Page 1

PSEN sg2c

Operating Manual 1003267-EN-04

} PSEN sensor technology

Page 2

Preface

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Source code from third-party manufacturers or open source software has been used for

some components. The relevant licence information is available on the Internet on the Pilz

homepage.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®,

SafetyEYE®, SafetyNET p®, the spirit of safety® are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries.

SD means Secure Digital

Page 3

Contents

Operating Manual PSEN sg2c

1003267-EN-04

3

Section 1 Introduction 5

1.1 Validity of documentation 5

1.2 Using the documentation 5

1.3 Definition of symbols 5

Section 2 Overview 7

2.1 Scope of PSEN sg2c Unit 7

2.2 Unit features 7

Section 3 Safety 8

3.1 Intended use 8

3.2 Safety regulations 8

3.2.1 Safety assessment 8

3.2.2 Use of qualified personnel 8

3.2.3 Warranty and liability 9

3.2.4 Disposal 9

3.3 For your safety 9

Section 4 Function description 10

4.1 Normal /Unlock mode 10

4.2 Escape release 11

4.3 Auxiliary release 13

4.4 Restart interlock 14

4.5 Holding forces 15

4.6 Pushbutton 16

4.7 Device types 17

4.8 Block diagram 21

Section 5 Wiring 22

5.1 Notes on cable run 22

5.2 Recommended cable cross sections 23

5.3 General wiring guidelines 23

5.4 Terminal configuration 24

5.5 Wiring the connection terminals 25

5.6 E-STOP pushbutton connection 26

5.7 Enabling switch connection 26

5.8 EMC requirements 26

5.9 Connection to evaluation devices 27

5.9.1 Connection examples PNOZmulti 27

5.9.2 Connection examples PSS 27

5.10 Single connection 27

5.11 Series connection 28

Section 6 Installation 30

6.1 Initial installation of safety switch 31

6.2 Initial installation of handle unit 36

Page 4

Contents

Operating Manual PSEN sg2c

1003267-EN-04

4

6.3 Second installation of safety switch and handle unit / upgrade for lefthinged gates

37

6.4 Labelling the pushbuttons 37

6.5 Dimensions in mm 39

6.5.1 Drill holes 39

6.5.2 PSEN sg2c-3xxx 40

6.5.3 PSEN sg2c-5xxxxx 41

6.5.4 PSEN sg2c-5xxxxx-M12/5 42

Section 7 Adjustment 43

Section 8 Maintenance 44

Section 9 Operation 45

9.1 Status table 47

9.2 Toggle normal/unlock mode 48

9.3 Remedy 49

Section 10 Technical Details Order No. 570800-570804 51

Section 11 Technical Details Order No. 570806-570810 56

Section 12 Technical Details Order No. 570812-570816 60

Section 13 Technical Details Order No. 570818-570822 65

Section 14 Technical Details Order No. 570824-570828 69

Section 15 Technical Details Order No. 570830-570834 74

Section 16 Technical Details Order No. 570880-570884 78

Section 17 Safety characteristic data 82

Section 18 Order reference 83

18.1 Unit 83

18.2 Safety switch 84

18.3 Handle unit with actuator 85

18.4 Accessories 85

Section 19 Supplementary data 87

19.1 Radio approval 87

19.2 EC declaration of conformity 87

Page 5

Introduction

Operating Manual PSEN sg2c

1003267-EN-04

5

1 Introduction

1.1 Validity of documentation

This documentation is valid for the product PSEN sg2c. It is valid until new documentation

is published.

This operating manual explains the function and operation, describes the installation and

provides guidelines on how to connect the product.

1.2 Using the documentation

This document is intended for instruction. Only install and commission the product if you

have read and understood this document. The document should be retained for future reference.

1.3 Definition of symbols

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses

an immediate threat of serious injury and death and indicates preventive

measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that could

lead to serious injury and death and indicates preventive measures that can

be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the product or devices could be damaged and also provides information on preventive measures that can be

taken. It also highlights areas within the text that are of particular importance.

Page 6

Introduction

Operating Manual PSEN sg2c

1003267-EN-04

6

INFORMATION

This gives advice on applications and provides information on special features.

Page 7

Overview

Operating Manual PSEN sg2c

1003267-EN-04

7

2 Overview

2.1 Scope of PSEN sg2c Unit

} Safety switch

} Handle unit with actuator

} Colour covers for illuminated buttons

} Pin for escape release

2.2 Unit features

} Safe guard locking (only for revolving gates and swing gates)

} Safe interlocking (position monitoring)

} Transponder technology

} 2 safety inputs for series connection of multiple safety switches

} 2 safety outputs

} Guard locking element keeps the safety gate from being opened unintentionally

} Detection of broken bolt tongue and broken guard locking element

} Handle unit with locking lever to attach padlocks as a restart interlock

} Auxiliary release for opening the safety gate, when the plant's voltage is switched off

} Escape release for fast manual release of the guard locking in emergency situations

from within the danger zone (revolving gates and swing gates)

} Suitable for left and right hinged safety gates

Note: The handle unit PSEN sg2c actuator is only suitable for revolving gates and

swing gates.

} Plug-in spring-loaded terminals

} LED indicator for:

– Supply voltage/fault

– Gate locked

– State of the hazardous machine

– Request to stop the machine

– State of the inputs

– Bolt tongue engaged

} Depends on device type

– Various control elements, for example integral E-STOP pushbutton, section stop

pushbutton, key-operated pushbutton, key switch...

– Coding:

- coded

- uniquely coded

See section entitled Device types

Page 8

Safety

Operating Manual PSEN sg2c

1003267-EN-04

8

3 Safety

3.1 Intended use

The safety gate system is used for guard locking and interlocking swing gates and revolving

gates.

It meets the requirements in accordance with:

} EN 60947-5-3

} EN ISO 14119

} EN 62061: SIL CL 3

} EN ISO 13849-1: Up to PL e (Cat. 4)

The safety level PL e (Cat. 4)/SIL CL 3 can be achieved when

} The safety outputs use 2-channel processing and

} The solenoid is operated 2-channel via safe relay outputs, suitable for PL e (Cat. 4)/SIL

CL 3 applications.

Wiring errors should be excluded using appropriate measures. The potential solutions

are the protected cable layout or the use of pulsed semiconductor outputs.

3.2 Safety regulations

3.2.1 Safety assessment

Before using a unit it is necessary to perform a safety assessment in accordance with the

Machinery Directive.

Functional safety is guaranteed for the product as a single component. However, this does

not guarantee the functional safety of the overall plant/machine. In order to achieve the required safety level for the overall plant/machine, define the safety requirements for the

plant/machine and then define how these must be implemented from a technical and organisational standpoint.

3.2.2 Use of qualified personnel

The products may only be assembled, installed, programmed, commissioned, operated,

maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the

work equipment, devices, systems, plant and machinery in accordance with the general

standards and guidelines for safety technology.

It is the company’s responsibility only to employ personnel who:

} Are familiar with the basic regulations concerning health and safety / accident preven-

tion

} Have read and understood the information provided in this description under "Safety"

} And have a good knowledge of the generic and specialist standards applicable to the

specific application.

Page 9

Safety

Operating Manual PSEN sg2c

1003267-EN-04

9

3.2.3 Warranty and liability

All claims to warranty and liability will be rendered invalid if

} The product was used contrary to the purpose for which it is intended

} Damage can be attributed to not having followed the guidelines in the manual

} Operating personnel are not suitably qualified

} Any type of modification has been made (e.g. exchanging components on the PCB

boards, soldering work etc.).

3.2.4 Disposal

} In safety-related applications, please comply with the mission time TM in the safety-re-

lated characteristic data.

} When decommissioning, please comply with local regulations regarding the disposal of

electronic devices (e.g. Electrical and Electronic Equipment Act).

3.3 For your safety

WARNING!

Potential loss of safety function during adjustment and repair work!

When carrying out adjustment and repair work, make sure that the power

supply of the plant is switched off and protected against switching on again.

WARNING!

Loss of safety function due to manipulative use of substitute actuating elements!

When substitute actuating elements are used, these have to be installed as

described in chapter Initial installation of safety switch [ 31]. When substitute actuating elements are used in a manipulative way to defeat the protective device, operating the plant presents a threat to life.

The operator has to consider this in the hazard analysis and he must determine possible countermeasures.

Page 10

Function description

Operating Manual PSEN sg2c

1003267-EN-04

10

4 Function description

The interlocking and guard locking system prevents the safety gates to the danger zone

from opening while the hazardous machine is switched on.

There is a high signal (safety gate closed and locked) at safety outputs X1-3 and X1-4 if the

following conditions are met simultaneously:

} Inputs X2-3 and X2-4 are high and

} The bolt tongue is within the response range and

} The guard locking element is engaged in the bolt tongue and

} The escape or auxiliary release pin is in the correct position.

Signal output X1-9 is high if:

} The bolt tongue is within the response rang

There is a low signal (safety gate open and hazardous machine function interlocked) at

safety outputs X1-3 and X1-4 if the following occurs:

} Inputs X2-3 or X2-4 are low or

} The guard locking element is outside the bolt tongue or

} The escape or auxiliary release has been operated or

} The guard locking element is not engaged in the bolt tongue.

If the safety outputs have been shut down by either of the inputs X2-3 or X2-4, they cannot

be switched back on until both inputs are low simultaneously.

To operate the solenoid, a high signal must be present at X1-6 (X2-6) and at X1-7 (X2-7)

after the hazardous movement has been ended.

4.1 Normal /Unlock mode

Normal mode:

The safety gate to the danger zone is not unlocked until the hazardous machine is stopped

and the pushbutton for access request has been operated.

} The guard locking element is disengaged from the bolt tongue as soon as there is a

high signal at terminals X1-6 and X1-7 or X2-6 and X2-7, followed by operation of the

pushbutton for access request.

Unlock mode:

The safety gate to the danger zone is unlocked when the hazardous machine is stopped.

This enables easier access for cleaning staff once the shift has ended, for example.

} The guard locking element is disengaged from the bolt tongue as soon as there is a

high signal at terminals X1-6 and X1-7 or X2-6 and X2-7.

Page 11

Function description

Operating Manual PSEN sg2c

1003267-EN-04

11

4.2 Escape release

The escape release enables the guard locking to be manually released from within the

danger zone.

[1]

[2]

[3]

[4]

[1]

[2]

Mode of operation

Within the danger zone, if the escape release pin [1] is pressed in the direction of the safety

gate, the cover on the escape release [2] detaches from the locked position and lifts upwards. The swivel piece [3] folds downwards. The bolt tongue [4] behind the swivel piece is

released. The safety gate can be opened immediately, enabling the operator to leave the

danger zone.

Page 12

Function description

Operating Manual PSEN sg2c

1003267-EN-04

12

WARNING!

Loss of safety function due to the incorrect installation of the escape release!

If the escape release pin is accessible from the outside, the guard locking

device can be released from the outside and the safety gates opened, although the hazardous machine is switched on.

Depending on the application, serious injury or death may result.

The escape release should be installed so that it is only accessible from inside the danger zone.

It is also important to refer to the maintenance instructions (see chapter entitled Maintenance [ 44])

INFORMATION

When the escape or auxiliary release is operated, there is a low signal at

the safety outputs X1-3 and X1-4. An error code is issued (see section entitled Remedy [ 49]). The PSENsgate is not ready for operation again

until the escape release or auxiliary release has been reset to its unoperated state and the error has been rectified and reset.

Please note that the cover of the escape release has to be checked and reinstalled after operation.

Page 13

Function description

Operating Manual PSEN sg2c

1003267-EN-04

13

4.3 Auxiliary release

When the plant is powered down, the auxiliary release enables the guard locking device to

be released from the access side to the danger zone.

[1]

[2]

[4]

[3]

Mode of operation:

Carefully remove the cover of the escape release (1) from the latch below. Use a screwdriver (2) to pull out the escape or auxiliary release pin (3) from the swivel piece (4). The

swivel piece folds downwards, the bolt tongue behind the swivel piece is released. The

safety gate to the danger zone can be opened.

INFORMATION

When the escape or auxiliary release is operated, there is a low signal at

the safety outputs X1-3 and X1-4. An error code is issued (see section entitled Remedy [ 49]). The PSENsgate is not ready for operation again

until the escape release or auxiliary release has been reset to its unoperated state and the error has been rectified and reset.

Please note that the cover of the escape release has to be checked and reinstalled after operation.

Page 14

Function description

Operating Manual PSEN sg2c

1003267-EN-04

14

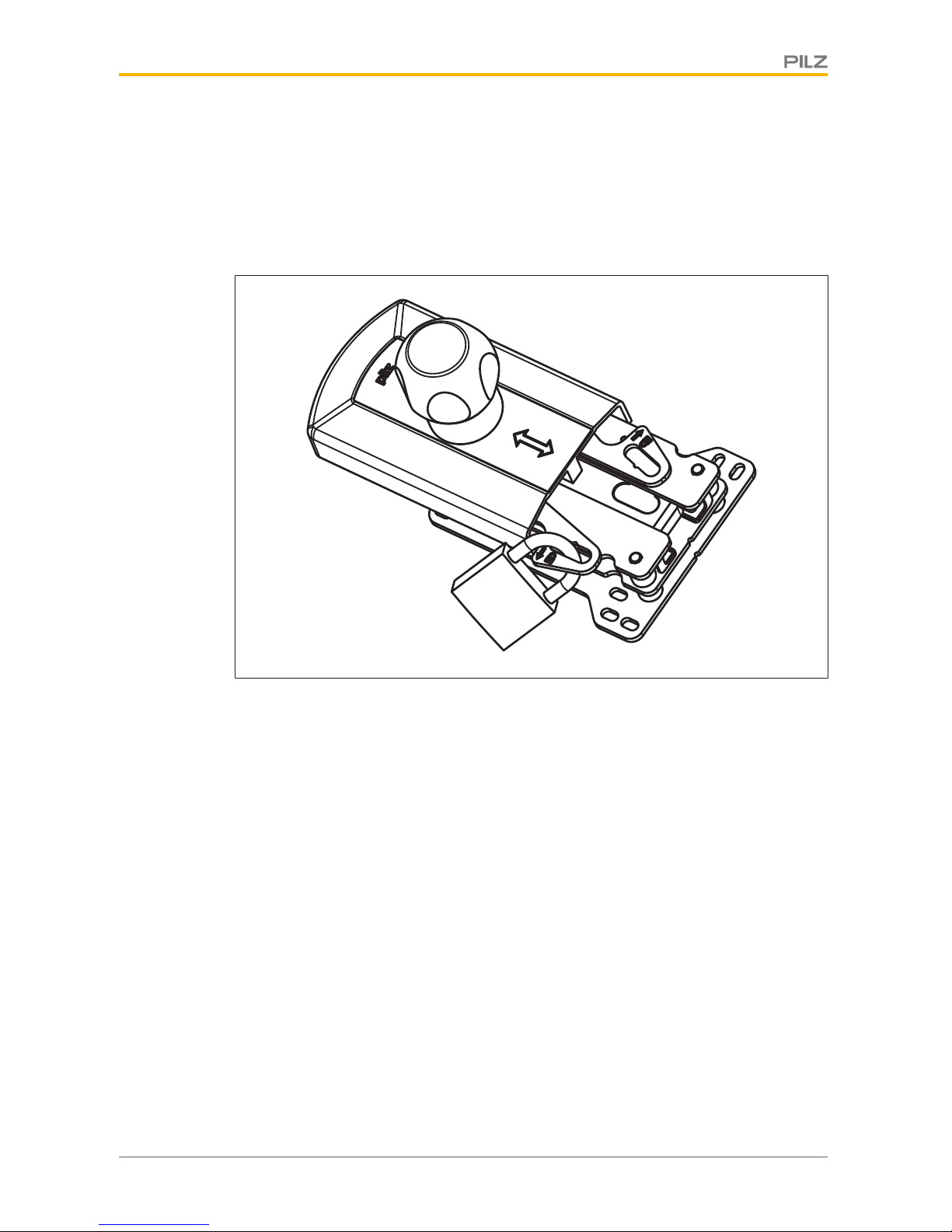

4.4 Restart interlock

To prevent the machine restarting while there is someone inside the danger zone, a padlock can be attached to one of the locking levers (see illustration). As a result, the guard

locking element cannot engage in the bolt tongue, the guard locking device is not activated

and the machine is prevented from restarting.

