Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

÷ When servicing this model, some service procedures may reset the customer settings

to the factory default settings. Make sure to explain this to the customer.

An HDD (Hard Disc Drive) is mounted in this product.

The HDD is a precision instrument very vulnerable to shock and electrostatic charges. Please read

"7.3 Cautions on Handling the HDD" in this manual and exercise sufficient caution when handling the

HDD itself, as well as the product with the HDD built in.

When an HDD becomes defective and inoperable, restoration of the user's data recorded on the HDD,

or copying of the user's recorded data to other media (such as a new HDD) is totally impossible.

Before servicing, OBTAIN THE USER'S PRIOR CONSENT to that effect.

The user must be made aware that all recorded data are deleted if the HDD is intialized.

HDD/DVD

HDD HDD DVD

DVR-640H-AV

ORDER NO.

RRV3368

DVD RECORDER

DVR-640H-AV

DVR-540H-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Serial No.

Model Type Power Requirement Region No.

DVR-640H-AV WYXK5 AC220-240V 2 &&UK######$$

DVR-640H-AV WYXV5 AC220-240V 2 &&DL######$$

DVR-540H-S WYXK5 AC220-240V 2 &&UK######$$

DVR-540H-S WYXV5 AC220-240V 2 &&DL######$$

DVR-540H-S WYXVRE5 AC220-240V 5 &&DL######$$

Please confirm 3rd & 4th

alphabetical letters.

For details, refer to "Important Check Points for Good Servicing" .

T-ZZV APR. 2006 printed in Japan

Page 2

1234

SAFETY INFORMATION

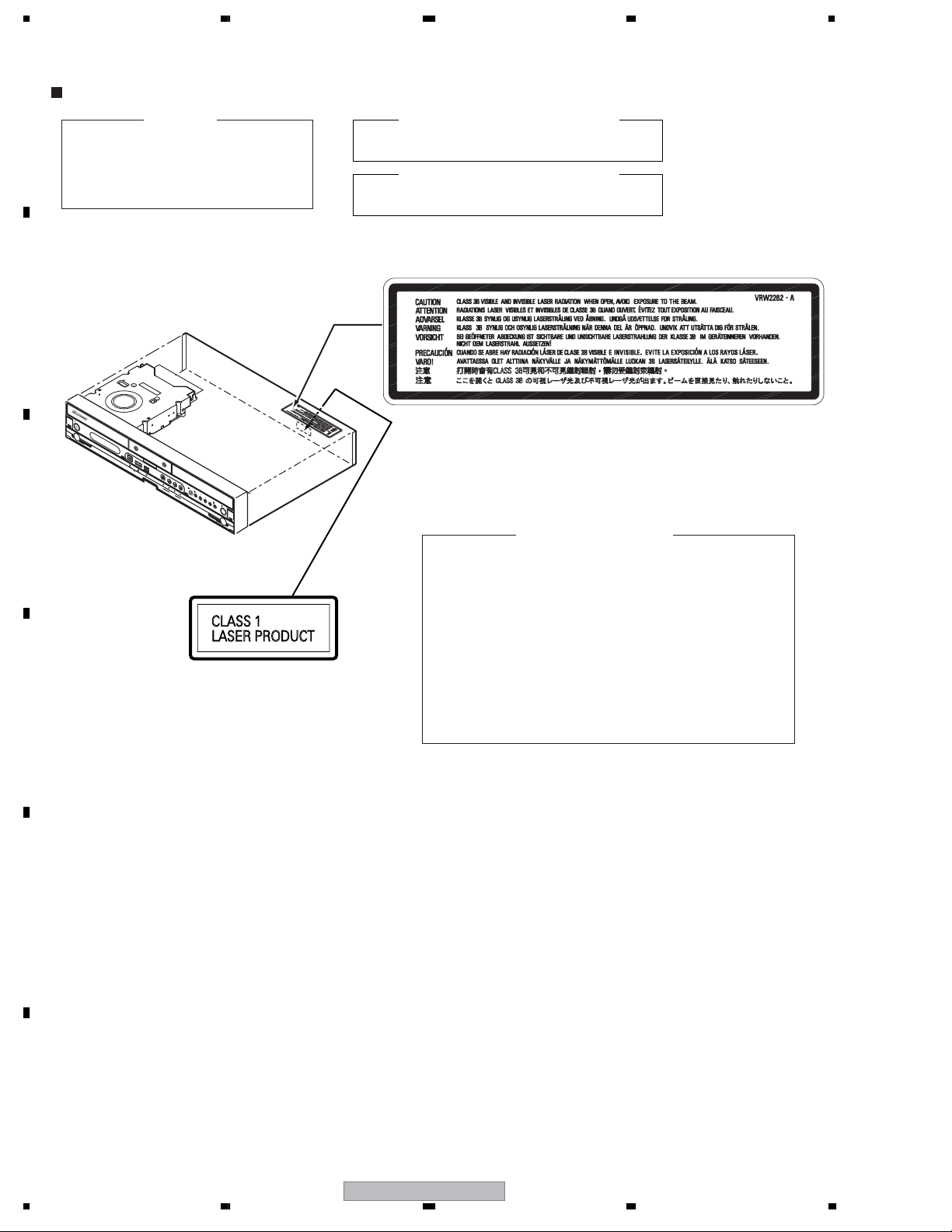

LABEL CHECK

A

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

B

MAXIMUM OUTPUT POWER: 100 mW

LASER DIODE CHARACTERISTICS

WAVELENGTH: 654 - 662 nm

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 770 - 810 nm

VRW2262

H

D

D

H

H

D

D

D

D

/

D

D

V

V

D

D

C

Additional Laser Caution

1. The ON/OFF(ON:low level,OFF:high level) status of the

CLAMP signals for detecting the loading state are detected

by the drive CPUs, and the design prevents laser diode

oscillation when the CLAMP signal turns OFF.

In normal operation, if no disc is clamped, the laser diode

oscillation is disabled.

However, the interlock does not always operate in the test

mode.

2. When the cover is opened, close viewing of the objective

D

lens with the naked eye will cause exposure to a Class 3A

laser beam.

E

F

2

DVR-640H-AV

1234

Page 3

5678

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

A

B

C

D

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

56

DVR-640H-AV

E

F

3

7

8

Page 4

1234

CONTENTS

SAFETY INFORMATION..................................................................................................................................... 2

1. SPECIFICATIONS ............................................................................................................................................ 5

2. EXPLODED VIEWS AND PARTS LIST............................................................................................................ 8

A

B

C

D

E

2.1 PACKING ...................................................................................................................................................8

2.2 EXTERIOR SECTION.............................................................................................................................. 10

2.3 FRONT PANEL SECTION ....................................................................................................................... 12

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM..........................................................................................14

3.1 BLOCK DIAGRAM ................................................................................................................................... 14

3.1.1 OVERALL BLOCK DIAGRAM............................................................................................................ 14

3.1.2 DETECTION AND ENCODE SYSTEM BLOCK DIAGRAM............................................................... 16

3.1.3 POWER BLOCK ................................................................................................................................17

3.2 OVERALL WIRING DIAGRAM................................................................................................................. 18

3.3 TUJB ASSY (1/4) ..................................................................................................................................... 20

3.4 TUJB ASSY (2/4) ..................................................................................................................................... 22

3.5 TUJB ASSY(3/4) ...................................................................................................................................... 24

3.6 TUJB ASSY(4/4) ...................................................................................................................................... 26

3.7 SCRB ASSY ............................................................................................................................................ 28

3.8 FJKB, FLKY and KEYB ASSYS............................................................................................................... 30

3.9 MAIN ASSY(1/4) ...................................................................................................................................... 32

3.10 MAIN ASSY(2/4) .................................................................................................................................... 34

3.11 MAIN ASSY(3/4) .................................................................................................................................... 36

3.12 MAIN ASSY(4/4) .................................................................................................................................... 38

3.13 DVJB ASSY (DVR-640H-AV Only)......................................................................................................... 40

3.14 USBB ASSY (DVR-640H-AV Only) ........................................................................................................ 42

3.15 ATAB ASSY ............................................................................................................................................ 43

3.16 POWER SUPPLY UNIT.......................................................................................................................... 44

3.17 WAVE FORMS ....................................................................................................................................... 48

4. PCB CONNECTION DIAGRAM ..................................................................................................................... 53

4.1 TUJB ASSY.............................................................................................................................................. 54

4.2 SCRB ASSY ............................................................................................................................................ 58

4.3 FJKB, FLKY and KEYB ASSYS............................................................................................................... 60

4.4 MAIN ASSY ............................................................................................................................................. 62

4.5 DVJB ASSY (DVR-640H-AV Only)........................................................................................................... 66

4.6 USBB ASSY (DVR-640H-AV Only) .......................................................................................................... 68

4.7 ATAB ASSY .............................................................................................................................................. 70

4.8 POWER SUPPLY UNIT............................................................................................................................ 72

5. PCB PARTS LIST ........................................................................................................................................... 76

6. ADJUSTMENT ............................................................................................................................................... 83

7. GENERAL INFORMATION............................................................................................................................. 85

7.1 DIAGNOSIS ............................................................................................................................................. 85

7.1.1 MODEL SETTING.............................................................................................................................. 87

7.1.2 CPRM ID NUMBER AND DATA SETTING......................................................................................... 88

7.1.3 FIRMWARE DOWNLOADING METHOD........................................................................................... 92

7.1.4 VIDEO ADJUSTMENT FOR SPECIFIC AREA.................................................................................. 95

7.1.5 SERVICE MODE................................................................................................................................ 99

7.1.6 DV SERVICE MODE........................................................................................................................ 111

7.1.7 EPG SERVICE MODE..................................................................................................................... 114

7.1.8 AGING MODE.................................................................................................................................. 116

7.1.9 HDD CHECK MODE........................................................................................................................ 118

7.1.10 DIAGNOSIS OF THE MAIN ASSY................................................................................................. 124

7.1.11 NOTE ON REPLACEMENT OF THE SDRAM............................................................................... 125

7.1.12 SETUP SEQUENCE...................................................................................................................... 126

7.1.13 DISASSEMBLY .............................................................................................................................. 127

7.2 IC ........................................................................................................................................................... 132

7.3 CAUTIONS ON HANDLING THE HDD.................................................................................................. 144

7.4 DISC/CONTENT FORMAT ....................................................................................................................146

8. PANEL FACILITIES ...................................................................................................................................... 149

F

4

1234

DVR-640H-AV

Page 5

5678

1. SPECIFICATIONS

General

Power requirements . . . . . 220 V to 240 V, 50 Hz / 60 Hz

Power consumption

DVR-640H-AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 W

DVR-540H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40 W

(DVR-440H-S/DVR-440H-K . . . . . . . . . . . . . . . . . . 39 W)

Power consumption in standby mode . . . . . . . . . . 0.61 W

(Front panel display: off)

Weight

DVR-640H-AV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.4 kg

DVR-540H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4.3 kg

(DVR-440H-S/DVR-440H-K . . . . . . . . . . . . . . . . . . 4.3 kg)

Dimensions . . . . 420 mm (W) x 69 mm (H) x 318 mm (D)

Operating temperature . . . . . . . . . . . . . . .+5 °C to +35 °C

Operating humidity . . . . . . . . . . . . . . . . . . . . .5 % to 85 %

(no condensation)

TV system . . . . . . . . . . . . . . . . . . . . . . . . . . PAL/SECAM/

NTSC (external input only)

Readable discs

DVD-Video, DVD-RW, DVD-R, DVD+R, DVD+RW,

DVD-RAM, Video CD, Super VCD, CD, CD-R/-RW

(WMA, MP3, JPEG, CD-DA)

Recording discs and formats

DVD-R/RW: VR mode and Video mode

DVD+R/+RW: +VR mode

DVD-RAM: VR mode

DVD-R DL: VR mode and Video mode

DVD+R DL: +VR mode

Video recording format

Sampling frequency . . . . . . . . . . . . . . . . . . . . . 13.5 MHz

Compression format. . . . . . . . . . . . . . . . . . . . . . . . MPEG

Audio recording format

Sampling frequency . . . . . . . . . . . . . . . . . . . . . . . .48 kHz

Compression format . . . . . . . Dolby Digital or Linear PCM

(uncompressed)

Recording time

HDD

DVR-640H-AV/DVR-540H-S (160 GB)

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 34 h

Standard Play (SP) . . . . . . . . . . . . . . . . . . . .Approx. 68 h

Long Play (LP) . . . . . . . . . . . . . . . . . . . . . . Approx. 136 h

Extended Play (EP) . . . . . . . . . . . . . . . . . . Approx. 204 h

Super Long Play (SLP) . . . . . . . . . . . . . . . Approx. 272 h

Super Extended Play (SEP) . . . . . . . . . . . .Approx. 340 h

Manual Mode (MN). . . . . . . . . . . . . Approx. 34 h to 455 h

DVR-440H-S/K (80 GB) (Reference)

Fine (XP). . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 17 h

Standard Play (SP) . . . . . . . . . . . . . . . . . . . .Approx. 34 h

Long Play (LP) . . . . . . . . . . . . . . . . . . . . . . . Approx. 68 h

Extended Play (EP) . . . . . . . . . . . . . . . . . . Approx. 102 h

Super Long Play (SLP) . . . . . . . . . . . . . . . .Approx. 136 h

Super Extended Play (SEP) . . . . . . . . . . . .Approx. 170 h

Manual Mode (MN). . . . . . . . . . . . . Approx. 17 h to 227 h

DVD-R/-RW, DVD+R/+RW, DVD-RAM

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 1 h

Standard Play (SP) . . . . . . . . . . . . . . . . . . . . . Approx. 2 h

Long Play (LP) . . . . . . . . . . . . . . . . . . . . . . . . .Approx. 4 h

Extended Play (EP) . . . . . . . . . . . . . . . . . . . . . Approx. 6 h

Super Long Play (SLP) . . . . . . . . . . . . . . . . . . Approx. 8 h

Super Extended Play (SEP) . . . . . . . . . . . . . .Approx. 10 h

(DVD-R/-RW, DVD-RAM only)

Manual Mode (MN)

DVD-R/-RW/-RAM . . . . . . . . . . . . . . Approx. 1 h to 13 h

DVD+R/+RW . . . . . . . . . . . . . . . . . . . Approx. 1 h to 8 h

DVD-R DL/DVD+R DL

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . .Approx. 1 h 51 m

Standard Play (SP) . . . . . . . . . . . . . . . . .Approx. 3 h 35 m

Long Play (LP) . . . . . . . . . . . . . . . . . . . . Approx. 7 h 11 m

Extended Play (EP) . . . . . . . . . . . . . . . Approx. 10 h 46 m

Super Long Play (SLP) . . . . . . . . . . . . .Approx. 14 h 21 m

Super Extended Play (SEP) . . . . . . . . . Approx. 17 h 57 m

(DVD-R DL only)

Manual Mode (MN)

DVD-R DL . . . . . . . . . . . . . . . . Approx. 1 h 51 m to 24 h

DVD+R DL . . . . . . . . . . . Approx. 1 h 51 m to 14 h 21 m

Timer

Programs . . . . . . . . . . . . . . . . . . . . . 1 month/32 programs

Clock . . . . . . . . . . . . . Quartz lock (24-hour digital display)

Tuner

Receivable channels

VHF (low)

VHF (high)

Hyper

UHF

VHF (low)

VHF (high)

Hyper

UHF

SECAM B/G

PAL B/ G

Frequency

47 MHz to 89 MHz

104 MHz to 300 MHz

302 MHz to 470 MHz

470 MHz to 862 MHz

SECAM L

Frequency

49 MHz to 65 MHz

104 MHz to 300 MHz

300 MHz to 470 MHz

470 MHz to 862 MHz

Channel

E2 to E4

X to Z

E5 to E12

S1 to S20

M1 to M10

U1 to U10

S21 to S41

E21 to E69

Channel

FB, FC1, FC

F1 to F6

B to Q

S21 to S41

21 to 69

PAL I

Frequency

44 MHz to 89 MHz

104 MHz to 300 MHz

302 MHz to 470 MHz

470 MHz to 862 MHz

SECAM D/K

PAL D/ K

Frequency

49 MHz to 94 MHz

104 MHz to 300 MHz

302 MHz to 470 MHz

470 MHz to 862 MHz

Channel

A to C

X to Z

D to J

11, 13

S1 to S20

S21 to S41

E21 to E69

Channel

R1 to R5

R6 to R12

S1 to S20

S21 to S41

E21 to E69

STEREO

B/G - A2

I - NICAM

L - NICAM

B/G - NICAM

D/K - NICAM

A

B

C

D

E

56

DVR-640H-AV

F

5

7

8

Page 6

1234

Input/Output

VHF/UHF antenna input/output terminal

A

B

C

D

. . . . . . . . . . . . . . . .VHF/UHF set 75Ω (IEC connector)

Video input . . . . . . . . . . . . . . . . . . . . . . . . . Input 2 (front)

Input level . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . AV connector 2 (Input 1),

Video output . . . . . . . . . . . . . . . . . . . . . . . . . AV1, Output

Output level . . . . . . . . . . . . . . . . . . . . . . . . 1 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . AV connector (AV1)

S-Video input . . . . . . . . . . . . . . . . . . . . . . . Input 2 (front)

Y (luminance) - Input level . . . . . . . . . . . . . 1 Vp-p (75Ω)

C (colour) - Input level . . . . . . . . . . . . . 300 mVp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . AV connector 2 (Input 1),

