Page 1

®

PSS

Programmable safety systems PSSmodular, PSScompact,

decentralised I/O system PSSuniversal, safe bus system SafetyBUS p,

wireless system InduraNET p, real-time Ethernet SafetyNET p

Programmable Safety and Control Systems

One system for safety and standard.

Page 2

Business activities

Excellent Components

Sensor

technology

Control and

communication

Motion Control

Operating and

monitoring

Software

• Safety switches

• Secure safety gate systems

• Optoelectronic

protective devices

• Safe camera systems

• Electronic monitoring relays

• Safety relays

• Programmable

safety and control systems

• Industrial communication

• Control systems

• Servo amplifi ers

• Motors

• Control and signal devices

• Operator terminals

• System software

• User software

• Software tools

Professional Services

Consulting and

engineering

Training

• Risk assessment

• Safety concept

• Safety design

• System implementation

• Safety validation

• CE services

• International compliance

services

• Plant assessment

• Inspection of ESPE

• Seminars

• Courses

Page 3

Support

Technical help round the clock!

Technical support is available

from Pilz round the clock. This

service is provided free of charge

beyond standard business hours.

Americas

• Brazil

+55 11 8245-8267

• Mexico

+52 55 5572 1300

• USA (toll-free)

+1 877-PILZUSA (745-9872)

Asia

• China

+86 21 62494658-216

• Japan

+81 45 471-2281

• Korea

+82 2 2263 9540

Australia

• Australia

+61 3 95446300

You can reach our

international hotline on:

Europe

• Austria

+43 1 7986263-0

• Belgium, Luxembourg

+32 9 3217575

• England

+44 1536 462203

• France

+33 3 88104000

• Germany

+49 711 3409-444

• Ireland

+353 21 4804983

• Italy

+39 031 789511

• Scandinavia

+45 74436332

• Spain

+34 938497433

• Switzerland

+41 62 88979-30

• The Netherlands

+31 347 320477

• Turkey

+90 216 5452912

+49 711 3409-444

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfi ldern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

Page 4

Why does Pilz offer more?

Because the integrality

of our business activities is

what sets us apart.

O

S

O

S

E

L

E

L

T

T

E

E

L

L

P

P

M

M

O

O

C

C

E

x

c

e

l

l

e

n

C

t

o

m

p

o

n

e

n

t

s

F

F

O

O

R

R

S

S

A

A

F

F

E

E

U

U

T

T

I

I

O

O

N

N

S

S

l

a

n

o

i

s

s

e

f

o

r

P

s

e

c

i

v

r

e

S

N

N

O

O

I

I

T

T

A

A

M

M

A

A

O

O

U

T

U

T

Pilz is a solution supplier for

all automation functions.

Including standard control functions. Developments from Pilz

protect man, machine and the

environment. That's why all our

experience and knowledge goes

into individual products as well

as consistently sophisticated

system solutions.

• Sensor technology

• Control and communication

• Motion Control

• Operating and monitoring

• Software

• Consulting and engineering

• Training

Appropriate services relating

to individual components and

independent generic services

guarantee that our customers

obtain customised automation

solutions, all from one source.

Pilz is a family business

that's closer to its customers.

Pilz has a tradition as a

family-run company stretching

back 60 years.

Real proximity to customers

is visible in all areas, instilling

confi dence through individual

consultation, fl exibility and

reliable service.

We are your contact, guide and

competency leader en route to an

optimum automation solution.

2

Page 5

E

C

x

o

c

e

m

F

F

O

O

C

C

l

p

O

O

l

e

o

R

R

M

M

n

n

S

S

P

P

t

A

e

A

L

L

n

F

F

E

E

Contents

O

S

O

S

E

E

T

T

t

s

E

E

A

A

U

U

T

T

L

L

O

O

U

U

M

M

P

S

T

T

I

r

e

A

A

I

o

O

O

r

T

T

v

f

N

e

I

I

N

c

i

O

O

S

s

S

N

N

s

e

• Pilz product areas ............................................. 4

• Product area

Control and communication ............................ 6

• Product group

Industrial communication ................................ 8

l

a

n

o

i

s

- SafetyNET p system features .......................... 10

- SafetyBUS p system features .......................... 14

- Safety Network International e. V. ................... 17

- InduraNET p system features .......................... 18

- General communication networks ................... 21

• Product group

PSS programmable safety

and control systems ......................................... 22

- PSSmodular systems ...................................... 24

- PSScompact systems ..................................... 32

- Decentralised periphery

and network components ................................ 40

- System software .............................................. 62

- Software function blocks ................................. 63

Safe automation from Pilz

As fl exible as your plant is

On complex machinery and distributed plants, PSS programmable safety and control systems

monitor safety-related functions

and/or undertake complete

control of the machine – whether

centralised or decentralised

via the safe, open bus system

SafetyBUS p.

Pilz PSS programmable safety

and control systems control

and monitor the widest range of

applications worldwide. The

comprehensive control system

portfolio provides fl exibility in

the way devices are combined,

so that numerous application

options are covered.

Innovation is our motto!

We work closely with customers

to continually develop the

PSS programmable safety and

control systems. New technologies – such as the real-time

Ethernet system SafetyNET p or

the wireless InduraNET p system

for industrial use – open up new

horizons in control technology.

• PVIS diagnostic concept .................................. 68

• Index ................................................................... 71

3

Page 6

O

C

Safety

Control

A

U

T

O

Pilz product areas

Solution suppliers for safety and standard

Pilz offers a universal concept

P

L

M

E

T

E

right across industry. Whether

you need safety or standard

control functions, machine or

for solutions that can be applied

N

O

I

T

M

A

plant, centralised or decentralised, a single product or a total

solution: With Pilz you will

defi nitely fi nd a solution for

your automation function.

Are you looking for a fl exible

solution for your automation

functions? Then you’ve come

to the right place!

Your requirements: Our solution:

PMDsrange

electronic monitoring relays

• PMDsrange: Electronic

monitoring relays for electrical

safety, such as voltage or true

power monitoring.

• PNOZ: Safety relays for

functional safety, for simple

plant and machinery with

up to 14 safety functions.

Safe monitoring of E-STOPs,

safety gates and light curtains/

light grids, in compliance with

the standards.

• PSS: Programmable safety

and control systems for use

on complex machinery or

distributed plants, to monitor

safety-related functions and/or

for complete machine control.

• Industrial communication:

Transfer input/output signals

and control data reliably

and safely.

PNOZ safety relays

PSS programmable

safety and control systems

Industrial

communication networks

4

Page 7

Supplementary

product areas:

Sensor technology

Products for safety

and standard

Besides “Control and

communication”, other product

areas also contain fi rst-class

components, which you can

use individually or combine to

form a system.

Sensor technology, used in

conjunction with Pilz safe control

technology, offers a co-ordinated,

complete solution that’s

economical, approved and safe.

The focus is always on the

protection of man and machine,

in compliance with the standards

and regulations.

Software includes system

software, user software and

software tools. Here you’ll fi nd

the right tool for every task.

From product-related software

to diagnostic software, through

to the PAScal Safety Calculator.

Services in the fi eld of machinery

safety are covered holistically

by Pilz. From risk assessment

through to ESPE inspection.

Pilz also offers a comprehensive

range of training courses and

seminars, covering generic issues

relating to machinery safety as

well as Pilz products.

Motion control

Operating and monitoring

Software

Services

Motion control offers complete,

safe, scalable drive technology

as part of the Pilz solution.

It provides overall solutions

for automating your machine,

from operation via the controller

through to the movement of

highly dynamic drives, including

all safety aspects.

Operating and monitoring

offers diagnostic and visualisation

devices, plus control and signal

devices as part of the Pilz

solution. The focus is always

on fast, simple confi guration.

Machine downtimes are clearly

reduced thanks to the overall

diagnostic concept PVIS.

The whole range

of business activities

at a glance:

Webcode 0326

Online information

at www.pilz.com

5

Page 8

O

C

Safety

Control

A

U

T

O

Product area

Control and communication

PSS® – The solution for standard and safety

Safe, economical, powerful

P

L

M

E

T

E

N

O

I

T

M

A

You can use Pilz PSS programmable safety and control systems

and the corresponding communication networks to implement

the widest range of automation

solutions – from the monitoring of

safety-related functions through

to the complete control of plant,

machinery and process cycles.

Your requirements

determine the system structure

• Stand-alone machine or plant

• Centralised or decentralised

architecture

• Safety-related or standard

control functions

Industrial communication

With Pilz industrial communication systems you can transfer

input/output signals safely

and reliably. Opt for the open,

real-time Ethernet SafetyNET p,

for example, which connects

the drive, safety and control

functions. Or you can network

your plant and machinery using

the safe, open bus system

SafetyBUS p. As a further

innovation, with the wireless

system InduraNET p Pilz has

developed a wireless solution

for an industrial environment.

6

Page 9

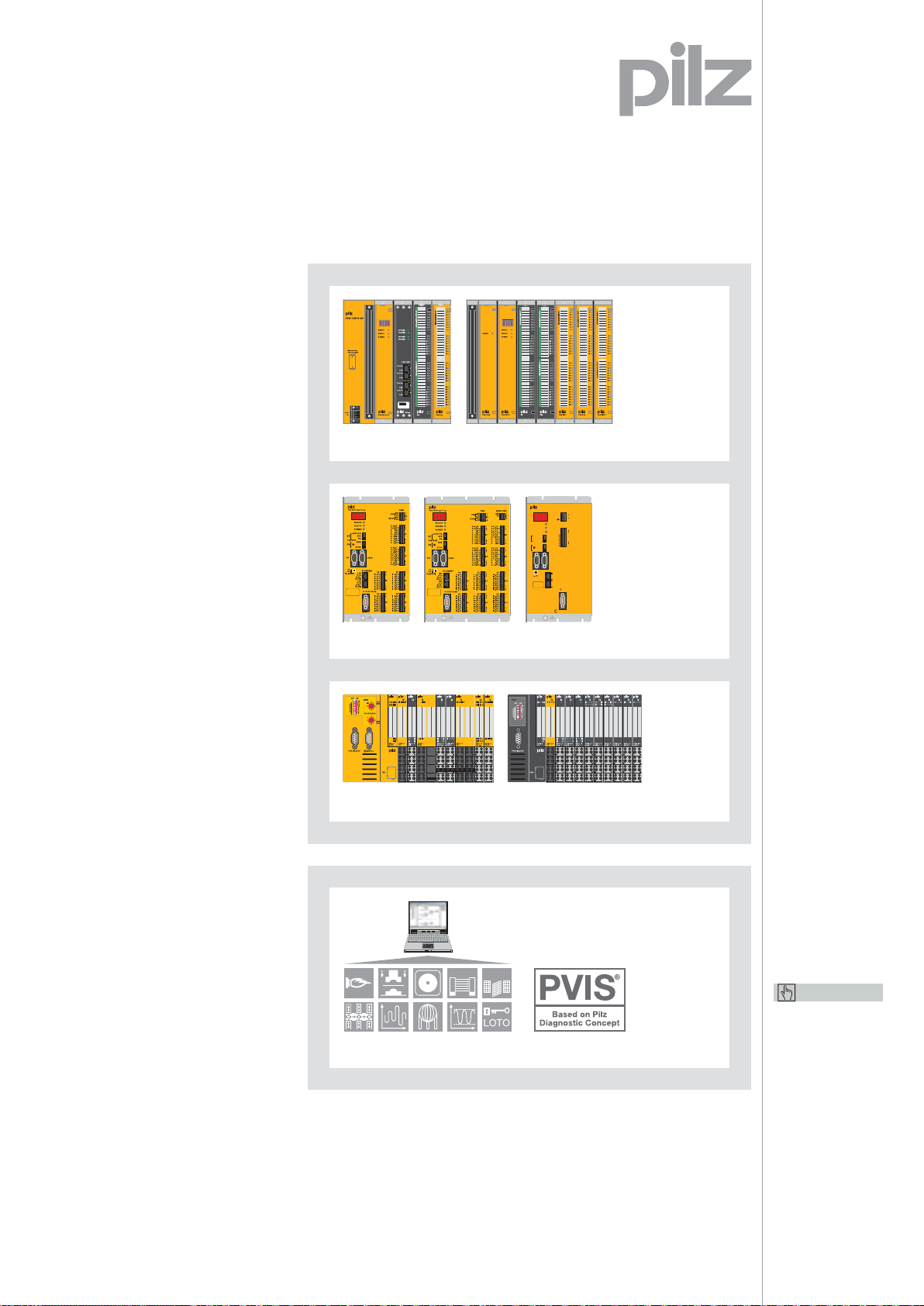

PSS programmable

safety and control systems

PSS programmable safety and

control systems are available in

a compact or modular design,

central and decentralised, for

direct fi eld application.

