Page 1

Programmable control systems PSS

®

PSS 3075-3 Series

Operating Manual – Item No. 21 071-10

Page 2

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p

®

, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

Page 3

1Operating Manual: PSS 3075-3 Series

Introduction 1-1

Validity of documentation 1-2

Overview of documentation 1-3

Definition of symbols 1-4

Overview 2-1

Front views 2-4

PSS 3075-3, PSS 3075-3 NR 2-4

PSS 3075-3 DP-S 2-6

PSS SB 3075-3 2-8

PSS SB 3075-3 DP-S 2-10

PSS SB 3075-3 ETH-2, PSS SB 3075-3 ETH-2 SE 2-12

PSS SB 3075-3 CANopen 2-14

PSS SB 3075-3 ETH-2 CANopen 2-16

Safety 3-1

Intended use 3-1

Product modifications 3-2

Categories in accordance with EN 954-1 3-2

Digital inputs (DI2) 3-2

Single-pole outputs (DOS) 3-3

Dual-pole outputs (DOZ) 3-3

Safety guidelines 3-3

Use of qualified personnel 3-4

EMCD 3-4

Warranty and liability 3-4

Disposal 3-4

Contents

Page 4

Contents

2 Operating Manual: PSS 3075-3 Series

Function Description 4-1

CPU 4-1

Interfaces 4-1

CPU interfaces 4-1

SafetyBUS p interface 4-1

Interfaces for standard bus systems 4-1

Inputs 4-2

Digital inputs (DI2) 4-2

Alarm inputs (DIF) 4-2

Outputs 4-3

Single-pole outputs (DOT/DOS) 4-3

Dual-pole outputs (DOZ) 4-7

Configuration coding 4-8

Installation 5-1

General requirements 5-1

Installing the safety system 5-1

Installing the safety system PSS 3075-3, PSS 3075-3 NR 5-2

Installing the safety system PSS 3075-3 DP-S,

PSS SB 3075-3, PSS SB 3075-3 ETH-2 and

PSS SB 3075-3 ETH-2 SE 5-3

Installing the safety system PSS SB 3075-3 DP-S,

PSS SB 3075-3 CANopen and PSS SB 3075-3 ETH-2 CANopen 5-4

Installing the safety system in a control cabinet 5-5

Supply Voltage 6-1

General requirements 6-1

Notes on wiring 6-3

Page 5

3Operating Manual: PSS 3075-3 Series

Wiring the Inputs and Outputs 7-1

Configuration of the terminals and connector description 7-1

Notes on wiring 7-2

Digital inputs (DI2) 7-4

Example: Single-channel, failsafe input device, without test pulse 7-6

Example: Dual-channel, failsafe input devices, without test pulses 7-8

Example: Single-channel, failsafe input device, with test pulse 7-10

Example: Dual-channel, failsafe input device, with test pulse 7-12

Alarm inputs (DIF) 7-14

Example: Alarm test 7-16

Single-pole outputs (DOS) 7-18

Dual-pole outputs (DOZ) 7-20

Interfaces 8-1

General requirements 8-1

Programming device interface (“PG”) 8-2

Programming device interface RS 232 8-3

Programming device interface RS 485 8-4

User interface (“USER”) 8-5

User interface RS 232 8-6

User interface RS 485 8-7

SafetyBUS p interface (“SafetyBUS p”) 8-8

Interfaces for standard bus connections 8-8

Operation and Maintenance 9-1

Commissioning 9-1

Faults 9-1

PSS and SafetyBUS p functionality 9-1

Standard bus functionality 9-1

Page 6

Contents

4 Operating Manual: PSS 3075-3 Series

Display elements 9-2

PSS functionality 9-2

SafetyBUS p functionality 9-2

Standard bus functionality 9-2

Changing the battery 9-3

Technical Details 10-1

Derating diagrams 10-6

Accessories 10-7

Appendix 11-1

Address of Safety Network International e.V. 11-1

Changes in the documentation 11-1

Page 7

1-1Operating Manual: PSS 3075-3 Series

This operating manual explains the function and operation of the

programmable safety system, describes the installation and provides

guidelines on how to connect the digital inputs, digital outputs and test

pulse outputs on programmable safety systems from the PSS 3075-3

series. A PSS in the PSS SB 3075-3 series is a 3rd generation

programmable safety system.

Depending on the unit type, an interface is available for connection to the

safety-related bus system SafetyBUS p. The SafetyBUS p interface is

described in this manual.

Different interfaces are available for connection to various non-safetyrelated standard bus systems, depending on the unit type. These

interfaces are described in separate operating manuals.

The necessary operating manuals are supplied with the relevant unit types.

Please refer to the PSS-range manuals, in particular the information and

requirements stated in the “PSS-Range Safety Manual”, “FS System

Description”, “ST System Description” and also the “SafetyBUS p Installation Manual” from the Safety BUS p manual package.

You will need to be conversant with the information in these manuals in

order to fully understand this manual.

This documentation is intended for instruction and should be retained for

future reference.

Introduction

Page 8

Introduction

1-2 Operating Manual: PSS 3075-3 Series

Validity of documentation

This documentation is valid for the following programmable safety systems

from the PSS 3075-3 series:

• PSS 3075-3 from Version 1.0

• PSS 3075-3 DP-S from Version 1.0

• PSS 3075-3 NR from Version 1.0

• PSS SB 3075-3 from Version 1.0

• PSS SB 3075-3 CANopen from Version 3.0

• PSS SB 3075-3 DP-S from Version 1.0

• PSS SB 3075-3 ETH-2 from Version 1.0

• PSS SB 3075-3 ETH-2 CANopen from Version 1.0

• PSS SB 3075-3 ETH-2 SE from Version 1.0

It is valid until new documentation is published. The latest documentation is

always enclosed with the unit.

Page 9

1-3Operating Manual: PSS 3075-3 Series

Overview of documentation

1 Introduction

The introduction is designed to familiarise you with the contents,

structure and specific order of this manual.

2 Overview

This chapter provides information on the most important features of

the programmable safety systems.

3 Safety

This chapter must be read as it contains important information on

safety regulations and intended use.

4 Function Description

This chapter describes the individual components of the

programmable safety systems: CPU, inputs, outputs and test pulse

outputs.

5 Installation

This chapter explains how to install the programmable safety

systems.

6 Supply Voltage

This chapter explains what you need to consider when connecting the

supply voltage.

7 Wiring the Inputs and Outputs

This chapter describes the safety-related wiring of the inputs, outputs

and test pulse outputs.

8 Interfaces

This chapter describes the configuration of the available interfaces.

9 Operation and Maintenance

This chapter explains how to commission the safety systems and

advises on what to do if a fault occurs.

10 Technical Details

11 Appendix

Page 10

Introduction

1-4 Operating Manual: PSS 3075-3 Series

Definition of symbols

Information in this manual that is of particular importance can be identified

as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that

poses an immediate threat of serious injury and death and indicates

preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that

could lead to serious injury and death and indicates preventive

measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also

provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special

features, as well as highlighting areas within the text that are of particular

importance.

Page 11

2-1Operating Manual: PSS 3075-3 Series

Overview

A PSS from the PSS 3075-3 series is a complete programmable safety

system in a single unit.

The device descriptions provide information on their function.

The description are made up of combinations of letters and numbers.

• The PSS 3075-3 contains:

- Power supply

- CPU

- 48 digital inputs, 6 of which are alarm inputs

- 18 single-pole outputs, 4 of which are test pulse outputs

- 9 dual-pole outputs

- Programming device interface

(combined RS 232/RS 485 interface)

- User interface

(combined RS 232/RS 485 interface)

• In addition to the features on the PSS 3075-3, the PSS SB 3075-3

contains:

- SafetyBUS p-interface

Additional functions

• DP-S

Interface for connection to PROFIBUS-DP

• ETH-2

Interface for connection to Ethernet

• CANopen

Interface for connection to CANopen

• SE

The name "SE“ can be found only on the type label of the PSS (e. g. PSS

SB 3075-3 ETH-2 SE). It is a PSS that is identical to the corresponding

serial device (e. g. PSS SB 3075-3 ETH-2). The PSS however is intended

for use with SafetyEYE and therefore delivered with a preinstalled user

program.

• NR

Safety system without battery

Operation without a battery results in the following restrictions:

- FS section: Remanant data blocks cannot be used.

- ST section: A general reset is performed each time the section

switches from STOP-RUN.

- Each time the PSS is restarted (voltage switched off and then on

again), the system time is reset to zero.

Page 12

Overview

2-2 Operating Manual: PSS 3075-3 Series

For non-safety-related applications, the PSS can be connected to various

standard bus systems (e.g. PROFIBUS-DP). The bus interfaces that are

available will depend on the unit type.

INFORMATION

• The standard bus interfaces are described in separate operating

manuals. The necessary operating manuals are supplied with the relevant unit types.

• Drivers (standard function blocks) from the corresponding Pilz software

package will be required in order to connect to the various standard bus

systems.

