Page 1

DVD PLAYER

Î

DV-545

8

7

3

STANDBY/ON

¡¢41

LEGATO

0

PRO

DVD PLAYER

DV-545

DV-444-S

DV-444-K

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Type

WYXJ ? −−AC220-240V 2

WVXJ ? −−AC220-240V 2

WYXQ − ??AC220-240V 2

WYXQ/FRGR − ??AC220-240V 2

WVXQ − ??AC220-240V 2

DV-545 DV-444-S DV-444-K

Model

Power Requirement Region No. Remarks

ORDER NO.

RRV2465

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS SERVICE, INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

c

PIONEER CORPORATION 2001

................................................

.....................................................

.......................................

.................

...

...........................

10

35

46

51

2

3

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SELF-DIAGNOSTIC FUNCTION OF

PICKUP DEFECTIVE

7.1.2 TEST POINTS LOCATION

7.1.3 TEST MODE SCREEN DISPLAY

7.1.4 TROUBLE SHOOTING

7.1.5 ERROR CODE

7.1.6 DISASSEMBLY

7.2 PARTS

7.2.1 IC

7.2.2 FL DISPLAY

8. PANEL FACILITIES AND SPECIFICATIONS

..................................................

..........................................................

..........................................................

................................

...........................

...................

........................

.....................................

....................................

.........................................

T – IZE JUNE 2001 Printed in Japan

........

....

57

57

57

58

59

63

64

68

74

74

93

94

Page 2

DV-545, DV-444-S, DV-444-K

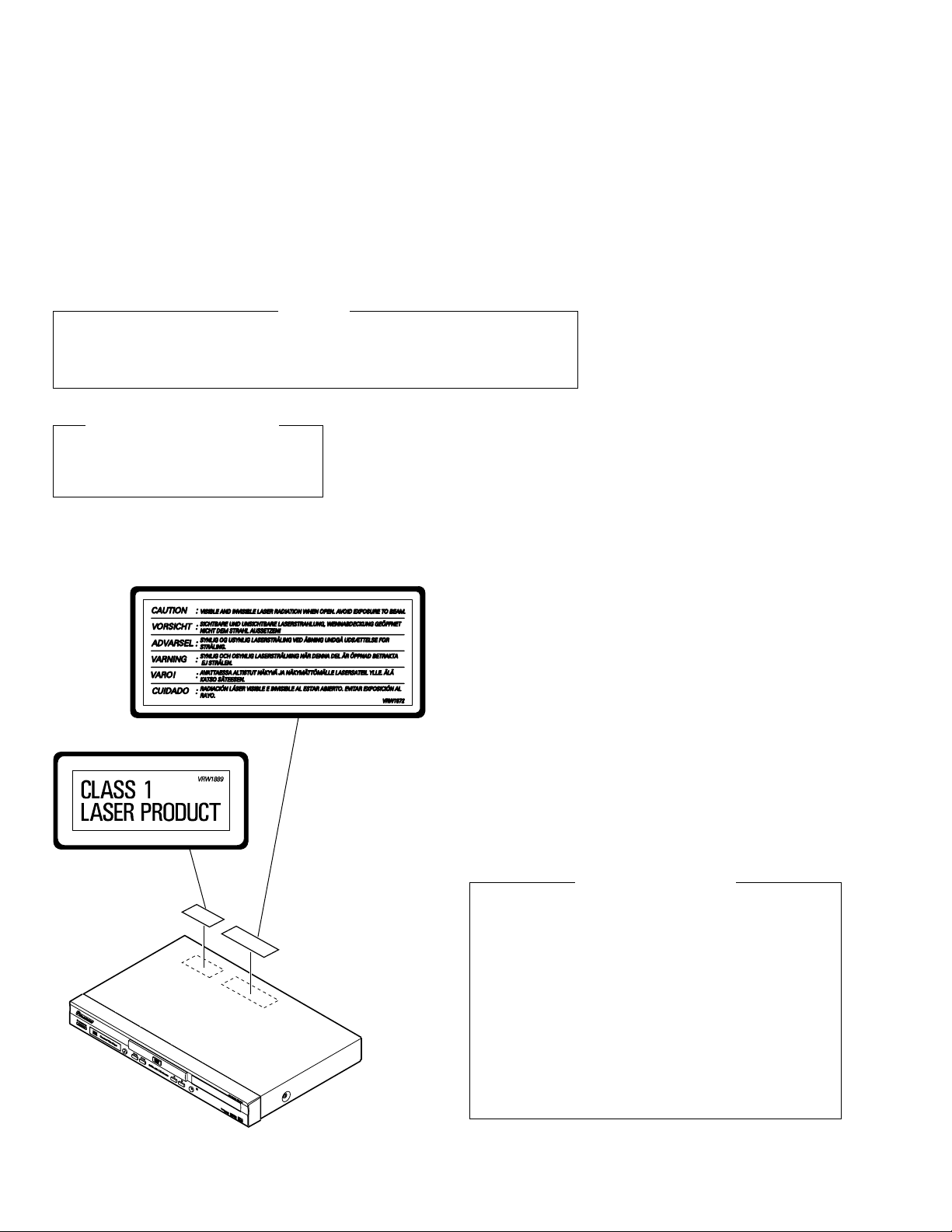

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING !

THE AEL (ACCESSIBLE EMISSION LEVEL) OF THE LASER POWER OUTPUT IS LESS THAN CLASS 1

BUT THE LASER COMPONENT IS CAPABLE OF EMITTING RADIATION EXCEEDING THE LIMIT FOR

CLASS 1.

A SPECIALLY INSTRUCTED PERSON SHOULD DO SERVICING OPERATION OF THE APPARATUS.

LASER DIODE CHARACTERISTICS

FOR DVD : MAXIMUM OUTPUT POWER : 5 mW

FOR CD : MAXIMUM OUTPUT POWER : 5 mW

WAVELENGTH : 650 nm

WAVELENGTH : 780 nm

LABEL CHECK

DV-545/WYXJ

Only

Additional Laser Caution

1. Loading-status detection switch (S101 on the LOAB assy) are detected

by the microprocessor (IC601 in the DVDM assy).

• To per mit the laser diode to oscillate, it is required to set the loadingstatus detection switch for the clamp position (the center terminal of S101

is shorted to +3V).

When the voltage of IC101-pin 20 is +3V and IC601 (microprocessor) pin 83 is +3V, 650nm laser diode for DVD oscillates in the DVDM Assy.

When the voltage of IC101-pin 20 is +3V and IC601 (microprocessor) pin 83 is 0V (GND), 780nm laser diode for CD oscillates in the DVDM

Assy.

In the test mode ∗ , the laser diode oscillates when microprocessor detects

a PLA Y signal, or when the PLAY key is pressed (S203 ON in the FLKB

assy), with the above requirements satisfied.

2. When the cover is open, close viewing through the objective lens with

the naked eye will cause exposure to the laser beam.

∗ : See page 53.

2

Page 3

DV-545, DV-444-S, DV-444-K

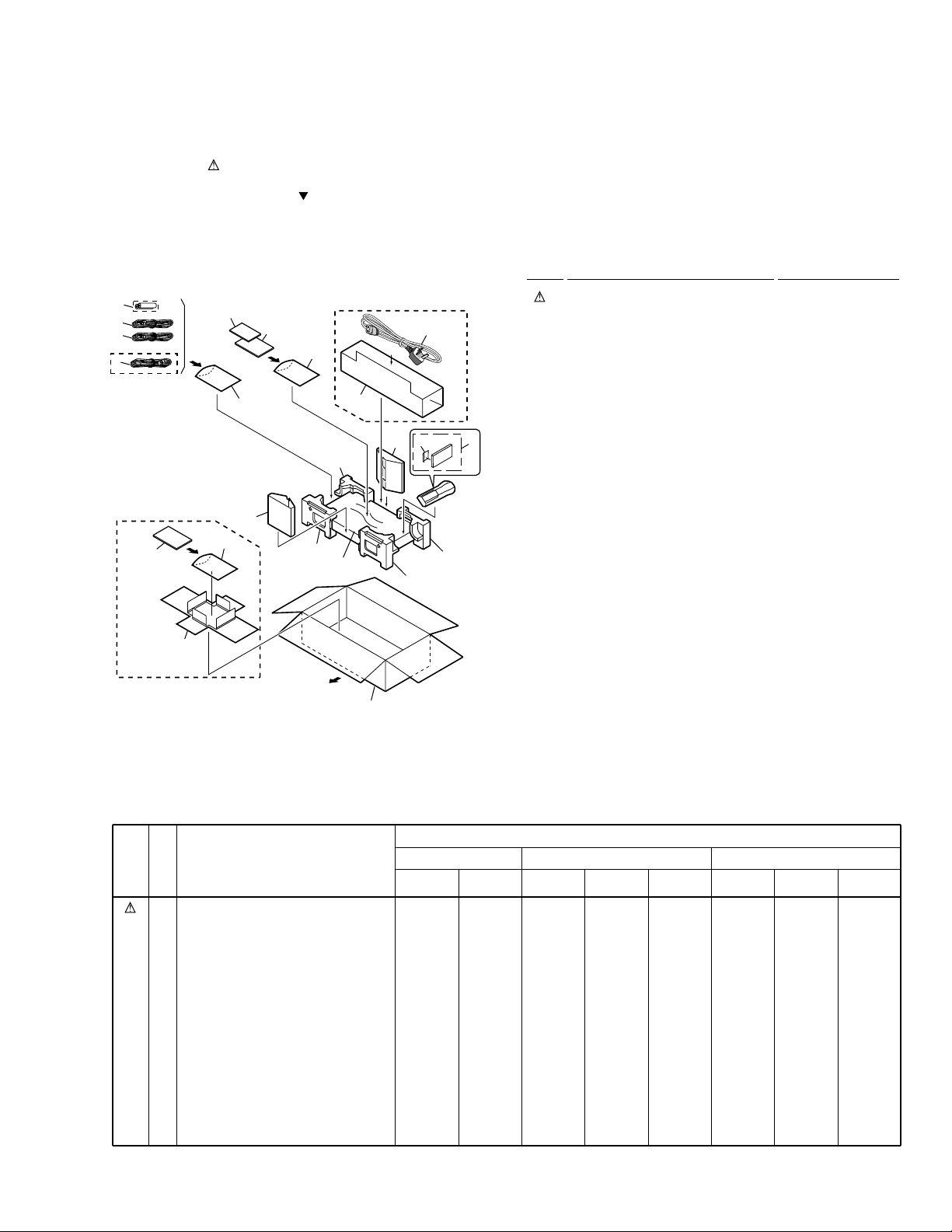

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

2.1 PACKING

6

2

3

1

Except

WVXJ and WVXQ

Types

18, 19

"Operating

Instructions"

14

WYXJ and WYXQ

Types Only

8

12

16, 17

"Operating

Instructions"

12

11

13

7 (1/2)

FRONT

WVXJ and WVXQ

Types Only

15

11

7 (2/2)

10

9

1

5

7 (2/2)

7 (1/2)

(1) PACKING PARTS LIST

Mark No. Description Part No.

1 Power Cord See Contrast table (2)

NSP 6 Dry Cell Battery (R6P, AA) See Contrast table (2)

NSP 8 Warranty Card ARY7022

4

NSP 11 Reinforcement Board VHC1083

NSP 13 Polyethylene Bag Z21-038

2 Audio Cord (L = 1.5m) See Contrast table (2)

3 Video Cord (L = 1.5m) See Contrast table (2)

4 Remote Control Unit See Contrast table (2)

5 Battery Cover See Contrast table (2)

7 Pad VHA1277

9 Packing Case See Contrast table (2)

10 Mirror Mat (0.5 × 750 × 600) Z23-007

12 Polyethylene Bag VHL1051

(0.03 × 200 × 300)

(0.03 × 230 × 340)

14 IM Holder See Contrast table (2)

15 Accessory Box See Contrast table (2)

16 Operating Instructions See Contrast table (2)

17 Operating Instructions See Contrast table (2)

18 Operating Instructions See Contrast table (2)

19 Operating Instructions See Contrast table (2)

(2) CONTRAST TABLE

DV-545/WYXJ, WVXJ, DV-444-S/WYXQ, WYXQ/FRGR, WVXQ, DV-444-K/WYXQ, WYXQ/FRGR and WVXQ are constructed

the same except for the following :

Part No.

Mark No. Symbol and Description

1

Power Cord

2

Audio Cord (L = 1.5m)

3

Video Cord (L = 1.5m)

4

Remote Control Unit

5

Battery Cover

NSP

6

Dry Cell Battery (R6P, AA)

9

Packing Case

14

IM Holder

15

Accessory Box

16

Operating Instructions (English/Italian)

17

Operating Instructions

18

Operating Instructions

19

Operating Instructions

(French/German)

(Dutch/Swedish)

(Spanish/Portuguese)

DV-545 DV-444-S DV-444-K

WYXJ WVXJ WYXQ

ADG1154

VDE1052

VDE1053

VXX2627

VNK4423

VEM-013

VHG2121

VHC1082

Not used

VRD1132

VRD1133

VRD1134

VRD1135

ADG1156

VDE1052

VDE1053

VXX2627

VNK4423

VEM-013

VHG2096

Not used

VHC1080

VRD1132

Not used

Not used

Not used

ADG1154

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2083

VHC1082

Not used

VRD1137

VRD1138

VRD1139

VRD1140

WYXQ

/FRGR

ADG1154

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2102

Not used

Not used

Not used

VRD1138

Not used

Not used

WVXQ WYXQ

ADG1156

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2103

Not used

VHC1080

VRD1137

Not used

Not used

Not used

ADG1154

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2080

VHC1082

Not used

VRD1137

VRD1138

VRD1139

VRD1140

WYXQ

/FRGR

ADG1154

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2100

Not used

Not used

Not used

VRD1138

Not used

Not used

WVXQ

ADG1156

VDE1054

VDE1055

VXX2702

VNK4631

VEM1010

VHG2101

Not used

VHC1080

VRD1137

Not used

Not used

Not used

3

Page 4

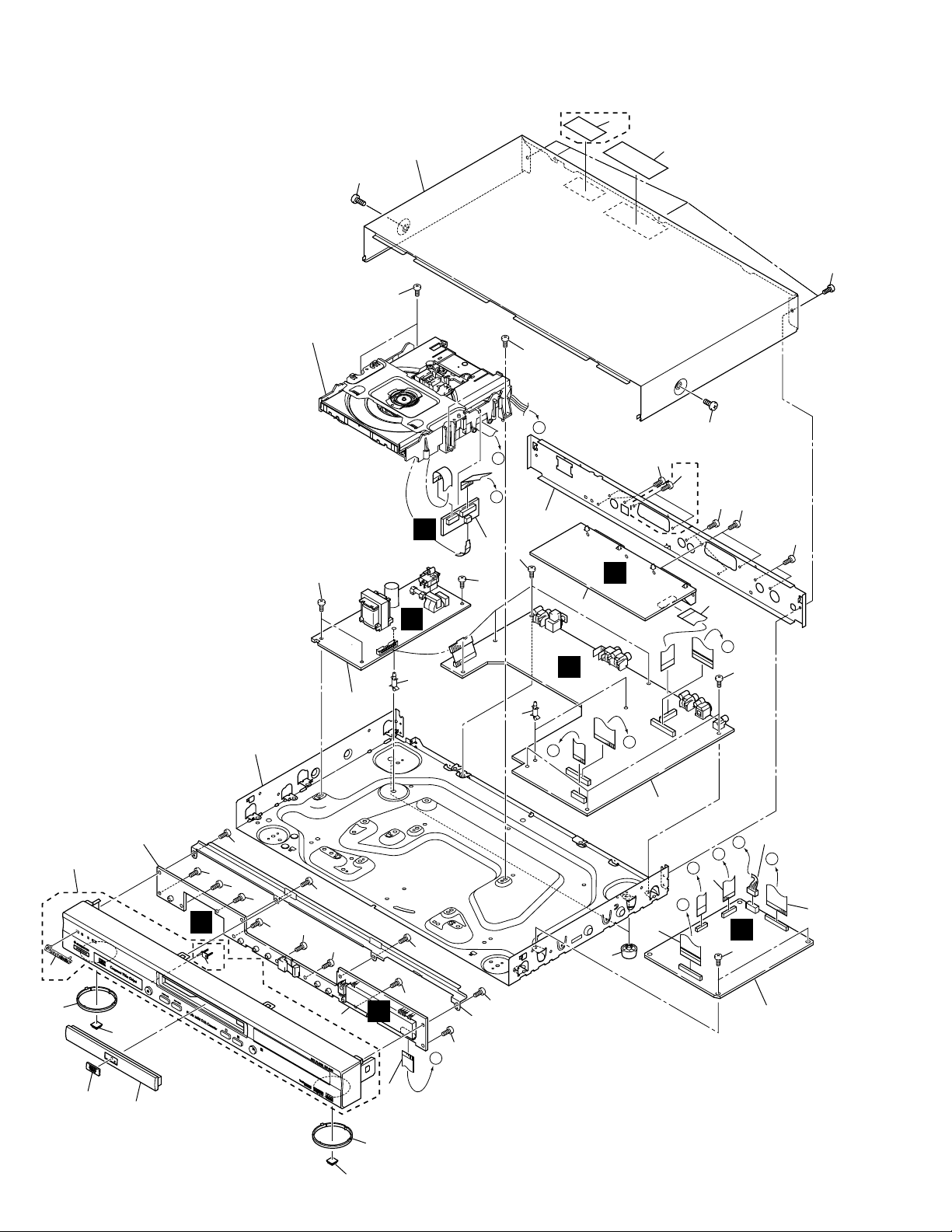

DV-545, DV-444-S, DV-444-K

2.2 EXTERIOR SECTION

29

18

DV-545 Only

33

32

28

Refer to

"2.3 LOADING MECHANISM ASSY".

2

27

17

28

28

C

27

F

D

E

16

3

27

28

E

7

28

29

DV-545

Only

28

19

28

28

H

C

15

8

14

D

A

B

27

26

24

4

13

F

E

C

11

B

27

1

25

20

21

23

6

G

30

31

30

30

DV-545

Only

30

30

30

30

30

D

10

B

11

30

30

F

5

A

9

24

21

30

22

30

12

4

Page 5

(1) EXTERIOR SECTION PARTS LIST

DV-545, DV-444-S, DV-444-K

Mark No. Description Part No.

NSP 2 Loading Mechanism Assy VWT1188

NSP 3 SSIB Assy VWG2292

NSP 5 FLKB Assy See Contrast table (2)

NSP 6 KEYB Assy See Contrast table (2)

NSP 14 PCB Support REC1285

NSP 17 Base Chassis VNA2300

1 DVDM Assy See Contrast table (2)

4 JACB Assy See Contrast table (2)

7 SRCB Assy See Contrast table (2)

8 POWER SUPPLY Unit VWR1340

9 Flexible Cable (16P) See Contrast table (2)

10 Flexible Cable (17P) See Contrast table (2)

11 Flexible Cable (30P) See Contrast table (2)

12 Leg Assy SX AEC7113

13 Connector Assy PG05KK-E30

15 PCB Support VEC2184

16 Rear Panel See Contrast table (2)

18 Bonnet See Contrast table (2)

19 Flexible Cable (19P) See Contrast table (2)

20 DVD-V Plate See Contrast table (2)

Mark No. Description Part No.

21 Rubber Foot VEB1325

22 FP Angle VNE2250

23 Tray Panel See Contrast table (2)

24 Ring VNK4840

25 Front Panel Assy See Contrast table (2)

26 Pioneer Name Plate See Contrast table (2)

27 Screw BBZ30P060FMC

28 Screw BBZ30P080FZK

29 Screw See Contrast table (2)

30 Screw BBZ30P100FZK

31 LED Lens See Contrast table (2)

32 Label VRW1872

33 CLASS 1 Caution Label See Contrast table (2)

(2) CONTRAST TABLE

DV-545/WYXJ, WVXJ, DV-444-S/WYXQ, WYXQ/FRGR, WVXQ, DV-444-K/WYXQ, WYXQ/FRGR and WVXQ are constructed

the same except for the following :

Part No.

