Page 1

Installation and Operating I n structi ons

V

Safety interlocking switch with solenoid lock

Intended use

PSEN me1 safety switches are interlocking devices equipped with a solenoid operated guard lock. When used together with a suitable machine

control system these switches also monitor the position of movable guards. When correctly installed the PSEN me1 ensures that movable machine

guards can only be opened when it is safe to do so. Machine start-up, which could cause hazardous situations, is only possible if the movable

machine guards are duly closed and the PSEN me1 locking device is latched in position.

Standards governing installation and operation: EN 954-1 safety-related parts of control systems

EN 1088 interlocking devices with and without movable machinery guards

EN 60 204-1 electrical equipment of industrial machinery

Risk assessment at the machine acc. to: EN 954-1 safety-related parts of control systems

EN 1050 safety of machinery, risk assessment

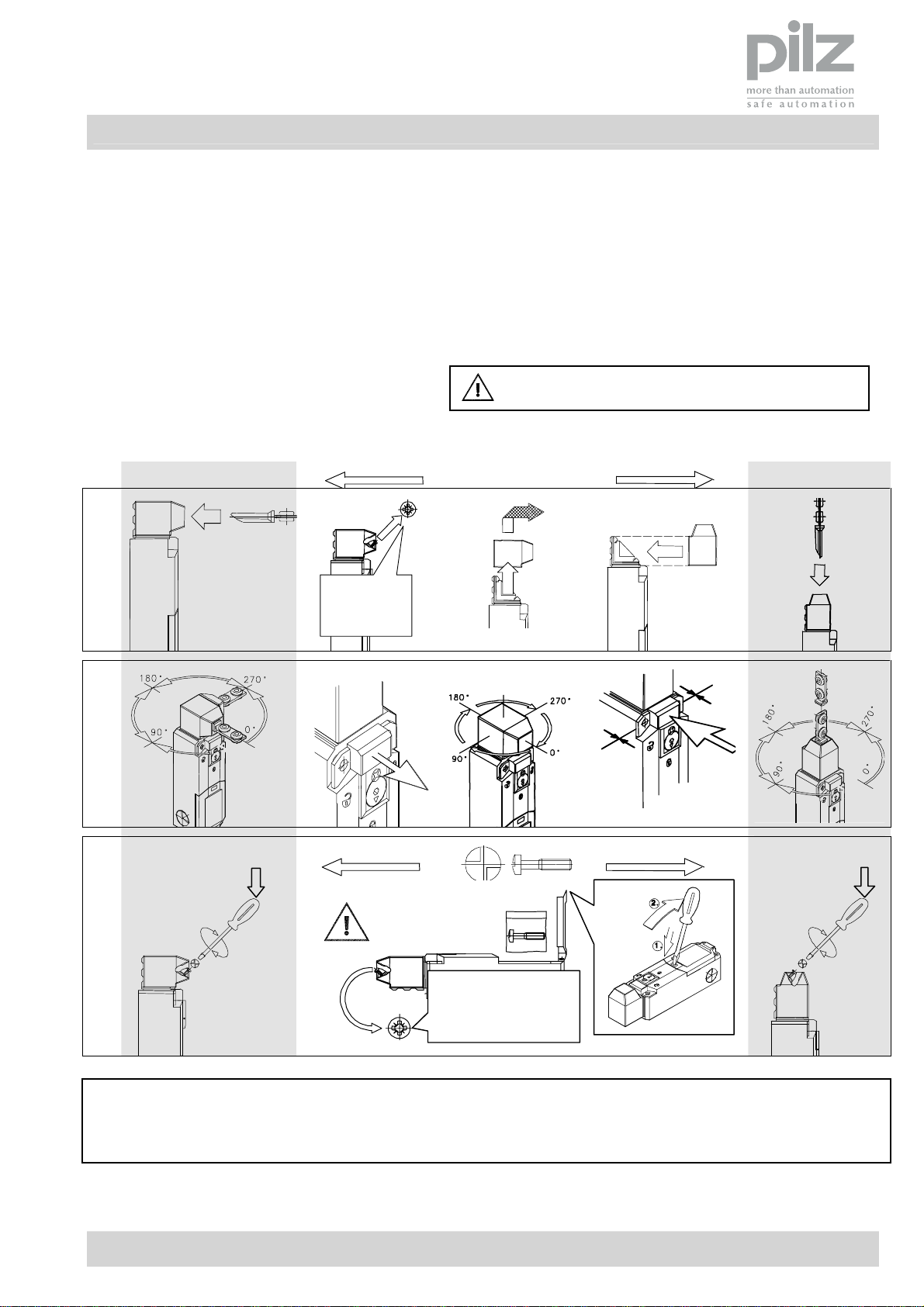

The mounting position is flexible, however the position should: 1- Allow authorized personnel to access the manual lock over-ride in order to control

and, if necess ary, exchange components. 2- Ensure that for eign objects c annot enter the ac tuator opening whilst the guard is open.

