Page 1

ORDER NO.

2012

RRV4322

X-HM81-K

NETWORK CD RECEIVER SYSTEM

X-HM81-K

X-HM81-S

X-HM71-K X-HM71-S

NETWORK CD RECEIVER

XC-HM81-K XC-HM81-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

X-HM81-K, X-HM81-S SYXE8 AC 220 V to 240 V

XC-HM81-K, XC-HM81-S SYXE8 AC 220 V to 240 V

X-HM71-K, X-HM71-S SYXE8 AC 220 V to 240 V

X-HM71-K CXE AC 120 V

X-HM71-S AXQ5 AC 220 V

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-MZV AUG.

2012 Printed in Japan

Page 2

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

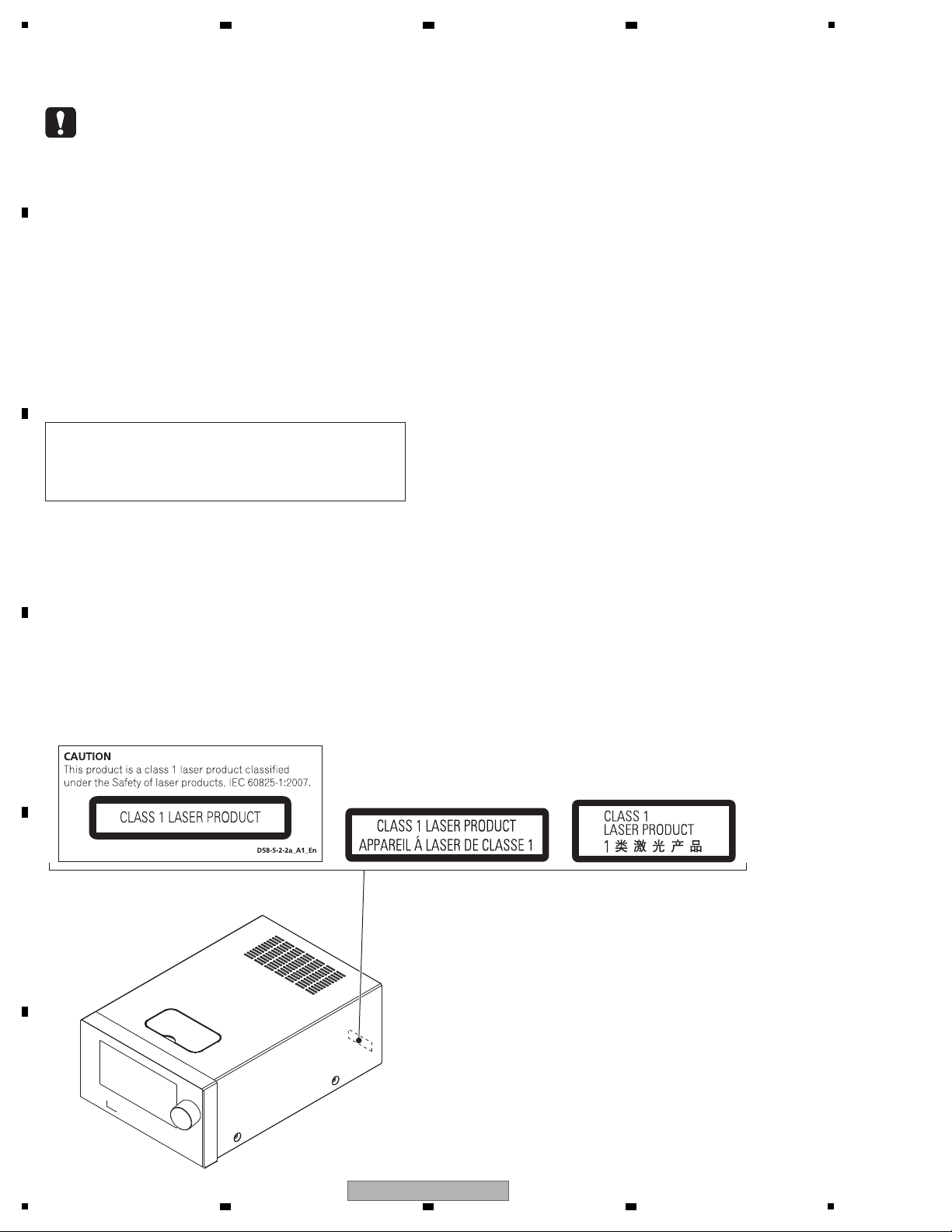

For CD Wave length (typ) : 790 nm

Operation output : 3 mW CW, Class 1

Maximum output : Class 1 (Under fault condition)

Laser Pickup specifications and Laser characteristics

LABEL CHECK

CXE model

SYXE8 model

AXQ5 model

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

X-HM81-K

Page 3

5

6 7 8

CONTENTS

SAFETY INFORMATION..........................................................................................................................................................2

1. SERVICE PRECAUTIONS....................................................................................................................................................4

1.1 NOTES ON SOLDERING........................................... ....................................................................................................4

1.2 WHEN REPLACING MECHA....................... ................................................ ... ...............................................................4

1.3 WHEN REPLACING CR870 (Module including BCO Assy)...........................................................................................4

2. SPECIFICATIONS.................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING .............................................. .............................................................................6

3.2 JIGS LIST............................................. .......................................... ................................................................................6

3.3 PCB LOCATIONS...........................................................................................................................................................7

4. BLOCK DIAGRAM..............................................................................................................................................................10

4.1 OVERALL WIRING DIAGRAM.....................................................................................................................................10

4.2 OVERALL BLOCK DIAGRAM............................. ..........................................................................................................12

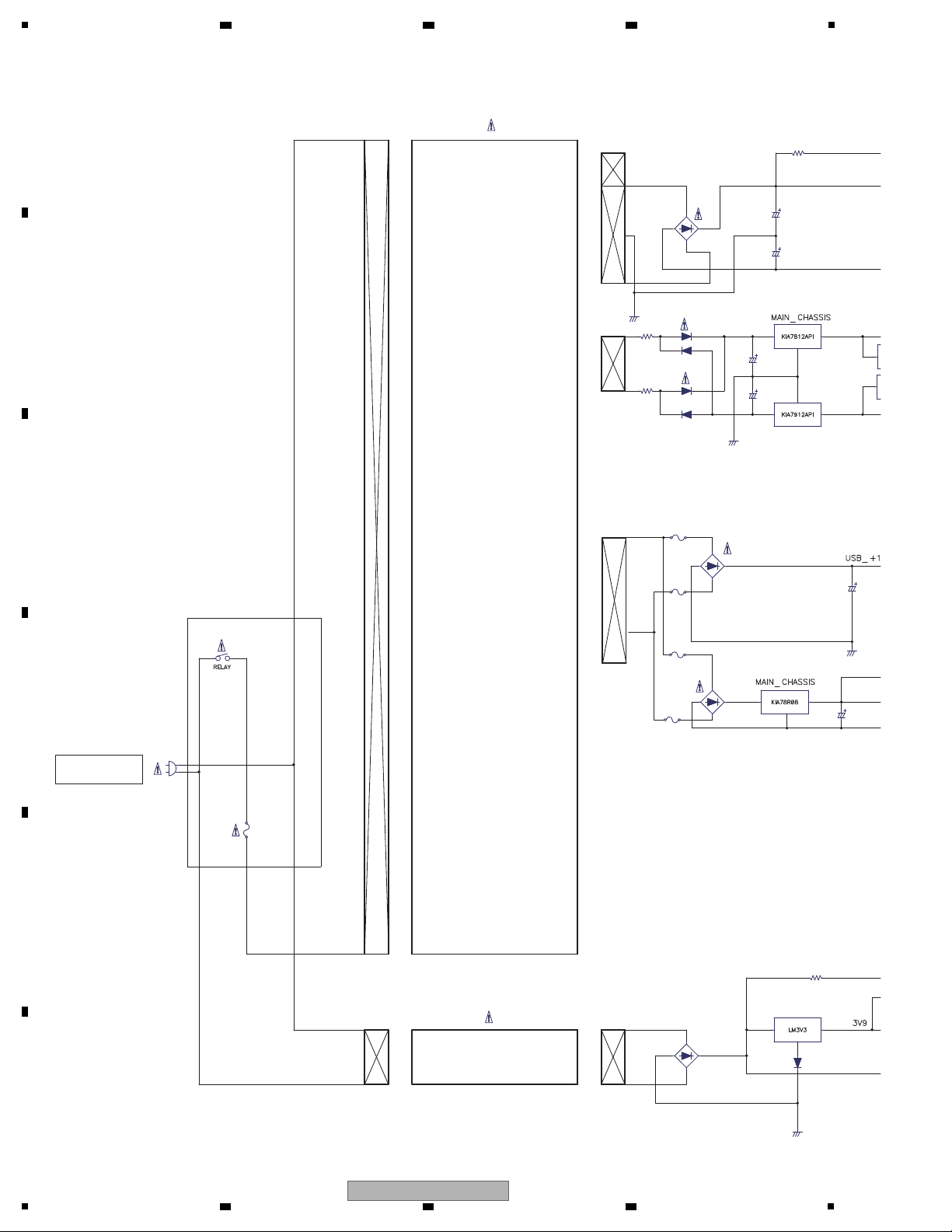

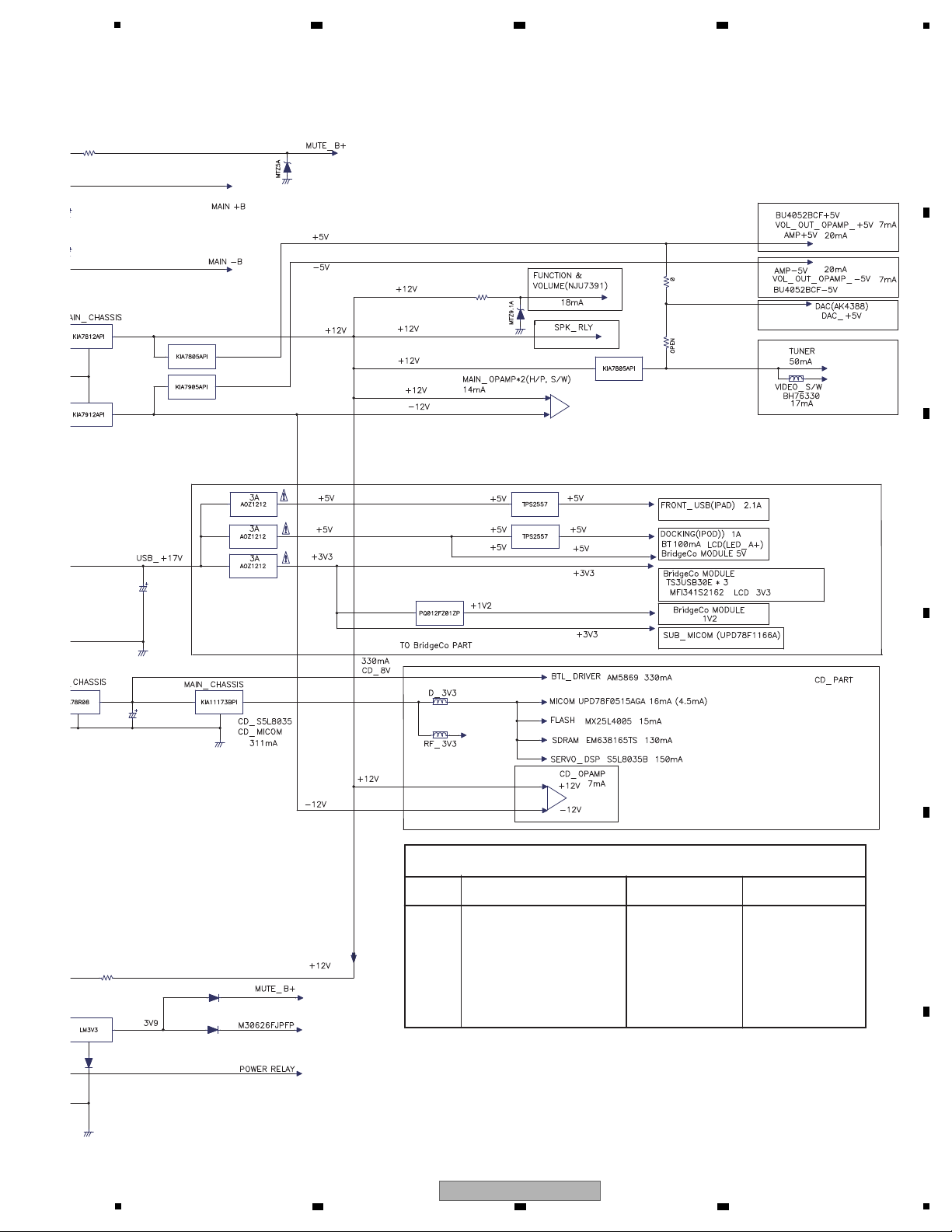

4.3 POWER SUPPLY BLOCK DIAGRAM...........................................................................................................................14

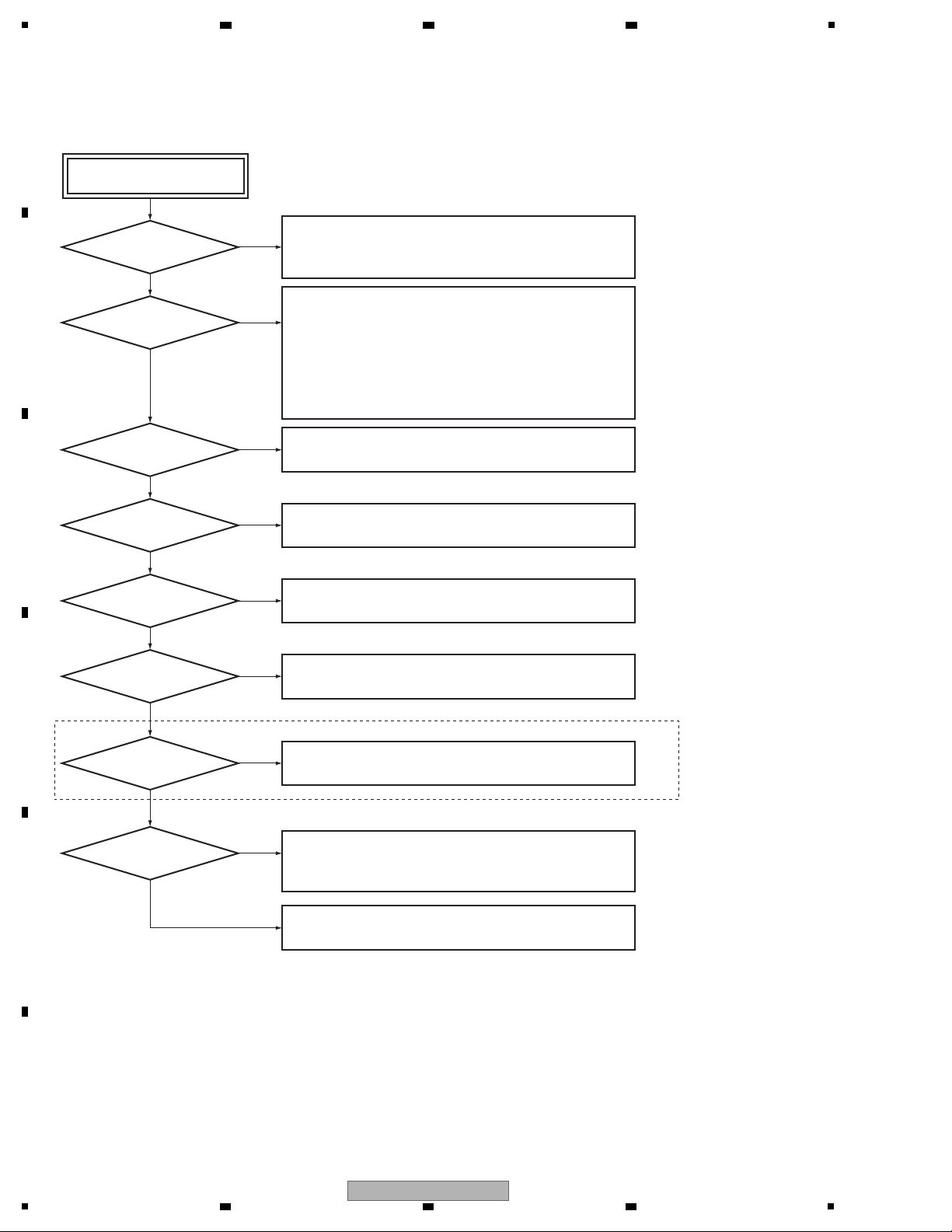

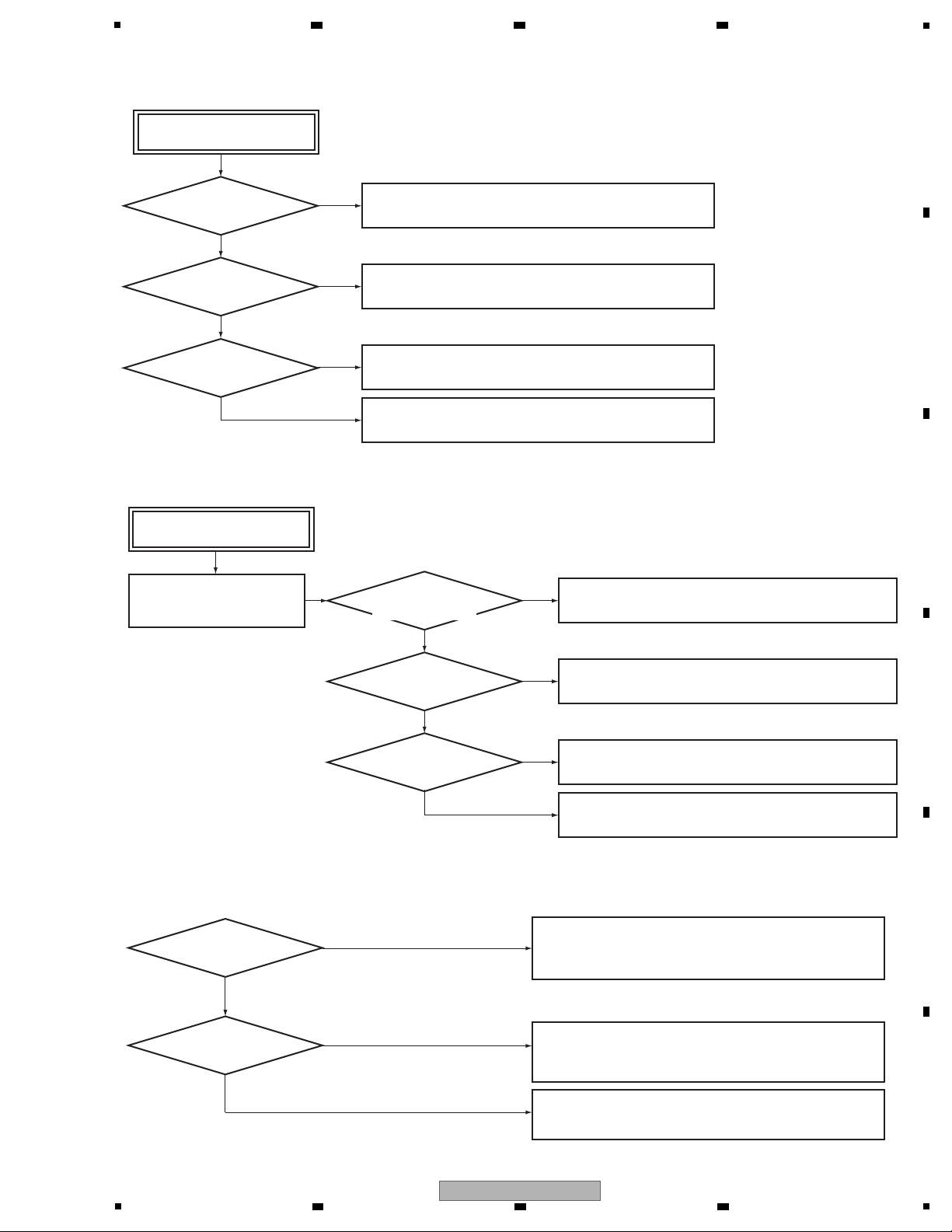

5. DIAGNOSIS........................................................................................................................................................................16

5.1 TROUBLESHOOTING..................................................................................................................................................16

5.2 PROTECTION CIRCUIT...............................................................................................................................................21

5.3 POWER MANAG EMENT....................................................... .......................................................................................24

5.4 CHECKING TERMINALS........................................... .......................................... ........................................................25

5.5 IC INFORMATION .................. .......................................... ............................................................................................28

6. SERVICE MODE.................................................................................................................................................................31

6.1 SERVICE MODE............................................. ... ..........................................................................................................31

6.2 PROTECT CHECK MODE ...........................................................................................................................................33

6.3 CHECKING THE LCD ............................. .......................................... ...........................................................................35

6.4 RDS CHARACTERS................................................... ..................................................................................................36

7. DISASSEMBLY ...................................................................................................................................................................37

8. EACH SETTING AND ADJUSTMENT................................................................................................................................45

8.1 UPDATING OF THE FIRMWARE.................................................................................................................................45

8.2 INITIAL SETTINGS......................................................................... ..............................................................................51

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................52

.........