DV-545 DV-444-S DV-444-K

Mark No. Symbol and Description

1

DVDM Assy

4

NSP

NSP

JACB Assy

5

FLKB Assy

6

KEYB Assy

7

SRCB Assy

WYXJ,

WVXJ

VWS1488

VWV1843

VWG2283

VWG2291

VWV1848

WYXQ,

WYXQ/FRGR,

WVXQ

VWS1487

VWV1842

VWG2282

VWG2290

VWV1847

WYXQ,

WYXQ/FRGR,

WVXQ

VWS1487

VWV1842

VWG2282

VWG2290

VWV1847

Remarks

NSP

9

Flexible Cable (16P)

10

Flexible Cable (17P)

11

Flexible Cable (30P)

16

Rear Panel

18

Bonnet S

18

Bonnet

19

Flexible Cable (19P)

20

DVD-V Plate

23

Tray Panel

25

Front Panel Assy

26

Pioneer Name Plate

29

Screw

31

LED Lens

33

CLASS 1 Caution Label

VDA1860

VDA1862

VDA1871

VNA2294

VXX2773

Not used

VDA1866

VAM1120

VNK4837

VXA2477

VAM1129

BCZ40P060FNI

VNK4841

VRW1889

VDA1861

VDA1863

VDA1872

VNA2344

Not used

VNA2333

VDA1867

VAM1121

VNK4837

VXA2469

VAM1129

BCZ40P060FNI

Not used

Not used

VDA1861

VDA1863

VDA1872

VNA2342

Not used

VNA2331

VDA1867

VAM1121

VNK4835

VXA2466

VAM1109

BCZ40P060FZK

Not used

Not used

5

Page 6

DV-545, DV-444-S, DV-444-K

2.3 LOADING MECHANISM ASSY

Note :

Refer to

" Apply Position of Lubricant".

Daifree

GEM1036

2

Refer to

"2.4 TRAVERSE MECHANISM

6

To DVDM

CN151

8

8

ASSY-S".

8

23

15

14

12

Lubricating Oil

GYA1001

13

22

9

22 22

16

8

20

3

17

21

7

A

11

1

A

A

4

5

22

10

Lubricating Oil

GYA1001

18

22

19

LOADING MECHANISM ASSY PARTS LIST

•

Mark No. Description Part No.

NSP 1 LOAB Assy VWG2279

2 Traverse Mechanism Assy-S VXX2782

3 Loading Motor Assy VXX2505

4 Motor Pulley PNW1634

5 Carriage DC Motor / 0.3W PXM1027

6 Flexible Cable (26P) VDA1864

7 Connector Assy 2P VKP2253

8 Float Rubber VEB1327

9 Belt VEB1330

10 Stabilizer VNE2253

6

Mark No. Description Part No.

11 Loading Base VNL1917

12 Float Base DVD VNL1918

13 Drive Cam VNL1919

14 Gear Pulley VNL1921

15 Loading Gear VNL1922

16 Drive Gear VNL1923

17 SW Lever VNL1925

18 Clamper Plate VNE2251

19 Bridge VNE2252

20 Clamper VNL1924

21 Screw JGZ17P028FMC

22 Screw Z39-019

23 Tray VNL1920

Page 7

Apply Position of Lubricant

No. 11

Loading Base

DV-545, DV-444-S, DV-444-K

Lubricating Oil

GYA1001

Around the shaft

Lubricating Oil

GYA1001

Rear View

No. 23

Tray

No. 13

Drive Cam

Inner side of a ditch

Lubricating Oil

GYA1001

Inner side of a ditch

Lubricating Oil

GYA1001

Daifree

GEM1036

Concave of unevenness

Top View

No. 23

Tray

Lubricating Oil

GYA1001

Lubricating Oil

GYA1001

No. 13

Drive Cam

Daifree

GEM1036

Concave of unevenness

Top View

Concave of unevenness

Daifree

GEM1036

Bottom View

Inner side of a ditch

Daifree

GEM1036

Side of the rib

Daifree

GEM1036

7

Page 8

DV-545, DV-444-S, DV-444-K

2.4 TRAVERSE MECHANISM ASSY-S

17 (Torque : 0.12 ± 0.01 N•m)

13

18

10

1

16

18

18

10

12

8

7

6

19

4 (Adjustment Screw)

4 (Adjustment Screw)

5

5

Screw Tight

GYL1001

17 (Torque : 0.12 ± 0.01 N•m)

Silicone Adhesive

GEM1037

3

14

9

Silicone Adhesive

GEM1037

17

(Torque : 0.12 ± 0.01 N•m)

15

Silicone Adhesive

GEM1037

11

TRAVERSE MECHANISM ASSY-S PARTS LIST

•

Mark No. Description Part No.

1 Spindle Motor VXM1088

2 Stepping Motor VXM1090

(CARRIAGE) (or VXM1091)

3 Pickup Assy-S OXX8003

4 Skew Screw VBA1080

5 Skew Spring VBH1335

6 Guide Bar VLL1514

7 Sub Guide Bar VLL1515

8 Hold Spring VNC1017

(or VXM1089)

16

2

Mark No. Description Part No.

9 Joint Spring VNC1019

10 Support Spring VNC1020

NSP 11 Mechanism Chassis VNE2248

12 Slider VNL1811

13 Spacer VNL1913

14 Joint VNL1914

15 FFC Holder VNL1915

16 Screw BBZ20P050FZK

17 Screw OBA8009

18 Screw PMA26P100FMC

19 Damper Sheet VEB1335

8

Page 9

DV-545, DV-444-S, DV-444-K

9

Page 10

1

23

DV-545, DV-444-S, DV-444-K

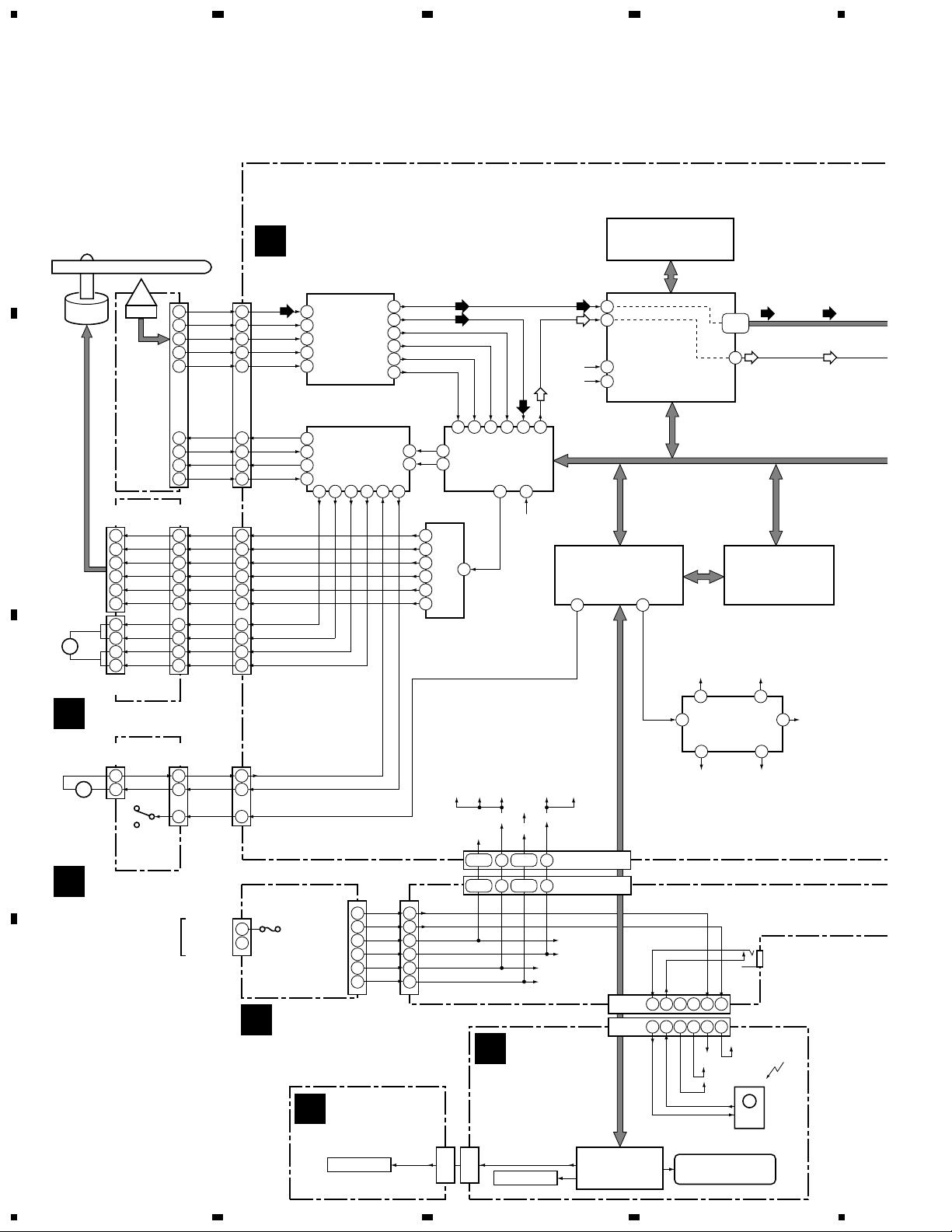

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

DVDM ASSY

B

4

IC712

MSM51V17805D-60TS

16M DRAM

CN151

(26P)

RF

B1

B2

B3

B4

(RF)

RF

16

7

6

12

11

3

B1

B2

B3

B4

6

LA9701M

7

8

9

IC101

RF IC

54

46

56

57

42

35

Spindle

Motor

PICKUP

(26P)

11

20

21

15

16

ASSY

T DRV

25

T RTN

24

F DRV

S101

Loading

Position

Switch

CN601

AC IN

23

F RTN

26

CN3

(17P)

H1+

9

H1-

10

H2+

11

H2-

12

H3+

13

H3-

14

ST1+

1

ST1-

2

ST2+

4

ST2-

5

(5P)

LOD- LOD-

1

LOD+ LOD+

2

SW2 LODPOS

4

LIVE

NEUTRAL

B

CN1

(12P)

9

8

7

6

5

4

3

M

Stepping

Motor

(Carriage)

C

C

A

4

2

1

CN2

(4P)

SSIB ASSY

CN602

(2P)

2

+-

1

M

Loading

Motor

Assy

LOAB ASSY

2

3

4

1

9

10

11

12

13

14

1

2

4

5

1

2

4

1

2

CN61

(17P)

CN51

(5P)

CN1

(2P)

T DRV

T RTN

F DRV

F RTN

F1

12

IC351

13

M56788AFP

9

FTS Driver

10

35 34 31 32 15 14

CN101

(14P)

14

10

8

6

4

2

-27V

EV+5V

+6V

+12V

+5V

+3.3V

POWER

H

SUPPLY

UNIT

D

KEYB ASSY

G

KEY SW

10

(RF) (RF)

RFO

DSP RF

(RF)

BH

PH

FE

TE

32 33 30 31 39 3

FDO

47

3

TDO

48

20

9

10

11

12

13

14

IC201

LC78652W

Servo DSP IC

SPDO

21

IC251

BA6664FM

Spindle

Driver

V+5VV+5S

SW+5

V+6M

28,30 21,23

1,3 8,10

-27V

EV+5V

1

5

7

9

11

13

CN101

(14P)

F

CN201

(4P)

CN102

(4P)

(RF)

46 14

16M

V+5D

V+3D

V3VD

29 22

2

FLKB

ASSY

KEY SW

ROMXA

(AD)

33M

16M

(AD)

System Control

57

LODPOS

V+12D V+12M

V12M

9

V+6M

V+12V

V+5V

V+3V

CN104

CN101

170

112

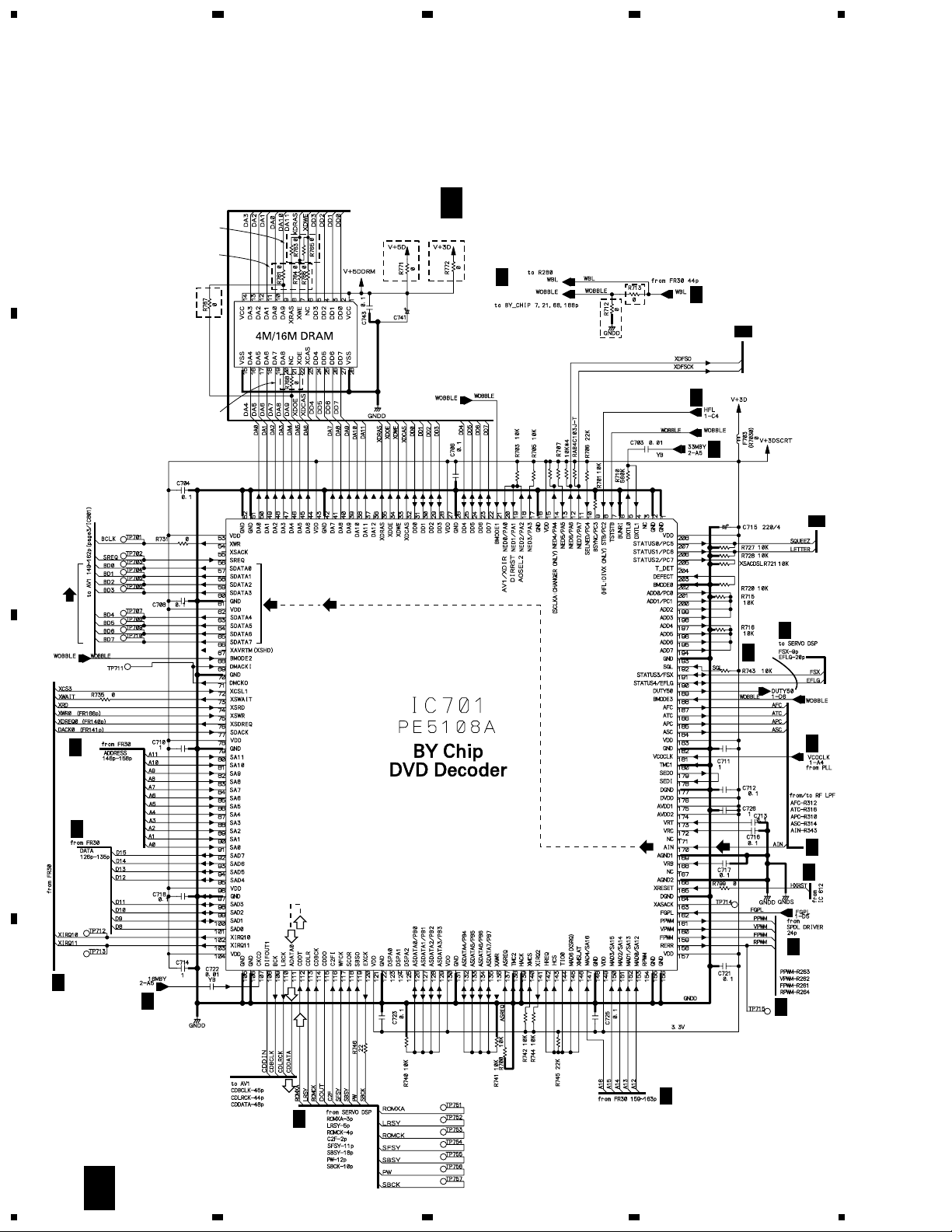

PE5108A

4

DVD Decoder

107

BY Chip

IC601

PD6345A

105

X48/44

X48/44

CONTROLCONTROLCONTROL

CN31 (2/2)

CN102 (2/2)

(16P)

(16P)

IC101

PE5251A

FL Control IC

IC701

27M

(for IC801)

3

IC481

14 15

BU2288FV

Clock Generator

10

22/24M

(for IC211)

(30P)

(30P)

IR

SEL IR

16

1

SEL IR

15

5

2

12116314215

IR

-27V

-27V

FLAC2

FLAC1

V101 VAW1063

FL Tube

(VD) (VD)

57-60

63-66

111

SD0-SD7

CDDATA

IC603

VYW1852

8M Flash Memory

16M

(for IC201, IC701)

13

33M

(for IC701)

9

36/16M

(for IC801)

JA150

CONTROL

EV+5V

E+5V

IR101

Remote

Receiver

Unit

1234

Page 11

5

678

DV-545, DV-444-S, DV-444-K

(RF)

(AD)

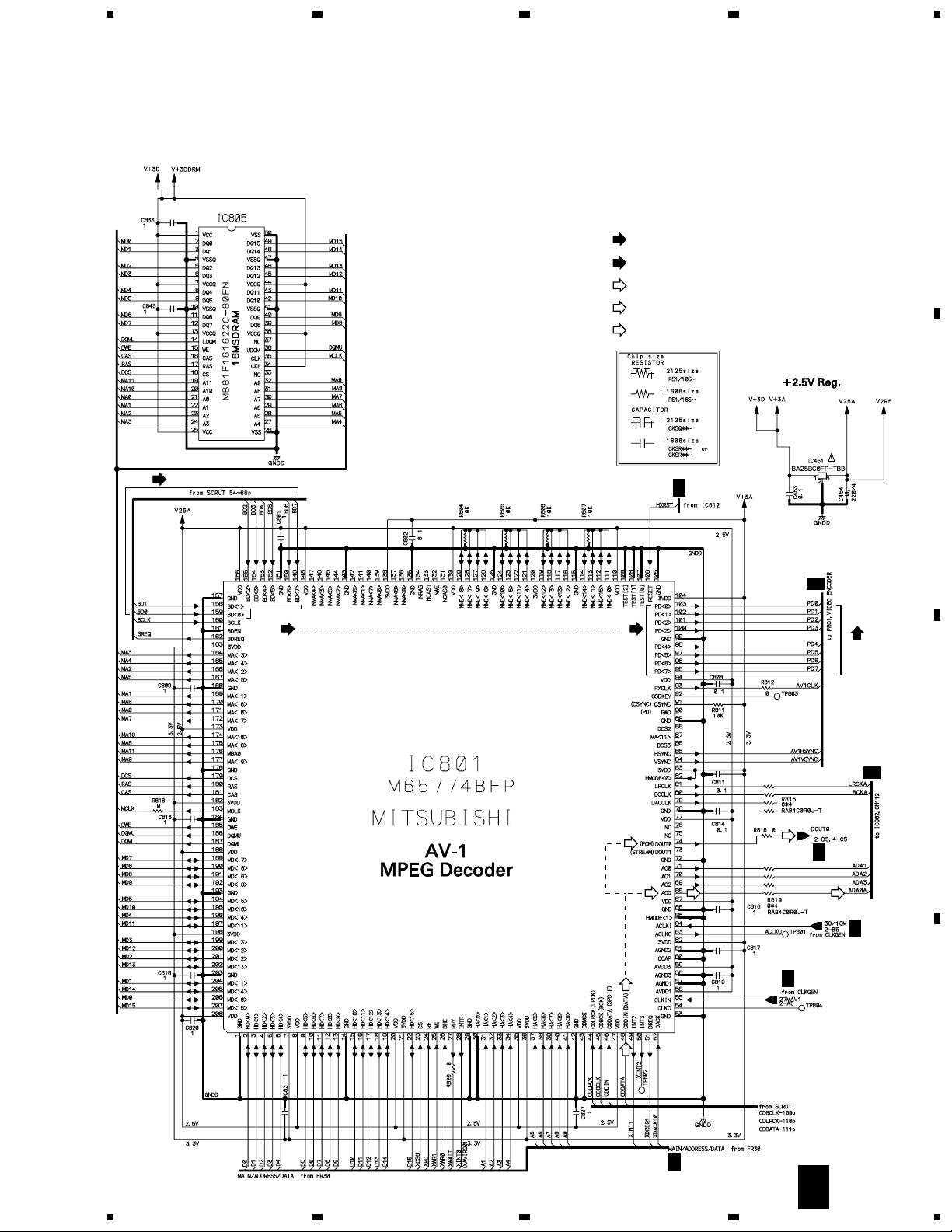

IC805

MB81F161622C-80FN

16M SDRAM

(VD)

