Page 1

Basics

Installation and adjustment

PSENmag

1.3

PSENmag1.32007-03BasicsInstallation and adjustmentPSENmagPSENmag PSENcode

Installation position

The unit can be installed in any position.

However, the sensing faces of the

safety switch and actuator should be

positioned opposite each other in parallel.

Operating distances may deviate if

other arrangements are used.

Further information about the operating distances and the maximum permitted lateral and vertical offset can be

found in the chapters entitled “Description” and “Units”.

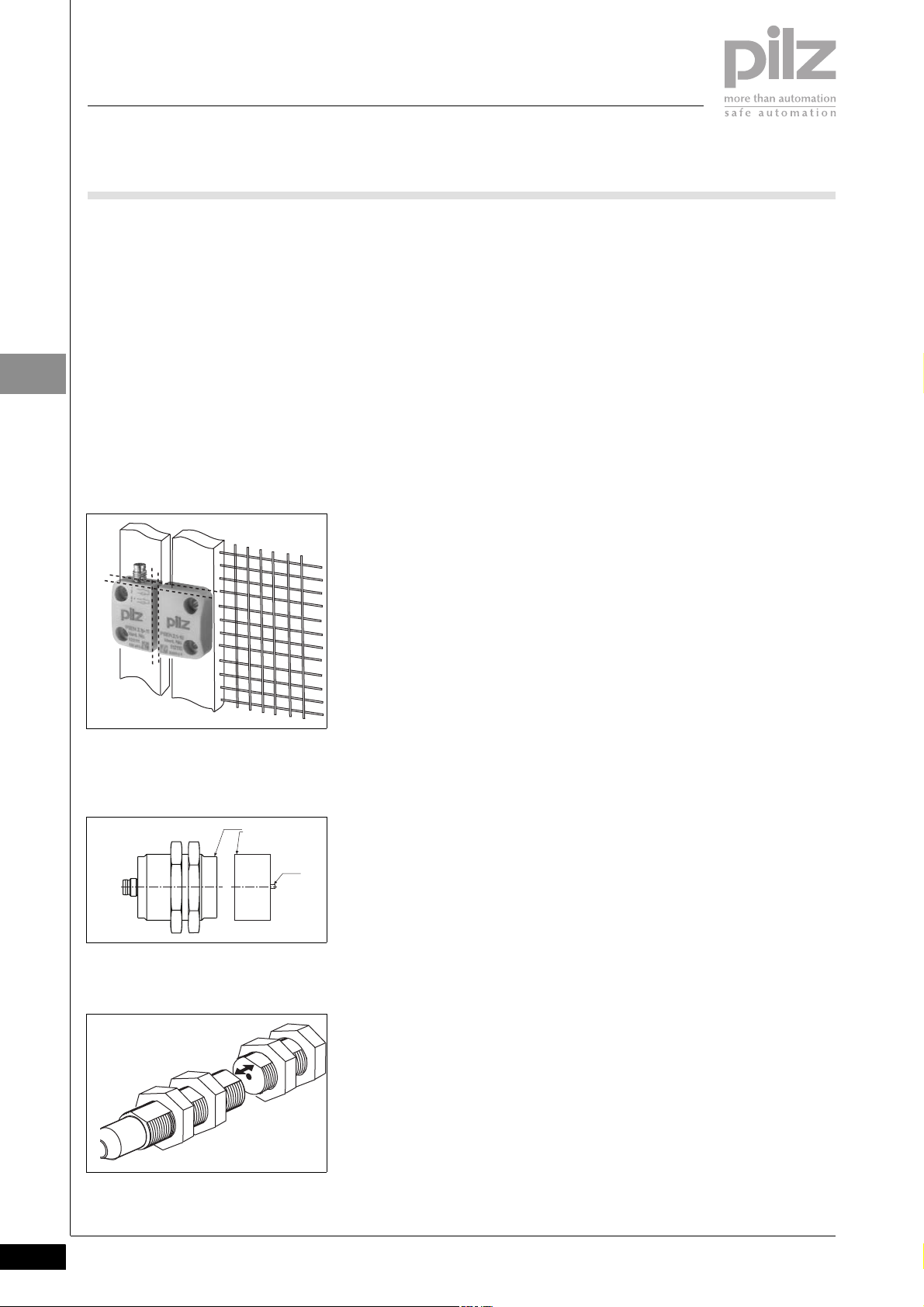

On units with a round M30 design,

make sure that the two notches are

exactly opposite each other. A nib on

the actuator prevents it twisting.

