Pioneer XV-DV434, XV-DV333, XV-DV535 Service Manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

DVD/CD RECEIVER

6

3

1

5

1

5

0

XV-DV333

XV-DV434

XV-DV535

8

XV-DV333

9

OPEN/CLOSEDVD/CD

2

FM/AM

4

9

PHONES

STANDBY/ON

VOLUME

8

2

9

ORDER NO.

RRV3171

9

TEL 13942296513 QQ 376315150 892498299

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

TEL

13942296513

Model Type Power Requirement

XV-DV333 MLXJ AC220-230V 3

XV-DV333 YLXJ/NC AC240V 3

XV-DV333 YPWXJ AC240V 4

XV-DV434 MLXJ AC220-230V 3

XV-DV434 YLXJ/NC AC240V 3

XV-DV434 YPWXJ AC240V 4

XV-DV535 MLXJ AC220-230V 3

XV-DV535 YLXJ/NC AC240V 3

For details, refer to "Important Check Points for Good Servicing".

Q

Q

3

7

6

3

1

5

1

5

Regional restriction

codes (Region No.)

0

8

9

2

4

9

2

8

Remarks

9

9

w

w

w

.

xia

o

y

u

1

6

3

.

c

o

m

T-ZZK JULY 2005 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-

Q

Q

it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this

manual.Improperly performed repairs can adversely affect the safety and reliability of the product

and may void the warranty. If you are not qualified to perform the repair of this product properly and

safely, you should not risk trying to do so and refer the repair to a qualified service technician.

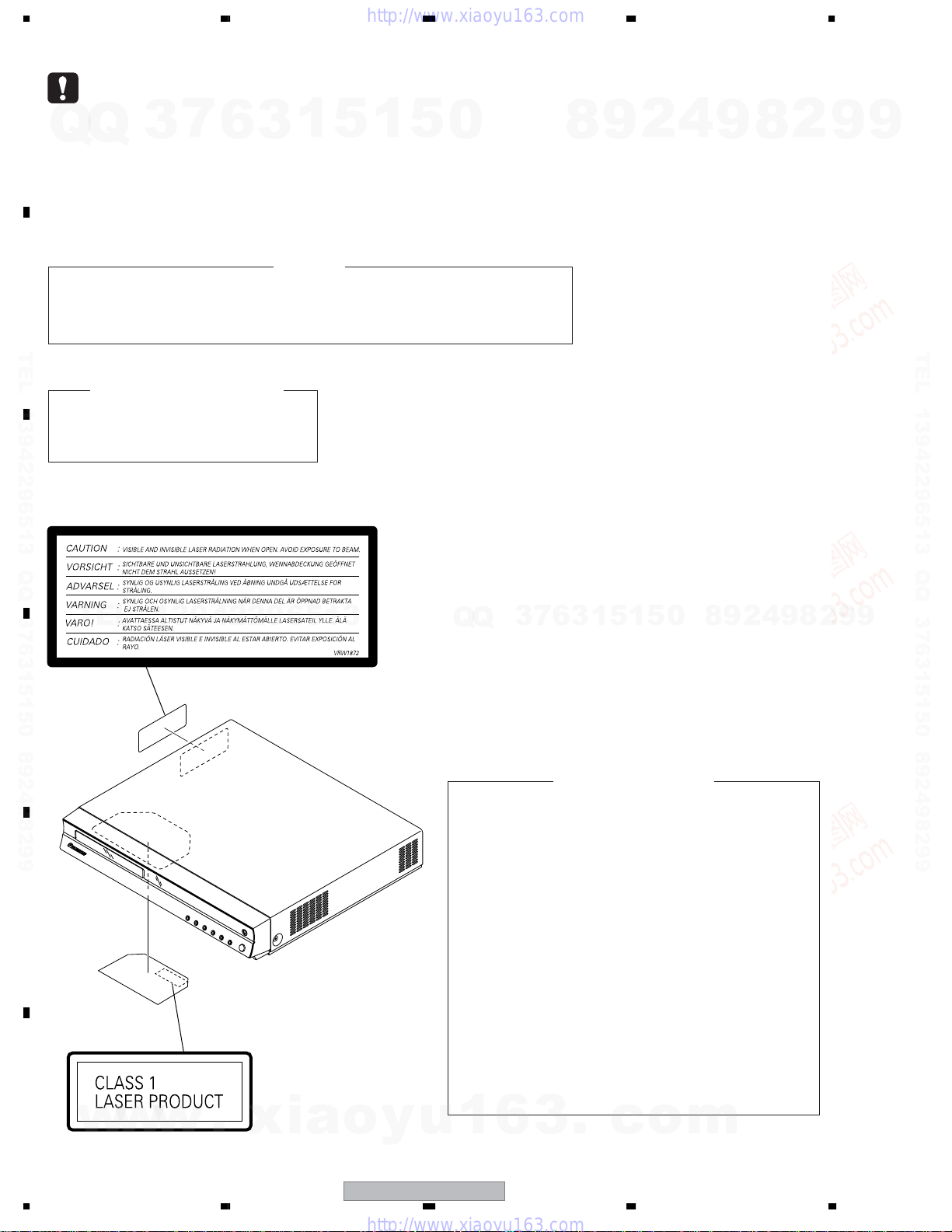

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

B

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

TEL 13942296513 QQ 376315150 892498299

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 650 nm

WAVELENGTH : 780 nm

3

7

6

3

1

WARNING !

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

LABEL CHECK

C

TEL

D

E

13942296513

Name Label

VRW1872

4

2

9

8

0

5

1

5

1

3

6

7

3

Q

Q

Additional Laser Caution

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (CLOSE) side (OPEN signal is

0V and CLOSE signal is 3.5V), a laser becomes the status which can

completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q307 (650nm LD) and Q308 (780nm LD)

on the DVDM Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

9

8

2

9

9

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

F

w

w

w

2

1234

.

xia

o

y

XV-DV333

∗ : Refer to page 67.

u

1

6

3

.

c

o

m

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

7

3

13942296513

6

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

3

1

5

1

5

0

Q

Q

3

7

6

8

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

9

D

w

w

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

w

.

xia

56

o

y

u

1

6

3

XV-DV333

.

c

7

o

E

F

m

3

8

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................ 6

A

B

TEL 13942296513 QQ 376315150 892498299

C

D

E

2.1 PACKING ................................................................................................................................................... 6

Q

Q

2.2 EXTERIOR SECTION................................................................................................................................ 8

2.3 FRONT PANEL SECTION ....................................................................................................................... 10

2.4 05 LOADER ASSY................................................................................................................................... 11

2.5 Traverse Mechanism Assy-S.................................................................................................................... 13

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM ................................................................................................................................... 14

3.2 OVERALL WIRING CONNECTION DIAGRAM........................................................................................ 16

3.3 DVDM ASSY (1/2).................................................................................................................................... 18

3.4 DVDM ASSY (2/2).................................................................................................................................... 20

3.5 DSP ASSY ............................................................................................................................................... 22

3.6 6CH AMP ASSY ...................................................................................................................................... 24

3.7 CONTROL (1/4) and TRADE 2 ASSYS................................................................................................... 26

3.8 CONTROL (2/4) ASSY............................................................................................................................. 28

3.9 CONTROL (3/4) ASSY............................................................................................................................. 30

3.10 CONTROL (4/4) ASSY........................................................................................................................... 32

3.11 POWER ASSY....................................................................................................................................... 34

3.12 TRADE 1 and VIDEO ASSYS ................................................................................................................ 36

3.13 DISPLAY and LED ASSYS .................................................................................................................... 38

3.14 WAVEFORMS ........................................................................................................................................ 40

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 41

4.1 LOAB ASSY............................................................................................................................................. 41

4.2 DVDM ASSY............................................................................................................................................ 42

4.3 DSP, TRADE 2 and TRADE 1 ASSYS ..................................................................................................... 44

4.4 6CH AMP ASSY ...................................................................................................................................... 46

4.5 CONTROL ASSY..................................................................................................................................... 48

4.6 DISPLAY, VIDEO and LED ASSYS.......................................................................................................... 52

4.7 POWER ASSY......................................................................................................................................... 54

5. PCB PARTS LIST ........................................................................................................................................... 56

6. ADJUSTMENT ............................................................................................................................................... 62

TEL

6.1 ADJUSTMENT ITEMS AND LOCATION ................................................................................................. 62

6.2 JIGS AND MEASURING INSTRUMENTS............................................................................................... 62

6.3 NECESSARY ADJUSTMENT POINTS ................................................................................................... 63

6.4 TEST MODE ............................................................................................................................................ 64

6.5 MECHANISM ADJUSTMENT.................................................................................................................. 65

7. GENERAL INFORMATION ............................................................................................................................. 67

7.1 DIAGNOSIS ............................................................................................................................................. 67

7.1.1 TEST MODE ...................................................................................................................................... 67

7.1.2 DISPLAY SPECIFICATION OF THE TEST MODE ............................................................................ 68

7.1.3 FUNCTIONAL SPECIFICATION OF THE SHORTCUT KEY ............................................................ 69

7.1.4 SPECIFICATION OF MODEL INFORMATION DISPLAY .................................................................. 70

7.1.5 FUNCTIONAL SPECIFICATION OF THE SERVICE MODE ............................................................. 71

7.1.6 SERVICE TEST MODE ..................................................................................................................... 72

7.1.7 METHOD FOR DIAGNOSING DEGRADATION OF THE LDs ON THE PICKUP ASSY ................... 74

7.1.8 DVD TROUBLE SHOOTING.............................................................................................................. 75

7.1.9 ID NUMBER AND ID DATA SETTING............................................................................................... 78

7.1.10 DSP TROUBLE SHOOTING ........................................................................................................... 81

7.1.11 DISASSEMBLY ................................................................................................................................ 83

7.2 PARTS...................................................................................................................................................... 92

7.2.1 IC ....................................................................................................................................................... 92

7.3 EXPLANATION ........................................................................................................................................ 96

7.3.1 SEQUENCE AFTER POWER ON..................................................................................................... 96

7.3.2 PROTECTION CIRCUIT.................................................................................................................... 97

8. PANEL FACILITIES ...................................................................................................................................... 102

3

7

6

3

1

13942296513

5

1

5

0

Q

Q

3

7

6

8

3

9

1

5

1

2

5

4

0

9

8

9

8

2

4

2

9

8

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

F

w

w

w

4

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

5678

1. SPECIFICATIONS

• Amplifier section

Front, Center. . . . . . . . . . . . . . . 100 W per channel

Subwoofer . . . . 100 W (100 Hz, 10 % T.H.D., 6 Ω)

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

TEL

3

13942296513

Accessories

• Power cord

(MLXJ, YLXJ/NC : ADG1154)

(YPWXJ : ADG7099)

6

• Disc section

Digital audio

characteristics . . . . . . . . . . DVD fs: 96 kHz, 24-bit

Type . . . . . . . . DVD system, Video CD/Super VCD

Frequency

response . . . . . . 4Hz to 44 kHz (96kHz sampling) /

Wow and Flutter Limit of measurement

• FM tuner section

Frequency range. . . . . . . . . 87.5 MHz to 108 MHz

Antenna . . . . . . . . . . . . . . . . . . . 75 Ω, unbalanced

• AM tuner section

Frequency range

With 9kHz step . . . . . . . . . 531 kHz to 1,602 kHz

With 10kHz step . . . . . . . . 530 kHz to 1,700 kHz

Antenna . . . . . . . . . . . . . . . . . . . . . . Loop antenna

• Miscellaneous

Power requirements:

Singapore / Indonesia / Hong Kong /

Phillipines model . . . . . AC 220-230 V, 50/60 Hz

Malaysia model. . . . . . . . . . AC 240 V, 50/60 Hz

Taiwan model. . . . . . . . . . AC 110-120 V, 60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . 175 W

Power consumption in standby (MLXJ). . . . . 0.5 W

Dimensions. . . . . 420 (W) x 70 (H) x 399.5 (D) mm

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.0 kg

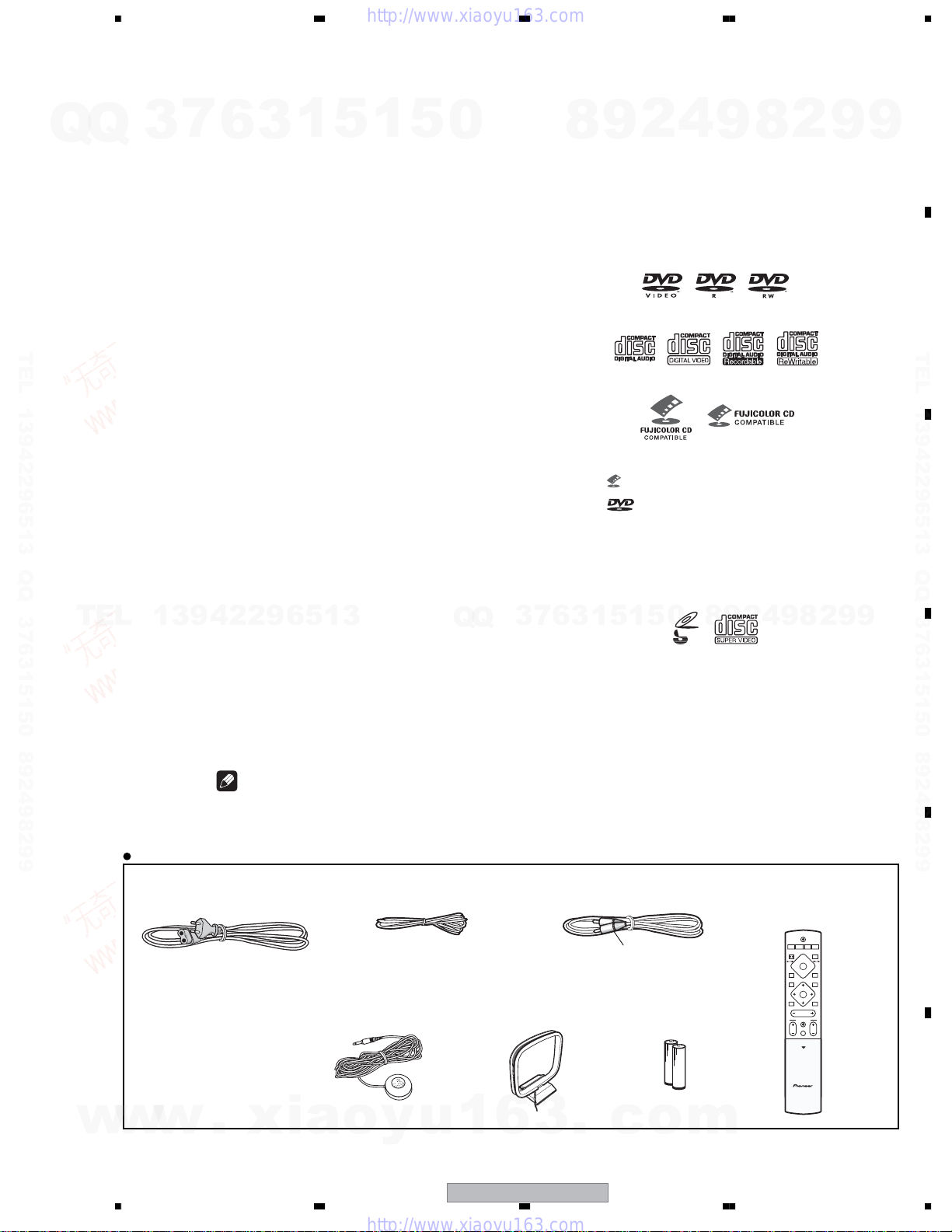

• Accessories (DVD/CD receiver)

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Microphone (for Auto MCACC setup) . . . . . . . . . 1

AA/R6 dry cell batteries . . . . . . . . . . . . . . . . . . . 2

Video cable (yellow plugs) . . . . . . . . . . . . . . . . . . 1

AM loop antenna . . . . . . . . . . . . . . . . . . . . . . . . . 1

FM antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Setup Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Operating instructions . . . . . . . . . . . . . . . . . . . . 1

Note

• Specifications and design subject to

possible modification without notice, due

to improvements.

1

3

(±0.001 % W.PEAK) or less (JEITA)

(1 kHz, 10 % T.H.D., 6 Ω)

5

1

5

0

system and Compact Disc

digital audio system

4 Hz to 22 kHz (48kHz sampling)

. . . . . . . . .

(YLXJ/NC, YPWXJ). . . . . 0.6 W

7

3

Q

Q

Manufactured under license from Dolby

Laboratories.“Dolby”, “Pro Logic” and the doubleD symbol are trademarks of Dolby Laboratories.

“DTS” and “DTS Digital Surround” are registered

trademarks of Digital Theater Systems, Inc.

• FM Antenna (ADH7030)

• Microphone (APM7006) • AM Loop Antenna

(ATB7013)

Disc / content format playback

compatibility

This player is compatible with a wide range of

9

8

disc types (media) and formats. Playable discs

will generally feature one of the following logos

on the disc and/or disc packaging. Note

however that some disc types, such as

recordable CD and DVD, may be in an

unplayable format.

See the Disc compatibility tablebelow for more

information.

Audio CD CD-R

• is a trademark of Fuji Photo Film Co. Ltd.

• is a trademark of DVD Format/Logo

Licensing Corporation

Also compatible with KODAK Picture CD

This player supports the IECís Su per VCD standard for superior picture quality, dual

soundtracks, and widescreen support.

