Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

2008

EJECT

POWER

STOP STOPREAR

DISC

1

USB

1

USB

2

DISC

2

EJECT

MEP-7000

MULTI ENTERTAINMENT PLAYER

TRACK SEARCH

CUE/LOOP

EJECT

TIME

A.CUE

IN/CUE

HOT LOOP

LOOP

RELOOP/EXIT

PITCH BEND

BROWSE MIX EFFECT UTILITY

MT

0

MASTER

TEMPO

TEMPO

6/10/16WIDE

OUT/ADJUST

FWD TEMPOREV

MEMORY CALL

SEARCH

QUE

J

O

G

B

R

E

A

K

S

C

R

A

T

C

H

TRACK SEARCH

CUE/LOOP

EJECT

TIME

A.CUE

IN/CUE

HOT LOOP

LOOP

RELOOP/EXIT

PITCH BEND

MT

0

MASTER

TEMPO

TEMPO

6/10/16WIDE

OUT/ADJUST

FWD TEMPOREV

MEMORY CALL

SEARCH

QUE

J

O

G

B

R

E

A

K

S

C

R

A

T

C

H

A

LOAD

B

MEP-7000

LOAD

MULTI ENTERTAINMENT PLAYER

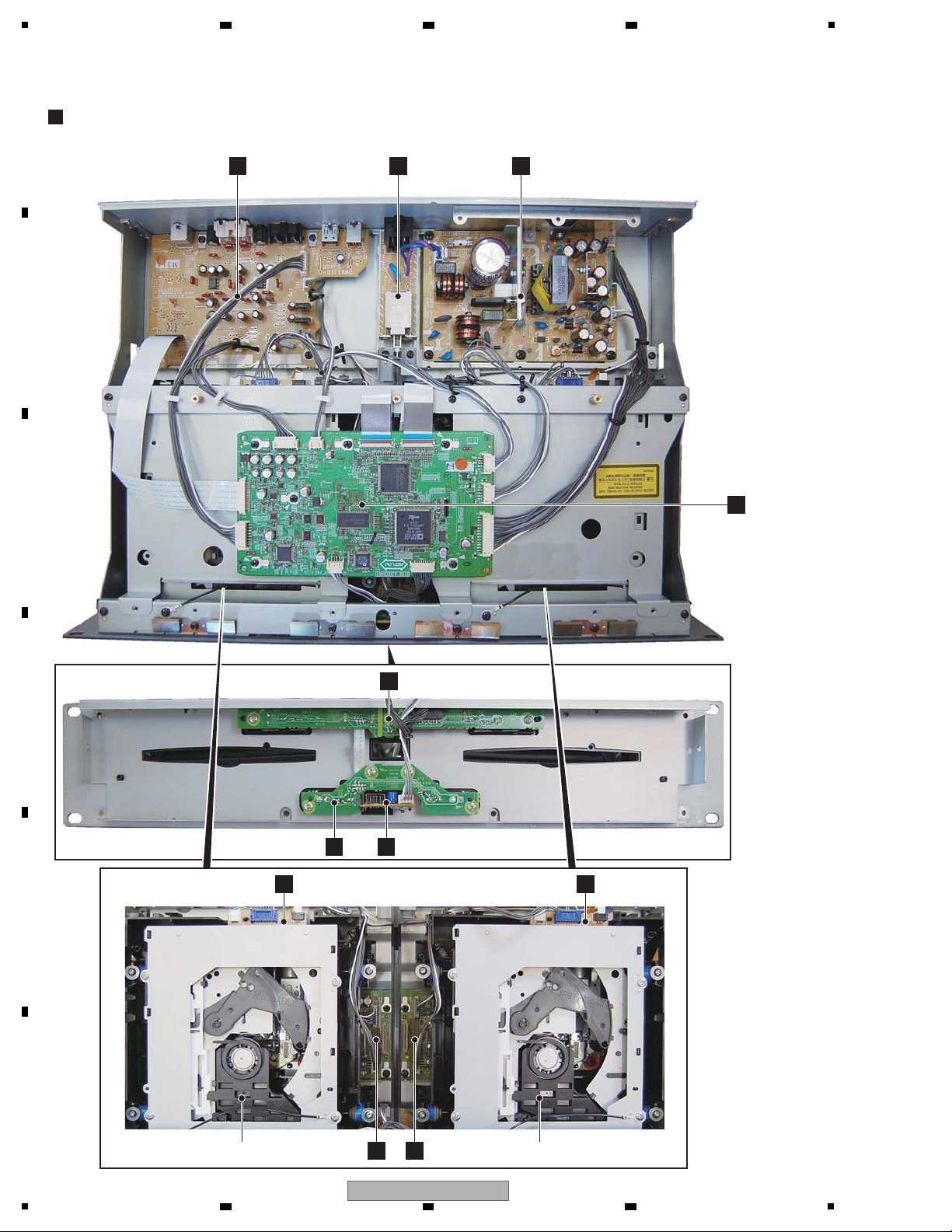

CONTROL UNIT

DRIVE UNIT

MEP-7000

MULTI ENTERTAINMENT PLAYER

MEP-7000

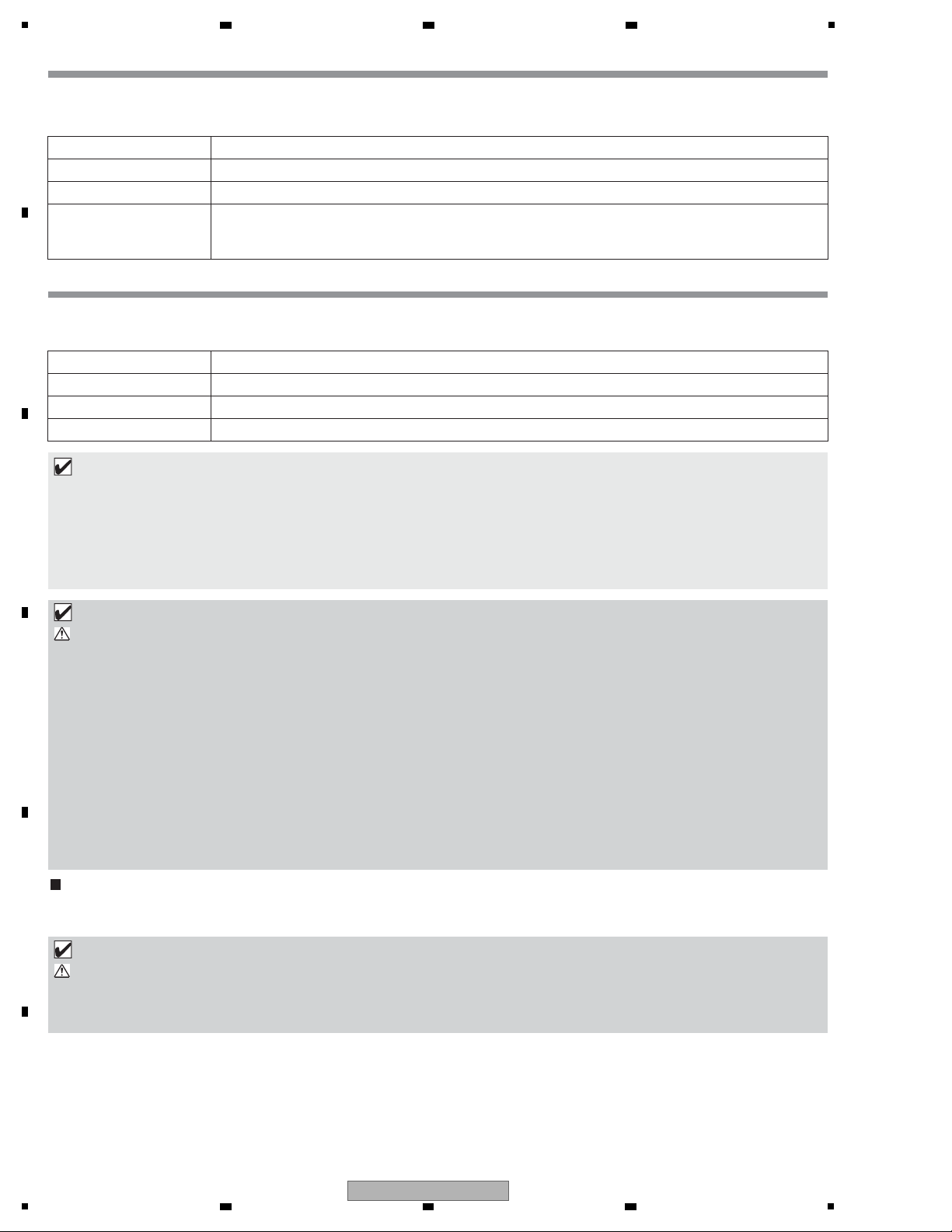

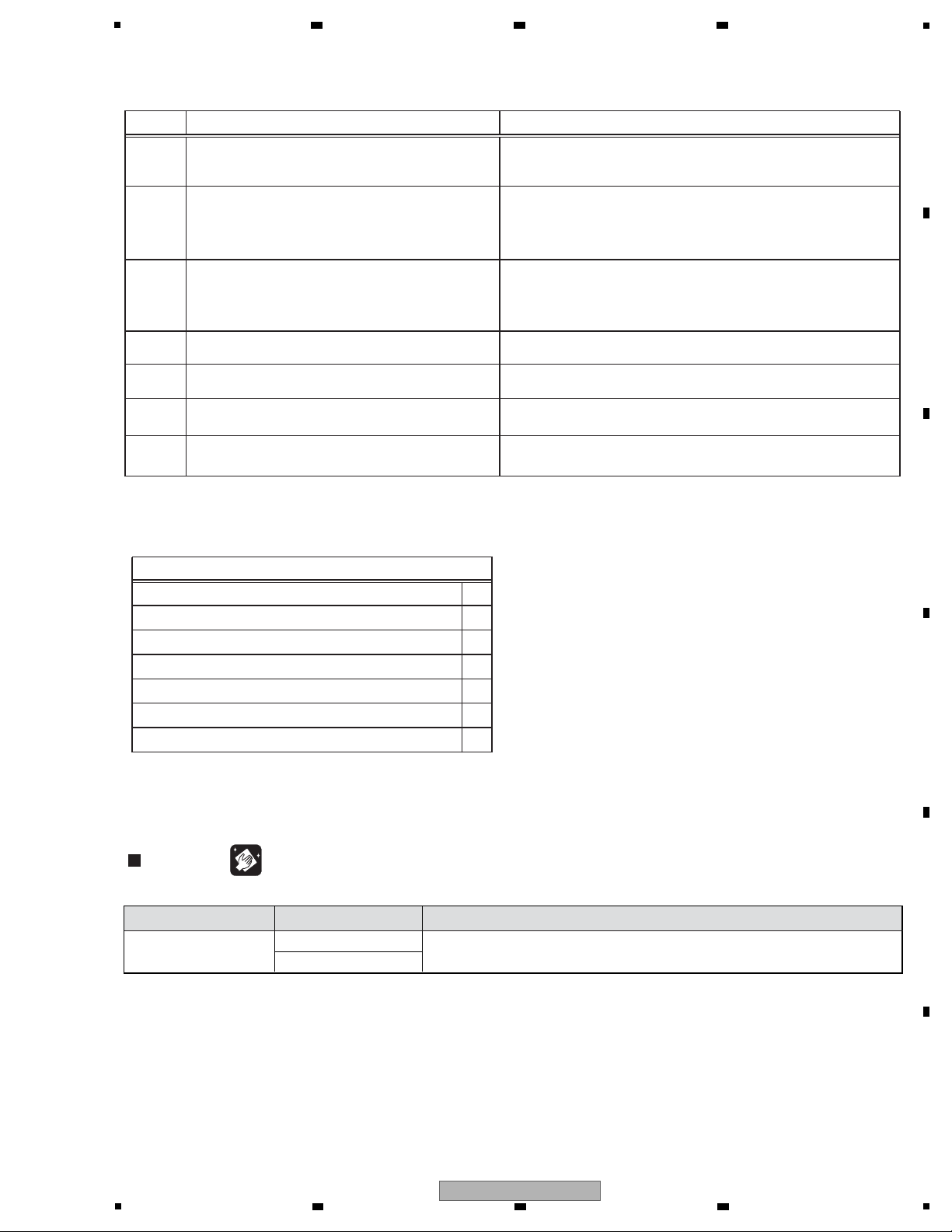

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks.

MEP-7000 KUCXJ AC 120 V

MEP-7000 WYXJ5 AC 220 V to 240 V

MEP-7000 TLFXJ AC 110 V to 240 V

MEP-7000 WAXJ5 AC 220 V to 240 V

ORDER NO.

RRV3719

: This product comprises a control unit (CU-V170) and a drive unit. Note that

a user should bring in both units for servicing.

For details, refer to "Important Check Points for good servicing".

