Pitney Bowes DI900, DI950 Configuration Manual

DI900 and DI950

Configuration Guide

A Supplement to the DI Series Guide

Revised August 2012

August 30, 2012 PBI Internal use only

1

Table of Contents

Descriptions/Definitions

Configuration Considerations

Towers and Feeders

Output Stackers

Universal Feeder

Exit Transport

System Measurements

Minimum Table Requirements

August 30, 2012 PBI Internal use only

2

Definitions

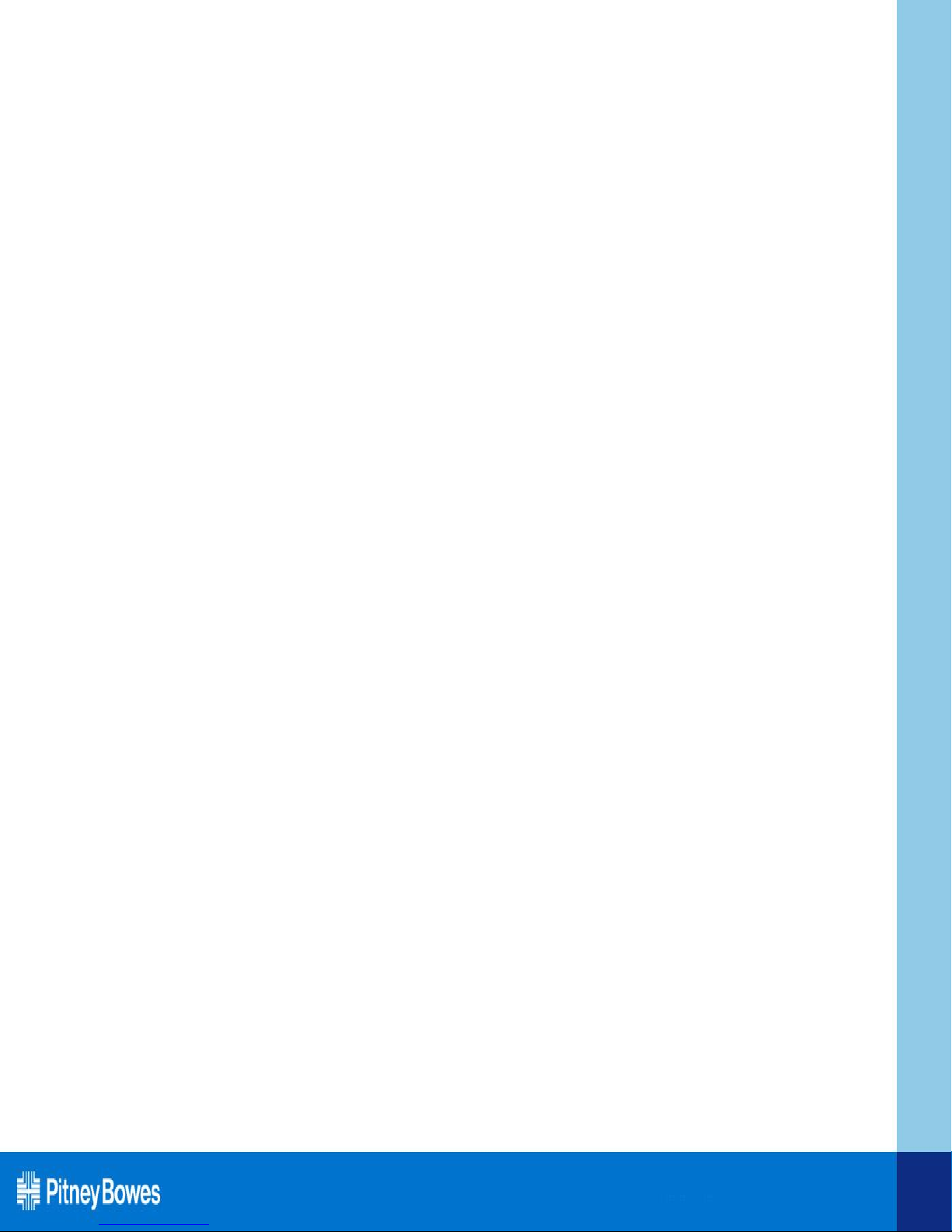

Base Unit- The DI900/DI950 Base unit is comprised of the Transport Deck, Folding, Inserting,

and Sealing modules. The Base unit does not include the Tower and the PacPilot Control Panel.