The padlock's shackle diameter may be max. 8 mm.

Page 15

Function description

Operating Manual PSEN sg2c

1003267-EN-04

15

4.5 Holding forces

The maximum holding forces that can be used to lock the safety gate are stated in the technical details.

A distinction is made between the following holding forces:

} Holding force in pan direction and

} Holding force in closing direction

Holding force in closing direction

Holding force in pan direction

Page 16

Function description

Operating Manual PSEN sg2c

1003267-EN-04

16

4.6 Pushbutton

Pushbutton 1

Pushbutton 2

Pushbutton 1

Pushbutton 2

Pushbutton 3

Pushbutton 4

PSEN sg2c-3... PSEN sg2c-5...

E-Stop/

Section stop

E-Stop/

Section stop

} Pushbutton 1: pushbutton for activating the safety gate guard locking device

By pressing the pushbutton for activating guard locking, the guard locking element is

engaged in the bolt tongue when the bolt tongue is detected by the sensor and a high

signal is present at X1-6 and X1-7 or at X2-6 and X2-7 (solenoid operation).

} Pushbutton 2: pushbutton for access request and release of the safety gate

– Pressing the pushbutton for access request disengages the guard locking element

from the bolt tongue when a high signal is present at X1-6 and X1-7 or at X2-6 and

X2-7 (solenoid operation).

– Pressing the pushbutton for access request switches output X1-5 (access request)

when a low signal is present at X1-6 and X1-7 or at X2-6 and X2-7 (solenoid operation).

Depending on the design, the device also has:

} E-STOP / or section stop pushbutton

} Pushbutton 3 and pushbutton 4

Pushbuttons that can be used depending on the application:

– Operating a pushbutton switches the pushbutton output

– The LEDs of the pushbuttons can be operated via the LED inputs.

Further information on the different types can be found in the section entitled Device

types [ 17].

Page 17

Function description

Operating Manual PSEN sg2c

1003267-EN-04

17

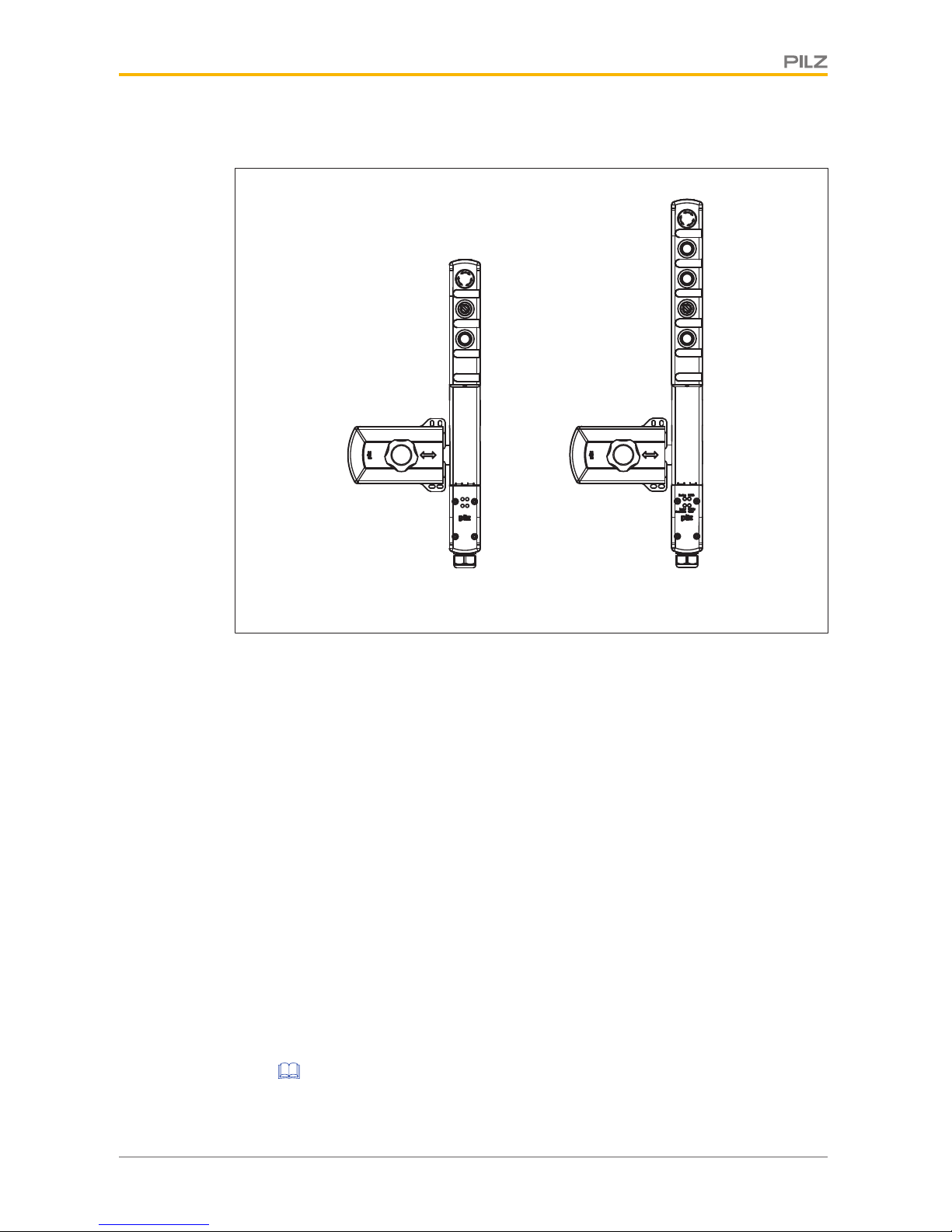

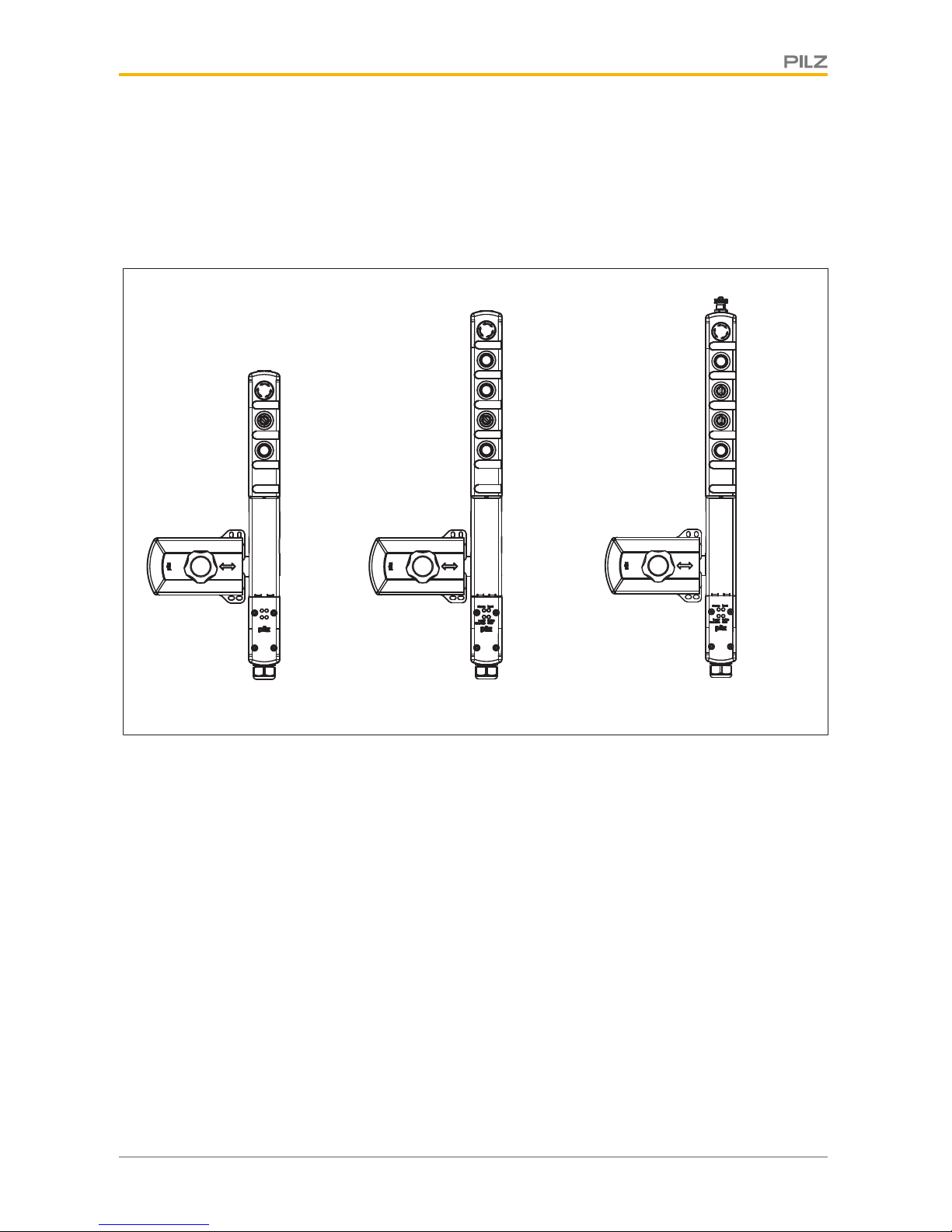

4.7 Device types

21 different versions are available. They differ as follows:

} Number and quality of the pushbuttons

} Coded or uniquely coded

} With or without M12 connection for enabling switch

PSEN sg2c-3xxx PSEN sg2c-5xxxxx

PSEN sg2c-5xxxxx-M12/5

[1]

[2]

[3]

[1]

[2]

[3]

[4]

[5]

[1]

[2]

[3]

[4]

[5]

[6]

Page 18

Function description

Operating Manual PSEN sg2c

1003267-EN-04

18

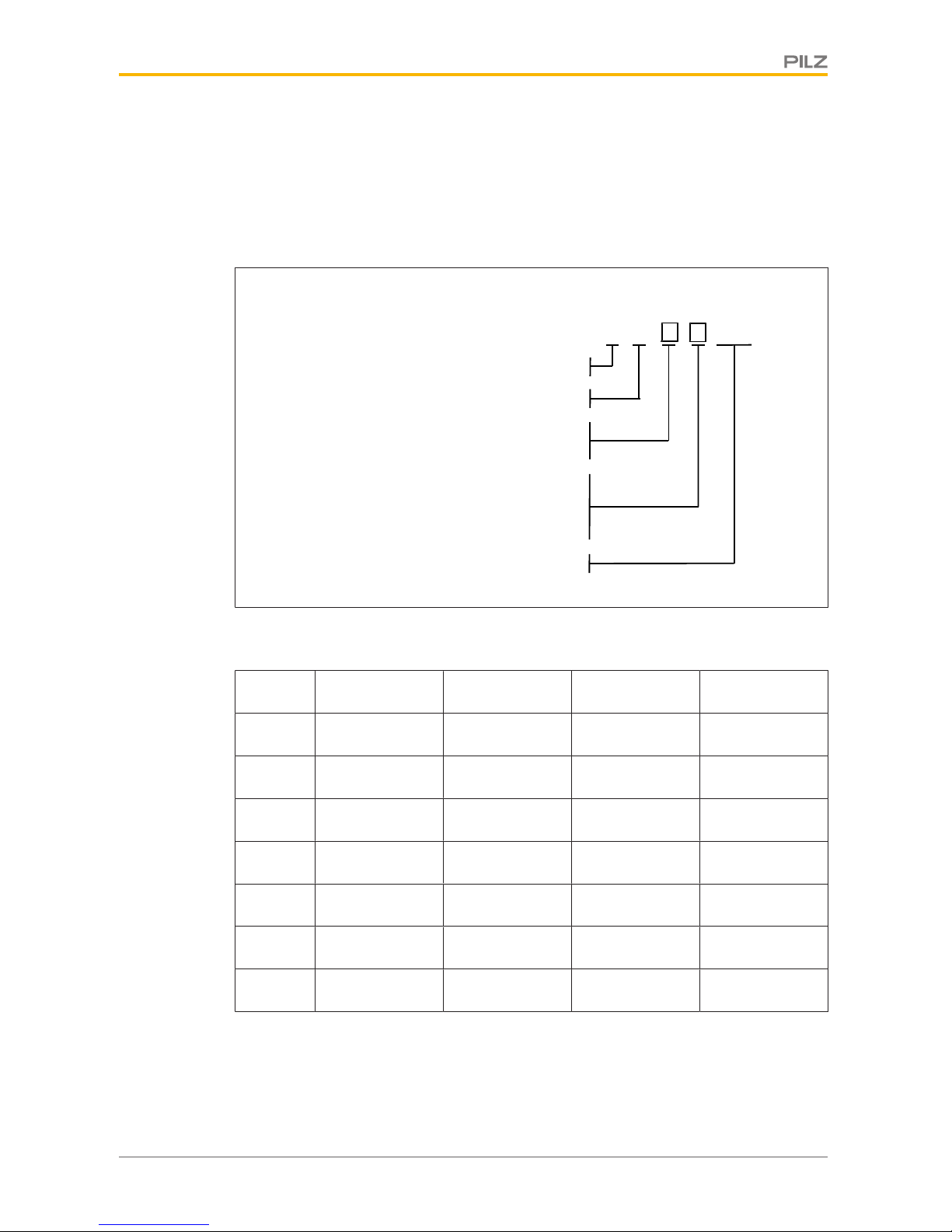

PSEN sg2c-3xxx (3 pushbuttons)

[1] Pushbutton 1: pushbutton for activating the safety gate guard locking device

[2] Pushbutton 2: pushbutton for access request and release of the safety gate

[3] E-STOP / or section stop pushbutton

Type code:

PSEN sg2c - 3 L X X 2.2*

3 pushbuttons = 3

Pushbutton illuminated = L

Pushbutton unilluminated = P

Key switch = B

E-STOP pushbutton = E

Section stop pushbutton = S

No pushbutton = C

uniquely coded

[1] [2] [3]

*not included with all versions

Types:

Pushbutton 1 Pushbutton 2 E-Stop/

Section stop

Coding

-3LPE Pushbutton

illuminated

Pushbutton

unilluminated

E-Stop coded

-3LBE Pushbutton

illuminated

Key

switch

E-Stop coded

-3LPS Pushbutton

illuminated

Pushbutton

unilluminated

Section

stop

coded

-3LBS Pushbutton

illuminated

Key-operated

pushbutton

Section

stop

coded

-3LPC Pushbutton

illuminated

Pushbutton

unilluminated

--- coded

-3LBC Pushbutton

illuminated

Key-operated

pushbutton

--- coded

-3LPE 2.2 Pushbutton

illuminated

Pushbutton

unilluminated

E-Stop uniquely coded

Page 19

Function description

Operating Manual PSEN sg2c

1003267-EN-04

19

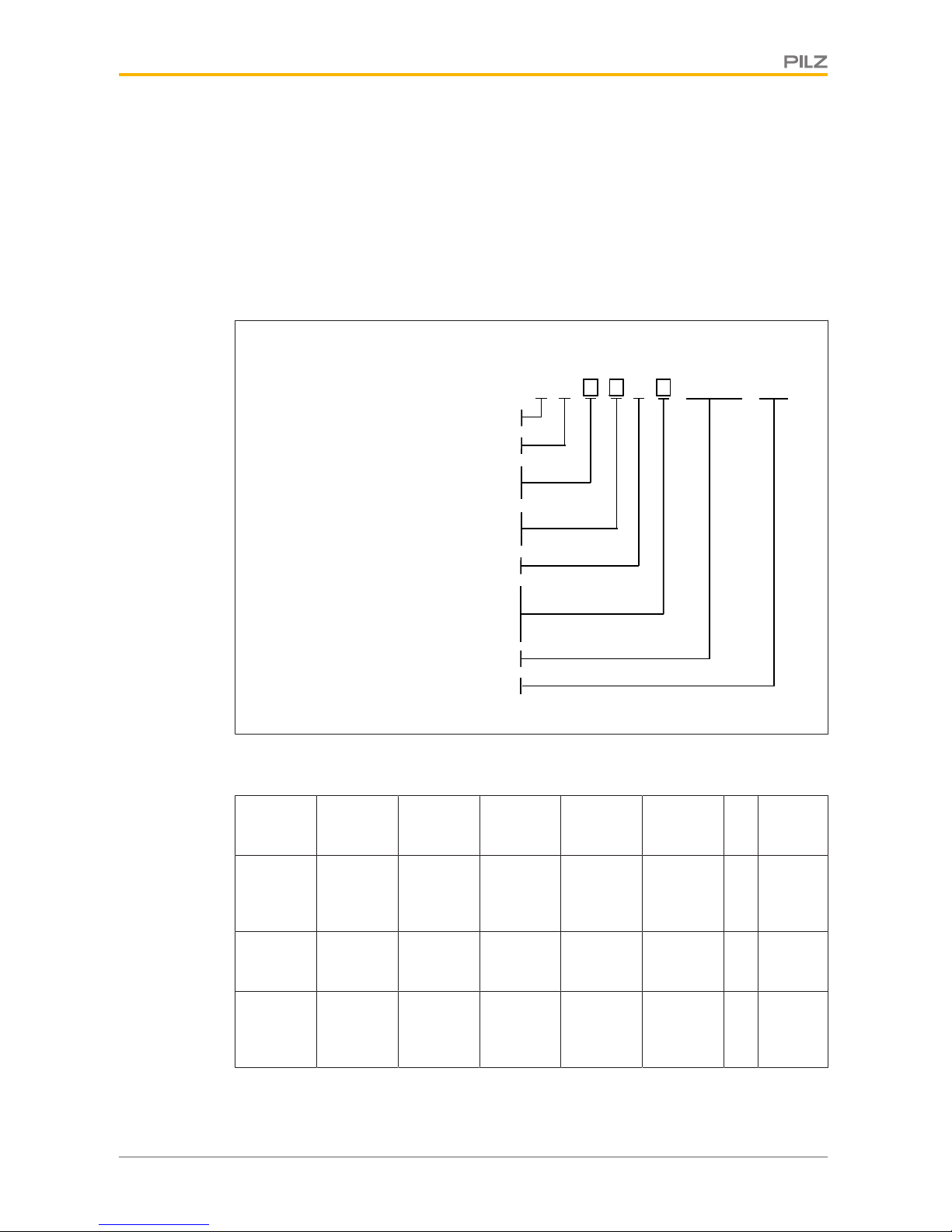

PSEN sg2c-5-xxxxx and PSEN sg2c-5-xxxxx-M12 (5 pushbuttons):

[1] Pushbutton 1: pushbutton for activating the safety gate guard locking device

[2] Pushbutton 2: pushbutton for access request and release of the safety gate

[3], [4] pushbuttons 3 - 4: can be used depending on the application

[5] E-STOP / or section stop pushbutton

[6] M12 connection for enabling switch

Type code:

PSEN sg2c - 5 L X X L X - M12/5* 2.2*

5 pushbuttons = 5

Enabling switch

Pushbutton illuminated = L

Pushbutton unilluminated = P

Key switch = B

E-STOP pushbutton = E

Section stop pushbutton = S

No pushbutton = C

uniquely coded

Pushbutton illuminated = L

Key switch = B

Pushbutton illuminated = L

[1] [2] [3] [4] [5] [6]

Fig.: *not included with all versions

Types:

Pushbut-

ton 1

Pushbut-

ton 2

Pushbut-

ton 3

Pushbut-

ton 4

E-Stop/

Section

stop

M12Coding

-5LPLLE Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

E-Stop --- coded

-5LBLLE Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

E-Stop --- coded

-5LPLLS Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

Section

stop

--- coded

Page 20

Function description

Operating Manual PSEN sg2c

1003267-EN-04

20

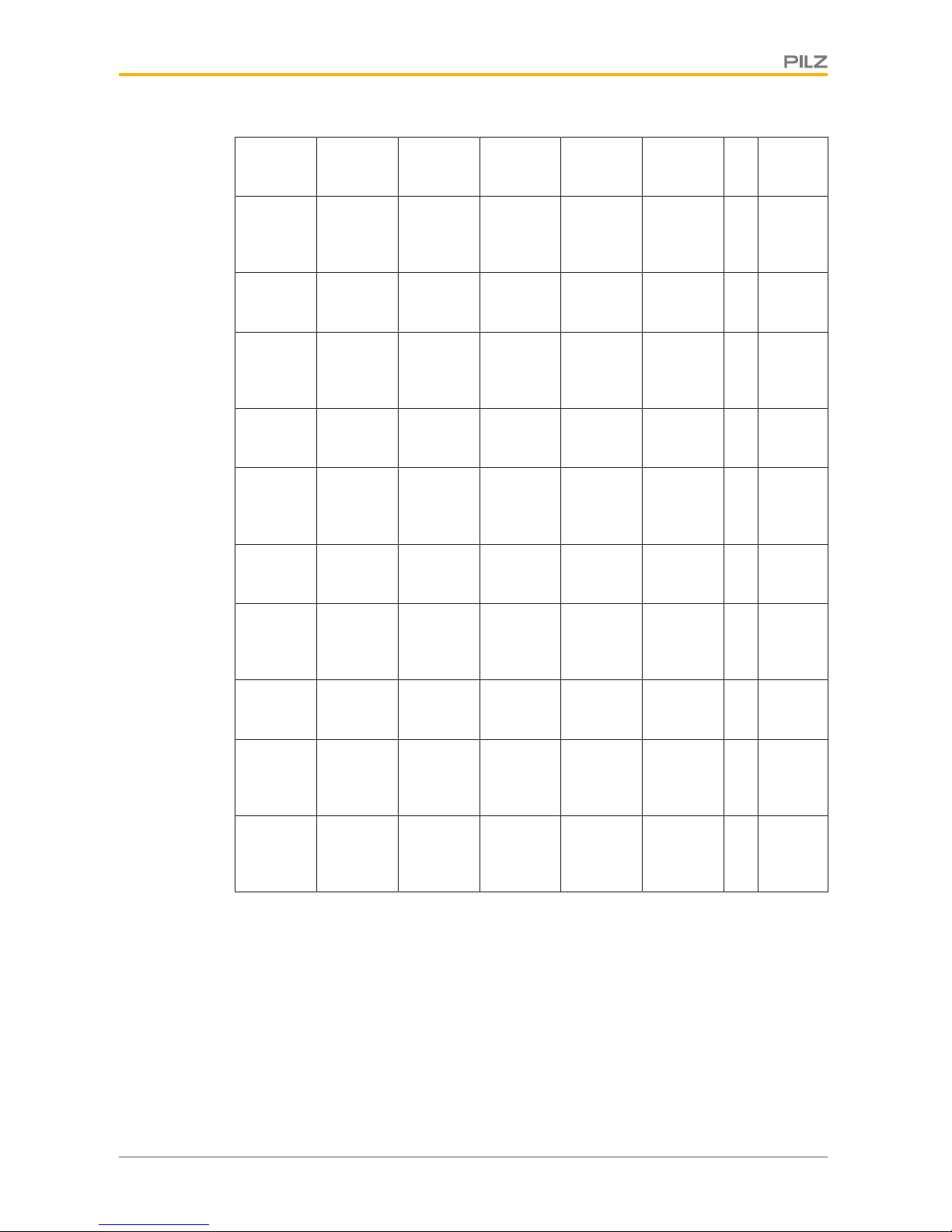

-5LBLLS Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

Section

stop

--- coded

-5LPLLC Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

--- --- coded

-5LBLLC Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

--- --- coded

-5LPKLEM12/5

Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Key

switch

Pushbut-

ton

illuminated

E-Stop Yes coded

-5LBKLEM12/5

Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Key

switch

Pushbut-

ton

illuminated

E-Stop Yes coded

-5LPKLSM12/5

Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Key

switch

Pushbut-

ton

illuminated

Section

stop

Yes coded

-5LBKLSM12/5

Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Key

switch

Pushbut-

ton

illuminated

Section

stop

Yes coded

-5LPKLCM12/5

Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Key

switch

Pushbut-

ton

illuminated

--- --- coded

-5LBKLCM12/5

Pushbut-

ton

illuminated

Key-oper-

ated

pushbutton

Key

switch

Pushbut-

ton

illuminated

--- Yes coded

-5LPLLE

2.2

Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Pushbut-

ton

illuminated

Pushbut-

ton

illuminated

E-Stop --- uniquely

coded

-5LPKLEM12/5 2.2

Pushbut-

ton

illuminated

Pushbut-

ton

unillumin-

ated

Key

switch

Pushbut-

ton

illuminated

E-Stop Yes uniquely

coded

Page 21

Function description

Operating Manual PSEN sg2c

1003267-EN-04

21

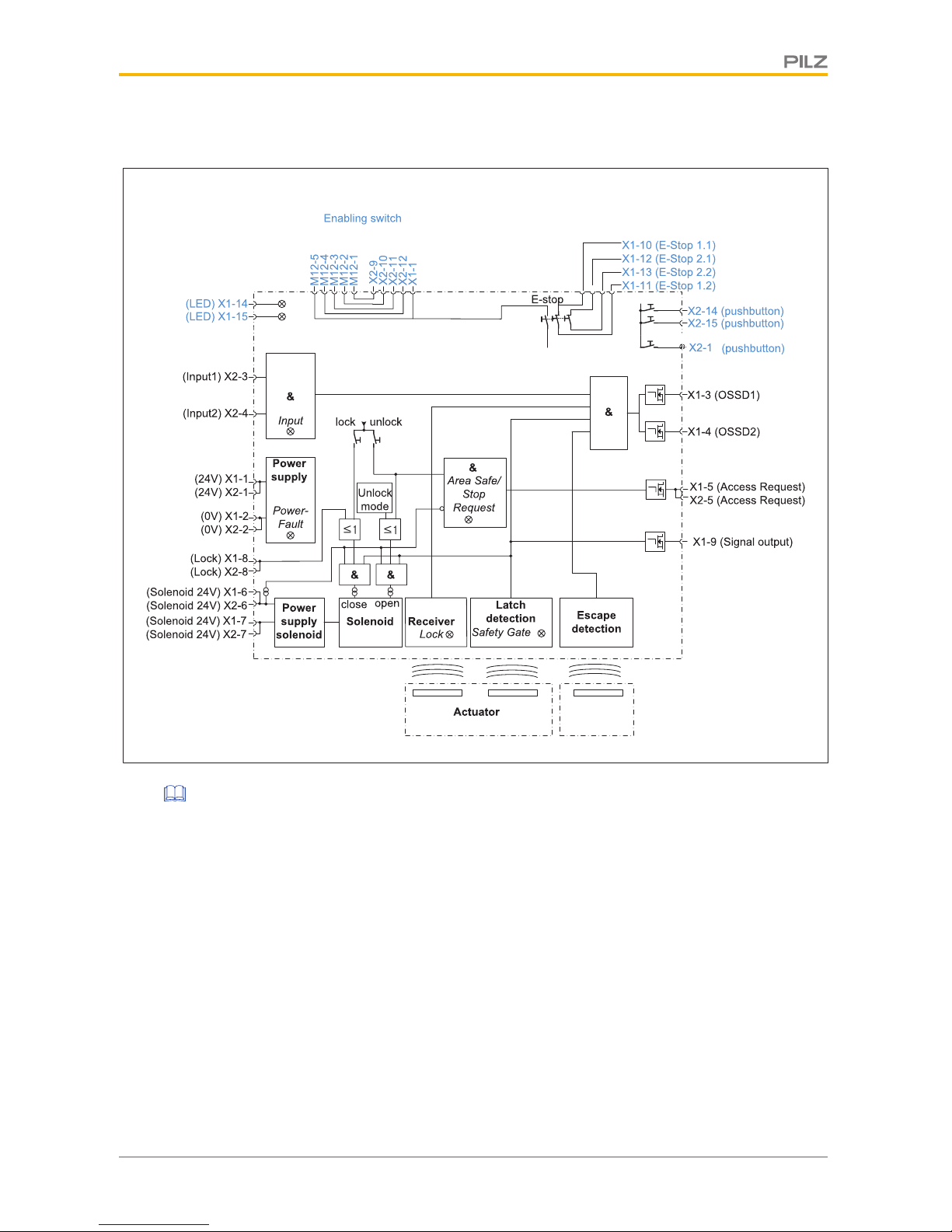

4.8 Block diagram

6

3

24 V

Escape

Release Pin

24 V

(Connector)

Fig.: The connections shown in blue are available depending on the device type (see section entitled Device

types [ 17]).

Page 22

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

22

5 Wiring

5.1 Notes on cable run

The maximum cable run depends on the voltage drop in the supply voltage conductors for

solenoid operation. The level of voltage drop is determined by the

} cable resistance of the cables

} solenoid current of the solenoid

If the voltage drop in the supply voltage conductors becomes too high, the voltage for

solenoid operation can permanently be set to the upper tolerance range (see Technical details).

The max. cable diameter is 10 mm.

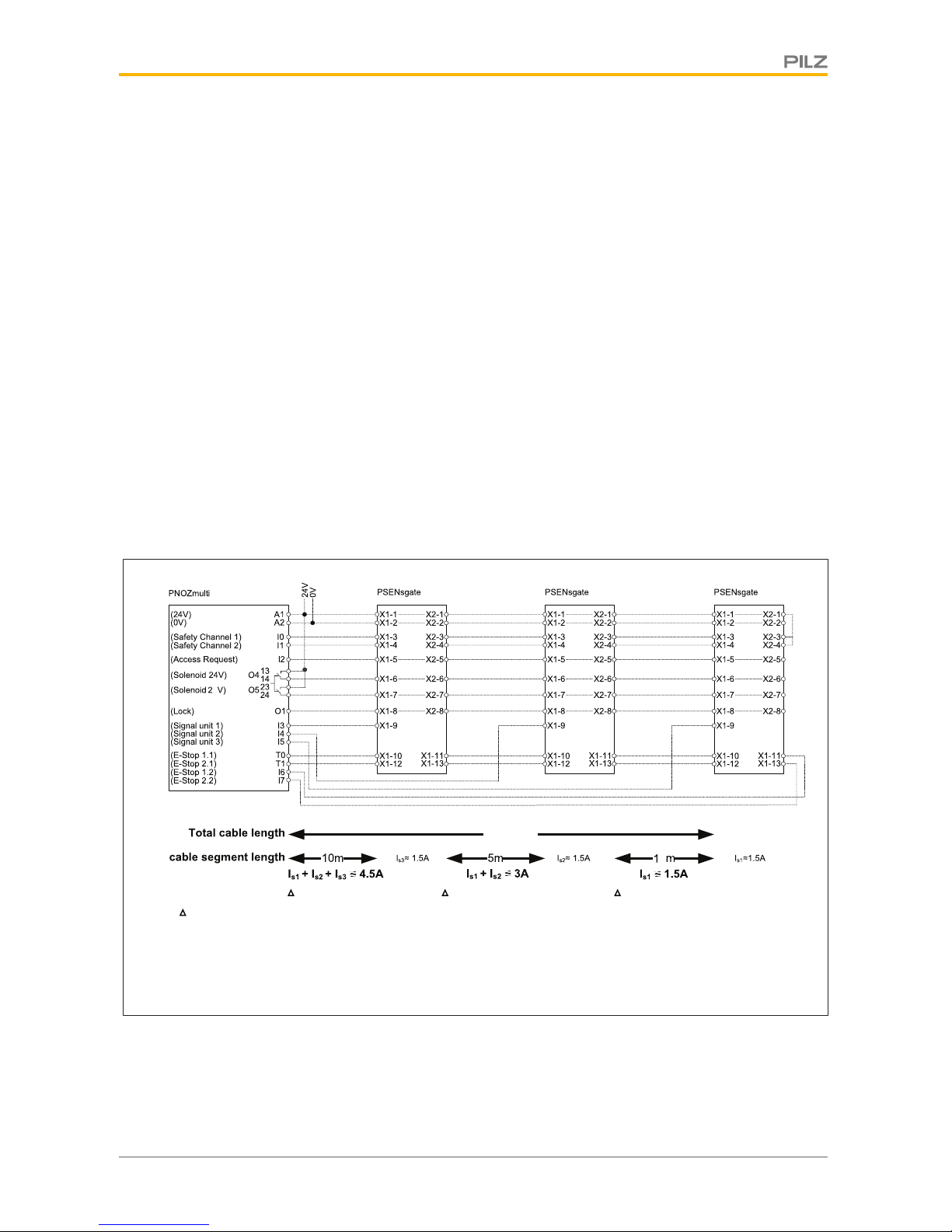

Example:

} Connecting 3 safety switches in series

} Total cable run: 25 m

} Conductor cross section: 0.5 mm

2

} Solenoid current per solenoid: 1.5 A

} Voltage for solenoid operation: 24 V

4

U~0.05*10*1.5*4.5~3.4 V U~0.05*5*1.5*3~1.1 V U~0.05*10*1.5*1.5~1.5 V

U~cable specific impedence*cable length*cable factor*current

Cable impedence(2x0.25 mm²)

=0.05 Ohm/meter

25 m

0

The voltage drop over all the safety switches is 6 V. This means, there are only 18.0 V at

the terminals of the last solenoid. The solenoid is no longer operated reliably. If the voltage

for operating the solenoid is increased by the max. permitted tolerance to 26.4, there are

still 20.4 V at the terminals of the last solenoid. The solenoid switches reliably.