PSSmodular

For safety and control:

Assemble your individual solution

for centralised and decentralised

tasks – in accordance with your

requirements.

PSScompact

Six series covering safety

and control: Benefi t from an

extensive selection of versatile,

space-saving control solutions.

PSSuniversal

The decentralised I/O system

for safety and control: Cover the

complete input/output level with

just one system.

System software for

PSS programmable safety

and control systems

Practical software tools and

an extensive selection of

approved software function

blocks provide support as you

design and program your PSS

safety and control systems – from

planning through to diagnostics.

PSSmodular

PSScompact

PSSuniversal

System software

PSS SB 3006-3 ETH-2

RUN ST

RUN FS

POWER

AUTO PG

SPS

ST

PG

F-STACK

RUN

FS

STOP

PG USER

ON OFF

R (USER)

T

PSS PWR

1

24 V

X0

0 V

3

0 V

1

T 0

T 1

I0.0

X1

I0.1

I0.2

I0.3

I0.4

9

I0.5

ETHERNET

LINK

10/100 BASE T

TRAFFIC

LINK

10/100 BASE T

TRAFFIC

STATUS SB

SafetyBUS p

Keep up-to-date on

PSS programmable

safety and control

systems:

Webcode 0527

Online information

at www.pilz.com

7

Page 10

O

C

Safety

Control

A

U

T

O

Product group

Industrial communication

Backbone of safe automation

Data transfer –

P

L

M

E

T

E

N

O

I

T

M

A

Safe and reliable

Automation solutions are based

on reliable communication

networks. With its different

networks, Pilz offers the solution

for a range of requirements.

Whether you want wireless data

transfer or real-time – you’re

well advised to go for Pilz

communication networks.

Thanks to interfaces to all

other common fi eldbus systems

and Ethernet, you remain

independent in your choice

of control concept.

SafetyNET p – Real-time Ethernet for complete automation.

SafetyBUS p – The safe, open bus system.

InduraNET p – Reliable wireless technology

for the rugged everyday industrial environment.

Optimum integration – Thanks to an open system connection.

8

Page 11

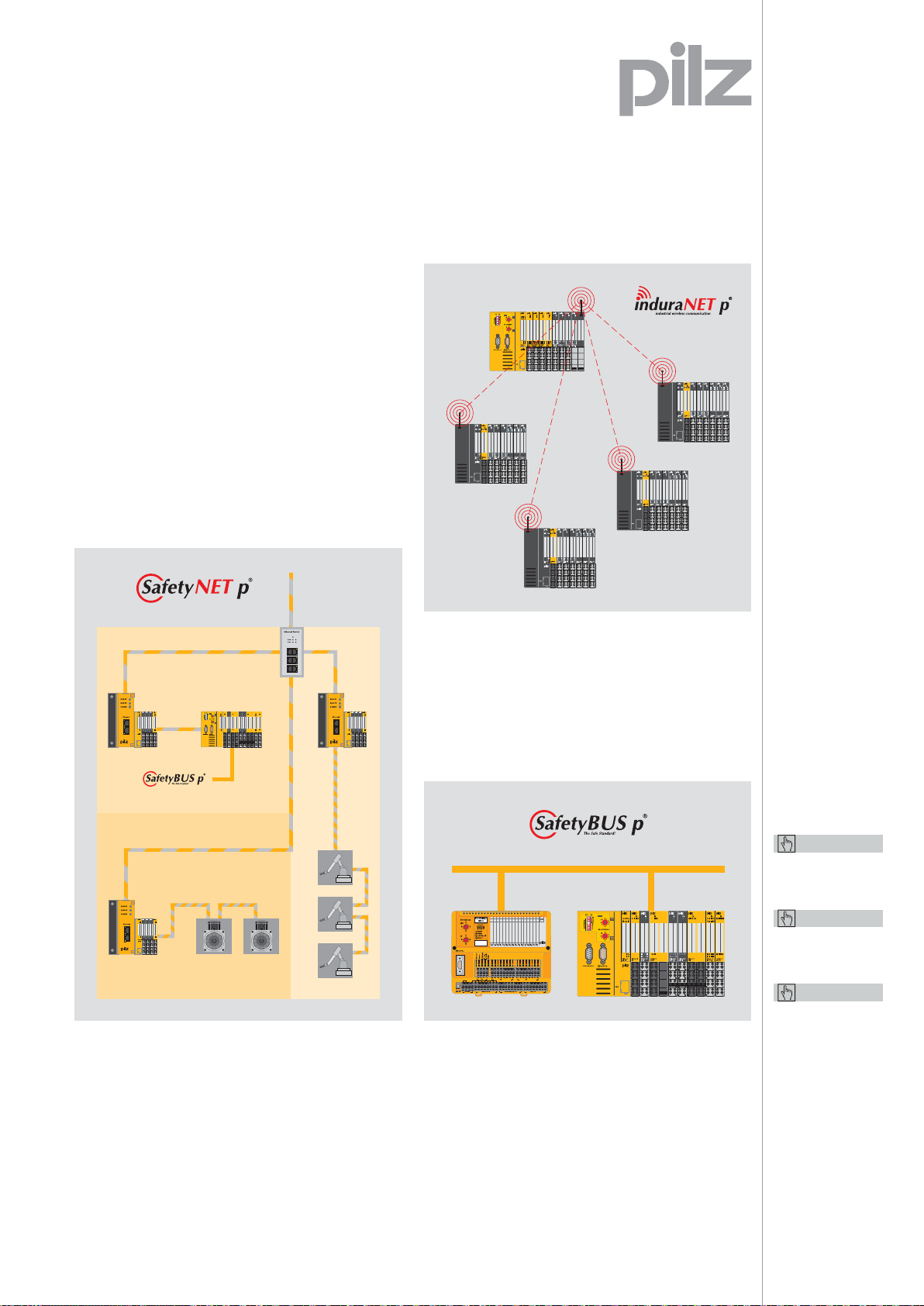

Pilz network systems

On large, complex and

distributed plants, control signals

are input/output directly in the

fi eld. This requires powerful,

available automation networks.

• With the wireless InduraNET p system, which

has been specially developed for industrial use,

signals can be exchanged with mobile devices,

for example.

• The open Ethernet system SafetyNET p can

be used for the safe transfer of time-critical data

as well as for standard communication of the

complete plant control system. With dynamic

applications, data is transmitted in real-time.

Keep up-to-date on:

• SafetyBUS p

Webcode 2469

• SafetyNET p

Webcode 2541

• InduraNET p

Webcode 2605

Online information

at www.pilz.com

• With the safe, open bus system SafetyBUS p,

time-critical information can safely be transmitted

decentrally at fi eld level.

9

Page 12

System features

SafetyNET p

SafetyNET p® – Networking of plant and ma

Investment protection

and independence with

an open system

• Existing SafetyBUS p and

fi eldbus installations can be

connected to SafetyNET p

and operate in co-existence

• Existing installations with other

industrial Ethernet systems

such as PROFINET and

Ethernet/IP can be connected

to SafetyNET p

• Any Ethernet device, e.g. PC,

camera, printer, etc. can be

Real-time Ethernet for

complete automation

SafetyNET p is based on

standard Ethernet and can be

used simultaneously for real-time,

standard and safety-related

communication functions in

industrial automation:

• For the safe transfer of

time-critical, safety-related data

• For transferring information

from the standard control

process

• For real-time communication

of all signals in highly dynamic,

synchronised applications

All of a plant and machine’s

control functions are networked

using a single system.

connected to SafetyNET p;

IP-based Ethernet utilities

such as E-Mail, Internet or

streaming can also be used

across the network

New horizons in

control technology

SafetyNET p enables new

fl exibility at optimum cost for

complete networking of plant

and machinery. So the system

based on the Ethernet standard

opens up new horizons in

control technology:

10

• Decentralisation of the control

intelligence directly to fi eld level

• Ability to maintain a

centralised view

• Long-term, implementation of

functional machine modules

Page 13

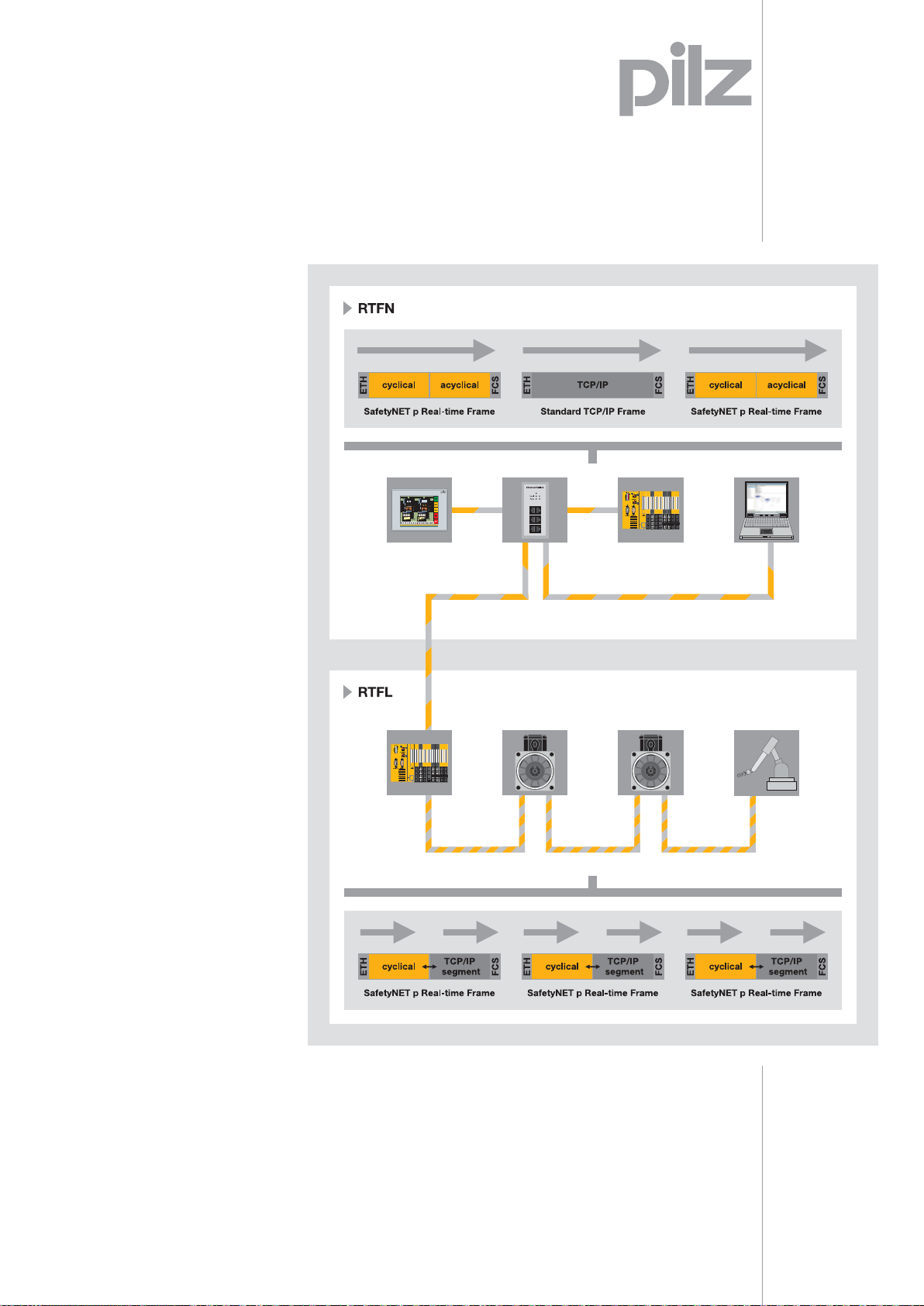

chinery

Individually adaptable

system standard with

two speed classes:

RTFN and RTFL

You can adapt SafetyNET p to

the widest range of automation

technology requirements and so

achieve the optimum cost-benefi t

ratio for your network design,

using just one system:

• For real-time communication

in highly dynamic applications,

e.g. on fi lling and packaging

machinery, use the RTFL speed

class (Real Time Frame Line)

with deterministically guaranteed scan times of 62.5 μs

and below

• For fi eldbus class

communication and for

networking individual production cells, use the RTFN speed

class with processing cycles of

approx. 1 ms – this is designed

for connecting a large number

of subscribers and for large

network extensions

11

Page 14

System features

SafetyNET p

SafetyNET p® – As fl exible as your plant is

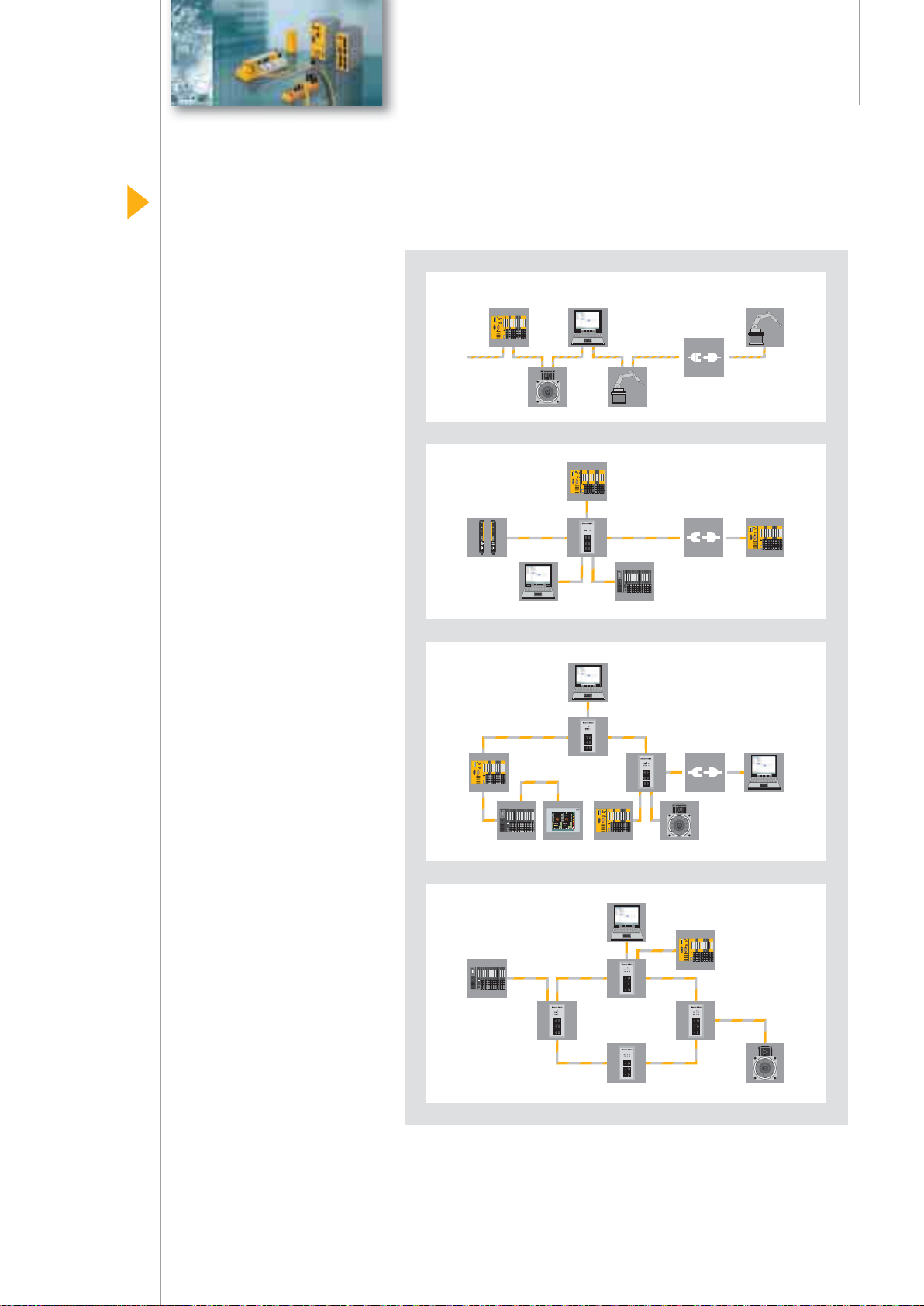

Flexible topologies

and dynamic structures

SafetyNET p supports the

widest range of topologies.

The application options are

many and varied:

• Linear structure – optimised

for rapid scan times and the

integration of existing bus

structures

• Star structure – data exchange

via a central node (e.g. CPU),

fl exibility in the way devices

can be connected and

disconnected from the network

• Tree structure – combination of

network segments with equal

or varied performance, ideal for

large, complex networks

• Ring structure – Redundancy

is guaranteed; if a component

should fail, a second route

can be used

Linear

Star

Tre e

OFF ON

-0

64

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

OFF ON

-0

64

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

21

21

21

21

21

21

21

12

12

12

12

12

12

12

22

22

22

22

22

22

22

13

13

13

13

13

13

13

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

24

24

24

24

24

24

24

OFF ON

-0

64

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

All of the structures are dynamic.

Network subscribers can be

deactivated and replaced without

the need to reconfi gure the network. So you can connect mobile

devices if necessary, during

maintenance and diagnostics for

example, and implement variable

confi gurations within the production process, e.g. tool change.

Ring

OFF ON

-0

64

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

OFF ON

-0

64

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

14

24

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

21

11

21

11

21

11

21

11

21

11

21

11

21

12

22

12

22

12

22

12

22

12

22

12

22

12

22

13

23

13

23

13

23

13

23

13

23

13

23

13

23

USB

14

24

14

24

14

24

14

24

14

24

14

24

14

24

OFF ON

-0

64

x10

32

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

21

21

21

21

21

21

21

12

12

12

12

12

12

12

22

22

22

22

22

22

22

13

13

13

13

13

13

13

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

24

24

24

24

24

24

24

12

Page 15

Benefi ts at a glance

SafetyNET p

Safety right from the start

With SafetyNET p, the transfer of

safety-related data and standard

control information across a

system is physically mixed but

logically separate, and therefore

free from feedback. The safety

protocol is considered within

the system right from the start

and not just added later: The

protocol structure guarantees

stable network communication;

telegrams containing safetyrelated information, such as

a person entering a plant’s

danger zone, arrive safely at

the intended recipient.

Your benefi ts at a glance

• Open, individually adapt-

able network solution for all

automation functions

• Safety right from the start

• Based on the

Ethernet standard

• Real-time communication

for highly dynamic applications

• Flexible topology design

• Dynamic structures when

swapping subscribers

• Short scan times of

up to 62.5 μs

• High performance through

cross-communication

• Open connection to existing

system architectures

High performance through

cross-communication

All network components

have equal rights and can

both use and provide utilities.

Cross-communication enables

the decentralised processing of

data between two subscribers,

without calling on a central

instance (producer/consumer

model). This saves time and

increases the network performance.

Keep up-to-date

on SafetyNET p:

Webcode 2541

Online information

at www.pilz.com

Rapid reaction to

time-critical events

When used with distributed

real-time applications, information processing is synchronous

in accordance with IEE 1588.

A guaranteed system reaction

occurs at a precisely defi nable

time. With SafetyNET p networking, each device has a real-time

clock with interrupt function

to enable a rapid reaction to

time-critical events.

13

Page 16

System features

SafetyBUS p

SafetyBUS p® – Safe communication

In the fast lane

with SafetyBUS p

SafetyBUS p is used for the

safe, fast transfer of time-critical

information on decentralised

control structures. In a range

of industries, such as the automotive or packaging industry,

for example.

The bus system is based on the

CAN fi eldbus that is widely used

worldwide and has an additional

safety protocol that has been

approved by TÜV and BG. So

SafetyBUS p meets the increased

requirements of a safety bus in

terms of reaction times, safety

and absence of feedback during

signal transfer.

Parallel structure of

safety bus and fi eldbus

A plant’s standard automation

process must not be able to

infl uence the safety functions

in the case of an emergency.

This guarantees safe communication with SafetyBUS p, without

feedback.

Design guidelines issued by manufacturers and users often call for

a strict separation of safety and

standard control technology –

particularly on hazardous process

and manufacturing cycles.

Separation guarantees transparency and the allocation of

responsibility is clearly defi ned.

