Page 1

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

PAUSE ATT

AVH-P6400CD/UC

AV RECEIVER/CD PLAYER WITH 6.5 INCH WIDE DISPLAY

CRT2853

AVH-P6400CD

AVH-P6400CD

AVH-P6450CD

This service manual should be used together with the following manual(s):

Model No. Order No. Mech.Module Remarks

CX-961 CRT2503 H2 CD Mech. module:Circuit Description, Mech.Description, Disassembly

--

--

The inverter of this unit is at a high voltage when electrified, so there is a risk of electric

shocks. Make sure that power supply to the unit is OFF once again before operation.

EW

ES

ORDER NO.

UC

For details, refer to "Important symbols for good services"

K-ZZU. APR. 2002.printed in Japan

Page 2

f

1234

SAFETY INFORMATION

- Service Precautions

CD section precaution

A

B

1. Before disassembling the unit, be sure to turn off

the power. Unplugging and plugging the connectors

during power-on mode may damage the ICs inside

the unit.

2. To protect the pickup unit from electrostatic

discharge during servicing, take an appropriate

treatment (shorting pin) by referring to "the

DISASSEMBLY" on page 98.

3. After replacing the pickup unit, be sure to check

the grating. (See p.92.)

UC

CAUTION

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk trying to do so

and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which ar

California to cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

e known to the state o

ES

C

Battery

Slide the tray out on the back of the

remote controller and insert the battery

with the (+) and (–) poles pointing in

the proper direction.

Note :

• Use a CR2025 (3V) lithium battery

only. Never use other types of battery

with this unit.

CAUTION

Danger of explosion if battery is incorrectly replaced.

D

Replaced only with the same or equivalent type.

2

1234

AVH-P6400CD/UC

Page 3

A

B

5678

EW

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-yourselfer.

Qualified technicians have the necessary test equipment and tools, and have been trained to properly and safely repair

complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may void the warranty.

If you are not qualified to perform the repair of this product properly and safely, you should not risk tr

and refer the repair to a qualified service technician.

1. Safety Precautions for those who Service this Unit.

• When checking or adjusting the emitting power of the laser diode exercise caution in order to get safe, reliable

results.

Caution:

1. During repair or tests, minimum distance of 13cm from the focus lens must be kept.

2. During repair or tests, do not view laser beam for 10 seconds or longer.

ying to do so

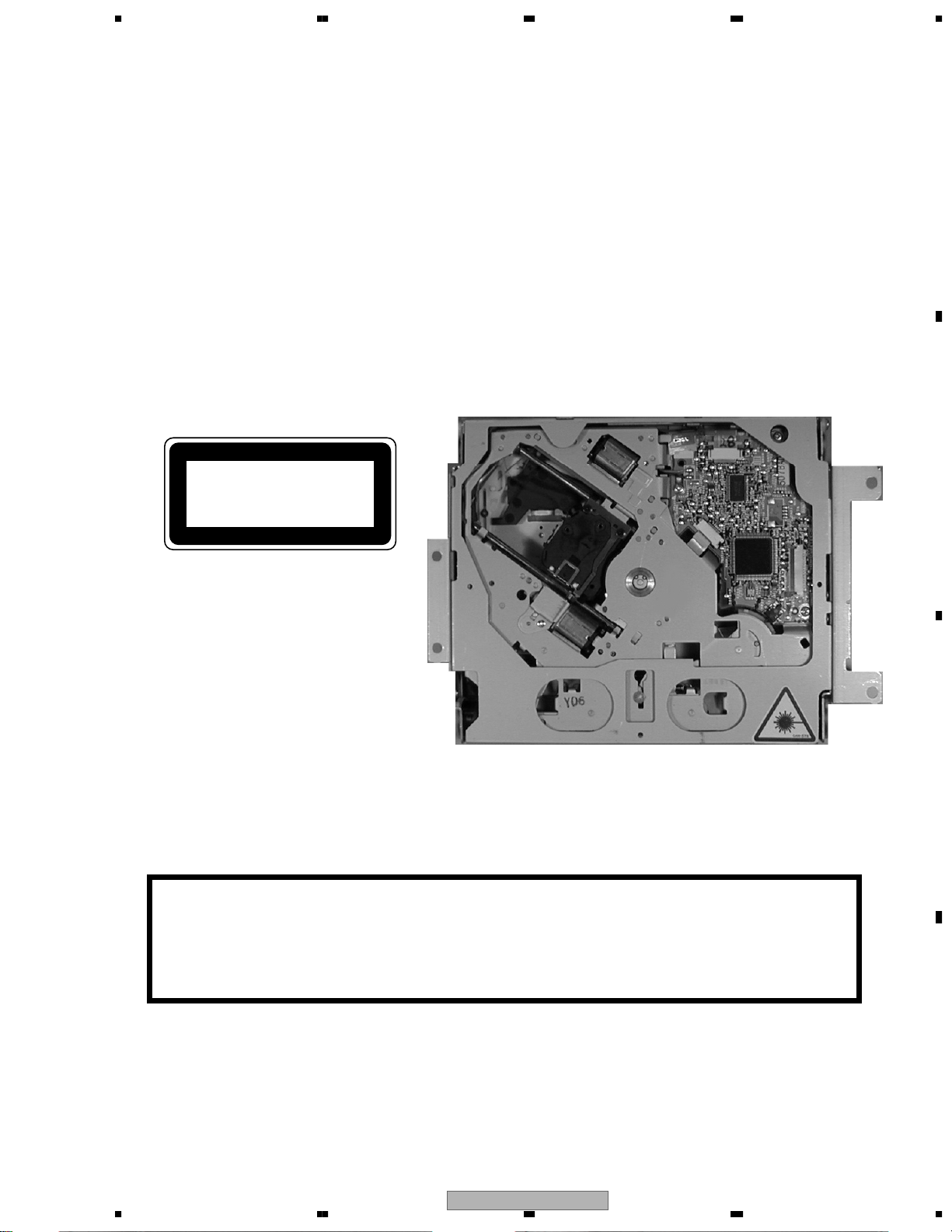

2. A “CLASS 1 LASER PRODUCT” label is affixed to the

bottom of the player.

3. The triangular label is attached to the mechanism

unit frame.

CLASS 1

LASER PRODUCT

4. Specifications of Laser Diode

Specifications of laser radiation fields to which human access is possible during service.

Wavelength =

800 nanometers

C

CAUTION

Danger of explosion if battery is incorrectly replaced.

Replaced only with the same or equivalent type recommended by the manufacture.

Discord used batteries according to the manufacture's instructions.

AVH-P6400CD/UC

56

7

D

3

8

Page 4

1234

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

A

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

B

C

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

ones should be used.

D

4

1234

AVH-P6400CD/UC

Page 5

A

B

5678

CONTENTS

SAFETY INFORMATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1. SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. EXPLODED VIEWS AND PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1 PACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2 EXTERIOR(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

2.3 EXTERIOR(2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

2.4 EXTERIOR(3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

2.5 CD MECHANISM MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

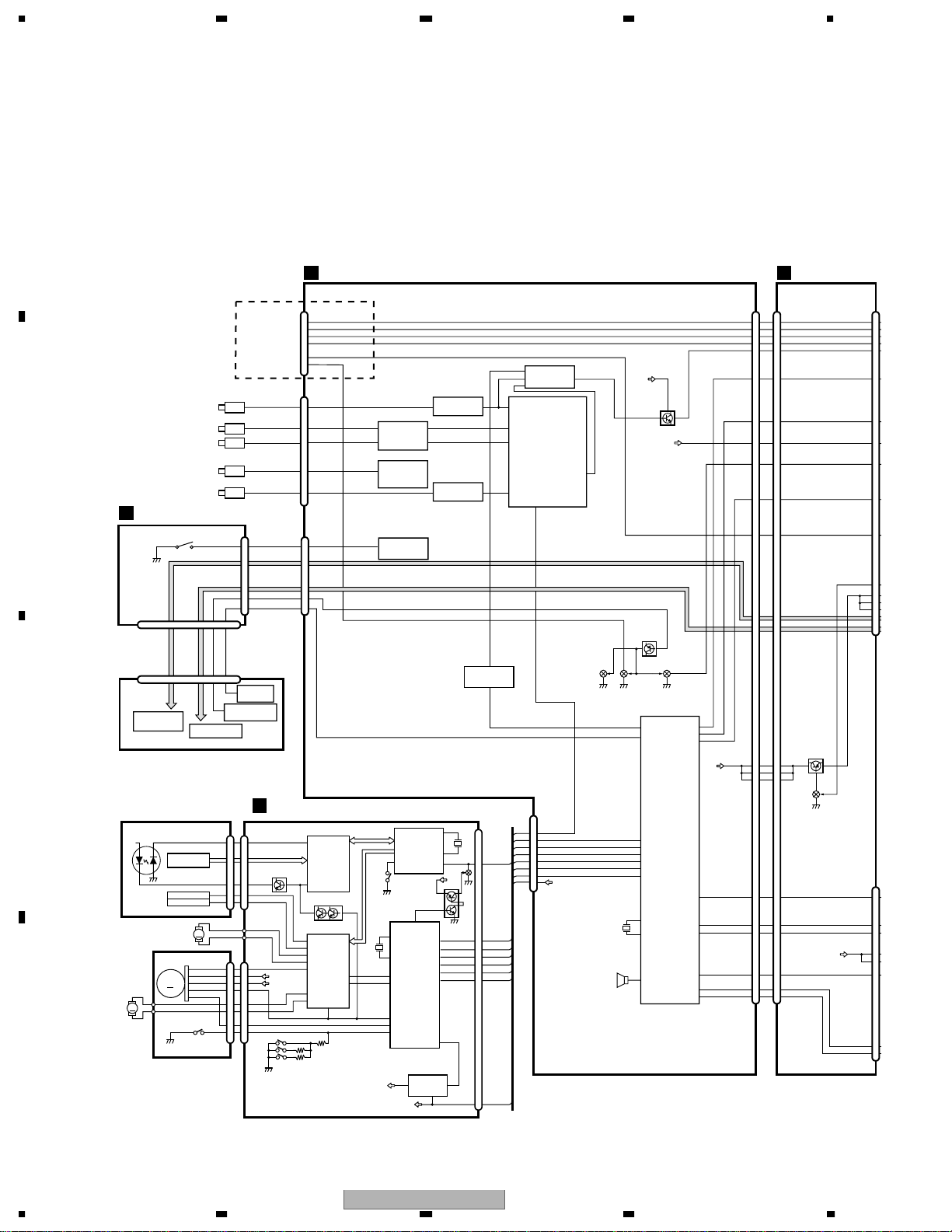

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM . . . . . . . . . . . . . . . . . . . . . . .18

