Page 1

PSEN op4F/H-A series

Safety light curtain

Operating Manual-1003067-EN-02

Page 2

Preface

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes. Suggestions and comments for improving this documentation will be

gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of Pilz GmbH

& Co. KG in some countries.

SD means Secure Digital

Page 3

1 GENERAL INFORMATION ......................................................... 5

1.1 General description ................................................................................................. 5

1.1.1 General description of the safety light curtain.......................................................... 5

1.1.2 Package content ..................................................................................................... 6

1.2 Guidelines for selecting the protective device ......................................................... 7

1.2.1 Resolution ............................................................................................................... 7

1.2.2 Height of protected field .......................................................................................... 8

1.2.3 Minimum safety distance ........................................................................................ 9

1.3 Typical application areas .......................................................................................12

1.4 Safety information ..................................................................................................13

2 INSTALLATION ........................................................................ 14

2.1 Precautions to be taken during selection and installation of a light curtain .............14

2.2 General information on positioning the device........................................................15

2.2.1 Minimum distance from reflective surfaces ............................................................16

2.2.2 Distances between identical light curtains ..............................................................17

2.2.3 Aligning transmitter and receiver ............................................................................20

2.2.4 Using deviating mirrors ..........................................................................................20

2.2.5 Inspections following a first-time installation ...........................................................21

3 MECHANICAL ASSEMBLY ...................................................... 23

4 ELECTRICAL CONNECTIONS ................................................. 25

4.1 Connection guidelines ............................................................................................28

5 ALIGNMENT ............................................................................. 31

6 SETTING THE FUNCTIONS ..................................................... 33

6.1 Reset to factory configuration ................................................................................35

6.2 Function list ...........................................................................................................36

7 FUNCTIONS .............................................................................. 38

7.1 Restart function ......................................................................................................38

7.2 Test .......................................................................................................................40

7.3 Reset .....................................................................................................................41

7.4 EDM ......................................................................................................................41

7.5 EDM selection ........................................................................................................43

7.6 Reduced range ......................................................................................................43

7.7 Muting ....................................................................................................................44

7.7.1 Disabling the muting function .................................................................................45

7.7.2 Muting display devices ...........................................................................................45

7.7.3 Typical muting application and sensor connection .................................................46

7.7.4 Muting direction .....................................................................................................46

7.7.5 Muting timeout .......................................................................................................50

7.7.6 Muting filter ............................................................................................................51

7.7.7 Partial muting .........................................................................................................52

7.8 Override .................................................................................................................53

7.8.1 Override mode .......................................................................................................54

7.8.2 Override timeout ....................................................................................................55

7.8.3 Override restart ......................................................................................................56

7.9 Blanking .................................................................................................................59

7.9.1 Fixed blanking ........................................................................................................60

7.9.2 Fixed blanking with increased tolerance .................................................................61

7.9.3 Floating blanking with total surveillance .................................................................61

7.9.4 Floating blanking with partial surveillance ..............................................................61

Page 4

7.9.5 Reduced resolution ................................................................................................62

7.9.6 Tolerance ...............................................................................................................62

7.9.7 Blanking mode in the basic configuration ...............................................................64

7.9.8 Blanking mode in advanced configuration ..............................................................65

7.10 Cascading ..............................................................................................................68

7.11 PNP/NPN ...............................................................................................................68

7.12 Coding ...................................................................................................................70

8 DIAGNOSTICS .......................................................................... 73

8.1 Status of LEDs .......................................................................................................73

9 REGULAR CHECKS AND MAINTENANCE ............................. 76

9.1 Regular checks ......................................................................................................76

9.2 Maintenance ..........................................................................................................76

10 TECHNICAL DETAILS .............................................................. 77

11 LIST OF AVAILABLE MODELS ............................................... 78

12 DIMENSIONS ............................................................................ 80

13 FITTINGS .................................................................................. 81

14 ACCESSORIES ........................................................................ 83

14.1 Rotating mounting bracket .....................................................................................83

14.2 Cascading cable ....................................................................................................84

14.3 Connection cable ...................................................................................................85

14.4 PSEN op Advanced Programming Adapter ............................................................86

14.5 Axial connection cable, unshielded ........................................................................88

14.6 Ethernet cable for PSEN op Advanced Programming Adapter ...............................88

Page 5

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

5

The information contained in paragraphs marked by this symbol is

particularly relevant to safety and is important for accident

strictly observed.

1 GENERAL INFORMATION

1.1 General description

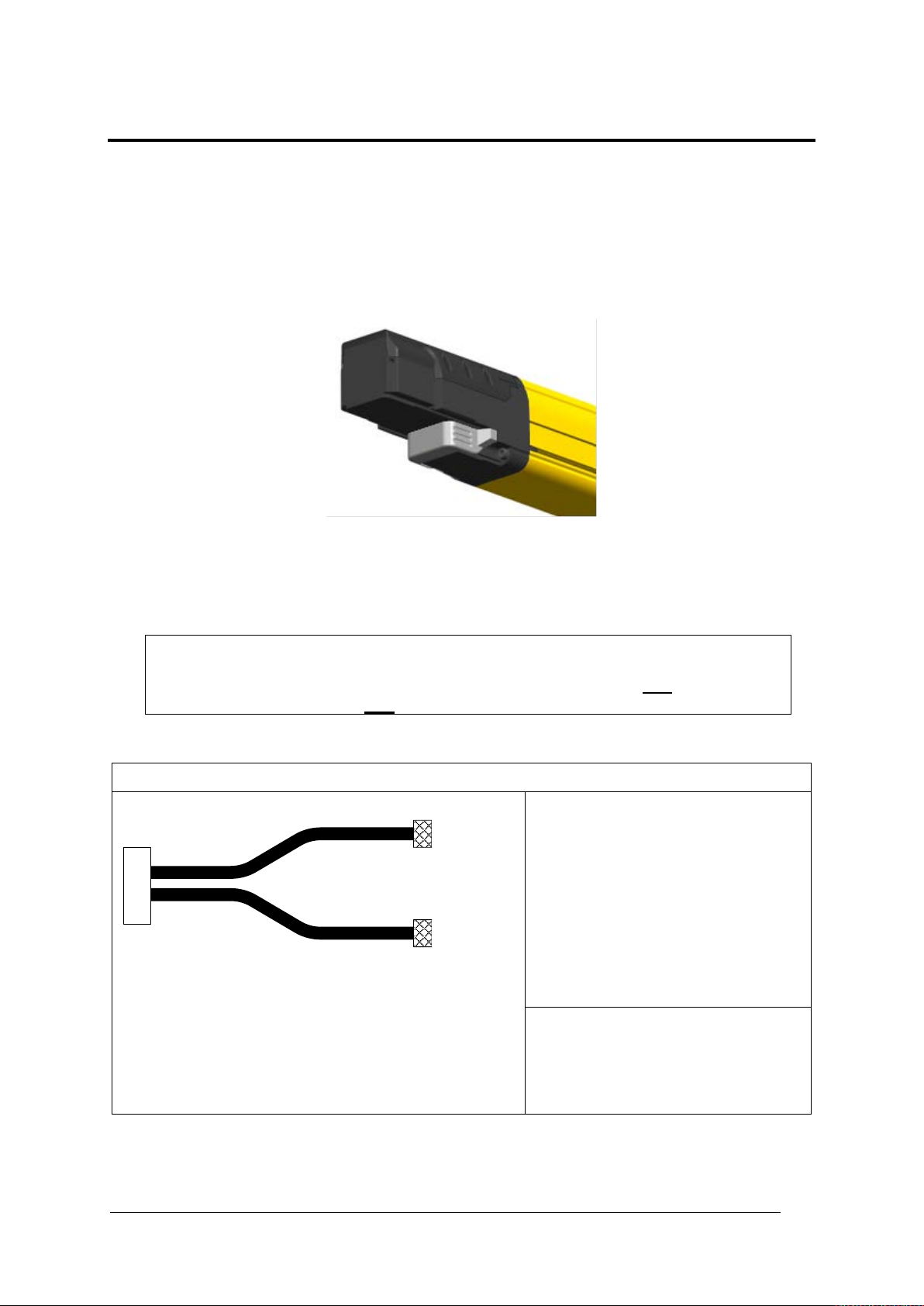

1.1.1 General description of the safety light curtain

The safety light curtains in the PSE N op4F/H-A series are multibeam active optoelectronic

protective devices for work areas in which machines, robots and automated plants in general

could endanger the physical integrity of operators who could come into contact with moving

parts, even if only by chance.

Light curtains in the PSEN op4F/H-A series are designed as inherent ly safe Type 4 systems

for accident prevention in accordance with applicable international safety standards, in

particular the following:

IEC 61496-1: 2004 Safety of machinery: Electrosensitive protective equipment. Part 1:

General requirement s and tests.

IEC 61496-2: 2006 Safety of machinery: Electrosensitive protective equipment –

Particular requirements for equipment using active optoelectronic protective devices.

A light curtain pair consists of a transmitter and a receiver. They produce an infrared

protected field, which is able to detect an opaque object within the specific resolution. Both

the transmitter and the receiver have control and monitoring functions. The connections are

made via an M12 connector, which is located in the lower profile area. The transmitter and

receiver are synchronised optically, so the two units do not have to be connected directly to

each other. The infrared beams that are transmitted and received are controlled and

monitored via a microprocessor, which provides the user with information about the operating

state of the lig ht curtain via LED indicators (see Chapter 8).

A light curtain pair consists of 2 units, which may comprise one or more transmitter and

receiver modules, depending on the respective model. The receiver is the main control unit

for all functions. If an error occurs, it checks all the safety actions and decides on the

measures that are to be implement ed in terms of safety, as well as performing other general

functions.

During the installation phase the user interface makes it easier to align the two units (see

Chapter 5).

As soon as the beams emitted from the transmitter are interrupted by an object, a limb or the

body of an operator, both output signal switching devices (OSSD) ar e opened immediately.

This controls the stopping of the corresponding machine, which is connected to the OSSD.

Some parts or paragraphs of this manual, which are of particular importance to the user or

installation engineer, are highlighted as follows:

prevention.

This information must be read with particular attention and must be

Page 6

PSEN op4F/H-A series OPERATING MANUAL

6

1003067-EN-02

This manual contains all the information you need to select and operate the protective

devices.

Specialised knowledge of safety issues is required to integ rate a safety light curt ain correctly

in a plant.

PILZ’s technical customer service team is available to provide any information you need

regarding the functionality of the PSEN op4F/H-A safety light curtains and the safety

regulations concerning correct installation.

1.1.2 Package content

The following components are included:

• Receiver (RX)

• Transmitter (TX)

