Pioneer DVDD-304 Service manual

DVD-ROM DRIVE UNIT

DVD-D304

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV2552

Type

ZUCYV/WL O DC Power supply from other system

Model

Power Requirement

DVD-D304

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM 10

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

................................................

.....................................................

.......................................

.................

...........................

20

24

26

Remarks

3

4

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 DISASSEMBLY

7.2 PARTS

7.2.1 IC

8. PANEL FACILITIES AND SPECIFICATIONS

...................................................

...........................................................

..........................................................

..................................

....................................

.......

31

31

31

33

33

34

For details, refer to "Important symbols for good services" on the next page.

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2001

T – ZZY NOV. 2001 Printed in Japan

DVD-D304

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

[ NOTES ON SERVICING ]

7 CLEARNING

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Pickup leneses Cleaning liquid : GEM1004

Cleaning paper : GED-008

2

DVD-D304

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 7 mw

WAVELENGTH: 650 nm (DVD) , 780 nm (CD-ROM)

Additional Laser Caution

1. The ON/OFF(ON:low level,OFF:high level) status of the

CLAMP signals for detcting the loading state are detected

by the drive CPUs, and the design prevents laser diode

oscillation when the CLAMP signal turns OFF.

In normal operation, if no disc is clamped, the laser diode

oscillation is disabled.

However, the interlock does not always operate in the test

mode.

*

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

* Refer to page 28.

3

DVD-D304

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

For the applying amount of lubricants or glue, follow the instructions in this manual.

•

(In the case of no amount instructions, apply as you think it appropriate.)

