Page 1

Page 2

MAIL MATERIALS REFERENCE GUIDE

Page 3

SV60822 Rev. A

First Edition, October 2000

©2000 Pitney Bowes Inc.

All Rights Reserved.

This book may not be reproduced in whole or in part in any fashion or stored in

a retrieval system of any type or transmitted by any means, electronically or

mechanically, without the express written permission of Pitney Bowes Inc.

We have made every reasonable effort to ensure the accuracy and usefulness

of this publication; however, we assume no liability for any errors or omissions,

or for the misuse or misapplication of our publications or products.

Due to our continuing program of product improvement, equipment and material

specifications as well as performance features are subject to change without

notice.

DocuMatch is a trademark of Pitney Bowes Inc. Lexmark and Optra S are

trademarks or registered trademarks of Lexmark International Inc. Canon is a

trademark or registered trademark of Canon Inc. Dow Window Film and Trycite

are trademarks or registered trademarks of The Dow Chemical Company.

Page 4

Contents

1 - Introduction

Purpose of This Guide...............................................1-2

Who Should Read This Guide....................................1-2

2 - General Material Specifications and Storage

Handling and Storage Tips........................................2-2

Definition of Mail Materials...................................2-2

Handling................................................................2-2

Storage..................................................................2-2

Rotation.................................................................2-3

Locally-Manufactured Materials...........................2-3

Mail Materials Reference Table..................................2-4

Collation Total Thickness Limits................................2-6

Materials Not Suited for DocuMatch™.......................2-7

3 - Paper for Document Printer

Recycled Paper...........................................................3-2

Paper Weights............................................................3-2

Grain............................................................................3-3

Methods for Determining Grain...........................3-3

Paper for DocuMatch™ Document Printer..................3-5

Document Printer Materials Reference Table.......3-5

Storage Tips.........................................................3-6

Loading Tips.........................................................3-6

Perforated Stock Specifications For

DocuMatch™ .........................................................3-8

Page 5

Contents

4 - Envelopes

Overview of Envelopes...............................................4-2

Envelope Quality...................................................4-2

Envelope Size.......................................................4-2

Envelope Type.......................................................4-2

Die-Cut............................................................4-2

Web-Fed..........................................................4-3

Envelope Style......................................................4-4

Envelope Curl........................................................4-4

Window Envelopes...............................................4-6

Standard Window Dimensions.......................4-7

Envelope Seal Flap and Gum...............................4-8

Storage..................................................................4-8

Loading Tips.........................................................4-9

Envelope Guidelines for DocuMatch™ ......................4-10

Envelope Style and Type......................................4-10

Envelope Size and Weight...................................4-10

#10 Envelope Specifications................................4-11

Envelope Materials Reference Table....................4-12

5 - Cut Sheet Feeder Material

Cut Sheets for DocuMatch

Grain Orientation...................................................5-2

Glossy Materials...................................................5-2

Static Charge........................................................5-2

Loading Tips.........................................................5-3

What to Watch For................................................5-3

Cut Sheet Feeder Materials Reference Table.......5-4

ii

™

.....................................5-2

Page 6

Contents

6 - Insert Feeder Material

Inserts and Business Reply Envelopes......................6-2

Loading Tips.........................................................6-2

Insert Feeder Materials Reference Table..............6-3

7 - Document Printer Preventive Maintenance

and Toner Usage

Scheduled Printer Preventive Maintenance...............7-2

Toner Yield..................................................................7-2

Setting the Printer Resolution to 300 DPI.............7-3

Setting the Print Darkness to Lighter or Lightest..7-3

Turning Toner Saver On........................................7-4

Page Coverage.....................................................7-4

Replica of Sample Page Showing

5% Print Coverage...............................................7-6

8 - General Machine Preventive Maintenance

System Preventive Maintenance................................8-2

General..................................................................8-2

Maintenance Log..................................................8-2

Pre-Service System Check with Remote

Diagnostics............................................................8-3

System Preventive Maintenance Schedule..........8-4

iii

Page 7

Contents

Appendices

A - Introduction to Paper

How Paper Is Made...................................................A-2

Paper Characteristics.................................................A-4

Moisture................................................................A-4

Wire and Felt Sides (of a Sheet of Paper)............A-5

Surface Coating or Finish....................................A-5

Body or Strength or Material................................A-5

Understanding Paper Ream Labels...........................A-6

B -Collation Total Thickness Limits

Total Thickness Limits................................................B-2

Total Thickness Worksheet........................................B-2

Index

iv

Page 8

Contents

List of Illustrations and Tables

Figure Description Page

3-1 Grain Long and Grain Short Direction...............3-3

3-2 Checking Grain Direction..................................3-4

3-3 Aerating Paper Before Loading.........................3-6

3-4 Flexing Paper Before Loading...........................3-7

3-5 Perforated Stock Specifications for

DocuMatch™.......................................................3-8

4-1 Envelope Curling Can Cause Problems............4-5

4-2 Window Envelope Standard for DocuMatch™...4-7

4-3 DocuMatch™ Specifications for #10

Envelope Dimensions........................................4-11

7-1 Reduced Replica of 8-1/2 x 11" Sample

Page With 5% Page Coverage..........................7-6

A-1 How Paper Is Made..........................................A-2

A-2 Two Sides of a Sheet of Paper...........................A-3

A-3 Understanding Paper Ream Labels..................A-6

Table Description Page

™

2-1A DocuMatch

2-1B DocuMatch™ Mail Materials Reference.............2-5

2-1C DocuMatch™ Mail Materials Reference.............2-6

3-1 Document Printer Materials Reference.............3-5

3-2 Letterhead Paper Loading Guidelines for

C-Fold and Z-Fold.............................................3-7

4-1 Envelope Trade Numbers and Sizes.................4-3

4-2 Envelope Materials Reference...........................4-12

5-1 Cut Sheet Feeder Materials Reference.............5-4

6-1 Insert Feeder Materials Reference....................6-3

7-1 Estimated Toner Yield........................................7-5

8-1 System Preventive Maintenance Schedule.......8-4

Mail Materials Reference.............2-4

v

Page 9

vi

Page 10

Chapter 1

Introduction

In this chapter:

Purpose of This Guide.....................................................1-2

Who Should Read This Guide..........................................1-2

1-1

Page 11

1 • Introduction

Purpose of This Guide

We have designed the DocuMatch™ Mail Materials Reference

Guide as a handy reference tool to provide you with useful

information about mailpiece materials. This guide will help you

to identify the proper materials to use and to determine

whether certain materials are within specifications. We have

also included some preventive maintenance

recommendations.

The ultimate goal of this guide is to help you to make your

DocuMatch system and your DocuMatch mail jobs run at

optimum efficiency.

Who Should Read This Guide

Our Pitney Bowes customers, Customer Service Field

Representatives, Sales Representatives, and visitors to our

Pitney Bowes internet/intranet web sites are encouraged to

refer to this guide frequently for quick access to information

about mailpiece materials.

This booklet is small enough to carry with you as needed for

visits to the post office, office supplies vendors, or your other

office locations.

1-2

DocuMatch™ Mail Materials Reference Guide

Page 12

Chapter 2

General Material Specifications and Storage

In this chapter:

Handling and Storage Tips..............................................2-2

Definition of Mail Materials............................................2-2

Handling.........................................................................2-2

Storage...........................................................................2-2

Rotation..........................................................................2-3

Locally-Manufactured Materials....................................2-3

Mail Materials Reference Table........................................2-4

Collation Total Thickness Limits.......................................2-6

Materials Not Suitable for DocuMatch™...........................2-7

2-1

Page 13

2 • General Material Specifications and Storage

Handling and Storage Tips

Definition of Mailing Materials

For the purposes of this guide, when we refer to mail materials, we mean:

• paper;

• envelopes;

• cut sheets;

• inserts.

Handling

Whenever you transport material, handle it with care. Careful

handling will extend the usable life of the material and maintain machine productivity.

Avoid exposing cartons of materials to the elements. Prolonged exposure to intense sunlight, high humidity, and so on,

can compromise the performance of material.

Storage

Store materials in a controlled environment. These cautions

apply:

• Store materials away from moisture if possible. A nominal

temperature range of 68-75 degrees F (21-24 degrees C),

50% humidity, is recommended. Since envelope formulations vary, it may be helpful to experiment with temperature and humidity limits above and below the specified

nominal figure. This will help determine the values for

achieving best productivity with material. It is best to

accumulate data over a period of several weeks for each

value of temperature and humidity.

2-2

DocuMatch™ Mail Materials Reference Guide

Page 14

General Material Specifications and Storage • 2

• Store cartons of materials at least six inches away from

masonry walls to prevent absorption of moisture. Keep

cartons on skids or shelves, but never directly on floors.

Remember that a very dry environment produces static,

which causes material to cling together. Humid conditions

may make paper limp and difficult to handle and may

cause curl.

• Do not stack cartons more than five feet high; any higher,

and you can deform the bottom cartons and damage the

envelopes. Stack cartons so that all envelopes stand on

edge. The lid of the box should be uppermost when

stacked. Boxes should remain closed until envelopes are

required.

