Page 1

Operating Manual PSENvip RL D P Set

Operating Manual PSENvip RL D P Set

PSENvip RL D P Set

Safe camera systems

Operating Manual — No. 1001641-EN-07

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz

®

, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of the documentation 1-2

1.2 Overview of documentation 1-3

1.3 Definition of symbols 1-5

Chapter 2 Overview

2.1 Scope of supply 2-3

Chapter 3 Safety

3.1 Intended use 3-1

3.1.1 Approvals 3-2

3.1.2 Safety during operation 3-2

3.1.2.1 Hazards arising from the installation of the

3-2

PSENvip

3.1.2.2 Hazards arising from a reduced protected

3-2

field

3.1.2.3 Hazards arising from incorrect handling of

3-3

the workpiece

3.1.2.4 Correct handling of the workpiece 3-3

3.1.3 Categories / SIL 3-6

3.1.4 Tool shapes 3-6

3.2 Standards 3-9

3.3 Safety guidelines 3-10

3.3.1 Use of qualified personnel 3-10

3.3.2 EMCD 3-10

3.3.3 Warranty and liability 3-11

3.3.4 Safety during commissioning, installation

3-11

and operation

3.3.5 Disposal 3-11

Chapter 4 Function description

4.1 Overview 4-1

4.2 Protected field 4-5

4.2.1 Dynamic muting 4-6

4.2.2 Standard interrupted press stroke 4-8

4.3 Overrun 4-10

4.4 Description of the units 4-11

4.4.1 Overview 4-11

4.4.2 Transmitter 4-11

4.4.2.1 Inputs 4-11

4.4.3 Receiver 4-12

4.4.3.1 Inputs 4-12

4.4.3.2 Outputs 4-14

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

4.4.3.3 LED 4-16

4.4.3.4 Key display and function 4-17

4.4.4 Communication with the safety system 4-20

4.5 Protected field modes 4-24

4.5.1 Standard protected field mode 4-24

4.5.2 Box bending protected field mode 4-25

4.5.3 Back gauge protected field mode 4-26

4.5.4 Box bending with back gauge protected

field mode

4.6 Operating modes during commissioning 4-28

4.6.1 Press brake setup mode 4-28

4.6.2 Adjustment during initial commissioning 4-28

4.6.3 Adjustment during tool change 4-28

4.7 System cycle 4-30

4.7.1 System cycle for standard press stroke 4-31

4.7.2 System cycle for box bending press stroke 4-34

4.7.3 System cycle for back gauge press stroke 4-37

4.7.4 System cycle for box bending with back

gauge press stroke

4-27

4-37

Chapter 5 Installation

5.1 General requirements 5-1

5.2 Install transmitter and receiver 5-2

5.3 Dimensions 5-4

5.3.1 Transmitter 5-4

5.3.2 Receiver 5-5

5.3.3 Fastening kit for the transmitter 5-5

5.3.4 Fastening kit for the receiver 5-6

5.3.5 Bracket for transmitter and receiver 5-7

Chapter 6 Wiring

6.1 Notes on wiring 6-1

6.2 Connections 6-4

6.2.1 Receiver 6-4

6.2.2 Transmitter 6-6

6.2.3 Supply voltage 6-6

6.2.4 Connection between transmitter and receiver

6.2.5 Connection diagram 6-7

Chapter 7 Commissioning

7.1 Commissioning guidelines 7-1

7.2 Initial commissioning 7-2

7.2.1 Align transmitter and receiver 7-2

7.2.1.1 Prepare for alignment 7-2

6-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

Contents

7.2.1.2 Adjustment templates 7-2

7.2.1.3 Adjustment directions of transmitter and

receiver

7.2.1.4 Align transmitter 7-5

7.2.1.5 Tool shapes 7-6

7.2.1.6 Align receiver 7-8

7.2.2 Adjustment template with bracket 7-11

7.3 Adjustment during tool change 7-13

7.3.1 Prepare for adjustment during tool change 7-13

7.3.2 Tool detection 7-13

7.3.3 Make adjustment during tool change 7-16

7.4 Enter overrun 7-19

7.5 Check protective equipment 7-21

7.5.1 Function test of the safety device 7-21

7.5.1.1 Test during initial commissioning 7-22

7.5.1.2 Test after machine modification 7-22

7.5.1.3 Regular check 7-22

7.5.1.4 Prepare for function test 7-23

7.5.1.5 Function test using the test piece 7-23

7.5.2 Visual inspection 7-25

7-3

Chapter 8 Operation

8.1 Safety guidelines 8-1

8.2 Operating notes 8-2

8.2.1 Switch on PSENvip 8-2

8.2.2 Muting lamp 8-2

8.2.3 Initial press stroke 8-2

8.2.4 Acknowledge protected field modes 8-3

8.2.5 Tool change 8-4

8.2.6 Error messages 8-4

8.2.7 Cleaning the front lenses 8-5

Chapter 9 Diagnostics and Troubleshooting

9.1 Error Management 9-2

9.1.1 Minor errors 9-2

9.1.2 Major errors 9-2

9.1.3 Fatal errors 9-3

9.2 Error messages 9-4

9.3 DIAGNOSTICS menu 9-6

9.3.1 Diagnostic blocks and diagnostic data 9-6

Chapter 10 System Connections

10.1 Requirements of the user program 10-1

10.2 Communication with the safety system 10-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3

Page 6

Contents

Chapter 11 Technical details

11.1 Technical details 11-1

11.2 Order reference 11-3

Chapter 12 Attachment

12.1 Check list 12-1

12.2 EC declaration of conformity 12-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

4

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

11000IntroductionIntroduction1-Einführung_PSENvip

Einf Aufbewahren

This operating manual contains information about the intended operation of the PSENvip. The PSENvip is a camera-based protection system

for press brakes.

This operating manual is aimed at manufacturers, company operators

and personnel involved in designing, maintaining and operating press

brakes, which are to be safeguarded using the PSENvip.

This operating manual is not an instruction manual for the press brake

that is safeguarded using the PSENvip. Please refer to the press brake

operating manual for this information.

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 8

1 Introduction

1.1 Validity of the documentation

1.1Validity of the documentation1100Validity of th e documentation1-Einf Gltigkeit der Dokumentation

This documentation is valid for the product PSENvip RL D P Set. It is

Einfuehrung_Doku_ab_Vers ion_2.0_2012

valid until new documentation is published.

This documentation is valid for the PSENvip from Version 2.2/year of

construction 2013.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-Einführung_Übersicht

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the PSENvip's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter provides an overview of the PSENvip's mode of operation.

It describes the units and the system procedures.

5 Installation

This chapter explains how to install the PSENvip.

6 Wiring

This chapter explains how to wire the inputs and outputs on the

PSENvip.

7 Commissioning

This chapter explains how to commission the PSENvip. It contains information on adjustments and on the tests performed on the safety device.

8 Operation

This chapter contains all the information required by the operator.

9 Diagnostics and Troubleshooting

This chapter describes the output of diagnostics on the display and explains how to handle errors.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 10

1 Introduction

1.2 Overview of documentation

10 System Connections

This chapter describes how the PSENvip is connected to the press

brake's programmable safety system.

11 Technical Details

12 Appendix

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 11

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-5

Page 12

1 Introduction

1-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

2 Overview

22000OverviewOverview2-Uebersicht_Allgemein

Uebersicht_Merkmale_Sender

Uebersicht_Merkmale_Empfaenger

Uebersicht_Merkmale_Empfaenger_Eingaenge

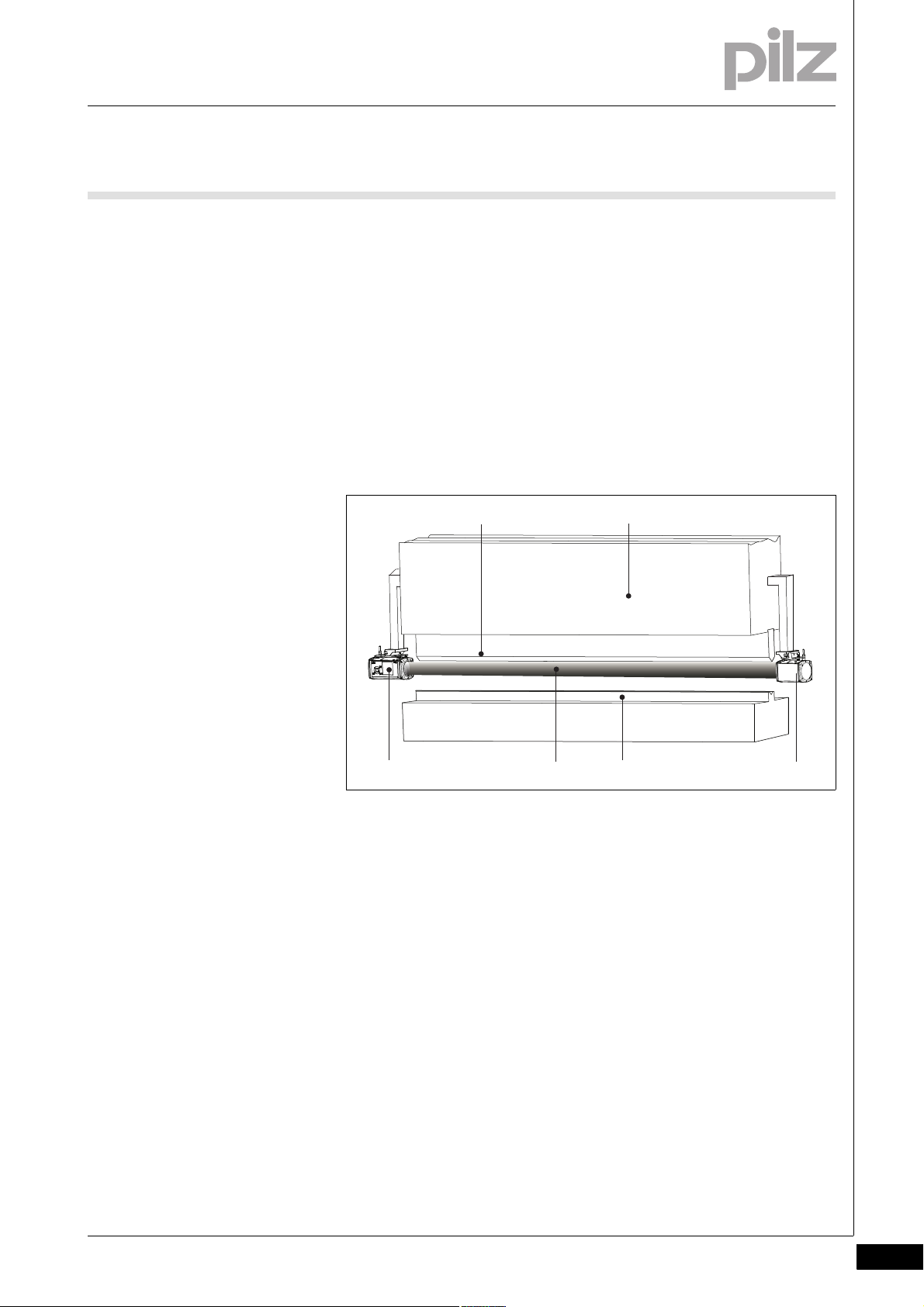

The PSENvip is a camera-based protection and measuring system

(electrosensitive protective equipment) for press brakes. It consists of a

transmitter and receiver. The PSENvip monitors the detection zone between the transmitter and receiver below the moving upper tool.

