Page 1

TECHNICAL MANUAL (Ver. 1.0)

FOR PIONEER PLASMA DISPLAY MONITOR WHEN USED WITH

VIDEO CARDS (EXPANSION SOLUTIONS CARDS)

PLASMA DISPLAY MONITOR: PDP-507CMX/PDP-427CMX

VIDEO CARD: PDA-5003/PDA-5004

TABLE TOP STAND: PDK-TS07

TILT MOUNT UNIT: PDK-5011

WALL MOUNT UNIT: PDK-WM01

CEILING MOUNT UNIT: PDK-5012

MOBILE CART: PDK-5014

PDP BRACKET: PDK-5005

SPEAKER SYSTEM: PDP-S53-LR/PDP-S56-LR

This manual provides precautions and information for installation, preparation, and handling of the Plasma Display and

its dedicated mounting hardware.

Before installation and preparatory work, choose a safe and appropriate site after thorough consideration of construction,

materials used, strength, and surroundings. If adequate safeguards are not in place, immediately halt the installation

process and discontinue marketing activities.

ABOUT MOUNTING/INSTALLATION

• This product is sold under the assumption that installation

will be performed by experienced, qualified experts.

Refer all mounting and installation work to qualified

personnel or consult the nearest PIONEER dealer for

assistance.

• We accept no responsibility for accident or loss resulting

from failure to select an appropriate installation site,

situations occurring during assembly, installation,

mounting, operation resulting from modifications made

to this product, or from natural disasters.

PRECAUTIONS:

• We accept no responsibility for losses resulting from the

use of parts other than those supplied by Pioneer or those

authorized by Pioneer.

• We guarantee the performance of our products only when

they are assembled and adjusted as described in this

manual.

• The specifications and external designs shown in this

manual are subject to change without notice.

To use this product safely

• When using this product attached to a ceiling or wall or

piled up, there is a danger that, according to its weight or

attachment method, it may fall down or fall over.

• In order to use this product safely, be sure to have a

professional installer or the retail agent perform the

installation work. Verify that it is appropriately attached and

take adequate safety measures.

Attention professional installer

• Install this product according to the instructions in the

owner’s manual or installation manual.

• To ensure safety when this product is installed on a ceiling,

wall or stacked be sure to take measures to prevent any

danger of the panel(s) falling down or falling over.

• Choose an installation or attachment location that has

sufficient strength to fully withstand its weight.

• When installing it on the floor, select an adequately stable,

flat, and level place.

• To prevent damage to the power or connection cords, take

great care not to place any equipment on them or pinch

them between any equipment.

• Absolutely do not alter the product or any of its attachment

hardware.

Page 2

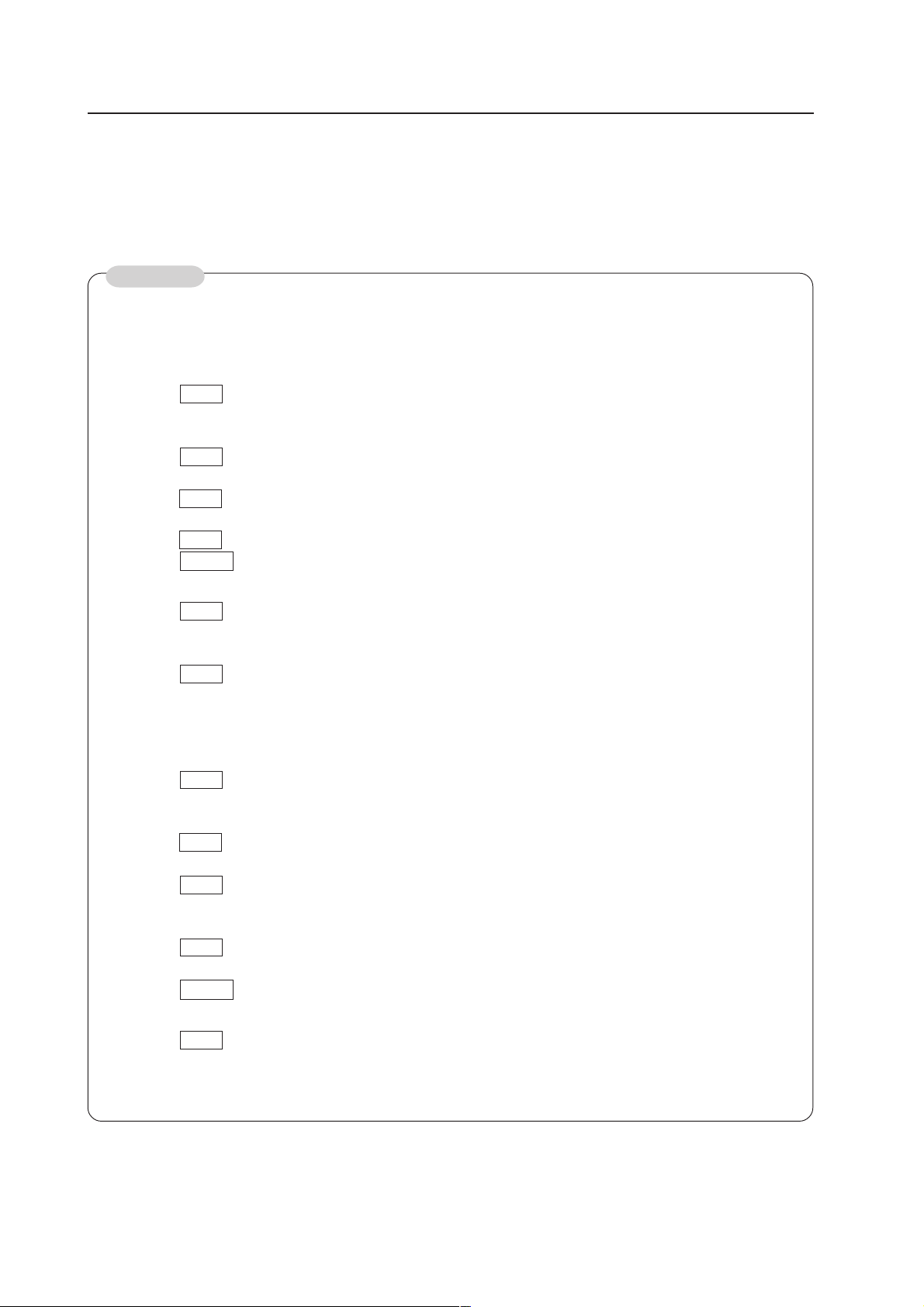

Table of Contents

INTRODUCTION ..................................................................... 4

FEATURES .............................................................................. 5

SPECIFICATIONS

2.1 Specifications ............................................................... 6

2.2 External Dimensions .................................................... 9

2.3 Controls and Connectors ........................................... 12

2.4 Pin layout .................................................................... 17

2.5 Remote Control Unit .................................................. 18

2.6 Remote Control Unit Holder (PDP-427CMX only) ... 19

INSTALLATION SITE REQUIREMENTS

3.1 Installation Site Requirements .................................. 20

3.2 Installation Conditions (PDP-507CMX) ..................... 22

3.2.1 Heat dissipation ................................................ 22

3.2.2 Calculating heat quantity ................................... 23

3.2.3 Product mounting holes .................................... 23

3.2.4 Mounting surface warping ................................ 25

3.3 Installation Conditions (PDP-427CMX) ..................... 26

3.3.1 Heat dissipation ................................................ 26

3.3.2 Calculating heat quantity ................................... 27

3.3.3 Product mounting holes .................................... 27

3.3.4 Mounting surface warping ................................ 29

3.4 Installation Procedures .............................................. 30

3.4.1 Transportation precautions ............................... 30

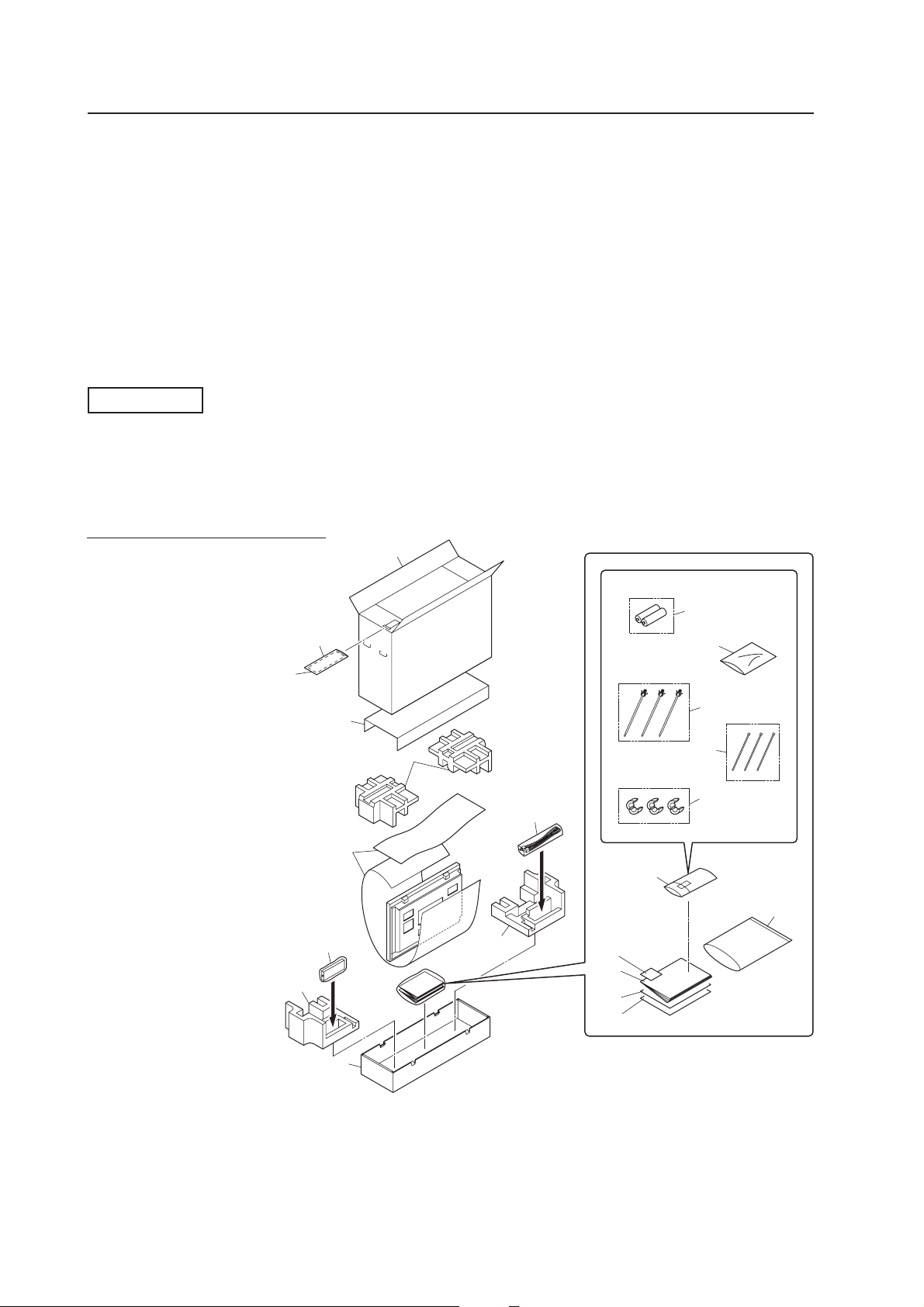

3.4.2 Unpacking ......................................................... 30

3.4.3 Mounting on the attachment stands

(PDP-427CMX only) .......................................... 32

3.4.4 Re-packing ........................................................ 33

3.4.5 Wiring ................................................................ 33

3.5 Special Installation (PDP-507CMX) ........................... 35

3.5.1 Mounting to fittings .......................................... 35

3.5.2 Hanging on the wall .......................................... 37

3.5.3 Embedding in the wall ...................................... 39

3.5.4 When the display is put in a box ....................... 42

3.5.5 Ceiling suspension (with wires) ........................ 43

3.5.6 Hanging on the wall lengthwise ........................ 45

3.5.7 Place product upright and flush into wall

(embedding in the wall) ..................................... 47

3.5.8 Installed facing upward ..................................... 51

3.5.9 Horizontal connections ...................................... 53

3.5.10

Multiple ............................................................. 54

3.6 Special Installation (PDP-427CMX) ........................... 55

3.6.1 Mounting to fittings .......................................... 55

3.6.2 Hanging on the wall .......................................... 57

3.6.3 Embedding in the wall ...................................... 59

3.6.4 When the display is put in a box ....................... 62

3.6.5 Ceiling suspension (with wires) ........................ 63

3.6.6 Hanging on the wall lengthwise ........................ 65

3.6.7 Place product upright and flush into wall

(embedding in the wall) ..................................... 67

3.6.8 Installed facing upward ..................................... 71

3.6.9 Horizontal connections ...................................... 73

3.6.10

Multiple ............................................................. 74

HOW TO USE THE STANDARD MOUNTING COMPONENTS

4.1 Standard Mounting Components Features and

Characteristics ............................................................ 76

4.2 Handling the Standard Mounting Components ...... 77

4.2.1 Handling precautions ........................................ 77

4.2.2 Precautions for installation contractors ............. 77

4.3 Installation of the Attachment Stand

(Can be used only with the PDP-427CMX) ............... 78

4.4 Video Card: PDA-5003/PDA-5004 .............................. 80

4.4.1 Specifications .................................................... 80

4.4.2 External Dimensions ......................................... 82

4.4.3 Installing procedures ......................................... 84

4.4.4 Input connectors on the Plasma Display with

video card .......................................................... 86

4.4.5 Connection to INPUT1 and INPUT5 .................. 86

4.4.6 Connection to INPUT1 or INPUT5 ..................... 87

4.4.7 Connection to INPUT2 ...................................... 92

4.4.8 Connection to INPUT3 ...................................... 92

4.4.9 Connection to INPUT4 ...................................... 92

4.4.10

About DTV set top box connection ................... 93

4.4.11

Audio connections ............................................ 94

4.5 Table Top Stand: PDK-TS07 ...................................... 98

4.5.1 Specifications .................................................... 98

4.5.2 Installation coordinates for screws used to

attach the stand to a surface ............................ 98

4.5.3 External Dimensions ......................................... 99

4.5.4 Stand assembling ............................................ 100

4.5.5 Attaching the Stand to the Plasma Display ..... 101

4.6 Tilt Mount Unit: PDK-5011 ....................................... 104

4.6.1 Specifications .................................................. 104

4.6.2 External Dimensions ....................................... 105

4.6.3 Assembling the mounting hardware and

mounting the Plasma Display ......................... 106

4.6.4 Angle setup ..................................................... 108

4.6.5 Measure to prevent shakiness when the

unit is installed at a slight tilt ........................... 109

4.7 Wall Mount Unit: PDK-WM01 ................................. 110

4.7.1 Specifications .................................................. 110

4.7.2 External Dimensions ....................................... 111

4.7.3 Assembling the mounting hardware and

mounting the display ....................................... 112

4.7.4 When removing the Plasma Display ............... 114

4.8 Ceiling Mount Unit: PDK-5012 ................................ 116

4.8.1 Specifications .................................................. 116

4.8.2 External Dimensions ....................................... 117

4.8.3 Installing the mounting hardware ................... 119

4.8.4 Attach the Plasma Display .............................. 120

4.8.5 Angle setup ..................................................... 121

4.9 Mobile Cart: PDK-5014 ............................................. 122

4.9.1 Specifications .................................................. 122

4.9.2 External Dimensions ....................................... 123

4.9.3 Disassembling the display stand ..................... 125

4.9.4 How to install .................................................. 125

4.10

PDP Bracket: PDK-5005

(Can be used only with the PDP-507CMX) ............. 130

4.10.1

Specifications .................................................. 130

4.10.2

External Dimensions ....................................... 131

4.10.3

Assembly Procedure ....................................... 132

4.10.4

An example of use .......................................... 133

4.10.5

Wire hanging ................................................... 134

4.11

Speaker System: PDP-S53-LR

(Can be used only with the PDP-507CMX) ............. 136

4.11.1

Specifications .................................................. 136

4.11.2

External Dimensions ....................................... 137

4.11.3

Installation on the Plasma Display .................. 138

4.12

Speaker System: PDP-S56-LR

(Can be used only with the PDP-427CMX) ............. 140

4.12.1

Specifications .................................................. 140

4.12.2

External Dimensions ....................................... 141

BEFORE BEGINNING ADJUSTMENT/SETTING

5.1 Before Beginning Adjustment ................................ 144

5.1.1 Operation Mode .............................................. 144

5.1.2 Combined Use of the Remote Control, Main-control

Panel, and RS-232C Commands ..................... 145

5.1.3 List of Input Correspondence Signals ............. 146

5.1.4 List of Adjustable and Settable Items ............. 162

5.1.5 Last Memory ................................................... 170

5.1.6 Aging ............................................................... 170

5.2 Normal Operation Mode ......................................... 171

5.2.1 About normal operation mode ........................ 171

2

Page 3

Table of Contents

5.3 Menu Mode ............................................................... 173

5.3.1 About menu mode .......................................... 173

5.3.2 Concerning the display of the OSD of

each item ........................................................ 173

5.3.3 Example of a Menu Mode Operation .............. 174

5.3.4 Adjustment and setting in the Menu Mode .... 175

1) Power Management Setting .................... 175

2) Signal Format Setting ............................... 176

3) Menu Language Display Setting ............... 177

4) Energy Saving Setting .............................. 178

5) Timer Setting ............................................ 180

6) Program/Repeat Timer Setting ................. 180

7) Orbiter Setting .......................................... 181

8) Soft Focus Setting .................................... 182

9) Auto Set Up Mode Setting ....................... 183

10) Screen Position, Clock Frequency and

Clock Phase Adjustment .......................... 184

11) Auto Function Mode Setting .................... 186

12) PIP DETECT Setting ................................. 187

13) SPLIT FREEZE Setting .............................. 188

5.3.5 Concerning the display of the OSD of each item

(Applicable only when a PDA-5003/PDA-5004

is installed.) ..................................................... 189

5.3.6 Example of a Menu Mode Operation

(Applicable only when a PDA-5003/PDA-5004

is installed.) ..................................................... 189

5.3.7 Adjustment and setting in the Menu Mode

(Applicable only when a PDA-5003/PDA-5004

is installed.) ..................................................... 190

1) Color Temperature Setting ....................... 190

2) Power Management and Auto Power

OFF Setting .............................................. 191

3) DNR (digital noise reduction) Setting ........ 192

4) MPEG NR Setting ..................................... 193

5) CTI Setting ................................................ 194

6) PURECINEMA Setting .............................. 195

7) Color Decoding Setting ............................. 197

8) Color System Setting ................................ 198

9) Signal Format Setting ............................... 199

10) DVI Setting ............................................... 201

11) Menu Language Display Setting ............... 202

12) Energy Saving Setting .............................. 203

13) Timer Setting ............................................ 205

14) Program/Repeat Timer Setting ................. 205

15) Orbiter Setting .......................................... 206

16) Soft Focus Setting .................................... 207

17) Auto Set Up Mode Setting ....................... 208

18) Screen Position, Clock Frequency and Clock

Phase Adjustment .................................... 209

19) Auto Function Mode Setting .................... 211

20) PIP DETECT Setting ................................. 212

21) SPLIT FREEZE Setting .............................. 213

5.4 Integrator Mode ....................................................... 214

5.4.1 About the Integrator Mode ............................. 214

5.4.2 Example of Integrator Mode Operation .......... 215

5.4.3 Adjustment and Setting in the Integrator

Mode ............................................................... 216

1) PICTURE Adjustment ............................... 216

2) WHITE BALANCE Adjustment ................. 217

3) COLOR DETAIL setting ............................ 218

4) GAMMA Setting ....................................... 219

5) SCREEN (Screen Position) Adjustment .... 220

6) Brightness Enhancement (BRT. ENHANCE)