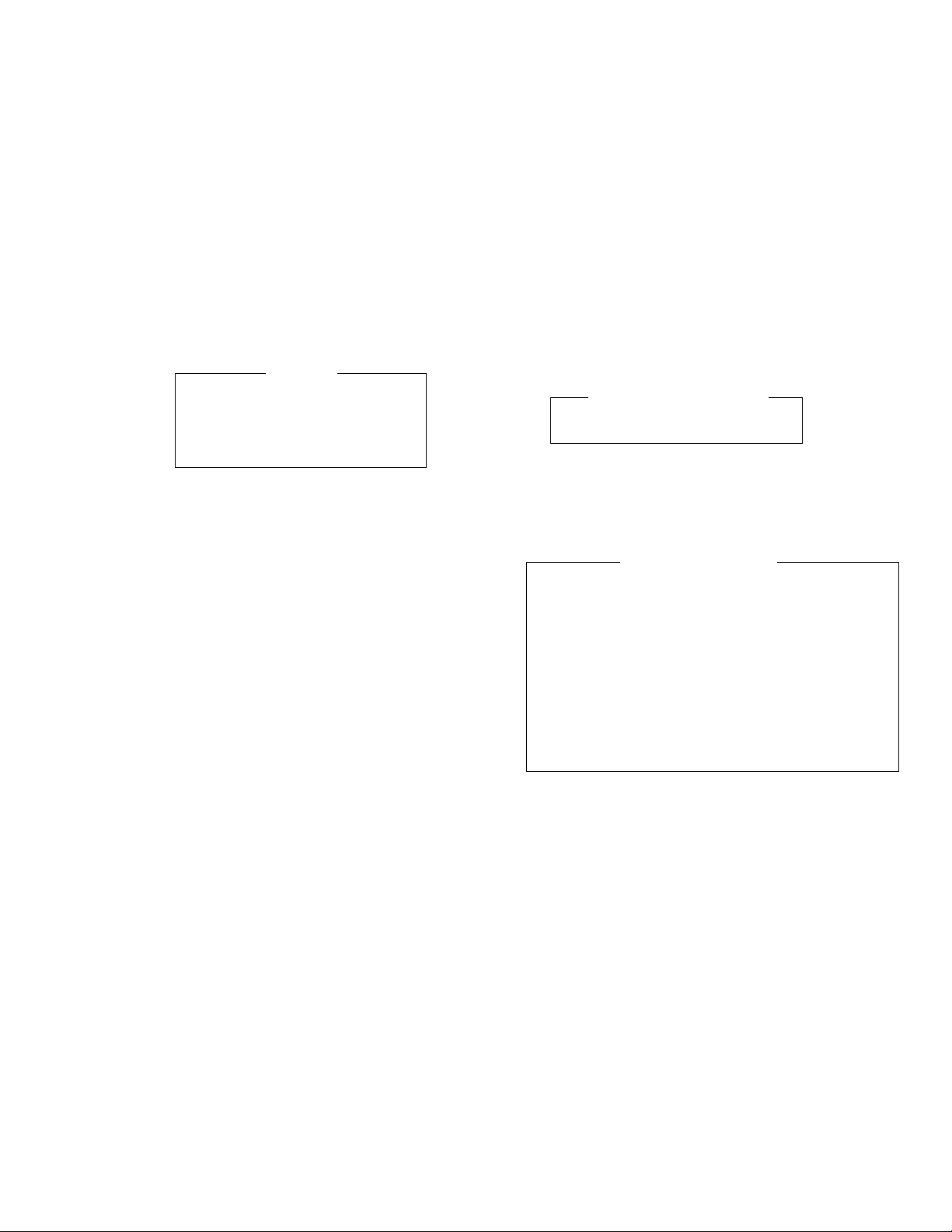

2.1 PACKING

10

2

7

4

5

9

11

1

3

8

6

4

PARTS LIST

Mark No. Description Part No.

NSP 1 Warranty Card ARY1093

2 Operating Instructions DRC1172

(English/ French/ German/ Japanese)

NSP 3 Polyethylene Bag Z21-010

(100x230x0.018)

NSP 4 Polyethylene Bag Z21-038

(230x340x0.03)

5 Pad DHA1479

6 Packing Case DHG2186

7 Bag DHL1052

NSP 8 Label VRW1629

9 Screw BBZ30P080FZK

10 SCSI Cable DDC1006

DVD-D304

NSP 11 Polyethylene Bag Z21-002

(50x70x0.03)

5

DVD-D304

Grease

(ZLB-PN397B)

2.2 EXTERIOR

81

25

82

17

Paint on side axle.

Grease

(GYA1001)

35

89

90

48

48

89

43

Refer to

Refer to

Refer to

"2.3 TRAVERSE

"2.3 TRAVERSE

"2.3 TRAVERSE

MECHANISM ASSY"

MECHANISM ASSY"

MECHANISM ASSY"

47

47

52

80

18

52

48

12

89

15

47

68

80

73

41

39

93

30

63

22

57

Paint on side axle.

Grease

(GYA1001)

80

33

28

29

73

26

21

80

37

41

91

20

34

83

73

76

87

Paint Grease the inner

surface of the wall.

Grease

(GYA1001)

73

70

Grease

(ZLB-PN397B)

63

80

16

79

36

71

66

81

Grease

(GYA1001)

72

32

27

73

31

Paint on side axle.

Grease

(GYA1001)

53

66

58

24

19

71

75

14

45

40

85

C

71

23

4

42

71

83

84

5

B

38

77

33

80

71

D

A

B

C

68

71

2

78

55

68

D

44

68

6

8

1

10

A

50

59

54

60

51

74

6

67

74

EXTERIOR PARTS LIST

Mark No. Description Part No.

DVD-D304

Mark No. Description Part No.

