Page 1

IntelliVue MP20/30

Service Guide

IntelliVue Patient Monitor

MP20/MP20Junior/MP30

Patient Monitoring

Page 2

Part Number M8001-9301F

453564112561

*M8001-9301F*

Page 3

Contents

1 Introduction 9

Who Should Use This Guide 9

How to Use This Guide 9

Abbreviations 9

Responsibility of the Manufacturer 10

Passwords 11

Warnings and Cautions 11

2 Theory of Operation 13

Monitor Theory of Operation 13

System Boundaries 14

Hardware Building Blocks 15

Data Flow 21

How does the Support Tool Work with the Monitor 24

Monitor Software Block Diagram 25

Block Diagram Legend 26

3 Testing and Maintenance 31

Introduction 31

Terminology and Definitions 32

Recommended Frequency 33

When to Perform Tests 34

Testing Sequence 37

Visual Inspection 38

Before Each Use 38

After Each Service, Maintenance or Repair Event 38

Power On Test 38

Safety Tests 39

Warnings, Cautions, and Safety Precautions 40

Safety Test Procedures 41

System Test 66

What is a Medical Electrical System? 66

General Requirements for a System 67

System Example 67

System Installation Requirements 69

Required Protective Measures at System Installation 70

System Test Procedure 80

Preventive Maintenance Procedures 81

Noninvasive Blood Pressure Measurement Calibration 81

Microstream CO2 Calibration 81

3

Page 4

Performance Assurance Tests

Basic Performance Assurance Test 82

Full Performance Assurance Test 82

ECG/Resp Performance Test 82

ECG Sync Performance Test 83

SpO2 Performance Test 83

NBP PerformanceTest 84

Invasive Pressure Performance Test 86

Temperature Performance Test 87

M3014A Capnography Extension Performance Tests 87

Microstream CO2 Performance Test 90

BIS Performance Test 95

Nurse Call Relay Performance Test 96

Power Loss Alarm Buzzer Performance Test (only if Multi-Port Nurse Call Connector Board is installed) 98

Docking Station Performance Test 98

IIT Communication Test 98

IntelliVue 802.11 Bedside Adapter Communication Test 99

81

Reporting of Test Results 101

Carrying Out and Reporting Tests 101

Evaluation of Test Results 104

Other Regular Tests 105

Touchscreen Calibration 105

Disabling/Enabling Touch Operation 106

Printer Test Report 107

Battery Handling, Maintenance and Good Practices 107

About the Battery 108

Checking the Battery Status 109

Battery Status on the Main Screen 110

Battery Status Window 112

Conditioning a Battery 114

Conditioning Batteries 115

After Installation, Testing or Repair 116

4 Troubleshooting 119

Introduction 119

How To Use This Section 119

Who Should Perform Repairs 119

Replacement Level Supported 120

Software Revision Check 120

Obtaining Replacement Parts 120

Troubleshooting Guide 120

Checks for Obvious Problems 121

Checks Before Opening the Instrument 121

Troubleshooting Tables 123

4

Page 5

Status Log 153

List of Error Codes 154

Troubleshooting with the Support Tool 155

Troubleshooting the Individual Measurements or Applications 155

5 Repair and Disassembly 157

Tools required 157

How to find the Correct Procedure 158

Removing Directly Accessible Parts 159

1.1 Removing the Handle 160

1.2 Removing the Measurement Server Holder 160

1.3 Removing the I/O Boards and Interface Board 162

1.4 Removing the Recorder 163

1.5 Removing the Navigation Point Knob 164

1.6 Removing the Quick Release Mount and Knob 164

1.7 Removing the Fix Mount 164

2.0 Opening the Front of the Monitor 166

2.1 Removing the Backlight Tubes 167

2.2 Removing the Backlight Inverter Board 168

2.3 Removing Power On LED board and Silicon Pad 169

2.4 Removing the HIF Board, Silicon Pad and Spacer 170

2.5 Removing the Flex Adapter Cable 171

2.6 Removing the Battery Board 172

2.7 Removing Recorder Board Assembly 173

2.8 Removing the Loudspeaker 174

2.9 Removing the Branding Cover 175

3.0 Separating the Front and Back Half of the Monitor 175

3.1 Removing the LCD Flat Panel Display, Touch Panel and Front Housing 176

3.2 Removing the Main Board 177

3.3 Removing the MSL Assembly 179

3.4 Removing the Power Supply 180

3.5 Removing the Frame Housing and Serial Number Plate 180

Multi-Measurement Module (MMS) Disassembly 181

Tools required 181

Removing the Front Cover 181

Removing the Mounting Pin 181

Removing the Top Cover 182

Removing the DC/DC Board 183

Removing the MSL Flex Assembly 183

Reassembling the MSL Flex Assembly 184

Removing the NBP pump 186

Refitting the new NBP Pump 186

Refitting the DC/DC board 188

Refitting the Cover 188

Refitting the Front Cover 189

5

Page 6

Final Inspection 190

MMS Extensions - Exchanging the Top Cover, MSL Flex Cable and the Dual Link Bar 190