Setting at the Center of the Screen .......... 221

7) SUB VOLUME Setting .............................. 222

8) Program Timer Setting ............................. 223

9) SCREEN MASK Setting ............................ 225

10) SIDE MASK Setting .................................. 226

11) VIDEO WALL Setting ............................... 228

12) BAUD RATE Setting ................................. 232

13) Assigning an ID ......................................... 233

14) Cooling Fan Control Setting ...................... 235

15) OSD Display Setting ................................. 236

16) FRONT INDICATOR Setting ..................... 238

17) COLOR MODE Setting ............................. 239

18) PRO USE Setting ...................................... 240

19) FRC Setting .............................................. 242

20) POWER ON MODE Setting ...................... 244

21) SEAMLESS SW Setting ............................ 246

22) MIRROR MODE Setting ........................... 247

23) MULTISCREEN Setting ............................ 249

24) REPEAT TIMER Setting ............................ 253

25) FUNCTIONAL LOCK ................................. 255

26) Center Position Display ............................ 256

5.4.4 PICTURE, White Balance and SCREEN Position

Adjustment Values Memory Area Tables ....... 257

5.5 RS-232C Adjustment ................................................ 262

5.5.1 About the RS-232C Adjustment ...................... 262

5.5.2 Interface .......................................................... 263

5.5.3 Combination Connection ................................. 264

5.5.4 ID Assignment ................................................ 265

5.5.5 List of RS-232C Commands ............................ 267

5.5.6 QUEST Commands ......................................... 275

5.6 Screen Burning ........................................................ 283

5.7 Precautions on Connecting Camera Images ......... 285

5.8 Concerning frame delay (lip sync) .......................... 285

PRECAUTION

6.1 Precautions ............................................................... 286

MAINTENANCE .................................................................. 287

CAUTION

• To prevent injury and material damage, thoroughly read

this manual and all labels found on the equipment before

attempting to mount, install, move, or adjust the product.

• Do not install the unit outside or in the open air. Doing

so will lead to water seepage into the system, resulting

in fire or electric shock.

• Be especially careful when working around parts of the

system that have sharp edges.

• When performing installation work from a height, take

suitable precautions to guard against falling. Set up a

barrier around the work site to prevent accidentally

dropped objects that can injure people standing or

walking below. Tampering with the unit may result in

fire or electrical shock.

• Keep all foreign objects out of the unit. Tampering with

the unit may result in fire or electrical shock.

• Observe the following operating environmental

limitations:

Temperature: 0 °C to 40 °C

Humidity: 20 % to 80 %

• Install the unit only in properly ventilated areas.

3

Page 4

Introduction

Introduction

The contents of “5.1 Before Beginning Adjustments (pg. 144)” and subsequent sections are premised on the PDP-

507CMX/PDP-427CMX being equipped with the PDA-5003 or PDA-5004. Items that apply only when the PDA-5003 or

PDA-5004 is installed are marked with a star ‘★’.

Precautions

With the PDA-5003 or the PDA-5004 installed, the PDP-507CMX/PDP-427CMX supports the following functions:

Input/output terminals

7 PDA-5003

INPUT 1 Input • Component video signal

• RGB signals from AV devices other than PCs

INPUT 2 Input • Digital video signal (HDCP supported)

INPUT 3 Input • Y/C separate video signal

INPUT 4 Input • Composite video signal

Output • Composite video signal

INPUT 3/ Input • Audio L/R signal

INPUT 4

INPUT 5 Input • Composite video signal

• RGB signals from AV devices or PCs

• Audio L/R signal

7 PDA-5004

INPUT 1 Input • Component video signal

• RGB signals from AV devices other than PCs

INPUT 2 Input • Digital video signal (HDCP supported)

INPUT 3 Input • Y/C separate video signal

• Audio L/R signal

INPUT 4 Input • Composite video signal

• Audio L/R signal

Output • Composite video signal

INPUT 5 Input • Composite video signal

• RGB signals from AV devices or PCs

• Audio L/R signal

4

Page 5

Features

Features and Functions of this device

PDP-507CMX

¶ Introduces newly developed Wide Plasma Panel

The new, wide, high-precision plasma panel (1365x768 /

16:9) pushes the envelope of previous high-luminance

panels, producing brighter, clearer images with higher

contrast.

¶ ES Slot interface for enhanced potential

The display has a built-in ES Slot Interface to allow card

installation for the connection of external devices, thus

enhancing its expansion potential.

¶ Supports wide range of computer signals

(analog/digital)

This panel supports a wide range of signals including

PC standard resolution XGA display, 1920x1080

1360x768, wide signals, DOT BY DOT, full display, etc.

It is possible to switch each signal between DOT BY

DOT, 4:3, and full display

1

*

Only during DVI input of PC signals (compressed

*2

.

display)

2

*

Screen size differs according to the signal

¶ Free Installation Configuration

– Broader installation possibilities with thinner,

lighter, high-endurance design –

While producing a large 50" screen image, the display is

only 99 mm (3.9") thick, and weighs in at only 35.5 kg

(78.3 lbs).

The efficient heat-radiating design greatly improves

environmental operating conditions. The thinner, lighter

design, coupled to high-endurance construction greatly

broadens the range of possible installation locations and

methods.

*1

,

PDP-427CMX

¶ Introduces newly developed Wide Plasma Panel

The new wide high-precision plasma panel (1024x768 /

16:9) pushes the envelope of previous high-luminance

panels, producing brighter, clearer images with higher

contrast.

¶ Provides an ES Slot interface for enhanced

potential

The display has a built-in ES Slot Interface for installing

third-party cards. Cards allow external devices to

communicate with the panel, enhancing and expanding

its potential.

¶ Supports wide range of computer signals

(analog/digital)

This panel supports a wide range of signals including

PC standard resolution XGA display, 1920x1080

1360x768, wide signals, DOT BY DOT, full display, etc.

It is possible to switch each signal between DOT BY

DOT, 4:3, and full display

1

*

Only during DVI input of PC signals (compressed

*2

.

display)

2

*

Screen size differs according to the signal

¶ Free Installation Configuration

– Broader installation possibilities with thinner,

lighter, high-endurance design –

While producing a large 42" screen image, the display is

only 98 mm thick and weighs in at only 30.5 kg. The

efficient heat-radiating design greatly improves

environmental operating conditions. The thinner, lighter

design coupled to high-endurance construction greatly

broadens the range of possible installation locations.

*1

,

¶ High reliability for commercial applications

This display has features that give it high dependability

in commercial applications. These features include the

ability to suppress peak luminance in accordance with

the viewing program and to adjust the cooling fan’s

speed with changes in operating environment. Such

features provide safety and high-endurance under

conditions of commercial use.

¶ Improved usability

User convenience has been improved by adding

features that make the display even more compatible

with your computer. Some of these include the onetouch screen adjustment, [AUTO SET UP] function for

computer connections, and the POINT ZOOM function

to enlarge local portions of the screen image to display

important detailed program data.

¶ High reliability for commercial applications

This display is highly dependable in commercial

applications because of its ability to supress peak

luminance during viewing and adjust cooling fan speeds

when the operating environment changes.

Such features provide safety and high-endurance under

conditions of commercial use.

¶ Improved usability

User convenience is improved by making the display

more compatible with your computer. Some of these

improvements include the one-touch screen

adjustment [AUTO SET UP] function for computer

connections and the POINT ZOOM function to enlarge

selected portions of the screen image to show detailed

program data.

¶ Power-Saving Design

The display has a variety of power-saving functions

including an automatic brightness function with ambient

light sensing.

5

Page 6

Specifications

2.1 Specifications

PDP-507CMX

Light-emitting panel ..................... 50V type AC Plasma Panel

110.36 cm (W) × 62.09 cm (H) × 126.63 cm (diagonal)

Aspect ratio .................................................................... 16 : 9

Pixels ...................................................................... 1365 × 768

Pixel pitch ..................... 0.81 mm (H•RGB trio) × 0.81 mm (V)

Input/output terminals

Video-related

INPUT 1

Input Mini D-sub, 15-pin connector (female)

• RGB signal (for SYNC ON G)

RGB ............................... 0.7 Vp-p/75 Ω/no sync

HD/VS, VD ........ TTL level/positive and negative

polarity/2.2 kΩ

SYNC ON G ............ 1 Vp-p/75 Ω/negative sync.

*Microsoft Plug & Play (VESA DDC 1/2B) supported

Output Mini D-sub, 15-pin connector (female)

.................................. 75 Ω/with buffer

INPUT 2

Input DVI-D 24-pin connector

Digital RGB signal (DVI compliant TMDS signal)

*Microsoft Plug & Play (VESA DDC 2B) supported

Audio-related

Input AUDIO INPUT (for INPUT1)

Stero mini jack

L/R ...................... 500 mVrms/more than 10 kΩ

AUDIO INPUT (for INPUT2)

Stero mini jack

L/R ...................... 500 mVrms/more than 10 kΩ

Power requirements ............ AC 100 V to 120 V, 50 Hz/60 Hz

(The power unit range is from AC100 V to 240 V (50 Hz/60 Hz))

In-rush ............................................................... less than 30 A

Power factor .................................................... more than 0.95

Consumption .........................340 W

External dimensions

........................... 1222 mm (W) × 736 mm (H) × 99 mm (D)

48-1/8 in. (W) × 28-31/32 in. (H) × 3-29/32 in. (D)

Weight .......................................................... 35.5 kg (78.3 lbs.)

Dimensions of packaging

......................... 1340 mm (W) × 900 mm (H) × 365 mm (D)

52-26/32 in. (W) × 35-1/2 in. (H) × 14-7/16 in. (D)

Weight when packaged .............................. 44.0 kg (97.1 lbs.)

Operating Temperature .... 0 °C to 40 °C (32 °F to 104 °F)

Operating Humidity .......................................... 20 % to 80 %

Operating atmospheric pressure .......... 800 hPa to 1100 hPa

Storage limitations (when installed)

Temperature .................. –20 °C to +60 °C (–4 °F to 140 °F)

Humidity ......................................................... 20 % to 90 %

Atmospheric pressure ......................... 700 hPa to 1114 hPa

Storage limitations (when in original package)

Temperature ................ –30 °C to +60 °C (–22 °F to 140 °F)

Humidity ......................................................... 20 % to 90 %

Atmospheric pressure ......................... 700 hPa to 1114 hPa

Stacking ............................................ Fewer than three tiers

Standard accessories

Power cord (2 m) .................................................................... 1

Ferrite core (for audio cables) ................................................. 3

Remote control unit ................................................................ 1

AA battery ............................................................................... 2

Wiping cloth (for screen) ......................................................... 1

Speed clamp ........................................................................... 3

Bead band ............................................................................... 3

Operating instructions ............................................................. 1

Warranty ................................................................................. 1

(NOTE 2)

(0.6 W in standby)

(NOTE 3)

Output AUDIO OUTPUT

Stero mini jack

L/R .......................... 500 mVrms/less than 5 kΩ

SPEAKER

L/R ................... 6 Ω to 16 Ω/9 W + 9 W (at 6 Ω)

Control-related

RS-232C terminal: D-sub, 9-pin (male)

(NOTE 1)

Combination In/Out Terminal: Mini-DIN, 6-pin

Specifications and external designs are subject to change without

notice.

(NOTE 1) The display is preset at the factory to 9600bps. This

setting can be changed using either the remote control

unit or a PC.

(NOTE 2) Allow for 370 W = 370 VA of consumption per unit.

(NOTE 3) The correct operating environmental temperature may

vary depending on the installation site (refer to

“Installation Site Requirements (pg. 20)”.

6

Page 7

PDP-427CMX

Specifications

Light-emitting panel ..................... 42V type AC Plasma Panel

92.16 cm (W) × 51.53 cm (H) × 105.59 cm (diagonal)

Aspect ratio .................................................................... 16 : 9

Pixels ...................................................................... 1024 × 768

Pixel pitch ..................... 0.9 mm (H•RGB trio) × 0.671 mm (V)

Input/output terminals

Video-related

INPUT 1

Input Mini D-sub, 15-pin connector (female)

• RGB signal (for SYNC ON G)

RGB ............................... 0.7 Vp-p/75 Ω/no sync

HD/VS, VD ........ TTL level/positive and negative

polarity/2.2 kΩ

SYNC ON G ............ 1 Vp-p/75 Ω/negative sync.

*Microsoft Plug & Play (VESA DDC 1/2B) supported

Output Mini D-sub, 15-pin connector (female)

.................................. 75 Ω/with buffer

INPUT 2

Input DVI-D 24-pin connector

Digital RGB signal (DVI compliant TMDS signal)

*Microsoft Plug & Play (VESA DDC 2B) supported

Audio-related

Input AUDIO INPUT (for INPUT1)

Stero mini jack

L/R ...................... 500 mVrms/more than 10 kΩ

AUDIO INPUT (for INPUT2)

Stero mini jack

L/R ...................... 500 mVrms/more than 10 kΩ

Output AUDIO OUTPUT

Stero mini jack

L/R .......................... 500 mVrms/less than 5 kΩ

SPEAKER

L/R ................... 6 Ω to 16 Ω/8 W + 8 W (at 6 Ω)

Control-related

RS-232C terminal: D-sub, 9-pin (male)

(NOTE 1)

Combination In/Out Terminal: Mini-DIN, 6-pin

Power requirements ............ AC 100 V to 120 V, 50 Hz/60 Hz

(The power unit range is from AC100 V to 240 V (50 Hz/60 Hz))

In-rush ............................................................... less than 30 A

Power factor .................................................... more than 0.95

Consumption .........................285 W

(NOTE 2)

(1.2 W in standby)

External dimensions (not including the handles and supplied stand)

........................... 1022 mm (W) × 610 mm (H) × 98 mm (D)

40-1/4 in. (W) × 24-1/32 in. (H) × 3-27/32 in. (D)

Weight (without attachment stand) ......... 30.5 kg (67.3 lbs.)

Dimensions of packaging

......................... 1177 mm (W) × 767 mm (H) × 354 mm (D)

46-11/32 in. (W) × 30-7/32 in. (H) × 13-31/32 in. (D)

Weight when packaged ................................. 38 kg (83.8 lbs.)

Operating Temperature .... 0 °C to 40 °C (32 °F to 104 °F)

(NOTE 3)

Operating Humidity .......................................... 20 % to 80 %

Operating atmospheric pressure .......... 800 hPa to 1114 hPa

Storage limitations (when installed)

Temperature .................. –20 °C to +60 °C (–4 °F to 140 °F)

Humidity ......................................................... 20 % to 90 %

Atmospheric pressure ......................... 700 hPa to 1114 hPa

Storage limitations (when in original package)

Temperature ................ –30 °C to +60 °C (–22 °F to 140 °F)

Humidity ......................................................... 20 % to 90 %

Atmospheric pressure ......................... 700 hPa to 1114 hPa

Stacking ............................................ Fewer than three tiers

Standard accessories

Power cord .............................................................................. 1

Ferrite core (for power cord) ................................................... 2

Ferrite core (for audio cables) ................................................. 3

Cable ties ................................................................................ 2

Remote control unit ................................................................ 1

AA battery ............................................................................... 2

Wiping cloth (for screen) ......................................................... 1

Speed clamp ........................................................................... 3

Operating instructions ............................................................. 1

Warranty ................................................................................. 1

Remote control unit holder ..................................................... 1

Display stand ........................................................................... 2

Washer .................................................................................... 2

Hexagon socket head screw (M8 x 40) .................................. 2

Specifications and external designs are subject to change without

notice.

(NOTE 1) The display is preset at the factory to 9600bps. This

setting can be changed using either the remote control

(NOTE 2) Allow for 320 W = 320 VA of consumption per unit.

(NOTE 3) The correct operating environmental temperature may

unit or a PC.

vary depending on the installation site (refer to

“Installation Site Requirements (pg. 20)”.

