Page 1

DVD RECEIVER

XV-HTD510

XV-HTD510-B

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

KUXJ – AC120V 1

KCXJ – AC120V 1

KUCXJ – AC120V 1

This product is component of system.

XV-HTD510 XV-HTD510-B

Model

Power Requirement Region No. Remarks

ORDER NO.

RRV2452

Component System Service Manual Remarks

DVD SURROUND SYSTEM

DVD RECEIVER

SPEAKER SYSTEM S-HTD510 S-HTD510-B RRV2444

XV-HTD510 XV-HTD510-B RRV2452 This service manual

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SELF-DIAGNOSTIC FUNCTION OF

PICKUP DEFECTIVE

7.1.2 TEST POINTS LOCATION

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 2001

................................................

.....................................................

..................................................

.......................................

.................

...

...........................

................................

...........................

...................

10

46

66

73

74

74

74

75

2

3

7.1.3 TEST MODE SCREEN DISPLAY

7.1.4 POWER ON SEQUENCE

7.1.5 TROUBLE SHOOTING

7.1.6 ERROR CODE

7.1.7 DISASSEMBLY

7.1.8 TROUBLE SHOOTING FOR

MECHANISM SECTION

7.2 PARTS

7.2.1 IC

7.2.2 DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS..118

..........................................................

..........................................................

........

....................

........................

.....................................

....................................

.......................

.............................................

T – IZK MAY 2001 Printed in Japan

76

78

79

80

84

95

98

98

117

Page 2

XV-HTD510, XV-HTD510-B

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

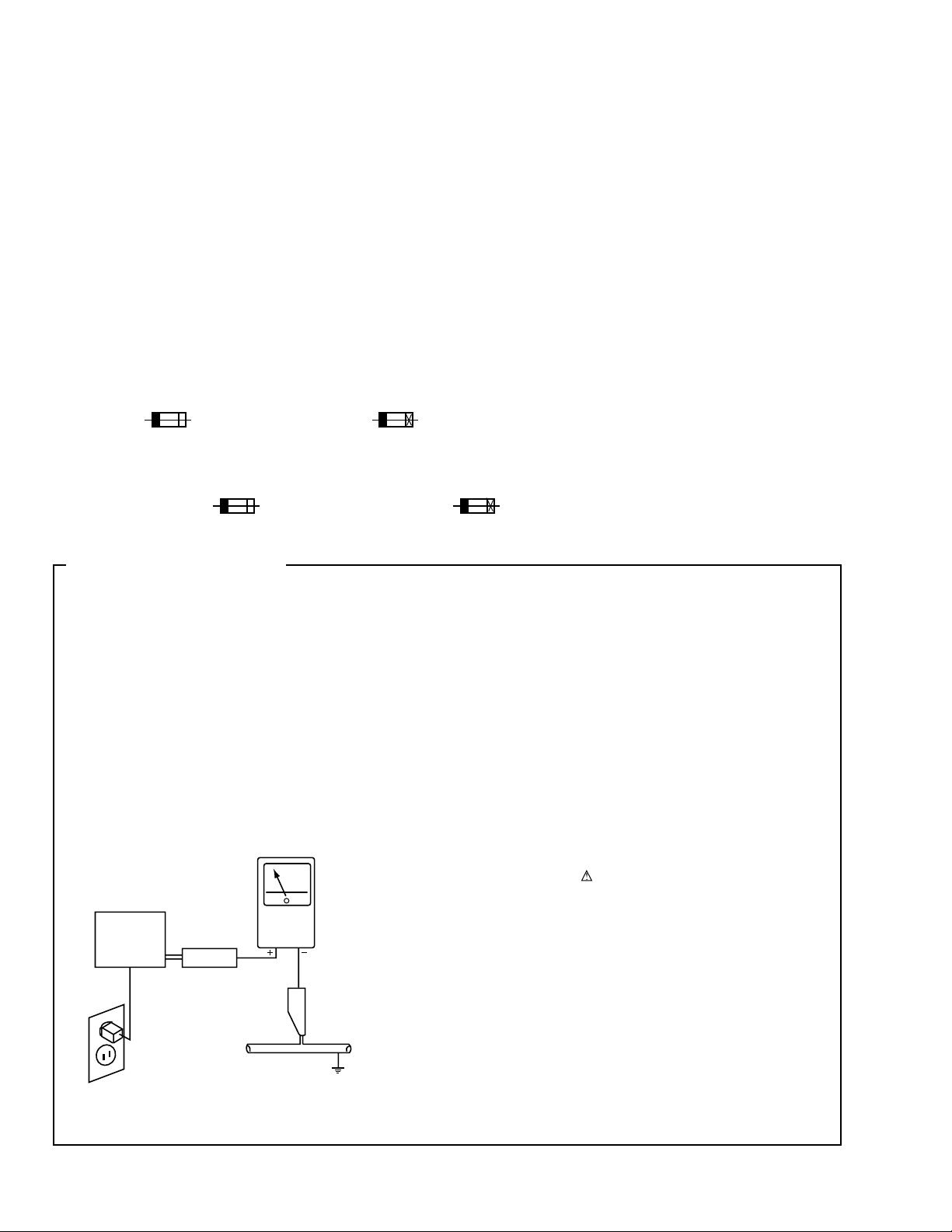

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

XV-HTD510, XV-HTD510-B

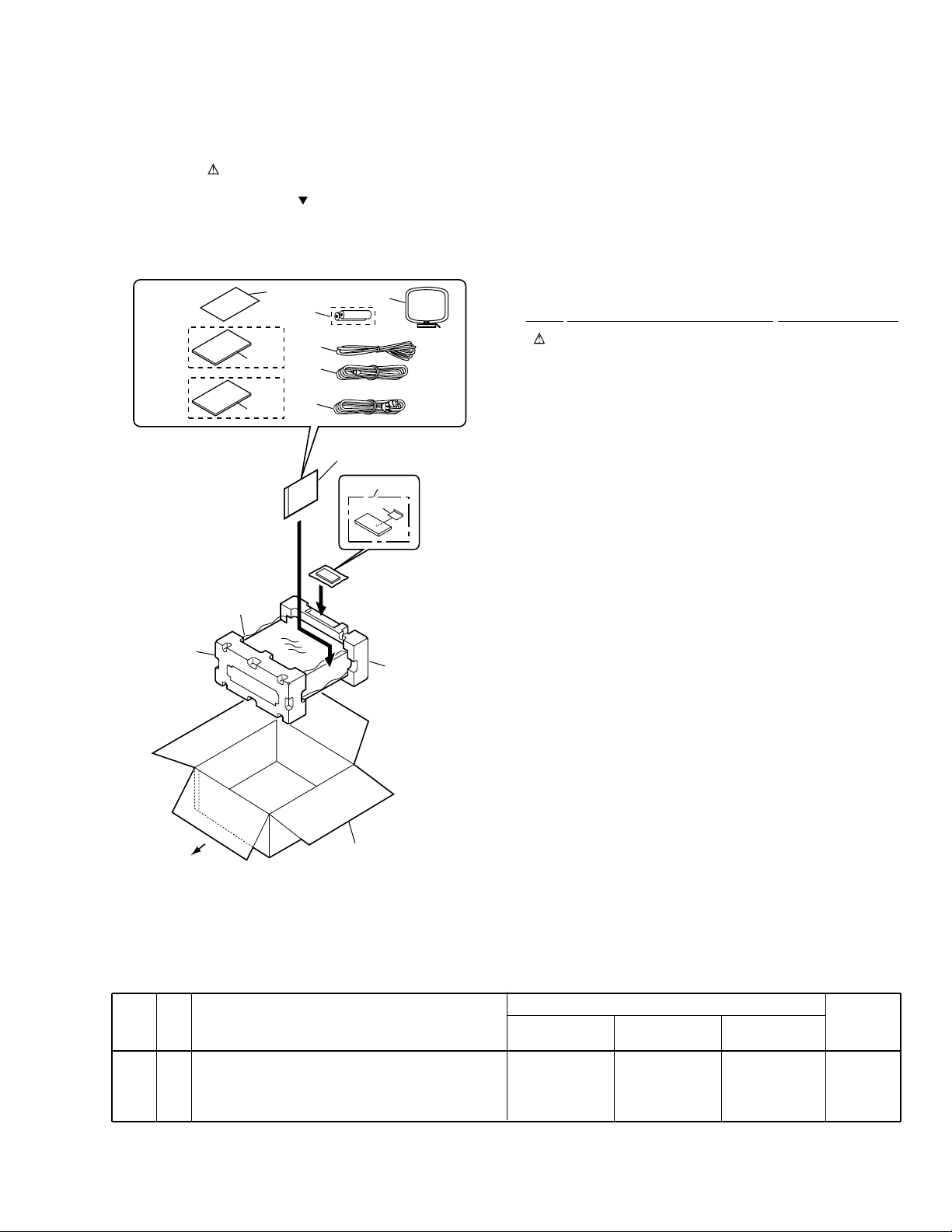

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

KUXJ

Type

Only

KCXJ,

KUCXJ

Types

Only

12

6

13

14

10

7

2

3

1

15

11

4

5

8

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Power Cord ADG7022

2 FM Antenna ADH7004

3 Video Cord (L = 1.5m) VDE1053

4 Remote Control Unit See Contrast table (2)

5 Battery Cover XZN3117

NSP 6 Dry Cell Battery (R6P, AA) VEM-013

7 Pad F XHA3124

8 Pad R XHA3125

9 Packing Case See Contrast table (2)

10 Packing Sheet AHG7010

NSP 11 Polyethylene Bag Z21-038

NSP 12 Warranty Card ARY7045

13 Operating Instructions (English) See Contrast table (2)

14 Operating Instructions See Contrast table (2)

(English/French)

15 AM Loop Antenna ATB7009

9

FRONT

(2) CONTRAST TABLE

XV-HTD510/KUXJ, KCXJ and XV-HTD510-B/KUCXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

4

Remote Control Unit

9

Packing Case

13

Operating Instructions (English)

14

Operating Instructions

(English/French)

XV-HTD510

/KUXJ

XXD3033

XHD3171

XRB3009

Not used

XV-HTD510

/KCXJ

XXD3033

XHD3171

Not used

XRE3039

XV-HTD510-B

/KUCXJ

XXD3032

XHD3192

Not used

XRE3039

Remarks

DSP Button

3

Page 4

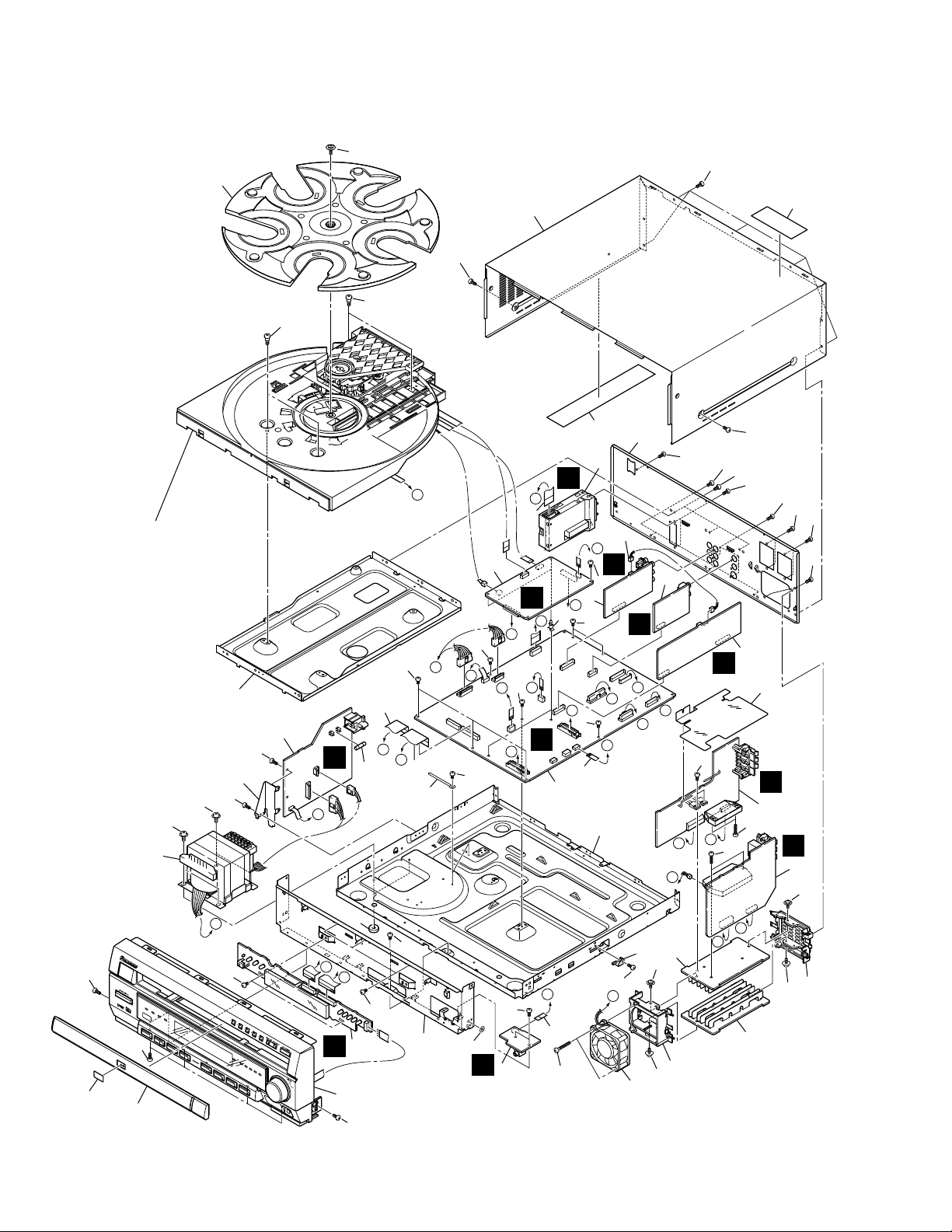

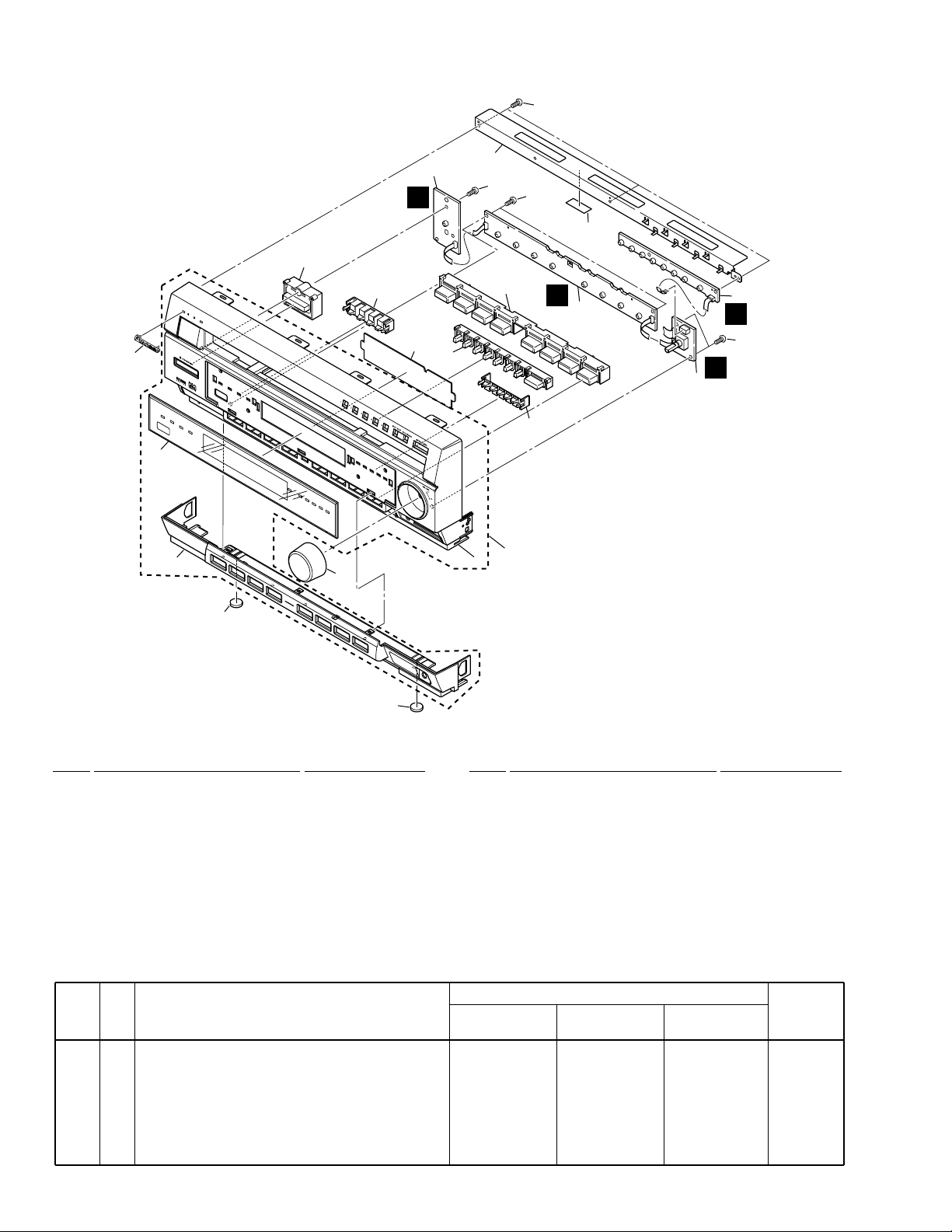

XV-HTD510, XV-HTD510-B

2.2 EXTERIOR

31

Refer to

"2.4 TABLE MECHANISM SECTION".

26

43

25

43

42

42

12

41

23

44

47

47

38

22

11

J

M

43

43

C

D

16

2

A

T

D

B

13 17

39

43

O

15

20

K

1

F

33

O

L

43

E

M

I

L

9

K

43

7

N

43

L

J

I

N

43

19

G

K

21

44

37

44

48

43

43

48

48

48

48

48

8

10

M

32

H

44

H

4

45

J

I

45

F

G

3

40

29

43

A

B

43

24

5

N

Refer to

"2.3 FRONT PANEL SECTION".

