Page 1

DI800 FastPac

Inserting System

™

SV40188-OG Rev. A

OPERATOR GUIDE

Page 2

WARNING

This equipment generates, uses and can radiate radio frequency

energy and if not installed and used in accordance with the

instruction manual, may cause interference to radio communications. It has been tested and found to comply with the limits for

a Class A computing device pursuant to Subpart B of Part 15 of

FCC Rules, which are designed to provide reasonable protection

against such interference when operated in a commercial environment. Operation of this equipment in a residential area is

likely to cause interference, in which case the user, at their own

expense, will be required to take whatever measures are required

to correct this interference.

Trademark Notice

FastPac™ is a trademark of Pitney Bowes, Inc.

First Edition, September 2002

©2002 Pitney Bowes Inc.

All rights reserved. This book may not be reproduced in whole or in part in any

fashion or stored in a retrieval system of any type or transmitted by any means,

electronically or mechanically, without the express written permission of

Pitney Bowes.

We have made every reasonable effort to assure the accuracy and usefulness of

this manual, however we cannot assume responsibility for errors or omissions

or liability for the misuse or misapplication of our products.

Page 3

FastPac™ Inserting System Contents

Chapter 1: Introduction................................... 1-1

In This Book .............................................................. 1-1

Introduction................................................................ 1-2

Safety ......................................................................... 1-7

A Note to the Operator .............................................. 1-8

Material Specifications .............................................. 1-9

Chapter 2: The Base Unit ................................ 2-1

Overview.................................................................... 2-1

Controls and Indicators .............................................. 2-5

Setup and Adjustments ............................................ 2-19

Running Test Material ............................................. 2-38

Tips to Reduce Setup Time ...................................... 2-40

Clearing Material From the Base Unit.................... 2-41

Maintaining the Base Unit ....................................... 2-44

Chapter 3: The Single Feeder Modules ......... 3-1

Overview.................................................................... 3-1

Controls and Indicators .............................................. 3-7

Setup and Adjustments ............................................ 3-17

Running Test Material ............................................. 3-33

Tips to Reduce Setup Time ...................................... 3-34

Clearing Material From the Feeder.......................... 3-35

Maintaining the Feeder ............................................ 3-38

What is OMR? ......................................................... 3-40

Page 4

ii

FastPac™ Inserting System — Contents

Chapter 4: The Folder...................................... 4-1

Overview.................................................................... 4-1

Controls and Indicators ............................................ 4-10

Setup and Adjustments ............................................ 4-16

Running Test Material ............................................. 4-25

Tips to Reduce Setup Time ...................................... 4-28

Clearing Material From the Folder ......................... 4-30

Maintaining the Folder ............................................ 4-32

Document Inverter Operation .................................. 4-33

Chapter 5: The Crossfolder ............................ 5-1

Overview.................................................................... 5-1

Controls and Indicators .............................................. 5-4

Setup and Adjustments ............................................ 5-11

Running Test Material ............................................. 5-32

Tips to Reduce Setup Time ...................................... 5-32

Clearing Material from the Crossfolder................... 5-34

Maintaining the Crossfolder .................................... 5-34

Chapter 6: The Burster Interface.................... 6-1

The Burster Interface ................................................. 6-1

Setup and Adjustments .............................................. 6-4

Chapter 7: Electronic Setup ........................... 7-1

Overview.................................................................... 7-1

Types of Operators ..................................................... 7-2

Page 5

FastPac™ Inserting System — Contents

Control Panel ............................................................. 7-3

Job Numbers .............................................................. 7-4

Startup ........................................................................ 7-5

Operator Functions .................................................... 7-6

Review any of the job settings: ...................... 7-7

Selecting another job to run: ........................ 7-11

Running test material and starting a run: ..... 7-12

Clearing the Deck: ....................................... 7-13

Resetting the Job Count: .............................. 7-14

Resetting the Base Cumulative Count: ........ 7-14

Key Operator, Module Functions ............................. 7-15

Module Options: .......................................... 7-16

Language:..................................................... 7-24

iii

Speed:........................................................... 7-25

Key Operator, OMR Setup ....................................... 7-26

Flowchart for OMR Setup Screens .............. 7-28

OMR Present/Off ......................................... 7-29

OMR Present/EOC Only.............................. 7-31

OMR Present/Multi Line ............................. 7-40

Chapter 8: Troubleshooting ............................ 8-1

Mechanical Problems................................................. 8-1

Messages on the Screen ............................................. 8-6

Page 6

iv

FastPac™ Inserting System — Contents

Appendix A: The Twin Feeder Modules ........ A-1

Overview................................................................... A-1

Controls and Indicators ............................................. A-7

Setup and Adjustments ........................................... A-17

Running Test Material ............................................ A-33

Tips to Reduce Setup Time ..................................... A-34

Clearing Material From the Feeder......................... A-35

Maintaining the Feeder ........................................... A-38

What is OMR? ........................................................ A-40

Is the Module Equipped with OMR? ...................... A-41

Key Operator, Module Functions ............................ A-44

Key Operator, OMR Setup...................................... A-49

Messages on the Screen .......................................... A-50

Index .................................................................. I-1

Page 7

Chapter 1: Introduction

In This Book

This book contains information that explains the FastPac™ Inserting System DI800. There are several chapters in this book.

The chapter you are now reading, Chapter 1, contains:

❑ System Introduction—describes the FastPac™ Inserting

System DI800 and how the system can fill your mailing needs.

❑ Safety—outlines safety practices that you should follow.

❑ A Note to the Operator—a reminder to read this manual

before operating your FastPac™ Inserting System DI800.

❑ Material Specifications—a listing of the kinds of material

appropriate to use in the FastPac™ Inserting System DI800.

Chapters 2 — 4 and Appendix A describe the Base Unit, the

Single Sheet Feeder and Insert Feeder, the Folder, and the Twin Sheet

Feeder and Insert Feeder. Chapters 5 and 6 describe the optional

Crossfolder Module and the Burster Interface. These chapters contain:

❑ An introduction to the module—a discussion of the module

and how it fits in the FastPac™ Inserting System DI800.

❑ Controls and Indicators—illustrates the various parts of the

modules and explains their usage.

❑ Mechanical Setup and Adjustments—step-by-step proce-

dures on how to make the necessary mechanical setup and

adjustments to the modules to get the system up and running.

❑ Running Test Material—how to test settings and adjustments.

❑ Maintaining the Module

Chapter 7 covers the electronic setup for the FastPac™ Inserting

System DI800. This chapter discusses the use of the Main Control

Panel located on the Base Unit. These functions are separated into

two categories: those functions available to all operators and those

available only to a key operator.

Chapter 8 covers troubleshooting for the FastPac™ Inserting

System DI800. Included are error messages, their meaning, and

suggestions for correcting the problem.

Page 8

1-2

Chapter 1: Introduction

Introduction

This manual is about the FastPac™ Inserting System DI800. The

FastPac™ Inserting System DI800 is a modular system, one machine made up of a group of compact, versatile, building blocks.

These building blocks, or “modules” work together to create a

“collation” or “mailpiece.” A collation or mailpiece is simply a

group of papers that go into one envelope to be mailed to one

addressee. That means the FastPac™ Inserting System DI800 must

have modules to feed paper, fold paper, add extra inserts to the

collation, insert that accumulated collation into an envelope, and

seal the envelope.

A FastPac™ Inserting System DI800 can also perform some more

complex tasks, such as “optical mark recognition” (OMR). That

means the system is equipped with a scanner, much like those used

for cash registers in check out lines, to read and process paper with

special dash mark codes.

The modular units of the FastPac™ Inserting System DI800 are

streamlined and compact. They are designed to fit on the top of

most work tables. Which components are included in your FastPac™

Inserting System DI800 depends on your application needs. During installation, your Pitney Bowes representative will fully explain all of the modules. During operator training, you will learn

what each module does and why it was included in your system.

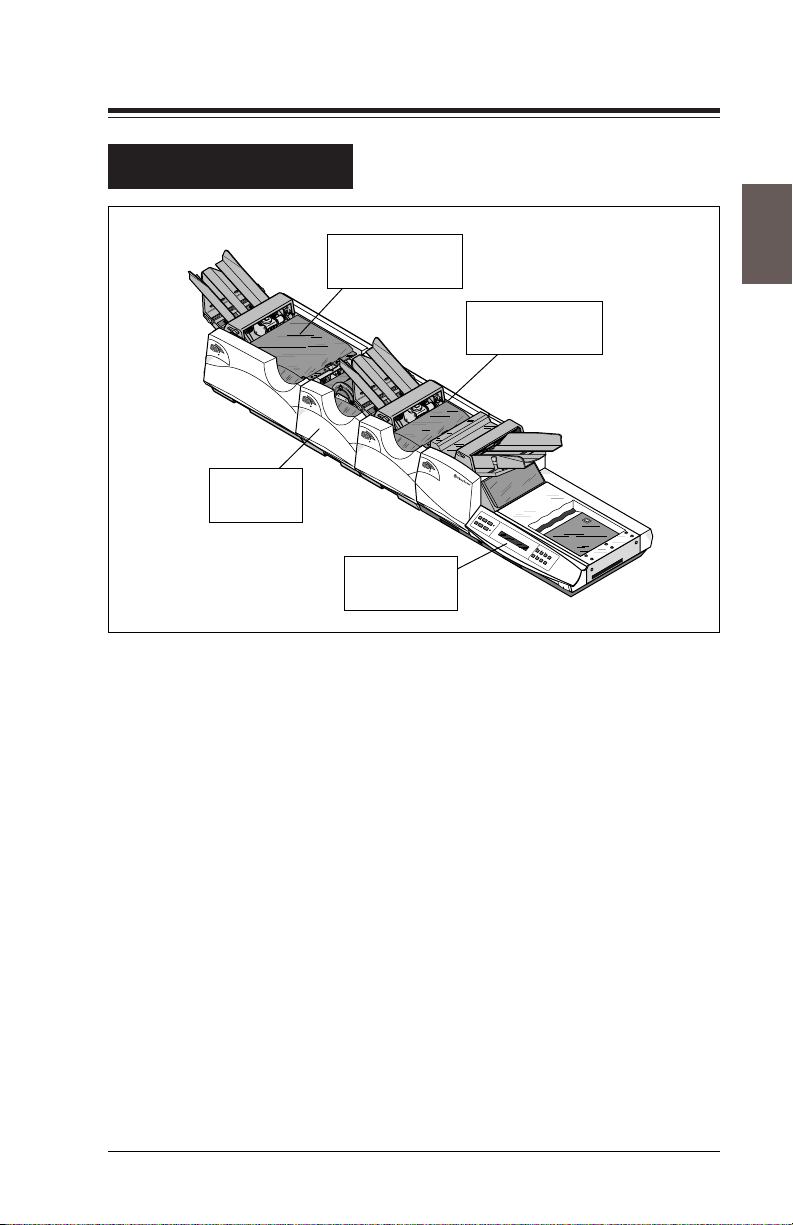

The simplest configuration for a FastPac™ Inserting System

DI800 is a Base Unit and one feeding module, such as an Insert

Feeder. More elaborate configurations are possible to fill a wide

range of needs. The illustration on the next page shows a simple

FastPac™ Inserting System DI800. The modules shown, a Sheet

Feeder, Folder, Insert Feeder, and Base Unit are all explained in

this manual.