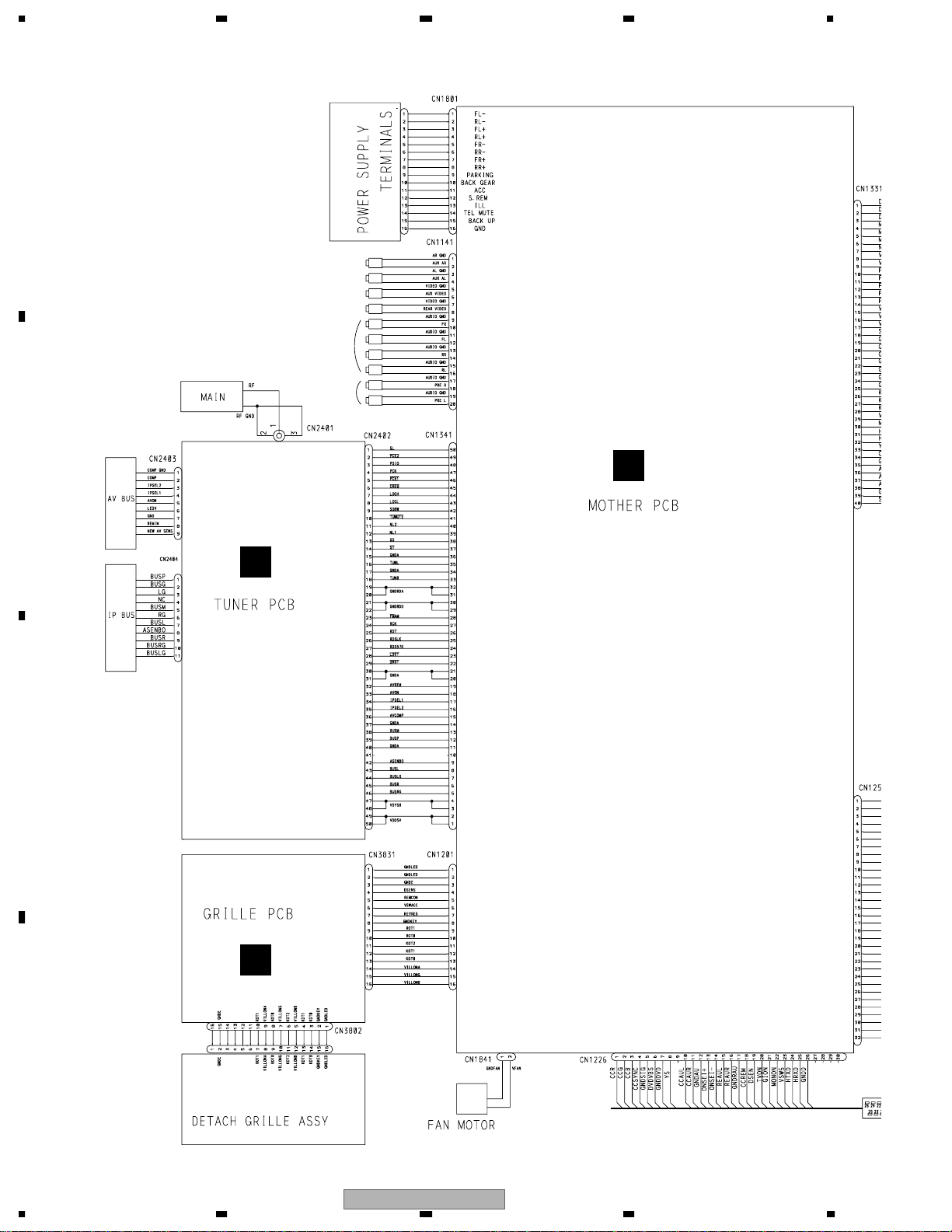

3.1 BLOCK DIAGRAM(1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

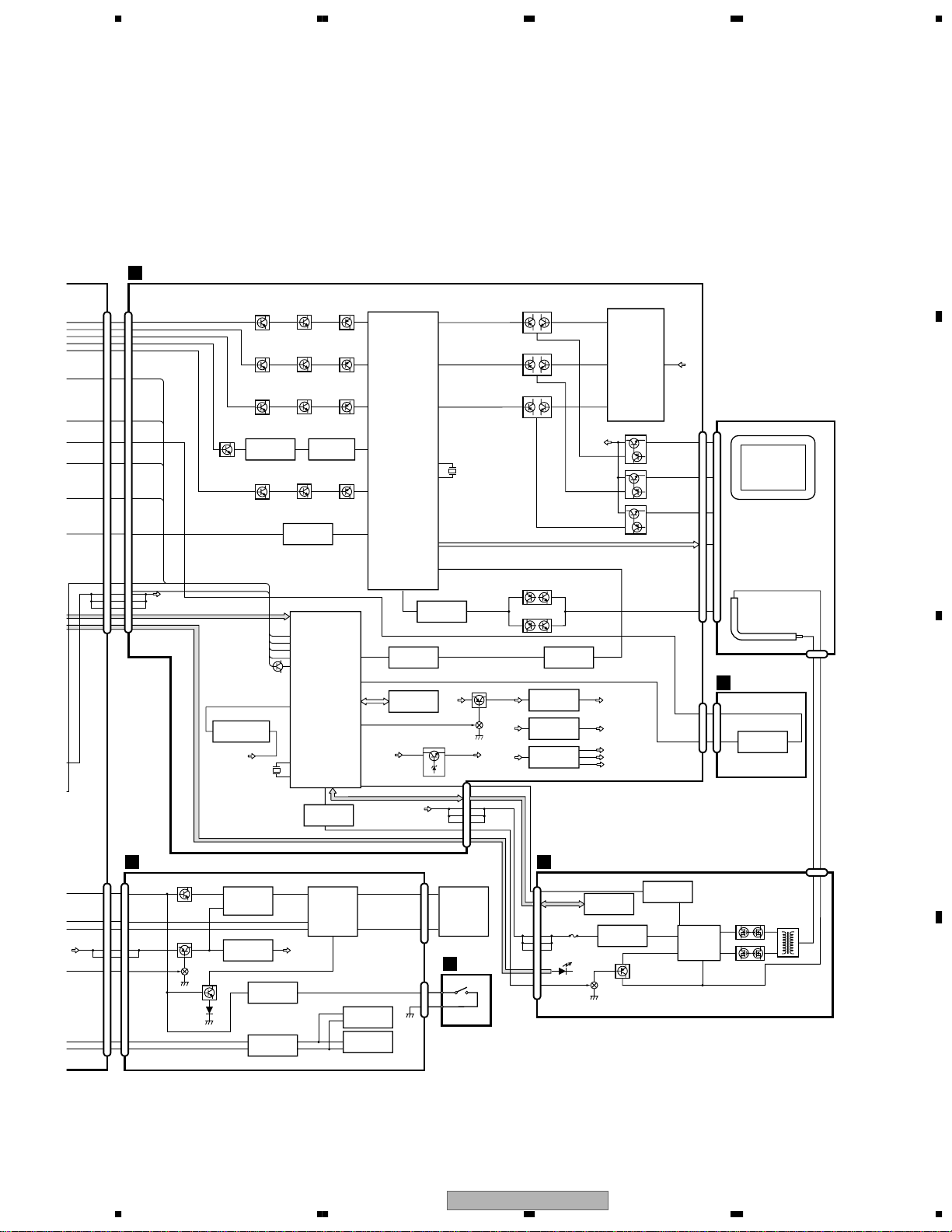

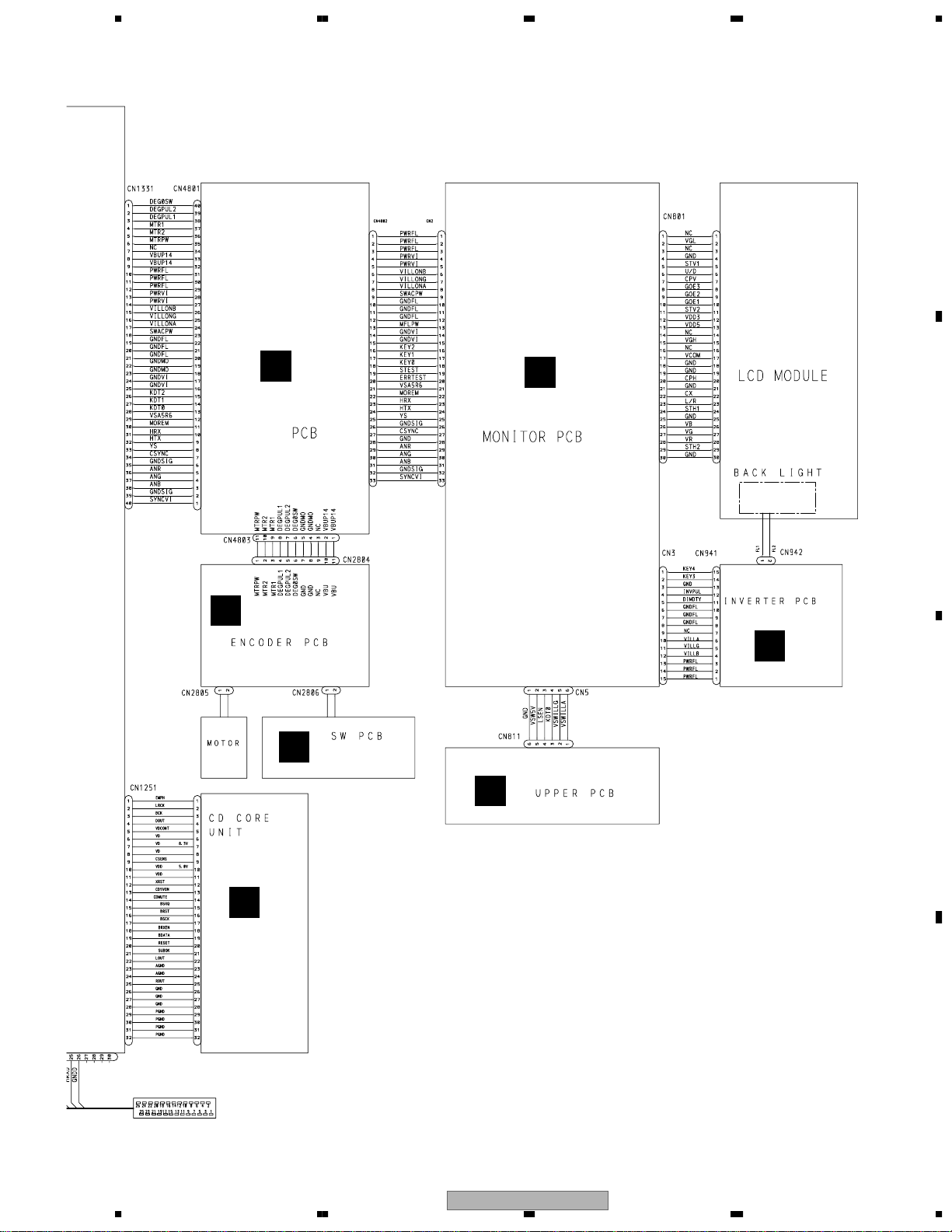

3.2 BLOCK DIAGRAM(2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

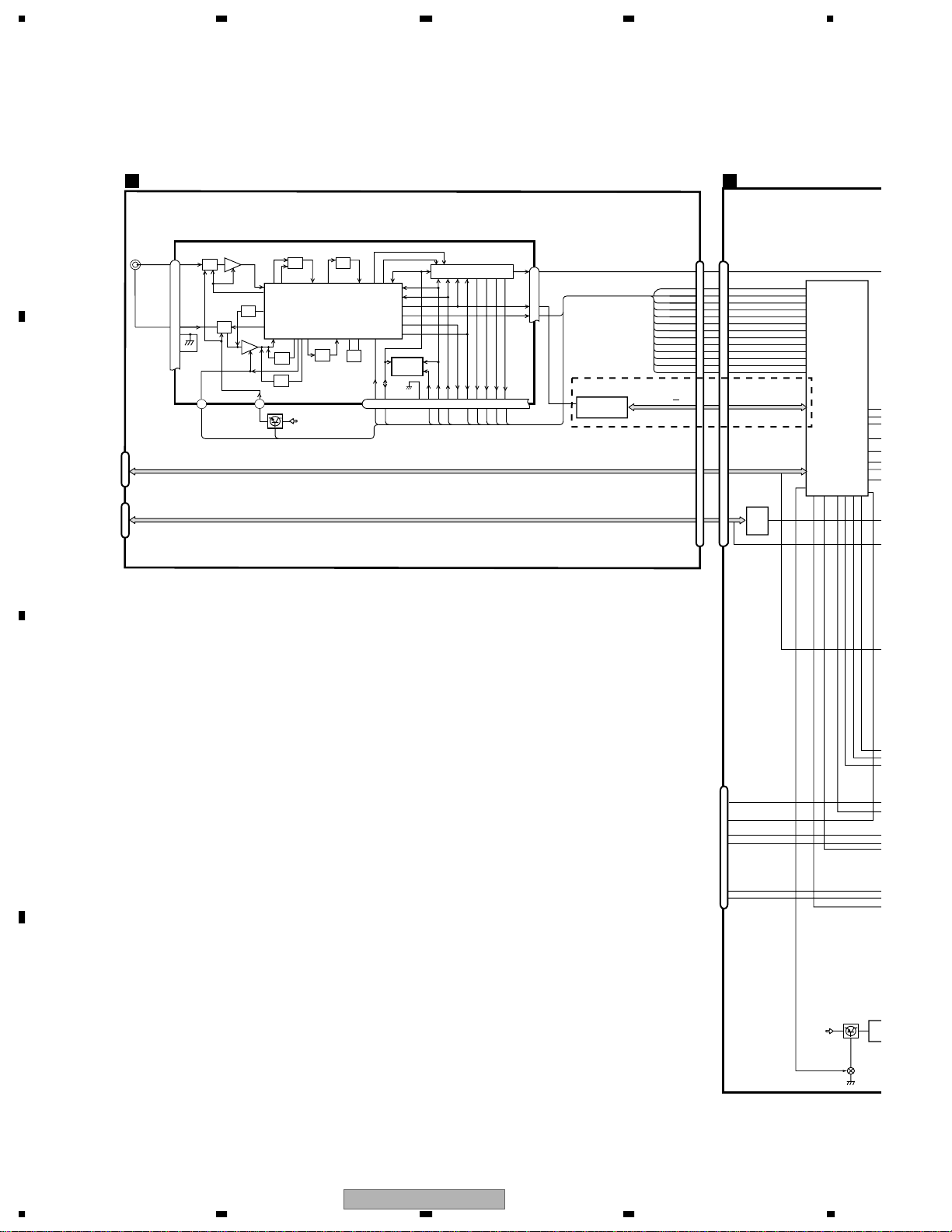

3.3 OVERALL CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . .22

3.4 MOTHER PCB(GUIDE PAGE). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

3.5 TUNER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

3.6 GRILLE PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

3.7 RELAY PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

3.8 INVERTER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

3.9 MONITOR UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

3.10 ENCODER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

3.11 CD MECHANISM MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

4. PCB CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.1 MOTHER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

4.2 TUNER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

4.3 GRILLE PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

4.4 INVERTER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

4.5 RELAY PCB,UPPER PCB. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .53

4.6 MONITOR PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .54

4.7 ENCODER UNIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

4.8 CD MECHANISM MODULE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

5. ELECTRICAL PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

6. ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

6.1 JIG CONNECTION DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

6.2 MOTHER PCB ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

6.3 INVERTER PCB ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

6.4 MONITOR PCB ADJUSTMENT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

6.5 MONITOR TEST MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

6.6 CD ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

6.7 CHECKING THE GRATING AFTER CHANGING THE PICKUP UNIT . . . . . . . . . .92

6.8 CD TEST MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

7. GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.1 DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.1.1 DISASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

7.1.2 CONNECTOR FUNCTION DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . 105

7.1.3 PCB LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

7.2 IC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

7.3 EXPLANATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.3.1 SCHEMATIC DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

7.3.2 MECHANISM DESCRIPTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

7.3.3 OPERATIONAL FLOW CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

7.4 CLEANING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

8. OPERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

C

D

AVH-P6400CD/UC

56

7

5

8

Page 6

1234

1. SPECIFICATIONS

A

General

Power source ............... 14.4 V DC

Grounding system ...... Negative type

Max. current consumption

..................................... 10.0 A

Backup current ............... Less than 3mA

Dimensions (W ×H ×D):

(DIN) ...................... Chassis 178 ×50 ×160 mm

Nose .............. 188 ×58 ×37.6 mm

(D) Chassis ........ 178 ×50 ×165 mm

Nose .............. 178 ×50 ×32.6 mm

Remote control ..... 51.5 ×123 ×10.9 mm

B

Weight

Main Unit

Remote control .....

Amplifier

UC,ES model

Continuous power output is 27 Wper channel min. into 4 ohms, both channels driven

50 to 15,000 Hz with no more than 5% THD.

Maximum power output 50 W ×4

50 W

×

2 ch/4 Ω+70 W ×1 ch/2 Ω(for Subwoofer)

EW model

Maximum power output....50 W ×4

50 W

×

C

2 ch/4 Ω+70 W ×1 ch/2 Ω(for Subwoofer)

Continuous power output ...27 W ×4

Load impedance ..........4Ω(4 – 8 Ω[2 Ωfor 1 ch]

[7 × 2× 6-5/16 in]

[7-3/8 × 2-1/4× 1−1/2 in]

[7 × 2× 6-1/2 in]

[7 × 2× 1−1/4 in]

[2-1/32 × 4-7/8×

.....

2.4 kg (5.3 lbs)

49.4 g (0.1 lbs)

(including battery)

allowable)

7/16 in]

25 W ×4(BRI)

(DIN 45324,+B=14.4V)

UC,EW model

(High)

Frequency ....... 3.15 k/8 k/10 k/12.5

k Hz

Q Factor .......... 0.35/0.59/0.95/1.15

(+6 dB when boosted)

Gain ................±12 dB

Loudness contour:

(Low) ..................... +3.5 dB (100 Hz)

+3 dB (10 kHz)

(Mid) ..................... +10 dB (100 Hz)

+6.5 dB (10 kHz)

(High) .................... +11 dB (100 Hz)

+11 dB (10 kHz)

(Volume: –30 dB)

Tone controls:

(Bass)

Frequency ....... 40/63/100/160Hz

Gain ................±12 dB

(Treble)

Frequency ....... 2.5 k/4 k/6.3 k/10 k

Hz

Gain ................±12 dB

HPF:

Frequency ....... 50/80/125 Hz

Slope ...............–12 dB/oct

Subwoofer:

Frequency ....... 50/80/125 12 dB/oct

Slope ...............–18 dB/oct

Gain ................±12 dB

Phase ............... Normal/Reverse

CD player

System ......................... Compact disc audio

system

Usable discs ................. Compact disc

Signal format:

Sampling frequency 44.1 kHz

Number of quantization bits

............................... 16; linear

Frequency characteristics

..................................... 5 – 20,000 Hz (±1 dB)

Signal-to-noise ratio ....... 94 dB (1 kHz)

(IHF-A network)

Dynamic range ............ 92 dB (1 kHz)

Number of channels ...... 2(stereo)

Preout maximum output level/output imped-

.....................................4.0 V/100 Ω

Equalizer (3-Band Parametric Equalizer):

(Low)

Frequency ....... 40/80/100/160 Hz

Q Factor .......... 0.35/0.59/0.95/1.15

Gain ................±12 dB

(Mid)

Frequency ....... 200/500/1 k/2 k Hz

Q Factor .......... 0.35/0.59/0.95/1.15

D

Gain ................±12 dB

6

ance

(+6 dB when boosted)

(+6 dB when boosted)

AVH-P6400CD/UC

1234

Page 7

A

B

5678

FM tuner

UC model

Frequency range ......... 87.9 – 107.9 MHz

EW,ES model

Frequency range ......... 87.5 – 108 MHz

Usable sensitivity ....... 9dBf (0.8 µV/75 Ω,

50 dB quieting sensitivity 14 dBf dBf

Signal-to-noise ratio 70 dB (IHF-A network)

Distortion ...............

Frequency response 30 – 15,000 Hz (±3

Stereo separation ........ 40 dB (at 65 dBf, 1

UC model

Selectivity .................... 70 dB (2ACA)

Three signal intermodulation

(Desire signal level) 30 dBf

(two undesire signal level: 100 dBf)

mono,

S/N: 30 dB)

µV/75 Ω, mono)

.......

0.3% (at 65 dBf, 1

kHz,

stereo)

.....

dB)

kHz)

UC model

AM tuner

Frequency range ......... 530 – 1,710 kHz (10

Usable sensitivity ........ 18 µV(S/N: 20 dB)

Selectivity ....................

Video

Composit input level 1Vp-p/75 Ω

Composit output level 1Vp-p/75 Ω

ES model

kHz)

50 dB (±10 kHz)

......

....

AM tuner

Frequency range ......... 531 – 1,602 kHz (9

Usable sensitivity ........ 18 µV(S/N: 20 dB)

Selectivity ....................

Video

Composit input level 1Vp-p/75 Ω

Composit output level 1Vp-p/75 Ω

EW model

kHz)

530 – 1,640 kHz (10

kHz)

50 dB (±9 kHz)

50 dB (±10 kHz)

......

....

MW tuner

Frequency range ......... 531 – 1,602 kHz (9

Usable sensitivity ........ 18 µV(S/N: 20 dB)

Selectivity .................... 50 dB (±9 kHz)

EW model

kHz)

LW tuner

Frequency range ......... 153 – 281 kHz

Usable sensitivity ........ 30 µV(S/N: 20 dB)

Selectivity ....................

Video

Composit input level 1Vp-p/75 Ω

Composit output level 1Vp-p/75 Ω

50 dB (±9 kHz)

......

....

Display

Screen size/Aspect ratio 6.5 inch wide/16:9

(effective display area: 146.72 ×79.10 mm)

Pixels ........................... 336,960 (1,440 ×234)

Type ............................. TFT active matrix,

Color system ............... NTSC Compatible

Operating temperature range

...................................... –10 to +50°C

Storage temperature range

...................................... –20 to +80°C

Angle Adjustment ....... 55 — 110°

Dimensions (W ×H ×D):

..................................... 155.54 × 89.2 × 6.1

ES model

Infrared remoto cntrol

Wavelength...................940nm ± 50nm

Output............................typ; 5 mw/sr per

Note

• Specifications and the design are subjeto possible modifications withoutct

notice due to improvements.

transmissive type

Initial setting angle:

100°

mm

[6-1/8 × 3-1/2 1/4

in]

infrared LED

C

AVH-P6400CD/UC

56

D

7

7

8

Page 8

1234

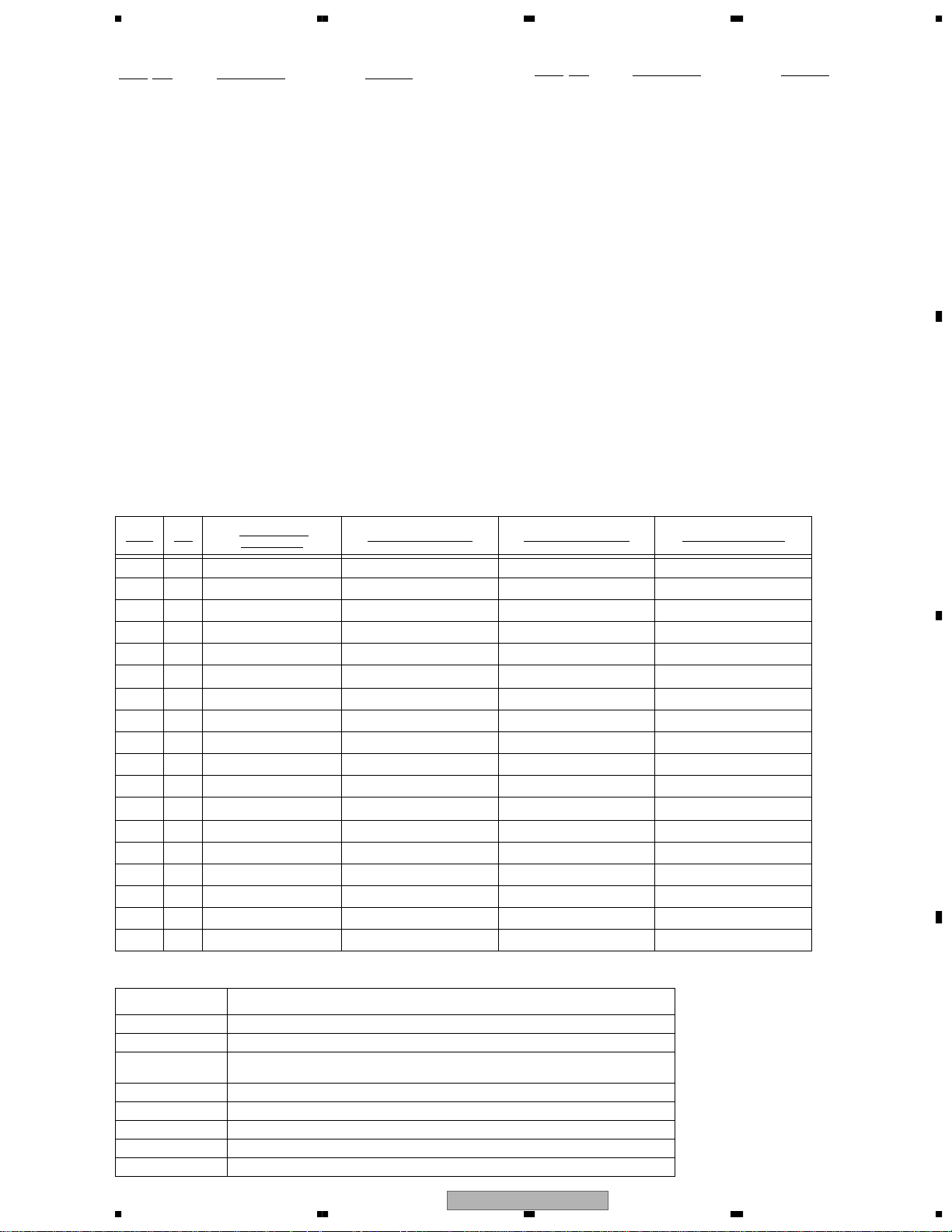

2. EXPLODED VIEWS AND PARTS LIST

NOTES : • Parts marked by " * " are generally unavailable because they are not in our Master Spare Parts List.

