Page 1

Operating Manual PSSu H m F DP ETH SD

Operating Manual PSSu H m F DP ETH SD

PSEN enc m1 eCAM, PSEN enc m2 eCAM

PSEN enc s1 eCAM, PSEN enc s2 eCAM

Position Monitoring

Operating Manual — No. 1002327-EN-04

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents .................................................................................................................. 1

1 General ................................................................................................................. 3

1.1 Scope ...................................................................................................................................... 3

1.2 Applied directives and standards ............................................................................................ 4

1.3 General function description ................................................................................................... 5

1.3.1 Main features .......................................................................................................... 5

1.3.2 Overall system overview ......................................................................................... 6

2 Essential safety information ............................................................................... 7

2.1 Definition of symbols and instructions .................................................................................... 7

2.2 General hazards when using the product ............................................................................... 8

2.3 Intended use ........................................................................................................................... 9

2.4 Warranty and liability .............................................................................................................. 10

2.5 Organisational measures ........................................................................................................ 11

2.6 Selection and qualification of personnel; fundamental obligations ......................................... 11

2.7 Safety information ................................................................................................................... 12

3 Transport / storage .............................................................................................. 14

4 Assembly .............................................................................................................. 15

4.1 Solid shaft version PSEN enc m2 eCAM ................................................................................ 15

4.1.1 Requirements .......................................................................................................... 15

4.2 Hollow shaft version PSEN enc m1 eCAM ............................................................................. 17

4.2.1 Requirements .......................................................................................................... 17

4.2.2 Dowel pin ................................................................................................................ 19

English

5 Installation / Preparation for commissioning .................................................... 21

5.1 EMC requirements .................................................................................................................. 21

5.2 SSI communication mode ....................................................................................................... 23

5.3 SSI, RS422 communication technology ................................................................................. 24

5.4 Cable specification .................................................................................................................. 26

5.5 Connection .............................................................................................................................. 27

5.5.1 Supply voltage, X1 .................................................................................................. 28

5.5.2 Measuring systems, X2 .......................................................................................... 29

5.6 Shield connection ................................................................................................................... 30

5.7 Count direction ........................................................................................................................ 34

5.8 SSI interface ........................................................................................................................... 35

5.9 Incremental interface .............................................................................................................. 37

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

5.10 LED status display ................................................................................................................ 39

6 SSI format ............................................................................................................. 40

6.1 Sign of life counter .................................................................................................................. 40

English

7 Replacing the measuring system ....................................................................... 41

8 Technical details ................................................................................................. 43

5.9.1 Signal characteristic of the incremental interface ................................................... 37

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2

Page 5

General

1 General

1.1 Scope

This operating manual includes the following topics:

● General function description

● Essential safety information with details of intended use

● Characteristic data

● Assembly

● Installation/commissioning

● SSI interface

This operating manual applies exclusively to the following measuring systems with

SSI interface:

● PSEN enc m1 eCAM

● PSEN enc m2 eCAM

● PSEN enc s1 eCAM

● PSEN enc s2 eCAM

The products are labelled via nameplates and form part of a system.

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3

Page 6

General

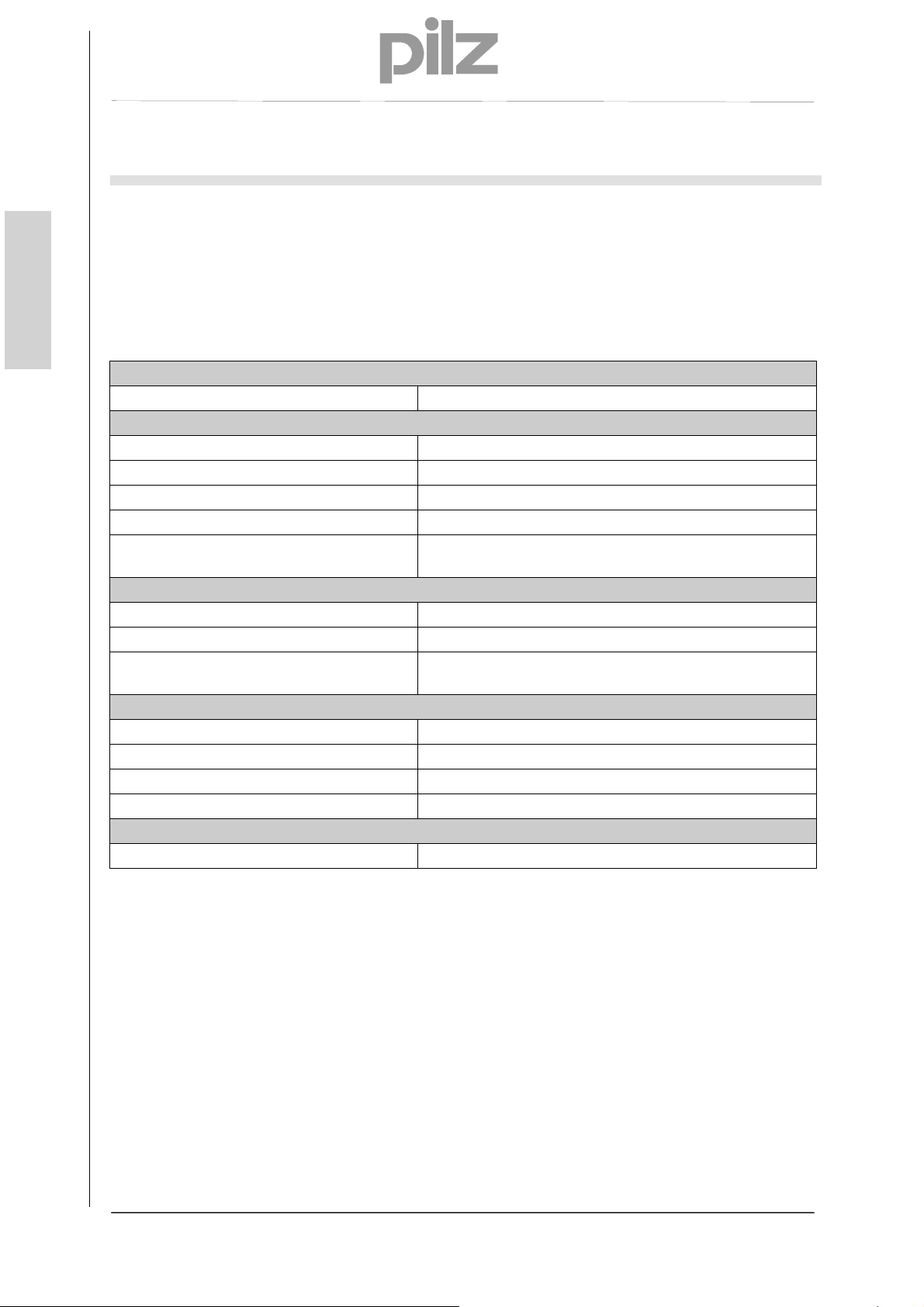

1.2 Applied directives and standards

The measuring systems PSEN enc m1 eCAM and PSEN enc m2 eCAM have been developed,

designed and manufactured in compliance with the applicable European and international standards,

English

directives and regulations.

