Pioneer DVJ-1000 Service manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2006

OFF ON

POWER

TIME

AUTO

MODE

CUE

TEXT MODE

DVD TITLE

ANGLE SUBTITLE AUDIO

MP3 FOLDER

REALTIME CUE

HOT CUE

IN

IN ADJUST

BACK & FORTH

REC MODE

DIRECTION

FWD

REV

PREVIOUS

NEXT

FWDREV

CUE

PLAY/PAUSE

DELETE

DISPLAY

RELOOP/

4-BEAT

OUT

EXIT

ONE-TRACK

LOOP

OUT ADJUST

REV

DVJ-1000

MEMORY MENU T.MENU

CUE / LOOP

CALL

JOG ADJUST

FWD

STOP

UNLOCK

LOCK

EJECT

RETURN

SETUP

TOUCH/BRAKE

ENTER

RELEASE/START

LIGHT

HEAVY

HYPERJOG MODE

JOG MODE

VINYL

WIDE

TEMPO

MASTER TEMPO

TEMPO

RESET

ORDER NO.

TEMPO

RRV3454

DVJ-1000

DVD PLAYER

DVJ-1000

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

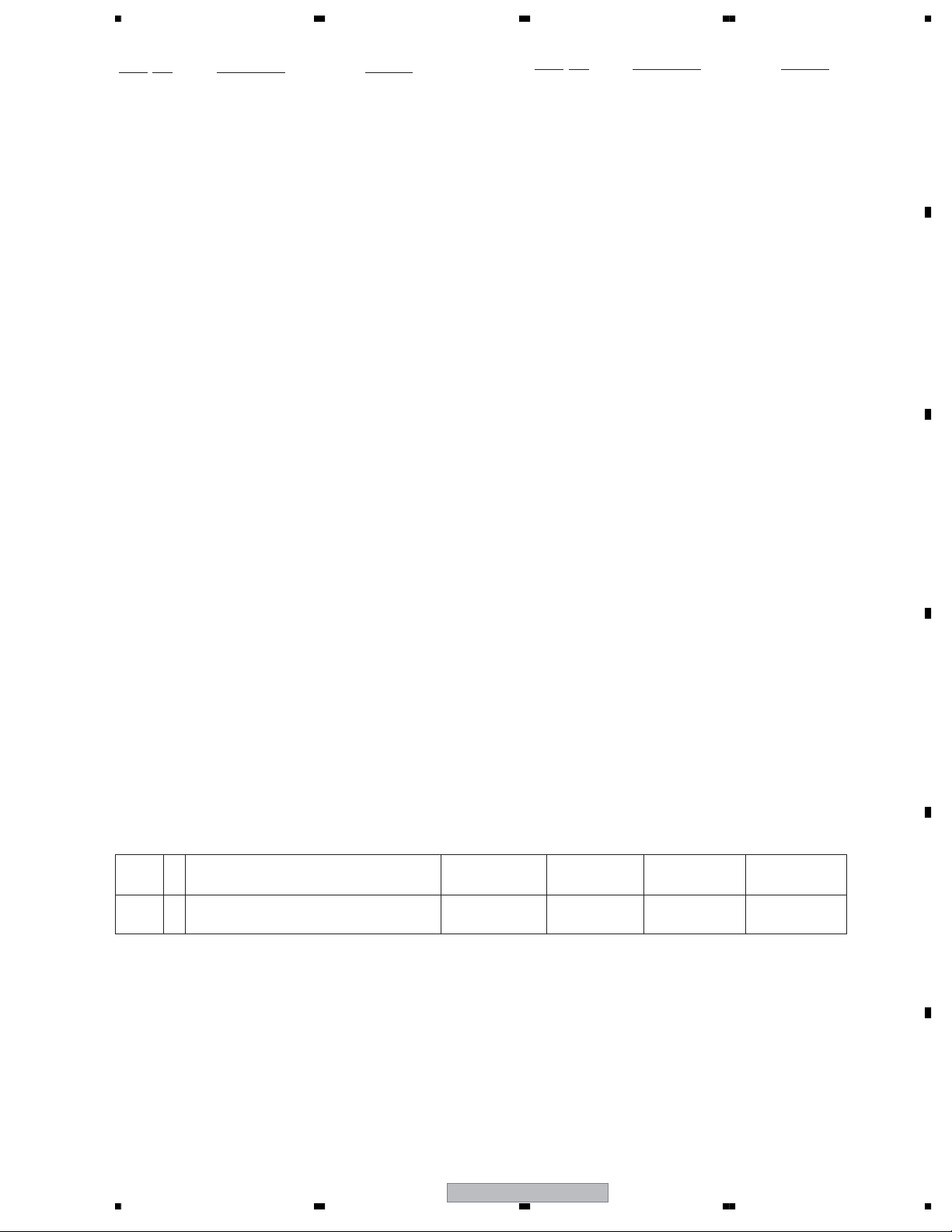

Model Type Power Requirement Region No. Remarks

DVJ-1000 KUCXJ AC 120 V 1

DVJ-1000 WYXJ5 AC 220 – 240 V 2

DVJ-1000 TLXJ/RD AC 110-120 V / 220-240 V 4

DVJ-1000 TLFXJ AC 110-120 V / 220-240 V 3

For details, refer to "Important symbols for good services" on the next page.

T-ZZR OCT. 2006 printed in Japan

-

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

causecancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement

parts must be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que

les pièces de remplacement doivent avoir la même désignation.

Health & Safety Code Section 25249.6 – Proposition 65

C

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and

service technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (waterpipe

, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

D

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

Leakage

Device

under

E

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

current

tester

not be above

0.5mA

Earth

ground

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a on the schematics and on the parts list

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge

from PIONEER.

AC Leakage Test

F

2

1234

DVJ-1000

5678

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 780 – 785 nm

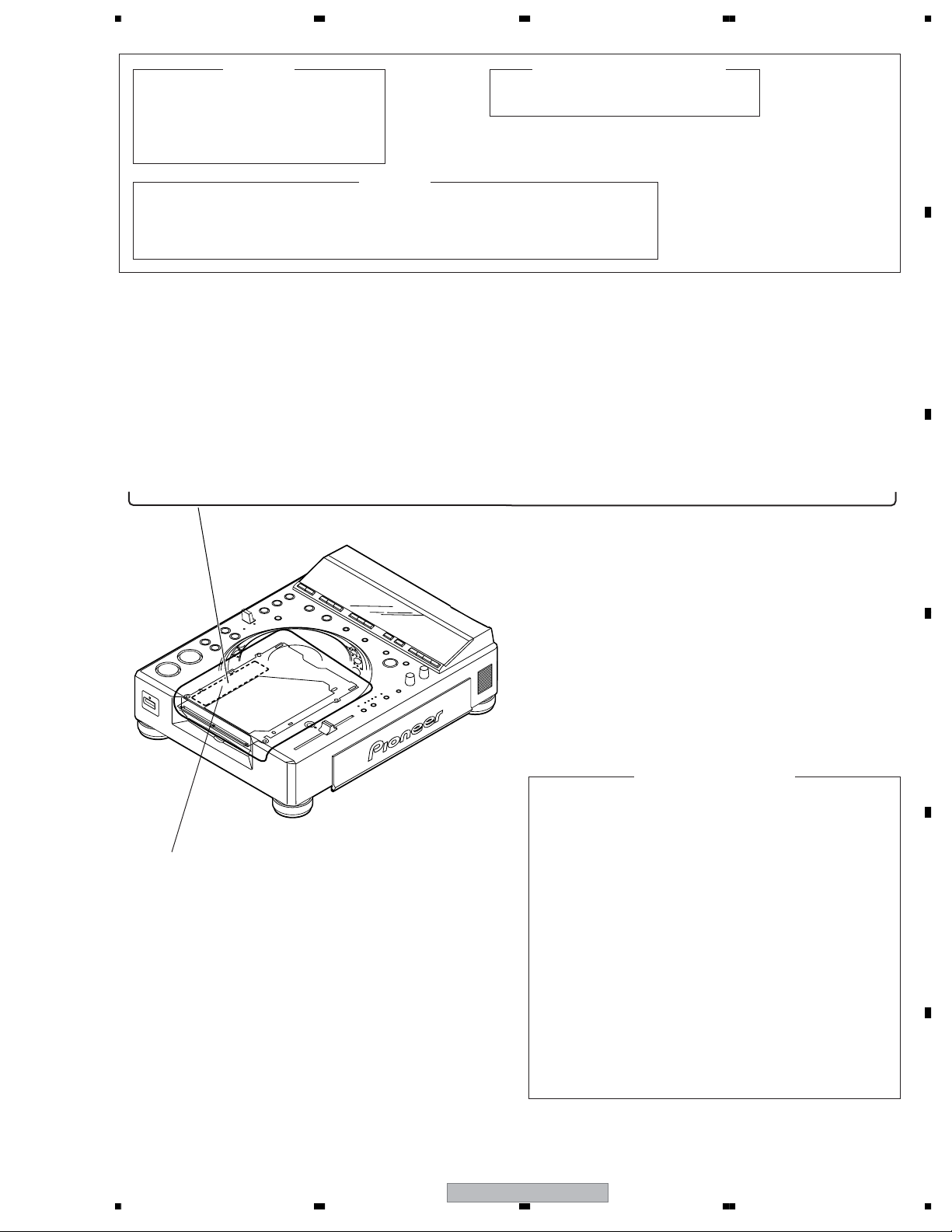

LABEL CHECK (for WYXJ5, KUCXJ and TLXJ/RD types)

for WYXJ5, KUCXJ and TLXJ/RD types

A

B

(DRW2317)

C

for TLFXJ type

(VRW2159)

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S2401) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not

in LPS1 terminal side (when the mechanism is not clamped

and LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side. ( if LPS1 signal is low

level ).

In the test mode∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 5 of AN22022A

(IC7000) on the DVPL Assy is connected to GND, or else the

terminals of Q7001(Q7002) are shorted to each other (fault

condition).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

D

E

F

56

DVJ-1000

3

7

8

1234

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

A

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

B

C

D

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

0 Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

E

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

F

4

1234

DVJ-1000

5678

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS.............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST .............................................................................................................8

2.1 PACKING ....................................................................................................................................................8

2.2 EXTERIOR SECTION ..............................................................................................................................10

2.3 CONTROL PANEL SECTION...................................................................................................................12

2.4 JOG SECTION .........................................................................................................................................14

2.5 SLOT-IN MECHANISM SECTION ............................................................................................................16

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................20

3.1 BLOCK DIAGRAM (1/2) ...........................................................................................................................20

3.2 BLOCK DIAGRAM (2/2) ...........................................................................................................................22

3.3 OVERALL WIRING DIAGRAM .................................................................................................................24

3.4 MAIN ASSY (1/8)......................................................................................................................................26

3.5 MAIN ASSY(2/8).......................................................................................................................................30

3.6 MAIN ASSY(3/8).......................................................................................................................................32

3.7 MAIN ASSY(4/8).......................................................................................................................................34

3.8 MAIN ASSY(5/8).......................................................................................................................................36

3.9 MAIN ASSY(6/8).......................................................................................................................................38

3.10 MAIN ASSY(7/8).....................................................................................................................................40

3.11 MAIN ASSY(8/8).....................................................................................................................................42

3.12 DVPL ASSY............................................................................................................................................46

3.13 STCN, SPCN, INSW and SDCB ASSYS................................................................................................48

3.14 MJCB ASSY ...........................................................................................................................................50

3.15 AUDB and AJCB ASSYS........................................................................................................................52

3.16 JFLB and JOGB ASSYS.........................................................................................................................54

3.17 DIPB and PSWB ASSYS........................................................................................................................56

3.18 DFLB ASSY............................................................................................................................................58

3.19 KSWB and SLMB ASSYS ......................................................................................................................60

3.20 SLDB, LED1, LED2 and PSWB ASSYS.................................................................................................62

3.21 POWER SUPPLY ASSY.........................................................................................................................63

3.22 WAVEFORMS.........................................................................................................................................64

3.23 VOLTAGES..............................................................................................................................................73

4. PCB CONNECTION DIAGRAM ......................................................................................................................77

4.1 MAIN ASSY ..............................................................................................................................................78

4.2 DVPL ASSY..............................................................................................................................................82

4.3 SPCN, STCN, INSW and SDCB ASSYS..................................................................................................84

4.4 MJCB ASSY .............................................................................................................................................86

4.5 JFLB ASSY...............................................................................................................................................88

4.6 DIPB and RSWB ASSYS..........................................................................................................................90

4.7 SLDB, LED1 and LED2 ASSYS ...............................................................................................................94

4.8 KSWB ASSY.............................................................................................................................................96

4.9 AJCB, SLMB, JOGB and PSWB ASSYS .................................................................................................98

4.10 POWER SUPPLY ASSY.......................................................................................................................100

4.11 AUDB ASSY .........................................................................................................................................102

5. PCB PARTS LIST..........................................................................................................................................103

6. ADJUSTMENT ..............................................................................................................................................110

7. GENERAL INFORMATION ...........................................................................................................................113

7.1 DIAGNOSIS............................................................................................................................................113

7.1.1 SERVICE MODE..............................................................................................................................113

7.1.2 HOW TO UPGRADE THE SOFTWARE OF THE MICROCOMPUTER ...........................................119

7.1.3 HOW TO INPUT THE ID NUMBER ..................................................................................................120

7.1.4 SEQUENCE .....................................................................................................................................122

7.1.5 DVJ-1000 BLOCK CHART (DJ MODE)............................................................................................124

7.1.6 DVJ-1000 BLOCK CHART (NORMAL MODE).................................................................................126

7.1.7 DISASSEMBLY ................................................................................................................................128

7.3 PARTS ....................................................................................................................................................140

7.3.1 IC......................................................................................................................................................140

8. PANEL FACILITIES .......................................................................................................................................156

A

B

C

D

E

56

DVJ-1000

F

5

7

8

1234

1. SPECIFICATIONS

A

Specifications

1. General

System ...............................................................DVD-Video, CD

Power requirements ................ AC 220 V to 240 V, 50 Hz/60 Hz

Power consumption .......................................................... 40 W

Operating temperature...................................... +5 ˚C to +35 ˚C

Operating humidity................................................. 5 % to 85 %

(There should be no condensation of moisture.)

