Page 1

PSS Standard Function Blocks

MBS Burner Management

Version 4.0

Programmable control systems PSS

®

Operating Manual – No. 19532-EN-07

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

®

SafetyNET p

, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Page 3

Contents

Introduction 1-1

MBS Modular Block System 1-2

Categories / requirement classes 1-3

Overview of manual 1-4

Definition of symbols 1-5

Terminology 1-6

Overview 2-1

Software package 2-1

Operation 2-1

Range 2-2

Safety 3-1

Safety guidelines 3-1

Use of qualified personnel 3-1

Warranty and liability 3-1

Application guidelines 3-2

Standards 3-3

Fault detection 3-4

Feasibility test 3-4

Fault prevention 3-4

Intended Use 4-1

Application 4-1

System software 4-1

Intended use of the standard function blocks 4-2

SB149: Sequence control 4-2

SB150: Flame monitoring 4-2

SB151: Transient suppression 4-2

SB152: Burner: start and operator elements 4-3

SB153: Control and position monitoring of flaps 4-3

1Modular Block System: Burner Management

Page 4

Contents

SB154: Control and position monitoring of valves 4-4

SB155: Pre-purge 4-4

SB156: Tightness control 4-4

SB157: Several ignition attempts 4-4

SB158: Ignition 4-5

SB159: Run 4-5

SB160: Blower 4-5

MBS Basics 5-1

Block design 5-1

Structure 5-1

Formal parameters and actual parameters 5-2

Administration data blocks DB015, DB016 and DB017 5-3

Structure of the administration data blocks 5-3

Blocks contained in the administration data blocks 5-5

Input parameter SSNR 5-7

Example 5-8

Fault diagnostics 5-9

Error types 5-9

Fault diagnostics using the administration data blocks 5-10

Temporary flag range in MBS blocks 5-11

Output parameter ENBL 5-11

Assignment of input and output parameters 5-12

Minimum scan time 5-12

Global parameters 5-13

Standard Function Blocks 6-1

SB149: Sequence control 6-1

Block header 6-1

Input parameters 6-1

Output parameters 6-2

Function: 6-2

Error messages 6-3

Blocks required 6-3

2

Modular Block System: Burner Management

Page 5

Programming guidelines 6-4

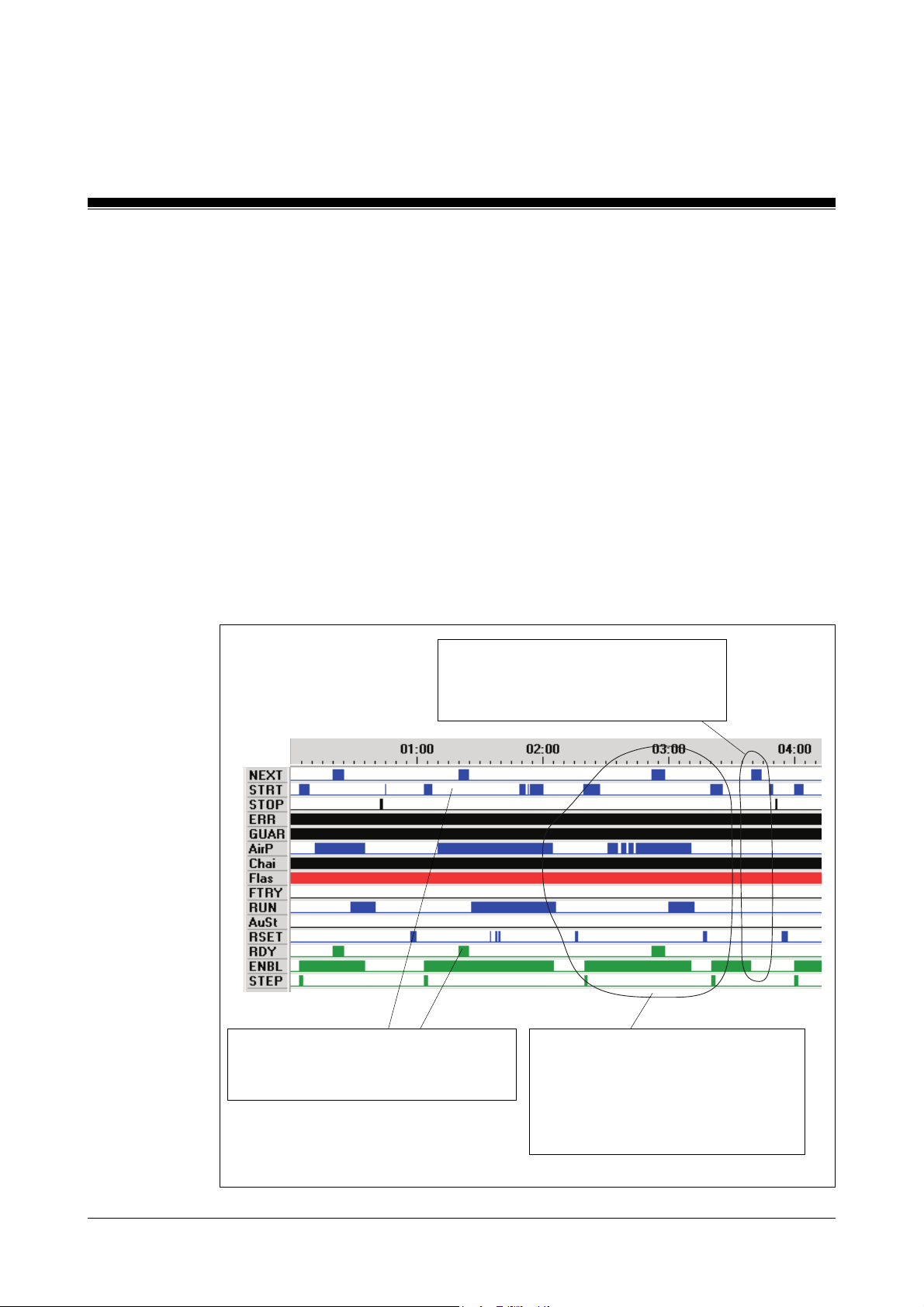

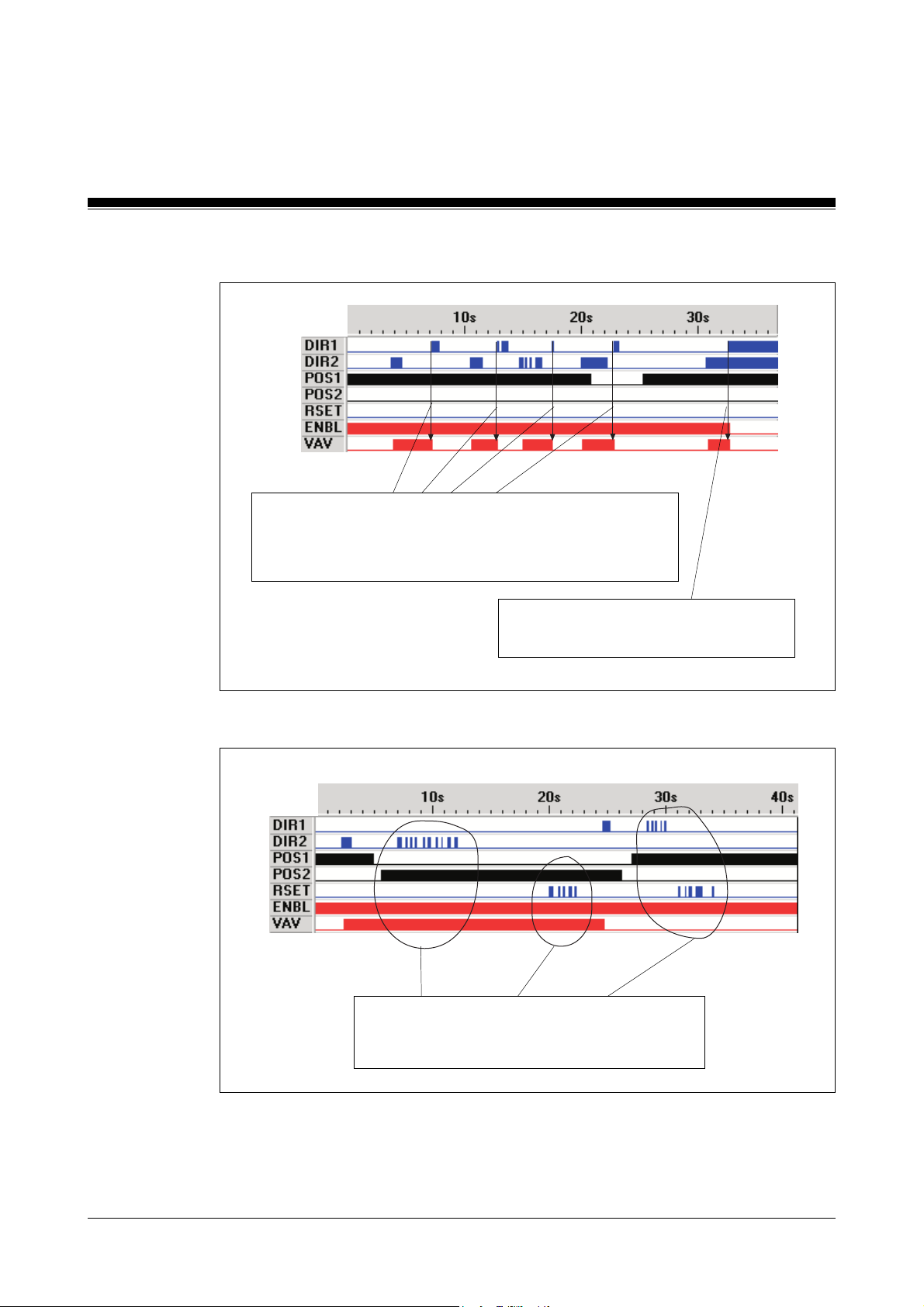

Timing diagrams 6-9

Setting / resetting the step without time delay and monitoring time 6-9

Setting/resetting the step with time delay but without monitoring

time 6-11

Setting/resetting the step without time delay but with monitoring

time 6-12

Setting/resetting the step with time delay and monitoring time 6-13

SB150: Flame monitoring 6-14

Block header 6-14

Input parameters 6-14

Output parameters 6-15

Function: 6-15

Error messages 6-15

Blocks required 6-16

Programming guidelines 6-17

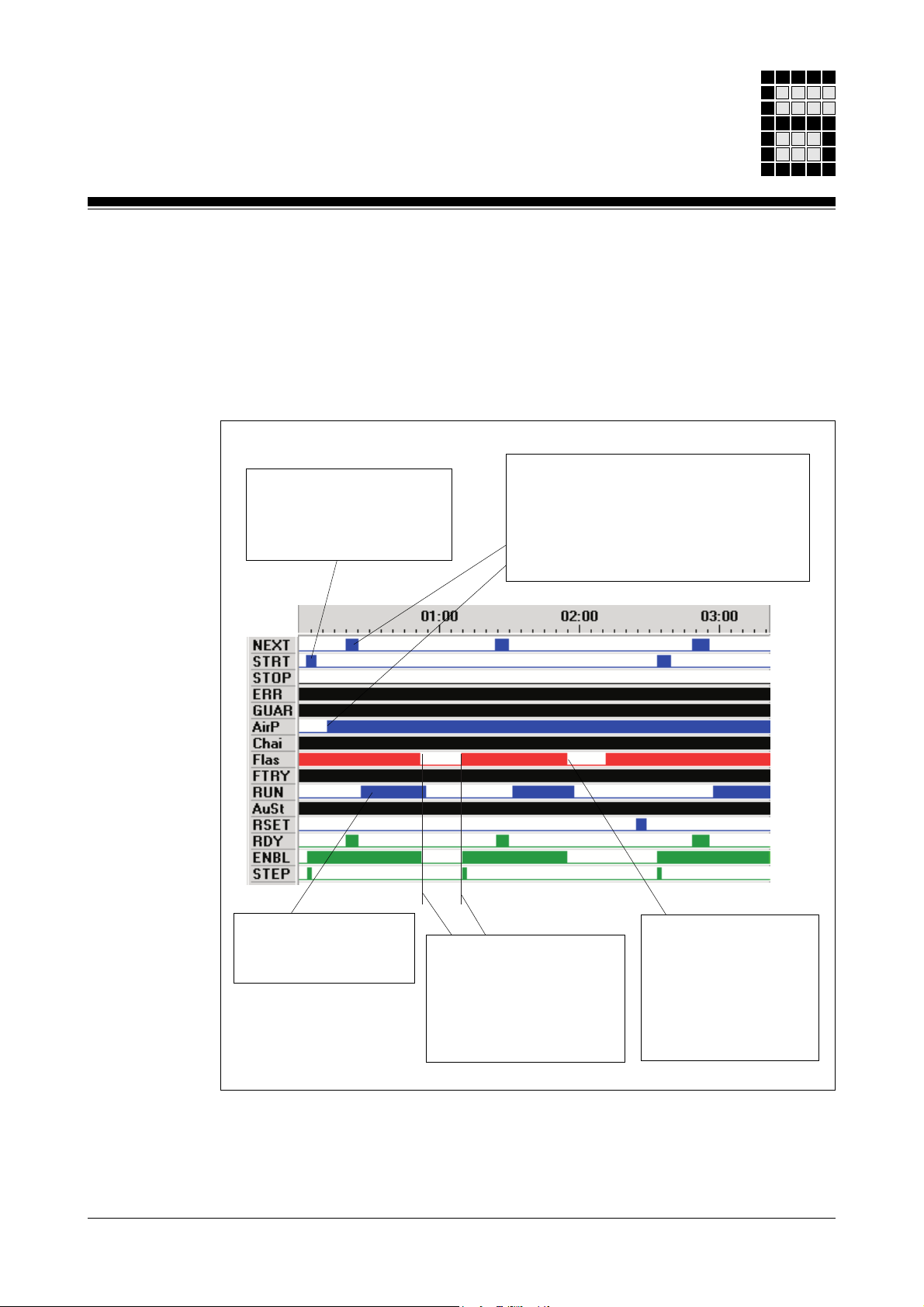

Timing diagrams 6-19

Signal cycle with an uninterrupted burner start-up or uninterrupted

burner stop sequence 6-19

Flame monitor error 6-20

Spurious signals when monitoring for “flame not established” 6-20

Spurious signals before and during monitoring for

“flame established” 6-21

Spurious signals during monitoring for “flame established” 6-21

SB151: Transient suppression 6-22

Block header 6-22

Input parameters 6-22

Output parameters 6-23

Function 6-23

Error messages 6-23

Blocks required 6-24

Programming guidelines 6-24

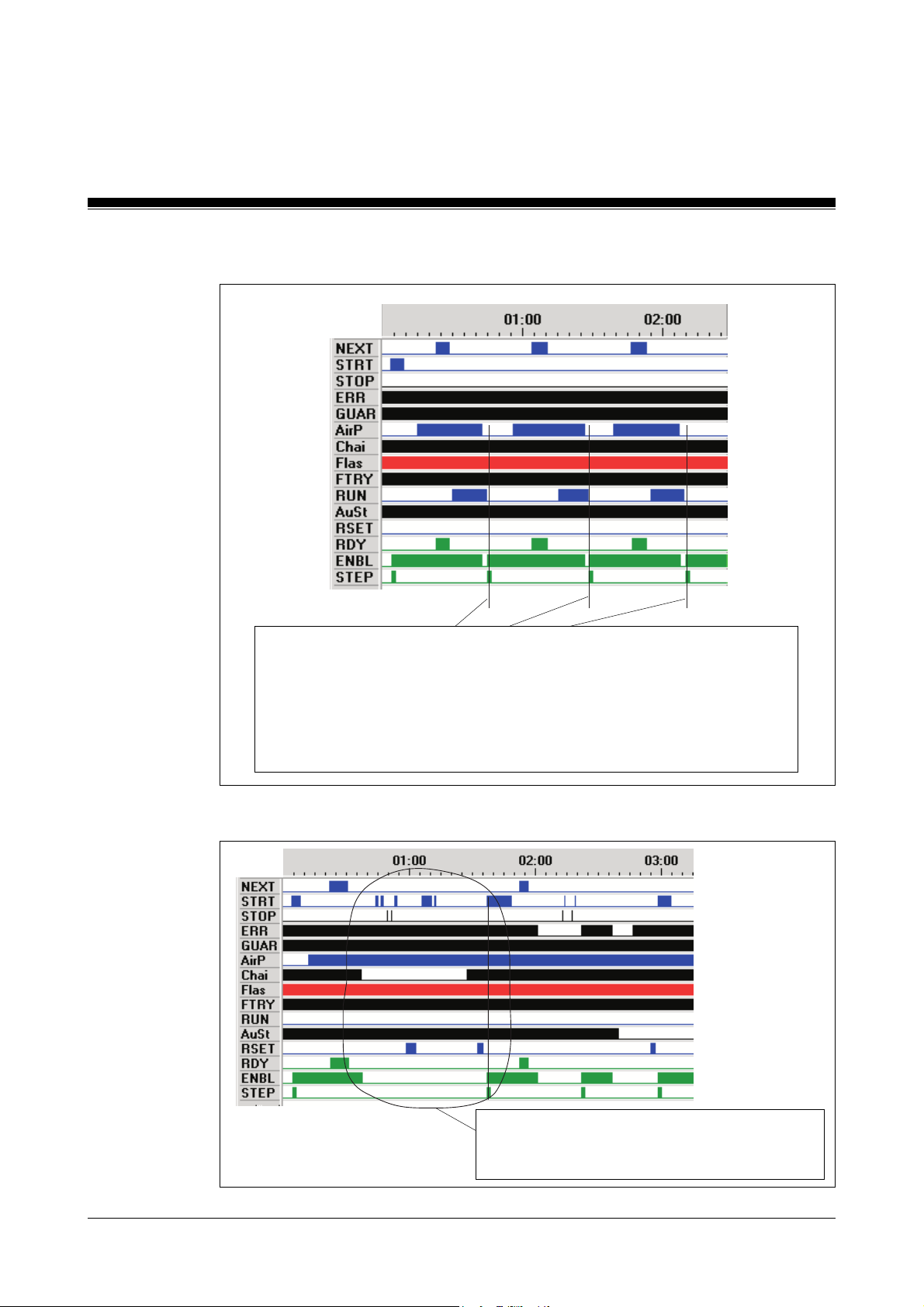

Timing diagrams 6-25

Setting the ENBL output automatically when the signal is

recovered 6-25

Setting the ENBL output after a reset when the signal is

recovered 6-25

Spurious signal sequence at BASE input 6-26

Spurious signal sequence at AuSt input 6-26

3Modular Block System: Burner Management

Page 6

Contents

SB152: Burner: start and operator elements 6-28

Block header 6-28

Input parameters 6-28

Output parameters 6-30

Function 6-30

Error messages 6-31

Blocks required 6-32

Programming guidelines 6-33

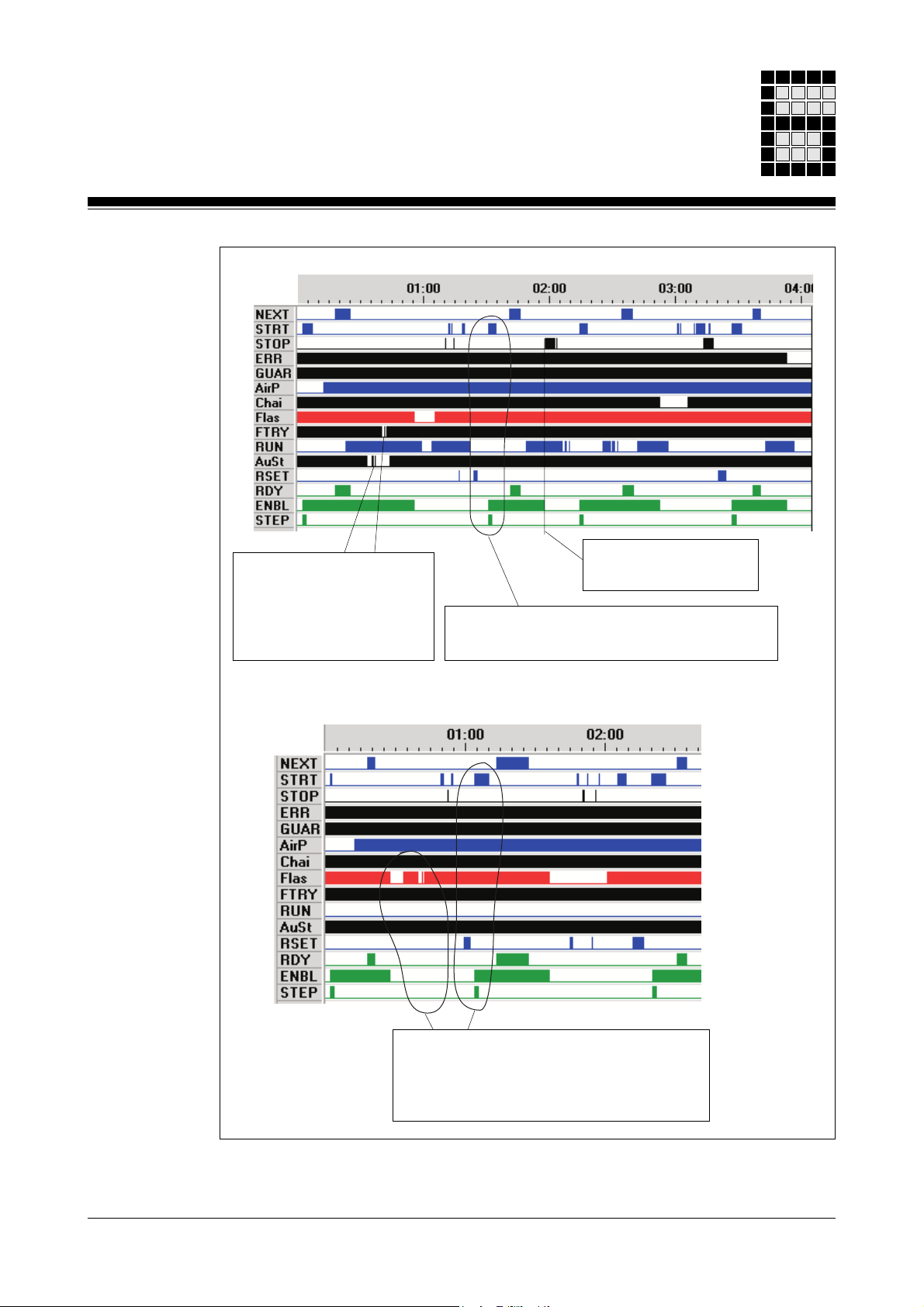

Timing diagrams 6-34

Burner start-up without automatic start after a controlled

shutdown 6-34

Failure of safety sequence, flame monitor sequence and general

faults 6-34

Failure of monitor sequence 6-35

Monitoring of air pressure 6-36

Restart after flame failure or flame monitoring fault 6-37

Automatic restart after air deficiency 6-38

Spurious signals 6-38

SB153: Control and position monitoring of flaps 6-40

Block header 6-40

Input parameters 6-40

Output parameters 6-41

Function 6-41

Error messages 6-41

Blocks required 6-42

Programming guidelines 6-43

Timing diagrams 6-44

No automatic start after controlled shutdown 6-44

Monitoring of end positions 6-44

Missing acknowledgement 6-45

Multiple drive commands 6-46

Spurious fault signal reset 6-46

Test to ensure safe monitoring time 6-47

SB154: Control and position monitoring of valves 6-48

Block header 6-48

Input parameters 6-48

Output parameters 6-49

Function 6-49

Error messages 6-49

Blocks required 6-50

Programming guidelines 6-51

4

Modular Block System: Burner Management

Page 7

Timing diagrams 6-52

Valve closed without power 6-52

Reset spurious acknowledgements 6-53

Spurious acknowledgement as valve opens 6-53

SImultaneous OPEN and CLOSE commands 6-54

Multiple recurring OPEN and CLOSE commands 6-54

SB155: Pre-purge 6-56

Block header 6-56

Input parameters 6-56

Output parameters 6-56

Function 6-56

Error messages 6-57

Blocks required 6-57

Programming guidelines 6-58

Timing diagrams 6-58

Signal cycle with interrupted and uninterrupted pre-purge

process 6-58

Spurious signal sequence at NEXT and RDY inputs 6-59

SB156: Tightness control 6-60

Block header 6-60

Input parameters 6-60

Output parameters 6-61

Function 6-61

Error messages 6-62

Blocks required 6-63

Programming guidelines 6-64

Timing diagrams 6-67

Signal cycle of uninterrupted tightness control on a plant with an

exhaust valve 6-67