Example:

PSS SB 3075-3 ETH-2

Safety systems PSS 3075-3 with SafetyBUS p- and Ethernet interface.

The digital inputs can be used for local emergency stop monitoring, for

example. They are suitable for connecting single or dual-channel input

devices, with or without test pulses. The test pulse outputs are suitable for

testing input devices.

The single or dual-pole outputs can be used to drive valves, for example.

SafetyBUS p enables you to establish a safe decentralised network of

several programmable safety systems and/or to connect decentralised

modules. The PSS can perform the function of a Management, Logic or

Input/Output Device on SafetyBUS p.

Page 13

2-3Operating Manual: PSS 3075-3 Series

Notes

Page 14

Overview

2-4 Operating Manual: PSS 3075-3 Series

Front views

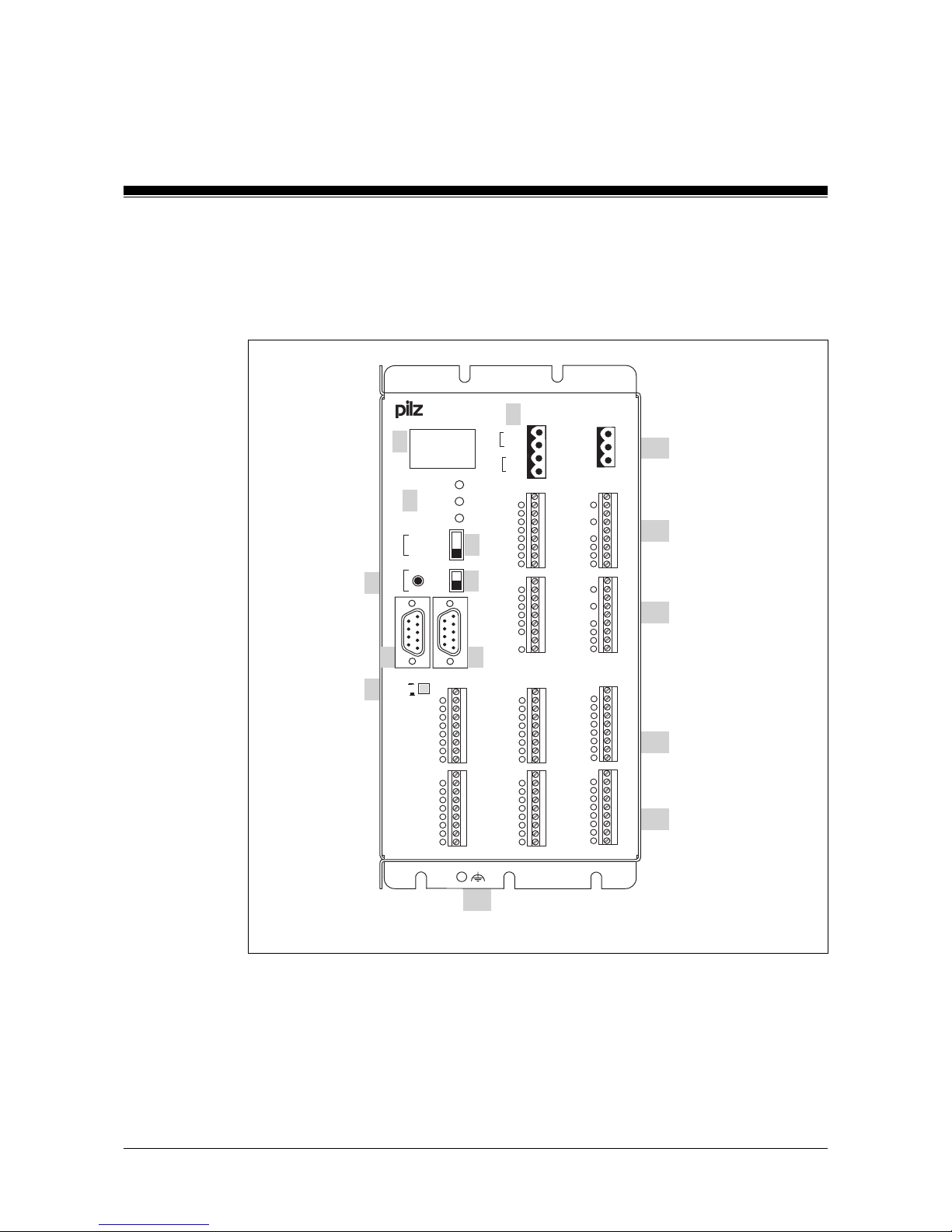

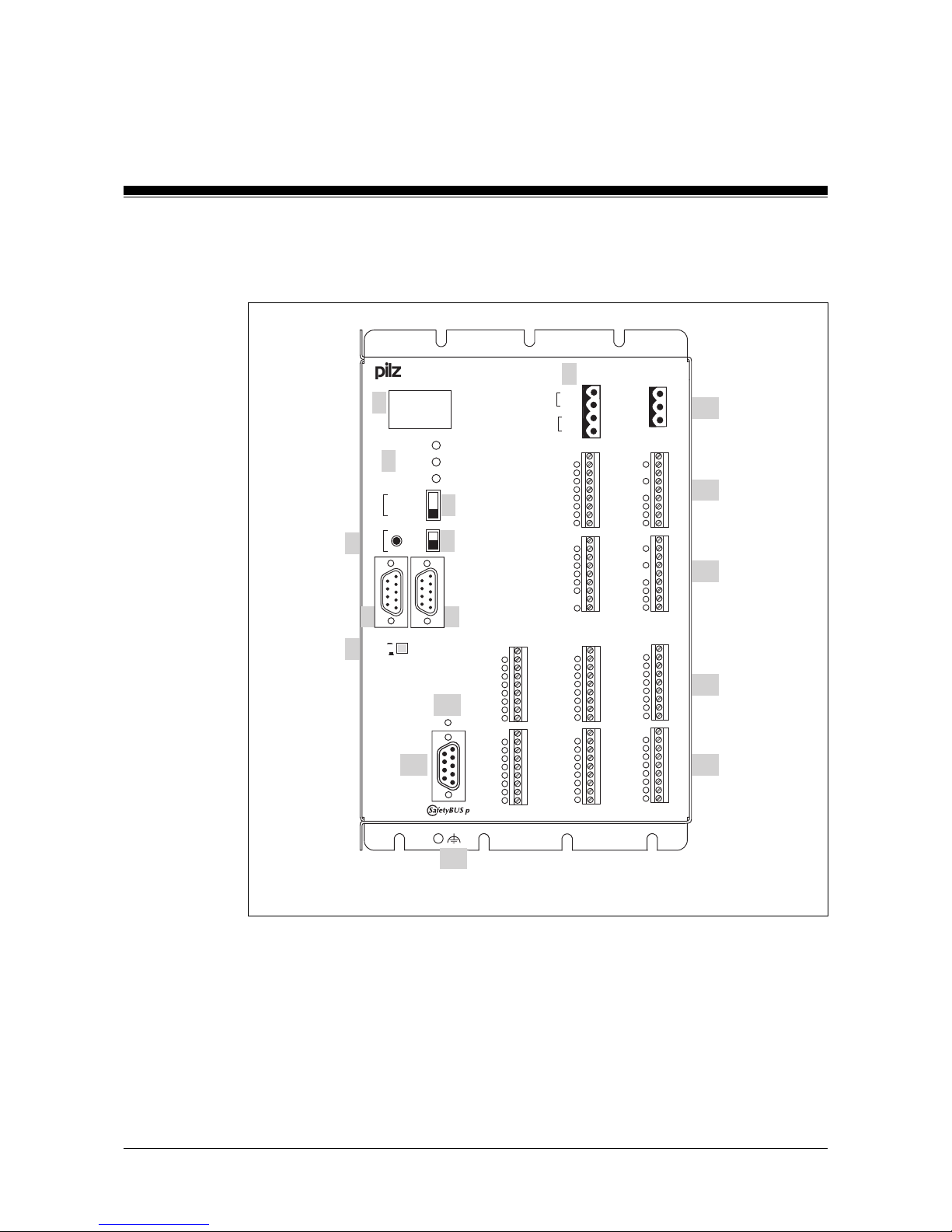

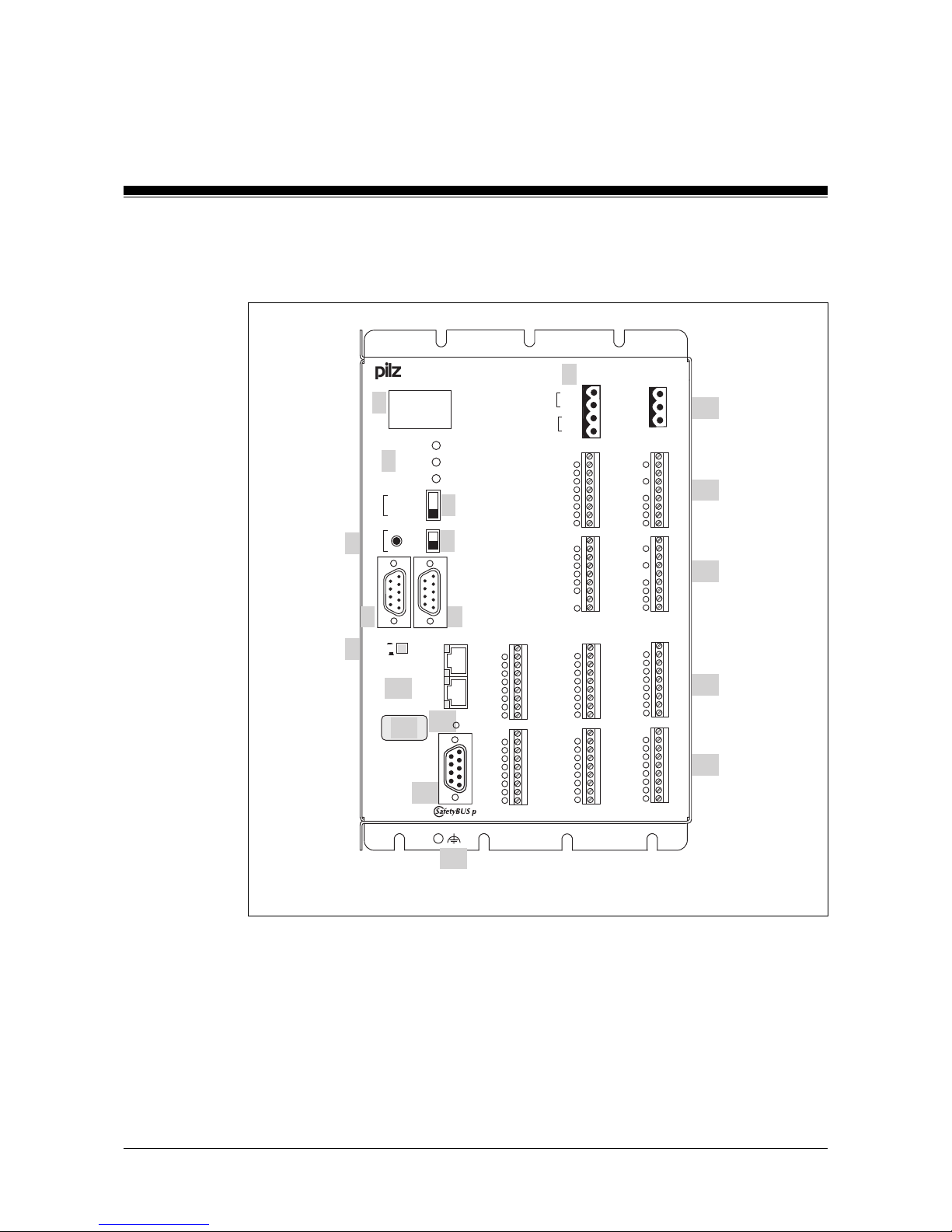

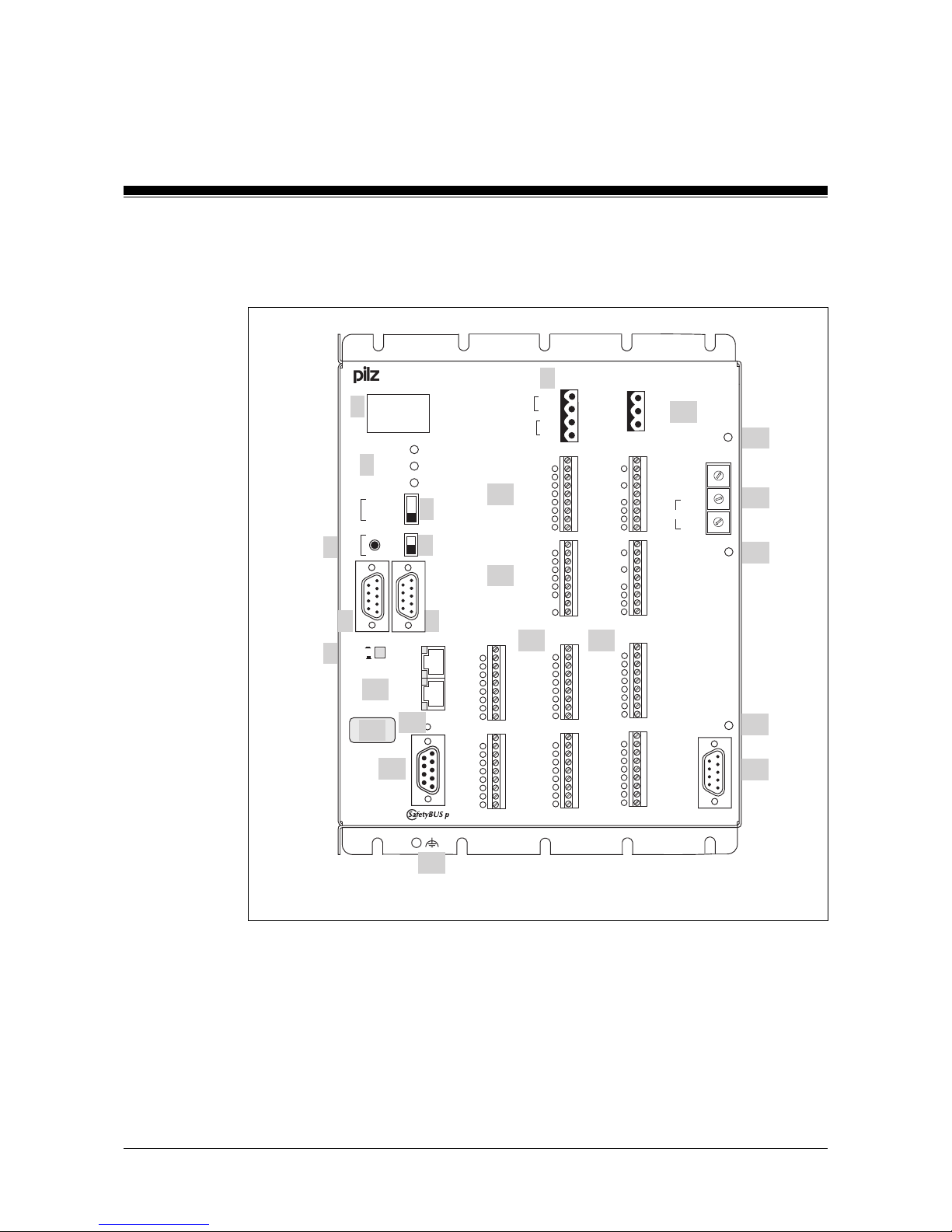

PSS 3075-3, PSS 3075-3 NR

Fig. 2-1: Front view of PSS 3075-3

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS 3075-3

1

·

X0

·

4

USER

F-STACK

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

RT (USER)

OFF

ON

PSS

X1/X2

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

2

4

5

10

12

9

11

11

1

3

6

8

7

PG

24 V

0 V

24 V

0 V

13

10

Page 15

2-5Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

Page 16

Overview

2-6 Operating Manual: PSS 3075-3 Series

PSS 3075-3 DP-S

Fig. 2-2: Front view of PSS 3075-3 DP-S

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS 3075-3 DP-S

1

·

X0

·

4

USER

F-STACK

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

RT (USER)

OFF

ON

PSS

X1/X2

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

2

4

5

10

12

9

11

11

1

3

6

8

7

PG

24 V

0 V

24 V

0 V

13

10

x10

x1

PROFIBUS-DP

+100

+0

RUNFAULT

6

7

8

9

4

3

2

1

5

0

6

7

8

9

4

3

2

1

5

0

ADDRESS

15

14

16

17

Page 17

2-7Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: 2-position switch for selecting the station address

(PROFIBUS-DP)

15: Rotary switch for setting the station address

(PROFIBUS-DP)

16: LED for status of PROFIBUS-DP

17: PROFIBUS-DP interface

INFORMATION

Please refer also to the manual: “PROFIBUS-DP for Compact 3rd Generation PSS”.