Directives

- 2004/108/EC (L 390/24) EMC Directive

EMC; Immunity in accordance with EN 61000-6-2:2005, industrial environment:

- DIN EN 61000-4-2:2009 Electrostatic discharge, ESD

- DIN EN 61000-4-3:2008 High frequency electromagnetic fields

- DIN EN 61000-4-4:2005 Fast transient electrical disturbances, burst

- DIN EN 61000-4-5:2007 Surge voltages

- DIN EN 61000-4-6:2009

EMC; Emissions in accordance with EN 61000-6-3:2007, residential environment:

- EN 55022:2006 Disturbance field strength, 30 MHz - 1 GHz

- EN 55022:2006 Interference voltage, < 30 MHz

- DIN EN 61326-3-2:2008

Environmental influences

- DIN EN 60068-2-6:2008 Sinusoidal vibration

- DIN EN 60068-2-64:2009 Broadband noise (digitally controlled)

- DIN EN 60068-2-29:1995 Shock and continuous shock tests

- DIN EN 60529:2000 Degrees of protection, IP code

Other requirements

- VDE 0100 Erection of low voltage installations

Conducted disturbances,

induced by high frequency fields

Immunity requirements for safety-related systems and

for equipment

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4

Page 7

General

1.3 General function description

The rotary measuring system

• PSEN enc mx eCAM is an absolute multi-turn position measuring system with

synchronous serial interface (SSI).

• PSEN enc sx eCAM is an absolute single-turn position measuring system with

synchronous serial interface (SSI).

The measuring system consists of a redundant, dual-channel system, in which

optical and magnetic sensing units are arranged on a drive shaft, designed as a

hollow shaft or solid shaft.

1.3.1 Main features

● SSI interface, to output data from measuring channel 1

● SSI interface, to output data from measuring channel 2

● Measuring channel 1:

- Single-turn: optical single-turn sensing via code disk (transmitted light)

- Multi-turn: optical single-turn sensing via code disk (transmitted light) and

magnetic multi-turn sensing

● Measuring channel 2:

- Single-turn: magnetic single-turn sensing

- Multi-turn: magnetic single and multi-turn sensing

● Additional incremental interface

● Mechanically, the two systems are connected only by the common drive shaft and

the housing

● Measuring channels have a common voltage terminal, but are electrically isolated

internally via two separate power supplies

● A common drive shaft

● 2 Installation Types:

- Hollow shaft version: PSEN enc m1 eCAM and PSEN enc s1 eCAM

- Solid shaft version: PSEN enc m2 eCAM and PSEN enc s2 eCAM

The optical system has greater accuracy due to the technology.

The magnetic sensing system is a fully-fledged second measuring channel and

operates independently from the first measuring channel. The two measuring systems

have their own SSI interfaces, which transmit the same data format.

The data from measuring channel 1 is also output via an incremental interface.

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5

Page 8

General

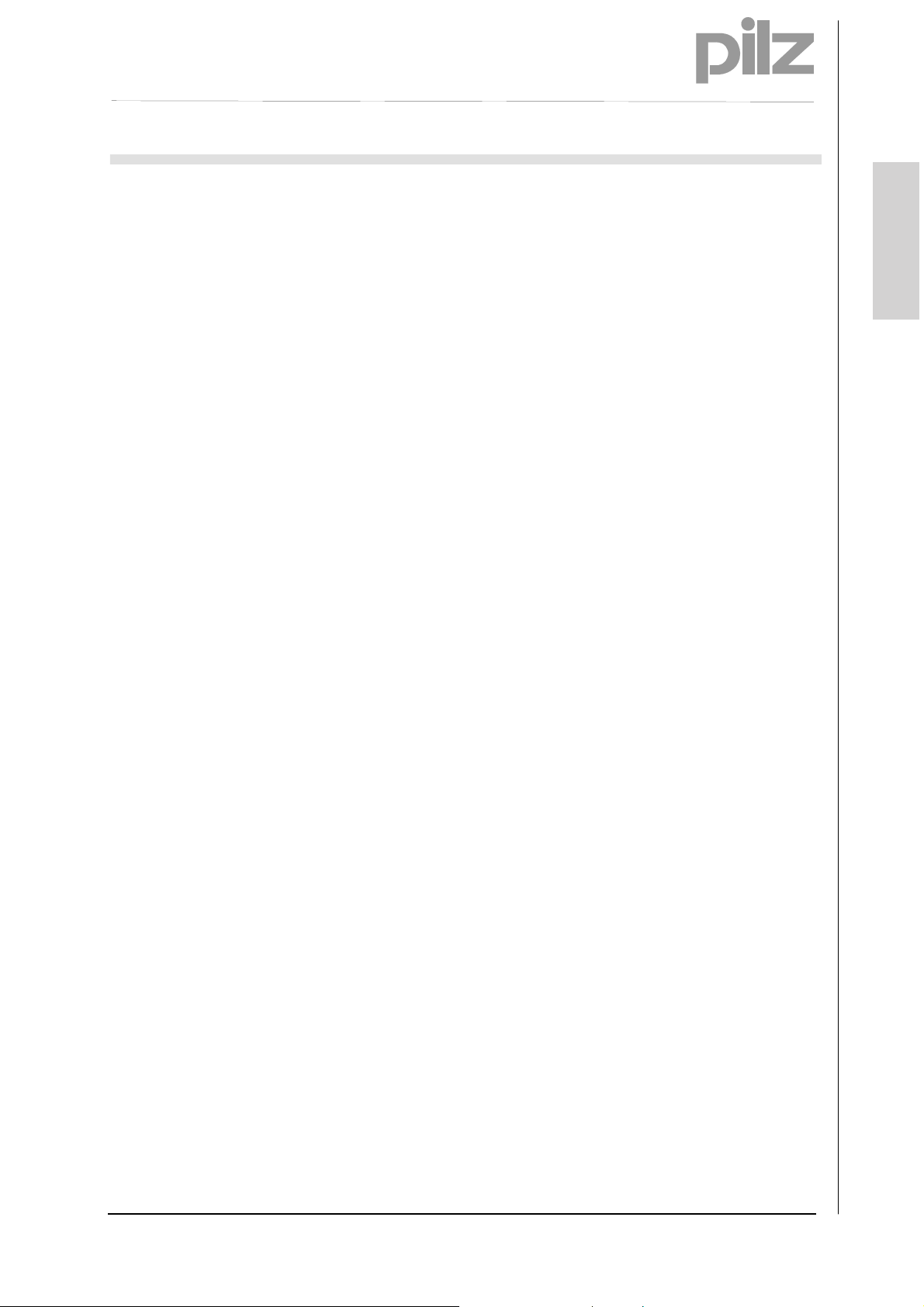

1.3.2 Overall system overview

English

A

Measuring channel 1, single-turn and multi-turn

● Optical detection of the number of steps/revolution

● Max. 8192 steps/revolution, accuracy: 13 Bit

● Synchronous serial interface (SSI)