Page 23

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

23

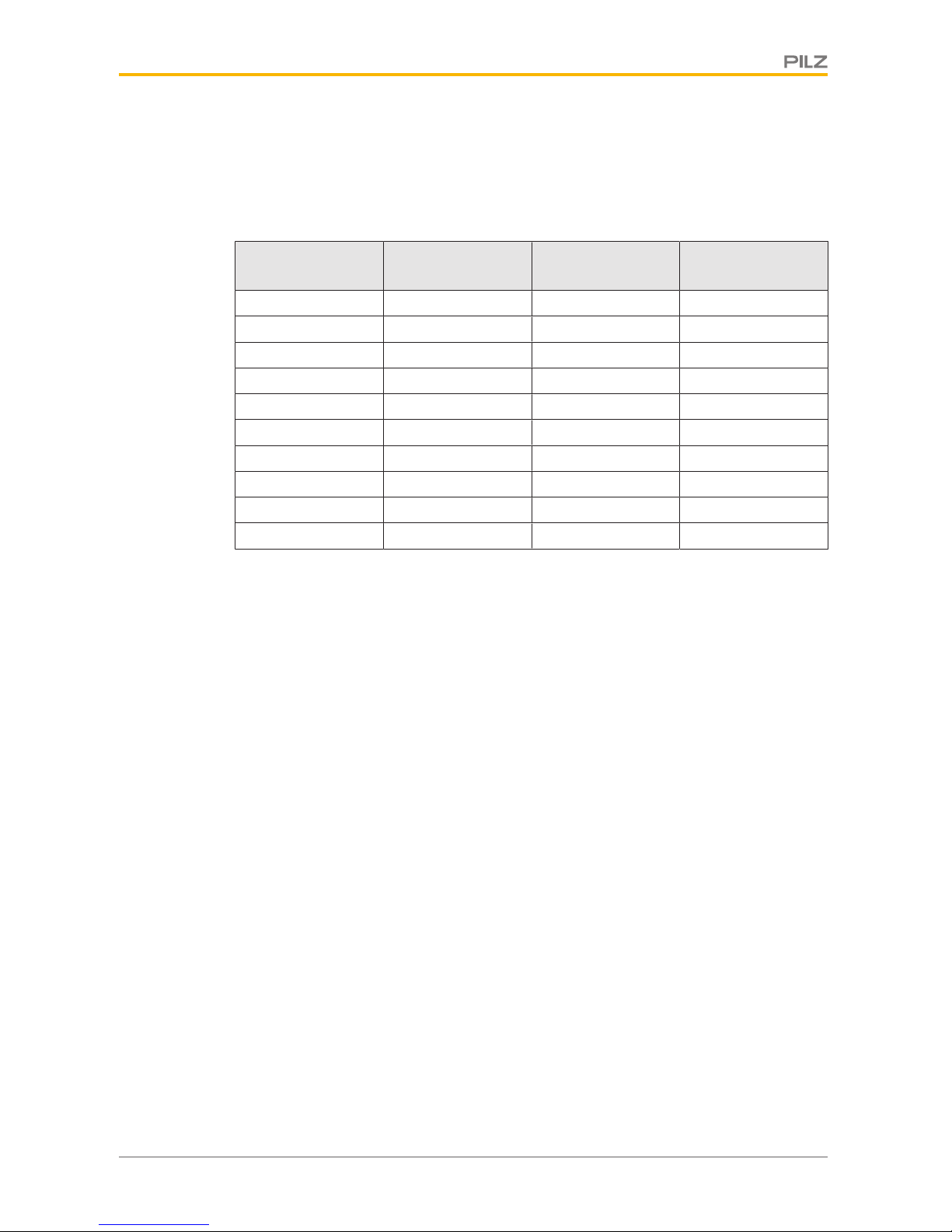

5.2 Recommended cable cross sections

The values in the table are valid for a series connection with max. 3 sensors and a voltage

for solenoid operation of 24 V. The solenoid current is 1.5 A per solenoid.

For differing values the conductor cross section must be calculated.

Total cable run [m]

1 safety switches 2 safety switches 3 safety switches

5 0.25 mm2, AWG24 0.25 mm2, AWG24 0.5 mm2, AWG21

10 0.25 mm2, AWG24 0.25 mm2, AWG24 0.5 mm2, AWG21

15 0.25 mm2, AWG24 0.25 mm2, AWG24 0.5 mm2, AWG21

20 0.25 mm2, AWG24 0.5 mm2, AWG21 x

25 0.25 mm2, AWG24 0.5 mm2, AWG21 x

30 0.25 mm2, AWG24 x x

40 0.5 mm2, AWG21 x x

50 0.5 mm2, AWG21 x x

60 0.5 mm2, AWG21 x x

70 x x x

Cable runs marked with an x are not recommended.

For operating several safety switches with greater cable runs, the cables for solenoid operation (terminals X1-6 and X1-7) have to be carried individually, or several cables have to be

used. If more than three safety switches are connected in series or cable runs over 60 m

are required, please contact Pilz.

The permitted conductor cross section is at least 0.25 mm². To have a higher conductor

cross section, two cable cores can be inserted into a terminal. This adds together the conductor cross sections and halves the cable resistances. In this case, use a terminal lug! The

signals important for cable resistance are:

} 24 V (X1-1 or X2-1)

} 0 V (X1-2 or X2-2)

} the two solenoid operation signals (X1-6 and X1-7 or X2-6 and X2-7).

5.3 General wiring guidelines

Please note:

} All metallic surfaces on the safety switch are connected to 0 V via a resistor (100

kOhm) for functional earthing.

} UL requirements:

– Use copper wiring with a temperature stability of 75 °C.

– Use an LVLC supply (LVLC: limited voltage, limited current).

– Use multicore cable with a cable diameter of 6 ... 10 mm.

} When 2 cables are used, make sure that both cables have the same cable diameter,

otherwise the strain relief will fail.

Page 24

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

24

} The permitted conductor cross section for the connectors is 0.25 - 1.0 mm², 23 - 17

AWG.

} When calculating the max. cable run, remember to take into account the chapter "Notes

on cable run".

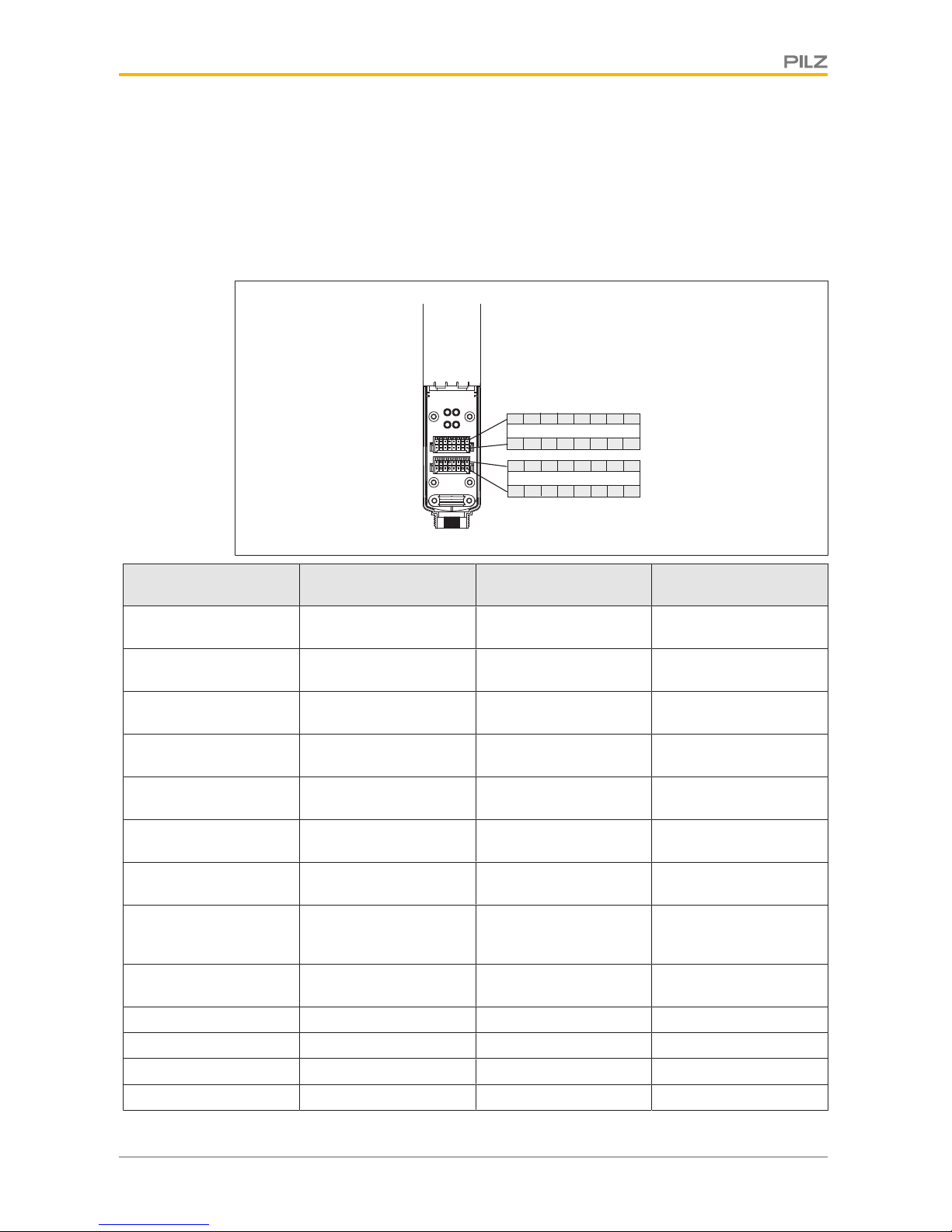

5.4 Terminal configuration

1

X2

3

5

7

9 11 13 15

246 8 10 12 14 16

1

X1

3

5

7

9 11 13 15

246 8 10 12 14 16

Terminal PSEN sg2c-3xxx PSEN sg2c-5xxxx

PSEN sg2c-5xxxxM12/5

X1-1 - X2-1

linked internally

+24 VDC supply voltage +24 VDC supply voltage +24 VDC supply voltage

X1-2 - X2-2

linked internally

0 V 0 V 0 V

X1-3 Safety output channel 1

(OSSD1)

Safety output channel 1

(OSSD1)

Safety output channel 1

(OSSD1)

X1-4 Safety output channel 2

(OSSD2)

Safety output channel 2

(OSSD2)

Safety output channel 2

(OSSD2)

X1-5 - X2-5

linked internally

Output pushbutton for access request [2]

Output pushbutton for access request [2]

Output pushbutton for access request [2]

X1-6 - X2-6

linked internally

Solenoid operation (24 V) Solenoid operation (24 V) Solenoid operation (24 V)

X1-7 - X2-7

linked internally

Solenoid operation (24 V) Solenoid operation (24 V) Solenoid operation (24 V)

X1-8 - X2-8

linked internally

Input for activating the

safety gate guard locking

device

Input for activating the

safety gate guard locking

device

Input for activating the

safety gate guard locking

device

X1-9 Signal output for state of

the bolt tongue

Signal output for state of

the bolt tongue

Signal output for state of

the bolt tongue

X1-10 E-STOP 1.1 E-STOP 1.1 E-STOP 1.1

X1-11 E-STOP 1.2 E-STOP 1.2 E-STOP 1.2

X1-12 E-STOP 2.1 E-STOP 2.1 E-STOP 2.1

X1-13 E-STOP 2.2 E-STOP 2.2 E-STOP 2.2

Page 25

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

25

Terminal PSEN sg2c-3xxx PSEN sg2c-5xxxx

PSEN sg2c-5xxxxM12/5

X1-14 n.c Pushbutton 3 LED3 n.c

X1-15 n.c Pushbutton 4 LED4 Pushbutton 4 LED4

X1-16 Signal output, E-STOP Signal output, E-STOP Enabling switch Pin5 and

signal output E-STOP

X2-3 Input, channel 1 Input, channel 1 Input, channel 1

X2-4 Input, channel 2 Input, channel 2 Input, channel 2

X2-9 n.c n.c Enabling switch M12 Pin

1 (optional)

X2-10 n.c n.c Enabling switch M12 Pin

2 (optional)

X2-11 n.c n.c Enabling switch M12 Pin

3 (optional)

X2-12 n.c n.c Enabling switch M12 Pin

4 (optional)