S-Video output . . . . . . . . . . . . . . . . . . . . . . . AV1, Output

Y (luminance) - Output level . . . . . . . . . . . . 1 Vp-p (75Ω)

C (colour) - Output level . . . . . . . . . . . 300 mVp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . AV connector 1 (AV1),

Component video output

Output level . . . . . . . . . . . . . . . . . . . . . Y: 1.0 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jacks

RGB input

Input level . . . . . . . . . . . . . . . . . . . . . . . . 0.7 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . AV connector 2 (Input 1)

RGB output

Output level . . . . . . . . . . . . . . . . . . . . . . . 0.7 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . AV connector 1 (AV1)

Audio input . . . . . . . . . . . . . . . . . . . . . . Input 2 (front) L/R

Input level

During audio input . . . . . . . . . . . . . . . . . . . . . . . 2 V rms

(Input impedance: more than 22 kΩ)

Jacks . . . . . . . . . . . . . . . . . . . .AV connector 2 (Input 1),

Audio output . . . . . . . . . . . . . . . . . . . . . . . . . AV1, Output

During audio output . . . . . . . . . . . . . . . . . . . . . . 2 V rms

(Output impedance: less than 1.5 kΩ)

Jacks . . . . . . . . . . . . . . . . . . . . . . AV connector 1 (AV1),

Control input . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mini jack

Digital audio ouptut . . . . . . . . . . . . . . . . . . . . . . . Coaxial

G-LINK™ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mini jack

RCA jack (Input 2)

RCA jack (Output)

4 pin mini DIN (Input 2)

4 pin mini DIN (Output)

P

, PR: 0.7 Vp-p (75Ω)

B

RCA jacks (Input 2)

RCA jacks (Output)

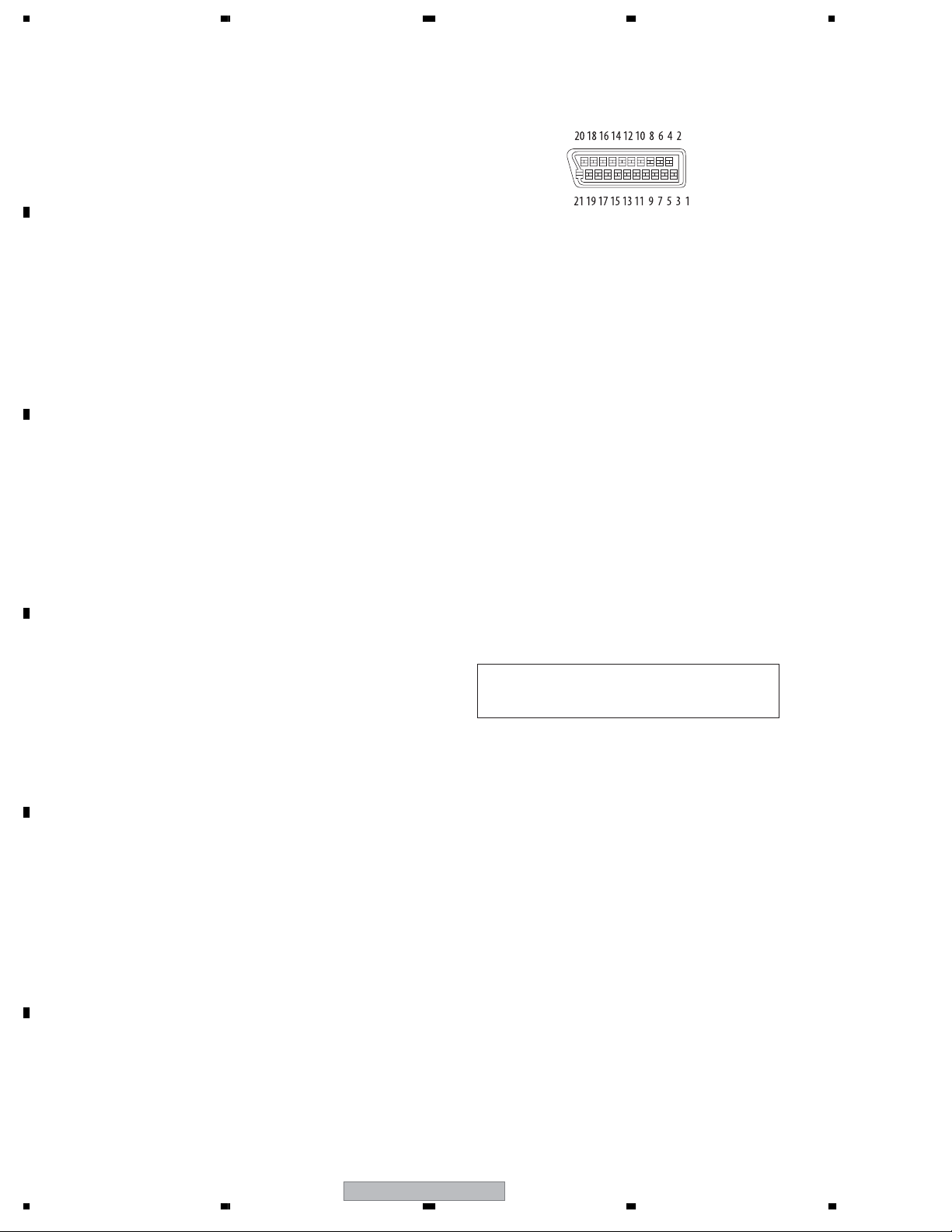

AV Connectors (21-pin connector assignment)

AV connector input/output . . . . . . . . 21-pin connector

This connector provides the video and audio signals

for connection to a compatible colour TV or monitor.

PIN no. AV1(RGB)-TV / AV2(INPUT 1)

1. . . . . . . . . . . . . . . . . . . . . Audio 2/R out / Audio 2/R out

2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . - / Audio 2/R in

11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G out / G in

3 . . . . . . . . . . . . . . . . . . . . . Audio 1/L out / Audio 1/L out

6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .- / Audio 1/L in

15 . . . . . . . . . . . . . . . . . . . . . . . . . . R or C out / R or C in

4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GND

17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GND

7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B out / B in

19 . . . . . . . . . . . . . . . . . . . Video out or Y out / Video out

20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . - / Video in or Y in

8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Status

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .GND

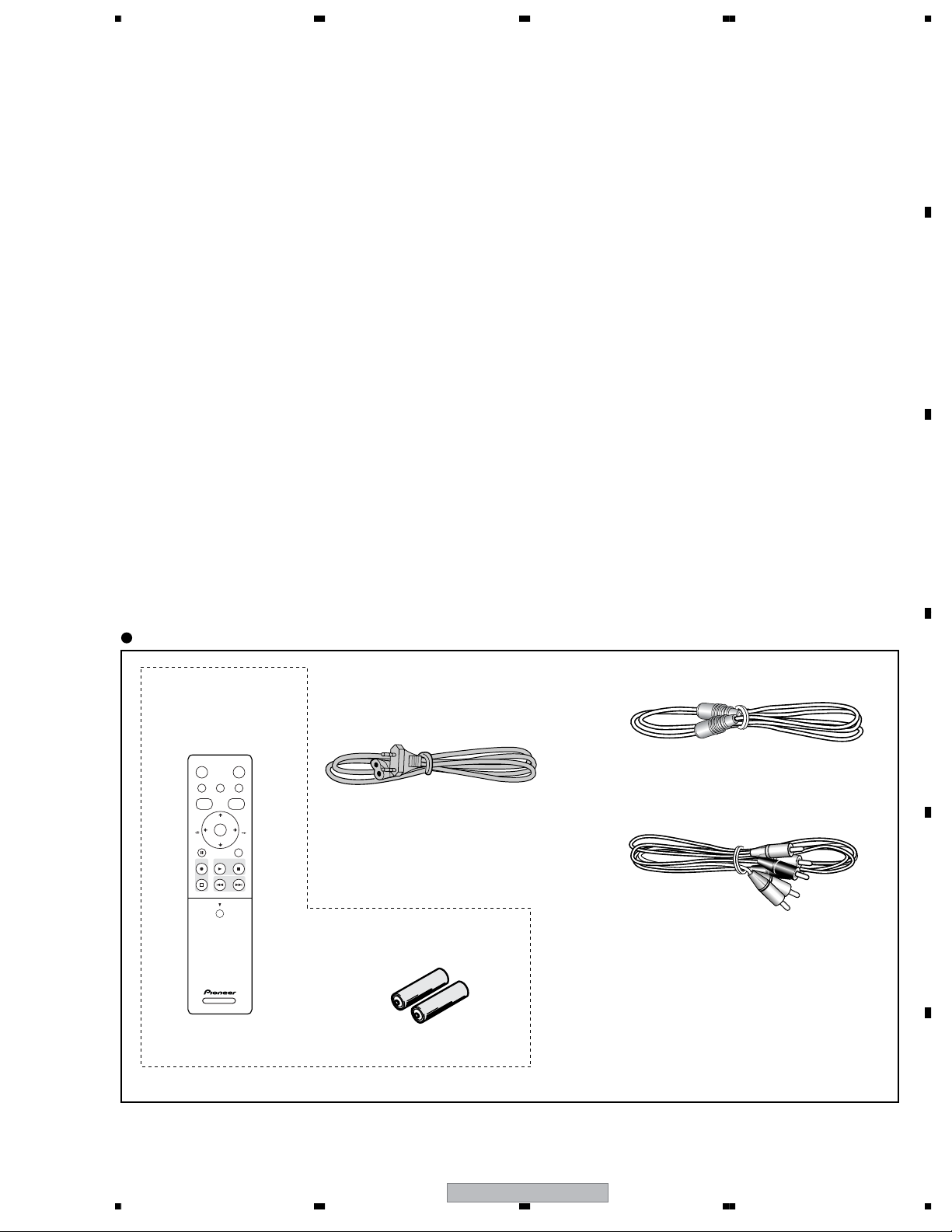

Supplied accessories

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Dry cell batteries (AA/R6P) . . . . . . . . . . . . . . . . . . . . . . 2

Audio / Video cable (red/white/yellow) . . . . . . . . . . . . . . 1

G-LINK™ cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

RF antenna cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Operating Instructions

Warranty card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Note: The specifications and design of this product are

subject to change without notice, due to improvement.

This product includes FontAvenue® fonts licenced

by NEC corporation. FontAvenue is a registered

trademark of NEC Corporation.

E

F

6

1234

DVR-640H-AV

Page 7

5678

A

B

Accessories

Except DVR-640H-AV

• Remote control ×1

(VXX3129)

STANDBY/ON

HDD/DVD

PAUSE LIVE TV HOME MENU INFO

TOP MENU

DISC

GUIDE

NAVIGATOR

CHANNEL

+

ENTER

PAUSE RETURN

CHANNEL

-

PLAYREC STOP

PREV NEXT

OPEN

CM

SKIP

CM

BACK

STOP REC

• Power cable ×1

(ADG1127 : WYXK5, WYXV5,

WYXVRE5 types)

• Dry cell batteries ×2

(AA/R6P)

C

• RF antenna cable(PAL) ×1

(VDE1075)

D

• Audio / Video cable(1.5m) ×1

(red/white/yellow)

(VDE1077)

E

• G-Link Cable (3m) ×1

(VDX1010)

DVD RECORDER

DVR-640H-AV

56

F

7

7

8

Page 8

1234

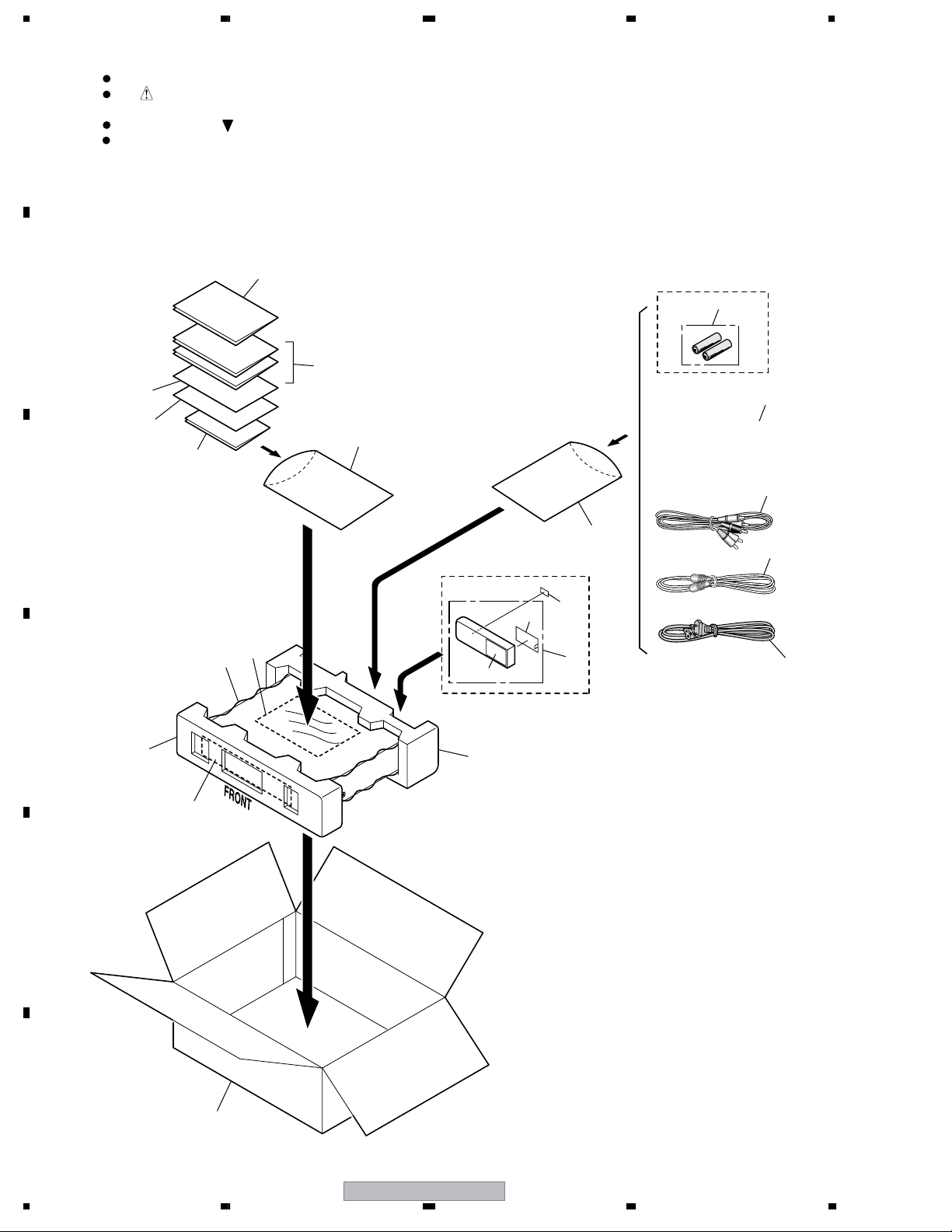

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

B

(DVR-540H-S

/WYXVRE5

only)

C

27

(DVR-540H-S/WYXVRE5

26

only)

20 to 24

(DVR-540H-S/WYXK5

and WYXV5 types

9

6

only)

7

5

Except

DVR-640H-AV models

18

4

3

2

14

16

8

13

D

10

19

(for door protect)

E

17

Except

DVR-640H-AV models

11

15

1

F

8

1234

12

DVR-640H-AV

Page 9

>

>

5678

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cord See Contrast table (2)

2 RF Antenna Cable (PAL) VDE1075

3Audio/Video Cable (1.5m) VDE1077

4 G-Link Cable (3m) VDX1010

5Polyethylene Bag B5 VHL1088

NSP 6 Warranty Card ARY7065

7Polyethylene Bag See Contrast table (2)

NSP 8 HDD Caution 8L B See Contrast table (2)

NSP 9 HDD Caution 8L See Contrast table (2)

10 Front Pad See Contrast table (2)

11 Rear Pad See Contrast table (2)

12 Packing Case See Contrast table (2)

13 Mirror Sheet See Contrast table (2)

14 WEEE Label See Contrast table (2)

15 Remote Control Unit See Contrast table (2)

16 Battery Cover See Contrast table (2)

No. Description Part No.

