7

Page 8

Installing Dust Hood

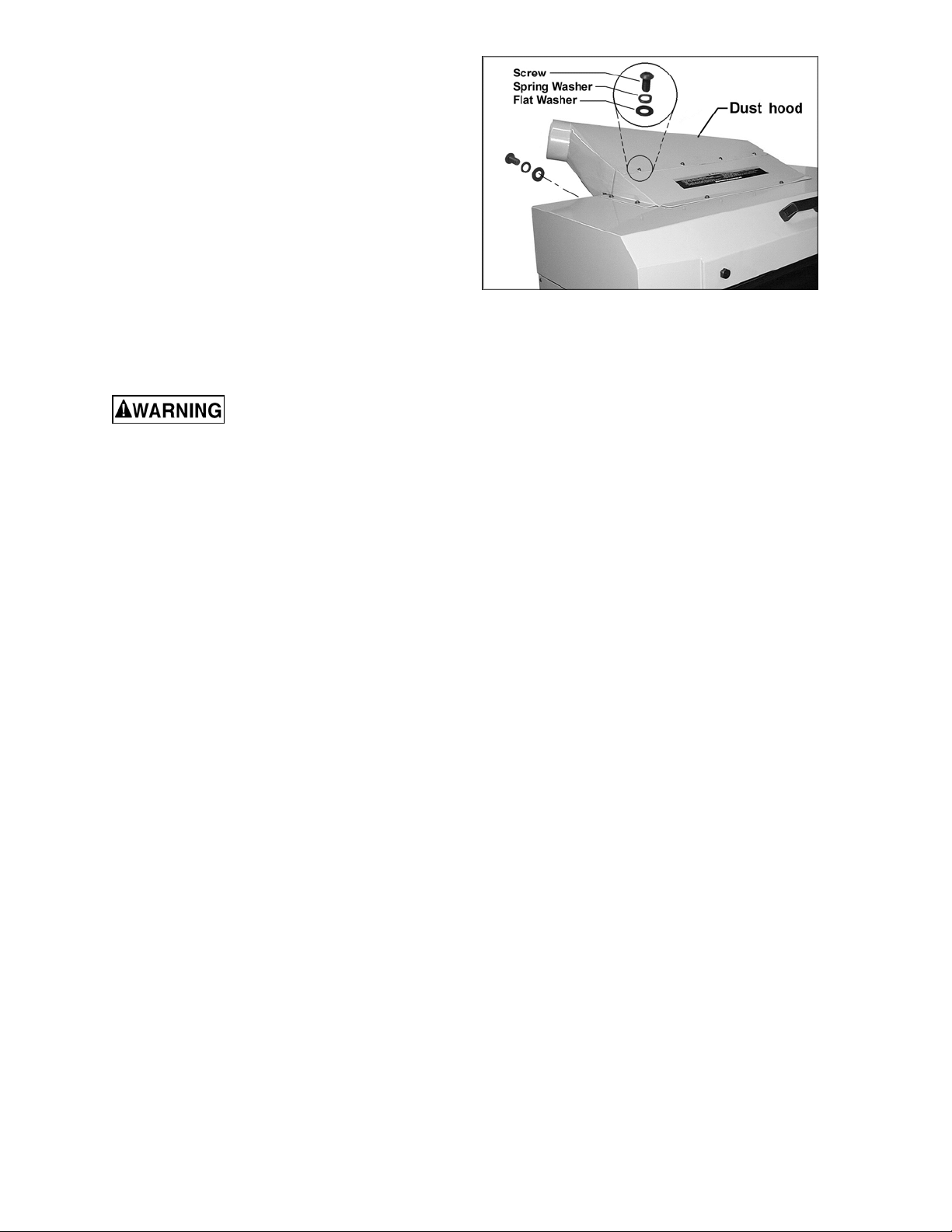

Mount the dust hood with t he eight M6 x 10mm

hex screws, eight spring washer s, and eight flat

washers. See Figure 3.

It is strongly recomm ended that a dust collection

system be connected to the 5” port on the

planer’s dust hood. The system should be of

sufficient volume for this size planer. If a dust

collection system is not used, the user is

cautioned against the health hazard and the

limitati ons in the OSHA regul ation for empl oyee

or student exposure t o dust par ticles.

Contact your deal er or visit waltermeier.com for

a line of availabl e dust c ollec tors.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

This mac hine m ust be grounded. I n the event of

a malfuncti on or break down, groundi ng prov i des

a path of least r esistance f or electric current to

reduce the ri sk of el ectri c shock .

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or . If r epair or replac em ent of

the electric cord or plug is necessary, do not

connect the equipment-groundi ng c onduc tor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the Planer. T he m achi ne shoul d be c onnec ted to

a dedicated cir c uit.

You may eit her install a pl ug or “hard-wire” the

Planer dir ectly t o a contr ol panel. If the Pl aner is

to be hard-wired to a panel, make sure a

disconnect is available for the operator. During

hard-wiring of the Planer, make sure the fuses

have been rem oved or the breakers have been

tripped i n the circuit t o whic h the machine will be

connected. Pl ace a warning placard on t he fuse

holder or circuit breaker to prevent it being

turned on while t he Pl aner is bei ng wir ed.

Figure 3

8

Page 9

Inspection

Before putt ing power to t he m achi ne, c heck that

all screws are tight, that all mec hanic al functions

work freel y and that the cutter head turns freel y

without knife contact with the chipbreaker or

pressure bar. On the helical cutterhead model,

check that all k nife inserts are properly torqued.

Adjustments

Tools required:

Philips screwdriver

Hex wrenches (provided)

Open-end wrench (provi ded)

