Page 1

8 Pitney Bowes

Shipping and Weighing Systems

Operator's Handbook

Model J640 / J641

Pro-MarkPrinter

: T...~~"7"" ;-:-T;.~~.,..-r , .'

r:; , ""!""'_.. ._~ ~ ~~-;-~ ,.- , -- "T" -~-:,.--'.-' :-~-.,,;.~.-;..'

~,.:-:o;;-,:,"-,.,,,,,M:~.,~:"!","._'."- ~~':~:-.~- :-r:~"'~~.'~"-~'~ ':':

SV60253 Rev. D 11/96

@1995Pitney Bowes, Inc. All Rights Reserved.

," ; ~.-

Page 2

Each product and program carries a respective written

warranty, the only warranty on which the customer can rely.

Pitney Bowes reserves the right to make changes in the

product and the programs and their availability at any time and

without notice. Although Pitney Bowes has made every effort

to provide complete and accurate information in this manual,

Pitney Bowes shall not be liable for any omissions or

inaccuracies. Any update will be incorporated in a later edition

of this manual.

WARNING

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to Part 15 of the FCC Rules. These

limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

CANADIAN D.C.C. WARNING

This digital apparatus does not exceed the Class A limits for radio noise

emissions from digital apparatus set out in the Radio Interference

Regulations of the Canadian Department of Communications.

Le present appareil numerique n'emet pas de bruits radioelectriques

depassant les limites applicables aux appareils numeriques de la classe

A prescrites dans Ie Reglement sur Ie brouillage radioelectrique edicte

par Ie ministere des Communications du Canada.

Trademarks

J640is atrademarkof PitneyBowes,Inc.

Page 3

Preface

This ma nual cont ains i nform atio n abou t the pr inte r ’s

You can also obtain an optional programmer’s manual (Pitney

Bowes form number SV60255).

✦ featur es an d func tion s

✦ general operation

✦ proced ures f or mai nten ance an d tro uble sho oting.

i

Page 4

J640 Operator’s Handb ook

Terms to Know –––––––––––––––––––––––––––––––––––––––––––––

continuous mode Print mode in which a format and data with a

specifi c quantity are sent to the print er to be

printed in one continuous strip.

download (send) Transmission of data from the host to your

printer.

format Data stream that contains the spec i fic label

design for printing data.

host Pitney Bowes device that the printer is

connected to.

label da ta Data stream that contains the act ual data

printed on a l a be l .

non-peel mode Feed mode in which the printer prints and

dispenses labels without peeling them from the

backing paper.

on-demand mode Print mode in which the printer prints and

dispens es one label at a time.

peel mode Feed mode in which the printer prints and

dispenses one peeled label at a time.

online Direct communication between a computer and

the printer.

System

Administrator

trigger Button used to feed and print labels, clea r

ii

Individual responsible for creating and

downloading data streams.

errors, and print a test label.

Page 5

Table of Contents

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

Connecting the Power Cord . . . . . . . . . . . . . . . . . . . . . . . . 1–2

Connecting the Communicati ons Cable . . . . . . . . . . . . . . . 1–3

Communication Values . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

Loading Ribbon and Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

Loading Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–3

Reloading a Ribbon Cassett e . . . . . . . . . . . . . . . . . . . . . . . 2–4

Loading Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–6

Loading for Peel Mode . . . . . . . . . . . . . . . . . . . . . . 2–7

Loading for Non-Pee l Mode . . . . . . . . . . . . . . . . . .2–11

Printing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3– 1

Printing in On-Demand Mode . . . . . . . . . . . . . . . . . . . . . . . 3–1

Canceling a Print Job . . . . . . . . . . . . . . . . . . . . . . . 3– 2

Printing in Continuous Mode . . . . . . . . . . . . . . . . . . . . . . . . 3–2

Using the Tear Bar . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

Interrupting a Print Job . . . . . . . . . . . . . . . . . . . . . . 3–4

Care and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

Clearing Label Jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–2

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–3

iii

Page 6

J640 Operator’s Handb ook

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

Problems and Solution s . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Label Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

Ordering Service and Supp lies . . . . . . . . . . . . . . . . . . . . . . 6–2

iv

Page 7

Chapter 1. Installation

This printer is a tabletop, online-only unit used to print labels.

A Pitney Bowes service representative should have installed

the printer for you, but the following information is provided for

reference.

Power Supply ––––––––––––––––––––––––––––––––––––––––––––––

The printer is shipped with an internal power supply that is

universal for all input power sources.

