Pioneer BDP-160, BDP-160-K, BDP-160-S Service Manual

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

2013

BDP-160-K

Blu-ray 3DTM PLAYER

BDP-160-K

BDP-160-S

BDP-160

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

ORDER NO.

RRV4456

Model Type Power Requirement

BDP-160-K YXE8 AC 110 V to 240 V 2 B &&&&######YY YY : Europe

BDP-160-K VXE8 AC 110 V to 240 V 2 B &&&&######GB GB : U.K

BDP-160-S YXE8 AC 110 V to 240 V 2 B &&&&######YY YY : Europe

BDP-160 FXE AC 110 V to 240 V 3 A &&&&######TA TA : Taiwan

BDP-160 LXE AC 110 V to 240 V 3 A &&&&######LL LL : Asean

BDP-160 PWXE AC 110 V to 240 V 4 B &&&&######PP PP : Oceania

BDP-160 SXE AC 110 V to 240 V 5 C &&&&######UR UR : Russia

BDP-160 AXQ5 AC 110 V to 240 V 6 C &&&&######CN CN : China

DVD

Region No.

BD

Region No.

Serial No. Remarks

K-ZZZ JULY

2013 Printed in Japan

1

This service manual is intended for qualified service technicians; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

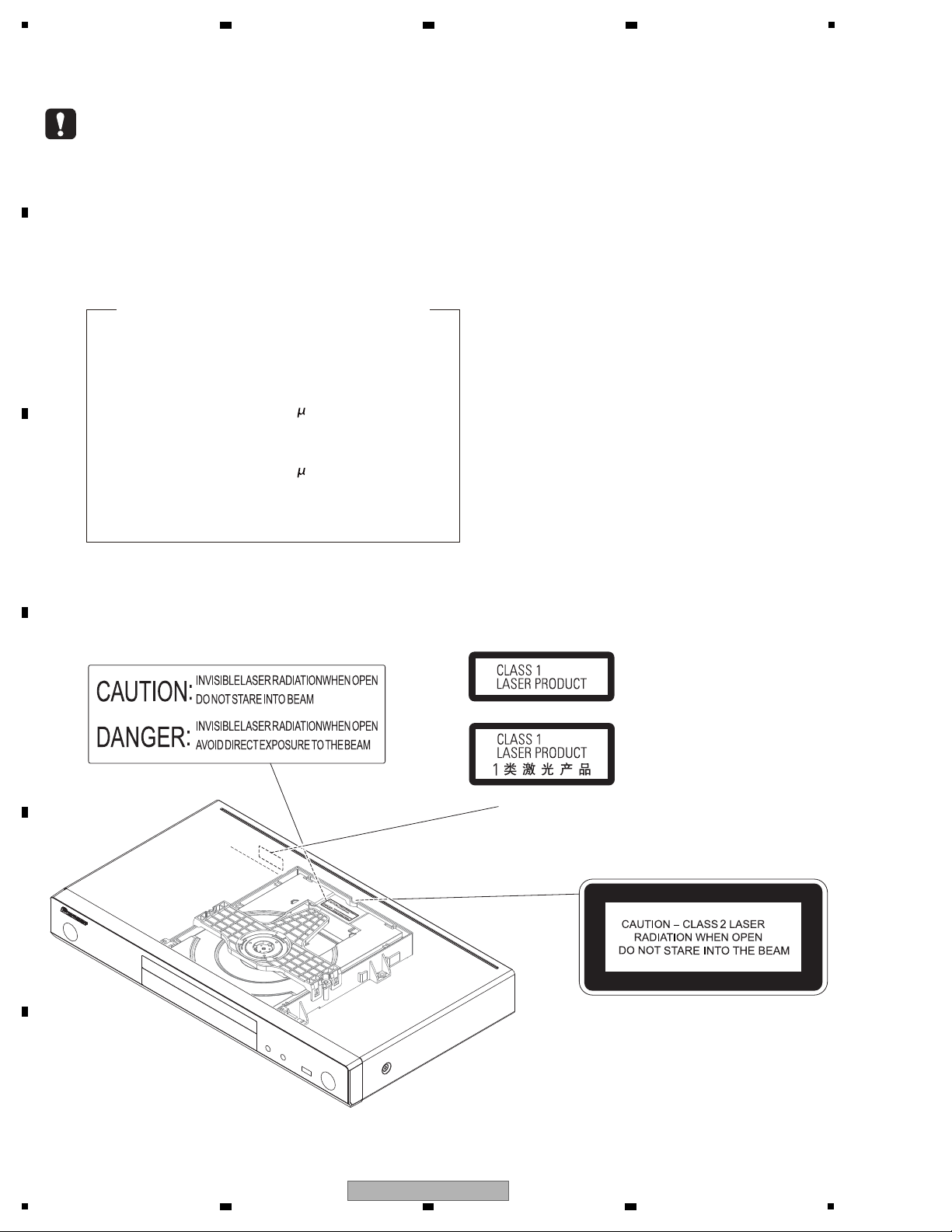

LABEL CHECK

The following caution appears on your unit.

Location: inside of the unit

BDP-160/AXQ5

(Printed on the Rear Panel)

BDP-160/YXE8, /VXE8,

/SXE, /PWXE, /LXE

Laser Pickup specifications and Laser characteristics

BD Wave length : 405 nm

Operating output : 1.16 mW CW, Class 1

Maximum output : Class 2 (under fault condition)

DVD Wave length : 658 nm

Operating output : 178 W CW, Class 1

Maximum output : Class 1 (under fault condition)

CD Wave length : 790 nm

Operating output : 174 W CW, Class 1

Maximum output : Class 1 (under fault condition)

The following caution label appears on

your unit.

Location: inside of the unit

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

BDP-160-K

5

6 7 8

CONTENTS

SAFETY INFORMATION ......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS.................................................................................................................................................... 4

1.1 NOTES ON SOLDERING...............................................................................................................................................4

2. SPECIFICATIONS................................................................................................................................................................. 5

2.1 ACCESSORIES.............................................................................................................................................................. 5

2.2 SPECIFICATIONS ..........................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ........................................................................................................................... 6