Transmitter

Generates parallel beam

2 inputs for controlling the light source

Receiver

Evaluates the light generated by the transmitter

Display for the operating statuses and inputs

Membrane keypad for operating the menus and for inputs

Max. distance between transmitter and receiver: 10 m

Uebersicht_Merkmale_Empfaenger_Ausgaenge

Uebersicht_Merkmale_Empfaenger_Ausgaenge_Mute

Uebersicht_Merkmale_Empfaenger_Ein_Aus_Zusatz

Uebersicht_Merkmale_Empfaenger_LED

Uebersicht_Merkmale_Betriebszustaende

Inputs

1 input for setup mode

1 input for signalling when the press brake is at top dead centre

2 inputs for controlling the protected field mode:

Protected field can be adapted to a range of bending functions: full

protected field, reduced protected field for box bending and lower

tools with back gauge

1 input for acknowledging the protected field mode

Outputs

2 output signal switching devices (OSSD) for signalling the status of

the protected field (clear or interrupted)

2 outputs for signalling that PSENvip is in dynamic muting

Some inputs and outputs are used for communication with the safety

system during the system status TEST:

Register tool class on safety system

Approve tool class for PSENvip

LED indicators for

Status of OSSDs

Operating statuses

Adjustment for initial commissioning

Tool change

Diagnostics

Uebersicht_Merkmale_Werkzeugerkennung

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 14

2 Overview

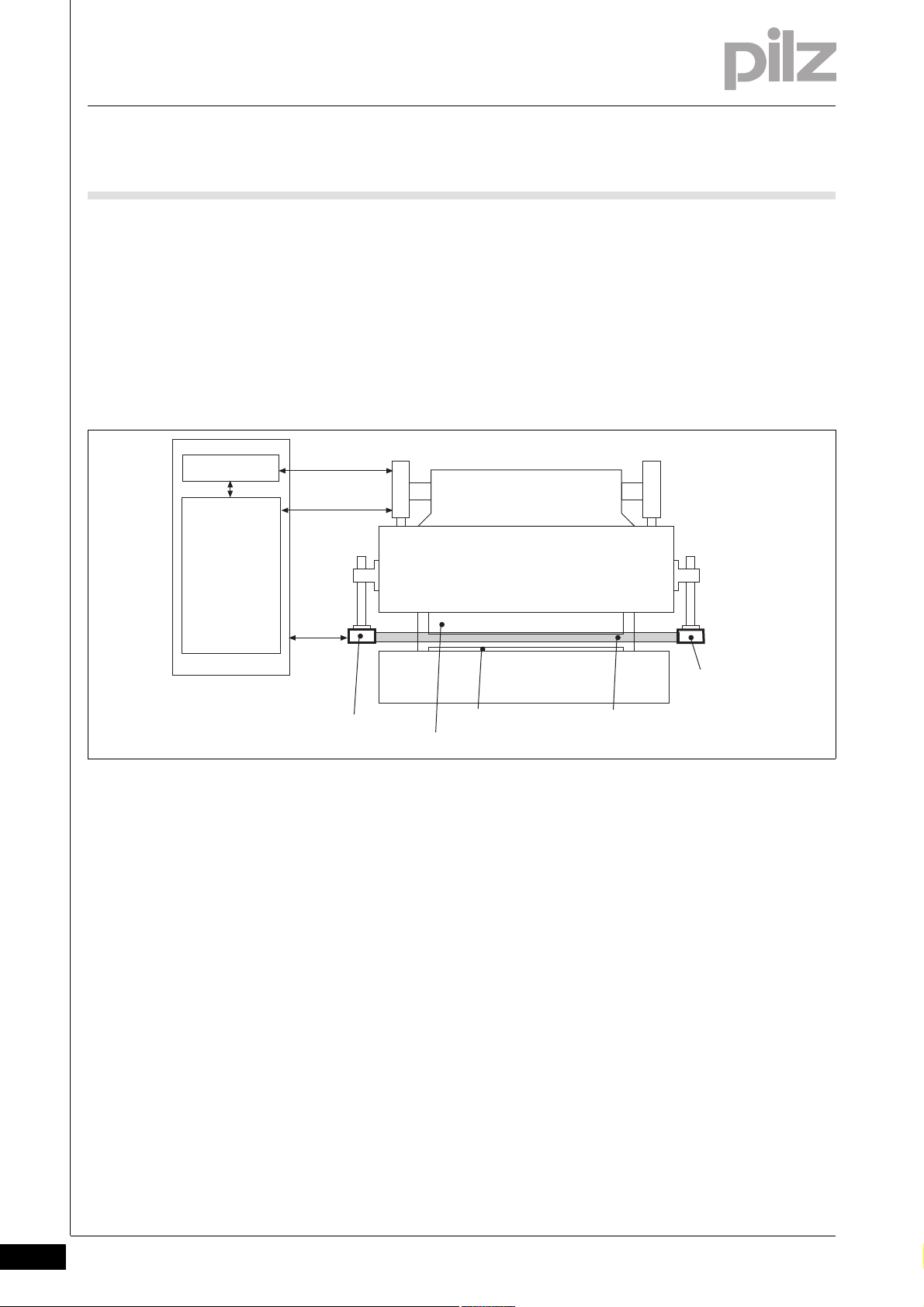

Upper die

Safety control

system

CNC

Receiver

Lower tool

Detection zone

Upper tool

Transmitter

Uebersicht_Gesamtsystem

Tool detection

Automatic detection of tool contour during tool change

Assignment of tool to a tool class

The whole system consists of:

Press brake

Numerical controller (CNC)

Programmable safety system

PSENvip (transmitter and receiver)

Fig. 2-1: Whole system

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

2 Overview

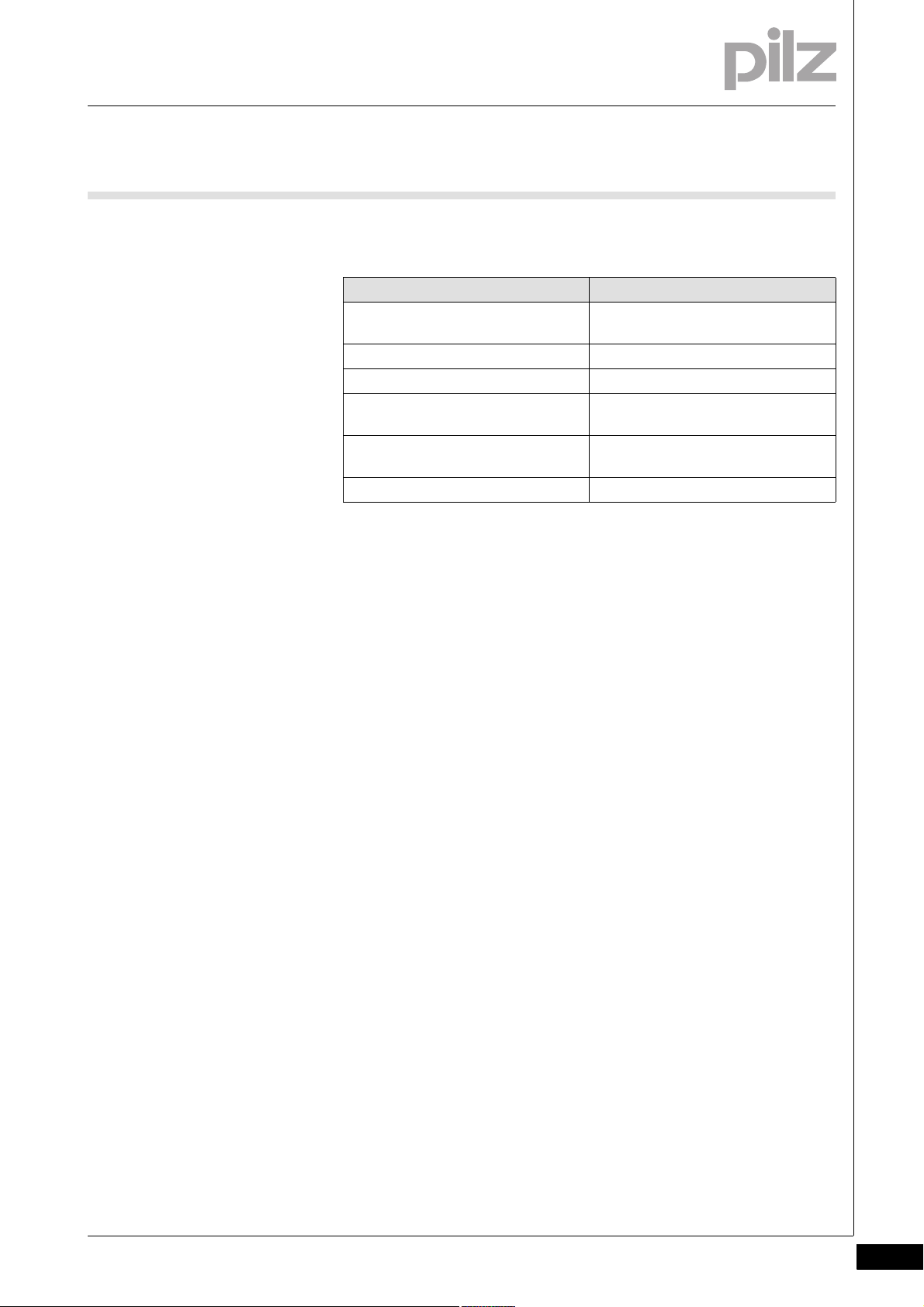

2.1 Scope of supply

2.1Scope of supply2100Scope of supply2-Grundlagen

PSENvip RL D P Set: complete set

Order reference Description

PSENvip RL D P PSENvip receiver, left, with display

and dynamic muting

PSENvip T PSENvip transmitter

PSENvip AT mag Adjustment templates with magnets

PSENvip AP Set of adjustment plates for transmit-

ter/receiver

PSENvip TP Test piece in accordance with

EN 12622, Annex H

DVD with operating manuals

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 16

2 Overview

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-Sicherheit_Bestimm_Allg

Sicherheit_Bestimm_Allg_dyn_Muting

The PSENvip is exclusively designed for stationary use on press brakes.

As electrosensitive protective equipment (ESPE), the PSENvip meets

the requirements of a type 4 ESPE in accordance with EN 61496-1.

The PSENvip safeguards the danger zone below the moving upper tool.

Danger zones outside of the protected field are not protected. Hazards

in the area of the lower tool and above the protected field must be protected by the press manufacturer with appropriate measures. Please refer to the guidelines given in the "Tool shapes" section in this chapter.

The protected field monitors the danger zone between upper tool and

plate up to a remaining gap of 6 mm (dynamic muting)

Sicherheit_Bestimm_Allg_NLW

Sicherheit_Bestimm_Allg_Zusaetze

The upward movement of the press is assumed as a safe movement.

Use of the PSENvip RL D P Set is only permitted with the automation

system PSS 4000 from Pilz. In the PSS 4000 user program, safety functions must be implemented to safeguard the dynamic muting of

PSENvip:

Monitoring of the pinch point

Monitoring of the press braking ramp

Definition of a safe position and safe speed for the upper tool

Activation of the entire protected field via System-Init = 1, when the

press stops during dynamic muting and then the upward movement

is initiated.

For this safety function Pilz provides a certified evaluation program for

the PSS 4000.

The press brake must observe a max. overrun of 14 mm.

The following is deemed improper use:

Any structural, technical or electrical modification to the PSENvip

Use of the PSENvip outside the zones described in this manual

Use of the PSENvip contrary to the documented technical details (see

chapter entitled "Technical Details")

Intended use includes making the wiring EMC-compliant. Please refer to

the guidelines stated in this manual, in the section entitled "Wiring".

