Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2005

÷ When servicing this model, some service procedures may reset the customer settings

to the factory default settings. Make sure to explain this to the customer.

An HDD (Hard Disc Drive) is mounted in this product.

The HDD is a precision instrument very vulnerable to shock and electrostatic charges. Please read

"7.3 Cautions on Handling the HDD" in this manual and exercise sufficient caution when handling the

HDD itself, as well as the product with the HDD built in.

When an HDD becomes defective and inoperable, restoration of the user's data recorded on the HDD,

or copying of the user's recorded data to other media (such as a new HDD) is totally impossible.

Before servicing, OBTAIN THE USER'S PRIOR CONSENT to that effect.

The user must be made aware that all recorded data are deleted if the HDD is intialized.

HDD/DVD

MENUTOP MENU

ENTER

HOME

STANDBY / ON

MENU

DVR-533H-S

ONE TOUCH

COPY

RETURN

REC

PULL - OPEN

ORDER NO.

RRV3173

DVD RECORDER

DVR-533H-S

DVR-633H-S

DVR-531H-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Serial No.

Model Type Power Requirement Region No.

DVR-533H-S KUXV AC120V 1 &&DL######$$

DVR-533H-S KCXV AC120V 1 &&DL######$$

DVR-633H-S KUXV/CA AC120V 1 &&DL######$$

DVR-531H-S KUXV/CA AC120V 1 &&DL######$$

DVR-531H-S KCXV AC120V 1 &&DL######$$

Please confirm 3rd & 4th

alphabetical letters.

For details, refer to "Important Check Points for Good Servicing" .

T-ZZV JUNE 2005 printed in Japan

Page 2

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

B

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

C

les pièces de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

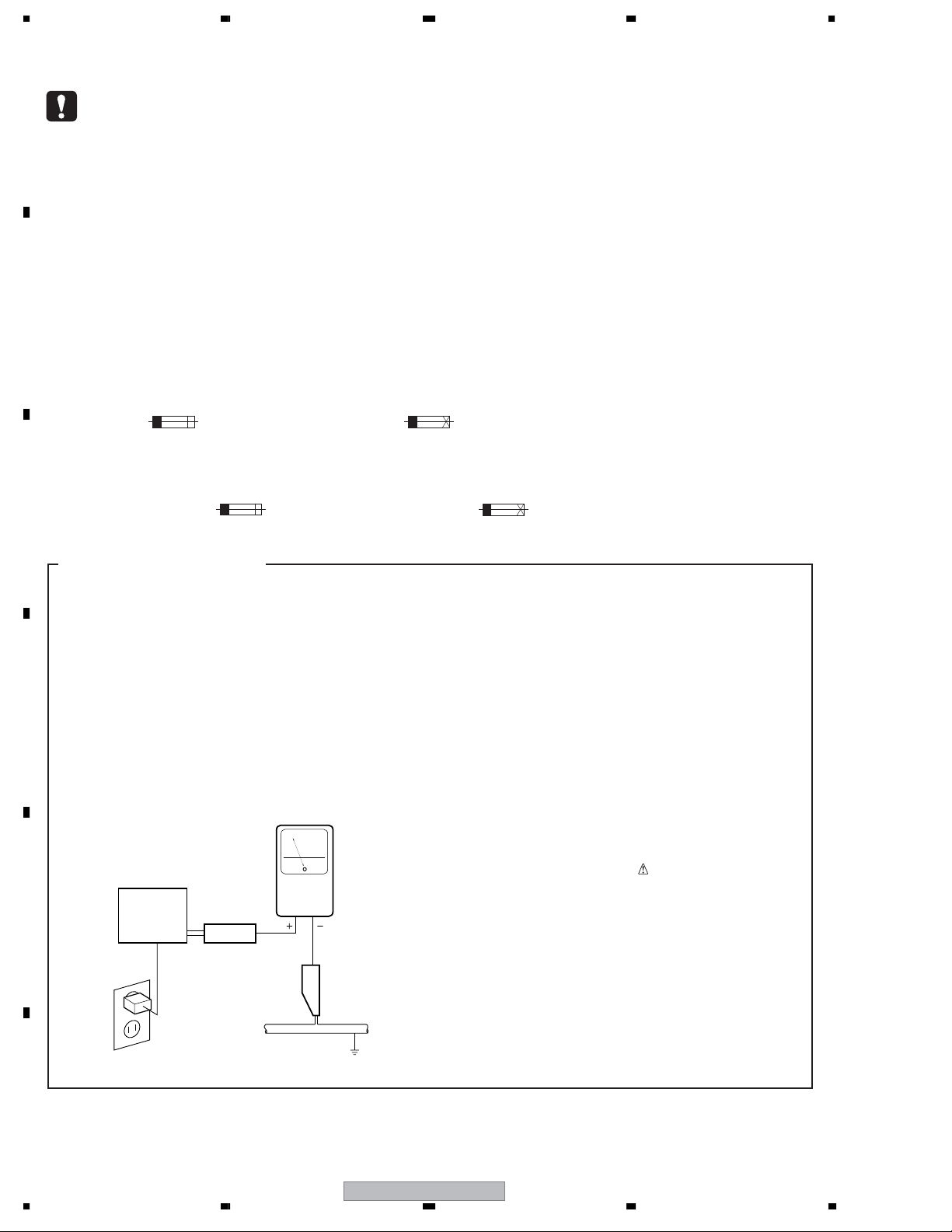

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Leakage

current

E

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

AC Leakage Test

tester

Reading should

not be above

0.5 mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE

LIMITS OUTLINED ABOVE ARE INDICATIVE

OF A POTENTIAL SHOCK HAZARD AND

MUST BE CORRECTED BEFORE RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the

protection afforded by them necessarily can be obtained

by using replacement components rated for voltage,

wattage, etc. Replacement parts which have these

special safety characteristics are identified in this

Service Manual.

Electrical components having such features are

identified by marking with a

on the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER

Service Manual. A subscription to, or additional copies

of, PIONEER Service Manual may be obtained at a

nominal charge from PIONEER.

on the schematics and

F

2

1234

DVR-533H-S

Page 3

5678

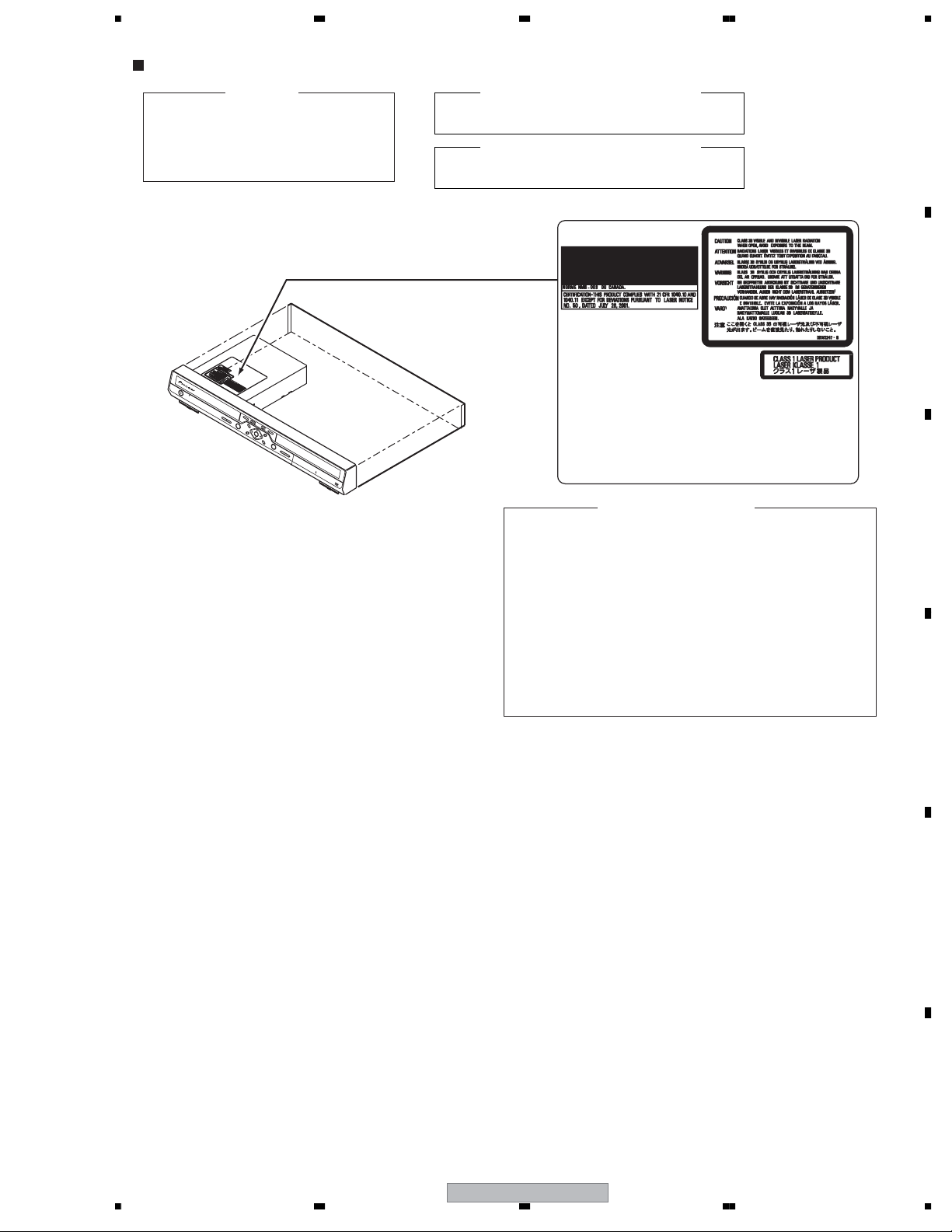

LABEL CHECK

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

S

T

A

N

D

B

Y

/

O

N

T

O

P

M

E

N

U

HOME

M

H

D

ENU

D

/

D

V

D

M

E

E

N

N

U

T

E

R

R

E

T

U

R

N

R

E

C

O

N

E

T

O

C

U

O

C

P

H

Y

P

U

L

L

O

P

E

N

MAXIMUM OUTPUT POWER: 100 mW

LASER DIODE CHARACTERISTICS

WAVELENGTH: 654 - 662 nm

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 770 - 810 nm

A

B

DRW2247

Additional Laser Caution

C

1. The ON/OFF(ON:low level,OFF:high level) status of the

CLAMP signals for detecting the loading state are detected

by the drive CPUs, and the design prevents laser diode

oscillation when the CLAMP signal turns OFF.

In normal operation, if no disc is clamped, the laser diode

oscillation is disabled.

However, the interlock does not always operate in the test

mode.

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 3A

laser beam.

D

E

56

DVR-533H-S

F

3

7

8

Page 4

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

A

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

E

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DVR-533H-S

Page 5

5678

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS.............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST.............................................................................................................8

2.1 PACKING....................................................................................................................................................8

2.2 EXTERIOR SECTION ..............................................................................................................................10

2.3 FRONT PANEL SECTION ........................................................................................................................12

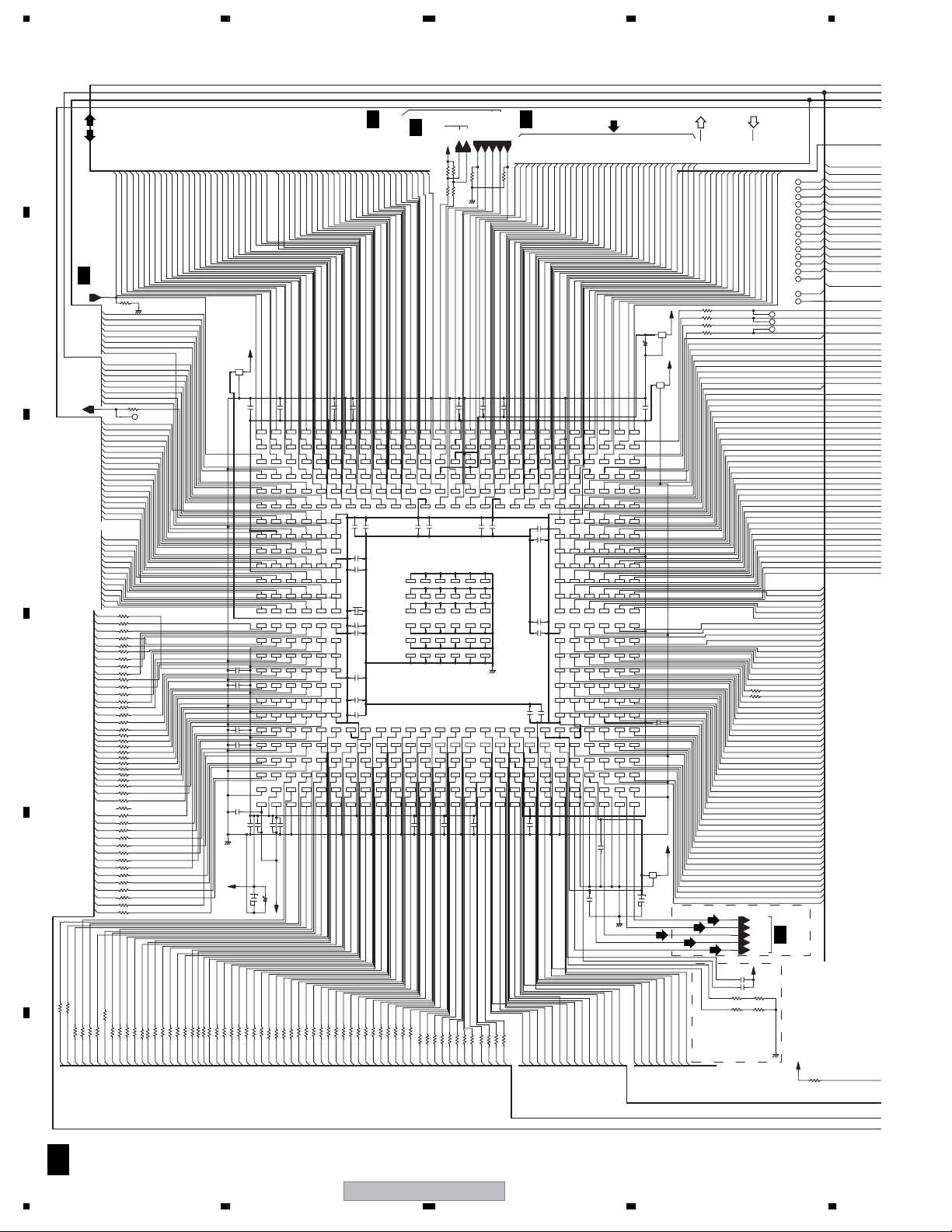

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................14

3.1 BLOCK DIAGRAM....................................................................................................................................14

3.1.1 OVERALL BLOCK DIAGRAM ............................................................................................................14

3.1.2 MAIN ASSY ........................................................................................................................................16

3.2 OVERALL WIRING DIAGRAM .................................................................................................................18

3.3 TUNB ASSY..............................................................................................................................................20

3.4 JACB(1/2) and FLJB ASSYS....................................................................................................................22

3.5 JACB ASSY(2/2).......................................................................................................................................24

3.6 DVJB ASSY..............................................................................................................................................26

3.7 ATAB ASSY...............................................................................................................................................27

3.8 PSWB and RSWB ASSYS .......................................................................................................................28

3.9 MAIN ASSY(1/5).......................................................................................................................................30

3.10 MAIN ASSY(2/5).....................................................................................................................................32

3.11 MAIN ASSY(3/5).....................................................................................................................................34

3.12 MAIN ASSY(4/5).....................................................................................................................................36

3.13 MAIN ASSY(5/5).....................................................................................................................................38

3.14 POWER SUPPLY UNIT ..........................................................................................................................40

3.15 WAVE FORMS........................................................................................................................................42