1 MAIN BOARD ASSY DWX2039

2 RIFB BOARD ASSY DWX2213

3 • • • • •

4 Capacitor (C1) CFTLA224J50

5 Connector Assy DKP3281

6 Connector Assy 50p DKP3354

7 • • • • •

8 Connector Assy DKP3484

9 • • • • •

10 Connector Assy DKP3488

11 • • • • •

NSP 12 P.U Flexible Wire 26P DNP1917

13 • • • • •

14 Connector Assy PF02PY-B15

NSP 15 Traverse Mechanism Assy DXB1725

16 Disc Holder Spring DBH1342

17 Spring DBK1134

18 Earth Plate DBK1139

19 Cushion DEB1355

20 Slide Sheet DEC2034

21 Disc Holder Sheet DEC2203

22 Clamper Stay S DND1239

23 Switch Bracket DNF1539

24 Clamper Base DNH2283

25 Joint Arm DNH2284

46 • • • • •

47 Floating Rubber D3 DEB1404

NSP 48 DRA Screw DBA1131

49 • • • • •

NSP 50 Silicon Sheet DEB1458

NSP 51 Silicon Sheet DEB1460

52 Washer DEC2213

NSP 53 Player Base D3 DNA1246

54 Bottom Plate DNF1654

55 Connector Plate 304 DNC1600

56 • • • • •

57 PL Angle 304 L DNF1670

58 PL Angle 304 R DNF1671

NSP 59 Silicon Sheet A DEB1519

NSP 60 Silicon Sheet B DEB1520

61 • • • • •

62 • • • • •

63 Screw DBA1133

64 • • • • •

65 • • • • •

66 Protector V2 DNK3393

67 65 Label ARW7050

68 Screw BBT30P060FZK

69 • • • • •

70 Screw BBZ30P040FZK

26 CL Disc Holder DNK3253

27 Motor Gear DNK3254

28 CL Gear (B) DNK3256

29 CL Gear (C) DNK3257

30 Disc Holder (L) DNK3289

31 Disc Holder (R) DNK3290

32 Disc Stopper DNK3291

33 Rack Plate DNK3292

34 CL Gear (A) DNK3363

35 Side Rack (L) DNK3364

36 Side Rack (R) DNK3365

37 Clamper Bracket D3 DNK3688

38 Lever Switch DSK1003

39 Clamper 98 AssY DXA1859

40 Motor (Clamp) PXM1002

41 Tape (G) REH1010

42 Damper Assy VXA1153

43 Floating Screw DBA1072

NSP 44 Locking Wire Saddle DEC1305

45 PL Fixing Metal DBK1108

71 Screw BBZ30P060FMC

72 Screw BBZ30P080FZK

73 Screw BPZ30P080FCU

74 Screw DBA1136

75 Screw PMA20P050FMC

76 Screw PMH20P040FMC

77 Screw PMH26P060FMC

78 Screw PMZ30P100FNI

79 Cord Clamper RNH-184

80 Washer WT26D047D050

81 Washer WT36D072D050

82 Ering YE30FUC

83 Binder ZCA-SKB90BK

84 Damper Braket DNF1541

85 Clamp Motor Assy-S DXX2336

86 • • • • •

87 Sheet DED1143

88 • • • • •

NSP 89 DRA Rubber DEB1429

NSP 90 DRA Weight DNH2429

91 Spacer DEB1518

92 • • • • •

93 G4 Servo Mechanism Assy DXX2480

(for Service)

7

DVD-D304

2.3 TRAVERSE MECHANISM ASSY

5

2

8

16

17

5

4

Cleaning liquid (GEM1004)

Cleaning paper (GED-008)

4

7

11

5

3

5

4

21

7

4

15

1

19

14

12

6

13

21

20

8

TRAVERSE MECHANISM ASSY PARTS LIST

Mark No. Description Part No.

