Page 1

2013

DDJ-SR

DJ Controller

DDJ-SR

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

DDJ-SR CKSUVYXE5 DC 5 V (USB-bus power only)

DDJ-SR XECN5 DC 5 V (USB-bus power only)

ORDER NO.

RRV4499

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-MZV NOV.

2013 Printed in Japan

Page 2

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

SAFETY INFORMATION

A

B

2 3 4

CONTENTS

C

SAFETY INFORMATION ..........................................................................................................................................................2

1. SERVICE PRECAUTIONS ....................................................................................................................................................3

1.1 NOTES ON SOLDERING ...............................................................................................................................................3

1.2 NOTES ON PARTS REPLACEMENT .............................................................................................................................3

1.3 ABOUT DEMO MODE ....................................................................................................................................................4

2. SPECIFICATIONS .................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE...............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING............................................................................................................................6

3.2 JIGS LIST .......................................................................................................................................................................6

3.3 PCB LOCATIONS ...........................................................................................................................................................7

4. BLOCK DIAGRAM.................................................................................................................................................................8

D

E

F

4.1 OVERALL WIRING DIAGRAM........................................................................................................................................8

4.2 OVERALL BLOCK DIAGRAM.......................................................................................................................................10

5. DIAGNOSIS.........................................................................................................................................................................12

5.1 TROUBLESHOOTING ..................................................................................................................................................12

5.2 BASIC OPERATION CHECK USING SERATO DJ .......................................................................................................14

6. SERVICE MODE .................................................................................................................................................................17

6.1 SERVICE MODE...........................................................................................................................................................17

7. DISASSEMBLY....................................................................................................................................................................27

8. EACH SETTING AND ADJUSTMENT ................................................................................................................................33

8.1 NECESSARY ITEMS TO BE NOTED...........................................................................................................................33

8.2 UPDATING OF THE FIRMWARE .................................................................................................................................33

8.3 ITEMS FOR WHICH USER SETTINGS ARE AVAILABLE ...........................................................................................35

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................38

9.1 PACKING SECTION .....................................................................................................................................................38

9.2 EXTERIOR SECTION...................................................................................................................................................40

10. SCHEMATIC DIAGRAM ....................................................................................................................................................44

10.1 MIC and HEADPHONE PCB ASSYS .........................................................................................................................44

10.2 I/O

10.3 MIXER and CROSS FADER PCB ASSYS..................................................................................................................48

10.4 PANEL-L and R PCB ASSYS......................................................................................................................................50

10.5 WAVEFORMS .............................................................................................................................................................52

11. PCB CONNECTION DIAGRAM ........................................................................................................................................56

11.1 MIC and HEADPHONE PCB ASSYS .........................................................................................................................56

11.2 I/O PCB ASSY ............................................................................................................................................................58

11.3 MIXER and CROSS FADER PCB ASSYS..................................................................................................................60

11.4 PANEL-L and R PCB ASSYS......................................................................................................................................62

12. PCB PARTS LIST ..............................................................................................................................................................64

PCB ASSY ............................................................................................................................................................46

2

1

2 3 4

DDJ-SR

Page 3

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

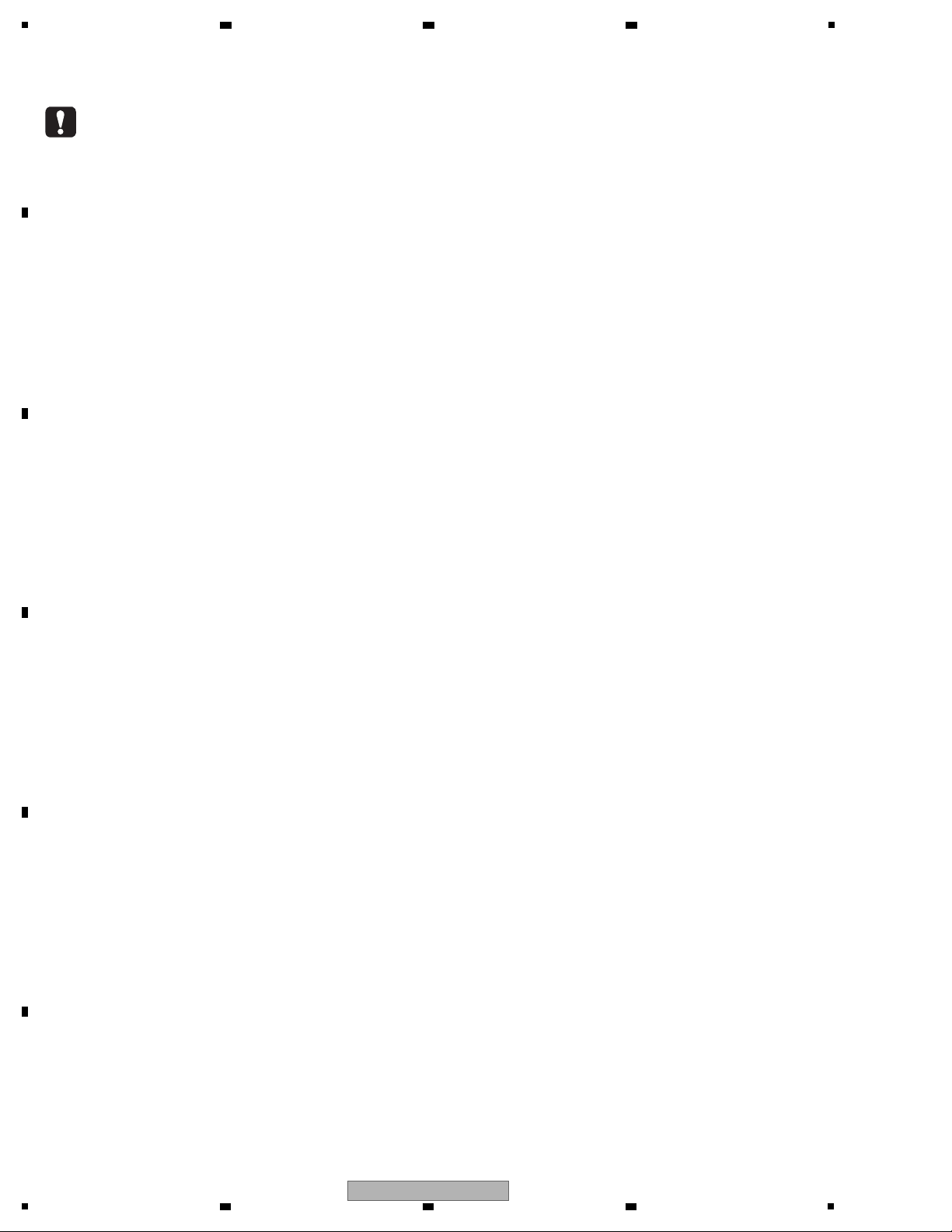

When you replacing Front panel, JW ring, it is necessary to remove Front panel.

NITTO No. 500

(5 mm × 30 mm)

NITTO No. 500

(5 mm × 40 mm)

When detaching the front panel

The front panel and the Chassis Assy are secured with 10 pieces of double-back tape at the locations shown in the illustration below.

Slowly peel off the tape, taking care that you will not deform the front panel.

When reattaching the front panel

1 Neatly remove any residue of double-back tape from the back of the front panel and the Chassis Assy.

2 Stick 10 pieces (5 mm) of NITTO No. 500 double-back tape to the locations shown in the illustration below then remove the paper liner.

Note: Even if double-back tape was not used in the initial state, be sure to attach double-back tape when reattaching the front panel.

Before securing the front panel to the Chassis Assy with screws, never press on the places where the pieces of double-back tape are

attached.

Press on the places where the pieces of double-bac

k tape are attached after securing the front panel to the Chassis Assy with screws.

Notes:

• Do not reuse the

double-back tape.

• Put the

double-back tape on the Chassis Assy side.

NITTO No. 500

(5 mm × 40 mm)

NITTO No. 500

(5 mm × 80 mm)

Detachment/Reattachment of the front panel

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

1.2 NOTES ON PARTS REPLACEMENT

C

D

E

DDJ-SR

5

6 7 8

F

3

Page 4

1

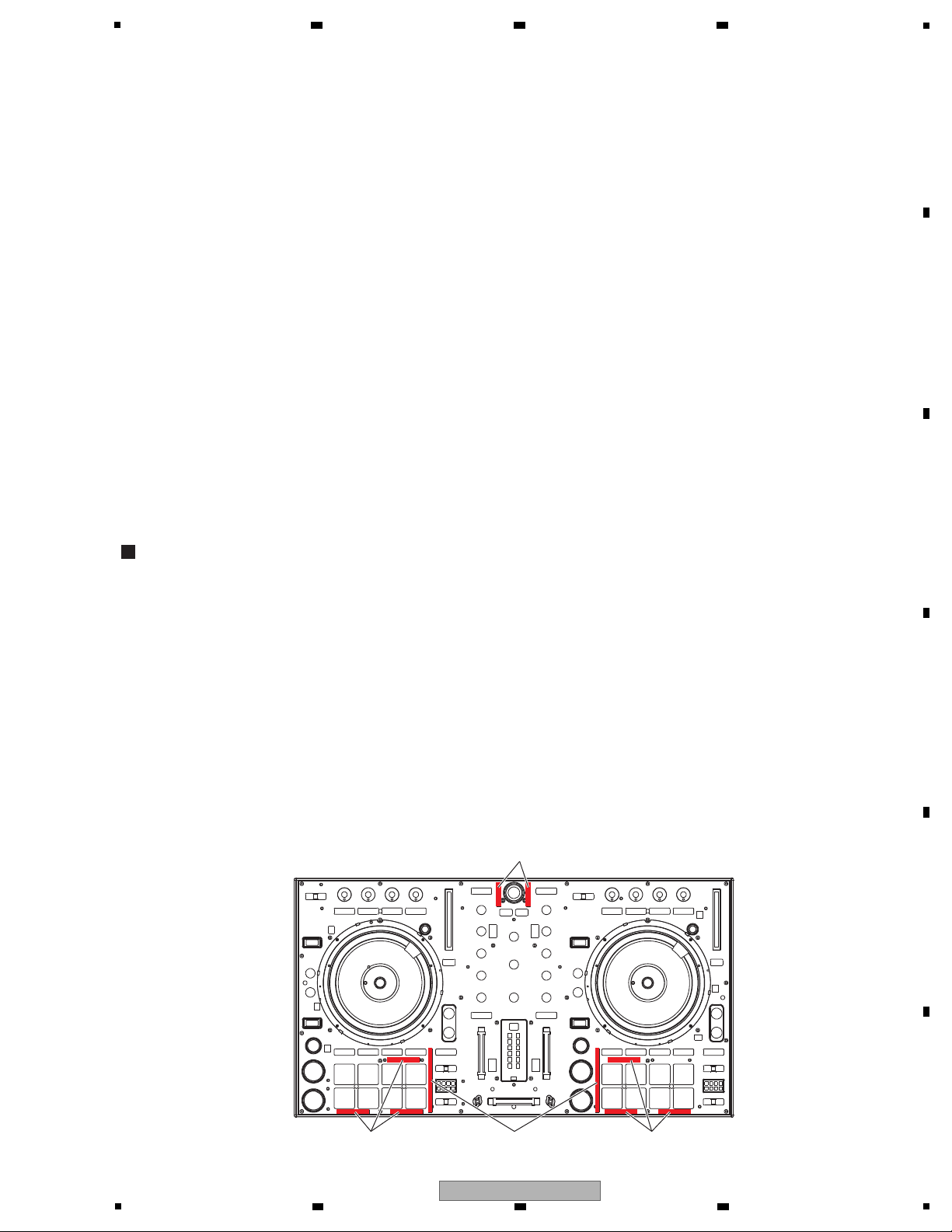

Four washers have been added to the screw-mounted parts of the Pad & FSR Plate Assy to solve the problem that

a performance pad is only pressed halfway although it is fully pressed. This problem was revealed during production.

This emergency measure will be taken care of in the future, but the exact date when the improved products will be produced is

not determined yet. At least the first 20,000 products will have the added washers.

The initial service parts for the Pad & FSR Plate Assy will also require attachment of washers.

To prevent the washers from not being attached during replacement of the Pad & FSR Plate Assy with the one for service,

the Pad & FSR Plate Assy and the washers are to be enclosed in the same package as a kit.

The part number of the kit for service is GXX1374.

When a new Pad & FSR Plate Assy for service is to be reassembled, be sure to attach the enclosed 4 washers to

the screw-mounted par

ts. (See the figure below.)

Note on Replacement of the Pad & FSR Plate Assy

Pad & FSR Plate Assy

Attach the washer.

This unit will automatically enter Demo mode if it is left unoperated for 10 minutes in Normal Operation mode, and a

demonstration with LED illumination will start.

To cancel this mode, operate any control or button of this unit.

To disable Demo mode, change the setting in the settings of Utilities mode 1. (For details, refer to the operating instructions.)

A

B

2 3 4

C

D

1.3 ABOUT DEMO MODE

E

F

4

1

2 3 4

DDJ-SR

Page 5

5

General – Main Unit

Power supply........................................................................ DC 5 V

Rated current....................................................................... 500 mA

Main unit weight..........................................................4.5 kg (9.9 lb)

Max. dimensions......553.6 mm (W) × 65.3 mm (H) × 319.1 mm (D)

(21.8 in. (W) × 2.6 in. (H) × 12.6 in. (D))

Tolerable operating temperature..............................+5 °C to +35 °C

Tolerable operating humidity............5 % to 85 % (no condensation)

Audio Section

Rated output level

MASTER OUT 1............................................................. 4.2 Vrms

MASTER OUT 2............................................................. 2.1 Vrms

BOOTH........................................................................... 2.1 Vrms

Total harmonic distortion

MASTER OUT..................................................................0.006 %

Frequency characteristic

USB, AUX, MIC ................................................... 20 Hz to 20 kHz

S/N ratio (when playing on computer)

MASTER OUT................................................................... 101 dB

Input impedance

AUX ..................................................................................... 47 kΩ

MIC...................................................................................... 10 kΩ

Output impedance

MASTER OUT....................................................................... 1 kΩ

PHONES ...............................................................................32 Ω

USB AUDIO.................................................... 24 bit/Fs : 44.1 kHz

Input / Output terminals

AUX IN input terminal

RCA pin jacks........................................................................1 set

MIC terminal

Phone jack (Ø 6.3 mm).......................................................... 1 set

BOOTH OUT/MASTER OUT2 output terminal

RCA pin jacks........................................................................1 set

MASTER OUT1 output terminal

Phone jack (Ø 6.3 mm).......................................................... 1 set

PHONES output ter

minal

Stereo phone jack (Ø 6.3 mm) ..............................................1 set

Stereo mini phone jack (Ø 3.5 mm)....................................... 1 set

USB terminal

B type ....................................................................................1 set

• CD-ROM (Installation Disc)

• USB cable

(408-SUB-132)

• Read Before Use (Important)/Quick Start Guide

(DDJ-SR/CKSUVYXE5: 502-DDJSRA-3325A, 502-DDJSRA-3326A)

(DDJ-SR/XECN5: 502-DDJSRB-3327)

• Warranty (for some regions)

The included warranty is for the European region.

• For the North American region, the corresponding information is

provided on the last page of both the English and French

versions of the “Read Before Use (Important)/Quick Start Guide”.

• For the Japanese region, the corresponding information is

provided on the last page of the Japanese version of the “Read

Before Use (Important)/Quick Start Guide”.

Accessories

2. SPECIFICATIONS

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

5

Page 6

1

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding audio.

