Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

ORDER NO.

PROVISIONAL

PDP-4270XD

PLASMA TELEVISION

PDP-4270XD

PDP-427XD

PDP-4270XA

PDP-427XA

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PDP-4270XD WYVIXK5 AC 220 V to 240 V

PDP-427XD WYVIXK5 AC 220 V to 240 V

PDP-4270XA

PDP-427XA

This service manual should be used together with the following manual(s).

PDP-4270XD, PDP-427XD,

PDP-4270XA, PDP-427XA

WYVIXK5 AC 220 V to 240 V

WYV5 AC 220 V to 240 V

WYVIXK5 AC 220 V to 240 V

WYV5 AC 220 V to 240 V

Model No. Order No. Remarks

ARP3392 SCHEMATIC DIAGRAM, PCB CONNECTION DIAGRAM

For details, refer to "Important Check Points for good servicing".

T-IZR SEP. 2006 printed in Japan

Page 2

1234

1. NOTES ON SERVICE VISIT

1.1 SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

Health & Safety Code Section 25249.6 - Proposition 65

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

C

de remplacement doivent avoir la même désignation.

SAFETY PRECAUTIONS

NOTICE : Comply with all cautions and safety related notes

located on or inside the cabinet and on the chassis.

The following precautions should be observed :

1. When service is required, even though the PDP UNIT an

isolation transformer should be inserted between the power line

D

and the set in safety before any service is performed.

2. When replacing a chassis in the set, all the protective devices

must be put back in place, such as barriers, nonmetallic knobs,

adjustment and compartment covershields, isolation resistorcapacitor, etc.

3. When service is required, observe the original lead dress. Extra

precaution should be taken to assure correct lead dress in the

high voltage circuitry area.

4. Always use the manufacture's replacement components.

Especially critical components as indicated on the circuit

diagram should not be replaced by other manufacture's.

Furthermore where a short circuit has occurred, replace those

E

components that indicate evidence of overheating.

5. Before returning a serviced set to the customer, the service

technician must thoroughly test the unit to be certain that it is

completely safe to operate without danger of electrical shock,

and be sure that no protective device built into the set by the

manufacture has become defective, or inadvertently defeated

during servicing. Therefore, the following checks should be

performed for the continued protection of the customer and

servicetechnician.

6. Perform the following precautions against unwanted radiation

and rise in internal temperature.

• Always return the internal wiring to the original styling.

• Attach parts (Gascket, Ferrite Core, Ground, Rear Cover,

Shield Case etc.) surely after disassembly.

7. Perform the following precautions for the PDP panel.

• When the front case is removed, make sure nothing hits the

panel face, panel corner, and panel edge (so that the glass does

not break).

• Make sure that the panel vent does not break. (Check that the

cover is attached.)

• Handle the FPC connected to the panel carefully.

Twisting or pulling the FPC when connecting it to the

connector will cause it to peel off from the panel.

8. Pay attention to the following.

• Pay extreme caution when the front case and rear panel are

removed because this may cause a high risk of disturbance to

TVs and radios in the surrounding.

F

2

1234

PDP-4270XD

Page 3

5678

Leakage Current Cold Check

With the AC plug removed from an AC power source, place a

jumper across the two plug prongs. Turn the AC power switch on.

Using an insulation tester (DC 500V), connect one lead to the

jumpered AC plug and touch the other lead to each exposed metal

part (input/output terminals, screwheads, metal overlays, control

shafts, etc.), particularly any exposed metal part having a return

path to the chassis. Exposed metal parts having a return path to

the chassis should have a minimum resistor reading of 0.3MΩ

and a maximum resistor reading of 5MΩ. Any resistor value

below or above this range indicates an abnormality which requires

corrective action. Exposed metal parts not having a return path to

the chassis will indicate an open circuit.

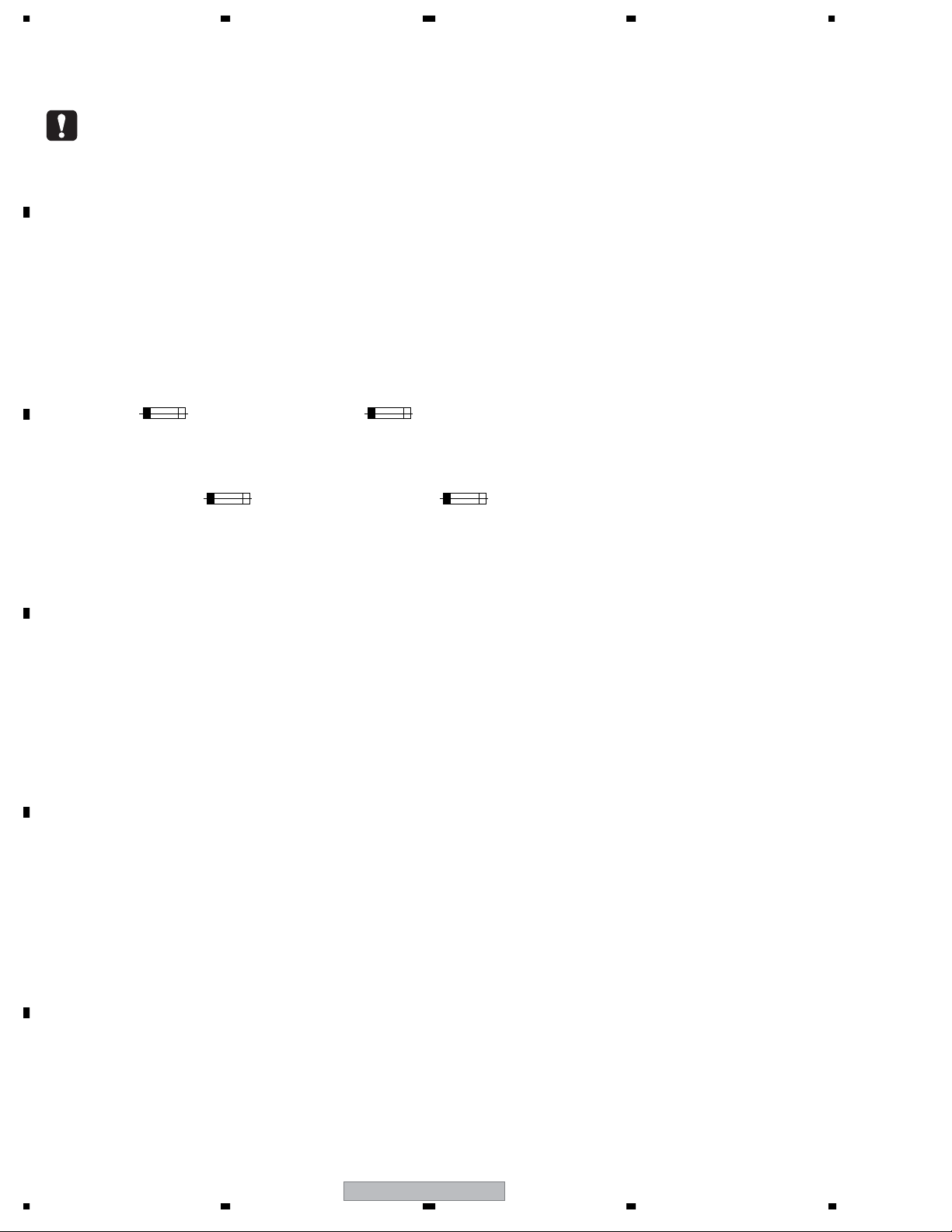

Leakage Current Hot Check

Plug the AC line cord directly into an AC power source (do not

use an isolation transformer for this check).

Turn the AC power switch on.

Using a "Leakage Current Tester (Simpson Model 229

equivalent)", measure for current from all exposed metal parts of

the cabinet (input/output terminals, screwheads, metal overlays,

control shaft, etc.), particularly any exposed metal part having a

return path to the chassis, to a known earth ground (water pipe,

conduit, etc.). Any current measured must not exceed 0.5mA.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in PIONEER set have

special safety related characteristics. These are often not evident

from visual inspection nor the protection afforded by them

necessarily can be obtained by using replacement components

rated for higher voltage, wattage, etc. Replacement parts which

have these special safety characteristics are identified in this

Service Manual.

Electrical components having such features are identified by

marking with a on the schematics and on the parts list in this

Service Manual.

The use of a substitute replacement component which dose not

have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in this

Service Manual, may create shock, fire or other hazards.

Product Safety is continuously under review and new instructions

are issued from time to time. For the latest information, always

consult the current PIONEER Service Manual. A subscription to,

or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

A

B

C

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE SET TO THE CUSTOMER.

D

E

56

PDP-4270XD

F

3

7

8

Page 4

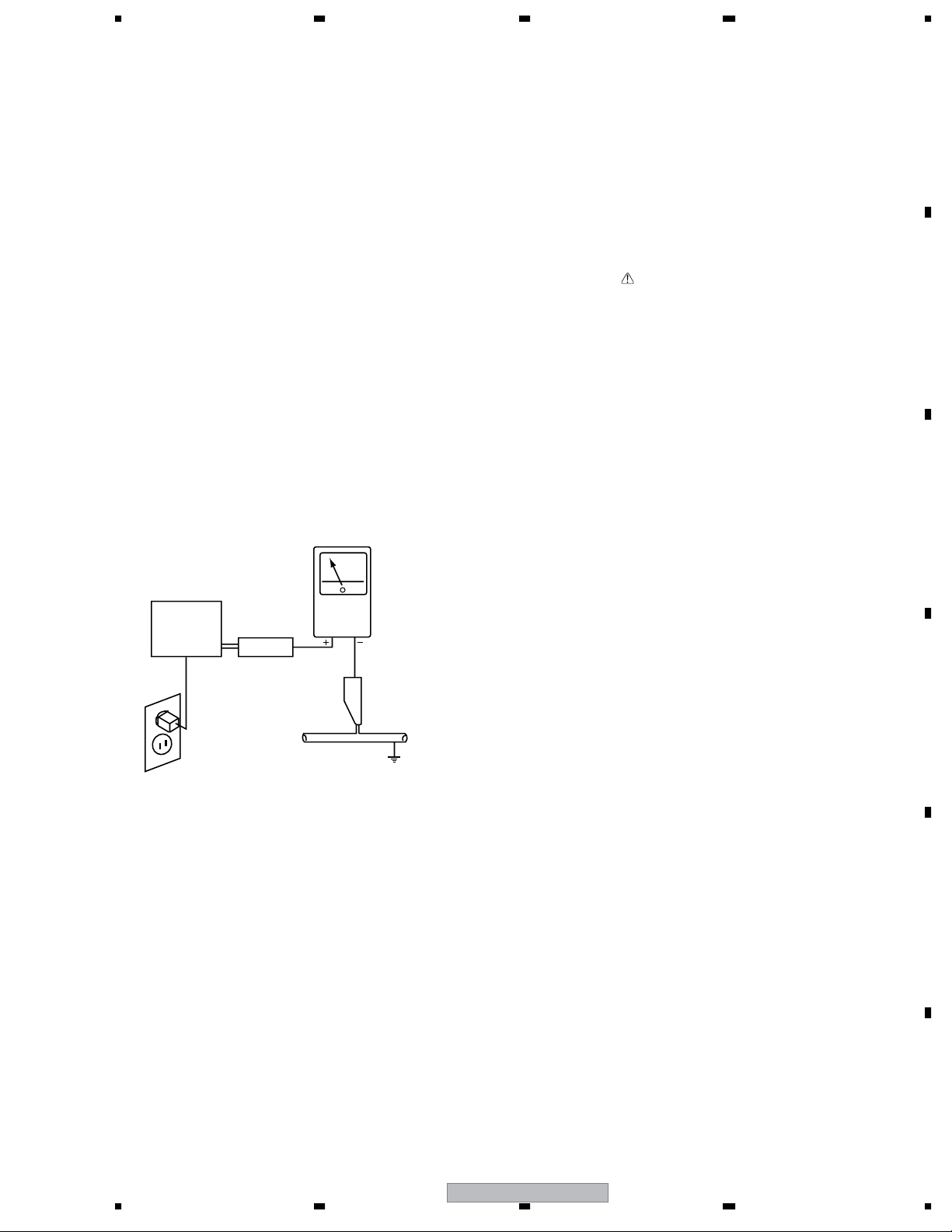

A

Charged Section

1234

High Voltage Generating Point

The places where the commercial AC power is used without

passing through the power supply transformer.

If the places are touched, there is a risk of electric shock. In

addition, the measuring equipment can be damaged if it is

connected to the GND of the charged section and the GND of the

non-charged section while connecting the set directly to the

commercial AC power supply. Therefore, be sure to connect the

set via an insulated transformer and supply the current.

B

1. Power cord

2. AC inlet

3. Power switch (S1)

4. Fuse (In the POWER SUPPLY Unit)

5. STB transformer and Converter transformer

(In the POWER SUPPLY Unit)

6. Other primary side of the POWER SUPPLY Unit

C

: Part is Charged Section.

: Part is the High Voltage Generating Points

other than the Charged Section.

42 SCAN B Assy

42 Y DRIVE Assy 42 X DRIVE Assy SUS CLAMP 1 AssyPOWER SUPPLY Unit

The places where voltage is 100 V or more except for the charged

places described above. If the places are touched, there is a risk of

electric shock.

The VSUS voltage remains for several minutes after the power to

the unit is turned off. These places must not be touched until

about 10 minutes after the power is turned off, or it is confirmed

with a tester that there is no residual VSUS voltage.

If the procedures described in “10.3 POWER ON/OFF

FUNCTION FOR THE LARGE-SIGNAL SYSTEM” are

performed before the power is turned off, the voltage will be

discharged in about 30 seconds.

POWER SUPPLY Unit........................................................(205 V)

42 X DRIVE Assy...............................................(–180 V to 205 V)

42 Y DRIVE Assy...............................................................(500 V)

42 SCAN A Assy............................................................... (500 V)

42 SCAN B Assy............................................................... (500 V)

SUS CLAMP 1 Assy...........................................(–180 V to 205 V)

SUS CLAMP 2 Assy...........................................(–180 V to 205 V)

Conductive plate X

D

E

F

AC inlet Power switch (S1)42 SCAN A Assy

SUS CLAMP 2 Assy

Fig. High Voltage Generating Point (Rear view)

4

1234

PDP-4270XD

Page 5

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

PDP-4270XD

E

F

5

7

8

Page 6

1234

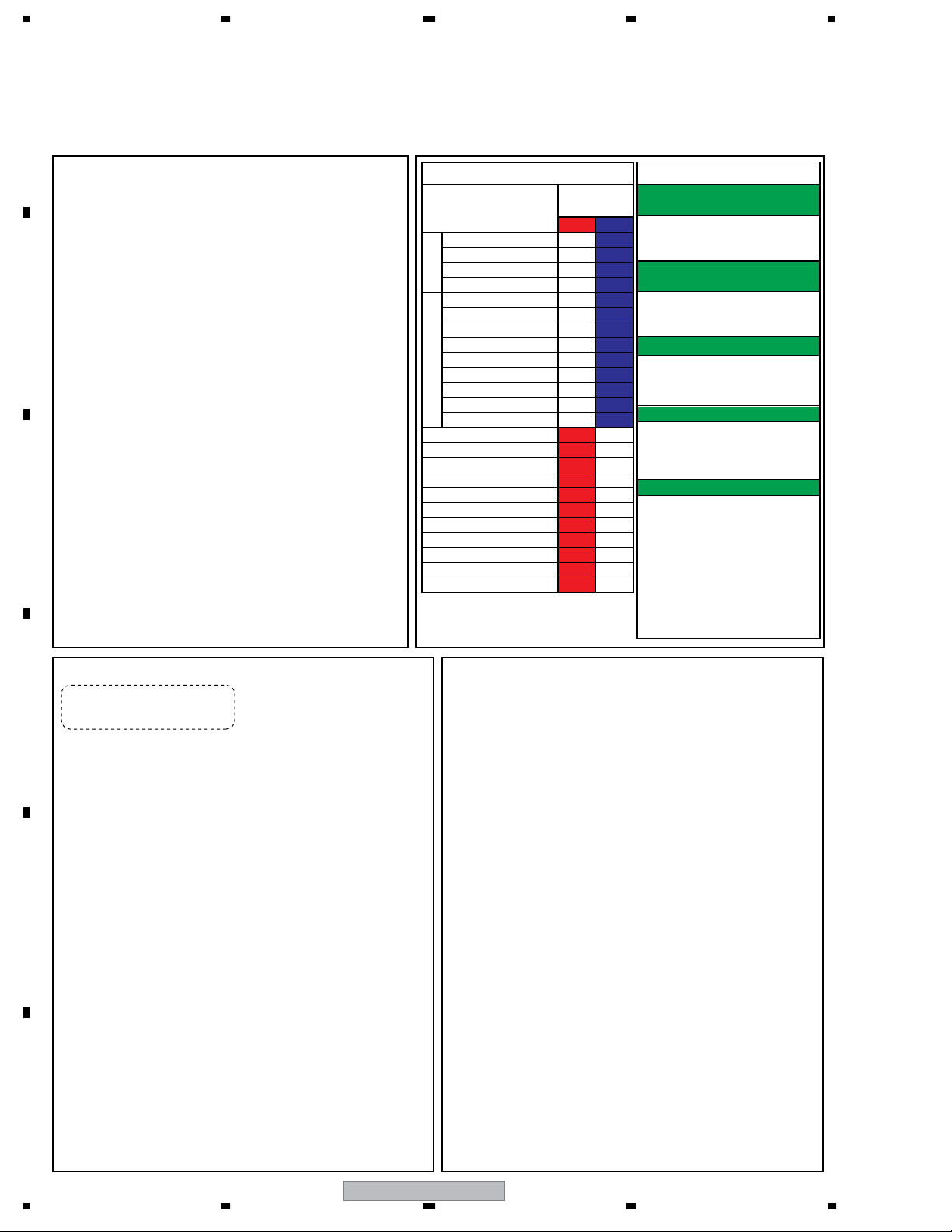

1.2 QUICK REFERENCE UPON SERVICE VISIT

A

Notes, PD/SD diagnosis, and methods for various settings

Notes when visiting for service

1. Notes when disassembling/reassembling

1 Rear case

When reassembling the rear case, the screws must be tightened in a

specific order. Be careful not to tighten them in the wrong order forcibly.

For details, see "Rear Case" in "6. DISASSEMBLY"

2 Attaching screws for the HDMI connector

When attaching the HDMI connector after replacing the Main Assy,

secure the HDMI connector manually with a screwdriver, but not

with an electric screwdriver. If you tighten the screws too tightly

B

C

with an electric screwdriver, the screw heads may be damaged, in

which case the screws cannot be untightened/tightened any more.

