Page 1

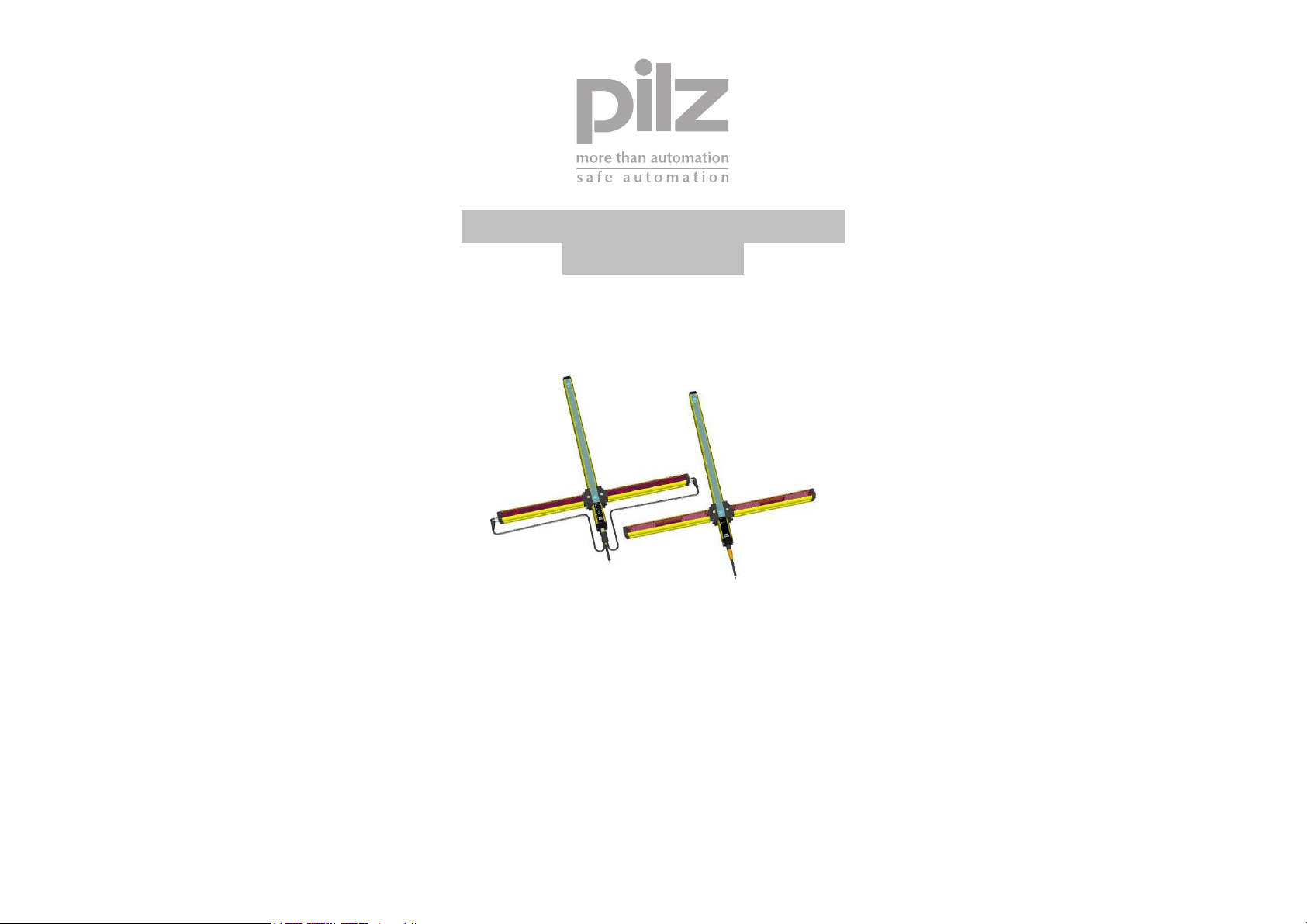

PSEN op4B-T, PSEN op4B-L,

PSEN op4B-S

Safety light curtains with infrared beams

OPERATING MANUAL

Page 2

A Pilz Ges.m.b.H., 01 7986263-0, Fax: 01 7986264, E-Mail: pilz@pilz.at AUS Pilz Australia Industrial

Automation LP., 03 95446300, Fax: 0395446311, E-Mail: safety@pilz.com.au

3217570, Fax: 09 3217571, E-Mail: info@pilz.be

4337-1241, Fax: 11 4337-1242, E-Mail: pilz@pilzbr.com.br

Fax: 062 88979-40,E-Mail: pilz@pilz.ch

pilz@pilz.dk

France Electronic, 03 88104000, Fax: 03 88108000, E-Mail: siege@pilz-france.fr

09 27093700, Fax: 09 27093709, E-Mail: pilz.fi@pilz.dk

Fax: 01536 460866, E-Mail: sales@pilz.co.uk

info@pilz.it

E Pilz lndustrieelektronik S.L., 938497433, Fax:938497544, E-Mail: pilz@pilz.es F Pilz

IRL Pilz Ireland Industrial Automation, 021 4346535, Fax: 021 4804994, E-Mail:sales@pilz.ie

BR Pilz do Brasil Sistemas Eletr¶nicosIndustriais Ltda., 11

CH Pilz lndustrieelektronik GmbH, 062 88979-30,

DK Pilz Skandinavien K/S, 74436332, Fax: 74436342, E-Mail:

GB Pilz Automation Technology, 01536 460766,

I Pilz ltalia Srl, 031 789511, Fax: 031 789555, E-Mail:

B L Pilz Belgium, 09

FIN Pilz Skandinavien K/S,

J Pilz Japan Co., Ltd., 045 471-2281, Fax: 045 471-2283, E-Mail: pilz@pilz.co.jp MEX Pilz de Mexico,

S. de R.L. de C.V., 55 5572 1300,Fax: 55 5572 4194, E-Mail: info@mx.pilz.com

320477, Fax: 0347 320485, E-Mail: info@pilz.nl

t.catterson@pilz.co.nz

P Pilz Industrieelektronik S.L., 229407594, Fax: 229407595, E-Mail: pilz@pilz.es

NZ Pilz New Zealand, 09-6345350, Fax: 09-6345350, E-Mail:

NL Pilz Nederland, 0347

PRC PilzChina Representative Office, 021 62493031, Fax: 021 62493036, E-Mail: sales@pilz.com.cn

ROK Pilz Korea Office, 031 8159541, Fax: 031 8159542,E-Mail: info@pilzkorea.co.kr SE Pilz

Skandinavien K/S, 0300 13990, Fax: 0300 30740, E-Mail: pilz.se@pilz.dk

Ürünleri veHizmetleri Tic. Ltd. ©Sti., 0224 2360180, Fax: 0224 2360184, E-Mail: pilz.tr@pilz.de

Automation Safety L.P., 734 354-0272, Fax: 734 354-3355,E-Mail: info@pilzusa.com

TR Pilz Elektronik Güvenlik

USA Pilz

www www.pilz.com

D Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straβe 2, 73760 Ostfildern, Deutschland,

+49 711 3409-0, Fax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

826003081 rev.B

Page 3

PSEN op4B Series Operating Manual

OVERVIEW OF CONTENTS

1 GENERAL INFORMATION.......................................................................................... 1

1.1 General description of the safety light curtain ..................................................... 1

1.2 How to select a safety light curtain...................................................................... 3

1.3 Typical application areas..................................................................................... 6

1.4 Safety information ............................................................................................... 7

2 INSTALLATION............................................................................................................ 8

2.1 Precautionary measures when selecting and installing the device ..................... 8

2.2 General information on positioning the device .................................................... 9

2.2.1 Minimum safety distance ...................................................................... 11

2.2.2 Minimum distance from reflective surfaces .......................................... 13

2.2.3 Installing several adjacent safety light curtains .................................... 15

2.2.4 Use of deviating mirrors........................................................................ 16

3 MECHANICAL ASSEMBLY....................................................................................... 17

3.1 Installing the integral muting sensor profiles with "L" and "T"

shaped configuration......................................................................................... 19

4 WIRING....................................................................................................................... 20

4.1 Electrical connections ....................................................................................... 20

4.2 Notes on wiring.................................................................................................. 21

5 ALIGNMENT............................................................................................................... 25

5.1 Alignment instructions ....................................................................................... 25

5.2 Aligning the muting sensors .............................................................................. 27

6 FUNCTIONS............................................................................................................... 28

6.1 Selecting the operating mode via DIP switches ................................................ 28

6.2 Standard configuration ...................................................................................... 28

6.3 Restart............................................................................................................... 29

6.4 Test function...................................................................................................... 31

6.5 Reset function ................................................................................................... 32

6.6 Feedback loop monitoring function ................................................................... 33

6.7 Muting function.................................................................................................. 35

6.7.1 Installing the muting sensors on PSEN op4B-S models ...................... 40

6.7.2 Installing the muting sensors on PSEN opB-L models ......................... 43

6.7.3 Installing the muting sensors on PSEN opB-T models......................... 44

6.8 Override function............................................................................................... 45

7 DIAGNOSTICS........................................................................................................... 47

7.1 Function indicators ............................................................................................ 47

7.2 Error messages and diagnostics....................................................................... 48

8 REGULAR CHECKS AND MAINTENANCE ............................................................. 50

8.1 Maintenance...................................................................................................... 51

8.2 General information and useful data ................................................................. 51

9 TECHNICAL DETAILS............................................................................................... 52

10 LIST OF AVAILABLE MODELS ................................................................................ 53

11 OVERALL DIMENSIONS........................................................................................... 53

12 ACCESSORIES.......................................................................................................... 54

12.1 Mounting bracket............................................................................................... 54

12.2 Deviating mirror................................................................................................. 55

12.3 Floor brackets.................................................................................................... 56

12.4 Laser pointer ..................................................................................................... 57

12.5 Connection box ................................................................................................. 58

Page 4

Page 5

Operating Manual PSEN op4B Series

1 GENERAL INFORMATION

1.1 General description of the safety light curtain

Safety light curtains from the PSENopt series are multibeam

optoelectronic protection devices. They secure work areas in which

operating personnel can come into contact with moving parts of

machinery, robots and automated systems in general, which present a

risk of physical injury.

The safety light curtains are designed as safe Type 4 systems for

accident prevention in accordance with applicable international

standards, in particular:

EN 61496-1: 2004

prEN 61496-2: 1997

The device consists of an emitter (TX) and a receiver (RX) housed in

robust aluminium profiles. It secures the protected area by generating

an infrared protected field, which will detect an opaque object as soon

as it enters the protected field.

Both the control and evaluation logic are located inside the two units;

the electrical connection is made via M12 connectors, which are

positioned underneath the profiles. The emitter (TX) and receiver (RX)

are synchronised optically. This means the two units do not have to be

connected directly to each other.

The infrared beams are controlled and monitored via a

microprocessor, which provides the user with information about the

operating status of the safety light curtain via LED indicators (see Ch.

7, “Diagnostics”).

Two yellow LEDs simplify the alignment of the two units during

installation (see Ch. 5 “Alignment”).

As soon as an object, a limb or the operator’s body interrupts the

beams sent by the emitter (TX), both outputs (OSSD) are immediately

opened and the machine connected to the OSSD is stopped.

Safety of machinery: Electrosensitive

protective equipment. Part 1: General

requirements and tests.

Safety of machinery - Electrosensitive

protective equipment. Part 2: Particular

requirements for equipment using active

optoelectronic protective devices.

1

Page 6

PSEN op4B Series Operating Manual

NB: This manual uses the following abbreviations as defined in

the applicable standards:

AOPD Active opto-electronic protective device

ESPE Electrosensitive protective equipment

MPCE Machine primary control element

OSSD Output signal switching device (switching output)

TX Transmitting device

RX Receiving device

Some sections or paragraphs in this manual contain information of

particular importance to those using or setting up the device. These

sections are highlighted using the following symbols:

Detailed notes and descriptions of specific features of the safety light

curtains, designed to explain their operation more clearly.

Specific installation guidelines.

This warning must be heeded! It warns of a hazardous situation that

could lead to serious injury and death and indicates preventive

measures that can be taken.

This manual contains all the information required for the selection and

operation of the safety light curtains.

Specialised knowledge of safety issues is required to integrate a safety

light curtain correctly on power-driven machinery.