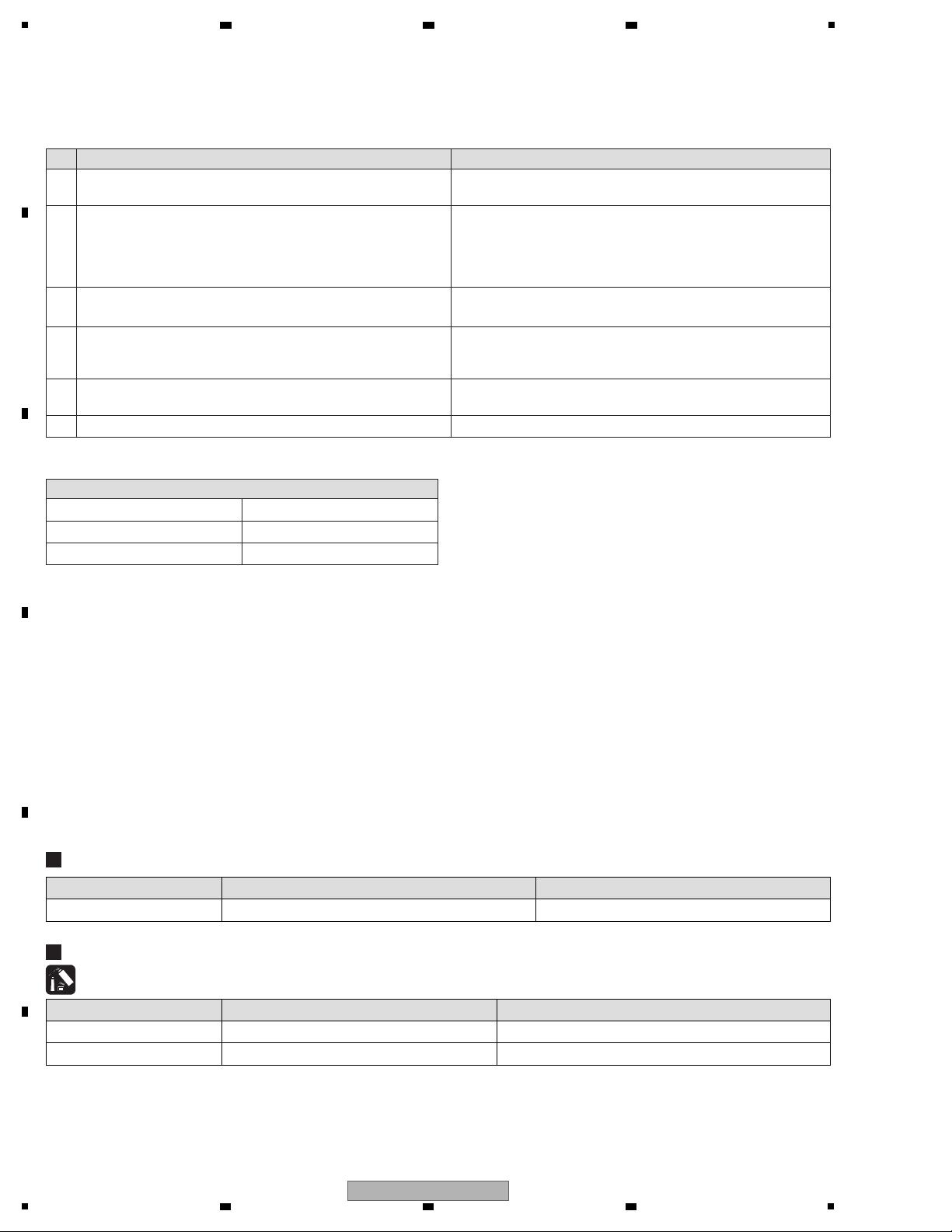

No. Procedures

Item to be checked regarding audio

Check points

1 Check the firmware version. The firmware version must be the latest one.

If it is not the latest one, be sure to update it.

Items to be checked after servicing

6 Check the appearance of the product. No scratches or dirt on its appearance after receiving it for service.

To keep the product quality after servicing, confirm recommended check points shown below.

2 Confirm that the customer complaint has been resolved.

If the problem pointed out by the customer occurs with a specific

source or operation, such as PC input, AUX/MIC input, Fader, or

VOL, input that specific source then perform that specific

operation for checking.

The symptoms in question must not be reproduced.

There must be no abnormality in audio signals or operations.

4 Check the analog audio output.

Connect this unit with a PC with the DJ application (Serato DJ)

installed, via USB, then play back audio.

There must be no errors, such as noise, in audio signals and

operations of the MASTER/HEADPHONES outputs.

5 Check the analog audio input.

Input an audio signal via AUX/MIC.

There must be no abnormality in audio signals or operations.

3 Check operations of the operating elements.

Enter Service mode.

There must be no errors in operations of each button, the jog dial,

LEDs, VOL, fader control, and rotary encoder.

Lubricants and Glues List

Name Part No. Remarks

Jigs List

Jig Name Part No. Purpose of use / Remarks

USB cable GGP1193 for PC connection

Adhesive GYL1001 Refer to “7. DISASSEMBLY”.

Grease GEM1096 Refer to “7. DISASSEMBLY”.