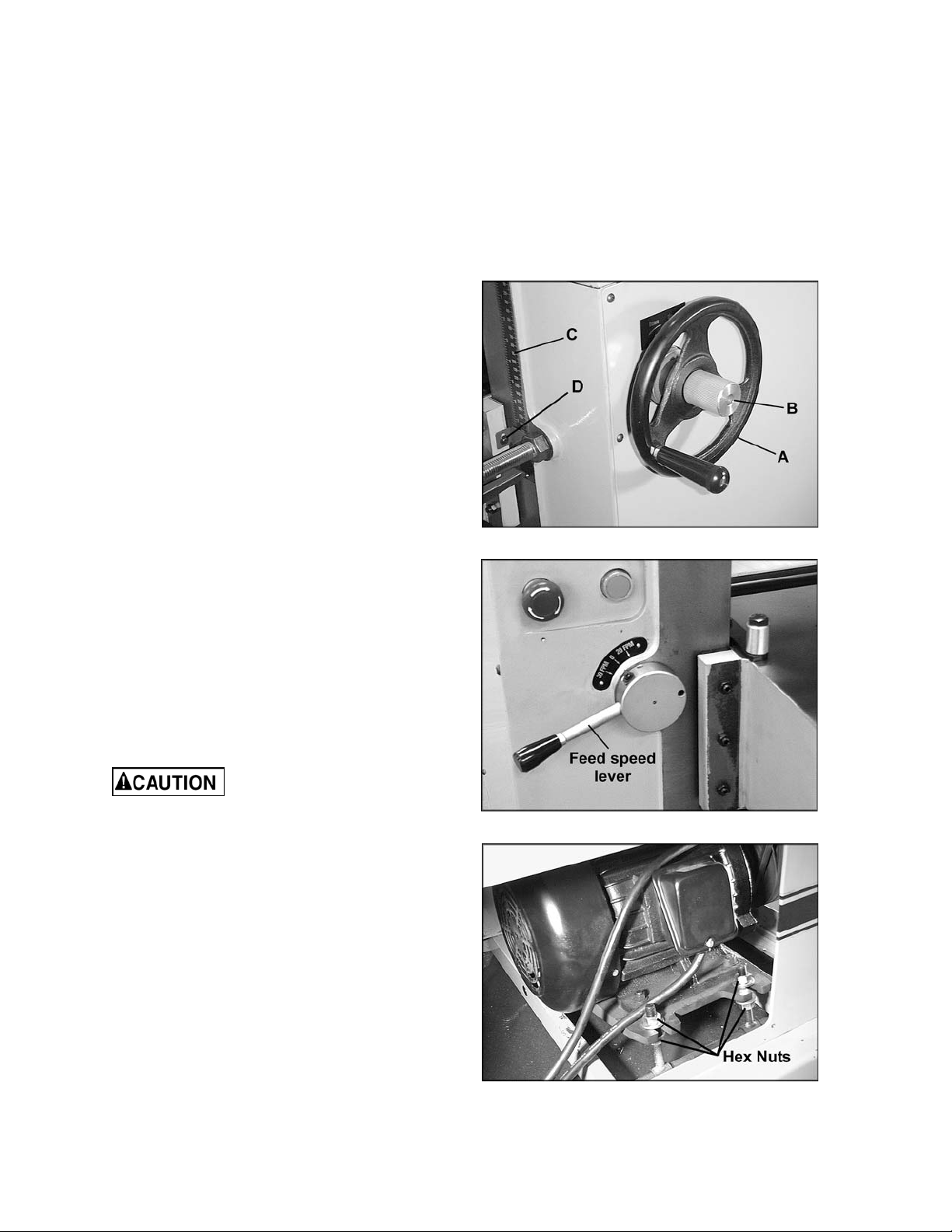

Depth of Cut

Depth of cut is controll ed by raising or l owering

the table. This is done by using the handwheel

(A), shown in Figure 4.

1. Loosen the lock knob (B , Fi gur e 4).

2. Raise or lower the table to the desired

position (c lockwise to raise). One revol ution

of the handwheel equals 1/16" . The distance

can be read on the scale (C, Fi gur e 4).

3. Retighten loc k knob (B, Fi gur e 4) .

Figure 4

4. The pointer (D, Figure 4) can be adjusted

slightly if the scale should ever need

recalibrating.

Feed Rate Adjustment

The Model 201 i s equi pped wit h select abl e f eed

speed roller s that feed stoc k at 20 and 30 feet

per minute. To adjust speed, turn l ever shown in

Figure 5, while the planer is r unning.

Alw ays change sp eeds whi le

the planer is running to avoid damage to the

gearbox.

Belt Tension

1. Disconnect machine from power source.

2. Remove lower rear cover of machine, and

use the hex nuts to adjust tension. See

Figure 6. A djust motor plate up or down until

correct belt tension is achieved. To lower

motor plate, loosen lower nuts and tighten

upper nuts. To raise motor plate, do the

opposite.

Figure 5

3. Correct tension is obtained when there is

approximately 1/4" deflection in the center

span of the belts using light finger pressure.

