Page 1

VSX-522-K

AV Receiver

VSX-522-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

VSX-522-K CUXESM AC 120 V

ORDER NO .

RRV4296

K-MZV FEB.

2012 Printed in Japan

Page 2

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

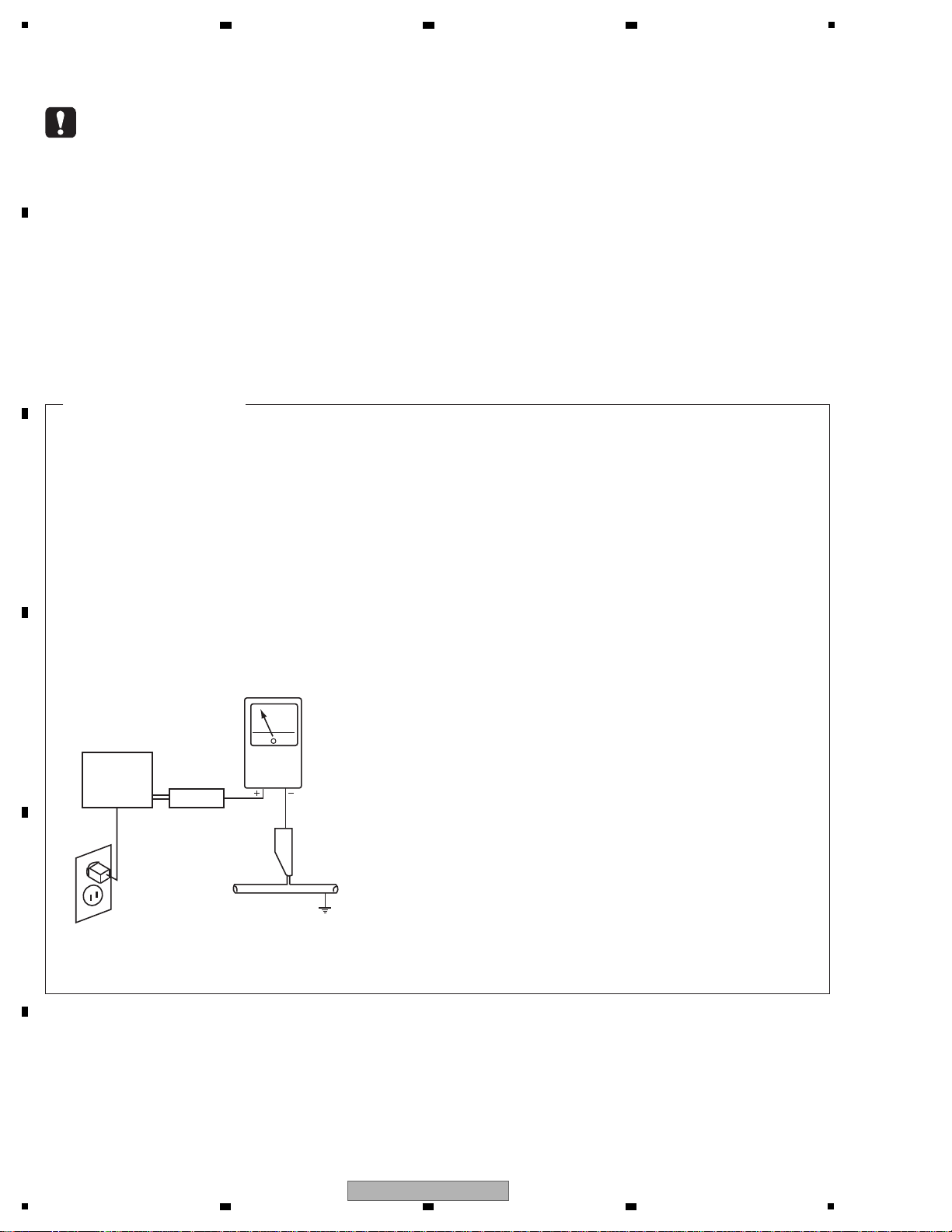

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120 V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

VSX-522-K

Page 3

5

6 7 8

CONTENTS

SAFETY INFORMATION..........................................................................................................................................................2

1. SERVICE PRECAUTIONS....................................................................................................................................................4

1.1 NOTES ON SOLDERING...............................................................................................................................................4

1.2 NOTES ON REPLACING PARTS.......................................... ... ... ............................... ... .................................................4

1.3 SERVICE NOTICE........................................ .............................................................. ... .................................................4

2. SPECIFICATIONS.................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ............................. ..............................................................................................6

3.2 JIGS LIST...... .. .............................................................. ... ..............................................................................................6

3.3 PCB LOCATIONS.................................... .. .....................................................................................................................7

4. BLOCK DIAGRAM................................................................................................................................................................8

4.1 OVERALL WIRING DIAGRAM .............................................. ... ......................................................................................8

4.2 AUDIO BLOCK DIAGRAM............................................. ... ............................... .. ...........................................................10

4.3 D-MAIN BLOCK DIAGRAM................................................................................................... ... ....................................12

4.4 POWER SUPPLY BLOCK DIAGRAM............................................. ... .................................... ... ... ... ..............................14

4.5 VIDEO BLOCK DIAGRAM.................................. ... .............................. ... .................................. ....................................16

5. DIAGNOSIS........................................................................................................................................................................17

5.1 TROUBLESHOOTING.................... ... .............................................................. .. ...........................................................17

5.2 USB/iPod ERROR MESSAGE......................................................................................................................................29

5.3 DETECTION CIRCUIT ......................... ... ............................................................. ... .....................................................30

5.4 IC INFORMATION .............................................. ... .......................................................................................................32

6. SERVICE MODE.................................................................................................................................................................38

6.1 SERVICE MODE...... ... .. ............................... ... .............................................................. .. .............................................38

7. DISASSEMBLY ...................................................................................................................................................................42

8. EACH SETTING AND ADJUSTMENT................................................................................................................................50

8.1 ADJUSTMENT REQUIRED WHEN THE UNIT IS REPAIRED OR REPLACED.......................................... .. ... ...........50

8.2 UPDATING OF THE FIRMWARE .................................................................................................................................51

8.3 IDLE CURRENT ADJUSTMENT..................................................................................................................................57

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................58

9.1 PACKING SECTION..................................................................................... ... .. ...........................................................58

9.2 EXTERIOR SECTION .................... ... ... ............................... .. .......................................................................................60

10. SCHEMATIC DIAGRAM.............................................................................. ... ... ................................................................64

UDIO ASSY

10.1 A

10.2 AMP5 ASSY (1/2).......................................................................................................................................................66

10.3 AMP5 ASSY (2/2).......................................................................................................................................................68

10.4 MAIN ASSY................................................................................................................................................................70

10.5 D-MAIN ASSY (1/4)....................................................................................................................................................72

10.6 D-MAIN ASSY (2/4)....................................................................................................................................................74

10.7 D-MAIN ASSY (3/4)....................................................................................................................................................76

10.8 D-MAIN ASSY (4/4)....................................................................................................................................................78

10.9 VIDEO, G-L, G-R, WG-B and WG-A ASSYS..............................................................................................................80

10.10 BRG-A, BRG-B and BRG-C ASSYS ........................................................................................................................82

10.11 FRONT, INSEL, HP, MIC, F-USB and WG ASSYS...................................................................................................84

10.12 STANDBY ASSY.......................................................................................................................................................86

11. PCB CONNECTION DIAGRAM............................................ ... .................................... ... ... ...............................................88

11.1 AUDIO ASSY..............................................................................................................................................................88

11.2 AMP5 ASSY ...............................................................................................................................................................90

A

11.3 M

IN ASSY................................................................................................................................................................92

11.4 D-MAIN ASSY ............................................................................................................................................................96

11.5 VIDEO ASSY............................................................................................................................................................100

11.6 G-L, G-R, WG-B and WG-A ASSYS.........................................................................................................................101

11.7 BRG-A, BRG-B and BRG-C ASSYS ........................................................................................................................102

11.8 FRONT, INSEL, HP, MIC, F-USB and WG ASSYS...................................................................................................106

11.9 STANDBY ASSY.......................................................................................................................................................110

12. PCB PARTS LIST................................... .............................................................. .. .........................................................111

..............................................................................................................................................................64

A

B

C

D

E

F

VSX-522-K

5

6 7 8

3

Page 4

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

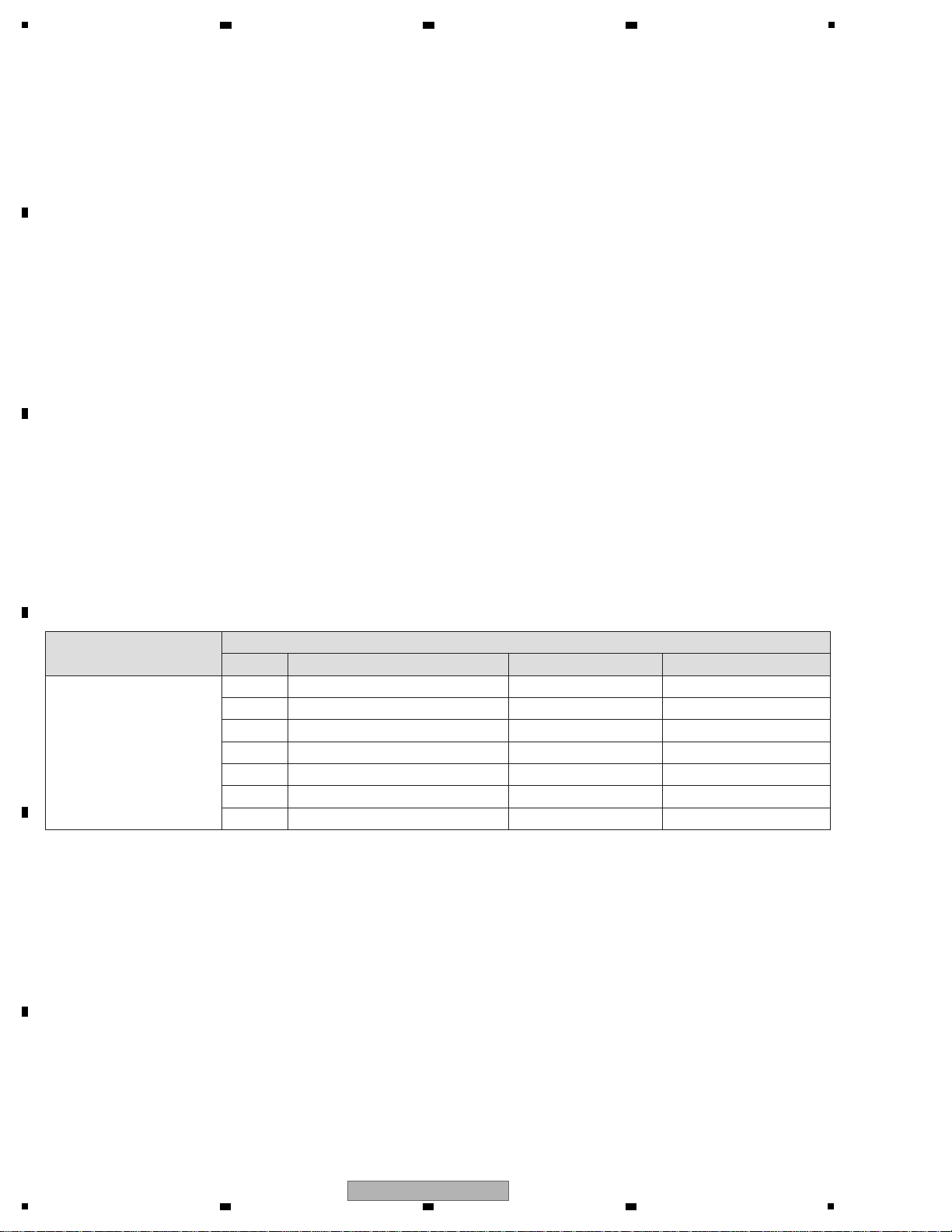

The part listed below is difficult to replace as a discrete component part.

When the part listed in the table is defective, replace whole Assy.