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

DDJ-SR

Page 7

5

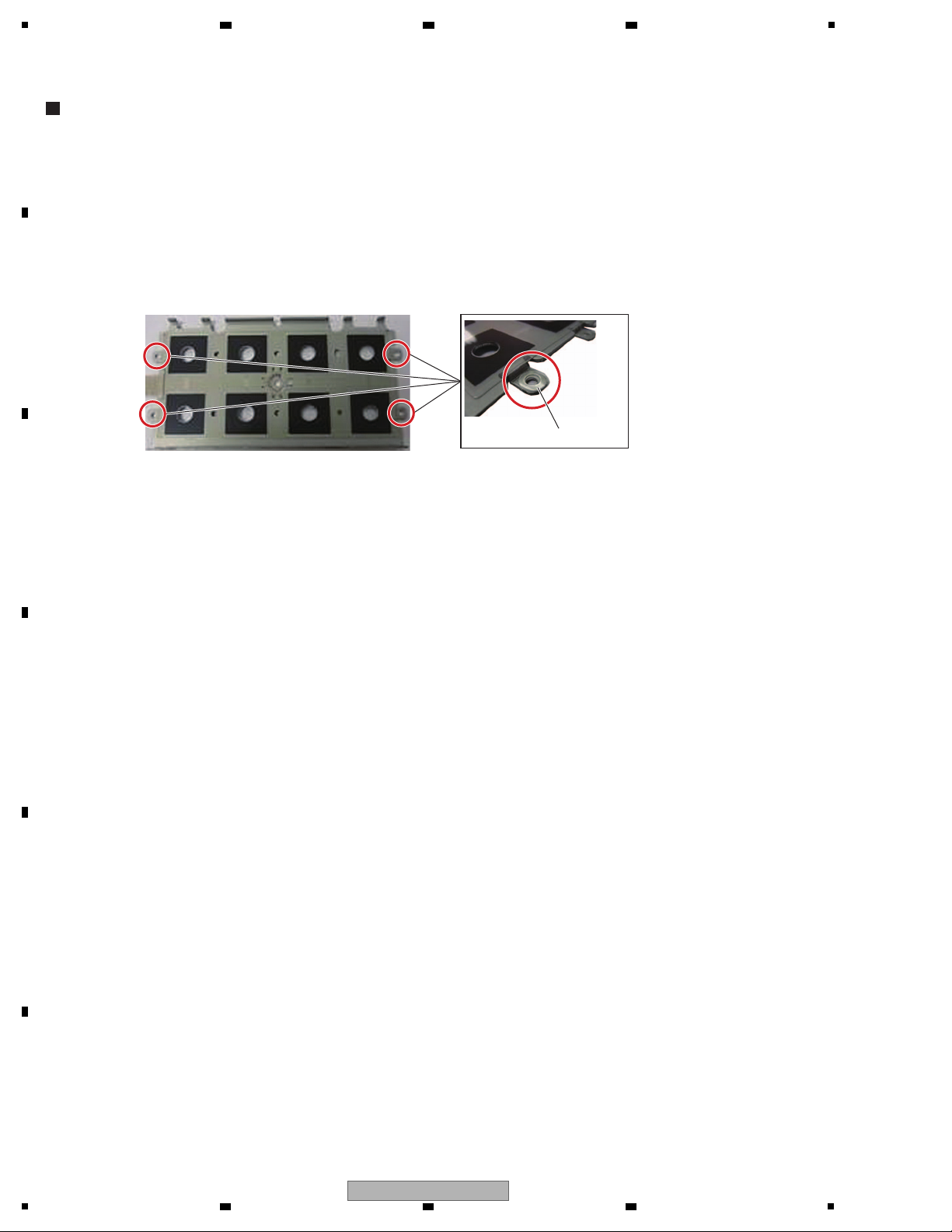

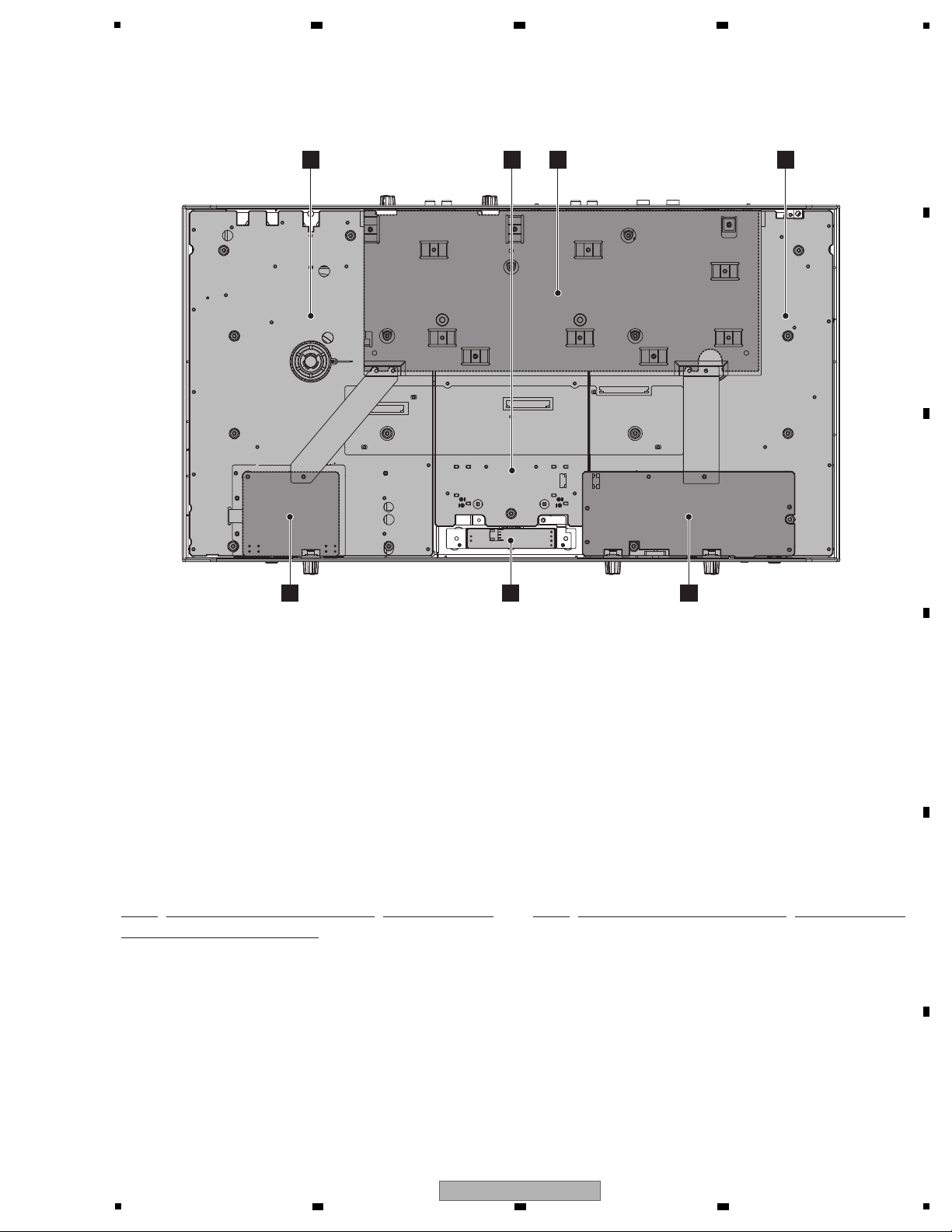

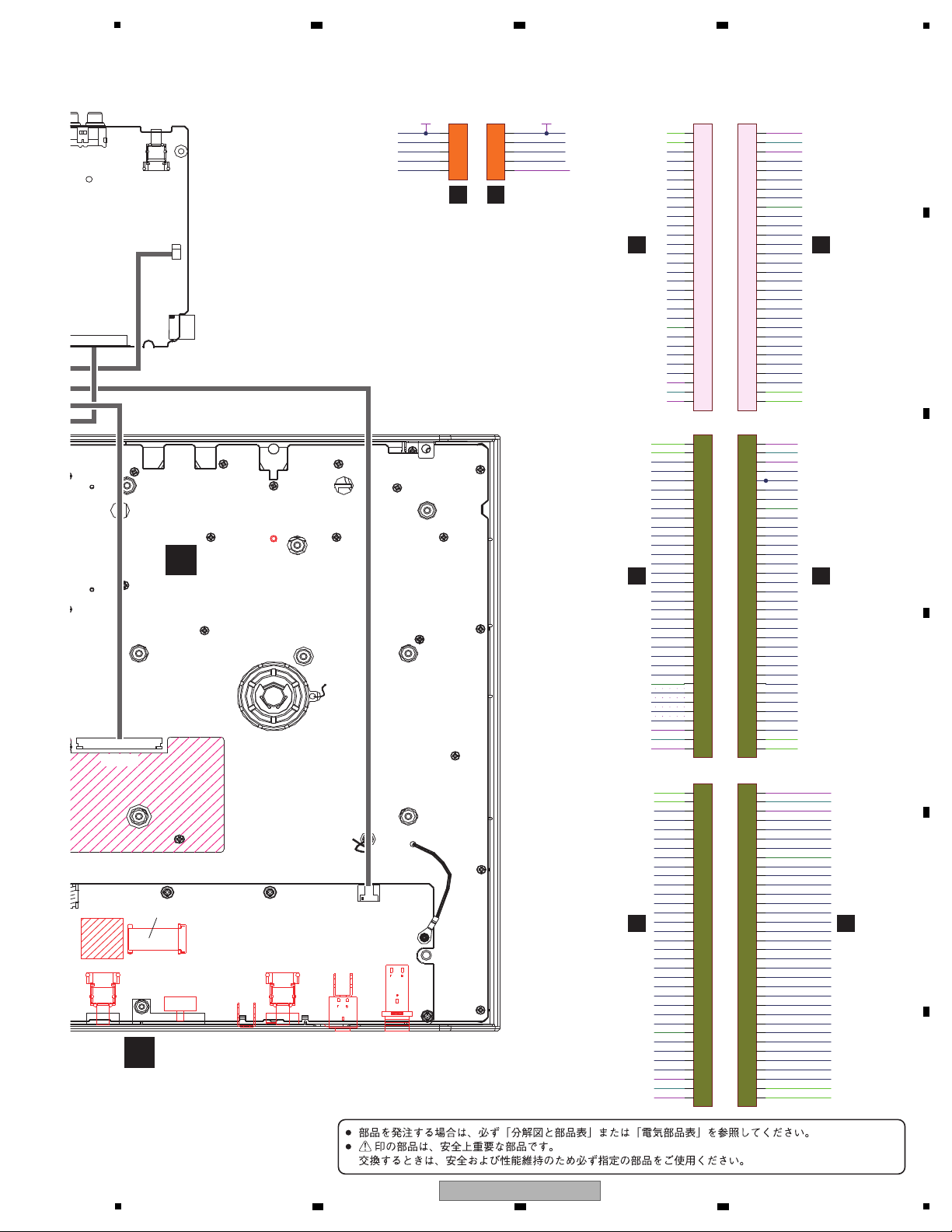

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

MIC PCB ASSY 704-SR-A601

HEADPHONE PCB ASSY 704-SR-A600

I/O PCB ASSY 704-SR-A596

MIXER PCB ASSY 704-SR-A597

CROSS FADER ASSY 704-DJM250-A032

PANEL-L PCB ASSY 704-SR-A599

PANEL-R PCB ASSY 704-SR-A598

C

I/O

PCB ASSY

G

PA NEL-R

PCB ASSY

D

MIXER

PCB ASSY

F

PA NEL-L

PCB ASSY

E

CROSS FADER

PCB ASSY

B

HEADPHONE

PCB ASSY

A

MIC

PCB ASSY

• Bottom view

3.3 PCB LOCATIONS

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

7

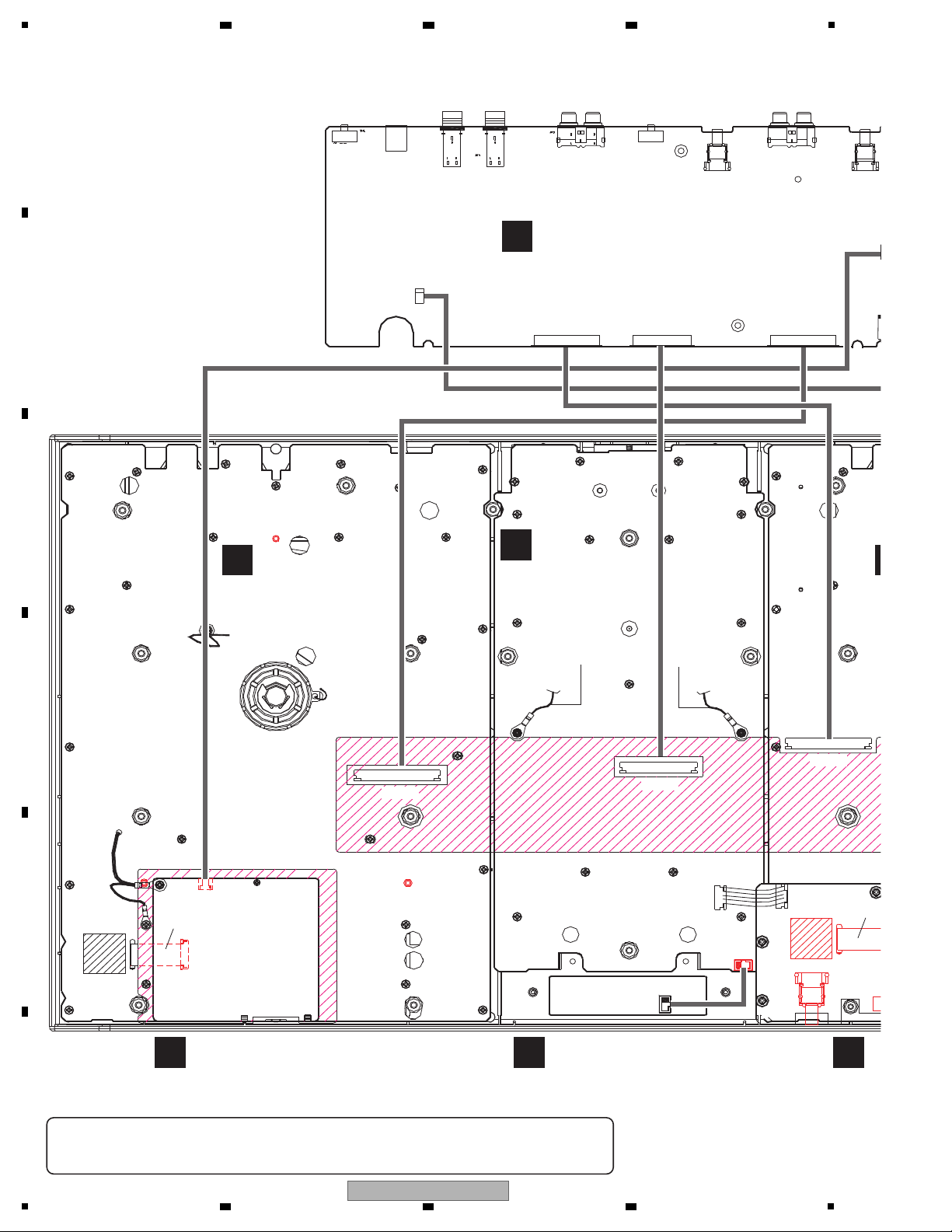

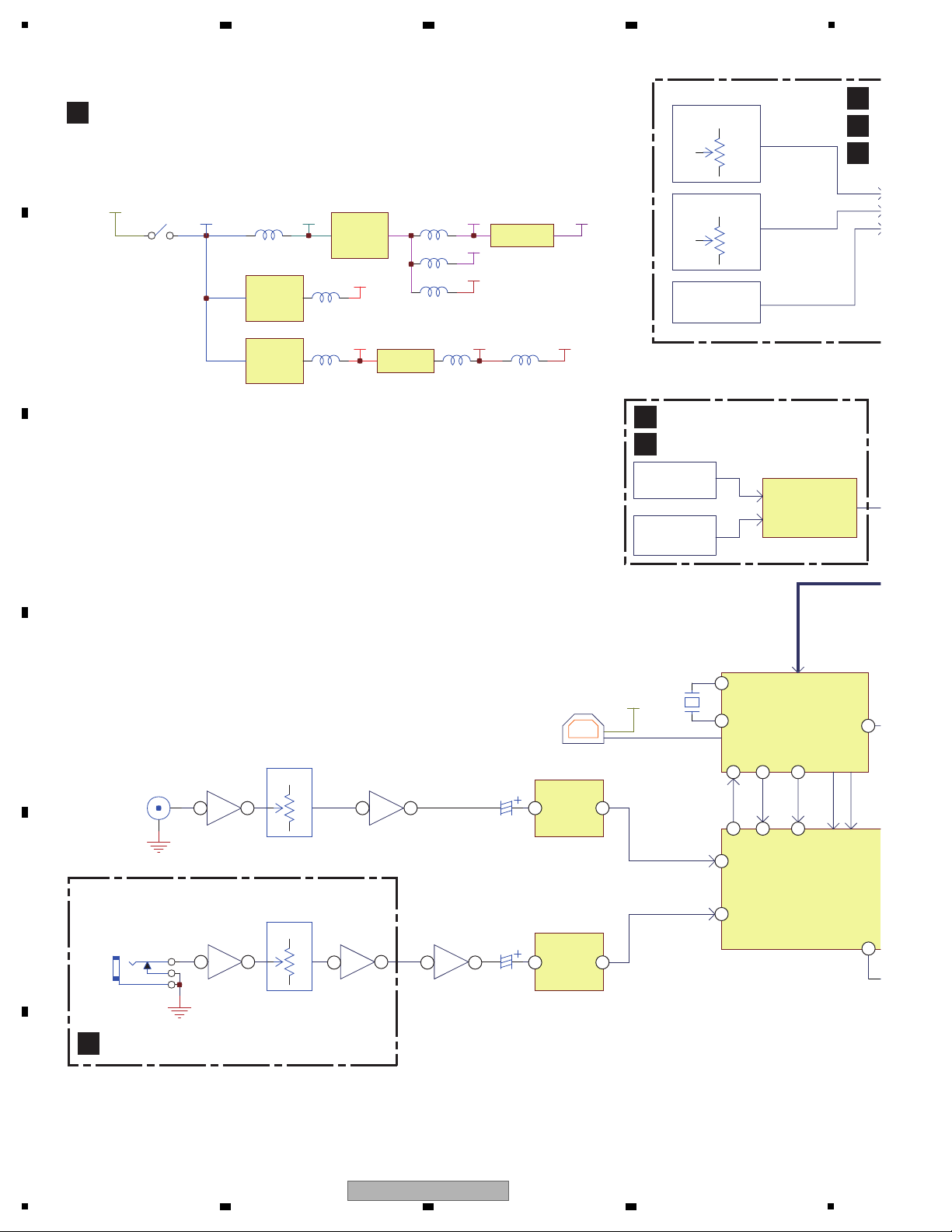

Page 8

1

W7

CN2C

CN6

CN500

CN1B

CN2B

W

CN2A

CN01

W700

CN701A CN701B

CN1A CN3A

CHASSIS

CHASSIS

CHASSIS

TO

OUTPUT BOARD

TO

CARBON PAD FFC WIRE

TO

CARBO

TO

OUTPUT BOARD

C

I/O PCB ASSY

(704-SR-A596)

A

MIC PCB ASSY

(704-SR-A601)

G

PANEL-R PCB ASSY

(704-SR-A598)

D

MIXER PCB ASSY

(704-SR-A597)

P

(

E

CROSS FADER PCB ASSY

(704-DJM250-A032)

B

H

(7

1

2

3

4

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the impor tance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

2 3 4

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

DDJ-SR

Page 9

CN500

CN2B

W6

CN701B

CN7

CN3A

CHASSIS

TO

CARBON PAD FFC WIRE

F

PANEL-L PCB ASSY

(704-SR-A599)

B

HEADPHONE PCB ASSY

(704-SR-A600)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

CN2C

LED6

LED7

LED8

KEY1

KEY3

KEY2

AD3.3V

ADGND

S1

LED- G

WL -B

S4

S3

S2

LED2

LED1

D3.3V

LED5

LED4

LED3

KEY4

KEY5

WL -A

B

A

AD9

AD8

AD6b

AD12

S5

S6

C

D5V

DGND

(AD7b)

(AD13)

(AD14)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

CN2B

LE

D6

LED7

LED8

KEY1

KEY3

KEY2

AD3.3V

ADGND

S1

LED- G

WL -B

S4

S3

S2

LED2

LED1

D3.3V

LED5

LED4

LED3

KEY4

KEY5

WL -A

B

A

AD9

AD8

AD6b

(WR- A)

(WR- B)

AD12

S5

S6

C

(AD15)

D5V

DGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

CN3A

LED6

LED7

LED8

KEY1

KEY3

KEY2

AD3.3V

ADGND

S10

WR- B

S13

S12

S11

LED2

LED1

D3.3V

LED5

LED4

LED3

KEY4

KEY5

WR- A

B

A

AD14

AD13

AD7b

AD15

S14

S15

C

D5V

LE

D-G

DGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

CN2A

LED6

LED7

LED8

KEY1

KEY3

KEY2

AD3.3V

ADGND

S1

WL -B

S4

S3

S2

LED2

LED1

D3.3V

LED5

LED4

LED3

KEY4

KEY5

WL -A

B

A

AD9

AD8

AD6b

AD12

S5

S6

C

D5V

LED- G

DGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN1A

ADGND

C

AD11

AD1

AD0

AD3

AD2

KE

Y3

S8

LED8

LED7

LED6

LED5

LED4

LED3

KEY2

LED1

LED2

ENCA

ENCB

A

B

AD3.3V

S9

S7

KEY1

D3.3V

D5V

LED- G

DGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

CN1B

ADGND

LED- G

C

AD11

AD1

AD0

AD3

AD2

KEY3

S8

LED8

LED7

LED6

LED5

LED4

LED3

KEY2

LED1

LED2

ENCA

ENCB

A

B

AD3.3V

S9

S7

KEY1

D3.3V

D5V

DGND

AD3.3V

1

2

3

4

5

CN701B

REV

CURVE

HPVR

ADGND

1

2

3

4

5

CN701A AD3.3V

REV

HPVR

ADGND

CURVE

D

MIXER

PCB ASSY

C

I/O

PCB ASSY

B

HEADPHONE

PCB ASSY

D

MIXER

PCB ASSY

1

2

G

PANEL-R

PCB ASSY

C

I/O

PCB ASSY

3

C

I/O

PCB ASSY

F

PANEL-L

PCB ASSY

4

4

5

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

9

Page 10

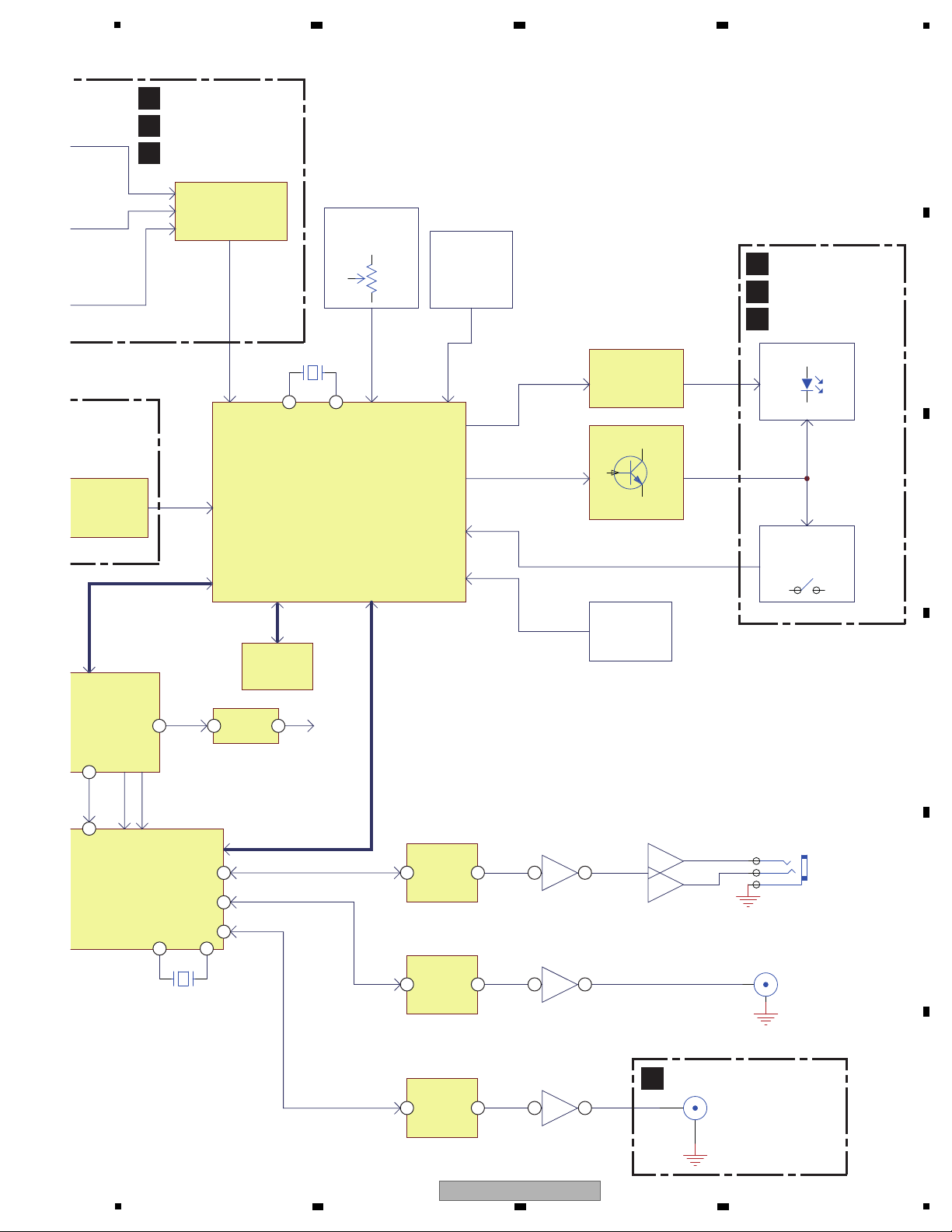

1

AD * 8

AD * 8

FSR PAD * 8

RIGHT

FSR PAD * 8

LEFT

AD Expansion

AD Port 4 TO 16

74HC4052 * 2

ROTATE VR * 23

ADSP-BF592

(I2S format for audio data)

(44.1K/24bit/512fs for A/D,D

24

AUX

MIC

USB PortB

TUSB3200

PCI-0

PCO-0

PCO-1

BCK

LRCK

6M

(12MHz or 48MHz)

VUSB

TEMPO VR * 2

SLIDER SW * 1

AD * 1

AD * 4

AD * 23

I2C

IC11

IC10

IC27

IC13

IC9

IC900IC900

IC3

IC23

IC22

IC1

IC2

IC15

X1

IC16

IC502

C

I/O PCB ASSY

D

M

A

MIC PCB ASSY

F

PANEL-L PCB ASSY

G

PANEL-R PCB ASSY

F

P

G

P

D5V D3.3V

BD12AK5FB

D1.2V

12

TPS54232

INVERTER

-6V

TPS61085

BOOST

6V

5V

BA05

A5V AD5V

A3.3V

VUSB

TPS54232

STEP DOWN

DA3.3V

ADC

PCM1803

-5.46dB

AUX

ADC

PCM1803

MIC

+20dB

L

3

G

1

S

4

LEVEL0dB

-5.46dB

LEVEL

+9.4dB

44

50

51

39

37

3

3 5 1

5 7

1

1

3 1 1 12

1 12

31

61

32

64 63

36 38

2 3 4

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

10

DDJ-SR

1

2 3 4

Page 11

8M

MKL15Z128VLK4

(24MHz )

32Bit MCU

AD * 4

ENCODE * 1

AD Expansion

74HC4052 * 2

EEPROM

24LC02BT

I2C1

CH FADER * 2

AD Expansion

AD Port 4 TO 32

74HC4051 * 4

Buffer

74HCT244 * 1

LED * 101 + 22 PCS

GPIO * 8

GPIO * 15

GPIO * 7

DATA * 8

SCAN * 15

GPIO * 5(KEY)

12

TACT SW * 58

SLIDER SW * 1

ENCODE SW * 1

CROSS FADER * 1

ADSP-BF592

24.576M

PCO-1

BCK

LRCK

SPI

MCLK

SN74LVC1G

SCHMITT

SCK

AD/DA CLK

JOG WHEEL *2

SLIDER SW * 1

BOOTH VR * 1

JOG TOUCH * 2

AD * 1

AD * 4

AD * 4

AD * 4 AD * 2

AD * 23

LPF&.

