Page 1

2011

DDJ-T1

For details, refer to "Important Check Points for good servicing".

DJ CONTROLLER

DDJ-T1

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

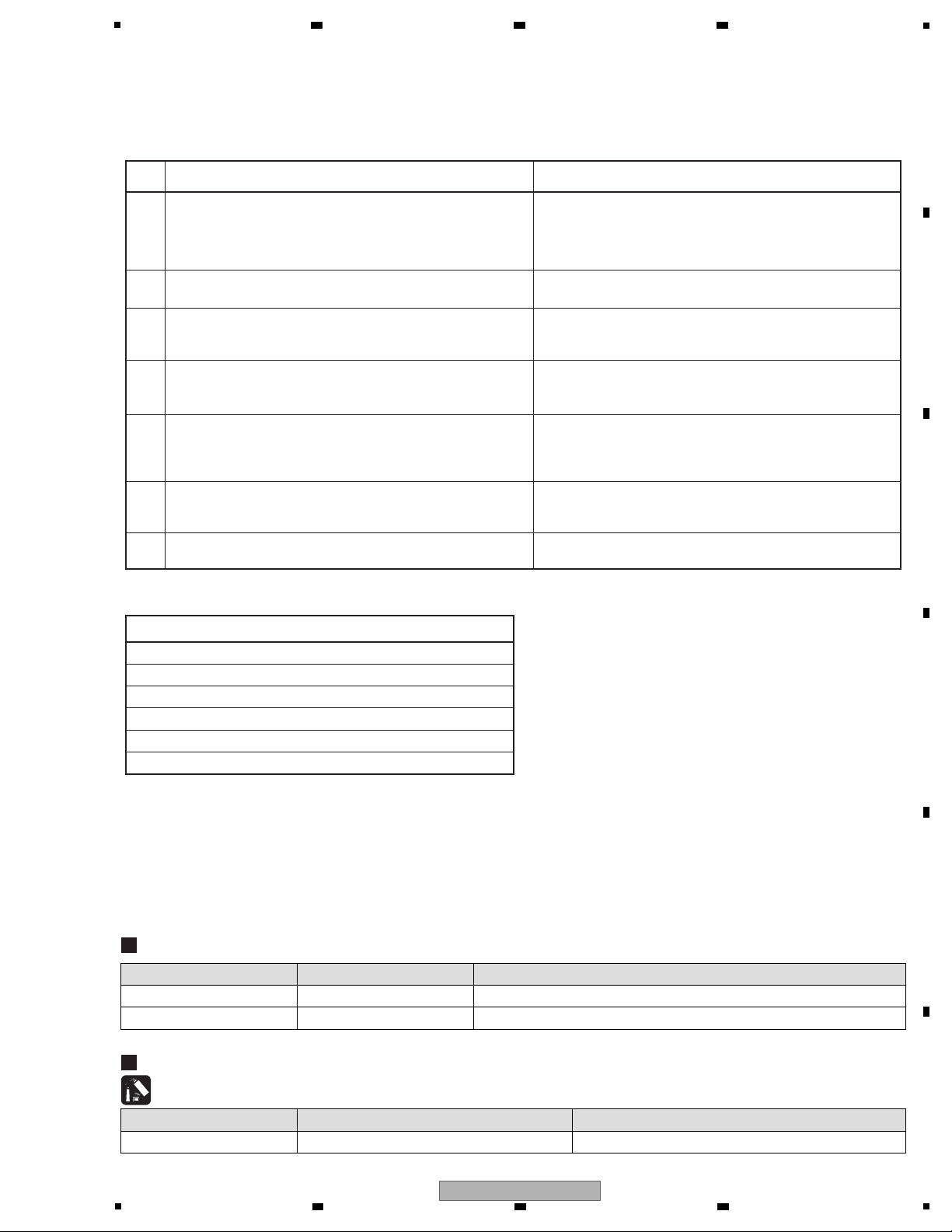

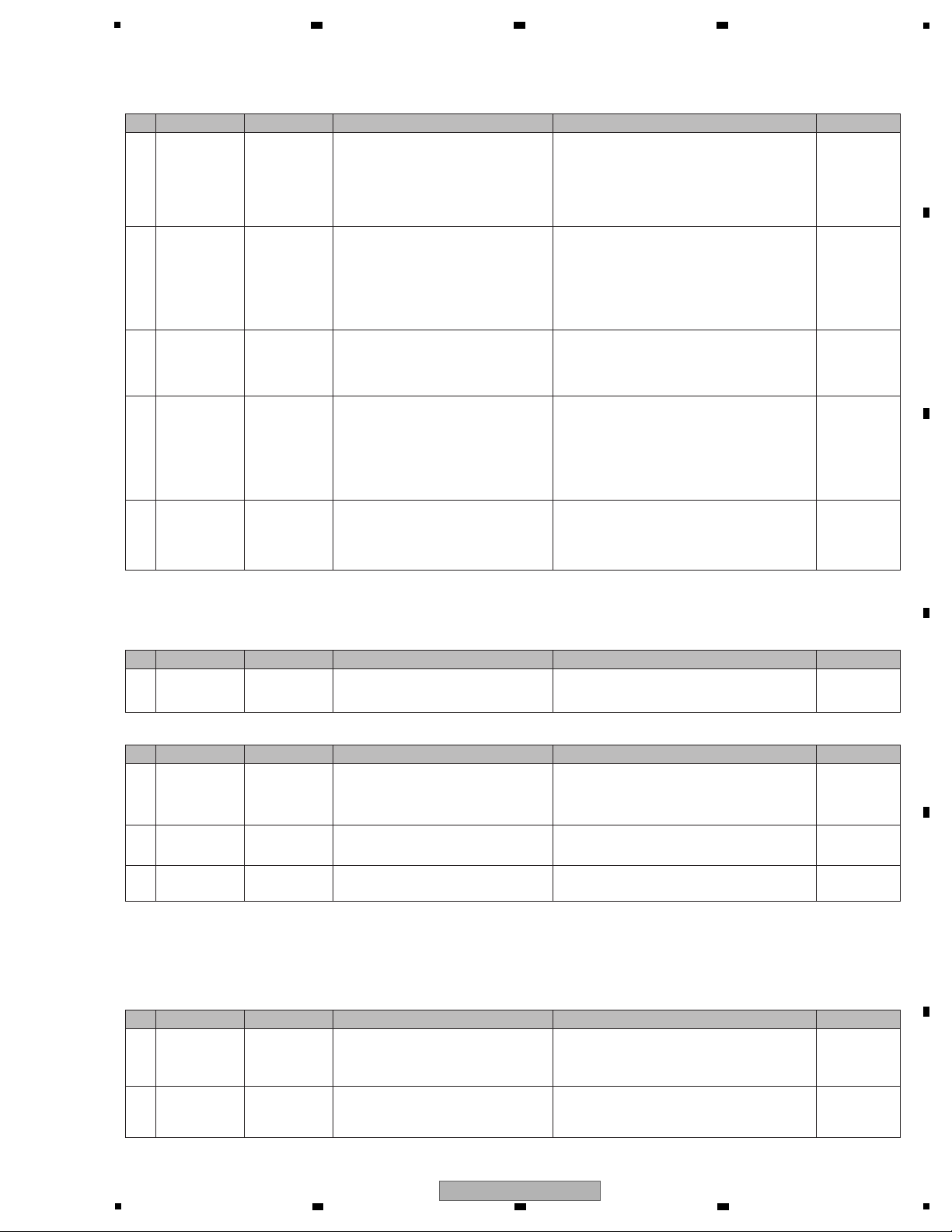

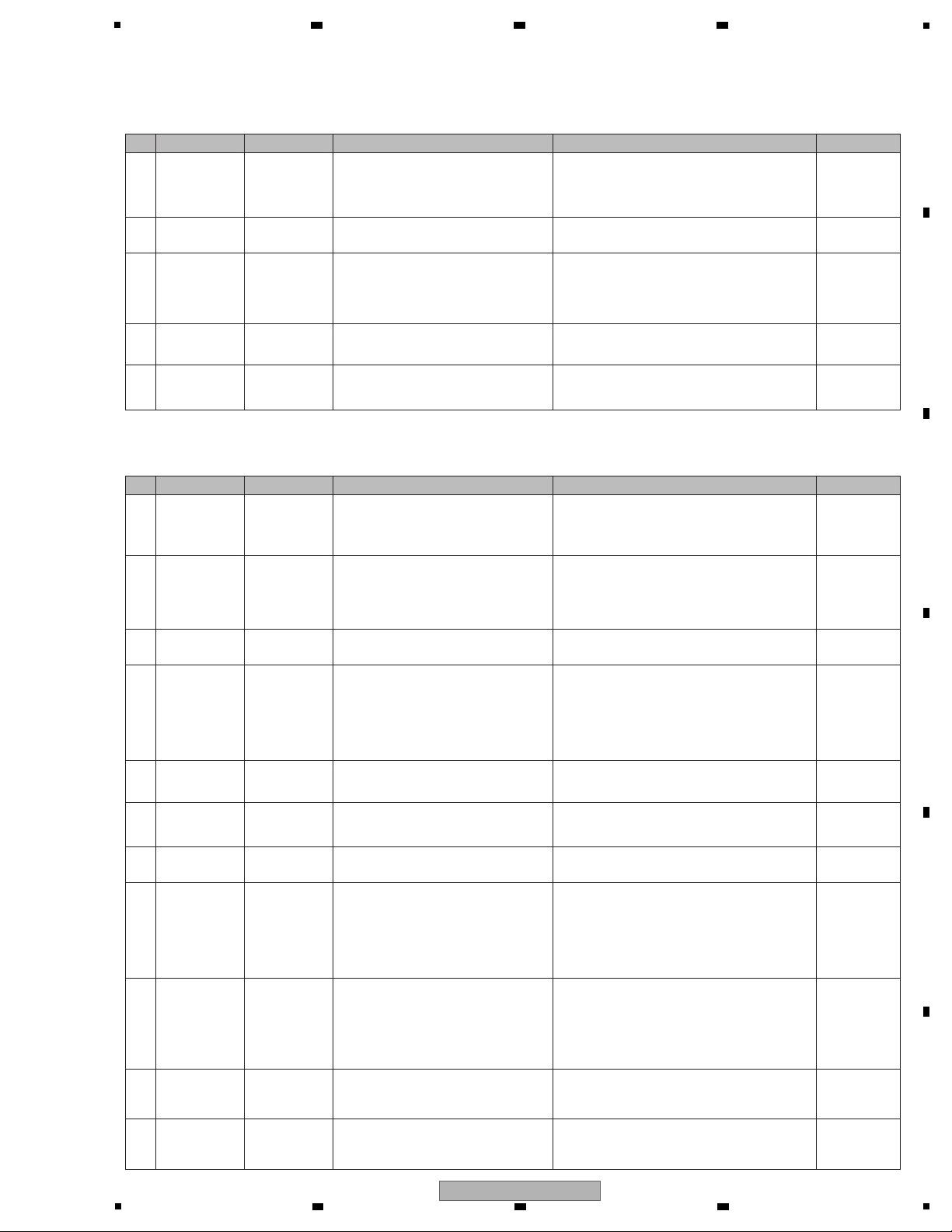

Model Type Power Requirement Remarks

DDJ-T1 SVYXJ8 AC 100 V to 240 V

DDJ-T1 UXJCB AC 100 V to 240 V

DDJ-T1 FLPXJ AC 100 V to 240 V

DDJ-T1 KXJ5 AC 100 V to 240 V

DDJ-T1 AXJ5 AC 100 V to 240 V

ORDER NO.

RRV4164

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZV FEB.

2011 Printed in Japan

Page 2

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

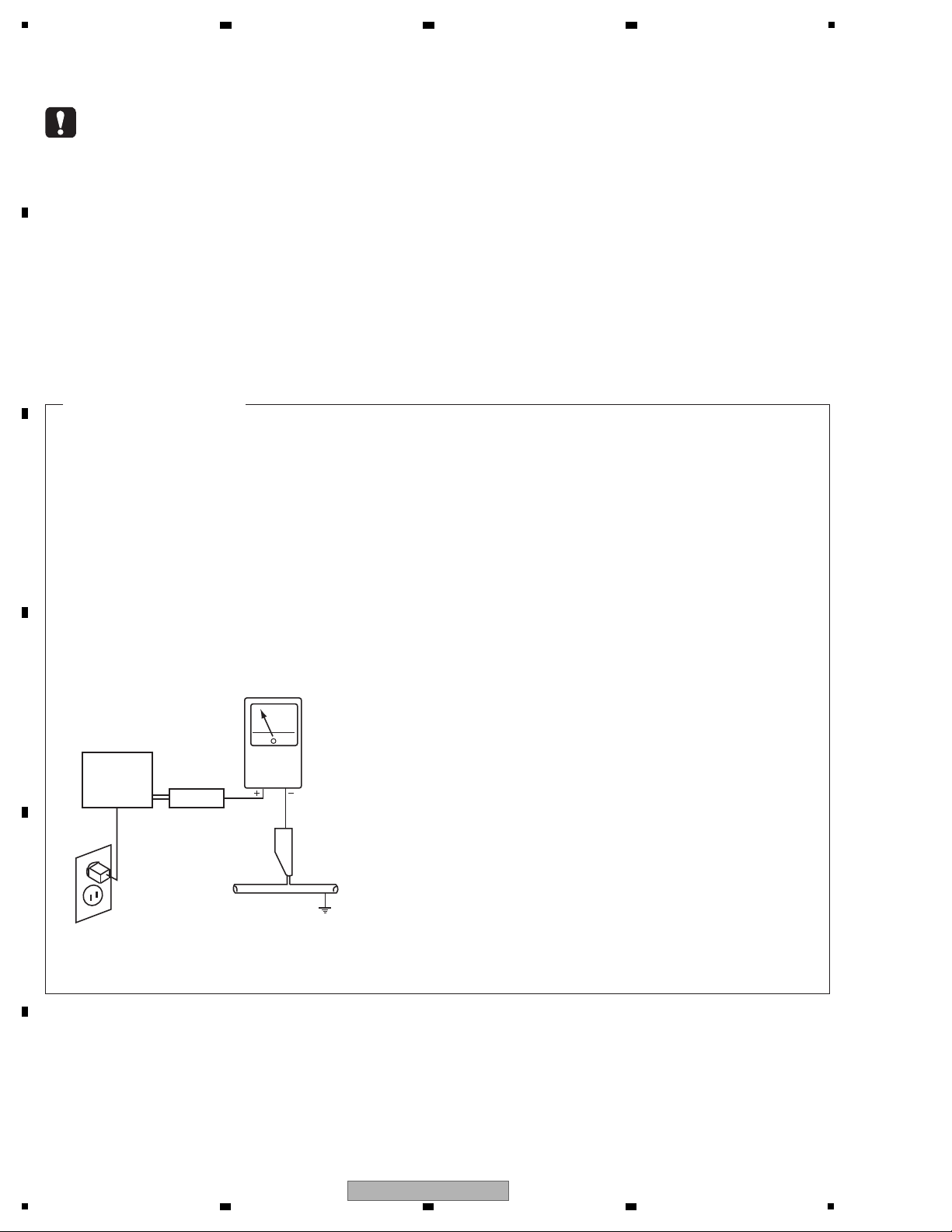

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120 V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage Test

(FOR USA MODEL ONLY)

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

DDJ-T1

Page 3

5

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

6 7 8

A

B

C

D

5

DDJ-T1

6 7 8

E

F

3

Page 4

1

2 3 4

CONTENTS

SAFETY INFORMATION ..........................................................................................................................................................2

1. SERVICE PRECAUTIONS ....................................................................................................................................................5

A

B

C

D

E

F

1.1 NOTES ON SOLDERING ...............................................................................................................................................5

1.2 SERVICE NOTICE ..........................................................................................................................................................5

2. SPECIFICATIONS .................................................................................................................................................................6

2.1 SPECIFICATIONS...........................................................................................................................................................6

2.2 PANEL FACILITIES .........................................................................................................................................................7

3. BASIC ITEMS FOR SERVICE.............................................................................................................................................13

3.1 CHECK POINTS AFTER SERVICING..........................................................................................................................13

3.2 JIGS LIST......................................................................................................................................................................13

3.3 PCB LOCATIONS .........................................................................................................................................................14

4. BLOCK DIAGRAM...............................................................................................................................................................16

4.1 OVERALL WIRING DIAGRAM......................................................................................................................................16

4.2 OVERALL BLOCK DIAGRAM.......................................................................................................................................18

4.3 POWER BLOCK DIAGRAM..........................................................................................................................................20

5. DIAGNOSIS.........................................................................................................................................................................22

5.1 POWER ON SEQUENCE .............................................................................................................................................22

5.2 TROUBLESHOOTING ..................................................................................................................................................23

5.3 VOLTAGE MONITORING ..............................................................................................................................................31

5.4 HOW TO CHECK OPERATIONS USING THE TRAKTOR SOFTWARE......................................................................32

6. SERVICE MODE .................................................................................................................................................................36

6.1 OUTLINE OF SERVICE MODE ....................................................................................................................................36

6.2 DETAILS ON SERVICE MODE.....................................................................................................................................37

6.3 ABOUT THE DEVICE ...................................................................................................................................................40

7. DISASSEMBLY ....................................................................................................................................................................41

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................49

8.1 NECESSARY ITEMS TO BE NOTED .................................................................................................