44

49

O

H

30

G

34

40

28

28

27

40

E

43

18

6

46

43

F

40

14

44

35

C

43

44

36

4

Page 5

(1) EXTERIOR PARTS LIST

XV-HTD510, XV-HTD510-B

Mark No. Description Part No.

1 DVDM Assy XWX3034

2 PRIMARY Assy XWZ3432

3 FRONT AMP Assy XWZ3438

4 REAR AMP Assy XWZ3442

5 DISPLAY Assy XWZ3446

6 MIC HP Assy XWZ3450

7 INPUT Assy XWZ3455

8 VIDEO Assy XWZ3459

9 MAIN Assy XWX3030

10 DSP Assy XWX3040

11 TUNER MODULE AXQ7228

12 T1 Power Transformer XTS3051

13 FU1 Fuse (5A) REK1067

14 DC Fan Motor AXM7014

15 13P F.F.C/60V XDD3089

(MAIN CN5701 – TUNER CN201)

16 19P F.F.C/60V XDD3090

(MAIN CN5509 – DISPLAY CN5801)

17 27P F.F.C/60V XDD3091

(MAIN CN5511 – DISPLAY CN5802)

18 5P F.F.C/60V XDD3093

(MAIN CN5501 – MIC HP CN5807)

19 7P F.F.C/60V XDD3094

(MAIN CN8902 – DVDM CN55)

20 Connector Assy 3P XDE3041

(INPUT CN5207 – DSP CN3703)

NSP 21 Chassis XNA3008

Mark No. Description Part No.

27 DV Bracket XNG3064

28 Heat Sink XNH3021

NSP 29 Spacer XEB3019

30 Fan Mold AMR7321

31 Rotary Tray VNK4739

32 Barrier H XEC3016

NSP 33 PCB Support XEC3020

34 Rear Mold XMR3038

35 DVDV Badge XAM3003

36 Tray Cap See Contrast table (2)

37 65 Label ARW7050

NSP 38 Large Label XAX3217

39 Cord Clamper RNH-184

40 Screw ABA1021

41 Screw ABA7069

42 Screw ASZ40P060FMC

43 Screw BBZ30P060FMC

44 Screw BBZ30P080FZK

45 Screw BBZ30P160FMC

46 Screw BPZ30P350FZK

47 Screw PBA1106

48 Screw VPZ30P080FZK

49 Washer VEC1254

22 Rear Panel See Contrast table (2)

23 Bonnet Case See Contrast table (2)

24 Front Frame XNG3056

25 PCB Angle XNG3057

26 Mecha Frame XNG3059

(2) CONTRAST TABLE

XV-HTD510/KUXJ, KCXJ and XV-HTD510-B/KUCXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

22

Rear Panel

23

Bonnet Case

36

Tray Cap

XV-HTD510

/KUXJ

XNC3094

XZN3118

XAN3032

XV-HTD510

/KCXJ

XNC3094

XZN3118

XAN3032

XV-HTD510-B

XNC3097

XZN3119

XAN3033

Remarks

/KUCXJ

5

Page 6

XV-HTD510, XV-HTD510-B

2.3 FRONT PANEL SECTION

12

13

7

6

9

14(1/2)

Q

15

19

10

16

19

19

18

11

8

5

P

14(2/2)

2

3

S

19

R

1

4

17

17

(1) FRONT PANEL SECTION PARTS LIST

Mark No. Description Part No.

NSP 1 JOG Assy XWZ3448

2 KEYB Assy XWZ3447

NSP 3 DISC KEY Assy XWZ3449

NSP 4 STBY SWITCH Assy XWZ3453

NSP 5 Front Panel Assy See Contrast table (2)

6 Front Cap See Contrast table (2)

7 Display Panel See Contrast table (2)

8 Front Panel See Contrast table (2)

9 Volume Knob See Contrast table (2)

10 Disc Button See Contrast table (2)

Mark No. Description Part No.

11 Function Button See Contrast table (2)

12 Power Button See Contrast table (2)

13 Pioneer Badge XAM3001

14 Lens XAX3216

15 FL Filter XEC3015

16 Top Frame XNG3063

17 Leg AEB7090

NSP 18 Small Label XAX3291

19 Screw VPZ30P080FZK

(2) CONTRAST TABLE

XV-HTD510/KUXJ, KCXJ and XV-HTD510-B/KUCXJ are constructed the same except for the following :

Part No.

Mark No. Symbol and Description

NSP

5

Front Panel Assy

6

Front Cap

7

Display Panel

8

Front Panel

9

Volume Knob

10

Disc Button

11

Function Button

12

power Button

XV-HTD510

/KUXJ

XXG3070

XAK3212

XAK3213

XMB3047

XAA3020

XAD3093

XAD3100

XAD3101

XV-HTD510

/KCXJ

XXG3070

XAK3212

XAK3213

XMB3047

XAA3020

XAD3093

XAD3100

XAD3101

XV-HTD510-B

Remarks

/KUCXJ

XXG3071

XAK3227

XAK3229

XMB3048

XAA3021

XAD3099

XAD3094

XAD3095

6

Page 7

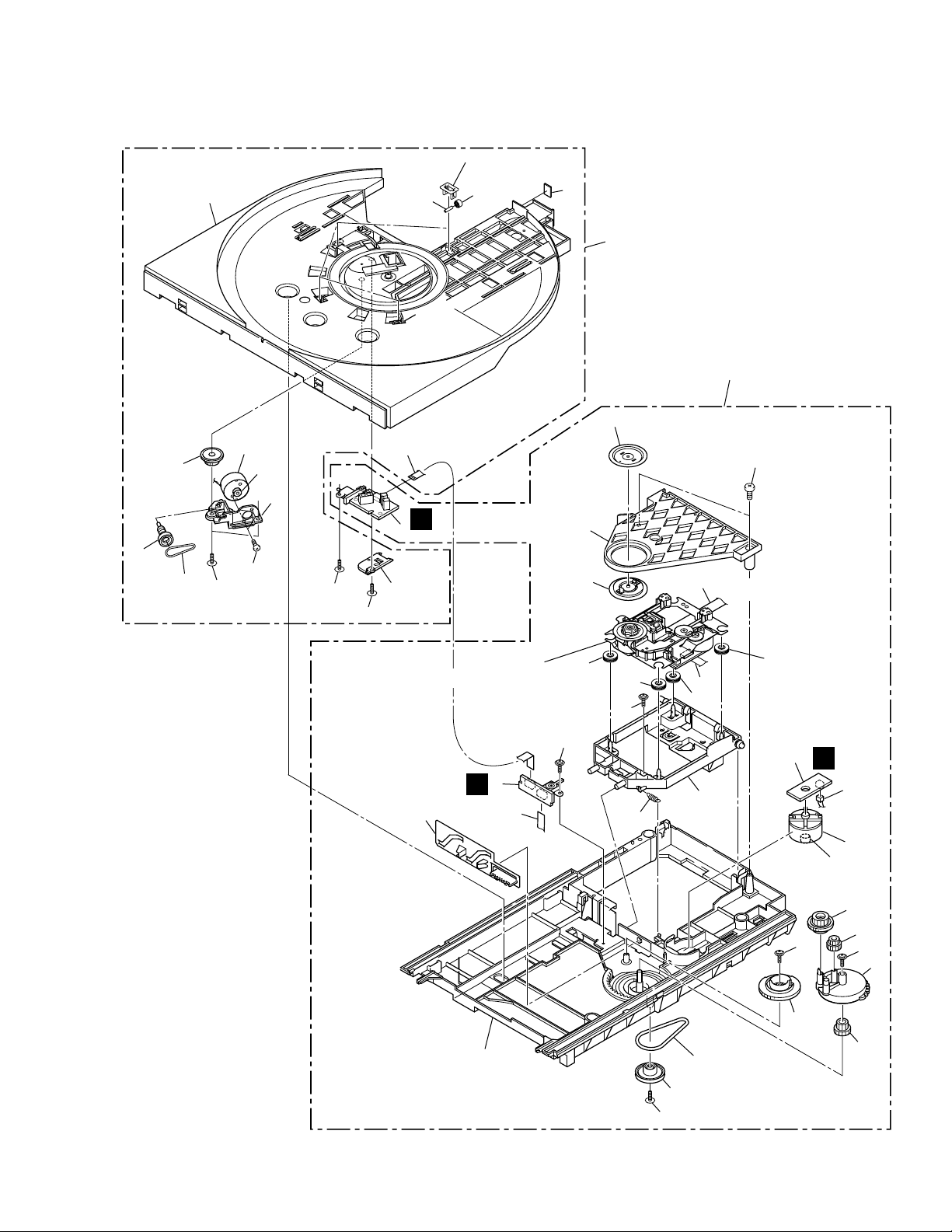

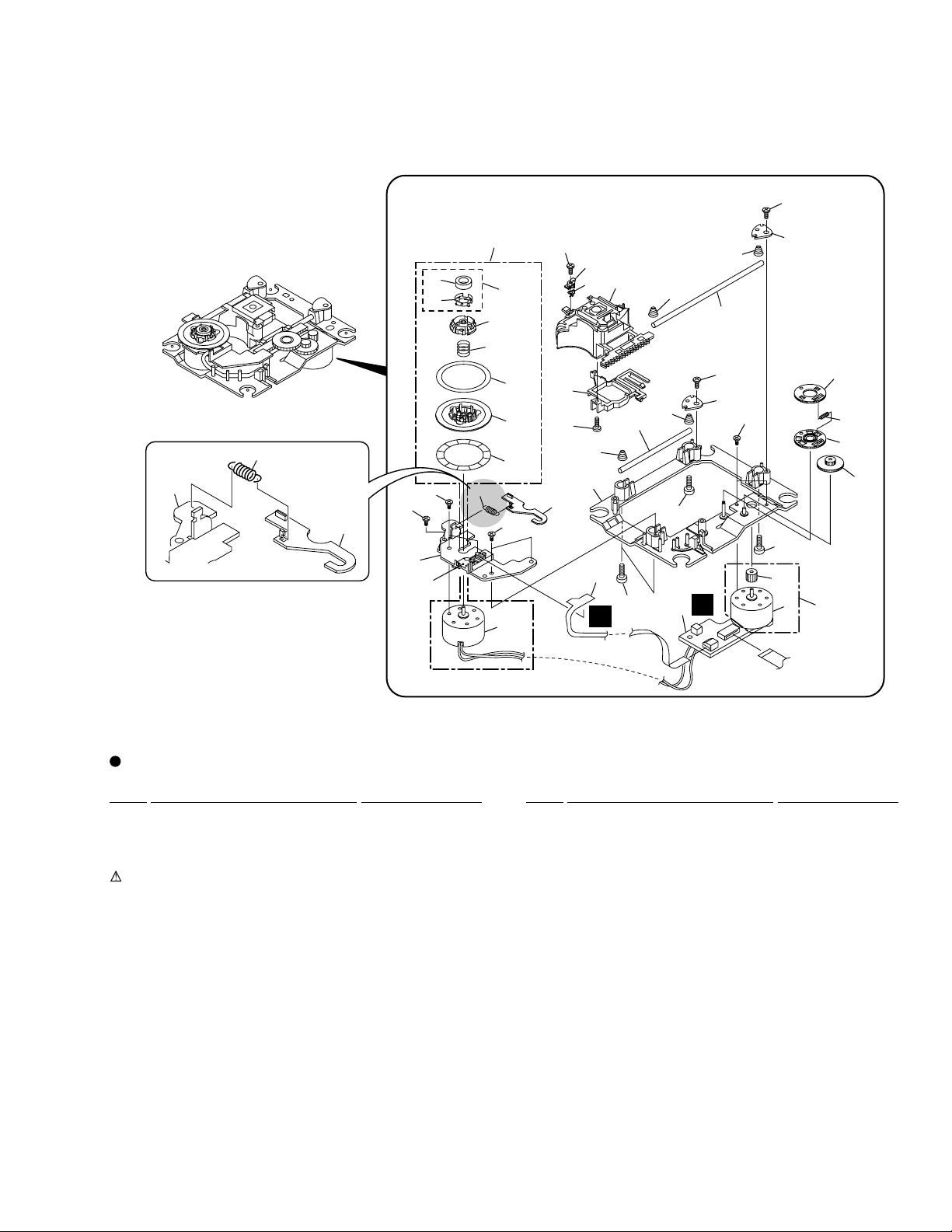

2.4 TABLE MECHANISM SECTION

37

(1/6)

37

(2/6 - 5/6)

[Roller Cover]

37

(6/6)

[PCB Cover]

36

35

2

1

16

29

20

18

14

30

28

21

14

14

19

32

13

14

11

12

26

25

30

30

27

22

15

17

38

33

40

34

42

39

31

10

5

7

8

3

4

42

9

6

From

DVDM CN555

From

DVDM CN2

Refer to

"2.5 TRAVERSE MECHANISM ASSY-S".

43

42

41

24

23

30

B

A

C

XV-HTD510, XV-HTD510-B

7

Page 8

XV-HTD510, XV-HTD510-B

TABLE MECHANISM SECTION PARTS LIST

Mark No. Description Part No.

NSP 1 5C Mech. Base Assy XXA3027

NSP 2 5C Table Mech. Assy VWT1175

NSP 3 TRSB Assy XWZ3461

NSP 4 SSRB Assy XWZ3462

NSP 5 LOMB Assy XWZ3463

6 Traverse Mechanism Assy-S VXX2653

7 Flexible Cable 24P XDD3074

8 Flexible Cable 8P (T) XDD3075

9 Flexible Cable 8P (M) XDD3076

10 Housing Assy 2P XDE3039

11 Slider Motor (LOADING) VXM1033

12 Motor Pulley PNW1634

13 Spring VBH1333

14 Floating Rubber VEB1286

15 Load Belt VEB1316

16 Clamper Plate VNE2162

17 Mechanism Base VNK4826

18 Clamper VNL1738

19 Float Base VNL1907

20 Clamper Holder VNL1872

21 Clamp Cam VNL1873

22 Planet Base VNL1874

23 Gear Pulley VNL1876

24 Loading Gear (1) VNL1877

25 Loading Gear (2) VNL1908

26 Drive Gear VNL1879

27 Change Gear VNL1904

28 Screw ABA7009

29 Screw BPZ30P080FMC

30 Screw Z39-019

31 Motor (TRAY) DXM1118

32 Flexible Cable (7P) VDA1835

33 Motor Pulley PNW1634

34 Tray Belt VEB1317

35 Rubber Roller VEB1318

36 Roller Shaft VLL1511

37 Slide Table VNK4751

38 Motor Holder VNL1880

39 Worm Gear VNL1881

40 Tray Gear VNL1882

41 Screw JGZ17P028FMC

42 Screw Z39-019

43 CR Cushion 2 XEB3020

8

Page 9

2.5 TRAVERSE MECHANISM ASSY-S

XV-HTD510, XV-HTD510-B

• Top View

17

37

32

29

18

26

11

25

27

7

3

36

35

30

16

9

31

37

21

17

24

34

19

8

6

20

12

9

37

4

21

22

33

33

23

28

10

15

2

E

10

5

10

13

37

10

14

7

18

7

1

D

To

DVDM Assy

CN3

TRAVERSE MECHANISM ASSY-S PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 SMEB Assy VWG2048

NSP 2 FGSB Assy VWG2009

NSP 3 Motor (CARRIAGE) VXM1079

NSP 4 Motor (SPINDLE) VXM1084

NSP 5 Pickup Assy VWY1055

6 Table Sheet DEC2040

7 Screw VBA1058

8 Centering Spring VBH1278

9 Hook Spring VBH1317

10 Skew Spring VBH1303

11 Gear Spring VBH1308

NSP 12 Reflected Sheet VEC1959

13 Guide Bar VLL1504

14 Sub-guide Bar VLL1505

15 Hold Spring VNC1017

NSP 16 Magnet Holder VNE2070

NSP 17 Motor Base VNE2154

NSP 18 Cover VNE2155

19 Centering Ring VNL1746

NSP 20 Disc Table VNL1747

NSP 30 Magnet VYM1024

21 Hook VNL1770

22 FFC Holder VNL1802

23 Mechanism Base VNL1806

24 FG Holder VNL1807

25 Gear A VNL1808

26 Gear B VNL1809

27 Gear C VNL1810

28 Slider VNL1811

29 Gear D VNL1814

31 Screw JFZ17P025FZK

32 Screw JGZ17P028FMC

33 Screw VBA1051

34 Magnet Holder Assy VXX2507

35 Spindle Motor Assy VXX2649

36 Carriage Motor Assy VXX2650

37 Screw PBA1069

9

Page 10

1

23

XV-HTD510, XV-HTD510-B

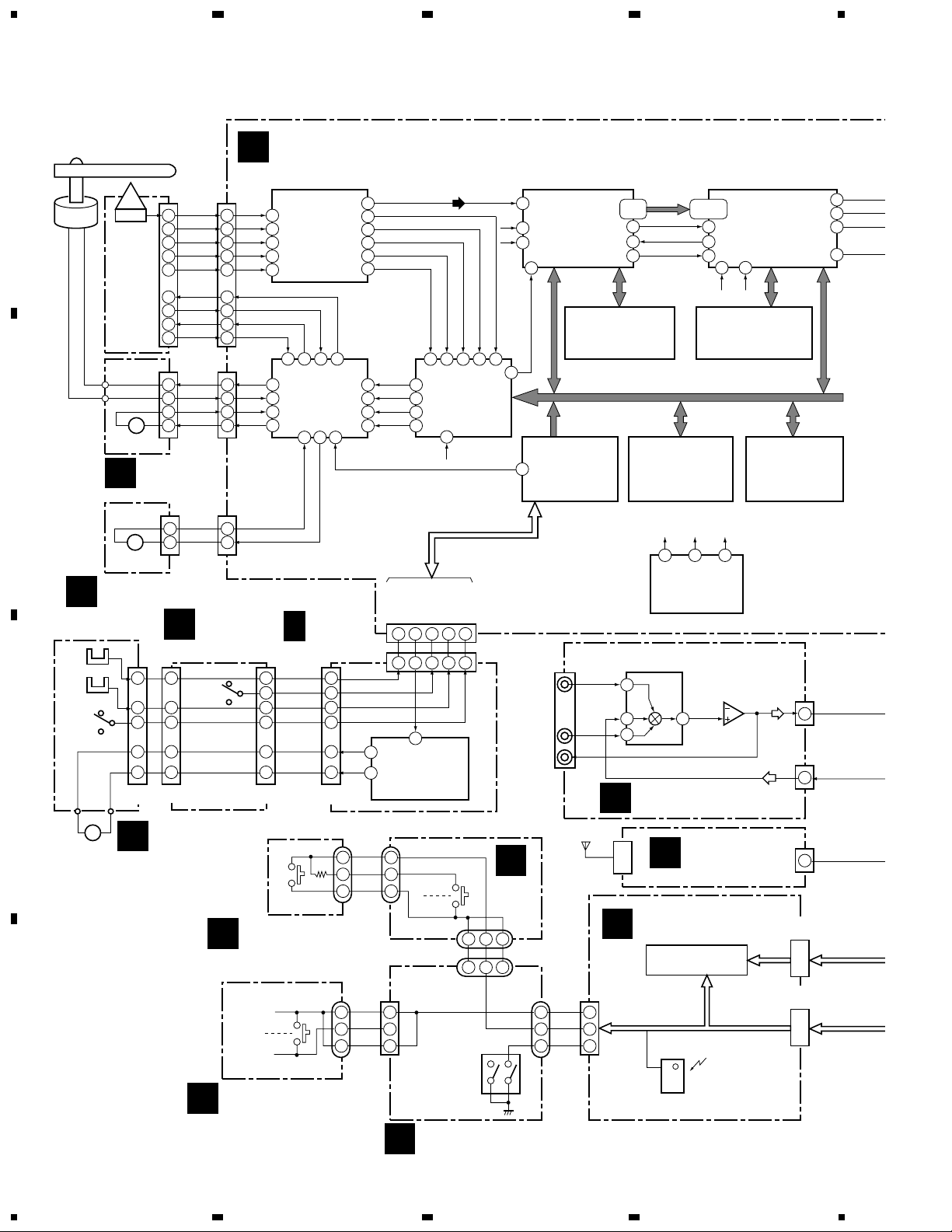

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

DVDM ASSY

S11

CN555

10

3

2

7

6

24

23

22

21

CN3

(8P)

