Pioneer DVR-940-HXS Service manual

ORDER NO.

RRV3517

DVD RECORDER

DVR-940HX-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Serial No.

Model Type Power Requirement Region No. Please confirm 3rd & 4th

DVR-940HX-S WYXK5 AC 220 V to 240 V 2 &&UK######$$

DVR-940HX-S WVXK5 AC 220 V to 240 V 2 &&UK######$$

alphabetical letters.

This service manual should be used together with the following manual(s):

Model

DVR-545HX-S/WYXK5

RRV3504

RemarksOrder No.

CONTENTS

1. CONTRAST OF MISCELLANEOUS PARTS

2. GENERAL INFORMATION

2.1 DIAGNOSIS OF THE HDMIB ASSY

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

...................................

.....................................

..........................

........

................

2

8

8

11

22

T – ZZV NOV. 2006 Printed in Japan

1

jpfy

23

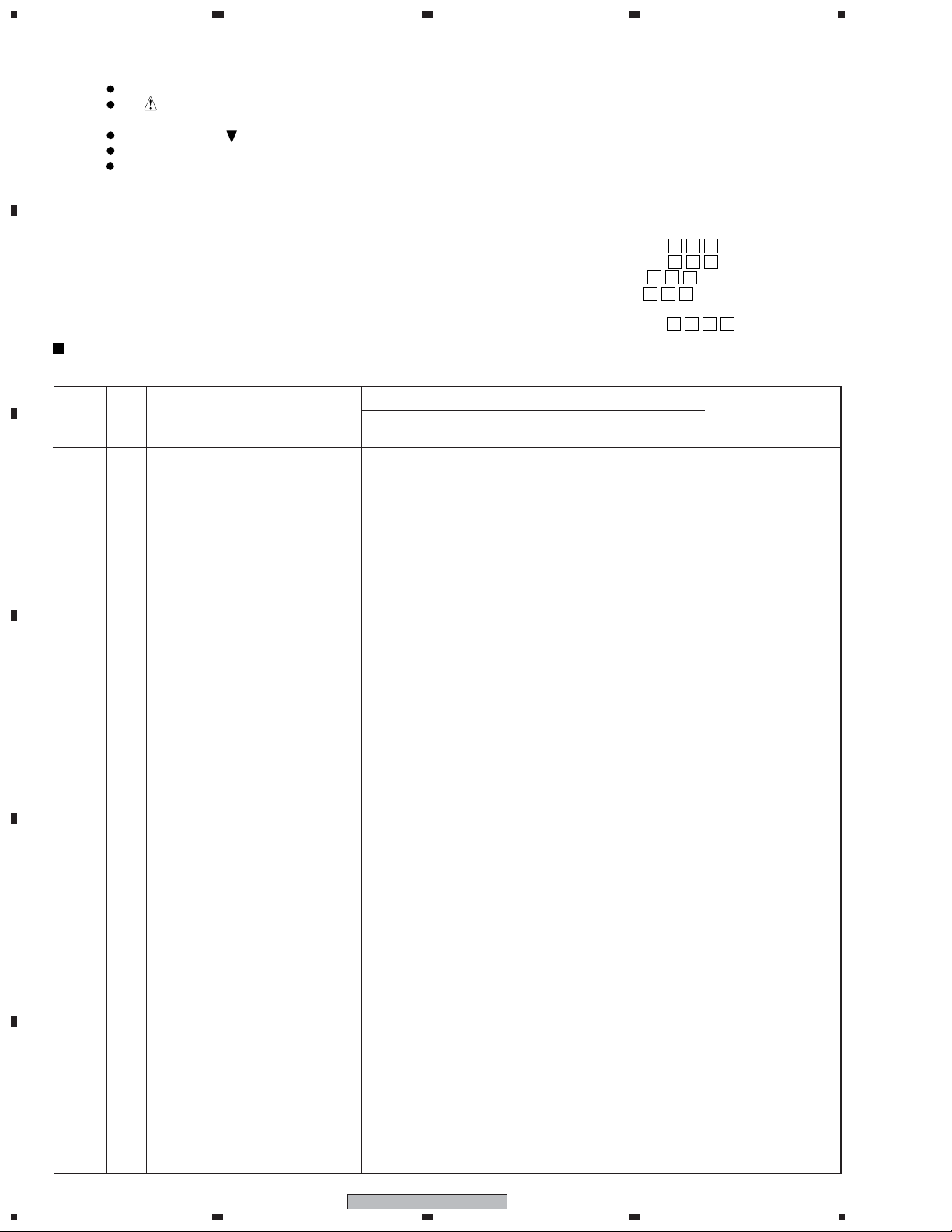

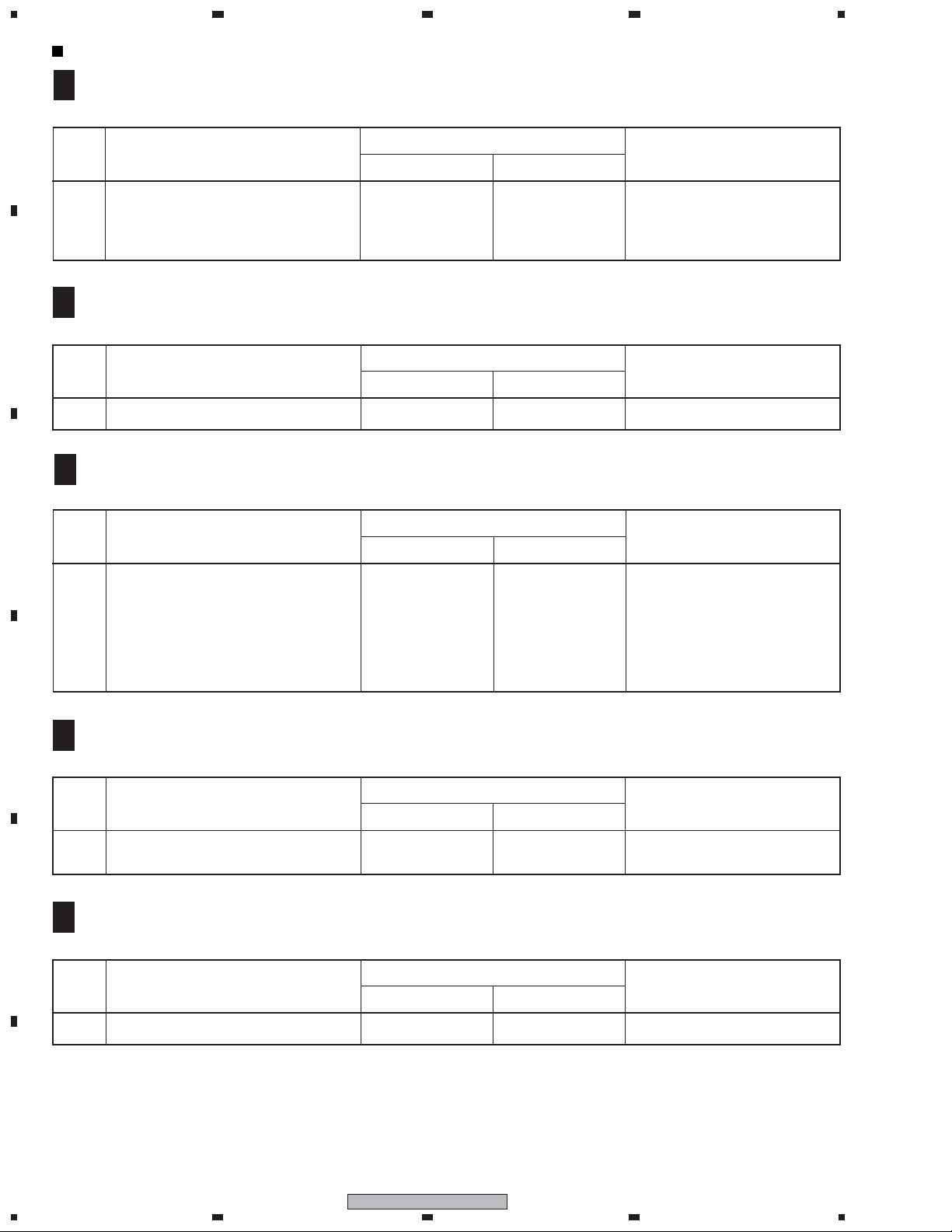

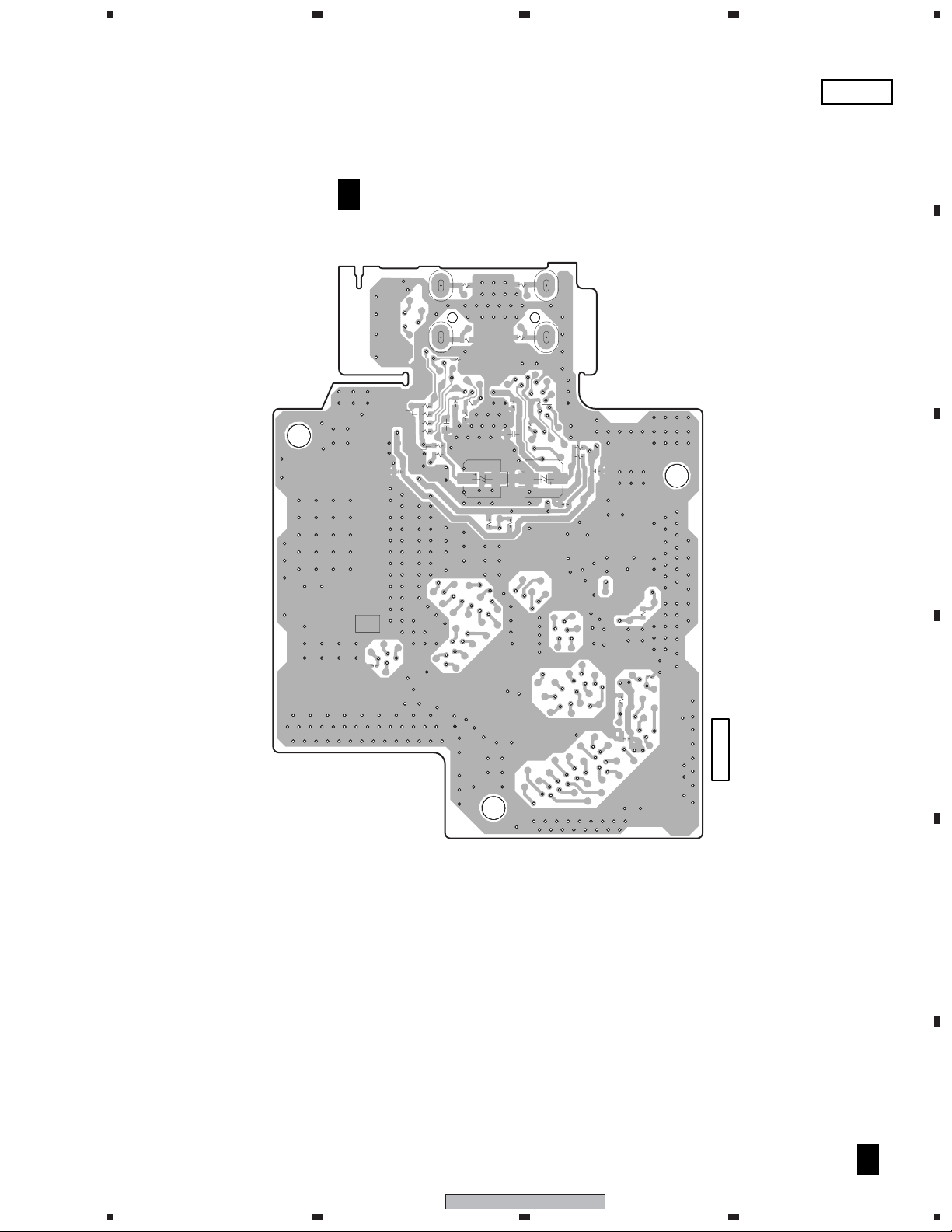

1. CONTRAST OF MISCELLANEOUS PARTS

NOTES:

A

B

CONTRAST TABLE

DVR-940HX-S/WYXK5, /WVXK5 and DVR-545HX-S/WYXK5 are constructed the same except for the following :

Ref.

No.

C

P11- 1 3..JACB ASSY (for Service) VXX3172 VXX3188 VXX3188

P11- 2 2..ATAB ASSY VWV2276 VWV2277 VWV2277

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

Reference Nos. indicate the pages and Nos. in the service manual for the base model.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

K

K

Part No.

Mark

Symbol and Description

DVR-545HX-S DVR-940HX-S DVR-940HX-S

/WYXK5 /WYXK5 /WVXK5

PCB ASSEMBLIES

NSP 1..JACB ASSY VWM2415 VWM2416 VWM2416

NSP 2..JACB ASSY VWV2266 VWV2275 VWV2275

4

Remarks

NSP 1..FLKB/FLJB ASSY VWM2413 VWM2414 VWM2414

NSP 2..FLKY/FLKB ASSY VWG2592 VWG2592 VWG2592

P15- 1 3..FLKY ASSY (for Service) VXX3177 VXX3187 VXX3187

P11- 3 3..FRJB ASSY (for Service) VXX3179 VXX3181 VXX3181

P11- 4 1..DTBR ASSY (for Service) VXX3174 VXX3189 VXX3189

P11- 6 1..HDMIB ASSY VWV2247 VWV2248 VWV2248

1..SATB ASSY Not used VWV2274 VWV2274 No.1

D

E

P9- 1 > Power Cord ADG1127 ADG1127 ADG7077

P9- 5 Remote Control Unit VXX3092 VXX3099 VXX3099

P9- 6 Battery Cover VZN1004 VZN1005 VZN1005

P9- 7 Top Cover VZN1009 VZN1007 VZN1007

P9-11 Operating Instructions (English) Not used Not used VRB1456

P9-12 Operating Instructions (French) VRC1373 VRC1373 Not used

P9-13 Operating Instructions (German) VRC1374 VRC1374 Not used

P9-14 Operating Instructions (Italian) VRC1375 VRC1375 Not used

P9-15 Operating Instructions (Dutch) VRC1376 VRC1376 Not used

P9-16 Operating Instructions (Spanish) VRC1377 VRC1377 Not used

P9-23 Front Pad VHA1408 VHA1418 VHA1418

P9-24 Rear Pad VHA1409 VHA1419 VHA1419

P9-25 Packing Case VHG2776 VHG2779 VHG2777

P9-26 Mirror Sheet VHL1107 Not used Not used

P9-26 Packing Sheet Not used AHG7015 AHG7015

PACKING SECTION

EXTERIOR SECTION

P11-11 HDD 160G ST3160212 S VXF1110 Not used Not used

P11-11 HDD 500G ST3500841 S Not used VXF1123 VXF1123

P11-19 Flexible Cable (30P) VDA2153 Not used Not used

P11-19 Flexible Cable (32P) Not used VDA2155 VDA2155

F

P11-24 Rear Panel VNA2957 VNA2959 VNA2959

2

1234

Flexible Cable (40P) Not used VDA2149 VDA2149 No.2

Connector Assy (4P) Not used PF04PP-S40 PF04PP-S40 No.3

DVR-940HX-S

1

234

Part No.

Ref.

Mark

No.

P11-25 NSP Chassis VNB1055 VXA2813 VXA2813

P11-38 Aluminum Tape 180x25 VEF1065 Not used Not used

P11-41 Tray Panel VNK5910 VNK6102 VNK6102

P11-54 NSP HDMI Stay VNE2441 VNE2445 VNE2445

P11-56 HDMI Shield VNF1137 VNF1138 VNF1138

P11-63 Aluminum Tape 8x100 VEF1066 Not used Not used

NSP SATA Stay Not used VNE2444 VNE2444 No.4

P15- 3 Flexible Cable (18P) VDA2154 Not used Not used

P15- 3 Flexible Cable (20P) Not used VDA2156 VDA2156

P15- 5 Door Spring VBK1159 Not used Not used

P15- 7 Main Key VNK5937 VNK6118 VNK6118

P15- 8 Key Base VNK5938 VNK6100 VNK6100

Symbol and Description

DVR-545HX-S DVR-940HX-S DVR-940HX-S

/WYXK5 /WYXK5 /WVXK5

EXTERIOR SECTION

Rear Foot H.S. Not used VNK6091 VNK6091 No.5

Insulator Not used VNK6143 VNK6143 No.6

Aluminum Tape 8x50 Not used VEF1067 VEF1067 No.7

Screw Not used AMZ30P060FTC AMZ30P060FTC No.8

FRONT PANEL SECTION

Remarks

A

B

P15-11 Center Lens VNK6117 Not used Not used

P15-12 Front Panel VNK6115 VNK6094 VNK6094

P15-13 FL Lens PTD VXA2815 Not used Not used

P15-13 FL Lens Not used VNK6096 VNK6096

P15-14 Door PTD VXA2816 Not used Not used

Door Panel Not used VNK6097 VNK6121 No.9

Door Base Not used VNK6098 VNK6098 No.10

Door Ring Not used VNK6099 VNK6099 No.11

Door Pad Not used VEC2545 VEC2545 No.12

Magnet Catcher Not used VNE2388 VNE2388 No.13

Magnet Holder Assy Not used AEC1077 AEC1077 No.14

Damper Assy Not used VXA2832 VXA2832 No.15

Black Spacer Not used VEC2491 VEC2491 No.16

Panel Base Not used VNK6095 VNK6095 No.17

NSP LED Lens Not used VNK6101 VNK6101 No.18

Notes : • For PCB ASSEMBLIES, Refer to “CONTRAST OF PCB ASSEMBLIES”, “PCB PARTS LIST”, “3. SCHEMATIC DIAGRAM”

and “ 4. PCB CONNECTION DIAGRAM.

• The numbers in the remarks column correspond to the numbers on "EXTERIOR SECTION" and “FRONT PANEL SECTION”.