1

5

1

3

6

• Video Cable

(L = 1.5m) (XDE3046)

Yellow

• Dry Cell Batteries

4

2

DVD-Video DVD-R DVD-RW

Video CD

Fujicolor CD

8

0

5

VIDEO

CD

Super Video CD (Super VCD)

8

9

CD-RW

9

4

2

9

• Remote Control

(XV-DV333 : XXD3093)

(XV-DV434 : XXD3093)

(XV-DV535 : XXD3095)

2

8

STANDBY/ON

CD FM/AM

DVD TUNER TV LINE

FRONT

SURROUND

1

4

7

DVD MENU

TUNE+

ST-

ENTER

TUNE-

MUTE

MASTER

VOLUME

TV CONTROL

CH VOL

INPUT

OPEN

OPEN CLOSE

¡83

ST+

L1/L2

0

RETURN

BASS

MODE

2

4

9

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

9

D

E

w

w

w

.

xia

56

o

y

u

1

6

XV-DV333

3

.

c

7

o

F

m

5

8

1234

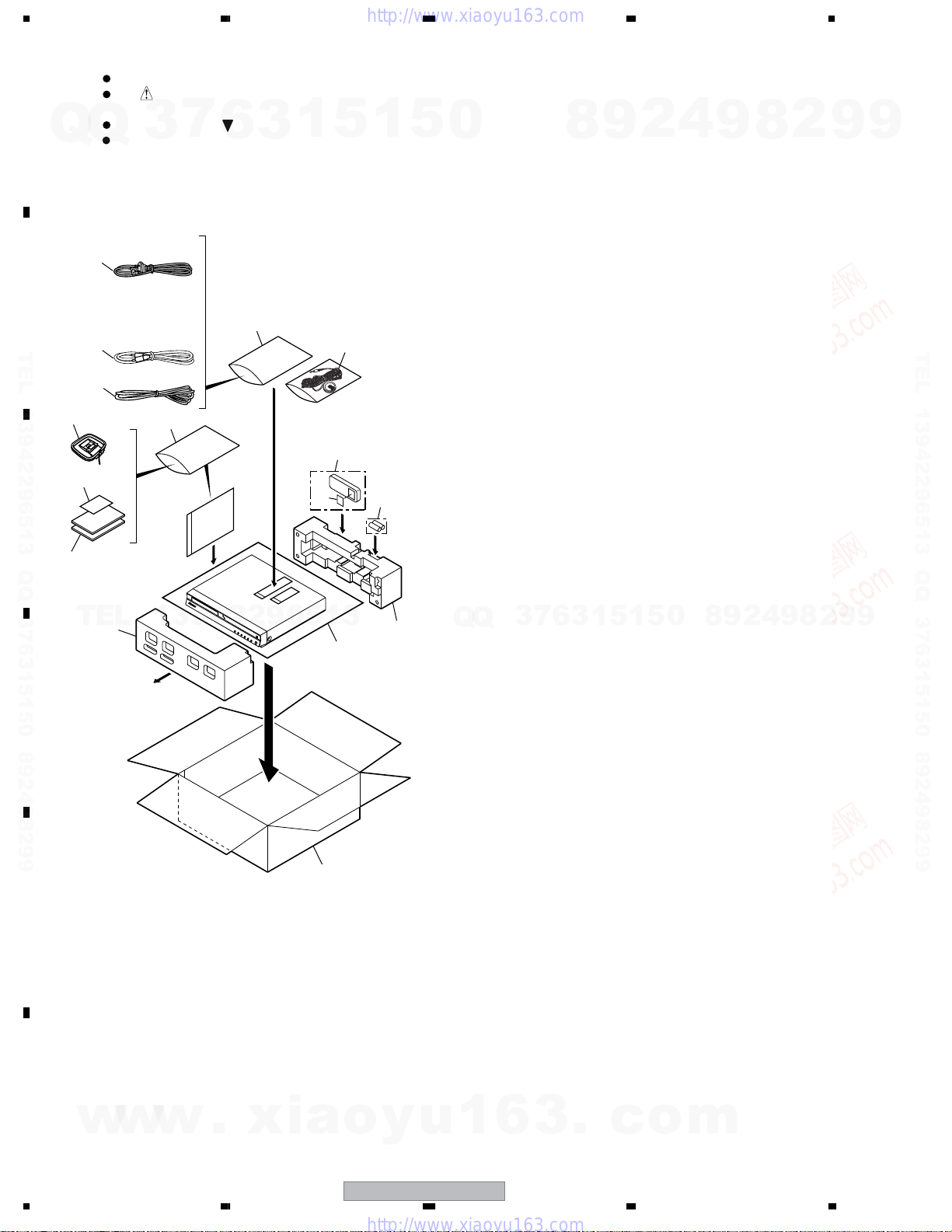

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Q

2.1 PACKING

B

TEL 13942296513 QQ 376315150 892498299

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

Q

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

1

6

2

4

7

3

18

7

6

3

18

1

16

5

3

15

1

5

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

8,9

TEL

20

D

E

13942296513

Front side

22

19

21

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

F

w

w

w

6

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

Q

>

>

5678

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cord See Contrast table(2)

2 FM Antenna ADH7030

3 Microphone APM7006

7

Q

3

4 AM Loop Antenna ATB7013

NSP 5 Dry Cell Batteries(R6P,AA) VEM1031

6

(for Auto MCACC setup)

3

1

5

1

5

0

No. Description Part No.

Mark

16 Battery Cover XZN3130

17 • • • • • •

NSP 18 Polyethylene Bag Z21-038

9

8

(0.03*230*340)

19 Packing Sheet AHG7010

20 Front Pad XHA3152

2

4

9

8

2

9

A

9

6 Video Cable XDE3046

NSP 7 Warranty Card See Contrast table(2)

8 Operating Instructions See Contrast table(2)

9 Setup Guide See Contrast table(2)

10 • • • • • •

TEL 13942296513 QQ 376315150 892498299

TEL

11 • • • • • •

12 • • • • • •

13 • • • • • •

14 • • • • • •

15 Remote Control See Contrast table(2)

(2) CONTRAST TABLE

XV-DV333/MLXJ, YLXJ/NC, YPWXJ, XV-DV434/MLXJ, YLXJ/NC, YPWXJ, XV-DV535/MLXJ and YLXJ/NC are constructed

the same except for the following:

Mark No. Description

1Power Cord ADG1154 ADG1154 ADG7099 ADG1154 ADG1154 ADG7099 ADG1154 ADG1154

NSP 7 Warranty Card Not used Not used ARY7047 Not used Not used ARY7047 Not used Not used

8 Operating Instructions XRC3201 XRC3201 Not used XRC3201 XRC3201 Not used XRC3205 XRC3205

13942296513

(English/Chinese)

8 Operating Instructions Not used Not used XRB3052 Not used Not used XRB3052 Not used Not used

(English)

XV-DV333

/MLXJ

XV-DV333

/YLXJ/NC

Q

XV-DV333

/YPWXJ

Q

3

7

21 Rear Pad XHA3153

22 Packing Case See Contrast table(2)

XV-DV434

/MLXJ

3

6

1

5

XV-DV434

/YLXJ/NC

0

5

1

XV-DV434

/YPWXJ

2

9

8

XV-DV535

/MLXJ

8

9

4

XV-DV535

/YLXJ/NC

9

2

B

TEL 13942296513 QQ 376315150 892498299

C

9

w

w

9 Setup Guide XRE3099 XRE3099 Not used XRE3103 XRE3103 Not used XRE3106 XRE3106

(English/Chinese)

9 Setup Guide Not used Not used XRE3098 Not used Not used XRE3102 Not used Not used

(English/French)

15 Remote Control XXD3093 XXD3093 XXD3093 XXD3093 XXD3093 XXD3093 XXD3095 XXD3095

22 Packing Case XHD3546 XHD3509 XHD3511 XHD3520 XHD3518 XHD3522 XHD3527 XHD3525

w

.

xia

o

y

u

1

6

3

.

c

o

m

D

E

F

56

XV-DV333

7

7

8

1234

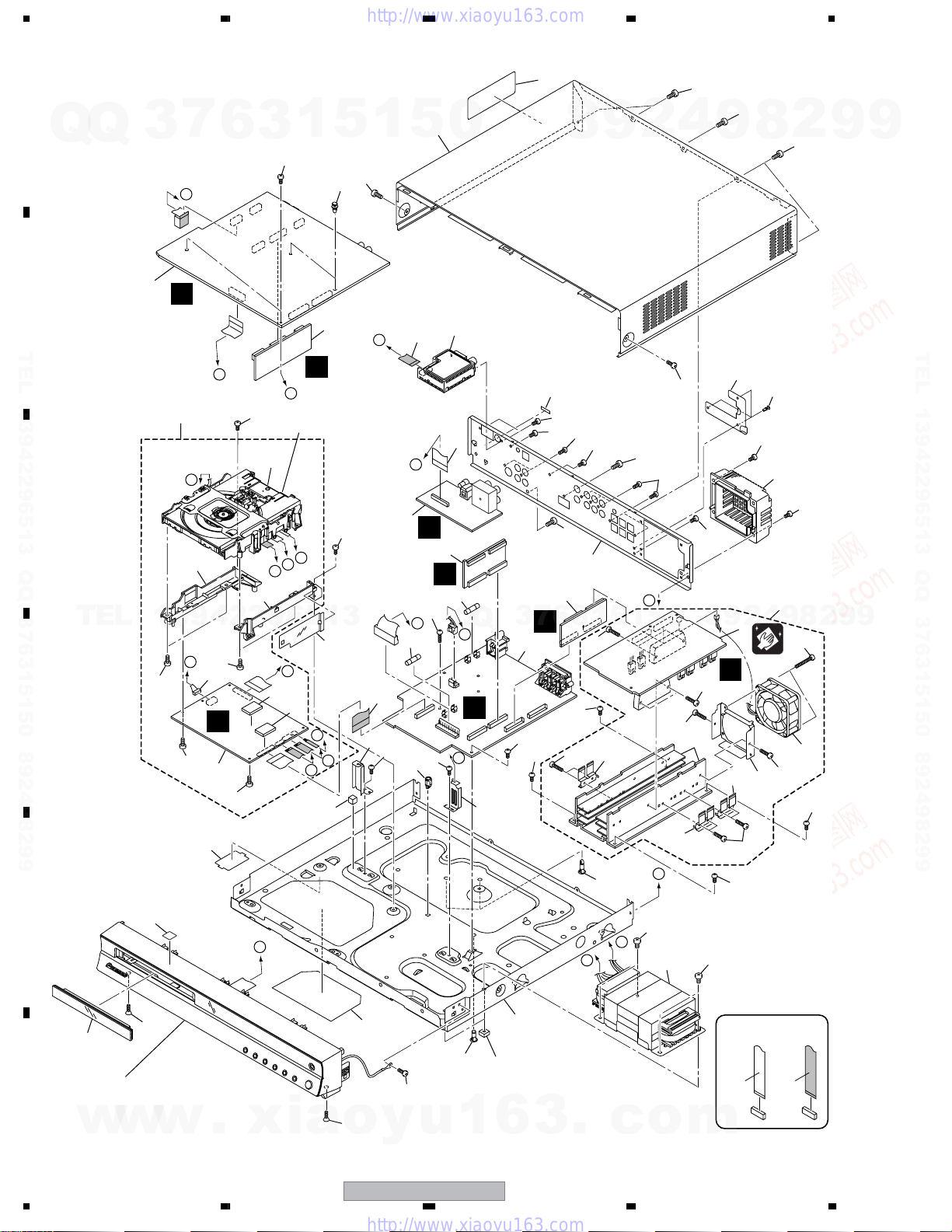

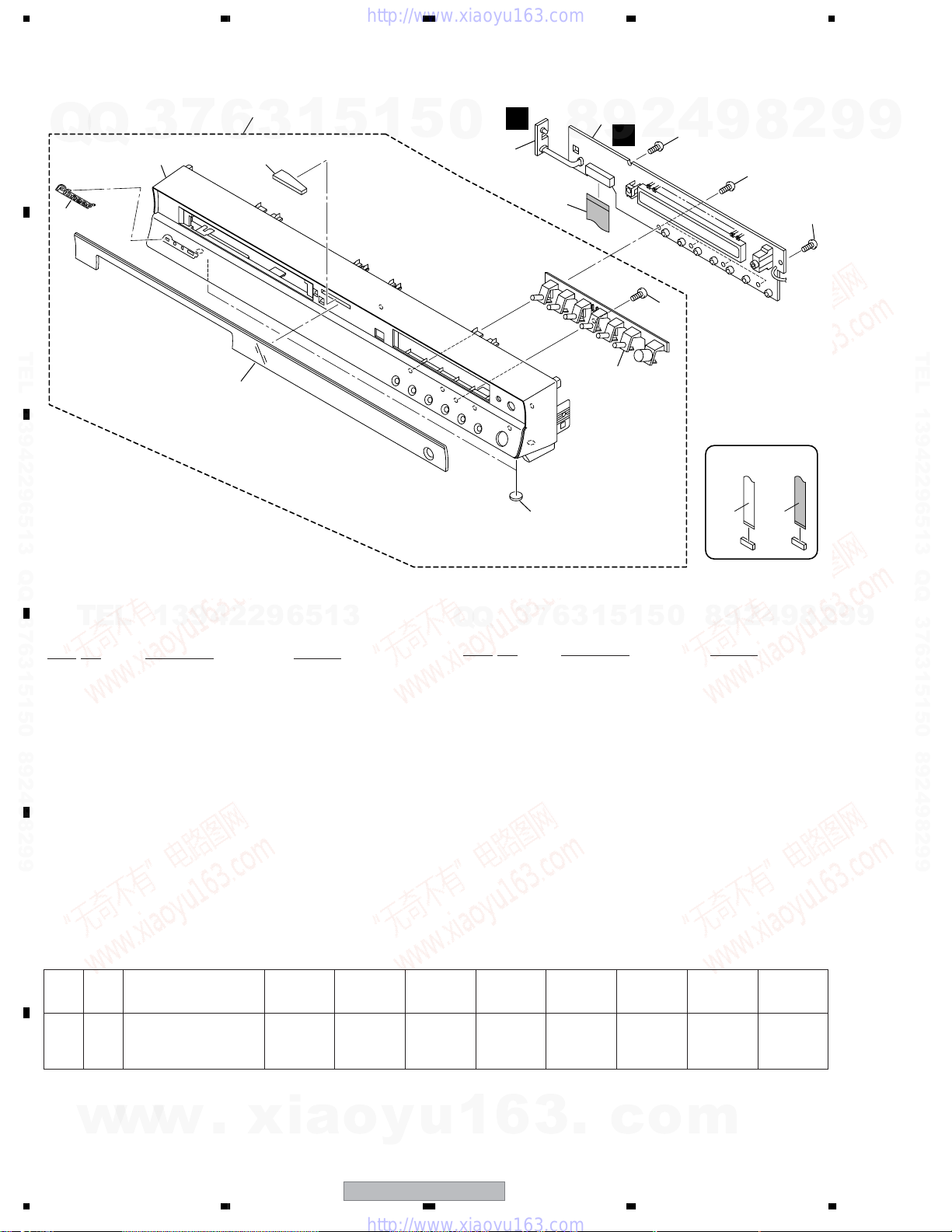

2.2 EXTERIOR SECTION

A

Q

Q

3

1

7

I

6

3

46

1

5

18

1

48

17

5

0

F

B

2

TEL 13942296513 QQ 376315150 892498299

A

27

K

C

29

TEL

D

13942296513

K

50

50

49

30

50

31

B

3

50

C

H

Refer to

"2.4 05 LOADER ASSY."

28

D

C

B

33

J

32

32

D

C

B

36

49

35

I

7

11

16

46

34

14

9

15

J

I

6

E

10

55

E

Q

F

Q

3

7

4

J

46

46

H

35

49

45

8

MLXJ only

57

46

46

46

5

3

6

G

49

52

47

22

46

1

52

9

5

26

56

1

2

47

G

5

4

48

0

52

25

48

52

46

8

48

9

20

9

D

26

8

Except

YPWXJ

19

46

21

23

4

2

8

Cleaning paper

GED-008

24

9

52

2

48

46

8

51

13

49

9

2

9

9

TEL 13942296513 QQ 376315150 892498299

9

37

38

E

43

F

w

8

YPWXJ only

58

A

40

6

39

3

.

54

Refer to

"2.3 FRONT PANEL SECTION."

w

w

1234

.

xia

42

41

46

54

o

y

u

1

XV-DV333

F

E

c

26

G

53

12

o

53

m

x4

52

49

NON-CONTACT

SIDE

CONTACT SIDE

Q

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 CONTROL Assy See Contrast table(2)

2 DSP Assy AWX8587

3DVDM Assy AWM7962

Q

7

3

4POWER Assy XWZ3975

5 TRADE1 Assy XWZ3997

6

3

1

>

>

>

>

5

1

5

0

No. Description Part No.