Rotation

Rotate the stock, noting the following points:

• Control the inventory. Rotate the stock, using the oldest

stock first (first in, first out).

• If your storage area is compatible with our storage envi-

ronment guidelines (see previous section) and your work

area is not, transfer cartons from the storage area to the

work area no more than several hours before use.

• If your work area is compatible with our storage environ-

ment guidelines (see previous section) and your storage

area is not, transfer cartons from the storage area to the

work area at least 24 hours before use.

• Do not remove envelope or enclosure boxes from their

cartons until you are ready to load them on the work table.

Locally-Manufactured Materials

If you live in an extreme climate, we recommend that you buy

mailing materials manufactured locally. By doing this, you may

avoid significant changes in environmental conditions that

may cause performance problems.

DocuMatch™ Mail Materials Reference Guide

2-3

Page 15

2 • General Material Specifications and Storage

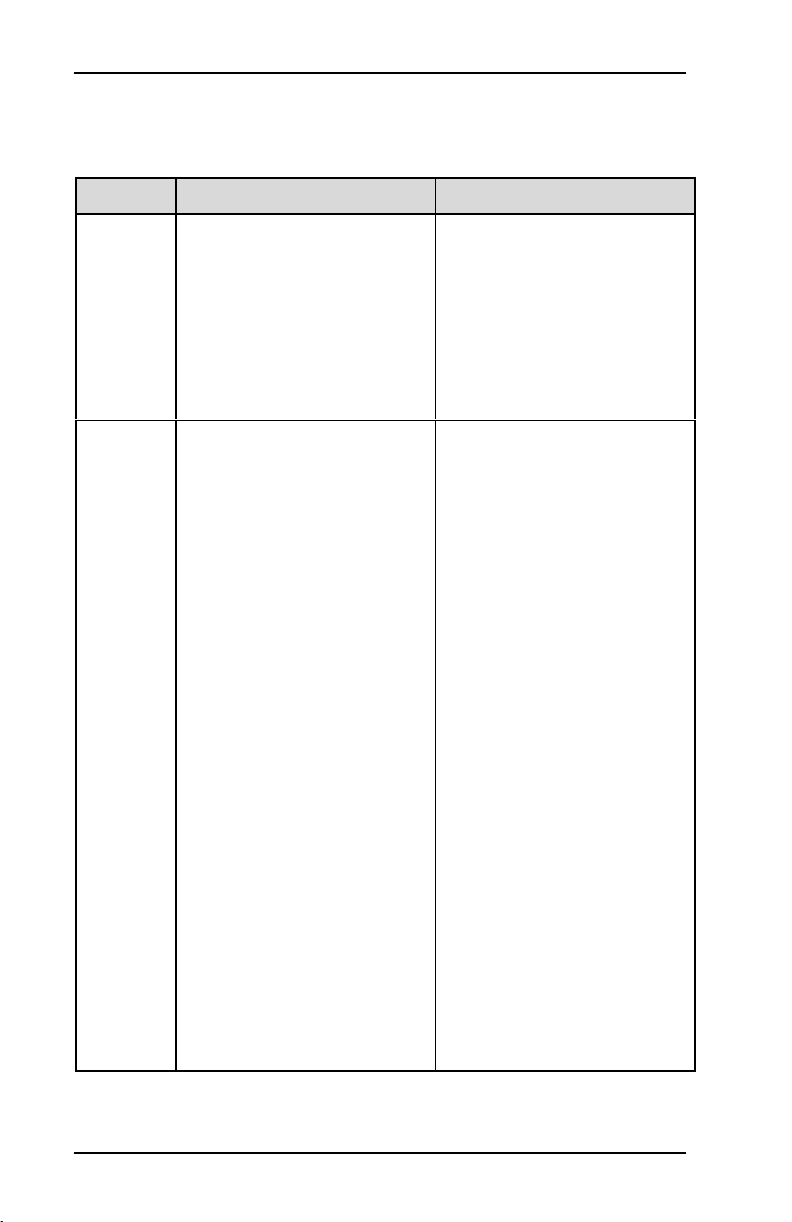

Table 2-1A

DocuMatch™ Mail Materials Reference

Source Minimum Requirements Performance Tips

Doc.

Printer

(Laser

Printer)

Insert

Feeder

• 8-1/2 x 11"

• Xerographic copy

paper, 20-24 lb. bond

• 24 lb. paper may be

microperfed (see page

3-8 for details).

• Grain long

Pre-folded Inserts (C-fold,

1/3 size):

• 3 x 5" to 3-7/8 x

8-7/8"

• 20 lb. bond

• 24 lb. bond

• 50-80 lb. coated offset

• 50-70 lb. uncoated

offset

• 80 lb. uncoated offset,

smooth

BREs:

• #9 standard envelope

(3-7/8 x 8-7/8")

• Check size

(3-5/8 x 8-5/8")

• Some preprinted

letterhead paper or

previously copied

paper may cause

feeder problems and

should be tested first.

• Avoid recycled

materials.

Pre-folded Inserts (C-fold,

1/3 size):

• Do not use Z-fold

material.

• Material that is highly

varnished will

contaminate the feed

belts.

• Do not use light-weight

inserts less than 16 lb.

• Do not use any inserts

with significant curl.

BREs:

• Closed flap with or

without window

• You may also use

#8-5/8 and #7 BREs.

2-4

• 20-24 lb. bond, all

types, smooth, glossy,

or flat

Postcards:

• As above (includes

7-point reply)

Postcards:

• Thickness range:

0.007" to 0.0095"

DocuMatch™ Mail Materials Reference Guide

Page 16

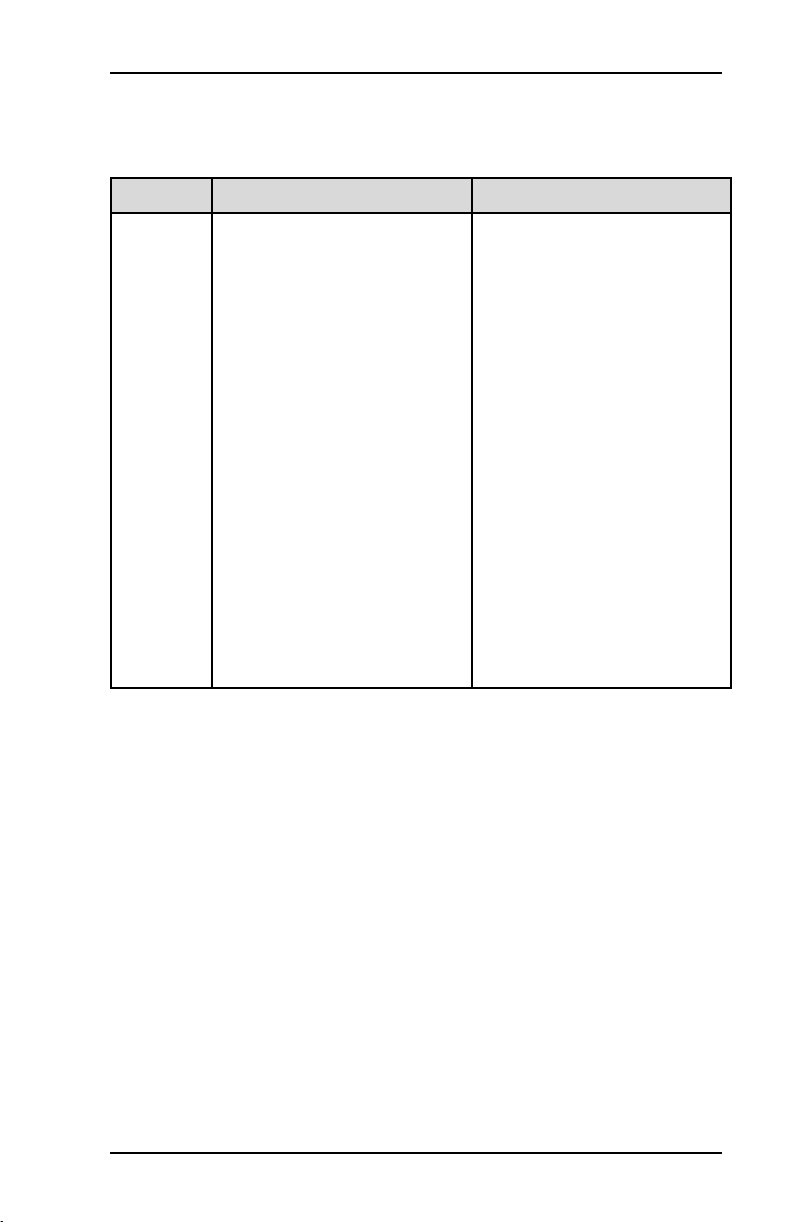

General Material Specifications and Storage • 2

Table 2-1B

DocuMatch™ Mail Materials Reference

Source Minimum Requirements Performance Tips

Cut

Sheet

Feeder

(Flat

Sheets)

• 8-1/2 x 11"

• Xerographic copy

paper 20-32 lb. bond

• 60-80 lb. offset

• Grain long

• 3/8" curl maximum

• Dimensional tolerance

is ± 1/32"

• Glossy materials may

be used but must not

be statically charged.