Mark

17 Top Cover See Contrast table (2)

NSP 18 Dry Cell Battery (R6P, AA) See Contrast table (2)

19 Mirror Sheet VHL1104

20 Operating Instructions See Contrast table (2)

21 Operating Instructions See Contrast table (2)

22 Operating Instructions See Contrast table (2)

23 Operating Instructions See Contrast table (2)

24 Operating Instructions See Contrast table (2)

25 Operating Instructions See Contrast table (2)

26 Operating Instructions See Contrast table (2)

27 EPG Caution Card See Contrast table (2)

A

B

(2) CONTRAST TABLE

DVR-640H-AV/WYXK5, WYXV5, DVR-540H-S/WYXK5, WYXV5 and WYXVRE5 are constructed the same except

for the following:

Mark No. Symbol and Description

1Power Cord ADG1127 ADG1127 ADG1127 ADG1127 ADG1127

7Polyethylene Bag VHL1051 VHL1088 VHL1051 VHL1088 VHL1088

NSP 8 HDD Caution 8L B VRR1046 VRR1062 VRR1046 VRR1062 VRR1062

NSP 9 HDD Caution 8L VRR1047 VRR1063 VRR1047 VRR1063 VRR1063

10 Front Pad VHA1404 VHA1415 VHA1404 VHA1415 VHA1415

11 Rear Pad VHA1405 VHA1416 VHA1405 VHA1416 VHA1416

12 Packing Case VHG2719 VHG2757 VHG2698 VHG2683 VHG2734

13 Mirror Sheet VHL1107 VHL1095 VHL1107 VHL1095 VHL1095

14 WEEE Label Not used Not used VRW2231 VRW2231 VRW2231

15 Remote Control Unit Not used Not used VXX3129 VXX3129 VXX3129

16 Battery Cover Not used Not used VZN1004 VZN1004 VZN1004

17 Top Cover Not used Not used VZN1009 VZN1009 VZN1009

NSP 18 Dry Cell Battery (R6P, AA) Not used Not used VEM1010 VEM1010 VEM1010

20 Operating Instructions (French) Not used Not used VRC1320 VRC1320 Not used

21 Operating Instructions (German) Not used Not used VRC1321 VRC1321 Not used

DVR-640H-AV

/WYXK5

DVR-640H-AV

/WYXV5

DVR-540H-S

/WYXK5

DVR-540H-S

/WYXV5

DVR-540H-S

/WYXVRE5

C

D

E

22 Operating Instructions (Italian) Not used Not used VRC1322 VRC1322 Not used

23 Operating Instructions (Dutch) Not used Not used VRC1323 VRC1323 Not used

24 Operating Instructions (Spanish) Not used Not used VRC1324 VRC1324 Not used

25 Operating Instructions (English) Not used Not used Not used Not used Not used

26 Operating Instructions (Russian) Not used Not used Not used Not used VRC1333

27 EPG Caution Card Not used Not used Not used Not used VRR1066

DVR-640H-AV

56

7

F

9

8

Page 10

1234

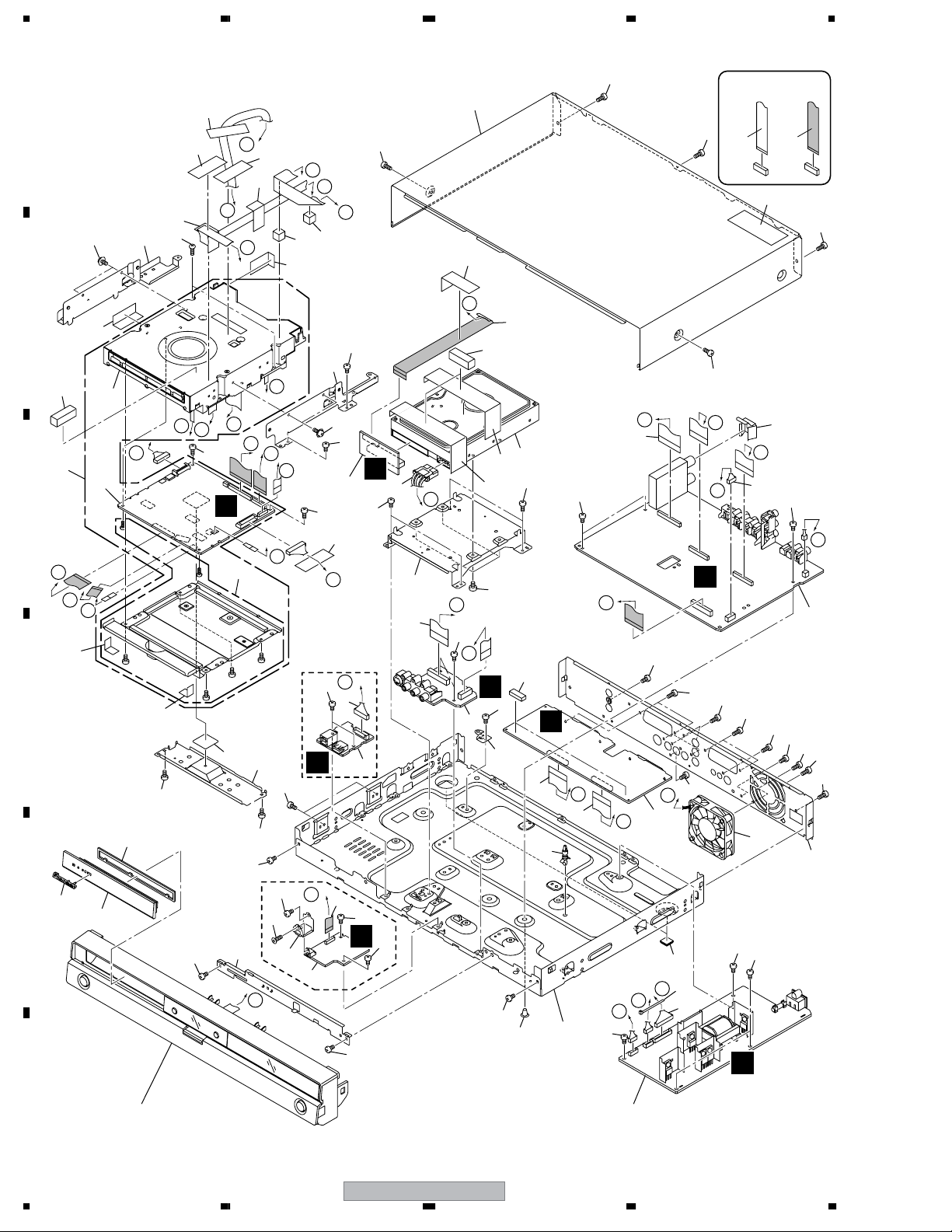

2.2 EXTERIOR SECTION

46

56

46

46

E b

E a

B a

A

51

34

46

46

46

39

I b

B b

39

I a

54

33

54

46

54

NON-CONTACT

SIDE

CONTACT SIDE

47

54

B

41

40

10

11

4

C

K

L

M

46

Reuse (*) marked

parts when exachanging

D

Service LOADER

Assy.

• Silicon Sheet R9B

(DEB1726) x3

• Case Screw S

(DBA1250) x2

• Frontboard Screw

R7C

(DBA1220) x2

43

E

45

(1/2)

44

(*)

E b

(*)

52

M

L

52

(*)

(*)

(*)

46

DVR-640H-AV

54

10

F

K

(2/2)

31

28

(*)

54

only

I a

15

52

35

J

46

H

I b

B b

J

(*)

37

52

52

54

57

27

A

52

7

52

52

46

D

DVR-640H-AV

only

E a

52

19

H

B a

6

14

52

G

5

54

I

30

C

36

16

52

40

54

H

18

9

42

56

42

55

F

52

A

32

52

F

54

C

52

3

26

54

23

17

21

B

25

17

O

C

52

G

1

P

D

N

22

38

13

54

53

A

O

N

53

52

53

52

12

20

29

P

52

G

2

53

54

53

53

56

24

J

F

10

Refer to

"2.3 FRONT PANEL SECTION".

DVR-640H-AV

1234

8

Page 11

>

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 SCRB Assy VWV2206

2 TUJB Assy (for service) See Contrast table (2)

3 FJKB Assy (for service) VXX3113

4 MAIN Assy (for service) See Contrast table (2)

5DVJB Assy See Contrast table (2)

No. Description Part No.

Mark

31 Radiation Sheet (Silicone) VEB1360

32 Rubber Spacer VEB1378

33 Bonnet VXX3105

NSP 34 Writer Stay L VNE2421

NSP 35 Writer Stay R VNE2422

A

6 USBB Assy See Contrast table (2)

7 ATAB Assy (for service) VXX3140

8POWER SUPPLY Unit VWR1399

9 HDD 160GB ST3160022RS VXF1086

10 LOADER Assy (for service) VXX3156

NSP 11 Service LOADER MAIN See Contrast table (2)

12 Connector Assy PF05PP-S07

13 Connector Assy PF13PP-S22

14 Flexible Cable 24P See Contrast table (2)

15 Flexible Cable 40P VDA2112

16 Flexible Cable 23P VDA2115

17 Flexible Cable 29P VDA2117

18 Flexible Cable 35P VDA2118

19 Housing USB (MAIN) See Contrast table (2)

20 DC Fan Motor 60 VXM1125

21 PCB Support AEC1215

22 Rubber Foot VEB1349

NSP 23 PC Support VEC1749

24 Rear Panel See Contrast table (2)

NSP 25 Chassis VNB1055

NSP 26 PCB Base VNE2378

27 DV Angle See Contrast table (2)

NSP 28 Bridge VNE2429

29 Earth Plate TU VBK1162

30 Housing Assy 4P VKP2357

NSP 36 HDD Stay VNE2423

37 Heatsink VNH1077

NSP 38 Binder (BK-1) ZCA-BK1

39 Rubber Spacer B VEB1380

40 Gasket 30 x 10T VEC2522

41 Aluminum Tape 25 x 25 VEF1060

42 Aluminum Tape 180 x 25 VEF1065

43 Pioneer Name Plate VAM1148

44 Tray Sheet VEC2500

45 Tray Panel VNK5910

NSP 46 Tape ZTA-156A-19

47 Laser Caution Label VRW2262

48 • • • • •

49 • • • • •

50 • • • • •

51 Screw AMZ30P040FTC

52 Screw BBZ30P060FTC

53 Screw BPZ30P080FTC

54 Screw BSZ30P040FTC

55 #6-32 Screw DBA1125

56 Screw PBZ30P080FTC

57 Screw M3 x 8 See Contrast table (2)

B

C

D

(2) CONTRAST TABLE

DVR-640H-AV/WYXK5, WYXV5, DVR-540H-S/WYXK5, WYXV5, WVXK5 and WYXVRE5 are constructed the same

except for the following:

Mark No. Symbol and Description

2 TUJB Assy (for service) VXX3109 VXX3109 VXX3108 VXX3108 VXX3108

4 MAIN Assy (for service) VXX3157 VXX3157 VXX3159 VXX3159 VXX3159

5DVJB Assy VWV2160 VWV2160 Not used Not used Not used

6 USBB Assy VWV2161 VWV2161 Not used Not used Not used

NSP 11 Service LOADER MAIN VXU1001 VXU1001 VXU1002 VXU1002 VXU1002

14 Flexible Cable 24P VDA2111 VDA2111 Not used Not used Not used

19 Housing USB (MAIN) VKP2380 VKP2380 Not used Not used Not used

24 Rear Panel VNA2903 VNA2931 VNA2894 VNA2916 VNA2915

27 DV Angle VNE2426 VNE2426 Not used Not used Not used

57 Screw M3 x 8 VBA1088 VBA1088 Not used Not used Not used

56

DVR-640H-AV

/WYXK5

DVR-640H-AV

/WYXV5

DVR-640H-AV

DVR-540H-S

/WYXK5

7

DVR-540H-S

/WYXV5

DVR-540H-S

/WYXVRE5

8

E

F

11

Page 12

1234

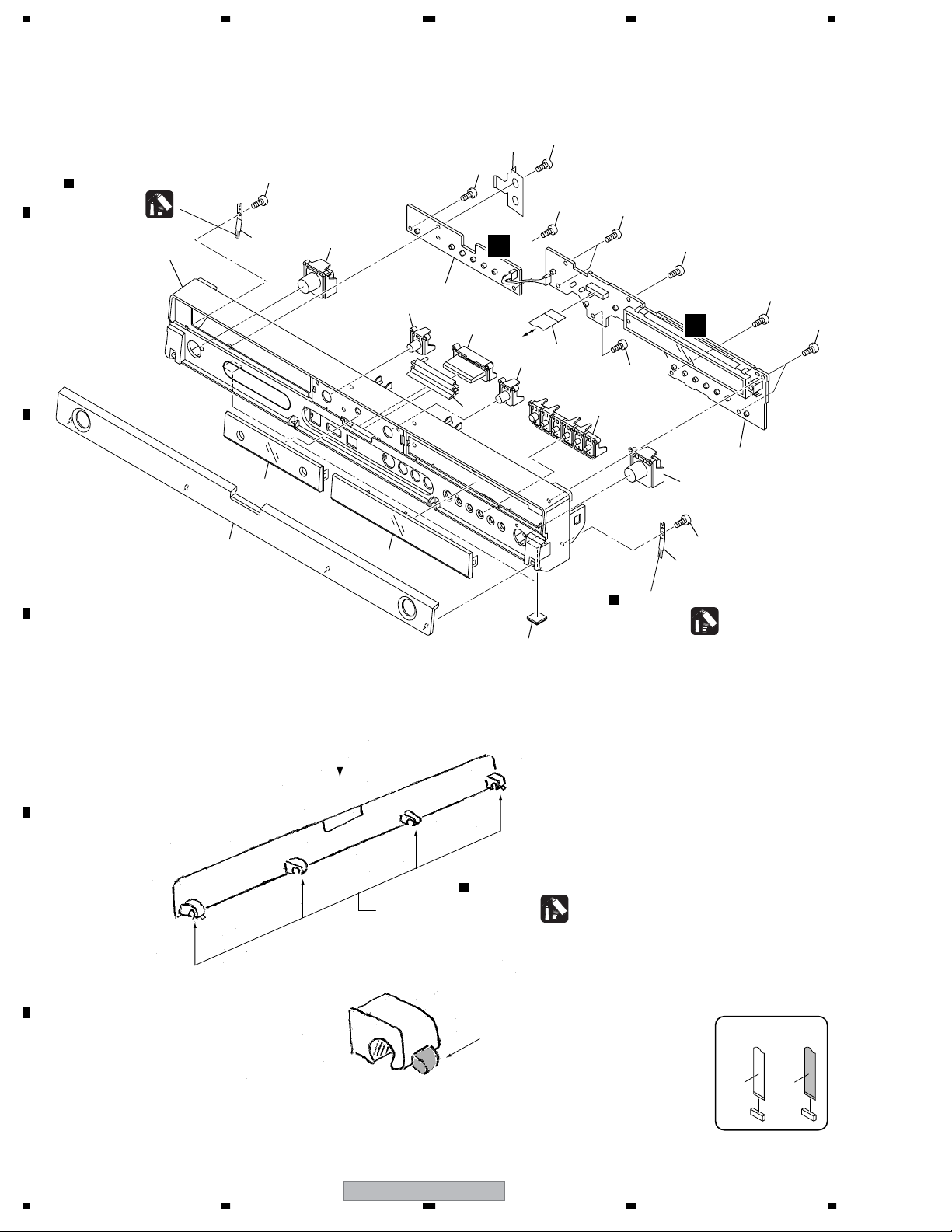

2.3 FRONT PANEL SECTION

A

Lubricant

Hanarl

GEM1041

12

16

4

10

(1/2)

16

5

16

16

E

16

16

2

14

7

13

9

FJKB

CN7302

3

7

16

11

4

10

D

(2/2)

16

B

8

C

15

16

16

1

Lubricant

Hanarl

6

D

GEM1041

Door Shaft

Lubricant

E

F

12

1234

to Door Shaft

DVR-640H-AV

Hanarl

GEM1041

Paste lubricant hanarl (GEM1041)

to salient points of both side of the

door.

NON-CONTACT

SIDE

CONTACT SIDE

Page 13

5678

(1) FRONT PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 FLKY Assy (for service) VXX3111

2 KEYB Assy (for service) VXX3112

3 Flexible Cable 12P VDA2116

4 Door Spring VBK1159

5 Earth Plate VBK1166

6 Rubber Foot VEB1349

7 Sub Key VNK5909

8 Center Cover VNK5911

9 LED Lens VNK5913

10 Main Key See Contrast table (2)

A

11 Function Key VNK5936

12 Front Panel See Contrast table (2)

13 Center Key See Contrast table (2)

14 FL Lens PTD See Contrast table (2)

15 Door PTD See Contrast table (2)

16 Screw BPZ30P080FTC

(2) CONTRAST TABLE

DVR-640H-AV/WYXK5, WYXV5, DVR-540H-S/WYXK5, WYXV5, WVXK5 and WYXVRE5 are constructed the same

except for the following:

Mark No. Symbol and Description

10 Main Key VNK5925 VNK5925 VNK5908 VNK5908 VNK5908

12 Front Panel VNK5957 VNK5957 VNK5923 VNK5923 VNK5923

13 Center Key VNK6026 VNK6026 VNK6025 VNK6025 VNK6025

14 FL Lens PTD VXA2741 VXA2741 VXA2740 VXA2740 VXA2740

15 Door PTD VXA2775 VXA2775 VXA2774 VXA2774 VXA2774

DVR-640H-AV

/WYXK5

DVR-640H-AV

/WYXV5

DVR-540H-S

/WYXK5

DVR-540H-S

/WYXV5

DVR-540H-S

/WYXVRE5

B

C

D

56

DVR-640H-AV

E

F

13

7

8

Page 14

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

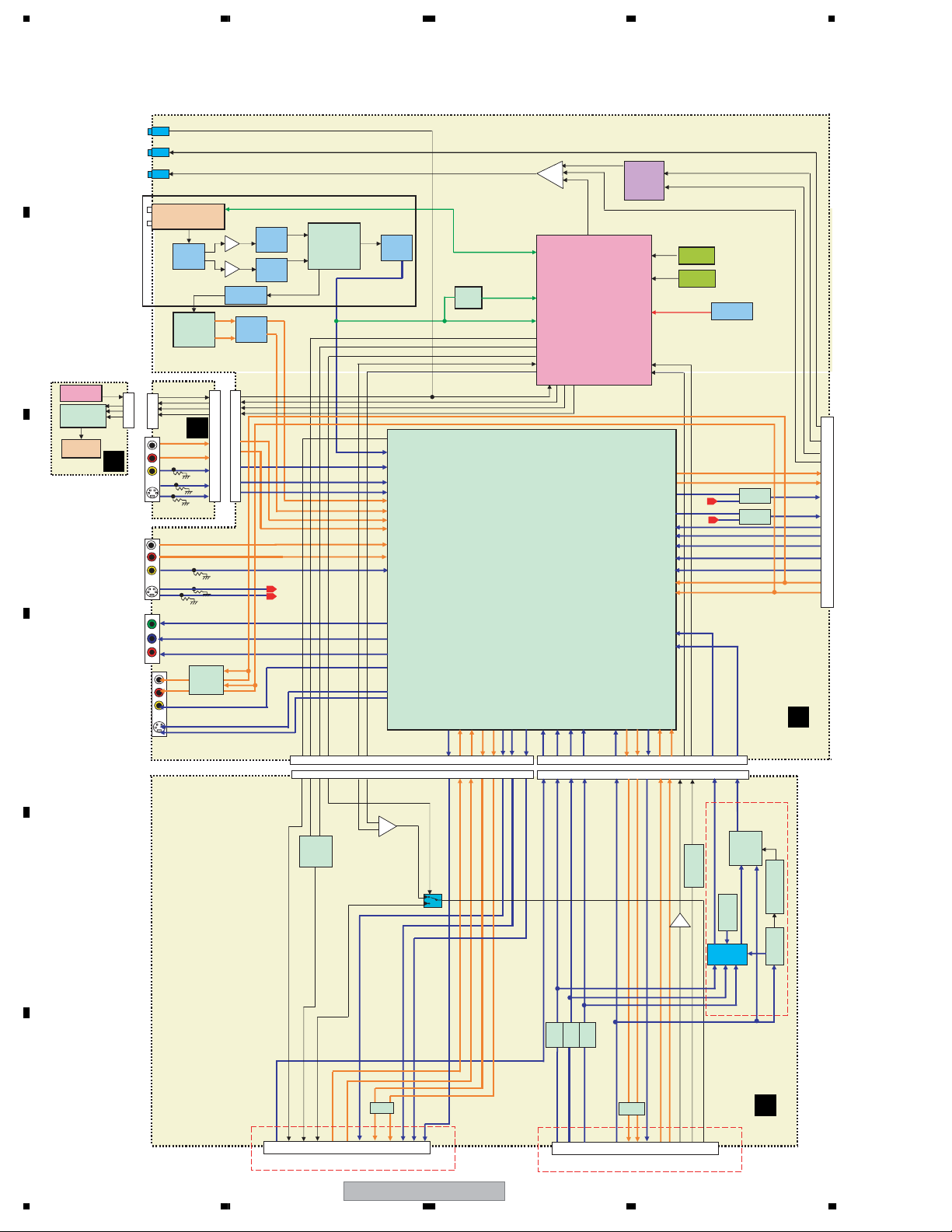

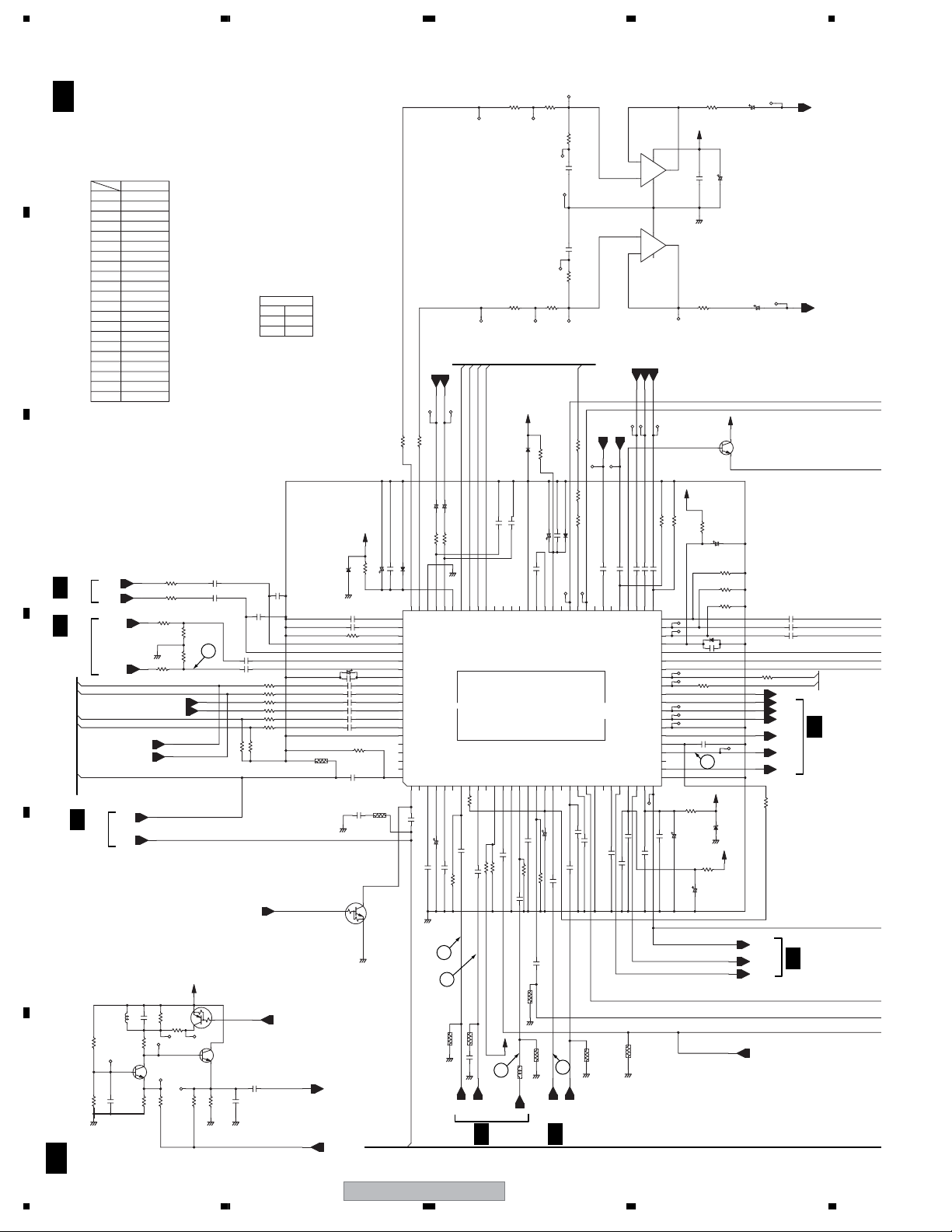

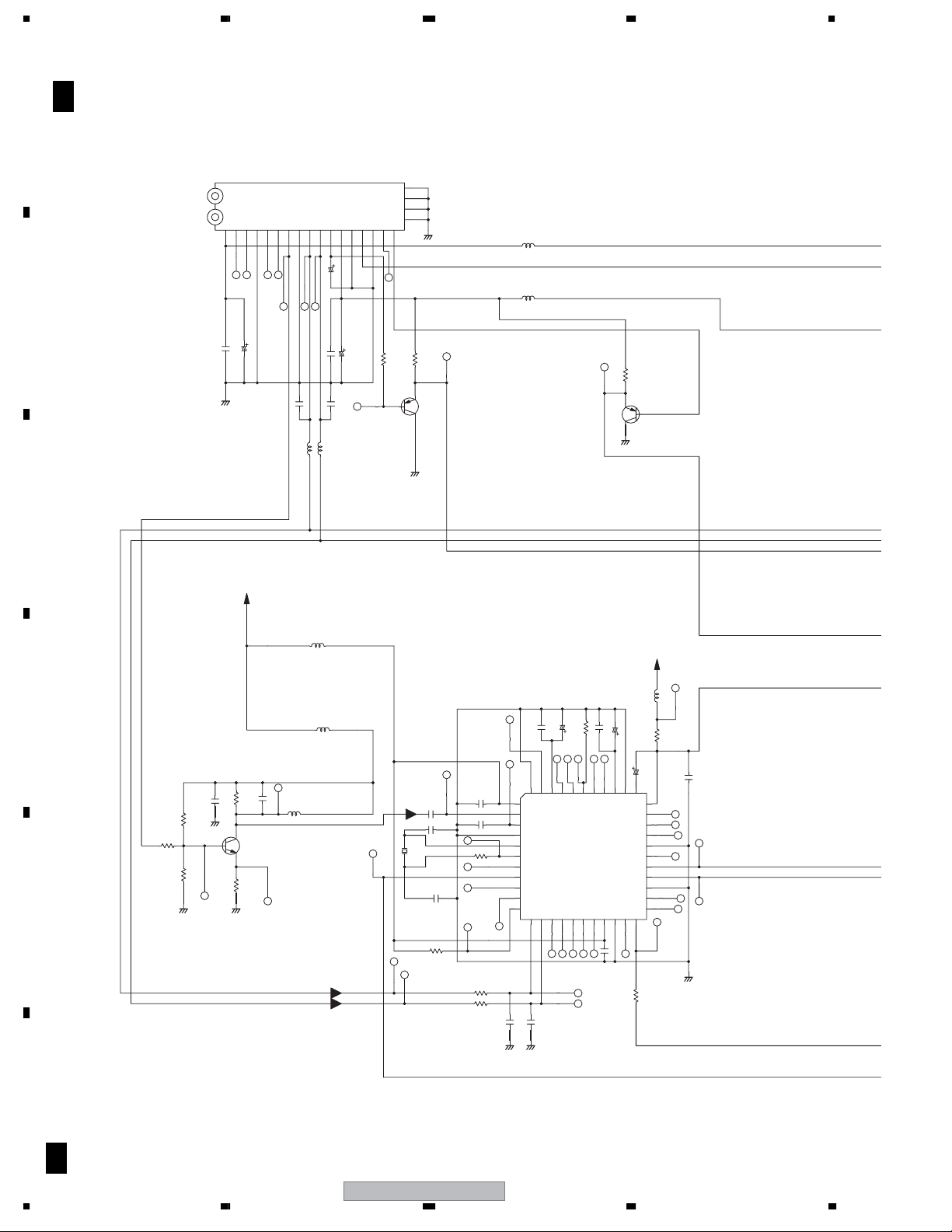

3.1.1 OVERALL BLOCK DIAGRAM

A

SEL_IR

OPTICAL

IR Blaster

VHF/UHF Tuner

IF Trap

B

IR Receiver

FL DRIVER

FL TUBE

FLKY

C

6

4

3

2

CN7001

D

INPUT 2

JA2010

COMPONENT

OUT

JA2001

7

9

10

11

JA7302

CN7302

Multisound

Decoder

FJKB

Y

Cb

Cr

Filter

C

CN7301

MUTE

18

20

21

22

9

11

7

5

1

PIF AMP

SIF AMP

4.5 - 6.7MHz

SIF BPF

LPF

CN101

6

4

3

2

15

13

17

19

23

SAW

Filter

SAW

Filter

D

OUTPUT

SEL_IR

Blaster

mic

PDF015A

Single/multista

ndard VIF/SIF-

PLL and FM-

PLL/AM

demodulators

BS IN

RGBOUT

V2

Y2C27

TU-L

TU-R

L2-L

L2-R

L3-L

L3-R

V3

Y3

C3

VOUT2

YOUT2

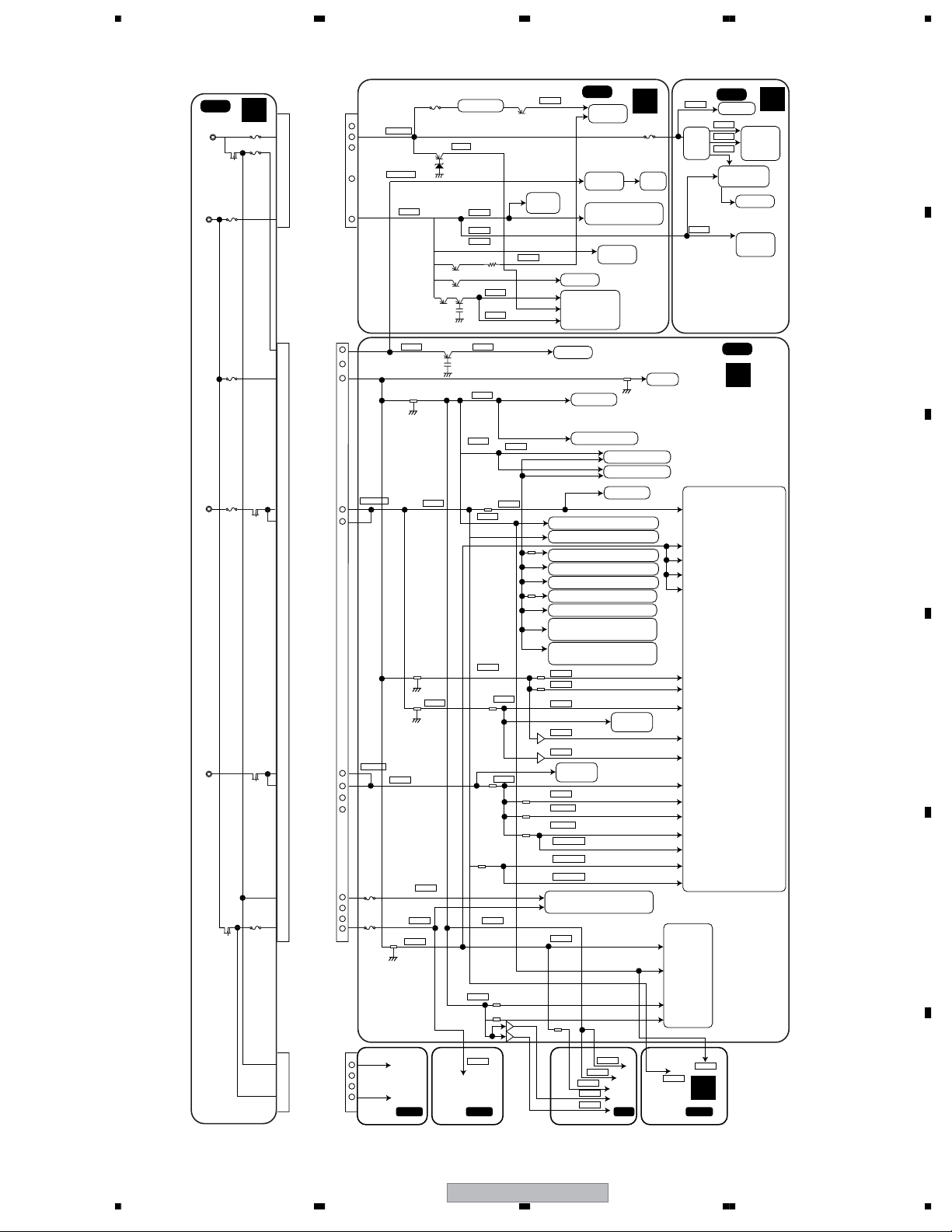

COUT2

CN604

28 1816 22 20 21 29 10 8 4 2 1224 26 2 8 1016 18 22 28 4 6 26 25 24 20 14

CN1

5.5M

Trap

Filter

Tuner

IR

FLDATA

FLCLK

FLSTB

18

14

9

87

86

92

91

85

84

20

40

39

38

32

36

34

VOUT1

SCL/SDA

27.28

81

TEXTV

6dBAMP

SYNCAFT

FUNC_ON

SQU

XAVLTH

AVLIN

AVLOU

306

94 93

44 46 16

73 74

L1R

L1L

L1R

L1L

GR/CB

Tuner Control U-CON

67

41

42

48

70 22

26

7123

RENESAS

HA118326PF

45

VIN1

49 48 50L312

G

71

BR/C

AV2LAV2RAV

72

12.13

10MHz

10.9

32.768k

BATTDEC

21

72

FUNC_IN

BLANK

80

79

61

59

55

57

51

53

52

76

1

100

BATT

4

1

2

3

AL

32

AR

CN4002

34

28

30

19

17

21

23

25

15

13

V/Y

MM1503

Y3

C

MM1501

C3

Y

C

Y/G

Cb/B

Cr/R

77

AL

AR

RGB_YIN

A

22

90

89

AV

AV

2R

2L

2V

CN605

CN2

TUJB

MUTE

AV1

B

B

G

R/C

R/C

GB

V/Y

DVR-640H-AV

LPF

BUF

LPF

Volt

age

chan

ge

B

LPF

BU

BUF

F

MUTE

V

2V/Y

BR/C G

Blank

FUNC

AV2

JA802JA801

BH7326AF

AV_LINK

Crystal

1201

VSS

FU

TC4W53

B

SCRB

TC74HC123AF

LA7213

Voltage

change

E

F

1V/Y

Blank AV_LINK

FUNC

INPUT1/OUTPUT1 INPUT3

14

1234

Page 15

_TO_

5

/

,

20

25

28

30

26

27

29

9

8

6

15

13

11

17

19

21

23

1

32

4

2

CVBS/Y

CN2301

5678

A

(DVR-640H-AV

Only)