NSP 1 Spindle Motor DXM1128

2 Motor (SLD) DXM1118

NSP 3 Pickup Assy VWY1056

NSP 4 Adjust Screw DBA1119

NSP 5 Skew Spring DBH1437

NSP 6 Rack Spring DBH1454

NSP 7 Guide Shaft DLA1840

NSP 8 Mechanism Flame DNA1248

9 • • • • •

10 • • • • •

11 Gear A DNK3698

12 Gear B DNK3699

13 Gear C DNK3486

14 Gear D Assy DXA1883

NSP 15 Motor Spacer DNK3703

NSP 16 Slider G4 DNK3733

17 Precision Screw VBA1051

18 • • • • •

19 Screw JGZ17P028FMC

20 Screw PMA26P080FMC

DVD-D304

21 Washer WT21D050D025

9

1

234

DVD-D304

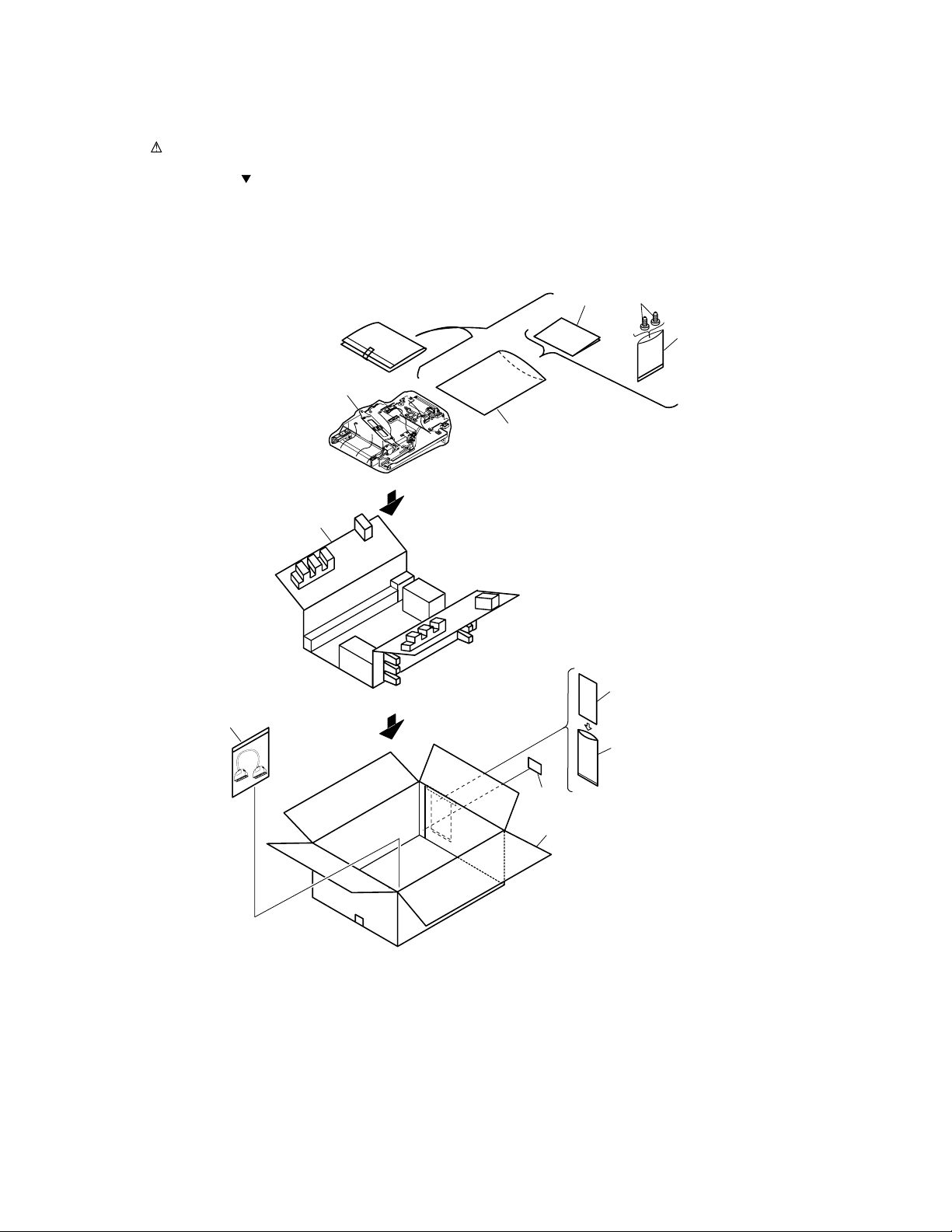

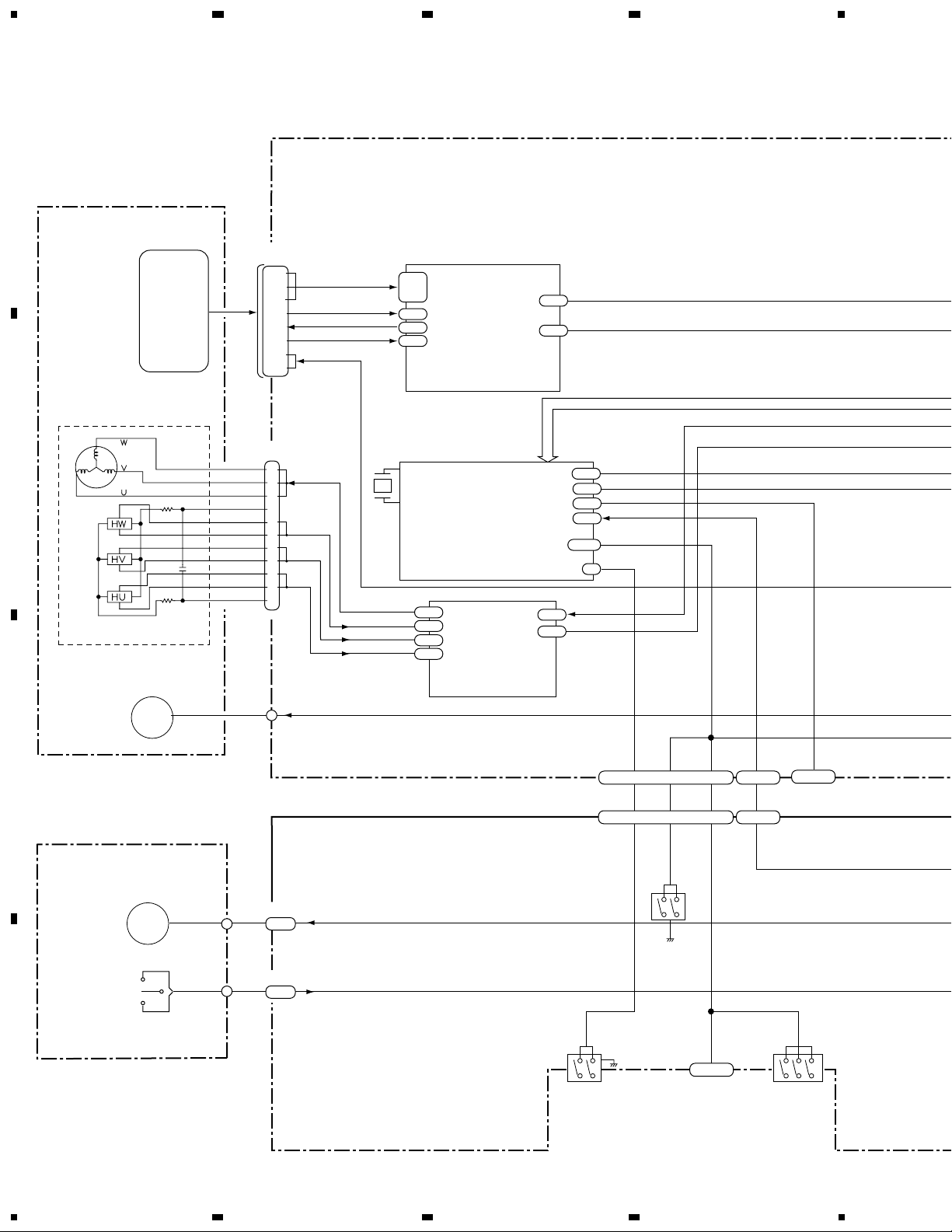

3. BLOCK DIAGRAM and SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

Servo Mechanism Assy

CN800

Pick UP

Assy

12

36

78

0$*

@&

)_

+¡

A,B,C

RF

LD1, LD2

MD1, MD2

FCS, TRK

49- 54

57- 60

62, 63

47,48

2, 4

1, 3

Front End

Procesor IC

IC800

(AN8702FH)

