2014

BDP-LX58-K

Blu-ray 3DTM PLAYER

BDP-LX58-K

BDP-LX58-S

BDP-LX58

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV4579

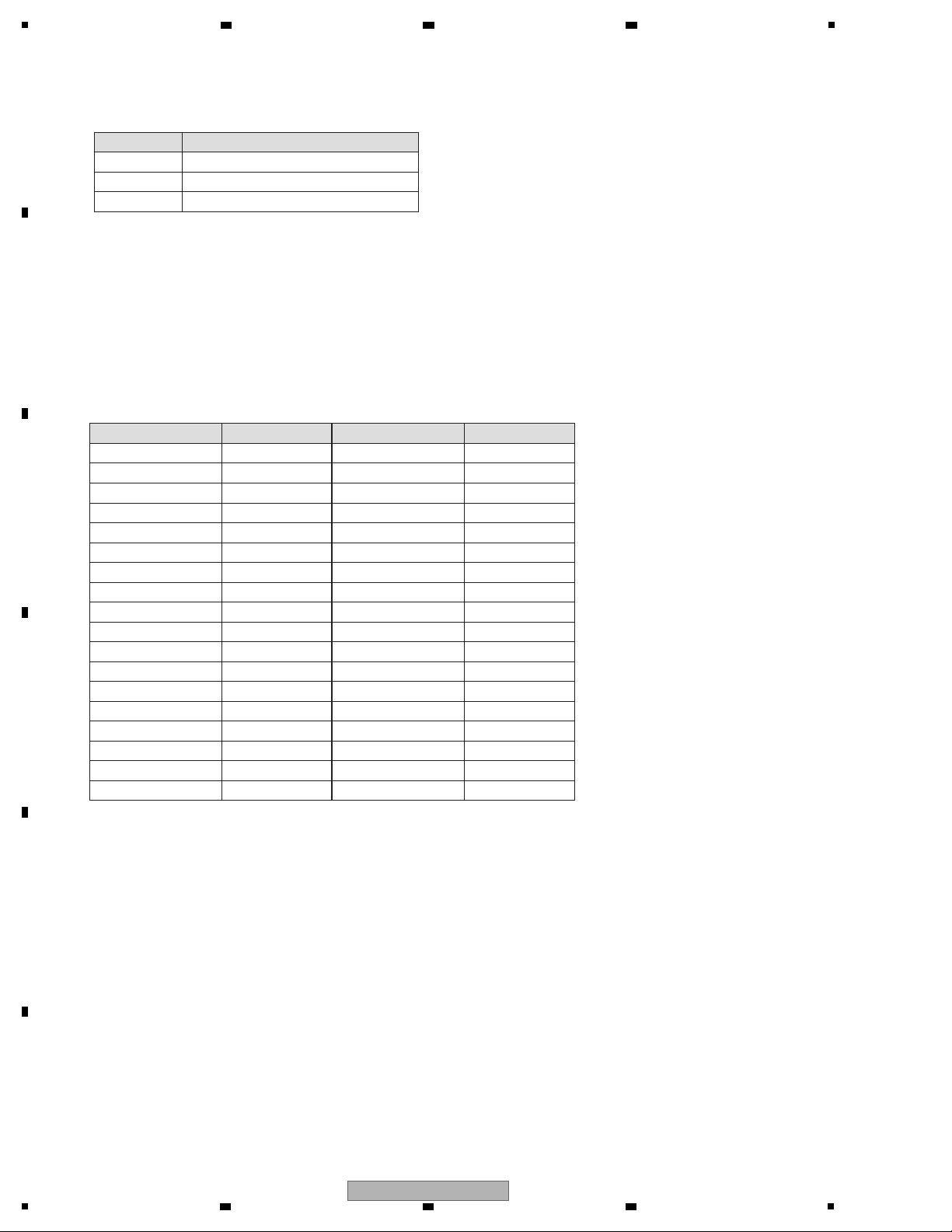

Model Type Power Requirement

BDP-LX58-K YXE8 AC 220 V to 240 V 2 B &&&&######YY YY: Europe

BDP-LX58-S YXE8 AC 220 V to 240 V 2 B &&&&######YY YY: Europe

BDP-LX58 LXE AC 220 V to 240 V 3 A &&&&######LL LL: Asean

BDP-LX58 FXE AC 110 V 3 A &&&&######TA TA: Taiwan

BDP-LX58 AXQ5 AC 220 V to 240 V 6 C &&&&######CN CN: China

DVD

Region No.BDRegion No.

Serial No. Remarks

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-MZV DEC.

2014 Printed in Japan

1

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

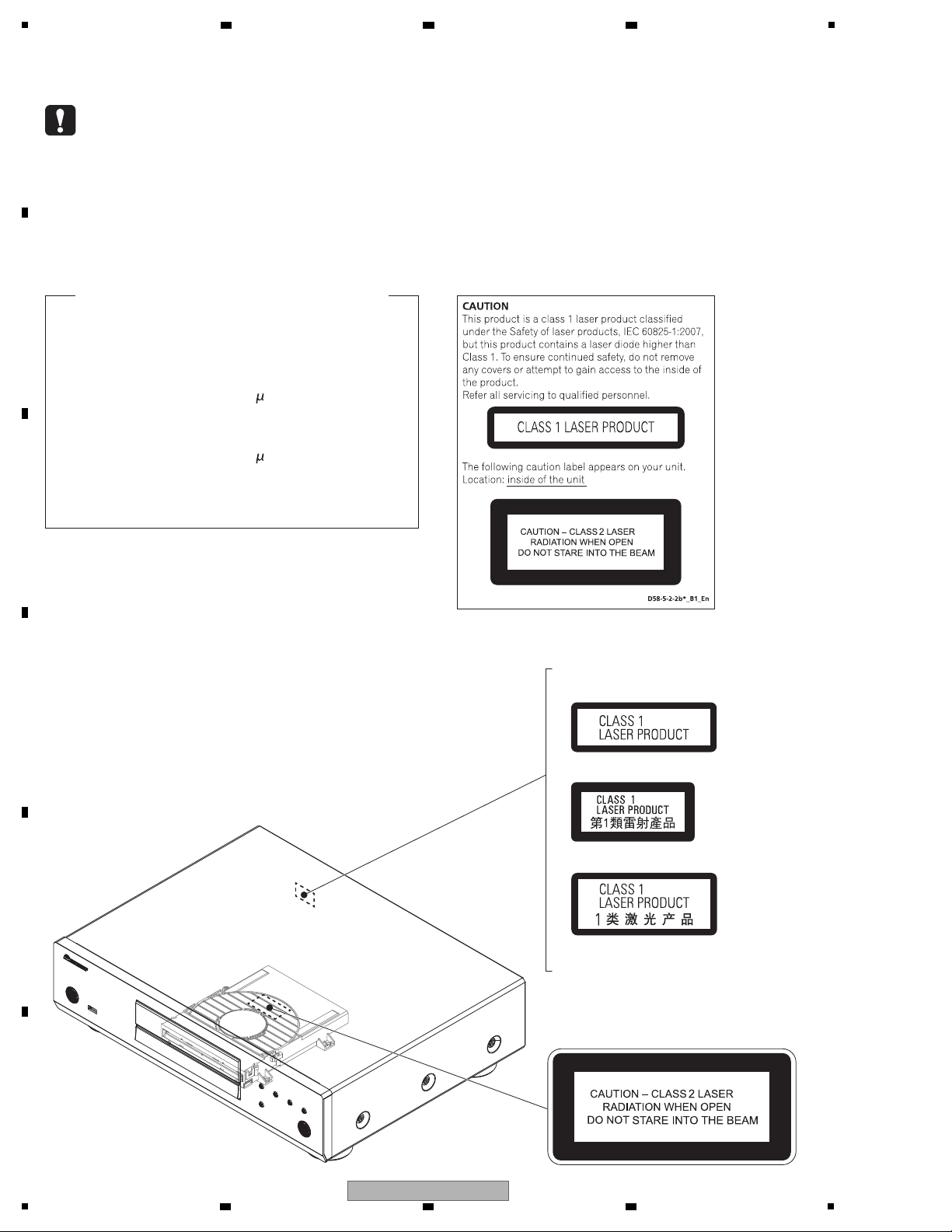

LABEL CHECK

BDP-LX58/AXQ5

(Printed on the Back chassis)

BDP-LX58-K, S/YXE8

BDP-LX58/LXE

BDP-LX58/FXE

The following caution label appears on

your unit.

Location: inside of the unit

Laser Pickup specifications and Laser characteristics

BD Wave length : 405 nm

Operating output : 1.16 mW CW, Class 1

Maximum output : Class 2 (under fault condition)

DVD Wave length : 657 nm

Operating output : 178 W CW, Class 1

Maximum output : Class 1 (under fault condition)

CD Wave length : 785 nm

Operating output : 174 W CW, Class 1

Maximum output : Class 1 (under fault condition)

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

BDP-LX58-K

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS ....................................................................................................................................................4

1.1 NOTES ON SOLDERING............................................................................................................................................... 4

2. SPECIFICATIONS .................................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ........................................................................................................................... 6

3.2 JIGS LIST .......................................................................................................................................................................6

3.3 PCB LOCATIONS ........................................................................................................................................................... 7

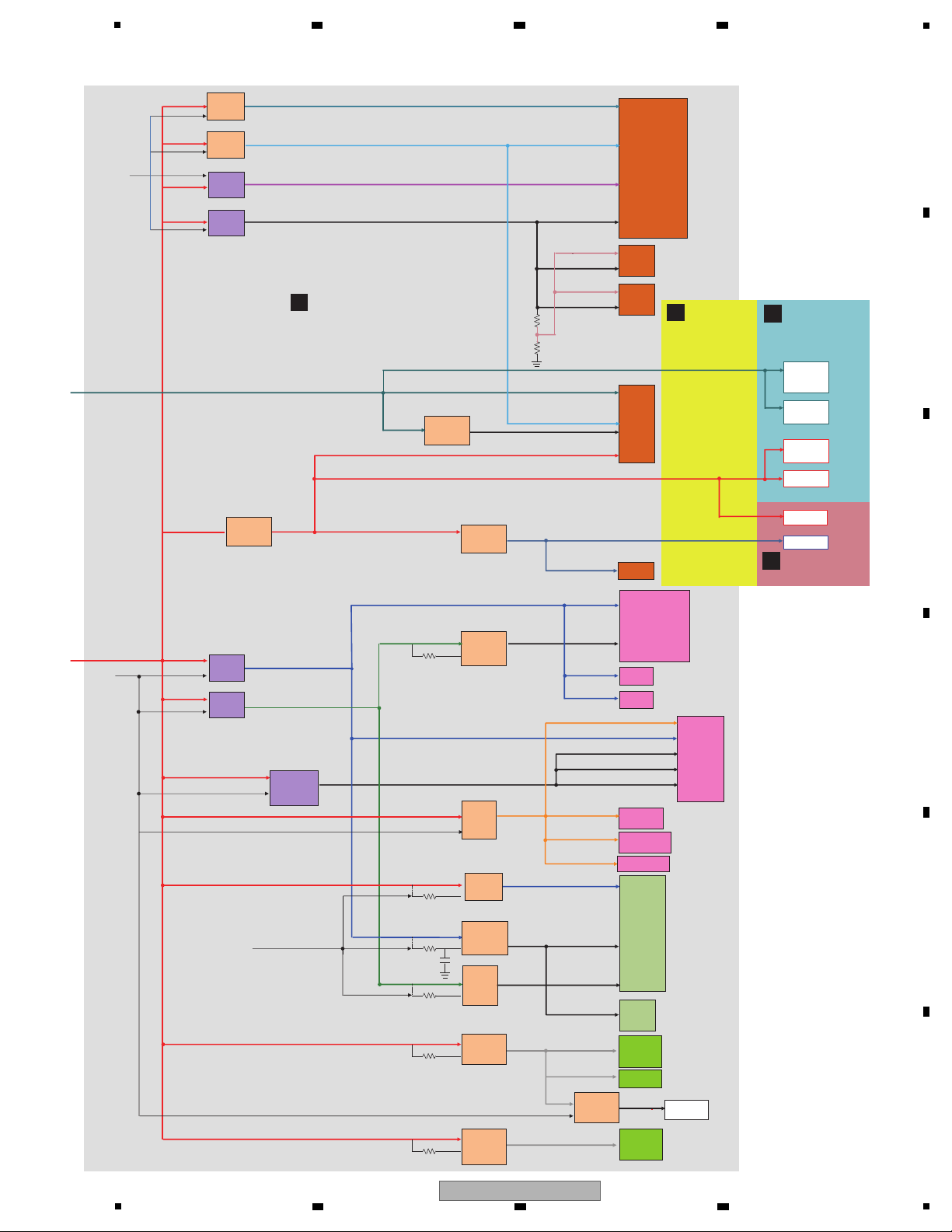

4. BLOCK DIAGRAM ................................................................................................................................................................8

4.1 OVERALL WIRING DIAGRAM .......................................................................................................................................8

4.2 OVERALL BLOCK DIAGRAM....................................................................................................................................... 10

4.3 POWER SUPPLY BLOCK DIAGRAM........................................................................................................................... 12

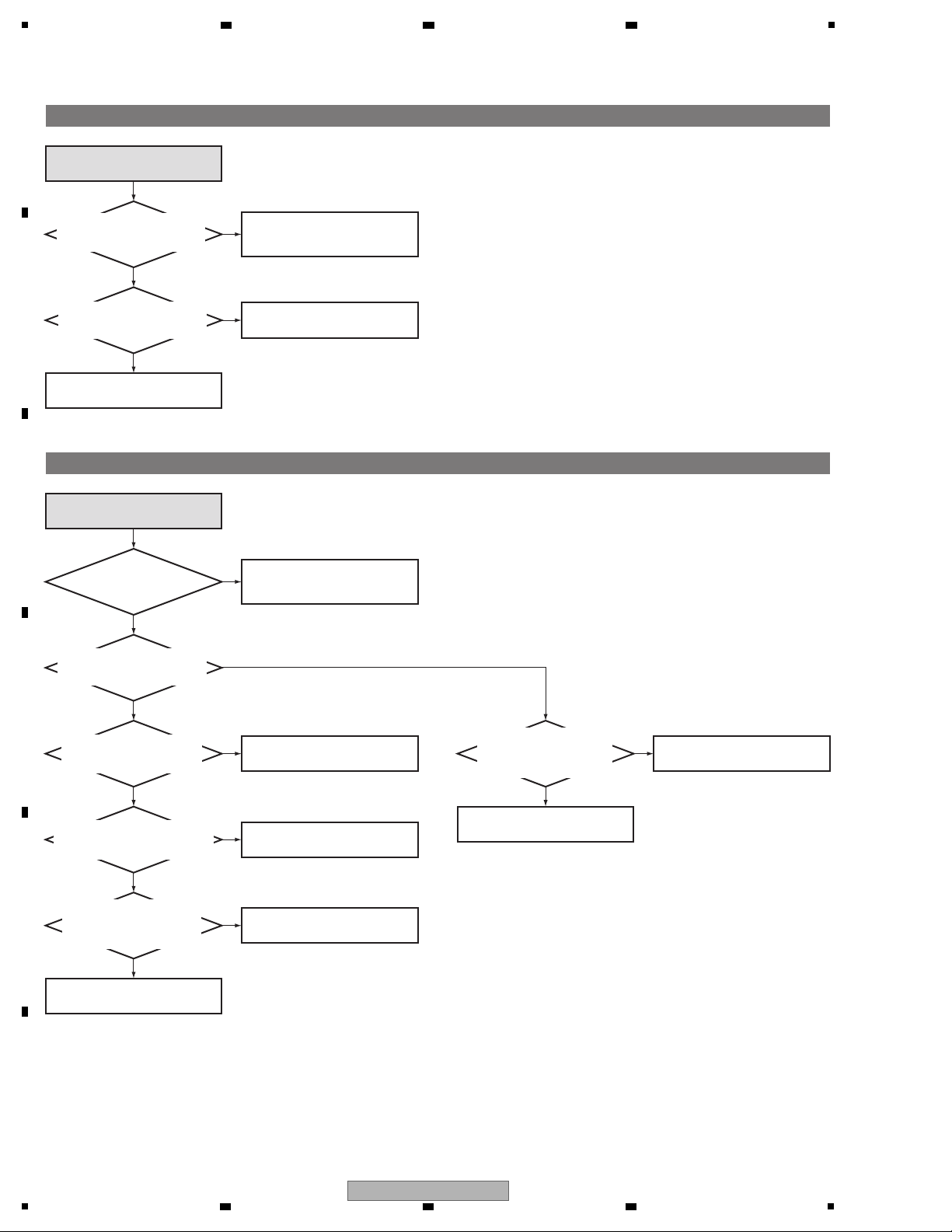

5. DIAGNOSIS ........................................................................................................................................................................ 14

5.1 TROUBLESHOOTING.................................................................................................................................................. 14

6. SERVICE MODE................................................................................................................................................................. 20

6.1 SERVICE MODE .......................................................................................................................................................... 20

7. DISASSEMBLY ................................................................................................................................................................... 27

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 36

8.1 NECESSARY ITEMS FOR ADJUSTMENTS................................................................................................................ 36

8.2 UPDATING OF THE FIRMWARE ................................................................................................................................. 37

8.3 HOW TO READ OUT BARCODE DATA USING A USB MEMORY DEVICE................................................................37

8.4 HOW TO WRITE BARCODE DATA USING A USB MEMORY DEVICE.......................................................................38

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................40

9.1 PACKING SECTION ..................................................................................................................................................... 40

9.2 EXTERIOR SECTION .................................................................................................................................................. 42

9.3 BD LOADER SECTION................................................................................................................................................ 45

10. SCHEMATIC DIAGRAM .................................................................................................................................................... 46

10.1 MAIN BOARD ASSY (1/10)........................................................................................................................................ 46

10.2 MAIN BOARD ASSY (2/10)........................................................................................................................................ 48

AIN BOARD ASSY (3/10) ........................................................................................................................................ 50

10.3 M

10.4 MAIN BOARD ASSY (4/10)........................................................................................................................................ 52

10.5 MAIN BOARD ASSY (5/10)........................................................................................................................................ 54

10.6 MAIN BOARD ASSY (6/10)........................................................................................................................................ 56

10.7 MAIN BOARD ASSY (7/10)........................................................................................................................................ 58

10.8 MAIN BOARD ASSY (8/10)........................................................................................................................................ 60

10.9 MAIN BOARD ASSY (9/10)........................................................................................................................................ 62

10.10 MAIN BOARD ASSY (10/10) ....................................................................................................................................64