LPF&.

LPF&.

BOOTH/MASTER2

(RCA)

NJM4580

NJM4556

MAS

HP

Headphone

(32 ohm/6.3mm & 3.5mm)

DAC

CS4344

DAC

CS4344

DAC

CS4344

NJM4580

NJM4580

L

3

R

2

G

1

MASTER1

BOOTH

Text

SD1757 * 15

Buffer

IC15

X2

X3

IC16

IC18

IC19

IC20

IC502

IC500, IC700, IC701

IC21

IC7

IC5

IC4

IC6

IC26

IC24

IC25

D

MIXER PCB ASSY

B

HEADPHONE PCB ASSY

Y

F

PANEL-L PCB ASSY

G

PANEL-R PCB ASSY

D

MIXER PCB ASSY

F

PANEL-L PCB ASSY

G

PANEL-R PCB ASSY

40 41

2344

36

5

1 7 6 7

1 7 6 7

1 7 2 1

4

61 62

63

38

5

6 7 8

A

B

C

D

5

DDJ-SR

6 7 8

E

F

11

Page 12

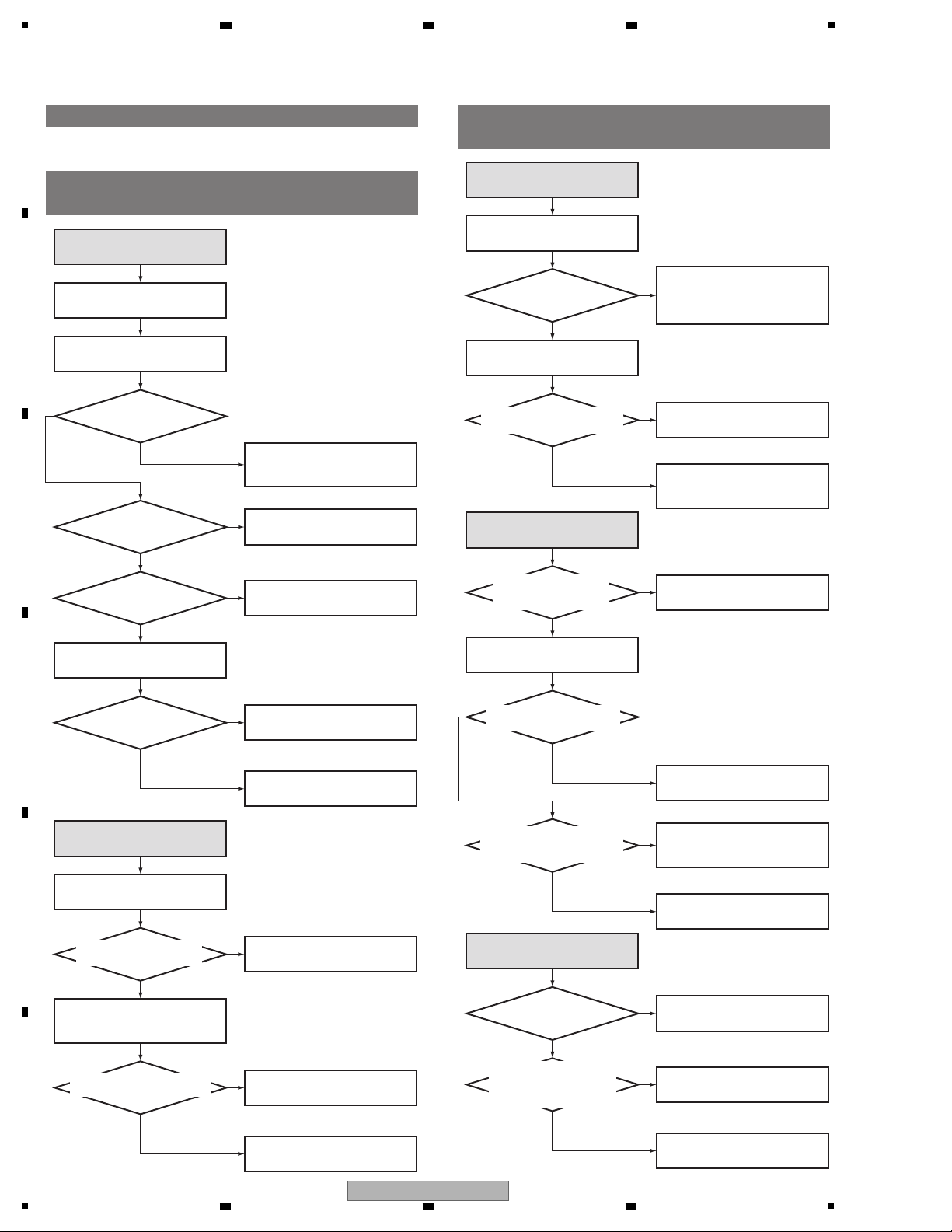

1

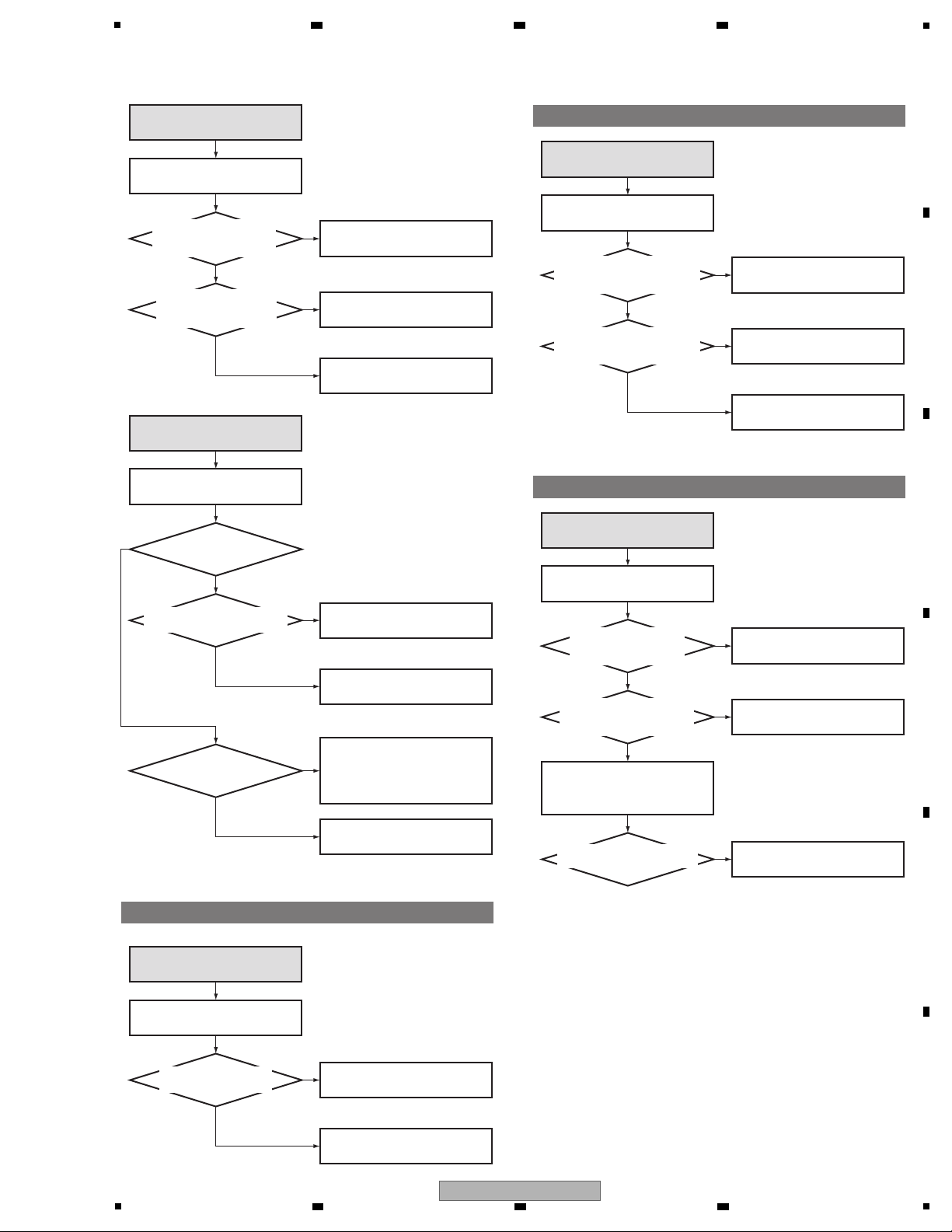

[0] Service mode

[1] Troubles of starting system and

communication

[2] Troubles of operation element

and LED

Conduct diagonosis on troubles using Service mode.

Does the MIDI

command output?

Is VUSB 5 V?

Does D3.3V become

3.3 V correctly?

Does oscillator (X3)

oscillate it? (8 MHz)

When you turn VR,

does the signal from VR

change?

Confirm input signal A,B,C.

Is the signal H or L?

When you turn VR,

does the output signal of

IC700, 701 change?

No

No

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

Check power switch turn on.

Confirm if the USB cable is

connected properly.

USB cable is defective.

Replace the USB cable.

No

Confirm that ON does SW, and

both ends do conduction.

When SW does not do conduction,

replace the SW.

No

X3 is defective.

Replace the X3.

No

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

No

VR is defective.

Replace the corresponding part.

No

Analog SW (IC700, 701) is

defective.

Replace the MIXER PCB Assy.

UCOM (IC20) is start-up

abnormality.

Ye s

Confirm analog SW where

a signal is connected to.

Ye s

Confirm whether a matrix circuit

is defective.

No

The power is turned on correctly,

there is a problem with the LED

circuit. See "LED does not lit"

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Power supply IC (IC27) is defective.

Replace the I/O PCB Assy.

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Ye s

Q500 to 505, 700 to 702 are

defective.

Replace the corresponding part.

The power is not turned on.

Is the buttons which does

not work the plural?

When you pressed on button,

is the target KEY signal "H"?

Buttons reads it in a matrix.

Buttons or slide SW does not work.

Rotary VR does not work.

Ye s

No

UCOM (IC16) is defective.

Replace the I/O PCB Assy.

No

UCOM (IC16) is defective.

Replace the I/O PCB Assy.

Ye s

Replace the corresponding part.

Is the communication line

of the USB "H" or "L"?

Is the abnormality in

the parts mentioned above?

Confirm whether a USB cable is

connected properly.

Confirm whether there is not the

part on the USB line abnormally.

Object: D11 - 14, L13

Cannot communicate USB.

Do not push and rotary

which work?

Check on 3 pin, 1 pin of

the rotary selector.

When you turned a rotary

selector, is the signal H?

See "Buttons or slide SW does

not work".

Push

Rotary

No

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Ye s

Rotary selector is defective.

Replace the rotary selector.

Rotary selector does not work.

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

12

1

DDJ-SR

2 3 4

Page 13

5

[3] Troubles of settings

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Ye s

Damage of the LED.

Replace the LED.

Confirm whether each cables is

connected properly.

When you pressed Pad,

does the voltage change

with CN500 pins 2 - 9?

When you touched Jog,

does the voltage change

with IC501 pin 5?

When you turned Jog,

does the voltage change

with IC20?

When you pressed Pad,

does the voltage change

by the output of IC502?

No

FSR PCB is defective.

Replace the FSR Plate Assy L, R.

No

IC502 is defective. Replace the

PA NEL L or R PCB Assy.

No

LED DRIVER (IC21) is defective.

Replace the I/O PCB Assy.

No

IC16 is defective.

Replace the I/O PCB Assy.

No

The abnormality of the IC which

LED is connected to if you confirm

that all keys work normally and do

not have any problem.

Replace the I/O PCB Assy.

Ye s

Pad does not work.

The LED lits by matrix drive.

Does not all LED lit?

Does not only

one LED lit?

Is the signal of "DATA1 - 8"

of the LED control signal "L"?

Ye s

LED does not lit.

No

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

No

E2ROM (IC19) is defective.

Replace the I/O PCB Assy.

The setting information is saved

in IC19.

Are SCL and the SDA

signals "H" or "L"?

Cannot store user settings.

[4] Troubles of Jog touch and Jog rotation

Ye s

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

No

IC501 is defective. Replace the

PA NEL-L or R PCB Assy.

No

UCOM (IC20) is defective.

Replace the I/O PCB Assy.

Confirm whether each cables is

connected properly.

Jog touch and Jog rotation does

not work.

[5] Troubles of sound input and output

Sound does not output.

Ye s

Confirm if the USB cable is

connected properly.

Ye s

Ye s

Sound signal does not have

abnormality, or confirm the

following part.

IC23 to 26 (A/D and D/A IC)

Does USB input signal

output it from pins 2

and 3 of JK1?

Ye s

Are the data control signals

in pins 34, 35 and 44

of IC16?

No

USB cable is defective.

Replace the USB cable.

No

A/D and D/A IC are defective.

Replace the I/O PCB Assy.

Is the abnormality in

the parts mentioned above?