7

8

5

3

CN2

1

2

F

(24P)

RF

B1

B2

B3

B4

LOADLOAD+

CN11

(8P)

3

6

7

8

9

31

32

34

35

4

3

5

6

7

8

DISC SENS

TRAY POS

LOAD POS

54

IC1

LA9701M

RF IC

9 12 13 10

IC3

M56788FP

SPDL & FTS

DRIVER

15 14 17

46

56

57

42

35

3

20

37

28

LODDRV LODDRV

I 1/2

MAIN ASSY

5

CLAMP

6

4

3

SEDR+

2

12

SEDR-

1

13

CN8903

(8P)

3

2

1

RFO

DSP RF

BH

PH

FE

TE

32 33 30 31 39

FDO

47

48

45

SERVO DSP

46

16M

DISC SENS

SEDO

34 125

54 763

25

LC78652W

14

CLAMP

TDO

SLDO

SPDO

IC8901

BA6195FP

5DISC

TURN DRIVER

KEYB ASSY

J5811J5811

3

2

1

IC2

TRAY POS

LOAD POS

CN55

CN8902

(7P)

(7P)

170

27M

4

DVD DECODER

16M

107

12

3

PD3410A

42

SYSTEM

CONTROL CPU

JA5201

TV/VCR

IN

AUX IN

AUX OUT

P

IC12

PE5108A

BY CHIP

IC15

MN414800CSJ-07

4M DRAM

IC11

IC5231

AUDIO SELECTOR

K

ANT

A

(24P)

Spindle

Motor

OEIC

PICKUP

ASSY

CN202

(8P)

+-

M

Carriage

Motor

B

D

SMEB

RF

15

B1

22

B2

23

B3

18

B4

19

F DRV

1

T RTN

2

T DRV

3

F RTN

4

SPDL+

7

SPDL-

8

SLDR R

5

SLDR F

3

ASSY

CN31

2

+-

1

M

Loading

Motor

LOMB ASSY

C

A

PC21

PC22

S21

LOADING

POSITION

DET. SW

C

+-

M

TRAY

Motor

SSRB ASSY

TRSB ASSY

3

5

1

7

5

3

2

6

4

4

CN12

CN21

(7P)

(7P)

B

DISC

CLAMP

DET. SW

SD0-SD7

57-60

63-66

111

56

55

CDDATA

SREQ

XSACK

80-84

78,86,87

54

91

89

MB811171622A-100FN

IC14

KM68V1000CLT-7L

WORK SRAM

(1M)

27M1316M936/16M

3

IC21

BU2288FV

CLOCK

GENERATOR

BU4052BCF

11

1314

15

INPUT ASSY

TUNER

J

MODULE

4

IC18

MB86373B

MPEG2

DECODER

AV-1

197

205

27M

36/16M

IC19

16M SDRAM

MEMORY (8M)

IC5352-1/2

CN5207

2

1

3

CN5208

IC13

VYW3003

FLASH

(3P)

(FL)

3

(19P)

(TX)

6

CN201

(13P)

7

45

39

36

64

L

TXL

L CH

STBY SWITCH

Q

ASSY

J5805

3

2

1

D

DISC KEY ASSY

S

J5808

J5808

CN5806

3

2

1

VOLUME

JOG ASSY

R

S5801

JOG

1

3

2

1

3

2

J5804

(5P)

4

3

2

4

3

2

DISPLAY ASSY

N

V5801 XAV3011

CN5803

(5P)

FL TUBE

REMOTE

SENSOR

CN5801

(19P)

CN5802

(27P)

10

1234

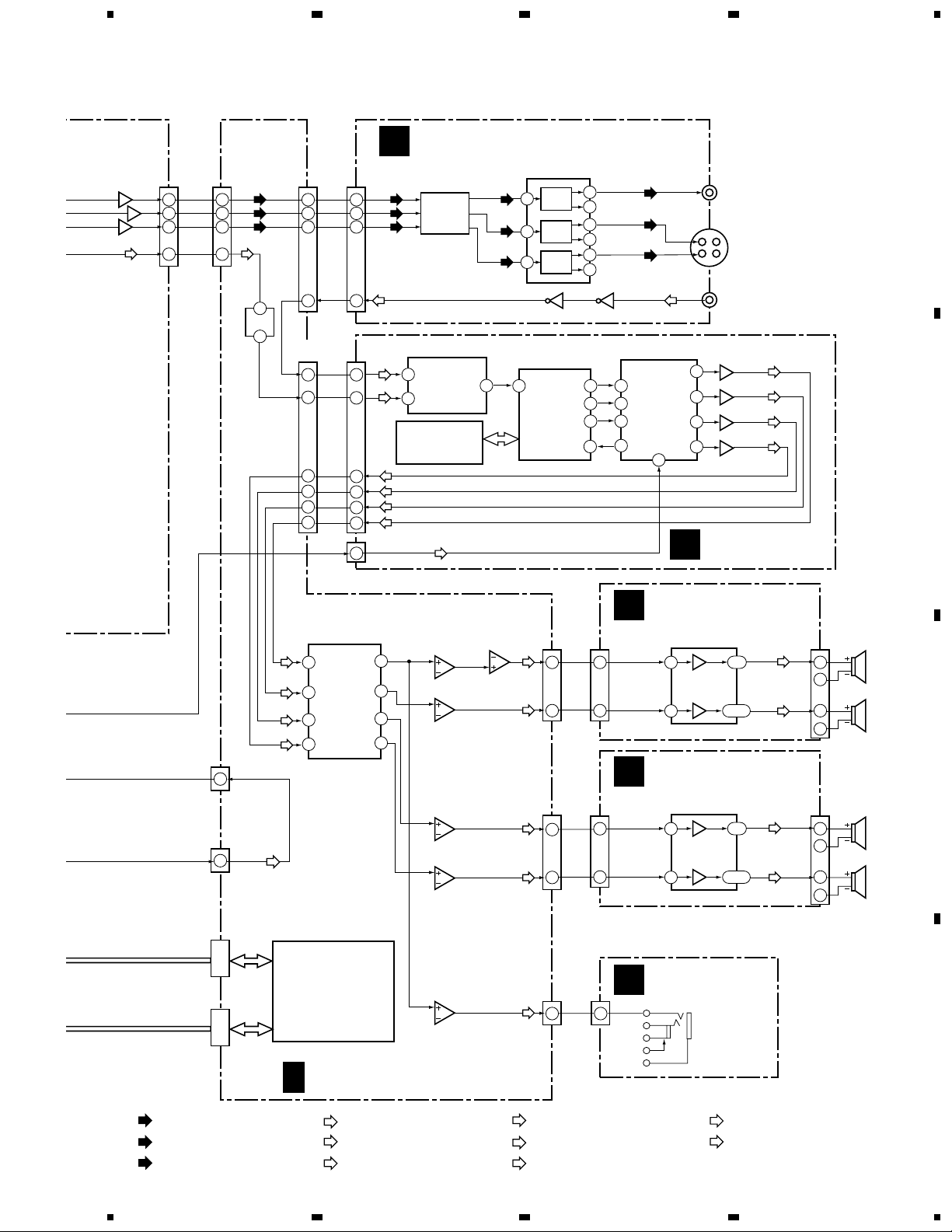

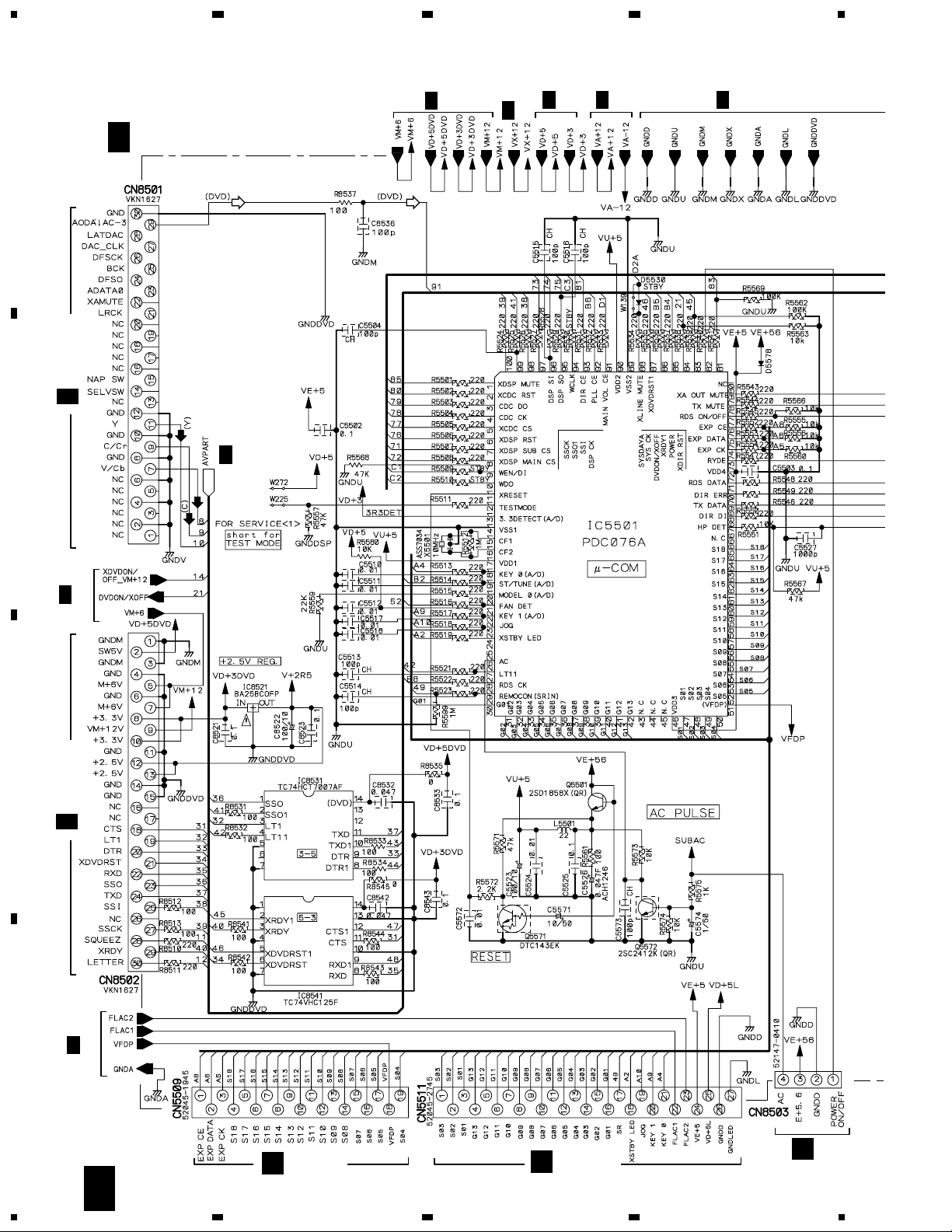

Page 11

(DVD)

CN15

(30P)

Q83

Q81

Q85

5

678

XV-HTD510, XV-HTD510-B

VIDEO ASSY

L

CN8501

CN5352

(30P)

11

29

7

9

(VCB)

(DVD)

IC8351

V/Cb

7

Y

11

C/Cr

9

AODAI

AC-3

29

(11P)

(Y)

(C)

13

12

TC74HCT7007AF

11

CN3001

(21P)

15

21

17

11

4

8

6

3

1

VIDEO

Y

C/Cr

DIN

DIN

AODAI

SW

C

SL

FL

CN5351

(11P)

4

8

6

11

CN3702

(21P)

(DI)

3

(DVD)

1

15

21

17

11

CN3703

(3P)

3

(VCB)

(Y)

(C)

3

4

W24257AJ-12

256k SRAM

(SW)

(C)

(SL)

(FL)

VIDEO

FILTER

IC8801

LC89056W-E

DIR

IC3851

(FL)

IC5351 LA7138M

VIDEO AMP

(VCB)

3

(Y)

10

(C)

6

IC5104-2/3 IC5104-1/3

16

85

IC3801

YSS912C-F

AMP

AMP

AMP

DSP

21

23

13

15

17

19

45

84

(VCB)

(Y)

(C)

IC3751

647

AK4527BVQ

746

6 ch

8

CODEC

9

30

JA5351

VIDEO OUT

Y

C

(DI)(DI)

M

JA5103

DIGITAL IN

IC8701-2/2

67

27

IC8703-1/2

21

25

IC8705-1/2

21

24

IC8705-2/2

6

23

DSP ASSY

CN5352

S-VIDEO OUT

(FL)

(SL)

(C)

(SW)

7

A

B

CN5209

(19P)

6

CN5701

(13P)

7

CN5509

(19P)

CN5511

(27P)

(FL)

17

(SL)

(C)

(SW)

(TX)

IC3001

9

M62446FP

E-VOL

11

6

IC5501

PDC076A

MICROCOMPUTER

IC3151,IC3152,IC3161,IC3171:

BA4558F

IC3151-1/2

31

36

34

33

5

6

IC3171-2/2

5

6

IC3161-1/2

5

6

IC3161-2/2

3

2

IC3902-1/2

5

6

7

7

7

1

7

IC3151-1/2

6

5

(FL)

7

(SW)

CN3051

(15P)

CN3052

(13P)

(SL)

(C)

(HP)

CN5501

(5P)

FRONT AMP ASSY

G

IC3301

CN3301

(15P)

FL IN

2

6

6

10

5

SW IN

SL IN

C IN

LOUT

2

6

CN3501

(13P)

6

10

1

CN5807

(5P)

REAR AMP ASSY

H

MIC HP ASSY

O

STK413-000

POWER AMP

13

18

IC3401

STK402-230

POWER AMP

1

15

PHONES

8,9

20,21

6,7

18,19

CN3303

(FL)

(SW)

CN3401

(SL)

(C)

(6P)

(6P)

6

5

2

1

FL

SP

SW

SP

C

1

2

5

6

SL

SP

C

SP

(VCB)

: VCB SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

I 2/2

(DVD)

MAIN ASSY

: DVD AUDIO SIGNAL ROUTE

(DI)

: DI AUDIO SIGNAL ROUTE

(FL)

: FL AUDIO SIGNAL ROUTE

(HP)

: HP AUDIO SIGNAL ROUTE

(SL)

: SL AUDIO SIGNAL ROUTE

(C)

: C AUDIO SIGNAL ROUTE

(SW)

: SW AUDIO SIGNAL ROUTE

(TX)