• Materials that are

varnished on both

sides and are very

slick must be tested

first.

• Avoid recycled

materials.

• Heavier materials may

not perform as well.

Test them first.

• The fourth sheet of a

four-page document

cannot be a 50 lb. or

60 lb. cut sheet.

• Do not use laser-

printed paper.

DocuMatch™ Mail Materials Reference Guide

2-5

Page 17

2 • General Material Specifications and Storage

Table 2-1C

DocuMatch™ Mail Materials Reference

Source Minimum Requirements Performance Tips

Envelope

Printer

• Use only #10 size

(4-1/8 x 9-1/2").

• Dimensions from

envelope to envelope

should not vary more

than ± 1/16".

• 24-28 lb. bond basis

weight

• Guidelines for curl:

» 1/4" curl maximum

on any one corner

» 3/8" combined curl

maximum for entire

envelope

» 1/8" curl maximum

on flap

• Guidelines for

window:

» 1-1/8" high

» 4-1/2" wide

» 7/8" from left edge

of envelope

» 5/8" from bottom

edge of envelope

• Avoid weights less

than 24 lb. bond.

• Web-fed preferred

over die-cut.

• Side seam better than

diagonal seam.

• Side seam preferred

over executive or

commercial.

• Avoid recycled

materials.

• Window envelopes

may be used, but any

window material must

be secured with no

loose edges.

• Do not use open-

faced window

envelopes.

Collation Total Thickness Limits

For reliable inserting, the total thickness of the entire collation

to be inserted into the envelope must be limited to 0.060 in.

You can estimate the thickness using the table in Appendix B.

2-6

DocuMatch™ Mail Materials Reference Guide

Page 18

General Material Specifications and Storage • 2

Materials Not Suitable for DocuMatch

The materials listed below are not suitable for use with the

DocuMatch system:

Blueprint and Brownprint

Book covering materials

Book papers—coated

Book papers—uncoated

Bristol

Carbon paper

Carbonless paper

Cut-size duplicating

Groundwood

Labels—dry gummed

Labels—heat sealed

Labels—pressure sensitive

Ledger

Lightweight

Manifold

Newsprint

Non-paper substrates

Paperboard

Pressure-sensitive paper,

films and foils

Publication paper—coated

Publication paper—uncoated

Recycled paper

Supercalendered paper

Ta g

Text and cover

Tyvek

DocuMatch™ Mail Materials Reference Guide

2-7

Page 19

Page 20

Chapter 3

Paper for Document Printer

In this chapter:

Recycled Paper.................................................................3-2

Paper Weights..................................................................3-2

Grain..................................................................................3-3

Methods for Determining Grain..................................3-3

Paper for DocuMatch™ Document Printer.......................3-5

Document Printer Materials Reference Table.............3-5

Storage Tips...............................................................3-6

Loading Tips...............................................................3-6

™

Perforated Stock Specifications For DocuMatch

....3-8

3-1

Page 21

3 • Paper for Document Printer

Recycled Paper

In the past few years recycled paper has grown in popularity.

Constant testing of recycled paper for feeding on DocuMatch

systems is ongoing. Sometimes recycled paper lacks body,

which can cause problems in paper feeding. Use of recycled

paper may also cause problems with the opening of envelope

flaps and the insertion of mailpieces into envelopes. Consequently, it is important to submit all samples of materials for

any application to your Pitney Bowes specialist for approval.

Paper Weights

An important specification to consider is paper weight. The

DocuMatch system has specific minimum and maximum

paper weights that can be processed. Staying within these

specifications will maximize the system's overall performance.

In the U.S., the weight is given in pounds for one ream (500

sheets) of a specific size of paper. For bond or copier paper

this specific size is 17 x 22 in. Since 8-1/2 x 11 in. paper is

one-fourth the size of 17 x 22, a ream of 20-pound bond

paper will weigh one-fourth of 20, or five pounds.

™

Other types of paper have different reference sizes. Offset or

book paper, often used for cut sheets in the DocuMatch, has

a reference size of 25 x 38 inches. Thus, 20-pound bond

paper corresponds to 50-pound offset paper.

Outside the U.S., paper weight is measured in grams per

square meter (gsm or g/m2). Twenty-pound bond paper

corresponds to 75 grams per square meter.

3-2

DocuMatch™ Mail Materials Reference Guide

Page 22

Paper for Document Printer • 3

Grain

Since it is easier to fold along the length of the fibers rather

than across them, consider the grain direction when folding

papers that are close to the machine's maximum weight

specifications. The bulk of the fibers will give resistance to

folding. Consideration must also be given to grain direction

when folding multiple sheets.

At times it may be necessary to determine paper grain direction. Often, the package of paper will have the grain direction

indicated, but if this is not the case, you can use one of the

following three methods to determine paper grain.

Methods for Determining Grain

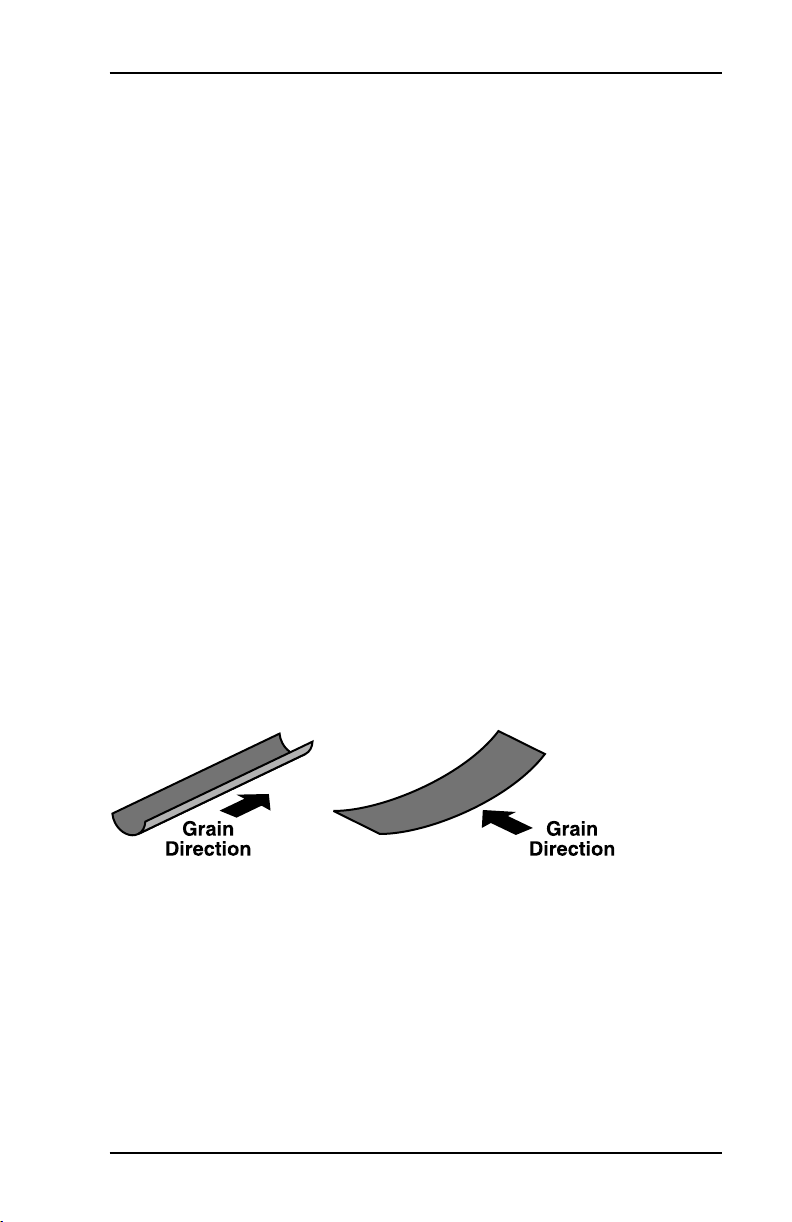

Method 1 (Figure 3-1)

From a sheet of paper, cut a strip approximately 1 inch

(25mm) wide. Moisten one side of the strip. This will cause the

paper to curl according to its grain direction as illustrated in

Figure 3-1. The fibers will not curl and therefore the paper

curls in such a way that it stays flat in the direction of the

grain.

Figure 3-1

Grain long direction (left) and grain short direction (right).

DocuMatch™ Mail Materials Reference Guide

3-3

Page 23

3 • Paper for Document Printer

Method 2 (Figure 3-2)

Tear off (as opposed to cutting) a piece of paper. A strip torn

with the grain will tend to have a much smoother edge than

one torn across the grain.

Some experience with paper is necessary to identify whether

the edge is smooth or rough when using this method. If in

doubt, use one of the other methods mentioned here.

When using Method 2 to

determine grain direction, the

paper will tear more evenly

along the grain and should

show a distinct curl in the

direction of the grain, when

moistened.

Figure 3-2

Checking grain direction.