149,150,

152-155,

158,159

48

IC801

M65774BFP

MPEG2 Decoder

AV-1

5564

27M36/16M

: RF SIGNAL ROUTE

: AUDIO DATA SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(D)

(D)

DOUT0

74

ADA0A

68

PD0-PD7

95-98,

100-103

(VD)

93

27M

(VD)

(VD)

2-9

27M

48

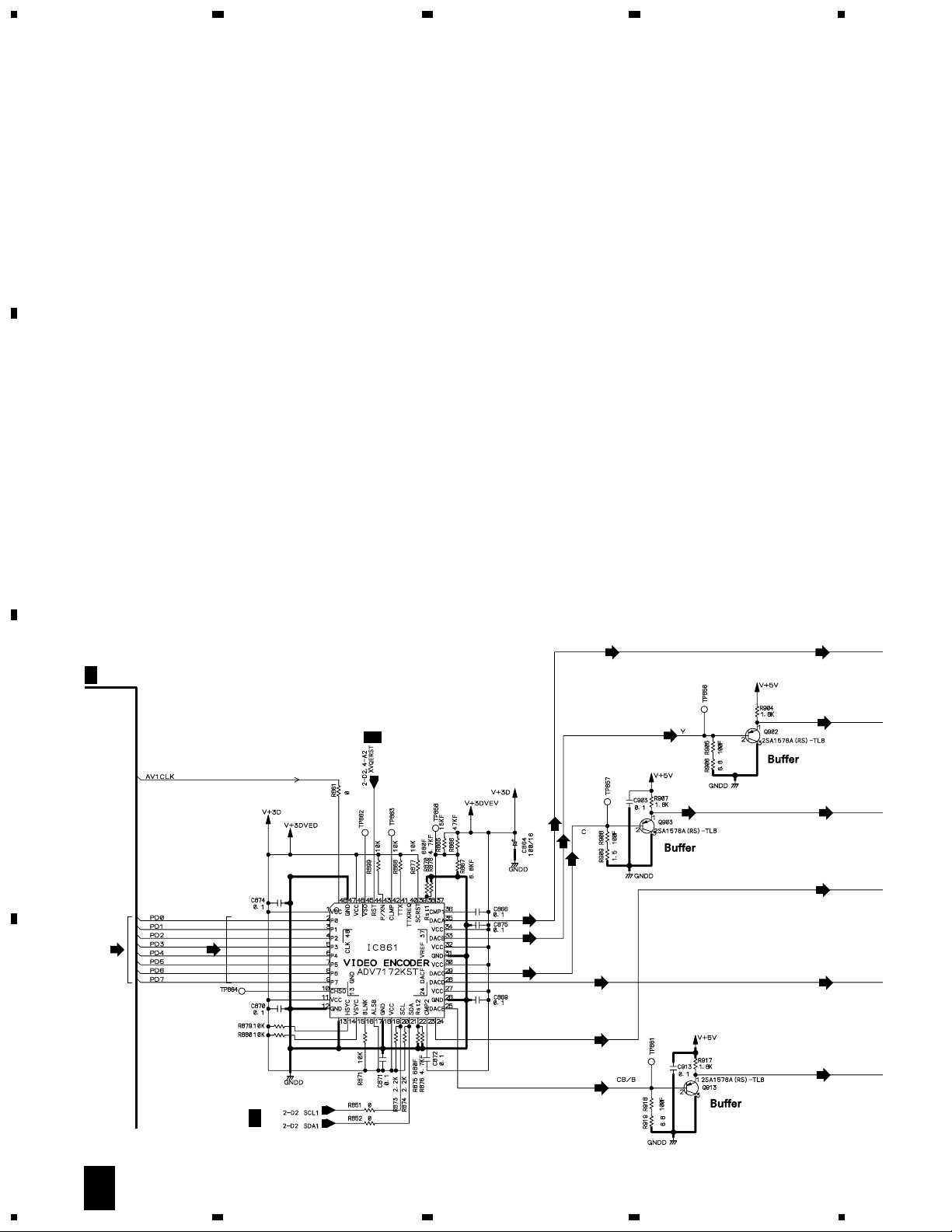

IC861

ADV7172KST

Video Encoder

DV-545 Only

IC807

PD0274A

AQE

Cr/R

24

Y/G

28

Cb/B

25

V

35

Y

33

C

29

(VD)

: VIDEO DATA SIGNAL ROUTE

: VIDEO SIGNAL ROUTE

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

CN31 (1/2)

(30P)

DOUT0

(D) (D) (D)

5 26

DOUT

CN102 (1/2)

(30P)

(C)

: C SIGNAL ROUTE

(R)

: R SIGNAL ROUTE

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

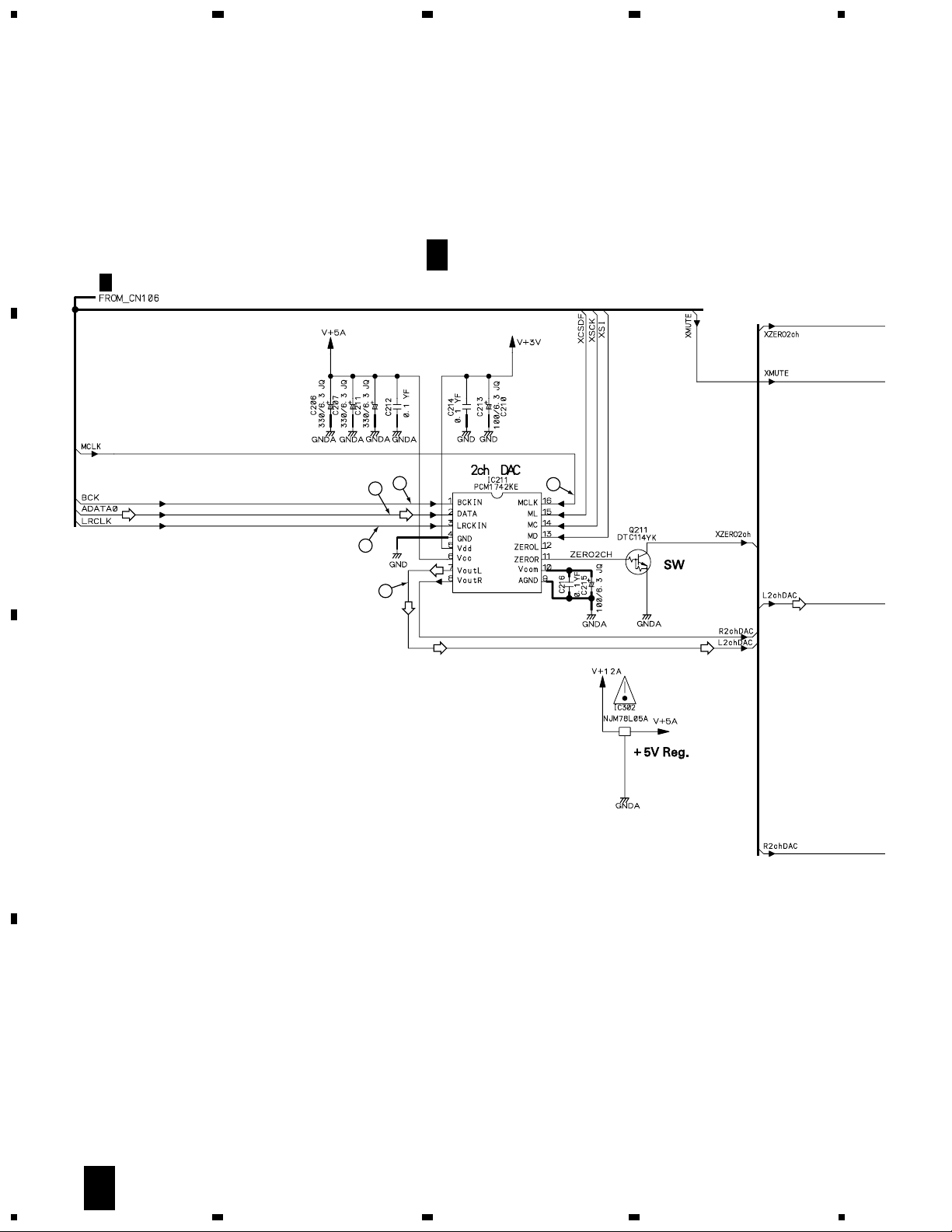

IC211

PCM1742KE

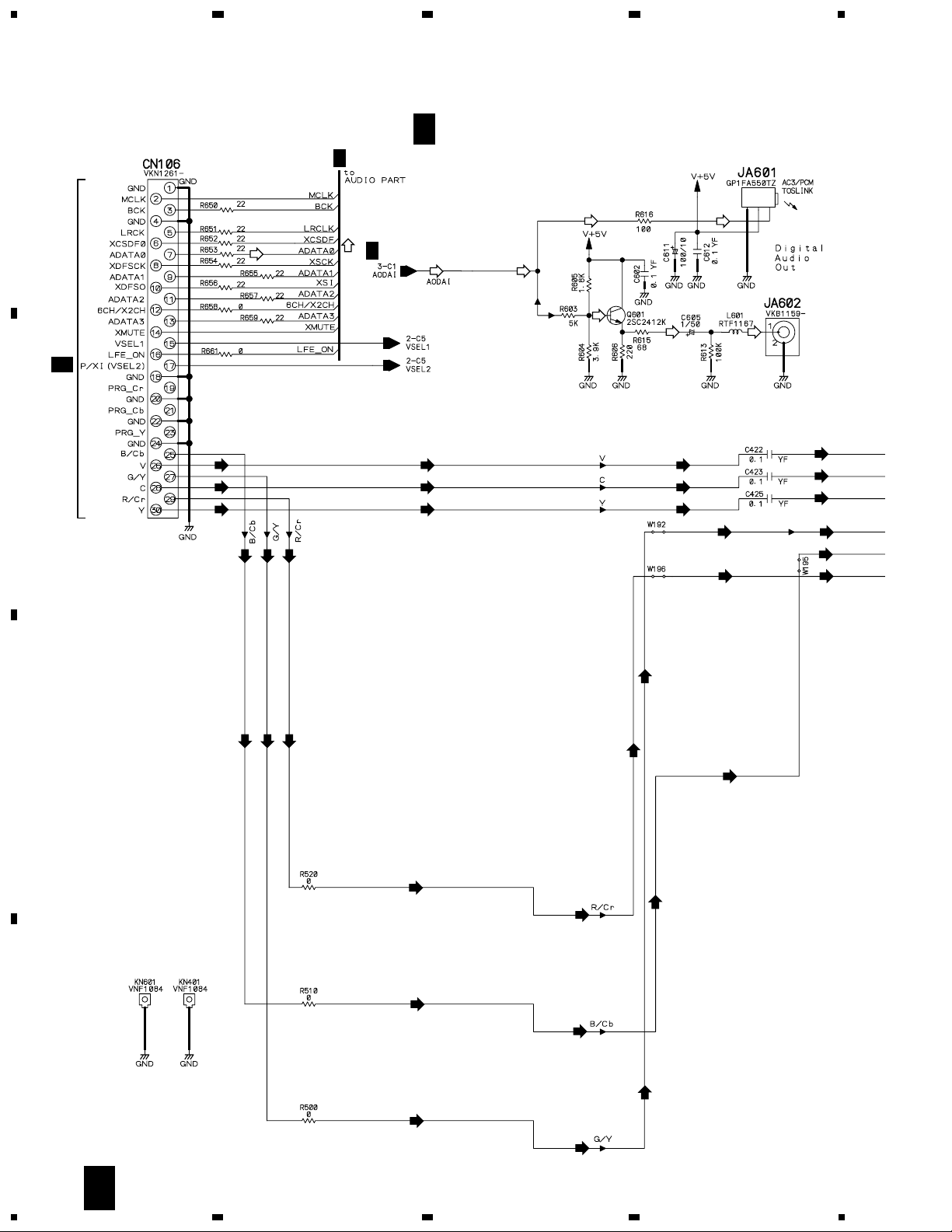

CN106

7

2

29

27

25

26

30

28

(30P)

22/24M

192kHz, 24bit

2ch DAC

2

16

(R)

Cr/R

Y/G

(Y)

Cb/B

(B)

V

(V)

(Y)

Y

C

(C)

7

8

13

9

11

2

6

4

2828

Q912

Q901

Q903

22/24M

Q911

Q913

Q902

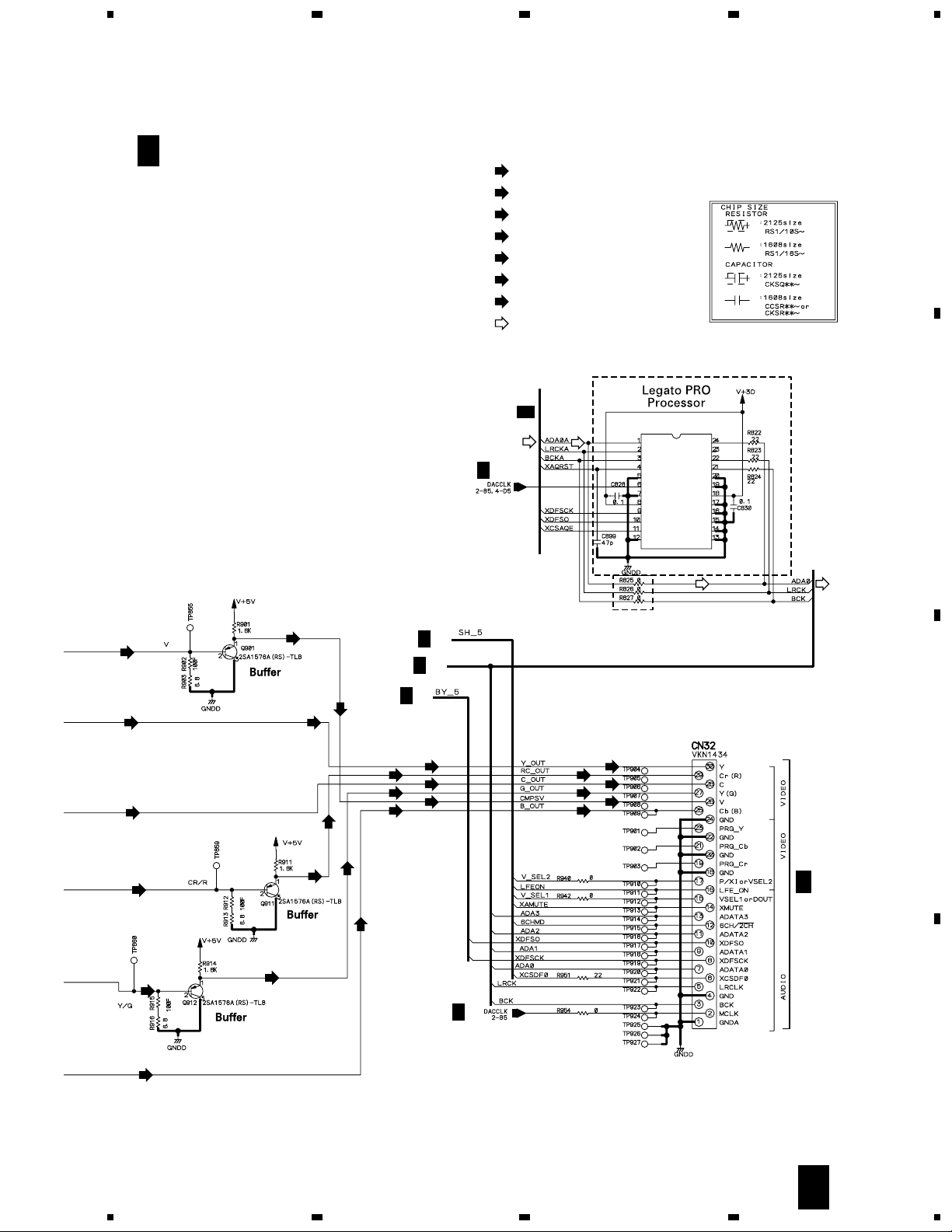

CN32

(30P)

7

2

29

27

25

26

30

28

ADATA0

Cr/R

Y/G

Cb/B

V

Y

C

IC411

MM1540BF

6ch Amp.

Driver with LPF

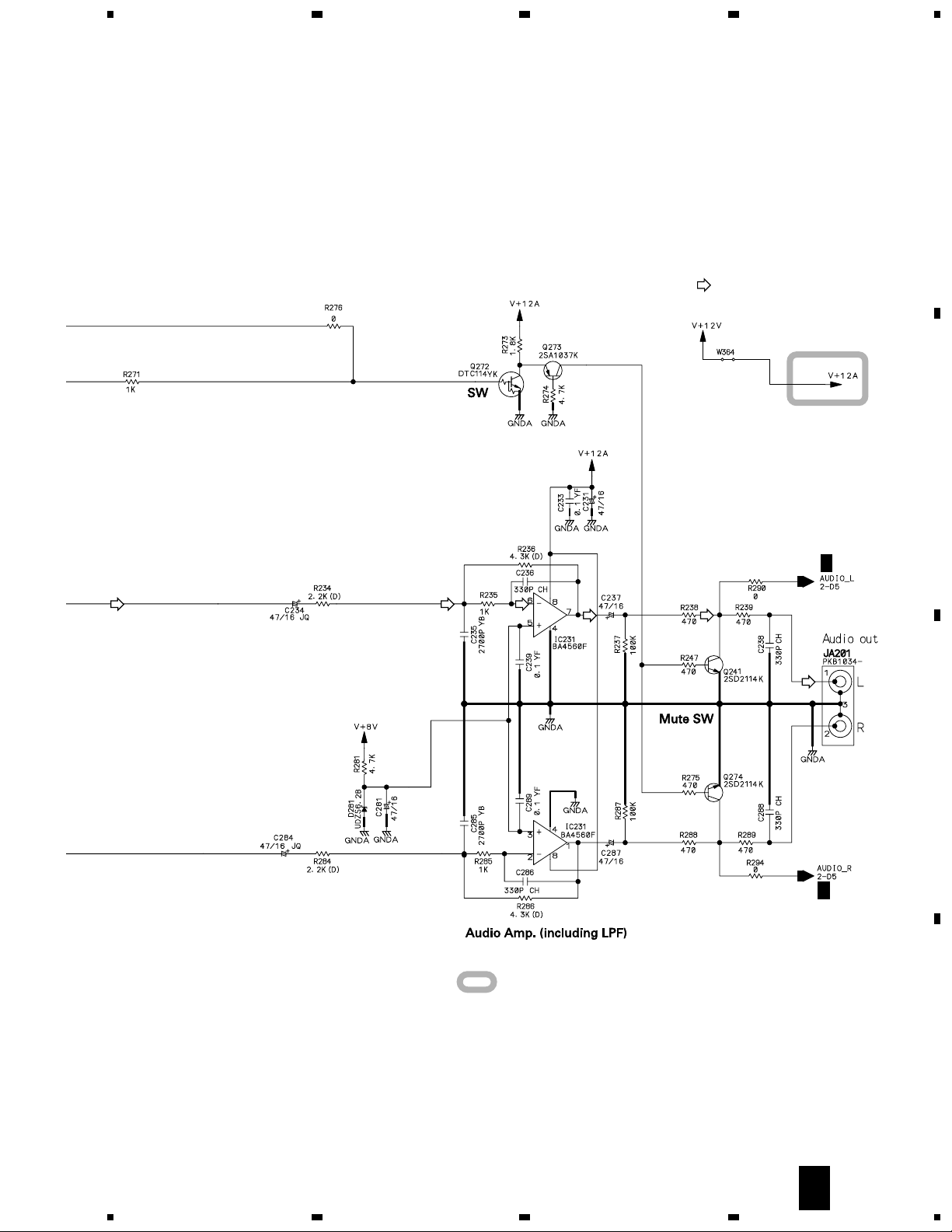

IC231

BA4560F

(V)