C

D

E

F

DVR-940HX-S

1

2

3

4

3

1

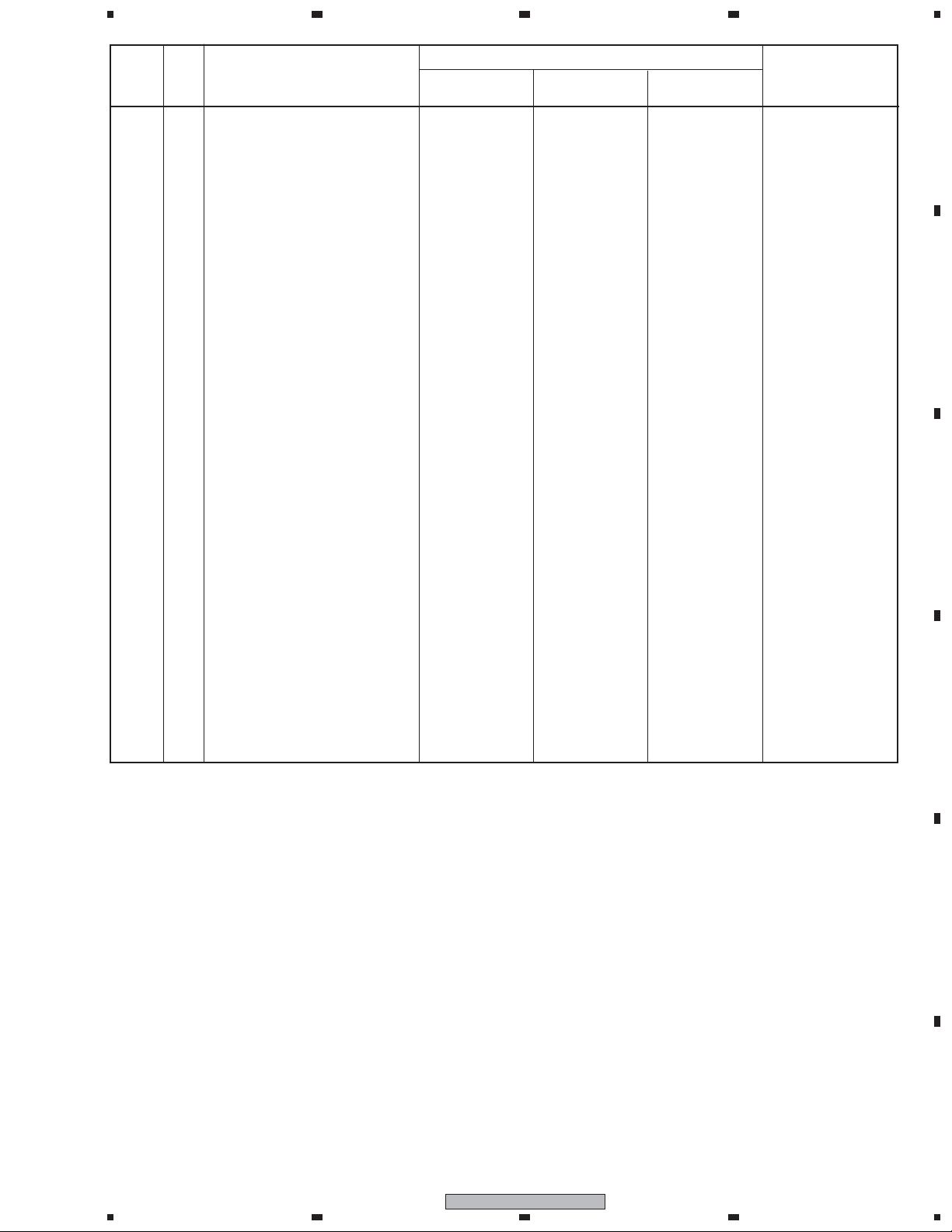

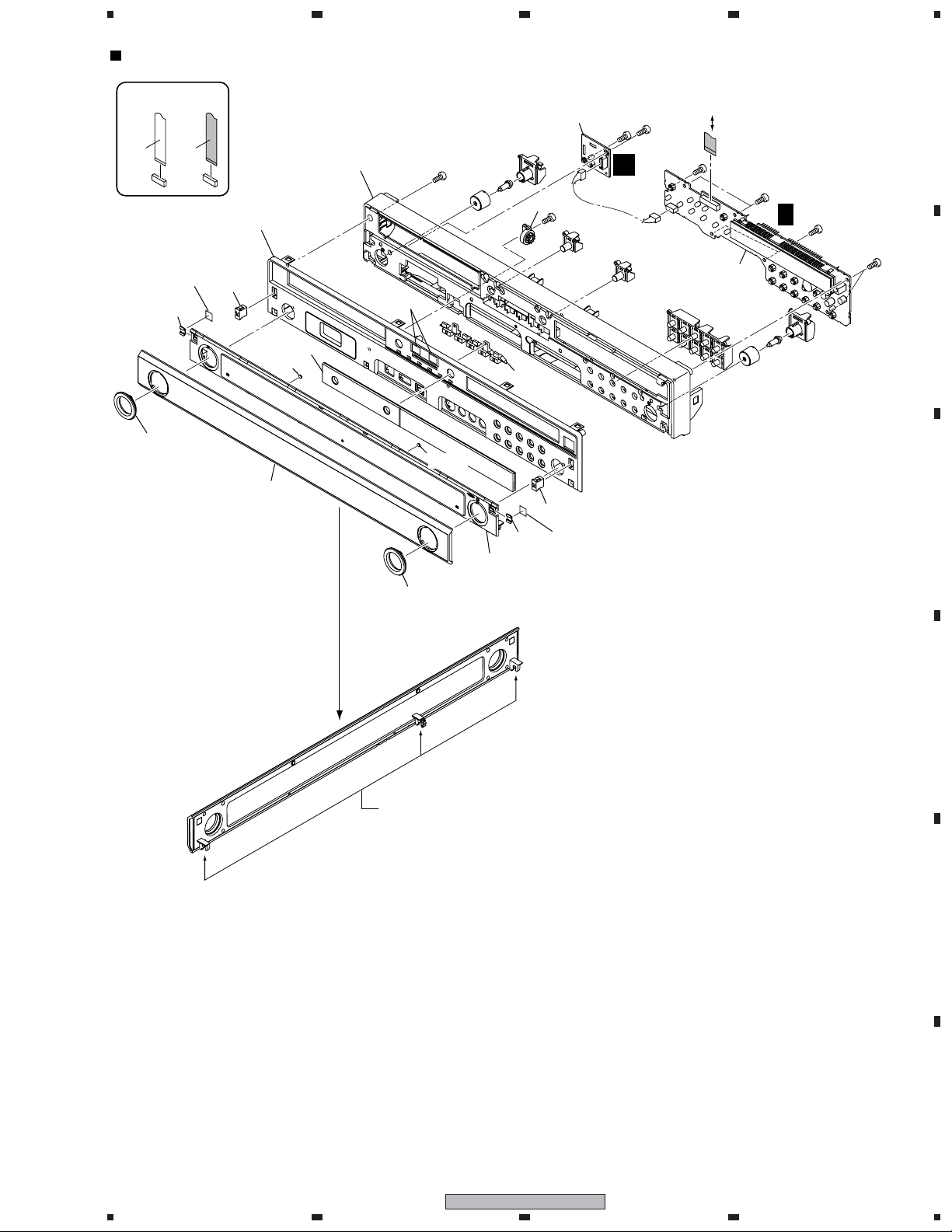

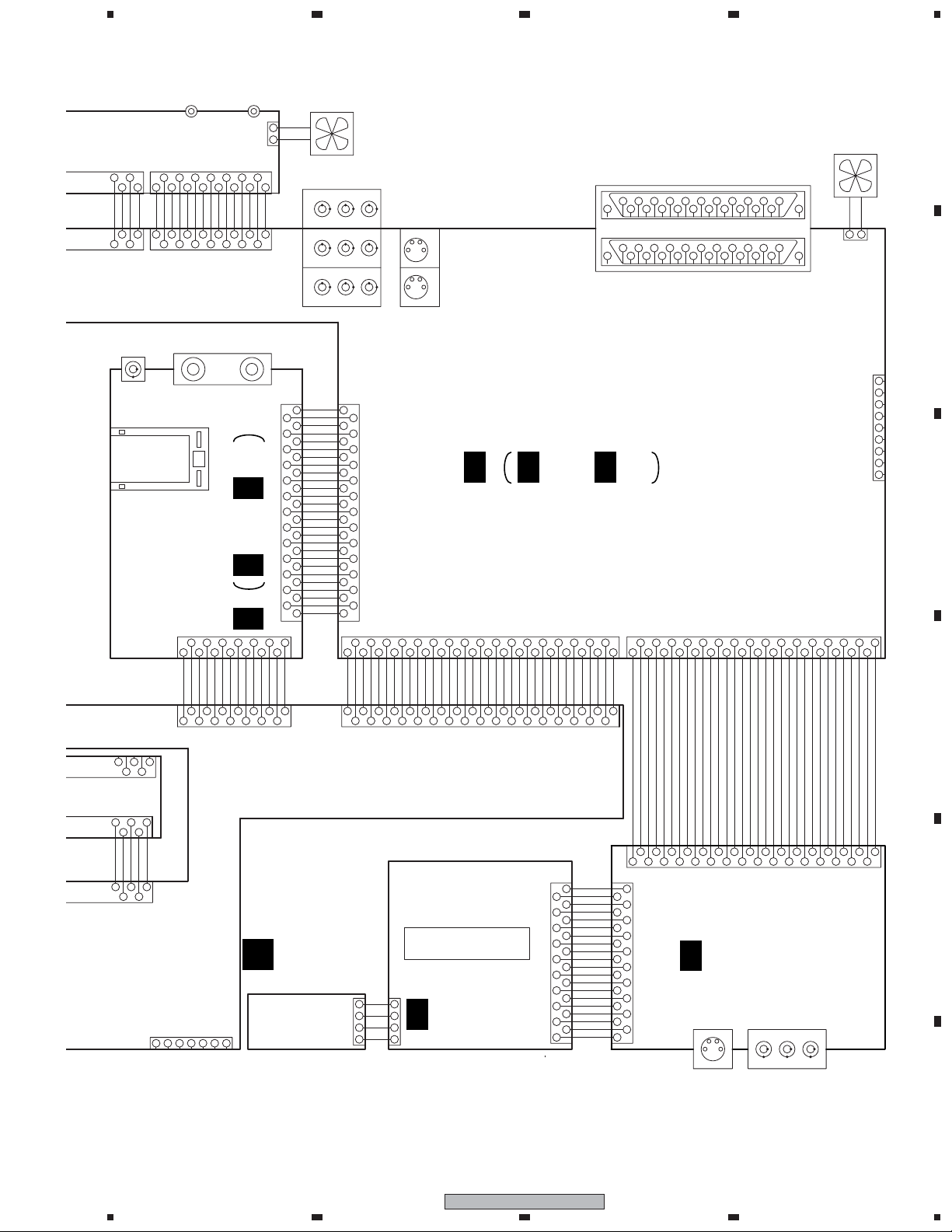

EXTERIOR SECTION

A

HDMI

Shield

HDMIB ASSY

H

F

23

4

NON-CONTACT

SIDE

CONTACT SIDE

P

Service

LOADER

MAIN

J

HDMI

Stay

B

C

D

No.7

O

b

No.8

O

No.1

No.3

U

b

O

B

a

Rubber

Spacer

V

ATAB

a

ASSY

P

M

USBB ASSY

K

V

B

b

K

F

Q

N

J

B

b

N

D

L

HDD Stay

O

a

C

HDD

F

J

M

F

W

No.2

No.7

W

L

K

No.4

B

a

E

BSZ30P040FTC

DVJB ASSY

A

I

No.5

Rubber

Foot

No.5

Rubber Foot

F

D

E

Chassis

POWER SUPPLY

UNIT

L

No.6

Rubber Foot

F

4

Refer to

"FRONT PANEL SECTION".