The protective function of the PSENvip must not be adversely affected

by sources of interference, e.g. wireless remote controls for cranes,

welding sparks, strobe lighting effects.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 18

3 Safety

4

4

4

3.1 Intended use

3.1.1 Approvals

Approvals3-Sicherheit_Zulassungen

3.1.2 Safety during operation

Safety during operation3-Sicherheit_Betrieb_Allg

Intended use also includes awareness of the hazards that arise during

operation, against which the PSENvip does not provide protection.

3.1.2.1 Hazards arising from the installation of the PSENvip

Hazards arising from the installation of the PSENvip3-Sicherheit_Betrieb_Montage

When installing the PSENvip, please note the following:

The PSENvip must be installed so that there are no crushing or shear-

ing hazards between the moving transmitter/receiver and the fixed

machine parts or any other parts around the machine.

If hazard areas cannot be avoided, other safeguards must be put in

place.

3.1.2.2 Hazards arising from a reduced protected field

Hazards arising from a reduced protected field3-Sicherheit_Betrieb_Schutzfeld_reduziert

The full protected field is only active in standard protected field mode.

In box bending or box bending with back gauge protected field mode,

the protected field is reduced. This means there can only be limited protection against trapping and crushing. The protected field is around the

tolerance zone behind the bending line. Any parts of the body within the

danger zone will only be detected behind the bending line. There is a risk

of injury from trapping or crushing.

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

3 Safety

3.1 Intended use

3.1.2.3 Hazards arising from incorrect handling of the workpiece

Hazards arising from incorrect handling of the workpiece3-Sicherheit_Betrieb_Handhabung_Werkstueck_falsch

The PSENvip does not protect against hazards arising from incorrect

handling of the workpiece.

When bending metal sheets on press brakes there is a risk of hand injuries

From the tool's closing movement

From the swivel movement of the parts of the metal sheet that pro-

trude from the tool and

From the dropping of the metal sheet when the tool is opened.

So please note the following:

You can avoid crushing and trapping of fingers or hands if the work-

piece is handled correctly.

Wear protective gloves to prevent cuts from edges, corners and ridg-

es.

3.1.2.4 Correct handling of the workpiece

Correct handling of the workpiece3-Sicherheit_Warnung_Quetschen_1

WARNING!

Crushing and trapping of fingers or hands!

With box bending and/or back gauge bending mode, the protected field is partly blanked.

Around the bending line there is an increased risk of crushing

and trapping of fingers or hands.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 20

3 Safety

3.1 Intended use

Sicherheit_Betrieb_Handhabung_Werkstueck_richtig

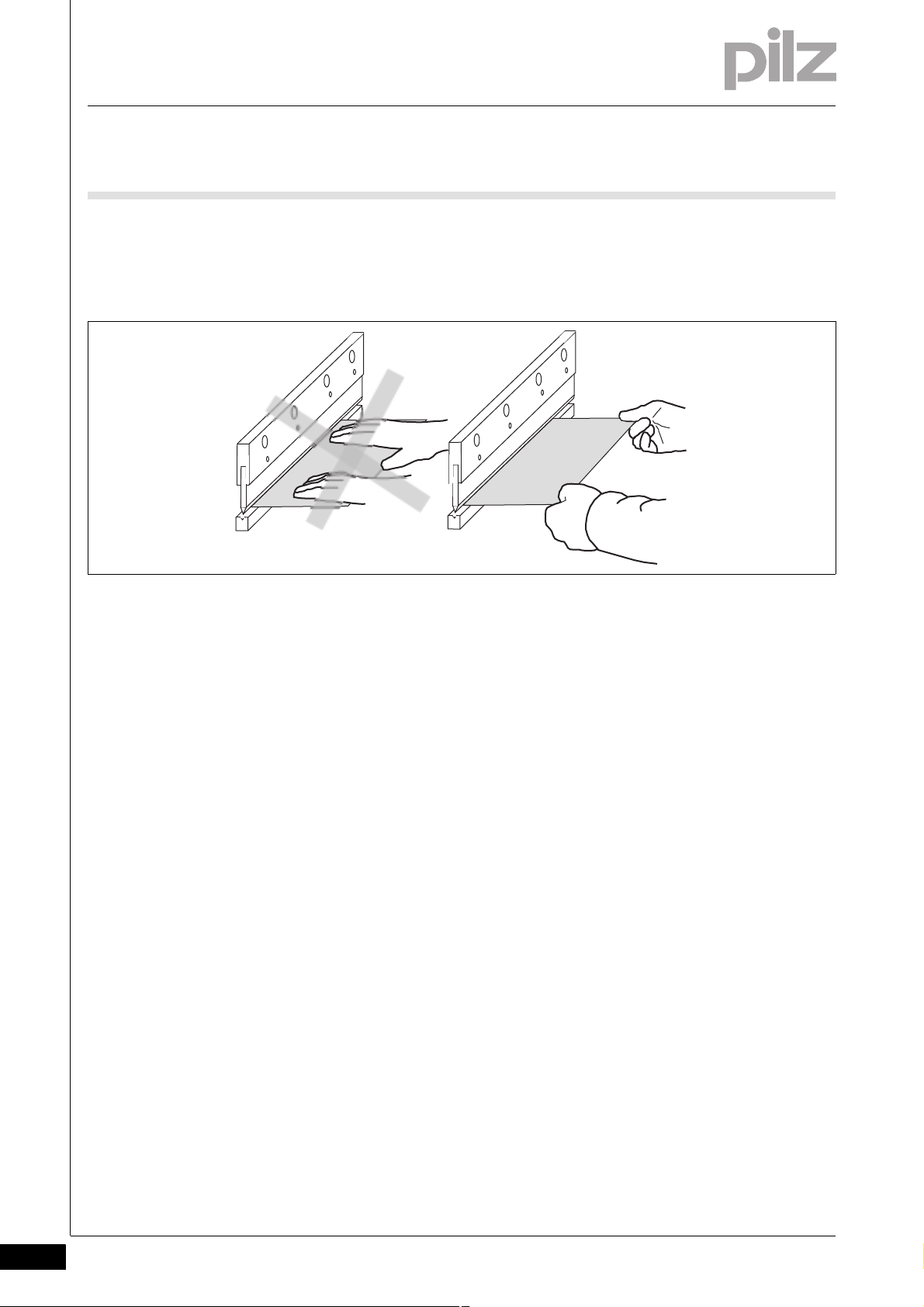

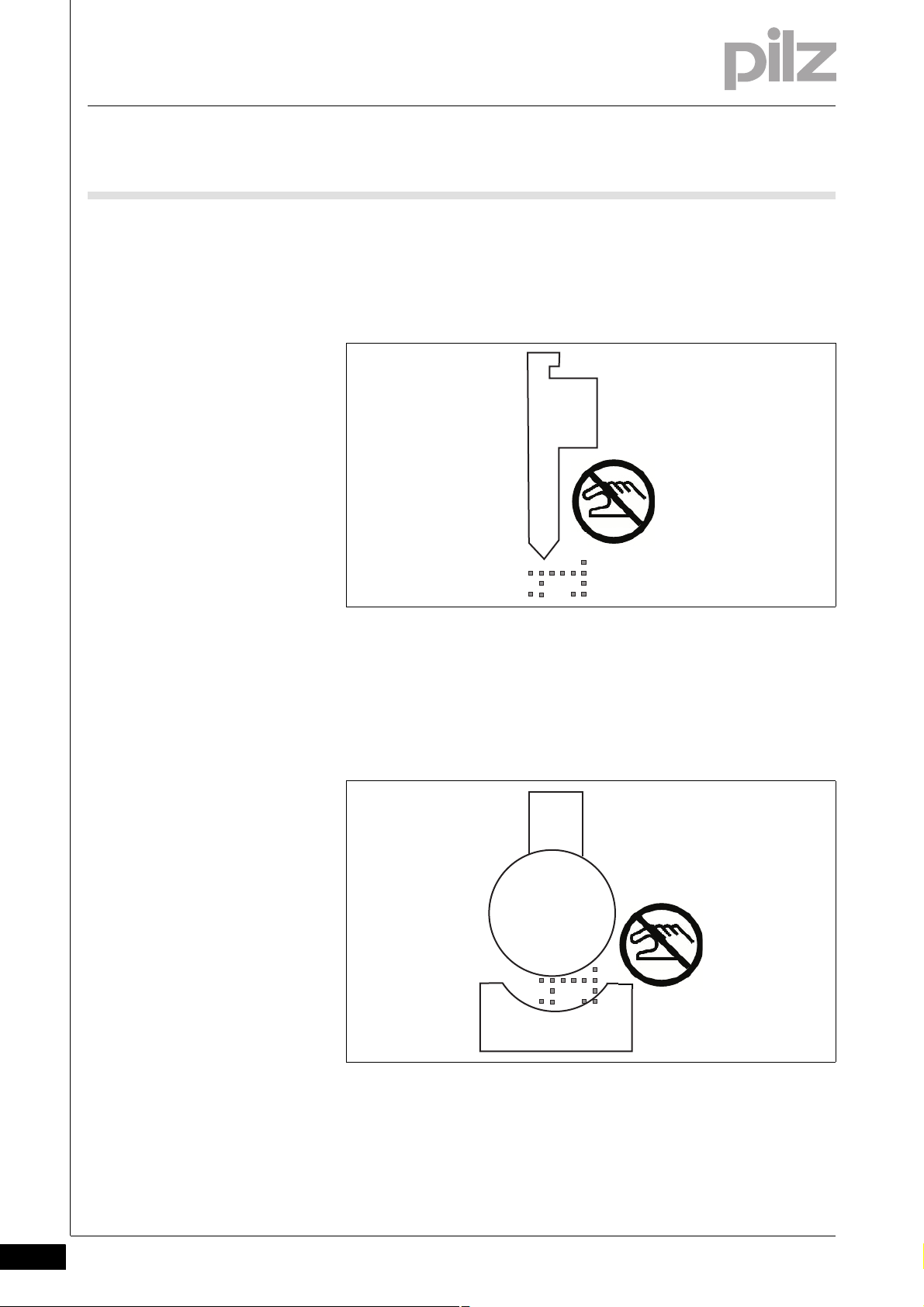

Correct handling with flat workpieces

Grip the metal sheet by the front corners. Thumbs should be on top

of the sheet, palms should hold the sheet from below.