CO

NFIRMATION OF THE VERSIONS OF THE FIRMWARE ......................................................................................49

8.2

..........................49

8.3 UPDATING OF THE FIRMWARE..................................................................................................................................50

8.4 COPYING THE PROGRAM FOR THE USB CONTROLLER .......................................................................................51

8.5 JOG DIAL ROTATION LOAD ADJUSTMENT ...............................................................................................................52

9. EXPLODED VIEWS AND PARTS LIST ...............................................................................................................................54

9.1 PACKING SECTION......................................................................................................................................................54

9.2 EXTERIOR SECION .....................................................................................................................................................56

9.5 JOG SECTION..............................................................................................................................................................62

10. SCHEMATIC DIAGRAM ....................................................................................................................................................64

10.1 JACB ASSY.................................................................................................................................................................64

10.2 UCOM ASSY (1/6) ......................................................................................................................................................66

10.3 UCOM ASSY (2/6) ......................................................................................................................................................68

10.4 UCOM ASSY (3/6) ......................................................................................................................................................70

10.5 UCOM ASSY (4/6) ......................................................................................................................................................72

10.6 UCOM ASSY (5/6) ......................................................................................................................................................74

10.7 UCOM ASSY (6/6) ......................................................................................................................................................76

10.8 CDCB 1, CDCB 2, TCHB and JOGB ASSYS .............................................................................................................78

................................................................................................................................................................80

10.9 LEDB A

SSY

10.10 CDJ1B ASSY ............................................................................................................................................................82

10.11 CDJ2B ASSY ............................................................................................................................................................84

10.12 DJMB ASSY..............................................................................................................................................................86

10.13 MICB ASSY...............................................................................................................................................................88

10.14 CHFD, CRFD and HPJK ASSYS ..............................................................................................................................90

10.15 USBB ASSY..............................................................................................................................................................92

10.16 VOLTAGES................................................................................................................................................................94

10.17 WAVEFORMS ...........................................................................................................................................................95

11. PCB CONNECTION DIAGRAM ......................................................................................................................................100

11.1 JACB ASSY...............................................................................................................................................................100

11.2 UCOM ASSY.............................................................................................................................................................102

11.3 CDCB 1 ASSY ..........................................................................................................................................................106

11.4 CDCB 2 ASSY ..........................................................................................................................................................107

CHB

11.5 T

, JOGB and LEDB ASSYS ..............................................................................................................................108

11.6 CDJ1B ASSY ............................................................................................................................................................112

11.7 CDJ2B ASSY ............................................................................................................................................................116

11.8 DJMB ASSY..............................................................................................................................................................120

11.9 CHFD and CRFD ASSYS .........................................................................................................................................124

11.10 MICB ASSY.............................................................................................................................................................128

11.11 HPJK ASSY ............................................................................................................................................................129

11.12 USBB ASSY............................................................................................................................................................130

12. PCB PARTS LIST ............................................................................................................................................................131

4

1

2 3 4

DDJ-T1

Page 5

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

• For checking of audio and operating elements, the DJ application (TRAKTOR) included with this product is used.

TRAKTOR must be installed in your PC. For details on installation, see "5.4 HOW TO CHECK OPERATIONS USING

THE TRAKTOR SOFTWARE."

For connection of this product with a PC, be sure to use the supplied USB cable (registered jig tool), whose operation

with this product is guaranteed.

Voltage Monitoring

This unit always monitors for power failure and will shut itself off immediately after an error is detected. All LEDs are unlit after

an error is generated. After the unit shuts itself off because of an error, disconnect the AC adapter and USB cable and wait at

least 1 minute before turning the unit back on. Repair the unit according to the diagnostic procedures described in

“5.3 VOLTAGE MONITORING.”

Limitations when the unit is operating on USB-bus power

There are some limitations in operations of this unit while it is operated on USB-bus power, as shown below.

• The JOG dial indicator does not light.

• Lighting of the indicators (excluding that for the JOG dial) becomes dim.

• The AUX IN and MIC connectors are disabled.

• The sound volume through the headphones is reduced.

On the EEPROM on the UCOM ASSY

No program has been stored in the EEPROM (IC2003) on the UCOM Assy (blank ROM) when it is supplied as a part for

service.

After the EEPROM is replaced, be sure to copy the program for the USB controller to it. For details, see “8.4 Copying the

Program for the USB Controller.”

Replacement of the MAIN_UCOM

When replacement of the MAIN_UCOM (IC701) is required, order a microcomputer dedicated for service (PEG850A8-K).

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

1.2 SERVICE NOTICE

DDJ-T1

5

6 7 8

C

D

E

F

5

Page 6

1

AC adapter

Power..................................AC 100 V to 240 V, 50 Hz/ 60 Hz

Rated current.............................................................300 mA

Rated output........................................................DC 5 V, 2 A

General – Main Unit

Power consumption (when using AC adapter)...........700 mA

Power consumption (when using USB bus power)....500 mA

Main unit weight.............................................4.9 kg (10.8 lb)

Max. dimensions.....680 mm (W) × 95.2 mm (H) × 317.7 mm (D)

(26.8 in. (W) × 3.7 in. (H) × 12.5 in. (D))

Tolerable operating temperature......+5 °C to +35 °C (+41 °F to +95 °F)

Tolerable operating humidity..................5 % to 85 % (no condensation)

Audio Section

Rated output level

MASTER OUT 1.................................................4.2 Vrms

MASTER OUT 2.................................................2.1 Vrms

Total harmonic distortion

MASTER OUT 1..................................................0.006 %

MASTER OUT 2..................................................0.006 %

Frequency characteristic

MASTER OUT 1......................................20 Hz to 20 kHz

MASTER OUT 2......................................20 Hz to 20 kHz

S/ N ratio (when playing on computer)

MASTER OUT 1.........103 dB or greater (at rated output)

MASTER OUT 2.........103 dB or greater (at rated output)

Input impedance

AUX..........................................................................24 kΩ

MIC..........................................................................10 kΩ

Output impedance

MASTER OUT 1............................................1 kΩ or less

MASTER OUT 2............................................1 kΩ or less

PHONES...................................................................41 Ω

Input / Output terminals

USB terminal

B type...................................................................1 set

MASTER OUT 1 output terminal

TRS phone jack (Ø 6.3 mm).................................1 set

MASTER OUT 2 output terminal

RCA pin jacks.....................................................1 sets

PHONES output terminal

Stereo phone jack (Ø 6.3 mm).............................1 set

Stereo mini phone jack (Ø 3.5 mm)......................1 set

AUX input terminal

RCA pin jack.......................................................1 sets

MIC input terminal

Phone jack (Ø 6.3 mm).........................................1 set

• For improvement purposes, specifications and design of

this unit and the included software are subject to change

without notice.

• TRAKTOR Pioneer DDJ-T1 EDITION software CD-ROM

(DXX2665)

• Driver software CD-ROM

(DXX2666)

• USB cable

(DDE1140)

• Operating instructions

(SVYXJ8: DRB1537, DRB1563)

(UXJCB: DRB1536)

(FLPXJ: DRB1539)

(KXJ5: DRB1541)

(AXJ5: DRB1540)

Accessories

• AC adapter

(DWR1491)

• Power plug

(SVYXJ8: DKX1048, DKX1049)

(UXJCB: DKX1047)

(FLPXJ: DKX1048, DKX1049, DKX1047, DKX1050, DKX1051)

(KXJ5: DKX1051)

(AXJ5: DKX1052)

