Pitney Bowes DI600 Operator Guide

Document Inserting System

DI500/DI600

Operator Guide

US/Canada English Version

FCC Compliance

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC rules. These limits

are designed to provide reasonable protection against interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause interference

to radio communications. Operation of this equipment in a residential area is

likely to cause interference, in which case the user will be required to correct

the interference at his own expense. Use only a shielded interface cable to

operate this equipment with a printer or other peripheral device.

CAUTION: Changes or modifications to this equipment not expressly

approved by the party responsible for compliance (Pitney Bowes) could void

the user’s authority to operate the equipment.

Canada EMC Compliance

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du

Canada.

SV40221 Rev. A 9/04

©2004 Pitney Bowes Inc. All rights reserved. This guide may not be

reproduced in whole or in part in any fashion or stored in a retrieval system

of any type or transmitted by any means, electronically or mechanically,

without the express, written permission of Pitney Bowes.

We have made every reasonable effort to ensure the accuracy and

usefulness of this manual; however, we cannot assume responsibility

for errors or omissions or liability for the misuse or misapplication of our

products.

Due to our continuing program of product improvement, equipment and

material specifications as well as performance features are subject to

change without notice. Your inserter system may not have some of the

features described in this book.

E-Z Seal and PacPilot are trademarks or registered trademarks of Pitney

Bowes Inc. ENERGY STAR is a reg is tered trademark of the United States

Environmental Pro tec tion Agency.

Printed in the USA or Canada.

Table of Contents

Pitney Bowes Contact Information List

Chapter 1 Introduction

Safety ................................................................................1-2

To The Operator ................................................................1-3

Machine Configurations .....................................................1-4

Machine Identification ........................................................1-6

PacPilot™ Control Panel ...................................................1-8

Control Panel Keys .................................................... 1-8

Mail Piece Icon Tree ................................................ 1-10

Common Terms ...............................................................1-14

Chapter 2 Using the Menus

The Home Screen .............................................................2-2

The Menu Structure ...........................................................2-4

iSV40221 Rev. A

Table of Contents

Chapter 3 Operator Functions

About this Chapter .............................................................3-2

Connecting Power .............................................................3-2

Running a Job ...................................................................3-3

SwiftStart™ ........................................................................3-6

Manual Feed ......................................................................3-9

Setting the Sheet Feeders ...............................................3-12

Setting the Envelope Feeder ...........................................3-14

Setting the Insert Feeder(s) .............................................3-16

Filling the Envelope Sealer ..............................................3-18

Menu ................................................................................3-19

Language ................................................................. 3-19

Display Adjustments ................................................. 3-19

Safe Seal ................................................................. 3-19

System Information .................................................. 3-19

Chapter 4 Supervisor Functions

About this Chapter .............................................................4-2

Supervisor Access Code ................................................... 4-2

Create Job .........................................................................4-3

Edit Job ..............................................................................4-4

Create From ......................................................................4-6

Delete Job .........................................................................4-7

OMR Menu ........................................................................4-8

System Menu .....................................................................4-8

Manual Feed Option .................................................. 4-8

ii SV40221 Rev. A

Table of Contents

Chapter 5 Optical Mark Recognition (OMR)

OMR Availability ................................................................5-2

What is OMR? ...................................................................5-2

OMR Marks Available ........................................................5-3

OMR Mark Options ............................................................5-6

OMR Specifications ...........................................................5-8

Creating, Deleting and Viewing OMR Codes ..................5-10

Create New OMR Code ...................................................5-11

Delete OMR Code ...........................................................5-13

View OMR Code ..............................................................5-14

Creating an OMR Job ......................................................5-15

OMR Scanner Adjustments ............................................5-18

Chapter 6 Troubleshooting

Troubleshooting Tips .........................................................6-2

General Troubleshooting ...................................................6-3

Machine ..................................................................... 6-3

Envelopes .................................................................. 6-4

Sheets ........................................................................ 6-5

Inserts ........................................................................ 6-6

Double Detect ............................................................ 6-7

Clearing Material Stalls ......................................................6-8

The Manual Advance Knob ........................................ 6-8

Removal/Replacement of Sheet Feeder Trays .......... 6-9

Removal/Replacement of Insert Tray(s) .................... 6-9

Access to Internal Areas 1 to 5 ................................ 6-10

Access to Area 6 ...................................................... 6-12

Access to Areas 7 and 8 .......................................... 6-12

Access to Removeable Paper Path ......................... 6-13

Access to Top Cover (Sheet Feed Area) .................. 6-13

Access to Envelope Exit Area .................................. 6-14

Access to Envelope Inserting/Sealing Area ............. 6-14

Envelope Stop Position ............................................ 6-15

iiiSV40221 Rev. A

Table of Contents

Chapter 7 Reference

Specifications ....................................................................7-2

Sheet Feeders ........................................................... 7-2

Fold Type and Overall Thickness Limits .................... 7-3

Insert Feeders ............................................................ 7-4

Envelope Feeder ........................................................ 7-4

Envelope Sealer ......................................................... 7-6

Drop Stacker .............................................................. 7-6

Material Requirements ............................................... 7-6

Machine Specifications .............................................. 7-7

Changing the Envelope Sealer Unit Felts ..........................7-8

Service .............................................................................7-10

Index I-i

iv SV40221 Rev. A

Pitney Bowes Contact

t

Information Lis

USA Contacts

Product Name - DI500 or DI600

For frequently asked questions, go to:

www.pb.com and click on Customer Support.

To place requests for service or training, go to:

www.pb.com and click on My Account.

To order PB supplies and accessories, go to:

www.pb.com and click on Online Store.

To view and pay invoices online, go to:

www.pb.com and click on My Account.

To view inventory, go to:

www.pb.com and click on My Account.

For direct questions, call: 1.800.522.0020. Customer

Service Representatives are available Monday through

Friday, 8:00 AM - 8:00 PM ET.

Canada Contacts

Product Name - DI500 or DI600

For frequently asked questions or to order supplies, go to:

www.pitneybowes.ca

For direct questions, call: 1.800.672.6937. Customer

Service Representatives are available Monday through

Friday, 8:30 AM - 4:00 PM ET.

vSV40221 Rev. A

vi SV40221 Rev. A

1 • Introduction

This chapter pre sents important safety information and describes the

main controls and features of your machine.

Important Safety Notes ...................................................... 1-2

To The Operator ................................................................ 1-3

Machine Configurations ..................................................... 1-4

Machine Identification ........................................................ 1-6

PacPilot™ Control Panel ................................................... 1-8

Control Panel Keys ..................................................... 1-8

Mail Piece Icon Tree ................................................. 1-10

Common Terms ............................................................... 1-14

1-1SV40221 Rev. A

1 • Introduction

Important Safety Notes

Follow these basic safety precautions when operating this machine:

• Use only Pitney Bowes approved supplies, in particular aerosol

dusters. Improper storage and use of aerosol dusters or

flammable aerosol dusters, can cause an explosive-like condition

that could result in a personal injury and/or property damage.