Signal cycle of uninterrupted tightness control on a plant without

an exhaust valve 6-69

Loss of minimum pressure signal as valve VAV1 is incorrectly

seated 6-70

Loss of maximum pressure signal as valve VAV3 or VAV4 is

incorrectly seated 6-71

Enable and cancel tightness control via SyOK 6-72

Spurious, undefined NEXT input combinations 6-73

5Modular Block System: Burner Management

Page 8

Contents

SB157: Several ignition attempts 6-74

Block header 6-74

Input parameters 6-74

Output parameters 6-75

Function 6-75

Error messages 6-75

Blocks required 6-76

Programming guidelines 6-76

Timing diagrams 6-80

Counting ignition attempts where time is not exceeded 6-80

Counting ignition attempts where time is exceeded 6-81

Successful ignition after first attempt failed 6-81

Spurious signals 6-82

SB158: Ignition 6-84

Block header 6-84

Input parameters 6-84

Output parameters 6-85

Function 6-85

Error messages 6-85

Blocks required 6-86

Programming guidelines 6-87

Timing diagrams 6-91

Automatic ignition cycle when no parameters are set for manual

ignition 6-91

Automatic ignition cycle when parameters are set for manual

ignition 6-93

Spurious signals at NEXT input 6-94

Failure of SyOK in all NEXT steps 6-95

Spurious signals at MANU and S_IG inputs 6-95

Error analysis during manual ignition start-up 6-96

SB159: Run 6-98

Block header 6-98

Input parameters 6-98

Output parameters 6-98

Function 6-99

Error messages 6-99

Blocks required 6-100

Programming guidelines 6-101

Timing diagrams 6-104

Uninterrupted burner start-up or uninterrupted burner stop

sequence 6-104

6

Modular Block System: Burner Management

Page 9

Failure of SyOK in all NEXT steps 6-106

Spurious signals at NEXT input 6-107

SB160: Blower 6-108

Block header 6-108

Input parameters 6-108

Output parameters 6-108

Function 6-109

Error messages 6-109

Blocks required 6-110

Programming guidelines 6-110

Timing diagrams 6-111

Uninterrupted blower control 6-111

Spurious, conflicting control signals 6-111

Connections required between the SBs 6-112

Sequence for calling SBs 6-115

Link Blocks 7-1

Check list 7-1

Examples 8-1

Application and parameters of individual blocks 8-1

Managing enables 8-2

Using step monitoring time W_E of SB149 8-6

W_E as ignition ready time 8-6

Using delay time D_E on SB149 8-8

Executing a function during

D_E as pre-purge time 8-8

Executing a function after D_E 8-10

Delayed shutdown of blower 8-10

Building-up minimum air pressure 8-12

Driving the air flaps 8-14

Nesting of step sequences 8-16

D_E 8-8

7Modular Block System: Burner Management

Page 10

Contents

Appendix 9-1

Assignment table: Category « Requirement class 9-1

Standard function blocks: current versions 9-2

Changes to the standard function blocks 9-3

SB 149: Sequence control 9-3

SB151: Transient suppression 9-4

SB152: Burner: start and operator elements 9-4

SB 153: Control and position monitoring of flaps 9-5

SB 154: Control and position monitoring of valves 9-5

SB 155: Pre-purge 9-6

SB156: Tightness control 9-6

SB 157: Several ignition attempts 9-6

Changes to the operating manual 9-7

Changes from Version I to Version II 9-7

Changes from Version II to Version III 9-7

Changes from Version III to Version IV 9-8

Changes in Version 05 9-8

Changes in Version 06 9-8

Changes in Version 07 9-8

8

Modular Block System: Burner Management

Page 11

Introduction

This manual describes how to manage the standard function

blocks in the “MBS Burner Management” software package in accordance

with their intended use.

Standard function blocks in the “MBS Burner Management” software

package are part of the Pilz MBS Modular Block System. They can be

used in the failsafe section of a PSS-range programmable safety system.

To fully understand this manual you will need to be conversant with the

information found in the general documentation for the PSS-range (System

Manual, Installation Manual for the modular/compact PSS, PSS WIN-PRO

Programming Manual).

In particular you should refer to the following documents from the System

Manual:

• Safety Manual

• FS System Description

• Error List

To fully understand the bus-specific requirements and correlations for

SafetyBUS p applications you will need some knowledge of the design and

management of SafetyBUS p.

Knowledge of the safety regulations for the particular area of application is

assumed.

This installation manual is intended for instruction and should be retained

for future reference.

1-1Modular Block System: Burner Management

Page 12

Introduction

MBS Modular Block System

Safety-related areas can be equipped with a multitude of safety devices

such as E-STOPs, safety gates, light barriers etc. Safety devices are

required in various quantities and combinations, depending on the object

requiring protection. The Pilz MBS Modular Block System was developed

to drive the various safety devices and to carry out process engineering

functions, The MBS is designed to help users save time and money.

The MBS consists of individual standard function blocks (SBs), which are

geared specifically towards the relevant safety device or process

engineering function. It allows standard function blocks to be used in any

combination. The standard function blocks can be combined in any

sequence (max. 600).

Standard function blocks are encoded by an authorised body so that they

cannot be modified. If encoded standard function blocks are used within a

user program, program testing may be restricted to the new parts of the

program, considerably reducing the test time.

1-2

Modular Block System: Burner Management

Page 13

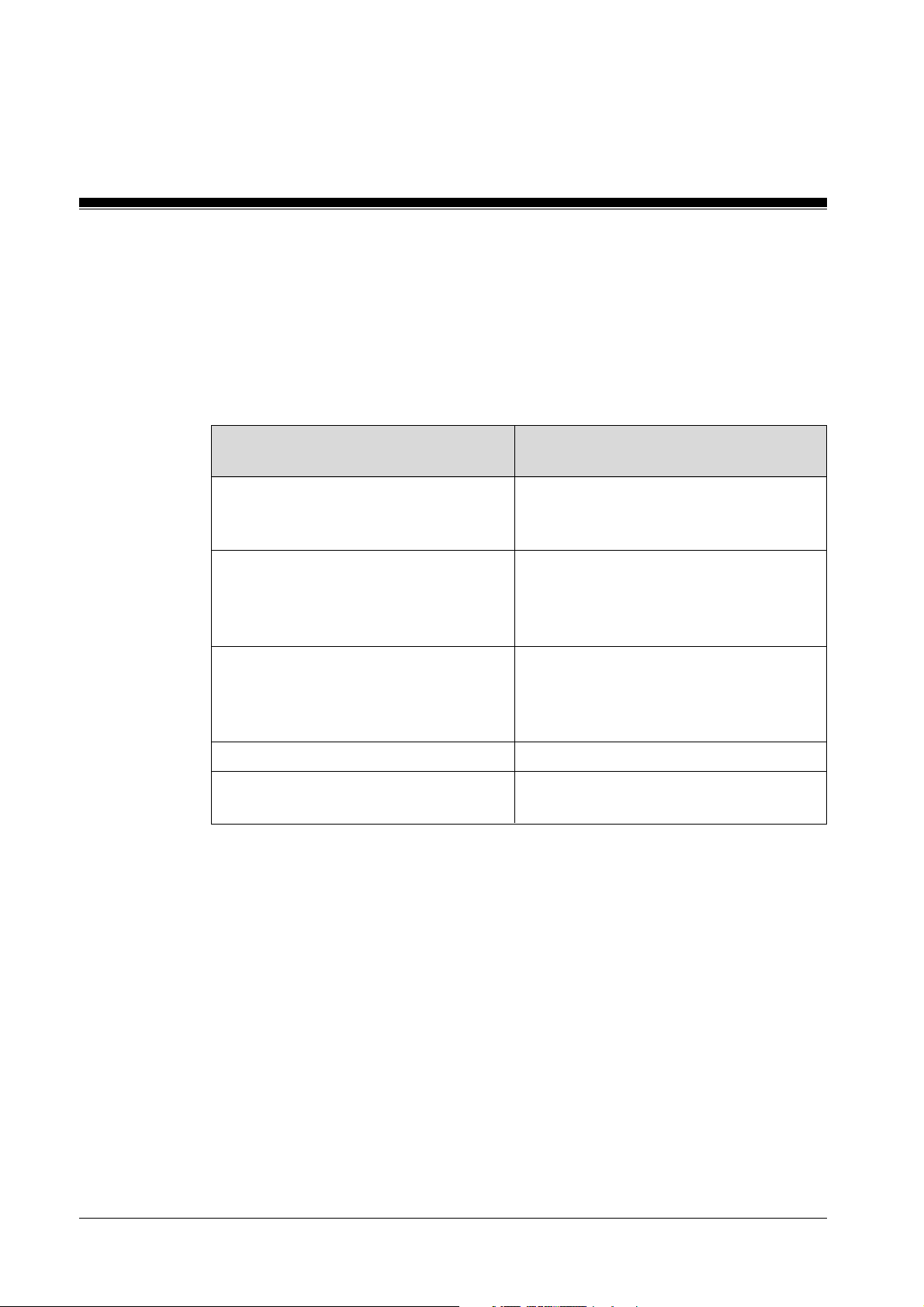

Categories / requirement classes

EN 954-1 divides safety devices into categories.