USB

1,2

3,4

6- 11

1,2

47,48

49,50

35,37

24,25,

33,34

WRITER

ATAB

B

C

HDD

D

P_CONT2

MRST

XRESET

DA T_TO_M

HS T

X525P

C

Yp

Cb

Cr

Y

C

L

R

ZEROR

buffer

L

R

CN5601

U2,V2

F1,G1

N21

B1,C1

N2

P2

P3

K2

M1

P2

IC5701

USB control IC

TDOTG242-

0F0C8

N1

P1

N3

SL1

SL2

MDRV

LO

FDRV

TDRV

FE

TE

RFEQO

95,96

512M SDRAM

K4H511638C-

512M SDRAM

K4H511638C-

28

29

24

26

53

52

87

85

uPC3345GC

16MHz

X1001

24MHz

X1002

27MHz

IC1201

UCB3

IC1221

UCB3

IC501

FTS driver

BD7997FS

IC101

RF IC

-YEB

X201

IC1102

64M FLASH

S29GL064M90TCI

R30

voltage

regulator

B7

V21

U17

N20

U21

R21

W15

W21

M17

N18

UPD61272F1-

C8

EMMA2RFE

C7

D6

C9

D10

B9

C10

D11

R18

A9

V15

C11

B6

A7

A6

B10

T20

External ROM I/F

DDR SDRAM I/F

IC1001

107KA3A

INT*2/U ART*2/

IC3707

RESET IC

SS T to M

IC3701

M

USBRST

IC2201

SW IC

MM1503XN

IC2202

SW IC

MM1501XN

IC3202

IC3101

audio ADC

AK5359ET

IC3102

TC7SZ126

IC3201

audio DAC

PCM

1742KE

IC3103

SELECT IC

TV74VHC15

7FT

5V to 3V

HS M to T

ASCK_NSCK

X525P SCL

USBRST SDA

buffer

buffer

buffer

buffer

buffer

buffer

buffer

BCKO

LRCKO

ADATAO

NSCS

DACCLKO

ADATAI

BCKI

LRCKI

ADCCLKO

AD POW

HS T to M

AMUTE

SPDIFO

CN101

36,37

34,35

1- 6

49,50

45,46

47,48

USBB

2,3

7-

10

H

ST1+/ST2+/-

CN502

SPDL

CN501

LOAD+/-

CN601

F+, FT+, T-

RF+, RF-

A- D

CN101

CN3801

DV LRCKI

12

PHY

DV LRCKI

IC 3802

Expand IO

PCA9557

PW

INT*2/U ART*2

21,20

4,5

INT*2/U ART*2/

DVout

DV_XADC

AD POW

F

MAIN

E

18,1711

7,8

(DVR-640H-AV

G

DVJB

Only)

F

DVR-640H-AV

7

8

15

SCL

SDA

USBRST

525P

DVRST

SCL

SDA

DV C I N

AMCLKI(STBY)

CN3802

CN101

DV Y/ V IN

7

3

1

22 24 10 11

18

6

SCL

SDA

DVRST

VENC IC

IC101

ADV7172KSTZ-K

LINK/DVCODEC

IC102

UPD72893BF1-FN3-K

16M SDRAM

IC103

K4S161622H-TC60-K

1 15

DV Y/ V IN

DV C I N

V ADATA I

DV BCKI

D

14 1319 6

14

ATA I

(STBY)

I

DV BCKI

AD

V

D

AMCLK

IC108

UPD72852AGB-8EU

56

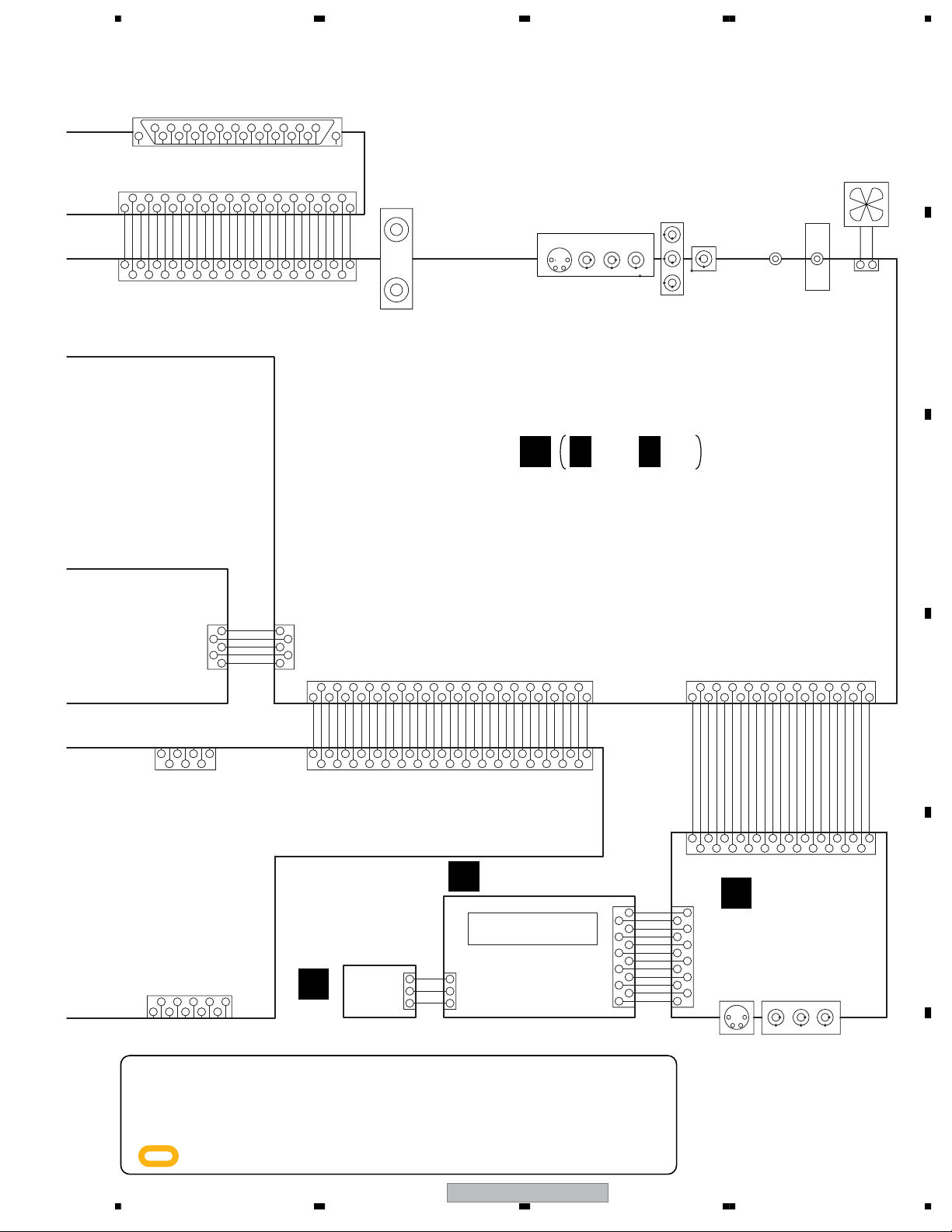

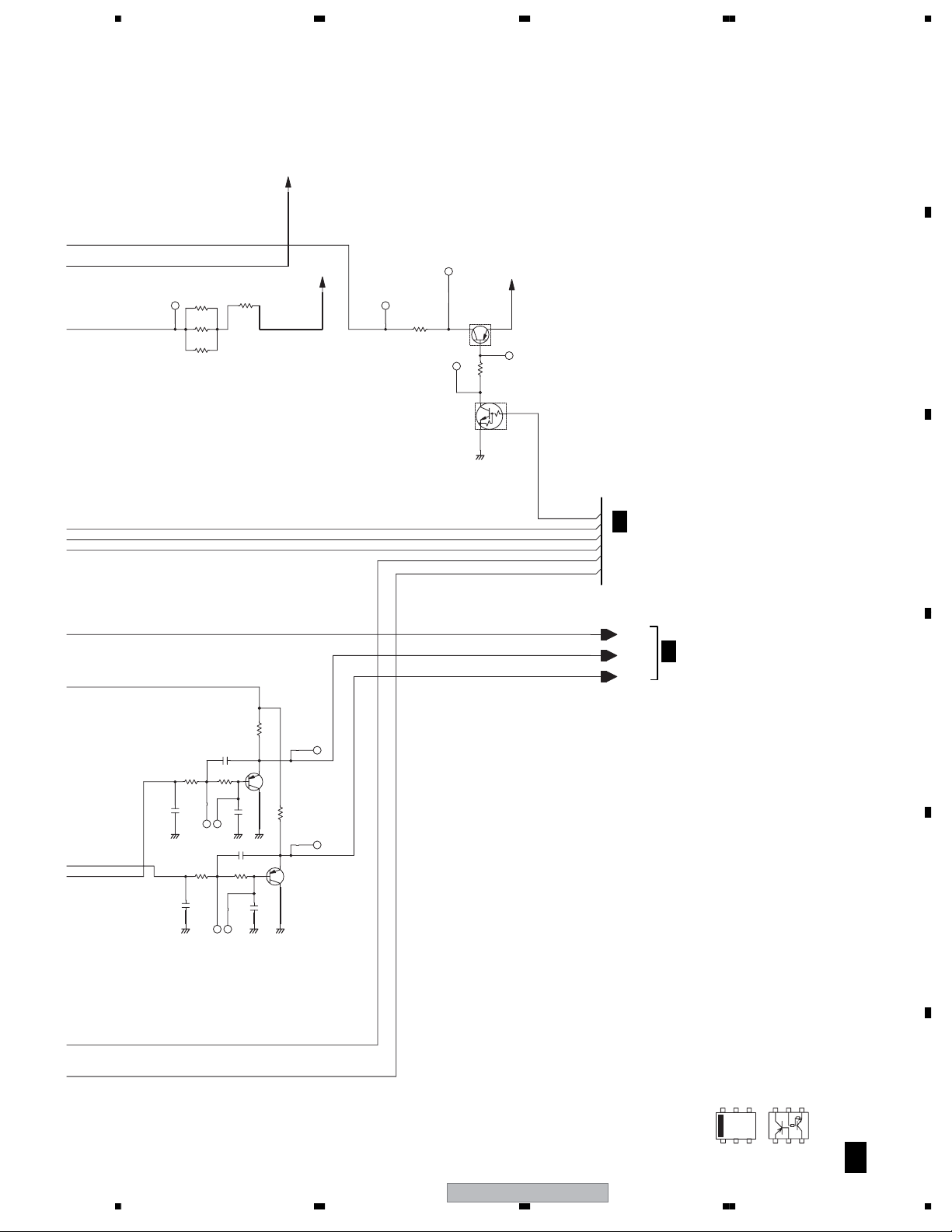

Page 16

DIGITAL UNIT

CYPb

Pr

Y

C

TV TUNER UNIT

Module

1234

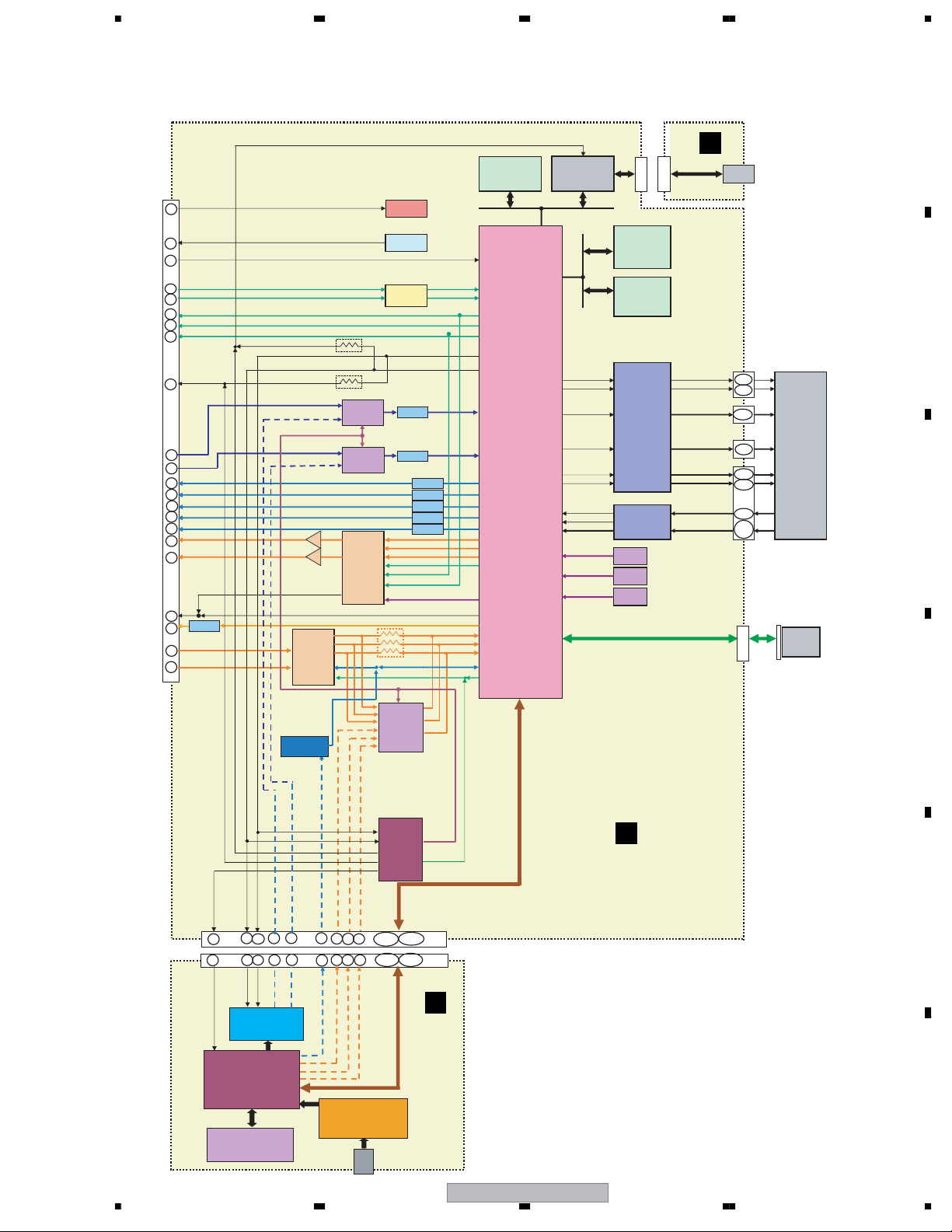

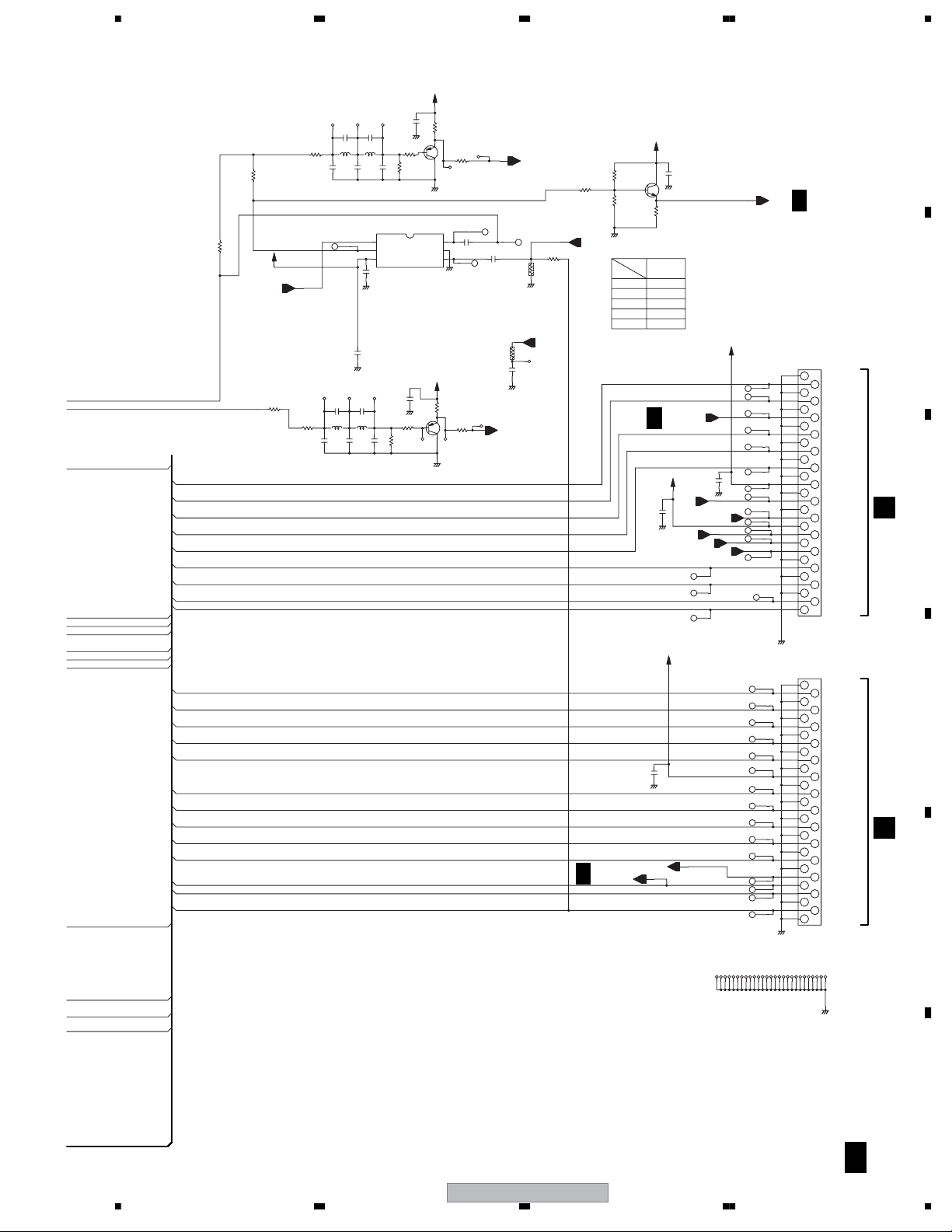

3.1.2 DETECTION AND ENCODE SYSTEM BLOCK DIAGRAM

A

/RGB IN

(Euro Scart)

ANTENNA IN

CVBS IN

S-Video IN

Tuner

Module

Input

Selector

&

Driver

Output

&

Euro

Scart

Interface

IC

B

TV TUNER UNIT

CVBS/S-Video

CVBS OUT

S-Video OUT

YC

MIX

YPbPr OUT

( 525I / 525P )

Euro

Scart

Inter

face

/RGB OUT

(Euro Scart)

Pb

R

Pb/B

Block

Video

Encoder

Progressive

C

Y/C

Sep.