T-ZZR JULY

2008 Printed in Japan

Page 2

1

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely,

you should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains certain electrical parts contain chemicals which are known to the State of California to cause cancer,

birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY )

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a on the schematics and

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

(FOR USA MODEL ONLY)

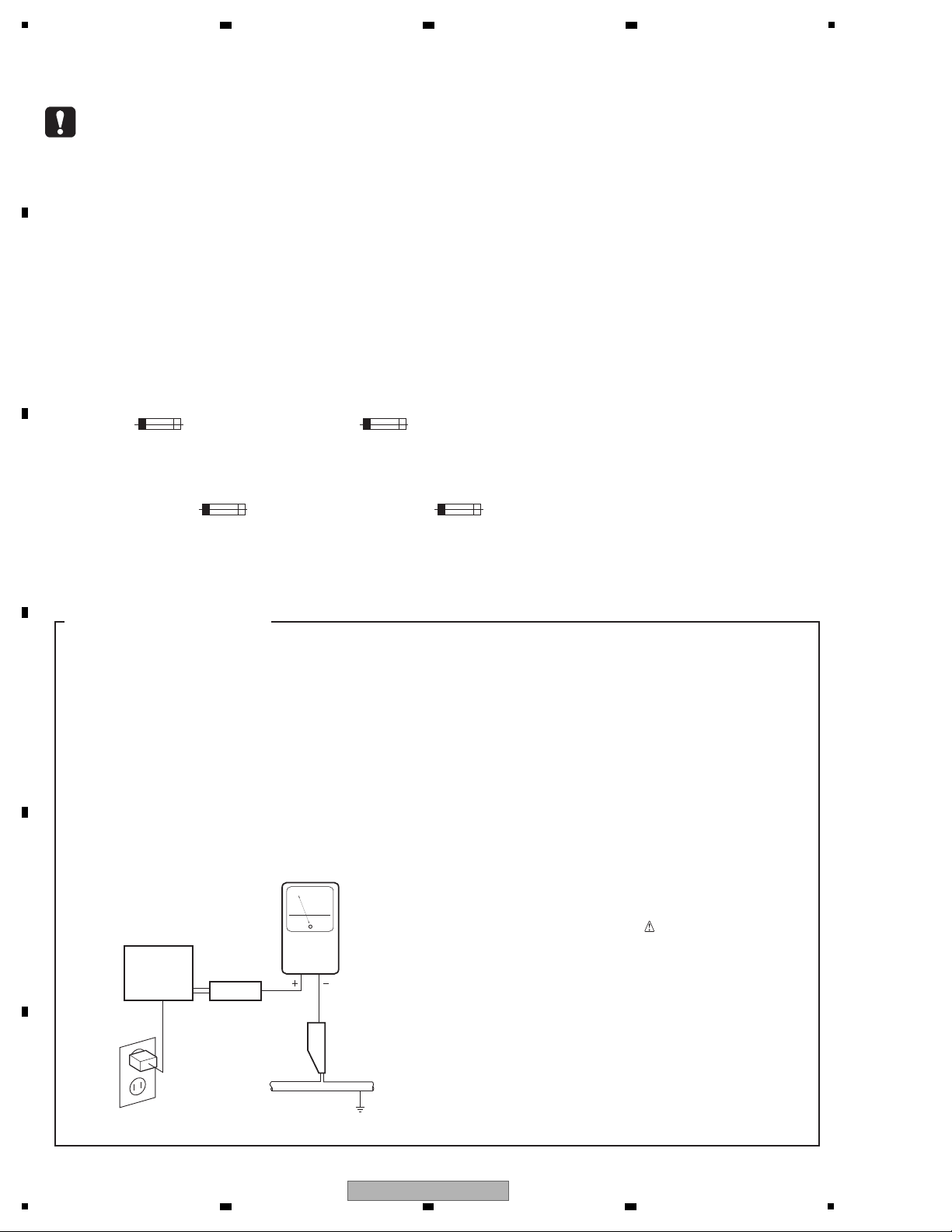

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Device

under

test

Leakage

current

tester

Earth

ground

Reading should

not be above

0.5 mA

Also test with

plug reversed

(Using AC adapter

plug as required)

Test al l

exposed metal

surfaces

AC Leakage Test

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

MEP-7000

Page 3

5

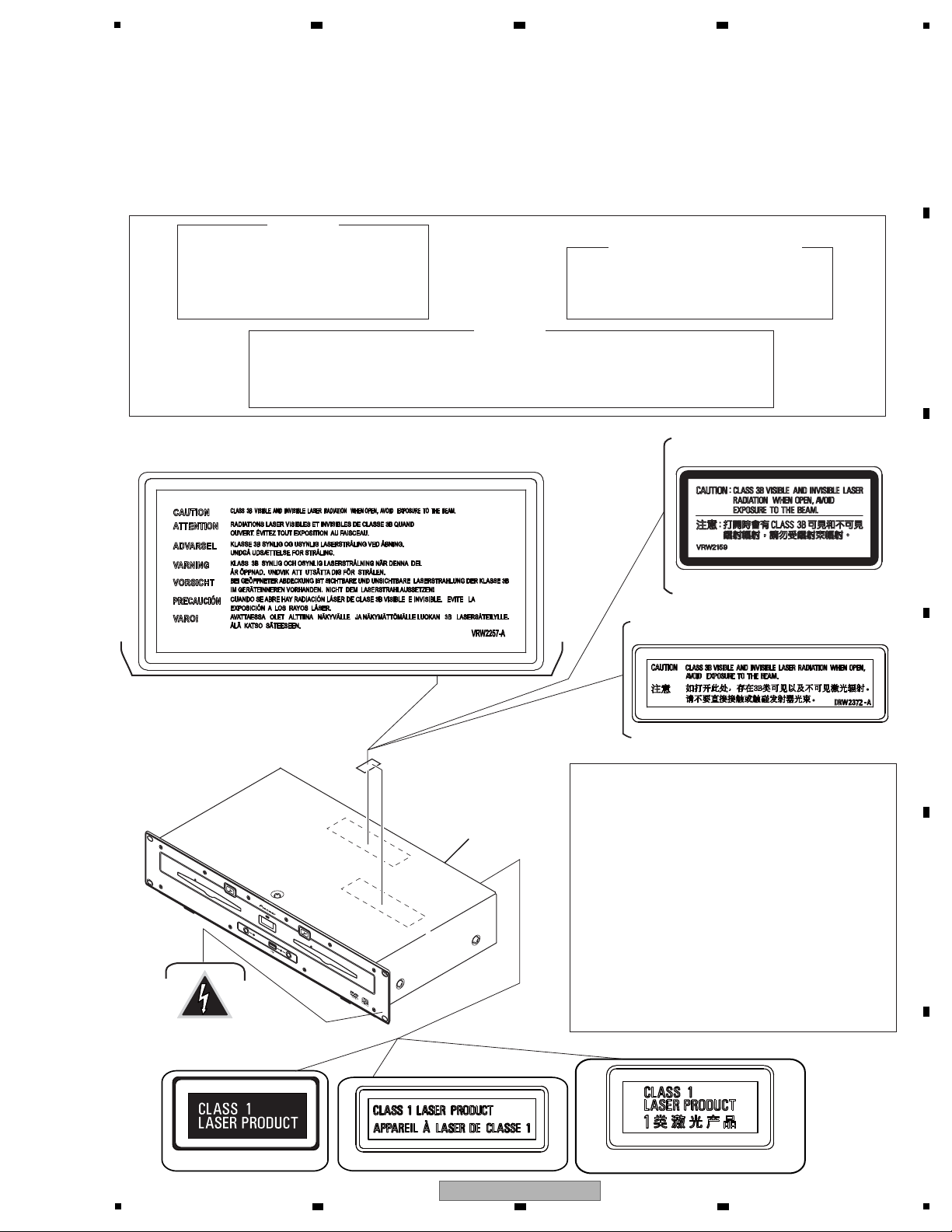

IMPORTANT

THIS PION EER APPARATUS CON TAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DON E BY A SPECIALLY

INSTRUCTED PERSON.

Additional Laser Caution

For TLFXJ

For WYXJ5 and KUCXJ

For WAXJ5

For TLFXJ

(VRW2257)

(DRW1975)

(VRW2159)

For WAXJ5

(DRW2372)

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

FOR CD : MAXIMUM OUTPUT POWER : 7 mW

WAVELENGTH : 780 nm

∗ : See page 160, 161, 164, 165.

1. Laser Interlock Mechanism

The position of the switch (S4400,S4500) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not

in LPS1 terminal side (when the mechanism is not clamped

and LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side. (if LPS1 signal is low

level ).

In the SERVICE MODE∗ the interlock mechanism will not

function.

Laser diode oscillation will continue, if pin 3 (pin 5) of

AN22022A (IC102, IC902) on the SRV1,SRV2 Assy is

connected to GND, or else the terminals of Q102

(Q103), Q902(Q903) are shorted to each other (fault

condition).

2. When the cover is opened, close viewing of the objective lens

with the naked eye will cause exposure to a Class 1 laser

beam.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

For WYXJ5 and KUCXJ

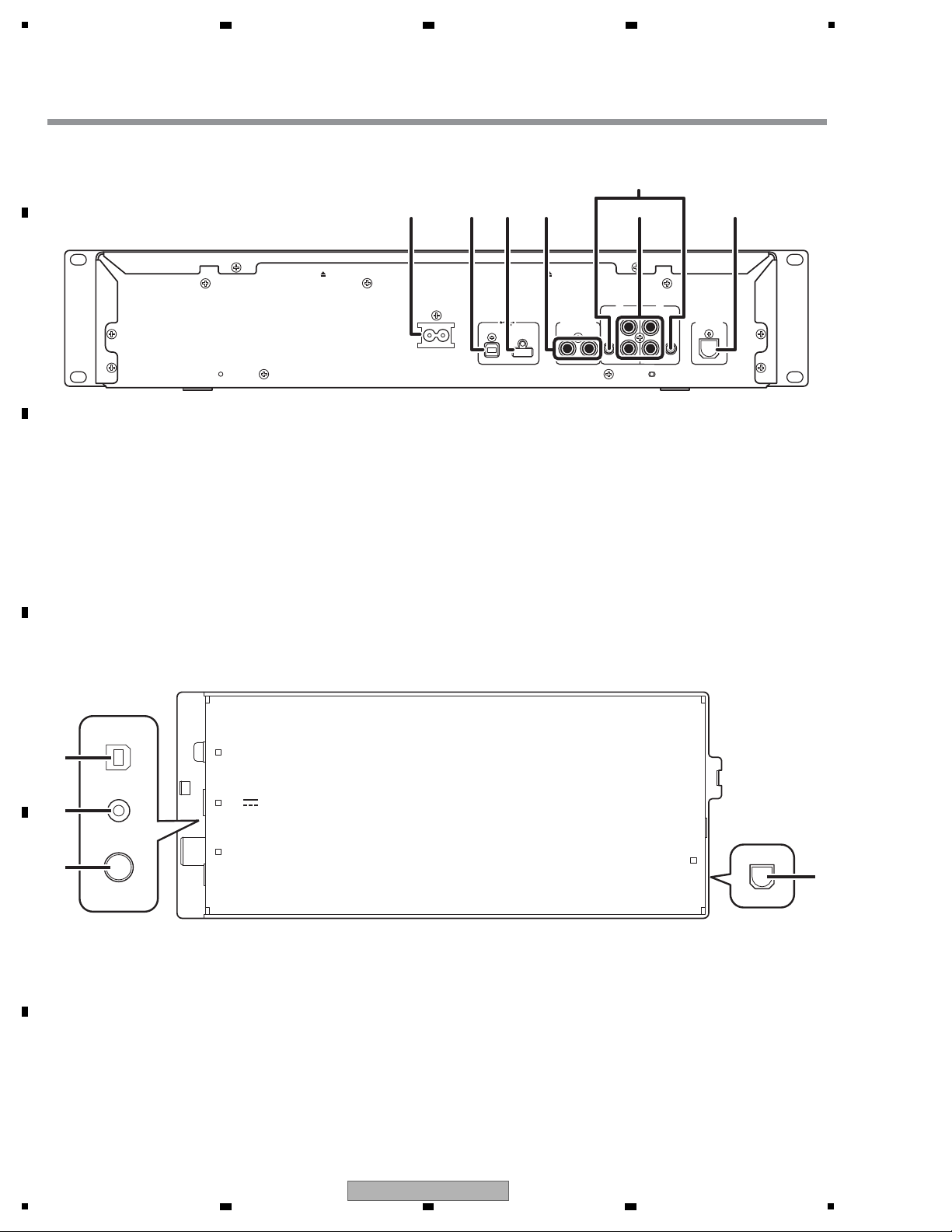

Rear Panel

LABEL CHECK

Printed on the Rear Panel

Printed on the Rear Panel

Printed on the Rear panel

For KUCXJ type Only

EJECT

POWER

S

TO

P

S

T

O

P

REAR

DIS

C

1

U

S

B

1

U

S

B

2

DIS

C

2

EJEC

T

MEP-7000

MU

L

TI ENTE

R

TAINMENT PL

AY

E

R

This product contains mercury. Disposal of this material may be regulated due to environmental

considerations. For disposal or recycling information, please contact your local authorities or the

Electronics Industries Alliance: www.eiae.org.

The backlighting lamp of LCD in this equipment contains mercury. Disposal of this material may

be regulated due to environmental considerations according to Local, State or Federal Laws.