Sequence of installation:

1. Select act uator head alignment

approach direction / 4 x 90° rotation / secured with single-way screw)

Horizon t al H

1.

Installation by trained and qualified personnel only!

Conversion

2 .

ertical V

3.

Remove

cross head

screw

Approach direction

2.

3.

4x90°

Max. 0.9 Nm

1.

max. 0.9 Nm

Tamperproof

safety!

Replace cross

way screw

Secured with one-

head screw with the

supplied one-way

screw.

Excess of the maximum torque of 0.9 Nm or installing the actuator so that it is subject to lateral forces may

damage the actuating mechanism of the switch gear. This can render the personal protection function useless

and cause serious injury or accidental death. Never use the safety switch and actuator as an end stop!

Date of issue: 22.02.2006 / Page 7 of 12

Document : 0800000458 / Version: 01 / 2196-06

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Template : 0850174292 Orig. 2

Page 2

Installation and Operating I n structi ons

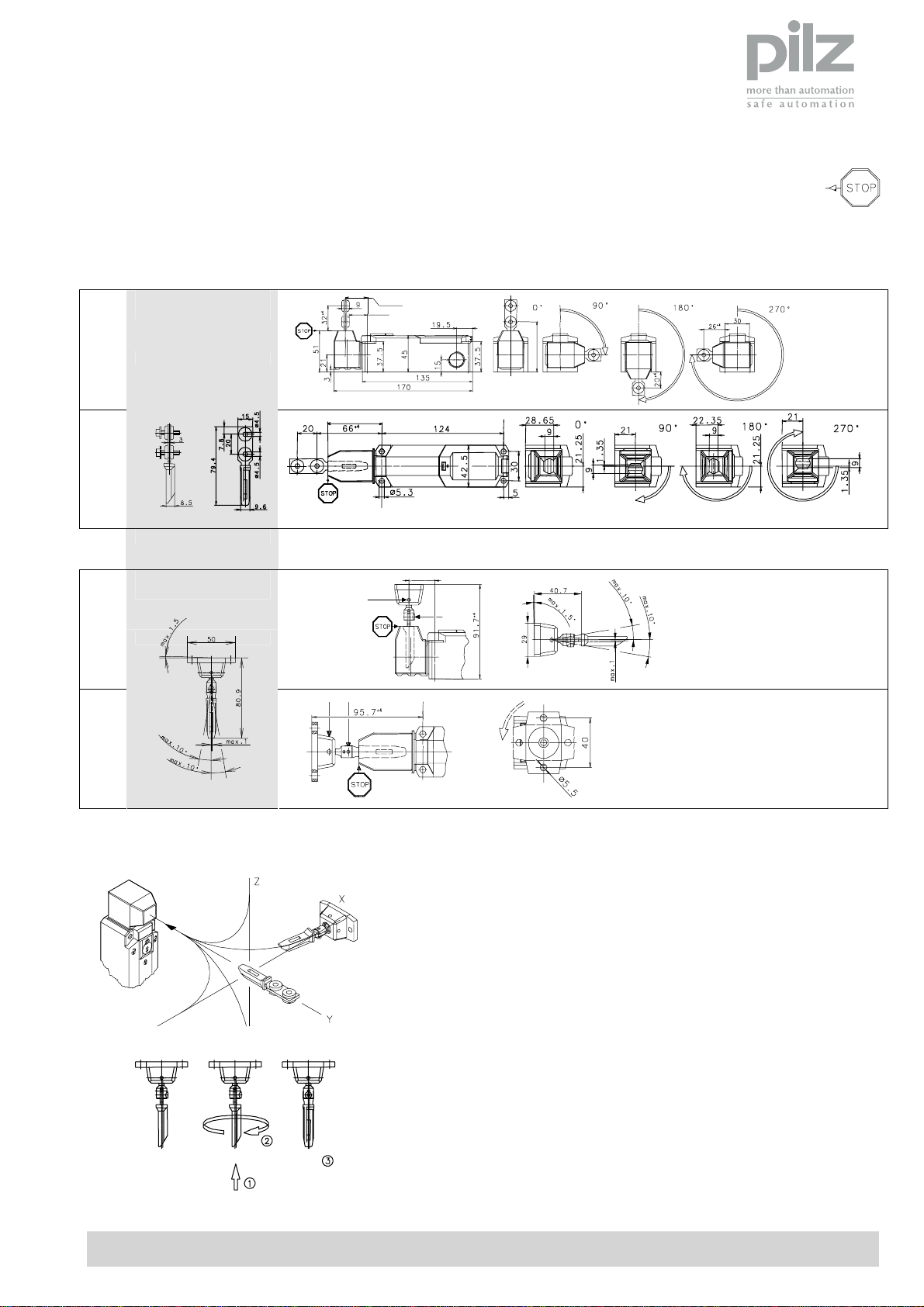

2.1 Securely fasten switching device; see illustrations fo r dimen sion s (mounting surface must be flat and plane).

2.2 Slide actuat or into housing until the upper edge of the act uat or i s f lush with the edge of t he housi ng.

Align the actuator wit h t he machine guard so that opening or closing the machine guard does not

apply lateral force t o the actuator head. Veri fy by opening and closing the guards several times.

2.3 Permanent l y m ount t he act uator to the m achi ne guar d usi ng r ivets or single- way screws.

Actuator 1AS

(Standard)

23.5

28.1

+4

63

Approach direction H

Approach

Use ∅12 washers

for M4 screws

(ISO7093/DIN

9021) for form-fit

installation.!

55

direction V

Actuator 1AR

28.1

(Universal)

Socket-head

screw DIN912,

Approach

direction H

Approach

direction V

size 2.5

In order to maintain the maximum level of safety, always order and use actuators together with the correct safety switches.

Actuator 1AS R min > 400 mm

Actuator 1AR R min > 150 mm

Actuator 1AR: Change of mounting flange only prior to installation

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 22.02.2006 / Page 8 of 12

Document : 0800000458 / Version: 01 / 2196-06

Template : 0850174292 Orig. 2

Page 3

Installation and Operating I n structi ons

5

Mechanical data

Enc los ure

Cover

Actuator head

Separate ac tuator

Ambient air temperature

Locking force FZh

Actuating force

Actuating speed

Electrical connection

thermoplastic glass fibre reinforced

(UL94-VO)

thermoplastic glass fibre reinforced