All standard function blocks are designed for the highest category

permitted for the safety device to be monitored. If safety devices with lower

categories are to be monitored, input parameters may be assigned

identical inputs (further information can be found in the description for the

relevant standard function block).

In process engineering, safety requirements must conform to DIN V 19250

(Fundamental Safety Aspects to be Considered for Measurement and

Control Equipment).

Requirement classes in accordance with DIN V 19250 may be referred to

the categories as per EN 954-1. The Appendix contains a table showing

the assignment of category and requirement class.

1-3Modular Block System: Burner Management

Page 14

Introduction

Overview of manual

1 Introduction

The chapter you are reading provides an introduction to the Modular

Block System (MBS). It is designed to familiarise you with the

contents, structure and specific order of this manual and also contains

terminology definitions.

2 Overview

This chapter provides information on the most important features of

the software package and provides a brief overview of the application

range.

3 Safety

This chapter must be read as it contains important information on

safety regulations.

4 Intended Use

This chapter must be read as it contains information on intended use.

5 MBS Basics

This chapter explains the basic functions and safety requirements of

the MBS.

6 Standard Function Blocks

This chapter explains the function of the package’s standard function

blocks.

7 Link Blocks

This chapter is designed to help you link the standard function blocks

into your project and to commission the safety functions.

8 Examples

This chapter is designed to give an overview of how the standard

function blocks may be applied and contains typical application

examples.

9 Appendix

The Appendix contains a table that explains the relationship between

categories and requirement classes, plus a list that documents the

current version status of the standard function blocks.

1-4

Modular Block System: Burner Management

Page 15

Definition of symbols

Information in this manual that is of particular importance can be identified

as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that

poses an immediate threat of serious injury and death and indicates

preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that

could lead to serious injury and death and indicates preventive

measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also

provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special

features, as well as highlighting areas within the text that are of particular

importance.

1-5Modular Block System: Burner Management

Page 16

Introduction

Terminology

• The term “input” is frequently abbreviated to “I” (e.g. I-Parameter).

• The term “output” is frequently abbreviated to “O” (e.g. O-Parameter).

• The term “PSS” is always used when the description is valid for all

applicable PSS programmable safety systems. If the description only

relates to a specific PSS series, the specific name for that series will be

used (e.g. PSS 3000 or PSS SB 3056).

• In this manual, the Pilz system software “PSS WIN-PRO” is referred to as

the “programming device” or “PG”.

1-6

Modular Block System: Burner Management

Page 17

Overview

Software package

The “MBS Burner Management” software package is part of the Pilz MBS

Modular Block System.

Standard function blocks in the “MBS Burner Management” software

package are used in the failsafe section of a PSS-range programmable

safety system.

The software package complies with the relevant standards and directives

for burners, steam boilers and thermoprocessing equipment.

The software package contains all the blocks necessary for burner control.

Operation

The individual standard function blocks perform individual functions such

as:

• Sequence control

• Flame monitoring

• Tightness control

• etc.

With these blocks the user can put the burner cycle together individually.

Details can be found in Chapter 6 of this manual, “Standard Function

Blocks”.

2-1Modular Block System: Burner Management

Page 18

Overview

Range

The software package consists of:

• The files for the software package on CD and

• An operating manual:

PSS Standard Function Blocks, MBS Burner Management.

The software package on the CD contains the following blocks:

• SB149 STEP

Sequence control

(approved safety block)

• SB150 FLAME_M

Flame monitoring

(approved safety block)

• SB151 BridgedS

Transient suppression

(approved safety block)

• SB152 BR_START

Burner: start and operator elements

(approved safety block)

• SB153 FLAP

Control and position monitoring of flaps

(approved safety block)

• SB154 VALVE

Control and position monitoring of valves

(approved safety block)

• SB155 PREPURGE

Pre-purge

(approved safety block)

• SB156 TIGHT_C

Tightness control

(approved safety block)

• SB157 IGNI_TRY

Several ignition attempts

(approved safety block)

2-2

Modular Block System: Burner Management

Page 19

• SB158 IGNITION

Ignition

(approved safety block)

• SB159 RUN

Run

(approved safety block)

• SB160 BLOWER

Blower

(approved safety block)

• SB071 INIT_MBS

Initialisation of administration data blocks (DB015/DB016/DB017)

(approved safety block)

• SB255 System block

SB255 is explained in the PSS System Description.

INFORMATION

Please refer to the Appendix, section entitled “Standard function blocks:

current versions”.

2-3Modular Block System: Burner Management

Page 20

Overview

Notes

2-4

Modular Block System: Burner Management

Page 21

Safety

Safety guidelines

These safety guidelines are an important part of this manual.

Failure to keep to these guidelines will render all warranty and liability

claims invalid:

• All health and safety / accident prevention regulations for the particular

area of application must be observed.

• Before using one or more of the standard function blocks in this software

package, it is necessary to perform a safety assessment in accordance

with the Machinery Directive.

Use of qualified personnel

The safety system may only be assembled, installed, programmed,

commissioned, operated, maintained and decomissioned by qualified

personnel. Qualified personnel are people who, because they are:

• Qualified electrical engineers and/or

• Have received training from qualified electrical engineers

are suitably experienced to operate devices, systems, plant and machinery

in accordance with the general standards and guidelines for safety

technology.

Warranty and liability

All claims to warranty and liability will be rendered invalid if:

• Standard function blocks are used contrary to the purpose for which they

were intended

• Damage can be attributed to not having followed the guidelines in the

manual

• Operating personnel are not suitably qualified.

3-1Modular Block System: Burner Management

Page 22

Safety

Application guidelines

• The instructions given in the “Safety Manual” and in the “Installation

Manual” must be followed.

• Please read the information in Chapter 4 concerning the proper

application of these blocks.

• The use of Pilz SBs does not detract from the fact that it is the

responsibility of the user to design appropriate safety systems for plant,

machinery and software.

• It is your responsibility to determine your application requirements by

carrying out a detailed risk analysis. This should take into account relevant standards and directives, etc.

WARNING!

Please note: To achieve the corresponding category or requirement class,

the whole system including all safety-related components (parts, devices,

user program etc.) must be included in the assessment. For this reason,

Pilz cannot accept liability for the correct classification into a category or

requirement class.

3-2

Modular Block System: Burner Management

Page 23

Standards

To use the SBs correctly you will need to have a good knowledge of the

relevant standards and directives. The following gives an overview of the

most important standards:

• Safety of machinery – Basic terminology

• Electrical equipment

• Safety of machinery; safety-related parts of

control systems

• Fundamental safety aspects to be considered

for measurement and control equipment

• Electrical equipment for furnaces

• Automatic gas burner control systems for gas

burners and gas burning appliances with or

without fans

• Monobloc oil burners

• Forced draught oil burners

• Automatic forced draught burners for gaseous

fuels

• Valve proving systems for automatic shut-off

valves for gas burners and gas appliances

• Electrical equipment for furnaces

EN 292-1:1991-11 and

EN 292-2:1995-06

EN 60 204-1:1998-11

EN 954-1:1997-03

DIN V 19250:1994-05

EN 50 156-1:2004

EN 298:2003

EN 230:1990

EN 267:1999

EN 676:2003

EN 1643:2000

VDE 0116/

EN 50156:2004

• Industrial thermoprocessing equipment

• Water-tube boilers and auxiliary installations

• Shell boilers

• Directive for appliances burning gaseous fuels

• Pressure equipment directive

• Oil firing systems for boilers

• Gas firing systems for boilers

EN 746-2:1997

EN 12952-8:2003

EN 12953-7:2002

90/396/EEC

97/23/EC

TRD 411:1997

TRD 412:1998

Please note this is not an exhaustive list of safety standards and directives.

3-3Modular Block System: Burner Management

Page 24

Safety

Fault detection

The detection of errors and defects is an important function of the PSS, in

addition to pure control tasks.

Further information on the fault detection concept can be found in the PSS

“System Description”.

WARNING!

It is particularly important to detect open circuits and shorts within the

safety circuits (e.g. two-hand control devices, E-STOP etc.).

It is the responsibility of the user to select and apply an appropriate fault

detection system.

Feasibility test

Fault prevention

Redundant input devices for safety functions must undergo a feasibility test

within the user program.

The plant must be stopped immediately if a feasibility error occurs. Similar

tests will also be required for other input devices.

If safety valves have feedback contacts, these must be evaluated

accordingly.

Not all potential faults can be detected and managed. Such faults must be

excluded by suitable wiring methods.

Additional information on how to exclude potential errors can be found in

the BIA Handbook (BG Institute for Occupational Safety, St Augustin) or in

the directive VDI 2854:1991-06 (safety requirements on automated

manufacturing systems).

3-4

Modular Block System: Burner Management

Page 25

Intended Use

Application

The software package “MBS Burner Management” is designed for

use within the failsafe section of the PSS-range of programmable safety

systems. With this MBS package it is possible to control and monitor

various status conditions on furnaces.

INFORMATION

• Use of standard function blocks outside the specifications described here

will be deemed as improper use.

• MBS blocks must be run through as part of each cycle.

Please refer also to the table showing the required connections for the

standard function blocks, at the end of Chapter 6.

INFORMATION

Always use the current version of the standard function block.

Please ensure you refer to the Appendix, sections entitled “Standard

function blocks: current versions” and “Changes to the standard function

blocks”.

System software

The software package “MBS Burner Management” can be used with the

PSS WIN-PRO system software.

Further information is available in the PSS WIN-PRO “Progamming Manual”.

4-1Modular Block System: Burner Management

Page 26

Intended Use

Intended use of the standard function blocks

SB149: Sequence control

SB149 is a standard function block designed to control operating cycles.

For this reason, several SB149 blocks can be arranged together to form a

sequence. Each SB149 in this sequence waits for the ready signal from the

previous step and for the step enabling conditions to be met, before it

becomes active.

A PSS can monitor and control several work cycles in which each cycle is

assigned a separate sequence.

NOTICE

During a sequence only one SB may be active. This requirement is only

met if output parameter

parameter

accordingly.

RDY

on the next step. Make sure the parameters are assigned

NEXT

from the current step is connected to input

SB150: Flame monitoring

SB150 is a standard function block for monitoring flames from the moment

the burner starts until the moment the burner stops. The block checks

whether the flame is present or absent, depending on the operating status.

SB151: Transient suppression

SB151 is a standard function block for monitoring a N/C contact, e.g. on a

pressure monitor. The N/C contact must be wired with a test pulse.

4-2

Modular Block System: Burner Management

Page 27

SB152: Burner: start and operator elements

SB152 is used to control the burner start and monitor the burner.

Use SB152 to:

• Carry out a delayed start after the controller has started

• Carry out a restart after a controlled shutdown

• Evaluate the reset, start and stop button

• Monitor the air pressure monitor

• Monitor the flames (pilot and main flame)

• Monitor the global messages from the error, monitor and safety

sequences and to carry out a controlled shutdown or safety lockout.

If the safety sequence is interrupted, the error must always be rectified,

followed by a manual reset via the reset button (

(

STRT)

. The block enable

ENBL

sequence is no longer interrupted. .

NOTICE

Error reaction is the sole responsibility of the user. All safety-related

aspects must be taken into account when selecting the elements for the

error and safety sequences!

RSET)

and start button

will only be issued when the safety

SB153: Control and position monitoring of flaps

SB153 monitors the status of a flap. It opens and closes the flap after the

corresponding input prompt, monitors the direction of a positional change

and checks the reaction time.

The contact bounce time lasts for one cycle, if a change in position occurs.

4-3Modular Block System: Burner Management

Page 28

Intended Use

SB154: Control and position monitoring of valves

SB154 monitors the status of a valve. It changes the valves' position after

the corresponding input prompt, monitors the direction of a positional

change and checks the reaction time.

The contact bounce time lasts for one cycle, if a change in position occurs.

SB155: Pre-purge

SB155 monitors the limit switch for the maximum position of the air

damper or the maximum air flow during the pre-purge time.

If the limit switch isn’t activated by the air damper during the pre-purge

time, or if the maximum air flow for pre-purge is not achieved, SB155

resets its enable.

SB156: Tightness control

SB156 checks the tightness (seal) of the safety valves, the main valves

and, if present, the exhaust valves.

Tightness monitoring must be called up separately. If an error occurs, the

enable is reset and a shutdown occurs.

SB157: Several ignition attempts

SB157 counts the number of ignition attempts. After a failed ignition, a

signal is issued for another attempt, after which the step sequence can

immediately start the initial ignition step.

SB157 also monitors the time between the ignition attempts and the

establishment of a flame.

4-4

Modular Block System: Burner Management

Page 29

SB158: Ignition

SB159: Run

SB158 controls the ignition and monitors the process. The ignition steps

must be called up individually. If a fault occurs, the enable is reset and a

shutdown occurs.

To ensure a fault-free ignition process, the safety valve must not be driven

from SB158 and another safety block at the same time.

SB159 is used to set up the burner. These set-up steps must be called up

individually. If an error occurs, the enable is reset and a shutdown occurs.

Following a fault-free start-up SB159 issues a control enable.

To ensure a fault-free start-up process, the main valve must not be driven

from SB159 and another safety block at the same time.

SB160: Blower

SB160 is used to control a blower/fan on force draught burners.

The blower is switched on by pressing a button on the input parameter

STRT

the input parameter

NEXT

on SB160. The blower is switched off either by pressing a button on

STOP

on SB160 or by setting the input parameter

via the sequence block “Blower overrun time”.

When controlling fans the rising edge of the signals on the input

parameters has priority.

4-5Modular Block System: Burner Management

Page 30

Intended Use

Notes

4-6

Modular Block System: Burner Management

Page 31

MBS Basics

Block design

Structure

Safety-related areas can be equipped with a multitude of safety devices such

as (e.g. E-STOPs, safety gates, light barriers). These safety devices are used

in various quantities and combinations, depending on the object requiring

protection.

The Modular Block System (MBS) is made up of individual standard function

blocks. A standard function block is geared towards the requirements of

specific safety devices (e.g. monitoring an E-STOP button, safety gate

monitoring).

A standard function block must be assigned to each safety device in order for

it to be evaluated and monitored using the MBS. This procedure enables any

combination of individual safety devices to be evaluated and monitored.

The standard function blocks can be combined in any sequence within the

user program (max. 600).

One exception to this are standard function blocks used to drive and monitor

contactors or valves. For control engineering reasons, these should be called

up at the end of the user program.

5-1Modular Block System: Burner Management

Page 32

MBS Basics

Formal parameters and actual parameters

Parameters can be set on the MBS standard function blocks. Formal

parameters are established in the block header. The user must assign a

corresponding actual parameter to each formal parameter. When the

standard function block is called up in the user program, the formal

parameters will be replaced by the user-specific actual parameters.