As this manual is unable to provide such information in full, please

contact the technical service department at Pilz for any information

about the operation of the safety light curtains and the safety

regulations relating to correct installation (see Ch. 8, “Regular checks

and maintenance”).

2

Page 7

Operating Manual PSEN op4B Series

1.2 How to select a safety light curtain

• Muting function

The safety light curtains are suitable for applications that require a

muting function. Safety light curtains PSEN op4B-T and PSEN

op4B-L are equipped with pre-assembled, pre-wired and prealigned muting sensors. The muting sensors are designed for one

or two-way muting applications in an "L" or "T" shaped

configuration. Safety light curtains PSEN op4B-S are linear models

without integrated muting sensors.

- "L" shape configuration: is suitable for applications in which an

object leaves the danger zone in one direction.

- "T" shape configuration: is suitable for applications in which an

object moves in two directions.

- Linear models: Are suitable for applications on which the

sensors are intended to be positioned individually. A plug

connector enables the muting sensors to be connected simply.

• Resolution, depending on the part of the body requiring protection.

R = 40 mm Body protection

The resolution (R) of a device is understood to be the minimum size

an opaque object must be in order to interrupt at least one of the

beams that form the sensing area.

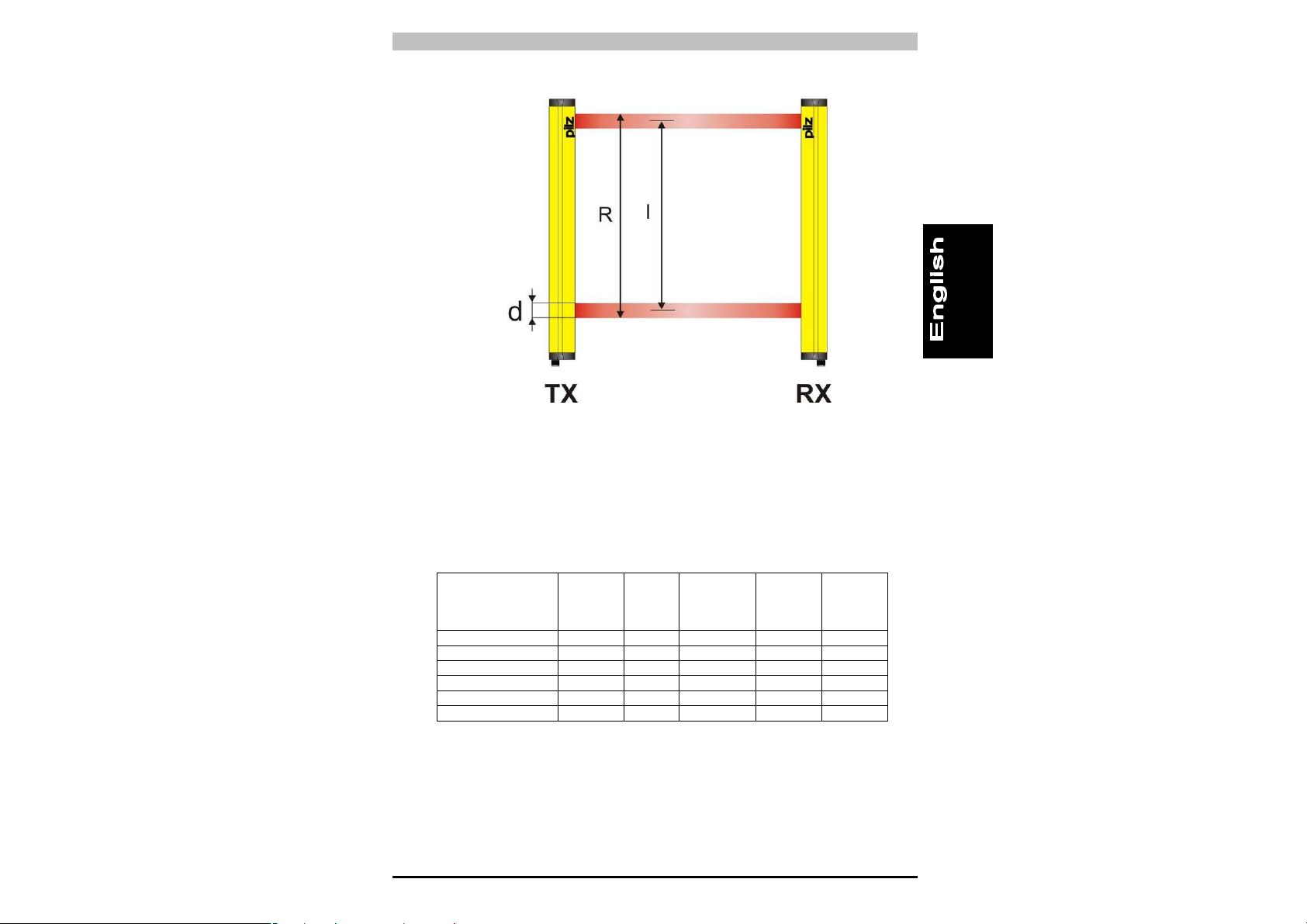

As shown in Fig. 1, the resolution depends exclusively on the

geometrical properties of the lenses, the diameter and the centre

distance; it is independent of the ambient and operating conditions

of the safety light curtain.

3

Type 4

Page 8

PSEN op4B Series Operating Manual

The resolution can be calculated using the following formula:

R = I + d

The table below specifies the values for the light curtains with regard to

the optical axis (I), the resolution (R) and the diameter of the optics (d).

Fig. 1

Model Optical

axis

mm

(I)

PSEN op4B-T-2-050 500 2 515 16 3

PSEN op4B-T-3-080 400 3 415 16 3

PSEN op4B-L-2-050 500 2 515 16 3

PSEN op4B-L-3-080 400 3 415 16 3

PSEN op4B-S-2-050 500 2 515 16 25

PSEN op4B-S-3-080 400 3 415 16 25

No. of

optics

(n)

Resolution

mm

(R)

Ø of optics

mm

(d)

Range

m

4

Page 9

Operating Manual PSEN op4B Series

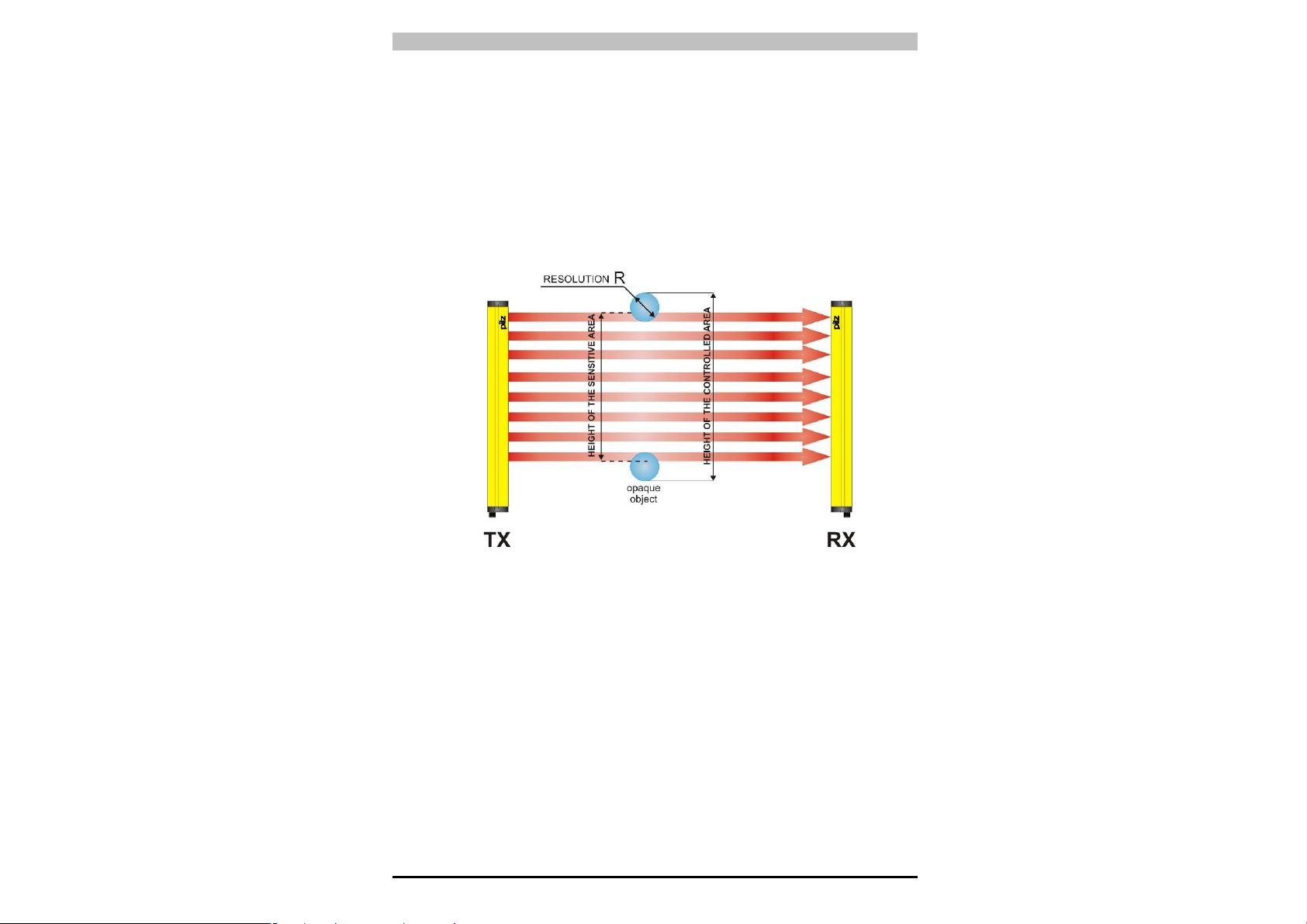

• Height of protected field: Here it is important to distinguish

between the “Height of the sensing area” and the “Height of the

protected area” (Fig. 2).

- The height of the sensing area is the distance between the

upper limit of the first lens and the lower limit of the last lens.

- The height of the protected area is the effective protected area,

in which an opaque object whose size is greater than or equal to

the resolution of the safety light curtain will safely interrupt the

beam.

Fig. 2

• Safety distance: Great care must be taken when calculating the

distance at which the safety light curtain should be positioned in

relation to the hazardous machinery. (Please see Chapter 2,

“Installation”, for details of how to calculate the safety distance.)

5

Page 10

PSEN op4B Series Operating Manual

1.3 Typical application areas

Safety light curtains can be used in all areas of automation where it is

necessary to control and guard access to danger zones.

In particular they are used to stop the hazardous movement of

mechanical parts on:

• Palletisers/depalletisers

• Packaging, handling and storage machinery

• Automatic or semi-automatic assembly lines

• Automated high-bay racking

With food industry applications, please contact customer services at

Pilz to check whether the safety light curtain’s housing material can

withstand the chemical substances that may be used in the production

process.