• Shortform for installing the safety light curtains in the PSEN op4F/H-A series

• CD with operating manual and other documents

• 4 fastening brackets and corresponding mounting accessories

• 2 fastening brackets for models with a height between 1200 and 1800 mm

Page 7

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

7

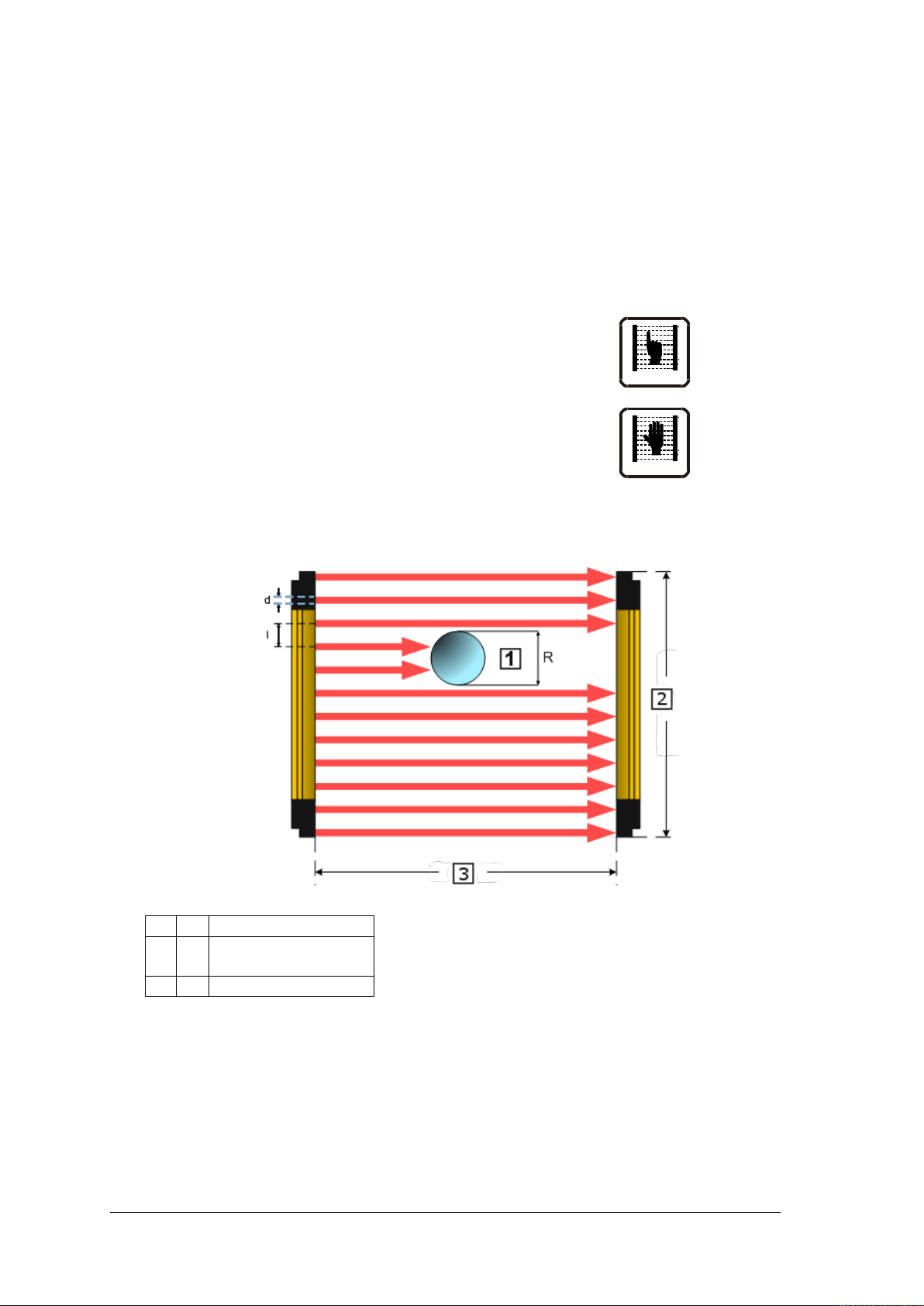

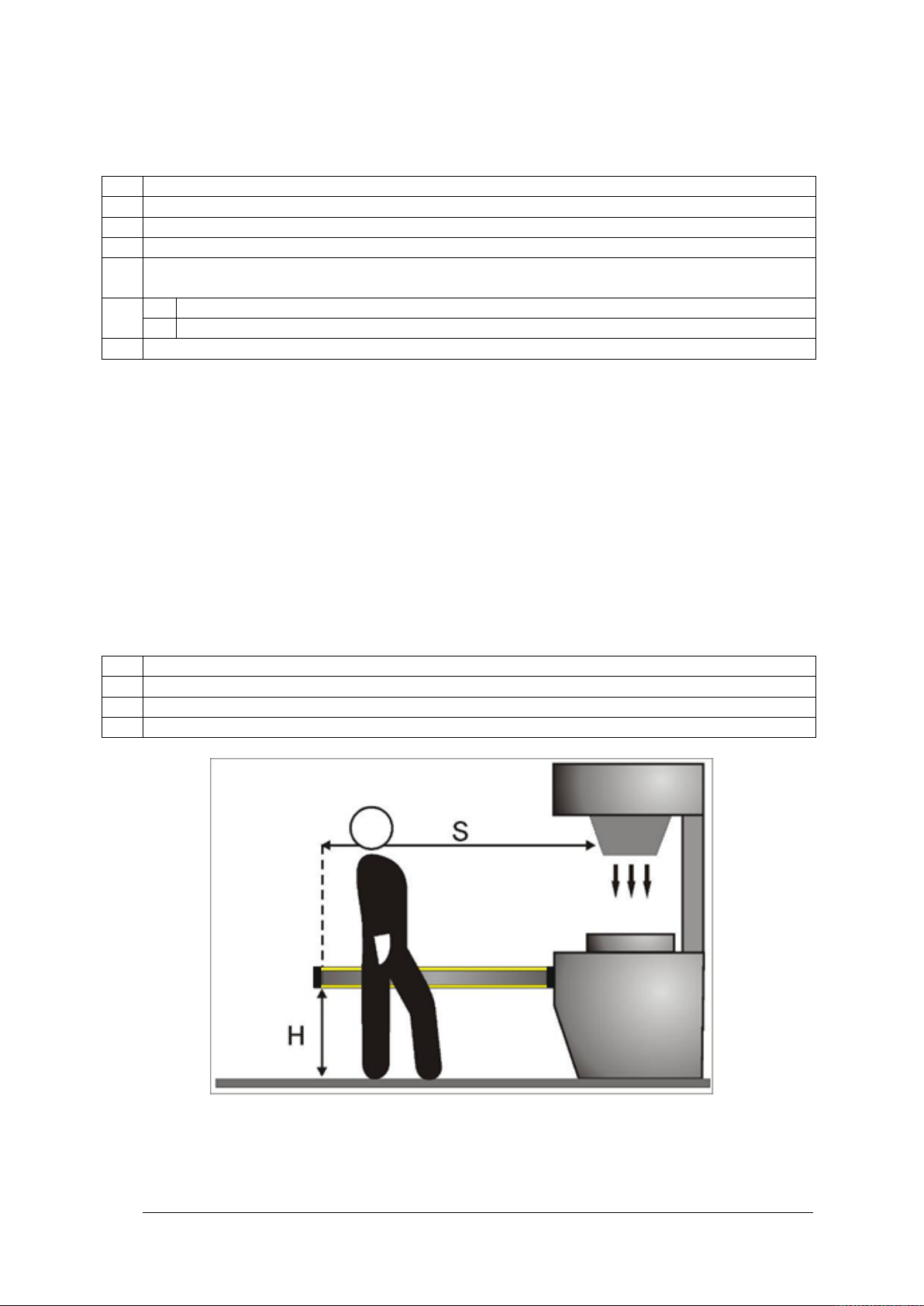

1 = Opaque object

2 = Height of protect ed

field

3 = Operating range

1.2 Guidelines for selecting the protective device

Once the hazards have been assessed appropriately, there are at least three essential

features to consider when selecting a safety light curtain:

1.2.1 Resolution

The device’s resolution is understood to be the minimum size that an opaque object must be

to safely interrupt at least one of the beams that form the area of the protected field.

The resolution is closely linked to the part of the body that requires protection.

R = 14 mm Finger protection

Type 4

R = 30 mm Hand protection

Type 4

As shown in Fig. 1, the resolution depends solely on the geometric properties of the lenses,

the diameter and the distance and so is unaffected by the light curtain’s ambient and

operating conditions.

The resolution value can be calculated using the following formula:

where:

I = Distance between two adjacent lenses

d = Lens diameter

Fig. 1– Resolution

R = I + d

Page 8

PSEN op4F/H-A series OPERATING MANUAL

8

1003067-EN-02

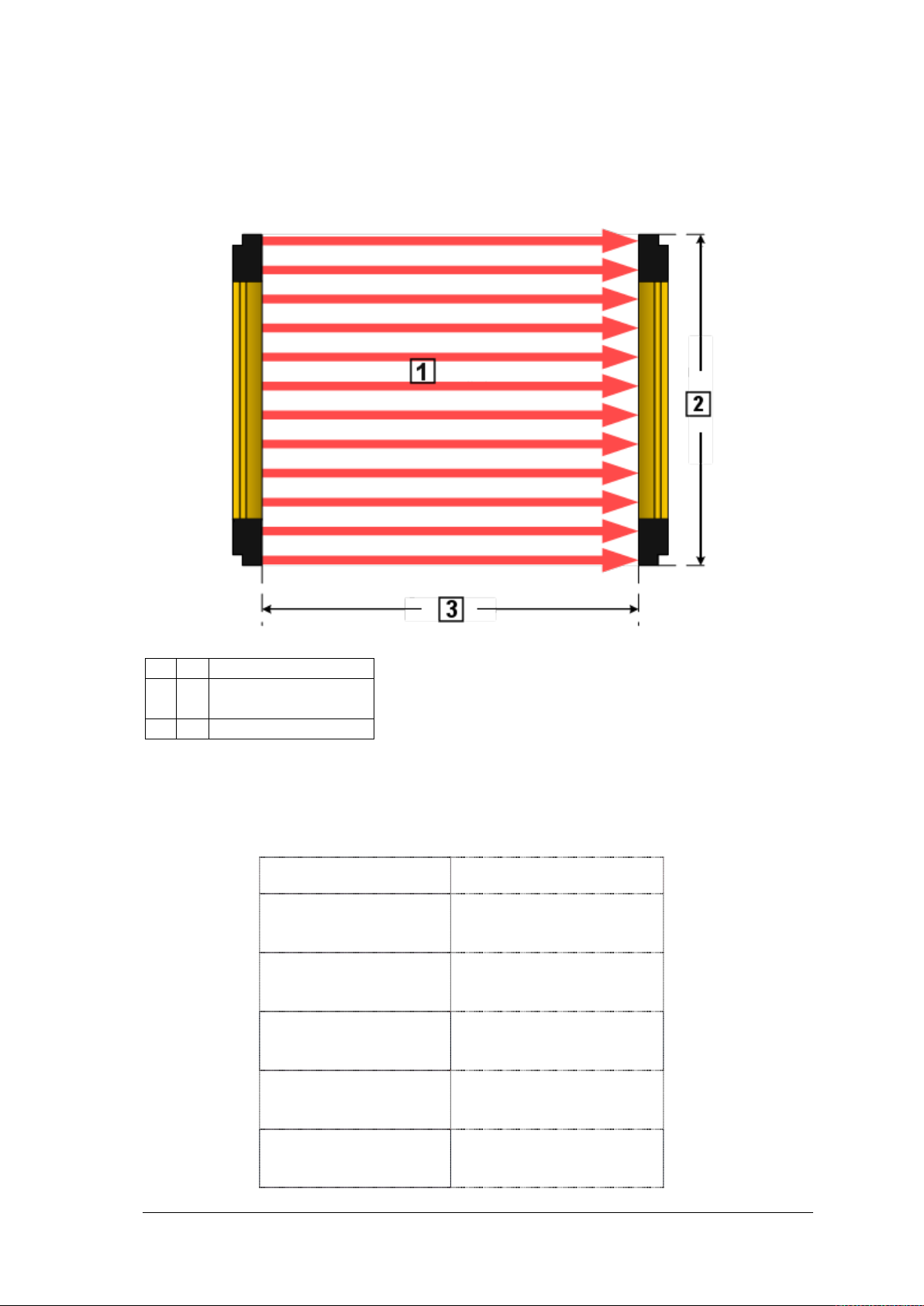

1 = Protected field

2 = Height of protect ed

field

3 = Operating range

Height of protected field

(mm)

1.2.2 Height of protected field

The height of the protected field is understood to be the height pr otected by the safety light

curtain.

Fig. 2 – Height of protected field

The height monitored by the PSEN op4F/H-A corresponds to the overall height of the light

curtain.

With reference to the previous diagram, the height of the protected field can be taken from

the table below.