2. SPECIFICATIONS

2.1 SPECIFICATIONS

A

2 3 4

B

C

D

E

F

6

1

2 3 4

DDJ-T1

Page 7

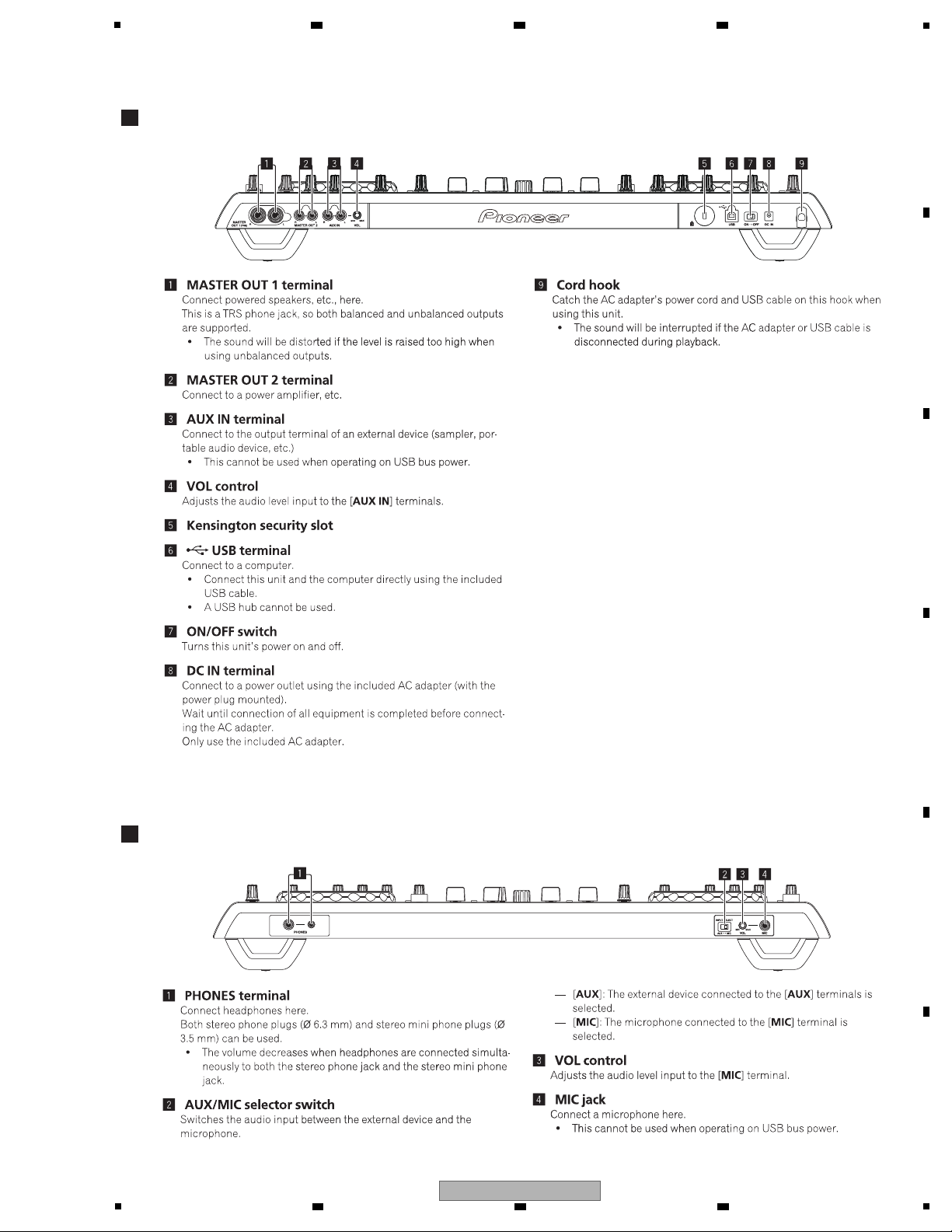

Rear panel

Front panel

5

2.2 PANEL FACILITIES

6 7 8

A

B

C

D

E

F

DDJ-T1

5

6 7 8

7

Page 8

1

Control panel

A

B

2 3 4

C

D

E

F

8

1

2 3 4

DDJ-T1

Page 9

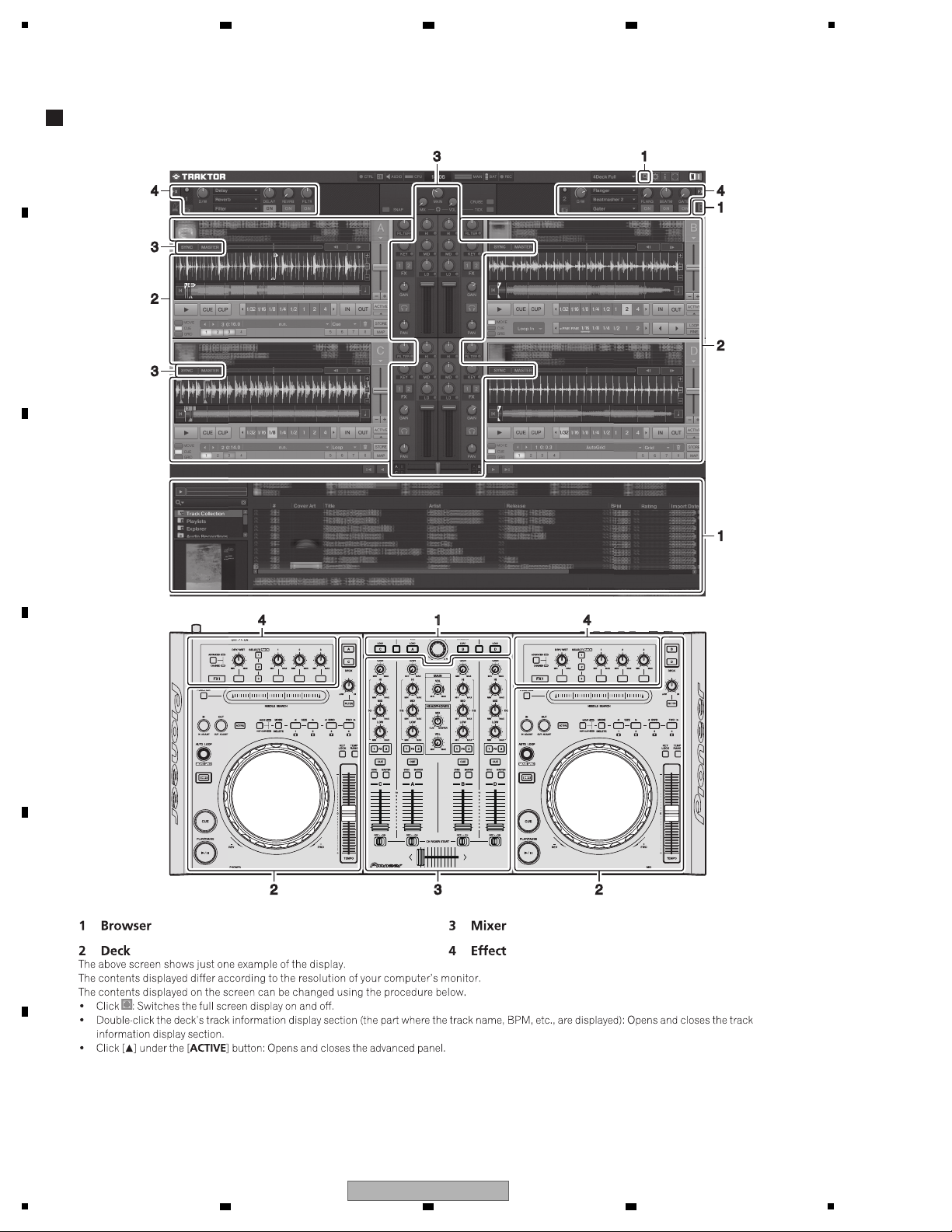

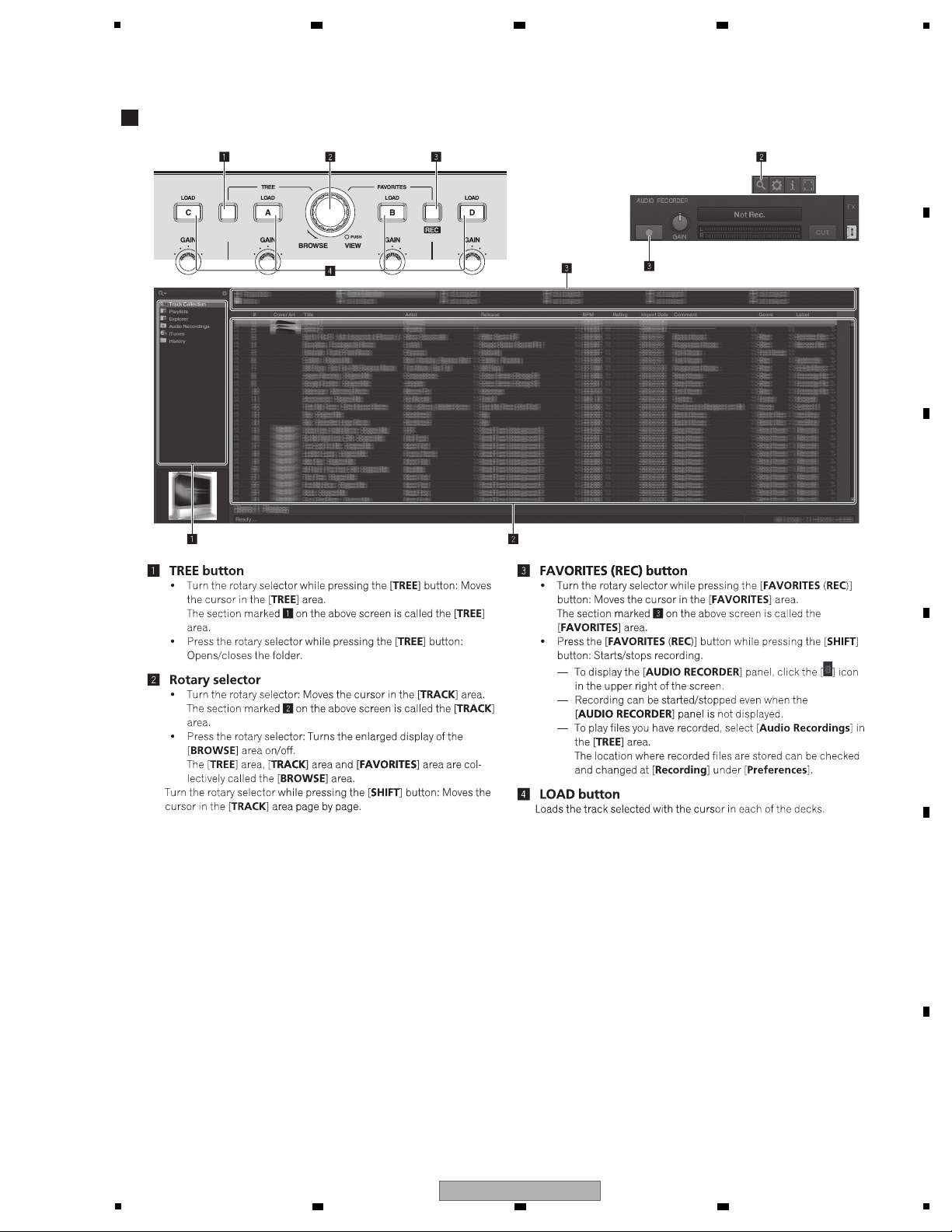

1 Browser

5

6 7 8

A

B

C

D

E

F

DDJ-T1

5

6 7 8

9

Page 10

A

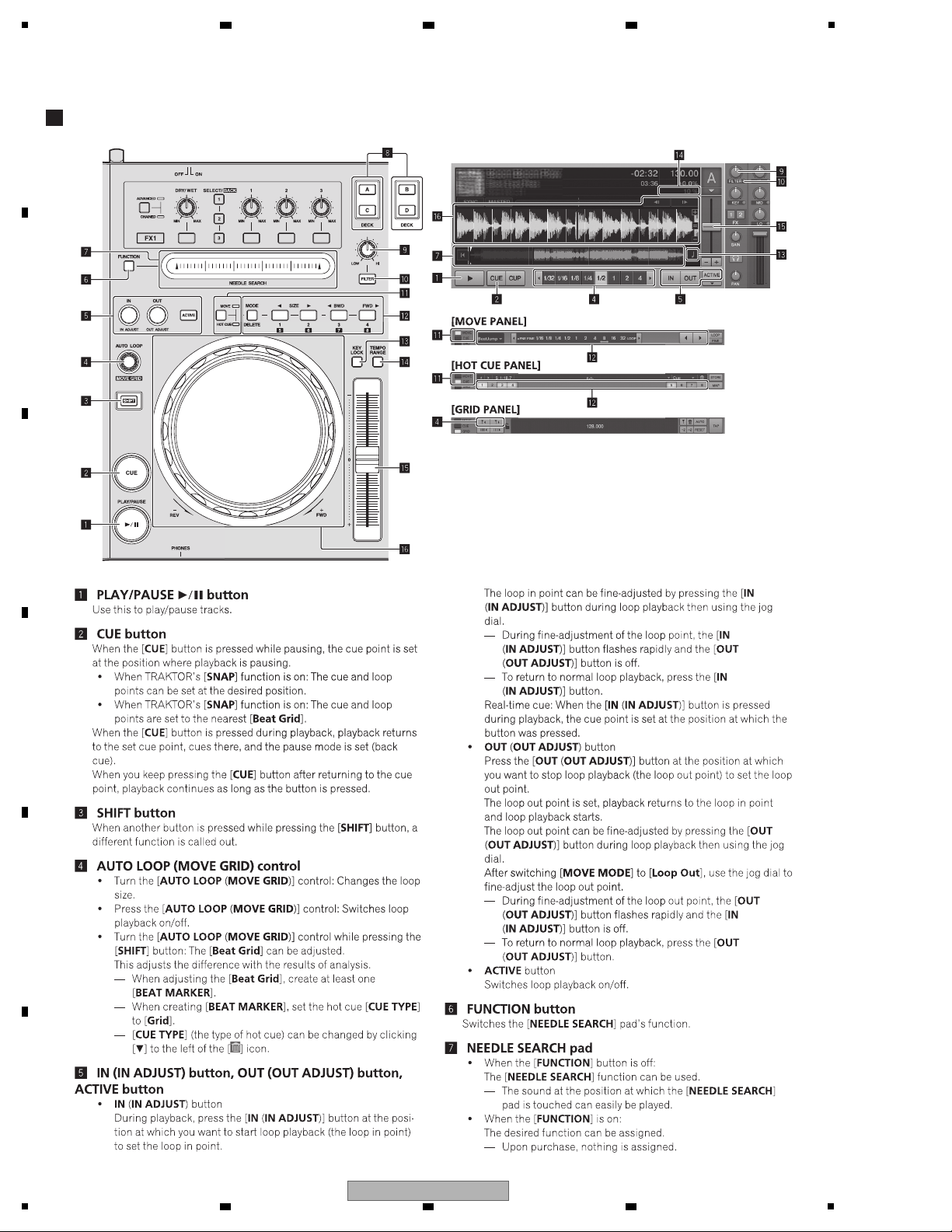

2 Deck

B

1

2 3 4

C

D

E

F

10

1

2 3 4

DDJ-T1

Page 11

5

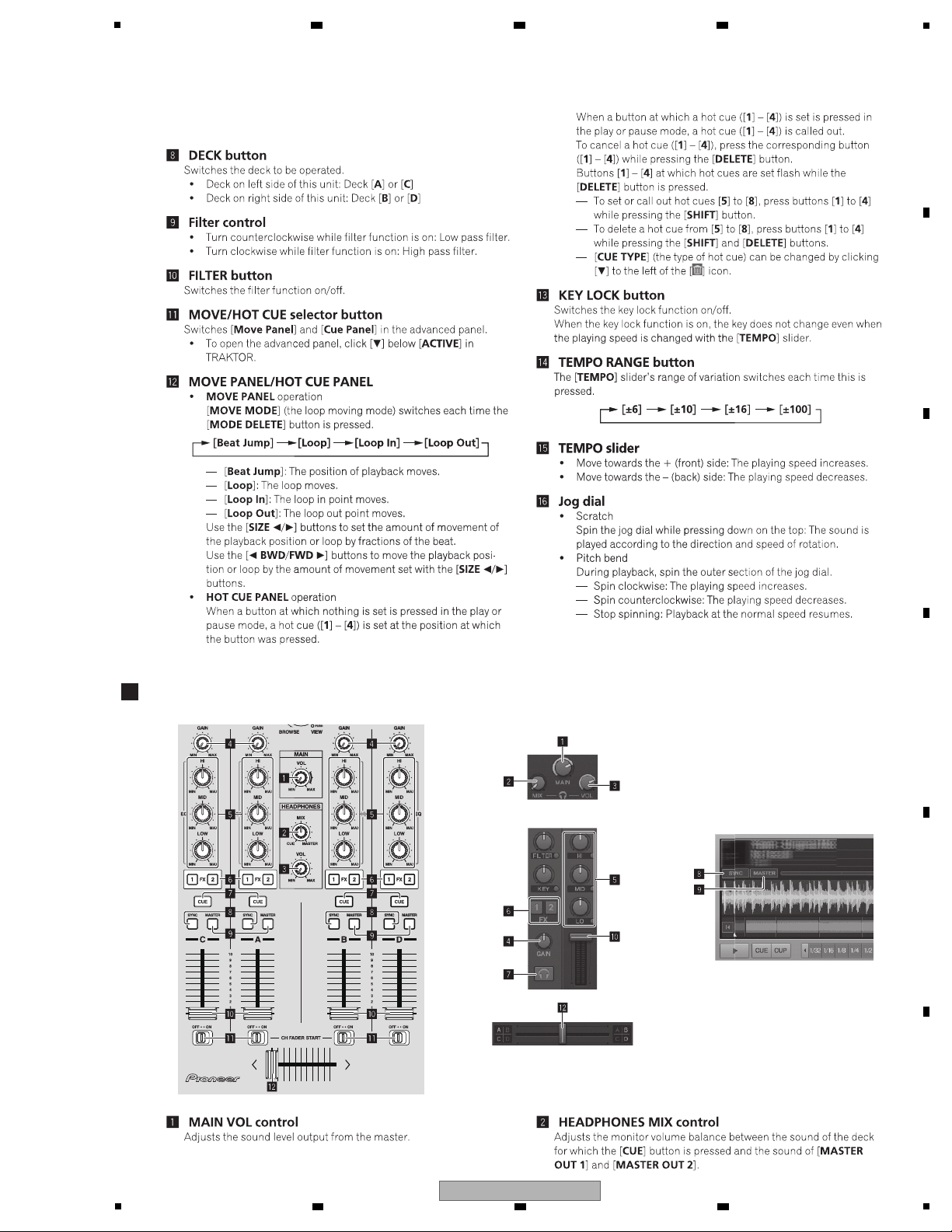

3 Mixer

6 7 8

A

B

C

D

E

F

DDJ-T1

5

6 7 8

11

Page 12

1

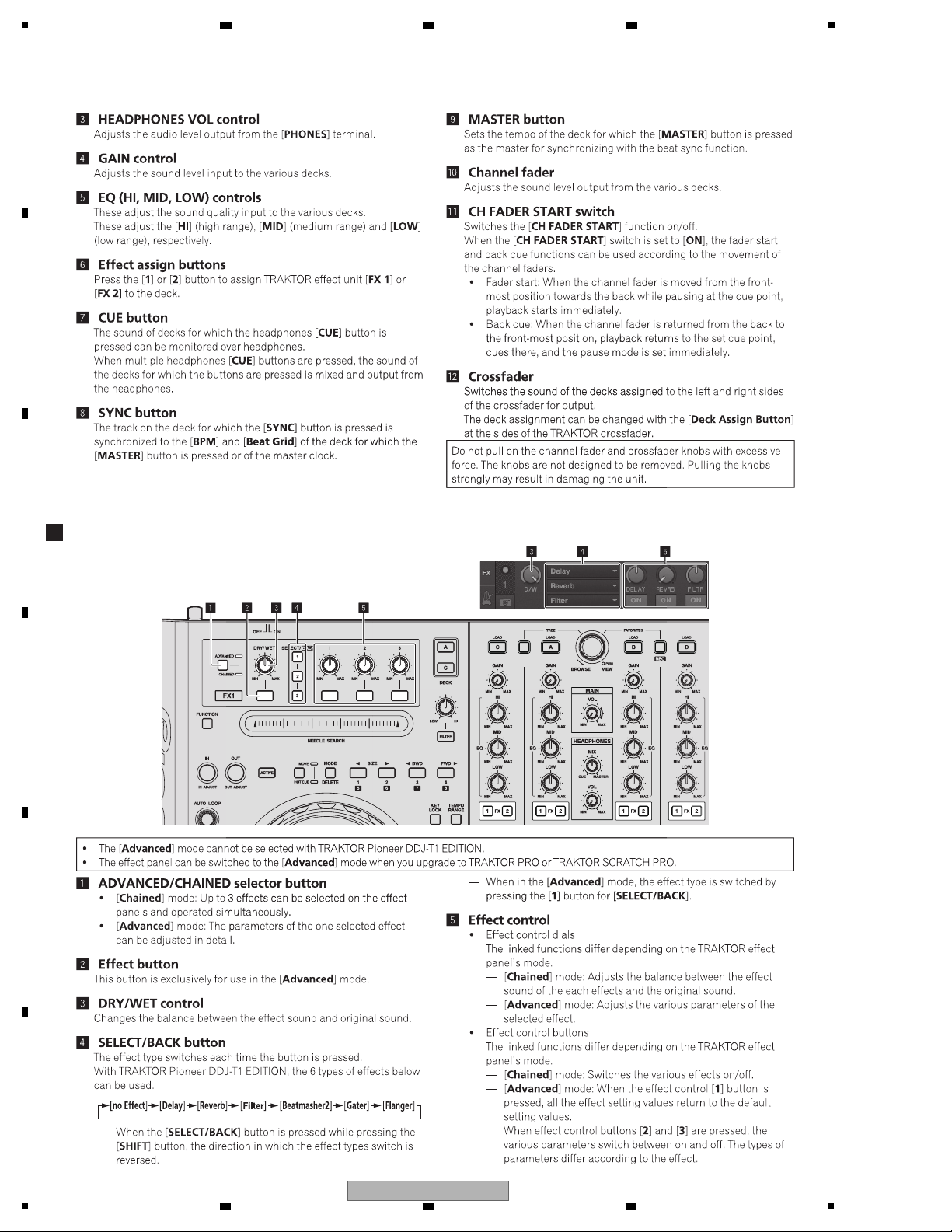

4 Effect

A

B

2 3 4

C

D

E

F

12

1

2 3 4

DDJ-T1

Page 13

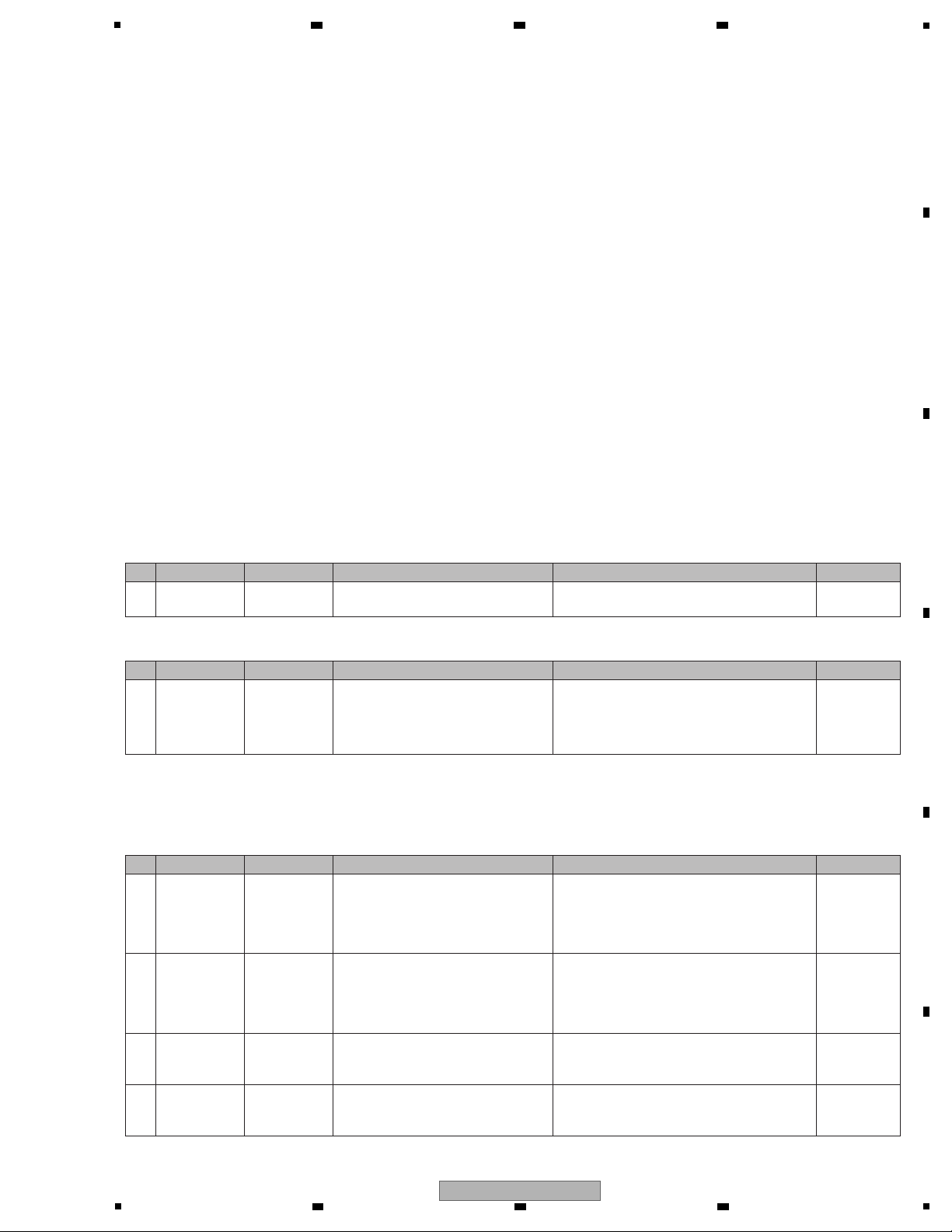

5

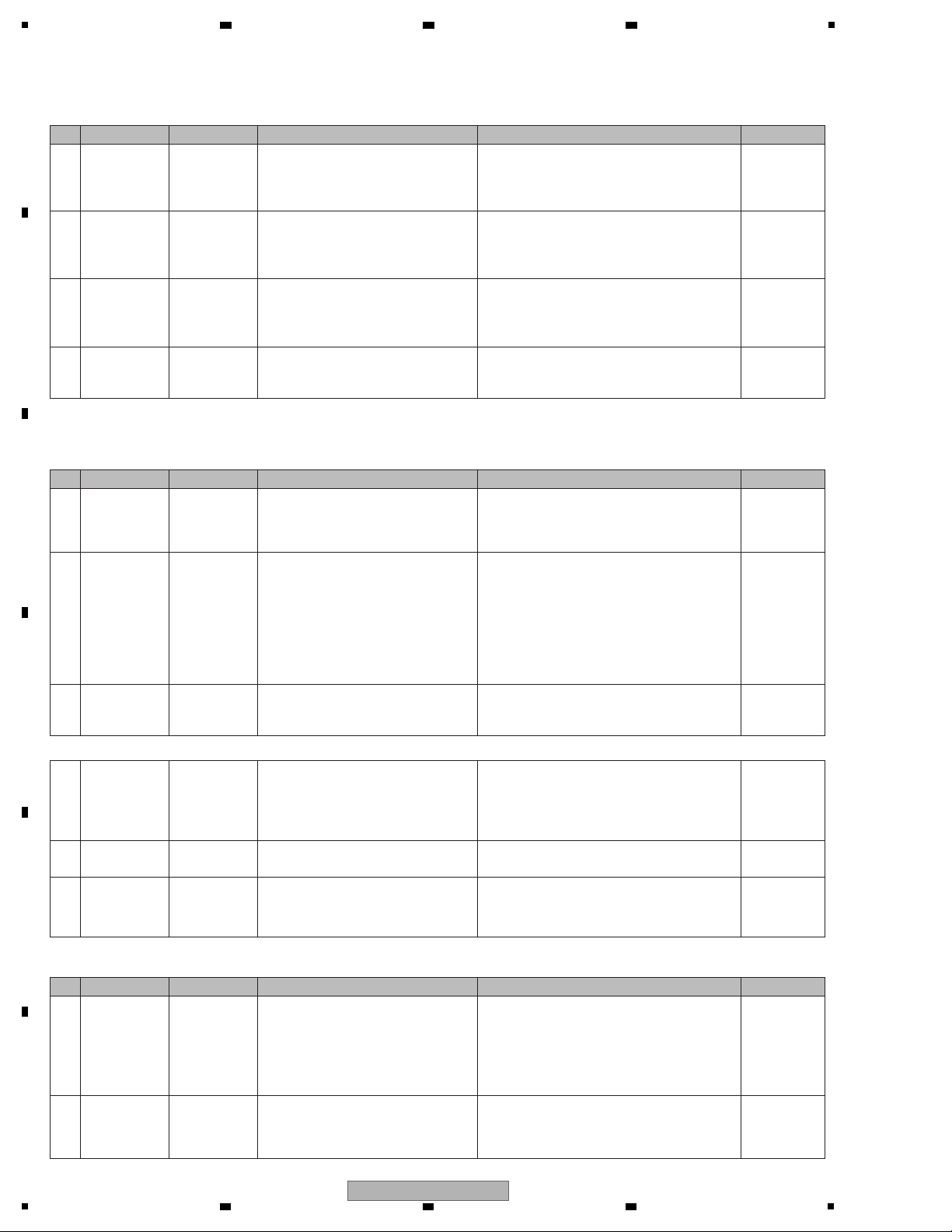

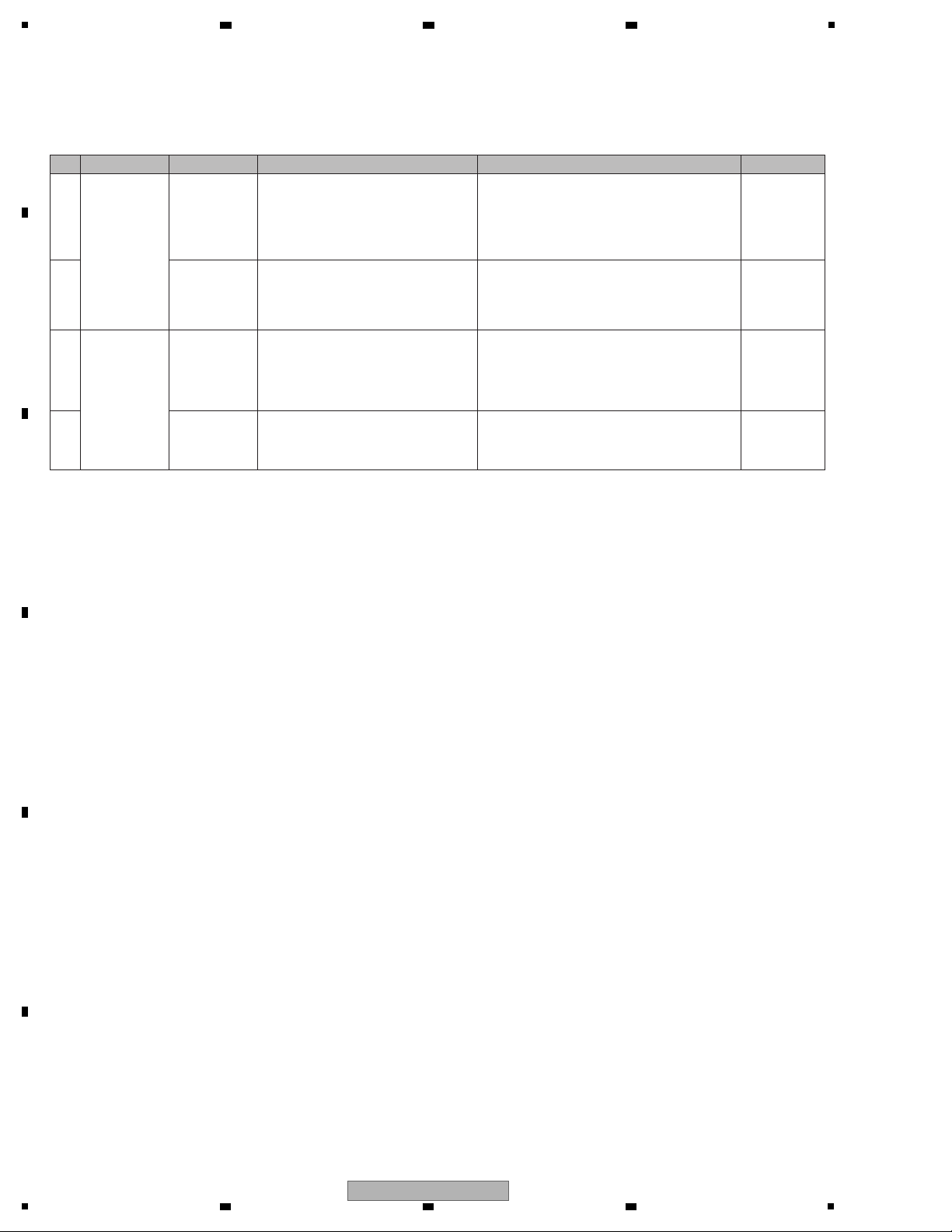

No.

Procedures Check points

1

2

3

4

5

7

6

Confirm that the customer complaint has been resolved.

If the problem pointed out by the customer occurs with a

specific source or operation, such as PC input, AUX/MIC input,

Fader, or VOL, input that specific source then perform that

specific operation for checking.

The customer complain must not be reappeared.

Audio and operations must be normal.

Confirmation of operation of operating elements 1

Enter Service mode.

There must be no errors in operations of each button, LED, the

JOG dial, and NeedleSearch.

Confirmation of operation of operating elements 2

Connect this unit with a PC with the DJ application (TRAKTOR)

installed, via USB.

There must be no errors in operations of volume controls,

faders, and rotary encoders.

Check the analog audio output.

Connect this unit with a PC with the DJ application (TRAKTOR)

installed, via USB, then play back audio

There must be no errors, such as noise, in audio signals and

operations of the MASTER/HEADPHONES outputs.

Check the analog audio input.

Input an audio signal via AUX/MIC. (Make the input settings,

referring to “Inputting Audio from Microphones or External

Equipment” in the Operating Instructions.)

Audio and operations must be normal.

Check the appearance of the product.

No scratches or dirt on its appearance after receiving it for

service.

Confirmation of USB-bus Power

Disconnect the AC adapter and operate the unit only on

USB-bus power.

Audio and operations must be normal.

(For details on limitations of USB-bus power, refer to the

Operating Instructions.)

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding audio.

Lubricants and Glues List

Name Part No. Remarks

Lubricating oil GYA1001 Refer to “9.5 JOG SECTION”.

Jigs List

Jig Name Part No. Purpose of use / Remarks

USB cable GGP1188 for PC connection, accessory

AC adapter DWR1491 Accessory (Note: The power plug part is different.)

6 7 8

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

3.2 JIGS LIST

C

D

E

5

6 7 8

DDJ-T1

F

13

Page 14

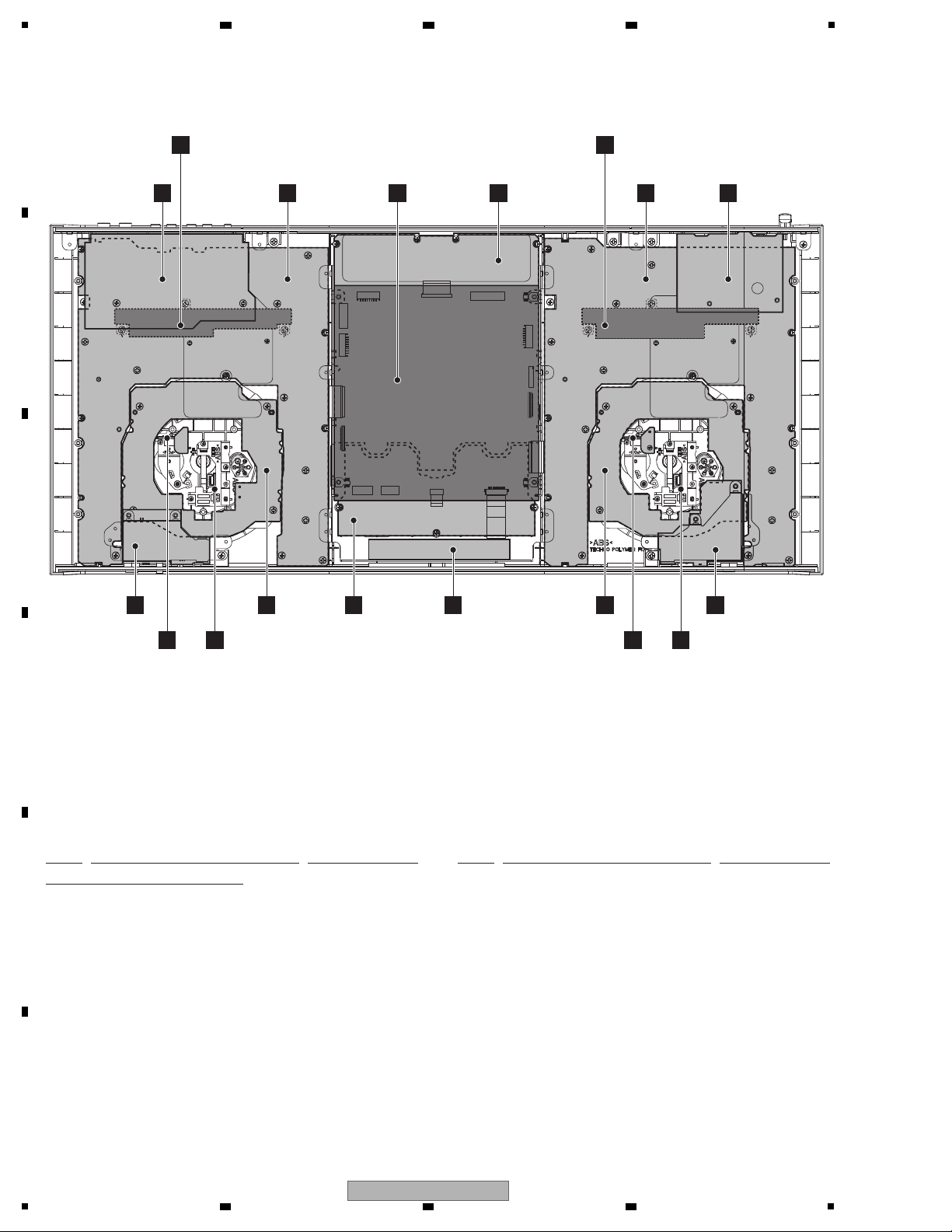

1

NSP 1..MAIN ASSY DWM2421

2..UCOM ASSY DWX3209

2..CDCB 1 ASSY DWX3210

2..CDCB 2 ASSY DWX3224

NSP 1..CDJ1 ASSY DWM2422

2..CDJ1B ASSY DWS1430

2..JOGB ASSY DWS1432

2..TCHB ASSY DWS1433

2..LEDB ASSY DWS1434

NSP 1..CDJ2 ASSY DWM2423

2..CDJ2B ASSY DWS1431

2..JOGB ASSY DWS1432

2..TCHB ASSY DWS1433

2..LEDB ASSY DWS1434

NSP 1..DJM1 ASSY DWM2424

2..CHFD ASSY DWX3212

2..CRFD ASSY DWX3213

2..MICB ASSY DWX3215

2..HPJK ASSY DWX3216

NSP 1..DJM2 ASSY DWM2426

2..DJMB ASSY DWX3211

2..JACB ASSY DWX3214

2..USBB ASSY DWX3222

A

JACB ASSY

D

CDCB 1 ASSY/CDCB 2 ASSY

(DWX3210/DWX3224)

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

C

CDCB 1 ASSY/CDCB 2 ASSY

(DWX3210/DWX3224)

K

MICB ASSY

E

TCHB ASSY

F