• Screw adjacent to mark on the product are used for disassembly.

• For the applying amount of lobricants or glue, follow the instructions in this manual.

A

(In the case of no amount instructions,apply as you think it appropriate.)

"

2.1 PACKING

B

C

D

8

1234

AVH-P6400CD/UC

Page 9

A

B

5678

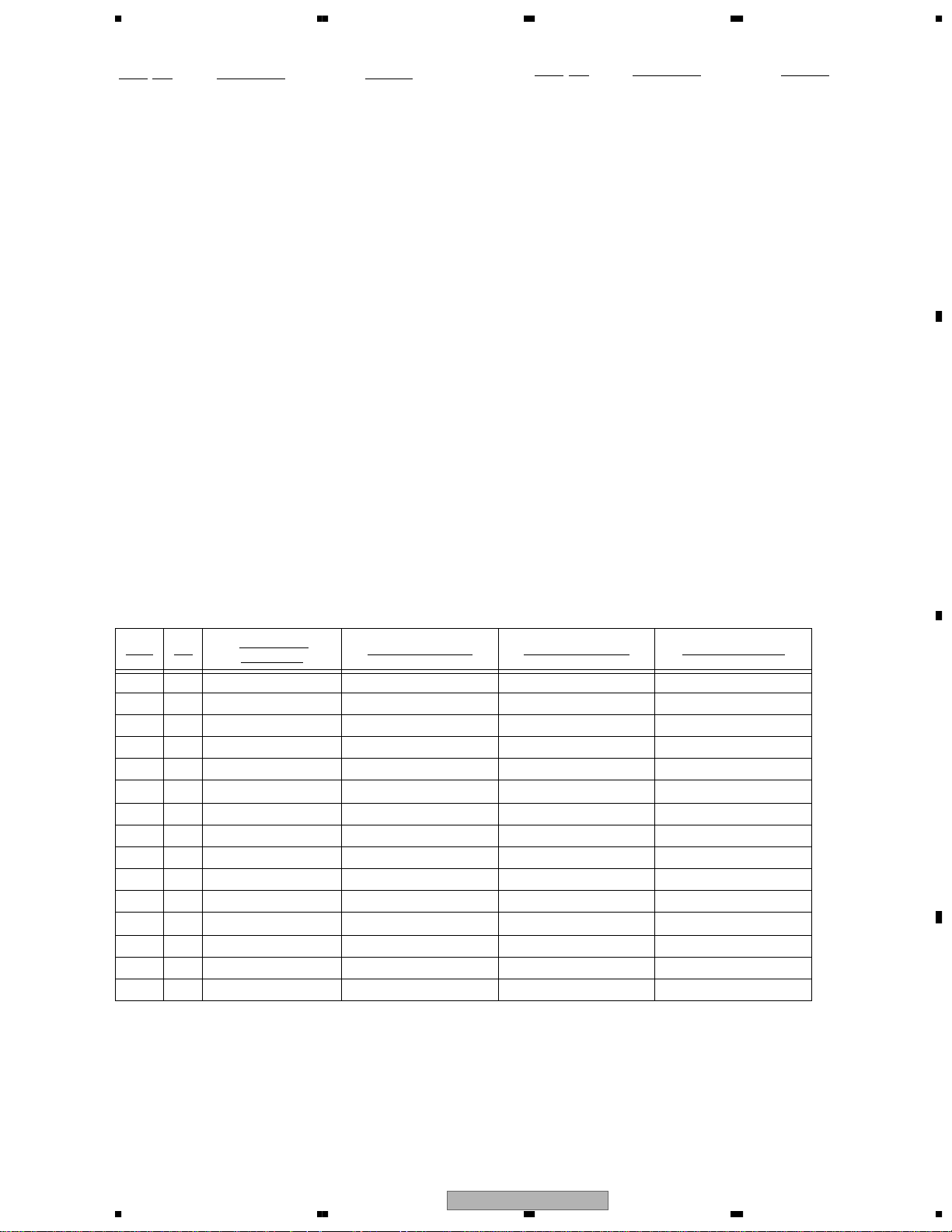

(1) PACKING SECTION PARTS LIST

Mark

No. Description Part No.

1 Carton See Contrast table(2)

2 Contain Box See Contrast table(2)

3 Cord Assy See Contrast table(2)

4 Cord Assy CDE7045

5 Screw Assy CEA2927

6 Screw BMZ50P060FMC

7 Screw CBA1468

8 Screw CMZ50P060FMC

* 9 Polyethylene Sheet CNM4338

10 Accessory Assy CEA3214

11 Screw CBA1002

12 Screw CBA1587

13 Bracket CNC9383

14 Bush CNV1917

* 15 Polyethylene Bag E36-615

16 Polyethylene Bag See Contrast table(2)

17-1 Polyethylene Bag CEG1116

17-2 Owner's Manual See Contrast table(2)

17-3 Owner's Manual See Contrast table(2)

(2) CONTRAST TABLE

Mark No. Description Part No.

17-4 Installation Manual See Contrast table(2)

17-5 Caution Card CRP1276

* 17-6 Passport See Contrast table(2)

* 17-7 Warranty Card See Contrast table(2)

* 17-8 Card See Contrast table(2)

18 Sub Box CHA3172

19 Remote Control Assy CXB9039

20 Case Assy See Contrast table(2)

21 Protector CHP2385

22 Protector CHP2445

23 Protector CHP2446

24 Protector CHP2555

25 Filter See Contrast table(2)

26 Cord Assy See Contrast table(2)

27 Sheet CNM7244

* 28 Polyethylene Bag See Contrast table(2)

29 Filter See Contrast table(2)

* 30 Polyethylene Bag See Contrast table(2)

AVH-P6400CD/UC,AVH-P6400CD/EW and AVH-P6450CD/ES are constructed the same except for the following:

Mar

k NO

1 Carton CHG4715 CHG4714 CHG4713

2 Contain Box CHL4715 CHL4714 CHL4713

3 Cord Assy Not used CDE6829 Not used

16 Polyethylene Bag CEG1185 CEG1088 CEG1088

*

*

*

20 Case Assy Not used CXB9182 CXB9182

* 28 Polyethylene Bag CEG1158 Not used Not used

* 30 Polyethylene Bag Not used CEG1250 Not used

17-2

17-3

17-4

17-6

17-7

17-8

25 Filter CTX1090 Not used Not used

26 Cord Assy CDE7008 Not used CDE7008

29 Filter Not used CTX1089 Not used

Symbol and

Description

Owner's Manual CRD3655 CRD3658 CRD3627

Owner's Manual Not used CRD3659 CRD3628

Installation Manual CRD3626 CRD3624 CRD3656

Passport Not used CRY1013 Not used

Warranty Card Not used CRY1157 Not used

Card ARY1048 Not used Not used

AVH-P6400CD/UC AVH-P6400CD/EW AVH-P6450CD/ES

Owner's Manual,Installation Manual

C

Part No. Language

CRD3658 English, Spanish,German

CRD3659 French,Italian,Dutch

CRD3624 English, Spanish,German,

French,Italian,Dutch

CRD3655 English, French,Spanish

CRD3626 English, French,Spanish

CRD3627 English, Spanish,Portuguese(B)

CRD3628 Casual Chinese,Arabic,Korean

CRD3656 English, Spanish,Portuguese(B),Casual Chinese,Arabic,Korean

AVH-P6400CD/UC

56

D

9

7

8

Page 10

1234

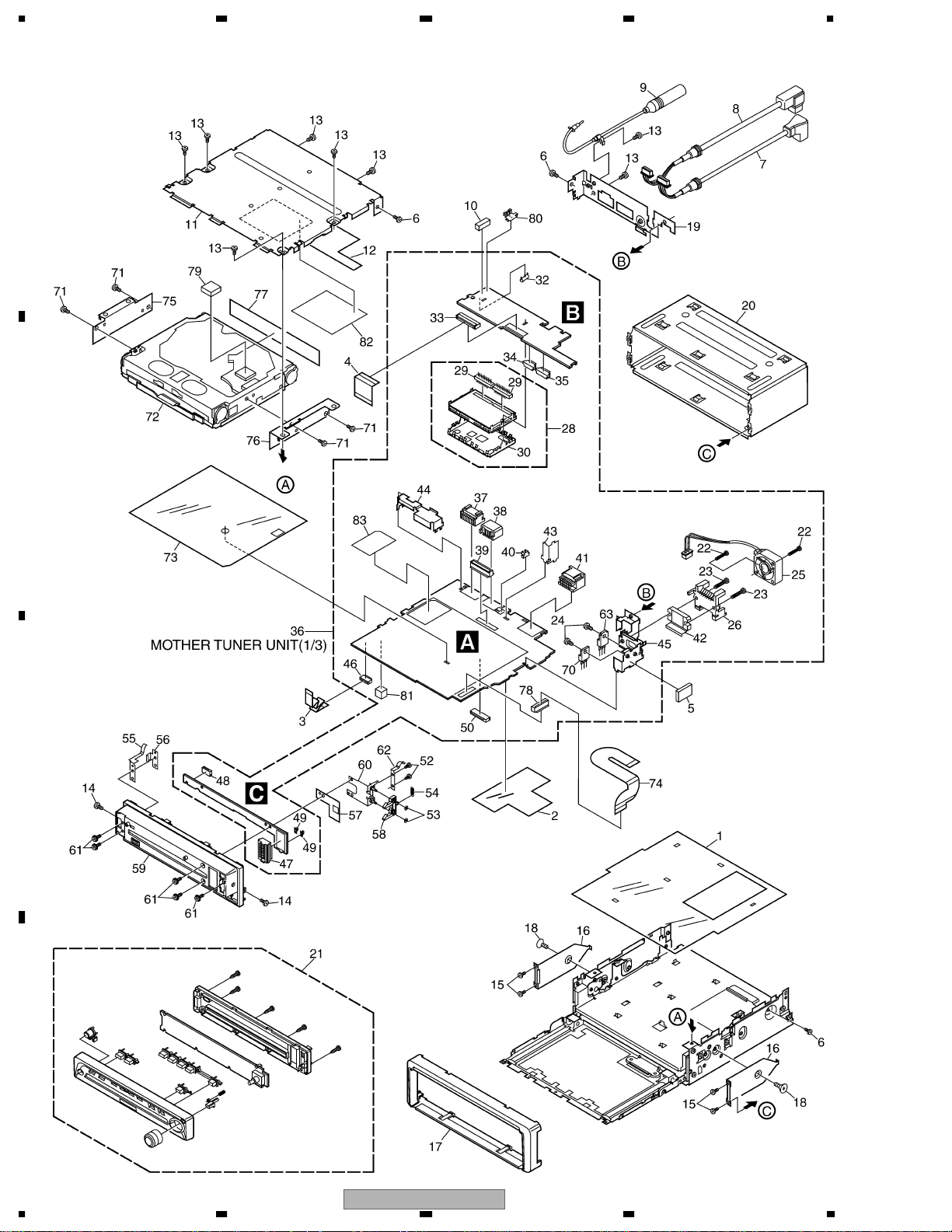

2.2 EXTERIOR(1)

A

B

C

D

10

1234

AVH-P6400CD/UC

Page 11

A

B

5678

(1) EXTERIOR(1) SECTION PARTS LIST

Mark

No. Description Part No.

1 Insulator CNM7689

2 Insulator CNM7690

3 FFC CDE7048

4 FFC CDE6831

5 Sheet CNM7865

6 Screw BMZ26P030FZK

7 Cord Assy CDE6826

8 Cord Assy CDE6827

9 Antenna Cable CDH1318

10 Gasket CNM7525

11 Case See Contrast table(2)

12 Insulator CNM7969

13 Screw BSZ26P060FMC

14 Screw CBA1475

15 Screw BMZ20P030FZK

16 Bracket CNC9389

17 Panel See Contrast table(2)

18 Screw CMZ50P060FMC

19 Panel See Contrast table(2)

20 Holder CNC9510

21 Detach Grille Assy See Contrast table(2)

22 Screw PMZ20P160FMC

23 Screw BMZ26P140FMC

24 Screw BMZ30P060FMC

25 Fan Motor(M1) CXM1193

26 Heat Sink CNR1642

27 •••••

28 FM/AM Tuner Unit See Contrast table(2)

29 Connector(CN1,2) CKS4244

30 Case CNC8709

31 •••••

32 Antenna Jack(CN2401) CKX1010

33 Connector(CN2402) CKS4512

34 Connector(CN2403) CKS3131

35 Connector(CN2404) CKS3133

36 Mother Tuner Unit(1/3) See Contrast table(2)

37 Connector(CN1141) CKM1365

38 Connector(CN1226) See Contrast table(2)

39 Connector(CN1341) CKS3930

40 Connector(CN1841) CKS3124

No. Description Part No.

Mark

41 Connector(CN1801) CKM1332

42 IC(IC1301) PAL006A

43 Holder CNC9867

44 Holder CNC9866

45 Holder CNC9865

46 Connector(CN1201) CKS4595

47 Connector(CN3802) CKS4606

48 Connector(CN3831) CKS4212

49 Terminal(CN3833,3834) CKF1068

50 Connector(CN1331) CKS3971

51 •••••

52 Screw BMZ20P025FMC

53 Washer CBF1038

54 Spring CBH2577

55 Spring CBL1583

56 Holder CNC9873

57 Insulator CNM7694

58 Arm CNV7127

59 Grille Unit CXB8638

60 Holder Unit CXB8738

61 Screw IMS20P040FZK

62 Spring CBL1582

63 IC(IC1861) BA00AST

64-69 •••••

70 Transitor(Q1931) 2SD2375

71 Screw BMZ26P030FMC

72 CD Mechanism Module(H2) CXK5356

73 Insulator See Contrast table(2)

74 Flexible PCB CNP6627

75 Holder CNC9869

76 Holder CNC9870

77 Insulator CNM7866

78 Connector(CN1251) CKS4248

79 Cushion CNM7907

80 Spring CBL1590

81 Gasket CNM8056

82 Insulator CNM8016

83 Shield See Contrast table(2)

C

(2) CONTRAST TABLE

AVH-P6400CD/UC,AVH-P6400CD/EW and AVH-P6450CD/ES are constructed the same except for the following:

Mark NO

11 Case CNB2739 CNB2738 CNB2739

17 Panel CNS7067 CNS7067 CNS7227

19 Panel CNB2740 CNB2740 CNB2741

21 Detach Grille Assy CXB9111 CXB8640 CXB9112

28 FM/AM Tuner Unit CWE1608 CWE1607 CWE1608

36

38 Connector(CN1226) CKS4497 CKS4497 Not used

73 Insulator CNM7688 CNM7995 CNM7688

83 Shield Not used CNM7972 Not used

Symbol and

Description

Mother T uner Unit(1/3)

AVH-P6400CD/UC AVH-P6400CD/EW AVH-P6450CD/ES

CXX1632 CXX1631 CXX1634

AVH-P6400CD/UC

56

7

8

D

11

Page 12

1234

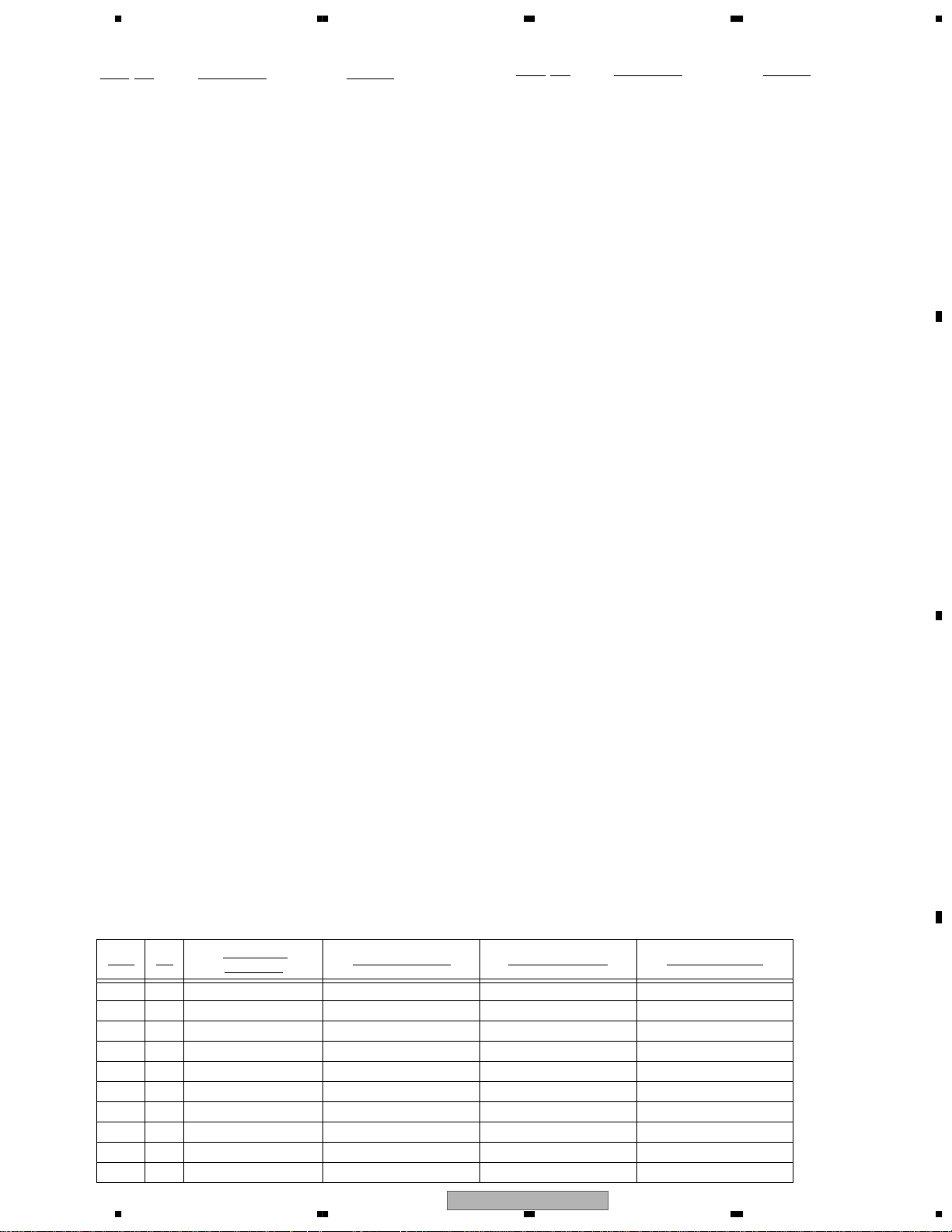

2.3 EXTERIOR(2)

A

B

C

D

12

1234

AVH-P6400CD/UC

Page 13

A

B

5678

(1) EXTERIOR(2) SECTION PARTS LIST

Mark

No. Description Part No.