The DI950 includes the High Capacity Envelope Feeder. The DI900 does NOT include a High

Capacity Envelope Feeder and the High Capacity Envelope Feeder CANNOT be installed in the

field.

DI900 Base

Tower- A DI900/DI950 Tower unit is comprised of the PacPilot Control Panel and either two

(A & B) or four (A, B, C, & D) feed stations. Regardless of whether a tower is ordered as part

of a pre-configured system or a custom configuration, Feed trays (either Insert or Sheet/Flat

Trays) are ordered separately to support specific customers applications.

High Capacity Envelope Feeder

DI950 Base

DI950 Base

A

B

C

A

D

B

Bottom Address Inverter Kit- The Bottom Address Inverter Kit is used for applications

where the address bearing portion of the document is on the bottom panel. This kit is similar in

function to the Document Inverter that was available on the DI800. The Inverter Kit upgrades

the folder to support tri-folded middle and bottom address applications at close to full speed

without requiring bottom-flap envelopes. The kit is installed on the top of the Folding Module.

Bottom Address Inverter

August 30, 2012 PBI Internal use only

3

Definitions (continued)

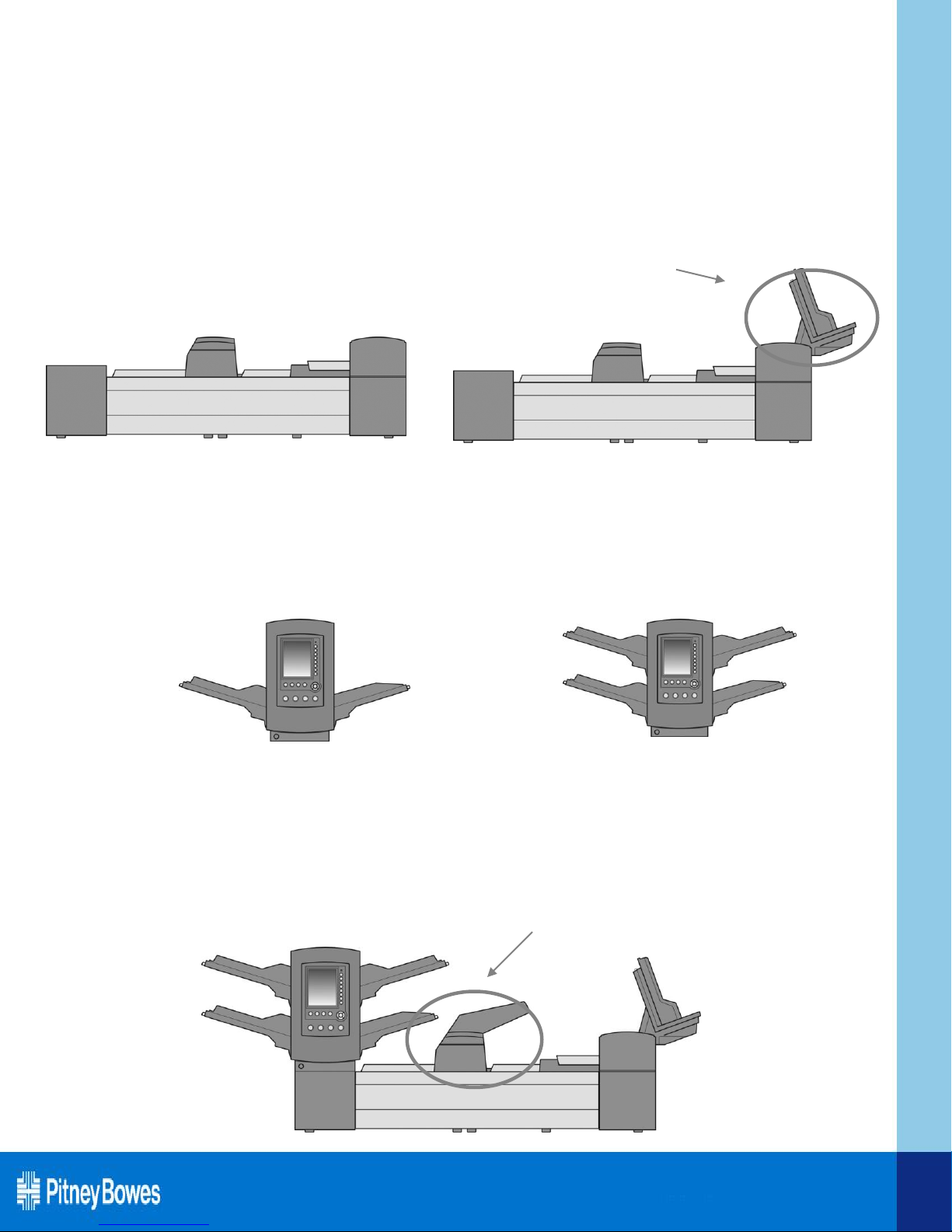

Special Tower Feeder Kit- The special feeder kit is for customers who might feed booklets or lightweight prefolded inserts (16lb or 60gsm

material) from the tower. In order to do this effectively, the Special Tower Feed Kit is available for inclusion on the configured

system. This kit can only be installed on the upper two stations (C, D, or both) of the DI 900/DI950 system. This means that the

Special Tower Feed Kit can ONLY be used with a Four Station Tower since the Two Station Tower does not have feeders on the

upper station.

Although some booklets can be fed in without it, the special feeder is recommended for booklets where the cover weight is close to the