4. Re-tighten the nuts and re-install cov er.

Figure 6

9

Page 10

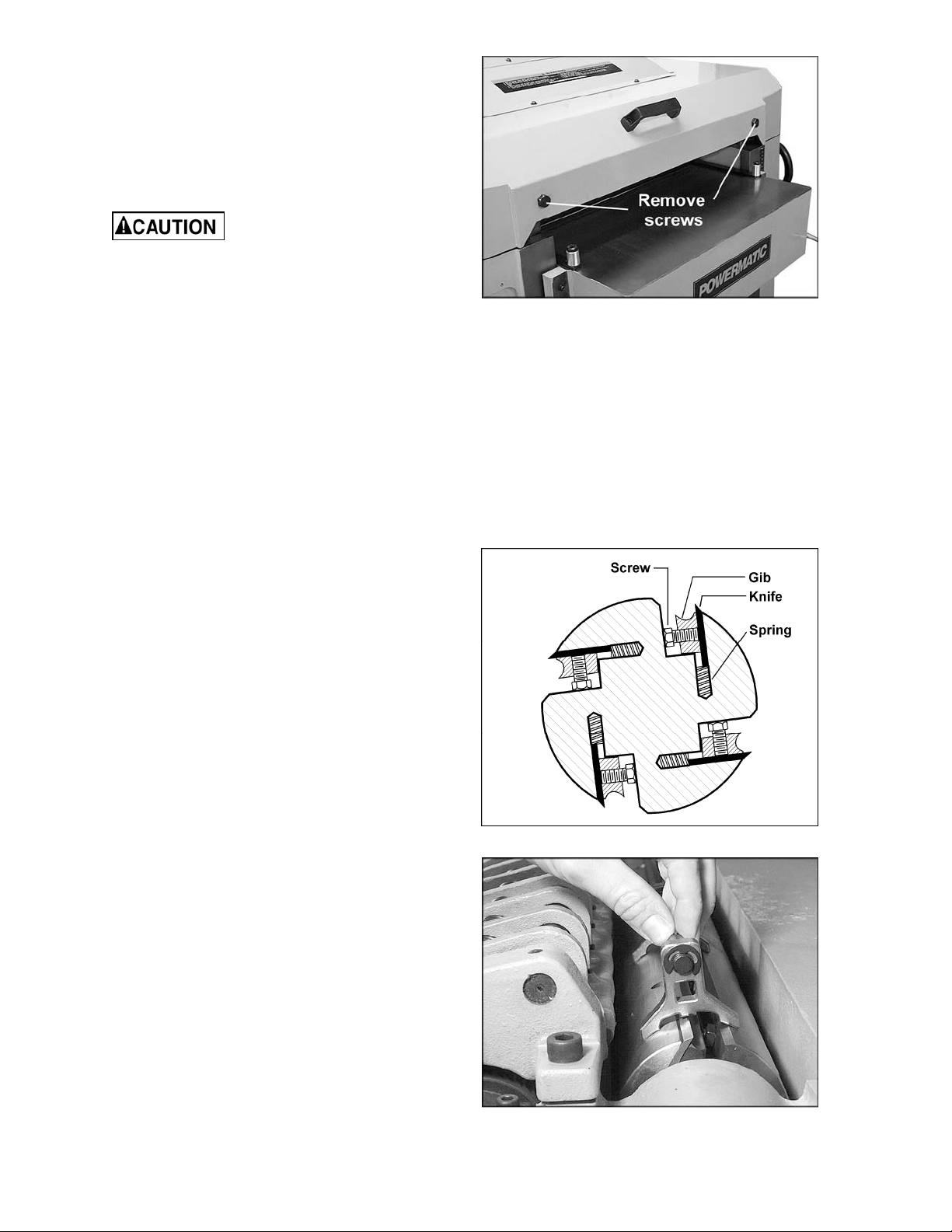

Opening Hood

To open the hood f or access to t he cutterhead,

remove the two hex screws with the 22mm

wrench provided. See Figure 7.

Knife Installation and Adjustment (Straight Cutterhead only)

Use care when p lacing hands

near knives as they are extremel y sharp and

can cause severe cuts.

Installing knives on a planer is an exacting

process. If the knives are not to be joi nted and

ground, end-to-end and knife-to-knife

relationship m ust be held within .001" (.03mm)

for accur ate and smooth plani ng. To help avoid

cutterhead distortion when changing out a set of

knives, rem ove and r eplac e the knife in one slot

before changing the next knife. Snug down each

knife until all four are ready to fully tighten, as

described below. It may be helpful to number

the knives with a f elt- tip marker to keep t rack of

progress.

Any knife adjustm ent or replacement should be

done to all four knives at t he same time. Failure

to do this may result in an out-of-balance

cutterhead which c an lead to bearing failure.

1. Disconnect machine from power source.

Figure 7

2. To remove a knife, loosen the ei ght screws

along its gib. See Fi gur e 8.

3. The springs will cause the knife to rise in the

slot. Carefull y remove knife from cutt erhead

by lifting straight out. Remove gib and

springs, and clean any dust, pitch or

accumulated foreign matter from the slot

and the gib.

4. Replace the springs and gib into the slot,

then insert new knife and lightly snug the

eight gib screws.

5. Place the knife-setting gauge on the

cutterhead as shown in Figure 9, with the

flanges resting upon t he cutterhead and the

center protr usion pu shing down upon t he ti p

of the knife. This will hold the high point of

the knife to the proper height above the

cutterhead (appr ox imately 1/8” or 3.18mm).

6. Use the gauge at both ends of the knife,

then check the center secti on to be sure it is

even. If the knife is low in the center, try

backing off slightl y on the center gib screw

to allow the blade to come up. Gently tap

blade down with a piece of wood until it

conform s to the gauge height. Re- check the

full length of the k nife.

Figure 8 – Model 201 only

Figure 9 – Model 201 only

10

Page 11

7. Rotate the cutterhead using the belt or

pulley, and repeat steps 2 through 6 for

each of the remaining three knives.

8. When all four knives have been installed

and made snug, begin the tightening

process.

NOTE: All knives and gibs should be in

place before tightening. Tightening one knife

in without the others in position can cause

cutterhead distortion.

9. The tightening process should proceed

working from the center outward on each

knife. Go onc e ar ound the cutterhead f ur ther

tightening all gib screws in sequence. Then

repeat the same sequence a second time,

this time full y tightening all screws.

After installing knives, re-

check all gib screws for tightness. Loose

gib screws can resu lt in knives b eing th rown

from the cu tterhead, cau sing severe damage

to the mach ine and possibl e serious or fat al

injury to t he ope r a t or or by s ta nders.

