Pioneer PDD-9-J, PDD-9-S Service manual

POWER

STANDBY

PURE AUDIO

ONOFF

PD-D9-J

D9

Super Audio CD Player

PD-D9-J

PD-D9-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

PD-D9-J WYXJ5 AC 220 V to 240 V

PD-D9-J KUCXJ AC 120 V

PD-D9-S LFXJ AC 110 V

PD-D9-S WLPWXJ AC 220 V to 240 V

ORDER NO.

RRV3684

For details, refer to "Important Check Points for good servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

T-FZV OCT. 2007 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type

de remplacement doivent avoir la même désignation.

rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

C

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

D

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.

). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

Leakage

Device

under

E

test

Te s t all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

current

tester

not be above

0.5 mA

Earth

ground

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement par ts which have these special safety

characteristics are identified

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, show

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

in this Service Manual.

n in the

of,

AC Leakage Test

F

2

1 234

PD-D9-J

5678

A

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 780 nm

FOR SACD : MAXIMUM OUTPUT POWER : 5 mW

LABEL CHECK

WAVELENGTH : 650 nm)

WYXJ5, KUCXJ types : PRW1608

(Printed on the Rear Panel )

1. Laser Interlock Mechanism

• Loading switch (S101 on the LOAB Assy) is used for interlock

mechanism of the laser.

When this switch turned ON in SW2 (CLOSE) side (OPEN signal is

0V and CLOSE signal is 3.5V), a laser becomes the status which can

completely oscillation.

Furthermore, the laser completely oscillates in the disc judgment and

disc playback.

When player is power ON state and laser diode is not completely

oscillating, 780nm laser diode is always oscillating by half power.

• Laser diode is driving with Q307 (650nm LD) and Q308 (780nm LD)

on the DVDM Assy.

Therefore, when short-circuit between the emitter and collector of these

transistors or the base voltage is supplied for transistors turn on, the

laser oscillates. (failure mode)

• In the test mode ∗ , there is the mode that the laser oscillates except

for the disc judgment and playback. LD ON mode in the test mode

oscillates with the laser forcibly.

The interlock mechanism mentioned above becomes invalid in this

mode.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

B

LFXJ, WLPWXJ type : PRW1609

C

D

Additional Laser Caution

E

∗ : Refer to page 27.

PD-D9-J

56

F

3

7

8

1234

[Important Chec k Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follo w these procedures.

A

1. Product safety

Please conform to product regulations (such as saf ety and radiation regulations), and maintain a safe servicing environment by

following the saf ety instructions described in this manual.

1 Use specified parts for repair .

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper

Please follo w the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder

Soldering should be finished with the proper quantity. (Ref er to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inser ted.

Please be sure that

all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cab les are set to their original state.

Please replace the wiring and cab les to the original state after repairs.

C

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and

soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the po wer cord.

Damaged power cords may lead to fire accidents , so please be sure

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the

connections and suitable usage. Please exchange the power cord if necessary .

D

a Safe environment should be secured during servicing.

When you perf orm repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and

instructions.

that there are no damages.

repair safely.

and other debris.

connection and advise on secure

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors , proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or f ailures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to f ollow this method especially if it is specified in this manual.

F

4

1 234

PD-D9-J

5678

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................6

1.1 NOTES ON SOLDERING...........................................................................................................................6

2. SPECIFICATIONS.............................................................................................................................................7

2.1 ACCESSORIES..........................................................................................................................................7

2.2 SPECIFICATIONS ......................................................................................................................................8

2.3 PANEL FACILITIES ....................................................................................................................................9

3. BASIC ITEMS FOR SERVICE........................................................................................................................11

3.1 CHECK POINTS AFTER SERVICING (SACD PLAYER)......................................................................... 11

3.2 PCB LOCATIONS.....................................................................................................................................12

3.3 JIGS LIST .................................................................................................................................................13

4. BLOCK DIAGRAM ..........................................................................................................................................14

4.1 OVERALL WIRING DIAGRAM.................................................................................................................14

4.2 OVERALL BLOCK DIAGRAM..................................................................................................................16

5. DIAGNOSIS ....................................................................................................................................................18

5.1 TROUBLESHOOTING..............................................................................................................................18

5.2 SEQUENCE AFTER POWER ON/OFF....................................................................................................22

5.3 METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY.........................26

6. SERVICE MODE.............................................................................................................................................27

6.1 TEST MODE.............................................................................................................................................27

7. DISASSEMBLY...............................................................................................................................................28

8. EACH SETTING AND ADJUSTMENT............................................................................................................36

8.1 ADJUSTMENT ITEMS AND LOCATION..................................................................................................36

8.2 JIGS AND MEASURING INSTRUMENTS ...............................................................................................36

8.3 NECESSARY ADJUSTMENT POINTS ....................................................................................................37

8.4 TEST MODE.............................................................................................................................................38

8.5 MECHANISM ADJUSTMENT...................................................................................................................40

9. EXPLODED VIEWS AND PARTS LIST ..........................................................................................................42

9.1 PACKING..................................................................................................................................................42

9.2 EXTERIOR SECTION ..............................................................................................................................44

9.3 CHASSIS SECTION.................................................................................................................................46

9.4 FRONT PANEL SECTION ........................................................................................................................48

9.5 LOADER ASSY ........................................................................................................................................50

9.6 TRAVERSE MECHANISM ASSY-S ..........................................................................................................52

10. SCHEMATIC DIAGRAM................................................................................................................................54

10.1 DVDM ASSY (1/2) ..................................................................................................................................54

10.2 DVDM ASSY (2/2) ..................................................................................................................................56

10.3 AJKB ASSY ............................................................................................................................................58

10.4 CONNECTOR ASSY..............................................................................................................................60

10.5 LCD, PLED, IR and KEY ASSYS ...........................................................................................................62

10.6 PRIMARY, MNSW and REGULATOR ASSYS .......................................................................................64

10.7 WAVEFORMS.........................................................................................................................................66

11. PCB CONNECTION DIAGRAM ....................................................................................................................69

11.1 LOAB ASSY............................................................................................................................................69

11.2 DVDM ASSY...........................................................................................................................................70

11.3 AJKB ASSY ............................................................................................................................................72

11.4 LCD ASSY ..............................................................................................................................................74

11.5 PLED, KEY and IR ASSYS.....................................................................................................................76

11.6 PRIMARY ASSY .....................................................................................................................................78

11.7 CONNECTOR and MNSW ASSYS ........................................................................................................80

11.8 REGULATOR ASSY ...............................................................................................................................82

12. PCB PARTS LIST.............................................................................................................

.............................84

A

B

C

D

E

PD-D9-J

56

F

5

7

8

1234

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

A

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free

solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the w

eight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

B

The following lead-free solders

are available as service parts:

• Par ts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

C

D

E

F

6

1 234

PD-D9-J

5678

2. SPECIFICATIONS

2.1 ACCESSORIES

• Power cable

(ADG7062 : WYXJ5)

(ADG7061 : KUCXJ)

(ADG7104 : WLPWXJ)

A

(ADG7076 : LFXJ)

• RCA/phono stereo audio cable

(XDE3047)

• SR control cable

(XDE3063)

• Remote Control

(PWW1175 : WYXJ5,KUCXJ)

(PWW1176 : LFXJ,WLPWXJ)

DIMMER

OPEN/CLOSE

PURE AUDIO

CLEAR

1

23

ENTER

456

7890

PROGRAM REPEAT

RANDOM TIME

LEGATO LINK

SACD SETUP

SUPER AUDIO CD PLAYER

• Lithium Battery (CR2025)

B

>

(Attached inside the remote control)

C

D

PD-D9-J

56

E

F

7

7

8

1234

2.2 SPECIFICATIONS

A

B

General

System .......................... Super Audio CD player

Power requirements

PD-D9-J/WYXJ5, PD-D9-S/WLPWXJ

........................AC 220 V to 240 V, 50 Hz/60 Hz

PD-D9-J/KUCXJ

................................................ AC 120 V, 60 Hz

PD-D9-S/LFXJ

......................................AC 110 V, 50 Hz/60 Hz

Power consumption....................................22 W

Power consumption (standby)...................0.4 W

Weight

PD-D9-J/WYXJ5

................................................................ 11.0kg

PD-D9-J/KUCXJ, PD-D9-S/LFXJ,

PD-D9-S/WLPWXJ

................................................................ 10.0kg

Disc/content format playback

compatibility

This player is compatible with a wide range of

audio disc types and media formats. Playable

discs will generally feature one of the following

logos on the disc and/or disc packaging. Note

however that some disc types, such as

recordable CDs, may be in an unplayable

format — see the Disc compatibility table below

for further compatibility information.

Please also note that recordable discs cannot be

recorded using this player.