2. On parts replacement

1 How to discharge before replacing the Assys

A charge of significant voltage remains in the Plasma Panel even

after the power is turned off. Safely discharge the panel before

replacement of parts, in either manner indicated below:

Let the panel sit at least for 3 minutes after the power is turned off.

A:

B: Turn the Large Signal System off before the power is turned off

then, after 1 minute, turn the power off.

For details, see "10.3 Power ON/OFF Function for the Large-Signal

System."

2 On the settings after replacement of the Assys

Some boards need settings made after replacement of the Assys.

For details, see "7. ADJUSTMENT"

3. On various settings

1 SR+

After a repair using a PC, be sure to restore the setting for the

RS-232C connector to SR+.

2 Setting in Factory mode

After a Mask indication into the panel is performed, be sure to

set the Mask setting to "OFF" then exit Factory mode.

Quick Reference upon Service Visit 1

PD/SD

Item

Communication with the panel drive IC

Communication with the module IIC

DIGTAL-RST2

Panel high temperature

Panel section

Audio

Communication with the Module microcomputer

Main 3-wire serial communication

Main IIC communication

Communication with the Main microcomputer

FAN

Main section

Unit high temperature

Communication with the D-TUNER

MTB-RST2/RST4

POWER

SCAN

SCN-5V

Y-DRIVE

Y-DCDC

Y-SUS

ADRS

X-DRIVE

X-DCDC

X-SUS

UNKNOWN

Red 2

Red 3

Red 4

Red 5

Red 6

Red 7

Red 8

Red 9

Red 10

Red 11

Red 15

No. of LEDs

flashing

Red Blue

Blue 1

Blue 2

Blue 3

Blue 4

Blue 5

Blue 6

Blue 7

Blue 8

Blue 9

Blue 10

Blue 11

Blue 12

Blue 13

Change of settings

How to enter Factory mode using

the supplied remote control unit

In the same way as with the remote

control unit supplied with the 6thgeneration model

How to enter Integrator mode using

the supplied remote control unit

1 Enter the Standby mode.

2 Press [MENU].

3 Press [TV ].

Release TRAP SW-ERR

1 Enter the Factory mode.

2 Select the INITIALIZE mode.

3 Hold [DISPLAY] pressed for at least

5 seconds.

How to switch UART 1 (Integrator)

1 Enter the Integrator mode.

2 Display "OFF" using [\].

3 Change the communication speed

using [«], then [\].

How to switch UART 2 (During Standby)

1 Enter the Standby mode.

2

Hold [VOL +] or [VOL -] pressed for 3 seconds.

3

Hold [SPLIT] pressed for 3 seconds.

4-1 To set to 232C, press [ENTER].

5-2

To set to SR+, press [HOME MENU].

Note:

If switching is completed successfully,

the red LED will flash twice.

Note 1:

Use a remote control unit supplied with

the 6th-generation models or later.

Note 2:

Do not hold a key pressed for more

than 5 seconds.

How to locate several items on the Factory menu

{ } : Item on the Factory menu

D

E

F

[ ] : Key on the remote control unit

" " : Screen indication

1. Confirmation of accumulated power-on time and power-on

count

Select {INFORMATION} then {HOUR METER}.

(After entering Factory mode, press [«] four times.)

2. Confirmation of the Power-down and Shutdown histories

1 Panel system

PD: Select {PANEL FACTORY} then {POWER DOWN}.

(After entering Factory mode, press [MUTING] once, press

[ENTER], then press [«] three times.)

SD: Select {PANEL FACTORY} then {SHUT DOWN}.

(After entering Factory mode, press [MUTING] once, press

[ENTER], then press [«] four times.)

2 Main Assy

Select {INFORMATION} then {MAIN NG}.

(After entering Factory mode, press [«] three times.)

3. How to display the Mask indication

1 Mask indication in the panel side

1. Select {PANEL FACTORY} then {RASTER MASK SETUP}.

(After entering Factory mode, press [MUTING] once, press [ENTER],

then press [«] 8 times.)

2. Press [ENTER], then select a Mask indication, using [»] or [«].

2 Mask (SG screen) indication in the Main Assy (MAIN VDEC)

1. Select either Input 1 or 2 or 4, to which no signal is input (

2. Select {INITIALIZE} then {SG MODE}. Press [|]. (After entering

Factory mode, press [MUTING] three times, then press [«] once.)

Then, the indication at the lower right of the screen changes from

"OFF" to "ANA AD YCBCR".

3. You can change Mask patterns by pressing [«] to select {SG

PATTERN} then using [|] or [\].

Note: When you switch "SG MODE" routes, some displays become

monochrome, as they are in Y-signal only mode.

black screen

Adjustments and Settings after replacement of the

Assys (Procedures in Factory mode)

1. Digital Video Assy: Transfer of backup data

1 Select {PANEL FACTORY}, {ETC}, then {BACKUP DATA}. (After entering Factory

mode, press [MUTING] once, press [ENTER], press [«] seven times, then press

[ENTER].)

2 Select {TRANSFER}, using [\], then hold [SET] pressed for at least 5 seconds.

3 After transfer of backup data is completed, {ETC} is automatically selected, and the

LED on the front panel returns to normal lighting.

2. MAIN Assy (U): Execution of FINAL SETUP.

1 Select {INITIALIZE} then {FINAL SETUP}, then press [ENTER]. (After entering

Factory mode, press [MUTING] three times, then press [«] four times.)

2 Select "YES", using [\]. Then hold [ENTER] pressed for at least 5 seconds.

3 After "FINAL SETUP IS COMPLETE" is displayed on the screen, turn the POWER

switch of the main unit off.

3. POWER SUPPLY Unit: Clearance of the accumulated power-on count

and maximum temperature value

1 Select {PANEL FACTORY}, {ETC}, then {P COUNT INFO}. (After entering Factory

mode, press [MUTING] once, press [ENTER], press [«] seven times, press [ENTER],

then press [«] six times.)

2 Press [\] to select "CLEAR". Hold [SET] pressed for at least 5 seconds.

After clearance is completed, "ETC" is automatically selected. Clear the maximum

temperature value (MAX TEMP) in the same manner.

4. Other Assys: Clearance of the maximum temperature value

1 Select {PANEL FACTORY}, {ETC}, then {MAX TEMP}. (After entering Factory mode,

press [MUTING] once, press [ENTER], press [«] seven times, press [ENTER], then

press [«] seven times.)

2 Press [\] to select "CLEAR". Hold [SET] pressed for at least 5 seconds.

After clearance is completed, "ETC" is automatically selected.

).

6

PDP-4270XD

1234

Page 7

5678

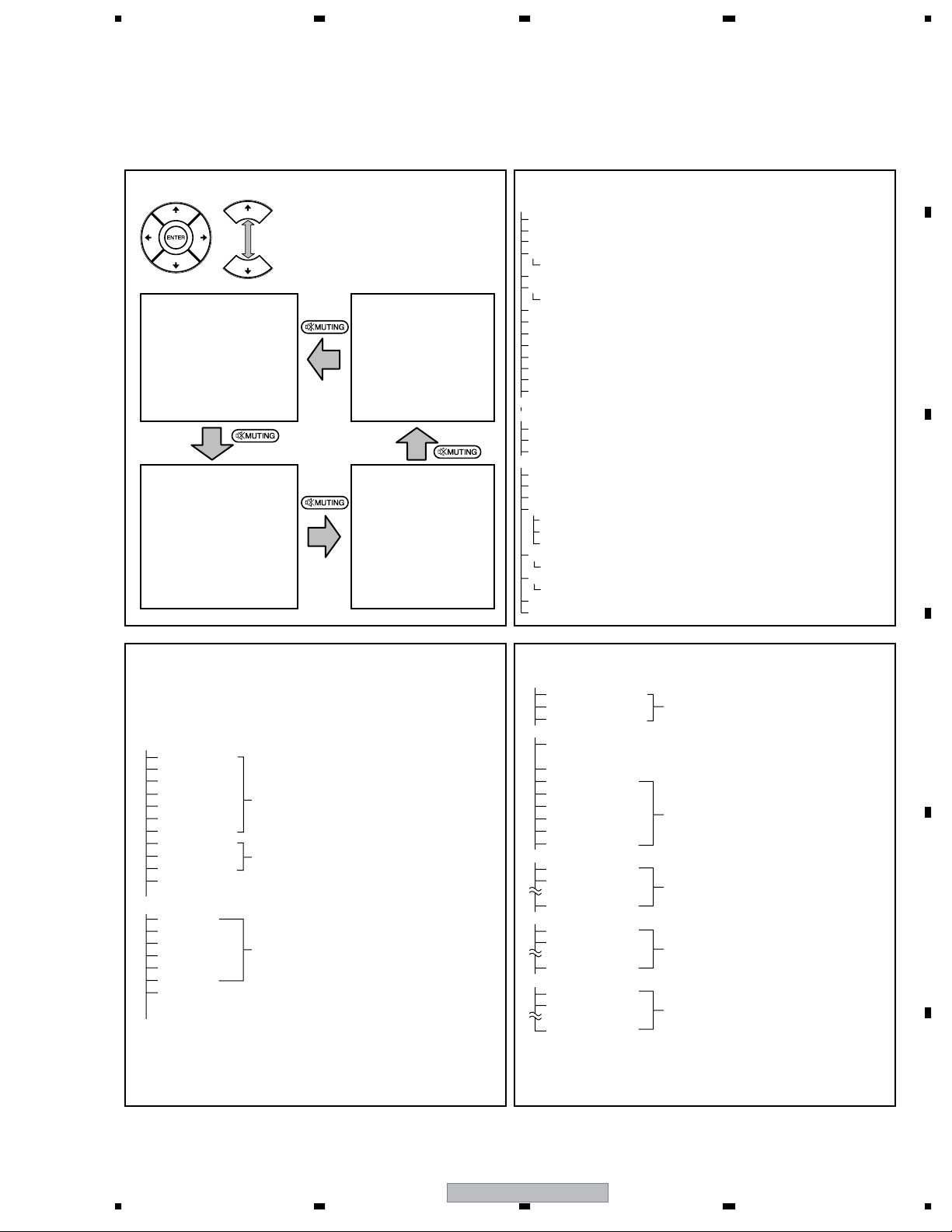

Quick Reference upon Service Visit 2

Mode transition and structure of layers in Service Factory mode

Mode transition in Service Factory mode

INFORMATION mode

1. VERSION (1)

2. VERSION (2), (3)

3. MAIN NG

4. TEMPERATURE

5. HOUR METER

6. HDMI SIGNAL INFO1, 2

7. VDEC SIGNAL INFO 2

8. DTV TUNING STATUS 1, 2, 3

9. DTV TV-GUIDE BER

10. DEBUG INFO

PANEL FACTORY mode

1. PANEL INFORMATION

2. PANEL WORKS

3. POWER DOWN

4. SHUT DOWN

5. PANEL-1 ADJ

6. PANEL-2 ADJ

7. PANEL REVICE

8. ETC.

9. RASTER MASK SETUP

10. PATTEN MASK SETUP

11. COMBI MASK SETUP

Up

Down

• To shift to another mode, press [MUTING].

• To shift to another item in a specific mode,

press [»] or [«].

• To shift to the next nested layer below for an

item with a "(+)" indication, press [ENTER].

To return to the next nested layer above,

also press [ENTER].

INITIALIZE mode

1. SYNC DET

2. SG MODE

3. SG PATTERN

4. SIDE MASK LEVEL

5. FINAL SETUP

6. HMG/HG SERVICE MODE

7. CVT AUTO

8. HDMI INTR POSITION

OPTION mode

1. EDID WRITE MODE

2. ANTENNA MODE

3. AFT

Structure of Layers in Service Factory Mode

INFORMATION mode

1. VERSION (1) Flash Versions for PANEL system and MAIN system

2. VERSION (2) Flash Versions for DTV system

3. VERSION (3) Flash Versions for CCD ucom and HM

4. MAIN NG SD histories for MAIN (Going Clear model by SET key)

4-1. CLEAR Select Yes by [\] key \ pushing and hold [SET] key

5. TEMPERATURE TEMP 1, TEMP2 and FAN mode are displayed

6. HOUR METER Hour meter and number of Power ON are displayed

6-1. CLEAR Select Yes by [\] key \ pushing and hold [SET] key

7. HDMI SIGNAL INFO 1 For factory use

8. HDMI SIGNAL INFO 2 Signal info of HDMI are displayed ( Detail are on SM )

9. VDEC SIGNAL INFO For factory use

10. DTV TUNING STATUS 1 Detail information for DTV is displayed

11. DTV TUNING STATUS 2 Detail information for DTV is displayed

12. DTV TUNING STATUS 3 Detail information for DTV is displayed

13. DTV TV-GUIDE BER For production line use

14. DEBUG INFO For factory use

PANEL FACTORY mode Refer to [PANEL FACTORY MODE]

OPTION

1. EDID WRITE MODE For factory use

2. ANTENNA MODE For production line use

3. AFT For production line use

INITIALIZE

1. SYNC DET (+) For factory use

2. SG MODE SG signal from MAIN VDEC (

3. SG PATTERN For factory use

4. SIDE MASK LEVEL(+) For factory use

4-1. R MASK LEVEL

4-2. G MASK LEVEL

4-3. B MASK LEVEL

5. FINAL SETUP Set to Factory default settings (it should perform after

5-1. DATA RESET replacing a MAIN board )

6. HMG/HG SERVICE MODE Information for a USB device is displayed

6-1. MODE SIFT

7. CVT AUTO For factory use

8. HDMI INTR POSITION(+) For factory use

Composite signal is required

A

B

)

C

Structure of Layers in Panel Factory Mode 1

1. PANEL INFORMATION Version indication of the panel

2. PANEL WORKS Indications of the accumulated power-on time, pulse-meter

3. POWER DOWN Indication of the Power-down history

4. SHUT DOWN Indication of the Shutdown history

5. PANEL-1 ADJ (+)

1. X-SUS B

2. Y-SUS B

3. Y-SUSTAIL T1

4. Y-SUSTAIL T2 Modification not required because these items are basically

5. Y-SUSTAIL W for factory presetting

6. XY-RST W1

7. XY-RST W2

8. VOL SUS

9. VOL OFFSET Settings required after replacement of the panel

10. VOL RST P

11. SUS FREQ. For AM noise prevention (Depending on the mode,

6. PANEL-2 ADJ (+)

1. R-HIGH

2. G-HIGH

3 .B-HIGH Parameters for the WB adjustment of the panel, which are

4. R-LOW required during adjustment after panel replacement

5. G-LOW

6. B-LOW

7. ABL Setting of the power consumption. A setting table is

To "Structure of Layers in Panel Factory Mode 2"

count, and power-on count of the panel

brightness of the screen changes.)

available for each vertical signal.

Structure of Layers in Panel Factory Mode 2

7. PANEL REVISE (+)

R-LEVEL

G-LEVEL Items for use by engineers

B-LEVEL

8. ETC (+)

1. BACKUP DATA For transferring backup data (after replacement of

2. DIGITAL EEPROM To clear data of the digital video

3. PD INFO.

4. SD INFO. For clearance of data for the corresponding items.

5. HR-MTR INFO. The clearing method is the same: Select "CLEAR",

6. PM/B1-B5 using [\], then hold [SET] pressed for at least 5

7. P COUNT INFO. seconds. After clearance is completed, {ETC} is

8. MAX TEMP. automatically selected.

9. RASTER MASK SETUP (+)

1. MASK OFF

2. RST MASK 01 For use while Raster Mask (full mask) is displayed.

• • • • • Use [»] or [«] to select the type of mask.

25. RST MASK 24

10. PATTEN MASK SETUP (+)

1. MASK OFF

2. PTN MASK 01 For use while Pattern Mask is displayed. Use [»] or

• • • • • [«] to select the type of mask.

40. PTN MASK 39

11. COMBI MASK SETUP (+)

1. MASK OFF

2. CMB MASK 01 For use while Combination Mask is displayed.

• • • • • Use [»] or [«] to select the type of mask.

11. CMB MASK 10

the DIGITAL Assy)

D

E

56

PDP-4270XD

F

7

7

8

Page 8

1234

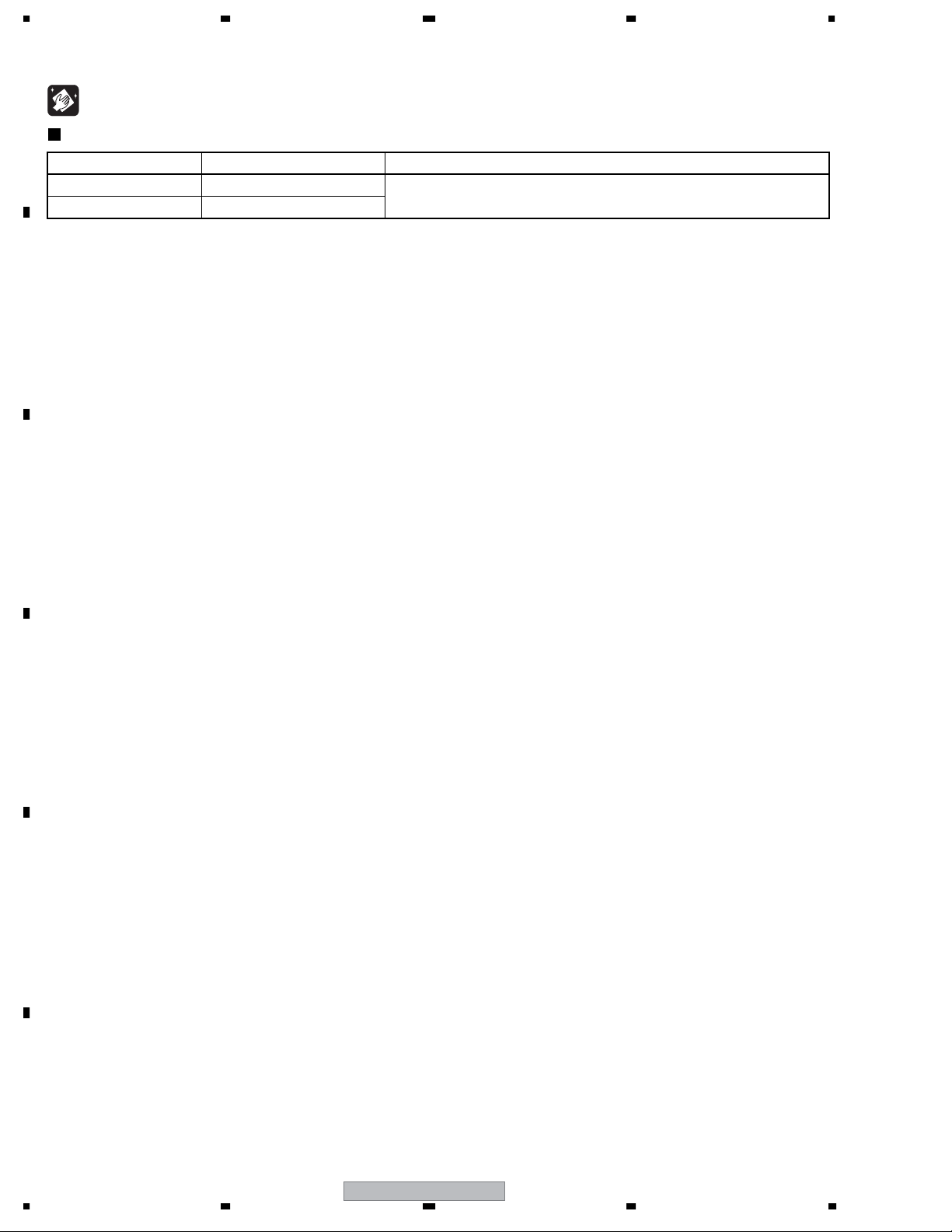

1.3 JIGS LIST

A

Cleaning

Name Part No. Remarks

Cleaning liquid GEM1004

Cleaning paper GED-008

Used to fan cleaning.