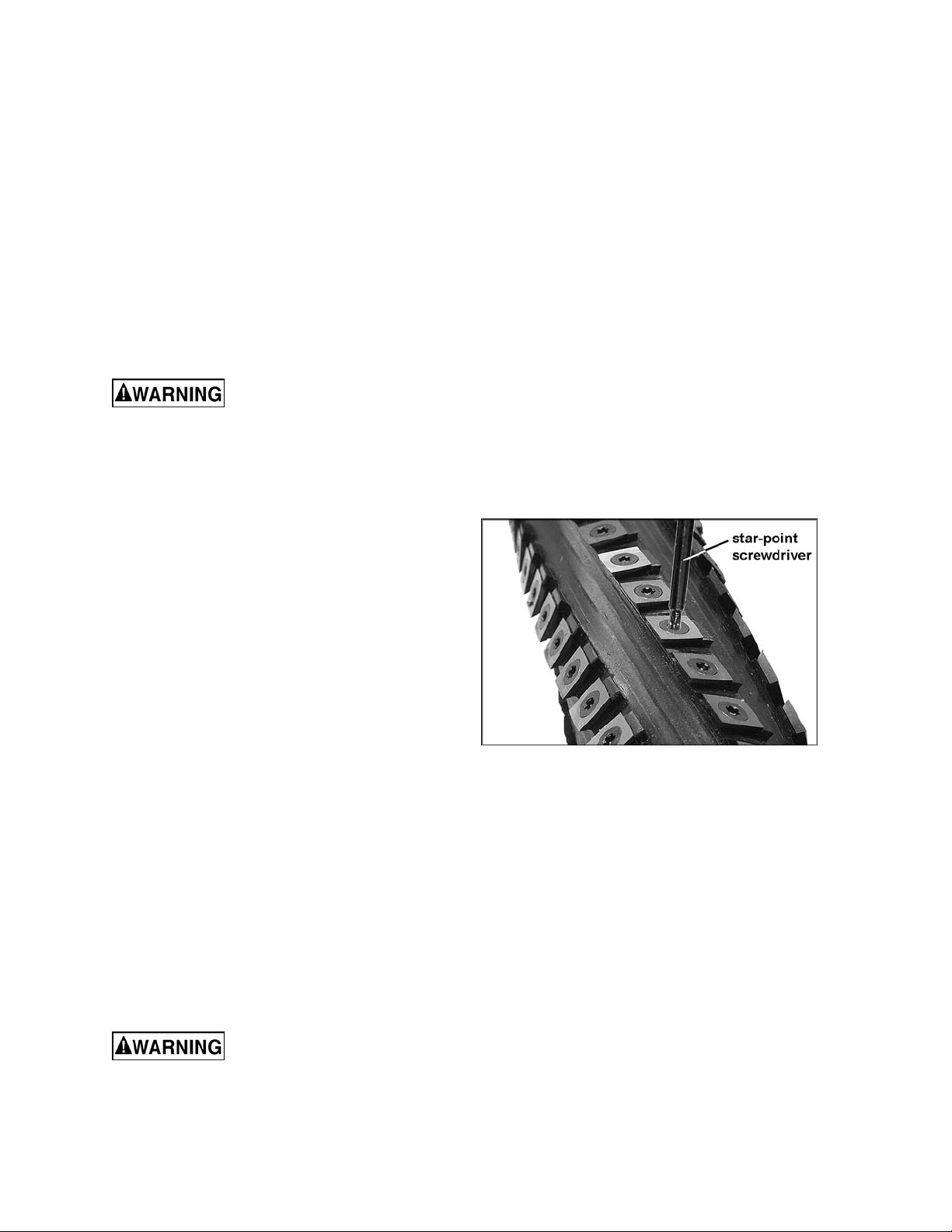

Replacing or Rotating Knife Inserts (Helical Cutterhead only)

The knife insert s on the model 201HH are f oursided. When dull, simply remove each insert,

rotate it 90° for a fresh edge, and re- install it.

No set-up gauge is necessary for the inserts.

Use the provided star point screwdriver to

remove the knif e insert screw. See Figure 10. It

is advisable to rotate all insert s at the same time

to maintain consistent cutting. However, if one

or more knife inserts develops a nic k , rotate only

those inserts that are affected.

Each knife insert has an etched referenc e mark

so that you can keep track of rotations.

IMPORTANT: When removing or rotating

inserts, clean saw dust from the screw, the

insert, and the cutterhead platform. Dust

accumulation between these elements can

prevent the insert from seating properly, and

may affect the quali ty of the cut.

Before installing each screw, lightly coat the

screw threads wit h m achine oi l and wi pe off any

excess.

Figure 10 – Model 201HH only

Securely tighten each screw which holds the

knife inserts before operating the planer!

Make sure all knife insert

screws are tigh ten ed secu rely. Loo se inserts

can be propelled at high speed from a

rotating cutterhead, causing injury.

11

Page 12

The Planer’s Feed System

(Refer to Figure 11)

1. Anti-kickback fingers

2. Infeed roller

3. Chipbreaker

4. Cutterhead

5. Pressure bar

6. Outfeed roller

Anti-Kickback Fingers

Anti-kickback fingers help prevent stock from

being thrown from the machine. These fingers

operate by grav ity and should be inspected f or

pitch or gum buildup befor e eac h day ' s us e. The

fingers must operate freely and move

independently for correct operation.

Infeed Roller

The function of the infeed roller is to feed the

material into the machine. It is a corrugated,

sectional roller with approximately 1/4"

independent movement of each section to

accommodate multiple board surfacing.

To provide pr oper drive, the infeed roll er should

be set so that the bottom of its arc is 1/16"

(1.6mm) bel ow the arc of t he cutt erhead k niv es.

The infeed r oller is under spring t ensi on and this

tension must be sufficient to feed the stock

uniformly through t he pl aner without slippi ng but

should not be so ti ght that i t causes damage to

the stock. T he tension should be equal at both

ends of the roller.

To adjust the infeed roller:

1. Disconnect machine from power source.

2. Place a dial gauge (not provided) under a

knife i n the c utt erhead. If a di al gauge i s not

available, use a finished block of wood with

notches cut out for the table rolls, in

conjunction wit h a feeler gauge. S ee Figure

13 for an exam ple of a wood block you can

make and use as a gauge.

3. Raise the tabl e with t he handwheel unt il the

gauge contacts a knife at the apex of its

curve. Zero the gauge at t hat position.

4. Move the gauge to the extreme left end of

the infeed roller and check the

measurement. It should be 1/16” bel ow the

knife measurement.

5. If it is not 1/16” below the k nife, correct by

loosening the hex nut and turning the

adjustment screw (A, Figure 14) with a hex

wrench.

Figure 11

Figure 12

12

Page 13

6. Move the gauge to t he extreme right end of

the infeed roller and check. Make similar

adjustments if needed.

7. Tighten hex nuts (A, Figure 14) when

finished.

IMPORTANT: The setting on both ends of the

infeed roll er must be the same to avoi d skewing

of the material as it is fed through the machine.

Chipbreaker

The chipbreak er is a sectionaliz ed type made of

spring-loaded secti ons mounted on a bar , which

complements the sectional infeed roller. The

functions of the chipbreaker are to break chips

into small pieces, help avoid splintering of the

wood, help avoid board bounce on thinner

boards, to direct the flow of chips out of the

machine, and to permi t multiple board surfacing.

The chipbreaker has been factory set at 1/32”

(0.8mm) below the cut ti ng arc of t he knives, and

has been spring-tensioned pr oper ly.

Figure 13

User-made Gauge Bloc k

A chipb reaker set too low or

with excessive tension may prevent stock

from feeding into th e machi ne.

Pressure Bar

Most planing problems can be traced to

improper sett ing of the pressure bar. It s f uncti on

is to hold down the mat eri al after it passes under

the cutter head and throughout the remainder of

the cut. I ts basic setting i s to be in li ne with the

arc of the cutterhead knives.

If the pressure bar is too high, a shallow "clip"

will occur at each end of the board. If it is too

low, stock will not f eed through.

Use a gauge to set the full length of the

pressure bar to be .000-.001" (.02mm) below

the arc of the cutter head.

Figure 15 shows the height adjustment screw

(C) and the spri ng ten sion adj ustm ent scre w (D)

for the pressure bar. Loosen the hex nut and

rotate the screw as needed. Make sure the

setting on both end s of the pressure bar is the

same. Tight en the hex nuts when adj ustment i s

complete.

Figure 14

This initial setup is a starting point and final

adjustment may have to be made during a test

cut.

Figure 15

13

Page 14

Outfeed Roller

The outfeed roller is of smooth, one-piece

construction to help avoid marring the finished

surface of the material being cut. It is spring

tensioned, and i ts f unct ion is to c onti nue to feed

the materi al through the machi ne after it leav es

the infeed roller. The correct free position

setting is 1/32" (0.8mm) below the arc of the

cutterhead knives.

Use a gauge, such as a bed and feed r oll gauge

or wood gauge block (see Figure 13) to check

the outf eed roll er i n the sam e manner as f or t he

infeed roller. Adjust as necessary using the

screws (E, Figur e 15). When fini shed adjusting,

tighten the hex nuts on the screws.