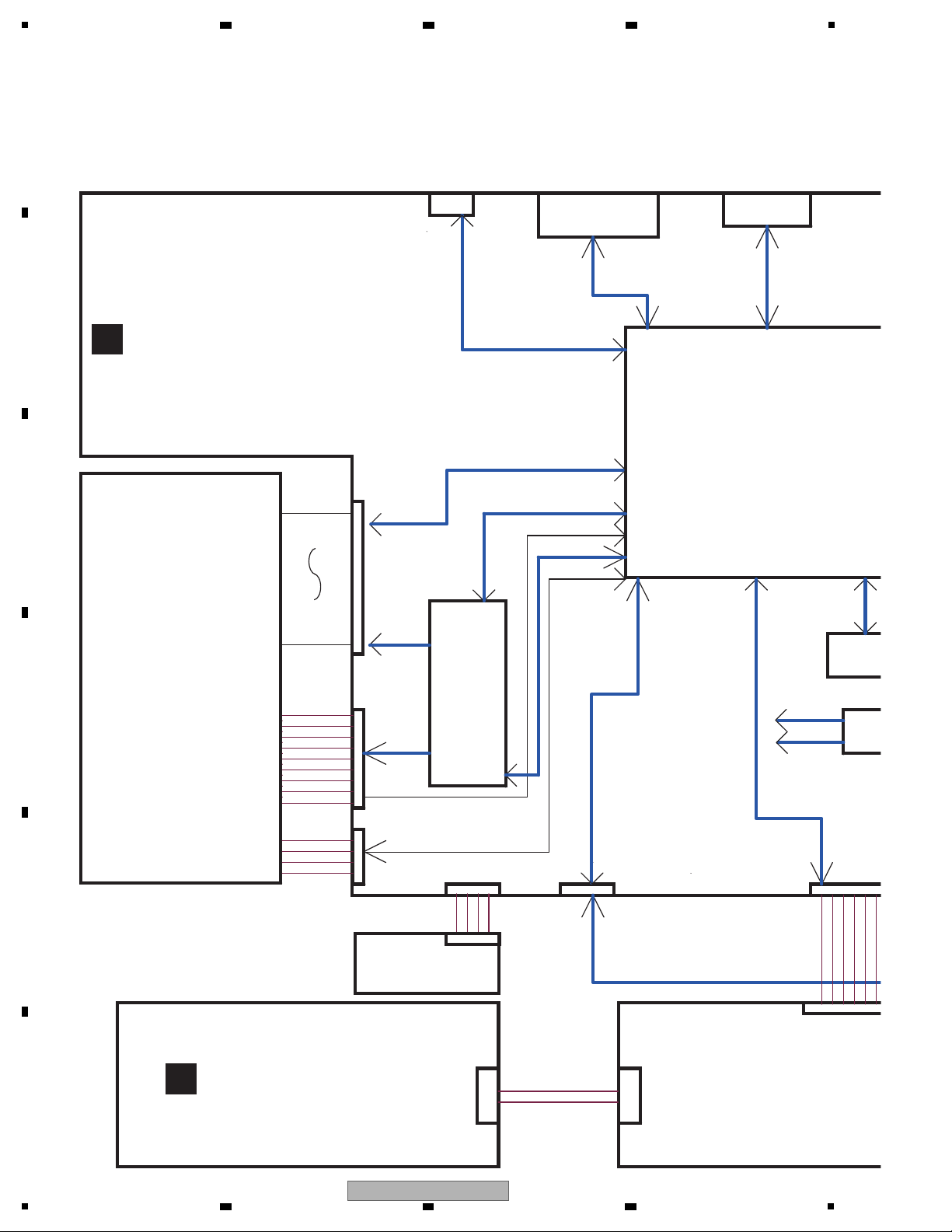

3.2 PCB LOCATIONS...........................................................................................................................................................7

3.3 JIGS LIST ....................................................................................................................................................................... 7

4. BLOCK DIAGRAM ................................................................................................................................................................ 8

4.1 OVERALL CONNECTION DIAGRAM ............................................................................................................................ 8

4.2 BLOCK DIAGRAM........................................................................................................................................................ 10

4.3 POWER BLOCK DIAGRAM .........................................................................................................................................12

5. DIAGNOSIS ........................................................................................................................................................................ 14

5.1 DIAGNOSIS FLOWCHART.......................................................................................................................................... 14

5.2 CONFIMATION OF THE Wi-Fi MODULE..................................................................................................................... 19

6. SERVICE MODE................................................................................................................................................................. 20

6.1 HOW TO ENTER TO SERVICE MODE ....................................................................................................................... 20

6.2 DESCRIPTION OF EACH ITEM................................................................................................................................... 20

6.3 DETAILED DESCRIPTION OF ITEMS USED IN SERVICE.........................................................................................21

7. DISASSEMBLY ................................................................................................................................................................... 24

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 32

8.1 NECESSARY ADJUSTMENT POINTS........................................................................................................................32

8.2 FIRMWARE UPDATE................................................................................................................................................... 33

8.3 METHOD OF READING OUT BARCODE DATA BY SERVICE MODE ....................................................................... 33

8.4 METHOD OF WRITING BARCODE DATA BY USING REMOTE CONTROL UNIT ....................................................34

8.5 METHOD OF READING OUT AND WRITING BARCODE DATA BY USING PC AND SERVICE JIG........................ 36

9. EXPLODED VIEWS AND PARTS LIST .............................................................................................................................. 40

9.1 PACKING SECTION.....................................................................................................................................................40

9.2 EXTERIOR SECTION .................................................................................................................................................. 42

10. SCHEMATIC DIAGRAM.................................................................................................................................................... 43

11. PCB CONNECTION DIAGRAM ........................................................................................................................................ 44

11.1 MAIN BOARD ASSY................................................................................................................................................... 44

11.2 FRONT BOARD and SWITCH BOARD ASSYS.........................................................................................................48

11.3 POWER BOARD ASSY ..............................................................................................................................................50

12. PCB PARTS LIST..............................................................................................................................................................52

A

B

C

D

E

F

BDP-160-K

5

6 7 8

3

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

2 3 4

BDP-160-K

5

• Remote control x 1 (YXE8, VXE8, FXE, LXE, PWXE, SXE : 06-T2446E-A005) (RC-2426)

(AXQ5 : 06-T2446E-A006) (RC-2428)

• AAA/R03 dry cell batteries x 2

• Power cord (YXE8, LXE, SXE : 51-DC0120-0CRA3)

(VXE8 : 51-DC0120-0CRD4)

(FXE : 51-NC0150-0LNA9)

(PWXE : 51-JC0120-0PNC7)

(AXQ5 : 51-GC0120-0CRA5)

• Warranty card (European models only)

• Software license notice (YXE8, VXE8, FXE, LXE, PWXE, SXE : ARC8260)

(AXQ5 : ARC8261)

• Operating instructions (YXE8 : 72-BDP160-EURB1)

(YXE8, VXE8, LXE, PWXE : 72-BDP160-GBRB1)

(FXE : 72-BDP160-TWNB1)

(LXE : 72-BDP160-TWNB1)

(SXE : 72-BDP160-RUSB1)

(AXQ5 : 72-BDP160-CHNB1)

Note

• The specifications and design of this product are subject to change without notice.

• This item incorporates copy protection technology that is protected by U.S. patents and other intellectual property

rights of Rovi Corporation. Reverse engineering and disassembly are prohibited.

Do not connect the unit through a VCR. Video signals fed through VCRs may be affected by copyright protection

systems and the picture will be distorted on the television.

• Corporation and product names mentioned herein are trademarks or registered trademarks of the respective

corporations.