Page 9

Chapter 1: Introduction

Introduction

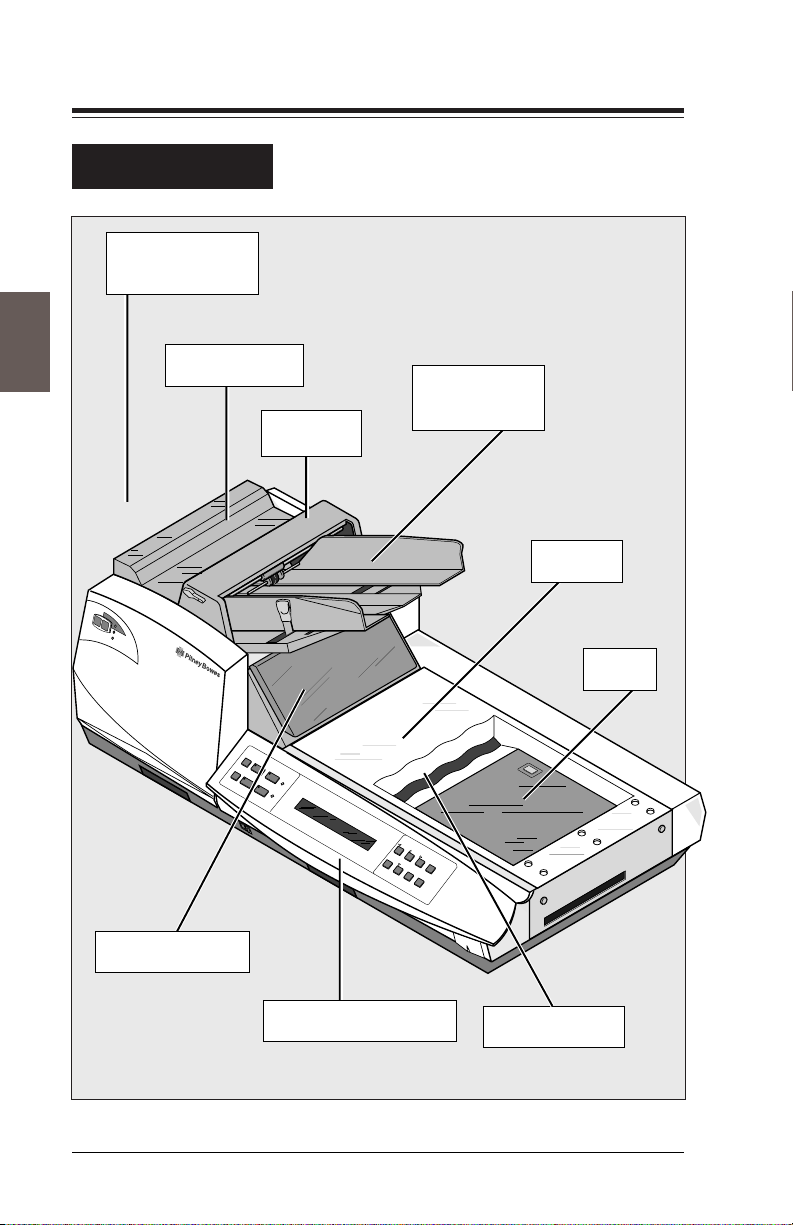

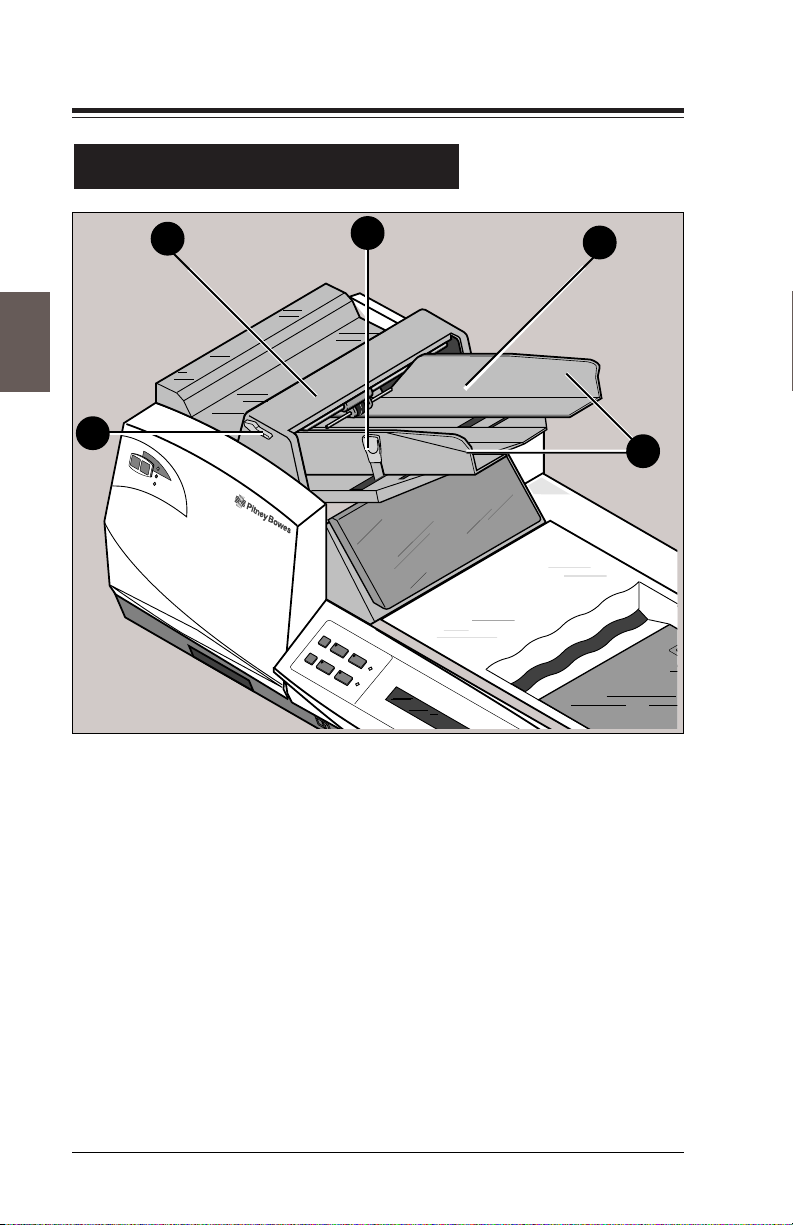

Single Sheet

Feeder (F583)

Single Insert

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

B

y

e

n

t

i

P

R

e

a

d

y

F

a

u

l

t

Feeder (F581)

s

e

w

o

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

T

ri

al

P

i

e

c

e

I

n

S

e

r

v

i

c

e

F

a

u

l

t

R

e

a

d

y

I

n

R

S

e

a

e

d

r

y

v

i

c

e

F

a

u

l

t

T

r

i

a

P

l

i

e

c

e

T

ri

al

P

ie

c

e

In

S

e

r

v

i

c

e

s

e

w

o

B

y

e

n

t

i

P

R

e

a

d

y

F

a

u

l

t

T

ria

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

s

e

w

o

B

y

e

n

t

i

P

R

e

a

d

y

F

a

u

l

t

Folder

(F582)

Base Unit

(F580)

Figure 1-1—A Simple FastPac™ Inserting System DI800

1-3

F500_029

Complete FastPac™ Inserting System DI800s always include the F580

Base Unit. Which modules are included in addition to the Base Unit

depends on your needs. A FastPac™ Inserting System DI800 can consist

of any of the following modules, up to a total of five plus the Base Unit.

❑ Base Unit (F580)—Every FastPac™ Inserting System DI800

must have the Base Unit. Consult Chapter 2 of this manual for

a detailed explanation of the Base Unit. You can't operate the

FastPac™ Inserting System DI800 without thoroughly understanding the Base Unit.

❑ Insert Feeder—The F581 Single Insert Feeder (Chapter 3)

and F587 Twin Insert Feeder (Appendix A) adds an insert to the

collation that is inserted in the envelope by the Base Unit. The

feeder is capable of feeding a wide variety of forms and

materials by moving the paper along with a belt and gate

system. The feeder holds material until the next module is

ready to accept it.

Page 10

1-4

Introduction

❑ Sheet Feeder—The F583 Single Sheet Feeder ( Chapter

3) and F588 Twin Sheet Feeder (Appendix A) can feed a

supply of single sheets or collect a set (up to six sheets)

from another module. The sheet feeder passes a complete

set to the next module (usually a folder).

❑ OMR capability—The F504/F516 OMR is an optional

feature, that can be attached to either the F581 Single Insert

Feeder or the F583 Single Sheet Feeder (Chapter 3). The

OMR option continuously scans enclosures as they leave

a feeder deck. If an End of Collation (EOC) mark is

recognized, it passes the collation to the next downstream

module for processing.

❑ Folder (F582)—The Folder (Chapter 4) is included in a

system to accept paper (from one to six sheets) from

upstream modules, fold it into one of four common folds

(single fold, letter fold, accordion fold, or double fold) and

pass it downstream to the Base Unit. The folder also has a

bypass mechanism to let paper pass through the folder if

you do not want the paper folded.

Chapter 1: Introduction

❑ Cross Folder (F407)—The Cross Folder (Chapter 5)

handles large pieces of paper by single folding a sheet once

and then changing the direction of the paper so that a

second fold module can fold it again.

❑ Different “input devices” such as bursters and cutters can

also be added to the FastPac™ Inserting System DI800.

These attach to the FastPac™ Inserting System DI800 at

the opposite end from the Base Unit, at the furthest

upstream point, to feed special forms into the FastPac™

Inserting System DI800. The F422 Burster Interface is

covered in Chapter 6. The 3324 Burster is covered in

SV40025.