7

Page 8

Specifications

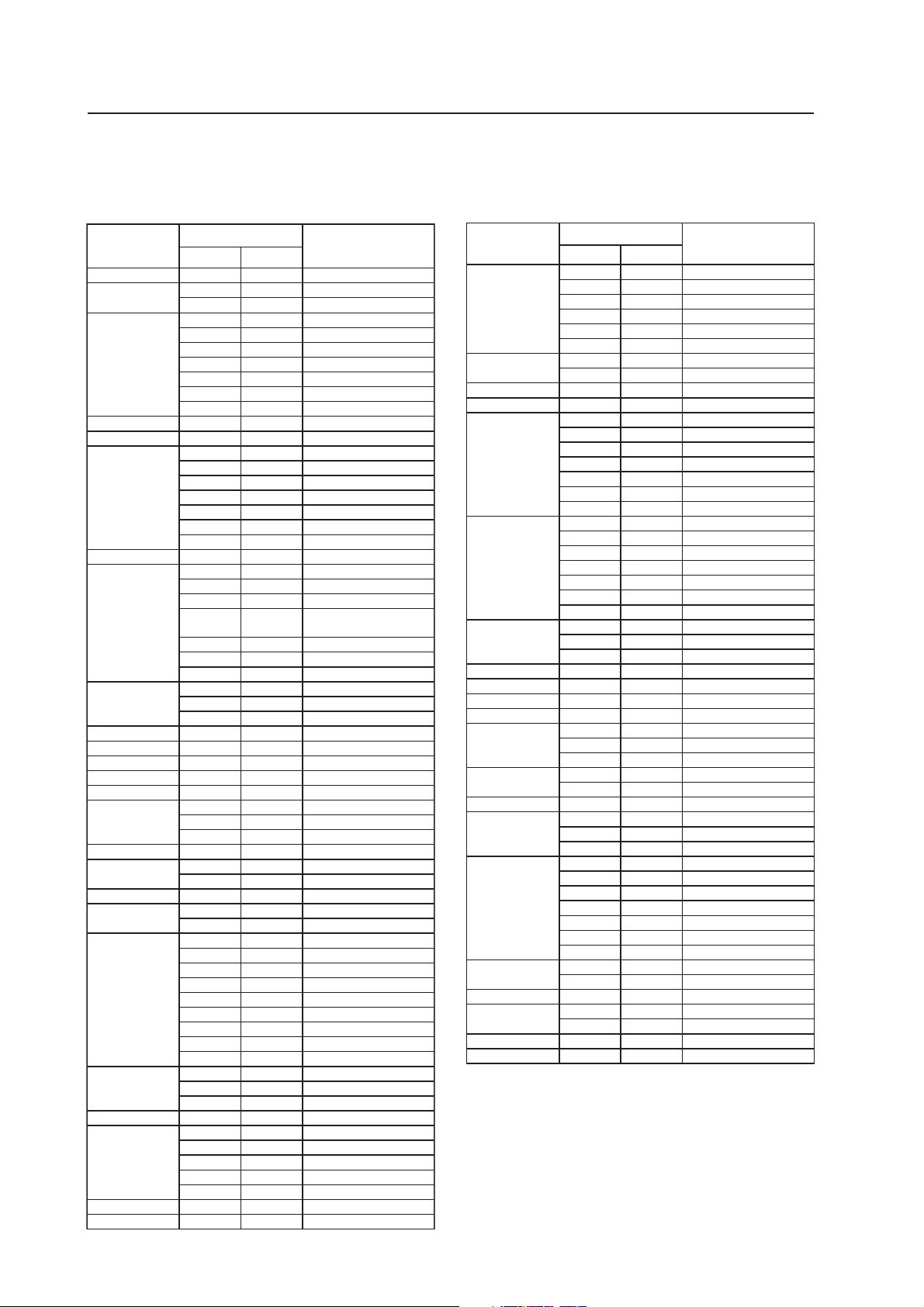

INPUT Response Signals

INPUT 1

7 PC signals supported

Resolution

(Dot x Line)

640x400 70.1 Hz 31.5 kHz NEC PC-9800

720x400 70.1 Hz 31.5 kHz NEC PC-9800

640x480 59.9 Hz 31.5 kHz

848x480 60 Hz 31.0 kH z

852x480 60 Hz 31.7 kH z

800x600 56.3 Hz 35.2 kHz

832x624 74.6 Hz 49.7 kHz Apple Macintosh 16”

1024x768 60 Hz 48.4 kH z

1280x768 56.2 Hz 45.1 kH z

1360x765

1360x768

1376x768 59.9 Hz 48.3 kHz I/O DATA

1280x800 59.8 Hz 49.7 kHz CVT

1280x854 60 Hz 53.1 kHz

1152x864 60 Hz 53.7 kH z

1152x870 75.1 Hz 68.7 kHz Apple Macintosh 21”

1152x900 66 Hz 61.8 kHz Sun Microsystems LO

1440x900 59.9 Hz 55.9 kHz Apple Macintosh 17”

1280x960 60 Hz 60.0 kH z

1280x1024 60 Hz 63.9 kHz Work station (SGI)

1400x1050 60 Hz 65.3 kH z

1680x1050 60 Hz 65.3 kH z

1600x1200 60 Hz 75.0 kH z

1920x1200 59.9 Hz 74.6 kHz CVT

1920x1200RB 60 Hz 74.0 kHz CVT

Refresh rate

Vertical

85.1 Hz 37.9 kHz

66.7 Hz 35.0 kHz Apple Macintosh 13”

72.8 Hz 37.9 kHz

75 Hz 37.5 kHz

85 Hz 43.3 kHz

100.4 Hz 51.1 kHz I/O DATA

120.4 Hz 61.3 kHz I/O DATA

60.3 Hz 37.9 kHz

72.2 Hz 48.1 kHz

75 Hz 46.9 kHz

85.1 Hz 53.7 kHz

99.8 Hz 63.0 kHz I/O DATA

120 Hz 75.7 kHz I/O DATA

60 Hz 49.7 kHz Work station (SGI)

70.1 Hz 56.5 kHz

75 Hz

(74.9 Hz )

85 Hz 68.7 kHz

100.6 Hz 80.5 kHz I/O DATA

119.4 Hz 95.5 kHz

59.8 Hz 48 kHz

69.8 Hz 56 kHz

60 Hz

60 Hz

72 Hz 64.9 kHz

75 Hz 67.5 kHz

76 Hz 71.7 kHz Sun Microsystems HI

85 Hz 85.9 kHz

60 Hz 64.0 kHz

60 Hz 64.6 kHz

71.2 Hz 75.1 kHz

72 Hz 78.1 kHz Work station (HP)

75 Hz 80.0 kHz

76.1 Hz 81.1 kHz Work station (SUN)

85 Hz 91.1 kHz

100.1 Hz 108.5 kHz I/O DATA

74.9 Hz 82.3 kHz

85 Hz 93.9 kHz

65 Hz 81.3 kHz

70 Hz 87.5 kHz

75 Hz 93.8 kHz

85 Hz 106.3 kH z

Horizontal

60.0 kHz

(60.2 kHz)

47.7 kHz

47.7 kHz

Remark

( ) indicates Apple

Macintosh 19

I/O DATA

PC

Work station (EWS4800)

Work station (EWS4800)

INPUT 2

7 PC signals supported

Resolution

(Dot x Line)

640x480 59.9 Hz 31.5 kHz

720x400 70.1 Hz 31.5 kHz NEC PC-9800

848x480 60 Hz 31.0 kH z

852x480 60 Hz 31.7 kH z

800x600 56.3 Hz 35.2 kHz

1024x768 60 Hz 48.4 kH z

1280x768 56.2 Hz 45.1 kH z

1280x800 59.8 Hz 49.7 kH z

1280x854 60 Hz 53.1 kH z

1360x768 60 Hz 47.7 kHz I/O DATA

1376x768 59.9 Hz 48.3 kHz I/O DATA

1152x864 60 Hz 53.7 kH z

1152x900 66 Hz 61.8 kHz Sun Microsystems LO

1440x900 59.9 Hz 55.9 kHz Apple Macintosh17“

1280x960 60 Hz 60.0 kH z

1280x1024 60 Hz 64.0 kH z

1400x1050 60 Hz 65.3 kH z

1680x1050 60 Hz 65.3 kH z

1920x1080 50 Hz 56.2 kH z

1600x1200 60 Hz 75.0 kH z

1920x1200RB 60 Hz 74.0 kHz CVT

Refresh rate

Vertical

72.8 Hz 37.9 kHz

75 Hz 37.5 kHz

85 Hz 43.3 kHz

100.4 Hz 51.1 kHz

120.4 Hz 61.3 kHz

85.1 Hz 37.9 kHz

60.3 Hz 37.9 kHz

72.2 Hz 48.1 kHz

75 Hz 46.9 kHz

85.1 Hz 53.7 kHz

99.8 Hz 63.0 kHz

120 Hz 75.7 kHz

60 Hz 49.7 kHz Work station (SGI)

70.1 Hz 56.5 kHz

75 Hz 60.0 kHz

85 Hz 68.7 kHz

100.6 Hz 80.5 kHz

119.4 Hz 95.5 kHz

59.8 Hz 48 kHz

69.8 Hz 56 kHz

72 Hz 64.9 kHz

75 Hz 67.5 kHz

76 Hz 71.7 kHz Sun Microsystems HI

85 Hz 85.9 kHz

60 Hz 63.9 kHz Work station (SGI)

60 Hz 64.6 kHz

71.2 Hz 75.1 kHz

72 Hz 78.1 kHz Work station (HP)

75 Hz 80.0 kHz

76.1 Hz 81.1 kHz Work station (SUN)

85 Hz 91.1 kHz

74.9 Hz 82.3 kHz

60 Hz 67.5 kHz

Horizontal

Remarks

Work station (EWS4800

Work station (EWS4800)

)

8

Page 9

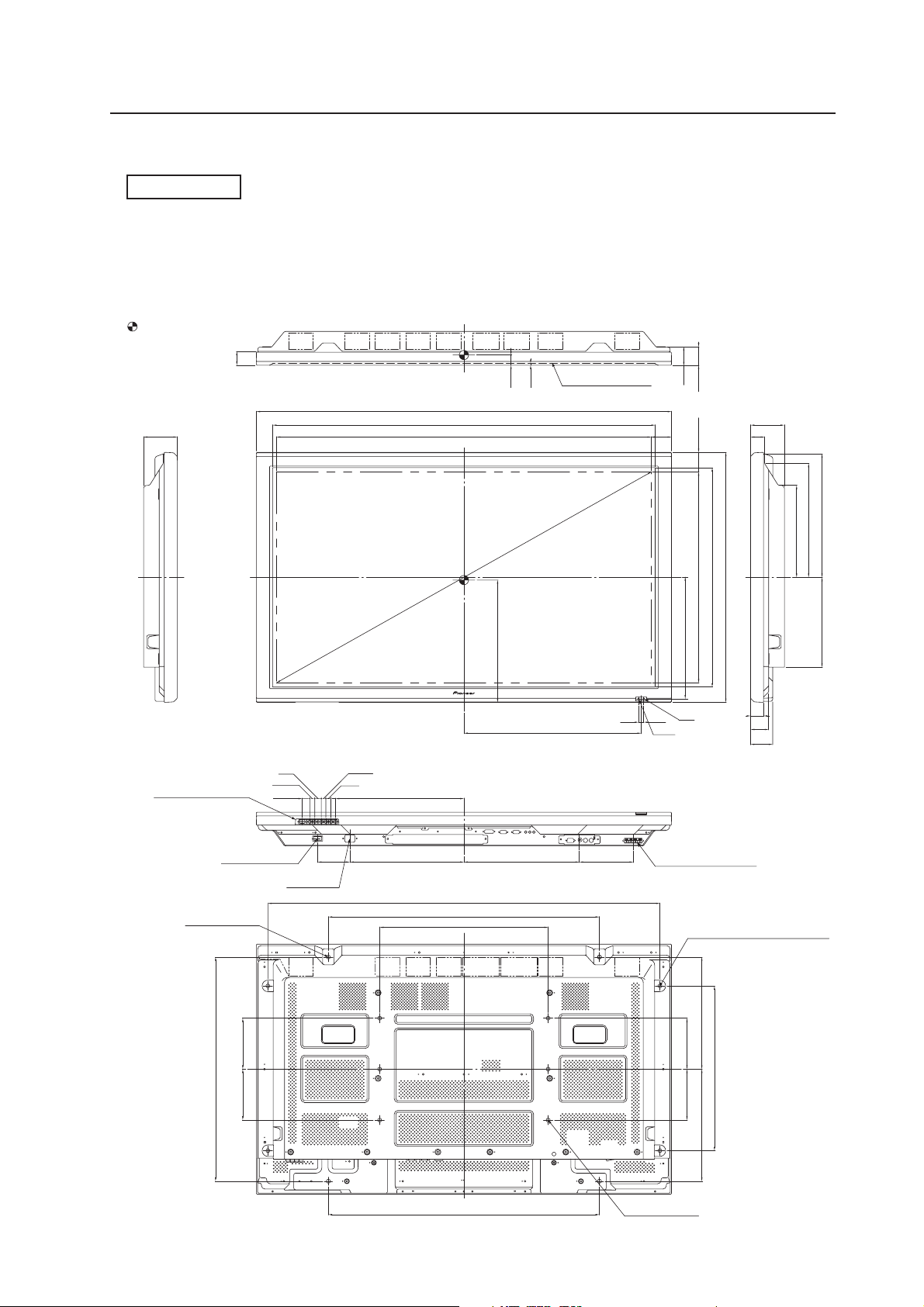

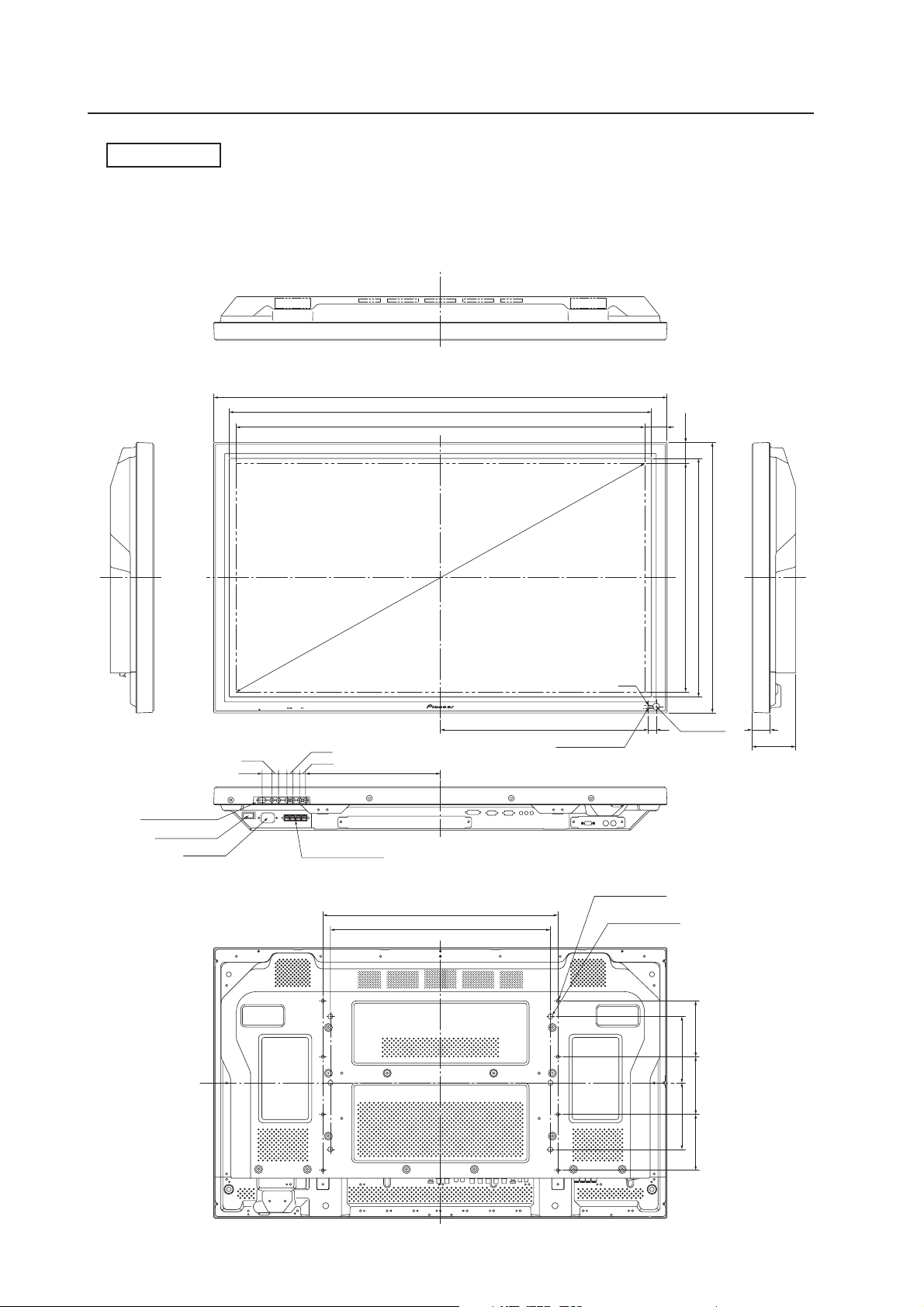

2.2 External Dimensions

PDP-507CMX

WEIGHT: 35.5 kg (78.3 lbs) (without stand)

MATERIAL: Front: Resin; Rear cover: Metal plate, Front protector panel: Glass

TREATMENT: Front: Paint; Rear cover: Paint (All paints are Pioneer original colors)

For packaging information, refer to “3.4.2 Unpacking” (pg. 30).