weight of the internal pages. (The cover weight should at least be as heavy as the internal pages). The special feeder only works

when the insert tray is installed, it will not work for sheets (stacks tray installed).

NOTE:Refer to Operator Guide for booklet/ insert material specifications.

Exit Transport- Extends the path of the letter envelope exit beyond the distance needed for flats stacking below. The Exit Transport connects

to the inserter and can be mounted to other output devices (belt stacker, vertical power stacker, mailing machine), while maintaining

flats envelope functionality. The Exit Transport also provides optimum operator access to the High Capacity Envelope Feeder in

certain configurations.

Flats Sealer- is an add-on module that attaches to the exit end of the base system to allow for the sealing of flat envelopes. The Flats Sealer

can seal flat envelopes up to 0.25 (6.5 mm) in thickness. While the Flats Sealer is designed specifically to seal flat envelopes, it has

an exit path for (sealed) letter envelopes exiting the system. The Flats Sealer also contains an envelope edge marker. The envelope

edge marker will apply a mark at least 0.5” (12.5mm) in length along the edge of the envelope facing the operator. Edge mark can be

used to indicate tray breaks, ZIP breaks, every 50th envelope, high value checks, etc.

Integrated Document Printing- builds on the DI900/950 platform by integrating inline document printing with real time automatic

regeneration of materials ensuring extremely high integrity tracking of each printed piece. This expanded solution includes a black

and white document laser printer.

C

A

Exit Transport

Flats Sealer

Black & White Integrated Printer

D

B

August 30, 2012 PBI Internal use only

4

Definitions (continued)