9.1 PACKING SECTION........................................... ...................................................................

9.2 EXTERIOR SECTION .................... ................................................................................. .............................................54

9.3 SPEAKER SECTION (S-HM81GB, S-HM81SA)..........................................................................................................58

9.4 SPAEKER SECTION (S-HM71)....................................................................................................................................59

10. SCHEMATIC DIAGRAM............................ ... ............................................... ... ...................................................................60

10.1 CD ASSY....................................................................................................................................................................60

10.2 TUNER and BT ASSYS..............................................................................................................................................62

10.3 MAIN ASSY (1/3)........................................................................................................................................................64

10.4 MAIN ASSY (2/3)........................................................................................................................................................66

10.5 MAIN ASSY (3/3)........................................................................................................................................................68

10.6 BCO ASSY (1/2).........................................................................................................................................................70

10.7 BCO ASSY (2/2).........................................................................................................................................................72

10.8 CNT1 ASSY................................................................................................................................................................74

10.9 CNT2 ASSY................................................................................................................................................................76

10.10 CNT3 ASSY ..............................................................................................................................................................78

10.11 F_AUX, F_USB, FRONT and KEY ASSYS ..............................................................................................................80

10.12 DOCKING ASSY ......................................................................................................................................................82

10.13 POWER ASSY..........................................................................................................................................................84

0.14 WAVEF

1

ORMS...........................................................................................................................................................86

11. PCB CONNECTION DIAGRAM........................ ................................................ ... .............................................................88

11.1 CD ASSY....................................................................................................................................................................88

11.2 TUNER and BT ASSYS..............................................................................................................................................90

11.3 MAIN ASSY................................................................................................................................................................92

11.4 BCO ASSY .................................................................................................................................................................96

11.5 CNT1, CNT2 and CNT3 ASSYS.................................................................................................................................98

11.6 F_AUX, F_USB, FRONT, KEY and DOCKING ASSYS............................................................................................102

11.7 POWER ASSY..........................................................................................................................................................106

12. PCB PARTS LIST..................... ... ................................................................................. ...................................................108

..............................52

A

B

C

D

E

F

X-HM81-K

5

6 7 8

3

Page 4

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

It is necessary to remove the soldering on the short circuit point after connecting the pickup flexible cable.

Short circuit point

After the CR870 module is replaced alone or the whole BCO Assy, including the CR870, is replaced, the MAC address will be

changed. Replace the MAC address seal with a new one, which you can find enclosed with the service part.

Attach the Mac Address label to the rear panel, above the WLAN antenna,

so that it will not block the ventilation holes on the rear panel.

MAC Address seal

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

1.2 WHEN REPLACING MECHA

D

1.3 WHEN REPLACING CR870 (Module including BCO Assy)

E

F

4

1

2 3 4

X-HM81-K

Page 5

5

Amplifier section

RMS Power Output ..................................................... 50 W + 50 W

(1 kHz, 10 % T.H.D., 4 ohms)

Guaranteed speaker impedance....................... 4 ohms to 16 ohms

Headphones.............................................. recommended: 32 ohms

Tuner section

Frequency Range (FM) ................................ 87.5 MHz to 108 MHz

Antenna Input (FM).........................................75 ohms unbalanced

Frequency Range (AM)..................................522 kHz to 1602 kHz

Antenna (AM) ............................................................Loop antenna

Video section

Signal level (Composite)...................................... 1 Vp-p (75 ohms)

Network section

LAN terminal................................................................Ethernet jack

10BASE-T/100BASE-TX

Other connectors

Power supply

USB connector...............................................................5 V, 2.1 A

iPod connector................................................................5 V, 1.0 A

ADAPTER Port (X-HM81 and XC-HM81 only) ...............5 V, 0.1 A

Miscellaneous

Power source............................................AC 220 V to 240 V, 50 Hz

Power consumption

Power on................................................................................75 W

Power standby.......................................................... 0.5 W or less

Network standby....................................................................17 W

Dimensions

Width ................................................................................215 mm

Height (X-HM71)..............................................................131 mm

Height (X-HM81 and XC-HM81)......................................32.2 mm

Depth................................................................................353 mm

Weight (X-HM71)................................................................... 5.0 kg

Weight (X-HM81 and XC-HM81)............................................5.5 kg

Speaker (X-HM81 only)

Type

2-way type speaker system

2.5 cm Dome-Tweeter

12 cm Woofer

Maximum input power..............................................................50 W

Impedance............................................................................ 4 ohms

Dimensions

Width ................................................................................156 mm

Height...............................................................................266 mm

Depth................................................................................258 mm

Weight ........................................................................... 4.3 kg/each

Speaker (X-HM71 only)

Type

2-way type speaker system

2 cm Dome-Tweeter

12 cm Woofer

Maximum input power..............................................................50 W

Impedance............................................................................ 4 ohms

Dimensions

Width ................................................................................148 mm

Height...............................................................................263 mm

Depth................................................................................208 mm

Weight ........................................................................... 2.7 kg/each

Note

• The specifications are applicable when the power supply is 230 V.

• Specifications and the design are subject to possible

modifications without notice, due to improvements.

• Corporation and product names mentioned herein are

trademarks or registered trademarks of the respective

corporations.

• This product is not designed for use in Japan.

• This product includes FontAvenue® fonts licensed by NEC

Corporation. FontAvenue® is a registered trademark of NEC

Corporation.

• Remote control

(SYXE8 model (AXD7676): 8300767600010-IL)

(CXE, AXQ5 model (AXD7680): 8300768000010-IL)

• AAA size IEC R03 dry cell batteries

(to confirm system operation) x 2

• AM loop antenna

(E601019000010-IL)

• FM wire antenna

(E605010140010-IL)

• WLAN antenna

(E600223170010-IL)

• Speaker x 2 (X-HM8

1 and X-HM71 only)

• Speaker wires x 2 (X-HM81 and X-HM71 only)

(X-HM81, X-HM71/AXQ5: 8952SHM810016-IL)

(X-HM71: 8952SHM700042-IL)

• Non skid pad x 8 (X-HM81 only)

(8952SHM810018-IL)

• Warranty card

• Quick Start Guide

(SYXE8 model: 5707000006940-IL)

(CXE model: 5707000006970-IL)

(AXQ5 model: 5707000006980-IL)

• Operating instructions (CD-ROM)

(6517000000821-IL)

Accessories

2. SPECIFICATIONS

6 7 8

A

B

C

D

5

X-HM81-K

6 7 8

E

F

5

Page 6

1

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding audio.

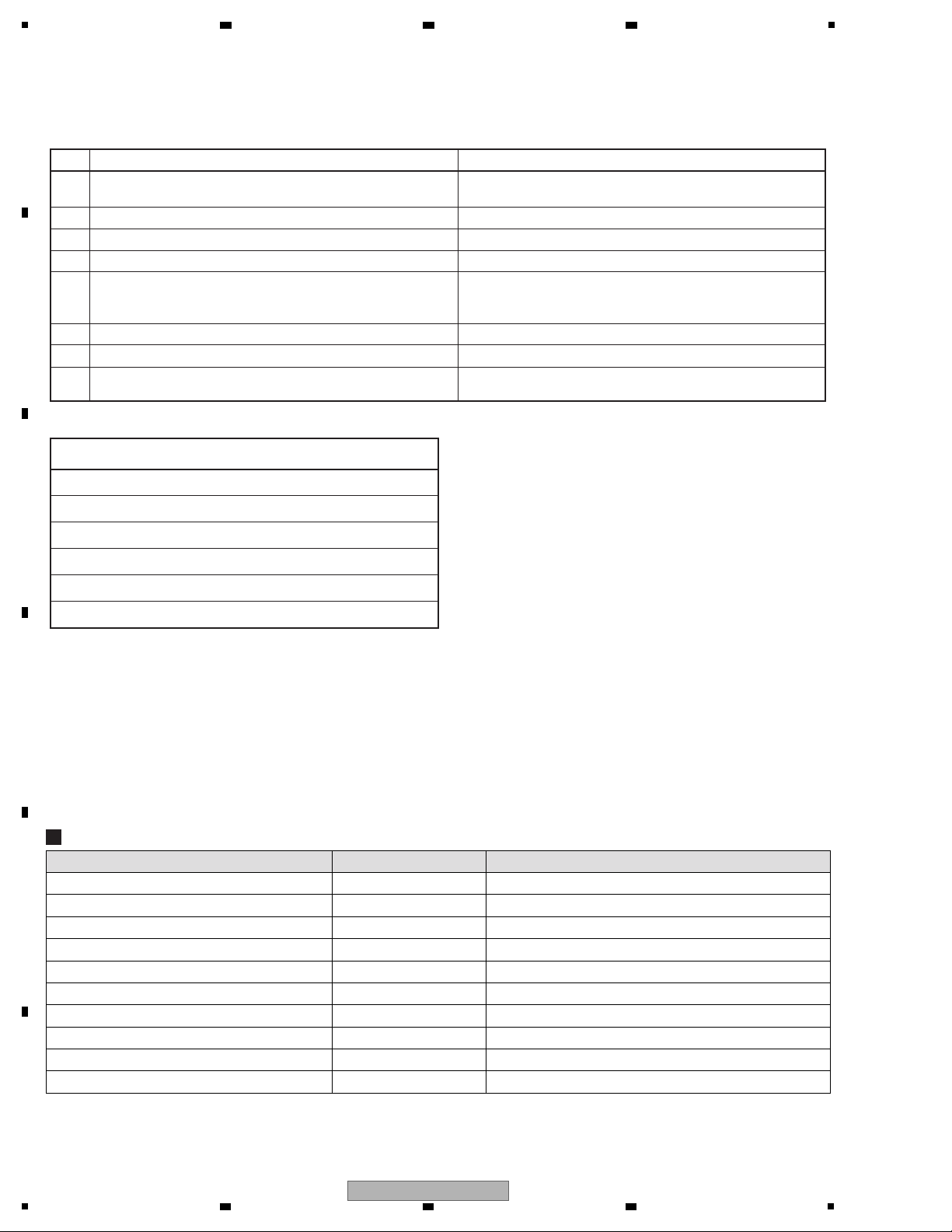

No. Check pointsProcedure

1

Confirm whether the customer complain has been solved.

The customer complain must not be reappeared.

Audio and operations must be normal.

6

Check the tuner operations.

Audio and operations (station search etc.) must be normal.

5

Check the Wi-fi antenna.

Confirm whether you refer to "5.4 CHECKING TERMINALS"

-"2. Checking the Wi-Fi Antenna", and the SSID of the wireless

LAN router is displayed.

7

Check the Line input playback. Audio and operations must be normal.

3

Check the USB playback.

Audio and operations must be normal.

4

Check the internet radio or Network audio playback.

Audio and operations must be normal.

2 Check the CD playback. Audio and operations (search etc.) must be normal.

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

8

Check the appearance of the product. No scratches or dirt on its appearance after receiving it

for service.

Jigs List

Jig Name Part No. Remarks

BtoB extension jig cable GGD1770 Diagnosis (POWER Assy ↔ CD Assy)

RS-232C update jig GGF1642 Firmware update

BtoB extension jig cable GGD1812 Diagnosis (MAIN Assy ↔ CD Assy)

BtoB extension jig cable GGD1811 Diagnosis (MAIN Assy ↔ CNT1 Assy)

FPC Extension jig GGD1813 Diagnosis (FRONT Assy ↔ CNT3 Assy)

Extension jig

FFC

GGD1774 Diagnosis (MECHA ↔ CD Assy)

3P Extension jig cable GGD1773 Diagnosis (MAIN Assy ↔ CNT2 Assy)

4P Extension jig cable GGD1809 Diagnosis (FRONT Assy ↔ CNT3 Assy)

Diagnosis (CNT2 Assy ↔ CNT3 Assy)BtoB extension jig cable GGD1810

Service remote control unit

GGF1381 Service mode

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

X-HM81-K

Page 7

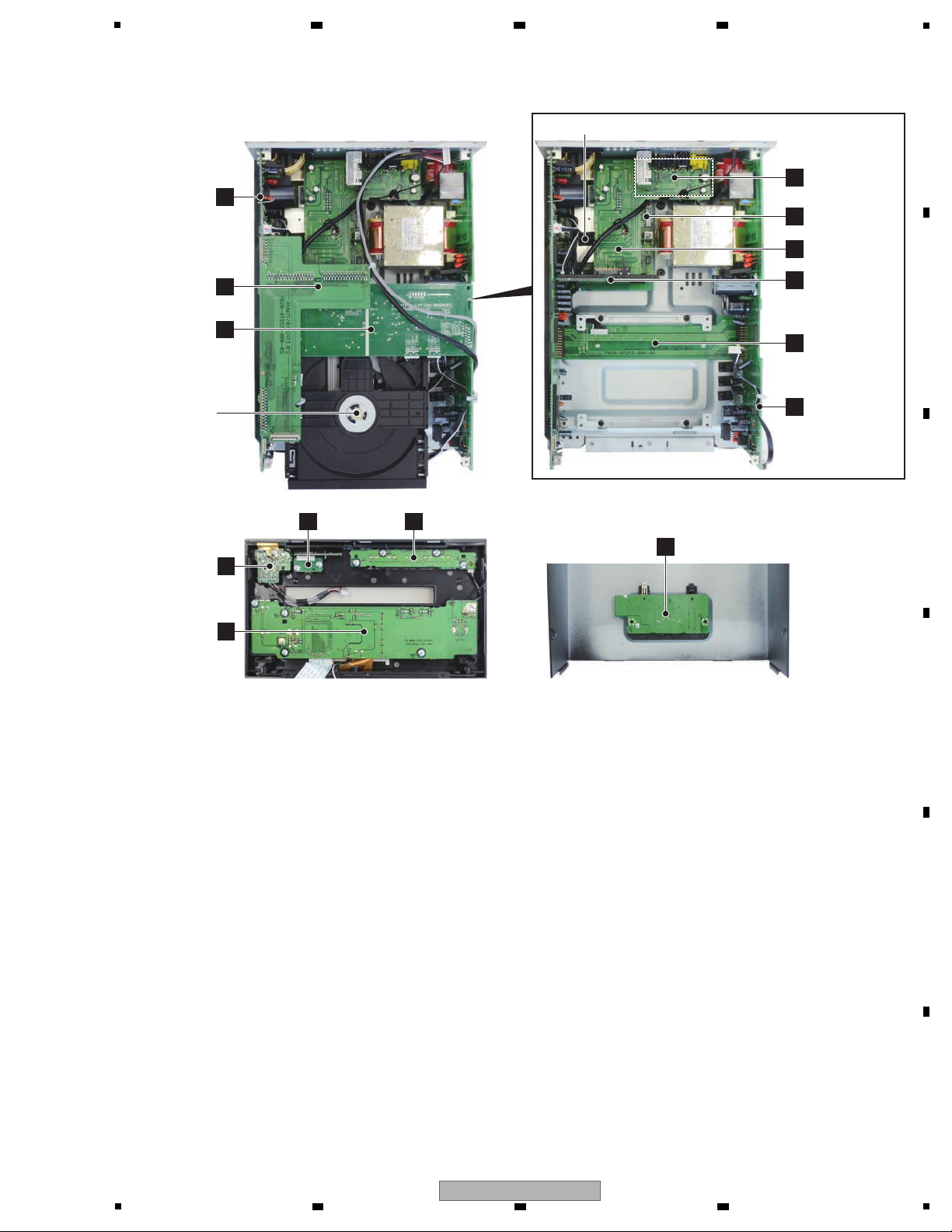

L

KEY ASSY

BCO_STOPPER ASSY

M

DOCKING ASSY

J

F_USB ASSY

H

CNT3 ASSY

A

CD ASSY

D

MAIN ASSY

I

F_AUX ASSY

K

FRONT ASSY

F

CNT1 ASSY

N

POWER ASSY

G

CNT2 ASSY

E

BCO ASSY

B

TUNER ASSY

C

BT ASSY

(X-HM81 only)

MECHA

Cabinet (Bottom view)