6 7 8

A

B

C

D

E

5

DDJ-SR

6 7 8

F

13

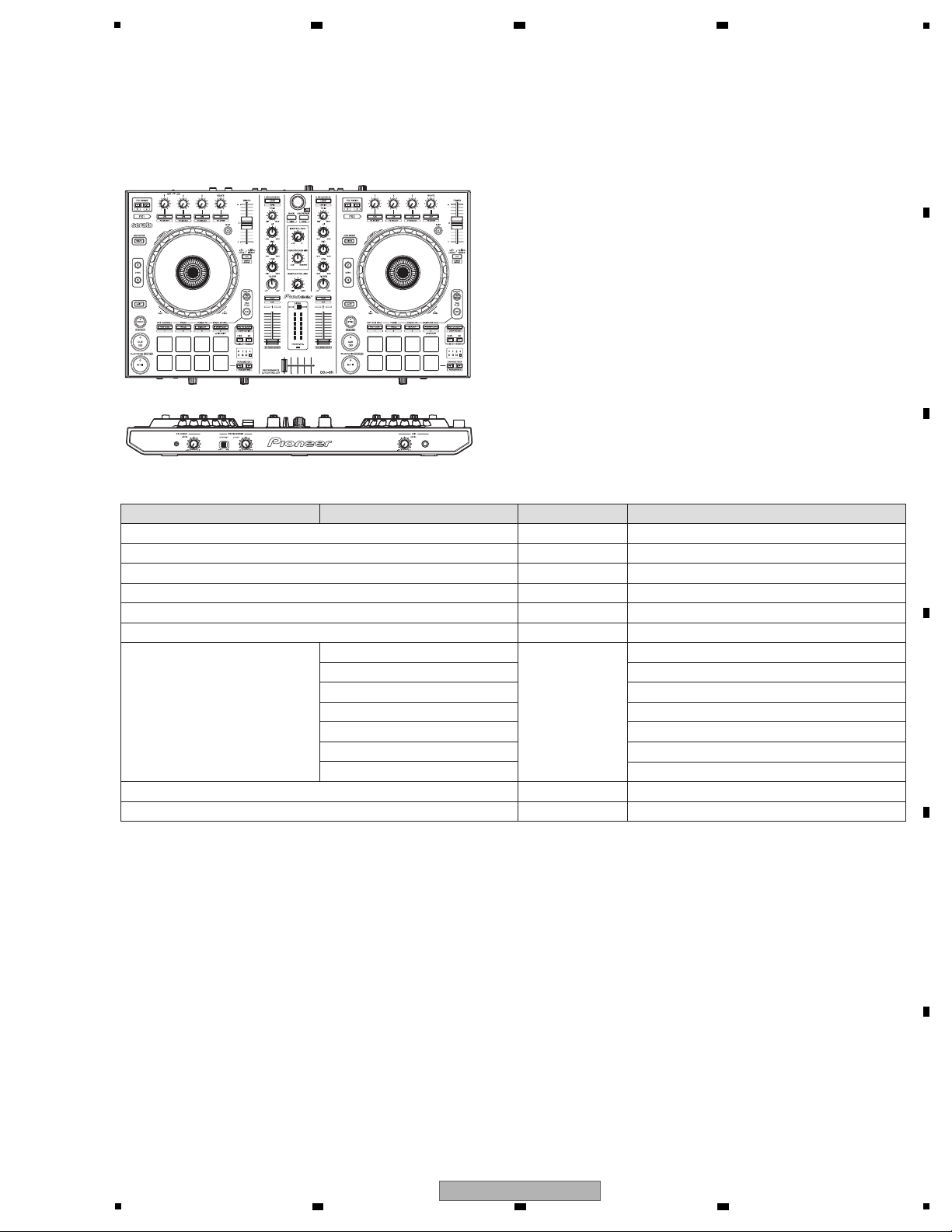

Page 14

1

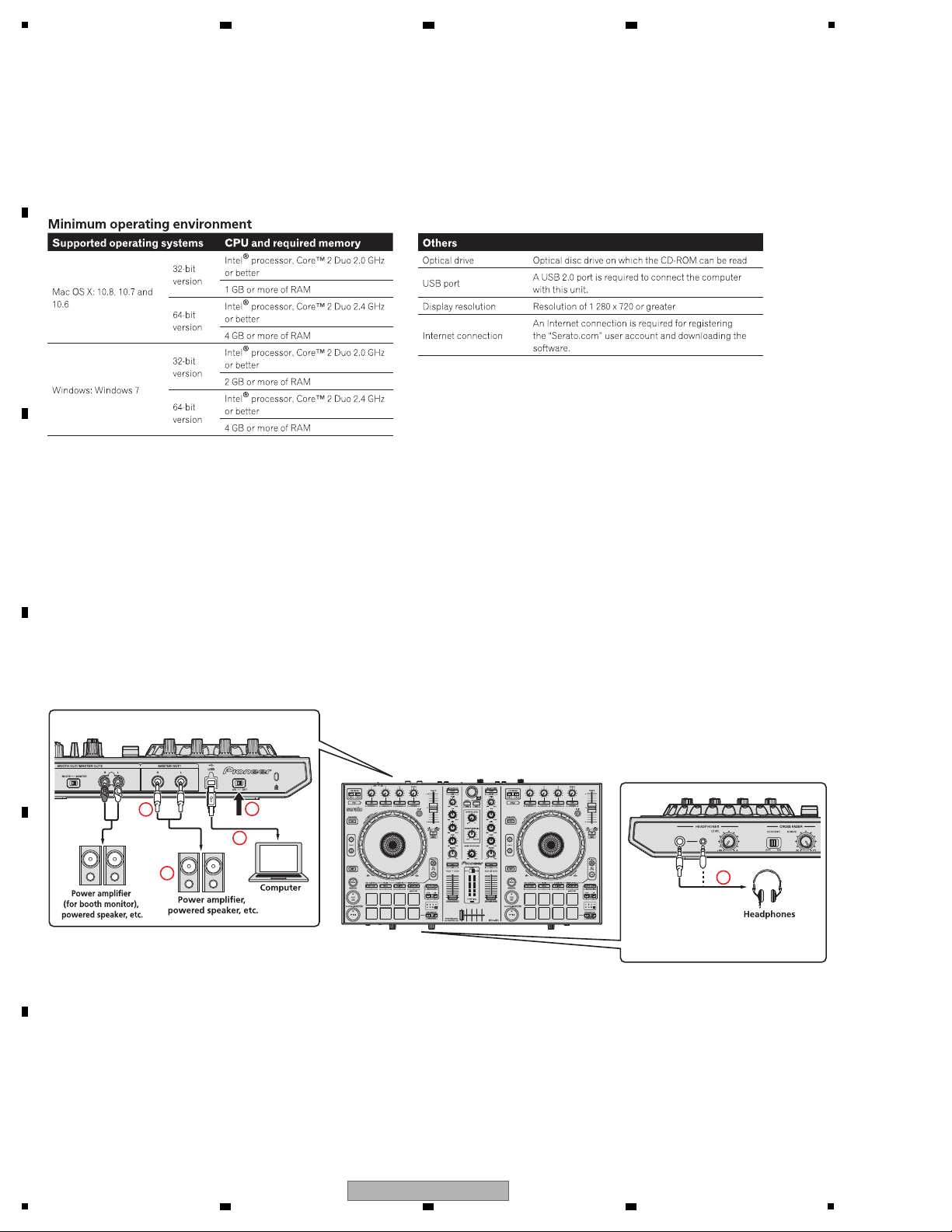

[Installation of Serato DJ]

[Connections]

[Operating procedures]

A brief explanation of how to install Serato DJ on a PC is given below. For details, refer to the operating instructions of the

software.

If the OS of the PC to be used is Windows, install the driver software that enables audio output from the PC beforehand.

The operating environment of the PC required for installation of Serato DJ is shown below.

• For the latest information on the required operating environment and compatibility as well as to acquire the latest operating

system, refer to “Software Info” under “DDJ-SR” on the Pioneer DJ support site below.

http://pioneerdj.com/support/

• Operating System support assumes you are using the latest point release for that version.

For the latest version of the Serato DJ software, access Serato.com and download the software from there.

For downloading, registration of a user account at "Serato.com" is required.

Unzip the downloaded file, then double-click the unzipped file to launch the installer.

Read the terms of the license agreement carefully

, and if you agree, select [I agree to the license terms and conditions],

then click [Install].

After installation is completed, the Installation Completed screen will be displayed. Click on [Close] to terminate the Serato DJ

installer.

1 Connect headphones to one of the [HEADPHONES] terminals.

2 Connect powered speakers, a power amplifier, components, etc., to the [MASTER OUT 1] or

[BOOTH OUT/MASTER OUT 2] terminals.

3 Connect this unit to your computer via a USB cable.

4 Turn on the computer’ s power.

5 Switch the [ON/OFF] switch on this unit’ s rear panel to the [ON] side to turn this unit’ s power on.

6 Turn on the power of the devices connected to the output terminals (powered speakers, power amplifier, components, etc.).

1

2

3

5

6

2 3 4

5.2 BASIC OPERATION CHECK USING SERATO DJ

A

B

C

D

E

F

14

DDJ-SR

1

2 3 4

Page 15

5

Starting the system

Launching Serato DJ

From the Windows [Start] menu, click the [Serato DJ] icon under [All Programs] > [Serato] > [Serato DJ].

When Serato DJ is launched after it is installed, a yellow icon saying “BUY/ACTIVATE” might be displayed in the License panel

on the right side of the Serato DJ screen.

DDJ-SR users do not have to activate or buy Serato DJ.

If you tick the check box of [DO NOT SHOW AGAIN] and click [Online], the icon will disappear thereafter.

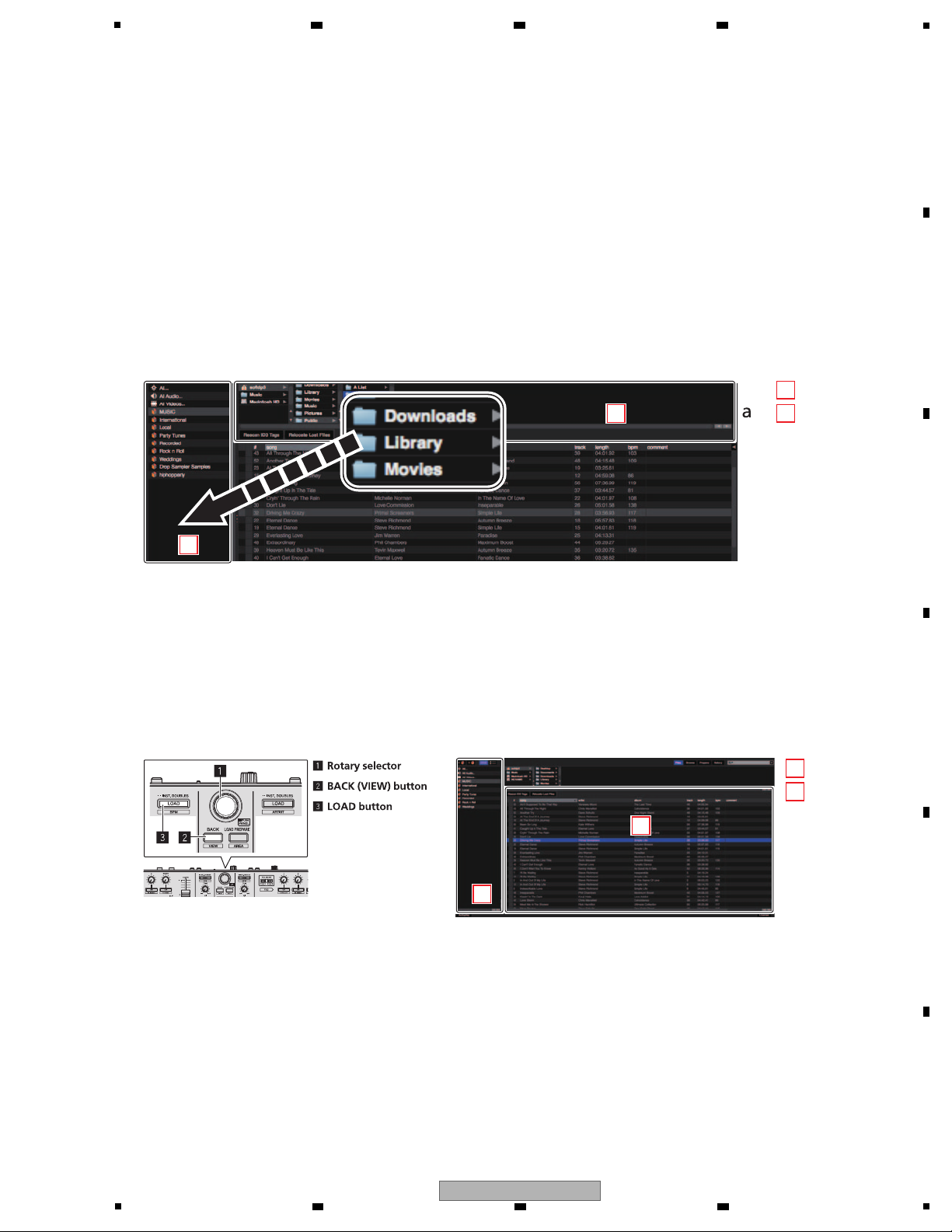

Importing tracks

1 Click the [Files] key on the Serato DJ software screen to open the [Files] panel.

2 Click the folder on the [Files] panel containing the tracks you want to add to the library to select it.

3 On the Serato DJ software screen, drag and drop the selected folder to the crates panel.

Loading tracks and playing them

1 Press this unit’ s [BACK (VIEW)] button, move the cursor to the crates panel on the computer’ s screen, then turn the

rotary selector to select the crate, etc.

2 Press the rotary selector, move the cursor to the library on the computer’ s screen, then turn the rotary selector and

select the track.

3 Press the [LOAD] button to load the selected track onto the deck.

: [Files] panel

b

a

a

: Crates panel

b

: Library

a

: Crates panel

b

b

a

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

15

Page 16

1

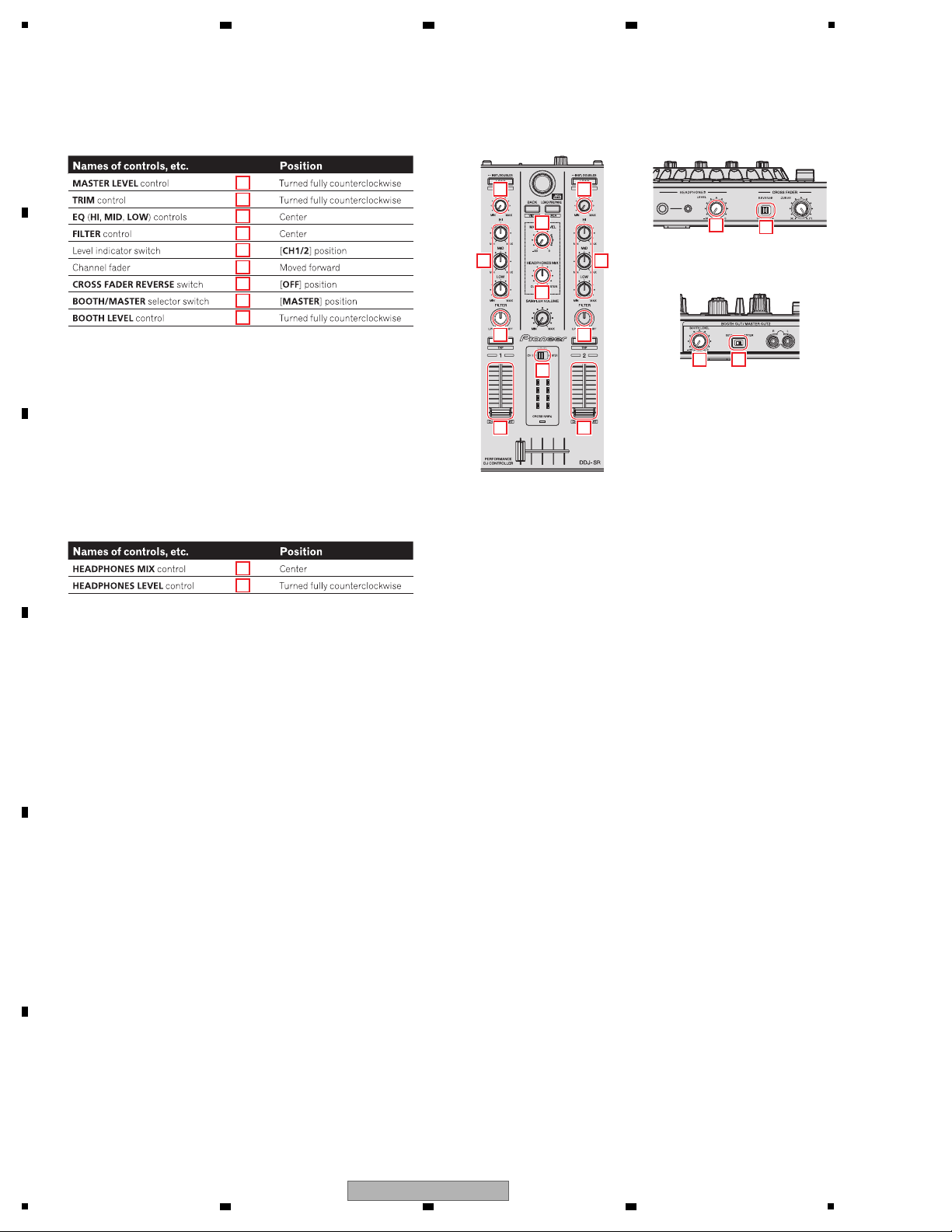

Playing tracks and outputting the sound

1 Set the positions of the controls, etc., as shown below.

2 Press the [f] button to play the track.

3 Move the channel fader away from you.

4 Turn the [TRIM] control.

Adjust [TRIM] so that the orange indicator on the

channel level indicator lights at the peak level.