(Unit: mm)

: center of gravity

41

5.5

FILTER SURFACE

TOP VIEW

1222

1126

99

1103.6(SCREEN AREA)

30

External Dimensions

53

54.5

59

57.55

99

41

363.7

335.5

271

LEFT SIDE VIEW

CONTROL BUTTONS

POWER BUTTON

4-M8.DEPTH14

19

14.7

22.3

AC INLET

736

646

1266.3

360

522

13.5

15

13.5

95

378

335.7 339.9 158.6

7.5

620.9(SCREEN AREA)

357.85

IR

7.5

LED

RIGHT SIDE VIEW

SPEAKER TERMINAL

264.6

38

53

65

BOTTOM VIEW

1154

798

496

FOR SPEAKER(M8.DEPTH12)

330330

660

150150

798

REAR VIEW

150150

485

6-M8.DEPTH18

9

Page 10

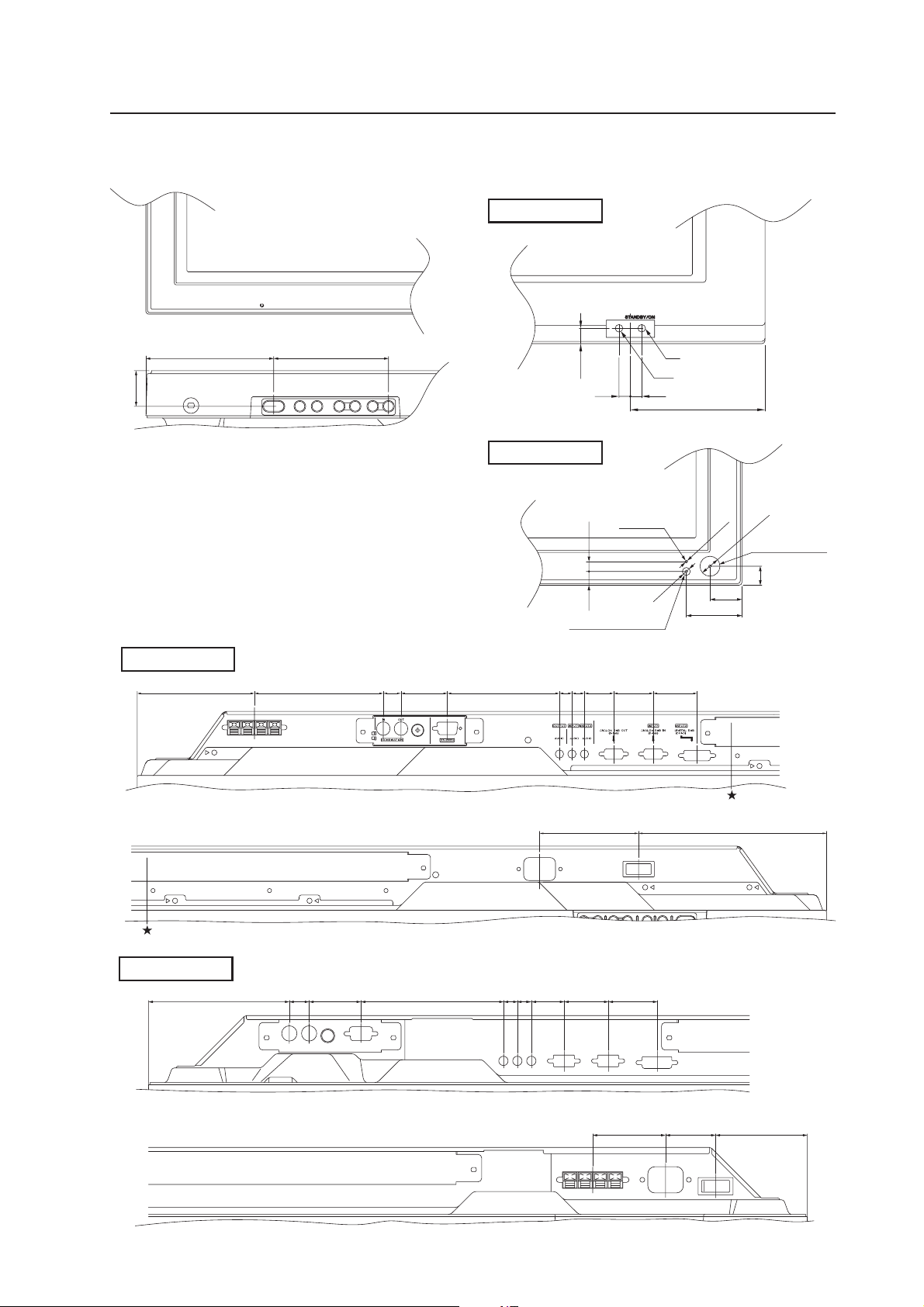

External Dimensions

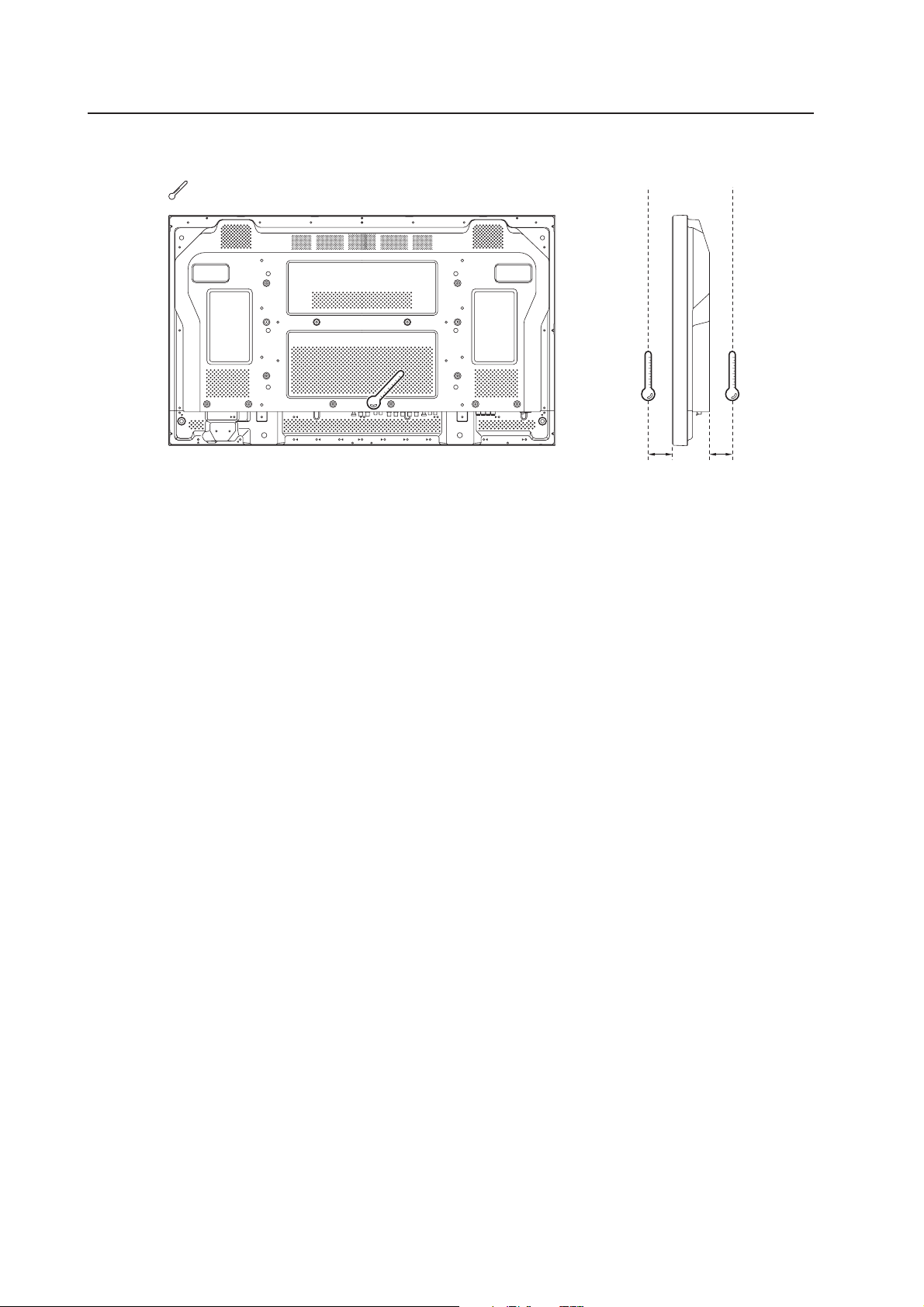

PDP-427CMX

WEIGHT: 30.5 kg (67.3 lbs) (without stand)

MATERIAL: Front: Resin; Rear cover: Metal plate, Front protector panel: Glass

TREATMENT: Front: Paint; Rear cover: Paint (All paints are Pioneer original colors)

For packaging information, refer to “3.4.2 Unpacking” (pg. 30).

(Unit: mm)

TOP VIEW

1022

952

921.6(SCREEN AREA) 50.2

LEFT SIDE VIEW

CONTROL BUTTONS

POWER BUTTON

AC INLET

22.3

14.7

15

19

SPEAKER TERMINAL

13.5

13.5

304

1055.89

BOTTOM VIEW

530

496

610

538

515.33(SCREEN AREA) 47.34

LED

468.6 18 40.4

Ambient light sensor

Light sensor

RIGHT SIDE VIEW

for mount unit

8-M4 DEPTH 16

for mount unit

6-M8 DEPTH 18

98

10

126130126

150150

REAR VIEW

Page 11

External Dimensions

<Main Unit Operation Panel> <Light Sensor for the remote/ambient light

sensor/indicator>

PDP-507CMX

109 98

30.3

<Connection panel>

PDP-507CMX

(112.5) 123.6 17 44.5 107.5 12 12 28 38 42

10.15

PDP-427CMX

Ambient light sensor

10.5 7.5

Indicator

IR

LED

7.57.5

89

ø2

ø15.2

Light sensor for

the remote

14.5

ø6

24.4

42.4

PDP-427CMX

(121) 17 44.5 122.6 12 12 28 38 42

(180.3)95

62.5 43 (78.8)

11

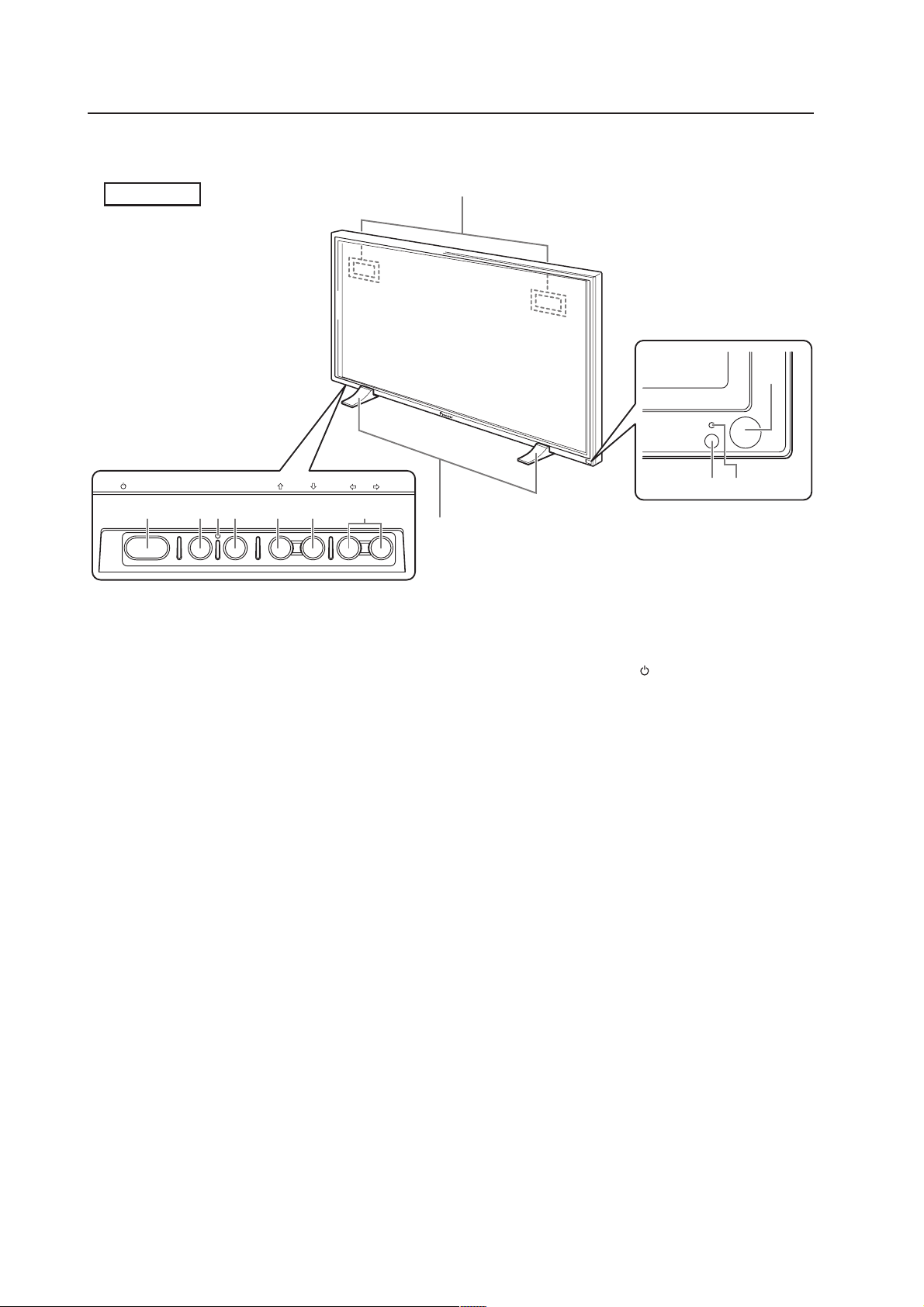

Page 12

Controls and Connectors

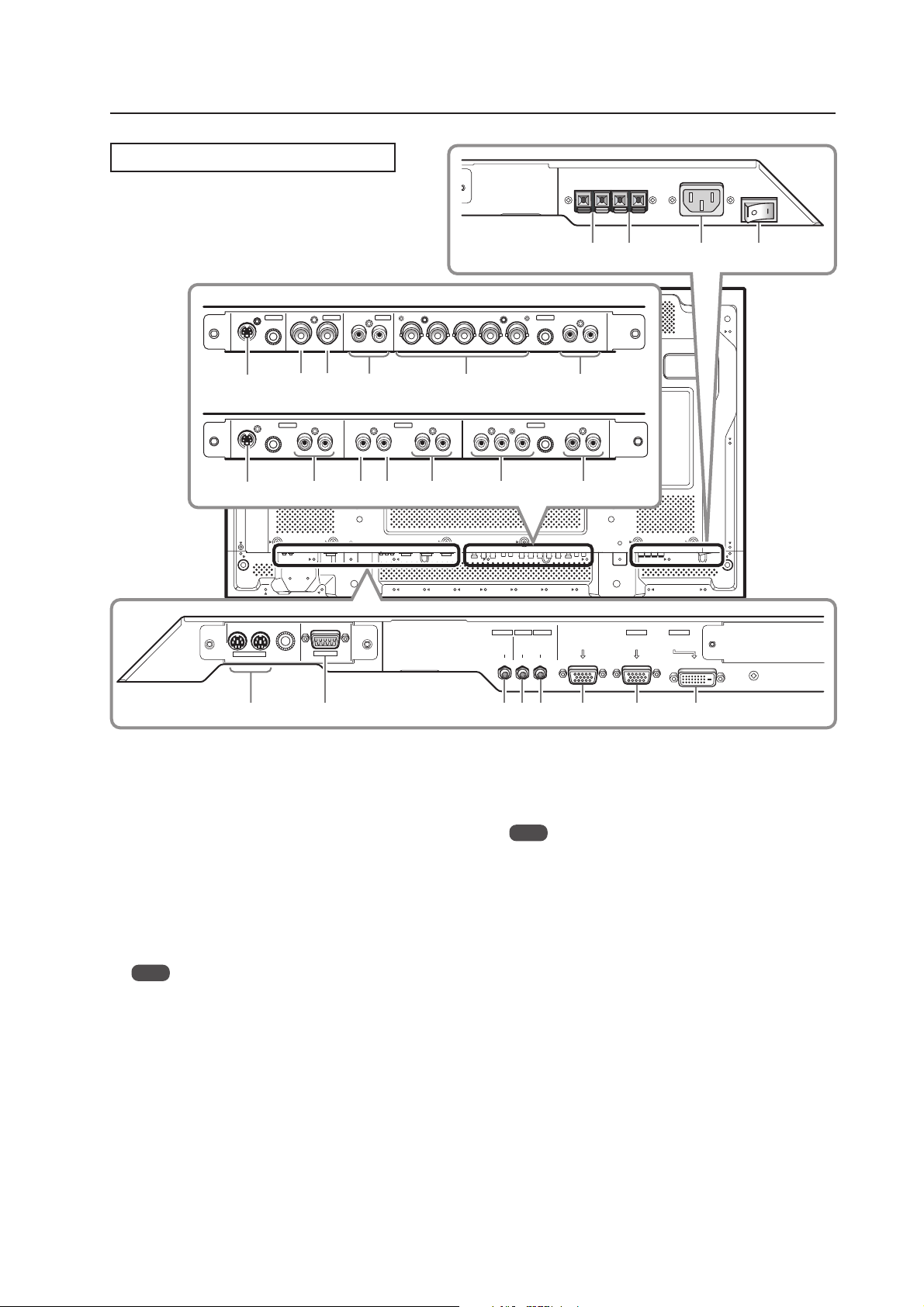

2.3 Controls and Connectors

Main unit

Main unit

Operation panel on the

main unit

STANDBY/ON MENU

DISPLAY

/ SET

7 8= 9 06

* Illustration depicts PDP-427CMX model.

– VOL +INPUT SCREEN SIZE

1

5

STANDBY

2

ON

3

4

Main unit

1 Display stand (PDP-427CMX only)

2 Remote control sensor

Point the remote control toward the remote sensor

to operate the unit.

3 Ambient light sensor

This sensor measures the level of light inside the

viewing room; it is enabled when the [ENERGY

SAVE] option is set to [AUTO].

4 STANDBY/ON indicator

When the unit is operating:

The indicator lights green.

When flashing, the light indicates an error.

The indicator flashes green once per second when

the [POWER MGT.] function is operating.

When the unit is in Standby, the indicator lights red.

When flashing, the light indicates an error.

5 Handles

Operation panel on the main unit

6 STANDBY/ON button ( )

Press to put the display in Standby or into operation.

7 MENU button

Press to open and close the on-screen menu.

8 DISPLAY/SET button

Use to confirm on-screen menu selections and to

change settings.

When not in use by on-screen menus, press to

display the current set status.

9 INPUT (’) button

Except when menu screen is displayed, this button

can change the input.

0 SCREEN SIZE (‘) button

Except when menu screen is displayed, this button

can change the screen size.

- VOL +/– (}/]) buttons

When not in use for by on-screen menus, these

buttons can adjust the sound volume.

= Functional lock button (concealed button)

This button is used to switch between permitted

and blocked operation of the control panel and the

remote control. It can also set the input function

memory.