● Incremental signals for position feedback

B

Measuring channel 1, multi-turn

● Magnetic detection of the number of revolutions

● Max. 4096 revolutions

● Synchronous serial interface (SSI)

C

Measuring channel 2, single-turn and multi-turn

● Magnetic detection of the number of steps/revolution

● Max. 8192 steps/revolution, accuracy: 8 Bit

● Synchronous serial interface (SSI)

D

Measuring channel 2, multi-turn

● Magnetic detection of the number of revolutions

● Max. 4096 revolutions

● Synchronous serial interface (SSI)

optische Abtastung

Antrieb

Fig. 1: System schematic

Inkremental-

Interface

SSI

Welle

Anschlussklemme

N

SSI

S

magnetische Abtastung

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6

Page 9

Essential safety information

2 Essential safety information

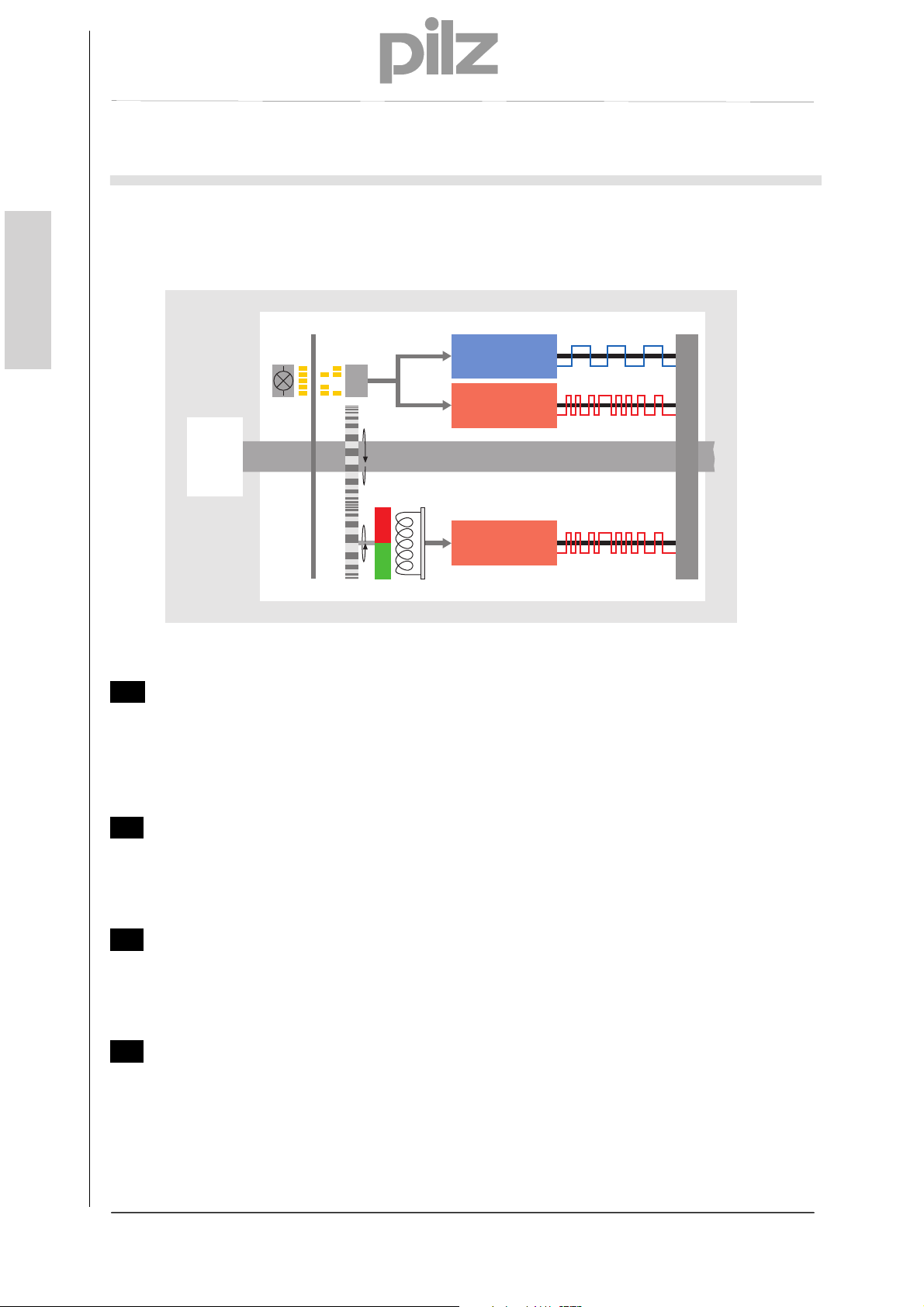

2.1 Definition of symbols and instructions

DANGER!

This means that death or serious injury will occur if the

relevant preventive measures are not taken.

WARNING!

This means that death or serious injury can occur if the

relevant preventive measures are not taken.

English

CAUTION!

This means that a minor injury can occur if the relevant

preventive measures are not taken.

NOTICE

This means that material damage can occur if the relevant

preventive measures are not taken.

INFORMATION

This indicates important information or features and

application tips for the relevant product.

This means that the relevant ESD protective measures must

be considered in accordance with DIN EN 100 015-1.

(Equipotential bonding between the body and the unit or

housing earth via a high impedance resistor (approx. 1

MOhm) e.g. using a standard ESD arm band).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7

Page 10

Essential safety information

2.2 General hazards when using the product

English

The product, described below as the measuring system, is manufactured using

state-of-the-art technology. Nevertheless, use of the system outside its intended

purpose may pose a risk to the life and limb of the user or third-party or

adversely affect the measuring system and other material assets!

The measuring system should only be used when in perfect working order, in

accordance with its intended use, in awareness of safety measures and hazards and

in compliance with the operating manual! In particular, errors that could adversely

affect safety must be rectified without delay!

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8

Page 11

Essential safety information

2.3 Intended use

The measuring system can be used to detect angular movement and to prepare

measured data for control systems within plants.