Refer to "2.4 CHASSIS SECTION (1/2).

CONTENTS

1. NOTES ON SERVICE VISIT.............................................................................................................................2

B

C

D

E

F

1.1 SAFETY INFORMATION ...........................................................................................................................2

1.2 QUICK REFERENCE UPON SERVICE VISIT........................................................................................... 6

1.3 JIGS LIST .................................................................................................................................................. 8

2. EXPLODED VIEWS AND PARTS LIST.......................................................................................................... 10

2.1 PACKING SECTION ................................................................................................................................10

2.2 REAR SECTION...................................................................................................................................... 12

2.3 FRONT SECTION.................................................................................................................................... 14

2.4 CHASSIS SECTION (1/2)........................................................................................................................16

2.5 CHASSIS SECTION (2/2)........................................................................................................................18

2.6 PANEL CHASSIS SECTION....................................................................................................................20

2.7 MULTI BASE SECTION........................................................................................................................... 22

2.8 PDP SERVICE PANEL ASSY 427 (AWU1208) .......................................................................................24

2.9 TABLE TOP STAND (PDP-4270XD ONLY)..............................................................................................25

3. PCB PARTS LIST ...........................................................................................................................................26

4. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................42

4.1 OVERALL WIRING DIAGRAM (1/2) ........................................................................................................42

4.2 OVERALL WIRING DIAGRAM (2/2) ........................................................................................................44

4.3 OVERALL BLOCK DIAGRAM (1/2) ......................................................................................................... 46

4.4 OVERALL BLOCK DIAGRAM (2/2) ......................................................................................................... 48

4.5 POWER SUPPLY UNIT............................................................................................................................ 49

4.6 42 X DRIVE, SUS CLAMP 1 and SUS CLAMP 2 ASSYS....................................................................... 50

4.7 42 Y DRIVE ASSY ................................................................................................................................... 51

4.8 POWER SUPPLY BLOCK of 42 X DRIVE and 42 Y DRIVE ASSYS....................................................... 52

4.9 42 SCAN A and 42 SCAN B ASSYS .......................................................................................................53

4.10 42 ADDRESS ASSY.............................................................................................................................. 54

4.11 42 DIGITAL ASSY..................................................................................................................................55

4.12 SIGNAL BLOCK DIAGRAM...................................................................................................................56

4.13 R07 DT ASSY (PDP-4270XD and PDP-427XD ONLY) ......................................................................... 58

4.14 POWER SUPPLY BLOCK of MAIN ASSY.............................................................................................59

4.15 42E AUDIO ASSY.................................................................................................................................. 60

4.16 POWER SUPPLY BLOCK of 42E AUDIO, LED IR and SIDE KEY ASSYS...........................................61

4.17 VOLTA GES.............................................................................................................................................62

4.18 WAVEFORMS........................................................................................................................................ 70

5. DIAGNOSIS.................................................................................................................................................... 74

5.1 TROUBLE SHOOTING............................................................................................................................74

5.2 DIAGNOSIS OF PD (POWER-DOWN)....................................................................................................92

5.3 DIAGNOSIS OF SD (SHUTDOWN).........................................................................................................96

5.4 INFORMATION ON SYMPTOMS THAT DO NOT CONSTITUTE FAILURE............................................98

6. DISASSEMBLY............................................................................................................................................... 99

6.1 PCB LOCATION....................................................................................................................................... 99

6.2 DISASSEMBLY ......................................................................................................................................100

7. ADJUSTMENT ............................................................................................................................................. 106

7.1 ADJUSTMENT REQUIRED WHEN THE SET IS REPAIRED OR REPLACED.....................................106

7.2 ADJUSTMENT REQUIRED WHEN PART IS REPLACED....................................................................107

7.3 BACKUP WHEN THE PANEL UNIT IS ADJUSTED .............................................................................. 108

7.4 HOW TO CLEAR HISTORY DATA.........................................................................................................111

7.5 ADJUSTMENT WHEN THE SERVICE PANEL ASSY IS REPLACED...................................................112

7.6 PROCEDURE WHEN REPLACING THE POWER SUPPLY UNIT........................................................ 114

8

1234

PDP-4270XD

Page 9

5678

8. SERVICE FACTORY MODE .........................................................................................................................115

8.1 OUTLINE OF THE SERVICE FACTORY................................................................................................115

8.1.1 SERVICE FACTORY MODE TRANSITION CHART.........................................................................115

8.1.2 HOW TO ENTER/EXIT SERVICE FACTORY MODE AND DO IT GO OUT ....................................115

8.1.3 STATE OF PRODUCT IN FACTORY MODE....................................................................................115

8.1.4 CORRESPONDENCE REMOTE CONTROL CODE.......................................................................116

8.1.5 FACTORY HIERARCHICAL TABLE .................................................................................................117

8.1.6 INDICATIONS IN SERVICE FACTORY MODE................................................................................118

8.2 SERVICE FACTORY MENU...................................................................................................................120

8.2.1 INFORMATION.................................................................................................................................120

8.2.2 PANEL FACTORY ............................................................................................................................128

8.2.3 OPTION............................................................................................................................................138

8.2.4 INITIALIZE........................................................................................................................................138

9. RS-232C .......................................................................................................................................................141

9.1 OUTLINE OF RS-232C COMMAND ......................................................................................................141

9.1.1 PREPARED TOOLS.........................................................................................................................141

9.1.2 USING RS-232C COMMANDS........................................................................................................141

9.1.3 COMMAND PROTOCOL..................................................................................................................142

9.1.4 COMMAND DEFINITION.................................................................................................................143

9.2 LIST OF RS-232C COMMANDS............................................................................................................145

9.3 OUTLINE OF EACH COMMANDS.........................................................................................................151

9.3.1 ACQUISITION OF PANEL STATUS • • • [QS1] ................................................................................151

9.3.2 ACQUISITION OF PANEL OPERATION DATA • • • [QS2]...............................................................152

9.3.3 ACQUISITION OF OTHER DATA ON THE PANEL • • • [QIP] ..........................................................153

9.3.4 ACQUISITION OF PANEL ADJUSTMENT DATA (COMMON DATA) • • • [QAJ] ..............................153

9.3.5 ACQUISITION OF ABL/WB ADJUSTMENT DATA • • • [QPW] ........................................................154

9.3.6 ACQUISITION OF PULSE METER VALUE • • • [QPM]...................................................................154

9.3.7 ACQUISITION OF PD LOGS • • • [QPD]..........................................................................................155

9.3.8 ACQUISITION OF SD LOGS • • • [QSD]..........................................................................................156

9.3.9 QS6..................................................................................................................................................157

9.3.10 QMT ...............................................................................................................................................157

9.3.11 QNG...............................................................................................................................................158

9.3.12 DRV................................................................................................................................................159

9.3.13 COMMANDS FOR PROHIBITION / PERMISSION OF DTV / HOMENET COMMUNICATION ....160

9.3.14 SETTING FOR FACTORY MODE PERMISSION / PROHIBITION • • • [FAY / FAN]......................161

9.3.15 BACKUP FUNCTION FOR ADJUSTMENT VALUE FOR THE MAIN UNIT • • • [FAJ / UAJ / CBU / BCP]161

10. GENERAL INFORMATION .........................................................................................................................162

10.1 POWER ON SEQUENCE.....................................................................................................................162

10.2 POWER SUPPLY TRANSITION STATUS.............................................................................................165

10.3 POWER ON/OFF FUNCTION FOR THE LARGE-SIGNAL SYSTEM..................................................166

10.4 LED INFORMATION.............................................................................................................................167

10.5 SPECIFICATION ABOUT THE THERMAL PROTECTION...................................................................168

10.6 PROCESSING IN ABNORMALITY ......................................................................................................169

11. SPECIFICATIONS.......................................................................................................................................171

11.1 SPECIFICATIONS................................................................................................................................171

11.2 ACCESSORIES....................................................................................................................................172

11.3 PANEL FACILITIES...............................................................................................................................173

12. IC INFORMATION.......................................................................................................................................178

A

B

C

D

56

PDP-4270XD

E

F

9

7

8

Page 10

1234

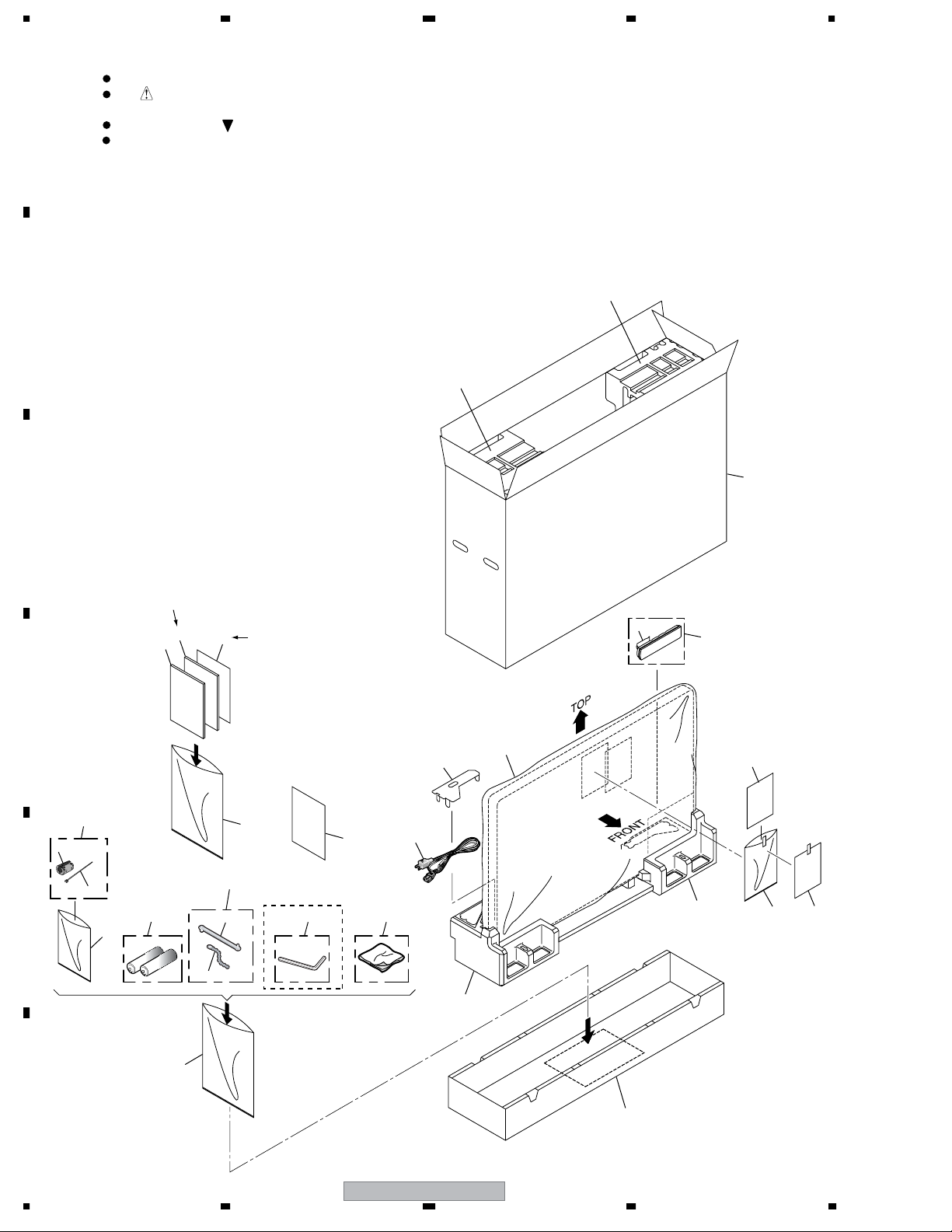

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING SECTION

B

C

20

19

24

D

E

9

Ferrite core

Cable tie

18

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5,

PDP-427XA/WYVIXK5, WYV5

only

5

7

6

Speed clamp ×3

8

Bead band ×3

WYVIXK5 model

only

16

10

PDP-4270XD,

PDP-4270XA only

11

14

12

4

25

2

1

21

22

3

15

13

17

16

F

10

1234

PDP-4270XD

23

Page 11

>

>

5678

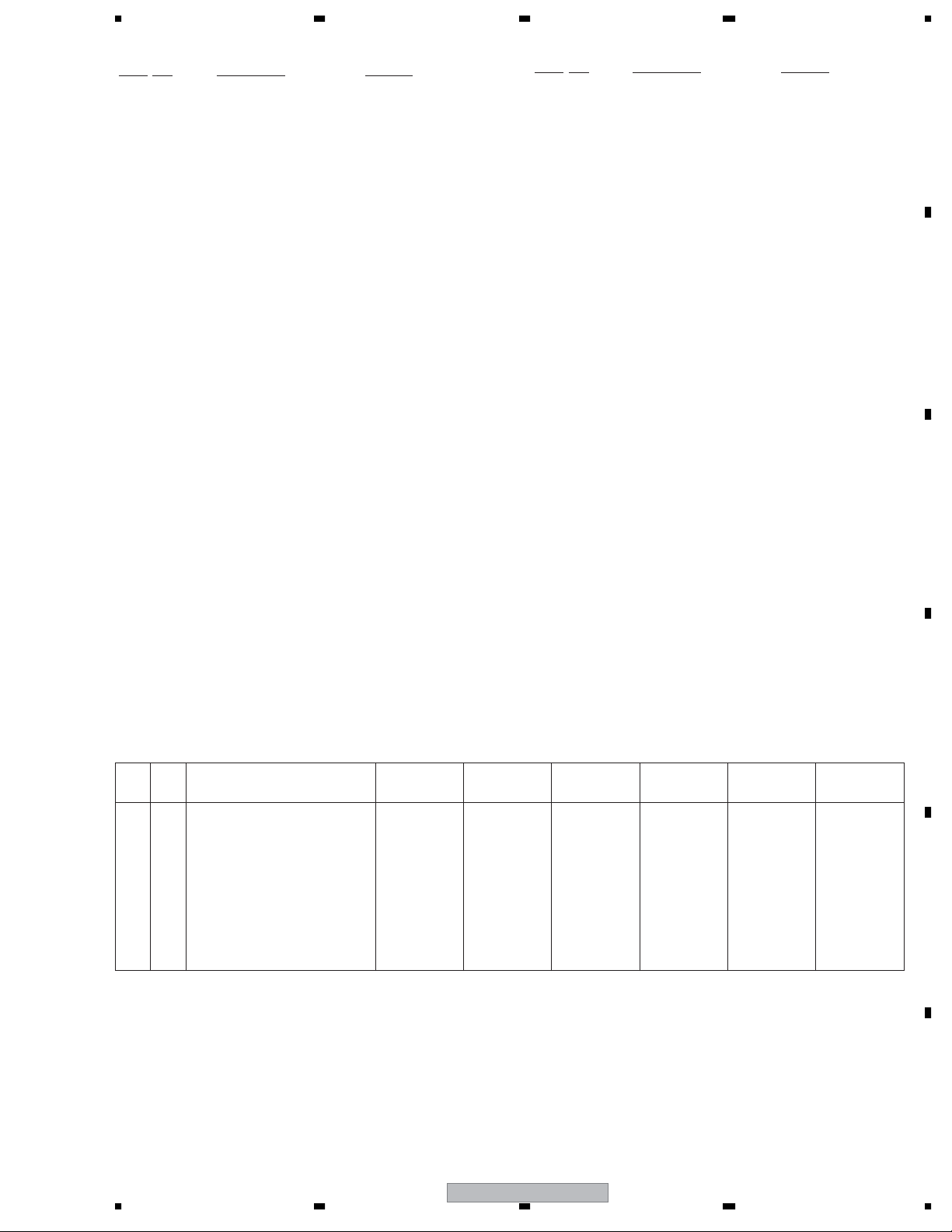

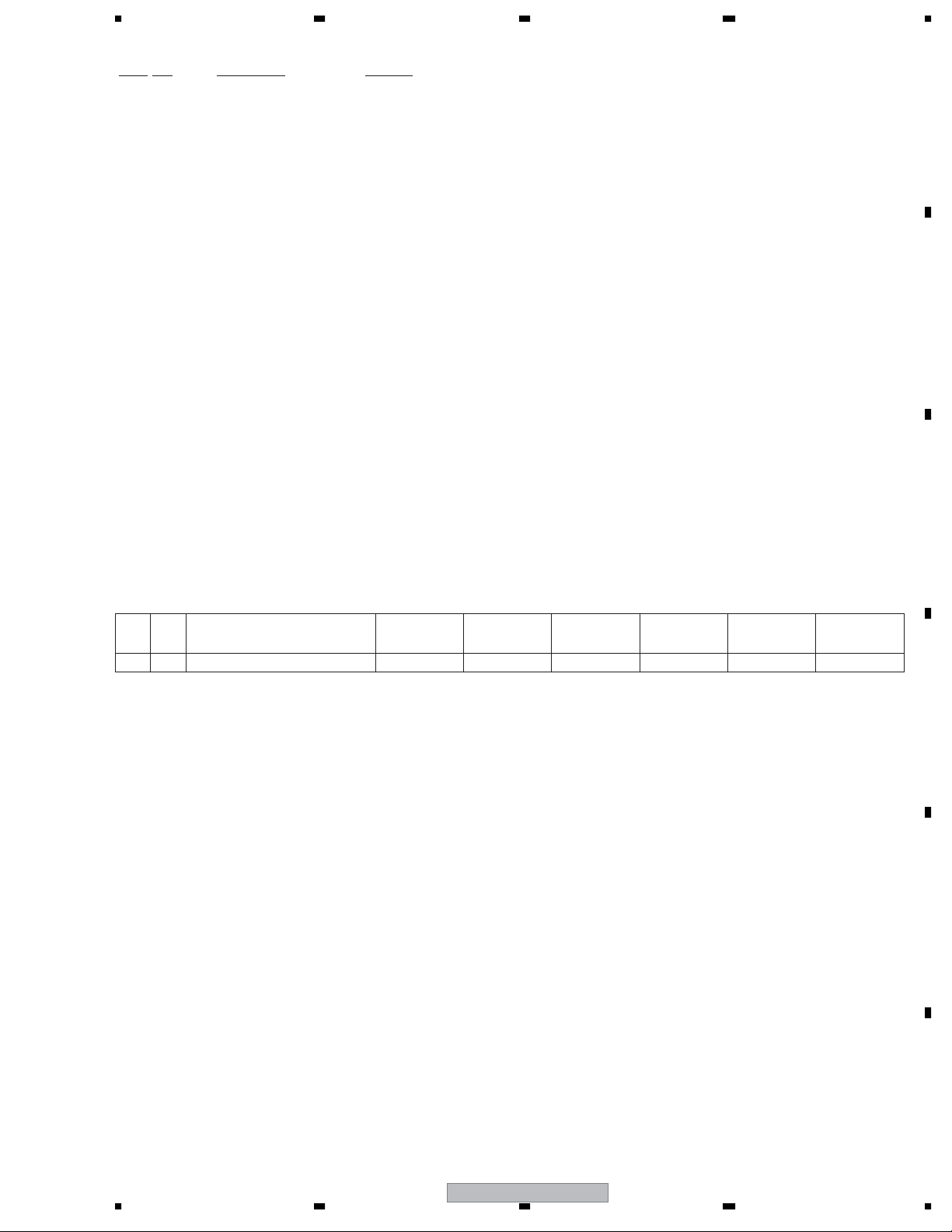

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cord (2 m) ADG1214

2Power Cord Lid See Contrast table (2)

3 Remote Control Unit See Contrast table (2)

4 Battery Cover See Contrast table (2)

5 Operating Instructions See Contrast table (2)

(?????)

