Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

Note:

Media Receivers up to Generation 5 (G5) cannot be connected with this unit.

Be sure to use a Media Receiver of Generation 6 (G6) (ex.: PDP-R06∗∗, etc.).

ORDER NO.

ARP3267

PDP-506PE

PLASMA DISPLAY

PDP-506PE

PDP-506PU

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

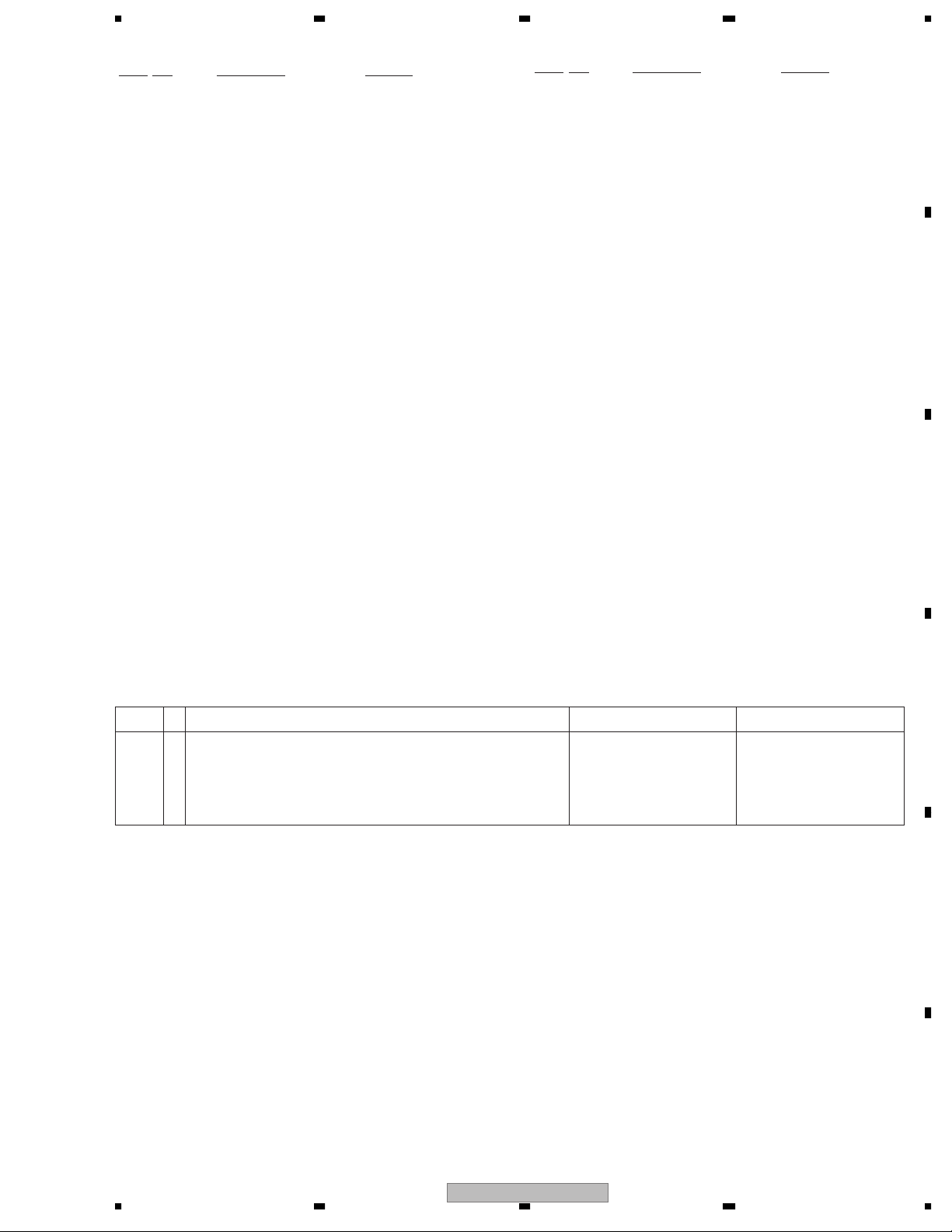

Model Type Power Requirement Remarks

PDP-506PE WYVI AC220 - 240V

PDP-506PU KUCXC AC120V

This service manual should be used together with the following manual(s).

Model No. Order No. Remarks

PDP-506PE, PDP-506PU ARP3268 SCHEMATIC DIAGRAM, PCB CONNECTION DIAGRAM

For details, refer to "Important Check Points for good servicing".

T-IZY SEPT. 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

Health & Safety Code Section 25249.6 - Proposition 65

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

C

de remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

D

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

E

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-506PE

Page 3

5678

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which requires

corrective action. Exposed metal parts not having a return path to

the chassis will indicate an open circuit.

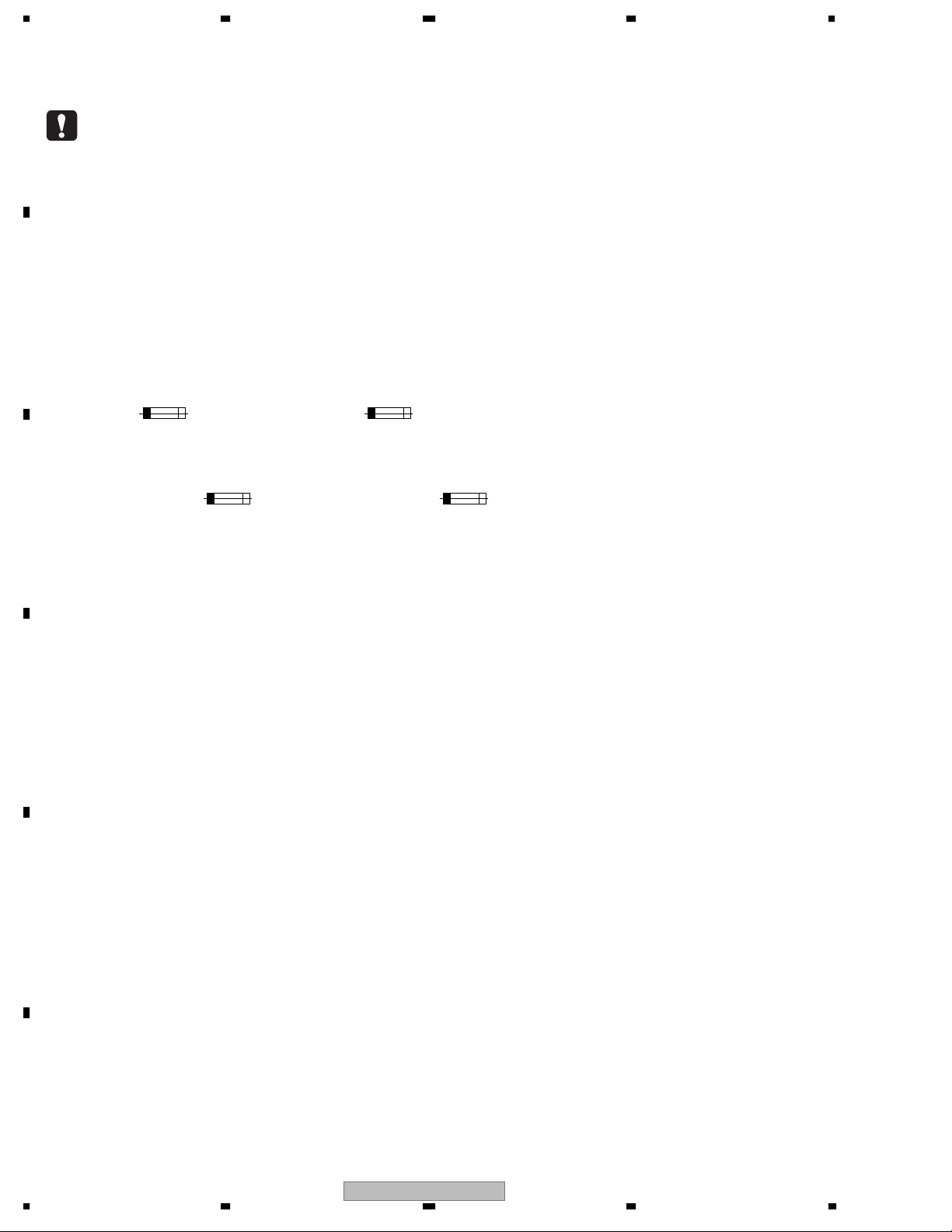

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

A

B

C

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

D

E

56

PDP-506PE

F

3

7

8

Page 4

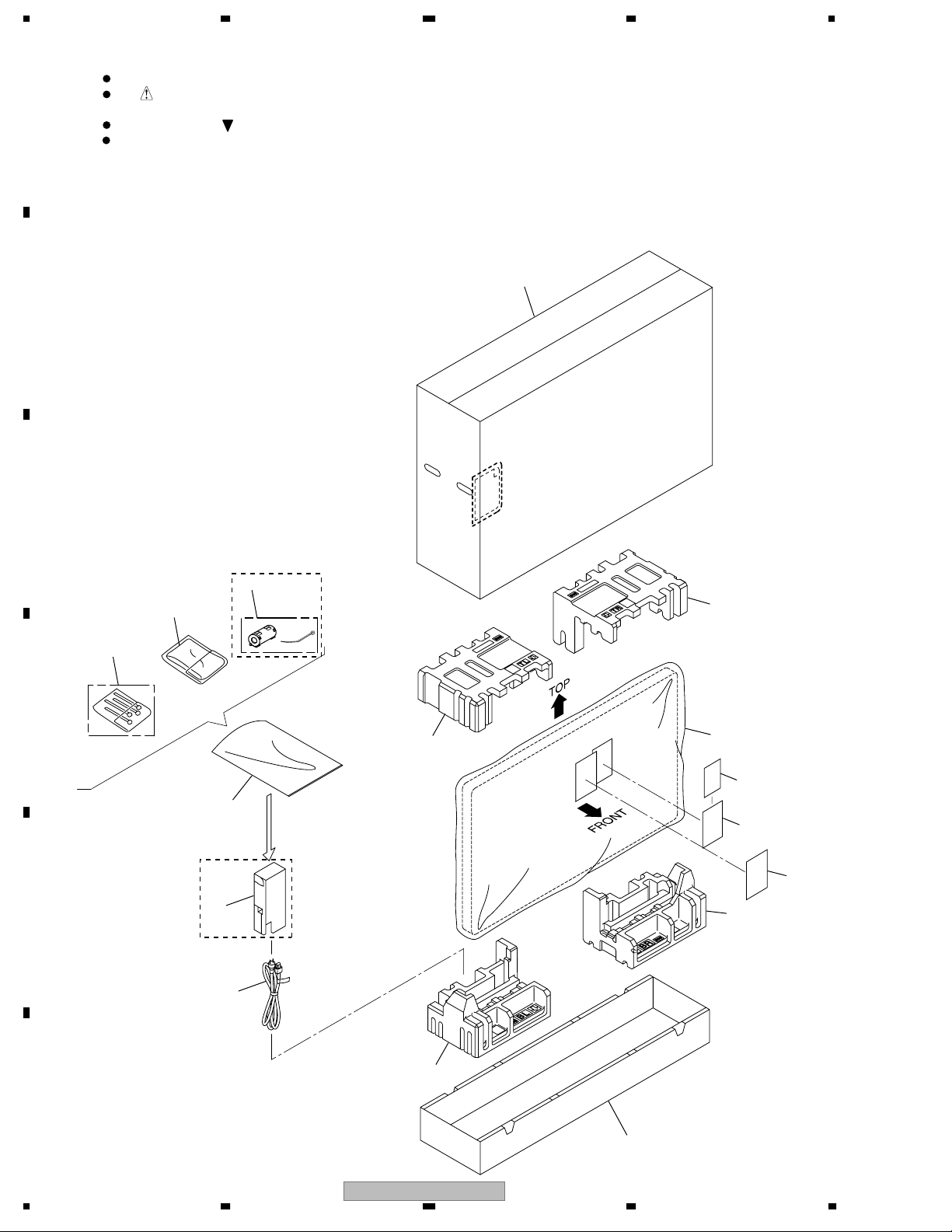

1234

A

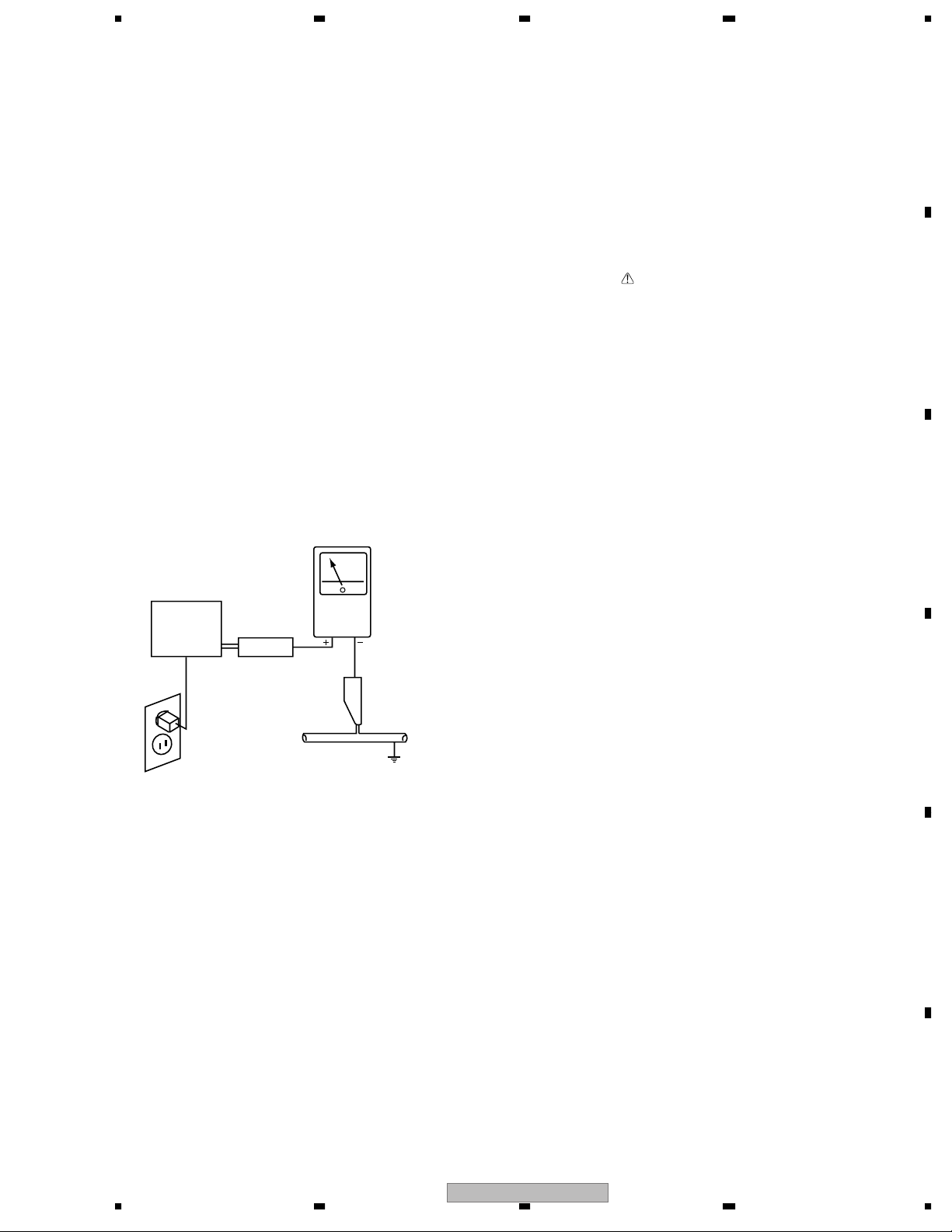

Charged Section

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

B

1. Power Cord

2. AC Inlet

3. Power Switch (S1)

4. Fuse (In the POWER SUPPLY Unit)

5. STB Transformer and Converter Transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

C

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

High Voltage Generating Point

The places where voltage is 100V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

If the procedures described in “7.1.5 POWER ON/OFF

FUNCTION FOR THE LARGE-SIGNAL SYSTEM” are

performed before the power is turned off, the voltage will be

discharged in about 30 seconds.

1. POWER SUPPLY Unit.....................................................(205V)

2. 50 X DRIVE Assy .......................................... (–180V to 205V)

3. 50 Y DRIVE Assy .......................................................... (500V)

4. 50 SCAN A Assy ............................................................ (500V)

5. 50 SCAN B Assy ............................................................(500V)

6. SUS CLAMP 1 Assy .......................................(–180V to 205V)

7. SUS CLAMP 2 Assy .......................................(–180V to 205V)

50 SCAN B Assy

D

E

50 Y DRIVE Assy 50 X DRIVE Assy SUS CLAMP 1 Assy

POWER SUPPLY Unit

F

50 SCAN A Assy SUS CLAMP 2 Assy Power Switch (S1)

AC Inlet

Fig.1 Charged Section and High Voltage Generating Point (Rear View)

4

1234

PDP-506PE

Page 5

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

PDP-506PE

E

F

5

7

8

Page 6

1234

CONTENTS

1. SPECIFICATIONS ............................................................................................................................................ 7

2. EXPLODED VIEWS AND PARTS LIST ............................................................................................................8

A

B

C

2.1 PACKING SECTION ..................................................................................................................................8

2.2 REAR SECTION ...................................................................................................................................... 10

2.3 FRONT SECTION.................................................................................................................................... 12

2.4 CHASSIS SECTION (1/2)........................................................................................................................ 14

2.5 CHASSIS SECTION (2/2)........................................................................................................................ 16

2.6 PDP SERVICE ASSY 506P (AWU1134) ................................................................................................. 18

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................20

3.1 OVERALL CONNECTION DIAGRAM...................................................................................................... 20

3.2 OVERALL BLOCK DIAGRAM.................................................................................................................. 22

3.3 50 ADDRESS ASSY ................................................................................................................................ 24

3.4 50 SCAN A and B ASSYS .......................................................................................................................25

3.5 50 X DRIVE, SUS CLAMP 1 and SUS CLAMP 2 ASSYS ....................................................................... 26

3.6 50 Y DRIVE ASSY ................................................................................................................................... 27

3.7 HD DIGITAL ASSY................................................................................................................................... 28

3.8 HD AUDIO ASSY..................................................................................................................................... 29

3.9 POWER SUPPLY UNIT............................................................................................................................ 30

3.10 WAVEFORMS........................................................................................................................................ 31

5. PCB PARTS LIST ........................................................................................................................................... 33

6. ADJUSTMENT ............................................................................................................................................... 41

6.1 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED ....................................... 41

6.2 RS-232C COMMAND .............................................................................................................................. 42

6.3 METHOD FOR REPLACING THE SERVICE PANEL ASSY.................................................................... 58

7. GENERAL INFORMATION............................................................................................................................. 62

7.1 DIAGNOSIS ............................................................................................................................................. 62

7.1.1 PCB LOCATION ................................................................................................................................62

7.1.2 DIAGNOSIS OF SHUTDOWN/POWER-DOWN INDICATED BY LEDS............................................ 63

7.1.3 OVERVIEW OF PANEL FACTORY MODE........................................................................................ 66