V

27

(Y)

Y

23

C

(C)

25

Cr/R

16

Y/G

20

Cb/B

18

(D)

Q601

(D)

(Y)

Y

C

(C)

AUDIO_L

AUDIO_R

(R)

(G)

(B)

V

C

Y

R

G

B

JA601

JA602

JA201

JA401

JA402

7

3

5

16

18

13

9

11

CN405

OPTICAL

DIGITAL

COAXIAL

L

AUDIO

R

S VIDEO

V

COMPOSITE

(19P)

A

B

C

CN701

(19P)

AUDIO_L

AUDIO_R

2

V

(V)

13

(Y) (Y)

Y

15

(C)

C

17

7

11

9

E

6

(R)

R

4

(G)

G

(B)

B

IC802

MM1505XN

SRCB ASSY

2

DV-545 Only

5

6

Relay

(V)

RY801

4

6

(R/C)

(V) (V)

(G)

(B)

DV-545 Only

IC801

MM1507XN

2

Relay

Relay

Relay

RY702

RY803

RY802

DV-545 Only

DV-545

Only

DV-545

Only

7

Relay

RY701

(V/Y)

(R/C)

(G)

(B)

JA701

(21P)

L OUT

34

R OUT

1

(V/Y)

V/Y OUT

19

R/C OUT

15

(R/C)

(B)

(V)

(G)

JA702

(21P)

G OUT

11

B OUT

7

DV-545

L OUT

3

Only

R OUT

1

V OUT

19

D

11

8

Page 12

1

23

DV-545, DV-444-S, DV-444-K

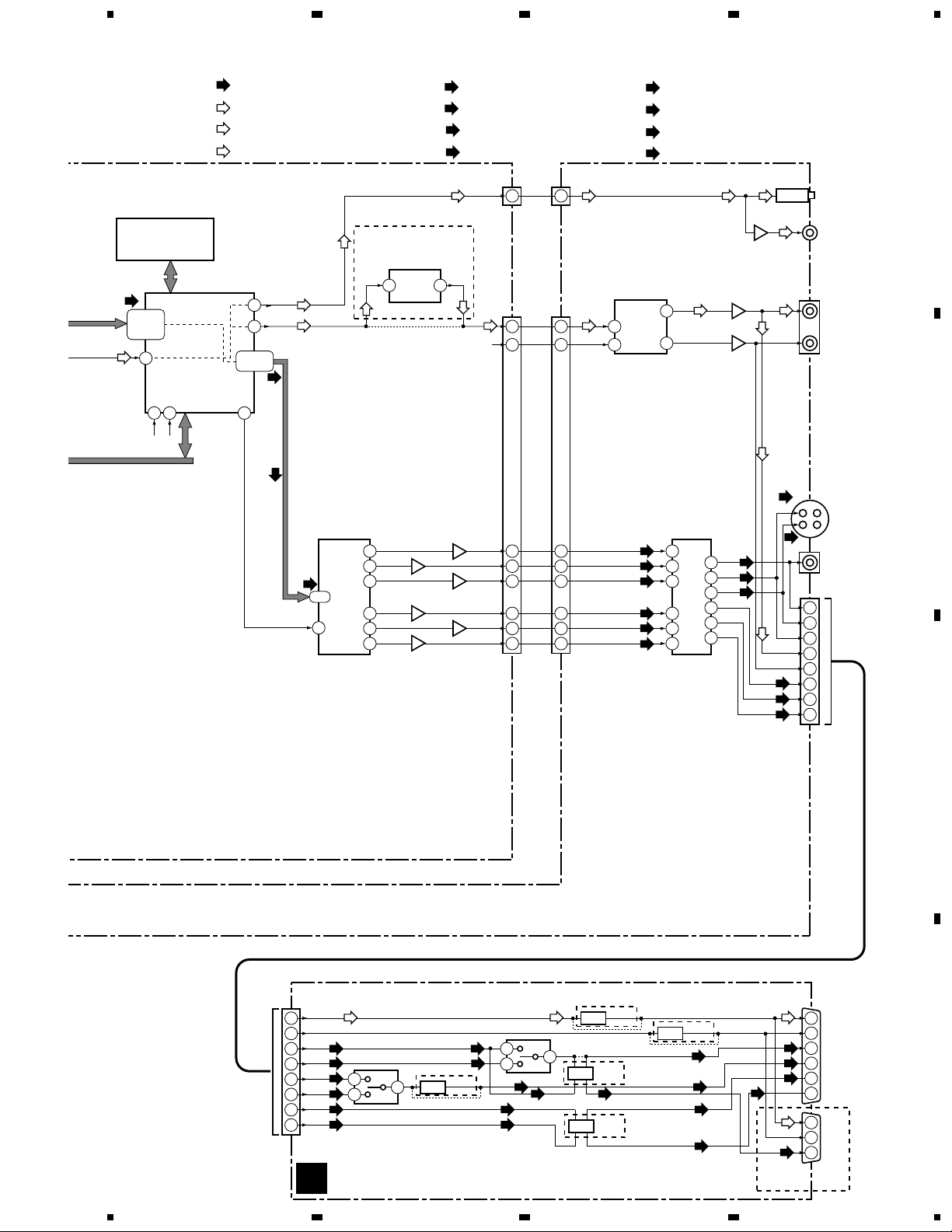

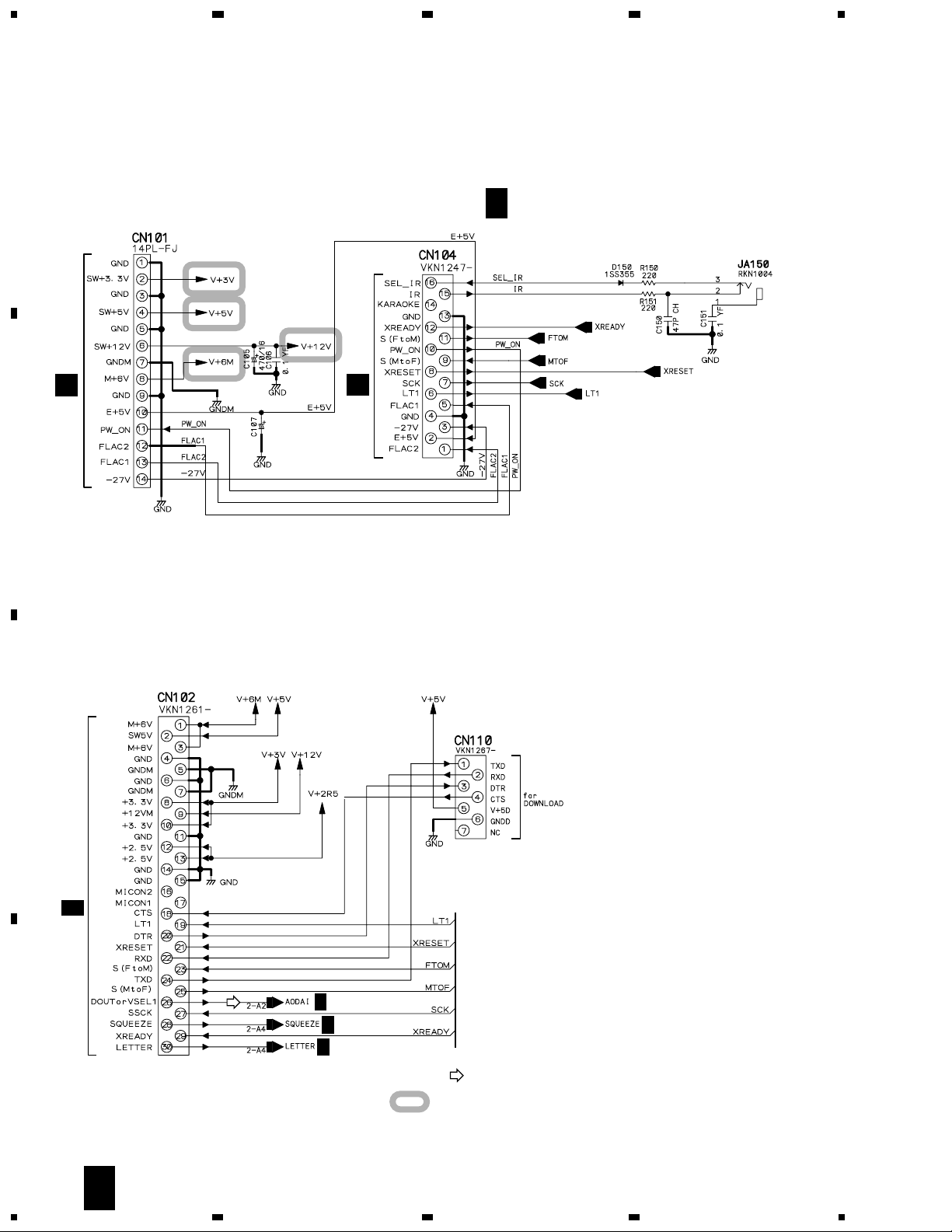

3.2 LOAB, SSIB ASSYS and OVERALL WIRING DIAGRAM

A

4

FLKB ASSY

F

(DV-545 : VWG2283)

(DV-444-S, K : VWG2282)

B

D

D 1/3- D 3/3

KEYB ASSY

G

(DV-545 : VWG2291)

(DV-444-S, K : VWG2290)

JACB ASSY

(DV-545 : VWV1843)

(DV-444-S, K : VWV1842)

C

D

E

SRCB ASSY

(DV-545 : VWV1848)

(DV-444-S, K : VWV1847)

JA702JA701

12

1234

DV-545 ONLY

Page 13

5

678

DV-545, DV-444-S, DV-444-K

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

(RF)

: RF SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

H

POWER SUPPLY

UNIT

(VWR1340)

PICKUP ASSY-S (OXX8003)

: SLIDER SERVO LOOP LINE

POWER CORD

WYXJ, WYXQ, WYXQ/FR/GR : ADG1154

WVXJ, WVXQ : ADG1156

AC110-127V, 220-240V

50/60Hz

A

B

B 1/4- B 4/4

B

DVDM ASSY

(DV-545 : VWS1488)

(DV-444-S, K : VWS1487)

(RF) (RF) (RF) (RF)

(F)

(F)

(T)

(T)

(F)

(F)

(F)

(T)

(T)

(F)

VKN1272

(S)

(S)

(S)

(S)

(S)

(S)

(S)

(S)

CN3

VKN1277

SSIB ASSY

C

(VWG2292)

VKN1264

CN1

(F)

(T)

(T)

(F)

CN2

(F)

(F)

(T)

(T)

(F)

(F)

(F)

(T)

(T)

(F)

STEPPING MOTOR

(CARRIAGE)

: VXM1090

SPINDLE MOTOR

: VXM1088

C

S101

: VSK1011

D

CN602

S2B-PH-K

CN601

S5B-PH-K

LOAB ASSY (VWG2279)

A

5

6

7

LOADING

MOTOR

ASSY

: VXX2505

CA

13

8

Page 14

1

23

DV-545, DV-444-S, DV-444-K

4

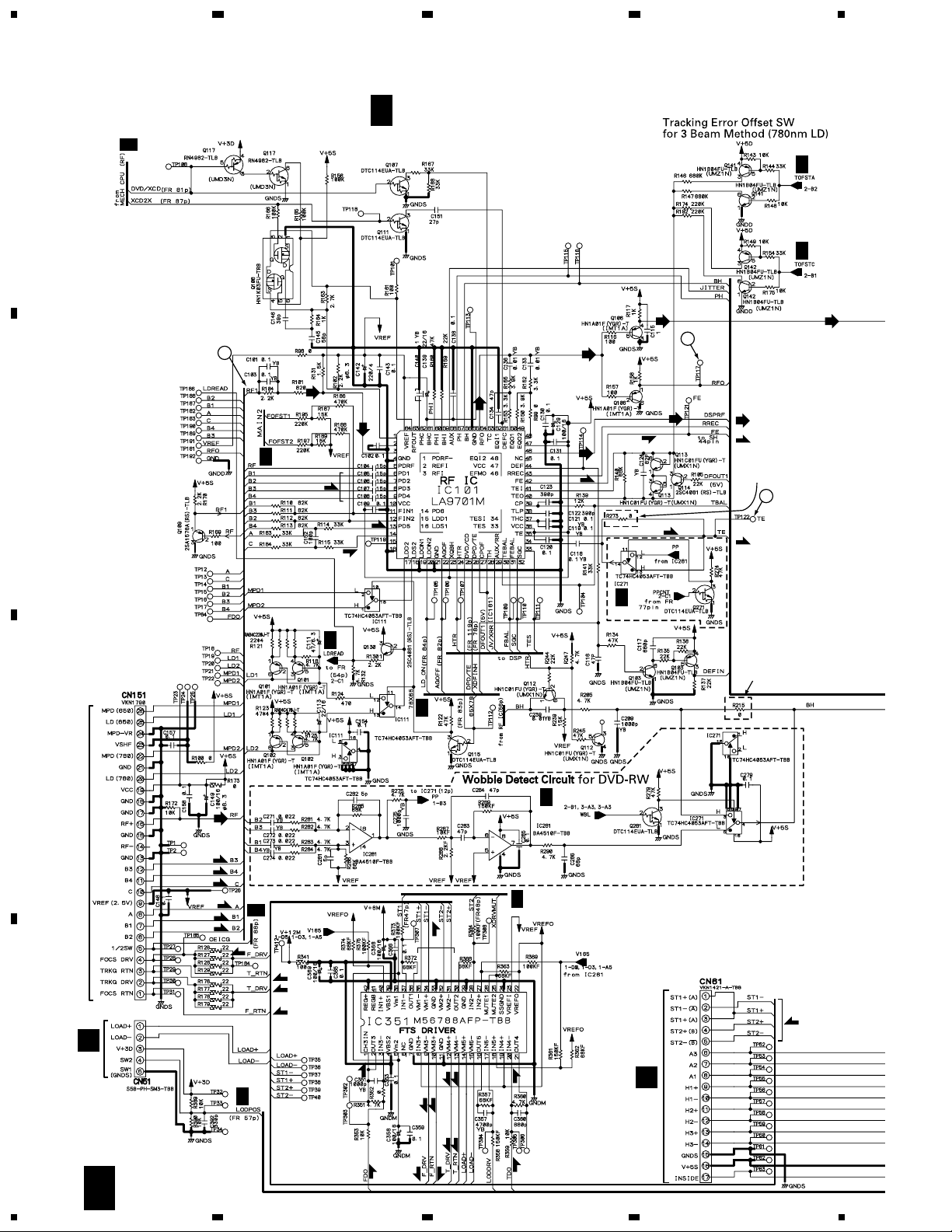

3.3 DVDM ASSY (1/4)

2/4

B

A

B

B 1/4

DVDM ASSY

(DV-545 : VWS1488)

(DV-444-S, K : VWS1487)

(V) (V)

1

(RF)

(RF)

B

2/4

(F)

(T)

(T)

(V)

(V)

(F)

(A)

(F)

B

2/4

2

(A)

(T)

(A)

(F)

(T)

DV-545

ONLY

B

B

DV-444-S, K

ONLY

4

2/4

2/4

B

2/4

DV-444-S, K

ONLY

B

2/4

C

(RF)

(F)

(F)

PICKUP ASSY

(T)

(T)

(F)

(F)

2/4

B

(F)

(T)

(T)

(F)

DV-545

ONLY

B

2/4,3/4

B

2/4

(S)

DV-545

ONLY

(S)

A

CN601

D

B

2/4

(F)

(T)(T)

(F)

(F)

(T)(T)

(T)

C

CN3

14

(F)

(F)

(F)

1/4

B

1234

(T)

Page 15

5

678

DV-545, DV-444-S, DV-444-K

DV-444-S,K

ONLY

B

(V)

3/4

DV-545

ONLY

DV-545

ONLY

R332

DV-545 : 470

DV-444-S, K : 330

IC304

R336

DV-545 : 100k

DV-444-S, K : 0

C322

DV-545 : 0.01

DV-444-S, K : 18p

R328

DV-545 : 1k

IC304

DV-545 : TC7SZU04F

DV-444-S, K : TC7SHU04F

R336

DV-545 : 3.3k

DV-444-S, K : 2.2k

DV-444-S, K : 1.8k

DV-545

ONLY

C314

DV-545 : 15p

DV-444-S, K : 22p

R314

DV-545 : 22k

DV-444-S, K : 10k

(V) (V)

R310

DV-545 : 82k

DV-444-S, K : 47k

R312

DV-545 : 10k

DV-444-S, K : 15k

2/4

B

B

3/4

(RF)

: RF SIGNAL ROUTE

(V)

: RF (VIDEO) SIGNAL ROUTE

(A)

: RF (AUDIO) SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(F)

: FOCUS SERVO LOOP LINE

(T)

: TRACKING SERVO LOOP LINE

(S)

: SLIDER SERVO LOOP LINE

DV-444-S, K

ONLY

DV-545 : 10k

FV-444-S, K : 33k

A

B

6

B

2/4

(AD)

3/4

B

(T)

(F)

(A)

(F)

(T)

B

2/4

(T)

(F)

5

(A)

(F)

(T)

B

3/4

B

2/4,3/4

C

8 9

7

B

2/4

B

3/4

1110

D

B

3/4

1/4

B

5

6

7

8

15

Page 16

1

23

DV-545, DV-444-S, DV-444-K

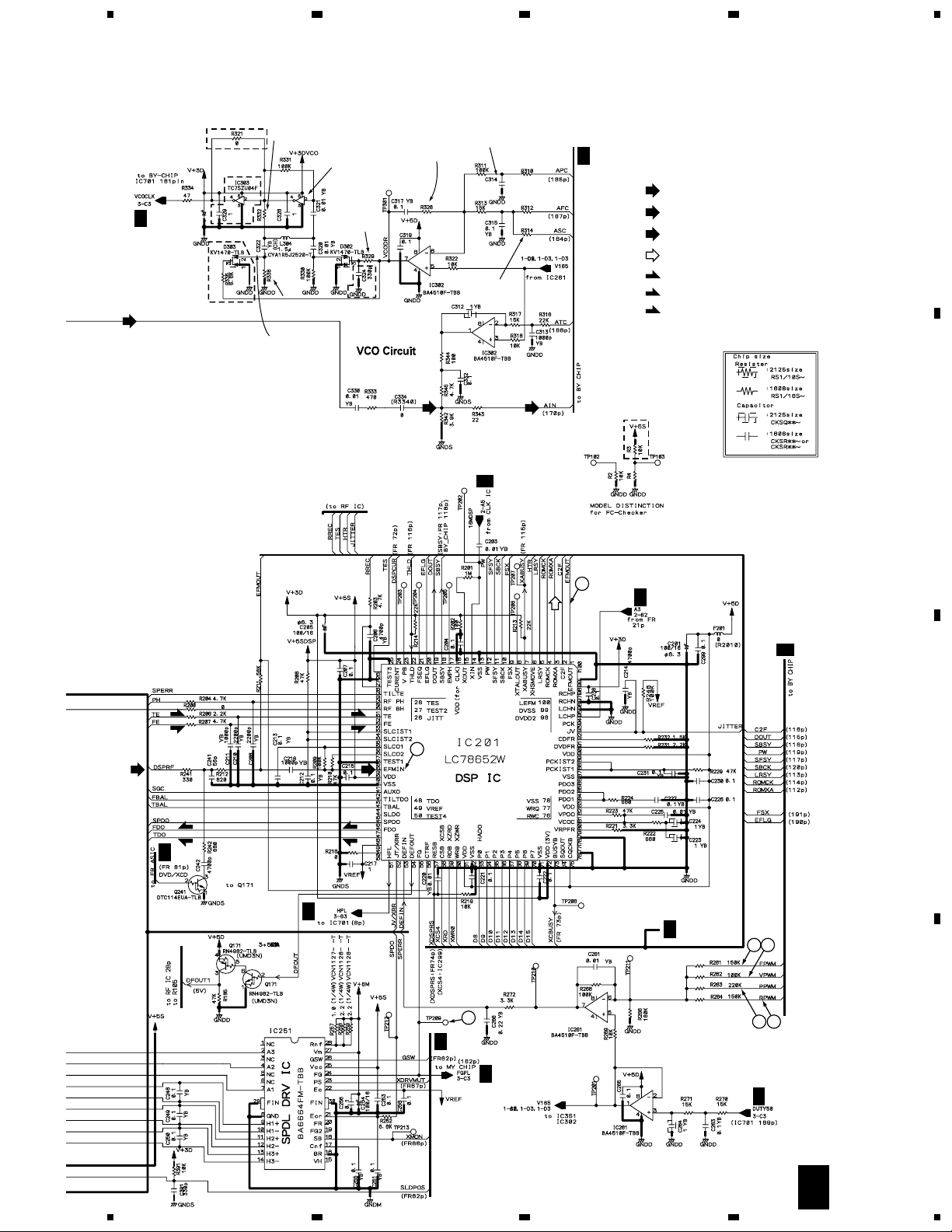

3.4 DVDM ASSY (2/4)

4

A

B 2/4

DVDM ASSY

(DV-545 : VWS1488)

(DV-444-S, K : VWS1487)

VYW1852

3/4

B

1/4

B

1/4

B

1/4,3/4

B

1/4

B

B

1/4

B

3/4

B

3/4

B

B

1/4

C

B

1/4

D

B

1/4

B

4/4

SH5

4/4

B

4/4

B

B

1/4

4/4

B

SH5

16

2/4

B

1234

Page 17

5

678

DV-545, DV-444-S, DV-444-K

VTL1078

B

3/4

B

4/4

B

3/4

B

3/4

B

3/4

B

1/4

B

B

3/4

1/4

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

A

B

1/4

B

C

D 1/3

CN102

(D)

(D)

B

3/4

B

3/4

: The power supply is shown with the marked box.