6 Operating Instructions See Contrast table (2)

(?????)

7 Block Diagram See Contrast table (2)

NSP 8 Dry Cell Battery (R06, AA) VEM1031

9Ferrite Core (L5321) ATX1039

10 Binder Assy AEC1908

NSP 11 Hexagonal Wrench (6 mm) See Contrast table (2)

12 Cleaning Cloth AED1285

13 Caution Card See Contrast table (2)

14 Cleaning Caution See Contrast table (2)

No. Description Part No.

Mark

NSP 15 Warranty Card ARY1114

16 Polyethylene Bag AHG1340

17 Polyethylene Bag AHG1326

18 Polyethylene Bag AHG1337

19 Pad (427 T-L) See Contrast table (2)

20 Pad (427 T-R) See Contrast table (2)

21 Pad (427 B-L) See Contrast table (2)

22 Pad (427 B-R) See Contrast table (2)

23 Under Carton (427) See Contrast table (2)

24 Upper Carton See Contrast table (2)

25 Mirror Mat See Contrast table (2)

A

B

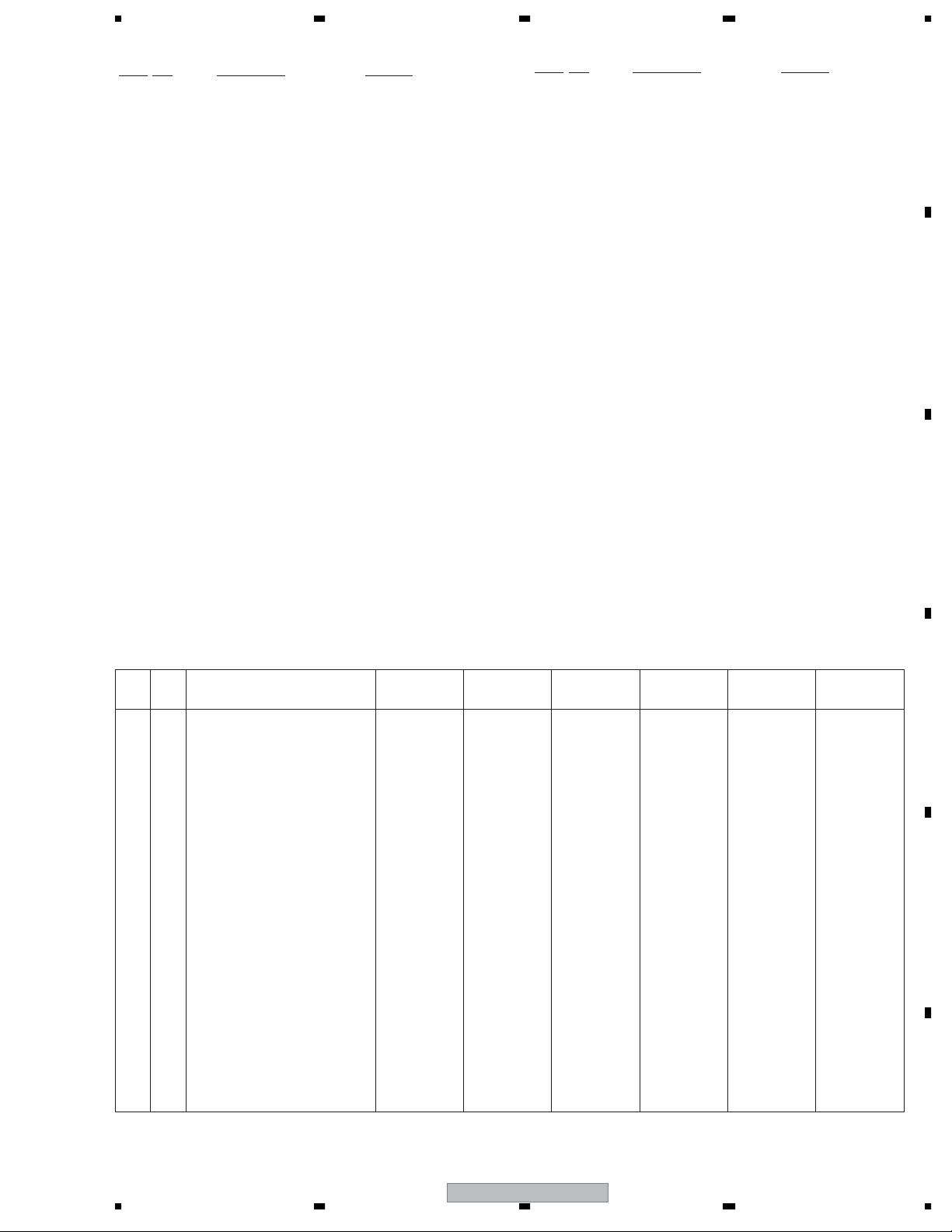

(2) CONTRAST TABLE

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5, PDP-4270XA/WYVIXK5, WYV5, PDP-427XA/WYVIXK5 and

WYV5 are constructed the same except for the following:

Mark No. Symbol and Description

2Power Cord Lid AHC1087 AHC1087 AHC1087 AHC1087 AHC1085 AHC1085

3 Remote Control Unit AXD1515 AXD1532 AXD1541 AXD1540 AXD1541 AXD1540

4 Battery Cover AZA7424 AZN2626 AZA7424 AZN2626 AZA7424 AZN2626

5 Operating Instructions

(?????)

6 Operating Instructions

(?????)

7 Block Diagram ARY1189 ARY1189 ARY1189 ARY1189 Not used Not used

NSP 11 Hexagonal Wrench (6 mm) AEF1029 Not used AEF1029 Not used AEF1029 Not used

13 Caution Card ARM1310 ARM1310 ARM1310 ARM1310 ARM1232 ARM1232

14 Cleaning Caution PTK ARM1311 ARM1311 ARM1311 ARM1311 Not used Not used

14 Wiping Cloth Caution Not used Not used Not used Not used ARM1283 ARM1283

PDP-4270XD

/WYVIXK5

ARC1565 ARC1562 Not used ARC1564 Not used ARC1563

ARE1431 ARE1428 ARE1433 ARE1430 ARE1432 ARE1429

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

PDP-427XA

/WYVIXK5

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

C

D

E

19 Pad (427 T-L) AHA2554 AHA2554 AHA2554 AHA2554 AHA2534 AHA2534

20 Pad (427 T-R) AHA2555 AHA2555 AHA2555 AHA2555 AHA2535 AHA2535

21 Pad (427 B-L) AHA2600 AHA2600 AHA2600 AHA2600 AHA2592 AHA2592

22 Pad (427 B-R) AHA2601 AHA2601 AHA2601 AHA2601 AHA2593 AHA2593

23 Under Carton (427) AHD3496 AHD3496 AHD3496 AHD3496 AHD3471 AHD3471

24 Upper Carton AHD3514 AHD3515 AHD3497 AHD3517 AHD3513 AHD3516

25 Mirror Mat AHG1327 AHG1327 AHG1327 AHG1327 AHG1284 AHG1284

PDP-4270XD

56

7

8

F

11

Page 12

1234

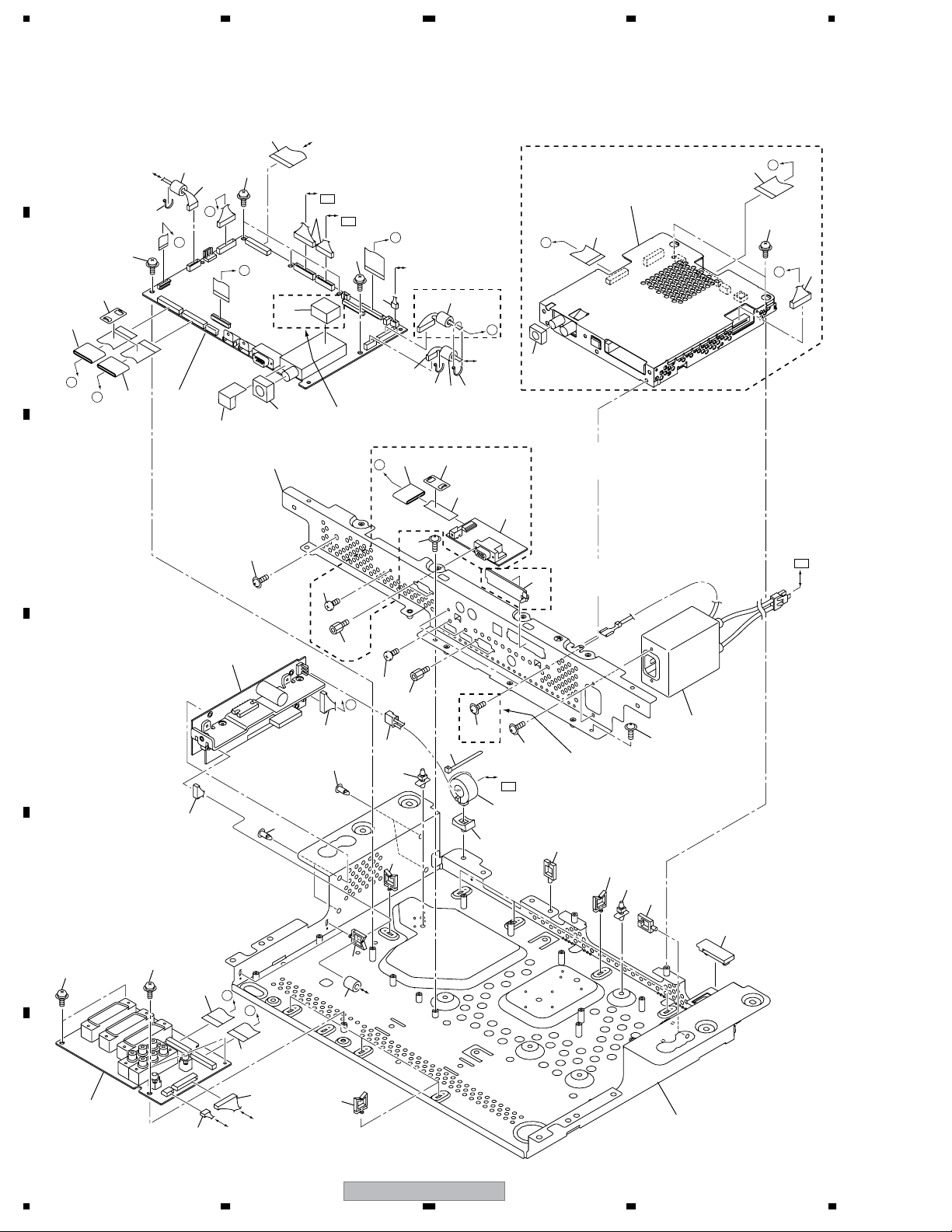

2.2 REAR SECTION

A

12

29

33

33

29

33

37

31

33

8

16

13

31

12

8

37

15

33

31

33

B

8

37

11

18

30

8

33

33

11

25

24

34

C

33

3

22

MAIN

CN4010

(Accessory of No.3)

Binder

35

33

5

33

1

35

32

10

7

32

17

28

14

6

33

29

29

27

35

35

D

4

2

26

33

23

9

A

B

33

36

33

36

20

33

36

B

A

33

E

33

35

TANSHI

33

F

19

21

12

1234

PDP-4270XD

CN9001, CN9002

Refer to

"2.3 FRONT SECTION".

Page 13

5678

(1) REAR SECTION PARTS LIST

No. Description Part No.

Mark

1 SIDE KEY Assy AWW1133

2 SIDE Assy AWW1162

3 Filter CTX1054

4 Side Input Panel (E) ANC2418

5 Function Button Base ANG2923

No. Description Part No.

Mark

21 Terminal Panel B See Contrast table (2)

22 Function Button Panel AMB2906

23 Side Input Cover AMB2911

24 Function Button (E) AAC1565

25 Function Button Sheet (E) AAK2896

A

6 Side Input Shield ANK1834

7 Function Button Shield ANK1835

8 Rear Case Cushion AEB1439

NSP 9 PCB Support AEC1288

10 Locking Card Spacer AEC2019

11 Protection Sheet C AED1300

12 Inner Grip Assy AMR3434

NSP 13 Name Label See Contrast table (2)

14 Coil Spring ABH1125

15 Bolt Caution Label See Contrast table (2)

16 Serial Seal AAX3143

17 Power Button AAD4145

18 Terminal Display Label A See Contrast table (2)

19 Terminal Display Label C See Contrast table (2)

20 Terminal Display Label B See Contrast table (2)

26 Input Cover Label E See Contrast table (2)

27 Rear Case (427) ANE1655

28 Power Button Holder AMR3539

29 Screw (3 x 40P) ABA1332

30 Screw ABA1341

31 Screw (4 x 18) ABA1353

32 Screw BPZ30P140FTB

33 Screw AMZ30P060FTB

34 Screw AMZ30P080FTC

35 Screw APZ30P080FTB

36 Screw BPZ30P080FTB

37 Screw TBZ40P080FTB

B

C

(2) CONTRAST TABLE

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5, PDP-4270XA/WYVIXK5, WYV5, PDP-427XA/WYVIXK5 and

WYV5 are constructed the same except for the following:

Mark No. Symbol and Description

NSP 13 Name Label AAL2801 AAL2804 AAL2803 AAL2806 AAL2802 AAL2805

15 Bolt Caution Label AAX3005 AAX3005 AAX3005 AAX3005 Not used Not used

15 Caution Label Not used Not used Not used Not used AAX3117 AAX3117

18 Terminal Display Label A AAX3343 AAX3337 AAX3399 AAX3398 AAX3344 AAX3332

19 Terminal Display Label C AAX3340 AAX3339 AAX3340 AAX3339 AAX3340 AAX3339

20 Terminal Display Label B AAX3419 AAX3417 AAX3419 AAX3417 AAX3419 AAX3417

21 Terminal Panel B ANC2429 ANC2403 ANC2429 ANC2403 ANC2429 ANC2403

26 Input Cover Label E AAX3397 AAX3396 AAX3397 AAX3396 AAX3376 AAX3375

PDP-4270XD

/WYVIXK5

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

PDP-427XA

/WYVIXK5

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

D

E

F

56

PDP-4270XD

13

7

8

Page 14

1234

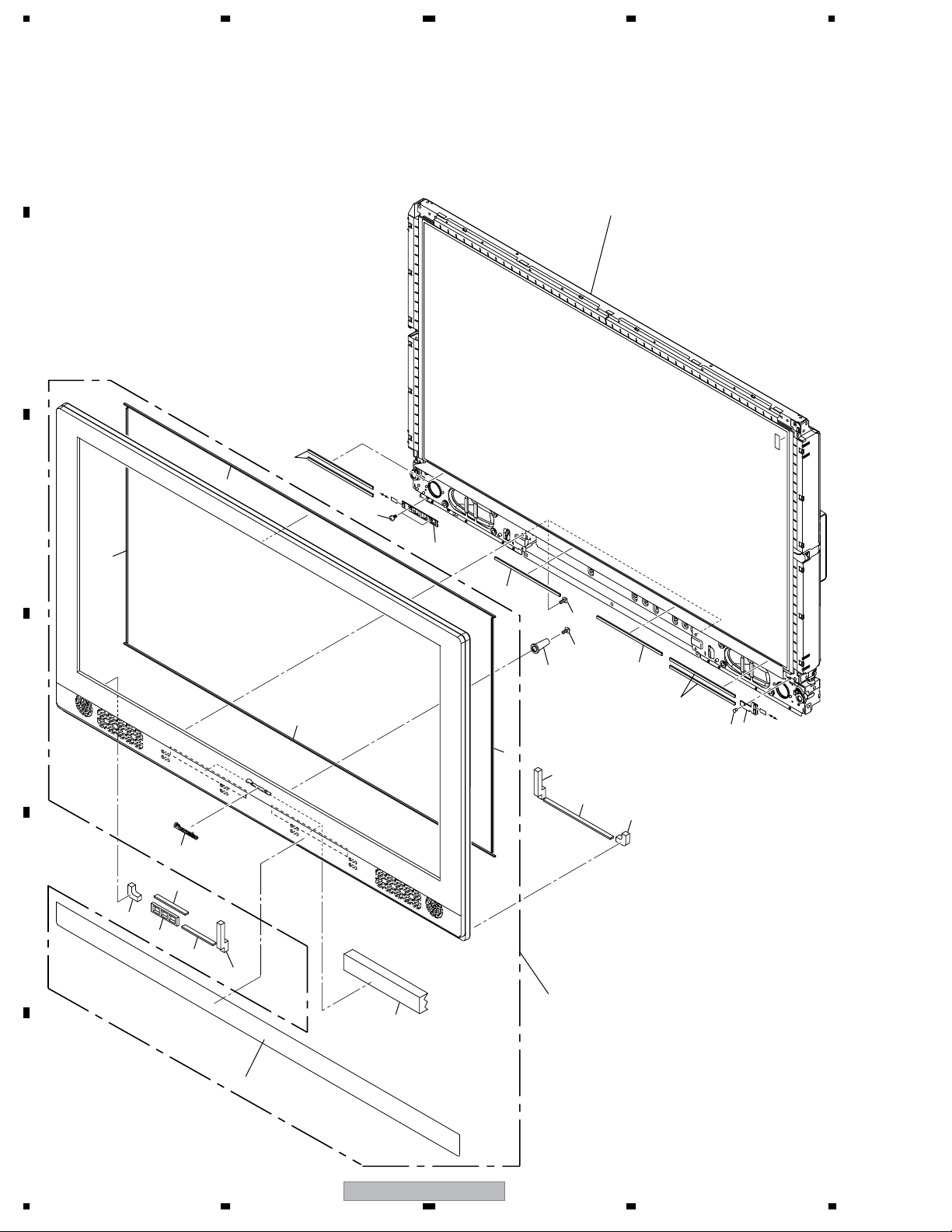

2.3 FRONT SECTION

A

B

Refer to

"2.4 CHASSIS SECTION (1/2)".