Method 3

Again, take a piece of paper, but this time fold it in half along

its length, open it, and then fold along its width. When you

open it again and look at the folded edges, you will see one

edge that is very fine where you have folded in the direction of

the grain, while the other edge is ragged where you have had

to bend the fibers across the grain.

3-4

DocuMatch™ Mail Materials Reference Guide

Page 24

Paper for Document Printer • 3

Paper for DocuMatch Document Printer

Table 3-1

Document Printer Materials Reference

Source Minimum Requirements Performance Tips

Doc.

Printer

(Laser

Printer)

• 8-1/2 x 11"

• Xerographic copy

paper, 20-24 lb. bond

• 24 lb. paper may be

microperfed (see pg.

3-6 for details).

• Grain long

• Some preprinted

letterhead paper or

previously copied

paper may cause

feeder problems and

should be tested first.

• Avoid recycled

materials.

The document printer works best with 20-pound Xerographic

paper made for use in laser printers or Xerographic copiers.

For mail generation, the printer accepts 8-1/2 x 11 in. paper

only. If you're using the printer in stand-alone mode, it accepts a wide range of sizes.

Avoid using offset printer paper, which looks like copier paper

but is made differently and tends to be very dusty.

Finally, document printer paper should always be “grain long.”

Paper made for laser printers is almost always grain long; but

if you have any doubts, check the wrapper or use the tear test

described in the previous section.

DocuMatch™ Mail Materials Reference Guide

3-5

Page 25

3 • Paper for Document Printer

Storage Tips

Here are some helpful storage tips.

• Always store paper in its moisture-proof wrapper until

you're ready to use it.

• Store preprinted forms and letterhead stock in moistureproof wrappers until needed.

• If the wrapper indicates a side to be imaged first (usually

this means the arrow on the wrapper points up) and you

are using a DocuMatch

system equipped with a Canon

printer, always load the paper with that side up.

• If the wrapper indicates a side to be imaged first (usually

this means the arrow on the wrapper points up) and you

are using a DocuMatch system equipped with a Lexmark

printer, always load that side down if you are printing one

side only (simplex), up if you are printing both sides

(duplex).

Loading Tips

• To reduce the chance of sheets sticking together, aerate

(fan) and flex the paper back and forth before loading. Do

NOT fold or crease the paper. Straighten the edges of the

pack by tapping it on a level surface. (See Figures 3-3 and

3-4).

™

™

3-6

Figure 3-3

Aerating paper before loading

DocuMatch™ Mail Materials Reference Guide

Page 26

Paper for Document Printer • 3

Figure 3-4

Flexing paper before loading

• CAUTION: Don't use torn, wrinkled, or creased paper, or

paper with a curled, bent, or wavy edge.

• Load the paper on the bottom of the paper trays about an

inch at a time. Line it up against the left side of the tray.

• Don't overfill the trays.

• If you're adding paper to a tray, put the new paper on the

bottom so that unused paper won't stay in the tray longer

than necessary.

Table 3-2 provides the proper guidelines for loading letterhead

paper which you intend to have either C-folded or Z-folded.

Table 3-2

Letterhead Paper Loading Guidlines for C-Fold and

Z-fold

Document

Printer

Lexmark

(Single-Sided)

Lexmark

(Duplex)

Canon

(Single-Sided)

DocuMatch™ Mail Materials Reference Guide

C-Fold Z-Fold

Load paper face

down, bottom edge

leading

Load paper face up,

top edge leading

Load paper face

down, top edge

leading

Load paper face up,

bottom edge

leading

Load paper face up,

top edge leading

Load paper face up,

bottom edge

leading

3-7

Page 27

3 • Paper for Document Printer

Perforated Stock Specifications for DocuMatch

Perforated paper can cause problems if you don't select it

carefully. For your perforated stock to work well with

DocuMatch, we suggest you follow the specifications listed

below when discussing your future perforated stock orders

with your business forms supplier.

• 24 lb. bond only

• Microperf should be 66 holes per inch (66 TPI) and have a

0.008 in. tie.

• Your business forms supplier may locate the perf at any

location on the page, but locating perfs on fold lines may

be difficult due to tolerances. For best performance, you

should located the perf within the bottom folded third of

the page (at the bottom end of the page). Since fold lines

are approximately 3-5/8 in. from either end of the page,

your supplier should avoid putting perfs in the range of

3-1/2 to 3-3/4 in. from the top or bottom edge of the page

to assure clean-tearing perfs.

• Another way to convey the required specifications to your

business forms suppliers is to simply show them the

illustration in Figure 3-5:

3-8

Figure 3-5

Graphic representation of perforated stock

specifications for DocuMatch

DocuMatch™ Mail Materials Reference Guide

Page 28

Paper for Document Printer • 3

If you have an application requiring the use of perforated

stock, please consult your local Pitney Bowes Customer

Service Representative. He or she will evaluate your application and recommend the best approach before you order

stock from your business forms supplier.

Important:

Do not use grain short paper, recycled paper, or paper coated

with lacquer. These materials can cause severe performance

problems with your DocuMatch mail jobs. Using out-of-spec

material will cause jams in the laser printer and the accumulator.

DocuMatch™ Mail Materials Reference Guide

3-9

Page 29

Page 30

Chapter 4

Envelopes

In this chapter:

Overview of Envelopes.....................................................4-2

Envelope Quality.........................................................4-2

Envelope Size.............................................................4-2

Envelope Type.............................................................4-2

Die-Cut..................................................................4-2

Web-Fed................................................................4-3

Envelope Style............................................................4-4

Envelope Curl.............................................................4-4

Window Envelopes.....................................................4-6

Standard Window Dimensions.............................4-7

Envelope Seal Flap and Gum.....................................4-8

Storage........................................................................4-8

Loading Tips...............................................................4-9

Envelope Guidelines for DocuMatch™.............................4-10

Envelope Style and Type...........................................4-10

Envelope Size and Weight.........................................4-10

#10 Envelope Specifications......................................4-11

Envelope Materials Reference Table..........................4-12

4-1

Page 31

4 • Envelopes

Overview of Envelopes

Envelope Quality

We cannot over-emphasize the importance of using good

envelopes. To maximize the productivity of the DocuMatch

system you should use high quality envelopes that are the

correct size and texture to accept materials consistently and

accurately.

To ensure the highest level of productivity, all envelopes

should conform to the guidelines discussed in this guide. You

may want to discuss these guidelines with your envelope

supplier. If you have any questions that are not covered here,

please contact your Pitney Bowes DocuMatch specialist for

additional technical assistance.

Envelope Size

One way we classify envelopes is by size. The envelope

manufacturing industry has assigned trade numbers for

various sizes of envelopes. Table 4-1 on the next page lists

these designated trade numbers with their respective envelope sizes.

™

Note that the envelope trade number is slightly larger than the

envelope width. For example, a #10 envelope is actually

9-1/2 inches wide.

Envelope Type

We also classify envelopes by type, that is, by the type of

manufacturing process that created them — die-cut or webfed. Each envelope type has unique characteristics as a result

of its manufacturing process, the main differences being in

flap and seam construction.

Die-Cut Envelopes

When die cut envelopes are manufactured, a die is placed

upon a ream of paper. The die is pressed down under pressure by machinery or by hand. It is then removed, emptied,

and the paper is moved to printing, gluing, and folding machines.

4-2

DocuMatch™ Mail Materials Reference Guide

Page 32

Table 4-1

Envelope Trade Numbers and Sizes

Trade Number Name Envelope Size (inches)

6 1/4 3-1/2 x 6

6 3/4 3-5/8 x 6-1/2

7 3-3/4 x 6-3/4

Monarch 3-7/8 x 7-1/2

Data Card 3-5/8 x 7-3/4

Check Size 3-5/8 x 8-5/8

9 3-7/8 x 8-7/8

10 4-1/8 x 9-1/2

11 4-1/2 x 10-3/8

12 4-3/4 x 11

14 5 x 11-1/2

Envelopes • 4

The die-cutting process is generally used for short runs and

specialty envelopes. Because of the height of the paper stack,

the dimensions for die cut envelopes tend to vary.

Web-Fed Envelopes

When web-fed envelopes are manufactured, a large roll of

paper called a web is fed into a machine where it is cut,

printed, glued, folded, and in some cases, a panel is cut out

and a window patch is added.

This process is generally used for large volume runs of envelopes. The quality of web-fed envelopes tends to be more

consistent compared to die-cut envelopes and is the preferred type.

DocuMatch™ Mail Materials Reference Guide

4-3

Page 33

4 • Envelopes

Envelope Style

Within the two basic envelope types (die-cut or web-fed) there

are several different envelope styles: commercial, side seam,

and executive. The commercial style envelope is by far the

most popular, followed by executive, then by side seam. For

DocuMatch use, side seam envelopes work best (see pages

4-10 and 4-12).

Envelope Curl

Envelope curl or twist (caused by improper storage or

handling) should not exceed 1/4 in. at any one corner

when the envelope is placed on a flat surface. Total com-

bined envelope curl (at the corners or in the body of the

envelope) should not exceed 3/8 in.

The flap must not exceed 1/8 in. curl.

Envelopes that have a curl at more than one location can

cause poor envelope feeding. Refer to Figure 4-1 on page

4-5.