5

3.3 PCB LOCATIONS

6 7 8

A

B

C

D

E

F

X-HM81-K

5

6 7 8

7

Page 8

1

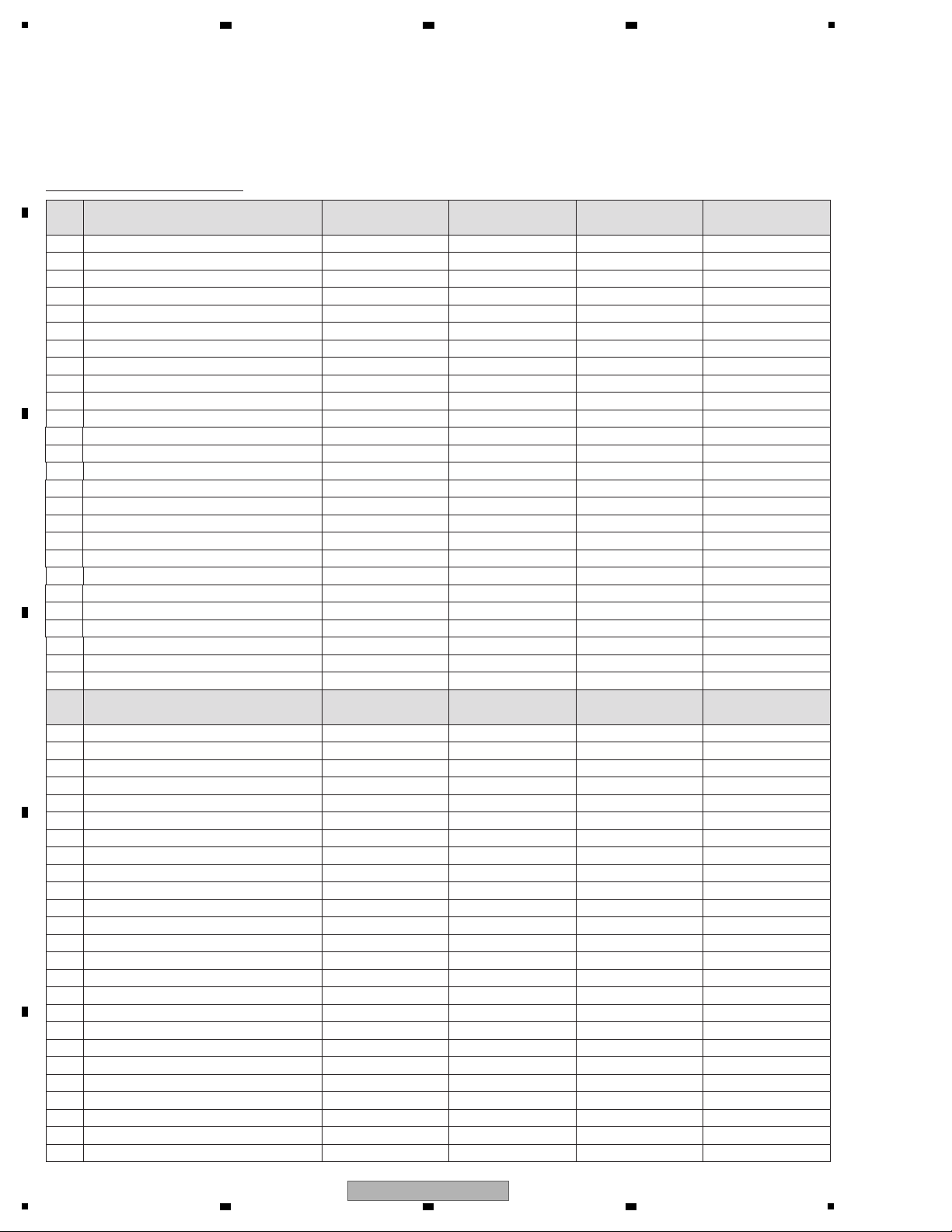

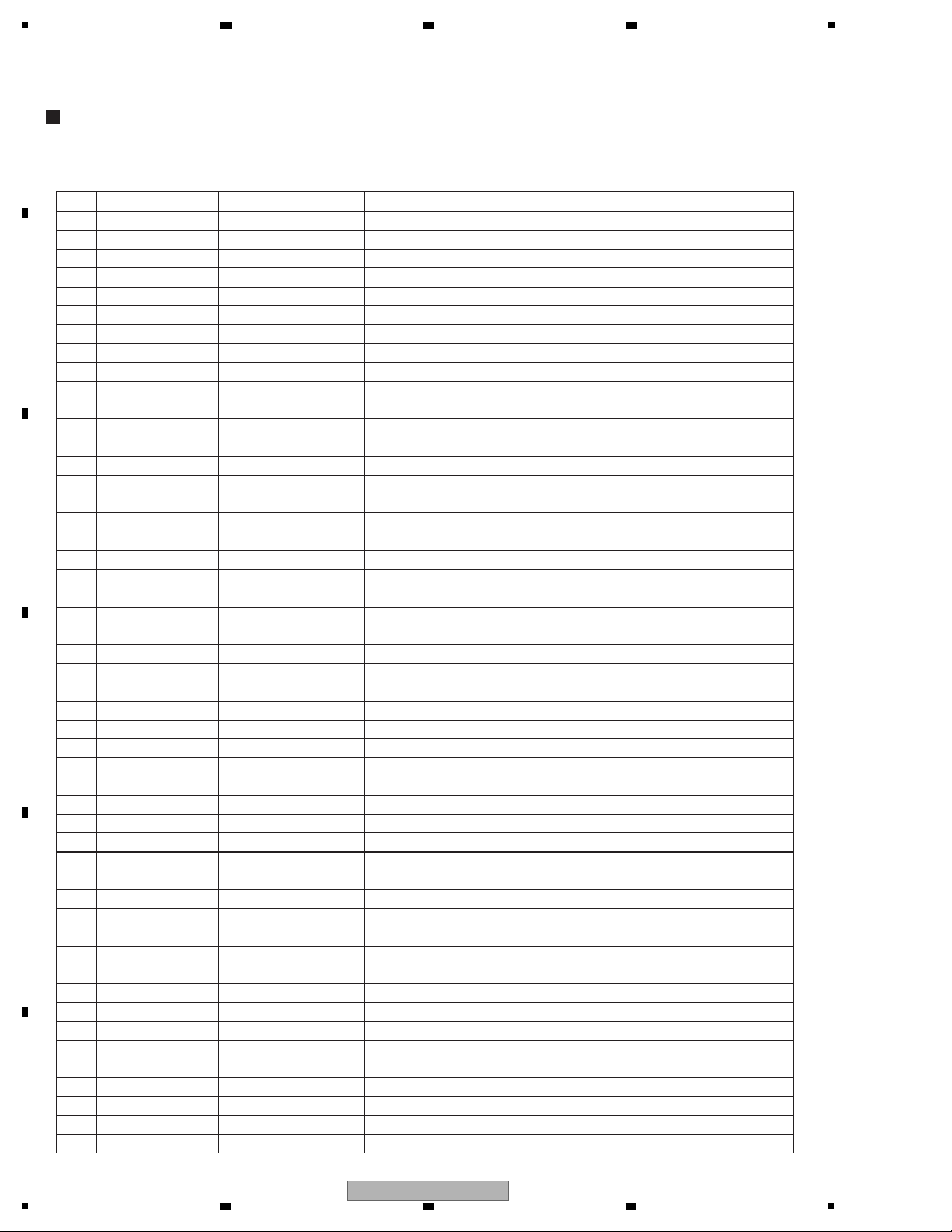

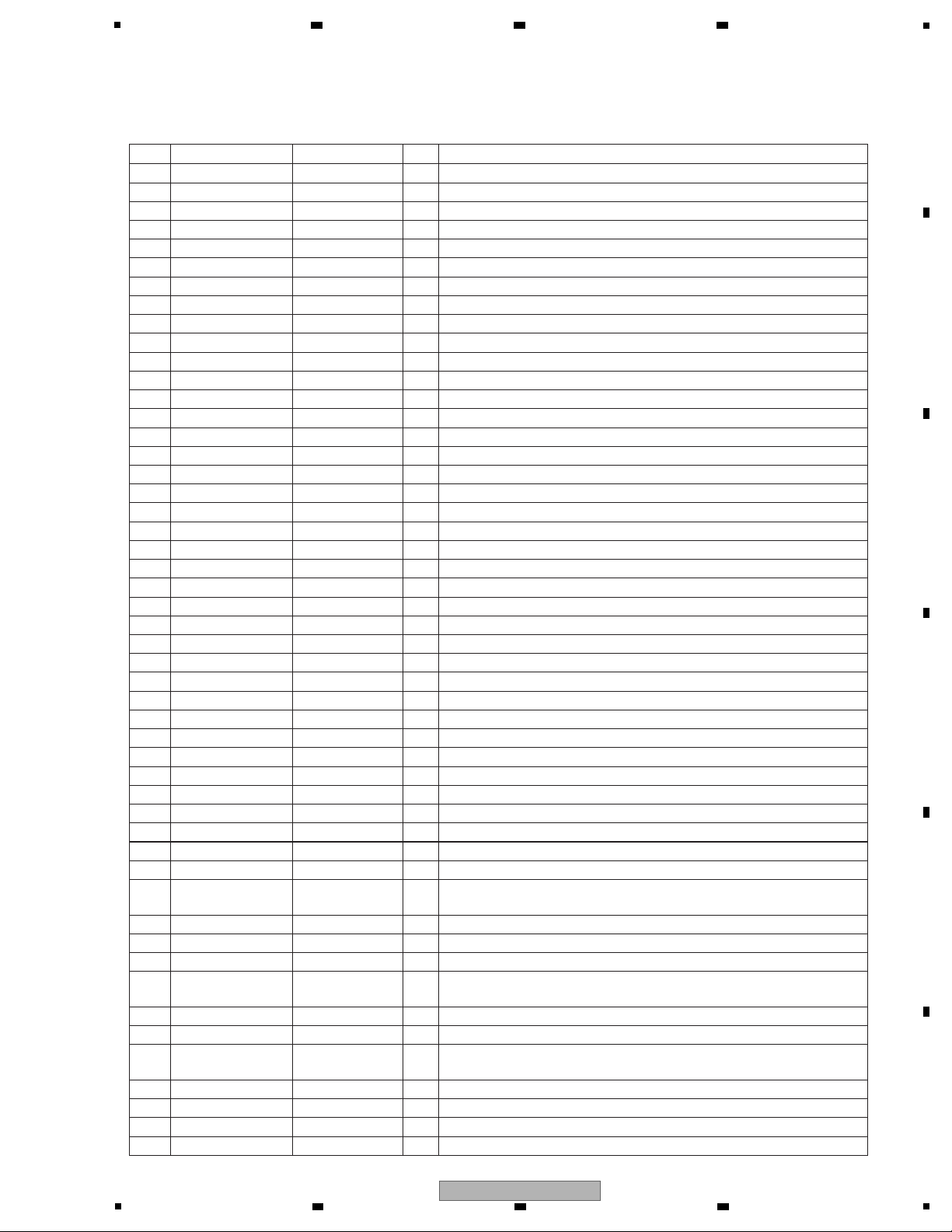

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Mark Symbol and Description

Mark Symbol and Description

X-HM81-K

/SYXE8

X-HM81-S

/SYXE8

XC-HM81-K

/SYXE8

XC-HM81-S

/SYXE8

X-HM71-K

/SYXE8

X-HM71-K

/CXE

X-HM71-S

/SYXE8

X-HM71-S

/AXQ5

NSP

NSP

1..PCB TOTAL ASSY FRONT 7025MU1105030-IL 7025MU1105030-IL 7025MU1105030-IL 7025MU1105030-IL

7025MU1106050-IL 7025MU1106020-IL 7025MU1106050-IL 7025MU1106020-IL

2..FRONT ASSY 7028072531010-IL 7028072531010-IL 7028072531010-IL 7028072531010-IL

7028072531010-IL 7028072531010-IL 7028072531010-IL 7028072531010-IL

2..KEY ASSY 7028072533010-IL 7028072533010-IL 7028072533010-IL 7028072533010-IL

2..CNT1 ASSY • • • • • • • • • • • • • • • • • • • •

NSP 2..CNT1 ASSY • • • • • • • • • • • • • • • • • • • •

NSP 2..CNT3 ASSY • • • • • • • • • • • • • • • • • • • •

NSP 2..CNT3 ASSY • • • • • • • • • • • • • • • • • • • •

NSP 2..BCO_STOPPER ASSY • • • • • • • • • • • • • • • • • • • •

NSP 2..BCO_STOPPER ASSY • • • • • • • • • • • • • • • • • • • •

7028072533010-IL 7028072533010-IL 7028072533010-IL 7028072533010-IL

2..TUNER ASSY 7028072534030-IL 7028072534030-IL 7028072534030-IL 7028072534030-IL

7028072534060-IL 7028072534040-IL 7028072534060-IL 7028072534040-IL

2..F_AUX ASSY 7028072535010-IL 7028072535010-IL 7028072535010-IL 7028072535010-IL

7028072535010-IL 7028072535010-IL 7028072535010-IL 7028072535010-IL

2..F_USB ASSY 7028072536010-IL 7028072536010-IL 7028072536010-IL 7028072536010-IL

7028072536010-IL 7028072536010-IL 7028072536010-IL 7028072536010-IL

2..BT ASSY 7028072537010-IL 7028072537010-IL 7028072537010-IL 7028072537010-IL

Not used Not used Not used Not used

NSP 1..PCB TOTAL ASSY POWER 7025MU1105031-IL 7025MU1105031-IL 7025MU1105031-IL 7025MU1105031-IL

7025MU1106051-IL 7025MU1106021-IL 7025MU1106051-IL 7025MU1106031-IL

2..MAIN ASSY 7028072541030-IL 7028072541030-IL 7028072541030-IL 7028072541030-IL

7028072541060-IL 7028072541040-IL 7028072541060-IL 7028072541050-IL

2..POWER ASSY 7028072542030-IL 7028072542030-IL 7028072542030-IL 7028072542030-IL

7028072542030-IL 7028072542040-IL 7028072542030-IL 7028072542030-IL

2..DOCKING ASSY 7028072544010-IL 7028072544010-IL 7028072544010-IL 7028072544010-IL

7028072544010-IL 7028072544010-IL 7028072544010-IL 7028072544010-IL

NSP 1..PCB TOTAL ASSY BRIDG 7025MU1105032-IL 7025MU1105032-IL 7025MU1105032-IL 7025MU1105032-IL

7025MU1106022-IL 7025MU1106022-IL 7025MU1106022-IL 7025MU1106022-IL

2..BCO ASSY 7028072551010-IL 7028072551010-IL 7028072551010-IL 7028072551010-IL

7028072551020-IL 7028072551020-IL 7028072551020-IL 7028072551020-IL

2..CNT2 ASSY 7028072552010-IL 7028072552010-IL 7028072552010-IL 7028072552010-IL

7028072552020-IL 7028072552020-IL 7028072552020-IL 7028072552020-IL

1...PCB TOTAL ASSY CD 7025MU1105034-IL 7025MU1105034-IL 7025MU1105034-IL 7025MU1105034-IL

7025MU1105034-IL 7025MU1105034-IL 7025MU1105034-IL 7025MU1105034-IL

2..CD ASSY 7028072301010-IL 7028072301010-IL 7028072301010-IL 7028072301010-IL

7028072301010-IL 7028072301010-IL 7028072301010-IL 7028072301010-IL

MECHA

NSP 1..PCB TOTAL ASSY FRONT

2..FRONT ASSY

2..KEY ASSY

2..TUNER ASSY

2..F_AUX ASSY

2..F_USB ASSY

2..BT ASSY

NSP 1..PCB TOTAL ASSY POWER

2..MAIN ASSY

2..POWER ASSY

2..DOCKING ASSY

NSP 1..PCB TOTAL ASSY BRIDG

2..BCO ASSY

2..CNT2 ASSY

1...PCB TOTAL ASSY CD

2..CD ASSY

MECHA

8030000010080-IL 8030000010080-IL 8030000010080-IL 8030000010080-IL

8030000010080-IL 8030000010080-IL 8030000010080-IL 8030000010080-IL

A

2 3 4

B

C

D

E

F

8

1

X-HM81-K

2 3 4

Page 9

5

6 7 8

A

B

C

D

E

F

X-HM81-K

5

6 7 8

9

Page 10

1

I

F_AUX ASSY

(7028072535010-IL)

J

F_USB ASSY

(7028072536010-IL)

K

FRONT ASSY

(7028072531010-IL)

LCD

H

CNT3 ASSY

CP30 CP31

CP607

CN510

CP19

CP18

FPC2

CP606

CP512

CP509

CP602

CP712

CP605

CP400

CN702

CP8

PN1702

1: A_+12V

2: A_+12V

3: A_GND

4: A_GND

5: A_-12V

6: A_-12V

7: A_GND

8: CD_L

9: A_GND

10: CD_R

11: M_GND

12: M_GND

13: CD_RX

14: CD_TX

15: CD_RST

16: MAIN_BUSY

17: NC

1: VFD_CE

2: VFD_CLK

3: VFD_DI

1: B+_27V

2: B+_27V

3: AMP_GND

4: AMP_GND

5: LCH_AMP_GND

6: LCH_AMP_GND

7: RCH_AMP_GND

8: RCH_AMP_GND

9: B-_27V

10: B-_27V

11: RLY_GND

12: RLY_GND

13: AMP_-5V

14: AMP_-5V

15: POWER_PROT

16: AMP_+5V

17: PD

18: STBY_RLY

19: M_GND

20: M_GND

21: MICOM_3V9

22: MICOM_3V9

23: DGND

24: DGND

25: NC

26: NC

1: SW_GND

2: SW_OUT

3: A_GND

4: BT/TU_R

5: A_GND

6: BT/TU_L

7: A_GND

8: USB_R

9: A_GND

10: USB_L

11: A_GND

12: LINE_IN_R

13: A_GND

14: LINE_IN_L

15: A_GND

16: A_GND

17: A_GND

18: +12V

19: +12V

1: SW_GND

2: SW_OUT

3: A_GND

4: BT/TU_R

5: A_GND

6: BT/TU_L

7: A_GND

8: USB_R

9: A_GND

10: USB_L

11: A_GND

12: LINE_IN_R

13: A_GND

14: LINE_IN_L

15: A_GND

16: A_GND

17: A_GND

18: +12V

19: +12V

1: +12V

2: +12V

3: A_GND

4: A_GND

5: -12V

6: -12V

7: A_GND

8: CD_L

9: A_GND

10: CD_R

11: M_GND

12: M_GND

13: CD_RX

14: CD_TX

15: CD_RST

16: MAIN_BUSY

17: NC

1: LCDGND

2: LCDGND

3: IOVCC(+3.3V)

4: IOVCC(+3.3V)

1: HP_R

2: H/P_GND

3: HP_L

4: H/P_GND

5: FAUX_R

6: AUX_GND

7: FAUX_L

8: HP_DET

1: GND

2: GND

3: IOVCC(+3.3V)

4: IOVCC(+3.3V)

1: CPU_GND

2: KEY2

1: GND

2: VCI(+3.3V)

3: RESX

4: DB0/B0

5: DB1/B1

6: DB2/B2

7: DB3/B3

8: DB4/B4

9: DB5/B5

10: DB6/G0

11: DB7/G1

12: DB8/G2

13: DB9/G3

14: DB10/G4

15: DB11/G5

16: DB12/R0

17: DB13/R1

18: DB14/R2

19: DB15/R3

20: DB16/R4

21: DB17/R5

22: CSX

23: SCL

24: DE

25: DOTCLK

26: HSYNC

27: VSYNC

28: SDA

29: LED-A+

30: LED-K1

31: LED-K2

32: LED-K3

33: LED-K4

34: IOVCC(+3.3V)

35: GND

1: USB_VCC

2: USB_VCC

3: USBHO_D-

4: USBHO_D+

5: USB_GND

6: USB_GND

7: NC

1: DAC_RST

2: AUDIO_SEL

3: SUB_PDN

4: SUB_IRQ

5: SUB_ON

6: SUB_RESET

7: MAIN_IRQ

8: SCDI_MAIN

9: SCDO_MAIN

10: CSCK_MAIN

11: I_POD_DET

12: GPIO2_DAB_RX

13: SDIO_DAB_TX

14: TU_SCLK

15: TU_SEN

16: TU/DAB_RST

17: SW_MUTEBASE

18: VIDEO_MUTE

19: IPOD_CHARGE_LED

20: POWER_ON_LED

21: KEY2

22: KEY1

23: REMOTE

24: TIMER_LED

25: VOLUME+

26: VOLUME27: M3V3

28: M3V3_SW

29: CPU_GND

30: CPU_GND

31: CPU_GND

1: HP_R

2: H/P_GND

3: HP_L

4: H/P_GND

5: FAUX_R

6: AUX_GND

7: FAUX_L

8: HP/DET

1: VIDEO_GND

2: VIDEO_GND

3: DOCK_CVBS

4: SW_GND

5: SW_OUT

6: A_GND

7: LINE_IN_R

8: A_GND

9: LINE_IN_L

10: A_GND

11: DAB/TU_R

12: A_GND

13: DAB/TU_L

14: A_GND

15: VIDEO_MUTE

16: SW_MUTEBASE

17: TU/DAB_RST

18: TU_SEN

19: TU_SCLK

20: GPIO2 DAB_RX

21: SDIO DAB_TX

22: A_GND

23: A_GND

24: TU_+5V

25: TU_+5V

CP31

1: USB_R

2: A_GND

3: USB_L

4: +12V

5: +12V

6: DAC_RESET

7: AUDIO_SEL

8: SW_GND

9: SW_OUT

10: A_GND

11: LINE_IN_R

12: A_GND

13: LINE_IN_L

14: A_GND

15: BT/TU_R

16: A_GND

17: BT/TU_L

18: A_GND

19: VIDEO_MUTE

20: SW_MUTEBASE

21: TU_RST(DAB_RST)

22: TU_SEN

23: TU_SCLK

24: SDIO DAB_RX

25: GPIO2 DAB_TX

26: I_POD_DET

27: CSCK_MAIN

28: SCDO_MAIN

29: SCDI_MAIN

30: MAIN_IRQ

31: SUB_RESET

32: SUB_ON

33: SUB_IRQ

CP30

1: RESX

2: DB0/B0

3: DB1/B1

4: DB2/B2

5: DB3/B3

6: DB4/B4

7: DB5/B5

8: DB6/G0

9: DB7/G1

10: DB8/G2

11: DB9/G3

12: DB10/G4

13: DB11/G5

14: DB12/R0

15: DB13/R1

16: DB14/R2

17: DB15/R3

18: DB16/R4

19: DB17/R5

20: SCL

21: DE

22: CSX

23: DOTCLK

24: HSYNC

25: VSYNC

26: SDA

27: LED-A+

28: LED-CTL

29: IOVCC(+3.3V)

30: IOVCC(+3.3V)