8

17

MAIN

CN4006

1

8

18

16

15

11

4

8

8

8

MAIN

2

6

5

CN4010

12

C

11

D

13

7

12

E

F

14

5

3

7

4

10

9

14

PDP-4270XD

1234

Page 15

5678

(1) FRONT SECTION PARTS LIST

No. Description Part No.

Mark

1 42 & 60 LED Assy AWW1134

2 LED IR Assy AWW1136

3 Blind Cushion (427HX) AEB1443

4 Speaker Cushion AEB1452

5 Speaker Cushion S See Contrast table (2)

6 Nyron Rivet AEC1671

7 Insulation Sheet B AED1284

8 Insulation Sheet AED1289

9 Reinforcement Frame AMR3620

10 Front Case Assy See Contrast table (2)

A

11 Panel Cushion V (42) AED1301

12 Panel Cushion H (42) AED1309

13 Pioneer Name Plate AAM1096

14 Punching Sheet See Contrast table (2)

15 Front Collar AMR3541

16 Screw (3 x 30P) ABA1350

17 Screw (M3 x 4) ABA1354

18 Screw APZ30P080FTB

19 Front Case Cushion See Contrast table (2)

20 IR Block Cushion AEB1465

21 IR Blind Sheet AAX3455

(2) CONTRAST TABLE

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5, PDP-4270XA/WYVIXK5, WYV5, PDP-427XA/WYVIXK5 and

WYV5 are constructed the same except for the following:

Mark No. Symbol and Description

5 Speaker Cushion S Not used AEB1460 Not used AEB1460 Not used AEB1460

10 Front Case Assy AMB2971 AMB2968 AMB2972 AMB2969 AMB2972 AMB2969

14 Punching Sheet AAS1015 AAS1014 AAS1015 AAS1014 AAS1015 AAS1014

19 Front Case Cushion (42B) AEB1464 AEB1462 AEB1464 AEB1462 AEB1464 AEB1462

PDP-4270XD

/WYVIXK5

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

PDP-427XA

/WYVIXK5

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

B

C

D

56

PDP-4270XD

E

F

15

7

8

Page 16

1234

2.4 CHASSIS SECTION (1/2)

A

35

31

31

B

31

32

22

31

36

31

10

26

19

35

36

Refer to

"2.7 MULTI BASE SECTION".

35

31

36

11

35

31

31

31

31

30

30

42E AUDIO

CN3753

31

1

C

31

24

42E AUDIO

CN3753

30

29

14

24

29

13

D

30

32

23

29

7

16

31

30

16

30

27

30

15

35

19

34

3

POWER

12

P3

6

29

28

34

AC inlet

32

2

22

18

18

18

MAIN

CN4009

4

18

33

15

25

E

33

25

29

8

9

25

25

20

23

32

29

21

5

30

13

14

F

30

Refer to

"2.5 CHASSIS SECTION (2/2)".

16

PDP-4270XD

1234

Page 17

5678

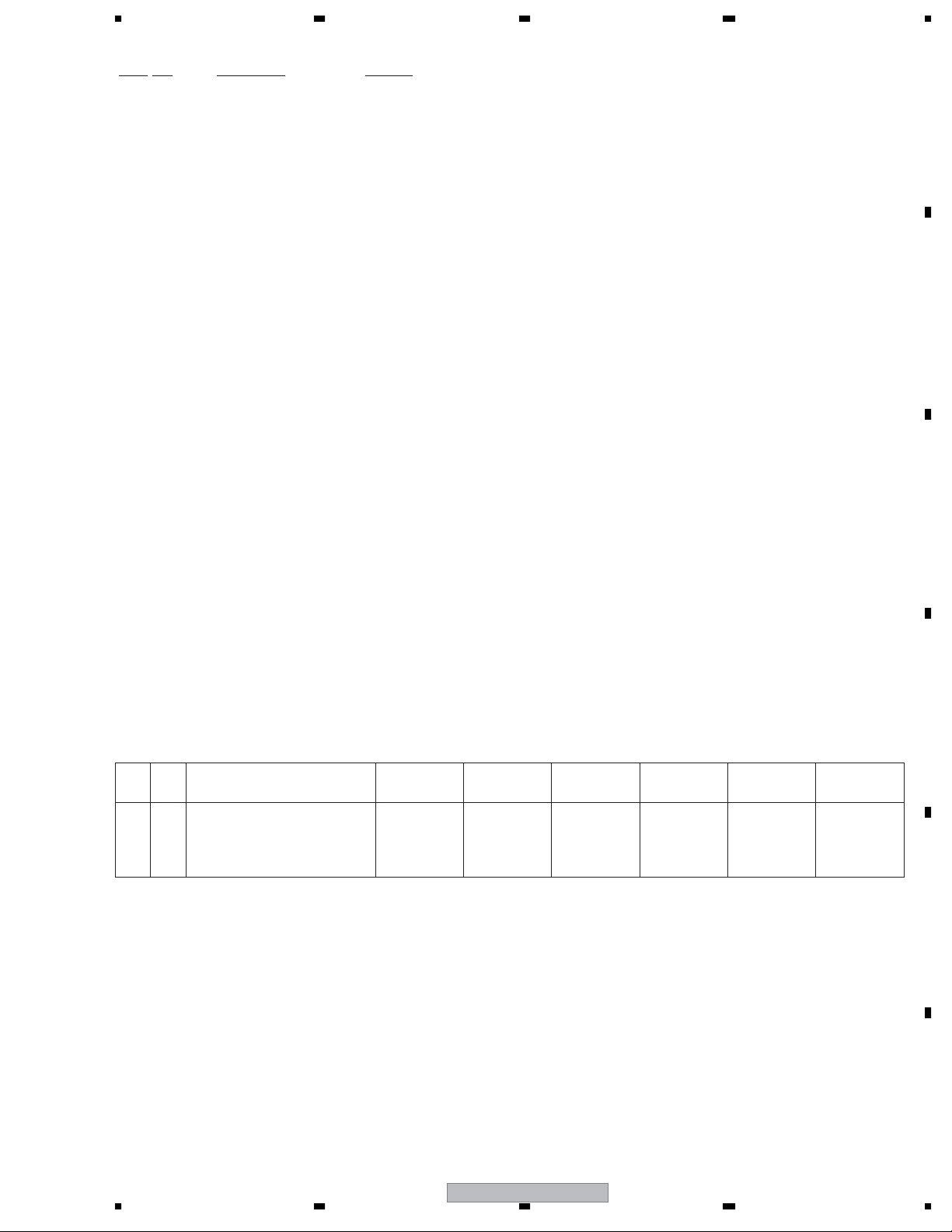

CHASSIS SECTION (1/2) PARTS LIST

No. Description Part No.

Mark

1 Speaker Box Assy L AMW1010

2 Speaker Box Assy R AMW1011

3Power Switch (S1) ASG1092

4Fan Motor 80 x 25L AXM1059

5Ferrite Core ATX1044

6 Housing Wire (42, 50)(J103) ADX3320

7Front Chassis VL (427) AMA1020

8Front Chassis VR (427) AMA1021

9Front Chassis H Assy (427) ANA2047

10 Sub Frame Assy L (427) ANA1943

>

>

>

A

11 Sub Frame Assy R (427) ANA1944

12 Fan Holder ANG2833

13 Panel Holder V1 (427) ANG2920

14 Panel Holder V2 (427) ANG2921

15 Panel Holder H (427) ANG2922

16 Multi Base Holder ANG2937

17 • • • • •

18 Floating Rubber 80 AEB1427

19 Wire Saddle AEC1745

20 Ferrite Core Holder AEC1818

21 Flat Clamp AEC1879

22 Locking Wire Saddle AEC1948

23 Mini Clamp AEC2090

24 Re-use Wire Saddle AEC2091

25 Address Gasket (42) ANK1877

26 Gasket D ANK1840

27 Switch Holder AMR3540

28 Re-use Wire Saddle AEC1945

29 Screw ABA1351

30 Screw ABZ30P080FTC

B

C

D

31 Screw AMZ30P060FTB

32 Screw APZ30P080FTB

33 Screw BBZ30P060FTC

34 Screw BPZ30P080FTB

35 Screw TBZ40P080FTB

36 Screw ABA1364

56

PDP-4270XD

E

F

17

7

8

Page 18

1234

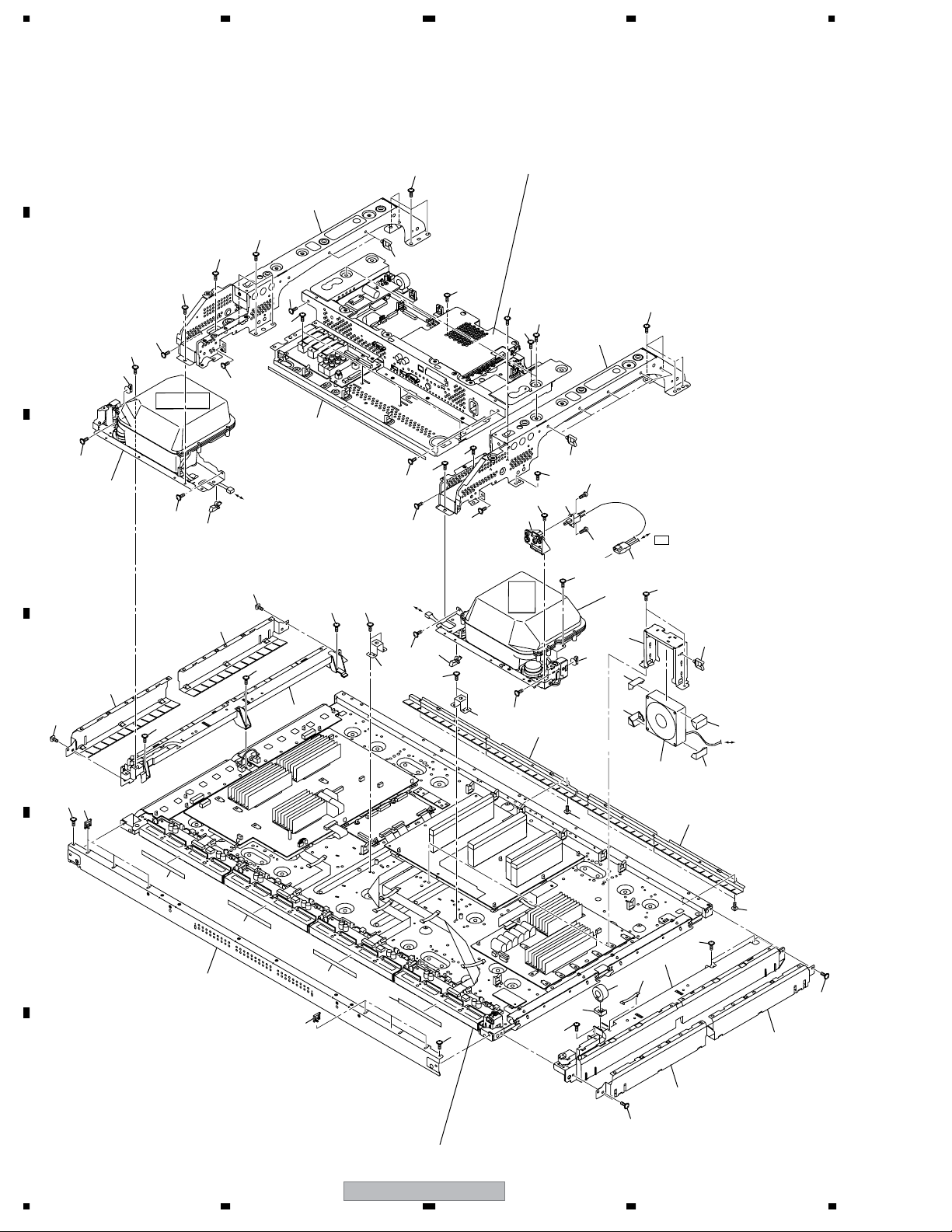

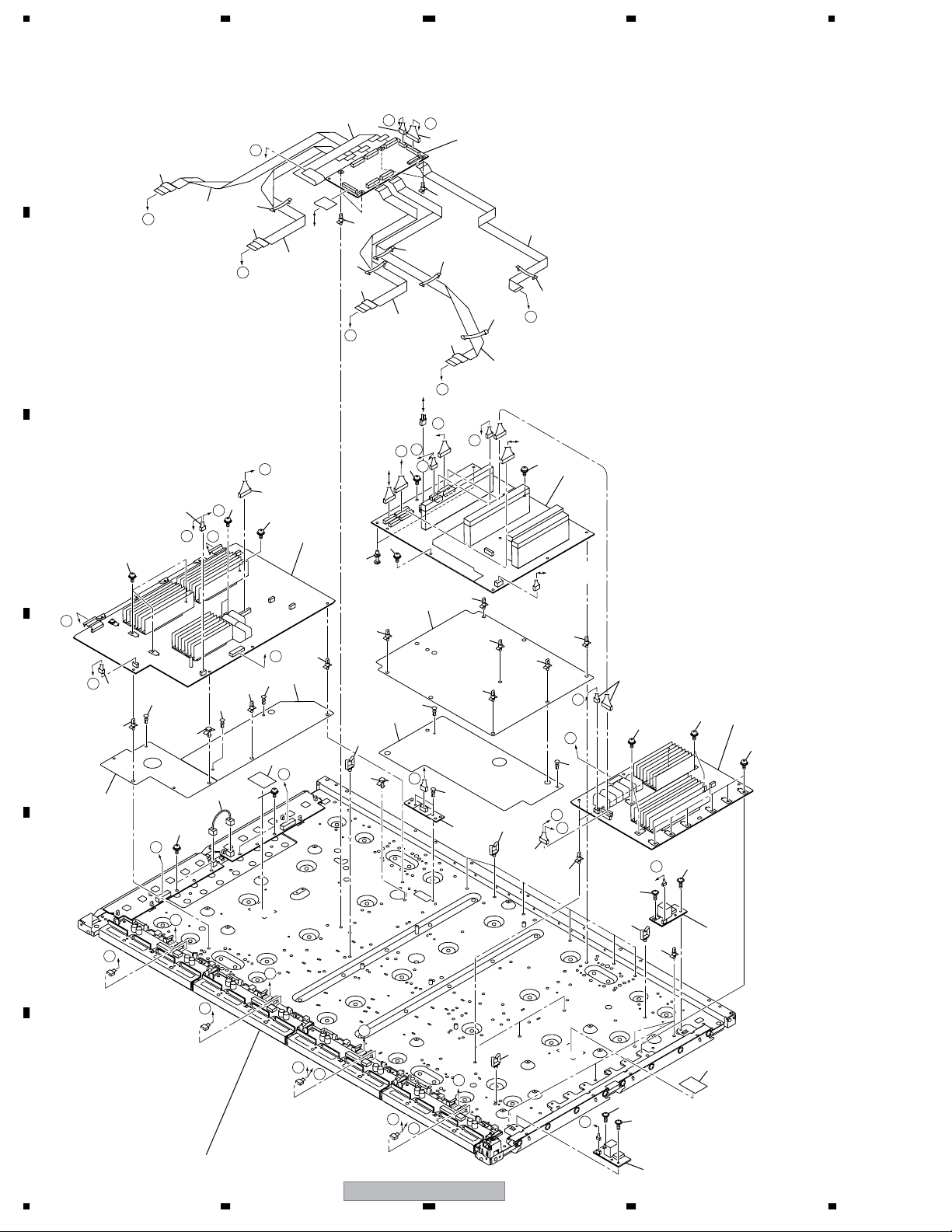

2.5 CHASSIS SECTION (2/2)

A

H

9

G

22

F

5

19

8

12

26

28

26

14

26

26

E

8

26

A

10

8

MAIN

CN4001

11

B

28

26

8

B

C

13

42E AUDIO

D

CN3751

I

J

F

MAIN

CN4008

37

I

17

C

20

36

36

J

K

L

36

4

23

K

37

33

M

28

H

32

N

21

D

34

28

34

27

28

34

28

34

30

25

Q

28

28

28

29

31

L

16

37

37

M

27

G

24

6

25

MAIN

CN4002

28

15

37

7

AC inlet,

Power switch

28

O

P

28

18

R

36

E

36

3

37

34

37

O

36

E

N

A

25

1

28

B

K

C

25

Q

R

F

Q

D

36

R

P

37

29

Refer to

18

"2.6 PANEL CHASSIS SECTION".