Mark

31 Connector Assy PG05KK-E07

32 Cushion AEB7267

33 Barrier VK1 AEC7533

9

8

NSP 34 Spacer PNY-404

35 Control Angle XNG3108

2

4

9

8

2

9

A

9

6 TRADE2 Assy XWZ3998

7 VIDEO Assy XWZ3980

86 CH AMP XWK3188

9 FM/AM TUNER Unit AXX7173

10 Fuse (FU1: T2.5A) REK1026

11 Fuse (FU2: T5.0A) REK1029

TEL 13942296513 QQ 376315150 892498299

TEL

12 Power Transformer (T1) See Contrast table(2)

13 DC Fan Motor XXM3009

14 11P F.F.C/60V XDD3152

15 27P F.F.C/60V XDD3188

16 25P F.F.C/60V XDD3157

17 Bonnet Case XZN3160

NSP 18 PCB Spacer(3X6) AEC7156

19 Push Rivet See Contrast table(2)

20 Fan Barrier See Contrast table(2)

21 Fan Cover XMR3086

22 Rear Panel See Contrast table(2)

NSP 23 AMP Unit 6ch XXQ3004

24 Fan Plate ANG7462

NSP 25 Heat Sink XNH3038

13942296513

26 FET Bracket A ANG7418

NSP 27 DVD Assy AXA7145

NSP 28 05 LOADER Assy VWT1219

29 Adaptor 05L ANW7282

30 Adaptor 05R ANW7283

Q

Q

3

7

36 PCB Spacer AEB7206

37 Bottom Plate XEC3058

38 Locking Card Spacer AEC7372

NSP 39 Chassis XNA3024

40 S Cover AEB7262

41 Card Spacer DNK2769

42 Name Label XAX3454

43 Tray Cap Assy See Contrast table(2)

44 • • • • • •

45 Caution Label VRW1872

46 Screw BBZ30P060FTC

47 Screw VPZ30P100FTC

48 Screw BBZ30P080FNI

49 Screw VBZ30P080FTC

50 Screw BPZ30P080FNI

51 Screw BBZ30P300FTC

52 Screw BBZ30P140FTC

53 Screw BBZ40P060FTC

54 Screw CBZ30P080FTC

55 Screw VPZ30P140FTC

5

1

3

6

56 Screw PPZ30P080FNI

NSP 57 SISIR Label See Contrast table(2)

NSP 58 Energy Star Label See Contrast table(2)

1

5

0

8

9

2

4

9

8

2

9

9

B

TEL 13942296513 QQ 376315150 892498299

C

D

(2) CONTRAST TABLE

XV-DV333/MLXJ, YLXJ/NC, YPWXJ, XV-DV434/MLXJ, YLXJ/NC, YPWXJ, XV-DV535/MLXJ and YLXJ/NC are constructed

the same except for the following:

Mark No. Description

1 CONTROL Assy XWZ3969 XWZ3969 XWZ3969 XWZ3984 XWZ3984 XWZ3984 XWZ3989 XWZ3989

12 Power Transformer (T1) XTS3077 XTS3078 XTS3078 XTS3077 XTS3078 XTS3078 XTS3077 XTS3078

19 Push Rivet XEC3034 XEC3034 Not used XEC3034 XEC3034 Not used XEC3034 XEC3034

20 Fan Barrier XMR3089 XMR3089 Not used XMR3089 XMR3089 Not used XMR3089 XMR3089

22 Rear Panel XNC3351 XNC3357 XNC3340 XNC3367 XNC3368 XNC3372 XNC3354 XNC3353

43 Tray Cap Assy XXG3207 XXG3207 XXG3207 XXG3207 XXG3207 XXG3207 XXG3211 XXG3211

NSP 57 SISIR Label XAX3513 Not used Not used XAX3514 Not used Not used XAX3515 Not used

NSP 58 Energy Star Label Not used Not used AAX8022 Not used Not used AAX8022 Not used Not used

w

w

w

.

xia

56

XV-DV333

/MLXJ

o

XV-DV333

/YLXJ/NC

y

u

XV-DV333

/YPWXJ

1

6

3

XV-DV333

XV-DV434

/MLXJ

.

XV-DV434

/YLXJ/NC

c

o

7

XV-DV434

/YPWXJ

m

XV-DV535

/MLXJ

XV-DV535

/YLXJ/NC

E

F

9

8

1234

2.3 FRONT PANEL SECTION

6

8

4

3

7

1

5

1

5

0

K

2

9

A

7

Q

Q

6

B

TEL 13942296513 QQ 376315150 892498299

C

3

5

8

3

1

9

H

10

2

11

12

4

9

2

8

12

12

NON-CONTACT

SIDE

CONTACT SIDE

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

(1) FRONT PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 DISPLAY Assy XWZ3979

2 LED Assy XWZ4000

D

E

3 19P F.F.C/60V XDD3158

NSP 4 Front Panel Assy See Contrast table(2)

5Front Panel See Contrast table(2)

6 Pioneer Name Plate VAM1129

7 Illumination Lens AAK8214

8 Display Window See Contrast table(2)

9 Leg AEB7090

10 FUNC. Button XAD3209

(2) CONTRAST TABLE

XV-DV333/MLXJ, YLXJ/NC, YPWXJ, XV-DV434/MLXJ, YLXJ/NC, YPWXJ, XV-DV535/MLXJ and YLXJ/NC are constructed

the same except for the following:

Mark No. Description

NSP 4 Front Panel Assy XXG3225 XXG3225 XXG3225 XXG3227 XXG3227 XXG3227 XXG3229 XXG3229

5Front Panel XMB3207 XMB3207 XMB3207 XMB3208 XMB3208 XMB3208 XMB3209 XMB3209

8 Display Window XAK3485 XAK3485 XAK3485 XAK3485 XAK3485 XAK3485 XAK3487 XAK3487

13942296513

XV-DV333

/MLXJ

XV-DV333

/YLXJ/NC

Q

XV-DV333

/YPWXJ

8

0

5

1

5

1

3

6

7

3

Q

No. Description Part No.

Mark

11 Screw BPZ30P080FTC

12 Screw VPZ30P100FTC

XV-DV434

/MLXJ

XV-DV434

/YLXJ/NC

XV-DV434

/YPWXJ

XV-DV535

/MLXJ

9

4

2

XV-DV535

/YLXJ/NC

9

8

2

9

9

F

w

w

w

10

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

5678

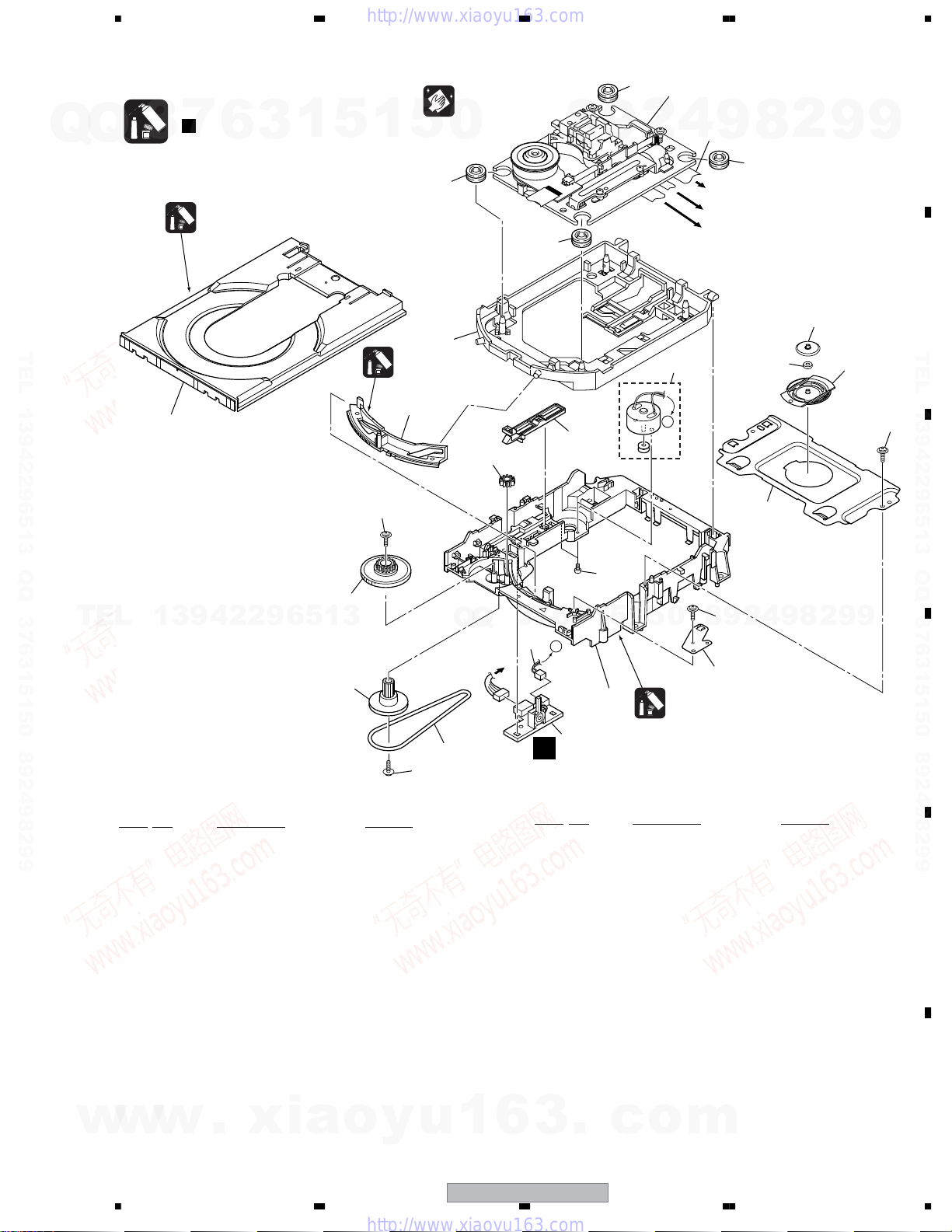

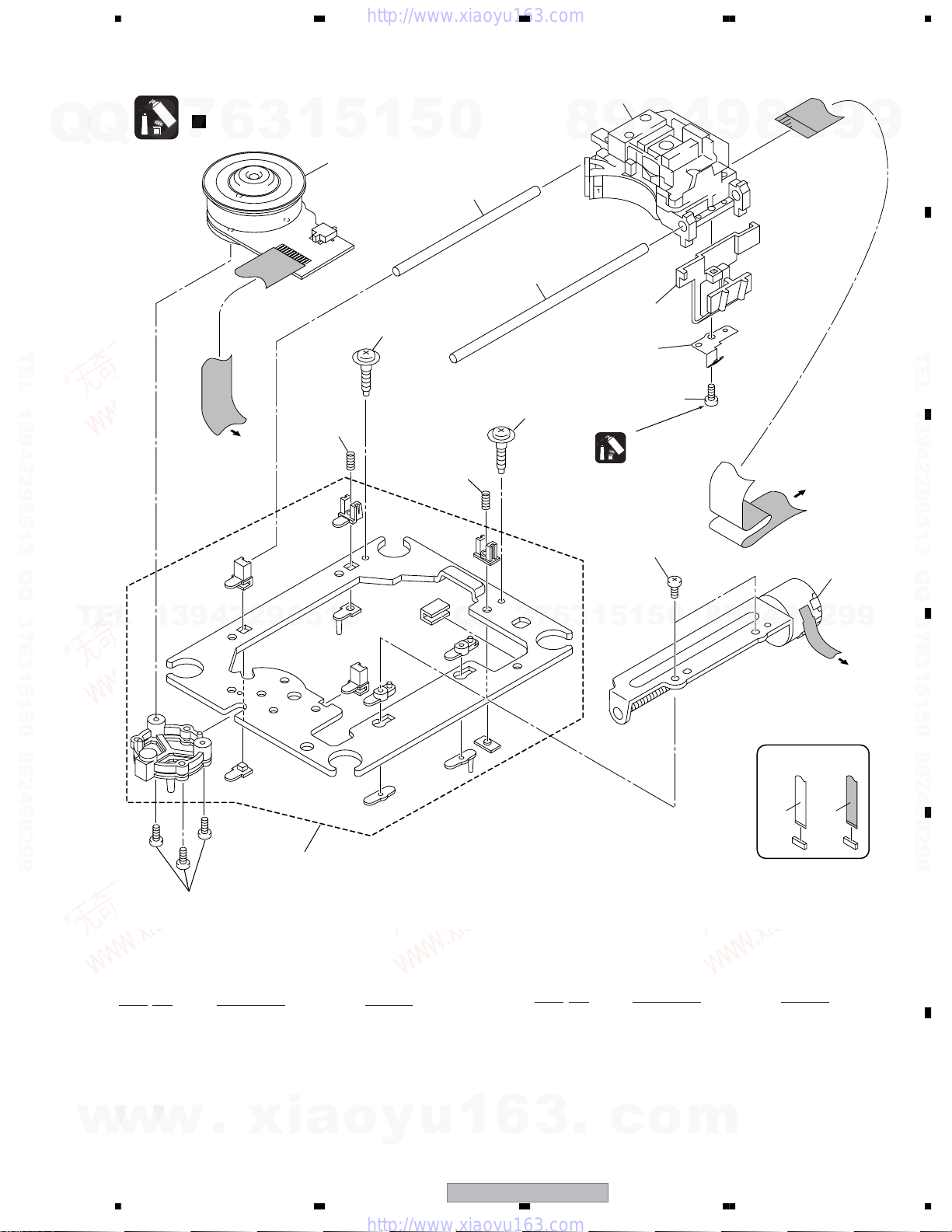

2.4 05 LOADER ASSY

Note :

Refer to

" Application of Lubricant".

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

23

6

Daifree

GEM1036

3

1

5

1

5

Lubricating Oil

GYA1001

13

22

Pickup leneses

Cleaning liquid

GEM1004

Cleaning paper

GED-008

0

8

12

16

8

8

17

9

8

2

Refer to

"2.5 Traverse Mechanism Assy-S".

4

2

A

6

3

8

9

8

To DVDM CN101 (Pickup)

To DVDM CN104 (Stepping Motor)

To DVDM CN102 (Spindle Motor)

24

19

2

18

9

20

A

9

B

TEL 13942296513 QQ 376315150 892498299

22

C

TEL

13942296513

05 LOADER ASSY PARTS LIST

No. Description Part No.

Mark

NSP 1 LOAB Assy VWG2346

2Traverse Mechanism Assy-S DXX2568

3 Loading Motor Assy VXX2912

4• • • • •

5• • • • •

6 Flexible Cable (24P) VDA2008

7 Connector Assy 2P VKP2253

8 Floating Rubber VEB1351

9 Belt VEB1358

10 Stabilizer VNE2253

15

14

22

Q

Q

To

DVDM CN103

9

3

21

22

4

2

9

8

0

5

1

5

1

3

6

7

7

A

10

11

1

A

No. Description Part No.

Mark

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate 04 VNE2342

19 Bridge 04 VNE2343

20 Clamper 04 VNL1969

21 Screw JGZ17P028FTC

22 Screw VBA1094

23 Tray VNL1920

24 Clamp Magnet VMG1029

Lubricating Oil

GYA1001

9

8

2

9

9

D

E

w

w

11 Loading Base VNL1917

12 Float Base 04 VNL1968

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

w

15 Loading Gear VNL1922

.

xia

56

o

y

u

1

6

3

XV-DV333

.

c

7

o

F

m

11

8

1234

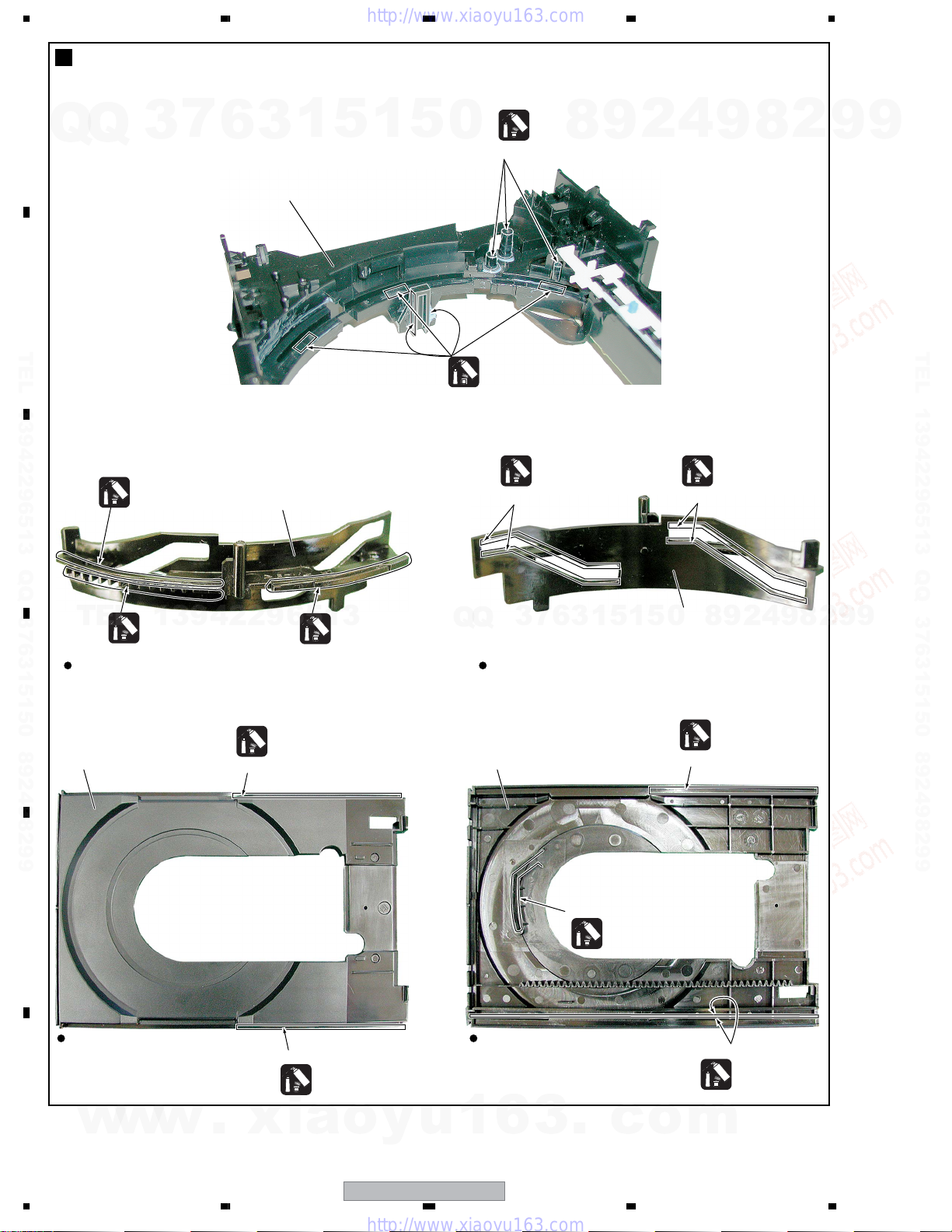

Application of Lubricant

A

7

Q

Q

B

TEL 13942296513 QQ 376315150 892498299

C

3

Lubricating Oil

GYA1001

6

1

3

No. 11

Loading Base

No. 13

Drive Cam

5

1

5

0

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

Around the shaft

Lubricating Oil

GYA1001

Inner side of a ditch

8

9

4

2

Inner side of a ditch

8

9

Lubricating Oil

GYA1001

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

Front View Rear View

D

No. 23

Tray

E

Top View Bottom View

F

w

13942296513

Lubricating Oil

GYA1001

Daifree

GEM1036

Concave of unevenness

w

w

.

xia

Lubricating Oil

GYA1001

Concave of unevenness

Daifree

GEM1036

o

y

Q

u

Q

1

3

No. 23

Tray

6

1

3

6

7

Inner side of a ditch

3

.