Page 11

Chapter 1: Introduction

Introduction

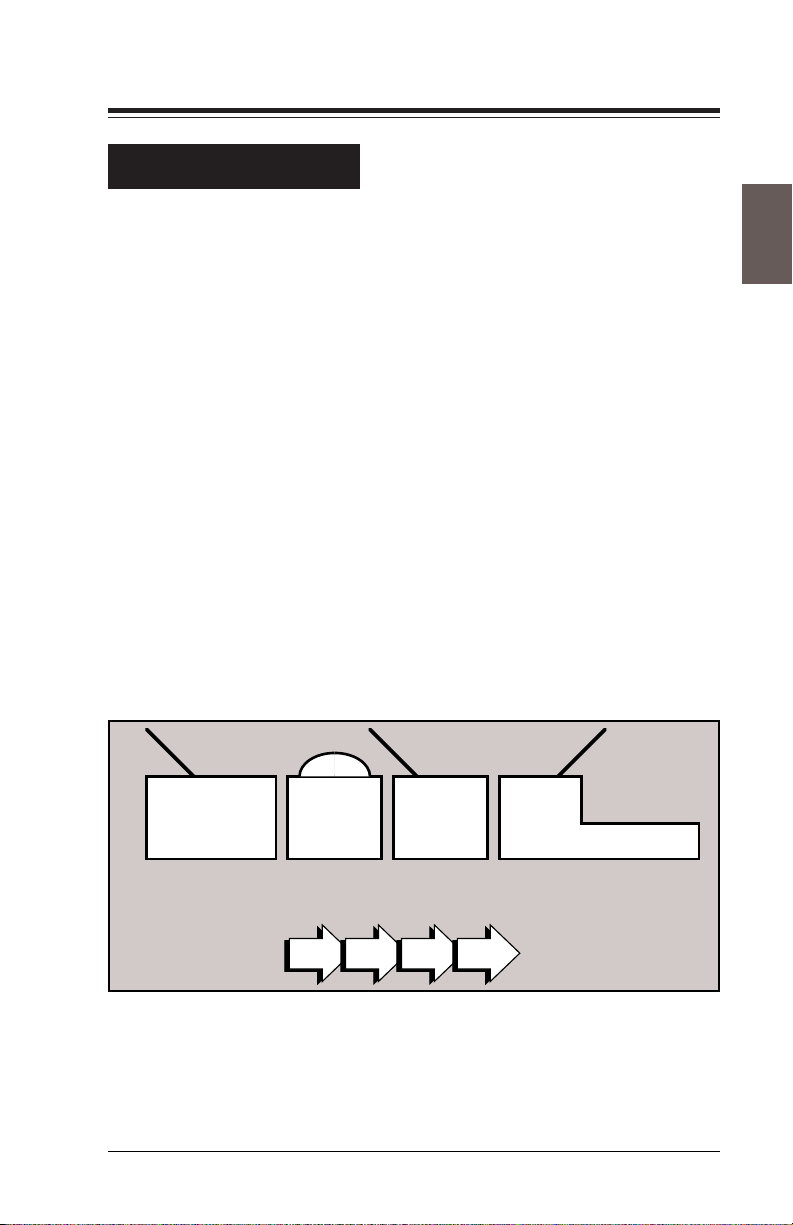

Components do not have to be in a specific order, but logically,

certain functions must follow other functions (i.e., sheets must be

fed before they can be folded, and they need to be folded before they

can fit in an envelope).

As paper moves through the FastPac™ Inserting System DI800 we

say it is flowing “downstream.” The Base Unit is always located at

the most downstream position, the position all the way to the right

when facing the operator side of the machine (the side with the

control panels). The furthest upstream module, usually a sheet

feeder, is all the way to the left.

In many of the messages displayed on the main control panel on the

Base Unit, modules are referred to by number. These are the

numbers that the FastPac™ Inserting System DI800 assigns to each

module based on its position in the system. The Base Unit is not

numbered and the most upstream module is always number one.

The numbers increase as you move downstream toward the Base

Unit. See Figure 1-2 below.

1-5

Sheet Feeder

Module

Number 1

Folder

Module

Number 2

Insert

Feeder

Module

Number 3

Base Unit

The Base Unit is

Not Numbered

UPSTREAM DOWNSTREAM

Figure 1-2—Paper flows downstream

Page 12

1-6

Chapter 1: Introduction

Introduction

Additional capabilities include Fold Only, Daily Mail, Continuous/Batching stacking modes, and Double Detect reference methods.

• Fold Only allows you to process material through the FastPac™

Inserting System DI800, but not insert it into an envelope.

• Daily Mail is a feature which allows you to interrupt a job to

process a small job, and then go back to the original job. Note

that new setup may be required for the Daily Mail and then a

return to the original setup.

• Continuous/Batching stacking modes allow you to process one

piece after another (Continuous), a counter counting continuously, or in batches of 25 with a counter counting the batches

from 25 down to zero (Maximum batch count is 250).

• Double Detection can be set up on Start where thickness of the

first piece through is measured and then used as a reference for

subsequent sheets. It can also be set up by using the Trial Piece

method. In Trial Piece, the envelope is not sealed, allowing you

to examine the collation to be sure it is correct.

Page 13

Chapter 1: Introduction

Safety

The Tabletop Inserting System is equipped with safety interlocks

that prevent operation under certain circumstances. Never attempt

to defeat these devices; you’ll endanger yourself and co-workers.

• Keep loose clothing, jewelry, and long hair away from all

moving parts.

• Avoid touching moving parts or materials while machine is in

use. Before clearing a jam, be sure mechanisms come to a stop.

• When removing jammed material, avoid using too much force to

protect against minor personal injury and damaging equipment.

• Use the power cord supplied with the machine and plug it into an

easily accessible, properly grounded wall outlet located near the

machine. Failure to properly ground the machine can result in

severe personal injury and /or fire.

• The power cord is the primary means of disconnecting the

machine from the AC supply.

• DO NOT use an adapter plug on the line cord or wall outlet.

• DO NOT remove the ground pin from the line cord.

• Avoid using wall outlets that are controlled by wall switches or

shared with other equipment.

• DO NOT route the power cord over sharp edges or trap it between

furniture.

• Ensure there is no strain on the power cord where it becomes

jammed between the equipment, walls, or furniture.

• Be sure the area in front of the wall receptacle into which the

machine is plugged is free from obstruction.

• Do not remove covers. Covers enclose hazardous parts that

should only be accessed by Pitney Bowes Customer Service.

Report any damage of covers to your Pitney Bowes Customer

Service representative.

• To prevent overheating, do not cover the vent openings.

• Read all instructions before attempting to operate the equipment.

• Use this equipment only for its intended purpose.

1-7

In addition, follow any specific occupational safety and health

standards for your workplace or area.

Page 14

1-8

Chapter 1: Introduction

A Note to the Operator

The instructions in this guide explain how to set up and use the

modules in a basic FastPac™ Inserting System DI800. Being

familiar with the information in this manual helps you keep

problems to a minimum and achieve the best possible performance

from your system.

Before setting up and using the system, you should be completely

familiar with the modules used in your application. Read each

chapter of this manual as your system may include any of the

available modules. This operating guide is meant to help you use

the equipment to its full potential. For additional assistance, contact

your Pitney Bowes Customer Service Representative.

Note that some of the instructions that follow tell you to use the

scales provided on the FastPac™ Inserting System DI800 to take

measurements. Always use these scales as instructed.

Page 15

Chapter 1: Introduction

Material Specifications

These material specifications apply to the FastPac™ Inserting

System DI800.

Envelopes for the F580 Base Unit:

• Envelopes must be flat, straight, and not glued together.

• Envelopes can be standard side seam, diagonal side seam,

executive, die cut, and closed window. The FastPac™

Inserting System DI800 does not run open window envelopes.

• Envelopes must be made from at least 16 lb. bond and no more

than 24 lb. bond material.

• Maximum acceptable envelope size is 6-7/16" (163mm) deep

by 10-3/8" (263mm) wide.

• Minimum acceptable envelope size is 3-1/2" (89mm) deep by

6-3/8" (162mm) wide.

1-9

• Flaps must be between 1-1/4" (32mm) and 2-1/4" (57mm) and

all envelopes must always have at least 1/4" (7mm) clearance

on each side, and a 1/4" (7mm) clearance between the crease

line of the flap and the edge of the insert.

Material for other system modules:

• Sheets for the F583 and F588 Sheet Feeder must be at least

5-1/2" (140mm) wide and no more than 9-7/8" (250mm) wide.

• Sheets for the F583 and F588 Sheet Feeder must be at least 4"

(102mm) deep, but no more than 14" (355mm) deep.

• Sheets must be made from at least 16 lb. bond and no more than

24 lb. bond material.

Page 16

1-10

Chapter 1: Introduction

Material Specifications

• The thickness of the full collation feeding through the sheet

feeder must not exceed .072" (2.0mm). If sheets are to be

folded, thickness must not exceed .024" (0.6mm) or 6 sheets.

• Inserts for the F581 and F587 Insert Feeder must be at least

5-1/2" (140mm) wide and no more than 9-7/8" (250mm) wide.

• Inserts for the F581 and F587 Insert Feeder must be at least 21/2" (64mm) deep, but no more than 6" (152mm) deep.

• Insert thickness must not exceed .100" (2.5mm).

• The depth of all material must be within 1/2" (12mm) of each

other in the accumulator section of the Insert Feeder.

• The depth of all inserts must be within 1/2" (12mm) of the depth

of a folded sheet.

• The folder is limited to six sheets of 20 lb. bond, or if the fold

desired is a Double Fold, then only 3 sheets may be folded.

• If input includes a crossfolded document, only a single sheet

may be added before the fold is made.

• Material to be fed and read by an OMR kit installed on an F583

and F588 Sheet Feeder is a single sheet of material within the

specification of the F583 and F588 Sheet Feeder.

• If the OMR is installed on an F581 and F587 Insert Feeder,

depth and width of material is the same as specified for F581

and F587.

• The thickness of the material when scanning cannot exceed

.020" (0.5mm). The thickness when not scanning can reach

.100" (2.5mm).

Page 17

Chapter 2: The Base Unit

Overview

The F580 Base Unit is the primary and required component of the

FastPac™ Inserting System DI800. The primary functions of the

Base Unit are to insert the collation into an envelope, process that

envelope, and control the system from commands entered at the

Main Control Panel.