✦ Voltage ran ge: 90–2 60v

✦ Freque ncy r ange : 50–6 0Hz

1-1

Page 8

J640 Operator’s Handb ook

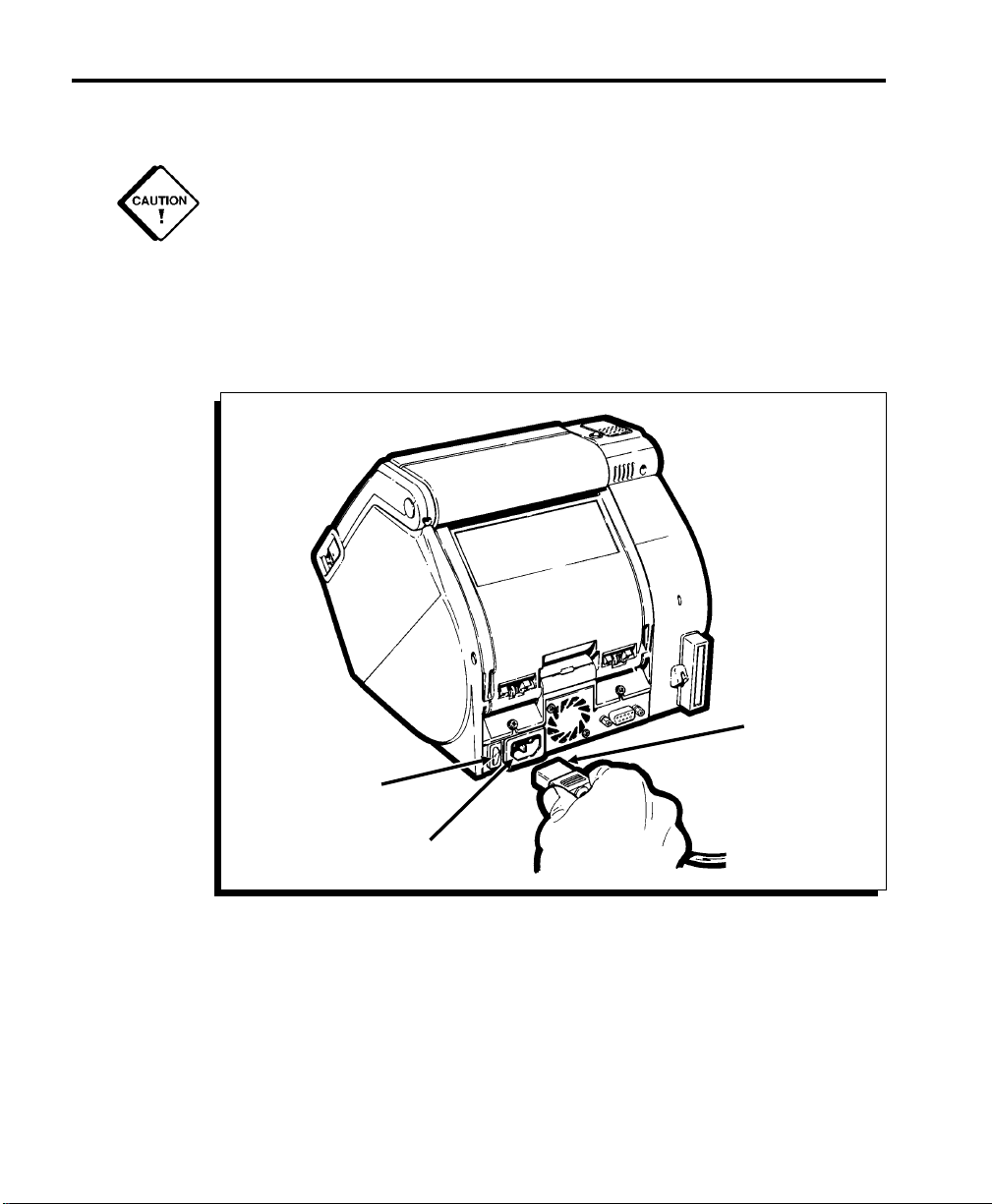

Connecting the Power Cord ––––––––––––––––––––––––––––––––––

Before you plug or unplug the power cord, turn the printer off.

To connect the power cord:

1. Turn the printer off. (I) indicates on and (O) indicates off.

2. Turn the printer as shown.

3. Insert the power cord into the socket as shown below.

1-2

Power Cord

On/Off

Switch

Socket

4. P lug the othe r end of t he pow er cor d into a grou nded

electrical outlet of the correct voltage.