For disposal or recycling information, please contact your local authorities or the Electronics

Industries Alliance: www.eiae.org

6 7 8

A

B

C

D

E

F

5

MEP-7000

6 7 8

3

Page 4

1

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

A

2 3 4

B

C

D

E

F

4

1

MEP-7000

2 3 4

Page 5

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS....................................................................................................................................................7

1.1 NOTES ON SOLDERING............................................................................................................................................... 7

1.2 BACKUP AND RESTORING OF USER DATA................................................................................................................7

1.3 NOTE ON ENTRAPMENT OF DIRT IN THE DISPLAY PANEL .....................................................................................8

1.4 REPAIR OF THE SJACK ASSY......................................................................................................................................8

1.5 CABLE DRESSING OF THE DRIVE UNIT.....................................................................................................................9

1.6 REASSEMBLING OF THE CONTROL UNIT ............................................................................................................... 14

2. SPECIFICATIONS...............................................................................................................................................................18

2.1 ACCESSORIES............................................................................................................................................................18

2.2 SPECIFICATIONS ........................................................................................................................................................ 19

2.3 REGARDING PLAYABLE DISCE AND FILES..............................................................................................................21

2.4 PANEL FACILITIES.......................................................................................................................................................25

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................ 29

3.1 CHECK POINTS AFTER SERVICING ......................................................................................................................... 29

3.2 PCB LOCATIONS .........................................................................................................................................................30

3.3 JIGS LIST .....................................................................................................................................................................32

4. BLOCK DIAGRAM .............................................................................................................................................................. 34

4.1 OVERALL WIRING (CONTROL UNIT).........................................................................................................................34

4.2 OVERALL WIRING (DRIVE UNIT) ...............................................................................................................................36

4.3 BLOCK DIAGRAM........................................................................................................................................................ 38

5. DIAGNOSIS ........................................................................................................................................................................48

5.1 POWER ON SEQUENCE.............................................................................................................................................48

5.2 CONFIRMATION OF COMMUNICATION WITH THE PC VIA USB .............................................................................55

5.3 TROUBLE SHOOTING .................................................................................................................................................56

5.4 DEFECT JUDGMENT OF THE PICKUP ASSY...........................................................................................................85

6. SERVICE MODE.................................................................................................................................................................86

6.1 TABLE OF CONTENTS ................................................................................................................................................86

6.2 SERVICE MODE FOR THE DRIVE UNIT ....................................................................................................................87

6.3 SERVICE MODE FOR THE CONTROL UNIT..............................................................................................................97

6.4 ERROR CODE LIST................................................................................................................................................... 103

6.5 STATUS LEDS ............................................................................................................................................................ 104

7. DISASSEMBLY .................................................................................................................................................................108

7.1 DRIVE UNIT ...............................................................................................................................................................108

7.2 CONTROL UNIT......................................................................................................................................................... 113

8. EACH SETTING AND ADJUSTMENT..............................................................................................................................115

8.1 CONFIRMATION MODE AND ADJUSTMENT METHOD FOR LOAD ON THE JOG DIAL .......................................115

8.2 RESET OF DVD/CD DRIVE DATA..............................................................................................................................

8.3 UPDATING/RECOVERY OF FIRMWARE...................................................................................................................117

8.4 MANUAL INPUT OF DVD/CD DRIVE DATA...............................................................................................................132

9. EXPLODED VIEWS AND PARTS LIST............................................................................................................................. 134

9.1 PACKING SECTION ...................................................................................................................................................134

: DRIVE UNIT

9.2 EXTERIOR SECTION ................................................................................................................................................ 136

9.3 FRONT PANEL SECTION ..........................................................................................................................................138

9.4 SLOT-IN MECHA SECTION .......................................................................................................................................140

: CONTROL UNIT

9.5 EXTERIOR SECTION ................................................................................................................................................ 142

9.6 CONTROL PANEL SECTION..................................................................................................................................... 144

10. SCHEMATIC DIAGRAM..................................................................................................................................................146

: DRIVE UNIT

10.1 SMAIN ASSY (1/5) ................................................................................................................................................... 146

10.2 SMAIN ASSY (2/5) ................................................................................................................................................... 148

10.3 SMAIN ASSY (3/5) ................................................................................................................................................... 150

10.4 SMAIN ASSY (4/5) ................................................................................................................................................... 152

10.5 SMAIN ASSY (5/5) ................................................................................................................................................... 154

10.6 EJTB ASSY ..............................................................................................................................................................156

10.7 FSWB ASSY............................................................................................................................................................. 157

10.8 SJACK ASSY............................................................................................................................................................158

10.9 SRV1 ASSY .............................................................................................................................................................. 160

10.10 SLMB1 ASSY .........................................................................................................................................................162

10.11 USBB ASSY ...........................................................................................................................................................163

10.12 SRV2 ASSY............................................................................................................................................................164

10.13 SLMB2 ASSY .........................................................................................................................................................166

10.14 ACIN ASSY............................................................................................................................................................. 167

MEP-7000

5

6 7 8

116

5

A

B

C

D

E

F

Page 6

1

2 3 4

10.15 POWER SUPPLY UNIT...........................................................................................................................................168

: CONTROL UNIT

10.16 NMAIN ASSY (1/5) .................................................................................................................................................170

10.17 NMAIN ASSY (2/5) .................................................................................................................................................172

A

10.18 NMAIN ASSY (3/5) .................................................................................................................................................174

10.19 NMAIN ASSY (4/5) .................................................................................................................................................176

10.20 NMAIN ASSY (5/5) .................................................................................................................................................178

10.21 NJACK ASSY..........................................................................................................................................................180

10.22 RENC ASSY ...........................................................................................................................................................182

10.23 DJACK ASSY..........................................................................................................................................................183

10.24 DISP ASSY.............................................................................................................................................................184

10.25 JOGT ASSY............................................................................................................................................................186

10.26 JOGR ASSY ...........................................................................................................................................................187

10.27 OELB ASSY............................................................................................................................................................188

10.28 VOLTAGES..............................................................................................................................................................189

B

10.29 WAVEFORMS.........................................................................................................................................................197

10.30 INFORMATION ON FUNCTIONS OF IC TERMINALS...........................................................................................237

11. PCB CONNECTION DIAGRAM ......................................................................................................................................253

: DRIVE UNIT

11.1 SMAIN ASSY............................................................................................................................................................254

11.2 EJTB and FSWB ASSYS..........................................................................................................................................258

11.3 SJACK ASSY ............................................................................................................................................................260

11.4 SRV1 ASSY ..............................................................................................................................................................262

11.5 SLMB1 ASSY............................................................................................................................................................264

11.6 USBB ASSY..............................................................................................................................................................265

11.7 SRV2 ASSY ..............................................................................................................................................................266

11.8 SLMB2 ASSY............................................................................................................................................................268

C

11.9 ACIN ASSY...............................................................................................................................................................269

: CONTROL UNIT

11.10 NMAIN ASSY..........................................................................................................................................................270

11.11 NJACK, RENC and DJACK ASSYS........................................................................................................................274

11.12 DISP ASSY.............................................................................................................................................................276

11.13 JOGT, JOGR and OELB ASSYS ............................................................................................................................278

12. PCB PARTS LIST ............................................................................................................................................................280

D

E

F

6

1

2 3 4

MEP-7000

Page 7

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

Before repair, back up user data, following the backup procedures shown below.

After repair, restore the user data backed up before repair, following the restoration procedures shown below.

Backup procedures

Copy cue/loop points of a disc stored in the built-in memory of the product and the playlist that is produced by the user to a

USB storage device. Before starting the backup procedures, make sure that no disc nor USB storage device is inserted.

1. Press the UTILITY key.

2. Press the function GENERAL key.

3. Select BACKUP MODE, by turning the rotary selector, then press the Select Down key or the rotary selector.

4. Select “Write to USB,” by turning the rotary selector, then press the rotary selector.

5. The message “Connect a USB storage device to the USB port” is displayed. Insert a USB storage device.

6. Data copying starts.

When “Done” is displayed and the UTILITY screen is restored, data copying is complete.

Note:

A file named “BACKUP.BIN” of approx. 1.3 MBytes is created in the root directory of the USB storage device.

Restoring procedures

The user data copied to the USB storage device are written to the built-in memory of this product.

1. Press the UTILITY key.

2. Press the function GENERAL key.

3. Select BACKUP MODE, by turning the rotary selector, then press the Select Down key or the rotary selector.

4. Select “Read from USB,” by turning the rotary selector, then press the rotary selector.

5. The message “Connect a USB storage device to the USB port” is displayed. Insert a USB storage device.

6. Data reading starts.

When “Done” is displayed and the UTILITY screen is restored, data reading is complete.

Note:

The data previously stored in the built-in memory are completely erased, and the data in the USB storage device will be

copied.

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

1.2 BACKUP AND RESTORING OF USER DATA

A

B

5

6 7 8

MEP-7000

C

D

E

F

7

Page 8

1

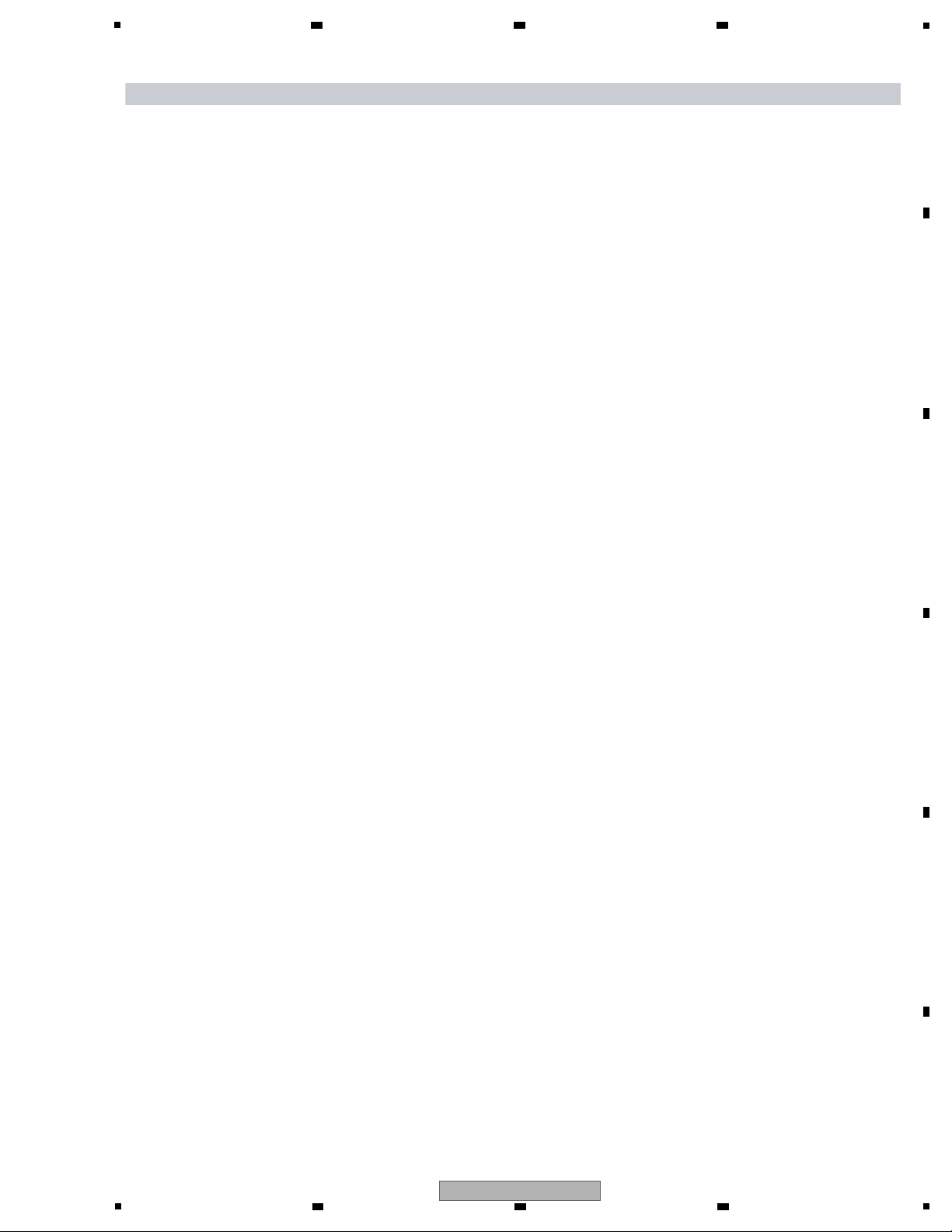

As the panels for the center display and controller displays are of transparent type, entrapment of dirt in the panel is highly

visible. Be careful not entrap dirt while reassembling, and check that there is no dirt entrapped after reassembling.