10.11 AUDIO BOARD ASSY ..............................................................................................................................................66

10.12 FRONT CONTROL BOARD ASSY........................................................................................................................... 68

10.13 SWITCH, LED and RS BOARD ASSYS................................................................................................................... 70

10.14 RELAY BOARD ASSY.............................................................................................................................................. 71

0.15 POWER BOARD ASSY............................................................................................................................................72

1

10.16 WAVEFORMS...........................................................................................................................................................74

11. PCB CONNECTION DIAGRAM........................................................................................................................................76

11.1 MAIN BOARD ASSY .................................................................................................................................................. 76

11.2 AUDIO BOARD ASSY ................................................................................................................................................80

11.3 FRONT CONTROL, SWITCH, LED and RS BOARD ASSYS .................................................................................... 82

11.4 RELAY BOARD ASSY................................................................................................................................................ 86

11.5 POWER BOARD ASSY..............................................................................................................................................88

12. PCB PARTS LIST .............................................................................................................................................................. 90

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

3

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

2 3 4

BDP-LX58-K

5

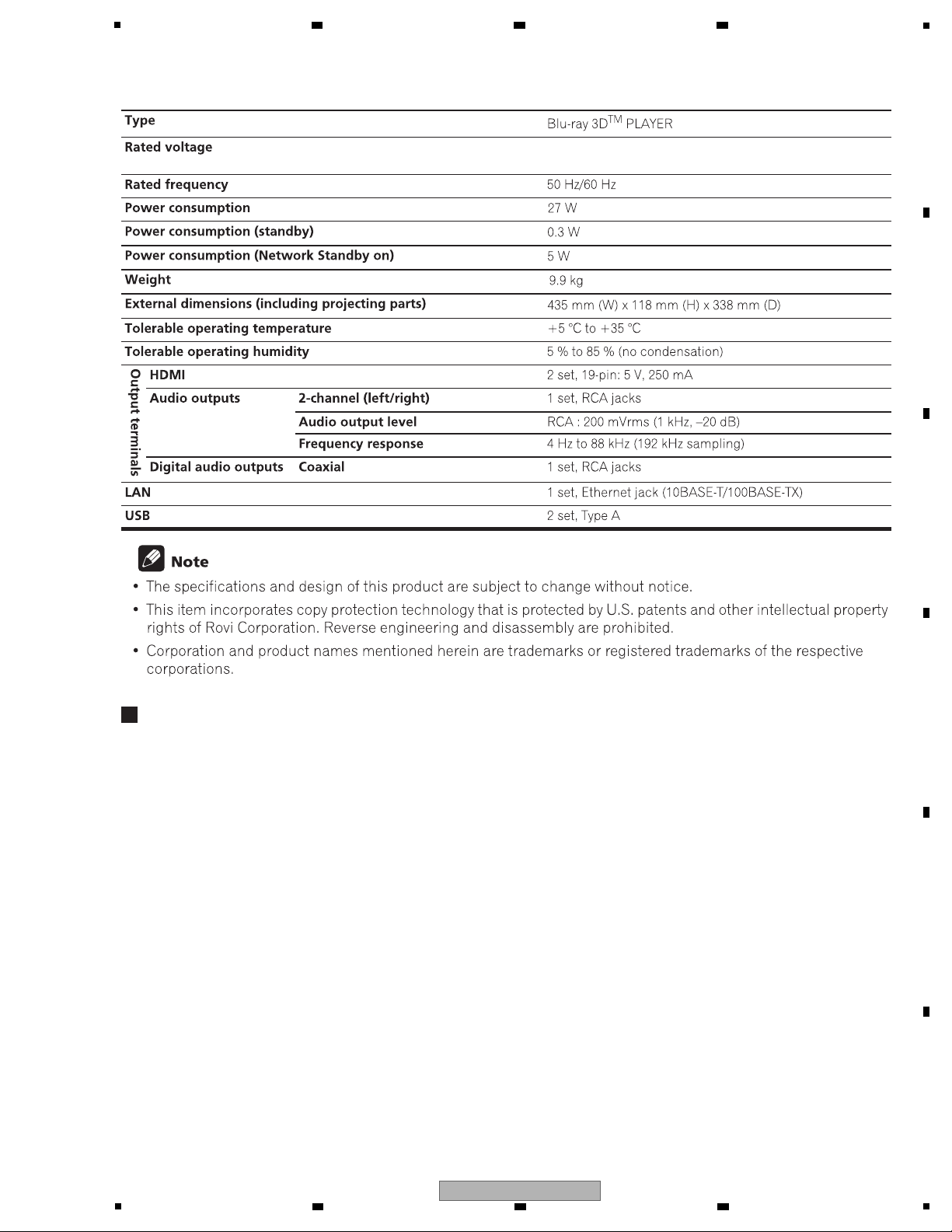

• Remote control x 1

(YXE8, LXE, FXE: VXX3392)

(AXQ5: VXX3393)

• AAA 700 size manganese batteries x 2

• Power cord

(YXE8, LXE: ADG7123)

(FXE: ADG7120)

(AXQ5: ADG7122)

• Warranty card (YXE8, AXQ5 only)

• Software license notice

(YXE8, LXE, FXE: 70-PONEER-LCSB4)

(AXQ5: 70-PONEER-LCSB5)

• Operating instructions

(YXE8: 72-BDPL88-GBRB1, 72-BDPL88-EURB1)

(LXE: 72-BDPL88-GBRB1, 72-BDPL58-TWNB1)

(FXE: 72-BDPL58-TWNB1)

(AXQ5: 72-BDPL58-CHNB1)

• Software update notice

(YXE8, LXE, FXE: 70-BDPX58-SHTB2)

(AXQ5: 70-BDPX58-SHTB1)

• Taiwan label (FXE only)

(71-BDPL88-FXEB1)

Accessories

AC 220 V to 240 V (YXE, LXE, AXQ5)

AC 110 V (FXE)

2. SPECIFICATIONS

6 7 8

A

B

C

D

E

5

BDP-LX58-K

6 7 8

F

5

1

7 Check the appearance of the product.

No scratches or dirt on its appearance after receiving it for service.

1 Confirm the firmware version on Test Mode. The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

2 Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Video, audio and operations must be normal.

6 Play back a BD.

(Menu operation, Title/chapter search)

Video, audio and operations must be normal.

3 Play back a CD.

(track search)

Audio and operations must be normal.

4 Play back a SACD. Audio and operations must be normal.

5 Play back a DVD.

(Menu operation, Title/chapter search)

Video, audio and operations must be normal.

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding video and audio.

No. Procedures

Item to be checked regarding audio

Block noise

Horizontal noise

Dot noise

Disturbed image (video jumpiness)

Too dark

Too bright

Color disappearance

Mottled color

Item to be checked regarding video

Check points

Items to be checked after servicing

To keep the product quality after servicing, confirm recommended check points shown below.

Position to be cleaned Name Remarks

Pickup lens

Cleaning liquied

Refer to "7. DISASSEMBLY".

Part No.

GEM1004

Cleaning paper GED-008

Cleaning

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

Jigs List

DVD Test Disc (DVD-Video) GGV1025 Check of DVD-Video

BD-ROM Test Disc GGV1350 Check of BD-ROM

BD-ROM Test Disc (One layer type) GGV1368 For Adjustment

Jig Name Part No.

Purpose of use / Remarks

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

3.2 JIGS LIST

E

F

6

1

2 3 4

BDP-LX58-K

5

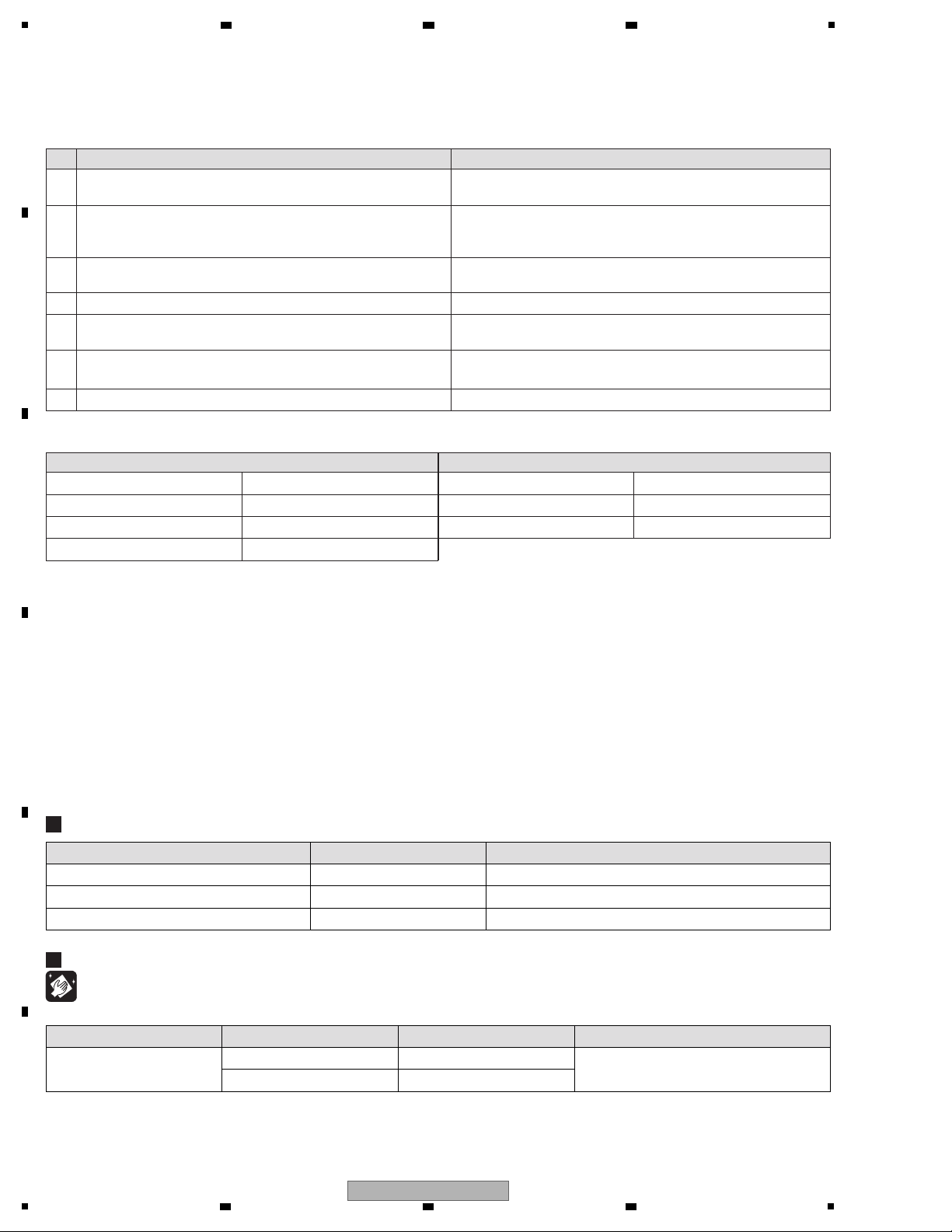

1..MAIN BOARD ASSY (YXE8) 08-BDLX58-MA1/Y

1..MAIN BOARD ASSY (LXE) 08-BDLX58-MA2

1..MAIN BOARD ASSY (FXE) 08-BDLX58-MA2/F

1..MAIN BOARD ASSY (AXQ5) 08-BDLX58-MA4

1..AUDIO BOARD ASSY 08-BDLX58-AD1

1..FRONT CONTROL BOARD ASSY 08-BDLX58-FV0

1..SWITCH BOARD ASSY 08-BDLX58-SW0

1..LED BOARD ASSY 08-BDLX58-LE0

1..LED BOARD ASSY 08-BDLX58-LE1

1..RS BOARD ASSY 08-BDLX58-RS0

1..RELAY BOARD ASSY 08-BDLX58-RL0

1..POWER BOARD ASSY 08-BDLX58-PW0

BD LOADER 08-BDLX58-SH0

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

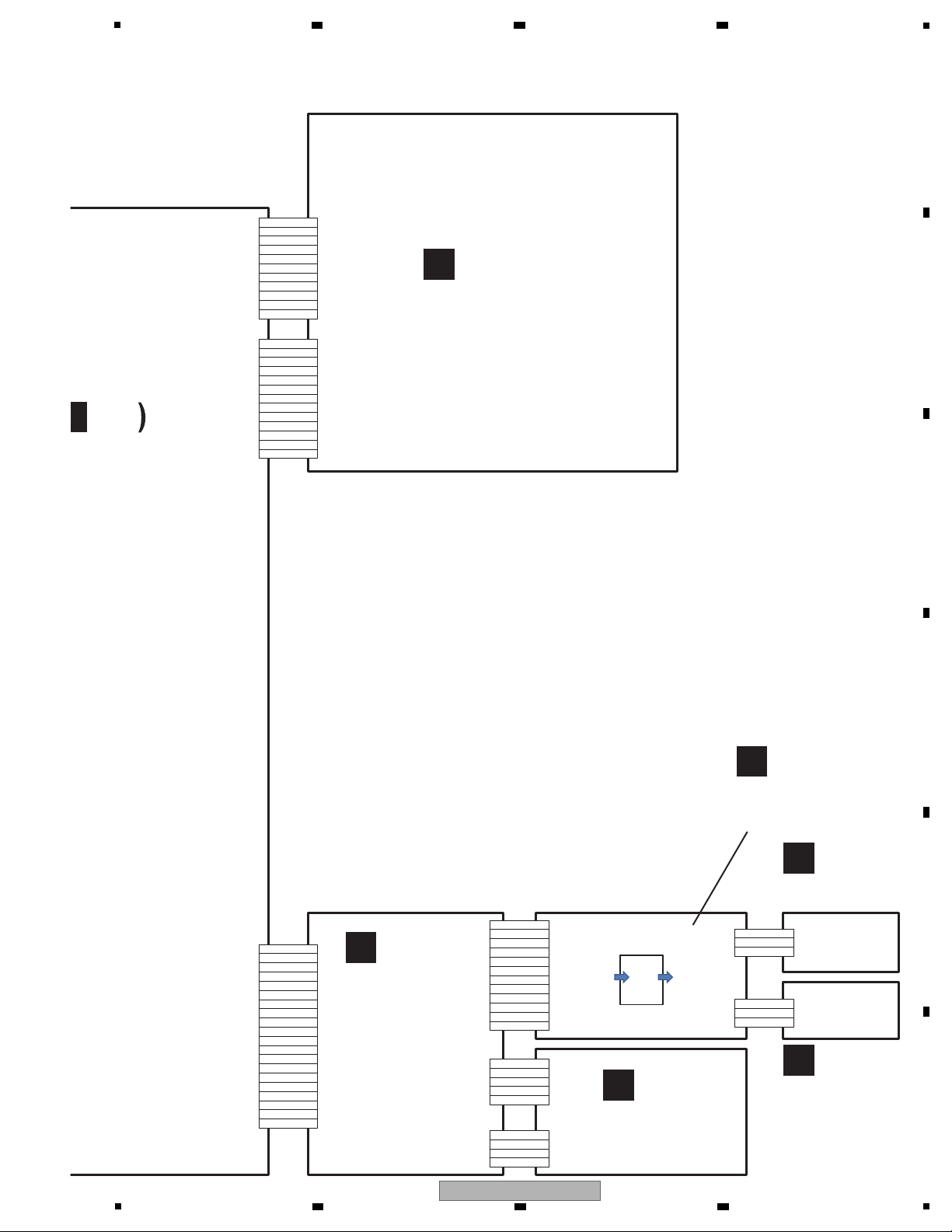

G

RS BOARD ASSY

I

POWER BOARD ASSY

D

SWITCH

BOARD ASSY

LED BOARD ASSY

H

RELAY BOARD

ASSY

A

MAIN BOARD ASSY

B

AUDIO BOARD ASSY

BD LOADER

C

FRONT CONTROL

BOARD ASSY

F

LED BOARD ASSY

E

3.3 PCB LOCATIONS

6 7 8

A

B

C

5

6 7 8

BDP-LX58-K

D

E

F

7

1

11pin

BtoB

9pin

BtoB

Taiko 11pin

TWG-P11X

Socket (Female)

Taiko 11pin

TWG-P11P

Plug (Male)

Taiko 9pin

TWG-P9X

Socket (Female)

Taiko 9pin

TWG-P9P

Plug (Male)