7.1.4 OPERATION WHEN THE MEDIA RECEIVER IS NOT CONNECTED.............................................. 75

7.1.5 POWER ON/OFF FUNCTION FOR THE LARGE-SIGNAL SYSTEM ............................................... 76

7.1.6 BACKUP WHEN THE MAIN UNIT IS ADJUSTED ............................................................................77

7.1.7 HOW TO CLEAR HISTORY DATA ..................................................................................................... 79

7.1.8 DISASSEMBLY.................................................................................................................................. 81

7.2 IC ............................................................................................................................................................. 85

8. PANEL FACILITIES ........................................................................................................................................ 94

D

E

F

6

1234

PDP-506PE

Page 7

5678

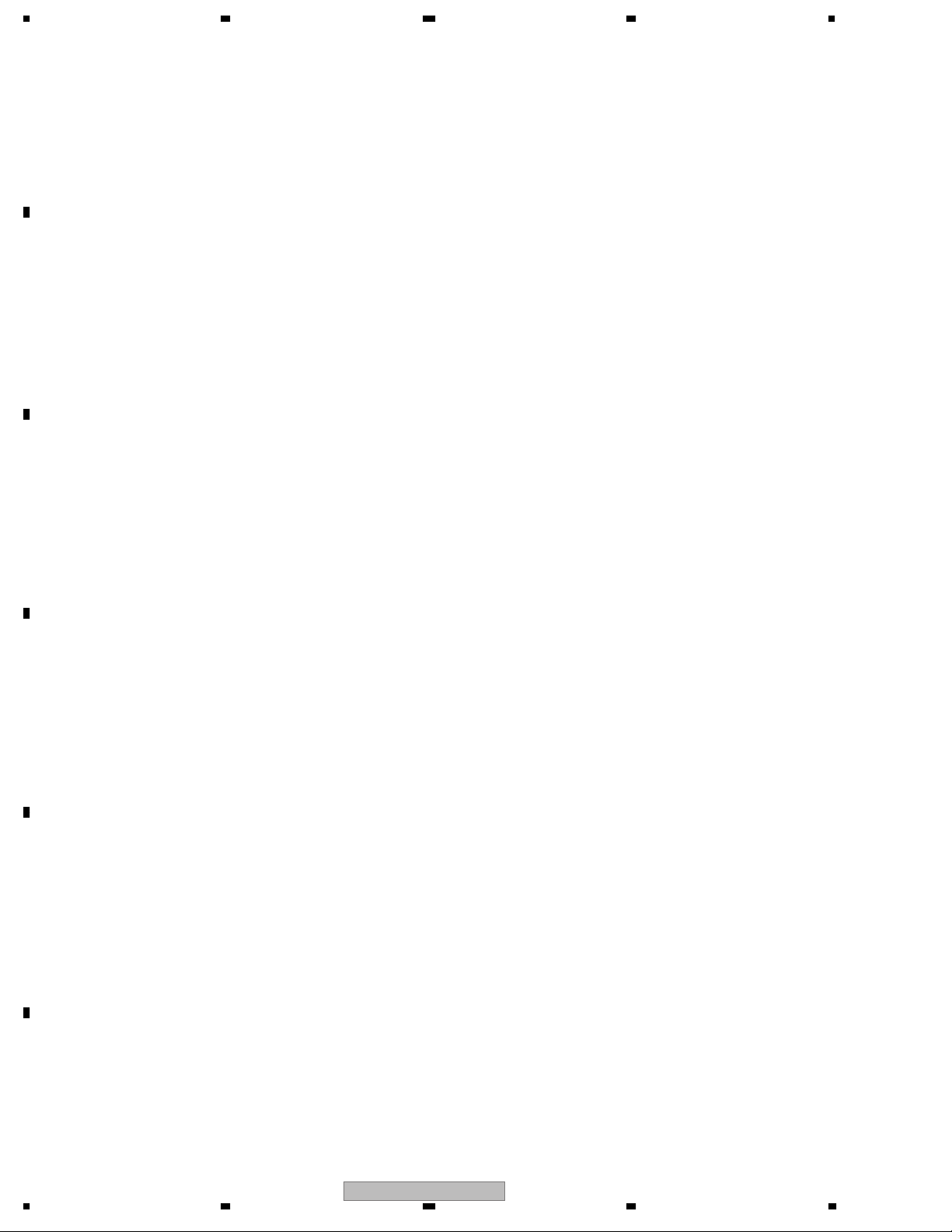

1. SPECIFICATIONS

Item 50" Plasma Display, Model: PDP-506PE 50" Plasma Display, Model: PDP-506PU

A

Number of Pixels 1280 × 768 pixels

Audio Amplifier

Surround System

Power Requirement

Dimensions

Weight

• Design and specifications are subject to change without notice.

13 W + 13 W (1 kHz, 10 %, 8Ω)

SRS/FOCUS/TruBass

220 - 240 V AC, 50/60 Hz, 344 W (0.4 W Standby)

1224 (W) × 717 (H) × 92 (D) mm

31.8 kg (70.1 lbs.)

1280 × 768 pixels

13 W + 13 W (1 kHz, 10 %, 8Ω)

SRS/FOCUS/TruBass

120 V AC, 60 Hz, 355 W (0.2 W Standby)

1224 (W) × 717 (H) × 92 (D) mm

(48 3/16 (W) × 28 1/4 (H) × 3 5/8 (D) inches)

31.8 kg (70.1 lbs.)

Trademarks

• FOCUS, WOW, SRS and (¶) symbol are trademarks of SRS Labs, Inc.

FOCUS and SRS technologies are incorporated under license from SRS Labs, Inc.

• This product includes FontAvenue fonts licensed by NEC Corporation.

FontAvenue is a registered trademark of NEC Corporation.

• HDMI, the HDMI logo and High-Definition Multimedia Interface are trademarks or registered trademarks of HDMI Licensing

LLC.

• The names of companies or institutions are trademarks or registered trademarks of the respective companies or institutions.

B

C

Accessories

Power cord (2 m)

For PDP-506PE For PDP-506PU

Warranty card

(ADG1214) (ADG1215)

Only the power cord that is appropriate in your country or region

is supplied.

Binder Assy (AEC1908) Ferrite Core (ATX1039)(PDP-506PE only)

Speed clamp x 3 Bead band x 3

Cable tie

Cleaning cloth

(AED1285)

D

E

Ferrite core

F

56

PDP-506PE

7

7

8

Page 8

1234

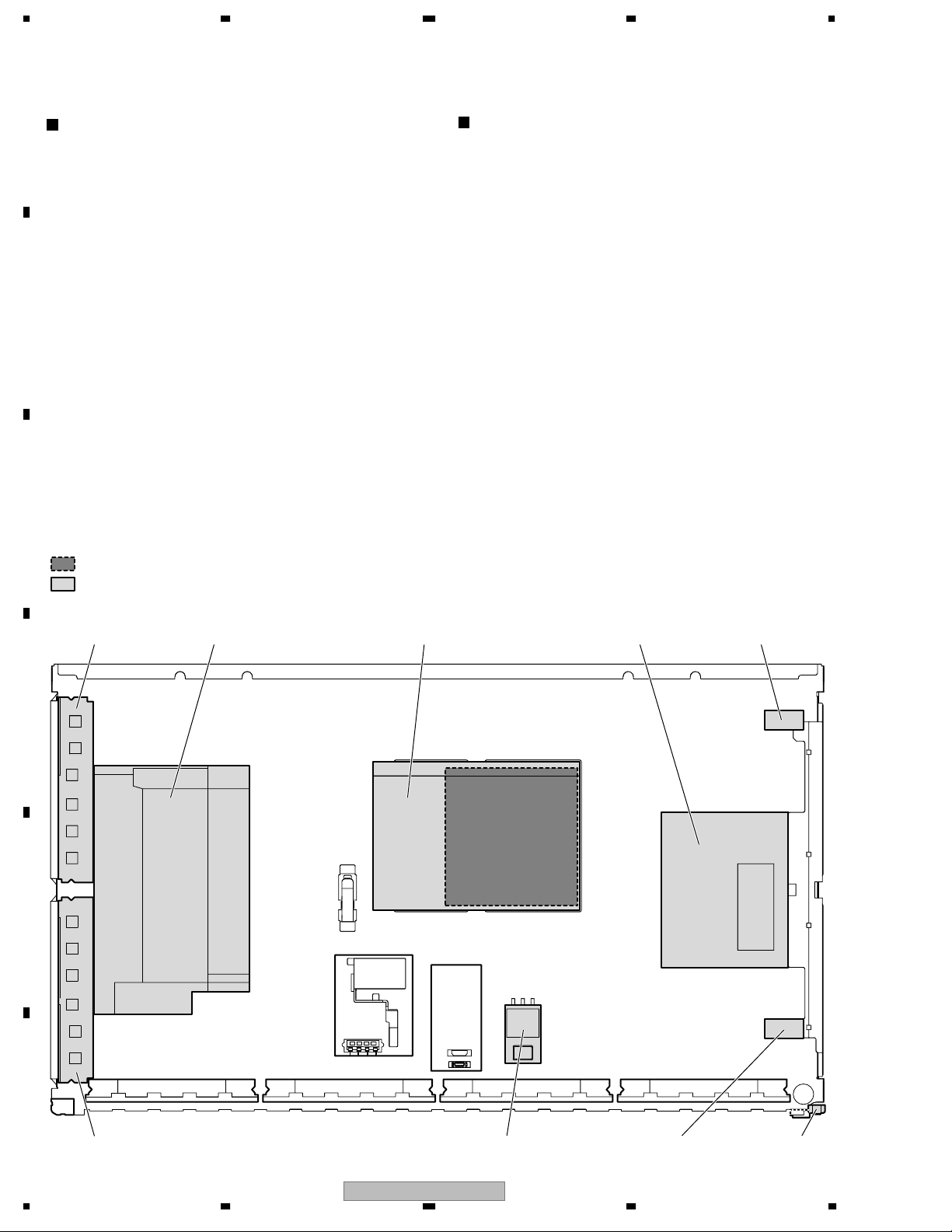

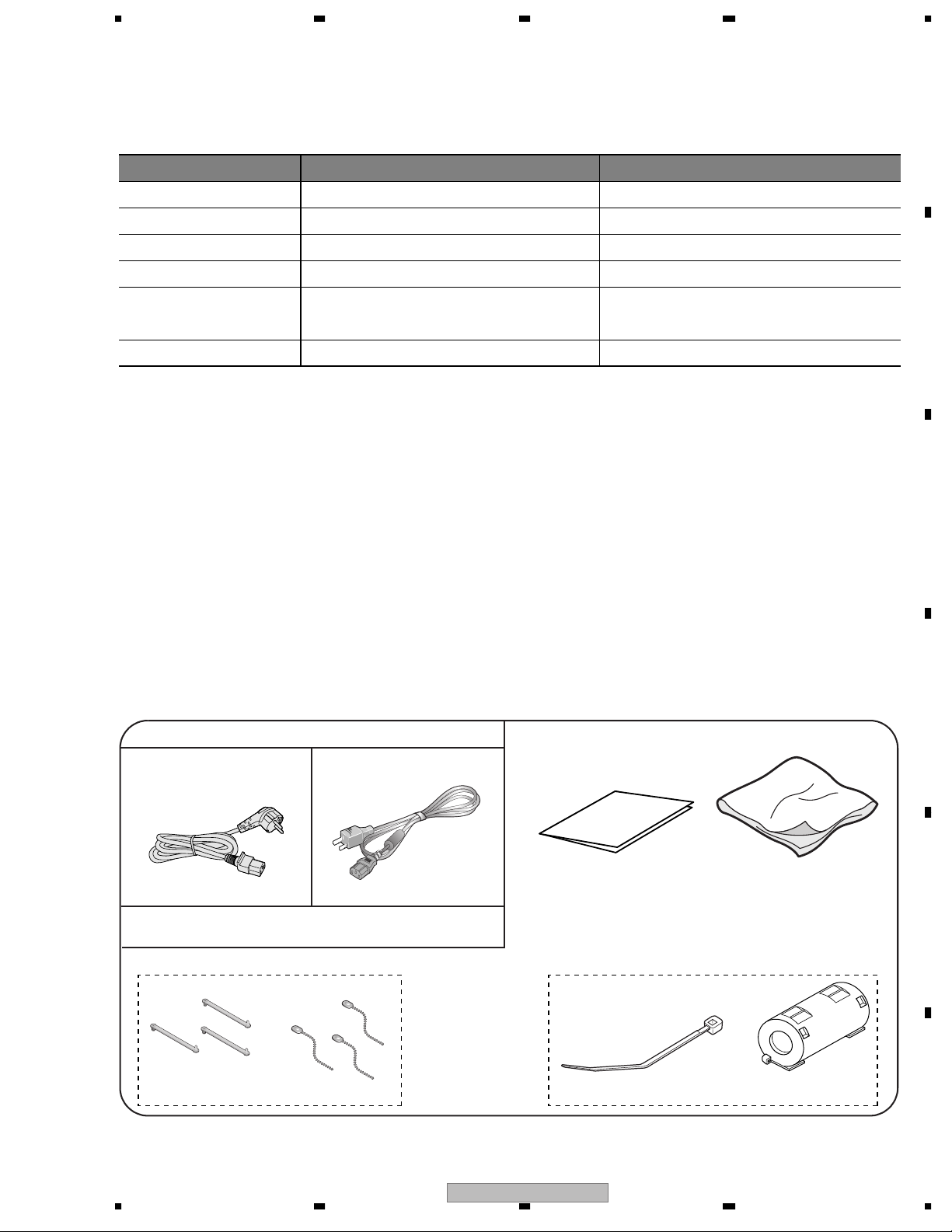

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

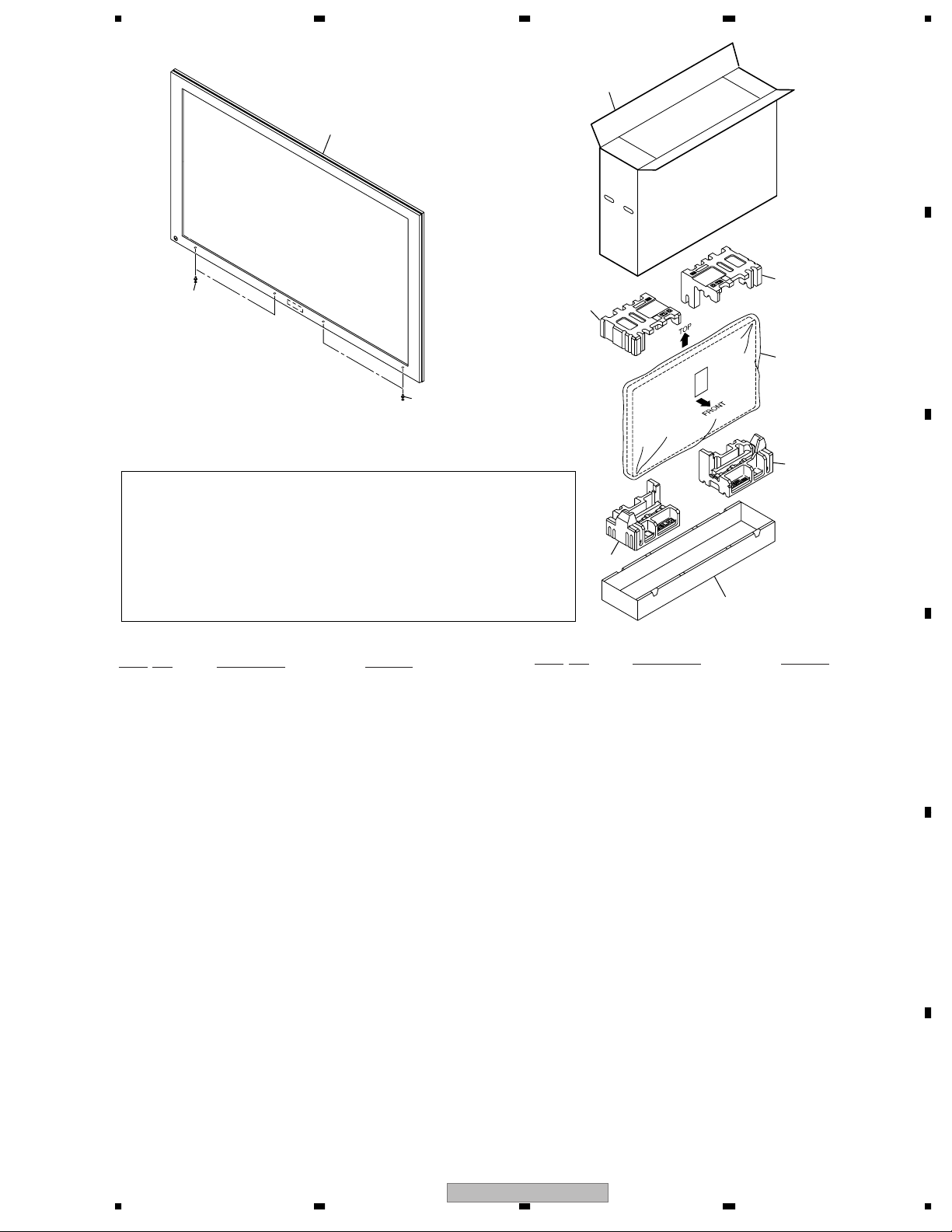

2.1 PACKING SECTION

B

C

14

PDP-506PEonly

PDP-506PE only

7

3

2

D

8

4

PDP-506PE

only

E

12

1

9

15

6

5

16

11

10

F

13

8

1234

PDP-506PE

Page 9

>

>

>

>

5678

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cord See Contrast table (2)

2 Binder Assy AEC1908

3 Cleaning Cloth AED1285

4Polyethylene Bag S See Contrast table (2)

NSP 5 Catalogue Bag See Contrast table (2)

NSP 6 Warranty card See Contrast table (2)

7Ferrite Core See Contrast table (2)

8Pad (50T-L) See Contrast table (2)

9Pad (50T-R) See Contrast table (2)

10 Pad (50B-L) See Contrast table (2)

A

11 Pad (50B-R) See Contrast table (2)

12 Power Cord Case See Contrast table (2)

13 Under Carton See Contrast table (2)

14 Upper Carton See Contrast table (2)

15 Mirror Mat See Contrast table (2)

16 Caution Card See Contrast table (2)

(2) CONTRAST TABLE

PDP-506PE/WYVI and PDP-506PU/KUCXC are constructed the same except for the following:

Mark No. Symbol and Description PDP-506PE/WYVI PDP-506PU/KUCXC

1Power Cord ADG1214 ADG1215

4Polyethylene Bag S AHG1338 AHG1348

NSP 5 Catalogue Bag AHG1340 AHG1347

NSP 6 Warranty Card ARY1114 ARY1145

7Ferrite Core ATX1039 Not used

8Pad (50T-L) AHA2427 AHA2459

9Pad (50T-R) AHA2428 AHA2460

10 Pad (50B-L) AHA2429 AHA2461

11 Pad (50B-R) AHA2430 AHA2462

12 Power Cord Case AHC1073 Not used

B

C

D

13 Under Carton (50) AHD3344 Not used

13 Under Carton (506PU) Not used AHD3379

14 Upper Carton (506PE) AHD3345 Not used

14 Upper Carton (506PU) Not used AHD3383

15 Mirror Mat AHG1284 AHG1352

16 Caution Card ARM1232 ARM1239

PDP-506PE

56

7

8

E

F

9

Page 10

1234

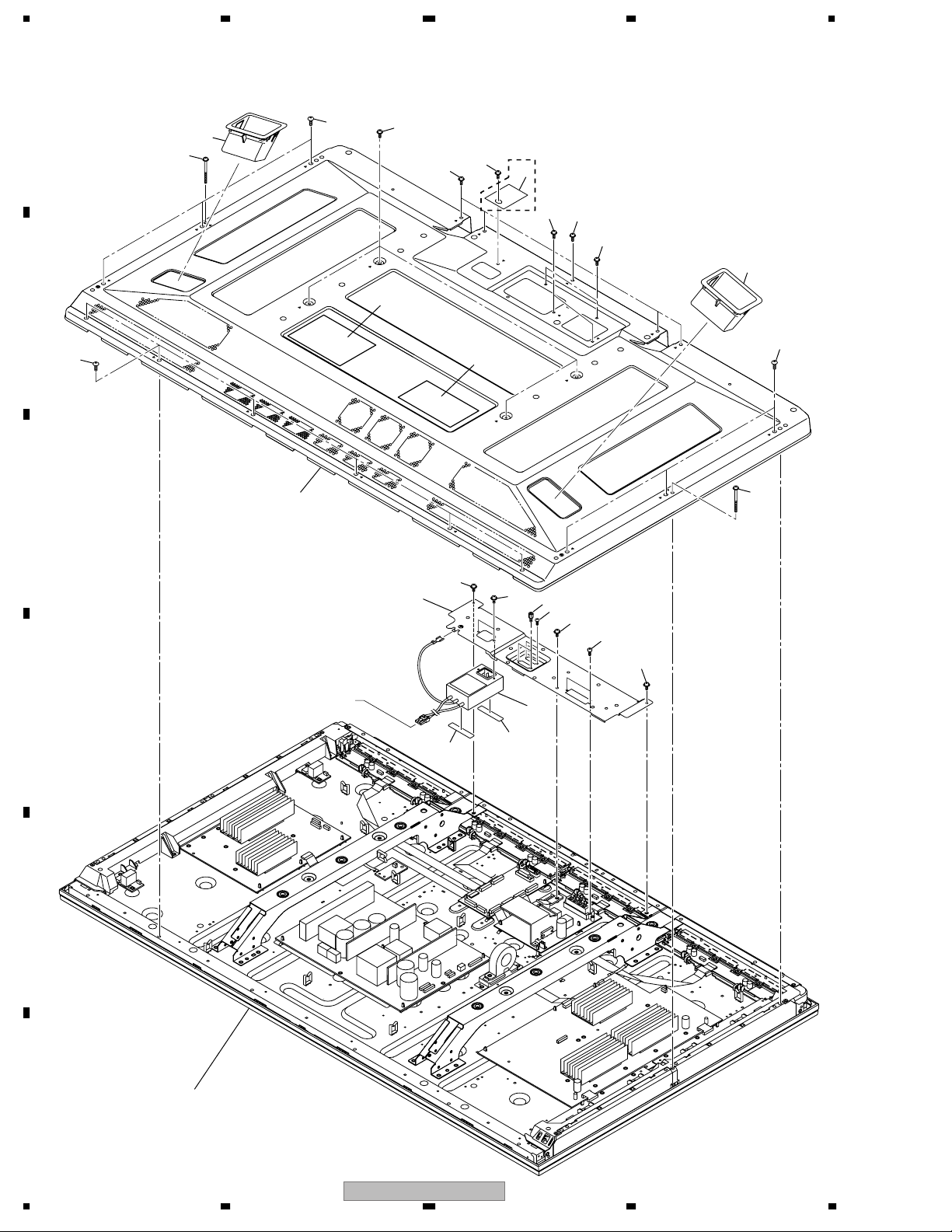

2.2 REAR SECTION

A

4

11

B

16

C

16

3

15

15

15

7

6

PDP-506PE

8

only

15

15

15

4

16

11

15

2

To Power Switch

D

5

E

15

12

13

15

14

15

1

5

Refer to

F

10

1234

"2.3 FRONT SECTION".

PDP-506PE

Page 11

>

5678

(1) REAR SECTION PARTS LIST

No. Description Part No.

Mark

1AC Inlet AKP1274

2 Control Plate AND1185

3 Rear Case (506) ANE1639

4 Inner Grip Assy AMR3434

5AC Cushion AEC2035

NSP 6 Model Label See Contrast table (2)

7 Caution Label See Contrast table (2)

8AC Label PE See Contrast table (2)

9• • • • •

10 • • • • •

A

11 Screw (3 x 40P) ABA1332

12 Hexagon Head Screw BBA1051

13 Screw PMZ26P060FTB

14 Screw BPZ30P080FTB

15 Screw AMZ30P060FTB

16 Screw TBZ40P080FTB

(2) CONTRAST TABLE

PDP-506PE/WYVI and PDP-506PU/KUCXC are constructed the same except for the following:

Mark No. Symbol and Description PDP-506PE/WYVI PDP-506PU/KUCXC

NSP 6 Model Label (506PE) AAL2661 Not used

NSP 6 Model Label (506PU) Not used AAL2679

7 Caution Label AAX3117 AAX3075

8AC Label PE AAX3194 Not used

B

C

D

56

PDP-506PE

E

F

11

7

8

Page 12

1234

2.3 FRONT SECTION

A

B

Refer to

"2.4 CHASSIS SECTION (1/2)",

C

D

PDP-506PE

only

E

7

7

5

4

9

2

8

10

6

3

7

1

7

8

10

F

12

1234

PDP-506PE

Page 13

5678

(1) FRONT SECTION PARTS LIST

No. Description Part No.

Mark

1Front Case Assy (506PE) AMB2861

2 Corner Cushion AEB1416

3 Pioneer Name Plate AAM1098

4Power Button AAD4133

5 Coil Spring ABH1120

6 Blind Cushion AEB1415

7 Insulation Sheet A AED1283

8 Insulation Sheet B AED1284

9Power Display Label (506) See Contrast table (2)

10 Screw Rivet AEC1877

(2) CONTRAST TABLE

PDP-506PE/WYVI and PDP-506PU/KUCXC are constructed the same except for the following:

Mark No. Symbol and Description PDP-506PE/WYVI PDP-506PU/KUCXC

9Power Display Label (506) AAX3217 Not used

A

B

C

D

E

56

PDP-506PE

F

13

7

8

Page 14

1234

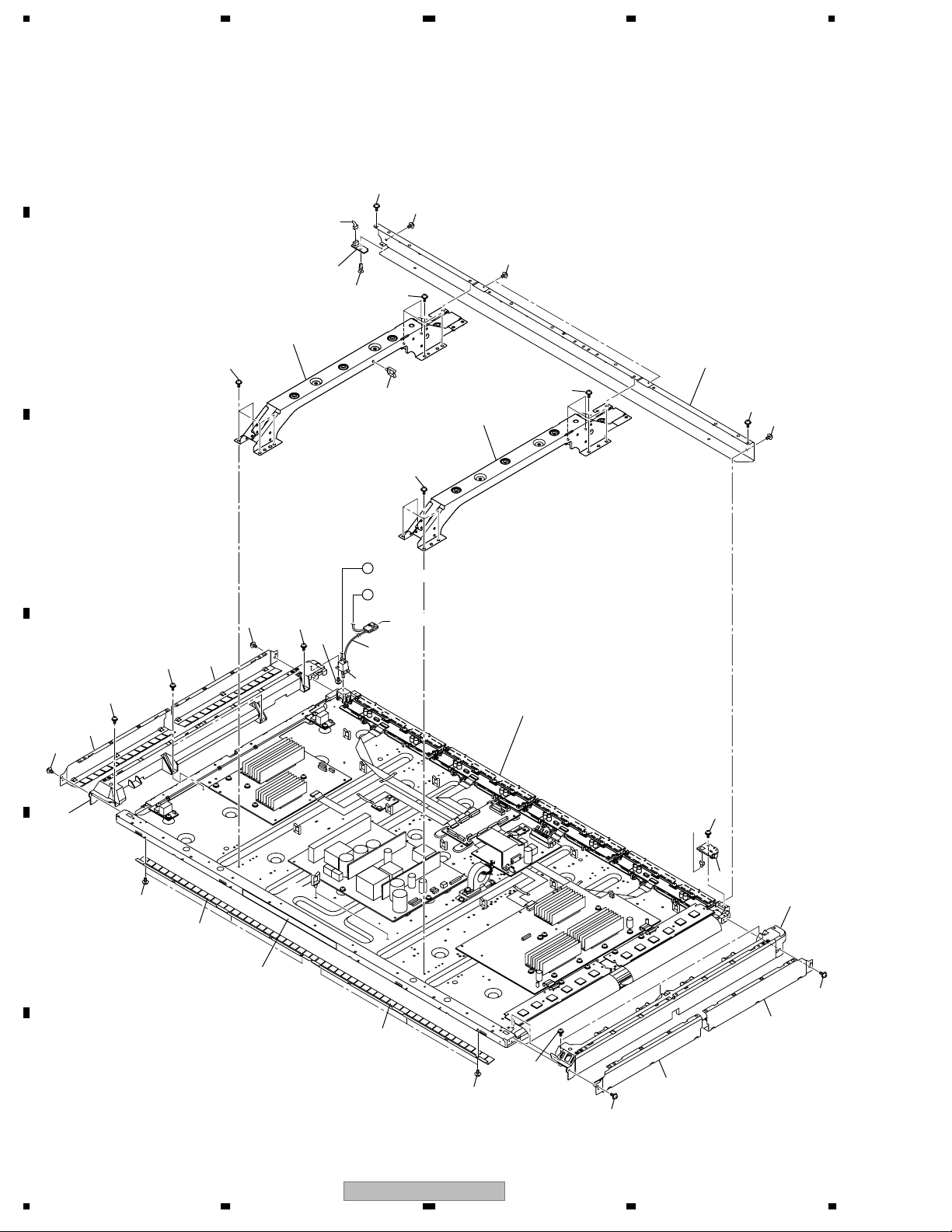

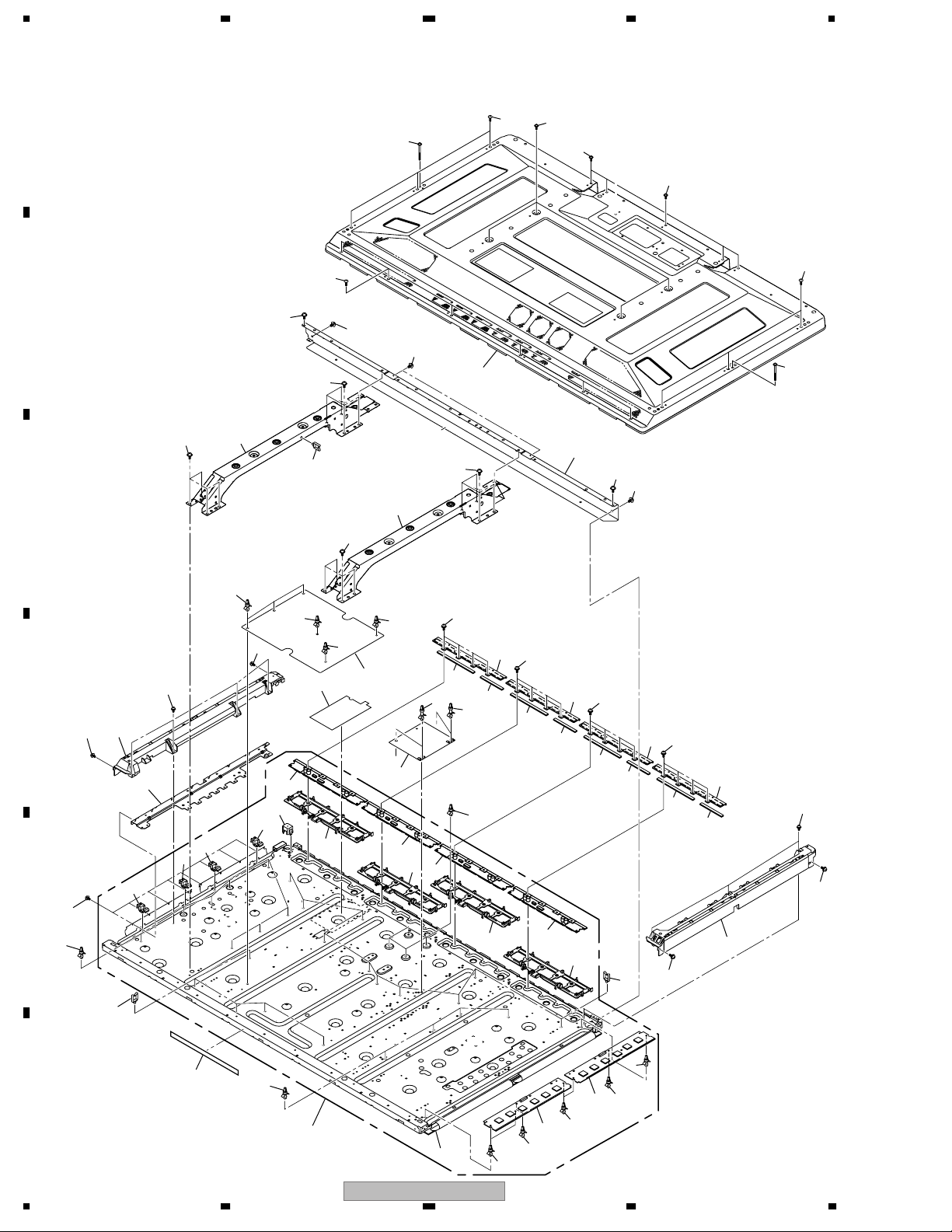

2.4 CHASSIS SECTION (1/2)

A

To HD DIGITAL

CN3003

19

17

1

18

16

22

B

8

22

14

22

7

9

19

17

22

C

2

From POWER SUPPLY

P3

1

17

23

From AC Inlet

21

12

23

23

D

4

3

Refer to

"2.5 CHASSIS SECTION (2/2)".

11

17

6

To HD DIGITAL

14

E

20

17

CN3003

2

5

10

13

17

10

11

23

20

F

14

1234

PDP-506PE

17

12

Page 15

5678

CHASSIS SECTION (1/2) PARTS LIST

No. Description Part No.

Mark

1 HD LED Assy AWW1029

2 HD IR Assy AWW1030

3Power Switch (S1) ASG1092

4 Housing Wire (50)(J103) ADX3112

5Front Chassis VL (50) AMA1014

6Front Chassis VR (50) AMA1015

7 Sub Frame L Assy (506) ANA1860

8 Sub Frame R Assy (506) ANA1861

9Front Chassis H Assy (50) ANA1883

10 Panel Holder H (50) ANG2769

>

A

11 Panel Holder V1 (50) ANG2770

12 Panel Holder V2 (50) ANG2771

13 Cushion AEB1424

14 Wire Saddle AEC1745

15 • • • • •

16 Nyron Rivet AEC1671

17 Screw ABZ30P080FTC

18 Screw AMZ30P060FTB

19 Screw APZ30P080FTB

20 Screw BBZ30P060FTC

21 Screw BPZ30P080FTB

22 Screw TBZ40P080FTB

23 Screw VBB30P080FNI

B

C

D

56

PDP-506PE

E

F

15

7

8

Page 16

1234

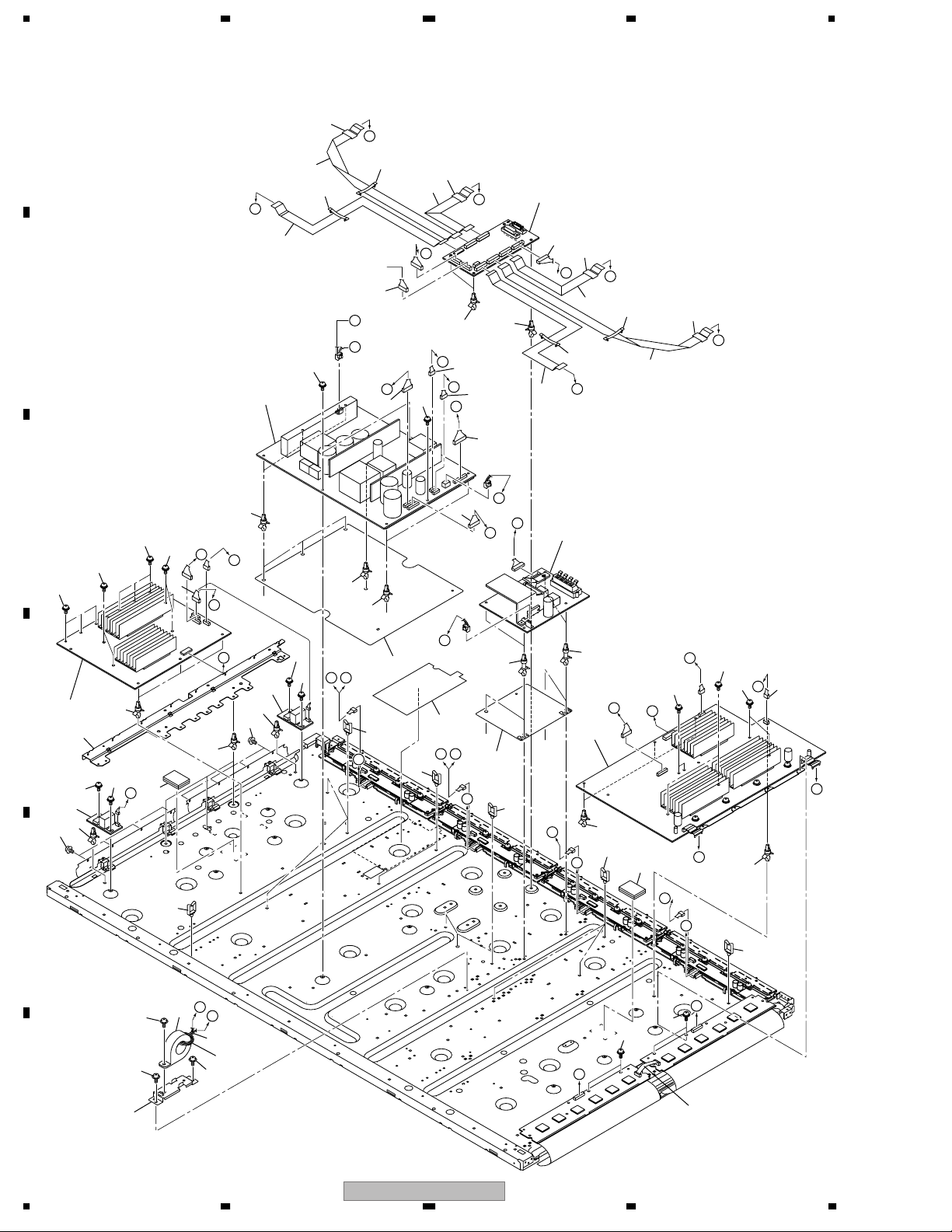

2.5 CHASSIS SECTION (2/2)

A

E

15

B

7

9

A

14

31

To HD LED CN1671

HD IR CN1681

19

1

To

Power Switch

2

41

31

24

9

13

B

N

32

R

25

41

O

26

N

J

32

10

5

18

9

Q

C

12

31

31

11

F

9

D

21

L

C

40

41

41

40

17

32

J

R

32

G

32

23

Q

K

6

36

M

37

R R

30

35

B

36

32

40

41

3

R R

34

36

A

E

1

D

27

32

40

32

41

40

33

G

2

32

40

E

36

30

K

O

41

41

16

41

F

P

4

I

O

32

36

C

33

H

32

P

D

36

I

40

41

39

L

8

M

29

40

22

41

H

F

16

28

PDP-506PE

20

1234

Page 17

5678

(1) CHASSIS SECTION (2/2) PARTS LIST

No. Description Part No.

