Pioneer PD-F957, PD-F907 Service Manual

Service

D

FILE–TYPE

COMPACT DISC PLAYER

PD-F905

ACSESS

PLAY

Î

SINGLE

LOADER

FILE –TYME CD MECHANISM

HI-LITE CLEARMODE

UNLOAD BEST PREVIOUS

OPEN/

CLOSE

TRACK MIN SECDISC

TITLE

TITLE

PROGRAM

INPUT

DISPLAY

DISC

Manual

FILE-TYPE CD PLAYER

PD-F957

PD-F907

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV1898

Type

PD-F957

KU – O AC120V

KC – O AC120V

KU/CA O – AC120V

Model

Power Requirement

PD-F907

CONTENTS

1. SAFETY INFORMATION....................................2

2. EXPLODED VIEWS AND PARTS LIST .............3

3. SCHEMATIC DIAGRAM................................... 11

4. PCB CONNECTION DIAGRAM .......................19

5. PCB PARTS LIST.............................................24

6. ADJUSTMENT.................................................. 28

7.GENERAL INFORMATION ............................... 36

7.1 PARTS........................................................36

7.1.1 IC ..........................................................36

7.1.2 DISPLAY...............................................37

Remarks

7.2 DIAGNOSIS................................................39

7.2.1 ERROR CORD DISPLAY .................39

7.2.2 ERROR HISTORY AND DISPLAY ... 39

7.2.3 ERROR HISTORY DISPLAY............ 40

7.2.4 DISASSEMBLY................................. 41

7.3 BLOCK DIAGRAM...................................... 49

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................................50

PIONEER ELECTRONIC CORPORATION 4-1, Meguro 1-Chome, Meguro-ku, Tokyo 153, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER ELECTRONIC (EUROPE) N.V . Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 501 Orchard Road, #10-00 Lane Crawford Place, Singapore 0923

CC

C PIONEER ELECTRONIC CORPORATION 1997

CC

T–ZZY DEC. 1997 Printed in Japan

PD-F957,PD-F907

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

Lead in solder used in this product is listed by the California Health and Welfare agency as a known reproductive toxicant which

may cause birth defects or other reproductive harm (California Health & Safety Code, Section 25249.5).

When servicing or handling circuit boards and other components which contain lead in solder, avoid unprotected skin contact with

the solder. Also, when soldering do not inhale any smoke or fumes produced.

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts

must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les

pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

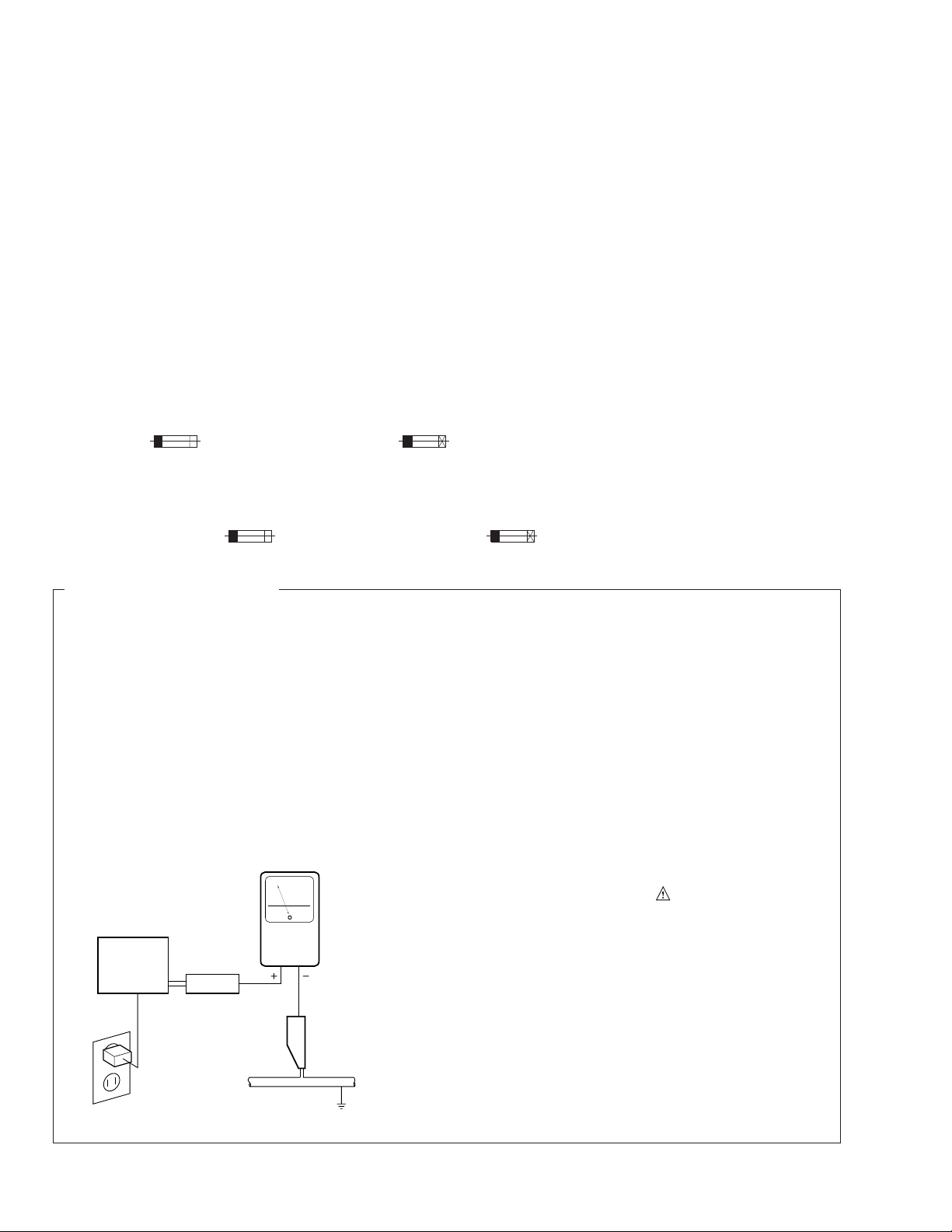

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 3.5 mA.

Reading should

not be above

3.5 mA

Earth ground

Device

under

test

Also test with plug

reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all exposed

metal surfaces

AC Leakage Test

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL SHOCK HAZARD AND MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE

TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance have special safety related characteristics. These

are often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained by using replacement components rated for

voltage, wattage , etc. Replacement parts which have

these special safety characteristics are identified in

this Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in

the parts list in this Service Manual, may create shock,

fire, or other hazards.

Product Safety is continuously under review and

new instructions are issued from time to time. For

the latest information, always consult the current

PIONEER Service Manual. A subscription to, or additional copies of, PIONEER Service Manual may be

obtained at a nominal charge from PIONEER.