Assy Name

D-MAIN Assy

HDMI Receiver —————— IC with heat-padIC2000

Parts that is Difficult to Replace

Ref No. Function Part No. Remarks

D-MAIN 3.3 V Power Supply IC —————— IC with heat-padIC2007

D-MAIN 5 V Power Supply IC —————— IC with heat-padIC2008

DSP 1.2 V Power Supply IC —————— IC with heat-padIC2013

DSP 1.8 V Power Supply IC —————— IC with heat-padIC2015

DSP IC —————— IC with heat-padIC2016

USB 5 V SW IC —————— IC with heat-padIC2024

• Discharging

For more detail, please refer to "7. DISASSEMBLY - 1. Discharging".

• Notes on Ground Points Connection

For more detail, please refer to "7. DISASSEMBLY - 2. Notes on Ground Points Connection".

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

1.2 NOTES ON REPLACING PARTS

D

E

F

1.3 SERVICE NOTICE

4

1

2 3 4

VSX-522-K

Page 5

5

Amplifier section

Continuous average power output of 80 watts* per

channel, min., at 8 ohms, from 20 Hz to 20 000 Hz with no

more than 0.08 %** total harmonic distortion.

Front (stereo)............................................................... 80 W + 80 W

Power output (1 kHz, 6 Ω, 1 %)...........................140 W per channel

Guaranteed speaker impedance.................................... 6 Ω to 16 Ω

* Measured pursuant to the Federal Trade Commission’s Trade

Regulation rule on Power Output Claims for Amplifiers

** Measured by Audio Spectrum Analyzer

Audio Section

Input (Sensitivity/Impedance)

LINE.........................................................................200 mV/47 kΩ

Signal-to-Noise Ratio (IHF, short circuited, A network)

LINE.......................................................................................98 dB

Signal-to-Noise Ratio [EIA, at 1 W (1 kHz)]

LINE.......................................................................................79 dB

Video Section

Signal level

Composite................................................................1 Vp-p (75 Ω)

Tuner Section

Frequency Range (FM) .................................87.5 MHz to 108 MHz

Antenna Input (FM)................................................75 Ω unbalanced

Frequency Range (AM)...................................530 kHz to 1700 kHz

Antenna (AM) .............................................................Loop antenna

Digital In/Out Section

HDMI terminal ...........................................................Type A (19-pin)

HDMI output type............................................................5 V, 100 mA

USB (iPod) terminal..............................USB2.0 Full Speed (Type A)

Miscellaneous

Power Requirements...............................................AC 120 V, 60 Hz

Power Consumption................................................................415 W

In standby...........................................................0.4 W (ARC OFF)

Dimensions....................435 mm (W) x 168 mm (H) x 342.5 mm (D)

17 3/16 in. (W) x 6 5/8 in. (H) x 13 1/2 in. (D)

Weight (without package).....................................8.7 kg (19 lb 3 oz)

Note

• Specifications and the design are subject to possible

modifications without notice, due to improvements.

Accessories

Remote control (AXD7660)

(8300766000010-IL)

AM loop antenna

(E601019000010-IL)

Warranty card

Quick start guide (5707000006490-IL)

Safety Brochure

Operating instructions (CD-ROM)(6517000000500-IL)

FM wire antenna

(E605010140010-IL)

Dry cell batteries

(AAA size IEC R03) x2

Microphone (for Auto MCACC setup)

(APM7010)

2. SPECIFICATIONS

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

5

Page 6

1

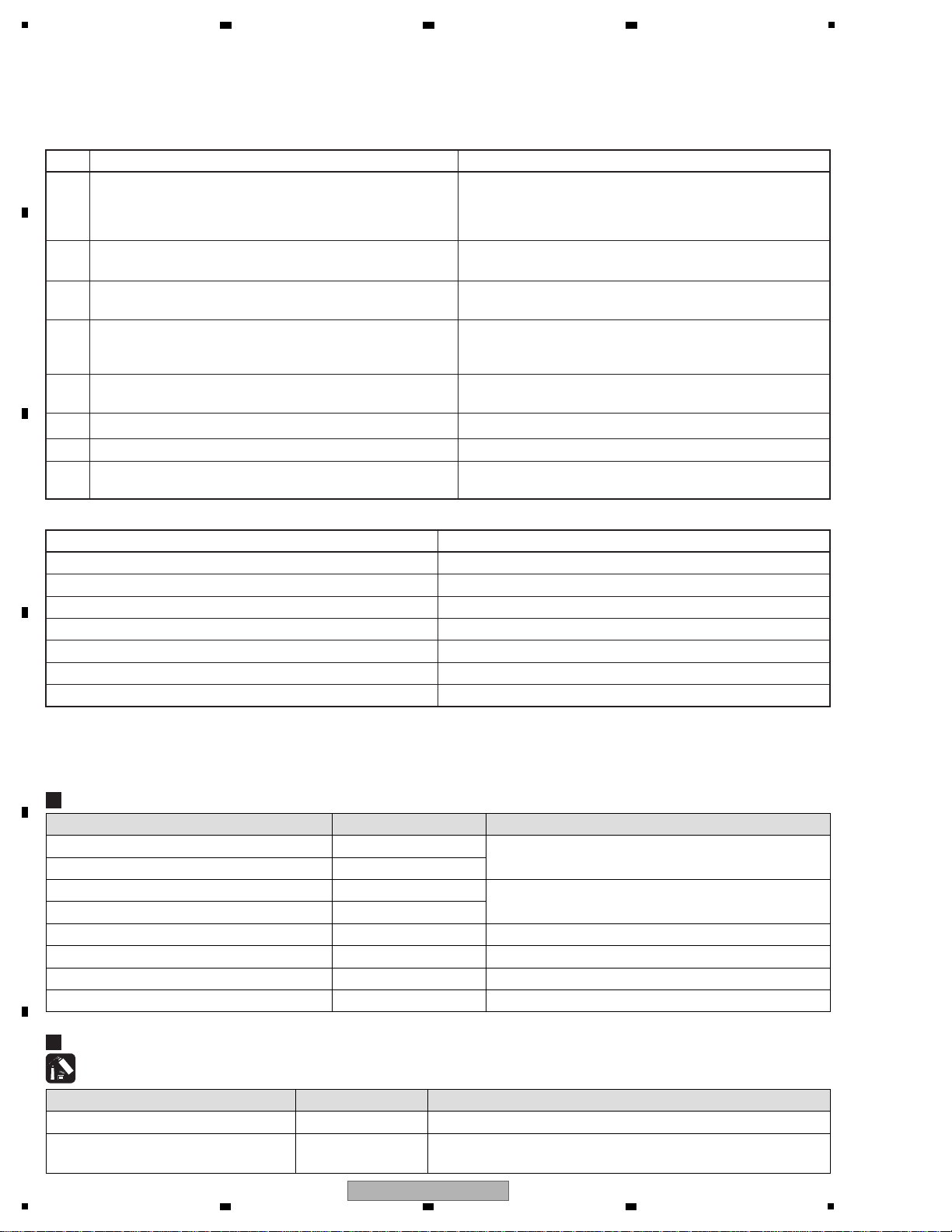

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding video and audio.

No.

Item to be checked regarding video Item to be checked regarding audio

Procedures Check points

1 Confirm whether the customer complain has been solved.

If the customer complain occurs with the particular source, such

as Dolby Digital, DTS, AAC, DVD-A and HDMI, input it for the

operation check.

The customer complain must not be reappeared.

Video, Audio and operations must be normal.

2 Check the analog audio playback.

(Make the analog connections with a DVD player.)

Each channel audio and operations must be normal.

3 Check the digital audio playback.

(Make the digital connections with a DVD player.)

Each channel audio and operations must be normal.

4 Check surround playback.

(Select Surround mode and check the multichannel operations

via the DSP circuit.)

Each channel audio and operations must be normal.

5 Check the video outputs.

(Connect with a DVD player.)

Video and operations must be normal.

6 Check the tuner (AM and FM) operations. Audio and operations must be normal.

7 Check the sound from headphone output. Sound must be normal, without noise.

8 Check the appearance of the product.

Block noise Distortion

Horizontal noise Noise

Flicker Volume too low

Disturbed image (video jumpiness) Volume too high

Too dark Volume fluctuating

Too bright Sound interrupted

Mottled color

No scratches or dirt on its appearance after receiving it for

service.

Jigs List

Jig Name Part No. Remarks

RS-232C update jig (Jig + 10P FFC) GGF1642

(Marketing product)

(Marketing product)

MAIN microcomputer firmware update

(RS-232C ↔ Rear panel)

RS-232C cable (9-pin to 9-pin, straight cable)

9P extension jig cable GGD1739 Diagnosis (AMP5 Assy ↔ AUDIO Assy)

Diagnosis (D-MAIN Assy ↔ BRG-C Assy)Board to board extension jig cable GGD1798

Diagnosis (D-MAIN Assy ↔ BRG-C Assy)Board to board extension jig cable GGD1799

Diagnosis (D-MAIN Assy ↔ BRG-A Assy)Board to board extension jig cable GGD1756

Lubricants and Glues List

Name Part No. Remarks

Silicon grease GEM1057 Refer to "9.2 EXTERIOR SECTION".

Silicon adhesive

GYA1011

(KE40RTV-W)

Refer to "9.2 EXTERIOR SECTION".

HDMI (SUB) & CEC microcomputer firmware update

(USB ↔ Rear panel)

RS-232C update jig GGF1646

USB cable (USB A-Type ↔ USB B-Type)