Type

Blu-ray 3D

TM

PLAYER

Rated voltage

AC 110 V to 240 V

Rated frequency 50 Hz/60 Hz

Power consumption 17 W

Power consumption (standby) 0.3 W

Power consumption (quick start) 7 W

Weight 2.0 kg

External dimensions (including projecting parts) 435 mm (W) x 58 mm (H) x 250 mm (D)

Tolerable operating temperature +5 °C to +35 °C

Tolerable operating humidity 5 % to 85 % (no condensation)

Output terminals

HDMI 1 set, 19-pin: 5 V, 250 mA

Audio outputs 2-channel (left/right) 1 set, RCA jacks

Audio output level 200 mVrms (1 kHz, –20 dB)

Frequency response 4 Hz to 88 kHz (192 kHz sampling)

Digital audio outputs Coaxial 1 set, RCA jacks

LAN 1 set, Ethernet jack (10BASE-T/100BASE-TX)

Wireless LAN (internal antenna) Integrated IEEE 802.11n (2.4 GHz band) wireless

networking access, compatible with 802.11b/g Wi-Fi

networks

USB 2 set, Type A

Model BDP-160

BDP-160-K

BDP-160-S

2. SPECIFICATIONS

2.1 ACCESSORIES

2.2 SPECIFICATIONS

6 7 8

A

B

5

6 7 8

BDP-160-K

C

D

E

F

5

1

Item to be checked regarding video Item to be checked regarding audio

Block noise Distortion

Horizontal noise Noise

Dot noise Volume too low

Disturbed image (video jumpiness) Volume too high

Too dark Volume fluctuating

Too bright Sound interrupted

Color disappearance

Mottled color

No. Procedures Check points

1

2

3

4

5

6

Confirm the firmware version on Test Mode. The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Video, audio and operations must be normal.

Play back a CD.

(track search)

Audio and operations must be normal.

Play back a DVD.

(Menu operation, Title/chapter search)

Video, audio and operations must be normal.

Play back a BD.

(Menu operation, Title/chapter search)

Video, audio and operations must be normal.

Check the appearance of the product. No scratches or dirt on its appearance after receiving it for

service.

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding video and audio.

Cleaning

Be sure to clean the following positions by using the prescribed cleaning tools shown below as occasion demands.

Refer to “7. DISASSEMBLY”.

NamePosition to be cleaned Part No. Remarks

Cleaning liquidPickup leneses GEM1004

Cleaning paper GED-008

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

6

1

2 3 4

BDP-160-K

5

POWER BOARD ASSY

FRONT CONTROL BOARD ASSY SWITCH BOARD ASSY

MAIN BOARD ASSY

A D

B

WIFI MODULE ASSY

Loader ASSY

C

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

DVD Test Disc (DVD-Video)

BD-ROM Test Disc

Name Jig No. Remarks

Check of DVD-Video

Check of BD-ROM

GGV1025

GGV1350

BD-ROM Test Disc (One layer type)

For Adjustment

GGV1368

Service Jig

Refer to “ 8.6 METHOD OF READING OUT AND

WRITING BARCODE DATA BY USING PC AND

SERVICE JIG ”

GGF1676

(Including a USB cable)

3.2 PCB LOCATIONS

6 7 8

A

B

Mark No. Description Part No.

LIST OF ASSEMBLIES

1..MAIN BOARD ASSY 08-BDP160-MA0/Y

(YXE8, VXE8, PWXE, SXE)

1..MAIN BOARD ASSY(FXE) 08-BDP160-MA2/F

1..MAIN BOARD ASSY(LXE) 08-BDP160-MA2/L

1..MAIN BOARD ASSY(AXQ5) 08-BDP160-MA1/A

3.3 JIGS LIST

Mark No. Description Part No.

1..FRONT BOARD ASSY 08-BDP160-FV0

1..SWITCH BOARD ASSY 08-BDP160-SB0

>

1..POWER BOARD ASSY 08-P015BE-PW0

C

D

E

5

6 7 8

BDP-160-K

F

7

1

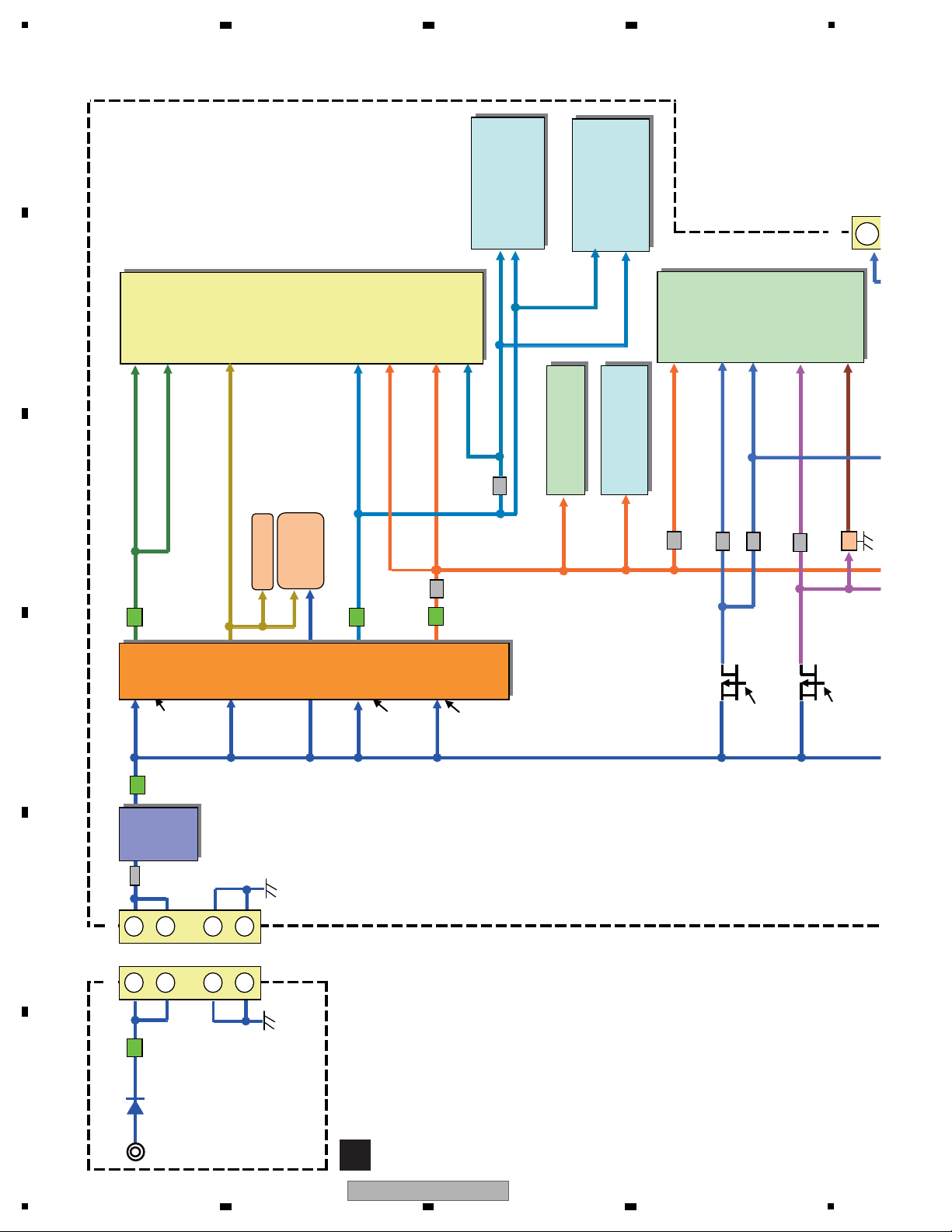

MT8560

XP1

3PIN*2.0

3

1

10

XS135 10

2

1

XS136

2PIN*2.0

45PIN*0.5

XP7

256M

N FLAS

XP1

9PIN*1.0

1

9

1

45

14

XP17 (USB_1)

4PIN*2.0

14

P2 (USB_2)

10

XP18

P1 (Ethernet )