The Base Unit consists of several main sections; see Figure 2-1,

next page:

• the envelope feeder

• the flapper

• the insert station

• the turner/ejection station

• the sealer

• the Main Control Panel

Other modules in the system are always located to the left (or

“upstream”) of the Base Unit. Paper flows from these modules

toward the Base Unit—often referred to as flowing “downstream”—

flowing toward the Base Unit.

!

WARNING: As we've stated, the Base Unit is just one

component of the entire FastPac™ Inserting System

DI800. Each module was “docked” to the other

modules in the system by your service representative

when it was installed.

Never attempt to separate the modules. This is for

service personnel only.

Page 18

2-2

Overview

Incoming

Collation Path

T

r

i

a

l

P

ie

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

Chapter 2: The Base Unit

Flapper Area

Envelope

Feeder

Bridge

Turner

Sealer

Reset/

Review

Trial Piece

JJob

Start

Pause

Add

Water

Clear Deck

Seal

Insert Station

Main Control Panel

Figure 2-1—The Base Unit (F580)

Setup

Report

Exit

Zero Count

Eject Station

F500_043

Page 19

Chapter 2: The Base Unit

Overview

The following describes how paper moves through the Base Unit.

• The envelope feeder holds a supply of envelopes and feeds

them to the flapper area of the Base Unit. Like the feeder

modules described later, the envelope feeder has a separating mechanism that separates individual envelopes from

the stack loaded in the feeder. The separating mechanism

peels them away, one at a time, from the stack and feeds

them down to the paper path.

• The flapper section of the Base Unit opens the flap on the

envelope. As the envelope feeds into the flapper, the lead

edge of the envelope, opposite the flap edge, enters a pair

of rollers. The bottom roller rotates, wrapping the envelope

around until the downstream edge of the envelope contacts

the flap openers. As the envelope continues to move, the

flap openers pull the flap away from the body of the

envelope. Once the flap is pulled open, the envelope enters

the insert station where a sensor detects its arrival. Another

sensor detects if the flap is open.

2-3

• In the insert station the envelope throat is opened to receive

the collation being fed from upstream modules. Three

throat openers (two located on either side of the envelope

and one in the center), are rotated into the throat of the

envelope, pulling the envelope open to receive a collation.

When the body of the envelope is open to receive the

collation, a signal is sent that the envelope is ready, and the

collation is fed from the upstream module into the open

envelope.

continued-->

Page 20

2-4

Overview

Chapter 2: The Base Unit

• A sensor verifies that the collation is inserted, causing the

Base Unit to pass the filled envelope to the turner section

where it is rotated 90˚. As the mailpiece exits the insert

station, the turner stops are raised to stop the mailpiece in

the turner area. When the leading edge of the mailpiece hits

the stops at the downstream end of the turner, the envelope

stops and is turned 90° to be properly aligned for the sealer.

• Defective pieces are ejected by an eject mechanism. This

provides a way to sort out unstuffed envelopes or incomplete collations. Ejection is done just after the insert

station, preventing the mailpiece from being turned, sealed,

and counted.

• The turned envelope feeds into the sealer where the flap is

guided back toward a partially closed position and then

passed over a moistener where moisture is applied to the

glue on the flap. The envelope then passes through a pair

of rollers that apply pressure to the wet, gummed surface

of the envelope flap, sealing the envelope. When you select

the no-seal option, the diverter prevents the flap from

passing over the moistener.

A drawer pulls out of the front of the Base Unit for adding

water to the sealer. A mechanical float is located in the

reservoir to indicate the water level and help avoid over

filling. A light on the Main Control Panel warns when the

water level is low.

• The Base Unit also houses the Main Control Panel with the

operator interface for all the modules in the system; these

are the buttons you use to perform electronic setup on the

entire FastPac™ Inserting System DI800.

• The On/Off power switch is also located on the front of the

Base Unit. This controls power for the entire system.

Page 21

Chapter 2: The Base Unit

Controls and Indicators

Controls and indicators on the Base Unit are described next. Each

illustration is labeled with numbers pointing out specific items in

the picture. An explanation of how the numbered control works or

what the indicator shows you is provided below the illustration.

Review these descriptions before you go on to the setup instructions that follow. Understanding where everything on the equipment is located will help you keep your FastPac™ Inserting System

DI800 running smoothly and help you set the machine properly to

get the most from it.

This section of the chapter is intended to show you where things are,

not necessarily how to use them. Study the illustrations to see where

things are located and use the section on Setup and Adjustments to

learn how to operate the controls.

2-5

Page 22

2-6

Controls and Indicators

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

lt

R

e

R

s

e

e

t

v

/

i

e

w

T

r

ia

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

le

a

r

D

e

c

3

1

k

S

e

a

l

2

Chapter 2: The Base Unit

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

F500_043

Figure 2-2—Major Controls

1. Power Switch—A rocker switch that controls power to the

Base Unit and the entire FastPac™ Inserting System DI800.

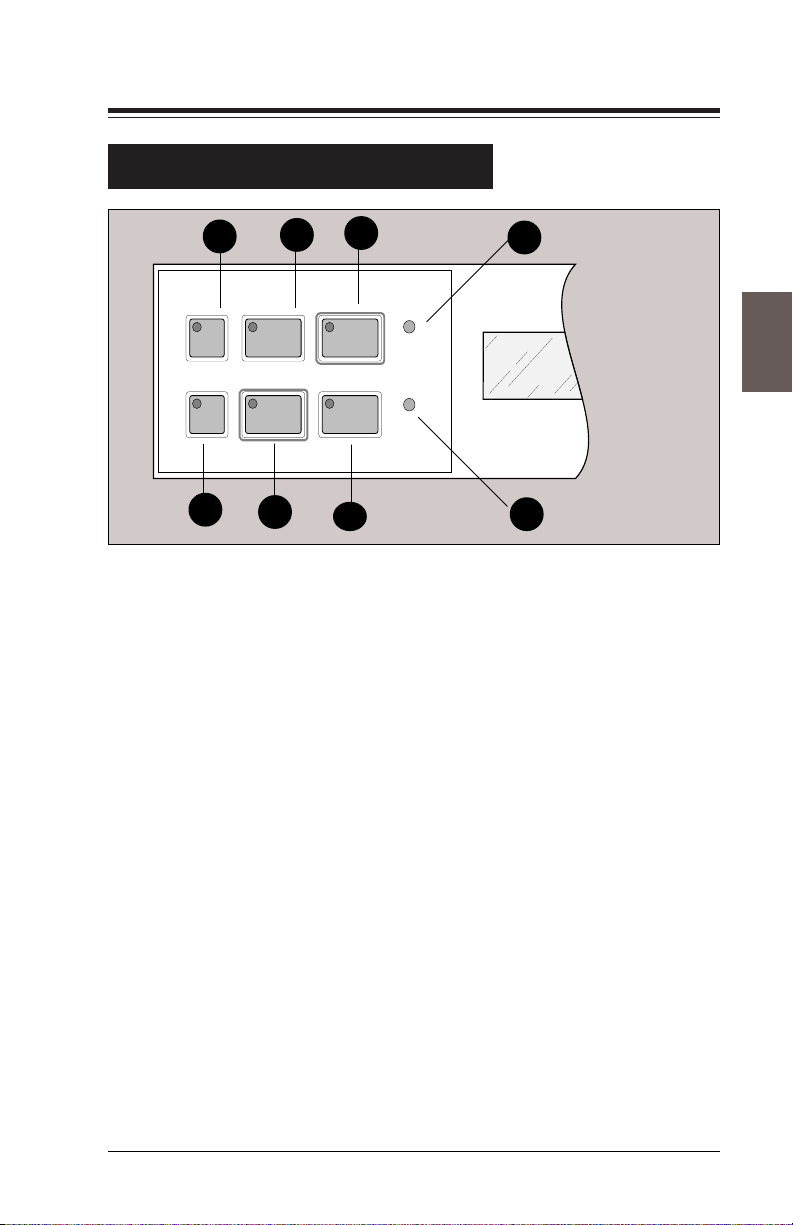

2. Main Control Panel—The Main Control Panel has fourteen

push buttons on the keypad, two status lights, and a display

screen. Use the keys to perform setup for the Base Unit and the

entire FastPac™ Inserting System DI800. If the LED on a key

is lit, that function is available; if the LED is dark, that function

is not currently available.

3. Mini Control Panel—A small control panel ( located on each

of the FastPac™ Inserting System DI800 modules) which

indicates if the module is on or off, ready, or has a fault. Use this

control panel to run a single trial piece through a specific

module.

Page 23

Chapter 2: The Base Unit

Controls and Indicators

2-7

1

Review Trial Piece Start

5

Figure 2-3—Main Control Panel, Left Side of Display

2

Stop Clear DeckJob

6

3

Add

Water

Seal

7

4

8

1. Review—Press for module-by-module review of the system

settings for the selected job.

2. Trial Piece—Press to assemble one complete inserted mail-

piece for inspection. The mailpiece will be ejected.

3. Start—Press to start continuous processing.

4. Add Water Light—Lights when the sealer requires more

water or sealing solution.

F400_096

5. Job—Press to change the selected job. Press as many times as

needed to display the desired job number. Up to ten different

jobs (groups of electronic setup commands) can be stored.

6. Stop—Press to halt the system.

7. Clear Deck—Always press before turning off the machine to

end a run or a job. The machine will cycle until all pieces on the

transport deck have been fully assembled, inserted and stacked.

Only pieces needed to complete collations will feed so that the

deck is clean when the machine stops.