Table Rollers

The Planer has two table rollers which help

reduce friction of the stock on the table as it

feeds through t he machine. It is not possibl e to

give exact height setting of the table rollers

because each ty pe of wood beh aves di fferent ly.

As a general rule, however, the table rollers

should be set high when planing rough stock,

and set low for fi nish cut s.

The planer is equipped with a quick set table

roller adjustment. With a single lever, you can

raise the roll s from their fi nishing board hei ght to

a roughing board height. The range is 0.00 to

0.05”.

Figure 15 (repeated)

To adjust the hei ght of the table rollers, loosen

the handle (A, Figure 16) and move the quickset lever (B, Figure 16) until the indicator is at

the desired setti ng on the scale. Re-tighten the

handle (A, Figure 16) to lock the setting.

NOTE: The handle (A) is adjustable. To reposition it , simply lift out on the handle, rotat e it

on the pin and release, making sure it seats

itself properly on the pin.

The table rollers are adjusted at the factory. If

they should need further or “fine” adjustment:

1. Disconnect machine from power source.

2. Loosen lock handle and positi on the quick-

set lever (Fi gur e 16) to zero.

3. Use a dial gauge (not provi ded) to find the

distance from table top to the apex of the

table roller. Zero the gauge at this position.

4. Place t he gauge over the ex treme right side

of the t able roller and fi nd the high point of

the table roller arc. The gauge should still

read zero.

Figure 16

14

Page 15

5. If the gauge reading i s greater or le ss than

zero, reach beneat h the table with a wrench

and loosen the hex nut (C, F i gure 17) which

is above the cam (D, Figure 17) near the

end of the roller that needs adjusti ng. Rotate

the hex cap screw (E, Figure 17) until the

gauge reads zero.

6. Repeat the process for the left side of the

table roll er, and then r e-check the right side.

It is important that both ends of the table

roller be the same height to help prevent

skewing of t he board a s it f eeds through t he

machine.

7. Re-tighten the hex nuts (C, Figure 17) on

both ends of the table roller.

8. Repeat the procedure for the second table

roller.

Table Adjustments

The planer table is raised and lowered by twin

screws supported on beari ngs, and is guided by

machined surfaces on the side panels. The fitup to prevent the table from rocking is cont roll ed

by two gibs in front . See Figure 18. These gibs

are pre-set at the factory and require no

attention. If, after extensive use of the planer,

some looseness in the table develops, these

gibs can be adjusted individually using the gib

screws provided so that the ways are lightly

contacti ng on all four surfaces. The gibs sho uld

be tight enough t o prevent rocki ng or m ovem ent

of the table when the pl aner is i n operation.

Figure 17

Figure 18

To perform accurate planing, t he table must be

parallel wit h the cutter head. Lack of parall elism

results in a taper ov er the width of the board. T o

check parallelism do the following:

1. Pl ace a gauge on t he table and c ontacti ng a

knife at t he apex of its arc. Do t his at each

end of the cutterhead and compare the

measurements.

2. If the table is not parall el to the cutterhead,

place the gauge at the end t hat needs to be

raised.

3. Loosen the three socket head cap screws

(A, Figure 19) beneath the table.

4. Place a rod-like object (such as a hex

wrench) into one of the open holes (B,

Figure 19) and t urn the shaft ( C, Figure 19)

to raise the t able until the gauge reads the

proper measurement. Or, the same effect

can be achiev ed by lowering the other side

of the table.

5. Re-tighten the screws (A, Figure 19).

NOTE: Thi s adjustment may generate the need

to recalibrate the table height pointer.

Figure 19

15

Page 16

Operating Controls

The stop button is a mushroom style button

which is conv enient for “ emergency ” shutdowns.

After being pushed, the stop button remains

engaged. To re-start the planer, twist the stop

button clockwise until it pops back out.

Test Cutting and Troubleshooting

Using a piece of semi-finished stock, set up for a

1/16" (1.59mm) deep cut with t he quick-set table

roller adjustment (shown in Figure 16) set at

zero. Start the machine and, standing to one

side of the table, begin feeding the stock into the

machine.

Never stand directly in line

with stock or al lo w anyone else to do so, and

do not bend down to see how stock is

feeding. Shoul d a kickback occur, seriou s or

fatal injury could resul t .

The infeed roller should take the material and

force it under the chi pbreaker and cut terhead. I f

the materi al feeds through effortlessly, examine

the finished cut carefully for imperfections.

Learning to read a board for imperfections will

save hours in adjusting a planer to operate

properly.

Following are some problems that may arise

and their probable remedies. The Figure

illustrations are exaggerated for clarity. (Pages

19-21 also contai n Troubleshooting remedies).

Washboard Finish

A very pronounced washboard finish down the

full length of the board results from one knife

being too high and forced to do all the cutting.

See Figure 20. Re-set the high knife

accordingly.

Clip Marks

If "clip" marks occur 6" (152mm) in from each

end of the board, the pressure bar is too high.

See Figure 21. Turn both right and left hand

adjusting screws (see Figure 15) the same

amount, 1/4 turn clockwise or less, and take

another 1/16" (1.59mm) deep cut. Re-examine

the board.

Continue the operat e-adjust procedure until t he

clip marks disappear. Should the board fail to

feed through, back off sli ghtly on both adj usting

screws until feeding is smooth and the

imperfections do not re-appear. Lock the

pressure bar adj usting scre ws with t he jam nuts

provided.

Figure 20

(washboard)

Figure 21

(clip marks)

16

Page 17

Snipe

Some amount of snipe may be inevitable with

many planer operations, but proper planer

adjustments can so minimize snipe as to make it

negligible.

If noticeabl e snipes appear on each end of the

material, as shown in Fi gure 22, a tabl e rol ler is

too high causing a sl ight lift of t he material as it

passes through the machine. Normally these

snipes are more notic eable on the traili ng end of

the board than on the l ead end, and most of ten

occur during planing of rough lumber.

Table roll ers must be el ev ated for runni ng r ough

or resaw lumber through the machine. When

material i s turned over t o surf ace the ot her side,

and you neglect to lower the table rollers for a

finish cut, then def init e snipes will appear on the

ends of the material.

Chatter

Chatter marks usually appear on thin material.

See Figure 23. Even at their lowest point, the

table roll ers are too high to handle t hin material.

Solve the problem by either using a slav e board

or making an auxiliary table out of Formica

countertop m aterial with cleati ng at each end to

keep it stati onar y ov er the planer table.