5

1

5

Daifree

GEM1036

c

o

No. 13

8

0

Drive Cam

Daifree

GEM1036

Concave of unevenness

Side of the rib

2

9

Daifree

GEM1036

4

m

9

8

2

9

9

12

XV-DV333

1234

5678

2.5 Traverse Mechanism Assy-S

>

Note :

Refer to

" Application of Lubricant".

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

To DVDM CN102

(Spindle Motor)

3

1

5

1

5

Note : When part #2 is replaced,

2

11

part #13 also need to be

replaced at the same time.

10

0

4

11

3

10

8

1

2

9

5

6

Silicone Adhesive

GEM1037

4

9

9

8

2

DVDM CN101

(Pickup Assy)

9

To

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

TEL

w

13942296513

8

Note : Spindle screw (DBA1252) of No.13 is the screw which applied special bond.

13

Traverse Mechanism Assy-S PARTS LIST

No. Description Part No.

Mark

1 05SD Pickup Assy-S OXX8014

2 Spindle Motor N200 DXM1197

3 Guide Shaft VK1 DLA1940

4 Sub Guide Shaft VK1 DLA1941

NSP 5 Joint VK1B DNK4272

w

w

6 Joint Spring VK1 DBK1235

7 Stepping Motor VK1 DXM1201

Therefore the adhesion becomes ineffective when takes it off once. Spindle screw is the part which cannot recycle.

When part #2 is replaced, part #13 also need to be replaced at the same time.

.

xia

o

y

u

Q

Q

1

12

9

8

0

5

1

5

1

3

6

7

3

Mark No. Description Part No.

NSP 8 Mechanism Frame VK1 DNK4160

9 Precision Screw VK1 DBA1209

10 Skew Screw VK1 DBA1211

11 Skew Spring VK1 DBH1516

NSP 12 Stepping Screw DBA1205

6

3

.

c

o

13 Spindle Screw VK1(for Service) DBA1252

m

9

4

2

NON-CONTACT

SIDE

7

9

2

8

DVDM CN104

(Stepping Motor)

CONTACT SIDE

9

To

D

E

F

56

XV-DV333

13

7

8

1234

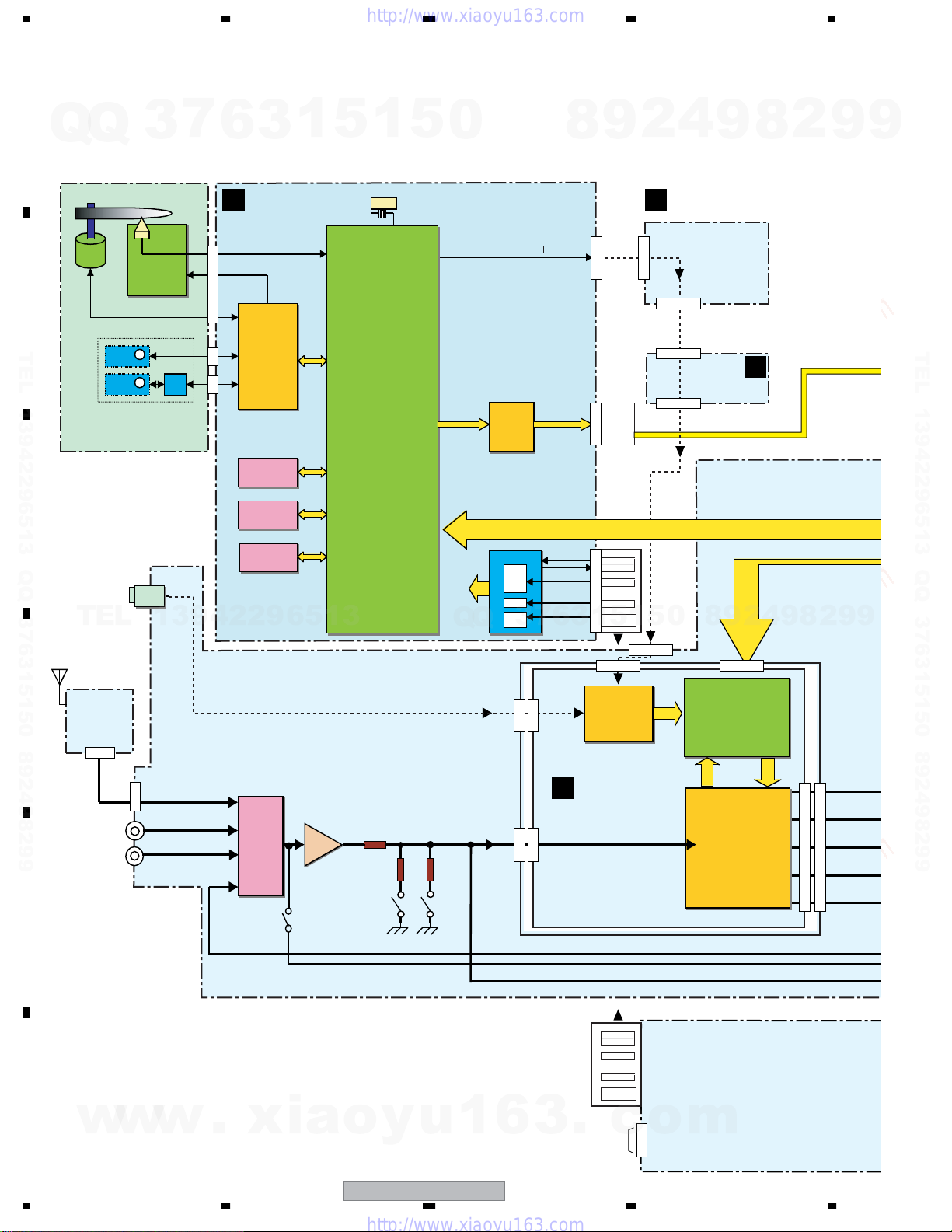

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

B

DVDM ASSY

Loading

Motor

Stepping

Motor

04SD PU

PlCK UP

ASSY

IC101

BD7995EFS

FTS &

SPDL DRlVER

IC202

64M SDRAM

IC203

16M

FLASH ROM

IC204

16K

EEPROM

+ -

+ -

M

LOAB

M

Ass'y

13942296513

IC3001

INPUT

SELECTOR

BUFFER

IC3003

SPINDLE

Motor

VK-1

B

TEL 13942296513 QQ 376315150 892498299

C

LINE 2 IN

(OPT DIGITAL)

TEL

D

FM/AM

TUNER

UNIT

LINE 1

IN

TV IN

27MHz

IC201

MT1389FE/C2-L-K

BACK END IC

• RF Amp

• Servo control

• Systemcontrol CPU

• AV decoder

• 108MHz 12bit Video DAC

ATTENUATOR

- 6dB - 10dB

Q

IC401

MM1623BF

VlDEO AMP

DRlVER

POWER SUPPLY

Q

1.8V

3.3V

5V

6.8V

12V

3

4

CN5613

313

7

4

1

DOUT

6

CN5613

DIN

CN901

C

LIN

RIN

CN901

3

CN901

##

CN903

V

SY

SC

CY/G

Cb/B

Cr/R

CN901

VDET

VPR+8

VPR+8M

VDVD+12

1

5

1

2

IC601

AK4117VF

DIR

DSP ASSY

J

POWER ASSY (2/2)

CN5102

CN5532

4

TRADE2 ASSY (2/2)

4

CN5522

E

CN5512

&

2

9

8

0

5

CN5502

&

IC801

DSPC56371AF180

• Dolby Digital Decoder

• Dolby PrologicII

• DTS Decoder

IC701

AK4628VQE

8ch

CODEC

4

CN5620

CN951

9

8

CN701

2

CN5612

9

TEL 13942296513 QQ 376315150 892498299

9

CN701

E

F

w

w

w

14

1234

.

xia

o

y

u

1

XV-DV333

CN5612

6

3

.

VDET

VPR+8

VPR+8M

VDVD+12

c

AC IN

CN5102

o

1

LIVE

2

NEUTRAL

CN3101

m

Q

Q

3

5678

7

6

I

VIDEO ASSY

3

1

5

1

5

0

8

9

2

4

9

8

K

LED ASSY

2

9

A

9

CN8801

TEL 13942296513 QQ 376315150 892498299

F

TEL

13942296513

Y

C

Y

Cb

Cr

V

CONTROL ASSY

S-VIDEO

OUT

CN8802

COMPONENT&

COMPOSITE

VIDEO OUT

JA8851

DTS,LFE

MIX/GAIN

JA101

IR

SENSOR

Q

Q

MICAMP

Headphone

AMP

ANDREW BYPASS

H

DISPLAY ASSY

PDC122

IC5501

micro

Processoer

7

3

KEY

6

3

1

5

1

5

0

FAN

FL Tube

8

9

2

IC5601

FL

Driver IC

PT6302

9

4

J5602

J5601

VFL+5

SR PLUS

2

8

MCACC

HEADPHONE

12

12

9

VFL+5

LED

9

B

TEL 13942296513 QQ 376315150 892498299

C

D

FL/FR

SW

Centre

SL/SR

REC OUT

w

w

+0dB

LPF

+0dB

+0dB

IC3002

J

POWER SUPPLY ASSY (1/2)

w

.

xia

56

+

WIRE LESS MODEL ONLY

+6dB

IC3062

BD3814FV

E-VOL

• 6ch E-vol

WIRELESS OUT

SELECT

IC9091

o

y

u

ANDREW

WIRELESS

OUT

TRADE2

ASSY

(1/2)

1

CN5521

CN5511

CN5501

E

6

3

XV-DV333

CN3032

CN5531

CN3012

CN3022

.