PDP-4270XD

2

1234

Page 19

5678

CHASSIS SECTION (2/2) PARTS LIST

No. Description Part No.

Mark

1 SUS CLAMP 1 Assy AWW1022

2 SUS CLAMP 2 Assy AWW1023

3 42 X DRIVE Assy AWW1196

4 42 Y DRIVE Assy AWV2400

5 42 DIGITAL Assy AWW1240

6 SENSOR Assy AWW1140

7POWER SUPPLY Unit AXY1153

8Ferrite Core ATX1048

9 Flexible Cable (J201) ADD1429

10 Flexible Cable (J202) ADD1430

>

A

11 Flexible Cable (J203) ADD1431

12 Flexible Cable (J204) ADD1432

13 Flexible Cable (J205) ADD1433

14 Flexible Cable (J206) ADD1434

15 6P Housing Wire (J118) ADX3118

16 3P Housing Wire (J119) ADX3122

17 9P Housing Wire (J101) ADX3318

18 8P&5/4P Housing Wire (J102) ADX3319

19 14P Housing Wire (J105) ADX3323

20 6P/4P Housing Wire (J108) ADX3326

21 4P Housing Wire (J109) ADX3327

22 5P Housing Wire (J110) ADX3328

23 Spacer AEC1065

24 Nyron Rivet AEC1671

25 Wire Saddle AEC1745

26 Flat Clamp AEC1879

27 PCB Support AEC1938

28 Re-use PCB Spacer AEC2087

29 Drive Silicone Sheet AEH1095

30 Power Supply Sheet B (507) AMR3555

B

C

D

31 Y Drive Protection Sheet A AMR3632

32 Y Drive Protection Sheet B AMR3633

33 Power Supply Sheet (427) A AMR3648

34 Rivet A BEC1158

35 • • • • •

36 Screw ABA1351

37 Screw ABA1368

56

PDP-4270XD

E

F

19

7

8

Page 20

1234

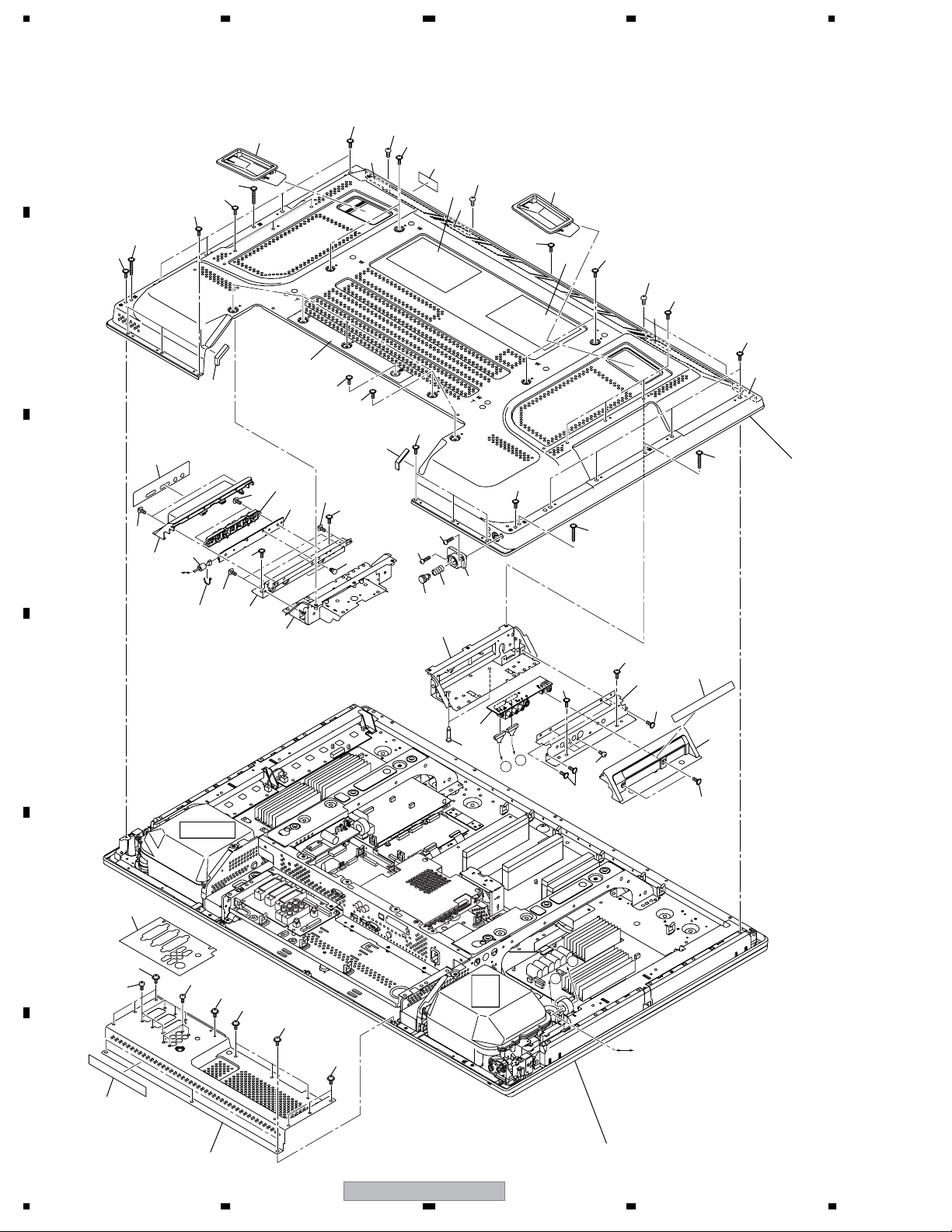

2.6 PANEL CHASSIS SECTION

A

5

B

4

8

8

8

8

8

7

8

C

10

13

6

D

E

3

2

11

14

9

1

12

F

20

1234

PDP-4270XD

Page 21

5678

(1) PANEL CHASSIS SECTION PARTS LIST

No. Description Part No.

Mark

NSP 1 Panel Chassis (427S) Assy See Contrast table (2)

NSP 2 Plasma Panel (42DC) Assy AWU1161

NSP 3 42 ADDRESS Assy AWV2335

NSP 4 42 SCAN A Assy AWW1182

NSP 5 42 SCAN B Assy AWW1183

6 Address Heatsink ANH1644

7 Conductive Plate X ANG2791

8 Re-use PCB Spacer AEC2087

9 Address Silicone A AEH1093

10 Conductive Plate Holder AMR3446

A

11 Address Holder Assy AMR3460

12 Screw ABA1364

13 Screw BBB30P120FNI

14 Tube Cover (FT) AMR3557

(2) CONTRAST TABLE

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5, PDP-4270XA/WYVIXK5, WYV5, PDP-427XA/WYVIXK5 and

WYV5 are constructed the same except for the following:

Mark No. Symbol and Description

NSP 1 Panel Chassis (427S) Assy AWU1185 AWU1185 AWU1185 AWU1185 AWU1207 AWU1207

PDP-4270XD

/WYVIXK5

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

PDP-427XA

/WYVIXK5

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

B

C

D

56

PDP-4270XD

E

F

21

7

8

Page 22

1234

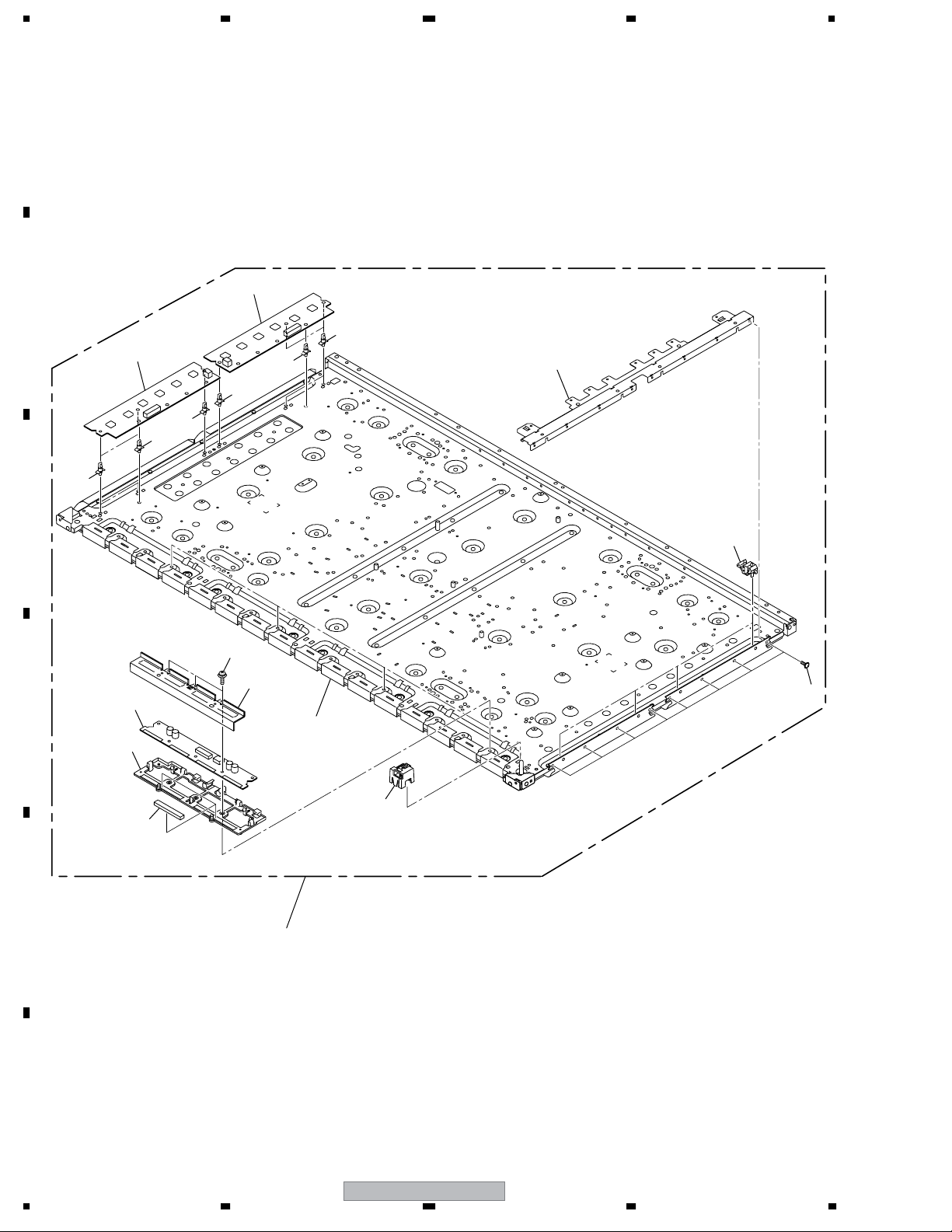

2.7 MULTI BASE SECTION

A

B

C

SIDE KEY CN9501

LED IR CN9701

(Accessory of No.42)

Binder

47

31

8

B

C

8

13

42

D

21

47

A

F

42 DIGITAL

CN3001

POWER

P8

17

POWER

P9

47

29

H

Fan

PDP-4270XD,

PDP-427XD only

42

5

F

15

PDP-427XD only

H

9

47

16

G

41

PDP-4270XD,

G

20

1

39

40

(Accessory of No.42)

PDP-4270XD,

PDP-427XD only

36

Binder

7

D

Binder

42

(Accessory of No.42)

31

38

PDP-427XD,

PDP-427XA only

14

3

47

46

43

PDP-4270XD,

34

PDP-427XD only

POWER

P3

4

44

46

18

25

44

24

45

POWER

P5

43

PDP-4270XD,

PDP-427XD only

10

43

D

A

19

33

6

23

33

30

27

26

30

25

26

E

28

47

47

12

B

C

42

30

Speaker

11

F

2

32

SIDE

CN9205

SIDE

CN9207

22

30

35

22

PDP-4270XD

1234

Page 23

5678

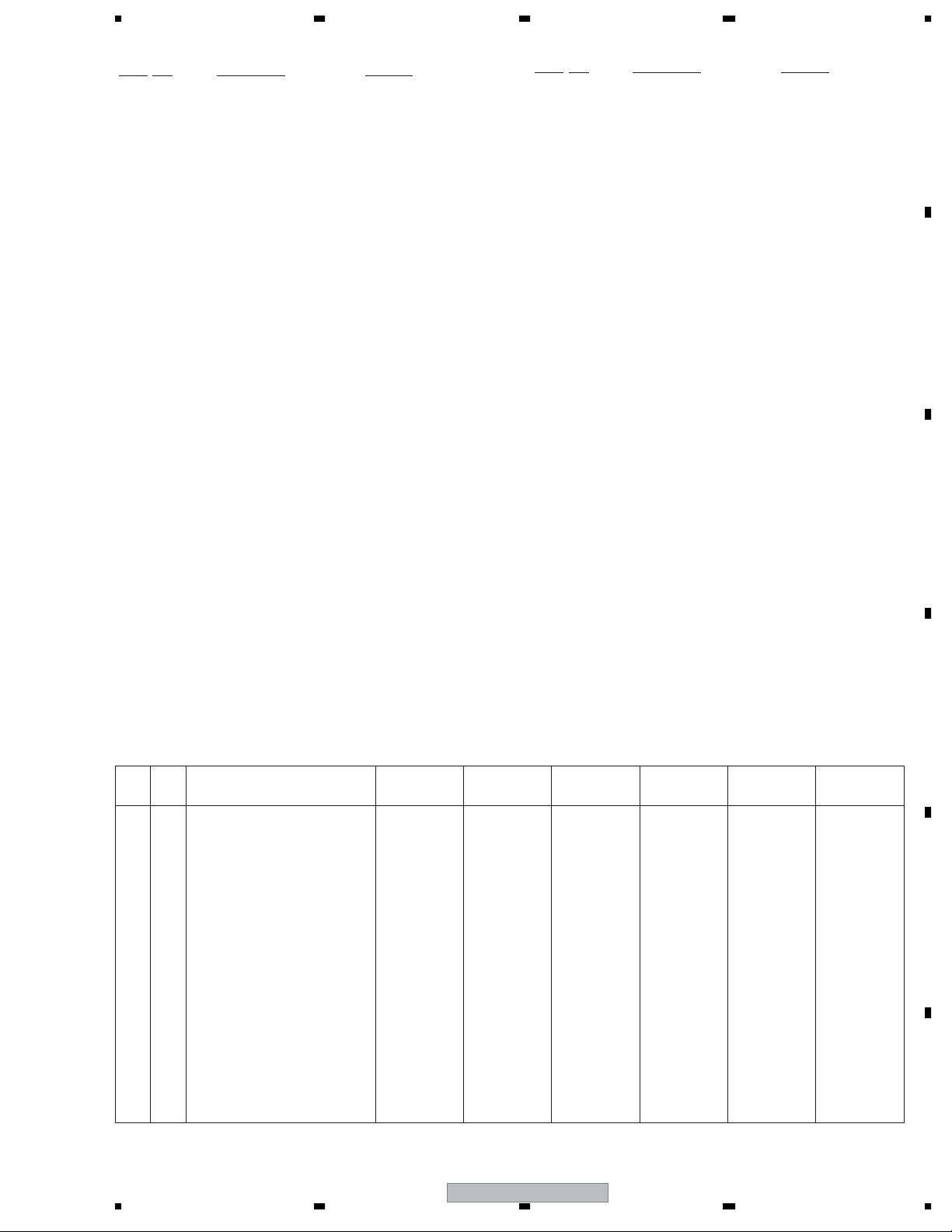

(1) MULTI BASE SECTION PARTS LIST

No. Description Part No.

Mark

1 MAIN Assy See Contrast table (2)

2TANSHI Assy See Contrast table (2)

3 PC Assy See Contrast table (2)

4 42E AUDIO Assy AWW1185

5 R07 DT Assy See Contrast table (2)

>

>

>

>

>

No. Description Part No.