Intended use includes:

● Compliance with all the instructions in this operating manual

● Compliance with the information on the nameplate and any prohibition or

instruction labels on the measuring system

● Compliance with the operating manual provided by the machine or plant

manufacturer

● Operation of the measuring system within the limit values stated in the technical

details

● Assurance that the failsafe processing unit (control system) fulfils all the required

safety functions

● Compliance with and use of the check list in the Appendix

● Assurance that the measuring system is mounted safely on the driving axis

In particular, the system shall not be used:

English

● In environments with an explosive atmosphere

● For medical purposes

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

9

Page 12

Essential safety information

2.4 Warranty and liability

English

All claims to warranty and liability will be rendered invalid if

● The product was used contrary to the purpose for which it is intended

● Damage can be attributed to not having followed the guidelines in the manual

● Operating personnel are not suitably qualified

● Any type of modification has been made (e.g. exchanging components on the

PCB boards, soldering work etc.).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

10

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

Essential safety information

2.5 Organisational measures

● The operating manual must always be kept ready-to-hand at the location where

the measuring system is used

● In addition to the operating manual there are also generally applicable legal and

other binding regulations regarding accident prevention and environmental

protection, which must be observed and communicated.

● The respective national, local and plant-specific provisions and requirements must

be observed and communicated

● It is the responsibility of the operator to advise staff of any special operational

features and requirements

● Before starting work, any staff charged with operating the measuring system must

have read and understood the operating manual, in particular the chapter entitled

“Essential safety information”.

● The nameplate and any prohibition or instruction labels on the measuring system

must always be maintained in a legible condition.

● No mechanical or electrical modifications may be made to the measuring system

except for those expressly described in the operating manual.

● Repairs may only be made by the manufacturer, or by a body or person

authorised by the manufacturer.

English

2.6 Selection and qualification of personnel; fundamental obligations

● All work on the measuring system must only be carried out by qualified technical

personnel.

Qualified personnel are those who have been authorised by those responsible for

plant safety to carry out the necessary work, based on their training, experience

and instruction, as well as their knowledge of the relevant standards, provisions,

accident prevention regulations and operating conditions. They are able to identify

and avoid potential hazards.

● For a definition of "Qualified personnel" you can also refer to the standards VDE

0105-100 and IEC 364 (sources: Beuth Verlag GmbH, VDE Verlag GmbH, for

example).

● Responsibility for assembly, installation, commissioning and operation must be

clearly defined. There is an obligation to supervise trainees or apprentices.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

11

Page 14

Essential safety information

2.7 Safety information

English

Please note:

– Wiring work should only be carried out when the supply voltage is

switched off; the same applies when opening and closing electrical

connections.

– Do not undertake any welding operations if the measuring system is

already wired / switched on.

– An appropriate heating/cooling measure should be used at the

installation site to prevent the ambient temperature exceeding or falling

below the permitted limit values.

– The measuring system must be installed so that direct moisture cannot

affect the measuring system.

– Appropriate ventilation/venting or heating/cooling measures at the

installation site must prevent values falling below the dew point

(condensation).

– If an overvoltage of >36 VDC is applied inadvertently, the measuring system

must be inspected on site and the reasons/circumstances stated.

– Checks must examine the potential hazards arising from interaction

with other systems and devices which are or will be installed in the

vicinity. It is the user’s responsibility to take appropriate measures.

– The supply voltage must be protected with a fuse appropriate for the

cable cross section.

– Cables must be suitable for the relevant temperature range.

– The measuring system should not be operated if it is defective.

– Ensure that the installation environment is protected from aggressive

media (acids etc.).

– Shocks to the shaft (e.g. hammer blows) should be avoided during

installation.

– The measuring system must not be opened.

– The nameplate specifies the technical properties of the measuring

system. If the nameplate is no longer legible or is missing altogether,

the measuring system must no longer be put into service.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

12

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

Essential safety information

The measuring system contains electrostatically sensitive

assemblies and components, which can be damaged if handled

incorrectly.

Avoid finger contact with the measuring system connection contacts and

apply the relevant ESD protective measures.

Disposal

If the device is to be disposed of after its service life, the applicable

country-specific regulations must be observed.

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

13

Page 16

Transport / storage

3 Transport / storage

English

● Transport instructions

– Do not drop the device or expose it to heavy impact!

The device contains an optical system.

– Only the original packaging should be used!

Inappropriate packaging material can result in the device becoming

damaged in transit.

● Storage

– Storage temperature: -30 to +80℃

– Store in a dry place

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

14

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

Assembly

4 Assembly

4.1 Solid shaft version

The measuring system is connected to the drive shaft via an elastic coupling. The

coupling absorbs any deviations in the axial and radial direction between the

measuring system and drive shaft. This prevents excessive load on the bearing.

The centering collar with selective fit is used for centering in relation to the shaft. The

device is fixed to the machine using three screws in the flange.

All the fixing screws must be secured to stop them coming loose unintentionally.

4.1.1 Requirements

As the installation is application-dependent, the following instructions do not

claim to be exhaustive.

English

An appropriate coupling with positive-locking connection must be used in

the application.

The instructions and installation specifications provided by the coupling

manufacturer must be observed.

In particular you must ensure that

– the coupling is suitable for the specified speed and the potential axial

offset

– the device must be installed on a greaseless shaft

– the coupling and measuring system must not have an axial load

– the clamping screws must be tightened with the torque defined by the

coupling manufacturer

– the coupling screws must be secured to stop them coming loose

unintentionally.

The coupling fixing should prevent axial slippage of the measuring

system on the drive shaft, see Figure 2, 1 .

Positive locking using a parallel key/groove combination (Fig. 2, 2 )

should prevent radial slippage of the measuring system on the drive

shaft; a coupling with groove should be used for this purpose.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

15

Page 18

Assembly

English

Fig. 2: Flange assembly

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

16

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

Assembly

4.2 Hollow shaft version

4.2.1 Requirements

English

As the installation is application-dependent, the following instructions do not

claim to be exhaustive.

The measuring system should be installed on a greaseless shaft.

The clamping ring fixing should prevent axial slippage of the measuring

system on the drive shaft, see Figure 3.

Additional measures may be required to prevent axial slippage of the

measuring system.

The clamping of the measuring system must not have an axial load.

The screw on the clamping ring must be tightened to 3 Nm using a

torque wrench.

The screw on the clamping ring must be secured to stop it coming loose

unintentionally.

Positive locking using a parallel key/groove combination should prevent

radial slippage of the measuring system on the drive shaft; the

measuring system must be fixed to the drive side using a dowel pin, see

Fig. 4.