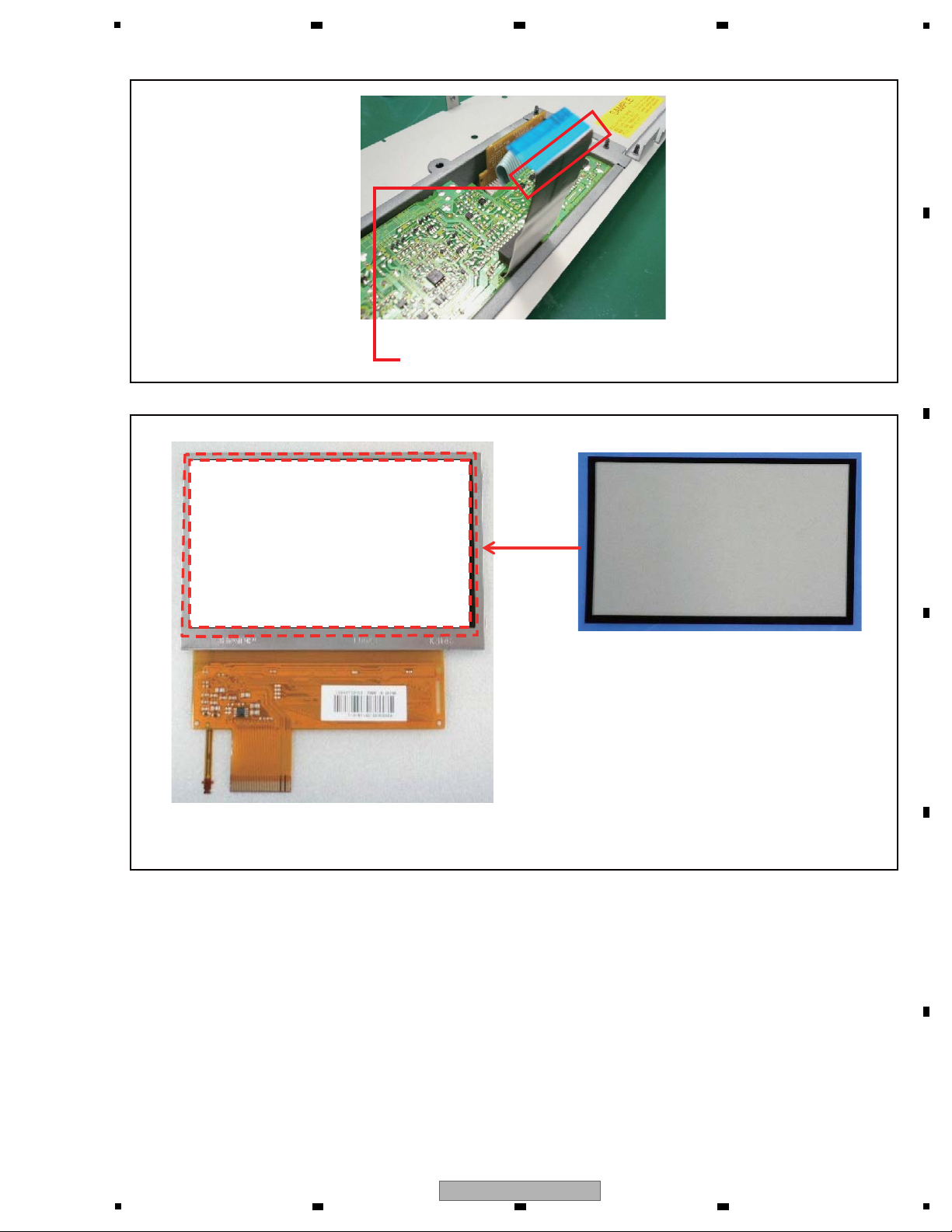

Before repairing the SJACK Assy, check its part number.

If the part number is “DWX2710,” replace it with a “DWX2896” instead of repairing it.

D

SJACK ASSY

2 3 4

1.3 NOTE ON ENTRAPMENT OF DIRT IN THE DISPLAY PANEL

A

1.4 REPAIR OF THE SJACK ASSY

B

1

C

CN11

4.DGND

1

3.D+

KN10

2.D-

DGND

1.V+5USB1D

J11

J30

FGND

C12

JA15

41

J43

DGND

SJACK

V+5DETD

J48

DWX2710-

FGND

J39

4.DGND3.D+

2.D- 1.V+5DETD

D

JA16

1

4

J35

FGND

1

DGND

J22

2

3

1

CN11

4.DGND

1

3.D+

KN10

2.D-

DGND

1.V+5USB1D

J11

J30

FGND

C12

JA15

41

J43

DGND

SJACK

JA16

1

4

J48

J35

FGND

1

DGND

J22

4.DGND3.D+

2

3

DWX2896-

V+5DETD

FGND

J39

2.D- 1.V+5DETD

E

F

8

1

2 3 4

MEP-7000

Page 9

5

How you dress the cables connected to the SJACK Assy greatly affects the sound quality from the unit. During

disassembly and reassembly of the drive unit, be careful of cable dressing. At the end of reassembly, be sure to

check that the cable dressing is performed as shown below.

For performance improvement, cable dressing methods have been changed several times in the middle of mass

production of this product.

During cable dressing of this product, be careful of the following points:

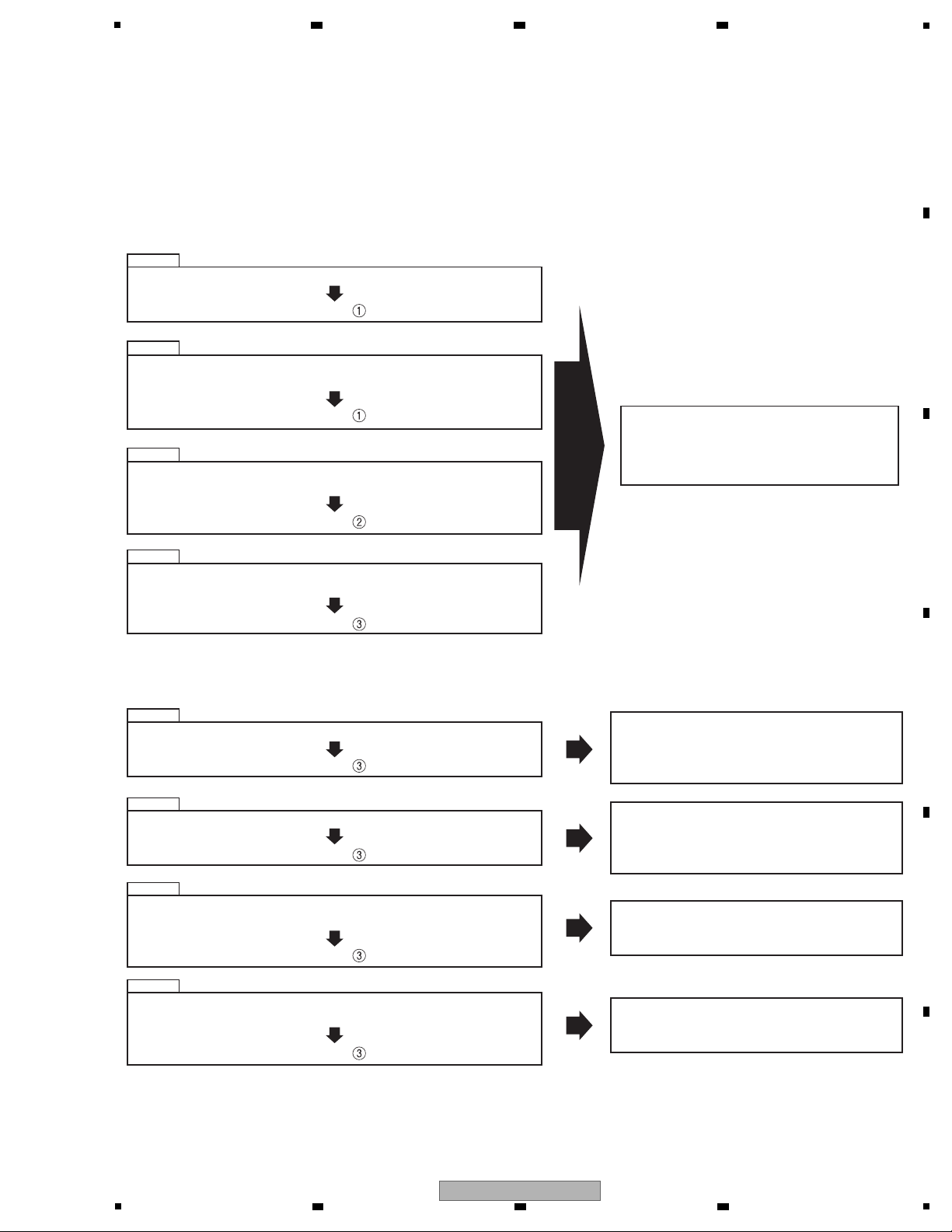

CASE 1

[1] When cables are disconnected from the SJACK Assy

[2] When the SJACK Assy is replaced

It is essential that the cables be dressed as

they originally were.

When the DWX2710 is replaced with the DWX2896 :

See Fig .

Parts to be added during servicing :

FFC guard (DEC2586) &

Shield Sheet (DEC3151) &

Locking Mini Clamp (DEC2439)

Parts to be added during servicing :

FFC guard (DEC2586) &

Shield Sheet (DEC3151) &

Locking Mini Clamp (DEC2439)

Parts to be added during servicing :

Locking Mini Clamp (DEC2439)

Parts to be added during servicing :

None

When the DWX2896 in the initial cable dressing state is replaced :

See Fig .

When cables are disconnected from the DWX2710 :

See Fig .

When cables in the initial dressing state are disconnected from

the DWX2896 :

See Fig .

When cables in the temporary dressing state are disconnected

from the DWX2896 :

See Fig .

When cables in the permanent dressing state are disconnected

from the DWX2896 :

See Fig .

CASE 2

CASE 3

CASE 4

CASE 5

CASE 6

When the DWX2896 in the temporary cable dressing state is

replaced :

See Fig .

CASE 7

When the DWX2896 in the permanent cable dressing state is

replaced :

See Fig .

CASE 8

6 7 8

1.5 CABLE DRESSING OF THE DRIVE UNIT

A

B

C

D

E

5

MEP-7000

6 7 8

F

9

Page 10

1

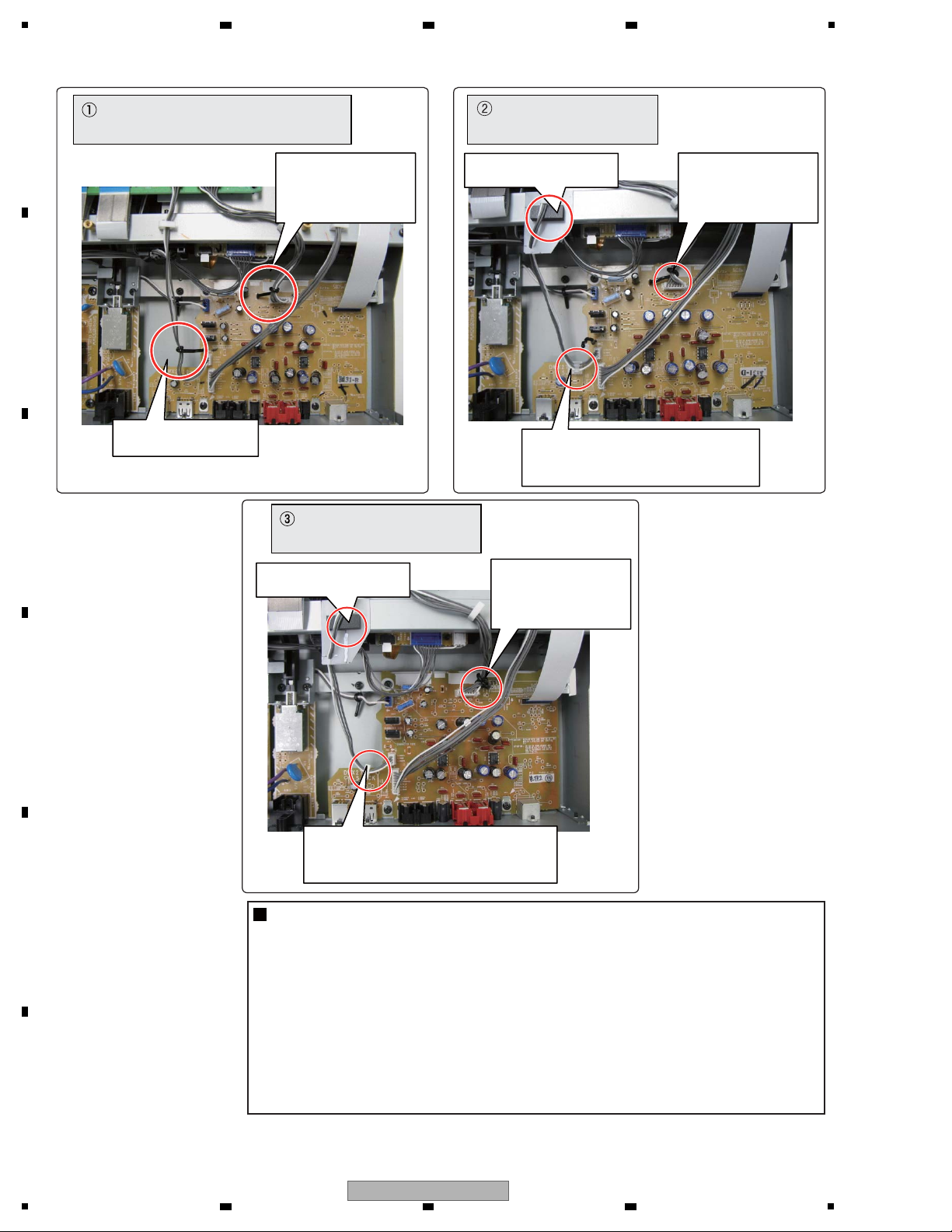

Tie the D-OUT cables

with the PCB binder.

Pass the D-OUT cables through the

clamp that has been attached to

the board.

Fix the D-OUT cables with the Locking

Mini Clamp that has been inserted in

the hole of the board.

Tie the cables for

analog signals

with the PCB binder

located on the left.

Tie the cables for

analog signals

with the PCB binder

located on the left.

Tie the cables for

analog signals

with the PCB binder

located on the right.

Add the Shield Sheet

and FFC guard.

Add the Shield Sheet

and FFC guard.

: Initial dressing

(for the DWX2710 and DWX2896)

: Temporary dressing

(for the DWX2896)

: Permanent dressing

(for the DWX2896)

[3] Differences in Cable Dressing States

Notes

1: Before replacing the Assy, be sure to check the current cable dressing.

2: Depending on the dressing state, some additional parts may be required:

If the previous board is in the initial cable dressing state:

FFC guard (DEC2586), Shield Sheet (DEC3151) and Locking Mini Clamp (DEC2439)

If the previous board is in the temporary cable dressing state:

Locking Mini Clamp (DEC2439)

If the previous board is in the permanent cable dressing state:

No additional parts needed

3: Permanent cable dressing is possible with the Assy for service.