Folds, especially along the bottom edge of the envelope,

should be crisp and uniform.

Executive and commercial envelopes are more susceptible

to curl because the grain direction is diagonal. That is why

side seam envelopes are preferable.

4-4

DocuMatch™ Mail Materials Reference Guide

Page 34

Curled Flap

Curling should not exceed 1/4" (6.4 mm) at any location.

Figure 4-1

Envelope curling can cause problems

Envelopes • 4

DocuMatch™ Mail Materials Reference Guide

4-5

Page 35

4 • Envelopes

Window Envelopes

Window envelopes come in different types and raise different

issues. The types used are open-face, glassine, DWF (Dow

Window Film

An envelope may have a window or be open-face (without a

patch). A patch is a transparent covering that is placed over

the window from the inside. Three different patch materials

are available for window envelopes.

Glassine This patch material is the most opaque and has

™

) and Trycite™.

rarely been used over the past 10 years. When

the glassine window (a paper product) is glued

to the envelope, both surfaces become wet.

They do not dry at the same rate. This results in

wrinkling and puckering of the patch. Since

glassine is a paper product, it is recyclable.

DWF Dow Window Film

(DWF) is by far the most

popular window patch. It will allow for scanning

readability while providing a measure of

security. By security, we mean if someone tries

to examine the contents of the envelope

through the window, the patch material will

cloud their vision. Readability is excellent only

when material is held against the patch

material. DWF is a petroleum, not paper-based

product, and does not wrinkle or pucker during

the drying process. Because it is petroleumbased, it is not recyclable like paper. DWF is

sometimes referred to as “Poly-Klear.”

Trycite This type of patch material is usually on

expensive, high grade envelopes. Readability

by post office scanning equipment is poor due

to the reflectiveness or glare of this patch

material. Trycite is also called cellophane or

“Krystal-Klear.”

4-6

DocuMatch™ Mail Materials Reference Guide

Page 36

Envelopes • 4

When using window envelopes, be sure they are made for

machine insertion. The patch has to be securely glued onto

the inside body of the envelope 1/8 in. over the edges of the

window opening. This helps the collated set to be inserted

cleanly without the edges of the material being caught by a

poorly glued window patch. An open-face envelope (no

patch) cannot be used on the DocuMatch

of a standard window envelope is shown below.

Standard Window Dimensions

Here is the industry standard for window dimensions (Figure

4-2).

• 1-1/8 in. high

• 4-1/2 in. wide

• 7/8 in. from left edge

• 1/2 in. from bottom edge (must be 5/8 in. for DocuMatch)

system. A figure

5/8"

Figure 4-2

The standard for window envelopes to be used with DocuMatch

DocuMatch™ Mail Materials Reference Guide

4-7

Page 37

4 • Envelopes

Envelope Seal Flap and Gum

Mechanical sealing requires seal flap gum that is uniform and

adheres quickly and firmly when moistened. To prevent the

inserting operation from pulling the envelope apart, the seams

must also be securely glued.

Any inserting machine will jam if there is even the slightest tendency for the seal flap to adhere to the envelope's

back. On many styles of envelopes, the seal flap gum is the

first adhesive applied, and it is dried before the envelope goes

through the folding and seam gumming process. During the

manufacturing of die-cut envelopes, for instance, the envelope does not go through another drying process. This translates to the seam gum being damp when the envelopes are

packed into boxes. The compression of the envelopes in the

boxes may cause the damp seam gum to remoisten the seal

flap gum, which in turn, may cause the flap to tack. This chain

of events can cause problems during the insertion process.

When you are ordering envelopes from your business forms

vendor or supplier, you should make it clear that you require

envelopes designed for automatic insertion. A knowledgeable

vendor should be able to review the DocuMatch

requirements in this chapter and supply you with the kinds of

envelopes that will optimize your DocuMatch mail jobs.

envelope

Storage

Because of the glue used in their construction, proper storage

is especially important for envelopes. If they become too dry,

some envelopes will develop curled flaps, which can cause

flap opening problems. Too much moisture can cause envelopes to warp or curl excessively, which can cause feeding

problems. Always store envelopes in closed boxes until ready

for use. It is best to remove the envelopes from the

DocuMatch™ hopper and return them to a box if you know the

system will be idle for several hours or overnight.

4-8

DocuMatch™ Mail Materials Reference Guide

Page 38

Envelopes • 4

Loading Tips

Always follow the envelope loading instructions on the envelope printer carefully. When you load envelopes correctly, the

back of the stack in the hopper will be smooth, with a smooth

curve near the bottom of the hopper directed toward the

printer, and no sudden offsets in the stack.

DocuMatch™ Mail Materials Reference Guide

4-9

Page 39

4 • Envelopes

Envelope Guidelines for DocuMatch

Envelope Style and Type for DocuMatch

For optimum DocuMatch performance, we recommend you

use high quality, web-fed, side seam envelopes designed for

automatic insertion. You may also use commercial style or

executive style, but side seam is preferable.

Make sure the flap and throat dimensions comply with our

published specifications (see Figure 4-3 on page 4-11).

For optimum DocuMatch performance, printed (non-window)

envelopes work best. If you are using window envelopes,

make sure they comply with our DocuMatch window envelope

requirements (see Figure 4-2 on page 4-7 and Table 4-2 on

page 4-12).

Envelope Size and Weight for DocuMatch

The envelope printer handles only #10 size envelopes

(9-1/2 x 4-1/8 in. ± 1/16 in.). Envelopes with a basis weight of

24 pounds work best, but you can use 28-pound envelopes

also. Lighter weight envelopes tend to cause problems in the

envelope transport.

Refer to Figure 4-3 on the following page for an illustration of

the DocuMatch specifications for #10 envelope dimensions.

4-10

DocuMatch™ Mail Materials Reference Guide

Page 40

Envelopes • 4

#10 Envelope Specifications for DocuMatch

Figure 4-3

DocuMatch specifications for #10 envelope dimensions

DocuMatch™ Mail Materials Reference Guide

4-11

Page 41

4 • Envelopes

Table 4-2

Envelope Materials Reference

Source Minimum Requirements Performance Tips

Envelope

Printer

• Use only #10 size

(4-1/8 x 9-1/2").

• Dimensions from

envelope to envelope

should not vary more

than ± 1/16".

• 24-28 lb. bond basis

weight

• Guidelines for curl:

» 1/4" curl maximum

on any one corner

» 3/8" combined curl

maximum for entire

envelope

» 1/8" curl maximum

on flap

• Guidelines for

window:

» 1-1/8" high

» 4-1/2" wide

» 7/8" from left edge

of envelope

» 5/8" from bottom

edge of envelope

• Avoid weights less

than 24 lb. bond.

• Web-fed preferred

over die-cut.

• Side seam better than

diagonal seam.

• Side seam preferred

over executive or

commercial.

• Avoid recycled

materials.

• Window envelopes

may be used, but any

window material must

be secured with no

loose edges.

• Do not use open-

faced window

envelopes.

4-12

DocuMatch™ Mail Materials Reference Guide

Page 42

Chapter 5

Cut Sheet Feeder Material

In this chapter:

Cut Sheets for DocuMatch™............................................5-2

Grain Orientation.........................................................5-2

Glossy Materials.........................................................5-2

Static Charge..............................................................5-2

Loading Tips...............................................................5-3

What to Watch For.....................................................5-3

Cut Sheet Feeder Materials Reference Table.............5-4

..

5-1

Page 43

5 • Cut Sheet Feeder Material

Cut Sheets for DocuMatch

The DocuMatch cut sheet feeders are designed to work

reliably with a wide range of materials, including 20- or 24pound Xerographic bond paper and 50- to 80-pound coated

and uncoated offset paper, with a variety of finishes. There

are, however, some materials and storage conditions that can

cause problems.

™

Grain Orientation

When you order offset printed materials for use in the DocuMatch, be sure to specify grain long orientation for the printed

sheets. Grain long paper feeds better because it's stiffer in the

direction of the feed. If you have feeding problems, check the

grain direction as described in Chapter 3, pages 3-3 through

3-4.

Glossy Materials

Spot varnished materials generally work well, but glossy stock

with varnish covering the whole sheet is sometimes so slippery that it causes problems in the folder.

Static Charge

Materials with a high static charge can cause feeding problems. This usually occurs when humidity is very low. If you

find that sheets tend to stick to each other and you can’t

correct the problem by aerating the paper stack, the static

charge is probably too high for reliable feeding. You may have

to operate the DocuMatch in a controlled environment. Sometimes the addition of a release agent (such as talc) in the

manufacturing process of the cut sheets helps to reduce

static problems.

5-2

DocuMatch™ Mail Materials Reference Guide

Page 44

Cut Sheet Feeder Material • 5

Loading Tips

• When loading the cut sheet feeders, start by pushing any

materials already in the feeder square against the feeder’s

left stop.

• Fan the new materials and load them so that the whole

stack is square against the left stop. Make sure you load

the newer materials under the older materials.

• Do not fill the feeders above the indicated line.

• Do not mix materials within a tray.