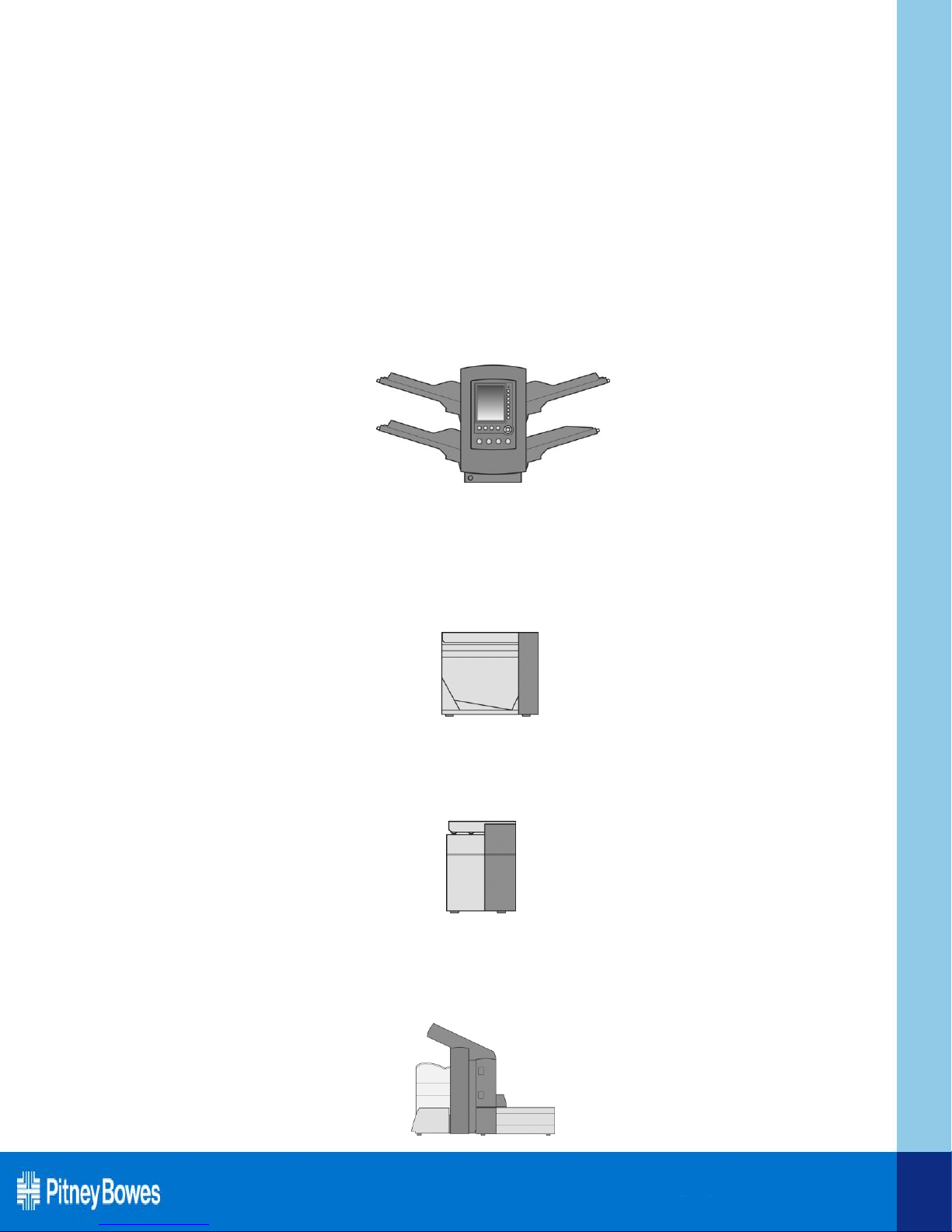

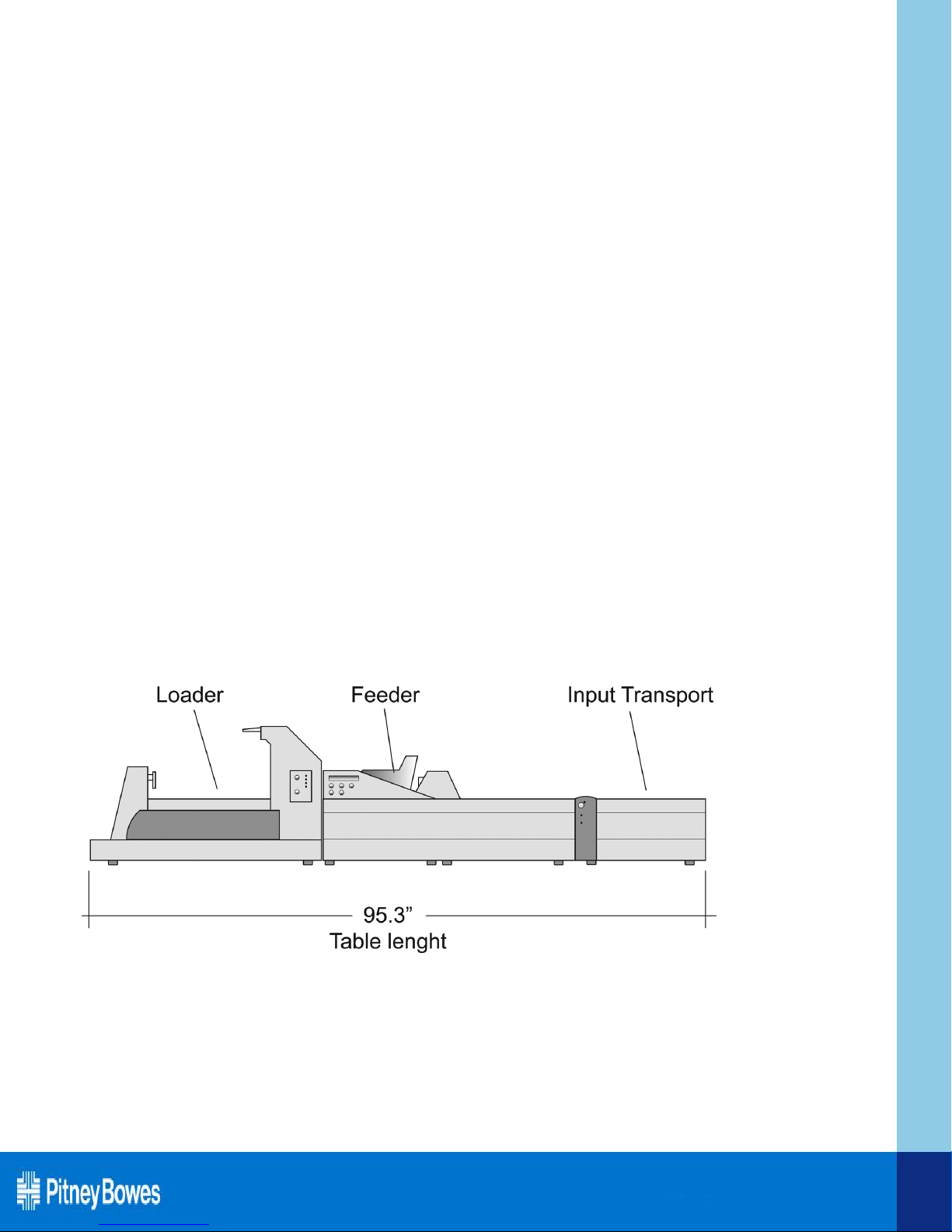

Universal Feeder- is an option for the enhanced DI950

Inserting System that offers high speed and capacity, flexible

scanning and enhanced booklet feeding capabilities. The

system will collate and pass complete sets to the DI950 and

accumulates 15,000+ sheets per hour. It will also support

feeding of booklets and inserts up to 0.16 (4mm) thick. An

optional loader is available that matches the sheet feeder

demand with a capacity of 4,500 letter size sheets. An input

transport acts as an interface for the Universal Feeder to the

DI950 Inserter. It is required on all systems and is bundled

into the configurations in Pathfinder. Flexible scanning

capabilities allow the system to read most PB codes (OMR

& Barcode) and many competitive scan codes.

Universal Feeder System w/ Loader

August 30, 2012 PBI Internal use only

5

Configuration Considerations

Towers and Tray Types-

Both the DI900 and the DI950 come with available two and four

station towers. Because of the highly configurable nature of the

system and the infinite number of customer applications, once you

have chosen either a two or four station tower, it is still necessary

to designate what trays will need to be included.

When configuring the DI900, be aware that you must order at

least ONE (1) Insert Tray to support the destination

envelopes. Failure to do so will result in an invalid

configuration that is un-useable by the customer.

Remember, just because a system is two or four station does not

mean that you are limited to selecting the same quantity of trays.

The flexibility and user-friendliness of the system allows for trays

to be swapped depending on the application. As a result, it is not

uncommon for a customer to request a four station tower and

more than four trays. For instance, a DI950 customer could have

one application that requires four Insert Trays and another that

requires four Sheet/Flats Trays. A four station tower could be

ordered with four Insert Trays and Four Sheet Trays. As the

customer changes from application to application, they would

simply replace trays as necessary to meet their applications. By

configuring the system as stated, the customer would be able to

process all of the following configurations:

4 Sheets and No Inserts

3 Sheets and 1 Insert

2 Sheets and 2 Inserts

1 Sheet and 3 inserts

0 Sheets and 4 Inserts

PLEASE NOTE: To avoid configuration errors, Pathfinder

requires you to select your feed trays.