Weight .............................................................................. 5.4 kg

Dimensions .............. 320 mm (W) 408 mm (D) 109 mm (H)

B

2. Video Output

Composite output (2)

Output level ..................................................... 1 V p-p (75 Ω)

Jack ................................................ RCA jack(1), BNC jack(1)

S-Video output

Y (luminance) ................................................... 1 V p-p (75 Ω)

C (color) ........................................ 286 mV p-p (75 Ω) (NTSC)

300 mV p-p (75 Ω) (PAL)

Jack ................................................................ 4-pin mini DIN

3. Preview Video Output

C

Composite output

Output level ..................................................... 1 V p-p (75 Ω)

Jack ......................................................................... RCA jack

S-Video output

Y (luminance) ................................................... 1 V p-p (75 Ω)

C (color) ........................................ 286 mV p-p (75 Ω) (NTSC)

300 mV p-p (75 Ω) (PAL)

Jack ................................................................ 4-pin mini DIN

4. Audio Output

Audio output (2 channels)

Output level ......................................... 2 V rms (1 kHz, 0 dB)

Channels .............................................................................. 2

Jack ......................................................................... RCA jack

Digital audio output

Frequency response (CD) ..............................4 Hz to 20 kHz

Frequency response (DVD, 96 kHz) ............... 4 Hz to 44 kHz

Signal-to-noise ratio .......................... 115 dB or more (JEITA)

Distortion ..................................................... 0.004 % (JEITA)

Digital output

Jack ......................................................................... RCA jack

5. Other jacks

CONTROL jack ................................ Mini phone jack (ø3.5 mm)

SYNC IN jack ............................................................... BNC jack

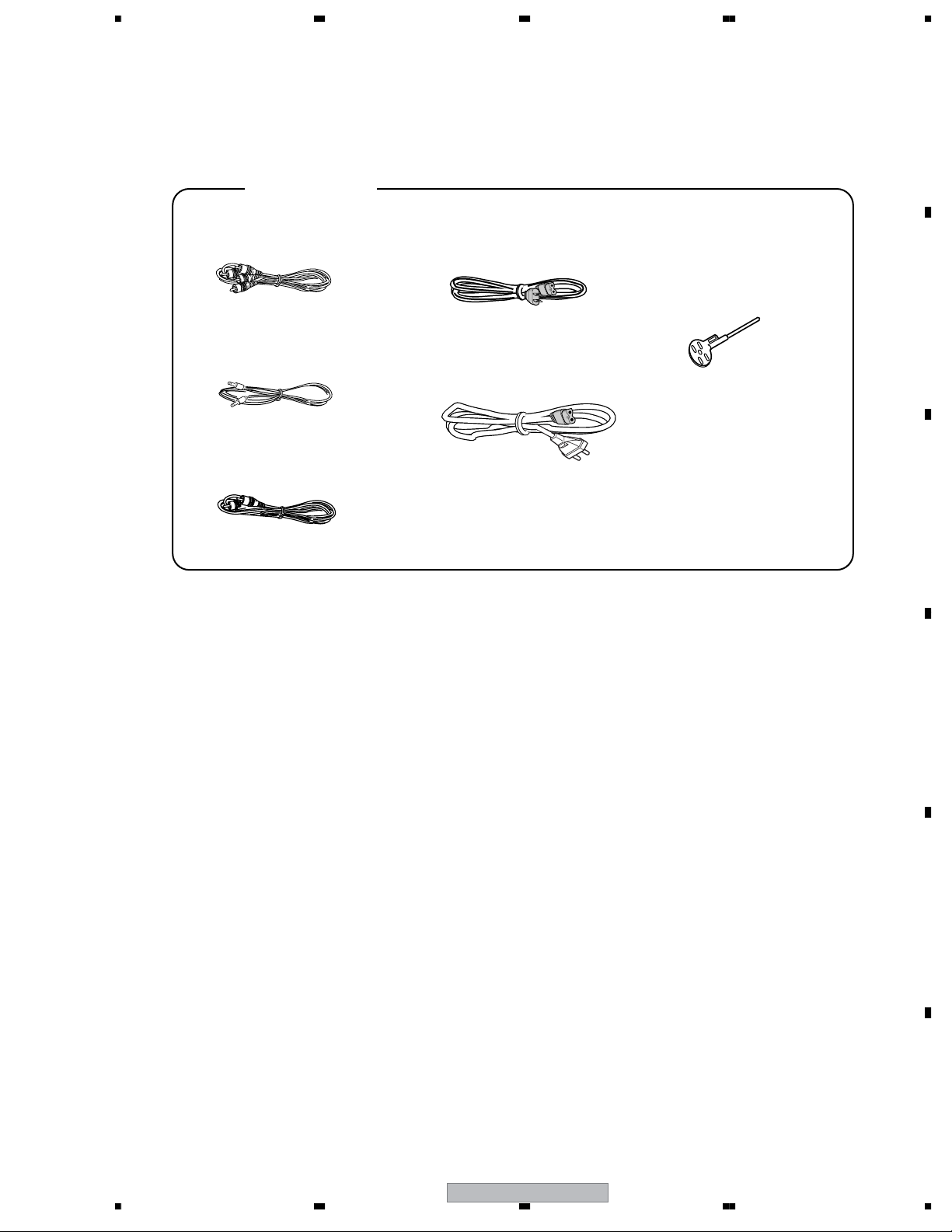

6. Accessories

Audio cable .......................................................................... 1

Video cable .......................................................................... 1

Control cord ......................................................................... 1

Power cord .......................................................................... 1

Forced eject pin ................................................................... 1

(housed in a groove in the bottom panel)

Operating instructions ......................................................... 1

Note:

Specifications and design are subject to possible modification

without notice.

D

E

F

6

1234

DVJ-1000

5678

A

Accessories

Audio Cable

(VDE1064) L=1.5m

Control Cord

(XDE3063) L=1 m

Video Cable

(VDE1065) L=1.5m

Power Cord

(ADG7021 : KUCXJ)

(ADG7097 : TLFXJ)

(ADG1154 : WYXJ5,TLFXJ

TLXJ/RD)

Forced Eject Pin

(housed in a groove in

the bottom panel)

(DEX1021)