Dimensions

..... 420 mm (W) x 113 mm (H) x 340 mm (D)

Operating temperature ...............+5°C to +35 °C

Operating humidity ..........................5 % to 85 %

(no condensation)

Audio CD CD-R CD-RW

Super Audio CD

Audio output (1 stereo pair)

Output level .........................During audio output

C

Number of channels .........................................2

Jacks ..........................................................RCA

200 mVrms (1 kHz, –20 dB)

Digital audio characteristics

Frequency response...... 4 Hz to 50 kHz (SACD)

S/N ratio:

CD .......................................................115 dB

SACD...................................................110 dB

Dynamic range:

CD .......................................................100 dB

SACD...................................................110 dB

Total harmonic distortion:

D

CD ..................................................... 0.002 %

SACD................................................. 0.003 %

Wow and flutter ................Limit of measurement

(±0.001 % W. PEAK) or lower

4 Hz to 20 kHz (CD)

Digital output

Coaxial digital output ........................... RCA jack

Optical digital output.............. Optical digital jack

Accessories

Remote control ................................................. 1

Lithium battery (CR2025) ................................. 1

RCA/phono stereo audio cable ........................ 1

E

F

8

SR control cable ............................................... 1

Power cable...................................................... 1

The specifications and design of this product

are subject to change without notice, due to

improvement.

PD-D9-J

1 234

5678

2.3 PANEL FACILITIES

Front Panel

7

1

POWER

1

POWER

2 5 6

STANDBY

PURE AUDIO

ONOFF

8

OFFON

2 STANDBY indicator

3Display

4 Disc tray

5

6

7Remote sensor

PURE AUDIO

8

3 4

indicator

A

D9

B

C

D

E

F

PD-D9-J

56

9

7

8

1234

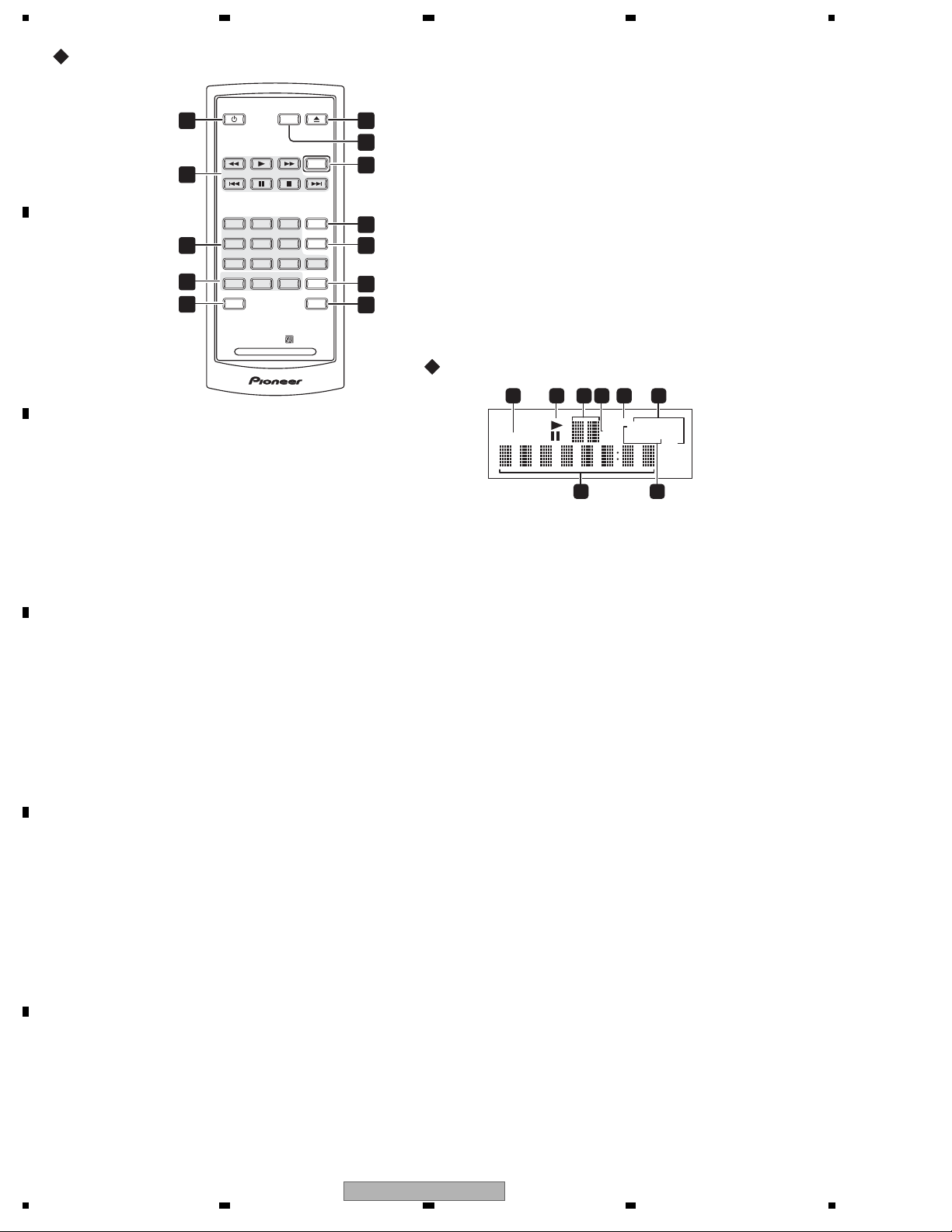

Remote Control

A

B

C

D

1

2

1

23

3

4

5

456

7890

PROGRAM REP EAT

SACD SETUP

SUPER AUDIO CD PLAYER

1

2Playback controls

3Number buttons

4

PROGRAM

REPEAT

RANDOM

5 SACD SETUP

6

OPEN/CLOSE

7

DIMMER

8

PURE AUDIO

9

CLEAR

10

ENTER

11

TIME

12

LEGATO LINK

DIMMER

OPEN/CLOSE

PURE AUDIO

CLEAR

ENTER

RANDOM TIME

LEGATO LINK

10

11

12

Using the remote control

Keep in mind the following when using the

remote control:

6

7

8

• Make sure that there are no obstacles

between the remote and the remote sensor

on the unit.

• The remote has a range of about 7 m at an

angle of about 30º from the remote sensor.

• Remote operation may become unreliable

if strong sunlight or fluorescent light is

9

shining on the unit’s remote sensor.

• Remote controllers for different devices

can interfere with each other. Avoid using

remotes for other equipment located close

to this unit.

• Replace the batteries when you notice a

fall off in the operating range of the remote.

Display

1 2 3 4 5 6

LEGATOLEGATO

ALLALL

REPEATREPEAT

TOTALTOTAL

REMAINREMAIN

RANDOMRANDOM

PGMPGM

TRACKTRACK

SACDSACD

7 8

1

TRACK – Lights when the track number is

indicated.

2

/ – Light during playback/when paused.

3Scan display

– Shows the scan speed.

4 SACD – Lights during SACD playback.

5

LEGATO – Lights when Legato Link Pro is

switched on.

6 (ALL)

REPEAT/RANDOM/PGM – Light to

indicate the playback mode.

7Character display

–

8 TOTAL/REMAIN

Indicate the disc/track

information currently displayed.

E

F

10

1 234

PD-D9-J

5678

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING (SACD PLAYER)

To keep the product quality after servicing, confirm recommended check points shown below.