5

6

7

(D)

B

2/4

8

D

17

Page 18

1

DV-545, DV-444-S, DV-444-K

3.5 DVDM ASSY (3/4)

A

23

4

DV-444-S, K

ONLY

DV-545

ONLY

DV-444-S, K

ONLY

DV-545

ONLY

B

DV-444-S, K

ONLY

DV-545

ONLY

DV-545 : 220/4

DV-444-S, K : 100/16

IC712

DV-545 : MSM51V17805D-60TS

DV-444-S, K : MNR4800DJ7

B 3/4

DVDM ASSY

(DV-545 : VWS1488)

(DV-444-S, K : VWS1487)

B

1/4

DV-545 ONLY

B

DV-444-S, K

ONLY

B

2/4

1/4

B

4/4

B

BY-5

2/4

2/4

B

(VD)

(VD)

(V)

B

1/4

B

1/4

B

B

2/4

C

B

2/4

(AD)

B

2/4

B

2/4

(AD)

D

B

2/4

B

1/4

18

3/4

B

1234

(V)(V)

1/4

B

1/4

B

2/4

B

1/4

B

1/4

Page 19

5

678

DV-545, DV-444-S, DV-444-K

A

(V)

: RF (VIDEO) SIGNAL ROUTE

(VD)

: VIDEO DATA SIGNAL ROUTE

(AD)

: AUDIO DATASIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

(VD)

(VD) (VD)

(D)

B

B

2/4

4/4

B

(VD)

(D)

4/4

B

B

2/4

C

B

2/4

B

2/4

D

B

2/4

3/4

B

5

6

7

8

19

Page 20

1

DV-545, DV-444-S, DV-444-K

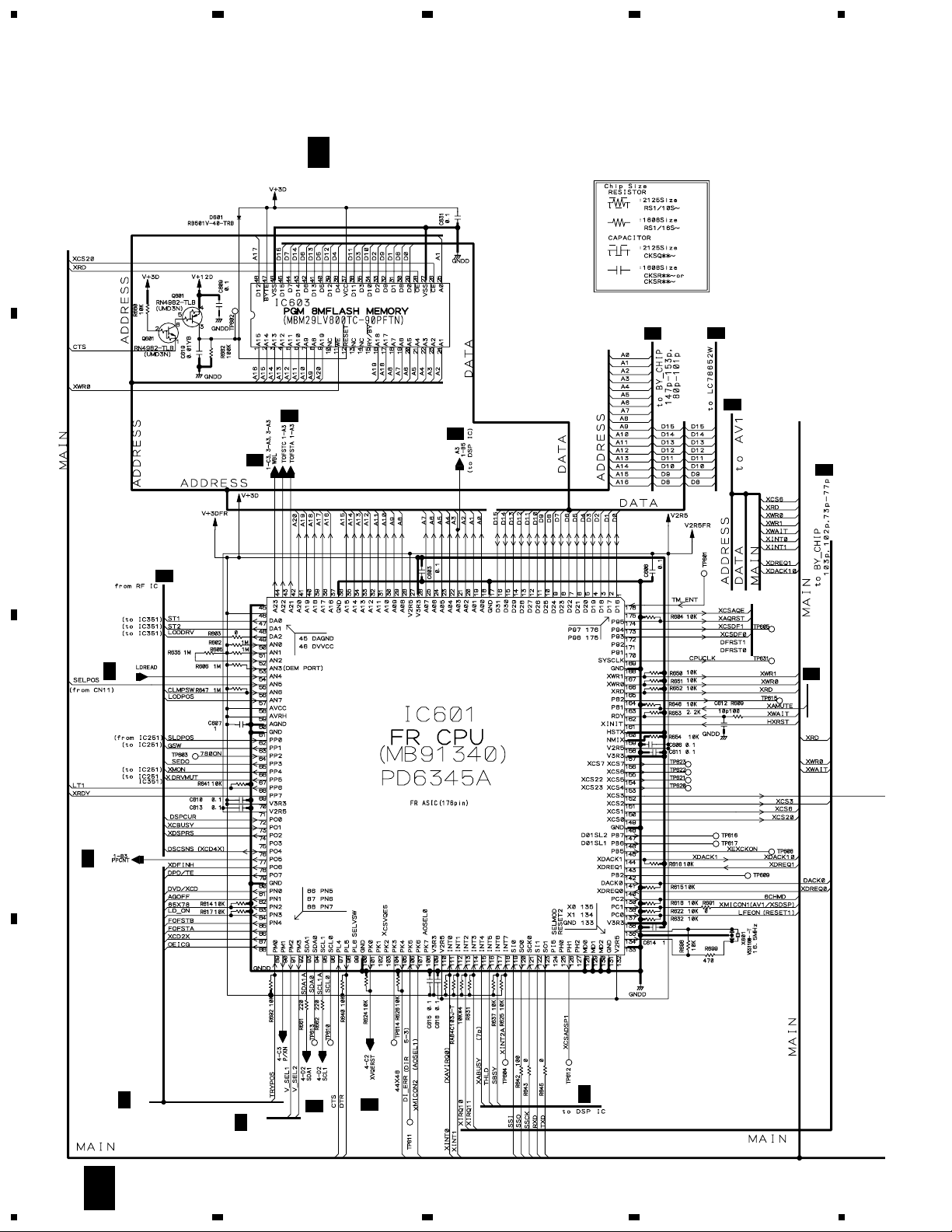

3.6 DVDM ASSY (4/4)

A

B

23

4

(V) (V)

B

3/4

2/4

B

C

(V)

(Y)

(C)

(V)

(VD) (VD)

D

(Y)

(C)

(R)

(B)

(Y)

(C) (C)

(Y)

(R)

(G)(G)

(B)

20

B

2/4

4/4

B

1234

Page 21

5

678

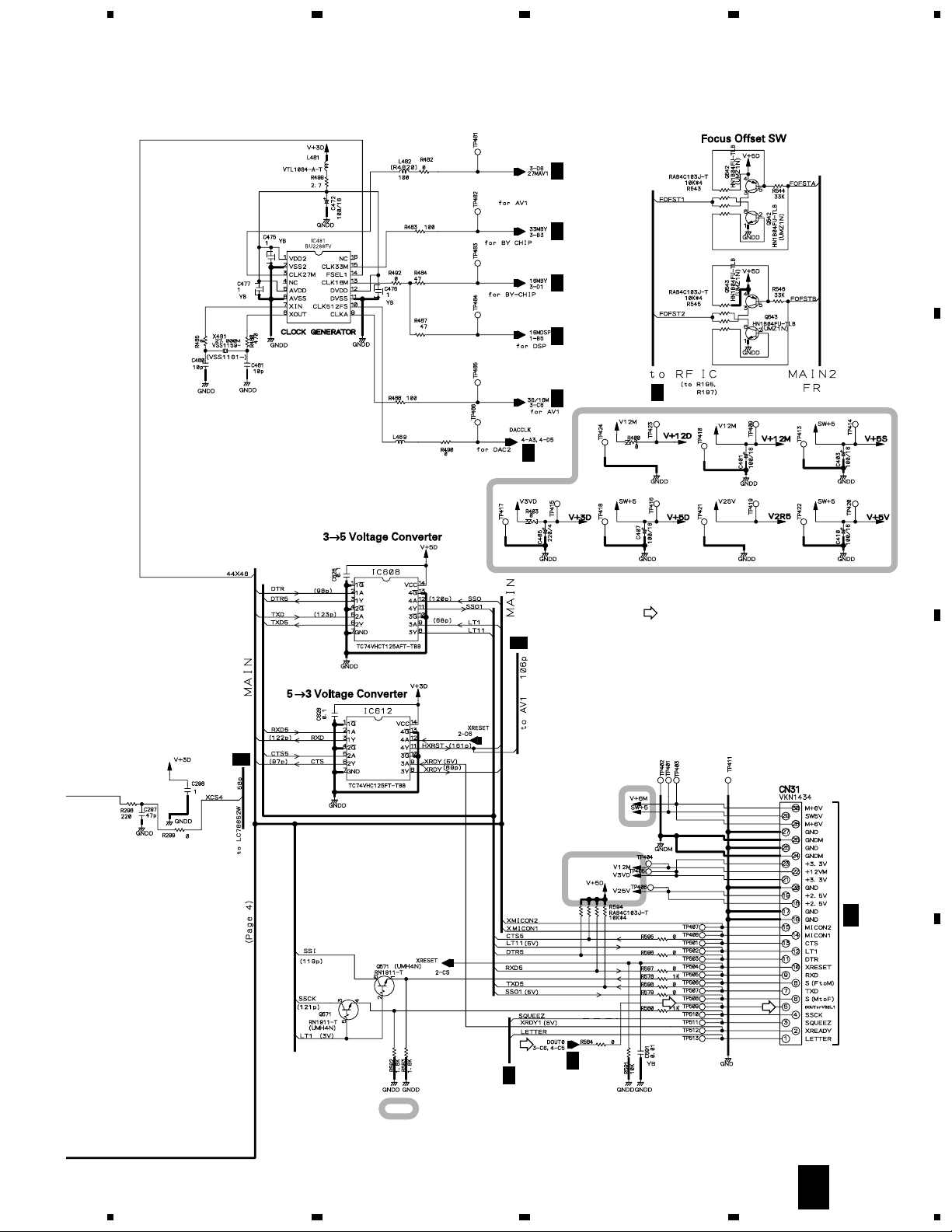

DV-545, DV-444-S, DV-444-K

B 4/4

DVDM ASSY

(DV-545 : VWS1488)

(DV-444-S, K : VWS1487)

(VD)

: VIDEO DATASIGNAL ROUTE

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(R)

: R SIGNAL ROUTE

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

3/4

B

B

2/4

DV-545 ONLY

PD0274A

A

B

IC807

(AQE)

(V)

(V)

(Y) (Y)

(C)

(R)

(G)

(G)

(B)

(R)

(R)

DV-444-S, K

B

2/4

B

3/4

B

(R)

(G)

3/4

(Y)

(C)

(V)

(B)

(R)

(G)

(V)

(G)

ONLY

(Y)

(C)

(V)

(B)

C

D 3/3

CN106

(B)

B

2/4

D

4/4

B

5

6

7

8

21

Page 22

1

DV-545, DV-444-S, DV-444-K

3.7 JACB ASSY (1/3)

A

23

4

D 1/3

JACB ASSY

(DV-545 : VWV1843)

(DV-444-S, K : VWV1842)

CONTROL

INPUT

CN101

G

B

CN101

F

C

CN31

B 2/4

(D)

D

22

1/3

D

1234

D

3/3

D

3/3

D

3/3

(D)

: AUDIO (DIGITAL) SIGNAL ROUTE

: The power supply is shown with the marked box.

Page 23

DV-545, DV-444-S, DV-444-K

23

Page 24

1

DV-545, DV-444-S, DV-444-K

3.8 JACB ASSY (2/3)

A

23

4

D 2/3

D

3/3

JACB ASSY

(DV-545 : VWV1843)

(DV-444-S, K : VWV1842)

B

3

1

4

2

5

C

D

24

2/3

D

1234

Page 25

5

678

DV-545, DV-444-S, DV-444-K

A

: AUDIO SIGNAL ROUTE

B

D

D

: The power supply is shown with the marked box.

3/3

C

3/3

D

2/3

D

5

6

7

8

25

Page 26

1

23

DV-545, DV-444-S, DV-444-K

4

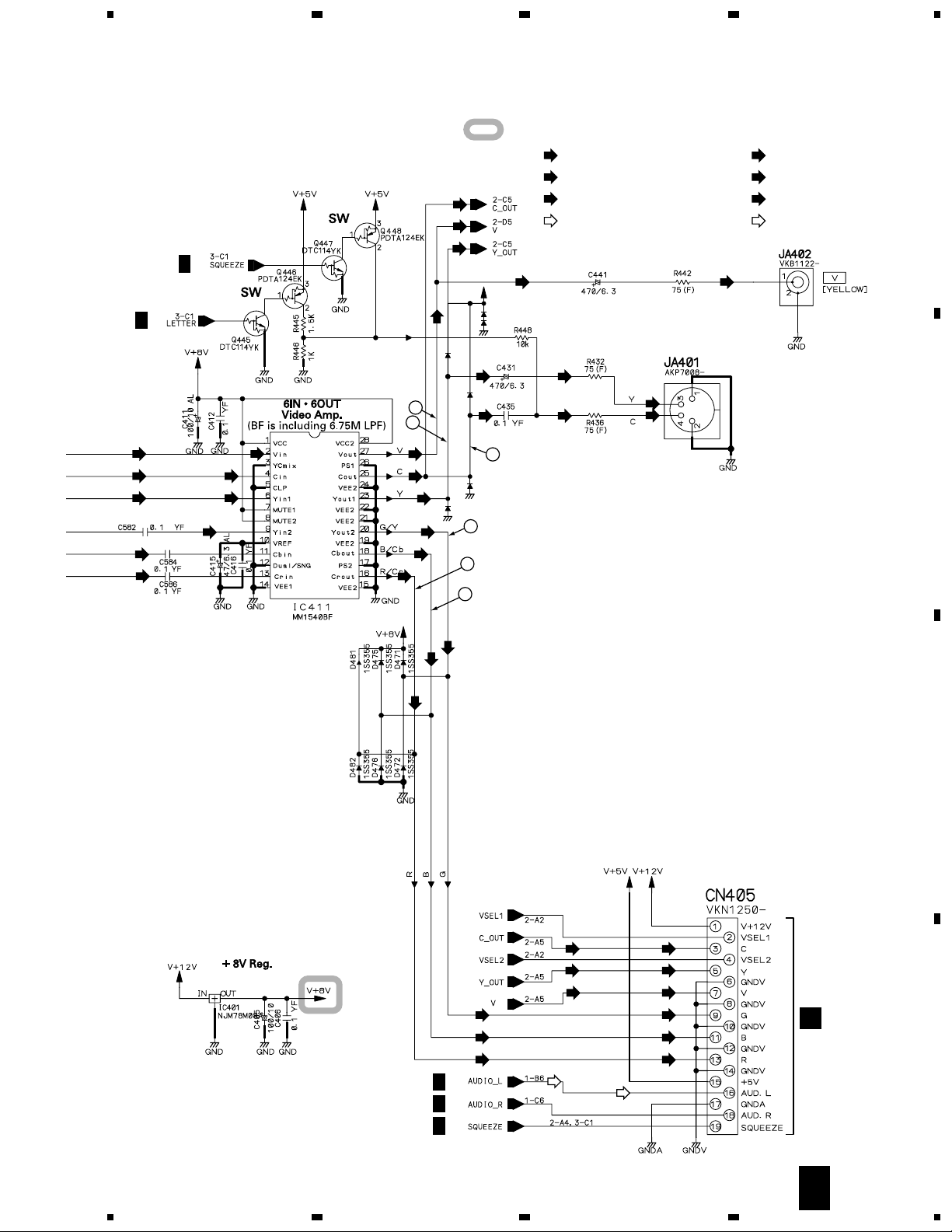

3.9 JACB ASSY (3/3)

A

CN32

B 4/4

B

(V)

(C)

(Y)

D 3/3

D

2/3

D

1/3

(D) (D)

(V)

(C)

(Y)

(B)

(R)

(G)

JACB ASSY

(DV-545 : VWV1843)

(DV-444-S, K : VWV1842)

(D)

(D)

(D) (D)

(V)

(C)

(Y)

(D)

(G)

(V)

(C)

(Y)

(G)

(B)

(R)(R)

(G)(G)

(B)

(R)

(G)

C

(R)

(R)

(B)

(B)

D

(G)

(G)

(R)

(B)

(B)

26

3/3

D

1234

Page 27

5

D

1/3

D

1/3

(V)

(C)

(Y)

(G)

(B) (B)

(R)

(C)

(Y)

(V)

678

DV-545, DV-444-S, DV-444-K

: The power supply is shown with the marked box.