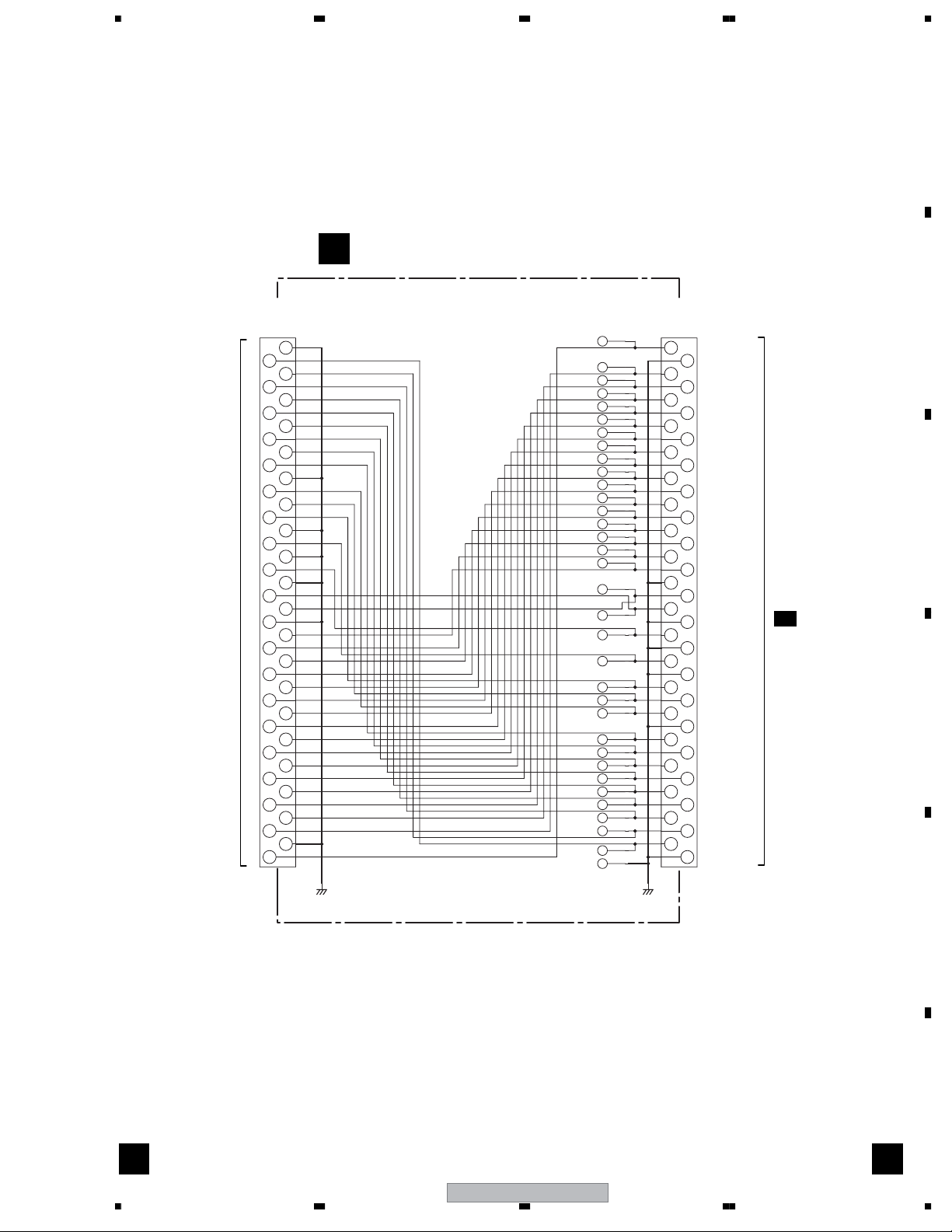

4. PCB CONNECTION DIAGRAM ......................................................................................................................45

4.1 TUNB ASSY..............................................................................................................................................46

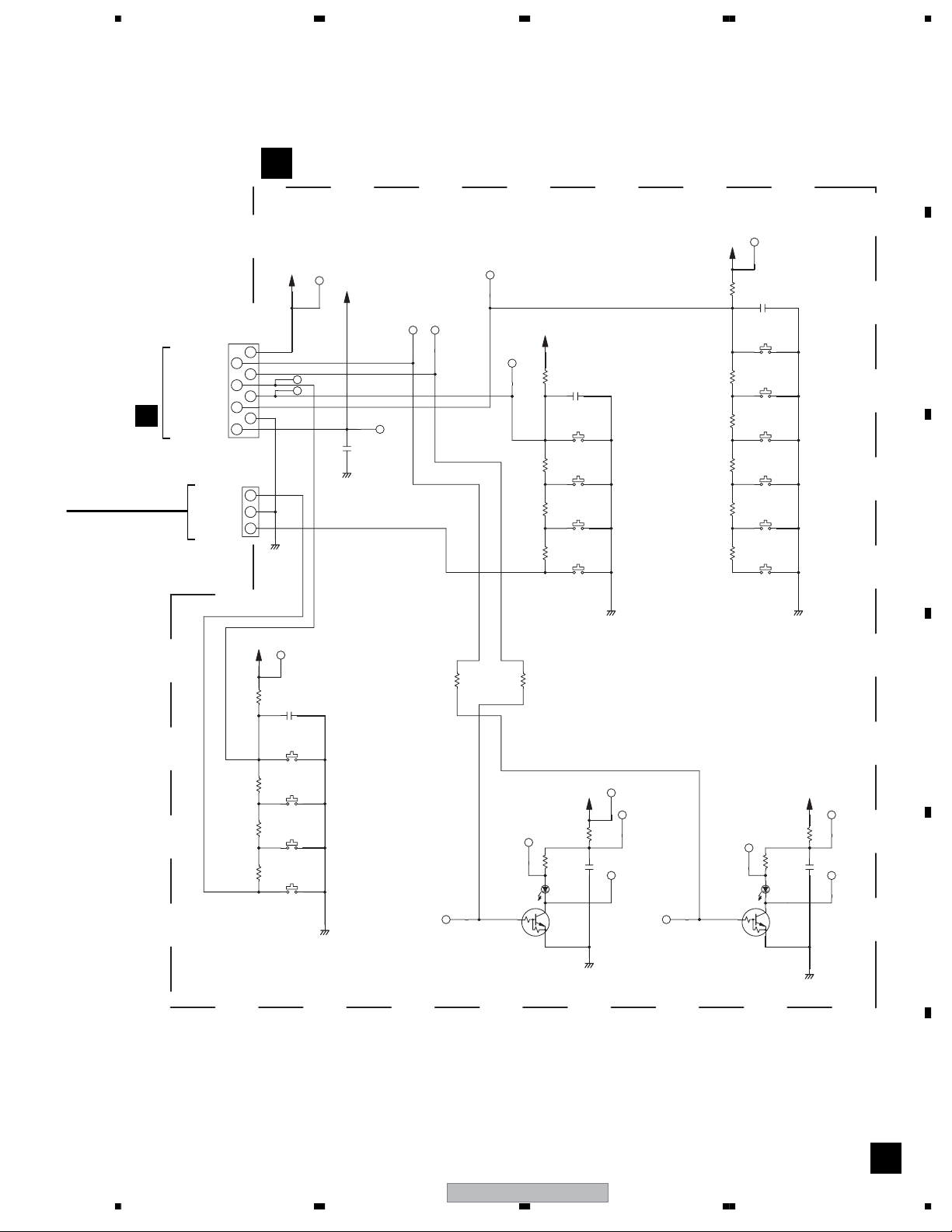

4.2 JACB, FLJB, DVJB and ATAB ASSYS ......................................................................................................48

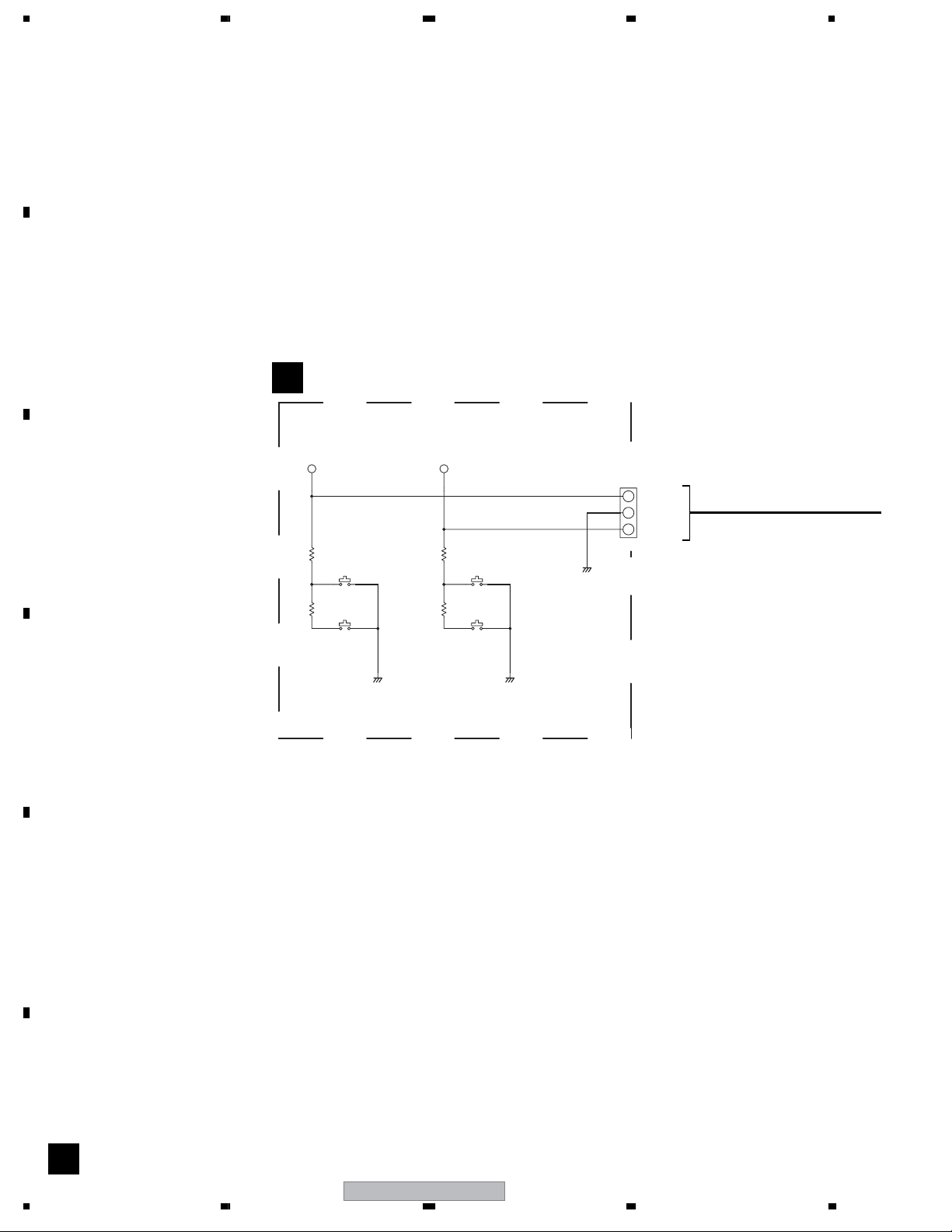

4.3 PSWB and RSWB ASSYS .......................................................................................................................52

4.4 MAIN ASSY ..............................................................................................................................................54

4.5 POWER SUPPLY UNIT ............................................................................................................................58

5. PCB PARTS LIST............................................................................................................................................60

6. ADJUSTMENT ................................................................................................................................................64

7. GENERAL INFORMATION .............................................................................................................................65

7.1 DIAGNOSIS..............................................................................................................................................65

7.1.1 MODEL SETTING ..............................................................................................................................67

7.1.2 CPRM ID NUMBER AND DATA SETTING .........................................................................................68

7.1.3 FIRMWARE DOWNLOADING METHOD ...........................................................................................72

7.1.4 VIDEO ADJUSTMENT FOR SPECIFIC AREA...................................................................................75

7.1.5 SERVICE MODE ................................................................................................................................79

7.1.6 DV SERVICE MODE...........................................................................................................................93

7.1.7 EPG SERVICE MODE........................................................................................................................96

7.1.8 AGING MODE ....................................................................................................................................99

7.1.9 HDD CHECK MODE.........................................................................................................................101

7.1.10 SETUP SEQUENCE.......................................................................................................................107

7.1.11 DISASSEMBLY ...............................................................................................................................108

7.2 IC ............................................................................................................................................................114

7.3 CAUTIONS ON HANDLING THE HDD...................................................................................................125

7.4 DISC/CONTENT FORMAT.....................................................................................................................127

8. PANEL FACILITIES .......................................................................................................................................129

A

B

C

D

E

56

DVR-533H-S

F

5

7

8

Page 6

1234

1. SPECIFICATIONS

A

B

C

D

E

General

System . . . . . . . . . . . . . . . . . . HDD, DVD-Video, DVD-R/RW,

Power requirements . . . . . . . . . . . . . . . . . . . . . . 120 V, 60 Hz

Power consumption

DVR-531H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 W

DVR-532H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 W

DVR-533H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43 W

DVR-633H-S . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46 W

Power consumption in standby mode 0.42 W

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.9 kg (8 lb 6 oz )

Dimensions . . . . . . . . . . . . . . .420 (W) x 59 (H) x 273 (D) mm

Operating temperature . . . . . . . . . . . . . . . . . +5°C to +35°C

Operating humidity . . . . . . . . . . . . . . . . . . . . . . . . . 5% to 85%

TV format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . NTSC

Recording

Recording format . . . . . . . . . . . . . . . . . DVD Video Recording

Recordable discs

DVD-RW (DVD Re-recordable disc)

DVD-R (DVD Recordable disc)

Video recording format

Sampling frequency . . . . . . . . . . . . . . . . . . . . . . . . . 13.5MHz

Compression format . . . . . . . . . . . . . . . . . . . . . . . . . . . MPEG

Audio recording format

Sampling frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48kHz

Compression format . . . . . . . . . . Dolby Digital or Linear PCM

Recording time

HDD (160GB)

XP+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 23 hours

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 34 hours

Standard Play (SP) . . . . . . . . . . . . . . . . . . . Approx. 68 hours

Long Play (LP) . . . . . . . . . . . . . . . . . . . . . . Approx. 136 hours

Extended Play (EP) . . . . . . . . . . . . . . . . . . Approx. 204 hours

Super Long Play (SLP) . . . . . . . . . . . . . . . Approx. 272 hours

Super Extended Play (SEP) . . . . . . . . . . . . Approx. 340 hours

Manual Mode (MN). . . . . . . . . . . . . . . . Approx. 23−455 hours

HDD (80GB)

XP+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 11 hours

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 17 hours

Standard Play (SP) . . . . . . . . . . . . . . . . . . . Approx. 34 hours

Long Play (LP) . . . . . . . . . . . . . . . . . . . . . . . Approx. 68 hours

Extended Play (EP) . . . . . . . . . . . . . . . . . . Approx. 102 hours

Super Long Play (SLP) . . . . . . . . . . . . . . . .Approx. 136 hours

Super Extended Play (SEP) . . . . . . . . . . . . Approx. 170 hours

Manual Mode (MN) . . . . . . . . . . . . . . . .Approx. 17−227 hours

DVD-R/DVD-RW

Fine (XP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Approx. 1 hour

Standard Play (SP) . . . . . . . . . . . . . . . . . . . . Approx. 2 hours

Long Play (LP). . . . . . . . . . . . . . . . . . . . . . . . Approx. 4 hours

Extended Play (EP) . . . . . . . . . . . . . . . . . . . . Approx. 6 hours

Super Long Play (SLP) . . . . . . . . . . . . . . . . . Approx. 8 hours

Super Extended Play (SEP) . . . . . . . . . . . . Approx. 10 hours

Manual Mode (MN) . . . . . . . . . . . . . . . . . Approx. 1−13 hours

CD-R/RW (WMA, MP3, JPEG, CD-DA)

(Front panel display: off)

(16

9/16 (W) x 2 3/8 (H) x 10 3/4 (D) in.)