IC3301

STK433-270

• 3ch Power Amp

IC3401

STK433-270

• 3ch Power Amp

CN3002

H

AMP UNIT 6CH

TRADE1 ASSY

G

c

o

7

m

CN3001

CN3011

CN3021

CN3031

8

FL/FR

OUT

SW

OUT

CENTRE

OUT

SL/SR

OUT

E

F

15

1234

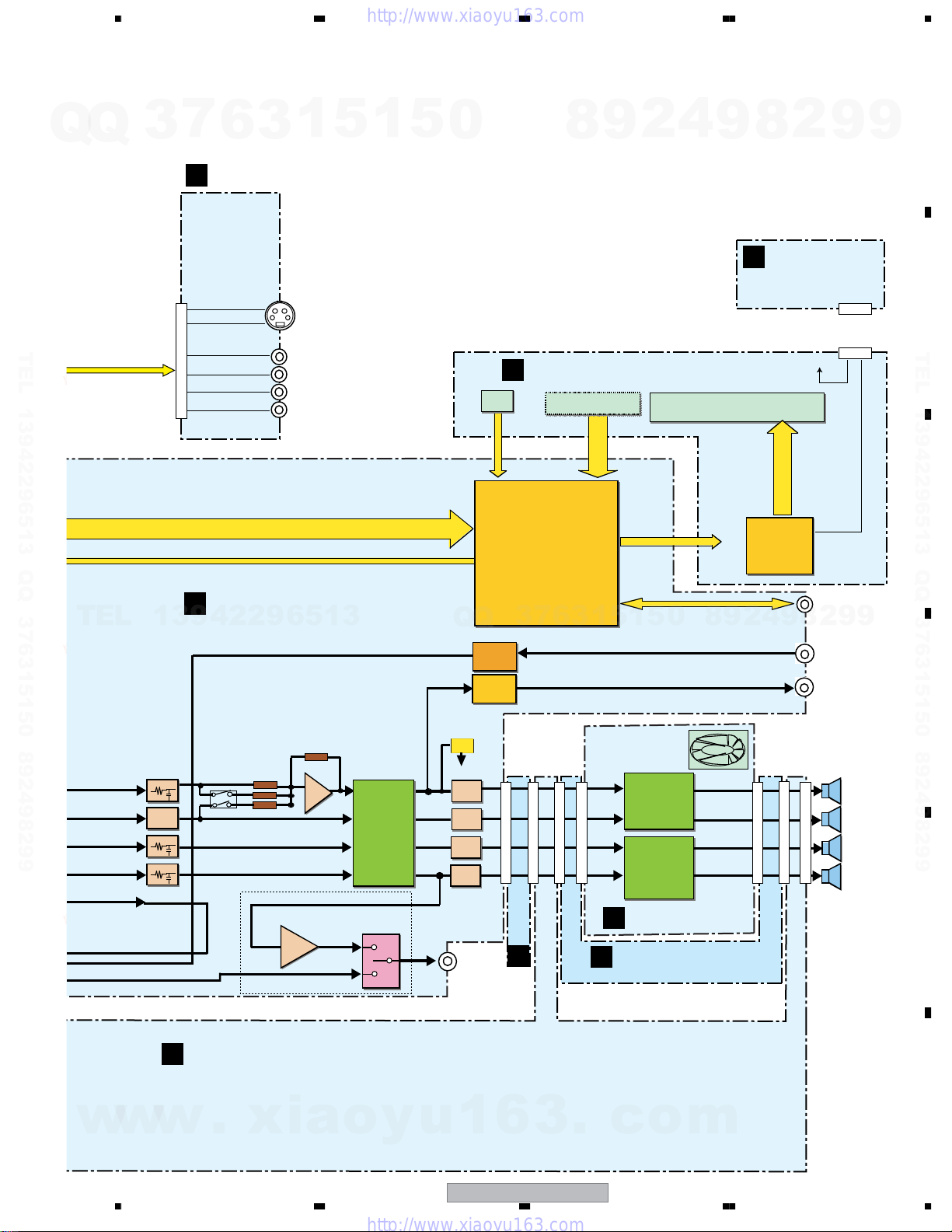

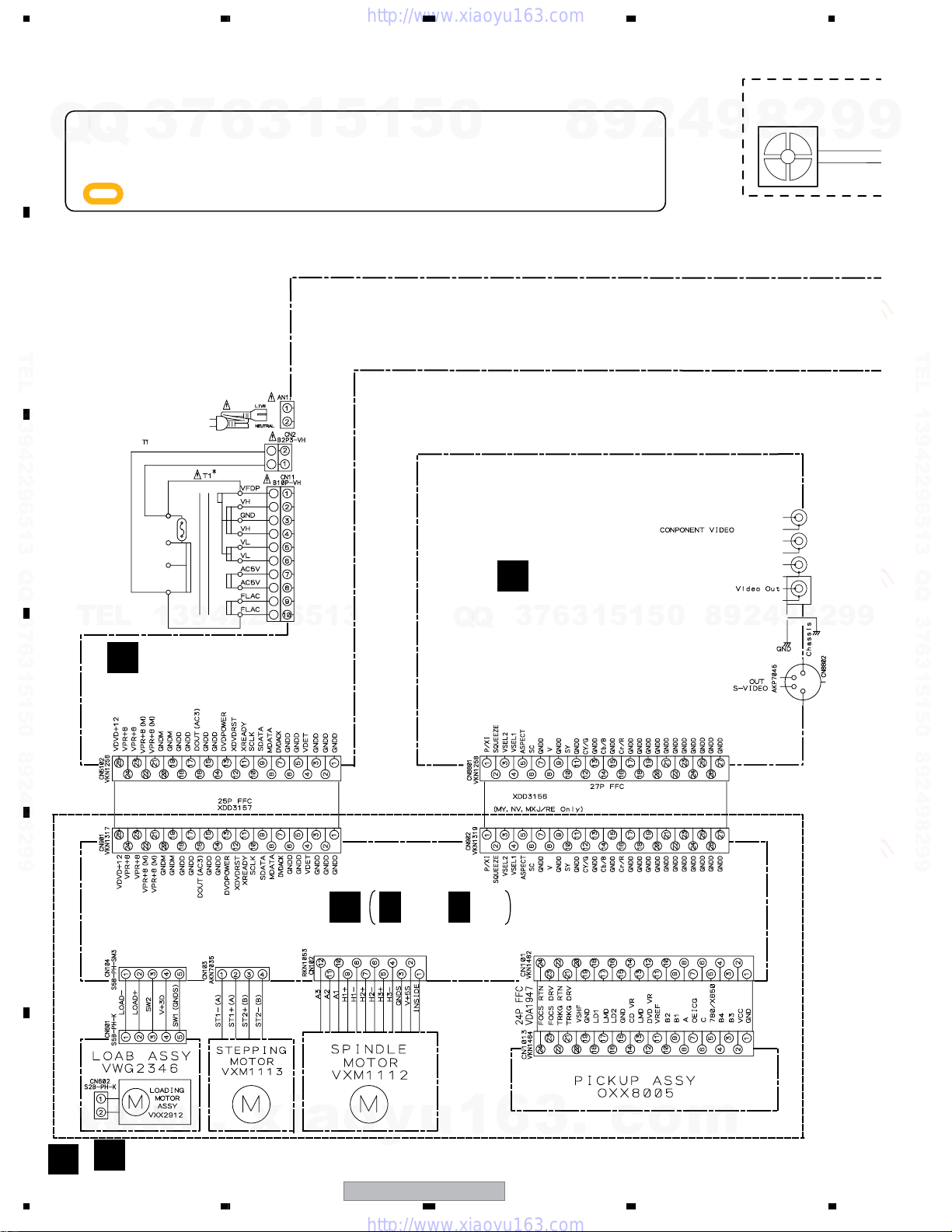

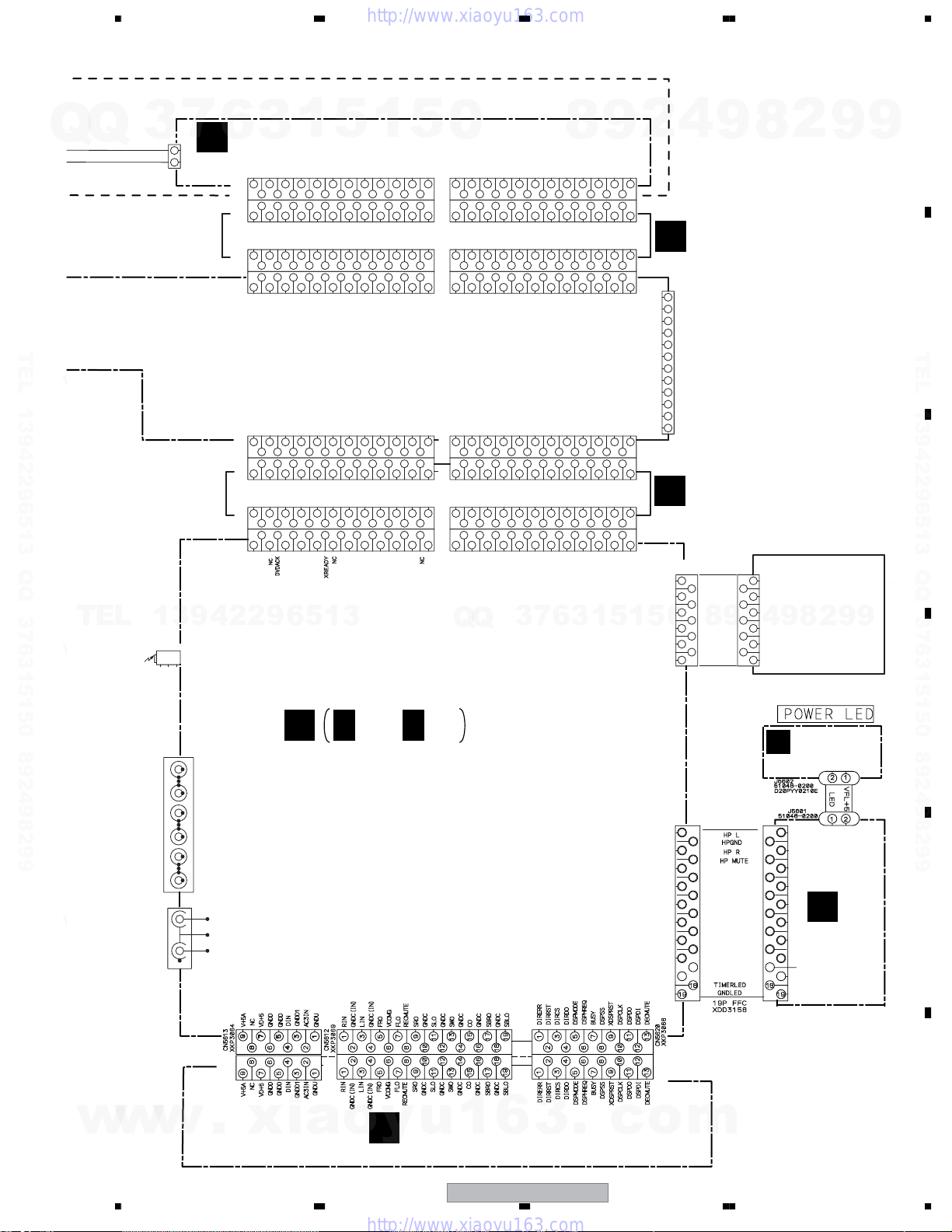

3.2 OVERALL WIRING CONNECTION DIAGRAM

A

B

TEL 13942296513 QQ 376315150 892498299

C

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

Q

Q

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

TEL

: The power supply is shown with the marked box.

7

3

MLXJ : XTS3077

YLXJ/NC, YPWXJ : XTS3078

13942296513

6

3

XKP3084

1

5

1

5

0

Q

Q

VIDEO ASSY

I

(XWZ3980)

7

3

6

8

3

9

1

5

1

2

5

4

0

9

8

9

8

2

YGND

YGND

CbGND

4

FAN

2

1

Y

2

1

Cb

2

3

Cr

JA8851

4

5

6

GND

2

8

9

9

9

9

TEL 13942296513 QQ 376315150 892498299

9

J

POWER ASSY(XWZ3975)

D

E

F

w

w

16

A

w

LOAB ASSY

A

(VWG2346)

1234

.

xia

B

DVDM ASSY (AWM7964)

B 1/2- B 2/2

o

y

u

1

6

XV-DV333

DVD ASSY (AXA7145)

3

.

c

o

m

5678

AMP UNT 6CH (XXQ3004)

CN3501

KM200SA2

Q

Q

3

FAN-

FAN+

7

2

1

6

6CH AMP (XWK3188)

D

XKP3071

CN3001

XKP3082

CN3011

XKP3082

CN3021

CN3031

XKP3071

3

VH-

VH-

1

3

246

2

1

3

1

3

2

2

1

3

VH-

VH-

FROUT

FROUT

4

4

FROUT

4

1

GNDP

FROUT

GNDP7FLOUT

5

56789

56789

56789

GNDP

GNDP

FLOUT

FLOUT

8

FLOUT

GNDS

9

GNDS

SWOUT

5

SWOUT

SWOUT

VH+

11

12

10

10

111213

111213

10

10

111213

VH+

SWOUT

13

VH+

VH+

COUT

COUT

14

14

14

14

COUT

15

15

15

15

COUT

1

VL+

VL+

SROUT

17

18

16

18

16

17

17

181820

16

16

17

VL+

VL+

SROUT

SROUT

19

19

19

19

SROUT

20

20

20

VL-

5

VL-

VL-

SLOUT

21

22

22

21

21

22

22

21

VL-

SLOUT

SLOUT

SLOUT

23

23

23

23

0

GNDF

17325

XKP3071

CN3002

1

XKP3082

CN3012

XKP3082

CN3022

1

XKP3071

CN3032

GNDF

2

2

UN+8V

UN+8V

UN+8V

3

321

3

UN+8V

GNDREG

GNDREG

4

4

567

5

4

4

567

GNDREG

GNDREG

TUNER

XPROTECT

6

8

8

7

8

6

8

TUNER

XPROTECT

VD+5

VD+5

9

9

9

VA-12

VA-12

VP+15

10

10

10

VP+15

TEL 13942296513 QQ 376315150 892498299

DVDON/OFF

TEL

HPAC

VPR+8(VD+5)

RYRC

RYFS

VX+12

XPROTECT

VA-12

3

1

CN5531

XKP3071

2

1

XKP3082

CN5521

2

CN5511

XKP3082

2

1156789

3

CN5501

XKP3071

HPAC

VPR+8(VD+5)

4

325

3

4

4

567

56789

4

RYRC

6

RYFS

8

789

VX–12

9

VX+12

13942296513

JA8602

TORX179PL

OPT IN

DIGITAL

213

GNDX

GNDX

10

10

VD+5

10

VA+12

111213

111213

111213

111213

MUTEC

VD+5

MUTE

VA+12

14

14

GNDA

FLIN

15

141016

15

14

15

FLIN

16

16

GNDA

GNDA

16

GNDA

FRIN

171715

17

17

FRIN

NCNCSRIN

SLIN

SWIN

CIN

21

23

19

22

18

20

22

18

20

19

23

21

21

23

19

22

18

20

22

18

20

19

21

23

CIN

SLIN

SRIN

SWIN

VE+56

CN5532

XKP3071

XKP3082

CN5522

CN5512

XKP3082

CN5502

XKP3071

GNDD

1

GNDD

Q

GNDD

321

GNDD

DOUT

GNDD

325

4

4

321

4

4

32165

DOUT

GNDD

Q

GNDU

567

5

GNDU

VE+56

6

6

7

SUBAC

SUBAC

7

8

7

8

VFL+5

FLAC1

8

9

8

9

FLAC1

3

FLAC2

9

9

FLAC2

SYSPOW

10

10

10

GNDFL

111213

111213

7

VFL+5

111213

111213

11

121410

111213

VFL+5

VFDP

VFL+5

111213

111213

VFDP

MUTE

SENSE+8

MUTEC

13

MUTE

MUTEC

GNDFL

14

MUTEC

6

8

FLIN

MUTE

GNDA

FRIN

151419

17

16

14916

15

15

16

14

16

15

CIN

FLIN

FRIN

GNDA

GNDFL

VDET

MDATA

ACK

172019

15

16

14

16

15

17

17

14

1615201922

161014

15

SCLK

SDATA

MDATA

XPROTECT

3

CIN

18

181720

181720

SWIN

SDATA

18

18

19

18

181720

VDET

1

SCLK

19

9

SRIN

SWIN

SLIN

21

202322

20

22

191817

21

21

19

22

22

19

21

SLIN

SRIN

GNDA

NC

XDVDRST

XREADY

21

20

22

21

21

22

21

NC

SYSPOW

XDVDRST

DVDON/OFF

5

VPR+8

VPR+8

22

23

23

1

VPR+8

23

23

23

VPR+8

NC

23

23

NC

2

G

JA3301

XKE3036

E

5

4

9

8

2

TRADE 1 ASSY (XWZ3997)

+

FL

-

+

FR

-

+

SW

-

6ch SPEAKER OUT

+

C

-

+

SL

-

+

SR

-

TRADE 2 ASSY (XWZ3998)

CN5701

52045-1145

GND

0

11

RDS

10

VSM

9

TXR

8

+9V

7

6

TXL

GND

5

DO

4

CLK

3

DI

2

CE

1

8

11pinFFC

11

10

9

FM/AM TUNER

8

7

UNIT

6

4

2

9

5

(AXX7173)

4

3

2

1

* No schematic diagram

9

8

2

9

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

9

w

w

JA3001

AKP7050

L

TV

R

L

LINE1LINEOUT

R

L

R

AKB1233

L

R

4

WIRELESS OUT

XV-DV535 only

w

JA9091

1

3

2

.

CN901

XKP3075

F 1/4- F 4/4

F

CONTROL ASSY

CN701

XKP3080

xia

o

(XWZ3969 : XV-DV333)

(XWZ3984 : XV-DV434)

(XWZ3989 : XV-DV535)

y

u

1

6

C DSP ASSY (AWX8587)

3

.

c

CN5611

52045-1545

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16 16

17 17

CN951

XKP3077

o

m

HPDET

VFDP

XFLRST

FLCS

FLCK

FLDATA

VFL+5

GNDFL

FLAC2

FLAC1

KEY1

REMOCON

VFL+5

LED ASSY

K

(XWZ4000)

CN5601

1

52044-1545

2

3

4

5

6

7

8

9

10

11

12

13

14

15

H

DISPLAY ASSY

D

E

(XWZ3979)

F

56

XV-DV333

17

7

8

1234

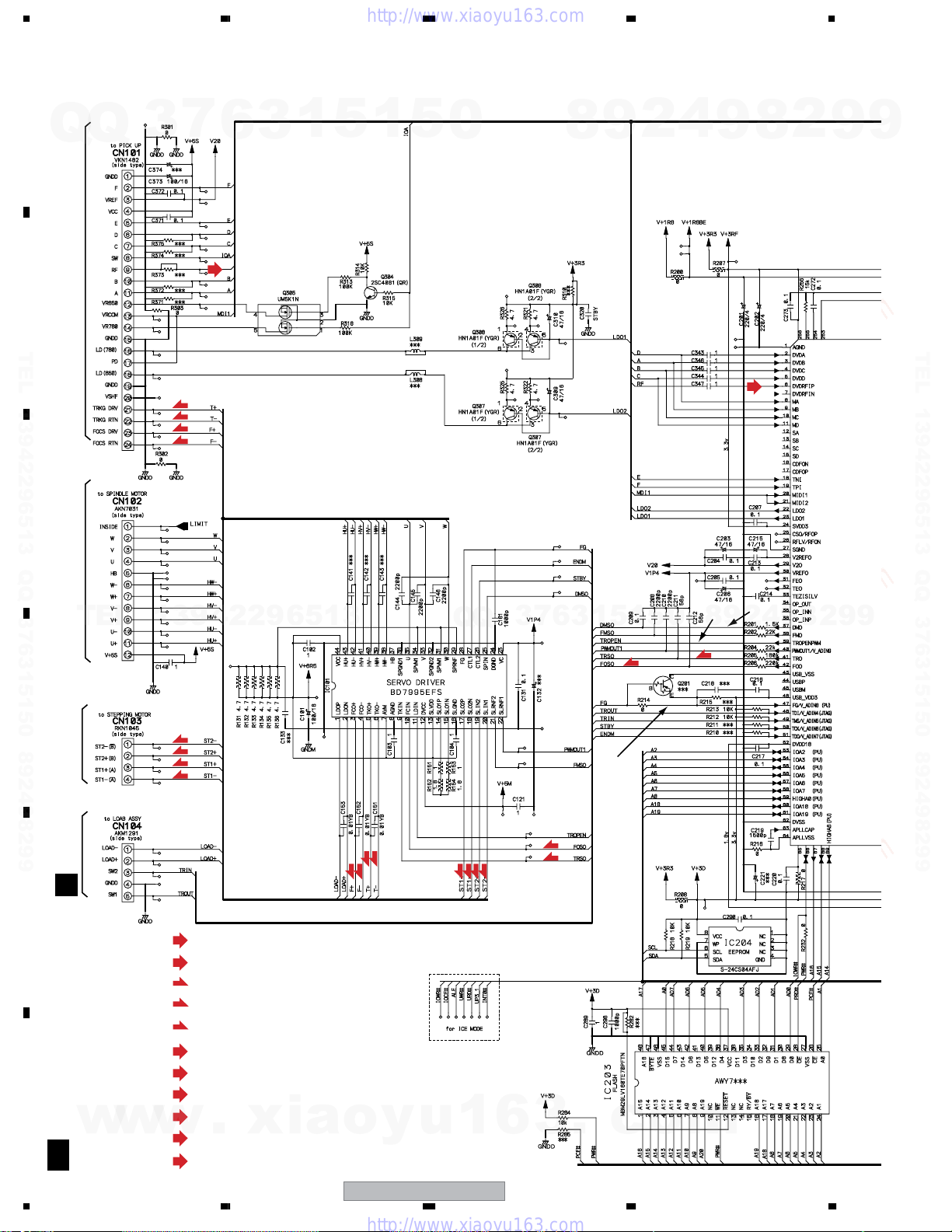

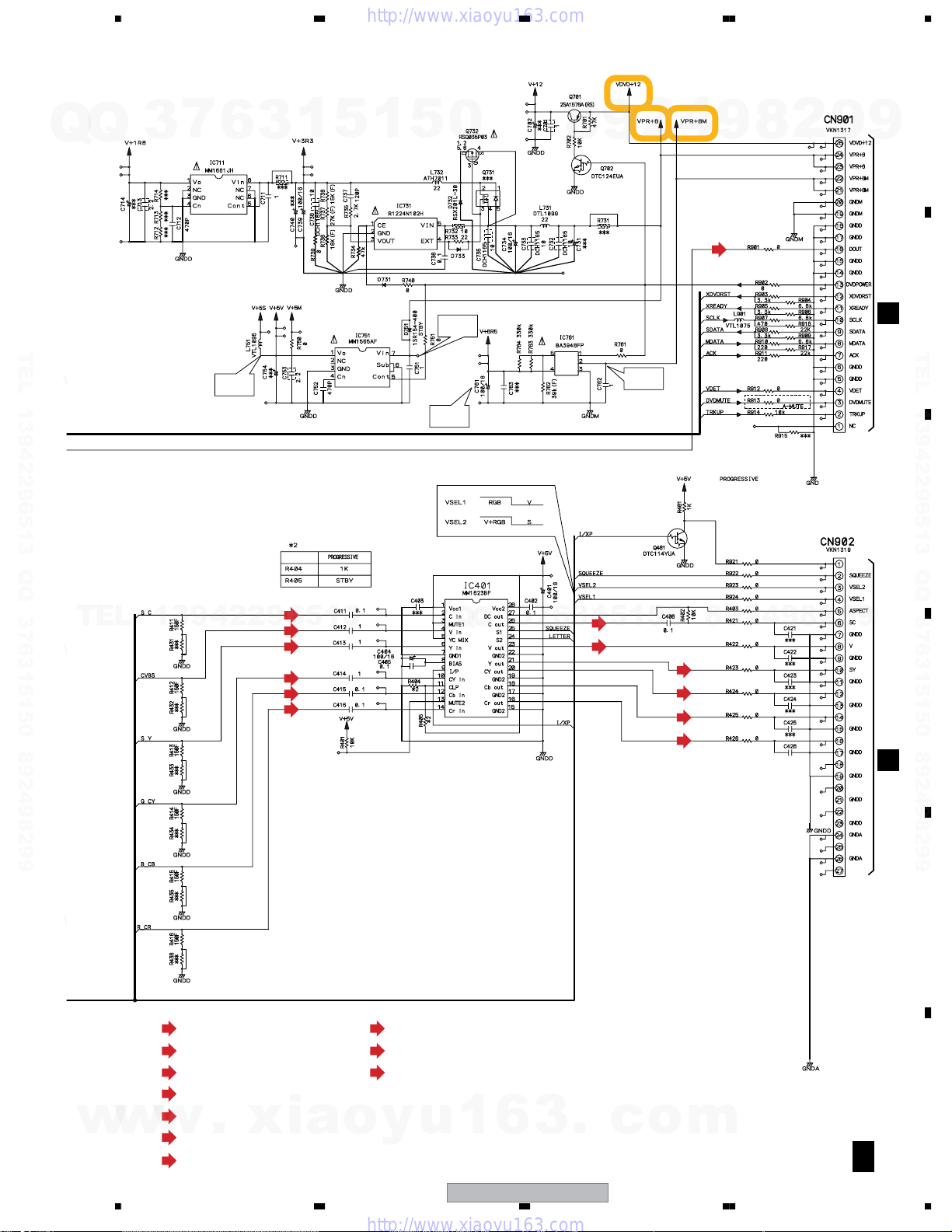

3.3 DVDM ASSY (1/2)

A

7

Q

Q

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

(RF)

B

TEL 13942296513 QQ 376315150 892498299

(T)

(T)

(F)

(F)

C

FTS DRIVER

TEL

13942296513

Q

Q

LD Driver for CD

LD Driver for DVD

7

3

6

3

1

5

1

(F)

5

0

2

8

TEL 13942296513 QQ 376315150 892498299

(RF)

3

2

9

(T)

4

9

8

2

9

9

D

E

F

B

18

MOTOR

STEPPING

CN601 PICKUP ASSY CN1013SPINDLE MOTOR

A

w

w

1/2

A

1234

(S)

(S)

(S)

(S)

(RF)

: RF SIGNAL ROUTE

(D)

: AUDIO SIGNAL ROUTE(DIGITAL)

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: STEPPING SERVO LOOP LINE

(C/V)

: VIDEO SIGNAL ROUTE

(R/Cr)

: VIDEO SIGNAL ROUTE(R/Cr)

(G/Y)

: VIDEO SIGNAL ROUTE(G/Y)

(B/Cb)

: VIDEO SIGNAL ROUTE(B/Cb)

(S_Y)

w

(S_C)

.