14

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

0

Usb 5V5VFS0 FS0

x10

369

SB ADDRESS

0

x1

369

PSSu H

SB DP

SafetyBUS p

USB

Err

Err Err Err

Err Err

Dev 24V 24V

I/O FS3SB

Run 21 SW 21 21 21

11

11142111

BF 24 24 24

14

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

4DI

BSW

4DO 0.5

2DO 2

11

11

11

11

11

21

21

21

21

12

12

12

12

12

22

22

22

22

13

13

13

13

13

23

23

23

23

14

14

14

14

14

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

11

11

11142111

BF 24 24 24

14

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

SB DP

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

0

x10

369

SB ADDRESS

0

x1

369

SafetyBUS p

USB

0

x10

369

SB ADDRESS

0

x1

369

SafetyBUS p

USB

Err

Err Err Err

Dev 24V 24V

Usb 5V5VFS0 FS0

I/O FS3SB

Run 21 SW 21 21 21

11

11142111

BF 24 24 24

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

SB DP

4DI

BSW

4DO 0.5

11

11

11

11

21

21

21

12

12

12

12

22

22

22

13

13

13

13

23

23

23

14

14

14

14

24

24

24

Err

Err Err Err

Dev 24V 24V

Usb 5V5VFS0 FS0

I/O FS3SB

Run 21 SW 21 21 21

11

11142111

BF 24 24 24

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

SB DP

4DI

BSW

4DO 0.5

11

11

11

11

21

21

21

12

12

12

12

22

22

22

13

13

13

13

23

23

23

14

14

14

14

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

Err11Err

Err Err

24V

FS1 FS1

FS2

11

14

PSSu E S

PSSu E F

PSSu E F

PSSu E F

2DO 2

PS1

4DO 0.5

2DO 2

11

11

11

11

11

21

21

21

21

21

21

12

12

12

12

12

22

22

22

22

22

22

13

13

13

13

13

23

23

23

23

23

23

14

14

14

14

14

24

24

24

24

24

24

Err11Err

Err Err

24V

FS1 FS1

FS2

11

14

PSSu E S

PSSu E F

PSSu E F

PSSu E F

2DO 2

PS1

4DO 0.5

2DO 2

11

11

11

11

11

21

21

21

21

21

21

12

12

12

12

12

22

22

22

22

22

22

13

13

13

13

13

23

23

23

23

23

23

14

14

14

14

14

24

24

24

24

24

24

8

4

2

ADDRESS

1

PROFIBUS DP

OFF ON

--

64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

369

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

BF 24 24 24

PSSu H

SB DP

SafetyBUS p

USB

0

Dev 24V 24V

Usb 5V5VFS0 FS0

x10

I/O FS3SB

369

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

BF 24 24 24

PSSu H

SB DP

SafetyBUS p

USB

11

11

11142111

14

14

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

24

Err

Err Err Err

Err11Err

Err Err

24V

FS1 FS1

FS2

11

11

11142111

14

14

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

11

11

11142111

BF 24 24 24

14

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

SB DP

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

11

11

11142111

BF 24 24 24

14

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

SB DP

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

11

11

11142111

BF 24 24 24

14

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

SB DP

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

Err11Err

24V

FS1 FS1

FS2

11

14

PSSu E F

PSSu E F

PSSu E F

PS1

4DO 0.5

2DO 2

11

11

11

11

21

21

21

21

21

12

12

12

12

22

22

22

22

22

13

13

13

13

23

23

23

23

23

14

14

14

14

24

24

24

24

24

OFF ON

Err

Err Err Err

Err11Err

Err Err

-0

Dev 24V 24V

24V

FS1 FS1

Usb 5V5VFS0 FS0

64

x10

32

I/O FS3SB

FS2

16

369

8

4

2

ADDRESS

1

SB ADDRESS

0

x1

369

Run 21 SW 21 21 21

11

11

11142111

BF 24 24 24

14

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

SB DP

4DI

BSW

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

SafetyBUS p

PROFIBUS DP

11

11

11

11

11

11

11

11

11

21

21

21

21

21

21

21

21

21

12

12

12

12

12

12

12

12

12

22

22

22

22

22

22

22

22

22

13

13

13

13

13

13

13

13

13

23

23

23

23

23

23

23

23

23

USB

14

14

14

14

14

14

14

14

14

24

24

24

24

24

24

24

24

24

PROFIBUS DP

OFF ON

-64

32

16

8

4

2

ADDRESS

1

PROFIBUS DP

SafetyBUS p

USB

0

x10

369

SB ADDRESS

0

x1

369

SafetyBUS p

USB

11

11

11

21

21

21

12

12

12

22

22

22

13

13

13

23

23

23

14

14

14

24

24

24

Err

Err Err Err

Dev 24V 24V

Usb 5V5VFS0 FS0

I/O FS3SB

Run 21 SW 21 21 21

11

BF 24 24 24

14

PSSu H

PSSu E FPSPSSu E S

PSSu E F

SB DP

4DI

BSW

11

11

11

21

21

21

12

12

12

22

22

22

13

13

13

23

23

23

14

14

14

24

24

24

2DO 2

11

11

11

11

11

11

21

21

21

21

21

21

12

12

12

12

12

12

22

22

22

22

22

22

13

13

13

13

13

13

23

23

23

23

23

23

14

14

14

14

14

14

24

24

24

24

24

24

Err11Err

Err Err

24V

FS1 FS1

FS2

11

11142111

14

PSSu E S

PSSu E S

PSSu E F

PSSu E F

PSSu E F

4DO 0.5

2DO 2

PS1

4DO 0.5

2DO 2

11

11

11

11

11

11

21

21

21

21

21

21

12

12

12

12

12

12

22

22

22

22

22

22

13

13

13

13

13

13

23

23

23

23

23

23

14

14

14

14

14

14

24

24

24

24

24

24

Page 17

Benefi ts at a glance

SafetyBUS p

Burner

not in operation

Burner in operation

Few downtimes thanks

to safe selective shutdown

Each SafetyBUS p subscriber

can be assigned to a group.

Within an application, plant

sections that belong together

logically can be confi gured

as groups and switched off

separately in the case of an error.

Modular

safety and

control system

PSS 3100

The rest of the production cycle

continues unhindered – enabling

productive work practices.

Generic functions, such as an

E-STOP of the entire plant,

are assigned to all groups.

With up to 32 groups within a

SafetyBUS p network, it is

possible to build up complex

structures.

Your benefi ts at a glance

• Decentralised, safe

networking of sensors

and actuators

• The safety technology

does not have to be hardwired, as the signal is transferred via the bus cable

• Meets the highest

safety requirements

in accordance with

international standards

• Rapid reaction times

to hazardous events

thanks to event-driven

communication

• Extremely short error

reaction times of 25 ms

and shorter

• Few downtimes thanks to

integrated diagnostics

• Large network extension

up to 4,032 inputs and

outputs

Keep up-to-date

on SafetyBUS p:

Webcode 2469

Online information

at www.pilz.com

Fast reaction times thanks to

event-driven communication

SafetyBUS p operation is

event-driven. This means that

messages are only sent when the

status changes at the centralised/

decentralised inputs/outputs or

at the bus subscribers. For this

reason, SafetyBUS p is especially

suitable for networking plants

with different signalling rates and

high reaction time requirements.

Short reaction times have the

additional advantage that

protective measures (e.g. safety

gates or light grids) can be

positioned close to the danger

zone – saving space and costs.

If a hazardous event occurs, the

PSS programmable safety and control

systems will react particularly quickly.

t = min

15

Page 18

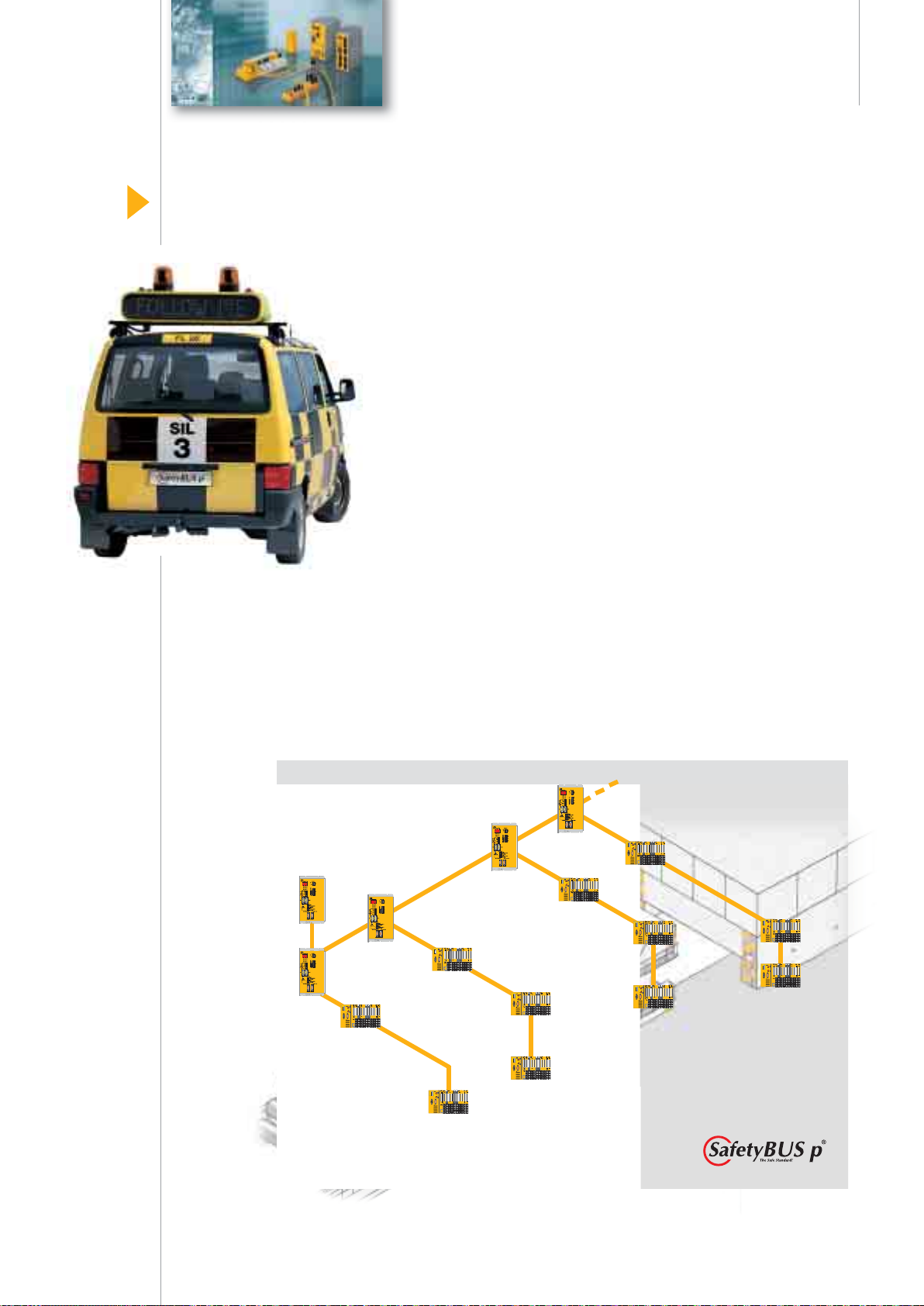

Applications and industries

SafetyBUS p

SafetyBUS p® – proven across industry

Visible success

The safe bus system

SafetyBUS p is used for the safe,

fast transfer of time-critical information on decentralised control

structures. It is used across a

range of industries in conjunction

with PSS programmable safety

and control systems: Automotive industry –

Monitoring production processes

in the press shop, body plant,

transmission, fi nal assembly

and paint shop

Cablecar technology –

Moni toring the entire route,

from entry to exit, distance

between the cars and recognition

of rope layers

Process technology –

Safe monitoring and control

of furnaces, monitoring valves,

fi ll levels and fuel/air ratios

Steel and aluminium

processing – Safe monitoring

during maintenance and restart

Conveyor technology –

Safe track and load monitoring,

collision detection on crane and

harbour applications, container

loading and lifting platforms

Packaging industry – Safe

monitoring of fi lling, picking and

packaging processes

Airport automation – Flexible

control and safe monitoring of

fi lling stations, combined heat

and power stations, rolling

hangar doors, baggage handling

systems and transport systems

Presses – Economical application

on stand-alone presses or on

press lines

16

Page 19

Safety Network

International e. V.