A

2 3 4

B

C

D

E

F

10

1

2 3 4

MEP-7000

Page 11

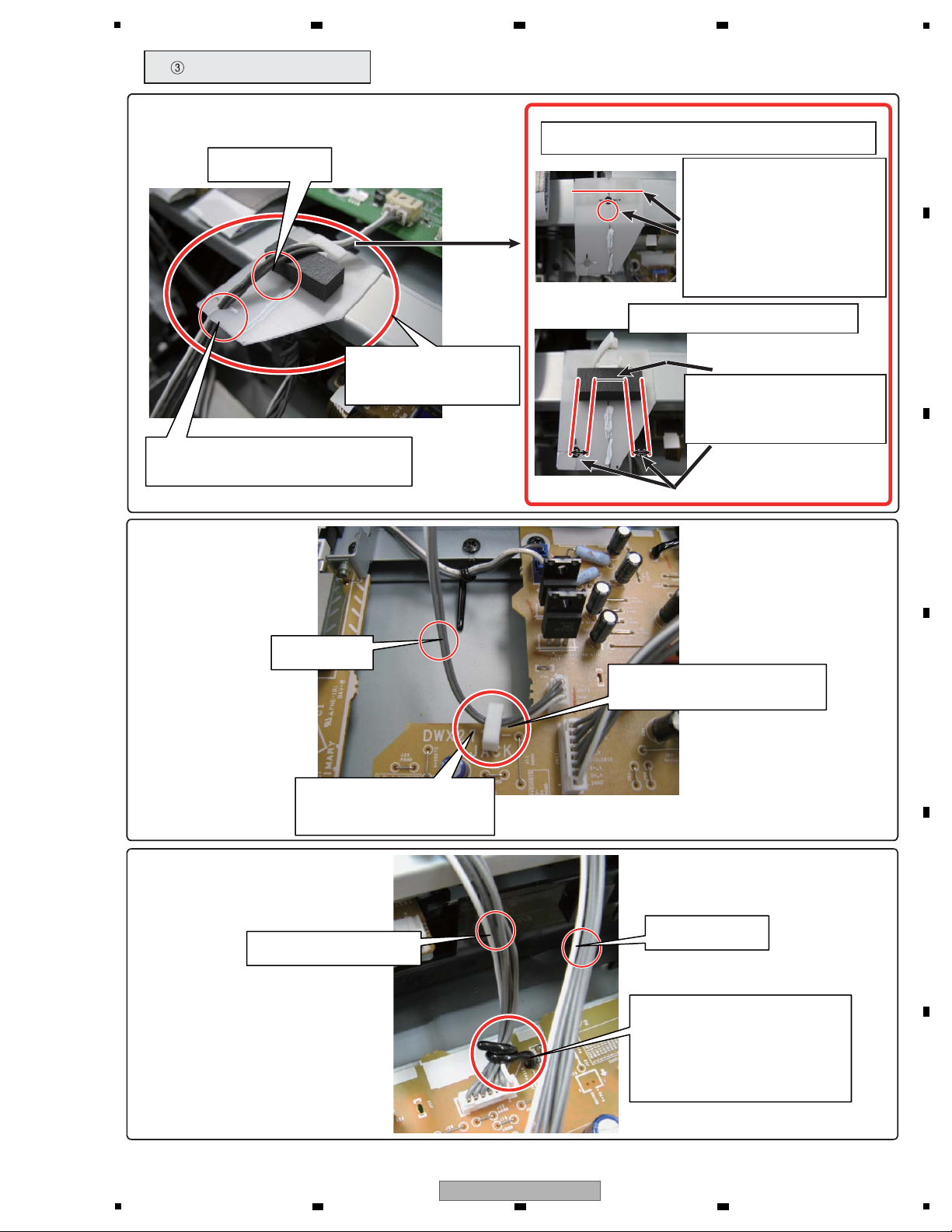

5

Regulator

D-OUT cables

USB cables

USB cables

Leave at least 10 mm.

Leave at least 5 mm.

Leave at least 10 mm.

D-OUT cables

SERVO cables

Cables for analog signals

Bind the cables for

analog signals and push

them downward so that

they are positioned as

far from the USB cables

as possible.

While dressing the cables,

be careful that the cables

for analog signals do not

touch the SLMB Assy.

Place the binder in

the upright position.

SLMB Assy

Leave at least 10 mm

between the D-OUT and

SERVO cables.

Leave at least 10 mm

between the D-OUT cables

and the regulator.

[4] Notes on Each Cable Dressing

Fig : Initial dressing

Leave at least 5 mm

between the D-OUT and

USB cables.

6 7 8

A

B

C

D

5

MEP-7000

6 7 8

E

F

11

Page 12

1

USB cables

Cables for analog signals

Push the cables for analog

signals downward so that

they are positioned as far

from the USB cables as

possible.

While dressing the cables,

be careful that the cables

for analog signals do not

touch the SLMB Assy.

SLMB Assy

D-OUT cables

Pass the D-OUT cables through the clamp.

Fig : Temporary cable dressing

How to attach the Shield Sheet and FFC guard

Add the Shield Sheet

(DEC3151) and

FFC guard (DEC2586).

Pass the D-OUT cables through

the slit of the Shield Sheet

1. Align the edge of the Shield

Sheet with that of the PCB

STAY Assy and the hole of the

Shield Sheet with that for the

locking mini clamp on the PCB

STAY Assy. Then paste the

Shield Sheet to the PCB STAY

Assy.

2. Attach the locking mini clamp.

D-OUT cables

3. Place the FFC guard in

contact with the clamp and

so that the clamp comes to

the middle of the FFC guard.

A

B

C

2 3 4

D

E

F

12

MEP-7000

1

2 3 4

Page 13

5

Fig : Permanent cable dressing

Insert the locking mini clamp

(DEC2439, additional part)

in the hole of the board.

D-OUT cables

Cables for analog signals

Pass the D-OUT cables

through the locking mini clamp.

Tie the cables for analog signals

with the PCB binder at the base.

Push the cables down toward

the board so that they are

positioned as far from

the USB cables as possible.

USB cables

How to attach the Shield Sheet and FFC guard

Add the Shield Sheet

(DEC3151) and

FFC guard (DEC2586).

Pass the D-OUT cables through

the slit of the Shield Sheet

1. Align the edge of the Shield

Sheet with that of the PCB

STAY Assy and the hole of the

Shield Sheet with that for the

locking mini clamp on the PCB

STAY Assy. Then paste the

Shield Sheet to the PCB STAY

Assy.

2. Attach the locking mini clamp.

D-OUT cables

3. Place the FFC guard in

contact with the clamp and

so that the clamp comes to

the middle of the FFC guard.

6 7 8

A

B

C

5

MEP-7000

6 7 8

D

E

F

13

Page 14

1

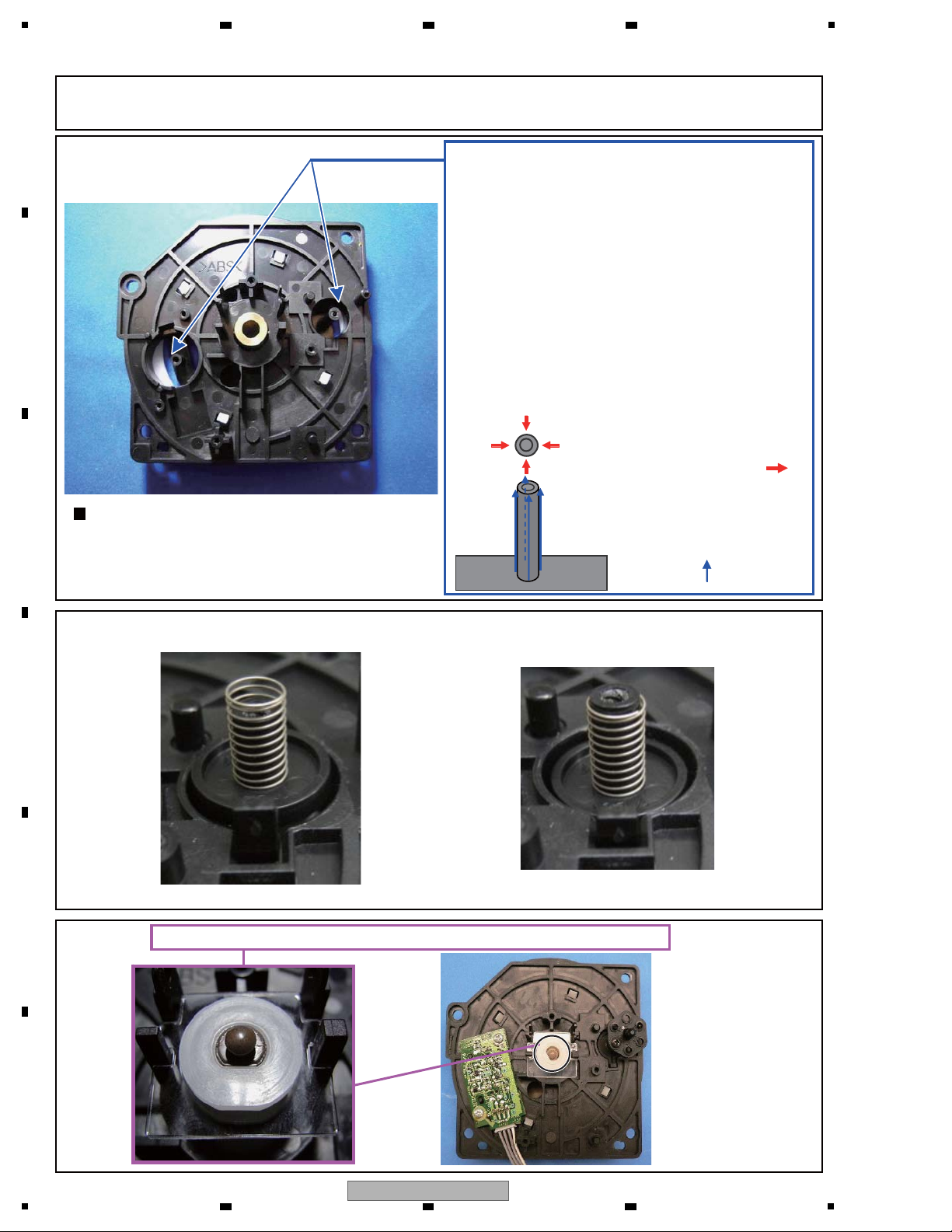

How to apply FL OIL is described below.

Make sure that the top end of the load spring is not higher than that of the shaft when it is inserted into the shaft. If it is,

turn the JOG dial a little so that the load gear and the gear of the JOG shaft will become properly engaged.

<Preparation>

Soak FL OIL into a sponge.

Dab a brush against the sponge to pick up oil.

Remove excess oil from the brush.

<Application of FL OIL>

1. Dab the brush against the sponge to pick up a little

oil with the brush.

2. With the brush, lightly apply oil from the base to the

tip of the shaft.

3. Apply oil from 4 directions, as shown below, at a time.

(NEVER replenish oil to the brush on the way.)

<Note>

1. NEVER apply oil more than 4 times to the shaft.

Avoid applying excess oil.

<TOP VIEW>

Apply oil from the 4 directions

indicated by the arrows ( ),

at a time.

<SIDE VIEW>

Apply oil from the base to the

tip of the shaft, as indicated by

the arrows ( ).

NGOK

Place the JOG smoother so that its convex surface faces the JOG smoother plate.

Note on gear insertion

When inserting the gear, do NOT forcibly push it.

Insert the gear while turning it slightly until it is properly

engaged.

After the JOG Assy is disassembled or JOG dial parts are replaced, be sure to measure the load on the JOG dial, as it may

have changed. (For details on how to measure the load on the JOG dial,

see “8.1 CONFIRMATION MODE AND ADJUSTMENT METHOD FOR LOAD ON THE JOG DIAL.”)

2 3 4

1.6 REASSEMBLING OF THE CONTROL UNIT

A

B

C

D

E

F

14

MEP-7000

1

2 3 4

Page 15

5

When reattaching the rear panel and panel base, be careful to properly position them.

The edge of the plate is disengaged.

NG

OK

Notes on replacement of the NMAIN Assy and LCD module

Remove the screw.

Remove the TFT shield.

Note: Engage the hooks to the slots when reassembling.

Remove the flexible cables.

Remove the screws. The NMAIN Assy

can be detached.

Remove the screws. The LCD module

can be detached.

Note: When reattaching the LCD module to the TFT holder,

engage the 4 hooks of the holder to the slots.

Note: Be careful that the aluminum sheet goes

above this level.

Fold the aluminum sheet.

Note: During detaching/reattaching

the LCD module, be careful not to apply excess

force to the 4 hooks of the TFT holder.

