Basics

Description

PSENcode

1.1

PSENcode1.12007-03BasicsDescriptionPSENcodePSEN

Operation of the safety switch

PSENcode safety switches act in conjunction with a coded actuator in noncontact operation (transponder). Each

safety switch has an actuator (transponder). Together with an authorised

evaluation device they form an approved, complete solution.

Two microcontrollers evaluate the input circuits and switch the outputs accordingly. The microcontrollers

monitor each other.

If the correct actuator (transponder) is

in the response range, signal output

Y32 will switch on. If the input circuits

are also closed, safety contacts 12

and 22 conduct and the "Input" LED illuminates yellow.

If the actuator is not within the response range (open safety gate) or the

input circuits are not closed, safety

contacts 12 and 22 and signal output

Y32 are blocked.

If the shutdown occurs via the inputs,

reactivation of the outputs is only possible after both safety inputs are

locked simultaneously (partial operation lock).

procedure at the safety switch

(max. 8 additional learning procedures).

` Safety switch with ATEX approval

for use in potentially explosive atmospheres.

Directions of actuation

PSENcode safety switches have 5 different sensing faces:

1.1-6

Protection against defeat

Safety switches from the PSEN range

are designed to guarantee security

against manipulation through protection against defeat in accordance with

VDE 0660.

Selection criteria

` Coding

– Coded actuator: Safety switch

only accepts PILZ actuators

– Fully coded actuator (unique

code): The actuator has a unique

electronic coding. The safety

switch only reacts to a single actuator.

– Fully coded actuator (unique

code, teachable): The actuator

has a unique electronic coding.