Page 18

Overview

2-8 Operating Manual: PSS 3075-3 Series

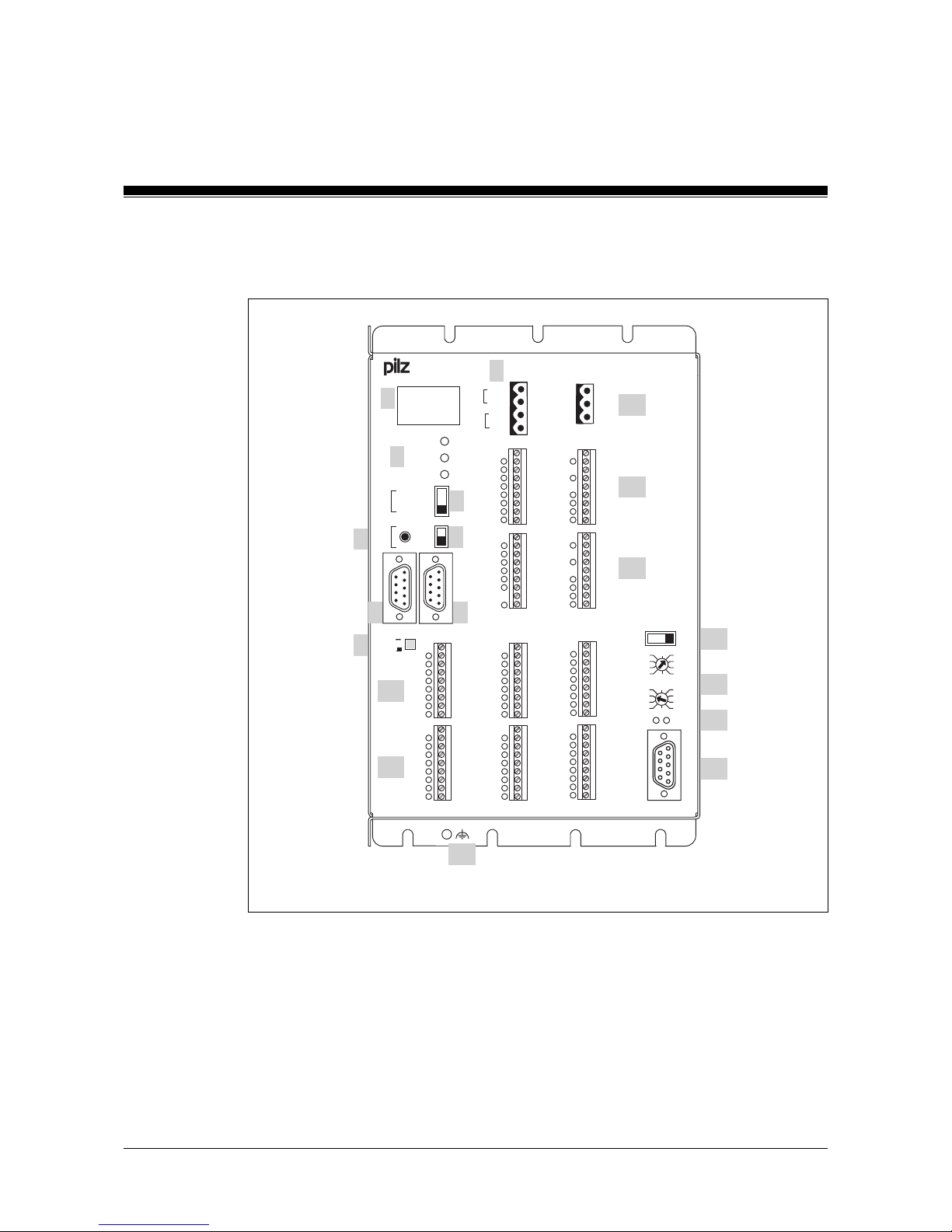

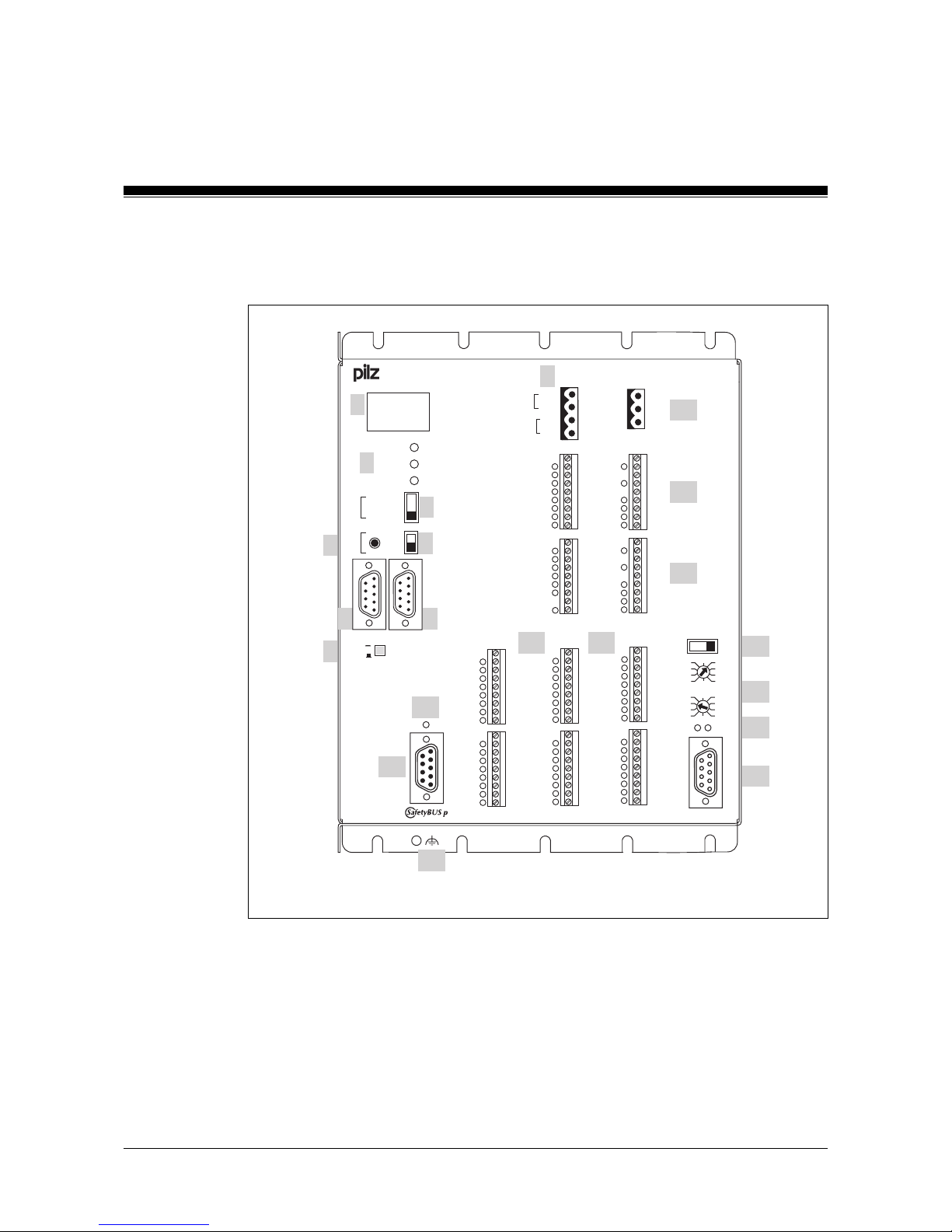

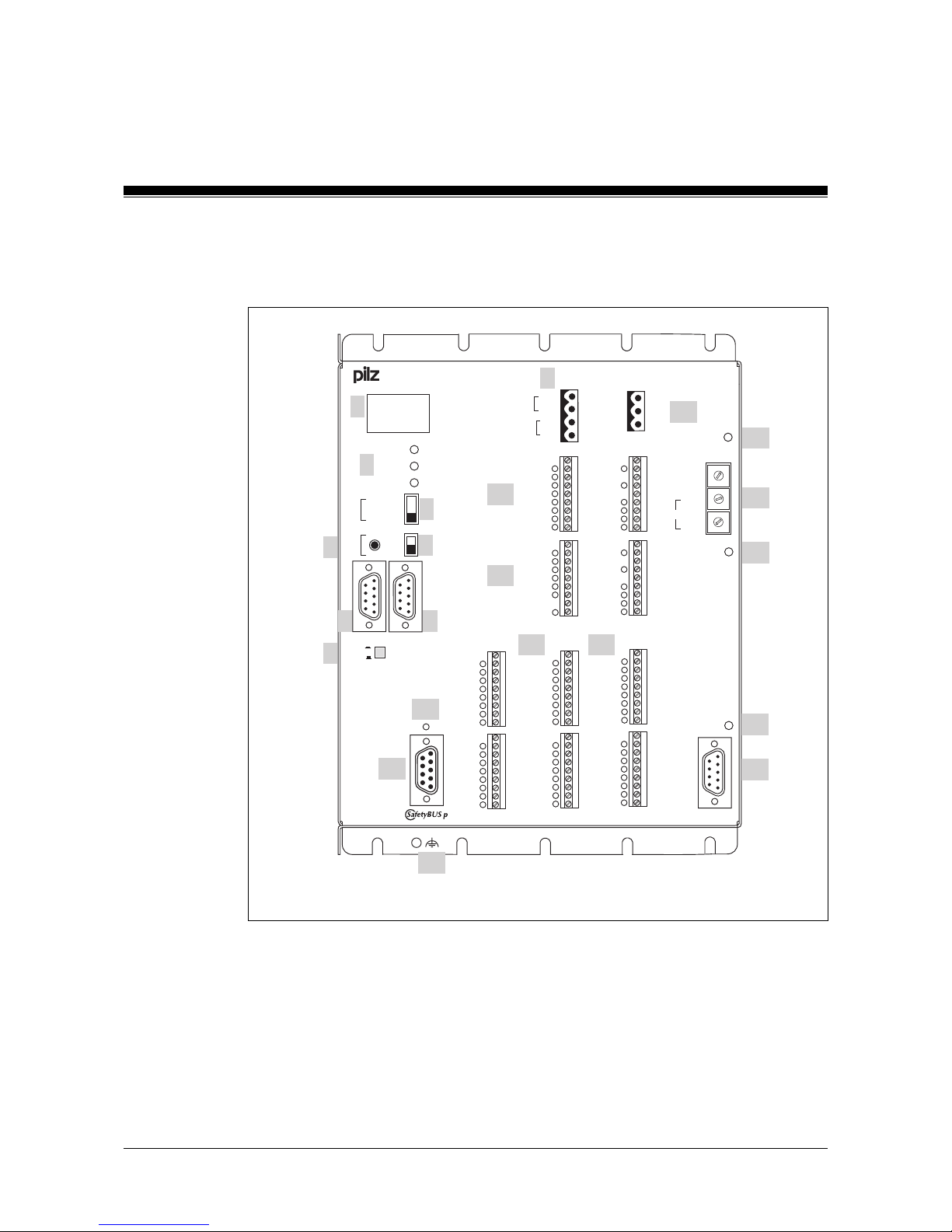

PSS SB 3075-3

Fig. 2-3: Front view of PSS SB 3075-3

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS SB 3075-3

USER

F-STACK

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

RT (USER)

OFF

ON

PSS

X1/X2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

2

4

5

12

11

11

1

3

6

8

7

PG

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

1

·

X0

·

4

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

10

9

24 V

0 V

24 V

0 V

13

10

15

14

STATUS SB

Page 19

2-9Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: LED for status of SafetyBUS p

15: SafetyBUS p interface

Page 20

Overview

2-10 Operating Manual: PSS 3075-3 Series

PSS SB 3075-3 DP-S

Fig. 2-4: Front view of PSS SB 3075-3 DP-S

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS SB 3075-3 DP-S

USER

F-STACK

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

RT (USER)

OFF

ON

PSS

X1/X2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

2

4

5

12

11

11

1

3

6

8

7

PG

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

1

·

X0

·

4

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

10

9

24 V

0 V

24 V

0 V

13

10

19

18

STATUS SB

x10

x1

PROFIBUS-DP

+100

+0

RUNFAULT

6

7

8

9

4

3

2

1

5

0

6

7

8

9

4

3

2

1

5

0

ADDRESS

15

14

16

17

Page 21

2-11Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: 2-position switch for selecting the station address

(PROFIBUS-DP)

15: Rotary switch for setting the station address

(PROFIBUS-DP)

16: LED for status of PROFIBUS-DP

17: PROFIBUS-DP interface

18: LED for status of SafetyBUS p

19: SafetyBUS p interface

INFORMATION

Please refer also to the manual: “PROFIBUS-DP for Compact 3rd Generation PSS”

Page 22

Overview

2-12 Operating Manual: PSS 3075-3 Series

PSS SB 3075-3 ETH-2, PSS SB 3075-3 ETH-2 SE

Fig. 2-5: Front view of PSS SB 3075-3 ETH-2

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS SB 3075-3 ETH-2

USER

F-STACK

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

RT (USER)

OFF

ON

PSS

X1/X2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

1

·

X0

·

4

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

2

4

5

12

11

11

1

3

6

8

7

PG

24 V

0 V

10

9

24 V

0 V

24 V

0 V

13

10

17

16

15

ETHERNET

LINK

10/100

BASE T

TRAFFIC

LINK

TRAFFIC

10/100

BASE T

14

STATUS SB

Page 23

2-13Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: Labelling strip for Ethernet address

15: ETH-2 interface with connection to ETHERNET via integrated switch

(2 free ports); LEDs on each port for

- Status of network connection (LINK)

- Status of data traffic (TRAFFIC)

16: LED for status of SafetyBUS p

17: SafetyBUS p interface

INFORMATION

Please refer also to the manual: “ETH-2 for Compact 3rd Generation PSS”.

Page 24

Overview

2-14 Operating Manual: PSS 3075-3 Series

PSS SB 3075-3 CANopen

Fig. 2-6: Front view of PSS SB 3075-3 CANopen

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS SB 3075-3 CANopen

USER

F-STACK

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

RT (USER)

OFF

ON

PSS

X1/X2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

1

·

X0

·

4

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

CANopen

CAN ERROR

CAN STATUS

BITRATE

HIGH

LOW

MODUL ID

CPU STATUS

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

2

4

5

12

11

11

1

3

6

8

7

PG

24 V

0 V

10

9

24 V

0 V

24 V

0 V

13

10

20

19

15

14

16

17

18

STATUS SB

Page 25

2-15Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: LED for data transfer errors