Model

PSEN op4F-A-14-030/1

PSEN op4H-A-30-030/1

PSEN op4F-A-14-045/1

PSEN op4H-A-30-045/1

PSEN op4F-A-14-060/1

PSEN op4H-A-30-060/1

300

450

600

PSEN op4F-A-14-075/1

750

PSEN op4H-A-30-075/1

PSEN op4F-A-14-090/1

900

PSEN op4H-A-30-090/1

Page 9

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

9

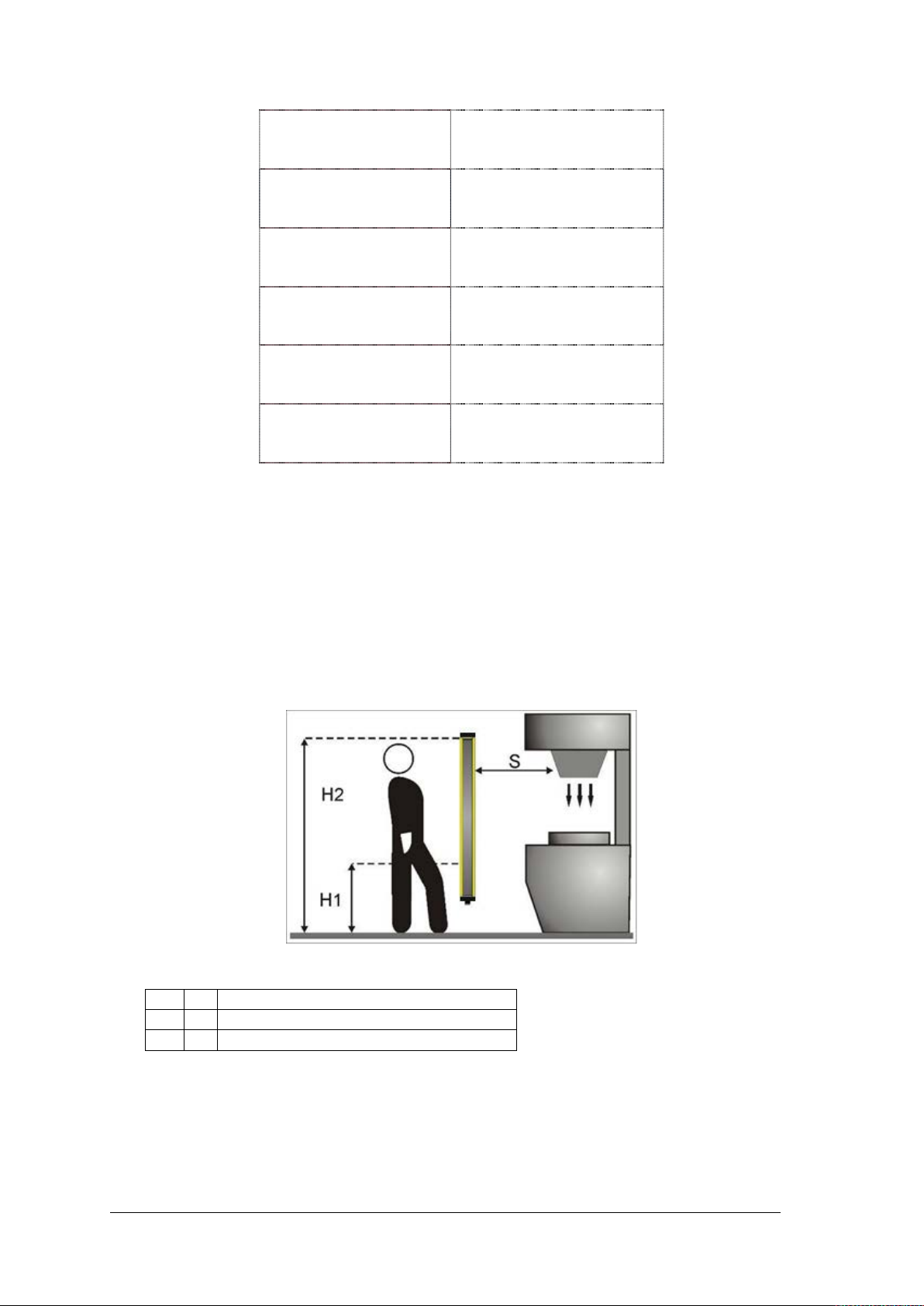

H1 = ≥ 900 mm at a resolution > 40 mm

H2 = ≤ 300 mm at a resolution > 40 mm

S = Minimum safety distance in mm

PSEN op4F-A-14-105/1

PSEN op4H-A-30-105/1

PSEN op4F-A-14-120/1

PSEN op4H-A-30-120/1

PSEN op4F-A-14-135/1

PSEN op4H-A-30-135/1

PSEN op4F-A-14-150/1

PSEN op4H-A-30-150/1

PSEN op4F-A-14-165/1

PSEN op4H-A-30-165/1

PSEN op4F-A-14-180/1

PSEN op4H-A-30-180/1

1050

1200

1350

1500

1650

1800

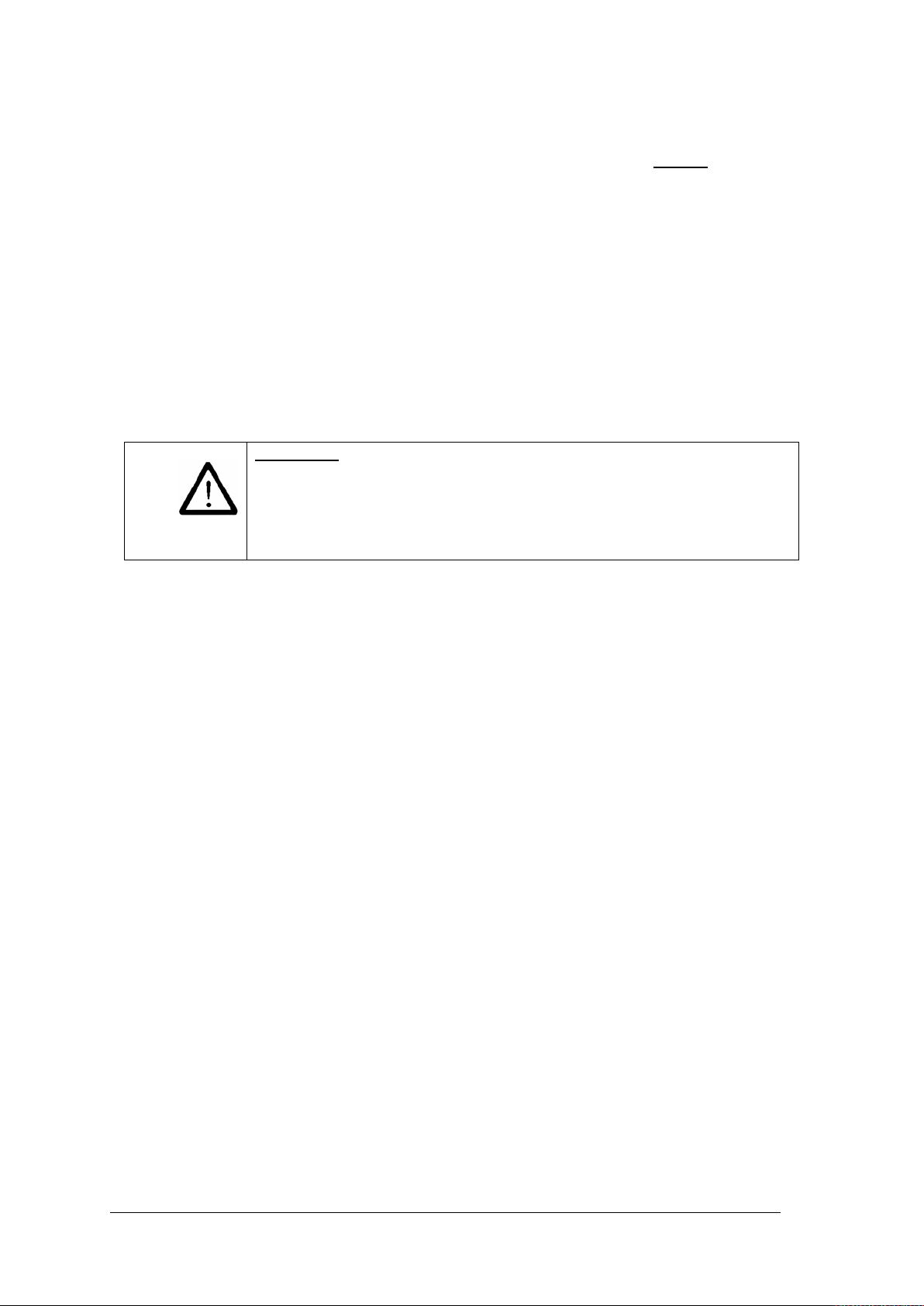

1.2.3 Minimum safety distance

The protective device must be positioned at a specific safety distance (Fig. 3), which

guarantees that the operator cannot reach the danger zone until the hazardous machine

movement has come to a standstill by triggering the light curtain.

In accordance with the standard ISO 13855, this distance depends on 4 factors:

• Response time of the light curtain (the time that elapses between the beams being

effectively interrupted and the OSSD contacts opening).

• Machine’s stopping performance (time that elapses between the light curtain contacts

opening and the hazardous machine movement effectively stopping).

• Light curtain’s resolution

• Approach speed of the object to be detected.

Fig. 3 – Safety distance (vertical)

Page 10

PSEN op4F/H-A series OPERATING MANUAL

10

1003067-EN-02

S

Minimum safety distance in mm

K

Speed of the object (limb or body) approaching the danger zone in mm/s

t1

Light curtain’s response time in seconds (see Chapter 11)

t2

Machine’s stopping performance in seconds

C

Additional distance based on the possibility of placing the body or limb into the danger

zone before the protective device responds

C

8 (d -14) for devices with a resolution ≤ 40 mm

C

850 mm for devices with a resolution > 40 mm

d

Device’s resolution

S

Minimum safety distance in mm

t1

Light curtain’s response time in seconds (see Chapter 11)

t2

Machine’s stopping performance in seconds

H

Height of the beams above the floor. This height must always be less than 1000 mm.

The safety dist ance is calculated using the following formula:

S = K (t1 + t2) + C

Therefore:

Note:

The value K corresponds to:

• 2000 mm/s, if the calculated value S is ≤ 500 mm

• 1600 mm/s, if the calculated value S is > 500 mm

When using light curtains with a resolution of > 40 mm, the upper beam must be posit ioned

at a height of ≥ 900 mm (H2) from the supporting base, while the lower beam must be

positioned at a height of ≤ 300 mm (H1).

Where the light curtain must be installed horizontally (Fig. 4), the distance between the

danger zone and the most distant optical beam must correspond to the value calculated

using the following formula:

S = 1600 mm/s (t1 + t2) + 1200 – 0.4 H

Therefore:

Fig. 4 – Safety distance (horizontal)

Page 11

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

11

WARNING: In this case the reference standard is EN ISO 13855

protective equipment in

binding. Please refer to the complete standard ISO

13855 for details of how to calculate safety distances correctly.

Application examples

This example is based on a light curtain with a height = 600 mm.

To calculate the distance of the device from the light curtain in a vertical position, the

following formula is applied:

S = K*T + C

Therefore:

T = t

t

1

With a reaction time of the light curtain of 15 ms the result is a max. of 35 ms for t

+ t2

1

= Response time of light curtain + release time of relay (specific tim e of PNOZ S3: 20ms)

1

t2 = Machine’s overall stopping performance in seconds

C = 8 * (d – 14) for devices with resolution <= 40 mm

D = Resolution

In each case, if K = 2000 mm/sec, then S > 500 mm. The safety distance will then need to be

recalculated, based on K = 1600 mm/sec.

“Safety of machinery – Positioning of

respect of approach speeds of parts of the human body”.

The information provided here should be regarded as a summary

and is non-

Page 12

PSEN op4F/H-A series OPERATING MANUAL

12

1003067-EN-02

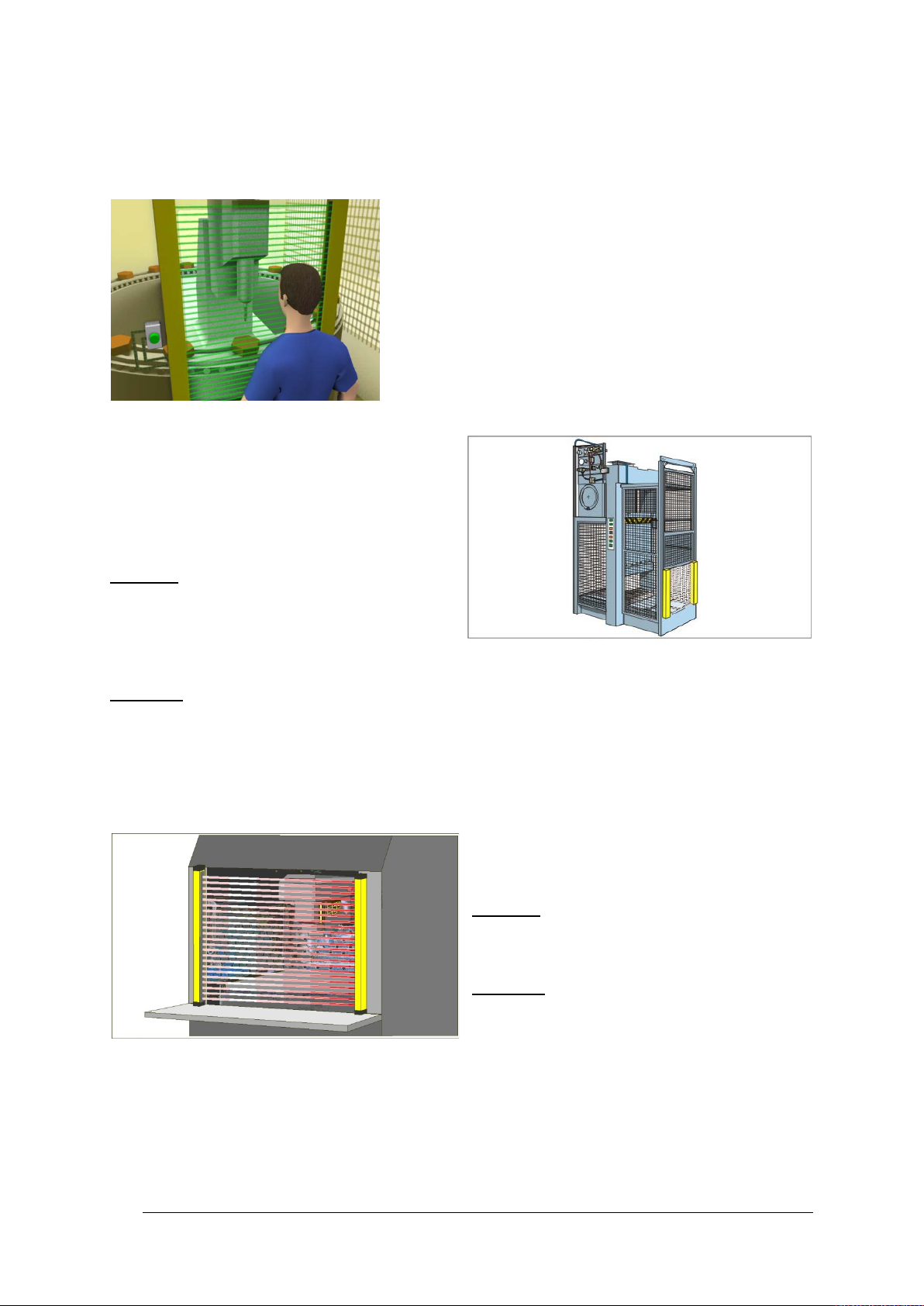

1.3 Typical application areas

Example 1: Protecting the operating area on drilling machines

The operator inserts the workpiece and removes it after

machining. The operator must be protected from injury

during the machining process.

Solution: The safety light curtain PSEN op4F/H-A is

particularly suitable for this application, as the device

needs to be installed directly on the machine.

Benefits: The small dimensions of the light curtain

guarantee maximum flexibility during installation, as it

can be adapted to the machine dimensions.

Rotatable mounting brackets are included,

guaranteeing fast, simple attachment.

Example 2: Bending presses

The safety device must protect the bending

process operator from the crushing hazard

that exists between the upper and lower tool

or from the workpiece that is being

machined, if this approaches at high speed.

Solution: Even if just one light axis on the

safety light curtain PSEN op4F/H-A is

interrupted during the downward phase, the

movable workpiece carrier is stopped

immediately.

Benefits: The simple installation options and the small dimensions of the safety light curtain

mean it can be used in most bending operations. PSEN op4F/H-A not only guarantees a high

level of reliability but also increases production on the plant, as the standstill times needed

for access, settings and machine maintenance can be reduced.

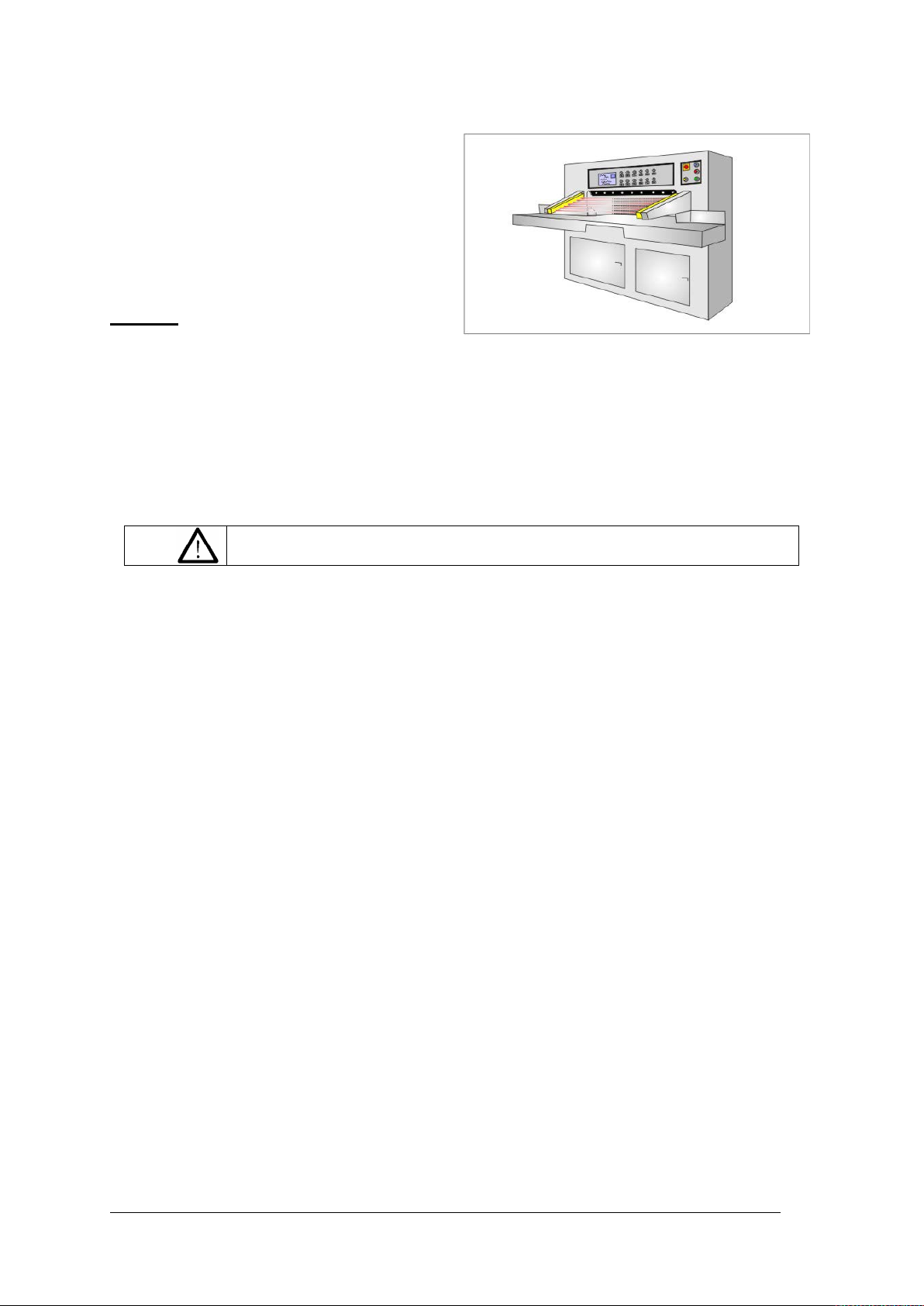

Example 3: Paper cutting machine

A typical application for these protective devices is on paper cutting machinery for magazines

and special formats. The purpose of the light

curtain is to pr otect the operator from cuts or

abrasions from the cutting machine.

Solution: The safety light curtain PSEN

op4F/H-A is particularly suitable for this

application, as the device needs to be

installed directly on the machine.

Benefits: The small dimensions of the light

curtain and the guide rails at either end

guarantee maximum flexibility, as they can

be adapted to the machine’s mechanical

dimensions.

Page 13

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

13

To use the safety light curtains in the PSEN op4F/H-A series safely

and correctly, the following information must be considered:

Example 4: Moulding machine

The moulding machine is used to create

complex shapes from metallic parts or parts

made from other materials. In this case it is

necessary to prevent the operator’s hands or

other limbs being dragged, entangled or cut

by the tool itself or being injured by the

spindle.