WARNING: The power supply cord is intended to serve as the

disconnect device. The socket-outlet shall be

near the equipment and shall be easily accessible.

Page 9

Chapter 1. Installation

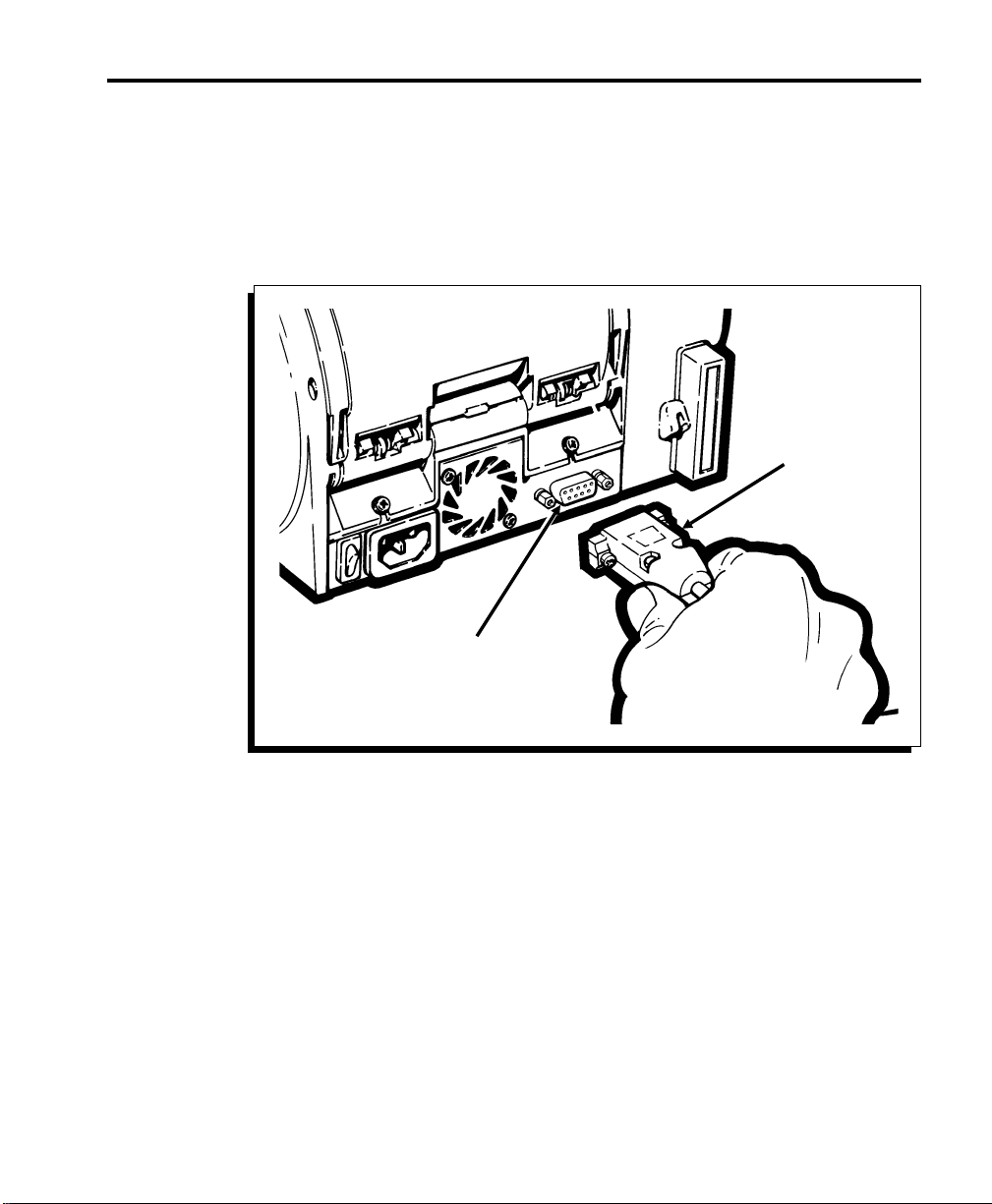

Connecting the Communications Cable ––––––––––––––––––––––––

Before receiving data, you must connect the communications

cable to the host and to the printer. Connect the

communications cable to your communications port as shown

below.

Communications

Cable

Communications

Port

1-3

Page 10

J640 Operator’s Handb ook

Communication Values –––––––––––––––––––––––––––––––––––––

In order for your printer to communicate with your host, you

must make sure the communication values are set to the same

values. Here are the default values with which the printer is

shipped:

These are no t fiel d-ch ange able in the p rint er.