Never use aerosol dusters labeled flammable and always read

instructions and safety precautions on the duster container.

• To obtain Pitney Bowes supplies, please contact our Supply

Line or on the web at PB.com (see the Pitney Bowes Contact

Information List at beginning of this guide). Material Safety Data

Sheets can also be acquired from the Supply Line or PB.com.

• Read all instructions before operating the equipment. Only use

the equipment for its intended purpose.

• Operation of this equipment without periodic maintenance will

inhibit optimum operating performance and could cause the

equipment to malfunction. Contact your Pitney Bowes Customer

Service Representative for required service schedule.

• Use the power cord supplied with the machine. Plug it and all

other supplied power cords into a properly grounded wall outlet

that is located near the machine and easily accessible, meaning

it is free from obstruction and there is enough room around the

unit for servicing.

• The power cord wall plug is the primary means of disconnecting

the machine from the AC supply.

• Do not use an adapter plug on the line cord or wall outlet. Do not

remove the ground pin from the line cord.

• Avoid using wall outlets controlled by wall switches or shared

with other equipment. Do not route the AC power cord over

sharp edges, or allow it to be trapped between furniture and/or

furniture and the wall.

• Avoid touching moving parts or materials while the machine is

in use. Keep hands, loose clothing, jewelry, and long hair away

from all moving parts.

• Do not remove covers. Covers enclose hazardous parts that

should only be accessed by properly trained service personnel.

1-2 SV40221 Rev. A

Introduction • 1

• Immediately report to Pitney Bowes Service any damaged or

nonfunctioning components. The unit may be unsafe for use.

• To prevent overheating, do not cover the vent openings. Allow

ample spacing around the unit for ventilation.

NOTE: Always follow the specific occupational safety and health

standards for your workplace.

To the Operator

Your new Folding/Inserting Machine has an easy to follow user

interface which makes it simple to set up, whilst offering the following

features:

• Envelope seal/no seal/safe seal.

• Fully automatic material separation on sheet feeders.

• Fully automatic fold adjustments.

• Fully automatic envelope separation.

• Fully automatic Double Detect, when selected.

• Fold only option (fold without insertion).

• Fully automatic insertion of single and multiple sheet inserts

(on models fitted with insert feeders only).

• Option of single fold, C fold, Z fold and double fold.

• 20 Job recall facility - User programmable.

• SwiftStart™ - allows you to quickly execute and save simple

jobs without programming.

• Linked Feeding - multiple feeders can be linked to allow

continuous operation.

• OMR functionality - storing up to 10 codes (on models where

OMR is enabled).

• Load on the fly operation.

• Manual Feed facility for occasional ‘one-off’ jobs.

1-3SV40221 Rev. A

1 • Introduction

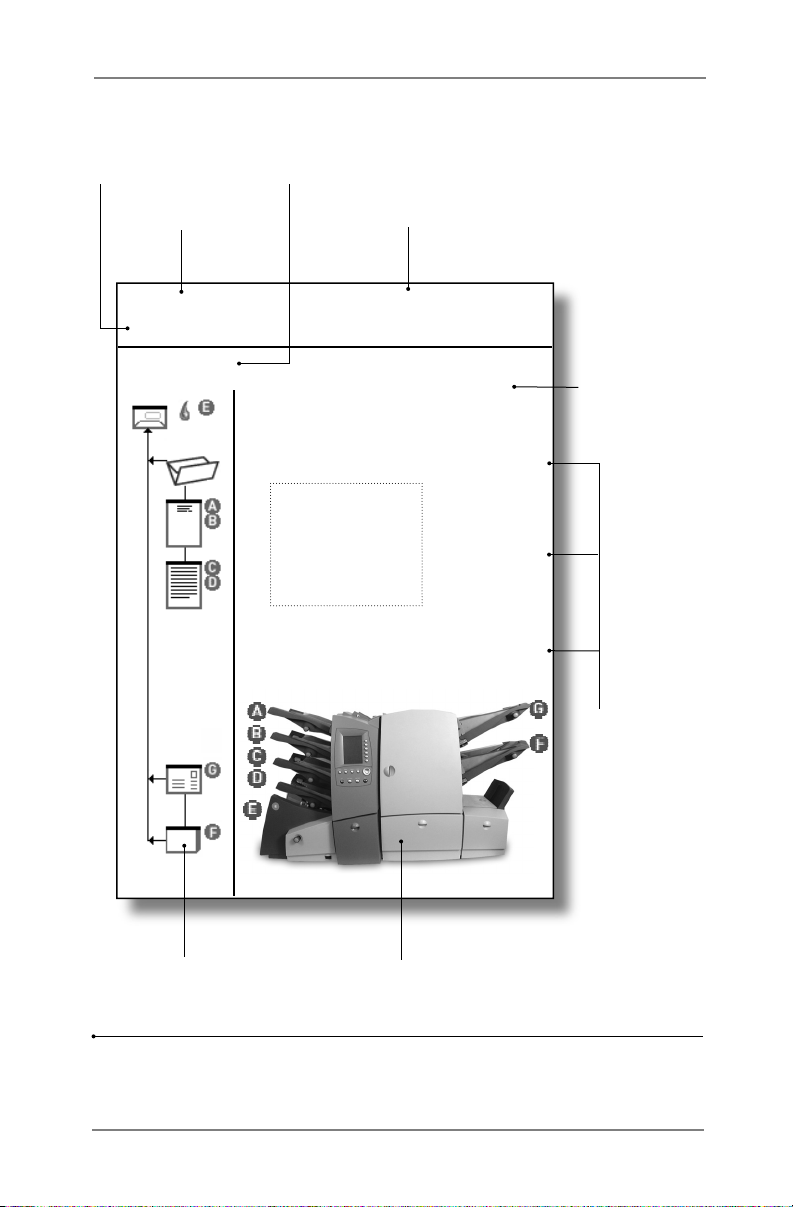

Machine Configurations

The following machine configurations are available, depending on

your local market:

• Two Sheet Feeders Only

• Four Sheet Feeders Only

• Two Sheet Feeders and One Insert Feeder

• Two Sheet Feeders and Two Insert Feeders

• Four Sheet Feeders and One Insert Feeder

• Four Sheet Feeders and Two Insert Feeders

Each feeder location has its own letter designation which remains

the same irrespective of machine configuration. Therefore, machine

configurations with less than the full complement of feeders will use

feeder designations which are not in alphabetical sequence – this is

normal.

The processing speed will also vary depending on machine

configuration. See ‘Specifications’ in Chapter 7 for further details.

The illustration on the next page shows feeder locations and

designations.