Block

C

Y

Detection

Block

D

DIGITAL UNIT

Detected Result

C

CVBS

/Y

Block

Video Decoder

Y,U,V

REC.656

DAC

Video

Interlace

Block

I/P

Video

Sel.

Block

Encoder

PAL Model Block Diagram

Block

Micro-

Controller

Enc.

/Dec.

MPEG

E

SystemLSI

uPD61272

Data

Recording Control

Block

Insertion

Encoder

Enc/Dec

CD/DVD

Block

Block

DSP

Encoder Control

Micro-

Controller

DVR-440H-S/DVR-540H-S/DVR-640H-S/DVR-440H-AV/DVR-640H-AV

: Refer to [05 DVR model list] No.A6-A17,A20-A26

Detection and Encode System Block Diaglam

&

(ASP

PickUp

HDD Unit

F

16

1234

DVR-640H-AV

DVD Unit

mecha)

Page 17

5678

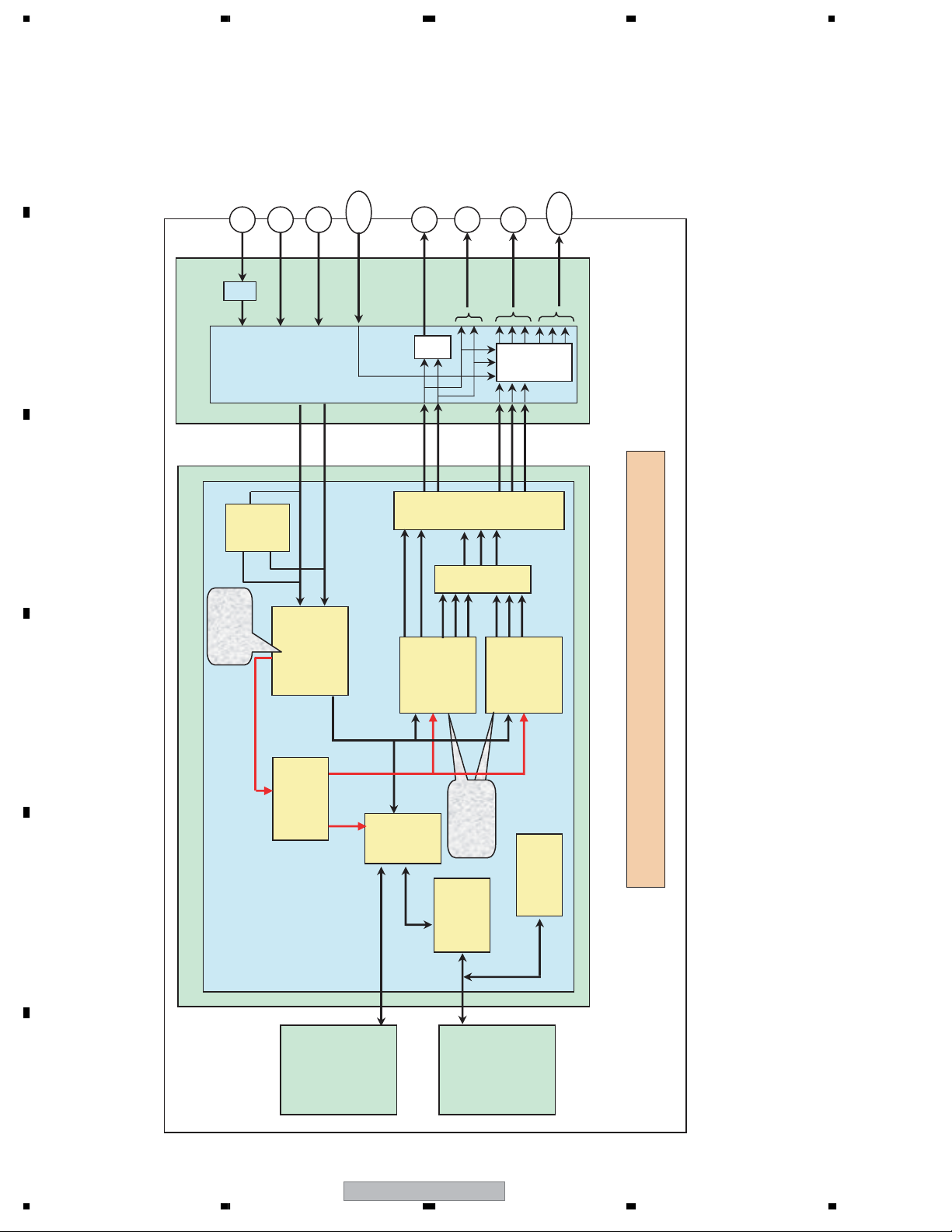

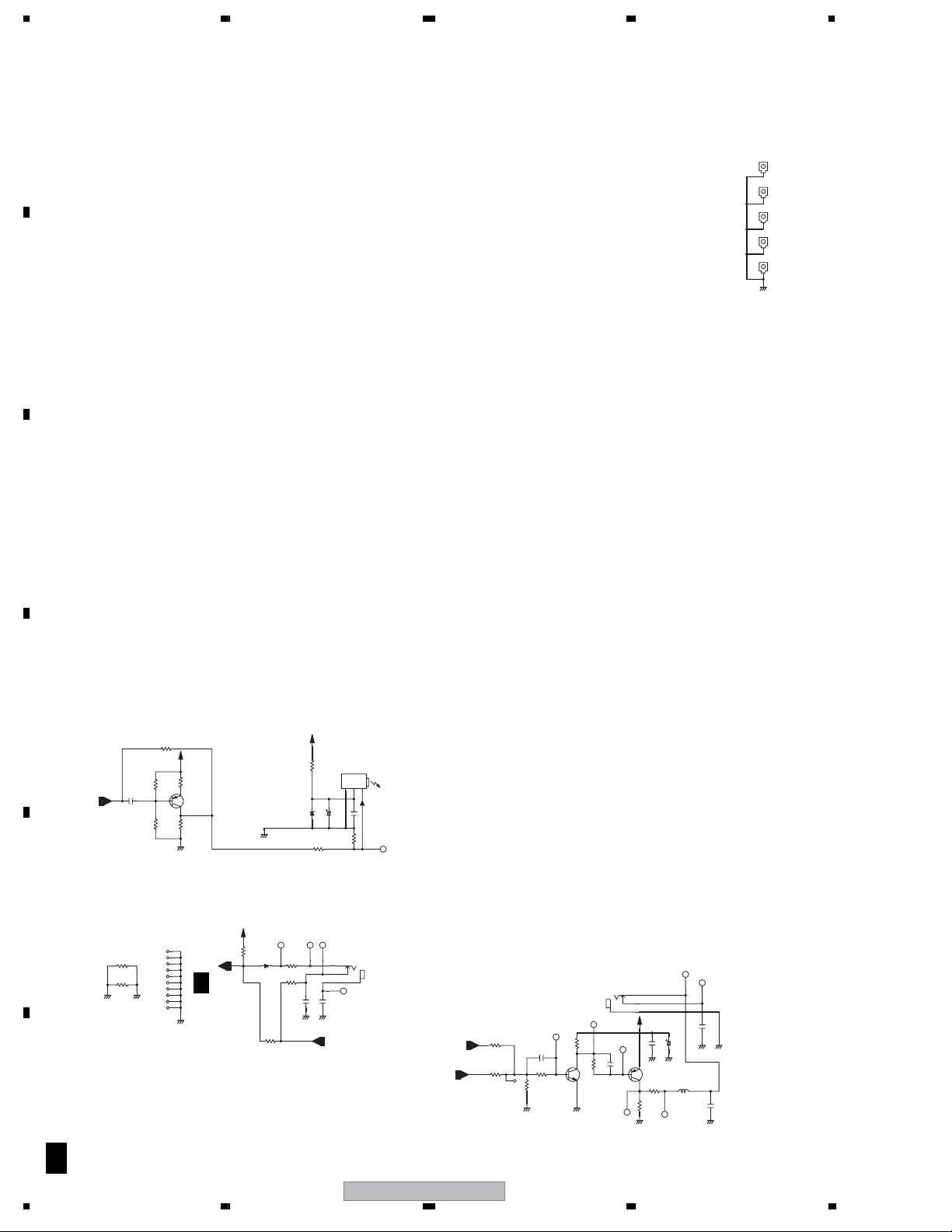

3.1.3 POWER BLOCK

SYPS

P201A

P204A

P501A

J

P401A

P402A

P202A

CN202 CN303

5

P_ON

4

EV+12.1V

3

GND

1

GND

2

EV+5.8V(T)

CN201 CN2401

5

EV+12.1V(J)

12

GND

13

EV+5.8V(M)

7

SW+3.33V(M)

8

SW+3.33V(M)

10

SW+1.53V(M)

11

SW+1.53V(M)

6

GND

9

GND

1

SW+1.21V(W)

2

GND

3

GND

4

SW+5V(W)

SW+3.33V

V+1R5_IN

IC2401

IC2402

IC5001

V+12R1E

V+12R1SW

V+5R8E

V+12A

IC4504

V+3D

IC4511

IC4512

V+2R5

V+1R5

V+12M

V+5M V+5L

IC4507

V+3FE

DCDC Con

V+9V

V+5V

V+5F

V+5M

V+5A

V+12A

V+5AVI

V+5VI

V+5VO

V+3FE

V+5TU

Audio

MUTE

V+31V

SPDIF

Interface IC

Audio LPF

Video buffer

INPUT Video filter

TUJB

Tuner

U301

FAN Circuit

RESET IC(Tu-con)

Tuner Con

IC100

IC102

IC101

IC5621

Audio DAC

A

IC1001

FAN

USB

IC3201

FLKY

V+12V

FLDC+

DC

FLDC-

DC

FL-28V

Con

BLUE LED

FL DRIVER

IC7001

FL TUBE

V7001

D

A

RED LED

V+5F

Infrared

Sensor

SW

B

MAIN

F

Audio ADC IC3101

3R3V

V+5D

RS-232C

FLASH IC1102

EJTAG

TC7SU04FU

IC3102

TC74VHC157FT IC3103

IC3701

TC7WH34FU

IC5701

USB driver

EMMA

for I/O_buffer

IC1001

M3, AD/DA/WBLSLICE

V2, EFMPLL/EFMCOMP

Y7, LVDS

Y8, APLL/DLYLINE/WCDLL

C

SPDIF

EMMA_Video_Decorder

External Filter

Pull-up for interface with Eriter,HDD

V+3V

V+DDR

1R5V

(ATA)

V_ADC

V_VENC

2R5V

VREF_V

VREF_D

RESET IC

IC3707

PVDD

VP VDD

V(DSP)

V_WP1(DSP)

V+3A(DSP)

V+3D(DSP)

6ch MOTOR DRIVER

V+3A

Video_Decorder_ADC

Video_Encorder

DDR x2

IC1201,IC1221

DDR_SDRAM

D

Video_DAC_Vref E8

DDR_VREF A15

Core E5,F5,J9,J13,N9,N13,U5,

U8,U14,U15

System_PLL D1

VDEC PLL J19,K19

R2,EFMPLL

AA10,WAPLL/DLYINE/WCDLL/

WRCHPLL/203MPLL

J20,VDEC HSCLAMP

L20,VDEC FSCLAMP

IC501

RF

IC101

REFI

E

Vcc6

V+5S

Vcc1,8,9

Vcc2,3,4,5,7

CN203

VD3V

VREF21

VREFFM

VA5V

VO5V

1

SW+12.1V(H)

2

GND

3

GND

4

SW+5V(H)

VCC

HDD P.U.