: TX AUDIO SIGNAL ROUTE

11

D

5

6

7

8

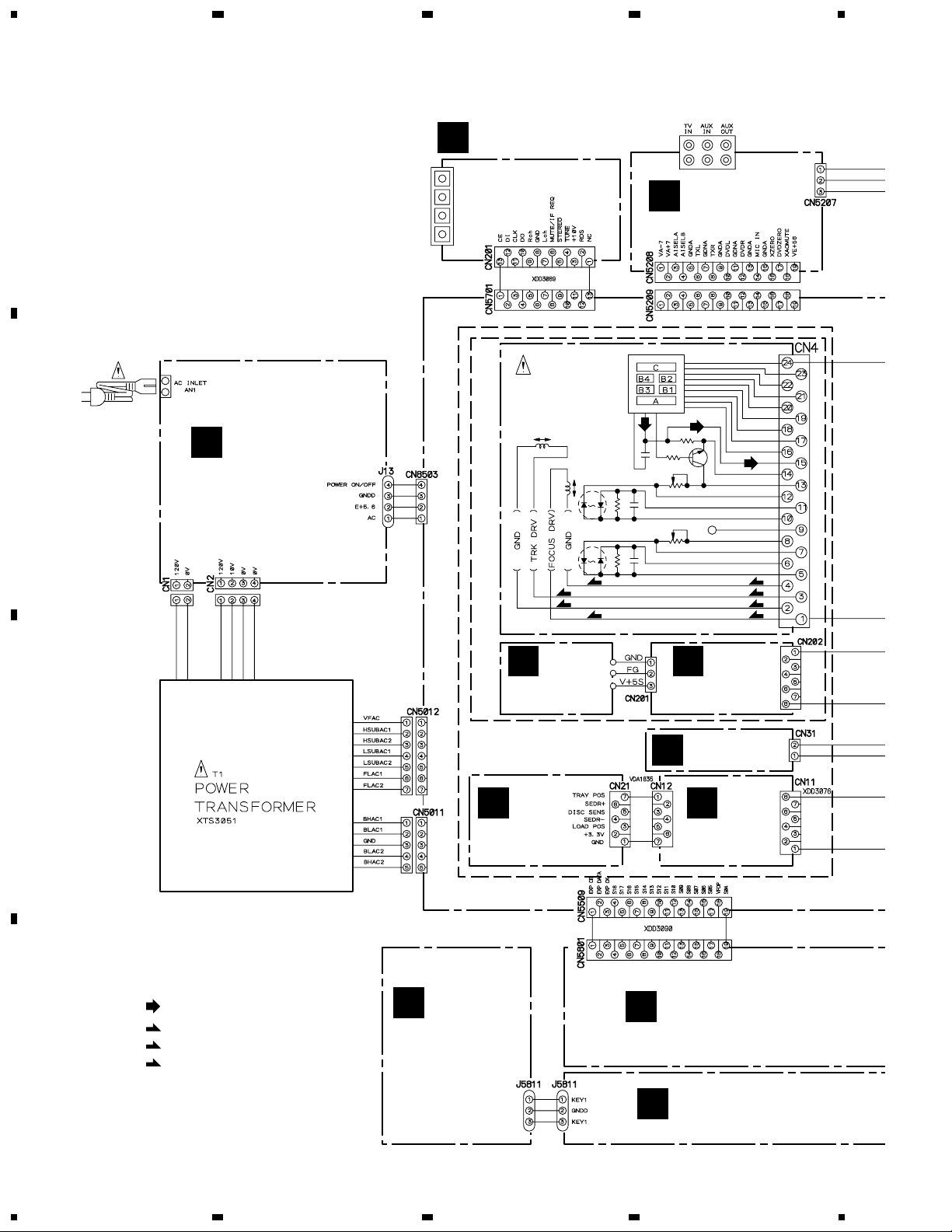

Page 12

1

XV-HTD510, XV-HTD510-B

3.2 OVERALL WIRING DIAGRAM

A

23

TUNER MODULE

J

(AXQ7228)

FM

AM

INPUT ASSY

K

(XWZ3455)

4

AC 120V

50/60Hz

POWER CORD

ADG7022

LIVE

NEUTRAL

PICKUP ASSY

(VWY1055)

T

B

C

PRIMARY ASSY

(XWZ3432)

(F)

(T)

(T)

(F)

E

TRAVERSE MECHANISM ASSY-S (VXX2653)

FGSB ASSY

(VWG2009)

5CH MECH.BASE ASSY

(XXA3027)

B

SSRB ASSY

(XWZ3462)

D

SMEB ASSY

(VWG2048)

LOMB ASSY

C

(XWZ3463)

A

TRSB ASSY

(XWZ3461)

(F)

(T)

(T)

(F)

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

D

: SLIDER SERVO LOOP LINE

Q

STBY SWITCH

ASSY

(XWZ3453)

DISPLAY ASSY

N

(XWZ3446)

KEYB ASSY

P

(XWZ3447)

12

1234

Page 13

5

678

XV-HTD510, XV-HTD510-B

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

M

DSP ASSY (XWX3040)

F

M 1/2- M 2/2

F 1/3- F 3/3

DVDM ASSY

(XWX3034)

VIDEO ASSY

L

(XWZ3459)

I 1/3- I 3/3

I

MAIN ASSY (XWX3030)

DC FAN MOTOR

AXM7014

G

FRONT AMP

ASSY

(XWZ3438)

A

B

H

C

D

R

JOG ASSY

(XWZ3448)

MIC HP ASSY

O

(XWZ3450)

REAR AMP

ASSY

(XWZ3442)

S

DISC KEY ASSY

(XWZ3449)

13

5

6

7

8

Page 14

1

23

XV-HTD510, XV-HTD510-B

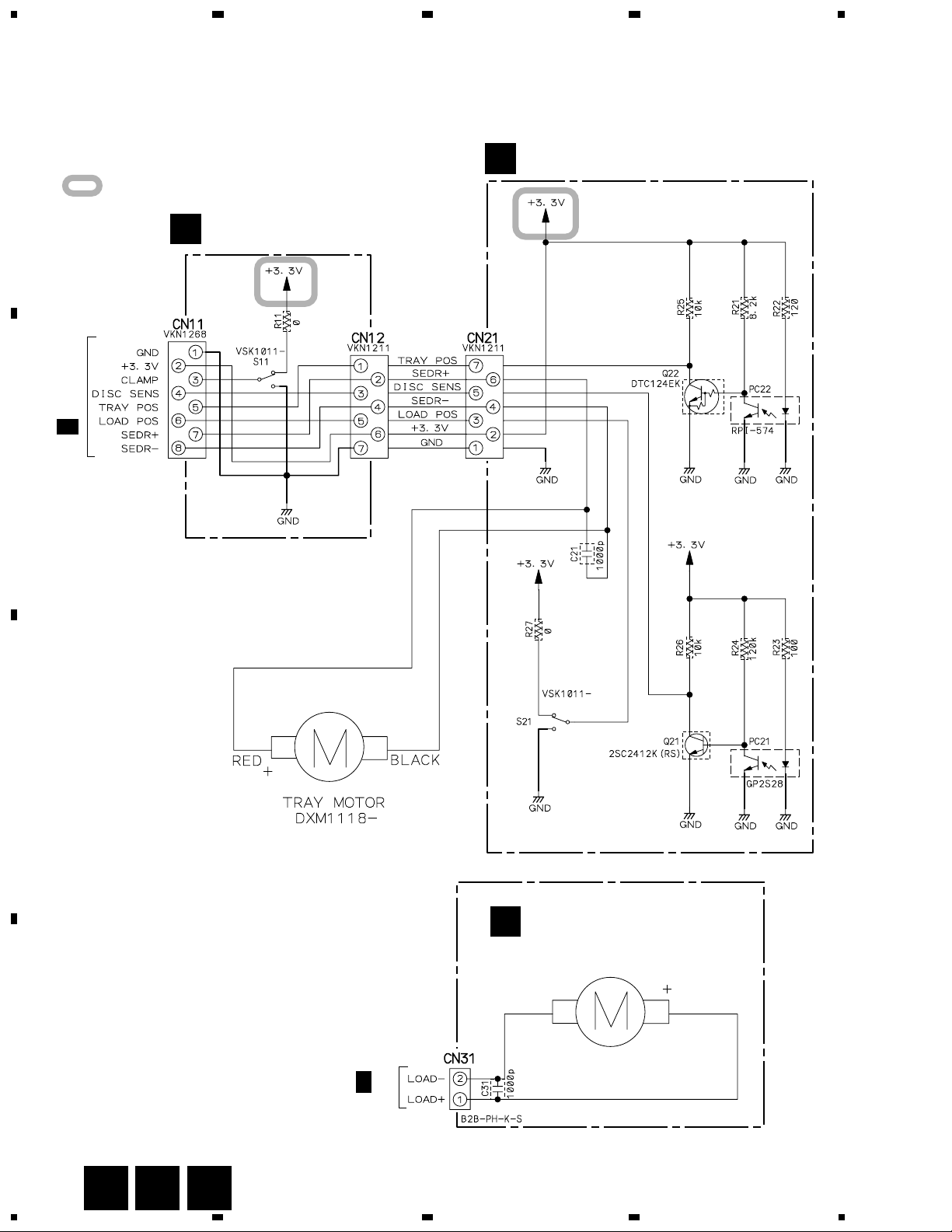

3.3 TRSB, SSRB, LOMB, SMEB and FGSB ASSYS

4

A

: The power supply is shown with the marked box.

TRSB ASSY (XWZ3461)

A

CN8903

SSRB ASSY (XWZ3462)

B

I 3/3

B

C

LOMB ASSY (XWZ3463)

C

CARRIAGE MOTOR (LOADING)

D

: VXM1033

F 1/3

CN2

14

A

B C

1234

Page 15

5

678

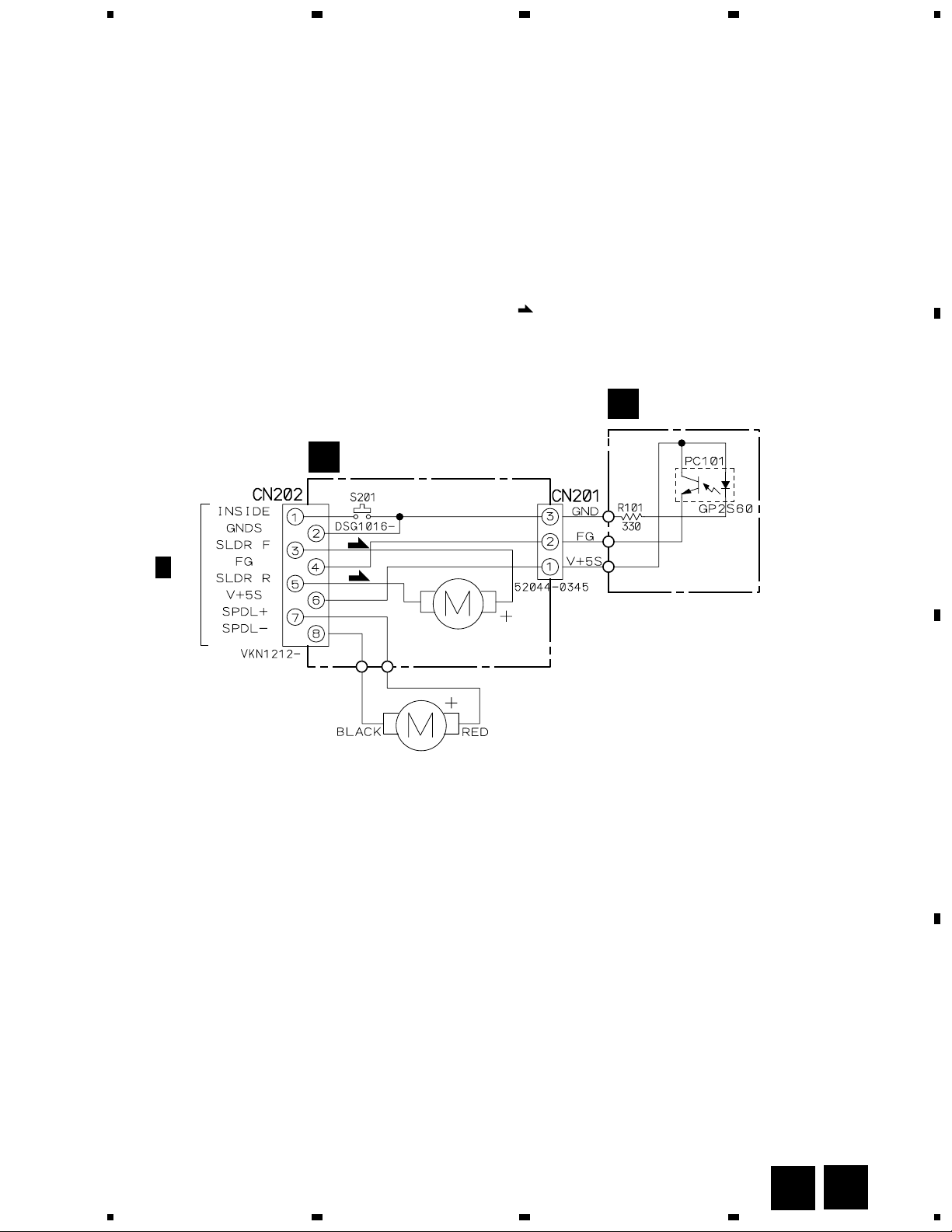

XV-HTD510, XV-HTD510-B

A

(S)

: SLIDER SERVO LOOP LINE

FGSB ASSY

E

(VWG2009)

SMEB ASSY (VWG2048)

D

B

F 1/3

CN3

(S)

(S)

CARRRIAGE MOTOR

ASSY : VXX2650

SPINDLE MOTOR ASSY

: VXX2649

C

D

D

5

6

7

E

8

15

Page 16

1

XV-HTD510, XV-HTD510-B

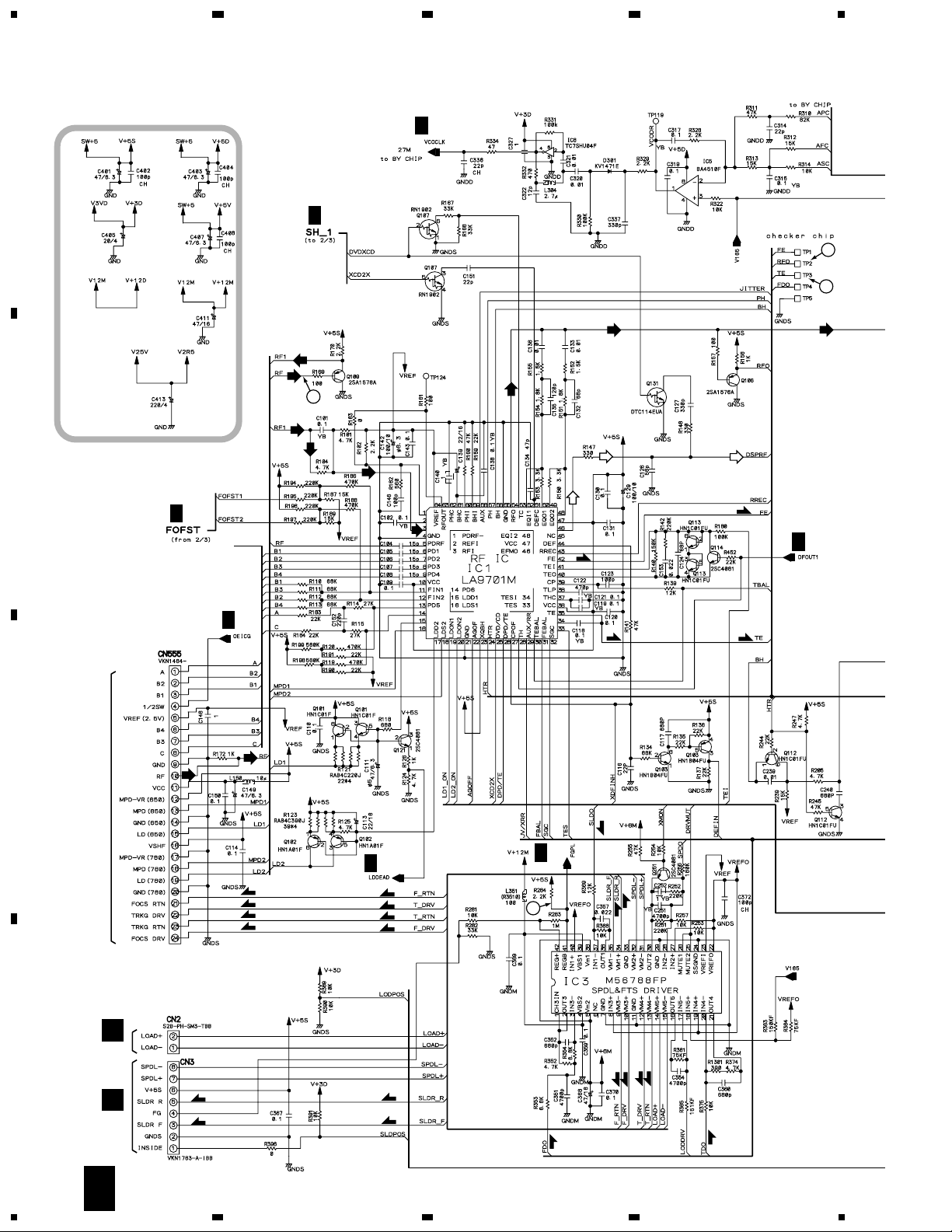

3.4 DVDM ASSY (1/3)

A

23

F

2/3

1/2

F

2/3

4

2

4

(V)

1

B

F

2/3

F

2/3

C

(V)

(A)

(A)

(A)

(F)

(F)

(T)(T)

(V)

F

2/3

(S)

PICKUP ASSY

F

2/3

(F)

(T)

(T)

(F)

(F)

(T)

(T)

(F)

F

2/3

7

(S)

(S)

C

CN31

D

(S)

(S)

(F)

16

D

CN202

1/3

F

1234

(S)

(S)

(T)

(T)

(F)

(F)

(T)

Page 17

5

678

XV-HTD510, XV-HTD510-B

F 1/3

(V) (V)

DVDM ASSY (XWX3034)

2/2

F

2/3

: RF SIGNAL ROUTE

(V)

: RF VIDEO SIGNAL ROUTE

(A)

: RF AUDIO SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

F

2/3

F

3/3

F

2/3

F

2/3

(AD)

6

A

B

(T)

(F)

(A)

(S)

(F)

(T)

F

2/3

F

2/3

F

2/3

(T)

(F)

(A)

5

(S)

(F)

(T)

F

2/3

F

2/3

8

9

F

2/3

F

19 20

2/3

VNK1493

I 3/3

2/2

1/2

10 11

F

2/3

C

D

CN8902

18

5

6

: The power supply is shown with the marked box.

F

7

1/3

8

17

Page 18

1

XV-HTD510, XV-HTD510-B

3.5 DVDM ASSY (2/3)

23

4

A

F 2/3

VYW3003

B

F

3/3

DVDM ASSY (XWX3034)

(V)

: RF VIDEO SIGNAL ROUTE

(VD)

: VIDEO DATA SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

F

3/3

3/3

F

1/3

F

F

3/3

(VD)

C

D

F

3/3

(VD)

(AD)

F

1/3

F

1/3

F

1/3

(V)

F

1/3

F

3/3

F

1/3

F

1/3

18

F

3/3

2/3

F

1234

(AD)

F

1/3

Page 19

5

678

XV-HTD510, XV-HTD510-B

F

1/3, 3/3

F

1/3, 3/3

F

F

3/3

20MHz

F

3/3

F

3/3

3/3

A

B

F

1/3

F

3/3

F

F

1/3

F

1/3

F

1/3

F

1/3

F

3/3

1/3

C

VNK1626

CN8502

I 3/3

F

F

1/3

F

1/3

5

6

3/3

D

F

1/3

: The power supply is shown with the marked box.