Safety Network International e. V.

The open forum for

safety and automation

Safety Network International e. V.

is an independent organisation

which, as well as promoting the

proven SafetyBUS p system, also

supports the Ethernet-based

system SafetyNET p.

Members include users, integrators and manufacturers of both

systems. The organisation was

founded in 1999 and now has

75 member companies.

The work carried out by

Safety Network International

e. V. guarantees users and

participating manufacturers that

the SafetyNET p system will

remain open and future-proof.

Tasks and projects:

• Investment protection for users

and manufacturers through

continual development and

support of SafetyBUS p and

SafetyNET p technology

• Sales promotion through

active press relations and

exhibition attendance

• Development of profi les

and specifi cations to simplify

handling of SafetyBUS p

and SafetyNET p

• Quality assurance through

the establishment of test

laboratories, device certifi cation,

monitoring of interoperability

and conformity

• Lobbying within standards

committees and associations

on behalf of the member

companies of Safety Network

International e. V.

• Assure worldwide propagation

by infl uencing international

standardisation

Machinery safety forum

With the machine safety forum,

Safety Network International e. V.

has created an important medium

for providing quick, effective

communication regarding

changes within the standards

fi eld and new regulations.

Safety Network Academy

Safety Network International e. V.

promotes the Safety Network

Academy in conjunction with

its member organisations.

The network's aim is to encourage knowledge transfer among

the participating institutions

and organisations.

Safety Network integration

As the umbrella organisation for

SafetyBUS p and SafetyNET p,

Safety Network International e. V.

hosts events to present automation suppliers with options for

implementing these technologies

in their own devices and components.

Find out more about Safety

Network International e. V.:

www.safety-network.org

17

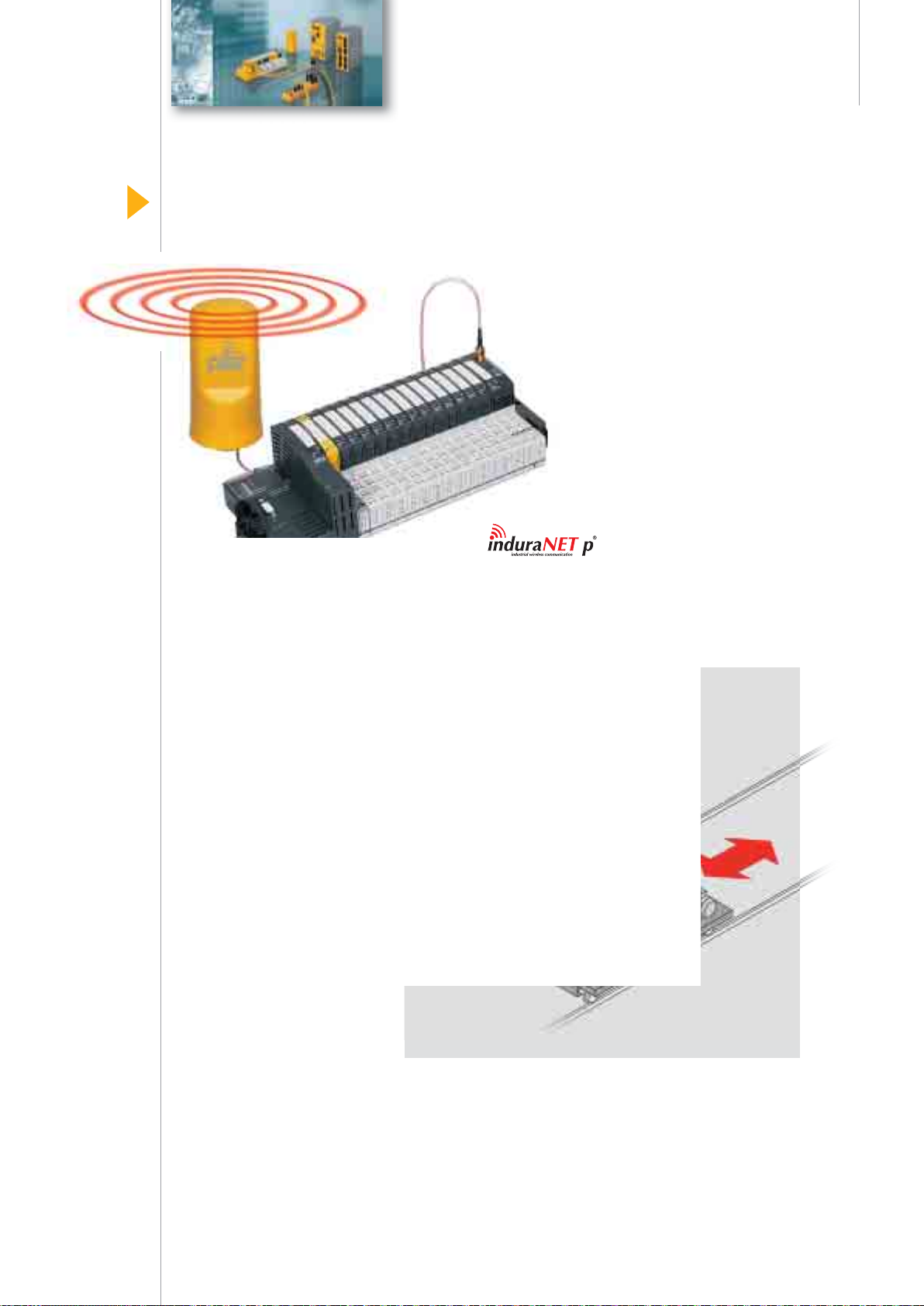

Page 20

System features

InduraNET p

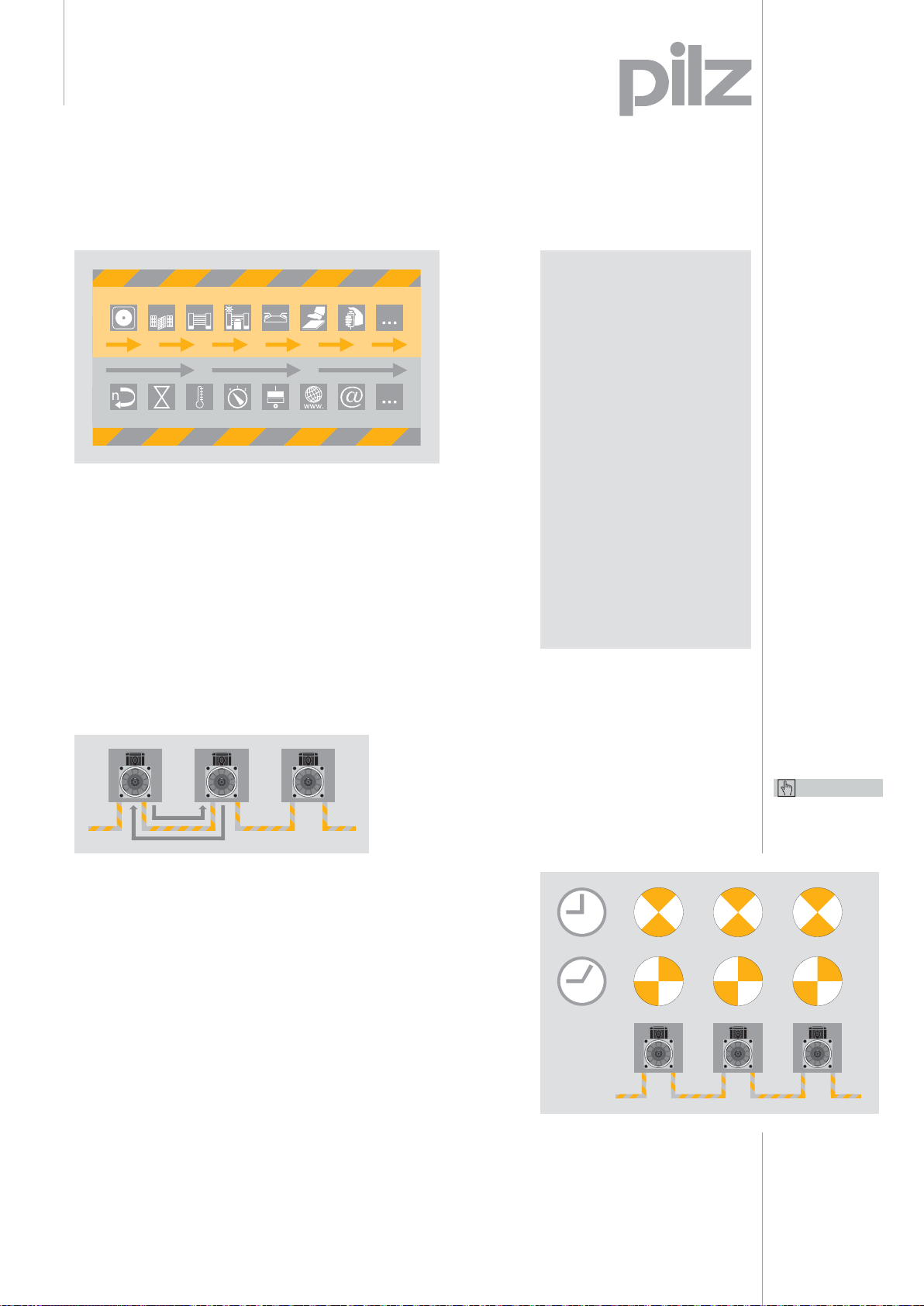

InduraNET p® – Reliable wireless technolo

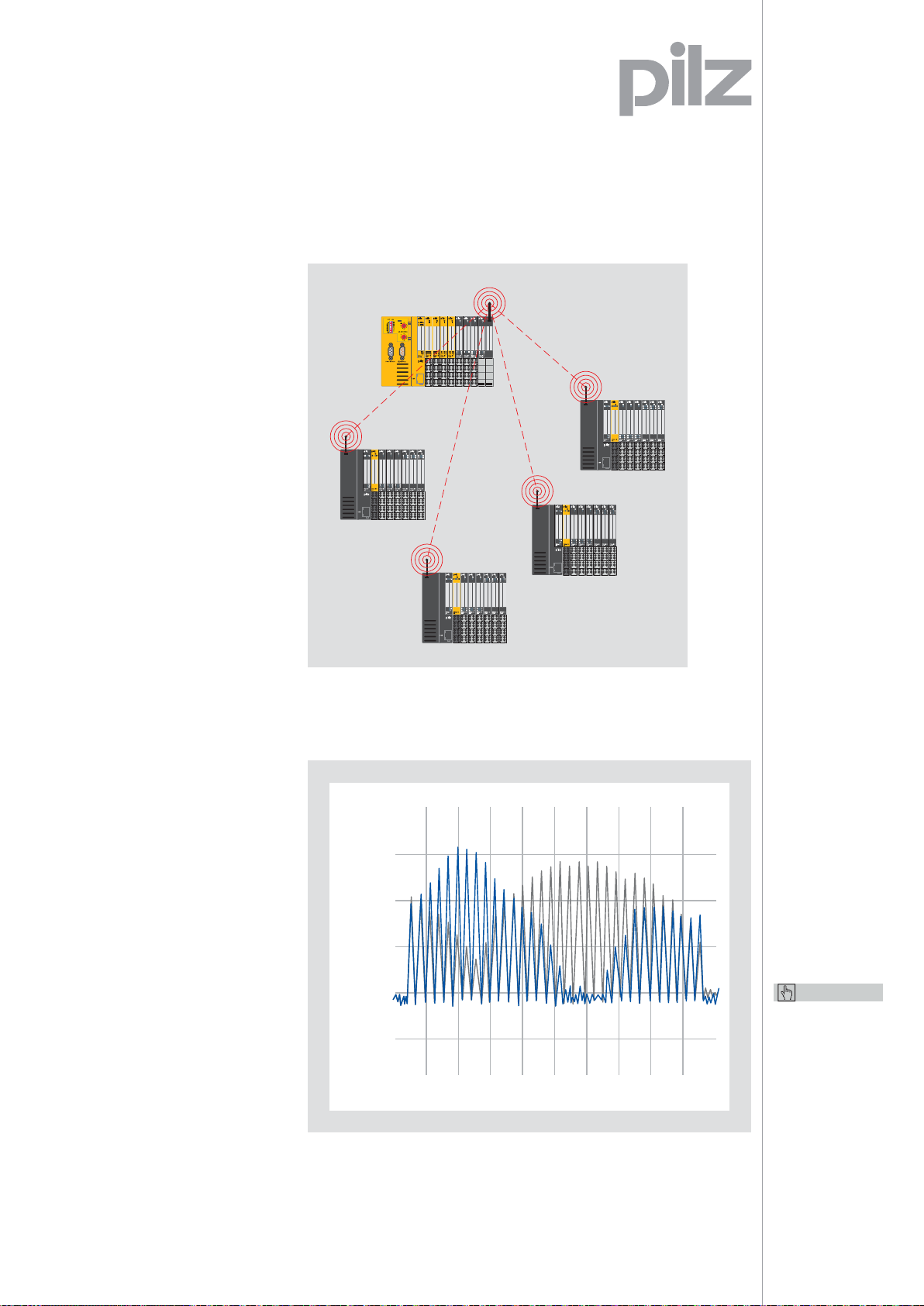

A different way of broadcasting

The wireless system InduraNET p

(Industrial Radio Network) is

specifi cally designed for use in

an industrial environment.

Anywhere that a cable-based

solution is diffi cult if not impossible to install, InduraNET p

can help. Key features include a

particularly robust communication technology, high availability

due to a new type of antenna

system and a high coexistence

capability with other wireless

services.

Wireless compensates

for the disadvantages

of contact-based solutions

Mobile devices frequently use

trailing cable and drag chains,

rotary transformers and slip ring

transmitters, as well as data

light beam devices and cables.

These moving parts are subject

to wear, maintenance intensive

and complex to install. With its

special technology, the wireless

InduraNET p system compensates for the weaknesses of

contact-based solutions.

Wireless signal transfer via InduraNET p

in plants with moving parts.

18

Page 21

gy for industry

System solution

with PSSuniversal

InduraNET p is integrated within

the decentralised I/O system

PSSuniversal. A module is incorporated into the base station in

order to be able to use the wireless

technology. All remote stations

follow the slot addressing of the

base station, without occupying

a slot themselves. The head

module on the base station

“sees” all the remote components as a series of electrical

modules. Up to four remote

stations that are used in parallel

can be connected to each

base station.

The wireless

modules, antennas

etc. for the

decentralised

I/O system can

be found on

page 52/53.

High availability thanks

to a special antenna system

Antennas are required to enable

the PSSuniversal head modules

to process wireless information.

Both a single and a dual antenna

are available for InduraNET p.

The dual antenna contains

multiple subantennas, from which

the best receiver at any given

time can be used. This compensates for any interference in the

wireless zone. The dual antenna

is mainly used where communication conditions are poor.

Decentralised signal transfer via InduraNET p –

Centralised view of a decentralised structure.

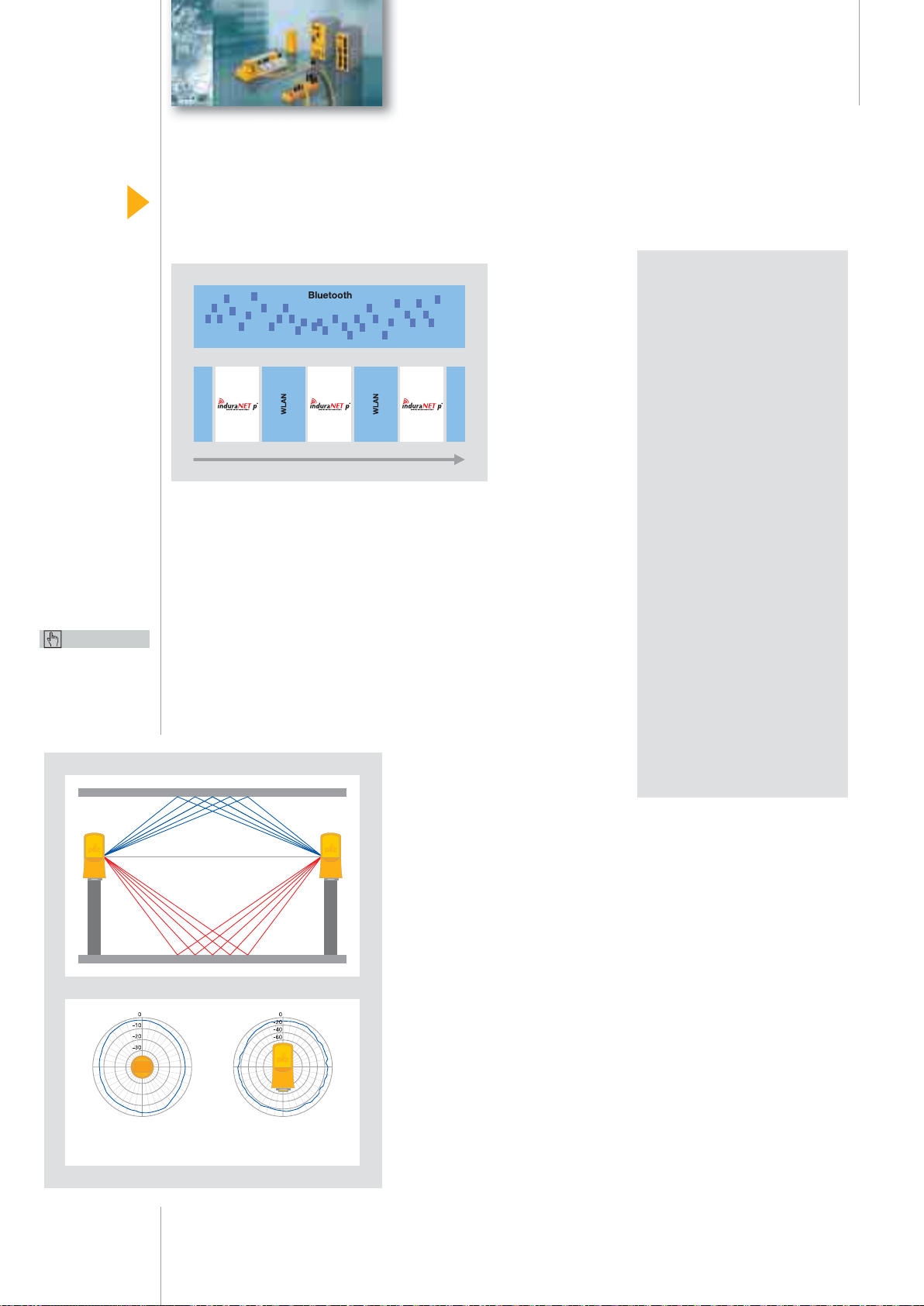

-65 dBm

-70 dBm

-75 dBm

-80 dBm

-85 dBm

CF 2.439 GHz Span 70.0 MHz

Keep up-to-date

on InduraNET p:

Webcode 2605

Online information

at www.pilz.com

Consistently high reception quality: If one subantenna is barely able

to receive a usable signal, the other antenna will have a good signal.

19

Page 22

Benefi ts at a glance

InduraNET p

InduraNET p® – Innovative wireless system

Keep up-to-date

on InduraNET p:

Webcode 2605

Online information

at www.pilz.com

Coexistence with

other wireless services

Unlike Bluetooth wireless systems, for example, InduraNET p

does not infl uence any other

industrial wireless systems

thanks to its intelligent frequency

management (CFM). In addition

to the protocol mechanism, the

Coexistence

with other

wireless services.

access mechanism “Listen before

talk” guarantees that the radio

channel is available and is not

in use by any other wireless services. At the same time, the WLAN

channels that are identifi ed as

busy are permanently “marked”

and hidden. This means that

collisions or mutual interference

with WLAN are excluded.

Your benefi ts at a glance

• Easy accessibility within

the zone, which would not

be achievable with such

fl exibility using a cable

connection

• Particularly robust

communication technology

• Constant high quality

wireless connection

thanks to the innovative

antenna system

• Coexists with other

wireless services thanks

to intelligent frequency

management

• Easy to expand the

existing infrastructure,

so the work involved in

project confi guration and

installation is reduced

• Licence-free, uses

the free worldwide

ISM frequency bands

• Cost savings, as there is

less planning, installation

and maintenance work

Ceiling

Floor

Receive diagram

horizontal

polarised

horizontally or vertically

circular

horizontal

polarised

Receive diagram

vertical

Environment infl uences

wireless quality

Walls, suspended ceilings,

shelves, door and window frames

and insulating glass panels

can all produce attenuation or

refl ection that would affect

wireless communication in the

2.4 GHz ISM band. To achieve

a wide operating range and con-

Appropriate antenna

technology compensates for

multipath fading and refl ection.

stant availability, it's important to

establish the optimum installation

site for the antenna. Analysis

methods and tools available with

InduraNET p enable the signal’s

fi eld strength to be assessed

quite easily. The high reception

dynamic of InduraNET p also

compensates for physical

properties such as refl ections,

which may lead to errors.