Mark

26 Wire Saddle AEC1745

27 Ferrite Core Holder AEC1818

28 Clamp AEC1884

29 3P Housing Wire (J127) ADX3421

30 Re-use Wire Saddle AEC1945

A

6Ferrite Core ATX1044

7Ferrite Core See Contrast table (2)

8Ferrite Core ATX1064

9 Flexible Cable (J214) See Contrast table (2)

10 AC Inlet (CN1) AKP1301

11 Flexible Cable (J210) ADD1441

12 Flexible Cable (J211) ADD1441

13 Flexible Cable (J207) ADD1445

14 Flexible Cable (J213) See Contrast table (2)

15 Flexible Cable (J215) See Contrast table (2)

16 12P Housing Wire (J126) See Contrast table (2)

17 13P&11P Housing Wire (J106) ADX3324

18 3P Housing Wire (J107) ADX3325

19 11P Housing Wire (J111) ADX3329

20 6P Housing Wire (J113) ADX3331

21 7/6/4P Housing Wire (J114) ADX3332

22 14P Housing Wire (J116) ADX3334

23 8/4P Housing Wire (J117) ADX3336

24 Binder AEC-093

25 Locking Card Spacer AEC1429

31 Ferrite Stopper AEC1981

32 5P Housing Wire (J125) ADX3388

33 Locking Card Spacer AEC2019

34 POD Cover See Contrast table (2)

35 Multi Base Assy See Contrast table (2)

36 Terminal Panel A See Contrast table (2)

37 • • • • •

38 Gasket N See Contrast table (2)

39 Gasket EA ANK1855

40 Gasket EB ANK1899

41 Gasket ED See Contrast table (2)

42 Filter CTX1054

43 Screw AMZ30P060FTB

44 Hex. Head Screw BBA1051

45 Screw See Contrast table (2)

46 Screw BMZ30P060FTB

47 Screw PMB30P080FNI

B

C

(2) CONTRAST TABLE

PDP-4270XD/WYVIXK5, PDP-427XD/WYVIXK5, PDP-4270XA/WYVIXK5, WYV5, PDP-427XA/WYVIXK5 and

WYV5 are constructed the same except for the following:

Mark No. Symbol and Description

1 MAIN Assy AWV2320 AWV2318 AWV2320 AWV2318 AWV2320 AWV2318

2TANSHI Assy AWW1178 AWW1161 AWW1178 AWW1161 AWW1178 AWW1161

3 PC Assy Not used AWW1163 Not used AWW1163 Not used AWW1163

5 R07 DT Assy AWE1311 AWE1311 Not used Not used Not used Not used

7Ferrite Core Not used ATX1063 Not used ATX1063 Not used ATX1063

9 Flexible Cable (J214) ADD1450 ADD1450 Not used Not used Not used Not used

14 Flexible Cable (J213) Not used ADD1452 Not used ADD1452 Not used ADD1444

15 Flexible Cable (J215) ADD1451 ADD1451 Not used Not used Not used Not used

16 12P Housing Wire (J126) ADX3390 ADX3390 Not used Not used Not used Not used

34 POD Cover AMR3542 AMR3542 Not used Not used Not used Not used

35 Multi Base Assy ANA1952 ANA1952 ANA2019 ANA2019 ANA2019 ANA2019

36 Terminal Panel A ANC2400 ANC2398 ANC2415 ANC2399 ANC2415 ANC2399

>

38 Gasket N ANK1776 ANK1776 Not used Not used Not used Not used

>

41 Gasket ED ANK1863 ANK1863 Not used Not used Not used Not used

45 Screw

PDP-4270XD

/WYVIXK5

BBZ30P060FTB BBZ30P060FTB

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

Not used Not used Not used Not used

PDP-427XA

/WYVIXK5

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

D

E

F

56

PDP-4270XD

23

7

8

Page 24

1234

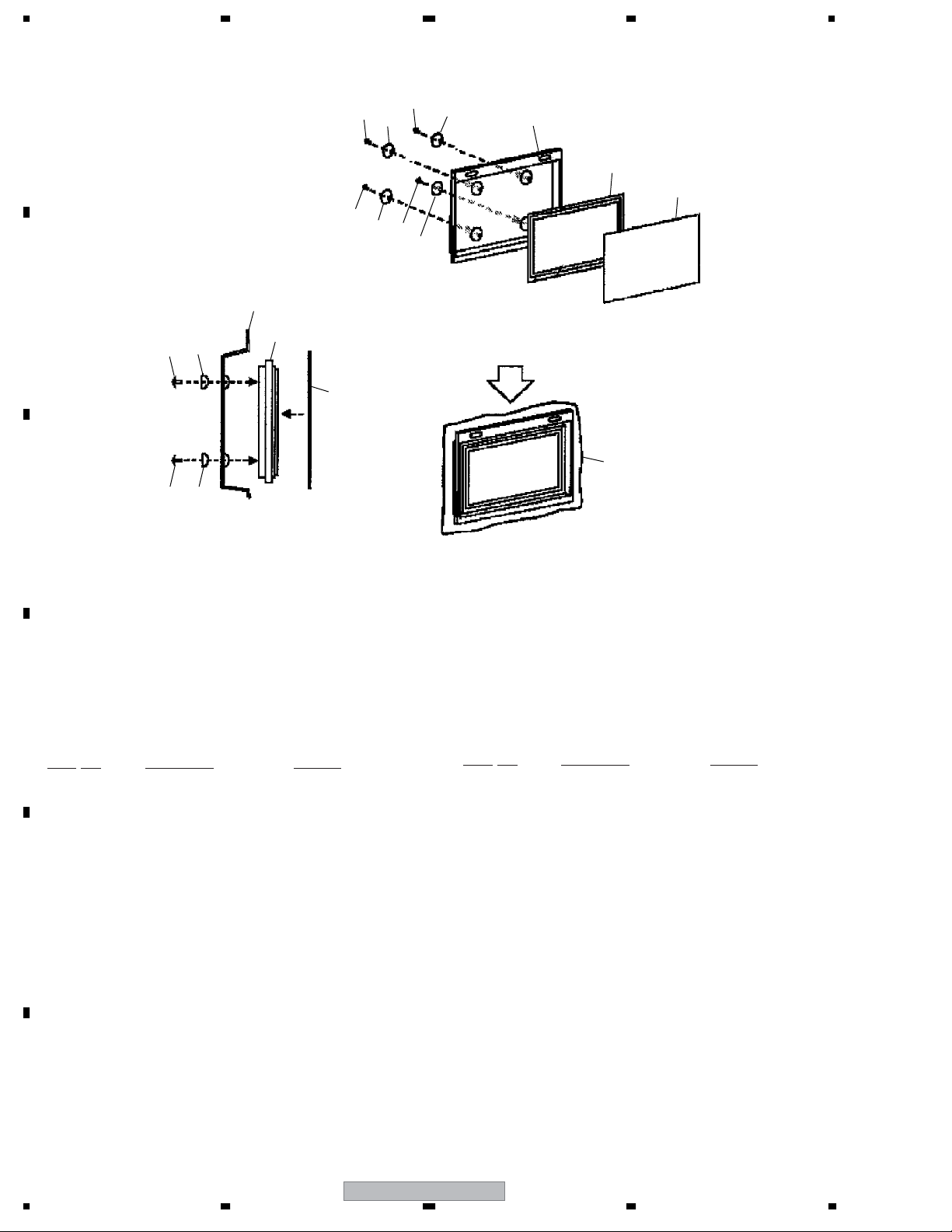

2.8 PDP SERVICE PANEL ASSY 427 (AWU1208)

4

A

4

23

4

23

23

4

23

22

1

21

B

23

4

23

4

C

D

22

1

21

PDP SERVICE PANEL ASSY 427 (AWU1208) PARTS LIST

Mark No. Description Part No.

NSP 1 Panel Chassis (427) Assy AWU1171

2 Caution Label AAX3031

NSP 3 Drive Voltage Label ARW1097

4 Screw PMB50P150FTC

5 Screw ABA1351

20

Mark No. Description Part No.

16 Pad 42SINGLE(B-L) AHA2552

17 Pad 42SINGLE(B-R) AHA2553

18 Upper Carton (42SINGLE) AHD3480

19 Under Carton (42SINGLE) AHD3481

20 Polyethylene Bag AHG1381

6 Wire Saddle AEC1745

E

7 PCB Support AEC1938

8 Vinyl Bag S AHG1338

NSP 9 Vinyl Bag AHG1340

10 Y Drive Protection Sheet A AMR3632

11 Power Sheet (427) A AMR3648

12 Address Gasket (42) ANK1877

13 Rivet A BEC1158

14 Pad 42SINGLE(T-L) AHA2550

15 Pad 42SINGLE(T-R) AHA2551

F

24

1234

21 Packing Sheet AHG1386

22 Tray (FT) AHX1158

23 Cup Spacer (15) ANG2936

PDP-4270XD

Page 25

5678

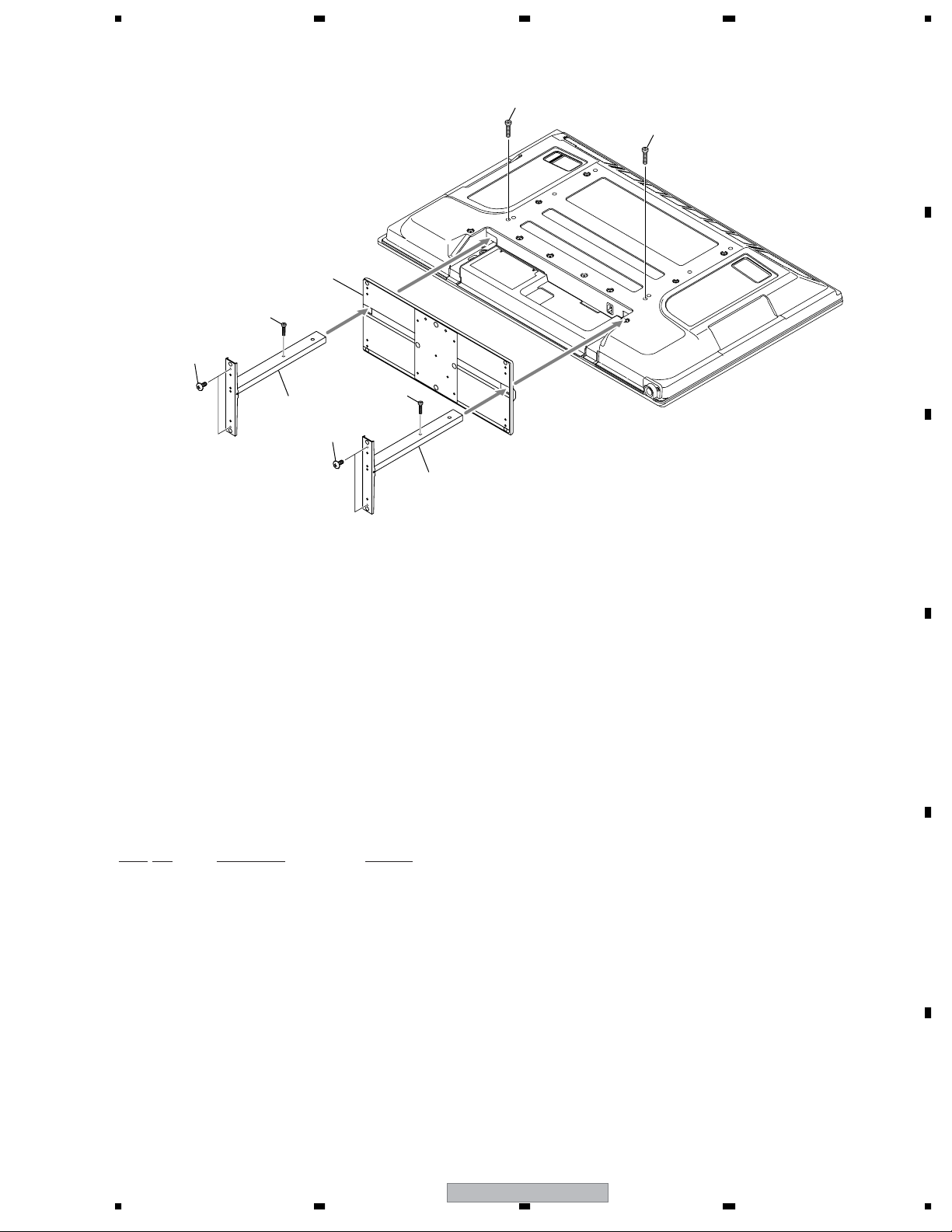

2.9 TABLE TOP STAND (PDP-4270XD ONLY)

5

5

2

4

3

1

3

4

1

A

B

C

TABLE TOP STAND PARTS LIST

Mark No. Description Part No.