P5 (HDMI)

USB_1

USB_2

G55

DC

SWIT

TI2050

GND

POWER_K-

TRAYIN#

GND

LOAD+

LOAD-

10PIN

U

COMMON

V

W

GND

B+

B-

A-

A+

POWER

+12V_D

VCC

GND

IR

WAKE_UP

REBEOOT

WiFi MODULE ASSY

(07-WN713N-M1B)

XP4

4PIN*2.0

XP2

4PIN*2.0

14

3.3V

GND

USBP0

USBM0

LOADER ASSY

(08-LTCBS9-222160)

SWITCH BOARD ASSY

(08-BDP160-SB0)

C

A

MAIN BOARD ASSY

(YXE8, VXE8, PWXE, SXE :08-BDP160-MA0/Y)

(FXE :08-BDP160-MA2/F)

(LXE :08-BDP160-MA2/L)

(AXQ5 :08-BDP160-MA1/A)

2 3 4

4. BLOCK DIAGRAM

4.1 OVERALL CONNECTION DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

BDP-160-K

5

4PIN*2.5

CN503

1

4

AMP&LPF DRV632

POWER AC IN

110

XS135 10PIN*2.0

256M

N FLASH

1Gbit DDR3 x 1

XS221

1

10

XP18

XP1

4PIN*2.5

1

4

VIDEO

LPF

4PIN*2.0

USB 1

R

L

COAXIAL

SPDIF

P3 (RCA port)

5V

USB_1

USB_2

G556B

DC

SWITCH

12V

12V

GND

GND

2Gbit DDR3 x 1

CVBS

CVBS

1

4

10PIN*2.0

POWER

+12V_D

VCC

GND

VD

VCLK

VSTB

IR

WAKE_UP

REBEOOT

DC-DC

DC-DC

5V

G5175

9.5V

12V

12V

AS1117

EUP3484S

1.2V

1.5V

3.3V

3.3V_STBY

9.5V REG.

FRONT BOARD ASSY

(08-BDP160-FV0)

B

POWER BOARD ASSY

(08-P015BE-PW0)