Figure 22

(snipe)

Figure 23

(chatter)

Tapers

If the machine planes a taper across the full

width of the board, as shown in Fi gure 24, the

table is not parallel with the cutterhead. First

check that al l knives are properly inst alled with

equal protrusi on from the c utterhead. If they are,

then the table itself must be adjusted. See

“Table Adjustm ents” on page 15.

Twisting

If material twists while feeding through the

planer, the pr essure bar, out feed roller or table

rollers may be out of level. Ref er to adj ustment

settings on pages 13 and 14.

Feed Restriction

This is caused either by the table rollers being

set too low for roughi ng operations or by a low

pressure bar. A bout 90 percent of t he time the

pressure bar is too l ow. As the sharp edge of the

planer knives wear, you must compensate for

this wear by raising the pressure bar an equal

amount on each side. Your first indication of

knife wear is hesitation in feed of the material

through the machine after it leaves the

corrugated infeed roller on its way out of the

machine. Disconnect machine from power

and adjust the pressure bar acordingly. The

material will free up and feed thr ough smoothly

when the planer is restart ed.

Figure 24

(taper)

17

Page 18

Never attempt pressure bar

adjustment while planer is connected to

power.

Feed restriction can also occur due to pitch

buildup on the table. Be sure the table surface is

clean. Occasi onally dusti ng the surface with talc

will aid in smoother feeding and help prevent

pitch buildup.

Halted Feeding

If the infeed roller takes the stock, the

chipbreakers l ift, and just as you hear t he kniv es

contact the material, it stops feeding, then the

pressure bar i s too low. Re set the pressure bar

(see page 13).

Maintenance

Periodic inspecti ons are required to ensure that

the machine is in proper adjustment, that all

screws are tight, that belt s are in good condition,

that dust has not accumulated in the electrical

enclosures, and that t here are no loose or worn

electric al c onnec tions.

Buildup of sawdust and other debris can cause

your machine to plane inaccurately. Periodic

cleaning is not only recommended but

mandatory for accurate planing.

Close-fitting parts, such as the table locking

rods, the cutterhead slot and gibs, should be

cleaned with a cloth or brush and nonflammable solvent and freed from clinging

foreign matter.

Lubrication

The gear box oil should be changed at least

once a year. Rem ove the drain pl ug (A, Figure

25) to drain t he oi l i nt o an appropri ate c ontai ner.

Replace the drai n plug and f ill t he gear box wit h

60 to 90 weight gear oi l through the fill hole (B,

Figure 25). Capacit y is 0.494 gall on (1. 87L). The

sight glass (C, Figure 25) should be checked

periodical ly and oil topped off as necessary.

Figure 25

The recommended lubrication for roller chains

used in medium to slow speed operation is to

simply wipe the chain clean. When there is an

appreciable buildup of dust, dirt or wood

shavings, use an oi l clot h but never pour t he oil

directly on the chain. Over-oiling defeats the

purpose of t he l ubricati on, sinc e it t ends to i nvite

the collection of dust, shavings, etc. and works

into members of the chain. This hastens wear

and leads to prematur e r eplac em ent.

Use caution and proceed

slowly when working with or around the

cutterhead kni ves.

Remove resin and other accumulations from

feed rolls and table with a non-flammable

solvent.

Periodically check all the chains and belts for

proper tension and adjust accordingly if

required.

TIP: If a f oreign object nicks the kniv es on the

straight cutterhead (Model 201), instead of

throwing them away or trying to grind out the

deep nick, simply stagger the knives in the

head, moving one k nife no mor e than 1/4” to the

right and another knif e no m ore than 1/4” t o the

left. The nick will not be noti c eable.

The bearings on the cutterhead are factory

lubricated and sealed. They require no further

attention.

Periodically oil the bearings on the infeed and

outfeed roll ers, through the oil cups located on

the bearing block s (Fi gur e 26) .

Figure 26

18

Page 19

Troubleshooting: Planer Operating Problems

Trouble Probable Cause Remedy

Table rollers not set pr oper ly. Adjust tabl e rollers to proper height.

Snipe.

Fuzzy grain.

Torn grain.

Inadequate support of long boards.

Uneven feed roller pr essure front to

back.

Dull knives.

Lumber not butt ed pr operl y .

Planing wood with a high moisture

content.

Dull knives.

Too heavy a cut. Adjust proper dept h of cut.

Knives cutti ng against grain. Try to cut with the grai n for finish cut.

Dull knives.

Dull knives.

Support long boar ds with a r oller

stand.

Adjust feed roller tension.

Sharpen or replac e k niv es.

Rotate or replace k nife inserts.

Butt end-t o- end eac h piec e of stock

as they pass through.

Remove moisture from wood by

drying, or use different stock.

Sharpen or replac e k niv es.

Rotate or replace k nife inserts.

Sharpen or replac e k niv es.

Rotate or replace k nife inserts.

Sharpen or replac e k niv es.

Rotate or replace k nife inserts.

Rough/raised grai n.

Rounded, glossy

surface.

Poor feeding of

lumber.

Excessive dept h of cut. Decrease cutti ng depth.

Moisture cont ent too high.

Dull knives.

Inadequate f eed r oller pressure.

Planer table r ough or dir ty.

Belts are slipping.

Surface of feed rollers has been worn

too smooth.

Remove moisture from wood by

drying, or use different stock.

Sharpen or replac e k niv es.

Rotate or replace k nife inserts.

Adjust feed roller tension. If proper

tension cannot be achieved, replace

feed roller(s).

Clean off pitch and r esi due; apply

light coat of paste wax to planer table.

Check belt tension and m ak e any

needed adjustments.

Lightly roughen t he feed roller surface

with sandpaper.

19

Page 20

Troubleshooting: Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Uneven depth of cut

side to side.

Board thickness does

not match dept h of

cut scale.

Chain is jumpi ng.

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blo ws fuses.

Knives not set corr ec tly.

Planer table not parallel to cutterhead.

Depth of cut scale is inc or r ect. Adjust pointer on depth of cut scale.

Inadequate chain tension. Adjust chai n tension.

Sprockets mi sali gned. Align sprockets.

Sprockets worn. Replace sprockets.

No incoming power. Verify machine is connected to power.

Stop button is stil l engaged. Rotate stop button to disengage.

Overload automatic reset has not

reset.

Planer frequently trips.

Building circuit breaker trips or fuse

blows.

Loose electri c al c onnec tions.

Make sure knives are set correctly

and securely in c utt er head.

Adjust tabl e parallel to cutterhead.

See page 15.

When the planer overloads on the

circuit breaker built into the motor

starter, it takes time for the machine

to cool down before restar t. Allow

machine to adequately cool before

attempting r estar t. If problem persists,

check amp setting on t he m otor

starter insi de the electrical box.