Video-CD, CD,

(+41°F to +95°F)

(no condensation)

DVD-VIDEO

(uncompressed)

Tuner

Receivable channels

VHF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2−13ch

UHF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14−69ch

CATV. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C1−C125ch

Timer

Programs . . . . . . . . . . . . . . . . . . . . . . . . 1 month/32 programs

Clock . . . . . . . . . . . . . . . . Quartz lock (12-hour digital display)

Power off memory . . . . . . Approx. 5 years (after manufacture)

Input/Output

VHF/UHF antenna input/output terminal . . . . . . .VHF/UHF set

Video input . . . . . . . . . . . . . . . . . . . . .Input 1,3 (rear), 2 (front)

Input level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jack

Video output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Output 1,2

Output level . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jack

S-Video input . . . . . . . . . . . . . . . . . . Input 1, 3 (rear), 2 (front)

Y (luminance) - Input level . . . . . . . . . . . . . . . . . 1 Vp-p (75Ω)

C (color) - Input level . . . . . . . . . . . . . . . . . . 300 mVp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 pin mini DIN

S-Video output . . . . . . . . . . . . . . . . . . . . . . . . . . . . Output 1,2

Y (luminance) - Output level . . . . . . . . . . . . . . . .1 Vp-p (75Ω)

C (color) - Output level . . . . . . . . . . . . . . . . 300 mVp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 pin mini DIN

Component video output

Output level . . . . . . . . . . . . . . . . . . . . . . . . .Y: 1.0 Vp-p (75Ω)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jacks

Audio input . . . . . . . . . . . . . . . . .Input 1, 3 (rear), 2 (front) L/R

Input level

During audio input . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2V rms

(Input impedance: more than 22 kΩ)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jacks

Audio output . . . . . . . . . . . . . . . . . . . . . . . . . . . Output 1,2 L/R

During audio output . . . . . . . . . . . . . . . . . . . . . . . . . . . 2V rms

(Output impedance: less than 1.5 kΩ)

Jacks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RCA jacks

Control input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mini jack

DV input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 pin (front)

(DVR-633/533H-S only) (i.LINK/IEEE 1394 standard)

G-LINK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mini jack

75Ω (F-shape connector)

, PR: 0.7 Vp-p (75Ω)

P

B

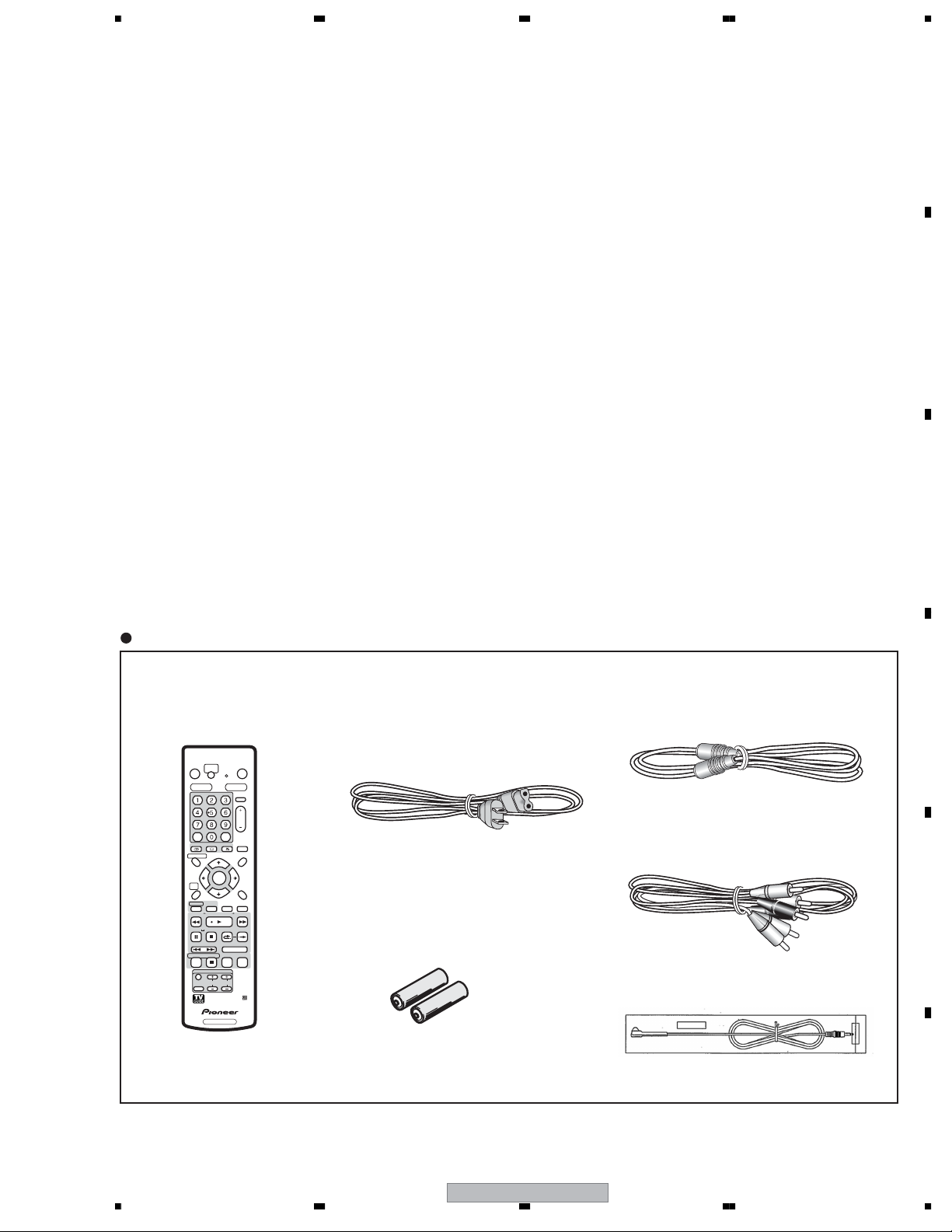

Supplied accessories

Remote control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Dry cell batteries (AA/R6P) . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Audio / Video cable (red/white/yellow) . . . . . . . . . . . . . . . . . . 1

G-LINK cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

RF antenna cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Blank DVD-RW disc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Quick Start Guide

Operating Instructions

Warranty card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Note: The specifications and design of this product are subject

to change without notice, due to improvement.

F

6

1234

DVR-533H-S

Page 7

5678

A

B

Accessories

• Remote control ×1

(VXX2967)

OPEN/CLOSE

STANDBY/ON

ONE TOUCH

COPY

HDD DVD

ABC

DEF

GHI JKL MNO

PQRS TUV WXYZ

+ CLEAR

CLEAR

AUDIO

SUBTITLE ANGLE

DISC NAVIGATOR

TOP MENU

ENTER

HOME

MENU

TV GUIDE

INFO HELP DISPLAY

REV SCAN

PLAY

PAUSE STOP

CMOK BACK SKIP

CASE

SELECTION

PREV

STEP/SLOW

NEXT

REC

REC MODE TIMER REC

STOP REC

TV CONTROL

INPUT

VOLUME

CHANNEL

SELECT

DVD RECORDER

INPUT

SELECT

CH

PLAY MODE

MENU

RETURN

FWD SCAN

• Power cable ×1

(ADG7075)

• Dry cell batteries ×2

(AA/R6P)

• RF antenna cable(PAL) ×1

(VDE1088)

• Audio / Video cable(1.5m) ×1

(red/white/yellow)

(VDE1077)

• IR Blaster ×1

(VDX1010)

C

D

E

56

DVR-533H-S

F

7

7

8

Page 8

1234

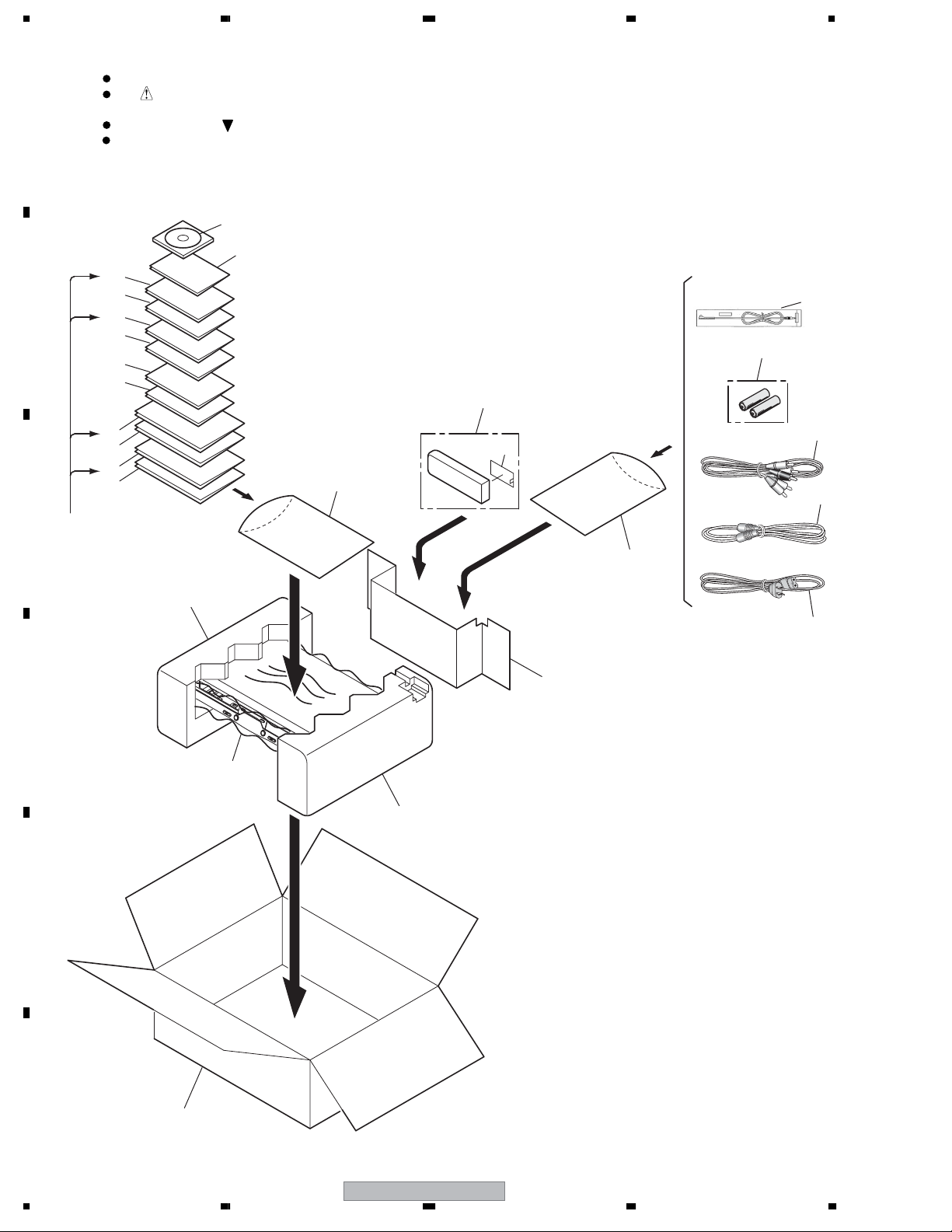

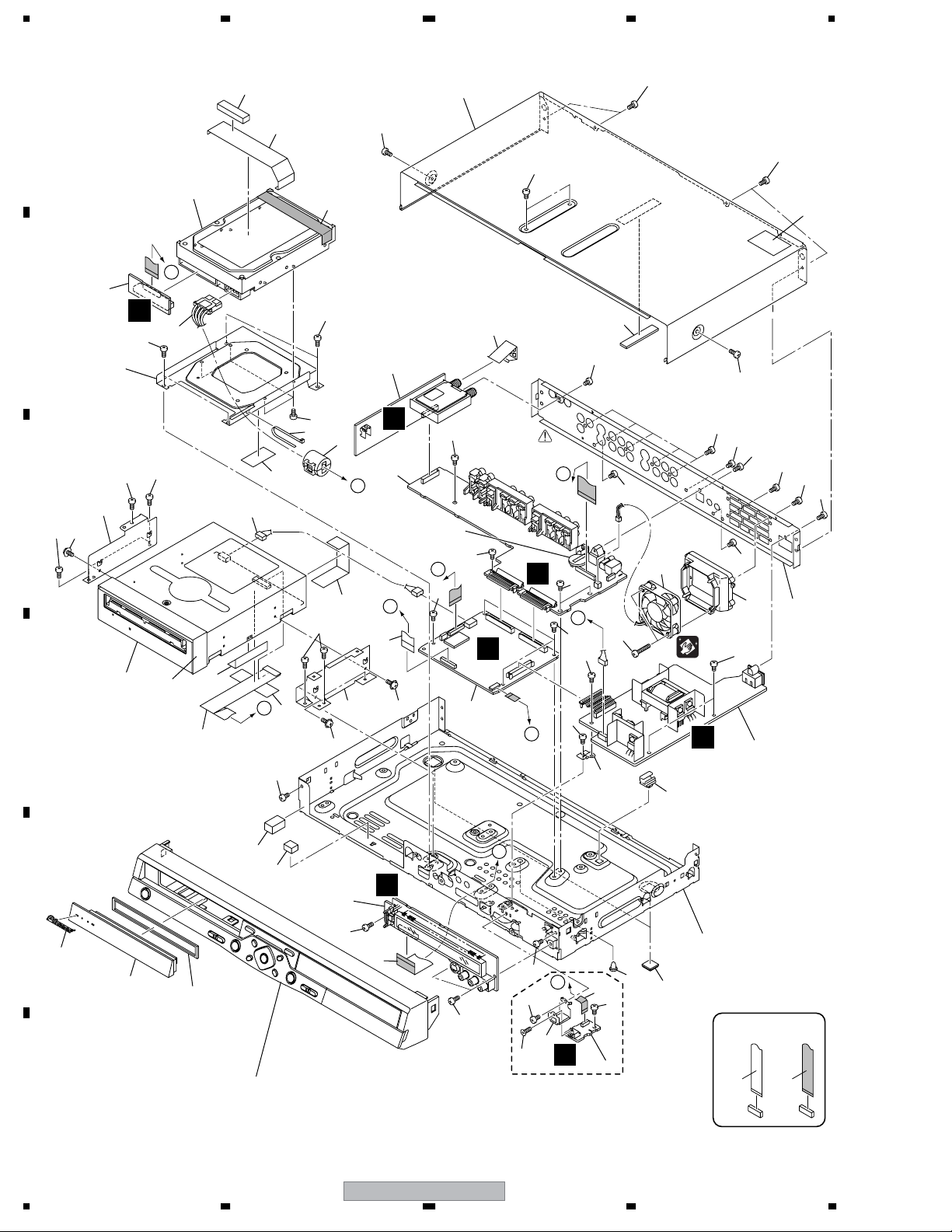

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

A

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

15

14

B

C

KCXV type only

17

16

19

18

13

12

11

10

7

9

8

6

4

2

5

20

3

20

21

1

23

D

25

22

E

F

8

1234

24

DVR-533H-S

Page 9

>

5678

(1) PACKING SECTION PARTS LIST

No. Description Part No.

Mark

1Power Cable ADG7075

2Audio / Video Cable (1.5m) VDE1077

3 RF Antenna Cable VDE1088

4 Remote Control Unit VXX2967

5 Battery Cover AZA7424

No. Description Part No.

Mark

16 Quick Guide (English) VRG1013

17 Quick Guide (French) See Contrast table (2)

18 HDD Caution 8L B VRR1062

19 HDD Caution 8L VRR1063

20 Polyethylene Bag B5 VHL1088

A

NSP 6 Dry Cell Battery (R6P, AA) VEM1030

NSP 7 DVD-RW Disc ver. 1.1 VZZ1003

8 IR Blaster VDX1010

NSP 9 Warranty Card ARY7045

10 Operating Instructions (English) VRB1407

11 Operating Instructions (French) See Contrast table (2)

12 Dual Layer IM (English) VRB1392

13 Dual Layer IM (French) See Contrast table (2)

14 Quick Start Guide (English) VRG1010

15 Quick Start Guide (French) See Contrast table (2)

21 Left Pad VHA1386

22 Right Pad VHA1387

23 Remote Control Holder VHC1139

24 Packing Case See Contrast table (2)

25 Mirror Mat VHL1089

(2) CONTRAST TABLE

DVR-533H-S/KUXV, KCXV, DVR-633H-S/KUXV/CA, DVR-531H-S/KCXV and KUXV/CA are constructed the same

except for the following:

Mark No. Symbol and Description

11 Operating Instructions (French) Not used VRC1306 Not used VRC1306 Not used

13 Dual Layer IM (French) Not used VRC1280 Not used VRC1280 Not used

15 Quick Start Guide (French) Not used VRL1010 Not used VRL1010 Not used

17 Quick Guide (French) Not used VRL1011 Not used VRL1011 Not used

24 Packing Case VHG2597 VHG2598 VHG2599 VHG2654 VHG2596

DVR-533H-S

/KUXV

DVR-533H-S

/KCXV

DVR-633H-S

/KUXV/CA

DVR-531H-S

/KCXV

DVR-531H-S

/KUXV/CA

B

C

D

E

F

56

DVR-533H-S

9

7

8

Page 10

1234

2.2 EXTERIOR SECTION

21

51

55

53

17

18

53

50

48

50

55

36

Cleaning paper

GED-008

49

I

7

53

41

50

50

54

29

24

A

8

E

5

B

C

49

47

D

33

31

49

E

14

49

52

42

26

12

9

15

27

42

49

44

37

42

49

D

42

49

47

16

42

53

C

11

34

1

A

2

Lithium Battery

E

47

49

(CR2032)

D

49

28

49

46

19

48

A

B

49

C

H

6

49

49

49

B

35

49

A

30

45

49

49

B

32

D

10

49

DVR-533H-S,

DVR-633H-S

only

4

22

20

NON-CONTACT

SIDE

CONTACT SIDE

25

23

C

E

38

40

F

39

Refer to

"2.3 FRONT PANEL SECTION".

10

1234

3

49

13

DVR-533H-S

Page 11

>

5678

(1) EXTERIOR SECTION PARTS LIST

No. Description Part No.

Mark

1 TUNB Assy (for service) VXX3024

2JACB Assy See Contrast table (2)

3 FLJB Assy VWG2536

4DVJB Assy See Contrast table (2)

5 ATAB Assy VWV2123

No. Description Part No.