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

VSX-522-K

Page 7

5

NSP 1..PCB TTL ASSY MAIN 7025HK1106010-IL

2..MAIN ASSY 7028071611060-IL

2..G-R ASSY 7028071614060-IL

2..G-L ASSY 7028071615060-IL

2..WG-A ASSY 7028071616060-IL

2..WG-B ASSY 7028071617060-IL

NSP 1..PCB TTL ASSY VIDEO 7025HK1106012-IL

2..VIDEO ASSY 7028071631010-IL

2..STBY ASSY 7028071632010-IL

2..BRG-A ASSY 7028071633010-IL

2..BRG-B ASSY 7028071634010-IL

2..BRG-C ASSY 7028071635010-IL

NSP 1..PCB TTL ASSY AUDIO 7025HK1106013-IL

2..AUDIO ASSY 7028071641060-IL

NSP 1..PCB TTL ASSY DMAIN 7025HK1106014-IL

2..D-MAIN ASSY 7028071651010-IL

NSP 1..PCB TTL ASSY AMP5 7025HK1106015-IL

2..AMP5 ASSY 7028070243010-IL

NSP 1.PCB TTL ASSY FRONT 7025HK1106011-IL

2..FRONT ASSY 7028071621060-IL

2..HP ASSY 7028071622060-IL

2..INSEL ASSY 7028071623060-IL

2..MIC ASSY 7028071624060-IL

2..F-USB ASSY 7028071625060-IL

2..WG ASSY 7028071627060-IL

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

D

D-MAIN ASSY

K

BRG-B ASSY

L

BRG-C ASSY

J

BRG-A ASSY

Q

F-USB ASSY

G

G-R ASSY

I

WG-A ASSY

P

MIC ASSY

R

WG ASSY

A

AUDIO ASSY

B

AMP5 ASSY

C

MAIN ASSY

H

WG-B ASSY

E

VIDEO ASSY

S

STBY ASSY

F

G-L ASSY

N

INSEL ASSY

O

HP ASSY

M

FRONT ASSY

3.3 PCB LOCATIONS

6 7 8

A

B

C

D

5

6 7 8

VSX-522-K

E

F

7

Page 8

1

FROM MAIN TRANS

CP1 CP2 CP3

1AC 1AC 1AC

2GND2AC 2AGND

3AC 3AC 3AC

CP403 CN3

+HIGHB 1 1 +HIGHB

+HIGHB 2 2 +HIGHB

+HIGHB 3 3 +HIGHB

-HIGHB 4 4-HIGHB

-HIGHB 5 5-HIGHB

-HIGHB 6 6-HIGHB

HIGHGND7 7HIGHGND

HIGHGND 88HIGHGND

HIGHGND9 9HIGHGND

PREGND10 10PREGND

CP402 CN1

FL 1 1 FL

FR 2 2 FR

C3 3C

SL 4 4 SL

SR 5 5 SR

1FL 6AGND

1 +9.1V

2AGND7SR

CN404

2GNDA

1HP_DET

3SL 8 AGND

DC_DET4 1

3 -9.1V

2HP_RO

4AGND9FR

DC_DET3 2

4MIC

3GNDA

5C 10AGND

ASO_DET 3

5MIC_DET

4HP_LO

RADI_THERMAL4

CN901 CN721 CP401 TR_THERMAL5

CN5

DGND1 1

CP901 CP721

DGND1

2

1M

IC DET 1HP LO

+12V

3

2MIC 2GNDHP

+12V

4

3 NC3HP RO

4 -9.1V 4HP DET

5GNDA

CP204

6 +9.1V

HP_DET 1

MIC_DET 2

VOL_DATA 3

VOL_CLK 4

SW_SUM 5

HP_RLY 6

A MUTE 7

SB MUTE 8

NC9

CN400

CP402 CN402

HP LO 1 1 HP_LO

1FL 6GNDA

GNDA 2 2 GNDA

2GNDA 7 SR

HP RO 3 3 HP_RO

3SL 8 GNDA

Z2 MUTE 4 4 Z2_MUTE

4GNDA 9 FR

SB MUTE 5 5 SB_MUTE

5 C 10 GNDA

AMUTE 6 6 A_MUTE

HPRLY 7 7 HP_RLY

SW SUM 88SW_SUM

Z2VOL DATA 9 9 Z2VOL_DATA

Z2VOL CLK10 10 Z2VOL_CLK

VOL DATA 11 11VOL_DATA

VOL CLK 12 12VOL_CLK

+12V 13 13+12V

GNDA 14 14GNDA

CN401

CP17

MIC 15 15 MIC

MUTE_B+ 1 1 MUTE_B+

GND

A

16 16 GNDA

+12V 2 2A+12V

-12V 17 17-12V

+12V 3 3A+12V

GNDA 4 4 AGND

GNDA 5 5 AGND

-12V 66A-12V

-12V 77A-12V

CP13

GNDA 88AGND

U/DGND1

1SBLIN 11SRIN

BT_R 9 9 BT_R

TUNER_INT2

2GNDA 12GNDA

GNDA 10 10 AGND

TUNER_SDIO3

3SBRIN 13 FLIN

BT_L11 11BT_L

TUNER_SCLK4

4GNDA 14GNDA

GNDA 12 12 AGND

TUNER_SEN5

5SWIN 15 FRIN

TUNER_R13 13 TU_R

TUNER_

RST 6

6GNDA 16GNDA

GNDA 14 14 AGND

2533_CTL 7

7CIN 17 AIN_L

TUNER_L15 15 TU_L

8 GNDA 18GNDA

9SLIN 19AIN_R

10 GNDA

CN403

CP403

1 SBL_OUT 11SR_OUT

CP16

2GNDA 12 GNDA

OSD_RST 1

3 SBR_OUT 13 FL_OUT

OSD_CE 2

4GNDA 14 GNDA

OSD_CLK 3

5SW_OUT 15FR_OUT

OSD_DATA 4

6GNDA 16 GNDA

CTL_A 5

7C_OUT 17AIN_L

CTL_B 6

8 GNDA 18GNDA

U/DGND7

9SL_OUT 19AIN_R

+5V8

10 GNDA

VIDEO_MUTE9

CP15

U/DGND1

CN9

CP9

MUT

E_B+ 2

OSD_RST 1 1 OSD_RST

U/DGND3

OSD_CE 2 2 OSD_CE

FBRL 4

OSD_CLK 3 3 OSD_CLK

SBRL 5

OSD_DATA 4 4 OSD_DATA

SURL 6

CTL_A 5 5 CTL_A

CRL 7

CTL_B 6 6 CTL_B

FRL 8

U/DGND 7 7 U/DGND

DC_PRO 9

+5V8 8+5V

-VF(-30V)10

VIDEO_MUTE9 9 VIDEO_MUTE

U/DGND11

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

B

B

1/2-B2/2

A

AUDIO ASSY

(7028071641060-IL)

J

BRG-A ASSY

(7028071633010-IL)

K

BRG-B ASSY

(7028071634010-IL)

E

VIDEO ASSY

(7028071631010-IL)

O

HP ASSY

(7028071622060-IL)

P

MIC ASSY

(7028071624060-IL)

H

WG-B ASSY

(7028071617060-IL)

C

MAIN ASSY

(7028071611060-IL)

AMP5 ASSY

(7028070243010-IL)

I

WG-A ASSY

(7028071616060-IL)

R

WG ASSY

(7028071627060-IL)

F

G-L ASSY

(7028071615060-IL)

G

G-R ASSY

(7028071614060-IL)

2 3 4

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

VSX-522-K

Page 9

5

CN702

CP702

STBY_KEY 4 1 STBY_KEY

INPUT_UP 3 2 INPUT_UP

GNDU 2 3 GNDU

INPUT_DOWN 14INPUT_DOWN

1-30V 13 FLR_DATA

2-30V 14 FLT_CLK

3CPU_ST_VCC 15 FLT_CE

1HDMI+12V

4CPU_ST_VCC 16 INPUT_UP

2 STBY RLY

5GNDU 17 KEY2

3PDN

6GNDU 18KEY3

4CPU ST VCC

7 CPU_+3.3V 19 KEY1 (STBY_KEY)

5 CPU_+3.3V

8 CPU_+3.3V 20 INPUT_DN

6GNDU

9ST_H+5V 21VOL_UP

1GNDUSB

7FL2

10 POWERDOWN 22VOL_DN

2D+

8 FLCT

11 RMC 23THRU_LED

3D-

9FL1

12 STBY_RLY

4GNDUSB

AC 1 AC

5U

S

B+5V

CN701 CN704AA

CN2006

CP301

LIVE1

CP701

AC CORD

1FLAC

NEUTRAL 2

2FLCT

3FLAC

CP303

4CPU G ND

CN704B

CP2006

1

5CPU+3.3V

1THRU LED 13RMC

1UCHGND

VOL SEL 2

6STBY VCC

2 VOL DN 14 POWER DN

2D+

3

7PDN

3 VOL UP 15 H+5V

3D-

8 STBY RLY

4IN DN 16 CPU+3.3V

4USBGND

CP302

9CPU_ST_VCC

5KEY1 17CPU+3.3V

5USB+5V

1

6KEY3 18 ST VCC

TRANS

7KEY2 19ST VCC

2

8 IN UP 20 GNDU

9 F

LT CE 21 GNDU

CP304

10 FLT CLK 22 FL-30V

FLAC 1

11 FLT DATA 23 FL-30V

TRANSFLCT 2

12 STBY RLY

FLAC 3

CP2005

1DC D ET4

2DC D ET3

3ASO_DET

4RADI_DET

5 TRTHER_DET

CN5

CP2004

DGND1 1 1D+12V

DGND1 2 2D+12V

+12V

3 3DGND

+12V

4 4DGND

CN204

1HP DET

2MIC DET

3 VOL DATA

4 VOL CLK

5SW SUM

6 HP RLY

7A MUT E

8 SB MUTE

9 NC

CP2001

CN2001

HP DET 1 1 HP DET

MIC DET 2 2 MIC DET

VOL DATA 3 3 VOL DATA

VOL CLK 4 4 VOL CLK

SB MUTE 5 5 SB MUTE

A MUTE 6 6 A MUTE

SW SUM 7 7 SW SUM

HP RLY 88HP RLY

CP13

CN13

GNDU 9 9 GNDU

U/DGND1 1GNDU

FL-30V 10 10 FL-30V

TUNER_INT2 2TUNER INT

DC DET11 11 DC DET

TUNER_SDIO3 3 TUNER SDIO

F RLY 12 12 F RLY

TUNER_SCLK4 4 TUNER SCLK

C RLY 13 13 C RLY

TUNER_SEN55TUNER SEN

S RLY 14 14S RLY

TUNER_RST6 6 TUNER RST

M

U

TE B+15 15 MUTE B+

2533_CTL 7 7 NC

GNDU16 16 GNDU

TUNER SCLK17 17TUNER SCLK

TUNER SDIO 1 8 18 TUNER SDIO

TUNER SEN19 19 TUNER SEN

TUNER RST20 20 TUNER RST

TUNER INT21 21 TUNER INT

V CTL B 22 22 BH76330 B

V CTL A 23 23 BH76330 A

OSD DATA24 24 OSD DATA

OSD CLK25 25 OSD CLK

OSD CE 26 26 OSD CE

OSD RST27 27 OSD RST

CP16

CN16

OSD_RST 1 1 OSD RST

OSD_CE 2 2 OSD CE

OSD_CLK 3 3 OSD CLK

OSD_DATA 4 4 OSD DATA

CTL_A 5 5 V CTL A

CP2002

CN2002

CTL_B 6 6 V CTL B

V+5V 11V+5V

U/DGND7 7GNDU

CPU+3.3V 2 2 CPU+3.3V

+5V8 8V+5V(A+5V)

VIDEO MUTE 3 3 VIDEO MUTE

VIDEO_MUTE9 9 VID

EO MUTE

SC

LK JTAG 4 4 SCLK JTAG

BUSY JTAG 5 5 BUSY JTAG

CE 6 6 CE

EPM UP 7 7 EPM UP

CP15

CN11

CNVSS UP 88CNVSS UP

U/DGND1 1GNDU

232 TX/U RX 9 9 232TX/U RX

1AINR11SL

MUTE_B+ 2 2 MUTE B +

232 RX/U TX 10 10 232RX/U T X

2AGND12AGND

U/DGND3 3GNDU

RESET11 11 RESET

3AINL13C

FBRL 4 4 NC

CEC RXD12 12 CEC RXD

4AGND14AGND

SBRL 5 5 NC

CEC TXD13 13 CEC TXD

5FR 15SW

SURL 6 6 S RLY

CEC OPO14 14 CEC OPO

6AGND16AGND

CRL 7 7 C RLY

SUB RXD15 15 SUB RXD

7FL 17SBR

FRL 88F RLY

SUB TXD 16 16 SUB TXD

8 AGND18 AGND

DC_PRO 9 9 DC DET

GNDD 17 17 GNDD

9SR 19SBL

-VF(-30V) 10 10 FL-30V

SUB OPO 18 18 SUB OPO

10 AGND

U/DGND1

1 1

1GNDU

H+5V 19 19 H+5V

CN2003

CP2003

1AIN R 11 SL OUT

2GNDA 12 GNDA

3AIN L13C OUT

4GNDA 14 GNDA

5FR OU T 15SW OUT

6GNDA 16 GNDA

7 FL OUT 17 SBR OUT

8 GNDA 18GNDA

9 SR OUT 19 SBL OUT

10 GNDA

STBYB'D

L

BRG-C ASSY

(7028071635010-IL)

S

STBY ASSY

(7028071632010-IL)

M

FRONT ASSY

(7028071621060-IL)

N

INSEL ASSY

(7028071623060-IL)

Q

F-USB ASSY

(7028071625060-IL)

611060-IL)

D

D

1/4-D4/4

D-MAIN ASSY

(7028071651010-IL)