DVR-940HX-S

1234

U

1

FRONT PANEL SECTION

234

FRJB

PWSB ASSY

CN302

A

NON-CONTACT

SIDE

No.16

CONTACT SIDE

No.14

No.13

No.11

Front Panel

FL Lens

No.12

No.9

No.17

Hologram

Label

No.11

No.12

No.10

No.15

No.18

No.13

No.14

No.16

F

E F

FLKY ASSY

B

C

Door Shaft

D

to Door Shaft

E

F

DVR-940HX-S

1

2

3

4

5

1

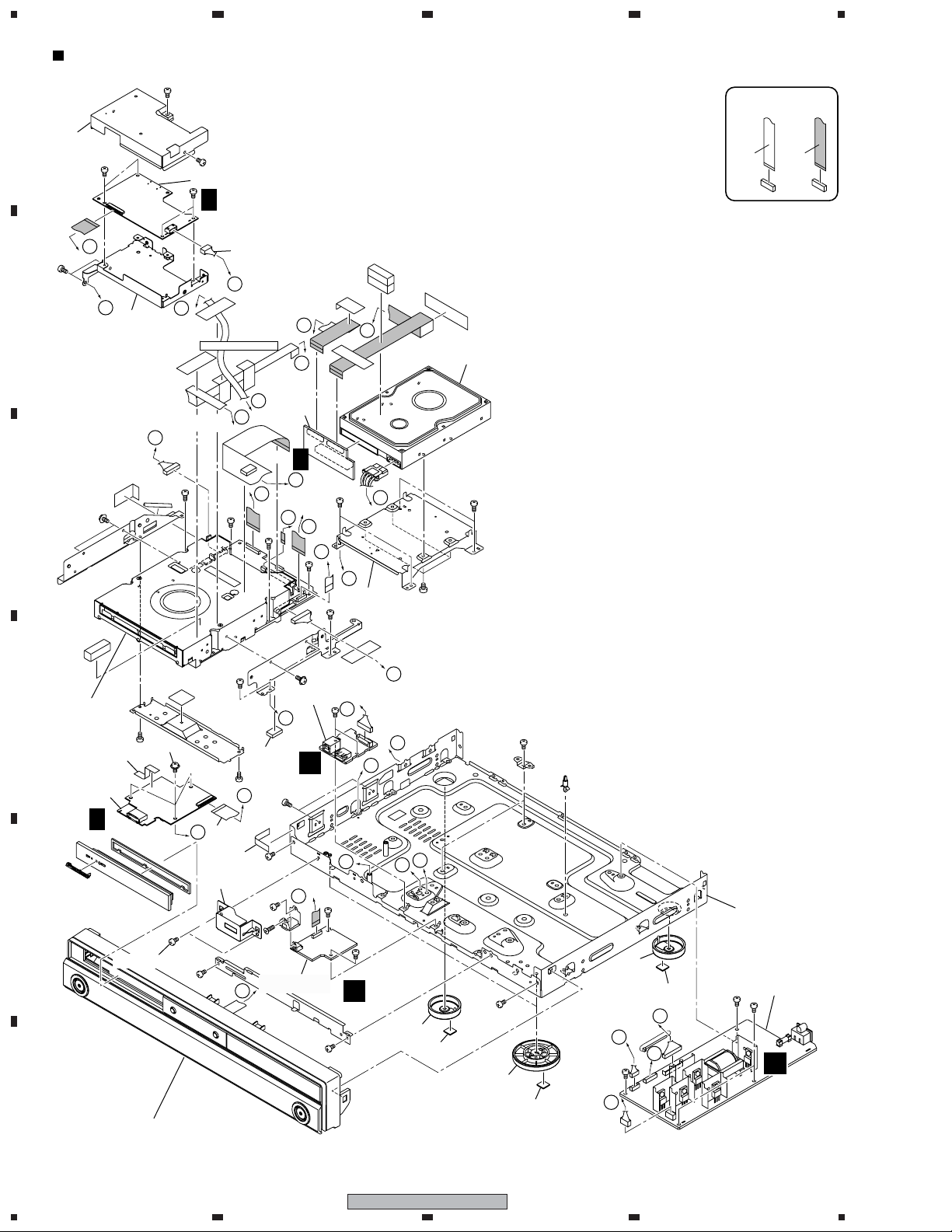

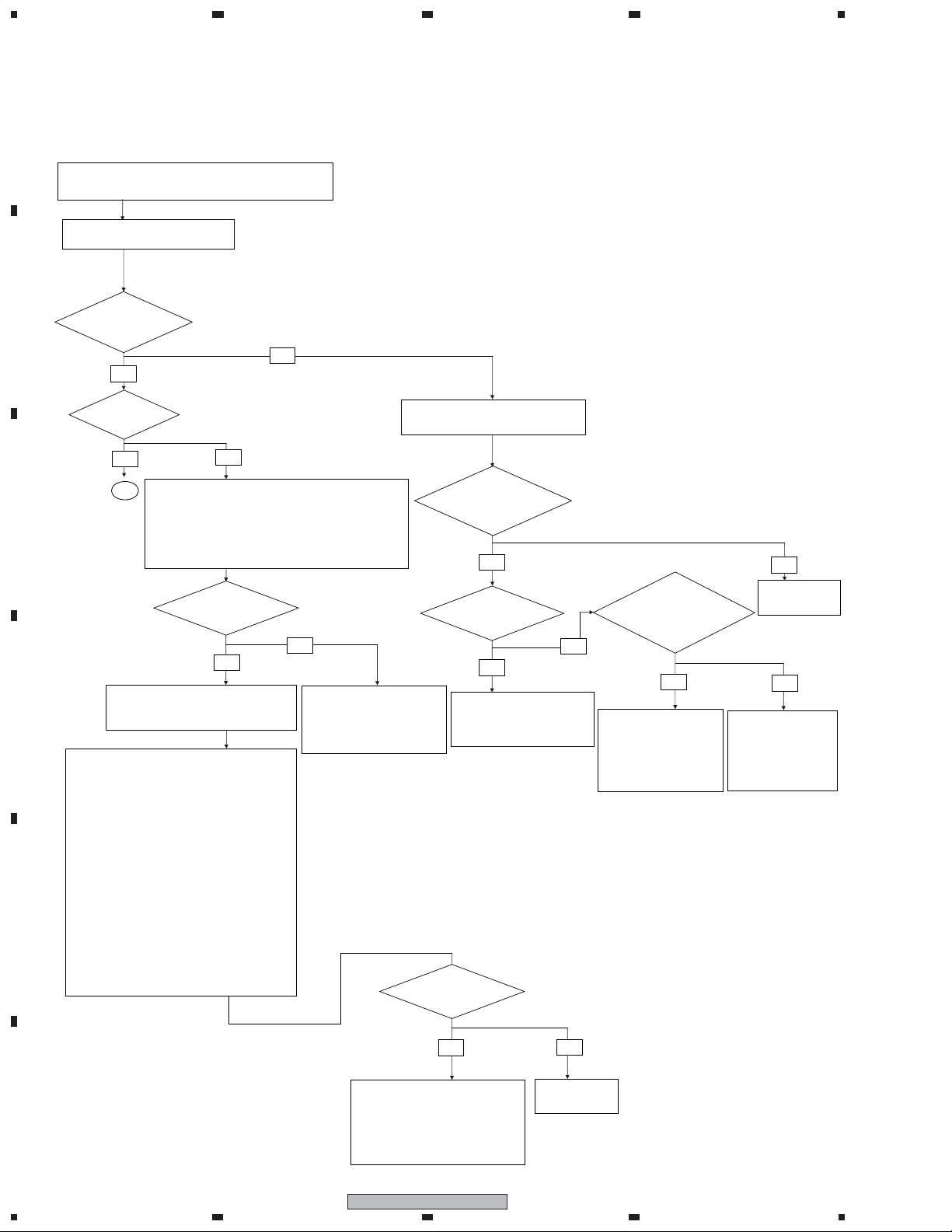

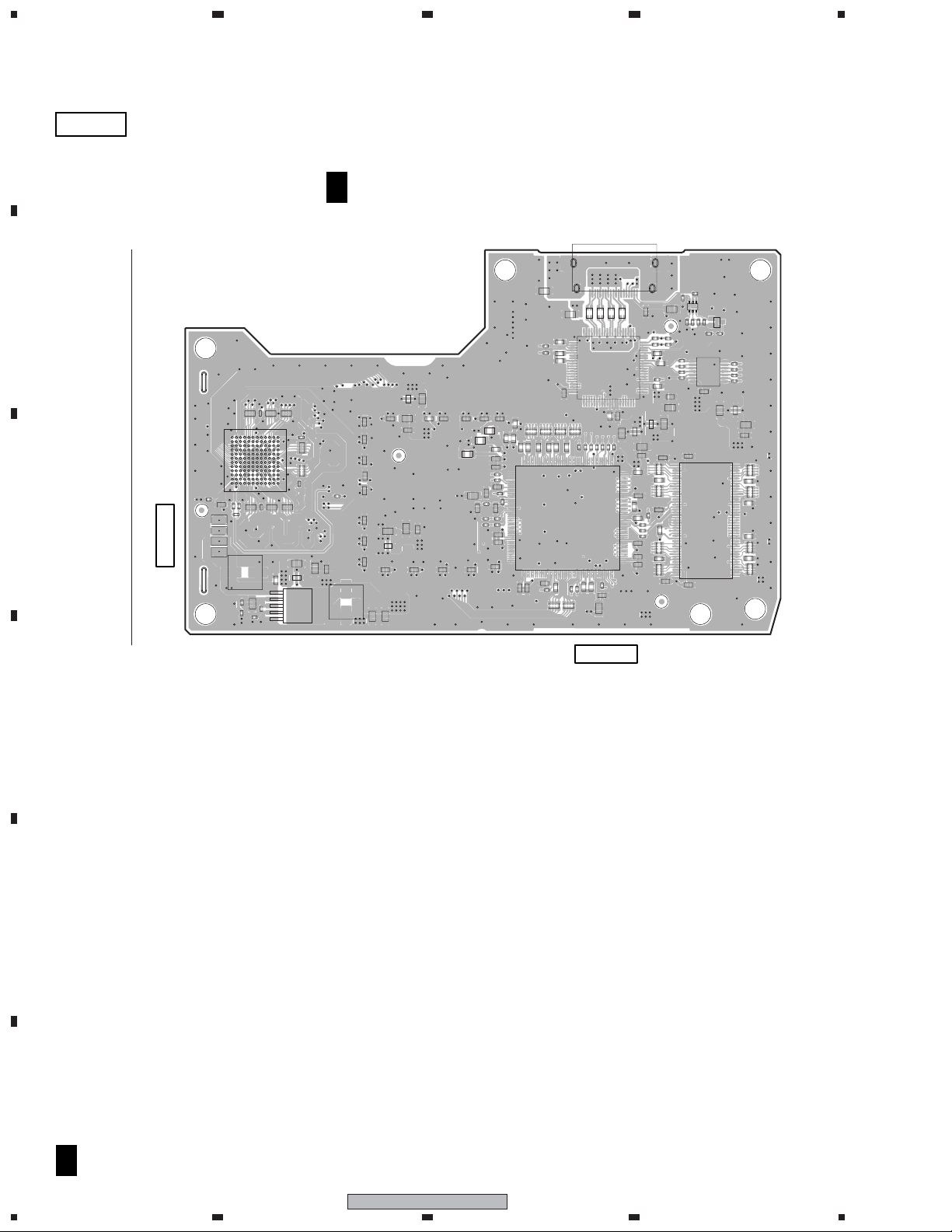

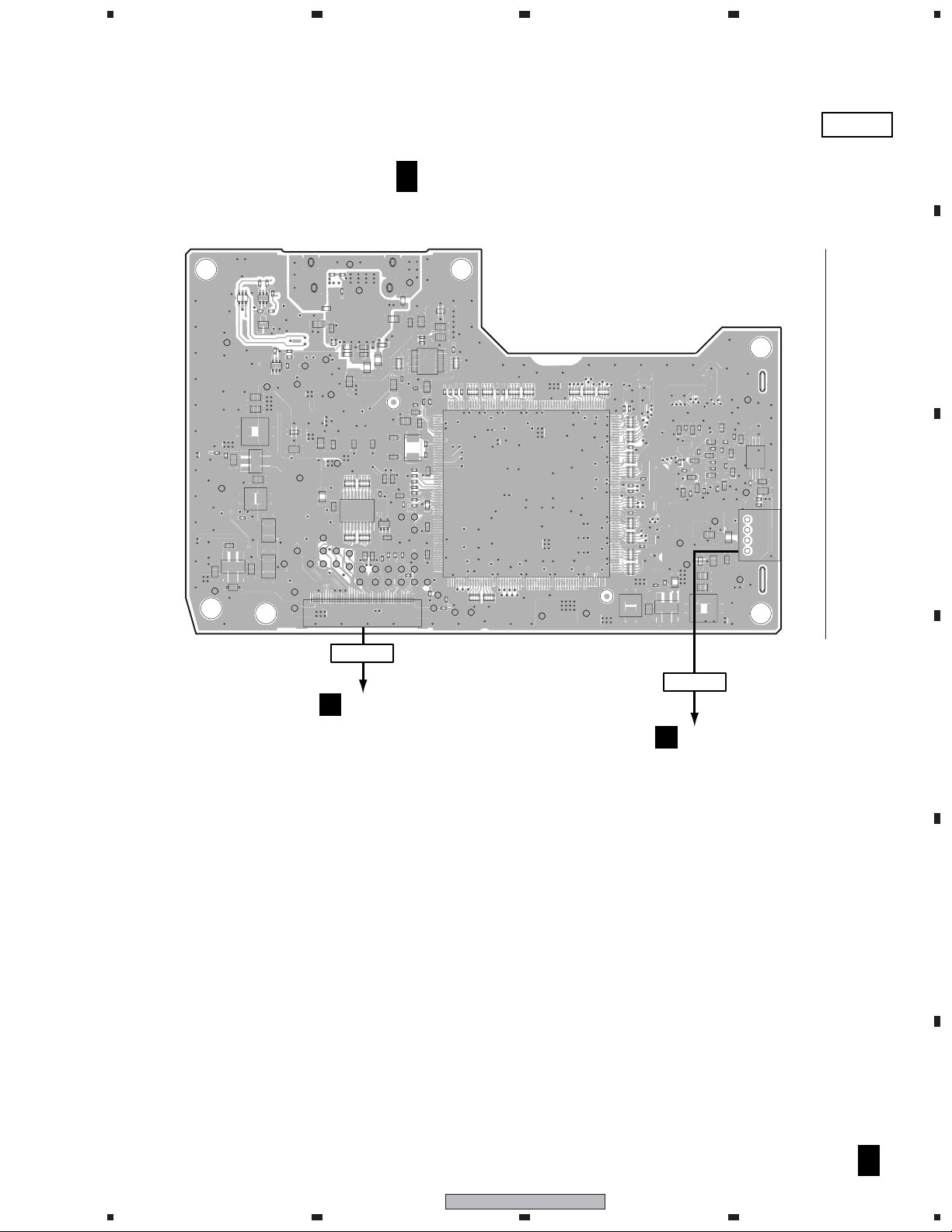

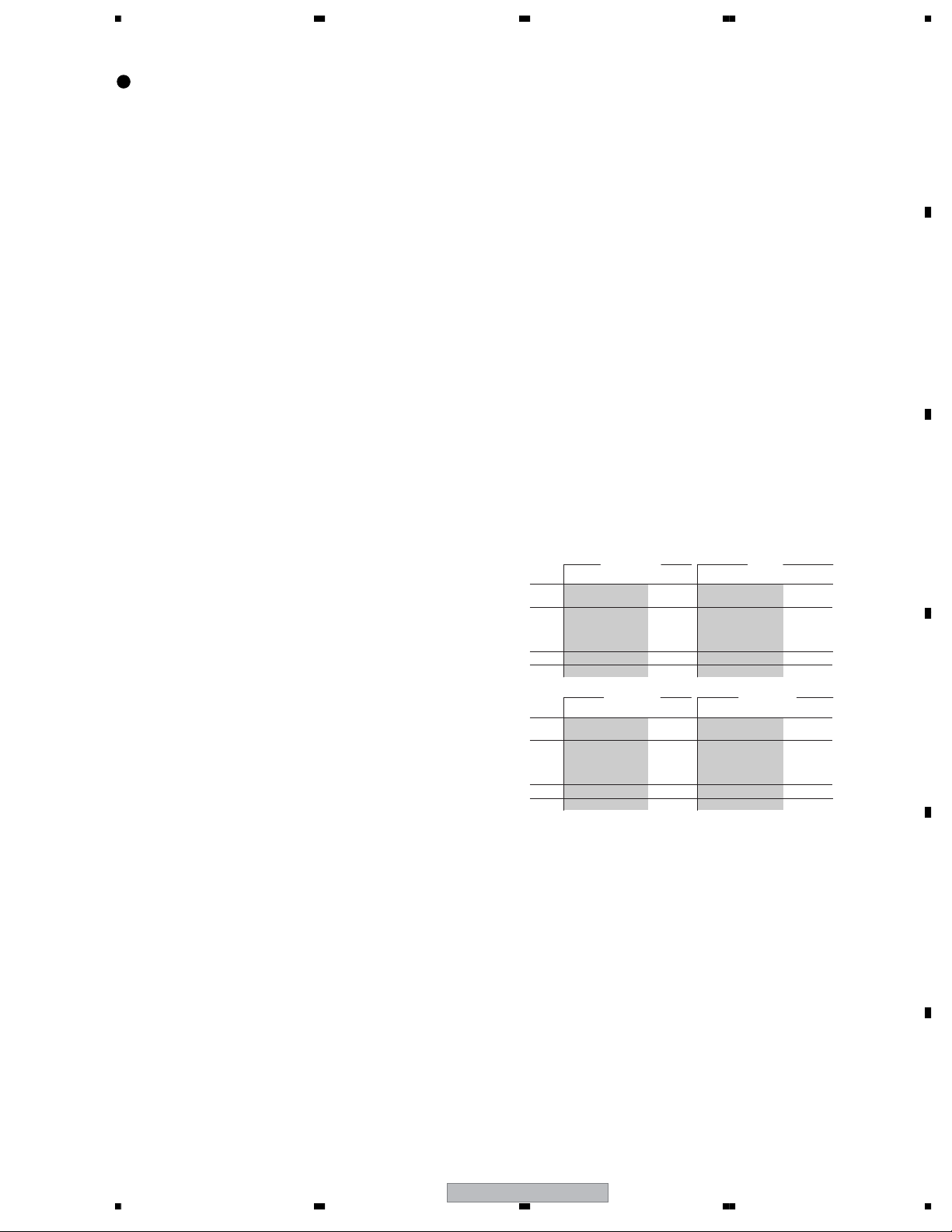

CONTRAST OF PCB ASSEMBLIES

JACB ASSY

A

F

A

VXX3188 and VXX3172 are constructed the same except for the following :

Mark Symbol and Description

301 (2P 4PIN MINIDIN(S)) AKP1234 AKP1235

CN105 (30P CONNECTOR) HLEM30S-1 Not used

CN105 (32P CONNECTOR) Not used HLEM32S-1

JA302 (9P PIN JACK) VKB1238 VKB1239

DTBR ASSY

C

B

F

VXX3189 and VXX3174 are constructed the same except for the following :

Mark Symbol and Description

JA101 (JACK_DIGITAL AUDIO OUT) VKB1241 VKB1242

23

Part No.

VXX3172 VXX3188

Part No.

VXX3174 VXX3189

4

Remarks

Remarks

FRJB ASSY

D

F

VXX3181 and VXX3179 are constructed the same except for the following :

C

Mark Symbol and Description

CN301 (30P CONNECTOR) HLEM30S-1 Not used

CN301 (32P CONNECTOR) Not used HLEM32S-1

CN302 (18P CONNECTOR) VKN1249 Not used

CN302 (20P CONNECTOR) Not used VKN1251

JA301 (4P MINIDIN SOCKET) AKP1238 AKP1239

JA302 (JACK) VKB1208 VKB1220

D

FLKY ASSY

E

F

VXX3187 and VXX3177 are constructed the same except for the following :

Mark Symbol and Description

CN101 (18P CONNECTOR) VKN1278 Not used

CN101 (20P CONNECTOR) Not used VKN1280

E

ATAB ASSY

K

F

VWV2277 and VWV2276 are constructed the same except for the following :

Mark Symbol and Description

VXX3179 VXX3181

VXX3177 VXX3187

VWV2276 VWV2277

Part No.

Part No.

Part No.

Remarks

Remarks

Remarks

CN13 (40P CONNECTOR) Not used VKN1818

F

6

1234

DVR-940HX-S

1

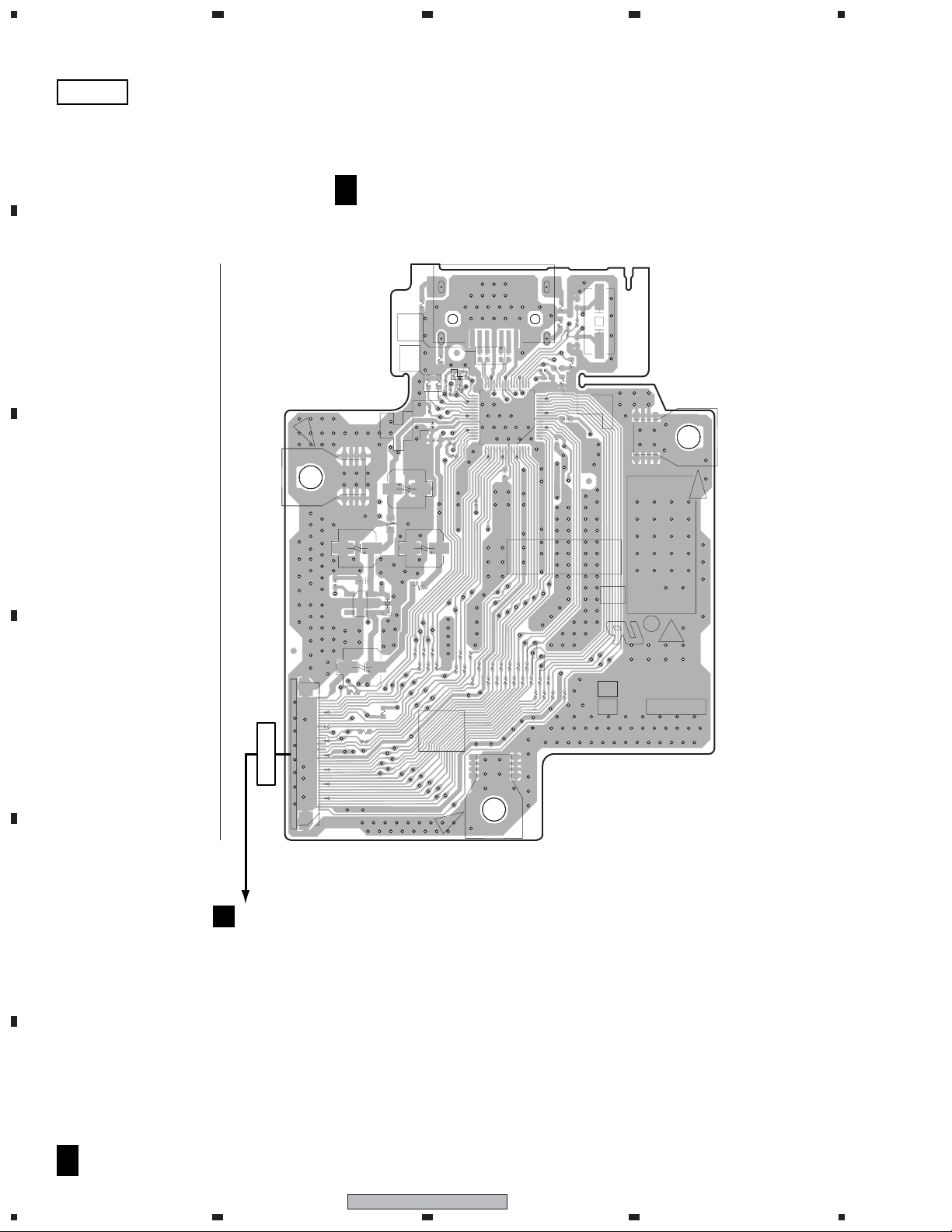

PCB PARTS LIST

Mark No. Description Part No.

234

Mark No. Description Part No.