August 30, 2012 PBI Internal use only

6

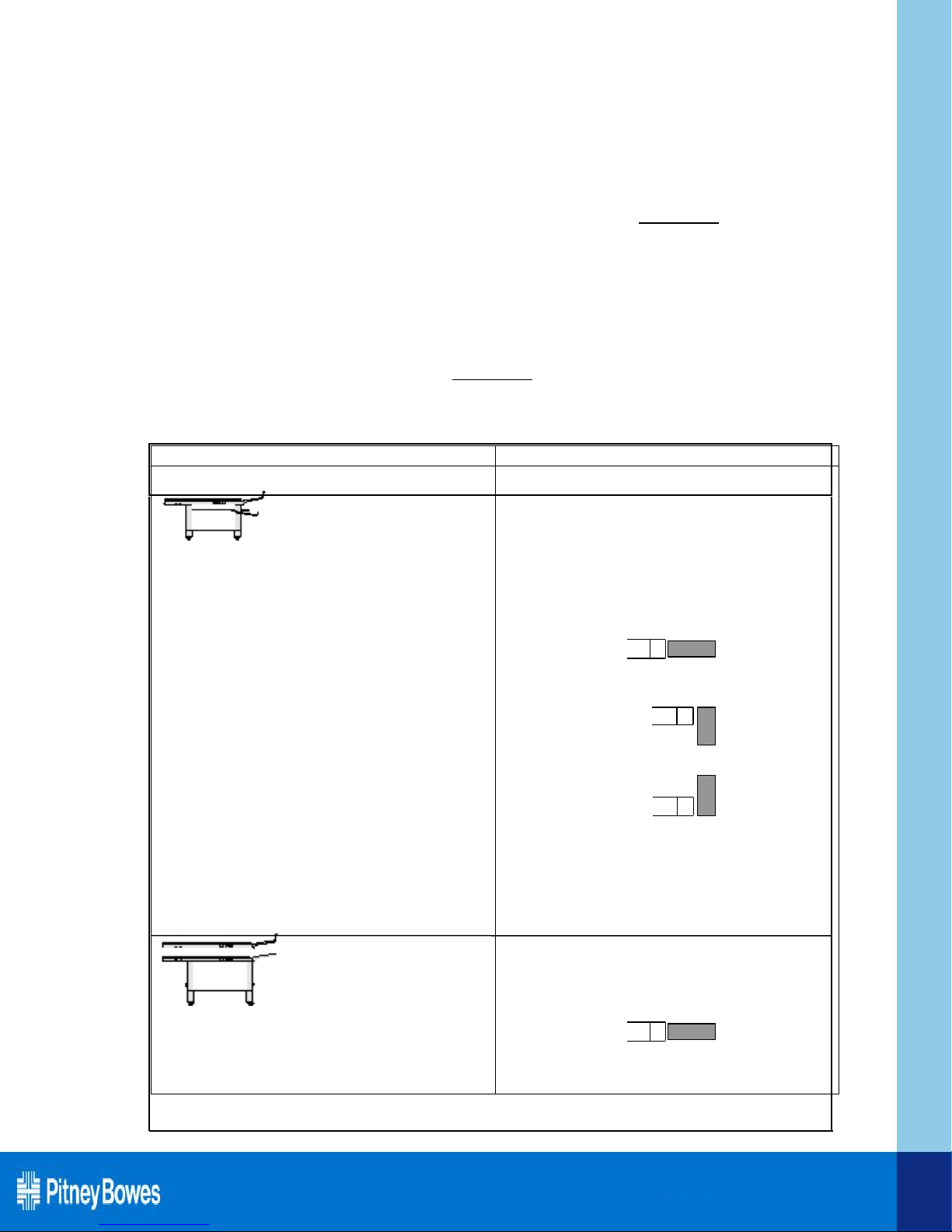

Configuration

Orientation

Stacks letters and flats

Height can be adjusted to match

the height of the letter and flats

output

Can be used with an exit transport

when stacking letters. (See Exit

Transport description on following

page)

OptiFlow Belt stacker. Stacks letters, flats

will drop into Drop Stacker (provided with

system).

OptiFlow Belt stacker. Stacks letters, flats

will drop into an Exist Transport (add on

option).

Simultaneous letters and flats OptiFlow

Tandem Belt Stacker stacks in tandem.