D

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

6 7 8

A

B

C

D

5

BDP-160-K

6 7 8

E

F

9

1

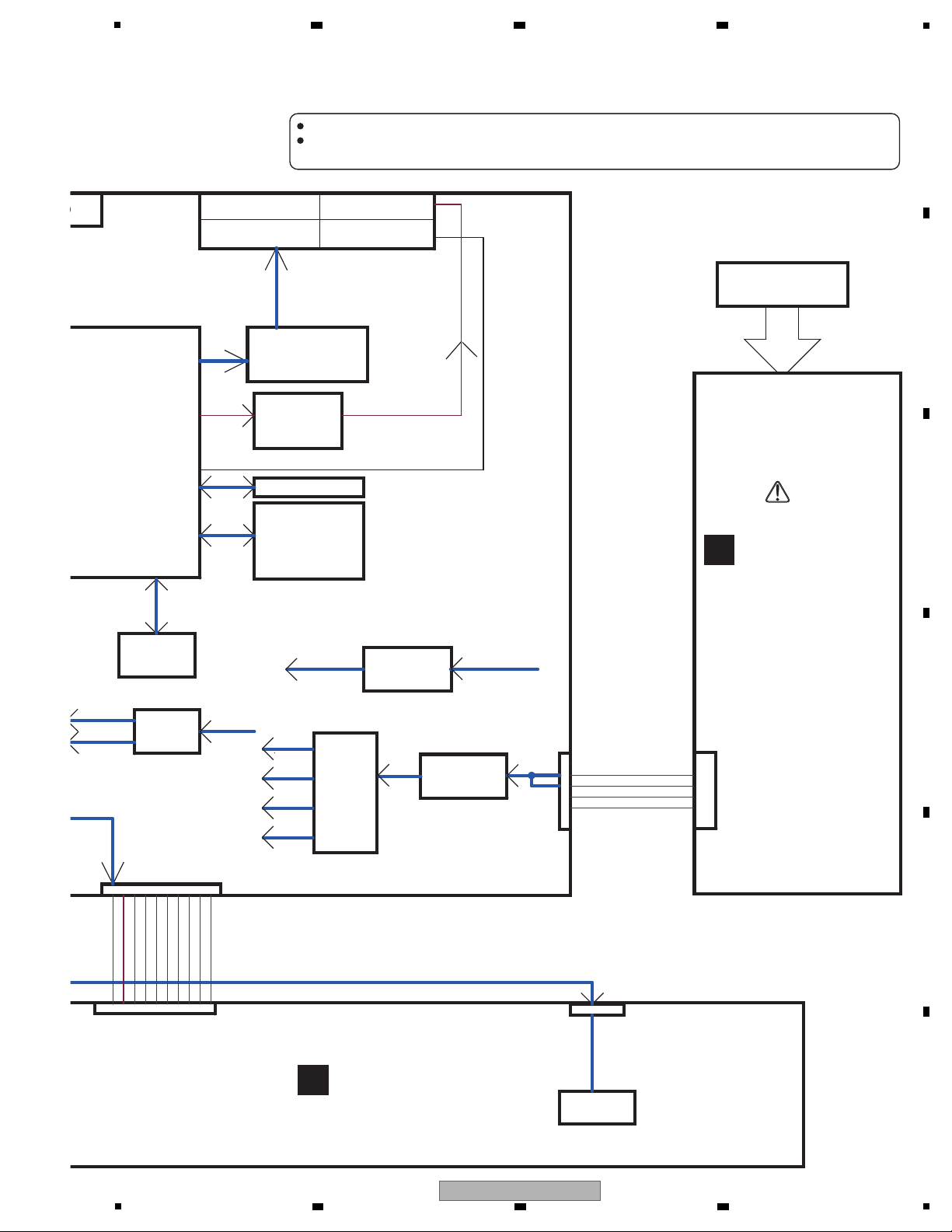

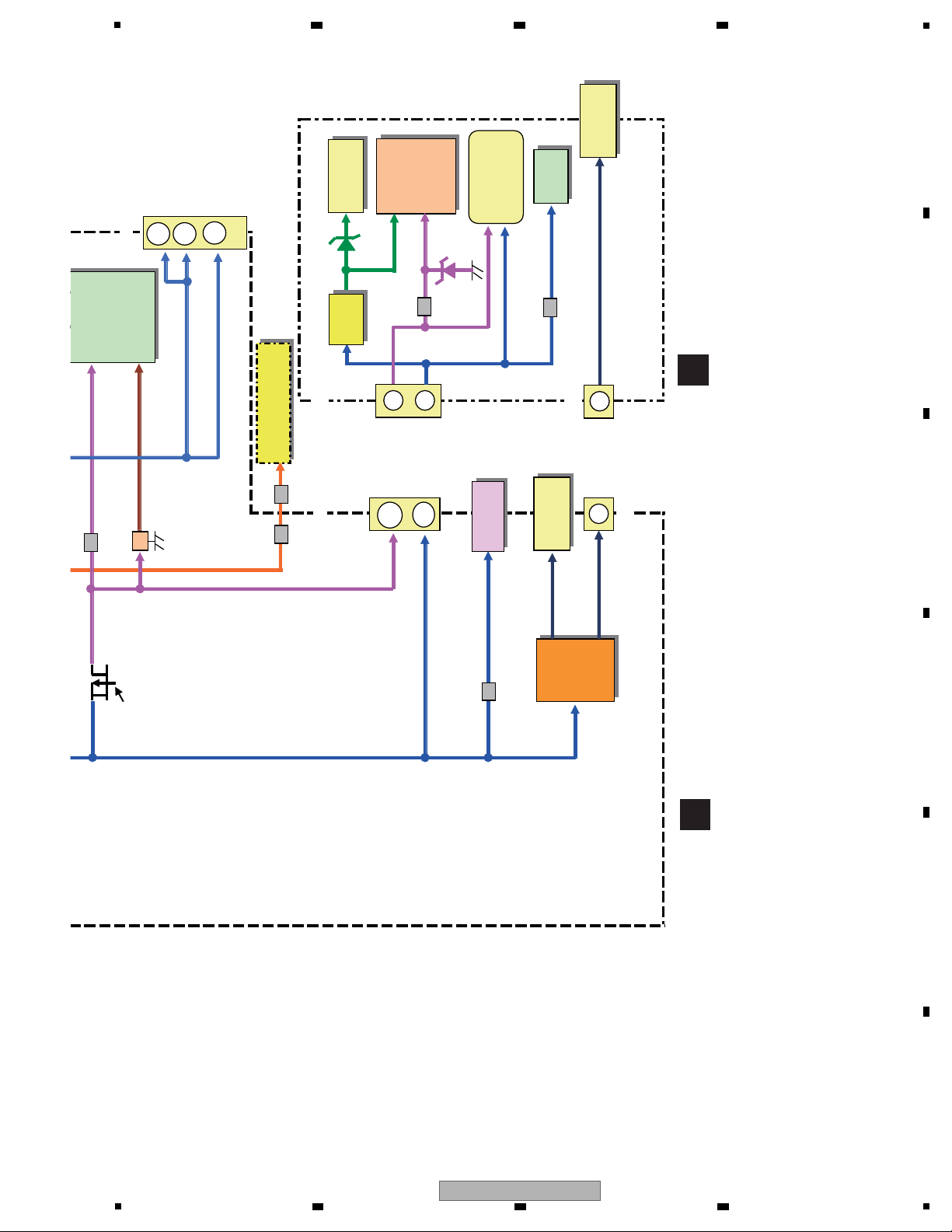

8

OPU

TRAY

IN/OUT

MOTOR

B CH D

45PIN FFC

9PIN FFC

4PIN

A CH DDR3

MOTOR

DRIVER

RESET

OSCILLATOR

(27MHz30ppm)

TRANSFO

RMER

RF SIGNAL

SPINDLE&SL

ED

MOTOR

TRAY TRAVERSE

MAIN BOARD

Front BOARD

BD

LOADER

LAN

USB

Data

Power

Others

Control

PSU BOARD

AC IN

100,110~22

0Vac

POWER

manageme

nt IC

12V

IR

TBL3000+

SANYO480

4PINS

WIFI port

BDP-160 Block Diagram:

LOADER ASSY

(08-LTCBS9-222160)