X2-13 n.c Pushbutton 3 channel 1 Pushbutton 3: Key switch

rotated 90° to the left

X2-14 n.c n.c Pushbutton 3: Key switch

rotated 90° to the right

X2-15 n.c Pushbutton 4 channel 1 Pushbutton 4 channel 1

X2-16 n.c n.c n.c

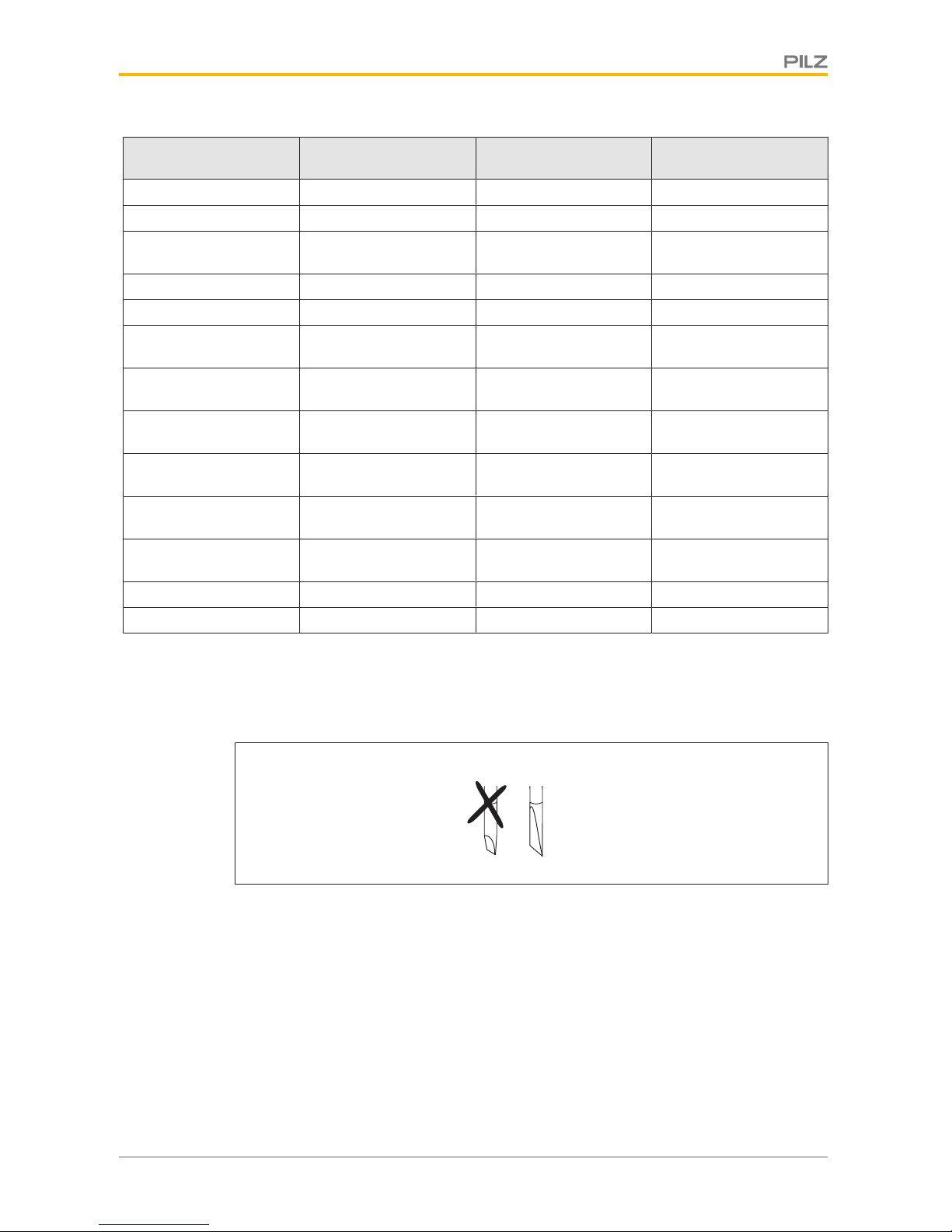

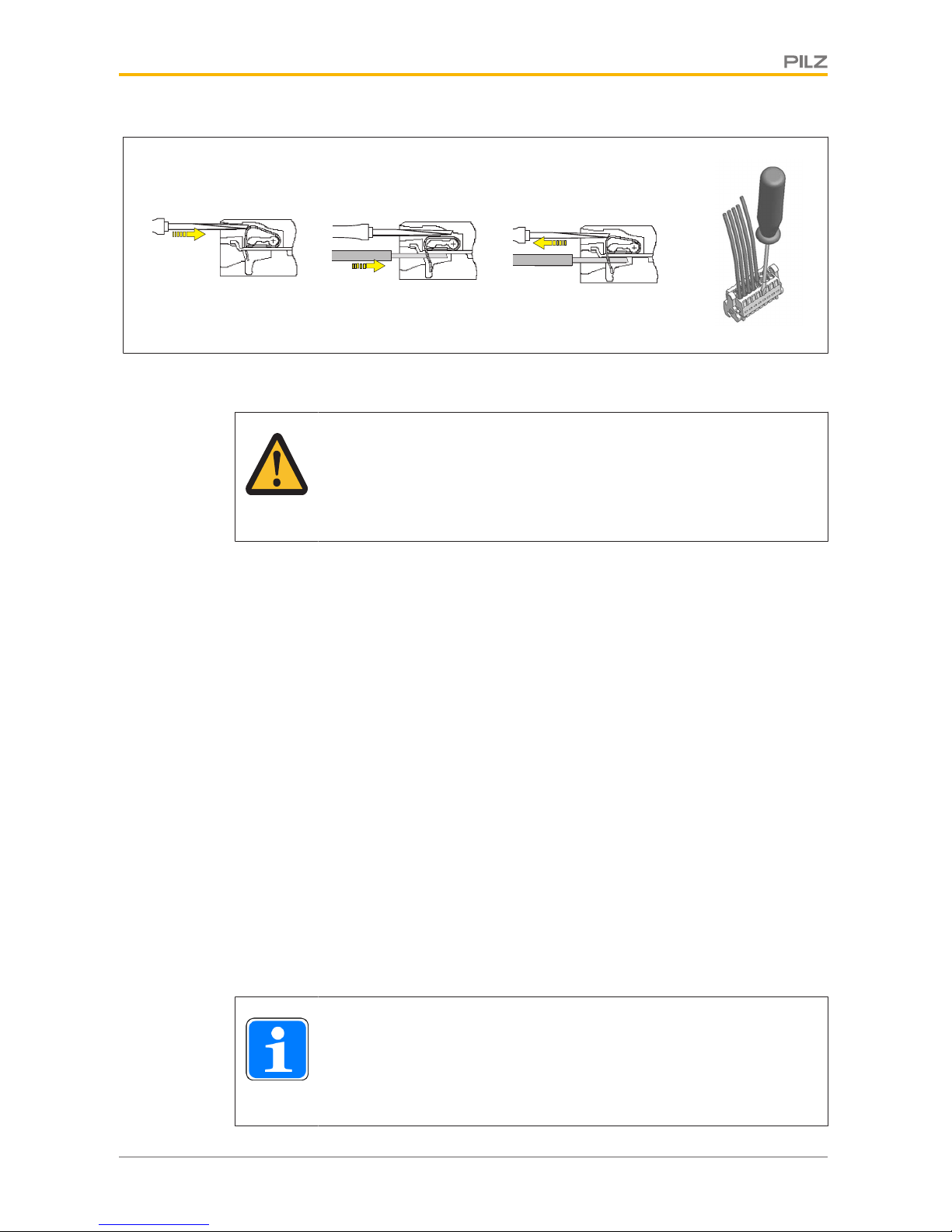

5.5 Wiring the connection terminals

Connecting the cables:

} Use a flat blade screwdriver (DIN 5264-A)!

DIN 5264-A

} Strip the wire back 7 mm.

} Insert the screwdriver into the square hole.

} Insert the stripped wire into the square hole as far as it will go.

} Pull out the screwdriver.

} Check that the cable is firmly seated.

Page 26

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

26

5.6 E-STOP pushbutton connection

CAUTION!

With versions with integral E-STOP pushbutton, the E-STOP pushbutton

(terminals X1-10 to X1-13) must be integrated into the plant/machine's ESTOP concept in accordance with EN/IEC 60204.

5.7 Enabling switch connection

Details of the pin assignment of the female 5-pin M12 connector for the enabling switch can

be found in the block diagram and the terminal configuration.

We recommend you use the PIT en1.0p-5m-s (order no. 401 110) as the enabling switch.

5.8 EMC requirements

Please note:

} The power supply must meet the regulations for extra low voltages with protective sep-

aration (SELV, PELV).

} The inputs and outputs of the safety switch must have a protective separation to

voltages over 60 V AC.

} The supply voltage has to be at the safety switch terminals within the indicated toler-

ances (see Technical details).

} the supply voltage of the safety switch must be secured with a fuse of type quick

between 2 A and 10 A.

} The electrical installation must be performed in accordance with IEC/EN 60204.

} The assured release distance (SaO) can be influenced by external influences (e.g.: tem-

perature, dirt, EMC) (see Technical details).

INFORMATION

Safety relays with a wide-range power supply or in AC device versions have

internal potential isolation and are not suitable as evaluation devices. Only

safety relays with a 24 VDC supply voltage are suitable.

Page 27

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

27

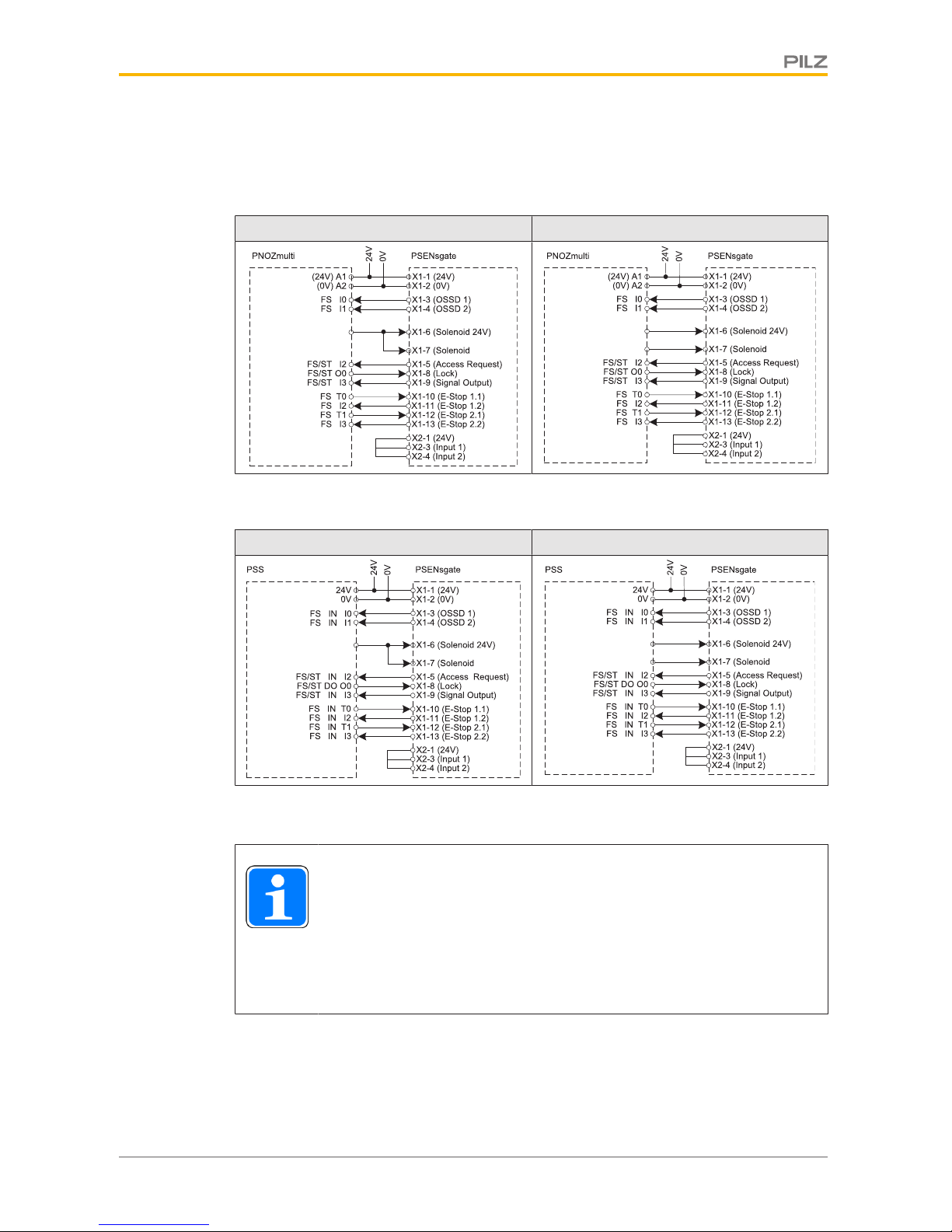

5.9 Connection to evaluation devices

5.9.1 Connection examples PNOZmulti

up to PL d/SIL CL 2 PL e/SIL CL 3

24 V)

FS O1

24 V)

FS O1

FS O2

5.9.2 Connection examples PSS

up to PL d/SIL CL 2 PL e/SIL CL 3

24 V)

FS DO O1

24V)

FS DO O1

FS DO O2

5.10 Single connection

INFORMATION

When the solenoid is operated in single-channel, only a safety level of PL d

(Cat.2)/SILCL2 can be achieved.

To achieve PLe(Cat.4/SILCL3, the solenoid must have dual-channel operation, e. g. via safe pulsed semiconductor outputs with high current load

capacity (0.9 A for 50 ms).

Page 28

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

28

X2-4

24 V

0 V

I1 (ST)

I3 (FS)

A1

A2

PSENsgate

O1 (FS)

Auswertegerät/

Evaluation device/

Appareil de surveillance/

Dispositivo di controllo

FS: Fail-safe

ST: Standard

I4 (FS)

X2-3

X1-3 X1-4

X1-1

X1-2

X1-6 X1-5

I2 (ST)

X1-9

O3 (ST)

X1-8

O2 (FS)

X1-7

5.11 Series connection

CAUTION!

Extension of delay-on de-energisation

When several (n) devices are connected in series, the delay-on de-energisation time adds with the number of interconnected safety switches.

The may. delay-on de-energisation is composed of

max. delay-on de-energisation actuator

+ (n-1) x max. delay-on de-energisation of the inputs

+ delay-on de-energisation of the evaluation device

INFORMATION

When the solenoid is operated in single-channel, only a safety level of PL d

(Cat.2) / SILCL2 can be achieved.

To achieve PLe(Cat.4)/SILCL3, the solenoid must have dual-channel operation.

For applications with single-channel operation of the solenoid (up to PL d/SIL CL 2) a momentarily overloadable safe output (1.8 A for 50 ms) can be used.

Page 29

Wiring

Operating Manual PSEN sg2c

1003267-EN-04

29

The device can be switched in series with all safety switches from Pilz. In the connection

example, the safety switch guard locking device is activated / deactivated via access request (X1-5). The maximum switching current of the solenoid is present only while switching the solenoids for about 50 ms. The solenoids of the safety switches are switched with a

low time offset of ca. 1 s, to avoid power surges at the evaluation device.

X2-3

24 V

A1

A2

PLC

PSENsgate

I1 (FS)

I2 (FS)

FS: Fail-safe

ST: Standard

PSENsgate

PSENsgate

Auswertegerät/

Evaluation device/

Appareil de surveillance/

Dispositivo di controllo

I1 (ST)

X2-3

X2-4

X1-3 X1-4

X1-9

X2-3

X2-4

X1-1

X1-1

X1-2

X1-2

X2-1

X2-2

X1-6

X2-6

X1-6

X2-6

X1-7

I2 (ST)

X1-9

I3 (ST)

X1-9

X1-2

X2-2

X2-7

I4 (ST)

X1-5

X2-7

X1-7

X1-7

X1-1

X2-1

X1-3

X1-4

X2-4

X1-3

X1-4

X2-5

X1-5

X2-5

X1-5

0 V

O1 (FS)

X1-6

O2 (FS)

X2-8

X1-8

X2-8

X1-8

O3 (ST)

X1-8

Page 30

Installation

Operating Manual PSEN sg2c

1003267-EN-04

30

6 Installation

} When installing make sure you comply with the requirements of EN ISO 14119.

} The safety switch and handle unit with actuator should be installed opposite each other

in parallel.

} The safety switch and handle unit with actuator should be secured only with socket

head cap screws M5 - DIN EN ISO 4762.

NOTICE

It must not be possible to operate or remove the handle unit from inside the

danger zone. Protect the handle unit from access, e.g. by covers on the

hazard side of the door.

INFORMATION

The handle unit should be protected from unauthorised removal and from

contamination.

CAUTION!

Safety switch and handle unit

– Should not be exposed to heavy shock or vibration

– Should not be used as a limit stop

Page 31

Installation

Operating Manual PSEN sg2c

1003267-EN-04

31

6.1 Initial installation of safety switch

} Open the cover for the escape release in the direction of opening and remove it.