In addition, an Optical Mark Recognition (OMR) option can be added

to any model. This allows control of machine functions and Mail

Piece make-up by ‘scanning’ material passing through the machine

for machine readable marks (OMR Marks). For further information,

refer to Chapter 5 of this guide.

This guide covers all models. If a function is dependent on machine

configuration, the accompanying text will explain this.

1-4 SV40221 Rev. A

Introduction • 1

Sheet Feeders

A

B

C

D

E

Envelope Feeder

Feeder Configuration

Insert Feeders

Manual Feeder

H

G

F

1-5SV40221 Rev. A

1 • Introduction

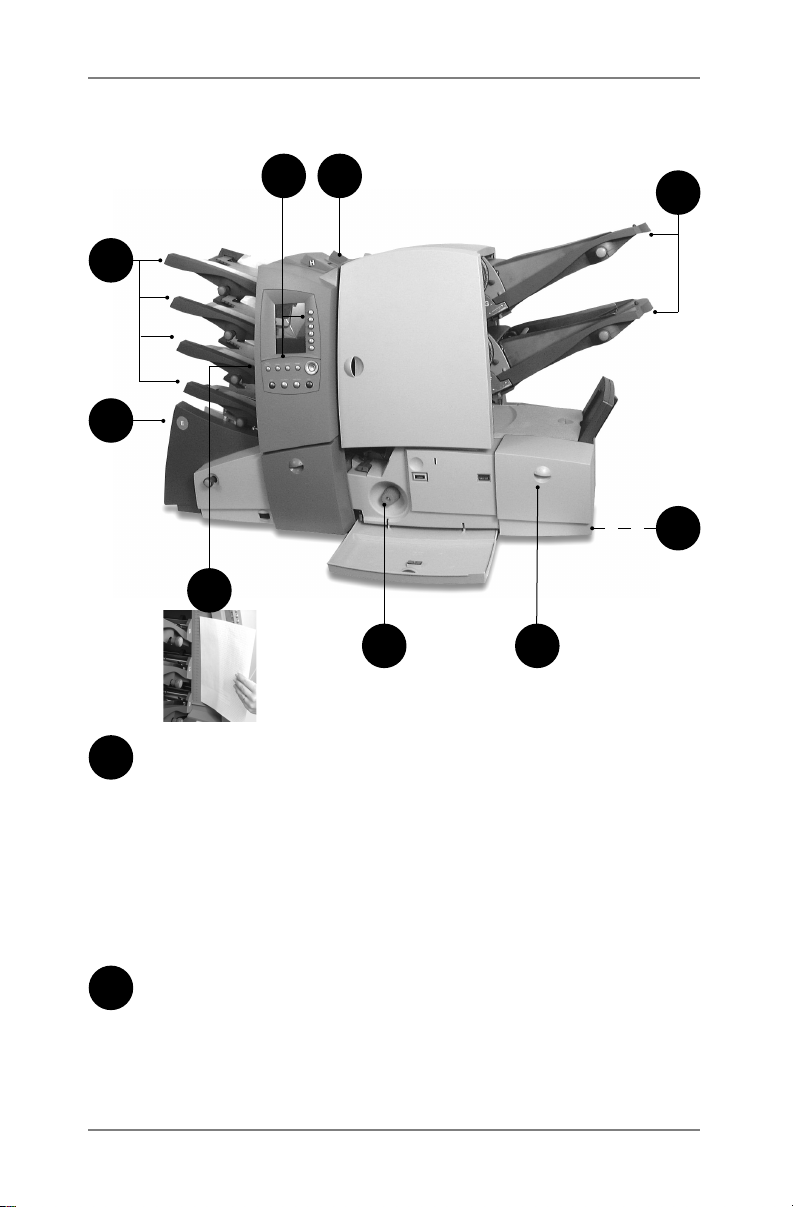

Machine Identification

32

1

9

8

7 6

Sheet Feeders

1

Use these feeders to feed sheets that require folding. They

automatically detect if more than one sheet feeds (double

detect), giving security to your mailings.

Depending on the job being run and availability of feeders,

there also is an option to ‘link’ these feeders so that when

the first feeder runs out of material, feed will automatically

switch to the next linked feeder. This allows a higher volume of

material to be processed before refilling is required.

PacPilot™ Control Panel

2

This is where you enter commands to run the machine or

configure Job Settings. The control panel display also shows

you the machine status, loading instructions and details of the

job. See 'Control Panel' on the page 1-8 for more details.

4

5

1-6 SV40221 Rev. A

Introduction • 1

Manual Feeder (also known as Convenience Feeder or Daily

3

Mail Feeder)

Use this feeder to manually feed stapled or unstapled sets of

up to 5 sheets (see specifications, page 7-2). The machine

waits for each set to be manually fed before folding and

inserting the set automatically into the envelope. A Supervisor

can also configure the machine to place insert(s) within the set

if Insert Feeder(s) are fitted.

Insert Feeder(s) (not on all model configurations)

4

Use these feeders to add additional inserts to your envelope.

Inserts fed from these feeders cannot be folded by the

machine, so they must already be folded or be a size that

does not require folding.

Drop Stacker (not illustrated)

5

A fold down stacker is located at the exit from the machine

to collect the finished Mail Pieces. This unit can be latched

against the machine when not in use.

Power stacker (not illustrated)

This is an optional extra which automatically collects and

neatly stacks finished Mail Pieces. It locates at the exit of the

machine, in place of the Drop Stacker.

Sealer Bottle

6

The sealer bottle is located inside an opening cover at the

front right side of the machine. It provides sealing solution to

the Envelope Sealer.

Manual Advance Knob

7

The Manual Advance Knob is located inside an opening cover

at the lower center of the machine. It can be used to manually

turn the machine mechanisms to assist in clearing a material

stoppage.

Measuring Scale

8

The scale is located on the left side of the machine near the

sheet feeders as an aid in measuring material and envelopes.

Envelope Feeder

9

This feeder feeds envelopes into the inserting area where they

are filled with the material requested from the other feeder(s).

1-7SV40221 Rev. A

1 • Introduction

PacPilot™ Control Panel

Control Panel Keys

Screen Keys

Navigation Keys

Reset Counters

If only piece count is displayed, press this key to reset the piece

count to zero. If both piece and batch counters are displayed,

pressing this key allows either or both counters to be reset.

Help (not available in some markets)

Press this key to view an electronic Quick Reference Guide giving

you quick access to basic information regarding operation of your

machine.

Cancel

Press this key to take you back to the previous screen. If you have

made changes or defined settings on the screen you are cancelling,

these will be lost. Multiple presses of the Cancel key will step you

back through the screens you have visited until you get back to the

Home Screen.

1-8 SV40221 Rev. A

Introduction • 1

Home

Press this key to take you back to the Home Screen. The Home

Screen is where you can run jobs and is the start point for accessing

the menus.