✦ Baud: 9600

✦ Word Length: 8-bit data frame

✦ Stop Bits : 1-sto p bit

✦ Parity: none

✦ Flow Co ntrol : D TR

If you h ave any ques tion s regar di ng your print er, contac t our

National Diagnostic Center at 1-800-537-2488.

1-4

Page 11

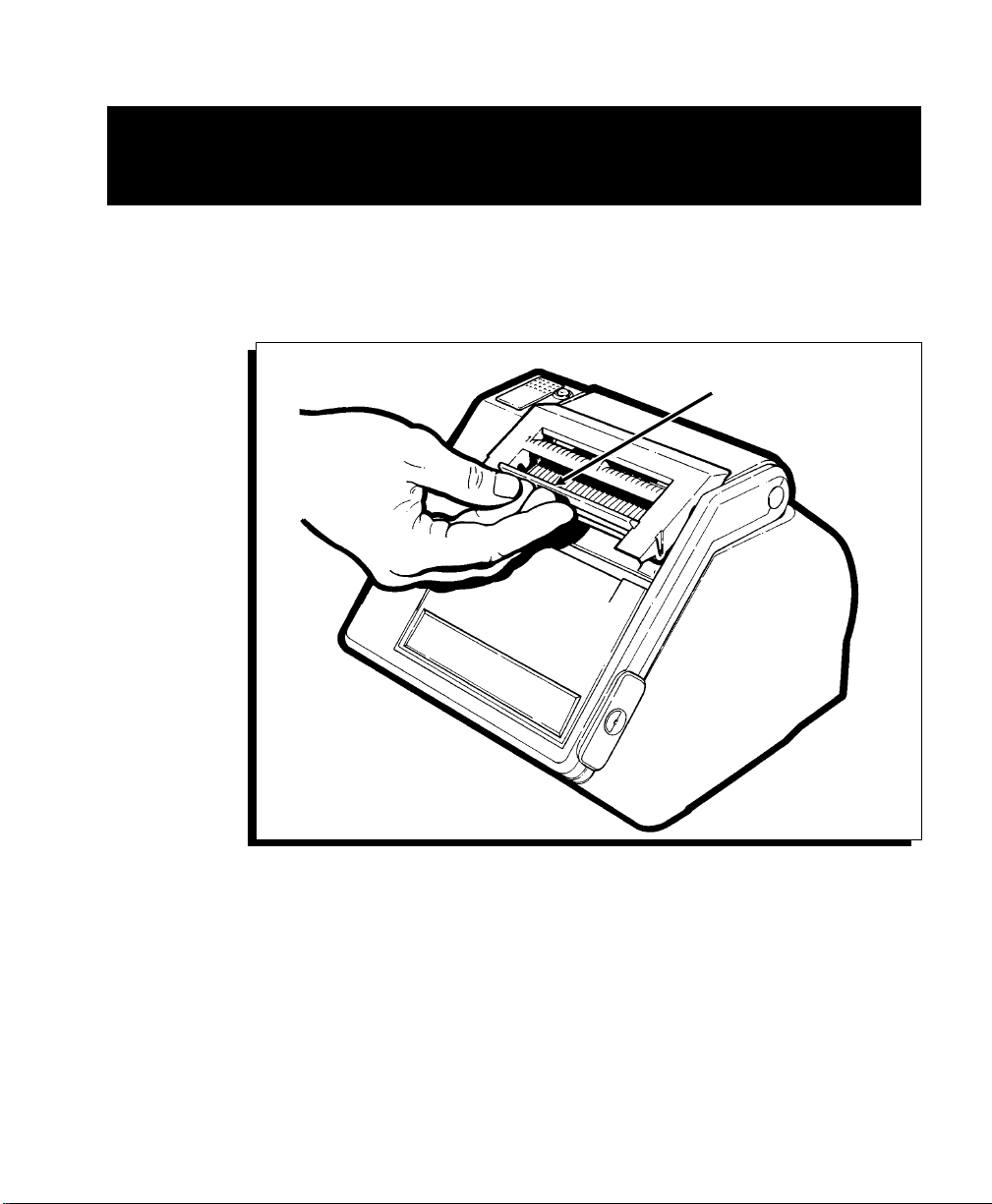

Chapter 2. Loading Ribbon and Supplies

Before loadin g ri bbon or label s, you must op en the p rin ter:

1. Insert your fingers into the depression beneath the face

plate and pull up.