B

C

D

E

F

56

DVJ-1000

7

7

8

1234

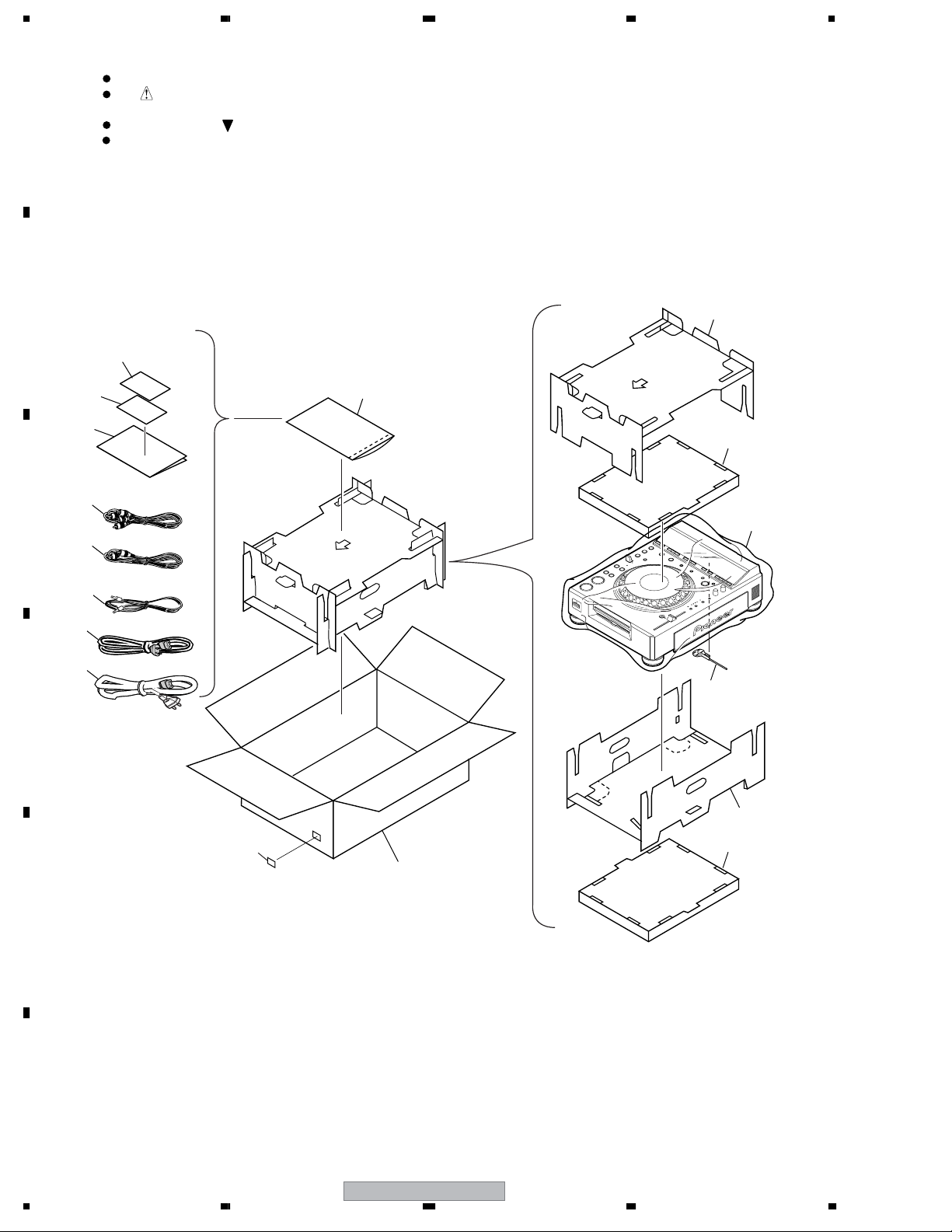

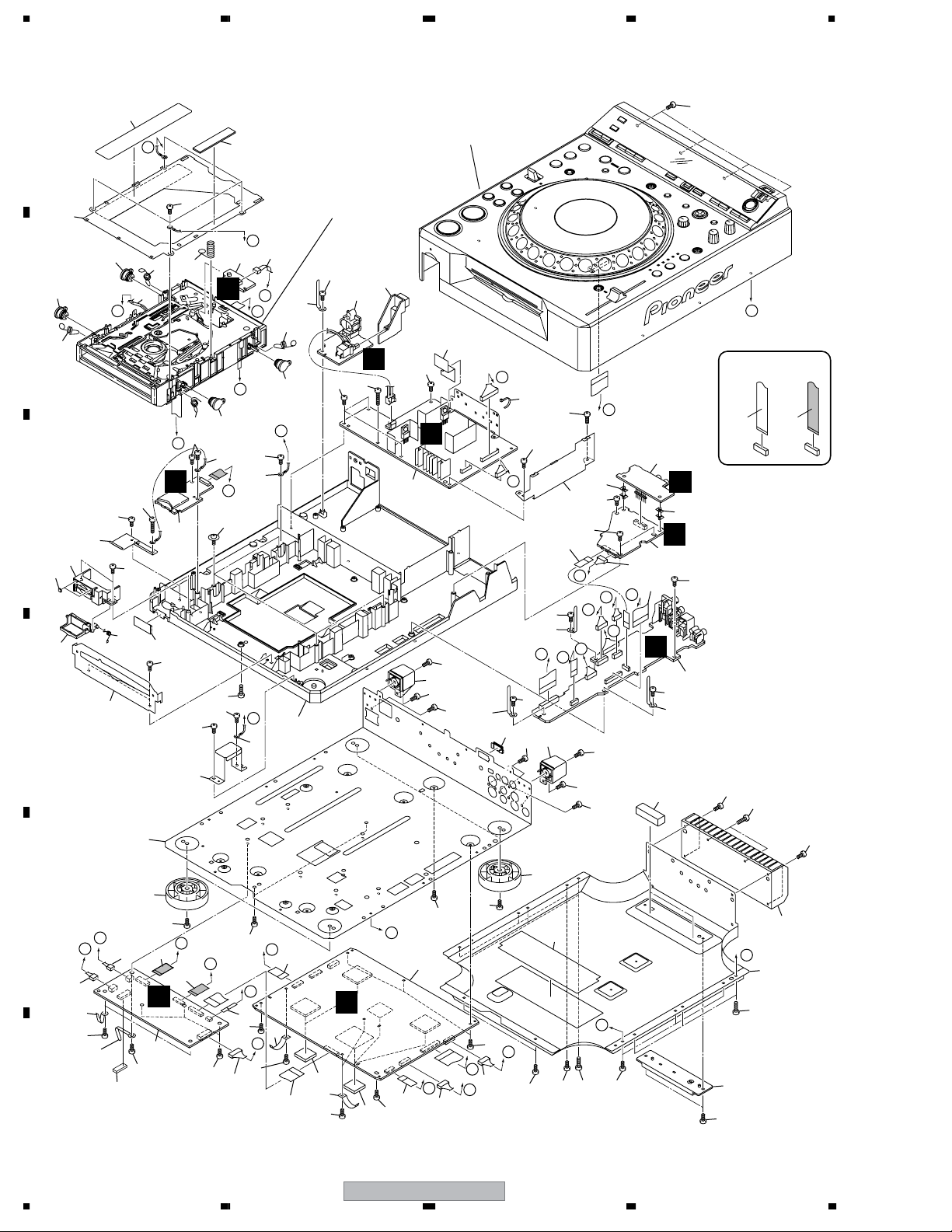

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

2.1 PACKING

B

18

6

9

C

3

4

12

11

14

16

2

1

1

8

D

13

17

15

E

14

F

8

1234

DVJ-1000

>

>

>

5678

PACKING parts List

No. Description Part No.

No. Description Part No.

Mark

1AC Power Cord See Contrast table(2)

2 Control Cord (L= 1m) XDE3063

3Audio Cable (L= 1.5m) VDE1064

4 Video Cable (L=1.5m) VDE1065

5• • • • •

NSP 6 Warranty Card See Contrast table(2)

7• • • • •

8Forced Eject Pin DEX1021

9 Operating Instructions(English) See Contrast table(2)

10 • • • • •

Mark

NSP 11 Polyethylene Bag AHG7117

(230 x 340 x 0.06)

12 Pad (A) DHA1716

13 Pad (B) DHA1717

14 Pad (C) DHA1718

15 Packing Case See Contrast table(2)

16 Mirror mat Sheet AHG7010

17 Label See Contrast table(2)

NSP 18 User Card DRM1262

(2) CONTRAST TABLE

DVJ-1000/KUCXJ, /WYXJ5, /TLXJ/RD and TLFXJ types are constructed the same except for the following:

A

B

Mark No. Symbol and Description

1AC Power Cord ADG7021 ADG1154 ADG1154

1AC Power Cord Not used Not used Not used

NSP 6 Warranty Card ARY7043 Not used Not used Not used

9 Operating Instructions (English)(KUCXJ) DRB1413 Not used Not used

9 Operating Instructions (WYXJ5)(English, Not used DRB1414 Not used

French, German, Italian, Dutch, Spanish)

9 Operating Instructions (TLFXJ) Not used Not used Not used DRB1415

(English, Chinese)

9 Operating Instructions (TLXJ/RD) Not used Not used DRB1416 Not used

(English, Spanish)

15 Packing Case DHG2636 DHG2637 DHG2639

NSP 17 Label DRW2311 VRW1629 VRW1629

DVJ-1000

/KUCXJ

DVJ-1000

/WYXJ5

DVJ-1000

/TLXJ/RD

DVJ-1000

/TLFXJ

ADG1154

ADG7097

Not used

Not used

DHG2638

VRW1629

C

D

56

DVJ-1000

E

F

9

7

8

1234

2.2 EXTERIOR SECTION

G

34

58

A

9

NON-CONTACT

SIDE

CONTACT SIDE

R

32

Q

8

57

4

57

53

58

60

A

52

49

B

51

C

45

30

26

D

44

57

37

49

62

56

58

49

19

E

55

63

Refer to "2.5 SLOT-IN

MECHANISM SECTION".

D

20

3

E

53

H

51

49

I

C

58

18

J

D

41

18

C

57

51

50

61

F

51

57

G

F

60

5

57

25

64

58

57

38

Refer to

"2.3 CONTROL PANEL SECTION".

58

57

60

24

7

65

S

57

T

6

58

42

58

57

53

Q

40

54

60

57

P

17

57

53

R

57

43

57

R

32

36

57

57

57

58

21

15

O

M

Q

N

K

P

L

58

48

47

47

E

F

E

20

28

58

53

F

10

29

61

58

12

B

2

57

H

10

G

58

23

58

13

57

58

J

14

I

A

27

K

31

27

11

58

31

58

B

1

L

16

DVJ-1000

1234

57

22

57

33

A

B

58

N

O

21

M

58

58

56

58

56

46

58

58

35

39

>

>

>

5678

EXTERIOR SECTION parts List

No. Description Part No.

Mark

1 MAIN Assy DWG1630

2DVPL Assy DWX2627

3 SLMB Assy DWS1395

4 MJCB Assy DWG1633

5 SDCB Assy DWX2630

6POWER SUPPLY Assy DWR1436

7 PSWB Assy See Contrast table(2)

8AUDB Assy DWG1638

9 AJCB Assy DWG1639

10 26P FFC/30V DDD1337

11 FFC/30V (40p) DDD1338

12 FFC/60V (13p) DDD1339

13 FFC/60V (4p) DDD1340

14 FFC/60V (13p) DDD1341

15 FFC/60V (27p) DDD1342

16 FFC/60V (10p) DDD1343

17 FFC/60V (9p) DDD1344

18 Earth Lead Unit DDF1032

19 Earth Lead Unit DDF1033

20 Connector Assy PF03PP-B35

21 Connector Assy DKP3778

22 6P Connector Assy PF06PP6D15

23 8P Connector Assy PF08PP-D25

24 Power Knob DNK4635

25 Door Spring DBH1565

26 Card Door DNK4651

27 Earth Plate 1(CU) DBK1300

28 Earth Plate 2(CU) DBK1301

NSP 29 Silicon Rubber D5 L DEB1456

30 Door Cushion DEB1780

31 Insulation Sheet DEC2694

32 PC Support DEC2736

33 Shield

34 Gasket L40 DEC2979

Cushion DEC2905

No. Description Part No.

Mark

35

NSP 36 Shield Plate 2 DNH2723

NSP 37 Front Plate DNH2724

NSP 38

39

40 Blind Cap DNK4218

NSP 41 Chassis DNK4591

42 Rear Protector (R) DNK4636

43 Rear Protector (L) DNK4637

44 Card Plate DBK1296

45 Door Holder DNK4652

46 Push Rod Holder DNK4671

47 Insulator Assembly DXA1904

48 Shield Plate 1 Assy See Contrast table(2)

49 Damper CNV6011

50 Earth Spring DBH1398

51 Float Spring G11 DBH1526

52 Mecha Plate DNH2339

53 Cord Clamper (STEEL) RNH-184

54 Binder ZCA-SKB90BK

55 DM Screw (FTC) DBA1260

56 Screw BPZ30P120FTB

57 Screw BPZ30P080FTB

58 Screw BBZ30P080FTC

59 Screw BPZ30P080FZK

60 Screw BBZ30P140FTC

61 2P Connector PF02PY-B37

62 Laser Caution (7L) See Contrast table(2)

63 Guard Cushion DEC2984

64 Door Plate DNK4650

65 Shield Sheet Assy DXB1941

Heat Sink DNG1098

Earth Plate DNH2726

Heat Plate See Contrast table(2)

A

B

C

D

(2) CONTRAST TABLE

DVJ-1000/KUCXJ, /WYXJ5, /TLXJ/RD and TLFXJ types are constructed the same except for the following:

Mark No. Symbol and Description

7 PSWB ASSY DWS1392 DWS1396 DWS1396 DWS1396

39 Heat

48 Shield Plate 1 Assy DXB1883 DXB1892 DXB1894 DXB1893

62 Laser Caution DRW2317 DRW2317 DRW2317 VRW2159

Plate DNH2744 DNH2749 DNH2750 DNH2750

DVJ-1000

/KUCXJ

DVJ-1000

56

DVJ-1000

/WYXJ5

DVJ-1000

/TLXJ/RD

7

DVJ-1000

/TLFXJ

8

E

F

11

1234

2.3 CONTROL PANEL SECTION

A

19

13

14

B

26

56

56

59

60

61

15

N

44

56

56

56

56

16

A

6

56

27

8

R

58

28

J

Refer to

"2.4 JOG SECTION".

I

NON-CONTACT

SIDE

CONTACT SIDE

56

12

17

52

38

56

25

56

E

34

56

54

53

B

56

49

29

37

34

35

A

I

B

20

18

29

C

D

E

F

K

5

42

45

47

F

7

56

P

F

24

56

62

L

E

4

47

47

11

H

C

56

56

2

C

D

O

56

30

34

32

31

50

1

D

51

32

63

33

39

M

56

10

I

56

H

9

56

J

55

58

56

36

G

41

56

45

56

G

3

49

12

DVJ-1000

1234

5678

CONTROL PANEL SECTION parts List

No. Description Part No.

Mark

1 DIPB Assy See Contrast table(2)

2 RSWB Assy DWS1391

3 SLDB Assy DWS1393

4 LED 1 Assy DWG1634

5 LED 2 Assy DWG1635

6 DFLB Assy DWG1632

7 KSWB Assy DWS1394

8 22P FFC/60V DDD1345

9 25P FFC/60V DDD1346

10 10P FFC/60V DDD1347

11 9P FFC/60V DDD1348

12 Adjust Knob DAC2350

13 Display Panel(PMMA) DNK4601

14 Top Panel DNK4599

15 Slide SW Knob DNK4592

16 Eject Knob DAC2335

17 Rotary Knob DAA1182

18 Slide Knob DAC2376

19 Jog Ring DNK4600

20 Control Panel DNK4598

21 • • • •

22 • • • •

23 • • • •

24 Card Lens DNK4596

25 SETKnob 1 DAC2331

26 SETKnob 2 DAC2332

27 SETKnob 3 DAC2333

28 SETKnob 4 DAC2334

29 TEMPO Lens DNK4593

30 SET Knob (H. C.) DAC2321

31 REC Knob DAC2322

32 SET Knob (LOOP) DAC2324

No. Description Part No.

Mark

33 RELOOP Knob DAC2325

34 ENTER Knob DAC2326

35 CALL Knob DAC2323

36 Shield Sheet 1 DEC2899

37 Cross Key DAC2327

38 Change Knob DAC2328

39 SET Knob (TEMPO) DAC2329

40 • • • •

41 Reflector DNK4597

42 Front Lens DNK4595

43 • • • •

44 Shield Sheet 2 DEC2909

45 Ring Lens DNK3880

46 • • • •

47 SET Knob (PLAY) Assy DXB1912

48 • • •

49 Earth Plate (CU) DBK1224

50 RESET Knob DAC2330

51 TEMPO RESET Lens DNK4708

52 Cross Key Holder DNK4798

53 VR Stay DNF1663

54 Flange Nut M9 DBN1008

55 Cord Clamper (steel) RNH-184

56 Screw BPZ30P080FTB

57 • • • •

58 Rivet (PLASTIC) RBM-003

59 TIMX Knob DAC2336

60 TEXT Knob DAC2338

61 STOP Knob DAC2354

62 Screw OBA8038

63 LOOP MODE Lens DNK4594

A

B

C

D

(2) CONTRAST TABLE

DVJ-1000/KUCXJ, /WYXJ5, /TLXJ/RD and TLFXJ types are constructed the same except for the following:

Mark No. Symbol and Description

1 DIPB ASSY DWG1631 DWG1640 DWG1642 DWG1641

DVJ-1000

/KUCXJ

DVJ-1000

56

DVJ-1000

/WYXJ5

DVJ-1000

/TLXJ/RD

7

DVJ-1000

/TLFXJ

8

E

F

13

1234

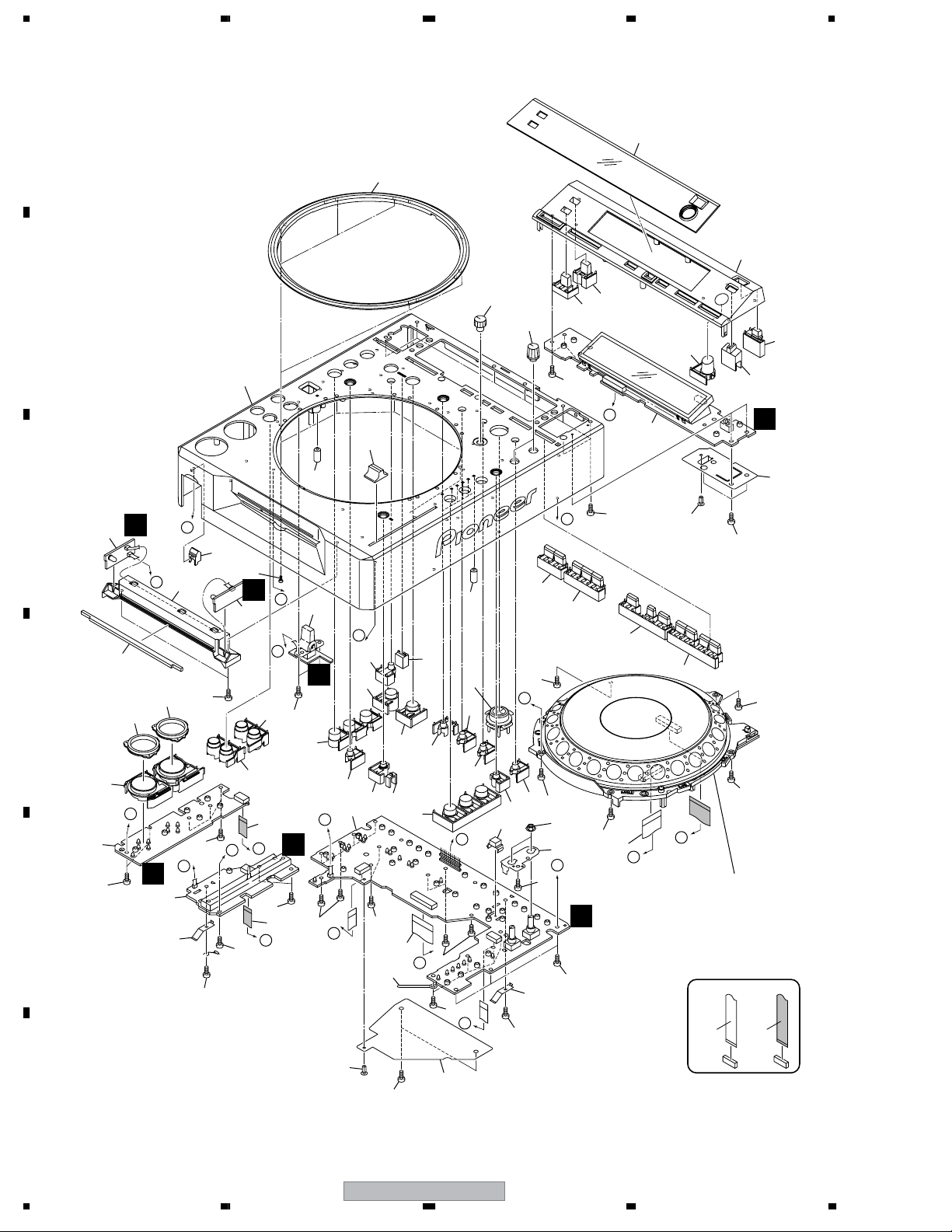

2.4 JOG SECTION

A

9

5

7

B

C

D

27

11

2

*

28

14

14

3

17

A

17

13

28

28

17

17

12

17

13

*

*

17

40x8

2

8

2

14

15

1

*

31

NON-CONTACT

SIDE

CONTACT SIDE

39

16

31

32

37

24

38

22

26

23

34

35

25

29

28

36

I

CN3002

DIPB to

18

27

30

1

G

19

20

A

MJCB to

CN4508

4

J

H

31

10

2

1

31

DVJ-1000

33

1.

Lubricating oil

*

E

GYA1001 (ZLB-PN397B)

2.

Lubricants : (ZLB-HPD1600)

*

21

27

*

F

14

1234

5678

JOG SECTION parts List

No. Description Part No.

Mark

1 JFLB Assy DWG1636

2 JOGB Assy DWG1637

3 Sheet SW DSX1065

4 Connector Assy PF04PP-B07

5 Jog Panel (PMMA) DAH2182

6• • • •

7 JOG Plate DAH2438

8 JOG A DNK4586

9 JOG B DNK4557

10 Protector Sheet DEC2945

A

11 SW Ring DNK4070

12 Roller A Assy DXB1825

13 SW Spring 25 DBH1514

14 Ring Cushion L24/2.0 DEC2958

15 JOG Stay Assy DXB1876

16 JOG Holder 1000 DNK4558

17 SW Cushion HH48/2 DEC2538

18 Arm Spring DBH1566

19 Gear DNK4560

20 ENCORDER Plate DEC2889

21 Gear Arm DNK4559

22 Load Gear A DNK4562

23 Smoother DNK4561

24 Adjust Plate DNK4178

25 Gear Spring 200 DBH1525

26 Washer WA52D120D025

27 Screw IPZ30P100FTC

28 Screw (FE) DBA1265

29 Screw BPZ20P100FTC

30 Screw BPZ20P060FTC

31 Screw BPZ30P080FTB

32 25P FFC / 60V DDD1346

33 FL Sheet DEC2946

34 CAM Plate DNK4567

35 PRESS Plate DNK4566

B

C

D

36 GEAR Plate DNH2713

37 Link Gear 3 DNK4565

38 Link Gear 2 DNK4564

39 Link Gear 1 DNK4563

40 Roller B Assy DXB1877

56

DVJ-1000

E

F

15

7

8

1234

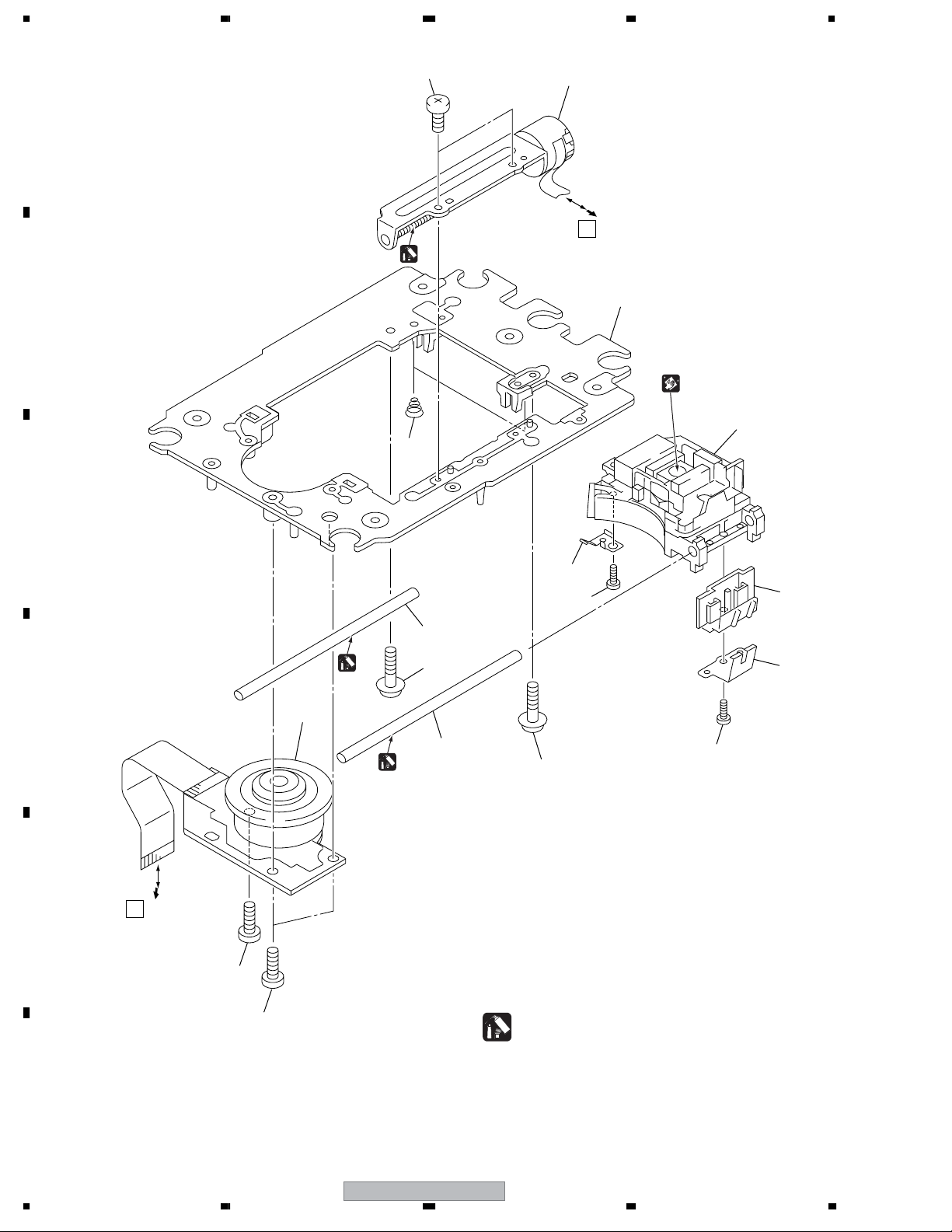

2.5 SLOT-IN MECHANISM SECTION

∗1 :

A

∗2 :

B

C

Lubricating oil

GYA1001

Daifree

GEM1036

37

38

25

42

31

NON-CONTACT

26

28

33

1

*

34

30

DVPL to

B

CN7005

29

32

36

35

∗1

∗1

∗2

∗2

2

*

41

40

∗2

43

27

∗1

SIDE

39

CONTACT SIDE

20

19

Refer to

"2.6 TRAVERSE MECHA.

ASSY-S".

D

DVPL to

B

CN7002

23

C

E

15

4

21

16

2

23

7

17

U

22

9

18

20

19

21

16

3

14

5

4

6

DVPL to

B

CN7001

23

8

1

D

12

DVPL to

B

10

13

CN7003

F

16

11

12

DVJ-1000

1234

5678

SLOT-IN MECHANISM SECTION parts List

No. Description Part No.

Mark

1 STCN Assy DWX2628

2 SPCN Assy DWX2629

3 INSW Assy DWS1398

4Traverse Mechanism G11 Assy-S DXX2566

NSP 5 Pickup Assy OWY8071

6 26P Flexible Cable/30V DDD1337

7 13P Flexible Cable/60V DDD1339

8 4P Flexible Cable/60V DDD1340

9 Connector Assy DKP3769

10 Vessel Cushion A DEC2852

A

11 Vessel Cushion B DEC2853

12 Vessel Cushion C DEC2854

13 Float Base (G11) Assy DXB1793

14 Spacer POR (T3) DEB1566

15 Front Sheet DED1132

16 Float Rubber D3 DEB1404

17 Inside SW Base DNK4236

18 Weight G11 DNH2775

NSP 19 DRA Rubber G5 DEB1454

20 DRA Screw R (G7) DBA1264

21 Float Fastener DBA1286

22 Screw VBA1062

23 Screw IPZ20P060FTC

24 • • • • •

NSP 25 Slot-in Mechanism G11 assy DXA2085

26 Loading Motor Assy-S DEA1008

NSP 27 Worm Gear DNK3910

NSP 28 DC Motor DXM1229

29 Connector Assy PF02PY-B37

30 Loading Base Assy-S DEA1022

31 Main Cam DNK3407

32 Driver Gear DNK3912

33 Loading Gear DNK3911

34 SW Lever Spacer DEC2420

35 Loading Lever Assy DXB1880

B

C

D

36 Clamper D4 Assy DXA2043

37 Clamper Spring DBH1374

38 Clamper Arm DNK3576

39 Eject Lever DNK3684

40 Lever AP DNK3835

41 Lever BP DNK3836

42 Guide Spring DBH1375

43 Disc Guide DNK3478

56

DVJ-1000

E

F

17

7

8

1234

2.6 TRAVERSE MECHA ASSY-S SECTION

12

A

1

STCN to

D

CN7406

∗1

B

5

C

10

Cleaning paper

GED-008

Cleaning liquid

GEM1004

3

7

11

8

∗2

4

8

4

Grease : GYA1001 (ZLB-PN397B)

1.

*

Grease : GEM1007 (ZLB-PN948P)

2.

*

11

∗1

D

SPCN to

E

C

CN7402

13

2

13

9

6

F

18

1234

DVJ-1000

5678

TRAVERSE MECHA ASSY-S SECTION parts List

No. Description Part No.