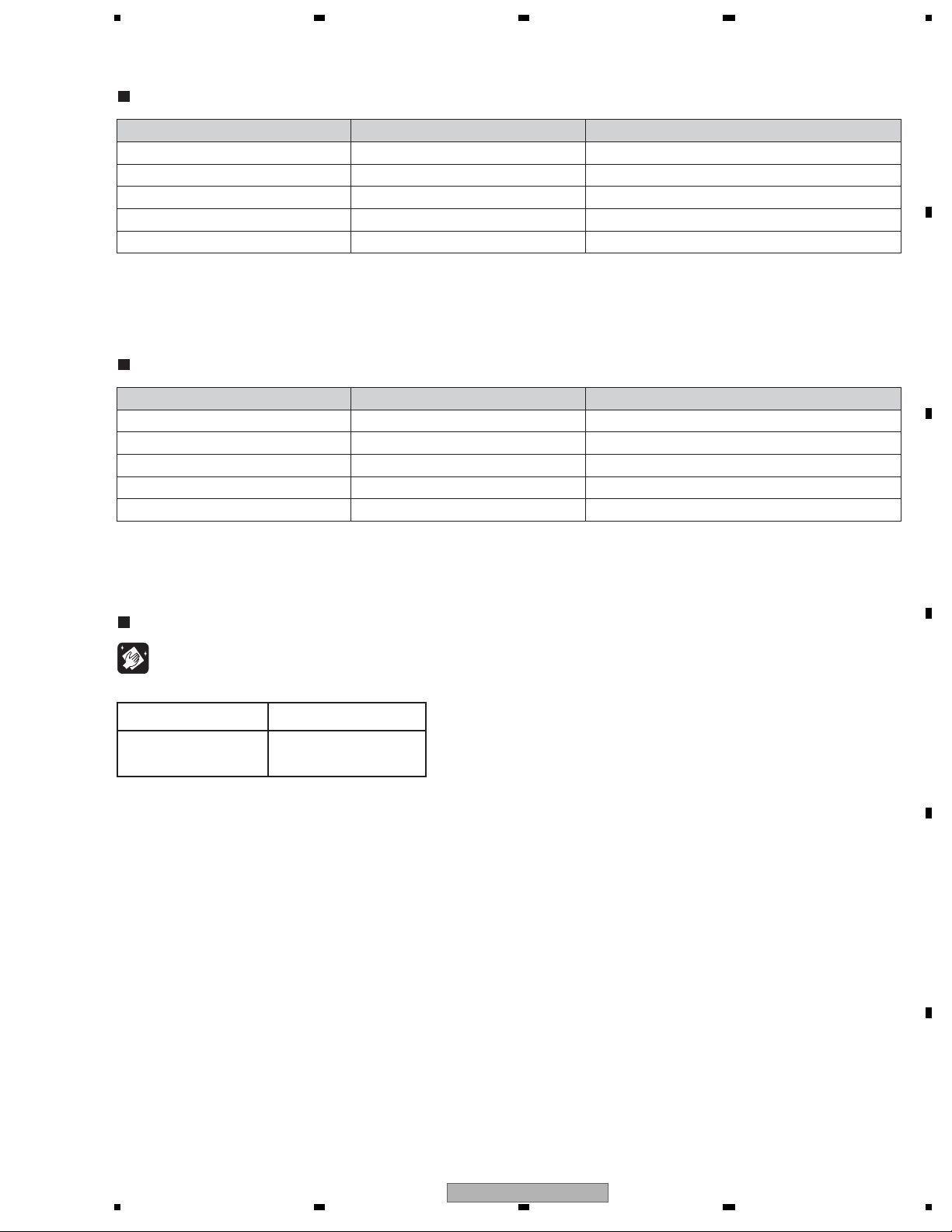

No.Procedure Check points

1 Confirm the firmware version on Service Mode. The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

Confirm whether the customer complain has been solved.

2

If the customer complain occurs with the specific disc,

The customer complain must not be reappeared.

Video, audio and operations must be normal.

use it for the operation check.

Confirm playback error rates at the innermost and

3

outermost tracks by using the following disc.

The error rates must be less than 5.0e-4.

DVD test disc (GGV1025)

Play back a CD/SACD.

4

(Menu operation, Title/chapter search)

Check the appearance of the product. No scratches or dirt on its appearance after receiving it

5

Audio and operations must be normal.

for service.

See the table below for the items to be checked regarding audio:

Item to be checked regarding audio

Distortion

Noise

A

B

C

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

D

E

PD-D9-J

56

F

11

7

8

1234

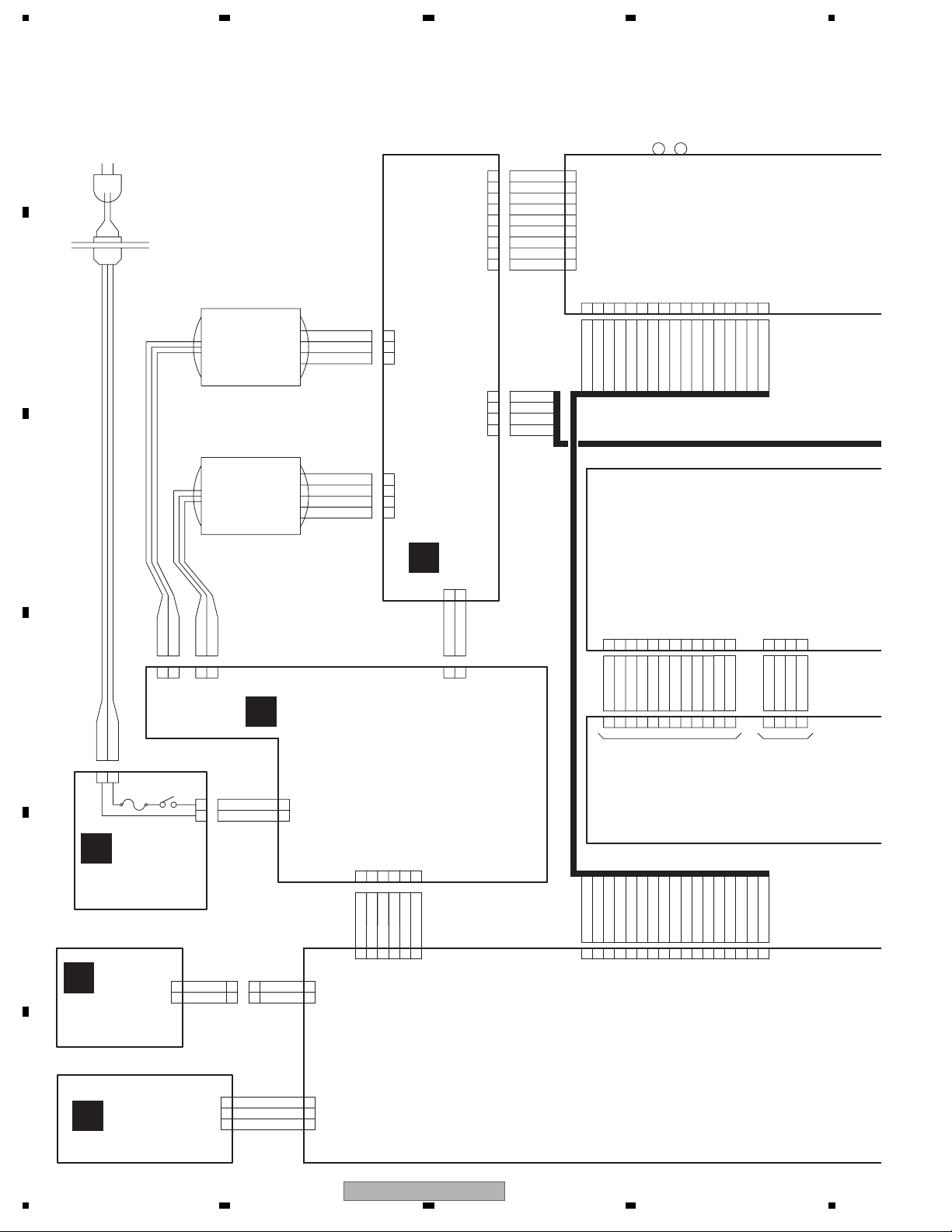

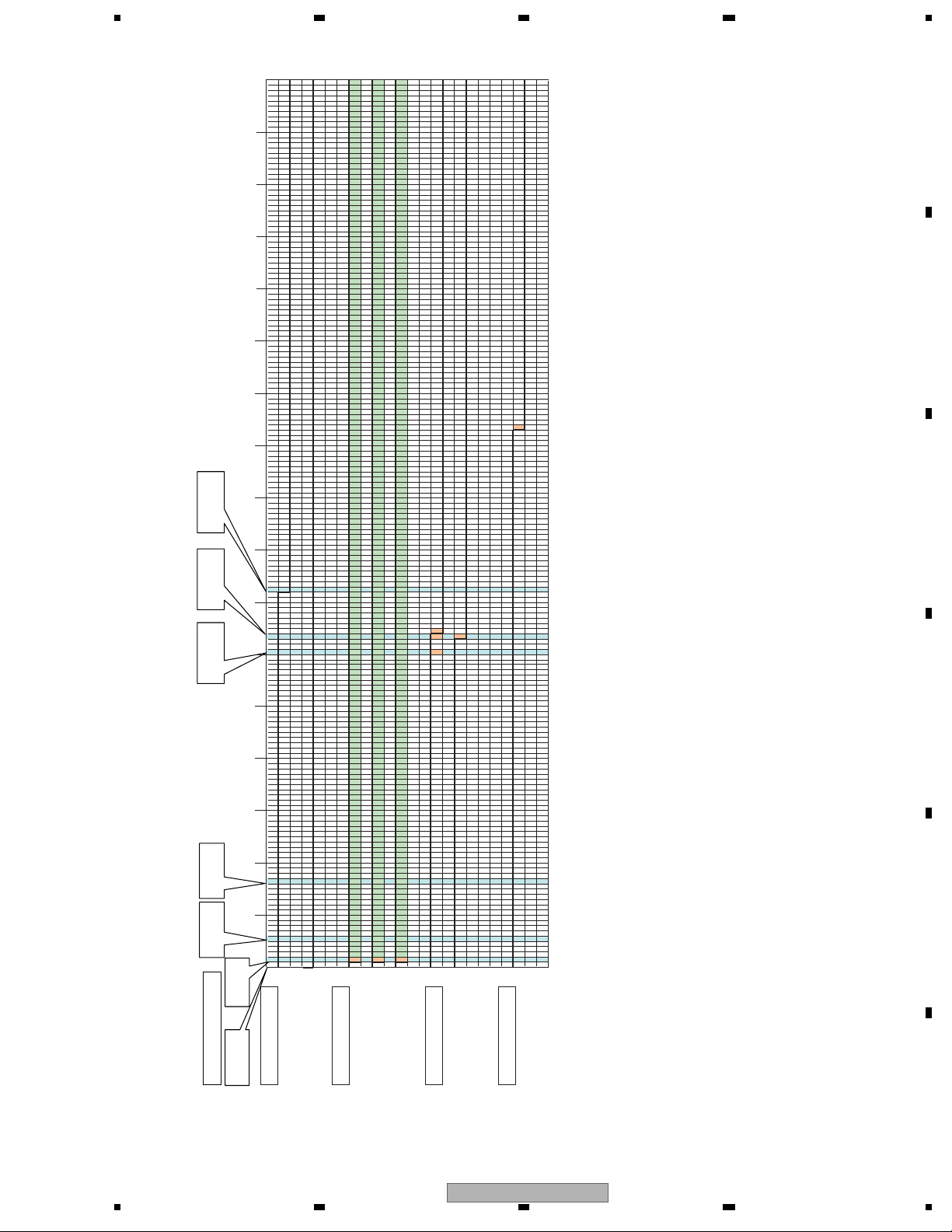

3.2 PCB LOCATIONS

A

G

KEY ASSY

B

H

CONNECTOR

ASSY

A

LOAB ASSY

D

LCD ASSY

E

PLED ASSY

K

IR ASSY

F

MNSW ASSY

I

PRIMARY ASSY

B

DVD M ASSY

C

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

D

LIST OF ASSEMBLIES

Mark No. Description

NSP 1..LOADER ASSY PXA1648 PXA1648 PXA1648 PXA1648

2..LOAB ASSYNSP VWG2346 VWG2346 VWG2346 VWG2346

1..DVDM ASSY AWM8069 AWM8069 AWM8069 AWM8069

1..AJKB ASSY PWM2359 PWM2359 PWM2359 PWM2359

2..AJKB ASSY PWX1661 PWX1661 PWX1661 PWX1661

E

2..CONNECTOR ASSY PWX1662 PWX1662 PWX1662 PWX1662

C

AJKB ASSY

PD-D9-J

/WYXJ5

PD-D9-J

/KUCXJ

J

REGULATOR ASSY

PD-D9-S

/LFXJ

PD-D9-S

/WLPWXJ

1..FLKB ASSY PWM2358 PWM2361 PWM2362 PWM2358

2..LCD ASSY PWX1651 PWX1651 PWX1651 PWX1651

2..PLED ASSY PWX1655 PWX1655 PWX1655 PWX1655

2..MNSW ASSY PWX1654 PWX1654 PWX1654 PWX1654

2..KEY ASSY PWX1652 PWX1652 PWX1652 PWX1652

2..PRIMARY ASSY PWX1657 PWX1659 PWX1660 PWX1657

2..REGULATOR ASSY PWX1656 PWX1663 PWX1663 PWX1656

2..IR ASSY PWX1653 PWX1653 PWX1653 PWX1653

F

12

1 234

PD-D9-J

5678

3.3 JIGS LIST

Jigs list

Name Jig No.Remarks

Service Remote Control Unit GGF1381

DVD Test Disc (DVD-Video) GGV1025

adjustment, diagnosis

Check of DVD -Video

CD Test Disc STD-905 Check of CD

5P FFC GGD1425 Diagnosis of DVDM ASSY

17P FFC GGF1157 Diagnosis of DVDM ASSY

Lubricants and Glues list

Name Lubricants and Glues No.Remarks

Lubricating Oil GYA1001

Daifree

GEM1036

GEM1037Silicone Adhesive

GYL1001Screw tight

Silicone Adhesive GYA1011

refer to "9.5 LOADER ASSY"

refer to "9.5 LOADER ASSY"

refer to "9.6 TRAVERSE MECHANISM ASSY-S"

refer to "8.5 MECHANISM ADJUSTMENT"

refer to "9.4 FRONT PANEL SECTION"

A

B

C

CLEANING

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Pickup leneses Cleaning liquid : GEM1004

Cleaning paper : GED-008

D

E

PD-D9-J

56

F

13

7

8

1234

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

E

PLED ASSY

(PWX1655)

WY : ADG7062

KUC : ADG7061

WLPW : ADG7104

LF : ADG7076

AC CORD

AC INLET

PKP1021

L=190mm

L=190mm

L=90mm

NEUTRAL

LIVE

2

1

CN12

B2P3-VH-Y

NEUTRAL

LIVE

1

2

FU1

VKN2024

CN2501

S2301

(Mechanical

F

Power SW)

MNSW ASSY

(PWX1654)

J2601

PKP1023

1

2

Power

Transformer

(AUDIO)

KUC,LF:PTT1371

WLPW,WY:PTT1372

Power

Transformer

(DIGITAL)

KUC,LF:PTT1373

WLPW,WY:PTT1374

LIVE

NEUTRAL

2

1

CN10

B2P3-VH

I

LIVE

2

NUETRAL

1

L=70mm

RKP1834

CN2502

V+5U

PLED

P=2.0mm

11

22

L=50mmL=50mm

P=2.0mm

1

2

3

B9B-EH

CN1802

4

5

6

7

8

9

CN1801

L=120mm

AUDIO 1

AUDIO 2

AUDIO CT

L=140mm

DIGITAL1

DIGITAL2

MECHA1

MECHA2

1

2

3

1

2

3

4

B3P-VH

CN1701

B4P-VH

REGULATOR ASSY

1

2

3

4

B4B-EH

CN1702

(PD-D9-J/WYXJ5, PD-D9-S/WLPWXJ:PWX1656)

(PD-D9-J/KUCXJ, PD-D9-S/LFXJ:PWX1663)

J

J1702

PF02PG-S05

B2B-PH-K-S

PRIMARY ASSY

(PD-D9-J/WYXJ5,

PD-D9-S/WLPWXJ:PWX1657)

(PD-D9-J/KUCXJ:PWX1659)

(PD-D9-S/LFXJ:PWX1660)

1

2

J11

PKP1022

6

543

GNDD

V+58U

GNDU

V+56STACSYSPOW

6

543

V+5U

PLED

J2102

PKP1024

1

2

2

1

P=2.0mm

L=50mm

GNDD

V+58U

CN13

2

1

CN11

B6B-PH-K-S

2

1

P=2.0mm

L=75mm

2

1

J2101 CN2105

PF06PG-D07

P=2.5mm

L=100mm

V+5A

GNDA

V+12A

GNDA

V-12A

GNDD

V+3D

GNDRY

V+12RY

V+9D

GNDD

V+6R5V

GNDM

PDD1235

L=290mm

P=1.25mm

FFC

9607S-17F

1

2

3

4

5

6

7

8

9

J1901

PKP1019

21543

GNDD

SROUT

FFC

P=1.0mm

GNDD

SROUT

1

254

SRIN

GNDD

XDFDT

10

12

11

U-

U+

V+5S

345

2

1

SPINDLE MOTOR

SRIN

GNDD

XDFDT

3

JA1601

GNDD

XDFCLK

987

V-

V+

GNDD

XDFCLK

SR-OUT

SR-IN

RKN1004

RKN1004

JA1602

9

876

10

XDFCS

XDFRST

XSYSMUTE

65431

W-

HB

W+

6

789

XSYSMUTE

XDFRST

XDFCS

9

876

10

11

GNDD

XSRRST

PKP1020

P=2.5mm

L=360mm

CN102

AKN7031

2

V

U

101112

XSRRST

GNDD

11

141312

LEGATO

XDACDT

XDACCK

W

INSIDE

STEPPING MOTOR

LEGATO

XDACDT

XDACCK

141312

CN1401

CKS3382

171615

XDACCS2

XDACCS1

CN103

RKN1045

4

FFC

ST1-(A)

P=1.0mm

412

XDACCS1

XDACCS2

171615

321

ST1+(A)

ST2+(B)

3

ST2-(B)

J2106

J2106A

F

IR ASSY

K

(PWX1653)

1

2

3

FLAT CABLE

VOUT

V+5U

GNDD

L=35mm

P=2.0mm

14

PKP1025

1

2

3

PD-D9-J

1 234

5678

T

A

Lch OUT

Rch OUT

OPT-OUT

COAX-OU

AKB7102

JA1101

JA1201

AJKB ASSY

C

(PWX1661)