HDMIB ASSY

H

F

SEMICONDUCTORS

IC0401 AVC2510VM

IC0101 CD0041AF

IC0102 EDS6432AFTA-6B-E

IC0305 NJM12904V

> IC0303 NJM2880U1-05

> IC0301 PQ070XZ02ZP

> IC0302 S-1170B25UC-OTK

> IC0304 S-1170B33UC-OTS

IC0201 SII9030CTU-7

IC0202 TC74LCX08FTS1

IC0103 TC74LCX573FTS1

IC0104 TC7SH04FUS1

Q0206 2SA1576A

Q0202 DTC124EUA

Q0205 HN1C01FU

Q0204 UM6K1N

Q0203 UMB1N

Q0201 UMD2N

D0302, D0303 1SR154-400

D0301 RB501V-40

COILS AND FILTERS

L0201-L0204 ATH7022

L0101, L0401-L0403 CTF1399

L0301 DTL1106

RESISTORS

R0124, R0125 RAB4CQ0R0J

R0502-R0506, R0515-R0517 RAB4CQ100J

R0122, R0123, R0147, R0148 RAB4CQ101J

R0140-R0142 RAB4CQ103J

R0402, R0403 RAB4CQ333J

R0152, R0153, R0156, R0157 RAB4CQ470J

R0128, R0129, R0139, R0143, R0144 RAB4CQ680J

R0435, R0436, R0438, R0451 RAB4CQ680J

R0457, R0458, R0469, R0470 RAB4CQ680J

R0475-R0478, R0481, R0482 RAB4CQ680J

R0485, R0486 RAB4CQ680J

R0115-R0119, R0217-R0222, R0224 RS1/10S0R0J

R0226, R0256, R0421-R0423, R0426 RS1/10S0R0J

R0519, R0520 RS1/10S0R0J

R0309, R0310 RS1/16SS1001D

R0301 RS1/16SS1001F

R0216 RS1/16SS3601F

R0225, R0302 RS1/16SS4700F

R0215 RS1/16SS5600F

Other Resistors RS1/16S###J

OTHERS

X0401 (20MHz) ASS7076

JA0201 HDMI CONNECTOR AKP7210

CN0301 KR CONNECTOR S4B-PH-K-S

CN0101 40P FFC CONNECTOR VKN1811

A

B

C

CAPACITORS

C0435, C0436 CCSRCH180J50

C0305, C0307 CEVW101M16

C0301, C0302 CEVW220M6R3

C0308, C0309 CEVW470M6R3

C0310, C0316, C0319 CKSQYB102K50

C0101, C0106, C0134, C0201, C0203 CKSQYB105K16

C0304, C0311, C0314, C0315 CKSQYB105K16

C0317, C0318, C0320-C0322, C0324 CKSQYB105K16

C0427, C0429, C0437 CKSQYB105K16

C0312 CKSQYB225K10

C0306 CKSQYB225K16

C0209, C0211 CKSRYB102K50

C0323, C0325 CKSRYB104K16

C0104 CKSRYB333K16

C0103, C0303 CKSRYB334K10

C0107-C0133, C0149-C0157 CKSRYF104Z25

C0159-C0161, C0221, C0222 CKSRYF104Z25

C0401-C0426, C0431-C0433, C0439 CKSRYF104Z25

C0501 CKSRYF104Z25

C0135, C0136, C0144, C0205-C0208 CKSRYF105Z10

C0210, C0212-C0218, C0220, C0223 CKSRYF105Z10

C0313, C0434, C0502, C0504, C0508 CKSRYF105Z10

C0510, C0512, C0514, C0516, C0518 CKSRYF105Z10

C0522, C0524, C0526, C0528, C0530 CKSRYF105Z10

C0532 CKSRYF105Z10

C0503, C0505, C0509, C0511, C0513 CKSSYF104Z16

C0515, C0517, C0519, C0523, C0525 CKSSYF104Z16

C0527, C0529, C0531, C0533 CKSSYF104Z16

M

SATB ASSY

F

SEMICONDUCTORS

IC0301 JM20330APB2-TGAA

> IC0302 S-1170B18UC-OTD

CAPACITORS

C0319 CCSRCH120J50

C0320 CCSRCH150J50

C0313, C0314, C0323, C0324 CEVW221M4

C0322 CKSQYF475Z10

C0305-C0308 CKSRYF103Z50

C0325 CKSRYF104Z25

C0301-C0304, C0310-C0312, C0315 CKSRYF105Z10

C0317, C0331 CKSRYF105Z10

C0329, C0330 CKSSYB103K16

RESISTORS

R0303, R0304 RS1/10S0R0J

R0332 RS1/16S1202F

Other Resistors RS1/16S###J

OTHERS

X0301 (25MHz) VSS1207

CN0302 40P FFC CONNECTOR VKN1879

CN0303 SATA CONNECTOR VKN2051

KN0301-KN0303 VNF1109

EARTH METAL FITTING

D

E

F

DVR-940HX-S

1

2

3

4

7

1

23

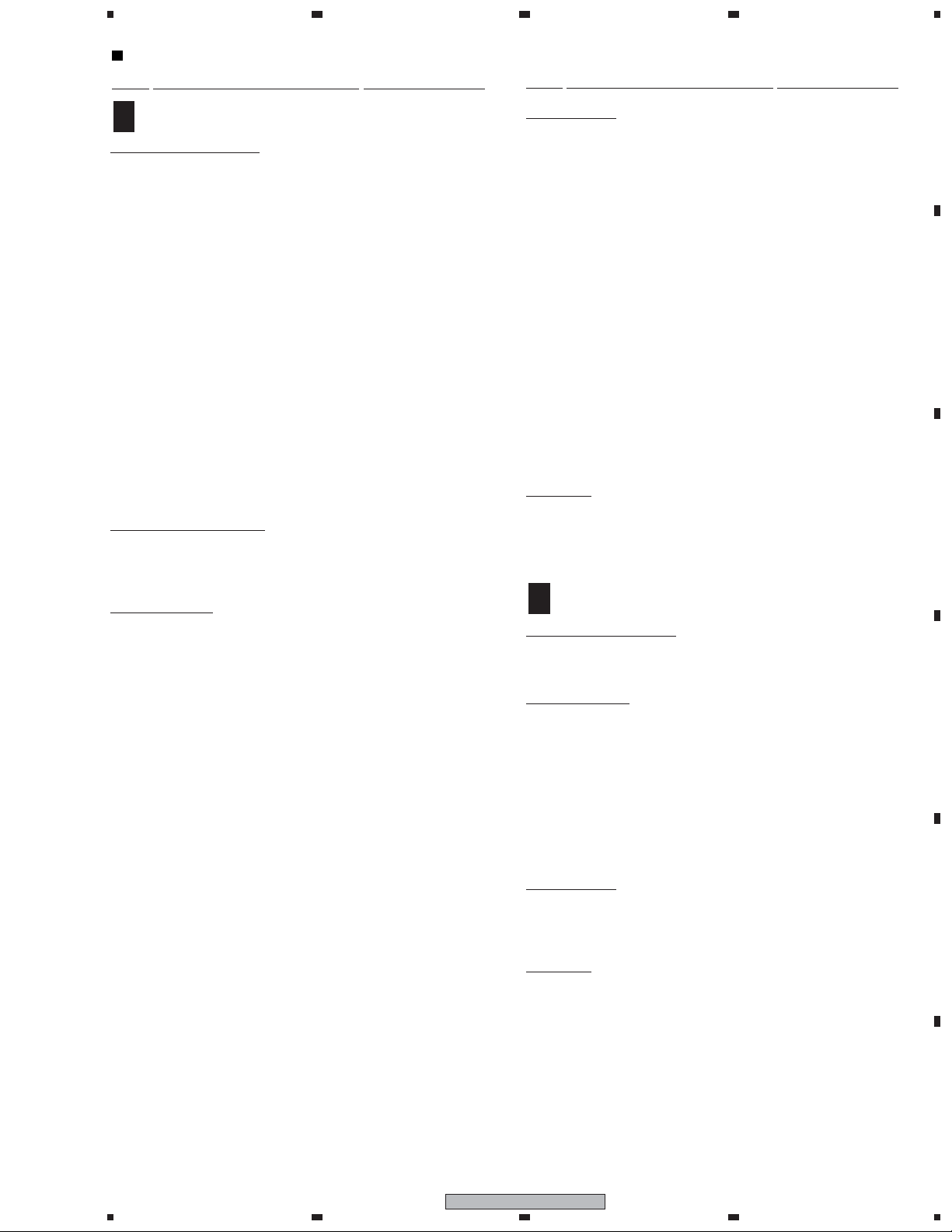

2. GENERAL INFORMATION

2.1 DIAGNOSIS OF THE HDMIB ASSY

A

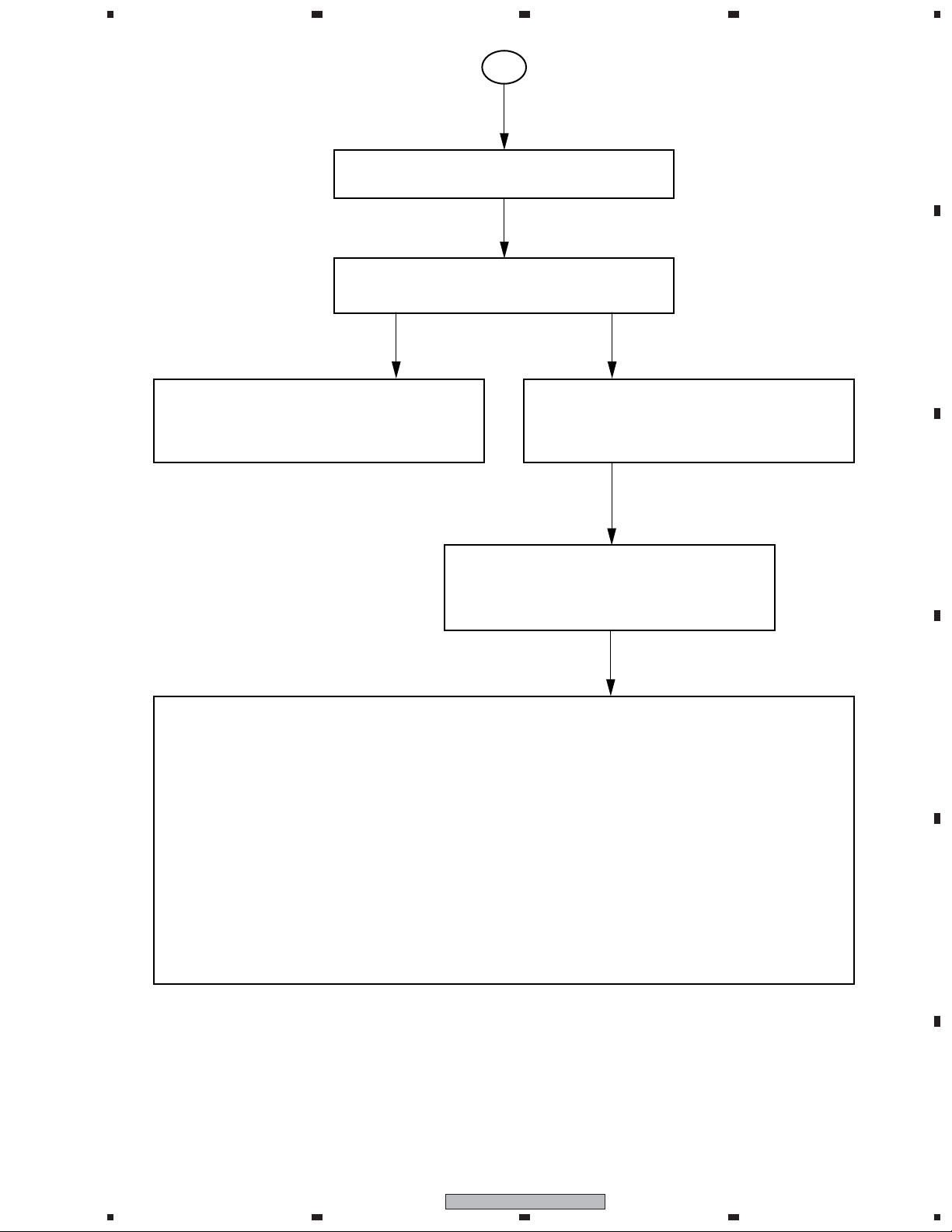

*This flowchart shows how to confirm the output from the HDMI block on the basis that an external input signal to the L1

connector is through-output from the analog output connector properly.

1. In a case when only the HDMI video is not outputted

Connect the unit to a DVI monitor that is provided

with the HDCP function (HDMI-DVI conversion

connector required), or to a monitor that supports HDMI.

Set the input setting to L1.

Input an external PAL signal to L1.

4

B

Is the HDMI indicator

of the unit lit?

No

YES

Is an image

properly

displayed?

YES

to AA

C

With the aid of an oscilloscope, check IC201 for the

points listed below. (Only checking with a PAL signal

is enough. Checking with an NTSC signal is not required):

• R242 (QCLK: 27 MHz/74.25 MHz/148.5 MHz @PAL)

From the following points, a 3.3-V swing signal must be output:

• R244 (H sync)

• R245 (V sync)

• R121-R126 (Video lines)

No

Are all the signals

mentioned above

output?

YES

No

Check the soldering at IC401 and IC201.

*Also check if there is pattern peeling if the

D

E

unit has undergone repair or rework.

Check the communication between IC401 and IC101.

• First check the soldering of IC101.

* Also check if there is pattern peeling if the unit has

undergone repair or rework.

• Next, with the aid of an oscilloscope, check IC401

for the points listed below.

In a case where the set number of pixels is 480i/576i:

• R149 (CLKO: 27MHz@PAL)

From the following points, a 3.3-V swing signal must

be output:

• R151 (H sync)

• R150 (V sync)

• R147, R148 (Video line)

In a case where the set number of pixels is 480p/576p

or larger:

• R150 (QCLK: 27MHz@PAL)

From the following points, a 3.3-V swing signal must

be output:

• R161 (H sync)

• R162 (V sync)

• R152, R153, R154, R155 (Video line: Y)

• R156, R157, R158, R159 (Video line: C)

It is most likely that IC201 and the

subsequent parts are in failure.

Check the soldering of the parts

listed below:

• IC201 itself

• L201-L204, JA201

Enter HDMI Service mode

then check if the HDMI indicator is lit.

Is the TMDS signal

properly output in

HDMI Service mode?

No

Is the FFC cable

properly connected

to CN101?

Yes

No

Reconnect the FFC cable and

CN101 correctly then repeat

the steps of this flowchart

from the beginning.

Are all the signals

mentioned above

properly output?

Check if the LSI power

at IC201 is active:

• 3.3-V system: R202

• 1.8-V system: R201

No

Replace the fuse on the

Power Assy.It is most

likely that inappropriate

connection of the FFC

cable caused short-circuiting

and that the fuse on the

Power Assy was blown.

Yes

Repeat the steps

of this flowchart

from the beginning.

Yes

It is most likely that

IC201 is in failure:

• Check the soldering

of IC201.

• Rework on IC201.

No

• Check if the FFC cable is properly

connected to CN101. (Also check the

connection on the DVDM Assy.)

F

8

• Rework on IC102.

• Rework on IC501.

If the condition does not improve, the

circuitry on the DVDM side is in failure.

DVR-940HX-S

YES

Repeat the steps

of this flowchart

from the beginning.

1234

1

234

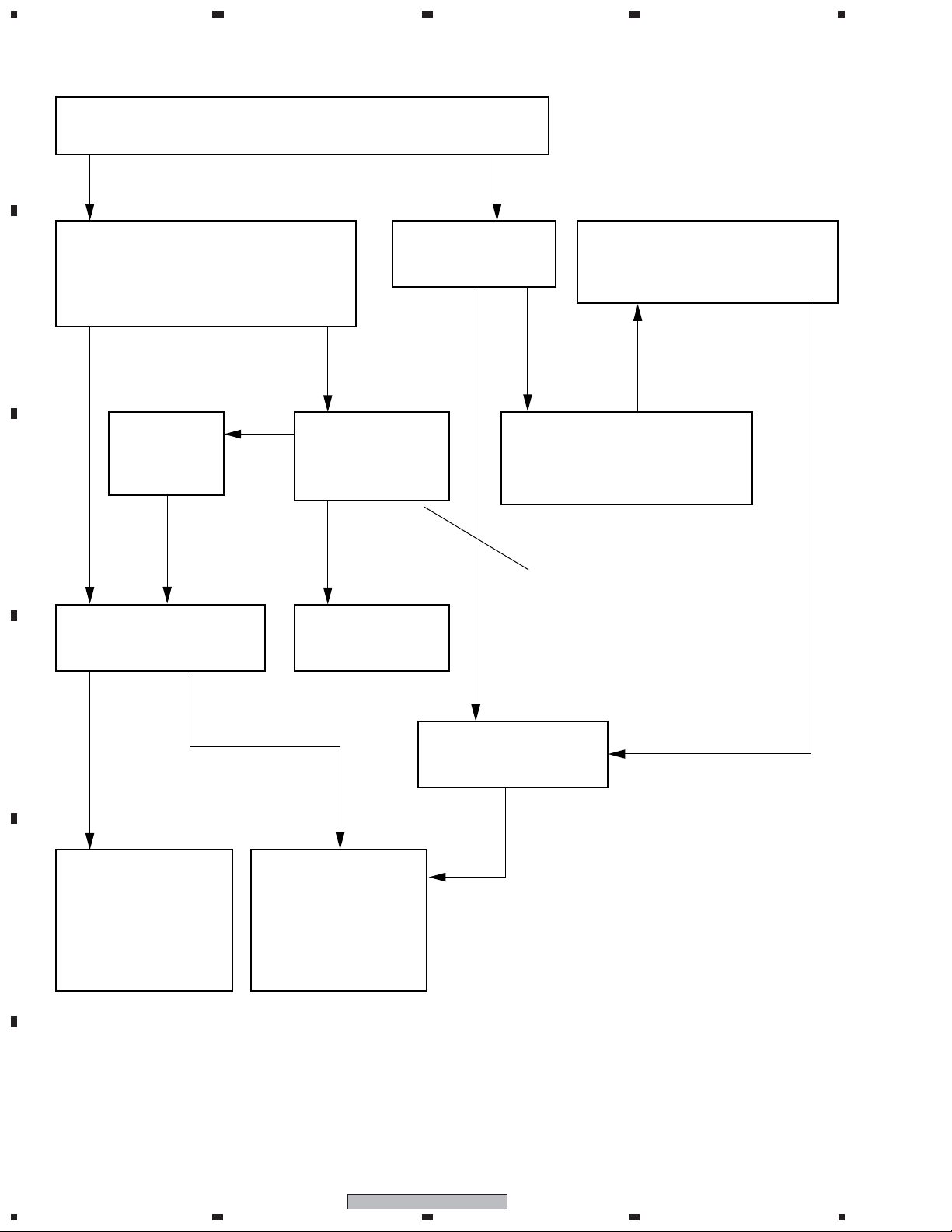

AA

A

The monitor owned by the user may not be compatible

with this unit.

Is a correct picture displayed when the monitor owned by

the user is connected with this unit using a 5-meter cable

made by JAE?

Ye s N o

B

The cable used by the user is in failure.

Is a momentary correct picture and a fully black or a

snowy screen alternately displayed? Or, another

symptom?

Confirm the manufacturer and model number, and check

symptoms in the following steps, then refer to similar

case examples that happened in the past. In some

cases, upgrading the software/firmware of this unit may

resolve the problem.

If there is no measure, ask us for product

quality information.

1 Does the symptom change when the HDMI cable between the monitor and recorder is disconnected then reconnected?

2 With the HDMI cable between the monitor and this unit connected, if the power to the monitor is turned off then back on

again, does the symptom change?

3 Tu rn off the power to both the recorder and monitor. Then, turn on the monitor, then after 30 seconds, turn on the

recorder. Does the symptom change?

4 Is the HDMI LED lit, unlit, or flashing?

C

D

5 What is the picture on the screen like? A fully black, snowy, combination of the both, or other (a fully green or pink

screen)?

6 Does the symptom change if the length of the cable (made by JAE) is different?

7 Are some spots missing by dots (missing pixels) on the screen? If so, there may be problems in the length or quality of

the cable or the reception capacity of the monitor. Check if the symptom disappears when a 5-meter or less cable made

by JAE is used.

DVR-940HX-S

1

2

3

E

F

9

4

1

23

2. In a case when only the HDMI audio is not outputted

4

A

B

C

D

Is a DVI device connected (with a DVI device, only the video signal is output, and no

sound is output)? Is an HDMI device that does not support the audio signals

connected?

No (Checking of the S/PDIF path)

Set the Dolby Digital output setting in "Audio

Output" of the home menu to PCM. Play back the

Dolby Digital audio signal of a DVD. Is the audio

signal correctly output from the HDMI and coaxial

output (S/PDIF)?

HDMI: No

S/PDIF: Yes

There may be a

problem with the

coaxial output

circuit.

In a case where S/PDIF

was "No" in the above

step (analysis in a case

where HDMI was "No")

Measure the signal at R229 of

IC201 (S/PDIF) with an

oscilloscope, using a probe, to

check if the signal is correct.

No

Ye s

Ye s

Coaxial

output

Measure the signal at

R*** (Note 1) (S/PDIF)

with an oscilloscope,

using a probe, to check

if the signal is correct.

There may be a failure

in the MAIN ASSY

(S/PDIF).

Play back a CD. Are the

HDMI and analog audio

signals correctly output?

HDMI: No

S/PDIF: No

No

Measure the signal at R229 of

IC201 (S/PDIF) with an

oscilloscope, using a probe, to

check if the signal is correct.

No (Checking of the AMCK_HDMI, DATA, LRCK,

and BCK paths)

Measure the signal at 1 Pin 5 of IC201

(AMCLK_HDMI) and 2 Pins 10, 11, and

12 of IC201 (DATA, LRCK, and BCK) with

an oscilloscope, using a probe, to check if

the signal is correct.

Note 1 : R135 of DTBR Assy (DT model)

R2008 of TUJB Assy (AT model :/WY)

R544 of TUJB Assy (AT model :/TF)

HDMI: No

Analog: Yes

Ye s

HDMI: No

Analog: No

1There may be a failure in : IC202

2There may be a failure in : MAIN Assy

• EMMA2RFE (DATA, LRCK, BCK)

• the audio DAC circuit or its subsequent

stage.

No

In a case where the analog audio

signal is not correctly output for

reason

(Analysis in a case where

HDMI was "No")

There may be a failure in

MAIN ASSY.

Check the soldering of signal

lines (incl. IC pins), short-

E

F

circuiting, and for breakage

of wires, and if a part shows

a problem, replace the part.

10

1234

HDMI

Replacement of IC201 HDMI

Tr ansmitter: There may be a

problem in the S/PDIF input

block. (After checking that the

soldering is all right, replace

the IC. If soldering is

defective, repair it and check

if the symptom disappears.)