Fig. 3: Friction locking

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

17

Page 20

Assembly

English

Fig. 4: Positive locking

Fig. 5: Requirements of the shaft mounting

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

18

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

Assembly

4.2.2 Dowel pin

Simultaneous rotation of the measuring system, caused by the resulting torque, is

prevented by a dowel pin on the machine side. The measuring system has a 6 mm

deep 4K7 groove insertion on the back to hold the dowel pin. The dowel pin must

reach at least 4 mm into the groove insertion.

English

Fig. 6: Using a dowel pin to prevent simultaneous rotation

When inserting the measuring system, position it so that the dowel pin is seated

correctly in the groove insertion. By tightening the clamping ring with the Allen key, the

measuring system is protected against slippage on the shaft.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

19

Page 22

Assembly

English

Fig. 7: Assembly schematic

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

20

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

Installation / Preparation for commissioning

5 Installation / Preparation for commissioning

5.1 EMC requirements

CAUTION!

Invalid measurement values due to radiated and

conducted interference!

• Radiated interference from hand-held radios, lightning

strikes on the network, mobile phones and emissions from

individual devices can cause the measuring system to

malfunction.

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

21

Page 24

Installation / Preparation for commissioning

English

• In particular, sources of conducted interference such as frequency-

controlled drives (circuit feedback) have a negative effect on the function of

the measuring system.

The 24 V power supplies must comply with SELV/PELV.

The shielding effect of cables must also be guaranteed after

installation (bending radius!) and after changing connectors. If in

doubt, use a more flexible cable with a higher current carrying

capacity.

For the drive/motor cabling, use a 5-core cable on which the PE

conductor is separate from the N-conductor (TN network). This will

largely prevent equipotential bonding currents and the development of

interference.

Shielded, stranded data cable must be used to make the system highly

resistant to electromagnetic interference. Where possible, the shield

should be connected to the protective earth at both ends and with

good conductivity using large screen clamps. Only if the machine earth

is subjected to heavy interference in comparison with the control

cabinet earth should the shield only be earthed at one end in the

control cabinet.

Equipotential bonding measures must be provided for the whole of the

plant’s processing chain.

Power and signal cables should be laid separately.

Comply with the manufacturer’s instructions when installing converters

and shielding the power cables between the frequency converter and

motor.

The energy supply should be adequately dimensioned.

The measuring system should be separated or segregated from

potential interfering transmitters.

Use of filters should be envisaged.

Internal and external protection against lightning should be considered.

The plant installer must adapt the cable routing to local conditions.

Compliance with the relevant standards and directives is essential to

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

22

guarantee safe, interference-free operation!

In particular, compliance with the applicable EMC Directive and shielding /

earthing guidelines should be guaranteed!

Page 25

Installation / Preparation for commissioning

5.2 SSI communication mode

SSI mode is a synchronous serial communication mode for the position of the

measuring system. By using the RS422 interface for communication, sufficiently high

transmission rates can be achieved.

The measuring system receives a sequence of clock signals from the data receiver

(control system) and responds with the current position value, which is transmitted

serially and synchronously with the sent clock pulse.

As data transfer is synchronised by the start of the clock signals, it is not necessary to

use single-step codes such as Gray code, for example.

The data signals Data+ and Data– are sent using cable transmitters (RS422). The

clock signals Clock+ and Clock- are received via optocouplers to protect against

damage resulting from interference, potential differences or reverse polarity.

+5V

Opto-Koppler

BAV99

65

English

Ω

SSI-Clock+

C

N.C.

GND

C

Fig. 8: SSI principle input circuit (Key: Opto-Koppler – Optocoupler)

Data+

RS422

Data-

Fig. 9: SSI output circuit

2.2 nF

65

Ω

SSI-Clock-

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

23

Page 26

Installation / Preparation for commissioning

5.3 SSI, RS422 communication technology

English

RS422 communication requires one cable pair for the signals Data+ and Data– and

one cable pair for the signals Clock+ and Clock–.

The serial data is transmitted without reference to earth as a voltage difference

between two corresponding cables.

The receiver simply evaluates the difference between two cables, so that commonmode interference on the transmission line does not corrupt the usable signal.

By using shielded stranded pair cable, data transmission can be realised over

distances of up to 500 metres at a frequency of 100 kHz.

Under load, RS422 transmitters provide output levels of ± 2 V between the two

outputs; the receivers still recognise levels of ± 200 mV as a valid signal.

Differential signal (A-B)

Idle signal = 3 V

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

24

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

Installation / Preparation for commissioning

Idle signal = 2 V

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

25

Page 28

Installation / Preparation for commissioning

5.4 Cable specification

English

Signal Cable specification

Data+ / Data–

(RS422+ / RS422–)

Min. 0.25 mm

2

, shielded stranded pair

Clock+ / Clock–

(RS422+ / RS422–)

A+ / A–

Min. 0.25 mm

2

, shielded stranded pair

B+ / B–

Supply

+24 VDC / 0 V

Min. 0.5 mm

2

, shielded stranded pair

The maximum cable length depends on the SSI clock frequency and cable

composition and should match the table below.

Please note that an additional delay time t

(Data+/Data–) of approx. 6 ns should be

v

calculated per metre of cable.

SSI clock frequency

[kHz]

Cable length [m]

810 750 570 360 220 120 100

Approx.

12.5

Approx.

25

Approx.

50

Approx.

100

Approx.

200

Approx.

400

Approx.

500

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

26

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

Installation / Preparation for commissioning

5.5 Connection

Connection data, terminal block X1, X2:

– Version with slider mechanism

– Grid dimension: 2.5 mm

– Cable cross section, strand: 20-28 AWG

– Rated current: 6 A

Handling:

Terminal assignment:

English

– Move slider mechanism to “1”

– Insert strand

– Move slider mechanism to “2” and lock

Guide/clamp for the

cable strands

Fig. 10: Connection cover open

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

27

Page 30

Installation / Preparation for commissioning

5.5.1 Supply voltage, X1

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

28

NOTICE

Risk of undetected damage to the internal

electronics due to incorrect overvoltages!

• If an overvoltage of >36 VDC is applied inadvertently,

the measuring system must be inspected on site.

The measuring system must be taken out of

service immediately

If returning the measuring system, the reasons or

circumstances under which the overvoltage

occurred should be stated

The power supply must satisfy the requirements

in accordance with SELV/PELV (IEC 60364-441:2005)

PIN Signal Description

1 + 24 VDC (11…28 VDC) Supply voltage

2 + 24 VDC (11…28 VDC) Supply voltage

3 0 V GND

4 0 V GND

Optical sensing unit and magnetic sensing unit have a common supply, but are

electrically isolated internally via two separate power supplies.

PIN 1/2

through-connected

PIN 3/4

through-connected

Page 31

Installation / Preparation for commissioning

5.5.2 Measuring systems, X2

PIN Signal Description

N.C.