What to Watch For

• Highly-charged (static) materials

• Curled or dog-eared materials

• Damaged materials

• Very high or very low humidity conditions

• Photocopied material

NOTE: The most difficult applications seem to be photocopied material, due to residual static charge and curl.

Allowing photocopied materials to “rest” for several hours

and then carefully fanning the materials often helps.

• Do not use paper run through a laser printer. Such sheets

will have a tendency to curl due to the nature of the print

generated by the laser printer.

DocuMatch™ Mail Materials Reference Guide

5 -3

Page 45

5 • Cut Sheet Feeder Material

Table 5-1

Cut Sheet Feeder Materials Reference

Source Minimum Requirements Performance Tips

Cut

Sheet

Feeder

(Flat

Sheets)

• 8-1/2 x 11"

• Xerographic copy

paper 20-32 lb. bond

• 60-80 lb. offset

• Grain long

• 3/8" curl maximum

• Dimensional tolerance

is ± 1/32"

• Glossy materials may

be used but must not

be statically charged.

• Materials that are

varnished on both

sides and are very

slick must be tested

first.

• Avoid recycled

materials.

• Heavier materials may

not perform as well.

Test them first.

• The fourth sheet of a

four-page document

cannot be a 50 lb. or

60 lb. cut sheet.

• Do not use laser-

printed paper.

5-4

DocuMatch™ Mail Materials Reference Guide

Page 46

Chapter 6

Insert Feeder Material

In this chapter:

Inserts and Business Reply Envelopes............................6-2

Loading Tips...............................................................6-2

Insert Feeder Materials Reference Table....................6-3

6-1

Page 47

6 • Insert Feeder Material

Inserts and Business Reply Envelopes

The insert feeder accepts materials ranging from 3 x 5 in.

(a minimum-size postcard) to #9 envelopes (3-7/8 x 8-7/8

in. ± 1/16 in.). You can also use C-folded 8-1/2 x 11 in.

sheets that have the same material characteristics as

those specified for the cut sheet feeders. Cards can range

in thickness from 0.007 to 0.0095 in. Envelopes can be

24- to 28-pound bond and should be loaded with the flaps

up and to the left.

Loading Tips

To load the insert feeder:

1. Push the paddle to the left and place the materials

vertically in the feeder.

2. Make sure all the materials are to the left of the tabs at

the bottom right-hand end of the feeder.

3. Adjust the side guides so that they rest gently on the

sides of the materials, leaving a gap of about 1/16 in.

(about the thickness of a dime).

4. If the tray is not full, slide the paddle to the right to

support the materials. Be careful not to overfill the tray

or push the paddle too hard against the stack. If the

materials are packed in too tightly, the first several

pieces won't feed reliably.

6-2

DocuMatch™ Mail Materials Reference Guide

Page 48

Insert Feeder Material • 6

Table 6-1

Insert Feeder Materials Reference

Source Minimum Requirements Performance Tips

Insert

Feeder

Pre-folded Inserts (C-fold,

1/3 size):

• 3 x 5" to 3-7/8 x

8-7/8"

• 20 lb. bond

• 24 lb. bond

• 50-80 lb. coated offset

• 50-70 lb. uncoated

offset

• 80 lb. uncoated offset,

smooth

BREs:

• #9 standard envelopes

(3-7/8 x 8-7/8")

• Check size

(3-5/8 x 8-5/8")

• 24-28 lb. bond, all

types, smooth, glossy,

or flat

Pre-folded Inserts (C-fold,

1/3 size):

• Do not use Z-fold

material.

• Material that is highly

varnished will

contaminate the feed

belts.

• Do not use light-weight

inserts less than 16 lb.

• Do not use any inserts

with significant curl.

BREs:

• Closed flap with or

without window

• You may also use

#8-5/8 and #7 BREs.

Postcards:

Postcards:

• As above (includes

7-point reply)

• Thickness range:

(0.007" to 0.0095")

DocuMatch™ Mail Materials Reference Guide

6-3

Page 49

Page 50

Chapter 7

Document Printer Preventive Maintenance and Toner Usage

In this chapter:

Scheduled Printer Preventive Maintenance.....................7-2

Toner Yield........................................................................7-2

Setting the Print Resolution to 300 DPI......................7-3

Setting the Print Darkness to Lighter or Lightest........7-3

Turning Toner Saver On..............................................7-4

Page Coverage...........................................................7-4

Replica of Sample Page Showing 5%

Print Coverage............................................................7-6

..

7-1

Page 51

7 • Document Printer Preventative Maint & Toner Usage

Scheduled Printer Preventive Maintenance

For a DocuMatch

™

equipped with a Lexmark

printer’s operator panel displays the message 80 Scheduled

Maintenance at each 250,000 page count interval. When this

occurs, call Pitney Bowes to perform preventive maintenance

on your printer.

For a DocuMatch equipped with a Canon™ printer, at each

200,000 page interval you must contact Pitney Bowes to have

a Customer Service Representative perform preventive

maintenance on your printer.

™

printer, the

Toner Yield

If you have the Lexmark printer version of DocuMatch, you

can achieve maximum toner yield by:

• setting the DocuMatch print resolution to 300 DPI;

• setting the print darkness to Lighter or Lightest;

• turning toner saver ON.

Refer to the steps listed on pages 7-3 and 7-4 to learn how to

make these adjustments.

7-2

DocuMatch™ Mail Materials Reference Guide

Page 52

Document Printer Preventative Maint & Toner Usage • 7

Setting Print Resolution to 300 DPI for a DocuMatch with Lexmark Printer

1. Check that the Lexmark printer operator panel displays

Ready.

2. Press the right Menu button until QUALITY MENU

appears.

3. Press the Select button.

4. Press the right Menu button until QUALITY MENU Print

Resolution appears.

5. Press the Select button.

6. Press the right or left Menu button to lower Print

Resolution to 300 dpi.

7. Press the Select button. The operator panel briefly

displays Print Resolution SAVED, then displays QUALITY

MENU Print Resolution.

8. Press the Return button twice to return to Ready.

Setting Print Darkness to Lighter or Lightest for a DocuMatch with Lexmark Printer

1. Check that the Lexmark printer operator panel displays

Ready.

2. Press the right Menu button until QUALITY MENU

appears.

3. Press the Select button.

4. Press the right Menu button until QUALITY MENU Print

Darkness appears.

5. Press the Select button.

6. Press the right or left Menu button to lower Print Darkness

as you wish: Darkest, Darker, Normal, Lighter, Lightest.

7. Press the Select button. The operator panel briefly

displays Print Darkness SAVED, then displays your new

default Print Darkness setting, for example, PRINT

DARKNESS=Lighter.

8. Press the Return button twice to return to Ready.

DocuMatch™ Mail Materials Reference Guide

7-3

Page 53

7 • Document Printer Preventative Maint & Toner Usage

Turning Toner Saver ON for a DocuMatch with Lexmark Printer

1. Check that the Lexmark printer operator panel displays

Ready.

2. Press the right Menu button until QUALITY MENU

appears.

3. Press the Select button.

4. Press the right Menu button until QUALITY MENU Toner

Saver appears.

5. Press the Select button.

6. If the operator panel displays Toner Saver=On, press the

Return button twice to return to Ready. Disregard the

remaining steps.

7. If the operator panel displays Toner Saver=Off, press the

right Menu button until Toner Saver=On appears.

8. Press the Select button. The operator panel briefly

displays Toner Saver SAVED, then QUALITY MENU Toner

Saver.

9. Press the Return button twice to return to Ready.

Page Coverage

Toner yield for the document printer is greatly affected by the

amount of page coverage on a particular document. In the

Lexmark version of DocuMatch, the 17,600-page yield is

based on 5% coverage. There are many other variables

(including the type of image on the page) that cause this yield

to vary by as much as ± 20%.

As of now, there is no commonly accepted industry standard

by which to measure cartridge yield. Manufacturers are

working to create a standard in the near future.

Table 7-1 lists estimated toner yield ranges in relation to page

coverage for a DocuMatch with Lexmark printer model

Optra S™.

7-4

DocuMatch™ Mail Materials Reference Guide

Page 54

Document Printer Preventative Maint & Toner Usage • 7

Table 7-1

Estimated Toner Yield

Coverage Nominal Min Max

5.0% 17,600 14,960 20,240

5.5% 16,000 13,600 18,400

6.0% 14,667 12,467 16,867

6.5% 13,538 11,508 15,569

7.0% 12,571 10,686 14,457

7.5% 11,733 9,973 13,493

8.0% 11,000 9,350 12,650

8.5% 10,353 8,800 11,906

9.0% 9,778 8,311 11,244

9.5% 9,263 7,874 10,653

10.0% 8,800 7,480 10,120

Estimated toner yield in relation to page coverage for a DocuMatch with

Lexmark printer model Optra S.

Note:

• A cartridge is considered to have reached end-of-life after

it has been removed, shaken, and reinstalled at Toner Low

notification 3 times.

• The estimates in Table 7-1 are for text-only documents.

Graphics will lower the yields by as much as 10%.

• Switching to Toner Saver mode can increase yield by as

much as 20%.