Mark

NSP 1 Spindle Motor DXM1227

NSP 2 Stepping Motor DXM1231

NSP 3 Pickup Assy-S OXX8071

NSP 4 Skew Screw DBA1263

NSP 5 Skew Spring DBH1437

NSP 6 Joint Spring DBK1261

NSP 7 Leaf Spring G11 DBK1262

NSP 8 Guide Bar (S) DLA1918

9 Joint DNK3858

NSP 10 Mecha.Chassis G11 DNK4307

A

11 Tapping Screw 04 VBA1092

12 Screw BPZ20P080FTC

13 Screw BPZ26P080FTC

B

C

D

56

DVJ-1000

E

F

19

7

8

O

O

D

N

B

A

N

B

1234

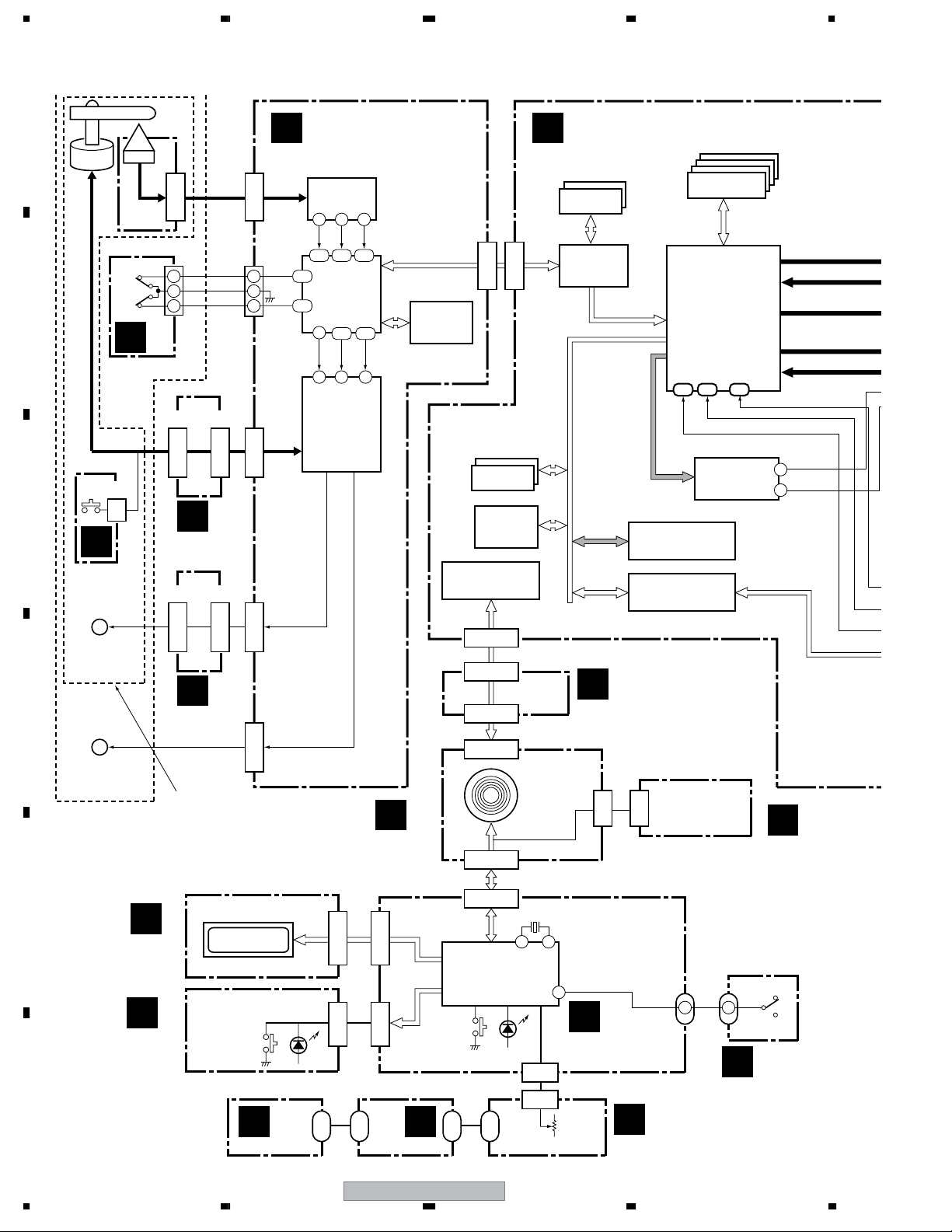

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

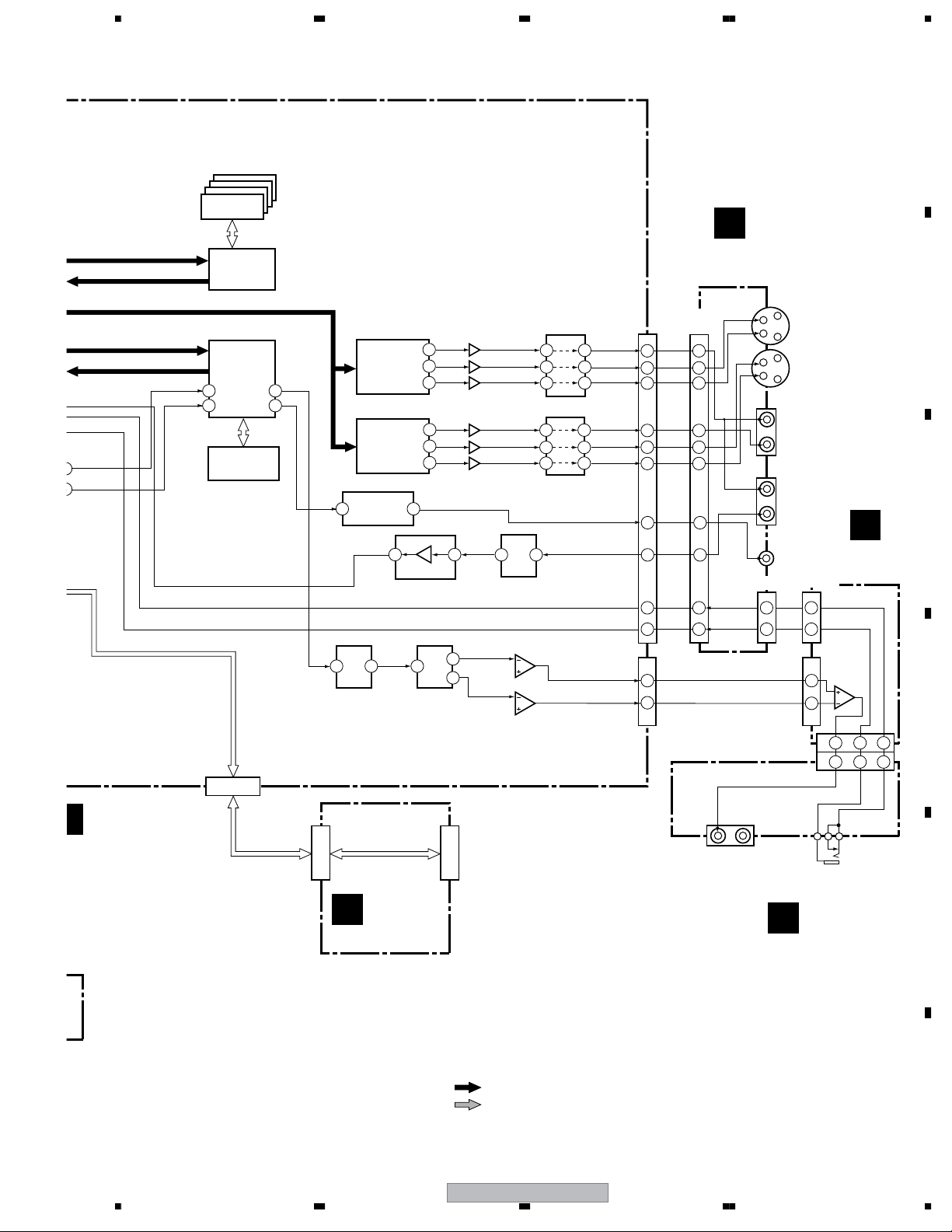

3.1 BLOCK DIAGRAM (1/2)

A

DVPL ASSY

B

SPINDLE

MOTOR

B

C

INSW

ASSY

OEIC

PICKUP

ASSY

S4402

S4401

E

SLMB ASSY

CN7404

U

1

2

3 3

LPS1 LPS1

GNDD

LPS2

CN7401CN7402

C

SPCN

ASSY

CN7405CN7406

CN7001

CN7004

1

2

LPS2

CN7002

CN7003

AN22022A

14

E

T

111

175

MN103S71F

176

67

DOL

A

26 53 52

BD7905BFS

6ch DRIVER

IC7000

FEP

18

E

F

109 112

IC7100

SODC

119 120

VREF

D

IC7200

29

VNER

F

VRRT

D

CN7007 CN701

ATAPI

IC7101

PEA006C8

FLASH ROM

(1M)

IC103, IC109

K4S561632H-UC75

SDRAM ×2

DYW1756

32M FLASH

IC111

HD6417709SHF200B

CPU

256M

IC113

ROM

CN1702

M

STEPPING

MOTOR

MAIN ASSY

A

IC702, IC703

K4S561632H-UC75

256M

SDRAM ×2

IC701

PE5337B

Giant Slalom

(GSL)

GSL

CONTROL

BUS

TMS320DA150PGE16D

CARD CONTROLLER

IC2001-IC2004

EDD5108AFTA-6B-E

DDR-SDRAM

IC2000

EP2C20F484C8

DMA/VMC/CAPT/FPGA

A17 A18B17

CONT1

CONT2

MOTOROLA

CONTROL

AUDIO DECODER

IC503 TE4300PF

SD/MMC MEMORY

DSPD56367PV150

BUS

IC505

512M

IC506

DSP

×4

C SYNC

4

27

MO DATA

MO DOUT

VDEC DATA BUS

VDEC DATA BUS

V

CO

CO

M

M

D

SLOT-IN

MECHANISM

G5 ASSY

E

F

M

LOADING

MOTOR

ASSY-S

TRAVERSE

MECHANISM

G11 ASSY-S

N

DFLB

ASSY

P

KSWB

ASSY

D

STCN

ASSY

V3200

DATA FL

CN7005

CN4201

JFLB

ASSY

LED1 ASSYLED2 ASSY

J3350J3350

H

CN3001CN3201

CN3005

LK

CN4502

CN4508

CN4000

V4000

JOG FL

CN4001

CN3002

15 13

IC3004

PEG237B

CONTROL CPU with

FL CONTROLLER

J3300J3300

G

MJCB ASSY

CN4003

X3001

16MHz

75

I

DIPB ASSY

CN3004

CN3300

M

SLDB ASSY

CN4100

J3006

J3006

SW0

2 2

O

RSWB ASSY

P

JOGB

ASSY

20

DVJ-1000

1234

VDEC DATA BUS

VDEC DATA BUS

MO DATA

MO DOUT

GB

SY

VDEC

CONTROL

BUS

AV

CONTROL

BUS

MO DATA

MO DOUT

5678

A

IC1904-IC1907

K4S641632K-UC75

64M SDRAM

×4

G

10

14

22

12

16

18

27

8

4

2

MJCB

ASSY

Y

C

Y

C

CN4506 CN4301

L+OUT

L-OUT

CN4300

LO

LR

AUDIO

OUT

JA4502

VIDEO

OUT S1/S2

PREVIEW

OUT S1/S2

JA4500

VIDEO OUT

COMPOSITE

PREVIEW OUT

COMPOSITE

JA4504

COMPOSITE

SYNC

IN

JA4503

DOUT

AUDB

ASSY

1

3

CN4302

CN4303

CONT1

9

CONT2

7

55

5

6

6

4 7 8

4 7 8

CONT2

CONTROL

CONT1

JA4301JA4300

R

AJCB ASSY

B

C

Q

7

D

E

IC903

PD6449A

MPEG VIDEO

DECODER

IC305

M65774BFPA

AV-1

46

48

IC303

K4S641632K-UC75

64M SDRAM

CN501

71

74

DOUT

AV

VIDEO

DATA

BUS

AV

DATA

8 4

AV

DOUT

1 24

AV DATA

IC1513

PQ0274A

CN7502

F

SDCB ASSY

ADV7172KST

ENCODER

ADV7172KST

ENCODER

IC1514

TC7SH08FU

C SYNC

AQE

IC1502

VIDEO

IC1506

VIDEO

2

TC7WH34FU

DATA

V

35

Y

33

C

29

V

35

Y

33

C

29

DOUT

6

IC1102

25

5

26

IC1510

PCM1738EG-3

AUDIO DAC

CN7501

1 2

LM1881M

IC1512 (1/2)

NJM5532MD

AUDIO IV CONV

SD/MMC

CARD

MONITOR

V

Y

C

IC1104

6

5

2

3

IC1501

LA73054

2

8

6

2 33

8 28

6 31

IC1505

LA73054

7

(2/2)