6 7 8

A

5

6 7 8

VSX-522-K

B

C

D

E

F

9

Page 10

1

A

AUDIO ASSY

M

FRONT ASSY

P

MIC ASSY

4.2 AUDIO BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

10

1

2 3 4

VSX-522-K

Page 11

5

O

HP ASSY

C

MAIN ASSY

Q

F-USB ASSY

B

AMP5 ASSY

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

11

Page 12

1

Q2035

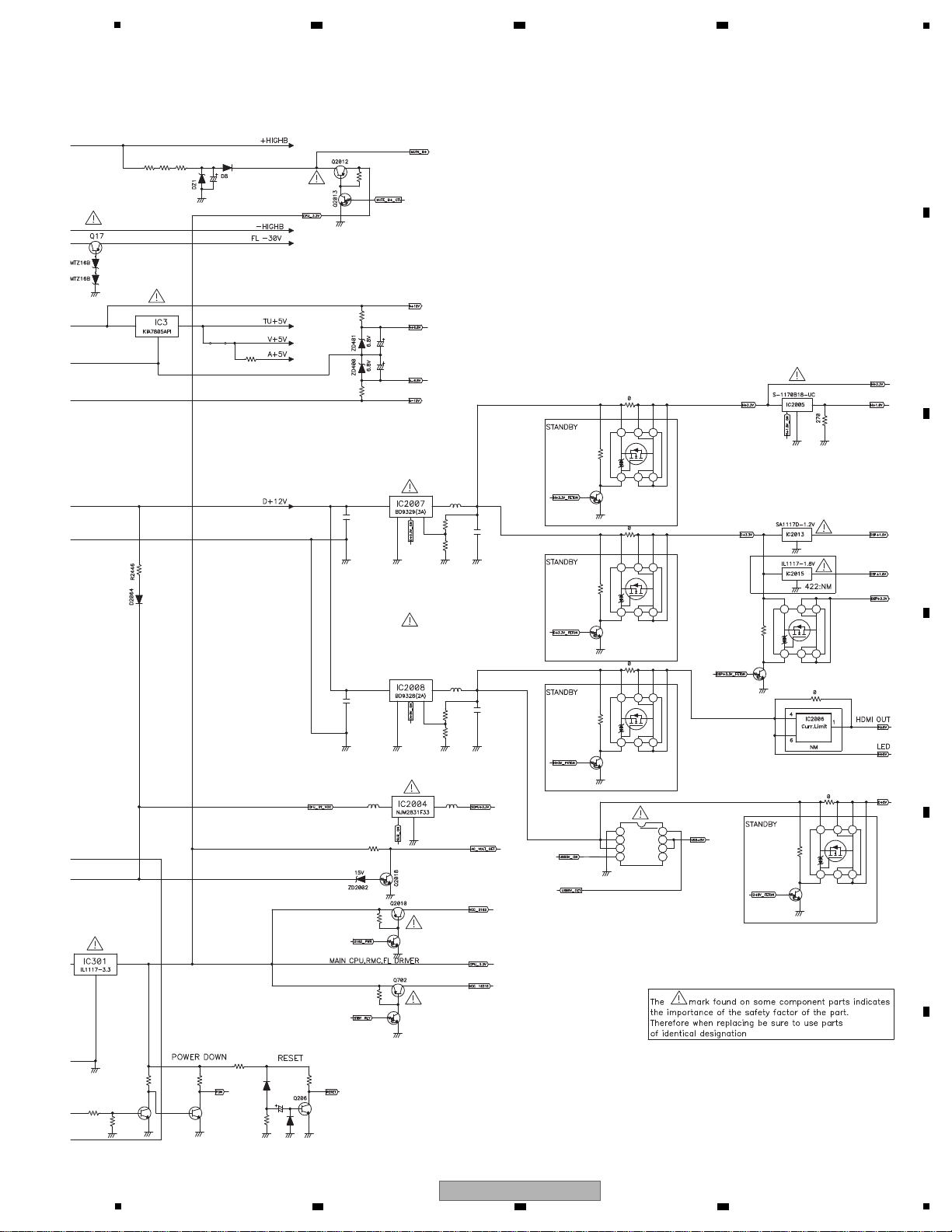

4.3 D-MAIN BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

12

1

2 3 4

VSX-522-K

Page 13

5

Q2035

1 6

2

3

5

4

Q2034

FDC608PZ

D

D-MAIN ASSY

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

13

Page 14

1

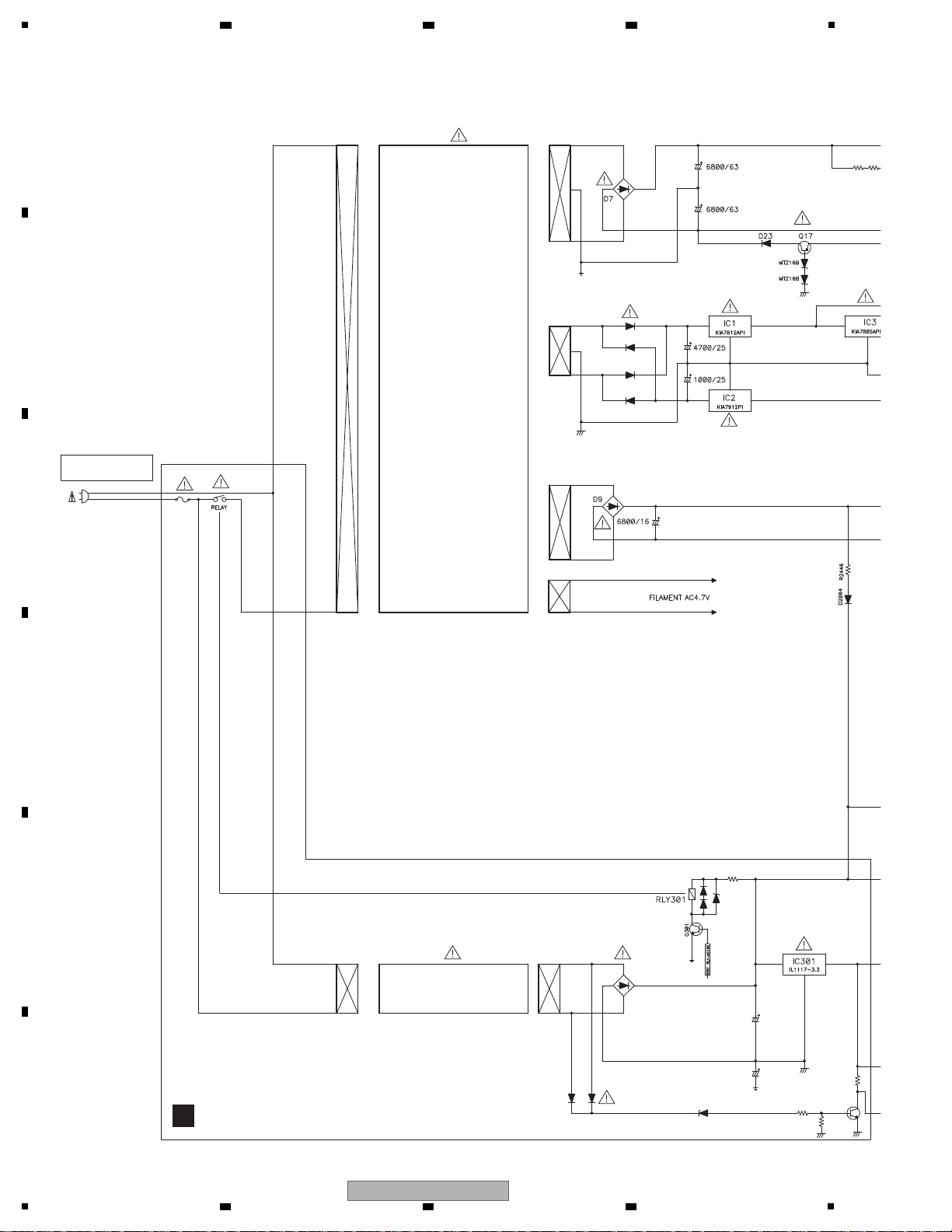

S4(FLT)

S2(+12V,-12V)

S1(AMP B+/B-)

AC CORD

(922L/822:USB)

S3(522:DSP, HDMI)