101 Cord Assy See Contrast table(2)

102 Fuse(10A) See Contrast table(2)

103 Resistor See Contrast table(2)

104 Cap See Contrast table(2)

105 Cord Assy See Contrast table(2)

106 Fuse(10A) See Contrast table(2)

107 Resistor See Contrast table(2)

108 Cap See Contrast table(2)

109 Cap See Contrast table(2)

110 Mother Tuner Unit(2/3) See Contrast table(2)

111 Grille Unit See Contrast table(2)

112 Shield CNM7563

113 Knob CAA2727

114 Button(EJ) CAC7556

115 Button(D,N/A,W:EW,UC) See Contrast table(2)

or (D,ENT,WI:ES)

116 Screw BPZ20P050FMC

117 Cushion CNM7827

118 Screw(M2x2) CBA1551

119 Cover See Contrast table(2)

120 Screw JFZ20P022FNI

121 Holder CNC9464

Mark No. Description Part No.

122 FFC CDE6540

123 Remote Control Assy CXB9039

124 Cover CZN5357

125 Holder CNC9907

126 Monitor Unit CWM8269

127 LCD Panel CWX2671

128 Sheet CNM7566

129 Insulator CNM7782

130 Sheet CNM7784

131 Sheet CNM7783

132 Flexible PCB CNP6628

133 FFC CDE6833

134 Connector(CN2) CKS3805

135 Connector(CN801) CKS3991

136 Connector(CN3) CKS4426

137 Connector(CN5) CKS4448

138 Connector(CN811) CKS4448

139 Cord Assy CDE7045

140 Cap CNV6727

141 Connector(CN941) CKS4426

142 Connector(CN942) CKS4428

143 Sheet CNM8058

(2) CONTRAST TABLE

AVH-P6400CD/UC,AVH-P6400CD/EW and AVH-P6450CD/ES are constructed the same except for the following:

Mar

k NO

101

102

103

104

105

106

107

108

109

110 Mother T uner Unit(2/3)

111

115

119

Symbol and

Description

Cord Assy CDE7008 Not used CDE7008

Fuse(10A) CEK1136 Not used CEK1136

Resistor RS1/2P102JL Not used RS1/2P102JL

Cap CNS1472 Not used CNS1472

Cord Assy Not used CDE6829 Not used

Fuse(10A) Not used CEK1136 Not used

Resistor Not used RS1/2P102JL Not used

Cap Not used CKX-003 Not used

Cap Not used CNS1472 Not used

Grille Unit CXB9090 CXB9089 CXB9091

Button CAC7557 CAC7557 CAC7687

Cover CNS7029 CNS7029 CNS7150

AVH-P6400CD/UC AVH-P6400CD/EW AVH-P6450CD/ES

CXX1632 CXX1631 CXX1634

C

AVH-P6400CD/UC

56

D

13

7

8

Page 14

1234

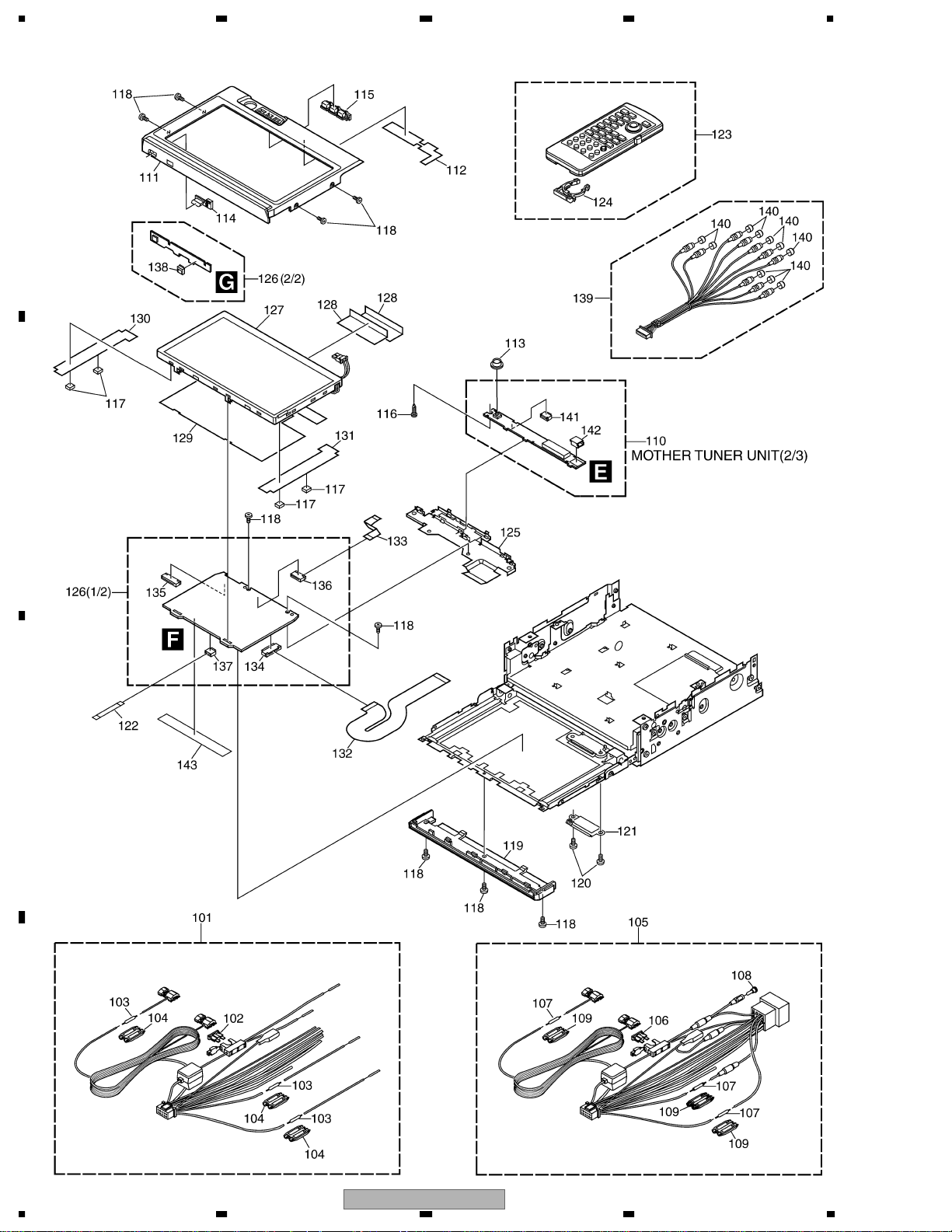

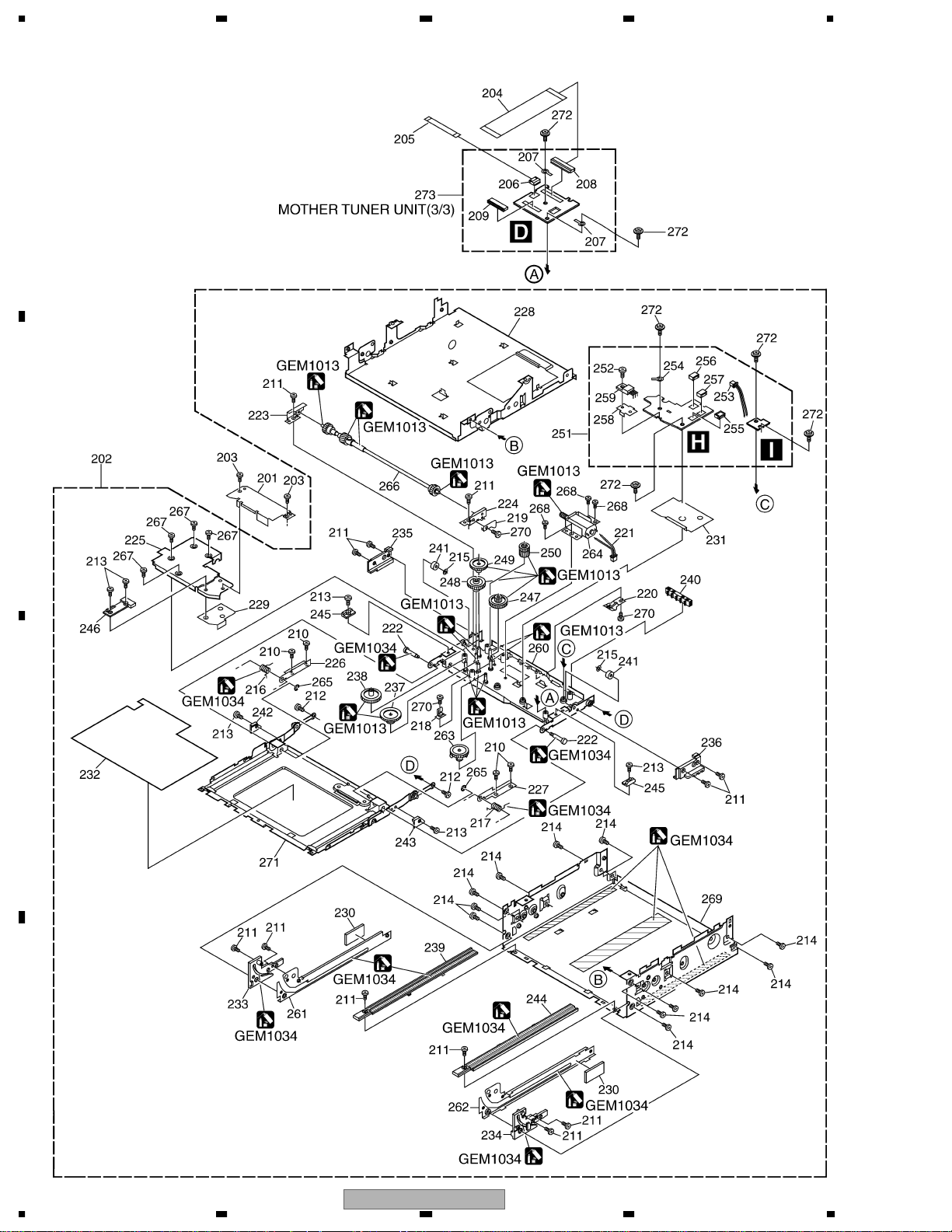

2.4 EXTERIOR(3)

A

B

C

D

14

1234

AVH-P6400CD/UC

Page 15

A

B

5678

(1) EXTERIOR(3) SECTION PARTS LIST

Mark

No. Description Part No.

201 Holder CNC9871

202 Drive Unit CXB9399

203 Screw(M2x2) CBA1551

204 Flexible PCB CNP6626

205 FFC CDE6555

206 Connector(CN4803) CKS4054

207 Terminal(CN4804,4805) CKF1064

208 Connector(CN4801) CKS3971

209 Connector(CN4802) CKS4281

210 Screw(M2x2.2) CBA1419

211 Screw(M2x2.5) CBA1447

212 Screw CBA1475

213 Screw CBA1484

214 Screw(M3x3) CBA1534

215 Washer CBF1064

216 Spring CBH2469

217 Spring CBH2470

218 Spring CBL1527

219 Spring CBL1534

220 Spring CBL1545

221 Cord Assy CDE6685

222 Shaft CLA4007

223 Holder CNC9302

224 Holder CNC9303

225 Cover CNC9304

226 Holder CNC9516

227 Holder CNC9517

228 Frame CNC9874

229 Insulator CNM7335

230 Cushion CNM7377

231 Insulator CNM7380

232 Sheet CNM7415

233 Rail CNS6492

234 Rail CNS6493

235 Guide CNS6494

236 Guide CNS6495

237 Gear CNV6654

No. Description Part No.

Mark

238 Gear CNV6655

239 Rack CNV6669

240 Guide CNV6672

241 Roller CNV6673

242 Guide CNV6750

243 Guide CNV6751

244 Rack CNV6752

245 Guide CNV6765

246 Guide CNV6766

247 Gear CNV6824

248 Gear CNV6825

249 Gear CNV6826

250 Gear CNV6827

251 Encoder Unit CWM7620

252 Screw BMZ26P050FMC

253 Cord Assy CDE6686

254 Terminal(CN2801) CKF1064

255 Connector(CN2804) CKS4054

256 Connector(CN2805) CKS4282

257 Connector(CN2806) CKS4282

258 Heat Sink CNC9312

259 IC(IC2801) TA7806S

260 Frame Unit CXB7051

261 Rail Unit CXB7064

262 Rail Unit CXB7065

263 Gear Unit CXB7437

264 Motor Unit(M1)(Drive Motor) CXB7612

265 Washer YE20FUC

266 Shaft Unit CXB8855

267 Screw JFZ20P040FZK

268 Screw JGZ20P020FMC

269 Chassis Unit CXB8959

270 Screw JFZ20P020FZK

* 271 Case Unit CXB9396

272 Screw IMS20P030FMC

273 Mother Tuner Unit(3/3) See Contrast table(2)

C

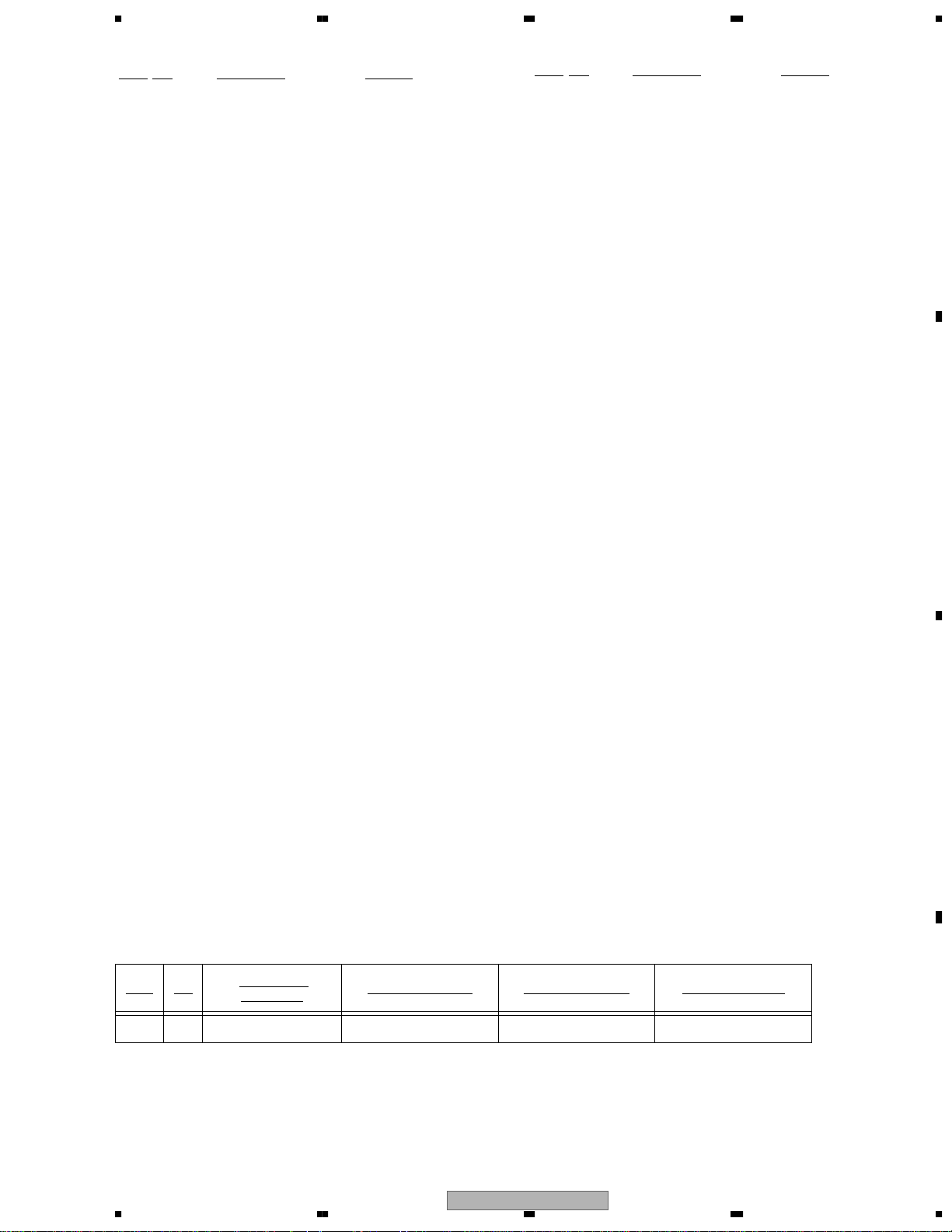

(2) CONTRAST TABLE

AVH-P6400CD/UC,AVH-P6400CD/EW and AVH-P6450CD/ES are constructed the same except for the following:

Mark NO

273

Symbol and

Description

Mother T uner Unit(3/3)

AVH-P6400CD/UC AVH-P6400CD/EW AVH-P6450CD/ES

CXX1632 CXX1631 CXX1634

AVH-P6400CD/UC

56

7

8

15

D

Page 16

1234

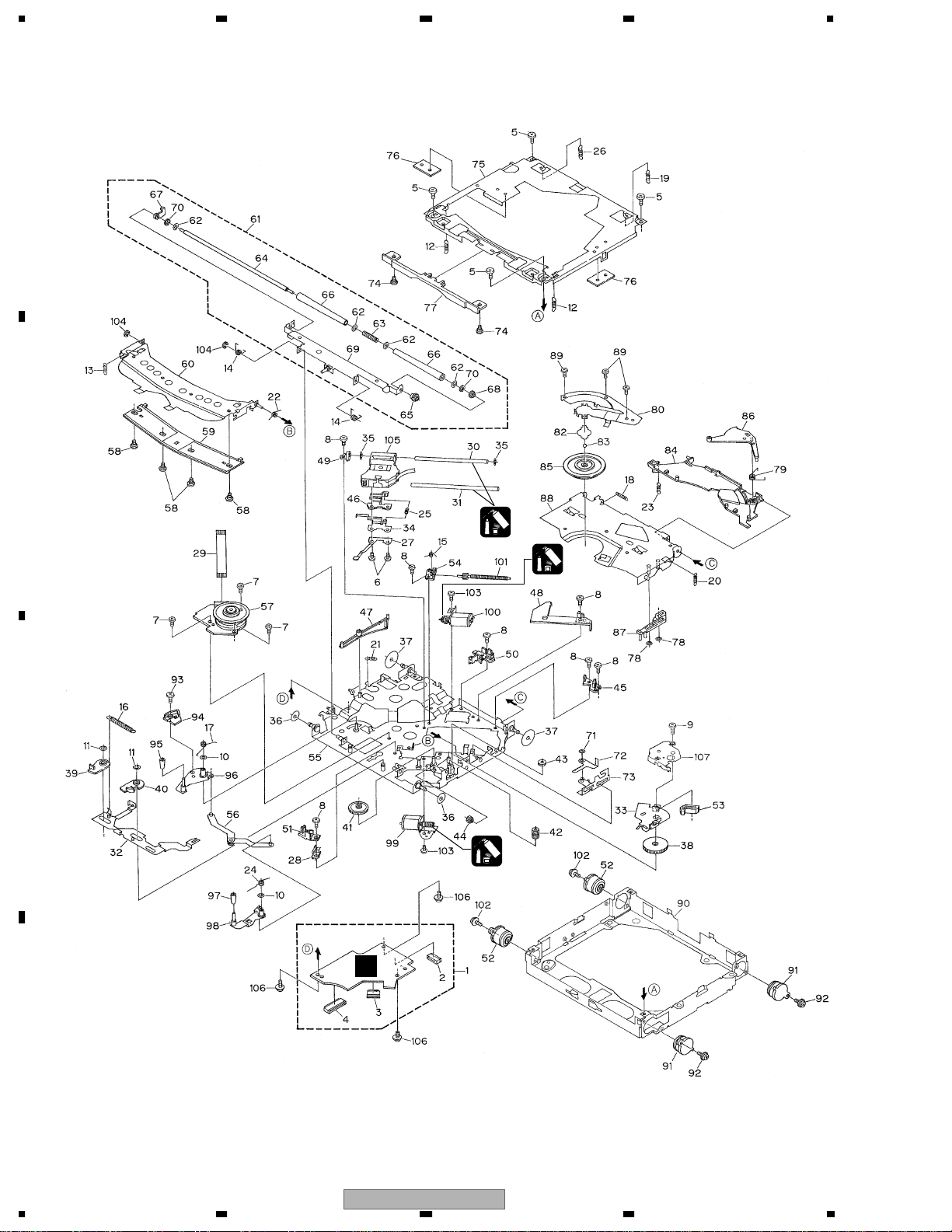

2.5 CD MECHANISM MODULE

A

B

GEM1030

GEM1030

C

GEM1029

J

D

16

1234

AVH-P6400CD/UC

Page 17

A

B

5678

CD MECHANISM MODULE SECTION PARTS LIST

Mark No. Description Part No.

1 CD Core Unit CWX2676

2 Connector(CN101) CKS3785

3 Connector(CN901) CKS4291

4 Connector(CN701) CKS4522

5 Screw BSZ20P035FMC

6 Screw(M2x4) CBA1362

7 Screw(M2x2.5) CBA1510

8 Screw(M2x3) CBA1511

9 Screw(M2x6.2) CBA1536

10 Washer CBF1037

11 Washer CBF1064

12 Spring CBH2291

13 Spring CBH2292

14 Spring CBH2293

15 Spring CBH2295

16 Spring CBH2297

17 Spring CBH2298

18 Spring CBH2299

19 Spring CBH2303

20 Spring CBH2304

21 Spring CBH2305

22 Spring CBH2308

23 Spring CBH2309

24 Spring CBH2332

25 Spring CBH2416

26 Spring CBH2434

27 Spring CBL1448

28 Spring CBL1466

29 Connector CDE6099

30 Shaft CLA3683

31 Shaft CLA3684

32 Lever CNC8501

33 Bracket CNC8507

34 Bracket CNC8509

35 Cushion CNM6301

36 Sheet CNM6773

37 Sheet CNM6774

38 Gear CNR1559

39 Arm CNV5928

40 Arm CNV5929

41 Gear CNV5930

42 Gear CNV5932

43 Gear CNV5931

44 Gear CNV5933

45 Holder CNV5943

46 Holder CNV5944

47 Arm CNV5948

48 Cover CNV5950

49 Holder CNV5951

50 Holder CNV6222

51 Holder CNV6223

52 Damper CNV6426

53 Holder CNV6446

54 Holder CNV6512

55 Chassis Unit CXB4501

No. Description Part No.

Mark

56 Arm Unit CXB4503

57 Motor Unit(M3) CXB6620

58 Screw(M2x1.2) CBA1495

59 Guide CNV5925

60 Arm Unit CXB5311

61 Loading Arm Assy(-G) CXB5715

62 Washer CBF1060

63 Spring CBH2170

* 64 Shaft CLA3678

* 65 Gear CNV5934

66 Roller CNV6068

67 Holder CNV6210

68 Collar CNV6439

69 Arm Unit CXB5686

70 Washer YE20FUC

71 Washer CBF1038

72 Arm CNC8498

73 Lever Unit CXB4502

74 Screw(M2x1.5) CBA1509

75 Frame CNC8497

76 Sheet CNM6951

77 Guide CNV5924

78 Washer CBF1037

79 Spring CBH2300

80 Spring CBL1446

81 •••••

82 Spacer CNM6467

83 Ball CNR1189

84 Guide CNV5945

85 Clamper CNV5946

86 Arm CNV5947

87 Lever CNV5949

88 Arm Unit CXB4505

89 Screw JFZ20P020FMC

90 Frame CNC8845

91 Damper CNV6426

92 Screw ISS20P060FMC

93 Screw(M2x3) CBA1511

94 Holder CNV6341

95 Roller CNV6389

96 Arm Unit CXB5970

97 Roller CNV6389

98 Arm Unit CXB5971

99 Load Motor Assy(-D)(M2) CXB6340

100 Carriage Motor Assy(-D)(M1) CXB6361

101 Screw Unit(-B) CXB6363

102 Screw ISS20P060FMC

103 Screw JFZ20P025FNI

104 Washer YE15FUC

105 Pickup Unit(Service)(P8) CXX1305

106 Screw IMS20P030FMC

* 107 Cover CNC9151

C

D

AVH-P6400CD/UC

56

7

8

17

Page 18

1234

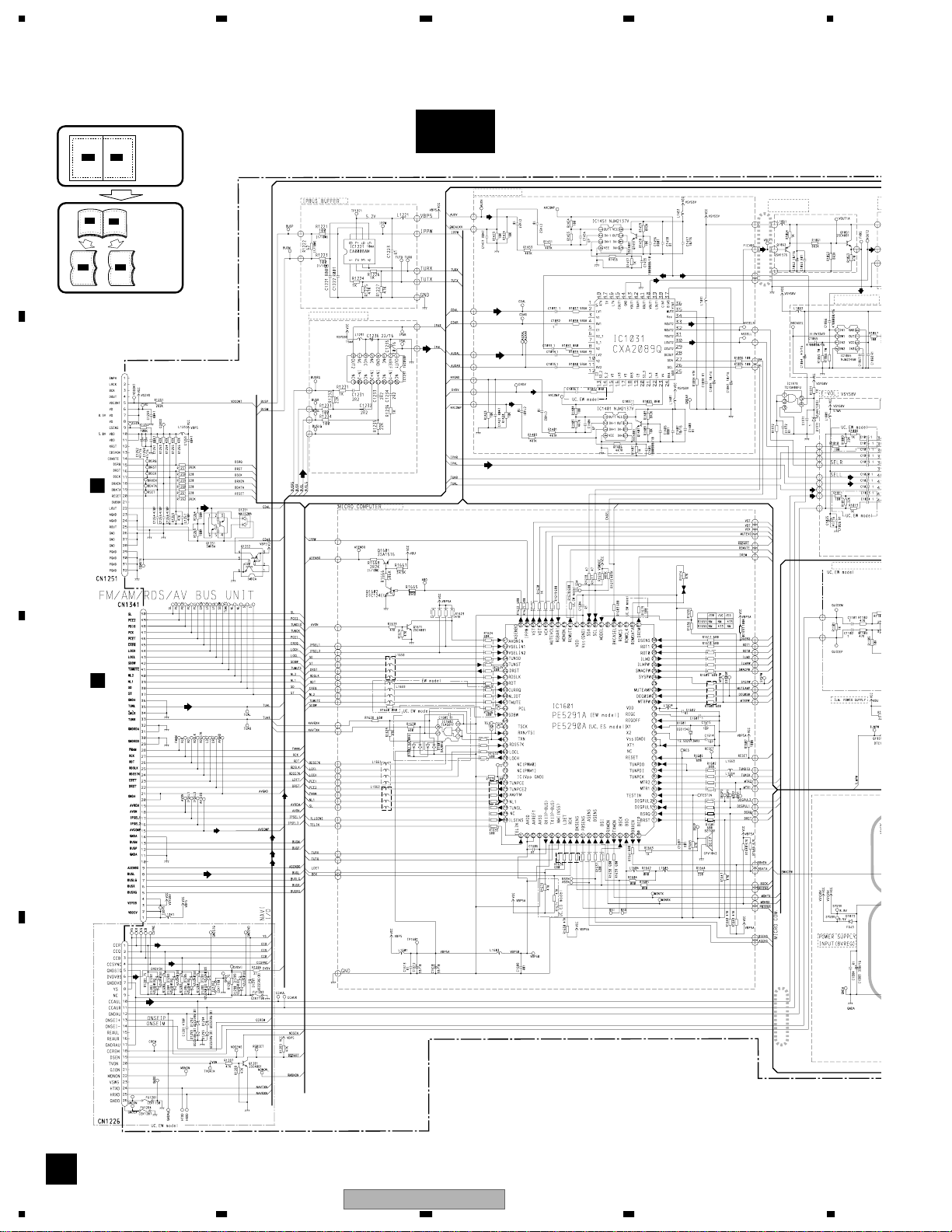

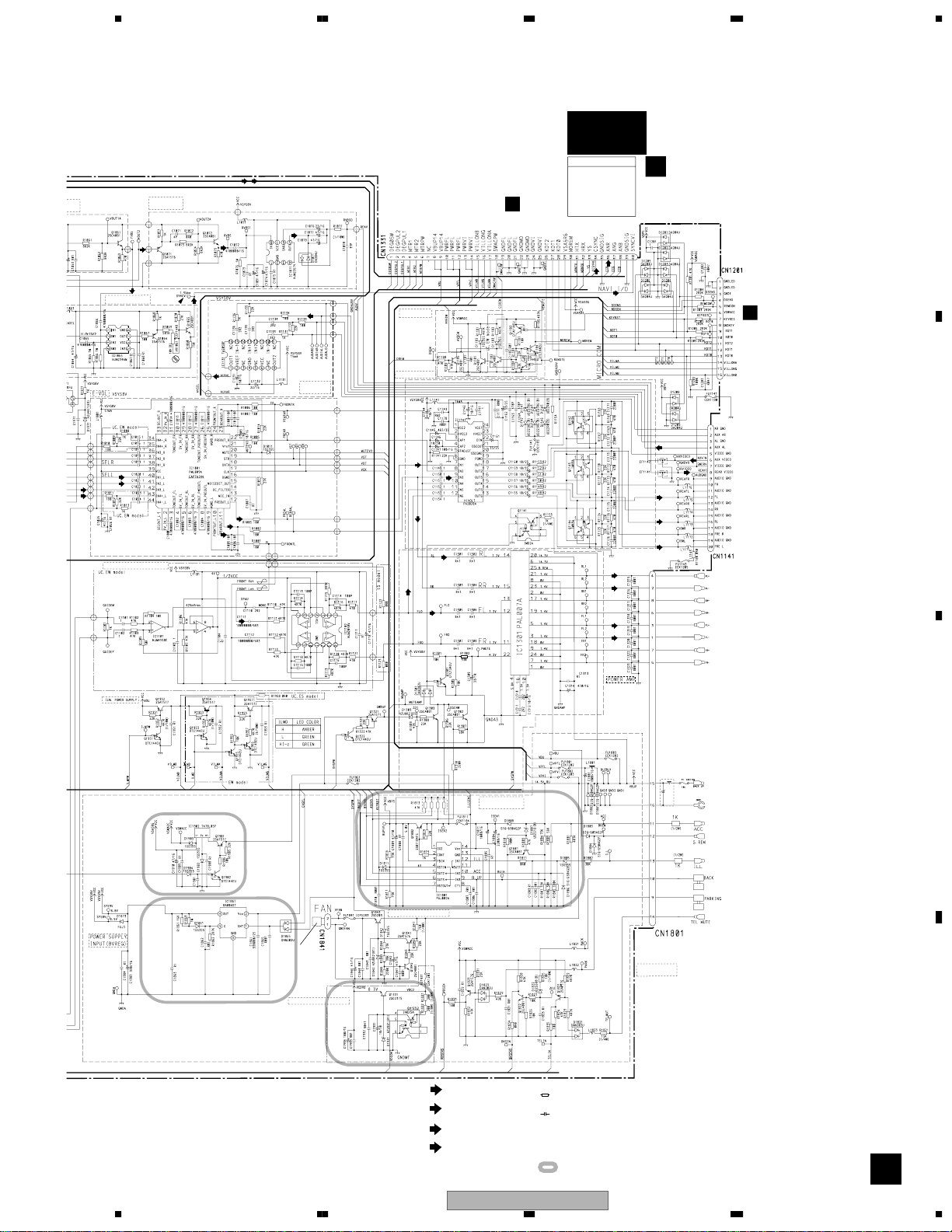

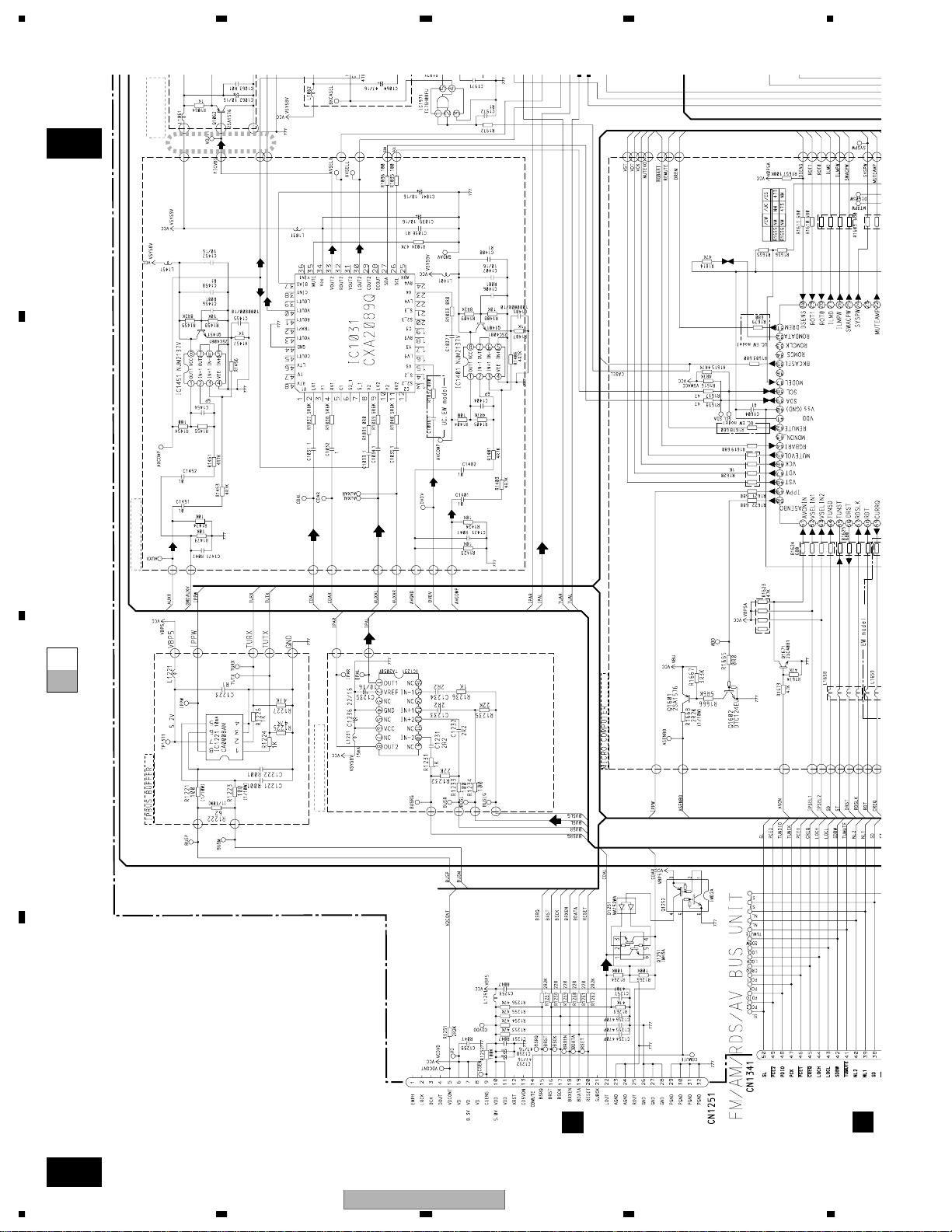

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM(1)

A

(2/2)MOTHER PCB

A

(UC,EW)

NAVI. INPUT

AUX VIDEO

VTR1LCH INPUT

VTR1RCH INPUT

B

FL,RL,PRE_L

REAR VIDEO

GRILLE PCB

C

RESET

7 7

KDT0-2

VILLONA,

VILLONG,

VILLONB

5

4

CN3831

16

11

CN3802

54

M

Remote control

MD

LD(—)

FO+

TO+

Detach

sensor

sensor

CN101

5

17

4

3

9

7

12

10

1

2

3

4

11

6

J

AC/F/E/BD

CN901

CONTST/SP

KDT0-2

KEY

MATRIX

ILLUMINATION

C

DETACH GRILLE ASSY

PU UNIT(SERVICE) (P8)

MONITOR

DIODE

+5V

HOLOGRAM

UNIT

LASER

DIODE

FOCUS ACT.

