Page 1

Installation and Operating Instructions

Plastic encased safety interlocking switch

Type

Intended use

The plastic encased safety switches PSEN me4 with separate actuator are suitable for the mounting on safety

guards. They are designated to trigger switching operations in control circuits.

Function

If the safety guard is opened the contact(s) with forced disconnection will break the safety control circuit (safety

contacts get opened).

Improper installation or manipulation of the safety switch renders the personal protection function useless and can

cause serious injury or accidental death.

In order to maintain the maximum level of safety, always order and use actuators together with the correct safety

switches.

PSEN me4

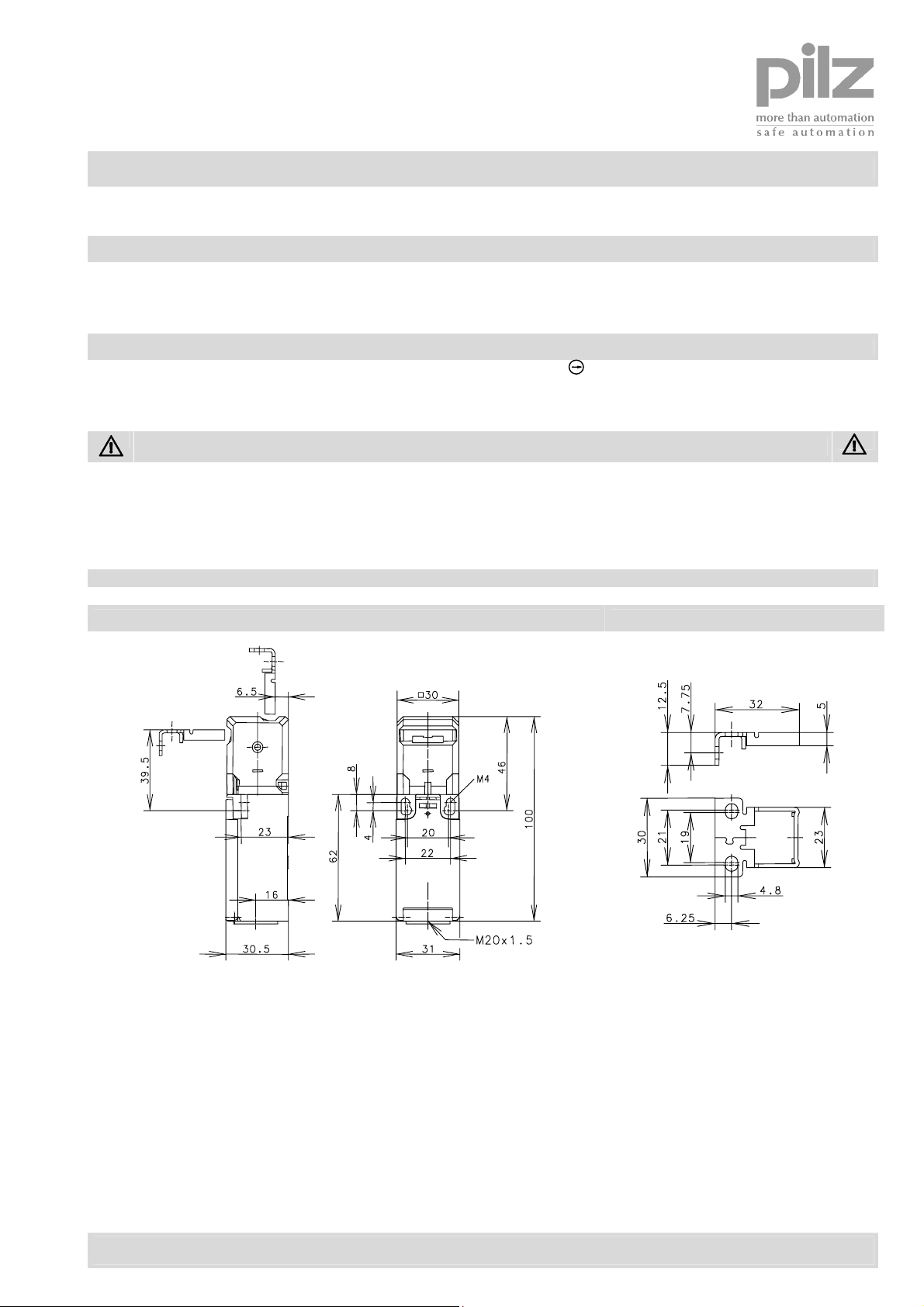

Dimensions [mm] Actuator

Safety instructions

PSEN me4AS

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 31.01.2005 / Page 1 of 5

Document: 0800000424_en / Version: 1

Template : 0850174292 Orig. 2

Page 2

Installation and Operating Instructions

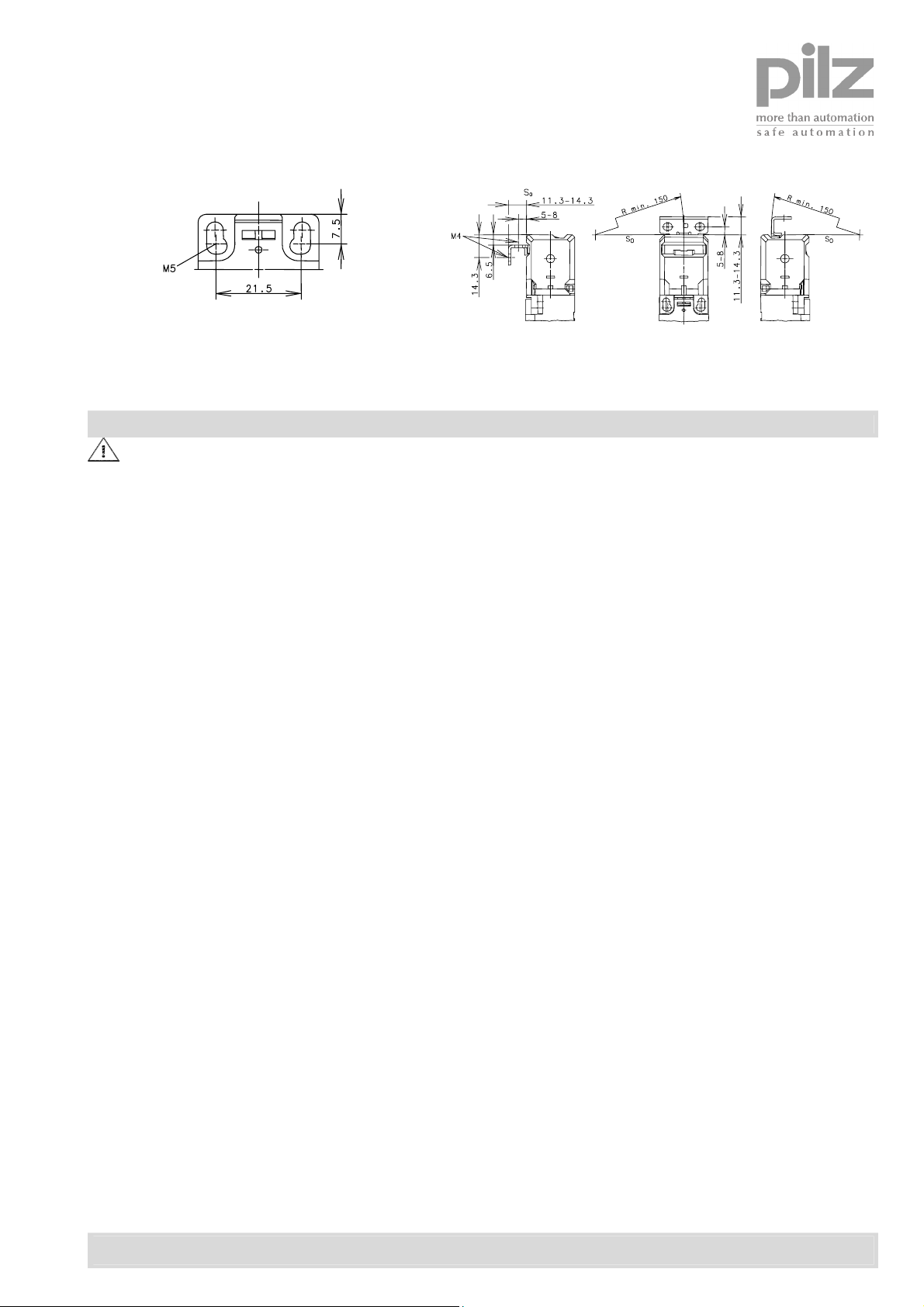

Fixed positioning for safety applications (M5)

Minimum radii reference to a point of rotation

on enclosure top edge S

0

Installation

Installation by trained and qualified personnel only!

To mount the switch gear 2 screws M5 shall be used.

Actuator PSEN me4AS:

The user shall make sure that the actuator is form-fit mounted. The actuator mounting should not be solvable with

simple tools. For a tamperproof mounting use one-way screws of M 4X8 size.

The switch and the actuator shall be aligned during installation in such a way that even after multiple actuations of

the safety guard no lateral forces affect the actuator head.

The mounting position is any desired but shall support inspection and replacement if necessary by qualified

personnel. Choose such a mounting position that no foreign parts seep into the opening of the actuating device.

The rated degree of protection (IP-Code) of the switch applies only with closed cover lid and when an at least

evenly matched cable gland with adequate cable is used.

The switches shall not be used as mechanical end stop.