1

CN703 CN4505

MAIN VOUT

33

MAIN YOUT

28

MAIN COUT

31

SUB VOUT

SUB YOUT

SUB COUT

LCH OUT_P

LCH OUT_N

18

14

6

16

12

10

1

20

24

26

6

CN1704

MAIN V

MAIN Y

MAIN C

PRE V

PRE Y

PRE C

DOUT

SYNC IN

CONT1

CONT2

SY

: VIDEO DATA BUS

: AUDIO DATA BUS

DVJ-1000

56

F

21

7

8

1234

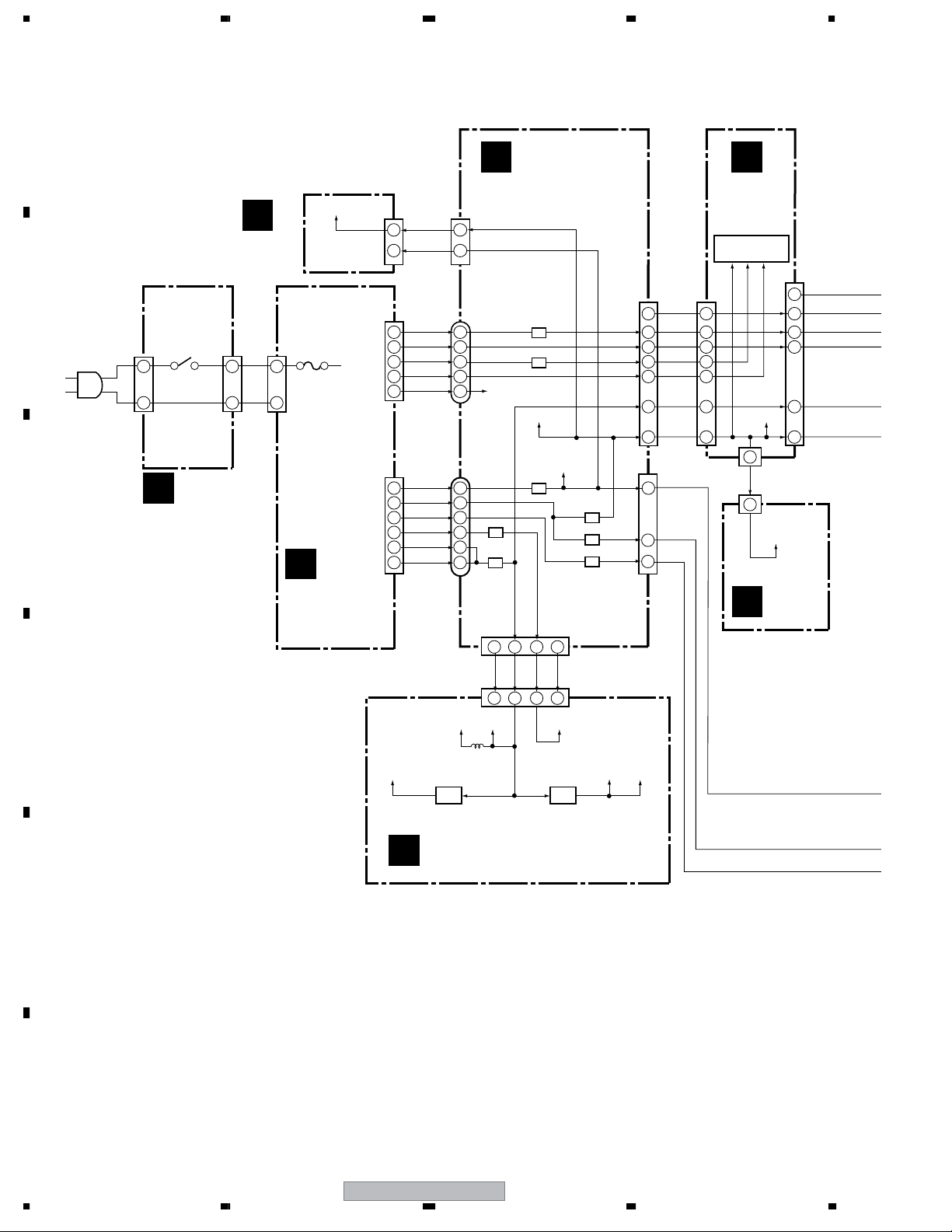

3.2 BLOCK DIAGRAM (2/2)

• POWER

A

2

10

8

6

4

14

18

H

JFLB

ASSY

V4000

JOG FL

V+5D

3

V+5D

3

V+5D

J

CN4001

5

3

2

4

8

25

CN4103

CN4100

JOGB

ASSY

VLDMFL

VLDMFL

FLAC1

FLAC2

VLED

V+5D

G

MJCB ASSY

CN1

T

V+5D

CN4301

CN101

CN102

V+5D

V+12S

1

FLAC1

1

FLAC2

2

FLAC3

3

FLAC4

4

VLOAD

6

V+12A

1

V+5D

3

V+5D

4

V+5S

7

V+12S

10

V+12S

11

Q

AUDB

ASSY

B

AC IN

LIVE

NEUTRAL

AN3400 J3400

1

2

ORG

WHT

1

2

S

C

PSWB ASSY

POWER

SUPPLY

ASSY

28

9

1

2

3

4

6

1

3

4

7

10

11

CN4506

J4501

VLOAD

J4507

IC4504

IC4507

IC4501

IC4502

IC4503

2 7

V+5D

V+12A

IC4510

IC4505

IC4506

CN4500

CN4508

CN4000

21

13

15

17

19

9

5

CN4504

5

1

2

VLDMFL

FLAC1

FLAC2

FLAC3

FLAC4

VLED

V+5D

V+12A

V+5D1

V+5D2

V+5S

V+5S

D

IC7301

BA15BC0WFP

VD1R5

+1.5V REG.

VD5V

V+12S

211 788

V12DRVA5V

MM1478DFBE

+3.3V REG.

V+12S

IC7300

RESET

CN7008

VD3V VA3V

B DVPL ASSY

E

F

22

DVJ-1000

1234

5678

A

VLDMFL

VLDMFL

FLAC1

FLAC2

VLED

V+5D

V+12A

V+5D1

V+5D2

CN3002

21

23

24

22

6

1

CN1701

5

1

2

DIPB ASSY

I

VLED

V+5D

IC2013

R1224N102H

DCDC CONV

IC2014

R1224N102H

DCDC CONV

IC912

NJM2872F33

+3.3V REG.

CN3201

15

14

13

2

CN4201

CN3300

1

10

VLED

V+5AD

V+5AD

CN3001

CN3005

CN3004

VLDMFL

2

FLAC1

3

FLAC2

4

V+5D

11

VLED

2 8

VLED

10

V+5AD

1

M

IC1507

NJM78L05UA

+5V REG.

V+3D1

V+3D2

V+3R3 V+2VDEC

V+5A

IC507

MM1661GH

+1.6V REG.

IC902

PQ070XZ02ZP

+2V REG.

V1R6TI

N

V3400

MAIN FL

KSWB

P

ASSY

VLED

SLDB ASSY

MAIN ASSY

A

IC121

PQ070XZ02ZP

+2V REG.

IC301

MM1562FF

+2V REG.

IC504

MM1561JF

+1.8V REG.

DFLB

ASSY

V+5D

J3300

V+2SH

V+2AV1

V1R8MOT

B

C

VLED

1

VLED

1

J3300

VLED

V3R3

5

9

L

1

1

K

V3R3

CN7502

LED1

ASSY

J3350

J3350

LED2

ASSY

F

D

SDCB

ASSY

E

IC2005

PQ070XZ02ZP

+2.5V REG.

IC2006

R1224N102H

DCDC CONV

V+2R5

V+1R2

V+2R5D

IC2011

LP2996M

VREF

DVJ-1000

56

VTT

F

23

7

8

1234

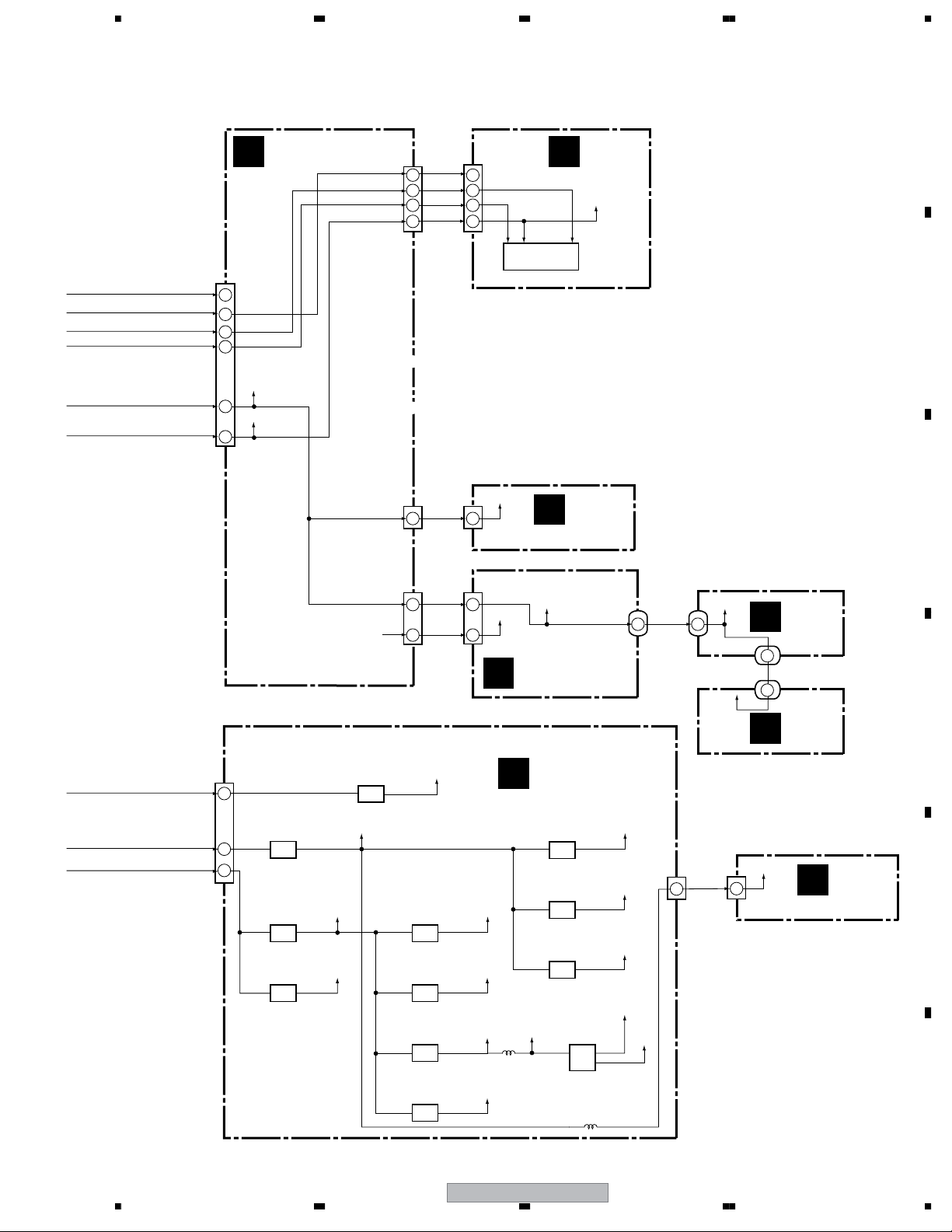

3.3 OVERALL WIRING DIAGRAM

A

INSW ASSY

U

(DWS1398)

C

B

C

S

SPCN ASSY

(DWX2629)

PSWB ASSY

DVPL ASSY (DWX2627)

B

POWER SUPPLY ASSY

T

(DWR1436)

MJCB ASSY

G

(DWG1633)

D

E

SLMB ASSY

E

(DWS1395)

STCN ASSY

D

(DWX2628)

SDCB ASSY

(DWX2630)

A 1/8 - A 8/8

A

MAIN ASSY (DWG1630)

F

F

24

DVJ-1000

1234

5678

A

JOGB ASSY

JFLB ASSY

H

(DWG1636)

(DWG1637)

J

AUDB ASSY

(DWG1638)

Q

AJCB ASSY

R

(DWG1639)

I

DIPB ASSY

LED2 ASSY

K

(DWG1635)

LED1 ASSY

L

(DWG1634)

N

SLDB ASSY

M

(DWS1393)

DFLB ASSY

(DWG1632)

B

C

D

P

÷

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or

"PCB PARTS LIST".