on the schematics and

2

PD-F957,PD-F907

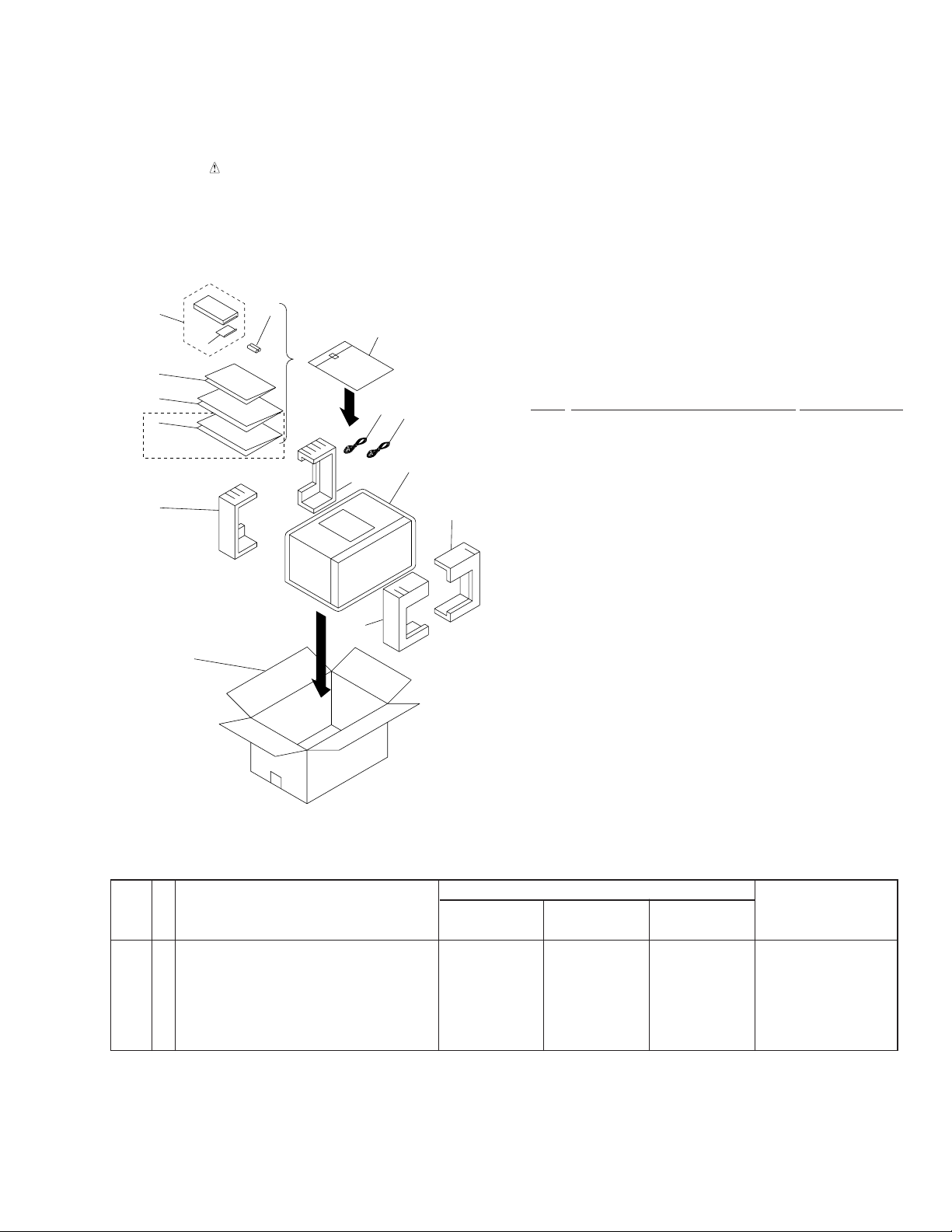

2. EXPLODED VIEWS AND PARTS LIST

NOTES : ÷ Parts marked by “ NSP ” are generally unavailable because they are not in our Master Spare Parts List.

÷ The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

÷ Screw adjacent to

2.1 PACKING

mark on the product are used for disassembly.

∞

10(1/2)

3

4

5

6

7

PD-F907/KC only

11

13

8

(1) PARTS LIST

Mark No. Description Parts No.

1 Control Cable (L=1.0m) PDE1247

2 Output Cable (L=1.0m) PDE1248

3 Remote Control Unit See Contrast table (2)

4 Battery Cover AZN7204

NSP 5 Warranty Card See Contrast table (2)

6 Operating Instructions (English) See Contrast table (2)

7 Operating Instructions (French)) See Contrast table (2)

8 Polyethlene Bag Z21 - 038

9 Styrol Protector F PHA1307

10 Styrol Protector R PHA1308

11 Packing Case See Contrast table (2)

12 Mirror Mat Z23 - 0204

NSP 13 Battery (R6P, AA) VEM - 013

10(2/2)

9(1/2)

Front

2

1

12

9(2/2)

(2) CONTRAST TABLE

PD-F907/KU,KC and PD-F957/KU/CA have the same construction except for the following:

Part No.

Mark No. Symbol & Description Remarks

3 Remote Control Unit PWW1130 PWW1132 PWW1132

NSP 5 Warranty Card ARY1044 ARY1044 ARY1039

6 Operating Instructions (English) PRB1264 PRB1263 PRB1263

7 Operating Instructions (French) Not used Not used PRD1023

11 Packing Case PHG2304 PHG2285 PHG2286

PD-F957/ PD-F907/ PD-F907

KU/CA KU KC

(CU-PD088) (CU-PD080) (CU-PD080)