Mark

NSP 31 HDD Stay VNE2369

32 DV Angle See Contrast table (2)

NSP 33 Writer Stay L VNE2371

NSP 34 Writer Stay R VNE2372

NSP 35 PCB Base VNE2378

A

6 MAIN Assy (for service) See Contrast table (2)

7POWER SUPPLY Unit VWR1391

8 HDD See Contrast table (2)

9 DRIVE Assy R9R VXX2987

10 Flexible Cable (16P) See Contrast table (2)

11 Flexible Cable (40P) VDA2065

12 Flexible Cable (40P) VDA2066

13 Flexible Cable (27P) VDA2067

14 Housing Assy (4P) VKP2357

15 Housing Assy (4P) VKP2358

16 Ferrite Core VTH1050

17 DC Fan Motor VXM1120

NSP 18 P. Plate Holder PNY-405

19 Earth Plate TU VBK1156

20 Rubber Foot VEB1349

21 Rubber Spacer (CR) VEB1373

NSP 22 PC Support VEC1749

23 Gasket 10 x 7T VEC2472

24 Gasket 40 x 5T VEC2473

25 Gasket 10 x 25T VEC2475

26 Aluminum Tape 50 x 25 VEF1058

27 Aluminum Tape 135 x 25 VEF1059

28 Bonnet Case S VXX3039

29 Rear Panel See Contrast table (2)

NSP 30 Base Chassis VNB1052

36 Fan Duct VNK5693

NSP 37 Binder (BK-1) ZCA-BK1

38 Pioneer Name Plate VAM1148

39 Tray Sheet VEC2467

40 Tray Panel A VNK5703

41 Bonnet Label VRW2171

NSP 42 Tape ZTA-156A-19

43 • • • • •

44 #6-32 Screw DBA1125

45 Screw See Contrast table (2)

46 Screw BSZ30P060FTC

47 Screw AMZ30P060FTC

48 Screw BSZ30P040FTC

49 Screw BBZ30P060FTC

50 Screw BPZ30P080FTC

51 Screw BPZ30P250FTC

52 Screw BSR30P060FTC

53 Screw BSZ30P060FTC

54 Screw PBZ30P080FTC

55 Screw BBZ30P060FTC

B

C

D

(2) CONTRAST TABLE

DVR-533H-S/KUXV, KCXV, DVR-633H-S/KUXV/CA, DVR-531H-S/KCXV and KUXV/CA are constructed the same

except for the following:

Mark No. Symbol and Description

2JACB Assy VWV2111 VWV2111 VWV2111 VWV2112 VWV2112

4DVJB Assy VWG2523 VWG2523 VWG2523 Not used Not used

6 MAIN Assy (for service) VXX2993 VXX2993 VXX2993 VXX2994 VXX2994

8 HDD 80G WD800BBJKC S VXF1066 VXF1066 Not used VXF1066 VXF1066

8 HDD 160G WD1600BBGUC S Not used Not used VXF1068 Not used Not used

10 Flexible Cable (16P) VDA2064 VDA2064 VDA2064 Not used Not used

29 Rear Panel VNA2771 VNA2771 VNA2792 VNA2794 VNA2794

32 DV Angle VNE2370 VNE2370 VNE2370 Not used Not used

45 Screw VBA1098 VBA1098 VBA1098 Not used Not used

56

DVR-533H-S

/KUXV

DVR-533H-S

/KCXV

DVR-533H-S

DVR-633H-S

/KUXV/CA

7

DVR-531H-S

/KCXV

DVR-531H-S

/KUXV/CA

8

E

F

11

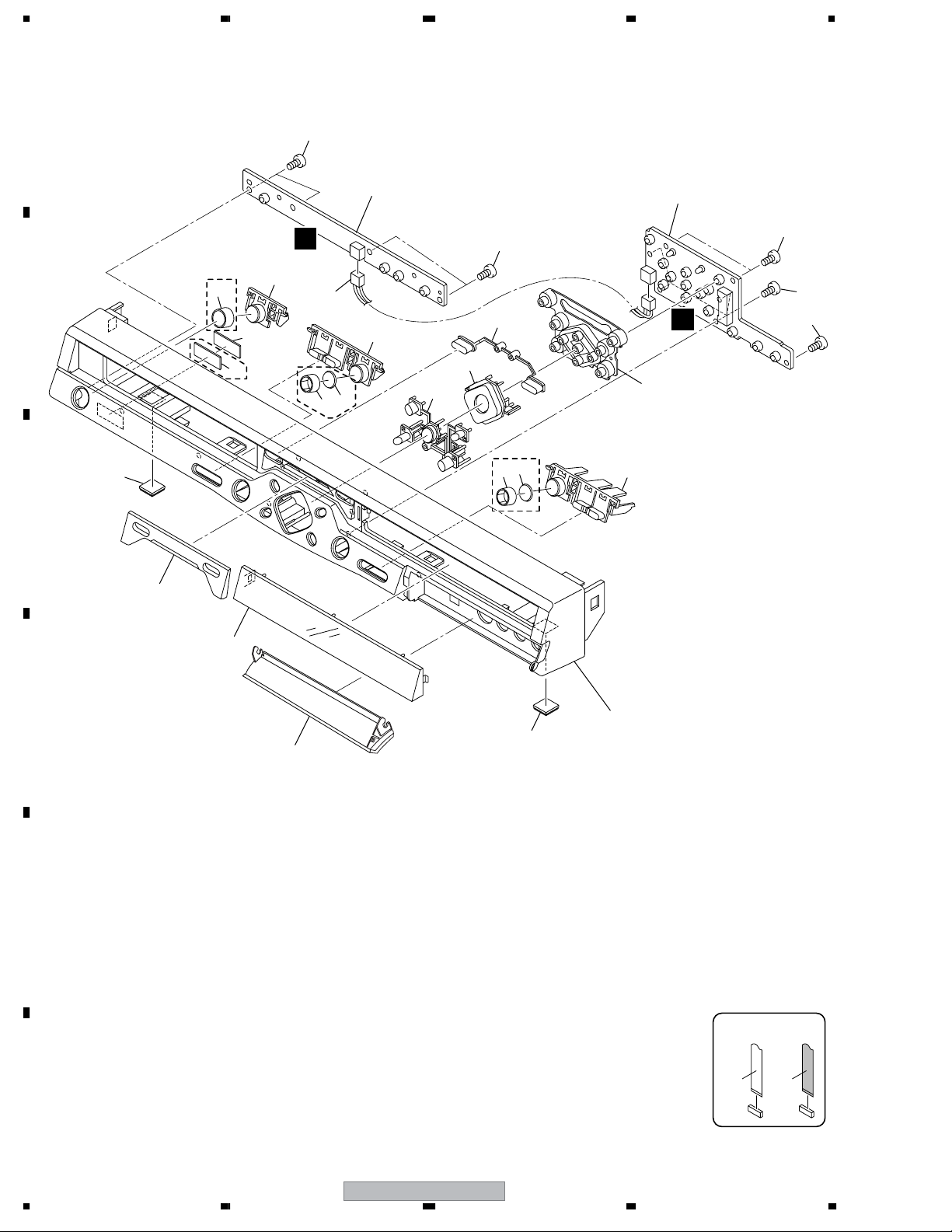

Page 12

1234

2.3 FRONT PANEL SECTION

A

19

1

F

DVR-633H-S

only

14

B

DVR-531H-S

only

4

C

10

18

11

11

(4/4)

(1/4)

DVR-633H-S

only

15

3

11

(2/4)

16

7

19

8

6

15

DVR-633H-S

only

17

11

5

(3/4)

2

G

19

19

19

9

D

4

12

E

13

F

12

1234

DVR-533H-S

NON-CONTACT

SIDE

CONTACT SIDE

Page 13

5678

(1) FRONT PANEL SECTION PARTS LIST

No. Description Part No.

Mark

1 PSWB Assy VWG2524

2 RSWB Assy VWG2528

3 Housing Assy (3P) VKP2360

4 Rubber Foot VEB1349

5 Rubber Hinge VEB1371

6 Cursor Key VNK5695

7 Enter Key VNK5696

8 Eject Key A VNK5697

9 FL Lens A VNK5698

10 Center Lens AC VNK5699

A

11 Main Key A See Contrast table (2)

12 Door A See Contrast table (2)

13 Front Panel A See Contrast table (2)

14 Key Top A See Contrast table (2)

15 Ring A See Contrast table (2)

16 PLAY Plate A See Contrast table (2)

17 REC Plate A See Contrast table (2)

18 Sensor-matic Seal See Contrast table (2)

19 Screw BPZ30P080FTC

(2) CONTRAST TABLE

DVR-533H-S/KUXV, KCXV, DVR-633H-S/KUXV/CA, DVR-531H-S/KCXV and KUXV/CA are constructed the same

except for the following:

Mark No. Symbol and Description

11 Main Key A VNK5701 VNK5701 Not used VNK5701 VNK5701

11 Main Key Base A Not used Not used VNK5737 Not used Not used

12 Door A VNK5702 VNK5702 VNK5702 VNK5815 VNK5815

13 Front Panel A VNK5730 VNK5730 VNK5818 VNK5817 VNK5817

14 Key Top A Not used Not used VNK5717 Not used Not used

DVR-533H-S

/KUXV

DVR-533H-S

/KCXV

DVR-633H-S

/KUXV/CA

DVR-531H-S

/KCXV

DVR-531H-S

/KUXV/CA

B

C

D

15 Ring A Not used Not used VNK5738 Not used Not used

16 PLAY Plate A Not used Not used VNK5739 Not used Not used

17 REC Plate A Not used Not used VNK5740 Not used Not used

18 Sensor-matic Seal Not used Not used Not used VAN1004 VAN1004

DVR-533H-S

56

7

8

E

F

13

Page 14

1234

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

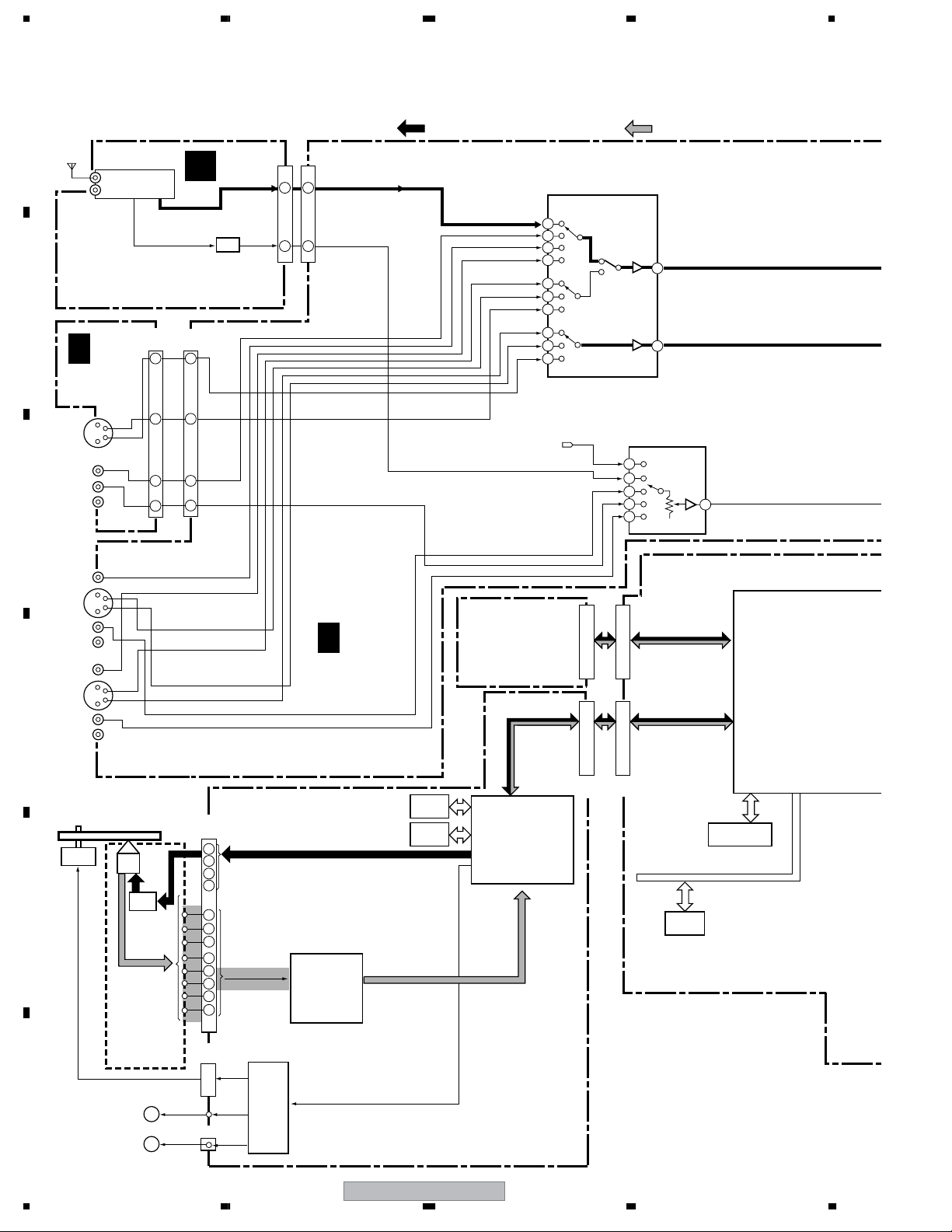

3.1.1 OVERALL BLOCK DIAGRAM

A

: Recording system signal route

U101 VXF1059

ANT

TV FRONT-END

RF IN

VOUT

AOUT

RF

OUT

17

6

B

CN301(1/2)

(27P)

C

1/2

CIN2

26 26

A

UVL

CN101(1/2)

(27P)

TUNB

ASSY

LPF

CN101

(17P)

10 8

8 10

UVV

UVL

CN403

(17P)

UVV

2V

1V

3V

3Y

1Y

2Y

3C

1C

2C

FLJB

ASSY

JA301

Y/C

VIDEO

C

INPUT2

Y

C

L

R

YIN2

24

24

VIN2

22

22

LIN2

20

20

44

42

40

18

20

22

10

12

1

8

MSL

LIN4

Video Selector

Video Driver

IC401

LA73031V

Audio Selector with Electirc ATT

2

4

6

8

10

: Playback system signal route

V/Y

29

C

31

IC103

BD3823FV

L

18

LIN1

HDD

DSP

IC201

LIN2

LIN3

DVD-VR

DVD-Video

CN202

(40P)

1

8

CN3801

(40P)

CN3802

(40P)

DVD-VR

DVD-Video

[ATA]

[ATAPI]

IC1301

Flash

64Mbit

IC1102

ATA SDRAM

512Mbit

IC1001

R8A34011BG-K

Sysytem Codec

JA103

INPUT1

VIDEO

Y/C

INPUT3

VIDEO

Y/C

D

MOTOR

Y

C

L

R

Y

C

L

R

SPDL

E

Pickup

LD

DRIVE

PICKUP

ASSY

VIN1

VIN3

YIN1

YIN3

CIN1

CIN3

LIN1

LIN3

CN101

A

B

C

D

S4

S3

S2

S1

CN501

(45P)

5

4

3

2

32

36

35

31

38

37

40

39

(12P)

PB DVD/CD

B

1/2

JACB ASSY

RF IC

IC101

UPC3340GC

IC202

IC203

SDRAM

16Mbit

FLASH

16M

UPD63641GM

6CH

F

LOADING

MOTOR

STEPPIONG

MOTOR

M

CN502

M

14

Driver

IC501

BD7997FS

DRIVE ASSY(R9R)

DVR-533H-S

1234

Page 15

5678

• R ch is same as L ch.