Start

Starts automatic operation.

Trial Piece

Press this key to run test piece(s) so that you can check the machine

setup. Trial Piece(s) must be run before automatic operation can be

commenced using the Start key. If double detection is in use, the

machine calibrates itself automatically as it runs the Trial Piece(s).

If the job includes an Outer Envelope, it will be unsealed so that the

contents can be easily checked.

Clear Deck

Press this key to drive the material through and out of the system. It

can be used to clear the machine ready for automatic operation after

a stoppage has occurred, etc.

Stop

Stops automatic operation at the end of the next cycle.

Navigation Keys (uvwtOK)

These keys are used to move a highlighted area around the display.

Once the desired area is highlighted, press the OK key to select it.

The u and t navigation keys can also be used to change values of

machine settings.

Screen Keys

These are the six round keys located directly to the right of the

display. These keys correspond to the changeable options on the

display alongside them and therefore are not labelled.

1-9SV40221 Rev. A

1 • Introduction

Mail Piece Icon Tree

The Mail Piece Icon Tree is located on the left side of the display.

It displays the Mailing Object Icons required, based on the Job

Definition.

The icons inform you which feeders to load, the type of object (sheet,

insert, etc.) to be loaded into each designated feeder and the loading

orientation of each object. It is therefore extremely important that you

become familiar with the icons themselves and the make-up of the

Mail Piece Icon Tree.

Loading Instructions

The u and t navigation keys can be used to scroll through the Mail

Piece Icon Tree. When an item is highlighted, the machine will give

you the loading instructions associated with that item.

When you have viewed the loading instructions, press Home or

Cancel to return to the Home Screen or press Start or Trial Piece to

immediately begin processing.

1-10 SV40221 Rev. A

Introduction • 1

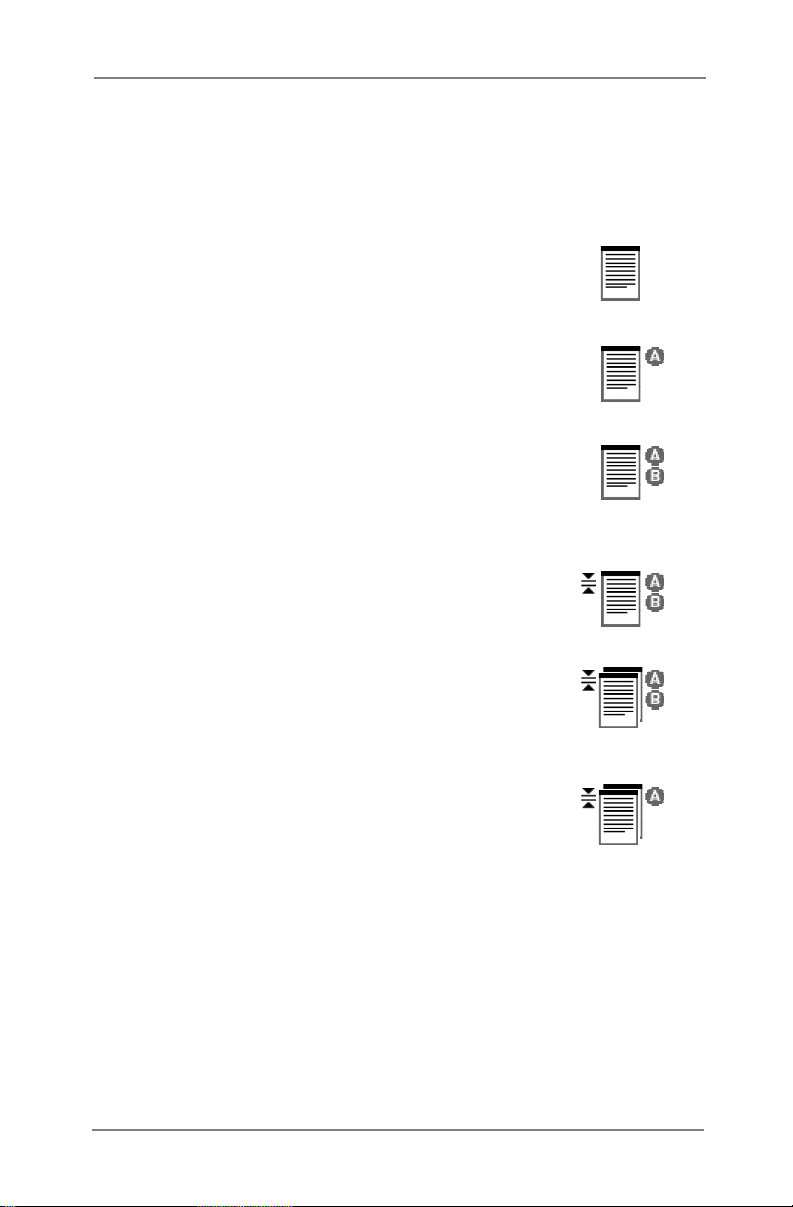

Mail Piece Icon Tree Icons

Each Mailing Object Icon has one darker edge either at the top or

bottom that indicates the leading edge of the object when loaded into

the assigned feeder. The leading edge of an object is the edge that

feeds into the machine first.

For example, a sheet that must be loaded face

up with the top of the sheet leading would be

represented by a “face-up” sheet icon containing a

“leading edge” line on top.

A feeder assignment letter (A to G) will be placed

alongside the Mailing Object Icon to indicate which

feeder the object should be loaded into.

Two or more feeder assignment letters alongside a

single Mailing Object Icon indicate that linked feeders

have been selected. The item should be loaded in

all the feeders indicated. When one feeder becomes

empty, feed will automatically switch to the next

linked feeder and so on, in a continuous cycle.

If Double Detect is in use, the Double Detect Icon will

appear immediately to the left of the relevant Mailing

Object Icon.

If any Sheet Feeder(s) are programmed to feed

Pre-Collated Sets (multiple sheets), a modified icon

indicating multiple sheets will appear, together with

a number showing the number of sheets in the PreCollated Set.

On an Optical Mark Recognition (OMR) job, a

variable number of pages might be fed under

control of the OMR marks and so a small letter ‘n’

will appear in place of the number. Also, an asterisk

) will be displayed in the Mail Piece Icon Tree to

(

*

remind you that the job is an OMR job.

Lines between the Mailing Object Icons indicate the flow of material

through the machine.

3

n

Refer to the table on the following page as a reference to all the

icons that might appear on the Mail Piece Icon Tree.