Solution: The safety light curtain from the

PSEN op4F/H-A series is the best solution

for protecting the operator in terms of the required safety level and the application type. As

soon as even a single beam on the light curtain is interrupted, the machine is stopped

immediately.

Benefits: The small dimensions of the light curtain with no dead zones guarantees maximum

flexibility during installation, as it can be adapted to the machine dimensions.

1.4 Safety information

• The system intended to stop the machine must be electrically controllable.

• This control system must be able to stop hazardous machine movements

- inside the overall stopping performance of the machine T,

- in accordance with the details in Chapter 1.2.3 of the operating manual (see CD provided)

- and in each phase of the processing cycle.

• The protective device must be positioned at a distance that exceeds the minimum safety

distance S or that correspo nds to it, so that the operator cannot reach the danger zone until the

movement of the hazardous object has come to a standstill by triggering the light curtain.

• The safety light curtains may only be installed and connected by qualified personnel. It is

essential to follow the instr uctions provided in the relevant sections of the manuals provided

(see Chapters 2, 3, 4 and 5) and to comply with the applicable directives.

• Ensure that the c orrect ope ration of the light cur tain is not distur bed by stron g electromagnet ic

interference.

• Ensure that the light curtain, particularly the receiver, is not installed close to particularly

intense and/or flashing light sources.

• The saf et y light curtain must be positioned so th at it saf ely preve nts ac cess to the dan ger zone

without interrupting the beams (see Chapters 2, 3).

• Only qualified personnel with appropriate knowledge of all the operating procedures of the

safety light curtain should be permitted to work within the danger zone.

• The RESET button must be positioned outside the area of the pr otected field and in such a

way that the operator can see into the danger zone when carrying out a reset and test

procedure.

• Reflective surfaces close to the beams emitted from the protective device (whether from

above, below or from the side) can cause passive reflections th at adversely affect the correct

operation of the light curtain.

The instructions provided for correct operation must be strict ly followed before switching on

the light curtain.

Page 14

PSEN op4F/H-A series OPERATING MANUAL

14

1003067-EN-02

Ensure that the safety level guaranteed by the PSEN op4F/H-A

to be monitored, as well as the level defined by the standard

EN ISO 13849.

Ensure that the light curtain’s outputs (OSSD) are used as

machine must have a separate START control.

Ensure that the correct operation of the light curtain is not

Ensure that the light curtain, particularly the receiver, is not

2 INSTALLATION

2.1 Precautions to be taken during selection and installation of a light curtain

(Type 4) complies with the actual risk assessment of the machine

machine stopping devices and not as control devices. The

disturbed by strong electromagnetic interference.

installed close to particularly intense and/or flashing light sources.

• The size of the smallest object to be detected must be greater than the device’s resolution.

• The light curtain must be installed in an env ironment t hat com plies with t he techn ical prop erties

stated in Chapter 11.

• Smoke, mist or dust in the working environment can reduce the operating range of the

protective device.

• Sudden, large-scale temperatur e variations, particularly with l ow temperatures can generate a

slight layer of condensation on the device’s lens, adversely affecting its function.

• Reflective surfaces close to the beam s em itted from the protect ive device ( whether from above,

below or from the s ide) can cause pas sive r eflect ions t hat adv ersel y aff ect the correct operation

of the light curtain.

• The protective device must be positioned at a distance that exceeds the minimum safety

distance S or that correspo nds to it, so that the operator cannot reach the dang er zone until the

movement of the hazardous object has come to a standstill by triggering the light curtain.

Page 15

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

15

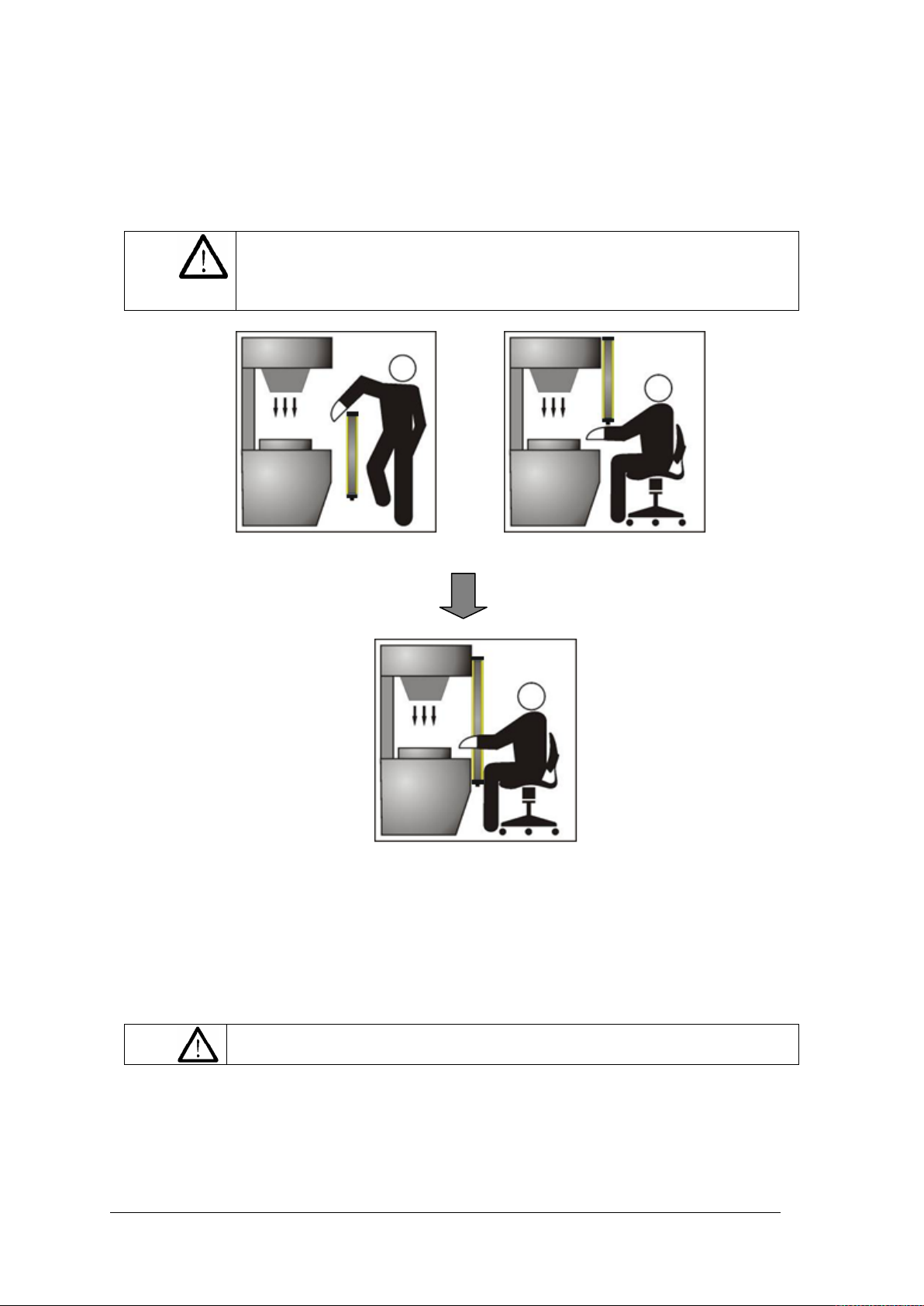

Fig. 5 shows some possibilities for accessing the machine from above

which access to the danger zone can be covered in full (Fig. 6).

If the operator is able to enter the danger zone, additional

mechanical protection must be installed to exclude access.

NO

YES

2.2 General information on positioning the device

Special care should be taken when positioning the safety light curtain to ensure it provides

efficient protection. The device must be installed so that the danger zone cannot be

accessed without interrupting the protected field.

and below. Situations like this could turn out to be extremely dangerous.

For this reason, the safety light curtain must b e installed at a height from

Fig. 5 – Device positioned incorrectly

Fig. 6 – Device positioned correctly

Under normal operating conditions, the machine may only be started if the operator is

outside the danger zone.

If it is impossib le to install the light curtain in the immediate vicinity of the danger zone, t he

possibility of access from the side must be excluded, for example, by installing a second

horizontal light curtain. See Fig. 8.

Page 16

PSEN op4F/H-A series OPERATING MANUAL

16

1003067-EN-02

Fig. 7

Fig. 8

NO

YES

2.2.1 Minimum distance from reflective surfaces

Reflective surfaces close to the beams emitted from the protective device (whether from

above, below or from the side) can cause passive reflect ions. These passive reflections can

adversely affect how the object is detected within the protected area. If the receiver RX

detects a secondary beam (reflected by the side-reflecting surface), the object may not be

detected even if it interrupts the main beam.

DANGER ZONE

Reflective surface

Reflective surface

Fig. 9 Minimum distance from reflective surfaces

When installing the safet y light curtain it is important to maintain a minimum distance from

reflective surfaces.

Page 17

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

17

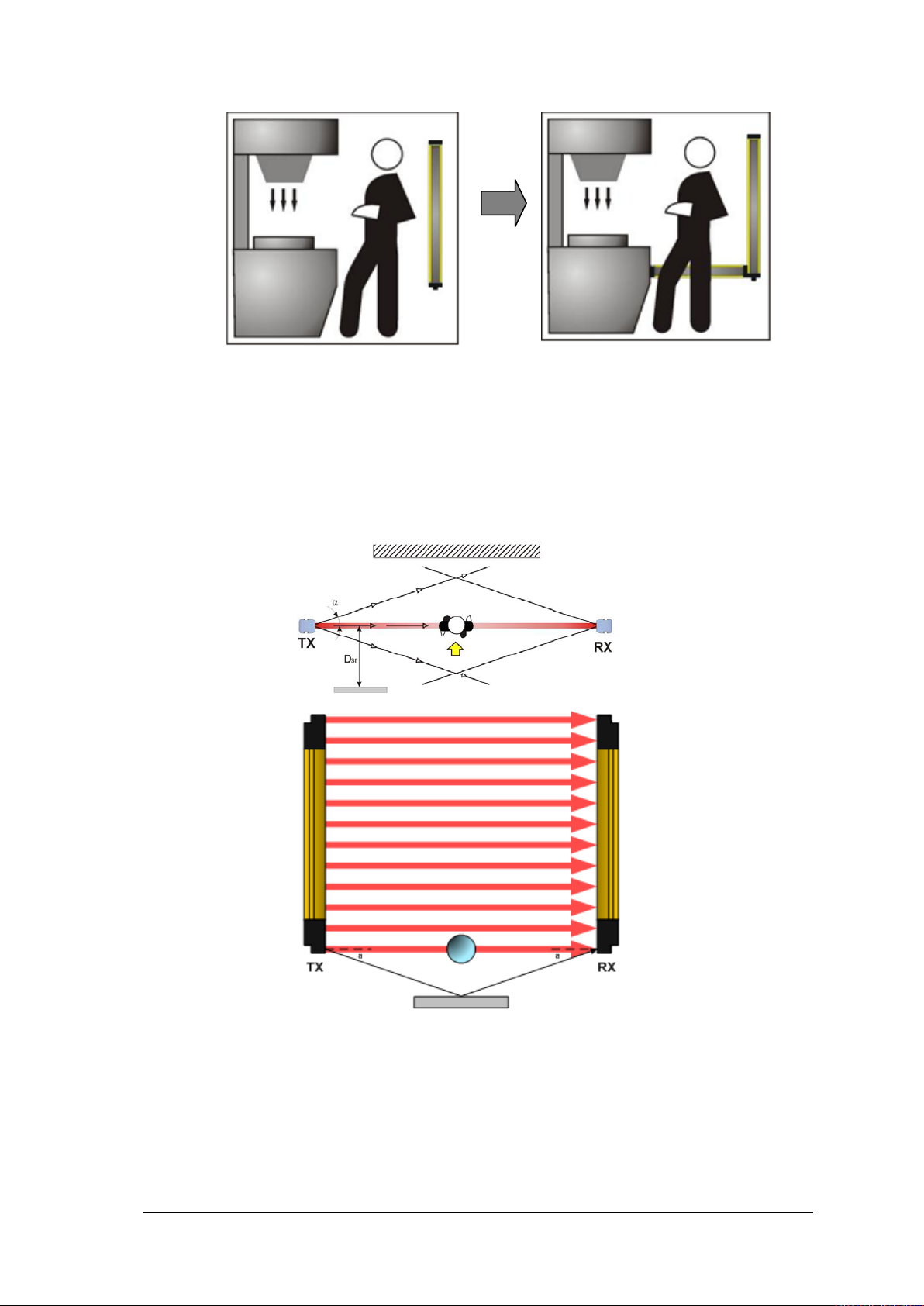

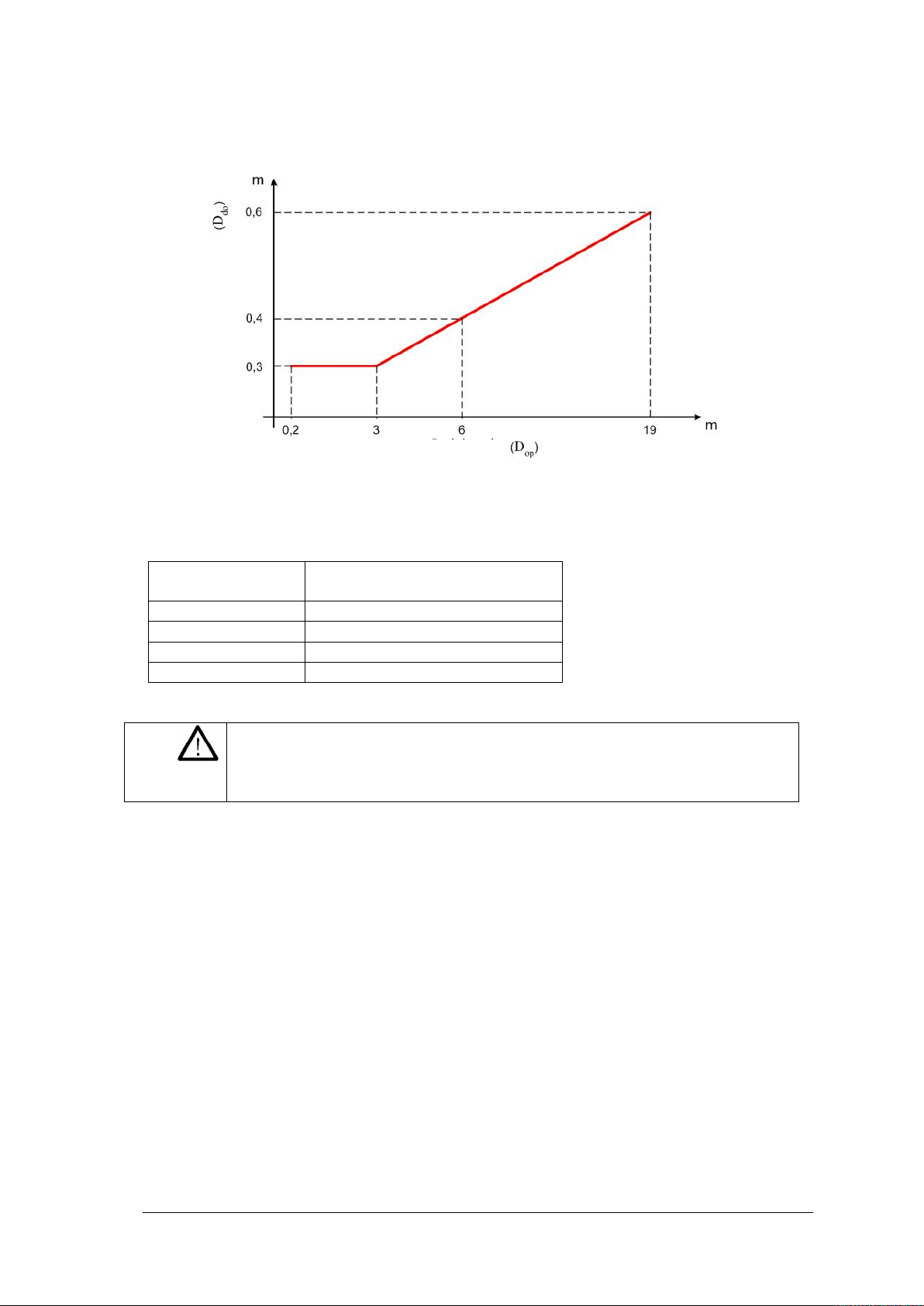

Dsr (m)