15: Rotary switch for setting the node number Bit rate (1st rotary switch)

and the Node-ID (2nd rotary switch)

16: LED for CPU status

17: LED for the CANopen data cable status

18: CANopen interface

19: LED for status of SafetyBUS p

20: SafetyBUS p interface

INFORMATION

Please refer also to the manual: “CANopen for Compact 3rd Generation

PSS”.

Page 26

Overview

2-16 Operating Manual: PSS 3075-3 Series

PSS SB 3075-3 ETH-2 CANopen

Fig. 2-7: Front view of PSS SB 3075-3 ETH-2 CANopen

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS SB 3075-3 ETH-2 CANopen

USER

F-STACK

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

RT (USER)

OFF

ON

PSS

X1/X2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

1

·

X0

·

4

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

CANopen

CAN ERROR

CAN STATUS

BITRATE

HIGH

LOW

MODUL ID

CPU STATUS

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

0

8

C

4

E

A

6

2

F

B

3

1

D

9

7

5

21

2

4

5

12

11

11

1

3

6

8

7

PG

24 V

0 V

10

9

24 V

0 V

24 V

0 V

13

10

20

15

14

16

17

18

22

ETHERNET

LINK

10/100

BASE T

TRAFFIC

LINK

TRAFFIC

10/100

BASE T

STATUS SB

19

Page 27

2-17Operating Manual: PSS 3075-3 Series

Key:

1: 4-digit display

2: LEDs for PSS operating mode and supply voltage

3: 3-position switch for selecting the standard section’s operating mode

4: Button for scrolling the error stack

5: 2-position switch for selecting the failsafe section’s operating mode

6: Programming device interface

RS 232 (minimum configuration: TxD, RxD, GND)/RS 485

7: User interface

RS 232/RS 485

8: Pushbutton for switching on and off the RS 485 termination on the

user interface

9: Supply voltage connection (24 VDC) for internal supply of the

safety system and the outputs at X1, X2

10: Digital outputs and test pulse outputs

11: Digital inputs

12: Functional earth connection

13: Supply voltage connection (24 VDC) for outputs at X8, X9

14: LED for data transfer errors

15: Rotary switch for setting the node number Bit rate (1st rotary switch)

and the Node-ID (2nd rotary switch)

16: LED for CPU status

17: LED for the CANopen data cable status

18: CANopen interface

19: Labelling strip for Ethernet address

20: SafetyBUS p interface

21: LED for status of SafetyBUS p

22: ETH-2 interface with connection to ETHERNET via integrated switch

(2 free ports); LEDs on each port for

- Status of network connection (LINK)

- Status of data traffic (TRAFFIC)

INFORMATION

Please refer also to the manual: “CANopen for Compact 3rd Generation

PSS” and “ETH-2 for Compact 3rd Generation PSS”.

Page 28

Overview

2-18 Operating Manual: PSS 3075-3 Series

Notes

Page 29

3-1Operating Manual: PSS 3075-3 Series

Safety

Intended use

Programmable safety systems from the PSS 3075-3 series are intended

for use as follows:

• Safety-related applications

in the PSS failsafe section

• Non-safety-related applications in the

PSS standard section

INFORMATION

The following system software is required in order to program the safety

systems:

• PSS WIN-PRO from Version 1.1.2 for

- PSS 3075-3

- PSS 3075-3 DP-S

- PSS SB 3075-3 DP-S

• PSS WIN-PRO from Version 1.3.1 for

- PSS SB 3075-3

- PSS SB 3075-3 ETH-2

- PSS SB 3075-3 ETH-2 SE

• PSS WIN-PRO from Version 1.5.2 for

- PSS SB 3075-3 CANopen

• PSS WIN-PRO from Version 1.8.0 for

- PSS SB 3075-3 ETH-2 CANopen

• PSS WIN-PRO from Version 1.8.2 for

- PSS 3075-3 NR

INFORMATION

Drivers (standard function blocks) from the corresponding Pilz software

package will be required in order to connect to the various standard bus

systems:

• ST-SB-DP-S: Driver for PROFIBUS-DP Slave

• ST SB CANopen: Driver for CANopen

For the standard bus interface ETH-2, the Ethernet Configurator is

available as part of the PSS WIN-PRO system software from Version 1.3.1.