V+5.6_EV

V+5.6_EV

GNDD

GNDD

+14V

+14V

GNDD

GND

4pin

FFC

EV.5V

232C_RXD

232C_TXD

GND

PCON

V+5.6_EV

V+5.6_EV

V+5.6_EV

GNDD

GNDD

+12V

GND_M

GNDD

GNDD

-14V

-14V

CN3023

CN504 CN1509

CN1505

CN501

AC IN

CN503

CN3007

CN3005

CN3004

XP6

45P FFC

0.5mm pitch

9P FFC

1mm pitch

4P wire

2mm pitch

TPIC_V

TPIC_W

MGND

TPIC_B+

TPIC_B-

TPIC_A+

TPIC_A-

TPIC_COMMON

TPIC_U

MGND

TPIC_TRAYIN

TPIC_LOAD-

TPIC_LOAD+

TPIC_CO_A+

TPIC_CO_A-

TPIC_CO_B+

TPIC_CO_B-

HAVC

AUX1

GND

INC

INA

IND

INF

INH

ING

VCC_PDIC

INE

INB

GND

GND

RFO-

FEGIO5

FEGAINSW1

RFO+

LDD_CLK

LDD_SDIO

FEGIO7

LDD_SEN

GND

VCC_LD

VCC_LD

VCC_BDLD

VCC_BDLD

GND

GND

TPIC_FR+

TPIC_FR-

TPIC_TR+

TPIC_TR-

TPIC_TL+

TPIC_TL-

FPDODVD

GND

GND

GND

GND

GND

1

2

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

1

2

3

4

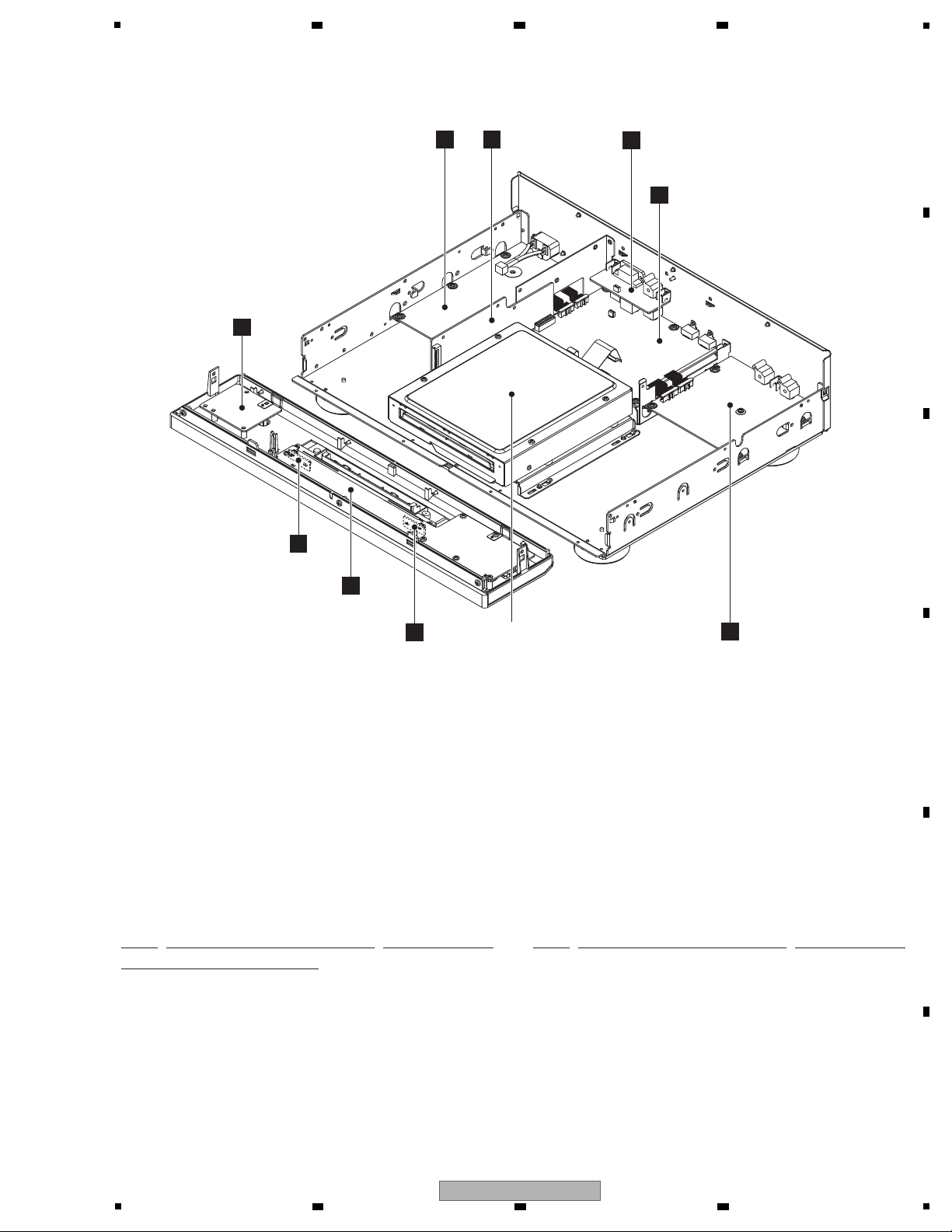

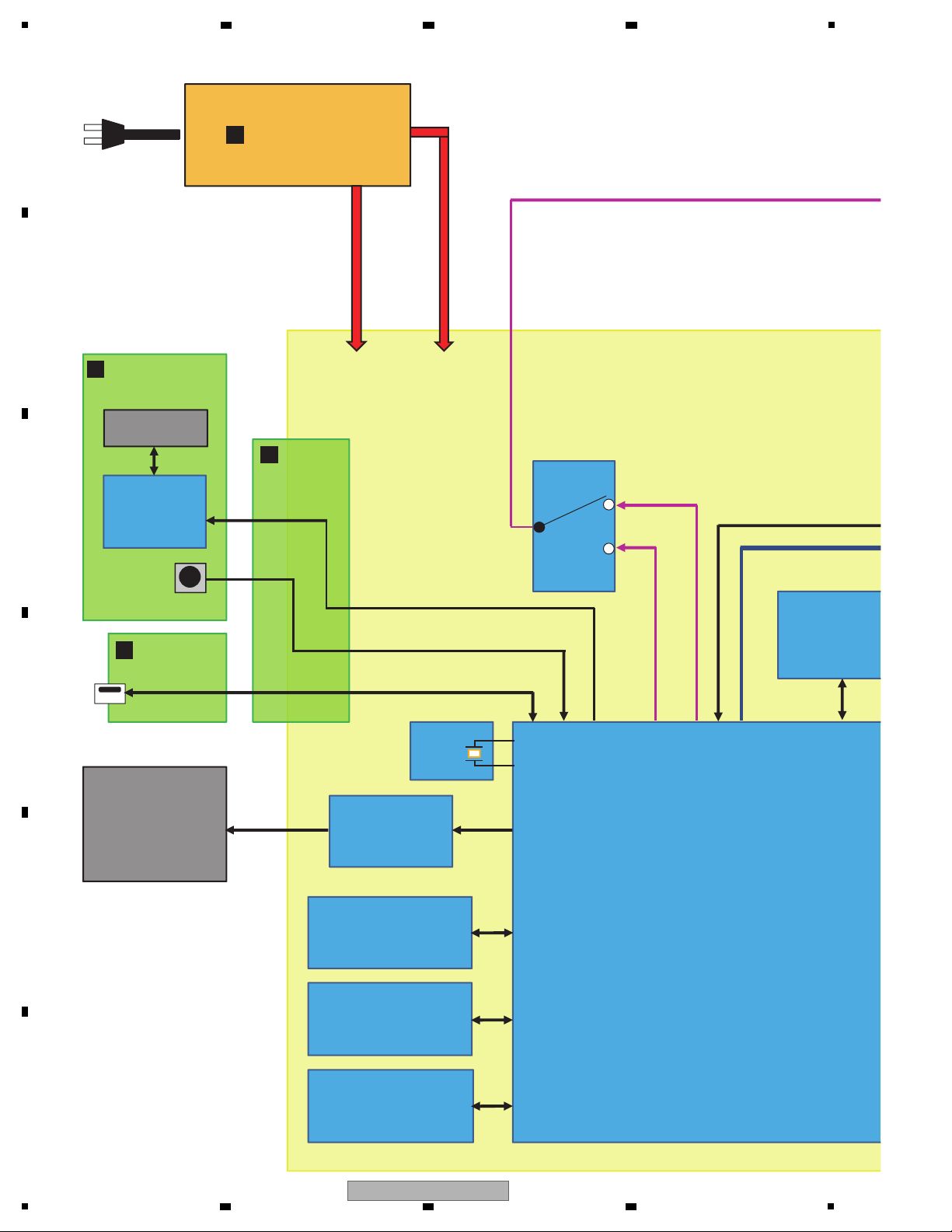

MAIN BOARD ASSY

(YXE8: 08-BDLX58-MA1/Y

(LXE: 08-BDLX58-MA2)

(FXE: 08-BDLX58-MA2/F)

(AXQ5: 08-BDLX58-MA4)

A

POWER BOARD ASSY

(08-BDLX58-PW0)

BD LOADER

(08-BDLX58-SH0)

I

RS BOARD ASSY

(08-BDLX58-RS0)

G

A A

1/10 - 10/10

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the impor tance of the

safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

2 3 4

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

BDP-LX58-K

Taiko 11pin

TWG-P11X

Socket (Female)

Taiko 11pin

TWG-P11P

Plug (Male)

Taiko 13pin

TWG-P13X

Socket (Female)

Taiko 13pin

TWG-P13P

Plug (Male)

V+14(14V)

V+14(14V)

GND_A

GND_A

GND_A

V-14A(-14V)

V-14A(-14V)

GND_AA

GND_AA

V+5(5.6V)

V+5(5.6V)

11pin

BtoB

RY

AMUTE

I2CSDA

I2CSCL

DACRST

GNDD

DATA/DSDFL

GNDD

DATA/DSDFR

GNDD

BCK

GNDD

LRCK/DSDFR

13pin

BtoB

IRISO 20pin

IMSA-9111S-20L

PH 12pin

PH 5Pin PH 5Pin

PH 4Pin PH 4Pin

PH 12pin

IRISO 3pin

IMSA-9120B

IRISO 3pin

IMSA-9120S

IRISO 20pin

IMSA-9111B-20

EV+5V

GND

+12V

+12V

GND

VSTB

VDATA

VCLK

GND

IR

GND

OPEN

POWER

POWERON LED

GND

GND

VCC

USB D+

USB D-

GND

20pin

BtoB

5pin

Wire

4pin

Wire

VCC

GND

+12V_D

GND

12V

AC1

AC2

EN-24V

GND

+12V_D

GND

VFD

DC-DC

VSTB

VDATA

VCLK

GND

IR

GND

GND

VCC

POWERLED

POWER_K

GND

GND

VCC_USB

GND

USBP0

USBM0

GND

XP2

XS1

XP1CN3003

XP2

XP3

XP4

XS1

XS2

CN5000

CN5001CN1511

CN1506

XP1 XP4

XP3

LED1

GND

IRISO 3pin

IMSA-9120B

IRISO 3pin

IMSA-9120S

GND

LED2

GND

AUDIO BOARD ASSY

(08-BDLX58-AD1)

B

FRONT CONTROL

BOARD ASSY

(08-BDLX58-FV0)

C

SWITCH

BOARD ASSY

(08-BDLX58-SW0)

D

LED BOARD ASSY

(08-BDLX58-LE0)

E

LED BOARD ASSY

(08-BDLX58-LE1)

F

RELAY BOARD ASSY

(08-BDLX58-RL0)

H

10/10

5

6 7 8

A

B

C

5

BDP-LX58-K

6 7 8

D

E

F

9

1

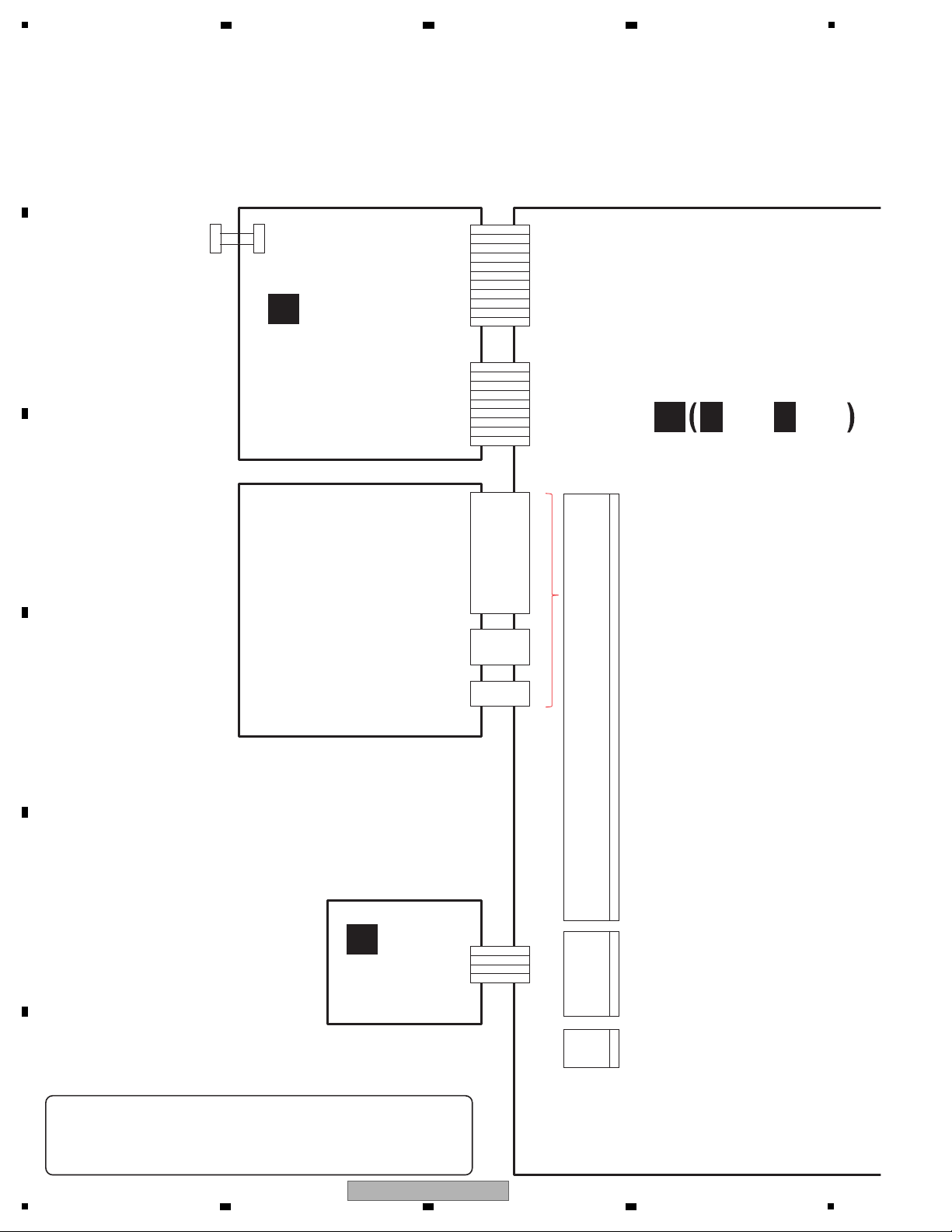

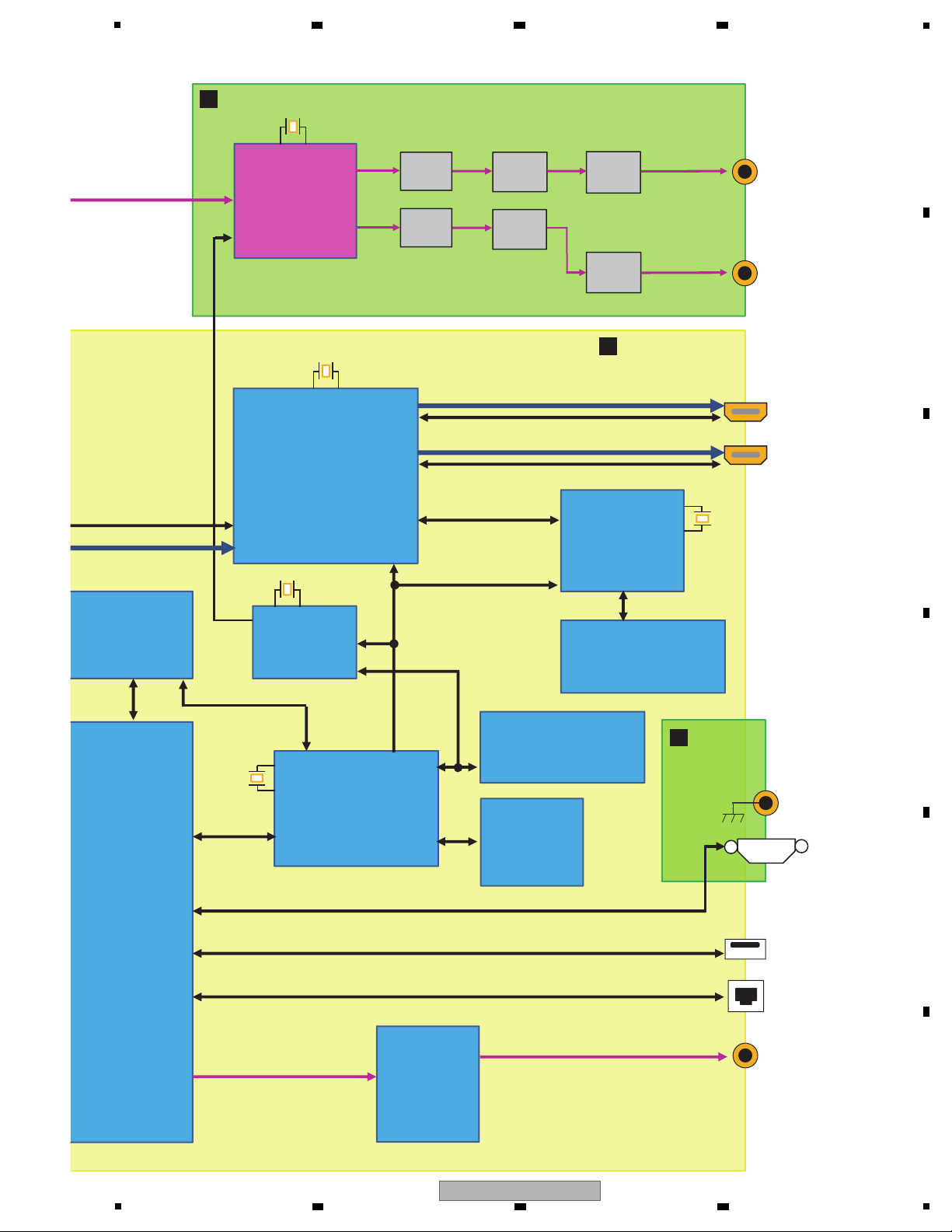

MPEG Decoder

(MTK)

IC3001

MT8560

Motor Driver

IC3409

TPIC2050

TC74VHC157FTS1

DDR3_2Gb

IC3002

NT5CB128M16FP-DI

DDR3_2Gb

IC3003

NT5CB128M16FP-DI

NAND Flash_2Gb

IC3008

MT29F2G08ABAEAWP

Event CPU

IC4001

R5F100MHAF

FRONT

USB

VFD Driver

U1

PT6302

VFD

IR

AC IN

USB D+/D-

IR

I2S / DSD

5.6V_EV

VCXO

X3001

27 MHz

DSD

I2S

SELECTOR

IC1501

±14V

I2C (SCL_1/SDA_1)

TMDS

UART (Tx/Rx)

I

POWER BOARD ASSY

C

FRONT CONTROL

BOARD ASSY

H

RELAY

BOARD ASSY

D

SWITCH

BOARD ASSY

BD LOADER

2 3 4

4.2 OVERALL BLOCK DIAGRAM

A

B

C

D

E

F

10

1

2 3 4

BDP-LX58-K

5

DAC

IC200

ES9011S

Vref

IC5007 IC5005

IC5009

IC5010

Vref

I/V

I/V

LPF

IC5008

IC5011

LPF

X2000

80 MHz

UNBAL-Lch OUT

UNBAL-Rch OUT

HDMI Transmitter

(Pana)

IC1602

MN8647771

SCALERIC

(Marvel)

IC1204

88DE2750

DDR2

IC1212

NT5TU32M16DG-AC

Sub MICON

(SH2)

IC101

R5S726B0D216FP

X101

12 MHz

Gate Array

IC603

PE7008A-K

Event CPU

IC4001

R5F100MHAFA

COAXIAL

REAR

HDMI (MAIN)