Formal parameters

PSS WIN-PRO: Pilz IL

X

B

W

D

Z

Further information is available in the PSS WIN-PRO “Progamming Manual”.

Actual parameters

PSS WIN-PRO: Pilz IL

Input bit E

Output bit A

Flag bit M

Input byte EB

Output byte AB

Flag byte MB

Constant KB

Input word EW

Output word AW

Flag byte MW

Constant KW

Data block DB

Timer or counter

5-2

Modular Block System: Burner Management

Page 33

Administration data blocks DB015, DB016 and DB017

Data blocks DB015, DB016 and DB017 are permanently specified within

the Modular Block System (MBS).

These data blocks are common administration blocks for fault and

diagnostic data from the MBS standard function blocks and for block and

parameter data that is required internally.

The administration data block DB015 must always be installed when using

MBS standard function blocks. Administration data blocks DB016 and

DB017 are installed when necessary.

The administration data blocks must always be installed with their full

length of 1024 data words and they must always have read/write status.

NOTICE

Data blocks DB015, DB016 and DB017 should only be used as MBS

administration data blocks and not for other data.

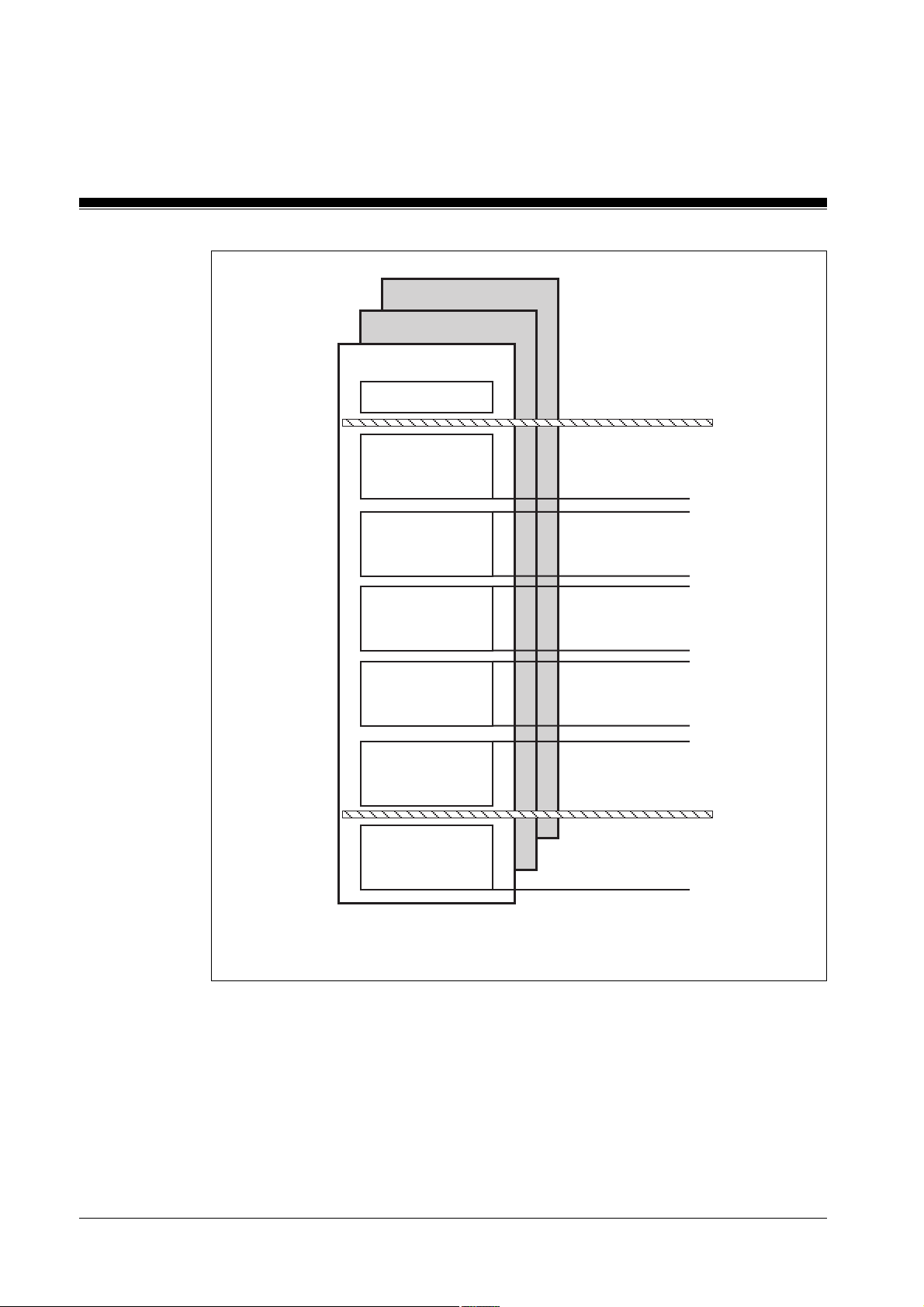

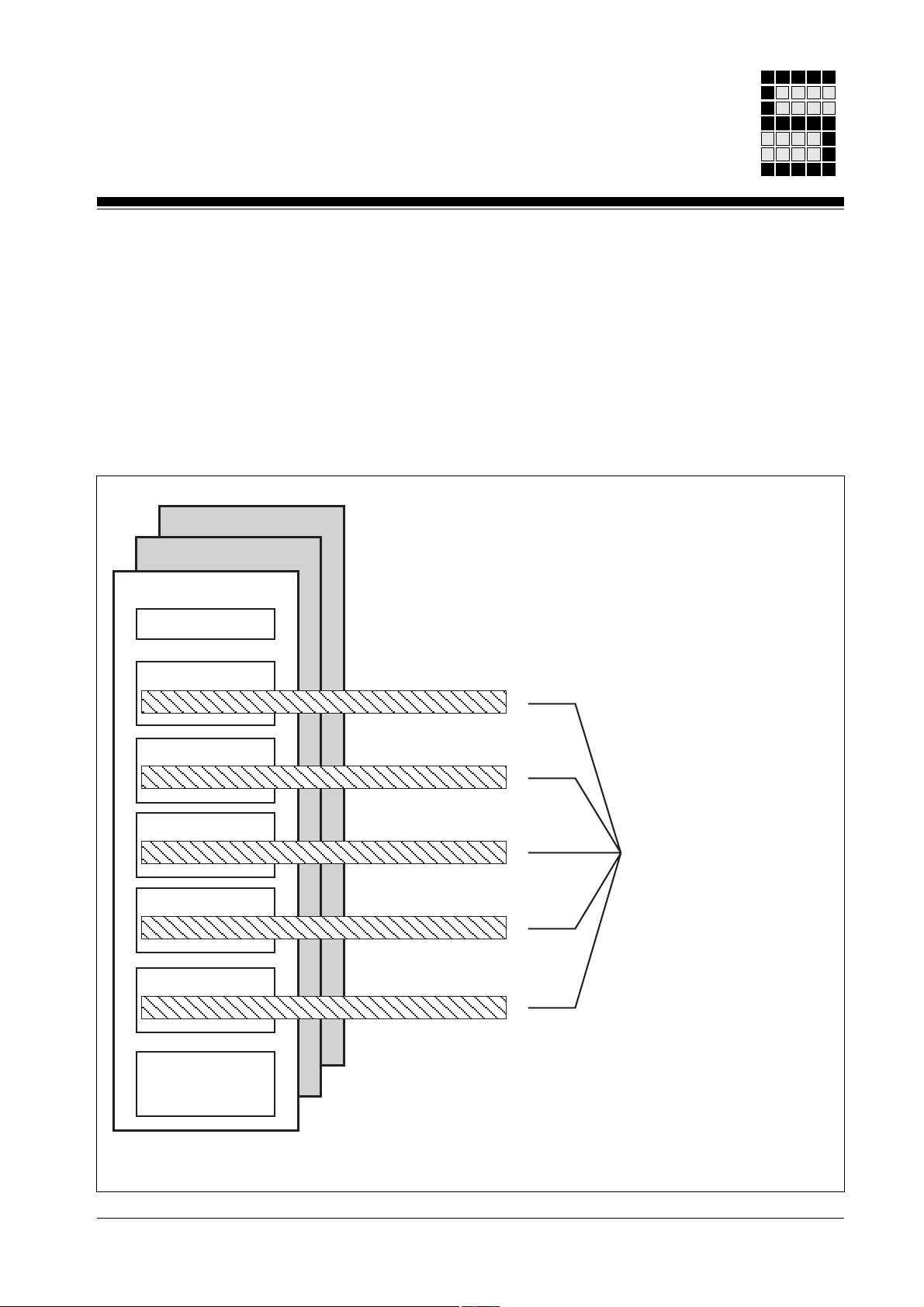

Structure of the administration data blocks

The administration data blocks DB015, DB016 and DB017 have the same

structure.

Each standard function block in the user program has 5 data words

available in one of the administration data blocks. These data words are

used to back up the temporary flags from the standard function block (see

section entitled “Temporary flag range in MBS blocks”).

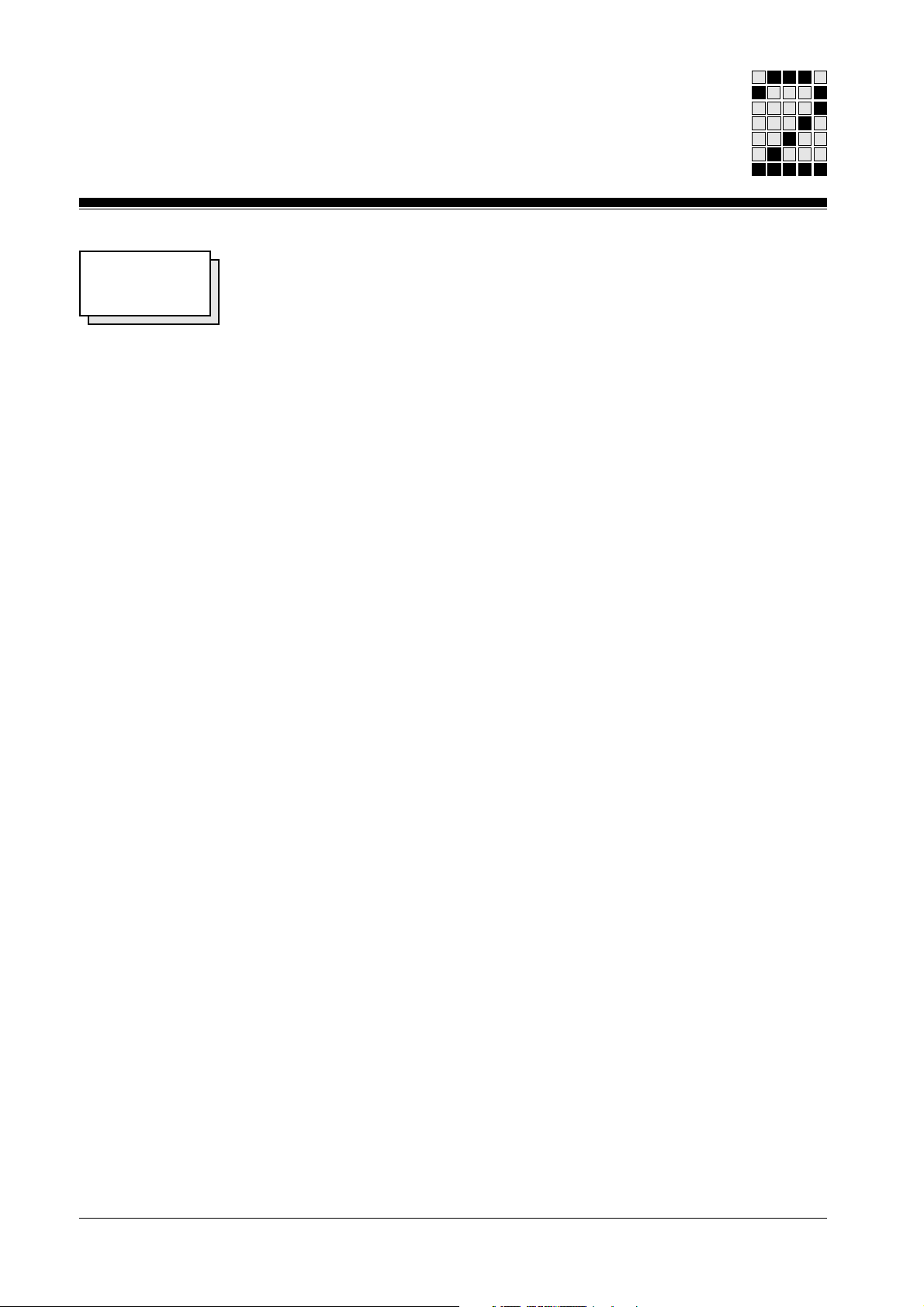

In each of the administration data blocks, the range DW0001 to DW1000 is

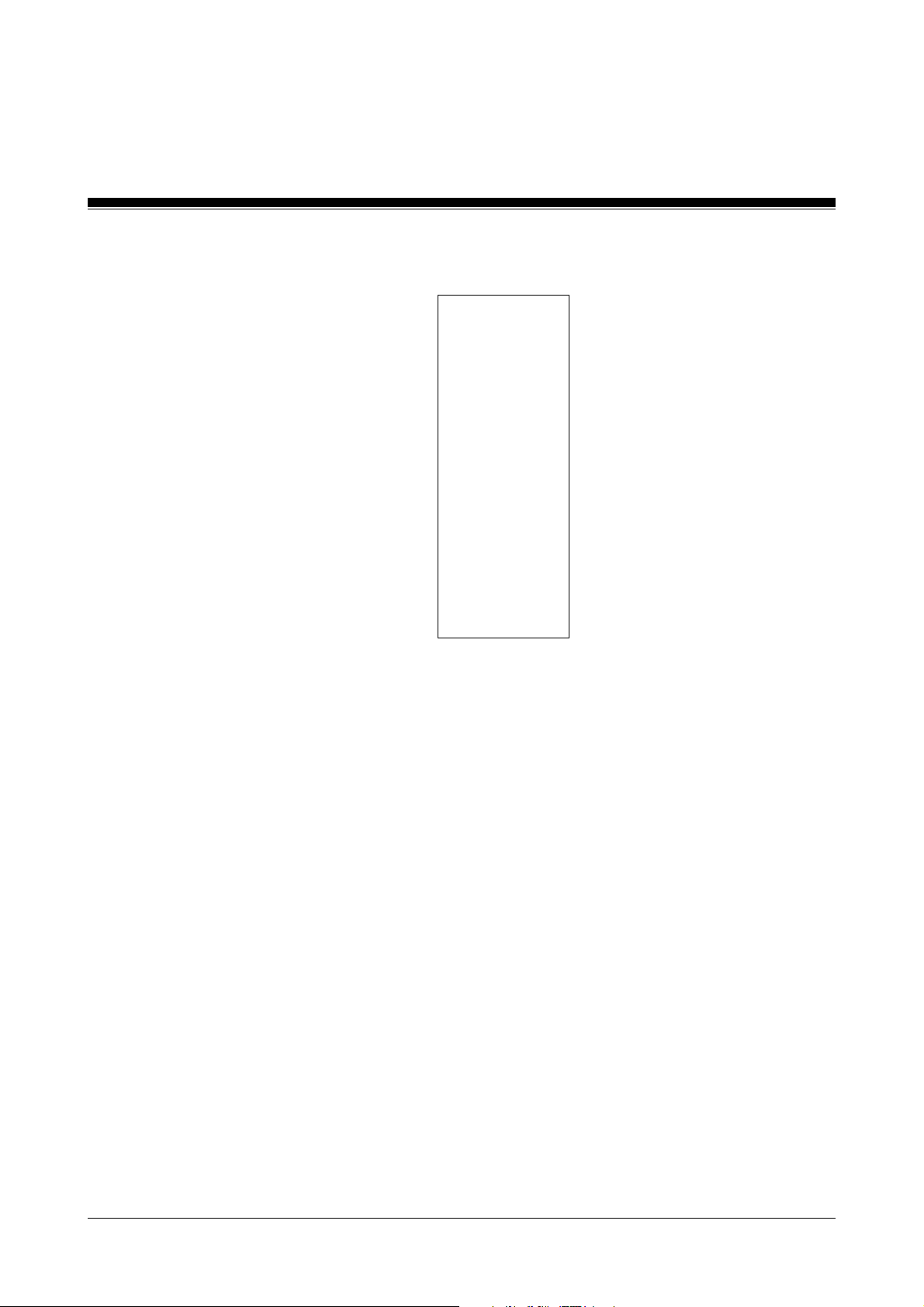

divided into 5 blocks, each with 200 data words (see Fig. 5-1).