: S VIDEO SIGNAL ROUTE

: S VIDEO SIGNAL ROUTE

xia

(F)

(F)

(T)

(T)

o

y

XV-DV333

u

(S)

(S)

(S)

1

(S)

6

3

1

(F)

(T)

.

c

o

m

5678

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

3

1

5

(D)

!

1

5

0

(R/CY)

(B/Cb)

(G/Y)

(C/V)

B

8

(S_C)

DVDM ASSY

1/2

(AWM7964)

2

9

(S_Y)

4

9

8

2

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

D

E

w

w

w

.

xia

56

o

y

u

1

6

XV-DV333

3

.

c

7

o

m

F

B

1/2

19

8

1234

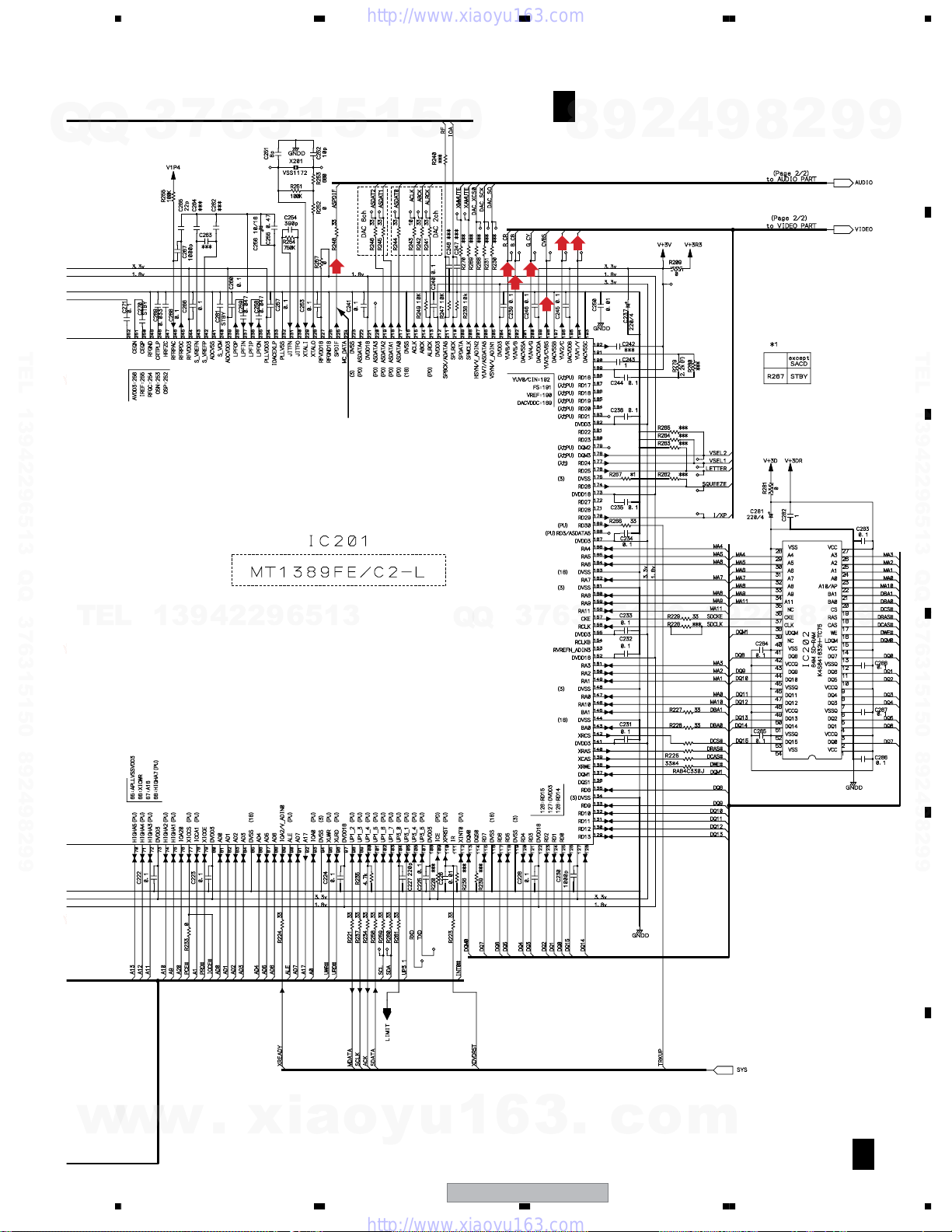

3.4 DVDM ASSY (2/2)

B

A

Q

B

TEL 13942296513 QQ 376315150 892498299

C

DVDM ASSY

2/2

(AWM7964)

Q

3

7

6

3

1

5

1

5

(D)

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

D

E

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

F

w

w

20

B

A

w

2/2

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

5678

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

6

1.8V Regulator

3

1

5

1

5

3V Regulator

5V Regulator

0

7.8V

9

8

6.5V Regulator

2

4

9

(D)

8

2

9

A

9

CN5102

B

TEL 13942296513 QQ 376315150 892498299

TEL

5.0V

13942296513

(S_C)

(C/V)

(C_Y)

(G/Y)

(B/Cb)

(S/Cr)

6.4V

Video Driver Amp

Q

Q

3

7

6

3

1

(S_C)

5

(C/V)

7.8V

1

5

0

(S_Y)

(G/Y)

(B/Cb)

(R/Cr)

8

9

2

4

9

8

2

9

NC

G

B

R

NC

NC

NC

C

9

D

CN8801

I J

w

w

(D)

: AUDIO SIGNAL ROUTE

(C/V)

: VIDEO SIGNAL ROUTE

(R/Cr)

: VIDEO SIGNAL ROUTE(R/Cr)

(G/Y)

: VIDEO SIGNAL ROUTE(G/Y)

(B/Cb)

: VIDEO SIGNAL ROUTE(B/Cb)

(S_Y)

w

(S_C)

.

: S VIDEO SIGNAL ROUTE

: S VIDEO SIGNAL ROUTE

xia

56

(R)

: VIDEO SIGNAL ROUTE(R)

(G)

: VIDEO SIGNAL ROUTE(G)

(B)

: VIDEO SIGNAL ROUTE(B)

o

y

u

1

6

XV-DV333

3

.

c

7

o

m

NC

NC

E

F

B

2/2

A

21

8

1234

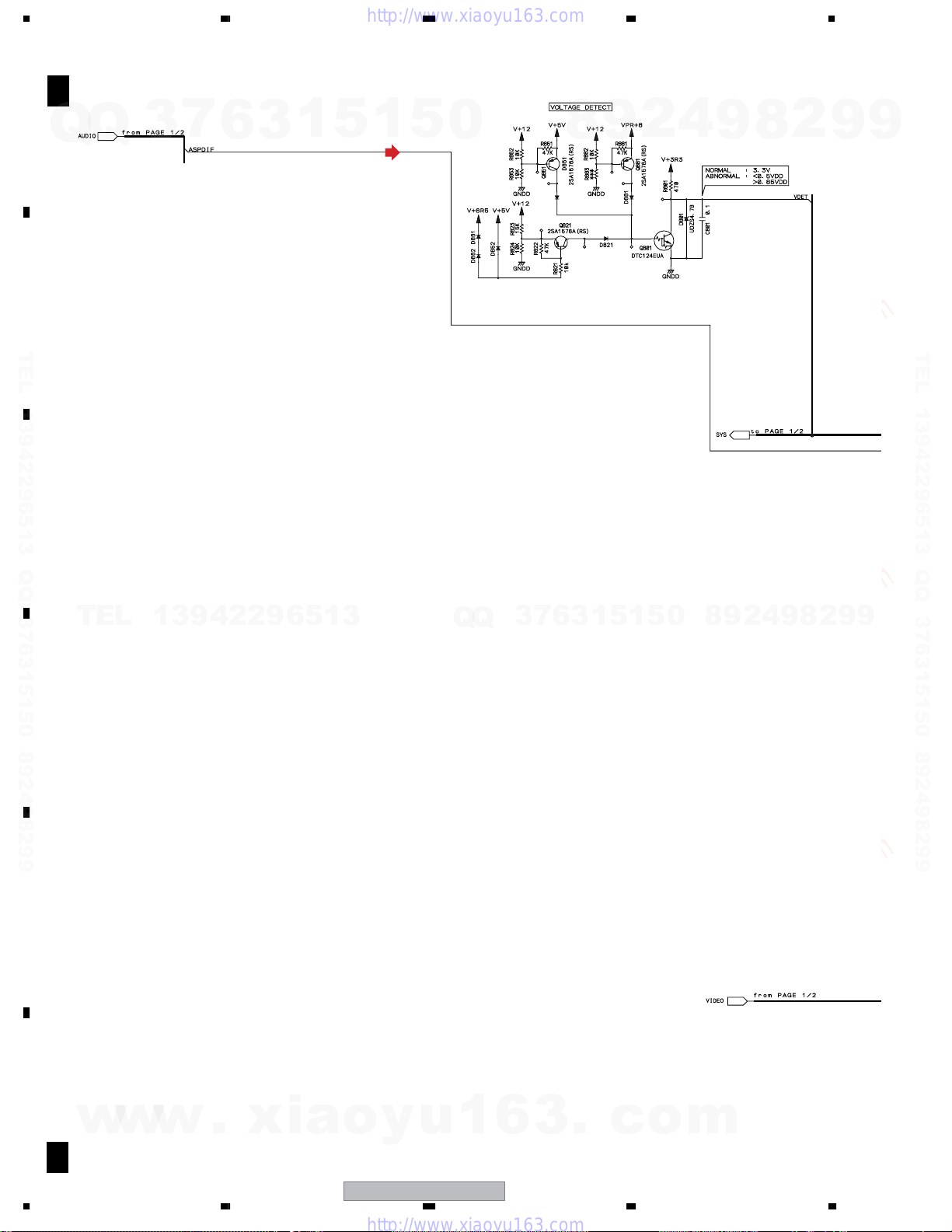

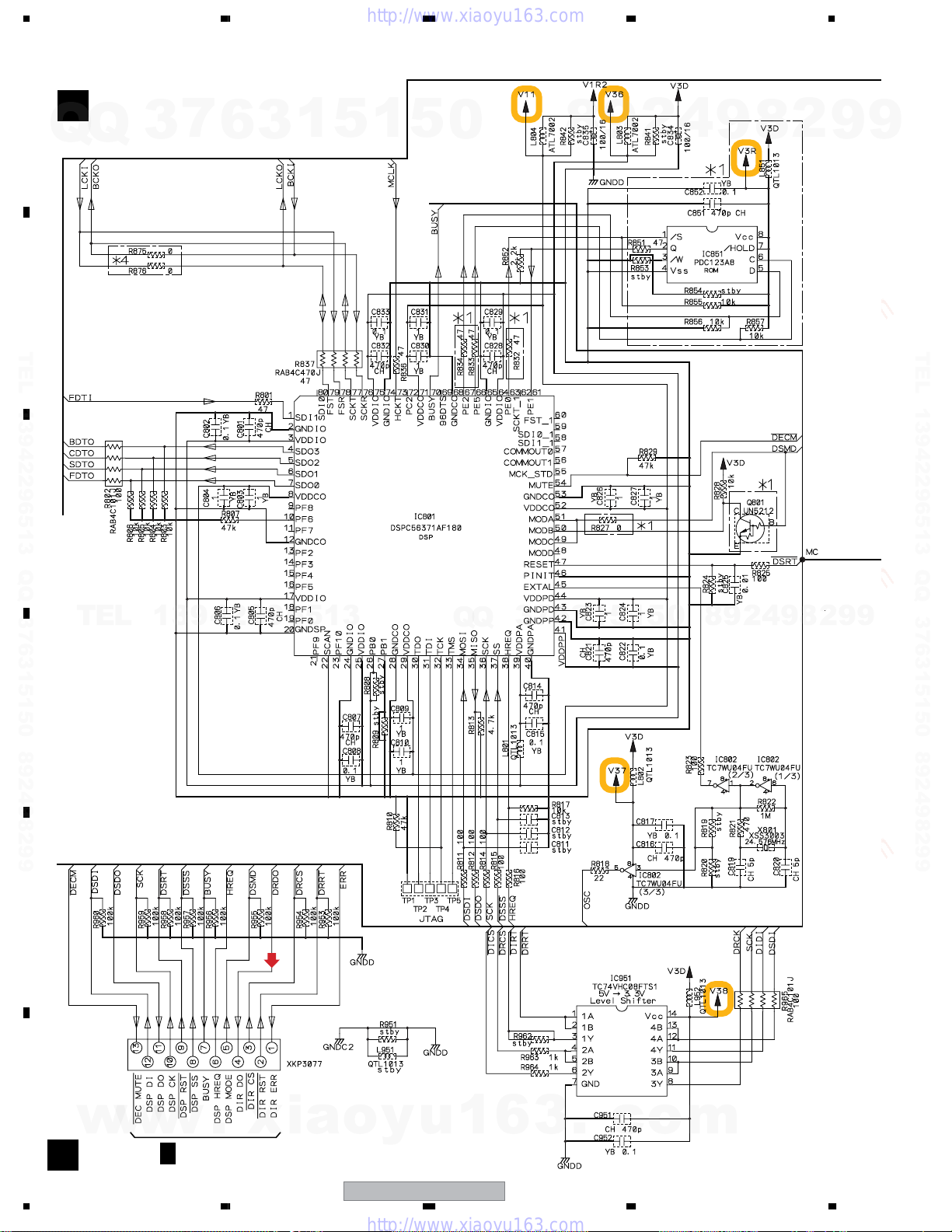

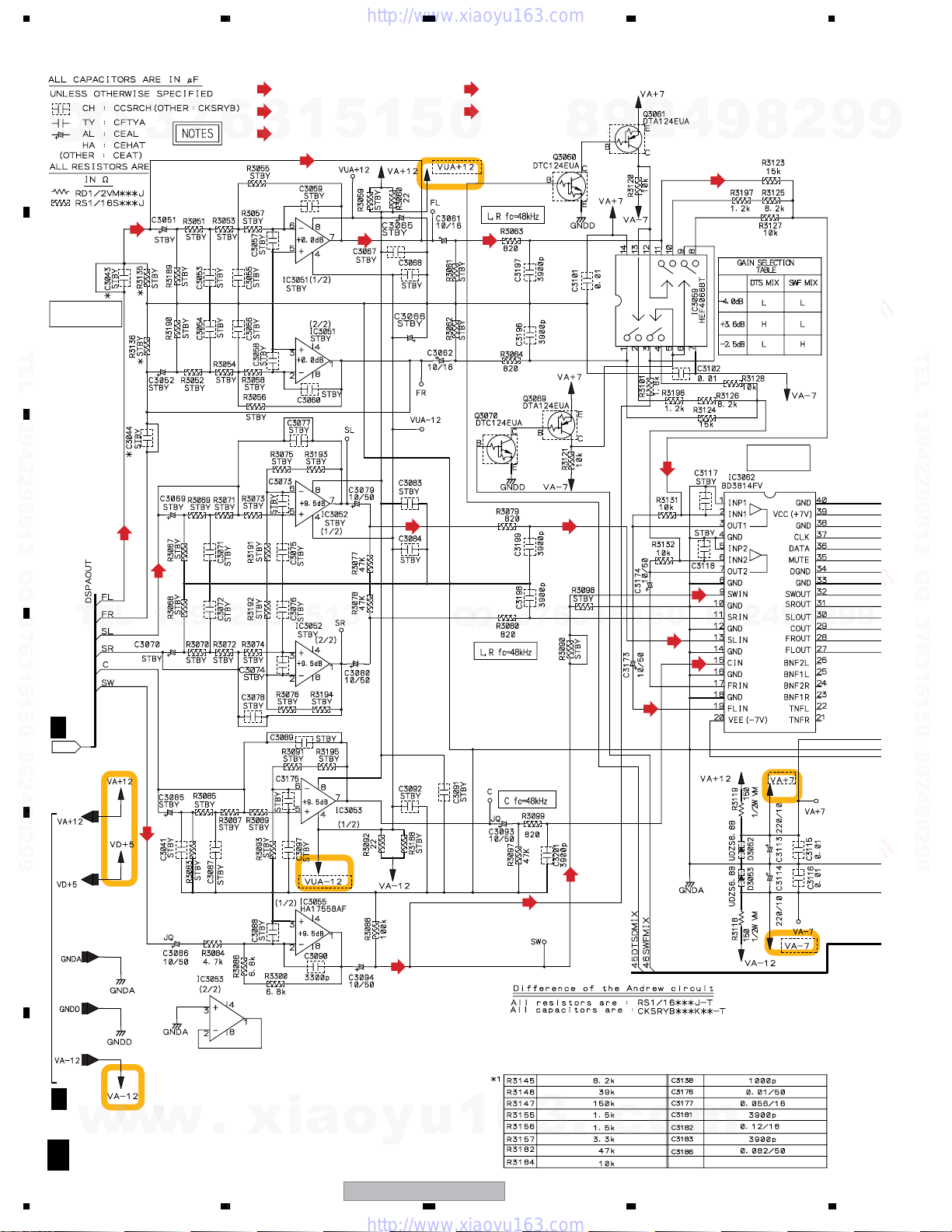

3.5 DSP ASSY

A

B

TEL 13942296513 QQ 376315150 892498299

C

DSP ASSY (AWX8587)

C

7

Q

Q

3

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

D

E

13942296513

(D)

CN951

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

F

w

w

22

C

w

F

1234

1/4

.