The safety switch only reacts to

a single actuator. New actuators

can be taught in via a learning

2007-03Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Basics

Description

PSENcode

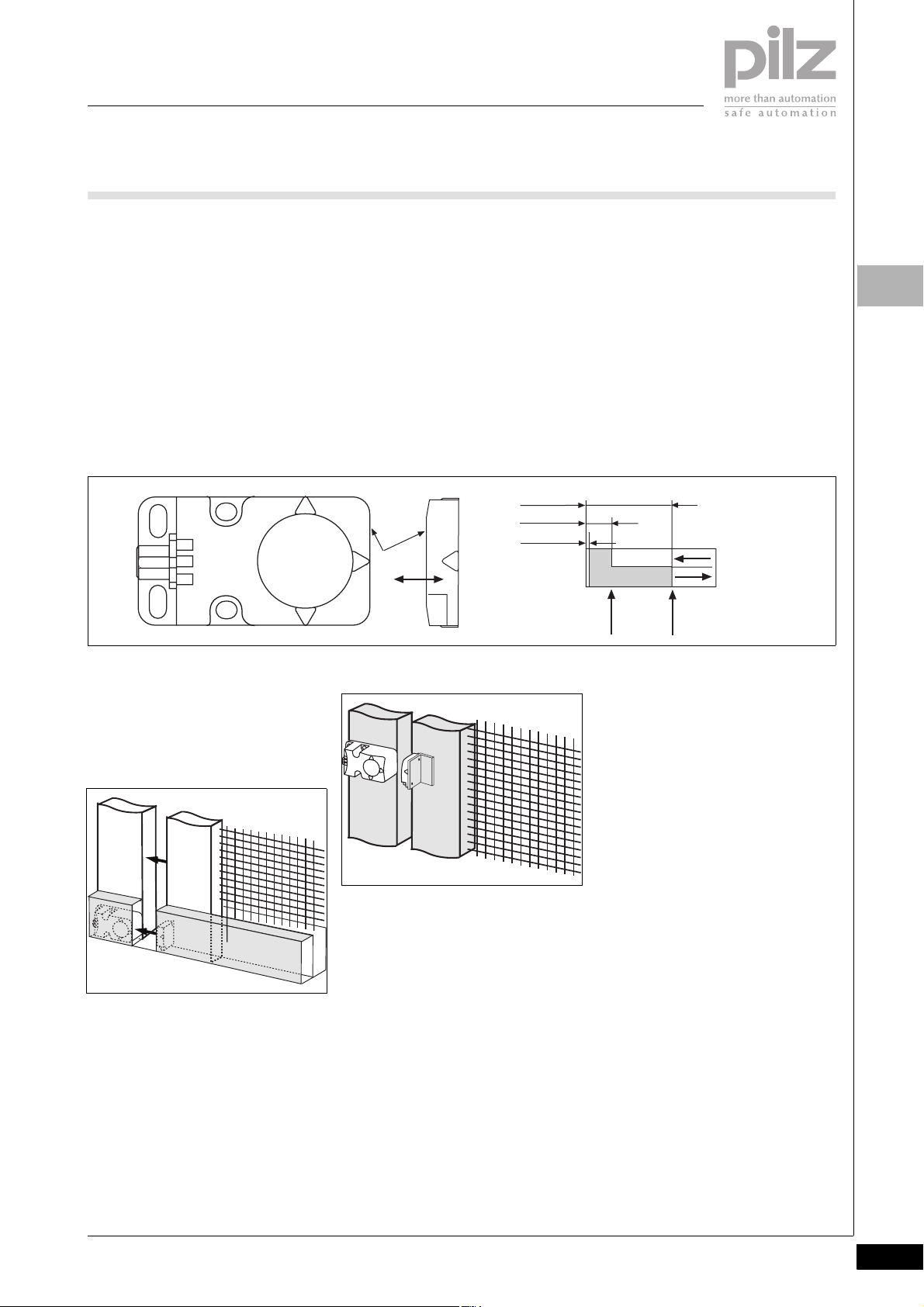

Operating distance

A high lateral and vertical offset can be

achieved with long operating distances. This will provide greater tolerances

for installation and even less sensitivy

towards spring-back or swinging from

safety gates.

Operating distances:

` Assured operating distance s

This is the distance from the sensing face, within which the presence

:

ao

of the specified target is correctly

detected under all specified environmental conditions, manufacturing tolerances and internal

component faults.

` Typical operating distance s

This is the distance from the sensing face, within which the presence

of the specified target is typically

detected correctly.

` Release distance S

This is the distance from the sensing face, beyond which the absence

active area

:

r

s

ar

s

ao

s

omin

Assured

operating distance

of the specified target is correctly

detected under all specified environmental conditions and manufacturing tolerances.

` Assured release distance S

o

This is the distance from the sensing face, beyond which the absence

of the specified target is correctly

detected under all specified environmental conditions, manufacturing tolerances and internal

component faults.

On

Off

Assured release

distance

:

ar

1.1

If you install safety switches and actuators in the vicinity of electrically or

magnetically conductive material,

check the operating distances, as

changes can be expected.

Example 1: Concealed installation with

4 mm aluminium, visual contact between actuator and safety switch

Example 2: Installation with actuator

on a 4 mm aluminium bracket and the

safety switch flush on to aluminium

Hysteresis:

The assured release distance is longer

than the assured operating distance

> sao). The safety switches there-

(s

ar

fore have a hysteresis. If the actuator

is within s

not cause the safety switch to de-energise.

vibrations up to sar will

ao,

Lateral and vertical offset:

The operating distances stated in the

technical datails only apply if the active areas of the sensing face and actuator are installed opposite each

other in parallel. Operating distances

may deviate if other arrangements are

used. The maximum permitted lateral

and vertical offset will depend on the

safety switch you are using (see chapter entitled “Unit-specific Descriptions”, section on“Max. lateral and

vertical offset in mm”).