DVR-940HX-S

1

234

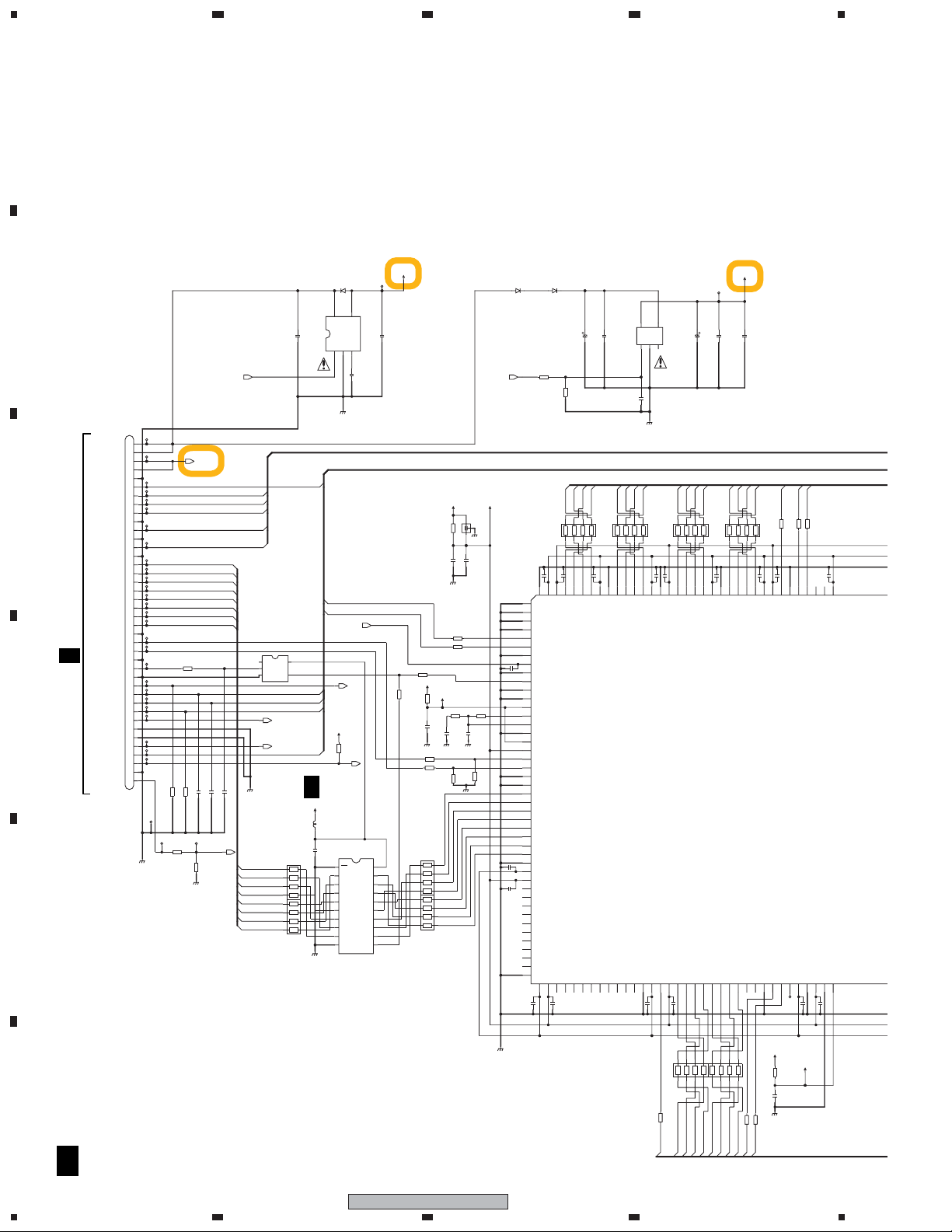

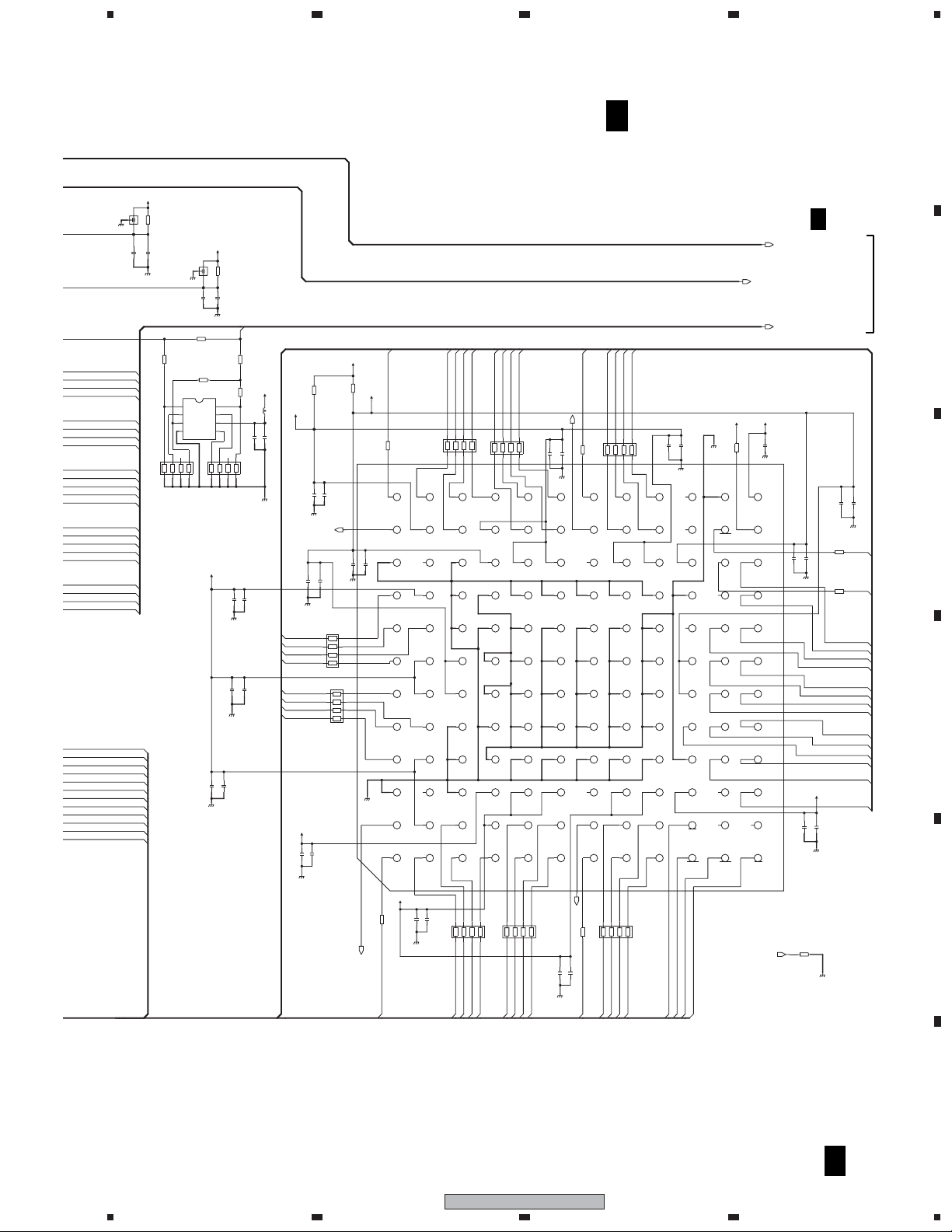

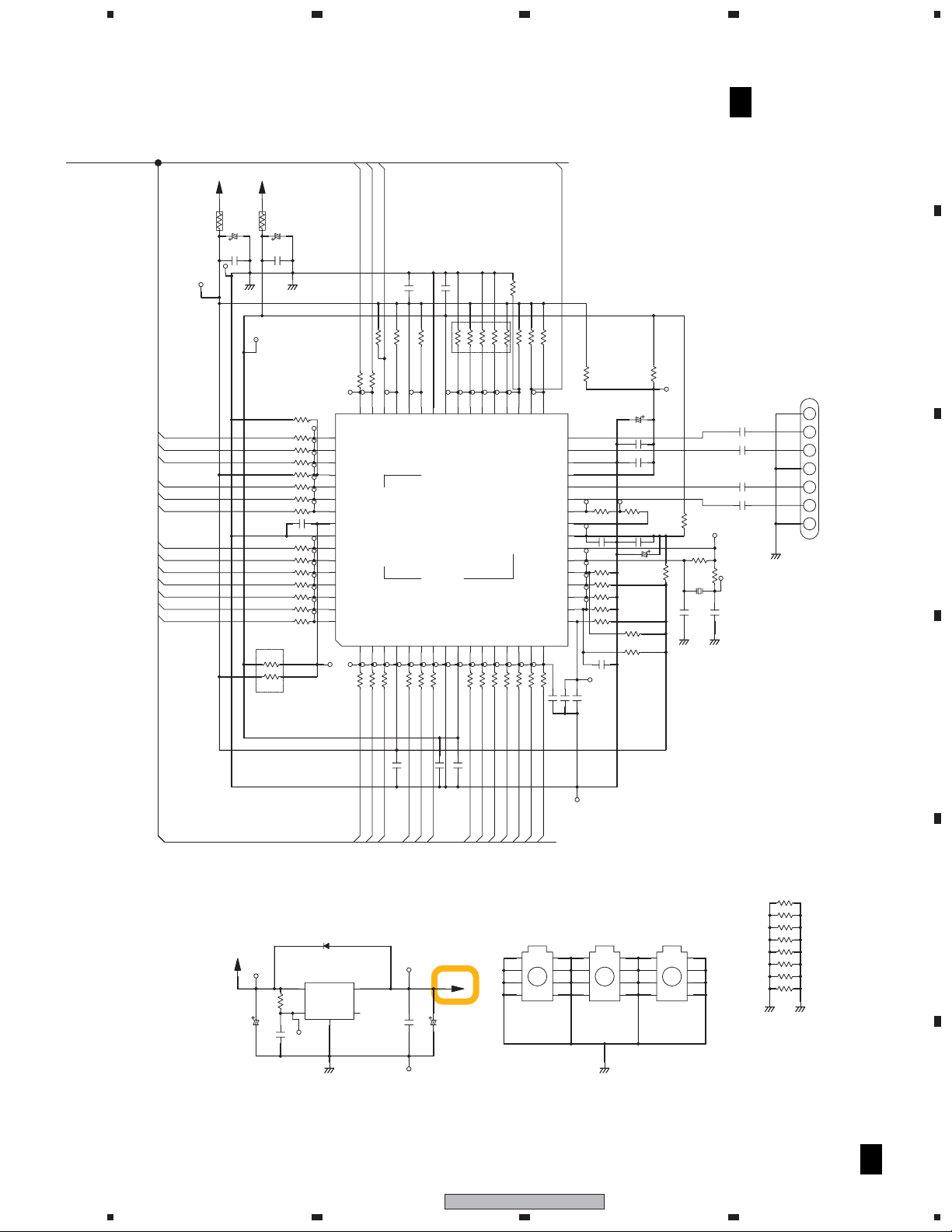

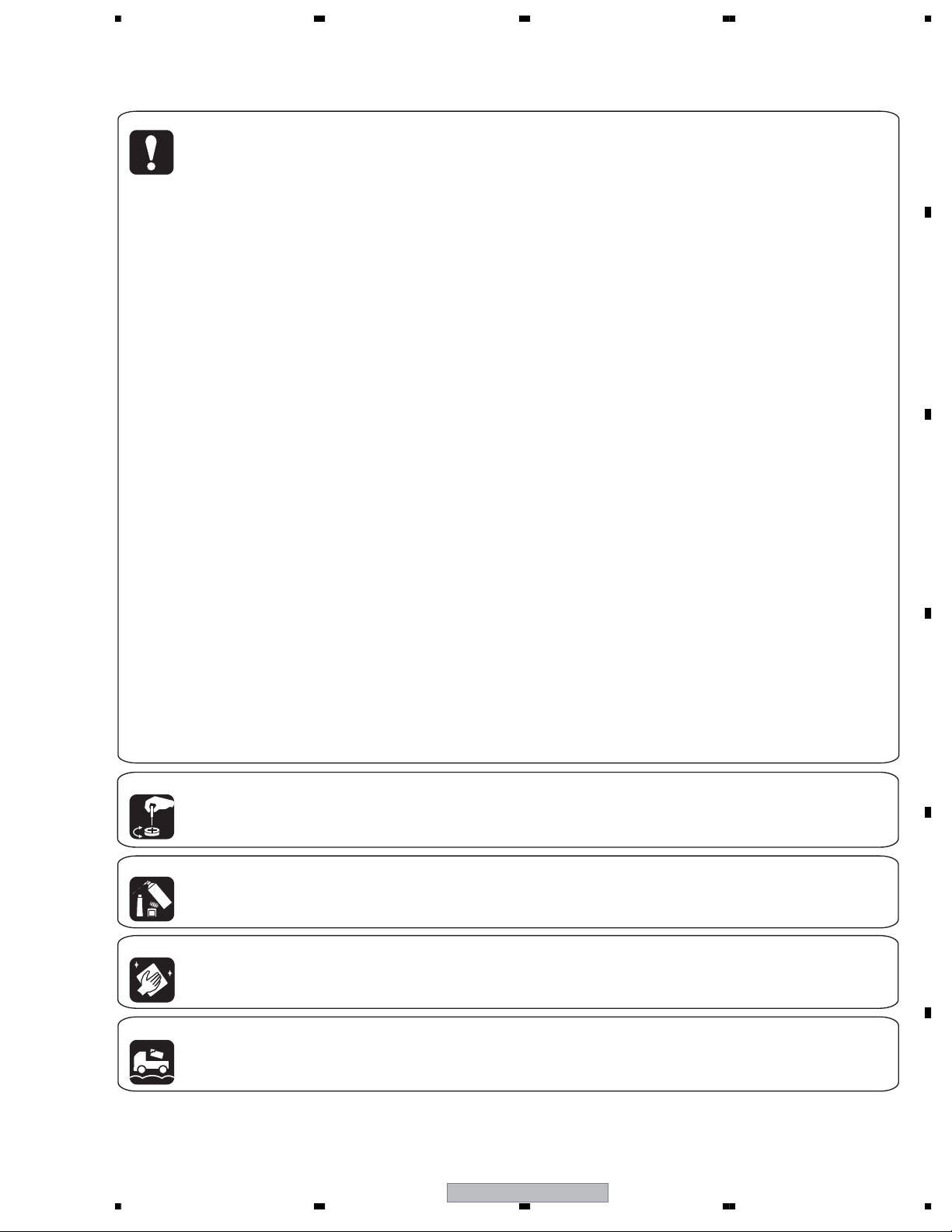

3. SCHEMATIC DIAGRAM

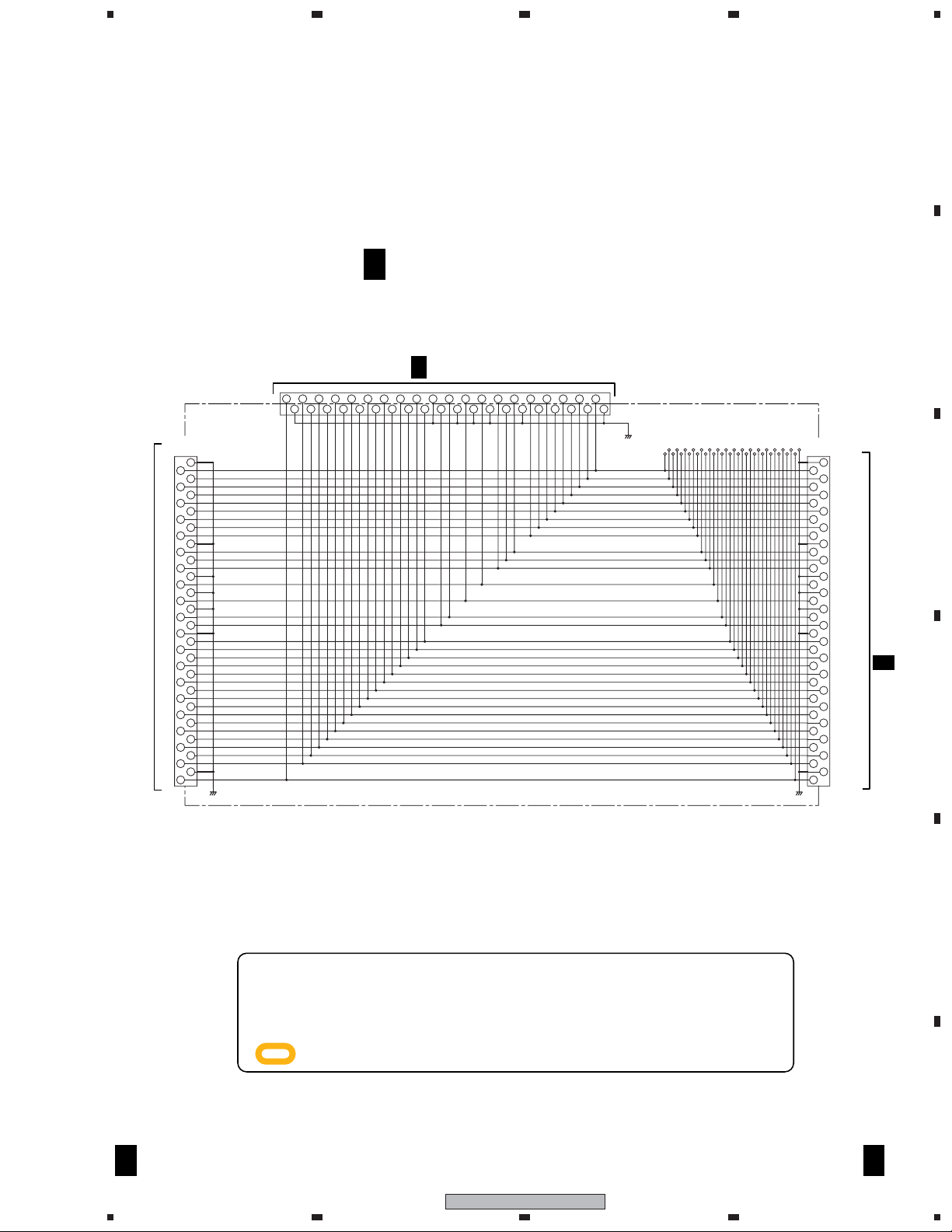

3.1 ATAB ASSY

ATAB ASSY (VWV2277)

K

F

M F

40373638

CN11

VKN1818- -TBB VKN1816-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

TO HDD

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

GND3 GND3

34

39 35 333231

28

24 22 20 18

26

30

29

27

25 23

CN302

1921

161514

12

1317

638

111095

24

71

CN13

VKN1818- -TBB

GND3

CN12

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

7

5

3

1

8

6

4

2

GND

DASP#

CS1#

CS0#

DA2

DA0

PDIAG#

DA1

RESERVED

INTRQ

GND

DMACK#

CSEL

IORDY

GND

DIOR#

GND

DIOW#

GND

DMARQ

(KEYPIN)

GND

DD15

DD0

DD14

DD1

DD13

DD2

DD12

DD3

DD11

DD4

DD10

DD5

DD9

DD6

DD8

DD7

GND

RESET#

A

B

C

CN3801

2/5

G

D

K

F

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

÷

: The power supply is shown with the marked box.