31: GND

32: GND

33: SUB_PDN

FPC2

1: CPU_GND

2: M3V3_SW

3: M3V3

4: KEY2

5: KEY1

6: CPU_GND

7: REMOTE

8: TIMER_LED

9: VOLUME+

10: VOLUME11: RESX

12: DB0/B0

13: DB1/B1

14: DB2/B2

15: DB3/B3

16: DB4/B4

17: DB5/B5

18: DB6/G0

19: DB7/G1

20: DB8/G2

21: DB9/G3

22: DB10/G4

23: DB11/G5

24: DB12/R0

25: DB13/R1

26: DB14/R2

27: DB15/R3

28: DB16/R4

29: DB17/R5

30: CSX

31: SCL

32: DE

33: DOTCLK

34: HSYNC

35: VSYNC

36: SDA

37: LED-A+

38: LED-CTL

39: LED_B

40: LED_A

1: CPU_GND

2: M3V3_SW

3: M3V3

4: KEY2

5: KEY1

6: CPU_GND

7: REMOTE

8: TIMER_LED

9: VOLUME+

10: VOLUME-

11: RESX

12: DB0/B0

13: DB1/B1

14: DB2/B2

15: DB3/B3

16: DB4/B4

17: DB5/B5

18: DB6/G0

19: DB7/G1

20: DB8/G2

21: DB9/G3

22: DB10/G4

23: DB11/G5

24: DB12/R0

25: DB13/R1

26: DB14/R2

27: DB15/R3

28: DB16/R4

29: DB17/R5

30: CSX

31: SCL

32: DE

33: DOTCLK

34: HSYNC

35: VSYNC

36: SDA

37: LED-A+

38: LED-CTL

39: LED_B

40: LED_A

1: BT

2: AG

3: BT

4: GN

5: SU

6: SU

7: SU

8: MA

9: CS

10: S

11: S

12: M

13: IP

14:

M

15: V

16: D

17: D

18: D

19: D

20: V

21: V

22: V

23: A

24: A

25: A

CP11

1: RESX

2: DB0/B0

3: DB1/B1

4: DB2/B2

5: DB3/B3

6: DB4/B4

7: DB5/B5

8: DB6/G0

9: DB7/G1

10: DB8/G2

11: DB9/G3

12: DB10/G4

13: DB11/G5

14: DB12/R0

15: DB13/R1

16: DB14/R2

17: DB15/R3

18: DB16/R4

19: DB17/R5

20: CSX

21: SCL

22: DE

23: DOTCLK(GND_S

24: HSYNC

25: VSYNC

26: SDA

27: LED-A+

28: LED-CTL(SPSW

29: IOVCC(+3.3V)

30: IOVCC(+3.3V)

31: GND

32: GND

33: GND

CP12

1: BT_R

2: AGND

3: BT_L

4: AGND

5: SUB_IRQ

6: SUB_RESET

7: SUB_PDN

8: MAIN_SUB_IPOD_DET

9: CSK_MAIN

10: SCDO_MAIN

11: SCDI_MAIN

12: MAIN_IRQ

13: DOCKING_CVBS

14: MAIN_USB_POWER

15: VGND

16: DM-870-SCLK

17: DM-870-MCLK

18: DM-870-LRCK

19: DM-870-DATA

20: VFD_DI

21: VFD_CLK

22: VFD_CE

23: AMP-5V

24: AMP+5V

25: NC

CN515

CP500

CP508

FPC515

MOD500

CP604

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

B

(7028072534030-IL: X-HM81, XC-HM81)

(7028072534060-IL: X-HM71/SYXE8)

(7028072534040-IL: X-HM71/CXE, AXQ5)

D

MAIN ASSY

(7028072541030-IL: X-HM81, XC-HM81)

(7028072541060-IL: X-HM71/SYXE8)

(7028072541040-IL: X-HM71/CXE)

(7028072541050-IL: X-HM71/AXQ5)

D

1/3-D3/3

TUNER ASSY

1: B+_27V

2: B+_27V

3: AMP_GND

4: AMP_GND

5: AMP_GND_L

6: AMP_GND_L

7: AMP_GND_R

8: AMP_GND_R

9: B-_27V

10: B-_27V

11: SPKRLY_GND

12: SPKRLY_GND

13: AMP_-5V

14: AMP_-5V

15: AMP_+5V

16: POWER_PROT

17: P/D

18: STBY_RLY

19: M_GND

20: M_GND

21: MICOM_3V9

22: MICOM_3V9

23: DGND

24: DGND

25: NC

26: NC

CP18

1: DAC_RST

2: AUDIO_SEL

3: SUB_PDN

4: SUB_IRQ

5: SUB_ON

6: SUB_RESET

7: MAIN_IRQ

8: SCDI_MAIN

9: SCDO_MAIN

10: CSCK_MAIN

11: I_POD_DET

12: GPIO2_DAB_RX

13: SDIO_DAB_TX

14: TU_SCLK

15: TU_SEN

16: TU/DAB_RST

17: SW_MUTEBASE

18: VIDEO_MUTE

19: IPOD_CHARGE_LED

20: POWER_ON_LED

21: KEY2

22: KEY1

23: REMOTE

24: TIMER_LED

25: VOLUME+

26: VOLUME27: M3V3

28: M3V3_SW

29: CPU_GND

30: CPU_GND

31: CPU_GND

2 3 4

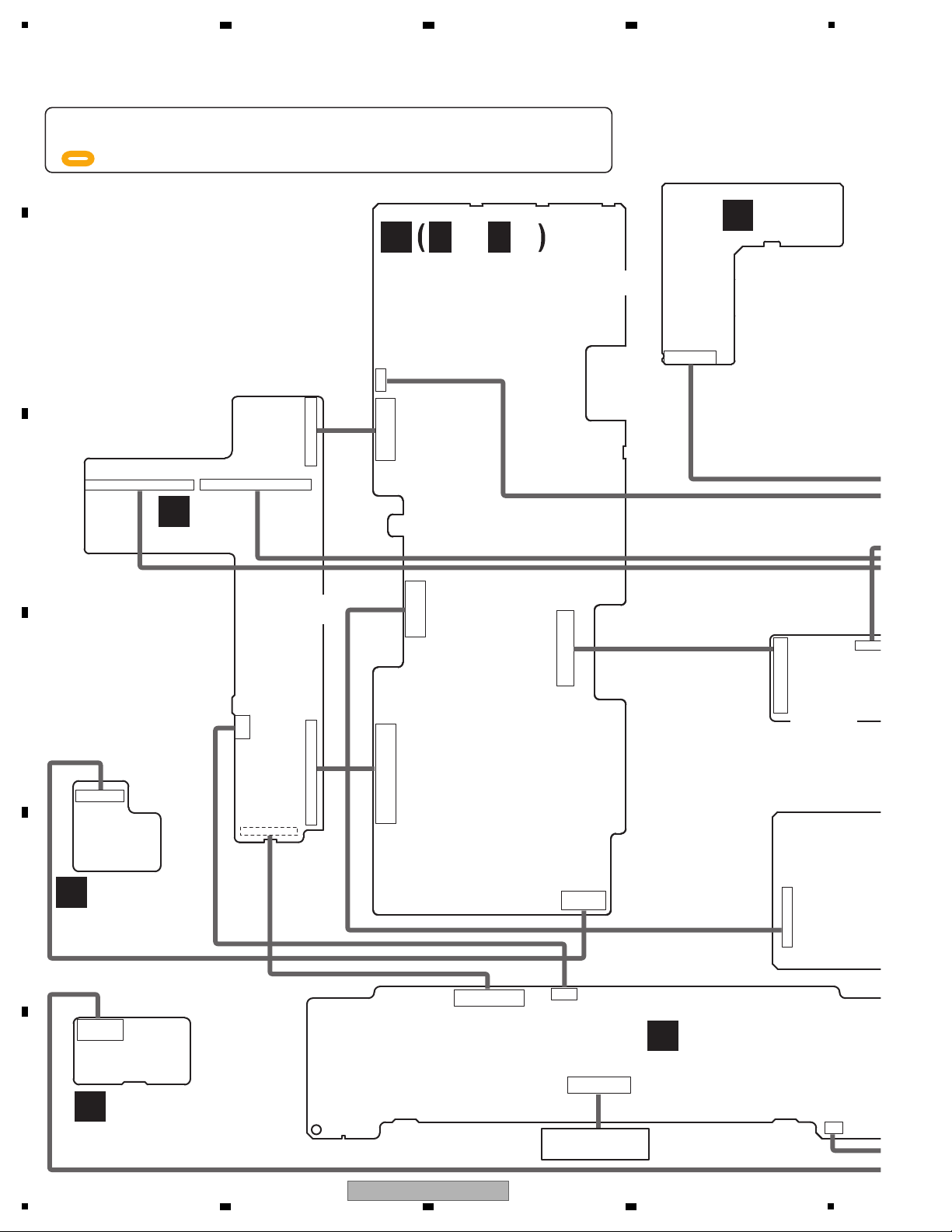

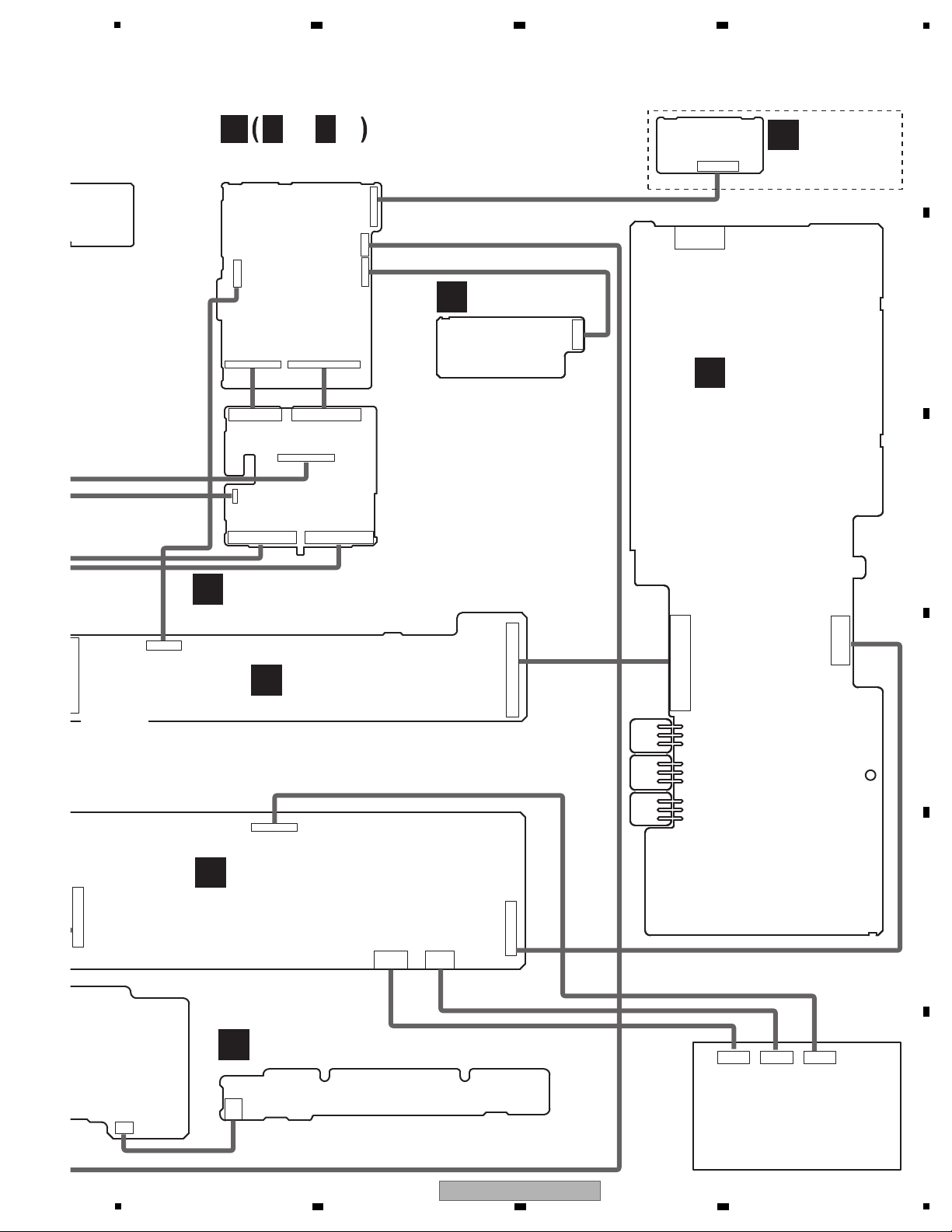

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

10

1

X-HM81-K

2 3 4

Page 11

C

BT ASSY

(7028072537010-IL)

MECHA

(8030000010080-IL)

M

DOCKING ASSY

(7028072544010-IL)

A

CD ASSY

(7028072301010-IL)

F

CNT1 ASSY

L

KEY ASSY

(7028072533010-IL)

PN1603

PN1602

PN1705

CP310

CP312

CP710

CP402

CP402

CN511

CP1001

CP6

CP2

CP4

CP1

CP5

CN702

CP8

CP8

CP7

CP7

CP12

CP505 CP506

CP11

CP301

AC IN

PN1702

1: A_+12V

2: A_+12V

3: A_GND

4: A_GND

5: A_-12V

6: A_-12V

7: A_GND

8: CD_L

9: A_GND

10: CD_R

11: M_GND

12: M_GND

13: CD_RX

14: CD_TX

15: CD_RST

16: MAIN_BUSY

17: NC

1: MOTRO_GND

2: MOTRO_GND

3: MOTRO_+8V

4: MOTRO_+8V

5: CD_GND

6: CD_GND

7: CD_3V3

8: CD_3V3

9: NC

10: A_+12V

11: A_+12V

12: A_GND

13: A_GND

14: A_-12V

15: A_-12V

1: MOT_GND

2: MOT_GND

3: MOT_+8V

4: MOT_+8V

5: CD3.3V_GND

6: CD3.3V_GND

7: CD_3.3V

8: CD_3.3V

9: NC

10: A_+12V

11: A_+12V

12: A_GND

13: A_GND

14: A_-12V

15: A_-12V

1: CPU_GND

2: KEY2

1: CPU_GND

2: KEY2

1: VIDEO_GND

2: VIDEO_GND

3: DOCK_CVBS

4: SW_GND

5: SW_OUT

6: A_GND

7: LINE_IN_R

8: A_GND

9: LINE_IN_L

10: A_GND

11: DAB/TU_R

12: A_GND

13: DAB/TU_L

14: A_GND

15: VIDEO_MUTE

16: SW_MUTEBASE

17: TU/DAB_RST

18: TU_SEN

19: TU_SCLK

20: DAB_RX GPIO2

21: DAB_TX SDIO

22: A_GND

23: A_GND

24: TU_+5V

25: TU_+5V

CP505

1: USB_R

2: A_GND

3: USB_L

4: +12V

5: +12V

6: DAC_RESET

7: AUDIO_SEL

8: SW_GND

9: SW_OUT

10: A_GND

11: LINE_IN_R

12: A_GND

13: LINE_IN_L

14: A_GND

15: BT/TU_R

16: A_GND

17: BT/TU_L

18: A_GND

19: VIDEO_MUTE

20: SW_MUTEBASE

21: TU_RST(DAB_RST)

22: TU_SEN

23: TU_SCLK

24: SDIO DAB_RX

25: GPIO2 DAB_TX

26: I_POD_DET

27: CSCK_MAIN

28: SCDO_MAIN

29: SCDI_MAIN

30: MAIN_IRQ

31: SUB_RESET

32: SUB_ON

33: SUB_IRQ

CP506

1: RESX

2: DB0/B0

3: DB1/B1

4: DB2/B2

5: DB3/B3

6: DB4/B4

7: DB5/B5

8: DB6/G0

9: DB7/G1

10: DB8/G2

11: DB9/G3

12: DB10/G4

13: DB11/G5

14: DB12/R0

15: DB13/R1

16: DB14/R2

17: DB15/R3

18: DB16/R4

19: DB17/R5

20: SCL

21: DE

22: CSX

23: DOTCLK

24: HSYNC

25: VSYNC

26: SDA

27: LED-A+

28: LED-CTL

29: IOVCC(+3.3V)

30: IOVCC(+3.3V)

31: GND

32: GND

33: SUB_PDN

1: BT_R

2: AGND

3: BT_L

4: GND

5: SUB_IRQ

6: SUB_RESET

7: SUB_PDN

8: MAIN_IPOD_DET

9: CSK_MAIN

10: SCDO_MAIN

11: SCDI_MAIN

12: MAIN_IRQ

13: IPOD_CVBS

14:

MAIN_USB_POWER (NC)

15: VGND

16: DM-870-SCLK

17: DM-870-MCLK

18: DM-870-LRCK

19: DM-870-DATA

20: VFD_DI

21: VFD_CLK

22: VFD_CE

23: AMP-5V

24: AMP+5V

25: AMP+5V

1: GND

2: GND

3: GND

4: IOVCC(+3.3V)

5: IOVCC(+3.3V)

6: LED-CTL(SPSW)

7: LED-A+

8: SDA

9: VSYNC

10: HSYNC

11: DOTCLK

12: DE

13: CLK

14: CSX

15: DB17/R5

16: DB16/R4

17: DB15/R3

18: DB14/R2

19: DB13/R1

20: DB12/R0

21: DB11/G5

22: DB10/G4

23: DB9/G3

24: DB8/G2

25: DB7/G1

26: DB6/G0

27: DB5/B5

28: DB4/B4

29: DB3/B3

30: DB2/B2

31: DB1/B1

32: DB0/B0

33: RESX

CP11

1: RESX

2: DB0/B0

3: DB1/B1

4: DB2/B2

5: DB3/B3

6: DB4/B4

7: DB5/B5

8: DB6/G0

9: DB7/G1

10: DB8/G2

11: DB9/G3

12: DB10/G4

13: DB11/G5

14: DB12/R0

15: DB13/R1

16: DB14/R2

17: DB15/R3

18: DB16/R4

19: DB17/R5

20: CSX

21: SCL

22: DE

23: DOTCLK(GND_SHIELD)

24: HSYNC

25: VSYNC

26: SDA

27: LED-A+

28: LED-CTL(SPSW)

29: IOVCC(+3.3V)

30: IOVCC(+3.3V)

31: GND

32: GND

33: GND

1: GND

2: GND

3: GND

4: VDD

5: VDD

6: VDD

7: +5V

8: -5V

1: VFD_DI

2: VFD_CLK

3: VFD_CE

1: -5V

2: +5V

3: BCO_+12V

4: BCO_+12V

5: BCO_+12V

6: BCO_GND

7: BCO_GND

8: BCO_GND

1: D-

2: D+

3: +5V

4: GND

5: GND

6: IPOD_DET

7: IPOD_CVBS

8: MIITXCLK

1: ACCESSORY_PWR

2: C_VID

3: IPOD_DET

4: D_GND

5: D_GND

6: USB_+5V

7: USB_D+

8: USB_D-

1: +5V

2: +5V

3: D-

4: D+

5: GND

6: GND

1: BT_MUTE

2: BT_R

3: AGND

4: BT_L

5: BCO_GND

6: BT_ON/CE

7: BT_+5V

8: BT_ID

9: BT_DET

10: BT_TX/U_RX

11: BT_RX/U_TX

12: BT_/OC

1: BT_MUTE

2: BT_R

3: A_GND

4: BT_L

5: BCO_GND

6: BT_ON/CE

7: BT_+5V

8: BT_ID

9: BT_DET

10: BT_TX/U_RX

11: BT_RX/U_TX

12: BT_/OC

1: SP+

2: SP-

3: SL+

4: SL-

5: Limit SW

6: GND

1: CLOSE_SW

2: GND

3: OPEN_SW

4: MOTOR_+

5: MOTOR_-

1: F-

2: T+

3: T-

4: F+

5: PD

6: VR

7: LD

8: GND

9: F

10: C

11: B

12: A

13: D

14: E

15: SVCC

16: VREF

CP508

CN502

PN1604

X-HM81,

XC-HM81

ONLY

(7028072551010-IL: X-HM81, XC-HM81)

(7028072551020-IL: X-HM71)

BCO ASSY

E

E

1/2-E2/2

N

POWER ASSY

(7028072542030-IL:

X-HM81,XC-HM81)

(7028072542030-IL:

X-HM71/SYXE8, AXQ5)

(7028072542040-IL:

X-HM71/CXE)

G

CNT2 ASSY

(7028072552010-IL: X-HM81, XC-HM81)

(7028072552020-IL: X-HM71)