1

2 INK A– Channel A –, RS422

3 INK A+ Channel A +, RS422

N.C.

4

5 INK B– Channel B –, RS422

6 INK B+ Channel B +, RS422

7 SL_m – Data –, measuring channel 1, differential RS422

8 SL_m + Data +, measuring channel 1, differential RS422

9 MA_m – Clock –, measuring channel 1, differential RS422

10 MA_m + Clock +, measuring channel 1, differential RS422

11 SL_s – Data –, measuring channel 2, differential RS422

12 SL_s + Data +, measuring channel 2, differential RS422

13 MA_s – Clock –, measuring channel 2, differential RS422

14 MA_s + Clock +, measuring channel 2, differential RS422

Do not connect!

English

Do not connect!

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

29

Page 32

Installation / Preparation for commissioning

5.6 Shield connection

English

The shield connection is made via special EMC-compliant cable screw connections, in

which the cable shield can be connected internally.

Cable screw connection assembly, type A

Pos. 1 Union nut

Pos. 2 Sealing insert

Pos. 3 Contact sleeve

Pos. 5 Screw socket

1. Trim the shield braid / shield foil to the dimension "X".

2. Slide the union nut (1) and sealing insert / contact sleeve (2) + (3) over the

cable.

3. Bend the shield braid / shield foil by approx. 90° (4).

4. Slide the sealing insert / contact sleeve (2) + (3) up to the shield braid / shield

foil.

5. Fit the screw socket (5) on the housing.

6. Push the sealing insert / contact sleeve (2) + (3) flush into the screw socket

(5).

7. Screw the union nut (1) to the screw socket (5).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

30

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

Installation / Preparation for commissioning

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

31

Page 34

Installation / Preparation for commissioning

English

Cable screw connection assembly, type B

Pos. 1 Union nut

Pos. 2 Clamping insert

Pos. 3 Inner O-ring

Pos. 4 Screw socket

1. Trim the shield braid / shield foil to the dimension "X" + 2 mm.

2. Slide the union nut (1) and clamping insert (2) over the cable.

3. Bend the shield braid / shield foil by approx. 90°.

4. Slide the clamping insert (2) up to the shield braid / shield foil and wrap the

braid back around the clamping insert (2), so that the braid goes over the

inner O-ring (3) but not over the cylindrical part or the torque supports.

5. Fit the screw socket (4) on the housing.

6. Push the clamping insert (2) into the screw sockets (4), so that the torque

supports fit into the lengthwise slots provided in the screw socket (4).

7. Screw the union nut (1) to the screw socket (4).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

32

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

Installation / Preparation for commissioning

1

English

2

3

4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

33

Page 36

Installation / Preparation for commissioning

5.7 Count direction

English

DIP 1 DIP-Schalter 2 Count direction

OFF ON

ON OFF

M1

M2

Fig. 11: Setting the count direction

M1: Setting for measuring channel 1

M2: Setting for measuring channel 1

Permitted switch settings measuring channel 1/ measuring channel 2:

Increasing in clockwise direction, viewed towards the flange

connection

Decreasing in clockwise direction, viewed towards the flange

connection

NOTICE

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

34

The count direction for measuring channel 1 and

measuring channel 2 must be set in opposite

direction!

Page 37

Installation / Preparation for commissioning

A

5.8 SSI interface

NOTICE

Risk of damage to subsequent electronics due to

overvoltages caused by a missing earth reference

point!

In the rest condition, Data+ and Clock+ are high. This corresponds to the time before

Point (1) in the diagram below.

The first time the clock signal changes from high to low (1), the internal retriggerable

monoflop is set with the monoflop time t

The time t

off frequency is calculated from the sum of all the signal run times and is also limited

by the built-in filter circuits.

With each additional falling clock edge, the active status of the monoflop is extended

by the time tM; this is the case by Point (4) at the latest.

By setting the monoflop (1), the bit-parallel data present on the internal parallel-serial

converter is stored in an input latch of the shift register via an internally generated

signal. This ensures that the data does not change as the position value is

transmitted.

The first time the clock signal changes from low to high (2), the most significant bit

(MSB) of the device information is connected to the serial data output. With each

additional rising edge, the next lower value bit is moved to the data output.

When the clock sequence is complete, the data lines are held at 0 V (Low) for the

duration of the monoperiod tM (4). This is also used to calculate the minimum pause time

t

t

The data is read in by the evaluation electronics from the first rising clock edge. Based

on various factors, a delay time of t

measuring system moves the data to the output after the delay time t

a “Pause-1” is read in at Point (2). This must be rejected or can be used in conjunction

with a “0” after the LSB data bit for open circuit monitoring. The MSB data bit is not

read in until Point (3). For this reason, the number of clock pulses must always be one

higher (n+1) than the number of data bits to be transmitted.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

determines the lowest transmission frequency (T = tM / 2). The upper cut-

M

that must be maintained between two consecutive pulse sequences and amounts to 2 *

p

.

M

• If the earth reference point is missing entirely, e.g. 0 V

of the power supply is not connected, voltages equal

to the level of the supply voltage can occur at the

outputs of this interface.

n earth reference point must be guaranteed to be

•

present at all times.

.

M

>100 ns results, without cable. As a result, the

V

. For this reason,

V

35

English

Page 38

Installation / Preparation for commissioning

p

p

English

t

p

Clock

Clock

Takt +

ulse

Pulse

Daten+

Data

Fig. 12: Typical SSI communication sequences

1 2

Takt+

Clock

ulse

Daten+

Data

intern

internal

Fig. 13: SSI communication format

re-triggerbares Monoflop

12 n

retriggerable monoflop

3

Monoflop time

Monoflopzeit

T

4

n+1

t

M

LSBMSB

t

V

High

Low

High

Low

High

Low

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

36

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

Installation / Preparation for commissioning

A

5.9 Incremental interface

To output the absolute position, the standard version of the measuring system also

has an incremental interface in addition to the SSI interface.

• The measuring system checks the outputs on this interface for external voltage

sources. The measuring system is shut down if voltages > 5.7 V arise. In this

state, the measuring system behaves as though it were not connected.

• The interface is generally used for position feedback on motor control

applications.

NOTICE

Risk of damage to subsequent electronics due to

overvoltages caused by a missing earth reference

point!

English

• If the earth reference point is missing entirely, e.g. 0 V

of the power supply is not connected, voltages equal

to the level of the supply voltage can occur at the

outputs of this interface.

n earth reference point must be guaranteed to be

•

present at all times.

5.9.1 Signal characteristic of the incremental interface

A corresponding number of pulses is output while completing a revolution. To

evaluate the count direction, a 2nd signal sequence with 90° phase offset is output for

the controller.