8. Seal Light—Lights when the seal option is activated.

Page 24

2-8

Controls and Indicators

Chapter 2: The Base Unit

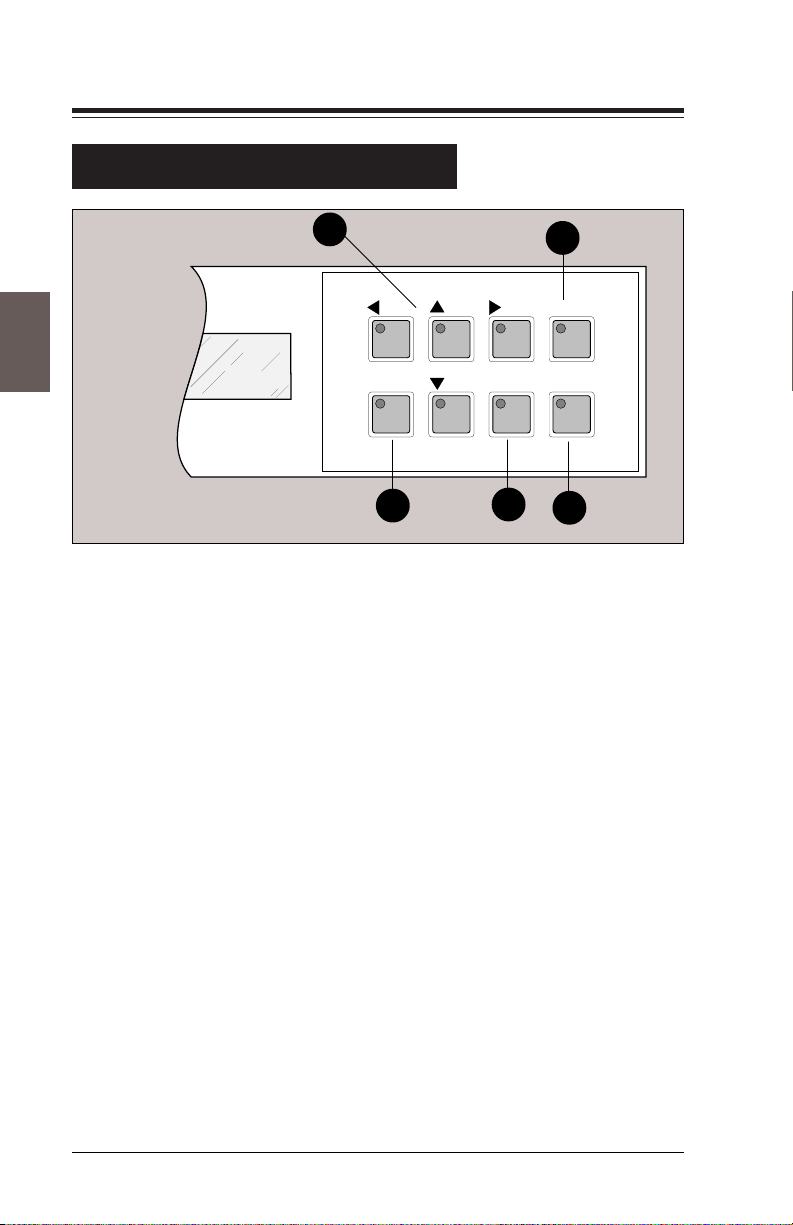

1

Setup Exit Zero Count

3

Figure 2-4—Main Control Panel, Right Side of Display

2

Report

4

5

1. Arrow Keys—Use as indicated on the display to move from

one choice to another or to make a selection.

2. Report—Press to display the current reading of the cumulative

counter. The cumulative counter keeps track of the number of

valid collations (pieces of mail) processed by the system. The

count is independent and not affected by the Zero Count key

(see below). You can use the cumulative counter as a general

purpose counter to track the daily piece count, an operator

piece count, or as a backup to the job counter.

3. Setup—After the job number you want is displayed on the

screen, press this key to enter the setup mode, then use the

arrow keys. A code is required to access the job setup functions.

4. Exit—Press to exit the setup mode.

5. Zero Count—Press to reset the piece counter to zero, e.g., at

the beginning of a new job or run.

Page 25

Chapter 2: The Base Unit

Controls and Indicators

5

Trial Piece In Service

2-9

3

2

Ready

Fault

4

F500_030

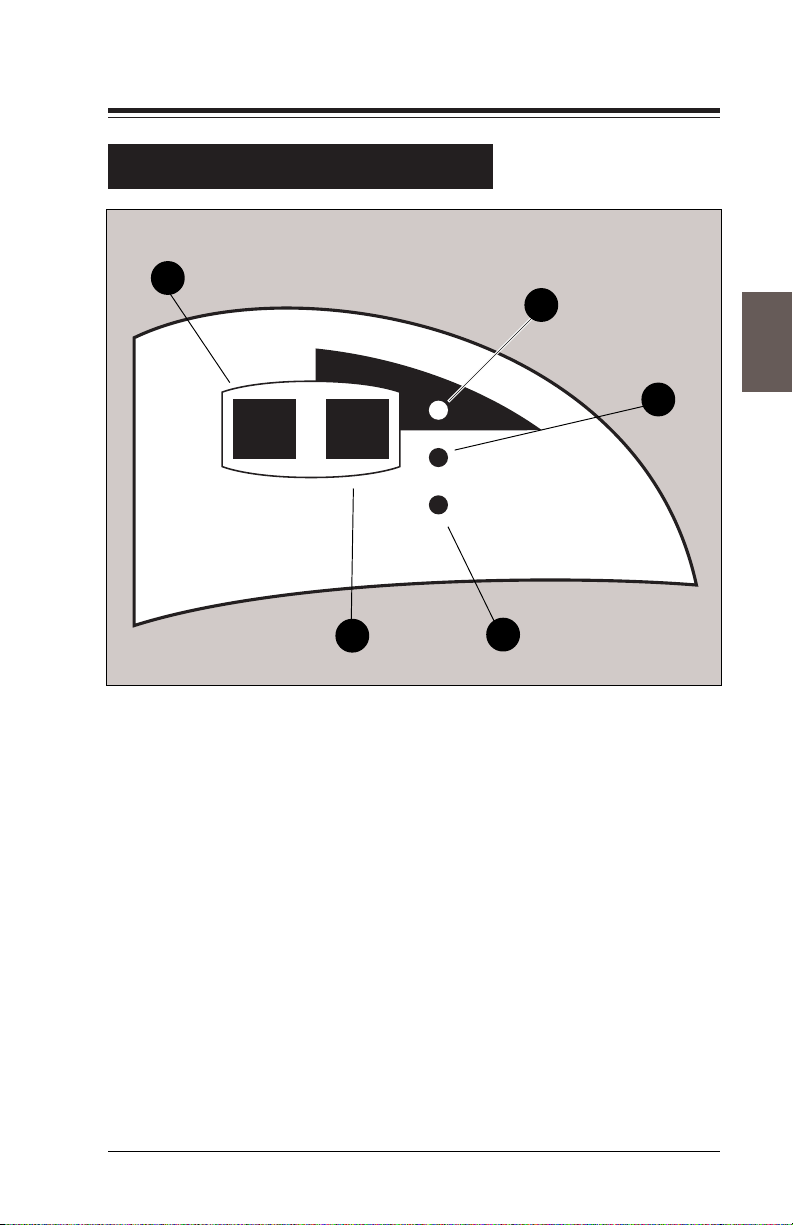

Figure 2-5—Mini Control Panel

1

1. Fault Light—Lights to indicate a fault has occurred at this

module.

2. Ready Light—Lights to indicate the module is ready for

operation.

3. In Service Light—Lights to indicate if the module is in

service, that is on, for the job being run.

4. In Service Control—Press this key to take the module in and

out of service (i.e., turns the feeder function on and off). The

unit is in service when the light (Item 3 above) is illuminated.

Turn the module off when using Fold Only mode (documents

not inserted into envelope, but material will still pass through).

5. Trial Piece—Press this key to cycle the module once.

Page 26

2-10

Controls and Indicators

Chapter 2: The Base Unit

4

5

T

r

ia

l P

ie

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

3

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

F500_043

Figure 2-6—Envelope Feeder

1. Envelope Feeder—Holds supply of envelopes.

1

2

2. Feeder Guides—Adjust these guides to hold the envelopes in

place as they feed down to the deck.

3. Feeder Guides Lock Lever—Blue lever pushes in to release

side guides so they can be adjusted.

4. Envelope Feeder Bridge—The piece that covers the separa-

tor gap. The main feed roller is located below this bridge.

5. Roller Release Lever—This is used to access paper under the

Main feed roller.

Page 27

Chapter 2: The Base Unit

Controls and Indicators

3

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

2-11

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

1

Figure 2-7—Stone and Shield

1. Envelope Feeder Stone—Works with the Main Feed Roller

to create the necessary friction for peeling one envelope at a

time away from the stack in the envelope feeder.

2. Envelope Feeder Stone Shield—Adjust to reveal more or

less of the stone.

3. Envelope Feeder Stone Shield Adjuster—Slide back and

forth to adjust the amount of shield which affects how much

friction is used to feed envelopes.

2

F500_048

Page 28

2-12

Controls and Indicators

1

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

Chapter 2: The Base Unit

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

2

F550_010

Figure 2-8—Separating Mechanism

1. Envelope Feeder Prefeed Rollers—Help move one envelope

to the separating stone and main feed roller.

2. Envelope Feeder Main Feed Rollers—Move envelopes one

at a time down from the feeder to the flapper.

3. Separator Gap Adjustment Wheel—Raises and lowers the

main feed rollers to adjust the “separating gap.” To adjust for

better separation, turn the adjustment wheel clockwise to raise

the rollers and counterclockwise to lower them.

3

Page 29

Chapter 2: The Base Unit

Controls and Indicators

3

1

2-13

4

Figure 2-9—Envelope Flapper Unit

1. Envelope Flapper Unit Safety Cover—Flip open to access

envelope flapper unit to remove envelope misfeeds.

2. Envelope Flapper Cover Lock Lever—Pull this lever to

release flapper unit. Flapper unit gently pivots when unlocked.

3. Recessed Area on Flapper Unit—Pull here after flapper unit

is unlocked to expose more of the flapper unit.

4. Tab on Flapper Unit—Pull here to gain access to the inside of

the flapper.

2

Page 30

2-14

a

Controls and Indicators

10

1

2

0

1

2

3

4

190

180

170

100

0

2

1

90

0

3

1

0

4

1

1

6

0

150

Chapter 2: The Base Unit

1

3

R

e

v

ie

w

T

r

i

Figure 2-10—Insert Station Envelope Side Guides

1. Envelope Side Guides—Guides in the insert area that hold the

envelope in place after it’s opened. The two guides keep the

envelope lined up with the oncoming mailpiece for insertion

(only one guide is visible here).

2. Envelope Side Guides Setting Knob—Small blue knob lo-

cated on the side frame of the module, under the cover. Turn the

knob to move the scale until the pointer indicates the measured

width of the envelope.

3. Scale and Pointer—Match the pointer to the measured width

of the envelope on the scale.

F400_133

Page 31

Chapter 2: The Base Unit

Controls and Indicators

1

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

0

1

1

1

0

0

0

2

1

9

0

0

3

1

0

1

2

3

140

1

4

6

0

150

210

200

190

180

170

160

R

e

R

s

e

e

t

v

/

i

e

w

T

r

ia

l

P

ie

c

e

J

J

o

0

10

01

0

2

0

3

0

4

0

1

5

0

2

6

0

3

7

0

4

8

0

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

1

0

2

2

0

2

3

0

b

P

a

u

s

e

C

le

a

r

D

2-15

110

100

120

0

1

2

3

4

S

t

a

r

t

A

d

d

W

a

te

r

e

c

k

S

e

a

l

S

e

tu

p

9

0

0

3

1

140

160

150

R

e

p

o

r

t

E

x

it

Z

e

ro

C

o

u

n

t

0

1

0

0

1

2

2

3

7

0

4

F500_045

Figure 2-11—Throat Opener Adjustment

1. Throat Opener Adjustment Knob—Turn to set stops in the

insert area. This moves the gear at the base of the knob, moving

the black scale until the pointer indicates the correct measurement. Pull this knob out and turn it to set the small pointer on

the inside to the number on the knob rim that coincides with the

number measured on the throat opening scale.