HDMI

LAN

ZERO SIGNAL

RS-232C

SPDIF

HEX INVERTERS

IC3901

SN74AHCU04PWR

SPDIF

USB D+/D-

Tx/Rx

UART Tx/Rx

X602

36.864 MHz

X1602

27 MHz

X1201

20 MHz

I2S / DSD

SPI

VIDEO DATA

TMDS

TMDS

I2C (DDC)

I2C (DDC)

I2C

(AUDIOSCL/AUDIOSDA)

I2C

(HDSCL/HDSDA)

TMDS

SPI

RT (Tx/Rx)

SDRAM

IC102

M12L128168A-5TG2N

MX25L6435EM2I-10G

SERIAL FLASH

IC103

A

MAIN BOARD ASSY

B

AUDIO BOARD ASSY

G

RS BOARD

ASSY

6 7 8

A

B

C

D

5

BDP-LX58-K

6 7 8

E

F

11

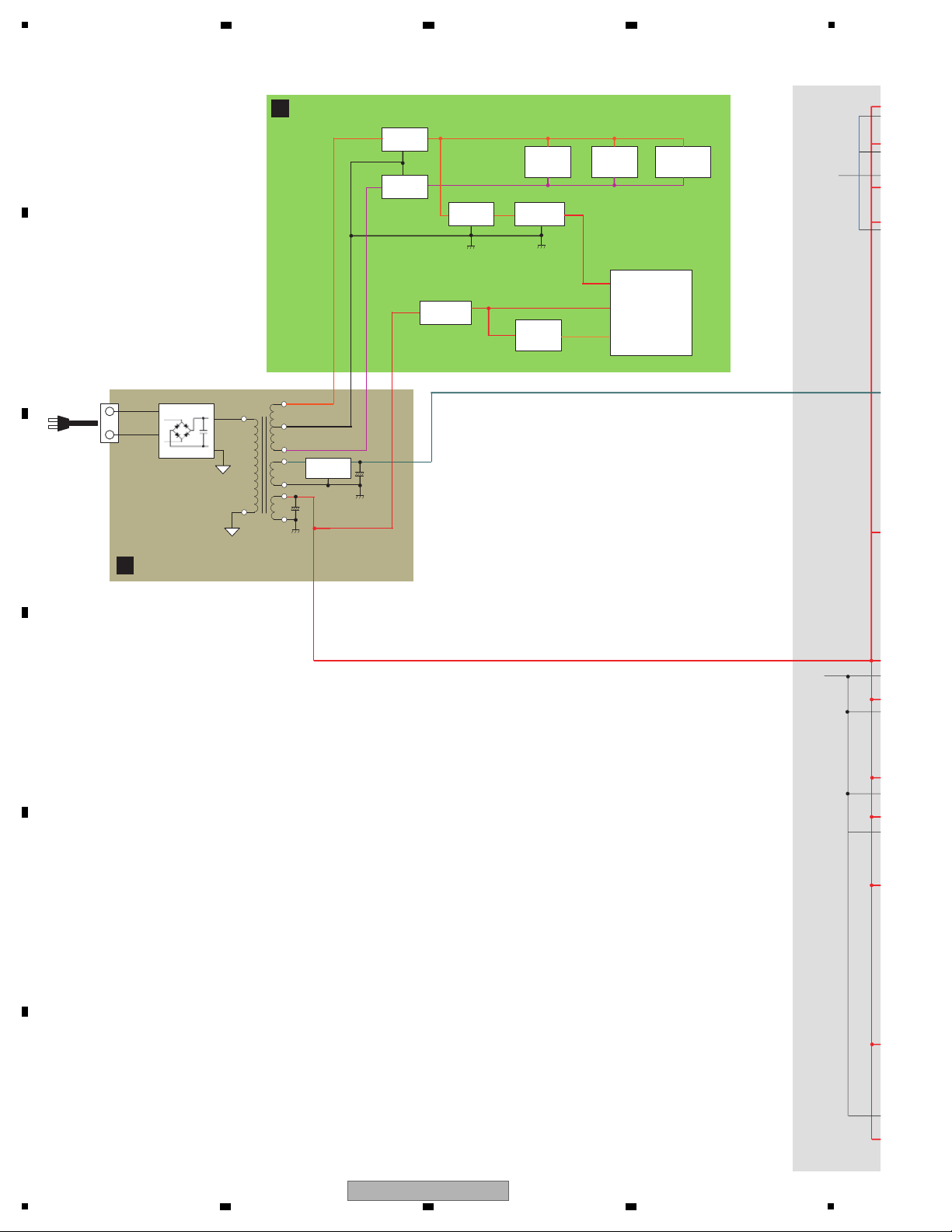

1

U505

BAJ2DD0WT

+12V

V+5.6_EV

IC5000

NJM2880U1-33

V+3R3_D

V+14V

V-14V

IC2402

S-1172B12-E6

V+1R2_D

DAC

IC5006

ES9011S

V+3R3_D

IC2401

NJM78M56FA

IC2405

NJM2872BF33

V+3R3_A

EN

from

MTK

DVCPOW

from

Eve-COM

Vref

IC5007

IC5010

I/V

IC5005

IC5009

LPF

Co

Ev.5.6V

DVCPOW

12V

IC5008

IC5011

V+12_AR / V+12_AL

V-12_AR / V-12_AL

AC IN

IC5003

NJM7812FA

IC5003

NJM7812FA

I

POWER BOARD ASSY

B

AUDIO BOARD ASSY

2 3 4

4.3 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

12

1

2 3 4

BDP-LX58-K

5.6V -> 5V 2A

V+1R8HHH

DVCPOW

DVCPOW

DVCPOW

V+3R3_MV

V+1R8_SC

V+1_SC

V+5_EV

FL

FL Driver

DIRECT LED

FL LED

KEY

KEY MCU

IR

POWER LED

FRONT USB

EN

from

MTK

DVCPOW

from

Eve-COM

IC9101

LDO

S-1112B33

MT8560

3.3V_STBY

3.3V

DDRVCCIO

DDR_VREF

V+12V_D

12V -> 8V

Variable type

IC101

RS5S726B0D216FP

(SH2)

SDRAM

IC1602

HDMI Tx

MN864777

(Pana)

Flash

IC9403

1.1V DCDC con

MM3542BF

Control another in Video QDEO

IC9404

1.8V LDO

Ripple Blocker

MIC94325YMT

IC9402

1V LDO

S-1172B10

IC9406

5V LDO

S-1170B50

IC9532

3.3V LDO

S-1172B33-E6

V+3R3_AUD

IC9408

2.5V LDO

Ripple Blocker

MIC94325YMT

VPPOW

3.3V

Ev.5.6V

DVCPOW

5V

V+5_VCC

V+5_USBFR

V+3R3_EM

V+1R25_SH2

V+1R1_HD

VDD11

AVDD11

AVDD11

V+3R3_HHH

3.3V

V+3R3_HHH

1.8V

USB Rear

TPIC2050

Driver IC

IC9103 LDO

NJM2830-8

200mA

IC9104 LDO

BA00DD0WHFP

5V

High Side SW

IC9515

1.25V LDO

Ripple Blocker

MIC94325YMT

IC9527

DCDC

BD9328

IC9528

DCDC

BD9329

IC9531

5V LDO

S-1170B50

JA1601

HDMI OUT1 5V

V+5_HD OTHER

IC1204

VIDEO

PROCESSOR

88DE2750

IC1212

DDR2 for

Scaler

Event

CPU

RS232C

Gate Array

Digital Audio

OUT

JA160x

HDMI OUT2/Z 5V

IC9525

LDO

S-1172B33

DDR3 for

SOC

1G

DDR3 for

SOC

2G

1.2V

1.5V

12V

IC9102

LDO

S-1172B33

IC9530

DCDC

BD9328

IC9529

DCDC

BD9328

A

MAIN BOARD ASSY

C

FRONT CONTROL

BOARD ASSY

H

RELAY

BOARD ASSY

D

SWITCH

BOARD ASSY

5

5

6 7 8

BDP-LX58-K

6 7 8

A

B

C

D

E

F

13

1

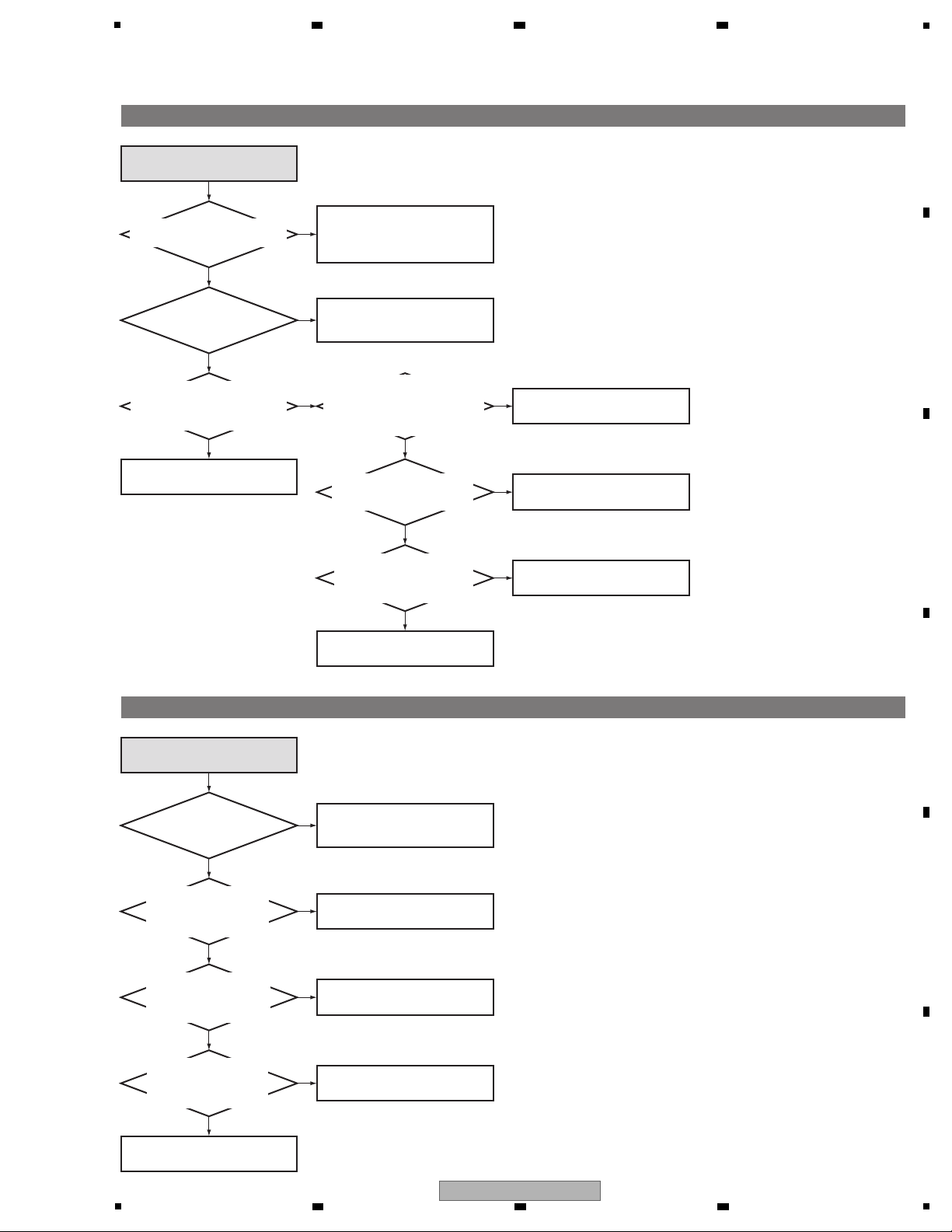

No power

Are the Power buttons on both

the remote control unit and

the main unit disabled?

Is the voltage at Pins 3, 4,

and 5 of CN1505 on the MAIN

BOARD Assy 5.6 V?

No

Ye s

Ye s

No power

Go to the flowcharts for "The buttons

do not function" and "The remote

control unit does not function."

No

Replace the POWER BOARD

Assy.

Replace the MAIN BOARD Assy.

No display on the VFD

Is the unit set to

FL OFF mode?

Are the voltages at Pin 1 of XP

on the RELAY BOARD Assy

5 V and at Pins 3 and 4 12 V?

Is the amount of solder at L1

on the FRONT CONTROL

BOARD Assy appropriate?

Is the voltage at the negative

electrode of CE3 on the FRONT

CONTROL BOARD Assy –24 V?

Is the soldering at the FL

display, U1, and U2 on the

FRONT CONTROL BOARD

Assy appropriate?

Are the voltages at Pin 1 of

CN3003 on the MAIN

BOARD Assy 5 V and at

Pins 2 and 3 12 V?

No

Ye s

Ye s

Ye s

Ye s

Ye s

Ye s

No display on the VFD

No

No

No

Press the DIMMER button on the

remote control unit to cancel

FL OFF mode.

Add solder to L1.

No

Replace the MAIN BOARD Assy.

Replace the RELAY BOARD Assy.

Replace the FRONT CONTROL

BOARD Assy.

Replace the FRONT CONTROL

BOARD Assy.

No

Resolder the parts whose solder

was inappropriate.

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

14

1

BDP-LX58-K

2 3 4

5

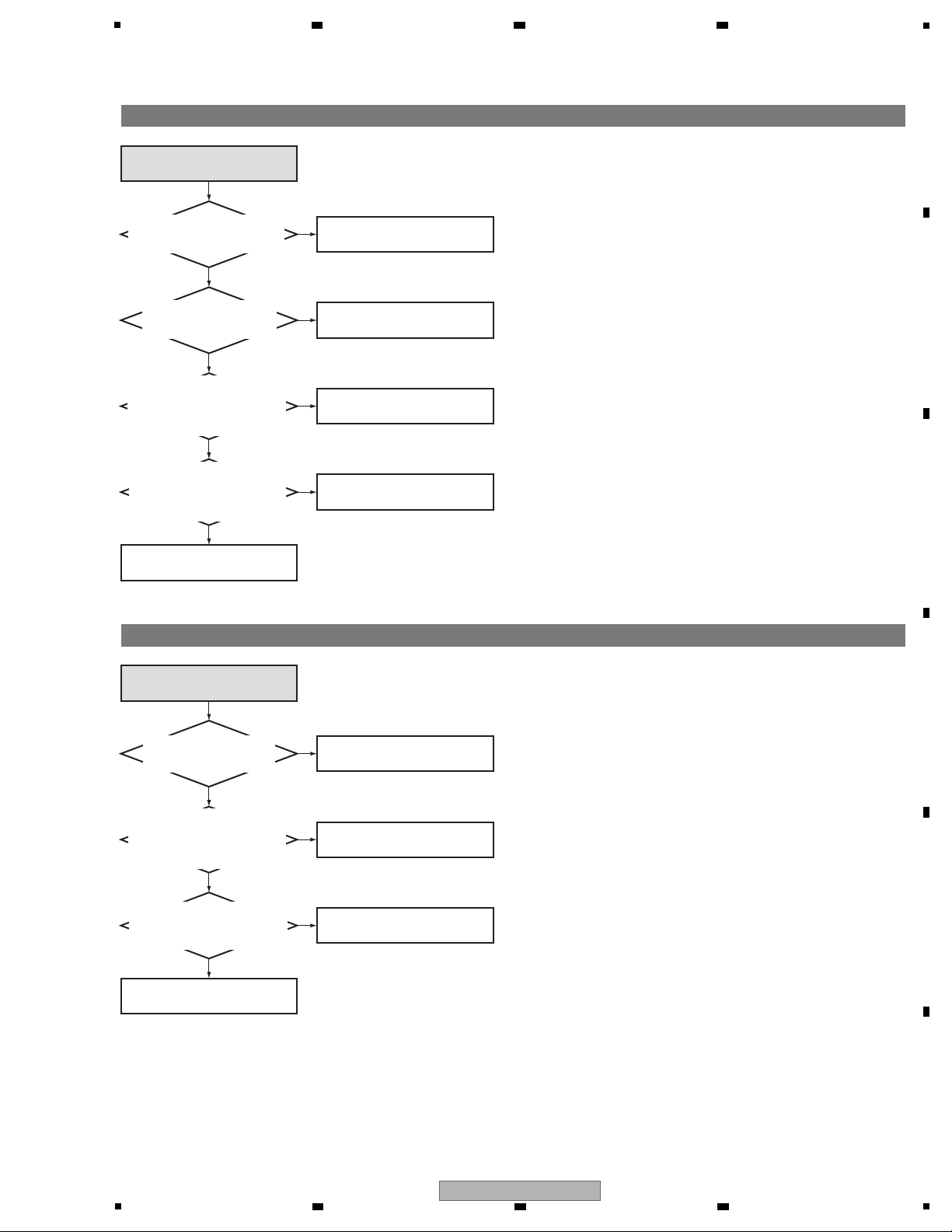

The buttons do not function.

Is the soldering at SW1 to SW6

on the FRONT CONTROL

BOARD Assy appropriate?

No

Ye s

The buttons do not function.

Repair inappropriate solder.

Is the soldering at U2 on

the FRONT CONTROL

BOARD Assy appropriate?

No

Ye s

Repair inappropriate solder.

Is the waveform of a signal from the

remote control unit observed at Pin 10

of XS1 on the FRONT CONTROL

BOARD Assy when any button on the

remote control unit is pressed?

No

Ye s

Replace the FRONT CONTROL

BOARD Assy.

Is the waveform of a signal from the

remote control unit observed at Pin 10

of XS1 on the FRONT CONTROL

BOARD Assy when the remote

control unit is used? (Waveform

1

)

No

Replace the FRONT CONTROL

BOARD Assy.

Is the waveform of a signal from the

remote control unit observed at Pin 10

of CN3003 on the MAIN BOARD Assy

when any button on the remote

control unit is pressed?

No

Ye s

Replace the RELAY BOARD Assy.

Replace the MAIN BOARD Assy.

Is the waveform of a signal from the

remote control unit observed at Pin 10

of CN3003 on the MAIN BOARD Assy

when the remote control unit is used?

No

Ye s

Replace the RELAY BOARD Assy.

Replace the MAIN BOARD Assy.

The remote control unit does not function.

Is the remaining battery

level of the remote control

unit enough?

No

Ye s

Ye s

The remote control unit does not

function.

Replace the battery of the remote

control unit with a new one.