2/3

F

7

8

19

Page 20

1

XV-HTD510, XV-HTD510-B

3.6 DVDM ASSY (3/3)

A

B

23

F

2/3

F

2/3

F

2/3

F

4

2/3

(VD)

AV-1

MPEG2 DECODER

(DVD)

1417

1316

F

2/3

F

2/3

F

C

2/3

(Y)

(C)

(VCB)

1215

(AD)

F

2/3

(DVD)

(VCB)

(Y)

(C)

D

20

3/3

F

1234

Page 21

5

678

XV-HTD510, XV-HTD510-B

A

F

F

F

2/3

F 3/3

2/3

2/3

1/3

(VCB)

F

2/3

F

2/3

(DVD) (DVD) (DVD)

F

(VCB)

DVDM ASSY (XWX3034)

(VD)

: VIDEO DATA SIGNAL ROUTE

(VCB)

: VCB SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(DVD)

: DVD AUDIO SIGNAL ROUTE

B

(VCB)

(V/Cb)

(Y)

(VCB)

(Y)

(C)

(Y)

(C)

(Y)

C

(C)

(DVD)

(VCB)

VNK1626

(C)

(Y)

CN8501

I 3/3

D

(DVD)

3/3

F

5

6

7

8

21

Page 22

1

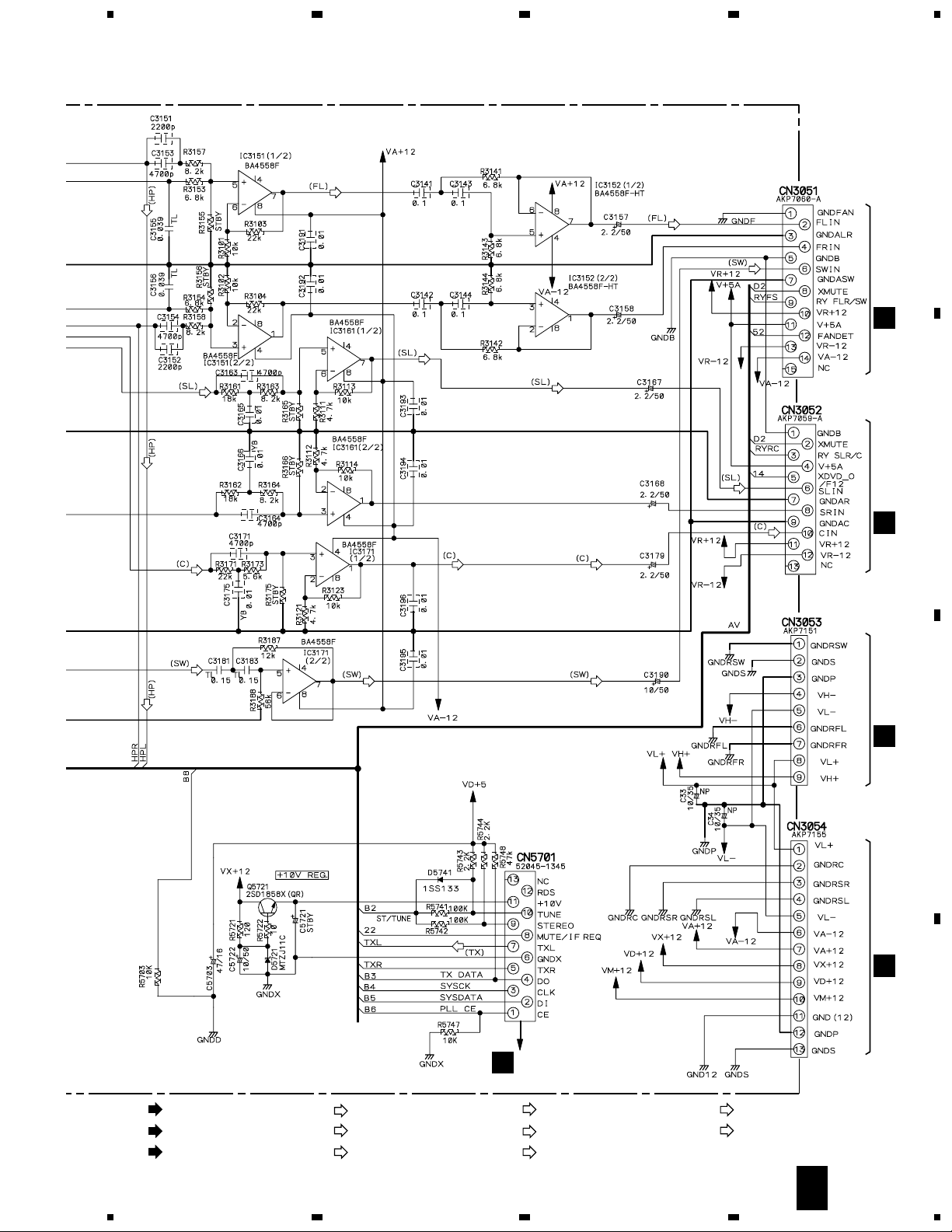

XV-HTD510, XV-HTD510-B

3.7 FRONT AMP ASSY

A

CN3051

G

I 2/3

B

23

FRONT AMP ASSY (XWZ3438)

4

CN3053

I 2/3

C

D

22

: The power supply is shown with the marked box.

G

1234

Page 23

5

678

XV-HTD510, XV-HTD510-B

A

SPEAKERS

B

C

DC FAN MOTOR

D

(FL)

: FL AUDIO SIGNAL ROUTE

(SW)

: SW AUDIO SIGNAL ROUTE

G

5

6

7

8

23

Page 24

1

XV-HTD510, XV-HTD510-B

3.8 REAR AMP ASSY

A

CN3052

H

I 2/3

B

23

REAR AMP ASSY (XWZ3442)

4

CN3054

I 2/3

C

D

: The power supply is shown with the marked box.

24

H

1234

Page 25

5

678

XV-HTD510, XV-HTD510-B

A

(SL)

: SL AUDIO SIGNAL ROUTE

(C)

: C AUDIO SIGNAL ROUTE

SPEAKERS

B

C

D

H

5

6

7

8

25

Page 26

1

XV-HTD510, XV-HTD510-B

3.9 MAIN ASSY (1/3)

23

4

A

B

I 1/3

MAIN ASSY (XWX3030)

C

D

: The power supply is shown with the marked box.

26

1/3

I

1234

Page 27

5

678

XV-HTD510, XV-HTD510-B

I

3/3

I

2/3

I

3/3

I

2/3, 3/3

I

2/3

I

3/3

I

2/3, 3/3

I

2/3

A

B

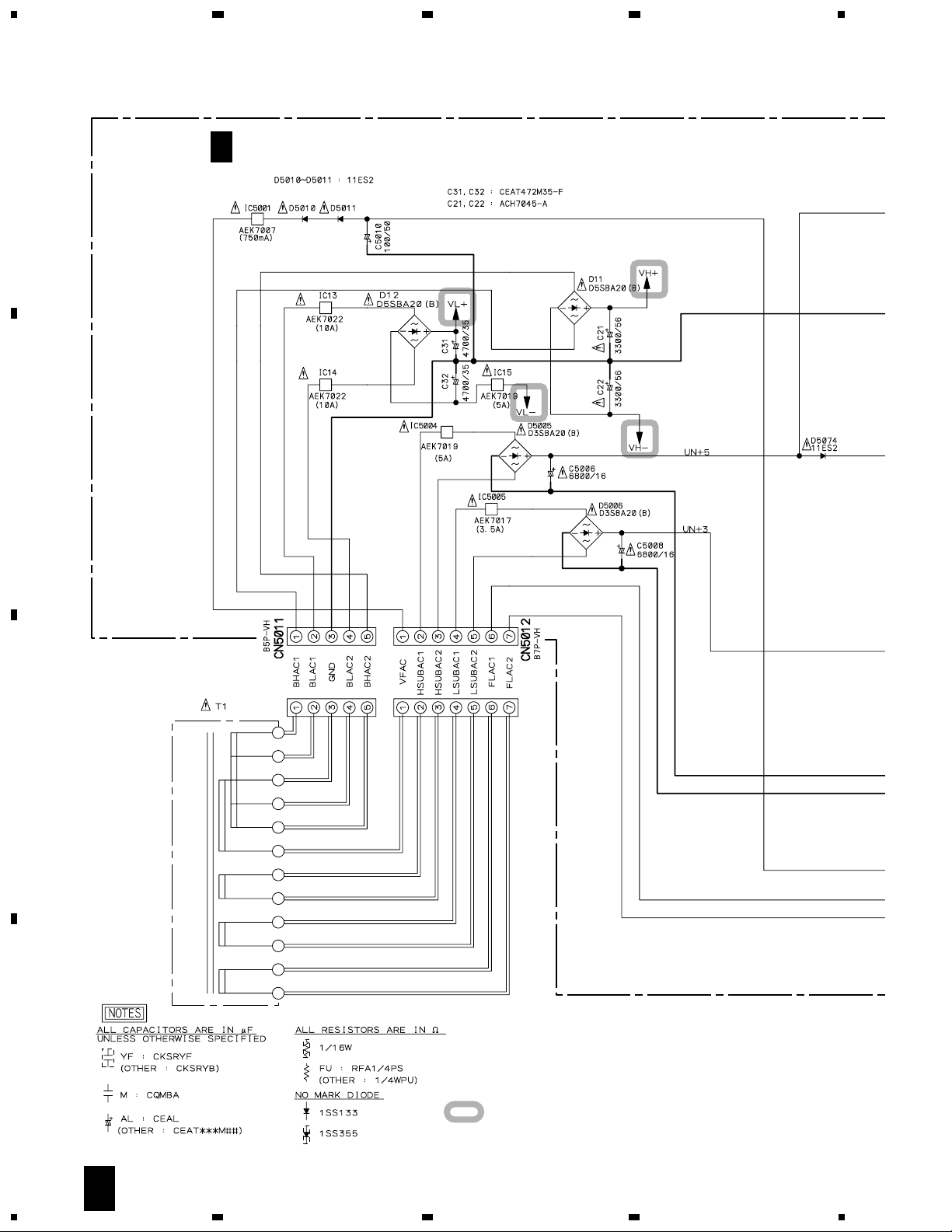

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491010 MFD, BY

LITTELFUSE INC. FOR IC13 AND IC14 (AEK7022).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 491005 MFD, BY

LITTELFUSE INC. FOR IC15 AND IC5004 (AEK7019).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 4910.75 MFD, BY

LITTELFUSE INC. FOR IC5001 (AEK7007).

CAUTION : FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE ONLY WITH SAME TYPE NO. 49103.5 MFD, BY

LITTELFUSE INC. FOR IC5005 (AEK7017).

I

I

3/3

I

2/3, 3/3

3/3

I

2/3

C

D

1/3

I

5

6

7

8

27

Page 28

1

XV-HTD510, XV-HTD510-B

3.10 MAIN ASSY (2/3)

A

CN3702

M1/2

B

23

I

3/3

I 2/3

MAIN ASSY (XWX3030)

4

I

1/3

I

C

3/3

(VCB)

I

1/3

K

CN5208

D

28

2/3

I

1234

L

CN5351

Page 29

5

678

XV-HTD510, XV-HTD510-B

A

CN3301

G

B

CN3501

H

CN3302

G

C

CN3502

H

(VCB)

: VCB SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

CN201

J

(DVD)

: DVD AUDIO SIGNAL ROUTE

(DI)

: DI AUDIO SIGNAL ROUTE

(FL)

: FL AUDIO SIGNAL ROUTE

5

6

(HP)

: HP AUDIO SIGNAL ROUTE

(SL)

: SL AUDIO SIGNAL ROUTE

(C)

: C AUDIO SIGNAL ROUTE

7

(SW)

: SW AUDIO SIGNAL ROUTE

(TX)

: TX AUDIO SIGNAL ROUTE

I

2/3

8

29

D

Page 30

1

XV-HTD510, XV-HTD510-B

23

4

3.11 MAIN ASSY (3/3)

I 3/3

A

CN15

MAIN ASSY (XWX3030)

F 3/3

B

(VCB)

I

1/3

I

2/3

I

I

2/3

1/3

I

2/3

I

1/3

I

1/3

C

CN5

F 2/3

I

1/3

D

30

T

N

N

CN5801

3/3

I

1234

CN5802

J13

Page 31

5

678

XV-HTD510, XV-HTD510-B

A

O

CN5807

3.1V

3.1V

0V

2.5V

2.5V

2.5V

LEVEL SHIFT

1.6V

1.6V

0V

0V

F 1/3

CN55

A

CN11

B

CN3701

C

M1/2

FOR DOWNLOAD

(VCB)

: VCB SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

5

6

(DVD)

: DVD AUDIO SIGNAL ROUTE

(HP)

: HP AUDIO SIGNAL ROUTE

(T)

: TRAY POSITION SERVO LOOP LINE

(S)

: SEDO SERVO LOOP LINE

7

I

3/3

8

31

D

Page 32

1

XV-HTD510, XV-HTD510-B

3.12 TUNER MODULE

A

TUNER MODULE (AXQ7228)

J

FM FRONT END

23

4

B

(FM) (FM)

(FM)

(AM)

C

(AM)

(FM)

AM RF TUNING BLOCK

(AM)

(FM)

(AM) (AM)

OSC : 981 - 2052kHz 9k step

(FM)

(FM)

(FM)

(FM) (FM)

(AM)

D

32

J

1234

Page 33

5

678

XV-HTD510, XV-HTD510-B

A

: The power supply is shown with the marked box.

(TX)

: TUNER AUDIO SIGNAL ROUTE

(AM)

: AM SIGNAL ROUTE

(FM)

: FM SIGNAL ROUTE

(AM)

(FM)

(AM)

(AM)

(AM)

(AM)

(FM)

(AM)

(AM)

(FM)

(AM)

L201

ATE7003

(AM)

(FM)

(TX)

(TX)

(TX)

(TX)

(TX)

B

CN5701

2/3

I

C

D

J

5

6

7

8

33

Page 34

1

XV-HTD510, XV-HTD510-B

3.13 INPUT and VIDEO ASSYS

A

B

23

INPUT ASSY (XWZ3455)

K

4

C

VIDEO ASSY (XWZ3459)

L

D

34

K

L

1234

Page 35

5

678

XV-HTD510, XV-HTD510-B

A

M1/2

CN3703

I 2/3

CN5209

B

: The power supply is shown with the marked box.

(VCB)

(VCB)

(VCB)

(VCB)

(VCB)

I 2/3

CN5352

C

(VCB)

(VCB)

: VCB SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

D

(DVD)

: DVD AUDIO SIGNAL ROUTE

(DI)

: DI AUDIO SIGNAL ROUTE

(FL)

: FL AUDIO SIGNAL ROUTE

5

6

(AI)

: AUX IN AUDIO SIGNAL ROUTE

(AO)

: AUX OUT AUDIO SIGNAL ROUTE

(TV)

: TV AUDIO SIGNAL ROUTE

7

(TX)

: TX AUDIO SIGNAL ROUTE

K

L

8

35

Page 36

1

XV-HTD510, XV-HTD510-B

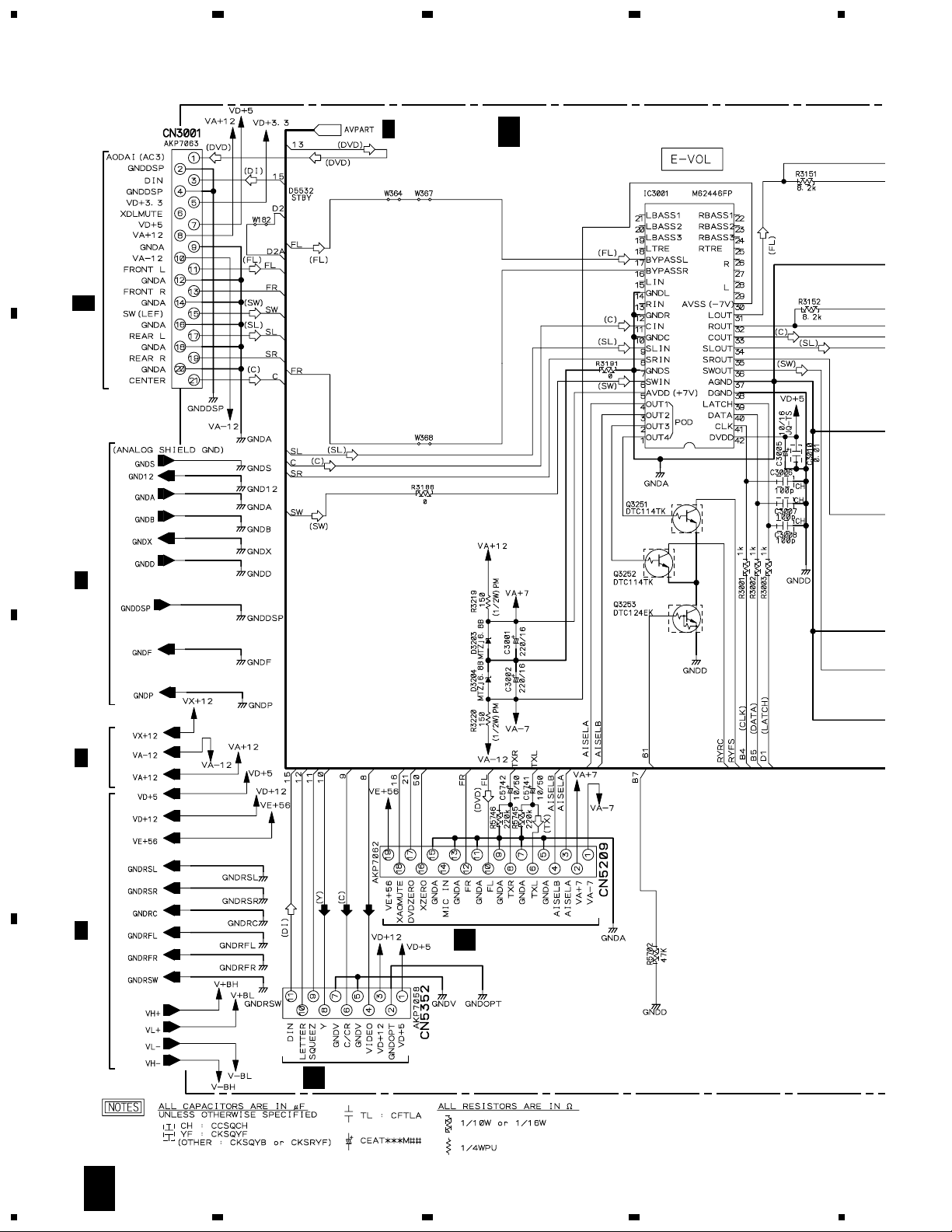

3.14 DSP ASSY (1/2)

23

4

A

M 1/2

DSP ASSY (XWX3040)

I 3/3

CN5503

B

C

I 2/3

CN3001

D

36

K

CN5207

: The power supply is shown with the marked box.