POWER BOARD ASSY

D

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

4.2 BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

10

1

2 3 4

BDP-160-K

5

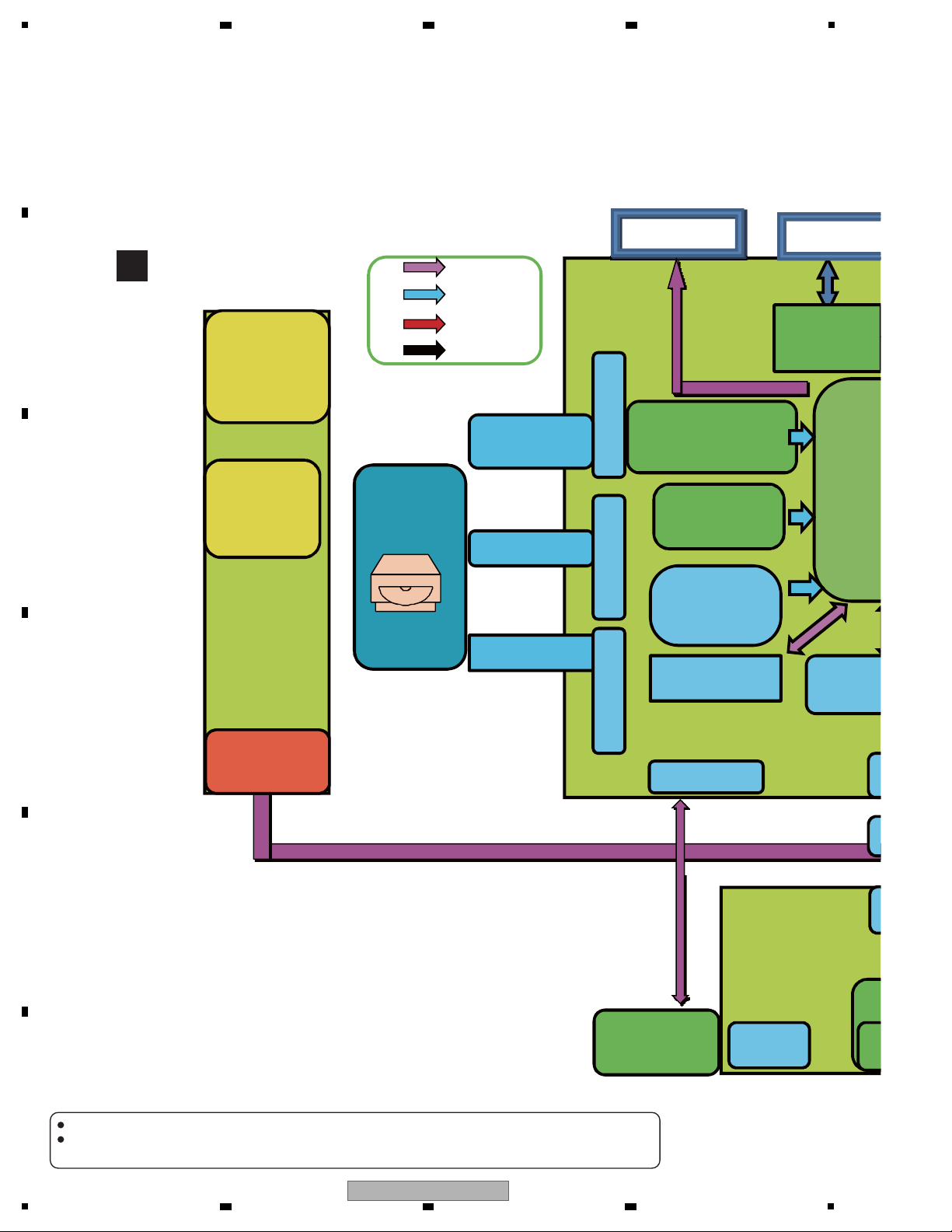

MTK

8560

10 PINS

DC-DC

LDO

Coaxial/L/R

B CH DDR3

DC-

DC

10PINS

5VSPI IR

MOS

NAND

FLASH

HDMI

TRANSFO

RMER

JTAG

12V

12V

5V

12V_

5V_D

USB_VCC

9V

1.5V

3.3V

3.3V_STBY

5V

5V

HDMI

LAN

COAXIAL/L/R

USB port

VFD

LED

KEYS

KEYS

Amplifier

1.2V

Power

switch

12V

USB

12V

USB

USB

12V

FRONT BOARD ASSY

B

A

MAIN BOARD ASSY

6 7 8

A

B

C

D

5

BDP-160-K

6 7 8

E

F

11

1

BDP-160

U4

OPWRSB

12V

1. 2V

U1

MT8560

1. 5V

OPWRSB

U10 1/2

1.2V

A1. 2V

1. 2V

R36

R37

DDR_VREF

3. 3V_STBY

CEC Circuit

U13

AS9632 AP

U8

256MB NAND Flash

R23

FB20

D3.3V

U409

TPIC2050G4

FTS Driver

VCC_D

FB19

FB32

MVCC_T

AVCC

+12V_D

1. 2V

FB18

M12V_T

U9

ASS1117

VCC_BD_LD

RESET

Circuit

XP7

1

2

3

4

U10 2/2

XP15

D552

CN503

PW Board

L550

3.3u

L1

2.2u

L4

2.2u

DDRIC_VREF

DCDC

Conv.

U5

FB1

12V

5V

DCDC

Conv.