Mark

1 50 X DRIVE Assy See Contrast table (2)

2 SUS CLAMP 1 Assy AWW1022

3 SUS CLAMP 2 Assy AWW1023

4 50 Y DRIVE Assy See Contrast table (2)

5 HD DIGITAL Assy AWW1028

>

No. Description Part No.

Mark

21 14P Housing Wire (J104) ADX3158

22 3P Housing Wire (J105) ADX3159

23 9P Housing Wire (J101) ADX3186

24 8P Housing Wire (J102) ADX3187

25 5P Housing Wire (J106) ADX3188

A

6 HD AUDIO Assy AWV2203

7POWER SUPPLY Unit AXY1112

8 Ring Core with Case ATX1042

9Ferrite Core ATX1048

10 Flexible Cable (J201) ADD1293

11 Flexible Cable (J202) ADD1294

12 Flexible Cable (J203) ADD1295

13 Flexible Cable (J204) ADD1296

14 Flexible Cable (J205) ADD1297

15 Flexible Cable (J206) ADD1298

16 4P Housing Wire (J108) ADX3117

17 6P Housing Wire (J109) See Contrast table (2)

18 12P Housing Wire (J110) See Contrast table (2)

19 6P Housing Wire (J111) ADX3120

20 3P Housing Wire (J113) See Contrast table (2)

26 6P Housing Wire (J107) ADX3189

27 Conductive Plate XA ANG2776

28 FC Stay ANG2815

29 Binder AEC-093

NSP 30 PCB Spacer AEC1188

31 Flat Clamp AEC1879

32 PCB Spacer AEC1941

33 Drive Silicone Sheet AEH1095

34 Power Supply Insulation Sheet AMR3447

35 Audio Insulation Sheet AMR3469

36 Wire Saddle AEC1745

NSP 37 Address Sheet AMR3491

38 • • • • •

39 Screw ABA1324

40 Screw PMB30P060FTC

41 Screw VBB30P080FNI

B

C

(2) CONTRAST TABLE

PDP-506PE/WYVI and PDP-506PU/KUCXC are constructed the same except for the following:

Mark No. Symbol and Description PDP-506PE/WYVI PDP-506PU/KUCXC

1 50 X DRIVE Assy AWW1075 AWW1020 or AWW1075

4 50 Y DRIVE Assy AWV2258 AWV2210 or AWV2258

17 6P Housing Wire (J109) ADX3118 ADX3132

18 12P Housing Wire (J110) ADX3119 ADX3133

20 3P Housing Wire (J113) ADX3122 ADX3136

D

E

F

56

PDP-506PE

17

7

8

Page 18

1234

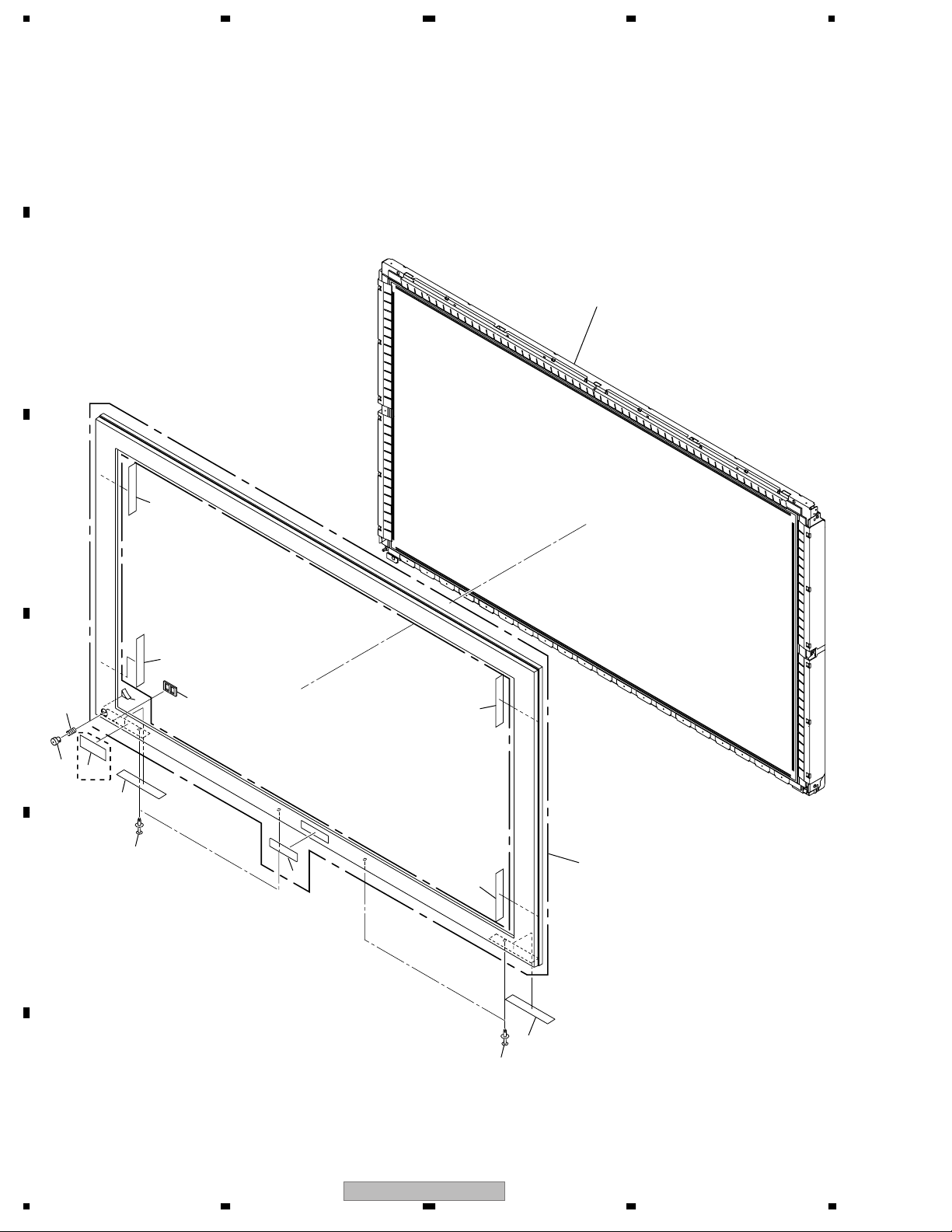

2.6 PDP SERVICE ASSY 506P (AWU1134)

A

29

34

B

34

C

16

32

21

30

31

34

34

15

34

34

37

(for transport)

31

31

17

32

31

34

29

30

23

23

30

35

D

14

30

18

6

6

6

E

33

23

21

2

8

6

23

26

7

23

24

25

2

12

9

12

11

20

10

11

23

7

20

7

2

9

12

10

11

10

2

7

21

12

9

9

11

10

13

30

35

30

19

F

18

1234

23

5

1

38

4

5

5

PDP-506PE

5

5

3

Page 19

5678

• Front Section • Packing Section

43

(for transport)

36

22

38

A

39

B

28

Note when replacing with the PDP Service Assy 506P

The Power Switch (S1), HD LED Assy, and HD IR Assy are not

included in the PDP Service Assy 506P. Before replacement with the

PDP Service Assy 506P, the following components of the Service Assy

must be temporarily detached to attach the above-mentioned parts

(parts from the original unit or newly purchased):

• Front Chassis H Assy (50) (ANA1883)

• Front Chassis VL (50) (AMA1014)

• Front Chassis VR (50) (AMA1015)

PDP SERVICE ASSY 506P (AWU1134) PARTS LIST

No. Description Part No.

Mark

NSP 1 Panel Chassis (506) Assy AWU1143

NSP 2 50 ADDRESS Assy AWV2208

NSP 3 50 SCAN A Assy AWW1026

NSP 4 50 SCAN B Assy AWW1027

5 PCB Spacer AEC1944

6 Conductive Plate Holder AMR3446

7 ADDRESS Holder Assy (50) AMR3454

8Tube Cover AMR3445

9 Address Heatsink (50) ANH1635

10 Address Silicone A AEH1093

11 Address Silicone B AEH1094

12 Screw BBB30P120FNI

13 Front Chassis VL (50) AMA1014

14 Front Chassis VR (50) AMA1015

15 Sub Frame L Assy (506) ANA1860

16 Sub Frame R Assy (506) ANA1861

17 Front Chassis H Assy (50) ANA1883

18 Conductive Plate XA ANG2776

19 Cushion AEB1424

NSP 20 PCB Spacer AEC1188

21 Wire Saddle AEC1745

22 Screw Rivet AEC1877

56

PDP-506PE

41

22

40

42

No. Description Part No.

Mark

23 PCB Spacer AEC1941

24 Power Supply Insulation Sheet AMR3447

25 Audio Insulation Sheet AMR3469

NSP 26 Address Sheet AMR3491

NSP 27 Chassis Assy (50) ANA1830

28 Protect Sheet AHG1331

29 Screw (3 x 40P) ABA1332

30 Screw ABZ30P080FTC

31 Screw AMZ30P060FTB

32 Screw APZ30P080FTB

33 Screw PMB30P060FTC

34 Screw TBZ40P080FTB

35 Screw VBB30P080FNI

NSP 36 Front Case Assy (506 serivice) AMB2889

(for transport)

NSP 37 Rear Case (506) ANE1639

(for transport)