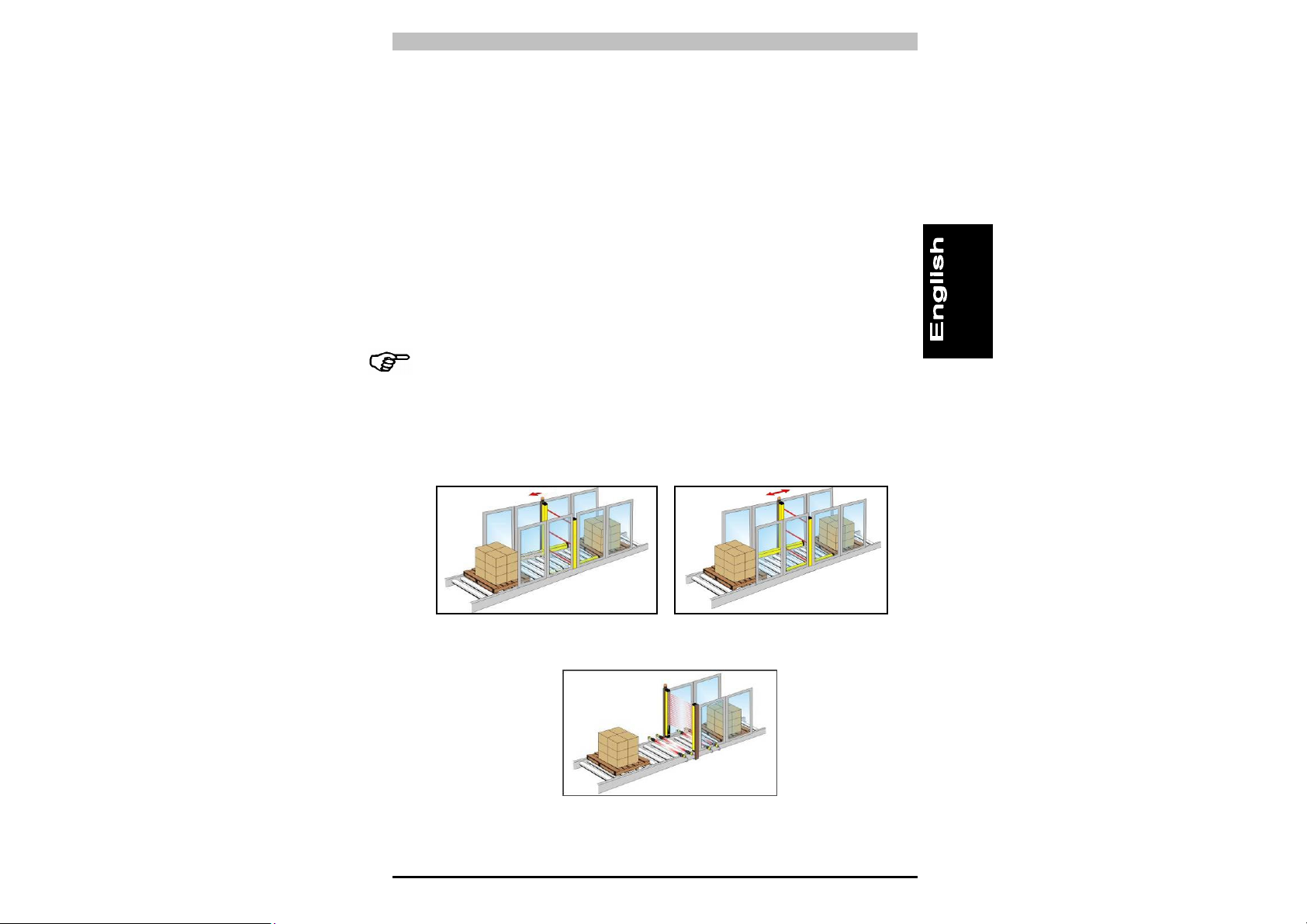

The following illustrations provide an overview of some of the main

application areas:

L-shape version with integral muting

sensors for muting in one direction

(leaving the danger zone)

T-shape version with integral muting

sensors for muting in two directions

Linear version with external muting sensors

6

Page 11

Operating Manual PSEN op4B Series

1.4 Safety information

For the proper, safe use of the safety light curtains, the following

guidelines must be followed:

• It must be possible to control the machine stop electrically.

• The control system must be able to stop the hazardous machine

movement immediately at any stage of the operating cycle.

• The safety light curtain and its respective electrical connections

must be installed by qualified personnel, in line with the guidelines

stated in the relevant chapters.

• The safety light curtain must be positioned in such a way that the

danger zone cannot be accessed without interrupting the beams

(see Chapter 2 “Installation”).

• Personnel working in the danger zone must be appropriately

trained with regard to the operation of the safety light curtain.

• The test/reset button must be positioned outside the danger zone

in such a way that operating personnel have a complete view of

the danger zone during all reset, test or override operations.

• The feedback loop monitoring function used to monitor the external

contactors will only be active if the corresponding wire is connected

to the device.

• The muting lamp that displays the activated muting function must

be visible from all sides of the work area.

• To ensure the correct operation of the muting switching devices,

follow the instructions provided in the installation manual.

• Before switching on the safety light curtain, make sure you comply

with the instructions regarding correct operation.

7

Page 12

PSEN op4B Series Operating Manual

2 INSTALLATION

2.1 Precautionary measures when selecting and installing the

device

• Make sure that the category guaranteed by the safety light curtain

(Type 4) matches the risk assessment for the machinery that is to

be monitored, as defined in the standard EN 954-1.

• The OSSD outputs on the safety light curtain must be used as

machine stop devices and not as command devices (the machine

must have its own START command).

• The dimensions of the smallest object to be detected must not be

less than the resolution level of the device.

• The environment in which the safety light curtain is installed must

comply with the technical details stated for the safety light curtain

in Chapter 10, “Technical details”.

• Avoid installing the device, particularly the receiver (RX), close to

intense and/or flashing light sources.

• Avoid strong electromagnetic interference as this can adversely

affect the proper operation of the device.

• Smoke, mist or dust within the operating environment can reduce

the range of the safety light curtain by up to 50%.

• Sudden temperature fluctuations beyond freezing point can cause

condensation to form on the surface of the lenses, adversely

affecting the proper operation of the safety light curtain.

• The activated muting function is displayed via an integral muting

lamp. Make sure that the intensity of the LED is appropriate and

that it is clearly visible, positioned close to the danger zone.

• Install and replace emitter and receiver only in pairs.

Emitter and receiver have the same serial number.

8

Page 13

Operating Manual PSEN op4B Series

• Make sure that the muting sensors are used appropriately and in

accordance with the following specifications. Avoid connections

that are inappropriate and unmonitorable, so that any accidental,

potentially hazardous activation can be prevented.

2.2 General information on positioning the device

For effective protection it is necessary to proceed very carefully when

positioning the device; in particular, the device must be installed in

such a way that the danger zone cannot be accessed without

interrupting the protected field.

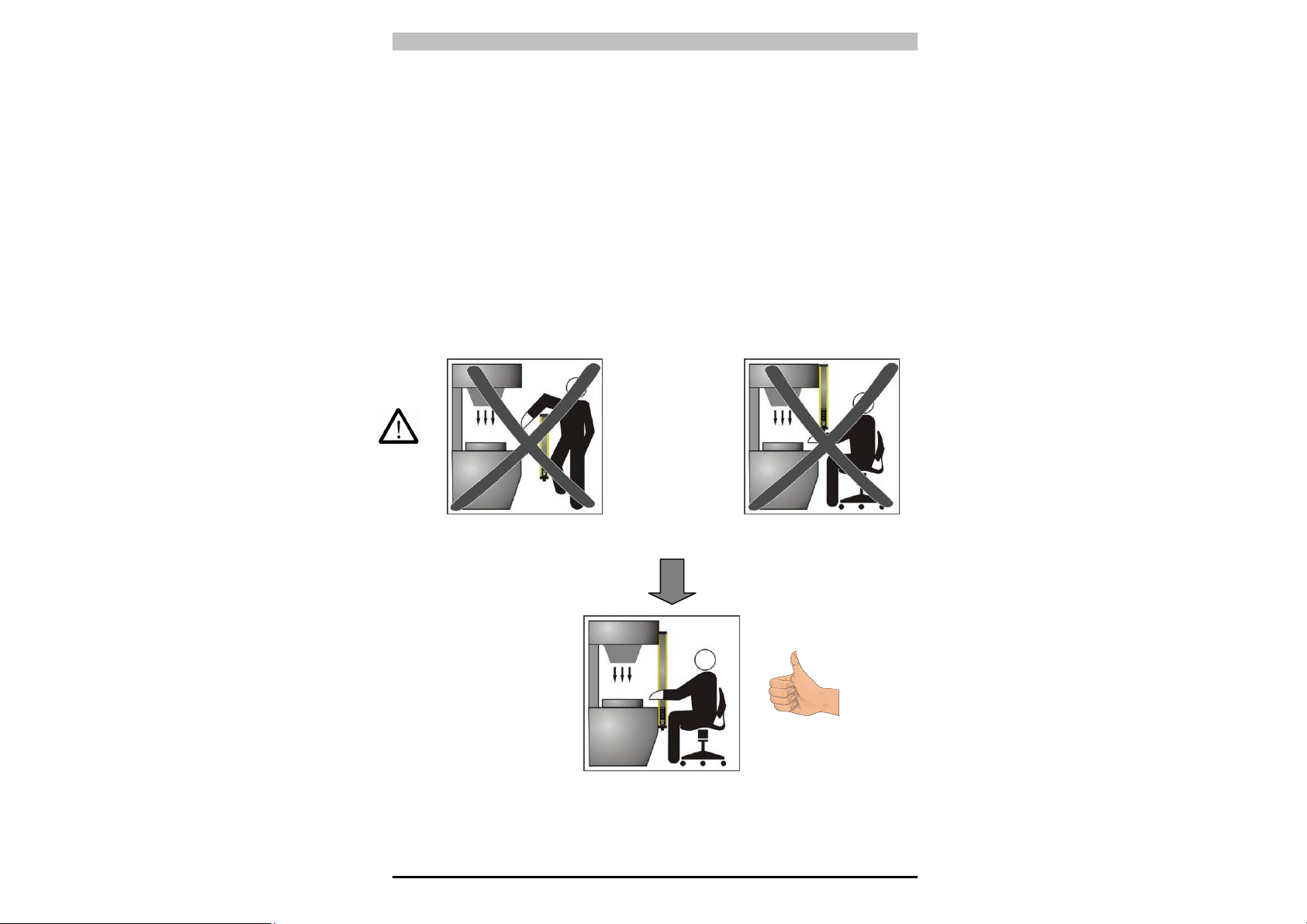

To exclude the possibility of the machine being accessed from above

or below (Fig. 3a), it is necessary to install a safety light curtain that is

long enough to completely cover access to the danger zone (Fig. 3b).

NO

Fig. 3a

Fig. 3b

9

Page 14

PSEN op4B Series Operating Manual

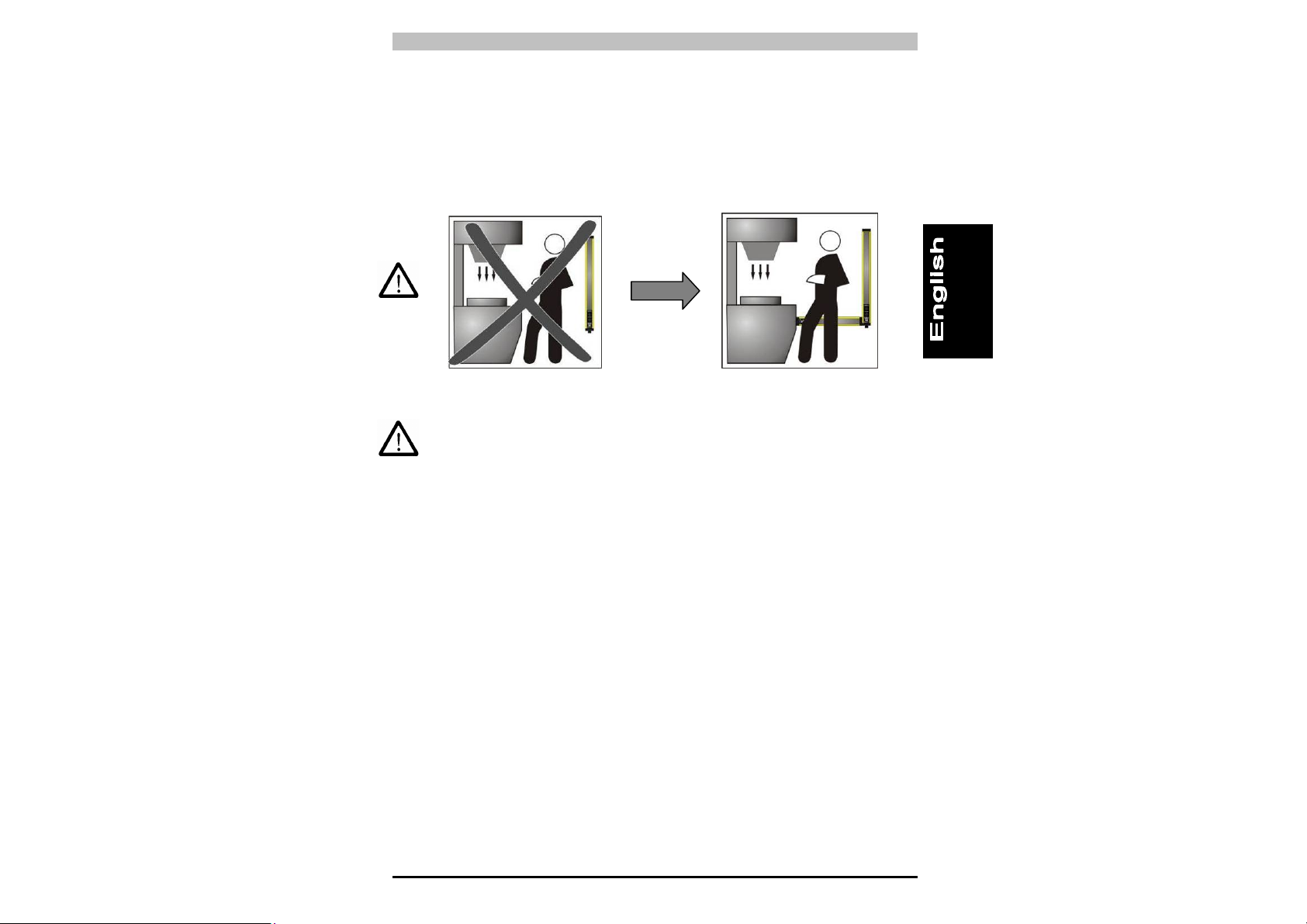

Also, under normal operating conditions, it must not be possible to

start the machine until the operator is outside the danger zone.