3

PD-F957,PD-F907

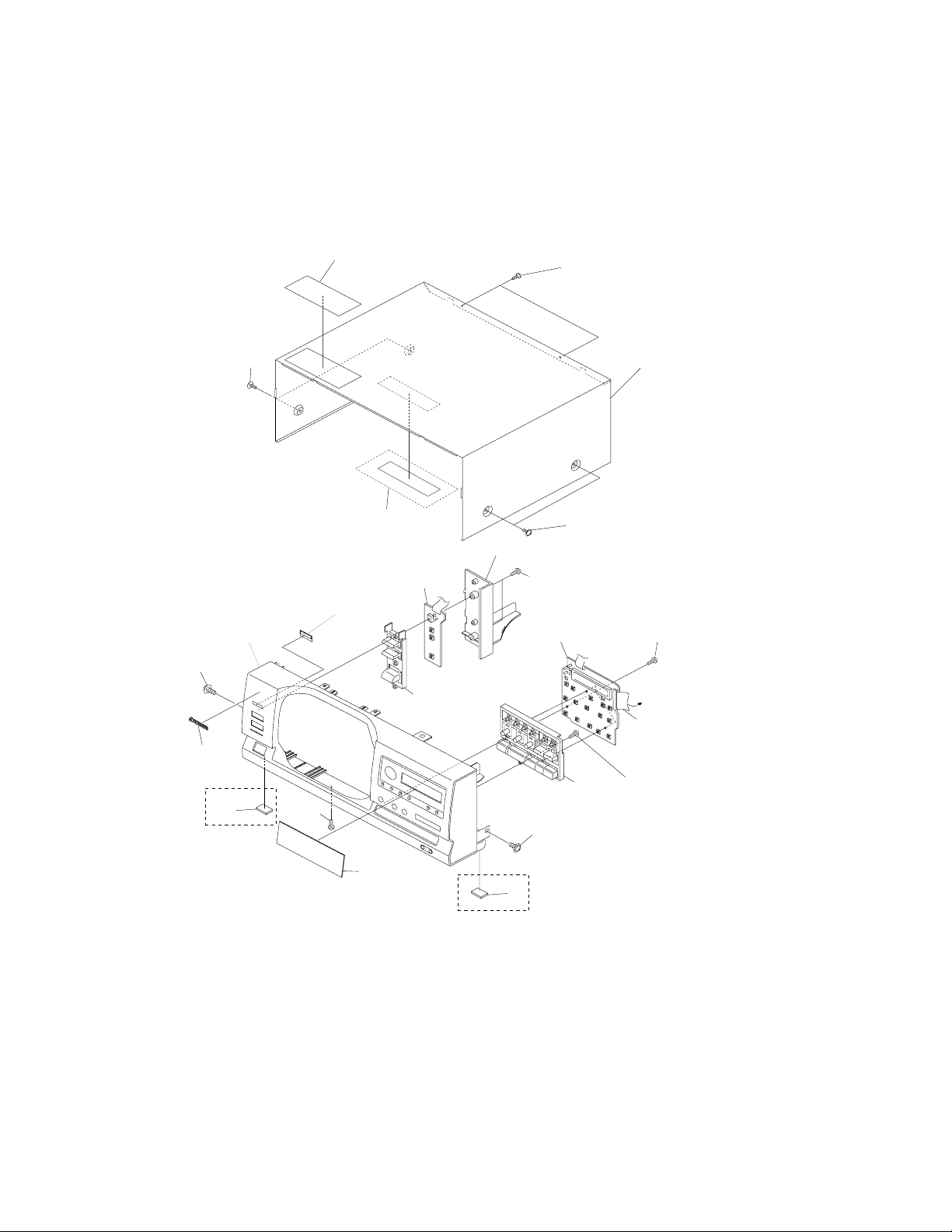

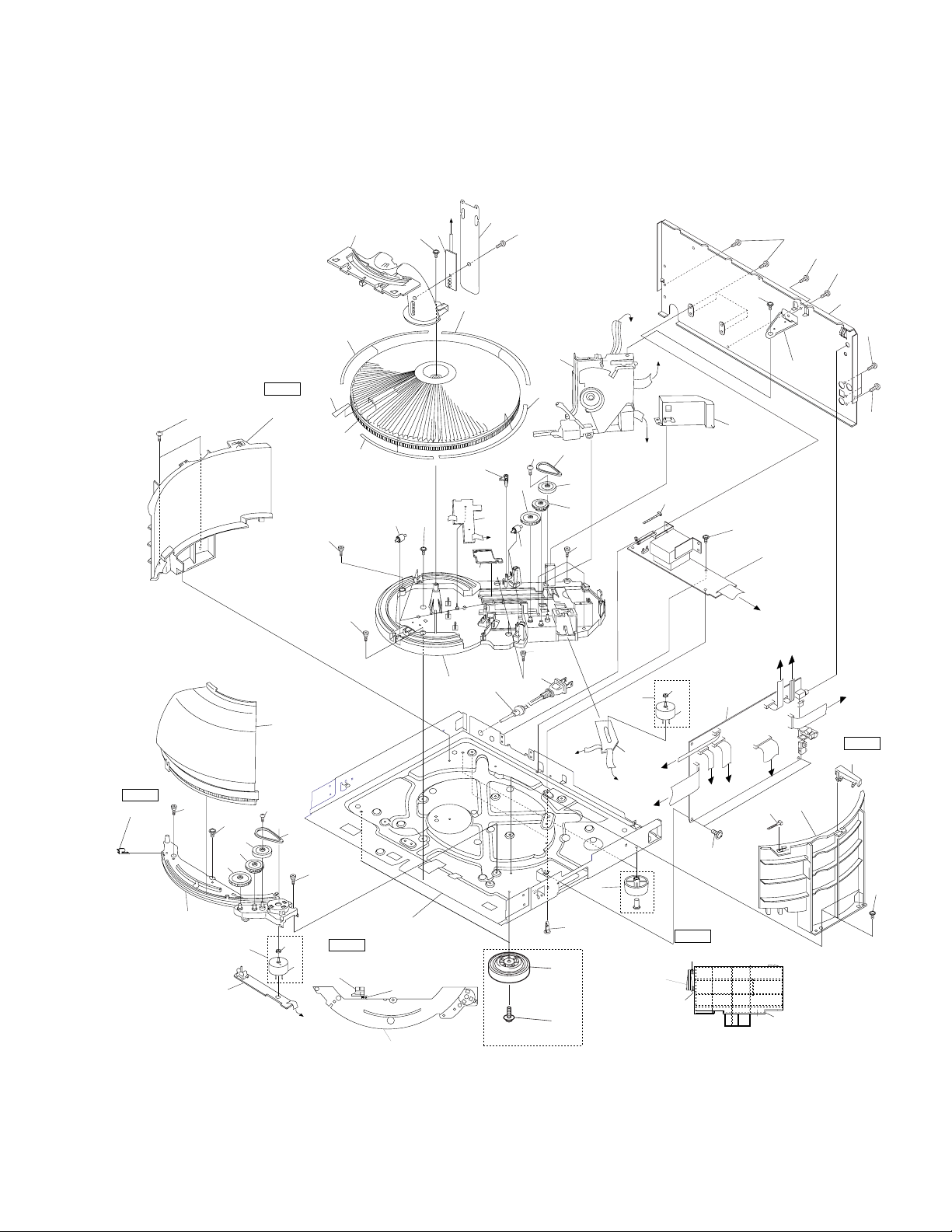

2.2 EXTERIOR

63

50

62

56

55

KU/CA,KU type only

4

54

45

53

68

61

51

62

3

68

A

11

46

68

13

PD-F907 only

44

61

63

47

13

PD-F907 only

4

27

65

PD-F957,PD-F907

D

6

24

67

61

61

61

Note2

26(2/2)

15

63

63

29

28

30

Note1

21(1/2)

52

64

23

57

15

15

32(4/4)

35

32(1/4)

15

42

63

32(3/4)

36

40

39

38

8

H

42

10

Refer to

''2.3 LOADING

MECHANISM

ASSY''

31

32(2/4)

33

64

43

37

15

15

12

H

14

C

25

7

16

J

F

41

E

69

63

34

59

D

A

63

B

1

C

G

G

69

2

E

19

J

21(1/2)

18

61

61

F

Note1

21 (2/2)

63

26(1/2)

17

25

5

34

59

26(2/2)

B

cutting position

Note2

No.26(Hood Base)

cutting

26(1/2)

PD-F957 Only

20

60

22

21(2/2)

cutting

cutting

cutting positionNote1

No.21(Back Fence)

21(1/2)

5

PD-F957,PD-F907

(1) EXTERIOR PARTS LIST

Mark No. Description Parts No. Mark No. Description Parts No.

1 Main Board Assy See Contrast table(2)

2 Power Board Assy See Contrast table(2)

3 Display Board Assy See Contrast table(2)

NSP 4 Switch Board Assy See Contrast table(2)

NSP 5 Door Board Assy See Contrast table(2)

36 Mecha Base PNW2639

37 Gear PNW2641

38 Gear PNW2642

39 Slider PNW2643

40 Lock Lever PNW2644

NSP 6 Center LED Board Assy See Contrast table(2)

NSP 7 Select Motor Board Assy PWZ3324

NSP 8 Sensor Board Assy PWZ3327

NSP 17 Under Base PNA2255

.............

9

10 Cord Stopper CM - 22C

11 F.F.C/30V See Contrast table(2)

12 AC Power Cord PDG1015

13 Rubber Sheet See Contrast table(2)

14 Foot Assy See Contrast table(2)

15 Screw C PBA1106

16 Screw PBA1108

18 Rear Base See Contrast table(2)

19 Stopper Angle PNB1559

Insulator See Contrast table(2)

20

21 Back Fence PNW2671

22 Locking Card Spacer VEC1596

23 Belt PEB1288

24 Cover PNM1294

25 Motor Assy PEA1333

26 Hood Base PNW2633

27 Center Pole PNW2634

28 Gear PNW2641

29 Gear PNW2642

30 Gear Pulley VNL1662

31 Loading Mechanism Assy PXA1589

32 Rack Label PAM1732

33 Belt PEB1288

34 Motor Pulley PNW1634

35 Disc Rack PNW2632

(2) CONTRAST TABLE

41 Mecha Stopper PNW2646

42 Roller PNW2647

43 Gear Pulley VNL1662

44 Control Button PAC1822

45 Power Button PAC1833

46 Name Plate VAM1073

47 Display Window See Contrast table(2)

.............

48

.............

49

50 Operation Panel See Contrast table(2)

51 Bonnet Case PYY1191

52 Hood PNW2732

53 Side Fence PNW2674

54 Sensor Acryl VNK1566

55 65 Label See Contrast table (2)

56 Label PRW1428

57 Label PRW1429

.............

58

59 Slider Motor VXM1033

Screw IBZ30P080FZK

60

61 Screw BBZ30P080FZK

62 Screw FBT40P080FZK

63 Screw IBZ30P060FMC

64 Screw IPZ20P080FMC

65 Screw IPZ30P080FCU

.............

66

67 Screw PPZ30P050FMC

68 Screw PPZ30P100FMC

69 Binder Z09 - 056

PD-F907/KU,KC and PD-F957/KU/CA have the same construction except for the following:

Part No.

Mark No. Symbol & Description Remarks

1 Main Board Assy PWZ3663 PWZ3400 PWZ3400

2 Power Board Assy PWZ3668 PWZ3414 PWZ3414

3 Display Board Assy PWZ3672 PWZ3426 PWZ3426

NSP 4 Switch Board Assy PWZ3675 PWZ3432 PWZ3432

NSP 5 Door Board Assy PWZ3681 PWZ3441 PWZ3441

NSP 6 Center LED Board Assy PWZ3683 PWZ3443 PWZ3443

11 F.F.C/30V PDD1186 PDD1167 PDD1167

13 Rubber Sheet Not Used AEB1111 AEB1111

14 Foot Assy REC1263 AEC1531 AEC1531

18 Rear Base PNA2405 PNA2389 PNA2389

20 Insulator PNW2766 Not Used Not Used

47 Display Window PAM1752 PAM1725 PAM1725

50 Operation panel PNW2786 PNW2773 PNW2773

55 65 Label ORW1069 ORW1069 Not used

6

PD-F957/ PD-F907/ PD-F907/

KU/CA KU KC

(40P F.F.C) (32P F.F.C) (32P F.F.C)