12

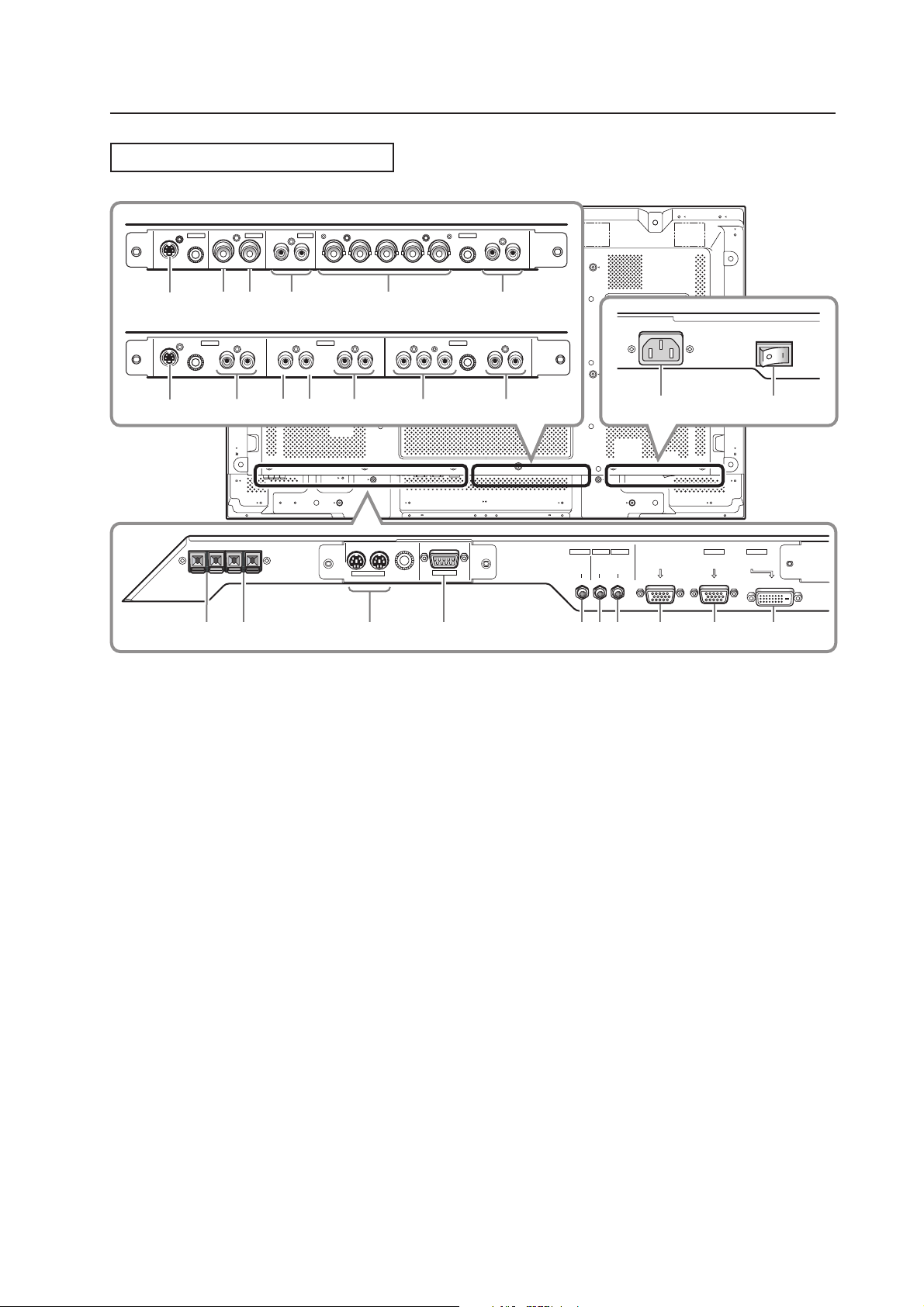

Page 13

Connection Panel (PDP-507CMX)

When installing PDA-5003

S-VIDEO

INPUT3

INPUT4

VIDEO

AUDIO

INPUT 3/4 ANALOG RGB AUDIO

Controls and Connectors

INPUT5

~

OUT R L

IN

!@

#

BR VD RL

G(ON SYNC)

$

When installing PDA-5004

IN OUT

COMBINATION

COMPONENT

VIDEO

S-VIDEO

INPUT3 INPUT4 INPUT5

^

AUDIO AUDIO AUDIO

VIDEO

RL RL RLY Pb/Cb Pr/CrIN OUT

&)_

*(

21 8 9 03567

Plasma Display Section

1 SPEAKER (R) terminal

For connection of an external right speaker.

Connect a speaker that has an impedance of 6 Ω to

16 Ω.

2 SPEAKER (L) terminal

For connection of an external left speaker. Connect

a speaker that has an impedance of 6 Ω to 16 Ω.

3 COMBINATION IN/OUT

Never connect any component to these

connectors without first consulting your Pioneer

installation technician.

These connectors are used for Plasma Display

setup adjustments.

4 RS-232C

Never connect any component to this connector

without first consulting your Pioneer installation

technician.

This connector is used for Plasma Display setup

adjustments.

5 AUDIO (OUTPUT) (Stereo mini jack)

Use to output the audio of the selected source

component connected to this unit to an AV amplifier

or similar component.

Note: No sound is produced from the AUDIO (OUTPUT)

jack when the MAIN POWER switch is set to OFF or when

set to Standby.

HD (H/V SYNC)

RS-232C

4

%

INPUT2

DIGITAL RGB

(DVI-D)

=-

+

INPUT1

OUTPUT INPUT2

AUDIO

AUDIO AUDIO

ANALOG RGB OUT

(D-Sub)

INPUT1

ANALOG RGB IN

(D-Sub)

6 AUDIO (INPUT1) (Stereo mini jack)

Use to obtain sound when INPUT1 is selected.

Connect the audio output jack of components

connected to INPUT1 to this unit.

7 AUDIO (INPUT2) (Stereo mini jack)

Use to obtain sound when INPUT2 is selected.

Connect the audio output jack of components

connected to INPUT2 to this unit.

8 ANALOG RGB OUT (INPUT1) (mini D-sub 15 pin)

Use the ANALOG RGB OUT (INPUT1) terminal to

output the video signal to an external monitor or

other component.

Note: The video signal is not output from the ANALOG

RGB OUT (INPUT1) terminal when the panel's main power

is OFF or the panel is in Standby.

9 ANALOG RGB IN (INPUT1) (mini D-sub 15 pin)

For connection of a personal computer (PC) or

similar component. Confirm that the connection

made corresponds to the signal output from the

connected component.

0 DIGITAL RGB (INPUT2) (DVI-D jack)

Use to connect a computer.

Note: This unit does not support the display of

copyguard-protected video signals.

- AC IN

Use to connect the supplied power cord to an AC outlet.

= MAIN POWER switch

Use to switch the main power of the unit on and off.

13

Page 14

Controls and Connectors

Video Card <PDA-5003> Section

The video card provides three video input connectors,

one video output connector, and two audio input

connectors. Consult the pages noted in parentheses ( )

for details regarding connections to the various jacks

and connectors.

~ S-VIDEO (INPUT3) (S-video jack)

Use this jack to connect components that have an

S-video output jack such as a video deck, video

camera, laser disc player, or DVD recorder.

! VIDEO IN (INPUT4) (BNC jack)

Use this jack to connect components that have a

composite video output jack such as a video deck,

video camera, laser disc player, or DVD recorder.

@ VIDEO OUT (INPUT4) (BNC jack)

Use this jack to output the video signal to an

external monitor or other component.

Note

The video signal is not output from the VIDEO OUT

(INPUT4) jack when the display is OFF or in the Standby

mode.

# AUDIO R/L (INPUT3/4) (RCA Pin jacks)

Use this jack to obtain sound when INPUT3 or

INPUT4 is selected. Connect these jacks to the

component’s audio outputs that are connected to

the video card’s INPUT3 or INPUT4.

$ ANALOG RGB (INPUT5) (BNC jacks)

Use this jack to connect components equipped with

RGB outputs jacks such as personal computers,

external RGB decoders, or components equipped

with component output jacks such as DVD

recorders. Verify that the connection corresponds to

the signal output from the connected component.

% AUDIO R/L (INPUT5) (RCA Pin jacks)

Use this jack to obtain sound when INPUT5 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT5.

Video Card <PDA-5004> Section

The video card provides three video input connectors,

one video output connector, and three audio input

connectors. Consult the pages noted in parentheses ( )

for details regarding connections to the various jacks

and connectors.

^ S-VIDEO (INPUT3) (S-video jack)

Use this jack to connect components that have an

S-video output jack such as a video deck, video

camera, laser disc player, or DVD recorder.

& AUDIO R/L (INPUT3) (RCA Pin jacks)

Use this jack to obtain sound when INPUT3 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT3.

* VIDEO IN (INPUT4) (RCA Pin jack)

Use this jack to connect components that have a

composite video output jack such as a video deck,

video camera, laser disc player, or DVD recorder.

( VIDEO OUT (INPUT4) (RCA Pin jack)

Use this jack to output the video signal to an

external monitor or other component.

Note

The video signal is not output from the VIDEO OUT

(INPUT4) jack when the display is OFF or in Standby.

) AUDIO R/L (INPUT4) (RCA Pin jacks)

Use this jack to obtain sound when INPUT4 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT4.

_ COMPONENT VIDEO (INPUT5) (RCA Pin jacks)

Use this jack to connect devices that have

component video output jacks such as DVD

recorders.

+ AUDIO R/L (INPUT5) (RCA Pin jacks)

Use this jack to obtain sound when INPUT5 is

selected.

Connect these jacks to the device’s audio outputs

that are connected to the video card’s INPUT5.

14

Page 15

Connection Panel (PDP-427CMX)

When installing PDA-5003

S-VIDEO

INPUT3

INPUT4

VIDEO

INPUT 3/4 ANALOG RGB AUDIO

AUDIO

Controls and Connectors

=-09

INPUT5

OUT R L

IN

~

! @

#

When installing PDA-5004

INPUT3 INPUT4 INPUT5

S-VIDEO

^

IN OUT

COMBINATION

13

AUDIO AUDIO AUDIO

VIDEO

RL RL RLY Pb/Cb Pr/CrIN OUT

* (

& ) _

RS-232C

2

Plasma Display Section

1 COMBINATION IN/OUT

These connectors are used for Plasma Display

setup adjustments.

2 RS-232C

This connector is used for Plasma Display setup

adjustments.

3 AUDIO (OUTPUT) (Stereo mini jack)

Use this port to output the audio of the selected

source component that is connected to the Plasma

Display, to an AV amplifier or similar component.

Note

No sound is produced from the AUDIO (OUTPUT) jack

when the display is OFF or in the Standby mode.

4 AUDIO (INPUT1) (Stereo mini jack)

Use this port to obtain sound when INPUT1 is

selected. Connect this jack to the audio output

connector on the device that is connected to the

plasma panel’s INPUT1.

5 AUDIO (INPUT2) (Stereo mini jack)

Use this port to obtain sound when INPUT2 is

selected. Connect this jack to the audio output

connector on the device connected to the Plasma

Display’s INPUT2.

BR VD RL

G(ON SYNC)

HD (H/V SYNC)

$

COMPONENT

VIDEO

INPUT1

OUTPUT INPUT2

AUDIO

AUDIO AUDIO

6 ANALOG RGB OUT (INPUT1) (mini D-sub 15 pin)

Use this connector to output the video signal to an

external monitor or other component.

Note

The video signal is not output from the ANALOG RGB OUT

(INPUT1) connector when the main power of this display is

OFF or in Standby mode.

7 ANALOG RGB IN (INPUT1) (mini D-sub 15 pin)

Use this input to connect components equipped

with RGB outputs jacks such as personal

computers. Verify that the connection corresponds

the signal output format from the connected

component.

8 DIGITAL RGB (INPUT2) (DVI-D jack)

Use this input to connect to a computer.

Connect to an AV component (HDCP supported)

equipped with DVI output connector.

9 SPEAKER (R) terminal

Use this port to connect an external right speaker.

Connect a speaker whose impedance is 6 Ω to 16 Ω.

0 SPEAKER (L) terminal

Use this port to connect an external left speaker.

Connect a speaker whose impedance is 6 Ω to 16 Ω.

%

+

ANALOG RGB OUT

(D-Sub)

6 7 845

INPUT1

ANALOG RGB IN

(D-Sub)

INPUT2

DIGITAL RGB

(DVI-D)

15

Page 16

Controls and Connectors

- AC IN

A power cable is furnished with the Plasma Display.

Connect one end of the power cable to this

connector and the other end to a standard AC

power source.

= MAIN POWER switch

Use this switch to toggle the panel’s main power

ON and OFF.

Video Card <PDA-5003> Section

The video card is provided with 3 video input

connectors, 1 video output connector and 2 audio input

connectors. Consult the pages noted in parentheses ( )

for details regarding connections to the various jacks

and connectors.

~ S-VIDEO (INPUT3) (S-video jack)

Use this jack to connect components that have an

S-video output jack such as a video deck, video

camera, laser disc player, or DVD recorder.

! VIDEO IN (INPUT4) (BNC jack)

Use this jack to connect components that have a

composite video output jack such as a video deck,

video camera, laser disc player, or DVD recorder.

@ VIDEO OUT (INPUT4) (BNC jack)

Use this jack to output the video signal to an

external monitor or other component.

Note

The video signal is not output from the VIDEO OUT

(INPUT4) jack when the display is OFF or in the Standby

mode.

# AUDIO R/L (INPUT3/4) (RCA Pin jacks)

Use this jack to obtain sound when INPUT3 or

INPUT4 is selected. Connect these jacks to the

component’s audio outputs that are connected to

the video card’s INPUT3 or INPUT4.

$ ANALOG RGB (INPUT5) (BNC jacks)

Use this jack to connect components equipped with

RGB outputs jacks such as personal computers,

external RGB decoders, or components equipped

with component output jacks such as DVD

recorders. Verify that the connection corresponds to

the signal output format from the connected

component.

% AUDIO R/L (INPUT5) (RCA Pin jacks)

Use this jack to obtain sound when INPUT5 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT5.

Video Card <PDA-5004> Section

The video card provides 3 video input connectors, 1

video output connector and 3 audio input connectors.

Consult the pages noted in parentheses ( ) for details

regarding connections to the various jacks and

connectors.

^ S-VIDEO (INPUT3) (S-video jack)

Use this jack to connect components that have an

S-video output jack such as a video deck, video

camera, laser disc player, or DVD recorder.

& AUDIO R/L (INPUT3) (RCA Pin jacks)

Use this jack to obtain sound when INPUT3 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT3.

* VIDEO IN (INPUT4) (RCA Pin jack)

Use this jack to connect components that have a

composite video output jack such as a video deck,

video camera, laser disc player, or DVD recorder.

( VIDEO OUT (INPUT4) (RCA Pin jack)

Use this jack to output the video signal to an

external monitor or other component.

Note

The video signal is not output from the VIDEO OUT

(INPUT4) jack when the display is OFF or in the Standby

mode.

) AUDIO R/L (INPUT4) (RCA Pin jacks)

Use this jack to obtain sound when INPUT4 is

selected.

Connect these jacks to the component’s audio

outputs that are connected to the video card’s

INPUT4.

_ COMPONENT VIDEO (INPUT5) (RCA Pin jacks)

Use this jack to connect devices that have

component video output jacks such as DVD

recorders.

+ AUDIO R/L (INPUT5) (RCA Pin jacks)

Use this jack to obtain sound when INPUT5 is

selected.

Connect these jacks to the device’s audio outputs

that are connected to the video card’s INPUT5.

16

Page 17

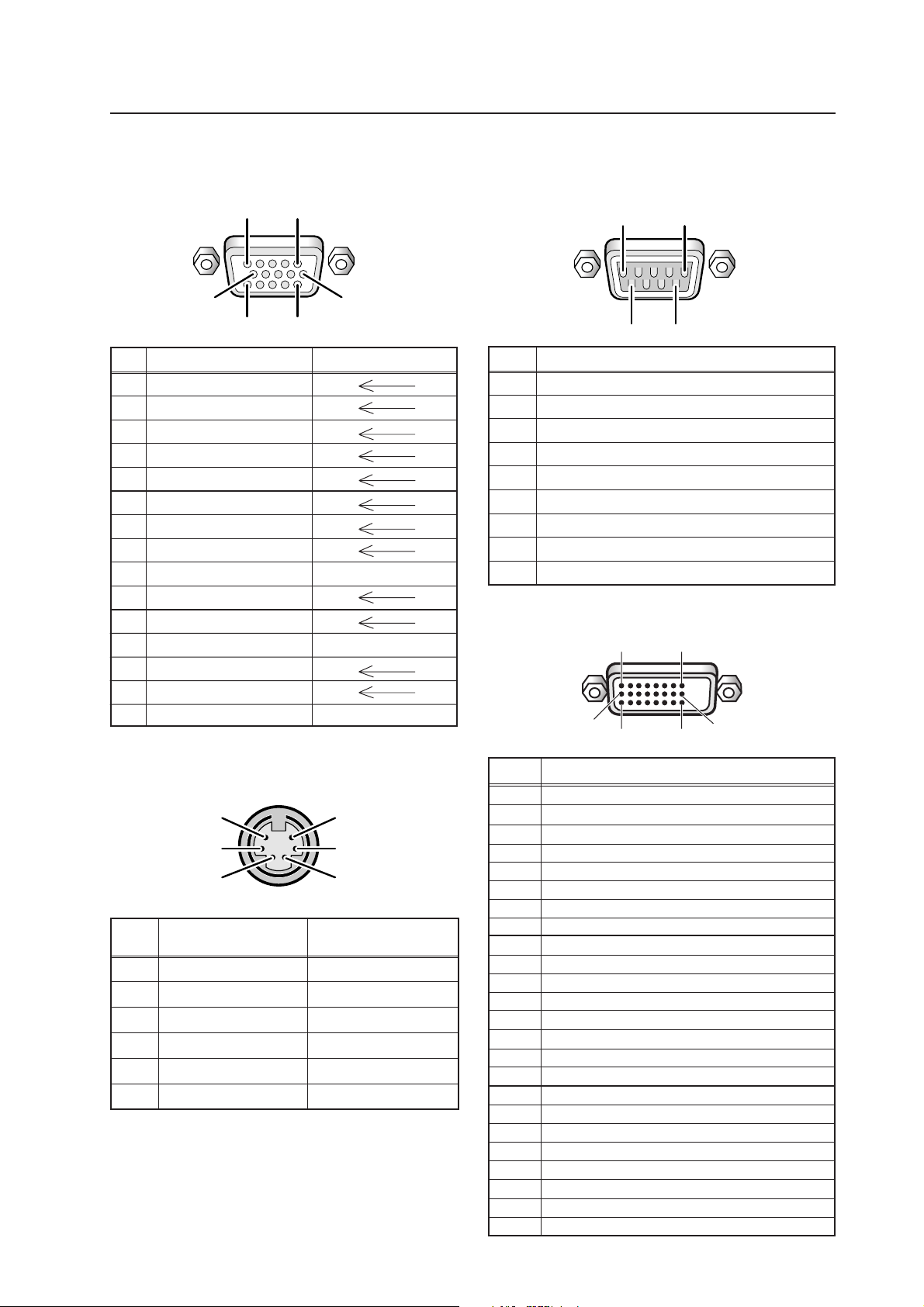

2.4 Pin layout

INPUT1 (Mini D-sub, 15-pin connector; female)

pin layout

5

1

Pin layout

RS-232C terminal (D-sub 9-pin connector; male)

pin layout (DCE format)

1

5

6

Pin No.