I

C101

PMC002A8

Tuner

U-com

Control

Data

CN402(1/2)

(27P)

6

8

L

4

SEL.V/Y

SEL.C

SEL.L

CN2201(1/2)

6

8

4

(27P)

A

Except DVR-531H types

DVJB ASSY

D

DV TERMINAL

TPBN

TPBP

TPAN

4 3 2 1

1 2 4 6

TPBP

TPBN

TPAN

1 2 4 6

IC5101

IEEE1394

Physical IC

TPAP

TPAP

B

C

JA601

CN601

(16P)

CN5601

(16P)

36 37 38 39

UPD72852AGB-8EU

IC1201

DDR

SDRAM

128Mbit

IC1221

DDR

SDRAM

128Mbit

H

MAIN ASSY

C

G

F

FLJB ASSY

2/2

RSWB ASSY

PSWB ASSY

IC3101

PCM1802DB1

10

Audio

11

12

1

A/D

48KHz 20Bit

PLL & VCXO

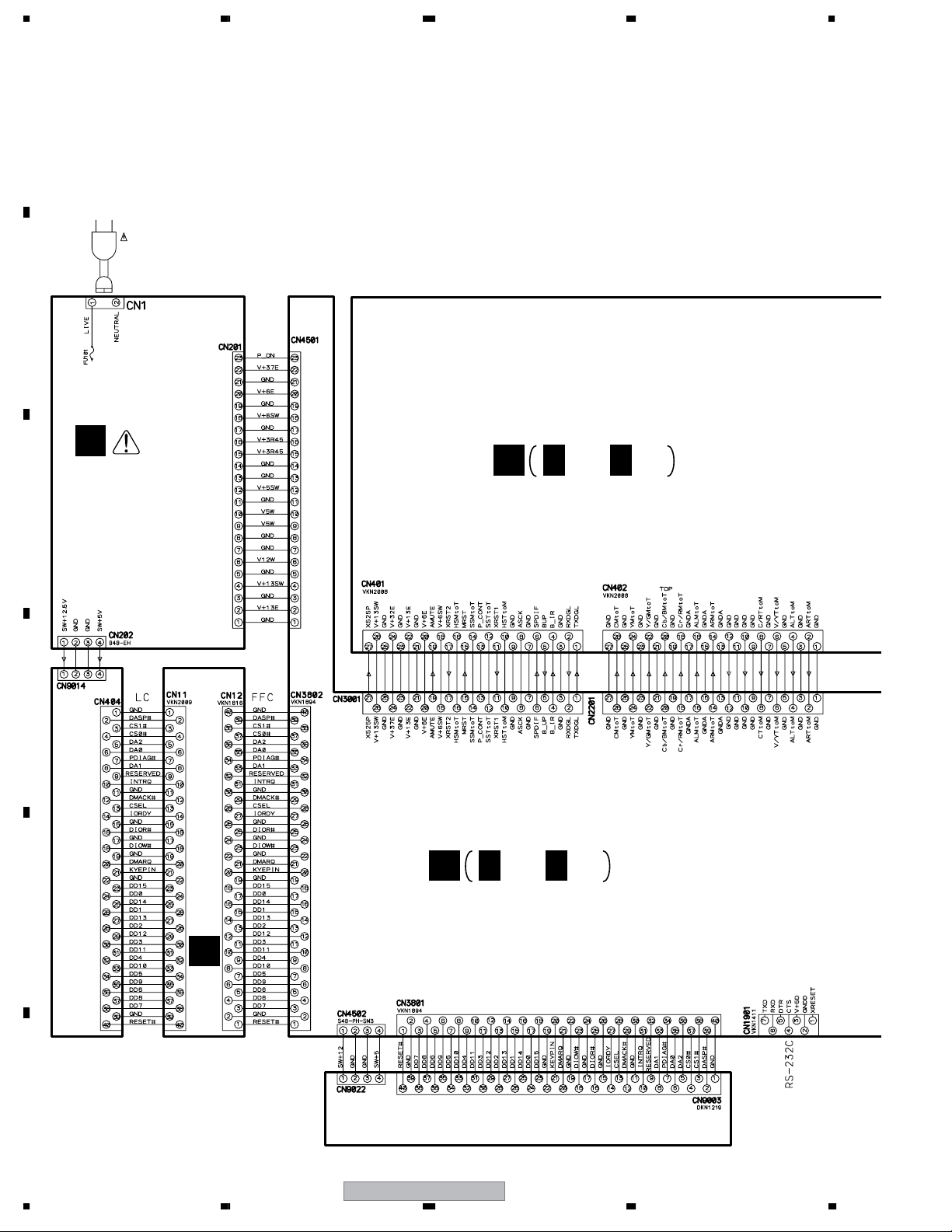

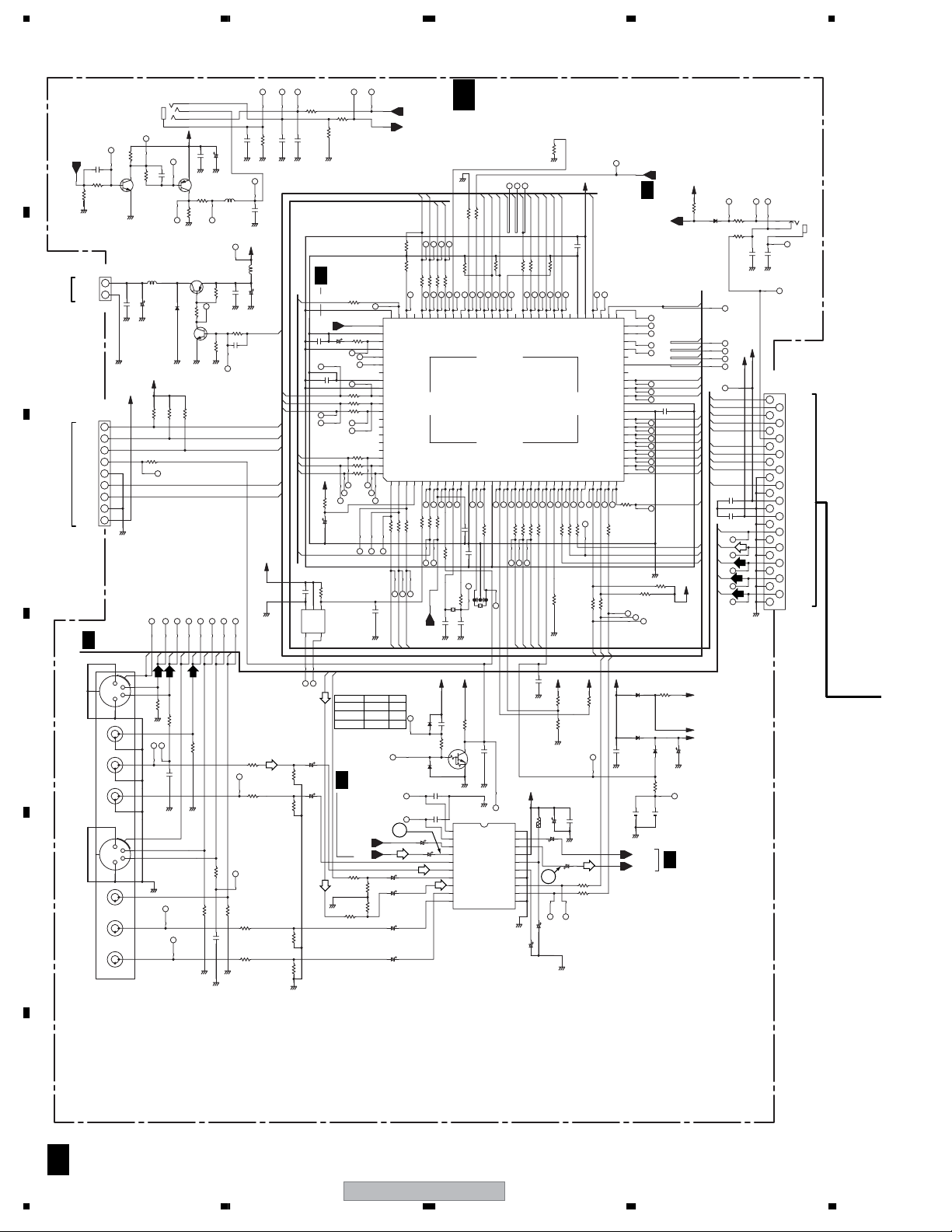

IC301 PT6315

FL Driver

V301

FL

IC3301

CY244ZXC

IC4201

CM0041BF-K

Video Decoder

IC3201

PCM1742KE

Audio

1-3

D/A Conv.

Key

SW

68

CVBS IN

29

6

7

5

IC3251-1/2

UPC4570G2

CN301(2/2)

(27P)

C IN

CN2201

(2/2)

Cr/R

Cb/B

Y/G

Y

C

7

CN3001

(27P)

18

20

22

24

26

16 16

SPDIF

6 6

(27P)

(27P)

CN402

(2/2)

(27P)

18

20

22

24

26

CN401

Cr OUT

Cb OUT

Y(G) OUT

Y OUT

C OUT

L OUT

Tuner U-com

DVR-533H-S

56

IC501

LA73054

16

14

11

8

6

CN101(2/2)

(27P)

7

B

25

23

21

28

31

33

Cb

Y(G)

Cr

Y

C

V

2/2

JACB ASSY

Y(G)

Cb

Cr

VOUT

YOUT

COUT

LOUT

MSL

MSL : Music Server Lch

JA502

JA503

Y

C

Y

C

JA501

8

Y(G)