One cause of overl oad trips which are

not electrical in nature is too deep a

cut. The solution is to take a lighter

cut. If too deep a cut is not the

problem, check the amp setting on

the overload r elay . Match the full load

amps on the motor as noted on the

motor plate.

If amp setting is corr ec t, then t here is

probably a loose electrical lead or a

failed component . S ee items below.

Verify that planer is on a circuit of

correct size. If circuit size is correct,

there is probabl y a loose el ectr ic al

lead. Check am p setting on motor

starter.

Go through all of the electrical

connections on the planer including

motor connecti ons, verifying the

tightness of eac h. Look for any signs

of electrical ar ci ng whic h is a sure

indicator of loose connections or

circuit overload.

20

Page 21

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blo ws fuses.

(continued)

Starter or motor failure (how to

distinguish).

Motor failure. If electri c mot or i s suspect, you have

Examine motor star ter for burned or

failed component s. If dam age is

found, replace motor starter.

If you have access to a voltmeter, you

can separate a starter f ailure from a

motor fai lu re by fi r st, verifyin g

incoming volt age at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20.

If incoming voltage is incorrect, you

have a power supply probl em .

If voltage between starter and motor

is incorrect, you have a starter

problem.

If voltage between starter and motor

is correct, you hav e a motor pr oblem.

two options: Have a qualified

electrican test the motor for function

or remove the motor and take it t o an

electric motor repai r shop and have it

tested.

Machine incorr ec tly wired. Double check to confi rm all electrical

connections are cor r ec t. Refer to

appropriate wir ing diagrams on pages

34-36 to make any needed

corrections.

Start/ stop switc h failure. If a start or stop switch is suspect, you

have two options: Have a qualified

electrician test the switch for function,

or purchase a new switch and

establish if t hat was the problem on

changeout.

Planer does not

come up to speed.

Low current. Contact a qualified electrician.

Replacement Parts

Replacement par ts are li sted on the f ollowing page s. To order parts or reac h our servi ce depar tm ent, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.powermatic.com).

Having the Model Number and Serial Number of your mac hine available when you cal l will allow us to

serve you quickly and accurately.

21

Page 22

Parts List: Base Assembly

Index No. Part No. Description Size Qty

1 ............... 6012068...................Rubber Boot .......................................................................................... 2

2 ............... 6012069...................Lead Screw ........................................................................................... 1

3 ............... 6293370...................Key.....................................................................5 x 5 x 10 ................... 2

4 ............... 6012070...................Screw w/ Washer............................M4x0.7Px8Lg / 4mmx10x0.8T ......... 4

5 ............... 6012071...................Bushing ................................................................................................. 2

6 ............... 6012072...................R-Ring ................................................................RTW-68 ...................... 2

7 ............... 6012073...................Ball Bearing ........................................................6008-2NSE ................. 2

8 ............... 6012074...................Bearing...............................................................51105 ......................... 4

9 ............... 6012066...................Socket Head Cap Screw .....................................M8 x 1.25P x 25Lg .... 11

10 ............. 6012075...................Bracket .................................................................................................. 2

11 ............. 6012076...................Sprocket ................................................................................................ 3

12 ............. 6012077...................Washer...............................................................25mm ......................... 2

13 ............. 6012078...................Nut .....................................................................M25 x 1.5 ................... 2

14 ............. 6012079...................Hex Nut .............................................................M10 x 1.5P ................. 5

15 ............. 6012080...................Flat Washe r ........................................................10mm x 25 x 3T .......... 1

16 ............. 6012081...................Rocker Arm ........................................................................................... 1

17 ............. 6012082...................Shaft ..................................................................................................... 1

18 ............. 6012083...................Flat Washe r ........................................................8.5mm x 19 x 2T ......... 2

19 ............. 6012067...................Spring Was her....................................................8.2 mm x 15.4.............. 5

20 ............. 6012084...................Lead Screw ........................................................................................... 1

22

Page 23

21 ............. 6292745...................Key.....................................................................5 x 5 x 16 ................... 2

22 ............. 6012085...................Chain .................................................................#40 x 79pcs ................ 1

23 ............. 6012086...................Bevel Gear ............................................................................................ 1

24 ............. 6012087...................Screw .................................................................M5 x 0.8P x 10Lg........ 4

25 ............. 6012088...................Strain Relief Clip .................................................ACC-3 ........................ 4

26 ............. 6012089...................Pin......................................................................................................... 4

27 ............. 6012090...................Base ...................................................................................................... 1

28 ............. 6012091...................Screw .................................................................M6 x 1.0P x 10Lg...... 12

29 ............. 6012092...................Cover .................................................................................................... 2

30 ............. 6012093...................Special Hex Screw ................................................................................ 4

31 ............. 6012094...................Hex Nut ..............................................................M16 x 2.0 ................... 4

32 ............. 6012095...................Foot ....................................................................................................... 4

33 ............. 6012096...................Set Screw ...........................................................M8 x 1.25P x 30Lg ...... 1

34 ............. 6012097...................Hex Nut ..............................................................M8 x 1.25 ................... 3

35 ............. 6012098...................Set Screw ...........................................................M5 x 0.8P x 5Lg ......... 2

36 ............. 6012099...................Bevel Gear ............................................................................................ 1

37 ............. 6012100...................S-Ring ................................................................STW-20 ...................... 1

38 ............. 6012101...................Ball Bearing ........................................................6204-ZZ ..................... 1

39 ............. 6012102...................Support Block ........................................................................................ 1

40 ............. 6012103...................Shaft ..................................................................................................... 1

41 ............. 6012104...................Key.....................................................................8 x 7 x 18 ................... 1

42 ............. 6012105...................Ball Bearing ........................................................6005-ZZ ..................... 1

43 ............. 6012106...................Chain .................................................................#40 x 107pcs .............. 1

44 ............. 6012107...................Sprocket ................................................................................................ 1

45 ............. 6012052...................S-Ring ................................................................STW-25 ...................... 1

46 ............. 6012109

47 ............. 6012110...................Power Cord ........................................................1Ph ............................ 1

................. 6012267...................Power Cord ........................................................3Ph ............................ 1

48 ............. 6012111...................Switch ................................................................ 460V/3Ph ................... 1

................. 6012045...................Switch ................................................................230V/1Ph ................... 1

................. 6012294...................Switch ................................................................230V/3Ph ................... 1

49 ............. 6012112...................Switch Plate .......................................................................................... 1

50 ............. 6012113...................Strain Relief Bushing ..........................................M20 ............................ 1