10

1115

Input Output

1R

2G

3B

4 NC (not connected)

5 GND

6 GND

7 GND

8 GND

9 DDC +5V NC (not connected)

10 GND

11 NC (not connected)

12 DDC SDA NC (not connected)

13 HD or H/V SYNC

14 VD

15 DDC SCL NC (not connected)

96

Pin No.

Signal

1 NC (not connected)

2 TxD (Transmit Data)

3 RxD (Receive Data)

4 NC (not connected)

5 GND

6 NC (not connected)

7 NC (not connected)

8 RTS (Request To Send)

9 NC (not connected)

INPUT2 (DVI-D 24 pin connector; female)

pin layout

12

9

16

2417

Combination IN/OUT terminal pin layout

6

4

2

Pin No.

Combination Combination

IN OUT

1 GND GND

2 NC (not connected) NC (not connected)

3 TxD (output) RxD (input)

4 NC (not connected) NC (not connected)

5 RxD (input) TxD (output)

6 NC (not connected) NC (not connected)

5

3

1

Pin No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Signal Assignment

T.M.D.S. Data2–

T.M.D.S. Data2+

T.M.D.S. Data2/4 Shield

NC (No connection)

NC (No connection)

DDC Clock

DDC Data

NC (No connection)

T.M.D.S. Data1–

T.M.D.S. Data1+

T.M.D.S. Data1/3 Shield

NC (No connection)

NC (No connection)

+5V Power

GND

Hot Plug Detect

T.M.D.S. Data0 –

T.M.D.S. Data0+

T.M.D.S. Data0/5 Shield

NC (No connection)

NC (No connection)

T.M.D.S. Clock Shield

T.M.D.S. Clock+

T.M.D.S. Clock–

17

Page 18

Remote Control Unit

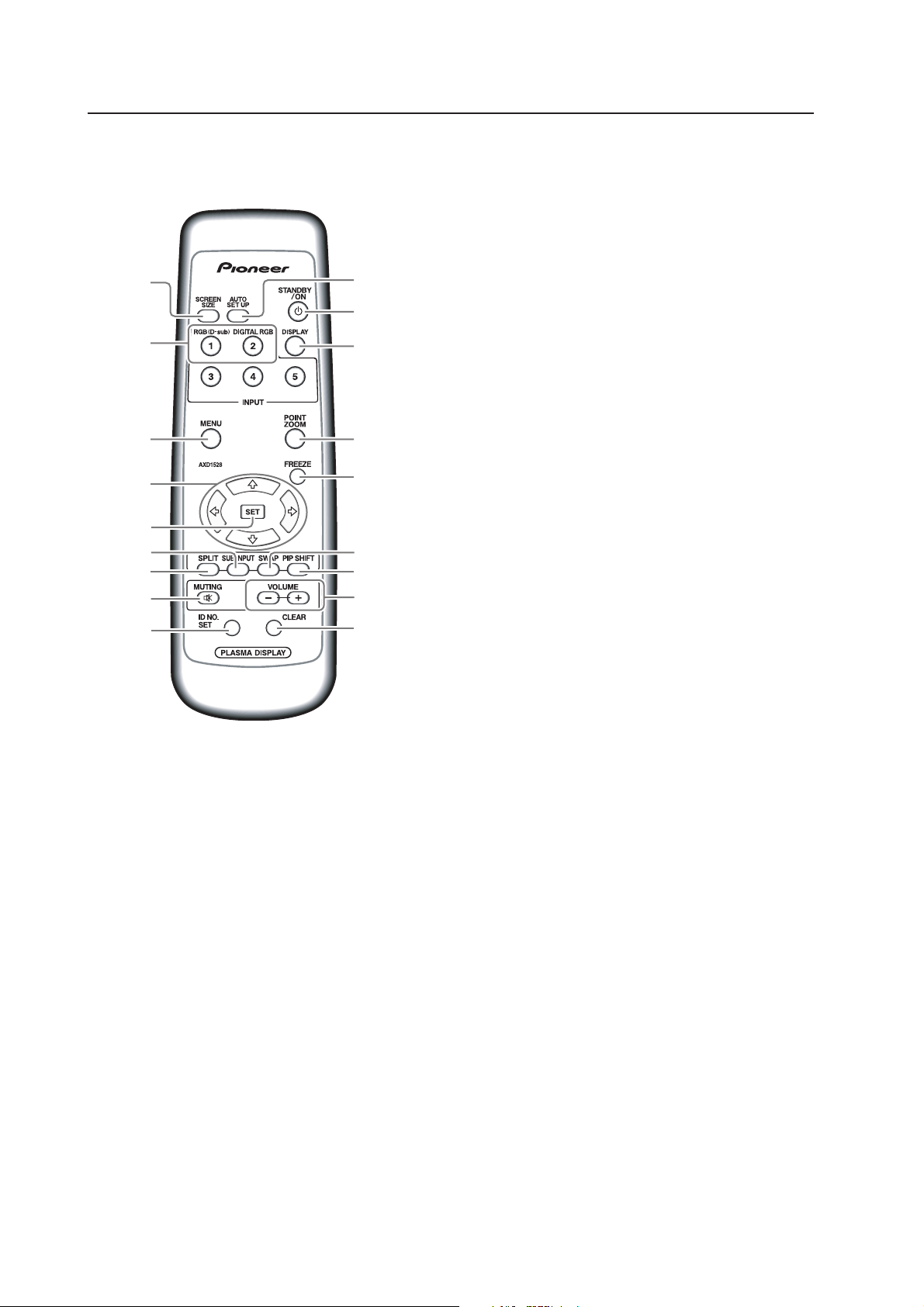

2.5 Remote Control Unit

1

2

3

4

0

-

=

~

!

1 SCREEN SIZE button

Press to select the screen size.

2 INPUT buttons

Press to select the input.

3 MENU button

Press to reveal and hide the on-screen menu.

4 ADJUST (5/∞/3/2) buttons

Press to navigate menu screens and adjust various

settings on the unit.

5 SET button

Press to adjust or enter various settings on the unit.

6 SUB INPUT button

Press to change subscreen inputs during multiscreen display.

5

7

8

9

@6

#

$

%

7 SPLIT button

Press to switch to multi-screen display.

8 MUTING button

Press to mute the volume.

9 ID NO. SET button

Press to select which position the panel holds in a

video wall.

0 AUTO SET UP button

Press to automatically set the [POSITION], [CLOCK].

and [PHASE] to optimum values when using a

computer signal.

- STANDBY/ON button

Press to activate the display or place in Standby.

= DISPLAY button

Press to view the unit’s current input and setup

mode.

~ POINT ZOOM button

Press to select and enlarge a portion of the screen.

! FREEZE button

Press to display a still image in the subscreen when

the memo screen function is enabled.

18

@ SWAP button

Press to switch between the main screen and the

subscreen during multi-screen display.

# PIP SHIFT button

Press to move the position of the subscreen when

viewing in PinP mode with multi-screen dsplay.

$ VOLUME (+/–) buttons

Press to adjust the volume.

% CLEAR button

Press to clear for program timer and ID assignment.

Page 19

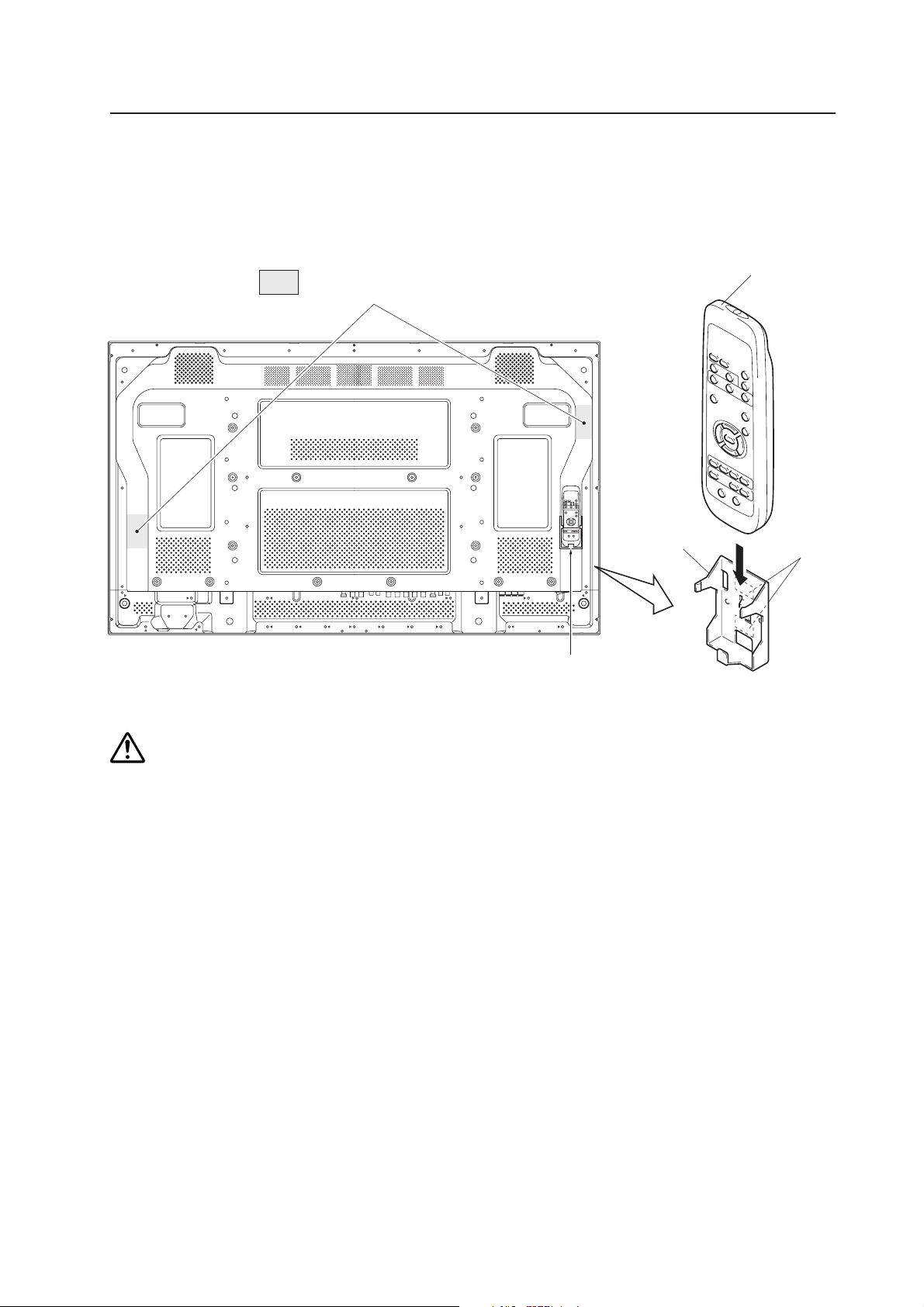

Remote Control Unit Holder

2.6 Remote Control Unit Holder (PDP-427CMX only)

Peel the sticker covers from the lower and upper mounting tapes on the rear of the remote control holder. Attach it to

the back of the main unit or on some other fixed surface so that it will be available for storing the remote control with

the panel.

Area of remote control

unit holder attachment

Remote control

unit holder

Example of remote control

unit holder attachment

Remote control unit

Upper and

lower tape

Do not block ventilation holes with the remote control holder.

Caution

19

Page 20

Installation Site Requirements

[507CMX : 427CMX]

3.1 Installation Site Requirements

If the site requires modifications or special preparations before installing the Plasma Display or its mounting hardware,

obtain permission in advance from the building owner or building authorities. To ensure safety, it is also important to

determine the strength of the installation site with the help of an authorized building contractor.

Safety Precautions

1) Structure of the installation site

Thoroughly study the structure of the installation site before determining the most suitable installation method.

Buildings vary in structure and materials, thus the best mounting choice differs at each location. When drilling into

walls, check for internal electrical wiring and hidden pipes.

2) Weight capacity of the installation site

Select a location sufficient to support the total weight of the display and mounting hardware.

3) Flat, level surfaces

Select a flat, level surface so that the mounting hardware is parallel to the proposed mounting surface.

Install the unit so that the load is evenly distributed along the ceiling or floor, as well as on mounting hardware such as

from hang bolts.

4) Sufficient work space

Select a location with sufficient space for installation preperations. The panel mounting should be conducted by two or

more people.

5) Nearby equipment

If air conditioning ducts, lamps, etc. are located near the installation site, dust, temperatures fluctuations, humidity, and

condensation may cause problems. Please take steps to avoid this possibility.

6) Safe locations

Do not install the unit where it may be easily touched or leaned against. Avoid locations subject to high vibration or

severe impacts.

7) Lighting conditions

• Check existing lighting and sunlight angles when considering an installation layout. Bright lighting can reduce the

visibility and quality of a displayed image.

• In very bright surroundings, adjusting screen intensity may not result in perceptibly brighter images. Extreme intensity

settings can reduce a system’s service life.

8) Other installation conditions

The panel is designed for indoor use and is not suited for open-air use. Installation in locations that are even partially

exposed to the elements may lead to malfunctions or breakdown. If there is a danger of being subjected to the conditions

listed below, it is necessary to limit the exposure as much as possible.

• Water or other liquids and dust

• Temperature and humidity changes

• Salt-bearing wind

• Direct sunlight (avoid sites exposed to direct sunlight upon the display as this can degrade image quality)

20

Page 21

[507CMX : 427CMX]

9) Temperature and humidity conditions

• The installation site should meet the following conditions:

• Operating temperatures: 0 °C to 40 °C (largely depending on installation conditions)

• Operating humidity: 20 % to 80 %

• Storage temperature: –20 °C to 60 °C

• Storage humidity: 20 % to 90 %

• Operating atmospheric pressure: 800 hPa to 1100 hPa

• Storage atmospheric pressure: 700 hPa to 1114 hPa

• We discourage installing electronic products such as this unit in locations subject to high humidity. If the unit is to be

installed in a location subject to relatively high humidity, observe the following:

• Failure to install the unit in acceptable ways may result in non-warranty damages.

• Make sure the unit is grounded.

• Do not allow water or other liquids to enter the unit.

10) Prevent condensation

A primary problem during the winter is condensation forming on or in electronic equipment. Rapid temperature fluctuations

can leave water vapor inside the unit or on the screen, degrading performance. If condensation occurs, turn the unit

OFF for an hour or more then increase the room temperature gradually before turning ON the unit.

Consult Pioneer authorized dealers for assistance.

Installation Site Requirements

11) Power requirements

• This unit functions properly when powered at ±10 % of its rated voltage. Characteristics of power lines may effect

the voltage output. If any of the following issues occur, contact an electrician to inspect the power source.

-- Significant voltage drop between the circuit panel and the Plasma Display

-- Significant changes in voltage when switching the display power ON or OFF

• Please allow the following margin for power consumption per unit.

PDP-507CMX: 370 W = 370 VA

PDP-427CMX: 320 W = 320 VA

(NOTE)

When powering up the unit, the in-rush current is approximately 30 A.

• A grounded three-core power cable is used by the Plasma Display in order to maintain its functions.

Connect the power cord by inserting it into a grounded electrical outlet.

When using a different power source, use a conversion plug. Insert it into a grounded electrical outlet and securely

attach the ground wire.

• A leakage current within a value, stipulated by standards in each country, flows from an internal noise filter through

devices installed inside switching power sources such as television sets or air-conditioners. Because these currents

are added together when multiple units are connected, take steps to prevent electric shock caused by ground wires,

etc. When a leakage breaker is installed in a power distribution series, choose the leakage breaker rating that is at

least two times the total leakage current.

When many devices are connected, increase the number of leakage breakers and form branches in the wiring system.

12) Effective remote control distance

The remote control of this display receives at the following angles and distances.

• Front: 8 m

• Left-right 45°: 3 m/Left-right 30°: 7 m

• Upward 30°: 3.5 m/Upward 15°: 5 m

• Downward 30°: 5 m

If other products controlled with infrared remote controls are placed nearby, remote control function may be affected.

In such cases, move other devices further away from the display or contact a Pioneer-authorized dealer for assistance.

Depending on installation conditions, the remote control range may be reduced by infrared radiation emitted by the

screen.

The screen’s infrared intensity varies, depending upon the displayed image.