5-3Modular Block System: Burner Management

Page 34

MBS Basics

DB017

DB016

DB015

DW0000

Block 1

200 data words

Block 2

200 data words

Block 3

200 data words

Block 4

200 data words

Block 5

200 data words

Block 6

Global

parameters

DW 0001

to

DW 0200

DW 0201

to

DW 0400

DW 0401

to

DW 0600

DW 0601

to

DW 0800

DW 0801

to

DW 1000

DW 1001

to

DW 1023

5-4

Fig. 5-1: Structure of the administration data blocks

Modular Block System: Burner Management

Page 35

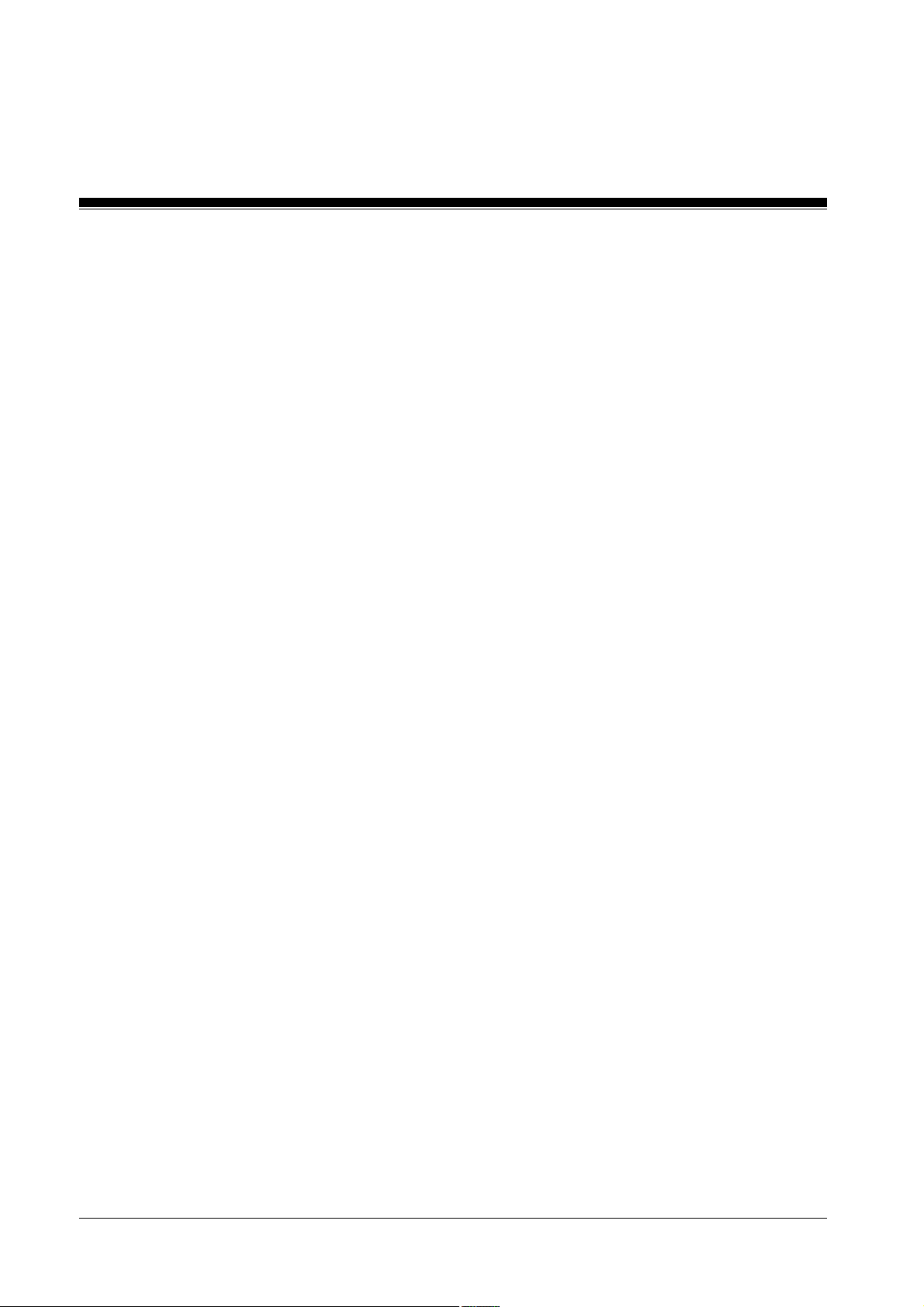

Blocks contained in the administration data blocks

Each standard function block occupies 1 data word per block (see Fig. 5-

2). This means a max. of 200 safety devices (e.g. E-STOP 1, E-STOP 2,

safety gate 1) can be managed per administration data block.

The PSS uses a standard function block’s SSNR to automatically generate

the corresponding data words (see “Input parameter SSNR”).

DB017

DB016

DB015

DW0000

Block 1

Data word 1

Block 2

Block 3

Block 4

Block 5

Block 6

Global

parameters

Data word 2

Data word 3

Data word 4

Data word 5

Fig. 5-2: Contents of the administration data blocks

Data words 1 to 5

of an MBS

standard function block

5-5Modular Block System: Burner Management

Page 36

MBS Basics

DW0000 (DB015)

1st data block (DB015/DB016/DB017):

DW 0001 ... DW0200 bits for hardware and operator errors

2nd data block ... 5. data block (DB015/DB016/DB017):

If parameters for a standard function block’s input parameter

SSNR are not within the permitted range, DW0000 of DB015

will contain the incorrect SSNR parameter. The standard

function block will not be enabled (output parameter ENBL= 0).

If the SSNR=0, DW0000 of DB015 will contain the decimal

value -1 or KH FFFF.

The significance of the individual bits can be found in the

description for the relevant standard function block (see section

entitled “Fault diagnostics”).

If a data word contains the value 0, no error has been found

DW0201 ... DW1000

Data blocks 2 ... 5 are used for internal block data.

6th data block (DB015/DB016/DB017)

DW1001 ... DW1023

Data block 6 contains the global parameters (see section

entitled “Global parameters”).

5-6

Modular Block System: Burner Management

Page 37

Input parameter SSNR

MBS standard function blocks have input and output parameters which can

be adapted to suit the respective control configuration. The input

parameter SSNR (safety subroutine number) is available on all MBS

standard function blocks. It is required to manage the administration data

blocks DB015, DB016 and DB017.

INFORMATION

MBS standard function blocks may differ in terms of the permitted value

range for the SSNR. The following value ranges are possible for the SSNR:

• Value range of input parameter SSNR: 1 ... 200

(byte constant type: KB001 ... KB200)

• Value range of input parameter SSNR: 1 ... 600

(word constant type: KF000001 ... KF000600)

The valid value range for the SSNR of a standard function block is

documented in the standard function block description.

The input parameter SSNR determines the administration data block plus

the 5 data words assigned in the administration data block of the

corresponding safety device (1 DW per block). The administration data

blocks are assigned the following SSNR ranges:

• SSNR 001 ... 200: DB015

• SSNR 201 ... 400: DB016

• SSNR 401 ... 600: DB017

The one data word per block is generated automatically internally (SSNR +

offset).

5-7Modular Block System: Burner Management

Page 38

MBS Basics

NOTICE

• One MBS standard function block must be used for each safety device.

• Each standard function block should be assigned its own SSNR.

• Make sure that each SSNR is assigned once only.

• Document the assignment of the safety device to the respective SSNR of

Example

Safety device 2 (E-STOP button) is monitored using SB061. The value

KB002 is assigned to input parameter SSNR of SB061.

If two SB calls have the same value for the SSNR, they will access the

same data word in the administration data block. This can lead to

malfunctions.

the standard function block.

The following DWs in DB015 are therefore assigned to safety device 2:

Block 1: DW0002

Block 2: DW0202

Block 3: DW0402

Block 4: DW0602

Block 5: DW0802

The user program has read-only access to these data words.

5-8

Modular Block System: Burner Management

Page 39

Fault diagnostics

Error types

On programmable safety systems from the PSS-range, a distinction is

made between two types of errors. On the one hand there are errors which

are detected and evaluated through the PSS operating system, and on the

other there are errors which are detected and evaluated through the user

program. The reaction to these two types of errors is different.

Where errors are detected through the operating system, the FS section of

the PSS will switch to a STOP condition and all outputs will be switched off

safely.

Where errors are detected through the user program, only the configured

error reaction will occur. Errors that are detected via an MBS standard

function block belong to this second type of error.

5-9Modular Block System: Burner Management

Page 40

MBS Basics

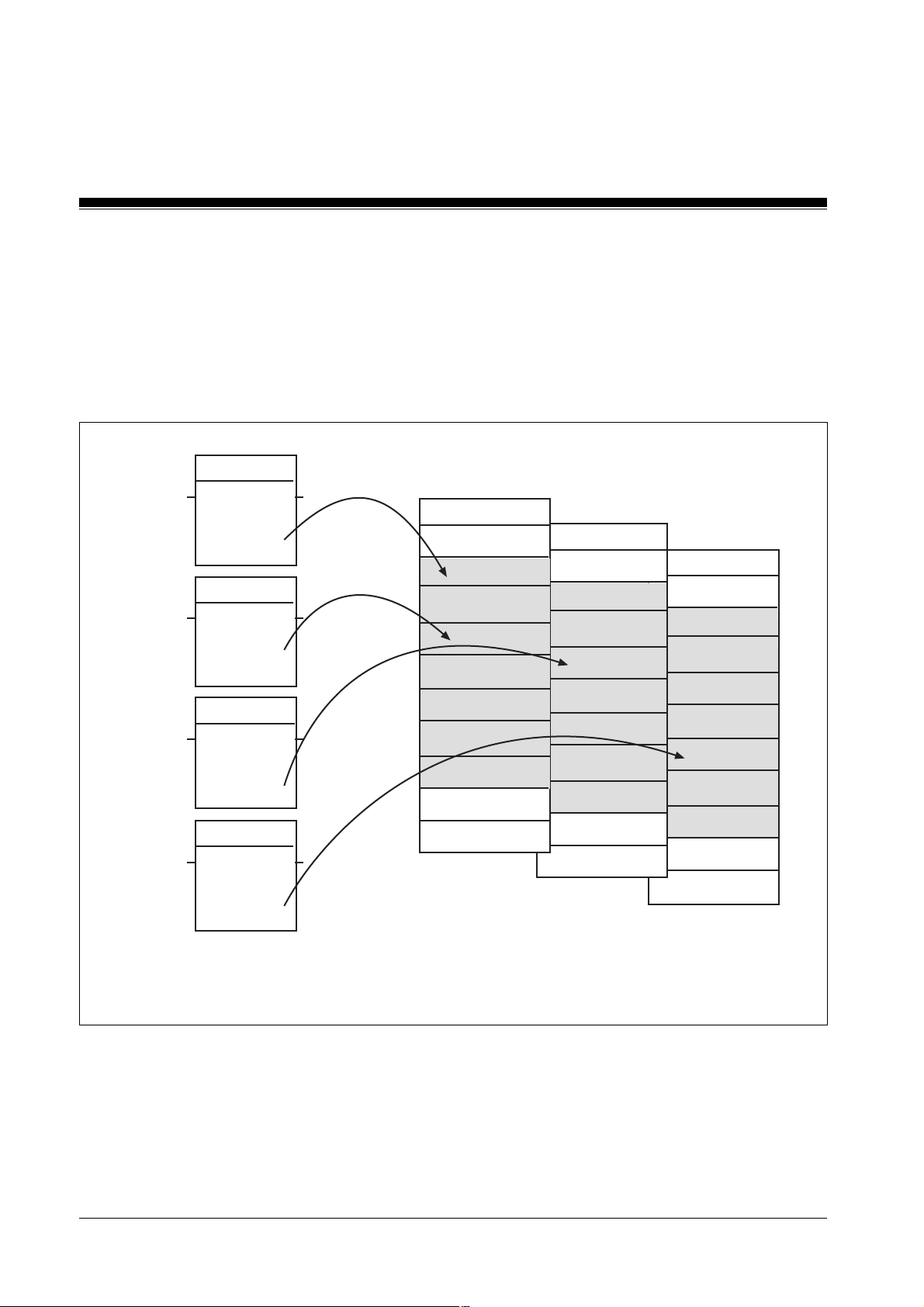

Fault diagnostics using the administration data blocks

Data words DW0001 ... DW0200 of an administration data block contain

the error messages from the individual MBS standard function blocks (see

Fig 5-3). 1 data word is reserved for each standard function block used.

The assignment is made using the SSNR.

SB061

KB001

KB005

KF000205

KF000427

SSNR

SB061

SSNR

SB065

SSNR

SB065

SSNR

FG

FG

ENBL

ENBL

DB015

DW0000

DW0001

...

DW0005

...

DW0027

...

DW0200

...

DW1023

DB016

DW0000

DW0001

...

DW0005

...

DW0027

...

DW0200

...

DW1023

DB017

DW0000

DW0001

...

DW0005

...

DW0027

...

DW0200

...

DW1023

Fig. 5-3: Managing the MBS error messages using the administration data blocks (example)

5-10

Modular Block System: Burner Management

Page 41

Temporary flag range in MBS blocks

Internally, MBS blocks use the flags in the range M 64.00 ... M69.31 as

temporary flags.

NOTICE

We recommend the following:

• Do not use flags from the temporary flag range for your own applications.

Malfunctions may occur if you use the temporary flag range M64.00 ...

M69.31 for your own applications.

• If it is absolutely necessary to use this flag range, under no

circumstances should you use the flags:

- in alarm OBs

- as input parameters for standard function blocks

- as output parameters for standard function blocks

- as global parameters

Output parameter ENBL

Many standard function blocks have an enable output ENBL. This output

parameter indicates the enable status of a standard function block. The

enable status results from the standard function block’s check of the

inputs.

ENBL = 1: No error found,

the function is enabled

ENBL = 0: An error has been found,

the function is not enabled.

5-11Modular Block System: Burner Management

Page 42

MBS Basics

Assignment of input and output parameters

Input and output parameters should be assigned in accordance with the

details given in the operating manual.

WARNING!

If several unused output parameters are connected to the same flag,

malfunctions may occur in the standard function blocks. If an unused

output has to be assigned a flag, make sure the output is assigned to a

flag that is not used anywhere else in the program.

Minimum scan time

Most of the timer functions required within the blocks are performed using

cycle counters. This means that almost all the timers are available for use

in applications.

INFORMATION

• If MBS blocks are used, a minimum scan time must always be

entered in the configurator. Empirical values should be used.

• If the error message F-20/06 (error category/error number) appears on

the CPU display, you must amend the minimum scan time appropriately.

This error message indicates that the minimum scan time has been

exceeded. The PSS must not be operated while this error message is

present.

SB070 and SB071 automatically enter the minimum scan time in DW1022

of the administration data blocks. In this way it is automatically available to

the MBS.

INFORMATION

Please note that the times are imprecise. The lack of precision on times is

due to the cyclical processing of the user program. It is determined by the

scan time of the respective user program.

In general:

The greater the ratio of time value to scan time, the greater accuracy you

will have with the required times.

5-12

Modular Block System: Burner Management

Page 43

Global parameters

Block 6 (DW1001 ... DW1023) of the administration data blocks contains

global parameters. These are parameters that are valid for several blocks.

For details of which global parameters a standard function block uses,

please refer to the description of the individual standard function blocks.

The data words in block 6 must be initialised when the program is started

(OB120) using SB070/SB071 (INIT_MBS).

The abbreviations in brackets {... : ...} at the end of each data word

correspond to the parameters in SB071. The times that are also specified

within the brackets are empirical values, unless stated otherwise.