Cb

Cr

VIDEO

LINE

OUT 1

L

R

VIDEO

LINE

OUT 2

L

R

OPTICAL

AC-3/PCM

DIGITAL

AUDIO

OUT

D

COMPONENT

VIDEO OUT

E

F

15

Page 16

1234

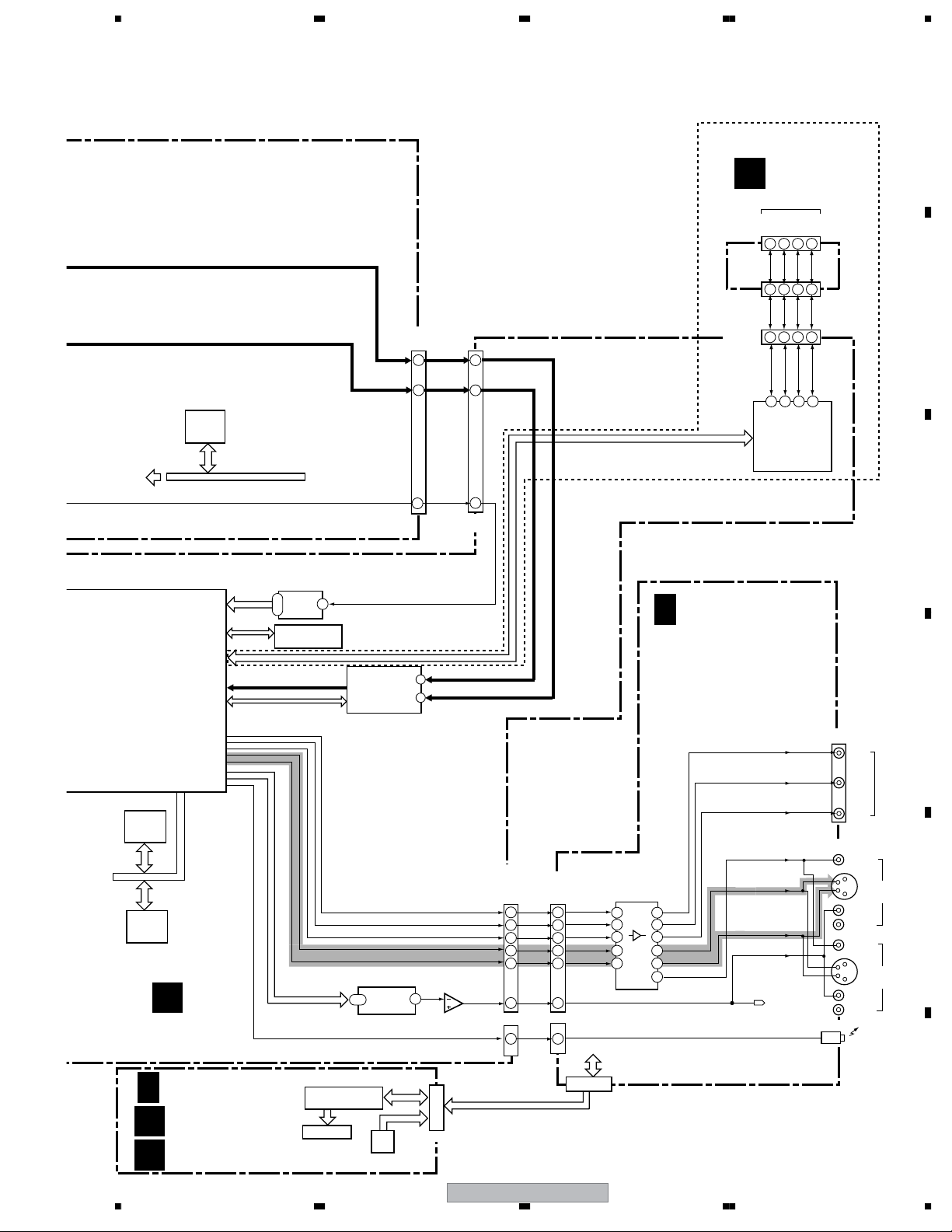

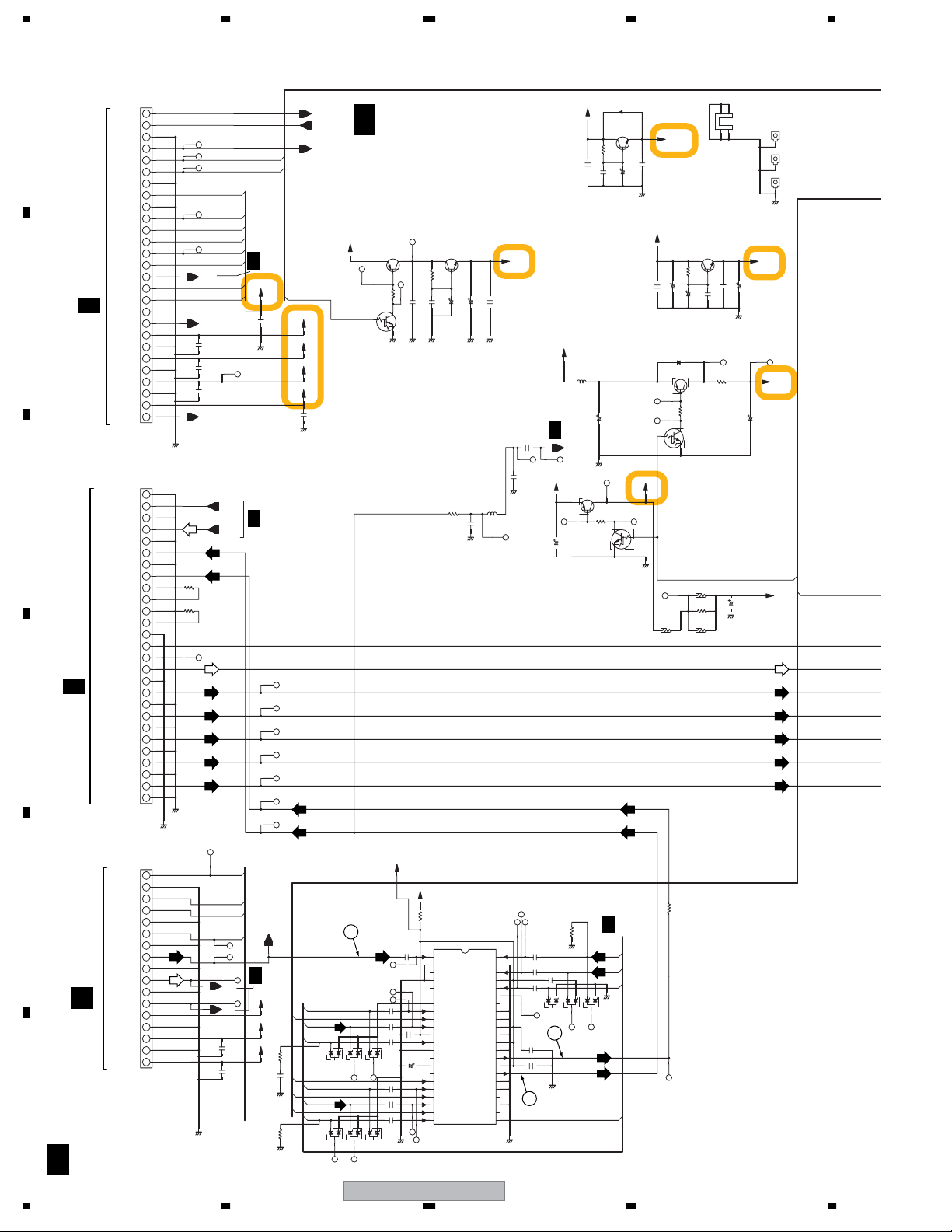

3.1.2 MAIN ASSY

A

MAIN ASSY

H

24M

B

33/36M

IC3201

DAC

IC3101

A/D

C

AUDIO LR IN

D

IC3202

18M

IC4201

Video

Decoder

IC3301

Play Mster clock

and PLL

36M

33M

27M

IC1001

System Codec

IC3303

Except DVR-531H types

HOST BUS

SERIAL

IC5101

Phy

DV_IN

IC1102

FLASH

CN5601

IC3001

VIDEO Y.C.IN

VIDEO Y.C.Yp.Cb.Cr OUT

E

AUDIO LR OUT

CN2201

To JCKB

F

16

1234

Blastor

IR

IC3401

IC1201, 1221

DDR SDRAM

128M x 2

To JCKB

DVR-533H-S

IC1301

DDR SDRAM

512M

To Writer

CN1901CN3801CN3001

To H.D.D

CN1901

Page 17

5678

A

B

C

D

E

56

DVR-533H-S

F

17

7

8

Page 18

1234

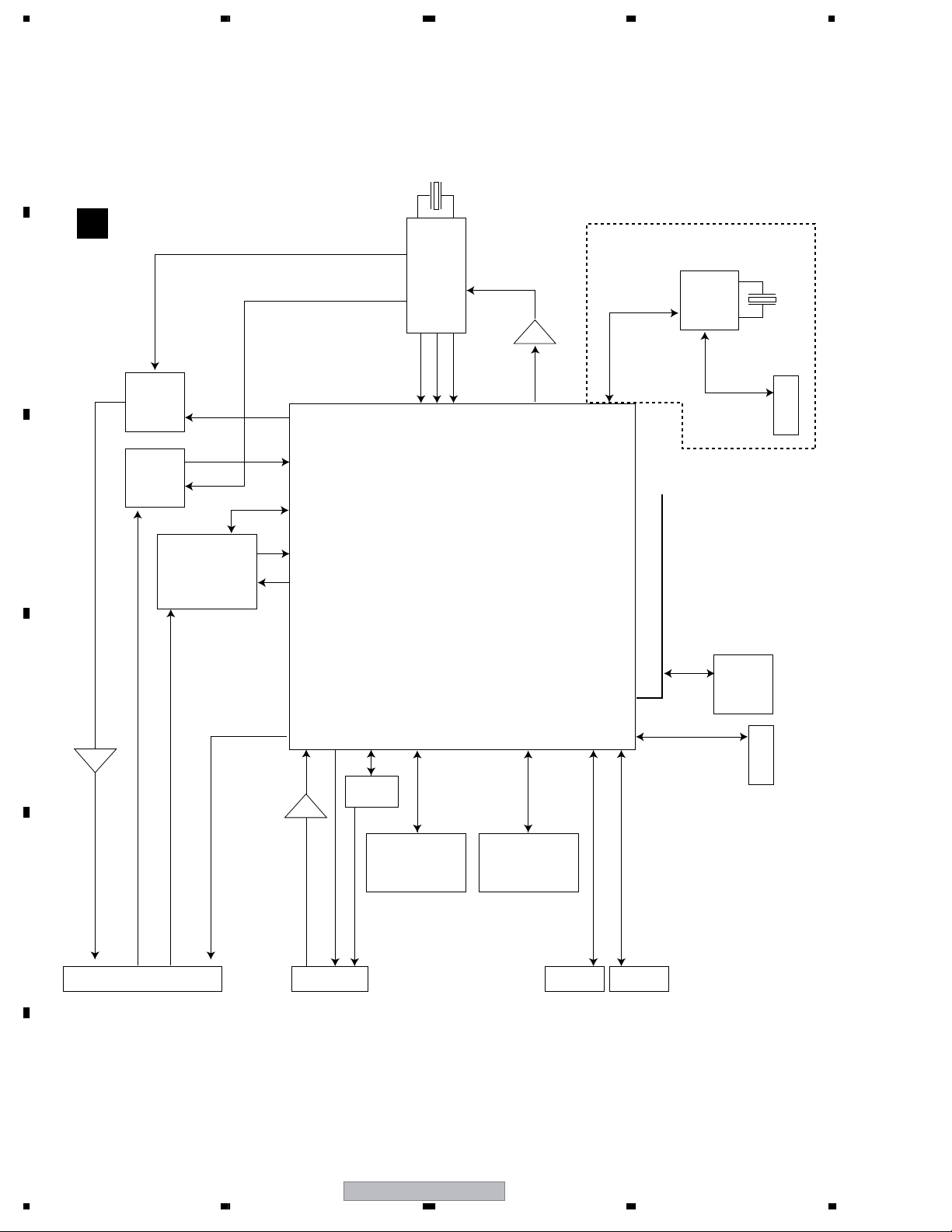

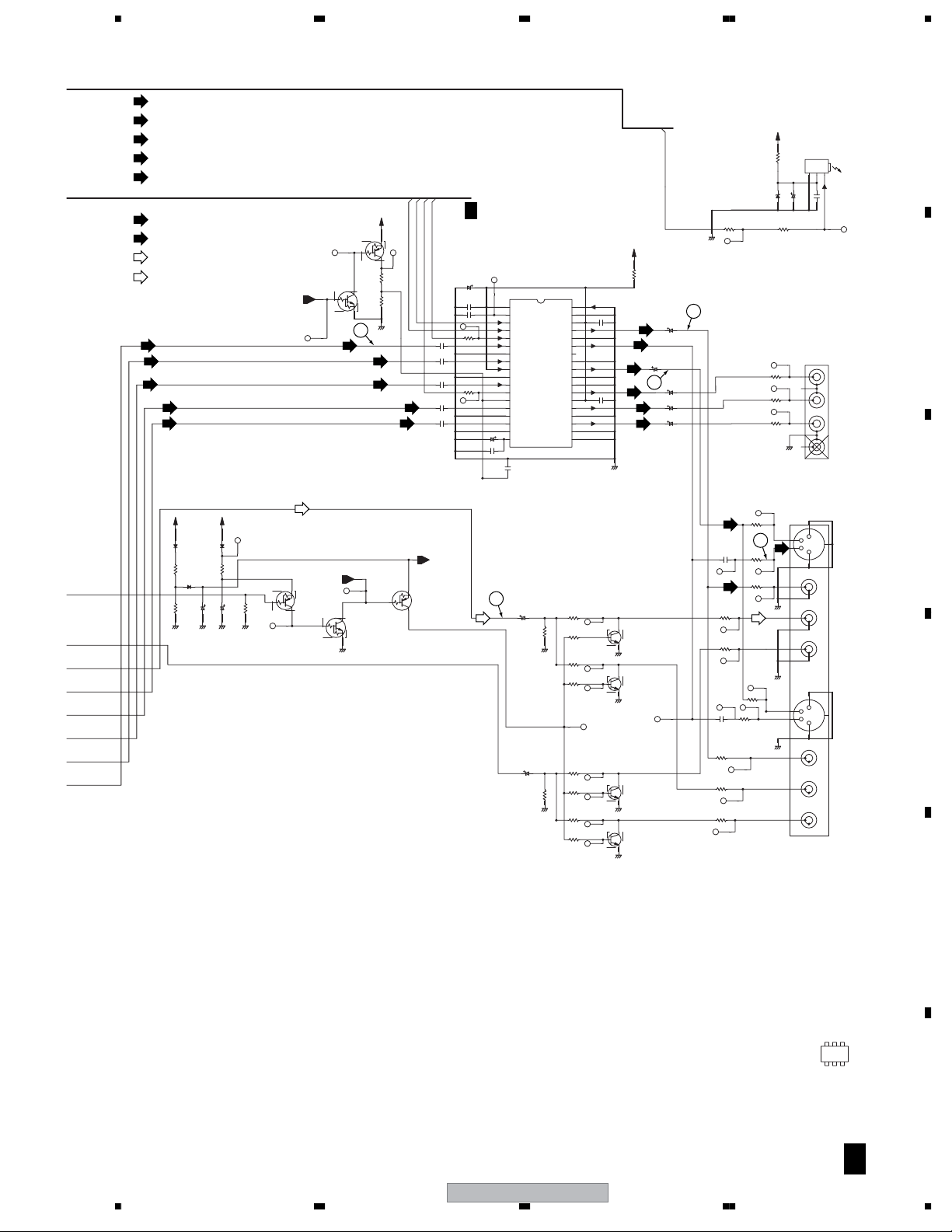

3.2 OVERALL WIRING DIAGRAM

A

AC IN

B

VKN2012

J

POWER SUPPLY

UNIT

C

D

(VWR1391)

VKN2011

H

B

JACB ASSY

H 1/5- H 5/5

B 1/2, B 2/2

(VWV2111:DVR-533H/633H)

(VWV2112:DVR-531H)

VKN2011

E

ATAB ASSY (VWV2123)

(VXX2993:DVR-533H/633H)

(VXX2994:DVR-531H)

E

HDD 80G (VXF1076) 531H/533H

HDD160G (VXF1068) 633H

MAIN ASSY

F

18

1234

DRIVE ASSY R9R (VXX2987)

DVR-533H-S

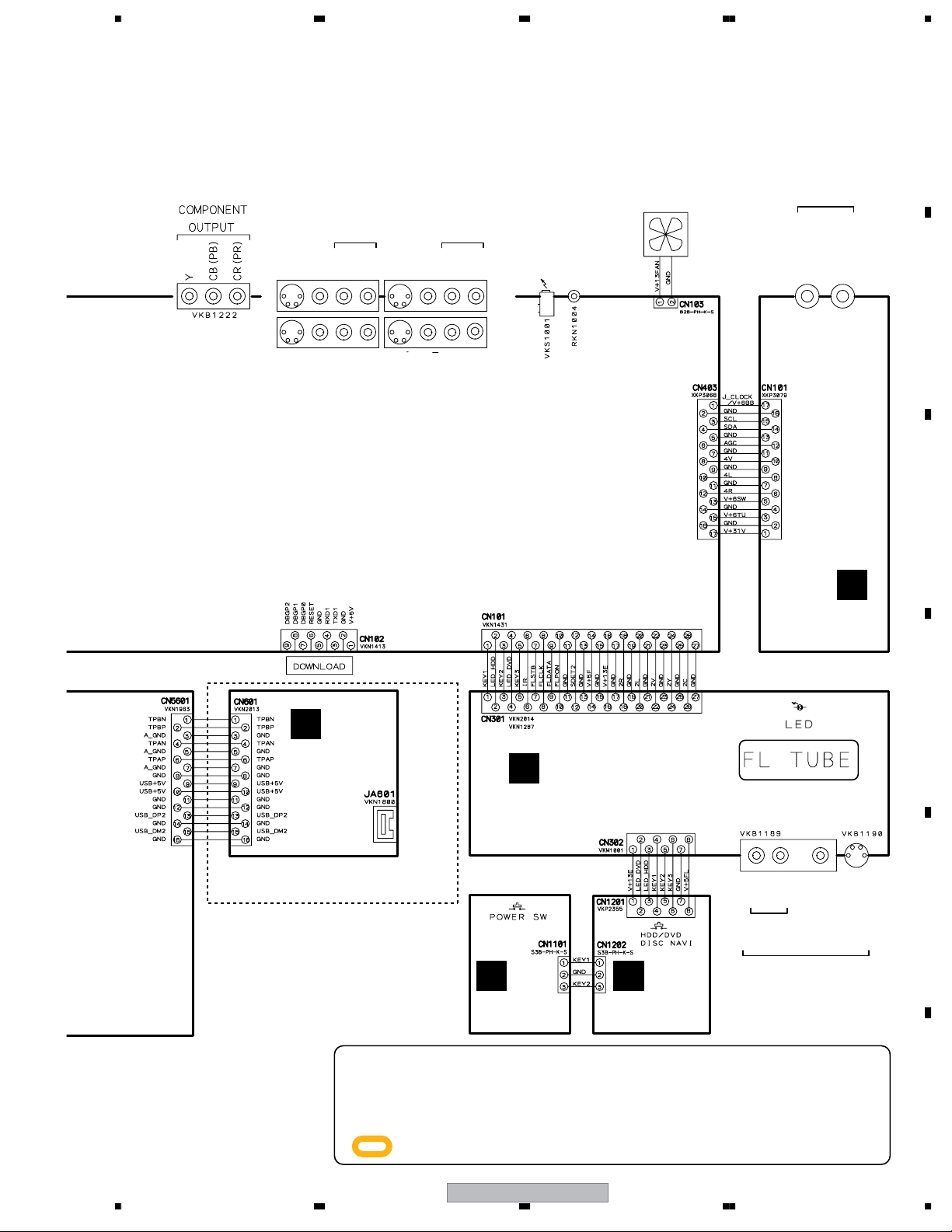

Page 19

5678

A

S VIDEO

OUTPUT 1OUTPUT 2

OUTPUT X2

VKB1184 - (02)

Video

Left

Audio

Right

Video

S VIDEO

INTPUT X2

VKB1183 - (02)

Left

Audio

Right

INPUT 1INPUT 3

Optical Digital

Audio Output

Control Input

DC FAN MOTOR

(VXM1120)

Antenna

from Antenna

INPUT

to TV

OUTPUT

B

C

TUNB ASSY (VXX3024)

A

D

DVJB ASSY

(VWG2535)

Except

DVR-531H types

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

÷

C

FLJB ASSY (VWG2536)

DV INPUT

F

PSWB ASSY

(VWG2524)

: The power supply is shown with the marked box.

G

RSWB ASSY

(VWG2528)

Right

Left

Audio

Video

INPUT 2

(Front)

S VIDEO

D

E

F

56

DVR-533H-S

19

7

8

Page 20

1234

3.3 TUNB ASSY

A

U101

VXF1059

21

20

19

NCNCASNCL OUTNCGND

14325678910 1211 13 14 1715 16

R OUT

SCL

SDA

RF_AGC

MB(5V)

IF_AGC

TU(30V)

GND

AFT

18

UVOUT

GND

B

YB

2200p

C102

CH

GND

C

C106

L102

CH

C107

39p

L103

VTL1081- -T

VTL1081- -T

39p

R104

1k

2SA1576A(QR)-TLB

Q102

R107

E

B

C

GND

TUNB ASSY (VXX3024)

A

<U/V TUNER BLOCK>

R105

0

(2125)

10k

D

R120

0

0

0

R101

YB

R102

E

4700p

GND

YB

F

C123 C122

4700p

GND

20

A

DVR-533H-S

1234

Page 21

5678

A

V+31V

2

1

43

V+5TU

KN101

VNE1948-

B

SCL

SDA

AGC

UVOUT

4L

4R

SW+6V

CN101

XKP3079-

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

J_CLOCK

GND

SCL

SDA

GND

AGC

GND

UVOUT

GND

4L

GND

4R

SW+6V

GND

V+5TU

GND

V+31V

C

D

CN403

B 2/2

E

HN1A01FU

CE2B2C

B2 E2

VC

EC2BE

BC2

DVR-533H-S

56

GND

F

A

21

7

8

Page 22

1234

3.4 JACB(1/2) and FLJB ASSYS

JA101

AKN1073-

A

B_IR

GND

/KU,/EU only

toFAN

V+13SW

B

B2B-PH-K-S

To FAN MOTOR

VKN1413- -TBB

DBGP2

DBGP1

DBGP0

RESET

C

D

E

V+5V

DOWNLOAD

INPUT1

INPUT3

2-A1

C164

R186

4.7K

R187

4.7K

CN103

GND

CN102

GND

RXD1

TXD1

GND

B

S

5

V

L

R

S

5

V

L

R

CH100p

1

2

98

1325476

2/2

7

Y

C

14

17

20

1

Y

C

14

17

20

JA103

VKB1183-

G-LINK IN

1K

R184

C

C165

4.7K

R185

B

GND GND

GND

9

10

8

3

4

2

Q112

E

2SC4081(QR)-TLB

GND

LTA102J-T

L102

1m

C103

0.1

C104

100/16

GNDGND

V+5V

V+5V

R177

R180

0

SDET1

11

R209

GND

13

16

19

6

12

15

18

100p CH

R178

100K

(Y)

1C

1Y

75F

R210

C134

GND GND

GND

2

4

3

1

V+5V

C163

GND GND

E

Q107

2SA1576A(QR)-TLB

B

C

R109 L103

150

1K

R110

GND

Q102

2SB1238X(PQ)-T

1

2

D102

4.7K

R103

C

E

1SR154-400-TRB

GND GND

R179

100K

100K

(C)

3Y3C1V

SDET3

75F

75F

R211

0.01 YB

R195

GND GND

C107

0.1

C124

GND GND GND

100/10

VTL1081- -T

V+13SW

EBC

2.2K

0.1

R101

C105

GND GND

Q101

2SC4081(QR)-TLB

R111

B

22K

220p

4.7K

C102

R104

CH

3V

R212

R213

75F

R208

75F

75F

R196

R197

YB

100

C142

0.01

R198

100

GND

C166

GND

L101

C106

100

100

***

FANCTL

DBGP2

DBGP1

DBGP0

RXD1

TXD1

0

R107

CH

100p

10u

470/16

V+5V

GND

R119

CH

CH

100p

100p

C108

C177

GND GND

/KU only

C139

10/50

100K

R190

10/50

100K

R191

100K

100K

R207 R204

GND

0

B

HST_TO_M

TEXTV

2-B2

C109

0.1

C111

0.1

DBGP2

DBGP1

DBGP0

DAT_TO_M

DAM_TO_T

ASCK

HSM_TO_T

0.1

G

IN

NC

4

C148

C149

R112

0

R116

***

2/2

R126

100

C128

2.2/50

R222

R223

R224

V+5V

47K

R165

C167

22/6.3

R113

10K

231

IC102

OUT

BD4846G-TRB

NC

5

2L

2R

Note 1

DVR-533H Not used 0

DVR-633H

DVR-531H

R188

100

GND

R200

100

R131

1K

R141

100

R142

100

R143

100

2/2B

100

100

100

2-D1

2-D1

TXDGL

2-A1

RXDGL

2-A1

R234 R231

7980 7778 727476 75 73 686971 70 64656667 63 59606162 5658 57 55

81

82

83

VDDODA

84

HST_TO_M

85

blank

86

blank

87

blank

88

GND

89

VDD3

90

DBGP2

91

DBGP1

92

DBGP0

93

blank

94

blank

95

blank

96

blank

97

blank

98

99

100

FLDATA

FLSTB

100

100

R153

R154

R152

C125

0.1

FLSTB

FLCLK

FLDATA

GND

R170 R172

Not used 0

39k 6.8k

1SS355-TRB

2

4R

(T)