JOGB ASSY

F

JOGB ASSY

E

TCHB ASSY

M

CRFD ASSY

• Bottom view

L

CHFD ASSY

N

HPJK ASSY

G

LEDB

ASSY

G

LEDB

ASSY

O

USBB ASSY

H

CDJ1B

ASSY

I

CDJ2B ASSY

J

DJMB ASSY

B

UCOM ASSY

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

3.3 PCB LOCATIONS

A

2 3 4

B

C

D

E

F

14

1

2 3 4

DDJ-T1

Page 15

5

6 7 8

A

B

C

D

E

F

DDJ-T1

5

6 7 8

15

Page 16

1

CN2001/CN2101

C D

CDCB 1 ASSY/CDCB 2 ASSY

(DWX3210/DWX3224)

/

MAIN ucom

M16C/65 128Pin

R5F3651ENFC

IC701

DYW1801-/J

PEG850A8-K

A

JACB ASSY

(DWX3214)

AUX IN

MASTER2 OUT

MASTER1_R OUT

MASTER1_L OUT

HP OUT

HP OUT (mini)

CDC_CS1

GND_D

CDC_SCLK

CDC_DSI

CDC_DSO

V+3R3_D

CDC_INT1

MUTE

V+6

V-6

GND_P

MASTER_L

GND_AM

GND_AM

V-6

V+6

GND_P

AUX_R_IN

GND_AA

AUX_L_IN

GND_AA

GND_D

LED_3

LED_5

GND_D

LED_4

LED_0

LED_2

GRID3

LED_1

GRID1

GRID2

GRID0

GND_D

JOG1_2

V+5_D

JOG_TCH_1

GND_D

JOG1_1

V+5_D

V+3R3_D

JOG1/2_1

JOG1/2_2

V+3R3_D

GND_D

V+3R3_D

JOG_TCH_1/2

GND_D

GRID2

GRID5

GND_D

GND_D

GRID7

GRID6

GRID3

GND_D

LED_14

GRID1

LED_12

GRID0

LED_13

GRID4

KEY_IN12

CUR_ENC1

GND_D

GND_D

KEY_IN11

KEY_IN9

KEY_IN10

CUR_ENC2

AD_SW_A

V+5_D

AD_4

AD_3

GND_AD

AD_1

AD_0

AD_2

GND_AD

V+3R3_AD

GND_D

V+6

HP_L

GND_P

V-6

GND_P

HP_R

GND_AH

GND_AH

MUTE

AD_SW_B

JOG_TCH_1

GRID4

GRID5

GRID6

GRID7

GND_D

KEY_IN1

KEY_IN2

KEY_IN3

KEY_IN4

GND_D

GND_D

LED_0

LED_1

GND_D

LED_2

LED_3

LED_4

LED_5

L_ENC1_1

L_ENC1_2

GND_D

GND_AD

GND_AM

MASTER_R

AD_DRYWET1

AD_EFF1_2

GND_AD

AD_EFF1_3

AD_EFF1_1

AD_FILTER1

AD_PITCH1_1

GND_AD

V+3R3_AD

AD_PITCH1_2

GND_AD

V+5_D

V+5_D

GRID0

GRID1

GRID2

GRID3

GND_D

JOG1_2

JOG1_1

V+3R3_D

GND_AM

CN902

AKM1294-

1234567

8

CN4402

KM200NA7L

1

V-6A

2

V+6A

3

GND_PA

4

AUX_IN_R

5

6

AUX_IN_L

7

CN302

AKM1293-

1234567

CN3002

VKN 1256-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

CN3001

VKN 1250-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CN6001

VKN 1279-

1

2

3

4

5

6

7

8

9

10

11

12

13

LED_1/7

14

LED_0/6

15

LED_2/8

16

17

LED_4/10

18

LED_3/9

19

LED_5/11

CN6002

KM200NA4L

1

2

3

4

PF04PG-B05

CN3201

123

4

51048-0300

JH6001

123

CN3301

52151-0310

1

2

3

CN1002

VKN 1300-

1234567

8

CN4001

VKN 1239-

1234567

8

JA4403

AKB7181-

54321

CN4801

KM200NA9

123456789

JA4802

CKS4124-

2

3

1

JA4801

DKN1622-

2

3

1

JA4404

DKN1622-

231

JA4402

DKN1622-

231

JA4401

AKB7181-

54321

VKN 1429-A

CN1001

123456789

101112131415161718192021222324

25

CN4002

VKN 1256-

123456789

101112

131415161718192021

222324

25

CN1004

AKM1299-

123456789

10

CN906

VKN 1424-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

AKM1279-

1

CDC_INT

2

CDC_CS

3

GND_CDC

4

5

GD_CDC

6

7

8

V+3R3_CDC

CN3003

VKN 1251-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CN301

AKM1295-

1

2

3456789

CN4401

KM200NA9L

123456789

CN501

AKM1295-

1

2

34567

8

9

VKN 1429-A

CN905

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

B2PS-VH

CN4403

1

2

DKP38942mm pitch

L=100mm

DKP39202mm pitch

L=210mm

DKP38972mm pitch

L=360mm

DKP39232mm pitch

L=610mm

FFC

DDD15431mm pitch /

L=90mm/

TAPE LENGTH=7mm

FFC

DDD15611mm pitch /

L=270mm/

TAPE LENGTH=8mm

FFC

DDD15451mm pitch /

L=130mm/

TAPE LENGTH=8mm

FFC

DDD15471mm pitch /

L=100mm/TAPE LENGTH=8mm,1

HP OUT

USB

AUX IN

MASTER OUT

CDC

SW

EEPROM

IC201

+

-

OP AMP

+

-

OP AMP

CERAMIC

X701

RESET IC

IC106

OP AMP

+

-

+

OP AMP

-

+

OP AMP

-

+

OP AMP

-

LED/KEY

MATRIX

VOL INPUT

LED/KEY MATRIX

VOL INPUT

LED/KEY MATRIX

VOL INPUT

LED/KEY MATR

FFC

DDD15431mm pitch /

L=90mm/

TAPE LENGTH=7mm

JP501

DKP3926-

3.96mm pitch

L=220mm

G

LEDB ASSY

(DWS1434)