1: B+_27V

2: B+_27V

3: AMP_GND

4: AMP_GND

5: AMP_GND_L

6: AMP_GND_L

7: AMP_GND_R

8: AMP_GND_R

9: B-_27V

10: B-_27V

11: SPKRLY_GND

12: SPKRLY_GND

13: AMP_-5V

14: AMP_-5V

15: AMP_+5V

16: POWER_PROT

17: P/D

18: STBY_RLY

19: M_GND

20: M_GND

21: MICOM_3V9

22: MICOM_3V9

23: DGND

24: DGND

25: NC

26: NC

1: MICOM_3V9

2: MICOM_3V9

3: M_GND

4: M_GND

5: STBY_RLY

6: P/D

7: NC

8: POWER_PROT

9: AMP_+5V

10: AMP_+5V

11: AMP_-5V

12: AMP_-5V

13: SPKRLY_GND

14: SPKRLY_GND

15: B-_27V

16: B-_27V

17: AMP_GND_R

18: AMP_GND_R

19: AMP_GND_L

20: AMP_GND_L

21: AMP_GND

22: AMP_GND

23: B+_27V

24: B+_27V

25: BCO_GND

26: BCO_GND

27: BCO_GND

28: BCO_+12V

29: BCO_+12V

30: BCO_+12V

1: MICOM_3V9

2: MICOM_3V9

3: M_GND

4: M_GND

5: STBY_RLY

6: P/D

7: NC

8: POWER_PROT

9: AMP_+5V

10: AMP_+5V

11: AMP_-5V

12: AMP_-5V

13: SPKRLY_GND

14: SPKRLY_GND

15: B-_27V

16: B-_27V

17: AMP_GND

18: AMP_GND

19: AMP_GND

20: AMP_GND

21: AMP_GND

22: AMP_GND

23: B+_27V

24: B+_27V

25: BCO_GND

26: BCO_GND

27: BCO_GND

28: BCO_+12V

29: BCO_+12V

30: BCO_+12V

5

6 7 8

A

B

C

D

5

X-HM81-K

6 7 8

E

F

11

Page 12

1

NAND_Flash

SDRAM

LCD

KEY

IC4

IC609

IC603

CR870

IC12, 18, 19

IC208

IC704

SYSTEM U

M3030

NJU7391

INPUT SELECT & VOLUME

K

FRONT ASSY

E

BCO ASSY

D

MAIN ASSY

G

CNT2 ASSY

LCD

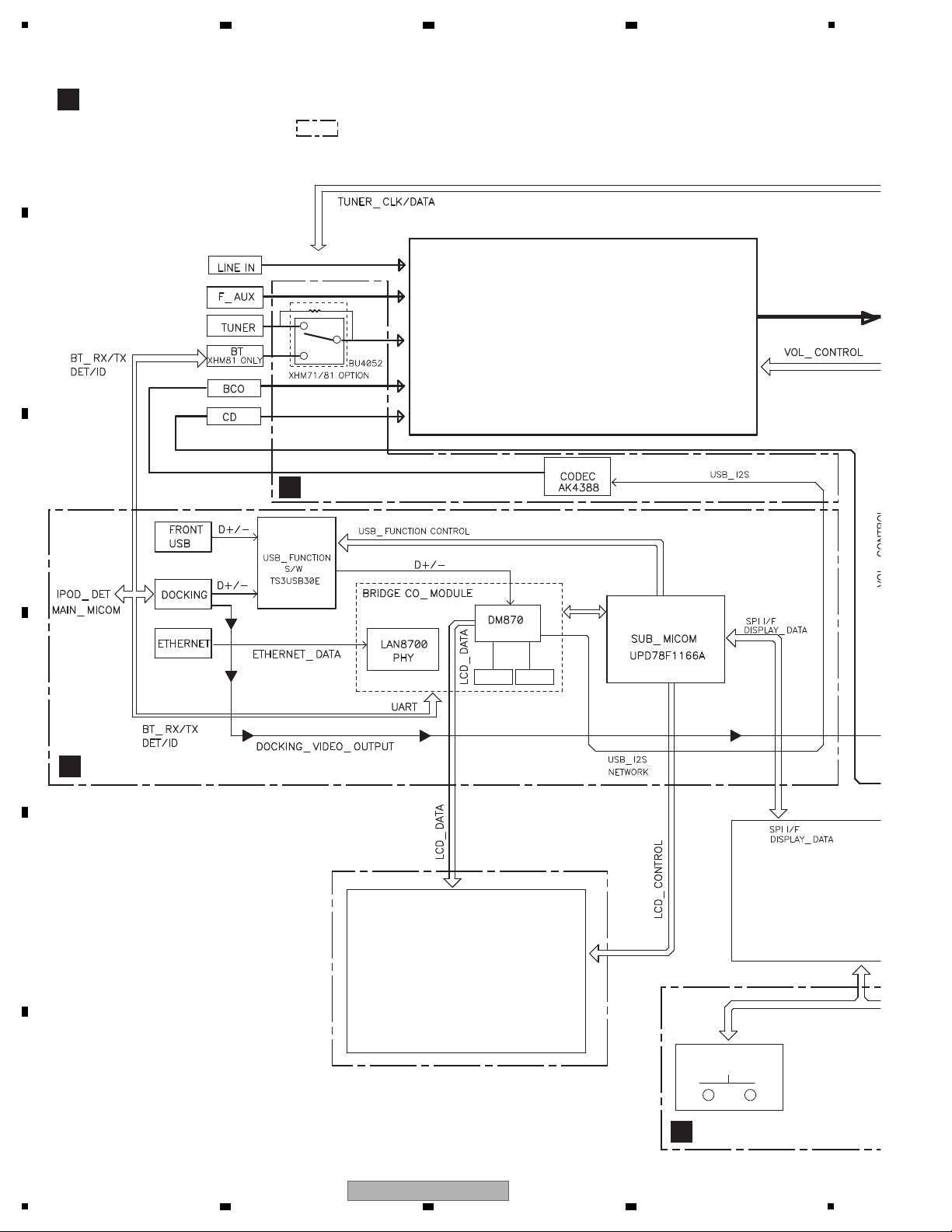

Note: Be blocks in MAIN ASSY other than blocks.

(There are some exceptions)

2 3 4

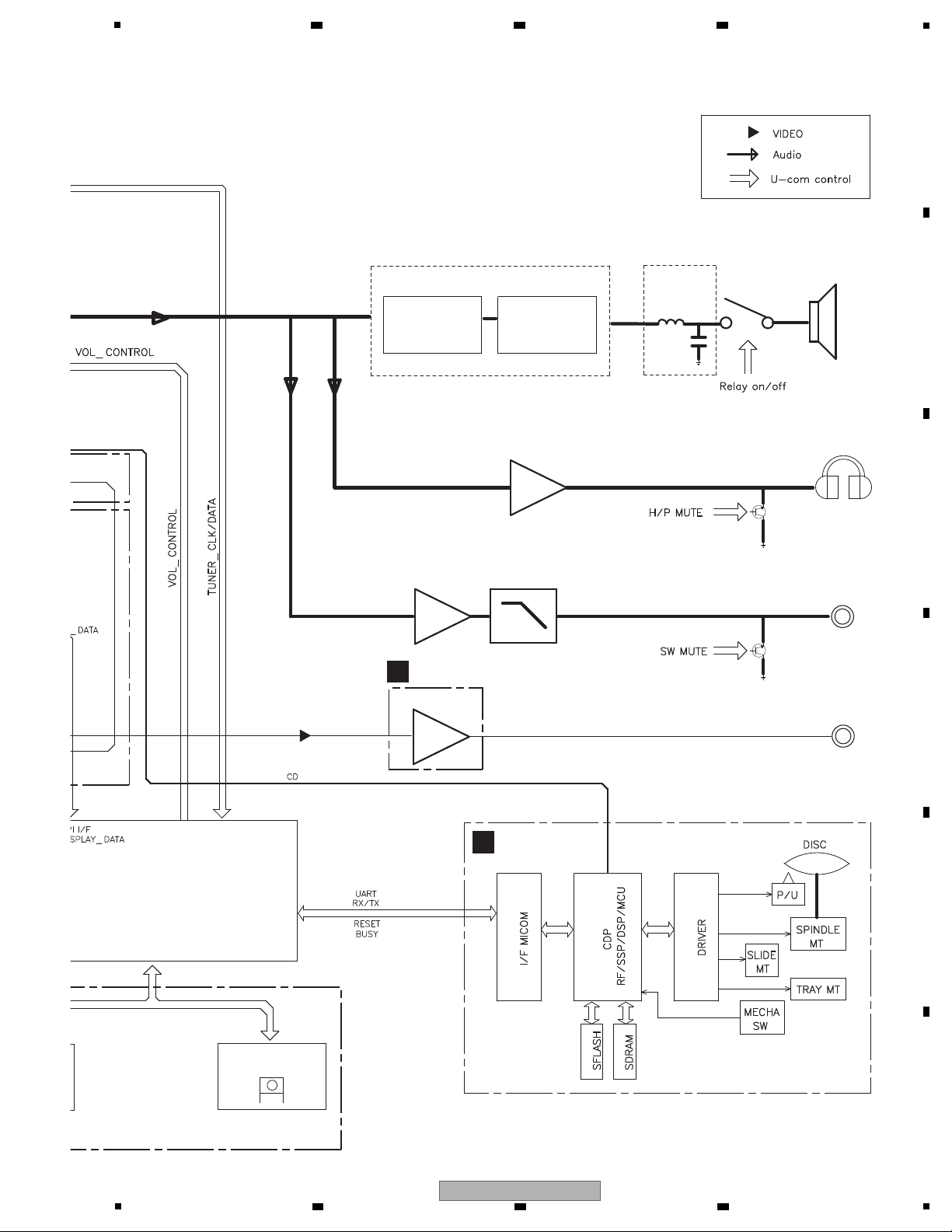

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

12

1

2 3 4

X-HM81-K

Page 13

5

-6dB

AMP

CVBS

OUT

IR

MOSFET

AMP BLOCK

CD BLOCK

IC1602

IC1603

IC1606

IC1604

IC609

IC608, 612

IC1601

IC605

Q610,615,619,621

IC606

IC400

RMC500

Headphone

OUT

+6dB

IRF6645

IRS2092S

Subwoofer

OUT

Speaker

OUT

DOCKING_VIDEO

LC_FILTER

SYSTEM U-com

M30302

B

TUNER ASSY

A

CD ASSY

6 7 8

A

B

C

D

X-HM81-K

5

6 7 8

E

F

13

Page 14

1

MAIN TRANS

AC CORD

B+_27V

BCO_+12V

MOT_+8V

MICOM_

B-_27V

IC301

IC303

IC311

IC315

S2(+12V,-12V)

SUB TRANS

S3(USB/CD)

S1(AMP +B)

2 3 4

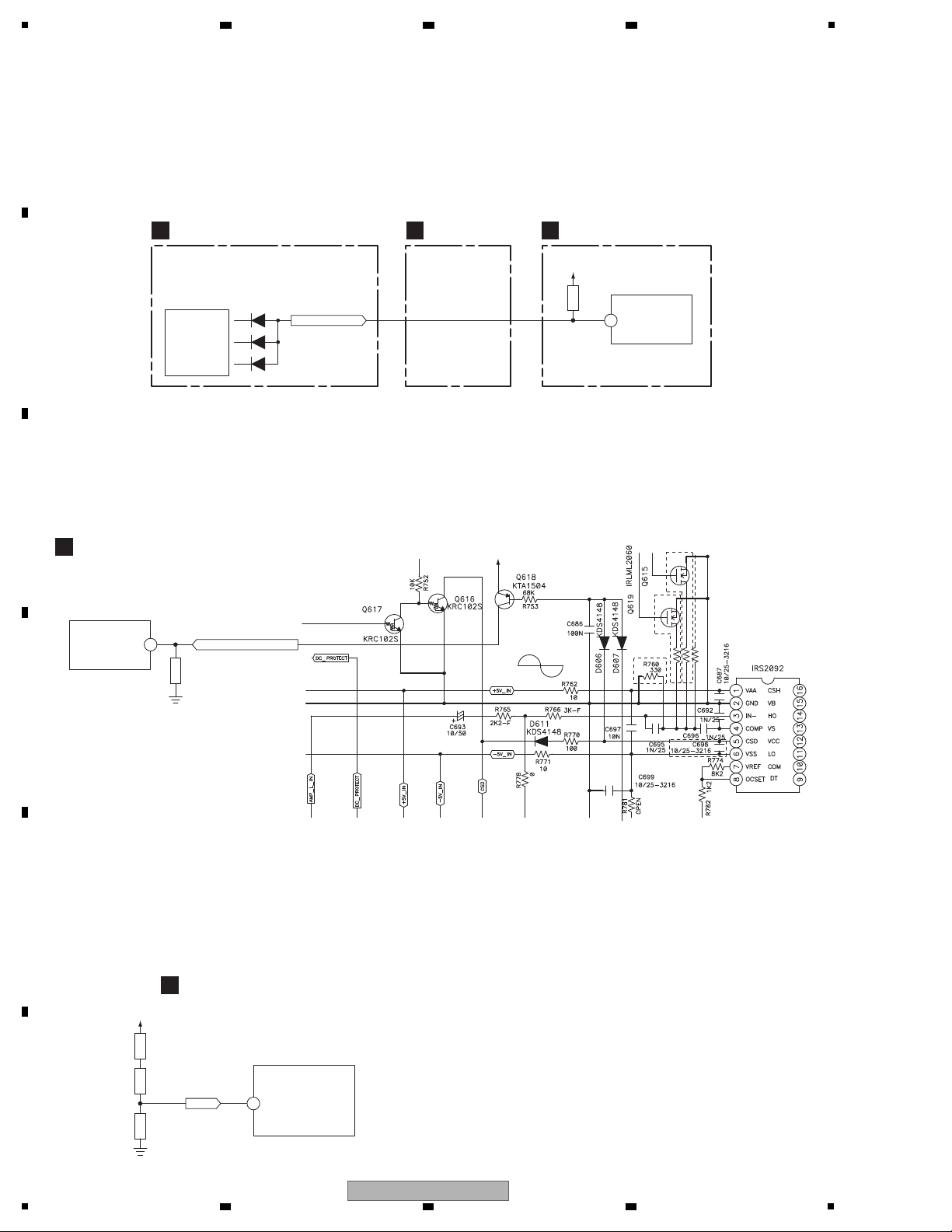

4.3 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

14

1

2 3 4

X-HM81-K

Page 15

5

S1

S2

21.5V

13.6V

0.46A

2.2A

33V

S3

8.7V

4.2A

-33V(NO LOAD)

+33V(NO LOAD)

B+_27V

A_+12V

AMP_+5V

AMP_-5V

A_-12V

BCO_+12V

MOT_+8V

MICOM_3V9

CD_+3.3V

B-_27V

IC301

IC303

IC701

IC11

IC14

IC2

IC9

IC5

IC313

IC315

IC13

IC305

IC307

20.2V

RATED_VOLTAGE

NO_LOAD

17.4V

MAIN TRANS SPEC(-)

CURRENT

6 7 8

A

B

C

D

E

F

X-HM81-K

5

6 7 8

15

Page 16

1

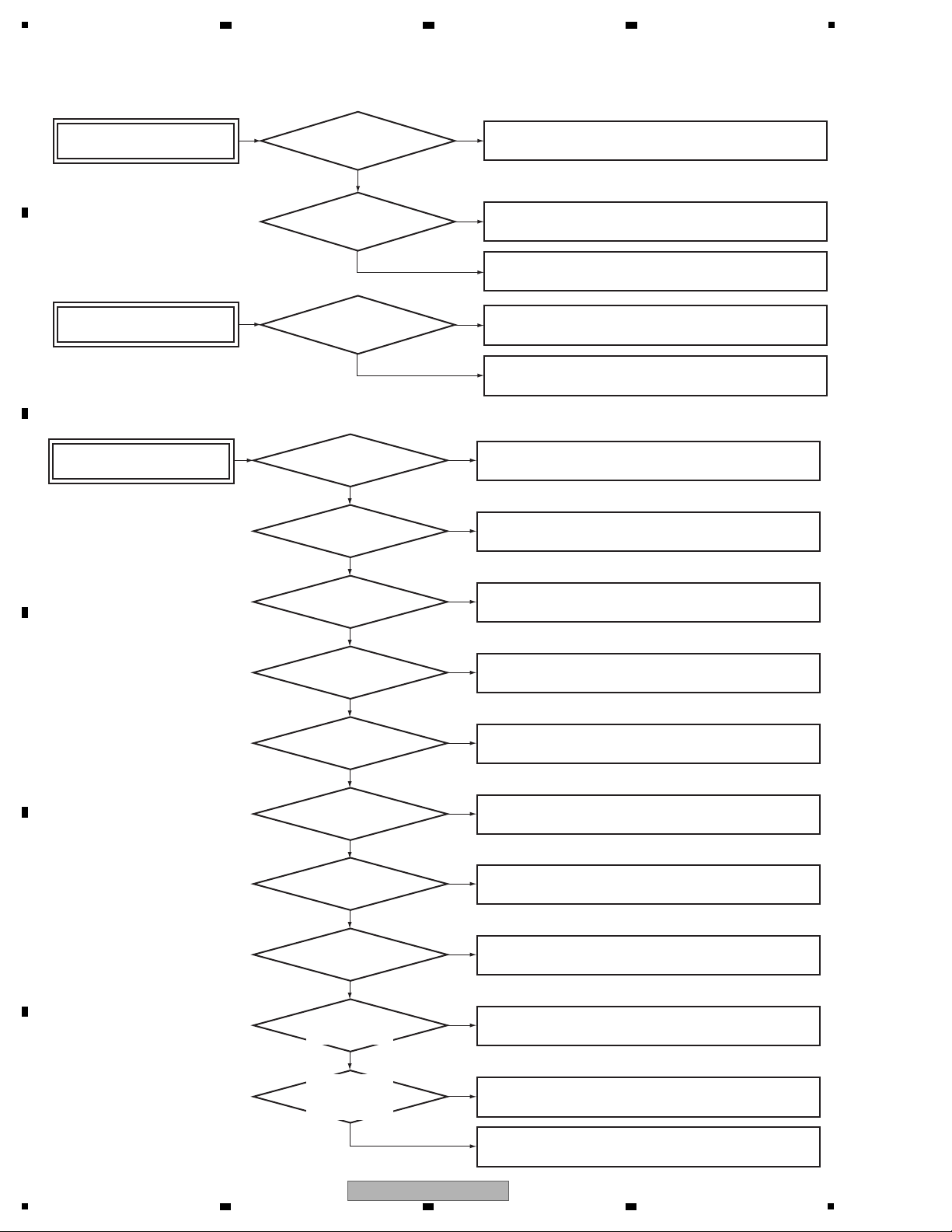

• No Power

• Detection DC from AMP circuit.

Check the IC608, IC612 and its peripheral circuits. (MAIN Assy)

• Detection overvoltage on +B line.

Check the D307 and its peripheral circuits. (POWER Assy)

Yes

• Detection abnormality of the AMP circuit.

Check the IC608, IC612 and its peripheral circuits. (MAIN Assy)

Yes

• Detection abnormal temperature of the AMP L ch circuit.

Check the IC608 and its peripheral circuits. (MAIN Assy)

Yes

• Detection short-circuit on power supply circuits.

D307: B+_27V, B-_27V

IC305, IC307: AMP_+5V, AMP_-5V

IC315: MICOM_3V9

IC301, IC303: A_+12V, A_-12V

IC313: CD_3.3V

Check each IC mentioned above and peripheral circuits.

• Check workings of primary relay (RLY301).

• Check whether secondary fuse (FU302 to 305) does not perform blowout.

(POWER Assy)

Yes

No

Protect (protection history)

Does DC protect work?

No

No

No

Does POWER protect

work?

Does AMP protect

work?

• Detection PWM abnormality output of the AMP circuit.

Check the IC608, IC612 and its peripheral circuits. (MAIN Assy)

Yes

Does PWM protect

work?

No

X-HM81, XC-HM81 only

No

• Detection an overcurrent of Bluetooth power

Check the IC600 and its peripheral circuits.

Check the short-circuit of BT_+5V power (BT Assy).

Yes

Yes

Does BT Protect

work?

No

• Detection an overcurrent of power of Front USB or iPod Dock.

Check the IC11 and IC14 and its peripheral circuits.

Check the short-circuit of 5V power of Front USB or iPod Dock

(BCO Assy/DOCKING Assy/F_USB Assy).