1-11SV40221 Rev. A

1 • Introduction

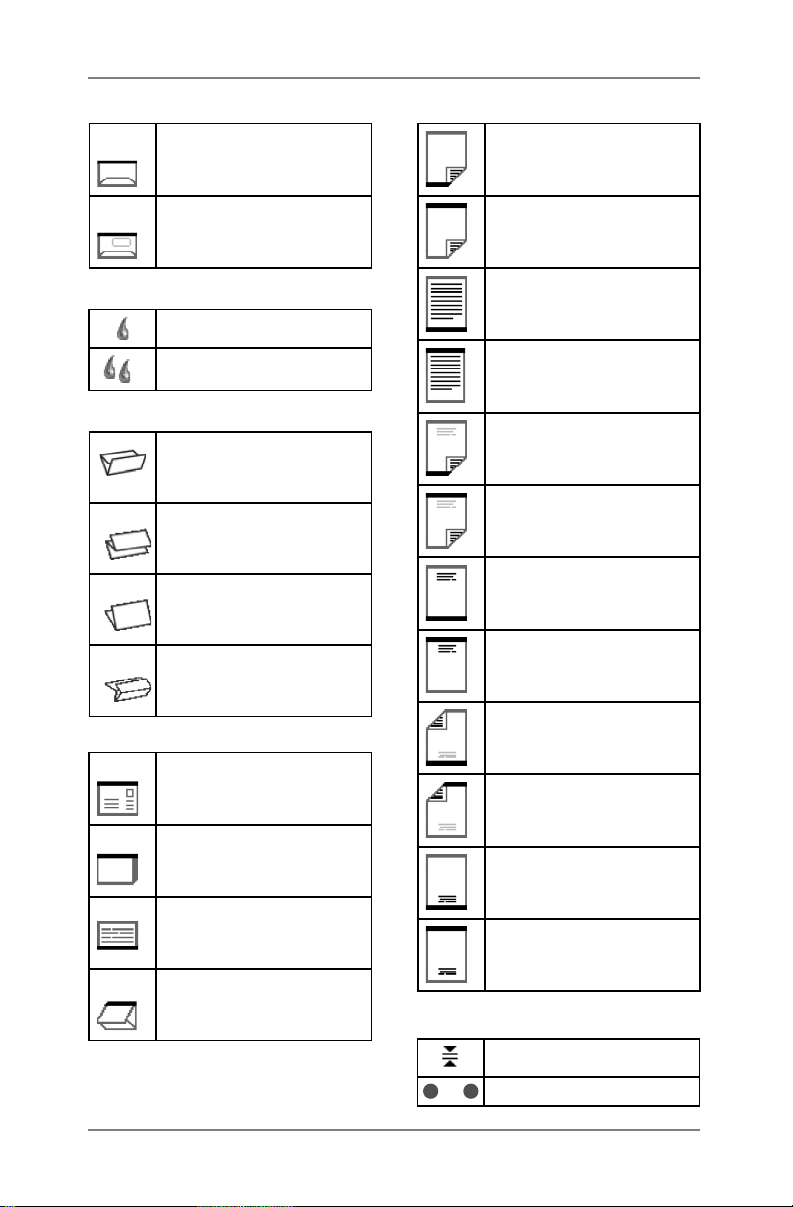

Envelope Icons

No Window,

Flap side up,

Flap Last

Window,

Flap side up,

Flap Last

Seal Icons

Seal On

Safe Seal On

Fold Icons

C Fold

(letter fold)

Z Fold

(accordion fold)