E

TCHB ASSY

(DWS1433)

F

N

JOGB ASSY

(DWS1432)

HPJK ASSY

(DWX3216)

J

DJMB ASSY

(DWX3211)

H

CDJ1B ASSY

(DWS1430)

UCOM ASSY

(DWX3209)

B

B B

1/6- 6/6

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

2 3 4

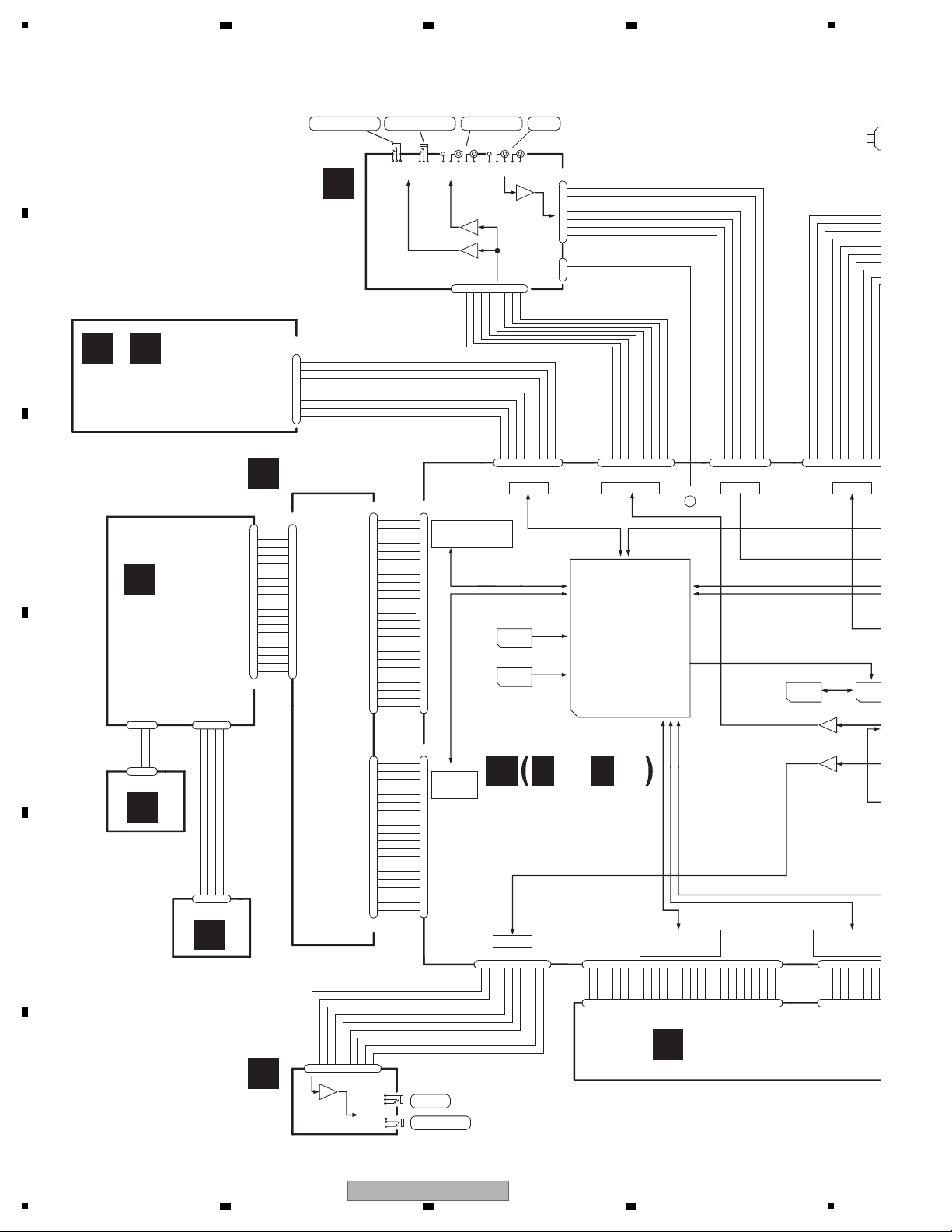

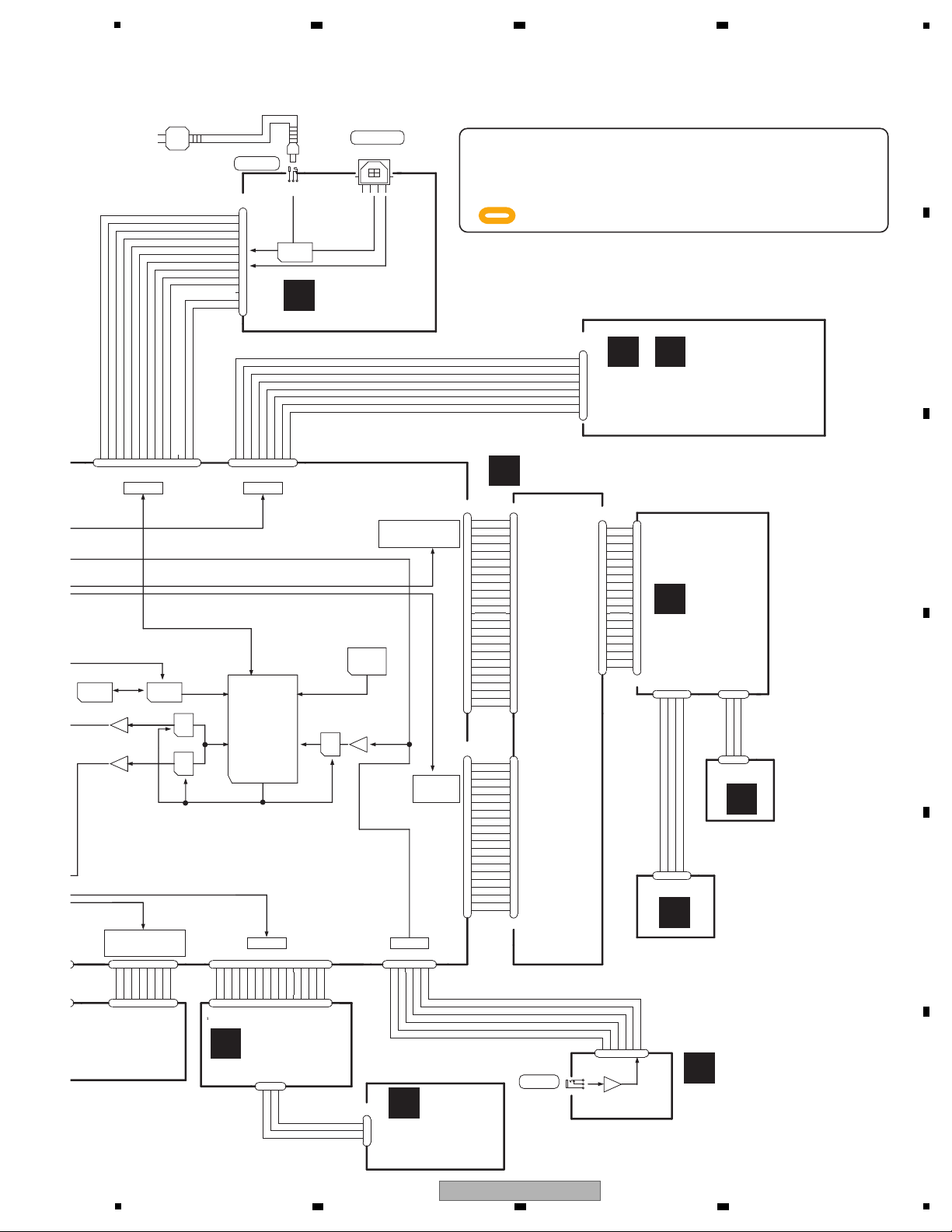

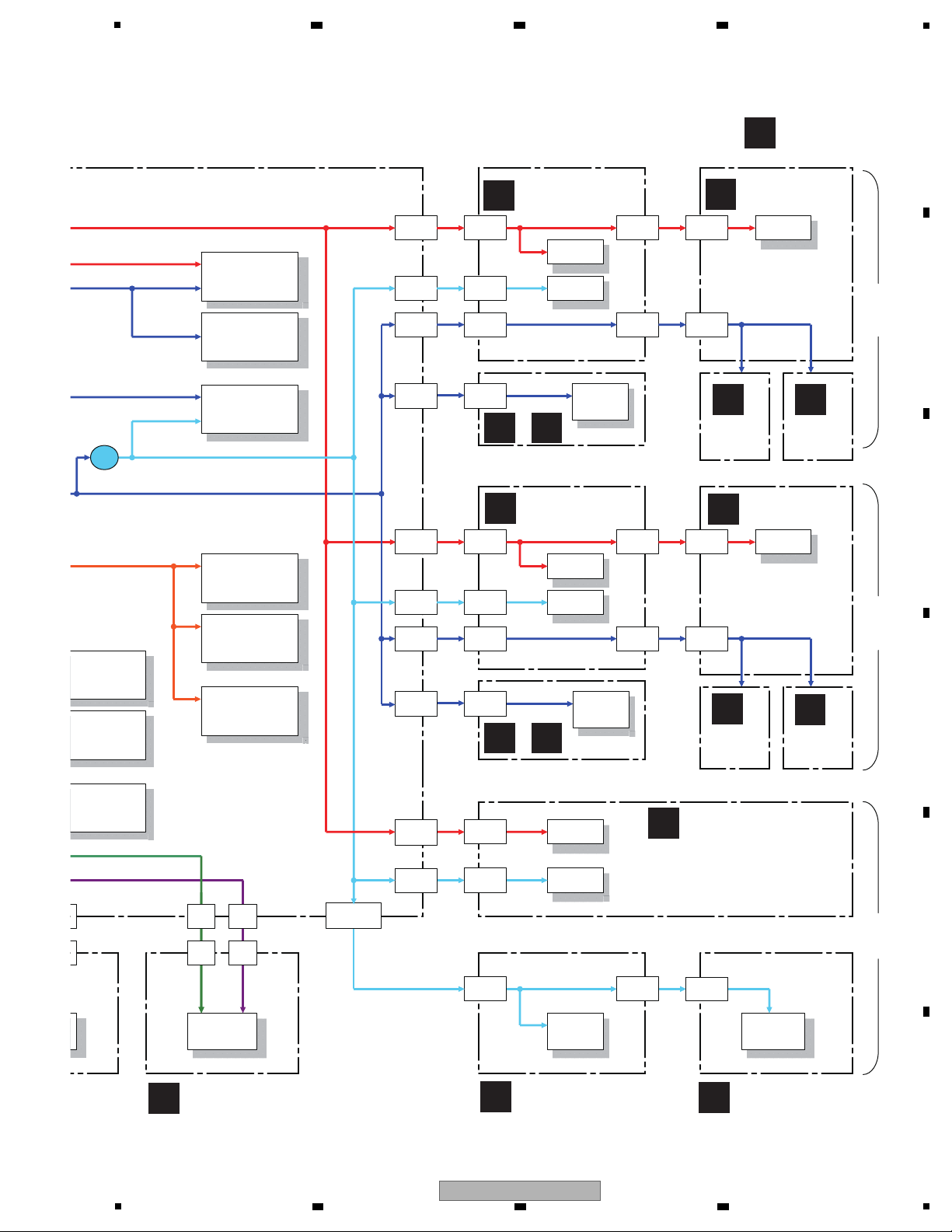

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

16

1

DDJ-T1

2 3 4

Page 17

5

CN2001/CN 2101

C D

CDCB 1 ASSY/CDCB 2 ASSY

(DWX3210/DWX3224)

/

MIC IN

USB B TYPE

DC JACK

CDC_DSO

CDC_DSI

GND_D

CDC_SCLK

GND_D

CDC_CS2

CDC_INT2

V+5_D

V+5_D

GND_D

V+4R7_STB

ADP_DET

P_SW1_ADP

P_SW2_USB

GND_D2

USB_DP

USB_DN

GND_D

JOG_TCH_2

GRID6

GRID7

GND_D

KEY_IN5

GRID5

GND_D

GRID4

KEY_IN8

LED_7

GND_D

GND_D

KEY_IN6

KEY_IN7

LED_9

LED_6

LED_8

GND_D

LED_11

LED_10

LED_11

LED_9

GND_D

LED_10

LED_8

LED_6

LED_7

GRID2

GND_D

GRID3

GRID0

GRID1

V+5_D

V+5_D

GND_D

JOG2_2

JOG2_1

V+3R3_D

JOG_TCH_2

JOG1/2_1

JOG1/2_2

GND_D

JOG_TCH_1/2

GND_D

V+3R3_D

AD_4

AD_3

GND_AD

AD_1

AD_0

AD_2

GND_AD

V+3R3_AD

KEY_IN13

GND_D

GRID3

GRID2

GRID1

GRID0

GND_D

GND_AD

AD_CROSSF

AD_FADER_C

AD_FADER_D

GND_AD

AD_FADER_B

AD_FADER_A

V+3R3_AD

GND_AD

AD_CROSSF

V+3R3_AD

V+3R3_D

V+6

MIC_IN

GND_P

GND_A

MIC_AUX_DET

V-6

V+5_USB

V+3R3_D

V+3R3_D

JOG2_1

JOG2_2

GND_D

L_ENC2_2

L_ENC2_1

GND_D

GRID3

GRID2

GRID1

GRID0

V+5_D

V+5_D

GND_AD

V+3R3_AD

AD_PITCH2_2

AD_PITCH2_1

GND_AD

AD_FILTER2

AD_DRYWET2

GND_AD

AD_EFF2_3

AD_EFF2_2

AD_EFF2_1

GND_AD

CN3501

VKN 1250-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

CN6001

VKN 1279-

1

2

3

4

5

6

7

8

9

10

11

12

13

LED_1/7

14

LED_0/6

15

LED_2/8

16

17

LED_4/10

18

LED_3/9

19

LED_5/11

CN6002

KM200NA4L

1

2

3

4

PF04PG-B05

CN3201

123

4

51048-0300

JH6001

123

CN3301

52151-0310

1

2

3

CN1002

VKN 1300-

1234567

8

CN4001

VKN 1239-

1234567

8

CN1003

VKN 1307-

123456789

1011121314

15

CN4201

VKN 1246-

123456789

101112

131415

CN4202

KM200NA3L

123

CN4301

KM200NA3L

1

2

3

CN3502

VKN 1256-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

JA2502

DKN1237-

1

2

3

4

RT1

RT2

JA2501

DKN1523-

2

3

1

KM200NA6

CN4601

1

2

345

6

CN303

AKM1292-

1

2

345

6

JA4601

DKN1614-

2

3

1

CN1004

AKM1299-

123456789

101112

13

KM200NA13L

CN2501

1

2

3

4

5

6

7

8

9

10

11

12

13

CN904

VKN 1242-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

AKM1279-

1

CDC_INT

2

CDC_CS

3

GND_CDC

4

5

GND_CDC

6

7

8

V+3R3_CDC

CN3503

VKN 1251-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CN901

AKM1294-

1234567

8

VKN 1429-A

CN903

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

DKP39002mm pitch

L=190mm

DKP39212mm pitch

L=260mm

DKP39222mm pitch

L=210mm

FFC

DDD15431mm pitch /

L=90mm/

TAPE LENGTH=7mm

FFC

DDD15611mm pitch /

L=270mm/

TAPE LENGTH=8mm

FFC

DDD15451mm pitch /

L=130mm/

TAPE LENGTH=8mm

FFC

DDD15471mm pitch /

L=100mm/TAPE LENGTH=8mm,15mm

FFC

DDD1548-

mm pitch /

L=85mm/TAPE LENGTH=6mm.15mm

PF03PP-C06

2mm pitch

L=60mm

USBucom

TUSB3200A

IC202

CHFD

MIC IN

CDC

USB

SW

EEPROM

IC201

Xtail

6MHz

X201

DAC1

DAC2

ADC

+

-

SWITCHED

OP AMP

+

-

OP AMP

+

-

OP AMP

-

+

OP AMP

FET SW

V+5_D

V+5_USB

LED/KEY

MATRIX

VOL INPUT

LED/KEY MATRIX

AC ADAPTER

VOL INPUT

LED/KEY MATRIX

O

USBB ASSY

(DWX3222)

G

LEDB ASSY

(DWS1434)

E

TCHB ASSY

(DWS1433)

F

JOGB ASSY

(DWS1432)

L

CHFD ASSY

(DWX3212)

M

CRFD ASSY

(DWX3213)

K

MICB ASSY

(DWX3215)

I

CDJ2B ASSY

(DWS1431)

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS

and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance

of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

6 7 8

A

5

DDJ-T1

6 7 8

B

C

D

E

F

17

Page 18

1

A

JACB ASSY

B

UCOM AS

K

MICB ASSY

J

N

G

HPJK ASSY

LEDB ASSY

I

CDJ2B ASSY

E

TCHB ASSY

F

JOGB ASSY

JA4402

Master1 L

Lch

Lch

Lch

Rch

Rch

L-

L+

R+

JA4404

Master1 R

Rch

R-

JA4403

CN4403

GND_AM

Master2

JA4401

Lch

AUX IN

GND_AM

Rch

1044RV

Lch

JA4801

S2I

)niP9(103NC

HP JACK

Lch

Rch

HP L

Lch

HP R

Rch

Rch

JA4802

KCAJiniM

suBS2IS2I

CN901(8Pin)

SPI Bus (CDC)

CN903(25Pin)

JOG2_1/2_2

JOG LED

]0:7[dirG

]0:3[dirG

Trim / Fader

CN904(20Pin)

Grid[7:4]

Key In [12:9][4:1]

Key In[8:5]

Key In[13][8:5]

LED[11:6]

S2I

2_HCT_GOJ

Rch

T

Lch

CN4601

JA4601

MIC IN

IC506

Master

DAC

IC304

Headphone

DAC

IC303

AUX/MIC

ADC

3

3

3

4

3

3

IC101

DC/DC Conv.