Face Plate

2-1

Page 12

J640 Operator’s Handb ook

2. P ull th e labe l guid e for ward a nd dow n as sh own .

Label Guide

Front View

2-2

3. Push the printhead assembly toward the rear of the printer

until it opens completely.

Supply Holder

Ribbon Cassette

Printhead

Rear View

Assembly

Page 13

Chapter 2. Loa ding Ribbon an d S u pplies

4. To close the printer, push the printhead assembly toward

the front of printer, close the label guide and latch the face

plate into place.

Loading Ribbon–––––––––––––––––––––––––––––––––––––––––––––

To load the ribbon cassette into the printer:

1. Open the printer and remove the ribbon cassette.

2. Slide a new ribbon cassette onto the printhead assembly

until it slips into place.

Ribbon Cassette

Printhead Assembly

3. Cl os e th e pr in ter.

Make sure the ribbon is wound tightly inside the cassette

befor e you c lose t he pri nter. See " Reloa din g a Ribb on

Cassette" to wind the ribbon. Always change the ribbon when

you load a new ro ll of l abel s.

2-3

Page 14

J640 Operator’s Handb ook

Reloading a Ribbon Cassette–––––––––––––––––––––––––––––––––

To reload your ribbon, remove the ribbon cassette from the

printer and follow these steps:

1. Locate the end of the cassette with the two latches.

Locate the International Symbols for opening and closing.

( )indicates the cassette is locked (closed). ( )indicates the

cassette is unlocked (open).

2. Rotate both latches until they snap into the unlocked

position.

3. Lift off the half of the cassette without the latches and set it

aside.

2-4

Take- up

Reel

T eeth End of

Take-up Reel

Latch

Gear

Ribbon

Roll

Spool

Foam

Washer

Latch

4. Remove the used ribbon and take-up reel and discard.

Open a package of new ribbon.

Page 15

Chapter 2. Loa ding Ribbon an d S u pplies

DO NOT wrinkle or crush the ribbon.

5. W ith the teeth e nd of the take -up re el fac ing do wn, pl ace

the ribbon roll on the spool with the foam washer (on the

half of the cassette with the latches).

Take-up

Reel

Ribbon

Roll

Teeth End of

T ake-up Reel

Latch

Gear

Spool

Foam

Washer

Latch

6. Fe ed th e ribb on ar ound the gui des an d plac e the t ake-u p

reel on to the s hor ter spoo l.

7. Twist t he rib bon rol l back and for th as y ou firm ly pu sh it

down un ti l it i s s eat e d on th e sp oo l.

Do not force the ribbon roll down onto the spool; you could

damage the foam washer. Also, make sure the preprinted side

of the ribbon faces out. Make sure the latches are still in the

unlocked position ( ) before fitting the two halves of the

cassette together.

2-5

Page 16

J640 Operator’s Handb ook

8. Replace the other half of the cassette. The two halves

should fit together completely.

9. Rotate the latches until they click into the locked

position ( ).

10. Ch eck t o make s ure th at the r ibbon is loa ded co rrect ly an d

that the ribbon is wound tightly inside the cassette. Turn

the gear coun ter clockw ise w ith your f inger s un til the b lack

portion of the ribbon is exposed.

11. If the ribbon does not advance, or if it is hard to turn the

gear, repeat the loading procedure.

Loading Supplies –––––––––––––––––––––––––––––––––––––––––––

We recommend you use Pitney Bowes label stock. For label

sizes, see Chapter 6, "Specifications and Accessories."

You can load your supplies to

✦ peel

2-6

✦ not peel.

Refer to the following sections for information on loading for

peel an d non- peel modes .

Page 17

Loading for Peel Mode

Peel mo de sepa rat es labe ls from the ba ckin g pape r. The

print er defa ult is on-dem and.

Before loading labels, make sure the label path is clean. See

Chapter 4, "Care and Maintenance."

To load your labels:

1. Open the printer.

2. Us e the h andle s on the sid es of t he supp ly ho lder s to

spread the sup ply hol ders apar t to th e widt h of you r supp ly.

Supply

Holder

Chapter 2. Loa ding Ribbon an d S u pplies

Supply

Holder

Handle

2-7

Page 18

J640 Operator’s Handb ook

3. Insert the roll of labels between the supply holders inside

the printer.

4. Use the handles on the supply holders to press the supply

holder s toge ther un til t hey fit snugg ly ag ainst the su pply ro ll.