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 31.01.2005 / Page 2 of 5

Document: 0800000424_en / Version: 1

Template : 0850174292 Orig. 2

Page 3

Installation and Operating Instructions

The safety switch shall not be used as

mechanical end stop!

Position of

mechanical stop adjustable

(not supplied with

safety switch)

4 different directions of actuation by turning the cap

from 0° to 270°:

1. draw clasp out

2. turn actuator head

3. press-on clasp

Cover for unused entry

Actuating forces (Extraction force):

Standard = 10 N

PSEN me4.01, PSEN me4.11,

PSEN me4.21 = 50 N

Connecting the cable:

Connection type:

2 or 4 screw connectors M3,5 or

6 screw connectors M3

Conductor cross section:

singl e core 0,5-1,5 mm²/litz wire with

connector sleeve 0,5-1, 5 mm²

Electrical connection

The electrical connection shall only be carried out by trained and qualified personnel!

The electrical contacts of switches PSEN me4, PSEN me4.01, PSEN me4.1 and PSEN me4.11 feature 4 screw

terminals M3,5.

Tightening torque M = 0,8 Nm.

The electrical contacts of switches PSEN me4.2 and PSEN me4.21 feature 6 screw terminals M3.

Tightening torque M = 0,6 Nm.

The connection requires a stranded wire with ferrule or a solid wire with a cross section of 0,5 – 1,5 mm².

For safety circuits acc. EN 60204 use the normally closed contact(s) (N.C.) only.

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 31.01.2005 / Page 3 of 5

Document: 0800000424_en / Version: 1

Template : 0850174292 Orig. 2

Page 4

Installation and Operating Instructions

Electrical data

PSEN me4

PSEN me4.01

Switching function 1 NO/1 NC (Zb) 2 NC (Zb) 1 NO/2 NC (Zb)

PSEN me4.1

PSEN me4.11

PSEN me4.2

PSEN me4.21

Switch symbol

Rated insulation voltage Ui 250 V AC 250 V AC 400 V AC

Conventional thermal current I

Utilization category

acc. IEC/EN 60947-5-1

10 A 10 A 5 A

the

AC-15, U

240 V/3A

e /Ie

AC-15, Ue /Ie

240 V/3 A

AC-15, Ue /Ie

240 V/1,5 A

Type of short-circuit protection 10 A gL/gG 6 A gL/gG 6 A gL/gG

Melting fuse acc. IEC/EN 60947-5-1, annex K

Forced disconnection (N.C.) IEC/EN 60947-5-1

Degree of protection

II, protective insulation

Mechanical data

Enclosure Thermoplastic, glass fiber reinforced (UL94-V0)

Cover Thermoplastic, glass fiber reinforced (UL94-V0)

Ambient air temperature -30°C to +80°C, -22°F to +176°F

Cable entry 1 x M20x1,5

Protection class IP65 acc. EN 60529; DIN VDE 0470 T1

Weight ≈ 0,13 kg

Actuating device 4AS

Actuator Separate actuator (St stainless)

Actuating radius

≥ 150 mm

Extraction force Standard 10 N

PSEN me4.01, PSEN me4.11, PSEN me4.21 50 N

Mechanical life 1 x 106 switching cycles

Mechanical life, extended actuation force 1 x 105 switching cycles

Switching frequency

≤ 30/minute

Standards

VDE 0660 T100, DIN EN 60947-1, IEC 60947-1

VDE 0660 T200, DIN EN 60947-5-1, IEC 60947-5-1

GS-ET-15

EU-Conformity

Approvals

BG (applied for)

UL/CSA A300 (applied for) for PSEN me4,

PSEN me4.01, PSEN me4.1, PSEN me4.11

UL/CSA B300 (applied for) for PSEN me4.2,

PSEN me4.21

Date of issue: 31.01.2005 / Page 4 of 5

Document: 0800000424_en / Version: 1

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Template : 0850174292 Orig. 2

Page 5

Installation and Operating Instructions

Start-up

Mechanical function test:

Actuate the safety guard und check the proper switching function.

Electrical function test in the safety control circuit:

- Opening the safety guard shall break off the energy of the drive.

- The drive shall only be energized when the safety guard is in its closed position.

Maintenance / Inspection

The switching device is maintenance-free. For trouble-free operation and a long service life the device should be

inspected regularly. Ensure that:

- all components are secure and tight

- switching functions operate properly

- all sealing gaskets are in proper condition

- the components show no signs of tear and wear.

If defects are detected the complete switching device and the actuator have to be replaced.

Liability disclaimer

By breach of the given instructions (concerning the intended use, the safety instructions, the installation and

connection through qualified personnel and the testing of the safety function) any liability expires.

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 31.01.2005 / Page 5 of 5

Document: 0800000424_en / Version: 1

Template : 0850174292 Orig. 2

Loading...

Loading...