=

0.15

With operating ranges < than 3 m

Dsr (m)

=

0.5 x operating range (m) x

tg 2α

Light

Operating range

This minimum distance depends on the following factors:

• The distance between the transmitter (TX) and receiver (RX)

• The actual opening angle of the light curtain; in particular:

when Type 4 light curtain = 5° (α = ± 2.5°)

The illustration in Fig. 10 shows the minimum distance from the reflective surface (D

) based

sr

on the operating range:

curtain

Type 4

Distance from

reflective surface

Fig. 10

Formula for calculating Dsr:

With operating ranges ≥ than 3 m

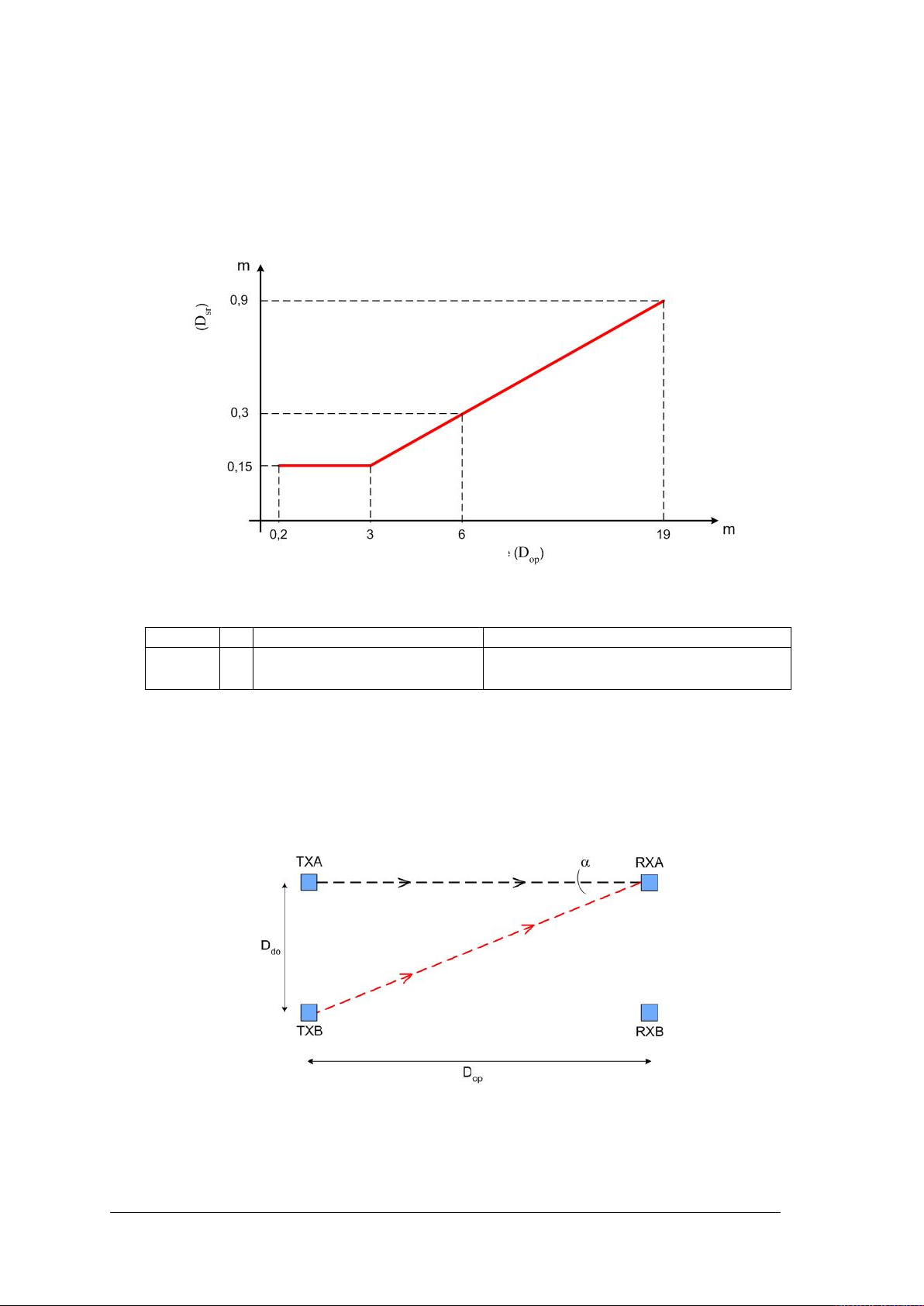

2.2.2 Distances between identical light curtains

Should it be necessary to install several protective devices in adjacent areas, care must be

taken to ensure that the transmitter on one of the pairs does not dangerously interfere with

the receiver on another pair.

The interfering transmitter, TX B, must be installed outside the minimum distance D

the TX A - RX A axis of the transmitter/receiver pair.

from

do

This minimum distance D

• The distance between the transmitter (TX A) and receiver (RX A);

• The actual opening angle of the light curtain.

Fig. 11 – Distance between devices of the same type

depends on the following factors:

do

Page 18

PSEN op4F/H-A series OPERATING MANUAL

18

1003067-EN-02

Operating range

(m)

Minimum safety distance

(m)

3

0.3 6 0.4

10

0.5

19

0.6

WARNING: The interfering transmitter (TX B) must be positioned at

even if the distance

RX A.

Reichweite

Operating range

Distance between two

The following graphic shows the distance from the interfering devices (Ddo), based on the

operating range (D

) of the pair (TX A – RX A).

op

devices of the same type

Fig. 12

For the purpose of simplification, the table below states the values of the minimum safety

distances required for installation, with reference to some operating ranges.

the same distance Ddo, as calculated above,

from the other transmitter TX A is shorter than from the receiver

Page 19

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

19

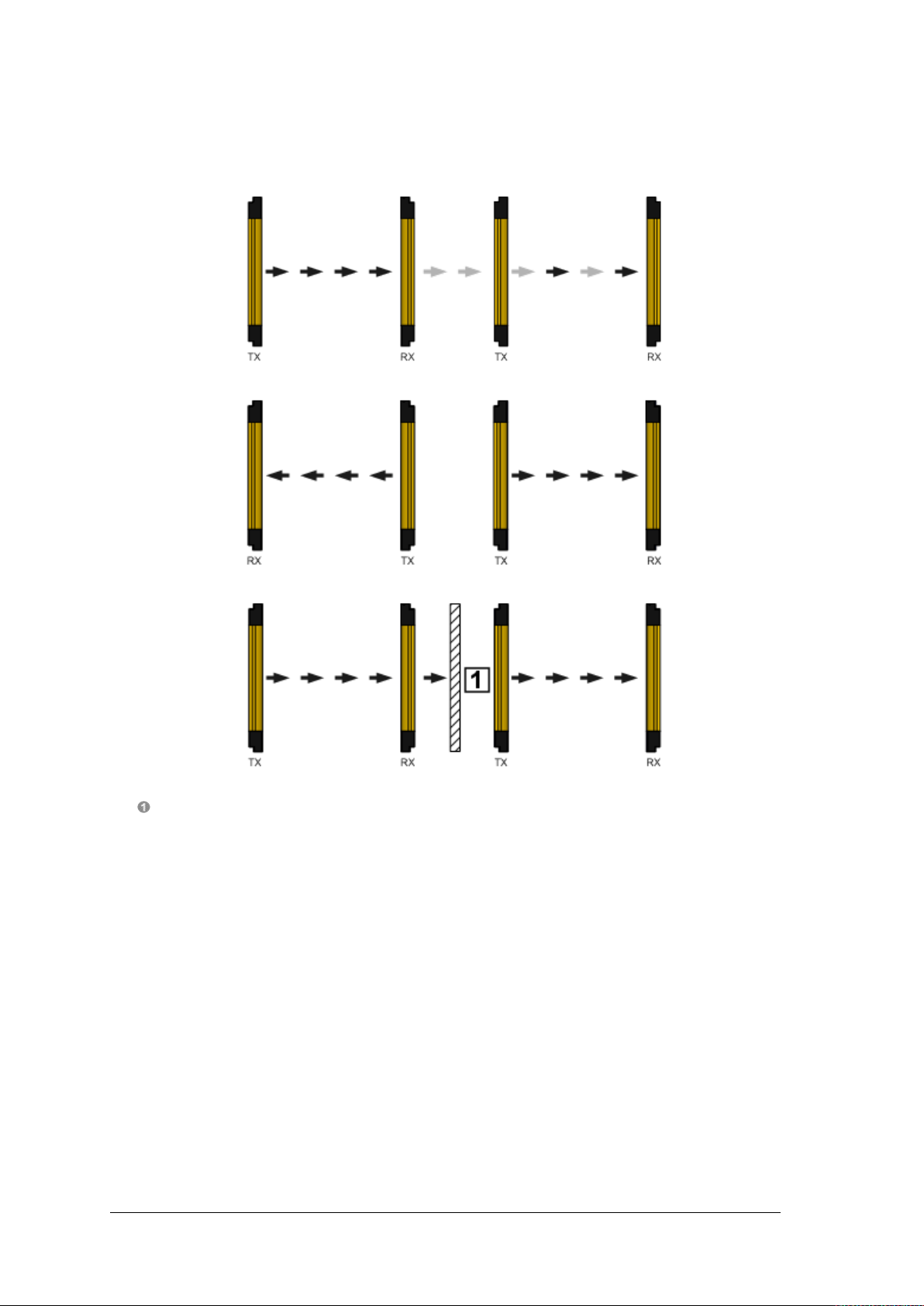

NO

YES

YES

Fig. 13 shows an example of an installation in which interference may occur, along with two

potential remedies.

Opaque partition

Fig. 13 – Interference between adjacen t lig ht cur tains

Should it be necessary to install two light curtains adjacently, as shown in the example in Fig.

13, the coding function is available as a possible solution (see section 7.12).

Page 20

PSEN op4F/H-A series OPERATING MANUAL

20

1003067-EN-02

NO

Mirror

Mirror

2.2.3 Aligning transmitter and receiver

The light curtain pair must be arranged in parallel to each other. Transmitter and receiver

have connections underneath. Both units must be installed at the same time.

Make sure that the light curtains are not configured as shown in Fig. 14.

NO

Fig. 14 – Light curtain alignment

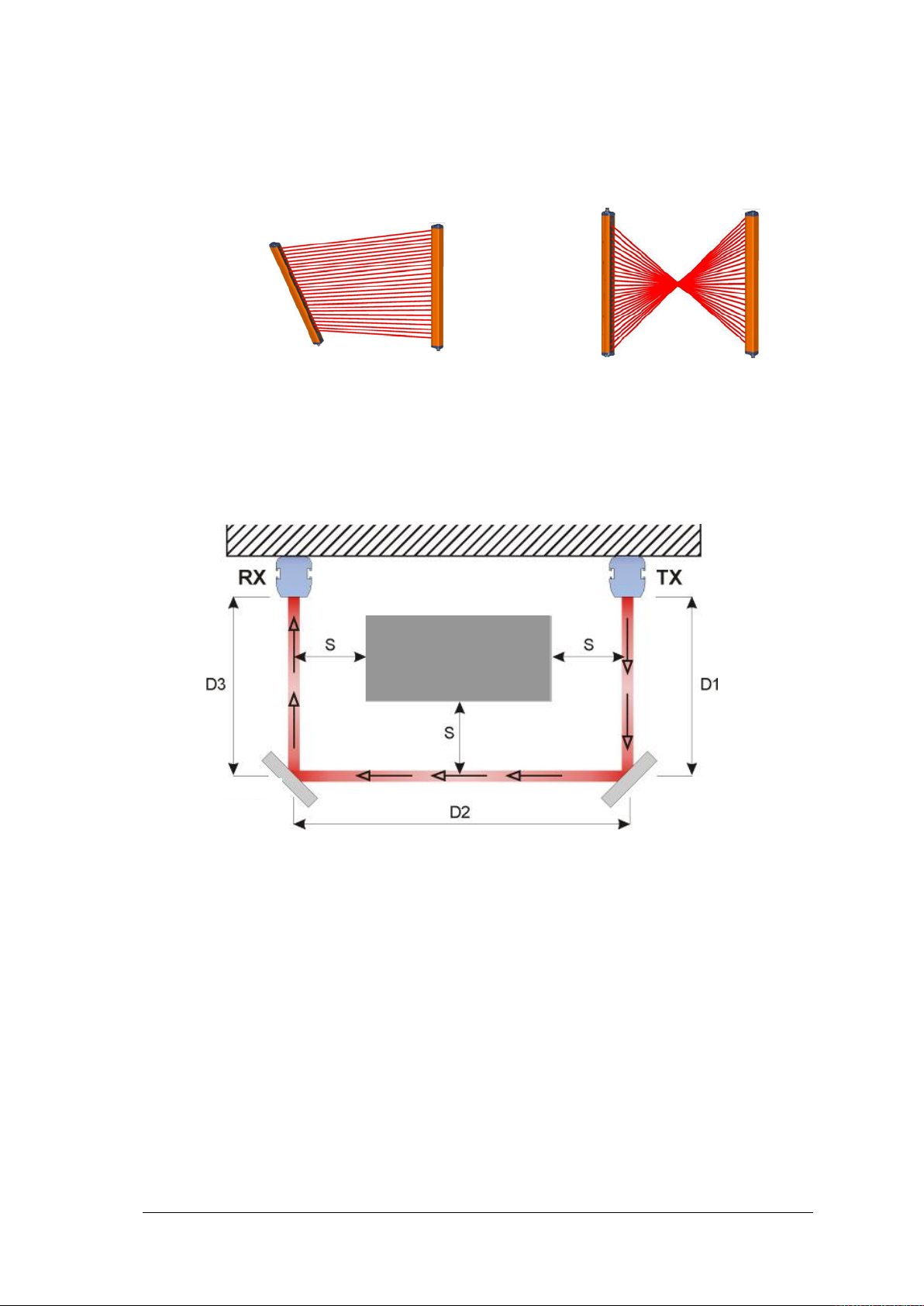

2.2.4 Using deviating mirrors

If a single safety device is used, danger zones with different but adjacent access sides can

be monitored using well-positioned deviating mirrors.