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2007-03

1.1-7

Basics

Description

PSENcode

1.1

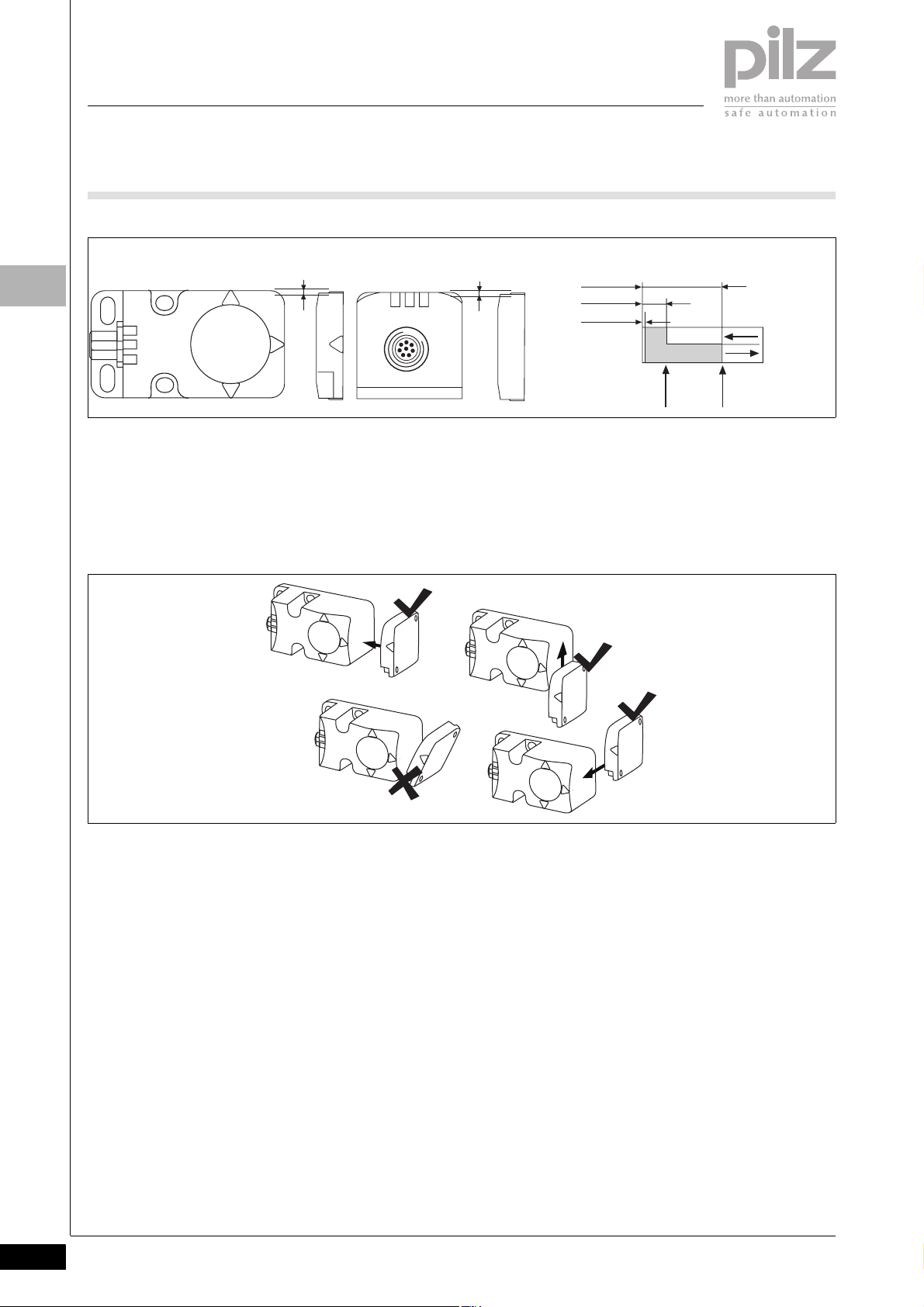

Lateral offset Height offset

active area

Actuator's direction of movement

The sensing face of the actuator is

permitted to move in parallel to the

sensing face on the safety switch.

Movements in which the actuator is

Operating distance

s

ar

s

ao

s

omin

Assured

operating distance

tilted in relation to the safety switch are

not permitted.

On

Off

Assured release

distance

1.1-8

Pass-by speed

If the safety switch is being used as a

position switch, the maximum permitted pass-by speed of the actuator is

important. This must be defined so

that the evaluation device can detect

the status of the safety switch. This

value is device-specific.

Evaluation devices

Each safety switch has an approved

evaluation device and possibly also an

interface.

INFORMATION

For details of which evaluation device

is approved for which safety switch,

please refer to the chapter entitled

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

“Wiring and Commissioning” or to the

details in the chapter entitled “Unitspecific Descriptions”.

Connecting safety switches in series

Several safety switches are connected

in series to an input on an evaluation

device via a junction. This means, for

example, that several safety gates on a

plant can be monitored using a single

evaluation device.

Up to 10 safety switches can be connected in series (can be used for applications up to Category 4 in

accordance with EN 954-1).

The switch status of the individual

safety switches (safety gate open or

closed) is displayed through LEDs and

can be evaluated via the auxiliary output, e.g. with a PLC.

Housing material

The housing of the PSENcode safety

switch is made from silicone-free PBT

plastic, which is insensitive to dirt. For

details of the chemical resistance of

the housing material, please refer to

the table in the chapter entitled

“Chemical resistance”.

2007-03Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Loading...

Loading...