38 Pad (50T-L) AHA2427

39 Pad (50T-R) AHA2428

40 Pad (50B-L) AHA2429

41 Pad (50B-R) AHA2430

42 Under Carton AHA3344

43 Upper Carton (506 S.V.C) AHA3430

7

8

C

D

E

F

19

Page 20

1234

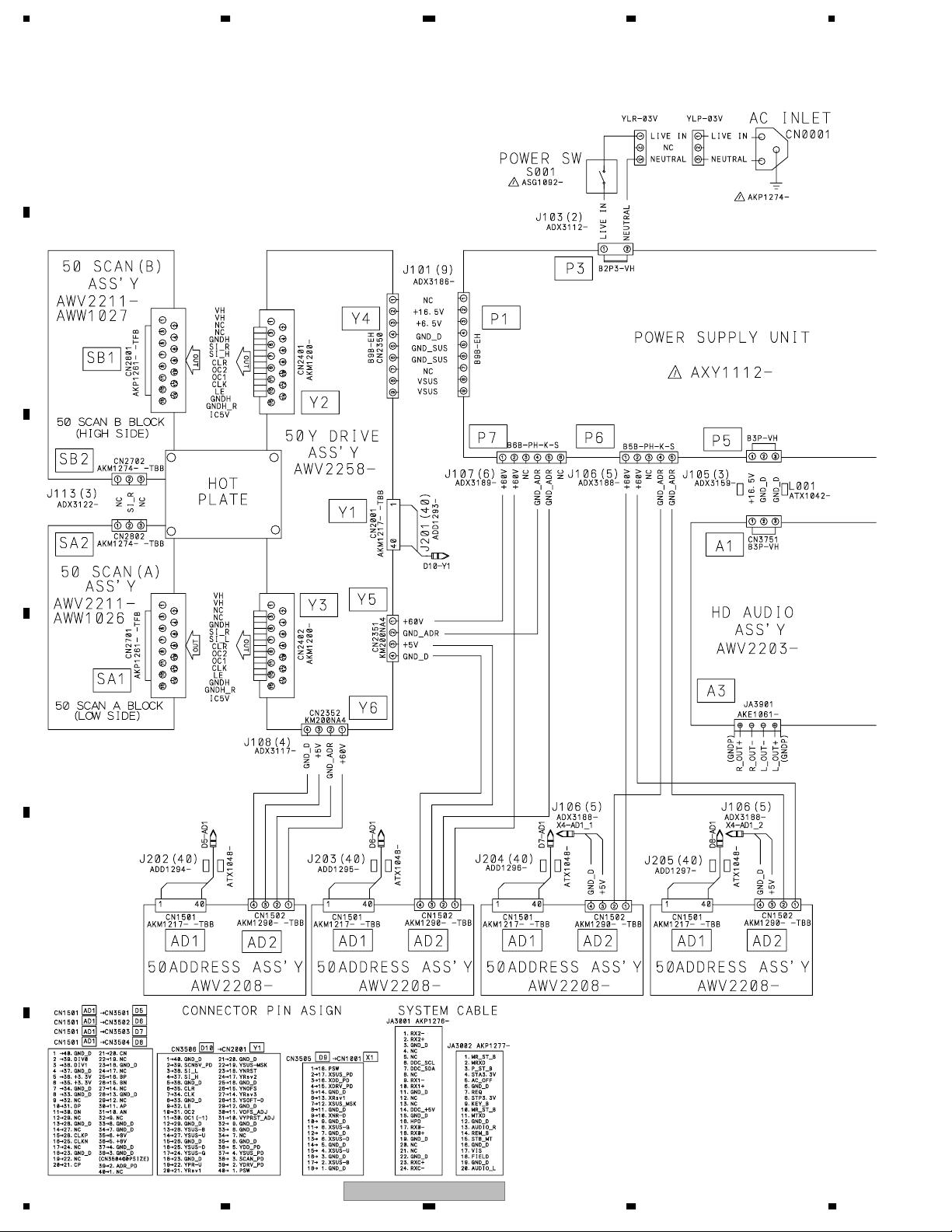

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

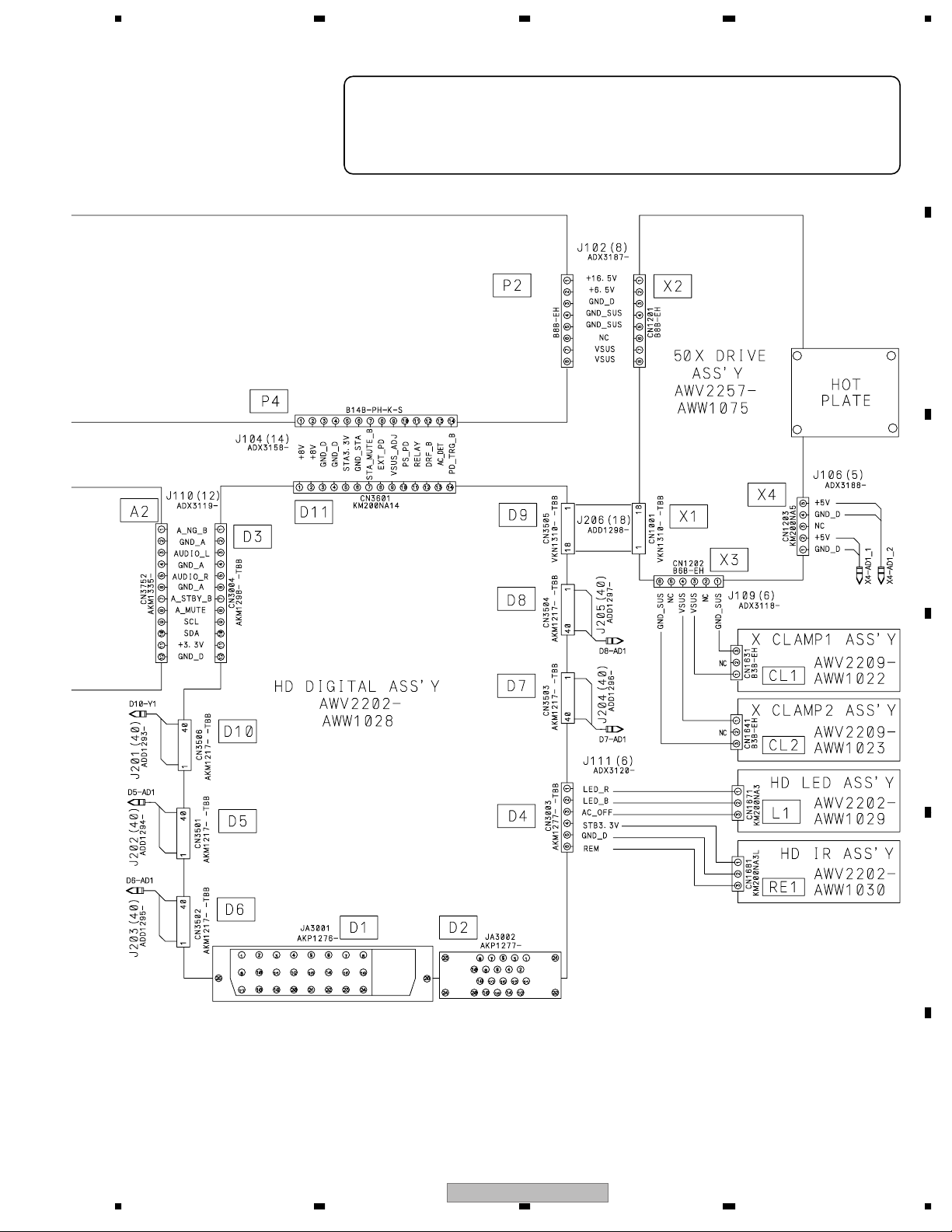

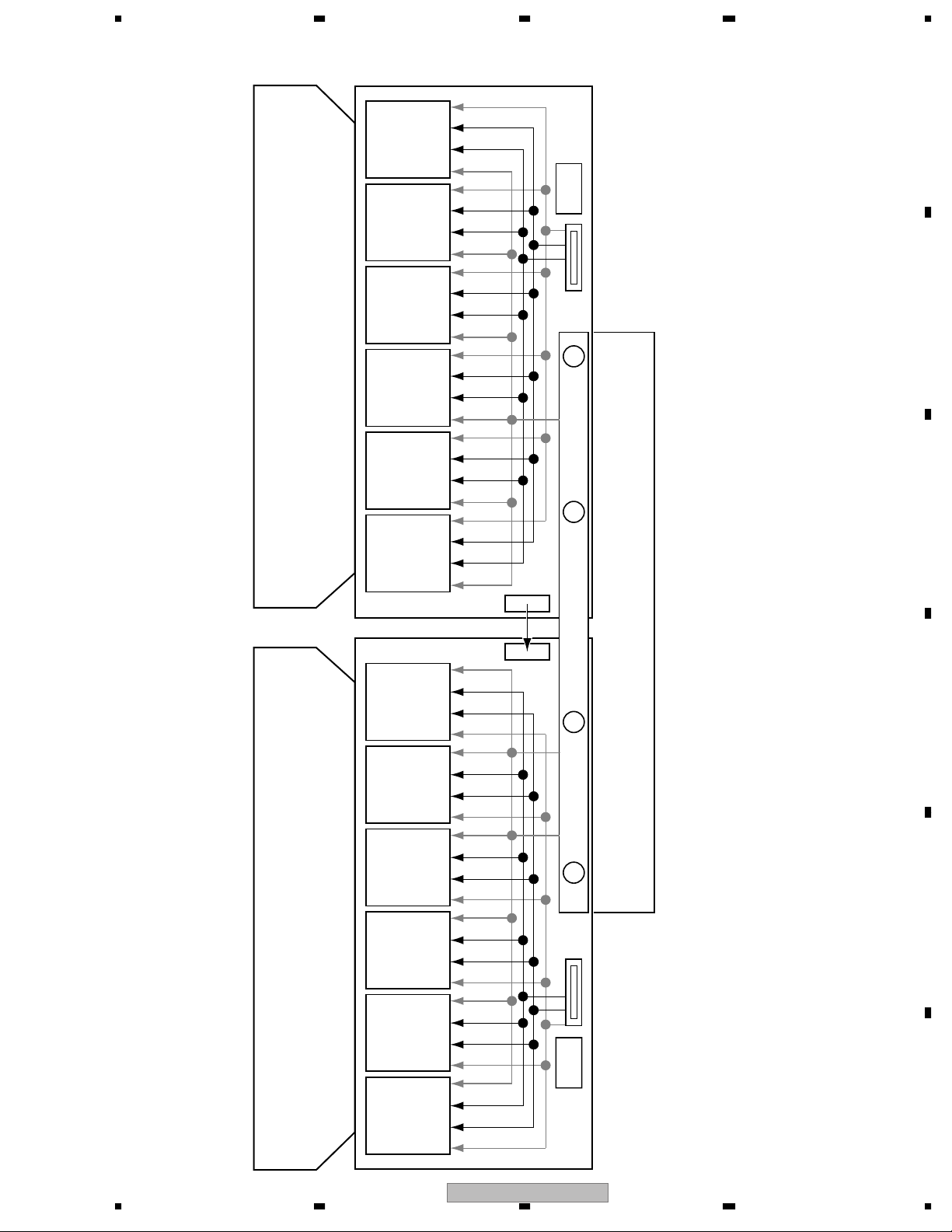

3.1 OVERALL CONNECTION DIAGRAM

A

B

C

D

E

F

20

1234

PDP-506PE

Page 21

5678

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

A

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

B

C

D

E

56

PDP-506PE

F

21

7

8

Page 22

1234

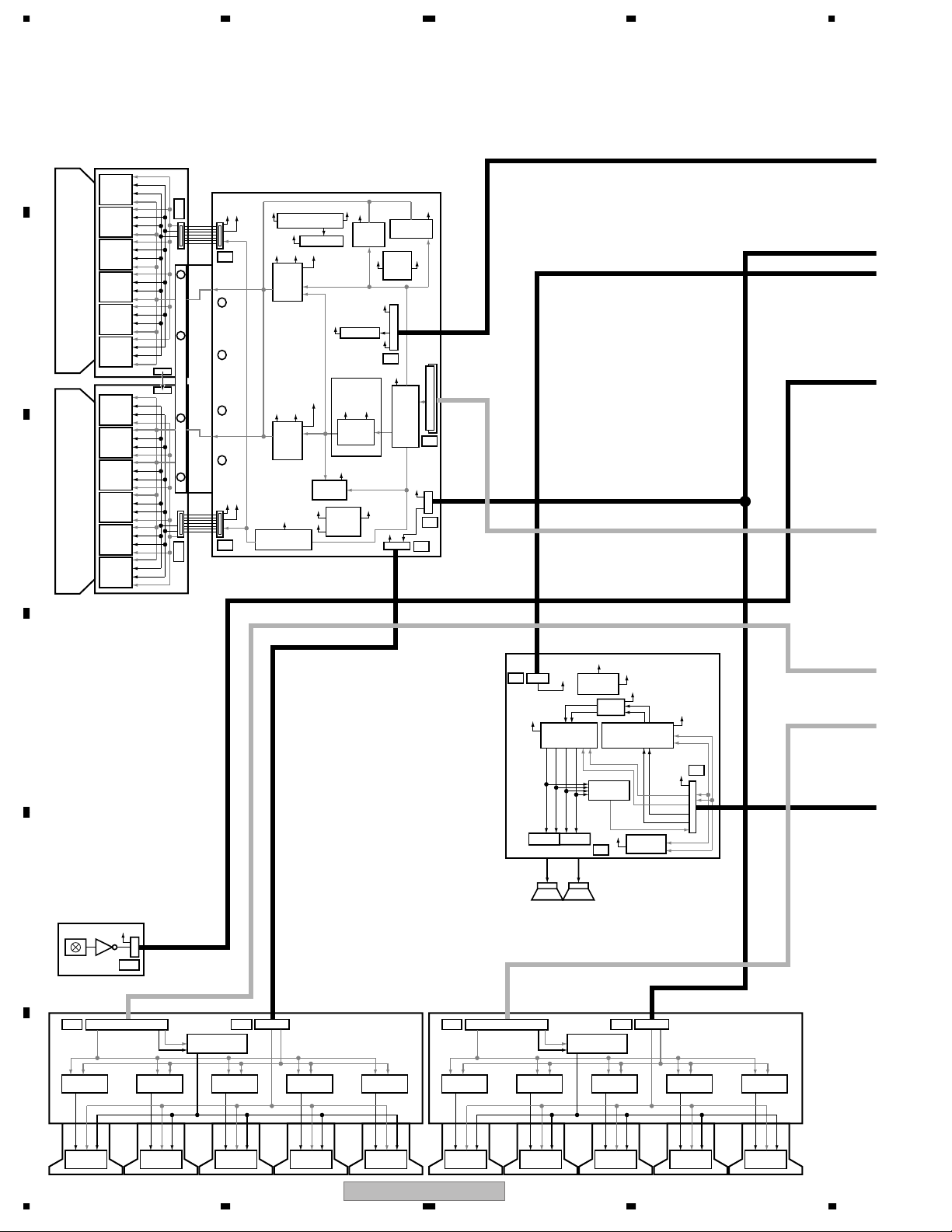

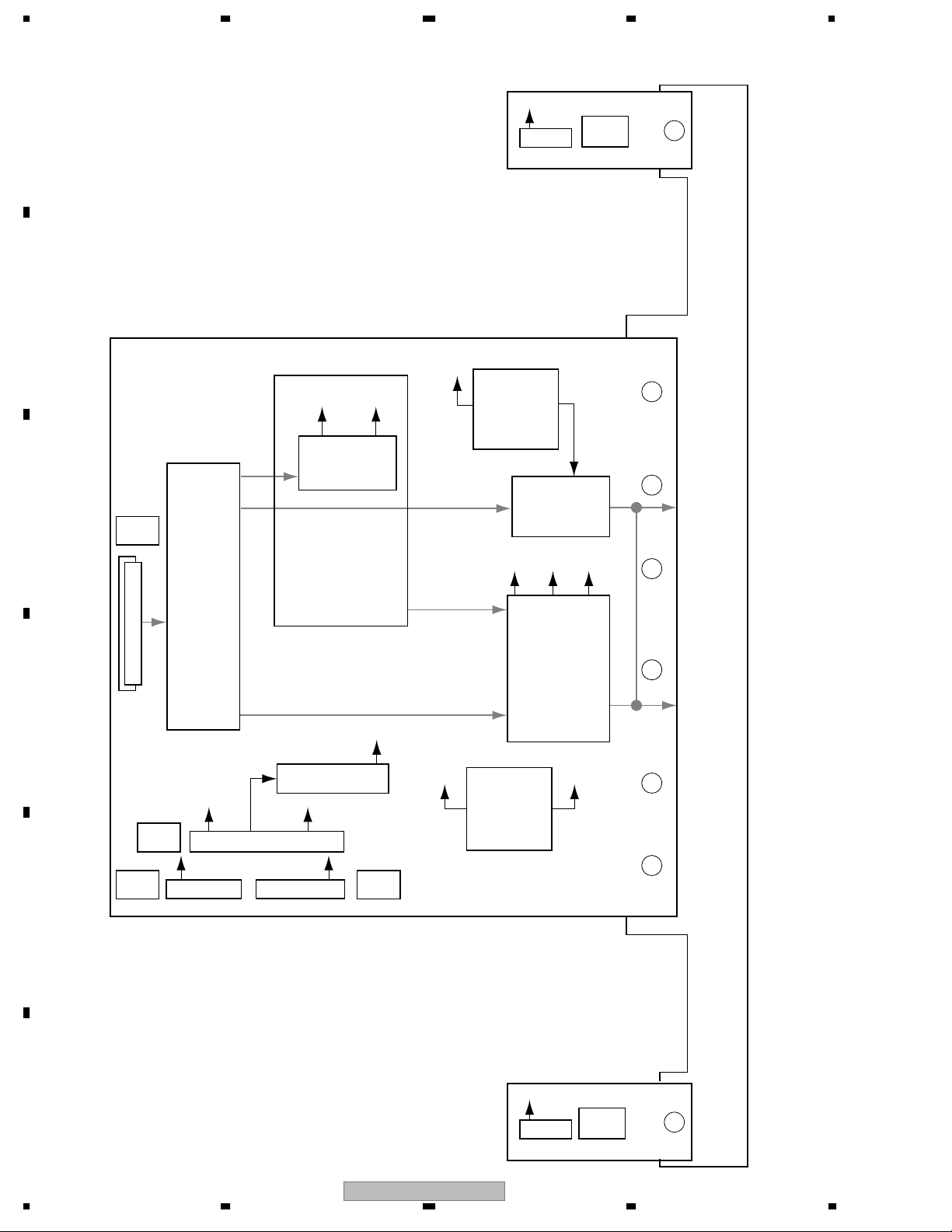

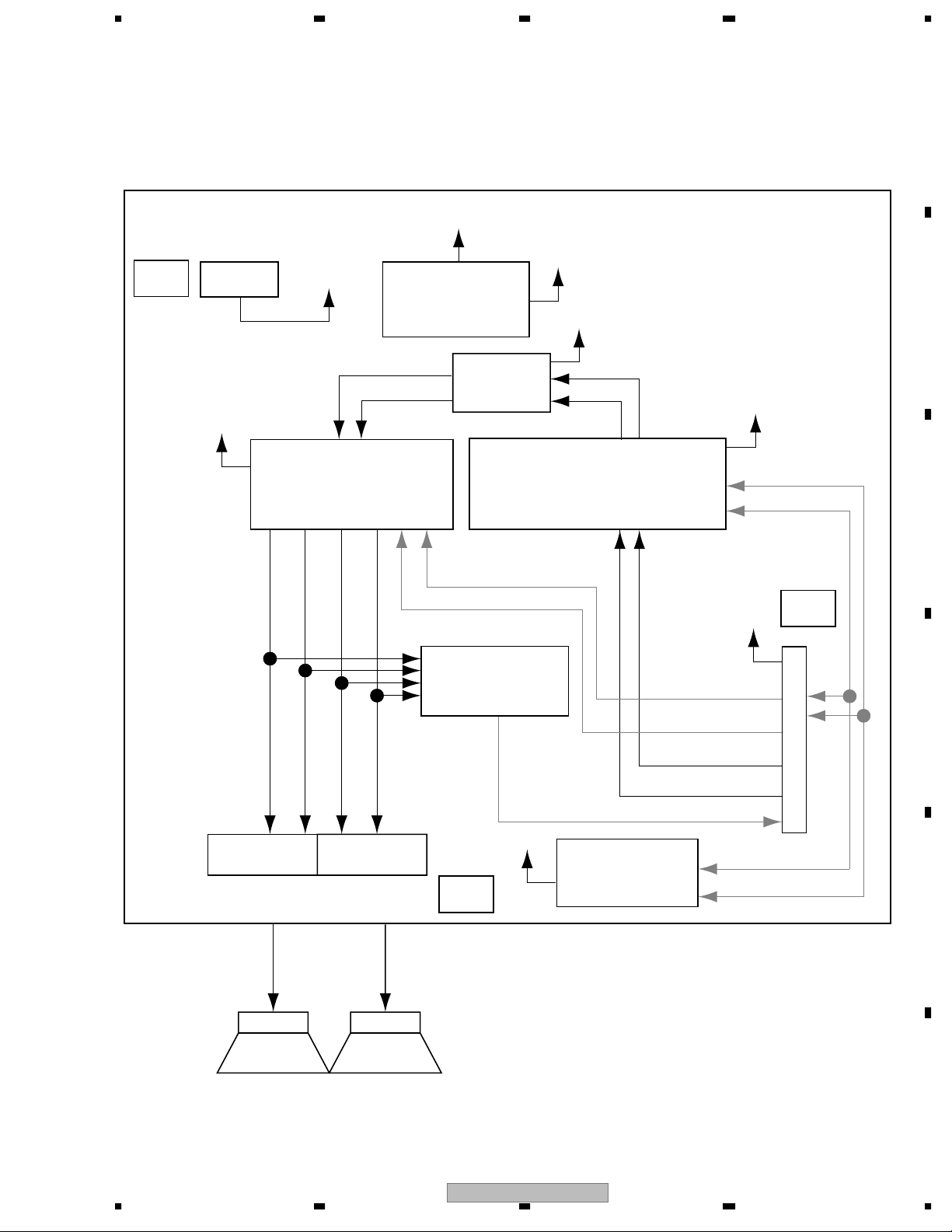

3.2 OVERALL BLOCK DIAGRAM

A

50 SCAN B ASSY

(UPPER)

Scan Signal

VH

IC2801

IC5V

Scan IC

PSUS

IC2802

Scan IC

IC2803

Scan IC

IC2804

Scan IC

B

C

IC2805

Scan IC

IC2806

Scan IC

CN2802

CN2702

IC2701

Scan IC

IC2702

Scan IC

IC2703

Scan IC

IC2704

Scan IC

IC2705

Scan IC

IC2706

Scan IC

Serial Data

PSUS

IC5V

VH

Scan Signal

50 SCAN A ASSY

(LOWER)

D

50 Y DRIVE ASSY

PSUS

PSUS

VH

IC5V

IC5V

VH VSUS

Vprst

+5V +16.5V

+5V

Photo Coupler

SB1

SA1

VH

Y2

Y3

VH DC/DC Conv.

Vprst Reg.

VSUS

IC2252

Mask

Mod.

VSUS

+16.5V

IC2253

Mask

Mod.

IC5V

IC5V

VF

Block

SUSOUT

Soft-D

Block

Vprst

+5V

Regulator

Resonance

Block

+5V

IC2101

DK Mod.

+16.5V

IC5V/VF

DC/DC

Conv.

Scan Signal

+ Reset

Block

VOFS

+16.5V

+16.5V

+16.5V

VSUS

+6.5V

+5V

VOFS

DC/DC

Conv.

Y4

+5V

Logic

Block

Offset

Block

+16.5V

Drive Signal

+5V

Y6

VOFS

Y1

Y5

60V

A1

+16.5V

+16.5V

IC3751

Power Amp IC

R_OUT +

R_OUT –

L_OUT +

Left

Right

SP TERMINAL

HD AUDIO ASSY

+16.5V

+9.0V

IC3752

Regulator

+9.0V

Buffer

IC3753

WOW + Volume IC

DC Detect

L_OUT –

Block

+3.3V

A3

A_STBY_B

IC3754

EEP ROM

A_Mute

R_Audio

L_Audio

A_NG_B

+9.0V

+3.3V

SCL

SDA

SDA

SCL

A2

E

HD IR ASSY

IR Receive unit

STB3.3V

U1681

RE1

CN1501

AD1 AD2

AN/P BN/P

V+8V

CN/P DN/P CLKN/P

Resonance

Block

V+ADR5

Resonance

Block

V+ADR4

F

IC1555

Driver IC

IC1554

Driver IC

22

1234

V+3V

IC1501

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

SPEAKERS

CN1502

V+5V

(PEE002A-K) (PEE002A-K)

CLK/LE/HBLK/LBLK

R/G/B

50 ADDRESS

V+60V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

AD1 AD2

Resonance

V+8V

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

IC1501

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CN1502

CLK/LE/HBLK/LBLK

R/G/B

PDP-506PE

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

Page 23

5678

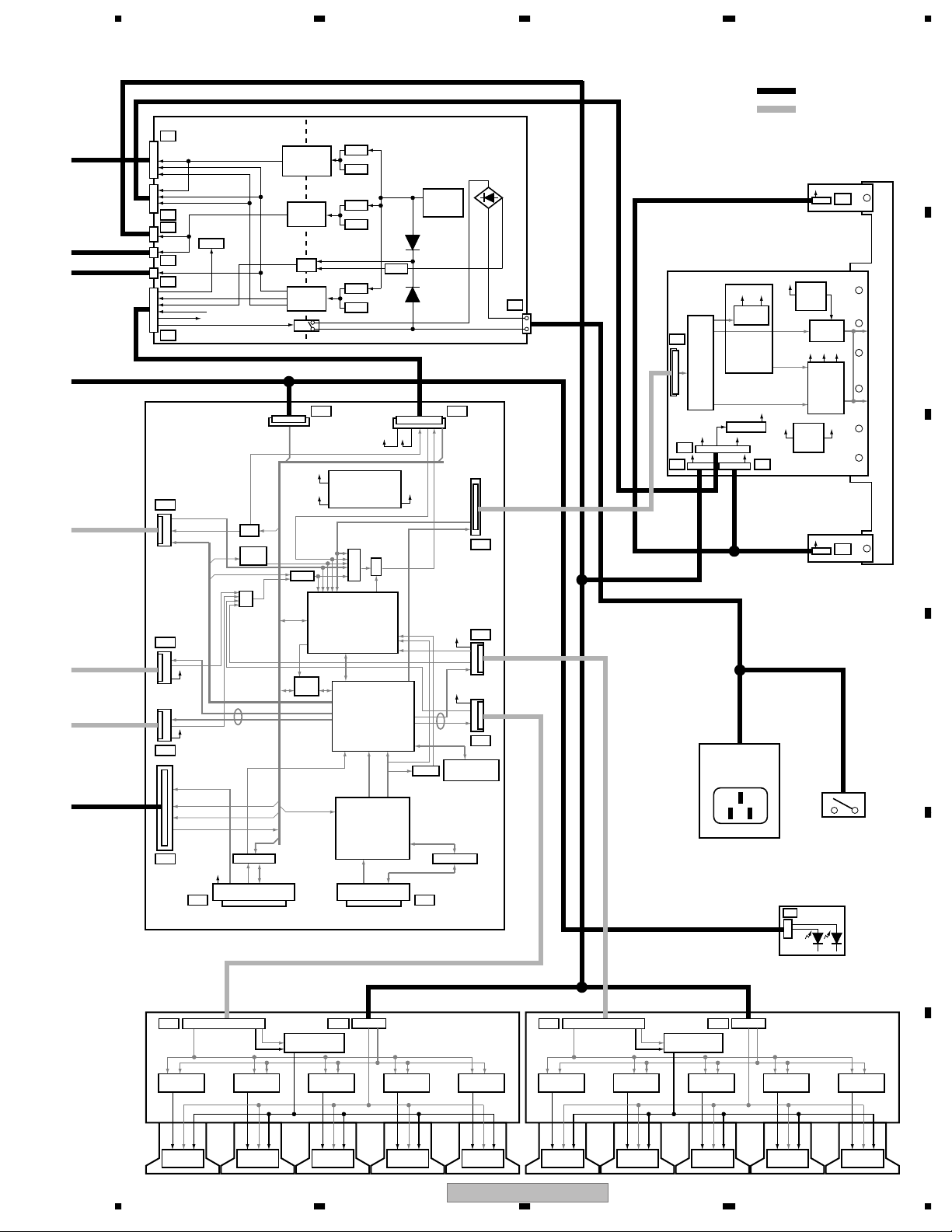

P1

P2

P7

+60V

P6

+16.5V

P5

VSUS_ADJ

+8V

STA3.3V

RELAY

P4

D10

Vofs_ADJ,VYPRST_ADJ

SCAN

YSUS

D5

V+8V

V+8V

D6

AUDIO L

AUDIO R

SCL, SDA

A_MUTE,A_STBY_B

A_NG

D3

SECONDARY PRIMARY

VSUS

+16.5V

+6.5V

VSUS_CONT

IC202

PS_PD

EXT_PD

LED_R

LED_B

REM

SCAN_PD

YDRV_PD

YSUS_PD

YDD_PD

SCN5V_PD

V+3V STB

D2 D1

DAC

Pulse

Width

OR

LVDS

Bus Buffer

SCL,

SCA

ADR_PD1

REM

STB_MT

HD DIGITAL ASSY

Switching

RY102

Q703

Q704

Switching

Switching

Q901

Q902

Switching

Switching

Q501

Q502

Switching

IC101

Switching

T702

T902

T101

T502

D4 D11

V+3V ACT

Vsus_ADJ

V+3V_D

DC-DC Converter

V+1V_D

PS_PWDN

SQ_PD

Mask

UART

SW

SCL, SDA

Module

(AXY1116)

OR

IC3151

(M30620FCPGP)

Module Ucom

IC3401

(PEG122C-K)

Sequence

Processor

FIELD

IC3001

TMDS Receiver

TMDS

DVI CONNECTORMDR CONNECTOR

PD

PD_MUTE

VD

HD

DCLK, DERA, GA, BA

POWER SUPPLY

UNIT

+390V

PFC Q101

Q102

Q103

D109

D107, D108

NEUTRAL

V+8V

DDC

XSUS

PSIZE

H DET

RELAY,

PD_TRIGGER

AC_DET,

DRF

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

V+8V

V+8V

LVDS

IC3301

Flash Memory

Bus Buffer

D9

D8

D7

V+8V

D103

LIVE

: Wire haerness

: FFC

A

SUS CLAMP 1

ASSY

VSUS

CL1

50 X DRIVE ASSY

+16.5V

VRN

+5V

Logic

Block

+5V

Drive Signal

+6.5V

+16.5V

IC1101

DK Mod.