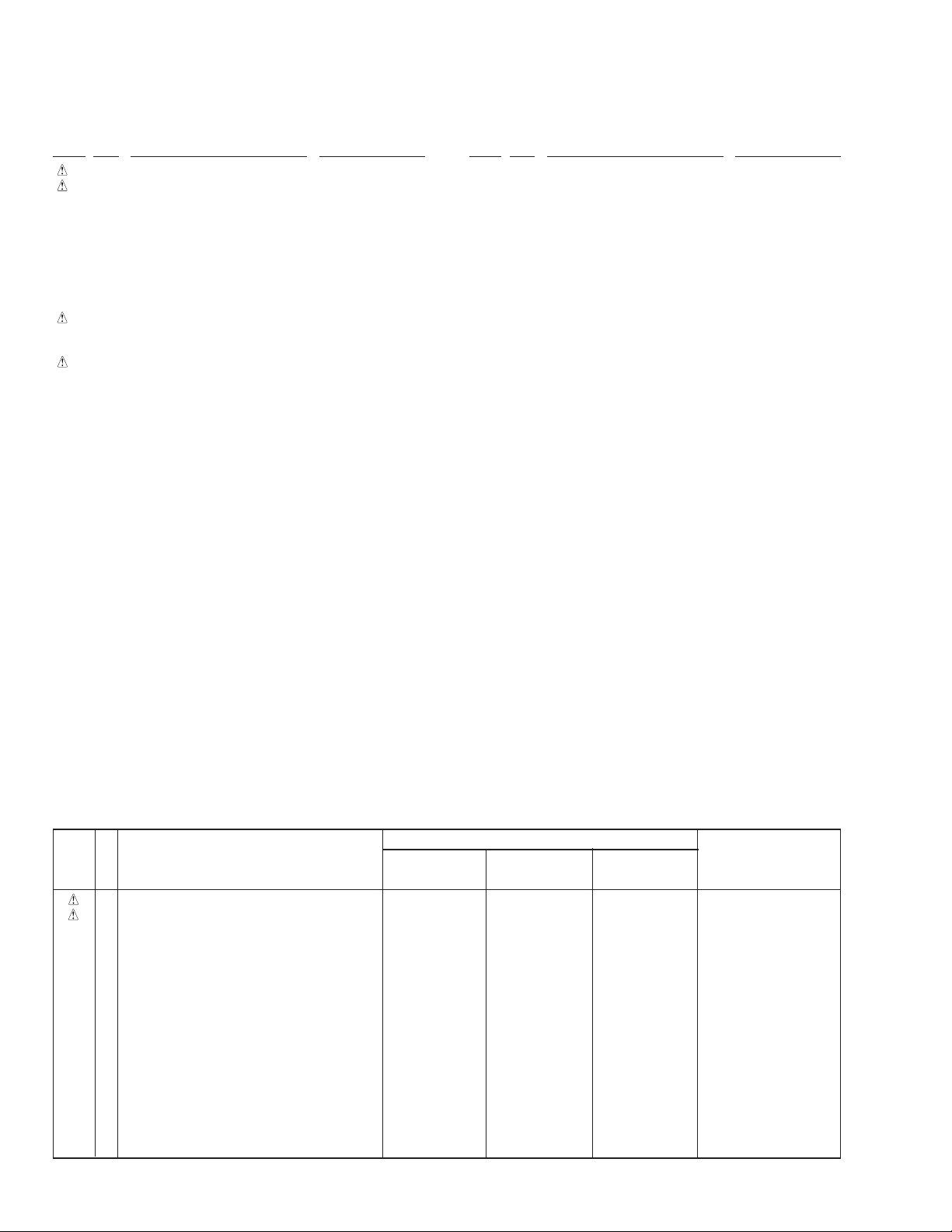

2.3 LOADING MECHANISM ASSY

PD-F957,PD-F907

7

PD-F957,PD-F907

LOADING MECHANISM ASSY PARTS LIST

Mark No. Description Parts No.

…………

1

…………

2

NSP 3 Loading Motor Board Assy PWZ3337

NSP 4 Load SW Board Assy PWZ3334

NSP 14 Servo Stopper S ANB7047

5 Arm A Spring2 ABH7124

6 Gear Plate Spring ABH7051

7 Clamp Spring ABH7107

…………

8

…………

9

10 Loading Belt AEB7029

…………

11

…………

12

…………

13

15 Loading Base ANW7086

16 Cam Cover ANW7052

17 Motor Holder ANW7053

18 Sensor Holder ANW7119

19 Float Base 96 PNW2700

20 Clamper Holder ANW7117

21 Arm (A) ANW7057

22 Arm (B) ANW7058

23 Drive Plate ANW7059

24 Arm Plate ANW7060

25 Gear Plate ANW7111

26 Gear Pulley (B) ANW7062

27 Gear A ANW7063

28 Drive Gear ANW7064

…………

29

…………

30

…………

31

…………

32

…………

33

34 Roller B ANW7075

35 Motor Pulley PNW1634

36 Clamper PNW2743

37 Float Spring ABH7049

38 Connector Assy (4P) RDE1043

39 Float Rubber AEB7028

NSP 40 Servo Mechanism Assy GM PXA1591

41 Screw IPZ20P080FMC

…………

42

…………

43

44 Motor Assy AEA7006

45 Loading Motor VXM1034

46 16P FFC/30V PDD1180

Froil (for Service) GYA1001

Ha Narl (for Service) GEM1016

8

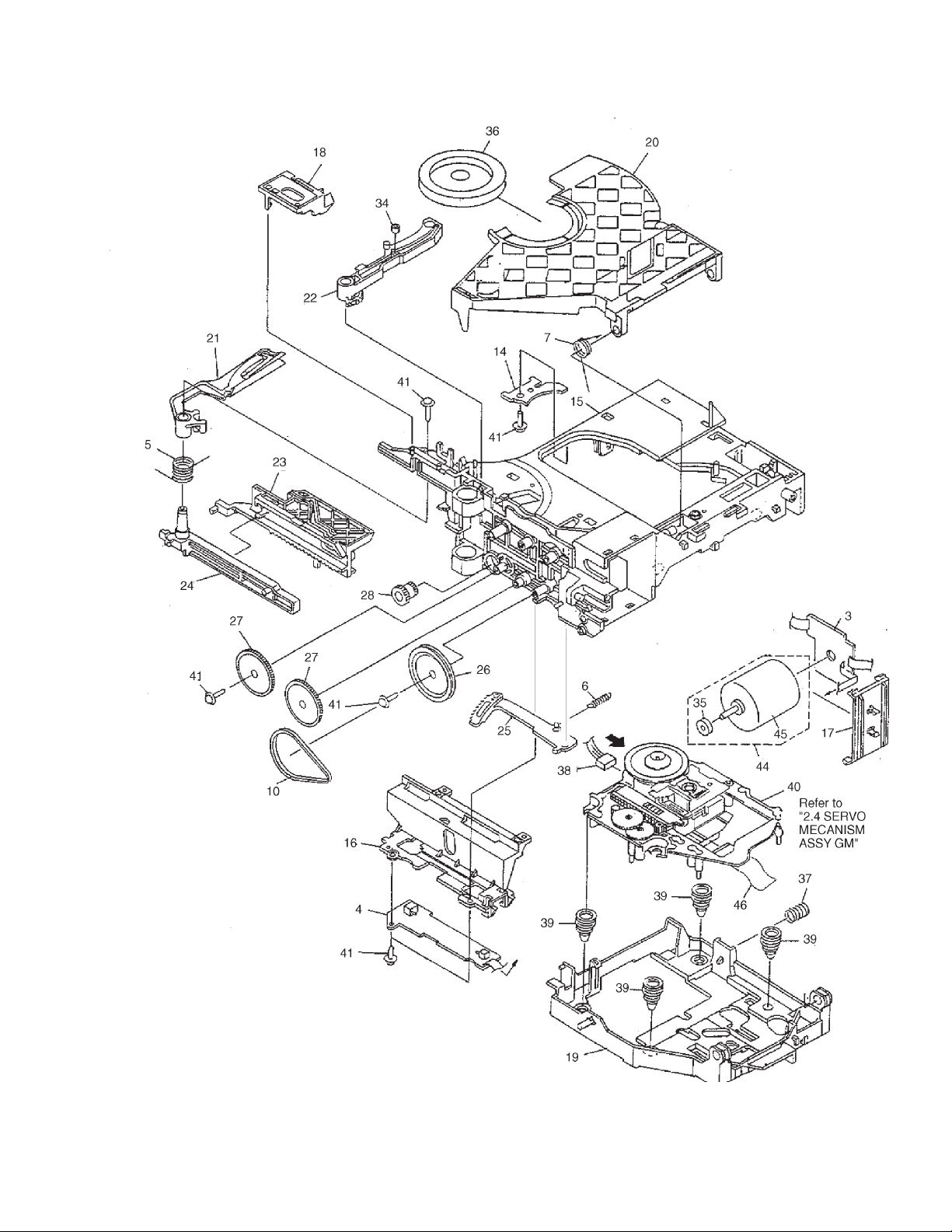

2.4 SERVO MECHANISM ASSY GM

PD-F957,PD-F907

How to Install the Disc Table

Use nipper or other tool to cut the three sections marked

1

A

in figure . Then remove the spacer

While supporting the spindle motor shaft with the

2

stopper, put spacer on top of the yoke M, and stick the

disc table on top (takes about 9kg pressure). Detach the

spacer.

1

Spacer

A

1

Float Base

2

Spacer

Yoke M

Spacer Setting

Position

Carriage Base

Spindle Motor

(Pressure of about 9 kg)

Disc Table

0.9mm

±0.05mm

1.2mm

Stopper

6.9mm

9

PD-F957,PD-F907

SERVO MECHANISM ASSY GM PARTS LIST

Mark No. Description Parts No.