MAIN TRANS

SUB TRANS

S

STBY ASSY

2 3 4

4.4 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

14

1

2 3 4

VSX-522-K

Page 15

5

Q2031

Q2029

Q2027

Q2035

1 6

2

3

5

4

Q2030

FDC608PZ

1234

5 6 7 8

IC2025

TPS2557

GND

IN

IN

EN

OUT

OUT

LIM

FAULT

1 6

2

3

5

4

Q2026

FDC608PZ

1 6

2

3

5

4

Q2028

FDC608PZ

1 6

2

3

5

4

Q2032

FDC608PZ

Q2033

1 6

2

3

5

4

Q2034

FDC608PZ

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

15

Page 16

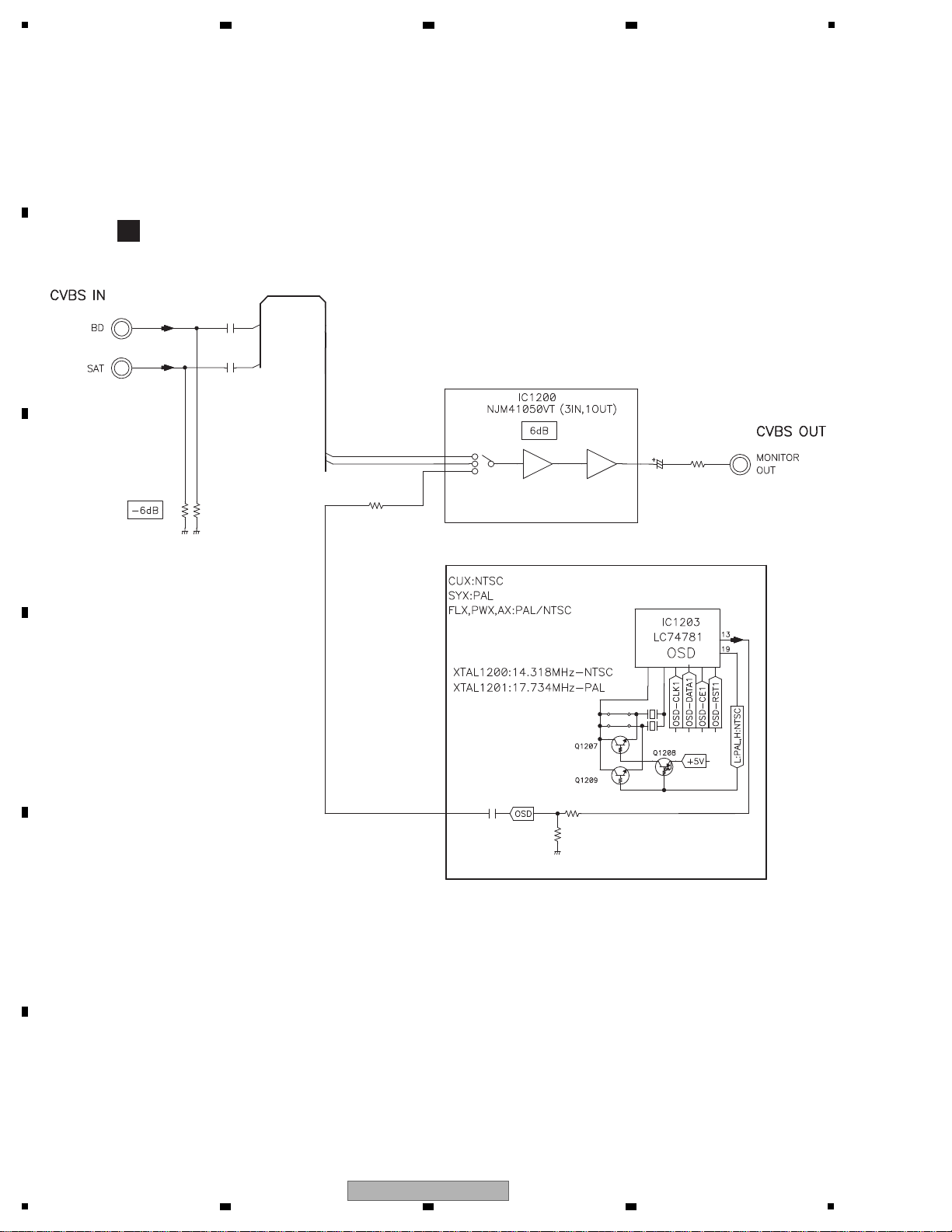

1

BD

75

75

SAT

E

VIDEO ASSY

4.5 VIDEO BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

16

1

2 3 4

VSX-522-K

Page 17

5

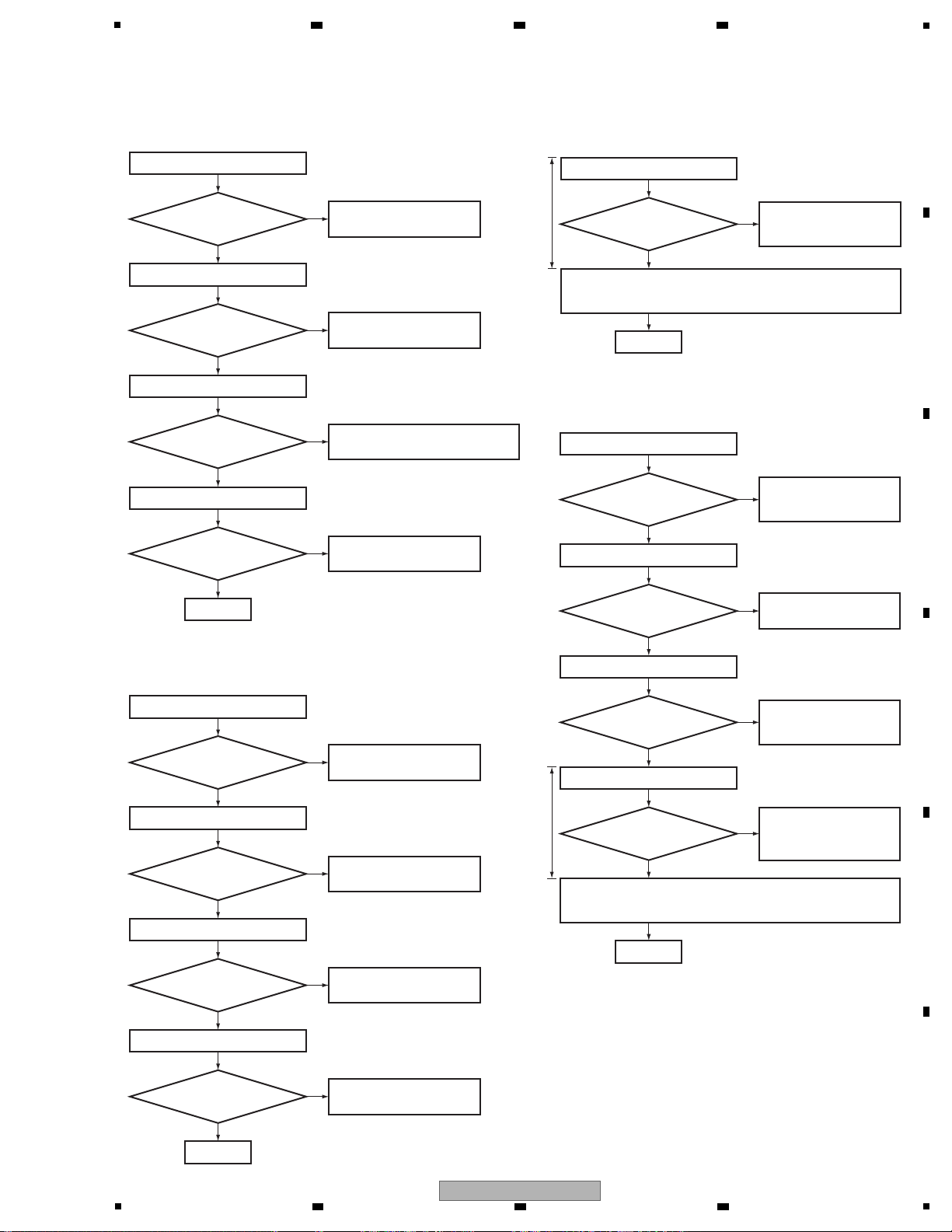

Step 0: Preliminary confirmation

CN2002, CN2001, CN2003, CP2004

To Step 1

Are the connectors

securely inserted?

Step 1: Fixed board

Confirm the following items before checking

To Step 2

Tighten screws securely.

Do screws of back chassis

securely tighten?

Yes

Yes

B to B connector, wire

Yes

No

Insert the connectors

completely.

No

Step 2: Power supply

IC2007 (pin 2)

L2007

Is the voltage 12 V?

Check the IC2007 and its

peripheral circuits.

Is the voltage 3.3 V output?

Is pin 7 (en) of IC2007 high?

Is the voltage of 1.2 V output?

IC2013 (pin 2)

Check the IC2016 DSP power pin (cvdd and

dvdd): cvdd: 1.2 V, dvdd: 3.3 V.

Yes

Yes

+3.3V line of D-MAIN Assy is OK.

OK

Yes

No OK

Check the peripheral circuits or the

MAIN microcomputer (IC2023).

Check the IC2016 DSP

power pin (cvdd and dvdd)

and its peripheral circuits

or must be replaced

IC2016, IC2013.

No

No

No

Replace IC2007.

OK

Replace IC2007 or

check the MAIN Assy.

12 V input

(to chassis)

Is the voltage of 1.8 V output?

IC2005 (pin 5)

Check the IC2000 HDMI power pin

(acvdd33 and advdd18): 3.3 V, 1.8 V.

+3.3V line of D-MAIN Assy is OK.

OK

Yes

Check the IC2000 HDMI

power pin (avdd33 and

advdd18) and its peripheral

circuits or must be replaced

IC2000, IC2005.

No

(to chassis)

[1] DSP TROUBLESHOOTING

TROUBLESHOOTING FOR ALL DESTINATION

5. DIAGNOSIS

5.1 TROUBLESHOOTING

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

17

Page 18

1

Yes

Step 3: Power supply

CP2004 (pins 1, 2)

IC2008 (pin 2)

L2008

Is the voltage of 12 V?

Check the wire between

D-MAIN and MAIN Assemblies.

Check the IC2008 and

its peripheral circuits.

Is the voltage of 1.2 V input?

Yes

No

No

Is the voltage of 5 V output?

Yes

No

NG

OK

Check the MAIN Assy.

Replace IC2008.

12 V input

12 V input

Is pin 7 (en) of IC2008 high?

Yes

Check the IC2011 power pin (dvdd and

avdd): dvdd: 5 V, avdd: 5 V.

+5V line of D-MAIN Assy is OK.

OK

Check the peripheral circuits or the

MAIN microcomputer (IC2023).

No

Replace IC2008.

OK

Yes

Step 4: X'tal

IC2011 (pins 6, 7)

IC2014 (pin 2)

Is there a 24.576 MHz

output?

Check the IC2011 and its peripheral

circuits or replace XTAL2002.

No

Yes

Is there a 24.576 MHz

input?

Check the IC2014 and its peripheral

circuits or replace IC2011.

No

To Step 5

A

2 3 4

B

C

D

E

F

18

1

2 3 4

VSX-522-K

Page 19

5

Yes

Step 5: DIR

IC2009 (pin 3)

IC2011 (pin 61)

IC2011 (pin 67)

Can observe the

digital signal?

Check the path to INPUT pin of

JACK2006 or replace JACK2006.

Check that the S/PDIF signal is input.

Check that changes by pulling out and inserting the digital input lines.

No

Yes

Can observe the

digital signal?

Check the pass to IC2009 pin 4

or replace IC2009.

Can observe the

digital signal?

Yes

No

Check the path to pins 8 to 11 of

IC2009 or replace IC2009.

No

coax

opt

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

IC2011 (pin 69)

Can observe the

digital signal?

Yes

Check the path to pin 5 of IC2009 or

replace IC2009.

No

HDMI

(0 V ↔ 3.3 V)

IC2011 (pin 59)

Can observe the

digital signal?

Yes

Check the path to pins 1, 12 of

IC2009 or replace IC2009.

No

ARC

(0 V ↔ 3.3 V)

SPDIF INPUT line is OK.

Yes

Yes

No

Check the IC2011 and its peripheral

circuits of IC2011.

No

Check the IC2014 and its peripheral

circuits of IC2014.

OK

Check the pin 58 of IC2023,

is the voltage 3.3 V?

No

No

Replace IC2011, IC2014.

Check the IC2023 and

its peripheral circuits or

replace IC2023.

Check the peripheral circuits

between IC2011 and IC2023.

OK

IC2011 (pin 10)

IC2011 (pin 16)

Yes

Is there a master clock

24.576 MHz output?

Is the voltage of PDN IC2011

pin 31 3.3V?

Is there a LR clock

output?

DIR_MCK (master clock)

DIR_LRCK (LR CLOCK)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

Check that the data and clock signals are output.

A

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

19

Page 20

1

Replace IC2011, IC2014.

Replace IC2014.

OK

IC2011 (pin 14)

Yes

Yes

Yes

IC2011 (pin 15)

IC2014 (pin 4)

DIR output is OK.

Is there a DATA output?

Is there a master clock

24.576 MHz output?

Yes

Is the voltage of IC2014

pin 1 0 V?

Is there a bit clock output?

DIR_SDTO (DATA)

DIR_BCK (bit clock)

DAI_MCK (MASTER CLOCK)

*IC2014 pin 1

0 V: DIR

3.3 V: HDMI

SWITCH

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

Check the IC2011 and its peripheral

circuits of IC2011.

No

Check the path between IC2014 pin 1

and IC2023 pin 70.

No

Replace IC2011.

OK

Check the IC2011 and its peripheral

circuits of IC2011.

Check the IC2014 and its peripheral

circuits of IC2014.

No

No

OK

A

Yes

Step 6: ADC

CN2003 (pins 1, 3)

IC2011 (pin 17)

IC2011 (pin 18)

Is there a analog audio

signal?

Is there a analog

audio signal of BRG-A Assy

CP403 pins 17, 19?

Check that the ANALOG input to DSP mode.

Yes

No

No

Replace CP2003 wafer of BRG-A Assy,

or reconnect BRG-A Assy.

Is there a data

output?

Yes

ANALOG AUDIO input

ADC_SDTO (ADC AUDIO OUT)

DSP_BCK

(0 V ↔ 3.3 V)

Check the AUDIO Assy.

No

Is there a bit clock

3.072 MHz input?

Yes

(0 V ↔ 3.3 V)

No

IC2011 (pin 19)

DSP_LRCK

Is there a LR clock

48 kHz input?

Yes

(0 V ↔ 3.3 V)

No

To Step 7

Check the path between IC2016 and data & address lines.

SDRAM (IC2018), FLASH ROM (IC2019), replace IC2016.

A

2 3 4

B

C

D

E

F

20

1

2 3 4

VSX-522-K

Page 21

5

Yes

Step 7: DSP mode audio output

IC2011(pin 18)

IC2011 (pin 19)

Is there a bit clock input?

Digital output of each CH when inputting the digital signal with audio.

Is there a LR clock

output?

Is there a data input?

Is there a data input?

Is there a data input?

Is there a data input?

Yes

IC2011 (pin 28)

IC2011 (pin 27)

Yes

IC2011 (pin 26)

Yes

IC2011 (pin 25)

Yes

Yes

DSP_BCK (BIT CLOCK)

DSP_LRCK (LR CLOCK)

front L/R data

surround L/R data

CENTER/LFE data

surround back L/R data

or front hight L/R data

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

To Step 8

No

No

No

No

No

No

Check the path between IC2016 and data & address lines.

SDRAM (IC2018), FLASH ROM (IC2019), replace IC2016.

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

21

Page 22

1

Yes

Step 8: CODEC output (ANALOG AUDIO OUT)

IC2011 (pin 49)

IC2011 (pin 47)

Is there a audio signal

output?

Analog output of each CH when inputting the digital signal with audio.

Analog output of each CH when inputting

the digital signal (-∞ dB(no signal)).

Yes

Is there a audio signal

output?

front R out

front L out

IC2011 (pin 45)

Yes

Is there a audio signal

output?

surround R out

IC2011 (pin 43)

Yes

Is there a audio signal

output?

surround L out

IC2011 (pin 43)

surround L out

IC2011 (pin 41)

Yes

Is there a audio signal

output?

center out

Yes

IC2011 (pin 41)

center out

IC2011 (pin 39)

Yes

Is there a audio signal

output?

LFE out

Yes

Yes

IC2011 (pin 39)

LFE out

IC2011 (pin 49)

Yes

Is the output 2.5 V fixing?

front R out

IC2011 (pin 47)

Yes

Is the output 2.5 V fixing?

front L out

IC2011 (pin 45)

Yes

Is the output 2.5 V fixing?

Is the output 2.5 V fixing?

Is the output 2.5 V fixing?

Is the output 2.5 V fixing?

surround R out

End

No

No

No

No

No

No

No

No

No

No

No

No

Replace IC2011.