Be not the trouble that each Protect circuit works.

Does USB protect

work?

Does

OVERTEMP1 protect

work?

• Detection abnormal temperature of the AMP R ch circuit.

Check the IC612 and its peripheral circuits. (MAIN Assy)

Yes

No

Does

OVERTEMP2 protect

work?

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

16

1

X-HM81-K

2 3 4

Page 17

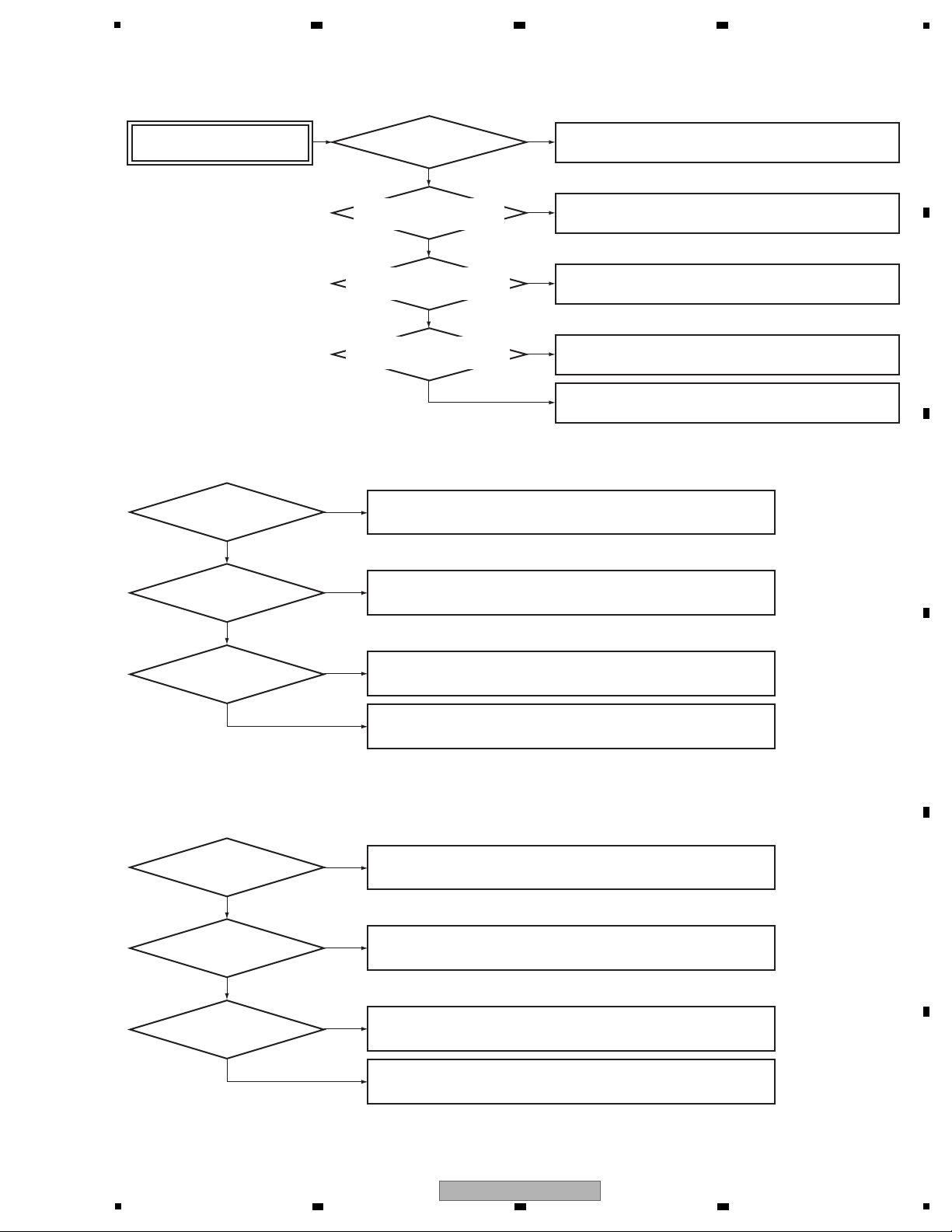

• No Sound

(*1) The confirmation that is in a state of each sound source

Check the state of each sound source. (*1)

Yes

No

A sound does not come out

of FRONT SP

The sound from a source of CD,

USB, TUNER, iPod, LINE, F.AUX

does not come out.

• Check the IC602 and its peripheral circuits. (MAIN Assy)

• Check the MAIN MUTE circuit.

No

[Failure in the individual analog-signal paths]

• Check each input circuit part and each Assy.

• Failure in connection for volume IC (IC603).

• Check the IC603 and its peripheral circuits.

No

Yes -> Check the BCO system audio.

(USB/iPod/Ethernet/WIFI/BT)

• Check the IC208 and its peripheral circuits. (CNT2 Assy)

• Check the digital audio path between the CR870 (MODULE on BCO

Assy) and IC208.

• Replace the CR870 (MODULE on BCO Assy).

None of the audio of BCO system

outputs it.

• Check the input blocks and its peripheral circuits and power

supply voltages.

• Replace the CR870 (MODULE on BCO Assy).

Output it depending on input

• Check the speaker realy. (MAIN Assy)

Yes

Does

a signal output it from

OP-AMP IC (IC602)

pin 1, 7?

• Check the IC608, IC612 and its peripheral circuits. (MAIN Assy)

• Check the Q621, Q623, Q640, Q641 and its peripheral circuits.

(MAIN Assy)

No

Yes

Does

a signal output it from

AMP IC (IC608, 612)

pin 13?

Does

the sound of CD, Analog

AUX, TUNER, LINE come

out?

Does

a signal output it from

DAC IC (IC208) pin 10,

11?

Check the IC315 and its peripheral circuits. (POWER Assy)

No

MAIN UCOM

Yes

Check the IC601 and its peripheral circuits. (MAIN Assy)

Is the

output voltage of the regulator

IC (IC315) for microcomputer power

supply 3.9 V?

• Check the D600. (MAIN Assy)

• Check connection between each Assy.

No

Yes

Is 3.3V supplied to

MAIN UCOM (IC601)?

Check the XTAL600 and its peripheral circuits. (MAIN Assy)

No

Yes

Does

the oscillator (XTAL600) for

MAIN UCOM (IC601) oscillate

it?

(POWER Assy)

(MAIN Assy)

(MAIN Assy)

(MAIN Assy)

(MAIN Assy)

(MAIN Assy)

(CNT2 Assy)

Does

the audio signal appear to

coupling condenser arround

volume IC (IC603)?

5

6 7 8

A

B

C

D

5

6 7 8

X-HM81-K

E

F

17

Page 18

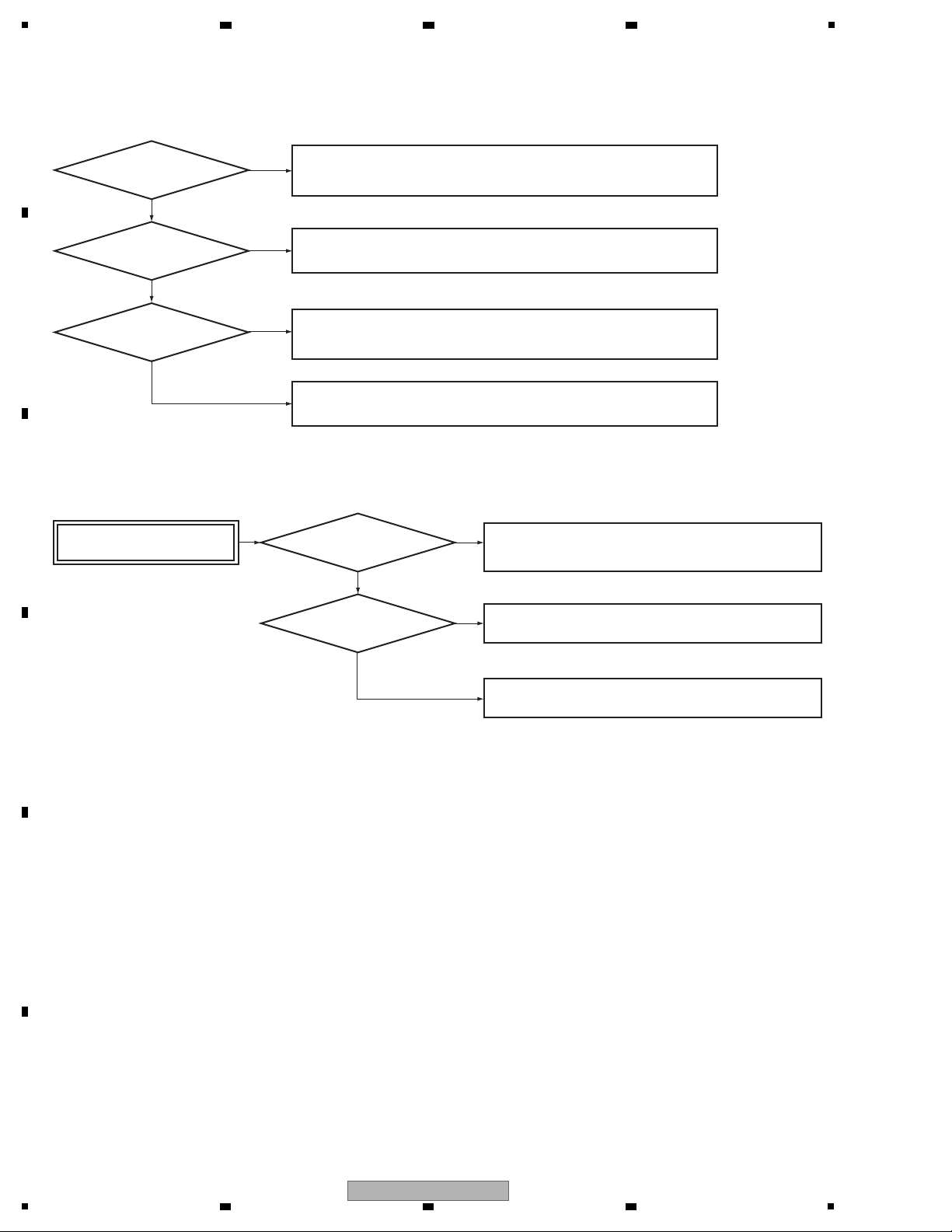

1

A sound does not come out

of headphones

• Check the HP DET signal and its peripheral circuits.

No

No

• Check the IC605 and its peripheral circuits. (MAIN Assy)

Yes

Yes

When you

connected HP, do hear the

working sound of the SP relay

(a snick sound)?

Does

a signal output it from

HP AMP IC (IC605)

pin 1, 7?

No

• Check the HP MUTE circuit. (MAIN Assy)

• Check the connection between the MAIN Assy and F_AUX Assy.

A sound does not come out

of SW PREOUT

• Check the IC606 and its peripheral circuits. (MAIN Assy)

Yes

Does

a signal output it from

OP-AMP IC (IC606)

pin 7?

• Check the SW MUTE circuit. (TUNER Assy)

• Check connection between each Assy.

• CD does not work

CD does not work (playback)

• Check connection between each cable.

No

Yes

Is FFC

to connect Pickup Assy and

CD Assy connected?

(MAIN Assy)

(MAIN Assy)

(CD Assy)

• Check whether a cable is arranged neatly.

(A cable do not touch a Disc rotate section)

No

Yes

Is the

cable arranged neatly

arround CD tray section?

• Check the IC311 and its peripheral circuits. (POWER Assy)

No

Yes

Is the

power supply voltage of

the BTL driver (IC1606)

8 V?

(CD Assy)

• Check the IC313 and its peripheral circuits. (POWER Assy)

No

Yes

Is the power

supply voltage of the CD UCOM

(IC1604), CD DSP (IC1601)

3.3 V?

(CD Assy)

• Check the IC1604, X1602 and its peripheral circuits. (CD Assy)

No

Yes

Does

the oscillator (X1602) for

CD UCOM oscillate it?

(CD Assy)

• Check the IC1601, X1601 and its peripheral circuits. (CD Assy)

No

Yes

Does

the oscillator (X1601) for

CD DSP (IC1601) oscillate

it?

(CD Assy)

• Check the IC1601, X1601 and its peripheral circuits. (CD Assy)

No

Yes

Does a

signal output it from CD DSP

(IC1601) pin 14

(DCLK)?

(CD Assy)

• Check the IC1604 and its peripheral circuits. (CD Assy)

• Check the IC601 pin 51 (CD RESET signal). (MAIN Assy)

No

Yes

Is the signal

of CD UCOM (IC1604) pin 40

(CD RESET) "H"?

(CD Assy)

• Check the IC1604 and its peripheral circuits. (CD Assy)

No

Yes

(CD Assy)

• Check the IC1604 and its peripheral circuits. (CD Assy)

No

Yes

• Check the IC1601, IC1606 and its peripheral circuits. (CD Assy)

Does signals

output from CD UCOM (IC1604)

pin 25, 27, 28 (MAIN_BUSY,

CD_RX, CD_TX)?

(CD Assy)

Is the signal

of CD UCOM (IC1604) pin 9

(8035 RESET) "H"?

A

2 3 4

B

C

D

E

F

18

1

2 3 4

X-HM81-K

Page 19

5

• Check the connection between the BCO Assy and FRONT Assy.

• Check the IC5 and IC13 and its peripheral circuits. (BCO Assy)

Yes

• Replace the LCD MODULE.

Is LCD

power supply normal?

MOD500 Pin 2,29,34

• Check the connection between the BCO Assy and FRONT Assy.

• Check the IC4 and its peripheral circuits. (BCO Assy)

No

No

Yes

Is the

reset signal of LCD normal?

If MOD500-Pin 3 is "H", its

normal.

• Check the connection between the BCO Assy and FRONT Assy.

No

Yes

Are the

other signals of MOD500

normal?

(FRONT Assy)

(FRONT Assy)

• LCD does not lit

• Do not recognize it in Front USB

• Check the connection of Lug wire between the F_USB Assy and F_AUX Assy.

• Replace the CR870 (MODULE on BCO Assy).

No: Both device NG

• Replace the CR870 (MODULE on BCO Assy).

Mass storage

Device is OK, and is only Apple

Device NG?

• Check the connection between the F_USB Assy and BCO Assy.

• Check the IC9 and its peripheral circuits. (BCO Assy)

No

Yes

Yes

Is the 5V

power supply supplied in 5 and

6 Pins of CP500?

• Check the connection between the F_USB Assy and BCO Assy.

• Check the IC12 and its peripheral circuits. (BCO Assy)

• Replace the CR870 (MODULE on BCO Assy).

No

Yes

Is there USB

signal at 3 and 4 Pins of

CP500?

(F_USB Assy)

CD tray does not do working

(OPEN/CLOSE)

• Check connection between each cable.

No

Yes

Are CD Mecha and

CD Assy connected?

(CD Assy)

Yes

(CD Assy)

• Check the IC1601 and its peripheral circuits. (CD Assy)

No

When operating any keys,

does the signals of CD DSP(IC1601)

pin 108, 114 switch to "H" / "L"?

Yes

(CD Assy)

• Check the IC1606 and its peripheral circuits. (CD Assy)

No

When operating any keys,

does the signals of BTL Driver(IC1606)

pin 9, 10 switch to "H" / "L"?

Yes

(CD Assy)

• Check the IC1601 and its peripheral circuits. (CD Assy)

• Replace the CD Deck Motor.

No

When operating any keys,

does the signals of connector (PN1603)

pin 1, 3 switch to H" / "L"?

6 7 8

A

B

C

D

E

F

X-HM81-K

5

6 7 8

19

Page 20

1

iPod video does not display.

• Check the VIDEO SW IC (IC400) and its peripheral circuits.

(TUNER Assy)

• Check connection between each Assy.

No

No

• Check the connection between the DOCKING Assy and

TUNER Assy.

Yes

Yes

Does a

CVBS signal output to

connector (CP400)

pin 3?

Does a

CVBS signal output to

connector (CP4)

pin 2?

• Check the internal circuits of the DOCKING Assy.

• Check the setting of iPod/iPhone that is external connection.

(DOCKING Assy)

(TUNER Assy)

Cannot recognize physical connection of iPod/iPhone.

• Check the path of the iPod DET signal between Pin 1 of CP1 (DOCKING Assy)

and Pin 55 of IC609 (MAIN Assy). ("L" is normal at iPod/iPhone is connected).

Yes

• Replace the CR870 (MODULE on BCO Assy).

Does the Charge LED

light?

• Check the connection between the DOCKING Assy and BCO Assy.

• Check the IC13 and its peripheral circuits. (BCO Assy)

No

No

Yes

Is the

5V power supply supplied

in 23 Pin of CP1?

• Check the connection between the DOCKING Assy and BCO Assy.

• Check the IC12 and its peripheral circuits. (BCO Assy)

• Replace the CR870 (MODULE on BCO Assy).

No

Yes

Is there USB

signal at 25 and 27 Pins of

CP1?

(DOCKING Assy)

• Do not recognize it in iPod Dock

• No Picture (iPod VIDEO)

A

2 3 4

B

C

D

E

F

20

1

2 3 4

X-HM81-K

Page 21

5

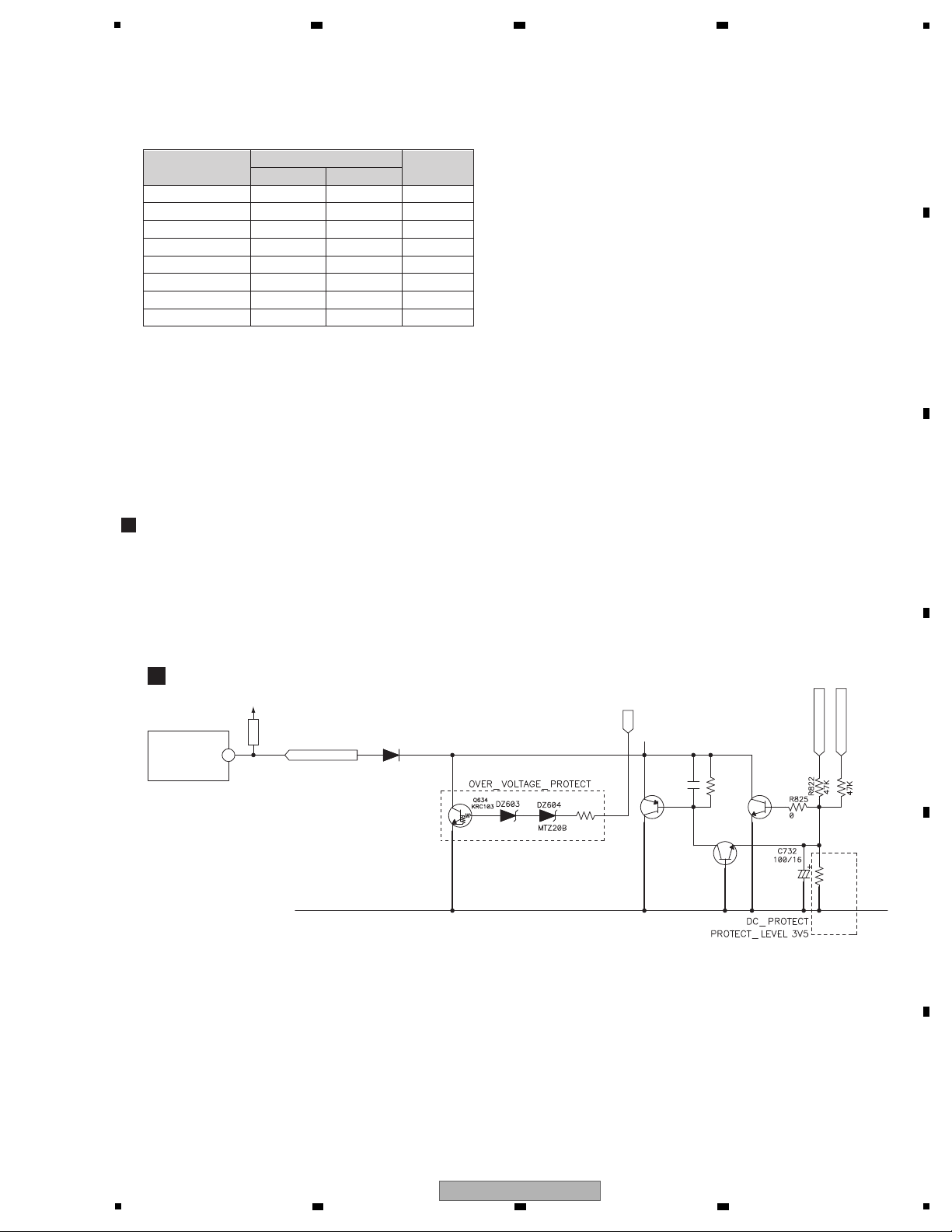

If a protection circuit is activated then the unit enters Standby mode, the LED flashes in accordance with the activated

protection function, as shown in the table below.