CN5620

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

5678

: AUDIO SIGNAL ROUTE(L ch)

(DVD)

: AUDIO SIGNAL ROUTE(DVD L ch)

(D)

7

Q

Q

TEL 13942296513 QQ 376315150 892498299

3

: AUDIO SIGNAL ROUTE(DIGITAL)

1

6

3

(AD)

: AUDIO DATA SIGNAL ROUTE

(AD)

(AD)

(AD)

5

(AD)

1

5

0

(DVD)

(SL)

8

(SW)

(DVD)

(FL)

: AUDIO SIGNAL ROUTE(Front L ch)

: AUDIO SIGNAL ROUTE(Surround L ch)

(C)

: AUDIO SIGNAL ROUTE(Center ch)

9

: AUDIO SIGNAL ROUTE(Sub Woofer ch)

2

4

9

(FL)

(SL)

(sw)

(C)

8

2

CN701

9

9

A

B

TEL 13942296513 QQ 376315150 892498299

CN5612

1/4

F

C

TEL

13942296513

(D)

(D)

(D)

(D)

(D)

Q

Q

3

7

6

3

1

5

1

5

(D)

0

8

(D)

CN901

9

2

4

9

8

2

9

9

D

E

w

w

w

.

xia

56

o

y

u

1

6

XV-DV333

3

.

F

c

1/4

7

CN5613

o

F

m

C

23

8

1234

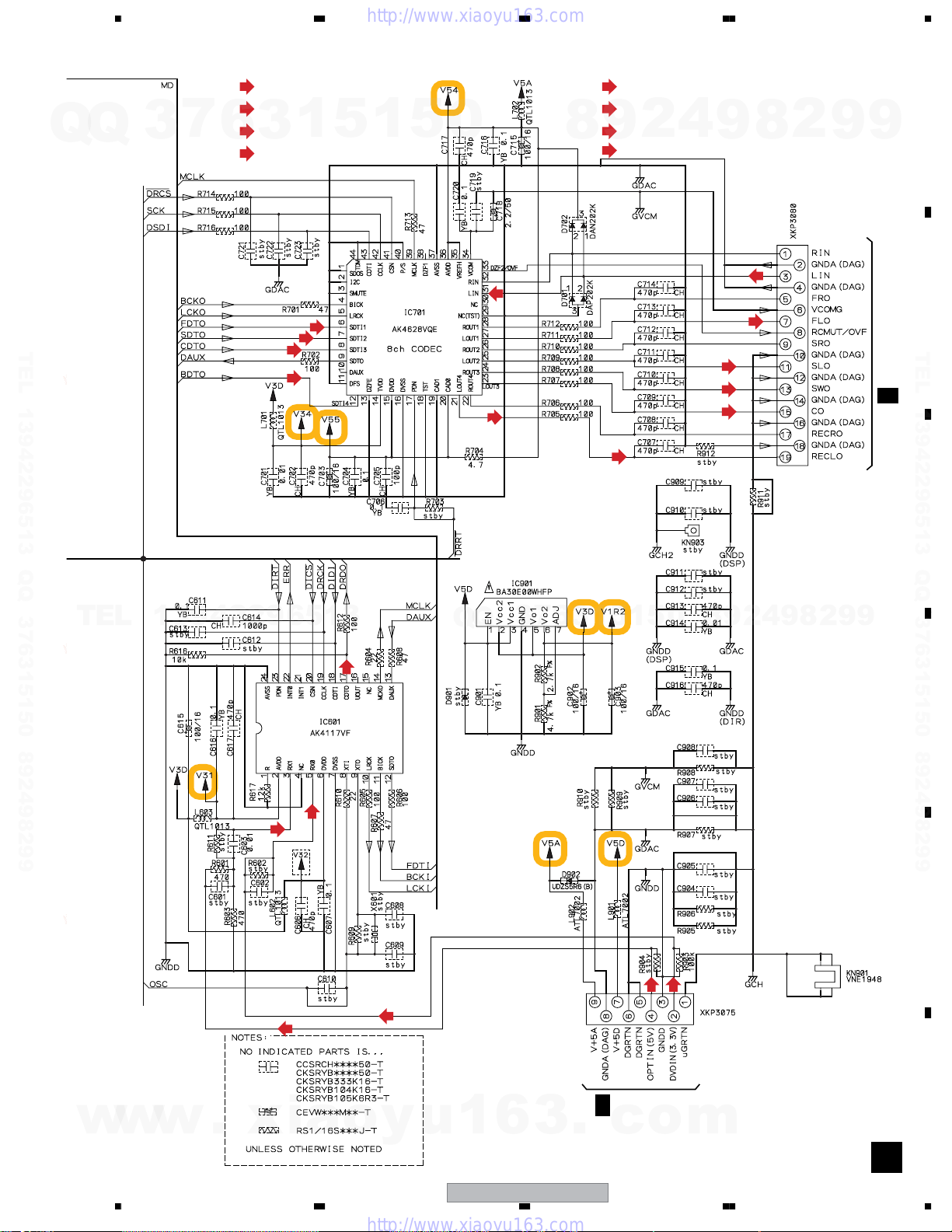

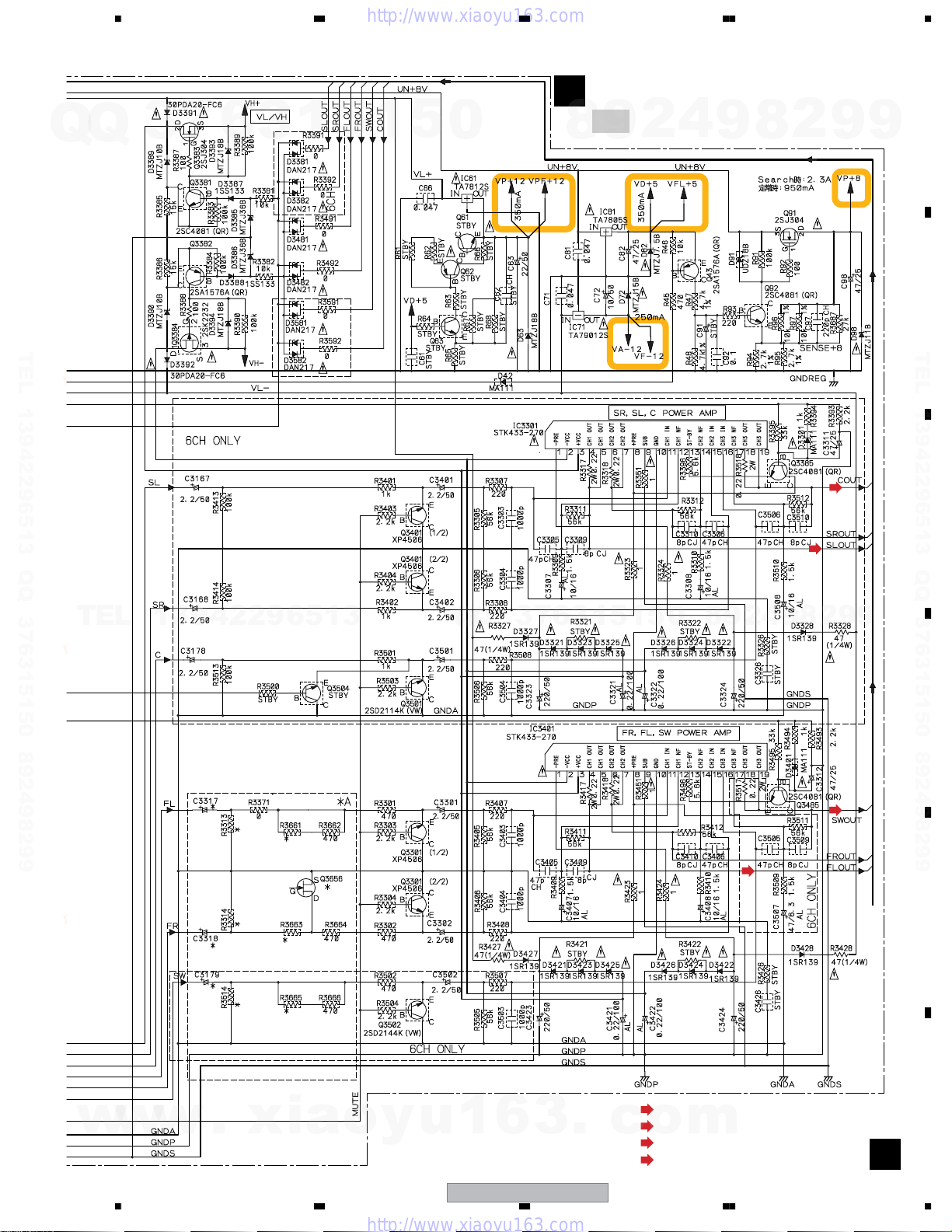

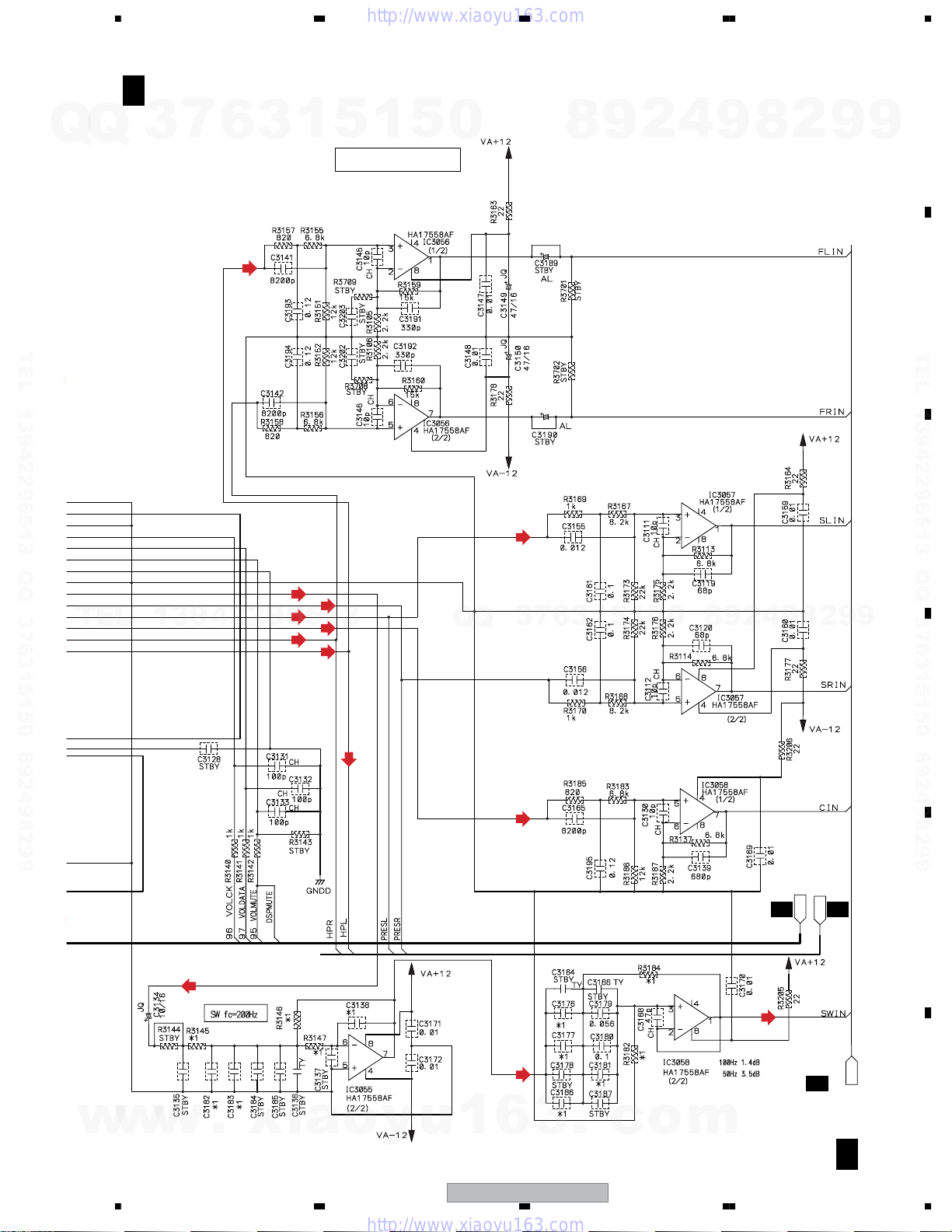

3.6 6CH AMP ASSY

A

7

Q

Q

B

CN3011

TEL 13942296513 QQ 376315150 892498299

G

3

6

3

1

(SL)

(C)

(SW)

(FL)

5

1

5

0

8

2

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

CN3001

C

D

CN3002

TEL

CN3012

G

13942296513

(FL)

(SL)

(C)

(SW)

5

3

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

E

F

w

w

w

D

24

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

Q

Q

3

5678

7

6

3

1

5

1

5

0

6CH AMP (XWK3188)

D

: Refer to "7.3.2 PROTECTION CIRCUIT.

4

2

9

8

9

8

2

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

4

9

(SL)

8

(C)

2

9

TEL 13942296513 QQ 376315150 892498299

C

9

D

w

w

w

.

xia

56

o

y

u

1

6

XV-DV333

3

.

(FL)

(FL)

: AUDIO SIGNAL ROUTE (Front L ch)

(SL)

: AUDIO SIGNAL ROUTE (Surround L ch)

c

o

(C)

(SW)

7

m

: AUDIO SIGNAL ROUTE (Center ch)

: AUDIO SIGNAL ROUTE (Sub Woofer ch)

(SW)