Supply

Supply

Holder

Peel

Bar

Lower

Opening

Upper

Opening

Spacer

Pinch

Rollers

Label

Guide

Make sure the supply holders are pressed against the supply

roll. Also, make sure the supply roll turns freely in the supply

well.

5. W hen usi ng co ntinuo us la bel st ock, re move a few in ches of

labels from the backing paper. Cut away the labels, leaving

the bac king pa per at tach ed to th e roll . Be sur e the lab els

have a square, straight edge. Feed the backing paper over

the peel bar and through the lower opening of the label

guide. Make sure the leading edge of the label is one inch

to two inches behi nd the bl ack platen roll er. Otherw ise, the

ribbon can be pull ed out alon g with the la bels, causi ng a

jam.

2-8

When loading die-cut label stock, remove a few inches of

labels from the backing paper. Feed the backing paper

over the peel bar an d thr ough the lo wer op ening of the l abel

guide.

Page 19

Chapter 2. Loa ding Ribbon an d S u pplies

Make su re the l eading edge of the la bel i s one t o two

inches behind the black platen roller. Otherwise, the ribbon

can be pu lle d out al ong w ith the label s, cau sin g a jam.

Do Not attempt to reload the backing paper into the printer.

The bac king p aper shou ld cont inue to dis pens e fro m the fr ont

of the printer, and be manually removed every few labels.

Label Guide

Rear View

Lower Opening

in Label Guide

6. K eep li ght ten sion on the la bel st rip whi le li ftin g the ba ck of

the pr inth ead asse mbl y.

Front View

Printhead

Assembly

2-9

Page 20

J640 Operator’s Handb ook

7. Cl os e th e pr in ter.

Make sure the ribbon is wound tightly inside the ribbon

cassette before you close the printer. See "Reloading a

Ribbon Cassette" to wind the ribbon.

Lower

Opening

Upper

Opening

Label

Guide

2-10

8. Turn the printer on.

9. Wait until the LED flashes one time (about five seconds)

and then press the trigger. The printer calibrates the label

strip for printing. When you print, labels peel automatically

through the upper opening in the label guide and the

backing paper exits out the lower opening.

Trigger

LED

The LED slowl y alt ernat es flas hin g ambe r and gr een to

indicate the printer is out of labels. When this happens, load a

new roll of labels and change the ribbon. Always change the

ribbon when y ou cha nge la bel ro lls.

Page 21

Loading for Non-Peel Mode

Non-peel mode feeds the labels through the printer without

peelin g the m from the ba ckin g pape r.

Before loading labels, make sure the label path is clean. See

Chapter 4, "Care and Maintenance."

To load your supplies:

1. Open the printer.

2. Us e the h andle s on the sid es of t he supp ly ho lder s to

spread the sup ply hol ders apar t to th e widt h of you r supp ly.

Supply

Holder

Chapter 2. Loa ding Ribbon an d S u pplies

Supply

Holder

Handle

2-11

Page 22

J640 Operator’s Handb ook

3. Insert the roll of supply between the supply holders inside

the printer.

4. Use the handles on the supply holders to press the supply

holder s toge ther un til t hey fit snugg ly ag ainst the su pply ro ll.

Supply

Supply

Holder

Peel

Bar

Lower

Opening

Upper

Opening

Spacer

Pinch

Rollers

Label

Guide

Make sure the supply holders are pressed against the supply

roll. Also, make sure the supply roll turns freely in the supply

well.

2-12

Page 23

Chapter 2. Loa ding Ribbon an d S u pplies

5. Fe ed th e labe l strip throug h the upper op enin g in th e labe l

guide.

Label Guide

Rear View

Upper Opening

in Label Guide

6. K eep li ght ten sion on the la bel st rip whi le li ftin g the ba ck of

the pr inth ead asse mbl y.

Printhead

Assembly

Front View

2-13

Page 24

J640 Operator’s Handb ook

7. Cl os e th e pr in ter.

Upper

Opening

Label

Guide

Lower

Opening

2-14

Make sure the ribbon is wound tightly inside the ribbon

cassette before you close the printer. See "Reloading a

Ribbon Cassette" to wind the ribbon.

8. Turn the printer on.

9. Wait until the LED flashes one time (about five seconds)

and then press the trigger. The printer calibrates the label

strip for printing.

Trigger

LED

The LED slowl y alt ernat es flas hin g ambe r and gr een to

indicate the printer is out of labels. When this happens, load a

new roll of labels and change the ribbon. Always change the

ribbon when y ou cha nge la bel ro lls.