notches at the top

nib

On units with a round M12 design,

make sure that the two bevelled surfaces are exactly opposite each other.

Installation guidelines

Safety switch and actuator

` Keep away from iron swarf

` Do not expose to strong magnetic

fields

` Do not expose to heavy shock or vi-

bration

` Do not use as a limit stop

` Where possible do not install on top

of ferromagnetic material (changes

in the operating distances can be

expected). In this case, units in the

square design can use the spacer,

order number 534 310.

The distance between two systems

made up of safety switch and actuator

must be at least 25 mm (see installation example, “Safety switches on

swing gates”)

Attachment

Attach the safety switch to the fixed

part of the safety device.

Square design:

` Safety switches and actuators

should only be secured using M4

screws with a flat head (e.g. M4

cheese-head or pan head screws).

Torque setting max. 1 Nm. Use

screws made of non-magnetic ma-

terial (e.g. Messing).

Round design:

` Secure the safety switch using the

M30 or M12 nuts provided. The

torque setting for the nuts is max.

300 Ncm.

The actuator should be secured permanently to guarantee security against

manipulation.

Adjustment

` The safety switch may only be used

with a corresponding actuator.

` The actuator must not make con-

tact with the safety switch. Please

note the minimum operating dis-

tance stated in the technical details.

` Always test the function with one of

the approved evaluation devices.

` Some safety switches have an LED.

There are 2 types:

– The LED lights when the con-

tacts are unoperated (safety de-

vice open or safety switch and

actuator wrongly adjusted). The

LED is in the safety switch's N/C

circuit. The LED goes out when

the contacts are operated.

– (PSEN with round M12 design

only): The LED lights when the

contacts are operated (safety

device closed). The LED goes

out when the contacts are unoperated.

Further information about the switching distances (operating and release

distance) and the maximum permitted

lateral and vertical offset can be found

in the chapters entitled “Description”

and “Units”.

Installing the interfaces PSEN i1 and

PSEN ix1

` The unit should be installed in a

control cabinet with a protection

type of at least IP54.

` Use the notch on the rear of the unit

to attach it to a DIN rail.

` Ensure the unit is mounted securely

on a vertical DIN rail (35 mm) by using a fixing element (e.g. retaining

bracket or an end angle).

Installation accessories

Spacer for safety switch in square

design

If the safety switch and actuator are installed on to ferromagnetic material,

the operating distances may vary. In

this case, use the spacer available under order number 534 310 (see chapter entitled "Accessories").

Bracket for safety switch in square

design

An aluminium bracket is available for

installing the safety switch and actuator at an angle. On this bracket it is

possible to adjust the position of the

safety switch and actuator (see chapter entitled "Accessories").