On the standard version, the incremental resolution of the measuring system is 4096

pulses / revolution. There is no zero pulse.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

37

Page 40

Installation / Preparation for commissioning

English

Measuring

system

single

Counter

evaluation

Fig. 14: Counter evaluation)

double

Edge evaluation

4096 pulses

4096 Counter pulses/rev.

8192 Counter pulses/rev.

16384 Counter pulses/rev. quadruple

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

38

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

Installation / Preparation for commissioning

5.10 LED status display

English

Fig. 15: LED status display

Power LED, green CH1: Measuring channel 1, CH2: Safety system

OFF

ON Ready for operation, normal condition

Error LED, red CH1: Measuring channel 1, CH2: Safety system

OFF Ready for operation, no fault

ON

Supply voltage absent or outside the range 11…28 VDC,

hardware error

Fault condition; general fault indicator for faults which

result in the data output being shut down.

Exception:

If there is a fault in the incremental channel, the LED is

also ON, but the SSI remains operational.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

39

Page 42

SSI format

6 SSI format

6.1 Multi-turn

English

6.2 Single-turn

Bit 0-11 Bit 12-24 Bit 25-39

MSB LSB

MT, 12 Bit ST, 13 Bit Err1, 1Bit Err2, 1 Bit SoL, 5 Bit 8 Bit

Multi-turn

resolution

224-213 2

Single-turn

resolution

12-20

2

Error bit

Measuring

channel 1

0

2

Error bit

Measuring

channel 2

0

2

Sign of life

counter

4-20

2

Reserved

7-20

Both measuring system channels use the same SSI data format.

Bit 0-12 Bit 13-16 Bit 17 Bit 18 Bit 19-23 Bit 24-31

MSB LSB

ST, 13 Bit 4 Bit Err1, 1Bit Err2, 1 Bit LZZ, 5 Bit 8 Bit

Single-turn

resolution

212-20 2

Both measuring system channels use the same SSI data format.

6.3 Sign of life counter

The 5-Bit sign of life counter is incremented based on the scanning procedures and is

inserted into the SSI telegram.

Place holder

3-20

2

INFORMATION

The sign of life counter is increased when the control system

has fetched the current position values and, internally, new

position values have been generated and provided. In other

words, if the sign of life counter has been incremented in

relation to the previous telegram, this guarantees that the

current data transmitted originates from a new position

scanning operation.

Error bit

Measuring

channel 1

0

2

Error bit

Meausuring

channel 2

Sign of life

counter

0

2

4-20

2

Reserved

7-20

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

40

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 43

Replacing the measuring system

7 Replacing the measuring system

The following points must be noted when replacing the measuring system:

● The new measuring system must have the same item number as the system

being replaced. Any deviations from this must be cleared with Pilz.

● You must ensure that the count direction set via hardware switches on the new

measuring system matches the previous count direction.

● The new measuring system must be installed in accordance with the

specifications and requirements stated in the chapter entitled “Assembly”.

● The new measuring system must be connected in accordance with the

specifications stated in the chapter entitled “Connection/Shield connection”.

● When recommissioning the replaced measuring system, a protected test run must

be carried out to ensure the system functions correctly.

English

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon +49 711 3409-0, Telefax +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