If it is impossible to install the safety light curtain in immediate

proximity to the danger zone, a second safety light curtain must be

installed and aligned horizontally, to exclude access from the side, as

shown in Fig. 4b.

Fig. 4a Fig. 4b

If the installation position of the safety light curtain still enables an

operator to access the danger zone without detection, an additional

mechanical barrier must be installed to prevent this.

10

Page 15

Operating Manual PSEN op4B Series

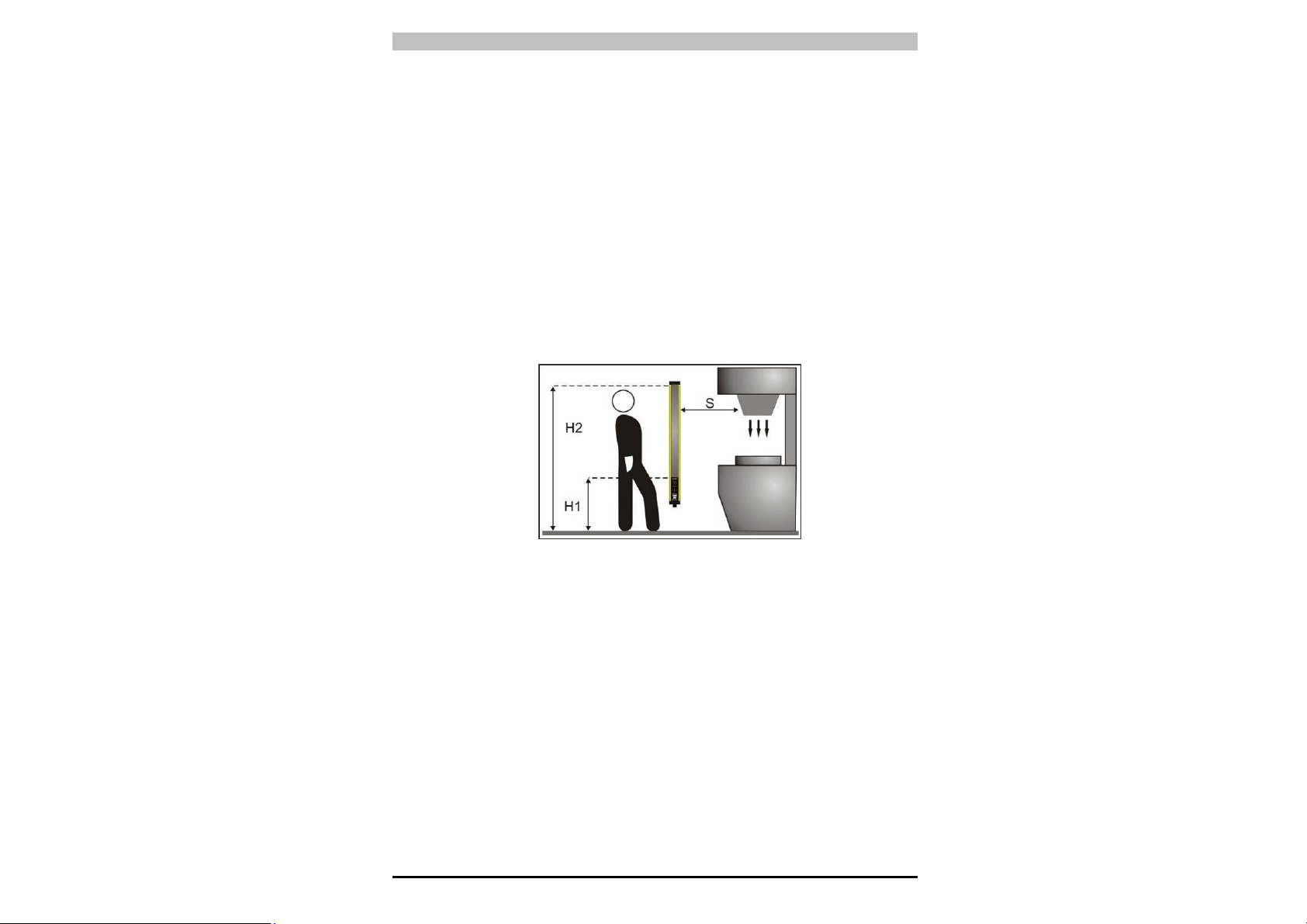

2.2.1 Minimum safety distance

The safety distance of the safety light curtain should be such that the

operator cannot reach the danger zone until the movement of the

hazardous machine part has come to a standstill (see Fig. 5).

According to the standards EN 999, 775 and 294, this distance

depends on four factors:

1 Reaction time of the safety light curtain (time it takes for the signal

at the OSSD output to switch from High to Low once the beams

have effectively been interrupted).

2 Machine's overrun time (time it takes for the machine to come to a

standstill once the reaction time of the safety light curtain has

elapsed).

3 Resolution of the safety light curtain.

4 Approach speed of the object requiring detection.

The formula for calculating the safety distance is as follows:

Fig. 5

S = K (t1 + t2) + C

where:

S = Minimum safety distance in mm between the protected field and

the danger zone

K = The speed at which the object requiring detection (body or parts

of the body) approaches the danger zone, in mm/s

t

= Reaction time of the safety light curtain in seconds (Ch. 10

1

“Technical details”).

t

= Machine’s overrun time in seconds

2

d = Resolution of the safety light curtain.

C = 850 mm for a safety light curtain with a resolution > 40mm

11

Page 16

PSEN op4B Series Operating Manual

Please note: The value of K is:

2000 mm/s, if the value calculated for S is ≤ 500 mm,

1600 mm/s, if the value calculated for S is > 500 mm.

If it is possible to access the danger zone from above and below (Fig.

5) and the devices used have a resolution of >40 mm, the upper beam

must be positioned at a height of 900 mm (H2), starting from the

reference plane (e.g. base of the machine), and the lower beam must

be positioned at a height of 300 mm (H1).

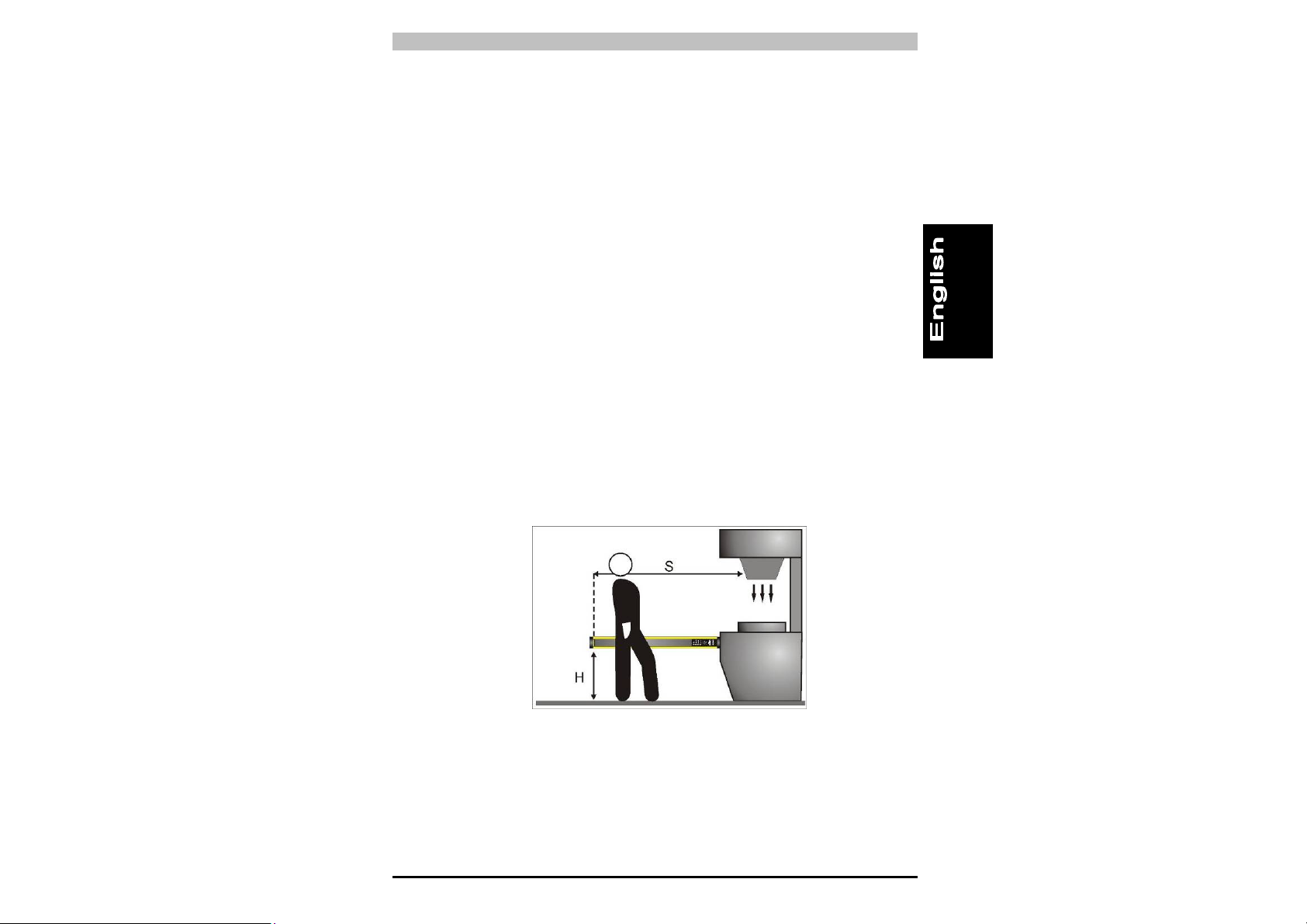

If the safety light curtain is to be installed horizontally

(Fig. 6), the distance between the danger zone and the furthest optical

beam must equal the value calculated using the following formula:

S = 1600 mm/s (t

+ t2) + 1200 – 0.4 H

1

where:

S = Minimum safety distance in mm between the protected field

and the danger zone

t

= Reaction time of the safety light curtain in seconds (Ch. 10

1

“Technical details”).

t

= Machine's overrun time in seconds

2

H = Height of the beams above the floor. This height must always

be less than 1000 mm.