6 7 8

A

B

C

D

5

BDP-LX58-K

6 7 8

E

F

15

1

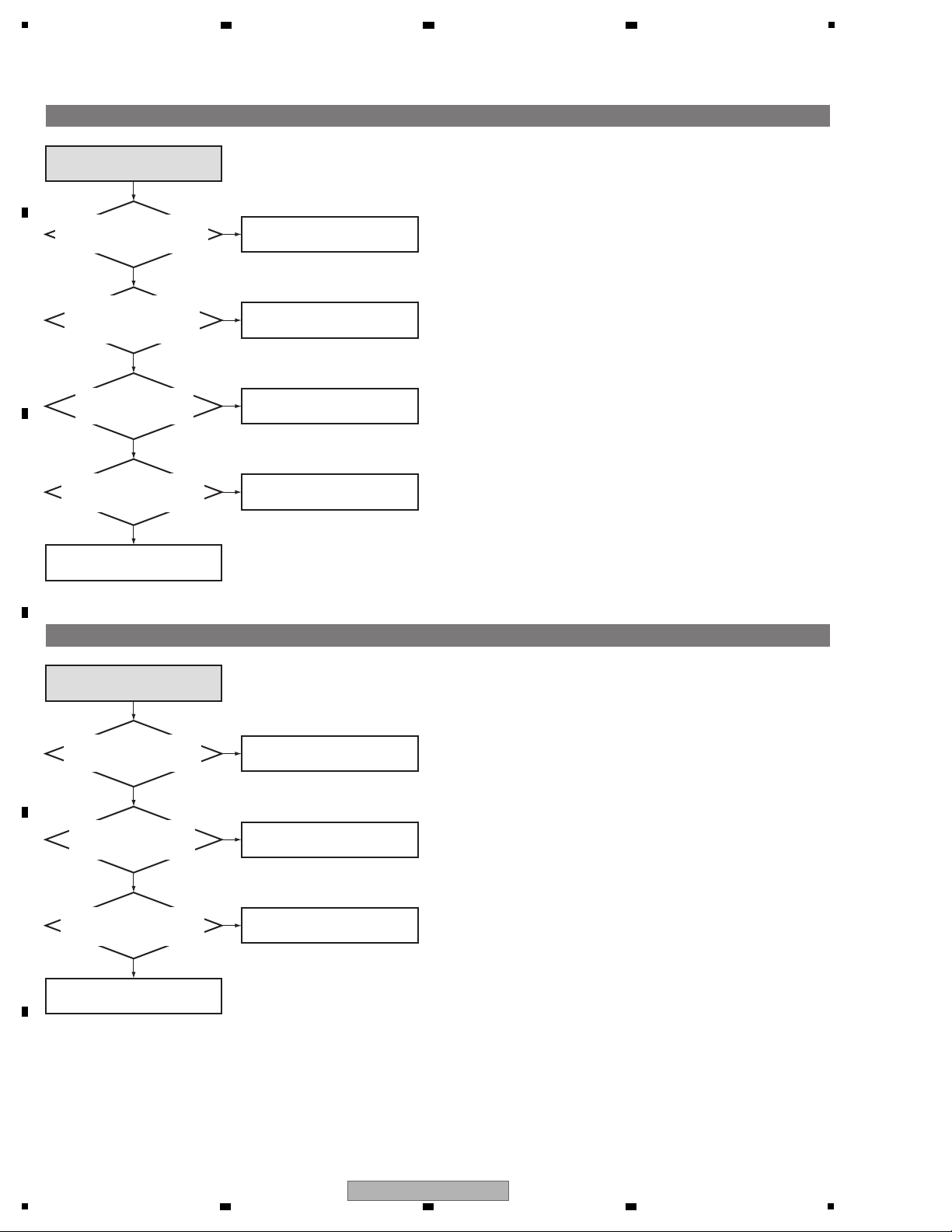

The disc tray does not open.

Are the cables from the

BD LOADER properly

connected to CN3004 on

the MAIN BOARD Assy?

No

Ye s

The disc tray does not open.

Properly connect the cables.

Is the soldering at IC3409

on the MAIN BOARD Assy

appropriate?

Is the soldering at IC3409

on the MAIN BOARD Assy

appropriate?

No

Ye s

Repair inappropriate solder.

Replace the BD LOADER.

Is the 45-pin FFC from the

BD LOADER properly

connected to CN3007 on

the MAIN BOARD Assy?

No

Ye s

Properly connect the cables.

Is the 9-pin FFC from the

BD LOADER properly

connected to CN3005 on

the MAIN BOARD Assy?

No

Ye s

Properly connect the cables.

No

Ye s

Repair inappropriate solder.

Is the voltage at Pin 4 of IC9103

on the MAIN BOARD Assy

8 V?

No

Ye s

Replace the MAIN BOARD Assy.

Replace the BD LOADER.

The unit does not recognize a disc.

The unit does not recognize a disc.

A

2 3 4

B

C

D

E

F

16

1

BDP-LX58-K

2 3 4

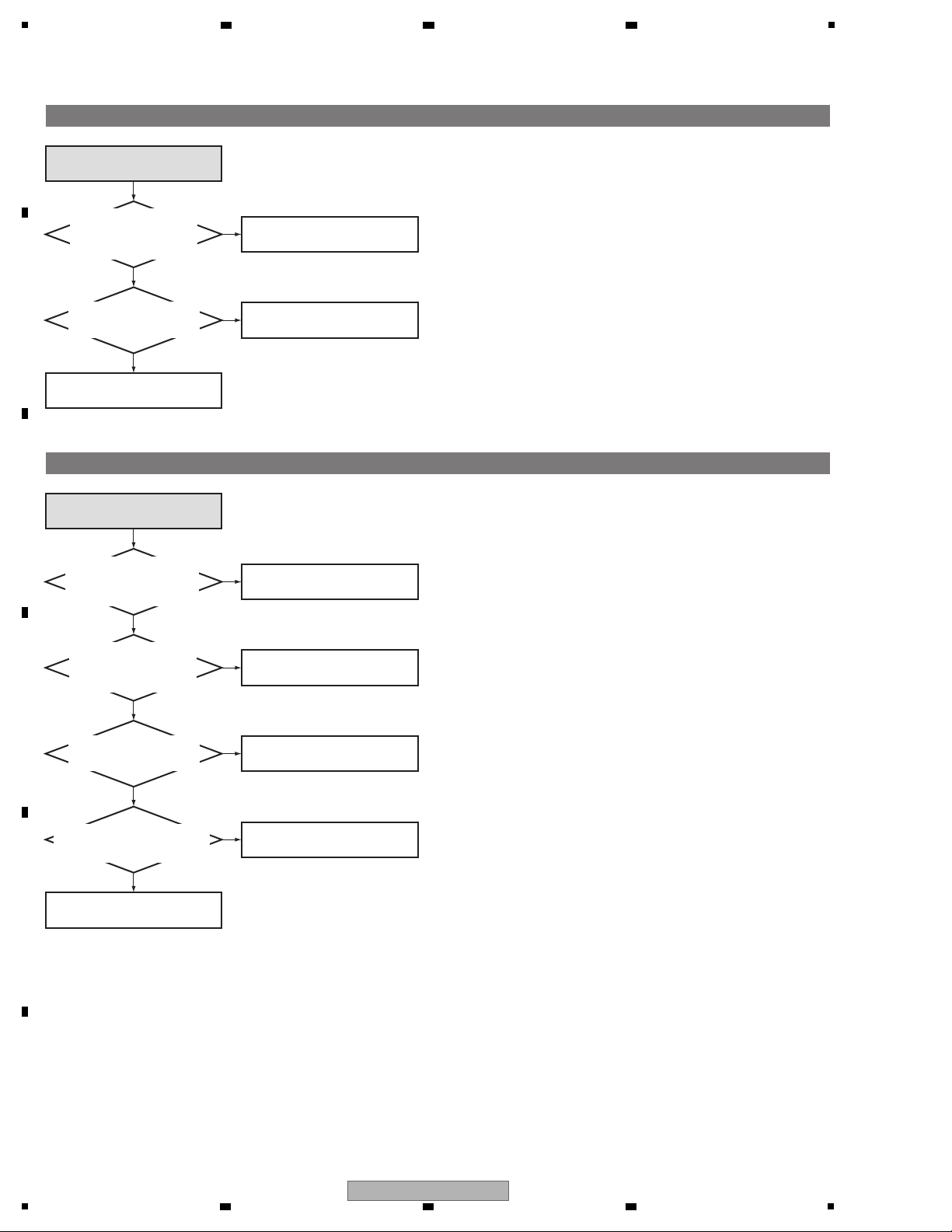

No HDMI output

Does the connected TV support

the output resolution of this unit?

No

Ye s

No HDMI output

Select an appropriate resolution,

using the Resolution Select button

on the remote control unit.

(AUTO recommended)

No digital (COAX) output

Is the digital output setting

enabled?

No

No digital (COAX) output

Select "Initial Setup," "Audio Output,"

then "Digital Output," in that order,

then select an option other than OFF.

Is the unit set to Direct OFF

mode?

Are the voltages at C9450 on

the MAIN BOARD Assy

1.2 V and at C9105 3.3 V?

Is a 27-MHz oscillation

signal output from X1602 on

the MAIN BOARD Assy?

(Waveforms

2, 3

)

Is the indication HDMI1 or HDMI2 on

the FL display lit when the HDMI cable

is connected to the corresponding

connector of the unit?

Is the soldering at IC1602, JA1601,

JA1603, L1609, L1610, L1611, L1612,

L1638, L1639, L1640, and L1641

on the MAIN BOARD Assy

appropriate?

No

No

Ye s

Ye s

Ye s

Set the unit to Direct OFF mode,

using the Direct button on the

remote control unit.

Replace the MAIN BOARD Assy.

Replace the MAIN BOARD Assy.

Replace the MAIN BOARD Assy.

Ye s

Is there an SPDIF signal

at R3004 on the

MAIN BOARD Assy?

(Waveform 5)

Ye s

Is there an SPDIF signal

at Pin 8 of IC3901 on the

MAIN BOARD Assy?

(Waveform 4)

Ye s

Ye s

No

Repair inappropriate solder.

No

Check the soldering at IC9527

and IC9403.

No

No

Check the soldering at IC3901.

No

Is there an SPDIF signal

at R3906 on the

MAIN BOARD Assy?

(Waveform 6)

Ye s

Ye s

Check the soldering at VL3901.

Check the soldering at JA3901.

No

Check the soldering at X1602.

5

6 7 8

A

B

C

5

BDP-LX58-K

6 7 8

D

E

F

17

1

The front USB connector does not function.

The front USB connector does not

function.

Is the soldering at P1

(USB terminal) on the SWITCH

BOARD Assy appropriate?

No

Properly connect the cables.

Is the connection between

the SWITCH BOARD Assy

and RELAY BOARD Assy

appropriate?

Ye s

Is the voltage at Pin 8

of IC3011 on the MAIN

BOARD Assy 5 V?

Ye s

No

Check the soldering at IC3011.

Repair inappropriate solder.

Repair inappropriate solder.

No

Is the soldering at R3477, R3478,

R3082, and R3083 on the MAIN

BOARD Assy appropriate?

Ye s

Ye s

No

Replace the MAIN BOARD Assy.

The rear USB connector does not function.

The rear USB connector does not

function.

Is the soldering at JA3002

(USB terminal) on the MAIN

BOARD Assy appropriate?

No

Ye s

Is the voltage at Pin 5 of

IC3011 on the MAIN

BOARD Assy 5 V?

Check the soldering at IC3011.

Repair inappropriate solder.

Repair inappropriate solder.

No

Is the soldering at R3475, R3476,

R3191, and R3192 on the

MAIN BOARD Assy appropriate?

Ye s

Ye s

No

Replace the MAIN BOARD Assy.

A

2 3 4

B

C

D

E

F

18

1

BDP-LX58-K

2 3 4

5

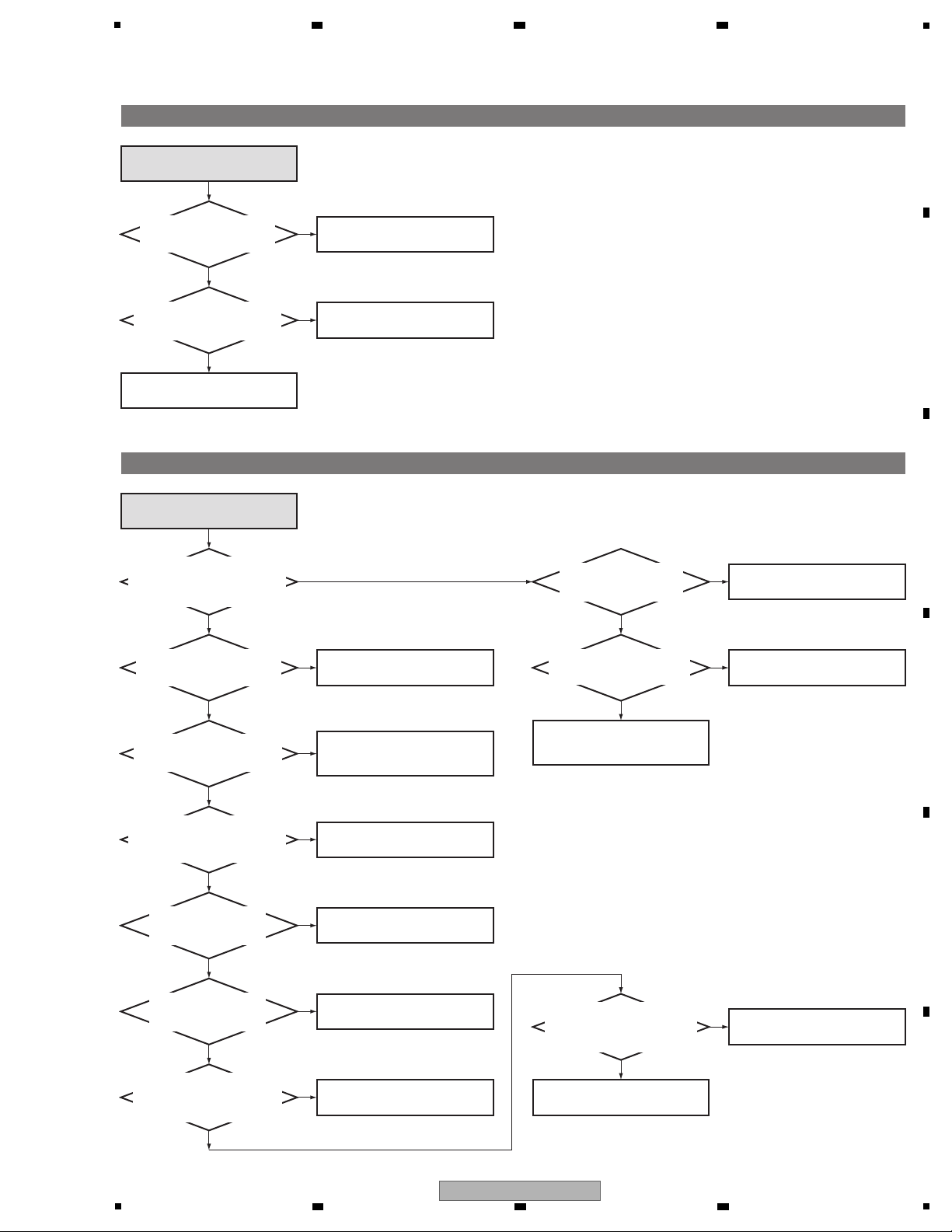

No analog audio output

No analog audio output

No

Ye s

Replace the MAIN BOARD Assy.

No

Ye s

Replace the POWER BOARD

Assy.

No

Ye s

Ye s

Check IC5001.

No

Ye s

Check IC5002.

No

Ye s

Ye s

Check IC5006, IC5005, IC5009,

IC5010 and IC5007.

Check IC5008 and IC5011.

(Waveforms

f, i

)

No

Ye s

Ye s

No

Ye s

No network connection through Ethernet

No network connection through

Ethernet

Is the soldering at JA3801

(LAN terminal) on the MAIN

BOARD Assy appropriate?

No

Ye s

Repair inappropriate solder.

Repair inappropriate solder.

Is the soldering at R3809 to R3812

and R3436 to R3439 on the MAIN

BOARD Assy appropriate?

Ye s

No

Replace the MAIN BOARD Assy.

Is the I2S signal at Pins 7, 9, 11,

and 13 of CN1506 on the MAIN

BOARD Assy normal?

(Waveforms

9, a, b

)

Is the I2S signal at

Pins 43 to 45 of IC5006 on the

MAIN BOARD Assy normal?

Is the I2S signal at R3005,

R3009, and R3010 on the

MAIN BOARD Assy normal?

Is the I2S signal at Pins 7, 9,

and 12 of CN1501 on the

MAIN BOARD Assy normal?

Check the soldering at IC1501.

No

Check the soldering at R1944,

R1945 and R1946 on the MAIN

BOARD Assy.

Is the AMUTE signal at Pin 2

of CN1506 on the MAIN

BOARD Assy H (5 V)?

Check IC1510 and IC1511.

No

Is an 80-MHz oscillation signal

output from Pin 3 of X5000

on the AUDIO BOARD Assy?

(Waveform c)

Check X5000 and R5090.

No

Is the voltage at C5041

on the AUDIO BOARD

Assy 1.2 V?

Is the voltage at C5037

on the AUDIO BOARD

Assy 3.3 V?

Is the voltage at Pins 1 and 2 of CN5001

on the AUDIO BOARD Assy 14 V?

Is the voltage at Pins 6 and 7 of CN5001

on the AUDIO BOARD Assy -14 V?

Check R5004, R5005, R5006,

R5060, R5061 and R5062 on the

AUDIO BOARD Assy.

Is there an analog audio signal

at Pins 1 and 7 of IC5005 and

IC5009 on the AUDIO BOARD Assy?