Page 25

Chapter 3. Printing

You can print labels in these modes:

✦ On-demand (peel mode)

✦ Continuo us ( non-pe el mode ).

Printing in On-Demand Mode ––––––––––––––––––––––––––––––––

In on-demand mode, the printer prints and dispenses one label

at a time until the quantity downloaded is reached. To print

labels on de mand:

1. L oad the labels for pe el mode . See Chapte r 2, "L oadi ng

Ribbon a nd Su ppl ie s. "

2. The host sends print data to the printer.

3. After the data packet is downloaded, the LED rapidly blinks

green (1/4 sec) to indicate the printer is ready to print. The

first la bel i n a batch pri nts abou t thre e seco nds af ter the

printer receives the data stream.

4. Remove the printed label. The next label in the batch will

print. If it doesn’t, press the trigger.

Trigger

Direct exposure to incandescent light may interfere with the

printer’s on-demand sensor. If you are operating close to an

incandescent light source, you may need to use the trigger to

print the ne xt lab el in th e bat ch.

LED

3-1

Page 26

J640 Operator’s Handb ook

Canceling a Pri nt Job

To cancel the current print job, hold down the trigger until the

LED sto ps bl inki ng and displ ays so lid gr een. The b atch is

canceled and the data is lost. To resume printing, you must

downlo ad th e batc h agai n.

Printing in Continuous Mode ––––––––––––––––––––––––––––––––

In this mode, a format and data packet with a specific quantity

of labels are sent to the print er. The labels print in one

contin uous s trip .

To print in Continuous Mode:

1. Load the supplies for non-peel mode. See Chapter 2,

"Loading Ribbon and Supplies."

2. The host sends the label data to the printer.

3. After the data packet is downloaded, the LED is solid

amber t o indi cate the pri nter is ready to pri nt and la bels will

print auto matically.

3-2

4. Af ter all the labels in the b atch print, remove the lab el strip

from the printer.

DO NOT jerk or pull labels strongly against the printhead. This

may cause a label jam.

The operator can switch between the continuous and

on-de mand mo des by hold ing the t rigg er fo r about two

secon ds, unti l the L ED chan ges to the a ppropr iate colo r for th e

mode de sired. Once c hange d, the o pera tor mu st th en turn the

printer off and on to reload the formats. If the LED is green, it

is in th e on- deman d mode . If it is ambe r, it is in the c ont inuo us

mode.

Page 27

Using the Tear Bar

When pr inti ng on c ontin uous suppl y, you can use t he tear bar

to remove the printed labels.

DO NOT use the tear bar to remove labels printed on die-cut

supply.

To remove a prin ted la bel st rip, start at one ed ge of th e stri p

and pull it up and toward the top of the printer until it tears

against the tear bar as shown.

Chapter 3. Printing

Tear Bar

3-3

Page 28

J640 Operator’s Handb ook

Interrup ti ng a Print Job

You can pause or cancel the current print job:

✦ To pa use th e curre nt pr int jo b, pres s the trig ger onc e.

The cur rent prin t job st ops te mpor ar ily. To resume

printi ng, pr ess th e trig ger a gain.

✦ To cancel the current print job, hold down the trigger

until the printing stops. The batch is canceled and the

data is lost. To resume printing, you must download the

batch da ta ag ain.

You canno t cance l a pri nt job w hen th ere is an erro r in th e

printer until you press the trigger to acknowledge the error.

Trigger

LED

3-4

Page 29

Chapter 4. Care and Maintenance

DO NOT use sharp objects to clean the printer. This may

damage the printer and void your warranty.

This chapter tells you how to:

✦ clear label jams

✦ clean the printhead, peel blade, tear bar, and platen

roller.

4-1

Page 30

J640 Operator’s Handb ook

Clearing Label Jams–––––––––––––––––––––––––––––––––––––––––

When you are pr inti ng and a jam oc curs, the LED flas hes

amber and green.

To clea r a label jam:

1. Turn the printer off and open the printer.

2. Remo ve the label roll.

4-2

3. Remove the jammed labels and reload the label roll.

4. Close the printer and turn it on.

5. Press the trigger to resynchronize the labels.

Page 31

Chapter 4. Care and Maintenance

Cleaning –––––––––––––––––––––––––––––––––––––––––––––––––––

You may nee d to cle an the pr in thead, platen roll er, peel bar,

pinch ro lle rs, pe el blad e and te ar bar :

✦ after 8 rolls of supplies

✦ daily if your printer is in an excessively dirty, hot, or

humid en viro nmen t

✦ when you see voids in the print.