Fig. 6

12

Page 17

Operating Manual PSEN op4B Series

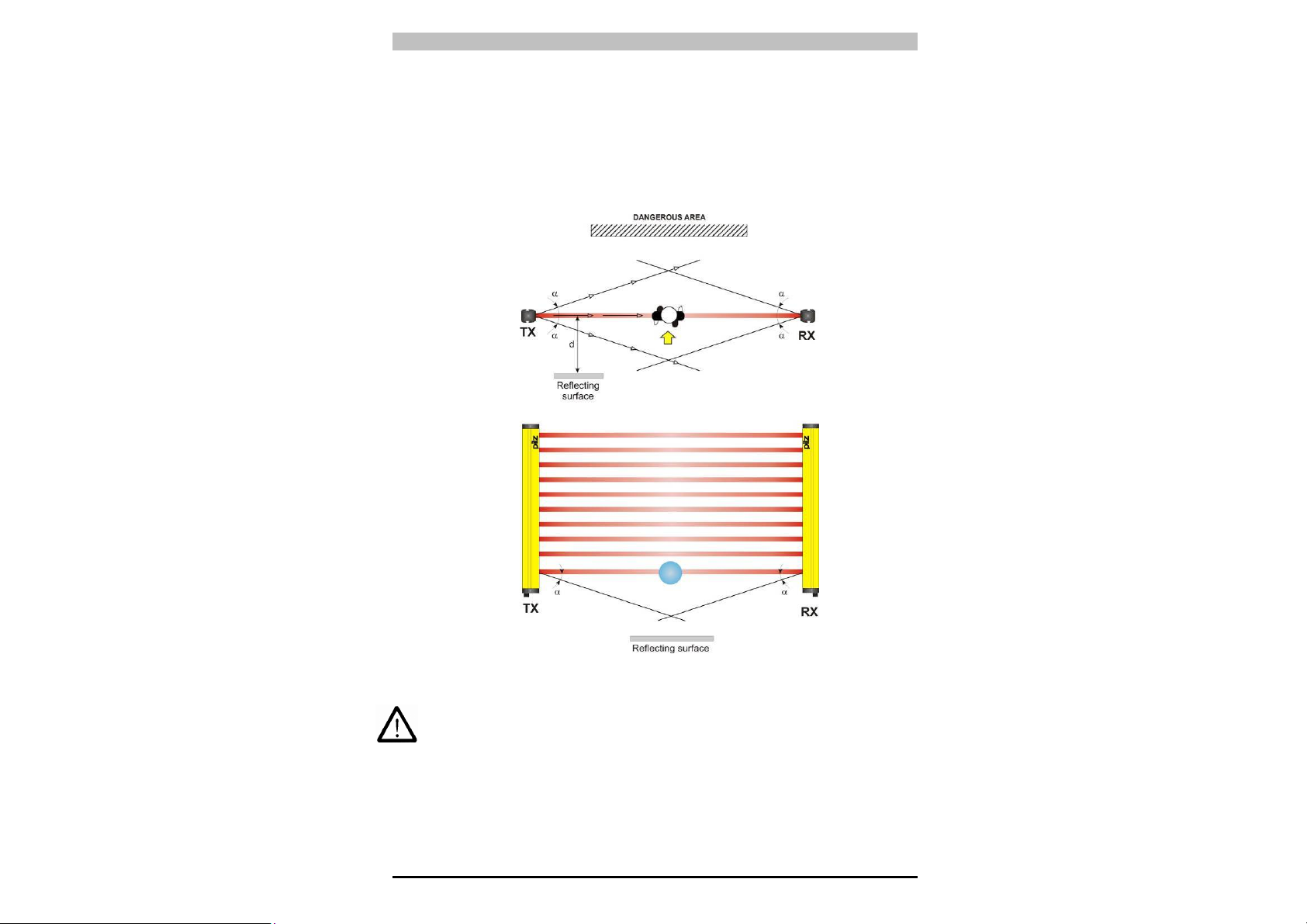

2.2.2 Minimum distance from reflective surfaces

Reflective surfaces close to the light beams emitted from the safety

device (whether above, below or to the side), may cause passive

reflections and adversely affect detection of the object within the

protected field (Fig. 7).

Fig. 7

Improper installation could mean that a protected field is interrupted

without detection, resulting in serious injury.

13

Page 18

PSEN op4B Series Operating Manual

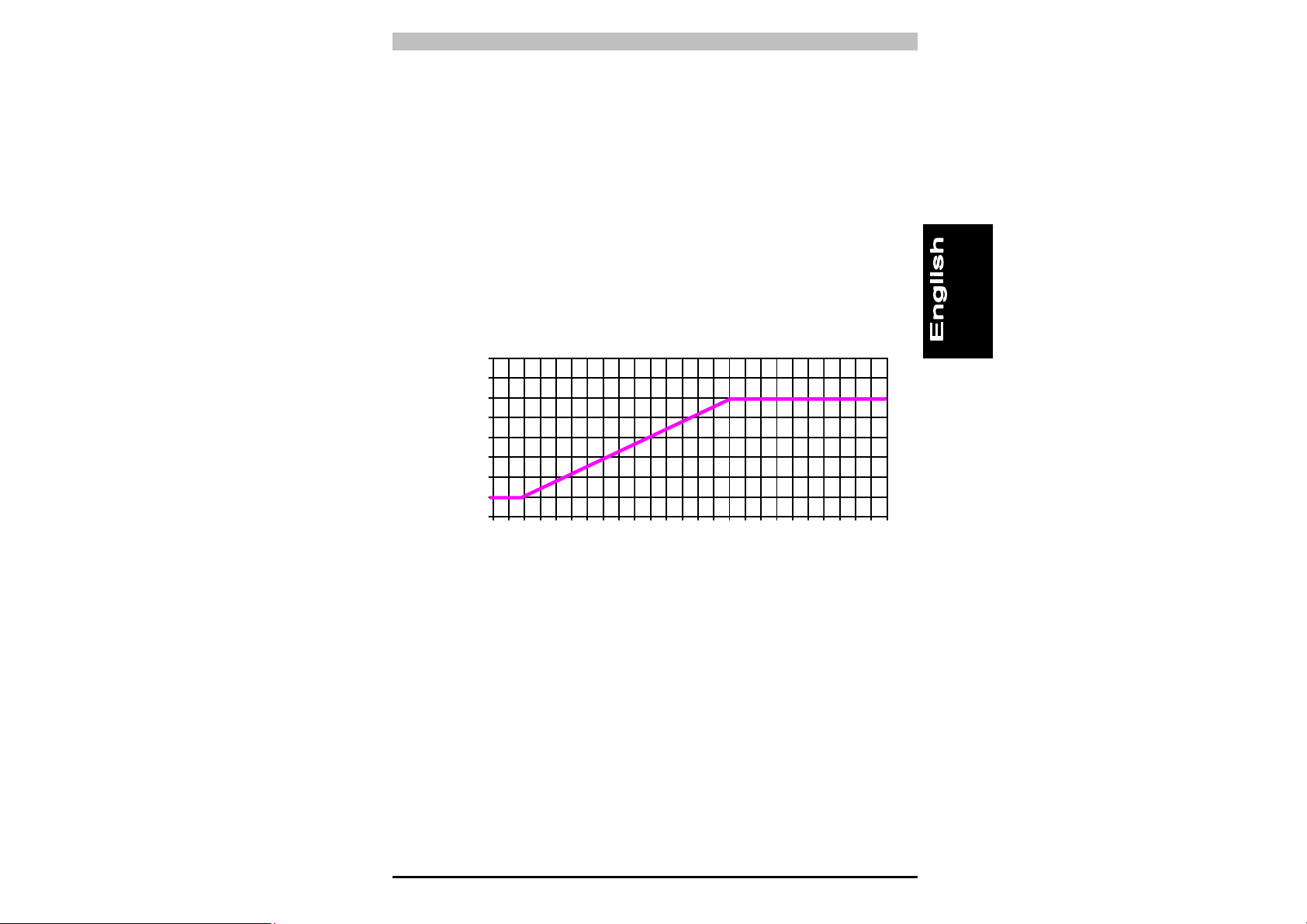

So, when installing the device close to reflective surfaces (metal walls,

floors, ceilings or workpieces), it is vital that the minimum distance in

relation to reflective surfaces is maintained, as shown in the diagram in

Fig. 8. This minimum distance depends on:

• The range between the emitter (TX) and receiver (RX)

• The maximum open angle of the light beams transmitted by the

emitter (TX):

5° for Type 4 ESPE (± 2.5° to light axis)

The values for the minimum distance in relation to the operating range

can be taken from the illustration in Fig. 8.

800

700

600

500

400

300

200

100

0

distanza superficie riflettente (mm)

reflecting surface distance (mm)

0 1 2 3 4 5 6 7 8 9 10111213141516171819202122232425

distanza operativa (m)

Operating distance (m)

Type 4

safety

light curtain

Fig. 8

14

Page 19

Operating Manual PSEN op4B Series

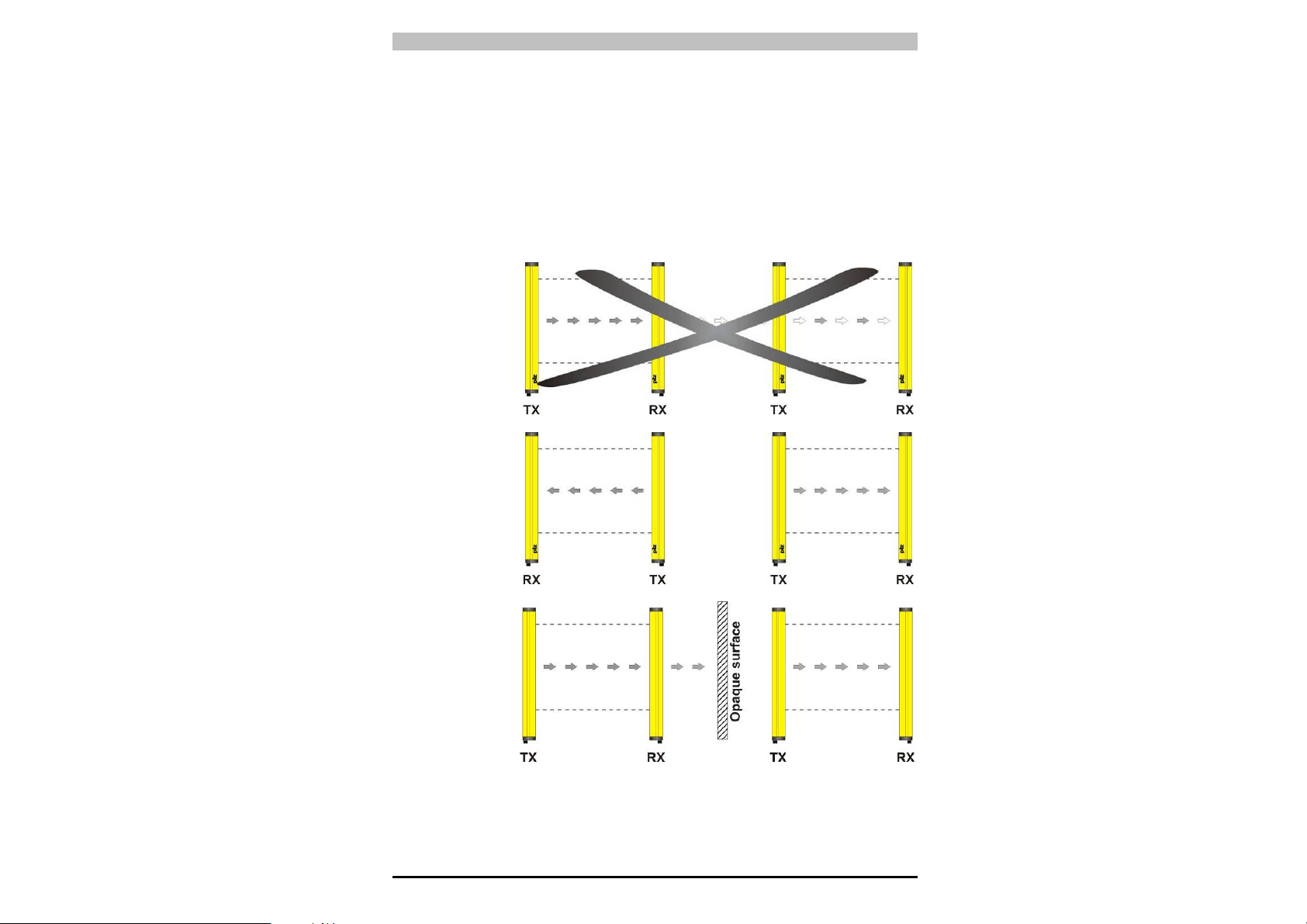

2.2.3 Installing several adjacent safety light curtains

If it is necessary to install several safety light curtains in adjacent

areas, you will need to ensure that the emitter (TX) on one device

cannot interfere with the receiver (RX) on another. To prevent this, the

devices will need to be installed conversely or must be separated via

screening (opaque surface).