(Waveforms

d, e, g, h

)

6 7 8

A

B

C

D

5

BDP-LX58-K

6 7 8

E

F

19

1

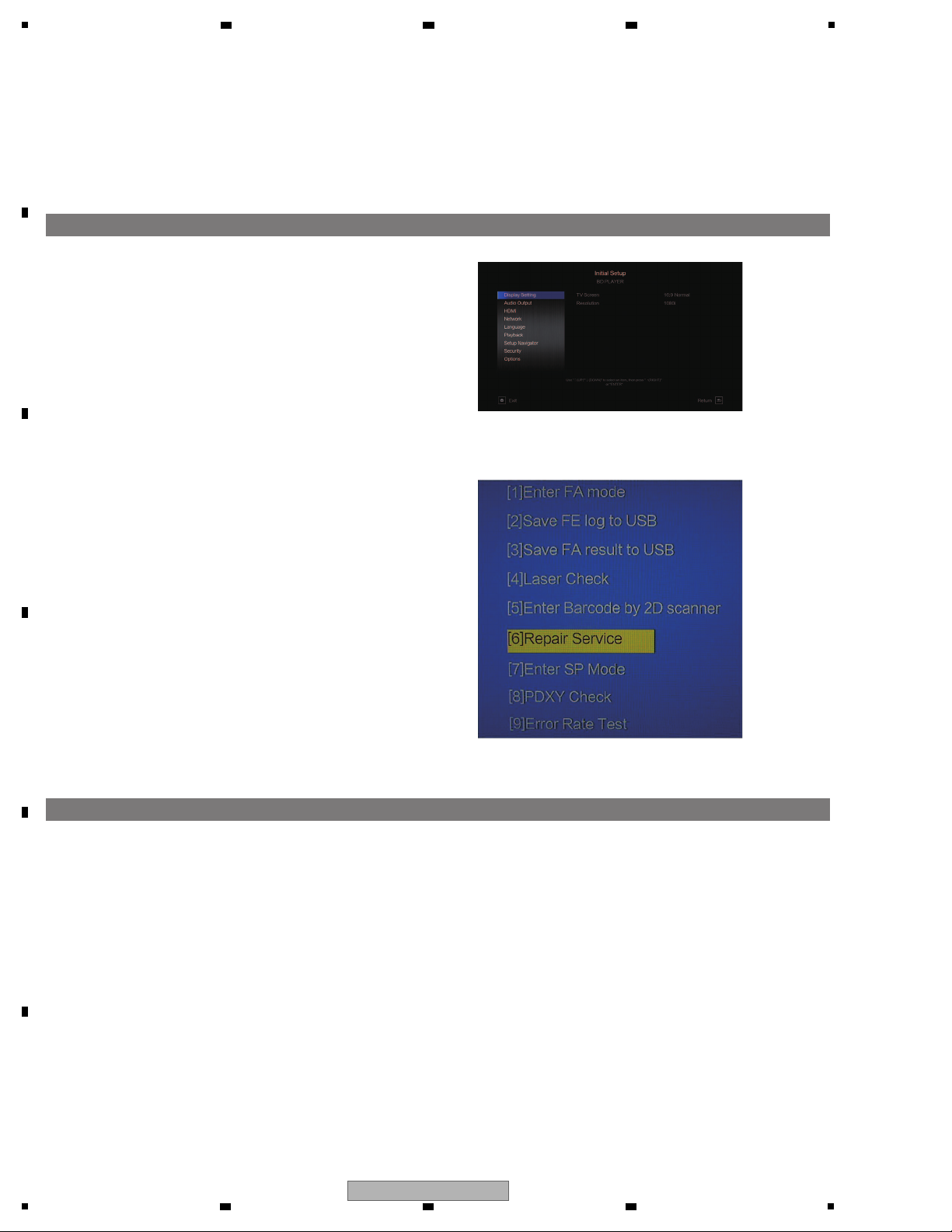

In Service Mode, there is a mixture of Design and Development, Production Line Menu and Service Menu.

Here, menu items that are usable in Service and instructions are listed.

Only use the menu explained in this document. Others are for Design and Product lines.

Each item of Service mode can be quit by pressing the [STOP] button. However, to check operations such as normal

playback, turn the unit OFF then back ON again.

1. HOW TO ENTER SERVICE MODE

2. DESCRIPTION OF EACH ITEM

1. Press [HOME MENU] button on the remote controller and

select "Initial Setup" from the home menu.

Note:

Be sure to set the display setting of the screen saver to "Off"

before entering Service mode, because the unit will

automatically quit Service mode once the screen saver is

displayed.

If this setting is changed during repair, be sure to restore to

the customer's original selection.

2. Pressing the number buttons on the remote control in the

following order [5] → [1] → [7] → [7] will display the Menu

screen.

(If it does not appear, slowly press the number keys with

a 1 second interval.)

[1] Enter FA mode

For the former model and will not be used to exchange this Loader.

[2] Save FE log to USB

For Design and Development purposes and cannot be used for Service.

[3] Save FA result to USB

For Design and Development purposes and cannot be used for Service.

[4] Laser Check

Verifies laser diode. Refer to "Laser Check" for details.

[5] Enter Barcode by 2D scanner

For Production line purposes and cannot be used for Service.

[6] Repair Service

Implemented when exchanging the BD LOADER and MAIN BOARD Assy.

Refer to "8.1 NECESSARY ITEMS FOR ADJUSTMENTS" for details.

[7]

Enter SP Mode

Mainly for Production Line, but some items can be used in Service. Please see "SP Mode" for details.

[8] PDXY Check

Verifies misalignment of optical axis. Refer to "PDXY Check" for details.

[9] Error Rate Test

Determine the error rate of the disc. Refer to "Error Rate Test" for details.

2 3 4

6. SERVICE MODE

6.1 SERVICE MODE

A

B

C

D

E

F

20

BDP-LX58-K

1

2 3 4

5

2. [7] Enter SP Mode

1 Select "[4] Laser Check" with the j button from the Service Mode screen and press the [ENTER] button.

(perform without disc in tray)

2

After a few seconds, measurement and judgment results will be displayed, as shown below.

If all measurement (Meas) values are 1/3 or greater or less than triple the target values (hex), [Pass] will be displayed.

If any of the measurement values is out of this range, [NG] will be displayed.

There are 17 items in the SP Mode, the main items being for Production line and Design/Development.

The following is to explain items usable in Service. Other items require time for completion, or are not suited for Service

purposes. If you select them by mistake, press the [STOP] button to end that item you accidentally selected.

(none of the items will affect the main unit)

1. [4] Laser Check

Example BD

Target: 0x01b

Meas: 0x01b OK

0x01b × 3 = 0x051 Meas is 0x051 or more : NG

0x01B × 1/3 = 0x009 Meas is 0x009 or less : NG

Verifies the output value of each laser diode inside the pick-up area. Implement according to the following procedures.

("0x" is simply to express the hex,

so it is not necessary in the calculation)

3. DETAILED DESCRIPTION OF ITEMS USED IN SERVICE

6 7 8

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

21

1

2-1. Start Up

[ Content of test ]

Implements initial movement of the disc servo continuously. Implement the following process 20,000 cycles.

2-2. Jitter Measure / BLER Measure

[ Content of test ]

Measures the Jitter or the Block Error Rate (BLER) of the disc inserted.

Only Pass or NG will be displayed, not Measurement values.

All of CD, DVD, and BD can be judged.

[ Instructions ]

1

Select "[7] Enter SP Mode" with the j button from the Service Mode screen, and press the [ENTER] button.

2

The SP Mode window menu will be displayed, so select either "Jitter Measure" "BLER Measure," and press the

[ENTER] button.

3

The tray will automatically open and the dedicated screen will appear. Place the disc you wish to use on the tray, and

push it in manually. ([Close] button will not function)

4

The tray will reopen automatically. Measurement will start when you push the tray in manually.

5

When test is completed, "Pass" or "NG" is displayed.

[ Effective indications ]

Defect related to playback (blocked noise, sound jumping, image jumping, disc is paused, freeze of screen etc.)

If an NG is generated in a specific disc only, the defect is likely to be caused by the disc. If an NG is generated in

other discs too, the defect is likely to be caused by the drive part.

However, even if Pass is displayed after this test, it is difficult to determine that the Driver is normal with these Pass

judgments only.

• Tray Close → • Foucus ON → • TOC Read → • Tray Open

(1 cycle 15 seconds x 20000=completed in approx. 83 hours 20 minutes)

Can be implemented on all of CD, DVD, and BD. Cannot change disc during process.

[ Instructions ]

1

Select "[7] Enter SP Mode" with the j button from the Service Mode screen, and press the [ENTER] button.

2

The SP Mode window menu will be displayed, so select "Start Up" and press the [ENTER] button.

3 The tray will automatically open and the dedicated screen will appear. Place the disc you wish to use on the tray, and

push it in manually. ([Close] button will not function)

4

Start Up mode will be initiated, and count will start. Implement 20,000 times (4E20 in hex), and if no errors occur,

"Pass" will appear.

If errors do occur, they will be counted. Therefore, errors can be identified without finishing the process.

[ Effective indications ]

Tray sometimes does not open, discs sometimes are not recognized, discs sometime do not playback,

(When indications are related to discs, implment on the type of disc which has been pointed out.

If it is the disc on which the indications occurred, possibility of reoccurrence is higher.)

A

2 3 4

B

C

D

E

F

22

1

2 3 4

BDP-LX58-K

5

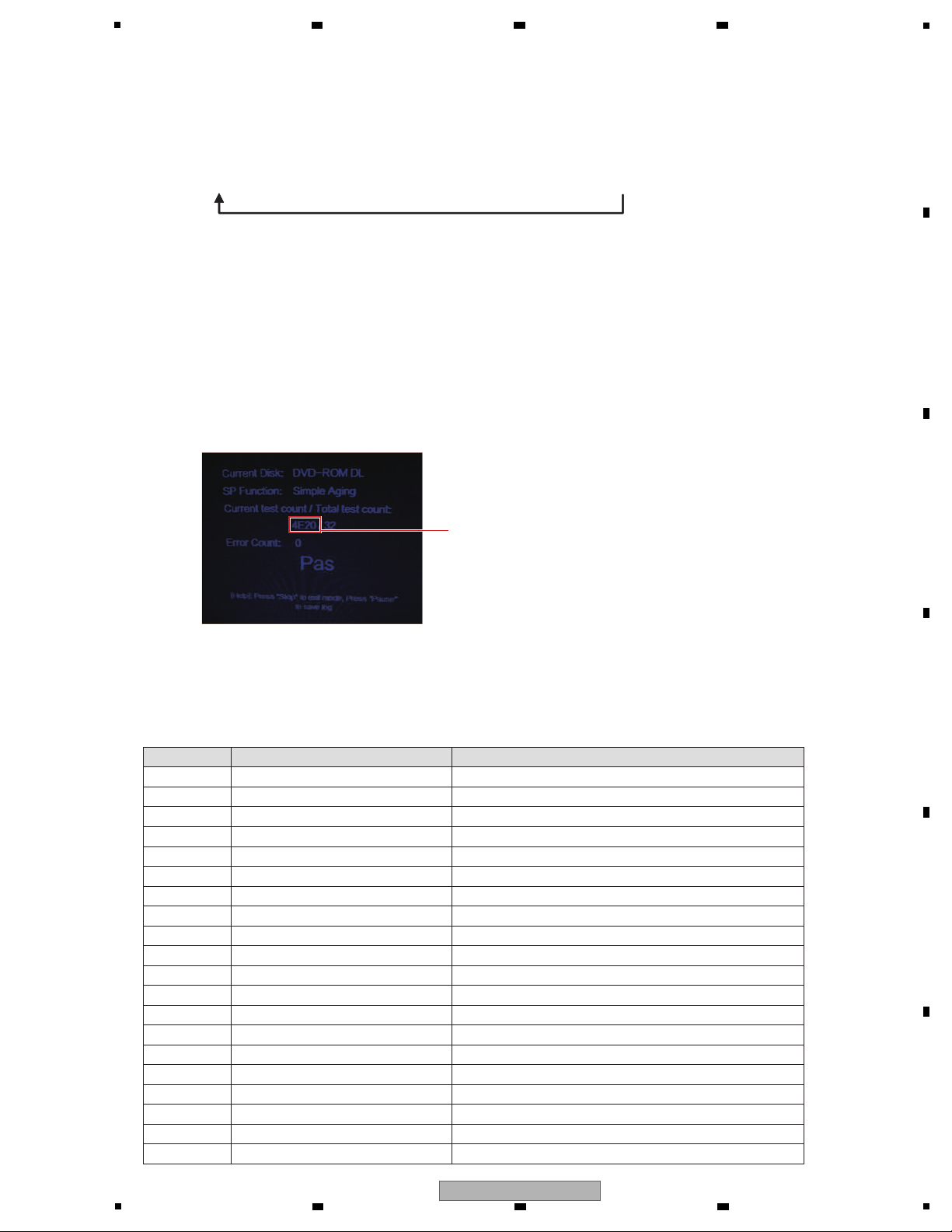

2-3. Simple Aging

[ Content of Test ]

[ Instructions ]

• Error List

Performs random playback of disc randomly. Implement the following process 400 cycles.

• Tray close → • 50 times of short playback on voluntary points → • Tray open

1cycle BD : 75 seconds x 400 times = Completed in a total of approx. 8 hours 20 minutes

DVD : Approx. 90 seconds x 400 times = Completed in a total of approx. 10 hours

CD : Approx. 95 seconds x 400 times = Completed in a total of approx. 10 hours 40 minutes

1 Select "[7] Enter SP Mode" with the j button from the Service Mode screen, and press the [ENTER] button.

2

The SP Mode window menu will be displayed, so select "Simple Aging" and press the [ENTER] button.

3

The tray will automatically open and the dedicated screen will appear. Place the disc you wish to use on the tray, and

push it in manually. ([Close] button will not function)

4

The tray will reopen automatically. Aging will start when you push the tray in manually.

5 After aging is successfully finished, the screen shown below will be displayed.

(The message "OK C3" will be displayed on the FL display.)

Note1: DVD and BD disc can be checked with Single Layer (SL) disc only.

If they are checked with Dual Layer (DL) disc, an Error is generated.

The following serves as the Error List generated in SP MODE.

Error Code Error Name Description

12 PWR_CURVE_ERROR Power curve chk-sum error

0x4E20 = 20000

(Fifty times of random playback multiplied by 400 cycles equals 20,000.)

22 STARTUP_TIMEOUT_ERROR Time-out criterion over

23 MEDIA_MISMATCH Wrong disc

25 DISCID_ERROR 0x25 Disc ID error

26 MEDIUM_SUPPORT_ERROR Unsupported disc

31 TRAYOUT_ERROR Tray-out time-out criterion over

32 TRAYIN_ERROR Tray-in time-out criterion over

33 FLASH_UPDATE_ERROR Updating FA result failed

36 OPU_TEMP_ERROR Abnormal OPU temperature

41 SEEK_TIMEOUT_ERROR Seek time-out criterion over

42 SEEK_CMD_FAIL_ERROR Seek command failed

51 READ_TOC_ERROR Read TOC command failed

52 TOC_TIMEOUT_ERROR TOC read time-out criterion over

61 PIPO_TIMEOUT_ERROR Time-out criterion over

62 PIPO_C1C2_ERROR Read PIPO command failed

63 PIPO_C1C2_OVER PIPO criterion over

71 RD_CMD_FAIL_ERROR Read command failed

72 RD_CMD_ERROR Command error or illegality mode

73 RD_TIME_OUT_ERROR Read command time-out criterion over

81 CHECK_FA_TABLE_ERROR FA table check-sum error

6 7 8

A

B

C

5

6 7 8

BDP-LX58-K

D

E

F

23

1

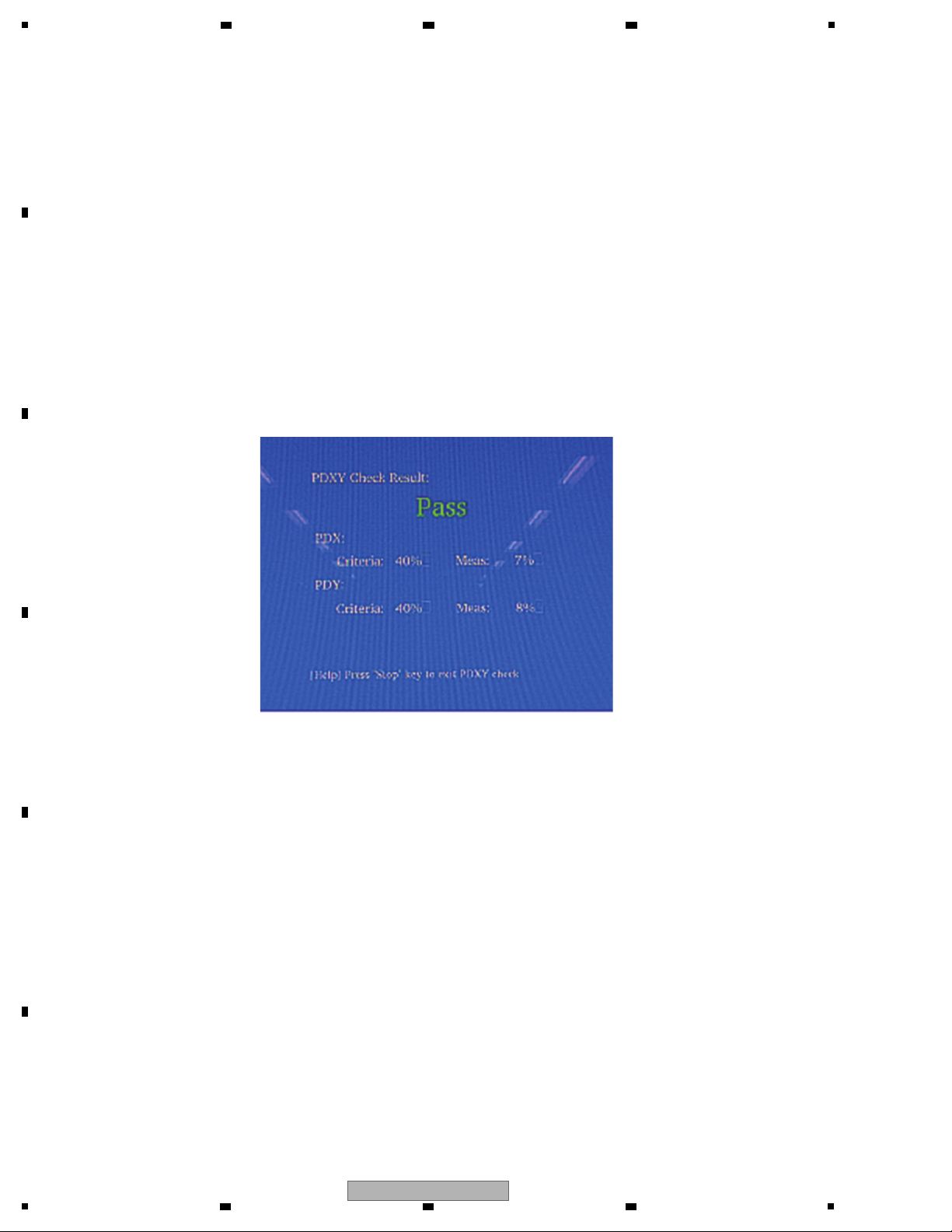

3. [8] PDXY Check

For PDXY Check, the misalignment of pick-up optical axis can be checked.

The optical axis misalignments of X-axis and Y-axis are displayed "PDX" and "PDY" with %, respectively.

All of CD, DVD, and BD can be measured.

The method for calculating PDX and PDY is shown below.