Fig. 15 shows a possible solution, which can be used to protect three access sides using two

mirrors. The deviating mirrors should be positioned at a 45° angle to the light axes.

DANGER

ZONE

Fig. 15- Using deviating mirrors

When deviating mirrors are used, the following precautions must be taken and conditions

considered:

• When deviating mirrors are used, the alignment of the transmitters and receivers requires

higher precision. Perfect ali gnment can be lost even with only a minor ang ular displacement of

the mirror. In this case we recommend you use the laser pointer, which is available as an

accessory.

• The minimum safety distance (S) must be maintained for all sections of the beam.

• Use of a single deviating mirror reduces the effective operating range by about 15%. This

percentage increases when two or more deviati ng mirrors are used (m ore detailed information

is provided in the technical specifications for the relevant mirror).

Page 21

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

21

Number

of mirror s

Operating range

(14 mm)

Operating range

(30 mm)

1

5.1 m

16.5 m

2

4.3 m

13.7 m

3

3.7 m

11.6 m

The table below states the operating ranges based on the number of mirrors used.

• Never use more than three mirrors per device.

• Any dust or dirt on the mirror’s reflective surface will drastically reduce the operating range.

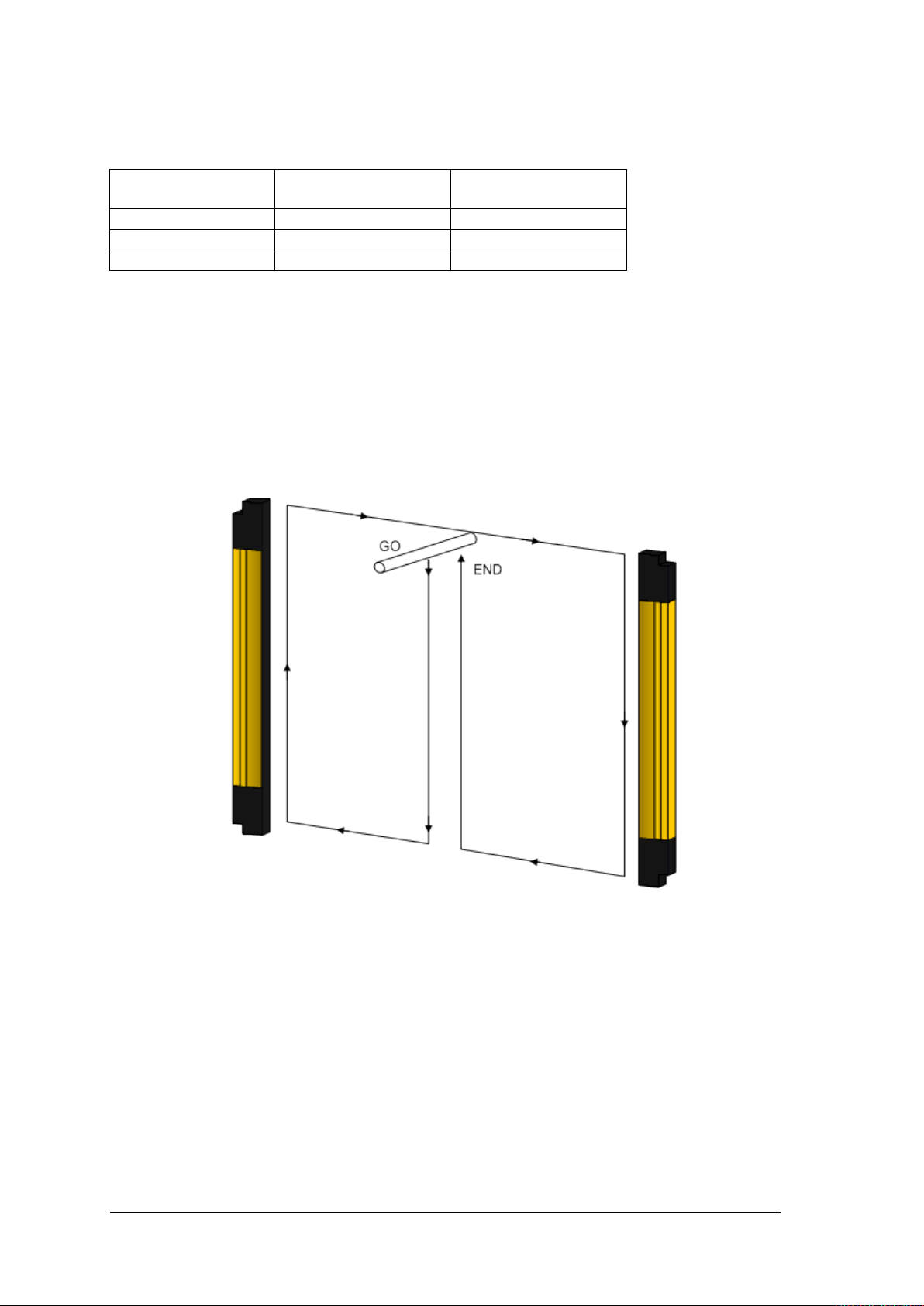

2.2.5 Inspections following a first-time installation

Listed below are the control measures that must be taken following a first-time installation,

prior to starting the machine. Tests must be carried out by qualified personnel or directly by

the person in charge of machinery safety / under his or her supervision.

Fig. 16 – Path of test object

Page 22

PSEN op4F/H-A series OPERATING MANUAL

22

1003067-EN-02

Perform the following checks:

• The light curtain is in a safe state (OSSDs off)

- T he beams are interrupted across the whole area of the protected field using a test

object (test rod) (TP-14 or TP-30) with an appropriate resolution, in accordance with

the diagram in Fig. 16.

• Is the light curtain aligned correctly?

- Press gently on the side of the product in both directions. The red LED must not lig ht

during this process

• Activate the TEST function on the TX side.

- The OSSD outputs are opened (r ed LED, OSSD on the RX side, ON and stop of the

controlled machine).

• The response time to the status of the machine STOP, including the response time of

the light curtain and machine, is within the limit values defined f or calculating the safety

distance (see Chapter 2.2).

• The safety distance between the danger zones and the light curtain complies with the

details specified in Chapter 2.2.

• Access and exposure of persons between the light curtain and hazardous machine

components is prevented.

• It is impossible to access the machine’s danger zones from an unprotected side.

• In order to guarantee that the light curtain remains in NORMAL FUNCTION MODE for at

least 10-15 minutes and, after positioning the specific test object in the protected field,

stays in a SAFE STATE for the same time span, there must be no interference from

external light sources.

• Check that all additional functions comply by activating them several times under

different operating conditions.

Page 23

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

23

3 MECHANICAL ASSEMBLY

The transmitter (TX) and receiver (RX) must be assembled with their sensing surfaces facing

each other. The connectors must be positioned on the same side and the distance must be

within the operating limits of the relevant model (see Chapter 11).

The pair of light cu rtains must be aligned to the best possible extent and must be as parallel

as possible.

The devices will be precision aligned in accordance with the description in Chapter 5.

When positioning the pair of light curtains, please note that the length of the receiver is

increased by 56.9 mm if the PSEN op Advanced Programming Adapter is used and is built

into the light curtain.

The fastening kit supplied can be used as follows (Fig. 17).

To assemble the kit with the mounting brackets, place the bolts into the dedicated side guide

rail. Slide the insert along the groove of the metal profile. Attach the bracket by tightening the

M5 hexagonal nuts on the profile. It is possible to slide the bracket unit along the dedicated

rail and then reposition it by tightening the above-mentioned nuts.

Fig. 17 – Procedure with fixed mounting brackets

On applications where there is particularly heavy vibration, we recommend that you use antivibration rubbers with the mounting brackets to alleviate the effects of the vibration.

Fig. 18 - Anti-vibration rubbers

Page 24

PSEN op4F/H-A series OPERATING MANUAL

24

1003067-EN-02

MODEL

L (mm)

L (mm)

adapter

A (mm)

B (mm)

C (mm)

PSEN op4H-A-30-030/1

PSEN op4H-A-30-045/1

PSEN op4H-A-30-060/1

PSEN op4H-A-30-075/1

PSEN op4H-A-30-090/1

PSEN op4H-A-30-105/1

PSEN op4H-A-30-120/1

PSEN op4H-A-30-135/1

PSEN op4H-A-30-150/1

PSEN op4H-A-30-165/1

PSEN op4H-A-30-180/1

The mounting positions recommended based on the length of the light curt ain are stated in

Fig. 19 and in the following table.

Fig. 19 – Light curtain dimensions

incl. PSEN op

advanced

programming

PSEN op4F-A-14-030/1

PSEN op4F-A-14-045/1

PSEN op4F-A-14-060/1

PSEN op4F-A-14-075/1

PSEN op4F-A-14-090/1

PSEN op4F-A-14-105/1

PSEN op4F-A-14-120/1

PSEN op4F-A-14-135/1

PSEN op4F-A-14-150/1

PSEN op4F-A-14-165/1

PSEN op4F-A-14-180/1

306.3

456.3

606.2

756.2

906.1

1056.1

1206

1356

1505.9

1655.9

1805.8

363.2

513.2

663.1

813.1

963.0

1113.0

1262.9

1412.9

1562.8

1712.8

1862.7

86.3 110 -

236.3 110 -

306.2 150 -

406.2 175 -

506.1 200 -

606.1 225 -

966 150 453

1066 175 503

1166 200 553

1266 225 603

1366 250 652.9

Page 25

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

25

NOTE: The RX connections on the 12-pin M12 cable for the muting model and

muting configuration and one M12 for the blanking configuration).

PSENopt Advanced RX Muting

18 pin

M12 12 pin

M12 5 pin

M12 12-Pin:

M12 5-Pin:

4 ELECTRICAL CONNEC TIONS

18-pin rectangular pigtail cables are used at the light curtain for electrical connections. The

pigtail cable has M12 connectors with a different number of pins on the opposite side.

On muting models, the receiver is equipped with one 12-pin M12 connector and one 5-pin

M12 connector.

On blanking models, the receiver is equipped with one 12-pin M12 connector.

The transmitter has one 5-pin M12 connector (on both muting and blanking models).

After removing the cap shown in grey (see Fig.) the cables must be connected at the bot tom

of the light curtain (the end with LEDs and buttons).

Make sure that the terminator cap (see Chapter 13) is connected on the top of the light

curtain. If this connection is missing, the Master and Slave units will switch to a critical

communication state.

the 12-pin M12 cable for the blanking model are different, so it is important to

use the right cable for each configuration (connector with two

M12s for the

1. 24 V (brown)

2. 0 V (blue)

3. RESET/RESTART/ALIGN (white)

4. OVERRIDE1 (green)

5. OSSD2 (pink)

6. EDM (yellow)

7. MUTING DEACTIVATION (black)

8. OSSD1 (grey)

9. OVERRIDE2 (red)

10. MUTING LAMP (purple)

11. OVERRIDE STATUS (grey-pink)

12. EARTHING (red-blue)

1. 24 V (brown)

2. MUTING2 (white)

3. 0 V (blue)

4. MUTING1 (black)

5. NC (grey)

Page 26

PSEN op4F/H-A series OPERATING MANUAL

26

1003067-EN-02

PSENopt Advanced RX Bl a nking

18 pin

M12 12 pin

M12 12-Pin:

12. EARTHING (red-blue)

PSENopt Advanced TX

18 pin

M12 5 pin

M12 5-Pin:

5. REDUCED RANGE (grey)

Assignment of M12 connector

12-pin

5-pin

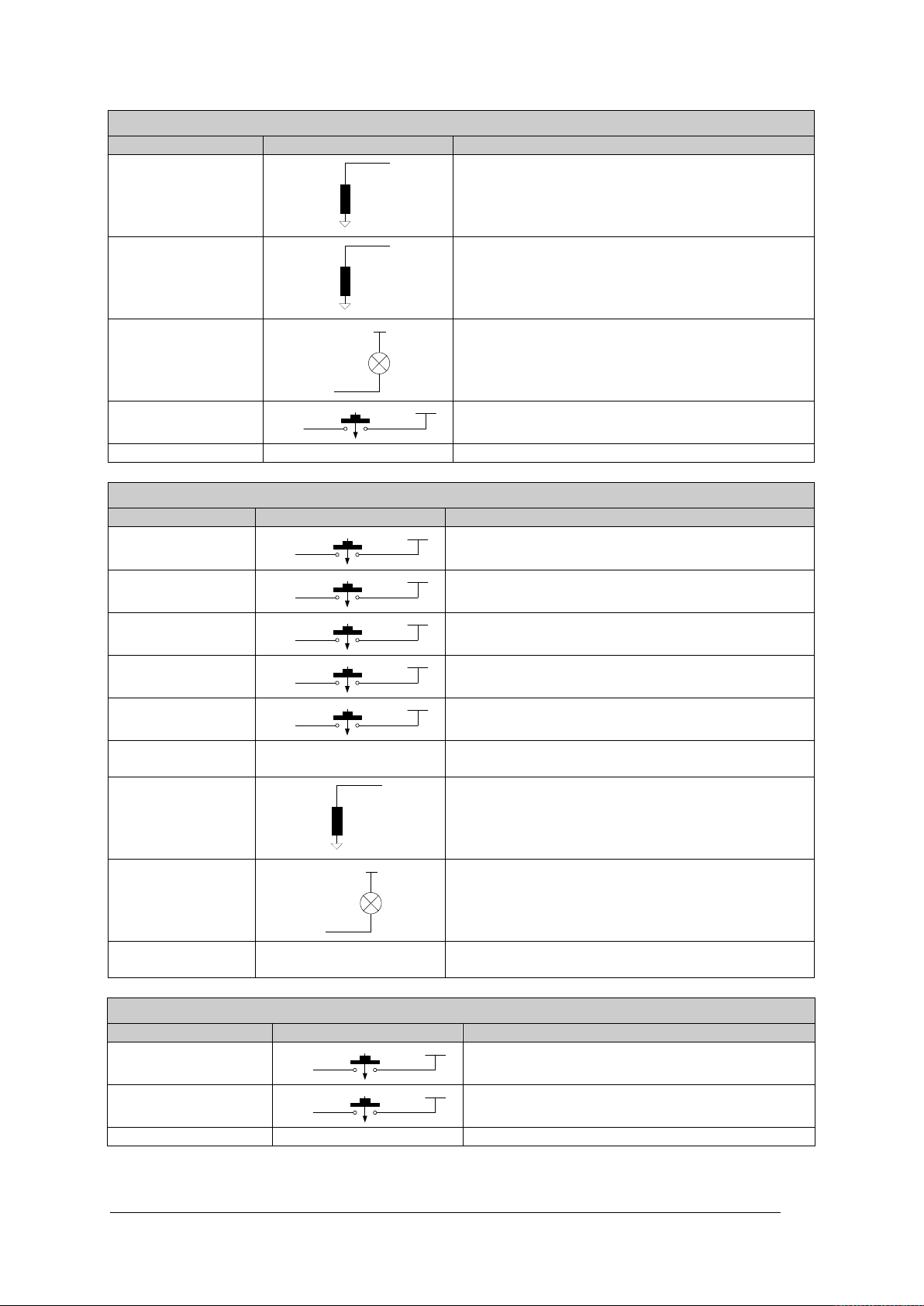

PSENopt Advanced RX Muting

CONNECTION

LINE

BEHAVIOUR

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

IN line

N.O.

connections

with EDM enabled

24Vdc

IN line

N.O.