SPDL

DVR-640H-AV

56

V+5D

V+3D

G

DVJB

7

8

F

17

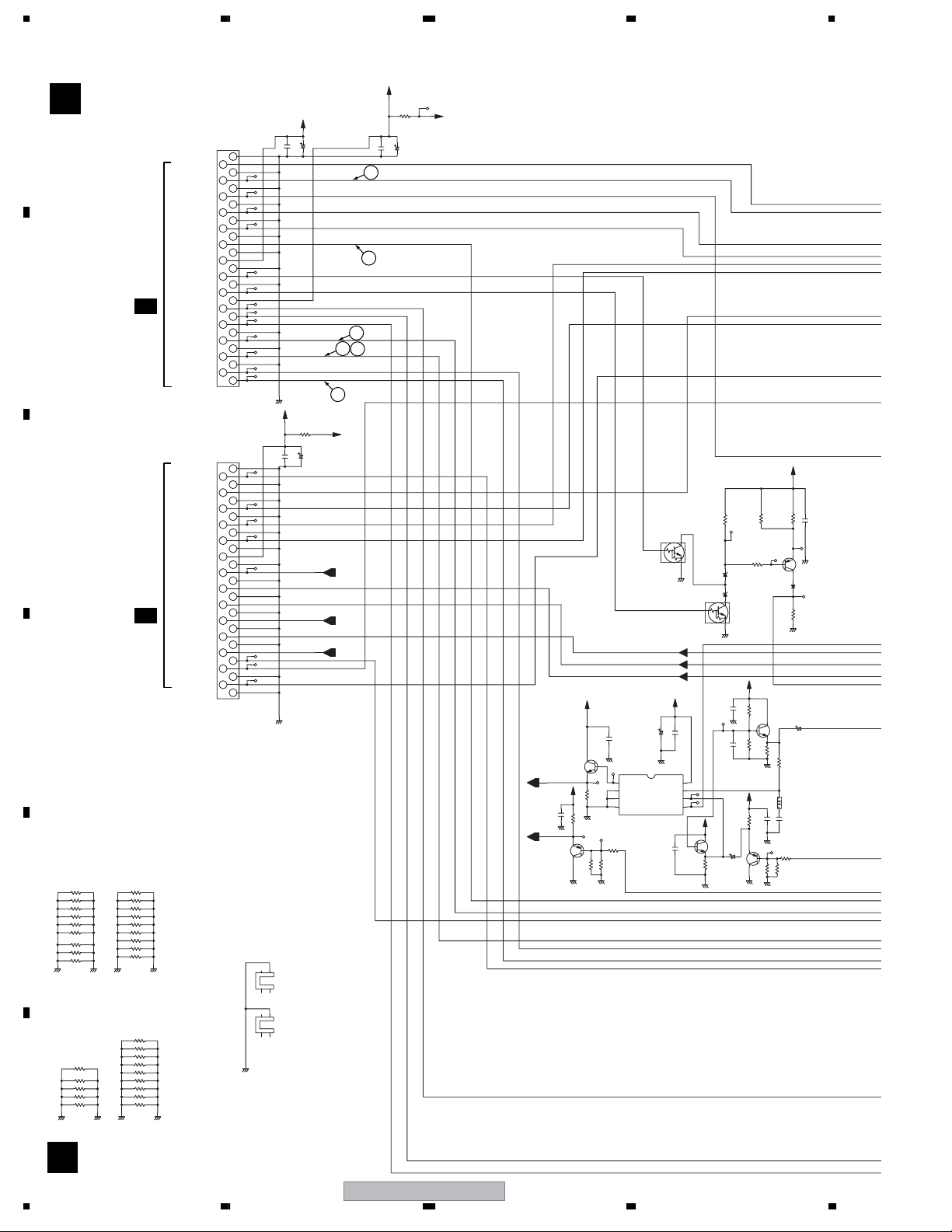

Page 18

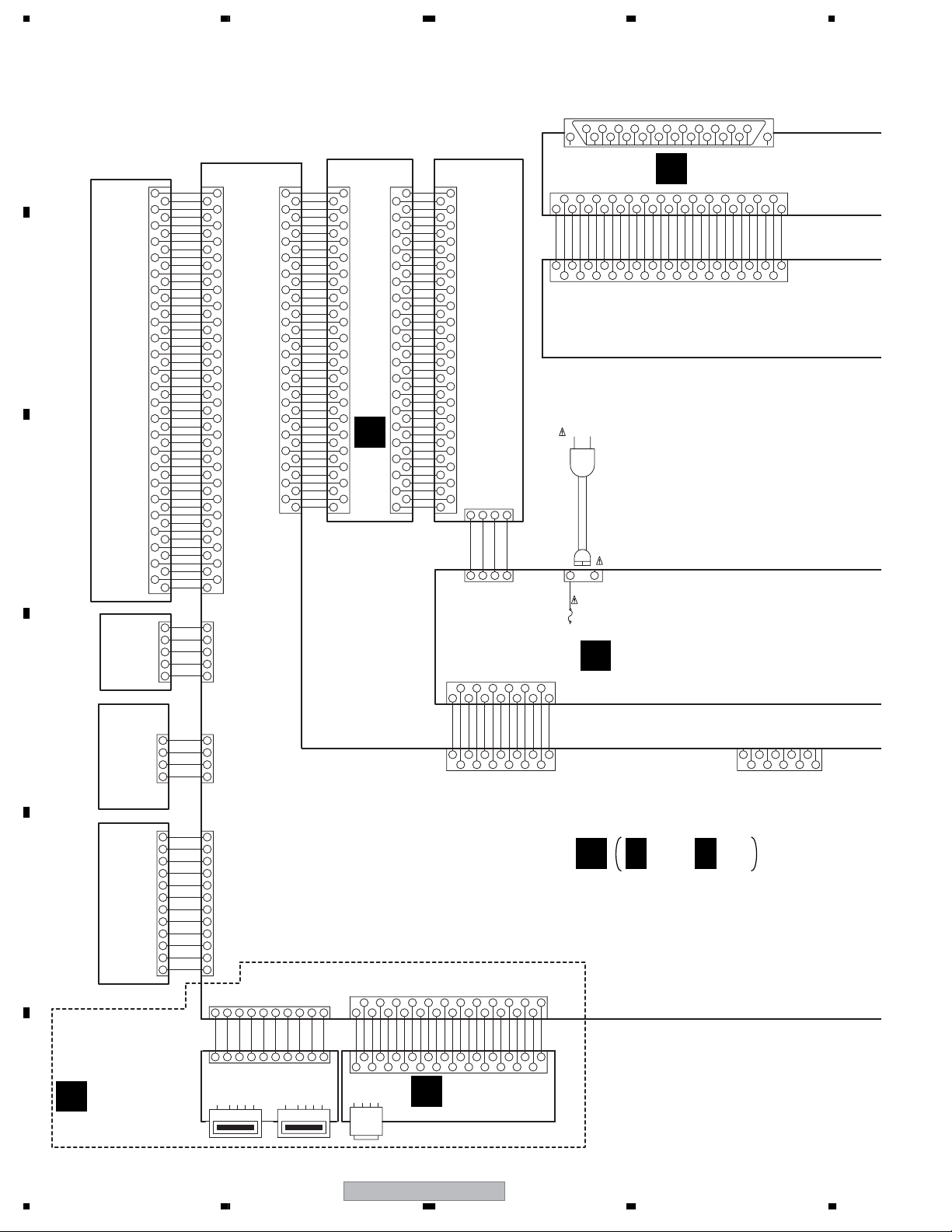

1234

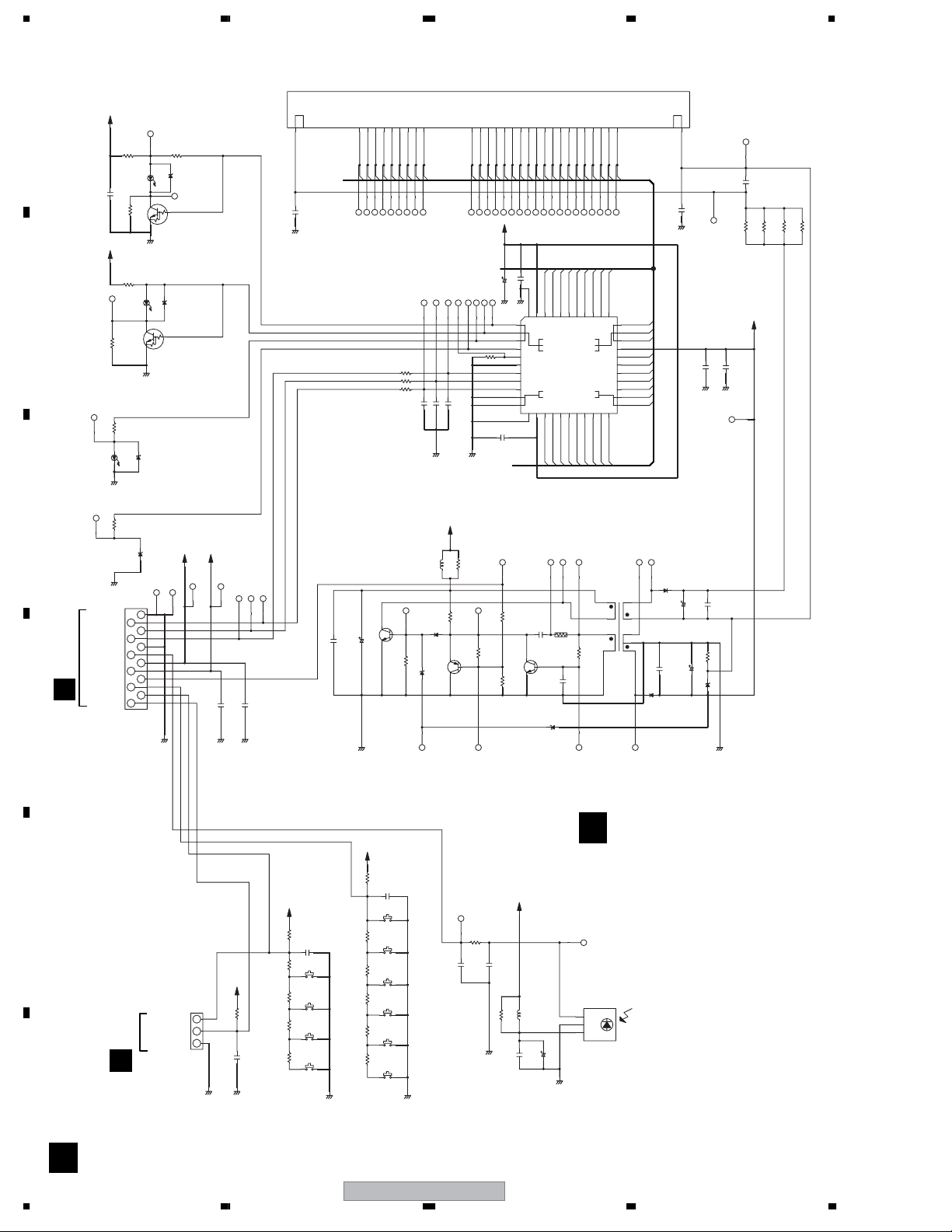

3.2 OVERALL WIRING DIAGRAM

A

JA801

CN101

TD

50

TR

49

49

FD

48

47

46

45

44

43

42

41

40

39

38

37

B

C

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

P. U.

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

5

4

3

2

1

FRONT

D

4

3

2

1

48

FR

47

SCLK

46

SEN

45

SDIO

44

VPP

43

RESET

42

RXW

41

VD3V

40

GNDD

39

TEMP

38

S1

37

S2

36

M1

35

M2

34

WRF

33

WPP2

32

VREFPD

31

WPP1

30

RF-

29

GNDS

28

RF+

27 17

VA5V

26

M3

25

M4

24

S3

23

S4

22

GNDS

21

VA5V

20

VREFFM

19

FMO

18

OSCEN-

17

OSCEN+

16

W3EN+

15

W3EN-

14

W2EN+

13

W2EN-

12

W1EN+

11

W1EN-

10

RDIS

9

W3SET

W2SET

7

W1SET

RSET

5

VO5V

VO5V

3

GNDO

GNDO

1

CN601

DKN1402-

LPS2

5

GNDD

4

LPS1

3

BLACK

2

RED

1

CN502

DKN1288-

ST2+

4

ST2-

3

ST1-

2

ST1+

1

CN3801

VKN2050-DKN1404-

4050

38

36

34

32

30

28

26

24

22

20

To HDD

18

16

14

12

10

8

6

4

2

8

6

4

2

CN11

VKN1818-

GND

DASP#

39 39

CS1#

CS0#

37

37

DA2

DA0

35

35

PDIAG#

DA1

33

33

RESERVED

INTRQ

31

31

GND

DMACK#

29

29

CSEL

IORDY

27

27

GND

DIOR#

25

25

GND

DIOW#

23

23

GND

DMARQ

21

21

KEYPIN

GND

19

19

DD15

DD0

17

DD14

DD1

15

15

DD13

DD2

13

13

DD12

DD3

11

11

DD11

DD4

9

9

DD10

DD5

7

7

DD9

DD6

5

5

DD8

DD7

3

3

GND

RESET#

11

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

CN12

VKN1816-

GND

1

DASP#

39

2

CS1#

3

CS0#

37

4

DA2

5

DA0

35

6

PDIAG#

7

DA1

33

8

RESERVED

9

INTRQ

31

10

GND

11

DMACK#

29

12

CSEL

13

IORDY

27

14

GND

15

DIOR#

25

16

GND

17

DIOW#

23

18

GND

19

DMARQ

21

20

KEYPIN

21

GND

19

22

DD15

23

DD0

17

24

DD14

25

DD1

15

26

DD13

27

DD2

ATAB ASSY(VXX3140)

I

13

28

DD12

29

DD3

11

30

DD11

31

DD4

32

34

36

9

DD10

33

DD5

7

DD9

35

DD6

5

DD8

37

DD7

3

38

GND

39

RESET#

1

40

40

38

36

34

32

30

28

26

24

22

20

18

16

14

12

10

8

6

4

2

SW+5V(H)

432211

CN204

CN201

12

13 11

GNDD

EV+5.8V

SW+1.53V

13 11

CN2401

S13B-PH-K-S

(160GB)

HDD

324

1

GND

GND

SW+12.1V(H)

CN101

10

SW+1.53V

10128246

46

82

531

7

9

GND

SW+3.33V

SW+3.33V

7

V+5M

GNDD

V+12V

531

GNDM

GNDD

9

1234567

GND

V+12M

Rin

Rout

3

1

2

22

VKB1157-

VKN1260-

CN1

GND

GND

GND

SAMUTE

AV1_R_OUT

AV1_L_OUT

3157

246

VKN1433- -TBB

CN604

AC POWER CORD

LIVE

(NEUTRAL)

J

Lout

FUNCTION

Bin

Lin

GNDV

GNDA

57

9

4

6

8

AV1(to TV)

12

8

13 192017

11109

GND

GND

GND

AV1_L_IN

AV1_R_IN

AV1_B_OUT

11

9

1081412161820

GNDV

10

N-LINK

B

V+12R1

BLANK

R/Cout

GNDV

GNDV

NC

Gout

111213

GNDV

GNDV

15

16

14

SCRB ASSY

(VWV2206)

161514

18

GND

SQU

GND

V+5V

AVL_IN

XAVLTH

AVL_OUT

FUNC_OUT

15 131719

212329 2527

GNDV

V/Yout

V/Yin

21171819

23

20

24

28

23212225 272629

GND

GND

GND

AV1_G_OUT

AV1_R/C_OUT

222428 26

BLANK_OUT

POWER SUPPLY UNIT

(VWR1339) or (VWR1400)

For EuDT

1236745

CN2601

VKN2038-

AV1_V/Y_OUT

9

8

10

STEPPER

CN501

DKN1312-

VCC

12

12

HU+

11

11

HU-

10

10

HV+

9

9

HV-

8

8

HW+

7

7

HW-

6

E

USBB ASSY

H

F

(VWV2161)

6

5

SPDL

4

3

2

1

HB

GNDD

U

V

W

5

4

3

2

1

CN5601

S10B-PH-K-S

10

USBDP1

10

CN101

B10B-PH-K-S

JA101

VKB1226-

6

GND

USBDM1

3

254

789645

GND

USBVFB

789645

1

7

V+5USB

JA102

6

1231

GND

GND

USBDM2

USBDP2

123

VKB1227-

5

47123

CN3802

VKN2045-

23456

GND

C_OUT

Y_OUT

242320

22

CN101

VKN2045-

2

3

GND

VENC_RST

21 19

JA101

VKN2028-

987

SCL

GND

SDA

V+3DV

17 15 11

18 16

G

DVR-640H-AV only

12

10

GND

11 151413

GND

V+3DV

13

ALRCK

12

ABCK

20

181916

22

17

PCM

GND

1014

DV_INT1

DV_INT2

DV_TX

DV_RST

6798

DV_RX

V+5D

DVJB ASSY

(VWGV2160)

23221

V+3D

F

24

V+3D

1345

F 1/4- F 4/4

MAIN ASSY

(VXX3157 : DVR-640H-AV)

(VXX3159 : DVR-540H-S)

18

DVR-640H-AV

1234

Page 19

5678

22

24

GND

AV1_V/Y_IN

2

Rout

2

31

57611

GND

GND

AV2_R_OUT

31

57119

46108

RinNCLout

GNDA

46

8

GND

AV2_R_IN

AV2_L_OUT

Lin

FUNCTION

GNDV

Bin

5713

9

8

AV2(from STB)

12

10

9

GND

GND

GND

V+5VI

AV2_L_IN

12

Gin

N-LINK

GNDV

GNDV

GNDV

15

11

13

10

12

14

14

1513161718192021222523

GND

GND

( )

Y RGB

AV2_G_IN

AV2_R/C_IN

15 13

17192125 2329 27

1820222428 26

16 14

CN605

R/Cin

BLANK

17

16

JA802

CN2

GND

GND

( )

C RGB

VKN1433- -TBB

GNDV

GNDV

192321

18

VKN1260-

AV2_B_IN

V/Yin

V/Yout

GNDV

20

VKB1157-

24 262928

GND

FUNC_IN

BLANK_IN

27

GND

GND

AV2_V/Y_IN

AV2_V/Y_OUT

U/V IN/OUT

U301

VXF1106-

COMPONENT

OUTPUT

JA2010

JA2003

VKB1193-(EU)

VKB1165-

OUTPUT1

Y

S-VIDEO

COMPOSITE

AUDIO (L/R)

Cb/Pb

Cr/Pr

A

A 1/4- A 4/4

TUJB ASSY

(VXX3109 : DVR-640H-AV)

(VXX3108 : DVR-540H-S)

COAXIAL

JA2004

JA536

VKB1159-

2

1

3

JA4002

SR IN

RKN1004-

IR BLASTER

JA4001

RKN1004-

/EU

only

FAN MOTOR

(VXM1125-)

FAN+

FAN-

1

CN5001

B2B-PH-K-S

FAN

A

2

B

C

GND

EV+5R8

GND

EV+12R1

P_ON

CN303

B5B-PH-K-S

1

2

3

4

5

34

32

33 313027 25

35

GND

R_IN

L_IN

AMUTE

1

468

2

CN2301

VKN1439-

C_IN

P_CONT2

5397

28 262924

GND

Y_IN

X525P

GND

GND

CR_OUT

11 13 15

101214

22 201918

2123

GND

CB_OUT

YP_OUT

14910

17 131615

GND

GND

MRST

GNDA

C_OUT

Y_OUT

L_OUT

1917 2321 25 273129

1816 2220 24 2826

12

R_OUT

SW+12V

11

XRST1

DAM_TO_T

CN4002

VKN2025-

82456

731

GND

ASCK

B_IR

SPDIF

HSM_TO_T

DAT_TO_M

HST_TO_M

34

323330

TXDGL

RXDGL

35

2146

CN1402

RKN1048-

CN202

1

2

3

4

5

537

FLKY ASSY

D

(VXX3111)

CN7001

9604S-12C

2

4

6

8

10

12

KEYB ASSY

V7001

VAW1091-

(VXX3112)

KEY2

1

CN401

VKN2029-

451236

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

10

8

9

7

E

CN7201

B3B-PH-K-S

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

÷

: The power supply is shown with the marked box.

1

KEY3

2

2

GND

3

3

J7001

PF03PG-B05

CN101

9604S-23C

6

2

1

8

4

3

5

12

10

14

16

9

7

13

11

202122

19

171815

23

D

IR

GND

FLSTB

23

FLCLK

FLDATA

21

22

JA7301

V+5F

KEY1

FLPON

V+12R1E

17

19

20

18

14

16

FJKB ASSY

C

(VXX3113)

S-VIDEO

INPUT2

AKP1238-

KEY2

GND

CN7302

9604S-12C

GND

FLSTB

FLCLK

FLDATA

GND

IR

V+5F

V+12R1E

FLPON

KEY1

KEY2

KEY3

12

11

10

9

8

7

6

5

4

3

2

1

1

3

5

7

9

11

2V

2L

2R

KEY3

GND

GND

9

11

13515

8

10

12

COMPOSITE

AUDIO (L/R)