Fig. 3-1: Handling flat workpieces

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

3 Safety

3.1 Intended use

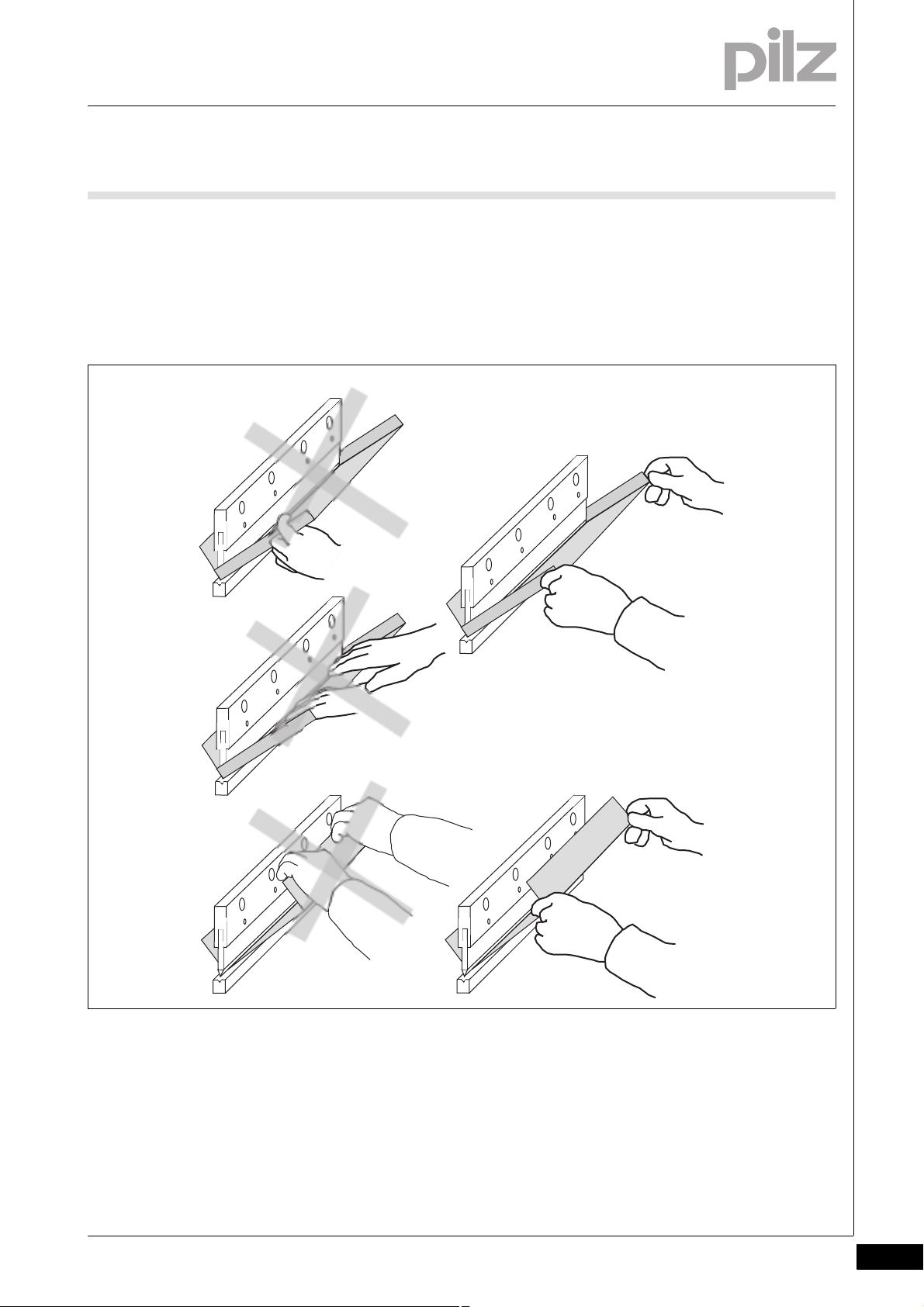

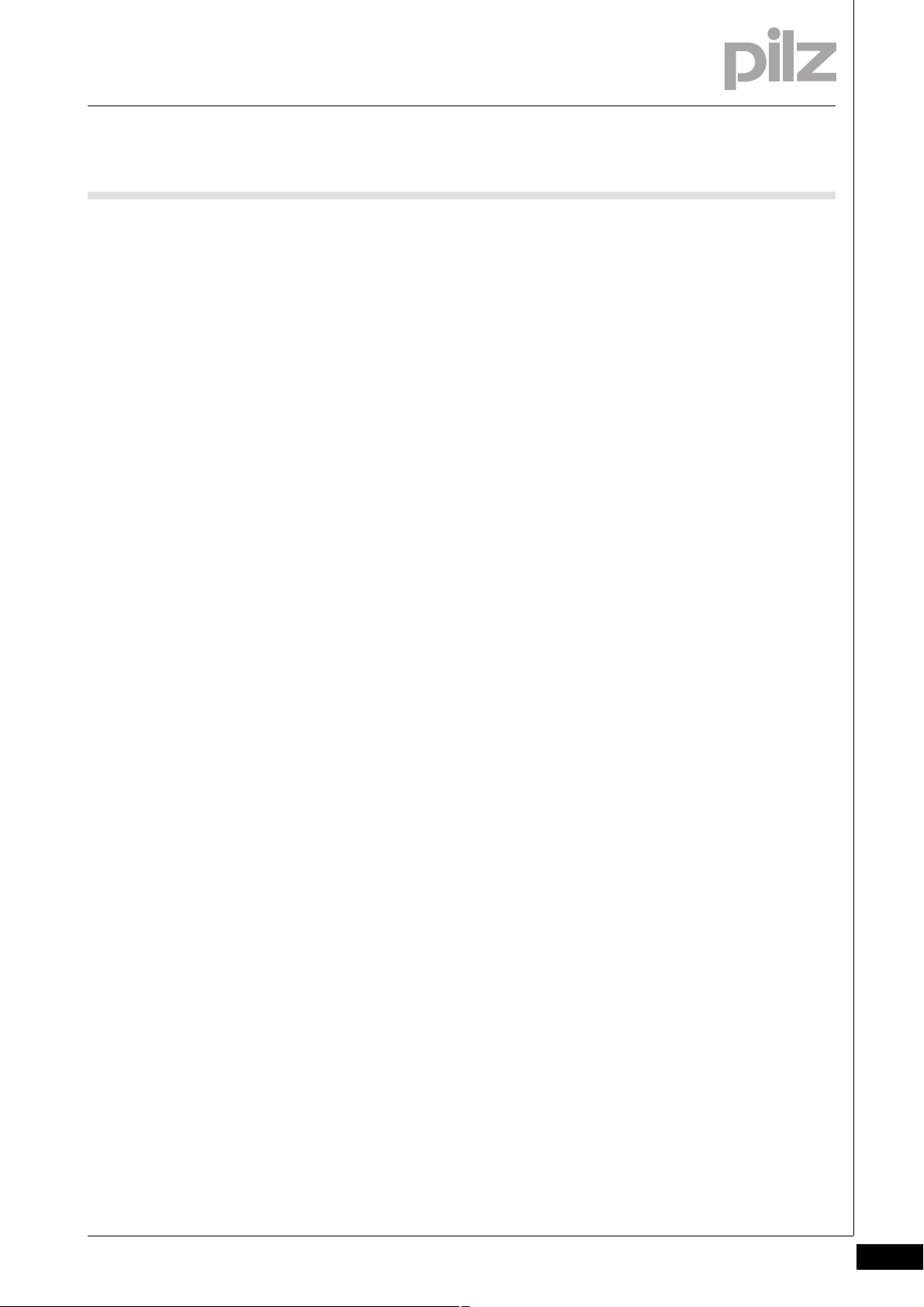

Correct handling with box bending

Hold the sheet on the right and left between the thumb and index fin-

ger.

As you hold the sheet, do not reach with your hands into the box. Dur-

ing the bending operation, fingers or hands can become crushed or

trapped between the workpiece and upper tool.

Fig. 3-2: Handling box bending

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-5

Page 22

3 Safety

3.1 Intended use

3.1.3 Categories / SIL

Categories / SIL3-Sicherheit_Kategorien_P_Variante

3.1.4 Tool shapes

Tool shapes3-Sicherheit_Werkzeugformen

The PSENvip may only be used with an automation system PSS 4000

from Pilz with SIL 3 of EN 61508 and PL e of EN ISO 13849-1.

Please note: To achieve the corresponding category or SIL, the whole

system including all safety-related components (parts, devices, user

program etc.) must be included in the assessment. For this reason, Pilz

cannot accept liability for the correct classification into a category or

SIL.

All tool shapes are permitted in principle. They are divided into tool

classes by the PSENvip. Classification is based on EN 12622, according

to which the protected field must safeguard areas lying 15 mm in front

of the bending line.

INFORMATION

Please refer to the information on tool classes

In the section entitled "Adjustment during tool change", under

"Commissioning".

In the section entitled "Requirements of the user program", un-

der "System Connections".

Please note the following when using tools:

Tool class 1

These tools can be safeguarded in compliance with the standards:

The front and rear bending lines are detected by the protected field

on the PSENvip. The front segments of the protected field are more

than 15 mm away from the front bending line.

Upper tools with a width of max. 32 mm or radius of max. 25 mm.

Press brakes can travel up to the regular switchover point at high

closing speed.

3-6

Tool class 2

These tools cannot be safeguarded in compliance with the standards:

The front and rear bending lines are detected by the protected field

on the PSENvip. The front segments of the protected field are less

than 15 mm away from the front bending line.

Upper tools with a width of max. 43 mm or radius of max. 50 mm.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

3 Safety

3.1 Intended use

The following safety guideline applies for press brakes with tools in

this tool class.

WARNING!

Crushing and trapping of fingers or hands!

There may be additional hazard areas in zones that are not monitored by the PSENvip.

In these zones there is an increased risk of crushing and trapping of fingers or hands.

Secure these zones with appropriate additional measures!

– Carry out a hazard analysis!

– Raise the regular switchover point, which initiates braking at

low speed! The switchover point must be monitored by the

safety system.

Tool class 3

These tools cannot be safeguarded in compliance with the standards:

The front and rear bending lines are not detected by the protected

field on the PSENvip.

The following safety guideline applies for press brakes with tools in

this tool class.

WARNING!

Crushing and trapping of fingers or hands!

There may be additional hazard areas in zones that are not monitored by the PSENvip.

In these zones there is an increased risk of crushing and trapping of fingers or hands.

Secure these zones with appropriate additional measures!

– Carry out a hazard analysis!

– Raise the switchover point, which initiates braking at low

speed. It must be placed even higher than the position used

for tools of tool class 2. The switchover point must be monitored by the safety system.

– Each press stroke must be acknowledged by the operator

prior to initiation.

Sicherheit_Werkzeugformen_Beispiele

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-7

Page 24

3 Safety

3.1 Intended use

Please also note the following guidelines in danger zones in areas that

cannot be detected and monitored by the safeguard.

Example: Upper tool with a danger zone outside the zone monitored by

the PSENvip

Fig. 3-3: Danger zone in unmonitored zone

Example: In unmonitored zones, the use of tools which are not fully detected by the protected field on the PSENvip (e.g. tools with a radius

greater than 25 mm) will lead to the risk of fingers or hands being

crushed or trapped!

3-8

Fig. 3-4: Crush points when the tool is wider than the protected field

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

3 Safety

3.2 Standards

3.2Standards3200St andards3-Sicherheit_Normen

To use the PSENvip correctly you will need to have a good knowledge

of the relevant standards and directives. The following gives an overview

of the most important standards:

EN 61496-1:2004: Safety of machinery - Electrosensitive protective

equipment, Part 1

CLC/TS 61496-2:2006: Safety of machinery - Electrosensitive protec-

tive equipment, Part 2

EN 12622:2009: Machine tools - Hydraulic press brakes

EN ISO 13849-1:2008: Safety of machinery – Safety-related parts of

control systems - Part 1: General principles for design

EN ISO 13849-2:2008: Safety of machinery – Safety-related parts of

control systems - Part 2: Validation

EN 61508:2001: Functional safety of safety-related electrical/elec-

tronic/programmable electronic systems

Please note this is not an exhaustive list of safety standards and directives.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-9

Page 26

3 Safety

3.3 Safety guidelines

3.3Safety guidelines3300Safety guidelines3-Sicherheit_Sicherheitsrichtlinien_Allgemein

Failure to keep to these guidelines will render all warranty and liability

claims invalid:

All health and safety / accident prevention regulations for the particu-

lar area of application must be observed.

Before using the unit it is necessary to perform a safety assessment

in accordance with the Machinery Directive 2006/42/EC.

Please note that manufacturers and company operators who use the

PSENvip are themselves responsible for agreeing the regulations with

the relevant authorities and complying with them.

3.3.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

Sicherheit_Qualifikation_BWS

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

Approved personnel must be familiar with how to use and test ESPE and

be authorised by the ESPE operator to do this.