Single Fold

Double Fold

Insert Icons

Reply envelope,

Flap side down,

Flap First

Booklet,

Face Down,

Bound Edge First

Slip,

Face Up,

Bottom First

Pre-Folded Insert,

Closed Side First

Sheet Icons

No address,

Face Down,

Bottom First

No address,

Face Down,

Top First

No address,

Face Up,

Bottom First

No address,

Face Up,

Top First

Top address,

Face Down,

Bottom First

Top address,

Face Down,

Top First

Top address,

Face Up,

Bottom First

Top address,

Face Up,

Top First

Bottom address,

Face Down,

Bottom First

Bottom address,

Face Down,

Top First

Bottom address,

Face Up,

Bottom First

Bottom address,

Face Up,

Top First

Other Icons

A

Double Detect On

H

Feeder Designators

to

1-12 SV40221 Rev. A

Introduction • 1

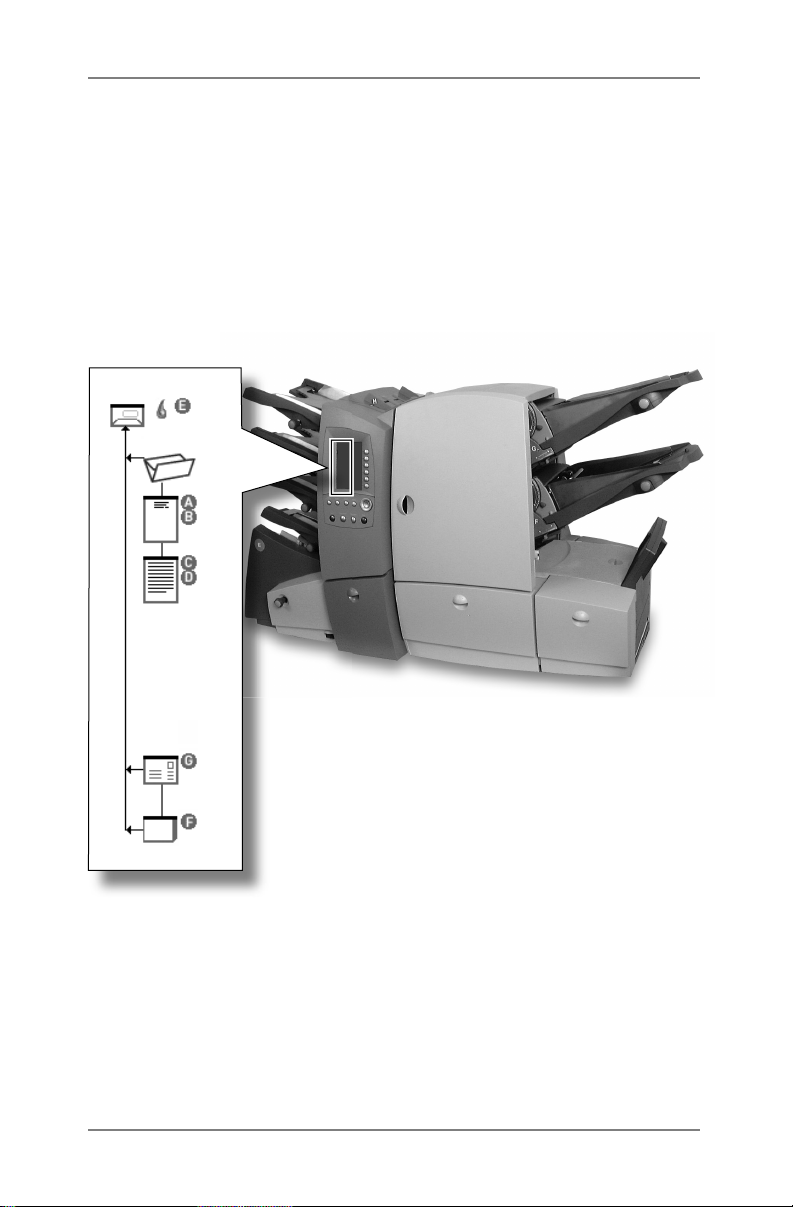

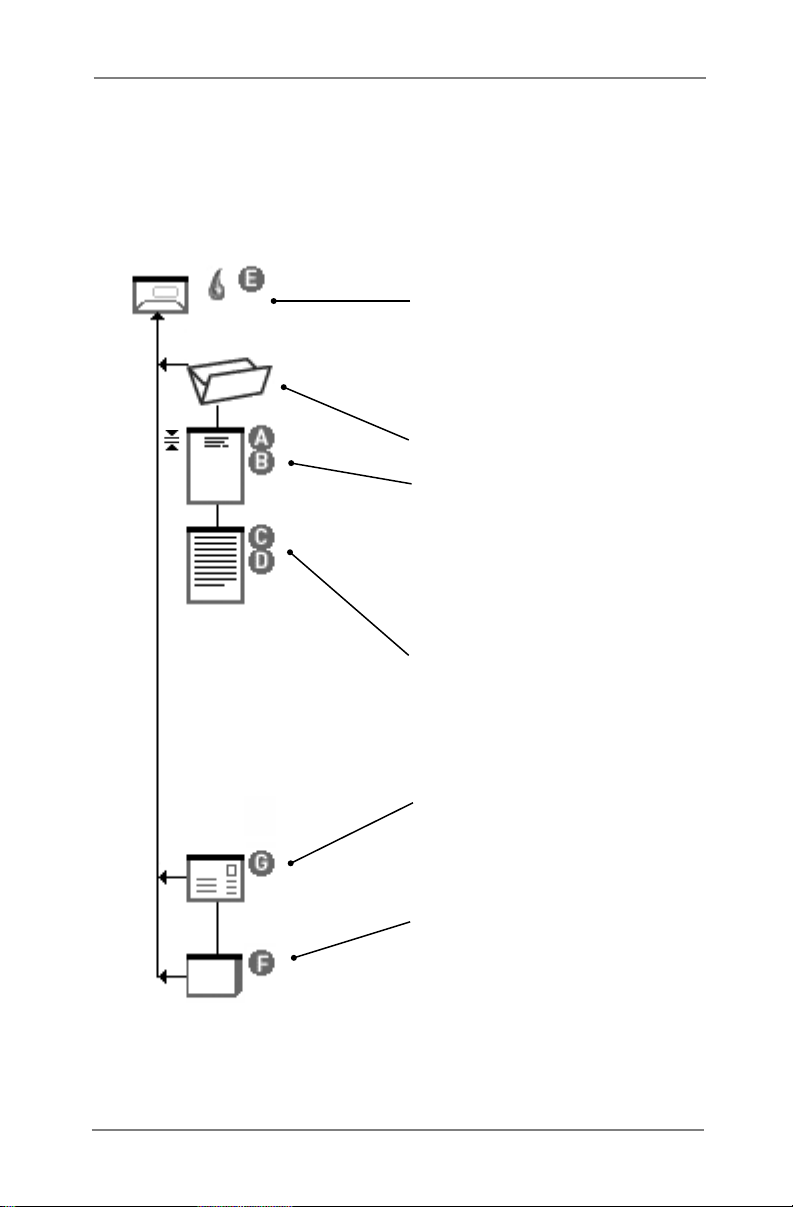

Mail Piece Icon Tree Example

An example Mail Piece Icon Tree is shown below. This explains the

information that is available and how it assists you in loading and

running a job.

Window Envelope

loaded Flap Side Up

fed Flap Last

Envelope sealing turned on

loaded into feeder E

C Fold selected

Prime Sheet with Top Address

loaded Face Up

fed Top First

loaded into feeders A and B

feeders A and B Linked

Double Detect turned on

Additional Sheet

loaded Face Up

fed Top First

loaded into feeders C and D

feeders C and D Linked

Reply Envelope

loaded Flap Side Down

fed Flap First

loaded into feeder G

Booklet

loaded Face Down

fed Bound Edge First

loaded into feeder F

1-13SV40221 Rev. A

1 • Introduction

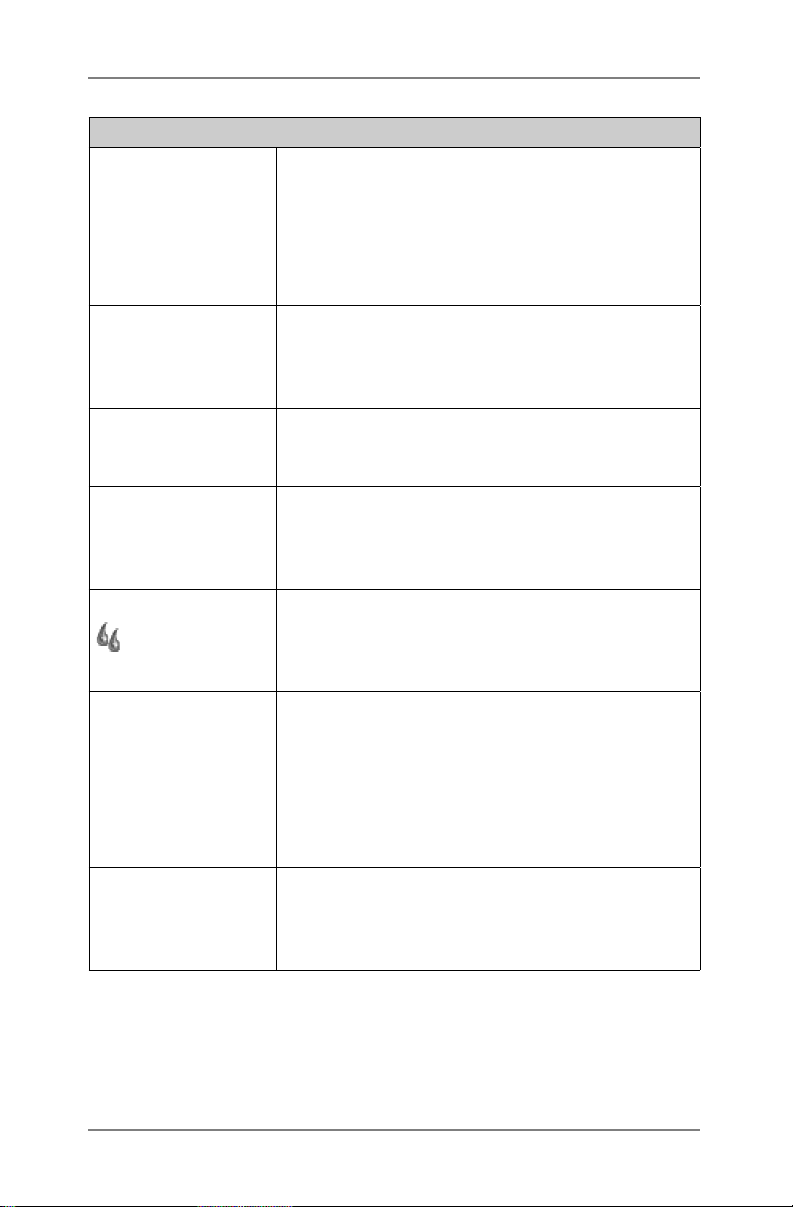

Common Terms

Throughout the machine screens and this guide, standard terms are

used to describe the elements of the Mail Piece and functions of the

equipment.