30, 31

18, 22

ARF, NARF

FE, TE

Serial Line

CN900

GND

W-

W+

V+

U+

VCC

W

-

W, V, U

V

0

U

9

8

7

HW-, HW+

6

V-

5

HV-, HV+

4

U-

HU-,

3

HU+

2

1

B

Spindle Motor

X300

20MHz

W, V, U

HW-, HW+

HV-, HV+

HU-, HU+

System Controller

IC300

(PD3427A9)

1,2,25

12,13

10,11

Spindle Driver

8, 9

SLDRV

85

XWR, XRD

70,71

TX, RX

13,15

XCLAMP, XSPST

55,56

IDSL, IDMA

21,23

BSIZ

19

24

FG

16

IC900

(LB11995)

MODE

Slider

Motor

C

SLDR,SLDF

CN251

BSIZ

9- 7@

1 - 5

1 - 967 59

CN506

XCLAMP, XSPST

CN300 CN301

1 - 3

1 - 3

CN505

Clamp Mechanism Assy

Clamp

Motor

CN503

12

OUT

1. TEST

2. MODE

S503

XTEST, MODE

TX, RX

34

Clamp SW

CN504

D

1- 3

IN

S502

BSIZ, TERM

1. TERM

2. BSIZ

CN501 S501

[CN901: DRIVE 1]

ID0 - ID2

1 - 4

SCSI ID SWTo IDSB BOARD ASSY

[CN902: DRIVE 2]

[CN903: DRIVE 3]

[CN904: DRIVE 4]