171516

GNDD

GNDD

MCLK(22M)

1243765

B

B 1/2, B 2/2

DVDM ASSY

(AWM8069)

201918171615141312

242322

21

VSHF

FOCS RTN

1

GNDD

TRKG RTN

FOCS DRV

TRKG DRV

432

VKS1002

AKB7102

141112

13

LRCK

GNDD

PD

LD(650)

DATA0

JA1502

GNDD

GNDD

LD(780)

98765

10

AKB7102

JA1501

(TOTX147L)

789

10

BCK

DATA1

GNDD

GNDD

XDACDT

XDACCK

9

8

11

10

9876543

11

10

A

B

VRCOM

VR650

131211

RF

14

15

VR780

PU

MECHA ASSY

(AWM7967)

456

XDACCS1

141312

SW

CN1402

312

PKN1033

XDACCS2

C

GNDD

FFC

L=60mm

P=1.0mm

PDD1234

XPCM/DSD

171615

CN953

CKS3885

CN101

CKS5045 AKM1291

1

2

F

E

D

VCC

VREF

GNDD

22212019181716

23

24

P=0.5mm

ADD7546

L=220mm

S5B-PH-K-S

A

FFC

CN601

524

5

SW1

CN104

3

SW1

SW2

GNDD

LOAD+

342

LOAD+

V+3D

SW2

LOAB ASSY

(VWG2346)

CN1501

345

2

1

05R-FJ

V+12A

DOUT

GNDD

GNDD

GNDD

V+6R5V

GNDM

V+9D

214

3

CN2704

S4B-EH

CN901

VKN1321

CVBS

1

TROUT

2

TRIN

3

TRGAIN

4

SPDIF_RQ

5

TRKUP

6

DVD MUTE

7

VDET

8

GNDD

9

GNDD

10

ACK

11

MDATA

12

SDATA

13

SCLK

14

XREADY

15

XDVD RST

16

DVD POWER

17

GNDD

18

GNDD

19

DOUT

20

GNDD

21

GNDD

22

GNDM

23

GNDM

24

V+6R5V

25

V+6R5V

26

V+9D

27

V+9D

28

V+12A

29

1

LOAD-

L=75mm

1

LOAD-

2

1

CN602

PG05KK-E07

LOADING

MOTOR

ASSY

: VXX2912

PDD1236

L=80mm

P=1.0mm

FFC

CN2701

VKN1205

29

28

27

26

25

24

23

22

21

20

19

18

17

16

H

15

14

CONNECTOR ASSY

13

12

(PWX1662)

11

10

9

8

7

6

5

4

3

2

1

32154

786

10

TROUT

TRGAIN

1411151213

TRIN

VDET

SPDIFP_RQ

10

GNDD

9

GNDD

SCLK

MDATA

ACK

756

8

119141312

SDATA

DVD MUTE

2

345

1

CN2704

B2P-SHF-1AA

GNDD

XREADY

XDVD RST

DVD POWER

3

4

2

P=2.0mm

CN2702

05PL-FJ

2

1

CVBS

CN2703

VKN1191

15

GNDD

1

CN2106

CKS3829

PDD1229

L=300mm

FFC

P=1.0mm

B

C

D

N.C.

WCLK

WEN/DI

RST

WD0

VCC

VSS

1

2

LCD ASSY

D

(PWX1651)

7

563

4

CN2101

52492-0720

1

2

3

P=2.0mm

L=200mm

KEY1

VE+5

GNDD

D20PYY0320E

J2104

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor

of the part. Therefore, when replacing, be sure to use parts of identical designation.

: The power supply is shown with the marked box.

PD-D9-J

56

7

J2104A

1

2

G

3

KEY ASSY

(PWX1652)

E

F

15

8

1234

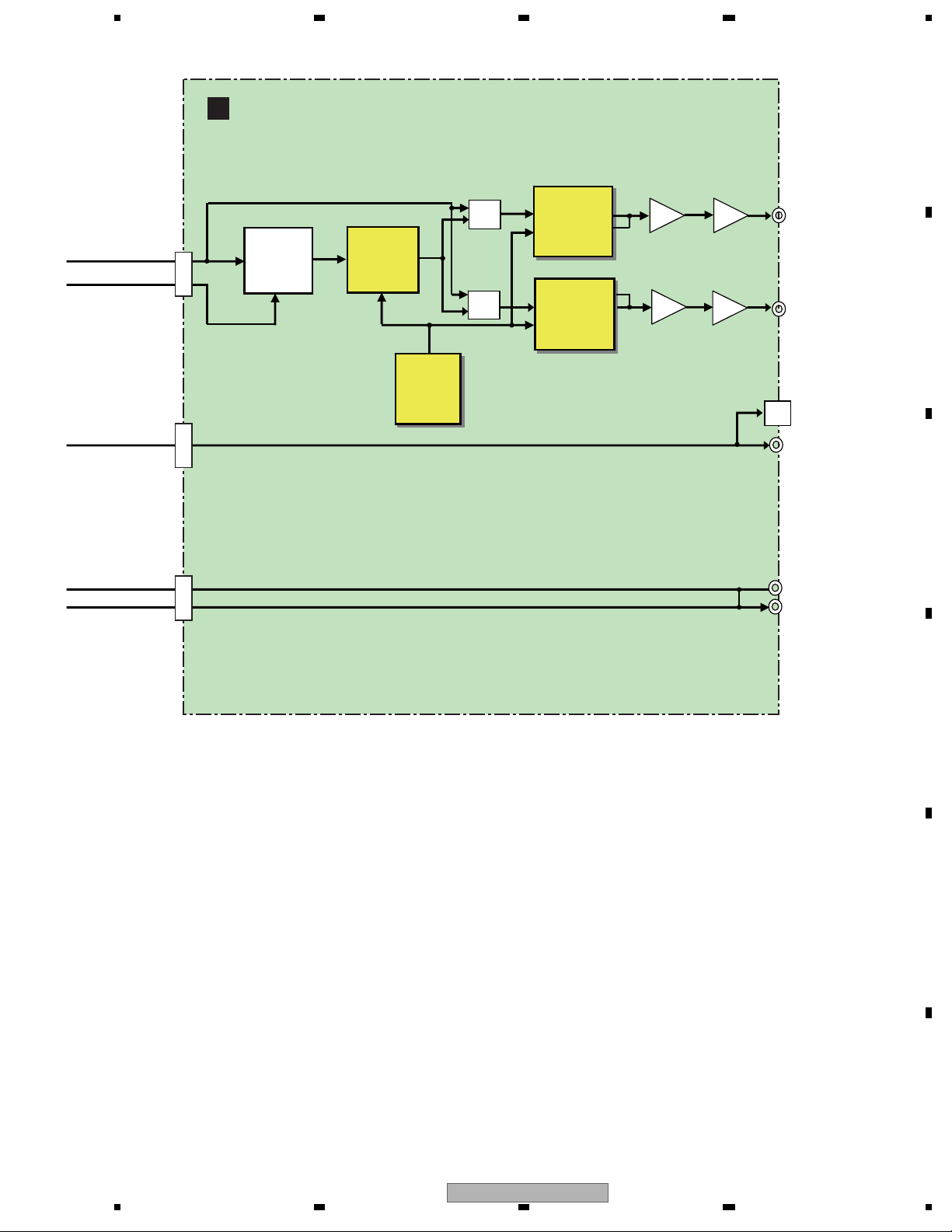

4.2 OVERALL BLOCK DIAGRAM

A

IC204

EEPROM

4k

S-24C04AFJ

3.3V

TRAVERSE

B

LOADING

MOTOR

C

D

SPDL

MOTOR

05 PICK

UP

PU

STEPPING

MOTOR

CN101

CN103

IC101

CN102

CN104

SERVO

DRIVER

BD7995EFS

6.5&5V

IR ASSY

K

IR

GP1UM28XK

5V

J2106A

IC203

PGM FLASH MEMORY

16M

AYW7197

3.3V

IC201

MAIN DECODER

(CD,SACD)

1389EE

3.3V&1.8V

CN901(2/2)

CN2106

IC2101

SYSTEM

CONTROL

CPU

PDC170A

5V

LCD Display

AAV7111

5V

CN1401

J2104

DVDM ASSY

B

IC202

64M SDRAM

KS641632H-TC75

3.3V

X202

Clock OSC

ASS7075

(27MHz)

3.3V

SPDIF

J2104A

S2301, S2302

G

KEY ASSY

CN953

CN901(1/2)

KEY

J2106

LCD ASSY

D

CN2105

Front Panel Block

E

F

16

1 234

PD-D9-J

5678

CN1402

CN1501

AJKB ASSY

C

(DSD)

(PCM)

MCLK

IC1401

AQE

PD0274A

3.3V

IC1402

SRC

SRC4192

3.3V

MCLK

X1401

Clock OSC

ASS7071

(22MHz)

3.3V

IC1152

SEL

IC1252

SEL

IC1151

192k,24bit,

2chDAC

WM8741

3.3V&5V

IC1251

192k,24bit,

2chDAC

WM8741

3.3V&5V

IC1101

(1/2)

IC1201

(2/2)

LPF

IC1101

(2/2)

IC1201

(1/2)

JA1101

L

JA1201

R

JA1502

OPTICAL OUT

COAXIAL OUT

JA1501

A

B

C

CN1401

JA1602

SR-IN

SR-OUT

JA1601

D

E

PD-D9-J

56

F

17

7

8

1234

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

B

C

Start

(Power → ON)

Lighting LCD

Yes

LCD

displays

correctly

Yes

No

come out of the pure audio

mode or dimmer mode

No

Appearance some waveform on

LCD communication line

(LCCDT,LCDCK,LCDCS,LCDRS)

Confirm the port logic of BLOFF

and DIMMER when operate

Working

at pure audio

mode or

dimmer?