U4

OPWRSB

L5

L2

2.2u

3. 3V

3. 3V

U2

DDR3-1333 1Gb

DDR3

U3

DDR3-1333 2Gb

DDR3

9

1

2

3

4

POWER BOARD ASSY

C

4.3 POWER BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

12

1

2 3 4

BDP-160-K

Se

+12V_D

1. 2V

16

XP1

FB18

M12V_T

U9

ASS1117

VCC_BD_LD

+12V_D

J1

HDMI

Terminal

F1

HDMI_VCC

High-

Side

SW

1

XP17

USB_VCC1

15

VCC

to Front

USB

to Front

XP7

30

10

VCC_PDIC

VCC_HFM

to Pickup

U10 2/2

U135

PT6312

FL Driver

FL_AC Circuit

IR1

IRM

VFD135

FL Display

6

9

R154

R155

1k

+5V

ZD136

R167

100

4

U11

G556B1

USB_VCC0

P2

USB Terminal

P221

USB Terminal

XS135

ZD135

XS221

Main Board

FV Board

-24V_D

+12V_D

VCC

VCC_USB

9

3. 3V

WIFI Board

R973 FB21

Boost

VCC

FRONT BOARD ASSY

B

A

MAIN BOARD ASSY

5

6 7 8

A

B

C

D

E

F

BDP-160-K

5

6 7 8

13

1

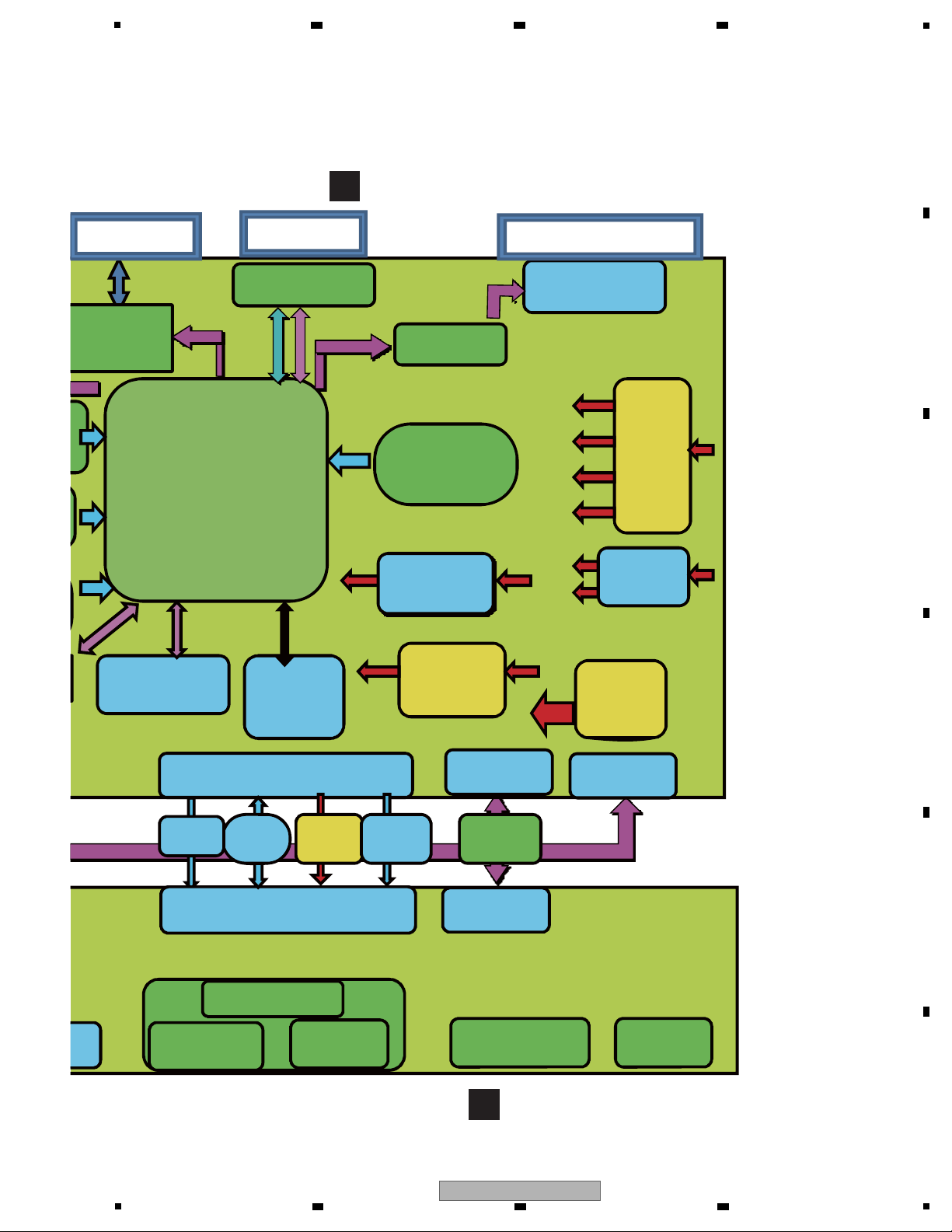

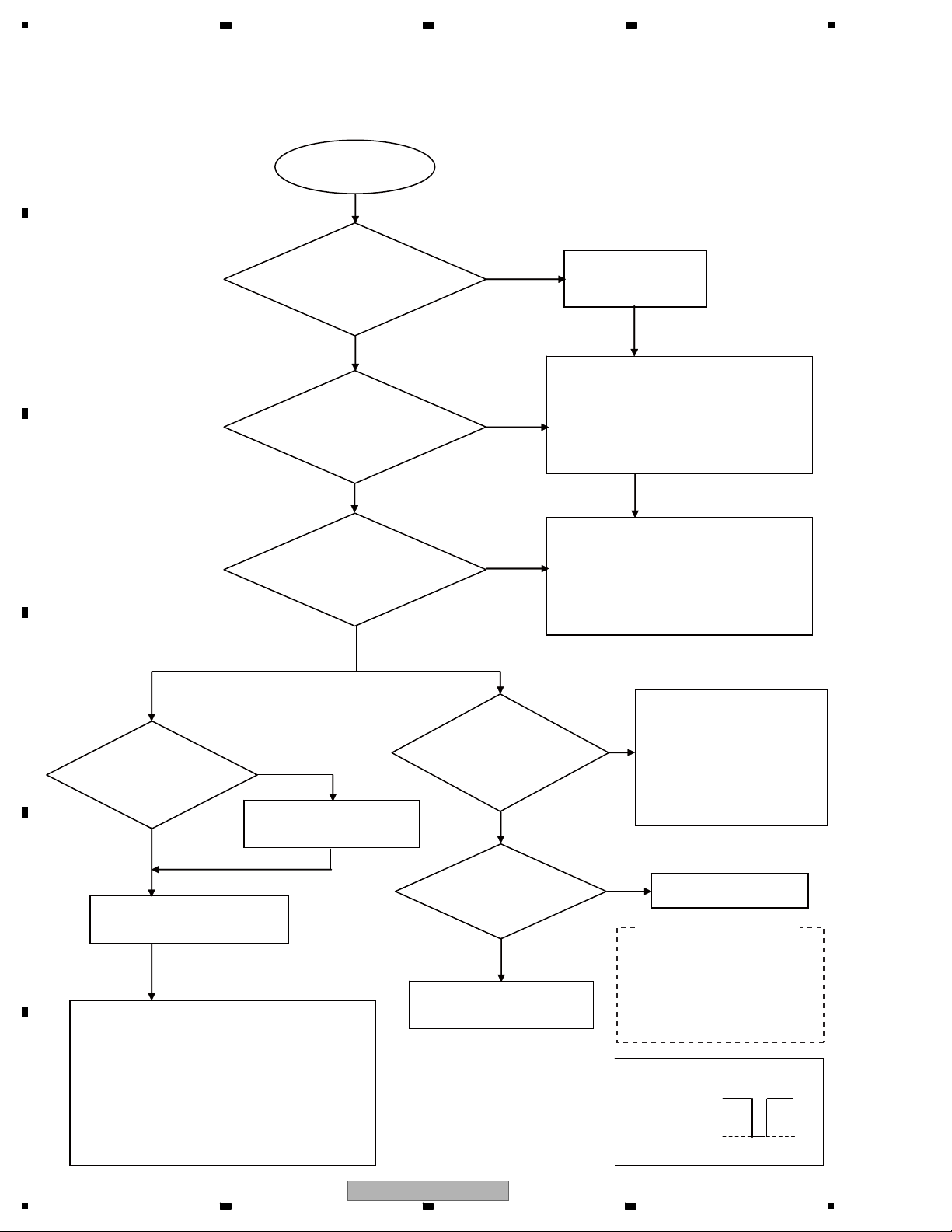

No

Yes

Yes

No

No

Yes

No

Yes

Yes

No

SW1 OFF : 5V

SW1 ON : 0V

(GND)

Check whether either the

remote controller or the Main Unit

power button can not turn

on the power supply.

Only the

remote controller

Go to the flowchart for

“Remote control does

not work”

Both or only the Main

Unit power button

Check whether the

voltage of XP1(pin 1 and

pin 2) on the MAIN BOARD ASSY

are 12 V

Check whether there is no problem in the

connector contact between the POWER

BOARD ASSY and the MAIN BOARD

ASSY.

If there is no problem, please replace

the POWER BOARD ASSY.

Check whether there is no problem in the

connector contact between the MAIN

BOARD ASSY and the FRONT BOARD

ASSY.

If there is no problem, please replace

the MAIN BOARD ASSY.

Check whether the

voltage of XS135(pin 6) on the

FRONT BOARD ASSY is 5 V and

X135(pin 9) is 12 V

When the remote controller and the Main

Unit power button cannot turn on the power

Check whether the

voltage of XP18(pin 10) on the

MAIN BOARD ASSY

is 0V

Replace K138 on the

FRONT BOARD ASSY

When there is no change

When there is no change

Replace the FRONT BOARD

ASSY

Replace the MAIN BOARD ASSY

* Because a failure in the hardware reset circuit

may be the cause of the inactive power supply,

please replace the MAIN BOARD ASSY.

About hardware reset sircuit.

(A circuit for providing a function to reset the

product by inserting a bar in the small hole

on the front panel)

When only the Main Unit power

button is not active to turn on the power

Check whether the

voltage of XP1(pin 1) on the

SWITCH BOARD

ASSY is 5V

Check whether there is no

problem in the connector

contact between the FRONT

BOARD ASSY and the

SWITCH BOARD ASSY.

If there is no problem, please

replace the FRONT BOARD

ASSY.

Check whether SW1

on the SWITCH BOARD ASSY

operation is

normal

Replace SW1

How to check the SW1

1. Check the conduction with

a tester after turning off the

power.

2. Check the waveform of the

XP18 (pin 7:POWER) on

the MAIN BOARD ASSY.

Replace the SWITCH

BOARD ASSY

Power does not turn on

Waveform (POWER)