2. Throat Opening Scale—Align edge and corner of the enve-

lope crease with this scale. Where the throat meets the vertical

line on the scale, read number to be set on throat opener

adjustment knob.

Page 32

2-16

Controls and Indicators

Chapter 2: The Base Unit

3

0

1

1

100

0

2

1

9

0

30

1

0

1

2

0

4

1

3

160

4

0

5

1

1

9

0

1

8

0

1

7

0

110

100

120

0

1

2

3

4

90

0

3

1

140

160

150

1

2

Figure 2-12—Turner Stop Adjustment

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

F500_060

1. Turner Stop—Set when you set the throat opener adjustment.

2. Turner Stop Adjustment Knob—The same as the Throat

Opener Adjustment Knob. Turn to set the pointer to the

measured depth of the envelope. This moves the gear at the

base of the knob which moves the black scale until the pointer

indicates the correct measurement. Note that turning this knob

also sets the stops in the insert area.

3. Turner Stop Pointer—Shows adjustment of the Turner Stop.

This black scale moves when you turn the knob.

Page 33

Chapter 2: The Base Unit

Controls and Indicators

1

2-17

3

2

Figure 2-13—Envelope Guide

1. Envelope Guide—Keeps the envelope straight as it comes out

of the turner, so that it travels into the sealer aligned properly.

2. Envelope Guide Adjustment Knob—Turn to unlock the

envelope guide and use to push the guide into place along the

scale. Move the pointer to the number on the scale that matches

the measured depth of the envelope and lock in place.

3. Envelope Guide Pointer and Scale—Shows the adjustment

of the envelope guide; should match the depth of the envelope.

F500_044

Page 34

2-18

Controls and Indicators

Chapter 2: The Base Unit

1

2

5

Figure 2-14—The Sealer Section

4

1. Sealer Cover—Squeeze latch to release cover, lift to access

the sealer below.

3

2. Sealer Ramp—Lower the ramp to seal envelopes, or to raise

the ramp when you don't want to seal the envelope.

3. Sealer Adjuster—Moves the sealer ramp to Seal or No Seal.

4. Sealer Moisteners—Apply moisture to flap of the envelope.

3

5. Sealer Refill Tray—Pull out to add water or sealing solution

when the control panel indicates that the water level is low,

being careful not to overfill.

Page 35

Chapter 2: The Base Unit

Setup and Adjustments

There is no required specific order to the mechanical setup of the

Base Unit. These instructions, however, follow the same order that

the paper flows through the Base Unit. Be sure to follow these

instructions when you are first learning how to set up the system so

that you make sure you learn all of the steps.

The following pages describe how to perform the mechanical setup

of the Base Unit in nine steps. These steps are:

1. Set the envelope feeder guides to best hold the envelopes

you'll be using.

2. Adjust the stone and shield to get the best separation.

3. Set the separator gap—the space between the main feed roller

and the stone—and the prefeed rollers to best accommodate

the material you're feeding.

4. Set the envelope side guides in the insert area.

2-19

5. Adjust the throat openers.

6. Set the envelope guide.

7. Select the seal or no seal option by positioning the sealer ramp

up for no seal and down for seal. Check the water level of the

sealer and fill if needed. Change moisteners periodically.

8. Load the envelope feeder with a supply of envelopes.

To perform the setup, use the detailed explanations that follow.

IMPORTANT: The values the pointers and indicators are

set to when you follow these instructions are to be

!

considered only as a starting point for setup. Due to

variations in material and environment, fine-tuning of

the adjustments may be necessary.

Page 36

2-20

Chapter 2: The Base Unit

Setup and Adjustments

To set up the Base Unit you take several measurements and make

your settings based on those measurements. Every envelope put

through the Base Unit has several important dimensions:

• Width

• Length

• Thickness

• Throat Opening

Be sure you know which dimension the instructions are telling you

to work with and measure carefully on the scales inside the Base

Unit front cover.

Throat Opening

(about 1/2” from

side of envelope)

○○○○○○

Depth

○○○○○○○○○○

Thickness

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

0

1

1

1

0

0

0

2

1

9

0

0

3

1

0

1

2

0

4

3

1

1

4

6

0

0

5

1

2

1

2

0

0

1

0

9

0

1

8

1

0

7

0

1

6

0

01

0

01

0

2

0

3

0

4

0

1

5

0

2

6

0

3

7

0

4

8

0

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

1

0

R

e

R

s

e

e

t/

v

ie

w

T

r

ia

l

P

ie

c

e

J

S

J

ta

o

b

r

tA

P

a

u

s

e

d

d

W

a

te

r

C

le

a

r

D

e

c

k

S

e

a

l

2

2

0

2

3

0

S

e

tu

p

R

e

p

o

r

t

E

x

it

Z

e

r

o

C

o

u

n

t

F500_059

Figure 2-15—Envelope Dimensions

Width

Use scale inside Base

Unit front cover to take

measurements.

Page 37

Chapter 2: The Base Unit

Setup and Adjustments

1. Set the Envelope Feeder Guides (see Figure 2-16)

A. Grasp the side guides while pushing the blue lever on the

side inward (toward the guide). Move the side guides in or

out to adjust for envelope size. Release the blue lever when

the side guides are at the proper width for the envelope (i.e.,

they have minimal clearance to the envelope pack).

B. Check the envelope width compared to the position of the

prefeed rollers. Move the outer prefeed roller along the

shaft to match the envelope width. If you moved the feeder

guides in for a small envelope, push the prefeed roller in

also.

2-21

Adjust feeder guides and

prefeed rollers to the width

of the envelope.

Prefeed

Rollers

Figure 2-16—Envelope Feeder Guide Adjustment

Side Guide

Adjustment

Lever

F550_004

Page 38

2-22

Chapter 2: The Base Unit

Setup and Adjustments

2. Adjust the stone and shield to get the best separation (see

Figure 2-17).

A. Prefeed rollers help grab a single envelope from the loaded

stack and feed it to the separating mechanism. You control

the position of the rollers above the deck by physically

moving them with your hand and locking them at the

desired position with a knurled knob that is located under

the bridge. The rollers can either be located up, off the

paper, or down, in contact with the paper.

Lift the roller shaft to move the prefeed rollers to the raised

position. While holding the rollers in the raised position,

use your other hand to turn the knurled knob under the

bridge until you feel it catch, locking the rollers into the

raised position.

B. The shield covers the stone and is located just under the

bridge. Use the sliding control in the bottom of the feeder

to expose or cover the stone with more or less shield. Slide

the shield away from the bridge to expose more stone,

toward the bridge to cover the stone.

C. Start with about 1/8" to 1/4" of the stone exposed. Push and

pull an envelope between the main feed roller and the stone

by hand; if it moves too easily, move the shield to expose

just a bit more stone. If an envelope can't move between the

main feed roller and stone at all, cover the stone with a bit

more of the shield. Exposing less stone will help move

envelopes; exposing more stone can help prevent doubles.

If envelopes “prefeed” too far (slide too far into the

separator gap) try exposing more stone.

Page 39

Chapter 2: The Base Unit

Setup and Adjustments

Move the prefeed

rollers to the raised

position, and lock

them in place by

turning the knurled

knob until it catches.

T

r

i

a

l

P

i

e

c

e

In

S

e

rv

ic

e

R

e

a

d

y

F

a

u

lt

2-23

Adjuster

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

le

a

r

D

e

c

k

S

e

a

l

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

Shield

Stone

Figure 2-17—Setting the Separator Stone Shield

F500_040

Page 40

2-24

Chapter 2: The Base Unit

Setup and Adjustments

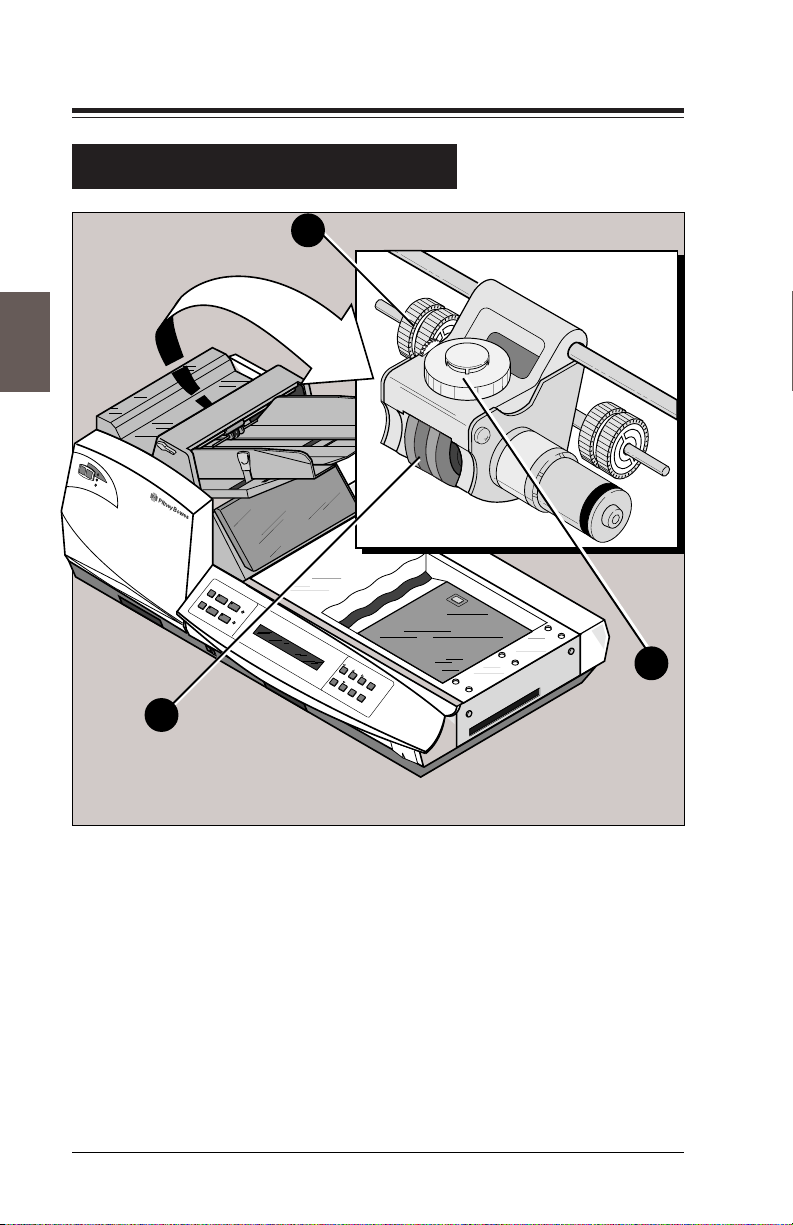

3. Set the separator gap—the space between the main feed

roller and the stone—and the prefeed rollers to best accommodate the material you're feeding (see Figure 2-18):

A. The separator gap is the space between the main feed

rollers and the stone. Set the separator gap to best accommodate the material you're feeding by using the thumbwheel

located on top of the feeder bridge.