DVR-940HX-S

1

2

3

E

F

K

F

11

4

1

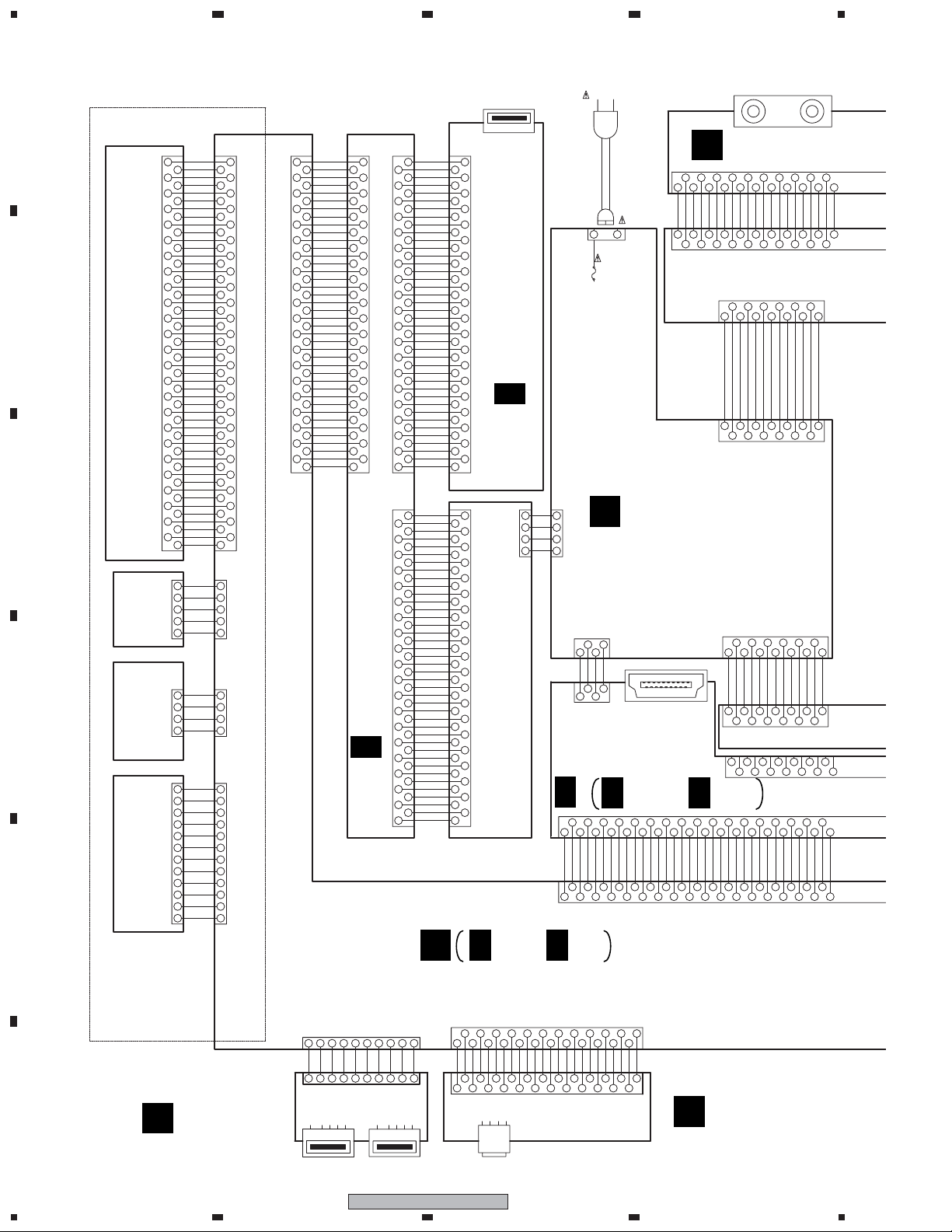

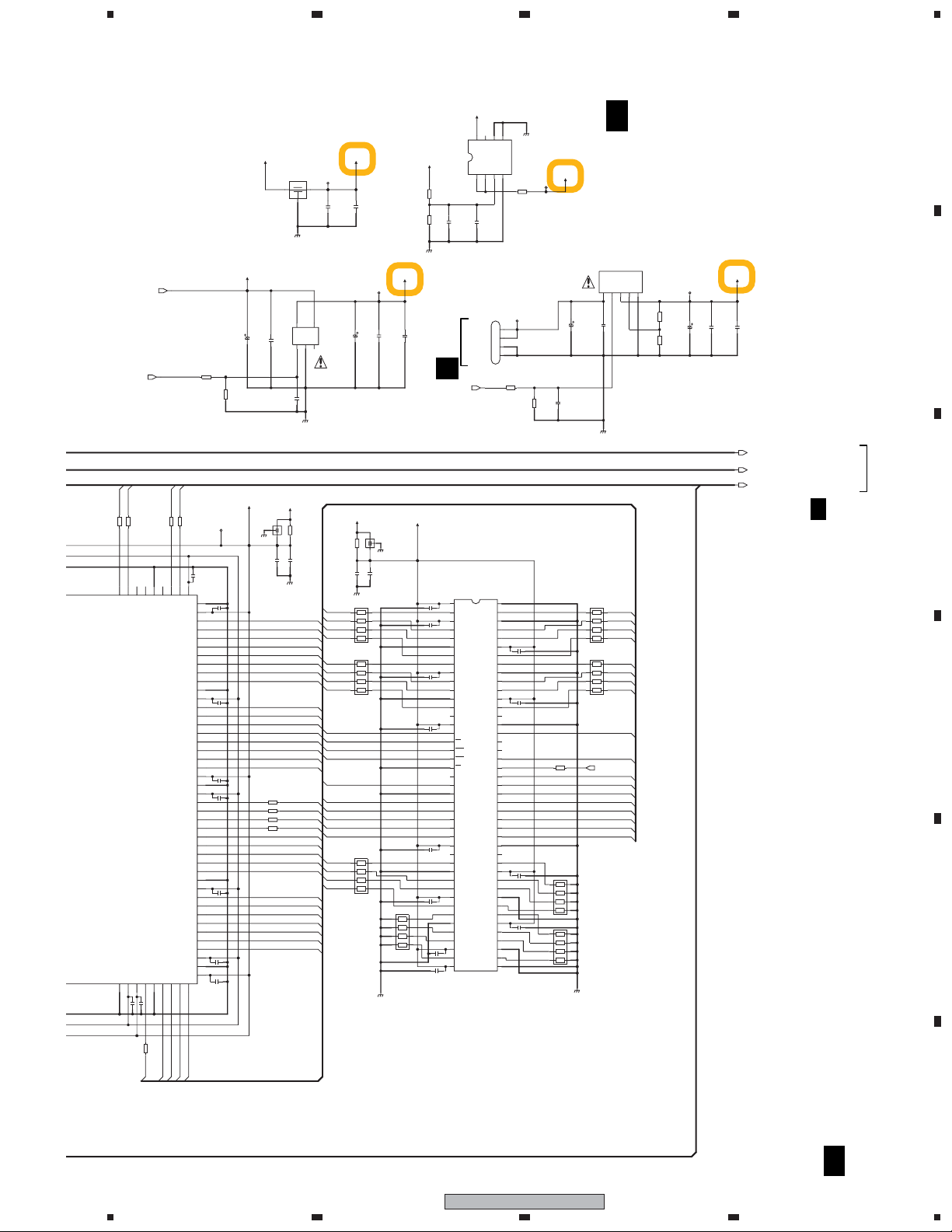

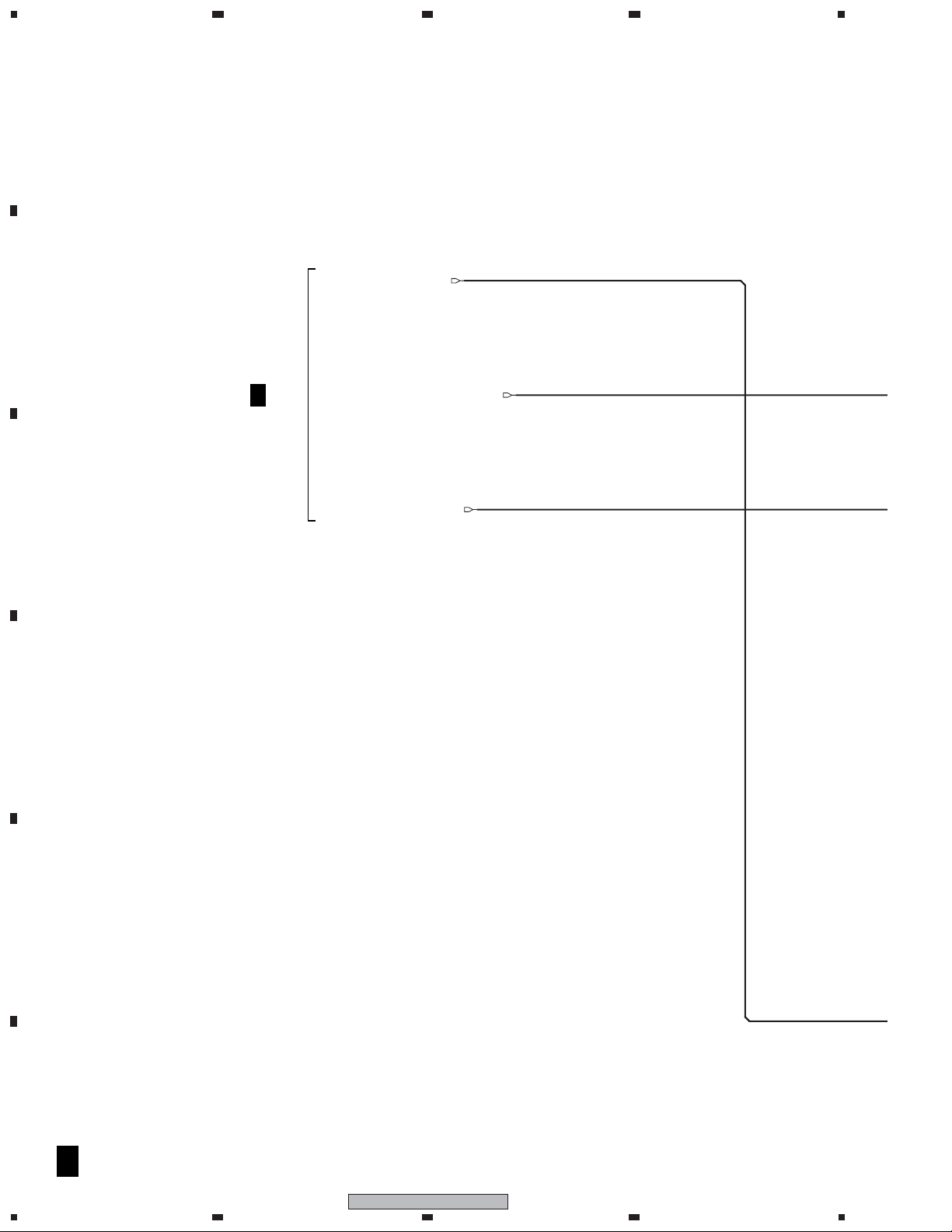

3.2 OVERALL WIRING DIAGRAM

A

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

B

P.U.

C

D

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

FRONT

12 534

4

3

2

1

STEPPER

1210 11

9

87

SPDL

213456

E

TR

FD

FR

SCLK

SEN

SDIO

VPP

RESET

RXW

VD3V

GNDD

TEMP

S1

S2

M1

M2

WRF

WPP2

VREFPD

WPP1

RFGNDS

RF+

VA5V

M3

M4

S3

S4

GNDS

VA5V

VREFFM

FMO

OSCENOSCEN+

W3EN+

W3ENW2EN+

W2ENW1EN+

W1ENRDIS

W3SET

W2SET

W1SET

RSET

VO5V

VO5V

GNDO

GNDO

LPS2

GNDD

LPS1

BLACK

RED

ST2+

ST2-

ST1-

ST1+

VCC

HU+

HU-

HV+

HV-

HW+

HW-

HB

U

V

W

GNDD

50 40

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

CN601

25341

CN502

4

3

2

1

CN501

12

10 11

9

8

7

6

5

34

21

CN101

TD

CN3801

To HDD

23

AC POWER CORD

S-ATA For HDD2

CN303

GND

DASP#

39

CS1#

38

CS0#

37

DA2

36

DA0

35

PDIAG#

34

DA1

33

RESERVED

32

INTRQ

31

GND

30

DMACK#

29

CSEL

28

IORDY

27 27

GND

26

DIOR#

25

GND

24

DIOW#

23

GND

22

DMARQ

21

KEYPIN

20

GND

19

DD15

18

DD0

17

DD14

16

DD1

15

DD13

14

DD2

13

DD12

12

DD3

11

DD11

10

DD4

9

DD10

8

DD5

7

DD9

6

DD6

5

DD8

4

DD7

3

GND

2

RESET#

1

CN13

CN12

40

39

2

38

37

4

36

35

6

34

33

8

32

31

10

30

29

25

23

21

19

17

15

13

11

9

7

5

3

1

11

12

28

13

14

26

15

16

24

17

18

22

19

20

20

21

22

18

23

24

16

25

26

14

27

28

12

29

30

10

31

32

8

33

34

6

35

36

4

37

38

2

39

40

2

4

6

8

10

12

14

16

18

20

21

22

23

24

25

26

ATAB ASSY

(VWV2277)

28

F

30

K

32

34

36

38

39

40

CN11

1

3

5

7

9

1

3

5

7

9

11

13

15

17

19

27

29

31

33

35

37

GND

DASP#

CS1#

CS0#

DA2

DA0

PDTAG#

DA1

RESERVED

INTRQ

GND

DMACK#

CSEL

IORDY

GND

DIOR#

GND

DIOW#

GND

DMARQ

KEYPIN

GND

DD15

DD0

DD14

DD1

DD13

DD2

DD12

DD3

DD11

DD4

DD10

DD5

DD9

DD6

DD8

DD7

GND

RESET#

GND

DASP#

CS1#

CS0#

DA2

DA0

PDIAG#

DA1

RESERVED

INTRQ

GND

DMACK#

CSEL

IORDY

GND

DIOR#

GND

DIOW#

GND

DMARQ

KYEPIN

GND

DD15

DD0

DD14

DD1

DD13

DD2

DD12

DD3

DD11

DD4

DD10

DD5

DD9

DD6

DD8

DD7

GND

RESET#

CN302

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SATB ASSY

(VWV2274)

F

M

132

4

HDD

500G

CN101

SW+12V

GND

2413

GND

SW+5V

CN203

H F

40 36 34 32

1

2

LIVE

(NEUTRAL)

AC-INLET

POWER SUPPLY UNIT

L

(VWR1404)

CN204

2

4

13

GND

GND

EV2R5

EV2R5

341

2

CN301

CN201

AKP7210-A

HDMIB ASSY

(VWV2248)

H 1/3F– H 3/3F

63428

7

15

NC

NC

1080P

XNS_RST

DDCDA

DDCCL

HDMI/XDVI

35373839

CEC

33 31

10

9

11

SCL

SDA

XHDMI_RST

30 28

12

13

GND

XPRV_RST

14

PRVCLK

272629

CN801

12345

GND

V+5BB

25

24

CN106

16

15

17

GND

HSYNC

VSYNC

25 23

24

4

U/V IN/OUT

U801

TUNB ASSY

B

(VWV2262)

8

6

7

9

GND

V+5TU

GND

GND

V+31V

V+5R1

GND

TU_VIN

21

23

22

1819201716

321

P_CONT

EV+12.1V

GND

EV+5.8V

13579

246108

CN202

CN201

12

10

13 11

GNDD

EV+5.8V

SW+1.53V

SW+1.53V

13 11

10

12

CN2401

19 17

18

24

22

20

18

21

25

23

19

PD1

PD2

PD4

PD6

PD5

PD3

PD0

GND

212019

17

22

161514

18

121110

GND

GND

TU_LIN

1514131211

CN401

674

5

GND

GND

EV+5.8V

8

9

GNDD

SW+3.33V

SW+3.33V

9

75

8

15

16 14

282726

PD7

GND

13

13

TU_RIN

8

SW+3.3V

7

GNDD

6

29

GND

SPDIF

12

161514

SDA

AGC

10

10

9

GND

SW+3.3V

456

GND

V+12V

4

111213

10

30

31 3533

GND

33/36_HDMI

11

10

17

SCL

XRST1

12

11

SW+1.5V

GND

11 13

12

3

V+5M

3

9

32

SD

9

18

20

19

STACHG

V+5V

7

896

13

SW+1.5V

2

1

V+12M

GNDM

1

2

7

8

34

BCK

LRCK

XHDMI_INT

7

86

21

SEL_IR

5

6

G

G 1/5– G 5/5

MAIN ASSY (VXX3176)

CN3802

131

USBDM2

1

VKN2045-

24

GND

C_OUT

Y_OUT

232021

22

24

CN101

5769

GND

VENC_RST

VKN2045-

8

141216 2018

111013 15

SDA

SCL

GND

GND

GND

V+3DV

19

17 15

16

18

JA101

VKN2028-

V+3DV

14

GND

ABCK

PCM

DV_INT1

ALRCK

9

13

11

8

10

12

1917 21

DV_RST

DV_INT2

7

6

DV_TX

5

DV_RX

412

2422

23

V+3D

V+3D

V+5D

3

DVJB ASSY

I

(VWV2160)

VWT1235-A/V

LOADER ASSY

F

12

USBB ASSY

J

(VWV2161)

CN5601

S10B-PH-K-S

10

89675 234

GND

USBDP1

10

98 567423

CN101

JA101 JA102

VKB1226- VKB1227-

GND

USBDM1

B10B-PH-K-S

USBVFB

V+5USB

GND

DVR-940HX-S

USBDP2

GND

1234

5

678

22

24

25

23

IR

V+12R1SW

IR_B

GND

3

1

2

4

DIGITAL

AUDIO OUT

COAXIAL

JA101

CN601

15

GND

V+5VI

GND

1

2

CN501

G-LINK

JA304

SR IN

JA305

CN901

8

6

9

GND

7

AV2_V/YIN

GND

8

5

R/CIN

GND

GIN

111215

10

4

12

131411

RGB_YIN

3

4

10

GND

RGB_CIN

579

6

D-TV IN/OUT

U301

CN201

DTBR ASSY

(VXX3189)

CN102

43126758

9

321

GND

GND

BIN

13

14

C 1/2– C 2/2

C F

10

111213

FAN+

FAN-

CN103

2

4

6

8

10

12

14

16

18

20

22

24

26

14

COMPONENT

DT_TUON

1

ANT5V_SW

DET_ANT

3

P_CONT2

GND

5

DTU_LIN

GND

7

DTU_RIN

GND

9

DTU_CIN

GND

11

DTU_YIN

GND

13

V+1.5SW

V+1.5SW

15

GND

V+3.3SW

17

V+3.3SW

GND

19

V+12SW

GND

21

V+5.8E

GND

23

V+5.8E

GND

25

V+31V

GND

27

Y

PBPR

LRV

VRL

JA302

CN102

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

323334

302326 242522

35

31

272829

S

S

JA301

OUTPUT

INPUT3

A F

A 1/3– A 3/3

JACB ASSY (VXX3188)

CN101

8

6

21 19

1820

171615

14 10

111213

95

214

7

3

AV2(INPUT1/DECORDER)

V/Yout

GNDV

222524

GNDV

R/Cin

GNDV

GNDV

BLANK

V/Yin

3

5

7

8

6214

26 3433323130 383736

23 292827

V/Yout

V/Yin

GNDV

GNDV

BLANK

R/Cout

GNDV

GNDV

GNDVNCGin

GNDVNCGout

N-LINK

131211109

N-LINK

GNDV

GNDV

AV1(to TV)

8

6

3

125

4

12

10

7

9

11

Lin

FUNCTION

GNDV

Bin

GNDA

171615

14

18

40

35 394241

FUNCTION

Bout

Lin

GNDV

GNDA

14

16

17

13

15

A

FAN MOTOR

VXM1125-

Rout

Rin

Lout

212019

FAN-

FAN+

1

2

CN104

JA501

Lout

Rin

Rout

1

2

3

4

5

6

7

8

9

CN103

B

C

20

22

18

19

21

CN105

26

24

23

25

32

28

30

27

31

29

321

5

4

CN201

VKN1811-A

CN101

38394036

37

EV5R8

GND

EV5R8

SW3R3

SW3R3

51

432

CN6001

VKN2050-A

CN1402

GND

GND

GND

SPDIF

AMCK_LL

1113

10

14

12

CN2601

3412 756

GND

SPDIFIN

9

8

RX1

GND

TX1

XRESET

RFE/XLL

XLL_REG

XLL_XADC

3

1

5

7

426

PWSB ASSY

F

(VXX3178)

AMUTE1

GND

R_IN

13

24 8

CN2301

CN211

4132

P_CONT2

L_IN

KEY1

GND

LED_PON

V+12V

GND

C_IN

795

6

CN102

4132

Y_IN

X525P

10

V101

E

GND

11 13 1715

GND

CR_OUT

CB_OUT

12

FL TUBE

F

YP_OUT

GND

GND

GND

Y_OUT

GNDA

L_OUT

MRST

C_OUT

R_OUT

XRST1

SW+12V

2119 23 25 2927

181614 3022 24 2820 26

FLKY ASSY

(VXX3187)

DAM_TO_T

DAT_TO_M

HSM_TO_T

CN101

2

4

6

8

10

12

14

16

18

20

ASCK

HST_TO_M

1

3

5

7

9

11

13

15

17

19

GND

SPDIF

31

GND

V+5F

GND

V+12R1E

IR

KEY1

KEY2

FLPON

FLDATA

FLCLK

FLSTB

GND

LED_HDD

LED_DVD

LED_ATT

LED_REC

LED_PON

LED_HDMI

RESET OUT

LED_HDD2

33 35

3432

RXDGLNCTXDGL

CN302

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

SDET2

32

D

2Y

2V

2C

GND

2L

2R

GND

GND

30

GND

GND

25

292731

23

24

26

28

IR

GND

GND

GND

V+5F

KEY1

V+12R1E

21

19

171513

182220

16

KEY2

GND

FLPON

FLCLK

FLSTB

FLDATA

LED_DVD

LED_ATT

LED_HDD

LED_REC

LED_PON

LED_HDD2

LED_HDMI

RESET OUT

1

957

11

14

12

3

4

2

6108

CN301

E

FRJB ASSY

D F

(VXX3181)

INPUT2

JA301

S

L

V

JA302

R

F

DVR-940HX-S

5

6

7

8

13

1

3.3 HDMIB ASSY (1/3)

A

23

4

4

3

C313

VOUT

1u/10

V+5HD

TP303

C314

1u/16

NJM2880U1-05

1SR154-400

YB(2125)

PCONT2SEQ

D301

RB501V-40

C312

2.2u/10

YB(2125)

IC303

5

VIN

CONT1GND2N.B

B

SW3R3

From DVDM

CN101

VKN1811-A

TP101

EV5R8

40

EV5R8

39

TP102

SW3R3

38

SW3R3

37

GND

36

TP103

35

XHDMI_INT

C

AMCK_HDMI

SPDIF_HDMI

CN6001

5/5

G

PRVCLK

XPRV_RST

D

XHDMI_RST

HDMI/XDVI

XNS_RST

PCONT2

LRCK

HSYNC

VSYNC

DDCCL

DDCDA

1080P

TP104

BCK

34

TP105

33

TP106

SD

32

GND

31

TP107

30

GND

29

TP108

28

GND

27

TP109

PD7

26

TP110

PD6

25

TP111

PD5

24

TP112

PD4

23

TP113

PD3

22

TP114

PD2

21

TP115

PD1

20

TP116

PD0

19

GND

18

TP117

17

TP118

16

TP119

GND

15

14

13

GND

TP120

12

TP121

11

SDA

TP122

10

SCL

TP123

9

TP124

8

CEC

7

6

TP127

5

TP130

4

TP131

3

2

GND

1

TP128

GND

E

REC656O[7]

REC656O[6]

REC656O[5]

REC656O[4]

REC656O[3]

REC656O[2]

REC656O[1]

REC656O[0]

R126

0

10k

R120

R121 10k

R171

6.8k

TP133TP132

GND

SW3R3

NM

C147

R172

PRVCLK1

NM

C148

10k

AMCK_HDMI

SPDIF_HDMI

NM

C145

BCK

LRCK

SD

IC104

TC7SH04FUS1

1

2

GND

PCONT2SEQ

REC656O[0]

REC656O[1]

REC656O[2]

REC656O[3]

REC656O[4]

REC656O[5]

REC656O[6]

REC656O[7]