6 7 8

A

B

C

D

5

MEP-7000

6 7 8

E

F

15

Page 16

1

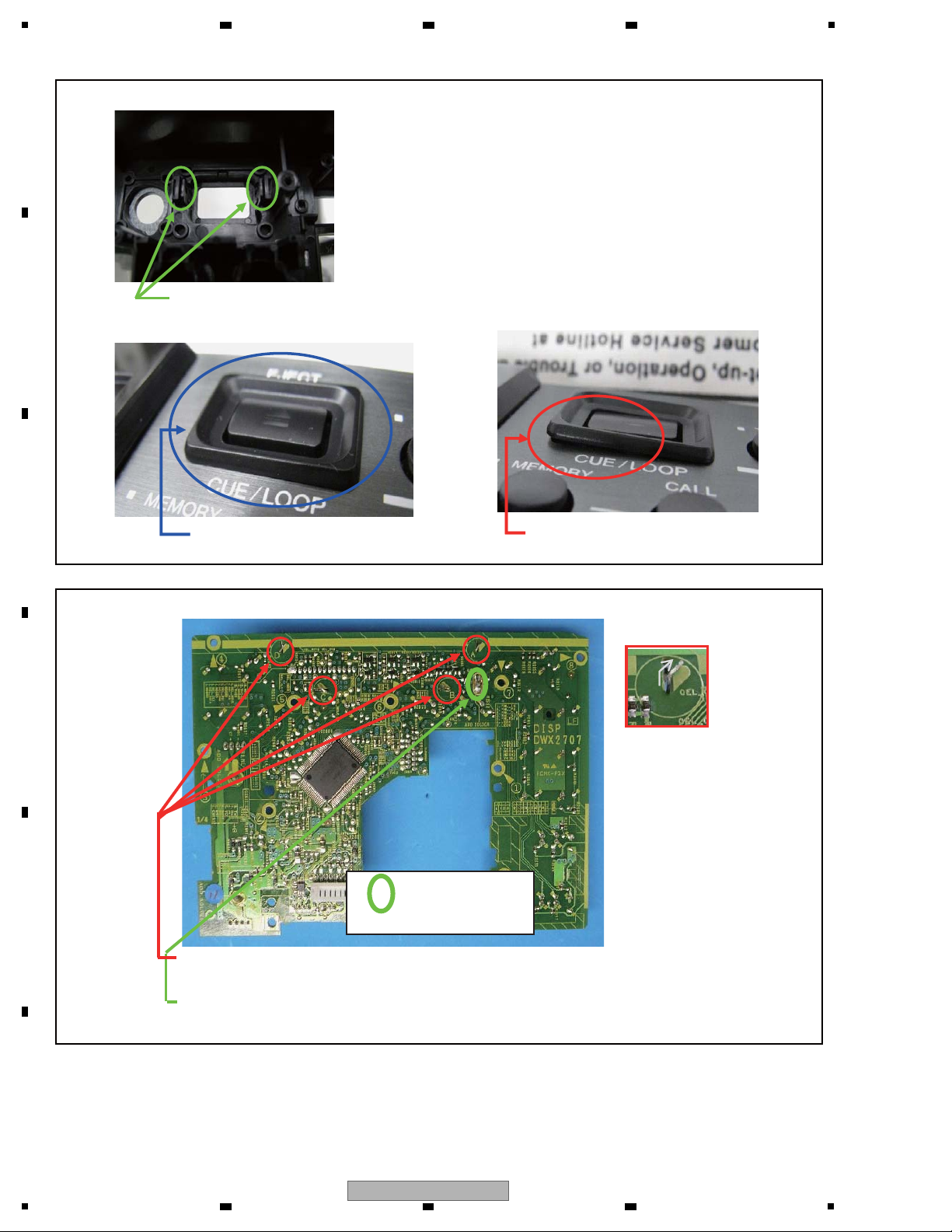

Points to be checked about the EJECT guard

Point to be checked when reassembling:

Check that the hooks are properly engaged.

OK: No lifting when visually checked

Bend the hooks according to the printed indications pointed out here, in the order of A, B, C, then D.

When attaching the OELB unit to the DISP Assy, perform additional soldering.

Point soldering

The holes need not be filled.

NG: Lifted

A

B

2 3 4

C

D

E

F

16

1

2 3 4

MEP-7000

Page 17

5

The FFC cables from the NJACK Assy to the NMAIN Assy

must be folded at a right angle at the base of the reinforcing plate.

Place on the LCD module so that it will not be positioned

outside the module.

Paste.

6 7 8

A

B

C

D

E

F

MEP-7000

5

6 7 8

17

Page 18

1

C

AUT

I

ON

Audio Cables

(XDE3045) L=1.5m

Forced Eject Pin

(DEX1008)

Caution Tag AP

(DRW1897)

Power Cord

(ADG7021 : KUCXJ)

(ADG7097 : TLFXJ)

(ADG7079 : WAXJ5)

(ADG1154 : WYXJ5,TLFXJ)

Control Cord

(XDE3063) L=1 m

Accessories

• Operating Instructions

(KUCXJ: DRB1455)

(WYXJ5: DRB1456, DRB1464)

(TLFXJ: DRB1457)

(WAXJ5: DRB1471)

DJS CD-ROM Assy

(DXX2585)

DJS installation key sticker

(DRM1300)

except WAXJ5

• Warranty Card

Dedicated remote control cable

(DDE1115)

USB Cable

(DDE1128)

USB auxiliary power cable

(DDE1129)

2. SPECIFICATIONS

2.1 ACCESSORIES

A

2 3 4

B

C

D

E

F

18

1

2 3 4

MEP-7000

Page 19

5

• KUCXJ type

• WYXJ5 type

1 General

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MEP-7000

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . Multi entertainment player

Normal style

Power voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . AC 120 V, 60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 W

Manipulator style

Power voltage . . . . . . . . . . . . . . . . . . . . DC 5 V (USB bus-power)

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 mA

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 W

Operating temperature . . . . . . +5 °C to +35 °C (+41 °F to +95 °F)

Operating humidity . . . . . 5 % to 85 % RH (without condensation)

Mass (Weight)

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg (3.75 lb.)

Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 kg (13.45 lb.)

Maximum external dimensions

Control unit . . . . . 482.6 mm (W) x 133.0 mm (H) x 83.5 mm (D)

19.0 in (W) x 5.24 in (H) 3.29 in (D)

Drive unit . . . . . . . 482.6 mm (W) x 90.5 mm (H) x 324.6 mm (D)

19.0 in (W) x 3.56 in (H) 12.78 in (D)

2 USB Upstream Section

Connector. . . . . . . . . . . . . . . . . . . USB B-type port (PC connector)

USB Downstream Section

Connector. . . . . . . . . . . . . . . USB A-type ports (USB1/USB2 ports)

Power supply . . . . . . . . . . . . . . . . . . . . 5 V/500 mA or less (at port)

3 Analog Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 Vrms (1 kHz)

Frequency response . . . . . . . . . . . . . . . . . . . . . . . . . 4 Hz to 20 kHz

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB or more (JEITA)

Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.006 % or less (JEITA)

* The above specifications refer to values for music CD (CDDA).

4 Digital Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output type. . . . . . . . . . . . . . . . . . . . . . . . . . Coaxial digital (S/PDIF)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 Vp-p (75

Ω)

Output format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.1 kHz/16 bit

5 Video Output Section

Output connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jack

Composite output level . . . . . . . . . . . . . . . . . . . . . . . . .1 Vp-p (75

Ω)

6 Center Display Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . . . TFT LCD active matrix display

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3” (WIDE)

Supported languages

. . . . . . 9 languages including English, Japanese, and Chinese

7 Controller Display A/B Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . OEL (Organic EL) Full segment

8 Other Connectors

Control unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

5 V connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DC jack

Drive unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

Control jack . . . . . . . . . . . . . . . . . . . . Mini-jacks (controller A/B)

Specifications and appearance are subject to change without

notice.

1 General

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MEP-7000

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . Multi entertainment player

Normal style

Power voltage. . . . . . . . . . . . . . . AC 220 V to 240 V, 50 Hz/60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 W

Manipulator style

Power voltage. . . . . . . . . . . . . . . . . . . . . DC 5 V (USB bus-power)

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 mA

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 W

Operating temperature . . . . . . . . . . . . . . . . . . . . . . +5 °C to +35 °C

Operating humidity . . . . . 5 % to 85 % RH (without condensation)

Mass (Weight)

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg

Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 kg

Maximum external dimensions

Control unit . . . . . 482.6 mm (W) x 133.0 mm (H) x 83.5 mm (D)

Drive unit . . . . . . . 482.6 mm (W) x 90.5 mm (H) x 324.6 mm (D)

2 USB Upstream Section

Connector. . . . . . . . . . . . . . . . . . . USB B-type port (PC connector)

USB Downstream Section

Connector. . . . . . . . . . . . . . . USB A-type ports (USB1/USB2 ports)

Power supply . . . . . . . . . . . . . . . . . . . . 5 V/500 mA or less (at port)

3 Analog Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 Vrms (1 kHz)

Frequency response . . . . . . . . . . . . . . . . . . . . . . . . . 4 Hz to 20 kHz

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB or more (JEITA)

Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.006 % or less (JEITA)

* The above specifications refer to values for music CD (CD-

DA).

4 Digital Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output type. . . . . . . . . . . . . . . . . . . . . . . . . . Coaxial digital (S/PDIF)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 Vp-p (75 Ω)

Output format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.1 kHz/16 bit

5 Video Output Section

Output connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RCA jack

Composite output level . . . . . . . . . . . . . . . . . . . . . . . . .1 Vp-p (75 Ω)

6 Center Display Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . . .TFT LCD active matrix display

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3” (WIDE)

Supported languages

. . . . . . . 9 languages including English, Japanese, and Chinese

7 Controller Display A/B Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . OEL (Organic EL) Full segment

8 Other Connectors

Control unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

5 V connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DC jack

Drive unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

Control jack . . . . . . . . . . . . . . . . . . . . Mini-jacks (controller A/B)

Specifications and appearance are subject to change without

notice.

2.2 SPECIFICATIONS

6 7 8

A

B

5

6 7 8

MEP-7000

C

D

E

F

19

Page 20

1

• TLFXJ type • WAXJ5 type

1 General

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MEP-7000

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . Multi entertainment player

Normal style

Power voltage. . . . . . . . . . . . . . . AC 110 V to 240 V, 50 Hz/60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 W

Manipulator style

Power voltage. . . . . . . . . . . . . . . . . . . . . DC 5 V (USB bus-power)

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 mA

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 W

Operating temperature . . . . . . . . . . . . . . . . . . . . . . +5 °C to +35 °C

Operating humidity . . . . . 5 % to 85 % RH (without condensation)

Mass (Weight)

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg

Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 kg

Maximum external dimensions

Control unit . . . . . 482.6 mm (W) x 133.0 mm (H) x 83.5 mm (D)

Drive unit . . . . . . . 482.6 mm (W) x 90.5 mm (H) x 324.6 mm (D)

2 USB Upstream Section

Connector. . . . . . . . . . . . . . . . . . . USB B-type port (PC connector)

USB Downstream Section

Connector. . . . . . . . . . . . . . . USB A-type ports (USB1/USB2 ports)

Power supply . . . . . . . . . . . . . . . . . . . . 5 V/500 mA or less (at port)

3 Analog Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 Vrms (1 kHz)

Frequency response . . . . . . . . . . . . . . . . . . . . . . . . . 4 Hz to 20 kHz

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB or more (JEITA)

Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.006 % or less (JEITA)

* The above specifications refer to values for music CD (CD-

DA).

4 Digital Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output type. . . . . . . . . . . . . . . . . . . . . . . . . . Coaxial digital (S/PDIF)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 Vp-p (75 Ω)

Output format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.1 kHz/16 bit

5 Video Output Section

Output connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RCA jack

Composite output level . . . . . . . . . . . . . . . . . . . . . . . . .1 Vp-p (75 Ω)

6 Center Display Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . . .TFT LCD active matrix display

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3” (WIDE)

Supported languages

. . . . . . . 9 languages including English, Japanese, and Chinese

7 Controller Display A/B Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . OEL (Organic EL) Full segment

8 Other Connectors

Control unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

5 V connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DC jack

Drive unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

Control jack . . . . . . . . . . . . . . . . . . . . Mini-jacks (controller A/B)

Specifications and appearance are subject to change without

notice.

1 General

Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . MEP-7000

Name . . . . . . . . . . . . . . . . . . . . . . . . . . . Multi entertainment player

Normal style

Power voltage. . . . . . . . . . . . . . . AC 220 V to 240 V, 50 Hz/60 Hz

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 W

Manipulator style

Power voltage. . . . . . . . . . . . . . . . . . . . . DC 5 V (USB bus-power)

Current consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . 600 mA

Power consumption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 W

Operating temperature . . . . . . . . . . . . . . . . . . . . . . +5 °C to +35 °C

Operating humidity . . . . . 5 % to 85 % RH (without condensation)

Mass (Weight)

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.7 kg

Drive unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.1 kg

Maximum external dimensions

Control unit . . . . . 482.6 mm (W) x 133.0 mm (H) x 83.5 mm (D)

Drive unit . . . . . . . 482.6 mm (W) x 90.5 mm (H) x 324.6 mm (D)

2 USB Upstream Section

Connector. . . . . . . . . . . . . . . . . . . USB B-type port (PC connector)

USB Downstream Section

Connector. . . . . . . . . . . . . . . USB A-type ports (USB1/USB2 ports)

Power supply . . . . . . . . . . . . . . . . . . . . 5 V/500 mA or less (at port)

3 Analog Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Frequency response . . . . . . . . . . . . . . . . . 20 Hz to 20 kHz +1/-3 dB

S/N ratio . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115 dB or more (JEITA)

Distortion . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.006 % or less (JEITA)

* The above specifications refer to values for music CD (CD-

DA).

4 Digital Audio Output Section

Output connector . . . . . . . . . . . . . . . . . RCA jacks (controller A/B)

Output type. . . . . . . . . . . . . . . . . . . . . . . . . . Coaxial digital (S/PDIF)

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5 ± 0.1 Vp-p (75 Ω)

Output format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.1 kHz/16 bit

5 Video Output Section

Output connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RCA jack

Composite output level . . . . . . . . . . . . . . . . . . . . . 1 ± 0.1 Vp-p (75 Ω)

6 Center Display Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . . .TFT LCD active matrix display

Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.3” (WIDE)

Supported languages

. . . . . . . 9 languages including English, Japanese, and Chinese

7 Controller Display A/B Section

Type. . . . . . . . . . . . . . . . . . . . . . . . . OEL (Organic EL) Full segment

8 Other Connectors

Control unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

5 V connector. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DC jack

Drive unit

Remote control connector . . . . . . . . . . . . . . . . . Mini-DIN 10-pin

Control jack . . . . . . . . . . . . . . . . . . . . Mini-jacks (controller A/B)

Specifications and appearance are subject to change without

notice.