21

Page 22

Installation Conditions

[507CMX]

3.2 Installation Conditions (PDP-507CMX)

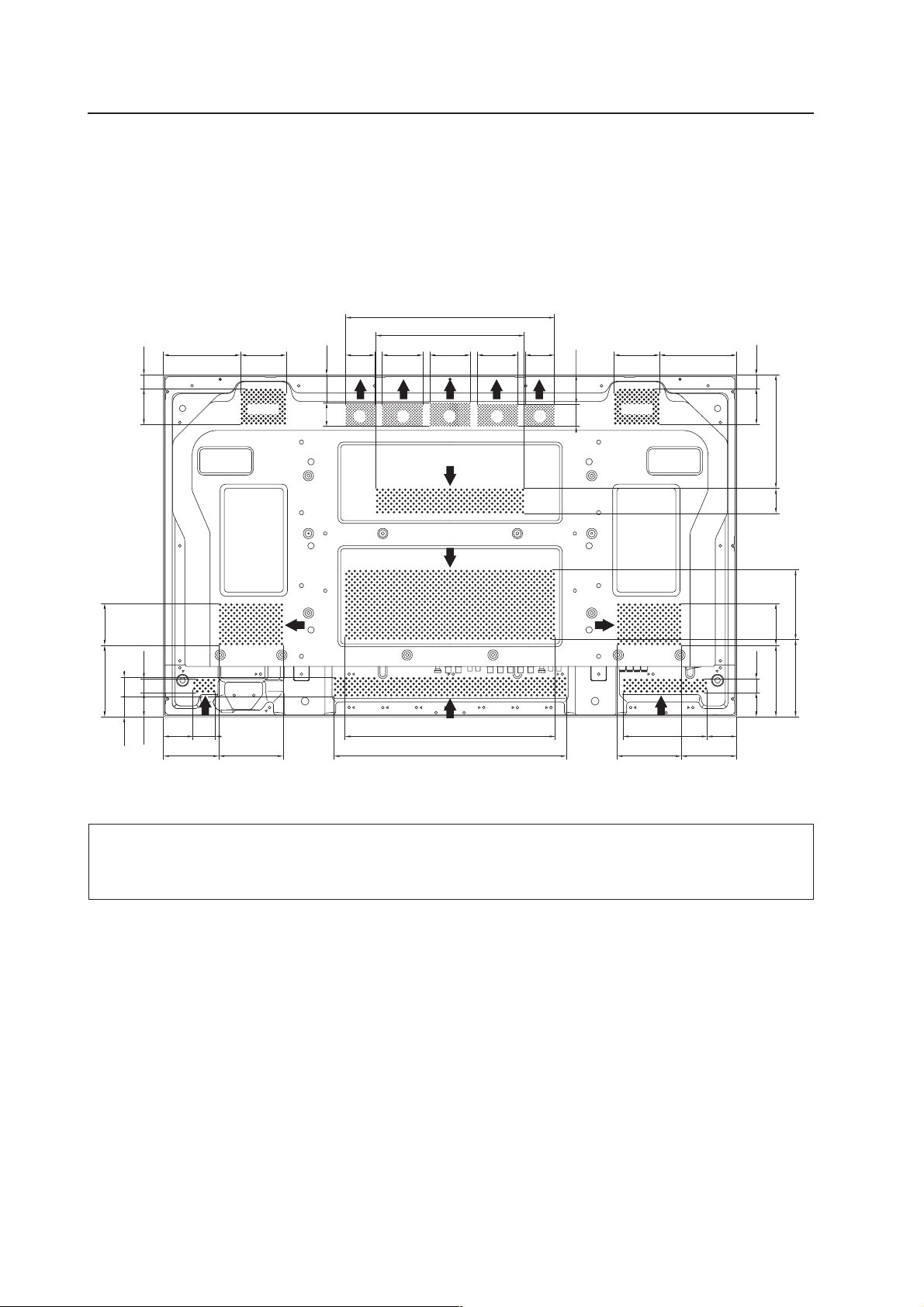

3.2.1 Heat dissipation

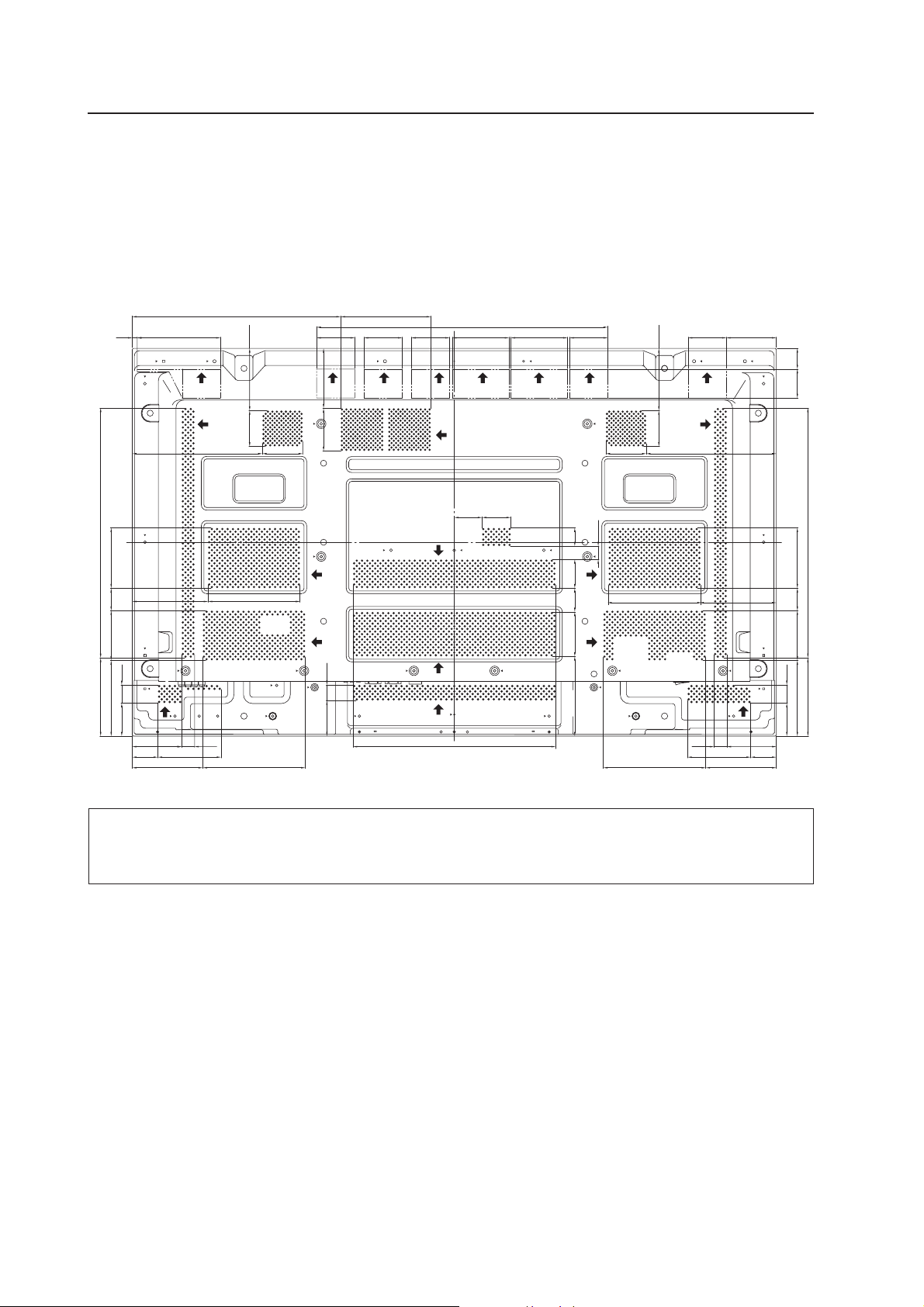

This unit has openings for effective ventilation. Vent locations are marked by arrows in the illustration below. The

arrows show the direction of airflow. To allow proper dissipation of heat from the unit, do not cover these openings.

(Unit : mm)

474.5

148.6

114.542.594.5

143.8

143.7

62.5 34.8

48.6 119.8

395.5

157.99.4

246.7

24.593.7

117.9

Fan

68.2

76.7

174.5

194.5133.7

72.5 72.5 72.5

113.7

81

29.8

67.5

171

552.5

107.4 107.4 72.5

52.8

54.5

384.5

34.5

54.54584.5151.3

25.5

117.9

Fan

68.2

76.7 246.7

174.5

24.5

72.5 94.7

AAAAAAAA

119.8

133.7194.5

143.7

93.7

48.6

34.862.5

39.454.8

114.542.594.5

143.8

474.5

148.6

In a standard installation, two fans and part A draw hot air from the unit. All openings not assisted by fans serve as

air inlets. If the unit is hung from or embedded into a wall, special operating temperature limits and other limitations

may apply. Refer to section “3.5 Special Installation (PDP-507CMX)” (pg. 35) for more information.

22

Page 23

[507CMX]

Installation Conditions

3.2.2 Calculating heat quantity

As a courtesy to our customers, we have included the power formula for calculating air conditioning needs.

For power consumption, allow 370 W = 370 VA per unit.

Since most of the power consumed is transformed into heat, power consumption may be regarded as roughly equal to

generated heat.

1 Conversion to calories

[W] × 0.86 = [kcal/h]

Heat generated per display: 370 W × 0.86 = 318 kcal/h

2 Conversion to British Thermal Units

[W] × 3.41 = [BTU/h]

Heat generated per unit: 370 W × 3.41 = 1262 BTU/h

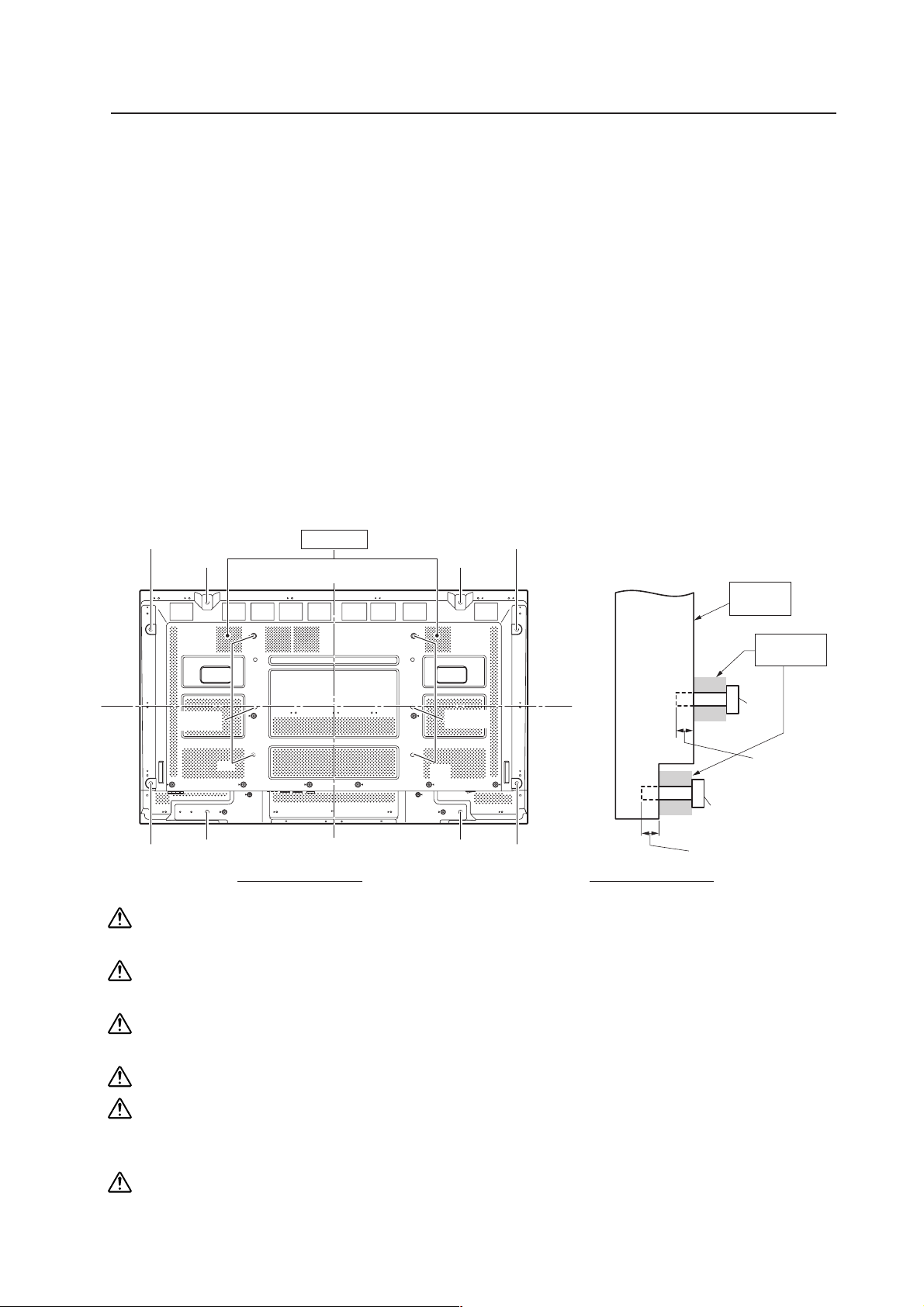

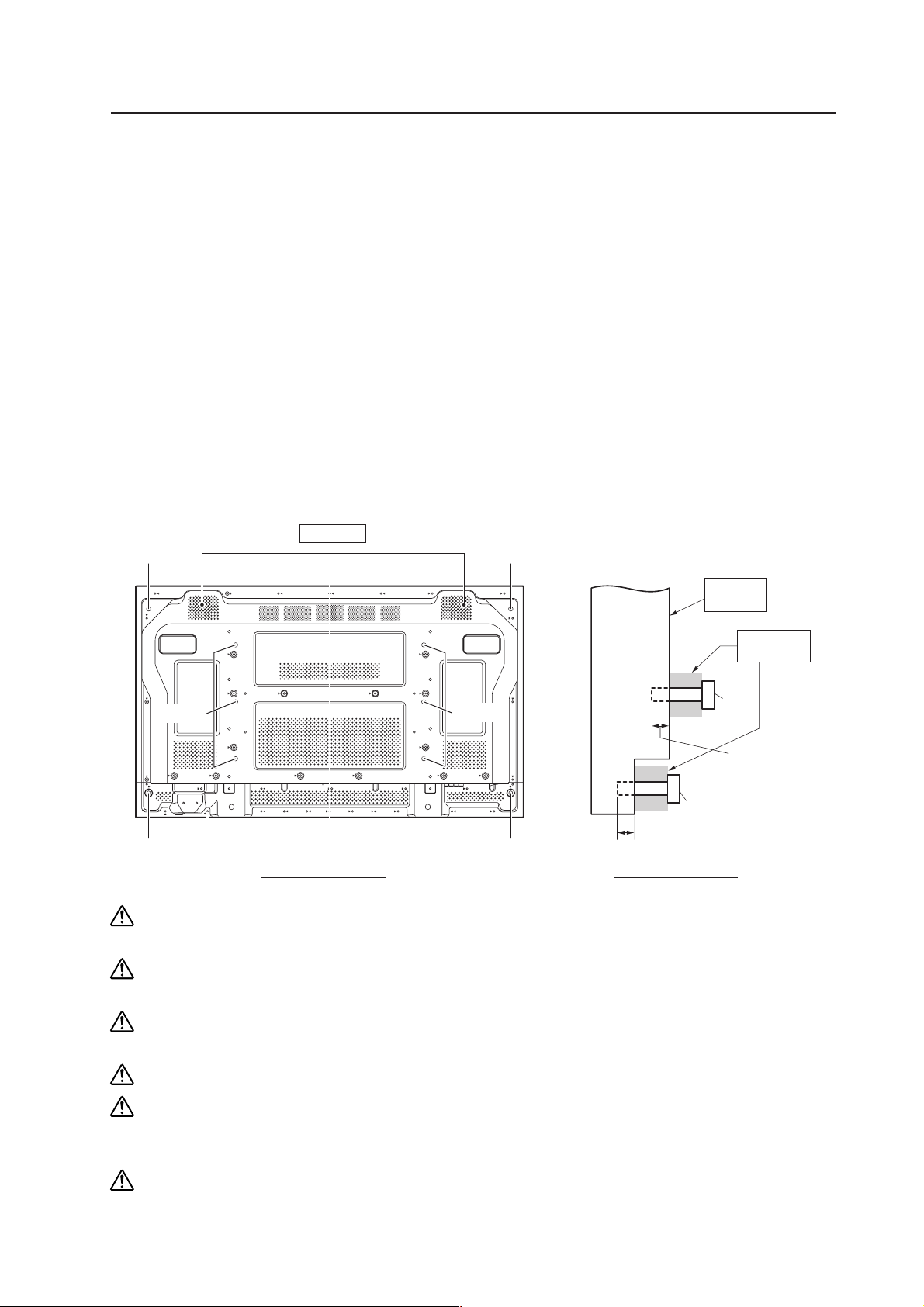

3.2.3 Product mounting holes

We recommend using mounting hardware available from Pioneer. If you use other mounting hardware, mount the

hardware to the unit using the M8-bolt holes on the unit. Tighten the bolts with a torque between 50 kg/cm and 80 kg/

cm. Applying a torque beyond these limits may lead to internal component failure.

Locations of usable mounting holes are shown below.

b hole

b hole

a hole

a holes

a hole

Vent (fan)

Center line

a hole

a holes

a hole

b hole

b hole

a Holes (10 places)

b Holes (4 places)

This unit

Attaching

surface

Installation

bracket etc.

a hole

Bolt

12 mm to

18 mm

b hole

Bolt

12 mm to 14 mm

Rear view diagram Side view diagram

Always use a minimum of 4 mounting holes that are evenly distributed on opposite sides of both the horizontal

and vertical center lines.

Use bolts that can be driven 12 mm to 18 mm into holes “a” and from 12 mm to 14 mm into holes “b” as shown

in the Side View above.

Do not block or cover vents on the rear panel.

Take precautions to prevent the walls from being soiled by the Plasma Display’s exhaust outlets.

This unit incorporates glass components. Install only on flat surfaces.

Always turn every bolt by hand two to three times then check to make sure the bolt is straight.

You may tighten using a tool but do not over-tighten the bolts.

Do not use

loctight

or similar bonding products.

Please use M8 (P=1.25) bolts. DO NOT use any other type of bolt.