41

Page 44

English

Technical details

110 00Technical detailsTechnical details1-Technische Daten

Technical details

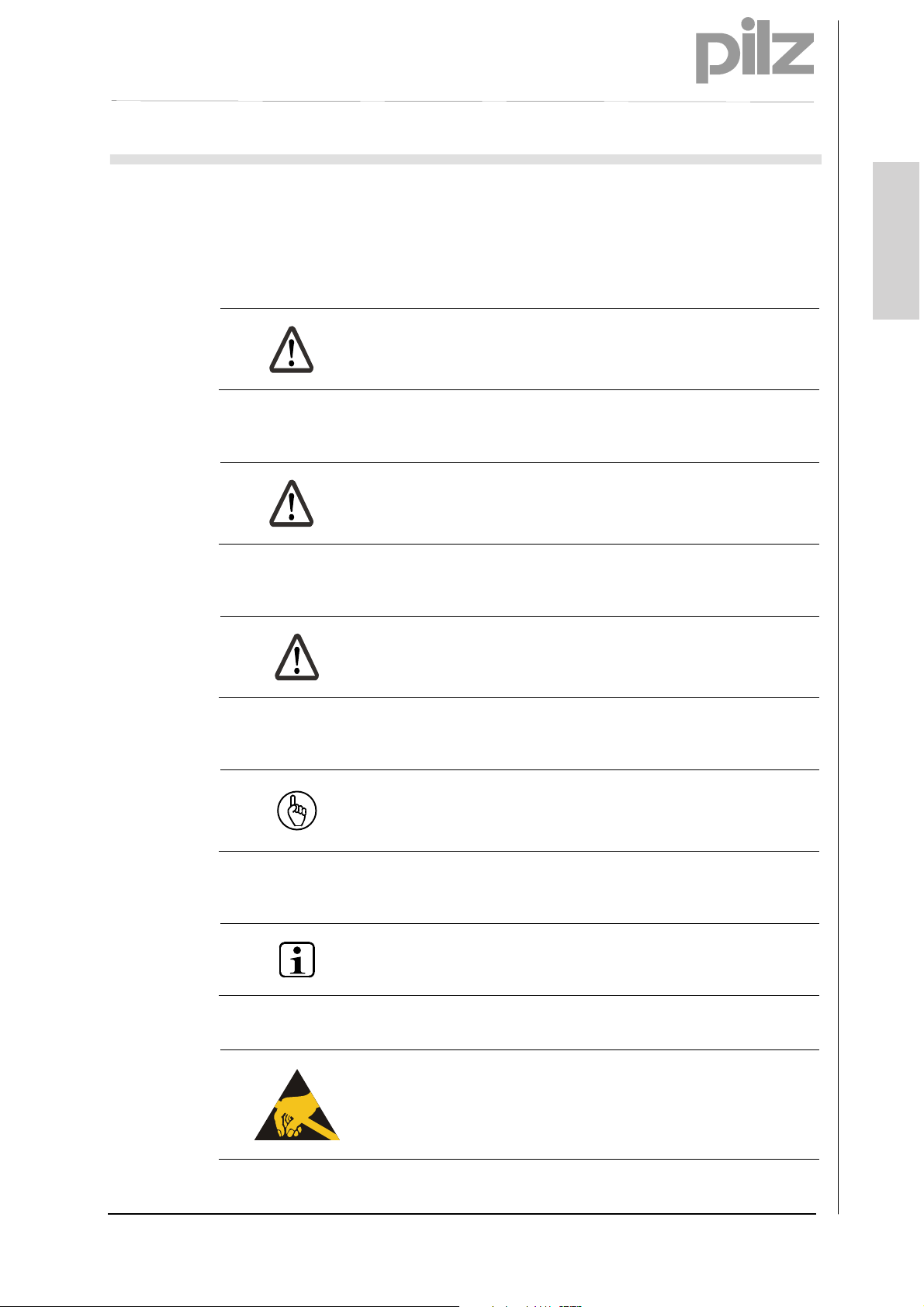

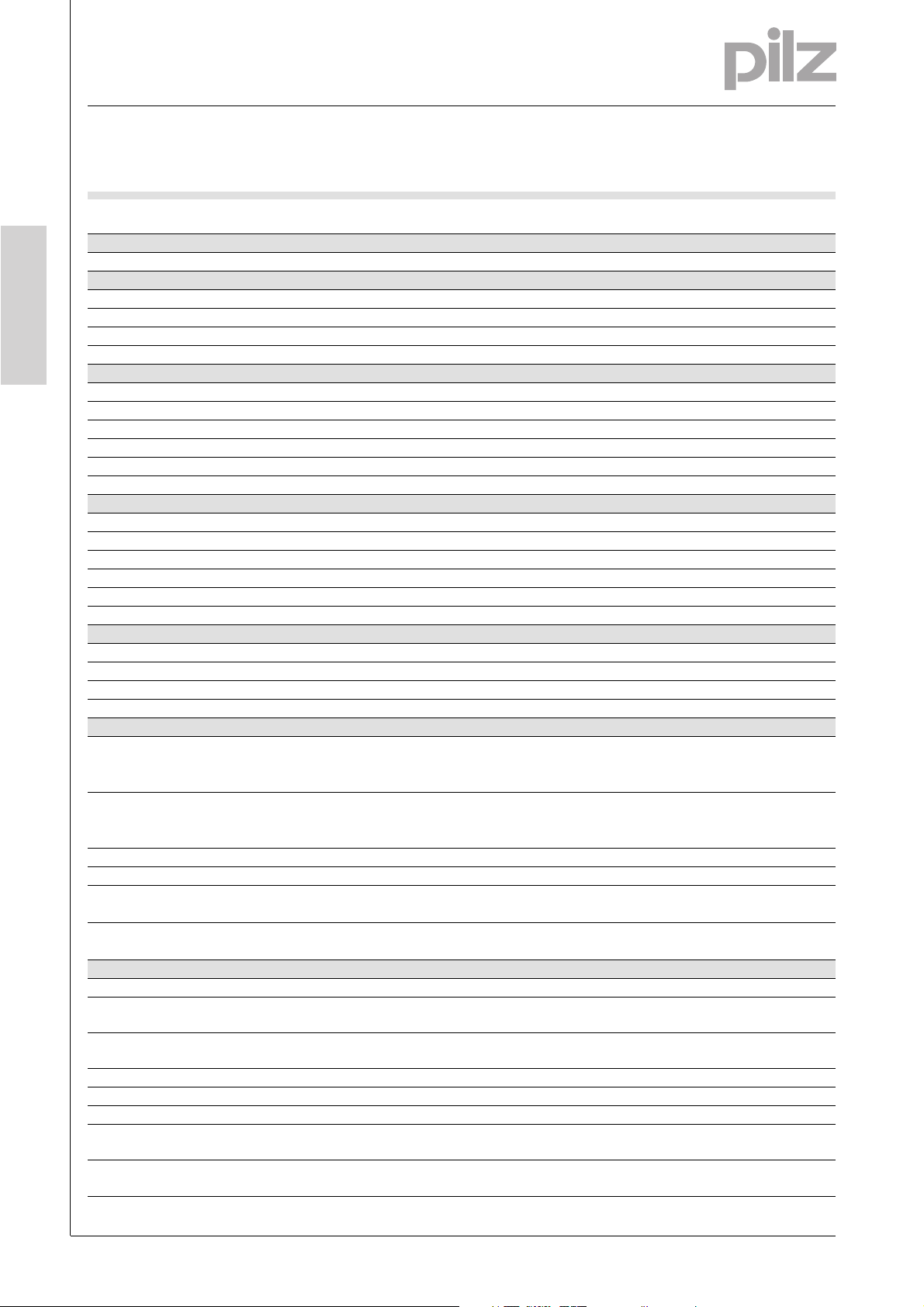

Electrical data

Supply voltage UB DC 24 V

Power consumption at U

Polarity protection yes

Scanning principle magnetic, optical

Absolute values, measuring channel 1

Interface SSI

Output driver RS422

Resolution per revolution 13 Bit

Number of revolutions 12 Bit No. 544021, 544022

Update rate 250 µs

Coding Binary

Absolute values, measuring channel 2

Interface SSI

Output driver RS422

Resolution per revolution 8 Bit

Number of revolutions 12 Bit No. 544021, 544022

Update rate 500 µs

Coding Binär

Incremental values

Interface TTL

Signal level 5 V

Number of increments 4096

Signal tracks A, /A, B, /B

Environmental data

Vibration to EN 60068-2-6

Frequency 55.0 - 2000.0 Hz

Max. acceleration 10g

Shock to EN 60068-2-27

Shock acceleration 60g

Shock time 6 ms

Continuous shock test 25g, 6ms

Ambient temperature -10 - 60 °C

Storage temperature -30 - 80 °C

Climatic suitability 98 %

Protection type EN 60529

Housing IP54

Mechanical data

Housing material Aluminium

Shaft design Hollow shaft No. 544011, 544021

Shaft diameter 10 mm No. 544012, 544022

Connection type Terminals

Connection direction radial

Angular acceleration 1E+04 rad/s²

Max. speed 3000 1/min No. 544011, 544021

Torque on start-up 0.006 Nm No. 544012, 544022

DC 3.6 W

B

Solid shaft No. 544012, 544022

20 mm No. 544011, 544021

6000 1/min No. 544012, 544022

0.060 Nm No. 544011, 544021

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

42

Page 45

Technical details

English

Mechanical data

Axial shaft load capacity 50 N No. 544012, 544022

Radial shaft load capacity 90 N No. 544012, 544022

Mechanical service life 3.9 x 10

Weight 850 g No. 544012, 544022

950 g No. 544011, 544021

10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

43

Page 46

© Pilz GmbH & Co. KG, 2011

1002327-EN-04, 2013-05 Printed in Germany

...

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

Technical support

+49 711 3409-444

support@pilz.com

are registered and protected trademarks

®

, the spirit of safety

®

, SafetyNET p

®

, SafetyEYE

®

, SafetyBUS p

®

, PVIS

®

, PSS

®

, PSEN

®

, Primo

®

, PNOZ

®

, PMI

®

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www .pilz.com

, PMCprotego

®

, PIT

®

, Pilz

®

InduraNET p

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Loading...

Loading...