DW1001 Number of cycles in the contact synchronisation time between

DW1002 Number of cycles in the feedback loop’s reaction time to a

DW1003 Number of cycles in the contact switchover time between a N/

DW1004 Number of cycles in the contact switchover time between a N/

DW1005 Number of cycles in the machine clock time

DW1006 Number of cycles in the permitted ESPE reaction time

DW1007 Reserved

DW1009 Reserved

DW1010 Reserved

DW1011 Reserved

DW1012 Reserved

DW1013 Reserved

DW1014 Reserved

2 N/O contacts or 2 N/C contacts (e.g. E-STOP button, reset

key, etc.)

{CoSy : 50ms}

change in the PSS output connected to the main contactor

{RFbL : 100ms}

O and N/C contact (pushbutton)

{CS_B : 100 ms}

O and N/C contact (relay)

{CS_R: 50 ms}

{MaCy : max. 30 s in accordance with EN 61496-1 section

A.8.4, 06/98}

{ESPE : max. 150 ms in accordance with EN 61496-1 section

5.2.4, 06/98}

5-13Modular Block System: Burner Management

Page 44

MBS Basics

DW1015 Counter for SSNR monitoring

DW1016 Reserved

DW1017 Reserved

DW1018 Reserved

DW1019 Reserved for administration

DW1020 Reserved

DW1021 Reserved for burner management

DW1022 Min. scan time from DB002/DW0002

DW1023 Reserved

5-14

Modular Block System: Burner Management

Page 45

Standard Function Blocks

SB149: Sequence control

Block header

Input parameters

•

•

SB149

STEP

X - RDY

X - COND

X - STEP

B - W_BA

W - W_V

Z - W_T

B - D_BA

W - D_V

Z - D_T

RDY

: Ready signal from the previous step

RDY

= 1: ready signal is present

COND

: Global input for step enabling conditions for next step

COND

= 1: all step enabling conditions fulfilled

NEXT - X

W_E - X

D_E - X

• STEP: Signals burner start-up for the duration of a cycle and

deactivates the step

STEP

= 1: first cycle of burner start-up and deactivating the

step

STEP

= 0: no burner start-up detected

This parameter must be assigned with the same operand used

for the output parameter

operator elements” and for the input parameter

STEP

from SB152 “Burner: Start and

STEP

SB157 “Ignition attempts” for the same burner.

•

W_BA

: Time base for step monitoring time (watchdog base)

Following values are valid:

0: 50 ms

1: 100 ms

2: 1 s

3: 10 s

4: 1 min

of

Modular Block System: Burner Management

6-1

Page 46

Standard Function Blocks

•

W_V

: Time value (watchdog value) of step monitoring time as

multiplier for

Permitted value range: - 32768 ... 32767

For W_V ≤ 0 to be valid: there is no step monitoring time,

the output parameter W_E is permanently 0.

• W_T: Timer (watchdog timer) for step monitoring time

• D_BA: Time base for step time delay

Following values are valid:

0: 50 ms

1: 100 ms

2: 1 s

3: 10 s

4: 1 min

•

D_V

: Time value of the time delay as multiplier for

Permitted vallue range: -32768 ... 32767

For

D_BA

the output parameter

soon as a step is activated.

≤ 0 to be valid: there is no time delay,

W_BA

D_BA

D_E

changes immediately from 0 to 1 as

SB149

•

D_T

Output parameters

•

NEXT

•

W_E

•

D_E

Function:

• Control of work cycles

• By adding together several SB149 blocks, a step sequence can be

• One PSS can control and monitor several work cycles (e.g. burner), in

: Timer for time delay

: Gives the status of the step

NEXT

: Output parameter for step monitoring time

W_E

: Output parameter for the time delay

D_E

established

which each cycle is allocated a separate sequence

= 1: step is active

= 1: timer for the step monitoring time has elapsed.

= 1: timer for the time delay has elapsed.

6-2

Modular Block System: Burner Management

Page 47

Error messages

• Each SB149 of this sequence waits for the ready signal from the

previous step and for the step enabling conditions to be fulfilled, before

it is active.

• Step monitoring time: a step provess can be monitored for a specific

time

• Time delay: a function process can be limited to a certain time, or the

process can be started after a specific time.

• Error messages in DB015

None

• Error messages on the CPU-display

Blocks required

E006: Parameter errors- the time base

W_BA

or

D_BA

does not lie

within the permitted range 0 to 4. The incorrect value will be

entered in DR0 (data byte right) of the administration data block

DB015.

• DB002: Will be made available when the configurator is called up

• DB015: Administration data block

DB015 must consist of its total length of 1024 data words and

have Read/Write access (see section “Administration data

blocks DB015, DB016 and DB017” in chapter 5).

• OB101: To call up SB149

• SB149: STEP

• SB255: To call up the operating system

Modular Block System: Burner Management

6-3

Page 48

Standard Function Blocks

Programming guidelines

•

STEP

The operand for the input parameter

assigned to the output parameter

input parameter

individual steps of the sequence to reset during burner start-up.

STEP

SB149

STEP

STEP

of SB157, if SB157 is used. This will enable the

of SB149 must also be

from SB152 and also to the

The operand for the parameter

STEP

has the value 1 for the duration of

a cycle when a positive edge of the ENBL of SB152 is detected.

If several burners are operated with one PSS, each burner must be

assigned its own STEP operand. This enables the burners to be

controlled and monitored independently.

Example:

SB157

IGNI_TRY

B - SSNR

X - SyOK

X - BIT0

X - BIT3

X - FLAs

B - ITRY

M 70.00 .Burner 1 - X - STEP

W - T_V

Z- T

RDY - X

6-4

X - RDY

X - COND

M 70.00 .Burner 1 - X - STEP

B - W_BA

W - W_V

Z - W_T

B - D_BA

W - D_V

Z - D_T

SB149

STEP

NEXT - X

W_E - X

D_E - X

Modular Block System: Burner Management

Page 49

SB152

BR_START

B - SSNR

X - NEXT

X - STRT

X - STOP

X - ERR

X - GUAR

X - AirP

X - CHAI

X - FLAs

X - FTRY

X - RUN

B - D_C

X - AuSt

X - RSET

IGNI_TRY

B - SSNR

X - SyOK

X - BIT0

X - BIT3

X - FLAs

B - ITRY

M 80.00 .Burner 2 - X - STEP

W - T_V

Z- T

ENBL - X

RDY - X

STEP - X - M 70.00 .Burner 1

SB157

RDY - X

M 80.00 .Burner 2 - X - STEP

Modular Block System: Burner Management

X - RDY

X - COND

B - W_BA

W - W_V

Z - W_T

B - D_BA

W - D_V

Z - D_T

SB149

STEP

NEXT - X

W_E - X

D_E - X

6-5

Page 50

Standard Function Blocks

SB149

SB152

BR_START

•

RDY

and

NEXT

The output parameter

the input parameter

B - SSNR

X - NEXT

X - STRT

X - STOP

X - ERR

X - GUAR

X - AirP

X - CHAI

X - FLAs

X - FTRY

X - RUN

B - D_C

X - AuSt

X - RSET

NEXT

RDY

from the current step must be supplied to

of the following step. This ensures that when

ENBL - X

RDY - X

STEP - X - M 80.00 .Burner2

the next step is activated, the previous step is deactivated, thereby

ensuring only one step is active at any given.

6-6

• Activating a step

- To activate a step: the ready signal from the previous step must be

present (

(

COND

RDY

= 1).

= 1) and all step enabling conditions must be fulfilled

- As soon as a step is active, the following occurs:

output parameter

°

the input parameter

°

parameter

if

W_V

°

if

D_V

°

otherwise

NEXT

> 0, step monitoring time

> 0, time delay

D_E

NEXT

from the step is set to 1

RDY

of the current step and also the output

from the previous step are reset to 0

W_V

is started

D_V

is started,

is immediately set to 1

Modular Block System: Burner Management

Page 51

• Deactivating a step

During burner start-up, the input parameter

STEP

is set for one cycle.

The burner’s corresponding blocks evaluate this signal and reset the

sequence.

• Starting the initial step in a sequence:

RDY

The input parameter

may not be assigned a communication flag

(M100.00 - M104.31) nor an input.

When using SB152 “Burner: Start and operator elements”, the output

parameter

STEP

is set for the duration of a cycle, and the enable

is set. This parameter can be used to start the initial step.

Version 1: no conditions for the start of the initial step

The operand for the parameter

parameter

to the input parameter

STEP

of SB149 and the same operand can also be assigned

RDY

The input for the step enabling conditions

.

STEP

can be assigned to the input

COND

can be permanently

assigned with RLO1 (M110.01).

Example:

SB149

STEP

ENBL

M 70.08 .Step_1 - X - RDY

M 110.01 .RLO1 - X - COND

M 70.08 .Step_1 - X - STEP

Version 2: conditions for the start of the initial step are present

The operand for the parameter

input parameter

Example:

L M 70.08 .Step_1

S M 70.10 .RDY Step_1

Modular Block System: Burner Management

RDY

.

B - W_BA

W - W_V

Z - W_T

B - D_BA

W - D_V

Z - D_T

STEP

NEXT - X

W_E - X

D_E - X

may not be assigned directly to the

6-7

Page 52

Standard Function Blocks

SB149

SB149

STEP

M 70.10 .RDY Step_1 - X - RDY

M 70.12 .COND Step_1 - X - COND

M 70.08 .Step_1 - X - STEP

B - W_BA

W - W_V

Z - W_T

B - D_BA

W - D_V

Z - D_T

• Step monitoring time

W_E

If the step monitoring time has elapsed and the output parameter

NEXT - X

W_E - X

D_E - X

W_E

changes from 0 to 1, this alarm must be evaluated. The responsibility for

this lies solely with the user.

An application example for step monitoring time can be found in

Chapter 8.

• Time delay

D_E

There are two options for time delay:

- Time delay can be used to carry out a function for the duration of the

time delay, or

- To start a function after this time (

D_E

= 1).

An application example for time delay can be found in Chapter 8.

• Active steps in a sequence

To avoid a dangerous situation occurring in a process, the user must

ensure that only one step is active in a sequence at any given time.

6-8

Modular Block System: Burner Management

Page 53

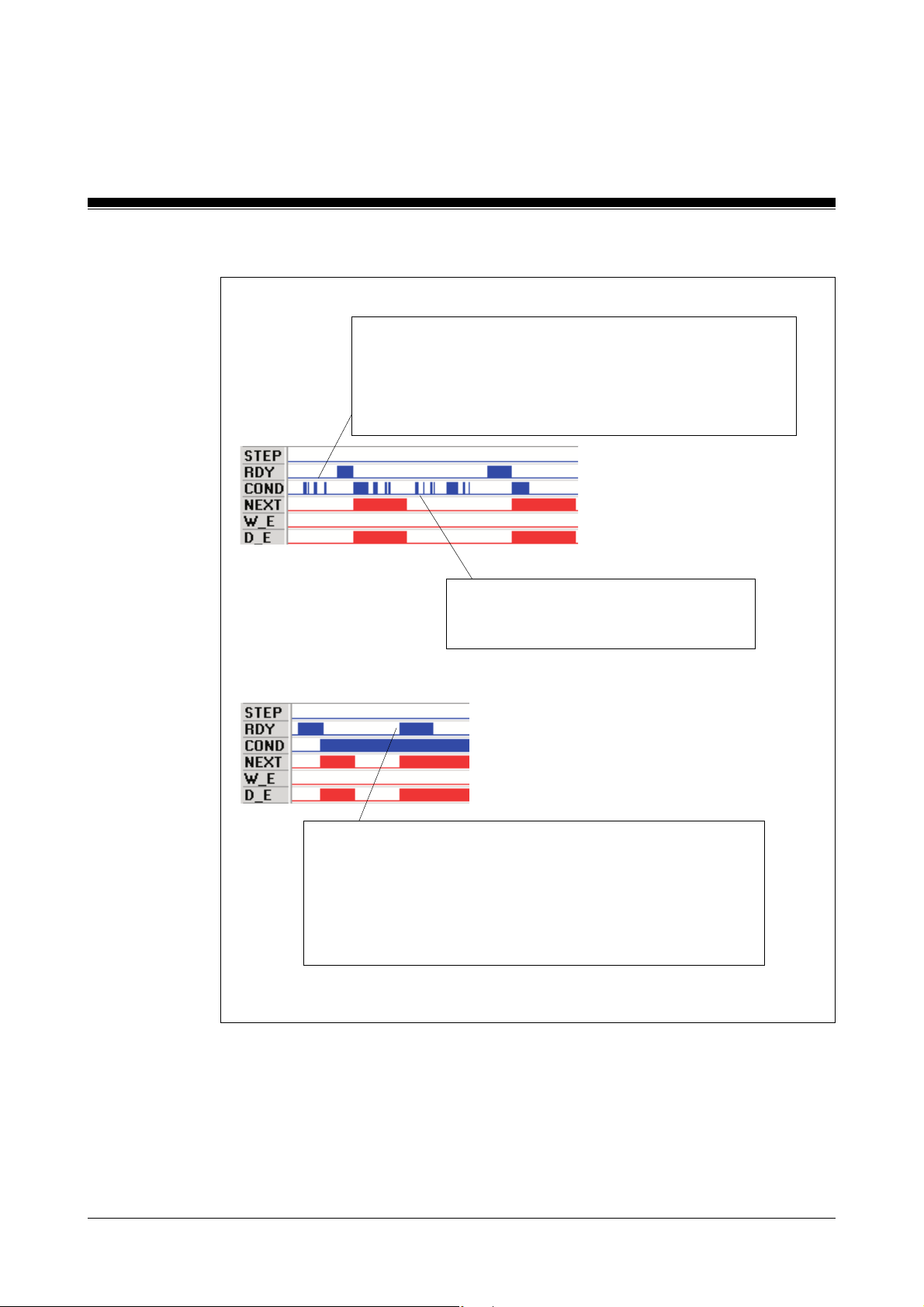

Timing diagrams

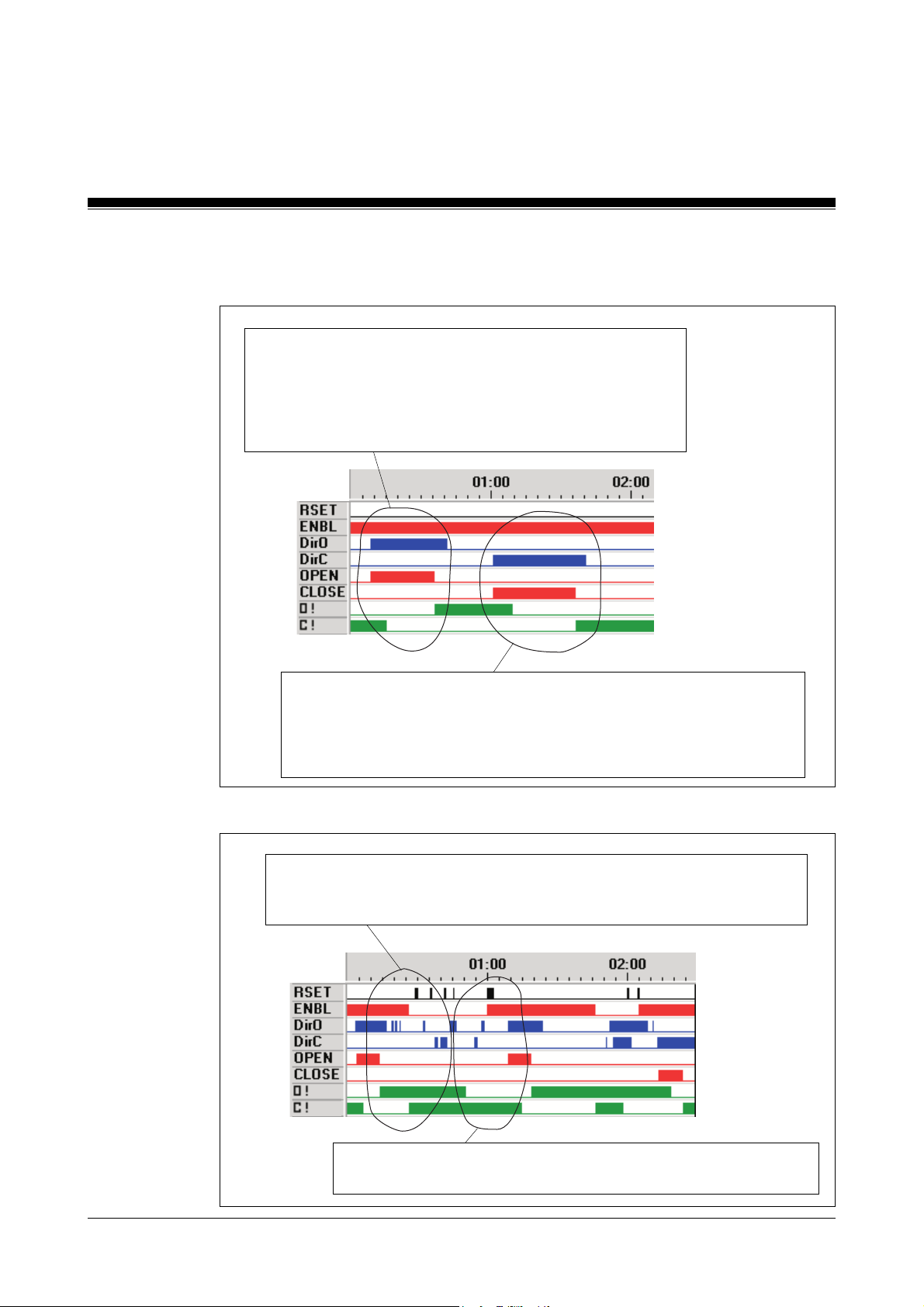

Setting / resetting the step without time delay and monitoring time

The step is activated by a “1”-Signal at the

waits for the step enabling condition at the

If the conditions are present, the

and at the same time the

When

NEXT

= 1, the

following step can be

activated.