3-10

3.3.2 EMCD

EMCD3-Sicherheit_EMVG

The PSENvip is designed for use in an industrial environment. It is not

suitable for use in a domestic environment, as this can lead to interference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

3 Safety

3.3 Safety guidelines

3.3.3 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

3.3.4 Safety during commissioning, installation and operation

Safety during commissioning, installation and operation3-Sicherheit_Inbetriebnahme_Montage_Betrieb

Please read the guidelines stated in the chapters entitled "Commissioning", "Installation" and "Operation".

3.3.5 Disposal

Disposal3-Si ch Entsorgung

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-11

Page 28

3 Safety

3-12

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

4 Function description

3

12

4 56

4.1 Overview

44000Function descriptionFunction description4-4.1Overview4100Overview4-Funktion_Ueberblick_P_Variante

The PSENvip is a camera-based protection system for press brakes. It

consists of a transmitter and receiver, which are fixed to the moving part

of the press brake, the upper die. The detection zone between the transmitter and receiver monitors the immediate danger zone below the moving upper tool.

The detection zone moves with the upper die, providing mobile safeguarding of the danger zone. If an object encroaches into the detection

zone, both output signal switching devices (OSSD1, OSSD2) on the

PSENvip will switch to the OFF-state. The safety system will use these

signals to initiate stopping of the press stroke.

Fig. 4-1: Press brake with PSENvip

1: Upper tool

2: Upper die

3: Receiver

4: Detection zone

5: Lower tool

Funktion_Gesamtsystem_P_Variante

6: Transmitter

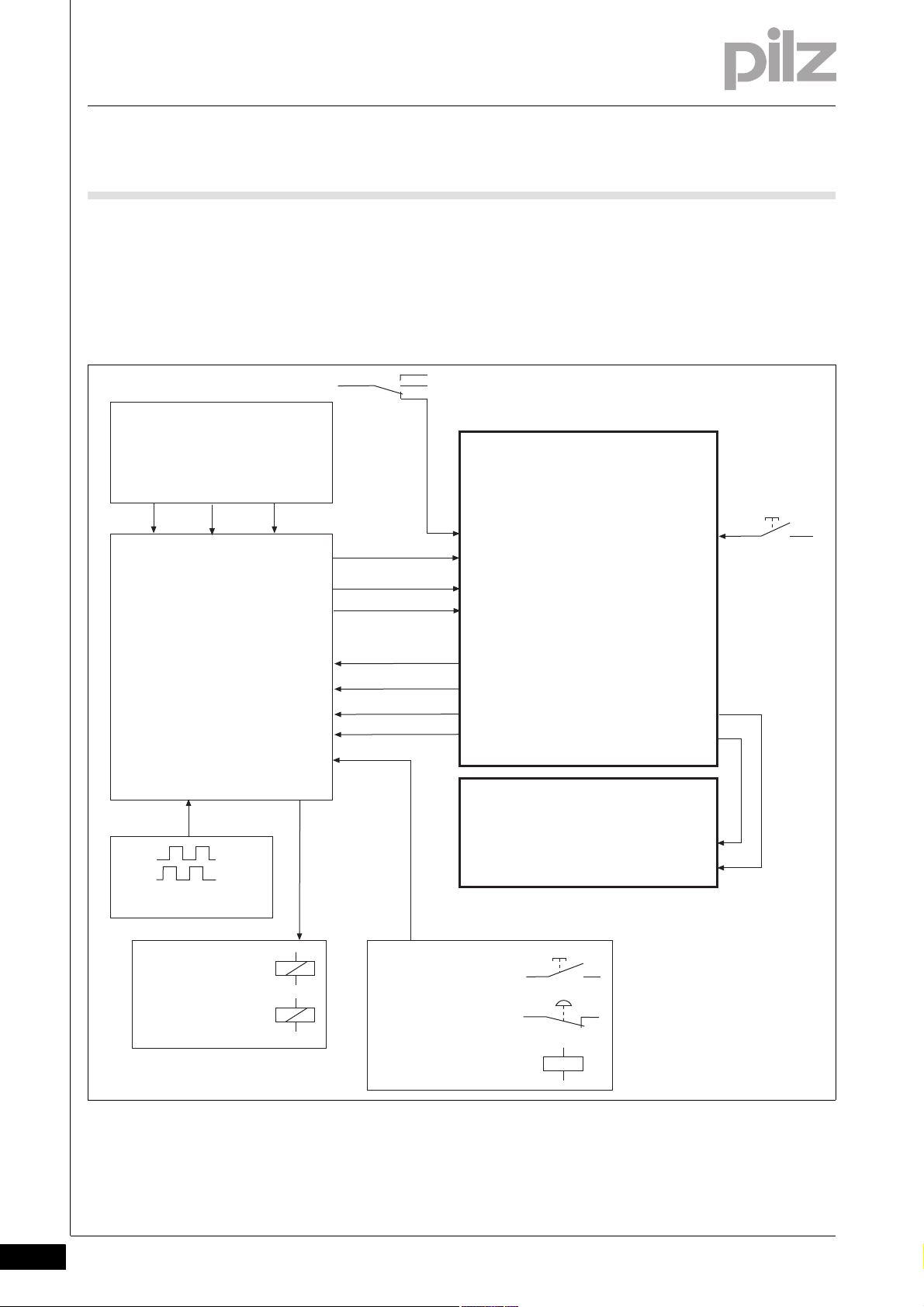

The PSENvip is part of an overall system comprising

PSENvip transmitter and receiver

Programmable safety system PSS 4000

CNC controller

Signals from incremental encoders for defining the position and

speed

External operator elements or signals (foot switch, reset button for re-

duced protected field or setup mode, E-STOP pushbutton)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 30

4 Function description

OSSD 1

OSSD 2

Mute 1

TRM_ON

TRM_SYNC

TRM_ON

TRM_SYNC

Programmable safety

system

PSS 4000

Incremental encoder

Mute 2

Pinch point

Up/

Down

Power Off

System-Init

Protected field mode

Acknowledgement of reduced

protected field

Inputs

Outputs

PSENvip receiver

PSENvip transmitter

CNC controller

Protected field mode

Setup

Foot switch

E-STOP

E-STOP contactor

User program

Safety valve

Prefill valve

4.1 Overview

Other safety devices (safety valves, prefill valve, contactor for E-

STOP)

The following overview shows the fundamentals of the whole system.

The signals from the PSENvip transmitter and receiver are explained in

the sections below.

Funktion_Geraete_Schutzfeldmodus

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Fig. 4-2: Overview of overall system

Page 31

4 Function description

4.1 Overview

INFORMATION

Some inputs and outputs on the receiver are also used for communication with the safety system (see section entitled "Communication with the safety system"). If communication is not

required, protected field mode can also be controlled directly via

the CNC controller.

Funktion_PSS_4000

The motion sequence of the press is monitored by the automation system PSS 4000. In the PSS 4000 user program safety functions must be

implemented to safeguard the dynamic muting of PSENvip. (see chapter

Funktion_Optik

10 "System Connections").

Funktion_Schutzraum

The receiver evaluates the parallel beams generated by the transmitter.

The beam is enclosed by the illuminated target area. The lens on the receiver only detects light that runs parallel to the optical axis. This guarantees stability against diffused light.

WARNING!

The light generated by the transmitter is not hazardous to the

human eye.

However, do not use additional optical aids, e.g. lenses, to look

at the light from the transmitter. This could damage the eye.

The receiver monitors and evaluates the detection zone between the

transmitter and receiver. The protected field is the cross section of the

detection zone. It consists of several segments.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 32

4 Function description

1

2

3

4

4.1 Overview

Funktion_Schutzfeld_allgemein

Fig. 4-3: Definitions

Key:

1: Light beam bundle

2: Illuminated target area

3: Protected field

4: Detection zone

The shape and size of the protected field depend on the bending function and the machine-dependent overrun. A reduced protected field is

possible for box bending and/or back gauge mode (for the size of the

protected field please see "Protected field" section and the chapter entitled "Technical Details").

If an object encroaches into the detection zone, both output signal

switching devices (OSSD1 and OSSD2) on the PSENvip will switch to

the OFF-state. The safety system will use these signals to initiate stopping of the press stroke.

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

4 Function description

Bending line

Upper tool

Illuminated target area

Rear segments

Workpiece

Lower tool

Adjustment line

Front segments

Central segments

44

max. 20

min. 8

6

1

Overrun distance 2 m

Overrun distance 14 mm

4.2 Protected field

4.2Protected field4200Protected field4-Funktion_Schutzfeld

The protected field consists of several segments. The front and rear segments (viewed from the operator's side) can be deactivated. This provides flexibility to adapt to the bending function:

Standard

Full protected field: all segments active

Box bending

Reduced protected field: front segments deactivated

Bending with back gauge

Reduced protected field: rear segments deactivated

Box bending with back gauge

Reduced protected field: front and rear segments deactivated

Funktion_Schutzfeld_Groesse

Funktion_Schutzfeld_Info_Kastenbiegen

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Fig. 4-4: Protected field definitions

The height of the protected field depends on the overrun. For the setting

range of the overrun please see following figure and Chapter 11, "Technical Details".

Fig. 4-5: Size of the detection zone

4-5

Page 34

4 Function description

max. 20

0,4

4.2 Protected field

INFORMATION

Please note that the central segments are 1 mm behind the

bending line. With box bending you must ensure that the side

panels of the box do not encroach into this area.

Funktion_Schutzfeld_Hinweise

The two following sections explain the basic mode of action of the protected field during a press stroke (interrupted and uninterrupted).

INFORMATION

The cycle of a press stroke with the corresponding inputs and

outputs is explained in this chapter, in the section entitled "System cycle".

4.2.1 Dynamic muting

Funktion_vorauseilendes_Messfeld_Muting_Allgemein

Dynamic muting4-

Funktion_vorauseilendes_Messfeld_Groesse

Funktion_vorauseilendes_Messfeld_Muting_Zustaende

An advance measuring field is located below the protected field. If is interrupted, the dynamic muting is started. The dynamic muting ensures

that the danger zone between upper tool and plate is monitored up to a

remaining gap of 6 mm during the downward movement.

The distance of the advance measuring field to the lower edge of the

protected field is constant. The distance to the top edge of the protected

field varies according to the length of the overrun.

Fig. 4-6: Distance of advance measuring field from protected field

4-6

Procedure:

1. The press is on downward movement. The protected field moves

down with the upper tool.

2. The advance measuring field touches the workpiece. The outputs

Mute1 and Mute2 at the receiver are set = 0.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

4 Function description

6 mm

4.2 Protected field

3. The advance measuring field is used to hold the protected field stationary at the pinch point on the workpiece. The segment division is

optimised for the dynamic muting process.

4. The respective upper segments are deactivated before the upper tool

enters the protected field.

NOTICE

The control system may only override the safety function from a

remaining gap of 6 mm.

Signal statuses of the outputs Mute1/Mute2 and OSSD1/OSSD2

full protected field active

OSSD1/ OSSD2 = 1

Mute1/Mute2 = 1

full protected field active

advance measuring field touches

plate

OSSD1/ OSSD2 = 1

Mute1/Mute2 = 1 -> 0

Remaining gap = 6mm

OSSD1/ OSSD2 = 1 -> 0

Mute1/Mute2 = 0

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-7

Page 36

4 Function description

4.2 Protected field

The signal statuses of the outputs Mute1/Mute2 and OSSD1/OSSD2

when interrupting the protected field by side intervention or interruption

of the advance measuring field before reaching the plate are described

in section entitled "Standard interrupted press stroke".