The DC outputs from AMP_OUT_L and AMP_OUT_R are detected to avoid DC current surge to the speakers and excess

voltage at B+ (+33 V).

The protection circuit is activated when the signal at Pin 3 of IC601 changes from H to L.

If the DC, POWER, or PWM protection circuit is activated, operation of the unit will be locked.

The buttons that can be used to release operation lock are as follows:

Simultaneously press the "INPUT" and "np" (Tune Up, Skip Up) buttons on the front panel,

or simultaneously press the "STANDBY/ON" and "g" (STOP) buttons on the front panel.

After operation lock is released and the unit is then turned ON, the unit will perform the following:

• Count the number of activations of protection circuits

• Cancel flashing of the LED

Protection

LED ON

DC

POWER

AMP

OVER TEMP1

OVER TEMP2

PWM

BT (*)

100 msec

500 msec

100 msec

100 msec

100 msec

900 msec

100 msec

LED OFF

LED flashing time Operation

Lock

900 msec

500 msec

100 msec

100 msec

100 msec

100 msec

100 msec

Lock

Lock

—

—

—

Lock

*X-HM81,XC-HM81 only

—

USB 100 msec 100 msec —

Description of Each Function

• DC Protect

KTA1268

Q635

R824

100K

B+

KDS4148U

D620

Q639

R867

KTC3198

R827

10K

C731

MTZ22B

100N-K

Q636

KTC3198

R826

47K(1/4)

AMP_OUT_R

AMP_OUT_L

DC_PROTECT

MAIN_MICOM

IC601_3 pin

DC_PROTECT

3

D

MAIN ASSY

M3V3_SW

R602

6 7 8

5.2 PROTECTION CIRCUIT

A

B

C

D

E

F

X-HM81-K

5

6 7 8

21

Page 22

1

The protection circuit is activated when short-circuiting is detected at the regulator output.

The circuit is activated when the signal at Pin 4 of IC601 changes from H to L.

Detected power: B+_27V, B-_27V, AMP_+5V, AMP_-5V, MICOM_3V9, A_+12V, A_-12V, CD_3.3V

Note: The above names are the indications on the POWER Assy. The indications of power may be different on other

Assys.

• Power Protect

The protection circuit is activated when excess current is detected from the AMP.

The circuit is activated when the signal at Pin 78 of IC601 changes from L to H.

• AMP_PROTECT

The protection circuit is activated when abnormally high temperature is detected by the P600 PTC thermistor near IC608

(AMP_Lch).

The circuit is activated when the signal at Pin 92 of IC601 changes from H to L.

• OVER_TEMPERATURE_PROTECT_1

POWER_PROT

M3V3_SW

MAIN_MICOM

IC601_4 pin

POWER_PROT

To

Power supply,

Regulator

4

N

POWER ASSY

F

CNT1 ASSY

D

MAIN ASSY

SELF

MODE1

R606

M3V3_SW

IC608

or

IC612

AMP_PROTECT_DET

MAIN_MICOM

IC601_78 pin

DC_PROTECT

OTP1

78

D

MAIN ASSY

D

MAIN ASSY

R660

M3V3_SW

MAIN_MICOM

IC601_92 pin

OVER_

TEMPERATURE_

PROTECT_1

92

P600 R751R748

A

2 3 4

B

C

D

E

F

22

1

X-HM81-K

2 3 4

Page 23

5

The protection circuit is activated when abnormally high temperature is detected by the P601 PTC thermistor near IC612

(AMP_Rch).

The circuit is activated when the signal at Pin 93 of IC601 changes from H to L.

• OVER_TEMPERATURE_PROTECT_2

D

MAIN ASSY

D

MAIN ASSY

M3V3_SW

MAIN_MICOM

IC601_93 pin

OVER_

TEMPERATURE_

PROTECT_2

93

MAIN_MICOM

IC601_2 pin

DC_PROTECT

2

OTP2

AMP_OUT_R

AMP_OUT_L

PWM_DETECT

P601 R788

M3V3_SW

R608

R787

The protection circuit is activated when abnormally PWM output is detected in the AMP_OUT_L and AMP_OUT_R.

The circuit is activated when the signal at Pin 2 of IC601 changes from H to L.

• PWM_PROTECT

The protection circuit is activated when overcurrent (0.55 A or over) of 5 V power supply supplied in Bluetooth adapter

from ADAPTER PORT terminal is detected.

The circuit is activated when the signal at Pin 104 of IC1 changes from H to L.

• BT_OVERLOAD_PROTECT (X-HM81 and XC-HM81 only)

D619

1SS355

C729

68N

10(1)

R820

R818

27K

1SS355

D621

100K

R821

KTC3875S

Q632

C728

68N

C730

10N

R859

10(1)

BT_OL

D3.3V

DM870

Y14 MICRS

BTSW

IC600_4 pin

C

BT ASSY

E

BCO ASSY

BCO MODULE (CR870)

R256

The protection circuit is activated when overcurrent (USB: 2.1 A or over, iPod Dock: 1 A or over) of 5 V power supply of

Front USB or iPod Dock.

The circuit is activated when the signal at Pin 70 of IC1 changes from H to L.

• USB_OVERLOAD_PROTECT

FAULT

F_USB SW

IC11_8 pin

DOCKING SW

IC14_8 pin

E

BCO ASSY

Y14

DM870

M2 VCO0

BCO MODULE (CR870)

M2

104

IC1

D3.3V

R26

70

IC1

6 7 8

A

B

C

D

5

6 7 8

X-HM81-K

E

F

23

Page 24

1

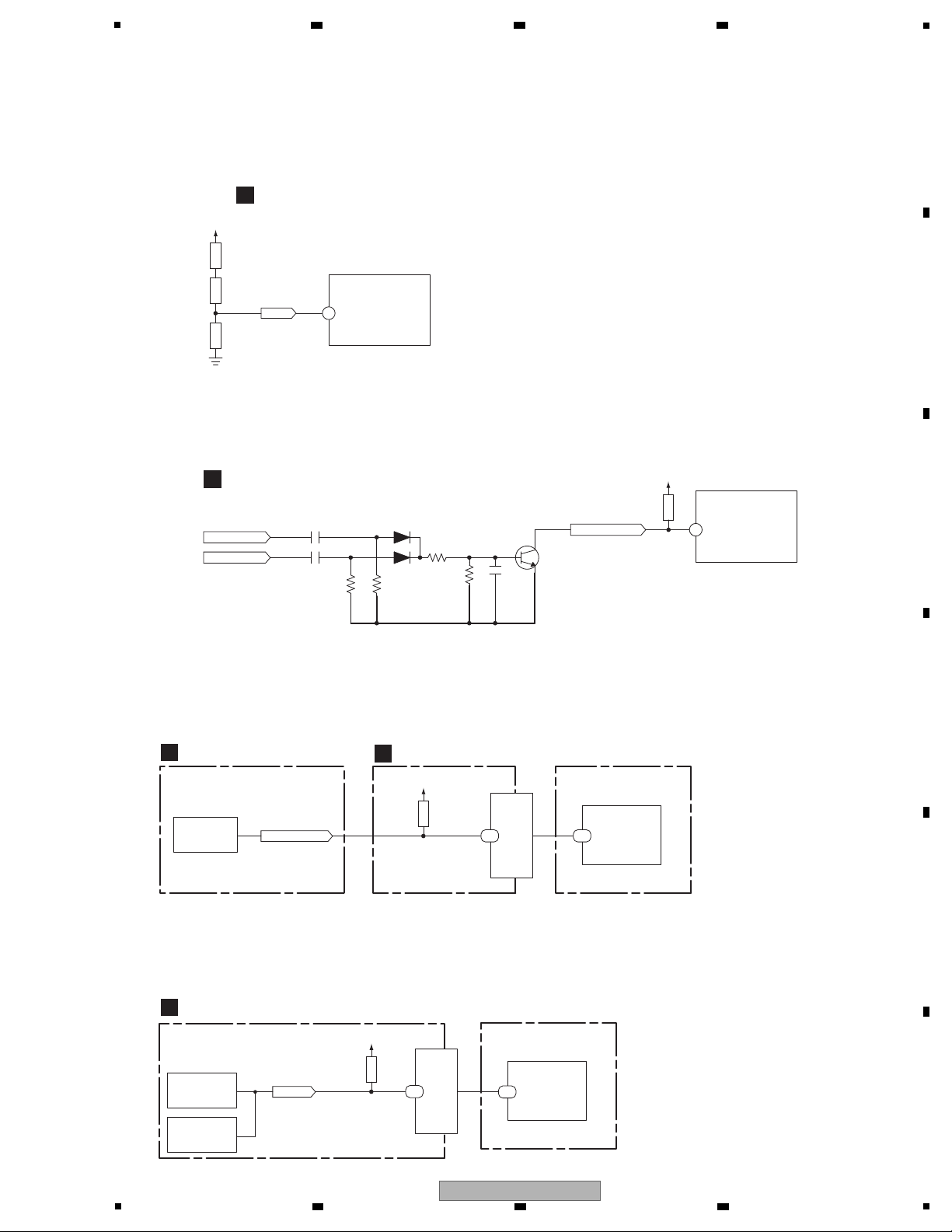

The power supply state transition of this unit becomes the right figure.

Cold Standby:

Mode in which power consumption becomes lowest

Only the main microcomputer among all the microcomputers

is powered.

Power On:

Mode in which AC Relay is turned ON and all microcomputers

are powered

iPod Charge:

Mode in which an iPod is inserted in its dock in modes other

than Power On

In this mode, an iPod device that is plugged into the USB

terminal or the dock can be charged.

The power-supply status is the same as that during

power-on with an HP inserted.

Network Standby:

Mode in which the LCD is unlit with Bco powered in order to

save startup time of Bco

The audio and video output signals are muted, and the keys

and buttons other than the STANDBY/ON key are masked.

Basically, this mode is the same as iPod Charge mode.

Note: The power-off status caused by activation of a protection circuit is not described in this section. See "5.2 Protection circuit."

Cold

Standby

Network

Standby

PowerOn

iPod

Charge

4

1

2

6

5

7

8

3

9

No. Shifting Factor

1 ColdStandby -> Power On

STANDBY/ON on the unit

STANDBY/ON on the remote control unit

WakeUpStart

2 Power On -> ColdStandby

STANDBY/ON on the unit

STANDBY/ON on the remote control unit

Sleep

AutoPowerOff

WakeUpEnd

FactoryReset

3 iPodCharge -> ColdStandby Dock removed

4 ColdStandby -> iPodCharge Dock inserted

5 Power On -> NetworkStandby

NetworkStandby on the remote control unit

ControlAppPowerOff

6 NetworkStandy -> Power On

STANDBY/ON on the unit

STANDBY/ON on the remote control unit

WakeUpStart

ControlAppPowerOn

Air Play started

DMR started

7 iPodCharge -> Power On

STANDBY/ON on the unit

STANDBY/ON on the remote control unit

WakeUpStart

ControlAppPowerOn

Air Play started

DMR started

8 Power On -> iPodCharge

STANDBY/ON on the unit

STANDBY/ON on the remote control unit

Sleep

AutoPowerOff

9 Returning to Network Standby

Removal/insert of the dock

2 3 4

5.3 POWER MANAGEMENT

A

B

C

D

E

F

24

1

X-HM81-K

2 3 4

Page 25

5

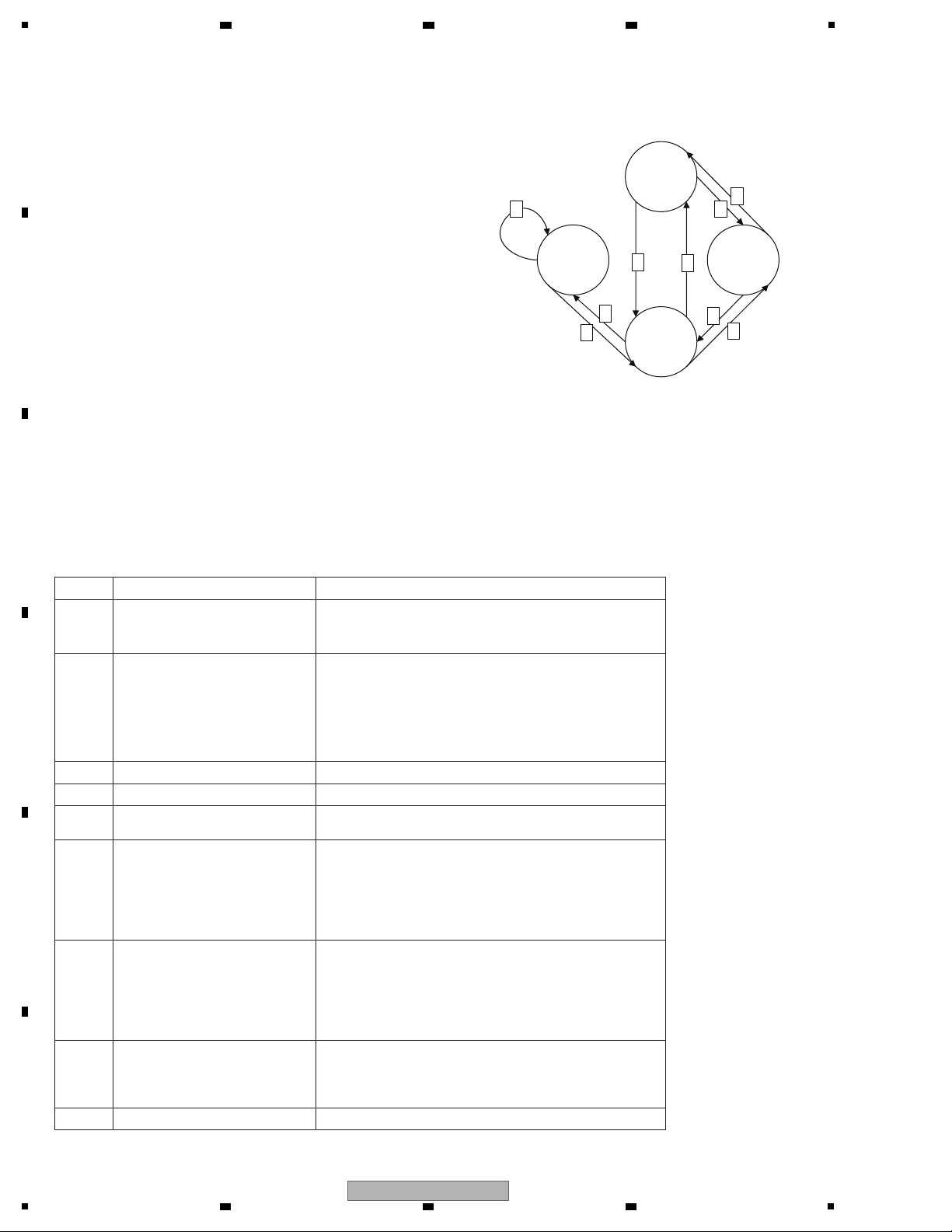

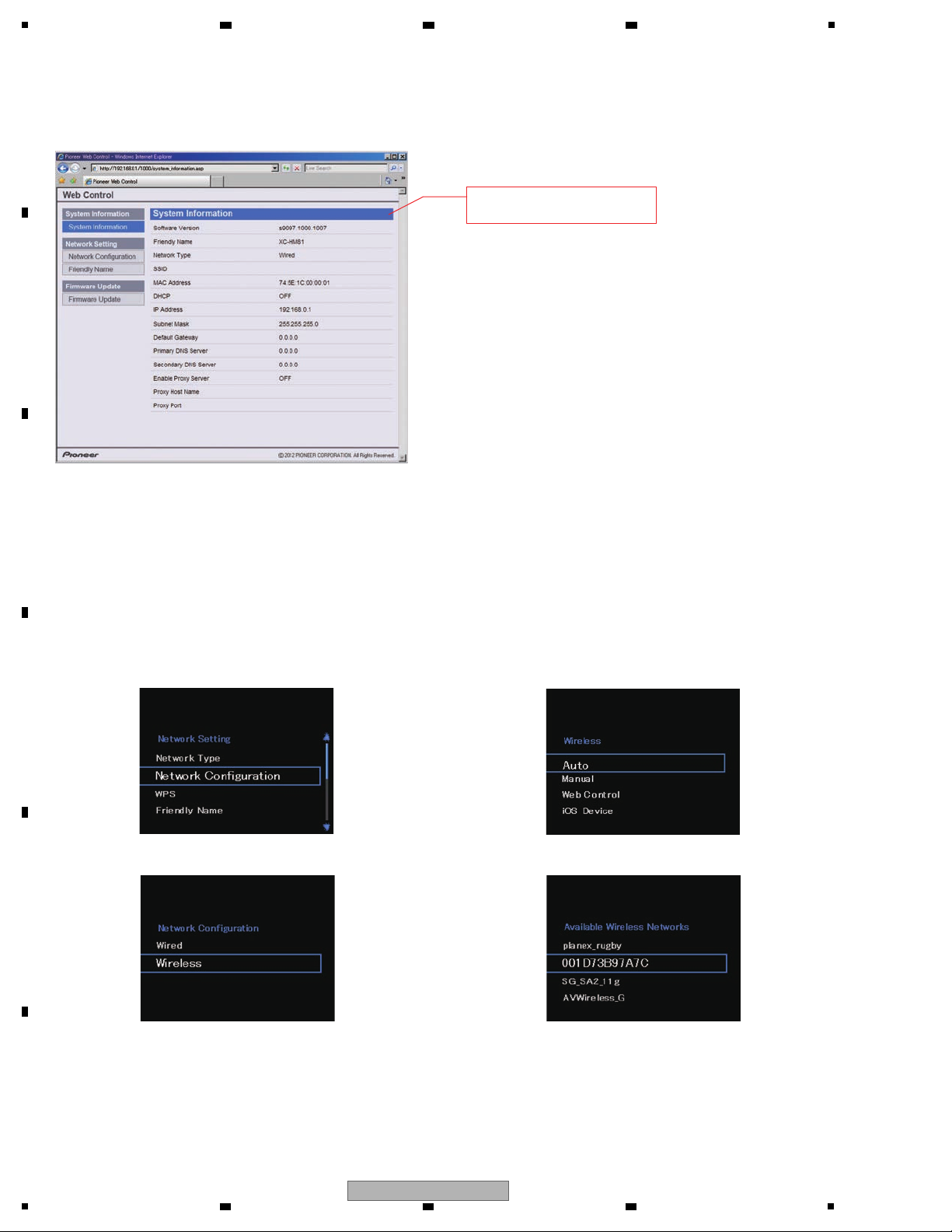

Connect the PC and this unit directly then set them up as indicated below. Then, access this unit from the PC via a Web

browser. If the indications shown in the figure below are displayed, the LAN terminal is normal.

If the LAN terminal is not normal, check the circuit between the LAN terminal and CR870 (Module on BCO Assy).

1 Turn the unit on.

2 Select the NETWORK function then press SETUP.

3 Select Network Setup > Connection Setup > Wired >

DHCP OFF.

4 Set the following items as shown below:

IP address: 192.168.0.1

Subnet mask:255.255.255.0

Gateway address: 0.0.0.0

DNS (1st): 0.0.0.0

DNS (2nd): 0.0.0.0

Proxy setting: Not to be used

5 After setting is finished, reboot the unit.

MAC Address seal

1 Click on Start > Settings > Control Panel.

2 Open Network Connections then Local Area Connection

by double-clicking on its icon.

3 Click on Properties to open the Properties window for

the local area connection.