4L

C157

10/50

C158

100K

R189

10/50

100K

R199

C159

10/50

C160

10/50

B 1/2

GND

100K

LED_DVD

LED_HDD

100

100

R129

R128

TXD1

BLANK

LEDHDD

LEDDVD

81. CVBSIN

82. GND

83. FILTSLC

84. VDDVCO

98. DAT_TO_M

99. DAM_TO_T

100.ASCK

XT1

HSM_TO_T

RESETIRCF2

100

330p

R145

C140

R155

100

R159

VSS1197-

X102

CH

15p

C117

1-A3

GND

GND

V+6E V+5M

YB1u

C130

R214

0

B

Q115

C181

GND GND

0.1

C182

0.1

1

2

L5

3

TunerR

4

TunerL

10/50

5

R1

6

7

R2

8

L2

9

R3

10

L3

100

CSYNC

J_CLOCK

R121

R151

XCHECKER

R123

100K

R233

100K

MRST

AVLIN

blank

SYNCAFT

XCHECKER

IC101

PMC002A8-K

GND

CF1

XT2

MODEL1

VDD1

330

R171

C116

0.1

1

23

560K

CH

X101

10p

C118

CSS1666- -T

10K

R183

C

0.1

C132

E

GND

SELECTR5

ROUT

LOUT

VCC

VRR

FILTERL1

GND

SCL

SDA

GND

IC103

BD3823FV-TBB

RXD1

TXD1

100K

100K

100

100

R225

R127

RXD2

TXD2

RXD1

WDT

ACDET

FLCLK

4312 9786513121110 17161514 211918 20 22 23 24 25 26 27 28 29 30

100

100

100

R114

R144

SELIR

D108

1SS355-TRB

D116

DTC124EUA-TLB

C151

10/50

C152

JACB ASSY (VWV2111: DVR-533H)

(VWV2111: DVR-633H)

(VWV2112: DVR-531H)

100K

R162

FLPON

STATCHG

XP_SAVE

XP_SAVE

J_CLOCK

STATCHG

50. blank

49. blank

48. XAVLTH

47. PSMUTE

33. AMUTE1

32. COMPMUTE

31. MUTEV

KEY1

MODEL2

100

100

R147

R146

KEY1

KEY2

20

19

18

17

16

15

14

13

12

11

GND

C155

SWVION

P_CONT

100

100

R124

R150

FLON

P_CONT

KEY2

KEY3

100

100

R148

R149

AGC

KEY3

C170

GND

V+12VOL

33

R158

C156

100/10

GND

TUON

R235

TUON

SWVION

AGC

BATTDET

R137

GND

V+5V

0.1

GND

C150

(2125)

C153

10/50

1

10/50

I_BG

MUTECTL

100K

I_BG

FUNC

R138

100k

R170

R172

100/16

C154

10/50

GND

V+5M

C110

blank

MUTECTL

SDET2

SDET3

1K1K1K

R139

R140

V+5V

Note 1

Note 1

C138

GND

R193

R192

0.1

GND

AVLOUT

SDET1

R173

0.1

100

100

FANCTL

VDD2

FANCTL

XTHROU

RGBSEL

SWSTBY

SDA

100

R168

R169

SDA

0

5254 53 51

blank

blank

VDD4

YVSEL

SELV3

SELV2

SELV1

SCL

100

R217

100

SCL

XRST1

SDA

SCL

SQU

LET

GND

50

49

48

blank

RFTHRU

47

46

S1

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

XRST2

XRST1

R216

100

V+6E

1SS355-TRB

D107

D118

1SR154-400-TRB

C178

0.1

GND

ST101

GND

MRST

2-A1

2/2B

SELIR

1-B2

RFTHRU

XAVLTH

PSMUTE

XTHROU

S1

RGBSEL

SQU

LET

C119

0.1

SWSTBY

YVSEL

SELV3

SELV2

SELV1

AMUTE1

COMPMUTE

MUTEV

XRST2

SDET1

SDET2

SDET3

GND

R166

V+5V

R167

4.7K

4.7K

R230

0

C129

D105

1SS352-TRB

GND

1K

R175

+

+

VEM1033-

BT101

Battery(3V)

Lithium Battery

ROUT

2-B1

LOUT

2/2

B

2-B1

V+5V

220K

R156

1SS355-TRB

V+5F

V+5V

V+5M

220/10

D114 R219

R221

V+13E

KEY1

LED_HDD

KEY2

LED_DVD

KEY3

FLSTB

FLCLK

FLDATA

FLPON

SDET2

C168

0.1

C169

0.1

2R

2L

2V

2Y

2C

220

220

CH

C175

680p

GND

V+5F

(Y)

(C)

GND

CONTROL

INPUT

JA102

RKN1004-

2

3

1

0.1

C176

GND

CN101

VKN1431- -TBB

1

KEY1

2

LED_HDD

3

KEY2

4

LED_DVD

5

KEY3

6

IR

7

FLSTB

8

FLCLK

9

FLDATA

10

FLPON

11

GND

12

SDET2

13

GND

14

V+5F

15

GND

16

V+13E

17

GND

18

2R

19

GND

20

2L

21

GND

22

2V

23

GND

24

2Y

25

GND

26

2C

27

GND

F

22

B 1/2

DVR-533H-S

1234

Page 23

5678

: Video Signal Route

(Y)

FLJB ASSY (VWG2536)

C

: Y Video Signal Route

(C)

: C Video Signal Route

: AUDIO SIGNAL ROUTE (L ch)

(T)

: AUDIO SIGNAL ROUTE (TUNER L ch)

A

CN302

VKM1001-

V+13E

LED_DVD

LED_HDD

KEY1

KEY2

CN1201

KEY3

GND

V+5FL

G

CN301

VKN2014-

(Nichiatsu)

VKN1287-

KEY1

LED_HDD

KEY2

LED_DVD

KEY3

IR

FLSTB

FLCLK

FLDATA

FLPON

GND

SDET2

GND

V+5F

GND

V+13E

GND

2R

GND

2L

GND

2V

GND

2Y

GND

2C

GND

C334

0.1

C323

GND1

1

2

3

4

5

6

7

8

(FCI)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

Q307

2SC5712-TLB

C

E

100/16

V+5F_2

V+13E_2

B

R319

LAU220J-TA

V+5FL

0.1

C325

C326

GND1 GND1

GND2GND1

L303

LAU220J-TA

D305

1SS355-TRB

D301

27k

UDZS15(B)-TRB

2SA1576A(QR)-TLB

1

C301

GND1

L301

22

C313

100/10

0.1

GND1

V+13E_2

0.1

C317

GND1 GND1

(Y)

22

R314

270k

Q306

10k

R317

E

B

C

D302

UDZS13(B)-TRB

2

YB

0.01

V+5FL

0.1

C312

VNF1084- -T

1k

C320

R315

0.022

YB

Q308

C

B

E

R320

1.0k

C321

2SC4081(QR)-TLB

V301

VAW1085

11 12 1310917161514 23 2524 26 3027 28 29 31 343332 36 393835 37 40 41 49

S1S5S3S2S4S8S7S6S9

R305

220

R306

220

R307

220

V+5F_2

C316

0.1

V+5FL

GND1

GND1

R304

82k

S10

C304

C308

S11

S13

S12

S14

0.1

4441434042

VSS

LED4

OSC

DOUT

DIN

CLK

9810 576 2341

STB

11

VSS

1215131614

0.1

S15

COM11

COM12

S16

COM8

COM10

COM9

COM1

COM3

COM2

COM5

COM4

COM6

3836373539

VDD

GRID1

GRID3

GRID2

GRID4

GRID5

GRID6

LED1

GRID10

LED2

GRID11

LED3

GRID12

IC301

PT6315

/UPD16315GB-3S

FL DRIVER

KEY1 SEG11

KEY2

SEG10

VDD

SEG1

SEG3

SEG2

SEG4

SEG5

SEG6

S1S3S2S8S7

S5S4S6

COM7

COM7

GRID7

SEG7

COM6

COM8

GRID8

VEE

SEG16

SEG15

SEG14

SEG13

SEG12

SEG8

2120191718

COM5

COM9

34

GRID9

SEG9

22

S9

COM4

23 2524 26 28 2927 30 3231 33

FL

FL-28V

FLDC+

FLDC-

COM3

(Y)

(C)(C)

KN301 KN302

GND1

R316

220

(2125)

VTT1166-

(162-1076-02)

91

82

6

R318

1.2k

YB

0.01

VNF1084- -T

T302

GND2

357

4

D306

RF101L2S-TRB

RF101L2S-TRB

D304

C322

(50V)

C324

C336

0.1

C335

0.1

100/16

10k

R321

10/50

UDZS2R4(B)-TRB

D303

GND1

12321132

D312 D310 D311

D310–312 :

DF3A5.6FU-TLB

COM2

COM1

COM10

COM11

COM12

S16

S15

S14

S13

S12

S11

S10

(Y)

(C)

VNF1130-FL Holder

48

YB

0.01

C303

C333

GND1

GND1

0

R309

FL-28V

0.1

(50V)

GND1 GND2

V+5FL

IC302

AT140BT-16GP(GOODTAKE)

RPM7140-H4(ROHM)

0

R337

(Y)

(C)

C318

GND1

0.1

TS

C319

100/10

JA301

VKB1190-

1

3

4

2

6

1

Vout

2

GND

3

Vcc

S

5

B

C

D

E

9

470p

GND2

R331

0

GND2

8

6

5

3

2

JA302

VKB1189-

3

GND2

R329

0

C331

R327

GND2

0

C332

470p

GND2

VIDEO

7

INPUT2

Lch

/MONO

4

Rch

1

GND2

F

56

DVR-533H-S

B 1/2

C

23

7

8

Page 24

1234

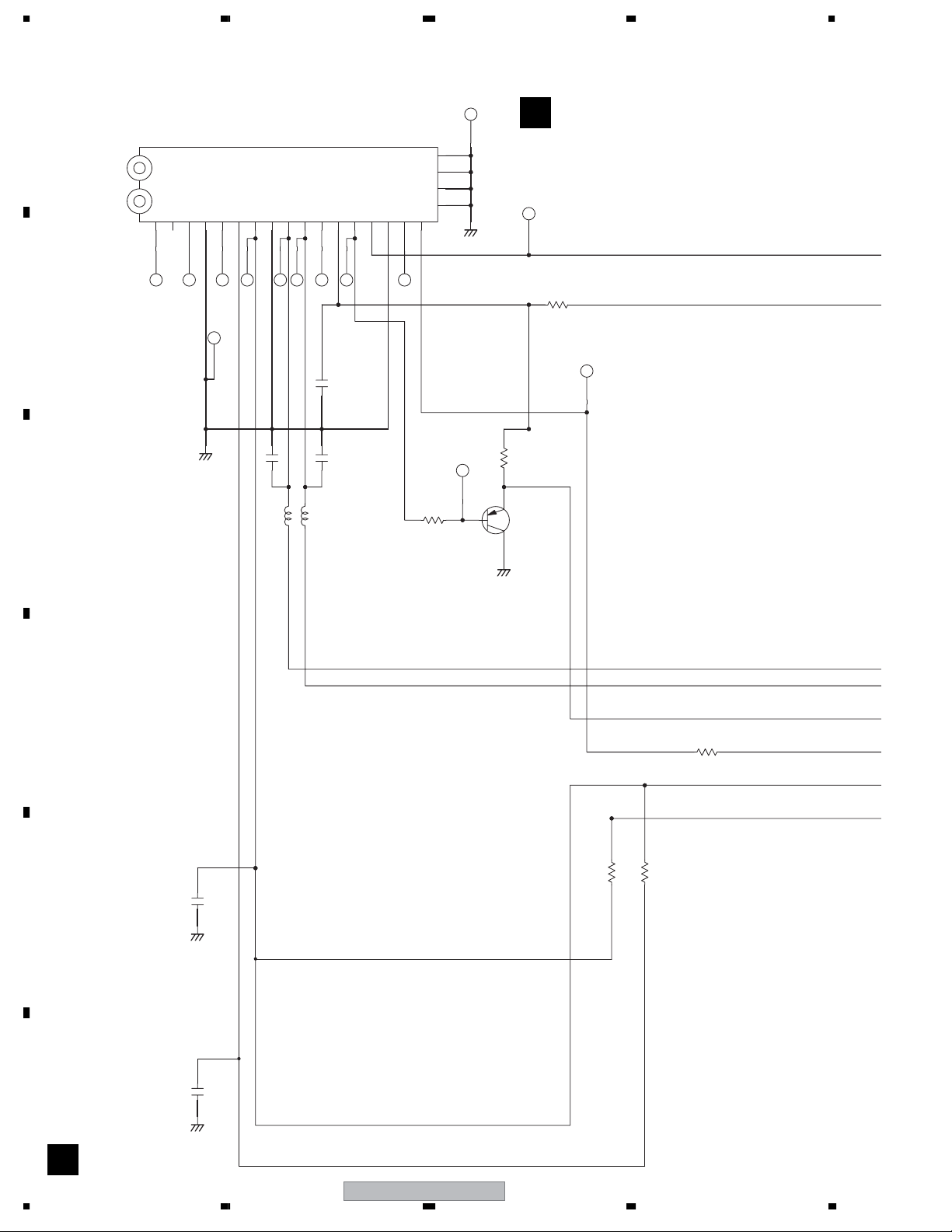

3.5 JACB ASSY(2/2)

CN401

VKN2008-

1

A

B

C

D

E

TXDGL

RXDGL

B_IR

SPDIF

ASCK

HSTtoM

XRST1

SSTtoM

P_CONT

SSMtoT

CN3001

MRST

HSMtoT

XRST2

H 3/5

V+6SW

AMUTE

V+6E

V+13E

V+32E

V+13SW

X525P

ARTtoM

ALTtoM

V/YTtoM

C/RTtoM

GND/GTtoM

CVBS_GR/BTtoM

GNDA

ARMtoT

CN2201

GNDA

ALMtoT

GNDA

H 2/5

Cr/RMtoT

Cb/BMtoT

Y/GMtoT

YMtoT

CMtoT

/V+6BB

CN101

A

V+6SW

V+6TU

V+31V

2

3

GND

4

5

BUP

6

7

GND

8

9

GND

10

11

12

13

14

15

16

17

18

19

20

21

GND

22

23

GND

24

25

GND

26

27

CN402

VKN2008-

1

GND

2

3

GND

4

5

GND

6

7

GND

8

9

GND

10

11

GND

12

13

14

15

16

17

18

19

GND

20

21

GND

22

23

GND

24

25

GND

26

27

GND

CN403

XKP3068-

1

2

GND

3

SCL

4

SDA

5

GND

6

AGC

7

GND

8

4V

9

GND

10

4L

11

GND

12

4R

13

14

GND

15

16

GND

17

GNDA

(T)

(T)

GND

GND

R405

R404

(Cb)

C409

C411 C410

0

0

(Cr)

(Yp)

(Y)

(C)

MRST

1-A3

AMUTE2

1-D3,2-B4

X525P

2-A4

F

GND

B 2/2

24

1234

ASCK

HST_TO_M

XRST1

DAT_TO_M

P_CONT

DAM_TO_T

HSM_TO_T

XRST2

0.1

0.1 0.1

(50V)

ROUT

1-C2

LOUT

1-C2

(Y)

(C)

4L

1-C2

4R

1-C2

C414

C415

SCL

SDA

AGC

0.1

0.1

(50V)

SPDIF

B

V+6SW

C408

GND

V+6SW

V+5TU

V+31V

BUP

1/2

0.1

1/2B

4V

1/2B

GND

GND

SWVION

V+6E

V+13E

V+32E

V+13SW

GND

1-D3

D404-D412

DF3A5.6FU-TLBx9

75F

R435

YB

C462

0.01

75F

R436

TXDGL

1-A2

RXDGL

1-A2

B_IR

1-A1

V+6E

0.1

C412

(C)

(Y)

3C

YVSEL

1C

(C)

2C

12 1212

333

SELV1

3Y

SELV2

(Y)

1Y

SELV3

2Y

12 1212

333

D407 D408

B 2/2

JACB ASSY

(VWV2111: DVR-533H

(VWV2111: DVR-633H)

(VWV2112 : DVR-531H)

2SA1036K(QR)-TLB

Q405

DTC124EUA-TLB

B

V+5VSEL

3

(T)