Resonance

Block

Regulator

VSUS

VSUS

SUS OUT

+5V

+16.5V VF

P3

X1

+16.5V

X2

X4 X3

DC/DC

Conv.

+16.5V

15V

DC/DC

Conv.

– Reset

Block

+5V

IC1202

Mask

Mod.

VRN

B

VSUS

PSUS

C

VSUS

CL2

SUS CLAMP 2

ASSY

D

POWER SW

AC INLET

HD LED ASSY

L1

E

V+8V

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

IC1501

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CLK/LE/HBLK/LBLK

AD1 AD2

Resonance

56

CN1502

(PEE002A-K) (PEE002A-K)

R/G/B

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

AD1 AD2

V+8V

Resonance

Block

V+ADR5

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Driver IC

Block

V+ADR4

IC1554

V+3V

LVDS Receiver

IC1501

Resonance

Block

IC1553

Driver IC

CN1502

V+ADR3

CLK/LE/HBLK/LBLK

R/G/B

PDP-506PE

7

50 ADDRESS

V+60VV+5V

ASSY

Resonance

Block

V+ADR2

IC1552

Driver IC

Resonance

8

Block

V+ADR1

IC1551

Driver IC

F

23

Page 24

1234

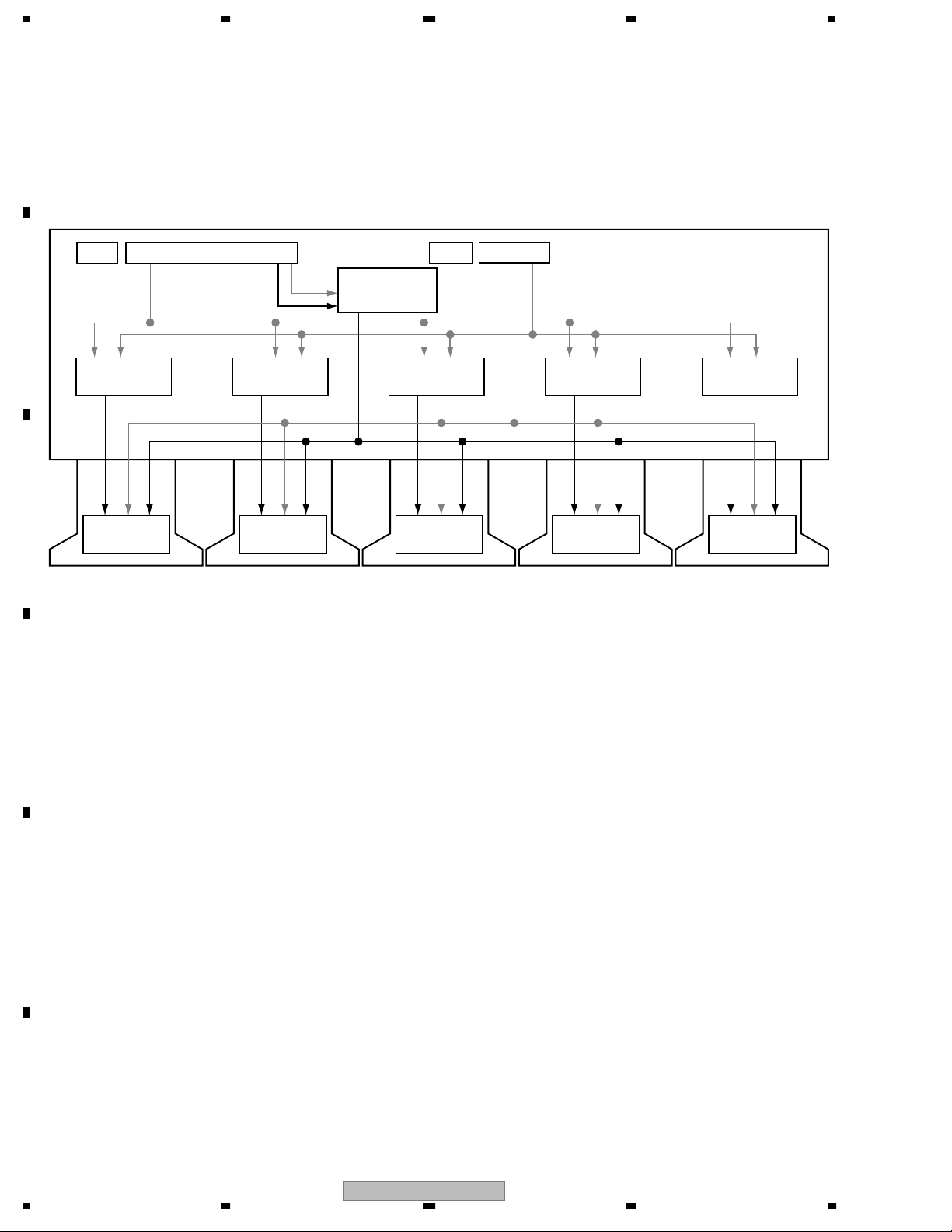

3.3 50 ADDRESS ASSY

A

AD1 AD2

V+8V

B

Resonance

Block

V+ADR5

C

IC1555

Driver IC

CN1501

AN/P BN/P

CN/P DN/P CLKN/P

Resonance

Block

IC1554

Driver IC

V+3V

V+ADR4

IC1501

(PEE002A-K)

LVDS Receiver

Resonance

Block

V+ADR3

IC1553

Driver IC

CN1502

V+60VV+5V

Resonance

CLK/LE/HBLK/LBLK

R/G/B

Block

V+ADR2

IC1552

Driver IC

Resonance

Block

V+ADR1

IC1551

Driver IC

D

E

F

24

PDP-506PE

1234

Page 25

5678

3.4 50 SCAN A and B ASSYS

IC2801

Scan IC

IC2802

Scan IC

IC2803

Scan IC

IC2804

Scan IC

IC2805

Scan IC

IC2806

Scan IC

Scan Signal

VH

IC5V

PSUS

50 SCAN B ASSY

(UPPER)

SB1

A

B

C

IC2701

Scan IC

IC2702

Scan IC

IC2703

Scan IC

IC2704

Scan IC

IC2705

Scan IC

CN2802

Serial Data

CN2702

D

E

SA1

IC2706

Scan IC

PSUS

IC5V

VH

Scan Signal

50 SCAN A ASSY

(LOWER)

PDP-506PE

56

F

25

7

8

Page 26

1234

3.5 50 X DRIVE, SUS CLAMP 1 and SUS CLAMP 2 ASSYS

A

ASSY

SUS CLAMP 1

VSUS

CL1

B

50 X DRIVE ASSY

+16.5V

+16.5V

DK Mod.

C

+5V

IC1101

VRN

DC/DC

Conv.

VRN

– Reset

Block

X1

Logic

Block

Resonance

Block

+16.5V

SUS OUT

+5V

VSUS

IC1202

Mask

Mod.

+6.5V

Drive Signal

Regulator

VSUS

+5V

PSUS

+16.5V VF

15V

DC/DC

Conv.

D

+16.5V

X2

+5V

VSUS

X4 X3

E

SUS CLAMP 2

F

ASSY

VSUS

CL2

26

PDP-506PE

1234

Page 27

5678

3.6 50 Y DRIVE ASSY

VH

IC5V

VH VSUS

VH DC/DC Conv.

Vprst

Vprst Reg.

Vprst

+ Reset

Block

Offset

Block

A

VOFS

Y2

PSUS

+5V +16.5V

IC2252

Mask

Mod.

+16.5V

+5V

VSUS

VSUS

+5V

SUSOUT

Regulator

Resonance

Block

+5V

+16.5V

VOFS

VSUS

+6.5V

+16.5V

VOFS

DC/DC

Conv.

Y4

+5V

+16.5V

B

Drive Signal

C

D

Logic

Block

PSUS

VH

Y3

IC5V

IC2253

Mask

Mod.

IC5V

Photo Coupler

Block

IC5V

VF

+16.5V

Soft-D

Block

IC5V/VF

DC/DC

Conv.

Scan Signal

PDP-506PE

56

IC2101

DK Mod.

+16.5V

7

+5V

+5V

60V

Y6

Y1

E

Y5

F

27

8

Page 28

1234

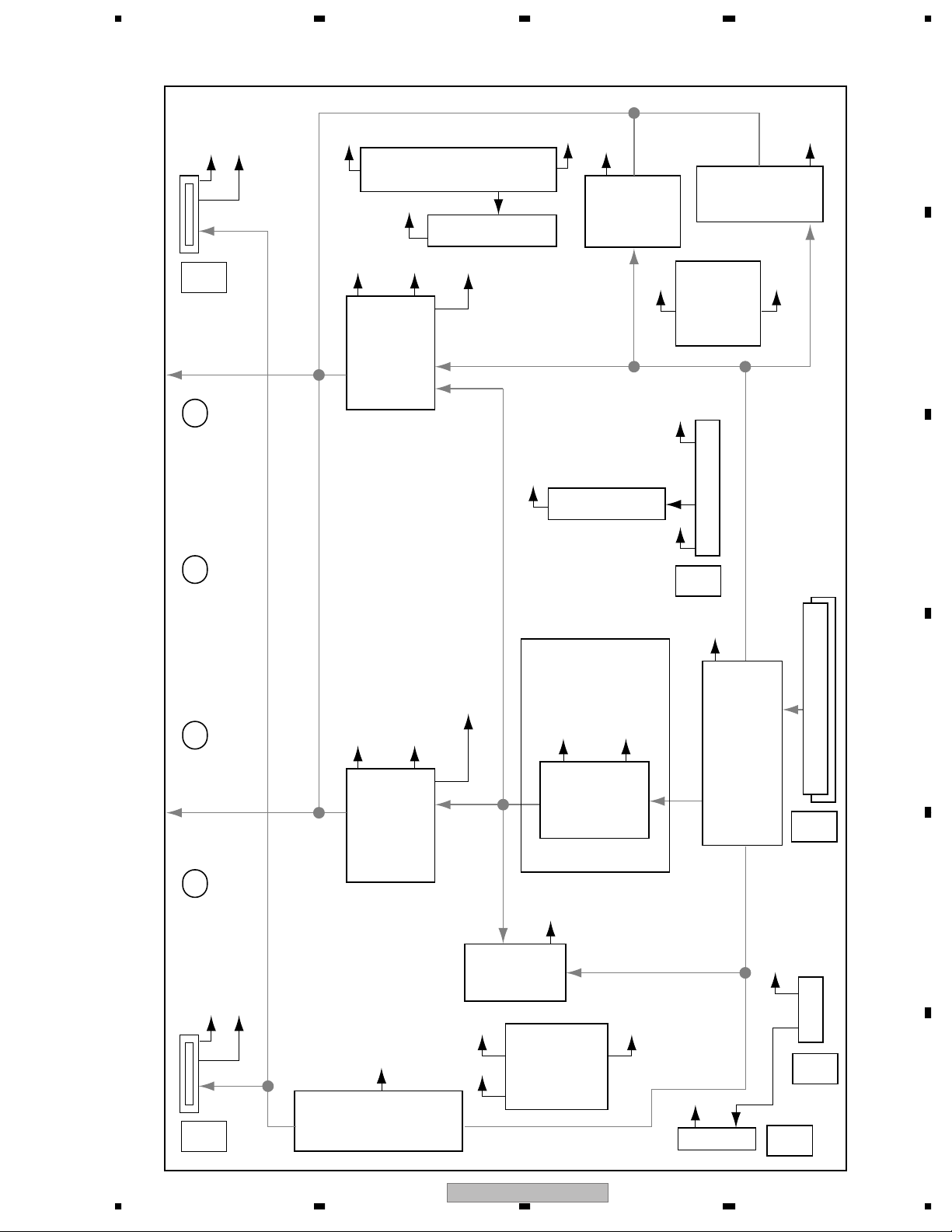

3.7 HD DIGITAL ASSY

A

LED_R

LED_B

REM

SCAN_PD

YDRV_PD

B

C

D10

YSUS_PD

YDD_PD

SCN5V_PD

Vofs_ADJ,VYPRST_ADJ

SCAN

YSUS

DAC

Pulse

Width

OR

SCL,

SCA

ADR_PD1

D4 D11

V+8V

V+8V

XSUS

PD

PD_MUTE

V+3V_D

V+1V_D

PS_PWDN

SQ_PD

Mask

V+3V ACT

Vsus_ADJ

DC-DC Converter

Module

(AXY1116)

OR

IC3151

(M30620FCPGP)

RELAY,

PD_TRIGGER

AC_DET,

DRF

XSUSTN_PD

XDD_CNV_PD

XDRIVE_PD

D9

Module Ucom

D5

V+8V

UART

SW

D

V+8V

LVDS

IC3401

(PEG122C-K)

Sequence Processor

PSIZE

LVDS

V+8V

V+8V

D8

D7

D6

FIELD

AUDIO L

AUDIO R

E

SCL, SDA

A_MUTE,A_STBY_B

A_NG

SCL, SDA

RA, GA, BA

IC3001

TMDS Receiver

VD

HD

DCLK, DE

H DET

IC3301

Flash Memory

D3

V+3V STB

F

28

D2

1234

Bus Buffer

REM

STB_MT

PDP-506PE

TMDS

DVI CONNECTORMDR CONNECTOR

DDC

Bus Buffer

D1

Page 29

5678

3.8 HD AUDIO ASSY

A1

+16.5V

+16.5V

+16.5V

IC3752

Regulator

Buffer

+9.0V

+9.0V

+9.0V

A

B

R_OUT +

Right

IC3751

Power Amp IC

R_OUT –

L_OUT +

SP TERMINAL

L_OUT –

Left

DC Detect

Block

A3

WOW + Volume IC

+3.3V

IC3753

EEP ROM

IC3754

SCL

SDA

+3.3V

A_Mute

A_STBY_B

R_Audio

L_Audio

A_NG_B

SDA

SCL

C

A2

D

E

SPEAKERS

PDP-506PE

56

F

29

7

8

Page 30

1234

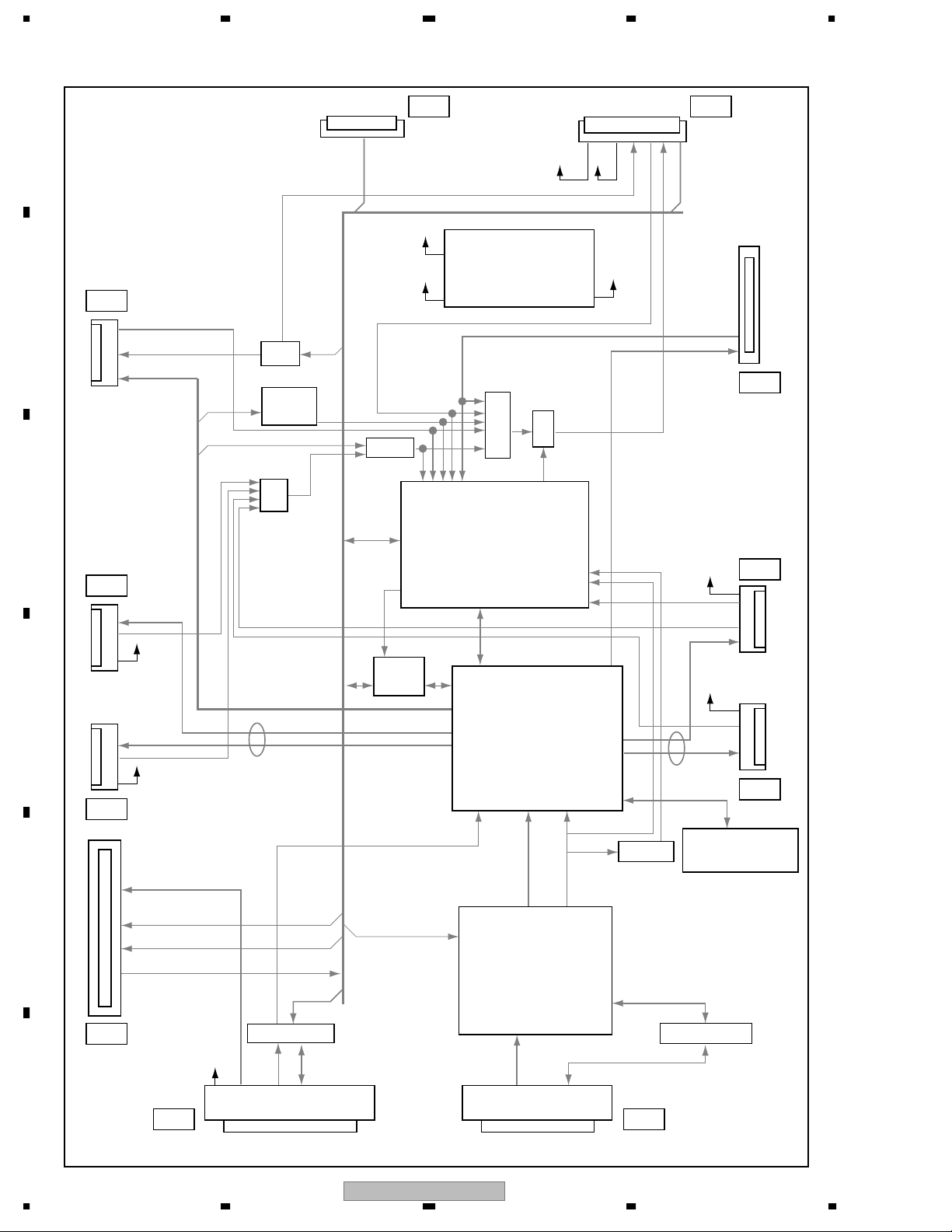

3.9 POWER SUPPLY UNIT

A

SECONDARY PRIMARY

P1

B

VSUS

+16.5V

+6.5V

P2

P7

C

+60V

VSUS_CONT

IC202

T702

T902

Switching

Q703

Q704

Switching

Switching

Q901

Q902

Switching

+390V

PFC Q101

Q102

Q103

D109

D103

P6

+16.5V

P5

VSUS_ADJ

+8V

STA3.3V

PS_PD

RELAY

EXT_PD

P4

D

E

T502

T101

RY102

Switching

Q501

Q502

Switching

IC101

Switching

D107, D108

P3

NEUTRAL

LIVE

F

30

1234

PDP-506PE

Page 31

5678

3.10 WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

Refer to service manual (ARP3268).