TRACKING ACT.

CARRIAGE

MOTOR

SPINDLE

MOTOR

EC

VM

VCC

M

LOADING

MOTOR

M

FG

CLAMPSW

D

CN1226 CN1331 CN4801 CN4802

CCR

1

CCG

2

CCB

3

CCSYNC

4

YS

8

CCREM

18

CN1141

AUXV

6

AUXIAL

4

AUXIAR

2

REAVI

8

CN1201

KEYRES

REMCOM

5

DSENS

4

CD CORE UNIT

RF AMP

8

MDI

IC 201

TA2153FN

Q101

9

LDO

Q102

13

11

15

IC 401

16

BA5811FM

22

VD

V+5

10

9

MUTE

21

SOUND INPUT ISO.

13 1

12 8

14,16,18

HIGH OUT

4

HOME

SW

X601

1

2

V+5

31

IC 1131

TA2050F

IC 1141

(1/2)

PA2028A

58

IC 1801(1/2)

PAJ002A

XI

IC 301

TC9495F2

HOME

CDMUTE

X2

IC 601

PE5273A

X1

CDLOAD

CDEJET

CONT

SPDIFG

DSCSNS

REGULATOR

4

VD

37

CD5VON

+5V

IC 801

BA05SFP

XO

LO

2

66

9

10

4

5

3

73

58

IC1451

NJM2137V

VIDEO AMP

IC1071

NJM2267V

CN701

77

X301

78

LOUT

85

Q302

VDD

Q301

RESET

RESET

7

7

BSRQ52

BRST77

BSCK

1

BRXEN29

BDATA2

31

1

VD

4

IC1971

IC1971

TC7SH08FU

TC7SH08FU

1,2

22

20

15

16

17

18

19

8

8

9

11

40

AUXV

LV2

RV2

VOUT1

2

3

1

IC 1065

NJM2246M

VIDEO/AUDIO

SELECTOR

IC 1031

CXA2089Q

(1/2)

2

LT1

CN1251

LOUT

22

BDATA

19

BSCK

17

BSRQ

15

BRXEN

18

BRST

16

RESET

20

VD

8

VOUT2

7

33

Q1181

X1601

2.582912MHz

BUZZER

VSYS8V

Q1183

Q1184

Q1182

(UC,EW)

35

BKCASEL

30

DSENS

CONTROLLER

PE5290A(UC,ES)

PE5291A(EW)

98

BSO

97

BSCK

2

BSRQ

99

BRXEN

100

BRST

11

RESET

15

16

100

Q1065

VCC

VSA5R6

SYSTEM

IC 1601

(2/2)

RXMON

TXMON

SWACPW

DEG0SW

MTR2

MTR1

MTRPW

DEGPUL2

DEGPUL1

95

96

25

BUP

DEG0SW

21

7

6

20

DEGPUL2

4

DEGPUL1

3

ANR

ANG

ANB

CSYNC

SYNCVI

HRX

HTX

VSA5R6

MOREM

YS

PWRFL PWRFL

MTR2

MTR1

MTRPW

RELAY PCB

D

Q922

BUP14V

CSYNC

SYNCVI

SWAC5R6

MOREM

SWACPW

MFLPW

PWRFL

CN4803

DEG0SW

MTR2

MTR1

BUP14

MTRPW

DEGPUL2

DEGPUL1

ANR

29

ANG

30

ANB

31

27

33

HRX

23

HTX

24

21

22

9

YS

25

13

1

1

2

2

32

3

6

10

9

2

1

11

7

8

ANR

36

5

18

18

ANG

37

4

19

19

ANB

38

3

17

17

CSYNC

34

7

20

20

SYNCVI

40

1

15

15

7

7

HRX

10

31

HTX

9

32

SWAC5R6

12

29

MOREM

11

30

SWACPW

23

18

YS

8

33

Q921

15

10

31

14

11

30

13

12

29

DEG0SW

1

40

MTR2

5

36

MTR1

4

37

MTRPW

6

35

DEGPUL2

2

39

DEGPUL1

3

38

18

AVH-P6400CD/UC

1234

Page 19

A

B

5678

CB

CN4802

ANR

ANG

ANB

CSYNC

SYNCVI

HRX

HTX

SWAC5R6

MOREM

SWACPW

YS

MFLPW

PWRFL

DEG0SW

MTR2

MTR1

BUP14 BUP14

V

MTRPW

DEGPUL2

DEGPUL1

F

CN2

29

29

30

30

31

31

27

27

33

33

23

23

TXD

24

24

SWAC56

21

21

REM

22

22

9

9

25

25

13 13

22

1

1

1

2

2

2

32

3

3

VILLMB,VILLMG,VILLMA

H

CN2804CN4803

DEG0SW

6

6

MTR2

2

10

MTR1

3

9

11

2

10

1

MTRPW

1

11

DEGPUL2

5

7

DEGPUL1

4

8

MONITOR PCB

ANR

ANG

ANB

CSYNC

CVBS

RXD

YS

MFLPW

PWRFL

ENCODER PCB

Q2803

Q2801

Q2804

FILTER

Q131

Q121

Q111

SYMC AMP

Q141

2,3 2

IC 142

TK15404MI

Q101

5->3V CHANGE

35

KEY0-2

Q603

RESET

12

IC 602

S-80835ANNP-EDZ

VACC5V

X601

10MHz

VILLMB,VILLMG,VILLMA

23

IC 2801

1

TA7806S

IC 2802

TA78L05F

4

7

5

3

IC 2804

TC7S14FU

IC 2807

TC7W14FU

1

Q2802

Q133

Q132

Q123

Q122

Q113

Q112

5->3 CHANGE

62

IC2(1/2)

TC7WH34FU

Q103

Q102

IC2(2/2)

TC7WH34FU

35

TSO

36

TSI

81

MFLPW

7

10

12

13

15

REMIN

VDDSENS

SYSTEM

CONTROLLER

RESET

IC 601

PD5747A

XOUT

XIN

DIMDTY

TC7S08FU

6

BA6951FS

5

10

VCC

2

1

3

24

2

IC 603

4

IC 2803

OSDCLK

LSEN

MVIPW

INVPUL

3

2

3

2

52

53

54

18

65

93

17

2

82

26

9

7

IC 2806

GP1S25

IC 2805

GP1S25

RIN

GIN

BIN

HDIN

CVI1

FNAVI

TWO PICTURES

CONTROL IC

IC 1

TC90A64AF

POLC

28

6

IC 92

TC7S08FU

IC 651

S-29131AFJ

EEP-ROM

8.0V

PWRFL

CN2805

MOP

MOM

CN2806

DEG0SEN1

RGB AMP

734

1

NJM2138V

1438

5.0V

1

3

3.3V

1

2.5V

15

8V

7

18V

8

-12V

Q832

14.4V

3.3V

3.3V

KEY3,4

Q153

Q152

Q151

Q182

Q183

7

IC 82

TC7WH34FU

IC 851

2

LT1376CS8

IC 841

2

R1130H251B

IC 861

4

MAX1748EUE

POWER SUPPLY

ROUT

36 4

GOUT

BOUT

82

X0

X1

42MHz

X1

83

101

SCKE

VCOM AMP

IC 181

NJM082BV

24

VCC

Q835

DIMDTY

1

Q831

5V

12

9

10

11

4

CN3

INVERTER PCB

E

1

MOTOR

2

SW PCB

I

S2801

1

2

CN941

1

2

3

8

PWRFL

DIMDTY

KEY

MATRIX

FU941

315,14,15

IC 942

TA78L05F

Q941

IC 151

Q156

Q155

Q154

Q942

1

TC7SH08FU

CN801

CN5 CN811

VACC 5

IC 945

4

18

7

8.0V

VR

28

VG

27

VB

26

VCOM

17

234

LSEN

7

INVERTER FOR

BACK LIGHT

IC 941

OZ961IS

10

LCD MODULE

LCD

LCD

BACK LIGHT

UPPER PCB

G

OUT OF LIGHT SENSOR

IC 811

NJM062V

Q943

20

Q944

11

37

CN942

T941

C

1

2

FL1

FL2

D

AVH-P6400CD/UC

56

7

8

19

Page 20

1234

N

A

W

T

C

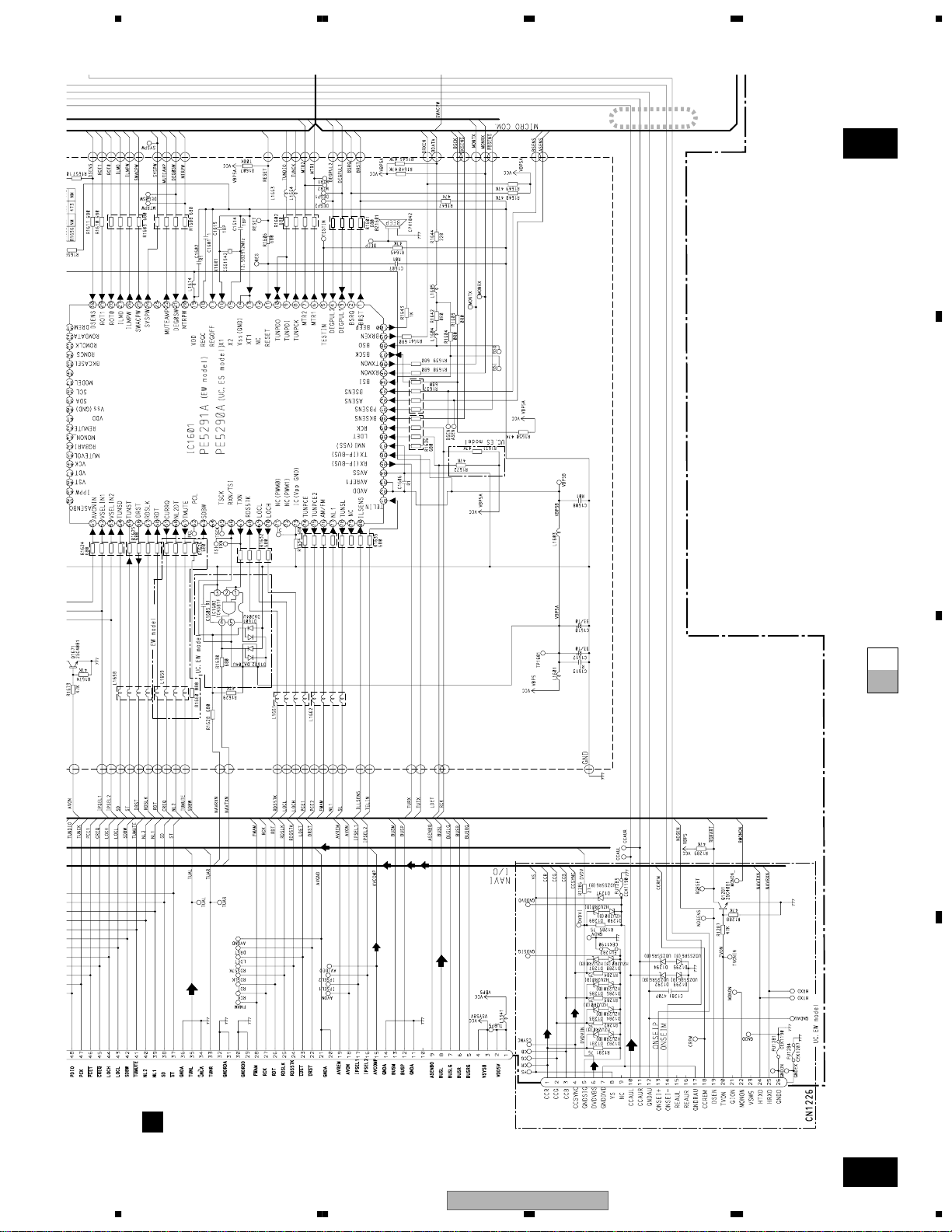

3.2 BLOCK DIAGRAM(2)

A

AV BUS CONNECTOR

B

MAIN ANT

CN2403

IP BUS INPUT

CN2404

TUNER PCB

B

FM/AM TUNER UNIT

CN2401

1

2

3

12

AVCOMP,AVON,IPSEL1,2

BUSP,BUSM,BUSL,BUSR,BUSRG,BUSLG

AMANT

FMANT

RFGND

AMPS

MOTHER PCB(2/2)

A

FM/AM 1ST IF 10.7MHz

AMRF

ATT

T51 Q51 CF51

ANT ADJ

ATT

FMRF

IMG ADJ

RF ADJ

LOCH

6

LOCL

4

Q2401

CF52 CF53

IC1

MIXER, IF AMP, DET.

CF202

AM 2ND IF

450kHz

VSYS8V

MPXREF 41kHz

AMDET

X901

10.25MHz

EEPROM

CREQcreq

DI/DO

10

15 17 14 13 21 16 27 26 25

PDIO

IC 3

CN2402

NL1(EW)

NL2(EW)

RDS57K,RDSLK,

RDT,RCK,DRST,FMAM

TUNL

PDIO

pce!

LOCL

LOCH

creq

ldet

pce@

PCK

COMP

LDET

L ch

23

8

11

IC 2 FM MPX

(EW)

NC

DGND

CE2

CKPCK

CE1

SDBWSLFMSD

18

pce!

pce@

STIND

NL1

NL2

28

SL

SD

NL1

NL2

st

20

RDS

IC 2451

PM4009A

CN1341

TUNL

16

35

28

23

2

49

SL

1

50

3

48

4

47

st

14

37

SD

13

38

46

5

43

8

44

7

45

6

39

12

40

11

AVCOMP,AVON,IPSEL1,2

TA2050F

BUSP

NL2DT(EW)

RDS57K,RDSLK,

RDT,RCK,DRST,FMAM

IC1231

IPAL

1

AVCOM

LDET

TUNPCE2

TUNSL

TUNPDIO

TUNPCK

TUNST

TUNSD

TUNPCE

LOCH

CURRQ

NL1(EW)

LOCL

88

75

78

9,10

8

55

54

74

69

70

59

77

60

SYSTEM

CONTROLLER

IC 1601

PE5290A(UC,ES)

PE5291A(EW)

25

SWACPW

91

81

TELIN

pbsens

(1/2)

90

BKSENS

80

ILSENS

93

BSENS11RESET

IPP

49

RX

85

TX

86

BK

35

TXN

67

ASE

92

RX

66

44

RGB

C

CN1226

CCAUL

10

TVON

20

HTXD

NAVI

24

I/O

HRXD

25

ONSEI +

13

ONSEI-

14

Q1901

VBU

D

SWACPW

3

Q1902

20

AVH-P6400CD/UC

1234

Page 21

A

B

4

S

5678

CN1801

12

5

7

1

3

6

8

2

4

15

+

16

S.ANT

+

RL

RL

+

RR

RR

+

FL

FL

+

FR

FR

BACK UP

GND

11

13

10

14

9

TEL MUTE

ACC

C

ILL

BACK

PAR KIN G

MOTHER PCB(2/2)

A

IC 1141

(2/2)

PA2028A

Q1822

R.REM

RL

RL

RR

RR

FL

FL

FR

FR

4

25

21

+

23

17

+

19

5

+

3

9

+

7

IC1861

BA00AST

BUP

FU1801

VPFL

FU1802

VPVI

FU1803

VBU

ACC

Q1821

2

1

BUP

GUIDE MIX

6

IC1101

Q1303

VBUP5V

IC 1801

(2/2)

PAJ002A

CONT

FL

1

Q1321

Q1802

2

Q1801

9

IN3

10

IN2

12

IN1

CN2402

TUNL

ldet

pce@

PDIO

PCK

pce!