Fig. 9 gives an example of an installation that could lead to

interference, plus two correct installations.

NO

YES

YES

Fig. 9

15

Page 20

PSEN op4B Series Operating Manual

2.2.4 Use of deviating mirrors

Deviating mirrors can be used to monitor danger zones where access

is possible from various sides.

Fig. 10 illustrates a potential solution for monitoring three different

access sides using two deviating mirrors positioned at an angle of 45°

to the safety light curtain.

Fig. 10

Please note the following precautions to take when using deviating

mirrors:

• The alignment of the emitter (TX) and receiver (RX) is particularly

critical when you use deviating mirrors; just a slight angular

displacement of the mirror is enough to lose the alignment. This

problem can be resolved by using a laser pointer, which is

available as an accessory.

• The minimum safety distance (S) must be maintained for each

section of the safety light curtain.

• Use of a deviating mirror reduces the effective operating range by

about 15%. If two or more deviating mirrors are used, the range will

be reduced still further (for more details please refer to the

technical specifications for the specific mirror).

• Never use more than three mirrors per device.

• Any dust or dirt on the mirror’s reflective surface will drastically

reduce the operating range.

16

Page 21

Operating Manual PSEN op4B Series

3 MECHANICAL ASSEMBLY

The emitter (TX) and receiver (RX)

must be assembled so that the

respective optical surfaces are aligned

in parallel and the connectors are

positioned on the same side. The

distance between the emitter (TX) and

receiver (RX) must be within the

operating range of the model you are

using (see type label or Chapter 9,

“Technical details”).

Align the devices precisely, following the guidelines given in Chapter 5,

“Alignment”.

Depending on the application, both units may either be screwed on

using the fixing bolts supplied or by using a rigid mounting bracket.

Fig.11

Fig. 12

Where there is particularly strong vibration, the muting sensor profiles

will also need to be screwed on using rigid mounting brackets (Fig.

13).

Fig. 13

17

Page 22

PSEN op4B Series Operating Manual

Rigid mounting brackets are suitable for installations that require no

large mechanical adjustments during alignment. Adjustable brackets

enable the units to be inclined by ± 5° and are available on request.

Where applications are subject to particularly strong vibration we

recommend the use of angle brackets with vibration dampers.

The drawing and table below indicate the recommended fixing points

in relation to the length of the safety light curtain.

MODEL L (mm) A (mm) B (mm)

PSEN op4B-T-2-050 642 342 150

PSEN op4B-T-3-080 942 542 200

PSEN op4B-L-2-050 642 342 150

PSEN op4B-L-3-080 942 542 200

PSEN op4B-S-2-050 642 342 150

PSEN op4B-S-3-080 942 542 200

18

Page 23

Operating Manual PSEN op4B Series

3.1 Installing the integral muting sensor profiles

with "L" and "T" shaped configuration

• Install the unit with the active muting

sensors on the receiver (RX) and the

unit with the reflectors on the emitter

(TX) of the safety light curtain.

• Use the fastening clip to attach the

muting sensor profile to the emitter

(TX) and receiver (RX) of the safety

light curtain. This ensures that the

muting sensor profiles are aligned

precisely and are perpendicular to the

light curtain units (Fig. 14a, Fig. 14b).

• With an "L" shape configuration:

Install the profile so that the object

can be detected before it reaches the

safety light curtain’s sensing area.

• Both muting sensor profiles must be

aligned in parallel. The muting

sensors are already aligned. Slight

adjustments may be made by moving

the fastening clip.

• For areas of heavy vibration

• You can choose where to position the

muting sensor profiles on the light

curtain units. (Typically 14 cm from

the bottom end of the light curtain unit).

Fig. 14a

Fig. 14b

Fig. 14c

19

Page 24

PSEN op4B Series Operating Manual

4 WIRING

4.1 Electrical connections

The electrical connections of the emitter (TX) and receiver (RX) are

made via M12 connectors, which are located on the bottom of both

units.

RECEIVER (RX):

8-pin M12 connector

OSSD1 PNP

OSSD2 PNP

0 V

+24 Vdc

1 = white = TEST/START

2 = brown = +24 Vdc

3 = green = OVERRIDE 1

4 = yellow = Feedback loop

5 = grey = OSSD1

6 = pink = OSSD2

7 = blue = 0V

8 = red = OVERRIDE 2

EMITTER (TX):

4-pin M12 connector

not connected

0 V

Feedback

loop

5

4

6

7

1

OVR1

3

2

8

+24 Vdc

OVR2

External N.C. contact

Externer N.O. contact

External N.O. contact

+24 Vdc

+24 Vdc

0 V

MUTING2

1 = brown = +24 Vdc

0 V

2

3

2 = white = MUTING 2

3 = blue = 0V

4 = black = MUTING 1

5 = grey = Not connected

1

4

+24 Vdc

not connected

MUTING1

+24 Vdc

2

3

1

4

not connected

1 = brown = +24 Vdc

2 = white = Not connected

3 = blue = 0 V

4 = black = Not connected

20

Page 25

Operating Manual PSEN op4B Series

4.2 Notes on wiring

To ensure the correct operation of the safety light curtain, please note

the following:

• Safe electrical isolation must be ensured for the external 24 V

supply. Failure to do so could result in electric shock. The supply

voltage must conform to EN 60950, 03/97, section 2.3, EN 60742,

9/95 or EN 50178, 10/97.

• Emitter and receiver must be connected using shielded cables

(accessories).

FIg. 14 shows how to connect the emitter and receiver properly.

Fig. 15

• At the point where the cable enters the cabinet, connect the screen

to the earth bar, without making a break in the cable. Use metal

cable clamps which cover the screen over a wide surface area.

• Under no circumstances should the connection cables come into

contact with or be laid in proximity to cables that generate strong

electromagnetic interference (e.g.: motor feeds, inverters etc.);

these could compromise the device’s ability to function.

• Multicore cables may not be used to connect the outputs of more

than one safety light curtain.

21

Page 26

PSEN op4B Series Operating Manual

• The TEST/RESET input must be connected to the supply voltage

on the ESPE via a button with a N/C contact. The test should be

performed manually (by pressing the button) at least once a day in

order to check the proper operation of the safety device.

• If the safety light curtain is started and there is no TEST/RESET

input connected to 24Vcc, it will switch to a monitoring condition, in

which the OSSD is not activated. In this case, set up the correct

connections and restart the system to restore operation under

normal safety conditions.

• The TEST/START button must be positioned in such a way that

the operator has a clear view of the protected area when reset, test

or override procedures are in progress (see Ch. 6 “Operating

mode”).

• The input for monitoring external contactors (feedback loop) must

be connected to 24 Vcc via a N/C contact before the safety light

curtain is switched on.

The monitoring function will not be activated if the input is not

connected properly when the safety light curtain is switched on. In

this case the safety light curtain will change to a fault condition.

• The device is already fitted with internal voltage and current

limitation. We would advise against the use of other external

components, even where this is permitted.

22

Page 27

Operating Manual PSEN op4B Series

• Earthing: If evaluation devices

are connected without safe

separation, the safety light

curtain must be operated in

protection class 1. In this case,

the emitter and receiver must

be labelled with the protective

earth symbol and must be

earthed via the fastening kit.

Both are supplied with the unit.

Assembling the fastening kit:

- Insert the slot nut (M4 x 0.7

mm tapped holes) into a

groove on the safety light

curtain.

- Screw the two threaded pins

(M4 x 14) into the external

tapped holes.

Fig. 16

- Fix the screws firmly in place

so that the cupped point on the threaded pin pierces the coating.

This way contact will be made with the metal housing.

- To prevent the threaded pin from working loose under heavy

vibration, attach two self-locking M4 nuts to the threaded pins.

Use a hexagonal wrench CH.7.

- Attach the earth lead to the middle tapped hole using the lock

washer (M4) and screw (M4).

23

Page 28

PSEN op4B Series Operating Manual

• Under no circumstances should safety contacts OSSD1 and

OSSD2 be wired in series or parallel; however, both may be used

separately.

If one of these two configurations should be used by mistake, the

safety light curtain will indicate an output malfunction (see Ch. 7

“Diagnostic functions”).

• Connect both OSSD outputs to the control element. If an OSSD

output is not connected to the control element, this will have a

negative effect on the safety level of the system in which the safety

light curtain is used.

Fig. 17

Fig. 19

24

Fig. 18

Fig. 20

Page 29

Operating Manual PSEN op4B Series

5 ALIGNMENT

The emitter (TX) and receiver (RX) must be aligned to ensure the

proper function of the device.

Perfect alignment is achieved when the optical axes of the first and last

beam from the emitter (TX) meet the optical axes of the corresponding

elements on the receiver (RX).

Two yellow LEDs on the receiver (RX), “HIGH ALIGN” and “LOW

ALIGN”, simplify the alignment process.

5.1 Alignment instructions

Once the mechanical assembly and the electrical connections have

been completed, the safety light curtain can be aligned as described

below:

• Disconnect the power supply to the safety light curtain.

• Press the TEST/START button and keep it held down (opens the

contact).

• Reconnect the power supply.

• You can now release the TEST/RESET button.

• On the emitter (TX), ensure that the green LED "POWER ON" and

the yellow LED "SAFE" are lit. This confirms that the transmitter is

operating correctly.

• Make sure that the status of the receiver is one of the following:

- BREAK Status: Green LED "POWER ON" is lit and LED

"SAFE/BREAK" lights up red (BREAK).

-> The safety light curtain is not aligned correctly.

- SAFE Status: Green LED "POWER ON" is lit and LED

"SAFE/BREAK" lights up green. The yellow LEDs “HIGH

ALIGN” and “LOW ALIGN” are lit.

-> The safety light curtain is aligned correctly.

25

Page 30

PSEN op4B Series Operating Manual

Follow the steps below to align the units:

• Hold the receiver (RX) steady and align the emitter (TX) so that the

yellow “LOW ALIGN” LED lights up, confirming that the first lower

beam has been aligned correctly.

• Rotate the emitter (TX) until the yellow “HIGH ALIGN” LED is also

lit. The “SAFE/BREAK” LED switches from red (BREAK) to green

(SAFE).

: Make sure that the “SAFE/BREAK” LED is constantly

NOTE

green.

• With a few small movements, define the area in which the

“SAFE/BREAK” LED is constantly green; do this first with one unit

and then with the other. Place both units in the centre of this area.

• Use the pins and/or mounting brackets to firmly secure both the

units.

• Disconnect the power supply to the safety light curtain.

• Reconnect the power supply.

• Make sure that the green “POWER ON” LED on the receiver (RX)

is lit (light beams are clear, “SAFE” operating status) and that this

switches to red if just a single beam is interrupted (detected object,

“BREAK” operating status).

• Perform this test using a cylindrical “test rod”, the diameter of

which should correspond to the resolution of the device (14 mm, 20

mm, 30 mm or 35 mm). The test rod is available as an accessory.

: If you pass the test rod from top to bottom along the

NOTE

length of the whole sensing area, at any distance from

either unit, the “SAFE/BREAK” LED must be constantly

red. We recommend that you perform this test daily.

26

Page 31

Operating Manual PSEN op4B Series

5.2 Aligning the muting sensors

• Once the safety light curtain has been aligned and the muting

sensor profiles have been installed and wired, you will need to

check that the sensors on the profiles are aligned correctly. Slight

adjustments may be made by moving the fastening clip.

Fig. 21

27

Page 32

PSEN op4B Series Operating Manual

6 FUNCTIONS

6.1 Selecting the operating mode via DIP switches

On the front of the receiver (RX) there is a cover flap (Fig. 22), which is

easy to open using a screwdriver and enables access to a row of DIP

switches for the following configurations:

- Muting function/muting timeout

- Feedback loop monitoring function

- Manual/automatic reset

The device will not accept configuration

changes during normal operation. A

configuration change will only take effect

once the device is reset.

Particular care should therefore be taken

when setting the DIP switches.