[ Instructions ]

1 Insert a disc (BD, DVD, CD) in a nomal mode. If the playback starts, pause it.

Display the home menu and enter into the Service Mode.

In this mode, the measurement can be carried out at an arbitrary place. After a disc is inserted, play and stop the

point you want to measure, and then enter into the Service Mode.

(The pickup position does not return even in this status. The measurement at the place is available.)

2 Select "[8] PDXY Check" with the

j

button from the Service Mode screen, and press the [ENTER] button.

3 After the measurement is started and completed, the measurement value is displayed. If the value is within the

reference value, "Pass" is displayed.

4 Quit Service mode by pressing the [STOP] button. (The home menu screen will be displayed.)

Note:

If you open the tray in this state then attempt to play a disc, the "Close" indication is displayed on the FL display and

playback will not start. To correct such a situation, turn the unit OFF then back ON again.

[Effective indications]

Defect related to playback (block noise, sound jumping, image jumping, disc is paused, freeze of screen etc.)

If an NG is generated in a specific disc only, the defect is likely to be caused by the disc. If an NG is generated in other

discs too, the defect is likely to be caused by the pickup part. If the measurement value is very close to 40% even if an NG

is not generated, the NG is likely to be caused by the disc.

PDX = ((A+B)-(C+D)) / (A+B+C+D)

PDY = ((A+D)-(B+C)) / (A+B+C+D)

A

2 3 4

B

C

D

E

F

24

1

2 3 4

BDP-LX58-K

5

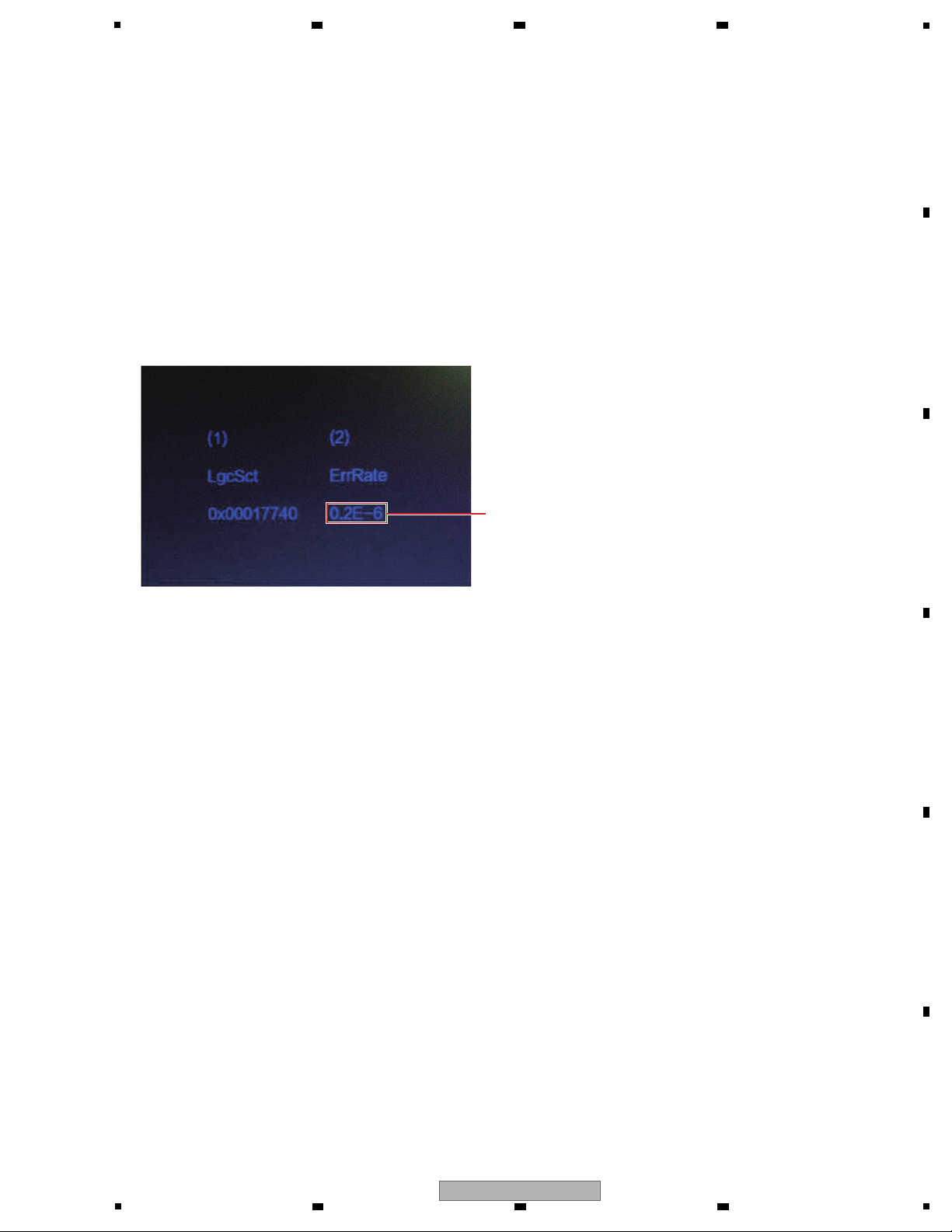

4. [9] Error Rate Test

[ Content of Test ]

With the Error Rate Test, the error rate for a DVD or BD disc can be measured.

However, for a dual-layer (DL) disc, the error rate for the second layer cannot be measured. For measurement of the error

rate of the second layer, use the necessary tools and application, referring to SKT13001B Service Knowhow manual.

[ Instructions ]

1 On the Service mode screen, select "[9] Error Rate Test," using the

j

button, then press the [ENTER] button.

2 The tray will automatically open then the Error Rate Measurement screen will be displayed. Place a disc whose error

rate is to be measured on the tray then manually push the tray in. (The [Close] button will not work.)

3 Measurement of the error rate will start.

4 After error-rate measurement is finished for the outermost track, measurement will be stopped then the tray will

automatically open.

(For a DL disc, measurement will be stopped after that for the outermost track of the first layer is finished then the tray

will automatically open.)

Note:

In Error Rate Measurement mode, if the AC power cord is unplugged with the tray open, the Error Rate Test will

automatically start and the normal operation screen will not be displayed after the AC power cord is plugged again and the

unit is turned ON.

In such a case, close the tray manually then press the [STOP] button to quit Error Rate Measurement mode.

(If the [STOP] button is pressed first, close the tray manually afterward to return to the Menu screen.)

5 Quit Service mode by pressing the [STOP] button.

(1) Physical address of the disc

(2) Error rate of the disc

The indication "x.xE-X" denotes the error rate.

Example: 3.5E-5 = 3.5 x 10

-5

6 7 8

A

B

C

D

BDP-LX58-K

5

6 7 8

E

F

25

A

[ Effective indications ]

Failure in the playback system (block noise, interrupted sound, jumpiness of images, playback stopped in mid-course,

frozen image, etc.)

Failure judgment of the pickup, by comparing the error rates before and after cleaning of the lens

Notes:

1. Even if the values surpass 1.0 x 10

-3

immediately after measurement starts, if they fall to be around the reference level

several tens of seconds after, the pickup is probably OK.

2. Even with a normal pickup, the values may surpass 1.0 x 10

-3

during short-time measurement (around 30 seconds),

depending on the disc to be measured.

3. In rare cases, "0.0E-0" may be displayed for a moment. This is not a problem of the pickup.

4. If the measured error rates of a particular disc frequently surpass the reference value, that disc may have a problem.

Compare the error-rate values of such a disc with those of another disc without any scratches or dirt for judgment.

The examples of measured error rates when a test disc (GGV1368) is used are shown in the table below.

(As there are more than a few variations in values across discs or BD players used, the results measured using the

GGV1368 will not be completely the same. Use these values just for reference.)

For error-rate measurement of an entire DL disc (including that of the second layer), it is recommended to measure the

error rate using a PC.

When a PC is used for measurement, measured error-rate values will be graphed, which makes this method suitable for

error-rate measurement of an entire DL disc.

(For details on measurement, refer to the SKH14001 manual.)

[OK/NG judgment]

Disc Reference value

BD 1.0 x 10

-3

LgcSct Error rate

0x0001FC80

DVD

4.72E-4

0X00020DC 0.6E-6

0X00021F00 0.1E-6

0X000227A0 0.3E-6

0X000238E0 0.1E-6

0X00025B60 0.6E-6

0X00026400 0.2E-6

0X00027540 0.4E-6

0X00028F20 0.0E-0

0X0002A060 9.9E-5

0X0002B1A0 3.62E-4

0X0002C2E0 0.3E-6

0X0002D860 1.1E-5

0X0002E9A0 0.5E-6

0X0002FAE0 0.6E-6

0X00030380 0.0E-0

0X000314C0 0.1E-6

0X00032600 0.1E-6

LgcSct Error rate

0X00032EA0

0.1E-6

0X00033FE0 0.2E-6

0X00035120 0.3E-6

0X00036260 0.0E-0

0X00036B00 0.4E-6

0X00037C40 1.4E-5

0X00038D80 0.3E-6

0X00039EC0 5.7E-5

0X0003A760 0.1E-6

0X0003B000 0.7E-6

0X0003C560 0.4E-6

0X0003CE00 1.3E-5

0X0003DF40 0.0E-0

0X0003F080 0.2E-6

0X000401C0 0.3E-6

0X00040A60 0.6E-6

0X00041BA0 0.0E-0

0X00042CE0 0.4E-6

1.0 x 10

-3

CD Error rate measurement not available

1

2 3 4

B

C

D

E

F

26

1

2 3 4

BDP-LX58-K

5

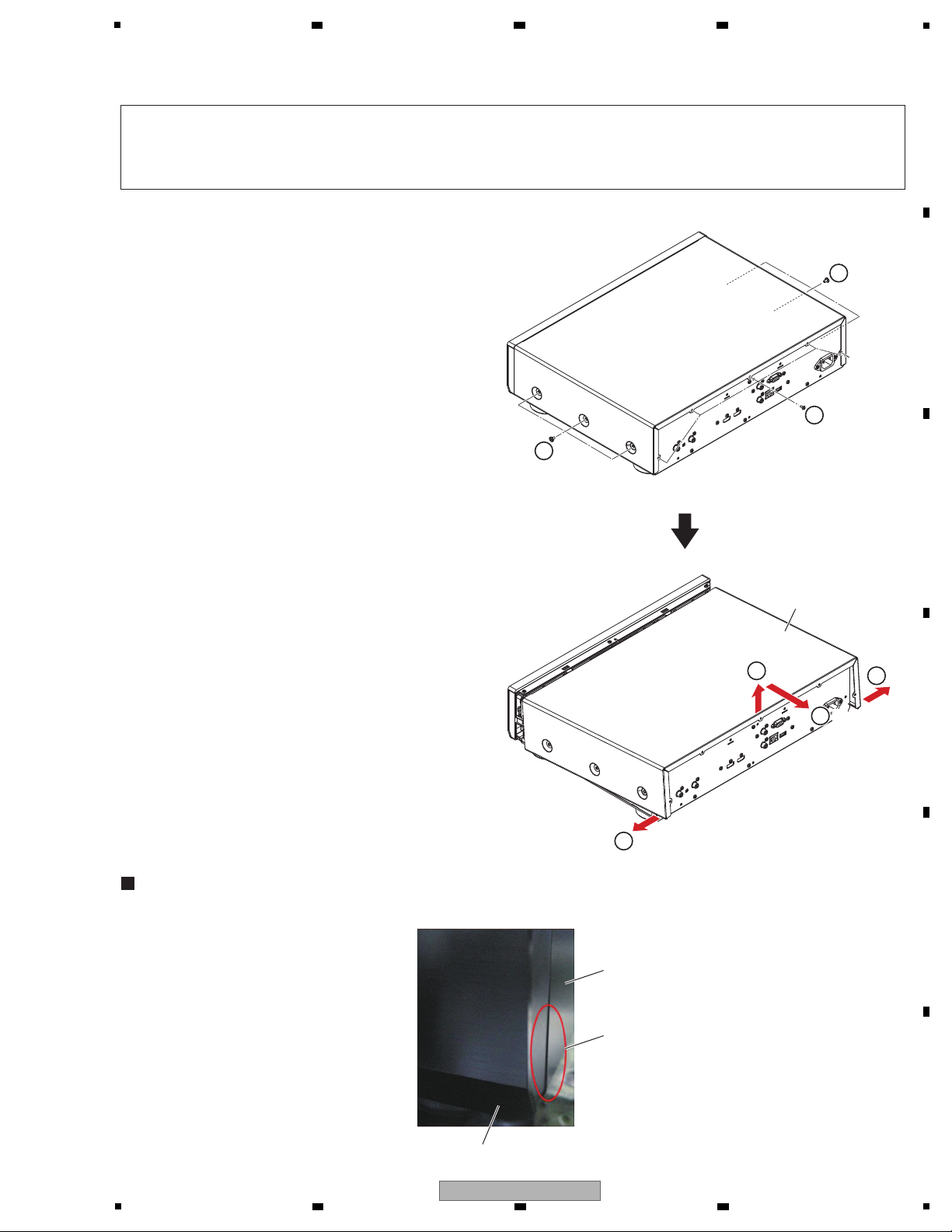

[1] Top cover

(1) Remove the 5 screws.

(IBZ30P060FCC)

(2) Remove the 6 HEX screws.

(Black model: 63-N40060-BF3)

(Silver model: 63-N40060-BF2)

(3) Separate the lower parts of both sides of the

top cover from the back chassis by wedging

your finger tips between them then lift the top

cover while spreading the lower parts of the

top cover. Then detach the top cover by pulling

it backward.

Note:

As the top cover is securely pressed into the front

panel, detaching it will require a strong pull.

When reattaching the top cover, be careful not to let it bulge beyond the level of the front panel.

1

-1

Top cover

NG: Top cover bulging out

Front panel (front, lower)

Top cover

• Rear view

• Rear view

×5

2

×3

2

3

-2

3

-3

3

-1

3

×3

Note on reassembly of the top cover

Note:

(1) Do NOT look directly into the pickup lens. The laser beam may cause eye injury.

(2) Even if the unit shown in the photos and illustrations in this manual may differ from your product, the

procedures described here are common.

6 7 8

7. DISASSEMBLY

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

27

1

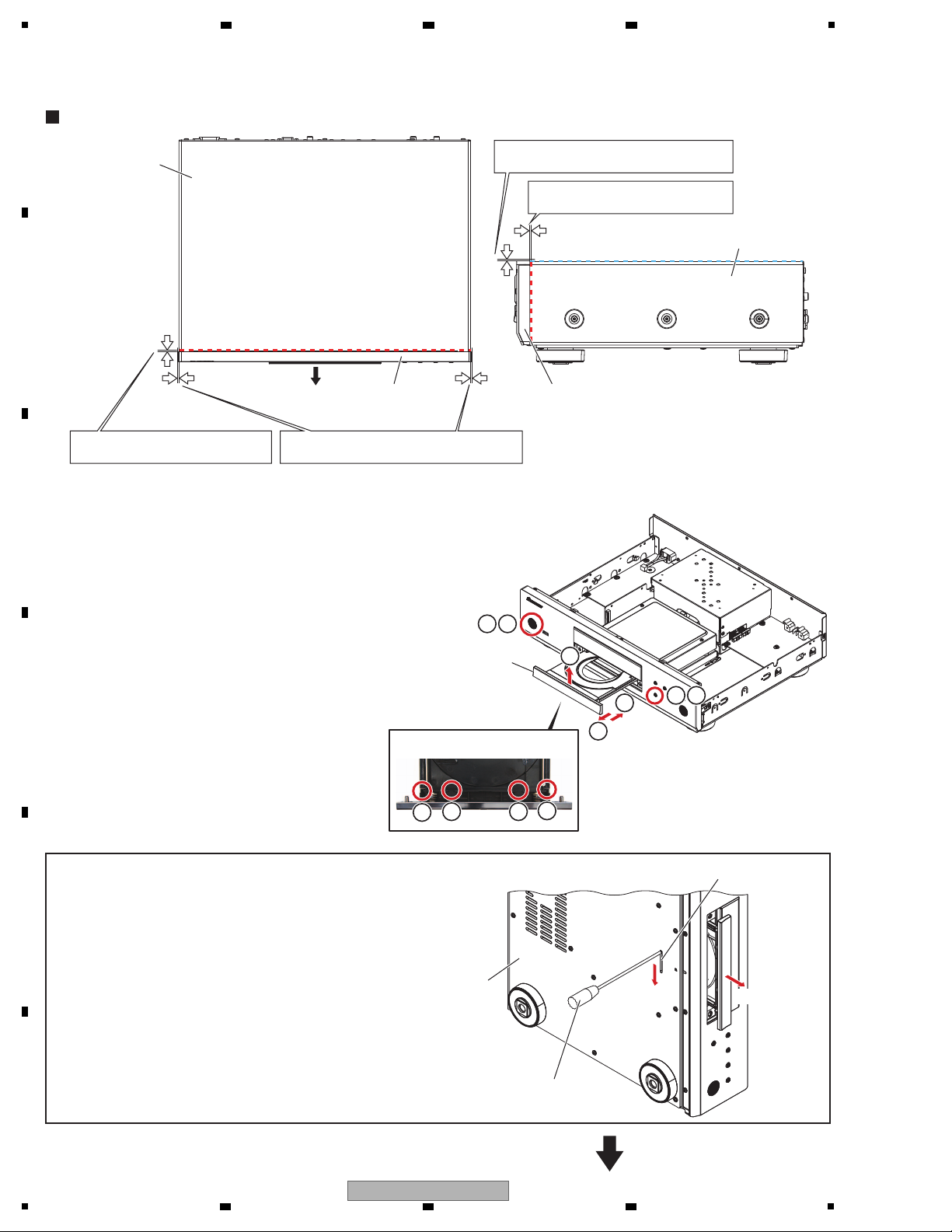

Clearance between the front panel

and the top cover: 0.2 mm or less

Guide of clearances and level differences during top cover reassembly

Clearance between the front panel

and the top cover: 0.2 mm or less

Downward level difference from the

Panel Base Assy to the bonnet: 0–0.5 mm

Downward level difference from the

Panel Base Assy to the bonnet: 0–0.5 mm

Front

Top cover

Top cover

Panel base Assy

• Side view

Panel base Assy

[2] Tray cap Section

(1) Press the u STANDBY/ON button to turn on

the power.

(2) Press the h button to open the tray.

(3) Remove the Tray cap section by removing

the 4 hooks.

(4) Press the h button to close the tray.

(5) Press the u STANDBY/ON button to turn off

the power.