} Prepare 9 mm hole for the escape release and attach profile nuts to the aluminium pro-

file (see also Dimensions for the drill holes [ 39]).

The escape release does not require a drill hole.

Page 32

Installation

Operating Manual PSEN sg2c

1003267-EN-04

32

} Align actuator guide plate and safety switch. Please note the distance between the

handle unit and the safety switch (see chapter entitled Adjustment [ 43]).

} Fix actuator guide plate and safety switch with M5 - DIN EN ISO 4762 - socket head

cap screws (hexagon socket, e.g.: Bossard: BN3 (without shaft), galvanised blue,

torque setting Ma = 5 Nm). Use washer M5 - DIN125A (e.g.: Bossard: BN 715, galvanised blue, dimension: 10 x 5.3 x 1) for this.

The fixing screws on the safety switch are located under the cover of the escape release. Use an appropriate screw adhesive (e.g. Loctite 2700) to protect the socket head

cap screws from working loose.

WARNING!

Risk of manipulation of the safety device if the actuator guide plate is not

secured permanently!

If the actuator guide plate is not secured permanently, there is a risk that the

safety function will be defeated through manipulation. Depending on the application, serious injury or death may result.

– If the actuator guide plate is installed using only the unprotected

screws [1] accessible from the side, then one-way screws must be

used for manipulation protection.

– If the screws used under the bolt tongue [2] are protected against

manipulation, then this is not necessary.

[1]

[2]

Page 33

Installation

Operating Manual PSEN sg2c

1003267-EN-04

33

} Unscrew the pressure screw [1] from the housing and remove the rubber seal [2].

} Thread the cable through the correctly oriented pressure screw and the rubber seal, re-

move the blind insert if necessary.

} Remove the countersunk screws [3] on the housing cover for the connection terminals

and slowly remove the housing cover [4]. In doing so, the spring mechanism moves the

cover of the escape release upwards.

} Unscrew the strain relief plate [5].

} Connect and insert connection terminals.

} Position cable and screw on the strain relief plate (torque setting Ma 0.9 Nm +/- 0.1 (8

in-lbs)).

} Fix housing cover with screws (torque setting Ma 1.7 Nm +/- 0.1 (15 in-lbs)).

} Move the rubber seal along the cables and position it in the housing.

} Screw pressure screw on the thread.

[1]

[2]

[3]

[4]

[5]

Page 34

Installation

Operating Manual PSEN sg2c

1003267-EN-04

34

} Insert the escape or auxiliary release pin [1] into the safety switch and push it right to

the back. The swivel piece [2] must be maintained in a vertical position, safe from the

escape or auxiliary release pin. Screw the ball head on to the escape release pin.

Check the escape release for ease of movement. Fold down the cover on the escape

release ② and lock into position.

} Screw the ball handle [4] into the handle unit, lock the bolt tongue of the handle unit [5]

into position in the actuator guide plate. (See section entitled Initial installation of handle

unit [ 36]

INFORMATION

If the escape or auxiliary release pin is not inserted into the swivel piece

correctly, commissioning of the PSENsgate will be aborted and an error

code will be issued.

[2]

[3]

[4]

[5]

[1]

Page 35

Installation

Operating Manual PSEN sg2c

1003267-EN-04

35

WARNING!

Loss of safety function due to the incorrect installation of the escape release!

If the escape release pin is accessible from the outside, the guard locking

device can be released from the outside and the safety gates opened, although the hazardous machine is switched on.

Depending on the application, serious injury or death may result.

The escape release should be installed so that it is only accessible from inside the danger zone.

It is also important to refer to the maintenance instructions (see chapter entitled Maintenance [ 44])

Shorten the escape release pin

The escape release pin can be shortened, if required, so that it does not extend too much

into the danger zone.

NOTICE

Inside the danger zone, the escape release pin must protrude at least 65

mm from the profile. After installation, the escape release must be checked

for proper operation. When shortening the escape release pin, the material

of the escape release must not exceed a temperature of 100°C

65 mm

45 mm

Pin for escape release

with ball handle

Pin for auxiliary release

If the escape release is not to be used, the escape release pin can be shortened to a length

of 45 mm and then be used for the auxiliary release. The auxiliary release pin is also available as an accessory (see order references for Accessories [ 85]).

NOTICE

Please note that the escape release pin must not be shorter than 45 mm, to

guarantee the full holding force.

Page 36

Installation

Operating Manual PSEN sg2c

1003267-EN-04

36

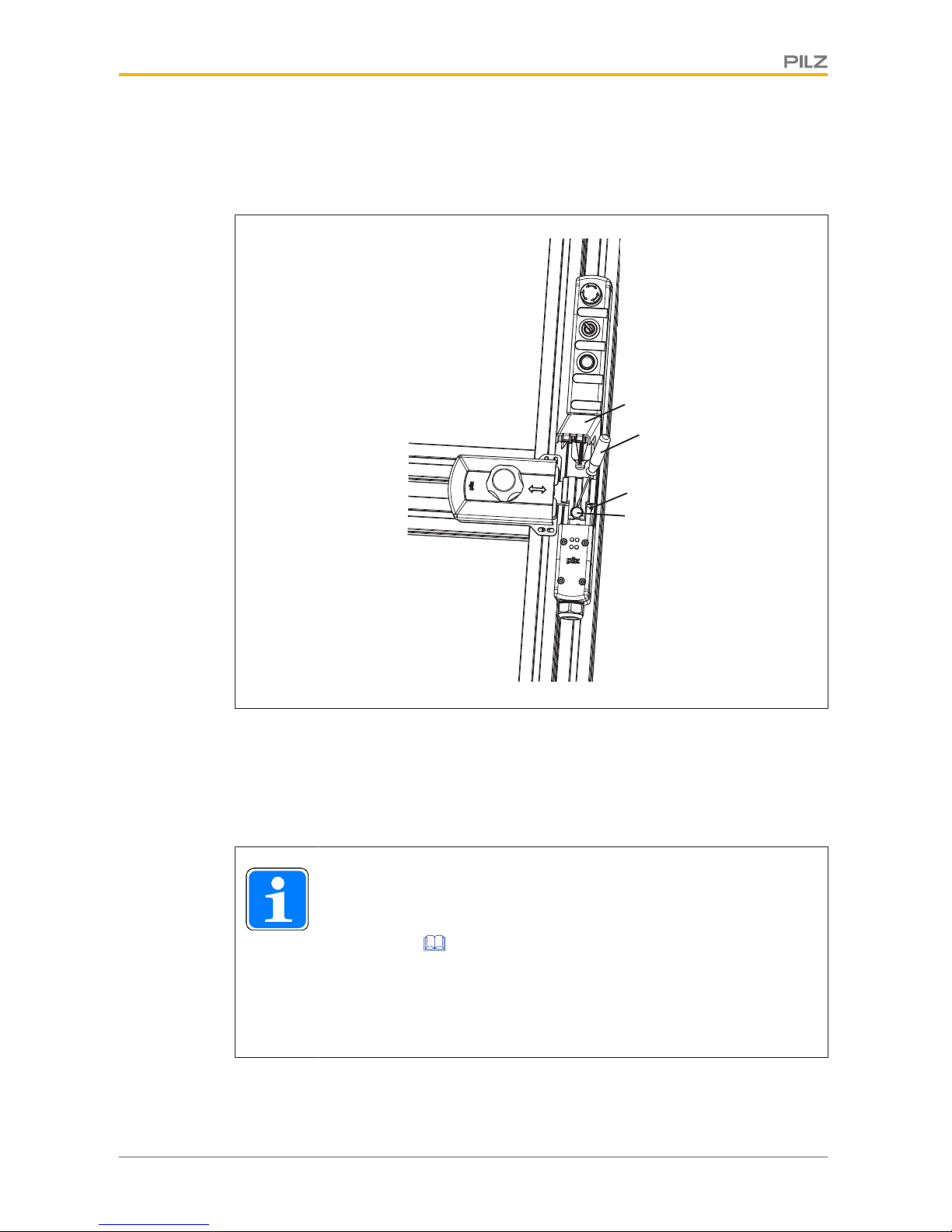

6.2 Initial installation of handle unit

} Check whether the present bolt tongue is correctly oriented at the handle unit. Standard

is right-hand door hinge at delivery (leave of the door opens to the right).

} Coat the thread of the ball handle with screw adhesive (e.g. Loctite 2700) and screw

firmly together with the handle unit by hand.

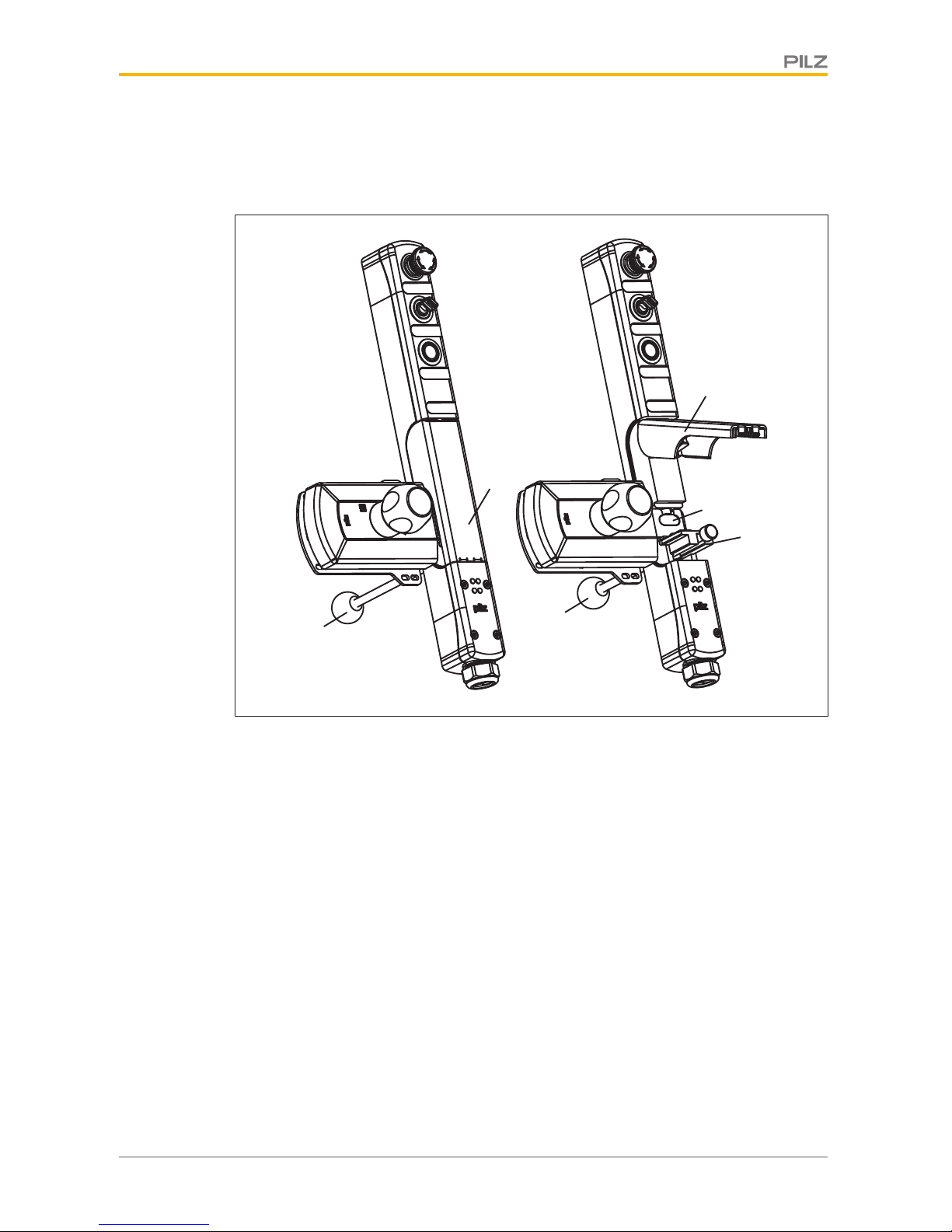

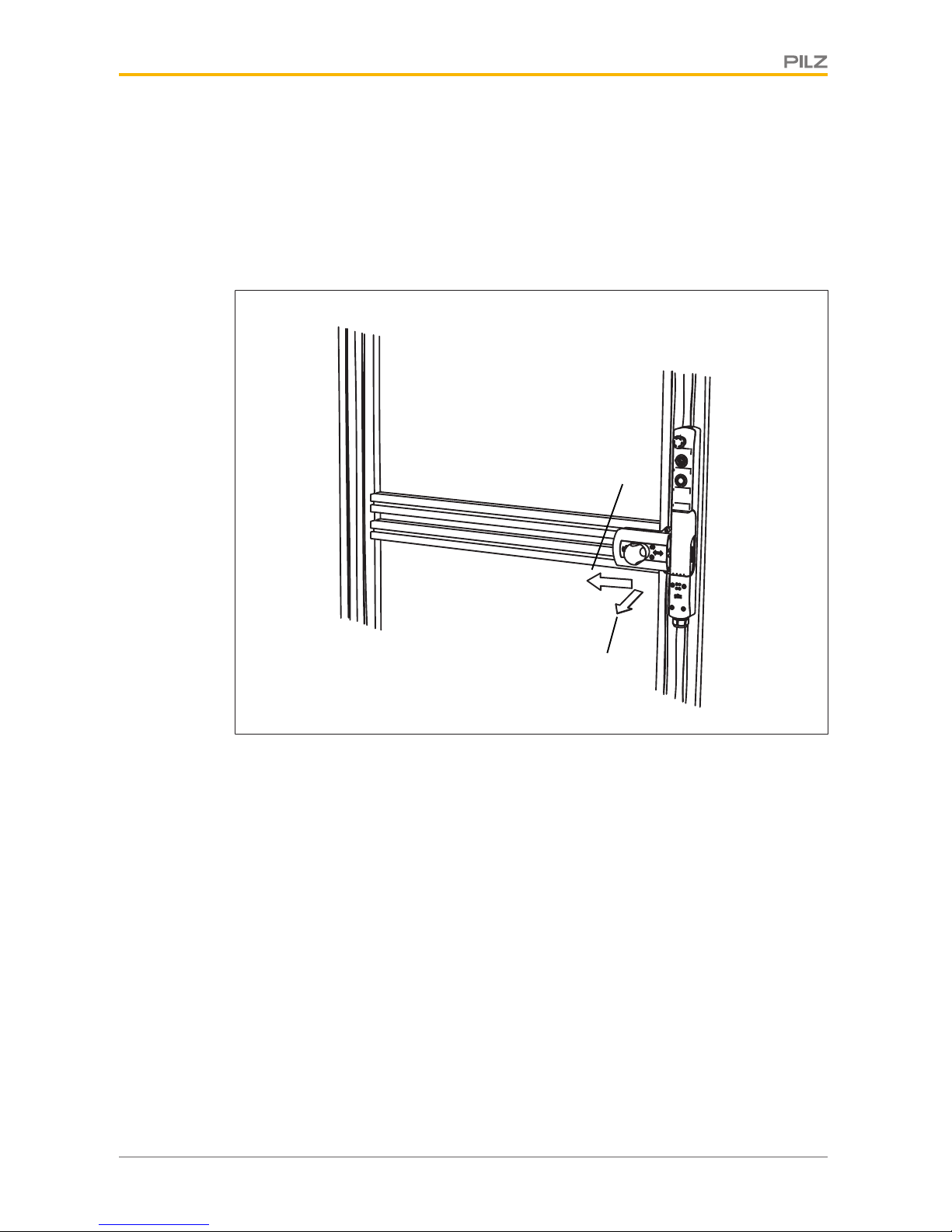

Install bolt tongue with handle unit:

} Remove the screw blocking the spring-loaded limit stop mechanism (see illustration

"Handle unit and actuator with screw").

} Position the screwdrivers in the slots provided on the limit stop mechanism (see illustra-

tion "Unlock bolt").