10

1234

5

67

8

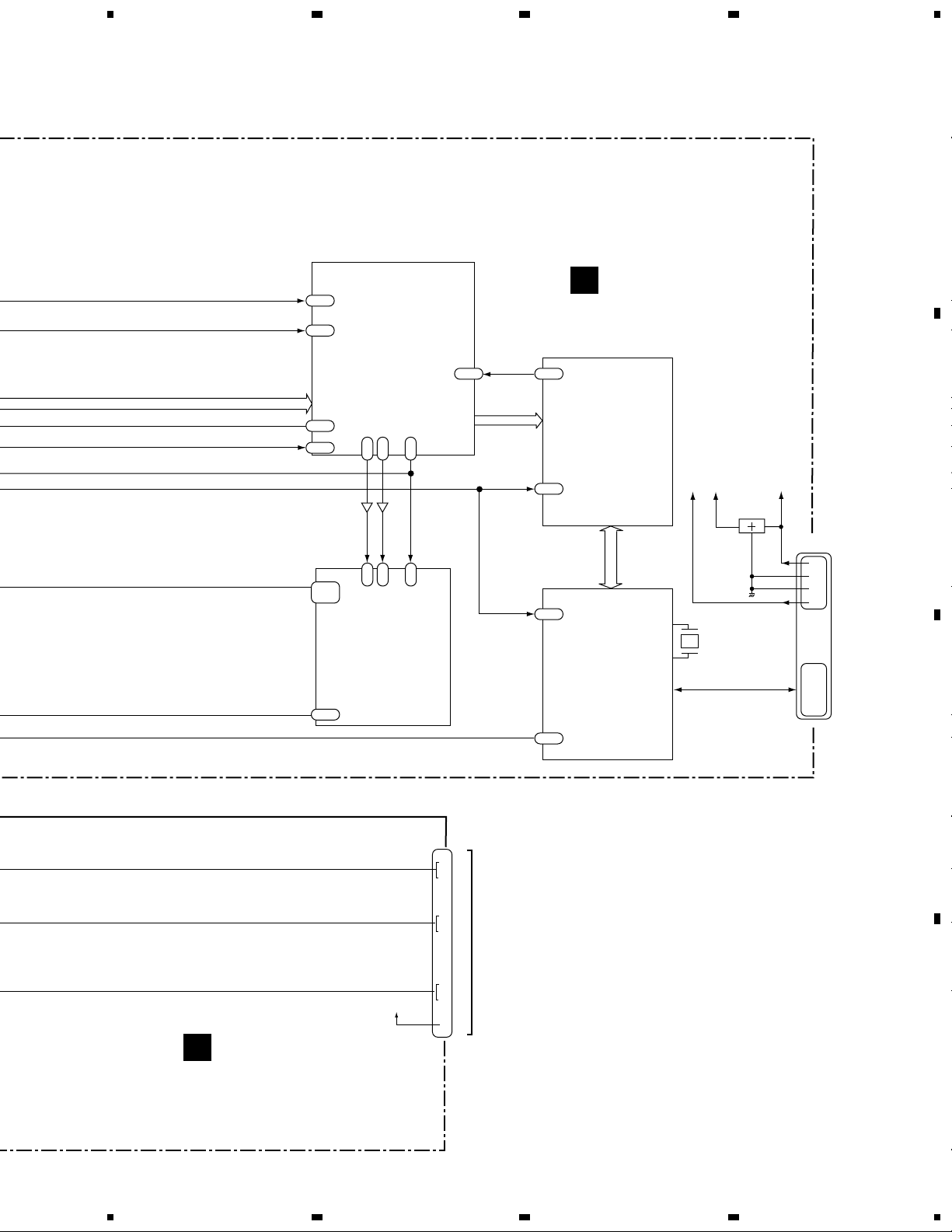

DVD-D304

A

ARF, NARF

FE, TE

SPDRV

FG

FCS, TRK

SLDR,SLDF

8, 9

Servo DSP

2, 3

IC700

(MN67706)

52

53

28,29

31,32

5

FODRV

TRDRV

8

6

10

4 ch Driver IC

IC950(LA6545M)

Focus

Trackin

Loading

Slider

26,27

51

TRSDRV

12

SYSCLK

Data

XWR, XRD

XWR, XRD

MODE SELECT

B

MAIN BOARD ASSY

8748

Optical Disk

Controller

IC100

(MN103S13B)

59,60

Data

19,20

SCSI Controller

IC250

(LC897128)

96- 99

BA178M05

GNDD

X250

40MHz

SCSI BUS

IC200

B

V12DRVA5VVD5V

CN250

}

+12V

|

GND

“

GND

‘

+5V

12

.

.

.

.

.

.

SCSI

.

.

—±

A

RIFB BOARD ASSY

5

XCLAMP, XSPST

CLS 0, 1

CLM +, CLM -

V+5D

C

CN502

2

4

To MMCB BOARD ASSY

7

8

9

0

-

[CN110: DRIVE 1]

[CN111: DRIVE 2]

[CN112: DRIVE 3]

[CN113: DRIVE 4]

D

11

6

7

8

Loading...

Loading...