(UL94-VO)

thermoplastic glass fibre reinforced

and Zn-GD

St/PA / Zn-GD

-25 °C to +70 °C, -13 °F to +158 °F

max. 1500 N

According to GS-ET-19

27 N min.

V=0.5 m/s max.

Mechanical lif e

Mounting

Tightening torque (max.)

Conductor cross-section

Termination cage clamp

Cable entry

Mounting position

Weight

1 million switching cycles at

max. 600 cycles/hour

4 M 5 screws ISO1207

ISO 4762

M= 2 Nm

1.5 mm² flex max.

3 (M20X1.5)

any orientation

approx. 0.3 kg (w/o actuator)

I

The electrical connection shall only be carried out

by trained and qualified personnel!

4

I Release snap-shut terminal lid with a screwdriver

II Screw cable gland into the chosen entry, this will

‘break-out’ blind hole, remove plastic disk.

1

Connecting to cage clamp terminals:

1) Insert screwdriver (blade width 2.5 mm) in

lower opening

2) Turn 45°

3) Insert flex. cable in upper opening

(Max. 1.5 mm

2

cross-section)

I

remove screwdriver.

III Snap terminal chamber lid shut

Electrical data

Protection class IP 67 acc. to IEC 60529 Approvals see label on housing

Switch function 4 slow-action contacts max.

Rated insulation voltage U

Utilization category AC 15 230V/2.5 A

Conventional thermal current I

Max. making current (4 contacts) 10 A

Type of short-circuit protection 4 A gl

Solenoid

Actuating cycles permanent 600 / hour Solenoid power consumption PSEN me1 15 VA (0.5 s) inrush

Operating voltage PSEN me1

PSEN me1.1

ON period 100 % duty cycle (to E1, E2) 1.1 VA continuous

Temperature class

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

B (130 °C), (266 °F)

250V

i

2.5 A

the

24 V AC/DC

24 V DC +24/110/230 V AC

Standards

PSEN me1.1 56 VA (0.2 s) inrush

BG (GS-ET-19) (applied for)

cCSAus B300, R300 (applied for)

VDE 0660 T100, EN 60947-1

VDE 0660 T200, EN 60947-5-1

IEC 60947-5-1 GS-ET-19

≤ 1.4 VA (24 V) continuous

Date of issue: 22.02.2006 / Page 9 of 12

Document : 0800000458 / Version: 01 / 2196-06

Template : 0850174292 Orig. 2

Page 4

Installation and Operating I n structi ons

I

Actuator inserted and locked

( guard closed and locked )

Switching function safety guard

II

Actuator inserted and unlocked

( guard closed but unlocked )

III

Actuator withdrawn

( guard open )

Switching function locking device (solenoid)

PSEN me1S

PSEN me1.1S

Locking principle : Spring lock (without power)

The safety guard is automatically locked when the actuator is correctly inserted. Supplying power to the solenoid unlocks the protective system

and the safety guard can then be opened.