÷

The > mark found on some component parts indicates the importance of the safety factor

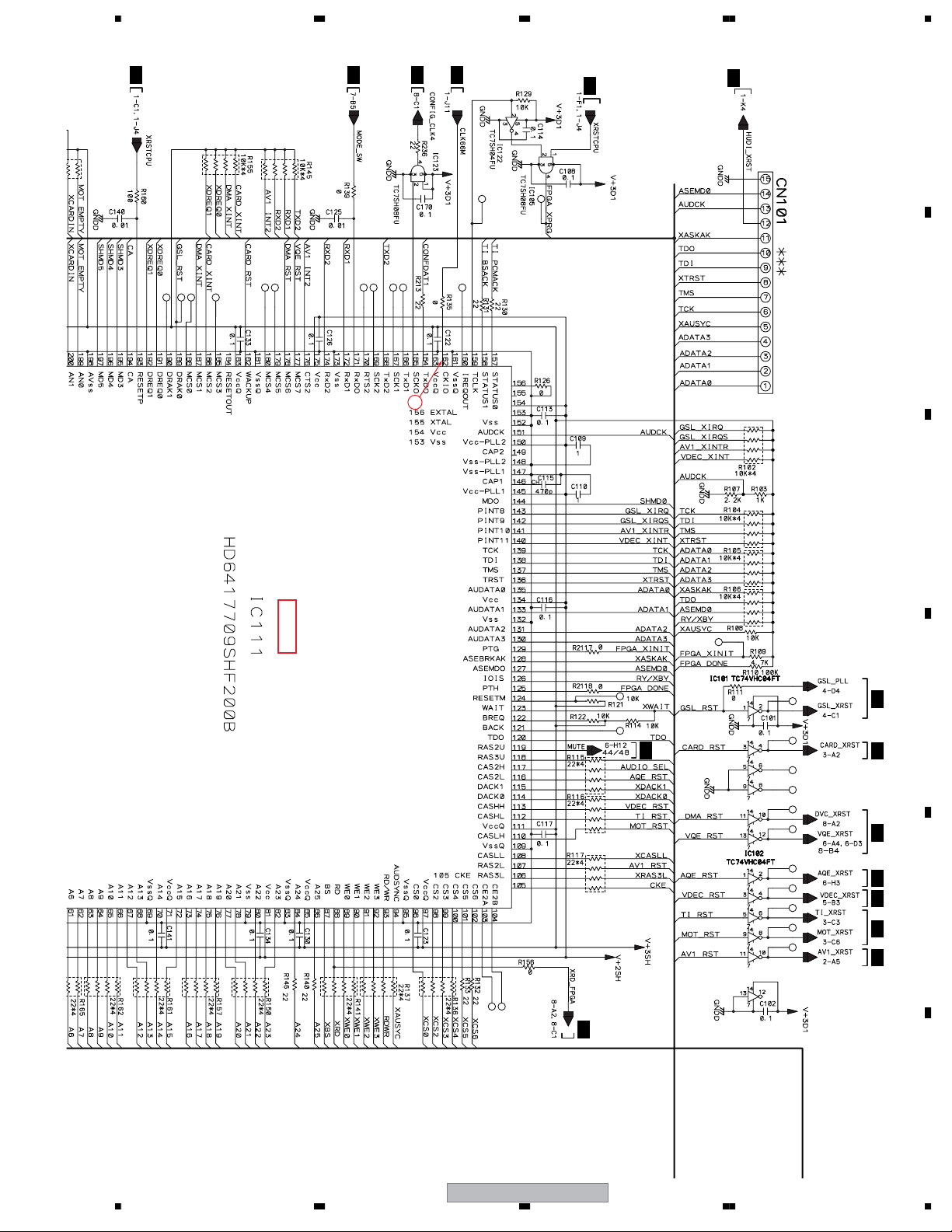

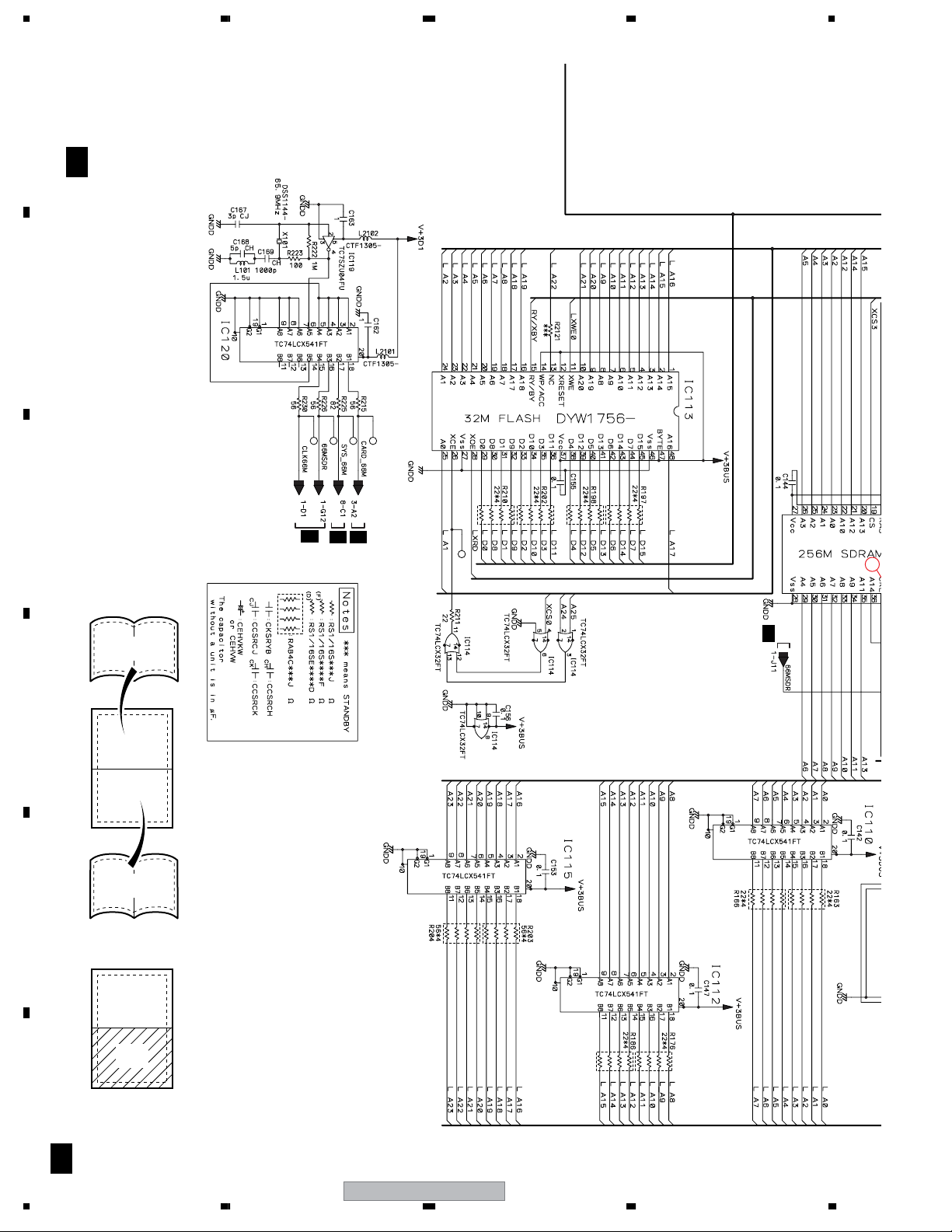

of the part. Therefore, when replacing, be sure to use parts of identical designation.

÷

56

: The power supply is shown with the marked box.

DVJ-1000

KSWB ASSY

(DWS1394)

7

RSWB ASSY

O

(DWS1391)