Page 30

Safety

3-2 Operating Manual: PSS 3075-3 Series

The following is deemed improper use:

• Any component, technical or electrical modification to the safety system

• Use of the safety system outside the areas described in this manual

• Use of the safety system outside the documented technical details (see

chapter entitled “Technical Details”).

Intended use includes making the installation EMC-compliant. Please

observe the guidelines given in this manual and in the “Safety Manual” for

the PSS-range. The “Safety Manual” also includes check lists designed to

help you with the safety-related planning, construction and operation of a

plant.

Product modifications

Details of the changes made to a unit from one version to the next are

described in the “Product Modifications” file. This file can be found on the

“Documentation PSS-Range/SafetyBUS p” CD or on the Internet

(www.pilz.com) with the unit’s documentation.

Categories in accordance with EN 954-1

WARNING!

Please note: To achieve the corresponding category or requirement class,

the whole system including all safety-related components (parts, devices,

user program etc.) must be included in the assessment. For this reason,

Pilz cannot accept liability for the correct classification into a category or

requirement class.

Digital inputs (DI2)

Depending on the application area and its respective regulations, the

inputs may be used without test pulses for applications up to category 3,

in accordance with EN 954-1. The possibility of a short circuit occurring in

the external wiring between different inputs or against L+ must be

eliminated through appropriate wiring.

Page 31

3-3Operating Manual: PSS 3075-3 Series

For category 4 applications, shorts between the input contacts must be

detected. This can be achieved through the use of test pulses on the PSS

or, depending on the type of input device, through a feasibility test or

through detection of shorts across the contacts on the input device (e.g.

light barrier) (for connection examples please see Chapter 7, “Wiring the

Inputs and Outputs”).

Single-pole outputs (DOS)

An additional shutdown route means that the outputs on the PSS can be

used in single-channel operation for applications up to category 3 in

accordance with EN 954-1 (03/97). Please note that in this case a

feedback circuit must be used.

To achieve category 4, two actuators must be connected in series to two

different outputs.

Dual-pole outputs (DOZ)

The dual-pole outputs can be used for applications up to

category 4 in accordance with EN 954-1 (03/97).

Safety guidelines

Failure to keep to these guidelines will render all warranty and liability

claims invalid:

• All health and safety / accident prevention regulations for the particular

area of application must be observed.

• Before using the unit it is necessary to perform a safety assessment in

accordance with the Machinery Directive 98/37/EC.

Page 32

Safety

3-4 Operating Manual: PSS 3075-3 Series

Use of qualified personnel

The safety system may only be assembled, installed, programmed,

commissioned, operated, maintained and decomissioned by qualified

personnel. Qualified personnel are people who, because they are:

• Qualified electrical engineers and

• Have received training from qualified electrical engineers,

are suitably experienced to operate devices, systems, plant and machinery

in accordance with the general standards and guidelines for safety

technology.

EMCD

The safety system is designed for use in an industrial environment.

Interference may occur if used within a domestic environment.

Warranty and liability

All claims to warranty and liability will be rendered invalid if:

• The safety system was used contrary to the purpose for which it was

intended

• Damage can be attributed to not having followed the guidelines in the

manual

• Operating personnel are not suitably qualified.

• Any type of modification has been made (e.g. exchanging components

on the PCB boards, soldering work etc.).

Disposal

The programmable safety system must be disposed of properly when it

reaches the end of its service life.

Page 33

Operating Manual: PSS 3075-3 Series

4-1

Function Description

CPU

The CPU controls the outputs, reads the inputs and processes / stores the

user program and variable data. The failsafe section is designed to be

multi-channel, i.e. different CPUs process the user program independently.

A four-digit display and several LEDs provide information on the status of

the safety system and indicate any errors.

Interfaces

CPU interfaces

The CPU of each programmable safety system in the PSS 3075-3 series

provides the following interfaces:

• Programming device interface

Combined RS 232 interface (minimum configuration: TxD, RxD, GND)/

RS 485

• User interface

Combined RS 232/RS 485 interface (termination is selectable)

For further information please refer to the “System Manual for the

PSS-Range”.

SafetyBUS p interface

The programmable safety system from the PSS 3075-3 series may have a

SafetyBUS p interface, depending on the unit type. For further information

on SafetyBUS p, please refer to the “System Manual for SafetyBUS p”.

Interfaces for standard bus systems

Different interfaces are available for connection to various standard bus

systems, depending on the unit type. The standard bus interfaces are

described in separate operating manuals. The necessary operating

manuals are supplied with the relevant unit types.

Page 34

Function Description

4-2 Operating Manual: PSS 3075-3 Series

Inputs

Programmable safety systems from the PSS 3075-3 series have 48 digital

inputs (DI2), 6 of which can be configured as alarm inputs (DIF).

The digital input signals must show a “High” (“1” signal) of 24 VDC (+15 ...

+30 VDC) or a “Low” (“0” signal) of 0 VDC (-3 ... +5 VDC).

LEDs are used as status indicators. An LED lights up as soon as a “1”

signal is present at the input. Inputs have input filters and are galvanically

isolated from the control electronics through optocouplers.

Digital inputs (DI2)

Internal diagnostic circuitry checks the function of the inputs, including the

optocoupler. If an error occurs, the PSS will switch to a STOP condition,

switch off the outputs and send a message to the CPU-display.

Alarm inputs (DIF)

The CPU program cycle will be interrupted if there is a signal change at an

alarm input. Depending on the configuration, rising, falling or both types of

pulse edges may trigger an alarm. Only those alarms triggered by a signal

change from “1” to “0” are safety-related. As soon as an alarm signal

(signal change) occurs at one of the alarm inputs, the signal is sent to the

CPU through a hardware connection. The CPU determines which input

triggered the alarm and, if the pulse edge is configured as active, calls up

the relevant alarm OB. The user can program whatever measures are

necessary into this alarm OB (see “FS System Description”).

Internal diagnostic circuitry checks the function of the inputs. If an error

occurs, the PSS will switch to a STOP condition, switch off the outputs and

send a message to the CPU-display. The input filter and optocoupler can

be tested using test pulses.

Page 35

Operating Manual: PSS 3075-3 Series

4-3

INFORMATION

For further information on alarm processing please refer to the “FS System

Description” from the “PSS System Manual for the compact/modular PSS”

Outputs

Programmable safety systems from the PSS 3075-3 series have 18 singlepole outputs (DOS) and 9 dual-pole outputs (DOZ). 4 of the single-pole

outputs can be configured as test pulse outputs (DOT).

INFORMATION

On programmable safety systems from the PSS 3075-3 series, only

outputs O1.16 ... O1.21, O/T2.0 ... O/T2.3, O2.8 ... O2.18, O4.0 ... O4.2

and O4.8 ... O4.10 are available at the terminals.

Please note: Unwired outputs O1.22 ... O1.31, O2.4 ... O2.7, O2.19 ...

O2.31, O4.3 ... O4.7 and O4.11 ... O4.15 cannot be configured in the

system software.

Single-pole outputs (DOT/DOS)

Programmable safety systems from the PSS 3075-3 series have 18 singlepole outputs with a load capacity of 1.5 A.

The 4 outputs O/T2.0 ... O/T2.3 can be configured together as test pulse

outputs.

Outputs configured as test pulse outputs supply the test pulses to check

the input filters and optocouplers on the inputs. The CPU checks whether

the inputs connected to a test pulse output can detect a signal change.

INFORMATION

Please note that unused test pulses must remain unconnected.

Page 36

Function Description

4-4 Operating Manual: PSS 3075-3 Series

Once the CPU sends a “1” signal via the system bus, the PSS will supply

24 VDC to the relevant output. The status of the outputs is displayed

through LEDs, which light as soon as a “1” signal (24 VDC) is present at

the output.

Internal diagnostic circuitry tests the function of the outputs. During each

cycle, the CPU compares the actual status of the outputs with the process

image of the outputs. Outputs that are switched on will be switched off

during each self test in order to check that the output transistors can be

switched. Outputs that are switched off will be switched on during each

self test in order to check the monitoring circuit. A test will also be carried

out to check for shorts between the outputs of a sub-slot (short circuits are

detected only when the outputs are switched on). If an error occurs, the

PSS will switch to a STOP condition, switch off the outputs and send a

message to the CPU-display.

If a plant is particularly sensitive to the pulses from the power-up test on

outputs that are switched off, individual outputs or all single-pole outputs

can be excluded from testing. This is achieved using operating system call

SB255, function 2 (see overleaf).

If you deactivate the output power-up test, please make sure you observe

the following guidelines:

NOTICE

On an output that is switched off, follow the instructions below: At a noncritical point in the program, switch the output on and then off again for

one PSS cycle. If the output does not switch correctly, the error will be

detected and registered by the operating system. To also detect shorts

between outputs that are switched off, outputs must be switched on at an

offset of one cycle.