B. Always make this adjustment with the prefeed rollers in the

up position. Open the gap by turning the thumbwheel

clockwise. This raises the rollers slightly. Now hold an

envelope in your right hand and slide it under the rollers

from the right of the bridge (just as it would feed). Turn the

wheel counterclockwise with your left hand to lower the

rollers closer to the envelope while at the same time

moving the paper back and forth under the main feed

rollers.

C. Use the thumbwheel to open or close the gap until the

resistance is correct. The resistance is about right when the

envelope turns the main feed rollers slightly as you pull it

back and forth under the roller. Turn the thumbwheel a bit

beyond the point when you first begin to feel a drag on the

envelope.

D. Set the prefeed rollers correctly for the type of material

you're running. Lower them for heavier material, such as

envelopes. Raise the rollers for lighter material, such as

single sheets, thin inserts, or light cards (see Figure 2-17).

Page 41

Chapter 2: The Base Unit

Setup and Adjustments

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

Be sure roller

release lever is in

the down position

before setting gap.

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

2-25

Use the horizontal

thumbwheel to adjust

the separator gap—the

space between the main

feed roller and the stone.

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

Horizontal

Thumbwheel

Shield

Envelope

Stone

Figure 2-18—Setting the Separator Gap

F550_013

Page 42

2-26

Chapter 2: The Base Unit

Setup and Adjustments

4. Set the Envelope Side Guides in the Insert Area (see Figure

2-19):

A. Using the scale inside the Base Unit front cover, measure

the width of the envelope.

B. Using the envelope side guide setting knob, the small knob

projecting from the left side of the scale, as shown, turn

until the pointer indicates the width you just measured.

C. Turning this knob moves the side guide in the insert area,

as shown in the illustration.

D. For the Fold Only feature, repeat Steps A-C above, but

substitute a pre-folded document instead of an envelope.

Page 43

Chapter 2: The Base Unit

Setup and Adjustments

These guides move

when the setting

knob is adjusted.

T

r

i

a

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

0

1

0

01

020304050607

t

1

8

1

7

0

1

6

0

1

2

3

08090100 1

4

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

1

7

0

1

8

0

1

9

0

2

0

0

2

102

2

0

1

1

1

0

0

0

2

1

90

0

3

1

0

1

2

0

3

14

1

4

6

0

150

2

1

2

0

0

1

0

9

0

0

R

e

R

s

R

e

e

t

e

v

/

R

s

i

e

e

e

w

t

v

/

i

e

w

T

r

i

a

T

l

P

r

i

a

i

e

l

c

P

e

i

e

c

e

J

S

J

t

o

b

J

S

J

t

o

a

b

r

P

a

u

P

s

e

a

u

s

e

C

l

e

a

C

r

l

e

D

a

e

r

c

D

k

e

c

k

S

S

e

0

2

3

0

2-27

a

r

t

t

A

d

d

W

A

a

d

t

d

W

e

r

a

t

e

r

e

a

l

a

l

S

e

t

u

S

p

e

t

u

p

R

e

p

R

o

e

r

t

p

o

r

t

E

x

i

t

E

x

i

t

Z

e

r

o

Z

e

C

r

o

o

u

C

n

o

t

u

n

t

Adjusting this

control moves the

160

guides inside the

150

insert area.

Figure 2-19—Insert Area Side Guide Adjustment

170

180

190

200

210

F500_036

Page 44

2-28

Chapter 2: The Base Unit

Setup and Adjustments

5. Set the Envelope Throat Opener (see Figure 2-20):

A. Begin by measuring the envelope throat. Open the flap of

an envelope, and fold the flap over completely behind the

envelope, giving it a strong crease and flattening it.

Place the envelope on the throat opening scale—the tab

located on the scale inside the cover of the Base Unit,

behind the sealer area (see the illustration on the following

page). For correct measurement, be sure the crease of the

folded back flap and the left edge of the envelope are

touching the scale.

With the top and left edge aligned properly, read the

number on the throat scale that corresponds to your

envelope's throat, about 1/2” from the edge of the envelope.

B. Pull the small throat opener adjustment knob out as far as

it will pull away from the body of the Base Unit. With the

knob pulled out, turn it until the pointer on the inside of the

knob indicates the number you measured for the throat of

the envelope on the rim of the knob.

Page 45

Chapter 2: The Base Unit

Setup and Adjustments

Pull this knob out, away from the

body of the module, then turn to align

the pointer with the number you read

from the scale, as shown above.

T

ri

a

l P

ie

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

180

170

160

0

1

0

010

2

0

3

0

40 5

1

0

2

6

0

3

7

0

4

8

090

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

1

5

0

1

6

0

17

0

18

0

1

90

2

0

0

2

1

0

22

110

10

0

120

9

0

0

3

1

0

1

2

0

4

3

1

1

4

6

0

0

5

1

210

200

190

R

e

R

s

e

e

t

v

/

ie

w

T

ria

l

P

ie

c

e

J

S

J

ta

o

b

r

tA

P

a

u

s

e

d

d

W

a

t

e

r

C

le

a

r

D

e

c

k

S

e

a

l

0

2

3

0

2-29

110

100

120

0

1

2

3

4

130

S

e

t

u

p

9

0

0

4

1

160

150

R

e

p

o

rt

E

x

it

Z

e

r

o

C

o

u

n

t

0

1

0

0

1

2

3

70

4

Place envelope on tab and read

number corresponding to the throat

opening, about 1/2” from the edge

of the envelope, “1” in this case.

F500_045

Figure 2-20—Setting the Throat Openers

Page 46

2-30

Chapter 2: The Base Unit

Setup and Adjustments

6. Set the Envelope Guide (see Figure 2-22):

A. Set the envelope guide to the same value you measured for

the depth of the envelope.

B. Loosen the envelope guide knob by turning it counterclock-

wise.

C. Slide the knob so that the pointer lines up with the measured

depth.

D. When the pointer indicates the depth, tighten the knob

again by turning it clockwise. The knob should stay in place

to keep the envelope aligned properly as it moves into the

sealer.

E. For the Fold Only feature, repeat Steps A-D above, but

substitute a pre-folded document instead of an envelope.

Page 47

Chapter 2: The Base Unit

Setup and Adjustments

Turn the knob to unlock

the guide and slide it

into place.

2-31

Figure 2-22—Setting the Envelope Guide

F500_044

Page 48

2-32

Chapter 2: The Base Unit

Setup and Adjustments

7. Select Seal or No Seal, Fill and Maintain the Sealer:

A. Unlatch and open the sealer cover. Use the sliding adjust-

ment to set the sealer ramp down for the seal option or the

ramp up for no seal.

Slide this adjustment into the

seal or no seal position.

Figure 2-23—Selecting Seal or No Seal

B. Fill the sealer tray whenever the “add water” light on the

Main Control Panel is illuminated, indicating that the

water level is low.

NOTE: Pitney Bowes E-Z Seal™ sealing solution is recommended

but not required. E-Z Seal™ helps prevent mineral and bacterial

build up in the reservoir.

F500_050

Page 49

Chapter 2: The Base Unit

Setup and Adjustments

Do this by pulling out the tray and adding water until the

float registers full and the control panel indicates the level

is sufficient. You can add water at any time, even when the

machine is running.

T

r

ia

l

P

i

e

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

R

e

R

1

2

1

1

s

e

e

t

v

/

ie

F

w

T

r

ia

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

s

e

C

le

a

r

D

e

c

k

S

e

a

l

2-33

A

d

d

W

a

te

r

Float to indicate

water level.

Figure 2-24—Filling the Sealer

CAUTION: Do not overfill the machine or water will

not stay contained in the tray. Pay careful attention

!

to the water level as indicated by the float when

filling the tray. Watch the float, not the indicator

light, while adding water to the machine.