It is therefore important that you fully understand the following basic

terms to get the best from your machine:

MATERIAL

Sheet A single piece of paper that will require folding

by the machine before it is placed into an

envelope.

Pre-Collated Set A set of sheets printed in a collated sequence

i.e. sheet 1, sheet 2, sheet 3, etc.

Stack A pile of paper as received from the printer

that will be loaded into a feeder (or feeders)

on the machine. A stack might consist of

numerous individual Sheets or numerous

Pre-Collated Sets, depending on how it was

printed.

Prime Sheet or

Prime Set

Additional Sheet

or Additional Set

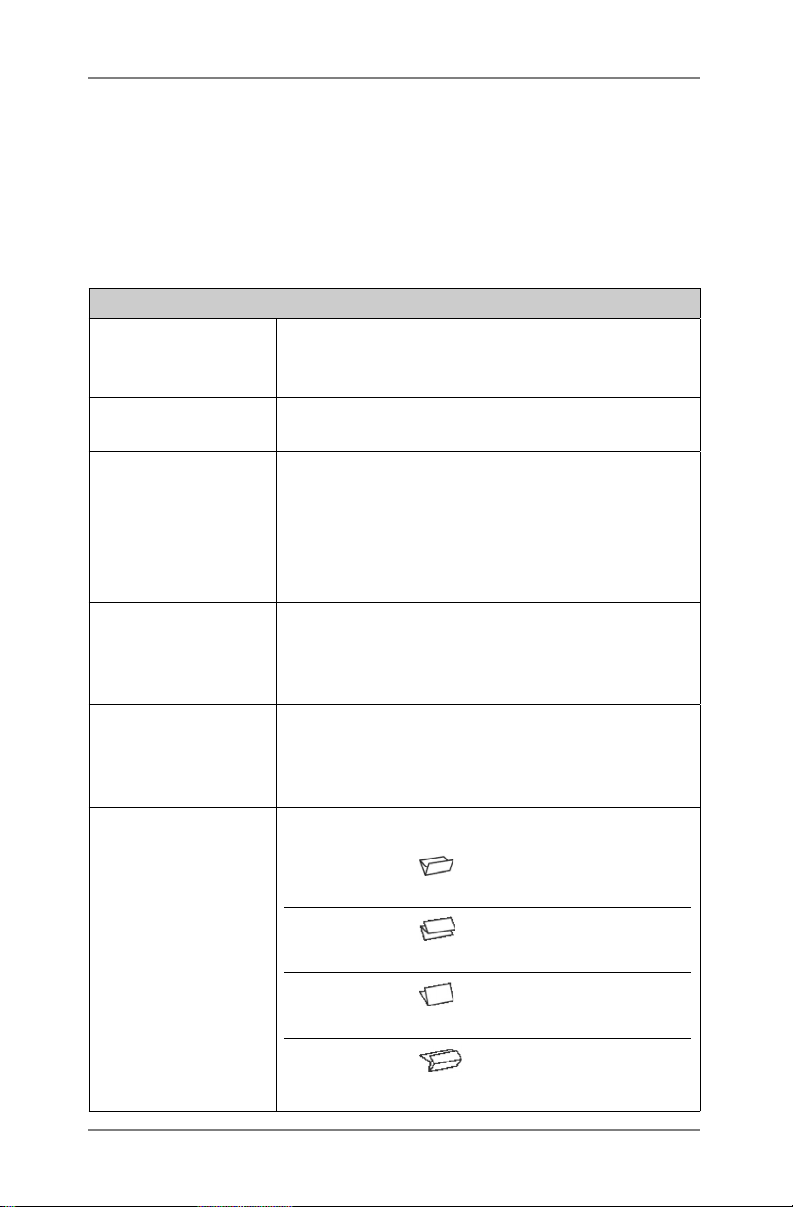

Fold Type The style of fold to be applied:

This sheet or set normally contains the

address. It will be positioned closest to the

envelope window, or the front face of a

windowless envelope.

Additional sheet(s) or set(s) can be added

to the Prime Sheet or Prime Set. They will

be fed from other Sheet Feeder(s) and are

placed into the envelope behind the Prime.

C Fold

Z Fold

Single Fold

Double Fold

1-14 SV40221 Rev. A

also know as ‘standard’

fold.

also known as

‘accordion’ fold.

one fold applied (usually

folded in half).

folded in half and then

in half again.

Introduction • 1

MATERIAL (continued)

Insert An item that doesn’t require folding before

being placed into an envelope. There are four

kinds of Inserts:

Reply Envelope A return envelope

placed into the Outer

Envelope with the

other Mail Piece

contents.

Booklet An item with a

stapled and folded

binding edge.

Slip A single thickness

piece of paper or

card.

Pre-Folded Insert A sheet that has

been folded prior to

loading and requires

no further folding by

the machine.

Outer Envelope The envelope which contains all the items

placed into it by the machine.

Mail Piece A single assembled article of mail, usually an

envelope with correct contents.

Fan The process of flicking through a stack of

material to separate the items prior to loading.

Shingle The method of loading Inserts into a feeder in

a partially overlapped manner, like tiles on a

roof.

1-15SV40221 Rev. A

1 • Introduction

MACHINE FUNCTIONS

Home Screen The initial screen displayed after turning

power on. From this screen you can select

pre-programmed Job Definitions, enter the

menu functions or run the machine.

Pressing the Home key on the Control Panel

will return you to this screen at any time.

Job Definition The collection of settings that define how a

Mail Piece is to be created by the machine.

Up to 20 Job Definitions can be stored for

instant recall.

Mail Piece Icon

Tree

Trial Piece Test piece run by the machine before

Safe Seal

Linked Feeders Allows more than one feeder to be configured

Optical Mark

Recognition

(OMR)

Situated down the left side of the display.

A graphical representation of the items that

make up the currently selected Job Definition.

automatic operation can be started. A Trial

Piece allows the machine to calibrate itself

and the Mail Piece make-up to be checked.