50 ADDRESS ASSY

50 ADDRESS RESONANCE BLOCK

Control signal of resonance circuit (1 field)

1

Input : VIDEO 60Hz

Signal : Color-bar (MKSS17)

CH1 : ADR_B2

1-1

V : 1V/div H : 2msec/div

CH2 : ADR_U2

1-2

V : 1V/div H : 2msec/div

CH3 : ADR_D2

1-3

V : 1V/div H : 2msec/div

Control signal of resonance circuit (2 FS)

1

Input : VIDEO 60Hz

Signal : Color-bar (MKSS17)

CH1 : ADR_B2

1-1

V : 1V/div H : 2msec/div

CH2 : ADR_U2

1-2

V : 1V/div H : 2msec/div

CH3 : ADR_D2

1-3

V : 1V/div H : 2msec/div

1-1

1-2

1-3

1-1

50 ADDRESS LOGIC BLOCK TCP LOGIC

VADR (1 field)

2

Input : VIDEO 60Hz

Signal : Color-bar (MKSS17)

CH2 : IC1555-pin 3 (VDD2)

V : 10V/div H : 2msec/div

VADR (1 field)

2

Input : VIDEO 60Hz

Signal : Checkered pattern of Black-White (MKSS13)

CH2 : IC1555-pin 3 (VDD2)

V : 10V/div H : 2msec/div

Incoming signal of TCP (1 field)

3

Input : VIDEO 60Hz

Signal : Color-bar (MKSS17)

CH1 : IC1555-pin 3 (VDD2)

3-1

V : 10V/div H : 2msec/div

CH2 : IC1555-pin 9 (A3)

3-2

V : 1V/div H : 2msec/div

CH3 : IC1555-pin 16 (CLK)

3-3

V : 1V/div H : 2msec/div

3-4

CH4 : IC1555-pin 14 (LE)

V : 1V/div H : 2msec/div

3-5

CH5 : IC1555-pin 19 (HBLK)

V : 1V/div H : 2msec/div

3-6

CH6 : IC1555-pin 17 (LBLK)

V : 1V/div H : 2msec/div

Incoming signal of TCP (1 field)

3

Input : VIDEO 60Hz

Signal : Checkered pattern of Black-White (MKSS13)

CH1 : IC1555-pin 3 (VDD2)

3-1

V : 10V/div H : 2msec/div

CH2 : IC1555-pin 9 (A3)

3-2

V : 1V/div H : 2msec/div

CH3 : IC1555-pin 16 (CLK)

3-3

V : 1V/div H : 2msec/div

3-4

CH4 : IC1555-pin 14 (LE)

V : 1V/div H : 2msec/div

3-5

CH5 : IC1555-pin 19 (HBLK)

V : 1V/div H : 2msec/div

3-6

CH6 : IC1555-pin 17 (LBLK)

V : 1V/div H : 2msec/div

3-1

3-2

3-3

3-4

3-5

3-6

3-1

3-2

A

B

C

D

1-2

1-3

VADR (2 FS)

2

Input : VIDEO 60Hz

Signal : Checkered pattern of Black-White (MKSS13)

CH2 : IC1555-pin 3 (VDD2)

V : 10V/div H : 200nsec/div

PDP-506PE

56

Incoming signal of TCP (Resonance part)

3

Input : VIDEO

Signal : Checkered pattern of Black-White (MKSS13)

CH1 : IC1555-pin 3 (VDD2)

3-1

V : 10V/div H : 200nsec/div

CH2 : IC1555-pin 9 (A3)

3-2

V : 1V/div H : 200nsec/div

CH3 : IC1555-pin 16 (CLK)

3-3

V : 1V/div H : 200nsec/div

3-4

CH4 : IC1555-pin 14 (LE)

V : 1V/div H : 200nsec/div

3-5

CH5 : IC1555-pin 19 (HBLK)

V : 1V/div H : 200nsec/div

3-6

CH6 : IC1555-pin 17 (LBLK)

V : 1V/div H : 200nsec/div

7

3-3

3-4

3-5

3-6

E

3-1

3-2

3-3

3-4

3-5

3-6

F

31

8

Page 32

1234

A

50 X DRIVE, 50 Y DRIVE ASSY

Drive output signal (1 field, Color-bar)

1

CH1 : R1277 (XPSUS) - K1203 (SUSGND)

1-1

V : 100V/div H : 2msec/div (X DRIVE Assy)

CH2 : K2701 (SCANOUT) - K2330 (SUSGND)

1-2

V : 100V/div H : 2msec/div (SCAN A Assy)

CH3 : F2301 (YPSUS) - K2330 (SUSGND)

1-3

V : 100V/div H : 2msec/div (Y DRIVE Assy)

B

1-1

1-2

C

X Drive pulse control signal (Color-bar)

2

CH1 : K1009 (XSUS-MSK) - K1001 (DGND)

2-1

V : 1V/div H : 2msec/div (X DRIVE Assy)

CH2 : K1005 (XNR-D) - K1001 (DGND)

2-2

V : 1V/div H : 2msec/div (X DRIVE Assy)

1-3

Scan control signal (1 field, Color-bar)

4

CH1 : TP2001 (LE) - K2002 (GND-D)

4-1

V : 1V/div H : 2msec/div (X DRIVE Assy)

CH2 : TP2008 (CLK) - K2002 (GND-D)

4-2

V : 1V/div H : 2msec/div (X DRIVE Assy)

CH3 : TP2003 (SI-H) - K2002 (GND-D)

4-3

V : 1V/div H : 2msec/div (X DRIVE Assy)

CH4 : TP2004 (CLR) - K2002 (GND-D)

4-4

V : 1V/div H : 2msec/div (X DRIVE Assy)

4-5

CH5 : TP2005 (OC2) - K2002 (GND-D)

V : 1V/div H : 2msec/div (X DRIVE Assy)

CH6 : TP2006 (OC1) - K2002 (GND-D)

4-6

V : 1V/div H : 2msec/div (X DRIVE Assy)

Reset pulse signal

5

CH1 : R1277 (XPSUS) - K1203 (SUSGND)

5-1

V : 100V/div H : 100µsec/div (X DRIVE Assy)

CH2 : K2701 (SCANOUT) - K2330 (SUSGND)

5-2

V : 100V/div H : 100µsec/div (SCAN A Assy)

CH3 : F2301 (YPSUS) - K2330 (SUSGND)

5-3

V : 100V/div H : 100µsec/div (Y DRIVE Assy)

4-1

4-2

4-3

4-4

4-5

4-6

Sustain signal

7

CH1 : F2301 (YPSUS) - K2330 (SUSGND)

7-1

V : 50V/div H : 500nsec/div (Y DRIVE Assy)

CH2 : K2004 (YSUS-G) - K2002 (DGND)

7-2

V : 5V/div H : 500nsec/div (Y DRIVE Assy)

CH3 : K2011 (YSUS-U) - K2002 (DGND)

7-3

V : 5V/div H : 500nsec/div (Y DRIVE Assy)

7-4

CH4 : K2009 (YSUS-B) - K2002 (DGND)

V : 5V/div H : 500nsec/div (Y DRIVE Assy)

7-5

CH5 : K2010 (YSUS-D) - K2002 (DGND)

V : 5V/div H : 500nsec/div (Y DRIVE Assy)

7-1

7-2

7-3

7-4

7-5

D

2-1

2-2

Y Drive pulse control signal (Color-bar)

3

CH1 : K2007 (YNOFS) - K2002 (GND_D)

3-1

V : 1V/div H : 2msec/div (Y DRIVE Assy)

CH2 : K2005 (YSUS-MSK) - K2002 (GND_D)

3-2

E

F

V : 1V/div H : 2msec/div (Y DRIVE Assy)

CH3 : K2008 (YNRST) - K2002 (GND_D)

3-3

V : 1V/div H : 2msec/div (Y DRIVE Assy)

3-4

CH4 : K2006 (SOFT-D) - K2002 (GND_D)

V : 1V/div H : 2msec/div (Y DRIVE Assy)

3-5

CH5 : K2023 (YPR-U) - K2002 (GND_D)

V : 1V/div H : 2msec/div (Y DRIVE Assy)

3-1

3-2

3-3

3-4

3-5

Sustain pulse signal (1 sub, sub field)

6

CH1 : R1277 (XPSUS) - K1203 (SUSGND)

6-1

V : 50V/div H : 5µsec/div (X DRIVE Assy)

CH2 : K2701 (SCANOUT) - K2330 (SUSGND)

6-2

V : 50V/div H : 5µsec/div (SCAN A Assy)

CH3 : F2301 (YPSUS) - K2330 (SUSGND)

6-3

V : 50V/div H : 5µsec/div (Y DRIVE Assy)

5-1

5-2

5-3

6-1

6-2

6-3

32

PDP-506PE

1234

Page 33

5678

5. PCB PARTS LIST

>

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω

47k Ω

0.5 Ω

1 Ω

56 x 10

47 x 10

R50

1R0

1

3

561

473

RD1/4PU J

RD1/4PU J

RN2H K

RS1P K

561

473

R50

1R0

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω

1

5621

RN1/4PC F562 x 10

5621

7777 LIST OF WHOLE PCB ASSEMBLIES

Mark Symbol and Description

NSP 1..PANEL CHASSIS (506) ASSY AWU1143 AWU1143

NSP 2..50 ADDRESS ASSY AWV2208 AWV2208

NSP 2..50 SCAN ASSY AWV2211 AWV2211

NSP 3..50 SCAN A ASSY AWW1026 AWW1026

NSP 3..50 SCAN B ASSY AWW1027 AWW1027

NSP 1..50 X DRIVE ASSY AWV2257 AWV2209 or AWV2257

2..50 X DRIVE ASSY AWW1075 AWW1020 or AWW1075

2..SUS CLAMP 1 ASSY AWW1022 AWW1022

2..SUS CLAMP 2 ASSY AWW1023 AWW1023

1..50 Y DRIVE ASSY AWV2258 AWV2210 or AWV2258

PDP-506PE

/WYVI

PDP-506PU

/KUCXC

A

B

C

NSP 1..HD DIGITAL ASSY AWV2202 AWV2202

2..HD DIGITAL ASSY AWW1028 AWW1028

2..HD LED ASSY AWW1029 AWW1029

2..HD IR ASSY AWW1030 AWW1030

1..HD AUDIO ASSY AWV2203 AWV2203

1..POWER SUPPLY UNIT AXY1112 AXY1112

50 X DRIVE ASSY

AWW1075 and AWW1020 are constructed the same except for the following :

Mark Symbol and Description AWW1075 AWW1020

IC1101 AXF1142 AXF1155

C1101 ACG1112

C1106-C1110 Not used ACE1178

C1112, C1113 (0.22U/250V) ACG1112 Not used

C1161-C1164, C1166 ACE1168 Not used

C1297, C1298 (3300p/630V) ACG1129 Not used

(0.22U/250V)

ACG1088

(0.1U/250V)

50 Y DRIVE ASSY

AWV2258 and AWV2210 are constructed the same except for the following :

Mark Symbol and Description AWV2258 AWV2210

IC2101 AXF1142 AXF1155

C2103 ACG1112

C2107, C2108 (0.22U/250V) ACG1112 Not used

C2131-C2134, C2136 ACE1168 ACE1178

(0.22U/250V)

ACG1088

(0.1U/250V)

D

E

C2271 ACG1124

C2272 (0.1U/100V) ACG1124 Not used

(0.1U/100V)

ACG1118

(0.33U/100V)

PDP-506PE

56

7

F

33

8

Page 34

1234

7777 PCB PARTS LIST FOR PDP-506PE/WYVI UNLESS OTHER WISE NOTED

Mark No. Description Part No.

50 ADDRESS ASSY

A

[50 ADR LOGIC BLOCK]

SEMICONDUCTORS

IC1501 PEE002A

COILS AND FILTERS

L1504 CHIP SOLID INDUCTOR QTL1013

CAPACITORS

C1501,C1502 CKSRYB105K6R3

C1509,C1510 CKSSYB102K50

C1503-C1507,C1551-C1555 CKSSYF104Z16

B

RESISTORS

R1530,R1531 RS1/16S0R0J

R1505-R1509 RS1/16SS1000F

Other Resistors RS1/16SS###J

OTHERS

CN1501 40P CONNECTOR AKM1217

CN1502 PH CONNECTOR 4P AKM1290

[50 ADR RESONANCE BLOCK]

SEMICONDUCTORS

IC1601,IC1602 TND307TD

C

Q1613 2SA1163

Q1614-Q1616 HAT1110R

Q1606,Q1608,Q1611 QSZ2

Q1612 RN1901

Q1601-Q1605 SP8M41

D1612 1SS302

D1625-D1629 1SS355

D1631-D1650 EP05FA20

D1601,D1605,D1607,D1610,D1613 UDZS15(B)

D1616,D1620,D1622 UDZS15(B)

D

COILS AND FILTERS

L1601-L1605 SMD COIL ATH1163

CAPACITORS

C1609 (0.1U/100V) ACG1098

C1601,C1606,C1610 (0.068U/100V) ACG1123

C1611,C1614 (0.068U/100V) ACG1123

C1602-C1605 (56UF/80V) ACH1405

C1613 CKSRYB104K25

C1619 CKSYB105K16

E

RESISTORS

R1606,R1611,R1613,R1621 RS1/16SS###J

Other Resistors RS1/16S###J

Mark No. Description Part No.

CAPACITORS

C2701,C2711,C2721 (0.1U/250V) ACG1088

C2731,C2741,C2751 (0.1U/250V) ACG1088

C2710,C2720,C2730,C2740,C2750 CCSRCH181J50

C2760 CCSRCH181J50

C2708,C2709,C2718,C2719 CCSRCH331J50

C2728,C2729,C2738,C2739 CCSRCH331J50

C2748,C2749,C2758,C2759 CCSRCH331J50

C2705-C2707,C2715-C2717 CCSRCH390J50

C2725-C2727,C2735-C2737 CCSRCH390J50

C2745-C2747,C2755-C2757 CCSRCH390J50

C2703,C2713,C2723,C2733,C2743 CKSRYB105K6R3

C2753 CKSRYB105K6R3

RESISTORS

R2705,R2710,R2713,R2716,R2719 RAB4C221J

R2722 RAB4C221J

Other Resistors RS1/16S###J

OTHERS

CN2702 PH CONNECTOR 3P AKM1274

CN2701 13P BRIDGE CONNECTOR AKP1261

50 SCAN B ASSY

SEMICONDUCTORS

IC2801-IC2806 AN16025A

IC2807 TC7SH08FUS1

D2801-D2807 1SS355

CAPACITORS

C2801,C2811,C2821 (0.1U/250V) ACG1088

C2831,C2841,C2851 (0.1U/250V) ACG1088

C2810,C2820,C2830,C2840,C2850 CCSRCH181J50

C2860 CCSRCH181J50

C2808,C2809,C2818,C2819 CCSRCH331J50

C2828,C2829,C2838,C2839 CCSRCH331J50

C2848,C2849,C2858,C2859 CCSRCH331J50

C2805-C2807,C2815-C2817 CCSRCH390J50

C2825-C2827,C2835-C2837 CCSRCH390J50

C2845-C2847,C2855-C2857 CCSRCH390J50

C2803,C2813,C2823,C2833,C2843 CKSRYB105K6R3

C2853,C2861 CKSRYB105K6R3

RESISTORS

R2803,R2808,R2811,R2814,R2817 RAB4C221J

R2820 RAB4C221J

Other Resistors RS1/16S###J

OTHERS

CN2802 PH CONNECTOR 3P AKM1274

CN2801 13P BRIDGE CONNECTOR AKP1261

50 SCAN A ASSY

SEMICONDUCTORS

IC2701-IC2706 AN16025A

D2701-D2707 1SS355

F

34

1234

50 X DRIVE ASSY

[50X LOGIC BLOCK]

SEMICONDUCTORS

IC1001 TC74ACT541FT

IC1002 TC74VHC00FTS1

PDP-506PE

Page 35

5678

Mark No. Description Part No.

CAPACITORS

C1003 CEHAT470M16

C1001,C1002 CKSRYB104K16

RESISTORS

R1001,R1003 RAB4C470J

R1008,R1009 RAB4C472J

Other Resistors RS1/16S###J

OTHERS

CN1001 18P FFC CONNECTOR VKN1310

Mark No. Description Part No.