NOTICE

To detect whether an output has been excluded from the output test

incorrectly, or whether the output test that the user has programmed is

effective, an error simulation must be carried out on each safety-related

output during commissioning. To do this, the affected output must be

switched off (output’s diode not lit up). If you then generate a short circuit

between the output and 0 V, the desired error reaction should occur. In the

worst case, the error reaction should occur within 30 minutes.

Page 37

Operating Manual: PSS 3075-3 Series

4-5

• The output power-up tests are a component part of the system’s self

check. The self check is carried out when voltage is returned, on start up

(transfer from STOP-RUN) and also during operation.

• Operating system call SB255, function 2 in OB120 is required to

deactivate the power-up test on start up. To deactivate the power up-test

during operation, the operating system call must be contained in a block

that is run as part of each cycle. The power-up test will be performed

again as soon as the operating system call is no longer present.

NOTICE

Each time SB255, function 2 is called, data words DW200, DW201 and

DW202 must be written in full to ensure that outputs are not excluded from

the power-up test unintentionally, due to data words being unwittingly

overwritten during the program cycle.

Page 38

Function Description

4-6 Operating Manual: PSS 3075-3 Series

Block

SB255

DB003

DB001

Input

FUNK = 2

DW200

DW201

DW202

Output

ERG = 1

DW200

Key

Deactivate output power-up test in bits

Function performed without error

Incorrect SB255 calls will lead to a STOP

condition

Slot number

on the PSS 3075-3 series: 2 / 4

Masks for outputs 2.00 ... 2.15 / 4.00 ... 4.15

If this is set on a bit belonging to an output, the

power-up test for this output will be deactivated.

For example: 0101

H

-> output 2.0 and 2.8

on the PSS 3075-3 series:

• Outputs 2.8 … 2.15, 4.0 ... 4.2 / 4.8 ...

4.10 can be masked

• Outputs 2.0 … 2.3 can only be masked if they

are not configured as test pulses

• Outputs 2.4 … 2.7, 4.3 ... 4.7 / 4.11 ... 4.15

(outputs not available at the terminals) cannot

be masked, their bits must always equal 0

Masks for outputs 2.16 ... 2.31 / 4.16 ... 4.31

on the PSS 3075-3 series: 0000

H

Outputs 2.16 ... 2.31 / 4.16 ... 4.31 cannot be

masked, their bits must always equal 0.

Fault detection:

0: No error

1: Invalid slot number

2: Slot not occupied

3: Not possible to deactivate the power-up test on

the stated outputs

4: Call of SB255, FUNK = 2 not permitted in alarm

OB

Page 39

Operating Manual: PSS 3075-3 Series

4-7

Dual-pole outputs (DOZ)

9 dual-pole outputs are available.

The load must be connected between the “+” and “-” terminals. When the

CPU sends a “1” signal via the system bus, the PSS supplies 24 VDC to

the relevant output. The status of the outputs is displayed through LEDs,

which light as soon as a “1” signal (24 VDC) is present at the output.

Internal diagnostic circuitry tests the function of the connected outputs. On

outputs that are switched on, the CPU will alternately switch off the “+” and

“-” terminals as part of each cycle. This is to check that the corresponding

output transistors can be switched off and that there is no interruption to

the load. In addition, outputs that are connected but switched off will be

switched on for approx. 100 µs during each self test. If an error occurs, the

PSS will switch to a STOP condition, switch off the outputs and send a

message to the CPU-display.

All outputs are protected against short-circuit, overload and excess

temperature. They can switch both resistive and inductive loads.

Page 40

Function Description

4-8 Operating Manual: PSS 3075-3 Series

Configuration coding

Inputs and outputs are located on a sub-slot, which is allocated a code:

Slot

0

1

2

3

4

Sub-slot

0

1

2

3

4

5

6

7

8

9

Inputs/outputs

I0.00 - I0.15

I0.16 - I0.31

I1.00 - I1.09

O1.16 - O1.21

O2.00 - O2.03

O2.08 - O2.15

O2.16 - O2.18

I3.00 - I3.05

...

O4.00 - O4.02

O4.08 - O4.10

...

Code

C003

H

C003

H

C003

H

C011

H

C017

H

C011

H

D002

H

...

C015

H

...

...

Page 41

5-1Operating Manual: PSS 3075-3 Series

General requirements

Please note the following:

• The safety system should be installed in an enclosure, e.g. control

cabinet, that conforms to the protection class required for the

environment.

• When installing the system in an enclosure such as a control cabinet, the

environmental data for the safety system must be taken into account.

Details can be found in the chapter entitled “Technical Details”.

• Ensure there is sufficient ventilation to prevent heat building up within the

control cabinet. Please note the ambient temperature of 0 ... 60 °C.

• In extreme ambient conditions, additional measures may be required in

order to keep within the prescribed value range.

• Use low interference panel lighting for inside the control cabinet.

• The safety system must be installed in such a way that there is adequate

protection against buttons and switches being operated unintentionally.

CAUTION!

Risk of burns!

Do not touch the metal parts of the housing.

If the safety system is operated at an ambient temperature of more than

45 °C, surface temperatures on the housing may reach more than 80 °C at

full load.

Installing the safety system

There are two options for installing the safety system. Both options are

shown in the following illustrations. Drill M4 holes in the control cabinet’s

mounting plate, as shown in the illustrations (tolerance: +/-0.3 mm/0.012").

Attach the safety system to the mounting plate in your control cabinet,

using washers.

Installation

Page 42

Installation

5-2 Operating Manual: PSS 3075-3 Series

Fig. 5-1:

Installation options for the programmable safety system PSS 3075-3 and

PSS 3075-3 NR

Dimensions stated in mm (")

Installing the safety system PSS 3075-3 and PSS 3075-3 NR

Option A:

Dimensions in mm (") excluding interfaces and operating controls :

H x W x D: 246.4 x 123.6 x 162 (9.70" x 4.87" x 6.38")

Option B:

120

(4.72")

120

(4.72")

21

(0.83")

21

(0.83")

40

(1.57")

17

(0.67")

37

(1.46")

40

(1.57")

40

(1.57")

236,4 (9.31")

236,4 (9.31")

Page 43

5-3Operating Manual: PSS 3075-3 Series

Installing the safety system PSS 3075-3 DP-S, PSS SB 3075-3,

PSS SB 3075-3 ETH-2 and PSS SB 3075-3 ETH-2 SE

Dimensions in mm (") excluding interfaces and operating controls :

H x W x D: 246.4 x 160.2 x 162 (9.70" x 6.31" x 6.38")

Fig. 5-2:

Installation options for the programmable safety system PSS 3075-3 DP-S,

PSS SB 3075-3, PSS SB 3075-3 ETH-2 and PSS SB 3075-3 ETH-2 SE

Dimensions stated in mm (")

Option A:

Option B:

40

(1.57")

40

(1.57")

40

(1.57")

17

(0.67")

21

(0.83")

21

(0.83")

37

(1.46")

40

(1.57")

40

(1.57")

60

(2.36")

60

(2.36")

60

(2.36")

60

(2.36")

236,4 (9.31")

236,4 (9.31")

Page 44

Installation

5-4 Operating Manual: PSS 3075-3 Series

Fig. 5-3:

Installation options for the programmable safety system PSS SB 3075-3 DP-S,

PSS SB 3075-3 CANopen and PSS SB 3075-3 ETH-2 CANopen

Dimensions stated in mm (")

Installing the safety system PSS SB 3075-3 DP-S, PSS SB 3075-3 CANopen and

PSS SB 3075-3 ETH-2 CANopen

Dimensions in mm (") excluding interfaces and operating controls :

H x W x D: 246.4 x 196.8 x 162 (9.70" x 7.58" x 6.38")

40

(1.57")

40

(1.57")

40

(1.57")

17

(0.67")

21

(0.83")

21

(0.83")

37

(1.46")

40

(1.57")

40

(1.57")

60

(2.36")

60

(2.36")

60

(2.36")

60

(2.36")

40

(1.57")

40

(1.57")

236,4 (9.31")

236,4 (9.31")

Option A:

Option B:

Page 45

5-5Operating Manual: PSS 3075-3 Series

Installing the safety system in a control cabinet

Fig. 5-4: Installing safety systems from the PSS 3075-3 series in a control cabinet

(example: PSS 3075-3), dimensions stated in mm (")

13 mm

(0.51")

No

minimum distance

from control cabinet

Distance from top

min. 130 mm (5.12")

Power section

min. 60 mm (2.36")

Cable duct max. (W x H):

100 x 50 mm (3.94" x 1.97")

220.4 mm

(8.68")

13 mm

(0.51")

Functional earth

connection

123 mm

(4.84")

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS 3075-3

1

·

X0

·

4

USER

F-STACK

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

RT (USER)

OFF

ON

PSS

X1/X2

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS 3075-3

1

·

X0

·

4

USER

F-STACK

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

RT (USER)

OFF

ON

PSS

X1/X2

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

PG

24 V

0 V

24 V

0 V

24 V

0 V

PG

24 V

0 V

24 V

0 V

Page 46

Installation

5-6 Operating Manual: PSS 3075-3 Series

Notes

Page 47

Operating Manual: PSS 3075-3 Series 6-1

General requirements

Please note the following:

• When selecting the power supply, please refer to the requirements stated

under “Technical Details”.