1 Gear 1 PNW2052

2 Gear 2 PNW2053

3 Gear 3 PNW2054

4 Carriage Base PNW2699

5 Pickup Assy - S PEA1335

6 D.C. Motor Assy (SPINDLE) PEA1235

7 Carriage DC Motor Assy PEA1246

8 Pinion Gear PNW2055

9 Carriage DC Motor/0.3W PXM1027

10 Disc Table Assy PEA1314

11 Mechanism Board Assy PWX1192

12 Guide Bar PLA1094

…………

13

14 Screw JFZ17P025FZK

15 Screw JFZ20P040FMC

16 Washer WT12D032D025

17 Clamp Magnet PMF1014

18 Yoke M PNB1312

NSP 19 Disc Table PNW2410

NSP 20 Float Angle ANB7020

21 Gear Stopper PNB1303

22 Screw BPZ20P060FMC

23 Screw BPZ26P100FMC

24 PU Rack Spring ABH7077

25 Rack Holder PNW2056

10

1

23

4

PD-F957,PD-F907

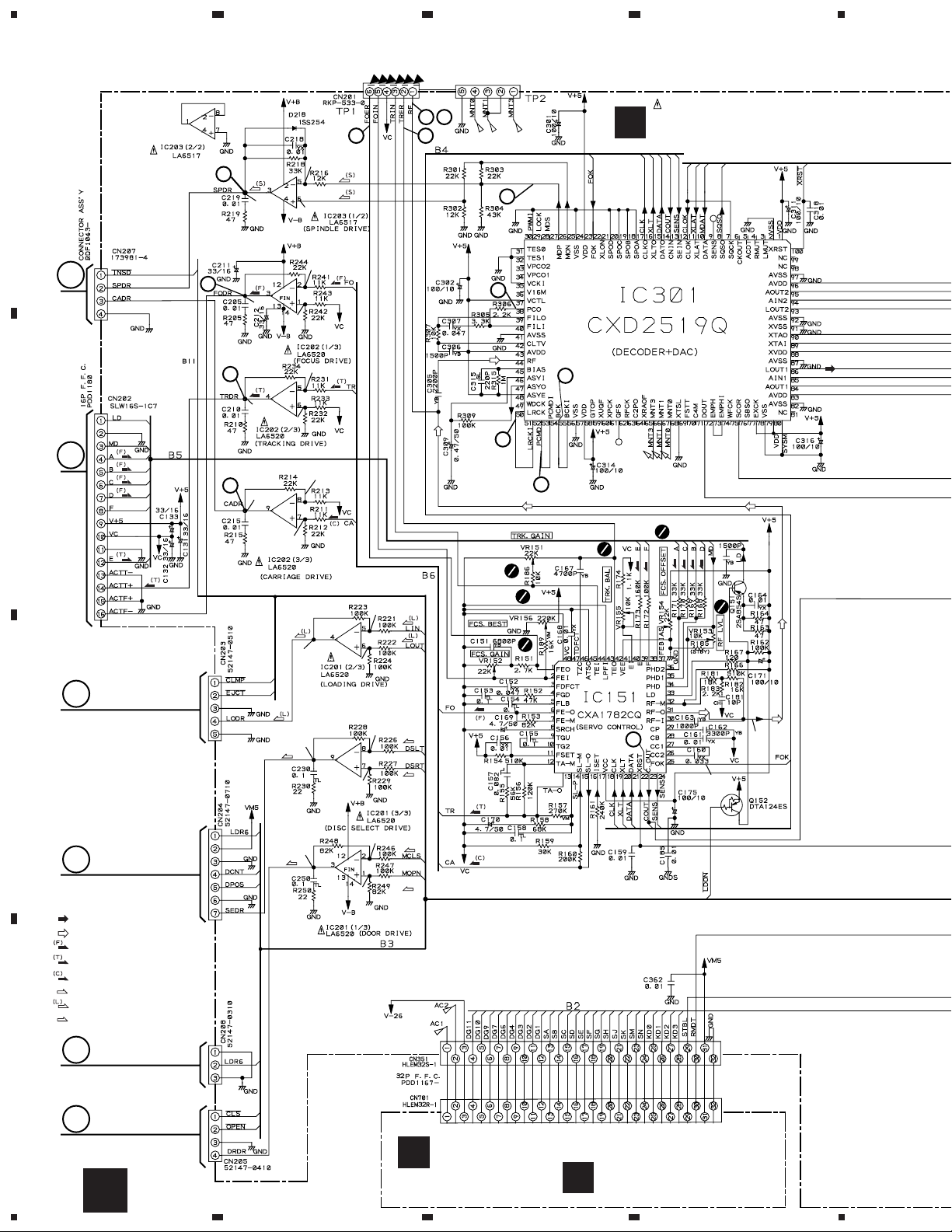

3. SCHEMATIC DIAGRAM

Note: When ordering service parts, be sure to refer to "EXPLODED VIEW AND PARTS LIST" or "PCB PARTS LIST".

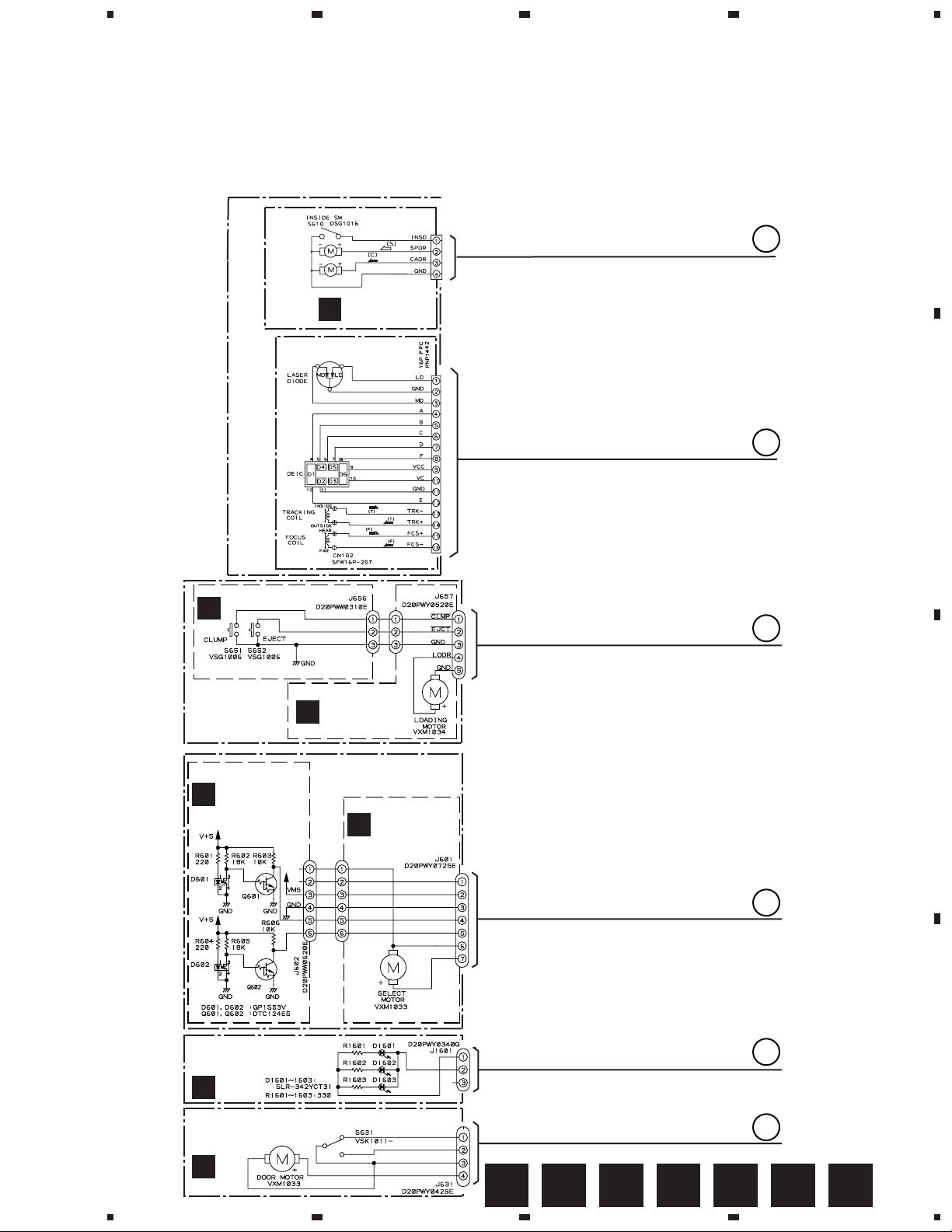

3.1 MECHANISM BOARD ASSY,SENSOR BOARD ASSY,LOAD SW BOARD ASSY,SELECT

MOTOR BOARD ASSY,LOADING MOTOR BOARD ASSY,CENTER LED BOARD ASSY,

DOOR BOARD ASSY AND PICKUP ASSY

A

SPINDLE

MOTOR

ASSY

PEA1235

CARRIAGE

MOTOR

ASSY

PEA1246

PICK UP ASSY

(PEA1335)

(PXA1591)

SERVO MECHANISM ASSY GM

LOAD SW BOARD

ASSY (PWZ3334 )

B

A

MECHANISM

BOARD ASSY

(PWX1192)

CN610

A

B

B

C

LOADING MECHA

BOARDASSY

(PWX1474)