A

2 3 4

B

C

D

E

F

22

VSX-522-K

1

2 3 4

Page 23

5

Cause for noncomplection of HDMI authentication between the source equipment and this unit.

(the HDMI indicator is unlit or flasher)

Causes for no display or sound from the monitor

[2] HDMI TROUBLESHOOTING

Replace the HDMI cable.

NG

OK

Replace the HDMI cable.

Connect the source equipment

(player) to the Sink equipment

(monitor) directly.

OK

Repare the Receiver.

NG

Replace the Player.

OK

Repare the Player.

NG

Replace the Monitor.

OK

Repare the Monitor.

HDMI T roubleshooting

HDMI Simple Diagnosis

Step 0: Preliminary confirmation

Confirm the following items before checking

To Step 1

Do screws of back chassis

securely tighten?

To Step 2

Tighten screws securely.

Yes

No

Step 1: Connect the HDMI equipment

Source equipment:

Connect a DVD player to DVD or SAT/CBL or GAME or BD

Sink equipment:

Connect a TV to HDMI OUT

Turn on the power of the receiver and equipments which was

connected with HDMI.

Switch the function that HDMI was assigned.

Factory shipments setting:

HDMI1: DVD

HDMI2: SAT/CBL

HDMI3: GAME

HDMI4: BD

Function switch (DVD or SAT/CBL or GAME or BD)

POWER ON

6 7 8

A

B

C

D

E

VSX-522-K

5

6 7 8

F

23

Page 24

1

Step 2: Power supply

IC2004 (pin 1)

IC2004 (pin 4)

Is the voltage 0 to 3.3 V?

Is the voltage 5 V?

Is pin 7 (en) of IC2008

high?

Yes

Yes

Is 3.3 V output voltage?

CP2004 (pins 1, 2)

Yes

L2007

Yes

IC2005 (pin 1)

Yes

Yes

L2008

Is pin 5 of IC2004

an above 6 V?

Yes

Check the parts and pattern in

the path. (CN704B pins 18, 19)

No

Check the IC2023 and its

peripheral circuit or replace IC2023.

No

Replace IC2004.

Replace IC2008.

Replace IC2007.

Replace IC2005.

Yes

No

No

Check the pin 73 of IC2023.

Is the voltage 0 to 3.3 V?

Check the circuit between

IC2023 and IC2004 .

Is the voltage 12 V?

Yes

No

Diagonose the MAIN Assy.

No

Diagonose the MAIN

microcomputer (IC2023).

No

Is pin 7 (en) of IC2007

high?

Yes

Yes

No

Diagonose the MAIN

microcomputer (IC2023).

Diagonose the MAIN

microcomputer (IC2023).

No

Is the IC2005 pin 1 high?

No No

Is the voltage 3.3 V?

Is the voltage 1.8 V?

S+3.3V_ON

D+12V

Is the voltage 3.3 V?

IC2005 (pin 5)

Yes

Check the parts and pattern in

the path. (IC2023 pin 55)

No

H+1.8V

DMAIN+5V

DMAIN+3.3V

H+1.8V on/off

To Step 3

A

2 3 4

B

C

D

E

F

24

VSX-522-K

1

2 3 4

Page 25

5

Diagonose the MAIN

microcomputer (IC2023).

Diagonose the MAIN

microcomputer (IC2023).

Diagonose the MAIN

microcomputer (IC2023) and IC2001

No

IC2023 (pin 77)

Is the voltage 0 to 3.3 V?

No

No

Is there a data output?

(0 to 3.3 V)

Is there a data input

and output? (0 to 3.3 V)

SUB_RST

CSCK_MAIN

IC2023 (pin 80)

Yes

SCDO_MAIN

IC2023 (pin 79)

Yes

Check the parts and patterns

in the path pin 53 of IC2001.

No

Is the voltage 0 to 3.3 V?

EXT_RSTb

IC2000 (pin 94)

Yes

Step 3: Diagnosis

Each data lines confirmation checks it after standby off/on.

Yes

To Step 4

To Step 5

Replace IC2001 or

XTAL2000.

No

Check the path to pin 42 of

IC2001. Replace IC2001.

No

Yes

IC2001 (pin 41)

Is there a 24 MHz input?

Is there a 24 MHz output?

IC2001 (pin 42)

Yes

Replace IC2000 or

XTAL2001.

No

Is there a 18.432 MHz

input?

IC2000 (pin 97)

Yes

Check the path to pin 98 of

IC2000. Replace 2000.

No

Is there a 18.432 MHz

output?

IC2000 (pin 98)

Yes

Step 4: X'TAL

* when connected the equipment

to IN1 (DVD):

+5V_R3

Check the JACK2000.

If JACK2000 is failure,

replace JACK2000.

JACK2001 (pin 18)//+5V_R2//IN2 (SAT/CBL)

JACK2002 (pin 18)//+5V_R1//IN3 (GAME)

JACK2003 (pin 18)//+5V_R0//IN4 (BD)

No

Repeat

Yes

JACK2000 (pin 18)

Is the voltage 5 V?

Step 5: INPUT/OUTPUT Diagnosis

Yes

To Step 6

* when connected the equipment

to IN1 (DVD):

Check the JACK2004.

If JACK2004 is failure,

replace JACK2004.

No

Check the JACK2000 and

IC2000. If JACK2000 or

IC2000 failure, replace

JACK2000 or IC2000.

No

JACK2001 (pin 19)//+5V_R2//IN2 (SAT/CBL)

JACK2002 (pin 19)//+5V_R3//IN3 (GAME)

JACK2003 (pin 19)//+5V_R4//IN4 (BD)

Yes

hot plug detect signal input

HPD1

Yes

JACK2004 (pin 19)

IC2001 (pin 29)

JACK2000 (pin 19)

Is the voltage 5 V?

Check the JACK2000.

If JACK2000 is failure,

replace JACK2000.

No

HP_DET

JACK2000 (pin 19)

Is the voltage 5 V?

Check the pattern and

parts.

No

Yes

Yes

Is the voltage 5 V?

Is the voltage 5 V when

selecting IN1?

Step 6: Hot Plug Detect

Yes

To Step 7

Repeat

6 7 8

A

B

C

D

E

F

5

VSX-522-K

6 7 8

25

Page 26

1

* when connected the equipment

to IN1 (DVD):

(0 to 5 V)

JACK2001 (pin 18)//+5V_R2//IN2 (SAT/CBL)

JACK2002 (pin 18)//+5V_R1//IN3 (GAME)

JACK2003 (pin 18)//+5V_R0//IN4 (BD)

DDC_SDA (HDMI_OUT)

check the JACK2004 and

IC2001. If JACK2004 or

IC2001 is failure, replace

JACK2004 or IC2001.

No

Check the JACK2004 and

IC2001. If JACK2004 or

IC2001 is failure, replace

JACK2004 or IC2001.

No

Repeat

Yes

IC2001 (pin 7)

Does a signal output

in constant period

(0 to 5 V)?

Does a signal output

in constant period

(0 to 5 V)?

DDC_SCK (HDMI_OUT)

IC2001 (pin 6)

Yes

Check the IC2000, IC2001

and IC2003. If they are

failure, replace them.

No

Is the voltage 0 to 3.3 V?

HSDA

IC2001 (pin 5)

Yes

Check the IC2000, IC2001

and IC2003. If they are

failure, replace them.

No

Is the voltage 0 to 3.3 V?

HSCL

IC2001 (pin 4)

Yes

Yes

DDC0_SDA (HDMI IN1(DVD))

IC2000 (pin 114)

Check the IC2000 and

JACK2000. If IC2000 or

JACK2000 is failure, replace

IC2000 or JACK2000.

No

Yes

Is there a same signal

as IC2000 pin 121 when

selecting IN1?

(0 to 5 V)

DDC0_SCL (HDMI IN1(DVD))

IC2000 (pin 115)

Check the IC2000 and

JACK2000. If IC2000 or

JACK2000 is failure, replace

IC2000 or JACK2000.

No

Is there a same signal

as IC2000 pin 122 when

selecting IN1?

Step 7: SDA /SCL

Yes

To Step 8

TMDS OUTPUT

Check the IC2000.

If IC2000 is failure, replace

IC2000

No

Yes

IC2000 (pins 67,68,70,71,72,73,75,76 )

Are there signals

(approx. 0.5 Vp-p)

IN all lines?

Step 8: TMDS

End

A

2 3 4

B

C

D

E

F

26

VSX-522-K

1

2 3 4

Page 27

5

Yes

Step 9: HDMI AUDIO

IC2000 (pin 109)

Is there a 24.576 MHz

output?

Is there a 12.28 MHz

output?

*play is Dolby thru HD @ dts master audio source

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

HDMI audio MASTER clock

output

IC2000 (pin 110)

HDMI audio BIT clock output

(0 V ↔ 3.3 V)

(0 V ↔ 3.3 V)

Is there a 192 kHz

output?

IC2000 (pin 111)

HDMI audio LR clock output

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2000 (pin 106)

HDMI audio SPDIF OUT

*SPDIF out:Dolby digital,dts..

* not output:Dolby thru HD & dts master audio

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2000 (pin 112)

HDMI audio front L/R OUT

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2000 (pin 92)

HDMI audio surround L/R OUT

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2000 (pin 91)

HDMI audio center/sw OUT

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2000 (pin 90)

HDMI audio surroundback OUT

HDMI audio front hight OUT

(0 V ↔ 3.3 V)

Can observe the

digital signal?

IC2016 (pins 1, 176, 175, 174)

HDMI AUDIO is OK

(0 V ↔ 3.3 V)

No

No

No

No

No

No

No

No

No

Check the VDD_PLL and GND

lines. Replace IC2000.

Check the switching IC.

IC2010, IC2014.

6 7 8

A

B

C

D

5

VSX-522-K

6 7 8

E

F

27

Page 28

1

[3] iPod TROUBLESHOOTING

Step 1: Power supply

Is pin 4 (en) of IC2024 high?

Is pin 8 of IC2024 high?

Is the voltage 5 V

pin 2 of IC2024?

5 V input

Step 0: iPod/USB Power supply

CP2006 (pin 1)

Is the voltage 5 V?

Check the wire between F-USB

and D-MAIN Assemblies.

No

Check the F-USB Assy.

No

Check the USB data line.

No

No

No

Check the path between

IC2023 (pin48).

No

Check the IC2008 DC/DC

convertor circuit.

No

Check the path between

IC2023 (pin57).

No

Replace IC2004.

To Step 1

CP2006 (pin 1)

Is the voltage 5 V?

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Yes

Replace IC2021.

No

When SCL and SDA are normal operation = high (3.3 V)

Connect iPod, and communicate it about 10 seconds later (authentication starts).

And communicate it about 60 seconds later (authentication is complete).

Step 2: Operation of iPod (Authentication process)

IC2016 (pins 137, 138)

IC2021 (pins 12, 13)

D_MAIN Assy

USB data D+,D-

SCL, SDA

(I2C between IC2021 and IC2023)

Do D+ and D-

communicate?

Do SCL and SDA

communicate?

Does reset_auth (pin 4)

reset it?

High after the reset.

iPod/USB power is OK.

Go to Step 2.

Operation of IC2021 is OK.

Go to Step 3.

Refer to Step 7 of

"[1] DSP TROUBLESHOOTING."

Replace IC2016.

Step 3: Audio out check

IC2016

Is there a signal?

No

DSP BCK, LRCK, SDINF

A

B

2 3 4

C

D

E

F

28

1

VSX-522-K

2 3 4

Page 29

5

Functional Name

iPod ERROR MESSAGE

Outline

Error message is displayed at abnormality time.