1.3-2

2007-03Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 2

Basics

Installation and adjustment

PSENmag

Swing gates

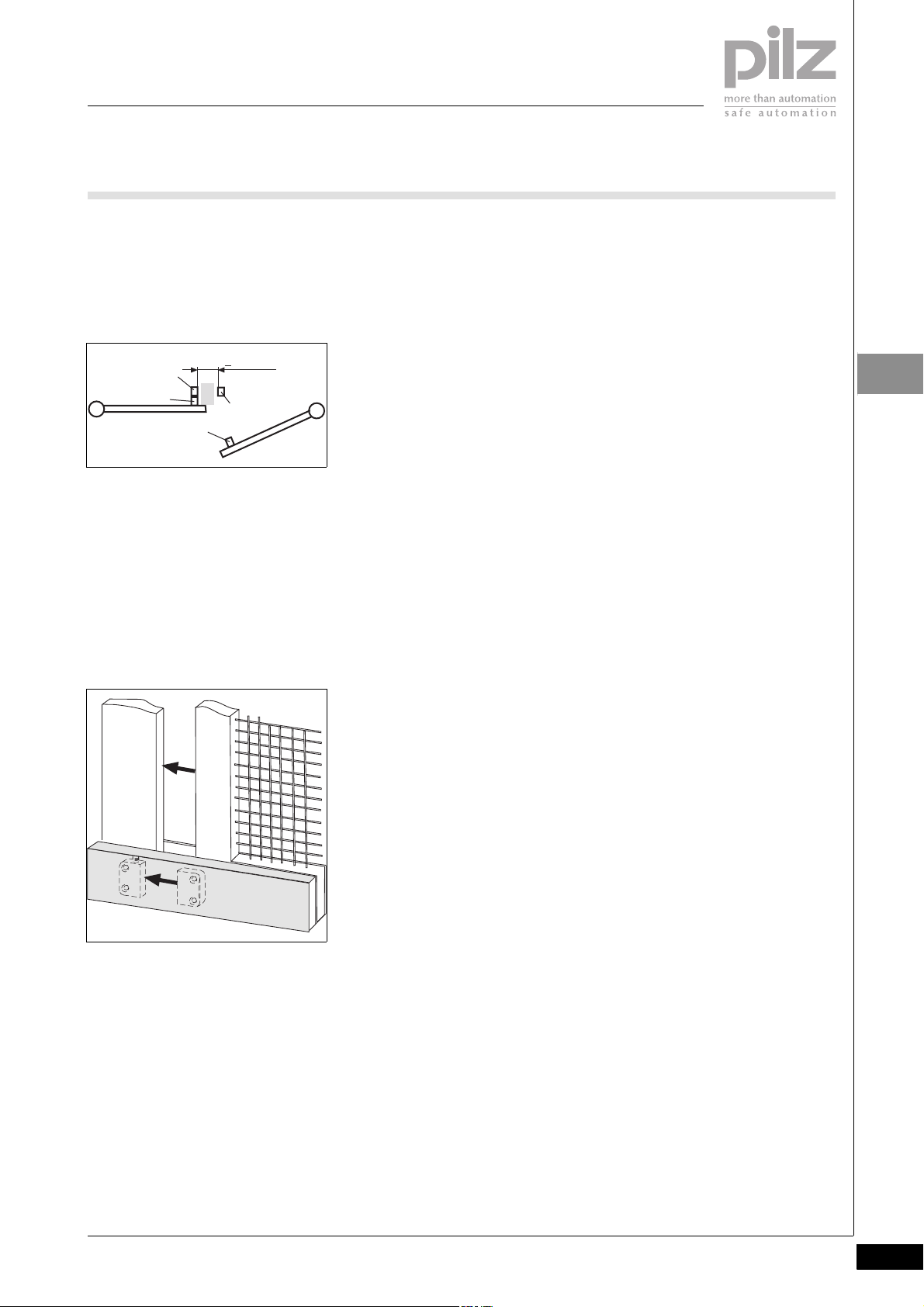

On swing gates the safety switch must

be positioned on the closed edge. The

distance between the two systems

comprising safety switch and actuator

must be at least 25 mm.

Safety switch

Actuator

Actuator

Concealed installation

To exclude the possibility of manipulation, the actuator must be fitted in

such a way that it cannot be removed

by the operator. (see section entitled

“Attachment”). Security against manipulation can also be guaranteed by

concealing the installation of the safety switch and actuator. A concealed

installation also reduces the risk of injury.

> 25 mm

Safety

switch

1.3

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2007-03

1.3-3

Loading...

Loading...