SENSOR BOARD

ASSY

(PWZ3327)

D

CENTER LED BOARD ASSY

PD-F957/KU/CA:(PWZ3683)

PD-F907/KU,KC:(PWZ3443)

C

F

DOOR BOARD ASSY

PD-F957/KU/CA:(PWZ3681)

PD-F907/KU,KC:(PWZ3441)

LOADING MOTOR

BOARD ASSY

(PWZ3337)

SELECT MOTOR

BOARD ASSY

(PWZ3324)

E

C

D

E

D

F

G

E F GA B C D

1

2

3

4

11

1

234

PD-F957,PD-F907

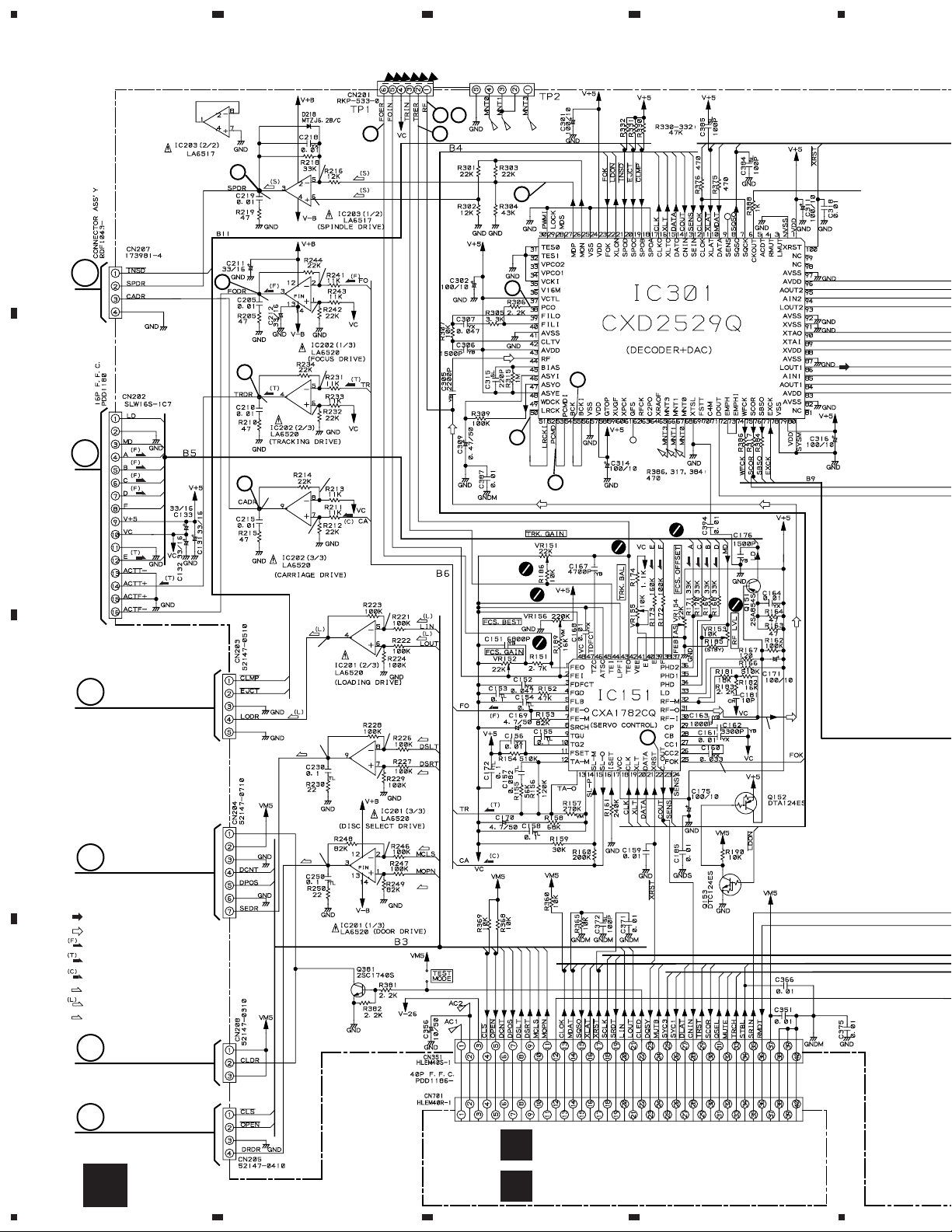

3.2 MAIN BOARD ASSY AND POWER BOARD ASSY (FOR PD-F957)

2

23

43

1.6V

1.6V

1.7V

1.8V

1.8V

1.6V

1.6V

1.7V

33

53

16

18

19

(F)

(F)

(F)

(F)

(T)

(T)

0V

A

A

B

B

7

-O.7V

5

OV

6

OV

8

0.2V

0V

0V

C

0V

0V

(SEL)

C

0V

0V

D

SIGNAL ROUTE

: AUDIO SIGNAL

: EFM SIGNAL

: FOCUS SERVO LOOP

: TRACKING SERVO LOOP

: CARRIAGE SERVO LOOP

(S)

: SPINDLE DRIVE

: LOADING DRIVE

(D)

: DOOR DRIVE

(D)

0V

(SEL)

(SEL)

0V

(D)

(D)

23

3.4V

5.0V

E

D

12

F

DISPLAY BOARD ASSY

L

H

1234

M

(PWZ3672)

SWITCH BOARD ASSY

(PWZ3675)

5

67

8

PD-F957,PD-F907

IC301(CXD2529Q) :PLAY MODE

PIN No.

Voltage(V)

PIN No.

Voltage(V)

PIN No.

Voltage(V)

10

1 2 3 - 4 7 8 9 10 11 12 13 14 16 17 23 24 25

5

26 27 38 39 40 41 42 43 44 45 46 47 48 50-55 56 57

5

2.6-2.7

61 71 75 78 79 82 83 87 88 89-9084-86 91-92 93-95 9796 100

5

2.5 2.5 2.5 2.5

4.7

2.5

3.1 3.12.5 2.5 0.9 2.5 2.5 2.5

00 505 0 5 0 50 5

0 50

1.6V

1.6V

55550 00

4.4 4.7 4.7 4.71.2-1.41.2-1.3

55

0V

0V

0.05

0V

-9.2

0V

-9.2

0V

LINE OUT

JACK

A

B

H

MAIN BOARD ASSY

(PWZ3663)

C

AC120V

60Hz

AC POWER CORD

:PDG1015

POWER BOARD ASSY

I

(PWZ3668)

D

P0WER TRANSFORMER

5

6

7

H

8

I

13

1

234

PD-F957,PD-F907

3.3 MAIN BOARD ASSY AND POWER BOARD ASSY (FOR PD-F907)

2

23

43

J

MAIN BOARD ASSY

(PWZ3400)

1.6V

1.6V

1.7V

1.8V

1.8V

1.6V

1.6V

1.7V

33

53

16

18

19

(F)

(F)

(F)

(F)

(T)

(T)

0V

A

A

B

B

7

-O.7V

5

OV

6

OV

8

0.2V

C

D

C

D

SIGNAL ROUTE

: AUDIO SIGNAL

: EFM SIGNAL

: FOCUS SERVO LOOP

: TRACKING SERVO LOOP

: CARRIAGE SERVO LOOP

(S)

: SPINDLE DRIVE

: LOADING DRIVE

(D)

: DOOR DRIVE

E

(SEL)

(D)

0V

0V

0V

0V

0V

(SEL)

0V

0V

(SEL)

0V

(D)

(D)

23

3.4V

5.0V

14

F

DISPLAY BOARD ASSY

N

(PWZ3426)

SWITCH BOARD ASSY

O

(PWZ3432)

J

1234

5

67

8

PD-F957,PD-F907

IC301(CXD2519Q) :PLAY MODE

PIN No.

Voltage(V)

PIN No.

Voltage(V)

PIN No.