Yes

V2201 1

is 4.4V and

V2201 2 is

5V

Yes

No

No

<confirmation>

Connection between CN1802 and J1901

Connection between CN1501 and CN2702

Connection between CN2701 and CN901

Connection between CN1702 and CN2704

No

LCD

disappers and

flashing pure

audio LED

Yes

Cathode of 1801,

CN1802 3 is +13V

<confirmation>

No

FU1

Connection between J1702 and CN13

Power line CN11 3 : 5.6V,CN11 5 : 5.8V

(V+12V line)

D1802 is

+17V

Yes

No

Confirmation HB at CN1801or change

D1801,D1802,D1803D1804

(V+5V line)

CN1802 1 is +5V

No

Change parts D1805,Q1801,

Q1802 in turn

No

<confirmation>

D1809 is shorten

HB at CN1802 and J1901

<confirmation>

input and output of F2201,Q2103 is 5V

Tray movement

(open/close)

D

E

spicdle movement

Yes

Focus

movement

OK?

Yes

Spindle

movement

OK?

Yes

Can stop

(stop key react)

Yes

No

Refer to Addendum No. 1.

No

Refer to Addendum No. 2.

No

Refer to Addendum No. 3.

No

Refer to Addendum No. 4.

Change parts D1807,Q1803,

in turn

D1701 1 is +7.5V

Yes

(V+9D line)

Yes

(V+3D line)

CN1802 3

is 3.3V

(V+6R5V line)

D1702 1

is +8.5V

Yes

No

<confirmation>

HB at IC1101,IC1201

No

No

No

Is status of

IC1701 OK?

Yes

<confirmation>

HB at CN1701

<confirmation>

HB at J1901,CN1802,

IC1151,IC1152,IC1251,IC1252,

IC1401-IC1406

Is status of

IC1702 OK?

Yes

<confirmation>

HB at CN1701

No

Change IC1701

No

Change IC1702

No

CN1702 3

F

is +6.5V

<confirmation>

HB at CN1702,CN2704,IC101

A

18

1 234

PD-D9-J

A

All output

audio signal

are OK?

5678

only analog output at

SACD mode

A

No

Audio

analog output

is OK?

No

(V-12V line)

anode of D1803,

D1804 is -17V

No

<confirmation>

HB of CN1801

Yes

no ploblem

(V+12RY line)

RY1302 1 is

Yes

<confirmation>

IC201-225

Connection between CN953and CN1402

Yes

Only

optical or coaxial

output

Yes

<confirmation>

Input and output of IC1501

V+3DO is 3.3V

NoNo

+12V

IC1707 1 is

+17V

Yes

Change IC1707

Yes

No

CN1802 is -13V

Change parts

D1808,Q1804,

in turn

<confirmation>

HB at IC1101,IC1201

status of IC1706

is OK?

Yes

Change IC1706

Yes

Yes

Yes

No

No

<confirmation>

No

HB at CN1701 or

change D1709,D1710

Change parts D1806,

Q1804,Q1805 in turn

B

C

RY1302 a

is 0V

Yes

Change RY1302

No

<confirmation>

XSYSMUTE : H

DVD MUTE : L

D

E

PD-D9-J

56

F

19

7

8

1234

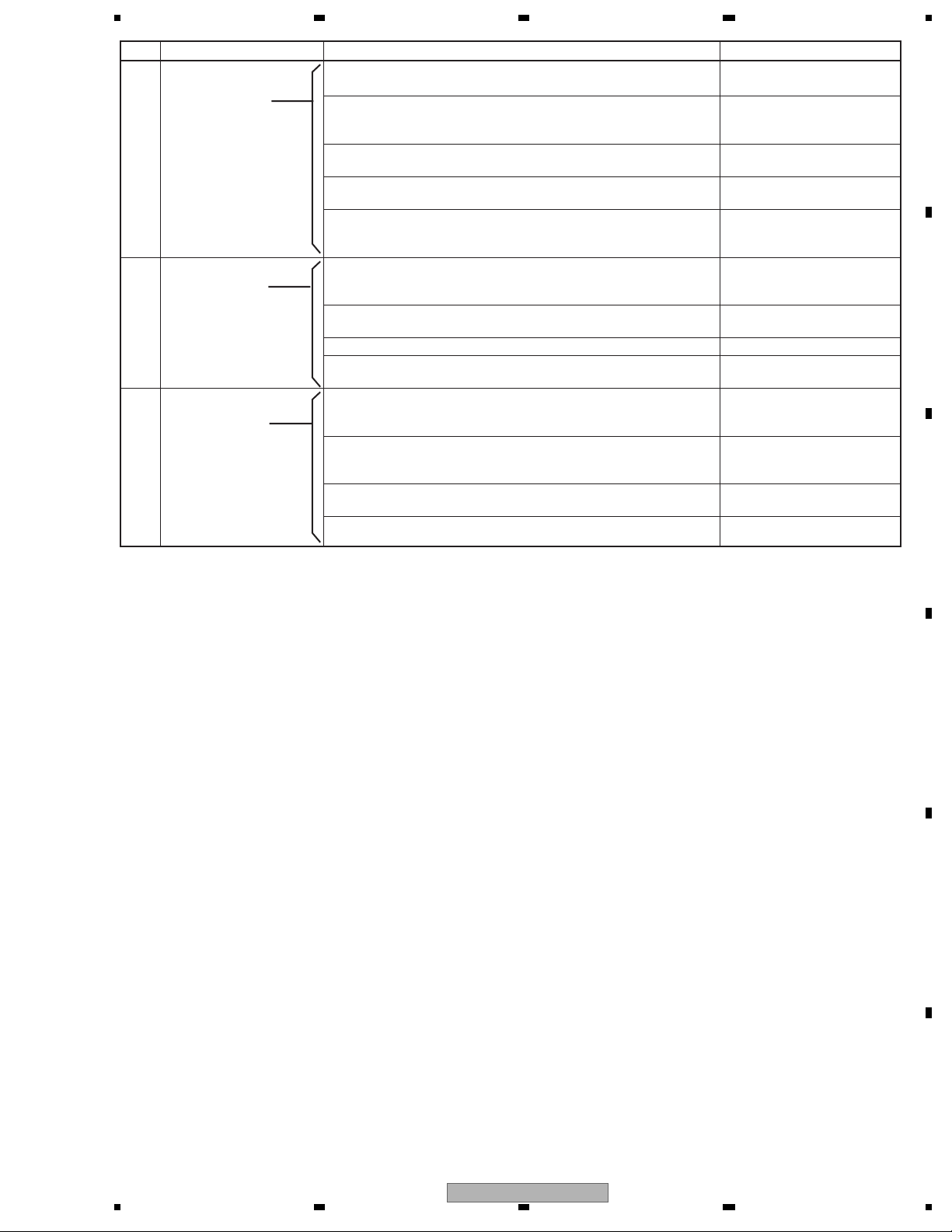

No.Symptoms Diagnosis Contents Possible Defective Points

1 The power is not turned on. Are wires of output connector (POWER SUPPLY Unit) and CN901

(DVDM Assy) disconnected or damaged ?

A

Check that the following voltage is output :

+ side of C739 : 3.3V

An opening screen is not

2

displayed on the monitor

(The FL display lights. The

mechanism does not work.)

Are the signals output from IC201-pin 98 (MDATA) and pin 99 (SCLK)

on the DVD M Assy ? (in the range of 0-3V)

Are the signals input into IC2101-pin 50 (MDATA) and pin 51 (SCLK) on

the LCD Assy ? (in the range of 0-3V)

Connector / cable

DVDM Assy

3.3V Regulator IC (IC341)

DVDM Assy

DVD IC (IC201)

LCD Assy

UCOM (IC2101)

Check that the following voltage are output :

IC751-pin 1 on the DVD M Assy : 5V

B

Is a resonator (X202: 27MHz) on the DVDM Assy oscillating ?