LOCL

LOCH

creq

NL1(EW)

NL2(EW)

RDS57K,RDSLK,

RDT,RCK,DRST,FMAM

51

09A

CN1341

TUNL

16

35

28

23

2

49

SL

1

50

3

48

4

47

st

14

37

SD

13

38

46

5

43

8

44

7

45

6

39

12

40

11

AVCOMP,AVON,IPSEL1,2

IC1231

TA2050F

BUSP

TUNPCE2

TUNSL

TUNPDIO

TUNPCK

TUNST

TUNSD

TUNPCE

CURRQ

NL1(EW)

NL2DT(EW)

RDS57K,RDSLK,

RDT,RCK,DRST,FMAM

IPAL

1

AVCOM

LDET

88

75

78

9,10

8

55

54

74

LOCL

69

LOCH

70

59

77

60

PE5290A(UC,ES)

PE5291A(EW)

25

SWACPW

91

SYSTEM

CONTROLLER

IC 1601

(1/2)

81

90

80

TELIN

ILSENS

pbsens

BKSENS

93

BSENS11RESET

GUIDE SOUND INPUT

+

IC1221

6

ASENS

3

2

Q1302

5

7

6

11

NJM4558E

OUT2

RSTOUT

OUT3

OUT1

ONSEI

IPPW

49

RX

85

TX

86

BKCASEL

35

TXN

67

ASENS

92

RXN

66

44

RGBARI

8

2

1

IC1602

TC4S81F

1,2

4

ONSEI

CA0008AM

CN1226

CCAUL

10

TVON

20

HTXD

NAVI

24

I/O

HRXD

25

ONSEI +

13

ONSEI-

14

IC 1102

NJM2058V

Q1301

BUP

Q1322

ACC

1

12

FLIN

4

SYSPW

POWER AMP

IC1301

PAL007A

22

MUTE

RLIN

14

10

11

9

7

12

11

41

42

43

IC 1001

PML009A

40

30

IC 1031

(2/2)

CXA2089Q

1

IC1401

NJM2137V

3

BUP

VSWACC

VSYS8V

VSYS9V

Q1823

VBU

SWACPW

Q1901

Q1902

3

IC 1902

TA78L05F

1

VSWACC

BUP

AVH-P6400CD/UC

56

Q1841

7

Q1842

Q1843

FU1841

CN1841

FAN

2

1

D

21

8

Page 22

1234

3.3 OVERALL CONNECTION DIAGRAM

A

VTR Sound input(R)

VTR Sound input(L)

VTR input

Rear Video output

Pre out

TENNA

AN

/FM

AM

Sub W

ofer

output

T PIN

TPU

AV OU

B

A

B

C

C

M

ACC

CO

VSW

DSENS

REM

VI I/O

A

N

S

M

ACC

CO

D

22

1234

DSEN

VSW

REM

AVH-P6400CD/UC

Page 23

A

B

5678

CN701

RELAY

H

D

F

E

I

C

G

J

AVH-P6400CD/UC

56

D

7

23

8

Page 24

1234

3.4 MOTHER PCB(GUIDE PAGE)

Note: When ordering service parts, be sure to refer to " EXPLODED VIEWS AND PARTS LIST" or

"ELECTRICAL PARTS LIST".

Large size

A-b

A-b

SCH diagram

Guide page

Detailed page

N

IO

T

A

L

O

IS

T

U

P

IN

D

N

U

O

S

IP

A

A-a A-b

A-a

A-a

A-a

M

I

ER

T

PU

M

O

C

O

R

IC

M

T

C

E

L

E

S

D

N

U

O

S

E

G

A

V

5R1K

5R1K

V

V

V

V

V

V

T

U

P

T

U

O

R

O

T

I

N

O

M

R

E

F

F

U

B

T

T

A

V

1

0K

82

R

B

V

V

T

C

L

E

S

A

R

E

M

A

C

K

C

A

B

B

J

CN701

CD

: 3.28dBs

13.7V

s

B

d

.5

9

1

: -

)

S

,E

C

U

(

M

F

C

U

(

M

A

M

F

M

A

R

E

IV

R

D

d

n

a

R

O

IT

N

O

M

S

IP-BU

s

B

d

.0

0

3

: -

)

S

,E

CD

s

B

d

.5

5

) : 1

W

E

(

VTR

s

B

d

.0

6

2

: -

)

W

E

(

VI

A

N

IS

T

U

P

IN

D

N

U

O

S

E

ID

U

G

B

CN2402

FM(UC,ES) : -19.50dBs

AM(UC,ES) : -30.00dBs

FM(EW) : -15.50,dBs

AM(EW) : -26.00dBs

C

V

V

S : 2.2dBs

IP-BU

R

S

V

2

>

V

R

S

s

VI : 2.2dB

A

A

A

2

>

N

2

D

A

2

>

A

5

.1

3

>

A

24

AVH-P6400CD/UC

1234

Page 25

A

B

5678

A-b

Mother Tuner Unit

R

S

R

O

IT

N

O

M

R

A

E

T

U

P

T

U

(

M

F

U

(

M

A

M

F

M

A

R

R

E

F

F

U

B

V

FM

A

O

S

IS

4.3V

4.3V

(U

(U

M

FM

M

A

4.3V

4.3V

IN

D

N

U

N

O

I

T

A

L

O

,ES) : -1.6dB

C

C,ES) : -6.9dB

) : 4.6dBs

(EW

) : -2.9dBs

(EW

68

R

E

F

F

U

. B

O

M

E

R

.

L

O

V

H

G

I

H

,

IN

P

A

C

S : 7.3dBs

: 7.33dBs

R

15.5V

T

U

P

U

IP-B

s

CD

s

TR : 7.33dBs

V

VI : 7.30dBs

A

N

V

V

T

C

L

E

S

A

R

E

M

A

C

K

C

A

B

s

B

d

.5

9

1

: -

)

S

E

,

C

.0

0

3

: -

)

S

,E

C

.5

5

: 1

)

W

E

(

.0

6

2

: -

)

W

E

(

O

S

E

ID

U

G

U

d

d

d

N

s

B

s

B

s

B

IN

D

IP-BU

CD

VTR : 2.23dBs

A

N

T

U

P

: 2.20dB

S

: 3.23dBs

VI : 2.20dB

. M

O

IS

s

s

.

IX

V

V

4.3V

D

CN4801

N

O

M

R

O

IT

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

R

E

IV

R

D

d

n

a

A

m

0

0

2

>

S

V

8

6

CD : 33.33dBs

A

VTR : 2.20dBs

>

MOTHER PCB

A

2

>

V

V

(

A

5

.2

1

)

C

CN3831

D

N

U

O

S

E

ID

U

G

4.3V

13.8V

>

>

µH

0

7

2

A

.6

1

A

.6

A

.6

1

>

5.0V

5.6V

S

R

E

W

O

P

7.5V

>

A

.3

2

FAN

MOTOR

M1

CXM1193

)

D

V

D

C

(

T

U

P

IN

Y

L

P

P

U

S

R

E

W

O

P

>

)

N

A

F

(

T

U

P

IN

Y

L

P

P

U

A

.6

1

>

S

: Composite Sync.

V

: Composite Video

R

: RGB_R

: Audio_L

TER

PU

COM

ICRO

M

m

0

0

4

,

Y

L

P

P

U

S

R

E

W

O

P

.

N

E

S

Y

L

P

P

U

S

R

E

W

O

P

A

NOTE :

Symbol indicates a resistor.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

identical designation.

AVH-P6400CD/UC

56

1

A

5

.2

1

>

P

P

U

S

R

E

W

O

P

E

,S

N

C

(

T

U

P

IN

: The power supply is shown with the marked box.

7

>

Y

L

)

E

S

N

Decimal points for resistor

and capacitor fixed values

are expressed as :

←

2.2 2R2

←

0.022 R022

C

D

A

25

8

Page 26

A

CN2402

A-b

1234

T

U

TP

U

O

R

FFER

O

U

IT

N

O

TT B

A

M

V

1

8

2

0K

R

IV

E

R

M

O

N

IT

O

R

an

d

D

V

V

V

1K

5R

5R

1

K

V

B

V

T

A-b

A-a

A-a

ELEC

S

D

N

U

O

E S

G

A

IM

V

M

ICRO COM

PUTER

V

C

D

A-a

26

N

IO

T

LA

O

T IS

PU

IN

D

N

U

O

IP S

13.7V

s

: 3.28dB

D

C

J

CN701

B

AVH-P6400CD/UC

1234

Page 27

A

B

5678

2

A-b

s

s

s

) : -30.00dB

) : -19.50dB

,ES

,ES

C

C

(U

(U

) : -15.50,dB

M

FM

A

(EW

FM

s

) : -26.00dB

(EW

M

A

A-b

A-a

A-a

VI : 2.2dBs

A

N

V

S

V

R

V

: 2.2dBs

S

IP-BU

S

R

V

2A

>

2A

>

2A

>

3.15A

>

C

D

B

CN2402

AVH-P6400CD/UC

56

A-a

7

27

8

Page 28

1234

C

CN3831

A

2A

MOTHER PCB

>

V

: 2.20dBs

TR

V

V

( )

1.25A

>

A

: 33.33dBs

D

R

Mother Tuner Unit

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

B

D

CN4801

V

S

6

8

>

20

0

m

E

IV

R

D

and

R

ITO

N

O

M

A

C

C

D

A-b

A-a

A-b

28

15.5V

L.

O

V

FFER

U

. B

O

EM

R

68

V

R

S

V

V

R

O

IT

N

O

M

R

FFER

U

EA

B

R

T

TPU

U

R O

FFER

U

ITO

N

O

TT B

A

M

V

V

ELCT

S

V

ERA

M

A

C

K

C

A

B

1

H

IG

,H

PIN

CA

R

CD : 7.33dBs

VTR : 7.33dBs

NAVI : 7.30dBs

IP-BUS : 7.3dBs

T

PU

N

IN

D

TIO

N

LA

U

O

O

IS

S

4.3V

4.3V

8

20

K

FM(EW) : 4.6dBs

4.3V

4.3V

AM(EW) : -2.9dBs

FM(UC,ES) : -1.6dBs

AM(UC,ES) : -6.9dBs

4.3V

CD : 3.23dBs

VTR : 2.23dBs

NAVI : 2.20dBs

IP-BUS : 2.20dBs

s

s

) : 15.5dBs

) : -26.0dB

) : -30.0dB

,ES

,ES) : -19.5dBs

(EW

(EW

C

C

M

FM

(U

(U

A

M

FM

A

G

U

ID

E

S

O

U

N

D

4.3V

.

IX

. M

O

T IS

PU

IN

D

N

U

O

E S

ID

U

G

M

O

N

IT

O

R

an

d

D

R

IV

E

R

AVH-P6400CD/UC

1234

Page 29

A

B

5678

D

←

←

Decimal points for resistor

and capacitor fixed values

are expressed as :

2.2 2R2

0.022 R022

>

E)

S

EN

PPLY

,S

N

SU

R

T(C

E

W

PU

IN

PO

>

1.6A

270µH

1.6A

>

1.25A

>

Symbol indicates a resistor.

: The power supply is shown with the marked box.

No differentiation is made between chip resistors and

discrete resistors.

Symbol indicates a capacitor.

No differentiation is made between chip capacitors and

discrete capacitors.

The > mark found on some component parts indicates

the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of

: RGB_R

identical designation.

: Audio_L

A-b

A-a

NOTE :

.

EN

S

,

PPLY

PPLY

U

U

S

S

ER

ER

W

W

PO

PO

A

400m

>

)

N

T(FA

U

P

IN

PPLY

SU

ER

W

PO

>

1

.6A

: Composite Sync.

: Composite Video

S

V

R

7.5V

1.6A

>

G

U

ID

E

S

O

U

N

4.3V

13.8V

5.0V

5.6V

2.3A

>

M1

MOTOR

FAN

)

D

V

D

T(C

PU

PPLY IN

SU

ER

W

CXM1193

PO

C

D

AVH-P6400CD/UC

56

2

A-b

7

29

8

Page 30

1234

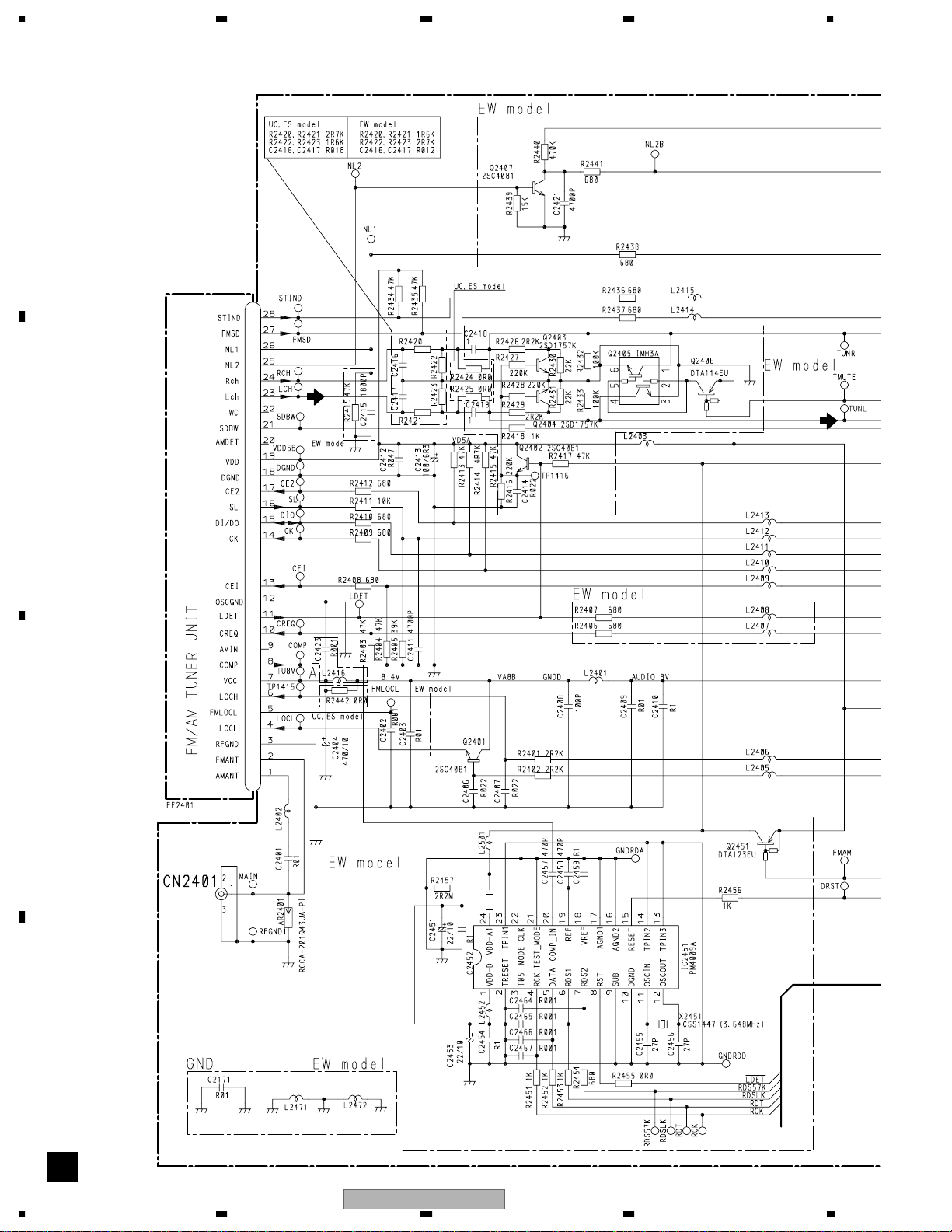

3.5 TUNER PCB

A

B

C

RDS decoder

0R0)

L2453

(R2460

D

B

30

1234

AVH-P6400CD/UC

Page 31

A

B

5678

V

: Composite Video

: Audio_L

Mother Tuner Unit

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

TUNER PCB

B

V

A

CN1341

2A

2A

>

>

V

C

A

200m

>

D

AVH-P6400CD/UC

56

B

7

31

8

Page 32

1234

3.6 GRILLE PCB

A

A

CN1201

B

C

GRILLE PCB

DETACH GRILLE ASSY

C

Mother Tuner Unit

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

D

C

32

1234

AVH-P6400CD/UC

Page 33

A

B

5678

3.7 RELAY PCB

D

RELAY PCB

A

CN1331

V

R

S

R

S

S

: Composite Sync.