• Remember the yield is number of prints! If a mailpiece has

two pages, the yield for mailpieces is half. If you use the

duplex function, the number of mailpieces is half.

Figure 7-1 on the following page shows a reduced replica of

an 8-1/2 x 11 in. sample printed page with 5% coverage.

DocuMatch™ Mail Materials Reference Guide

7-5

Page 55

7 • Document Printer Preventative Maint & Toner Usage

INTEROFFICE MEMORANDUM

TO: Cathy Jones

FROM: Michael Smith

SUBJECT: The Typical Printed Page

DATE: 10/11/2000

What does the typical printed document look

like? Well, across the diverse business community it

would be impossible to capture all aspects of printing

style within a single page document. However, if

attention is focused on the majority of printing volume,

text and simple business graphics would stand out

as the most prevalent output from laser printers. This

sample memo represents a reasonable example of

the typical business document.

This memo covers approximately 5% of a letter or A4-sized piece of paper. This

number (5%) has historically been called the “average” page coverage by laser printer

manufacturers. It may seem to the naked eye that there is much more than 5%, but in fact,

alphanumeric characters rely on a large portion of white space for their composition.

There are many factors that can influence the actual page coverage of a document

as well as the page-yield of a toner cartridge. Testing parameters such as font size and

style, internal printer settings, print environment, paper stock, sample size, job length and

criteria for determining “end-of-life”, can all influence how long a toner cartridge will last.

The best competitive analysis of printer page yield should occur under similar conditions

using industry standards for the variables listed above.

Figure 7-1

Reduced replica of an 8-1/2 x 11" sample page with 5% page coverage

7-6

DocuMatch™ Mail Materials Reference Guide

Page 56

Chapter 8

General Machine Preventive Maintenance

In this chapter:

System Preventive Maintenance......................................8-2

General........................................................................8-2

Maintenance Log........................................................8-2

Pre-Service System Check with Remote

Diagnostics..................................................................8-3

System Preventive Maintenance Schedule................8-4

8-1

Page 57

8 • General Machine Preventive Maintenance

System Preventive Maintenance

General

To ensure smooth, trouble-free operation of your

DocuMatch™, we recommend you review the information

outlined in this chapter and familiarize yourself with the System Preventive Maintenance Schedule (Table 8-1, page 8-4).

This schedule lists procedures performed at various intervals

by your Pitney Bowes Customer Service Representative.

Periodically monitor your DocuMatch cycle count. To determine your current cycle count:

1. Press the following options on the control panel:

System Options/More/System Counters/Display Counter.

2. Press Next or Previous to navigate to the desired cycle

count: Machine Cycles, Insert Fdr Cycles, Top Cut Sheet

Cycles, Bot Cut Sheet Cycles, Env Ptr Cycles.

Following the guidelines in the System Preventive Maintenance Schedule, contact your Pitney Bowes Customer Service Representative at the appropriate intervals to request the

necessary scheduled maintenance. You can also contact

Pitney Bowes if your system is operating at a reduced efficiency.

The amount of preventive maintenance for your DocuMatch

system will vary significantly depending on the types of paper

you use.

Maintenance Log

The maintenance log is located inside the right-hand door of

the DocuMatch. It is maintained by your Pitney Bowes Customer Service Representative, who records all actions by date

and cycle count.

8-2

DocuMatch™ Mail Materials Reference Guide

Page 58

General Machine Preventive Maintenance • 8

Pre-Service System Check with Remote Diagnostics

All DocuMatch systems are equipped with remote diagnostic

capabilities. Through Remote Diagnostics, Pitney Bowes can

quickly diagnose obscure problems and provide you with

fixes you can download. To use this feature, you need to have

an analog phone line connected to your DocuMatch (we

recommend a dedicated line). This feature is provided to you

at no cost except for the phone line.

To request a remote diagnosis of your DocuMatch:

1. Make sure that all the system feeders are loaded.

2. Generate a test piece using the DocuMatch control panel

(System Options/Print Demo Piece), or run a 10-piece job

from your host computer using all the feeders.

3. Note the system serial number.

4. Call the Pitney Bowes Technical Operations Center at

1-800-253-6565* and ask for a “Remote Diagnostic

Analysis” of your DocuMatch system.

The Technical Operations representative will call into the

analog phone line connected to your DocuMatch system to

obtain system data and other specific information. This data

will be used to analyze the configuration of the system and to

check for obvious system problems.

When Remote Diagnostics is complete, the Technical Operations representative will give you the results and provide

additional instructions and trouble-shooting assistance, or

may dispatch a Pitney Bowes Customer Service Representative if necessary.

*(Monday through Friday, 8AM-8PM, ET)

DocuMatch™ Mail Materials Reference Guide

8-3

Page 59

8 • General Machine Preventive Maintenance

Table 8-1

System Preventive Maintenance Schedule

Subsystem or Area

Pre-Service System

Check

Document Printer

(Lexmark™)

Document Printer

(Canon™)

Envelope Feeder/

Printer Rollers

Cut Sheet Feeders

Insert Feeder Belts

and Rollers

Main Drawer

Assembly

Cycles Between

Variable

250,000

200,000

50,000/300,000

When dusty

When worn or very

dusty

When very dusty

Remarks

Run as required to

verify system.

Install PM kit for

Lexmark.

Install PM kit for

Canon.

Turn/replace retard

rollers.

Remove paper dust.

Clean or replace

staging belts and

rollers (water only).

Clean dust, paper

fragments. Check all

main drawer

functions.

Main Drawer

Assembly

8-4

200,000 or when

skewing, jamming,

or improper folding

of paper is determined to be caused

by worn urge roller

tires

Replace urge roller

tires.

DocuMatch™ Mail Materials Reference Guide

Page 60

Appendix A

Introduction to Paper

In this appendix :

How Paper Is Made.........................................................A-2

Paper Characteristics.......................................................A-4

Moisture......................................................................A-4

Wire and Felt Sides (of a Sheet of Paper)...................A-5

Surface Coating or Finish..........................................A-5

Body or Strength of Material......................................A-5

Understanding Paper Ream Labels.................................A-6

A-1

Page 61

A • Introduction to Paper

How Paper Is Made

Both the letter to be folded (material or inserts), and the

envelope into which it is inserted, are generally made of

paper. Most paper is made from wood pulp. However, other

sources of cellulose fiber such as certain grasses, cotton,

hemp, and jute are also used for manufacturing paper. In

addition, recycled paper is increasingly being used in bond

paper and envelopes (but recycled materials are not recommended for use with DocuMatch

overall quality of paper in the folding/inserting process, since

paper characteristics can affect the production process.

The ingredients that make up paper are ground up, bleached,

cooked, strained, and mixed with water and other chemicals

to form a syrup-like mixture. This mixture is poured onto a

conveyer belt consisting of a fine wire cloth. Some of the

water drains through the wire cloth by gravity or is pulled

through by vacuum. The conveyer then passes under a set of

felt rollers that press more moisture through the wire cloth as

though it were a sieve (Figure A-1).

™

). What is important is the

Figure A-1

How paper is made

A-2

DocuMatch™ Mail Materials Reference Guide

Page 62

Introduction to Paper • A

Left on the wire cloth is a thin sheet of fibers that, when dried

and given a finish, becomes paper. The fibers in the sheet are

crisscrossed in all directions. Because of the motion of the

conveyer, however, most of the fibers align themselves along

the direction of the sheet motion. This alignment of fibers

gives paper its grain.

There are two sides to a sheet of paper – the wire side and the

felt side (Figure A-2). The wire side is the side next to the wire

cloth. Generally more fibers are found on the wire side of a

sheet of paper. Because the fibers tend to hang through the

mesh, the wire side tends to have a rougher finish than the felt

side. The felt side, as you might expect, is the side next to the

felt rollers. It is the smoother side of a sheet of paper and is

the side printed on (and the first side printed on when in

duplex mode). You can determine which is the felt side and

which is the wire side by examining both sides of a sheet of

letterhead paper closely.

Figure A-2

The two sides of a sheet of paper

DocuMatch™ Mail Materials Reference Guide

F400_024

A-3

Page 63

A • Introduction to Paper

Paper Characteristics

There are several paper characteristics that can prevent your

application from being an accurate and productive process.

The paper characteristics listed below have a direct affect on

the folding/inserting process.

• Moisture

• Wire and felt sides (of the paper)

• Surface coating or finish

• Body or strength of material

Moisture

As paper is rolled, it has a moisture content of about 92-94%

pulp and 6-8% water. Moisture content can change due to

local atmospheric conditions. On rainy days, paper will tend

to absorb more moisture, while on dry days it will tend to lose

moisture. This process causes the paper to swell or shrink

depending on the condition. Consequently, two identical

reams of paper stored under different conditions of humidity

can be two different sizes when the time comes for folding

and inserting.

Laser-printed material can also affect reliability because laser

printing tends to dry paper out excessively. Dry paper is more

prone to curl and accumulates static charges more readily.

Laser printing also hardens the paper due to pressure. Both

the dryness and hardening of paper will change its folding and

feeding characteristics.