1/2

M

1234

Page 37

5

678

XV-HTD510, XV-HTD510-B

A

M

2/2

B

(DVD)

: DVD AUDIO SIGNAL ROUTE

(DI)

: DI AUDIO SIGNAL ROUTE

(FL)

: FL AUDIO SIGNAL ROUTE

5

(SL)

: SL AUDIO SIGNAL ROUTE

(C)

: C AUDIO SIGNAL ROUTE

(SW)

: SW AUDIO SIGNAL ROUTE

6

: AUDIO SIGNAL ROUTE

7

M

2/2

M

M

2/2

1/2

8

C

D

37

Page 38

1

XV-HTD510, XV-HTD510-B

3.15 DSP ASSY (2/2)

M

1/2

A

(FL)

23

4

(FL)(FL)

M 2/2

B

(SL)

DSP ASSY (XWX3040)

(SL)(SL)

C

M

1/2

D

38

2/2

M

1234

(C)

(SW)

(C)(C)

(SW)(SW)

Page 39

5

678

XV-HTD510, XV-HTD510-B

(FL)

(FL)

(SL)(SL)

(FL)

: FL AUDIO SIGNAL ROUTE

(SL)

: SL AUDIO SIGNAL ROUTE

(C)

: C AUDIO SIGNAL ROUTE

(SW)

: SW AUDIO SIGNAL ROUTE

A

B

(C)

(SW)

(C)

(SW)

2/2

M

5

6

7

8

39

C

D

Page 40

1

23

XV-HTD510, XV-HTD510-B

3.16 DISPLAY, MIC HP, KEYB, STBY SWITCH, JOG and DISC KEY ASSYS

CN5509

I 3/3

A

B

I 3/3

4

CN5511

DISPLAY ASSY (XWZ3446)

N

C

D

DISC KEY ASSY (XWZ3449)

S

40

N

S

1234

Page 41

5

678

XV-HTD510, XV-HTD510-B

SWITCHES

JOG ASSY

S5801 : VOLUME

DISC KEY ASSY

S5803 : 0 OPEN/CLOSE

S5804 : EXCHANGE

S5805 : DISC SKIP

S5806 : 5

S5807 : 4

S5808 : 3

S5809 : 2

S5810 : 1

STBY SWITCH ASSY

S5811 : STANDBY/ON

O

DISC

MIC HP ASSY (XWZ3450)

A

KEYB ASSY

S5802 : ¡•¢ (FORWARD)

S5812 : DVD/CD

S5813 : TUNER/BAND

S5814 : TV/AUX

S5815 : CD MODE

S5816 : 7 (STOP)

S5817 : 6 (PLAY/PAUSE)

S5818 : 4•1 (REVERSE)

B

I 3/3

CN5501

JOG ASSY (XWZ3448)

R

5

KEYB ASSY (XWZ3447)

P

: The power supply is shown with the marked box.

6

N

7

STBY SWITCH ASSY

Q

(XWZ3453)

O

P

Q

R

8

C

D

41

Page 42

1

XV-HTD510, XV-HTD510-B

3.17 PRIMARY ASSY

A

I 1/3

B

CN5011

23

XTS3051

4

I 1/3

CN5012

C

I 3/3

CN8503

D

ATT7049

42

T

1234

Page 43

5

• NOTE FOR FUSE REPLACEMENT

CAUTION -

PRIMARY ASSY (XWZ3432)

T

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE,

REPLACE WITH SAME TYPE AND RATINGS OF FUSE.

678

XV-HTD510, XV-HTD510-B

A

B

C

FU1: REK1067

5A

2.2M,1/2W

D

T

5

6

7

8

43

Page 44

1

23

XV-HTD510, XV-HTD510-B

WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

Measurement condition : No. 1 to 4 and 6 to 11 : MJK1, Title 1-chp 1

A

No. 5 : CD, ABEX-784 Track 1

No. 12 to 14 : MJK1, Title 1-chp 4

No. 15 to 17 : MJK1, Title 1-chp 5

4

Foot of R169 (RF)

1

V: 100mV/div. H: 0.2µsec/div.

TP2 (RFO)

2

V: 500mV/div. H: 0.1µsec/div.

GND

Foot of R261 (FPWM)

8

V: 1V/div. H: 5msec/div.

Foot of R262 (VPWM)

9

V: 1V/div. H: 5msec/div.

GND

IC18 - pin 36 (C output)

14

V: 0.2V/div. H: 5msec/div.

IC18 - pin 45 (CB output when

15

selecting color difference output)

V: 0.2V/div. H: 5msec/div.

GND

IC18 - pin 39 (Y output when

16

selecting color difference output)

V: 0.2V/div. H: 5msec/div.

IC18 - pin 36 (CR output when

17

selecting color difference output)

V: 0.2V/div. H: 5msec/div.

GND

B

TP3 (Tracking Error)

4

(AI-Inner Tracking Off)

V: 500mV/div. H: 2msec/div.

IC2 - pin 39 (EFM before slice)

5

V: 1V/div. H: 1µsec/div.

GND

Foot of R263 (PPWM)

10

V: 1V/div. H: 5msec/div.

Foot of R264 (RPWM)

11

V: 1V/div. H: 5msec/div.

GND

GND

CN55 - pin 5 (DISC SENS)

18

V: 2V/div. H: 1sec/div.

CN55 - pin 2 (TRAY POS)

19

V: 2V/div. H: 1sec/div.

18

GND

C

GND

GND

IC2 - pin 1 (EFM)

6

V: 1V/div. H: 0.2µsec/div.

IC3 - pin 41 (REGB)

7

V: 1V/div. H: 5msec/div.

GND

GND

IC18 - pin 45

12

(Composite Video output)

V: 0.2V/div. H: 1msec/div.

IC18 - pin 39 (Y output)

13

V: 0.2V/div. H: 5msec/div.

19

CN55 - pin 4 (SED0)

20

V: 2V/div. H: 5sec/div.

CLOSE

Tray Close

OPEN DISC CHANGE

GND

D

GND

GND

44

1234

Page 45

1

VOLTAGES

234

XV-HTD510, XV-HTD510-B

I 3/3

IC5501 (PDC076A)

Pin No. Voltage (V) Pin No. Voltage (V) Pin No. Voltage (V) Pin No. Voltage

MAIN ASSY

• Mode: DVD Play

1 4.8 26 2.4 51 -30.8 76 0

2 4.8 27 0 52 ∗ 77 0

3 3.3 28 0 53 ∗ 78 0

4 4.8 29 4.6 54 ∗ 79 4.7

5 4.8 30 ∗ 55 ∗ 80 −

6 4.8 31 ∗ 56 ∗ 81 4.7

7 4.8 32 ∗ 57 ∗ 82 4.5

8 4.8 33 ∗ 58 ∗ 83 0

9 3.3 34 ∗ 59 ∗ 84 4.7

10 3.4 35 ∗ 60 ∗ 85 0

11 4.8 36 ∗ 61 ∗ 86 0

12 0 37 ∗ 62 ∗ 87 4.8

13 3.2 38 ∗ 63 ∗ 88 0

14 0 39 ∗ 64 ∗ 89 0

15 2.5 40 ∗ 65 ∗ 90 4.8

16 2.5 41 ∗ 66 − 91 0

17 4.8 42 ∗ 67 0 92 0

18 4.8 43 − 68 5.0 93 0

19 4.9 44 − 69 4.2 94 0

20 0 45 − 70 0 95 0

21 0 46 4.8 71 0 96 0

22 4.8 47 ∗ 72 4.8 97 4.8

23 0.2 48 ∗ 73 4.9 98 0

24 4.7 49 ∗ 74 0 99 4.8

25 − 50 ∗ 75 0 100 4.6

A

B

C

Note ∗ : FL drive voltage, pulse waveform of Low level is VFDP (about -31V) and High level is VDD (+5V).

1

2

3

D

45

4

Page 46

1

23

XV-HTD510, XV-HTD510-B

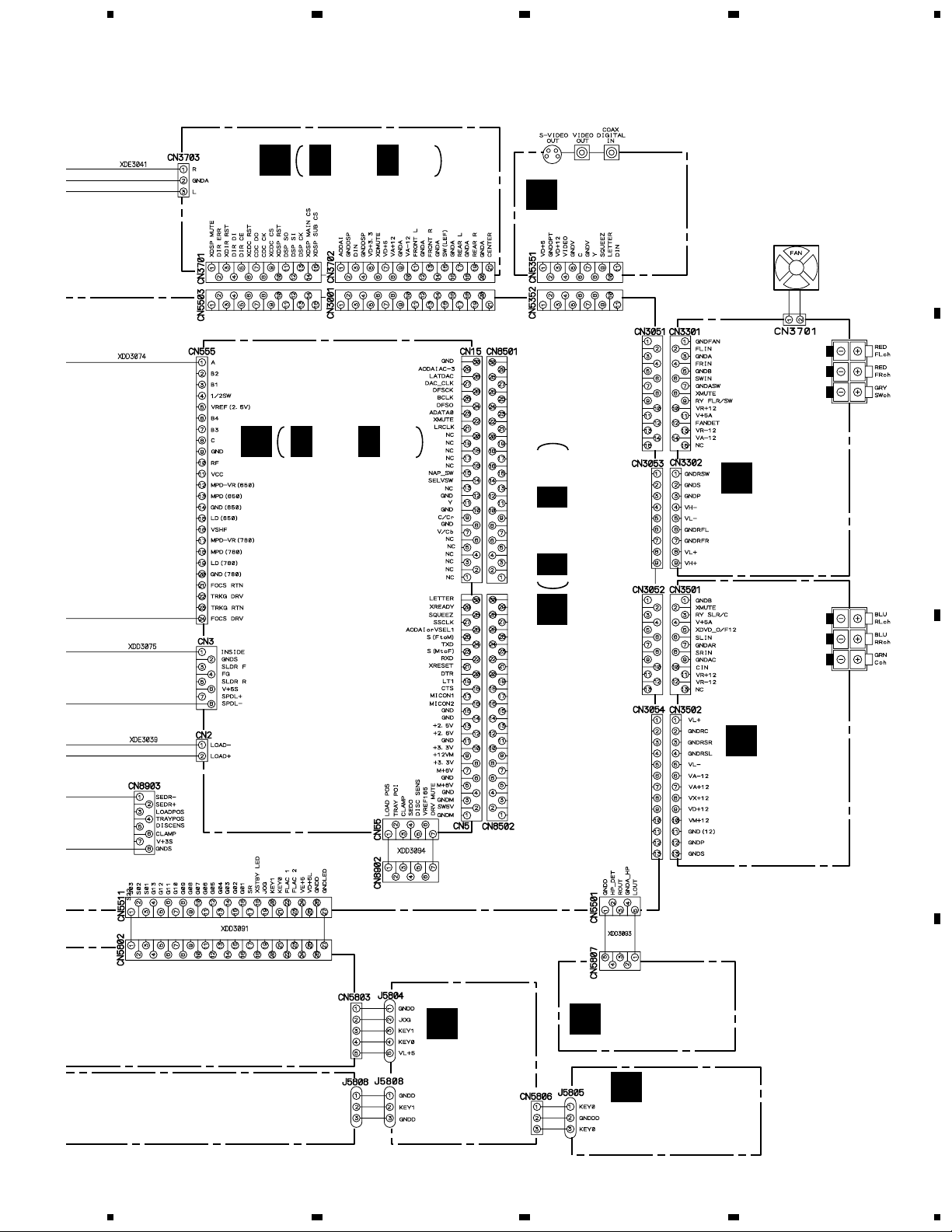

4. PCB CONNECTION DIAGRAM

A

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

B

Symbol In Schematic

Diagrams

BCEBCE

BCE

BCE

DGS

DGGSS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

4

4.1 TRSB, SSRB, LOMB, SMEB and FGSB ASSYS

CN8903

TRSB ASSY

A

(XNP3042-A) (XNP3042-A)

C

(XNP3042-A)

SSRB ASSY

B

SMEB ASSY

D

I

CN2

F

M

C

LOADING

MOTOR

LOMB ASSY

CN3

F

TRSB ASSY

A

TRAY

M

MOTOR

(XNP3042-A)

SSRB ASSY

B

(XNP3042-A)(XNP3042-A)

SIDE B

E

FGSB ASSY

M

D

CARRIAGE

MOTOR

BLK

RED

(VNP1722-A)

M

SPINDLE

MOTOR

R101

PC101

(VNP1784-A)

SIDE A

46

A B C D E

1234

Page 47

1

4.2 TUNER MODULE

234

XV-HTD510, XV-HTD510-B

J

TUNER MODULE

SIDE A

A

B

J

TUNER MODULE

I

CN5701

Q202

(ANP7338-B)

SIDE B

C

D

Q201

1

2

IC201 Q205

3

Q203

IC202

(ANP7338-B)

Q204

J

4

47

Page 48

1

XV-HTD510, XV-HTD510-B

4.3 DVDM ASSY

A

23

4

F

DVDM ASSY

Q3

IC23

IC7 IC5

B

Q7

IC8

IC11

IC15

Q101Q121

Q6

SIDE A

IC21 Q4

Q103

Q5 Q102

C

PICKUP ASSY

IC1

IC18

Q109

Q107

Q81 IC3

Q83Q91

D

48

(VNP1817-A)

CN8902

I

F

1234

Page 49

1

234

XV-HTD510, XV-HTD510-B

A

C

CN31

SIDE B

CN8502

I

F

DVDM ASSY

Q1

IC14IC13IC12

B

Q112

CN202

D

IC2

IC19

Q114

Q113

Q131

Q106

IC26 IC27

Q251

Q85 Q89 Q87

C

D

CN8501

I

1

2

3

(VNP1817-A)

F

4

49

Page 50

1

XV-HTD510, XV-HTD510-B

4.4 FRONT AMP ASSY

A

B

I

CN3051

23

FRONT AMP ASSY

G

4

Q3701

C

D

I

CN3053

(XNP3044-C)

Q3714

Q3713

IC3301

IC3321

Q3351

Q3352

Q3651

Q3372

50

DC FAN MOTOR

SIDE A

G

1234

Page 51

1

FRONT AMP ASSY

G

234

XV-HTD510, XV-HTD510-B

A

Q3703

Q3705

Q3715

B

Q3603

Q3302

Q3301

Q3711

Q3712

Q3717

Q3716

C

Q3773

Q3771

Q3774

(XNP3044-C)

D

SIDE B

G

1

2

3

4

51

Page 52

1

XV-HTD510, XV-HTD510-B

4.5 REAR AMP ASSY

A

Q3813

Q3702

Q3814

IC3322

B

IC3401

23

REAR AMP ASSY

H

4

I

CN3052

IC5021

I

CN3054

C

D

IC5007

Q5021

(XNP3044-C)

52

SIDE A

H

1234

Page 53

Q3816

Q3817

Q3811

Q3704

Q3706

Q3812

Q3452

Q3815

Q3451

1

234

XV-HTD510, XV-HTD510-B

A

REAR AMP ASSY

H

B

Q3551

Q3501

Q3401

Q3402

C

D

(XNP3044-C)

SIDE B

H

1

2

3

4

53

Page 54

1

T

XV-HTD510, XV-HTD510-B

4.6 MAIN ASSY

23

4

A

B

G

CN3301

H

CN3501

M

CN3702

MAIN ASSY

I

G

CN3302

H

CN3502

M

CN3701

C

D

L

CN5351

K

CN5208

54

CN201

J

IC3151 IC3152

I

1234

IC3002

IC3171 IC3161

IC3181

Q5721 IC15

CN5807

O

IC14

IC13 IC18

Page 55

5

678

XV-HTD510, XV-HTD510-B

N3701

F

CN15

F

CN55

A

CN11

F

CN5

A

B

IC17

N

CN5802

C

N

CN5801

D

SIDE A

Q5041

(XNP3043-C)

55

I

8

T

Q5072

5

IC5001 IC5004 IC5005

T1T1 J13

Q5071Q5501 IC5081 Q5043

IC5071

6

Q5031

7

Page 56

1

MAIN ASSY

I

IC8541 IC8531 IC8901 IC5401IC8521

IC5081

IC5501

Q5042 Q5032

Q5551-Q5554

Q5571Q5572

Q3905

Q3906

XV-HTD510, XV-HTD510-B

A

B

23

4

C

D

56

I

1234

Page 57

5

678

XV-HTD510, XV-HTD510-B

A

B

C

D

SIDE B

IC8802 Q3252Q3251 Q3253 IC3001

5

6

IC5701 Q3919Q3904 Q3903

7

(XNP3043-C)

57

I

8

Page 58

1

23

XV-HTD510, XV-HTD510-B

4.7 INPUT and VIDEO ASSYS

4

A

B

I

CN5209

INPUT ASSY

K

M

CN3703

INPUT ASSY

K

Q5272

Q5271

IC5353

IC5352

Q5273

Q5254

Q5231

IC5231

C

D

I

CN5352

VIDEO ASSY

L

VIDEO ASSY

L

Q5232

(XNP3048-C)(XNP3048-C)

IC5104

IC5351

Q5351

Q5181

Q5171

Q5161

58

K L

(XNP3048-C)(XNP3048-C)

SIDE A SIDE B

1234

Page 59

1

4.8 DSP ASSY

234

XV-HTD510, XV-HTD510-B

A

I

CN3001

DSP ASSY

M

Q8713

Q8718

Q8717

Q8716

IC8701

Q8710

Q8709

DSP ASSY

M

Q8711

Q8712

Q8714

Q8715

IC8703

IC8705

B

K

CN5207

I

CN5503

IC8801

IC3751

IC3801

IC3851

(XNP3045-C) (XNP3045-C)

C

D

SIDE A SIDE B

M

1

2

3

4

59

Page 60

1

23

XV-HTD510, XV-HTD510-B

4.9 DISPLAY, MIC HP, KEYB, STBY SWITCH, JOG and DISC KEY ASSYS

A

DISPLAY ASSY

N

B

4

CN5509

I

KEYB ASSY

P

(XNP3044-C)