PSEN me1M

Locking principle : magnetic force (With power applied)

The locking device is only activated when power is applied to the solenoid. NB. If there is a power failure or there is a trigger error, the safety guard

can be opened.

Standard circuit

PSEN me1

Control

contacts

Manual lock override

PSEN me1S

PSEN me1.1S

1. Loosen loc king s crew.

2. Rotate over-ride cam 90° with Allen key.

The actuator can now be withdrawn.

Rotate over-ride cam back to original position.

3. Screw and tighten locking screw and seal with sealing

lacquer. ( M = 0.5 Nm)

The manual lock over-ride should only be used with a 3mm socket

screw key if the guard locking device fails.

E1: Operating voltage L+ E2 : Neutral N

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

The acc ess point shall be sealed af ter installation.

( e.g. with sealing lacquer)

Date of issue: 22.02.2006 / Page 10 of 12

Document : 0800000458 / Version: 01 / 2196-06

Template : 0850174292 Orig. 2

Page 5

Installation and Operating I n structi ons

A

r

y

System descrip t ion / Suggested applicat ion

When the machine guard is closed, the actuator is engaged and locked in the safety switch. In this state the safety outputs in

the safety control module are closed and the contact in the control module (for the solenoid) is open - the machine can now

operate.

In order to carry out maintenance work behind the safety guard the operator has to switch off the machine. This will cause

opening of the outputs of the control module and shutoff of the machines power line. As the dangerous movement of the

machine may not stop immediately, the safety switch lock should only release the actuator after the machine has come to a

complete stop. A suitable control module, e.g. a lost-motion monitor or a delay module (safety timer) can be used for that

purpose.

The safety contacts (force disconnected N.C.) inhibit the machine from restarting whilst the machine guard is open. The

additional N.O. contacts can be used as signaling contacts, they do not have a safety function and are normally used for

indication only. These functions do not conduce safety, just availability of machinery. When used in conjunction with suitable

control modules the NO contacts may be used only for additional

The set of contacts monitoring the safety guard is form-fit driven by the actuator, so that the position of the safety guard is

directly monitored. The set of contacts monitoring the locking device has a positive drive connection to the lock. Thus ensures

that any failure of the locking device will be immediately detected by the safety control system. An integrated mechanical

mechanism ensures that the lock cannot be engaged whilst the actuator is removed from the safety switch.

The safety switch PSEN me1 can be applied in combination with other safety switching devices and safety control modules in

systems up to control category 4 acc. to DIN EN 954-1 when the applicable standards are maintained.

verification of the safety circuit.

Maintenance / Inspection

The switching device is

maintenance-free. F or trouble-free

operation and a long s ervice life

the device should be inspected

regularly. Ensure that:

- all components are s ecure and tight

- switching functions operat e properly

- all sealing gaskets are in proper

condition

- the components show no signs

of tear and wear.

If defects are the detected the

complete switching device and the

actuator have to be replac ed.

Liability disclaimer

By breach of the given instructions

(concerning the intended use, the

safety instructions, the installation

and connection through qualified

personnel and the testing of the

safety function) any liability

expires.

Control voltage

- actuator inserted and locked

- solenoid un-energised

Control contact

ctuato

contacts

(guard position)

Solenoid contacts

(guard locking)

analysing

module

control

module

Contact assignment

illustrated for standard type :

PSEN me1S/1AS

570000

Hazardous machiner

Date of issue: 22.02.2006 / Page 11 of 12

Document : 0800000458 / Version: 01 / 2196-06

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Template : 0850174292 Orig. 2

Page 6

Installation and Operating I n structi ons

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, D-73760 Ostfildern, Deutschland

Phone: +49 711 3409-0, Fax: +49 711 3409-133, E-Mail: techsupport@pilz.de, www.pilz.com

Date of issue: 22.02.2006 / Page 12 of 12

Document : 0800000458 / Version: 01 / 2196-06

Template : 0850174292 Orig. 2

Loading...

Loading...