Single Belt Stacker will orient 3 ways

depending on the application

In-Line

Orientation

Tandem & In-Line

In-Line

Kits

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F785800AAA

Manual Adjust Lift

F784801

240VAC Electronic Lift

Leg Type

KIT

BS04

KIT

BS03

KIT

BS02

KIT

BS01

Sales

kit No.

Not Required for IN-LINE

configuration

F785801AAA

Roller bridge for Right

Angled Belt Stacking

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F680

F680 Belt Conveyor Stacker

F680

F680 Belt Conveyor Stacker

2 x F680

F680 Belt Conveyor Stacker

F785802AAA

2 x C Brackets for Tandem

Belt Stacking

Simulteneous Flats drop stacking not

advisable as Right Angled Front

configuration

F785803AAA

Sensor Bracket for

Flats Belt Stacking

Customers Own

Table

Customers Own

Table

Right

Angled

Rear

Right

Angled

Front

KIT

BS09

F784802

100VAC Electronic Lift

KIT

BS11

F784800

120VAC Electronic Lift

(Letters only)

(Letters only)

Tandem Belt Stacker available

In-Line only

In-Line

Orientation

Tandem & In-Line

In-Line

Kits

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F785800AAA

Manual Adjust Lift

Leg Type

KIT

BS03

KIT

BS02

KIT

BS01

Sales

kit No.

F785801AAA

Roller bridge for Right

Angled Belt Stacking

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F680

F680 Belt Conveyor Stacker

F680

F680 Belt Conveyor Stacker

2 x F680

F680 Belt Conveyor Stacker

F785802AAA

2 x C Brackets for Tandem

Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

Customers Own

Table

Customers Own

Table

Configuration Considerations

OptiFlow Belt Stacker

OptiFlow Tandem Stacker

The OptiFlow Belt Stacker can be used to stack letters in Right Angled or In-Line

configurations with the Di900/950 inserters. In Line mode is required for running

“Flats”.

The OptiFlow Tandem Stacker allows for the stacking of “Letters” and “Flats”

simultaneously. The Stacker consists of two stacker units mounted onto one set of

legs or one table at the correct vertical spacing to receive “Letters” and “Flats”

output from the Inserter. In Line mode is required for running “Letters” and “Flats”

simultaneously. The stacker can be placed on the height adjustable DI950 table

eliminating the need for the dedicated stacker table.

(Letters or Flats)

August 30, 2012 PBI Internal use only

7

When is an Exit Transport Necessary?

In-Line

Orientation

Tandem & In-Line

In-Line

Kits

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F785800AAA

Manual Adjust Lift

F784801

240VAC Electronic Lift

Leg Type

KIT

BS04

KIT

BS03

KIT

BS02

KIT

BS01

Sales

kit No.