DIP-sw FUNCTION ON OFF

1 Muting timeout 10 min Infinite

2 Muting

Feedback loop

3

4 Restart Automatic Manual

monitoring

T-shape

configuration, linear

configuration

Deactivated Activated

6.2 Standard configuration

DIP SWITCHES

Abb. 22

L-shape

configuration

The device is supplied with the following standard configuration:

- Muting timeout: 10 min

- Muting: In T shape configuration

- Feedback loop monitoring function: Deactivated

- Restart: Automatic

NOTE: The muting function can only be activated if muting inputs

1 and 2 and the muting lamps are connected correctly.

Detailed information on this function can be found in

chapters 6.3 and 6.4.

28

Page 33

Operating Manual PSEN op4B Series

6.3 Restart

If the beams between the emitter (TX) and receiver (RX) are

interrupted by an opaque object, the OSSD outputs will switch and the

safety contacts will open (“BREAK” operating status).

There are two different ways to restart normal mode (“SAFE” operating

status):

• Automatic reset: After the protected field has been interrupted, the

safety light curtain returns to its normal mode as soon as the

detected object has been removed from the protected field.

• Manual reset: After the protected field has been interrupted, the

safety light curtain does not return to its normal mode until the

object has been removed from the protected field and the restart

button (TEST/RESET button) has been operated for at least 0.5 s.

Timing diagram for manual reset (local or external activation of restart

function)

29

Page 34

PSEN op4B Series Operating Manual

Fig. 23 shows the two operating modes:

BREAK

Automatic

reset

SAFE

TX

BREAK

TEST/RESET

button

SAFE

Normal mode

Beams clear

SAFE

RX RX RX

TX

OSSD OFF OSSD ON

Beams

interrupted

TX

BREAK

Beams clear

Manual

reset

OSSD ON

OSSD OFF

OSSD OFF

OSSD ON

Fig. 23

Automatic or manual reset can be selected via the DIP switches on the

receiver (RX).

• Automatic reset: Set position 4 on both DIP switches to ON

• Manual reset: Set position 4 on both DIP switches to OFF

ON

1 2 3 4

ON

1 2 3 4

NOTE: DIP switches that are not used for this function are shown

in grey in the diagram.

30

Page 35

Operating Manual PSEN op4B Series

6.4 Test function

The test function can be used to carry out a function test on the safety

light curtain. The test function is activated via the input (TEST/RESET)

on the receiver (RX). The function is activated when the TEST/RESET

button has been operated for at least 0.5 s.

AUTOMATIC RESET

MANUAL RESET

31

Page 36

PSEN op4B Series Operating Manual

6.5 Reset function

The safety light curtain has a reset function which is used in the case

of internal errors. To cancel the reset lock and restore the normal

operating status, press the TEST/RESET button for at least 5 s.

Carry out the reset function in the following cases:

• Irregular output function

• Irregular optical function

• Irregular operation of the feedback loop monitoring function

• Irregular muting display function

Timing diagram for the reset function

32

Page 37

Operating Manual PSEN op4B Series

6.6 Feedback loop monitoring function

The safety light curtain has a feedback loop for

monitoring the externally connected contactors. The

opening/closing of the electrical contacts is

monitored by a N/C contact.

Activate the feedback loop monitoring function:

- Select the relevant DIP switch

- Connect the feedback loop input to a 24 Vcc N/C

contact on the device to be monitored.

The diagram on the right shows the correct layout of the DIP

switches (DIP switch 3 OFF) to activate the feedback loop.

ON

1 2 3 4

ON

1 2 3 4

33

Page 38

PSEN op4B Series Operating Manual

This function monitors the switching of the N/C contacts when the

OSSD output status changes.

TC ≤ 350 ms Time after which the feedback loop contacts open once

the OSSD outputs switch from OFF-ON

T

≤ 100 ms Time after which the feedback loop contacts close once

0

the OSSD outputs switch from ON-OFF

Use control elements whose dynamics are compatible with the time

constraints stated above.

If inappropriate devices are used, the safety light curtain may switch to

a fault condition.

We recommend that this function is checked regularly.

34

Page 39

Operating Manual PSEN op4B Series

6.7 Muting function

The muting function enables the safety light curtain to be suspended

temporarily while material is transported through the protected field

(Fig. 24).

• "L" shape configuration: is suitable for applications in which an

object leaves the danger zone in one direction.

• "T" shape configuration: is suitable for applications in which an

object moves in two directions.

• Linear models: Are suitable for applications on which the sensors

are intended to be positioned individually. A plug connector

enables the muting sensors to be connected simply.

L-shape version with integral muting

sensors for muting in one direction

(leaving the danger zone)

Linear version with external muting sensors

T-shape version with integral muting

sensors for muting in two directions

Fig. 24

35

Page 40

PSEN op4B Series Operating Manual

To comply with current regulations the safety device has two inputs

(muting 1 and muting 2) for activating the muting function.

For example, the muting function can be used when objects need to

pass through the protected field, but operating personnel still require

protection.

Muting duration:

• Muting timeout 10 min.: Set position 1 on both DIP switches to ON

• Muting timeout infinite: Set position 1 on both DIP switches to OFF

Muting configuration:

• T-shape configuration or linear configuration: Set position 2 on

both DIP switches to ON

• L-shape configuration: Set position 2 on both DIP switches to OFF

When using the muting function, please note the following:

• The muting function represents a forced situation for the whole

system and as such should be applied with due care.

• The muting sensors must be connected and positioned properly,

so that personnel are not exposed to unwanted muting activations

or hazardous situations.

• Muting cannot be activated if the protected field is interrupted

(“SAFE” LED lights up red).

• When you have different conveyor speeds in muting mode, you will

need to consider the effect this will have on the overall duration of

the muting process.

• The receiver has a muting lamp which displays the

status of the muting function (Fig. X). If the muting

lamp is defective, activating muting or override will

cause the safety contacts to open and the plant will

be disabled due to a muting lamp malfunction

(see Chapter 8.2 “Error messages and diagnostics”).

The muting lamp must be clearly visible from all

sides of the work area.

Fig. 25

36

Page 41

Operating Manual PSEN op4B Series

• The vehicle should be designed to make it impossible for

people to ride on it.

• Limit the size of the entry area by applying appropriate safety

measures. People must not be permitted to enter the danger

area during the muting phase.

• Make sure that you select the correct muting configuration

(DIP switch position 2). The "OFF" position is provided

exclusively for safety light curtains with an L-shape

configuration. Any discrepancy in the configuration may

cause the muting function to operate incorrectly and reduce

the level of safety.

• In each case, the muting sensors must be positioned so that

muting cannot be activated by somebody passing through the

protected field.

• Muting can be activated in 2 ways:

- Activation of both muting inputs simultaneously (not in the case

of L-shaped muting)

- Activation of muting input 1 and then muting input 2, or viceversa.

• Muting cannot be activated if the protected field is interrupted

(“SAFE” LED lights up red).

• An "infinite" muting timeout does not conform to the

specifications of EN 61496-1. If the muting timeout has been

set to "infinity", the muting sensors must be tested at

intervals that are compatible with the process. This can be

done by shutting down the plant or by idling the muting

channel, for example.

• If the muting timeout is set to “infinity”, the level of safety that

can be achieved may be reduced.

37

Page 42

PSEN op4B Series Operating Manual

Fig. 26 shows an example of a muting function application.

Lamp flashes when

muting is active

OSSD ON

SAFE

MUTING OFF

SAFE

OSSD ON

Fig. 26

MUTING OFFMUTING ON

SAFE

OSSD ON

38

Page 43

Operating Manual PSEN op4B Series

Timing diagram of the muting function for configurations with 2 sensors

(L-shaped version or linear version with 2 intersecting beams)

Timing diagram of the muting function for configurations with 4 sensors

(T-shaped version or linear version with 4 sensors)

39

Page 44

PSEN op4B Series Operating Manual

A

A

6.7.1 Installing the muting sensors on PSEN op4B-S models

As the package passes through, the safety function is temporarily

suspended via the muting sensors. The outputs on these sensors are

connected to the muting inputs MUTING 1 and MUTING 2 on the

safety light curtain receiver (RX).

The contacts for these sensors are monitored via the receiver (RX).

Optoelectronic, mechanical, proximity sensors etc. can be used as

muting sensors, using a closed contact when the object requiring

detection is present.

The following examples illustrate the application of the muting function:

- Application with four optoelectronic sensors: Configured with

parallel light axes

This solution is suitable for applications in which the object can be

moved in two directions.

For correct operation set position 2 on the DIP switch to ON.

2B2

PSEN

d1 d1

D

L

v

1B1

Connecting the muting sensors:

V4

CONTACT A1

CONTACT A2

CONTACT B1

CONTACT B2

Receiver connector

Pin 3

MUTING 1

Pin 7

MUTING 2

• The distance between B2 and A2 or B1 and A1 should be as long

as possible, but distance D between A2 and A1 must be less than

the object size L

• A2 and B1 must be positioned as close as possible in front

of/behind the safety light curtain.

40

Page 45

Operating Manual PSEN op4B Series

• The maximum possible distance of d1 between B2 and A2 or B1

and A1, depends on the object’s approach speed:

d

d

• Muting sensors A1 and B1 or A2 and B2 must be operated within

4 s.

[cm]= v [m/s] * t

1max.

[cm] ≥ 0.1 cm

1min.

[s] * 100

Gl

41

Page 46

PSEN op4B Series Operating Manual

A

A

- Application with two optoelectronic sensors: configured with

parallel intersecting beams

This solution is suitable for applications in which the object can only be

moved in one direction.

For correct operation set position 2 on the DIP switch to ON.

Danger zone

B

PSEN

D

L

Contact from

V=const.

Connecting the muting sensors:

24 Vcc

4-pin M12 connector

PSEN receiver

Pin 2

MUTING 1

Pin 4

MUTING 2

Contact from B

• The beams must always intersect within the danger area.

• Muting sensors A and B must be operated within 4 s.

42

Page 47

Operating Manual PSEN op4B Series

A

6.7.2 Installing the muting sensors on PSEN opB-L models

The integrated muting function in an L-shaped configuration enables

the muting sensors to be easily installed and is suitable for applications

in which the object is to travel out of the danger zone.

For correct operation set position 2 on the DIP switch to OFF.

Contact from A

V=const.

Contact von B

PSEN

L

B

D

D

Moff

• The distance d1 between A and B is 16.5 cm

• Muting sensors A and B must be operated consecutively within

4 s.

Connecting the muting sensors:

24 Vcc

4-pin M12 connector

PSEN receiver

Pin 2

MUTING 1

Pin 4

MUTING 2

• Once muting sensor A has been cleared, the muting function is

held for another 4 s. After this time the muting function switches off

and the safety light curtain returns to normal mode.

• You should also secure the light curtain area outside the danger

zone, e.g. using a safety fence, so that it is impossible for anyone

to access the danger zone during the 4 s in which the muting

function is held.

43

Page 48

PSEN op4B Series Operating Manual

A

A

V

6.7.3 Installing the muting sensors on PSEN opB-T models

The integrated muting function in a T-shaped configuration enables the

muting sensors to be easily installed and is suitable for applications in

which the object is moved in two directions.

For correct operation set position 2 on the DIP switch to ON.

Contact from A1

L

=cons

Contact from A2

2B2

PSEN

D D

d

1B1

Contact from B1

Contact from B2

• The distance d1 between A1 and B1 or A2 and B2 is 16.5 cm.

• The distance D between A1 and A2 or B1 and B2 is 34.5 cm.

• Muting sensors A and B must be operated consecutively within

4 s.

Connecting the muting sensors:

24 Vcc

4-pin M12 connector

PSEN receive r

Pin 2

MUTING 1

Pin 4

MUTING 2

44

Page 49

Operating Manual PSEN op4B Series

6.8 Override function

This function can be used to activate the muting function when the

plant needs to be started even though there is an object within the

protected field. The aim is to clear the danger zone of any material that

may have accumulated due to a fault in the operating cycle.

Example:

There is a pallet within the protected field and the conveyor cannot be

switched on because the safety light curtain will not enable its outputs

(one or more of the beams are interrupted), so the accumulated

material cannot be transported away. Activating the override function

enables this type of intervention.

Activate the override function:

• With manual reset: When the protected field has been interrupted,

the override function cannot be activated until the TEST/RESET

button has been pressed.