51 ............. 6012114...................Cover .................................................................................................... 1

52 ............. 6012115...................Motor Cord .........................................................1Ph ............................ 1

................. 6012266...................Motor Cord .........................................................3Ph ............................ 1

53 ............. 6012048...................Socket Head Cap Screw .....................................M10 x 1.5P x 20Lg ...... 1

54 ............. 6012116...................Washer.................................................................................................. 1

55 ............. 6012117...................Belt.....................................................................A56 ............................ 1

56 ............. 6012118...................Motor Pulley .......................................................................................... 1

57 ............. 6012108...................Motor ..................................................................7.5HP 1Ph 230V ......... 1

................. 6012108-SC.............Start Capacitor ...................................................200MFD, 250VAC ...... 2

................. 6012108-RC ............Run Capacitor ....................................................20μF,450VAC ............. 1

................. 6012108-RC2 ..........Run Capacitor ....................................................35μF,450VAC ............. 1

................. 6012119...................Motor ..................................................................7.5HP 3Ph 230/460V .. 1

................. 2210-271 .................Key.....................................................................8x7x40 mm.................. 1

58 ............. 6012120...................Flat Washe r ........................................................10.3mm x 23 x 2T ....... 8

59 ............. 6012121...................Hex Nut ..............................................................M12 x 1.75 ................. 4

60 ............. 6012122...................Flat Washe r ........................................................13mm x 28 x 3T .......... 4

61 ............. 6012123

62 ............. 6012124...................Set Screw ...........................................................M8 x 1.25P x 12Lg ...... 5

63 ............. 6012125...................Spacer................................................................................................... 2

64 ............. 6012126...................Shaft ..................................................................................................... 2

65 ............. 6012127...................Motor Plate ............................................................................................ 1

66 ............. 6012128...................Hex Screw ..........................................................M10 x 1.5P x 40Lg ...... 4

67 ............. 6012129...................Set Screw ...........................................................M8 x 1.25P x 20Lg ...... 2

68 ............. 6012130...................Flat Head Screw .................................................M6 x 1.0P x 20Lg........ 4

69 ............. 6012269...................Terminal Cover ...................................................................................... 1

70 ............. 6012270...................Screw .................................................................3/16-24NC x 1/4 ......... 1

71 ............. 6012271...................Screw .................................................................M5 x 0.8P x 20L ......... 2

72 ............. 6012272...................Termina l Plate ....................................................................................... 1

...................Switch Cord ........................................................................................... 1

...................Adjusting Bolt ........................................................................................ 2

23

Page 24

Gearbox Assembly

24

Page 25

Parts List: Gearbox Assembly

Index No. Part No. Description Size Qty

................. 201-100 ...................Gearbox Assembly ................................................................................ 1

1 ............... 6012034...................Gearbox Body ....................................................................................... 1

2 ............... 6012035...................Ball Bearing ........................................................6201-2NSE ................. 6

3 ............... 6012036...................S-Ring ................................................................STW-16 ...................... 2

4 ............... 6012037...................Gear ...................................................................................................... 2

5 ............... 6012038...................Ball Bearing ........................................................6204-2NSE ................. 2

6 ............... 6012039...................Oil Seal ..............................................................TC24 x 40 x 8 ............. 1

7 ............... 6012040...................Shaft ..................................................................................................... 1

8 ............... 6293370...................Key.....................................................................5 x 5 x 10 ................... 4

9 ............... 6012041...................Gear ...................................................................................................... 2

10 ............. 6012042...................Gasket................................................................................................... 1

11 ............. 6012043...................Pin......................................................................................................... 4

12 ............. 6012044...................Gearbox Cover ...................................................................................... 1

13 ............. 6012142...................Hex Socket Ca p Sc re w .......................................M10 x 1.5P x 25Lg ...... 4

14 ............. 6012046...................Pulley .................................................................................................... 1

15 ............. 6012047...................Flat Washe r ........................................................10mm x 25 x 3T .......... 2

16 ............. 6012048...................Socket Head Cap Screw .....................................M10 x 1.5P x 20Lg ...... 1

17 ............. 6012049...................Socket Head Cap Screw .....................................M8 x 1.25P x 20Lg ...... 1

18 ............. 6012050...................Sprocket ................................................................................................ 1

19 ............. 6292789...................Oil Plug ..............................................................PT1/4"-19UNF ............ 2

20 ............. 33-1051-00-1 ...........Oil Seal ..............................................................TC20 x 40 x 7 ............. 1

21 ............. 6012051...................Shaft ..................................................................................................... 1

22 ............. 6012052...................S-Ring ................................................................STW-25 ...................... 1

23 ............. 6292745

24 ............. 6012053...................Shaft ..................................................................................................... 1

25 ............. 6012054...................Gear ...................................................................................................... 1

26 ............. 6012055...................Shaft ..................................................................................................... 1

27 ............. 6012056...................Gear ...................................................................................................... 1

28 ............. 6012057...................Gear Assembly ...................................................................................... 1

29 ............. 6012058...................Set Screw ...........................................................M5 x 0.8P x 5Lg ......... 1

30 ............. 6012059...................Spring Pin...........................................................4mm x 25Lg ............... 1

31 ............. 6012060...................Shift Fork ............................................................................................... 1

32 ............. 6012061...................Lever ..................................................................................................... 1

33 ............. 6012062...................E-Ring ................................................................ETW-12 ...................... 1

34 ............. 6012063...................Shift Shaft.............................................................................................. 1

35 ............. 6012064...................Eye Glass Oil Lev el ............................................................................... 1

36 ............. 6012065...................Spring Pin...........................................................5mm x 26Lg ............... 1

37 ............. 6012066...................Socket Head Cap Screw .....................................M8 x 1.25P x 25Lg ...... 3

38 ............. 6012067...................Spring Was her....................................................8.2 mm x 15.4.............. 4

39 ............. 6012082...................Shaft ..................................................................................................... 1

40 ............. 6012286...................Idle Sprocket ......................................................................................... 1

41 ............. 6012287...................Bracket .................................................................................................. 1

42 ............. 6012079...................Hex Nut ..............................................................M10 x 1.5P ................. 1

43 ............. 6012288...................Stand Off ............................................................................................... 1

44 ............. 6012289...................Check Nut ..........................................................M10 x 1.5P ................. 1

45 ............. 6012290...................E-Ring ................................................................ETW-7 ........................ 1

46 ............. 6012291...................Spring .................................................................................................... 1

47 ............. 6012292...................Stand Off ............................................................................................... 1

...................Key.....................................................................5 x 5 x 16 ................... 2

25

Page 26

Column Assembly

26

Page 27

Parts List: Column Assembly