NC

INA

GND3OUTY

XHDMI_INT

VCC

XHDMI_RST

CEC

HDMI/XDVI

R124

8

7

6

5

8

7

6

5

5

4

R125

GND

V+3R3PRV

V+3R3

NM

L104

3

2

0

R115

1

(2125)

GND

NM

YB

C102

C101

1u/16

YB(2125)

R110 0

0

R118

GND

R111

R112 NM

R122

100

8

7

6

5

8

7

6

5

R123

100

(2125)

0

C135

V+3R3

1u/10

1

2

3

4

1

2

3

4

GND

NM

GND

V+3R3PLL

R109

820

C103

R113

R105

R106

0.33u/10

GND

0

0

0

R108

3.3k

C104

0.033u/16

0

R114

GND

C107

0.1u/25

C108

0.1u/25

SDA

SCL

XPRV_RST

PRVCLK2

SDA

XPRV_RST

SCL

R127

V+3R3

1080P

R138

33k

XNS_RST

2/3FH

V+3R3

L101

CTF1399-A-T

0

C144

1u/10

20

1

1

2

3

4

1

2

3

4

0

GND

Vcc

OE

2

D0

3

D1

4

D2

5

D3

6

D4

7

D5

8

D6

9

D7

10

GND11LE

IC103

TC74LCX573FTS1

19

Q0

18

Q1

17

Q2

16

Q3

15

Q4

14

Q5

13

Q6

12

Q7

C143

D303

D302

1SR154-400

4

5

VIN

VOUT

C302

C320

IC304

1u/16

22u/6.3

1

2NC3

VSS

170

VDDE15

R157

C131

169

47

0.1u/25

VSS16

ON/OFF

S-1170B33UC-OTS

C317

1u/16

YB(2125)

GND

QY8

QC3

658

3

C130

166

QR1

QY9

QC2

7

214

165

QR0

0.1u/25

164

VDDE14

163

R152

VSS15

47

162

VDDI10

C129

658

3

0.1u/25

160

161

QG6

QG7

QC5

QC4

167

168

QR2

QR3

SD to HD Scaler

R306

3.3k

NM

R305

QC6

QC9

QC8

QC7

658

7

47

R156

214

3

0.1u/25

C132

0.1u/25

C133

1

2

TEST0

3

TEST1

TEST2

4

ALSB

5

SDA

6

SCL

7

TEST3

8

NM

NRST

9

TEST4

10

CLKI

11

TEST5

12

AVS1

13

AVD1

14

CPO

15

VCI

16

AVS2

17

AVD2

18

NTEST

19

VI

20

HI

21

SI0

22

SI1

23

SI2

24

SI3

25

SI4

26

SI5

27

SI6

28

SI7

29

SI8

30

SI9

31

VSS1

32

VDDI1

33

VDDE1

34

CO9

35

CO8

36

CO7

37

CO6

38

CO5

39

CO4

40

CO3

41

CO2

CO1

42

CO0

VSS2

43

44

171

172

173

174

175

176

QR4

QR5

QR6

QR7

VSS17

VDDI11

VDDE16

VDDI245VDDE246YO947YO848YO749YO650YO551YO452YO353YO254YO155YO056VSS357VDDI358CLKO59VDDE360SO961SO862SO763SO664SO565SO466SO367SO268SO169SO070TEST671HO72VO73FILM74VDDI475VSS476VDDE477AVSP78AVDP VDDE11

TP304

C309

C318

47u/6.3

QY7

QY6

7

R153

214

C128

0.1u/25

156

157

158

159

QG4

QG5

VDDE13

IC101

CD0041AF

PROV

1u/16

47

155

VSS14

QY5

QG3

V+3R3

C319

YB(2125)

QY4

658

3

C127

154

QG2

QY3

153

1000p/50

QY2

7

214

0.1u/25

152

QG0

QG1

YB(2125)

151

VDDE12

QC1

QC0

QCLK

47

47

82

R160

R159

R158

0.1u/25

C125

C126

0.1u/25

143

144

145

146

147

148

149

150

VDDI9

QCLK

VSS13

QB4

QB5

QB6

QB7

0.1u/25

C109

C110

0.1u/25

GND

C111

0.1u/25

100

R147

C112

0.1u/25

658

7

214

3

658

3

7

214

100

F

R149

656[07]

656[06]

656[05]

656[04]

656[03]

656[02]

656[01]

CLKO

656[00]VOHO

R151

100

R148

100

R150

V+1R8

R119

C136

GND

100

0

1u/10

TP129

0.1u/25

C113

V+1R8PLL

(2125)

C114

0.1u/25

H 1/3F

14

1234

DVR-940HX-S

5

678

SW3R3

PCONT2SEQ

QY1

QY0

47

47

R154

R155

137

138

139

140

141

142

QB0

QB1

QB2

QB3

VSS12

VSS580VDDE581VDDI582MCLK83VSS684MD1985MD1886MD1787MD16

79

C115

C116

0.1u/25

0.1u/25

V+2R5

L301

DTL1106-A

3

2

GND

SW3R3

5

VOUT

C301

C311

1

22u/6.3

R307

1k R303

NM

R308

QH

QV

V+1R8PRV

100

100

TP135

R162

R161

C124

0.1u/25

133QV134QH135

136

C123

0.1u/25

132

QDE

131

VDDE10

VSS11

130

VDDI8

MD15

129

MD0

128

MD14

127

MD1

126

MD13

125

MD2

124

MD12

123

MD3

C122

122

VSS10

0.1u/25

121

VDDE9

120

MD11

119

MD4

118

MD10

117

MD5

116

MD9

115

MD6

114

MD8

C121

113

MD7

0.1u/25

112

VDDI7

111

VSS9

110

VDDE8

VDDE7

VDDE6

VDDI6

109

WE

108

CAS

107

DQM

106

RAS

105

MA9

104

MA11

103

MA8

102

MA10

101

MA7

100

VSS8

99

98

MA0

97

MA6

96

MA1

95

MA5

94

MA2

93

MA4

92

MA3

91

VSS7

90

89

88

C119

0.1u/25

C118

0.1u/25

C117

0.1u/25

C120

0.1u/25

R101 68

R102

R103

R104 68

2NC3

1u/16

YB(2125)

ON/OFF

C321

1u/16

GND

V+1R8

NM

L102

3

2

0

1

R116

GND

YB

NM

C106

C105

GND

MD15 MD1

MD14

MD13

MD12

MD11

MD10

68

0

MA11

MA10

1u/16

MD0

MD1

MD2

MD3

MD4

MD5

MD9

MD6

MD8

MD7

CAS

DQM

RAS

MA9

MA8

MA7

MA0

MA6

MA1

MA5

MA2

MA4

MA3

1

TP306

4

VIN

VSS

YB(2125)

(2125)

YB(2125)

WE

C322

IC302

MD0

MD2

MD3

MD4

MD5

MD6

MD7

DQM

WE

CAS

RAS

MA11

MA10

MA0

MA1

MA2

DQM

MD16

MD17

MD18

MD19

1u/16

S-1170B25UC-OTK

YB(2125)

R117

C134

V+3R3

0

1u/16

V+DDR

C323

C308

(2125)

YB(2125)

GND

R128

1

2

3

4

68

R129

1

2

3

4

68

R139

1

2

3

4

68

0.1u/16

TP305

47u/6.3

3

1

V+DDR

V+2R5

C316

1u/16

YB(2125)

1000p/50

YB(2125)

V+3R3M

NM

NM

YB

C156

0.1u/25

C149

0.1u/25

C157

0.1u/25

C150

0.1u/25

C159

0.1u/25

C151

0.1u/25

R140

8

1

7

2

6

3

5

4

10k

0.1u/25

R309

R310

GND

C152

0.1u/25

C153

EDS6432AFTA-6B-E

YB

C315

L103

2

GND

C146

8

7

6

5

8

7

6

5

8

7

6

5

GND

V+3R3

IC305

NJM12904V

123

1k

(D) (D)

C324

C325

1u/16

1k

YB(2125)

CN301

EV2R5

EV2R5

GND

CN204

GND

L

SW3R3

1

VDD1

2

DQ0

3

VDDQ1

4

DQ1

5

DQ2

6

VSSQ1

7

DQ3

8

DQ4

9

VDDQ2

10

DQ5

11

DQ6

12

VSSQ2

13

DQ7

14

NC1

15

VDD2

16

DQM0

17

WE

18

CAS

19

RAS

20

CS

21

NC2

22

BA0

23

BA1

24

A10(AP)

25

A0

26

A1

27

A2

28

DQM2

29

VDD3

30

NC3

31

DQ16

32

VSSQ3

33

DQ17

34

DQ18

35

VDDQ3

36

DQ19

37

DQ20

38

VSSQ4

39

DQ21

40

DQ22

41

VDDQ4

42

DQ23

43

VDD4

IC102

64M SDRAM

678

GND

V+

B+INPUT

B-INPUT

BOUTPUT

AOUTPUT

A-INPUT

A+INPUT

GND

45

TP307

R311

47

YB

0.1u/16

From SYPS

TP302

1

2

3

4

4.7k

R304

86

VSS4

85

DQ15

84

VSSQ8

83

DQ14

C161

82

DQ13

81

0.1u/25

VDDQ8

80

DQ12

79

DQ11

78

VSSQ7

77

DQ10

76

C160

DQ9

75

0.1u/25

VDDQ7

74

DQ8

73

NC7

72

VSS3

71

DQM1

70

NC6

69

NC5

68

CLK

67

CKE

66

R145 0

A9

65

A8

64

A7

63

A6

62

A5

61

A4

60

A3

59

DQM3

58

VSS2

57

NC4

C154

56

DQ31

0.1u/25

55

VDDQ6

54

DQ30

53

DQ29

52

VSSQ6

51

DQ28

50

DQ27

49

VDDQ5

48

DQ26

C155

47

DQ25

0.1u/25

46

VSSQ5

45

DQ24

44

VSS1

HDMIB ASSY

H 1/3F

VREF_D

IC301

PQ070XZ02ZP

Vin2VC3VO4Vadj5GND

1

C303

C307

100u/16

0.33u/10

NM

C306

2.2u/16

YB(2125)

GND

(VWV2248)

TP301

470

R302

C305

C304

100u/16

1k

(F) (F)

R301

1u/16

V+1R8

C310

YB(2125)

YB(2125)

1000p/50

A

B

Transmitter Audio_IN

AVC2510 & Transmitter control

AVC2510 Video_IN

2/3FH

R143

MD15

8

1

MD14

7

2

MD13

6

3

MD12

5

4

68

R144

MD11

8

1

MD10

7

2

MD9

6

3

MD8

5

4

68

DQM

MCLK

XPRV_RST

MA9

MA8

MA7

MA6

MA5

MA4

MA3

DQM

R141

10k

8

1

7

2

6

3

5

4

8

1

7

2

6

3

5

4

R142

10k

GND

C

D

E

R146

MCLK

82

MD17

MD18

MD19

MD16

F

H 1/3F

DVR-940HX-S

5

6

7

8

15

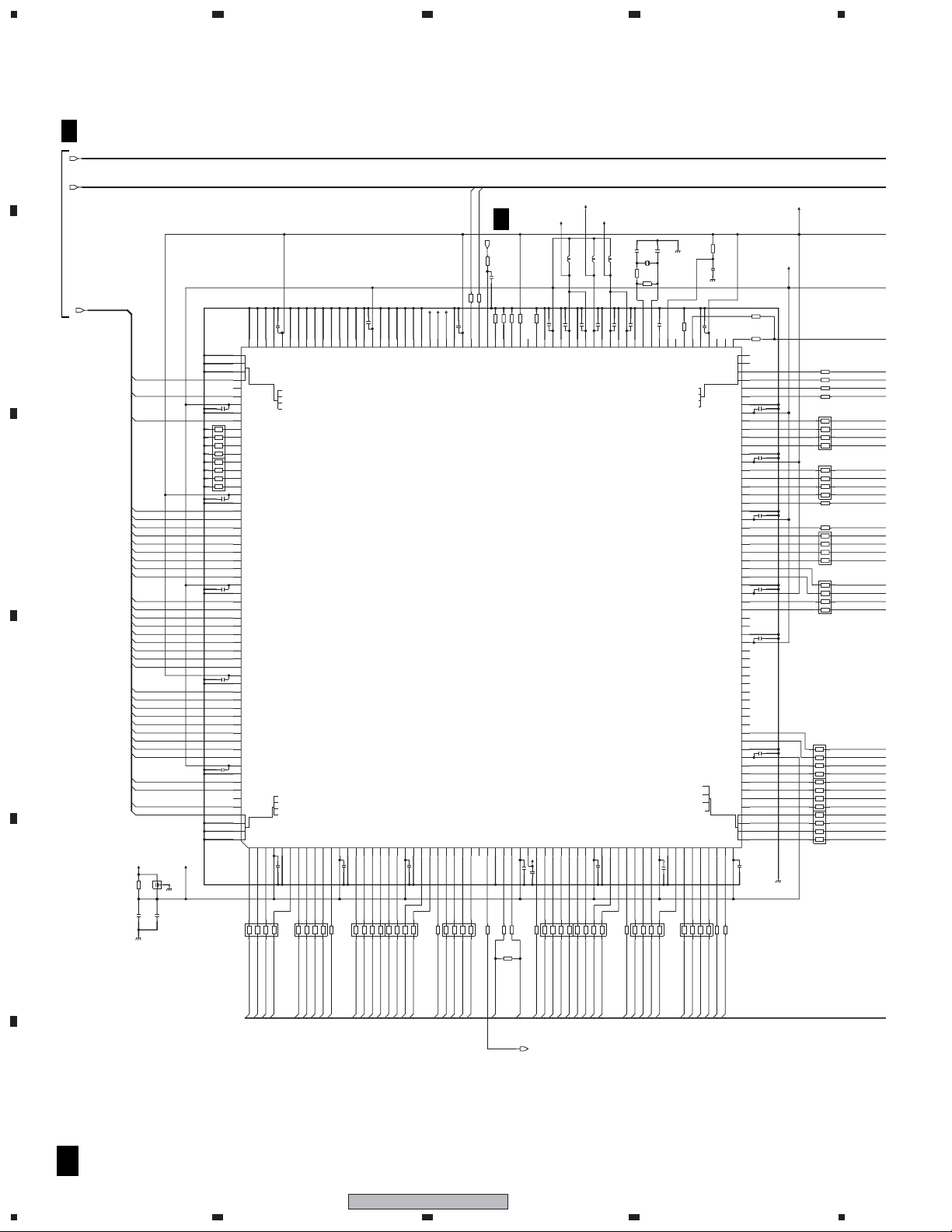

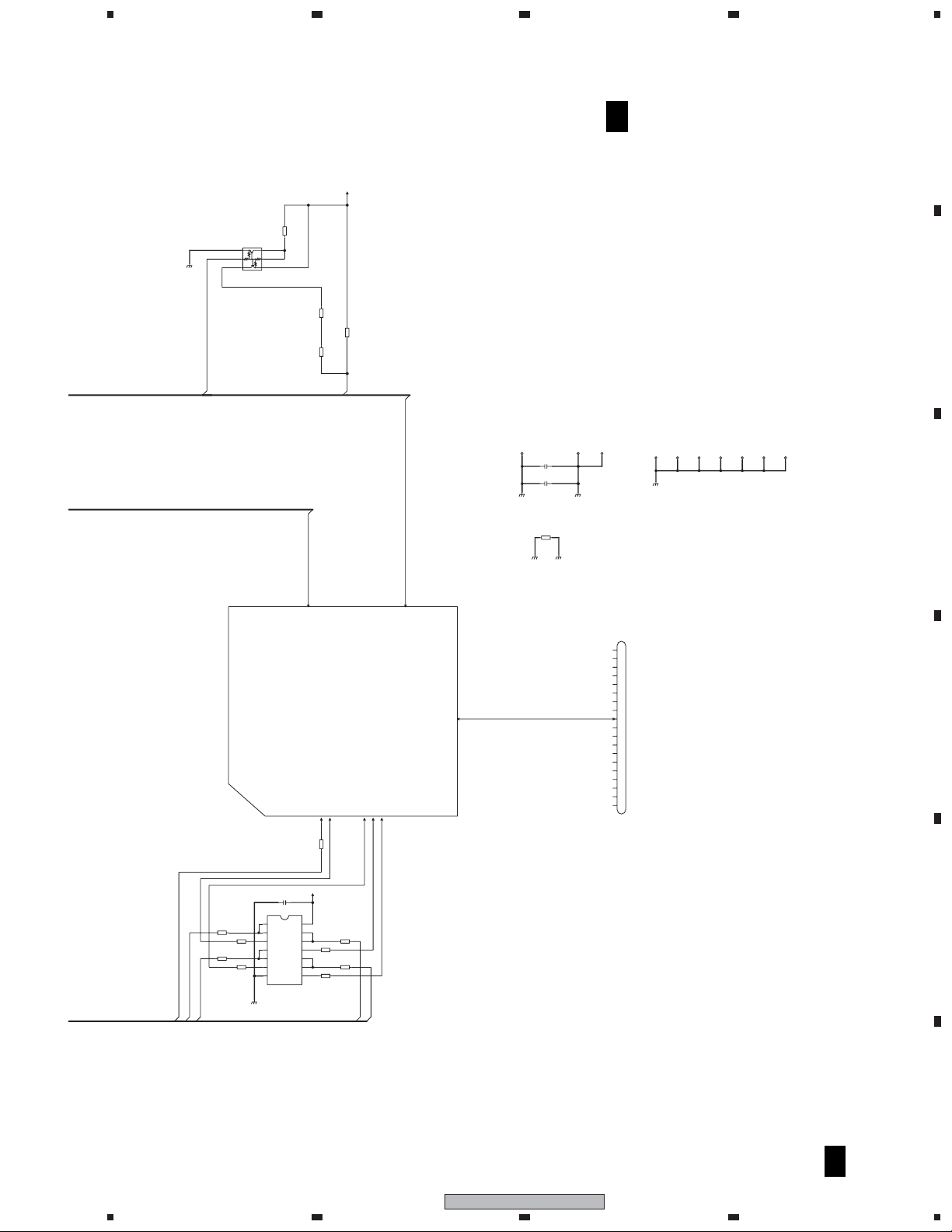

1

3.4 HDMIB ASSY (2/3)

A

1/3FH

Transmitter Audio_IN

AVC2510 & Transmitter_control

B

C

D

E

AVC2510 Video_IN

0

R426

C437

1u/16

V+2R5

CLKO

HO

VO

656[07]

656[06]

656[05]

656[04]

656[03]

656[02]

656[01]

656[00]

QY9

QY8

QY7

QY6

QY5

QY4

QY3

QY2

QY1

QY0

QC9

QC8

QC7

QC6

QC5

QC4

QC3

QC2

QC1

QC0

QCLK

QH

QV

(2125)

YB(2125)

GND

V+2R5NS

NM

L407

3

2

1

GND

NM

C438

23

SDA

SCL

1/3F

H

XNS_RST

0

R489

NM

C442

0

33k

33k

33k

R428 0

R427

C419

0.1u/25

151

152

153

154

155

SDA

SCL

VSS20

VDD33TO4

IC401

AVC2510VM

NM

214

3

658

7

R462

68

R478

33k

R432

150

RESETZ

TEST

R429

R430

R431

147

148

149

TCK

TRST

C409

0.1u/25

R448 56

R449 56

R468

NM

TP401

TP403

TP402

0.1u/25

C421

172

173

174

175

176

177

178

179

180

181

182

183

184

185

C422

186

0.1u/25

187

188

189

190

8

1

191

7

2

R402

33k

192

6

3

193

5

4

194

8

1

195

7

2

R403

33k

196

6

3

197

5

4

198

199

200

C423

0.1u/25

201

202

203

204

205

206

207

C424

208

0.1u/25

209

210

211

212

213

214

215

216

217

218

C425

219

0.1u/25

220

221

222

223

224

225

226

227

228

229

C426

230

0.1u/25

231

232

233

234

235

236

237

238

239

240

YB

VSS22

OSDIN[0]

OSDHREFIN

OSDVREFIN

HD1_FD

HD1_HS

VDD18_6

VSS23

HD1_VS

HD1[15]

HD1[14]

HD1[13]

HD1[12]

HD1[11]

HD1[10]

HD1[9]