To clean t he pr inth ead, platen rol ler, peel bar, pinc h rol lers ,

peel blade, and tear bar:

1. Tur n the po wer off and op en the p rint er.

2. Remove the label roll and ribbon cassette (when cleaning

the pr inth ead) .

DO NOT touch the printhead with your hands. This may

damage the printhead.

4-3

Page 32

J640 Operator’s Handb ook

3. In a holder mounted on the back side of the printer, there

should be a cleaning pen. Using this cleaning pen or a

cotton swab moistened with alcohol, rub back and forth

across the pri nthea d, plat en ro ller, peel bar, pinch rolle rs,

and peel blade to remove any build up. Make sure the

printhead, platen roller, peel bar, pinch rollers, peel blade,

and tear bar are clean.

Printhead

Platen

Roller

4-4

Tear Bar

Pinch

Roller

Peel Blade

4. Let the printer dry and reload your supplies.

Page 33

Chapter 5. Troubleshooting

The pri nter uses a comb inat ion of light s to dis pla y a var iety of

printer states. See the "Problems and Solutions" section for

those requiring further actions.

LED Indicator ––––––––––––––––––––––––––––––––––––––––––––––

This t able e xpla ins th e mean ings of var ious LED st ates. Use

the colo r of the LED an d whet her it is so lid, bl inki ng slow ly, or

blinking rapidly to determine the meaning of the indicator.

LED States Solid Fast Blink

(1⁄4 second)

GREEN Ready...

On-Demand

AMBER Ready...

Continuous

AMBER/

GREEN

N/A Hardware

Label Ready N/A

Error Printh ead H ot...Wa it

Error

Slow Blink

(2 seconds)

Firmware

Error

5-1

Page 34

J640 Operator’s Handb ook

Problems and Solutions –––––––––––––––––––––––––––––––––––––

This section helps you correct some problems that may occur.

If you ca nnot fix a pr oblem , pl ease co ntac t Ser vice.

Problem Solution

Prints blank labels. Check ribbon and reload if necessary.

Printed supply has

voids or is too light.

Printer does not start. Make sure the power cord is connected to the

Printer does not print. Make sure the power cord is connected to the

Printer does not feed. Reload the supplies.

Make sure the supplies are loaded correctly.

Check the supplies for damage or defects.

Reload supplies or ribbon if necessary.

Check the roller for jammed labels.

Clean the printhead. See "Care and

Maintenance."

printer and plugged into a live outlet. Call

Service.

printer and plugged into a live outlet.

Make sure the printer is not paused.

Make sure the supplies are loaded correctly.

Make sure the communications cable is

connected.

Verify that the ribbon is not out and that a

label is not jammed in the label path.

5-2

Slow or sluggish

feeding.

Make sure the supplies are loaded correctly.

Check for adhesive build-up in the feed path

and on the peel blade.

Page 35

Chapter 5. Troubleshooting

Problem Solution

Label Jam. Remove jammed labels.

Clean the printer.

No LED. Make sure the power is on.

Make sure the power supply is connected to

the printer and plugged into a live outlet.

5-3

Page 36

J640 Operator’s Handb ook

5-4

Page 37

Chapter 6. Specifications and Accessories

Specifications ––––––––––––––––––––––––––––––––––––––––––––––

Height: 8 inches (203 mm)

Wi dth: 8.1 i nches (206 mm)

Depth: 10.5 inches (267 mm)

Weight: 6.3 lb. (2. 86 kg.) wit hout supplies

S t o r a g e L i mi t s: 15˚F to 120˚F

(-9˚C to 49˚C)

Operating Limits: 40˚F to 95˚F (4˚C to 35˚C)

P ower Sou rce: Internal, universal power supply

(Voltage range: 90–260v. Frequency range:

50–60Hz)

P rinting: Thermal tra nsfer

Calling for Service and Supplies–––––––––––––––––––––––––––––––

For Ser vice , call 1- 800- 537- 2488

For Sup plies, ca ll 1- 800- 243- 7824

Pitney Bowes Supply Numbers Description

665-7 = 2" x 1.5" Die Cut Label

665-1 = 4" x 3" Die Cut Label

665-9 = 2" x 4" Die Cut Label

665-5 = 2" Co ntin uous La bel

665-3 = 4" Co ntin uous La bel

6-1

Page 38

J640 Operator’s Handb ook

6-2

Page 39

Page 40

Printed in U.S.A.

Loading...

Loading...