IC702

3-8 Decoder

IC1101

Key Buffer

IC1102

Key Buffer

IC301

IC302

IC501

IC305

3

5

1

7

11

10

11

10

3

5

1

7

3

5

5

9

Master R

Master L

5

5

7

2

7

2

1

4

6

2

AUX R In

AUX L In

4

MIC In

IC2001/2101

CDC

Neadle Search

5

9

6

4

CN501(9Pin)

1

7

3

5

1

7

3

5

2044CI1044CI

3

2

3

2

5

2

7

1

IC4405

5

2

7

1

IC4403

5

3

7

1

IC4404

3

5

1

7

IC4801

3

5

3

2

3

2

1

7

3

5

IC4601

4

CN4001

CN3201

CN3301

CN3502

CN3503

CN3501

JH6001

CN6002

CN6001

SWICSW

IC

VOL

AUX/MIC SW

JOG

LED

MATRIX

Circuit

KEY

LED

Trim

JOG

VR4601

CN1002(8Pin)

SW

CN303(6Pin)

CN302(7Pin)

CN4401

CN4402

CN4801

CN2001/CN2101

C D

CDCB 1 ASSY/CDCB 2 ASSY

/

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

2 3 4

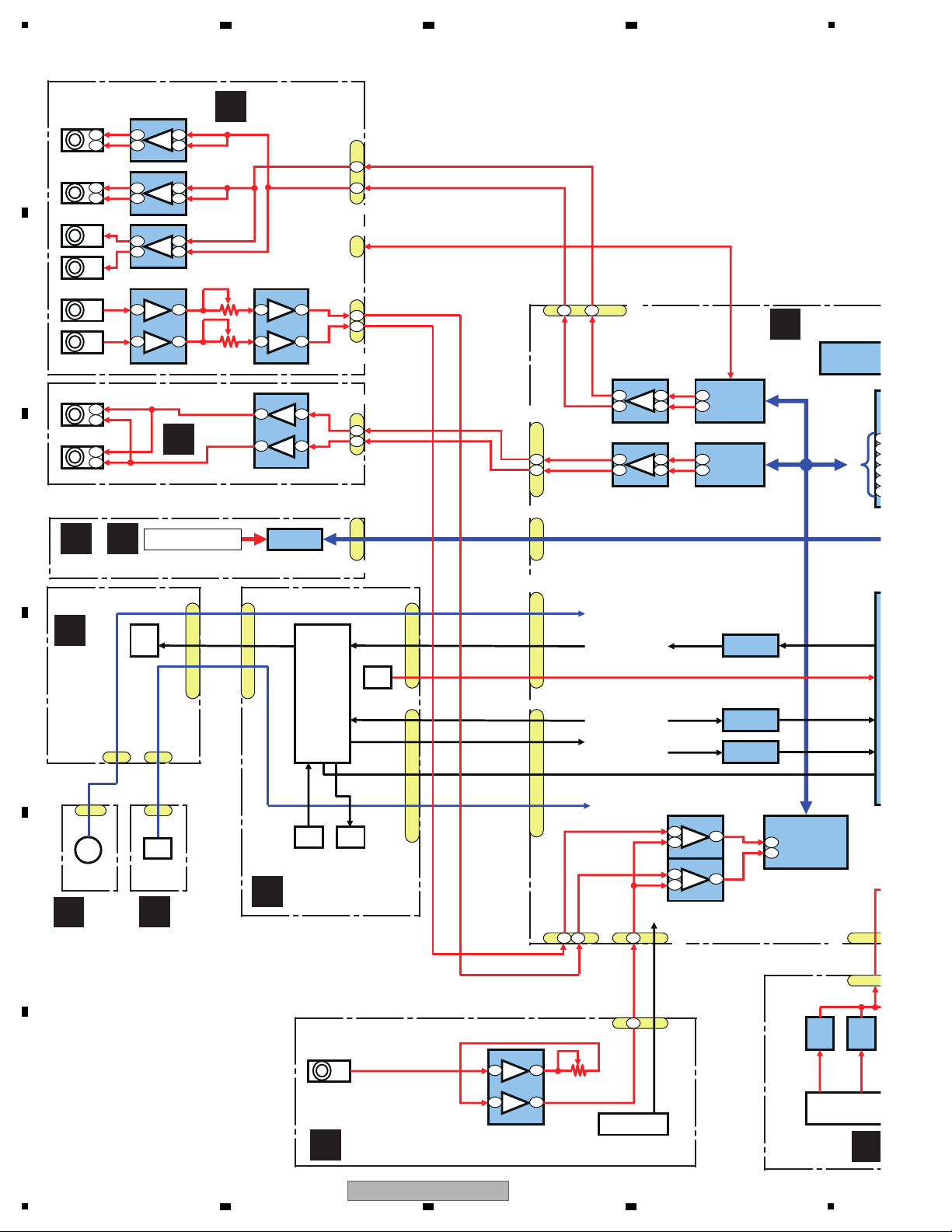

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

18

1

2 3 4

DDJ-T1

Page 19

UCOM ASSY

J

DJMB ASSY

L

CHFD ASSY

M

CRFD ASSY

G

LEDB ASSY

H

CDJ1B ASSY

E

TCHB ASSY

F

JOGB ASSY

O

USBB ASSY

USB Dp/Dn

* V+USB5 or V+ADP5

CN1004(13Pin)

ADP_DET

P_SW2_USB/PSW1_ADP

USB Dp/Dn

POWER SUPPLY

POWER SUPPLY

S2I

I2C

suBS2IS2I

)niP8(209NC

)CDC(suBIPSsuBIPS

CN2001/CN2101

I2C

CN906(20Pin)

JOG_TCH_1

Grid[7:4]

DELGOJ

]1:4[nIyeK

LED[5:0]

CN905(25Pin)

Trim / Fader

Grid[3:0]

JOG1_1/1_2

S2I

Trim

Fader

FD SATRT SW

CRFD

IC202

USB_UCOM

TUSB3200A

IC701

MAIN_UCOM

IC203

SW

IC201

EEPROM

IC303

AUX/MIC

ADC

39

38

36

44

34

35

Master Data

HP Data

MIC/AUX Data

BCL

LRCK

MCLK

41

42

SDA

SCL

5

42

43

6

IC101

DC/DC Conv.

2

1

7 8

910

10

32

IC2001/2101

CDC

Neadle Search

LED [14:12]

Grid[7:0]

Key In[12:9]

IC106

Reset IC

17

Fault_Det

Circuit

23

CN4002

CN4301

CN4202

CN4001

CN2001

JA2502JA2501

SW

Circuit

CN2501

CN3301

CN3201

CN6002

JH6001

CN6001

CN3001

CN3002

CN3003

MATRIX

Circuit

MATRIX

Circuit

MATRIX

Circuit

JOG

LED

KEY LED

Trim

KEY LED

SWICSWICSW

IC

VOL

JOG

CN1003(15Pin

CN1002(8Pin)

CN1001(25Pin)

SW

Reset

DYW1801

PEG850A8-K

C D

CDCB 1 ASSY/CDCB 2 ASSY

/

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

5

5

6 7 8

DDJ-T1

6 7 8

A

B

C

D

E

F

19

Page 20

1

AUDIO AMP(MASTER)

RNB4580F

IC501

AUDIO AMP(HP)

NJM4565MD

IC305

SW AMP(AUX/MIC)

NJM2121MD x2

IC301, IC302

V+5_D

V+5_DV+5_D

POWER SLIDE SW

ASG1100

S2502

OPAMP x1

V+6 V-6

OPAMP x4

V+6

V-6

V+6 V-6

V+6

V-6

V+5

_USB

V+5

_USB

V+4R7

_STB

V+4R7

_STB

IC105

3.3V_REG

4.7V→3.3V

S-1200B33

IC102

3.3V_REG

5V→3.3V

S-1200B33

IC102

3.3V_REG

5V→3.3V

S-1200B33

V+5_U

V+3R3_

V+3R3_

V+3R3_U

V+3R3_D

V+3R3_

L707

V+USB5

V+ADP5

IC103

5V_REG

6V→5V

S-1200B50

V+5_A

IC101

D/D_CONV

5V→6V

BD9851EFV

IC101

D/D_CONV

5V→-6V

BD9851EFV

V+6

V+6

V+6

V+5_D

V-6

V-6

V+5_D

V+5_D

V+5_D

V+5_USB

V+5_USB

V+4R7_STB

USB

CABLE

AC

ADAPTER

V+6

V-6

FET RELAY SW

RTQ040P02

Q2522, Q2524

FET RELAY SW

RTQ040P02

Q2523, Q2525

V+6

V-6

A

JACB ASSY

B

UCOM ASSY

K

MICB ASSY

N

O

USBB ASSY

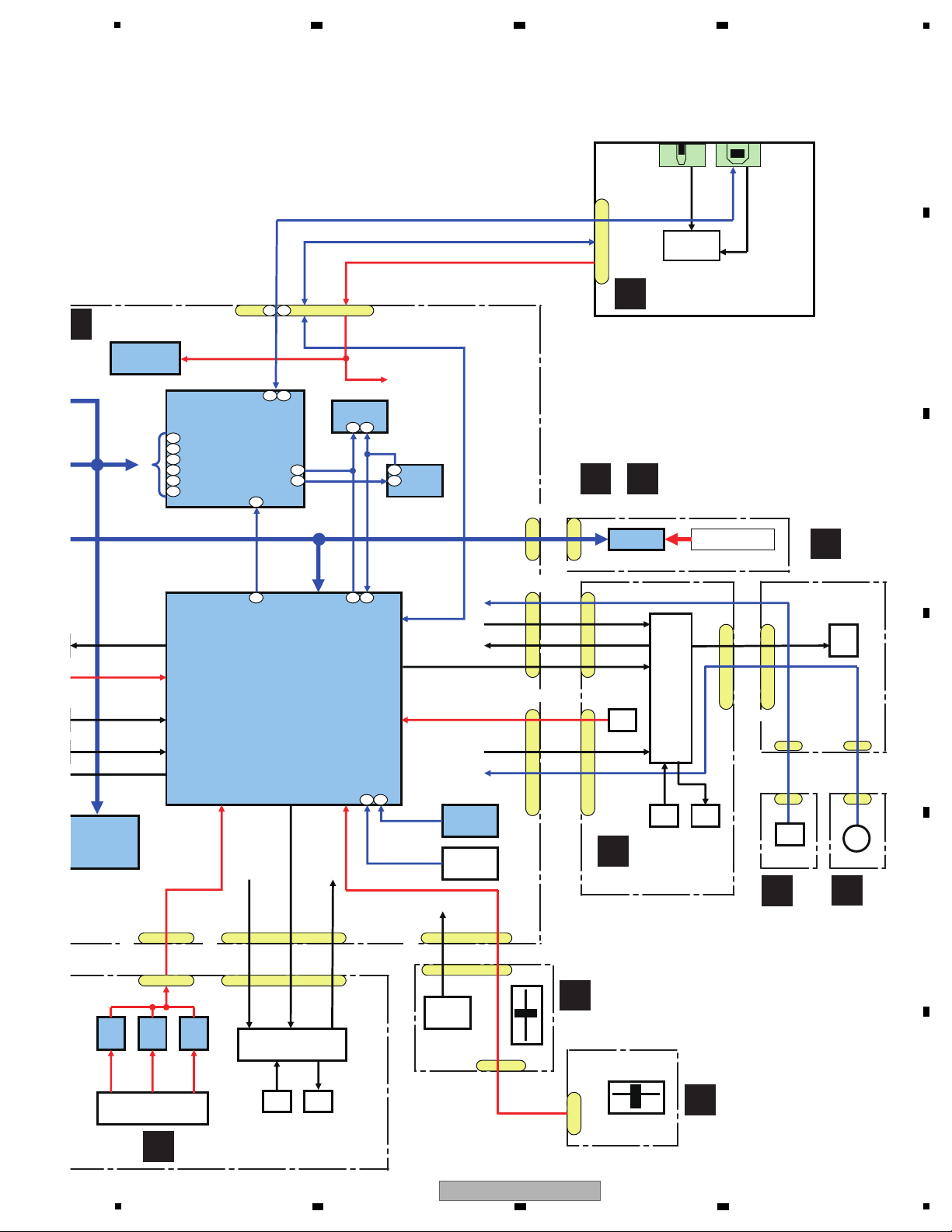

4.3 POWER BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

20

DDJ-T1

1

2 3 4

Page 21

MAIN ucom

DYW1801

PEG850A8-K

IC701

USB ucom

TUSB3200A

IC202

EEPROM

IC201

HP DAC

AK4387ET

IC304

MASTER DAC

AK4387ET

IC506

AMP(MASTER)

IC501

IC305

V+5_D

V+3R3_D

301, IC302

V+5_D

LED

NEEDL

SEARCH

VR

LED

VR

V+3R3_AD

V+5_D

V+5_D V+5_D

LED

V+3R3_AD

CH FADER

x4

CROSS

FADER

V+3R3_D

V+3R3_D V+3R3_D

V+3R3_AD

V+3R3_AD

V+3R3_D V+3R3_D

OPAMP x1

V+6

V+6

V-6

V-6

V+3R3_AD

V+5_D

V+3R3_D

V+5_D

LED

NEEDL

SEARCH

VR

V+5_D V+5_D

LED

V+3R3_D

V+3R3_D

V+3R3_D

V+3R3_D V+3R3_D

V+5_D

V+5_USB

V+3R3_USB

V+3R3_USB

V+3R3_UCO

V+3R3_D

V+3R3_AD

V+3R3_AD

L707

V+3R3_AD V+3R3_AD

V+3R3_AD V+3R3_AD

V+5_D

V+3R3_AD

V+5_A

V+3R3_D

ADC

AK5358AET

IC303

J

DJMB ASSY

L

CHFD ASSY

M

CRFD ASSY

N

HPJK ASSY

I

CDJ2B ASSY

G

LEDB ASSY

G

LEDB ASSY

H

CDJ1B ASSY

E

TCHB

ASSY

F

JOGB

ASSY

E

TCHB

ASSY

F

JOGB

ASSY

C

CDCB 1 ASSY

CDJ1

DECK

A,C

CDJ2

DECK

B,D

DJM

MIXER

C D

CDCB 1 ASSY/CDCB 2 ASSY

CDCB 1 ASSY/CDCB 2 ASSY

/

C D

/

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

Either the CDCB 1 Assy or CDCB 2 Assy is assembled here. The CDCB 1 Assy

and CDCB 2 Assy are interchangeably used and handled similarly in their production

management.

5

6 7 8

A

B

C

D

E

5

6 7 8

DDJ-T1

F

21

Page 22

1

• With AC adaptor and USB connection

• With AC adaptor and w/o USB connection

• W/O AC adaptor and with USB connection (USB-bus power)

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Note: The TUSB3200A is started up after loading

the program from the EEROM.

Note: Start the updating

program on the PC.

Normal mode

To normal main loop processing

• Power monitoring/switching

• MIC/AUX switching

• Detection of change in operating elements

• USB transmission (transmission of operating element data)

• USB reception (reception and indication of display data)

Power ON

Clock multiplying -> 32 MHz

Port initial setting

I2C serial initial setting

Checking and setting

of the power supply

Has the

power-supply status

changed?

Power failure?

Unit stopped by power

failure (All LEDs unlit)

With USB

connection?

Canceling reset of the USB

Controller and the TUSB3200A

Opening indication

Opening indication

Checking of communication

with the TUSB3200A

Has

communication been

established?

Alarm indication of abnormal

stopping of the TUSB3200A

CRC check of the main flash

CRC error?

(FLASH NG?)