(R)

(V)

(C)

(G)

D432

1SS355

7

8

(Y)

D431

1SS355

(V)

(Y)

(C)

(V)

(Y)

V+8V

(V)

1SS355

1SS355

(Y)

D435

1SS355

(C) (C)

(C)

(D)

(V)

D441

D442

6

D436

1SS355

8

10

9

: V SIGNAL ROUTE

: Y SIGNAL ROUTE

: C SIGNAL ROUTE

(Y)

(C)

(Y)

(R)

(V)

S TERMINAL

OUTPUT

: R SIGNAL ROUTE

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

: AUDIO SIGNAL ROUTE: AUDIO (DIGITAL) SIGNAL ROUTE

COMPOSITE

VIDEO

OUTPUT

A

B

(G)

(B)

(R)

C

(C)(C)

(Y)(Y)

(V)(V)

(G)

(B)

(R)

(G)

(B)

(R)

E

CN701

D

D

2/3

D

2/3

D

1/3

3/3

D

5

6

7

8

27

Page 28

1

DV-545, DV-444-S, DV-444-K

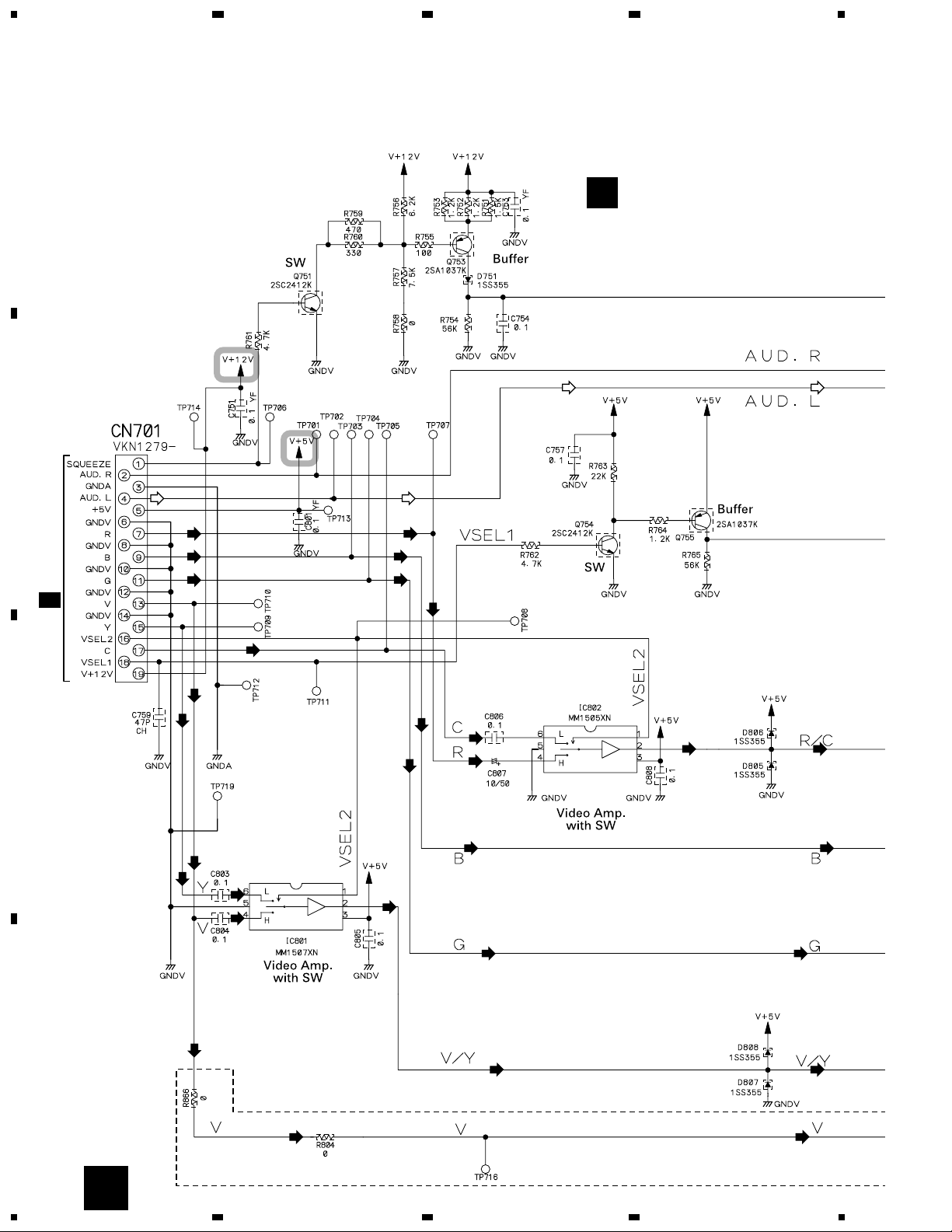

3.10 SRCB ASSY

A

B

23

E

SRCB ASSY

(DV-545 : VWV1848)

(DV-444-S, K : VWV1847)

4

(R)

(B)

CN405

(G)

D 3/3

(C)

(V)

(Y)(Y)

C

(V)

(Y)

(V)

(V/Y)

(B)

(G)

(R)

(G)

(R)

(B)

(C)

(R)

(B)

(G)

(R/C)

(R/C)

(B)

(G)

(V)

D

28

E

1234

DV-545

ONLY

(V)

(V/Y)

(V/Y)

(V)

Page 29

5

678

DV-545, DV-444-S, DV-444-K

: The power supply is shown with the marked box.

DV-545

ONLY

1SS355

DV-444-S, K

ONLY

DV-545

ONLY

DV-444-S, K

ONLY

DV-444-S, K

ONLY

(V)

: V SIGNAL ROUTE

(Y)

: Y SIGNAL ROUTE

(C)

: C SIGNAL ROUTE

(R/C)

DV-545

ONLY

(V/Y)

(G)

(B)

(R)

: R SIGNAL ROUTE

(G)

: G SIGNAL ROUTE

(B)

: B SIGNAL ROUTE

: AUDIO SIGNAL ROUTE

(R/C)

A

B

DV-545

ONLY

(R/C) (R/C)

(B) (B)

(G)

DV-444-S, K

ONLY

(V/Y)

(V/Y)

DV-545

ONLY

(V)

(G)

DV-444-S, K

ONLY

(V)

(V)

DV-444-S, K

ONLY

(B)

(G)

(V/Y)

(R/C)

DV-545

ONLY

(V/Y)

(V)

(V/Y)

DV-545

ONLY

(B) (B)

(V/Y)

(G)

DV-545

ONLY

(V)

C

(V)

DV-545

ONLY

(V)

D

E

5

6

7

8

29

Page 30

1

23

DV-545, DV-444-S, DV-444-K

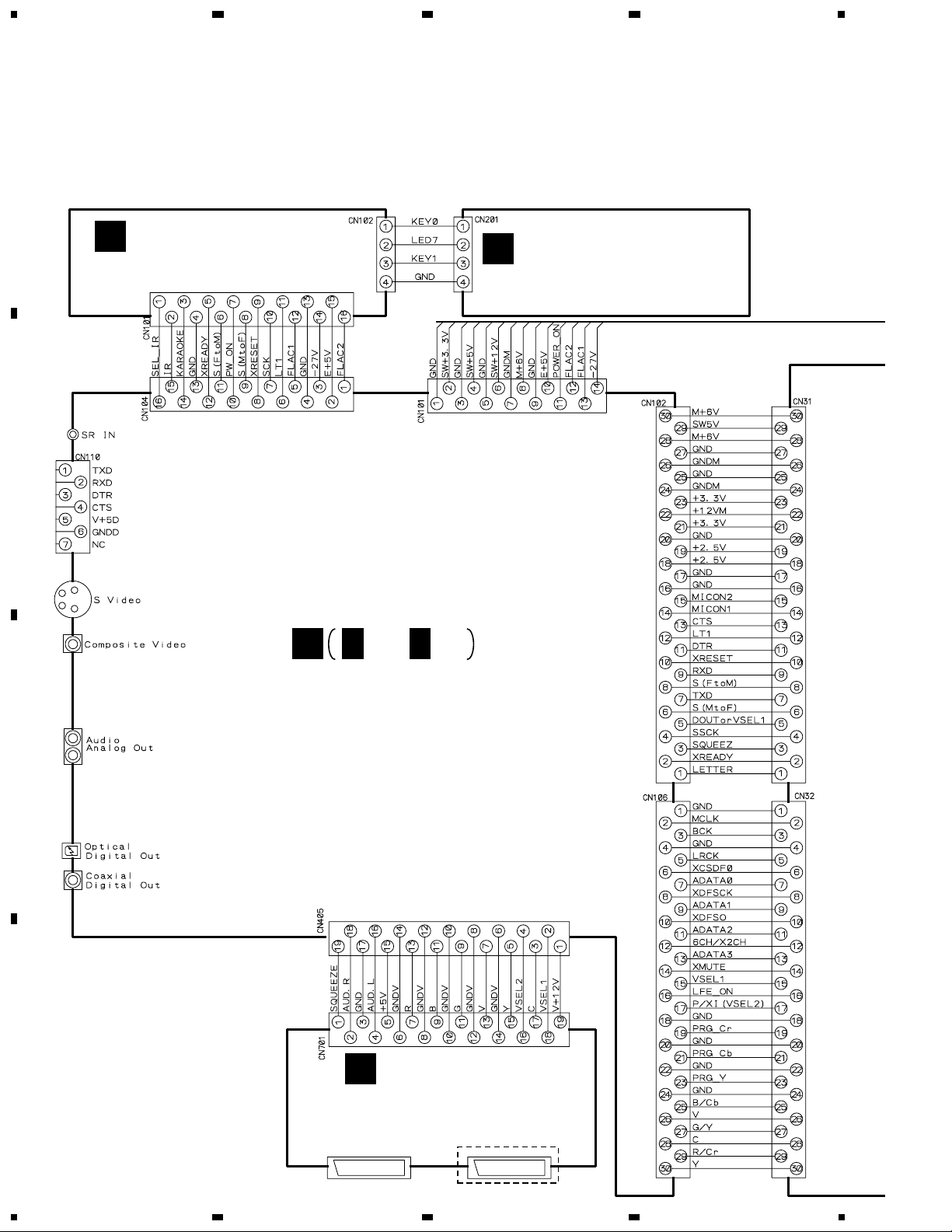

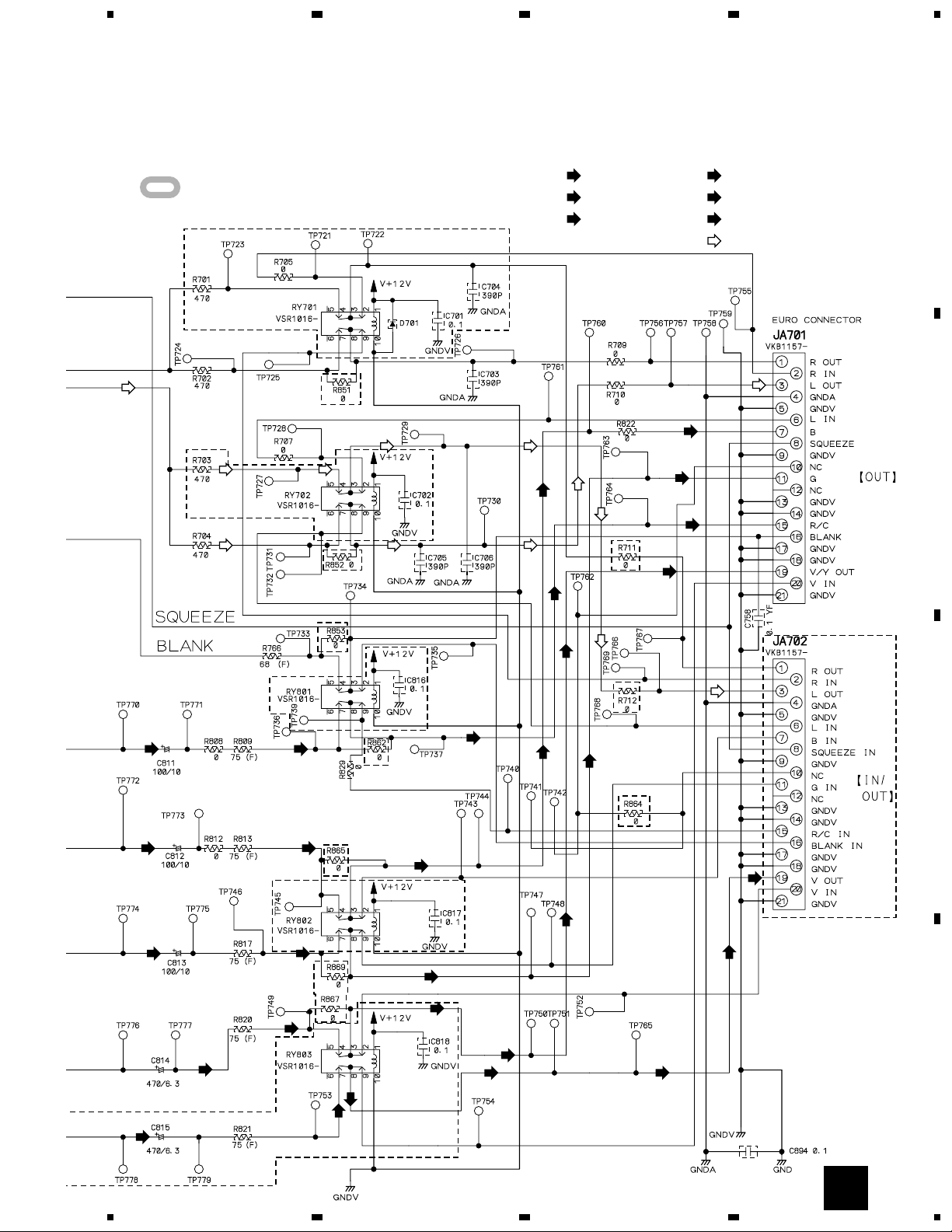

3.11 FLKB and KEYB ASSYS

4

A

FLKB ASSY (DV-545 : VWG2283)

F

(DV-444-S, K : VWG2282)

DV-545

ONLY

DV-545

ONLY

B

DV-444-S, K

ONLY

DV-545

ONLY

DV-444-S, K

ONLY

DV-545

ONLY

C

D

30

F

1234

Page 31

5

678

DV-545, DV-444-S, DV-444-K

G

Remote Control

IR Signal

Receiver Unit

KEYB ASSY (DV-545 : VWG2291)

(DV-444-S, K : VWG2290)

DV-545

ONLY

: The power supply is shown with the marked box.

FLKB ASSY

S101 : 8 (PAUSE)

S102 : 7 (STOP)

S203 : 3 (PLAY)

KEYB ASSY

S103 : ¡ ¢ (FWD)

S104 : 4 1 (REV)

S105 : Legato PRO (DV-545 ONLY)

S201 : 3 (PLAY)

S202 : (STANDBY/ON)

A

B

C

D 1/3

CN104

D

GF

5

6

7

8

31

Page 32

1

CN1

CN101

AC IN

A

A

B

B

6

8

4

2

1

10

11

14

12

13

12V

6V

EV5V

SW5V

PO CONT

SW3.3V

GND

–27V

FLAC (B)

FLAC (A)

GND

3

GND

5

GND

7

GND

9

CN101

D 1/3

F101

REK1102

2.5A

Z1

C1

LIVE

NEUTRAL

C2

C5

C5

C82

C8

C7

GND

BEA1

BEA2

R2

R71

R72

Q71

D71

R74 R73

D72

D7

D23

D24

C22

C11

C108

R301

R304

C302

R302

R307

R104

R403

R404

R405

Q401

Q402

D402 D403

R401

R420

R303

R410

Q412

R402

C110

R414

R407

R408

R409

D404

R103

R10

C9

R8

C21

C10

D25

R20

R12

D5

R17

D9

R23

R201

R202

R205

R203

R204

VR201

C201

R24

R25

R11

R22

D8

D4

PC1

D6

R9

Q20

Q1

Q2

PC2

PC1

IC201

R7

R6

R5

R19

R1

D14

D13

T1

D11

D12

D81

D82

D83

R84 R85

Q81

R82R83

C81

L1

D105

D104

C107

D103

D102

P101

AEK7063

P102

AEK7066

C105

C106

C410

L101

C109

Q411

Q410

D111

D407

D112

D405

D406

D107

D301

D108

D109

D304

C112

PC2

C111

C411

IC103

IC102

C301

C303

800mA

1.6A

NOTE OF SPARE PARTS IN POWER SUPPLY (SYPS) UNIT

• In case of repairing, use the described parts only to prevent an accident.

• Please write the red mark on the board when the primary section of POWER SUPPLY (SYPS) Unit is repaired.

• Please take care to keep the space, not touching other parts when replacing the parts.

POWER SUPPLY UNIT (VWR1340)

H

BEA401

BEA3

DV-545, DV-444-S, DV-444-K

3.12 POWER SUPPLY UNIT

A

23

4

B

C

D

32

H

1234

Page 33

WAVEFORMS

Note : The encircled numbers denote measuring point in the schematic diagram.

DV-545, DV-444-S, DV-444-K

DVDM ASSY

B

Measurement condition : No. 1 to 4 and 6 to 11 : MJK1, Title 1-chp 1

No. 5 : CD, ABEX-784 Track 1

Foot of R104 (RF)

1

V: 100mV/div. H: 0.2µsec/div.

TP117 (RFO)

2

V: 500mV/div. H: 0.1µsec/div.

3

GND

GND

TP209 (FG)

7

V: 1V/div. H: 5msec/div.

Foot of R261 (FPWM)

8

V: 1V/div. H: 5msec/div.

Foot of R262 (VPWM)

9

V: 1V/div. H: 5msec/div.

JACB ASSY

D

Measurement condition : No. 1 to 5 : DVD-REF-A1, T1-Chap.1

No. 6 to 10 : DVD-REF-A1, T1-Chap.19

IC211 - pin 2 (ADATA)

1

V: 1V/div. H: 500nsec/div.

IC211 - pin 7, 8 (AUDIO L, R)

2

V: 1V/div. H: 50µsec/div.

IC211 - pin 1 (BCK)

3

V: 1V/div. H: 100nsec/div.

IC411 - pin 27 (V)

7

V: 1V/div. H: 10µsec/div.

IC411 - pin 20, 23 (G)

8

V: 1V/div. H: 10µsec/div.

IC411 - pin 18 (B)

9

V: 1V/div. H: 10µsec/div.

TP122 (Tracking Error)

4

(AI-Inner Tracking Off)

V: 500mV/div. H: 2msec/div.

IC201 - pin 39 (EFM before slice)

5

V: 1V/div. H: 1µsec/div.

IC201 - pin 1 (EFM)

6

V: 1V/div. H: 0.2µsec/div.

GND

GND

Foot of R263 (PPWM)

10

V: 1V/div. H: 5msec/div.

Foot of R264 (RPWM)

11

V: 1V/div. H: 5msec/div.

IC211 - pin 3 (LRCK)

4

V: 1V/div. H: 5µsec/div.

IC211 - pin 16 (MCK)

5

V: 1V/div. H: 20nsec/div.

IC411 - pin 25 (C)

6

V: 1V/div. H: 10µsec/div.

IC411 - pin 16 (R)

10

V: 1V/div. H: 10µsec/div.