1 5

3

3 3

3

3

224

4

Tray cap section

Screwdriver

(3 mm in dia. or less)

• Bottom view

• How to open the tray when the unit cannot be turned ON

Forced ejection hole

Bottom plate

Insert a screwdriver or tweezers of 3 mm or less

in dia. into the forced ejection hole on the bottom

plate then slide it in the direction of the arrow, as

indicated in the figure.

When the tray pops out a little, pull it manually.

Tray opens.

A

2 3 4

B

C

D

E

F

28

1

2 3 4

BDP-LX58-K

[3] BD LOADER

• D Main shield top

(1) Remove the 1 screw.

(IBZ30P060FCC)

(2) Remove the 3 screws.

(BBZ30P080FTB)

(3) Remove the 1 rivet.

• BD LOADER

(1) Disconnect the 2 flexible cables and 1

connector.

(CN3004, 3005, 3007)

(2) Remove the 4 screws.

(BBZ30P080FTB)

(3) Remove the 2 rivets.

(4) Remove the Mecha shield top.

Mecha shield top

4

(4) Remove the D Main shield top.

MAIN BOARD Assy

BD LOADER

2

2

2

2

33

Front side

1

1

1

CN3007

CN3005

CN3004

• Remove the Top cover.

(See "[1] Top cover".)

• Remove the Tray cap section.

(See "[2] Tray cap section".)

D Main shield top

4

1

2 2

2

3

• Rear view

Front side

Front side

5

6 7 8

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

29

1

Side cushion F

Side cushion F

Side cushion R

Side cushion R

5

5

(5) Remove the 2 Side cushion F and

2 Side cushion R.

• Dressing Cables of the BD LOADER Assy

Mecha sheild top

1

1 Dress the cables of the 4P connector Assy so that they are located as far as possible from the FFC.

2 Be careful that the 4P connector Assy and FFC are not pinched by the Mechanical Shield top.

2

Bend the cables around the edge of the FFC spacer.

Fit the cables into the gap between the BD LOADER

and the Mecha shield bottom.

After replacing the BD LOADER, fit the cables of the

4P connector Assy into the gap between the BD LOADER

and the Mecha shield bottom, as shown in the photo above,

then dress the cables so that they are bent around the

edge of the FFC spacer.

After the BD LOADER is detached for replacement,

reattach the BD LOADER so that the FFC spacer can

be seen.

FFC spacer

A

2 3 4

B

C

D

E

F

30

BDP-LX58-K

1

2 3 4

Lens Cleaning and Replacement of the Rubber Belt

(1) Remove the 4 screws.

Front side

11

1

1

(7) Remove the BD LOADER.

7

BD LOADER

Top cover

(6) Remove the 4 screws.

(BBZ30P080FTB)

6

6

6

6

BD LOADER

5

6 7 8

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

31

1

Pickup lens

Top cover Top cover

Front side

(4) Unhook the hooks on the rear of the BD

LOADER, using a screwdriver or similar tool.

(Unhooking is not possible when the entire

surface of the rear-rubber tape is glued.)

(5) Unhook the two hooks, one on each side of

the BD LOADER, in the same manner then

remove the top cover.

(6) Cleaning of the pickup lens becomes possible

in this state.

4 4

55

• Rear view

Front side

Clean the pickup lenses when it is stained, using

the following cleaning materials:

Cleaning liquid : GEM1004

Cleaning paper: GED-008

(2) Peel off only the upper parts of the two

side-rubber tapes, one on each side of the

BD LOADER. (Don't peel off the entire

surface of a side-rubber tape. Only peel off

the parts that are glued to the top cover of the

BD LOADER.)

(3) Peel off only the upper part of the rear-rubber

tape that is glued to the rear of the BD LOADER.

Front side

2 2

3

Side rubber Side rubber

Rear rubber

• Rear view

A

2 3 4

B

C

D

E

F

32

BDP-LX58-K

1

2 3 4

5

(3) Remove the 2 screws.

(64-T30040-103)

(4) Remove the 1 screw.

(BBZ30P080FTB)

• Rear view

343

• Cable dressing between the FRONT CONTROL BOARD Assy/SWITCH BOARD Assy and the RELAY BOARD Assy

RELAY BOARD

Assy

FRONT CONTROL BOARD Assy,

SWITCH BOARD Assy

• The cables must not touch metallic parts.

• Secure sufficient distances between the cables

and metallic parts.

[4] RELAY and MAIN BOARD Assemblies

(1) Remove the 2 rivets.

(2) Remove the RELAY BOARD Assy by

disconnect the 3 connectors, 1 BtoB connector.

(XP1 to 4)

RELAY BOARD Assy

XP1

XP2

XP3

XP4

×3

1 1

2

2

• Remove the Top cover.

(See "[1] Top cover".)

• Remove the D Main shield top.

(See "[3] BD LOADER".)

Rubber belt

7

(7) Remove the tray to change the rubber belt.

(As the tray has no holddown in this state, it

can be pulled upward. When returning the tray

back, place it without changing the Loader

position.)

6 7 8

A

B

C

D

BDP-LX58-K

5

6 7 8

E

F

33

1

• POWER BOARD Assy

(1) Disconnect the 2 bridge connectors and

1 connector.

(CN501, 5000, 5001)

(2) Remove the 1 screw.

(64-W30060-105)

(3) Remove the POWER BOARD Assy by removing

the 5 screws.

(IBZ30P060FCC)

POWER BOARD Assy

2

3

3 3

3

3

×2

1

1

CN1509

CN1505

CN501

[5] AUDIO and POWER BOARD Assemblies

• AUDIO BOARD Assy

(1) Remove the 1 screw.

(IBZ30P060FCC)

(2) Remove the 2 screws.

(BBZ30P080FTB)

(3) Disconnect the 2 bridge connectors.

(CN5000, 5001)

(4) Remove the 1 screw.

(64-W30060-105)

(5) Remove the AUDIO BOARD Assy by removing

the 4 screws.

(IBZ30P060FCC)

AUDIO BOARD Assy

• Rear view

1

2 2

×2

3

CN5000

CN5001

4

5

5

5

5

• Remove the Top cover.

(See "[1] Top cover".)

• Remove the D Main shield top.

(See "[3] BD LOADER".)

(5) Disconnect the 4 bridge connectors, 3 flexible

cables and 1 connector.

(CN1505, 1509, 3004, 3005, 3007, 3023,

5000, 5001)

(6) Remove the MAIN BOARD Assy by removing

the 5 screws.

(IBZ30P060FCC)

AUDIO BOARD AssyPOWER BOARD Assy

MAIN BOARD AssyRS BOARD Assy

×3

6 6

6

6

6

5

×2

5

×2

5

5

CN3007

CN5000

CN5001

CN3023

CN1509

CN1505

CN3005

CN3004

A

2 3 4

B

C

D

E

F

34

1

BDP-LX58-K

2 3 4

5

[6] Front panel Section

(2) Disconnect the 3 connectors.

(CN501, 5000, 5001)

(3) Remove the Front panel Section.

(1) Remove the 6 screws.

(Black model: BBZ30P080FTB)

(Silver model: BBZ30P080FNI)

• Bottom view

1

1

1 1 1

1

3

Front panel Section

RELAY BOARD Assy

XP2

XP3

XP4

×3

2

• Remove the Top cover.

(See "[1] Top cover".)

• Remove the Tray cap section.

(See "[2] Tray cap section".)

• Note on replacement of the AC inlet (on the Power Connection Assy)

Turn the AC inlet clockwise 360° to twist

the cables.

6 7 8

A

B

C

D

E

BDP-LX58-K

5

6 7 8

F

35

1

[How to read and write the barcode data to the unit]

In addition to the two conventional methods of reading/writing barcode data, a new method using a USB memory device has been added.

It is recommended to use the new method if you have a USB memory device, because with this method setting is easier and input errors

will be less likely to be generated.

For details on the conventional methods (with the aid of the remote control unit or a combination of a PC and a special tool for servicing),

refer to the Service Manual of the BDP-160.

Please perform either method when replacing MAIN BOARD Assy or BD LOADER.

USB memory device (one that can be

recognized in Normal Operation mode)

3 It is easy to read and write the barcode data. It is necessary to prepare a USB memory device.

Note:

• Change the Destination setting after MAIN BOARD Assy is replaced. After that, update the latest firmware.

• Please confirm that the USB memory device is recognized after inserting the USB memory device to the USB port.

(Due to protect wrong connection)

Note: Be sure to update the firmware before starting adjustments or settings.

——————————

This time Adjustment Points

Adjustment Points

[1] When replace the BD LOADER

Mechanical

point

Write barcode data for pickup adjustment

Electric

point

When replace

the BD LOADER

——————————

This time

[2] When replace the MAIN BOARD Assy

Mechanical

point

• Read out barcode data for pickup adjustment

(Before replacing MAIN BOARD Assy)

• Write barcode data for pickup adjustment

(After replacing MAIN BOARD Assy)

Electric

point

When replace

the MAIN BOARD Assy

[About barcode data for pickup adjustment]

A new BD LOADER is installed in this model and it has 64 bit barcode data for pickup adjustment.

Therefore when replacing a new BD LOADER, it is necessary to write barcode data of the new BD LOADER.

The barcode data is stored in a MAIN BOARD Assy. Therefore when replacing the MAIN BOARD Assy, it is necessary to

read out the original barcode data before replacing it and write the data to a new MAIN BOARD Assy after installing it.

Necessary tools Good Point Bad Point

Remote control unit1 It is not necessary to prepare other tools such as

Service jig and PC.

Need to enter 64 letters barcode data by using

a Remote control unit.

Service jig (GGF1676), PC,

Driver and Read/Write program

2 It is very easy to read and write the barcode data. It is necessary to prepare other tools such as

Service jig and PC.

(But Service Jig is very cheap.)

[Attention point when replacing MAIN BOARD Assy]

When the unit is no power condition due to defective of a MAIN BOARD Assy, original barcode data is not able to read

out from it. In such a case, read out the data of the barcode label attached to the BD LOADER, referring to the SKH15002

Service Knowhow manual.

2 3 4

8. EACH SETTING AND ADJUSTMENT

8.1 NECESSARY ITEMS FOR ADJUSTMENTS

A

B

C

D

E

F

36

BDP-LX58-K

1

2 3 4

5

The procedure for firmware updating is described below.

1. Before performing updating, check the version of the current firmware installed in the unit.

To display the current firmware version, press the [HOME MENU] button to enter the menu, select "Home Menu,"

"Initial Setup," "Options," "System Information," then "Next Screen," using the i/j/k/l buttons, then press the [ENTER]

button.

The firmware version for the AVX controller will be displayed at the same time for the BDP-LX58/BDP-LX88.

2. Download the DLdiscidentifier.txt, DVD.bin, AVX15I_xxxx.FW, and BDP-LX88_Vxx.xx.bin updater files from the Web site to

store them in the root directory of the USB memory device plugged into the PC.

Note: The same updater files are used for the BDP-LX58 and BDP-LX88.

3. After storage is completed, unplug the USB memory device from the PC then plug it into the unit. While a message that

a USB memory device is connected is displayed on the screen, press the [HOME MENU] button to enter the menu, then

select "Home Menu," "Initial Setup," "Options," "Update," then "USB Storage."

After you press the [ENTER] button, the system will search for the updater files. After the updater files are found, press the

[ENTER] button again to start updating.

Note: As the updating process of the AVX Controller is skipped when no updating is required for it, the time required for

updating varies greatly, as follows:

Time required for normal updating: 13 to 20 min.

Time required without updating of the AVX Controller: 30 sec. to 1 min.

4. After updating is completed, the unit will automatically restart.

Be sure to confirm the firmware version after restart. Updating is completed when the firmware version has been updated to

the appropriate one.

If the firmware version is not updated to the appropriate one, check the updater files then perform the updating procedure again.

Not to be used

DSP version

Note: As no DSP is mounted in the BDP-LX58, "###" will be displayed in this place.

Event Controller version

AVX Controller version

1. Plug a USB memory device into this unit in Normal mode.

(Make sure that the USB memory device is recognized.)

2. Enter Service mode.

(See "HOW TO ENTER SERVICE MODE .")

3. Select "[6] Repair Service" then press the [ENTER] button.

4. Select "Readout 480 2D barcode to USB memory"

then press the [ENTER] button.

5. The message "OK" will be displayed on the screen when

copying of the barcode data to the USB memory device

is finished.

At that moment, a "2D_barcode_data.txt" file, in which

64-bit barcode data have been written, is stored in the

USB memory device.

6. Quit Service mode by pressing the [STOP] button.

6 7 8

8.2 UPDATING OF THE FIRMWARE

A

B

8.3 HOW TO READ OUT BARCODE DATA USING A USB MEMORY DEVICE

C

D

E

5

6 7 8

BDP-LX58-K

F

37

1

• If the BD LOADER is replaced, follow the procedure from

Step 1 below.

• If the MAIN BOARD Assy is replaced, follow the procedure

from Step 5 below.

1. Open Notepad from Accessories on your PC.

Plug the USB memory device into the PC.

2. Type the 64-digit barcode that is attached to the back of

the BD LOADER for service into a Notepad file.

(Be careful of input errors, because the barcode data are

adjustment data for the new part.)

3. Store the Notepad file as "2D_barcode_data.txt " in the

root directory of the USB memory device.

After storage, remove the USB memory device from the

PC.

4. Plug the USB memory device in which the

"2D_barcode_data.txt" file is stored into the BDP unit

whose BD LOADER has been replaced.

(Make sure that the USB memory device is recognized.)

5. Enter Service mode.

(See "HOW TO ENTER SERVICE MODE.")

6. Select "[6] Repair Service" then press the [ENTER] button.

7. Select "Write 2D barcode from USB memory" then press

the [ENTER] button.

8. The message "OK" will be displayed on the screen when

copying of the barcode data from the USB memory device

is finished.

9. Quit Service mode by pressing the [STOP] button.

Note:

To prevent a future possible writing error, delete the

"2D_barcode_data.txt" file from the USB memory device on

the PC.

• If the MAIN BOARD Assy is replaced, the procedure is

completed at Step 9.

• If the BD LO

ADER is replaced, continue the remaining

Steps below.

10. Enter Service mode again.

11. Select "[6] Repair Service" then press the [ENTER]

button.

12. Select "Show 480 2D barcode" then press the

[ENTER] button.

13. Check that the 64-digit barcode being displayed is the

same as that attached to the BD LOADER.

If the barcode is not the same, perform the procedure

from Step 1 again.

2 3 4

8.4 HOW TO WRITE BARCODE DATA USING A USB MEMORY DEVICE

A

B

C

D

E

F

38

1

2 3 4

BDP-LX58-K

5

6 7 8

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

39

1

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

Screws adjacent to b mark on product are used for disassembly.

-

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

AAA 700 size manganese batteries

YXE8, AXQ5

only

or or

FXE

only

2 3 4

9. EXPLODED VIEWS AND PARTS LIST

A

9.1 PACKING SECTION

B

C

D

E

F

40

1

2 3 4

BDP-LX58-K

5

6 7 8

(1) PACKING SECTION PARTS LIST

Mark No. Description Part No.

1 1..Remote Control See Contrast table (2)

2 2..Battery Cover AZN8047

> 3 Power Cord See Contrast table (2)

4 Software License Notice See Contrast table (2)

5 Operating Instructions See Contrast table (2)

6 Operating Instructions See Contrast table (2)

7 Operating Instructions See Contrast table (2)

8 Operating Instructions See Contrast table (2)

9 Software Update Notice See Contrast table (2)

10 One Blue Label 71-BLURAY-EXTB1

A

NSP 11 Warranty Card See Contrast table (2)

12 Poly Bag See Contrast table (2)

13 Pad R 75-LX58R1-EA0

14 Pad L 75-LX58L1-EA0

15 Packing Sheet 74-150085-50GB1

16 Packing Case See Contrast table (2)

NSP 17 Corrugated Board 76-184810-0AP

18 Taiwan Label See Contrast table (2)

(2) CONTRAST TABLE

BDP-LX58-K/YXE8, BDP-LX58-S/YXE8, BDP-LX58/LXE, FXE and AXQ5 are constructed the same except for the following:

Mark No. Symbol and Description

1 Remote Control VXX3392 VXX3392 VXX3392 VXX3392 VXX3393

> 3 Power Cord ADG7123 ADG7123 ADG7123 ADG7120 ADG7122

4 Software License Notice 70-PONEER-LCSB4 70-PONEER-LCSB4 70-PONEER-LCSB4 70-PONEER-LCSB4 70-PONEER-LCSB5

5 Operating Instructions (En) 72-BDPL88-GBRB1 72-BDPL88-GBRB1 72-BDPL88-GBRB1 Not used Not used

6

Operating Instructions

(Fr, De, It, Nl, Es)

7 Operating Instructions (Zhtw) Not used Not used 72-BDPL58-TWNB1 72-BDPL58-TWNB1 Not used

8 Operating Instructions (Zhcn) Not used Not used Not used Not used 72-BDPL58-CHNB1

9 Software Update Notice 70-BDPX58-SHTB2 70-BDPX58-SHTB2 70-BDPX58-SHTB2 70-BDPX58-SHTB2 70-BDPX58-SHTB1

NSP 11 Warranty Card 70-PIONBD-WARD4 70-PIONBD-WARD4 Not used Not used 70-BDPL58-WARB2

12 Poly Bag 74-024035-50CD2 74-024035-50CD2 74-024035-50CD2 74-024035-50CD2 74-024035-50CD3

BDP-LX58-K

/YXE8

72-BDPL88-EURB1 72-BDPL88-EURB1 Not used Not used Not used

BDP-LX58-S

/YXE8

BDP-LX58

/LXE

BDP-LX58

/FXE

BDP-LX58

/AXQ5

B

C

D

18 Taiwan Label Not used Not used Not used 71-BDPL88-FXEB1 Not used

BDP-LX58-K

5

6 7 8

E

F

41

1

D

F

E

a

c

b

C

D

F

E

A

C

B

c

Cable tie

Refer to

“9.3 BD LOADER SECTION”.

9.2 EXTERIOR SECTION

A

B

2 3 4

C

D

E

F

42

1

BDP-LX58-K

2 3 4

5

D

F

C

G

G

H

I

I

H

B

A

E

a

b

K

K

J

J

L

L

CONTACT SIDE

NON-CONTACT

SIDE

A

B

G

H

I

A

C

B

.

6 7 8

A

B

C

D

E

F

BDP-LX58-K

5

6 7 8

43

1

2 3 4

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No.

1 MAIN BOARD Assy See Contrast table (2)

A

2 AUDIO BOARD Assy 08-BDLX58-AD1

FRONT CONTROL BOARD Assy

3

08-BDLX58-FV0