Not Required for IN-LINE

configuration

F785801AAA

Roller bridge for Right

Angled Belt Stacking

F785802AAA

2 x C Brackets for

Tandem Belt Stacking

F785803AAA

Sensor Bracket for

Flats Belt Stacking

F680

F680 Belt Conveyor Stacker

F680

F680 Belt Conveyor Stacker

2 x F680

F680 Belt Conveyor Stacker

F785802AAA

2 x C Brackets for Tandem

Belt Stacking

Simulteneous Flats drop stacking not

advisable as Right Angled Front

configuration

F785803AAA

Sensor Bracket for

Flats Belt Stacking

Customers Own

Table

Customers Own

Table

Right

Angled

Rear

Right

Angled

Front

KIT

BS09

F784802

100VAC Electronic Lift

KIT

BS11

F784800

120VAC Electronic Lift

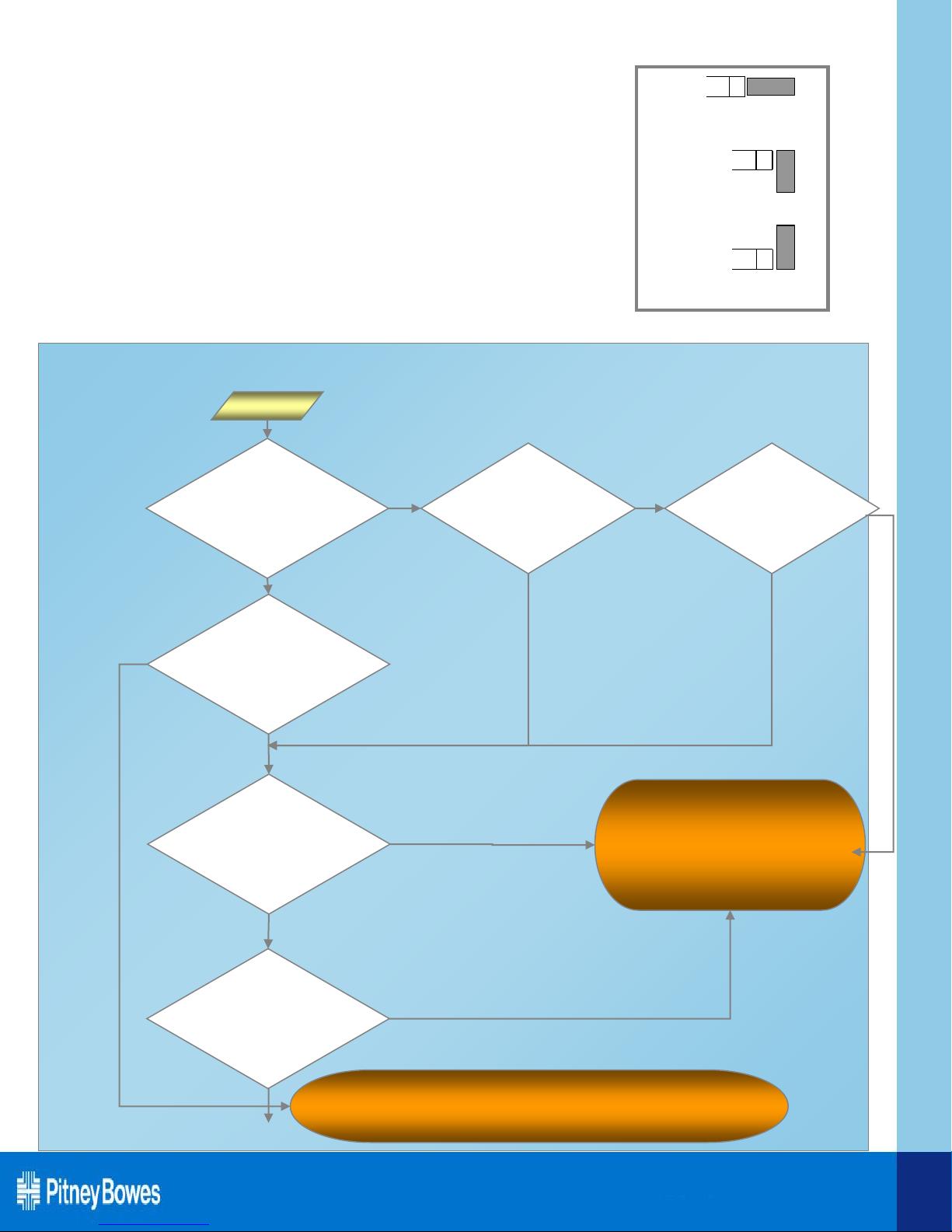

The DI900 and DI950 are offered with an Exit Transport assembly that

extends the path of the letter envelope exit beyond the distance needed

for flats stacking below. The Exit Transport Assembly measures

approximately 18” in length and allows the DI900 and DI950 to be

connected to and mount other output devices while maintaining flats

envelope functionality. The Exit Transport also provides optimum

operator access to the High Capacity Envelope Feeder (DI950) in certain

configurations

Use the flowchart below to determine if an Exit Transport Assembly is required

for your customer’s application.

Exit Transport Assembly Decision Tree

Start

Stacker Orientation

No

Are you

Proposing a DI950?

No (DI900)

Does the application

Include inserting

Into Flats?

Yes

Is there a right-

angle belt stacker

towards operator?

No

Yes

Have you

included a

Flats Sealer?

Yes

Yes

No

Are you using

a Vertical Power

Stacker?

No

You require an

Exit Transport Assembly.

Yes

Are you including

a Mailing Machine

Interface?

No

Yes

You do not need an Exit Transport Assembly.

August 30, 2012 PBI Internal use only

8

Loading...

Loading...