33

Page 34

DV-545, DV-444-S, DV-444-K

34

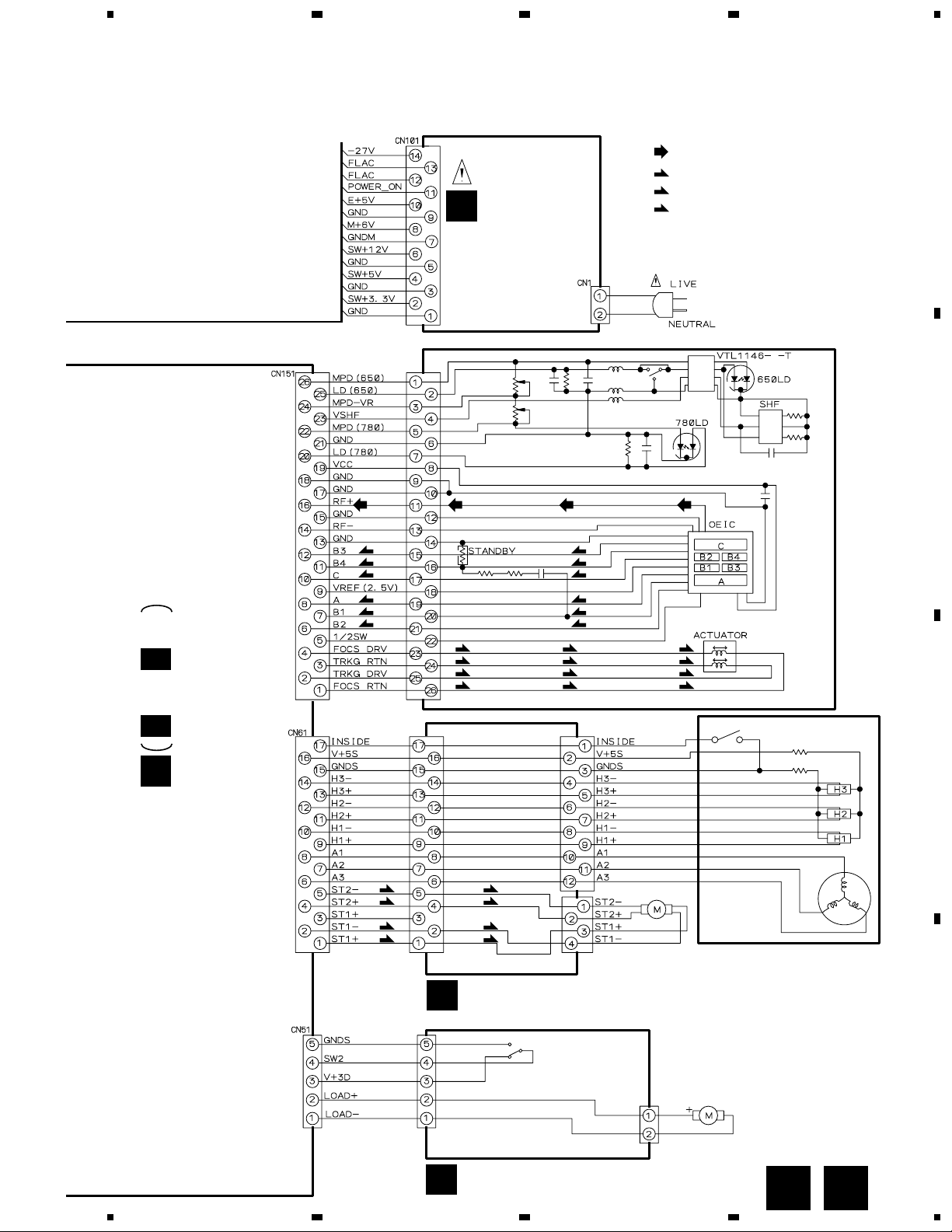

Page 35

1

SIDE A SIDE B

4.1 LOAB and SSIB ASSYS

(VNP1836-B)

(VNP1820-B)

(VNP1820-B)

(VNP1836-B)

CN51

B

LOAB ASSY

A

SSIB ASSY

C

SSIB ASSY

C

LOAB ASSY

A

CN61

B

LOADING

MOTOR

ASSY

M

SPINDLE

MOTOR

M

STEPPING

MOTOR

(CARRIAGE)

M

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Symbol In PCB

Diagrams

Symbol In Schematic

Diagrams

Part Name

BCE

D

DGGSS

BCE

BCE

DGS

BCEBCE

BCE

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3-terminal

regulator

Capacitor

Connector

P.C.Board

Chip Part

SIDE A

SIDE B

4. PCB CONNECTION DIAGRAM

234

DV-545, DV-444-S, DV-444-K

A

B

C

1

2

D

CA

3

4

35

Page 36

1

23

DV-545, DV-444-S, DV-444-K

4.2 DVDM ASSY

4

CN102

A

B

DVDM ASSY

B

D

PICKUP ASSY

Q601

IC608

IC612

IC601

IC712

Q141

IC481

Q111

IC451

Q115

IC281

Q571

Q107

Q114

IC302

IC261

Q117

Q108

Q118

Q116

IC304

IC303

Q109

C

(DV-545 : VNP1822-A)

(DV-444-S, DV-444-K : VNP1823-A)

D

CN106

D

SIDE A

A

CN601

C

IC805 IC806

IC861

IC881

Q911 Q913 Q902

Q922

Q923

CN3

Q102

IC201

IC351

36

B

1234

Page 37

SIDE B

DVDM ASSY

B

IC603

IC701

IC299

Q542

Q543

Q106

Q103

Q271

Q171

Q281

Q112

Q130

Q241

Q292

Q901 Q903 Q912

Q921

IC101

IC271

IC291

IC111

IC251

IC807

Q142

IC801

(DV-545 : VNP1822-A)

(DV-444-S, DV-444-K : VNP1823-A)

1

234

DV-545, DV-444-S, DV-444-K

A

B

C

D

B

1

2

3

4

37

Page 38

1

23

DV-545, DV-444-S, DV-444-K

4.3 JACB ASSY

4

A

JACB ASSY

D

F

CN101

B

CN31

B

C

B

CN32

E

CN701

D

38

IC571

D

1234

IC411

IC401

IC301

IC211

IC302IC311

IC331IC325

Page 39

5

678

DV-545, DV-444-S, DV-444-K

SY

A

SIDE A

B

(VNP1820-B)

H

CN101

C

D

IC201IC371IC351IC231IC331 Q291

D

5

6

7

8

39

Page 40

1

A

3

23

DV-545, DV-444-S, DV-444-K

4

A

D

J

SIDE B

B

(VNP1820-B)

C

D

40

IC602

IC371

Q399

IC351Q301-Q303Q601

Q334-Q337Q391-Q397

IC231

Q241

D

1234

Q272-Q274

Q351

Q331 Q251

IC331

Q

I

Page 41

5

678

DV-545, DV-444-S, DV-444-K

JACB ASSY

D

A

B

4

Q331 Q251

Q351

IC331

Q352

IC325

C

D

Q276 Q211 IC211

Q261-Q264

5

IC301

6

IC311

IC221 Q314

IC180

Q541 Q531Q321

Q501 Q511

Q521

Q551

IC571

7

Q445-Q448

Q571Q572IC411

D

8

41

Page 42

1

23

DV-545, DV-444-S, DV-444-K

4.4 SRCB ASSY

4

A

SRCB ASSY

E

B

Q801 Q802

CN405

D

(VNP1820-B)

SIDE A

SRCB ASSY

E

C

D

(VNP1820-B)

Q754 Q755 IC802 IC801 Q752

Q753

Q751

42

SIDE B

E

1234

Page 43

1

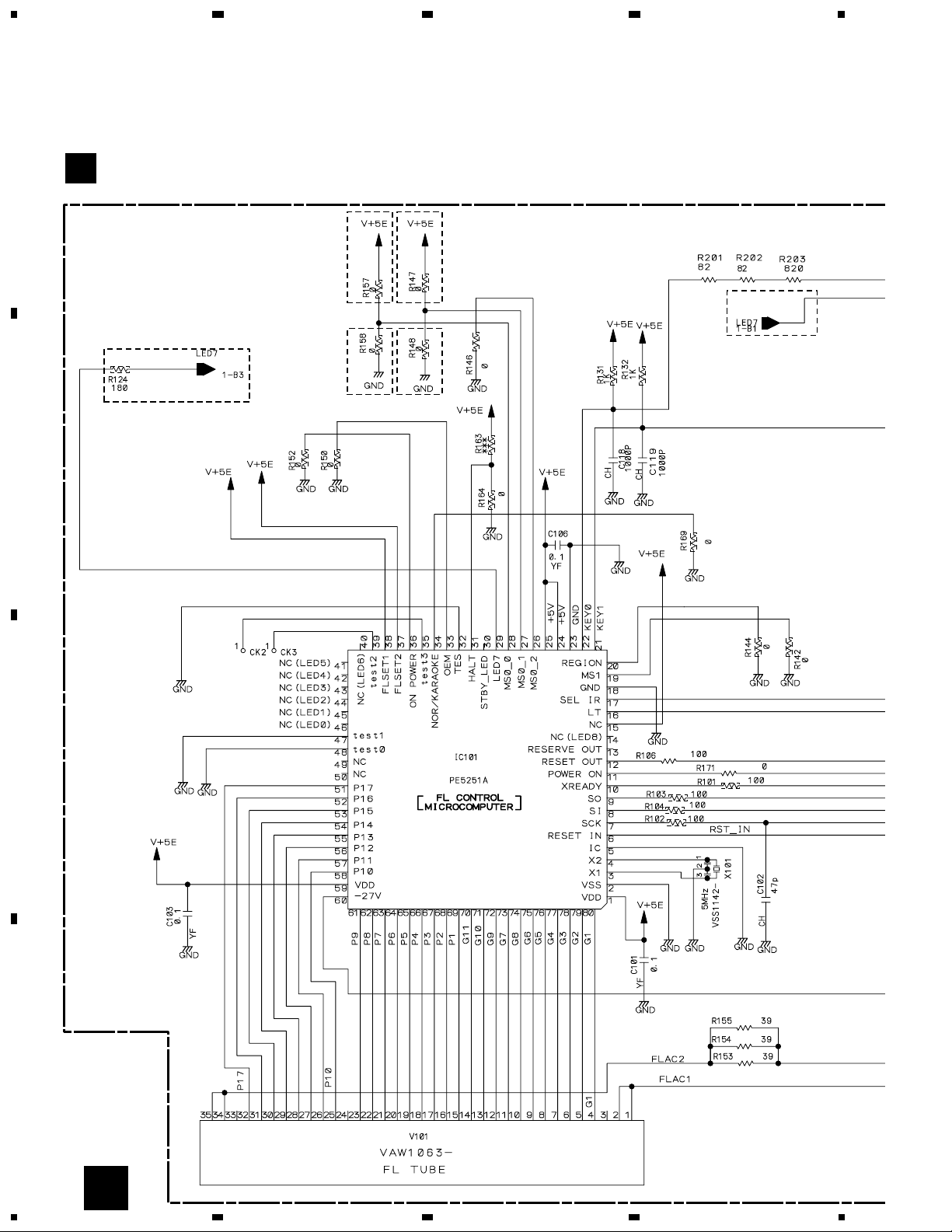

4.5 FLKB ASSY

234

DV-545, DV-444-S, DV-444-K

FLKB ASSY

F

D

CN104

FLKB ASSY

F

A

IC102

B

IC101

(DV-545 : VNP1832-A)

(DV-444-S, DV-444-K : VNP1833-A)

SIDE A SIDE B

1

C

(DV-545 : VNP1832-A)

(DV-444-S, DV-444-K : VNP1833-A)

D

G

CN201

F

2

3

4

43

Page 44

1

23

DV-545, DV-444-S, DV-444-K

4.6 KEYB ASSY

4

A

B

KEYB ASSY

G

KEYB ASSY

G

C

D

(DV-545 : VNP1834-A)

(DV-444-S, DV-444-K : VNP1835-A)

F

SIDE A SIDE B

44

CN102

G

1234

Page 45

1

4.7 POWER SUPPLY UNIT

234

DV-545, DV-444-S, DV-444-K

AC IN

POWER SUPPLY UNIT

H

Q71Q2

Q1

A

B

Q401

Q402

Q412

Q20

IC201

IC103

IC102

Q410

Q411

VR

201

C

D

CN101

D

SIDE A

H

1

2

3

4

45

Page 46

DV-545, DV444-S, DV-444-K

Mark No. Description Part No. Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

Mark Symbol and Description

NSP

NSP

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

560 Ω→56 × 10

47k Ω→47 × 10

0.5 Ω→R50 ..................................................................................... RN2H

1 Ω→1R0 ..................................................................................... RS1P

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62k Ω→ 562 × 10

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

3

→ 473 ........................................................ RD1/4PU 4 7 3 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

K

K

LIST OF HOLE PCB ASSEMBLIES

Part No.

DV-545 DV-444-S DV-444-K

WYXQ,

WYXQ/FRGR,

WVXQ

Loading Mechanism Assy

LOAB Assy

WYXJ,

WVXJ

VWT1188

VWG2279

WYXQ,

WYXQ/FRGR,

WVXQ

VWT1188

VWG2279

Remarks

DVDM Assy

NSP

JSMB Assy

SSIB Assy

JACB Assy

SRCB Assy

NSP

FLKB Assy

NSP

KEYB Assy

POWER SUPPLY Unit

JACB ASSY

D

VWS1488

VWM2084

VWG2292

VWV1843

VWV1848

VWG2283

VWG2291

VWR1340

VWS1487

VWM2083

VWG2292

VWV1842

VWV1847

VWG2282

VWG2290

VWR1340

Although VWV1843 and VWV1842 are different in part number, they consist of the same components.

SRCB ASSY

E

VWV1848 and VWV1847 are constructed the same except for the following :

Mark Symbol and Description

D701

C701, C702, C816-C818

C704, C706

C815

RY701, RY702, RY801-RY803

VWV1848 VWV1847

1SS355

CKSRYF104Z25

CCSRCH391J50

CEAT471M6R3

VSR1016

Part No.

Not used

Not used

Not used

Not used

Not used

Remarks

46

R701, R703

R705, R707, R711, R712, R804, R829, R864

R866

R821

R851-R853, R862, R865, R867, R869

JA702 RGB Connector

RS1/16S471J

RS1/16S0R0J

RS1/16S0R0J

RS1/16S75R0F

Not used

VKB1157

Not used

Not used

Not used

Not used

RS1/16S0R0J

Not used

Page 47

DV-545, DV444-S, DV-444-K

Mark No. Description Part No. Mark No. Description Part No.

DVDM ASSY

B

VWS1488 and VWS1487 are constructed the same except for the following :

Mark Symbol and Description

IC271

IC281

IC303

IC304

IC712

VWS1488 VWS1487

TC74HC4053AFT

BA4510F

TC7SZU04F

TC7SZU04F

MSM51V17805D-60TS

Part No.

Remarks

Not used

Not used

Not used

TC7SHU04F

MNR4800DJ7

IC807

Q271, Q281

D303

C271-C274

C275

C279, C285, C828, C830

C281, C282

C283, C284, C899

C286

C314

C322

C324

C329

C741

R3, R622

R4

R215, R273, R321, R712, R763, R765, R767

R771, R825-R827

R274, R279

R275, R281-R284, R290

R285, R286

R287

R288

R289

R310

R312

R314

R328

R329

R332

PD0274A

DTC114EUA

KV1470

CKSRYB223K50

CKSRYB102K50

CKSRYF104Z25

CCSRCH5R0C50

CCSRCH470J50

CCSRCH680J50

CCSRCH150J50

CKSRYB103K50

CCSRCH331J50

CKSRYF105Z10

CEV221M4

Not used

RS1/16S103J

Not used

Not used

RS1/16S473J

RS1/16S472J

RS1/16S683J

RS1/16S1002F

RS1/16S2201F

RS1/16S1503F

RS1/16S823J

RS1/16S103J

RS1/16S223J

RS1/16S102J

RS1/16S332J

RS1/16S471J

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

CCSRCH220J50

CCSRCH180J50

Not used

Not used

CEV101M16

RS1/16S103J

RS1/16S333J

RS1/16S0R0J

RS1/16S0R0J

Not used

Not used

Not used

Not used

Not used

Not used

RS1/16S473J

RS1/16S153J

RS1/16S103J

RS1/16S182J

RS1/16S222J

RS1/16S331J

R335

R336

R713, R761, R764, R766, R768, R772

R822, R823, R824

NSP

PC Board DVDM

FLKB ASSY

F

RS1/16S682J

RS1/16S104J

RS1/16S0R0J

RS1/16S220J

VNP1822

VWG2283 and VWG2282 are constructed the same except for the following :

Mark Symbol and Description

R124

R147, R158

R148, R157

PC Board FLKB

VWG2283 VWG2282

RS1/16S181J

Not used

RS1/16S0R0J

VNP1832

Part No.

Not used

RS1/16S0R0J

Not used

Not used

VNP1823

Remarks

Not used

RS1/16S0R0J

Not used

VNP1833

47

Page 48

DV-545, DV444-S, DV-444-K

Mark No. Description Part No. Mark No. Description Part No.

KEYB ASSY

G

VWG2291 and VWG2290 are constructed the same except for the following :

Mark Symbol and Description

D202

S105

R184

PC Board KEYB

VWG2291 VWG2290

SLR-343DC

ASG7013

RS1/16S151J

VNP1834

PCB PARTS LIST FOR DV-545/WYXJ UNLESS OTHERWISE NOTED

Part No.

Remarks

Not used

Not used

Not used

VNP1835

Mark No. Description Part No.

LOAB ASSY

A

SWITCH

S101 VSK1011

OTHERS

CN602 KR CONNECTOR S2B-PH-K

CN601 KR CONNECTOR S5B-PH-K

DVDM ASSY

B

PC BOARD LOAB VNP1836

SEMICONDUCTORS

IC451 BA25BC0FP

IC861 ADV7172KST

IC261,IC281,IC302 BA4510F

IC251 BA6664FM

IC481 BU2288FV

IC101 LA9701M

IC201 LC78652W

IC351 M56788AFP

IC801 M65774BFP

IC805 MB81F161622C-80FN

IC712 MSM51V17805D-60TS

IC807 PD0274A-TFB

IC601 PD6345A

IC701 PE5108A

IC111,IC271 TC74HC4053AFT

IC612 TC74VHC125FT

IC608 TC74VHCT125AFT

IC303,IC304 TC7SZU04F

IC603 VYW1852

Q109,Q901-Q903,Q911-Q913 2SA1576A

Q114,Q130 2SC4081

Q107,Q111,Q115,Q241,Q271 DTC114EUA

Q281 DTC114EUA

Q101,Q102,Q106 HN1A01F

Q103,Q141,Q142,Q542,Q543 HN1B04FU

Q112,Q113 HN1C01FU

Q108 HN1K03FU

Q571 RN1911

Q117,Q171,Q601 RN4982

D302,D303 KV1470

D601 RB501V-40

Mark No. Description Part No.

COILS

L304 LCYA1R5J2520

L481 CHIP BEAD VTL1084

L489 CHIP BEAD VTL1078

CAPACITORS

C480,C481,C612 CCSRCH100D50

C152 CCSRCH101J50

C104-C108,C314 CCSRCH150J50

C151 CCSRCH270J50

C324,C391,C392 CCSRCH331J50

C146 CCSRCH390J50

C122,C123 CCSRCH391J50

C116,C134,C283,C284,C297 CCSRCH470J50

C899 CCSRCH470J50

C145,C241 CCSRCH560J50

C281,C282 CCSRCH5R0C50

C286 CCSRCH680J50

C117,C360 CCSRCH681J50

C124 CCSRCH820J50

C129,C149,C201,C205,C254 CEV101M16

C358,C368,C369,C401,C403,C410 CEV101M16

C407,C472,C864 CEV101M16

C113,C139 CEV220M16

C142,C405,C454,C715,C741 CEV221M4

C111 CEV470M6R3

C140,C223,C224,C264,C312 CKSQYB105K10

C475-C477 CKSQYB105K10

C209,C211,C216,C275,C313 CKSRYB102K50

C351 CKSRYB102K50

C133,C136,C203,C220,C225 CKSRYB103K50

C239,C261,C320-C322,C330 CKSRYB103K50

C591,C619,C703,C722 CKSRYB103K50

C101,C103,C118,C119,C121 CKSRYB104K16

C212,C213,C227,C231 CKSRYB104K16

C248-C251,C255,C263,C315 CKSRYB104K16

C317 CKSRYB104K16

C208,C210 CKSRYB222K50

C271-C274 CKSRYB223K50

C266 CKSRYB224K10

C206,C214,C242,C357 CKSRYB472K50

C102,C109,C120,C130,C131 CKSRYF104Z25

C138,C143,C148,C154 CKSRYF104Z25

C157,C158,C204,C207,C215 CKSRYF104Z25

C221,C222,C226,C230,C236 CKSRYF104Z25

C253,C256,C258,C265,C279 CKSRYF104Z25

48

Page 49

DV-545, DV444-S, DV-444-K

Mark No. Description Part No. Mark No. Description Part No.