S

e

t

u

p

R

e

p

o

r

t

E

x

it

Z

e

r

o

C

o

u

n

t

F500_046

Page 50

2-34

Setup and Adjustments

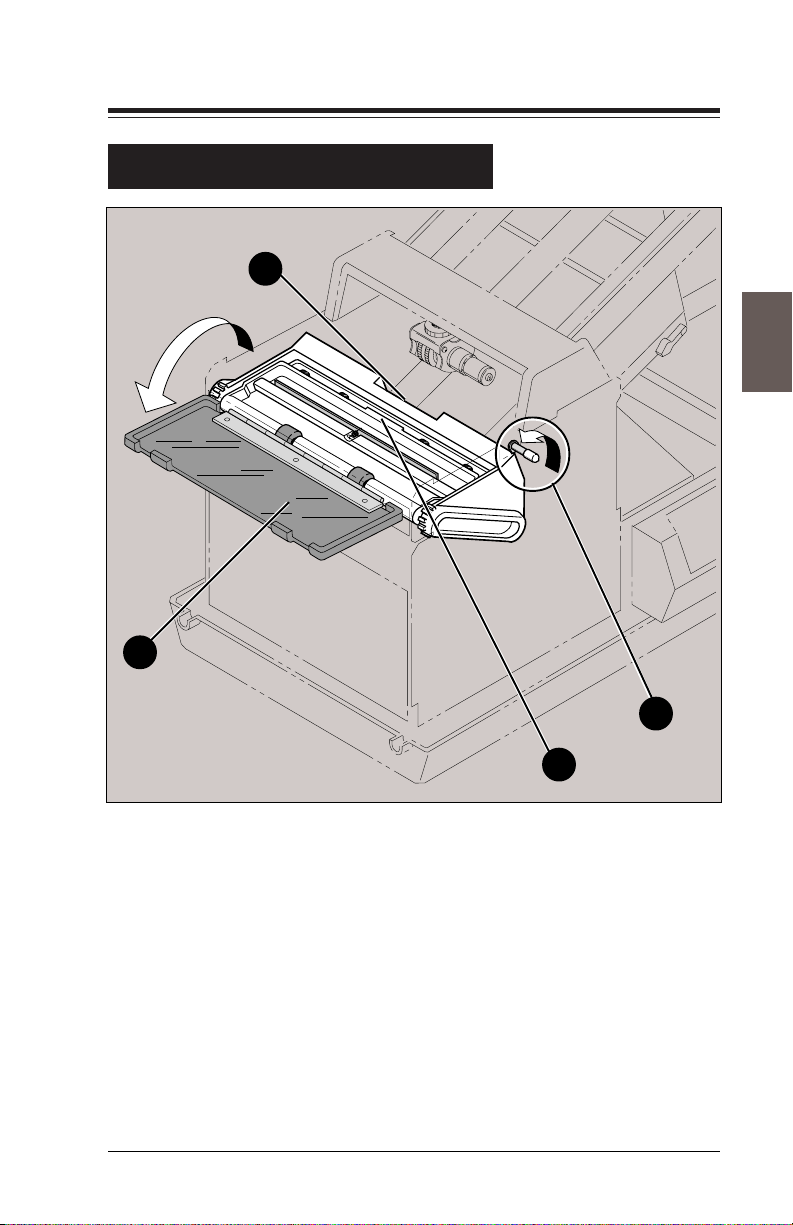

C. Maintain the sealer by periodically (approximately four

times a year) changing the moisteners in the sealer unit.

• Open the sealer unit.

• Slide the soiled moistener out and insert a new one. See

Figure 2-25.

• Pry the cover off of the lower moistener, pull out the

cube of moistener material, and replace with a fresh

moistener.

OTE: The upper moistener develops a “fringe” as it is

N

used. This is completely normal and does not interfere with

the moistening process at all. The fringe, however, may be

trimmed occasionally.

Chapter 2: The Base Unit

Page 51

Chapter 2: The Base Unit

Setup and Adjustments

1

5

1

6

0

2-35

Pull the upper moistener out and slide a new

one into its place.

9

0

1

0

0

1

1

0

1

2

0

1

3

0

1

4

0

0

Push the edge of the small

cover over the lower

moistener to gain access

to the moistener below.

F500_052

Figure 2-25—Changing the Sealer Moistener

Page 52

2-36

Chapter 2: The Base Unit

Setup and Adjustments

8. Loading the Envelope Feeder (see Figures 2-26 and 2-27):

A. Before filling the envelope feeder, take a handful of

envelopes and aerate them by holding one end of the stack

and fanning the other. Then hold the other end of the stack

and fan the opposite end.

B. Be sure the envelope flaps are not glued shut or together.

Hold one end of the stack and give the whole stack a shake

in an up and down motion to break any glue spots.

C. Load the envelopes flap-up and bottom-leading. Fan the

stack out away from the feeding rollers.

Aerate

Figure 2-26—Aerate and Flex the material

Flex

Page 53

Chapter 2: The Base Unit

Setup and Adjustments

Envelopes loaded flap-up and

bottom-leading. Fan the stack out

behind the top envelope. The top

envelope feeds first.

2-37

Figure 2-27—Loading the Feeder

F550_005

Page 54

2-38

Chapter 2: The Base Unit

Running Test Material

Once you've made the proper adjustments detailed in steps one to

nine on the previous pages, test the accuracy of the base unit

mechanical settings by running a few pieces of test material through

the module.

There are two ways to run test material through the base unit:

1. To ensure that envelopes are feeding properly, perform

steps one to nine, setting and loading the Base Unit, and

press

Trial Piece on the Mini Control Panel. This feeds one

envelope, turns it, seals it and stacks it. This checks that

envelopes are separating and feeding properly (see Figure

2-28).

2. To ensure that collations are getting inserted properly,

perform mechanical setup on the other modules in the

system, or at least on the one module immediately upstream of the base unit. Press Trial Piece on the Main

Control Panel located on the base unit. This causes the

system to build one test collation, feeding the collation

downstream to the base unit where an envelope will be fed

and opened. The collation will be inserted and the envelope

ejected. This helps you see if the collations are building

properly and being inserted correctly because you can

inspect what's in the envelope.

Page 55

Chapter 2: The Base Unit

rial Piece

ault

Read

In Ser

vice

Running Test Material

T

r

ia

l P

ie

c

e

I

n

S

e

r

v

i

c

e

R

e

a

d

y

F

a

u

l

t

R

e

R

s

e

e

t

v

/

i

e

w

T

r

i

a

l

P

i

e

c

e

J

S

J

t

o

a

b

r

t

P

a

u

A

s

e

d

d

W

a

t

e

r

C

l

e

a

r

D

e

c

k

S

e

a

l

Review Trial Piece Start

Add

Water

2-39

Trial Piece

In Ser

vice

Read

y

Fault

S

e

t

u

p

R

e

p

o

r

t

E

x

i

t

Z

e

r

o

C

o

u

n

t

Stop Clear DeckJob

Seal

F500_034

Figure 2-28—Trial Piece on both the Mini and Main Control Panels

Page 56

2-40

Chapter 2: The Base Unit

Tips to Reduce Setup Time

Note the settings you make to the base unit under a specific job

number on a Job Card located in the Instruction Cards found in the

front of each machine. This helps you remember proper settings for

specific jobs performed repeatedly, saving setup time in the future.

An illustration of a Job Card is shown below. The left side of the

illustration shows how to fill out a job card to show the settings you

made. The right side is still blank.

1

Job #

Job Name

Envelope

1

Throat

Opener

240

Side

Guides

Example Job

No. 10 Window

Prefeed

Rollers

Up

✓

Down

(Check Stone

Shield &

Separator Gap)

240

Feeder

Guides

104

Envelope

Guide

Seal

No Seal

✓

Job #

Job Name

Envelope

Throat

Opener

Side

Guides

Prefeed

Rollers

Up

Down

(Check Stone

Shield &

Separator Gap)

Feeder

Guides

Envelope

Guide

Seal

No Seal

Check

Water

Figure 2-29—An Example of a Job Card

Check

Water

Page 57

Chapter 2: The Base Unit

Clearing Material From the Base Unit

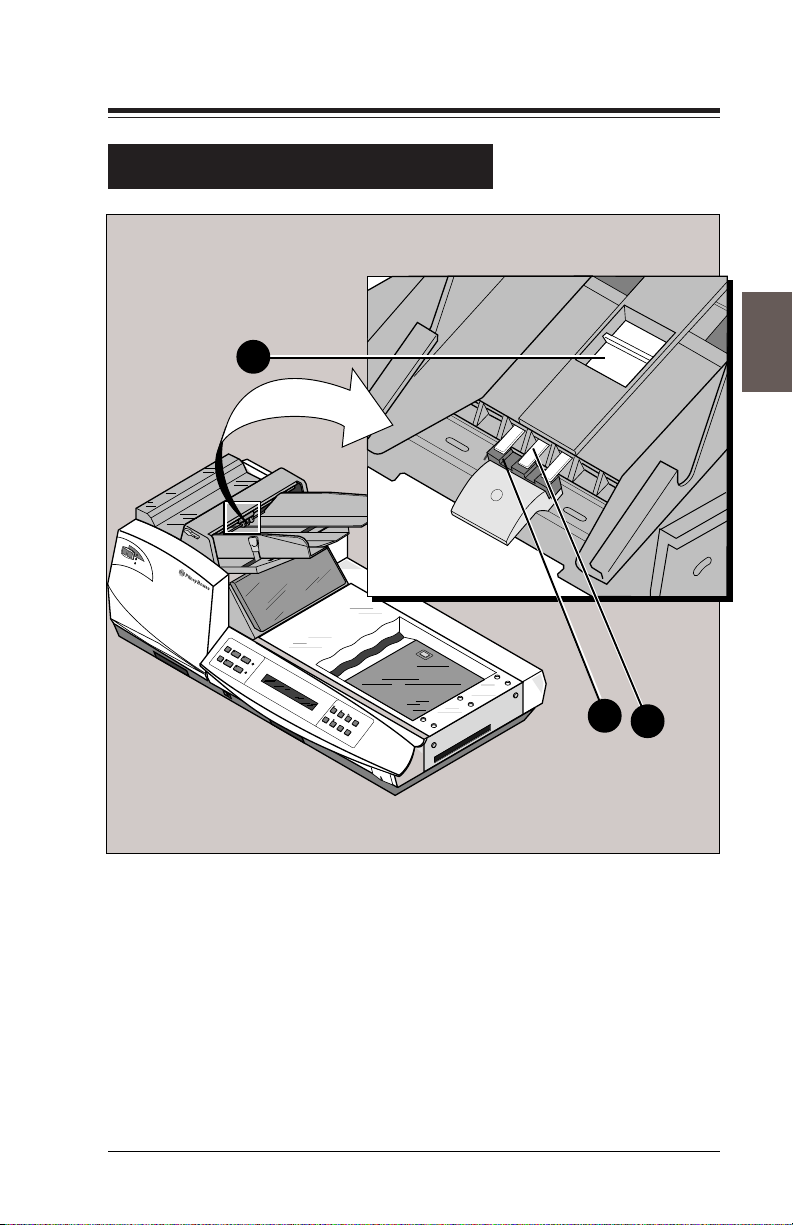

When clearing jammed material, make sure you are moving/

pulling/removing material in the direction it is supposed to flow

through the machine. If you go against the natural feeding direction

of the machine, you could dislodge and/or damage feeding components not designed for this stress.

Use the roller release lever on the side of the

bridge to raise the main feed rollers to help

clear material out from under them. Remember

to close this release lever again.

Use your other

hand to hold the

material in the

feeder back.

2-41

Bowes

Pitney

e

c

i

v

r

e

S

n

I

y

e

d

c

a

e

e

i

R

P

l

a

i

r

T

t

l

u

a

F

F550_0411

Pull out jammed

material in the

Ready

Trial Piece In Service

Fault

direction of the

normal paper flow

Figure 2-30–Raising the Main Feed Rollers to Remove Jams

PitneyBowes

F550_012

Page 58

2-42

Chapter 2: The Base Unit

Clearing Material From the Base Unit

Flip open the flapper unit safety cover to

access the envelope flapper unit to

remove envelope misfeeds. Pull the lock

lever to release flapper unit. Flapper unit

gently pivots upward when unlocked.

Lock Lever