20

Page 23

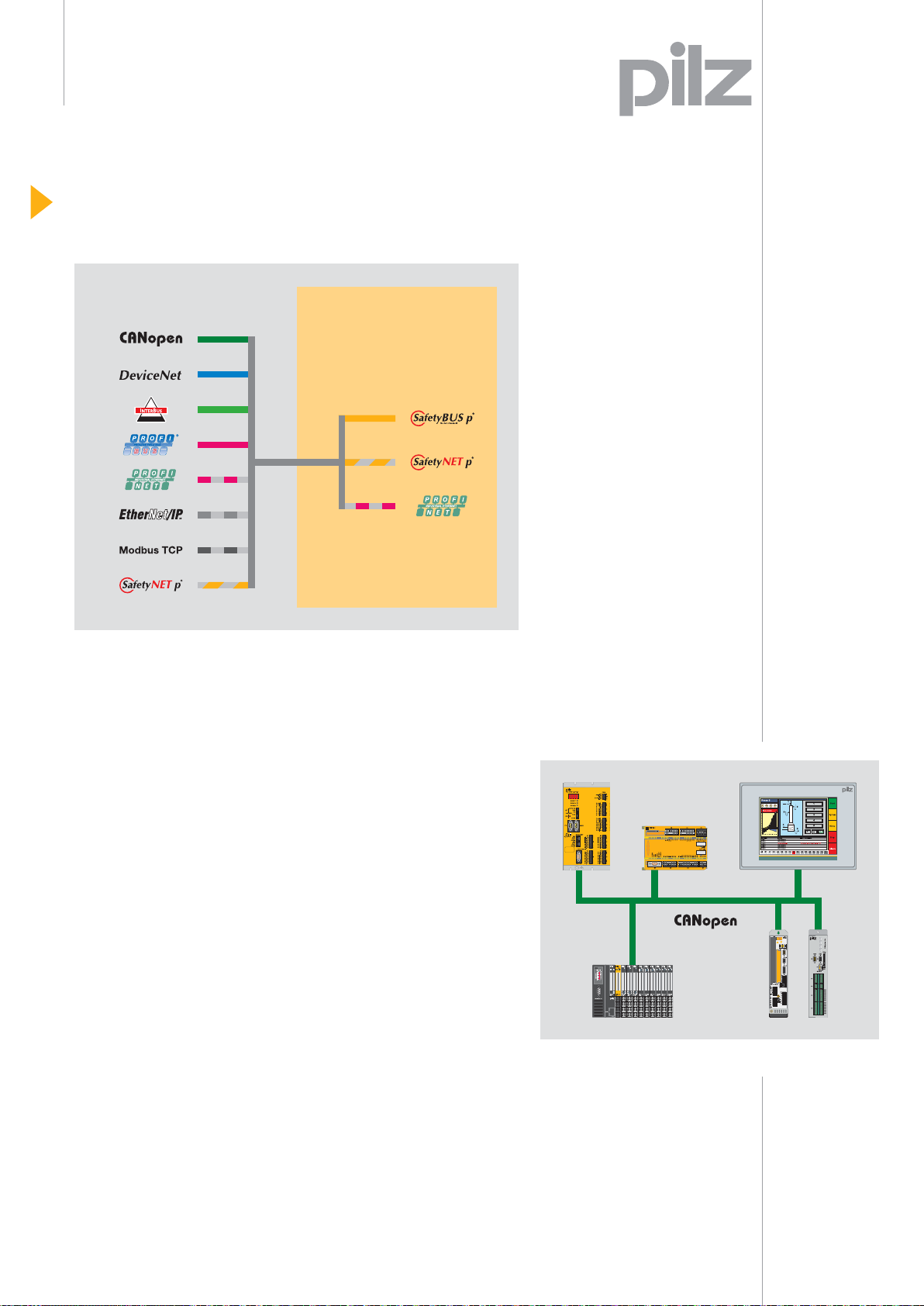

General

communication networks

Networks – Open, safe, economical

Networks – Reliable

Standard Failsafe

data transfer medium

The openness and fl exibility of

individual bus systems and their

various topologies enable you to

incorporate systems and their

add-ons. The use of standardised

bus systems means that standardcompliant components made by

a variety of manufacturers may

easily be connected. You can

quickly and easily integrate

PSS programmable safety and

control systems into existing

architectures or adapt them

to suit changed system requirements. That way you maintain

your independence in your

choice of control concept.

Ethernet interface ETH-2 –

Remote diagnostics

Lengthy travel times are now a

thing of the past. When servicing

is required, diagnostic data can

be accessed simply and quickly

from a remote location via the

ETH-2 Ethernet interface on

the PSS programmable safety

and control systems PSS

(PSS 3047-3 ETH-2,

PSS SB 3047-3 ETH-2 and

PSS SB 3075-3 ETH-2).

Complete networks can be

built up thanks to its master

functionality.

The complete solution for

your automation function

with CANopen

Combined with PSS

programmable safety and control

systems and other products with

CANopen interfaces, you now

have total fl exibility in your applications. Pilz offers a co-ordinated

solution comprising control

system, actuator technology

and visualisation.

Complete solution from Pilz with CANopen.

21

Page 24

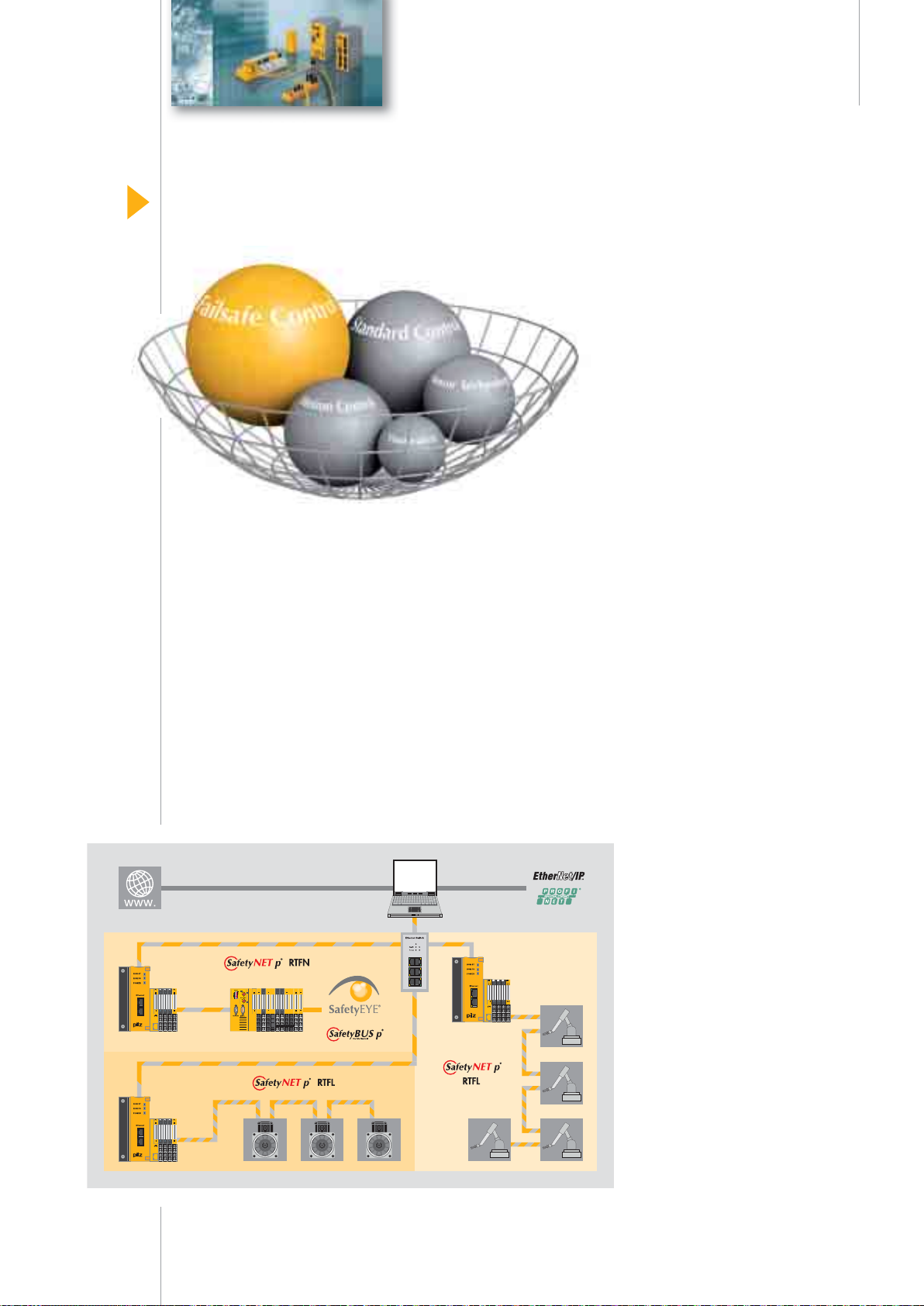

Intelligent, future-proof control

Cost effectiveness

O

C

Safety

Control

A

U

T

O

PNOZmulti

Product group

PSS programmable safety and control systems

P

L

M

E

T

E

N

O

I

T

M

A

PSSmodular

systems

PSScompact

systems

PSS SB 3006-3 ETH-2

ST

F-STACK

FS

PG USER

R (USER)

PSS PWR

24 V

0 V

RUN ST

RUN FS

0 V

T 0

POWER

T 1

I0.0

AUTO PG

I0.1

SPS

I0.2

PG

I0.3

I0.4

RUN

I0.5

STOP

ETHERNET

LINK

10/100 BASE T

ON OFF

TRAFFIC

T

LINK

10/100 BASE T

TRAFFIC

SafetyBUS p

1

X0

3

1

X1

9

STATUS SB

Decentralised

periphery

PNOZelog

PNOZsigma

1 4 14 47 75 96 160 1 028 2 056 8 064

Complexity/number of safety functions

The appropriate solution – meeting your exact requirements: For simple plants with up to four safety functions,

safety relays PNOZ X, PNOZsigma or PNOZelog; for four safety functions and above, the PNOZmulti safety system;

for complex plant and machinery, PSS programmable safety and control systems.

Keep up-to-date on

PNOZ safety relays:

Webcode 0199

Online information

at www.pilz.com

The appropriate solution

for every requirement

With the extensive control

portfolio from Pilz you can cover

a wide range of applications.

PSS programmable safety and

control systems are the ideal

solution for safety-related and

standard control functions:

• For complex stand-alone

machines with high safety

requirements, such as presses

• For interlinked plants with

decentralised networking,

such as packaging machines

• For complete plant lines with

decentralised networking,

such as transfer lines

Intelligent, future-proof

investment

The complete solution from Pilz

is perfectly compatible. The

programmable safety and control

systems are subject to continuous

development, based on many

years of experience and in

constant consultation with

customers, guaranteeing longterm investment protection. Thus

they meet both current and future

requirements for safe, economical

automation solutions. In addition

to the PSS product group, the

Pilz portfolio also includes the

PNOZ product group, which

also stands for safe control.

22

Page 25

Standards for safety

Compliance with

international safety standards

Pilz’s thorough expertise in

safety technology pays off.

PSS programmable safety and

control systems meet the highest

safety requirements and therefore

comply with international standards for machine safety:

• EN 954-1 up to Category 4

• EN IEC 61508 up to SIL3

• EN IEC 62061 up to SIL3

• EN ISO 13849 up to PL e

• EN 60204-1

• NFPA 79

Represented in

various industries

The programmable safety

and control systems are easy to

use in the most wide-ranging

applications and industries.

They comply with various

application-specifi c standards.

Presses

EN 692,

EN 693,

EN 12622

Traffi c systems

EN 50126,

EN 50128,

EN 50129

each to SIL3,

EN 50159-1,

EN 50159-2

Cablecar

technology

EN 13243 AK4

PSS programmable safety and

control systems

are approved by

BG, TÜV and

UL/cUL.

Burner

management,

process technology

EN 289

Keep up-to-date

on laws and

standards:

Webcode 0240

Online information

at www.pilz.com

23

Page 26

O

C

Safety

Control

A

U

T

O

Product range

PSSmodular systems

PSSmodular systems

P

L

M

E

T

E

N

O

I

T

M

A

PSS 3000/PSS 3100

PSS 3000/PSS 3100

PSS 3000

and PSS 3100 –

Make your control

solution fl exible

and individual.