1) Power does not turn on

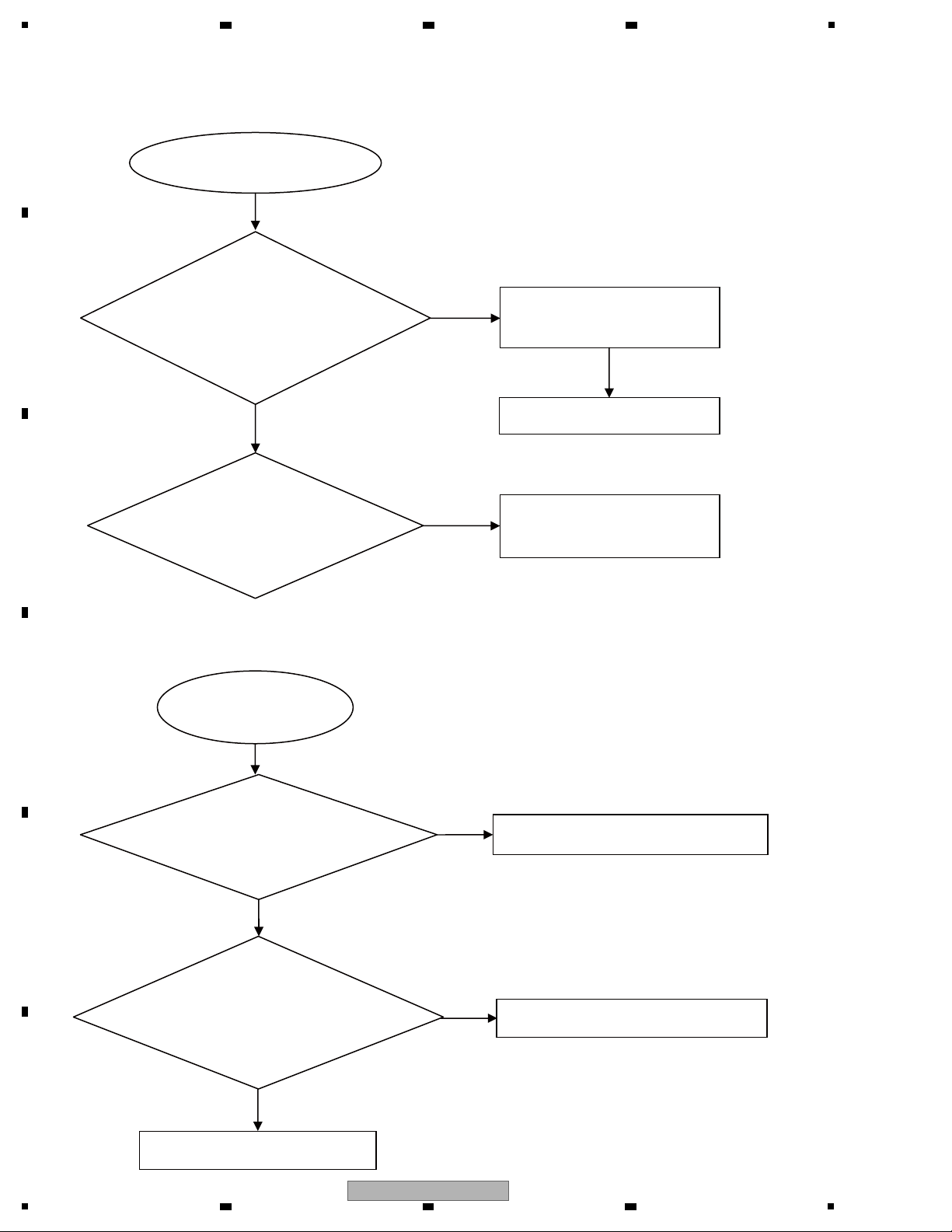

5. DIAGNOSIS

5.1 DIAGNOSIS FLOWCHART

A

B

C

2 3 4

D

E

F

14

1

BDP-160-K

2 3 4

5

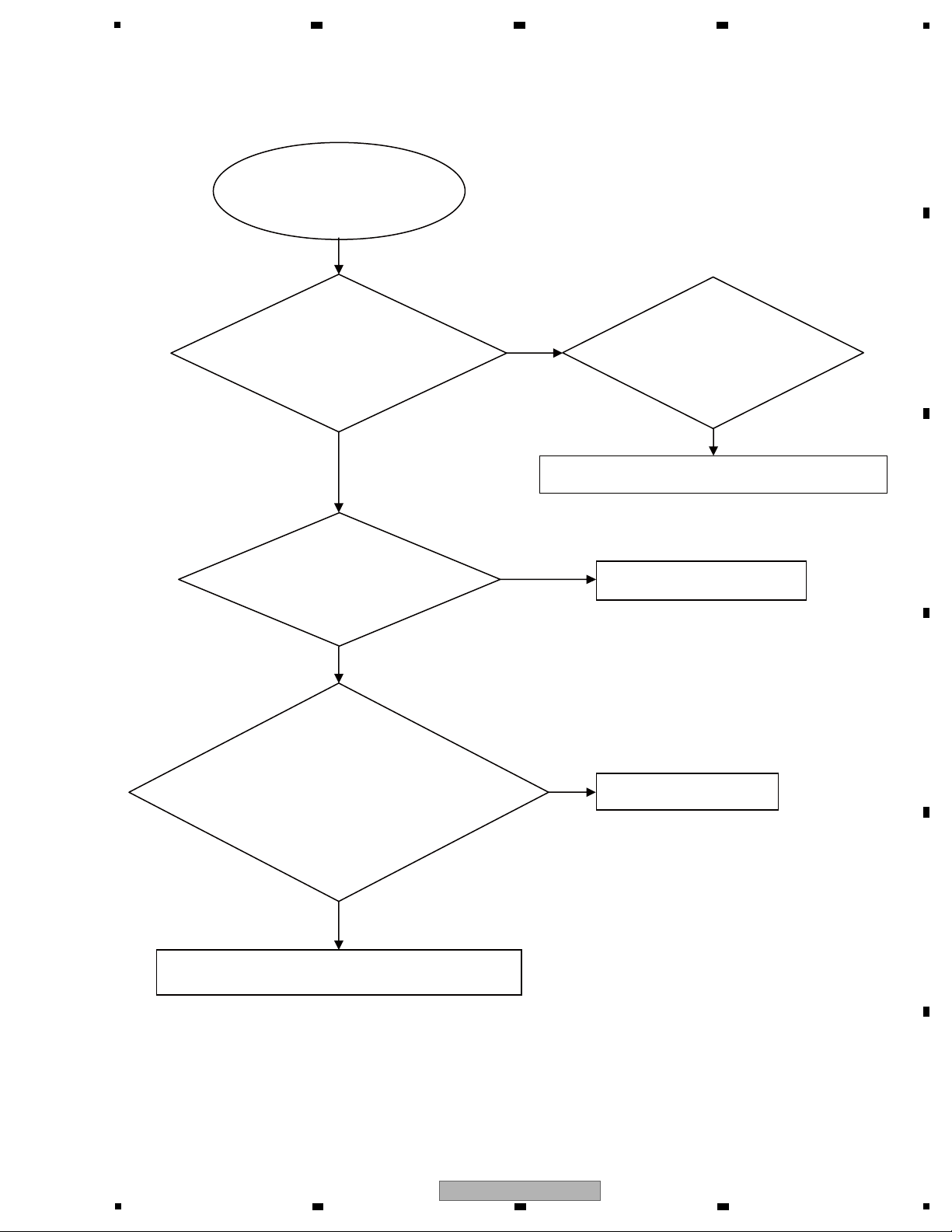

No

No

Yes

Yes

No display on VFD, and

buttons do not work

Check every supply voltage on the

MAIN BOARD ASSY is normal

Check the connect line is OK

Correct connection

Replace K135, K136, K137 and K138.

If still same situation, replace the FRONT BOARD ASSY.

Yes

No

No

Check the FRONT BOARD

ASSY signals VCLK, VSTB, VD

(XS135 : pin 1,2,3)

1.Check whether the bad solder exists

U135 and pins of VFD on the FRONT

BOARD ASSY

2.Check whether the circuit

connected to K135, K136, K137, and

K138 are broken.

Check if U10 are

soldering normally on the

MAIN BOARD ASSY

Resolder Q150 and U25.

If still same situation, replace the MAIN BOARD ASSY

Yes

2) No display on VFD, and buttons do not work

6 7 8

A

B

C

D

5

BDP-160-K

6 7 8

E

F

15

1

No

Remote control

does not work

Replace the battery for remote controller

Check whether the remote

controller’s battery is

exhausted or not.

Check the IR1(ET3050)

power supply is OK,

IR1(pin 3) is about 3V

Check the VCC line(net) on the FRONT

BOARD ASSY

Replace the FRONT BOARD ASSY

Yes

Yes

No

Yes

Check the U13 power supply

(U12 : pin 9 = 3.3V)

Check whether the audio

signal is right from the

U13 (pin 3 and pin 12) on the

MAIN BOARD ASSY

Check If R76 and R108 are

soldering normally on the MAIN

BOARD ASSY

Resolder R310 and R311.

If still same situation, replace the

MAIN BOARD ASSY

Yes

No analog audio output

Replace MAIN BOARD ASSY

Yes

No

No

NO

3) No analog audio output (video output is normal)

4) Remote control does not work

A

2 3 4

B

C

D

E

F

16

1

2 3 4

BDP-160-K

Loading...

Loading...