8

E

F

25

1234

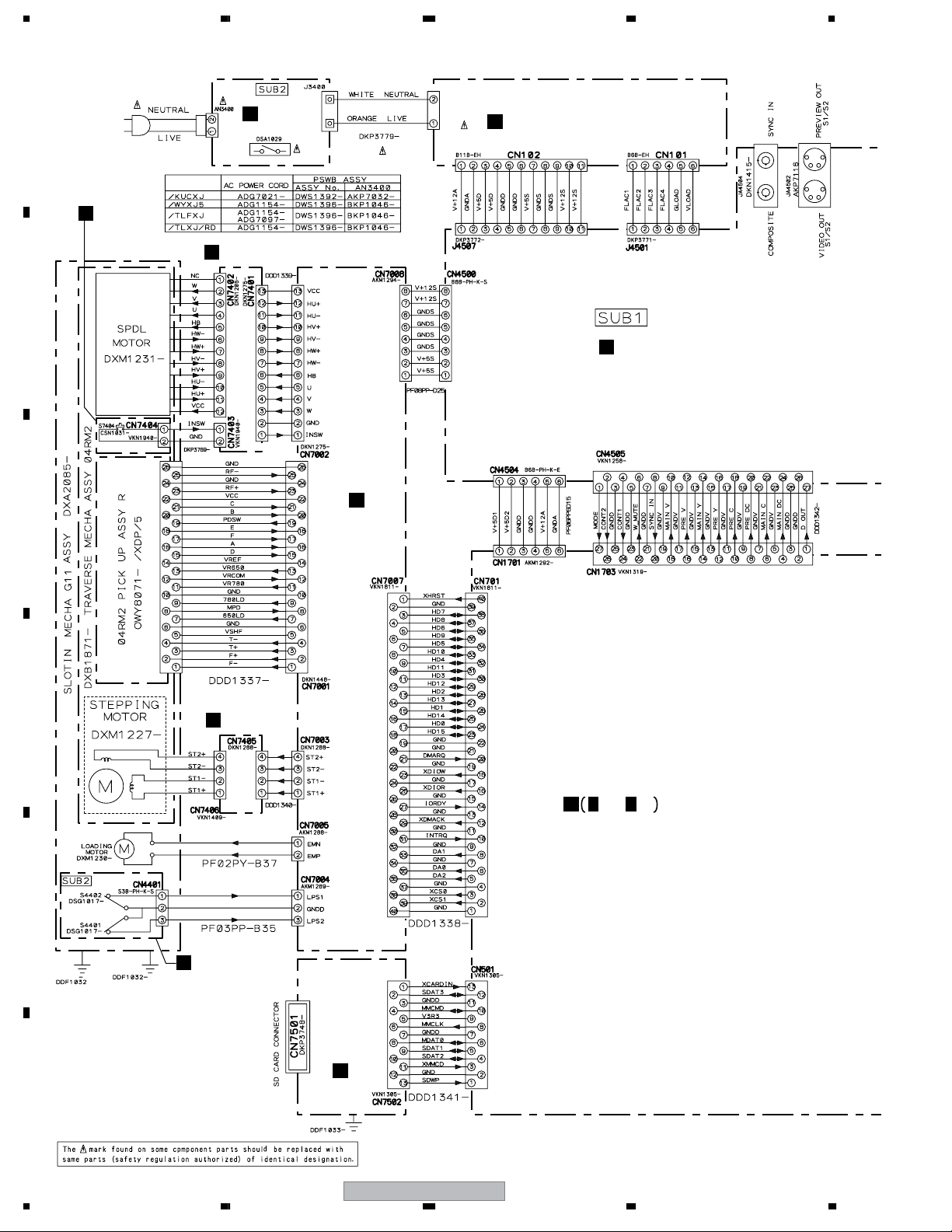

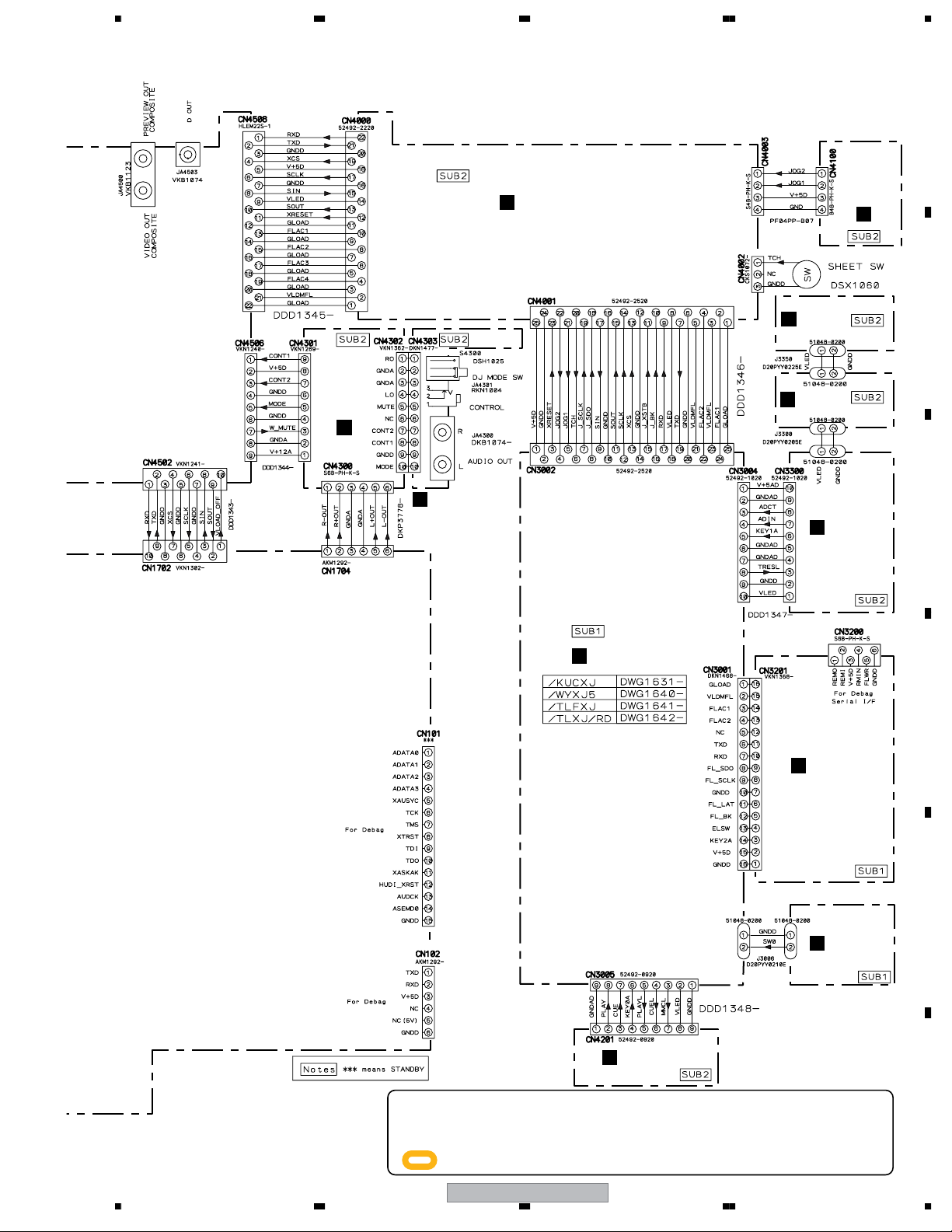

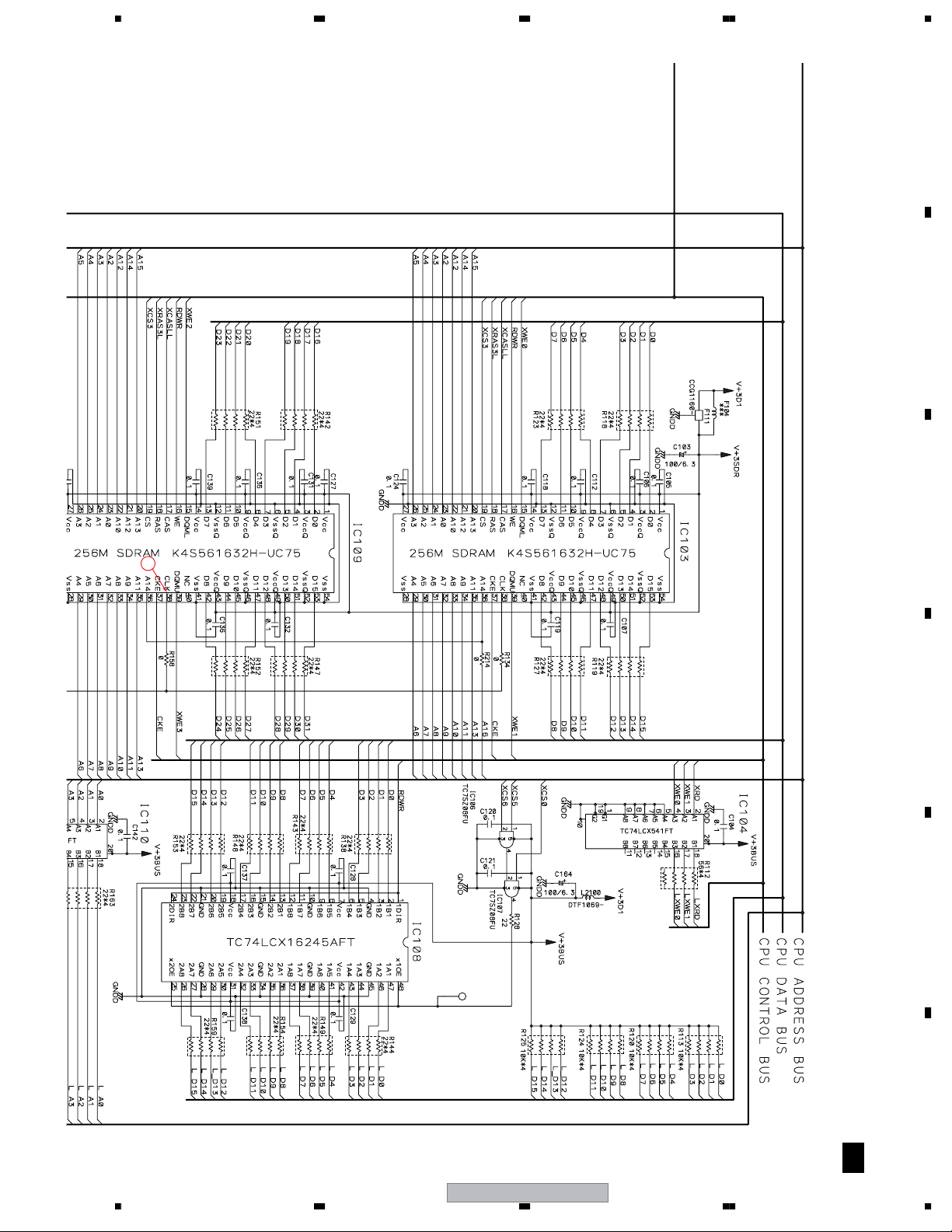

3.4 MAIN ASSY (1/8)

A 1/8

A

MAIN ASSY (DWG1630)

1/8A

Large size

SCH diagram

1/2

B

C

2/2

1/8A 7/8A

7/8A

7/8, 8/8A

1/8A

1/2

D

E

F

26

1234

DVJ-1000

5678

1/8A8/8A7/8A1/8A

1

1/8A

1/87A

A

B

C

CPU

4/8A

D

6/8A

3/8A

8/8A

6/8A

5/8A

E

3/8A

2/8A

8/8A

56

DVJ-1000

F

27

7

8

1234

A

A 1/8

B

C

MAIN ASSY

1/8A

8/8A

3/8A

2

Large size

SCH diagram

1/8A

1/2

D

2/2

E

2/2

F

28

A 1/8

DVJ-1000

1234

5678

A

B

C

2

D

E

56

DVJ-1000

F

A 1/8

29

7

8

1234

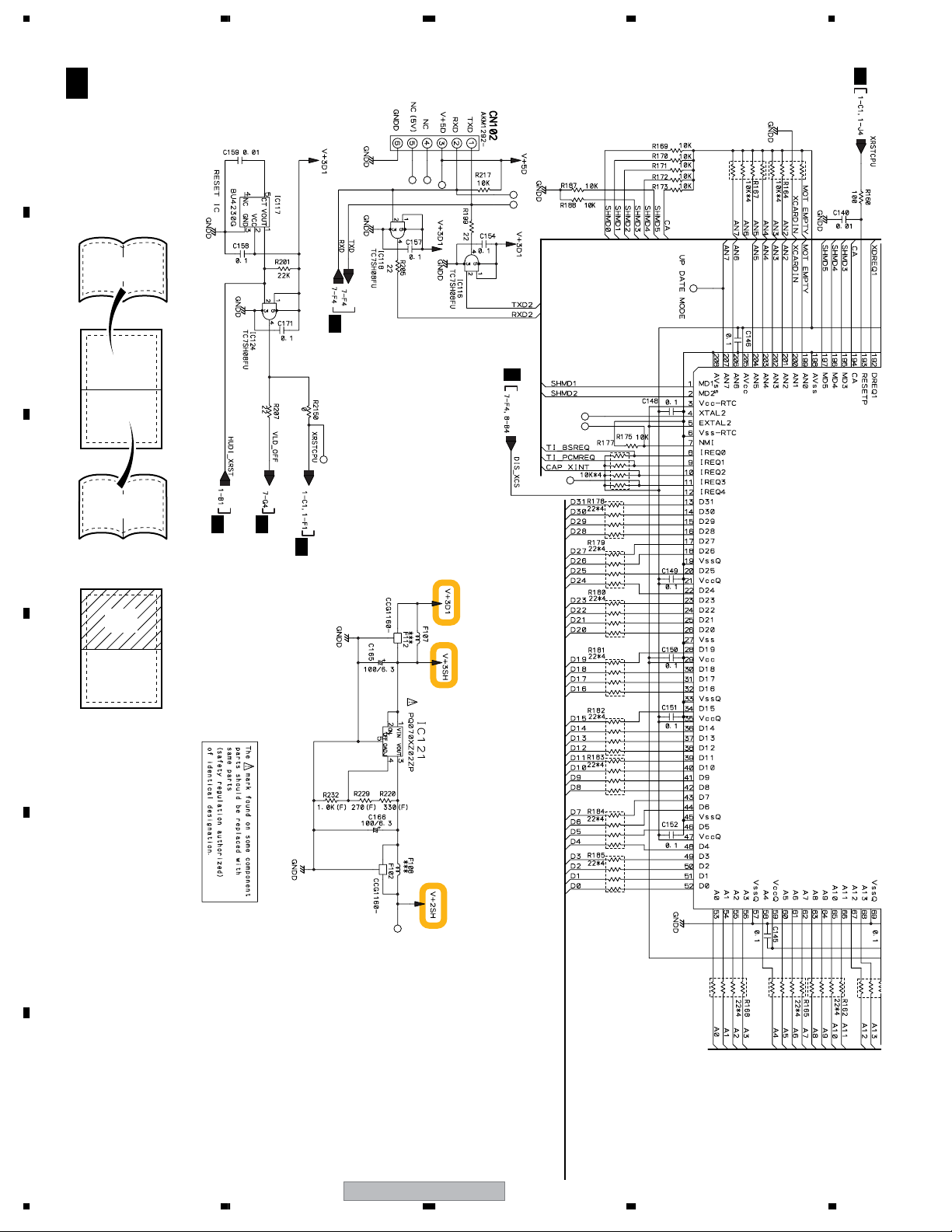

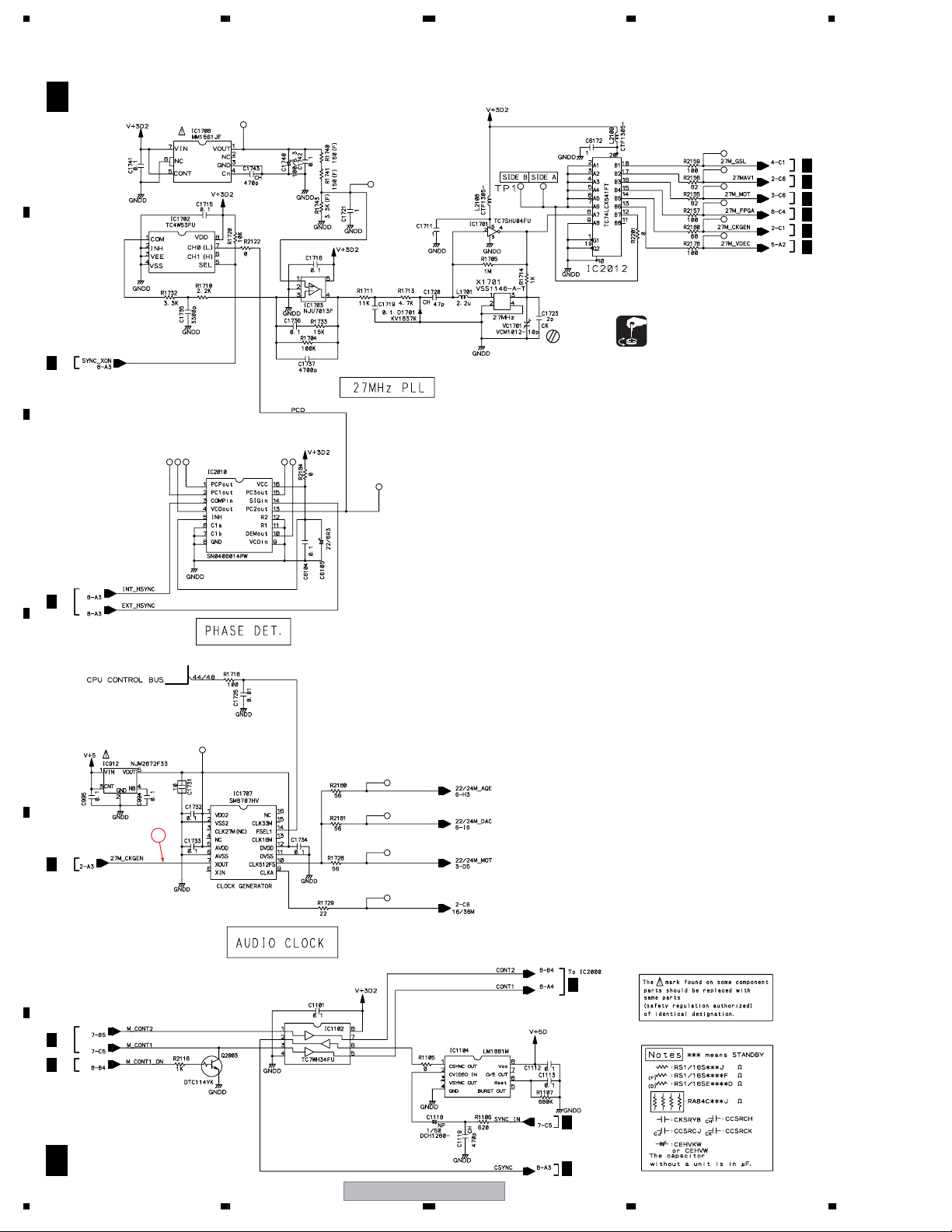

3.5 MAIN ASSY(2/8)

A

B

C

A 2/8

8/8A

MAIN ASSY (DWG1630)

4/8A

2/8A

3/8A

8/8A

2/8A

5/8A

Master Clock ADJ

8/8A

D

3

2/8A

E

8/8A

7/8A

8/8A

F

A 2/8

30

7/8A

8/8A

DVJ-1000

1234

Loading...

Loading...