1 Stand Pipe Assy AXY1144

2 Base Cover Assy AXY1143

3 Screw ABA1357

4 Screw (HEX) SMZ80H300FTC

5 Screw (HEX) ABA1365

D

E

F

56

PDP-4270XD

25

7

8

Page 26

1234

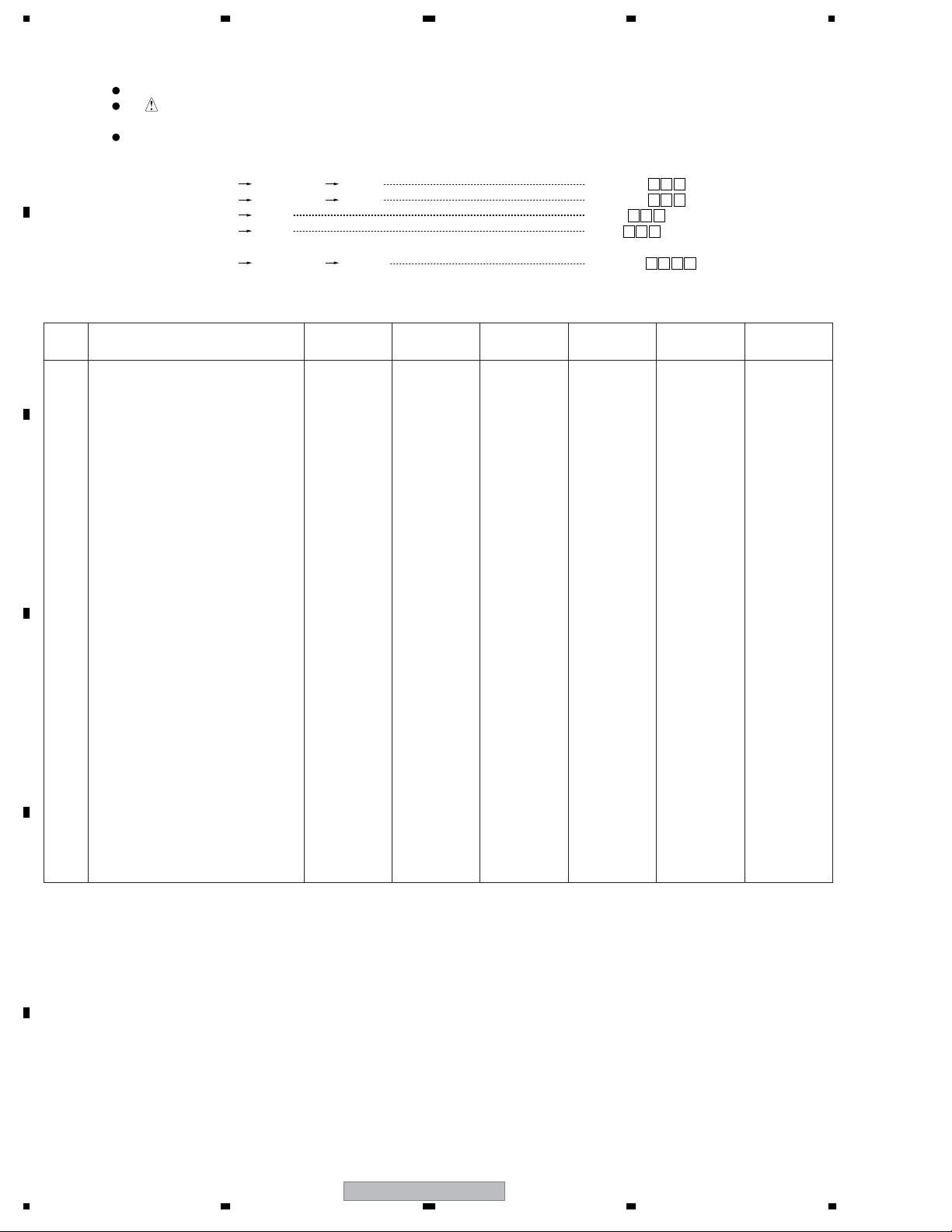

3. PCB PARTS LIST

>

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω

47k Ω

0.5 Ω

1 Ω

56 x 10

47 x 10

R50

1R0

1

3

561

473

RD1/4PU J

RD1/4PU J

RN2H K

RS1P K

561

473

R50

1R0

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω

77

77

LIST OF WHOLE PCB ASSEMBLIES

B

Mark Symbol and Description

1..R07 DT ASSY AWE1311 AWE1311 Not used Not used Not used Not used

1..MAIN ASSY AWV2320 AWV2318 AWV2320 AWV2318 AWV2320 AWV2318

NSP 1..IO ASSY AWV2321 AWV2319 AWV2321 AWV2319 AWV2321 AWV2319

2..TANSHI ASSY AWW1161 AWW1178 AWW1161 AWW1178 AWW1161 AWW1178

2..SIDE ASSY AWW1162 AWW1162 AWW1162 AWW1162 AWW1162 AWW1162

2..PC ASSY Not used AWW1163 Not used AWW1163 Not used AWW1163

NSP 1..42E AUDIO ASSY AWV2369 AWV2369 AWV2369 AWV2369 AWV2369 AWV2369

C

2..SIDE KEY ASSY AWW1133 AWW1133 AWW1133 AWW1133 AWW1133 AWW1133

2..42 & 60 LED ASSY AWW1134 AWW1134 AWW1134 AWW1134 AWW1134 AWW1134

2..LED IR ASSY AWW1136 AWW1136 AWW1136 AWW1136 AWW1136 AWW1136

2..42E AUDIO ASSY AWW1185 AWW1185 AWW1185 AWW1185 AWW1185 AWW1185

1

5621

PDP-4270XD

/WYVIXK5

PDP-427XD

/WYVIXK5

PDP-4270XA

/WYVIXK5

RN1/4PC F562 x 10

PDP-427XA

/WYVIXK5

5621

PDP-4270XA

/WYV5

PDP-427XA

/WYV5

NSP 1..42 X DRIVE ASSY AWV2399 AWV2399 AWV2399 AWV2399 AWV2399 AWV2399

2..SUS CLAMP 1 ASSY AWW1022 AWW1022 AWW1022 AWW1022 AWW1022 AWW1022

2..SUS CLAMP 2 ASSY AWW1023 AWW1023 AWW1023 AWW1023 AWW1023 AWW1023

2..42 X DRIVE ASSY AWW1196 AWW1196 AWW1196 AWW1196 AWW1196 AWW1196

1..42 Y DRIVE ASSY AWV2400 AWV2400 AWV2400 AWV2400 AWV2400 AWV2400

NSP 1..42 DIGITAL ASSY AWV2435 AWV2435 AWV2435 AWV2435 AWV2435 AWV2435

D

E

2..SENSOR ASSY AWW1140 AWW1140 AWW1140 AWW1140 AWW1140 AWW1140

2..42 DIGITAL ASSY AWW1240 AWW1240 AWW1240 AWW1240 AWW1240 AWW1240

NSP 1..PANEL CHASSIS (427S) ASSY AWU1185 AWU1185 AWU1185 AWU1185 AWU1185 AWU1185

NSP 2..42 ADDRESS ASSY AWV2335 AWV2335 AWV2335 AWV2335 AWV2335 AWV2335

NSP 2..42 SCAN ASSY AWV2362 AWV2362 AWV2362 AWV2362 AWV2362 AWV2362

NSP 3..42 SCAN A ASSY AWW1182 AWW1182 AWW1182 AWW1182 AWW1182 AWW1182

NSP 3..42 SCAN B ASSY AWW1183 AWW1183 AWW1183 AWW1183 AWW1183 AWW1183

1..POWER SUPPLY UNIT AXY1153 AXY1153 AXY1153 AXY1153 AXY1153 AXY1153

F

26

1234

PDP-4270XD

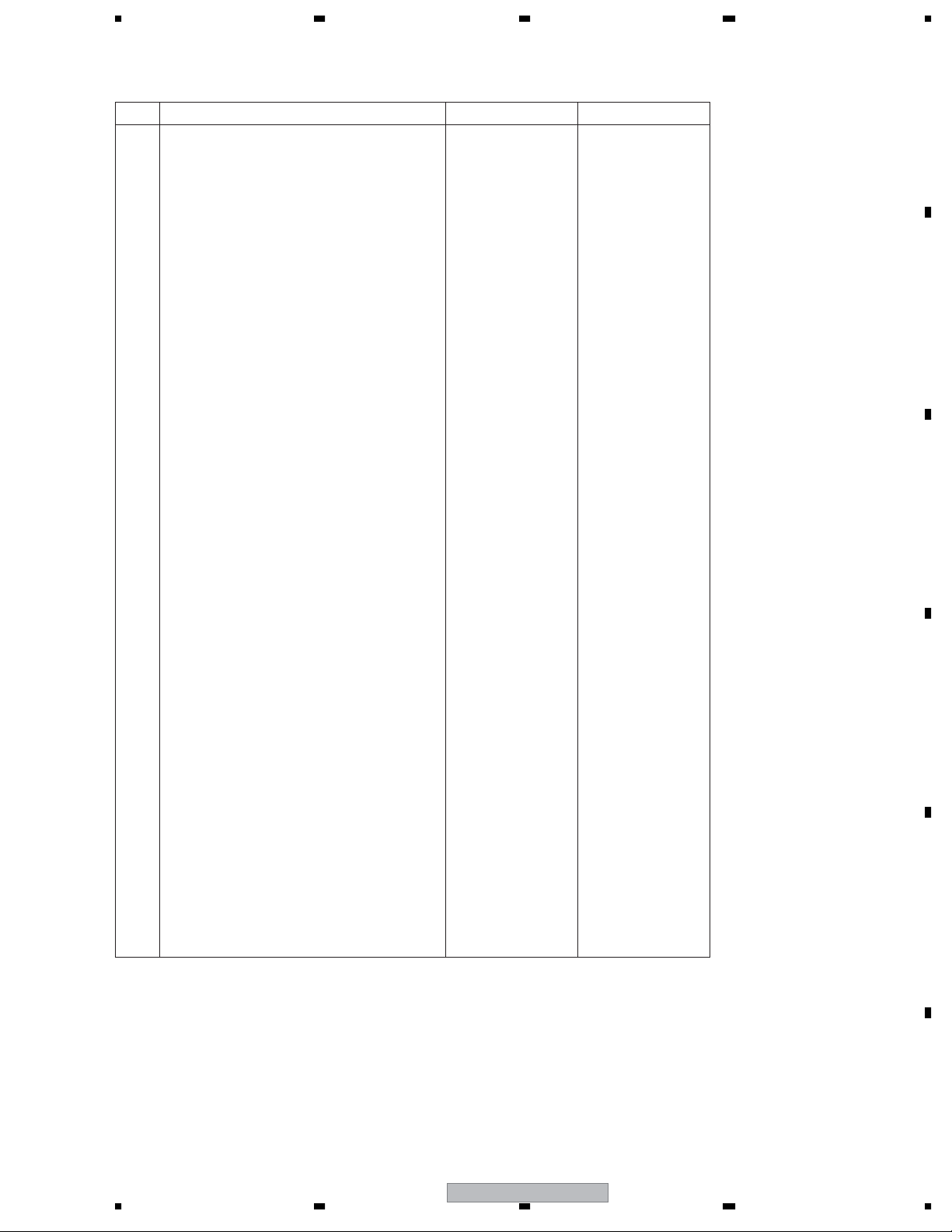

Page 27

5678

77

77

CONTRAST OF PCB ASSEMBLIES

MAIN ASSY

AWV2320 and AWV2318 are constructed the same except for the following :

Mark Symbol and Description AWV2320 AWV2318

IC5103 Not used TVP5150AM1PBS-K

IC5404 Not used BR24L02FJ

IC8305 Not used TC74VHC00FTS1

Q5402 Not used HN1K02FU

Q5408 Not used UMD2N

Q5414 Not used RN1902

Q8302 Not used 2SA1586

Q8303, Q8304 Not used DTC124EUA

Q8311 Not used 2SJ461A

D5402 Not used 1SS301

D5408 Not used UDZS6R8(B)

D8301 - D8303 Not used 1SS355

C4922, C4932, C4933, C5101, C5102, C5103 Not used CKSRYB105K10

C5104, C5105 Not used CCSSCH100D50

C5117, C5123, C5125, C5126, C5449 - C5451 Not used CKSSYF104Z16

C5121, C5122, C5124, C8320 Not used CKSSYB104K10

C5452, C8319 Not used DCH1201

C5453 Not used CCSSCH101J50

R4031 Not used RS1/16S0R0J

R4056, R8344 Not used RS1/16SS0R0J

R4057 RS1/16SS0R0J Not used

R4728, R4729, R4904, R4905, R4910 Not used RS1/16SS220J

R4809, R4810 Not used RS1/16SS562J

R4964, R4965, R4966 Not used RS1/16S75R0F

R5103 Not used ACN1246

A

B

C

R5121, R8347, R8359 Not used RS1/16SS332J

R5122, R5419, R8476 Not used RS1/16SS103J

R5124, R5125, R5126 Not used RS1/16SS470J

R5147 Not used RAB4CQ220J

R5421, R8364 Not used RS1/16SS101J

R5422 Not used RS1/16SS473J

R5423, R5424 Not used RS1/16SS100J

R5433, R8353 Not used RS1/16SS102J

R8354 Not used RS1/16SS122J

R8355 Not used RS1/16SS104J

R8356, R8358 Not used RS1/16S122J

R8357 Not used RS1/16S220J

R8376 RS1/10S0R0J Not used

R8379, R8380 RS1/16SS223J Not used

R8477, R8480 RS1/16SS103J Not used

X5101 CRYSTAL Not used ASS1189

CN4018 12P FFC CONNECTOR Not used AKM1233

JA5402 HDMI CONNECTOR Not used AKP1278

D

E

56

PDP-4270XD

F

27

7

8

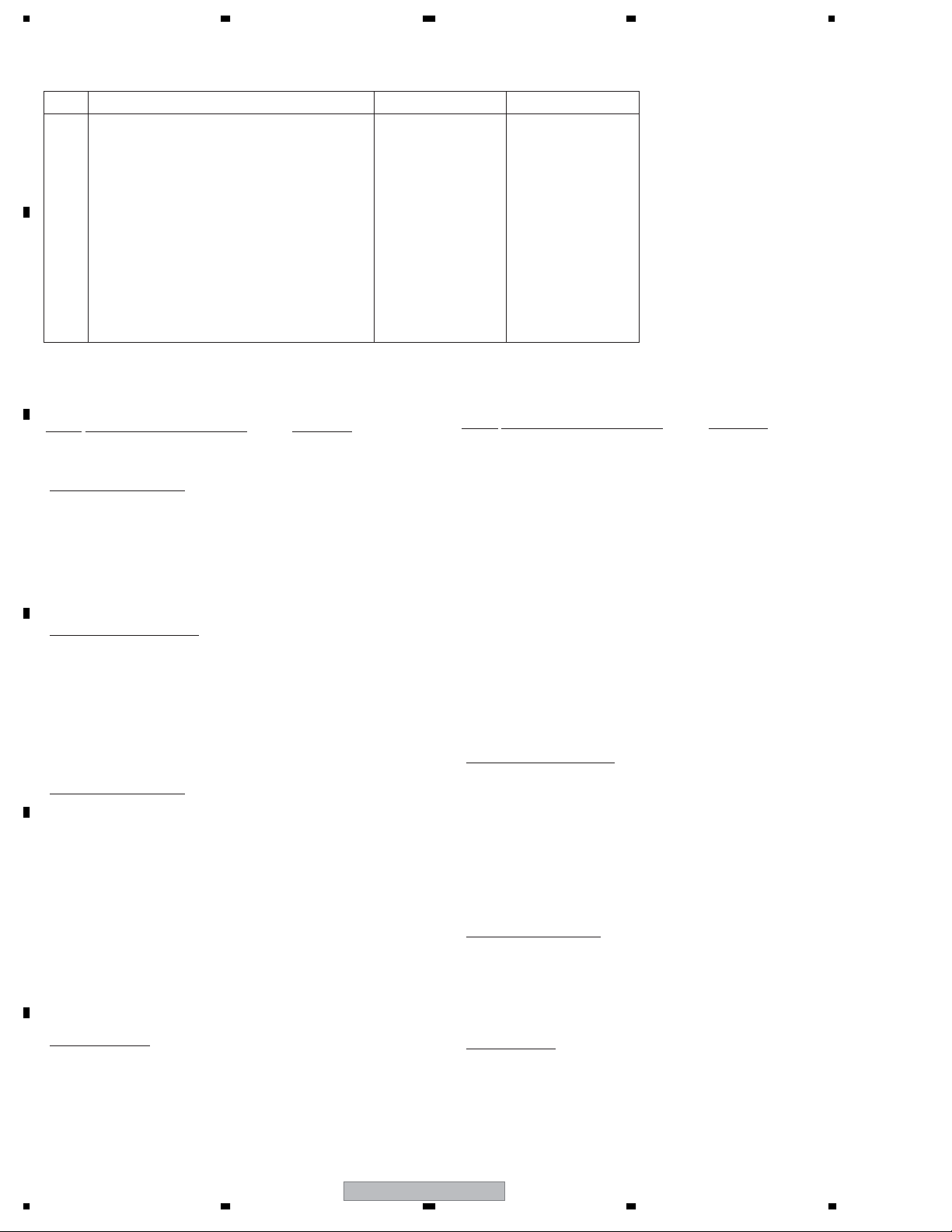

Page 28

1234

TANSHI ASSY

AWW1178 and AWW1161 are constructed the same except for the following :

Mark Symbol and Description AWW1178 AWW1161

A

B

77

77

Mark No. Description Part No.

C

Q9012 Not used HN1A01FU

Q9015 Not used 2SC4116

Q9016 Not used 2SD2114K

F9001 - F9007 Not used CTF1557

C9037 Not used CCG1205

C9022, C9025 Not used CKSRYB105K10

C9010 - C9012 Not used CKSSYB471K50

C9023, C9026 Not used CKSRYB102K50

C9043 Not used CKSRYB224K10

JA9005 2P PINJACK AKB1331 AKB1340

JA9002 Not used VKN1449

JA9004 Not used AKN1081

PCB PARTS LIST FOR PDP-427XD/WYVIXK5 UNLESS OTHER WISE NOTED

Mark No. Description Part No.

R07 DT ASSY

MISCELLANEOUS

9 XNG1002

11 ANG2673

12-15 SCREW PMZ20P100FNI

16-18 SCREW ABZ30P060FTC

[TUNER BLOCK]

C1018,1027,1029,1050 CEHVKW470M16

C1019 CEHVKW100M50

C1020 CEHVKW100M16

C1025,1026,1030-1035 CKSRYB104K16

C1028,1038,1042,1046 CCG1205

C1036 CKSRYB105K10

C1037,1039,1049,1053 CKSRYB104K16

C1043,1044 CCSRCJ3R0C50

C1045 CKSRYB103K50

C1051 CCG1205

>

>

SEMICONDUCTORS

IC1000 UPC3221GV

IC1001 STV0361L

Q1001 2SC2412K

Q1002 DTC124EUA

Q1003,1004 RK7002

D

>

D1000 SM15T6V8A

D1001 1SS355

MISCELLANEOUS

L1000 XTX1005

L1002 LCYAR82J2520

L1004 XTX1003

L1200 XTX1001

F1000 XTF1002

F1001,1003-1010 VTF1091

E

F1012-1014,1100,1101 VTF1091

F1202-1204 VTF1091

X1100 CRYSTAL (27 MHz) XSS1010

All Resistors RS1/16S###J

>

FU1200 CHIP FUSE (0.25A) XEK1003

>

M1000 FRONT END XXF1007

CAPACITORS

C1001-1003,1017,1022 CKSRYB104K16

C1004,1055 CEHVKW101M6R3

C1010 CEHVKW2R2M50

C1013,1021,1040,1041 CKSRYB103K50

F

C1015 CKSRYB102K50

C1054 BCG1050

C1056,1057 CEHVKW470M16

C1058-1062 CKSRYB104K16

C1102 CEHVKW331M6R3

[DEMUX BLOCK]

SEMICONDUCTORS

IC2000 STI5517DW AL

IC2001 SN74LVU04APW

IC2002 TC74VHC08FTS1

Q2000 2SC4081

D2000 DA204U

D2001 UDZS8R2(B)

D2002 HVU307

D2005,2009 RB501V-40

MISCELLANEOUS

L2000 XTX1003

F2000-2003 VTF1091

CRYSTAL RESONAT OR (27 MHz)

X2000

X2001 CRYSTAL OSCILLATOR ASS1172

VA2002 VARISTOR

BSS1112

AVR-M1608C120MT2AB

RESISTORS

R2010,2018,2042 RAB4C103J

R2070,2071 RAB4CQ220J

Other Resistors RS1/16S###J

28

PDP-4270XD

1234

Page 29

5678

Mark No. Description Part No.

CAPACITORS

C2000,2026,2030 CCSRCH101J50

C2001 CKSRYB471K50

C2002,2003,2005,2006 CKSRYF104Z16

C2004 CKSRYF474Z16

C2007 CCSRCH471J50

Mark No. Description Part No.

CAPACITORS

C4000,4002 CCG1205

C4001,4014,4032,4033 CKSRYB103K50

C4003,4005,4017,4018 CKSRYF104Z16

C4004 CEHVKW2R2M50

C4006 CKSRYB102K50

A

C2008,2017,2020,2021 CKSRYB102K50

C2009 CCSRCH330J50

C2011,2012 CCSRCH390J50

C2013 CKSRYB105K10

C2014,2016 CCSRCH100D50

C2015 CKSRYF105Z10

C2018,2019,2022-2025 CKSRYF104Z16

C2027,2029,2042,2046 CKSRYF223Z50

C2028,2035,2037-2041 CKSRYF104Z16

C2032-2034,2036 CEHVKW470M16

C2043-2045,2047,2048 CKSRYF104Z16

[MEMORY BLOCK]

SEMICONDUCTORS

IC3000,3003 K4S281632I-UC75

IC3002 XGC1003

MISCELLANEOUS

L3003 XTX1003

L3005 XTX1001

RESISTORS

R3004-3014 RAB4CQ470J

Other Resistors RS1/16S###J

CAPACITORS

C3000,3003,3007,3008 CKSRYF104Z16

C3001,3002,3004,3014 CKSRYF223Z50

C3010 CEHVKW470M16

C3012,3017,3020-3022 CKSRYF104Z16

C3015,3018,3019,3023 CKSRYF223Z50

C4007,4013 CCSRCH220J50

C4008,4009 CCSRCH121J50

C4010,4011,4042 CCSRCH101J50

C4012,4022,4023,4029 CEHVKW470M16

C4019,4102-4104 CEHVKW100M16

C4021,4024,4043 CKSRYF104Z16

C4038 CKSRYB103K50

C4039 CEHVKW470M16

C4040,4041 CKSRYB105K10

C4105-4107 CKSRYF104Z16

C4108-4113 CEHVKW100M16

[CI BLOCK]

SEMICONDUCTORS

IC5000 ST890CDR

IC5001 CIMAXSP2L

IC5002 TC74LCX245FTS1

IC5003,5004 TC74LCX373FT

Q5000 2SC4081

Q5001 DTA143EUA

Q5002 DTC124EUA

MISCELLANEOUS

CN5000 PCMCIA CONNECTOR XKP1003

RESISTORS

R5014,5019,5022,5024 RAB4CQ470J

R5030,5032,5036-5038 RAB4CQ470J

R5045-5050 RAB4CQ470J

Other Resistors RS1/16S###J

B

C

D

C3024 CKSRYF223Z50

[AV BLOCK]

SEMICONDUCTORS

IC4000 CS4334-KS

IC4001 SN74LVU04APW

IC4002 RC4558D

IC4003 CS8406CZZ

IC4100 PCM1803DB

Q4001,4002 2SC4081

MISCELLANEOUS

F4000,4100 FERRITE CORE VTF1091

JA4000 OPTICAL OUT MOD. GP1FM513TZ

X4000 CRYSTAL (12.288 MHz) XSS1006

CN4000 40P CONNECTOR AKM1348

RESISTORS

R4042,4045,4046 RS1/16S2000F

Other Resistors RS1/16S###J

56

CAPACITORS

C5001 CKSRYB105K10

C5003,5004,5006 CKSRYF104Z16

C5005,5100 CEHVKW470M16

C5008-5013 CKSRYF104Z16

[POWER BLOCK]

SEMICONDUCTORS

IC6001 M5291FP

IC6002 BA05FP

IC6003 FPF2003

IC6200 TC74LCX245FTS1

IC6300 SN74LVC1G08DCK

Q6001,6009,6011,6200 DTC124EUA

Q6003,6005,6010 DTA143EUA

Q6006 2SB1188

Q6008 TPC8209

Q6100 2SC4081

D6001 RSX201L-30

D6003,6100-6102 1SS355

D6103 UDZS30(B)

PDP-4270XD

E

F

29

7

8

Page 30

1234

Mark No. Description Part No.

MISCELLANEOUS

L6000 LCYAR82J2520

L6001,6100,6101 XTH1001

A

F6000 FERRITE CORE VTF1091

CN6000 12P CONNECTOR AKM1298

CN6003 50P CONNECTOR AKM1349

RESISTORS

R6012-6014 RAB4C2R2J

R6031 RAB4C221J

R6204,6205 RAB4CQ101J

Other Resistors RS1/16S###J

CAPACITORS

C6000,6026,6104-6106 CEHVKW331M6R3

C6001,6011,6013-6015 CEHVKW470M16

B

C6002,6035 CKSRYF223Z50

C6003,6005,6006,6012 CKSRYF104Z16

C6004 CEHVKW100M50

C6008,6016 CKSRYF474Z16

C6010 CCSRCH331J50

C6017,6028,6036,6042 CEHVKW101M6R3

C6018,6020,6021,6025 CKSRYF104Z16

C6019,6023,6100 CEHVKW470M16

C6022 CKSRYB103K50

C6027 CCSRCH101J50

C6029,6030,6033,6038 CKSRYF104Z16

C

C6031 CEHVKW2R2M50

C6044 CEHVKW101M6R3

Mark No. Description Part No.

[REG 0 BLOCK]

SEMICONDUCTORS

IC4101,4114,4115 S-1132B18-U5

IC4102 LTC3414EFE

IC4103 LTC3412EFE

IC4104,4111,4113 NJM2846DL3-05

IC4105 S-1170B25UC-OTK

IC4106 S-1170B15UC-OTA

IC4107 NJM2846DL3-33

IC4108 NJM2846DL3-18

IC4109,4110 PQ090DNA1ZPH

Q4101,4103 RN1902

Q4102 HN1C01FU

Q4104 DTC124EUA

Q4105,4106 UPA1917TE

Q4107-4109 2SC4116

Q4110 2SD2114K

D4101-4110,4112-4118 1SS355