C442

C443

D405D404 D406

C445

C446

C447

D409

Q403

E

B

R408

C

E

GND

YB0.1

YB0.1

C444

YB0.1

YB0.1

YB0.1

YB0.1

GND

DVR-533H-S

Q404

2SC2411K(QR)-TLB

C

C

E

B

R406

100

1K

0.1

0.1

C417

GND GND GND GND

V+5VI

R420

C438

YB0.1

C450

0.1

C452

470/6.3

C432

C431

R403

470

100/10

100/6.3

C401

180P

GND

/KU, /IBD only

V-DET OUT

V-DET-FIL

V.SYNCOUT

C.SYNCOUT

V-DET-IN

C-OUT

Y-OUT

LPF-CTL

STBY_H

V3-IN

V2-IN

VCC

V1-IN

GND

VCC

GND

VCC

GND

C419

100µ

L405

NC

NC

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

C418

0

VIDEO SELECTOR

IC401

LA73031V-TBB

144

V4-IN

2

V-DET-CTL

3

NC

4

COMP-H

5

NC

6

NC

7

GAIN-CTL

8

C-IN1

9

YOUT-SEL

10

C-IN2

11

VCC

12

C-IN3

13

GND

14

NC

15

REG

16

NC

17

INSEL1

18

Y-IN1

19

INSEL2

20

Y-IN2NCTEST MODE

21

INSEL3

22

Y-IN3

V+5VI

0.1

C425

1u

C427

470P

GND

<VIDEO SELECTOR BLOCK>

C439

0.1

C440

0.1 0.1YB

C441

0.1 YB

4

GND

V+13SW

C457

V+32E

L401

CTF1399- -T

1/2B

TEXTV

1-A2

V+6E

YB

12 1212

YB

C456

0.1

C453

0.1

GND

GND

Q402

UMF21N-TLB

E

B

UMF21N-TLB

C403

100/10

75F

R437

GND

C455

333

D410 D411 D412

5

(C)

(Y)

SWSTBY

D414

1SS355-TRB

Q412

2SC4081(QR)-TLB

C

B

R432

100

0.1

0.1

C459

C458

C405

10/50

C

R402

560

C2

Q402

E2

B

1/2

2V

1V

3V

GND

E

100/16

GND

V+6TU

B2

C460

GND

(C)

(Y)

0.1

V+6SW

C421

B2

(2125)x 4

V+12VOL

2SC2411K(QR)-TLB

C434

0.1

100/10

D403

1SS355-TRB

Q413

UMF23N-TLB

E

R441

C2

E2

R445

0

0

R423

Q406

C

B

100

R409

C423

C436

100/10

C

B

33K

UMF23N-TLB

Q413

R446

12

R447

12

R448

8.2

0.1

R442

2

413

E

220

C422

0.1

GND

KN401

VNE1948-

C435

100/6.3

GND

C407

C474

1000/6.3

V+5VO

10/50

(Cr)

(Cb)

(Yp)

(Y)

(C)

KN403

KN404

KN405

GND

V+31V

TUON

VNF1084- -T

VNF1084- -T

VNF1084- -T

V+5TU

AMUTE1

Page 25

5678

: Video Signal Route

(T)

: Video Signal Route (TUNER)

(Y)

: Y Video Signal Route

(C)

: C Video Signal Route

(Cr)

: Cr Video Signal Route

(Cb)

: Cb Video Signal Route

(Yp)

: Yp Video Signal Route

: AUDIO SIGNAL ROUTE (L ch)

(T)

: AUDIO SIGNAL ROUTE

(TUNER L ch)

(C)

(Y)

(Yp)

(Cb)

(Cr)

X525P

2-B1

Q503

UMD2N-TLB

B

(C)

Q503

UMD2N-TLB

B2

C

E

7

(Y)

(Yp)

V+5VO

R513

GND

R511

E2

C2

(Cb)

(Cr)

A

V+6SW

SPDIF

LET

SQU

MUTEV

COMPMUTE

100

820

0.1

0.1

0.1

0.1

0.1 YB

C507

C508

C509

C511

C512

C504

C505

YB

1/2B

<VIDEO DRIVER BLOCK>

C515

100/10

YB

YB

R508

YB

R507

0

0

1

0.1

2

0.1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

C516

18

100/10

C513

0.1

C514

75W DRIVER with LPF

VCCVCC

CVBS IN 1/2DRIVE1

SQUEEZE

LETTER

MUTE1

C IN

GND ASPECT

Y1 IN

YCMIX

Y2/G SW

Y2(G)IN

MUTE2

LPF SW

Cb(B)IN

GAIN SW2

Cr(R)IN

GND

0.1

IC501

LA73054-TBB

GAIN SW1

VCC

CVBS OUT

GND

C OUT

GND

Y OUT1

GND

GND

Y OUT2

VCC

Cb OUT

GND

Cr OUT

GND

1/2DRIVE2REG

R504 R505

0

C517

C519

1000/6.3

C520

470/6.3

C521

470/6.3

GND

9

V+5VO

0

R506

36

35

C506

34

33

0.1

32

31

30

29

28

27

26

25

C510

24

0.1

23

22

21

20

19

GND

(C)

(Y)

(Y)

(Cb)

(Cr)

C518

1000/6.3

1000/6.3

8

<OUTPUTS>

R501

39

1

D508

C503

2

UDZS5R1(B)-TRB

0

R521

75F

R520

75F

R522

75F

GND

/KU,/IBD,/EU only

JA501

VKS1001-

312

C502

100/10

JA502

VKB1222-

6

1

3

5

4

2

OPTICAL

0.1

Y

Cb/Pb

Cr/Pr

OPTICAL DIGITAL

AUDIO OUTPUTS

B

COMPONENT

V+13E V+5V

D509

D507

1SS355-TRB

1SS355-TRB

1K

680

R570

GND GND GND GND

D506

1SS355-TRB

2.7k

R540

C547

100/16

R556

C548

220/6.3

R562

R530

75F

R529

75F

R523

R525

R526

JA503

VKB1184-

75F

10

75F

75F

(C)

GND

GNDA

GND

7

9

Y

S1

5

C

10

8

13

V1

14

L1

16

17

19

20

1

3

Y

5

C

4

2

12

14

15

17

18

20

OUTPUT 1

R1

S2

V2

OUTPUT 2

L2

R2

(Y)

C523

0.1

R532

75F

R533

100

100

C522

R527

R528

0.1

100

100

AMUTE2_1

B

1-D3

E

Q511

DTA124EUA-TLB

C

11

VCH1241- -T

(47/16)

C549

C550

VCH1241- -T

(47/16)

R557

470

R559

R558

22K

3.9K

R560

470

R561

3.9K

R563

470

R564

3.9K

R565

22K

R566 R534

GNDA

470

R567

3.9K

B

B2

B

B2

C

Q514

HN1C03FU(AB)-T

E

GNDA

C2

Q514

HN1C03FU(AB)-T

E2

GNDA

C

Q515

HN1C03FU(AB)-T

E

GNDA

C2

Q515

HN1C03FU(AB)-T

E2

GNDA

Q510

UMD2N-TLB

AMUTE2

1-D3,2-A1

E2

B2

10K

Q510

UMD2N-TLB

C2

C

B

E

GND GNDA

C

D

E

56

DVR-533H-S

B2C

4E25

6

C232B1E

F

B 2/2

25

7

8

Page 26

1234

3.6 DVJB ASSY

A

B

CN601

16

GND

USB_DM2

GND

USB_DP2

12

GND

C

CN5601

H 5/5

D

GND

USB+5V

USB+5V

GND

GND

TPAP

GND

TPAN

GND

TPBP

TPBN

10

VKN2013- -TFB

15

14

13

11

9

8

7

6

5

4

3

2

1

GND4

DVJB ASSY (VWG2523)

D

JA601

VKN1800- -TLB

6

TPAP

TPAN

TPBP

TPBN

547

8

DV Input

GND4

1

2

3

E

F

D D

26

1234

DVR-533H-S

Page 27

5678

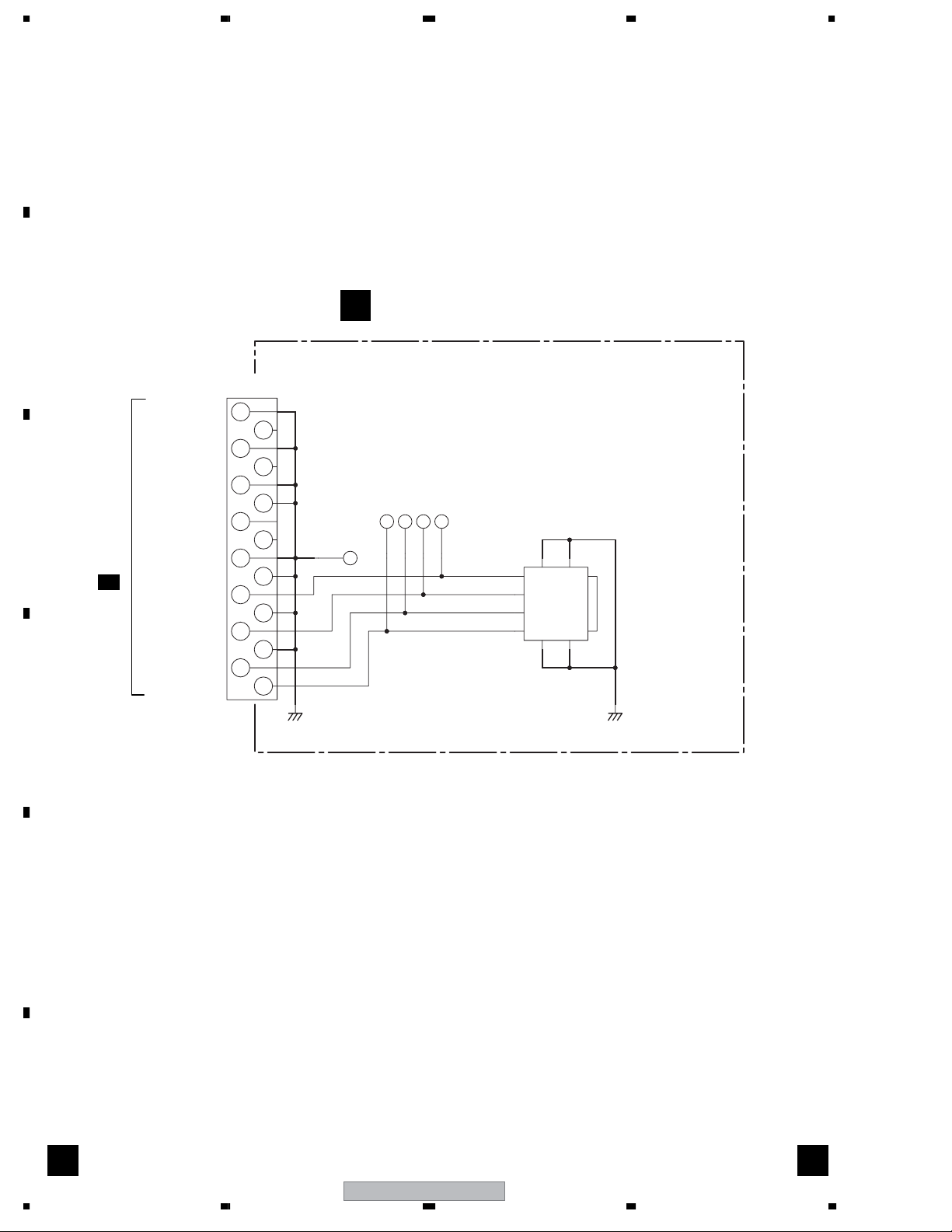

3.7 ATAB ASSY

ATAB ASSY (VWV2123)(for HDD)

E

A

CN11

VKN2009- -TBB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

To HDD CN404

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

CN12

VKN1816-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

(KEYPIN)

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

RESET#

GND

DD7

DD8

DD6

DD9

DD5

DD10

DD4

DD11

DD3

DD12

DD2

DD13

DD1

DD14

DD0

DD15

GND

DMARQ

GND

DIOW#

GND

DIOR#

GND

IORDY

CSEL

DMACK#

GND

INTRQ

RESERVED

DA1

PDIAG#

DA0

DA2

CS0#

CS1#

DASP#

GND

B

C

CN3802

H 3/5

D

GND3 GND3

DVR-533H-S

56

E

F

EE

27

7

8

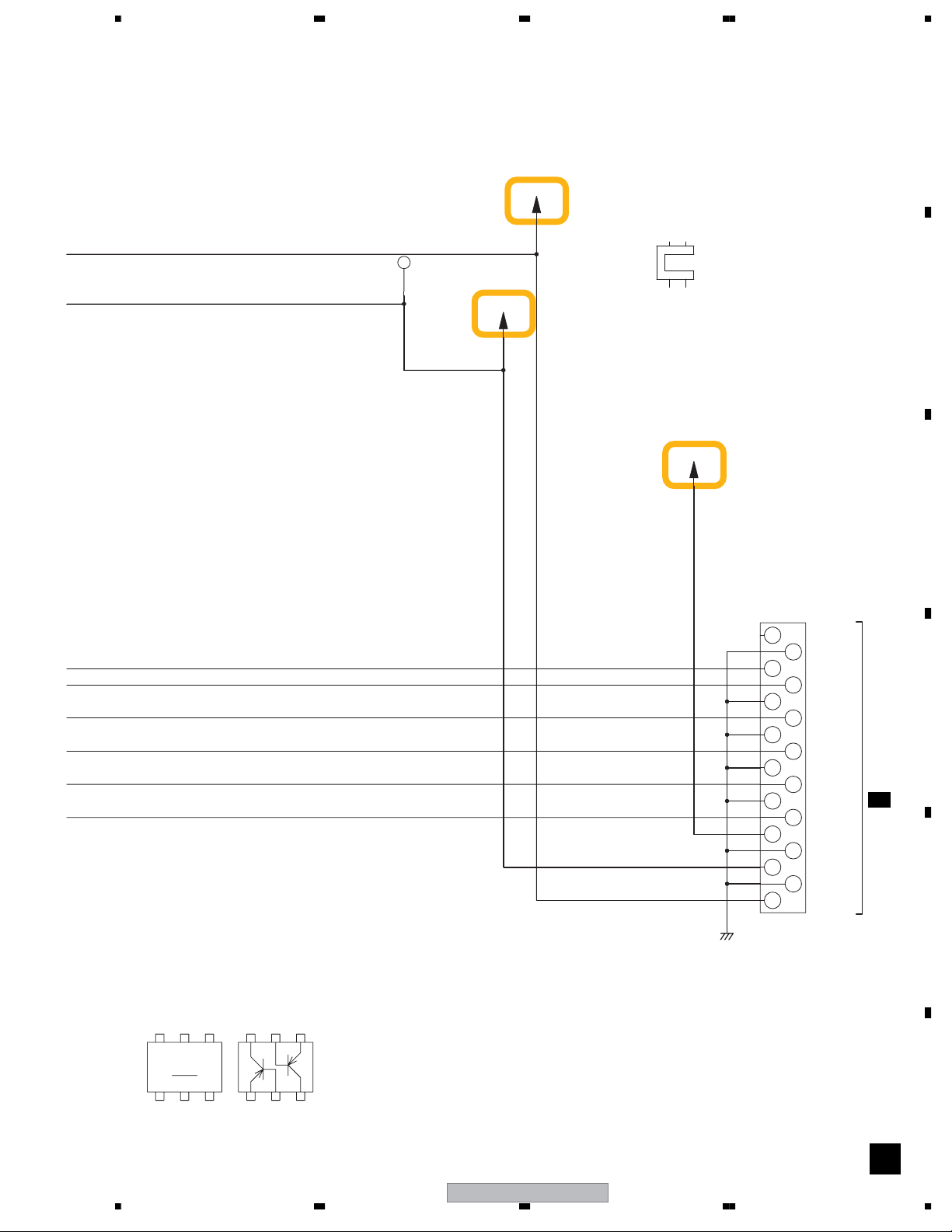

Page 28

1234

3.8 PSWB and RSWB ASSYS

A

B

F

PSWB ASSY (VWG2524)

TP116

C

Switches

S1212:PAUSE

S1213:STOP

S1405:PLAY

S1406:POWER

R1405R1406

5.6k

S1405 S1212

VSG1024- -T VSG1024- -T

S1406 S1213

12k

VSG1024- -T

PLAY

2.85V 2.85V

POWER

3.58V 3.58V

GND2 GND2

TP117

R1212

5.6k

12k

R1213

VSG1024- -T

PAUSE

STOP

GND2

CN1101

S3B-PH-K-S

1

2

3

KEY1_1

GND

KEY2_1

D

E

F

F

28

1234

DVR-533H-S

Page 29

CN302

to FLJB ASSY

C

5678

A

RSWB ASSY (VWG2528)

G

RSWB ASSY

V+13E

LED_DVD

LED_HDD

KEY1

KEY2

KEY3

GND

V+5FL

KEY1_1

KEY2_1

CN1201

VKP2355-

2

4

6

8

CN1202

S3B-PH-K-S

GND

1

3

5

7

1

2

3

VWG2528

VWG2531

V+13E

TP125

GND1

TP122

TP124

V+5FL

GND1

C1204

TP126

TP114 TP115

TP123

YF

0.1

TP128

V+5FL

10k

R1208

VSG1024- -T

R1209

2.2k

VSG1024- -T

R1210

2.2k

VSG1024- -T

R1211