RDY

input. The block

COND

input.

NEXT

output is set immediately,

RDY

input is reset.

The step enabling condition

must be present at the

input once only, so that the

NEXT

output is set.

If the step enabling condition is met during the

next step, then the

previous step is reset.

NEXT

COND

-

output from the

Modular Block System: Burner Management

6-9

Page 54

Standard Function Blocks

With spurious signals:

SB149

If a step enabling condition is met at the

cause the outputs to set too early.

Only if the step block was activated with

outputs react to the step enabling condition.

Repeated “1”-Signals at the

not cause malfunctions further on in the

process.

COND

RDY

COND

input, it will not

= 1 do the

input do

6-10

The

RDY

output may not be set a second time after the step

block has been run through once.

Therefore, in the FS program it must be monitored that only one

individual

have a “0”-Signal. Should it be detected that more than one

NEXT

NEXT

output is active and all other

output has a “1”-Signal, an immediate fault lockout

Modular Block System: Burner Management

NEXT

outputs

Page 55

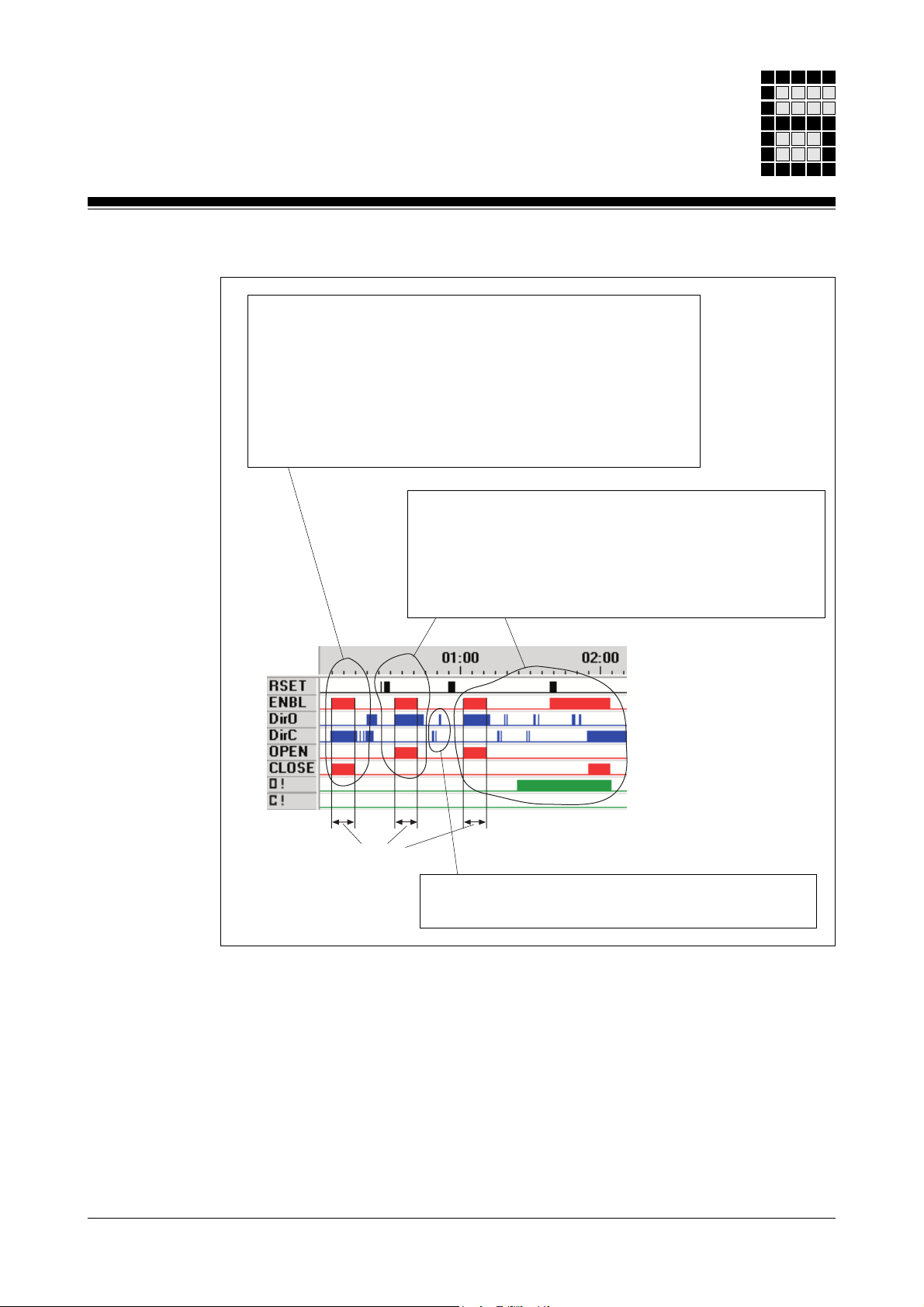

Setting/resetting the step with time delay but without monitoring time

Instead of the next step being

activated immediately with the

NEXT

output, it can be delayed

using the

D_E

output.

The time delay

After the time has elapsed the

D_V

is started if the step enabling condition is met.

Spurious signals

Time delay

D_E

output is set.

Multiple-recurring step enabling conditions have no negative influence on the function.

The time delay

0-1 edge at the

D_V

is started once only with the initial

COND

input.

Modular Block System: Burner Management

In each case: a “1”-Signal at the STEP-input resets the

outputs NEXT and D_E.

6-11

Page 56

Standard Function Blocks

Setting/resetting the step without time delay but with monitoring time

The step enabling condition needs to be

present once only at the

NEXT

output.

COND

SB149

input to set the

The monitoring time

If the

NEXT

-output is not reset before the monitoring time cycle, the

set. This means that the step enabling condition from the following step was not

met within the permitted time.

If the step enabling condition is met later during the next step, the

and

D_E

output are reset simultaneously.

The

W_E

output can be processed further according to user requirements.

W_V

is started if all the step enabling conditions are met.

W_E

NEXT, W_E

Spurious signals:

Multiple-recurring step enabling conditions have no negative influence on the function.

The monitoring time

initial 0-1 edge at the

W_V

is started once only with the

COND

input.

output is

6-12

Monitoring time

In each case: a “1”-Signal at the

STEP input resets the outputs

NEXT, W_E and D_E.

Modular Block System: Burner Management

Page 57

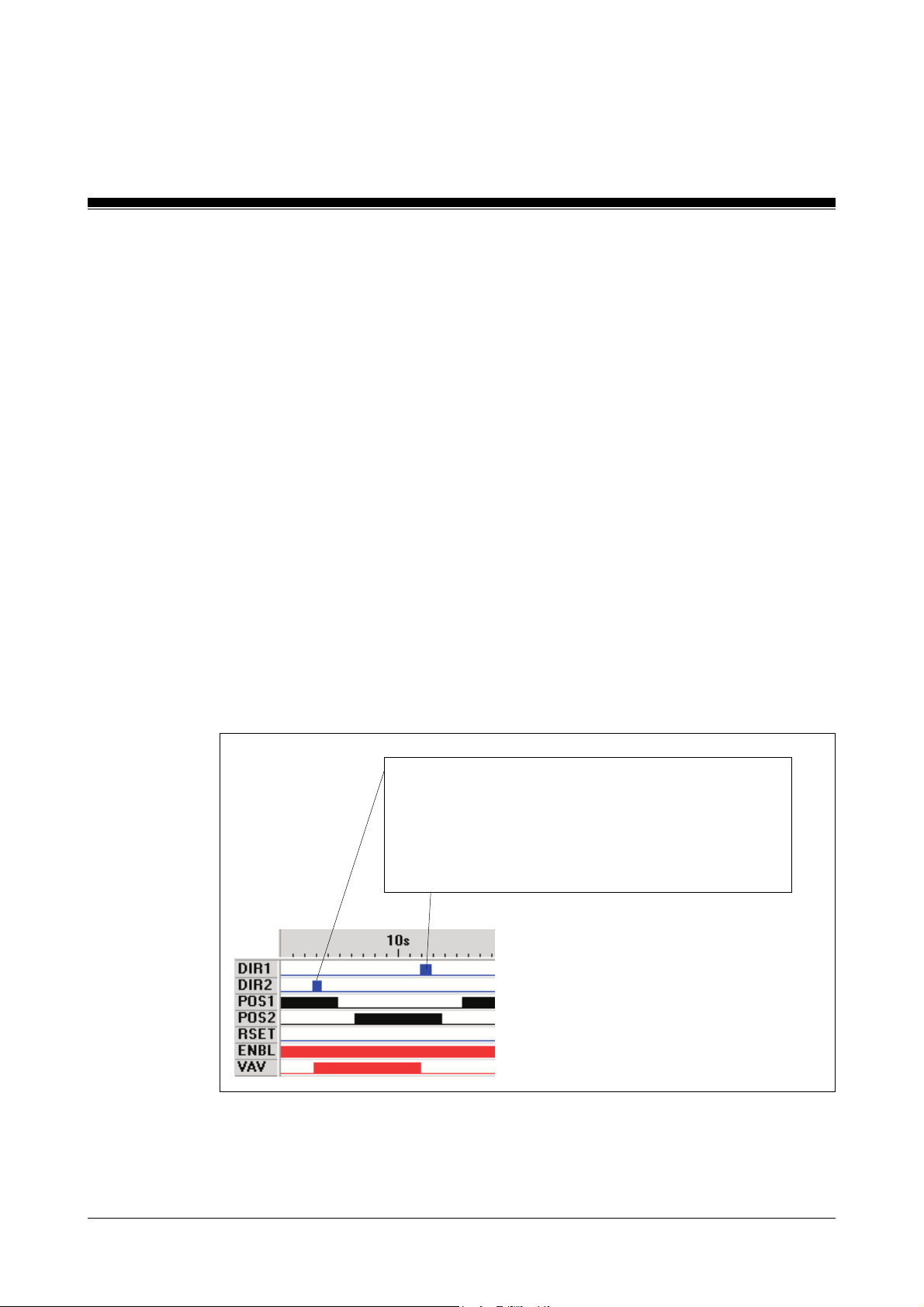

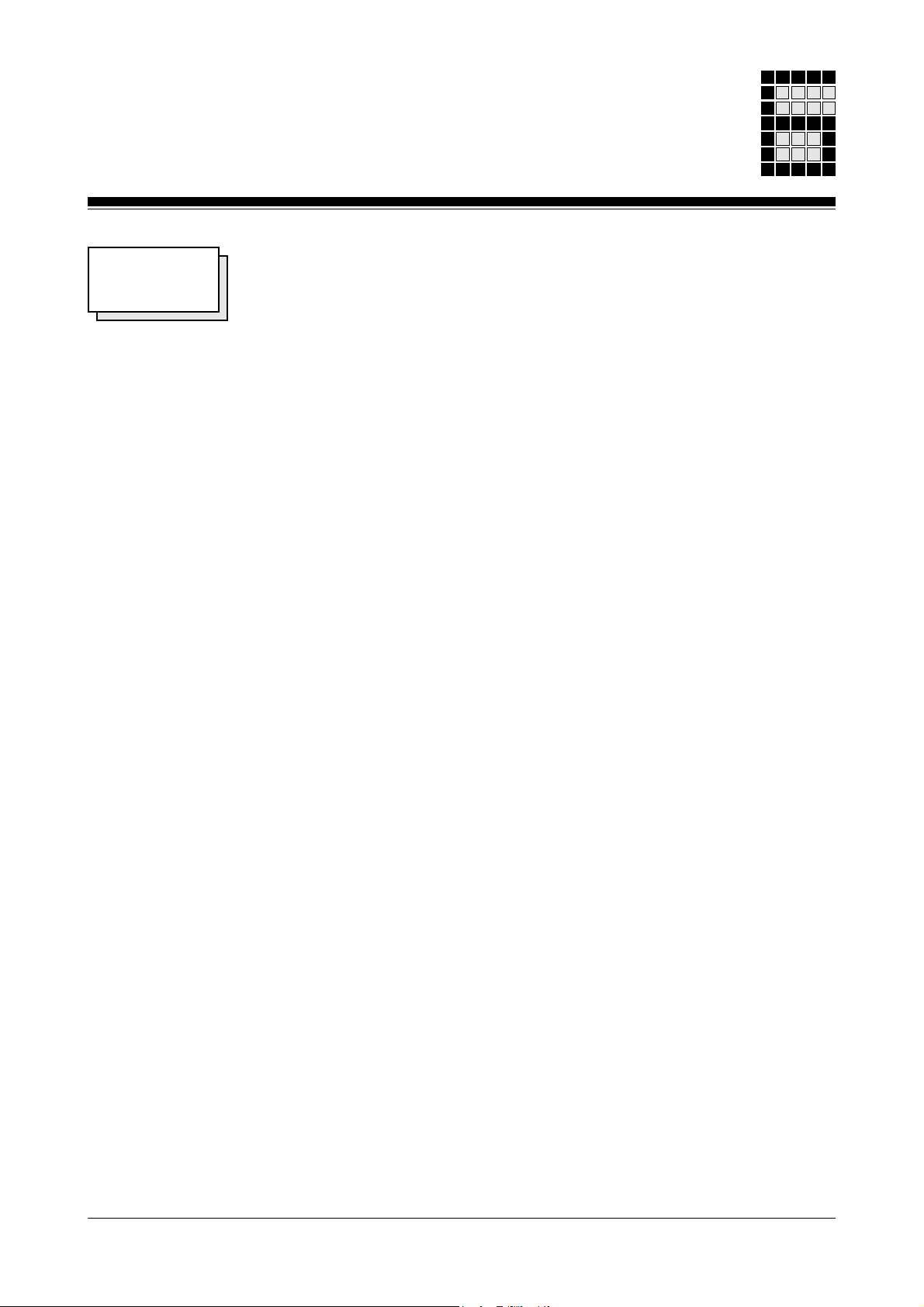

Setting/resetting the step with time delay and monitoring time

Spurious signals:

The monitoring time

D_E

are started if the step enabling

condition is met.

Further processing of

is guided according to the technical

requirements of the cycles.

Multiple-recurring, fulfilled step enabling conditions have

no negative influence on the function.

The monitoring time

started once only with the initial 0-1 edge at the

input.

W_V

W_V

and the time delay

W_E

and

D_E

and the time delay

outputs

D_V

are

COND

Modular Block System: Burner Management

In each case: a “1”-Signal at the

STEP input resets the outputs

NEXT, W_E and D_E.