} Press screwdriver towards the base plate to release the spring-loaded limit stop mech-

anism.

} Engage bolt tongue with handle unit in the actuator guide.

} Ensure by moving backwards and forwards towards the limit stop that the handle unit

cannot be removed from the actuator guide.

} Re-attach the screw with a torque setting of 2 Nm +/-0.1. Use an appropriate screw ad-

hesive (e.g. Loctite 2700) to protect the screw from working loose.

Fig.: Handle unit and actuator with screw

Page 37

Installation

Operating Manual PSEN sg2c

1003267-EN-04

37

Fig.: Unlock bolt

6.3 Second installation of safety switch and handle unit /

upgrade for left-hinged gates

} Remove the screw blocking the spring-loaded limit stop mechanism (see illustration in

previous section "Handle unit and actuator with screw").

} Uninstall the safety switch from the installation site (compare steps in section en-

titledInitial installation of safety switch [ 31] in reverse order).

} Uninstall handle unit from the gate. To do this, position the screwdrivers in the slots

provided on the limit stop mechanism (see graphic "Unlock bolt").

} Press screwdriver towards the base plate to release the spring-loaded limit stop mech-

anism.

} Disengage bolt tongue with handle unit in the actuator guide.

} Remove exposed fixing screws.

} Unscrew ball handle from the handle unit.

} Remove the cover of the handle unit from the bolt tongue (2 countersunk screws).

} Take limit stop from the bolt tongue and insert it from the other side into the location

hole.

} Turn bolt tongue around its longitudinal axis and screw together with the cover of the

handle unit.

} Carry out the steps from the sections entitled Initial installation of handle unit [ 36]

and Initial installation of safety switch [ 31].

6.4 Labelling the pushbuttons

Colour covers are supplied with the PSEN sg2c Unit; these must be attached to the pushbuttons, based on their function (see also order references for Accessories [ 85]).

} Press the colour covers into the pushbuttons in accordance with the required function.

The colour covers lock into position on the pushbuttons.

Page 38

Installation

Operating Manual PSEN sg2c

1003267-EN-04

38

NOTICE

The safety switch may only be operated with colour covers correctly locked

into position. Once the colour covers have locked into position, they can no

longer be removed.

The fields below the pushbuttons can be used for inscribing the pushbuttons. The pushbuttons can be written with a lettering device for 12 mm lettering band or with 32 x 10mm labels (e.g. AVERY(R) article number: 3320).

Page 39

Installation

Operating Manual PSEN sg2c

1003267-EN-04

39

6.5 Dimensions in mm

6.5.1 Drill holes

1

1

8

,

5

1

2

,

9

±

1

1

3

9

,

6

±

1

1

6

0

7

6

(29,5)

8 ± 1

20 ± 1

22,5 ± 1

74,75 ± 1

127 ± 1

133 ± 1

4

1

,5

±

5

9

5

±

1

1

4

±

1

7

2

±

1

7

6

1

6

0

1

1

±

±

ø9,0

90°

±

3°

The bore diameter for all drill holes = M5.

Exception: Drill hole for the escape release (see value stated in the drawing).

Page 40

Installation

Operating Manual PSEN sg2c

1003267-EN-04

40

6.5.2 PSEN sg2c-3xxx

2

1

4

6

5

1

1

0

8

6

1

4

1

,

4

49,7

8

Ø

173

108,2

44,2

30

1

7

0

33SW

7

6

146,5

74,5

46,3

±

Page 41

Installation

Operating Manual PSEN sg2c

1003267-EN-04

41

6.5.3 PSEN sg2c-5xxxxx

33SW

2

1

1

6

9

,

7

1

1

0

8

6

7

6

146,5

5

5

5

46,3

±

49,7

108,2

44,2

8

173

1

4

1

,

4

30

74,5

Page 42

Installation

Operating Manual PSEN sg2c

1003267-EN-04

42

6.5.4 PSEN sg2c-5xxxxx-M12/5

33SW

2

1

1

7

0

8

6

1

1

0

146,5

5

7

8

7

6

46,3

30

173

1

4

1

,

4

108,2

44,2

49,7

18,2

74,5

8

±

Page 43

Adjustment

Operating Manual PSEN sg2c

1003267-EN-04

43

7 Adjustment

} Make sure that the safety switch and handle unit with actuator are aligned correctly and

that the distances are maintained, as stated in the drawing, otherwise the correct functionality is not guaranteed.

} Always check the function of the safety switch in conjunction with the handle unit with

actuator, using one of the approved evaluation devices.

1,5 °

2,5

3,0

Page 44

Maintenance

Operating Manual PSEN sg2c

1003267-EN-04

44

8 Maintenance

Maintenance of the escape release:

} Check the correct functionality of the escape release at least every once per month.

When dust, humidity, chemical or dirt exposure is high we recommend that you keep to

shorter intervals.

Please note that the cover of the escape release must also be checked for damage and

then re-installed.

} Clean the escape release and the bolt tongue and test their mobility.

} If there are signs of wear on the safety switch or the mechanics are sluggish, check that

the handle unit with actuator is correctly aligned with the switch. If necessary, re-adjust

the handle unit with actuator.

Otherwise no maintenance work needs to be performed on the interlocking and guard locking system PSEN sg2c. Please return any faulty devices to Pilz.

Page 45

Operation

Operating Manual PSEN sg2c

1003267-EN-04

45

9 Operation

NOTICE

The safety function should be checked after initial commissioning and each

time the plant/machine is changed. The safety functions may only be

checked by qualified personnel.

Teaching in the actuator

} PSEN sg2c-xxx (coded version)

Any corresponding Pilz actuator (see Technical details) is detected as soon as it is

brought into the response range.

} PSEN sg2c-xxx 2.2 (uniquely coded version)

The first corresponding actuator to be detected by the safety switch (see Technical details) is taught in automatically as soon as it is brought into the response range.

NOTICE

Please note: No other actuator may be taught in once an actuator has been

taught.

Status indicators

} "Device" LED illuminates green: The unit is ready for operation

} "Safety Gate" LED lights up yellow: Bolt tongue is engaged

} "Input" LED lights up yellow: Input circuits are closed or a HIGH signal is present

} "Lock / Area safe" LED illuminates blue: The guard locking element is engaged in the

bolt tongue, guard locking is active. Signals X1-6 and X1-7 (or X2-6 and X2-7) are

present.

} "Lock / Area safe" LED illuminates green: The guard locking element is engaged in the

bolt tongue, guard locking is active. Signals X1-6 and X1-7 (or X2-6 and X2-7) are not

present.

} "Lock / Area safe" LED flashes green and blue: Pushbutton 2 for access requirement

was confirmed and the machine stop was requested.

Page 46

Operation

Operating Manual PSEN sg2c

1003267-EN-04

46

Device Input

Lock /

Area Safe

Safety

Gate

Pushbutton status indicators

(for details of the various pushbuttons see Device types [ 17])

} Pushbutton LED [1] is illuminated: The guard locking element is engaged in the bolt

tongue, guard locking is active. Signals X1-6 and X1-7 (or X2-6 and X2-7) are not

present.

Pushbuttons 3 and 4 can be used depending on the requirement and device version.

} Pushbutton LED [3] can be used depending on the application. It is operated via the in-

put (see Terminal assignment) by applying an external +24 VDC.

} Pushbutton LED [4] can be used depending on the application. It is operated via the in-

put (see Terminal assignment) by applying an external +24 VDC.

Page 47

Operation

Operating Manual PSEN sg2c

1003267-EN-04

47

9.1 Status table

This table shows the change of states of the inputs and outputs and the LEDs when switching from the "Lock" operating mode to the "Interlock" operating mode.

--- --- --- 0 V 0 V --- --- 0 V 0 V 0 V ---

--- --- --- 24V0 V --- --- 0 V 24V0 V ---

--- 24V0 V --- --- 24V24V0 V ---

24V24

V

--- 24V24V24V24

V

24V24

V

--- 24V0 V 24V24

V

24V24V--- 24V24V0 V 0 V ---

--- --- 24V0 V --- 24V0 V 24V24V---

--- --- 24V0 V --- --- 0 V 24V24V---

--- --- --- 24V0 V --- --- 0 V 24V24V---

* The guard locking element can be engaged either by pressing the pushbutton key for activating the guard locking of the safety gate or by operating the input X 1-8.

Legend

LED on

LED flashes

LED off

Page 48

Operation

Operating Manual PSEN sg2c

1003267-EN-04

48

9.2 Toggle normal/unlock mode

The device is in normal mode when delivered.

Normal mode

In this mode, the guard locking element is not disengaged from the bolt tongue until pushbutton 2 for access request is operated, when there is a high signal at X1-6 and X1-7 or at

X2-6 and X2-7 (solenoid operation).

Unlock mode

In this mode, the guard locking element is disengaged from the bolt tongue when a high

signal is present at X1-6 and X1-7 or at X2-6 and X2-7 (solenoid operation).

Switching between normal mode and unlock mode

} Switch off supply voltage

} Press and hold the pushbutton 2 for access request and the pushbutton 1 for activating

the guard locking simultaneously

} Switch on the supply voltage and hold both pushbuttons until "Device" LED lights up

blue. Then release the pushbuttons.

} The active mode is signalled by quick flashing of one of the LEDs:

– Normal mode: LED of pushbutton 1 for activating the guard locking and LED

"Safety Gate" are flashing

– Unlock mode: "Input" LED flashes

} To switch to the required mode, press pushbutton 1 for normal mode or pushbutton 2

for unlock mode. The "Device" LED will quickly light up green again and the device is

ready for operation.

Reset function

After an error that was signalled by the red "Device" LED the device can be restarted by a

reset:

} Rectify the error.

} Press the pushbutton for access request [2] and hold the pushbutton for at least 5

seconds.

Page 49

Operation

Operating Manual PSEN sg2c

1003267-EN-04

49

9.3 Remedy

Fault conditions are indicated by flashing the LEDs. Some errors are displayed through

periodic flashing (see table); with other errors it is possible to establish an error code

through the number of flashes.

Error Cause Remedy

Safety switch does not react, LED "Device" does not

light

Supply voltage missing/too

low

} Check supply voltage and apply 24 V

"Safety Gate" LED flashes a

code and "Device" LED

flashes red

See section on Error codes

} See section on Error codes

"Device" LED illuminates

red

Internal error

} Please contact Pilz

"Input" LED flashes yellow,

only one safety output

switches

Only one channel of the input circuit is open (partial

operation)

} Open both channels of the input circuit and

close them again

Only one safety output

switches

Only one channel of the input circuit is open, wiring error

} Check wiring of terminals X2-3 and X2-4

Signal output does not

switch when actuator is engaged, "SafetyGate" LED

does not light up

Actuator not detected

} Insert actuator as far as it will go

Solenoid does not switch Supply voltage or voltage

for solenoid operation is too

low, error in the wiring

} Check voltages and apply 24 V, check wir-

ing,

} Increase voltage for solenoid to increase

tolerance,

} reduce cable run,

} Use cable with a greater conductor cross

section

Solenoid does not switch,

"SafetyGate" LED does not

light up

Actuator not detected

} Insert actuator as far as it will go

Safety outputs fail to switch,

"Lock /Area Safe" LED

flashes red

Escape or auxiliary release

pin is not correctly in position

} Position the escape or auxiliary release pin

as far as it will go

} Perform reset

"Device" and "Lock/Area

safe" LEDs flash red

Guard locking is active, 24V

is present at inputs X2-3

and X2-4, escape or auxiliary release pin has been

operated

} Position the escape or auxiliary release pin

as far as it will go

} Perform reset

"Safety Gate" LED lights up

and guard locking element

is engaged, but the outputs

are not switching.

Wrong actuator, e.g. 1.1coded actuators with 2.2coded safety switch

} Insert correct actuator

Page 50

Operation

Operating Manual PSEN sg2c

1003267-EN-04

50

Error Cause Remedy

When pushbutton 1 or 2 is

operated, all LEDs go out

and the system starts up

again

Supply voltage or voltage

for solenoid operation is too

low or wiring error

} Check voltages and apply 24 V, check wir-

ing,

} reduce cable run,

} Use cable with a greater conductor cross

section

Error codes

Error codes are issued after 90 seconds at the latest at the "Safety Gate" LED. The number

of LED flashes corresponds to the error code. The error code consists of one digit. (4 x

flashing: error code 4). The flashing sequence is constantly repeated and separated from

each other by longer periods.

Error code Description Remedy

1 Short circuit to 0 V DC on at least

one of the two safety outputs X1-3

and X1-4

Check the wiring of terminals X1-3 and

X1-4, rectify the wiring error, then reset

2 During operation, short circuit

between safety output X1-3 and 24

V DC

Rectify wiring error at terminal X1-3,

then reset

3 During operation, short circuit

between safety output X1-4 and 24

V DC

Rectify wiring error at terminal X1-4,

then reset

4 At least one of the two safety out-

puts X1-3 and X1-4 have voltage

applied during system run-up

Check the wiring of terminals X1-3 and

X1-4, rectify the wiring error, then reset

Page 51

Technical Details Order No. 570800-570804

Operating Manual PSEN sg2c

1003267-EN-04

51

10 Technical Details Order No. 570800-570804

General 570800 570802 570804

Approvals CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL

Sensor's mode of operation Transponder Transponder Transponder

Coding level in accordance with EN ISO 14119 Low Low Low

Design in accordance with

EN ISO 14119

4 4 4

Pilz coding type Coded Coded Coded

Electrical data 570800 570802 570804

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -15 %/+10 % -15 %/+10 % -15 %/+10 %

Output of external

power supply (DC) 2 W 2 W 2 W

Max. inrush current at UB 5 A 5 A 5 A

Max. switching frequency 1 Hz 1 Hz 1 Hz

Magnet. supply voltage 24 V 24 V 24 V

Max. solenoid current t

<150 ms 1,5 A 1,5 A 1,5 A

Max. cable capacitance at

the safety outputs

No-load, PNOZ with re-

lay contacts 40 nF 40 nF 40 nF

PNOZmulti, PNOZelog,

PSS 70 nF 70 nF 70 nF

Max. inrush current impulse

Current pulse, A1 5 A 5 A 5 A

Pulse duration, A1 0,0002 ms 0,0002 ms 0,0002 ms

Max. unit fuse protection

in accordance with UL 3 A 3 A 3 A

Inputs 570800 570802 570804

Number 2 2 2

Voltage at inputs 24 V DC 24 V DC 24 V DC

Input current range 5 mA 5 mA 5 mA

E-STOP 570800 570802 570804

Number of N/C contacts 2 2 –

E-STOP release type Turn release Turn release –

Page 52

Technical Details Order No. 570800-570804

Operating Manual PSEN sg2c

1003267-EN-04

52

E-STOP 570800 570802 570804

Utilisation category

In accordance with the

standard EN 60947-5-1 EN 60947-5-1 –

Contacts, AC15 at 24 V 24 V –

Current 1,5 A 1,5 A –

Contacts, DC13 at 24 V 24 V –

Current 1,5 A 1,5 A –

Mechanical life 6050 cycles 6050 cycles –

Signal output

Output voltage 24 V 24 V –

Max. current 100 mA 100 mA –

Section stop 570800 570802 570804

Number of N/C contacts – – 2

Release type – – Turn release

Utilisation category

In accordance with the

standard – – EN 60947-5-1

Contacts, AC15 at – – 24 V

Max. current – – 1,5 A

Contacts, DC13 at – – 24 V

Max. current – – 1,5 A

Mechanical life – – 6050 cycles

Signal output

Output voltage – – 24 V

Max. current – – 100 mA

Semiconductor outputs 570800 570802 570804

OSSD safety outputs 2 2 2

Signal outputs 2 2 2

Switching current per output 500 mA 500 mA 500 mA

Breaking capacity per output 12 W 12 W 12 W

Residual current at "0"

signal 0,5 mA 0,5 mA 0,5 mA

Short circuit-proof yes yes yes

Pushbuttons 570800 570802 570804

Utilisation category

In accordance with the

standard EN 60947-5-1 EN 60947-5-1 EN 60947-5-1

Contacts, AC12 at 24 V 24 V 24 V

Max. current 0,1 A 0,1 A 0,1 A

Contacts, DC12 at 24 V 24 V 24 V

Max. current 0,1 A 0,1 A 0,1 A

Electrical life 1,000,000 cycles 1,000,000 cycles 1,000,000 cycles

Mechanical life 1,000,000 cycles 1,000,000 cycles 1,000,000 cycles

Contact material AgNi AgNi AgNi

Page 53

Technical Details Order No. 570800-570804

Operating Manual PSEN sg2c

1003267-EN-04

53

Times 570800 570802 570804

Test pulse duration, safety

outputs 450 µs 450 µs 450 µs

Switch-on delay

after UB is applied 1,1 s 1,1 s 1,1 s

Inputs typ. 15 ms 15 ms 15 ms

Inputs max. 20 ms 20 ms 20 ms

Actuator typ. 90 ms 90 ms 90 ms

Actuator max. 120 ms 120 ms 120 ms

Delay-on de-energisation

Inputs typ. 15 ms 15 ms 15 ms

Inputs max. 20 ms 20 ms 20 ms

Actuator typ. 30 ms 30 ms 30 ms

Actuator max. 260 ms 260 ms 260 ms

Supply interruption before

de-energisation 20 ms 20 ms 20 ms

Simultaneity, channel 1

and 2 max. 7 ms 7 ms 7 ms

Environmental data 570800 570802 570804

Temperature of metal surface at ambient temperature: 25 °C 40 °C 40 °C 40 °C

Ambient temperature

In accordance with the

standard

EN 60068-2-14 EN 60068-2-14 EN 60068-2-14

Temperature range -20 - 55 °C -20 - 55 °C -20 - 55 °C

Storage temperature

In accordance with the

standard EN 60068-2-1/-2 EN 60068-2-1/-2 EN 60068-2-1/-2

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

In accordance with the

standard EN 60068-2-78 EN 60068-2-78 EN 60068-2-78

Humidity 93 % r. h. at 40 °C 93 % r. h. at 40 °C 93 % r. h. at 40 °C

EMC EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 55 Hz 10 - 55 Hz 10 - 55 Hz