1. 24 V (brown)

2. 0 V (blue)

3. RESET/RESTART/ALIGN (white)

4. TEACH IN (green)

5. OSSD2 (pink)

6. EDM (yellow)

7. NC (black)

8. OSSD1 (grey)

9. TOLERANCE (red)

10. LAMP (purple)

11. NC (grey-pink)

1. 24 V (brown)

2. TEST (white)

3. 0 V (blue)

4. EARTH (black)

RESET

RESTART

ALIGNMENT

OVERRIDE 1

Is connected – when in disabled state the

RESET/RESTART/ALIGN button is operated

Is connected – when during operation the

RESET/RESTART/ALIGN button is operated

Has to be set to 24 V DC at startup

Is connected – when Override is active during

operation

OVERRIDE 2

EDM

MUTING

DEACTIVATION

No voltage – during operation

See section 7.4 for

Must be non-equiva lent to OSSD during oper at io n

Muting is disabled when connecting

Page 27

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

27

PSENopt Advanced RX Muting

CONNECTION

LINE

BEHAVIOUR

0V

OSSDs

0V

OSSDs

This line signals the state of the override

24Vdc

LAMP

24Vdc

IN line

N.O.

FUNCTION EARTH

Connect to earth

PSENopt Advanced RX Blanking

CONNECTION

LINE

BEHAVIOUR

24Vdc

IN line

N.O.

Is connected – when in disabled state the

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

24Vdc

IN line

N.O.

connections

with EDM enabled

0V

OSSDs

24Vdc

LAMP

FUNCTION

EARTH

PSENopt Advanced TX

CONNECTION

LINE

BEHAVIOUR

24Vdc

IN line

N.O.

is connected, when the RESET button is

24Vdc

IN line

N.O.

FUNCTION EARTH

Connect to earth

OSSD1 / OSSD 2

OVERRIDE

STATUS

MUTING LAMP

MUTING1/MUTING2

RESET

RESTART

ALIGNMENT

Protected field clear

No voltage = Protected field not clear

High level = Override function active

Low level = Override function inactive

NOTE:

signal inputs

The open collector connection is activated when

muting is activated.

Is connected – when muting is active during

operation

RESET/RESTART/ALIGN button is operated

Is connected – when during operation the

RESET/RESTART/ALIGN button is operated

Has to be set to 24 V DC at startup

TEACH-IN

TOLERANCE

EDM

OSSD1 / OSSD 2

BLANKING LAMP

TEST

REDUCED RANGE

See Chapter 7.4 for

Is connected – when TEACH-IN button is operated

during operation

Has to be set to 24 V DC at startup

Must be non-equiva lent to OSSD during oper at io n

Protected field clear

No voltage = Protected field not clear

The open collector connection is switched when

blanking is activated.

Connect to earth

operated during operation

Has to be set to 24 V DC at startup

Page 28

PSEN op4F/H-A series OPERATING MANUAL

28

1003067-EN-02

The RESET button must be positioned so that the user can check

the protected field during each test.

The RESET/RESTART/ALIGN button m ust be positioned so that the

user can check the protected field during all reset operations.

4.1 Connection guidelines

The following section contains some guidelines regarding the connections, which should be

followed to ensure the correct operation of the safety light curtain from the PSEN op4F/HA series.

• Never place connection cable close to or in contact with cables featuring high voltage

ratings and/or current fluctuations (e.g.: motor supply, inverters etc.).

• Never combine the OSSD wires from several safety light curtains into one multi-pole

cable.

• The TEST wire must be connected to the light curtain’s operating voltage via a

pushbutton with N/O contact.

• Use the light curtain with protection class III and SEL/PELV power supplies for the

voltage.

• Use the light curtain with protection class III and SELV/PELV power supplies for the

voltage supply.

Example: Connection to the safety relay

Automatic start

Fig. 20 – Connection to safety relay – automatic start

Page 29

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

29

connection (I)

(II)

connection (III)

NO

NO

YES

NO

Manual start

Fig. 21 – Connection to safety relay – manual start

The diagrams show the connection between the safety light curtains and the safety relay

PNOZ s3 in automatic start mode (Fig. 20) and monitored manual start mode (Fig 21).

• Avoid using varistors, RC circuits or LEDs in parallel to the relay inputs or in series

connection to the OSSD outputs.

• The safety contacts of OSSD1 and OSSD2 may not be connected in series or in

parallel, but must be used separately (Fig. 22).

• Should one of these configurations be used by mistake, the device switches to an

output error condition (see Chapter 8.).

• Connect both OSSDs outputs individually to the safety relay. Other configurations have

a negative effect on the safety of the system and are not permitted.

Fig. 22 – Correct OSSD signal load connection Fig. 23 – Incorrect OSSD signal load

Fig. 24 – Incorrect OSSD signal load connection

Fig. 25 – Incorrect OSSD signal load

Page 30

PSEN op4F/H-A series OPERATING MANUAL

30

1003067-EN-02

NOTE: The OSSDs are pulsed. The following diagram shows the time

characteristic of the OSSDs.

115 µs

500 ms

1000 ms

OSSD in safe state

OSSD2

OSSD1

24 V DC

GND

24 V DC

GND

Fig. 26 – Time characteristic of the OSSDs

Page 31

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

31

1 = First beam SYNC1

2 = Beam of protected field

3 = Last beam SYNC2

OFF

ON

RESET/RESTART/ALIGN

STATE OF LIGHT CURTAIN (POWER ON)

0 V DC

24 V DC

ON

OFF

RED LED FLASHES

ON

OFF

STATE OF LIGHT CURTAIN (ALIGN)

5 ALIGNMENT

The transmitter and receiver must be aligned to ensure the device operates correctly.

Good alignment prevents the light curtain switching incorrectly due to dust or vibration.

The optimum alig nment is achieved when the optical axes of the first and last beam from the

transmitter coincide with the optical axes of the corresponding elements on the receiver.

The light curtain has two synchronisation beams. The lower synchronisation beam, the first

beam in the protected field, is called SYNC1 and the synchronisation beam on the opposite

side of the light curtain, the last beam in the protected field, is called SYNC2.

The illustration shows that the first beam is on the lower edge of the light c urta in, next to the

LED display. The last beam is on the opposite side, next to the terminator cap.

Fig. 27 – Beam description

The alignment function can be activated by simultaneously switching 24 V at the input

RESET/RESTART/ALIGN (Pin 3/ 12-pin connect or) during startup. The activated alignment

mode is shown when the second LED starts flashing (red) (see Fig. 28). Then the

RESET/RESTART/ALIGN input can be switched without voltage again. When successful

alignment has been reached, the light curtain is returned to normal operating mode by

switching off and then on again.

Fig. 28 – Alignment timings

Page 32

PSEN op4F/H-A series OPERATING MANUAL

32

1003067-EN-02

Alignment

operating mode

No sync, check

SYNC1

One or more

not aligned

All light axes are

aligned

POOR

All light axes are

aligned

All light axes are

aligned

All light axes are

aligned

In alignment mode, the light curtain is always in a safe state and the OSSD outputs are OFF.

The quality and level of the alignment is determined via the signal strength of each individual

beam in alignment mode. The two synchronization beams have a higher value level. The

user can see the alignment quality from the LED state at the lower end of the receiver.

A. Hold the receiver in a stable position and align the transmitter until the yellow SYNC1

LED goes out. This state confirms that the first synchronisation beam has been

aligned.

B. Rotate the transmitter around the axis of the lower lens until the yellow SYNC2 LED

goes out.

C. For precision adjustment, m ake minor movements of the transmitter and receiver to

achieve the optimum quality

D. Attach both units firmly using the mounting brackets. Check that the LEVEL of the

receiver does not decrease in quality and that the light axes are not interrupted. Then

check that all LEDs on the LEVEL display go out, even if only one beam is

interrupted. This test is conducted using a test object TP-14 or TP-30 corresponding

to the resolution (see Chapter 2.2.5).

E. Switch off the light curtain pair and then switch it back on in normal operating mode.

The alignment level is also monitored by the display during normal operation (see

Chapter 8.1). Once the light curtain has been aligned and fastened appropriately, the

LED display proves perfect for checking the alignment and displaying any change in

the ambient conditions (e.g. dust).

Display Configuration LED RX

Alignment

status

Status of OSSD

in normal

NONE OFF

SYNC1 aligned

SYNC2 aligned

intermediate

beams

NONE OFF

NONE OFF

NONE OFF

ON

ON

EXCELLENT

ON

ON

Fig. 29 –Status of the LED displays in alignment mode

Page 33

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

33

CAUTION: Configuration via ACM will overwrite a configuration

accidental changes.

6 SETTING THE FUNCTIONS

There are two options for configuring the light curtain’s functions and operating

configurations:

- Basis configuration mode (BCM):

In basic configuration mode you have the option to use the buttons and the LED interface

(transmitter/receiver) to select basic functions/parameters.

- Advanced configuration mode (ACM):

In advanced configuration mode you have the option to use the PC software

PSENopt Configurator (only for the receiver) to select advanced functions/parameters. For

configuration via software the PSEN op Advanced Programming Adapter is required.

created via BCM! A new BCM configuration can only be created when

the ACM configuration is deleted. This protects the light curtain from

Basic configuration mode

The user interface consists of 8 LEDs and 3 protected pushbuttons and enables the user to

perform the basic configuration. The LEDs are the same LEDs used to display status in

normal operating mode.

A plastic pen is provided (see Chapter 13), which the user must use to activate the

pushbuttons, thus preventing unwanted access to the safety configuration.

Basic configuration steps

On the right-hand side of the operator panel at transmitter and receiver there is a settings

interface, consisting of three pushbuttons. The interfaces give users the option to set the lig ht

curtain locally, without using the PSENopt Configurator.

• CONFIRM button activates the BCM configuration mode

• SELECT button: The different functions are run through.

• ENABLE button: Activates and deactivates the currently selected function.

The individual steps are described below:

1. Press the CONFIRM button and keep it held down to switch to basic configuration

mode.

2. The light curtain runs through a test cycle. With the transmitter the LEDs 2 and 3 light

up one after the other, with the receiver the LEDs 2 to 8. The Power LED 1 is

constantly lit.

After the test cycle is completed, the current configuration is displayed

3. Use the SELECT function to choose the function that is to be set. The LED for the

selected function will flash.

4. Now configure the selected function by pressing the ENABLE but t on (LED lights/goes

out).

5. Repeat steps 3 and 4 until the required configuration is displayed.

6. Press the CONFIRM button and keep it held down to save the new configuration.

If an advanced configuration has already been set on the light curtain (via the

PSENopt Configurator on the PC), pressing the button just once dur ing s tep 2 will generate a

Page 34

PSEN op4F/H-A series OPERATING MANUAL

34

1003067-EN-02

Operator

Password

System integrator

SystemIntegrator

Maintenance engineer

Maintainer

Machine operator

No password required

light curtain configuration error, which prevents non-authorised changes to the advanced

configuration.

Advanced configuration mode

With the PSENopt Configurat or (graphical user interface for PC), t he user has the option to

configure advanced light curtain parameters. A variety of parameters can be used to adapt

the light curtain operation to your applications.

As the configuration of the light curtain is a safety-related component, the software must only

be handled by qualified personnel.

Such qualified personnel must ensure that nobody has access to the hazardous parts of the

machinery during the configuration procedure.

PSENopt Configurator has three different user levels with different authorizations.

System integrator: Has all possible access rights and can modify any setting in the

PSENopt Configurator.

Maintenance engineer: Can upload a configuration stored in the PSENopt Config urator to

the light curtain and use the PSENopt Configurator to monitor the system. He cannot create

any new configurations.

Machine operator: Uses the PSENopt Configurator exclusively to monitor the system.

Each user category is assigned different passwords to protect some functions.

1) Selecting the light curtain: User selects the light curtain to be configured from

among the light curtains that are identified within the network.

2) Configuring the parameters: User sets the configuration for the selected light

curtain.

Once completed, the user saves the configuration; the light curtain switches to a

SAFE state; the “Configuration in progress” message is displayed on the light

curtain’s LED interface and the previous light curtain configuration is deleted.

3) Checking the report: The light curtain sends the received configuration back to the

PSENopt Configurator and PSENopt Configurator generates a printable SAFETY

REPORT, which contains all the safety-related information about the present

configuration (Fig. 30). Once all the content of the report has been checked, the user

can accept the configuration: the light curtain restarts normal operation with the new

configuration.

4) Checking the light curtain: User checks that the light curtain is operating in

accordance with the specifications in the SAFETY REPORT (checks the resolution

using the appropriate test object, parameter check, ...).

Page 35

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

35

Identification of light curtain

Configuration ID (check sum of configuration parameters)

Position of light curtain in a cascading

Model name and characteristic data of the light curtain (resolution)

Current protected field configuration (muting or blanking)

Configuration parameters for blanking/muting

NOTE: Restoring the factory settings will delete the BCM and the ACM

configuration.

Fig. 30 – Safety report

• Serial no.

• Firmware version

•

6.1 Reset to factory configuration

The user has the option to re -establish the light curtain’s factory configuration by operating

the pushbuttons as described below:

1. Press the CONFIRM button and keep it held down for at least 9 s (but not more than

30 s, so that the light curtain is not blocked)

2. The LEDs flash briefly, indicating that the light curtain has been reset to the factory

configuration

3. After the reset has occurred, the light curtain resumes its normal operation with the

factory configuration.

Page 36

PSEN op4F/H-A series OPERATING MANUAL

36

1003067-EN-02

Legend for LED display in RX/TX function list

LED off, LED is not relevant for the information in the “Function” column

LED off, LED is relevant for the information in the “Function” column

“Function” column

LED red, value in the “Setti ng” column is valid for the inf ormation in the “Functi on”

column

“Function” column

List of RX functions in muting mode

(LED 3 lights up yellow)

PWR

OSSD

EDM

ACM

LEVEL

Coding

Selection of

EDM

4

Restart mode

5

Muting direction

Activation of

6.2 Function list

PSEN op4F/H-A has two main operating modes: blanking and muting. The settings of the

functions at the receiver associated with LEDs 5 to 8 will change, depending on whether

blanking or muting is selected.