4.2.2 Standard interrupted press stroke

Standard interrupted press stroke4-Funktion_Pressenhub_mit_Unterbrechung_dyn_mute

It is necessary to distinguish between

Interruption of the advance measuring field

and

Side intervention with full protected field and reduced protected field

during the dynamic muting

Interruption of the advance measuring field

1

Downward movement

Object interrupts advance

measuring field, starts dynamic muting

OSSD1/OSSD2 = 1

Mute1/Mute2 = 1 -> 0

Safety system initiated the

stopping of the press,

measuring field was not interrupted in the expected

position (pinch point)

2

Upper tool continues moving for the overrun distance.

Protected field interrupted

Object is removed Protected field cleared. Press

stroke can be resumed.

4-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

4 Function description

4.2 Protected field

Side intervention with full protected field or reduced protected field

during the dynamic muting

1

Object interrupts the protected field to the side:

OSSD1/OSSD2= 1 -> 0

Mute1/Mute2 = 1

Safety system initiates the

stopping of the press stroke

2

Upper tool continues moving for the overrun distance.

Protected field interrupted

Object is removed Protected field cleared. Press

stroke can be resumed.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-9

Page 38

4 Function description

4.3 Overrun

4.3Overrun4300Overrun4-Funktion_Nachlaufweg_Allgemein

The max. overrun is a press brake variable that will depend on the machine type. Once the closing movement has stopped, the max. overrun

must not be exceeded.

The overrun is entered during configuration via the keypad on the

PSENvip receiver.

INFORMATION

Please refer to chapter 11, "Technical Details", for more information about the input area of the overrun.

Details on how to enter the overrun are described in Chapter 7,

“Commissioning”, section entitled “Enter overrun”.

Funktion_Nachlaufweg_P_Variante

Funktion_Nachlaufweg_Warnung_3

Normally, the factory-assigned overrun is sufficient and does not have

to be configured.

WARNING!

If you require a different overrun path than the factory-set path,

then use the value indicated by the manufacturer on the nameplate of the press brake, or a higher value.

If you enter a lower value for the overrun, the protected field will

also be reduced to an unpermitted level.

Failure to comply could result in a hazardous situation, which

could lead to serious injury and death.

4-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

4 Function description

1

2

3

4

4.4 Description of the units

4.4Description of the units4400Descriptio n of the units4-

4.4.1 Overview

Overview4-Funktion_Geraete_Sender_Empfaenger

The transmitter and receiver form one unit. The receiver contains all the

inputs and outputs required for communication with the CNC controller,

programmable safety system, transmitter and press brake. The trans-

Funktion_Geraete_Sender_Empfaenger_RL_D

mitter merely contains the inputs for controlling the light source.

4.4.2 Transmitter

Transmitter4-Funktion_Geraete_Sender_Stecker

4.4.2.1 Inputs

Inputs4-Funktion_Geraete_Sender_Eingang_TRM_ON_TRM_SYNC

Fig. 4-7: Transmitter and receiver

1: Display

2: Receiver

3: LED: OSSD status

4: Transmitter

The top of the transmitter has a 4-pin M12 connector.

The receiver uses these standard inputs to control the transmitter's light

source. The user cannot influence these internal signals.

TRM_ON

The receiver uses this signal to switch the transmitter's light source

on and off.

TRM_SYNC

The receiver uses this signal to control the intensity of the transmitter's light source.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-11

Page 40

4 Function description

4.4 Description of the units

4.4.3 Receiver

Receiver4-Funktion_Geraete_Empfaenger_Stecker

The top of the receiver has two 8-pin M12 connectors.

4.4.3.1 Inputs

Inputs4-Funktion_Geraete_Empfaenger_Eingaenge_1_P

Funktion_Geraete_Empfaenger_Eingaenge_2

System-Init

Input whose signal comes from the safety system PSS 4000.

System-Init = 1: Press at top dead centre or in an upward movement

System-Init = 0: Downward movement

The PSENvip can perform internal availability tests and completely

activate the protected field when System-Init = 1. The outputs OSSD

and mute are in the OFF state (OSSD = 0, Mute = 0).

Funktion_Geraete_Empfaenger_Eingaenge_3

INFORMATION

Please note that the PSENvip independently carries out an internal safety test every 2 minutes, if such a test is not requested

within this time by an external control system through SystemInit = 1. The PSENvip switches the OSSDs off during the safety

tests. For this reason you should ensure that the safety tests are

requested by an external control system before these 2 minutes

have elapsed. The best time to do this is when the OSSDs are

already switched off due to the position within the press stroke,

e.g. at top dead centre.

Power Off

Input signalling that the press brake is in setup mode.

Power Off = 1: Setup mode activated

All safety functions are deactivated in setup mode.

– The display is switched on.

–The OSSD LED on the receiver lights up red.

– The light source is switched off.

4-12

INFORMATION

The Power Off input has another function during the system status TEST. It is used for communication with the safety system.

See "Communication with a safety system" in this section.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

4 Function description

4.4 Description of the units

Acknowledgement

Input to acknowledge that a press stroke is to be performed with a

reduced protected field (front and/or rear segments blanked). The

protected field mode selected is shown on the receiver's display.

Acknowledgement = 0/1 pulse edge via pushbutton: Run selected

protected field mode

Protected field mode 1/protected field mode 2

Two safe inputs for setting the protected field mode. The CNC or

safety system provides the signal. It is only absolutely necessary to

connect the inputs to a safety system if communication is needed for

tool detection.

Protected

field mode

12

0 0 Standard

10Box bending

0 1 Bending with back gauge

1 1 Box bending with back gauge

INFORMATION

The inputs for protected field mode have another function during

the system status TEST. They are used for communication with

the safety system. See "Communication with a safety system" in

this section.

Bending function

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-13

Page 42

4 Function description

4.4 Description of the units

4.4.3.2 Outputs

Outputs4-Funktion_Geraete_Empfaenger_Ausgang_OSSD

OSSD1/OSSD2 in accordance with EN 61496-1, type 4

Two safe outputs that signal the status of the protected field:

OSSD = 1: Protected field clear

Funktion_Geraete_Empfaenger_Ausgang_Mute

OSSD = 0: Protected field broken

Mute1/Mute2 in accordance with EN 61496-1, type 4

Two safe outputs that signal the dynamic muting

Mute1/Mute2 = 1: no dynamic muting

Mute1/Mute2 = 0: dynamic muting active

INFORMATION

The outputs Mute1/Mute2 have another function during the system status TEST. They are used for communication with the

safety system. See "Communication with a safety system" in

this section.

Funktion_Geraete_Empfaenger_Ausgang_Ausgangstest_Info

Funktion_Geraete_Empfaenger_Ausgang_Ausgangstest

INFORMATION

For details of the output behaviour during a press stroke please

refer also to the section entitled "System cycle", in this chapter.

INFORMATION

The outputs OSSD1/OSSD2 and Mute1/Mute2 are checked via

regular output tests.

Output test

Outputs that are switched on are checked via regular off tests.

Test pulses for outputs that are switched on: see Technical Details

Outputs that are switched on are switched off for the duration of the

test pulse.

The load must not switch off because of the test.

Outputs that are switched off are checked via regular on tests.

Test pulses for outputs that are switched off: see Technical Details

Outputs that are switched off are switched on for the duration of the

test pulse.

4-14

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

4 Function description

1

t

2

t

1

t

1

t

3

t

1

t

t

2

t

1

U

0

4.4 Description of the units

The load must not switch on because of the test.

Testing for shorts

A test is regularly carried out to check for shorts between the outputs.

][Funktionsbeschreibung_BA_Zusatz Einschalttest

Fig. 4-8: Test pulses

Key:

t

: Pulse length of on test (40 μs)

1

t

: Repetition length of on test (100 μs ... 3 ms)

2

t

: Cycle time of on test (30 μs ... 5 min)

3

WARNING!

When wiring an output with capacitance it is essential to note

the pulse duration, repetition period and scan time of the powerup test, otherwise the load may switch on unintentionally.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-15

Page 44

4 Function description

1

4.4 Description of the units

4.4.3.3 LED

LED4-Funktion_Geraete_Empfaenger_LED_OSSD

OSSD

The OSSD LED on the receiver indicates the status of the protected

field.

Green: The protected field is clear

Funktion_Geraete_Empfaenger_LED_RL_D_Abbildung

Red: Protected field is interrupted

Fig. 4-9: LED on receiver

1: OSSD LED

4-16

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 45

4 Function description

PSENvip

12 3

46

MODE

ESC

5

MODE

ESC

4.4 Description of the units

4.4.3.4 Key display and function

Key display and function4-Funktion_Display_Allgemein

The PSENvip receiver has an integrated display. Data can be entered via

Funktion_Display_Pilz

a membrane keypad.

Funktion_Display_Legende

Funktion_Display_Tasten

Fig. 4-10: Display on the receiver

Key:

1: Navigation keys

2: <MODE> key

3: Display

4: <ESC> key

5: Tool change

6: <ENTER> key

Key functions

Key Description

Move in the direction of the arrows (scroll function) (up/

down)

Confirm entry - together with the <ENTER> key when confirming the entered overrun and making adjustments during

a tool change

Call up the operating modes: tool change and adjustment

during initial commissioning. The DIAGNOSTICS menu is

also available.

Close current window, cancel entry

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-17

Page 46

4 Function description

SYSTEM OK

OSSD ON

NORMAL OPERATION

À

Ã

Â

Á

4.4 Description of the units

Key Description

Funktion_Display_Abbildung

Display

Call up tool change operating mode directly

Confirm entry or menu option selection

Funktion_Display_Systemzustand

Fig. 4-11: Information on the display

The display is divided into 4 segments:

1: System status

2: Status of the OSSD

3: Input and display field

4: Operating status

4-18

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 47

4 Function description

4.4 Description of the units

System status

Status Description

SYSTEM OK The PSENvip is performing the specified operating mode

TEST The PSENvip is performing calibration and internal tests.

STANDBY The PSENvip is deactivated when the press is in setup

ERROR An error has occurred (HOLD, STOP, FATAL). See

Funktion_Display_OSSD

Status of the OSSD

Status Description

OSSD ON The output signal switching devices OSSD1 and OSSD2

OSSD OFF The output signal switching devices OSSD1 and OSSD2

Funktion_Display_Betriebszustand_P_Variante

without error, see table: "Operating status"

mode.

Chapter 9, "Diagnostics and Troubleshooting"

are in the ON state.

The protected field is clear.

are in the OFF state.

The protected field is interrupted. Or the PSENvip is not in

the status: SYSTEM OK or NORMAL OPERATION

Funktion_Display_Eingabe feld

Operating state

State Description

NORMAL OPERATION

SETUP This is the operating mode in which you enter the overrun.

TOOL CHANGE This is the operating mode in which you track the adjust-

ADJUSTMENT This is the operating mode in which you set up the trans-

DIAGNOSTICS System data and error codes are displayed in this menu.

MENU On pressing the <MODE> key, you can choose between

One of the protected field modes is activated.

See Chapter 8, "Operation"

See Chapter 7, "Commissioning"

ment line to the tip of the tool during a tool change.

See Chapter 7, "Commissioning"

mitter and receiver mechanically so that they are calibrated

with each other.

See Chapter 7, "Commissioning"

Pilz technical support can use these to locate errors.

See Chapter 9, "Diagnostics and Troubleshooting"

the following

options:

- TOOL CHANGE: Adjustment during tool change

- ADJUSTMENT: Adjustment during initial commissioning

- DIAGNOSTICS: Display error codes

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-19

Page 48

4 Function description

4.4 Description of the units

The input and display field is used to

Display the active protected field mode

See chapter 8, "Operation"

Enter the overrun

See chapter 7, "Commissioning"

Menu Selection

Display the adjustment image during initial commissioning

See chapter 7, "Commissioning"

Display the adjustment image during a tool change

See chapter 7, "Commissioning"

Display of error messages and system data

See Chapter 9, "Diagnostics and Troubleshooting"

4.4.4 Communication with the safety system

Communication with the safety system4-Funktion_Kommunikation_Allg

Communication between the PSENvip and safety system is required if

you use tools that cannot be safeguarded in compliance with the standards (see section entitled "Tool shapes", under "Safety"). This is the

case with tool classes 2 and 3. User programs that do not support communication with the PSENvip can be used if you only intend to safeguard

tools of tool class 1. This is the case with older versions of the PSENvip,

for example.