Waiting for a recovery

/updating request

Interruption initial setting

Serial communication

initial setting

Timer initial setting

A/D conversion initial setting

A

A

MIC/AUX initial setting

Needle initial setting

Operation mode

judgment

Service mode

(Test mode)

JOG Load

Measurement mode

LED luminance setting

Display initial setting

Headphones level setting

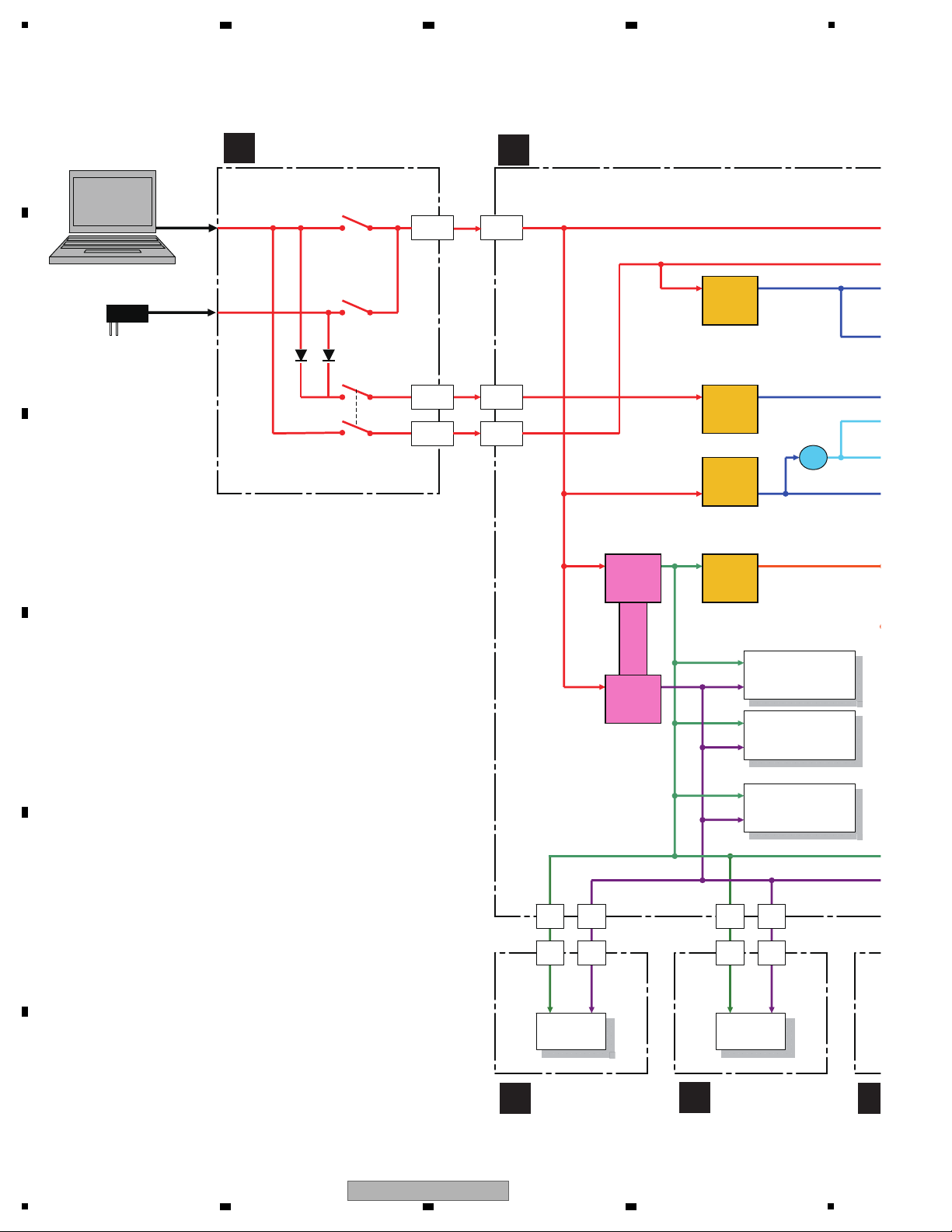

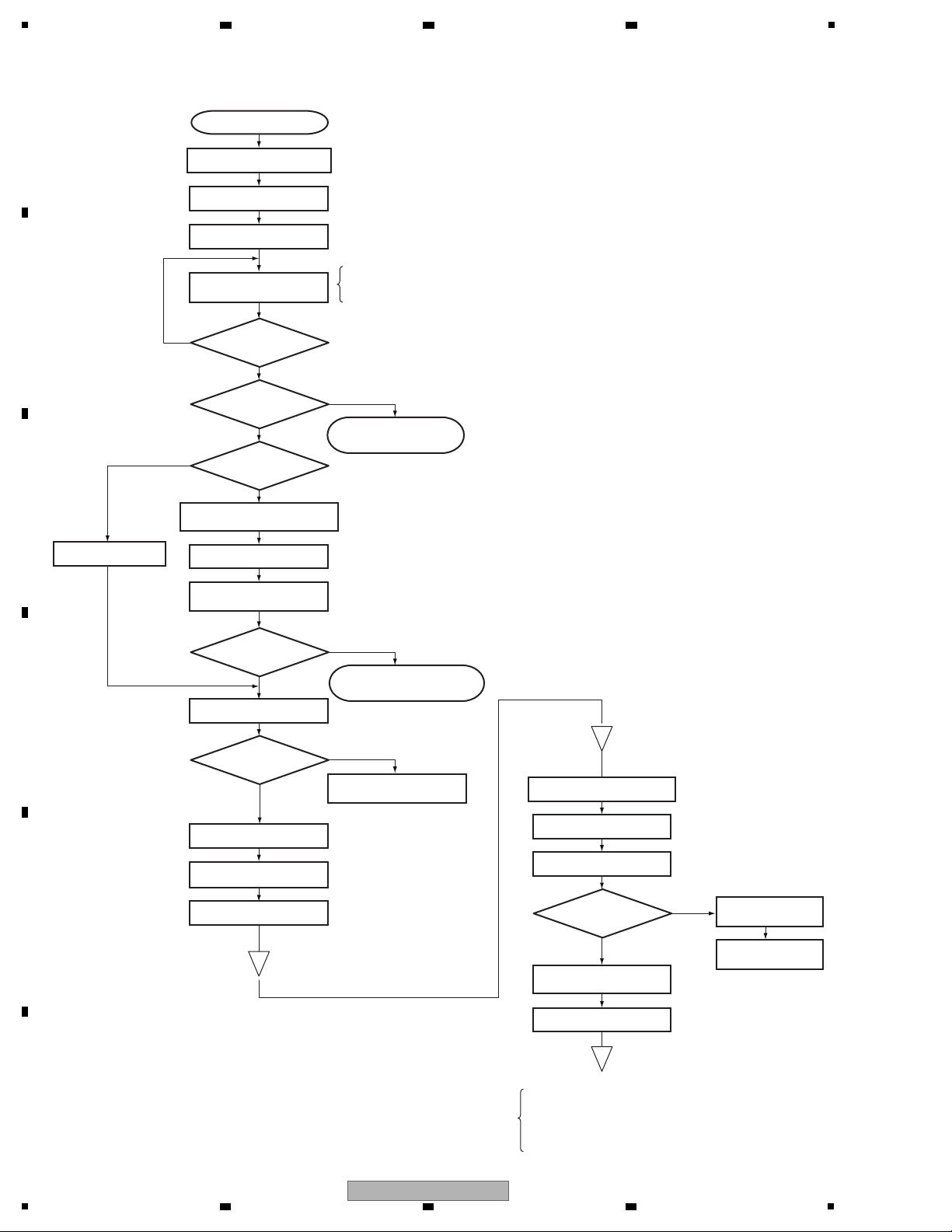

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

A

B

C

2 3 4

D

E

F

22

DDJ-T1

1

2 3 4

Page 23

5

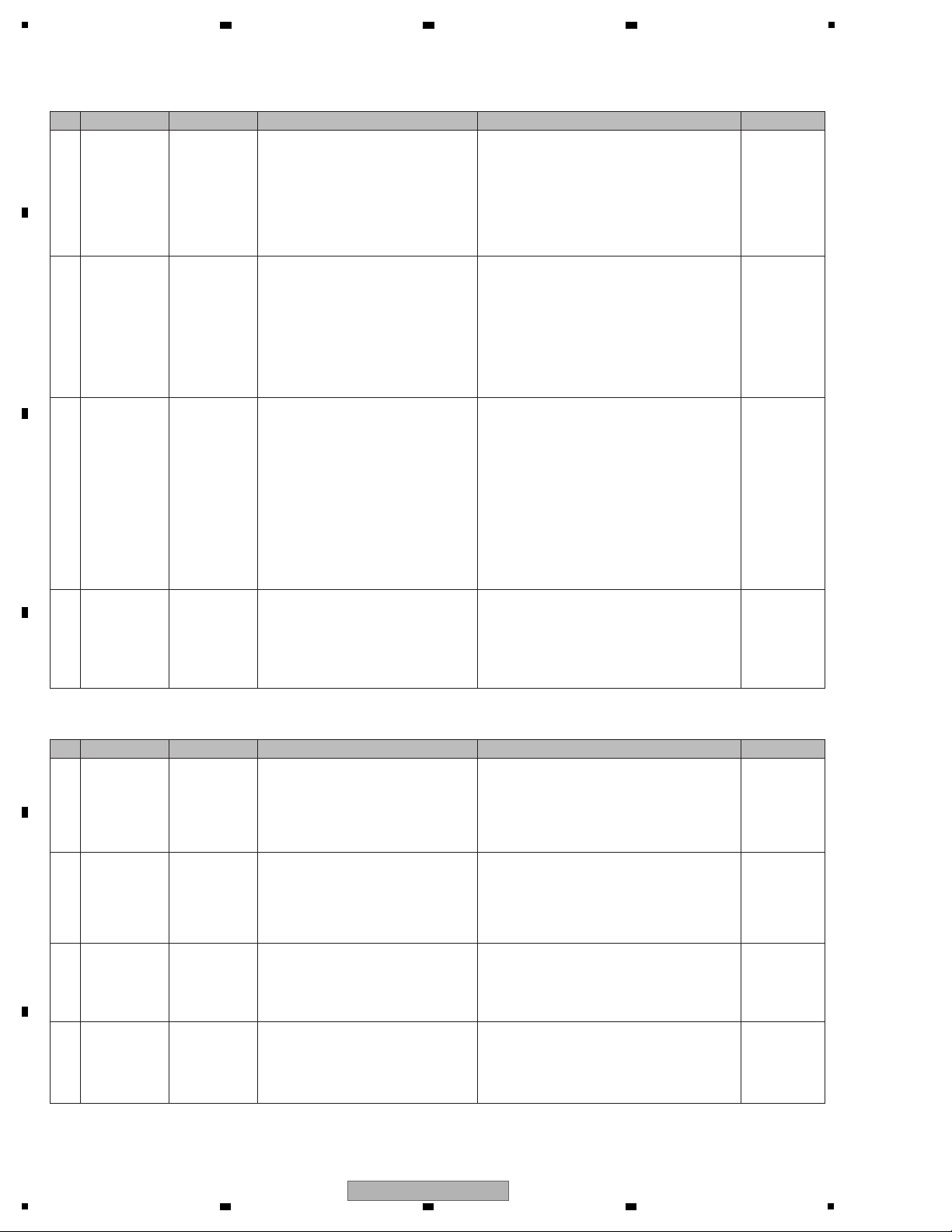

[0] Prior Confirmation

[0-1] Checking in Service Mode

[0-2] Checking Internal Cables

[1] Failure in Startup (Failure in power-on, all LEDs unlit)

[1-1] Failure in the power system

In this section, causes of failure, diagnostics points, and corrective measures can be searched for according to symptoms.

Before disassembling this unit, it is recommended to infer a failure point by referring to the error code.

For the relationship of each power-supply system, see “4.3 POWER SUPPLY BLOCK DIAGRAM.”

If software of the product is updated before performing diagnostics, check that software updating has been performed

properly before proceeding to diagnostics.

If software updating has not been performed properly, update the software, following the instructions in

“8.3 UPDATING OF THE FIRMWARE.”

Contents

[0] Prior Confirmation

[1] Failure in Startup (Failure in power-on, all LEDs unlit)

[2] Display (LED indicators)

[3] Operations (Buttons/VRs/Sliders/NeedleSearch/JOG)

[4] USB connection

[5] AUDIO OUT

[6] AUDIO IN

[7] Basic Operation Check of the MAIN_UCOM

The waveform numbers and voltage confirmation-point numbers described in this section correspond to the numbers on the

schematic diagrams and PCBs.

Be sure to check the failure points, as well as checking for failure in their peripheral circuits.

In a case where the unit does not start up, even after it is turned ON, when it is powered via the AC adapter or USB-bus power connection.

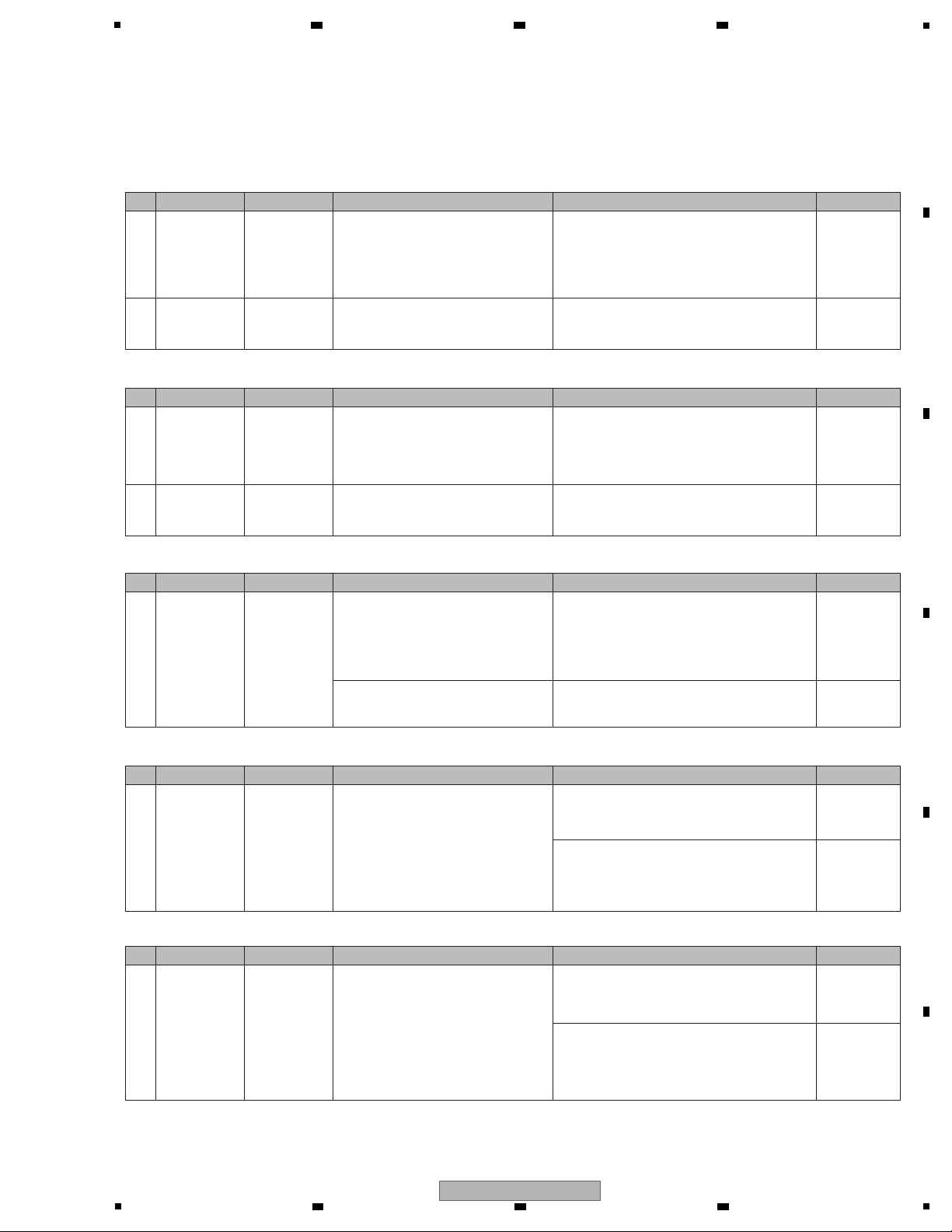

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

1 – Service Mode Identify a failure point.

After a failure point is identified, see the section

referenced in this manual.

6. SERVICE

MODE

No.

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

1

Disconnection,

breakage, or

loose connection

of internal cables

Cables

Check that all the cables are securely

connected. Check that there is no breakage

in the cables.

Securely connect a cable if it is not connected.

If a cable is broken, replace it.

Note: If an FFC cable is disconnected, be careful of

the orientation of the contacts when reconnecting it,

referring to the printed guide on the board.

4.1 OVERALL

CONNECTION

DIAGRAM

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

1

Failure in the

AC adapter

USBB Assy

V+ADP5

Set the POWER switch to OFF.

Check that the voltage of the V+ADP5

power line is in the range of 4.75–5.25 V.

If the voltage is outside the range of 4.75–5.25 V,

failure in the AC adapter and its periphery may be

suspected. AC adapter (DWR1491), DC jack

(JA2501), FETs (Q2523, Q2525), Tra ( )

4.3 POWER

SUPPLY BLOCK

DIAGRAM

4.3 POWER

SUPPLY BLOCK

DIAGRAM

4.3 POWER

SUPPLY BLOCK

DIAGRAM

4.3 POWER

SUPPLY BLOCK

DIAGRAM

2

Failure in USBbus power

USBB Assy

V+USB5

Set the POWER switch to OFF.

Check that the voltage of the V+ADP5

power line is in the range of 4.75–5.25 V.

If the voltage is outside the range of 4.75–5.25 V,

failure in the USB-bus power and its periphery may

be suspected. Check the USB cable and USB

connector.

3-1

Power failure in the

MAIN_UCOM on

the UCOM Assy

UCOM Assy

MAIN_UCOM

Set the POWER switch to ON.

If V+3R3_UCOM is abnormal (2.7 V or less)

and V+4R7_STB is normal (4.2–5.0 V)

The regulator (IC105), the MAIN_UCOM (IC701),

or their peripheral circuits may be defective.

3-2

Power failure in the

USB_UCOM on

the UCOM Assy

UCOM Assy

USB_UCOM

Set the POWER switch to ON.

If V+3R3_USB is abnormal (2.7 V or less)

and the V+5_USB is normal (4.5 V–5.25 V)

The regulator (IC102), the USB_UCOM (IC202),

or their peripheral circuits may be defective.