6-13

Page 58

Standard Function Blocks

SB150: Flame monitoring

Block header

Input parameters

•

•

SSNR

MONI

SB150

FLAME_M

B - SSNR

X - MONI

X - F_S1

X - F_S2

X - RUN

ENBL - X

: Safety subroutine number

Permitted value range: 1 ... 200

Format: Byte constants KB 001 ... KB 200

(further information about the SSNR can be found in the

sections “Administration data blocks DB015, DB016 and

SB017” and “Input parameter

SSNR

” in chapter 5).

Value of DW0000/DB015 = 0: no error present

:

MONI

When

When

The output parameter

= 1: carries out flame monitoring:

RUN

= 1: monitoring for “ flame established”

RUN

= 0: monitoring for “flame not established”

FLAI

from SB158 “Ignition” must be

supplied to this parameter when using SB150 for pilot flame

monitoring, and the output parameter

FLAM

from SB159 “Run”

must be supplied to this parameter when using SB150 for main

flame monitoring.

6-14

•

F_S1

•

F_S2

•

RUN

: Flame signal (N/O contact)

F_S1

= 1: flame established

: Flame signal (N/C contact)

F_S2

= 1: flame not established

: The output parameter

RUN

from SB158 “Ignition” must be

supplied to this parameter when using SB150 for pilot flame

monitoring, so that information about the status of the pilot

flame can be obtained. The output parameter

RUN

SB159 “Run” must be supplied to the input parameter

from SB150 when using SB150 for main flame monitoring.

RUN

= 1: monitoring for “flame established”

Modular Block System: Burner Management

from

RUN

Page 59

Output parameters

Function:

Error messages

ENBL

Pilot and main flame monitoring from burner start-up to operating position,

through to burner switch-off.

Any fault that is detected will be stored statically in the corresponding error

data word (SSNR) of DB015 (1st data block).

• Error messages in DB 015

: Enable flag bit

ENBL

(refer also to the Programming guidelines)

- Bit00: Burner in operating position but no flame established

- Bit01: Burner not in the operating position, but the flame is established

= 1: this function is fault-free

Remedy: Exit operating position (

and bring SB150 to the start position (

F_S2

Remedy: Bring SB150 to the start position (

0,

= 1,

F_S2

RUN

= 1,

= 0).

RUN

= 0).

RUN

= 0),

MONI

= 1,

MONI

F_S1

= 1,

= 0,

F_S1

=

- Bit02: Burner in the operating position and both flame monitor

contacts (

Remedy: Exit operating position (

monitors' contacts and bring SB150 to the start position

(

MONI

- Bit03: Burner in operating position and both flame monitor contacts

(

F_S1

Remedy: Exit operating position (

monitor contacts and bring SB150 to the start position (

= 1,

- Bit04: Burner not in the operating position and both flame monitor

contacts (

Remedy: Check flame monitor contacts and bring SB150 to the

start position(

- Bit05: Burner not in the operating position and both flame monitor

contacts (

Remedy: Check flame monitor contacts and bring SB150 to

the start position (

= 1,

and

F_S1

F_S1

F_S1

F_S2

= 0,

F_S1

MONI

F_S1

and

F_S2

) have the value 1.

= 0,

F_S2

= 1,

) have the value 0

F_S2

and

and

MONI

= 1,

RUN

F_S2

) have the value 1

= 1,

F_S1

F_S2

) have the value 0

= 1,

F_S1

RUN

RUN

RUN

= 0).

= 0,

= 0), check flame

= 0).

= 0), check flame

F_S2

= 1,

RUN

= 0,

F_S2

= 1,

= 0).

RUN

MONI

= 0).

Modular Block System: Burner Management

6-15

Page 60

Standard Function Blocks

- Bit07: Flame established but does not correspond to the expected

status

Remedy: Exit operating position (

to the start position (

- Bit08: Flame monitoring switched off

Remedy: Switch on flame monitoring (

SB150 to the start position (

RUN

= 0).

• Error messagess on the CPU-display

E001: Parameter errors

The

SSNR

SSNR

“Administration data blocks DB015, DB016 and DB017” in

chapter 5).

does not lie within the limits 1 ... 200. The incorrect

is stated in DB015/DW0000 (see the section

MONI

= 1,

F_S1

MONI

RUN

= 0) and bring the SB150

= 0,

F_S2

= 1,

MONI

= 1,

= 1) and bring

F_S1

= 0,

F_S2

SB150

RUN

= 0).

= 1,

Blocks required

• DB002: Will be made available when the configurator is called up.

• DB015: Administration data block

DB015 must consist of its total length of 1024 words and have

Read/Write status (refer also to the section “Administration data

blocks DB015, DB016 and DB017" in chapter 5).

• OB101: To call up SB(s)150 directly in OB101 or, for example, together

in an FB.

• SB150: FLAME_M

• SB152: BR_START for evaluating the flame monitor global signal

FLAs.

• SB157: IGNI_TRY for evaluating the flame monitor global signal

when carring out several ignition attempts.

FLAs

6-16

Modular Block System: Burner Management

Page 61

• SB158: IGNITION for deciding about pilot flame monitoring.

• SB159: RUN for decision about monitoring the main flame.

• SB255: To call up the operating system.

Programming guidelines

•

ENBL

The enables for all SB150 blocks must be AND-connected in the

application program after being called up. The result of this bit operation

must be supplied to the input parameter

and operator elements”.

The enables of the active SB150 blocks for pilot flame monitoring must

be supplied and additionally AND-connected to the input parameter

FLAs

of SB157 “Ignition attempts”, if SB157 is used.

A programming example can be found in Chapter 8 under “Managing

enables”.

• Main flame monitoring after an error

FLAs

of SB152 “Burner: Start

If the main flame is in the operating position and the plant is shutdown

because an error occurs (e.g. monitor sequence broken), the flame

monitor receives the command to check the flame for “flame established”

in the next cycle. On some plants, the flame does not extinguish

immediately after switch-off i.e. within a cycle. In these cases, a fault will

result. To avoid this, a time

negative edge at the plant enable (

this time, the flame monitor will not be evaluated (

D_V

can be started via step (SB149) when a

ENBL

of SB152) is detected. During

MONI

= 0). After this

time cycle SB159 “Run” assumes control of flame monitoring.

Programming example:

LN M74.00 .ENBL SB 152

U M73.01 .Auxiliary flag, negative edge ENBL

= M73.02 .Pulse flag

R M73.01 .Auxiliary flag, negative edge ENBL

1

L M74.00 .ENBL SB 152

S M73.01 .Auxiliary flag, negative edge ENBL

Modular Block System: Burner Management

6-17

Page 62

Standard Function Blocks

SB159

RUN

SB150

SSNR

NEXT

SyOK

SB152

BR_START

SSNR

NEXT

STRT

STOP

ERR

GUAR

AirP

CHAI

FLAs

FTRY

RUN

D_C

AuSt

RSET

ENBL

RDY

VAV3

REGL

RUN

FLAM

ENBL

RDY

STEP

Pulse

1

Time value for

time delay

&

RDY

COND

STEP

W_BA

W_V

W_T

D_BA

D_V

D_T

SB149

STEP

NEXT

W_E

D_E

&

&

&

S R Q

>1

SB150

FLAME_M

SSNR

MONI

F_S1

F_S2

RUN

ENBL

Fig. 6-1: Main flame monitoring after a fault

6-18

Modular Block System: Burner Management

Page 63

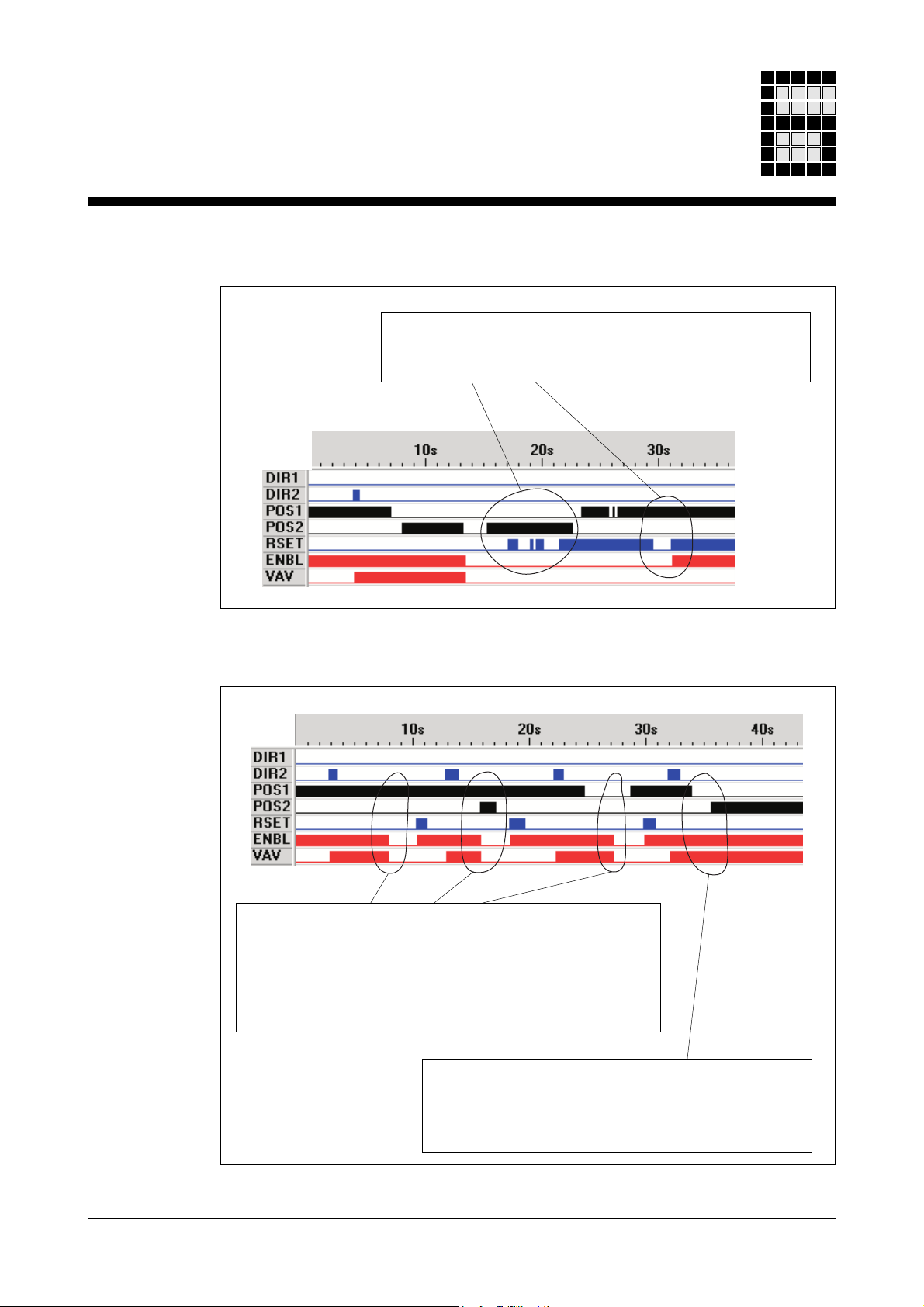

Timing diagrams

Signal cycle with an uninterrupted burner start-up or uninterrupted burner stop sequence

Monitoring for “Flame not established”

A “1”-Signal at the

F_S2

are monitored for “0” and “1” respectively, i.e. for “flame not established”.

During the ignition process, the signals at

SB 150 must change from detecting for “flame not established” to detecting

for “flame established”. During this switching time the

are not evaluated: they can have any status.

MONI

input and a “0”-Signal at the

Monitoring for “flame established”

A “1”-Signal at the

Signal at the

monitored for “1” and

”flame not established”.

RUN

input,

F_S1

and

F_S1

and

F_S2

must change, i.e.

F_S1/F_S2

MONI

RUN

-input means

If the

MONI

input is reset,

monitoring is deactivated and the

flame can be extinguished

without the block generating an

error message (

ENBL

-inputs

input and a “1”-

F_S1

F_S2

for “0”, i.e. for

= 0).

is

Modular Block System: Burner Management

6-19

Page 64

Standard Function Blocks

Flame monitor error

Flame monitor fault when monitoring for

“flame not established”.

SB150

After the

Signals at

Monitoring for “flame established” must be first run through without

error, before switching to monitoring for “flame established” can be

carried out.

ENBL

-output is reset, an enable is not set even with valid “1”-

F_S1

and

RUN.

Spurious signals when monitoring for “flame not established”

Spurious signals /

signal combinations

at

F_S1

and

F_S2

do

have no effect on the

block’s function.

If there is a “1”-Signal at

the MONI input,

F_S2

monitoring is active

and reacts immediately

when the

reset.

ENBL

F_S1/

output is

Only the permitted signal

combination at

F_S2

can reactivate the

enable.

F_S1/

6-20

Invalid signals deactivate the enable. The enable signals processed in other

program sections (flame monitor sequence, SB 152) will, via this program

section, trigger the burner to shutdown.

The enable signal will be issued again only if the inputs are

F_S1

= 0. With other signal combinations, the enable remains cancelled.

Modular Block System: Burner Management

F_S2

= 1 and

Page 65

Spurious signals before and during monitoring for “flame established”

No spurious enable via

interference signals

possible.

Spurious signals during monitoring for “flame established”

Flame established,

monitoring active.

Only the fault-free signals

F_S2

= 1,

F_S1

= 0 and the

MONI

input set the

output.

Shutdown due to flame

failure.

No spurious enable can be

generated due to

interference signals.

ENBL

Modular Block System: Burner Management

6-21

Page 66

Standard Function Blocks

SB151: Transient suppression

Block header

Input parameters

•

SSNR

SB151

BridgedS

B - SSNR

X- S1

X - BASE

W - T_V

Z- T

X - AuSt

X - RSET

ENBL - X

: Safety subroutine number

Permitted value range: 1 ... 200

Format: Byte-constants KB001 ... KB200

(further infotmation about the

SSNR

can be found in the

sections “Administration data blocks DB015, DB016 and

DB017” and “Input parameter

SSNR

” in chapter 5).

Value of DW0000/DB015 = 0: no error present

•S1: N/C contact to be monitored (check with test pulse)

•

BASE

•

T_V

: Setting the time base

BASE

T_V

BASE

by

: Multiplier for

= M110.00 (RLO = 0): time base of 50 ms, multiplied by

gives a possible range of 50 ms to 27.3 min

= M110.01 (RLO = 1): time base of 100 ms, multiplied

T_V

gives a possible time range of 100 ms to 54,6 min

BASE

, to determine the length of time the enable

signal should be delayed

Permitted value range: 1 ... 32767

•T: Timer, which measures the set time

•

AuSt

: Automatic start (reset)

AuSt

= M110.01 (RLO =1): automatic start (without reset)

AuSt

= M110.00 (RLO =0): no automatic start

•

RSET

: Reset button (N/O)

6-22

Modular Block System: Burner Management

Page 67

Output parameters

Function

Error messages

ENBL

: Enable flag bit

ENBL

= 1: the signal at the N/C contact S1 is fault-free

(refer also to Programming guidelines)

Spurious signals at the monitored input (e.g. a pressure monitor) cancels

the enable after a set time.

If the N/C contact functions without fault, SB151 sets the enable

ENBL

. If

interference occurs, the enable is cancelled after a set time period. Short,

fleeting interferences, for example, pressure swings after the valve has

opened will have no effect on the enable.

Any fault that is detected will be stored statically in the corresponding error

data word (SSNR) of DB015 (1st data block).

• Error messages in DB015

- Bit 09: Suppression time has elapsed, the signal is spurious

Remedy: check contact S1 and if

button

RSET

.

AuSt

= 0, press the reset

- Bit 14: Reset button

RSET

pressed continuously or pressed too soon.

Remedy: Release reset button and press again.

- Bit 15: Signal is fault-free, but the error which occurred was not reset

(

RSET

Remedy: press the reset button

missing)

RSET

.

• Error Messages on the CPU-display

- E001: Parameter errors

The

SSNR

incorrect

does not lie within the limits of 1 ... 200. The

SSNR