CAPACITORS

C1214-C1217 ACE1178

C1212,C1213 ACH1423

C1231 CEHAT101M10

C1206 CEHAT101M25

C1283 CEHAT2R2M2E

C1208 CEHAT470M16

C1222,C1272 CEHAT470M25

C1221 CKSRYB105K6R3

C1204,C1207,C1223,C1251,C1253 CKSRYF104Z50

C1273 CKSRYF104Z50

A

[50X RESONANCE BLOCK]

SEMICONDUCTORS

IC1101 AXF1142

IC1141 BA10393F

Q1141 2SC4116

D1101-D1105 D1FL40

COILS AND FILTERS

L1103,L1104 CHOKE COIL ATH1119

L1101,L1102 CHOKE COIL ATH1187

L1105,L1106 CHOKE COIL ATH1187

CAPACITORS

C1161-C1164,C1116 (3.3U/250V) ACE1168

C1101,C1112,C1113 (0.22U/250V) ACG1112

C1121 (470p/630V) ACG1126

C1105 CCG1186

C1141,C1142,C1144,C1145 CKSRYB104K16

C1102,C1146 CKSRYB105K6R3

C1103 CKSYB105K25

RESISTORS

R1101 ACN1168

R1142,R1146 RS1/10S1003F

R1122,R1123 RS1/10S104J

R1148,R1150 RS1/16S5601F

R1151,R1155 RS1/16S6801F

R1106,R1121 RS2MMF100J

Other Resistors RS1/16S###J

[50X SUS BLOCK]

SEMICONDUCTORS

IC1202 AXF1140

IC1201 MM1565AF

IC1252 PS9117

IC1251 TND301S

IC1271 TND307TD

Q1251 2SC2412K

Q1272 2SK3325-Z

D1281 1SS302

D1201 1SS355

D1252 CRH01

D1282 UDZS16(B)

D1251 UDZS5R6(B)

COILS AND FILTERS

L1204,L1211 INDUCTOR ATH1186

F1201 INDUCTOR CTF1449

L1201,L1205,L1231 LFEA100J

C1220 CKSYB105K25

RESISTORS

R1204 ACN1166

R1213 ACN1168

R1276,R1277 RS3LMF470J

Other Resistors RS1/16S###J

OTHERS

KN1201-KN1206 GROUND PLATE ANK-142

KN1208-KN1211 GROUND PLATE ANK-142

CN1202 6P TOP POST B6B-EH

CN1201 8P TOP POST B8B-EH

[50X D-D CON BLOCK]

SEMICONDUCTORS

IC1321 PS2701A-1(L)

IC1326 TA76431FR

Q1324 2SA1037K

Q1302 2SC4081

Q1301,Q1323 2SD1898

Q1321,Q1325,Q1351 HN1C01FU

D1303,D1324 1SS301

D1304,D1307,D1325,D1328 1SS355

D1301,D1302,D1326,D1327 CRH01

D1321 D1FK60

D1329,D1330 UDZS4R7(B)

D1306,D1323,D1331 UDZS5R1(B)

COILS AND FILTERS

>T1301 SWITCHING TRANS. ATK1159

>T1321 SWITCHING TRANS. ATK1160

CAPACITORS

C1325 ACH1428

C1326 CEHAT100M50

C1302,C1321 CEHAT101M25

C1301,C1303,C1323 CKSRYB103K50

C1304,C1306,C1327 CKSRYB104K16

C1307,C1324 CKSYB105K25

RESISTORS

R1337 RAB4C472J

R1321,R1322,R1326,R1339 RS1/10S224J

VR1321 CCP1392

Other Resistors RS1/16S###J

B

C

D

E

F

56

PDP-506PE

35

7

8

Page 36

1234

Mark No. Description Part No.

SUS CLAMP 1 ASSY

SEMICONDUCTORS

D1631 DF20L60U

A

CAPACITORS

C1632 ACE1179

OTHERS

KN1632 GROUND PLATE ANK-142

CN1631 3P TOP POST B3B-EH

KN1631 WRAPPING TERMINAL VNF1084

Mark No. Description Part No.

C2141,C2143,C2144 CKSSYB104K10

C2102 CKSYB105K25

RESISTORS

R2101 ACN1174

R2142,R2143 RS1/10S1003F

R2103,R2107 RS1/10S104J

R2146,R2149 RS1/16S5601F

R2147,R2151 RS1/16S6801F

R2102 RS2MMF100J

R2108 RS3LMF100J

Other Resistors RS1/16S###J

SUS CLAMP 2 ASSY

B

SEMICONDUCTORS

D1641 DF20L60U

CAPACITORS

C1642 ACE1179

OTHERS

KN1642 GROUND PLATE ANK-142

CN1641 3P TOP POST B3B-EH

KN1641 WRAPPING TERMINAL VNF1084

C

50 Y DRIVE ASSY

[50Y LOGIC BLOCK]

SEMICONDUCTORS

IC2002 TC74ACT540FT

IC2001,IC2004 TC74ACT541FT

IC2003,IC2005 TC74VHC08FTS1

CAPACITORS

C2003 CEHAT470M16

C2001,C2002,C2004-C2006 CKSSYB104K10

D

RESISTORS

R2003,R2006 RAB4C101J

R2001,R2002,R2017,R2021 RAB4C470J

R2004,R2005,R2019,R2020 RAB4C472J

Other Resistors RS1/16S###J

OTHERS

CN2001 40P CONNECTOR AKM1217

[50Y RESONANCE BLOCK]

SEMICONDUCTORS

E

IC2101 AXF1142

IC2141 BA10393F

Q2141 2SC4081

D2101-D2105 D1FL40

COILS AND FILTERS

L2103,L2104 CHOKE COIL ATH1119

L2101,L2102 CHOKE COIL ATH1187

L2105,L2106 CHOKE COIL ATH1187

[50Y SUS BLOCK]

SEMICONDUCTORS

IC2252,IC2253 AXF1141

IC2350 MM1565AF

IC2250 PS9117

IC2231,IC2251 TND301S

IC2203,IC2221 TND307TD

Q2202 2SA2142

Q2250 2SC4081

Q2290 2SK3050

Q2221 2SK3325-Z

Q2280,Q2281 2SK3399

D2233 1SS301

D2213 1SS302

D2203,D2212,D2351 1SS355

D2202,D2204,D2205,D2234 CRH01

D2251,D2252,D2272 CRH01

D2211 D1FK60

D2232,D2271 UDZS16(B)

D2250 UDZS5R6(B)

COILS AND FILTERS

L2353 INDUCTOR ATH1186

F2301-F2320 FERRITE BEAD ATX1055

F2352 INDUCTOR CTF1449

L2350,L2351,L2354 LFEA100J

CAPACITORS

C2330,C2335,C2341,C2342 ACE1178

C2231 (0.33U/100V) ACG1118

C2271,C2272 (0.1U/100V) ACG1124

C2336,C2337 ACH1423

C2270 ACH1426

C2226 ACH1427

C2207 CCSRCH102J50

C2355,C2369 CEHAT101M10

C2357 CEHAT470M16

C2208,C2221,C2339,C2364 CEHAT470M25

C2356 CKSRYB104K16

C2353,C2358,C2359 CKSRYB105K6R3

C2363 CKSRYB473K16

C2209,C2222,C2230,C2252 CKSRYF104Z50

C2250 CKSSYB104K10

CAPACITORS

C2131-C2134,C2136 (3.3U/250V) ACE1168

C2103,C2107,C2108 (0.22U/250V) ACG1112

F

C2104 (470p/630V) ACG1126

C2106 CCG1186

C2101,C2145 CKSRYB105K6R3

36

1234

C2354,C2360 CKSYB105K25

PDP-506PE

Page 37

5678

Mark No. Description Part No.

RESISTORS

R2352 ACN1166

R2304 ACN1174

R2360,R2362 ACN1178

R2277-R2279,R2281 ACN1241

R2210,R2211 RS1/10S151J

Mark No. Description Part No.

CAPACITORS

C2531 ACE1177

C2516 ACH1360

C2532 ACH1425

C2513 ACH1428

C2520 CEHAT101M16

A

R2290 RS1MMF331J

R2222,R2224 RS2MMF5R6J

R2203 RS3LMF821J

Other Resistors RS1/16S###J

OTHERS

KN2350,KN2352 GROUND PLATE ANK-142

KN2354 GROUND PLATE ANK-142

KN2356,KN2357 GROUND PLATE ANK-142

KN2359-KN2363 GROUND PLATE ANK-142

CN2351,CN2352 KR CONNECTOR B4B-PH-K

CN2350 9P TOP POST B9B-EH

[50Y SCAN BLOCK]

SEMICONDUCTORS

IC2403,IC2405,IC2406,IC2408 PS9117

IC2401 PS9851-2(P)

IC2402,IC2407 TC74ACT540FT

COILS AND FILTERS

L2401-L2403 LFEA100J

CAPACITORS

C2404,C2411 ACH1413

C2401,C2407,C2414 CEHAT101M10

C2402,C2403,C2405,C2408-C2410 CKSSYB104K10

C2412 CKSSYB104K10

RESISTORS

R2407,R2421 RAB4C220J

R2402,R2409 RS1/10S0R0J

Other Resistors RS1/16S###J

OTHERS

CN2401 15P BRIDGE CONNECTOR AKM1200

CN2402 15P BRIDGE CONNECTOR AKM1200

C2515 CEHAT101M25

C2528 CEHAT221M16

C2514,C2525,C2534 CKSRYB104K16

C2521,C2533,C2535 CKSRYB104K25

RESISTORS

R2553 RAB4C472J

R2558 RS1/10S0R0J

R2533,R2556 RS1/10S104J

R2534,R2535,R2541 RS1/10S2203F

R2548 RS1/16S1003F

R2550 RS1/16S1802F

R2549,R2557 RS1/16S4702F

R2542,R2545 RS1/16S5601F

VR2503 CCP1390

VR2531 CCP1392

Other Resistors RS1/16S###J

[50Y D-D CON BLOCK]

SEMICONDUCTORS

IC2602 BA10358F

IC2601,IC2603,IC2606 PS2701A-1(L)

IC2605,IC2614 TA76431FR

Q2610 2SA1163

Q2601,Q2609 2SA1576A

Q2608 2SA2005

Q2607 2SC2713

Q2612 2SC4081

Q2605,Q2606 2SD1898

Q2603,Q2604,Q2611 DTC143EUA

Q2602,Q2613,Q2641 HN1C01FU

D2611 1SS226

D2604,D2612 1SS301

D2602,D2613-D2615 1SS355

D2601,D2603,D2609,D2618 CRH01

B

C

D

[50Y VH D-D CON BLOCK]

SEMICONDUCTORS

IC2531 BA10358F

IC2502 MIP2E3DMC

IC2503 PS2701A-1(L)

IC2534,IC2535 TA76431FR

Q2533 2SC2412K

Q2531 2SC3425

Q2532 2SD2568

Q2511 HN1C01FU

D2534 1SS355

D2522,D2524 CRH01

D2523,D2532 D1FK60

D2533 UDZS33(B)

D2536 UDZS4R7(B)

D2530,D2531 UDZS8R2(B)

COILS AND FILTERS

>T2503 CONVERTER TRANS. ATK1158

L2501 LFEA101J

56

D2610 D1FL40

D2617 UDZS15(B)

D2607,D2608 UDZS4R7(B)

D2605 UDZS5R1(B)

D2616 UDZS5R6(B)

COILS AND FILTERS

>T2602 CONVERTER TRANS. ATK1156

>T2601 SWITCHING TRANS. ATK1161

CAPACITORS

C2608,C2610 CEHAT101M25

C2613 CEHAT221M25

C2606 CEHAT221M6R3

C2607 CKSRYB102K50

C2605,C2612,C2614 CKSRYB103K50

C2601,C2604,C2609 CKSRYB104K16

C2602,C2615 CKSRYB105K6R3

C2603 CKSRYF104Z50

C2611 CKSSYB104K10

PDP-506PE

E

F

37

7

8

Page 38

1234

Mark No. Description Part No.

RESISTORS

R2613 RAB4C472J

R2641,R2642 RS1/10S224J

A

R2629 RS1/16S1002F

R2625,R2626 RS1/16S1501F

R2608,R2612,R2630,R2632,R2635 RS1/16S4701F

Mark No. Description Part No.

OTHERS

CN3003 PH CONNECTOR 6P AKM1277

CN3004 PH CONNECTOR 12P AKM1298

JA3001 DVI CONNECTOR AKP1276

JA3002 MDR CONNECTOR AKP1277

R2618 RS1/16S4702F

R2636 RS1/16S5601F

R2652 RS1/16S6801F

R2627 RS3LMF151J

VR2601 CCP1390

Other Resistors RS1/16S###J

B

HD DIGITAL ASSY

OTHERS

DD CON UNIT AXY1116

REMOTE RECEIVER UNIT RPM7240-H4

HD DIGITAL ASSY

[TMDS RX BLOCK]

SEMICONDUCTORS

IC3002 BA8274F

IC3001 SII1169CTU

C

IC3004 SN74AHC32PW

Q3009 2SC4081

Q3007 DTA143EUA

Q3004 DTC124EUA

Q3005 DTC143EUA

Q3002,Q3006,Q3008 RN1901

Q3003 RN2901

D3001,D3002 1SS355

D3012 DA204U

D3007-D3011 RB751V-40

D3003 UDZS6R8(B)

D

COILS AND FILTERS

F3005 CHIP SOLID INDUCTOR QTL1011

L3003 CHIP SOLID INDUCTOR QTL1013

CAPACITORS

C3030 ACH1357

C3034,C3036,C3038,C3040,C3042 ACH1396

C3003,C3005,C3009,C3014,C3019 CCSRCH331J50

C3046 CCSRCH470J50

C3044,C3045 CCSSCH101J50

E

C3001,C3008,C3011,C3020,C3022 CCSSCH820J50

C3025-C3027 CCSSCH820J50

C3018,C3021,C3023,C3024 CKSRYF105Z10

C3015-C3017,C3028,C3029 CKSSYF104Z16

C3031,C3032,C3035,C3037,C3039 CKSSYF104Z16

C3041,C3043 CKSSYF104Z16

RESISTORS

R3007 RAB4C220J

R3008-R3013 RAB4C470J

R3018 RAB4C472J

R3021 RS1/16S3900F

F

Other Resistors RS1/16S###J

[MODULE UCOM BLOCK]

SEMICONDUCTORS

IC3156 BR24L04FJ-W

IC3151 M30620FCPGP-U5C

IC3157 M62334FP

IC3158 MM1522XU

IC3155 SN74AHC08PW

IC3152,IC3153 SN74AHC541PW

IC3160 TC74VHC123AFTS1

IC3159 TC7W126FU

Q3151 2SJ461A

D3156,D3159,D3161-D3163 1SS355

D3151,D3152,D3154,D3155,D3158 DAN202U

CAPACITORS

C3151 ACH1357

C3164 CCSSCH101J50

C3171,C3172,C3180 CKSRYB105K6R3

C3154 CKSSYB102K50

C3152,C3153,C3155-C3158 CKSSYF104Z16

C3160-C3163,C3165,C3166,C3170 CKSSYF104Z16

RESISTORS

R3160,R3171,R3176 RAB4C101J

R3174 RAB4C103J

Other Resistors RS1/16S###J

OTHERS

>

X3151 CERAMIC RESONATOR ASS1178

[PANEL FLASH BLOCK]

SEMICONDUCTORS

IC3301 MBM29PL160TD75TN

IC3304 PST3610UR

IC3302,IC3305 PST3628UR

IC3303 SN74AHC08PW

Q3302 HN1C01FU

Q3301 RN1901

CAPACITORS

C3311 CCSRCH470J50

C3317 CCSRCH471J50

C3304,C3307,C3309 CKSRYB472K50

C3305,C3310 CKSSYB102K50

C3315 CKSSYB104K10

C3301-C3303,C3306,C3308,C3316 CKSSYF104Z16

RESISTORS

All Resistors RS1/16S###J

OTHERS

>

X3302 CRYSTAL OSCILLATOR ASS1188

38

PDP-506PE

1234

Page 39

5678

Mark No. Description Part No.

[SQ ASIC BLOCK]

SEMICONDUCTORS

IC3401 PEG122C

COILS AND FILTERS

F3401,F3402 EMI FILTER CCG1162

L3401-L3403 CHIP SOLID INDUCTOR QTL1013

CAPACITORS

C3402,C3419 (100UF/6.3V) ACH1396

C3425,C3441 (100UF/6.3V) ACH1396

C3414-C3416,C3426-C3438 CKSRYF105Z10

C3403-C3410,C3412,C3413 CKSSYF104Z16

C3417,C3418,C3420-C3424 CKSSYF104Z16

C3439,C3440,C3442-C3449 CKSSYF104Z16

RESISTORS

R3402,R3412 RAB4C101J

R3405-R3407,R3409,R3410 RAB4C220J

R3416,R3417 RAB4C220J

R3425 RS1/16S5601F

Other Resistors RS1/16S###J

Mark No. Description Part No.

HD IR ASSY

SEMICONDUCTORS

Q1681 2SC4116

D1681 DA204U

CAPACITORS

C1681 CEVW470M6R3

C1682 CKSRYB103K50

C1683 CKSSYB102K50

C1684 CKSSYF104Z16

RESISTORS

All Resistors RS1/16S###J

OTHERS

CN1681 3P L TYPE PLUG KM200NA3L

V1681 REMOTE RECEIVER UNIT RPM7240-H4

HD AUDIO ASSY

OTHERS

J3901 1P BOARD IN WIRE ADX3123

A

B

[ADDRESS BLOCK]

SEMICONDUCTORS

D3501,D3502 DAN202U

CAPACITORS

C3501-C3504 CKSSYB102K50

RESISTORS

R3521,R3522,R3525 RAB4C101J

R3524 RAB4C222J

R3519,R3520 RAB4C472J

Other Resistors RS1/16S###J

OTHERS

CN3501-CN3504 40P CONNECTOR AKM1217

CN3506 40P CONNECTOR AKM1217

CN3505 VKN1310

[DIGITAL DD CON BLOCK]

CAP

ACITORS

C3609 CKSSYF104Z16

RESISTORS

R3611 RAB4C101J

Other Resistors RS1/16S###J

HD LED ASSY

SEMICONDUCTORS

D1671 SML-311UT

D1672 SML512BC4T

COILS AND FILTERS

>

F1671-F1673 CHIP SOLID INDUCTOR QTL1011

[AUDIO AMP BLOCK]

SEMICONDUCTORS

IC3754 BR24L02FJ-W

IC3751 LA4625

IC3752 NJM7809FA

IC3753 NJW1183L

Q3751,Q3754,Q3755,Q3757 2SA1576A

Q3756,Q3759 2SC4081

Q3758,Q3760 DTC124EUA

CAPACITORS

C3797,C3808,C3812,C3814 CEAT1R0M50

C3775,C3777,C3788,C3790,C3791 CEHAT100M50

C3799 CEHAT100M50

C3761,C3764,C3786,C3798 CEHAT101M16

C3766,C3780,C3783-C3785 CEHAT1R0M50

C3762 CEHAT220M50

C3752,C3753,C3819,C3820 CEHAT2R2M50

C3759 CEHAT331M16

C3757 CEHAT471M25

C3755 CEHAT472M25

C3763 CEHATR47M50

C3754,C3805 CFTLA103J50

C3767,C3770,C3772-C3774 CFTLA104J50

C3781,C3782,C3789,C3792-C3795 CFTLA104J50

C3806,C3807,C3813 CFTLA104J50

C3810 CFTLA223J50

C3778 CFTLA334J50

C3758,C3760,C3796 CKSRYB103K50

C3769,C3815 CKSRYB222K50

C3779 CKSRYB822K50

C3816 CKSRYF104Z16

C

D

E

RESISTORS

R3768-R3770,R3782 RD1/2MMF2R2J

R3752 RD1/2MMF4R7J

Other Resistors RS1/16S###J

PDP-506PE

56

F

39

7

8

Page 40

1234

Mark No. Description Part No.

OTHERS

CN3752 12P PH CONNECTOR AKM1335

3771 AUDIO HEATSINK ANH1636

A

CN3751 3P TOP POST (VH) B3P-VH

3772-3775 SCREW VBB30P100FNI

KN3751 WRAPPING TERMINAL VNF1084

KN3752 WRAPPING TERMINAL VNF1084

[ST TERMINAL BLOCK]

COILS AND FILTERS

>

L3901,L3902 LINE FILTER ATF1206

CAPACITORS

>

C3906,C3908,C3914,C3916 CCSRCH101J50

B

C3903,C3911 CKSRYB332K50

C3904,C3912 CKSRYF473Z50

RESISTORS

R3901-R3904 RD1/2MMF100J

OTHERS

JA3901 SPEAKER TERMINAL AKE1061

POWER SUPPLY UNIT

C

POWER SUPPLY Unit has no service part.

D