A

B

2 3 4

C

D

E

F

20

1

2 3 4

MEP-7000

Page 21

5

TYPES OF DISCS PLAYABLE ON THIS UNIT

• Playable discs will display one of the following logo marks on the disc label, packaging, or jacket:

About disc playback

This unit can play CD-R/CD-RW discs recorded in music CD (CDDA) or CD graphics (CD-G) format, and CD-R/-RW, DVD-R/-RW,

DVD+R/+RW, and DVD±R dual layer discs recorded in MP3/AAC

file format.

The following discs cannot be played on this unit

CDs: DTS-CDs, photo-CDs, video-CDs, and unfinalized CDs

DVDs: DVD video, DVD audio, DVD-RAM, unfinalized DVDs, MPEG

moving picture files

Backup your discs!

Due to structural characteristics of CD-R/-RW, DVD-R/-RW,

DVD+R/+RW, and DVD±R dual layer media, if such discs are left

for extended periods in the pause (or cue standby) mode, they

become unplayable or difficult to play at that point on the disc. The

same symptom may occur if the loop function is used to repeat the

same section of a disc for an extremely large number of times.

When using discs holding important files or tracks, always make

backups first.

About copy-control CDs

This unit is designed to comply with music CD standards. We

cannot guarantee operation or performance when using discs that

do not comply with these standards.

[DualDisc] playback

This unit is designed to comply with music CD standards. We

cannot guarantee operation or performance when using discs that

do not comply with these standards.

About 8 cm single CDs

8 cm single CDs cannot be played on this unit. Also, do not

attempt to attach an 8 cm adapter to a disc and play it in this unit,

since the adapter may become detached during playback, causing

damage to the disc or player.

About CD-TEXT on music CDs

This unit supports CD-TEXT, and displays track titles, album titles,

and artist names recorded in CD-TEXT. Supported character codes

include ASCII, ISO-8859, MS-JIS, and Mandarin Chinese. When

multiple text data are recorded, the first text data is displayed.

Playable disc types and logos

CD CD-TEXT CD-R CD-RW CD-G DVD-R DVD-RW

The DVD mark is a

trademark of DVD Format/

Licensing Logo Corporation.

NOTE

• CD-R/-RW, DVD-R/-RW, DVD+R/+RW, and DVD±R dual

layer discs recorded on a standalone recorder or computer

may not play properly on this unit for a variety of reasons,

including individual characte ristics of the disc, scratches

or soiling of the disc, or dirt or condensation on the player’s

laser lens.

• Discs recorded on a computer’s disc drive may not play

properly due to variations in the recording software settings

or computer environment. Besure to record discs in the

proper format (for details, consult the distributor of the

recording software application).

• For detailed information regarding the handling and use of

your disc media, consult the precautions and instructions

furnished with the discs.

6 7 8

2.3 REGARDING PLAYABLE DISCE AND FILES

A

B

C

D

E

F

MEP-7000

5

6 7 8

21

Page 22

1

ABOUT MP3/AAC DISC PLAYBACK

This unit can play compressed music files (MP3/AAC) recorded on CD-R/-RW, DVD-R/-RW, DVD+R/+RW,

and DVD±R dual layer media.

• Startup time will increases as the number of folders and files increases.

ABOUT PLAYBACK FROM USB STORAGE DEVICE

By connecting a USB storage device to this unit, MP3/AAC/WAV/AIFF files recorded on the device can be played on this unit.

To disconnect a USB storage device

Hold the STOP button depressed for two seconds or more. Wait to remove the device until after the red indicator changes from flashing

to off.

Folder levels Maximum 8 levels; if more than 8 levels exist,files in the 9th and further levels cannot be played.

Maximum folders 2 000 per disc. If more than 2 000 folders exist, those beyond 2 000 cannot be displayed.

Maximum files 3 000 per disc. If more than 3 000 files exist, those beyond 3 000 cannot be displayed.

Recording format Supports discs recorded using the ISO9660 file system.

When recording is performed using the UDF file system, the disc cannot be played if the ISO9660 file

system is not recorded jointly. For details, consult the author of the application.

Folder levels Maximum 8 levels; if more than 8 levels exist, files in the 9th and further levels cannot be played.

Maximum folders No specific folder limit is made for a device, but folders exceeding 10 000 in a folder cannot be displayed.

Maximum files No specific file limit is made for a device, but a files exceeding 10 000 in a folder cannot be displayed.

Supported file systems FAT, FAT32, HFS+

MEMO

• USB storage devices supported by this unit are of the class of USB mass storagedevices including external hard discs,

portable flash memory devices, and digital audio player.

However, optical disc devices such as external DVD/CD drives cannot be used.

• When connecting a USB storage device containing a large number of folders and files, some time may be required to read

in the device contents.

• When a connected USB storage device contains multiple partitions, only the initial partition can be used.

CAUTION

Depending on the device used, proper playback may not be possible with all USB storage devices.

Pioneer assumes no responsibility for any loss of data resulting from connecting any given USB device to this

unit.

• Proper operation may not be possible when a USB storage device is connected through a USB hub.

• Even if a USB hub is used to connect multiple USB storage devices, the second and later devices cannot be used.

• Operation cannot be guaranteed when using a USB storage device with installed flash card reader.

• When connecting a USB storage device utilizing two USB cables, connect both cables to this unit’s USB ports.

• If an electrical current stronger than the allowable current is applied to the unit’s USB1 port or USB2 port, the unit may stop

supplying power to the USB storage device, thus terminating transmission. In this case, a message will be displayed in the

center display of the unit, and the stop indicators for USB1 and USB2 will flash red simultaneously. To restore normal

operation, disconnect all USB storage devices connected to the unit, then hold either of the USB STOP buttons depressed

for two seconds or more. Avoid connecting the USB storage device from which the excess current was detected and other

USB storage devices connected through a bus-powered USB hub. If normal operation is not restored through this method,

turn the power of this unit off, and then turn it back on.

CAUTION

When disconnecting a USB storage device, always be sure to perform the STOP operation first. If the STOP

operation is not completed before disconnection, cue/loop memory and playlist update may not occur properly,

resulting in the loss of data. Also, the USB storage device may becomes unreadable, or other substantial damage

may occur. Always disconnect the USB storage device before turning off the power to this unit.

A

2 3 4

B

C

D

E

F

22

MEP-7000

1

2 3 4

Page 23

5

ABOUT MP3 FILES

MP3 files may be found in two types, those with Constant Bit Rate (CBR), and those with Variable Bit Rate (VBR). This player supports

playback and DJ play of both CBR and VBR type files, but VBR files may exhibit slower performance when using search and super fast

search functions, compared to CBR files. When playback performance is preferred, record your files using CBR.

This unit supports MP3 files subject to the following formats:

*1 In order to display characters written in a local code other than Unicode, the UTILITY function must be used to set the language.

*2 Files with original image size larger than 800 x 800 pixels cannot be displayed.

ABOUT AAC FILES

AAC is an abbreviation for Advance Audio Coding, a basic format relating the audio compression technology used for MPEG-2 and

MPEG-4.

AAC data differs in file format and extension depending on the application used to create the data file.

The MEP-7000 is capable of playing iTunes -encoded AAC files with extension .m4a, as well as .aac and .mp4 files. However, copy-

®

protected files purchased at places like iTunes Music Store cannot be played. Further, some files may not be playable, depending on

the version of iTunes in which they were encoded.

Apple and iTunes are trademarks of Apple Inc., registered in the U.S. and other countries.

This unit supports AAC files subject to the following formats:

*1 In order to display characters written in a local code other than Unicode, the UTILITY function must be used to set the language.

*2 Files with original image size larger than 800 x 800 pixels cannot be displayed.

Supported formats MPEG-1 Supports Audio Layer-3 sampling frequencies 32 kHz, 44.1 kHz, 48 kHz, with bit

rates of 32 Kbps to 320 Kbps.

MPEG-2 Supports Audio Layer-3 sampling frequencies 16 kHz, 22.05 kHz, 24 kHz, with bit

rates of 16 Kbps to 160 Kbps.

Supports ID3 tag Ver 1.0/1.1/2.2/2.3/2.4.Track data

Displays title, album name, artist’s name. *1

JPEG images embedded in ID3 tag are displayed as jacket photographs. *2

.mp3File extensions

Supported formats MPEG-4 AAC LE Sampling frequency 16 kHz, 22.05 kHz, 24 kHz, 32 kHz, 44.1 kHz, 48 kHz,

with bit rates of 8 Kbps to 320 Kbps.

Track data AAC files

Supports ID3 tag Ver 1.0/1.1/2.2/2.3/2.4.

Displays title, album name, artist’s name. *1

JPEG images embedded in ID3 tag are displayed as jacket photographs. *2

Non-AAC files

Support metatags (embedded tags).

Displays title, album name, artist’s name. *1

JPEG images embedded in tag are displayed as jacket photographs. *2

.m4a, .aac, .mp4File extensions

6 7 8

A

B

C

D

MEP-7000

5

6 7 8

E

F

23

Page 24

1

ABOUT WAV FILES

This unit supports WAV files subject to the following formats:

*1 In order to display characters written in a local code other than Unicode, the UTILITY function must be used to set the language.

ABOUT AIFF FILES

This unit supports AIFF files subject to the following formats:

*1 In order to display characters written in a local code other than Unicode, the UTILITY function must be used to set the language.

Supported formats Supports 16-bit non-compressed PCM, with sampling frequency of 44.1 kHz.

Track data

Supports LST chunk.

Displays title, album name, artist’s name. *1

File extension .wav

MEMO

• WAV files recorded in disc media are not supported.

Supported formats Supports 16-bit non-compressed PCM, with sampling frequency of 44.1 kHz.

Displays title, album name, artist’s name. *1

File extension .aif .aiff

MEMO

• AIFF files recorded in disc media are not supported.

A

2 3 4

B

C

D

E

F

24

1

2 3 4

MEP-7000

Page 25

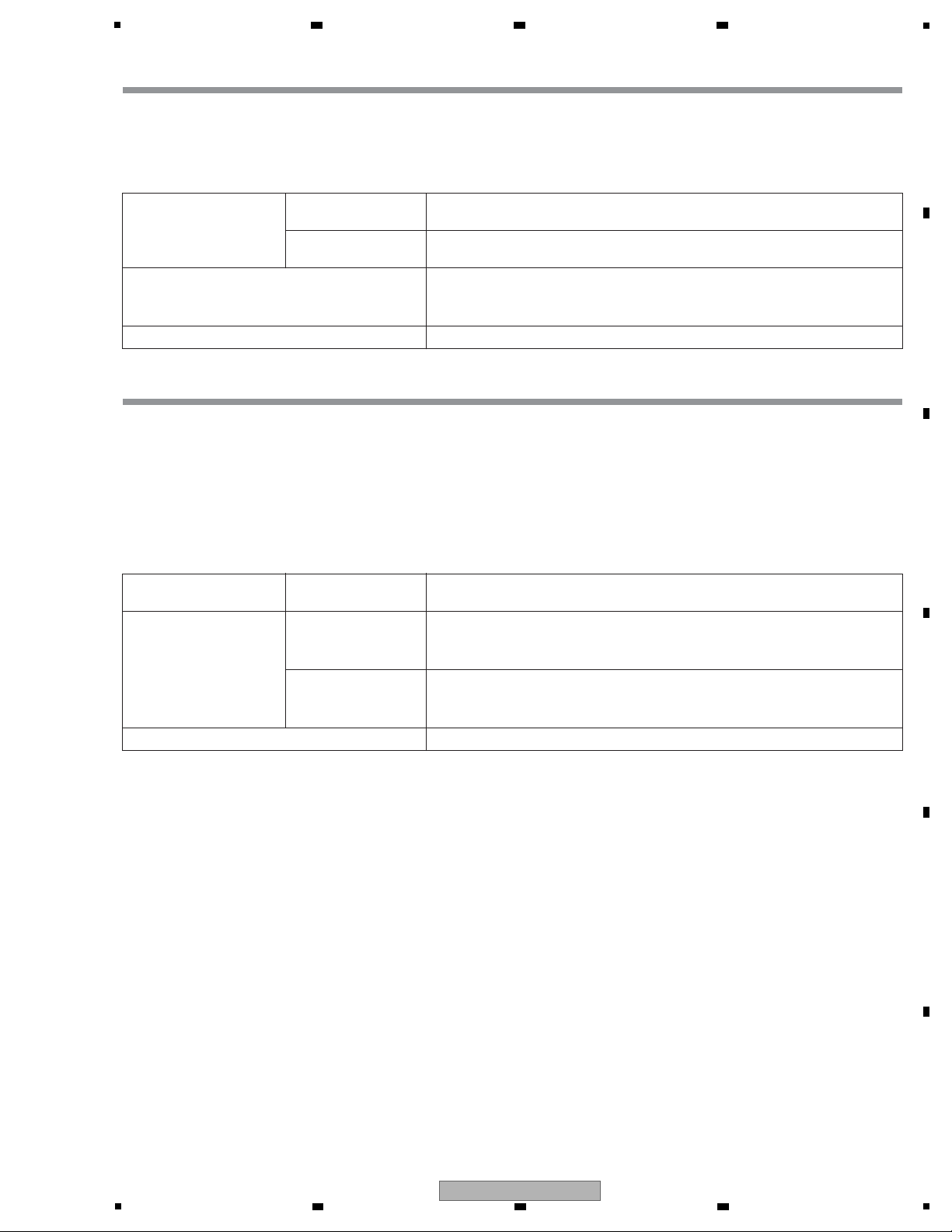

2.4 PANEL FACILITIES

FRONT PANEL

Drive Unit

1 Forced eject hole

2 Disc loading slot

3EJECT () button

To eject a disc from the disc loading slot, press this button

during the cue standby or pause mode, or when no tracks are

being loaded from the disc.

