Pilz PSENcode Installation Guide

Basics

Installation and adjustment

PSENcode

1.3

PSENcode1.32007-03BasicsInstallation and adjustmentPSENcodePSENmag PSENcode

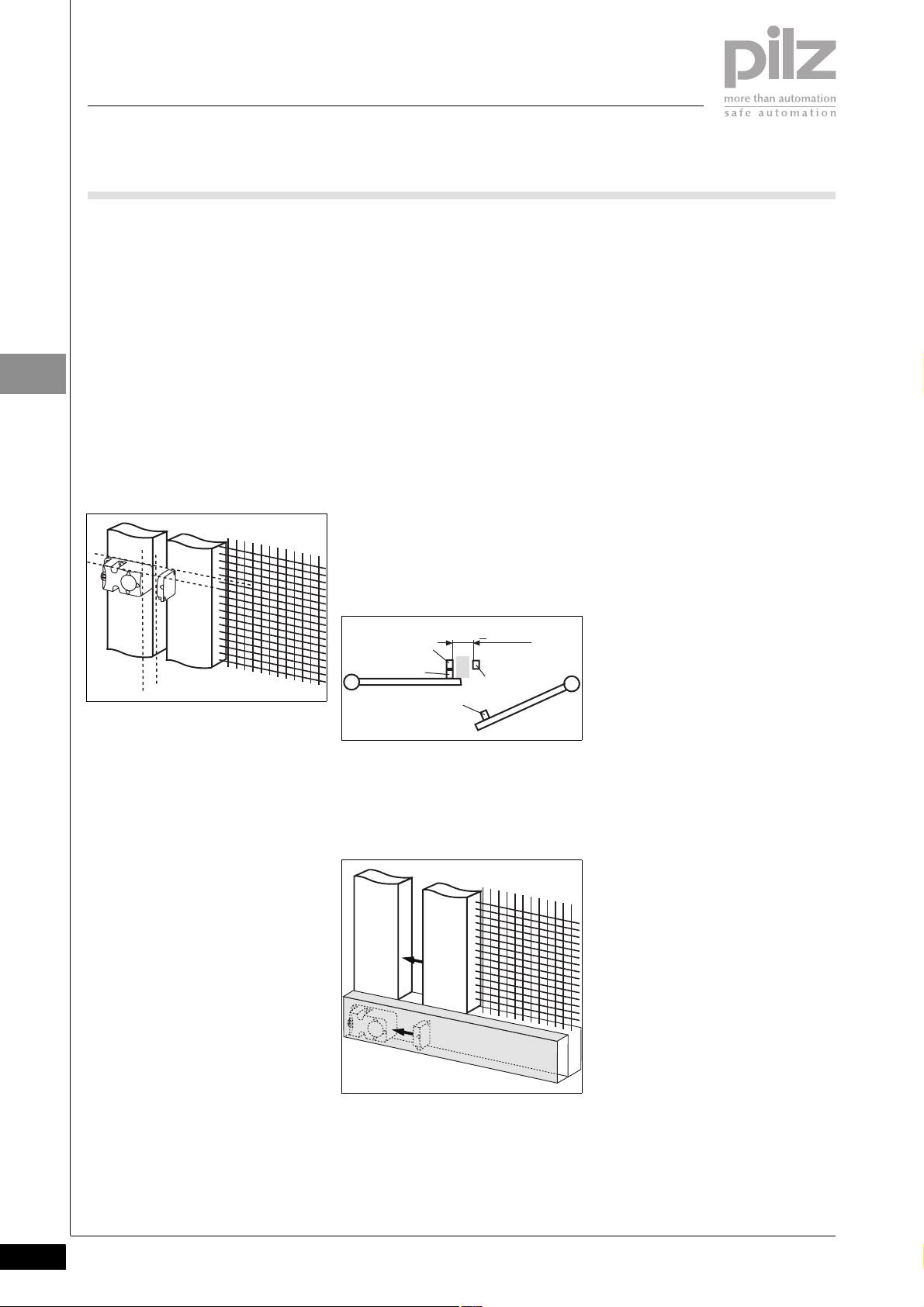

Installation position

The unit can be installed in any position.

However, the sensing faces of the

safety switch and actuator should be

positioned opposite each other in parallel.

Operating distances may deviate if

other arrangements are used.

Further information about the operating distances and the maximum permitted lateral and vertical offset can be

found in the chapters entitled “Description” and “Units”.

Installation guidelines

Adjustment

` The safety switch can only be used

with a corresponding actuator.

` The actuator must not make con-

tact with the safety switch. Please

note the minimum operating distance stated in the technical details.

` Always test the function with one of

the approved evaluation devices.

` The “Safetygate” LED on the safety

switch illuminates yellow when the

actuator is in the response range

(guard closed, safety switch and

actuator adjusted).

Swing gates

On swing gates the safety switch must

be positioned on the closed edge. The

distance between the two systems

comprising safety switch and actuator

must be at least 40 cm.

Safety switch

Actuator

Actuator

> 40 cm

Safety

switch

` If you install safety switches and ac-

tuators in the vicinity of electrically

or magnetically conductive material, check the operating distances,

as changes can be expected.

` Safety switches and actuators

should only be secured using M5

screws with a flat head (e.g. M5

cheese-head or pan head screws).

Torque setting max. 1 Nm.

` The distance between two trans-

ponder systems must be at least 40

cm (see installation example, “Safety switches on swing gates”).

Safety switch and actuator

` Do not expose to heavy shock or vi-

bration

` Do not use as a limit stop

Attachment

Attach the safety switch to the fixed

part of the safety device.

The actuator should be secured permanently to guarantee security against

manipulation.

Concealed installation

Concealing the installation of the safety switch and actuator increases security against manipulation and reduces

the risk of injury.

1.3-4

2007-03Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Loading...

Loading...