DVDM Assy

5V Regulator IC (IC751)

DVDM Assy

Crystal resonator (X202)

• Is a signal input into IC203-pin26 (PCE#) on the DVD M Assy ?

(Is a signal "H" for 80 mS and then "L" after the power is turned

Addendum No.1

on ?)

→ Communication with flash ROM.

• Are the signals input into IC202-pin 16 (DWE#), pin 19 (DCS#)

and pin 38 (SDCLK) on the DV DM Assy ?

(Is a signal fluctuating ?)

DVDM Assy

DVD IC (IC201)

Flash ROM (IC203)

SDRAM (IC202)

→ Communication with SDRAM

Is a signal output from IC203-pin 28 (PRD#) on the

C

(Is a signal fluctuating for several hundred mS after the power is turned

on ?)

Is a signal input into IC2101-pin 67 (DVD ACK) on the LCD Assy ?

(Is a signal fluctuating ?)

→ Communication with FL Control IC

Is a signal output from IC2101-pin 30 (XREADY) on the LCD Assy ? (Is

a signal fluctuating in the range of 0-5V ?)

DVD M Assy?

DVDM Assy

Flash ROM (IC203)

DVDM Assy

DVD IC (IC201)

LCD Assy

UCOM (IC2101)

LCD Assy

UCOM (IC2101)

DVDM Assy

Are the signals output from IC2101-pin 49 (SDATA) on the LCD Assy ?

(in the range of 0-5V)

D

DVD IC (IC201)

LCD Assy

UCOM (IC2101)

Are the signals of IC204-pin 5(SDA) and pin 6(

fluctuating for one or two seconds after the power is turned ?

SCL) on the DVD M Assy

DVDM Assy

EEPROM (IC204)

Does the voltage of CN104-pin 3 and pin 5 on the DVDM Assy change

normally ?

Pin 3 (SW2(TRIN)): Tray is fully closed: "L"

Pin 5 (SW1(TROUT

)): Tray is fully opened: "L"

Is the signal input into IC101-pin 11 (TROPEN) on the DVDM Assy ?

At open: 3.3V, At close: 0V

A tray cannot be opened.

3

E

(An opening screen is

displayed on the monitor)

Are the signals output from IC101-pin 1 and pin 2 (CN103-pin 1 and

pin 2) on the DVD M Assy ?

Pin 2: Approx. 6V during opening tray approx. 0V during closing tray.

LOAB Assy

Tray SW (S101)

DVDM Assy

DVD IC (IC201)

DVDM Assy

FTS Driver IC (IC101)

Pin 1: Approx. 0V during opening tray approx. 6V during closing tray.

Are wires of CN104 and CN103 on the DVD M Assy disconnected or

damaged ?

Does the voltage of CN102-pin 1 on the DVDM Assy change to 0V by

pressing the Inside switch.

F

20

1 234

PD-D9-J

Connector / cable

Inside switch

5678

No.Symptoms Diagnosis Contents Possible Defective Points

Addendum No.2

Playback impossible

4

(no focusing)

Addendum No.3

Playback impossible

5

(Spindle does not turn)

Addendum No.4

Playback impossible

6

(Playback stops)

Are the signals output from IC101-pin 3 (FOCS_DRV) and pin 4

(FOCS_RTN) on the DVDM Assy ?

Does 650-nm LD emit light ?

Does a pickup lens move up / down ?

Does an actuator spring bend ?

Are plastic parts damaged ? Or is a shaft detached ?

Is the turntable detached or tilted ?

Is flexible cable of CN101 on the DVDM Assy disconnected or

damaged ?

Is signal output from IC201-pin 42 (FOSO) on the DVD M Assy ?

(Device control of about 1.4 V is output usually. It is fluctuated by about

250 mV with focus up / down.)

Are the signals output from IC101-pin 30 (W), pin 33 (V) and pin 35 (U)

on the DVD M Assy ?

Is pin 26 (STBY) fixed LOW ? (pin 26 is High at playback: 3V)

Is there any part detached from the spindle motor ?

Or Is there any foreign object lodged in it ?

Are wires of CN102 on the DVD M Assy disconnected or damaged ? Flexible cable / connector

Is signal output from IC201-pin 37 (DMSO) on the DVD M Assy ?

Does 650-nm LD deteriorate ?

If the voltage at each both ends of R322 and R325 on the DVDM Assy

is 0.4 V or more, the 650-nm LD is definitely deteriorated.

Does 780-nm LD deteriorate ?

If the voltage at each both ends of R321 and R326 on the DVDM Assy

is 0.4 V or more, the 780-nm LD is definitely deteriorated.

Is there abnormality in FG

waveform ? (IC201-pin 47)

Are there scratches or dirt on the disc ? Disc

DVDM Assy

FTS Driver IC (IC101)

Pickup

Mechanism section (motor)

Flexible cable / connector

DVDM Assy

DVD IC (IC201)

DVDM Assy

FTS Driver IC (IC101)

Mechanism section

(Spindle motor)

DVDM Assy

DVD IC (IC201)

650-nm LD deteriorated.

(When playback of a DVD is

impossible)

780-nm LD deteriorated.

(When playback of a CD is

impossible)

DVDM Assy

FG output : FTS Driver IC (IC101)

A

B

C

D

E

F

PD-D9-J

56

21

7

8

1234

5.2 SEQUENCE AFTER POWER ON/OFF

Normal POWER-ON sequences

Set time for the current step Elapsed time Details on control

A

0 msec

+ 60 msec 60 msec

+ 240 msec 300 msec

+ 60 msec 360 msec

B

+ 240 msec 600 msec

+ 300 msec 900 msec

POWER ON start, Various initial settings 1

All keys are masked.

XSYSMUTE ON

Various initial settings 2

SYSPOW ON

When the power is turned on, the HELLO display is requested (3.5 sec).

Various initial settings 3

RESET L ⇒ H

Various initial settings 4

Control of the LCD driver starts.

Data transmission

Various initial settings 5

SRC reset

RESET L ⇒ H

Various initial settings 6

DAC setting

+ 480 msec 1380 msec

+ 390 msec 1770 msec

C

+ 120 msec 1890 msec

+ 3120 msec 5010 msec

+ 30 msec 5040 msec

Various initial settings 7

Bus communication starts.

Various initial settings 8

Various initial settings 9

Masking of all keys is canceled.

Various initial settings a

Temporary data transmission

POWER ON completed

Normal POWER-OFF sequences

Set time for the current step Elapsed time Details on control

D

0 msec

POWER OFF start, Various settings 1

The mask flags for all keys are set.

Various settings 2

+ 30 msec 30 msec

(Note 1)

+ 120 msec 150 msec

Whether the DVD is turned power-off or not is checked.

Bus communication is terminated.

Various settings 3

+ 330 msec 480 msec

E

+ 1320 msec 1800 msec

+ 90 msec 1890 msec

+ 240 msec 2130 msec Processing for the ports required when the power is turned off

+ 30 msec 2160 msec

Note 1: In this step, the unit wait for the DVD module to turn the power off. If the DVD module takes a longer time to turn itself off,

F

the elapsed time will become longer, by just that much.

22

1 234

Various settings 4

Various settings 4

All the indications on the LCD are deleted.

Various settings 5

Bus communication is terminated.

POWER OFF completed

(passes every loop in the POWER OFF)

PD-D9-J

5678

Display only POWER-ON sequences

Set time for the current step Elapsed time Details on control

Display only POWER ON start, Various initial settings 1

0 msec

Masking of all keys is canceled.

The normal operation keys are masked.

POWER MUTE ON

SYSTEM POWER1 ON (Pin 91: H)

A

+ 60 msec 60 msec

Various initial settings 2

Various initial settings 3

+ 240 msec 300 msec

+ 60 msec 360 msec

+ 330 msec 690 msec

Switched 5 V ON completed (power supply is stabilized)

Masking of the normal operation keys is canceled.

SYSTEM POWER2 ON (Pin 92: H)

Various initial settings 4

Power-on of the LCD driver starts.

Display Only POWER ON completed

Display only POWER-OFF sequences

Set time for the current step Elapsed time Details on control

Display only POWER OFF start, Various settings 1

0 msec

+ 4120 msec 4120 msec

• The mask flags for all the keys are set.

• The mask flags for the normal operation keys are set.

• Muting the power system (SYSTEM MUTE REQUEST)

• Power-off of the LCD driver starts.

Various settings 2

B

C

D

+ 120 msec 4240 msec

Various settings 3

Various settings 4

+ 760 msec 5000 msec

+ 240 msec 5240 msec

• Masking of all keys is canceled.