NOTE: The table highlights the default configuration in bold.

LED yellow, value in the “Setting” column is valid for the information in the

LED green, value in the “Setting” column is valid for the information in the

Function

muting/blanking

LED

No.

2

3

6

Code 1

Code 2

No code

Muting

Blanking

Activated

Deactivated

Auto

Manual

T (bidirectional)

Setting

LED status

L (one-directional)

Muting timeout 7

override

8

10 min

Infinite

Level

Edge

Page 37

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

37

List of RX functions in blanking mode

(LED 3 OFF)

LED status

PWR

OSSD

EDM

ACM

LEVEL

Coding

2

Selection of

3

EDM

4

Restart mode

5

Floating blanking

deactivated

Selection of fixed

8

List of TX functions

LED status

PWR

TST

SR

LR

CODE

Selection of

3

Function

muting/blanking

Selection of

floating blanking

LED

No.

Code 1

Code 2

No code

Muting

Blanking

Activated

Deactivated

Auto

Manual

Setting

6-7

blanking

Coding

operating range

Function

LED

No.

2

Floating blanking 1 beam

Floating blanking 2 beams

Reduced resolution 4 beams

1 fixed blanking zone

2 fixed blanking zones

Setting

Code 1

Code 2

No code

Normal

Reduced

Page 38

PSEN op4F/H-A series OPERATING MANUAL

38

1003067-EN-02

7 FUNCTIONS

7.1 Restart function

If the beams detect an opaque object, the OSSD output switching elements will switch (i.e.

the safety contacts will open, SAFETY conditions). The restart f unction enables the user to

define how the light curtain returns from the safe state to normal operation.

There are two ways to restart the light curtain (i.e. close the OSSD safety contacts –

SAFETY condition): automatic or manual restart.

Automatic restart: If an opaque object is detected, the light curtain switches to a SAFE

CONDITION. If the object is then removed from the protected field, the light curtain will

resume its normal operation.

The response time is the time that elapses between the object being introduced to the

protected field and the OSSD achieving the OFF state (SAFETY); the reset time is the time it

takes for the OSSD to switch to the ON state (SAFETY) after all the objects have been

removed.

All these times are functions that are dependent on length, as illustrated below.

Fig. 31 – Restart timings (auto)

In automatic restart mode, the RESET/RESTART/ALIGN input (Pin 3 of the 12-pin M12

connector – RX-side) must not be activated.

Fig. 32 – Restart connection (auto)

Page 39

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

39

WARNING: Hazardous conditions and the reset mode should be

When access to danger zones is protected,

manual restart on the relay PNOZ s3 (see Chapter 4.).

Manual restart: W hen the light curtain has detected an opaque object in the protected f ield,

the light curtain does not resume its normal operation until the object has been removed from

the protected field and the reset button has been operated.

The OSSD output switching elements switch back to normal operation when the RESTART

signal voltage is removed again, and not after 500 ms. If the RESTART signal is present for

longer than 5 s an error is generated, which blocks the light curtain.

Fig. 33 – Restart timings (manual)

In manual restart mode, the RESET/RESTART/ALIGN input (Pin 3 of the 12-pin M12

connector – RX-side) must be connected to a 24 VDC N/O contact.

Fig. 34 – Restart connection (manual)

assessed carefully.

automatic reset mode is potentially unsafe if it enables the operator

to pass through the zone before the sensing area is active. In this

case it will be necessary to use a manual restart or, for example, the

Page 40

PSEN op4F/H-A series OPERATING MANUAL

40

1003067-EN-02

PWR

OSSD

EDM

ACM

LEVEL

The section below describes how the restart mode can be selected via the pushbutton as

well as via the user interface.

BCM configuration: Restart mode

Auto LED 5 red (ON)

Manual LED 5 OFF

ACM configuration: Restart mode

7.2 Test

The TEST function can be activated by operating the 24 VDC N/O pushbutton connected to

the TEST input on the TX device (Pin 2 of the 5-pin M12 connector) for at least 0.5 seconds.

The TEST disables the transmission level, so the RX-side sees the beams as interrupted and

the OSSD go low within the response time. As shown on the timing diagram below, the

OSSDs switch to the OFF state (INTERRUPTION STATE) after 500 ms (plus one cycle time)

and after the light curtain's response time.

Fig. 35 – Test timings

Page 41

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

41

PNP configuration

NPN configuration

7.3 Reset

If the light curtain is blocked in a fault state, you can restore normal operation by switching

the light curtain on and off or by activating the RESET function (only with critical errors).

To activate the RESET function, the RESET/RESTART/ALIGN connection (Pin 3 of the 12pin connector) must be supplied with 24 V for at least 5 seconds.

If the light curtain does not return to normal operating mode, the light curtain has to be

switched off and on again

. Errors in the internal connections can be cancelled this way.

Fig. 36 – Reset timings

If the error has not been rectified, the light curtain will again switch to a blocked state.

7.4 EDM

The external device monitoring function (EDM) monitors the external devices and checks the

OSSD status.

EDM enabled:

If EDM is enabled in the PNP configuration, the EDM input (Pin 6 of the 12-pin M12

connector - RX) must be connected to a 24 VDC N/C contact on the device to be monitored.

If the EDM is enabled in the NPN configuration, the EDM input (Pin 6 of the 12-pin M12

connector - RX) must be connected to a 24 VDC N/O contact on the device to be monitored.

NOTE: In normal operating mode, the third LED switched on in the user interface

indicates that the function is active.

The following diagrams describe how to connect the EDM input in the event of a PNP

and NPN configuration.

The function monitors the switching of the 24 VDC N/C contact, based on the OSSD status

changes.

Page 42

PSEN op4F/H-A series OPERATING MANUAL

42

1003067-EN-02

PNP configuration

NPN configuration

PNP configuration

NPN configuration

Fig. 37 – EDM timings

The EDM status is not equivalent to that of the OSSD: the timing diagram illustrates the

relationship between cause (OSSD) and effect (EDM), with the maximum permitted delay.

Tc ≥ 350 ms (time betwee n t he O SSD transition from OFF-O N a nd t he EDM test)

To ≥ 100 ms (time betwee n t he O SSD transition from OFF-O N a nd the EDM test)

(two different times for the mechanical, positive-guided contact)

EDM disabled:

If EDM is disabled, the EDM input may not be connected.

Fig. 38 – EDM connections

Page 43

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

43

PWR

OSSD

EDM

ACM

LEVEL

Resolution 30 mm

RX long range

RX short range

TX long range

20 m

6 m

TX short range

12 m

4 m

Resolution 14 mm

RX long range

RX short range

TX long range

7 m

2 m

TX short range

4 m

1 m

7.5 EDM selection

This function enables users to select or exclude monitoring of the external switching devices.

BCM configuration: EDM selection

Activated LED 4 ON yellow

Deactivated LED 4 OFF

ACM configuration: EDM selection

To increase the safety level when EDM is OFF when the light curtain is commissioned,

ensure that the EDM input is not connected.

7.6 Reduced range

This function enables you to select the maximum operating range for the light curtain’s

assembly.

The table below summarises the different operating ranges for both resolutions, if the

reduced operating range is changed.

You can select this function via ACM for the receiver and via BCM for the transmitter.

Fig. 39 – Reduced range

Page 44

PSEN op4F/H-A series OPERATING MANUAL

44

1003067-EN-02

PWR

OSSD

EDM

ACM

LEVEL

L-Version with integrated

one direction

T-Version with integrated muting

directions

Linear version with external

BCM configuration (TX-side): Reduced range

Long LED 3 ON yellow

Reduced LED 3 OFF

ACM configuration (RX-side): Reduced range

If long range is selected, the TX and RX can be installed at the maximum permitted operating

range. A reduced operating range is recommended for cases in which several pairs of light

curtains need to be assembled side by side and the coding function cannot be used.

7.7 Muting

The muting function guarantees that the safety function is automatically disabled over all or

part of the height of the detection zone, to enable specific, cyclical work operations to be

carried out without having to stop the machine operation.

In accordance with safety requirements, the light curtain is equipped with two inputs for

activating the muting function, MUTING1 and MUTING2.

The muting sensors must be able to detect the conveyed material (pallets, vehicles,…)

based on their length and speed. Where there are variable conveyor speeds within the

muting area, you must consider the effect this will have on the overall duration of the muting

process.

• The muting function excludes the light curtain during operation and maintains the

OSSD output switching elements in an activated state, based on the specific operating

requirements (Fig. 40).

muting sensors for muting in

• In accordance with the applicable standards, the safety light curtain has two inputs

(MUTING1 and MUTING2) to activate this function.

• This function is particularly suitable for cases in which an object, but not a person,

needs to pass through the danger zone under certain conditions.

sensors for muting in two

Fig. 40 – Application examples for the muting function

muting sensors

Page 45

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

45

Particular attention should be paid to the choice of configuration, as

incorrectly and reduce the safety level.

The muting sensors must be arranged in such a way that the

• It is important to not e that the muting function represents a hazardous situation of the

device. So it must be applied only in keeping with the necessary preventive measures.

• The muting sensors must be corr ectly positioned t o avoid unintended mut ing becom ing

potentially dangerous for the operator.

• MUTING1 and MUTING2 cannot be activated simultaneously.

• The muting status is displayed via an external muting lamp (which can be connected to

the light curtain via Pin 10 of the 12-pin M12 connector) and via various LEDs on the

user interface. If the muting function is ON, the LAMP and LEDs start to flash.

• During installation, ensure that the lamp is positioned so that it is as visible as possible.

• If the external lamp is broken and/or not connected, a muting call will result in a

SAFETY BLOCKING CONDITION and the relevant error message will be displayed.

an incorrect configuration can cause the muting function to operate

muting function cannot be activated by an operator who happens to

pass through.

7.7.1 Disabling the muting function

The muting function can be enabled and disabled dynamically during operation of the PSEN

op4F/H-A. When disabled, no muting call is accepted at the inputs MUTING X and the safety

function is constantly active.

Users can deactivate the muting function during operation by applying 24 V at the DISABLE

signal (Pin 7 of the 12-pin connector).

7.7.2 Muting display devices

The corresponding display device (lamp) must be connected in order to use the muting

function. If this device is not present, the light curtain will switch to a blocked state due to a

defect.

Both incandescent lamps and LED lamps are permitted. If you are using an LED lamp, make

sure that the connection has the right polarity.

When the lamp is switched on, a lamp TEST is carried out as part of each cycle, to ensure

that any functional failure is detected. If the lamp is found to be broken, the light curtain will

switch to a safe s t ate and a corresponding message is shown on the display (see Chapter 10

for further informatio n on the lam p).

Page 46

PSEN op4F/H-A series OPERATING MANUAL

46

1003067-EN-02

A11

A12

A21

A22

Safety sensor

7.7.3 Typical muting application and sensor connection

Fig. 41 – Typical muting application

The diagram above shows a typical muting application: t he protection device installed on t he

conveyor must allow the package to pass through but not the operator. The light curtain

temporarily suspends its safety function when the sensors A11, A21, A12, A22 are activated

in the correct sequence.

These may be optical or mechanical sensors that switch 24 V when the object is detected.

7.7.4 Muting direction

The light curtain can be used for bidirectional muting (T-type, four sensors) as well as onedirectional muting (L-type, two sensors).

• T-muting is used when objects can move through the light curtain in both directions.

• L-muting is used when objects move only in one direction.

In BC M mode the maximum activation delay between MUTING1 and MUTING2 (T12max) is

4 seconds

T-Muting

With T-type operation, the device switches to the muting function if the signal from the

MUTING2 input switches within a fixed T12max, after the MUTING1 signal has switched (or

vice versa). The muting function ends as soon as the sig nal at MUTING1 or MUTING2 goes

low. Users can set the maximum activation delay between MUTING1 and MUTING2 (or vice

versa) from a minimum of 1 second to a maximum of 16 seconds (T12max). Once this time

has elapsed, if users wish to switch to muting st atus they will need to deactivate the muting

input and start the sequence again.

Page 47

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

47

Fig. 42 – T muting timings

The sensors labelled A1/A2 are connected to the muting input (MUTING1) and the sensors

labelled B1/B2 are connected to the MUTING2 input. Sensors ending in “1” are on the same

side of the light curtain and therefore on the opposite side to the sensors ending in “2”.

“D” stands for the distance at which the sensors A1/A2 or B1/B2 must be installed and

depends on the package length (L):

D < L

“d1” stands for the maximum distance required between the muting sensors and depends on

the package speed (V):

d1

[cm] = V [m/s] * T12 [s] * 100,

max

“d2” stands for the maximum distance required to accept a muting request and depends on

the package speed (V):

d2

[cm] = V [m/s] * T12 [s] * 100,

max

“T12” stands for the activation delay between MUTING1 and MUTING2, which the operator

can select via ACM.

Fig. 43 – T-Muting connection

Page 48

PSEN op4F/H-A series OPERATING MANUAL

48

1003067-EN-02

L-Muting

With L-muting, the light curtain is muted if the input signals switch to 24 VDC in accordance

with a certain sequence: MUTING1 must be activated first; only then can MUTING2 be

activated.

If MUTING2 should activate before MUTING1, the device will not switch to muting mode;

“T12” represents the activation delay between MUTING1 and MUTING2, which users can

select via ACM.

The muting function ends once the time has elapsed, which corresponds to a multiple of the

activation delay between the two sensors (this time corresponds to m * T12). The value “m”

(multiplier T12) must be selected by the user. With BCM, 2 is the default value.

In the ACM configuration, users can set the maximum activation delay between MUTING1

and MUTING2 (or vice versa) from a minimum of 1 second to a maximum of 16 seconds

(T12max). Once this time has elapsed, if users wish to switch to muting status they will need

to deactivate the muting input and start the sequence again.

Fig. 44 – L-muting timings

The sensor labelled A is positioned furthest away from the light curtain, which is why its

beam is recorded first. With reference to the diagram below and in consideration of the fact

that the package only passes from right to left, sensor B cannot be recorded first. If this

should happen, the light curtain is not muted.

“V” indicates a constant velocity. As a result, “d1” can be calculated in accordance with the

following formula:

d1 [cm] = V [m/s] * T12 [s] * 100

Fig. 45 – L-Muting connection

Page 49

OPERATING MANUAL PSEN op4F/H-A series

1003067-EN-02

49

PWR

OSSD

EDM

ACM

LEVEL

BCM configuration: Muting direction

T (bidirectional) LED 6 ON green

L (one-directional) LED 6 OFF

ACM configuration: Muting direction

Page 50

PSEN op4F/H-A series OPERATING MANUAL

50

1003067-EN-02

NOTE: This does not comply with the standard IEC 61496-1 and the user is