Communication between the PSENvip and the PLC safety system is

conducted via digital inputs and outputs. Some inputs and outputs on

the PSENvip have another function compared to normal mode.

Communication only occurs in the system status TEST. This status is

adopted

After power-up.

After a tool change.

After a 0/1 pulse edge at the input System-Init.

Funktion_Kommunikation_P_Variante

Periodically every 2 minutes.

4-20

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 49

4 Function description

X1, 1

PLC Ready

X2, 1

X1, 6

X2, 6

X2, 2

PSENvip

Tool class PLC -> PSENvip Bit 1

Acknowledge PSENvip -> PLC

Tool class PSENvip -> PLC Bit 1

X1, 3

X1, 4

Activate

Tool class PSENvip -> PLC Bit 2

Tool class PLC -> PSENvip Bit 2

PLC

I1

I4

I3

I2

O3

O2

O1

4.4 Description of the units

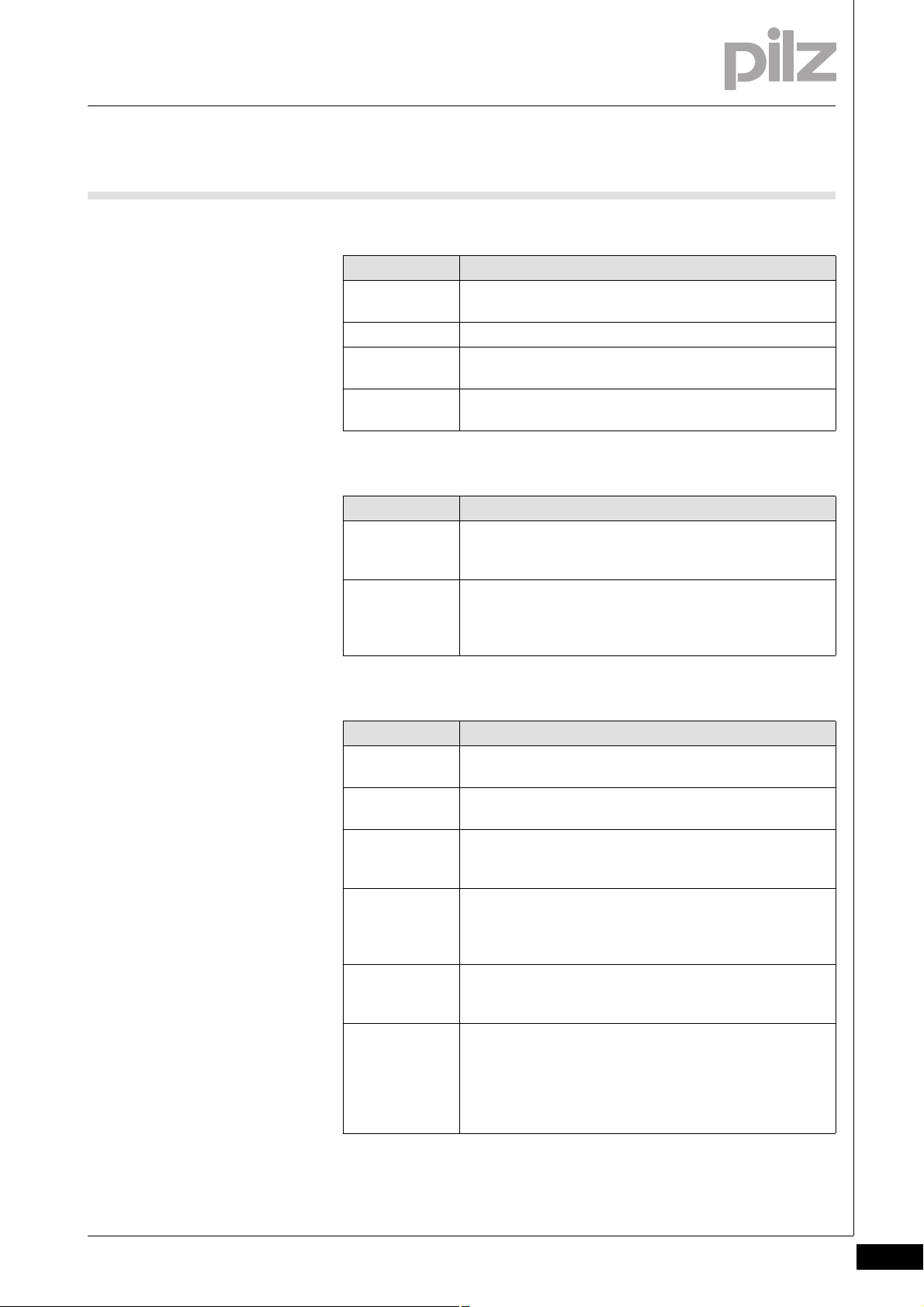

Terminal Input/output Normal mode Communication with safety sys-

X1, 1 Output No function Activate The PSENvip starts com-

X2, 1 Output No function Acknowledge PSENvip -> PLC The PSENvip confirms

X1, 6 Output Mute1 Tool class PSENvip -> PLC Bit 1 The PSENvip sends Bit 1

X2, 6 Output Mute2 Tool class PSENvip -> PLC Bit 2 The PSENvip sends Bit 2

X2, 2 Input Power Off PLC Ready The safety system is

X1, 3 Input Protected field

X1, 4 Input Protected field

Funktion_Kommunikation_Ablauf

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Fig. 4-12: Digital inputs and outputs for communication

Key to inputs and outputs:

tem

Tool class PLC -> PSENvip Bit 1 The safety system re-

mode 1

Tool class PLC -> PSENvip Bit 2 The safety system re-

mode 2

Notes

munication.

the validity of the tool

class registered on the

safety system.

of the detected tool class

to the safety system.

of the detected tool class

to the safety system.

ready for communication.

flects Bit 1 of the tool

class.

flects Bit 2 of the tool

class.

4-21

Page 50

4 Function description

PLC Ready

1

0

1

0

1

0

1

0

1

0

Activate

Acknowledge PSENvip -> PLC

1

0

Tool class PSENvip -> PLC Bit 1

1

0

Tool class PSENvip -> PLC Bit 2

Tool class PLC -> PSENvip Bit 1

Tool class PLC -> PSENvip Bit 2

12345 6 7

max. 600 ms

max.

200 ms

max.

200 ms

max.

200 ms

4.4 Description of the units

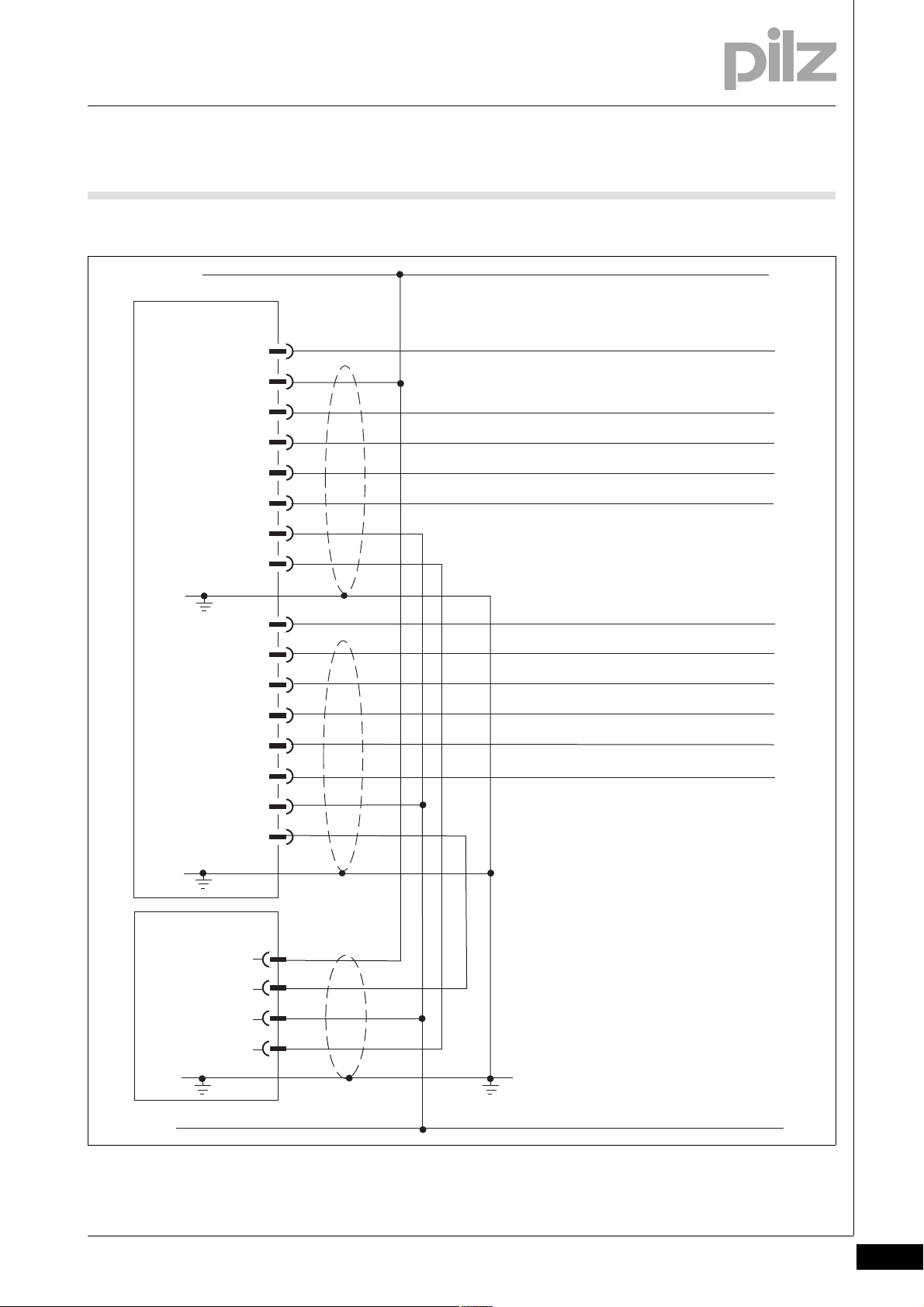

Communication sequence:

4-22

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

– The PSENvip starts communication.

Activate = 0/1 pulse edge

– Tool class PLC -> PSENvip Bit 1/2: Bits can have any status

2

– The safety system is ready for communication.

PLC Ready = 0/1 pulse edge

– Tool class PLC -> PSENvip Bit 1/2 = 0 to step 5

3

The PSENvip sends the detected tool class to the safety system.

Tool class PSENvip -> PLC Bit 1 0 1 1

Tool class PSENvip -> PLC Bit 2 1 0 1

4

The PSENvip confirms the validity of the tool class registered on the

safety system in step 3.

Acknowledge PSENvip -> PLC = 0/1 pulse edge

5

– The safety system reflects the tool class transmitted by the PSEN-

vip.

– Tool class PLC -> PSENvip Bit 1/2 = 0 or 1, depending on the tool

class

Tool class

123

Page 51

4 Function description

4.4 Description of the units

Tool class PLC -> PSENvip Bit 1 0 1 1

Tool class PLC -> PSENvip Bit 2 1 0 1

6

The PSENvip ends communication.