C285,C299,C319,C332,C353 CKSRYF104Z25

C359,C365,C366,C453,C603 CKSRYF104Z25

C606,C608-C611,C613,C615 CKSRYF104Z25

C618,C626,C628,C631,C704 CKSRYF104Z25

C706,C708,C712,C713 CKSRYF104Z25

C716-C718,C721,C723,C725 CKSRYF104Z25

C743,C802,C808,C811,C814 CKSRYF104Z25

C828,C830,C866,C869-C872 CKSRYF104Z25

C874,C875,C903,C913 CKSRYF104Z25

C115,C217,C328,C329,C607,C614 CKSRYF105Z10

C710,C711,C714,C726,C801,C809 CKSRYF105Z10

C813,C816-C821,C827,C833,C843 CKSRYF105Z10

RESISTORS

R815,R819 RAB4C0R0J

R543,R545,R594,R631,R707 RAB4C103J

R121 RAB4C220J

R123 RAB4C470J

R400,R403 RS1/10S0R0J

R341 RS1/10S101J

R126-R129,R176-R179 RS1/10S220J

R902,R905,R908,R912,R915 RS1/16S1000F

R918 RS1/16S1000F

R287 RS1/16S1002F

R364,R369,R373,R375 RS1/16S1003F

R865 RS1/16S1502F

R289,R358,R361 RS1/16S1503F

R288 RS1/16S2201F

R876,R878 RS1/16S4701F

R866 RS1/16S4702F

R870,R875 RS1/16S6800F

R867 RS1/16S6801F

R357,R362,R363,R368,R372 RS1/16S6802F

R374 RS1/16S6802F

R257 (1Ω) VCN1127

R258,R259 (2.2Ω) VCN1128

Other Resistors RS1/16S J

OTHERS

CN51 PH CONNECTOR S5B-PH-SM3

9007 FLEXIBLE CABLE (07P) VDA1681

CN61 17P FFC CONNECTOR VKN1421

CN31,CN32 30P FFC CONNECTOR VKN1434

CN151 26P FFC CONNECTOR VKN1790

X481 CRYSTAL RESONATOR VSS1159

X601 CERAMIC RESONATOR VSS1160

SSIB ASSY

C

(27.000MHz)

(16.5MHz)

OTHERS

CN2 4P FFC CONNECTOR VKN1264

CN1 12P FFC CONNECTOR VKN1272

CN3 17P FFC CONNECTOR VKN1277

JACB ASSY

D

SEMICONDUCTORS

IC231 BA4560F

IC302 NJM78L05A

IC411 MM1540BF

IC401 NJM78L08A

IC211 PCM1742KE

Q273 2SA1037K

Q601 2SC2412K

Q241,Q274 2SD2114K

Q211,Q272,Q445,Q447 DTC114YK

Q446,Q448 PDTA124EK

D150,D431,D432,D435,D436 1SS355

D441,D442,D471,D472 1SS355

D475,D476,D481,D482 1SS355

D281 UDZS6.2B

COIL

L601 NOISE FILTER RTF1167

CAPACITORS

C236,C238,C286,C288 CCSRCH331J50

C150 CCSRCH470J50

C411 CEAL101M10

C415 CEAL470M10

C405,C611 CEAT101M10

C605 CEAT1R0M50

C231,C237,C281,C287 CEAT470M16

C105 CEAT471M16

C431,C441 CEAT471M6R3

C213,C215 CEJQ101M6R3

C206,C211 CEJQ331M6R3

C234,C284 CEJQ470M16

C235,C285 CKSRYB272K50

C106,C151,C212,C214,C216 CKSRYF104Z25

C233,C239,C289,C406,C412 CKSRYF104Z25

C416,C422,C423,C425,C435 CKSRYF104Z25

C582,C584,C586,C602,C612 CKSRYF104Z25

RESISTORS

R234,R284 RN1/16SE2201D

R236,R286 RN1/16SE4301D

R273 RS1/10S182J

R432,R436,R442 RS1/16S75R0F

Other Resistors RS1/16S J

OTHERS

CN101 FJ CONNECTOR 14P 14PL-FJ

CN401 4P MINI DIN SOCKET AKP7008

JA601 OPTICAL LINK OUT GP1FA550TZ

JA201 2P PIN JACK PKB1034

JA150 REMOTE CONTROL JACK RKN1004

9001 PCB BINDER VEF1040

JA402 1P PIN JACK VKB1122

JA602 1P PIN JACK (BLK, NI) VKB1159

CN104 16P FFC CONNECTOR VKN1247

CN405 19P FFC CONNECTOR VKN1250

CN102,CN106 VKN1261

30P FFC CONNECTOR

CN110 7P FFC CONNECTOR VKN1267

KN401,KN601 VNF1084

EARTH METAL FITTING

49

Page 50

DV-545, DV444-S, DV-444-K

Mark No. Description Part No. Mark No. Description Part No.

SRCB ASSY

E

SEMICONDUCTORS

IC802 MM1505XN

IC801 MM1507XN

Q753,Q755 2SA1037K

Q751,Q754 2SC2412K

D701,D751,D805-D808 1SS355

RELAYS

RY701,RY702,RY801-RY803 VSR1016

CAPACITORS

C703-C706 CCSRCH391J50

C759 CCSRCH470J50

C807 CEAT100M50

C811-C813 CEAT101M10

C814,C815 CEAT471M6R3

C701,C702,C751,C753,C754 CKSRYF104Z25

C757,C758,C801,C803-C806 CKSRYF104Z25

C808,C816-C818,C894 CKSRYF104Z25

RESISTORS

R766 RS1/16S68R0F

R809,R813,R817,R820,R821 RS1/16S75R0F

Other Resistors RS1/16S J

OTHERS

JA701,JA702 RGB CONNECTOR VKB1157

CN701 19P FFC CONNECTOR VKN1279

KEYB ASSY

F

SEMICONDUCTOR

D202 SLR-343DC(NPQ)

SWITCHES

S103-S105,S201,S202 ASG7013

RESISTORS

All Resistors RS1/16S J

OTHERS

CN201 FJ CONNECTOR 4P 04R-FJ

POWER SUPPLY UNIT

G

PC BOARD KEYB VNP1834

OTHERS

P101 PROTECTOR (800mA) AEK7063

P102 PROTECTOR (1.6A) AEK7066

F1 FUSE (2.5A) REK1102

FLKB ASSY

F

SEMICONDUCTORS

IC101 PE5251A

IC102 PST3242

SWITCHES

S101,S102,S203 ASG7013

CAPACITORS

C111,C114,C118,C119 CCSRCH102J50

C102 CCSRCH470J50

C122 CEAL101M6R3

C101,C103,C106,C112,C121 CKSRYF104Z25

C131 CKSRYF104Z25

C105 CKSRYF104Z50

RESISTORS

All Resistors RS1/16S J

OTHERS

CN102 FJ CONNECTOR 4P 04P-FJ

IR101 REMOTE RECEIVER UNIT GP1U27X

V101 FL TUBE VAW1063

CN101 16P FFC CONNECTOR VKN1276

X101 CERAMIC RESONATOR VSS1142

SPACER VEC2220

FL HOLDER VNF1122

PC BOARD FLKB VNP1832

(5MHz)

50

Page 51

6. ADJUSTMENT

DV-545, DV-444-S, DV-444-K

6.1 ADJUSTMENT ITEMS AND

LOCATION

Adjustment Items

[Mechanism Part]

1

Tangential and Radial Height Coarse Adjustment

2

DVD Jitter Adjustment

3

Initialize the Focus Sweep Setting

[Electrical Part]

Electrical adjustments are not required.

Adjustment Points (Mechanism Part)

Cautions: After adjustment, adjustment screw locks with the

Screw tight.

6.2 JIGS AND MEASURING

INSTRUMENTS

Screwdriver (large)

TV monitor

Screwdriver (medium)

Test mode remote control

unit (GGF1067)

1 2

Tangential

adjustment

screw

1 2

Radial

adjustment

screw

Precise screwdriver

Screw tight

(GYL1001)

DVD test disc

(GGV1025)

51

Page 52

DV-545, DV-444-S, DV-444-K

6.3 NECESSARY ADJUSTMENT POINTS

When Adjustment Points

Exchange Parts of Mechanism Assy

Exchange the Pickup

Exchange the Traverse Mechanism

Exchange the Spindle Motor

Exchange PCB Assy

Exchange PC Board

Mechanical

point

Electric

point

Mechanical

point

Electric

point

Mechanical

point

Electric

point

Mechanical

point

~, Ÿ, !

!

Ÿ, !

∗ After adjustment, screw locks

with the Screw tight.

∗ After adjustment, screw locks

with the Screw tight.

SSIB, LOAB, DVDM ASSY

∗

Purpose: To set the sweep which was correct with the

individual Traverse mechanism.

Be sure to perform the following step finally when replaced

Pickup, Traverse Mechanism and Spindle Motor.

ESC CLEAR

GGF1067

Test mode

remote control

unit

(It is necessary when performed adjustment procedure Ÿ.)

Electric

point

52

Page 53

TEST MODE: ON

TEST MODE: DISC SET

DSC -

&&&

GGF1067

Test mode

remote control

unit

GGF1067

Test mode

remote control

unit

POWER

ON

<TRAY OPEN>

OPEN/CLOSE

(Player or Remote

Control Unit)

OPEN/CLOSE

(Player or Remote

Control Unit)

DVD disc

TEST MODE: PLAY

TEST MODE: OFF

An address is displayed

For example, when playback with # 30000

During PLAY

Press keys in order

OR

ESC

OFF

POWER

6.4 TEST MODE

030000

<PLAY>

< When playback with the target address of disc (DVD)>

TV/LDP

+10 3 0 0 0 0 CHP/TIM

ESC TEST

CHECK

DVD, CD

DV-545, DV-444-S, DV-444-K

53

Page 54

DV-545, DV-444-S, DV-444-K

6.5 MECHANISM ADJUSTMENT

Tangential and Radial Height Coarse Adjustment

1

START

• Remove the servo mechanism.

• Remove a Spacer for height adjustment

attached to the back side (shaded area)

of the Servo Mechanism (Float Base) with

nippers.

Servo Mechanism

Float Base

Spacer for Height adjustment

Note:

Turn the Short switch to Short side when

removing the Pickup Flexible Cable.

(Refer to "7.1.6 DISASSEMBLY".)

Cautions:

Because there is not a Spacer for height adjustment in

adjustment after the second time, will keep it at need.

(This parts is Traverse mechanism exclusive use of a model

for 2001 years)

7.3mm

Put a spacer between a Tangential (or Radial) adjustment

screw and Mechanism Base and turn each screw to adjust

the height. (Refer to "6.1 ADJUSTMENT ITEMS AND

LOCATION".)

Turn a flat side

into bottom

54

Page 55

DVD Jitter Adjustment

2

DV-545, DV-444-S, DV-444-K

• Playback method of inner and outer address for the purpose is refererd to "6.3 TEST MODE".

• Jitter indication of the monitor is refererd to "7.1.3 TEST MODE SCREEN DISPLAY".

START

• Test mode

• Play the DVD test disc

at outer track

(around #200000)

Mechanism Assy

Adjust the Tangential

Adjustment Screw so that

jitter becomes minimum.

J4 : Min

Use disc: GGV1025

• Play the DVD test disc

at inner track

(around #30000)

Mechanism Assy

Adjust the Radial

Adjustment Screw so that

jitter becomes minimum.

J4 : Min

Turn the POWER OFF in

case of NG once, and

perform the adjustment

once again.

If error rate is OK,

locks a root of

tangential and radial

adjustment screws with

the Screw tight, and

go to step

!

.

CHECK

NG

OK

J4 : - - - -

Player

Monitor

Confirm the error rate that is

displayed "OK"

(Example ER (av): 2.5e - 5-*OK )

Disc playback normally.

• The measurement of block error rate

5ESC

• Play the DVD test disc

at outer track

(around #200000)

Mechanism Assy

Readjust the Tangential

Adjustment Screw so that

jitter becomes minimum.

J4 : Min

ESC

Screw tight : GYL1001

Test mode end

55

Page 56

DV-545, DV-444-S, DV-444-K

Initialize the Focus Sweep Setting

3

Purpose: To set the sweep which was correct with the individual Traverse mechanism.

Turn on the Player

ESC CLEARPOWER

Note: Be sure to perform this step when replaced the Pickup or Traverse mechanism.

56

Page 57

DV-545, DV-444-S, DV-444-K

7. GENERAL INFORMATION

7.1 DIAGNOSIS

7.1.1 SELF-DIAGNOSTIC FUNCTION OF PICKUP DEFECTIVE

This unit can confirm the laser diode current value (DVD: 650nm, CD: 780nm) of pickup on the Test Mode screen.

(Press the ESC → TEST keys in order on the test mode remote control unit (GGF1067) to enter the test mode.)

It's effective in case of the following condition.

Symptom

• Indicates "No Disc" in FL display.

• Player does not playback, etc..

Procedure of Self-Diagnosis

1 Enter the Test mode.

2 When diagnosing the 650nm laser diode:

Press the → keys in order, and turn on the laser diode (It light-up for nine seconds.).

When diagnosing the 780nm laser diode:

Press the → keys in order, and turn on the laser diode (It light-up for nine seconds.).

TEST 1

TEST 4

When let it turn on once again after performed 2 once,

After pressed REP.B key once

650nm: Press the → keys in order

780nm: Press the → keys in order

3 Confirm the indicated value of the laser diode current (LDI). (Refer to following figure.)

4 When indicated value is more than 100, pickup is defective. → Replacement is necessary

Replace the Traverse Mechanism Assy or Pickup.

Note :

When a DVD disc or a CD disc is played in the test mode, this function is effective.

Laser diode current value

TEST 1

TEST 4

Character in bold : Item name

: Information display

Test Mode Screen Display

57

Page 58

DV-545, DV-444-S, DV-444-K

7.1.2 TEST POINTS LOCATION

This model has not test terminal.

Please use following points on the DVDM Assy when checking RF, FE and TE, etc..

DVDM ASSY

CN61

CN151

CN51

RF

(R169)

IC201

CN13

IC351

BCLK

LRCLK

DATAO

for Audio DAC

(IC211)

TE

FE

CN32

Prog. Cr

Color

difference

Cb (/B)

Cr (/R)

Color

Y (/G)

difference

C

V

Y

IC861

IC806 IC805

22M/24M (for DAC)

16M/36M (for AV1)

27M (for AV1)

Prog. Y

Prog. Cb

IC881

Vref

(IC101-pin 64)

RFO

IC712

VCO DRV

CN31

SIDE A

IC481

33M (for BY Chip pin 15)

16M

(for BY Chip pin 13, DSP)

IC601

Front Side

58

Page 59

DV-545, DV-444-S, DV-444-K

7.1.3 TEST MODE SCREEN DISPLAY

TEST MODE SCREEN DISPLAY

When the test mode is entered, press the ESC button and the TEST button in order of the test mode remote control unit (GGF1067).

Consecutive double-OSD display is supported during test mode. The screen is composed 10 lines with a maximum of 32 characters per line.

It can't be used with the debugging display mode together.

• Screen Composition

Address

Background color

Tracking status and

Laser diode current value

Spindle status and AFB status

AGC setting

FTS servo IC information

C1 error value of CD and DVD

Internal operation mode of

the mechanism control

Disc judgment and

CD 1/3 beam switch

Equalizer value and

jitter value

Character in bold : Item name

: Information display

Test Mode Screen Display

(First Screen Display)

Caution :

The first screen and second screen switch by pressing [DISPLAY]

key of the remote control unit.

It is only a version display part on the lower right of the screen

those contents of display change.

ATB : ON/OFF information display and AGC manual setting display

deleted with the second generation.

The displays of Tilt error value, Tilt servo status and pickup

DVD/CLD display deleted with the third generation becomes LD

part is deleted.

Remote control code

Key code

Mechanism position value and

slider position

Output video system and

Skirt terminal output

AV1 chip version

FL controller version and

region setting for the player

FL controller destination setting

Port No. of Flash ROM and

system controller

Flash ROM version and Flash ROM size

System controller revision

DVD mechanism controller revision

(Control and part No. of GUI-ROM)

• Description of Each Item on the Display

(1) Address indication

The address being traced is displayed in number.

DVD : ID indication (hexadecimal number, 8 digits)

[ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ]

CD : A-TIME (min. sec.) [ 0 0 0 0 ∗ ∗ ∗ ∗ ]

(Note : For DVDs, decimal-number indication is possible.)

(2) Code indication of the remote control unit [R – ∗ ∗ ∗ ∗]

The code for the key pressed on the remote control unit, which

is received by the FL controller, is displayed while the key is

pressed. In the case of the double code, the second code will

be displayed.

(3) Key code indication for the main unit [K – ∗ ∗ ]

The code for the key pressed on the main unit, which is

received by the system controller, is displayed while the key is

pressed.

(4) Background color indication [C – R∗ ∗ G∗ ∗ B∗ ∗]

(5) 1 Tracking status [TRKG – ∗∗∗]

Tracking on [ON ]

Tracking off [OFF]

2 Laser diode current value [LDI – ∗∗∗]

(6) 1 Spindle status [SPDL – ∗ ∗ ∗]

Spindle accelerator and brake, free-runnimg [A/B]

FG servo [FG]

Rough, velocity phase servo [SRV]

Offset addition, rough, velocity phase servo [O_S]

2 AFB status [AFB – ∗ ∗]

ON [ON ]

OFF [OFF]

(7) Mechanism position value [M – ∗]

Position code [1] to [3]

(8) Slider position [S – ∗ ∗ ∗ ∗]

CD TOC area [IN ]

CD active area [CD ]

(9) AGC setting [AGC – ∗ ∗]

AGC on [AGC-ON]

AGC off [AGC-OFF]

59

Page 60

DV-545, DV-444-S, DV-444-K

(10) Output video system [V – ∗ ∗ ∗ ∗]

NTSC system [NTSC]

PAL system [PAL ]

Auto-setting [AUTO]

Skirt terminal output [SK – ∗ ∗]

VIDEO [00]

S-VIDEO [01]

RGB [02]

Note : Display only the model which can do the output setting of

skirt terminal.

(11) FTS servo IC information

DSP coefficient indication [KS – [∗ ∗ ∗ ∗] ∗ ∗ ∗ ∗ ]

Displays the address (four digits) of the specified coefficient

and the setting value (four digits) with [TEST] and [9] keys.

(12) Error rate indication

1 C1 error value of CD [ER – C1 ∗ ∗ ∗ ∗ ]

2 C1 error value of DVD [ER – ∗ ∗ ∗ ∗ ∗ ∗ ∗ ∗ ]

(13) Internal operation mode of mechanism controller

[MM – ∗ ∗ : ∗ ∗]

Internal mechanism mode (2 digits) and internal mechanism

step (2 digits) of the mechanism controller

(14) 1 Disk sensing [DSC – ∗ ∗ ∗]

The type of discs loaded is displayed.

[DVD], [CD ], [VCD], [ ]

2 CD 1/3 beam switch [BM – ∗ ∗]

(20) 1 Version of the flash ROM [V : ∗ . ∗ ∗ ∗]

2 Flash ROM size [FLSH = ∗]

(21) Revision of the system controller [S : ∗ . ∗ ∗ ∗ / ∗ . ∗ ∗ ]

1 Revision number of the external ROM part (flash ROM) of

the system controller <Front>

2 Revision of the internal ROM part of the system controller

<Back>

(22) Revision of the DVD mechanism controller

[M : ∗ . ∗ ∗ ∗]

Revision number of the external ROM part (flash ROM) of the

DVD mechanism controller

(23) Control and part numbers of the GUI-ROM

[GUI : ∗ ∗ ∗ ∗]

No GUI model displays as "––– / ––––".

OEM model displays the part number of GUI-ROM

[GUI : * * * *]

(15) 1 Equalizer value [E – ∗ ∗]

2 Jitter value [J – ∗ ∗]

Make the jitter four times, and renew it in every 0.5

second. [J4 – * *]

CD is effective only in the jitter value.

(16) Version of the AV-1 chip [ AV : ∗ . ∗ ∗' ∗' ]

(17) 1 Version of the FL controller [FL : ∗ ∗ ∗ ∗]

2 Region setting of the player [REG : ∗ ]

Setting value [1] to [6]

(18) Destination setting of the FL controller

[MDL : ∗ ∗ ∗ ∗ / ∗ ∗ ∗ ]

Four charactors in the front represent the type of model :

three charactors in the back represent the destination code.

J : /J, K : /KU, /KC, /KU/KC, R : /RAM, /RL, /RD, /LB,

WY : /WY

(19) The part number of the flash ROM and system