• Muting of the power system is canceled.

• Other than in an emergency power-off, the unit awaits for a while.

• SYSTEM POWER2 OFF (Pin 92: H)

Display only POWER OFF completed

• SYSTEM POWER1 OFF (Pin 91: H)

PD-D9-J

56

E

F

23

7

8

1234

A

Mute cancel

5040msec

PON10

B

PON9

C

PON8

PON7

D

PON6

900msec 1380msec 1770msec 1890msec 5010msec

PON5

PON4

600msec300msec 360msec

300 600 900 1200 1500 1800 2100 2400 2700 4800 5100

E

Subsequently, H or L is output, as appropriate.

PON2PON3

(Port setting)

PON1

60msec

(38pin)

(41pin )

1 Standby → On

0msec

POWER-ON timing waveform

F

KEY input

SYSTEM

ok SYSPOW

ok XSYSMUTE

DVD control

DVD ON/OFF

24

1 234

(DVD)

ok SYSTEM BUS

XDVD RESET

XSRCRST

SRC control

(79pin)

ok LCD reset

XDACCS1 (63pin)

XDACCLK (65pin)

XDACDT (64pin)

DAC control

ok LCD setting

LCD control

XDACCS2 (62pin)

others

Other output port

PD-D9-J

5678

A

B

POFF6

POFF5

POFF4

POFF3

POFF2

150msec 480msec 1800msec 1890msec 2130msec

300 600 900 1200 1500 1800 2100 2400 2700 3000 3300 3600 3900 4200 4500 4800

C

D

E

POFF1

30msec

POWER-OFF timing waveform

2 On → Standby

POFFGO

0msec

SYSTEM

SYSPOW

DVD control

XSYSMUTE

(41pin )

(1pin/DVD ON/OFF)

(38pin)

DVD ON/OFF

XDVDRESET

(93pin/XDVDRST)

(30,49,50,51,67pin)

SYSTEM BUS(DVD)

LCD control

LCD setting

(26,27,28pin)

(36pin/XLCDRST)

LCD reset

Others

PD-D9-J

56

XDimmer

(70pin/DIMMER)

F

25

7

8

1234

D

Q

Q

0

9

2

V

5

5.3

METHOD FOR DIAGNOSING DEGRADATION OF THE LDS ON THE PICKUP ASSY

Case when this diagnosis is required :

When playback of any disc, including a test disc (DVD: GGV1025, CD: STD-905), won't play or doesn't play

A

How to diagnose

In the case mentioned above, degradation of the laser diodes (LDs) mounted on the 05SD Pickup Assy is suspected.

Measure the voltage between the two ends of one of the resistors mentioned below.

No playback of a CD :

Measure the voltage between the both ends of R321 or R326 on the DVDM

Assy. If the voltage is 0.4 V or higher, the 780-nm LD is degraded.

B

If the measurements show degradation

of an LD, replace the 05SD Pickup Assy.

No playback of a DVD (Test Mode), No playback of a SACD :

Measure the voltage between the both ends of R322 or R325 on the DVDM

Assy. If the voltage is 0.4 V or higher, the 650-nm LD is degraded.

05SD PICKUP ASSY

C

8V

Q702

C1002

DVDM ASSY

B

D

E

D751

C751

5

7

R761

1

4

5

L751

R750

R736

13

R734

R712

3.3V

5

8

C221

C713

R2

6

R901

IC761

R751

R737

R713

IC711

1

64

4

GNDD

E

C

R714

C712

C752

R904

D

Q881

C206

A

R906

R762

D881

UP SIDE

6.5V

C761

R214

C146

C132

Q801

C131

C145

C144

CN901

GNDM

C801

C204

C101

C143

R131

R154

22

R132

1

R153

C161

D801

R152

R134

R801

C203

C140

R151

C347

C213

12

CN102

R314

R918

R912

R911

R910

R907

R905

R903

R913

R915

LD_CD

C345

R207

1

C346

C310

C343

R914

R919

C103

C152

C151

C153

1

IC101

C102

LD_DVD

L308

L309

R322

R322

25

C104

R321

R321

3.3V

C215

C344

BOTTOM SIDE

3.3V

C309

R594

C202

1

R133

Q308

Q307

R135

C141

C142

C133

R326

R326

C320

C505

R502

Q304

R136

R325

R325

R310

C506

R595

24

31

R315

R318

R313

C503

C502

R5

CN101

CN101

54

R373

Q305

C371

BOTTOM SIDE

R504

UP SIDE

CN103

41

1

C373

C374

LF

CN953

C509

17

C508

R601

R602

BOTTOM SIDE

1

R520

Q506

R507

R508

R509

R940

R939

R938

R937

R936

R935

R934

R933

R932

R931

R505

IC501

R506

1

9

Front side

SIDE A

F

26

1 234

PD-D9-J

5678

2

60

6. SERVICE MODE

6.1 TEST MODE

The Version Display Mode Functional Specification

Mechanical control computer

How to display the version of the mechanical control computer

1

Power-on in DVD mode

With the AC power off, turn the AC power on by pulling up Pin 44 of IC2101 with 5 V (by short-circuiting R2109).

Note: When the unit is turned on in DVD mode, "-DV D-" is indicated on the LCD.

2 Displaying the version of the mechanical control computer

Press the [ESC] then the [CHAP] key on the remote control unit for DVD Test mode (GGF1381) to indicate the version of

the mechanical control computer.

Ex. (1) : This means that the part number is " AYW7153 ".

(2) : This means that the version is " 1.06 ".

3 Canceling version display

• Press the [ESC] key on the remote control unit.

• Press the [POWER] button to turn the unit off.

Note: Even if you intend to continuously use the unit after displaying the error rate, be sure to turn the power off then back

on again.

System control computer

Displaying the version of the system control computer

1

With the unit on, press and hold the [/] key on the main unit for 8 seconds. The version (part number) of the system

control computer will be displayed.

71 5 3 1 - 0 6

(1)(2)

Displaying the version of the system control computer

A

B

C

Ex.

P D C1 48 A

2 Canceling version display

The version display will automatically disappear after a while.

D

LCD ASSY

D

R2109

SIDE B

E

R2176

1

D2204

C2205

D2203

C2204

C

E

R

3.GNDD

1.KEY1

2.V+5U

3

F

51

L2104

L2102

R2146

17.GNDD

16.SROUT

15.SRIN

14.SRIN

13.XDFDT

12.GNDD

11.XDFCLK

10.XDFCS

9.XDFRST

8.XSYSMUTE

13.TRIN

12.VDET

A

11.SPDIF_RQ

L2105

R2102

9.10.GNDD

6.SCLK

8.MDATA

R2156

7.ACK

5.SDATA

4.XDVDRST

R2145

3.XREADY

R21

R2152

R2112

R2150

R2151

7.GNDD

6.XSRRST

5.LEGATO

4.XDACCK

3.XDACDT

2.XDACCS1

1.XDACCS2

C2107

1.GNDD

2.DVDPOWER

R2149

R2144

50

50

R2147

R2119

C2112

R2109

51

L2103

Short

R2142

B

17

1

15

C2211

R2143

DVD MODE

TEST MODE

15.TROUT

14.TRGAIN

1

PD-D9-J

56

27

7

8

1234

7. DISASSEMBLY

Note 1: Do NOT look directly into the pickup lens. The laser beam may cause eye injury.

Note 2: Even if the unit shown in the photos and illustrations in this manual may differ from your product, the procedures

A

described here are common.

Note 3: For performing the diagnosis the DVDM ASSY side B, the following jigs for service is required:

• Cable for service (GGD1425)

Diagnosis of PCB's

1

Top Panel, Side Panel L and R, Tray Panel

B

C

D

E

Remove the Top Panel by removing the twelve screws.

1

×8

1

1111

Remove the Side Panel L and R by removing the ten screws.

2

×2

2

Side Panel R

Side Panel L

Press the STANDBY/ON button to turn on the power.

3

Press the OPEN/CLOSE button to open the Tray.

4

Remove the Tray Panel.

5

Set the Test Disc.

6

Press the OPEN/CLOSE button to close the Tray.

7

(Test Disc is clamped.)

Press the STANDBY/ON button to turn off the power.

8

Pull out the Power cord.

9

Te st Disc

Top Panel

×6

2

×2

2

How to open the Tray when the power cannot be on

Insert a Screwdriver (small) into the Slit located at the bottom of

the unit, and slide the projection of the Drive Cam in the LOADER

ASSY in the direction of the arrow, as indicated in the photo. If the

Tray pops out a little, fully pull it out by hand.

Slit

Tray open

Projection

Screwdriver (small)

Screwdriver (small)

6

5

83

4

7

Tray Panel

F

28

1 234

Tr ay

74

PD-D9-J

Drive cam

LOADER ASSY

Bottom view

Loading...

Loading...