• The override function is activated via the local input (OVR1 and

OVR2) on the receiver (RX). To do this, connect a pushbutton with

N/O contacts to OVR1 and 24 Vcc and PVR2 and 0 Vcc.

• The override function is active when both N/O contacts close

simultaneously (simultaneity between the contacts max. 400 ms).

• Press the OVERRIDE button and keep it held down until all the

accumulated material has been cleared away.

While the override function is active the muting lamp will flash to signal

the suspension of the safety light curtain.

The maximum duration of the override function is 120 s. After this time

the override function switches off, even if the “OVERRIDE” button is

operated. If the button is released before this time has elapsed, the

override function switches off immediately.

45

Page 50

PSEN op4B Series Operating Manual

The override function is ended automatically when:

• There are no muting sensors active

• Muting timeout is exceeded

• At least one override input is deactivated

Timing diagram: Override function

24 Vcc

OVR1

0 V

24 Vcc

0 V

OVR2

Override function

ON

OFF

0 ≤ ΔT < 400ms

46

Page 51

Operating Manual PSEN op4B Series

7 DIAGNOSTICS

7.1 Function indicators

4 LEDs on the receiver (RX) and 2 LEDs on the emitter (TX) provide

the user with information about the operating status of the safety light

curtain.

Fig. 27

The key to the LEDs on the receiver (RX) depends on the operating

mode.

47

Page 52

PSEN op4B Series Operating Manual

7.2 Error messages and diagnostics

The LEDs that display the function can also be used by operators to

evaluate the main causes of an error.

RECEIVER:

Defect Cause Checks and remedy

Flashing red

Flashing yellow

Flashing yellow

Constant green

Flashing red

Off

Flashing yellow

Constant green

Off

Flashing yellow

Flashing yellow

Constant green

Constant red

Flashing yellow

Off

Constant green

Constant red

Flashing yellow

Flashing yellow

Constant green

Off

Off

Flashing yellow

Constant green

Malfunction of the

outputs

Malfunction of the

external control unit

(function of the

feedback loop

monitoring test)

Malfunction of the

microprocessor

Override function can

be called up

Irregular override

function

Optical fault

- Check the output connections.

- Check that the load is compatible

with the specifications given in the

TECHNICAL DETAILS table (Ch.

9).

- Check the feedback loop

monitoring connections

- Check the compatibility of the

external unit and the test times for

feedback loop monitoring

- Switch the unit off and then on

again; if the problem persists,

change the external unit.

- Check the correct position of the

DIP switches.

- Switch the device off and then on

again; if the problem persists,

contact PILZ.

- The display is indicating that there

is no defect

- Activate the override function in

order to remove the material from

the area of the protected field.

- Check the contacts for the

override function. If the fault

persists, contact Pilz.

- Check the alignment of emitter

and receiver

- Switch the device off and then on

again; if the fault persists, contact

PILZ.

48

Page 53

Operating Manual PSEN op4B Series

EMITTER:

Defect Cause Checks and remedy

Flashing green

Flashing yellow

Flashing yellow

Constant green

Off

Off

Off

Off

Off

Off

Off

Constant green

Irregular function of the

integral muting display

Supply voltage error - Check the supply voltage

The supply voltage is

outside the permitted

range

Malfunction of the main

microprocessor

- Switch the device off and then

on again; if the fault persists,

contact PILZ.

- If the fault persists, contact Pilz.

- Check the supply voltage

- If the fault persists, contact Pilz.

Defect Cause Checks and remedy

Flashing yellow

Constant green

Off

Off

Off

Constant green

General irregularity on

the emitter

Supply voltage error - Check the supply voltage

The supply voltage is

outside the permitted

range

Malfunction of the main

microprocessor

- Check the supply voltage; if the

display does not go out, contact

Pilz.

- If the fault persists, contact Pilz.

- Check the supply voltage

- If the fault persists, contact Pilz.

49

Page 54

PSEN op4B Series Operating Manual

8 REGULAR CHECKS AND MAINTENANCE

Qualified personnel must carry out the following checks regularly.

Ensure that:

• The “SAFE/BREAK” LED is constantly red when you pass the test

rod from top to bottom along the length of the whole sensing area,

at any distance from either unit.

• The safety light curtain switches to an OFF state when the

test/reset button is operated (“SAFE/BREAK” LED lights up red OSSD outputs open - monitored machine switches to a safe

condition).

• The reaction time at a machine stop, incl. the reaction time of the

safety light curtain and the machine overrun time, is within the

limits defined through the calculation of the safety distance (see

Chapter 2 “Installation”).

• The minimum safety distance between the danger zone and the

protected field is in accordance with the details stated in Chapter 2

“Installation”.

• Nobody can access and remain in the danger zone between the

safety light curtains and the hazardous machine parts.

• The danger zone cannot be accessed from any unprotected area.

• There is no visible damage to the safety light curtain and/or the

external electrical connections.

We recommend a yearly inspection.

50

Page 55

Operating Manual PSEN op4B Series

8.1 Maintenance

Safety light curtains require no particular maintenance, except for

cleaning the optical covers. Moist cotton cloths should be used for

cleaning.

We recommend that you do not use:

• Alcohol or solvents,

• Cloths made of wool or synthetic material

8.2 General information and useful data

Safety devices are only beneficial if they are installed correctly, in

accordance with the regulations.

If you find that you do not have the necessary expertise to install the

safety devices correctly, please contact our technical support.

Electronic fuses protect the devices against short circuit. Once these

have reacted you will need to disconnect the power supply for at least

20 seconds and rectify the short circuit. When you reconnect the

power supply the fuses will have reset and the safety light curtain can

automatically resume normal operation.

Faults that result in a power supply failure may cause the outputs to

open temporarily, but do not adversely affect the safe operation of the

safety light curtain.

Install and replace emitter and receiver only in pairs.

Emitter and receiver have the same serial number.

Guideline for repair: Always send both emitter and receiver for repair.

(During repair, both units are programmed with the current software

version).

51

Page 56

PSEN op4B Series Operating Manual

r

9 TECHNICAL DETAILS

Supply voltage

Internal capacity 23 nF (Tx) / 120 nF (Rx)

Current consumption, emitter (TX) Max. 30 mA / 0.9 W

Current consumption, receiver (RX) Max. 75 mA (without load) / 2.2 W

Current consumption, muting senso

profiles

Outputs:

Output current: Max. 0.5 A / each output

Output voltage ON - min.: Vdd –1 V

Output voltage OFF - max. 0.2 V

Capacitive load (pure) Max. 65 nF at 25°C

Resistance load (pure)

Leakage current < 1 mA

Reaction time 14 ms

Emitter, wavelength Infra-red (880 nm)

Resolution 415 mm (2 optics)

Operating range 0.5…3 m (PSEN op4B-T/L), 0.5…25 m (PSEN op4B-S)

Category Type 4

Timeout points Muting: 10 min / infinity

Operating temperature -10 … +55 °C

Storage temperature -25 … +70 °C

Humidity 15 ... 95 % (non-condensing)

Protection class Class 1 (see section 4.2 "Wiring guidelines", "Earthing"

Protection type IP65 (EN 60529)

Ambient brightness IEC-61496-2

Vibration Amplitude 0.35 mm, frequency 10 ... 55 Hz, 20 sweeps

Shock resistance 16 ms (10 G) 1,000 shocks for all axes

Reference standards IEC 61496-1; IEC 61496-2

Housing material Varnished aluminium (yellow RAL 1003)

Material of upper and lower cover PC MAKROLON

Material for optics PMMA

Connections 4-pin M12 connector on TX

Cable runs

Supply

Weight Max. 1.2 Kg / m per unit

* If a longer cable is used, you will need to make sure that the relevant specifications are met.

24 VDC ±20% (SELV/PELV)

Max. 35 mA / 1 W (when sensors switched to 'OFF')

2 PNP

Max. short circuit stability: 1.4 A at 55°C

min: 1.1A at -10°C

Min. 56Ω at 24 Vcc

515 mm (3 optics)

Override: 2 min

section)

for all axes; 1 octave/min., (EN 60068-2-6)

(EN 60068-2-29)

8-pin M12 connector on RX

Max. 50 m*

52

Page 57

Operating Manual PSEN op4B Series

10 LIST OF AVAILABLE MODELS

PSEN op4B-T-2-050

PSEN op4B-T-3-080

PSEN op4B-L-2-050

PSEN op4B-L-3-080

PSEN op4B-S-2-050

PSEN op4B-S-3-080

MODEL

Length of

sensing

Distance

area

515 500 2 515 14 0.5…3 m

415 400 3 415 14 0.5…3 m

515 500 2 515 14 0.5…3 m

415 400 3 415 14 0.5…3 m

515 500 2 515 14 0.5…25 m

415 400 3 415 14 0.5…25 m

No. of

beams

Resolution

mm

Reaction

time (ms)

Operating

range (m)

11 OVERALL DIMENSIONS

All dimensions are stated in mm.

35

35

40

691 373

MODEL A (mm) B (mm) C (mm)

PSEN op4B-T-2-050 120…260 653 690

PSEN op4B-T-3-080 120…260 953 990

PSEN op4B-L-2-050 120…260 653 690

PSEN op4B-L-3-080 120…260 953 990

PSEN op4B-S-2-050

PSEN op4B-S-3-080

120…260

120…260

53

C

B

A

653 690

953 990

Page 58

PSEN op4B Series Operating Manual

12 ACCESSORIES

12.1 Mounting bracket

MODEL DESCRIPTION

Bracket kit PSEN 4 (1) Bracket (4-part kit)

Bracket kit PSEN 4 anti vibr. (2) Anti-vibration brackets (4-part kit)

Bracket kit PSEN 4 adjust. (3) Adjustable brackets (4-part kit)

Mounting type A Mounting type B

.nim 2.14

.278

3am .45.x

Standard mounting bracket (1)

m 7.xa9

2am .05.x

°5±

°5±

7m 5.xa4.

Standard mounting bracket + adjustable bracket (1 + 3)

.278

5.25

2.65

.xam 75

.65 2

021.

.162

2

502Ø

73.4

52Ø

0

2

Standard mounting bracket + anti-vibration bracket (1 +2)

m857.xa9

°5±

m 9.27.xa

Ø52

02

Standard bracket+adjustable bracket+anti-vibration bracket (1 + 2 + 3)

8.97.xam

±°5

.m xa

75

6.52

5

202Ø

54

Page 59

Operating Manual PSEN op4B Series

12.2 Deviating mirror

MODEL DESCRIPTION

Mirror 550mm Deviating mirror H= 550 mm

Mirror 700mm Deviating mirror H= 700 mm

Mirror 900mm Deviating mirror H= 900 mm

Mirror 1000mm Deviating mirror H= 1000 mm

Mirror 1270mm Deviating mirror H= 1270 mm

Mirror 1600mm Deviating mirror H= 1600 mm

Mirror 1800mm Deviating mirror H= 1800 mm

L1 (mm) L2 (mm)

554 384

704 534

904 734

1004 834

1264 1094

1604 1434

1804 1634

55

Page 60

PSEN op4B Series Operating Manual

12.3 Floor brackets

MODEL DESCRIPTION

Stand 1000mm Floor brackets H= 1000 mm

Stand 1200mm Floor brackets H= 1200 mm

Stand 1500mm Floor brackets H= 1500 mm

Stand 1800mm Floor brackets H= 1800 mm

L (mm) X (mm)

1000 30x30

1200 30x30

1500 45x45

1800 45x45

56

Page 61

Operating Manual PSEN op4B Series

12.4 Laser pointer

The laser pointer in the PSEN op2/4 series is a valuable guide when

aligning and installing the safety light curtains. The pointer can be

moved along the light curtain profile to check the overall alignment of

the safety light curtain.

MODEL DESCRIPTION

LaserPointer for PSEN 4/2 Laser pointer for alignment

Fig. 28

57

Page 62

PSEN op4B Series Operating Manual

12.5 Connection box

The connection box PSEN iop1 makes it easier to connect and operate

the safety light curtains.

Features:

• Key switch for the override function

• TEST/RESET button for activating the test, restart and reset

function

• Connections for:

- Receiver (RX)

- Emitter (TX)

- Supply voltage

- Relay outputs

- External control unit

MODEL DESCRIPTION

PSEN iop1 Connection box

Fig. 29

58

Loading...

Loading...