5 Turn the [MASTER LEVEL] control to adjust the audio

level of the speakers.

Monitoring sound with headphones

Set the positions of the controls, etc., as shown below.

1

1

10

3

2

2

3

4

5

6

7

8

9

10

11

11

2

4 4

5

6

9

6

3

7

8

A

2 3 4

B

C

D

E

F

16

DDJ-SR

1

2 3 4

Page 17

5

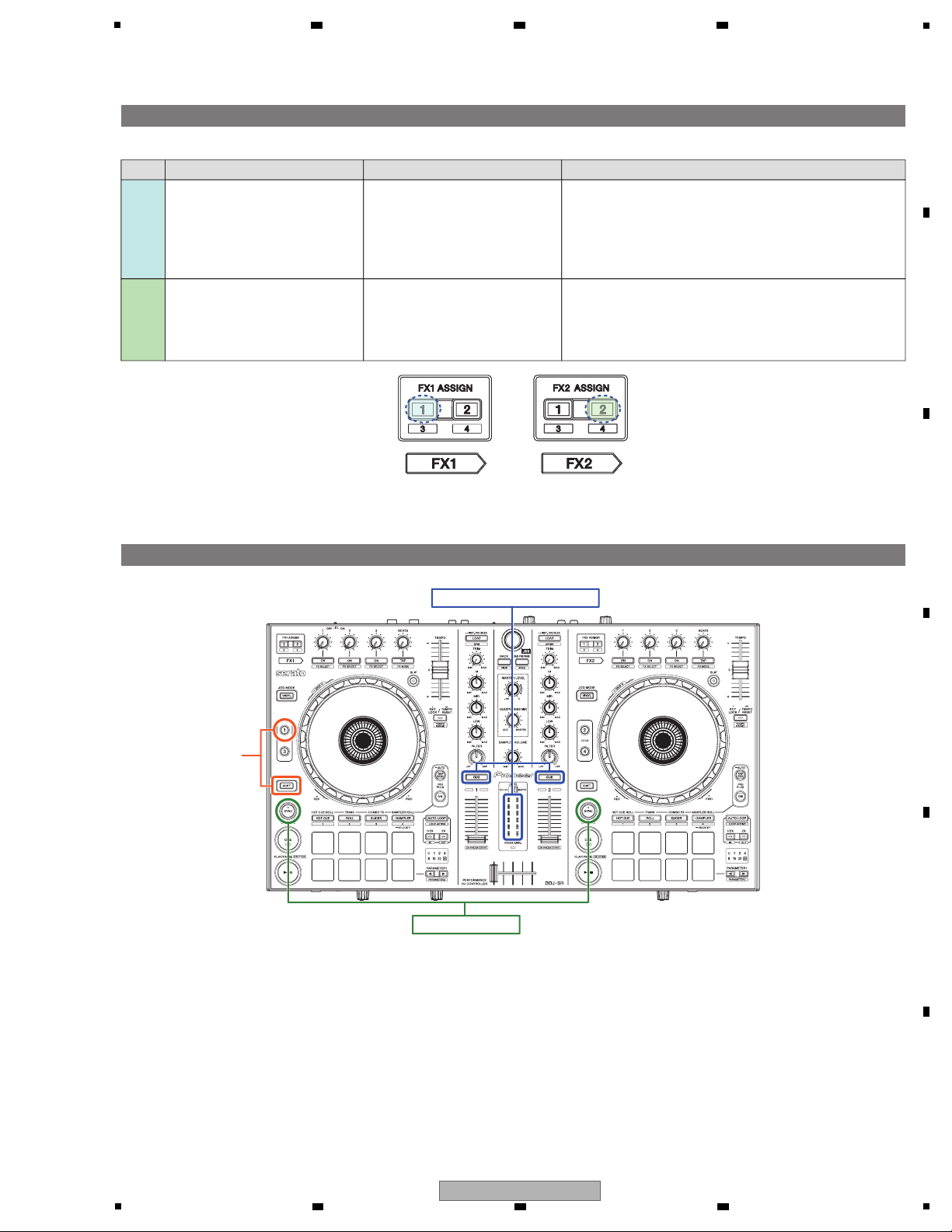

[1] Error Alarming

If unusual detection is occurred during Power on or working, Indicate notice by LED.

Error LED Remarks

1

Abnormalities in

FLASH-ROM of MAIN_UCOM

The "FX1 Assign" LED of Deck1

Blinks in a cycle of 1 second.

When update goes wrong and FLASH-ROM is not written

correctly, it will be in this state.

If the last update failured, the LED blinks when next Power-on.

Perform updating again. If this error warning persists, replace

the USB cable. If this error warning persists more, replace the

I/O PCB Assy.

2 Abnormalities of USB controller The "FX2 Assign" LED of Deck4

Blinks in a cycle of 1 second.

When the time when it cannot communicate with USB

controller correctly although USB cable is connected at the

time of starting, it will be in this state.

Replace the USB cable. If this error warning persists, replace

the I/O PCB Assy.

1

2

[2] Service mode

Press and hold the left DECK "SHIFT" button and the left "DECK 1" button, then Power-ON.

The firmware version is displayed first. LED except it turn off.

[Method to enter]

Power-OFF

[Method to exit]

When in this mode, the firmware version display appear first.

In this mode, it does not work to communicate with computer via USB.

In this mode, LED dimmer is not available.

[Note]

into

Service mode

Firmware version (x.xx)

Factory Reset

6 7 8

6. SERVICE MODE

6.1 SERVICE MODE

A

B

C

D

E

5

6 7 8

DDJ-SR

F

17

Page 18

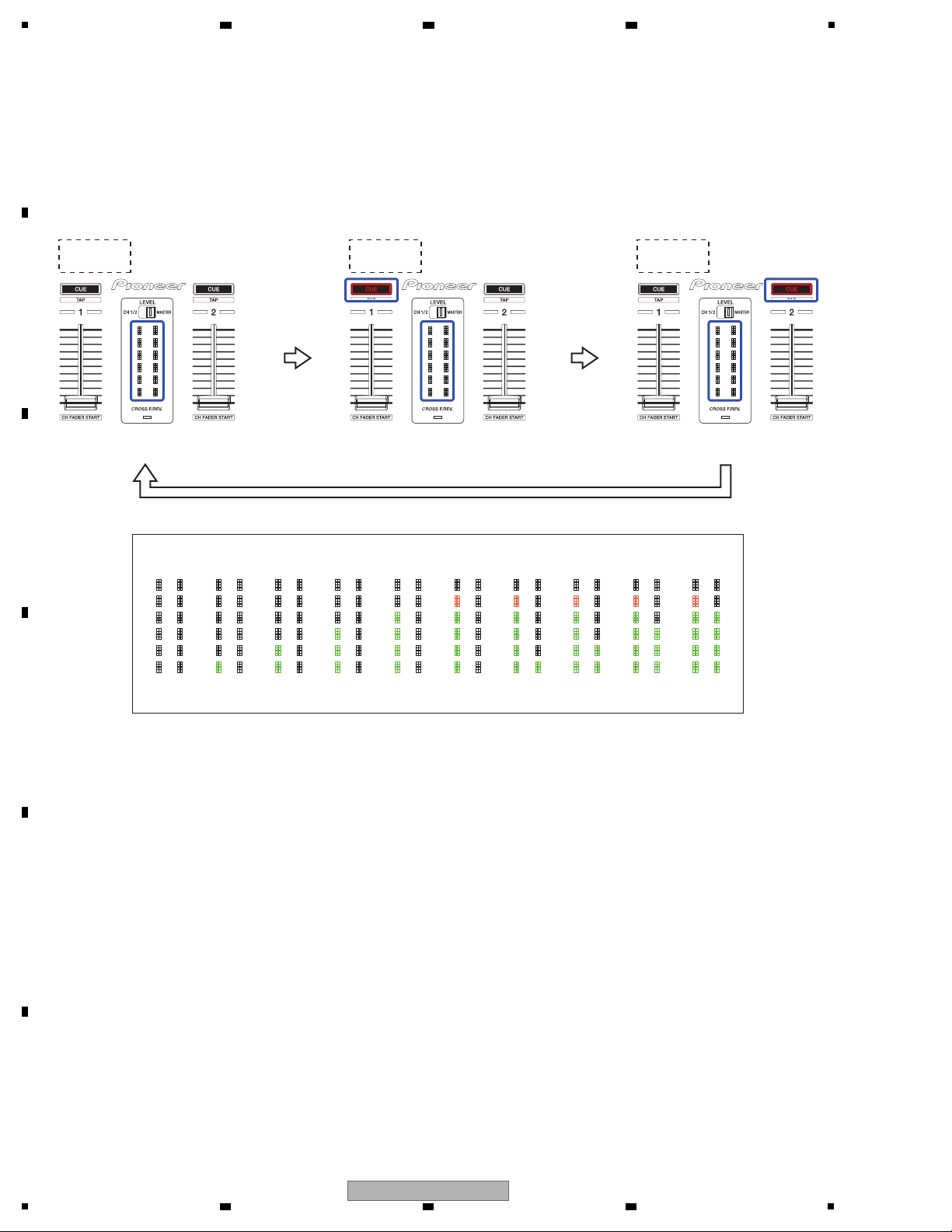

1

The format of the firmware version is "x.xx". (x: decimal)

It is displayed by the Headphone CUE/TAP buttons (Deck1 / Deck 2) and Level indicator.

The firmware display the three-digit every 2 seconds in three times.

The digits express by Headphone CUE/TAP buttons, and the numbers express by Level Indicator.

1. Check of the Firmware Version

2 seconds later

[Numerics expressed with the number of lit LEDs]

0123456789

X.XX X.XX X.XX

2 seconds later 2 seconds later

A

2 3 4

B

C

D

E

F

18

1

2 3 4

DDJ-SR

Page 19

5

In case of the left parts, the left parts LED are lit.

In case of the right parts, the right parts LED are lit.

In case of the center parts, the right&left parts LED are lit.

All buttons other than the Rotary selector, LED will light only while it is pressed.

[Note]

LED lighting specification for parts type

After checking the firmware version, you can check if each UI parts (button/jog dial/knob/fader etc.) are not abnormal.

All UI parts of top&front panel are objects to check.

2. Check of UI parts & LED

Parts type UI Parts Name Function LED to check

Push switches (with LED)

Rotary selector

Press Own LED

Turn All LED (*7)

Jog dial (rotate operation) Turn "Level indicator" LED (*1)

Volume knob, TEMPO slider Turn "Level indicator" LED (*2)

Channel fader Slide "Level indicator" LED (*3)

Cross fader Slide "Beat indicator" LED (*4)

CROSS FADER REVERSE switch Slide "CROSS F. REV. indicator" LED (*5)

Level indicator switch Slide "Level indicator" LED (*1)

Push switches (without LED)

Rotary selector

BACK (VIEW) button

LOAD PREPARE (AREA) button

Jog dial (touch operation) (Deck 1)

Jog dial (touch operation) (Deck 2)

SHIFT button (Deck 1)

SHIFT button (Deck 2)

Press

All LED (*6)

"Headphones CUE/TAP button" LED (Deck 1)

"Headphones CUE/TAP button" LED (Deck 2)

Level indicator left side

Level indicator right side

"HOT CUE" LED (Deck 1)

"HOT CUE" LED (Deck 2)

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

19

Page 20

1

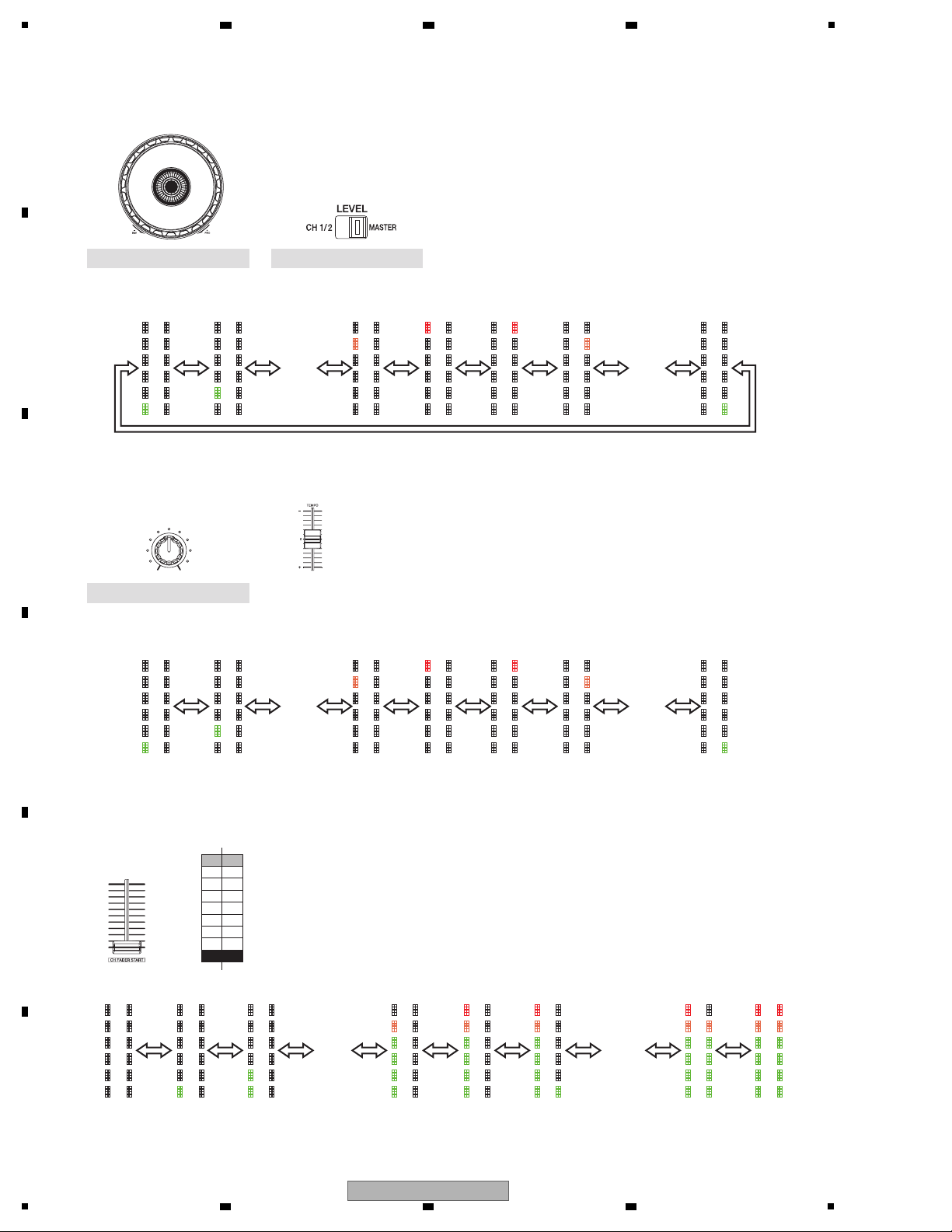

In these type, the position is indicated in 12 steps from minimum to maximum.