JA7302

VKB1208-

2Y

GND

7

6

CN7301

9604S-23C

GND

4

SDET2

GND

2C

123

E

F

56

DVR-640H-AV

19

7

8

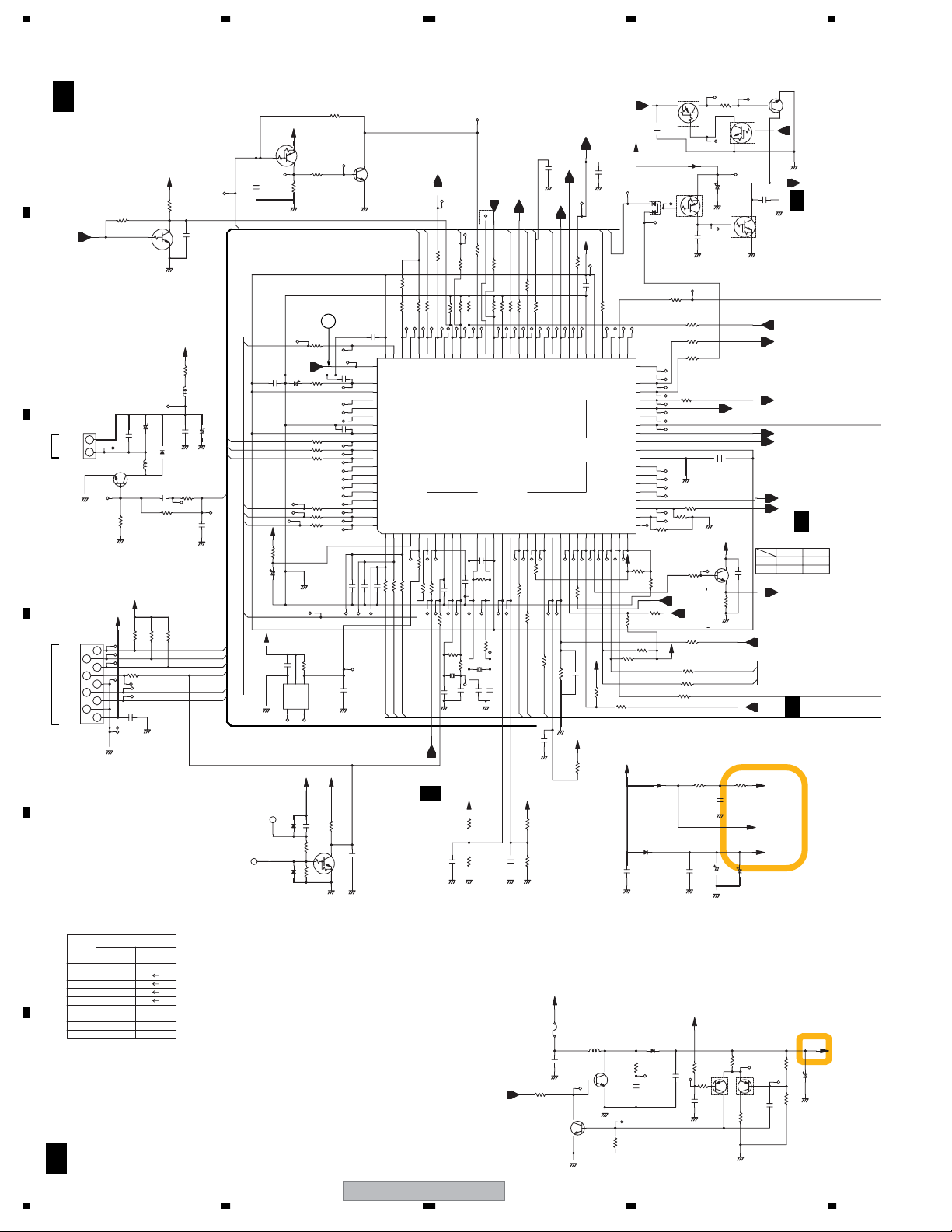

Page 20

1234

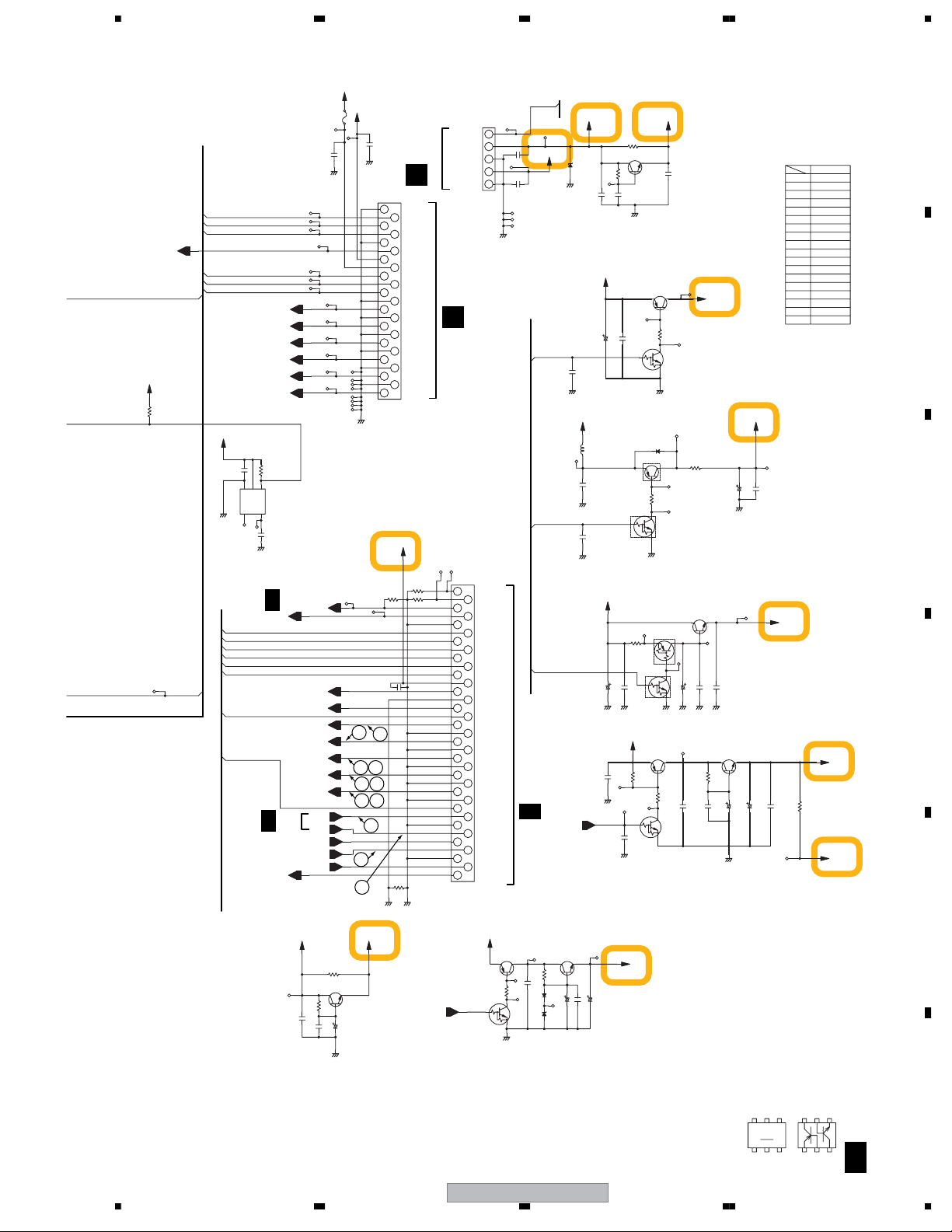

3.3 TUJB ASSY (1/4)

A 1/4

A

TUJB ASSY(1/4)

(VXX3109 : DVR-640H-AV)

(VXX3108 : DVR-540H-S)

V+5V

R101

R166

***

Q101

BLANK

B

toFAN

CN5001

FAN+

1

2

FAN-

B2B-PH-K-S

DBGP2

DBGP1

DBGP0

RESET

GND

RXD1

TXD1

GND

V+5V

GND

CN102

8

6

4

2

VKN2015-

NOTE3

type

ASSY

U301

IC901

R910

R153

R154

R155

R156

9

7

5

3

1

640H/WY

VWM2371

VWV2169

VXF1106-

MSP3417G

C

D

E

F

DTC114TUA-TLB

C5010

0.1/25

Q5006

E

C

B

2SD2114K(VW)-TLB

2.2K

R5002

GND

V+5V

V+5V

R106

R109

100

C103

***

GND

EU

***

***

15K

39K 39K

B

***

C5011

L5005

ATH1109- -T

CH

R107

100K

GND

540H/WY

440H/WY

VWM2370

39K

6.8K

15K15K

1

D5004

2

C5013

470p

R5001

3.3K

100K

GND

R108

A 1/4

20

1234

10K

C

C106

E

V+12R1SW

0

L501

C5014

1SS355-TRB

GND GND

R5003

100K

***

R319

12µ

LCYA120J2520-T

0.1/25

47µ/16

C5015

FANCTL

0

***

C5002

CH

GND

DBGP2

DBGP1

DBGP0

RESET

RXD1

TXD1

C107 R110

******

MRST

TU_CON

HST_TO_M

C120

DBGP2

DBGP1

DBGP0

DAT_TO_M

DAM_TO_T

ASCK

V+5V

HSM_TO_T

TU_CON

GND

1SS355-TRB

B

***

R115

47K

C111

22/25

V+5V

D4002

DTC124EUA-TLB

V+5V

Q103

E

***

C

GND

TEXTV

C119

2.2/50

R158

R159

R160

R146

R147

R148

GND

0.1

R4001

C4001

123

G

IN

NC

NC

4

5

V+5R8E V+5M

D4001

C4003

1SS355-TRB

R4005 R4004

R111

***

24

R144

100

R145

1K

C121

***

100

100

100

100

100

100

10K

BD4846G-TRB

IC4001

OUT

YB1u

0

B

***

Q4001

GND

R185

R4003

C

E

0

C134

C4002

GND

10K

Q104

***

C4004

GND

C

B

E

GND

C123

***

81

***

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

***

***

C109

C110

0.1

0.1

TU_DCCON

1-D3

180

TXD1

RXD1

X525P

R1101

100

R5015

R167

100k

Note1

***

100

100

R125

100K

R143

100K

R142

TXD2

WDT

100

R4002

RXD1

ACDET

R116

SEL_IR

TXD1

LEDDVD

TU_DCCON

81. CVBSIN

82. GND

83. FILTSLC

84. VDDVCO

98. DAT_TO_M

99. DAM_TO_T

100.ASCK

HSM_TO_T

RESET

IR

***

100

C112

100

R117

100

R119

R120

***

VSS1197-

X102

C113

10p

GND

R162

BLANK

XT1

330p

C4009

R121

C114

X525P

XT2

0

10p

R173

78 777980 737476 75 6971 7072 6768 646566 61 606263

RXD2

VDDODA

HST_TO_M

XMSST

XMSPI

XMSRST

GND

VDD3

DBGP2

DBGP1

DBGP0

blank

blank

blank

blank

blank

FLCLK

FLDATA

FLSTB

23417865

100

100

100

***

C108

R114

R112

R113

FLSTB

FLCLK

FLDATA

3/4

A

V+5V V+5V

R155

***

C127

R156

GND GND GND

GND

DVR-640H-AV

1-A3

MUTECTL

0.1

C136

XP_SAVE

SYNCAFT

1-C5,1-D5

GND

EPGEXT

STACHG

100

0

R1115

FLPON

R140

R137

R139

100K

Note1

***

R141

AVLIN

GND

1211910 1413 171615 20 211918 22 23 24 25 28 29 3026 27

R164

1M

X101

12p

C117

39K RD

15K RD

TU_DCCON

MRST

CF1

C115

0

R122

GND

Note13

R161

100K

J_CLOCK

CSYNCIN

XCHECKER

IC101

PMC006A8-K

VDD1

MODEL1

CF2

0.1/25

CSS1653- -T

CH

12p

C129

C126

1-A2

100

100

R104

R174

XP_SAVE

STATCHG

50. blank

49. blank

48. XAVLTH

47. PSMUTE

33. AMUTE2

32. COMPMUTE

31. MUTEV

MODEL2

KEY1

R135

100

R123

R124

KEY1

KEY2

R153

***

R154

2SC4081(QR)-TLB

P_CONT

100

R136

FLON

KEY2

100K

100

Note1

C4005

GND

Note3

Note13

R5009

100

blank

P_CONT

AGC

KEY3

100

R126

AGC

C5016

GND

820

TUON

TUON

BATTDET

4.7K

R127

***

V+5V

V+12R1E

21

IC5001

V+5M

R1112

***0

58 57 5659 53 52 515455

EPGEXT

MUTECTL

P_CONT2

SDET2

FUNC

SDET3

R4009

1K

V+5V

0.1

Note1

Note1

C101

GND

R4026

CEK1278- -T

***

2SC5876(QR)-TLB

C

Q5011

E

GND

1-C4

P_CONT2

C135

GND

FANCTL

C118

GND

VDD2

P_SAVE2

TU_XMODE

SDET1

AVLOUT

100K

R193

R128

Note1

10K

L5003

LRCA331J-T

Q5010

B

GND

B

0.1

0

R149

FANCTL

BLAIR

CONDET

SWSTBY

YVSEL

SELV3

SELV2

SELV1

SDA

Note1

C

E

UMD2N-TLB

AMUTE1

1-C4

***

C3320

V+5R8E

D105

DAP202U-TLB

21

3

B2

UMD2N-TLB

RESET

R1111

50

49

48

blank

blank

RFTHRU

47

46

45

44

43

SQU

42

LET

41

VDD4

40

GND

39

38

37

36

35

34

33

32

31

***

SCL

TUDET

XRST1

R201

V+5V

Note2

10K

***

R163

R152

Note2

R4008

***

Note1

R188

100K

Note1

V+5V

R131

4.7K

R134

4.7K

R1116

***

V+5R8E

D107

1SS355-TRB

1SR154-400-TRB

D106

***

C132

GND GND

1SS355-TRB

D5006

***

R5004

***

C5003

10K

R5005

Q3011

E2

B2

D101

1SS355-TRB

Q105

C2E2B

C140

GND GND

0

R102

0

R157

100

R175

0

R1114

Note1

C116

***

GND

0

R1107

***

R1108

GND

2SC4081(QR)-TLB

R150

100

1-B4

SDET2

SDET3

R105

6.8K

Note1

100

R132

100

R130

100

R171

0

***

C133

V+5R8E

21251u/50

22K

R5010

C5004

C5005

0.1/25

GND

HN1A01FU(YGR)-T

HN1A01FU(YGR)-T

2SD2114K(VW)-TLB

R3318

C2

1K

C

E

C139

100/10

GND

***

UMD2N-TLB

100

B_IR3

V+5V

Q102

C

B

E

R186

470

GND

C131

***

GND

C128

470/6.3

GND

R5011

EBE2

R5008

0

CB2C2

Q5007

UMD2N-TLB

Q3011

Q105

0.1

C102

SCL

SDA

R165

0

C130

1000/6.3

180K

R5014

0

GND

Q3010

B

C

E

Note2

Q5007

B

C153

P_SAVE2

R152

R163

FUNC_IN

TU_CON

SDET1

V+5V

C5018

E

C

MUTECTL

***

GND

AVLIN

XAVLTH

SQU

FUNC_ON

SELV1

AMUTE2

AVLOUT

V+5F

V+5M

R5007

CH

R5006

***

1-A3

GND

A

A

***

0 ***

A

3/4

120K

C341

GND

27K

TU_CON

SAMUTE

2/4

3/4

Tuner OldTuner New

10 k

V+31E

10/50

Page 21

5678

V+5V

R184

V+12R1E

V+5F

12

IC1001

CEK1278-A-T

C4017

C4018

GND

FLSTB

FLCLK

FLDATA

IR

FLPON

KEY1

KEY2

RFTHRU

Note1

***

XRST1

GND

V+5M

TU_CON

C104

X525P

0.1

R172

321

G

IN

NC

4

C105

GND

HST_TO_M

ASCK

DAT_TO_M

HSM_TO_T

DAM_TO_T

XRST1

MRST

L2_RIN

L2_LIN

2VIN

Y2IN

SDET2

1-B3

C2IN

10K

BU4220G-TRB

IC102

OUT

CT

5

YB0.1

A

3/4

B_IR

SPDIF

R_OUT

L_OUT

C_OUT

Y_OUT

YP_OUT

CB_OUT

CR_OUT

A

Y_IN

2/4

C_IN

P_CONT2

R_IN

1-A3

AMUTE1

SW+12R1V V+12R1SW

2SC4081(QR)-TLB

***

C349

1-A3

L_IN

C350

YF

R317

R202

Q310

100

0.1

***

***

GND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

9604S-23C

CN101

GND

SW+12R1V

Note1

R4020

***

C5001

***

8

9

1013

1114

12

15

19

23

R170

20

GNDA0GND

***

E

C

B

100/16

C351

GND

GND

FLSTB

FLCLK

FLDATA

GND

IR

V+5F

V+12R1E

FLPON

KEY1

KEY2

GND

2R

GND

2L

GND

2V

GND

2Y

GND

SDET2

GND

2C

Note1

1M

R169

R168

1M

1-A2,1-C5

XP_SAVE

from SYPS

CN202

J

P_ON

EV+12R1

GND

EV5R8

GND

CN303

B5B-PH-K-S

CN7301

C

CN4002

VKN1439- -TBB

RXDGL

1

TXDGL

2

B_IR

3

SPDIF

4

GND

5

HST_TO_M

6

ASCK

7

DAT_TO_M

8

HSM_TO_T

9

DAM_TO_T

10

XRST1

11

SW+12R1V

12

R_OUT

13

GNDA

14

L_OUT

15

MRST

16

C_OUT

17

GND

18

Y_OUT

19

GND

20

YP_OUT

21

GND

22

CB_OUT

23

GND

24

CR_OUT

25

GND

26

X525P

27

Y_IN

28

GND

29

C_IN

30

P_CONT2

31

L_IN

32

GND

33

R_IN

34

AMUTE1

35

V+12R1E

DTC124EUA-TLB

5

4

3

2

1

GND

TU_CON

Q811

E

R811

C

B

E

Q810

GND

C309

***

C302

*** GND

2SA1036K(QR)-TLB

C

B

1K

P_CONT

V+5R8E

TUON

TUON

P_CONT

CN2301

3/4

F

XP_SAVE

1-A2,1-D5

1K

R810

1SS355-TRB

D811

0.1

C810

C812

D810

1

2

UDZS9R1(B)-TRB

TU_CON

UDZS15(B)-TRB

D301

***

C346

GND

V+31E

L302

C332C348

GND

GND

2SC2411K(QR)-TLB

Q812

C

E

B

100/10

C811

0.1

V+12R1E

0

R151

C

B

***

R337

***

C334

C335

***

GND

V+5R8E

2SA1036K(QR)-TLB

100/16

C319

***

C320

CTF1399- -T

B2

*** ***

V+5R8E

R6316

470

Q6008

RN4903-TRB

***

C6425

C6647

***

GND

GND GND GND GNDGND

V+5R8E

***

C314

R310

GND

***

C347

Q307

DTC124EUA-TLB

GND

V+9V

100/10

C813

V+12R1