Voltage(V)

10

1 2 3 - 4 7 8 9 10 11 12 13 14 16 17 23 24 25

5

26 27 38 39 40 41 42 43 44 45 46 47 48 50-55 56 57

5

2.6-2.7

61 71 75 78 79 82 83 87 88 89-9084-86 91-92 93-95 9796 100

5

4.7

2.5

3.1 3.12.5 2.5 0.9 2.5 2.5 2.5

00 505 0 5 0 50 5

2.5 2.5 2.5 2.5

0 50

1.6V

1.6V

55550 00

4.4 4.7 4.7 4.71.2-1.41.2-1.3

55

0V

0V

0.05

0V

-9.2

0V

-9.2

0V

LINE OUT

JACK

A

B

POWER BOARD ASSY

K

(PWZ3414)

(BACK UP)

POWER TRANSFORMER

AC 120V

60 Hz

AC POWER CORD

C

D

J

5

6

7

8

K

15

1

234

PD-F957,PD-F907

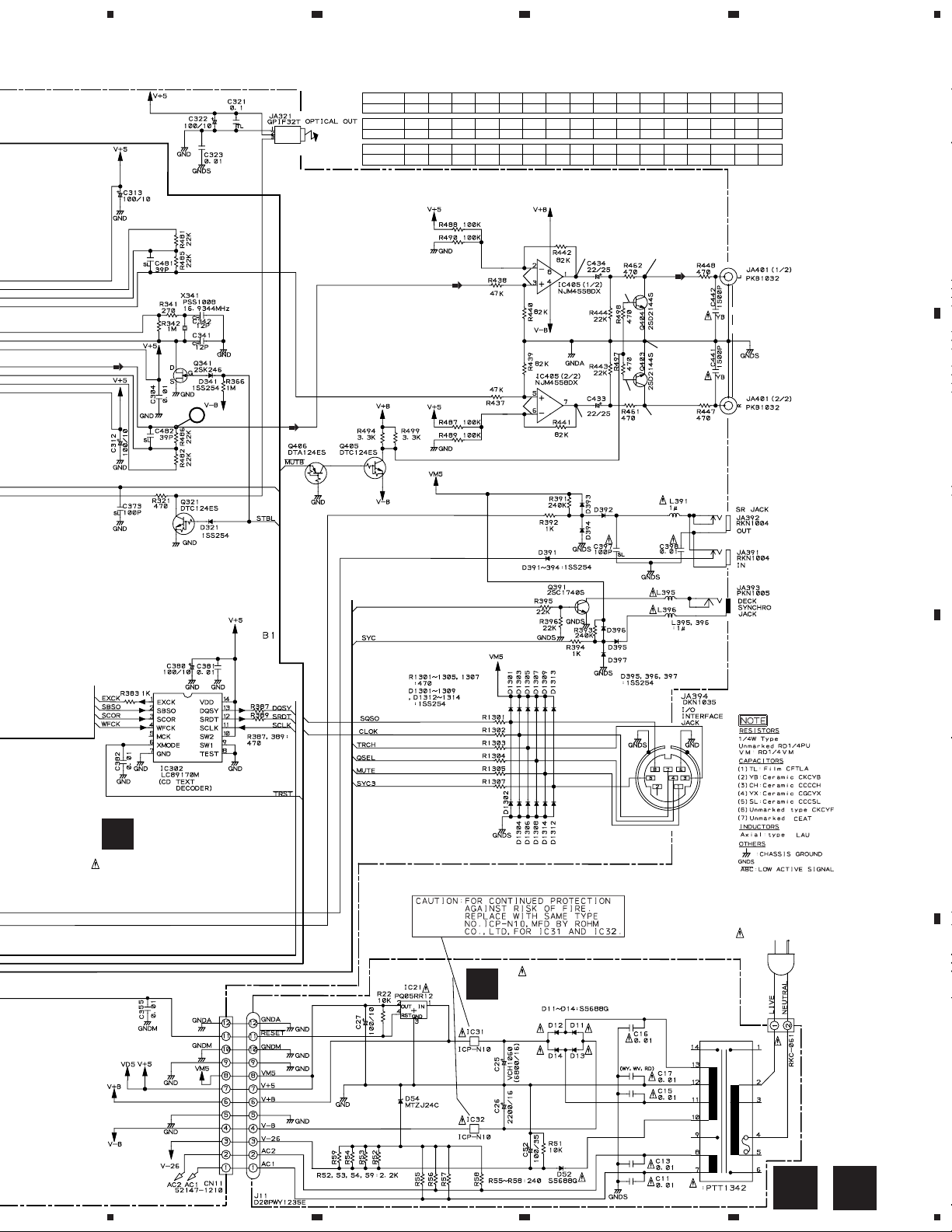

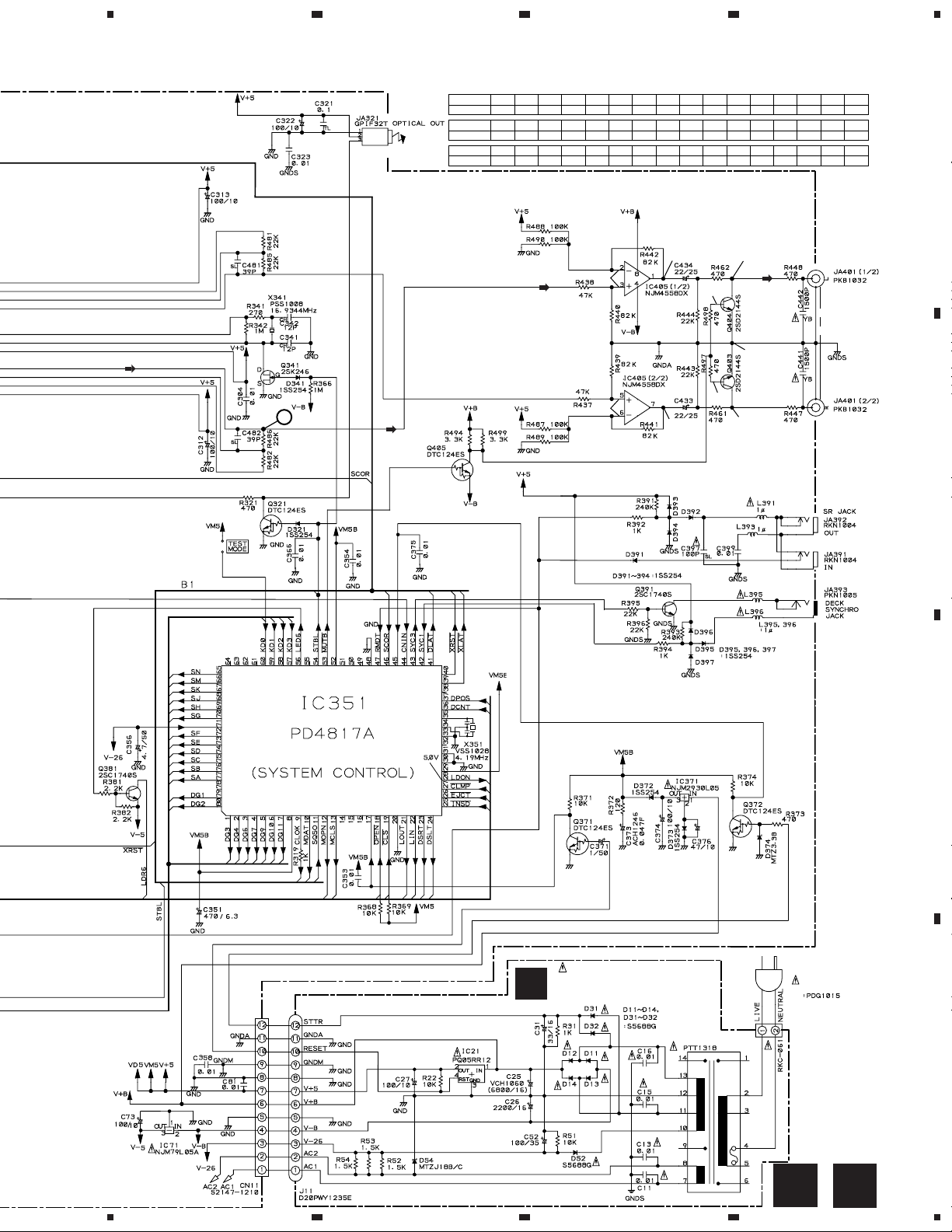

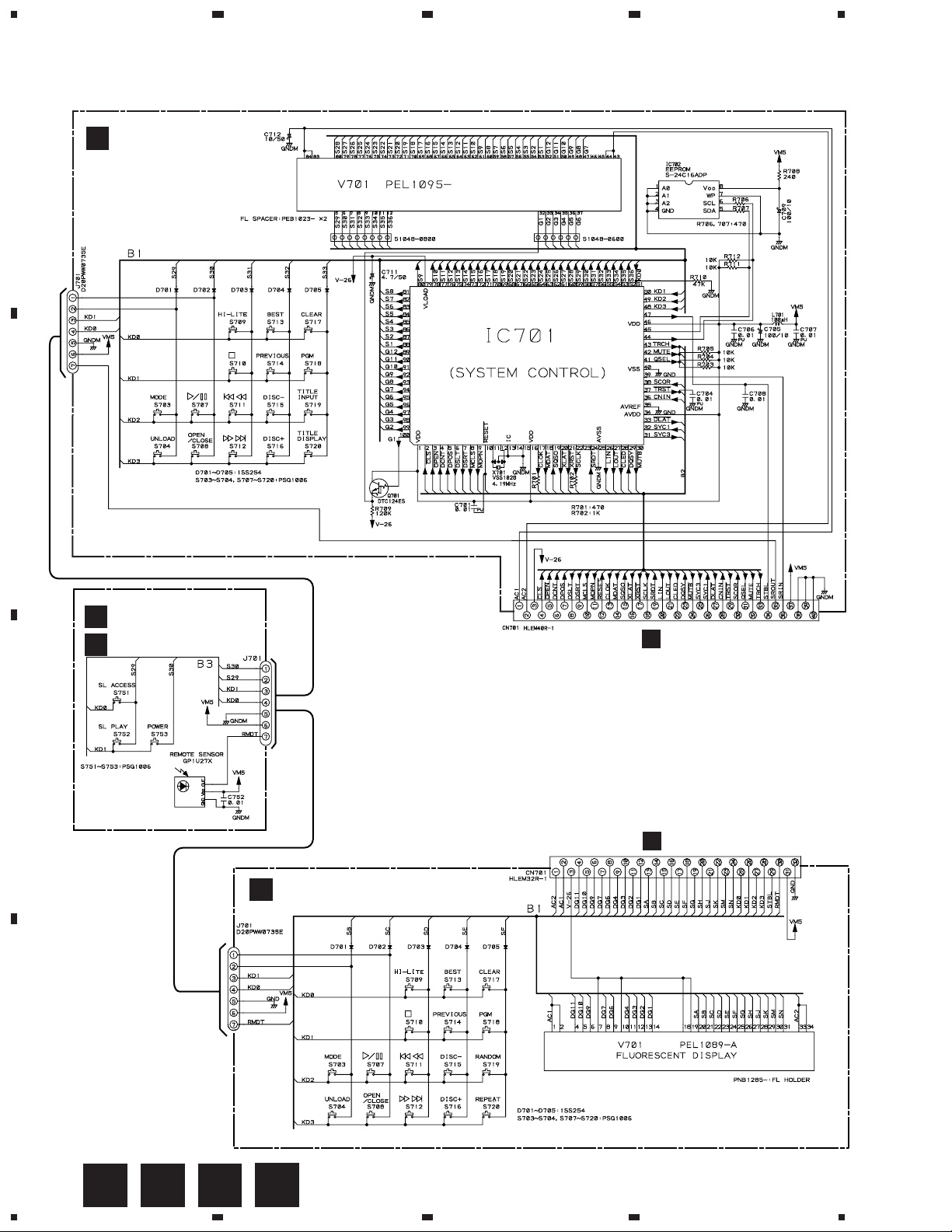

3.4 DISPLAY BOARD ASSY AND SWITCH BOARD ASSY

L

A

B

DISPLAY BOARD ASSY

PD-F957/KU/CA:(PWZ3672)

PD4934B

SWITCH BOARD ASSY

PD-F957/KU/CA:(PWZ3675)

M

H

PD-F907/KU,KC:(PWZ3432)

O

SWITCHES

SWITCH BOARD ASSY

S751 : SL ACCESS

S752 : SL PLAY

S753 : POWER STAND/ON

C

DISPLAY BOARD ASSY

N

PD-F907/KU,KC:(PWZ3426)

DISPLAY BOARD ASSY

S703 : MODE

S704 : UNLOAD

S707 : 6

S708 : OPEN/CLOSE

S709 : HI-LITE

S710 : 7

S711 : 4 1

S712 : ¡ ¢

S713 : BEST

S714 : PREVIOUS

CN351

S715 : DISC –

S716 : DISC +

S717 : CLEAR

S718 : PGM