In channel fader, the position is indicated in 13 steps from minimum to maximum.

MIN

MAX

MAX

MAX

MIN

MIN

(*2) Volume knob, TEMPO slider

(*3) Channel fader

The starting position depends on the last position.

Jog dial

Volume type

Level indicator switch

(*1) Jog dial (Rotate operation), Level indicator switch

1 2 5 6 7 8

• • •

12

• • •

1 2 5 6 7 8

• • •

12

• • •

1 2 3 6 7 8

• • •

12 13

• • •

A

2 3 4

B

C

D

E

F

20

1

DDJ-SR

2 3 4

Page 21

5

In Crossfader, the position is indicated in 9 steps from minimum to maximum.

Mode: LED BRIGHTNESS Mode

When Rotary selector is pressed,"LED BRIGHTNESS Mode" is changed cyclically as follows.

• • • → A → B → C → D → A → • • •

When Rotary selector is pressed, "LIGHTING COLOR Mode" does not change.

(*4) Cross fader

OFF ON

MIN MAX

(*5) CROSS FADER REVERSE switch

(*6) Press the Rotary selector

Mode All LED

A FULL BRIGHTNESS: 100 %

B MID BRIGHTNESS: 20 %

CLOW BRIGHTNESS: 10 %

D OFF

Mode: LIGHTING COLOR Mode

(Each mode is indicated with the combination of lighting colors of the LOAD button and the HOT CUE, ROLL, SLICER,

and SAMPLER buttons.)

*As two LEDs of different colors each are embedded in the LOAD button and the HOT CUE, ROLL, SLICER, and

SAMPLER buttons, LIGHTING COLOR mode can be used for failure diagnosis of each LED.

When Rotary selector is rotated clockwise,"LIGHTING COLOR Mode" is changed cyclically as follows.

• • • → 1 → 2 → 3 → 4 → 5 → 1 →• • •

When Rotary selector is rotated counterclockwise,"LIGHTING COLOR Mode" is changed cyclically as follows.

• • • → 5 → 4 → 3 → 2 → 1 → 5 →• • •

When Rotary selectoris rotated, "LED BRIGHTNESS Mode" does not change.

(*7) Rotate the Rotary selector

Mode

LIGHTING COLOR of LED

LOAD

HOT CUE, ROLL,

SLICER, SAMPLER

1 RED & AMBER

2 AMBER

3 AMBER

4 RED

5 RED

BLUE & RED

BLUE

RED

BLUE

RED

• • • • • •

123 5 6 89

MIN MAX

Other LEDs

State of (*6) retained

6 7 8

A

B

C

D

5

6 7 8

DDJ-SR

E

F

21

Page 22

1

into

Measurement mode

Jog dial Rotation Time measurement mode

Volume value fluctuation check mode

[3] Measurement mode

This is the mode to measure jog dial rotation time and the fluctuation of knobs/faders.

(1) Jog dial Rotation Time measurement mode

(2) Volume value fluctuation check mode

Press and hold the "SHIFT"+"DECK3" buttons then Power-ON.

During this mode, "DECK 3" and "DECK 4" LEDs are lit.

[Method to enter]

Power-OFF

[Method to exit]

The following data is reset to the factory default settings by "Factory reset" operation.

• Setting data in Utility mode

• Last memory of users

3. Factory Reset

Press and hold the left DECK "SYNC" button and the right DECK "SYNC" button.

Then factory reset starts and "SYNC"LEDs are lit.

After completing reset, "SYNC" LEDs are turned off.

[Method to reset]

A

2 3 4

B

C

D

E

F

22

1

2 3 4

DDJ-SR

Page 23

5

This is the mode to measure the JOG rotation time which is specified at "Jog dial Performance specification".

The specified range is 100 ± 40 msec.

(1) Jog dial Rotation Time measurement mode

1 Yo u spin Jog dial more than 33*7 = 231 rpm.

*1 In case of less than 231 rpm, it is failure. Then "SLIP" LED (Deck1) is lit.

*2 You must measure by either clockwize or counterclockwize.

2 The controller measures "T1".

*T1: The time that Jog dial rotation speed slow down from 100 rpm to 50 rpm.

3 The controller display result with three Channel level indicators. Refer to below.

The format of the result is "XXX" msec. (X: 0-999 msec .decimal)

It is displayed by the Headphone CUE/TAP buttons (Deck1 / Deck 2) and Level indicator.

Display of the 1st digit Display of the 2nd digit Display of the 3rd digit

[Method to measure]

XXX XXX XXX

[Numerics expressed with the number of lit LEDs]

0123456789

If the measurement result is outside the specified range, check the amount of grease for the Jog dial and the chassis.

6 7 8

A

B

C

D

E

DDJ-SR

5

6 7 8

F

23

Page 24

1

11 2 3 4

1515

1212

1313

1414

2222 2323 2424 2525

5 2626

6

7

8 9 1010 1717 1818 1919 2020

1616

2121

1111

Test subjects to move by turning right / left-turn Rotary selector.

A/D conversion value observation start/reset by push the Rotary selector.

Will be tested fluctuation of voltage (A/D conversion value) which is made each Fader and Rotary volume by Level indicator.

[Overview]

Knobs under test operation are filled blue as below.

[Knobs under test operation]

• For failure judgment of the rotary VRs

As a guide, amplitude values higher than +4 or lower than -4 may be judged as failure.

The VRs can be set to any position during measurement. Possible symptoms are shown below.

• The volume changes arbitrarily.

• Interrupted sound leakage occurs even if the volume is decreased to the minimum at the Master or Booth Monitor.

• The MIDI signal is output even if the corresponding VR is not operated.

• For operation check of a rotary VR after replacement

[Use of this mode during repair]

(2) Volume value fluctuation check mode

1 Choose the test subject by turn left and right Rotary selector.

The LED is lit with the following turns every 1 click.

Turn right: 1 → 2 → 3 → 4 → . . . . . → 25 → 26 → 1 → . . .

Turn left: 26 → 25 → 24 → . . . . . → 2 → 1 → 26 → . . .

Note: Regarding No.15, both LED are lit.

2 Yo u can see what knob/fader is selected by Lighting LED on each button as shown in the above figure.

For example ,LED to test Channel fader is "Headphone CUE/TAP" button's LED.

3 When targeted knob is decided, push the Rotary selector and start observation of A/D conversion value.

Get the A / D conversion value immediately after the start. It will be reference value.

*A/D conversion value to be monitored is Raw data.

4

Start monitoring and later to monitor the A/D conversion value, do the following actions depending on its value with

Master level indicator.

[Test detail]

A

2 3 4

B

C

D

E

F

24

1

2 3 4

DDJ-SR

Page 25

5

1 2 3 4 5 6 7 8 910

* Keep the lighting position at the time of maximum fluctuation of each of the positive & negative direction

Level indicator

5 By pushing the Rotary selector while monitoring the conversion value A/D, it is possible to reset the state of the fluctuations

of the past.

Ex.)

1. Turn EQ HI knob (for DECK 1) to the position you want to

measure.

7. More time has elapsed, Level indicator is lit as

follows: become the value 758 of the A/D.

8. More time has elapsed, To maintain the above display

759 even though the value of the A/D.

9. More time has elapsed, Level indicator is lit as

follows: become the value 757 of the A/D.

10. Off all the LED on Level indicator When you push

the Rotary selector, and this value will be new reference

value.

2. Turn the Rotary selector until the 7th LED (Performance

pad) lights.

3. Start A/D conversion value monitoring to push Rotary

selector. If A/D value of push the Rotary selector is 760,

to monitor the amount of change in the value of A/D as

a reference value 760.

4. After a while, Level indicator is lit as follows:

become the value 763 of the A/D.

5. More time has elapsed, to maintain the above display

762 even though the value of the A/D.

6. More time has elapsed, Level indicator is lit as

follows: become the value 764 of the A/D.

DECK1

Result Fig No.

+1 from the reference value A/D conversion value

* Display at the same time both fall / rise direction from the reference value of the conversion value A/D.

1

+2 from the reference value A/D conversion value2

+3 from the reference value A/D conversion value3

+4 from the reference value A/D conversion value4

Over +5 From the reference value A/D conversion value

5

-1 from the reference value A/D conversion value6

-2 from the reference value A/D conversion value7

-3 from the reference value A/D conversion value 8

-4 from the reference value A/D conversion value9

Less than -5 from the reference value A/D conversion value

10

6 7 8

A

B

C

D

E

5

DDJ-SR

6 7 8

F

25

Page 26

1

Testing the velocity sensitivity and aftertouch of the operating elements shown below.

[Description of the modes]

• Values obtained in response to the speed of an initial keypress (velocity sensitivity) or the amount of force applied after initial

impact (aftertouch) will be converted to 8-step data (3-bit resolution).

• If the Performance pad on the left deck is held pressed, the number of the lit rubber pads on the right deck will

increase/decrease in response to force applied to the Performance pad on the left.

• If the Performance pad on the right deck is held pressed, the number of the lit rubber pads on the left deck will

increase/decrease in response to force applied to the Performance pad on the right.

(With the minimum amount of force applied, one LED is lit, and with the maximum amount of force applied, all 8 LEDs are lit.)

[4] Operation Test of the Velocity Sensitivity and Aftertouch for the Performance pads

To enter the mode for testing the velocity sensitivity and aftertouch of the operating elements, after the unit starts in Service

mode, press the Rotary selector over 1 second. Performance pads 1 on both decks are lit and other LEDs are unlit.

[Method to enter]

Power-OFF.

Or, if the Rotary selector is pressed over 1 second again, all of Performance pad on both decks are unlit.

And the unit returns to normal Service mode.

[Method to exit]

Press Performance pad or hold Performance pad pressed.

[Operation method]

[Display examples]

• When the amount of force applied is medium

(the converted value is "3"), Performance pad LEDs 1–4

on the left (right) deck are lit and the other LEDs are unlit.

• When the amount of force applied is minimum

(the converted value is "0"), only Performance pad LED 1

on the left (right) deck is lit.

• When the amount of force applied is maximum

(the converted value is "7"), all Performance pad LEDs

on the left (right) deck are lit.

A

2 3 4

B

C

D

E

F

26

DDJ-SR

1

2 3 4

Page 27

5

A

100-S1-3006

×14

A AB E CD

A

B

White

Black

White

Black

White

Black

Red

Black

White

Black Black

White

Black

White

Black

B

100-S1-3005

×2

C

100-S1-3008

×7

D

100-DDJLE-2944

×2

E

100-S1-3010

×1

F

100-S1-3009

×2

G

100-SR-3008

×1

H

100-22-2824

×3

F

A

F

C C

G

HC C

Knobs and Volumes Location

Note:

Even if the unit shown in the photos and illustrations in this manual may differ from your product, the

procedures described here are common.

6 7 8

7. DISASSEMBLY

A

B

C

D

E

F

DDJ-SR

5

6 7 8

27

Page 28

1

• I/O PCB Assy

(1) Remove the four screws.

(602-B300-041)

(2) Remove the Phone ground plate and

MIC ground plate by removing the two screws.

(602-DJ5500-452)

Base

MIC ground plate Phone ground plate

• Bottom view

• Bottom view

1

2

3

4

5

6

7

8

9

10

11

12

13

1415

16

17

18

1

×18

1

2 2

×2

1

×2

[1] I/O, MIC, HEADPHONE PCB Assemblies

• Base

(1) Remove the Base by removing the 18 screws.

(602-PTP3012-571)

Screw tightening order

Disassembly

A

2 3 4

B

C

D

E

F

28

1

DDJ-SR

2 3 4

Page 29

5

(3) Remove the two screws.

(602-ST306-728B)

(4) Remove the one screw.

(602-QMX2BPM-322)

(5) Release the two jumper wires from the clamper.

(6) Disconnect the three flexible cables and two

connectors.

(CN1B, 2B, 2C, 6, 7)

(7) Remove the I/O PCB Assy with Output board

by removing the six screws.

(602-DJ5500-452)

• Bottom view

• Rear view

3 3

4

5

6

6

6

5

Earth lead

MIC PCB Assy

I/O PCB Assy

Output board

Earth lead Earth lead

Earth lead

HEADPHONE PCB Assy

6

7

7

7

2

4

4

4

4

4

1

1

1

3

7

7

7

6

CN2C

CN1B

CN2B

CN6

CN7

CN701B

• Bottom view

• Front view

MIC PCB Assy HEADPHONE PCB Assy

1

A

1

2

3

5

6

4

B

C

2

3

6

5

4

Screw tightening order

Screw tightening order

• MIC and HEADPHONE PCB Assemblies

(1) Remove the three screws.

(602-ST306-728B)

(2) Remove the MIC PCB Assy by removing the

one screw.

(602-DJ5500-452)

(3) Disconnect the one flexible cable.

(CN701B)

(4) Remove the HEADPHONE PCB Assy by

removing the five screws.

(602-DJ5500-452)

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

29

Page 30

1

[2] Jog dial section

(1) Remove the two solders.

(2) Remove the two E rings.

(606-C304-209)

(3) Remove the two Wheel Assemblies.

• Bottom view

PA NEL-R PCB Assy

E ring

PA NEL-L PCB Assy

1 1

2

E ring

2

Wheel Assy

Wheel Assy

3

3

(1) Remove the all knobs.

1

×27

[3] Each PCB Assemblies

Note:

When you remove each PCB Assemblies, it is not necessary to remove a jog dial section.

A

2 3 4

B

C

D

E

F

30

DDJ-SR

1

2 3 4

Page 31

5

• CROSS FADER PCB Assy

(1) Disconnect the one connector.

(CN01)

(2) Remove the one screw.

(602-QMX2BPM-322N)

(3) Remove the CH ground plate and

CROSS FADER PCB Assy by removing the two screws.

(602-SW3008-737B)

• Shield

(1) Remove the FFC isolation slice by removing

the four screws.

(602-SL24F-099)

(2) Remove the MIC isolation slice by removing

the three screws.

(602-SL24F-099)

FFC isolation sliceEarth lead

MIC isolation slice

CROSS FADER PCB Assy

CH ground plate

• Bottom view

• Bottom view

1

2

3 3

1

1

1

1

2

2

2

1

1

2

3

A

B

C

2

4

3

Screw tightening order

Screw tightening order

CN01

• MIXER, PANEL-L and R PCB Assemblies

(1) Disconnect the two flexible cables.

(CN500)

(2) Remove the two solders.

(3) Remove the MIXER PCB Assy by removing

the 20 screws.

Remove the PANEL-L and R PCB Assemblies

by removing the 52 screws.

(602-SL24F-099)

MIXER PCB Assy

PA NEL-R PCB Assy PA NEL-L PCB Assy

• Bottom view

2 2

1

CN500

1

CN500

3

×72

6 7 8

A

B

C

D

5

6 7 8

DDJ-SR

E

F

31

Page 32

1

MIXER PCB Assy PANEL-R PCB Assy

The other screws are random order.

PA NEL-L PCB Assy

Screw tightening order

1

1

2

3

4

5

6

7

8

9

2

3

4

5

6

7

8

9

10

10

11

12

13

14

15

16

17

18

19

20

21 22

23

24

25

26

28

29

30

27

11

12

13

14

15

17

18

20

19

16

The Application Position of Adhesive and Grease

Adhesive

(GYL1001)

Adhesive

(GYL1001)

Adhesive

(GYL1001)

Adhesive

(GYL1001)

Chassis Assy

I/O PCB Assy

Adhesive

(GYL1001)

Adhesive

(GYL1001)

Adhesive

(GYL1001)

MIXER PCB Assy

Mixer fixed plate

CF fixed plate

Grease

(GEM1096)

Grease

(GEM1096)

Grease

(GEM1096)

• Bottom view

• Bottom view

Wheel Assy

Washer

CROSS FADER PCB Assy

Phone ground plateMIC ground plate

A

B

2 3 4

C

D

E

F

32

1

DDJ-SR

2 3 4

Page 33

5

After repairing, be sure to check the version of the firmware, and if it is not the latest one, update to the latest version.