A-4

DocuMatch™ Mail Materials Reference Guide

Page 64

Introduction to Paper • A

Wire and Felt Sides

Having felt and wire sides, combined with its ability to hold

moisture, can make paper very susceptible to curl. The wire

side has more fibers exposed than the felt side. This causes

the wire side to absorb and lose moisture at a faster rate than

the felt side. As it loses moisture, it shrinks faster and curls

toward the wire side.

As an example, on a normal day, the paper may lay flat on a

table. The next day may be very dry and the paper would take

an upward curl. The day after, wet weather would cause the

paper to take a downward curl. All of these characteristics

could have an adverse affect in feeding paper.

Surface Coating or Finish

The amount of sizing and finish applied to paper must be

given consideration. Glossy finish paper is usually more

difficult to separate by the rubber covered rollers than flat

finish paper. If you will be using glossy paper in your application, give samples to your Pitney Bowes specialist for testing

just to be sure it is suitable for the machine (in most cases it

will not be a problem if a release agent was used in the manufacturing process).

Body or Strength of Material

The body of the paper can also affect the folding operation.

Paper that is loose, openly-fibered, and contains no sizing

(such as news print, chemically treated, or onion skinned

paper), could burst when gripped by the rollers within the

folding module. Close-fibered and treated paper, such as

writing paper, has more strength, thereby making the bursting

point much higher. Lack of body may cause misfolds and

stalls in the folder.

Other Characteristics

Refer to Chapter 3 for information on recycled paper, paper

weights, and paper graIn.

DocuMatch™ Mail Materials Reference Guide

A-5

Page 65

A • Introduction to Paper

Understanding Paper Ream Labels

In a ream (500 sheets) of paper, an arrow on the label usually

indicates the felt side, while the bottom side is the wire side

(paper reams are normally shipped felt side up). Information

generally marked on the outside wrapper of a ream includes:

• type (bond, offset, bristol, ledger, tissue, etc.);

• size (dimensions);

• weight;

• color and finish;

• long grain (aligned along the longest dimension) or short

grain (aligned along the shortest dimension). The dimension (length or width) which is underlined on the ream

label indicates the direction of the grain. In Figure A-3

below, note the length (11 in.) is underlined, thereby

indicating the paper is grain long.

Underlined Length

Felt Side

Indicates Grain Long

Wire Side

Figure A-3

Understanding paper ream labels

A-6

DocuMatch™ Mail Materials Reference Guide

GRAIN LONG

FIRST

Page 66

Appendix B

Collation Total Thickness Limits

In this appendix :

Total Thickness Limits..............................................B-2

Total Thickness Worksheet......................................B-2

B-1

Page 67

B • Collation Total Thickness Limits

Total Thickness Limits

For reliable inserting, the total thickness of the collation to be

inserted into the envelope must be limited to 0.060 in. You

can estimate the thickness using the worksheet in Table B-1.

Table B-1

Collation Total Thickness Worksheet

Material thickness factors (shown in gray shaded areas):

Document printer paper: 20# 24#

bond paper 12 14

Cut sheet feeders

bond paper same as doc. printer paper above

offset book paper 50# 60# 70# 80#

Coated Gloss 8* 9* 11 12

Coated Dull 10 11 12 14

Uncoated 12 14 16 18

* not recommended

Insert feeder 20# 24# 28#

Business Reply Envelope 12 14 16

Tri-folded insert Use cut sheet value

Business Reply Card 10

Folded brochure Use thickness in 0.001 in.

Envelope Content Thickness Evaluation:

Folded portion (4 sheets max.) Pages x Factor = Total

Laser printed sheets _____ _____ _____

1st Cut Sheet (0 or 1) _____ _____ _____

2nd Cut Sheet (0 or 1) _____ _____ _____

Insert _____

Total thickness (must be less than or equal to 60) _____

B-2

DocuMatch™ Mail Materials Reference Guide

Page 68

Index

I-1

Page 69

Index

Index

A

Aerating Paper Before

Loading 3-6

B

Body or Strength of Paper

Material A-5

Business Reply Envelopes

(BREs)

Minimum Requirements

2-5, 2-6, 6-3

Performance Tips 2-5,

2-6, 6-3

C

C-Fold

and Loading Sheets in

Insert Feeder 6-2

Cards

in Insert Feeder 6-2

Cellophane Window

Envelopes. See

Envelope: Window

Envelopes: Trycite™

Climate

Extreme Climate and Mail

Materials 2-3

Collation

Total Thickness Limits

2-6, B-2

Total Thickness Worksheet

B-2

Commercial Envelopes 4-4

Curl

High Curl in Cut Sheets

5-3

Paper Curl A-4, A-5

Cut Sheet Feeder

Materials

Minimum Requirements

5-4

Performance Tips 5-4

Minimum Requirements

2-4

Performance Tips 2-4

Cut Sheet Folder

Problems Caused by

Glossy Materials 5-2

Cut Sheets 5-2

Feeding Problems

Static Charge 5-2

Glossy Materials

Spot Varnished Materials

5-2

Varnish Covering Whole

Sheet 5-2

Grain Orientation

Grain Long 5-2

High Curl 5-3

Loading 5-3

Photocopied Materials 5-3

What to Watch Out for 5-3

D

Die-Cut Envelopes 4-2

Document Printer (Laser

Printer)

Paper. See Paper: for

Document Printer

I-2

DocuMatch™ Mail Materials Reference Guide

Page 70

Index

Scheduled Preventive

Maintenance 7-2, 8-4

Dry Environment

and Storage of Mailing

Materials 2-3

Duplex Function (Lexmark™

Printer) 3-6, 3-7

E

Envelope

Flap 4-8

Flap Gum 4-8

Grain Direction

Diagonal 4-4

in Insert Feeder 6-2

Loading 4-9

Materials Reference Table

4-12

Open-Face (Open-Window)

4-7

Quality 4-2

Seam 4-8

Size

General 4-10

Trade Numbers with

Dimensions 4-3

Specifications

#10 Envelope for

DocuMatch 4-11

Storage 4-8

Style

Commercial 4-4

Executive 4-4

Side Seam 4-4

Type

Die-Cut 4-2

Web-Fed 4-3

Weight 4-10

Window Envelopes

Dow Window Film™ 4-6

Glassine 4-6

Standard Window

Envelope 4-7

Trycite™ 4-6

Envelope Printer

Minimum Requirements

2-4

Performance Tips 2-4

Environmental Conditions

and Mail Materials 2-3

Executive Envelopes 4-4

F

Fanning Paper Before

Loading 3-6

Felt Side of Sheet of Paper

A-3, A-5, A-6

Finish or Surface Coating of

Paper A-5

Flap

Curl Limits 4-4

Seal Flap 4-8

Seal Flap Gum 4-8

Flat Sheets. See Cut Sheet

Feeder

Flexing Paper Before Loading

3-7

Folder

Cut Sheet Folder

Problems Caused by

Glossy Materials 5-2

G

General Machine Preventive

Maintenance 8-2

Glossy Finish Paper A-5

DocuMatch™ Mail Materials Reference Guide

I-3

Page 71

Index

Grain

Grain Direction

Caused by Alignment of

Fibers A-3

Grain Long 3-3, 3-5

Grain Short 3-3, 3-9

Methods for Determining

3-3

Overview 3-3

Gum

Seal Flap Gum 4-8

Seam Gum 4-8

H

Hardening of Paper A-4

Humidity

and Storage of Mailing

Materials 2-2

I

Insert Feeder

Belt and Rollers

and Dust Problems 8-4

Loading 6-2

Materials 6-2

Minimum Requirements

6-3

Performance Tips 6-3

Materials Reference Table

6-3

Minimum Requirements

2-5, 2-6

Performance Tips 2-5, 2-6

Preventive Maintenance

8-4

Inserts

Business Reply Envelopes

(BREs)

Minimum Requirements

2-5, 2-6, 6-3

Performance Tips

2-5, 2-6, 6-3

Postcards

Minimum Requirements

2-5, 2-6, 6-3

Performance Tips

2-5, 2-6, 6-3

Pre-Folded

Minimum Requirements

2-5, 2-6, 6-3

Performance Tips

2-5, 2-6, 6-3

K

Krystal-Klear Window

Envelopes. See

Envelope: Window

Envelopes: Trycite™

L

Lacquer Coated Paper 3-9

Laser Printer. See Document

Printer

Loading

Envelopes 4-9

Paper for Document Printer

Aerating (Fanning) 3-6

Caution 3-7

Flexing 3-6

M

Mail Materials

Definition 2-2

DocuMatch™ Mail

Materials Reference Table

2-4, 2-5, 2-6

I-4

DocuMatch™ Mail Materials Reference Guide

Page 72

Index

Cut Sheet Feeder (Flat

Sheets) 2-4

Envelope Printer 2-4

Insert Feeder 2-5, 2-6

Laser Printer 2-4

Handling 2-2

Locally-Manufactured

Materials 2-3

Not Suitable for

DocuMatch 2-7

Rotation of Stock 2-3

Storage 2-2

Dry Environment 2-3

Humidity 2-2

Masonry Walls 2-3