C

MIC HP ASSY

O

I

CN5501

(XNP3044-C)

D

STBY SWITCH

Q

ASSY

60

N O P Q

1234

Page 61

5

678

XV-HTD510, XV-HTD510-B

A

509 CN5511

I

(XNP3044-C)

JOG ASSY

R

B

DISC KEY ASSY

S

(XNP3044-C)

SIDE A

(XNP3044-C)

C

(XNP3044-C)

D

N P R S

5

6

7

8

61

Page 62

1

XV-HTD510, XV-HTD510-B

A

23

DISPLAY ASSY

N

4

IC5801 Q5804

B

C

JOG ASSY

R

(XNP3044-C)

DISC KEY ASSY

S

KEYB ASSY

P

Q5803

(XNP3044-C)

D

SIDE B

62

N P R S

1234

Page 63

5

678

XV-HTD510, XV-HTD510-B

A

(XNP3044-C)

Q5802

B

MIC HP ASSY

O

IC5802

(XNP3044-C)

STBY SWITCH

Q

ASSY

(XNP3044-C)

(XNP3044-C)

C

D

N O P Q

5

6

7

8

63

Page 64

1

XV-HTD510, XV-HTD510-B

4.10 PRIMARY ASSY

A

AC IN

B

23

PRIMARY ASSY

T

4

T1

C

IC41

Q41

I

CN8503

(XNP3044-C)

D

SIDE A

64

T

1234

Page 65

1

PRIMARY ASSY

T

234

XV-HTD510, XV-HTD510-B

A

B

C

(XNP3044-C)

D

SIDE B

T

1

2

3

4

65

Page 66

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

K

K

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP 5C MECH. BASE ASSY XXA3027

NSP MECB ASSY XWM3197

NSP TRSB ASSY XWZ3461

NSP SSRB ASSY XWZ3462

NSP LOMB ASSY XWZ3463

Traverse Mechanism Assy-S VXX2653

NSP SMEB ASSY VWG2048

NSP FGSB ASSY VWG2009

NSP COMPLEX ASSY XWM3187

PRIMARY ASSY XWZ3432

FRONT AMP ASSY XWZ3438

REAR AMP ASSY XWZ3442

DISPLAY ASSY XWZ3446

KEYB ASSY XWZ3447

NSP JOG ASSY XWZ3448

NSP DISC KEY ASSY XWZ3449

MIC HP ASSY XWZ3450

NSP STBY SWITCH ASSY XWZ3453

NSP CONNECT ASSY XWM3193

INPUT ASSY XWZ3455

VIDEO ASSY XWZ3459

DVDM ASSY XWX3034

MAIN ASSY XWX3030

DSP ASSY XWX3040

TUNER MODULE AXQ7228

Mark No. Description Part No.

SSRB ASSY

B

SEMICONDUCTORS

Q21 2SC2412K

Q22 DTC124EK

PC21 GP2S28

PC22 RPI-574

SWITCH

S21 VSK1011

CAPACITOR

C21 CKSQYB102K50

RESISTORS

All Resistors RS1/10S J

OTHERS

CN21 7P FFC CONNECTOR VKN1211

LOMB ASSY

C

CAPACITOR

C31 CKSQYB102K50

TRSB ASSY

A

SWITCH

S11 VSK1011

RESISTORS

R11 RS1/10S0R0J

OTHERS

CN12 7P FFC CONNECTOR VKN1211

CN11 8P FFC CONNECTOR VKN1268

66

OTHERS

CN31 KR CONNECTOR B2B-PH-K

SMEB ASSY

D

SWITCH

S201 DSG1016

OTHERS

CN201 3P FFC CONNECTOR 52044-0345

CN202 8P FFC CONNECTOR VKN1212

PC BOARD SMEB VNP1722

Page 67

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

C124,C132 CCSRCH680J50

FGSB ASSY

E

SEMICONDUCTOR

PC101 GP2S60

C117,C240,C352,C360 CCSRCH681J25

C129,C142,C842 CEV101M10

C113,C139 CEV220M16

C405,C413,C700,C808 CEV221M4

RESISTOR

R101 RS1/10S331J

DVDM ASSY

F

SEMICONDUCTORS

IC5,IC7 BA4510F

IC21 BU2288FV

IC14 KM68V1000CLT-7L

IC1 LA9701M

IC2 LC78652W

IC3 M56788FP

IC19

IC18 MB86373B

IC15 MN414800CSJ-07

IC11 PD3410A

IC12 PE5108A

IC8 TC7SHU04F

IC13 XYW3003

Q106,Q109,Q81,Q83,Q85 2SA1576A

Q114,Q121,Q251 2SC4081

Q131 DTC114EUA

Q102 HN1A01F

Q103,Q6,Q7 HN1B04FU

Q101 HN1C01F

Q112,Q113 HN1C01FU

Q107,Q4,Q5 RN1902

Q3 RN1911

Q1 RN4982

D301 KV1471E

D6 RB501V-40

COILS

L150,L330 LCYA100J2520

L304 LCYA2R7J2520

L81 CHIP COIL VTL1067

L9170 CHIP BEAD VTL1084

CAPACITORS

C845,C846,C849-C852 CCSRCH100D50

C123,C146,C613,C806,C843 CCSRCH101J50

C372,C402,C404,C408 CCSRCH101J50

C322 CCSRCH120J50

C135 CCSRCH121J50

C104-C108 CCSRCH150J50

C206,C210,C211 CCSRCH151J50

C333 CCSRCH180J50

C314,C336 CCSRCH220J50

C152 CCSRCH221J50

C151 CCSRCH270J50

C127,C209,C337 CCSRCH331J50

C116,C134,C236 CCSRCH470J50

C122,C208 CCSRCH471J50

C126,C335 CCSRCH560J50

C334 CCSRCH5R0C50

MB811171622A-100FN

C368,C411 CEV470M16

C111,C149,C205,C207,C401 CEV470M6R3

C403,C407 CEV470M6R3

C140,C223,C224,C252,C264 CKSQYB105K10

C312 CKSQYB105K10

C216,C313 CKSRYB102K50

C133,C136,C203,C220,C225 CKSRYB103K50

C239,C320,C321,C330,C625 CKSRYB103K50

C703,C711 CKSRYB103K50

C101,C102,C114,C118,C119 CKSRYB104K25

C121,C138,C204,C212,C213 CKSRYB104K25

C227,C231,C263,C315,C317 CKSRYB104K25

C332,C804,C604,C606,C609 CKSRYB104K25

C611,C612,C614,C617,C619 CKSRYB104K25

C705,C707,C709,C710,C713 CKSRYB104K25

C714,C722,C724,C807,C809 CKSRYB104K25

C811,C812,C814,C815,C817 CKSRYB104K25

C819,C821 CKSRYB104K25

C153,C266,C357 CKSRYB223K50

C214,C251,C261,C351,C354 CKSRYB472K50

C109,C110,C120,C130,C131 CKSRYF104Z50

C143,C150,C1901,C1902,C202 CKSRYF104Z50

C215,C221,C222,C226,C230 CKSRYF104Z50

C235,C265,C299,C319,C359 CKSRYF104Z50

C367,C369,C370,C601,C605 CKSRYF104Z50

C607,C608,C610,C615,C618 CKSRYF104Z50

C620,C626,C701,C702,C704 CKSRYF104Z50

C706,C708,C712,C715-C721 CKSRYF104Z50

C723,C726,C820,C844 CKSRYF104Z50

C148,C217,C327,C801,C802 CKSRYF105Z10

C810,C813,C818,C828,C830 CKSRYF105Z10

RESISTORS

R632 RAB4C0R0J

R657,R658 RAB4C103J

R121,R663 RAB4C220J

R123 RAB4C390J

R202,R3510 RS1/10S101J

R700 RS1/10S1R0J

R807 RS1/16S1201F

R806 RS1/16S1501F

R363,R365 RS1/16S1503F

R825-R827 RS1/16S2000F

R805 RS1/16S2701F

R361,R364 RS1/16S7502F

Other Resistors RS1/16S J

OTHERS

X2 CHIP CERALOCK DSS1110

CN2 PH CONNECTOR S2B-PH-SM3

CN555 24P FFC CONNECTOR VKN1464

CN55 7P FFC CONNECTOR VKN1493

CN15,CN5

CN3 8P FFC CONNECTOR VKN1763

X1

(20MHz)

FLEXIBLE CABLE(07P) VDA1681

B TO B CONNECTOR 30P

CRYSTAL RESONATOR

(27.000MHz)