All outputs are set = 0:

– Activate = 0

– Acknowledge PSENvip -> PLC = 0

– Tool class PSENvip -> PLC Bit 1 = 0

– Tool class PSENvip -> PLC Bit 2 = 0

7

– The safety system ends communication.

PLC Ready = 1/0 pulse edge

– Tool class PLC -> PSENvip Bit 1/2 = 0 or 1, depending on the orig-

inal status

Tool class

123

INFORMATION

The requirements of the user program in the safety system are

described under "System Connections".

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-23

Page 52

4 Function description

4.5 Protected field modes

4.5Protected field modes4500Protected field modes4-Funktion_Schutzfeldmodus

Four protected field modes are available for adapting to different bending functions:

Full protected field: Standard press stroke

Reduced protected field:

– Box bending press stroke

– Back gauge press stroke

– Box bending with back gauge press stroke

Funktion_Schutzfeldmodus_Werkzeugklasse

Use of the protected field modes depends on the tool class. Not all protected field modes can be selected with tool class 2 and 3.

Protected field mode Tool class

Standard

Full protected field

Box bending

Front segments blanked

Back gauge

Rear segments blanked

123

Yes Yes Yes

Yes Yes No

Yes No No

4.5.1 Standard protected field mode

Standard protected field mode4-Funktion_Schutzfeldmodus_Standard

The full protected field is available with standard protected field mode.

This protected field mode is applied for flat workpieces.

Fig. 4-13: Standard protected field mode

4-24

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 53

4 Function description

1

4.5 Protected field modes

4.5.2 Box bending protected field mode

Box bending protected field mode4-Funktion_Schutzfeldmod us_Kastenbiegen

With box bending protected field mode, the front segments of the protected field are blanked. This protected field mode is used for workpieces that need to be bent several times, e.g. a box. Interruption of the front

segments is to be expected and does not cause the press stroke to

stop.

The central segments of the protected field are behind the bending line.

The box's side panels must not encroach into the central segments.

If the central or rear segments of the protected field are interrupted, the

OSSDs switch to the OFF state.

Sicherheit_Warnung_Quetschen_Kastenbiegen

Fig. 4-14: Box bending protected field mode

1: Front segments of protected field are blanked

The box bending protected field mode is only active for one press stroke

and must be acknowledged by the operator before it is initiated.

WARNING!

Crushing and trapping of fingers or hands!

With box bending protected field mode, the front segments of

the protected field are blanked.

Around the bending line there is an increased risk of crushing

and trapping of fingers or hands.

Make sure that the workpiece is handled correctly (see

Chapter 3, “Safety”).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-25

Page 54

4 Function description

1

4.5 Protected field modes

4.5.3 Back gauge protected field mode

Back gauge protected field mode4-Funktion_Schutzfeldmodus_Anschlag

With back gauge protected field mode, the rear segments of the protected field are blanked. This protected field mode is used when the rear

back gauge extends into the vicinity of the bending line. Interruption of

the rear segments is to be expected and does not cause the press

stroke to stop.

If the front and central segments of the protected field are interrupted,

the OSSDs switch to the OFF state.

Sicherheit_Warnung_Quetschen_Anschlag

Fig. 4-15: Back gauge protected field mode

1: Rear segments of protected field are blanked

The back gauge protected field mode is only active for one press stroke

and must be acknowledged by the operator before it is initiated.

WARNING!

Crushing and trapping of fingers or hands!

With back gauge protected field mode, the rear segments of the

protected field are blanked.

Around the bending line there is an increased risk of crushing

and trapping of fingers or hands.

Make sure that the workpiece is handled correctly (see

Chapter 3, “Safety”).

4-26

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 55

4 Function description

1

2

4.5 Protected field modes

4.5.4 Box bending with back gauge protected field mode

Box bending with back gauge protected field mode4-Funktion_Schutzfeldmodus_Kaste mbiegen_mit_Anschlag

With box bending with back gauge protected field mode, both the rear

and front segments of the protected fields are blanked. This protected

field mode is applied for workpieces that need to be bended several

times, e.g. boxes, and when the rear back gauge extends into the vicinity of the bending line. Interruption of the front and rear segments is to

be expected and does not cause the press stroke to stop.

The central segments of the protected field are behind the bending line.

The box's side panels must not encroach into the central segments.

If the central segments of the protected field are interrupted, the OSSDs

switch to the OFF state.

Fig. 4-16: Box bending with back gauge protected field mode

1: Rear segments of protected field are blanked

2: Front segments of protected field are blanked

The box bending with back gauge protected field mode is only active for

one press stroke and must be acknowledged by the operator before it is

initiated.

Sicherheit_Warnung_Quetschen_Kastenbiegen_Anschlag

WARNING!

Crushing and trapping of fingers or hands!

With box bending with back gauge protected field mode, both

the front and rear segments of the protected fields are blanked.

Around the bending line there is an increased risk of crushing

and trapping of fingers or hands.

Make sure that the workpiece is handled correctly (see

Chapter 3, “Safety”).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-27

Page 56

4 Function description

4.6 Operating modes during commissioning

4.6Operating modes during commissioning4600Operating modes during commissioning4-Funktion_Betriebsarten_Inbetriebnahme_Allg

The PSENvip has the following options for commissioning:

Press brake setup mode

Adjustment during initial commissioning

Adjustment during tool change

4.6.1 Press brake setup mode

Press brake setup mode4-Funktion_Betriebsarten_Inbetriebnahme_Einrichten

Setup mode must be activated when work is to be carried out on the

press brake. The transmitter and receiver must be switched off. The display is switched on. By switching off the transmitter's light source the

tool setter has visual communication that there is no safety function via

the protected field. The OSSD LED on the receiver lights up red.

The input Power Off = 1 switches off the transmitter's light source.

4.6.2 Adjustment during initial commissioning

Adjustment during initial commissioning4-Funktion_Betriebsarten_Inbetriebnahme_Justage_Erstinbetriebnehme

The transmitter and receiver are aligned to each other during initial commissioning. The vertical and horizontal alignment is performed using

templates and is displayed on the receiver.

In this operating mode

The protected field is inactive.

The OSSDs are switched off.

There is no protection via the PSENvip.

INFORMATION

Details of the adjustments made during initial commissioning are

described in Chapter 7, "Commissioning", section entitled "Initial commissioning".

4-28

4.6.3 Adjustment during tool change

Adjustment during tool change4-Funktion_Betriebsarten_Inbetriebnahme_Justage_Werkzeugwechsel_1

The tool is assigned to a tool class in "Tool change" operating mode.

Once the tool data has been saved it is downloaded to the safety system.

Funktion_Betriebsarten_Inbetriebnahme_Justage_Werkzeugwechsel

The adjustment line is automatically tracked to the tip of the tool. The

tracking is shown on the display. This makes it easier to adjust to the different tool sizes.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 57

4 Function description

4.6 Operating modes during commissioning

INFORMATION

Generally you should not have to mechanically realign the transmitter and receiver during a tool change.

In this operating mode

The protected field is inactive.

The OSSDs are switched off.

There is no protection via the PSENvip.

INFORMATION

Details of the adjustments made during a tool change are

described in Chapter 7, "Commissioning", section entitled

"Adjustment during tool change".

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-29

Page 58

4 Function description

TDC

6 mm

BDC

v = 0

v > 0

v < 0

v = 0

6 mm

KP

Mute 1/2

4.7 System cycle

4.7System cycle4700System cycle4-Funktion_Systemablauf_Muting

This section illustrates the interdependencies of the parameters on the

press brake, PSENvip and safety system during a press stroke. The following parameters are illustrated:

Status: Describes the cycle status. The upward movement of the

press is assumed as a safe movement.

Foot switch: Start/stop press stroke

System-Init: Press brake is at top dead centre

OSSD: Output signal switching devices of the PSENvip

Protected field: Free, interrupted

Mute 1/2: signals whether dynamic muting is activated or deactivat-

ed.

Mute 1/2 are reset to "1" when the protected field is completely ac-

tivated and the advance measuring field is free.

A protected field that has already been partly deactivated can be

completely reactivated by

– side intervention

– the signal System-Init = 1

Dynamic muting:

– reset: advance measuring field touches pinch point on the work-

piece

– End: Tool centre point reaches the 6 mm point

4-30

Fig. 4-17: Definitions

Legend:

TDC top dead centre

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6 mm: 6 mm point, end of dynamic muting

PP: Pinch point

BDC bottom dead centre

v = 0 mm/s closing speed at top/bottom dead centre

v > 0 mm/s downward movement

Page 59

4 Function description

v = 0

TDC

v > 0

4.7 System cycle

v > 0 mm/s upward movement

Mute 1/2: Segment switches outputs Mute 1 and Mute 2

4.7.1 System cycle for standard press stroke

System cycle for standard press stroke4-Funktion_Systemablauf_Pressenhub_Standard_Muting

Inputs on the PSENvip receiver:

Protected field mode 1 = 0

Protected field mode 2 = 0

Power Off = 0

1

Status Press is at top dead centre

Foot switch 0

System-Init 1

OSSD 0

Protected field Free

Mute 1/2 0

Dynamic muting Inactive

2

Status Downward movement

Foot switch 1

System-Init 0

OSSD 1

Protected field Free

Mute 1/2 1

Dynamic muting Inactive

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-31

Page 60

4 Function description

v > 0

KP

v > 0

KP

8 mm

v > 0

6 mm

6 mm

4.7 System cycle

3

Status Downward movement

Advance measuring field touches

plate (pinch point)

Foot switch 1

System-Init 0

OSSD 1

Protected field Free

Mute 1/2 1 -> 0

Dynamic muting Start

4

Status Downward movement

Tool centre point reaches the 8 mm

point

Foot switch 1

System-Init 0

OSSD 1

Protected field Free

Mute 1/2 0

Dynamic muting Active

5

Status Downward movement

Tool centre point reaches the 6 mm

point

Foot switch 1

System-Init 0

OSSD 1 -> 0

Muting of the OSSD in steps 5 to 8 in

the safety system

Protected field Interrupted

Mute 1/2 0

Dynamic muting End

4-32

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 61

4 Function description

v > 0

6 mm

v = 0

BDC

v < 0

4.7 System cycle

6

Status Downward movement

Foot switch 1

System-Init 0

OSSD 0

Protected field Interrupted

Mute 1/2 0

Dynamic muting Inactive

7

Status Press is at bottom dead centre

Foot switch 1

System-Init 0

OSSD 0

Protected field Interrupted

Mute 1/2 0

Dynamic muting Inactive

8

Status Upward movement

Advance measuring field is cleared

Foot switch 1

Generally, the press travels up auto-

matically, the operator can release the

foot switch.

System-Init 1

OSSD 1 or 0

Protected field Free or interrupted

Mute 1/2 0 - > 1

Dynamic muting Inactive

Continue with step 1

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-33

Page 62

4 Function description

TDC

v = 0

v > 0

4.7 System cycle

4.7.2 System cycle for box bending press stroke

System cycle for box bending press stroke4-Funktion_Systemablauf_Pressenhub_Kastenbiegen_Muting

Inputs on the PSENvip receiver:

Protected field mode 1 = 0

Protected field mode 2 = 1

Acknowledgement of reduced protected field = Press pushbutton

and then release

1

Status Press is at top dead centre

Foot switch 0

System-Init 1

OSSD 0

Protected field Free

Mute 1/2 0

Dynamic muting Inactive

2

Status Downward movement

Foot switch 1

System-Init 0

OSSD 1

Protected field Free

Mute 1/2 1

Dynamic muting Inactive

4-34

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 63

4 Function description

v > 0

KP

v > 0

KP

8 mm

v > 0

6 mm

6 mm

4.7 System cycle

3

Status Downward movement