Basic Operation

Front Key Sequence Change OSD display Time (sec) FL Display

Over Current Error

I/U ERR4

No T rac k Caution

NOTRACK

5.2 USB/iPod ERROR MESSAGE

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

29

Page 30

1

[1] Overload and DC Protection Circuit

C

MAIN ASSY

D

D-MAIN ASSY

B

AMP5 ASSY

B

AMP5 ASSY

2 3 4

5.3 DETECTION CIRCUIT

A

B

C

D

E

F

30

1

2 3 4

VSX-522-K

Page 31

5

[2] TEMP Protection Circuit

B

AMP5 ASSY

D

D-MAIN ASSY

B

AMP5 ASSY

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

31

Page 32

1

(M3030RFGPFP_256K)(D-MAIN ASSY: IC2023)

MAIN Microcomputer

• Pin Function

Pin Symbol I/O Description

1 A_MUTE O Audio output control pins at Mute Tr (active at L)

2 SB_MUTE O SB ch. Audio output control pins at Mute Tr (active at L)

3 F_RLY O Tr driven control pins at the Front speaker output Relay. (active at H)

4 S_RLY O Tr driven control pins at the Surround speaker output Relay. (active at H)

5 C_RLY O Tr driven control pins at the Center speaker output Relay. (active at H)

6AC_VOLT_DET I AC x2 Voltage detection pin (normal: H)

7 RMC I Remote control signal input pin

8 BYTE I The data bus is 16 bits long when the this pin is held "L" (GND)

9CNVSS_UP I Switches processor mode

10 24C16_SDA I/O Data signal input & output for data backup of main CPU

11 24C16_SCL O Clock signal output for data backup of main CPU

12 /RESET I Micom reset signal input pin (active at L)

13 XOUT O Output for 16 MHz Crystal

14 VSS Ground

15 XIN I Input for 16 MHz Crystal

16 VCC1 +3.3 V power supply

17 /NMI I Input pin for the NMI interrupt

18 TUNER_INT I Tuner Interrupt signal input pin

19 PDN I Power down signal input pin

20 OSD/FLT_DATA O OSD & FL drive IC output pin of the Data

21 MUTE_B+_CTL O Power control pin mute B+

22 VIDEO_MUTE O Not used

23 HP_DET I Monitoring the input pin headphone connection

24 OSD_CE O OSD IC enable signal output pin

25 V+5V_DET I VIDEO +5 Voltage monitor input pin DC protection

26 V_CTL_B O IC control signal B output pin for selecting the video input

27 V_CTL_A O IC control signal A output pin for selecting the video input

28 OSD/FLT_CLK O OSD & FL drive IC output pin of the Clock

29 H+3.3V_FETON O Not used

30 H+5V_FETON O Not used

31 232_RX/U_TX O Output for Upgrade (UART)

32 232_TX/U_RX I Input for Upgrade (UART)

33 SCLK_JTAG I Serial clock input pin

34 BUSY_JTAG O BUSY signal output pin

35 2162_SDA I/O MFI IC serial data I/O PIN

36 2162_SCL I/O MFI IC transfer clock I/O PIN

37 D+5V_FETON O Not used

38 D+3.3V_FETON O Not used

39 OSD_RST O OSD IC Reset signal output pin

40 TUNER_SCLK O Clock signal output for Tuner Pack

41 EPM_UP I Upgrade

42 TUNER_SDIO I/O Data signal input & output for Tuner Pack

43

TU

NER_SEN O Output for Tuner Pack Serial Enable Input (active at L)

44 TUNER_RST O Output to reset Tuner Pack (active at L)

45 TR_DET I Output for HDMI_HD / SACD_DSD Select (L: HDMI_HD, H: SACD_DSD)

46 CE O Upgrade

47 2162_PWR O MFI IC pin of the power control

48 2162_RST O MFI IC Reset signal output pin

49 VOL_DATA O Data signal output for R2A15219 (I2C)

50 VOL_CLK O CLK signal output for R2A15219 (I2C)

2 3 4

5.4 IC INFORMATION

A

B

C

D

E

F

32

1

2 3 4

VSX-522-K

Page 33

5

• Pin Function

Pin Symbol I/O Description

51 SW_SUM O Output for Sub Woofer SUMMING Control (H: SUMMING)

52 MIC_DET I Monitoring the input pin microphone connection (detection: L)

53 HP_RLY O Headphone audio output control pins at Mute Tr (active at L)

54 DSP+3.3_FETON O DSP 3.3 V Power on/off control pin (on: H)

55 H+1.8V_ON O Control pin HDMI IC +1.8 V REG. IC (on: H)

56 D+3.3V_ON O Control pin digital +3.3 V DC/DC IC (on: H)

57 D+5V_ON O Control pin digital +5 V DC/DC IC (on: H)

58 4588_PDN O Output for AK4588 power down

59 4588_SDA O Data signal output for AK4588 (I2C)

60 4588_SCL O Clock signal output for AK4588 (I2C)

61 DSP_SIMO O Data signal output for DA808 (SPI)

62 VCC2 +3.3 V power supply

63 DSP_SPICLK/B7 O Clock signal output for DA808 (SPI)

64 VSS Ground

65 DSP_RST O Output to reset DA808

66 USB5V_DET I USB+5 Voltage monitor input pin overcurrent protection.

67 DSP_SOMI I Data signal Input from DA808

68 DSP_SPICS O Chip select signal output for DA808

69 DSP_SPIEN I SPI Enable signal input from DA808

70

HDMI_SEL O

IC signal of the control pins at select HDMI or analog audio

71 PROTECT2 I AMP Assy input signal of the RADIATOR THERMAL pin (L = PROTECTION)

72 MAIN_IRQ O Interrupt Output to sub CPU

73 S+3.3V_ON O Output for sub CPU Power ON/OFF cotrol pin

74 SUB_IRQ I Interrupt Iuput from sub MICOM

75 HDMI_AMUTE I Input for HDMI_RX_MUTE condition

76 USB5V_ON O Output for power down of SUB microcomputer

77 SUB_RST O Output to reset sub CPU

78 DSD_SEL O Output for DSD audio signal selector ic contol pin.

79 SCDO_MAIN O Data signal output to SUB microcomputer

80 CSCK_MAIN O Clock signal output for SUB microcomputer

81 SET OPTION I Input for Set option

82 STEP OPTION I Input for Step (Group) option

83 NCONot used

84 NCONot used

85 PROTECT1 I AMP Assy Protection detection signal input pin (ASO = 0.82 V, DC = 1.39 V)

86 VOL_DN I Data input for VOLUME encoder (VOLUME DOWN is counterclockwise direction)

87 VOL_UP I Data input for VOLUME encoder (VOLUME UP is clockwise direction)

88 IN_DN I Data input for INPUT selector encoder

89 NCINot used

90 KEY1 I Data input for Key1 scan

91 KEY3 I Data input for Key3 scan

92 KEY2 I Data input for Key2 scan

93 IN_UP I Data input for INPUT selector encoder

94 FLT_CE O Output for chip enable of SC16315

95 NCONot used

96

G

ND Ground

97 NCONot used

98VREF Reference voltage (Connected to +3.3 V)

99 AVCC +3.3 V power supply

100 STBY_RLY O Output to ST-BY Relay ON/OFF (active at H)

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

33

Page 34

1

(EPF021A)(D-MAIN ASSY: IC2001)

SUB Microcomputer

• Pin Function

Pin Symbol I/O Description

1 NCINot used

2 CSCK_MAIN I Clock signal input from MAIN microcomputer

3 SCDO_MAIN I Data signal Input from MAIN microcomputer

4 HSCL O IIC clock signal output pin (EP94A1K & EPF011C)

5 HSDA I/O IIC data signal in/output pin (EP94A1K & EPF011C)

6 DDC_SCK O IIC clock signal output pin for HDMI output jack

7 DDC_SDA I/O IIC data signal in/output pin for HDMI output jack

8VDD +3.3 V power supply

9GND Ground

10 NCINot used

11 NCINot used

12 VDD +3.3 V power supply

13 NCINot used

14 NCINot used

15 SUB_RST I SUB microcomputer reset signal input pin

16 SUB_OPO I Chip operation mode select signal input pin (0: normal)

17 GND Ground

18NCINot used

19 NCONot used

20 NCONot used

21 NCONot used

22 NCONot used

23 NCONot used

24 NCONot used

25 NCONot used

26 NCONot used

27 NCONot used

28NCONot used

29

HPD_I

N I HDMI Hot plug detect signal input pin

30 NCINot used

31 NCINot used

32 NCINot used

33 NCINot used

34 NCINot used

35 MAIN_IRQ I Interrupt sinal Input pin from MAIN microcomputer

36 SUB_IRQ O Interrupt signal output pin to MAIN microcomputer

37 THRU_LED O HDMI LED on/off control pin

38NCONot used

39 VDD +3.3 V power supply

40 GND Ground

41 XIN I Input for 24 MHz Crystal

42 XO O Output for 24 MHz Crystal

43 VDD +3.3 V power supply

44 GND Ground

45 NCONot used

46 NCONot used

47 CEC_MCU_RST O CEC microcomputer Reset signal output pin

48NCINot used

49 HT0_CTLB O Hot plug detect signal output pin (DVD FUNCTION)

50 HT1_CTLB O Hot plug detect signal output pin (SAT/CBL FUNCTION)

A

2 3 4

B

C

D

E

F

34

1

2 3 4

VSX-522-K

Page 35

5

• Pin Function

Pin Symbol I/O Description

51 HT2_CTLB O Hot plug detect signal output pin (GAME FUNCTION)

52 HT3_CTLB O Hot plug detect signal output pin (BD FUNCTION)

53 EP94A1K_RST O Reset signal output pin for EP94A1K IC

54 NCONot used

55 NCONot used

56 NCINot used

57 NCINot used

58 CEC MCU_IIC_SCL O IIC clock signal output pin for CEC microcomputer

59 CEC MCU_IIC_SDA I/O IIC data signal in/output pin for CEC microcomputer

60 NCINot used

61 NCINot used

62 SUB_RXD I Soft update UART comunication data input pin (UPDATE JIG B'D)

63 SUB_TXD O Soft update UART comunication data output pin (UPDATE JIG B'D)

64 INTb I Interrupt signal input pin from EP94A1K & EPF011C

(EPF011C)(D-MAIN ASSY: IC2003)

CEC Microcomputer

• Pin Function

Pin Symbol I/O Description

1 RXD I Soft update UART comunication data input pin (UPDATE JIG B'D)

2 TXD O Soft update UART comunication data output pin (UPDATE JIG B'D)

3 CECin I HDMI CEC signal input pin

4 DDC_SCL I IIC clock signal input pin from SUB microcomputer

5 DDC_SDA I/O IIC data signal in/output pin from SUB microcomputer

6 SCL I IIC clock signal input pin (EP94A1K & EPF011C)

7 SDA I/O IIC data signal in/output pin (EP94A1K & EPF011C)

8 RSTb I CEC microcomputer Reset signal input pin

9 OP_MODE I Chip operation mode select signal input pin(0:normal)

10 IO3 − Not used (PULL_UP)

11 IO2 − Not used (PULL_UP)

12 INTb I Interrupt signal input pin from EP94A1K

13 A0 − Ground

14 A1 − Ground

15 A15 − Ground

16 VDD +3.3 V power supply

17 VSS Ground

18 XIN I 24 MHz Crystal input

19 XO O Not used

20 VDD +3.3 V power supply

21 VSS Ground

22 CECO O HDMI CEC signal output pin

23 A6 − Ground

24 BIST − Ground

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

35

Page 36

1

J005253200020-IL (W25Q32BV_SS1G)(D-MAIN ASSY: IC2019)

32M-bit Serial Flash Memory with uniform 4KB sectors and Dual/Quad SPI

• Pin Arrangement (Top View)

/CS

DO(IO

1

)

/WP(IO

2

)

GND

VCC

/HOLD(IO

1

)

CLK

DI(IO

0

)

1

2

3

4

8

7

6

5

• Pin Function

Pin Name I/O Function

/CS I Chip select input

DO(IO

1

)

I/O Data output (Data input output 1) *1

/WP(IO

2

) I/O Write protect input (Data input output 2) *2

GND Ground

DI(IO

0

) I/O Data input (Data input output 0) *1

CLK I Serial clock input

/HOLD(IO

0

) I/O Hold input (Data input output 3) *2

VCC Power supply

No.

1

2

3

4

5

6

7

8

*1 IO0 and IO1 are used for Standard and Dual SPI instructions.

*2 IO0 - IO3 are used for Quad SPI instructions.