S719 : TITLE INPUT (PD-F957)

: RANDOM (PD-F907)

S720 : TITLE DISPLAY (PD-F957)

: REPEAT (PD-F907)

J

CN351

D

16

L

M N

1234

O

PD-F957,PD-F907

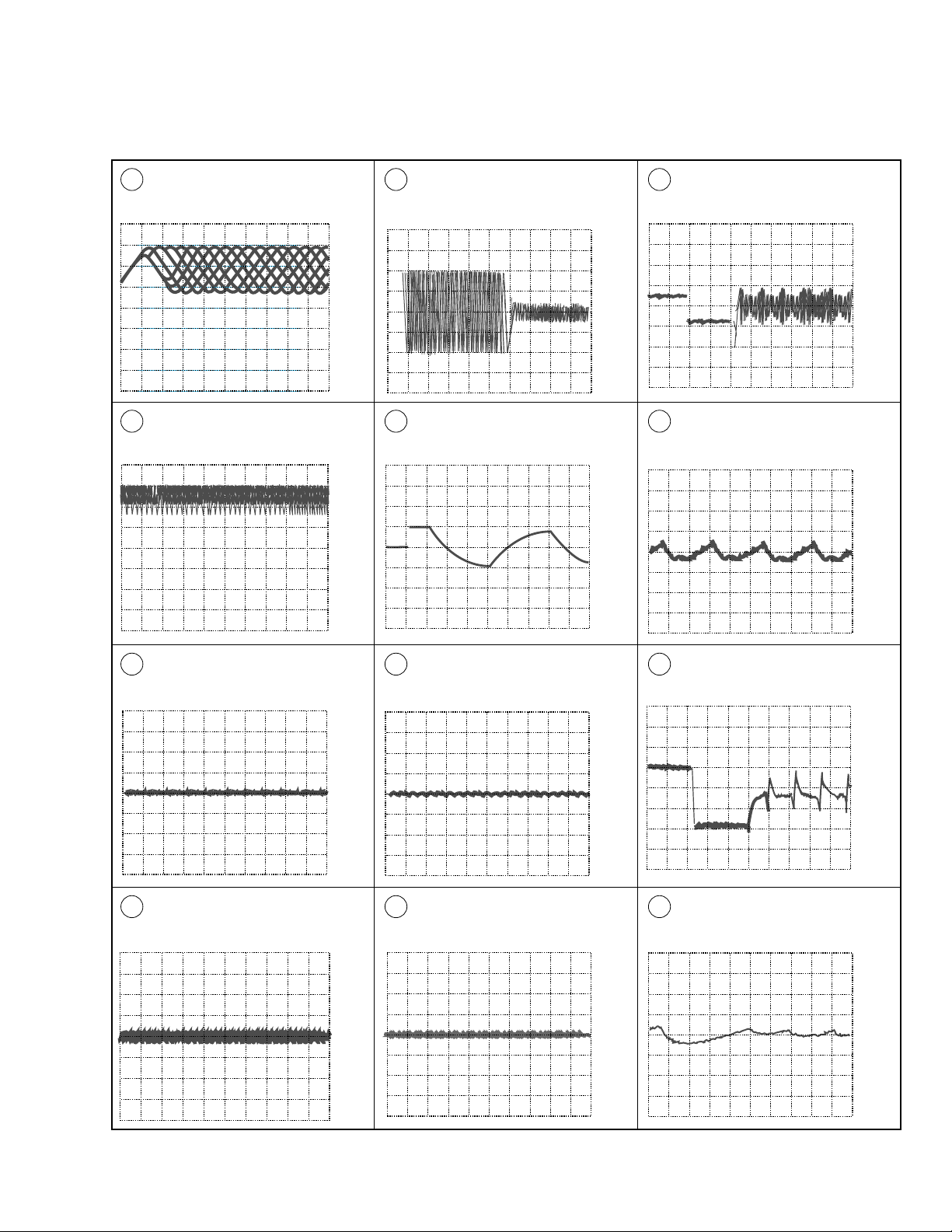

Waveforms

Note: The encircled numbers denote measuring point in the schematic diagram.

TP1-Pin 1: PLAY MODE (RF)

2

500mV/div 500nsec/div

– VC

TP1-Pin 1: TRACK SEARCH MODE

25

(RF)

500 mV/div 200 µsec/div

– VC

TP1-Pin 2: 50T - JUMP (*1) MODE

(TRER)

200mV/div 1msec/div

– VC

IC202-Pin 3: FOCUS-IN (*2) MODE

(FODR)

1V/div 200msec/div

– GND

∗1 50T-JUMP: After switching to the pause mode, press

the manual search key.

∗2 FOCUS-IN: Press the play key without loading a disc.

IC202-Pin 4: 50T - JUMP (*1) MODE

6'4'

(TRDR)

500mV/div 1msec/div

– GND

IC203-Pin 3: PLAY MODE (SPDR)

7

1V/div 50msec/div

– GND

TP1-Pin 6: PLAY MODE (FOER)

3

100mV/div 10msec/div

TP1-Pin 2: PLAY MODE (TRER)

4

200mV/div 1msec/div

– VC

– VC

IC202-Pin 3: PLAY MODE (FODR)

5

1V/div 1msec/div

IC202-Pin 4: PLAY MODE (TRDR)

6

500mV/div 1msec/div

– GND

– GND

IC203-Pin 3: TRACK SEARCH MODE

7

(SPDR)

2V/div 50msec/div

IC202-Pin 9: PLAY MODE (CADR)

8

0.2V/div 2sec/div

– GND

– GND

17

Loading...

Loading...