HD1[8]

VDD33TO6

VSS24

HD1[7]

HD1[6]

HD1[5]

HD1[4]

HD1[3]

HD1[2]

HD1[1]

HD1[0]

SYNCLK[5]

VDD18_7

VSS25

SYNCLK[4]

SYNCLK[3]

SYNCLK[2]

HD2[15]

HD2[14]

HD2[13]

HD2[12]

HD2[11]

HD2[10]

VDD33TO7

VSS26

HD2[9]

HD2[8]

HD2[7]

HD2[6]

HD2[5]

HD2[4]

HD2[3]

HD2[2]

HD2[1]

VDD18_8

VSS27

HD2[0]

HD2_CLK

HD2_FD

HD2_HS

SDDAT[0]1SDDAT[1]2SDDAT[2]

R436

3

658

68

OSDIN[3]

OSDIN[2]

OSDIN[1]

VDD33TO5

OSDCLKIN

YS

YM

HD1_CLK

HD2_VS

FSEL

SYNCLK[1]

SYNCLK[0]

VDDMEM14VSS15SDDAT[3]6SDDAT[4]7SDDAT[5]8SDDAT[6]9SDDAT[7]10DQS[0]11VDDMEM212VSS213SDDAT[8]14SDDAT[9]15SDDAT[10]16SDDAT[11]17SDDAT[12]18SDDAT[13]19VDDMEM320VSS321SDDAT[14]22SDDAT[15]23DQS[1]24WEZ25CASZ26RASZ27CSZ[1]28CSZ[2]29DQM30VSS431CLK32CLKZ33VDDMEM434DDRREF35DQS[2]36SDDAT[16]37SDDAT[17]38SDDAT[18]39SDDAT[19]40SDDAT[20]41SDDAT[21]42VDDMEM543VSS544SDDAT[22]45SDDAT[23]46DQS[3]47SDDAT[24]48SDDAT[25]49SDDAT[26]50VDDMEM651VSS652SDDAT[27]53SDDAT[28]54SDDAT[29]55SDDAT[30]56SDDAT[31]57BA[0]58BA[1]

3

0.1u/25

C406

3

214

658

7

68

R435

171

OSDIN[5]

OSDIN[4]

214

7

170

C407

169

OSDIN[7]

OSDIN[6]

0.1u/25

R437 68

168

OSDIN[8]

C420

167

OSDIN[9]

0.1u/25

166

R438

VSS21

165

VDD18_5

3

658

68

156

157

158

159

160

161

162

163

164

OSDCLKOUT

OSDIN[15]

OSDIN[14]

OSDIN[13]

OSDIN[12]

OSDIN[11]

OSDIN[10]

OSDHREFOUT

OSDVREFOUT

VIDEO FORMAT CONVERTER

0.1u/25

C408

68

214

3

214

658

7

7

R443

68

R475

V+1R8PLAB

V+1R8PLAA

V+1R8PLAD

L401

L402

CTF1399-A-T

C432

C401

33k

R401

145

146

TDO

TMS

C402

0.1u/25

0.1u/25

0.1u/25

138

139

140

141

142

143

144

TDI

VSS17

VSS18

VSS19

VDD18_4

VDD18PLLAB

VDD18PLLAA1

VDD18PLLAA2

L403

CTF1399-A-T

C403

C404

0.1u/25

135

136

137

VSS16

VDD18PLLAD2

R424

CTF1399-A-T

C405

0.1u/25

133

134

VSS14

VSS15

VDD18PLLAD1

R425

18p/50

C435

2.2k

1M

0.1u/25

132

XTALO

131

XTALI

C436

X401

ASS7076-A

C433

130

BGAP

PRIOPFID[1]

PRIOPFID[0]

18p/50

GND

20M

0.1u/25

129

VDD33XTAL

PRIOPVS[0]

PRIOPHS[0]

33k

R404

128

EXTPLLOUT

SDADR[2]

SDADR[1]

SDADR[0]

SDADR[10]

127

EXTPLLIN

VREF_D

C410

0.1u/25

C439

214

3

R450 68

658

7

68

R451

0.1u/25

214

3

658

7

R456 68

68

R476

R457

3

658

68

0.1u/25

C411

214

7

126

PRIOPCK[1]

R458

125

VSS13

3

658

68

R423

C434

GND

124

VDD33TO3

PRIOUT[19]

PRIOUT[18]

PRIOUT[17]

PRIOUT[16]

PRIOUT[15]

PRIOUT[14]

PRIOUT[13]

PRIOUT[12]

PRIOUT[11]

PRIOUT[10]

PRIOUT[9]

PRIOUT[8]

PRIOUT[7]

PRIOUT[6]

PRIOUT[5]

PRIOUT[4]

PRIOUT[3]

PRIOUT[2]

PRIOUT[1]

PRIOUT[0]

AUXOUT[0]

AUXOUT[1]

AUXOUT[2]

AUXOUT[3]

AUXOUT[4]

AUXOUT[5]

AUXOUT[6]

AUXOUT[7]

SDADR[11]

214

7

0

1u/10

C418

0.1u/25

123

PRIOPVS[1]

VDD18_3

VDD33TO2

VDD18_2

VDD33TO1

AUXOUTVS

AUXOUTHS

VDD18_1

AUXOUTFD

AUXOUTCK

SDADR[9]

VDDMEM8

SDADR[8]

SDADR[7]

SDADR[6]

SDADR[5]

SDADR[4]

SDADR[3]

4

(2125)

R492 NM

R433 82

121

122

PRIOPCK[0]

PRIOPHS[1]

VSS12

VSS11

VSS10

VSS9

VSS8

VSS7

VDDMEM7

59

60

68

R461 68

R460

V+3R3NS

V+1R8NS

120

119

118

117

116

C417

115

0.1u/25

114

113

112

111

110

C416

109

0.1u/25

108

107

106

105

104

103

102

0.1u/25

101

100

99

98

97

96

95

94

C415

93

0.1u/25

92

91

90

89

88

C414

87

0.1u/25

86

85

84

83

82

81

80

79

78

77

76

75

74

C413

73

0.1u/25

72

71

70

69

68

67

66

65

64

63

62

61

C412

0.1u/25

R479 100

R480 100

R487 68

R488 68

4

5

R486

3

6

68

2

7

1

8

4

5

R485

3

6

68

2

7

1

C431

8

R484 68

R483 68

4

5

R482

68

3

6

2

7

1

8

R481

68

4

5

3

6

2

7

1

8

R477

4

5

68

3

6

2

7

1

8

R469

4

5

68

3

6

2

7

1

8

R470

4

5

68

3

6

2

7

1

8

GND

DDATA4

DDATA5

DDATA6

DDATA2

DDATA1

DDATA0

DDATA3

DDATA7

DDQS0

DDATA8

DDATA9

DDATA10

DDATA11

DDATA12

DDATA13

DDQS1

DWE

DCAS

DRAS

DDATA14

DDATA15

DCS

DCLK

DCLKZ

DDQS2

DDATA16

DDATA17

DDATA18

DDATA19

DDATA20

DDATA21

DDQS3

DDATA24

DDATA25

DDATA26

DDATA28

DDATA29

DDATA30

DDATA31

DBA0

DDATA22

DDATA23

DDATA27

DBA1

DDQM

F

H 2/3F

16

1234

DVR-940HX-S

5

678

L405

GND

NM

C430

PY9

PY8

PY7

PY6

PY5

PY4

PY3

PY2

PY1

PY0

PC9

PC8

PC7

PC6

PC5

PC4

PC3

PC2

PC1

PC0

DADRS11

DADRS9

DADRS8

DADRS7

DADRS6

DADRS5

DADRS4

DADRS3

DADRS2

DADRS1

DADRS0

DADRS10

H 2/3F

V+3R3

NM

3

2

0

R422

1

(2125)

YB

C429

1u/16

GND

R490

PV

PH

NM

R464

V+1R8

NM

L406

3

2

YB(2125)

NM

1

2

3

45

3

658

0

R421

1

GND

C428

IC402

REF

CLK2

CLK1

GND

214

7

(2125)

NM

YB

C427

1u/16

YB(2125)

GND

R463

PCLK

0

R491

R465

NM

NM

R467

8

CLKOUT

7

CLK4

6

VDD

CLK3

214

3

NM

658

7

R466

V+DDRQ

C522

1u/10

GND

C524

1u/10

GND

1u/10

C508

C509

0.1u/16

GND

NM

V+3R3

NM

C441 NM

R520

V+DDRQ

NM

L404

NM

C440

GND

C526

C523

0.1u/16

DDATA28

DDATA29

DDATA30

DDATA31

DDATA0

C525

DDATA1

0.1u/16

DDATA2

DDATA3

V+DDRD

C528

1u/10

GND

V+DDR

DDQS3

0

0

V+DDRD

R519

(2125)

(2125)

10

R510

B13

R514 10

DDQS0

DQS3

B12

DM3

B11

VSSQ2

B10

DQ28

DQ29

DQ31

DQ0

DQ2

DQ3

VSSQ1

DM0

DQS0

B9

B8

B7

B6

B5

B4

B3

B2

V+DDRQ

C13

DQ27

C12

VDDQ6

C11

NC2

C10

VDDQ5

DQ30

VDDQ4

VDDQ3

DQ1

VDDQ2

NC1

VDDQ1

DQ4

1u/10

C530

GND

C503

C502

1u/10

0.1u/16

GND

DDQM

C505

C504

1u/10

0.1u/16

GND

C527

0.1u/16

1u/10

GND

R517

10

4

5

3

6

2

7

1

8

4

5

3

6

2

7

1

8

R502

10

GND

C529

0.1u/16

DDQM

DDATA24

DDATA25

DDATA26

DDATA27

10

R504

DQ25

DQ26

VSSQ8

VSSQ7

C9

VSSQ6

C8

VDD2

C7

VDD1

C6

VSSQ5

C5

VSSQ4

C4

VSSQ3

C3

C2

C531

0.1u/16

DDATA4

D13

D12

D11

D10

DQ5

DQ6

3

658

D9

D8

D7

D6

D5

D4

D3

D2

DDATA5

214

7

3

658

DDATA6

214

7

DDATA7

10

R515

E13

DQ24

E12

VDDQ8

E11

VDD4

E10

VSS4

VSSQ10

VSS3

VSS2

VSSQ9

VSS1

VDD3

VDDQ7

DQ7

DDATA14

DDATA13

DDATA12

DDATA15

214

3

658

7

F13

DQ14

F12

DQ15

F11

VDDQ10

F10

VSSQ12

E9

F9

VSS8

E8

F8

VSS7

E7

F7

VSS6

E6

F6

VSS5

E5

F5

VSSQ11

E4

F4

VDDQ9

E3

F3

DQ16

E2

F2

DQ17

214

3

10

R505

658

7

DDATA16

DDATA17

DDATA18

DDATA19

DDQS1DDQS2

DDATA9

DDATA8

DDATA11

DDATA10

DDQM

214

3

10

R507

0.1u/16

C518

C519

1u/10

658

7

GND

G13

H13

DDQM

R508

0.1u/16

DQS1

H12

DM1

H11

NC4

H10

VSSQ16

VSS16

VSS15

VSS14

VSS13

VSSQ15

NC3

DM2

DQS2

10

J13

DQ10

J12

DQ11

J11

VDDQ14

J10

VSSQ18

H9

J9

VSS20

H8

J8

VSS19

H7

J7

VSS18

H6

J6

VSS17

H5

J5

VSSQ17

H4

J4

VDDQ13

H3

J3

DQ20

H2

J2

DQ21

214

3

658

7

DDATA20

DDATA21

DDATA23

DDATA22

R516

DQ12

G12

DQ13

G11

VDDQ12

G10

VSSQ14

G9

VSS12

G8

VSS11

G7

VSS10

G6

VSS9

G5

VSSQ13

G4

VDDQ11

G3

DQ18

G2

DQ19

10

C532

1u/10

GND

C533

HDMIB ASSY

(VWV2248)

IC501

K4D263238I-VC50

128M GDDR

10

C516

R506

C517

1u/10

0.1u/16

GND

K13

L13

DQ8

NC6

K12

L12

DQ9

NC5

K11

L11

VDDQ16

VDD8

L10

K10

VSSQ20

VSS26

L9

K9

RFU1

VSS24

L8

K8

VDD7

VSS23

L7

K7

VDD6

VSS22

L6

K6

A10

VSS21

L5

K5

VSS25

VSSQ19

L4

K4

VDD5

VDDQ15

L3

K3

WE

DQ23

K2

L2

DQ22

CAS

10

R503

DWE

DCAS

DRAS

DCS

3/3FH

Transmitter Audio_IN

AVC2510 & Transmitter_control

Transmitter VIDEO_IN

V+DDR

VREF_D

GND

M13

MCL

M12

CK2

M11

CK1

M10

RFU2

M9

A5

M8

A9

M7

A11

M6

A2

M5

BA1

M4

NC8

M3

NC7

M2

RAS

C501

R509

10k

0.1u/25

GND

N13

VREF

A8/AP

N12

CKE

N11

N10

A7

N9

A6

N8

A4

N7

A3

N6

A1

N5

A0

N4

BA0

N3

NC9

N2

CS

DDQM

C513

C512

1u/10

0.1u/16

C514

V+DDRD

GND

GND

GND

R533

DCLKZ

22

1u/10

R531

DCLK

22

DADRS8

DADRS7

DADRS6

DADRS5

DADRS4

DADRS9

DADRS3

DADRS11

DADRS1

DADRS2

DADRS10

DADRS0

DBA1

DBA0

C510

1u/10

0.1u/16

C515

GND

C511

0.1u/16

R501

33k

A

B

C

D

E

F

H 2/3F

DVR-940HX-S

5

6

7

8

17

1

3.5 HDMIB ASSY (3/3)

A

B

23

Tr ansmitter Audio_IN

4

2/3FH

C

D

AVC2510 & Transmitter_control

Tr ansmitter VIDEO_IN

E

F

H 3/3F

18

1234

DVR-940HX-S

5

678

H 3/3F

V+3R3

Q201

UMD2N

1

2E

2

2B

GND

1C31E

1080P

10k

R214

6

2C

5

1B

4

(F)(F)

R216

3.6k

470

(F)

R225

180

R215

EXT_SWING

TP221

TP203TP202

C221

0.1u/25

C222

0.1u/25

GNDA

GNDS

(VWV2248)

TP217TP216TP215TP214TP213TP212TP211

GND

HDMIB ASSY

A

B

C

R259

NM

GND GNDS

SPDIF_HDMI

AMCK_HDMI

JA201

AKP7210-A

1

2

3

4

5

6

7

IC201

HDMI Transmitter

8

9

10

11

12

13

14

15

16

17

18

19

D

HDMI OUTPUT

22

R242

V+3R3

C223

1u/10

1

14

1A

R252

R251

0

100

R250

R249

0

470

SD

2

3

4

5

6

7

TC74LCX08FTS1

GND

VCC

13

1B

4B

R245

12

1Y

4A

R246

0

11

2A

4Y

470

10

2B

3B

R247

9

2Y

3A

R248

0

8

GND

3Y

IC202

V+3R3

100

BCK

LRCK

E

F

H 3/3F

DVR-940HX-S

5

6

7

8

19

1

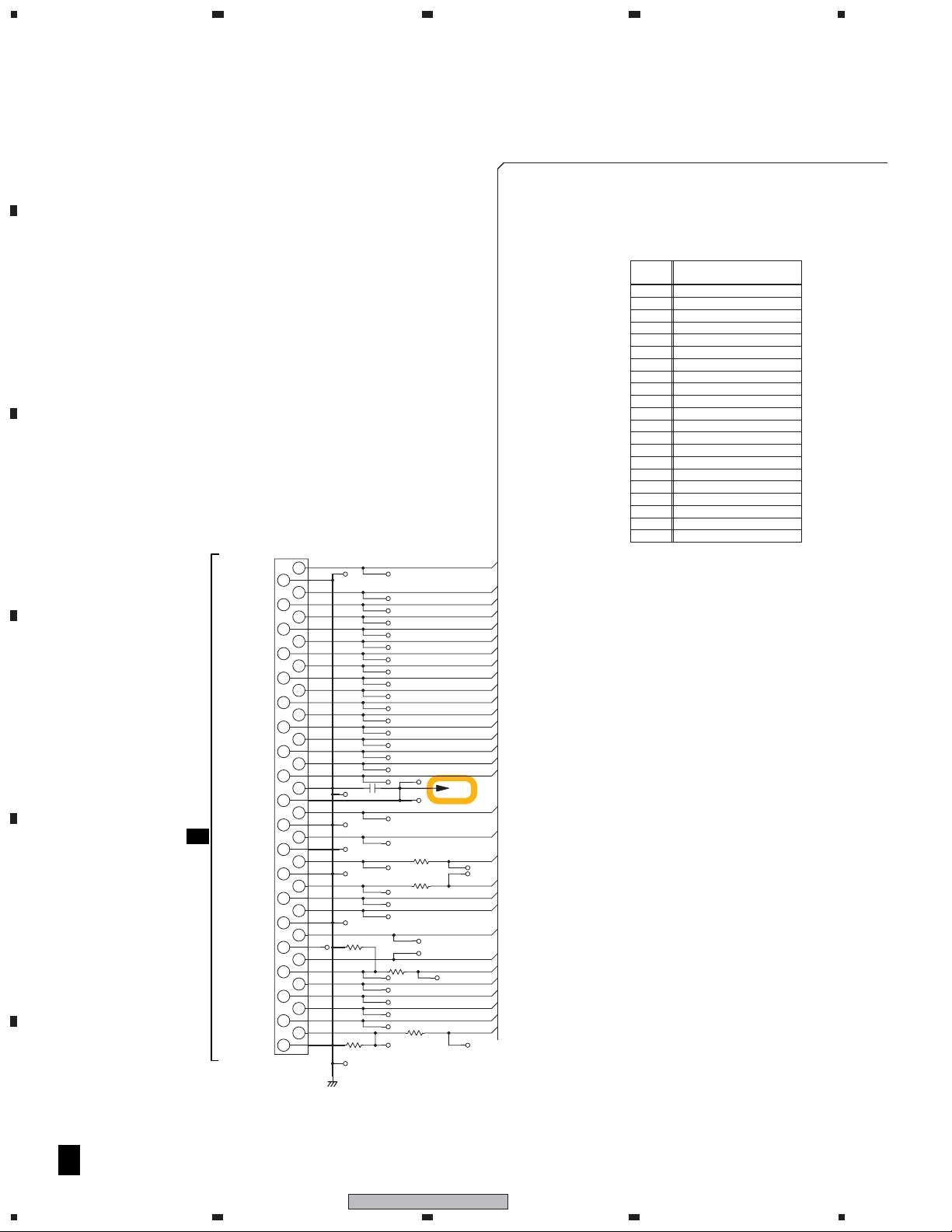

3.6 SATB ASSY

A

B

C

D

E

CN13

K F

DMACK#

RESERVED

VKN1879- -TBB

RESET#

GND

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

GND

KEYPIN

DMARQ

GND

DIOW#

GND

DIOR#

GND

IORDY

CSEL

GND

INTRQ

DA1

PDTAG#

DA0

DA2

CS0#

CS1#

DASP#

GND

CN302

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

23

(NOTE1)

R328

C325

R329

R349

C326

R350

R351

R352

R332

R356

R313

R341

R340

R339

R357

R354

R322

R326

R327

R348

IC301

0(S)

0

RESET#

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

V+3D

DMARQ

DIOW#

DIOR#

IORDY

CSEL

DMACK#

INTRQ

DA1

PDIAG#

DA0

DA2

CS0#

CS1#

DASP#

***

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

R337

R376

C332

820

820(S)

***

R377

R374

R375

***

R378

4

VWV2274- /V

10K

0.1

10K

STBY

STBY

STBY

0

STBY

12K(F)

100

10K(S)

10K

10K

10K(S)

STBY

STBY

STBY

0

STBY

10K

JM20330APB2-TGAA-K

GND

F

M F

20

1234

DVR-940HX-S

5

678

C313

220/4

C301

DA2

DA0

DA1

INTRQ

DMACK#

IORDY

DIOR#

DIOW#

DMARQ

DD15

DD0

DD14

DD1

1

V+3D