E

F

D

25

8

1234

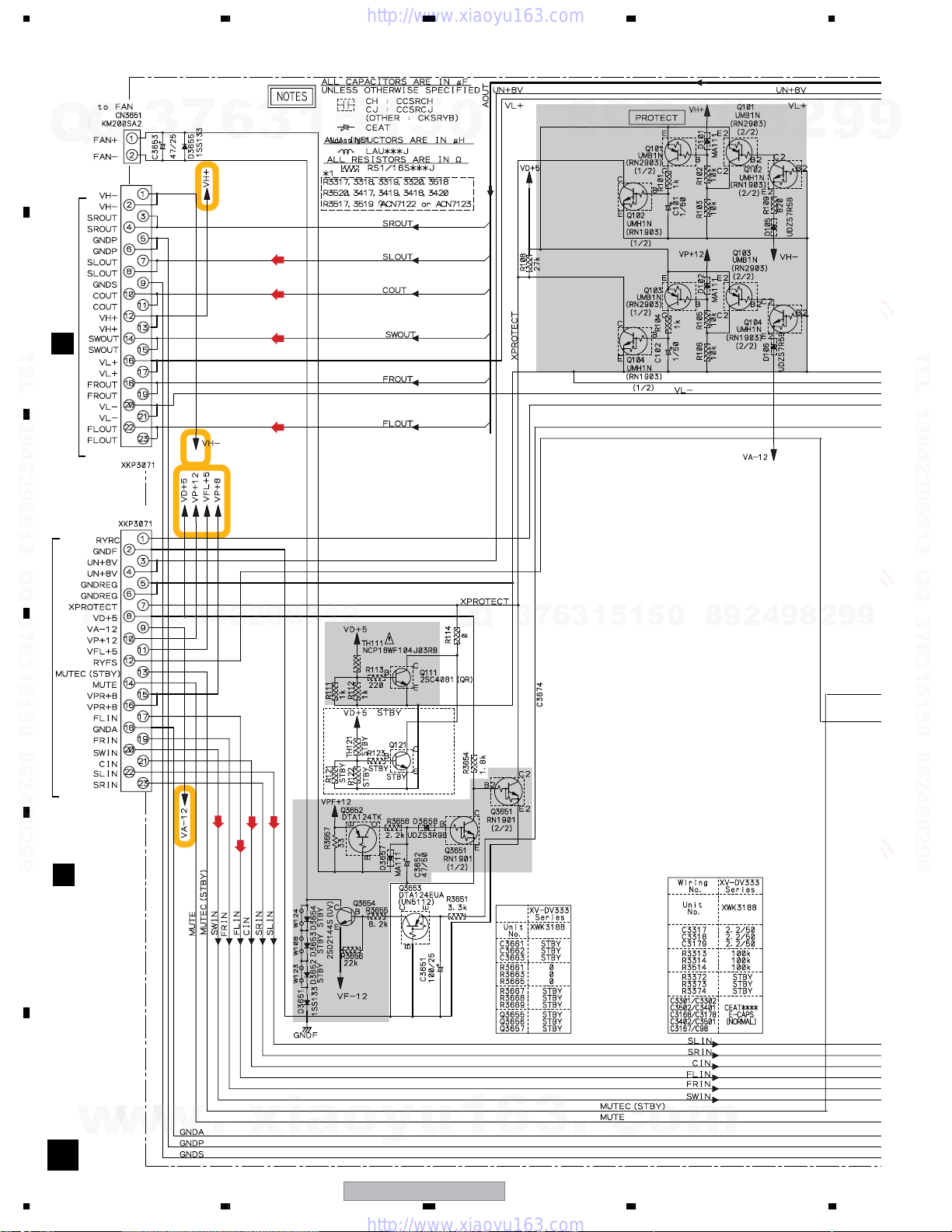

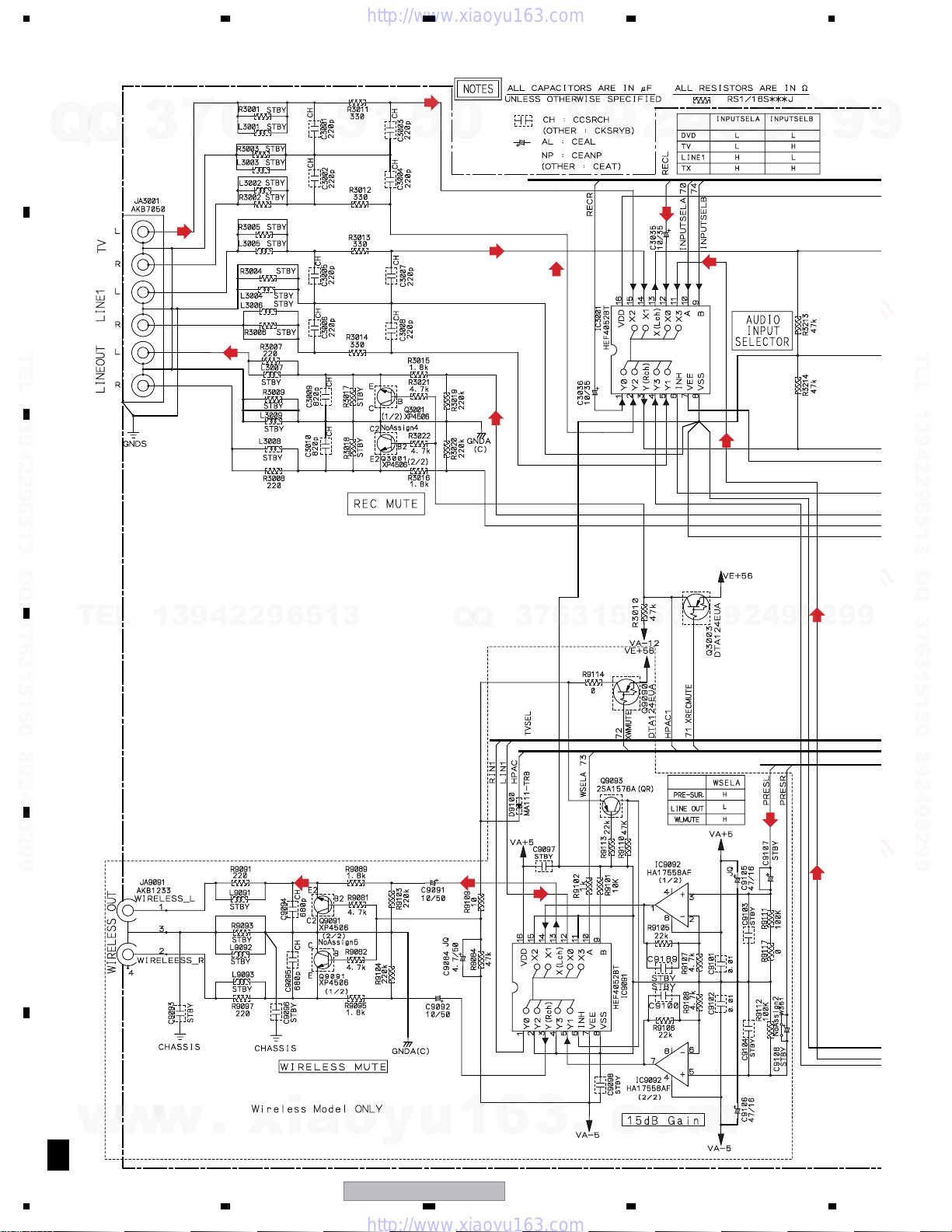

3.7 CONTROL (1/4) and TRADE 2 ASSYS

A

F

Q

Q

2/4-4/4

F

B

TEL 13942296513 QQ 376315150 892498299

F

4/4

F

2/4-4/4

F

4/3

F

2/4-4/4

XV-DV535

XV-DV333

C

XV-DV333

CONTROL ASSY (XWZ3969 : XV-DV333)(XWZ3984 : XV-DV434)

1/4

(XWZ3989 : XV-DV535)

XV-DV434

3

XV-DV535

7

6

3

1

5

1

5

0

8

9

2

4

9

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

CN5613

TEL

CN901

CCC

D

E

CN5612

CN701CN951

CN5620

13942296513

(D)

(D)

(D)

(D)

(DVD)

(DVD)

(DVD)

(D)

(D)

Q

Q

3

7

6

3

1

5

1

(DVD)

5

(D)

0

(D)

8

9

2

4

9

8

2

9

9

F

w

w

26

F

A

w

1/4

1234

.

DSPAOUT

xia

F

2/4

o

y

u

1

6

XV-DV333

3

.

c

o

m

Q

Q

3

5678

7

6

3

1

5

1

5

0

F

4/4

HPINPUT

CN5611

8

H

2

9

CN5601

4

9

8

2

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

TEL

13942296513

(FL)

(SW)

(C)

(SL)

Q

(FL)

(SW)

(SL)

Q

(C)

3

CN5501

7

3

6

CN5511

: Refer to "7.3.2 PROTECTION CIRCUIT.

TRADE 2 ASSY (XWZ3998)

E

4

2

9

8

0

5

1

5

1

(FL)

(SW)

(C)

(SL)

CN5521

9

8

2

9

TEL 13942296513 QQ 376315150 892498299

C

9

CN5531CN5532

JJ

D

w

w

w

CN5502

(D)

F

2/4

EVOLAOUT

U-COM

I/O

.

xia

56

F

3/4,4/4

F

3/4,4/4

o

: AUDIO SIGNAL ROUTE (L ch)

(DVD)

: AUDIO SIGNAL ROUTE (DVD L ch)

(D)

: AUDIO SIGNAL ROUTE (DIGITAL)

y

u

(FL)

: AUDIO SIGNAL ROUTE (Front L ch)

1

(D)

6

XV-DV333

CN5512

3

.

(SL)

(C)

(SW)

c

7

CN5522

(D)

: AUDIO SIGNAL ROUTE (Surround L ch)

: AUDIO SIGNAL ROUTE (Center ch)

: AUDIO SIGNAL ROUTE (Sub Woofer ch)

o

m

F

8

1/4

E

F

E

27

1234

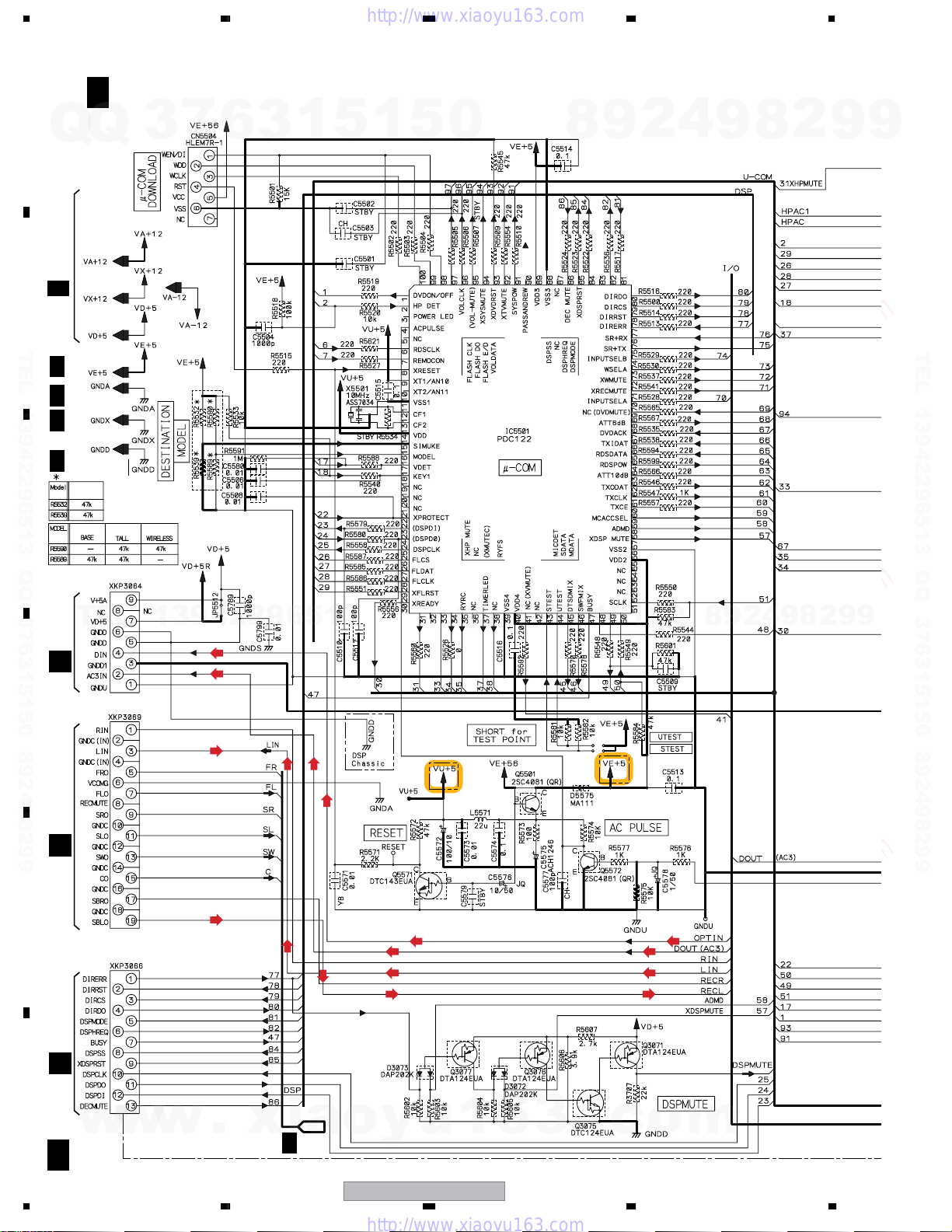

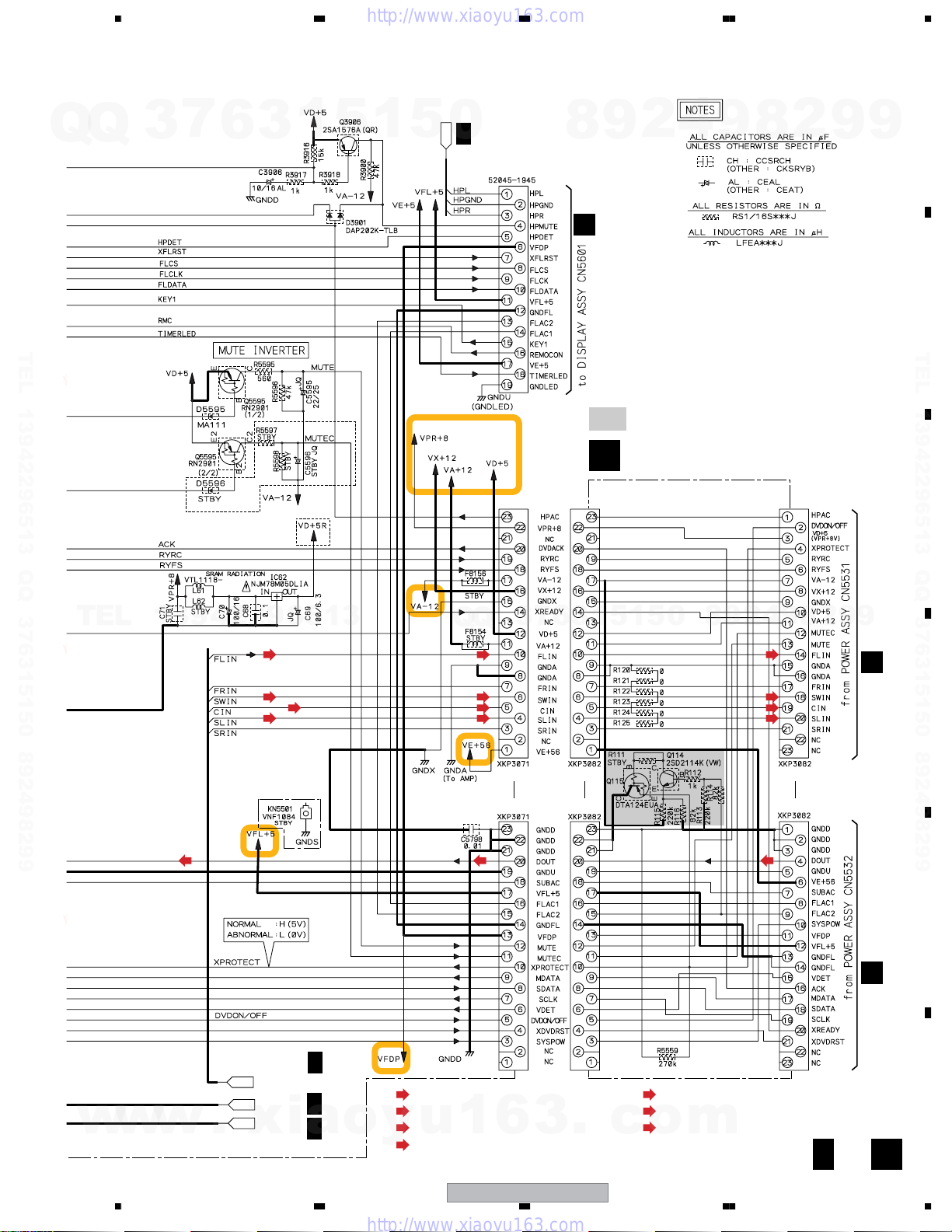

3.8 CONTROL (2/4) ASSY

(SL)

6

(SW)

(SW)

A

Q

Q

3

7

: SLch AUDIO SIGNAL ROUTE

: SWch AUDIO SIGNAL ROUTE

: SWch AUDIO SIGNAL ROUTE(THEATER BASS)

1

5

3

1

5

(FL)

0

: AUDIO SIGNAL ROUTE

: FLch AUDIO SIGNAL ROUTE

9

8

2

4

9

8

2

9

9

(FL)

(FL)

B

LPF & GAIN

TEL 13942296513 QQ 376315150 892498299

C

(FL)

(SL)

(FL) (FL)

(SL) (SL)

(SW)

(FL)

(FL)

TEL 13942296513 QQ 376315150 892498299

E-VOL

D

F

DSPAOUT

E

TEL

1/4

13942296513

(SW)

(SW)

Q

Q

3

(SW)

7

6

3

1

(SW)

5

1

(FL)

5

(SL)

0

(C)

8

9

2

4

9

8

2

9

9

F

F

1/4,2/4-4/4

w

F 2/4

28

w

w

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

5678

F 2/4

Q

TEL 13942296513 QQ 376315150 892498299

(XWZ3969 : XV-DV333)

Q

(XWZ3984 : XV-DV434)

(XWZ3989 : XV-DV535)

CONTROL ASSY

7

3

6

(FL)

3

1

5

ANDREW CIRCUIT

1

5

0

(SL)

8

9

2

4

9

8

2

9

A

9

B

TEL 13942296513 QQ 376315150 892498299

C

TEL

(SW)

(SR)

13942296513

(SW)

(SL)

(FR)

(C)

(FL)

(FL)

Q

Q

(C)

3

7

6

3

1

5

1

5

0

8

9

2

(SW)

2

8

9

4

U-COM

ANALOGOUT

F 1/4, 3/4, 4/4

9

9

F 3/4,4/4

D

E

w

w

w

(SW)

.

xia

56

o

y

u

1

6

XV-DV333

3

.

c

7

o

m

F 1/4

F

EVOLAOUT

F 2/4

29

8

1234

3.9 CONTROL (3/4) ASSY

A

7

Q

Q

B

TEL 13942296513 QQ 376315150 892498299

C

3

(TVL)

6

(FL)

3

1

5

1

(PRETVL)

5

0

(LINE1L)

(LOUT)

8

(TVL)

9

2

4

9

(TXL)

(TXL)

8

2

9

9

TEL 13942296513 QQ 376315150 892498299

TEL

D

E

13942296513

(WIRELESS_L)

Q

Q

3

7

6

3

1

5

1

5

0

8

9

2

9

4

(PRESL)

8

2

9

(TXL) (TXL)

9

F

30

w

F 3/4

XV-DV535

w

w

1234

.

xia

o

y

u

1

6

XV-DV333

3

.

c

o

m

Loading...

Loading...