VKN1626

VSS1159

67

Page 68

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

FRONT AMP ASSY

G

SEMICONDUCTORS

IC3301 STK413-000

Q3351,Q3352,Q3651 2SC2240

Q3716,Q3717 2SC2412K

Q3701 2SD1858X

Q3301,Q3302,Q3603 2SD2114K

Q3772 2SD2144S

Q3713,Q3714 DTA123JS

Q3771 DTA124EK

Q3773 DTA124TK

Q3703,Q3715 DTA143EK

Q3705 DTC123TK

Q3774 DTC124EK

Q3711,Q3712 DTC143EK

D3771 11ES2

D3351-D3354,D3361,D3371,D3372 1SS133

D3651,D3653,D3705,D3706,D3772 1SS133

D3774,D3775 MTZJ15B

COILS

L3361,L3362,L3661 ATH1004

RELAYS

RY3361,RY3362 XSR3002

CAPACITORS

C3305,C3306,C3312 CCSRCH101J50

C3309-C3311 CCSRCJ3R0C50

C3713 CEAL101M10

C3771 CEAT101M16

C3322-C3325 CEAT101M63

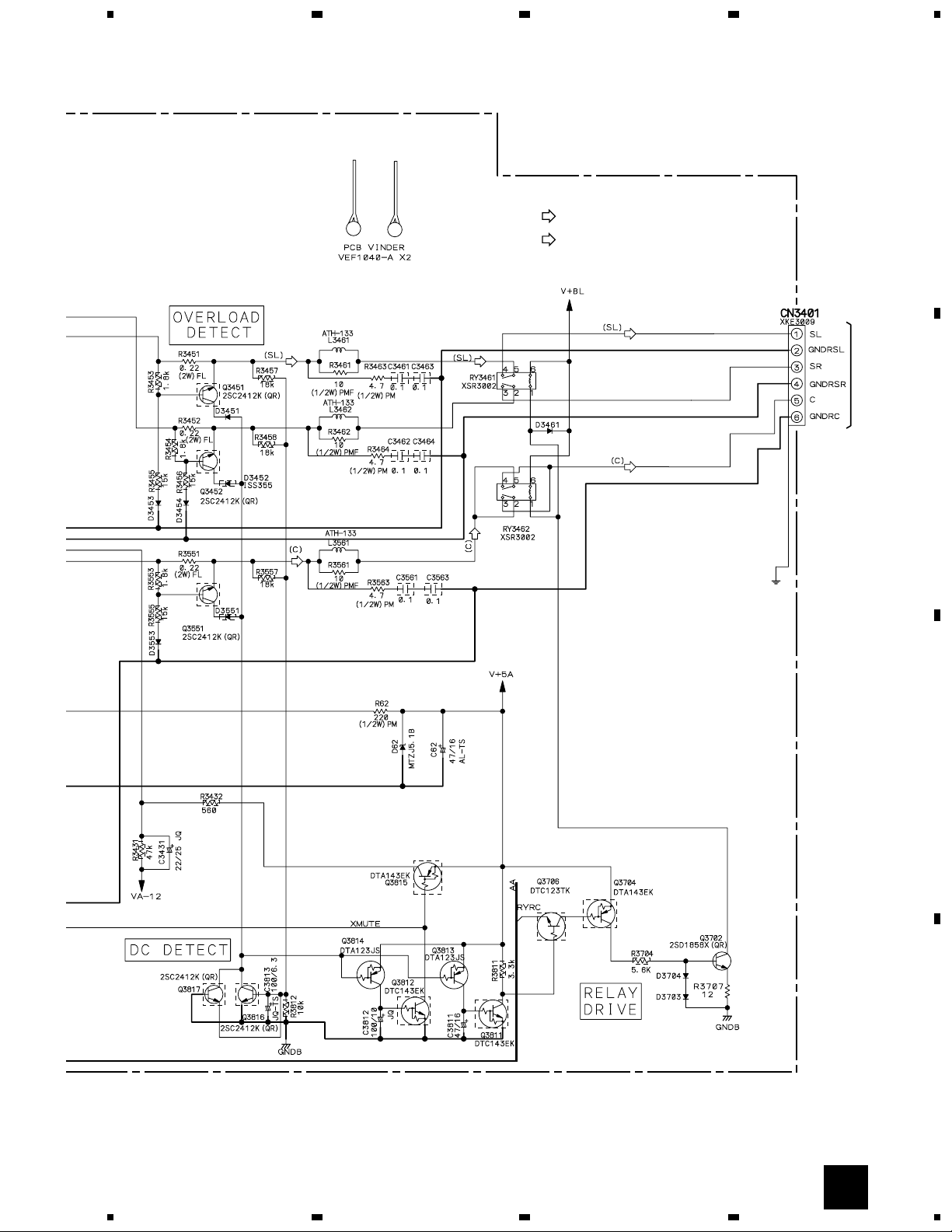

REAR AMP ASSY

H

SEMICONDUCTORS

IC5021 NJM7812FA

IC5007 NJM7912FA

IC3401 STK402-230

Q5021 2SB1237X

Q3451,Q3452,Q3551,Q3816,Q3817 2SC2412K

Q3702 2SD1858X

Q3401,Q3402,Q3501 2SD2114K

Q3813,Q3814 DTA123JS

Q3704,Q3815 DTA143EK

Q3706 DTC123TK

Q3811,Q3812 DTC143EK

D5013-D5018 11ES2

D3451,D3453,D3454,D3461,D3551 1SS133

D3553,D3703,D3704,D5022 1SS133

D3452 1SS355

D5021 MTZJ15B

D62 MTZJ5.1B

COILS

L3461,L3462,L3561 ATH-133

RELAYS

RY3461,RY3462 XSR3002

CAPACITORS

C3409,C3410,C3509 CCSRCH330J50

C62 CEAL470M16

C3811 CEAT470M16

C3407,C3408,C3507,C5012,C5022 CEJQ100M35

C3812 CEJQ101M10

C3772 CEAT2R2M50

C3601 CEJQ100M35

C3712,C3774,C3775 CEJQ101M10

C3331 CEJQ220M25

C3301,C3302 CEJQ2R2M50

C3711,C3776 CEJQ470M16

C3307,C3321 CEJQNP330M35

C3609 CKSRYB102K50

C3603 CKSRYB103K50

C3361-C3364,C3661,C3663 CKSRYB104K25

C3303,C3304 CKSRYB222K50

RESISTORS

R3363,R3364,R3663 RD1/2PM4R7J

R3361,R3362,R3661 RD1/2PMF100J

R3321,R3322 RD1/4MUF101J

R3708 RD1/4PU120J

R3776,R3777 RD1/4PU152J

R3773 RF1/4PS330J

R3324-R3329 RS2LMFR22J

R3351,R3352,R3651 (0.22Ω/5W) XCN3001

Other Resistors RS1/16S J

OTHERS

CN3302 09P CONNECTOR PLUG AKM7063

CN3301 15P SOCKET AKP7071

CN3701 PLUG(2P) KM200SA2

CN3303 SPEAKER TERMINAL 6-P XKE3008

C3423,C3424 CEJQ101M35

C3813 CEJQ101M6R3

C3431 CEJQ220M25

C3401,C3402,C3501 CEJQ2R2M50

C5023 CEJQ470M16

C3425,C3461-C3464,C3561,C3563 CKSRYB104K25

C3405,C3406,C3505 CKSRYB221K50

C3403,C3404,C3503 CKSRYB471K50

C5011,C5021 CKSRYF104Z50

RESISTORS

R62 RD1/2PM221J

R3463,R3464,R3563 RD1/2PM4R7J

R3461,R3462,R3561 RD1/2PMF100J

R3421,R3422 RD1/4MUF101J

R3707 RD1/4PU120J

R3451,R3452,R3551 RS2LMFR22J

Other Resistors RS1/16S J

OTHERS

CN3502 13P CONNECTOR PLUG AKM7067

CN3501 13P SOCKET AKP7070

PCB BINDER VEF1040

CN3401 SPEAKER TERMINAL 6P XKE3009

68

Page 69

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

C3157,C3158,C3167,C3168,C3179 CEAT2R2M50

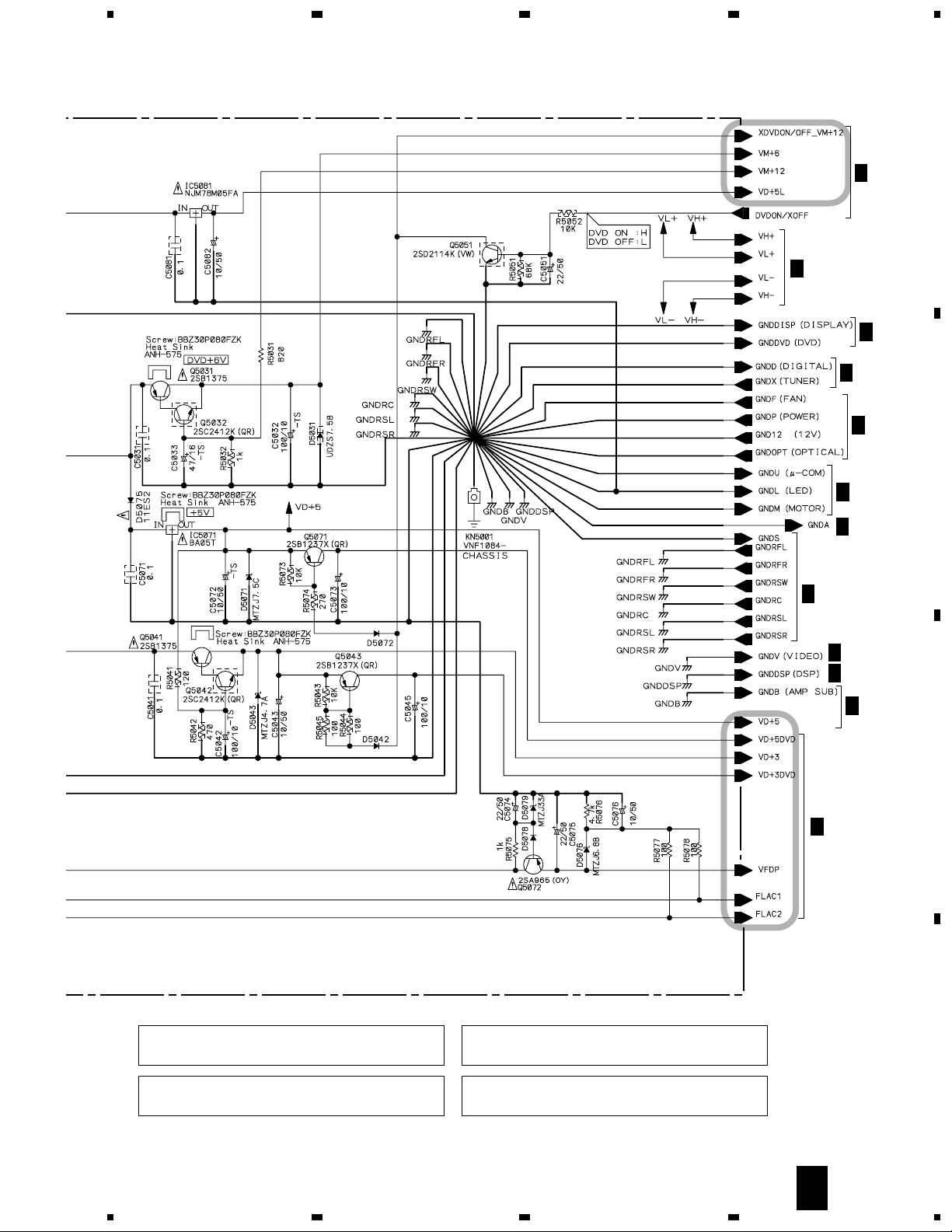

MAIN ASSY

I

SEMICONDUCTORS

IC5001 PROTECTOR (750mA) AEK7007

IC5005 PROTECTOR (3.5A) AEK7017

IC15,IC5004 PROTECTOR (5A) AEK7019

IC13,IC14 PROTECTOR (10A) AEK7022

IC5071 BA05T

C5006,C5008 CEAT682M16

C5033,C5703 CEAT470M16

C31,C32 CEAT472M35

C3005 CEJQ100M16

C3181,C3183 CFTLA154J50

C3155,C3156 CFTLA393J50

C3913,C3914,C5527 CKSRYB102K50

IC8521 BA25BC0FP

IC3151,IC3152,IC3161,IC3171 BA4558F

IC3902 BA4560F

IC8901 BA6195FP

IC3001 M62446FP

IC5081 NJM78M05FA

IC5501 PDC076A

IC8531 TC74HCT7007AF

IC8541 TC74VHC125F

Q3906 2SA1037K

Q5072 2SA965

Q5043,Q5071 2SB1237X

Q5031,Q5041 2SB1375

Q5032,Q5042,Q5572 2SC2412K

Q5501,Q5721 2SD1858X

Q3903,Q3904,Q3919,Q3920,Q5051 2SD2114K

Q3905 DTA124EK

Q5553,Q5554 DTA143EK

Q3251,Q3252 DTC114TK

Q8922 DTC114YK

Q3253 DTC124EK

Q5551,Q5552,Q5571 DTC143EK

D5010,D5011,D5074,D5075 11ES2

D3901,D5042,D5072,D5078,D5578 1SS133

D5741 1SS133

D5005,D5006 D3SBA20(B)

D11,D12 D5SBA20(B)

D5721 MTZJ11C

D5079 MTZJ33A

D5043 MTZJ4.7A

D3203,D3204,D5076 MTZJ6.8B

D5071 MTZJ7.5C

D5031 UDZS7.5B

COIL

L5501 LAU220J

CAPACITORS

C5526 (0.047F) ACH1246

C21,C22 (3300µF/56V) ACH7045

C3006-C3008,C5504,C5513-C5516 CCSRCH101J50

C5573,C8536,C8914 CCSRCH101J50

C8910-C8913,C8916 CCSRCH221J50

C9004 CCSRCH331J50

C8907 CEAL101M10

C33,C34 CEANP100M35

C3190,C3903-C3908,C3917,C5043 CEAT100M50

C5072,C5076,C5082,C5571,C5722 CEAT100M50

C5741,C5742 CEAT100M50

C5032,C5042,C5045,C5073,C5523 CEAT101M10

C8522,C8909 CEAT101M10

C5010 CEAT101M50

C5574 CEAT1R0M50

C5051,C5074,C5075 CEAT220M50

C3001,C3002 CEAT221M16

C3010,C3165,C3166,C3175 CKSRYB103K50

C3191-C3196,C5510-C5512 CKSRYB103K50

C5517,C5518,C5524,C5572,C8902 CKSRYB103K50

C8908,C9003 CKSRYB103K50

C3141-C3144,C5031,C5041,C5071 CKSRYB104K25

C5081,C5502,C5503,C5525,C8521 CKSRYB104K25

C8523,C8533,C8543,C8905,C8906 CKSRYB104K25

C8915 CKSRYB104K25

C3911,C3912 CKSRYB221K50

C3151,C3152 CKSRYB222K50

C3153,C3154,C3163,C3164,C3171 CKSRYB472K50

C8532,C8542 CKSRYB473K25

RESISTORS

R3219,R3220 RD1/2PM151J

R5077,R5078,R8533,R8534 RD1/4PU101J

R5075 RD1/4PU102J

R5580 RD1/4PU103J

R3909,R3910 RD1/4PU470J

R5076 RD1/4PU472J

R5568 RD1/4PU473J

R5031 RD1/4PU821J

R8930 RS1/16S1002F

R8909 RS1/16S1502F

R8914,R8928 RS1/16S2402F

R8927 RS1/16S2701F

R8929 RS1/16S5601F

Other Resistors RS1/16S J

OTHERS

CN5501 5P FFC CONNECTOR 52045-0545

CN5701 13P FFC CONNECTOR 52045-1345

CN5509 19P FFC CONNECTOR 52045-1945

CN5511 27P FFC CONNECTOR 52045-2745

CN8503

CN5352 11P PLUG AKP7058

CN3052 13P PLUG AKP7059

CN3051,CN5503 15P PLUG AKP7060

CN5209 19P PLUG AKP7062

CN3001 21P PLUG AKP7063

CN3053 09P CONNECTOR AKP7151

CN3054 13P CONNECTOR AKP7155

CN5011 5P-VH CONNECTOR B5P-VH

CN5012 7P-VH CONNECTOR B7P-VH

CN5507,CN8902 VKN1211

CN8501,CN8502 VKN1627

CN8903 8P FFC CONNECTOR VKN1707

KN5001 EARTH METAL FITTING VNF1084

X5501 CERAMIC RESONATOR ASS7034

4P JUMPER CONNECTOR

SOCKET

SOCKET

HEAT SINK ANH-575

SCREW BBZ30P080FZK

7P FFC CONNECTOR

B TO B CONNECTOR 30P

(10MHz)

52147-0410

69

Page 70

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

TUNER MODULE

J

SEMICONDUCTORS

IC201 BA1451F

IC202 LC72131MD

Q201,Q204,Q205 2SC2412K

Q202 DTA124ES

Q203 DTC124EK

D201 1SS133

D202 MTZJ5.1C

COILS AND FILTERS

L201 ATE7003

F202 ATF-107

F201 ATF-119

F203 ATF1155

CAPACITORS

C206 CCSRCH100D50

C212,C213,C226,C233-C235 CCSRCH101J50

C240 CCSRCH101J50

C231,C232 CCSRCH150J50

C223 CEAT100M50

C229 CEAT101M10

C224 CEAT1R0M50

C227 CEAT220M25

C241 CEAT2R2M50

C243 CEAT330M16

C228 CEAT3R3M50

C237 CEAT470M10

C211 CEJA1R0M50

C210 CEJA470M16

C204,C238,C602 CKSRYB102K50

INPUT ASSY

K

SEMICONDUCTORS

IC5352 BA4558F-HT

IC5231 BU4052BCF

Q5271,Q5272 2SD2114K

Q5273 DTA124EK

Q5231,Q5232 DTC124EK

D5253 1SS181

D5252 1SS355

COILS

L5201,L5202,L5205,L5207,L5208 VTL1112

L5211,L5271,L5272,L5280 VTL1112

CAPACITORS

C5201-C5204,C5207-C5210 CCSRCH101J50

C5271,C5272 CCSRCH101J50

C5239,C5240 CEAT100M50

C5212-C5215,C5231,C5232 CEAT470M16

C5229,C5230,C5233,C5234 CKSRYB103K50

C5244-C5246 CKSRYB103K50

RESISTORS

Other Resistors RS1/16S J

OTHERS

JA5201 PIN JACK (6P) AKB7113

CN5208 19P SOCKET AKP7073

CN5207 KR CONNECTOR S3B-PH-K

C101,C102,C208,C220,C239 CKSRYB103K50

C242,C601 CKSRYB103K50

C216,C217 CKSRYB123K50

C225 CKSRYB153K50

C201,C205,C209,C214,C230 CKSRYB223K50

C236,C603 CKSRYB223K50

C221 CKSRYB224K10

C202,C222 CKSRYB473K16

C215 CKSRYB681K50

RESISTORS

R211 RD1/4PU221J

R221 RD1/4PU222J

R233 RD1/4PU391J

R243 RS1/10S0R0J

R103 RS1/10S331J

R104 RS1/10S391J

Other Resistors RS1/16S J

OTHERS

CN201 13P CONNECTOR 52044-1345

BN201 TERMINAL 4P AKA7003

X201 CRYSTAL RESONATOR ASS1093

SHIELD CASE T ANK7072

SHIELD CASE B ANK7073

(7.2000MHz)

FM FRONT END AXF7003

AM RF TUNING BLOCK AXX7071

VIDEO ASSY

L

SEMICONDUCTORS

IC5351 LA7138M

IC5104 TC7WU04F

Q5161,Q5171,Q5181,Q5351 2SA1037K

COILS AND FILTERS

L5161,L5171,L5181 LCTB120K1608

F5101 VTF1096

L5371,L5378,L5379 VTL1087

CAPACITORS

C5106 CCSRCH100D50

C5163,C5173,C5183 CCSRCH180J50

C5371,C5379 CCSRCH331J50

C5161,C5162,C5171,C5172 CCSRCH6R0D50

C5181,C5182 CCSRCH6R0D50

C5354,C5356,C5360 CEAT101M16

C5105 CEAT470M16

C5372,C5380 CEAT471M6R3

C5107,C5392 CKSRYB102K50

C5101,C5103,C5104,C5164,C5174 CKSRYB104K25

C5184,C5351-C5353,C5357,C5361 CKSRYB104K25

C5381 CKSRYB104K25

RESISTORS

Other Resistors RS1/16S J

70

Page 71

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

OTHERS

JA5103 PIN JACK (1P) AKB7111

CN5352 4P MINI DIN SOCKET AKP7008

CN5351 11P SOCKET AKP7069

JA5351 PIN JACK (1P) VKB1063

DSP ASSY

M

SEMICONDUCTORS

IC3751 AK4527BVQ

IC8701,IC8703,IC8705 BA4558F-HT

IC8801 LC89056W-E

IC3851 W24257AJ-12

IC3801 YSS912C

Q8709-Q8714 2SD2114K

Q8715,Q8716,Q8718 DTA124EK

Q8717 DTC124EK

D8701,D8702 1SS181

D8703 1SS184

FILTERS

F3731-F3736,F3801,F3802,F3851 DTF1064

F8801,F8802 DTF1064

F3751,F3752 DTF1067

CAPACITORS

C3807,C3810,C3814,C3817,C3821 CCSRCH101J50

C3825,C3828,C3854,C8825 CCSRCH101J50

C8733 CCSRCH121J50

C3803,C3804,C8816,C8817 CCSRCH200J50

C3820 CCSRCH221J50

C8709,C8710 CCSRCH470J50

C3811 CCSRCH471J50

C8721,C8722 CCSRCH820J50

C8711,C8712,C8723,C8724 CEAT100M50

C8735,C8736,C8741-C8746 CEAT100M50

RESISTORS

R3751,R3757,R3809,R3813,R3822 RAB4C101J

R3827,R3830,R8801,R8825 RAB4C101J

R3817 RAB4C102J

Other Resistors RS1/16S J

OTHERS

CN3701 15P SOCKET AKP7071

CN3702 21P SOCKET AKP7074

CN3703 CONNECTOR POST S3B-PH-K

X3801,X8801 CRYSTAL VSS1140

DISPLAY ASSY

N

RESONATOR (12.288MHz)

SEMICONDUCTORS

IC5801 HEF4794BT

Q5803,Q5804 2SC2412K

Q5802 DTA143EK

D5801-D5808 MPG5064X

D5809 SLR-343VC(NPQ)

CAPACITORS

C5825-C5827 CCSRCH101J50

C5902 CEAL470M16

C5802 CKSRYB104K25

C5901 CKSRYB473K25

RESISTORS

Other Resistors RS1/16S J

OTHERS

X5901 REMOTE RECEIVER UNIT GP1U27X

CN5802 27P FFC CONNECTOR HLEM27R-1

V5801 FL TUBE XAV3011

FL HOLDER(FE) VNF1085

C8761-C8766 CEAT100M50

C3709,C3710,C3756,C3759,C3801 CEAT101M10

C3851,C8801 CEAT101M10

C3705,C3706,C3802 CEAT220M25

C3856 CEAT221M6R3

C8812,C8915,C8917 CEAT470M16

C3752 CEJQ470M10

C3783-C3785 CKSRYB102K50

C3732,C3734,C3765,C3786 CKSRYB103K50

C8701,C8702,C8751,C8753 CKSRYB103K50

C8755-C8758,C8808,C8811 CKSRYB103K50

C3711,C3712,C3754,C3755,C3758 CKSRYB104K25

C3833,C3834,C3855,C8802,C8803 CKSRYB104K25

C8805,C8806,C8809,C8810,C8814 CKSRYB104K25

C8818,C8820,C8821,C8916,C8918 CKSRYB104K25

C8715,C8716,C8727 CKSRYB122K50

C8713,C8714,C8725 CKSRYB152K50

C3707,C3708 CKSRYB222K50

C8728 CKSRYB224K10

C8703,C8704,C8734 CKSRYB472K50

C3805,C3809,C3813,C3816,C3819 CKSRYB473K25

C3822,C3824,C3827,C3830,C3831 CKSRYB473K25

C3852 CKSRYB473K25

MIC HP ASSY

O

CAPACITORS

C5822 CKSRYB104K25

C5819,C5821 CKSRYB223K50

RESISTORS

Other Resistors RS1/16S J

OTHERS

CN5807 5P FFC CONNECTOR 52044-0545

JA5802 MINI JACK AKN7003

KN5801 EARTH METAL FITTING VNF1084

KEYB ASSY

P

SWITCHES

S5802,S5812-S5818 ASG7013

RESISTORS

Other Resistors RS1/16S J

OTHERS

3P CABLE HOLDER 51048-0300

71

Page 72

XV-HTD510, XV-HTD510-B

Mark No. Description Part No. Mark No. Description Part No.

STBY SWITCH ASSY

Q

SWITCH

S5811 ASG7013

RESISTORS

Other Resistors RS1/16S J

OTHERS

3P CABLE HOLDER 51048-0300

J5811 JUMPER WIRE 03P D20PYY0310E

JOG ASSY

R

SWITCH

S5801 XSX3003

CAPACITOR

C5801 CKSRYB102K50

RESISTORS

Other Resistors RS1/16S J

CAPACITORS

C1,C3 (0.01µF) ACE7027

C42 CEAT102M16

C41 CEJQ100M35

C44 CKSRYB104K25

RESISTORS

R1 (2.2MΩ, 1/2W) RCN1080

R43 RS1/16S102J

Other Resistors RD1/4PU J

OTHERS

4P CABLE HOLDER 51048-0400

AN1 AC INLET 1P XKP3042

H1,H2 FUSE CLIP AKR7001

CN1 2P-VH CONNECTOR B2P3-VH

J13 JUMPER WIRE 5P D20PYY0420E

KN2 EARTH METAL FITTING VNF1084

OTHERS

3P CABLE HOLDER 51048-0300

CN5806

J5808 JUMPER WIRE 3P D20PYY0310E

J5804 JUMPER WIRE 5P D20PYY0515E

DISC KEY ASSY

S

5P CABLE HOLDER 51048-0500

3P JUMPER CONNECTOR

52147-0310

SWITCHES

S5803-S5810 ASG7013

RESISTORS

Other Resistors RS1/16S J

OTHERS

3P CABLE HOLDER 51048-0300

J5805 JUMPER WIRE 3P D20PYY0310E

PRIMARY ASSY

T

SEMICONDUCTORS

IC41 NJM78M56FA

D41 DF06SA

Q41 2SD1859X

D42,D44,D45 1SS133

COIL AND TRANSFORMER

L1 ATF7018

T2 ATT7049

RELAY

RY41 XSR3004

72

Page 73

6. ADJUSTMENT

6.1 TUNER SECTION

AM Tuner Section

• There is no adjustment in the AM tuner.

FM Tuner Section

• Set the mode selector to FM BAND.

• Connect the wiring as shown in Fig. 1.

Step

No.

1

Adjustment

Title

T-METER

Adjustment

ANT. Input level and signal condition

Frequency

(MHz)

98 OFF 80

Modulation

Input Level

(dBµV)

Adjust

point

L201

XV-HTD510, XV-HTD510-B

Adjustment

Contents

Adjust L201 so that the DC voltage between Pin

21 and Pin 23 of IC201 (Test point Vtm) gets

within 0 ± 50mV.

MPX SG FM SG

FM75Ω antenna terminal

Fig.1 Adjustment Wiring Diagram

TUNER MODULE

J

IC201

L201

pin 21

pin 23

PRODUCT

DC

Voltmeter

SIDE B

Fig.2 Adjustment Point

73

Page 74

XV-HTD510, XV-HTD510-B

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SELF-DIAGNOSTIC FUNCTION OF PICKUP DEFECTIVE

Symptom

• Indicates "No Disc" in FL display.

• Player does not playback, etc..

Procedure of Self-Diagnosis