Amplitude 1 mm 1 mm 1 mm

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Acceleration 30g 30g 30g

Duration 11 ms 11 ms 11 ms

Page 54

Technical Details Order No. 570800-570804

Operating Manual PSEN sg2c

1003267-EN-04

54

Environmental data 570800 570802 570804

Airgap creepage

Overvoltage category III III III

Pollution degree 3 3 3

Rated insulation voltage 30 V 30 V 30 V

Rated impulse withstand

voltage 1 kV 1 kV 1 kV

Protection type

Housing IP54 IP54 IP54

Mechanical data 570800 570802 570804

Escape release available yes yes yes

Mechanical life 200,000 cycles 200,000 cycles 200,000 cycles

Max. holding force in closing direction 1000 N 1000 N 1000 N

Max. holding force in pan

direction 2000 N 2000 N 2000 N

Max. vertical offset +/-2,5 mm +/-2,5 mm +/-2,5 mm

Max. lateral offset +/-3,0 mm +/-3,0 mm +/-3,0 mm

Max. angular offset +/-1,5 deg +/-1,5 deg +/-1,5 deg

Max. retract speed of actuator 0,5 m/s 0,5 m/s 0,5 m/s

Actuator 1 PSEN sg2 actuator PSEN sg2 actuator PSEN sg2 actuator

Operating distances

Assured operating dis-

tance Sao 2 mm 2 mm 2 mm

Min. operating distance

Somin 3 mm 3 mm 3 mm

Typical operating dis-

tance So 3 mm 3 mm 3 mm

Assured release dis-

tance Sar 4 mm 4 mm 4 mm

Change of operating

distance with temperat-

ure changes +-0,01mm/°C +-0,01mm/°C +-0,01mm/°C

Typ. Hysteresis 0,1 mm 0,1 mm 0,1 mm

Connection type Spring-loaded terminal,

plug-in

Spring-loaded terminal,

plug-in

Spring-loaded terminal,

plug-in

Cable LiYY 24 x 0.5 mm2 LiYY 24 x 0.5 mm2 LiYY 24 x 0.5 mm2

Material

Top Valox 553 Valox 553 Valox 553

Actuator Stainless steel 1.4301 Stainless steel 1.4301 Stainless steel 1.4301

Dimensions

Height 465 mm 465 mm 465 mm

Width 200 mm 200 mm 200 mm

Depth 108 mm 108 mm 108 mm

Page 55

Technical Details Order No. 570800-570804

Operating Manual PSEN sg2c

1003267-EN-04

55

Mechanical data 570800 570802 570804

Actuator dimensions

Height 110 mm 110 mm 110 mm

Width 195 mm 195 mm 195 mm

Depth 108 mm 108 mm 108 mm

Weight of actuator 1.390 g 1.390 g 1.390 g

Weight 2.570 g 2.570 g 2.570 g

Where standards are undated, the 2013 latest editions shall apply.

Page 56

Technical Details Order No. 570806-570810

Operating Manual PSEN sg2c

1003267-EN-04

56

11 Technical Details Order No. 570806-570810

General 570806 570808 570810

Approvals CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL

Sensor's mode of operation Transponder Transponder Transponder

Coding level in accordance with EN ISO 14119 Low Low Low

Design in accordance with

EN ISO 14119

4 4 4

Pilz coding type Coded Coded Coded

Electrical data 570806 570808 570810

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -15 %/+10 % -15 %/+10 % -15 %/+10 %

Output of external

power supply (DC) 2 W 2 W 2 W

Max. inrush current at UB 5 A 5 A 5 A

Max. switching frequency 1 Hz 1 Hz 1 Hz

Magnet. supply voltage 24 V 24 V 24 V

Max. solenoid current t

<150 ms 1,5 A 1,5 A 1,5 A

Max. cable capacitance at

the safety outputs

No-load, PNOZ with re-

lay contacts 40 nF 40 nF 40 nF

PNOZmulti, PNOZelog,

PSS 70 nF 70 nF 70 nF

Max. inrush current impulse

Current pulse, A1 5 A 5 A 5 A

Pulse duration, A1 0,0002 ms 0,0002 ms 0,0002 ms

Max. unit fuse protection

in accordance with UL 3 A 3 A 3 A

Inputs 570806 570808 570810

Number 2 2 2

Voltage at inputs 24 V DC 24 V DC 24 V DC

Input current range 5 mA 5 mA 5 mA

Section stop 570806 570808 570810

Number of N/C contacts 2 – –

Release type Turn release – –

Page 57

Technical Details Order No. 570806-570810

Operating Manual PSEN sg2c

1003267-EN-04

57

Section stop 570806 570808 570810

Utilisation category

In accordance with the

standard EN 60947-5-1 – –

Contacts, AC15 at 24 V – –

Max. current 1,5 A – –

Contacts, DC13 at 24 V – –

Max. current 1,5 A – –

Mechanical life 6050 cycles – –

Signal output

Output voltage 24 V – –

Max. current 100 mA – –

Semiconductor outputs 570806 570808 570810

OSSD safety outputs 2 2 2

Signal outputs 2 2 2

Switching current per output 500 mA 500 mA 500 mA

Breaking capacity per output 12 W 12 W 12 W

Residual current at "0"

signal 0,5 mA 0,5 mA 0,5 mA

Short circuit-proof yes yes yes

Pushbuttons 570806 570808 570810

Utilisation category

In accordance with the

standard EN 60947-5-1 EN 60947-5-1 EN 60947-5-1

Contacts, AC12 at 24 V 24 V 24 V

Max. current 0,1 A 0,1 A 0,1 A

Contacts, DC12 at 24 V 24 V 24 V

Max. current 0,1 A 0,1 A 0,1 A

Electrical life 1,000,000 cycles 1,000,000 cycles 1,000,000 cycles

Mechanical life 1,000,000 cycles 1,000,000 cycles 1,000,000 cycles

Contact material AgNi AgNi AgNi

Times 570806 570808 570810

Test pulse duration, safety

outputs 450 µs 450 µs 450 µs

Switch-on delay

after UB is applied 1,1 s 1,1 s 1,1 s

Inputs typ. 15 ms 15 ms 15 ms

Inputs max. 20 ms 20 ms 20 ms

Actuator typ. 90 ms 90 ms 90 ms

Actuator max. 120 ms 120 ms 120 ms

Delay-on de-energisation

Inputs typ. 15 ms 15 ms 15 ms

Inputs max. 20 ms 20 ms 20 ms

Actuator typ. 30 ms 30 ms 30 ms

Actuator max. 260 ms 260 ms 260 ms

Page 58

Technical Details Order No. 570806-570810

Operating Manual PSEN sg2c

1003267-EN-04

58

Times 570806 570808 570810

Supply interruption before

de-energisation 20 ms 20 ms 20 ms

Simultaneity, channel 1

and 2 max. 7 ms 7 ms 7 ms

Environmental data 570806 570808 570810

Temperature of metal surface at ambient temperature: 25 °C 40 °C 40 °C 40 °C

Ambient temperature

In accordance with the

standard EN 60068-2-14 EN 60068-2-14 EN 60068-2-14

Temperature range -20 - 55 °C -20 - 55 °C -20 - 55 °C

Storage temperature

In accordance with the

standard EN 60068-2-1/-2 EN 60068-2-1/-2 EN 60068-2-1/-2

Temperature range -25 - 70 °C -25 - 70 °C -25 - 70 °C

Climatic suitability

In accordance with the

standard EN 60068-2-78 EN 60068-2-78 EN 60068-2-78

Humidity 93 % r. h. at 40 °C 93 % r. h. at 40 °C 93 % r. h. at 40 °C

EMC EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

EN 55011: class A, EN

61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN

61000-4-5, EN 61000-4-6,

EN 61000-4-8

Vibration

In accordance with the

standard EN 60068-2-6 EN 60068-2-6 EN 60068-2-6

Frequency 10 - 55 Hz 10 - 55 Hz 10 - 55 Hz

Amplitude 1 mm 1 mm 1 mm

Shock stress

In accordance with the

standard EN 60068-2-27 EN 60068-2-27 EN 60068-2-27

Acceleration 30g 30g 30g

Duration 11 ms 11 ms 11 ms

Airgap creepage

Overvoltage category III III III

Pollution degree 3 3 3

Rated insulation voltage 30 V 30 V 30 V

Rated impulse withstand

voltage

1 kV 1 kV 1 kV

Protection type

Housing IP54 IP54 IP54

Mechanical data 570806 570808 570810

Escape release available yes yes yes

Mechanical life 200,000 cycles 200,000 cycles 200,000 cycles

Max. holding force in closing direction 1000 N 1000 N 1000 N

Page 59

Technical Details Order No. 570806-570810

Operating Manual PSEN sg2c

1003267-EN-04

59

Mechanical data 570806 570808 570810

Max. holding force in pan

direction 2000 N 2000 N 2000 N

Max. vertical offset +/-2,5 mm +/-2,5 mm +/-2,5 mm

Max. lateral offset +/-3,0 mm +/-3,0 mm +/-3,0 mm

Max. angular offset +/-1,5 deg +/-1,5 deg +/-1,5 deg

Max. retract speed of actuator 0,5 m/s 0,5 m/s 0,5 m/s

Actuator 1 PSEN sg2 actuator PSEN sg2 actuator PSEN sg2 actuator

Operating distances

Assured operating dis-

tance Sao 2 mm 2 mm 2 mm

Min. operating distance

Somin 3 mm 3 mm 3 mm

Typical operating dis-

tance So 3 mm 3 mm 3 mm

Assured release dis-

tance Sar

4 mm 4 mm 4 mm

Change of operating

distance with temperat-

ure changes +-0,01mm/°C +-0,01mm/°C +-0,01mm/°C

Typ. Hysteresis 0,1 mm 0,1 mm 0,1 mm

Connection type Spring-loaded terminal,

plug-in

Spring-loaded terminal,

plug-in

Spring-loaded terminal,

plug-in

Cable LiYY 24 x 0.5 mm2 LiYY 24 x 0.5 mm2 LiYY 24 x 0.5 mm2

Material

Top Valox 553 Valox 553 Valox 553

Actuator Stainless steel 1.4301 Stainless steel 1.4301 Stainless steel 1.4301

Dimensions

Height 465 mm 465 mm 465 mm

Width 200 mm 200 mm 200 mm

Depth 108 mm 108 mm 108 mm

Actuator dimensions

Height 110 mm 110 mm 110 mm

Width 195 mm 195 mm 195 mm

Depth 108 mm 108 mm 108 mm

Weight of actuator 1.390 g 1.390 g 1.390 g

Weight 2.570 g 2.570 g 2.570 g

Where standards are undated, the 2013 latest editions shall apply.

Page 60

Technical Details Order No. 570812-570816

Operating Manual PSEN sg2c

1003267-EN-04

60

12 Technical Details Order No. 570812-570816

General 570812 570814 570816

Approvals CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL CE, FCC, TÜV, UL/cUL

Sensor's mode of operation Transponder Transponder Transponder

Coding level in accordance with EN ISO 14119 Low Low Low

Design in accordance with

EN ISO 14119

4 4 4

Pilz coding type Coded Coded Coded

Electrical data 570812 570814 570816

Supply voltage

Voltage 24 V 24 V 24 V

Kind DC DC DC

Voltage tolerance -15 %/+10 % -15 %/+10 % -15 %/+10 %

Output of external

power supply (DC) 2 W 2 W 2 W

Max. inrush current at UB 5 A 5 A 5 A

Max. switching frequency 1 Hz 1 Hz 1 Hz

Magnet. supply voltage 24 V 24 V 24 V

Max. solenoid current t

<150 ms 1,5 A 1,5 A 1,5 A

Max. cable capacitance at

the safety outputs

No-load, PNOZ with re-

lay contacts 40 nF 40 nF 40 nF

PNOZmulti, PNOZelog,

PSS 70 nF 70 nF 70 nF

Max. inrush current impulse

Current pulse, A1 5 A 5 A 5 A

Pulse duration, A1 0,0002 ms 0,0002 ms 0,0002 ms

Max. unit fuse protection

in accordance with UL 3 A 3 A 3 A

Inputs 570812 570814 570816

Number 2 2 2

Voltage at inputs 24 V DC 24 V DC 24 V DC

Input current range 5 mA 5 mA 5 mA

E-STOP 570812 570814 570816

Number of N/C contacts 2 2 –

E-STOP release type Turn release Turn release –

Page 61

Technical Details Order No. 570812-570816

Operating Manual PSEN sg2c

1003267-EN-04

61

E-STOP 570812 570814 570816

Utilisation category

In accordance with the

standard EN 60947-5-1 EN 60947-5-1 –

Contacts, AC15 at 24 V 24 V –

Current 1,5 A 1,5 A –

Contacts, DC13 at 24 V 24 V –

Current 1,5 A 1,5 A –

Mechanical life 6050 cycles 6050 cycles –

Signal output

Output voltage 24 V 24 V –

Max. current 100 mA 100 mA –

Section stop 570812 570814 570816

Number of N/C contacts – – 2

Release type – – Turn release

Utilisation category

In accordance with the

standard – – EN 60947-5-1

Contacts, AC15 at – – 24 V

Max. current – – 1,5 A

Contacts, DC13 at – – 24 V

Max. current – – 1,5 A

Mechanical life – – 6050 cycles

Signal output

Output voltage – – 24 V

Max. current – – 100 mA

Semiconductor outputs 570812 570814 570816

OSSD safety outputs 2 2 2

Signal outputs 2 2 2

Switching current per output 500 mA 500 mA 500 mA

Breaking capacity per output 12 W 12 W 12 W

Residual current at "0"