A modified sealing mode that allows better

sealing of ‘poor’ envelopes. Safe Seal will

allow more time for the envelope flap gum to

soften, but will slow machine operation.

to run the same Stack. When the first feeder

runs out of material, feed will automatically

switch to the next ‘linked’ feeder, and so on,

in a continuous cycle. This allows empty

feeder(s) to be loaded while another linked

feeder is feeding material.

The process of controlling machine functions

and Mail Piece make-up by ‘scanning’

material passing through the machine for

machine readable marks (OMR Marks).

1-16 SV40221 Rev. A

2 • Using the Menus

This chapter explains the Home Screen and the menu structure

accessed via the PacPilot™ Control Panel

The Home Screen ............................................................. 2-2

The Menu Structure ........................................................... 2-4

2-1SV40221 Rev. A

2 • Using the Menus

The Home Screen

The Home Screen is the first screen shown on the display after the

machine has finished powering up.

The last Job Definition selected is displayed with the relevant Mail

Piece Icon Tree on the left hand side.

The u and t navigation keys can be used to scroll through the

icon tree and highlight individual items. As you do this, the loading

instructions associated with the highlighted item will be shown.

From this screen you can run the job displayed. Alternatively, press

the relevant Screen Key to:

Select Another Job from those already programmed into

the machine. See page 3-3.

Initiate the SwiftStart™ feature. See page 3-6.

Select the Menu Screen Key to access:

Operator Functions. See page 3-19.

Supervisor Functions. See page 4-2.

You can also use the Manual Feed feature. See page 3-9.

2-2 SV40221 Rev. A

Using the Menus • 2

Machine

Status

Screen

Name

Home Piece Count:

READY Batch Count:

Invoice Job

Use u , t to view loading

instructions

Name of

selected Job

Counter(s)

Select Job

Job comments

text area

SwiftStart

Menu

Instructional

Tex t

>

>

>

Screen

Key

Selections

Mail Piece Icon Tree Machine Graphic

The Home Screen

2-3SV40221 Rev. A

2 • Using the Menus

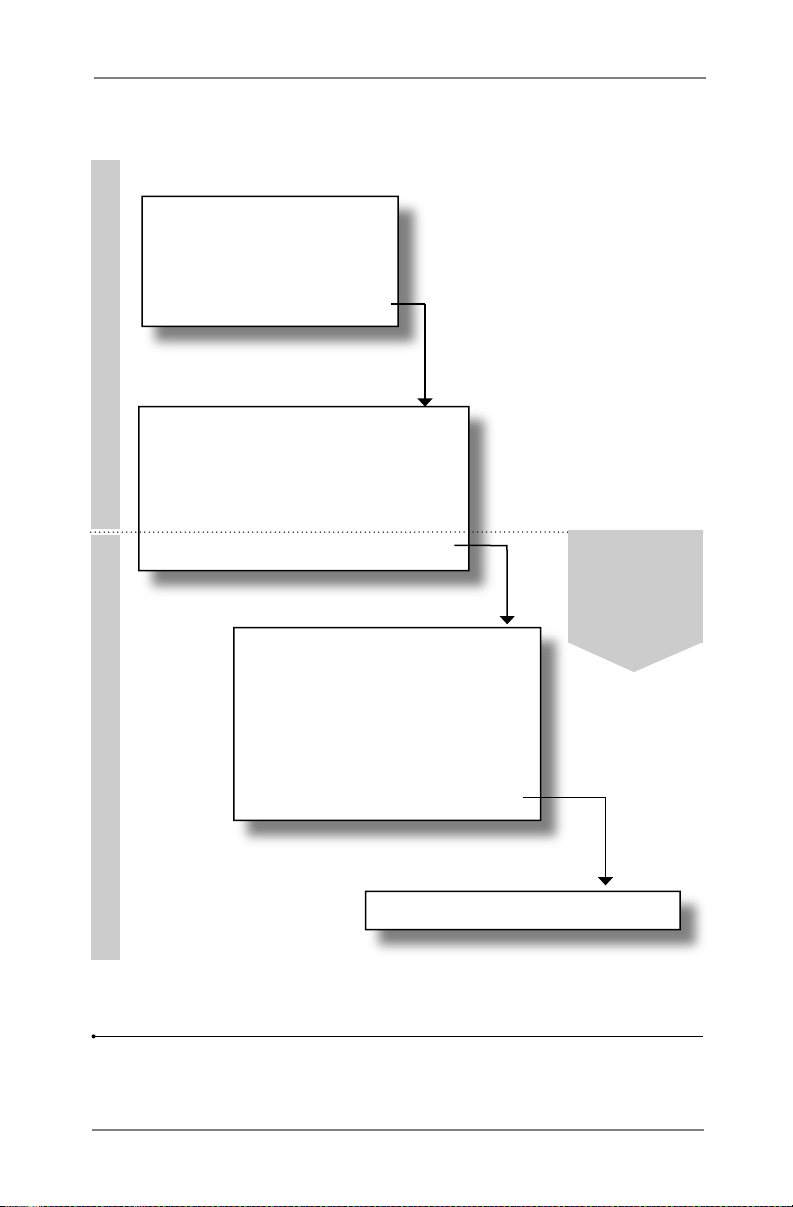

The Menu Structure

The diagram on the facing page shows the menu structure available

when you press the Menu Screen Key.

You will see that the menu follows a logical structure with similar

functions grouped together.

The menu structure is split into two sections:

The first section is available to all Operators and contains

settings and adjustments that might be required when

running jobs on the machine.

The second section is only available to a 'Supervisor' upon

entry of a Supervisor Access Code. This section allows

supervisors to create, edit and delete jobs as well as set

more advanced features.

The following two chapters in this guide; 'Operator Functions' and

'Supervisor Functions' give details of the functions available to each

level of user.

Use this diagram as a quick reference to find the function(s) that you

require, then refer to the relevant page in this guide.

Each screen can be identified by its title located in the top left corner.

2-4 SV40221 Rev. A

Home Screen

Select Job

SwiftStart

Menu

(p.3-3) >

(p.3-6) >

(p.3-19) >

Language (p.3-19) >

OPERATOR FUNCTIONS SUPERVISOR FUNCTIONS

Display Adjustments

Safe Seal (p.3-19) >

System Information

Supervisor Functions (p.4-1) >

Create Job (p.4-3) >

Edit Job (p.4-4) >

Create From

Delete Job

OMR Menu

Systems Menu

Using the Menus • 2

(p.3-19) >

(p.3-19) >

Menu items

below this

line require

a Supervisor

Access Code

(p.4-6) >

(p.4-7) >

(p.4-8) >

(p.4-8) >

The Menu Structure

Manual Feed Option (p.4-8) >

2-5SV40221 Rev. A

2 • Using the Menus

2-6 SV40221 Rev. A

Loading...

Loading...