4 POWER switch and indicator

Turns unit power ON/OFF.

5 USB1 STOP button and indicator

Press when removing a USB memory device from USB1 port.

6 USB2 STOP button and indicator

Press when removing a USB memory device from USB2 port.

7 USB2 input port (type A)

Use to connect a USB memory device.

Control Unit

1 EJECT ( ) button

To eject a disc from the disc loading slot, press this button

during the cue standby or pause mode, or when no tracks are

being loaded from the disc.

2 LOOP operation button

3 TEMPO control section

TEMPO control range button (±6/10/16/WIDE):

Each time the button is pressed, the variable range of the

TEMPO adjust slider changes.

MASTER TEMPO button and indicator (MT):

Each time the button is pressed, the master tempo function

alternates ON/OFF.

TEMPO adjust slider:

From the center detent position, pull the slider towards you (+)

to increase the tempo, and push the slider away from you (–)

to slow down the tempo.

PITCH BEND +/– buttons:

When pressed during play, the pitch bend function is enabled.

Pressing the “+” button accelerates the pitch bend speed, and

pressing the “–” button decelerates the pitch bend speed.

The speed of the pitch change can be modified by holding the

button depressed while rotating the jog dial.

EJECT

POWER

STOP STOPREAR

DISC 1

USB 1 USB 2

DISC 2

EJECT

MEP-7000

MULTI ENTERTAINMENT PLAYER

1 2 3 4

56

7

TRACK SEARCH

CUE/LOOP

EJECT

TIME

A.CUE

IN/CUE

HOT LOOP

LOOP

RELOOP/EXIT

PITCH BEND

BROWSE MIX EFFECT UTILITY

MT

0

MASTER

TEMPO

TEMPO

6/10/16WIDE

OUT/ADJUST

FWD TEMPOREV

MEMORY CALL

SEARCH

QUE

J

O

G

B

R

E

A

K

S

C

R

A

T

C

H

TRACK SEARCH

CUE/LOOP

EJECT

TIME

A.CUE

IN/CUE

HOT LOOP

LOOP

RELOOP/EXIT

PITCH BEND

MT

0

MASTER

TEMPO

TEMPO

6/10/16WIDE

OUT/ADJUST

FWD TEMPOREV

MEMORY CALL

SEARCH

QUE

J

O

G

B

R

E

A

K

S

C

R

A

T

C

H

A

LOAD

B

MEP-7000

LOAD

MULTI ENTERTAINMENT PLAYER

1

15

4 22 2 3 10 11 12 13

18

18 14 20

21

1923

179

16

8

7

5

6

5

6 7 8

A

B

5

6 7 8

MEP-7000

C

D

E

F

25

Page 26

1

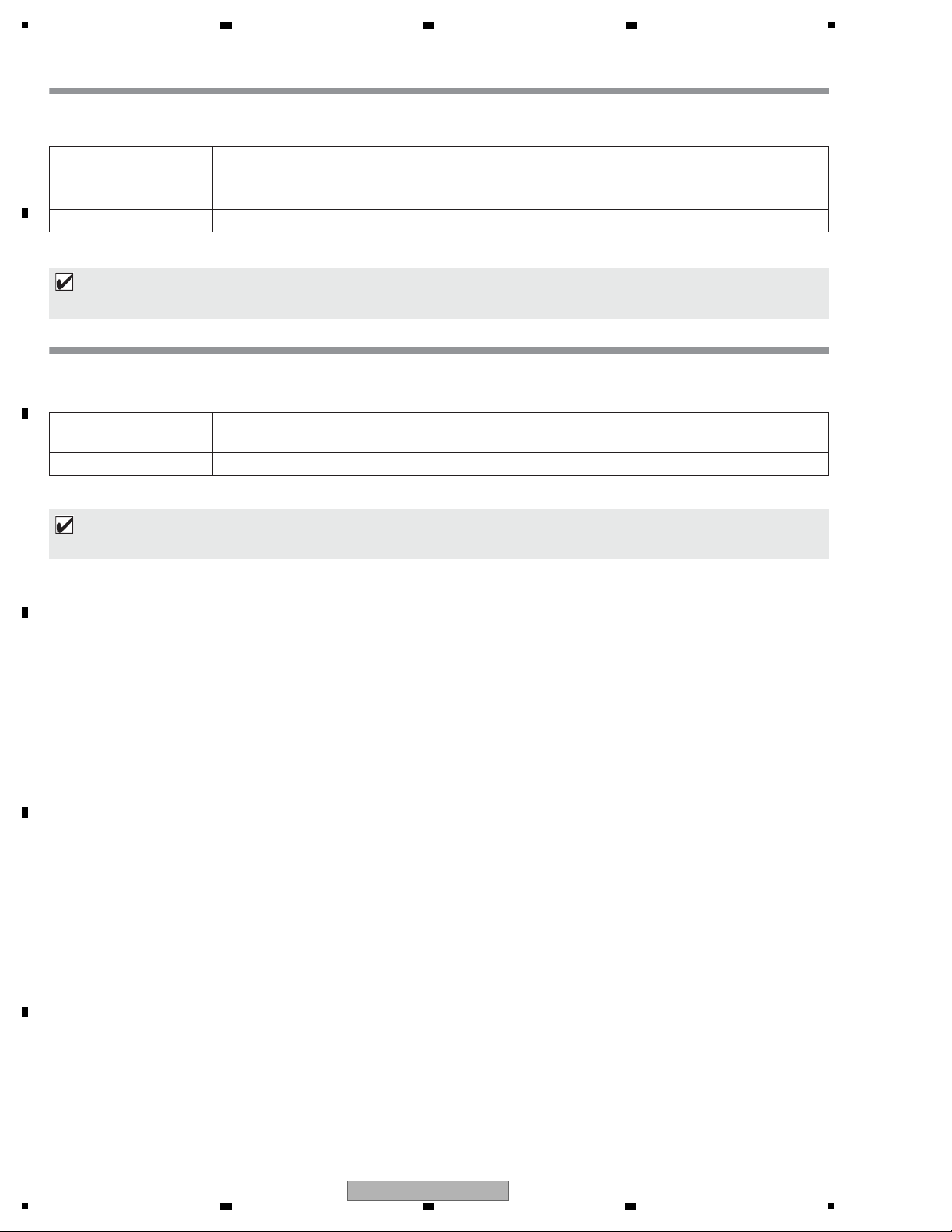

4 Time mode/auto cue button (TIME/A.CUE)

TIME:

Each time the button is pressed, the display’s time display

alternates between the currenttrack’s elapsed playing time,

and the remaining time (REMAIN).

A.CUE:

5 TRACK SEARCH ( , ) buttons

6 SEARCH ( , ) buttons

7 CUE button and indicator

Setting a cue point

Cue point sampler

Back-cue

Modifying a cue pint

8 Play/pause ( ) button and indicator

9 SCRATCH/JOG BREAK buttons and indicators

Use to select jog mode, including SCRATCH, JOG BREAK, or

OFF (neither indicator lighted).

10 BROWSE button

Use to select the BROWSE screen.

11 MIX button

Use to select the MIX screen.

12 EFFECT button

Use to select the EFFECT screen.

13 UTILITY button

Use to select the UTILITY screen.

14 Rotary selector dial

Rotate clockwise/counterclockwise for track selection and to

move cursor between setting items. Press to confirm

selection.

15 CUE/LOOP MEMORY button

Use to store cue points and loop points in memory.

Hold the button depressed to cancel a loop point.

16 CUE/LOOP CALL button

Use to call up cue and loop points stored in memory.

17 Function buttons (F1 to F6, from left)

Switching between the functions allocated to the six function

buttons can be performed by using the menu shown on the

center display.

On BROWSE screen:

“SELECT THE TRACK”

On MIX screen:

“MIX SCREEN”

On EFFECT screen

“[1] Scratch effect”

“[2] Jog break effect”

On UTILITY screen:

“USING MIDI FOR COMPUTER CONTROL”

“USING THE UTILITY”

18 LOAD A/B buttons

Sets the selected track in the controller A/B.

19 Select up ( ) button

Each time this button is pressed, the display returns to the next

higher menu level.

20 Select down ( ) button

Each time this button is pressed, the display advances to the

next lower menu level.

21 Center display

22 Display A/Display B

23 Jog dial (+FWD/–REV)

A

2 3 4

B

C

D

E

F

26

1

2 3 4

MEP-7000

Page 27

5

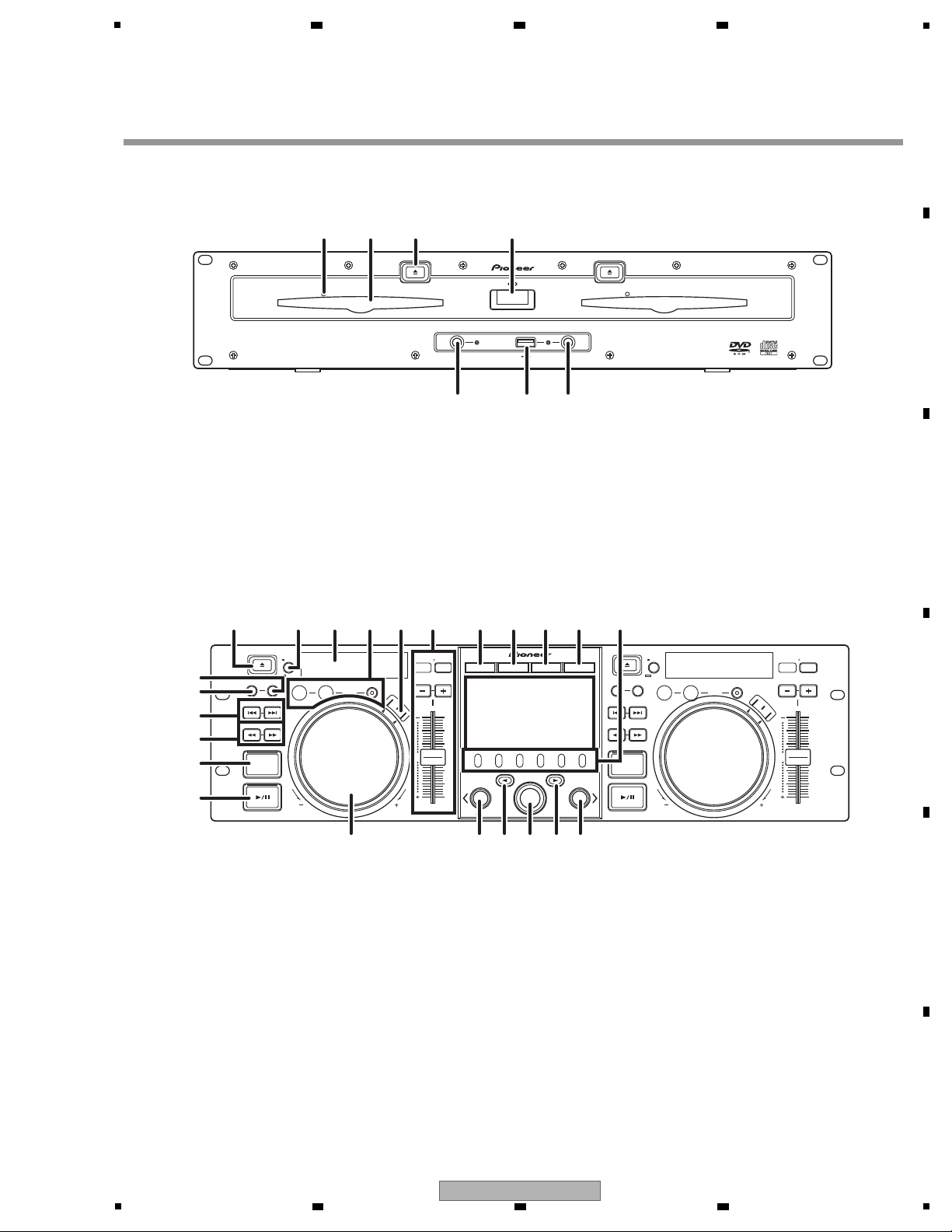

Center Display

1 Main menu display

The center display’s menus are changed by using the

BROWSE button, MIX button, EFFECT button, and UTILITY

button. The function buttons, select up ( )/down( ) buttons,

LOAD A/B buttons, and the rotary selector dial are used to

manipulate the contents of each menu.

BROWSE

screen

Use to select tracks and construct playlists.

MIX screen

Use to perform mixing operations, including auto mix using

playlists.

EFFECT

screen

Use to select scratch play and various effects used in jog break

play.

UTILITY

screen

Use to make unit settings.

2 Function tab

Displays items that can be changed using the six function

buttons. Items displayed differ depending on the contents

shown on the main menu display.

3 A/B track information display

Displays track information and current status for tracks

playing on controller A/B.

Play status

Display A/Display B

1 Track number display

Displays the number of the track currently playing.