23

Page 24

Installation Conditions

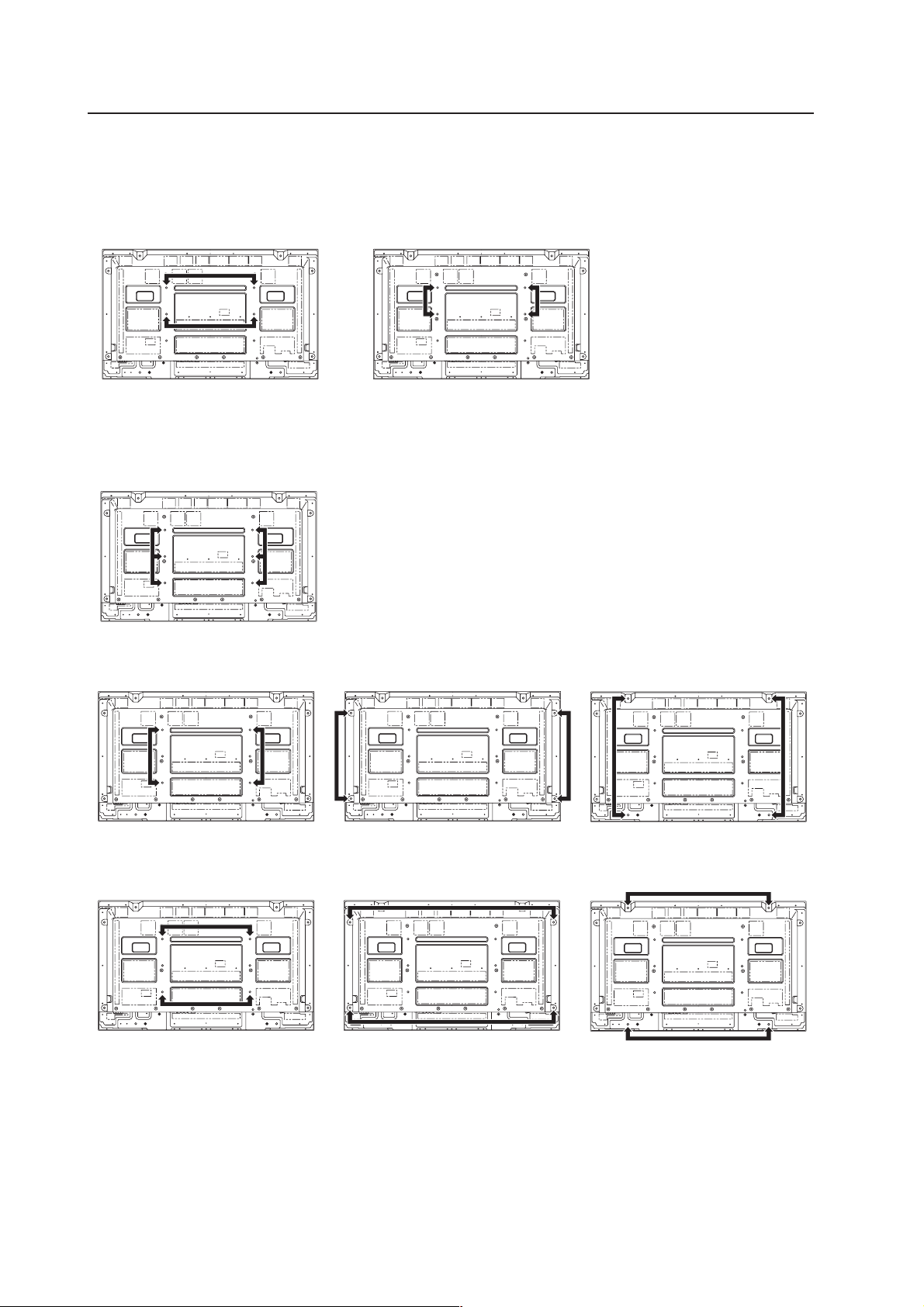

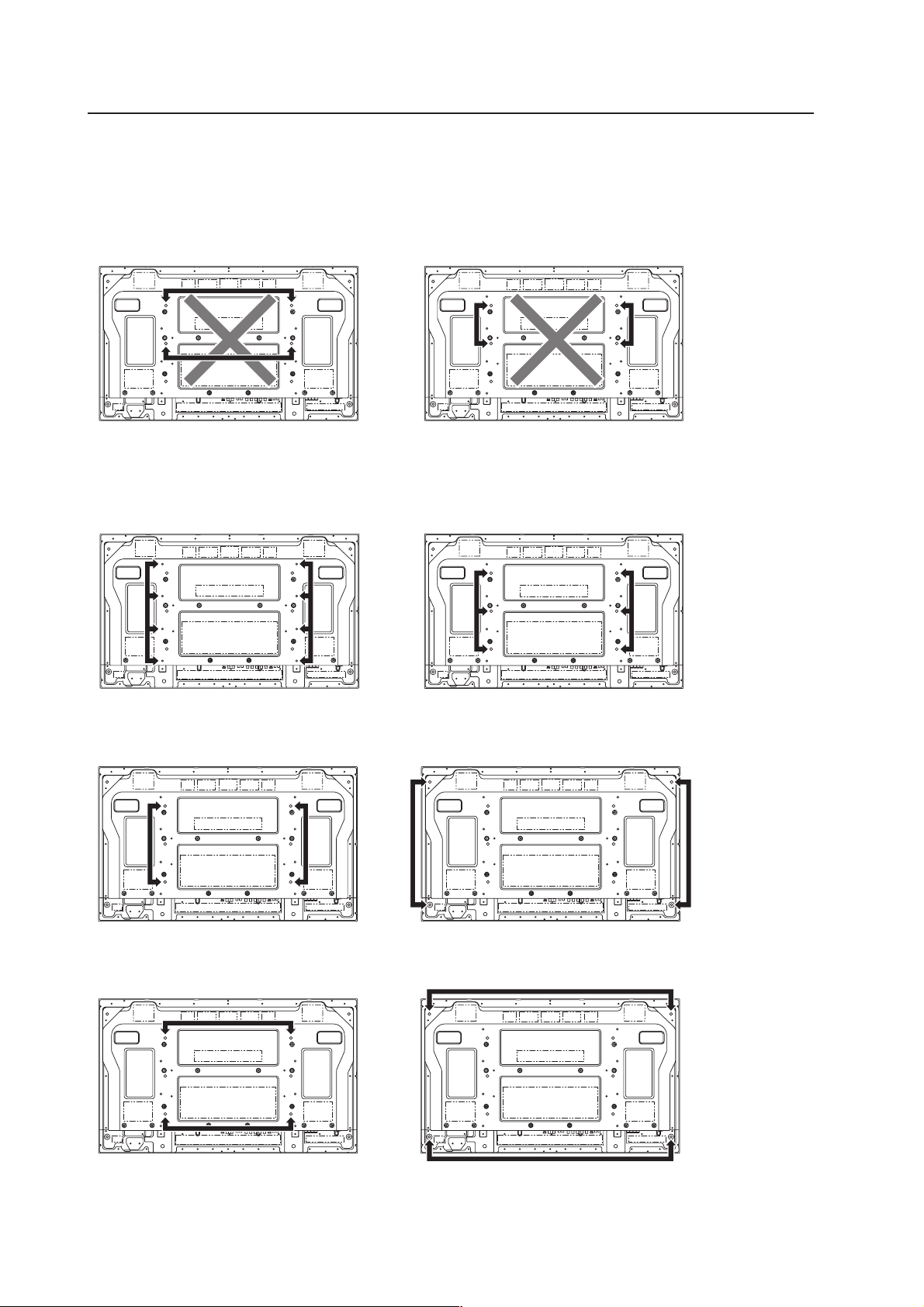

This unit is designed to be mounted using four bolt holes. For additional safety, we recommend securing it at four or six

points on opposite sides of the horizontal and vertical center lines, as shown in the drawing below.

Poor methods for securing

Suggested methods for securing

Secured at six points

*Attach using M8x6.

[507CMX]

Secured at four points (with mounting hardware attached to the top and bottom)

*Attach using M8x4.

Secured at four points (with mounting hardware attached to the sides)

*Attach using M8x4.

Take proper precautions to prevent pinching the power cord or signal cables.

24

Page 25

[507CMX]

Installation Conditions

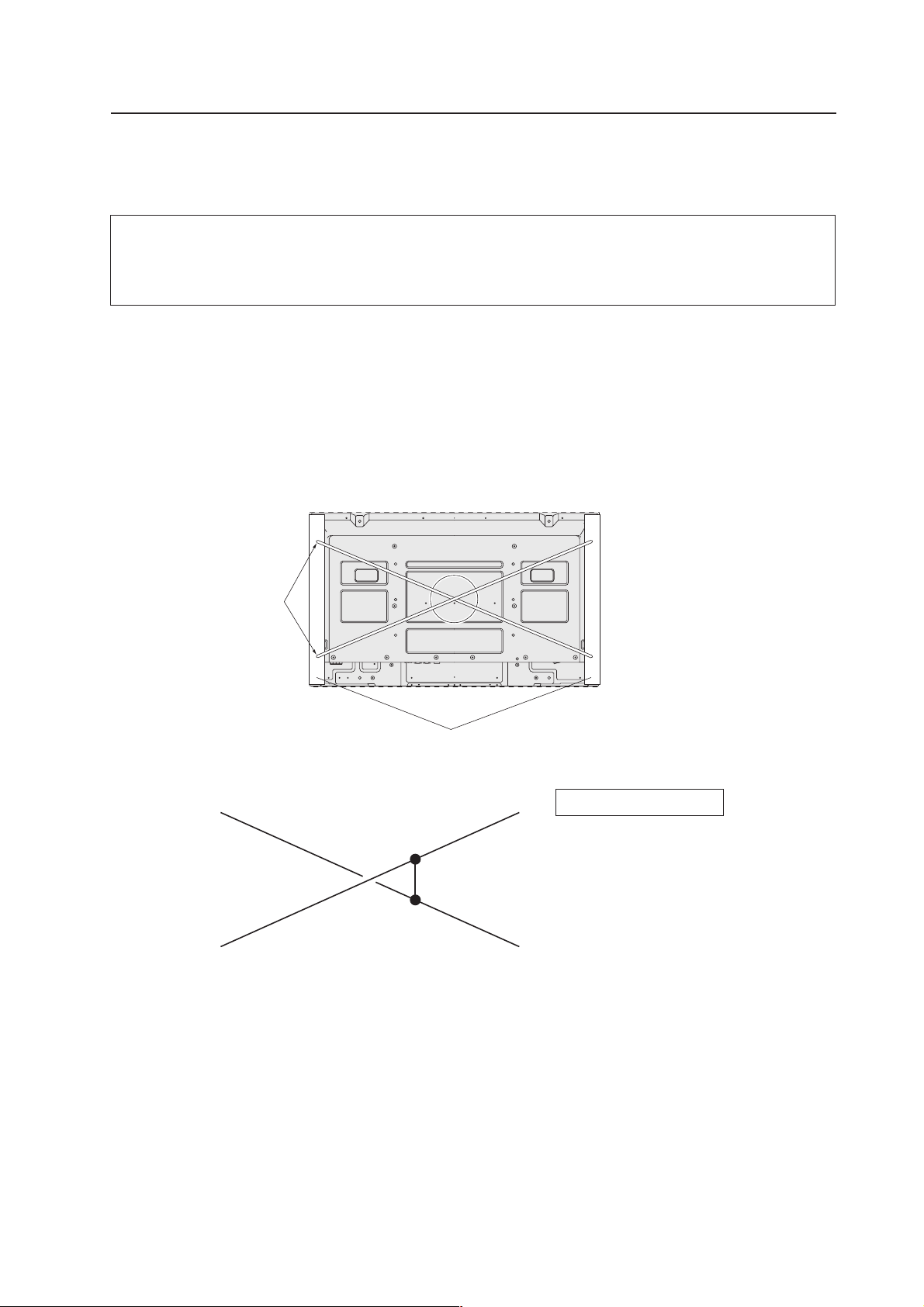

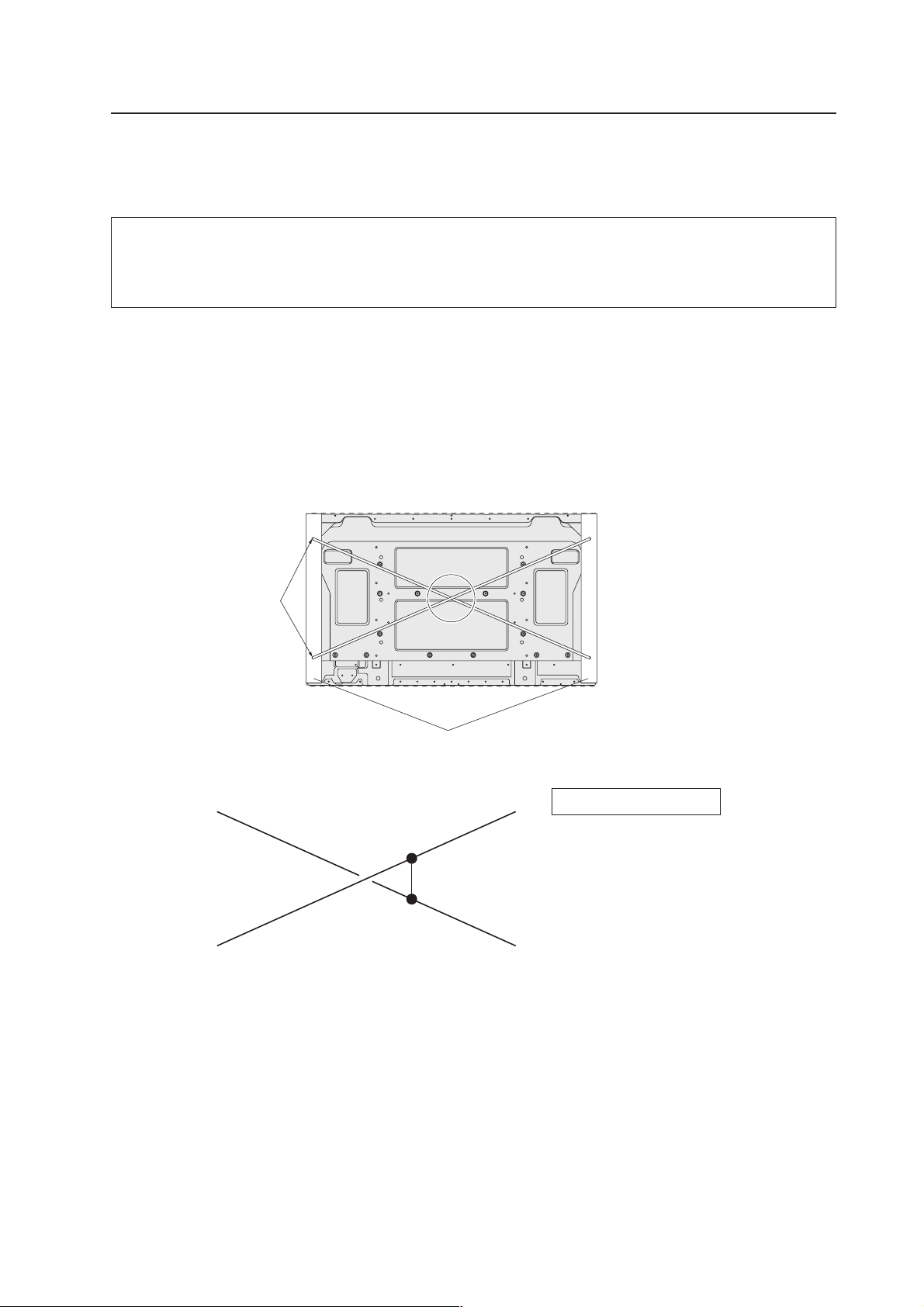

3.2.4 Mounting surface warping

The display incorporates glass. Before mounting the panel using hardware other than that provided by Pioneer, perform

the following checks to confirm that the display is free from warps exceeding 1 mm*.

Regarding the 1 mm limit:

The panel frame may have a warp of up to 3 mm. If the total warp (the warp of the frame plus the warp of the

mounting surface) exceeds 4 mm then the glass in the display may experience excessive stress. To ensure that

the total warp is less than 4 mm, verify that the warp of the mounting surface is less than 1 mm.

φ

1 Referring to the illustration below, diagonally extend string (maximum diameter

mount openings. Strings should be completely free of slack.

2 Measure the clearance (L) between the strings where they cross.

Distortion is expressed by: [Distortion] = L × 2.

3 If L is found to be 0, pass the strings through the other bolt mount openings then repeat the measurements. Any

value of L greater than 0 indicates the presence of distortion. If the measured value in both cases is 0, the

distortion is negligible.

0.1- mm) through the bolt

Mount bolt holes

A

String

String

C

A

Plasma Display Mount Surface (Mount Brackets)

Magnified view of section A

D

F

L

E

Point E is the center point of string

segment A-B.

Point F is the center point of string

segment C-D.

Clearance between points E and F = L

(Points E and F are shown displaced

for illustrative purposes).

B

25

Page 26

Installation Conditions

[427CMX]

3.3 Installation Conditions (PDP-427CMX)

3.3.1 Heat dissipation

This unit has openings for effective ventilation. Vent locations are marked by arrows in the illustration below. The

direction of the arrows shows the direction of airflow. To allow proper dissipation of heat from the unit, do not

cover any of these openings.

(Unit : mm)

127.7 74.5

36.3 34.7

24.564.3

43.1 24.8

52.6 39.8

98.8 114.5

372.4

264.5

49.742.4

Fan Fan

A A A A A

72.4 72.4 52.472.452.4

39.9 52.2

374.5

414.5

137.381.3137.3 81.3

98.8114.5

24.564.3

202.8

44.5

124.5

137.7

127.7 74.5

43.1 24.8

52.6149.8

In a standard installation, two fans and part A draw hot air from the unit. All openings not assisted by fans serve as

air inlets. If the unit is hung from or embedded into a wall, special operating temperature limits and other limitations

may apply. Refer to section “3.6 Special Installation (PDP-427CMX)” (pg. 55) for more information.

26

Page 27

[427CMX]

Installation Conditions

3.3.2 Calculating heat quantity

As a courtesy to our customers, we have included the power formula for calculating air conditioning needs.

For power consumption, allow 320 W = 320 VA per unit.

Since most of the power consumed is transformed into heat, power consumption may be regarded as roughly equal to

generated heat.

1 Conversion to calories

[W] × 0.86 = [kcal/h]

Heat generated per display: 320 W × 0.86 = 275 kcal/h

2 Conversion to British Thermal Units

[W] × 3.41 = [BTU/h]

Heat generated per unit: 320 W × 3.41 = 1019 BTU/h

3.3.3 Product mounting holes