10.17

WAVEFORMS

AC adapter

4

10.17

WAVEFORMS

Power bus power

1

6 7 8

5.2 TROUBLESHOOTING

A

B

5

DDJ-T1

6 7 8

C

D

E

F

23

Page 24

1

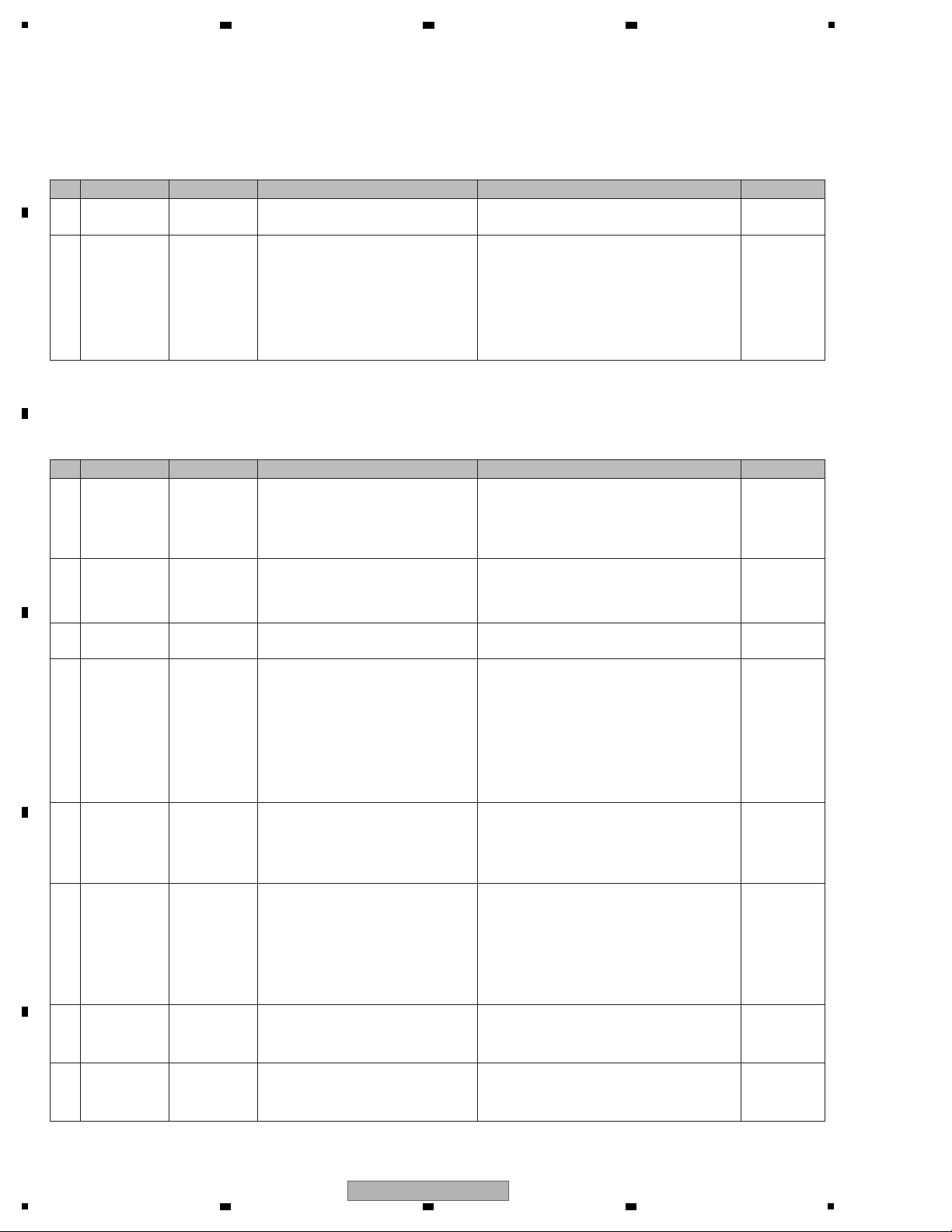

[1-2] Failure in the microcomputer system

4-1 Power failure 1

UCOM Assy

FAULT_DET

Check if the voltage monitoring circuit was

activated:

Turn the unit ON then check the voltages

shown below.

V+5_D:

FAULT_DET, R147 (0 Ω) :

Turn the unit ON then check the voltages shown below.

V+5_D: 2 V or less (abnormal voltage), 4.5 V or higher

(normal voltage)

FAULT_DET, R147(0

Ω

): 0 V (abnormal voltage detection),

3.3 V (normal voltage)

In a case of abnormal voltage detection, see [4–2] Power

failure

2

.

In a case of normal voltage, poor control over the

microcomputer system may be suspected.

4.3 POWER

SUPPLY BLOCK

DIAGRAM

5.3 VOLTAGE

MONITORING

4.3 POWER

SUPPLY BLOCK

5.3 VOLTAGE

MONITORING

4.1 OVERALL

CONNECTION

DIAGRAM

4.3 POWER

SUPPLY BLOCK

4.1 OVERALL

CONNECTION

DIAGRAM

4.3 POWER

SUPPLY BLOCK

5.3 VOLTAGE

MONITORING

4-2

Power failure 2

Identification of

defective Assy

UCOM Assy

FAULT_DET

CDJB

CDCB

DJMB

JACB

HPJK

MICB

Identify the Assy on which a voltage error

was generated.

Remove all cables other than the cable for

CN1004 (USBB to UCOM) from the UCOM

Assy.

Turn the unit ON then check the V+5_D

voltage.

V+5_D:

FAULT_DET, R147 (0 Ω):

Remove all cables other than the cable for CN1004 (USBB

to UCOM) from the UCOM Assy.

Turn the unit ON then check the V+5_D voltage.

V+5_D: 4.5 V or higher (normal)

FAULT_DET, R147(0 Ω): 3.3 V normal, no detection of a

voltage error)

In a case of normal voltage, see [4–3] Abnormal voltage

detection

3

.

In a case of abnormal voltage detection, see [4-4] Power

failure, UCOM Assy.

4-3

Power failure 3

Identification of

defective Assy

UCOM Assy

FAULT_DET

CDJB

CDCB

DJMB

JACB

HPJK

MICB

With all cables other than the cable for

CN1004 (USBB to UCOM) disconnected

from the UCOM_ASSY, identify the defective

Assy by connecting each connector on the

UCOM Assy one by one for voltage checks.

Identify the defective ASSY, by connecting each connector

on the UCOM Assy, as shown below, one by one for

voltage checks:

CDJ1B: CN905, CN906

CDJ2B: CN903, CN904

CDCB: CN901, CN902

DJMB: CN1001, 1002

JACB: CN302, CN501

HPJK: CN301

MICB: CN303

Repair the defective part of the defective Assy.

If further identification of defective Assys is required, see

the notes in “5.3 Voltage Monitoring” before proceeding to

further diagnostics.

4-4

Power failure 4

UCOM Assy

Identification of

defective Assy

UCOM Assy

FAULT_DET

Deactivate the voltage monitoring circuit

then check the section with improper

voltage.

The voltage monitoring circuit can be deactivated by

removing R147 (0 Ω) on the FAULT_DET.

See the notes in “5.3 Voltage Monitoring” before

proceeding to further diagnostics.

To identify the section with improper voltage, check

the voltage at each point on the UCOM Assy.

1

Power failure in

the MAIN_UCOM

UCOM Assy

Check if a voltage error was detected.

Check the power terminal of the

MAIN_UCOM (IC701).

If the detected voltage error is confirmed, check conduction

between the power supply and GND.

Check the power line and the parts, such as coils (beads),

resistors, and capacitors.

If no problem was found with the parts, power line, and

conduction between the power supply and GND, the

MAIN_UCOM

(IC701) may be defective.

Abnormal

Voltage Detection

2

MAIN_UCOM

Reset circuit

error

UCOM Assy

Check the Reset terminal (Pin 17) of the

MAIN_UCOM (IC701). (High/Low)

In normal operation, the voltage of the Reset terminal

(Pin 17) is high.

If the voltage of the Reset terminal is low, check the power

line, resistors, capacitors, and the Reset IC (IC106).

If the voltage level remains low after the Reset IC (IC106)

is replaced, the

MAIN_UCOM

(IC701) may be defective.

3

MAIN_UCOM

X'tal error

UCOM Assy

Check the oscillation waveforms of the

X'tal (X701).

Check the waveforms of the X'tal (X701).

If an error is found, check the power line, resistors, and

capacitors.

If the waveform remains abnormal after the X'tal (X701) is

replaced, the

MAIN_UCOM

(IC701) may be defective.

4

MAIN_UCOM

startup error

UCOM Assy

After startup, check the lighting statuses of

the LEDs.

(For example, although some of the LEDs

light properly, the unit is not started up

properly.)

Refer to “[4] Error Indications” in the 6. Service Mode.

If there is no corresponding error indication, reload the

program via USB.

If the normal status is not recovered after all above steps

are performed, the

MAIN_UCOM

(IC701) may be

defective.

6. Service Mode

[4]

Error Indications

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

10.17

WAVEFORMS

Abnormal voltage

detection

k, p

10.17

WAVEFORMS

Abnormal voltage

detection

k, p

10.17

WAVEFORMS

MAIN UCOM

start up

10.17

WAVEFORMS

MAIN UCOM

start up

i

10.17

WAVEFORMS

MAIN UCOM

start up

j

A

2 3 4

B

C

D

E

F

24

1

DDJ-T1

2 3 4

Page 25

5

[2] Display (LED indicators)

[2-1] Any one of the LEDs does not light.

[3] Operations (Buttons/VRs/Sliders/NeedleSearch/JOG)

[3-1] The push buttons are disabled.

5

Power failure in

the USB_UCOM

UCOM Assy

Check if a voltage error was detected.

Check the power terminal of the

USB_UCOM (IC202).

If the detected voltage error is confirmed, check conduction

between the power supply and GND.

Check the power line and the parts, such as coils (beads),

resistors, and capacitors.

If no problem was found with the parts, power line, and

conduction between the power supply and GND, the USB_

UCOM (IC202) may be defective.

Abnormal

Voltage Detection

6

USB

_UCOM

Reset circuit

error

UCOM Assy

Check the Reset terminal (Pin 10) of the

USB_UCOM (IC202). (High/Low)

In normal operation, the voltage of the Reset terminal

(Pin 10) is high.

If the voltage level at the Reset terminal is low, check for

abnormal voltage detection, and check the power line,

resistors, and capacitors. If no problem was found with the

above circuit, parts, and power line, and if the voltage level

is low, the USB_UCOM (IC202) or the MAIN_UCOM

(IC701) may be defective.

Abnormal

Voltage Detection

7

USB

_UCOM

X'tal error

UCOM Assy

Check the oscillation waveforms of the

X'tal (X201).

If an error is found, check the power line, resistors, and

capacitors.

If the waveform remains abnormal after the X'tal (X201) is

replaced, the USB_UCOM (IC202) may be defective.

8

USB

_UCOM

I2C communication error

UCOM Assy

Check the I2C communication waveforms of the

EEPROM (IC201) immediately after startup.

Data of the EEPROM (IC201) are loaded only during

startup.

If an error is generated, check the power supply to the

EEPROM, resistors, capacitors, and SW IC (IC203) on the

communication line.

If no problem is found with the power supply, communication line, and parts, the EEPROM (IC201) or USB_UCOM

(IC202) may be defective.

9

EEPROM error

UCOM Assy Reload the program via USB.

If no problem is found with the communication waveform in

[8] above, reload the program via USB.

If reloading is successfully performed, the USB_UCOM

(IC202) may be defective.

If reloading fails, the EEPROM (IC201) may be defective.

1 Defective LED LERelated point

Check the connections of the LED then

check the forward voltage (approx. 2.2 V)

between both ends of the LED.

If the forward voltage is abnormal, the LED may be

defective.

LED waveform

10.SCHEMATIC

DIAGRAM

[2-2] Several LEDs do not light.

1 Signal errors

UCOM Assy

CDJ1B

CDJ2B

DJMB

Check for any loose connections between

the MAIN_UCOM (IC701) and the LEDs.

Check also that the control signal for the

LEDs is output.

If the control signal is not output, check the

mounting status of the MAIN_UCOM (IC701).

If it is properly mounted, then the IC701 itself may

be defective.

Basic Operation

Check of the

MAIN_UCOM

Basic Operation

Check of the

MAIN_UCOM

2 Defective LEDs Related point

Check the forward voltage (approx. 2.2 V)

between both ends of the LEDs.

If the forward voltage is abnormal, the LEDs may be

defective.

LED waveform

10.SCHEMATIC

DIAGRAM

3

Defective

transistors

Related point Check the transistors. The transistors may be defective.

10.SCHEMATIC

DIAGRAM

Operation of all buttons, variable controls, and the JOG dial can be confirmed in Service mode.

1

Loose connection

or defective

switches

Related point

Check for any loose connections on the

signal line from the switch to GRID_IC

(IC702), KEY_BUFFER (IC1101, 1102),

and main microcomputer (IC701).

If other SWs connected to the same signal line

function properly and if the connections are properly

made, the SW may be defective.

Each Signal

Levels

2

Defective MAIN_

UCOM (IC701)

UCOM Assy

If the symptom persists after the above

corrections.

Go to [7-1] Basic Operation Check of the

Microcomputer.

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

No.

Cause/Symptom

Point to be checked

Item to be checked

How to distinguish a defective point and/or corrective action

Reference

10.17

WAVEFORMS

USB UCOM

start up

10.17

WAVEFORMS

USB UCOM

start up

c

10.17

WAVEFORMS

USB UCOM

start up

d

10.17

WAVEFORMS

I2C USB UCOM

EEPROM

8.4 COPYING THE

PROGRAM FOR THE

USB CONTROLLER

6 7 8

A

B

C

5

DDJ-T1

6 7 8

D

E

F

25

Page 26

1

[3-2] Rotary selector not controllable

1

Defective

AUTO_LOOP

of the CDJ1

CDJ1 Assy

Check that the signal lines (L_ENC1_1/

L_ENC1_2) are normal during rotation of

the rotary selector.

L_ENC1_1: CN3002-1 pin

L_ENC1_2: CN3002-2 pin

If the signals are not normal, check the connections of the

signal lines. If the connections are properly made, the

rotary selector (S3030) may be defective. Replace it.

Each Signal

Levels

2

Defective

AUTO_LOOP

of the CDJ2

CDJ2 Assy

Check that the signal lines (L_ENC2_1/

L_ENC2_2) are normal during rotation of

the rotary selector.

L_ENC2_1: CN3502-6 pin

L_ENC2_2: CN3502-5 pin

Check that the signal lines (CUR_ENC1/

CUR_ENC2) are normal during rotation of

the rotary selector.

CUR_ENC1: CN4002-21 pin

CUR_ENC2: CN4002-22 pin

If the signals are not normal, check the connections of the

signal lines. If the connections are properly made, the

rotary selector (S3527) may be defective. Replace it.

Each Signal

Levels

3

Defective

DJM

BROWSE

DJMB Assy

If the signals are not normal, check the connections of the

signal lines. If the connections are properly made, the

rotary selector (S4027) may be defective. Replace it.

Each Signal

Levels

4

Defective

MAIN_UCOM

(IC701)

UCOM Assy

If the symptom persists after the above

corrections.

Check the mounting status of the MAIN_UCOM (IC701).

If it is properly mounted, then the IC701 itself

may be defective.

Basic Operation

Check of the

MAIN_UCOM

Basic Operation

Check of the

MAIN_UCOM

Basic Operation

Check of the

MAIN_UCOM

[3-3] VRs or sliders not controllable

The variable controls on the CDJ1 and CDJ2 Assys or the sliders on the CHFD and CRFD ASSYs are not controllable.

VRs on the DJMB ASSY not controllable.

1

Loose

connection

CDJ1/CDJ2 Assy

CHFD Assy

CRFD Assy

Check for any loose connections on the

signal line from the MAIN_UCOM (IC701)

to each variable control or slider.

If any connection on the signal line is improper, resolder

the parts.

—

2

Defective

sliders or VRs

CDJ1/CDJ2 Assy

CHFD Assy

CRFD Assy

VRs: Check the signal level.

Tempo slider: Check the levels of the

ADCT and ADIN signals.

CHFD, CRFD: Check the signal level.

VRs: If the voltage of the signal from a VR (Pin 2) does not

change between 3.3 V and 0 V, that VR may be defective.

Tempo slider: If the value of the voltage of the ADCT signal

(Pin 4) is other than 1.65 V, or if the voltage of the ADIN

signal (Pin 2) does not change between 3.3 V and 0 V, the

tempo slider may be defective.

CHFD, CRFD: If the voltage of the signal from the CHFD

or CRFD (Pin 2) does not change between 3.3 V and 0 V,

the slider may be defective.

Each Signal

Levels

Each Signal

Levels

3

Defective

MAIN_UCOM

(IC701)

UCOM Assy

If the symptom persists after the above

corrections.

Check the mounting status of the MAIN_UCOM (IC701).

If it is properly mounted, then the IC701 itself

may be defective.

4

Loose

connection

DJMB Assy

Check for any loose connections on the signal

line from each VR to Analog SW_IC (IC4001,

IC4002, IC4003) and the main microcomputer

(IC701).

Signal line: AD_0–4, AD_SW_A, AD_SW_B

If any connection on the signal line is improper, resolder

the parts.

—

5 Defective VRs DJMB Assy VRs: Check the signal level.

VRs: If the voltage of the signal from a VR (Pin 2) does not

change between 3.3 V and 0 V, that VR may be defective.

6

Defective

MAIN_UCOM

(IC701)

UCOM Assy

If the symptom persists after the above

corrections.

Check the mounting statuses of the MAIN_UCOM (IC701)

and the Analog SW_IC (IC4001, IC4002, IC4003).

If they are properly mounted, then the IC701, IC4001,

IC4002, or IC4003 may be defective.

[3-4] NeedleSearch error

1

CDC IC Error/

Needlepad disabled (Incl. steps 4

and 5 of [4] Error

indications in the

6. Service Mode)

UCOM/CDCB

Assy

Check the communication waveform

between the needlepad and the MAIN_

UCOM (IC701).

If the waveform is not proper, check the communication

line, resistors, and capacitors.

Check also that the cables between the boards and their

connections are proper.

If the normal status is not recovered after all above steps