INFORMATION

The output circuits have been designed to guarantee maximum safety.

To achieve this, extensive tests are carried out internally. If the supply

voltage is interrupted briefly during a test function, the relevant test pulse

output will be deemed to be defective.

The normal error reaction will occur: the PSS switches to a STOP

condition.

Remedy: The PSS supply voltage must be buffered.

• Overvoltage and spikes of interference outside the specifications can

damage the PSS. In this case the PSS will switch to a safe condition.

You should therefore ensure that appropriate EMC measures are taken.

• To achieve the lowest possible residual ripple (< ± 1.2 V), we

recommend that you install a three-phase bridge rectifier or regulated

supply.

• The size of the fuse will depend on the system’s technical details, the

cable cross section and on local regulations.

• The external 24 V supply must be able to provide the following current:

Connectors X0 and X7: the current for the internal supply to the PSS,

depending on the unit type (see “Technical Details”), plus the maximum

permitted load current at connectors X1 and X2 / X8 and X9. The overall

load at full load may be a maximum of 10 A each.

WARNING!

Electric shock!

Safe electrical isolation must be ensured for the external 24 V supply.

Failure to do so could

result in electric shock. Power supplies must conform

to EN 60950, 03/97,

section 2.3, EN 60742, 9/95 or EN 50178, 10/97.

Supply Voltage

Page 48

Supply Voltage

6-2 Operating Manual: PSS 3075-3 Series

• The external power supply for the programmable safety system should

be connected as shown in Fig. 6-1.

Fig. 6-1: Supplying programmable safety systems from the PSS 3075-3 series

• The external power supply for the outputs on the programmable safety

system should be connected as shown in Fig. 6-2.

Fig. 6-2: Supplying the outputs on programmable safety systems

from the PSS 3075-3 series

~

=

PSS 3075-3

L1

N

+24 V

0 V

External power supply

X7

X8/X9 PWR

Functional

earth

Connect in star to the central

earth bar

Optional:

Connect to the 0 V supply and

earth at a single point

X0

PSS

X1/X2

PWR

24 V

0 V

24 V

0 V

24 V

0 V

~

=

PSS 3075-3

L1

N

+24 V

0 V

External power supply

X7

10 A

10 A

X0

PSS

X1/X2

PWR

X8/X9 PWR

Functional

earth

Connect in star to the central

earth bar

Optional:

Connect to the 0 V supply

and earth at a single point

24 V

0 V

24 V

0 V

24 V

0 V

Page 49

Operating Manual: PSS 3075-3 Series 6-3

NOTICE

There must be no direct connection between “N” and the 0 V output on

the external power supply!

• Please note:

Always connect the supply voltage to X0 and X7. If not, the

programmable safety system will not be able to perform various function

tests.

• Depending on the relevant national regulations, it may be necessary to

connect the 0 V supply to the central earth bar or to use some form of

earth fault monitoring (e.g. EN 60204-1, NFPA 79:17-7, NEC: Article

250).

INFORMATION

We recommend that the programmable safety system (“PSS”

connection) and the digital outputs (“X1/X2”, “X8/X9” connection) are fed

from separate power supplies, to increase the availability of the

programmable safety system.

CAUTION!

The maximum permitted load current at connectors X0 and X7 should

not be exceeded. Connectors X0 and X7 should therefore be fused (see

Fig. 6-1 and 6-2):

“PSS” connections: depending on the unit type (see “Technical details”)

“X1/X2” and “X8/X9” connections: 10 A each

INFORMATION

If the inputs on the PSS are being used with test pulses, connect L- on

the input device supply to the 0 V terminal for the supply voltage (“PWR”

connection, connectors X1/X2, X8/X9). Please refer to Chapter 7, “Wiring

the Inputs and Outputs”.

Notes on wiring

• Minimum range for cable cross sections on field connection terminals in

mm2:

- Power supply: 1.5 (AWG16) ... 2.5 (AWG12)

- Functional earth: 2.5 (AWG12)

Page 50

Supply Voltage

6-4 Operating Manual: PSS 3075-3 Series

• Use copper wiring.

• The torque setting on the terminals should be 0.5 … 0.6 Nm.

• Earthing:

- Connect the housing to the central earth bar.

- A cable cross section of at least 2.5 mm2 should be used.

- Connections should be kept as short as possible.

Page 51

Operating Manual: PSS 3075-3 Series 7-1

Configuration of the screw terminals and connector description

Fig. 7-1: Terminal configuration on programmable systems from the

PSS 3075-3 series (Example: PSS 3075-3)

Wiring the Inputs and Outputs

Supply voltage

X8

O1.16 ... O1.18: dual-pole

O4.0 ... O4.2: single-pole

X5

I1.0 ... I1.7

X1

O2.16: dual-pole

O2.8 ... O2.14: single-pole

X2

O2.17 ... O2.18: dual-pole

O2.15: single-pole

O/T2.0 ... O/T2.3: single-pole

(test pulse outputs)

Digital outputs:

X9

O1.19 ... 1.21: dual-pole

O4.8 ... O4.10: single-pole

Digital inputs

X3

I0.0 ... I0.7

X10

I0.16 ... I0.23

X6

I1.8, I1.9

I3.0 ... I3.5 (alarm

outputs)

X4

I0.8 ... I0.15

X11

I0.24 ... I0.31

O -1.19

O +1.19

O -1.20

O +1.20

O - 1.21

O +1.21

O 4.8

O 4.9

O 4.10

1

·

X7

·

3

1

·

·

·

X8

·

·

·

9

1

·

·

·

X9

·

·

·

9

1

·

·

·

X10

·

·

·

9

1

·

·

·

X11

·

·

·

9

X8/X9 PWR

PWR

RUN FS

PG

RUN ST

POWER

RUN

STOP

AUTO PG

SPS

ST

FS

PSS 3075-3

1

·

X0

·

4

USER

F-STACK

0 V

I 0.8

I 0.9

I 0.10

I 0.11

I 0.12

I 0.13

I 0.14

I 0.15

0 V

I 0.0

I 0.1

I 0.2

I 0.3

I 0.4

I 0.5

I 0.6

I 0.7

0 V

I 1.0

I 1.1

I 1.2

I 1.3

I 1.4

I 1.5

I 1.6

I 1.7

0 V

I 1.8

I 1.9

I 3.0

I 3.1

I 3.2

I 3.3

I 3.4

I 3.5

1

·

·

·

X3

·

·

·

9

1

·

·

·

X4

·

·

·

9

1

·

·

·

X5

·

·

·

9

1

·

·

·

X6

·

·

·

9

1

·

·

·

X1

·

·

·

9

1

·

·

·

X2

·

·

·

9

O -2.17

O +2.17

O 2.15

O/T 2.0

O/T 2.1

O/T 2.2

O/T 2.3

O -2.18

O +2.18

RT (USER)

OFF

ON

PSS

X1/X2

O -2.16

O +2.16

O 2.8

O 2.9

O 2.10

O 2.11

O 2.12

O 2.13

O 2.14

O -1.16

O +1.16

O -1.17

O+1.17

O -1.18

O +1.18

O 4.0

O 4.1

O 4.2

0 V

I 0.24

I 0.25

I 0.26

I 0.27

I 0.28

I 0.29

I 0.30

I 0.31

0 V

I 0.16

I 0.17

I 0.18

I 0.19

I 0.20

I 0.21

I 0.22

I 0.23

24 V

0 V

PG

24 V

0 V

24 V

0 V

X0

PSS PWR

X1/X2 PWR

X7

X8/X9 PWR

Page 52

Wiring the Inputs and Outputs

7-2 Operating Manual: PSS 3075-3 Series

Notes on wiring

Where safety-related applications are concerned, it is essential that short

circuits and open circuits are unable to cause a hazardous condition within

a plant.

The way in which this is done will depend on the degree of hazard within

the plant itself, the switching frequency of the input devices and the level of

safety of the input devices and actuators. You should assess these points

in conjunction with the relevant standards or approvals body (e.g. BG or

TÜV).

Please observe the following when wiring:

• Earthing:

- Connect the housing to the central earth bar.

- A cable cross section of at least 2.5 mm2 should be used.

- Connections should be kept as short as possible.

• Open circuits, short circuits and earth faults:

- In principle it is possible to eliminate short circuits between signals

within electrically-enclosed areas and also outside electrically-enclosed

areas when the signals are conducted in different multicore cables.