4 Double-click on Internet Protocol.

1. Checking the LAN terminal

5 Set the items as shown below.

Setup on this unit:

Setup on the PC:

6 7 8

5.4 CHECKING TERMINALS

A

B

C

D

E

F

X-HM81-K

5

6 7 8

25

Page 26

1

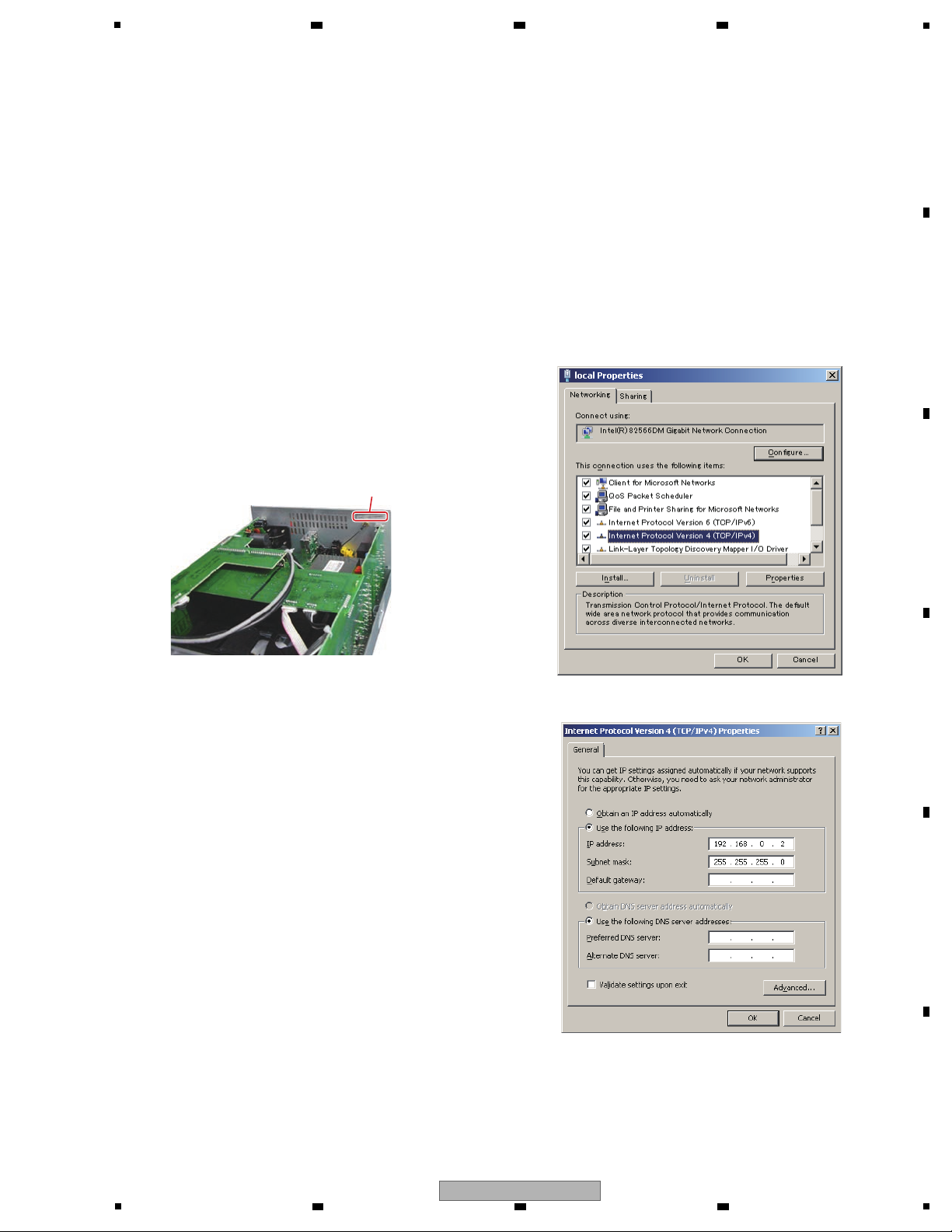

Make preparations on the wireless LAN router side then check that the SSID for that router is displayed, following the

procedure shown below. If the SSID is displayed on the LCD, the Wi-Fi antenna works properly.

If the SSID is not displayed, check the wireless LAN antenna, CR870 (Bco Module), and the cable that connects them.

(In the following LCD-display examples, the language setting is English.)

2. Checking the Wi-Fi Antenna

Start the Web browser, input http://192.168.0.1 as a URL. If the screen as indicated below is displayed,

the LAN terminal works properly.

If this screen is displayed,

the LAN terminal works properly.

If the SSID for the prepared router is displayed on the list,

the Wi-Fi antenna works properly.

Note:

As the SSID name for a wireless LAN router supports only

one-byte alphanumerics, if two-byte characters are used in

an SSID name, rename it.

1. Select the NETWORK function then press SETUP.

2. Select Network Setting → Network Configuration.

3. Select Wireless.

4. Select Auto.

5. SSID list is displayed.

A

2 3 4

B

C

D

E

F

26

1

2 3 4

X-HM81-K

Page 27

5

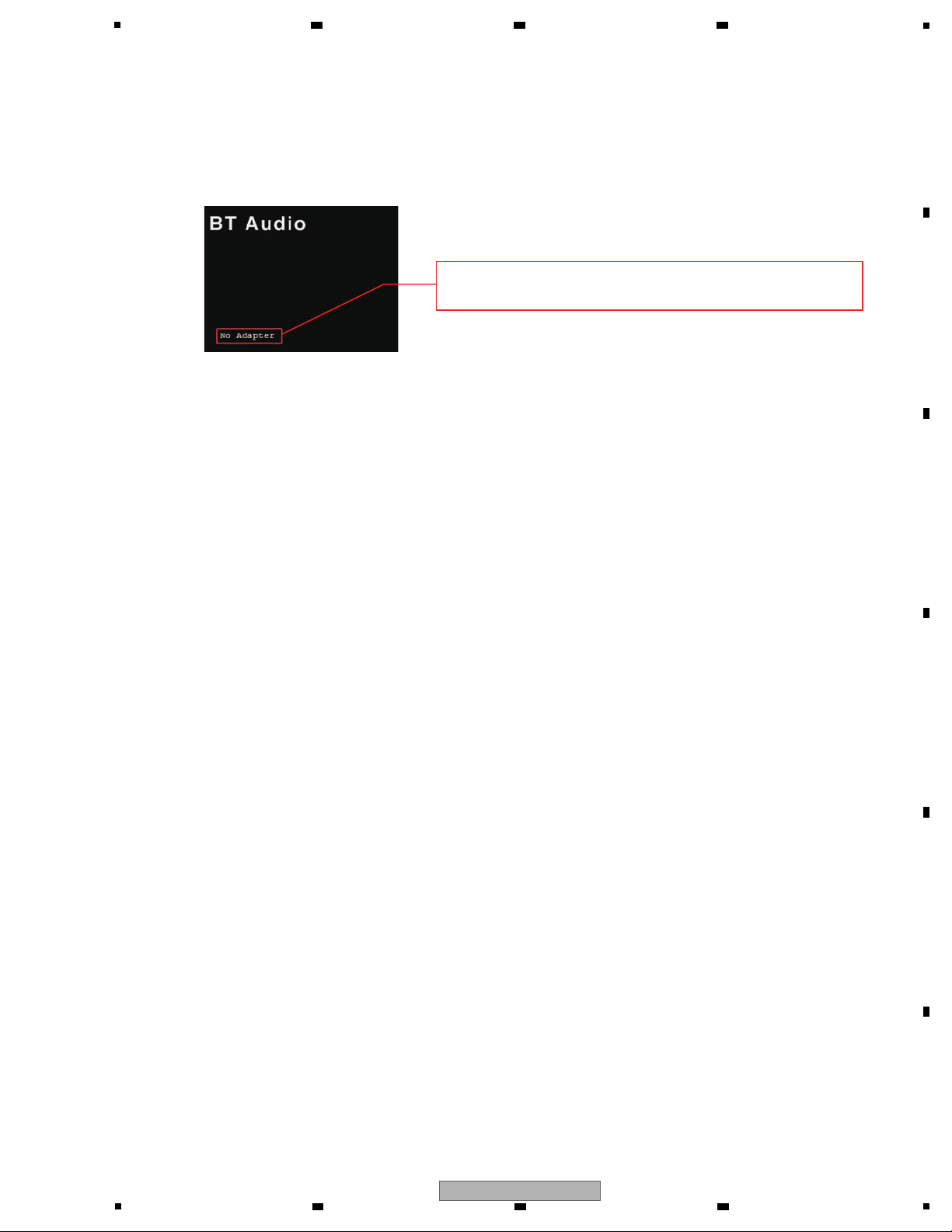

3. Checking the BT Adapter Terminal

If you connect the AS-BT100 or AS-BT200 as shown in the following steps, you can recognize if this unit works properly:

1. Select the BT function, connect the AS-BT100 or AS-BT200, then check that the indication changes as shown in the

figure below.

4. Checking the USB Terminal

This unit is provided with a USB-path switch (IC12) that switches the paths to the CR870, module on BCO Assy, between

the front USB terminal and the upper Docking Terminal, according to the selected function. Accordingly, the behavior of

the USB terminal differs, depending on which path is selected. Therefore, checking is required both with the USB and iPod

functions.

1. Select the USB function then connect an Apple Device (iPod, etc.) to the USB terminal.

If the Apple device is recognized, it is OK.

If "No Data" on the LCD disappears, the device is recognized.

If possible, with the device connected, play a track to check the audio signal for confirmation.

2. Select the iPod function then connect an Apple Device (iPod, etc.) to the USB terminal.

If charging of the Apple device starts, it is OK.

If charging does not start, refer to the diagnosis flowchart for a case in which the USB terminal cannot be recognized on

"5.1 TROUBLESHOOTING".

5. Checking the Docking Terminal

The check procedure is similar to that for "4. Checking the USB Terminal," except for one additional verification.

The Docking Terminal is provided with a function that detects a connection of an Apple device during power-off and starts

charging. This additional function must be also verified.

1. Select the iPod function then put an Apple device (iPod, etc.) in the Dock.

If the Apple device is recognized, it is OK.

If "No Data" on the LCD disappears, the device is recognized.

If possible, with the device connected, play a track to check the audio signal for confirmation.

2. Select the USB function then put an Apple device (iPod, etc.) in the Dock.

If charging of the Apple device starts, it is OK.

3. Disconnect the Apple device from the dock then turn the unit off.

Reconnect the Apple device to the Dock. If the CHARGE LED lights and charging starts, it is OK.

If charging does not start, refer to the diagnosis flowchart for a case in which the Docking Terminal cannot be recognized

on "5.1 TROUBLESHOOTING"..

If the indication does not change as shown in the above figure, possible causes are as follows:

"No Adapter" remains displayed:

The CR870, module on BCO Assy, cannot detect connection of the AS-BT100/200. Check BT_DET.

The indication stops at "Starting":

The CR870, module on BCO Assy, cannot communicate with the AS-BT100/200.

Check power supply to the AS-BT100/200 and the UART communication line.

Signal lines to be checked: BT_ON/CE, BT_+5V, BT_TX/U_RX, BT_RX/U_TX

2. If the indication changes properly in Step 1, perform pairing with a player then check the audio output signals.

If no audio signal is output, check BT_L, BT_R, and BT_MUTE.

After the AS-BT100/200 is connected, the indication will change as follows:

No Adapter -> Starting -> Waiting Device.

6 7 8

A

B

C

D

E

X-HM81-K

5

6 7 8

F

27

Page 28

1

8952HM7100020-IL (UPD78F1166AGF-GAS)(BCO ASSY: IC4)

16-bit Single-chip Microcontrollers

• Pin Function

No. Mark Pin Name I/O Pin Function

1 P60/SCL0 O

2 P61/SDA0 O

3 P62 O

4 P63 XRST_NWONetwork module communication reset

5

P31/TI03/TO03/INTP4

USB_DOCK_OVERLOAD

I Detect that BridgeCo detected a USB overcurrent. Active: L

6 P64/RD USB_DATA_SW O DOCK USB DATA switching output L:USB / H: DOCK

7 P65/WR0 DOCK_RESISTER O ChargeResister control of USB DATA lines of DOCK Active: L

8 P66/WR1 USB_RESISTER O ChargeResister control of USB DATA lines of USB-A Active: L

9 P67/ASTB USB_START I Detect that BridgeCo started USB control. H: Start Active: H

10

P77/EX23/KR7/INTP11

I

11

P76/EX22/KR6/INTP10

DOCK_SEL I USB connection switching request of BridgeCo Active: H

12

P75/EX21/KR5/INTP9

USB_SEL I USB connection switching request of BridgeCo Active: H

13

P74/EX20/KR4/INTP8

HSYNC I HSYNC monitor of LCD communication

14 P73/EX19/KR3 O NC

15 P72/EX18/KR2 XCS_LCD O LCD communication chip select output (Flow control-Subcon request)

16 P71/EX17/KR1 O

17 P70/EX16/KR0 O NC

18 P06/WAIT O NC

19 P05/CLKOUT O NC

20 EVSS1 EVSS1 - Ground of port block (except P20-P27, P110, P111, P121-P124, P150-P157)

21 P80/EX0 DOCK_PWR_ON O DOCK BUS POWER ON/OFF control output Active: H

22 P81/EX1 USB_PWR_ON O USB BUS POWER ON/OFF control output Active: H

23 P82/EX2 O NC

24 P83/EX3 O NC

25 P84/EX4 O NC

26 P85/EX5 O NC

27 P86/EX6 O NC

28 P87/EX7 O NC

29

P30/INTP3/RTC1HZ

VFD_CE O FL CE

30 EVDD1 EVDD1 -

Positive power supply of port block (except P20-P27, P110, P111, P121-P124, P150-P157)

31 P50/EX8 O NC

32 P51/EX9 O NC

33 P52/EX10 O NC

34 P53/EX11 O NC

35 P54/EX12 O NC

36 P55/EX13 USB_DATA_EN O Switch enable output of USB DOCK DATA switch Active: L

37 P56/EX14 O NC

38 P57/EX15 O NC

39

P17/EX31/TI02/TO02

O NC

40

P16/EX30/TI01/TO01/INTP5

O NC

41

P15/EX29/RTCDIV/RTCCL

O NC

42 P14/EX28/RxD3 DEBUG_RX I 232C DEBUG RX

43 P13/EX27/TxD3 DEBUG_TX O 232C DEBUG TX

44

P12/EX26/SO00/TxD0

TX0_DI_NW O Data output of network module communication (Sub->DM860)

45

P11/EX25/SI00/RxD0

RX0_DO_NW I Data input of network module communication (DM860->Sub)

46 P10/EX24/SCK00 CLK_NW O Clock output of network module communication

47 AVREF1 AVREF1 -

48 P110/ANO0 BT_MUTE O BT MUTE Active: L

49 P111/ANO1 CS_NW O Chip select output of network module communication

50 AVREF0 AVREF0 -

2 3 4

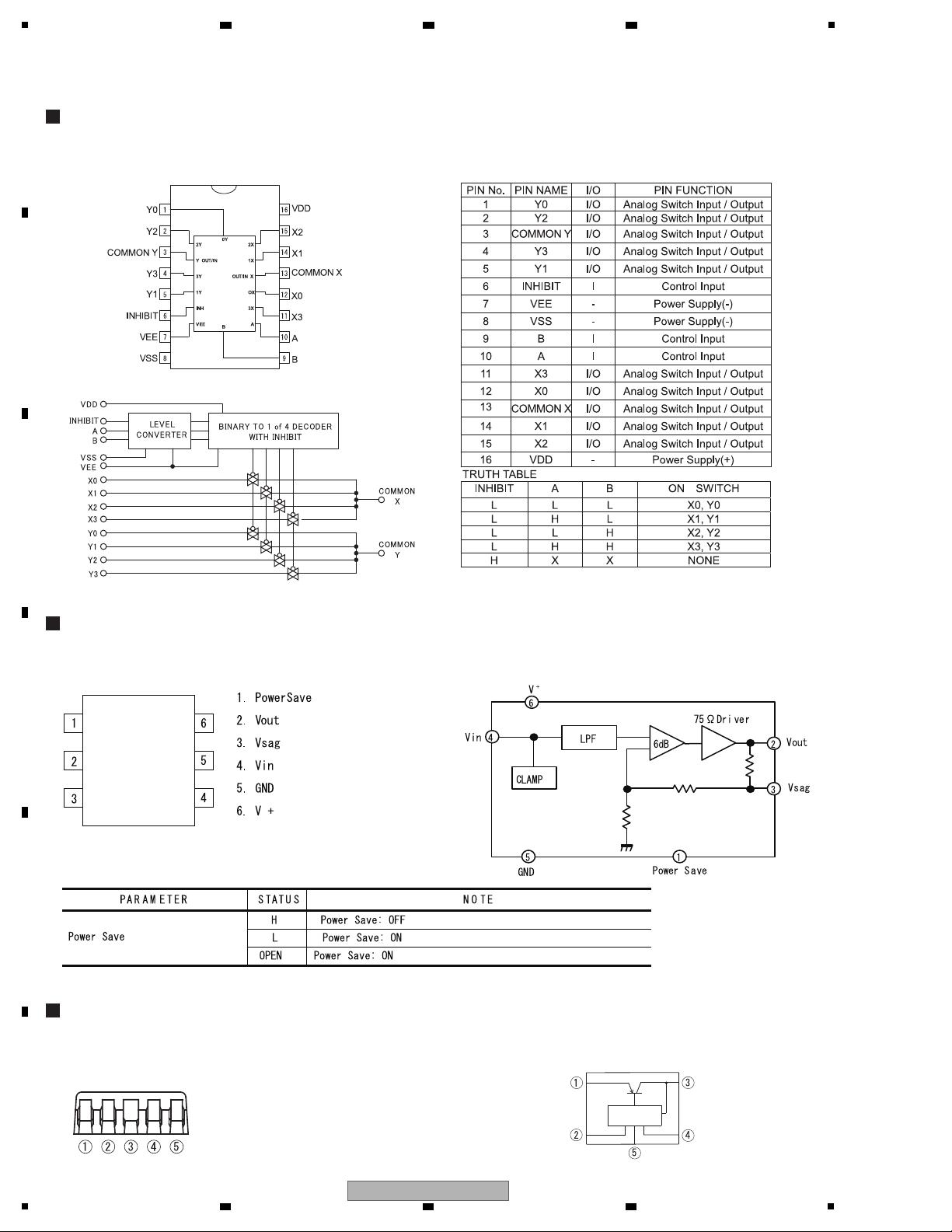

5.5 IC INFORMATION

A

B

C

D

E

F

28

1

X-HM81-K

2 3 4

Page 29

5

• Pin Function

No. Mark Pin Name I/O Pin Function

51 AVSS AVSS 52 P157/ANI15 O NC

53 P156/ANI14 O NC

54 P155/ANI13 O NC

55 P154/ANI12 O NC

56 P153/ANI11 O NC

57 P152/ANI10 O NC

58 P151/ANI9 O NC

59 P150/ANI8 O NC

60 P27/ANI7 SUB_IRQ O SUB → MAIN REQUEST output

61 P26/ANI6 O NC

62 P25/ANI5 XRST_LCD O LCD communication reset

63 P24/ANI4 O NC

64 P23/ANI3 O NC

65 P22/ANI2 O NC

66 P21/ANI1 O NC

67 P20/ANI0 O NC

68 P130 O NC

69 P131/TI06/TO06 O NC

70 P04/SCK10/SCL10 CSK_MAIN O Communication clock of MAIN ⇔ SUB

71

P03/SI10/RxD1/SDA10

SCDO_MAIN I Communication data of SUB ← MAIN

72 P02/SO10/TxD1 SCDI_MAIN O Communication data of SUB → MAIN

73 P01/TO00 I NC

74 P00/TI00 REM I IR remote control signal input (NC. only WS)

75 P145/TI07/TO07 PWM_LCD O Backlight control (PWM) of LCD communication

76 P144/SO20/TxD2 DI_LCD O Data output of LCD communication

77

P143/SI20/RxD2/SDA20

DO_LCD I Data input of LCD communication

78

P142/SCK20/SCL20

CLK_LCD O Clock output of LCD communication

79

P141/PCLBUZ1/INTP7

ONC

80

P140/PCLBUZ0/INTP6

ONC

81 P120/INTP0/EXLVI MAIN_REQ I MAIN REQUEST input