V

: Composite Video

R

V

: RGB_R

F

CN2

Mother Tuner Unit

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

S

R

V

C

H

CN2804

D

AVH-P6400CD/UC

56

D

7

33

8

Page 34

1234

3.8 INVERTER PCB

A

F

CN3

1R5K

1R5K

EW

m

odel

1

B

C

>

D

E

34

1234

AVH-P6400CD/UC

Page 35

A

B

5678

o

Mother Tuner Unit

INVERTER PCB

E

Consists of

Mother PCB

Tuner PCB

Grille PCB

Relay PCB

Inverter PCB

del

SELECT

1

2

3

1

2

3

To Back light

2

3

C

AVH-P6400CD/UC

56

560

D

E

7

35

8

Page 36

1234

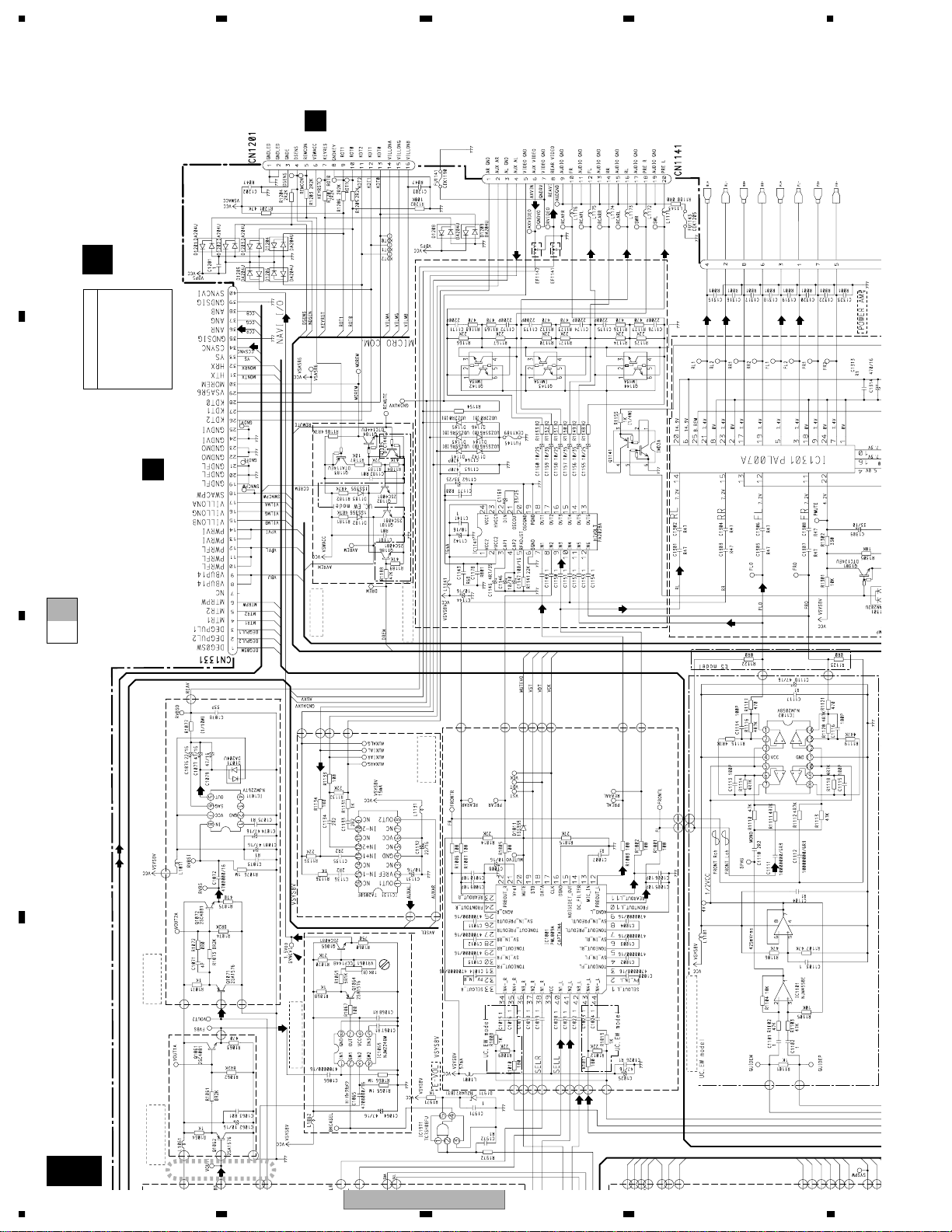

3.9 MONITOR UNIT

A

For

test mode

V

R

R

V

R

V

B

2-3

6-3

V

E

CN941

CN2

D

CN4802

C

2-1

S

R

V

S

6-2

S

R

V

3-1

6-1

4-1

S

5-2

5-4

5-3

INTERFACE

D

F G

36

2-2

O

G

PEN/CLOSE

UPPER PCB

Monitor Unit

Consists of

Monitor PCB

Upper PCB

AVH-P6400CD/UC

1234

Page 37

A

B

5678

Monitor Unit

Consists of

Monitor PCB

Upper PCB

MONITOR PCB

F

>

R

3-2

4-2

V

R

S

S

5-1

1-1

3-3

1-2

1-3

1-4

3-4

R

8-2

R

7-1

8-1

8-4

7-2

TERFACE

alti Pictues

M

Processing

age

Im

Processing

S

AVH-P6400CD/UC

56

R

S

: Composite Sync.

V

: Composite Video

R

: RGB_R

7

LCD

MODULE

C

8-3

D

F

37

8

Page 38

1234

- Waveforms

A

B

1-1 IC851 3pin 5V

1.00µs

Note: The encircled numbers denote measuring pointes in the circuit diagram.

Ch1 1-2 IC861 15pin 5V

Ch2 1-3 IC861 12pin 5V

Ch3 1-4 IC861 10pin 5V

400µs

Ch1 2-1 DIMDTY 2V

Ch2 2-2 LSEN 2V

1.00µs

Ch1 2-3 INVPUL 2V

frequency : 98.09 kHz

Ch2 2-3 INVPUL 2V

frequency : 104.2 kHz

4.0µs

Ch1 3-1 ANG 500mV

Ch2 3-2 ANG2 500mV

Ch3 3-3 GOUT 500mV

Ch4 3-4 VG 500mV

20.0µs

Ch1 Input 10 STEP VTR IN

Ch2 4-1 CVBS 500mV

Ch3 4-2 CVBS2 500mV

200µs

C

Ch1 Input 10 STEP VTR IN 1V

Ch2 4-2 CVBS 2V

D

Ch3 3-3 GOUT 1V

Ch4 3-4 VG 5V

Ch1

Ch2

Ch3

Ch4

5-1 V33 2V

5-2 PIPRES 5V

5-3 PIPCK 5V

5-4 PIPDA 5V

10.0µs

Ch1

Ch2

Ch3

Ch4

5-1 V33 2V

5-2 PIPRES 5V

5-3 PIPCK 5V

5-4 PIPDA 5V

20.0µs

38

AVH-P6400CD/UC

1234

Page 39

A

B

5678

Input 10 STEP VTR IN 1V Ch1

6-1 OSDH 5V

Ch2

6-2 OSDV 5V

Ch3

6-3 OSDBLK 5V

Ch4

Input SG10 step VIRIN

Input 10 STEP VTR IN 1V Ch1

8-1 CX 5V

Ch2

8-2 STH1 5V

Ch3

Ch4

3-4 VG 5V

1.0µs

20.0µs

Input 10 STEP VTR IN 1V Ch1

6-1 OSDH 5V

Ch2

6-2 OSDV 5V

Ch3

6-3 OSDBLK 5V

Ch4

Input SG10 step VIRIN

Input 10 STEP VTR IN 1V Ch1

8-1 CX 5V

Ch2

8-2 STH1 5V

Ch3

Ch4

3-4 VG 5V

20.0µs

400µs

Ch2

Ch3

Ch4

Input 10 STEP VTR IN 1V Ch1

7-1 POL 5V

7-2 VCOM 5V

3-4 VG 5V

20.0µs

Input 10 STEP VTR IN 1V Ch1

8-4 CPH 2V

Ch2

3-4 VG 5V

Ch3

400µs

Ch2

Ch3

Input 10 STEP VTR IN 1V Ch1

8-4 CPH 2V

3-4 VG 5V

20.0µs

AVH-P6400CD/UC

56

C

D

39

7

8

Page 40

1234

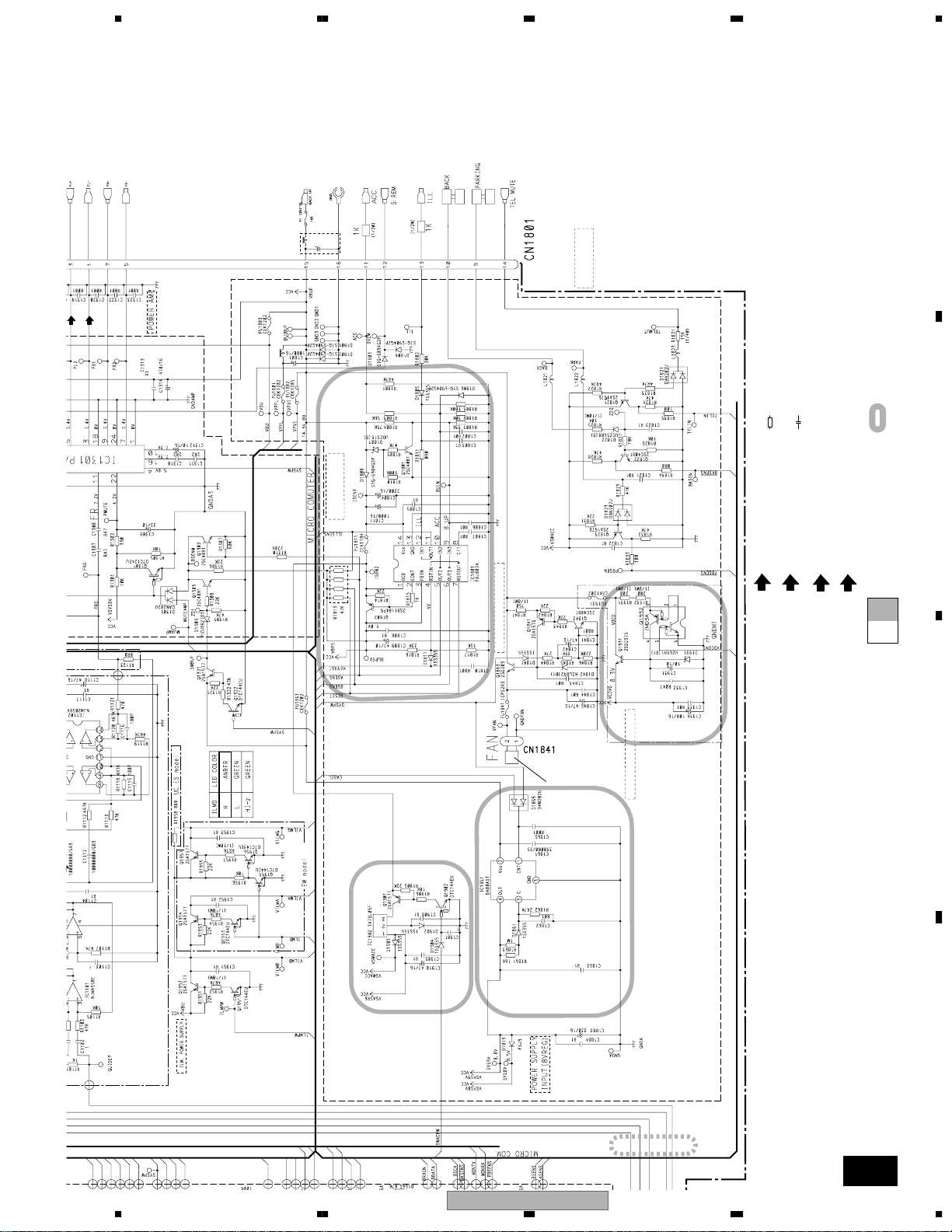

3.10 ENCODER UNIT

A

M1

CXB7612

Drive Motor

M

White

Red

DEG0

ENCODER PCB

H

Black

Yellow

Encoder Unit

Consists of

Encoder PCB

SW PCB

B

SW PCB

I

C

D

H I

40

D

CN4803

AVH-P6400CD/UC

1234

Page 41

A

B

5678

C

AVH-P6400CD/UC

56

D

41

7

8

Page 42

1234

3.11 CD MECHANISM MODULE

CD CORE UNIT

J

A

PICKUP UNIT(SERVICE)(P8)

F

SL

SL

220K

RF AMP

SL

SL

SL

F

330K

B

SL

SIGNAL LINE

F

FOCUS SERVO LINE

T

TRACKING SERVO LINE

C

CARRIAGE SERVO LINE

S

SPINDLE SERVO LINE

C

SWITCHES:

CD CORE UNIT

S901 : LOAD,EJ SWITCH………ON-OFF

S902, 903 : LOAD,EJ SWITCH………ON-OFF

S904 : HOME SWITCH …………ON-OFF

The underlined indicates the switch position.

LOADING MOTOR

M2 CXB6340

T

T

F

SL SL

F

T

F

T

CARRIAGE MOTOR

M1 CXB6361

C

C

RED

BLACK

WHITE

F

SL

T

T

F

F

T

F

T

!

F

SL

T

T

5

T

SL

4

F

8200P

SL

F

T

F

T

6

T

C

C

F

T

C

2

7

1

#

T

T

F

5V

REGULATOR

F

F

T

ACT / MOTOR DRIVE

3

F

T

S

C

C

)

S

S

9

C

C

S

C

S

S

D

SPINDLE MOTOR

M3 CXB6620

S

S

0

J

42

1234

AVH-P6400CD/UC

Page 43

A

B

5678

33P

220K

330K

Q301

CDMUTE

SL

F

T

F

T

SERVO CONTROL / DSP / DAC / LPF

C321

SL

4R7/35

C322

4R7/35

R307

1K

R306

1K

R317

R318

22K

22K

6

5

4

D301

MA151WA

SL

SL

IMD2A

5

4

3

Q302

FMG12

1

2

3

1

2

&

LOUT

*

ROUT

S

C

(

@

8

R319

330

CSS1525

16.934MHz

X301

S

C

SL

)

VDCONT

⁄

R713

CSENS

PE5273A

CD MECH. CONTROLLER

S

R605

R606

22K

47K

BSRQ

BSCK

BRXEN

BDATA

SUBOK

R702

R711

R701

220

220

0R0

CDMUTE

SL

R709

0R0

CSENS

XRST

CD5VON

CDMUTE

BSRQ

BRST

BSCK

BRXEN

BDATA

RESET

SUBOK

SL

C

D

A

CN1251

AVH-P6400CD/UC

56

J

7

43

8

Page 44

1234

- Waveforms

Note:1. The encircled numbers denote measuring pointes in the circuit diagram.

2. Reference voltage

VREF:2.1V

1 CH1:DSCSNS 5V/div.

A

2 CH2:CDLOAD 5V/div.

3 CH3:CDEJET 5V/div.

⁄ CH4:VD 5V/div.

8cm LOAD

→

GND

→

GND

→

GND

→

GND

1 CH1:DSCSNS 5V/div.

2 CH2:CDLOAD 5V/div.

3 CH3:CDEJET 5V/div.

B

12cm EJECT

→

GND

→

GND

→

GND

500ms/div.

500ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CDLOAD 5V/div.

3 CH3:CDEJET 5V/div.

⁄ CH4:VD 5V/div.

12cm LOAD

→

GND

→

GND

→

GND

→

GND

4 CH1:RFO 500mV/div.

5 CH2:TEY 500mV/div.

Tracking open

→

VREF

→

VREF

500ms/div.

2ms/div.

1 CH1:DSCSNS 5V/div.

2 CH2:CDLOAD 5V/div.

3 CH3:CDEJET 5V/div.

8cm EJECT

→

GND

→

GND

→

GND

5 CH1:TEY 500mV/div.

6 CH2:FEY 500mV/div.

Setup

→

VREF

→

VREF

500ms/div.

200ms/div.

7 CH1:FD 1V/div.

8 CH2:fok 5V/div.

9 CH3:SINY 5V/div.

Setup

C

→

VREF

→

VREF

→

VREF

6 CH1:FEY 500mV/div.

@ CH2:foon 5V/div.

Setup(Focus close)

→

VREF

D

→

VREF

500ms/div.

1ms/div.

7 CH1:FD 2V/div.

8 CH2:fok 5V/div.

0 CH3:FG 5V/div.

9 CH4:SINY 5V/div.

Setup(In focus)

→

VREF

→

VREF

→

VREF

→

VREF

6 CH1:FEY 200mV/div.

7 CH2:FD 500mV/div.

Setup(Focus AGC)

→

VREF

→

VREF

100ms/div.

1ms/div

7 CH1:FD 1V/div.

! CH2:FOP 2V/div.

Setup(In focus)

→

VREF

→

VREF

5 CH1:TEY 200mV/div.

.

# CH2:TD 200mV/div.

Setup(Tracking AGC)

→

VREF

→

VREF

200ms/div.

1ms/div.

44

AVH-P6400CD/UC

1234

Page 45

A

B

5678

6 CH1:FEY 500mV/div.

7 CH2:FD 500mV/div.

4 CH3:RFO 1V/div.

Setup(FE Bias adjustment)

→

VREF

→

VREF

→

VREF

9 CH1:SINY 100mV/div.

Play

→

VREF

4 CH1:RFO 2V/div.

( CH2:dfct 5V/div.

7 CH3:FD 1V/div.

# CH4:TD 2V/div.

Play(The defect part passes)

10ms/div.

200ms/div.

500µs/div.

4 CH1:RFO 0.5V/div.

Play

→

VREF

6 CH1:FEY 500mV/div.

7 CH2:FD 500mV/div.

5 CH3:TEY 500mV/div.

# CH4:TD 500mV/div.

Play

→

VREF

→

VREF

→

VREF

→

VREF

4 CH1:RFO 1V/div.

5 CH2:TEY 500mV/div.

( CH3:dfct 5V/div.

CRG move

0.5µs/div.

1ms/div.

50µs/div.

& CH1:LOUT 2V/div.

* CH2:ROUT 2V/div.

Play

→

VREF

→

VREF

5 CH1:TEY 500mV/div.

) CH2:CIN 500mV/div.

Search

200µs/div.

200ms/div.

→

VREF

→

VREF

→

VREF

→

VREF

4 CH1:RFO 1V/div.

5 CH2:TEY 1V/div.

# CH3:TD 1V/div.

Test mode 100TRjump

→

VREF

→

VREF

→

VREF

5ms/div.

→

VREF

→

VREF

→

VREF

4 CH1:RFO 1V/div.

5 CH2:TEY 500mV/div.

# CH3:TD 1V/div.

Test mode 1TRjump

→

VREF

→

VREF

→

VREF

500µs/div.

→

VREF

→

VREF

4 CH1:RFO 1V/div.

5 CH2:TEY 1V/div.

# CH3:TD 1V/div.

Test mode 32TRjump

→

VREF

→

VREF

→

VREF

C

5ms/div.

D

AVH-P6400CD/UC

56

7

8

45

Page 46

1234

4. PCB CONNECTION DIAGRAM

4.1 MOTHER PCB

A

B

NOTE FOR PCB DIAGRAMS

1.The parts mounted on this PCB

include all necessary parts for

several destination.

For further information for

respective destinations, be sure

to check with the schematic dia gram.

2.Viewpoint of PCB diagrams

Connector

P.C.Board

Capacitor

Chip Part

SIDE A

SIDE B

MOTHER PCB

A

D

CN4801

1

1

C

D

A

46

1234

AVH-P6400CD/UC

Page 47

A

B

5678

SIDE A

1

C

FRONT

AVH-P6400CD/UC

56

D

CN3831

C

A

7

47

8

Page 48

1234

A

B

MOTHER PCB

A

AV OUTPUT PIN

CN2402

B

NAVI I/O

C

SYNCVI

D

A

48

1234

AVH-P6400CD/UC

Page 49

A

B

5678

SIDE B

CN1801

FAN MOTOR M1

POWER SUPPLY TERMINALS

AVH-P6400CD/UC

56

C

CN701

J

D

A

7

49

8

Page 50

1234

4.2 TUNER PCB

TUNER PCB

B

A

B

SIDE A

IP-BUS

AV BUS

TUNER PCB

B

SIDE B

A

CN1341

C

D

B

50

AM/FM

ANTENNA

AVH-P6400CD/UC

1234

Page 51

A

B

5678

4.3 GRILLE PCB

GRILLE PCB

C

RESET

SIDE A