PSS 3000/PSS 3100

Two series covering

safety and control:

PSS 3000 and PSS 3100

The modular safety and control

systems PSS 3000 and PSS 3100

monitor safety-related functions

and perform standard control

functions at the same time:

Number of inputs/outputs

• Centrally – on complex,

independent stand-alone

machines, or

• Decentrally – on interlinked

plants extending over a

wide area

Communication interfaces to

fi eldbus systems, to the safe,

open bus system SafetyBUS p

and to Ethernet, enable the units

to be integrated quickly into the

plant’s full control sequence.

24

Page 27

Benefi ts at a glance

PSSmodular systems

When do I use which system?

The PSS 3000 modular system

is suitable for rugged application

conditions, e.g. for press controllers, fairground rides or in cablecars. All components feature

a sturdy aluminium housing

and can withstand increased

mechanical loads. In applications

requiring a large number of

standard inputs and outputs,

additional standard I/O modules

can be added to the PSS 3000

via 2 expansion module racks.

On the PSS 3100, the modules

are not enclosed in a housing

and the printed circuit boards

are visible, so they are suitable

for production environments with

low mechanical stress.

Modular hardware structure

Just assemble the hardware

components to match your own

individual project requirements:

• Module rack – with optional

integral power supply

• Central processing unit CPU –

with optional SafetyBUS p

connection

• Digital and analogue input/

output modules – for safetyrelated control functions

• Digital and analogue input/

output modules – for standard

control functions

• Communication modules

for all common fi eldbuses

and Ethernet

Your benefi ts at a glance

• One control system

for safety-related and

standard control functions

• Flexible and adaptable

thanks to the modular

hardware structure

• Highest performance

thanks to fast program

processing

• Wide range of application

areas thanks to digital and

analogue processing

• Open connection to

standard fi eldbuses,

Ethernet and SafetyBUS p

• Modules are simple and

quick to install

For decentralised

input/output,

use one system

for safety and

standard:

PSSuniversal –

Read more

from page 40.

Safety and control –

One system for all control

functions, e.g. on cablecars,

fairground rides, presses,

and many more

Keep up-to-date

on PSSmodular

systems:

Webcode 0911

Online information

at www.pilz.com

25

Page 28

Selection guide

PSSmodular systems

Selection guide – PSSmodular systems

Central processing units – PSSmodular controller

PSS 3000 series

Type

Order number

PSS CPU3 ............................................ 301 064 -

PSS SB CPU3 ...................................... 301 071 -

PSS SB CPU3 ETH-2 .......................... 301 081 -

- PSS1 CPU3 .......................................... 302 064

- PSS1 SB CPU3 .................................... 302 071

PSS1 SB CPU3

- PSS1 SB CPU3 ETH-2 ......................... 302 081

Module racks – PSSmodular controller

PSS 3000 series

Type

Order number

PSS BM 4 ............................................. 301 001 -

PSS BMP 4/2 ....................................... 301 006 -

PSS BM 8 ............................................. 301 000 -

PSS BMP 8 .......................................... 301 005 -

PSS 3100 series

Type

Order number

PSS 3100 series

Type

Order number

PSS1 BMPS 3/3

- PSS1 BMPS 3/3 ................................... 302 008

- PSS1 BMP 5/2 ..................................... 302 006

Power supplies – PSSmodular controller

PSS 3000 series

Type

Order number

PSS PS ................................................. 301 050 -

PSS PS 24 ............................................ 301 051 -

- PSS1 PS 24 .......................................... 302 051

PSS1 PS 24

PSS 3100 series

Type

Order number

26

Page 29

Features Communication

SafetyBUS p

• Data memory: Failsafe section: 64 KByte, standard section: 170 KByte

• Program memory:

Failsafe section: Integral 512 KByte Flash-EPROM memory,

Standard section: Integral 512 KByte Flash-EPROM memory

• Dimensions (H x W x D): 257 x 41 x 220 mm (PSS 3000), 265 x 41 x 218 mm (PSS 3100)

• Application range: Failsafe applications to EN 954-1, EN IEC 61508

• Interfaces:

Combined RS 232/RS 485 interface for programming device,

Combined RS 232/RS 485 interface as user interface

-

1

1

-

1

1

Electrical data

Free slots Size

(H x W x D)

Supply voltage

Number Use

- 4 For failsafe modules 277.5 x 280 x 244 mm

- 4 For failsafe modules,

277.5 x 280 x 244 mm

2 can be used for standard modules

- 9 For failsafe modules 277.5 x 482.6 x 244 mm

- 9 For failsafe and standard modules,

277.5 x 482.6 x 244 mm

plug in anywhere

24 VDC 3 For failsafe and standard modules,

266 x 259.4 x 245 mm

plug in anywhere, integral power supply

- 5 For failsafe modules,

2 can be used for standard modules

Electrical data

Supply voltage

Power consumption Continuous current

115/230 VAC, selectable 80 W 10 A

24 VDC 80 W 10 A

24 VDC 50 W 5 A

266 x 340.6 x 241 mm

Technical

documentation

on PSSmodular

systems:

Webcode 0685

Online information

at www.pilz.com

27

Page 30

Selection guide

PSSmodular systems

Selection guide – PSSmodular systems

Input/output modules for functional safety – PSSmodular I/O

PSS DI2O T

PSS1 DOR

PSS 3000 series

Type

Order number

PSS AI ....................301 121 PSS1 AI ..................302 121 - 6

PSS AI Ip ................301 123 PSS1 AI Ip ..............302 123 - -

PSS DI 2 .................301 101 PSS1 DI 2 ............... 302 101 32 -

PSS DIF ..................301 105 PSS1 DIF ................302 105 16 -

PSS DIF 2 ...............301 106 PSS1 DIF 2 .............302 106 16 -

PSS DI2O T ............301 112 PSS1 DI2O T .......... 302 112 16 -

PSS DI2O Z ............301 109 PSS DI2O Z ............302 109 16 -

PSS DOS ................301 111 PSS1 DOS ..............302 111 - -

PSS DOR ...............301 122 PSS1 DOR .............302 122 - -

PSS 3100 series

Type

Order number

Inputs

Digital

Common features:

• Application range: Failsafe applications to EN 954-1, EN IEC 61508

Inputs

Analogue

-10 V … +10 V

28

Input/output modules for standard applications – PSSmodular I/O

PSS 3000 series

Type

Order number

P10 AIO ..................304 120 P9 AIO ....................303 120 - 6

P10 DI ....................304 100 P9 DI ......................303 100 32 -

P10 DIO ..................304 107 - 16 -

- P9 DIO .................... 303 108 16 -

P10 DO ...................304 110 - - -

PSS DIO

- P9 DO .....................303 111 - -

P10 DOR 16 ...........304 122 P9 DOR 16 .............303 122 - -

PSS 3100 series

Type

Order number

Common features:

• Application range: Non-safety-related standard applications

Inputs

Digital

Inputs

Analogue

-10 V … +10 V

0 … 20 mA

Page 31

Outputs Features

4 … 20 mA Single-pole Dual-pole Relay

- - - - Analogue voltage inputs

6 - - - Analogue current inputs

1)

1)

- - - - Digital inputs to EN 954-1

up to Cat. 4 with test pulses

- - - - Digital inputs for alarms,

input delay 0.5 ms

- - - - Digital inputs for alarms,

input delay 3 ms

- 16 - - Digital inputs to EN 954-1 up to Cat. 4 with test pulses;

digital 2 A outputs, can also be used as test pulses

- - 8 - Digital inputs, dual-pole outputs (2 A)

- 32 - - Digital 1.5 A outputs

- - - 12 Relay outputs with positive-guided contacts

AC1: max. 250 V/0.1 … 4 A/1 000 VA

DC1: max. 250 V/0.4 A/100 W, 24 V/4 A/100 W

Outputs Features

Digital Analogue

-10 V … +10 V

Semi-

Relay 0 … 20 mA

conductor

- - 2 Analogue current/voltage inputs and outputs

- - - Digital inputs

16 - - Digital inputs, digital 2 A outputs

16 - - Digital inputs, digital 0.5 A outputs

32 - - Digital 2 A outputs

32 - - Digital 0.5 A outputs

Technical

documentation

on PSSmodular

systems:

Webcode 0685

Online information

at www.pilz.com

- 16 - Relay outputs

AC: max. 250 V/2 A/500 VA

DC: max. 100 V/0.5 A/50 W

1)

not for input/output modules for standard applications

29

Page 32

Selection guide

PSSmodular systems

Selection guide – PSSmodular systems

Communication modules for fi eldbus systems and Ethernet – PSSmodular COM

PSS ETH-2

PSS1 DN-S

PSS 3000 series

Type

Order number

PSS Ethernet ....................................... 301 157 PSS1 Ethernet ..................................... 302 157

PSS ETH-2 ........................................... 301 160 PSS1 ETH-2 ......................................... 302 160

PSS DP-S ............................................. 301 151 PSS1 DP-S ........................................... 302 151

PSS DN-S ............................................ 301 152 PSS1 DN-S .......................................... 302 152

PSS IBS-S PCP ................................... 301 154 PSS1 IBS-S PCP ................................. 302 154

PSS ControlNet Adapter .................... 301 156 PSS1 ControlNet-Adapter .................. 302 156

PSS CANopen ..................................... 301 155 PSS1 CANopen ................................... 302 155

PSS 3100 series

Type

Order number

PSS1 SER

PSS SER .............................................. 301 159 PSS1 SER ............................................ 302 159

30

Page 33

Function Features

Ethernet

Ethernet • Ethernet interfaces: Twisted Pair (RJ45)/AUI (IEEE 802.3)

Ethernet • Ethernet interfaces: Twisted Pair (RJ45)/4 Ports

PROFIBUS-DP • Device type: Slave

DeviceNet • Device type: Slave

Interbus • Device type: Slave with PCP channel

ControlNet • Device type: Adapter

CANopen • Device type: Slave

Serial interface • COM1/COM2: RS 232/RS 485 (combined)

• IP address: Selectable via confi guration software or DHCP

• Transmission rate: 10 MBit/s

• IP address: Selectable via confi guration software or DHCP

• Transmission rate: 10/100 MBit/s

• Transmission rate: 9.6/19.2/93.75/187.5/500 kBit/s, 1.5/3/6/12 MBit/s

• Data length: max. 488 Bytes

• Transmission rate: 125/250/500 kBit/s, selectable via rotary switch

• Data length: 0 ... 32 words, selectable

• Transmission rate: 500 kBit/s or 2 MBit/s, selectable

• Data length: 0 … 32 words, selectable (incl. PCP)

• PCP channel: 0, 1, 2 or 4 words, selectable

• ControlNet interface in accordance with ControlNet International

• Transmission rate: 5 MBit/s

• Data length: scheduled messages 0 … 128 words, unscheduled messages 32 words

• CANopen interface in accordance with CiA DS 301 V3.0 and CiA DS 102 V2.0

• Transmission rate: 6/10/12.5/20/33/50/66/100/125/333/500/666/1 000 kBit/s

• Data length: max. 512 Words

• Transmission rate: 150/300/600/1 200/2 400/4 800/9 600/19 200/38 400/57 600/76 800/115 200 Bit/s

• Data length: 1 024 Words