Perform the each item when the following parts are replaced.

• IC storing firmware

IC20 (I/O PCB Assy)

• Confirmation of the version of the firmware

• Updating to the latest version of the firmware

• IC storing utility settings

IC19 (I/O PCB Assy)

• Factory reset

• Be changed user setting to condition before the repair

(when be possible)

• PCB Assy storing firmware and utility settings

I/O PCB Assy

• Confirmation of the version of the firmware

• Updating to the latest version of the firmware

• Factory reset

• Be changed user setting to condition before the repair

(when be possible)

• Wheel Assy • Confirmation of the specified value by the mode which

measures rotary decline time of the jog dial

PC

USB cable

1 Connect your computer to DDJ-SR via the USB cable

included with the product.

2 Turn on the power of DDJ-SX while pressing the [SHIFT]

button and the [SYNC] button on the LEFT deck ensure

the Level meter LEDs flash before releasing your finger

from the these buttons.

3 When the update file for DDJ-SR (DDJ-SR_Vxxx.jar) is

activated, the following dialogue is displayed. Click the

[Start] button.

Approximately a few minutes are required for updating.

4 When the firmware update process is complete, click the

[OK] button.

Updating Procedures

• Unzip the downloaded update fife for updating.

Place the update file on the desktop.

• ASIO driver exclusively for DDJ-SX is required to be installed for Windows PC users.

• If Java has not been installed, please download the Java Runtime Environment (JRE) at: http://java.com and install

it on your computer.

Preparations

Note: Turn the power off and disconnect all the cables from the unit.

And close all applications on your computer before running this updating procedure.

Note: Please note that if you fail to update, turn on the

power of DDJ-SR again and start from Step 2 of the

above Updating Procedures.

6 7 8

8. EACH SETTING AND ADJUSTMENT

8.1 NECESSARY ITEMS TO BE NOTED

8.2 UPDATING OF THE FIRMWARE

A

B

C

D

E

5

6 7 8

DDJ-SR

F

33

Page 34

1

How to check the Firmware Version

From the [Start menu], Run [All Programs] → [Pioneer] →

[DDJ-SR] → [DDJ_SR Version Display Utility].

*Click [DDJ_SR Version Display Utility] tile on the Start

Screen for Windows 8.

For Windows

Open the Apple menu while pressing the option key, then

select “System Profiler” or “System Information.”

Select the [USB] from the [Hardware] to display the name of

the controller. Select the controller to display the firmware

version.

For Mac

A

2 3 4

B

C

D

E

F

34

1

2 3 4

DDJ-SR

Page 35

5

This unit is provided with user settable items, as shown below.

Although no serious operational problems occur even if data for such user settable items are cleared during repair, it is

recommended that you take note of those settings before starting repair.

Use the Check Sheet shown next page, to which you can transcribe the settings.

If the corresponding part or board Assy is replaced for repair, change the user resettable settings to those noted on the Check

Sheet before starting repair. If resetting is not possible, when returning the repaired product, be sure to tell the customer that

the Utility settings have been cleared and will have to be reset, as required.

Each of the above items can be set in Utility mode.

To enter Utilities mode 1, terminate the application, turn the unit OFF, then while holding the [SHIFT] and

[PLAY/PAUSE] buttons on the left deck pressed, set the [ON/OFF] switch on the rear panel of the unit to ON.

T

o enter Utilities mode 2, terminate the application, turn the unit OFF, then while holding the [SHIFT] and

[PLAY/PAUSE] buttons on the right deck pressed, set the [ON/OFF] switch on the rear panel of the unit to ON.

(For details, refer to the operating instructions of the unit.)

Item for Which User's

Setting is Available

Part Name

IC19

(I/O PCB Assy)

UTILITY

setting

Content to

be Stored

Utilities mode 1Utilities mode 2

Settings for DJ software

other than Serato DJ

Channel fader start setting

Sampler velocity

mode setting

Setting Value (The factory default

settings are indicated in bold.) / Indication method

Setting to use Serato DJ • Setting to use DJ software other than Serato DJ

Left Deck [KEY LOCK] button unlit • [KEY LOCK] button lit

Default value of the beat for

the hot cue roll function setting

1/32 • 1/16 • 1/8 • 1/4 • 1/2 • 1

Left Deck Beat indicator indication: 1/32 • 1/16 • 1/8 • 1/4 • 1/2 • 1

Default value of the beat for

the sampler roll function setting

1/32 • 1/16 • 1/8 • 1/4 • 1/2 • 1

When a Performance pad is pressed after the ROLL button on the

right deck is pressed, a value (1, 2, 3, or 4) will be indicated with the

right-column LEDs of the LEVEL indicator.

A default value can be set separately for each of the 6 Performance

pads (1, 2, 3, 5, 6, or 7).

Left Deck Beat indicator indication: 1/32 • 1/16 • 1/8 • 1/4 • 1/2 • 1

When the SAMPLER button on the left deck is pressed, a value is

indicated with the Beat indicator on the left deck

Momentary mode setting Settings enabled • Settings disabled

Left Deck [PAD PLUS ON]button lit • [PAD PLUS ON] button unlit

Pad Plus mode flashing operation

setting

Settings enabled • Settings disabled

Left Deck [PAD PLUS TAP] button lit • [PAD PLUS TAP] button unlit

Level 12 • Level 50 • Level 75 • Level 100

When the HOT CUE button on the left deck is pressed, a value is

indicated with the Beat indicator on the left deck.

Right Deck Level indicator lighting LED number: 1 • 2 • 3 • 4

Velocity curve setting

FX level Default value of the

Combo FX level setting

Off • Slow • Quick • LFO

When a Performance pad is pressed after the HOT CUE button on

the right deck is pressed, a value (1, 2, 3, or 4) will be indicated with

the left-column LEDs of the LEVEL indicator.

A default value can be set separately for each of the 6 Performance

pads (1, 2, 3, 5, 6, or 7).

Level indicator lighting LED number: 1 • 2 • 3 • 4

Default value of the Combo FX

filter operation mode setting

Curve 1 • Curve 2 • Curve 3 • Curve 4

[1/2X (IN)] button lit • [2X (OUT)] button lit •

[PARAMETER <] button lit • [PARAMETER >] button lit

After touch setting Settings enabled • Settings disabled

[SAMPLER] mode button lit • [SAMPLER] mode button unlit

Jog dial MIDI message sending interval

setting

3 ms • 4 ms • 5 ms • 6 ms • 7 ms • 8 ms • 9 ms •

10 ms • 11 ms • 12 ms • 13 ms

Level indicator lighting LED number:

0 • 1 • 2 • 3 • 4 • 5 • 6 • 7 • 8 • 9 • 10

Slip mode flashing setting Settings enabled • Settings disabled

Left Deck [SLIP]

button lit • [SLIP]

button unlit

Demo mode setting Demo mode enabled • Demo mode disabled

Left Deck

[TAP (FX MODE)]

button lit •

[TAP (FX MODE)] button unlit

With SYNC, without SYNC, function disabled

Left Deck Effect parameter 1 button lit • Effect parameter 2 button lit •

Effect parameter 3 button lit

Master output’ s attenuation

level setting

0 dB (no attenuation) • −3 dB • −6 dB

Left Deck [HOT CUE]

mode

button lit • [ROLL]

mode

button lit •

[SLICER]

mode

button lit

6 7 8

8.3 ITEMS FOR WHICH USER SETTINGS ARE AVAILABLE

5

6 7 8

DDJ-SR

A

B

C

D

E

F

35

Page 36

1

Sheet for confirmation of the user setting

Velocity curve selection

Sampler velocity mode

Jog dial MIDI message sending interval setting

Curve1 3 ms 4 ms 5 ms 6 ms 7 ms 8 ms 9 ms

10 ms 11 ms 12 ms 13 ms

Curve2

Setting of DJ software to be used

Serato DJ

Other than Serato DJ

Channel fader start setting

With SYNC Without SYNC disabled

Master output’ s attenuation level setting

0 dB -3 dB -6 dB

After touch setting

enabled disabled

Demo mode setting

enabled disabled

Utilities mode 1

Utilities mode 1

Slip mode flashing setting

enabled disabled

Utilities mode 1

Curve3 Curve4

Level 12 Level 50 Level 75 Level 100 Off Slow Quick LFO

Default value of the beat forthe hot cue roll function setting

1/32 1/16 1/8 1/4 1/2 1

Default value of the beat forthe sampler roll function setting

1/32 1/16 1/8 1/4 1/2 1

Momentary mode setting

enabled disabled

Pad Plus mode flashing operation setting

enabled disabled

Utilities mode 2

Utilities mode 2

Utilities mode 2

Default value of the Combo FX level setting

Combo FX

Performance pad 1

Performance pad 2

Performance pad 3

Performance pad 5

Performance pad 6

Performance pad 7

Performance pad 1

Performance pad 2

Performance pad 3

Performance pad 5

Performance pad 6

Performance pad 7

Default value of the Combo FX filter operation mode setting

A

2 3 4

B

C

D

E

F

36

1

2 3 4

DDJ-SR

Page 37

5

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

37

Page 38

1

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

Screws adjacent to b mark on product are used for disassembly.

-

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

or

2 3 4

9. EXPLODED VIEWS AND PARTS LIST

A

9.1 PACKING SECTION

B

C

D

E

F

38

1

2 3 4

DDJ-SR

Page 39

5

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 USB Cable (L = 1500 mm) 408-SUB-132

2 CD-ROM (Installation Disc)

3 Polyfoam 506-SR-657

4 Soft Bag 509-SR-328

5 Paster Board 507-SR-3440

6 Handle 100-SX-3017

7 Handle Base 100-SX-3018

8 Gift Box See Contrast table (2)

9 Read Before Use (Important)/ See Contrast table (2)

Quick Start Guide

• • • • • (To Be Determined)

6 7 8

A

10 Read Before Use (Important)/ See Contrast table (2)

Quick Start Guide

11 Read Before Use (Important)/ See Contrast table (2)

Quick Start Guide

12 PE Bag 505-DJM250-014

(2) CONTRAST TABLE

DDJ-SR/CKSUVYXE5 and XECN5 are constructed the same except for the following:

Mark No. Symbol and Description

8 Gift Box 507-SRA-3449A 507-SRB-3449

9 Read Before Use (Important)/Quick Start Guide (En, Fr, De, It, Nl) 502-DDJSRA-3325A Not used

10 Read Before Use (Important)/Quick Start Guide (Es, Pt, Ru, Ko, Ja) 502-DDJSRA-3326A Not used

11 Read Before Use (Important)/Quick Start Guide (Zhcn) Not used 502-DDJSRB-3327

DDJ-SR

/CKSUVYXE5

DDJ-SR

/XECN5

B

C

D

E

F

DDJ-SR

5

6 7 8

39

Page 40

1

Wheel plate

(NSP)

Screw

(NSP)

Spring

(NSP)

Wheel & shaft Assy

(NSP)

FSR fixed plate

(NSP)

Carbon pad

(NSP)

9.2 EXTERIOR SECTION

A

2 3 4

B

C

D

E

F

40

DDJ-SR

1

2 3 4

Page 41

5

A

B

C

D

E

F

G

Bar-code

(NSP)

: Accessories of VR

(NSP)

6 7 8

A

B

C

D

E

F

DDJ-SR

5

6 7 8

41

Page 42

1

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 MIC PCB Assy 704-SR-A601

A

2 HEADPHONE PCB Assy 704-SR-A600

3 MIXER PCB Assy 704-SR-A597

4 CROSS FADER PCB Assy 704-DJM250-A032

5 PANEL-L PCB Assy 704-SR-A599

2 3 4

No. Description Part No.

Mark

46 On/On Button 100-ON-3055

47 Hot Cue/Roll Button 100-ROLL-3055

48 Slice/Sampler Button 100-SLICER-3055

49 On/Tap Button 100-TAP-3055

50 On Button 100-ON-3056

6 PANEL-R PCB Assy 704-SR-A598

7 Wheel Assy 701-SR-5350

8 I/O PCB Assy 704-SR-A596

9 Output Board 300-SR-2089

10 Screw 602-HP1010K-181

B

11 Screw 602-MK7-131

12 Screw 602-QMX2BPM-322N

13 1..Pad & FSR Plate Assy kit GXX1374

14 2..Pad & FSR Plate Assy 704-SR-A629

15 2..Washer 606-SR-270

16 30P 1.0 FFC Cable 406-SR-1259

17 5P 1.0 FFC Cable 406-SR-1260

18 1P Ground Wire (L=70 mm) 406-SR-1267

19 1P Lead Wire 406-S1-1231

C

20 Push Button 100-22-2824

21 Little Round Button 100-S1-2991

22 2 Key Button 100-S1-2992S

23 Deck 1 Button 100-S1-2990

24 Deck 2 Button 100-S1A-2990

25 Deck 3 Button 100-S1B-2990

26 Deck 4 Button 100-S1C-2990

27 Jog Tuning Knob 100-DDJLE-2944

28 CF Button 100-S1-3003

D

29 Button 100-S1-3004

30 Speed Push Button 100-S1-3005

51 Tap Hold Button 100-TAP-3056

52 JW Ring 100-SR-3060

53 Locking Cable Clip 300-HM510B-224

54 Fixed Cover 300-33-1918

55 Front Panel 300-SR-2086

56 Mixer Fixed Plate 300-SR-2088

57 K Lock Plate 300-SR-2091

58 CF Fixed Plate 300-SR-2102

59 MIC Ground Plate 300-SR-2104

60 Phone Ground Plate 300-SR-2105

61 CF Ground Plate 300-SR-2106

62 FFC Isolation Slice 501-SR-2589

63 MIC Isolation Slice 501-SR-2590

64 Spring 603-C304-335

65 Velocity Soft Knob 604-SR-618

66 Sponge 612-4MIX-416

67 Foot Mat 612-S1-445

68 Sponge (8*6*18 mm) 612-S1-451

69 Square Pad 612-SR-478

70 1..Play Button Assy 701-DDJSR-5397

NSP 71 2..Play Sync Button 100-SR-3057

NSP 72 2..Lens 100-SR-3058

NSP 73 2..Little Lens 100-SR-3063

74 Numeral Lens 501-SR-2574

75 LM Lens 501-SR-2575

31 FX Rotate Knob 100-S1-3006

32 Gain Rotate Knob 100-S1-3008

33 Gain Rotate Knob 100-SR-3008

34 Filter Rotate Knob 100-S1-3009

35 Browser Rotate Knob 100-S1-3010

36 Base See Contrast table (2)

37 Shift Button 100-SHIFT-3053

E

38 Rectangular Button 100-SR-3053

39 Vinyl Button 100-VINYL-3053

40 1/2 Button 100-12-3054

41 Rectangular Button 100-DJSR-3054

42 -/- Button 100-SR-3054

43 Auto Button 100-AUTO-3055

44 Cue Button 100-CUE-3055

45 Load Button 100-LOAD-3055

F

76 VR Cushion 612-HDJ7000-056A

77 VR Cushion 612-IM-296

78 Chassis Assy 701-DDJSR-5398

79 Quant Lens 501-SR-2573

80 34P 1.0 FFC Cable 406-SR-1258

81 Nut 601-A100-004

82 E Ring 606-C304-209

83 Washer (20*11*0.25T) 606-C304-210

84 Screw 602-B300-041

85 Screw 602-SL24F-099