A

2 3 4

B

C

D

E

F

36

1

2 3 4

VSX-522-K

Page 37

5

J127410500010-IL (NJM41050V)(VIDEO ASSY: IC1200)

47µF AC-Coupling Capacitor 3-Input 1-Output Video Driver with LPF

• Pin Arrangement (Top View)

• Block Diagram

1

2

3

4

5

6

7

NC

SSIGV

Vsag

SREFV

Vcc

GND

Vout

14

13

12

11

10

9

8

Vin1

SW1

Vin2

SW2

Vin3

Mute

NC

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

37

Page 38

1

[1] Display mode for numbers of protection detections

[Purpose]

[Basic operations]

FL Display Description of IndicationsKey Operation

(STANDBY state)

[PRESET k] +

[STANDBY/ON] keys

(Initial display)

[ENTER] key

[ENTER] key

[ENTER] key

(Initial display)

5 (-> normal) *1

5 (-> normal) *1

5 (-> normal) *1

Number of DC error detections

Number of OVERLOAD error detections

Number of abnormal-temperature

error detections

Time (sec.)

The numbers of detections for various protection processes are displayed.

*1 "5 (-> normal)" denotes that the display will return to the normal indication when no key operation is performed

for 5 seconds.

*2 Variable range: 0 to 255

[How to enter/exit]

During Standby mode, simultaneously press and hold the [PRESET k] and [STANDBY/ON] keys for 2 seconds to enter

this mode.

The display will return to the normal indication when no key operation is performed for 5 seconds.

Counter

Counter

Counter

*2

*2

*2

The above-mentioned Display mode is available only when the product operates properly.

If any protection function is activated while the product is in use, the product cannot be turned ON and enter the above

Display mode. In such a case, cancel the protection function, referring to “3.4 How to cancel the status after detection of the

DC error." If a protection function is activated immediately after the previous protection function is canceled, cancel that

protection function again then enter STBY mode immediately. You can then see the error logs, following the above procedures,

until a next protection function is activated.

2 3 4

6. SERVICE MODE

6.1 SERVICE MODE

A

B

C

D

E

F

38

1

2 3 4

VSX-522-K

Page 39

5

[2] Reset mode for numbers of protection detections

[Purpose]

[Basic operations]

FL Display Description of IndicationsKey Operation

(STANDBY state)

[ALC/STANDARD SURR]

+ [STANDBY/ON] keys

(press and hold the keys

for 10 seconds.)

(Counter Clear end)

[ENTER] key

(Normal display)

5 (-> normal) *1

5 (-> normal) *1

usually

*2

Time (sec.)

For clearing all the counts of protection detections.

(This mode resets the counts of protection detections.)

1. When the procedures for Reset mode for numbers of protection detections are completed, all the counters will be

reset to "000."

2. Prohibitions:

The protection detection counts cannot be cleared (reset to 000) with the MEMORY CLEAR process.

They can only be cleared when the procedures of Reset mode are completed.

*1 "5 (-> normal)" denotes that the display will return to the normal indication when no key operation is performed

for 5 seconds.

*2 Indication when the BD function is selected

[How to enter/exit]

During Standby mode, simultaneously press and hold the [ALC/STANDARD SURR] and [STANDBY/ON] keys

for 10 seconds to enter this mode.

The display will return to the normal indication when no key operation is performed for 5 seconds.

[Detailed explanations]

6 7 8

A

B

C

D

E

F

VSX-522-K

5

6 7 8

39

Page 40

1

[3]

The unit’s operation when a error is detected

[Purpose]

[Basic operations]

FL Display Description of IndicationsKey Operation

3.1 DC (AMP is abnormality) error detection

(Normal display)

(DC detection)

(Auto)

(RECEIVER POWER OFF)

usually

*1, *2

Normal display

Time (sec.)

• The unit’s operation when a DC/OVER/TEMP error is detected is described here.

• How to cancel the status after detection of a DC error is described here, because no key input will be accepted after

a DC error detection.

FL Display Description of IndicationsKey Operation

3.2 OVERLOAD (overcurrent) error detection

(Normal display)

(OVERLOAD detection)

(Auto)

(RECEIVER POWER OFF)

usually

*1

Normal display

Time (sec.)

A

2 3 4

B

C

D

E

F

40

1

2 3 4

VSX-522-K

Page 41

5

Simultaneously holding the [ADVANCD SURROUND] and [STANDBY/ON] keys on the

front panel pressed for 2 seconds will cancel Key Input Inhibition mode after a DC error

detection and turn the unit ON.

[Detailed explanations]

3.3 TEMP (AMP overheat) error detection

For detection of a TEMP error, the unit monitors both the TR_DET and PROTECT2 signals. If a TEMP error is detected,

the processes shown below will be performed. The processes shown below are rough operational specifications and are

not the actual commands from the mounted components.

After a TEMP error is detected, the count of protection activation detections will be updated.

FL Display Description of IndicationsKey Operation

3.4 How to cancel the status after detection of the DC error

(STANDBY state)

(Normal display)

usually

Normal display

Time (sec.)

[ADVANCED SURROUND]

+ [STANDBY/ON] keys

(press and hold the keys

for 2 seconds.)

Counter: T emp2

TR_DET

P6_4 (34 pin)

(TRTHER_DET from AMP Assy)

Normal Operations

Deduct 3 from the current VOL

value. Have "TEMP" flashing

on the FL display for 3 sec.

POWER OFF (STBY)

*1

*1: The detection interval must be 1 sec or less.

*2: If PROTECT 2 is detected while TR_DET detection

is prohibited for 2 min, the PROTECT 2 function will

be activated.

Prohibit detection of

TR_DET for 2 min.

*2

Is TR_DET detected?

Is the VOL value 5

or less?

No

No

No

Yes

Yes

Yes

Detection of TR_DET

is resumed after 2 min.

Is TR_DET detected?

Counter: T emp1

PROTECT2

PL2_1 (71 pin)

(RADI_DET from AMP Assy)

Normal Operations

MUTE ON and ALL Speakers/

Phones Relay are set to OFF.

Have "OVERHEAT" flashing

on the FL display for 3 sec.

*3

*3: The detection interval must be 1 sec or less.

Timer START is performed

for 3 sec.

PROTECT2 detected?

No

No

Yes

Yes

After 3 sec,

PROTECT 2 is rechecked.

Is PROTECT 2 detected?

POWER OFF (STBY)

6 7 8

A

B

C

D

5

6 7 8

VSX-522-K

E

F

41

Page 42

1

1. Discharging

(1) Unplug the power cord.

(2) Disconnect the 10P connector from CP403 of the AMP5 Assy between CN3 of the MAIN Assy.

(3) Connect +B and –B terminal of the D7, using resistor leads with 47 - 100 ohms (2 W or higher), for discharging.

∗ Discharging time: 30 - 60 seconds, depending on the level of resistance.

(4) Check that the voltage between the +B and –B terminals is less than 1 V, using a tester.

∗ Be sure to connect the GND terminal of the tester to the chassis.

∗ If the voltage is still 1 V or higher, repeat Step (3).

[1] MAIN Assy Capacitor (C55, C58)

[Procedures]

(1) Unplug the power cord.

(2) Connect –30V and GND terminal of the BRG-C Assy,

using resistor leads with 47-100 ohms (2 W or higher),

for discharging.

∗ Discharging time: 5 - 10 seconds, depending on the

level of resistance.

(3) Check that the voltage between the –30V terminal is less

than 1 V, using a tester.

∗ Be sure to connect the GND terminal of the tester to

the chassis.

∗ If the voltage is still 1 V or higher, repeat Step (2).

[2] FL-30 V Capacitor (MAIN Assy C101)

[Procedures]

47 - 100 ohms

(2 W or higher)

47 - 100 ohms

(2 W or higher)

C55

+B

GND−30V

–B

D7

CP403

C58

Note:

(1) Even if the unit shown in the photos and illustrations in this manual may differ from your product, the

procedures described here are common.

(2) For performing the diagnosis shown below, the following jigs for service is required:

• 9P extension jig cable (GGD1739)

• Board to board extension jig cable (GGD1756)

• Board to board extension jig cable (GGD1798)

• Board to board extension jig cable (GGD1799)

MAIN Assy

AMP5 Assy

BRG-C Assy

2 3 4

7. DISASSEMBLY

A

B

C

D

E

F

42

1

2 3 4

VSX-522-K

Page 43

5

2. Notes on Ground Points Connection

During repair, before checking the MAIN Assy, etc., with the rear chassis removed, be sure to connect the

GND terminal of the main capacitor to the back chassis (speaker chassis), as shown below, then connect the

power cord.

Without grounding connection, the protection circuit will be activated.

After repairing, be sure to remove the ground wire before reassembling.

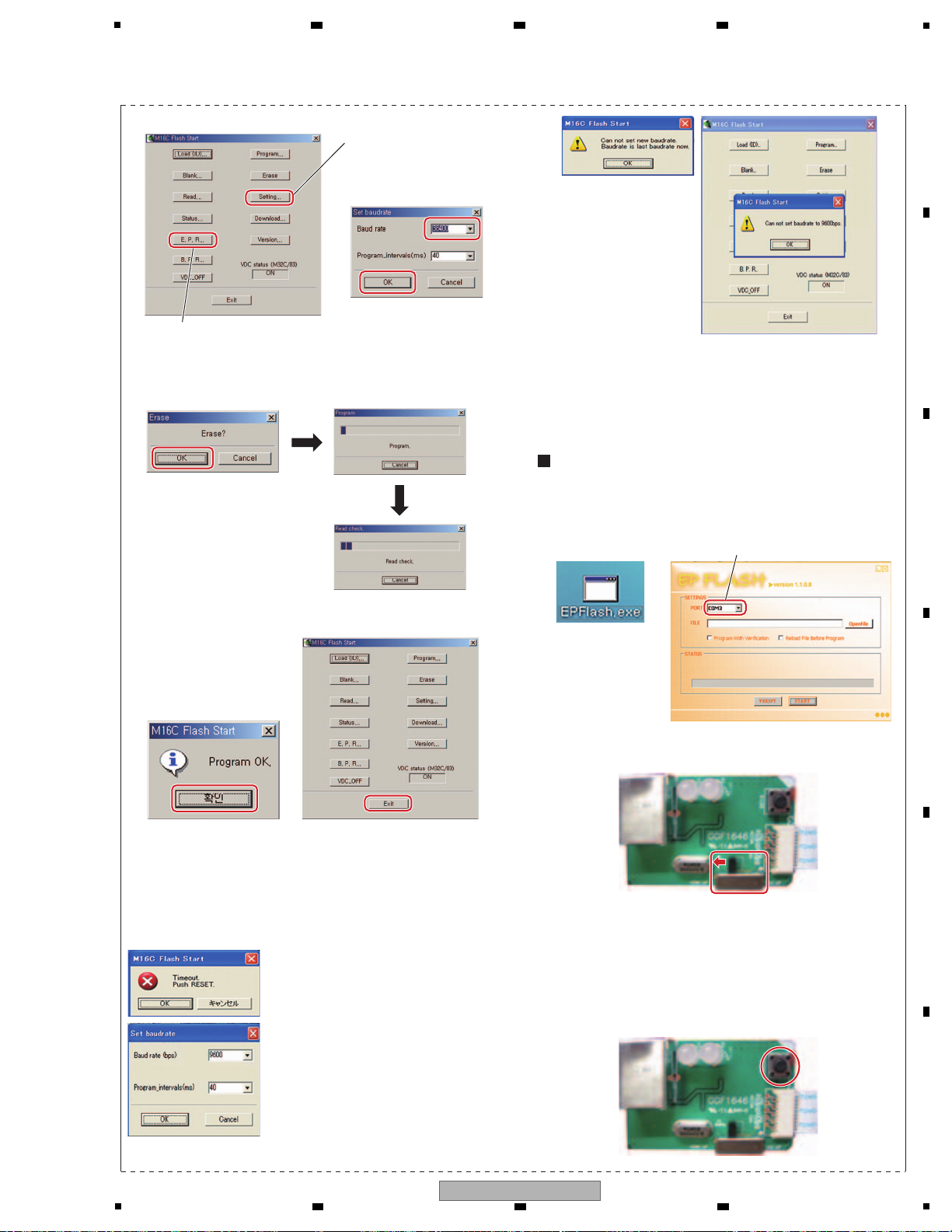

[Note]