Exchange Procedures 191

Disassembly Procedures for the M3015A MMS Extension (HW Rev. A) 202

Removing the Front Cover 202

Refit Procedures for the MMS Extension 206

Smart Battery Charger LG1480 (M8043A) 207

Cleaning the Air Filter Mats 208

Replacing the Fan 208

IntelliVue Instrument Telemetry (IIT) 210

Docking Station 211

Exchanging the Main Board 211

Exchanging the Flex Cable 214

6 Parts 217

MP20/MP30 Parts 218

Multi-Measurement Module (MMS) Parts 223

MMS Part Number Overview and Identification 223

MMS Firmware Overview 225

MMS Part Numbers - Front Bezel for M3001 #A01 & #A03 226

MMS Part Numbers - Front Bezel for M3001 #A02 226

MMS Part Numbers - Top Cover and MSL Assembly 227

MMS Exchange Part Numbers 228

MMS Part Numbers - Label Kits 230

MMS Part Numbers - NBP Assembly 230

MMS Extension Parts (M3012A, M3014A, M3015A and M3016A) 230

MMS Extension Part Numbers - Release Mechanisms 231

MMS Extension Part Numbers - Top Cover, Flex Cable and Link Bar 231

MMS Extension Part Numbers - Front Bezels 231

Exchange Parts List 233

IntelliVue X2 Part Numbers 234

BISx Solution Replacable Parts 234

Smart Battery Charger Part Numbers 235

IntelliVue Instrument Telemetry Part Numbers 236

IntelliVue 802.11 Bedside Adapter Part Numbers 236

Docking Station Part Numbers 237

External Display Part Numbers 237

Remote Alarm Device Part Numbers 239

Remote Extension Device Part Numbers 240

7 Installation Instructions 241

Installation Checklist 241

Unpacking the Equipment 242

Initial Inspection 242

6

Page 7

Mechanical Inspection 242

Electrical Inspection 242

Claims For Damage and Repackaging 243

Mounting Instructions 243

Connecting the Monitor to AC Mains 245

Connections 246

Installing Interface Boards 247

Connection of Devices via the MIB/RS232 Interface 250

Connection of USB Devices 250

Installing the Docking Station 254

Installing Remote Devices 254

Mounting the 15” Remote Display (M8031A) 254

Mounting the 15” Remote Display (M8031B) 255

Mounting the 17” Remote Display (M8033A/B/C) 255

Multi-Measurement Module 257

PS/2 Keyboard/Mouse 266

Philips Clinical Network (Wired) 266

Philips Clinical Network (Wireless) 266

Nurse Call Relay 267

Connections 267

ECG Out Functionality 267

Connections 267

Configuration Tasks 268

Checking Country-Specific Default Settings 268

Setting Altitude, Line Frequency, ECG Cable Colors and Height & Weight Units 269

Setting Altitude and Line Frequency 269

Configuring the Equipment Label 269

Configuring the printer 270

Configuring IP Address, Subnet Mask and Default Gateway 270

Configuration Settings for CSCN Routed Bedside Monitors (RBM) 271

Configuring Routed Bedside Monitors Support 271

Handing Over the Monitor 272

8 Site Preparation 275

Introduction 275

Site Planning 275

Roles & Responsibilities 276

Monitor M8001A and M8002A Site Requirements 278

Space Requirements 278

Environmental Requirements 278

Electrical and Safety Requirements (Customer or Philips) 279

Remote Device Site Requirements 280

Connecting Non-Medical Devices 281

Multi-Measurement Module (MMS) M3001A and IntelliVue X2 M3002A 281

7

Page 8

Remote Displays (M8031A) 284

Remote Displays (M8031B) 285

Remote Displays - M8033A 286

Remote Displays - M8033B 287

Remote Displays - M8033C 288

Remote Alarm Devices 290

Remote Extension Device 291

Local Printer 292

Philips Medical LAN 293

RS232/MIB/LAN Interface 293

Nurse Call Relay Interface 294

ECG Out Interface 294

9 Gas Analyzers 297

10 Index 299

8

Page 9

1

1Introduction

This Service Guide contains technical details for the IntelliVue MP20, MP20 Junior and MP30

Patient Monitor, the Multi-Measurement Module (MMS), the IntelliVue X2, and the

Measurement Server Extensions.

This guide provides a technical foundation to support effective troubleshooting and repair. It is

not a comprehensive, in-depth explanation of the product architecture or technical

implementation. It offers enough information on the functions and operations of the monitoring

systems so that engineers who repair them are better able to understand how they work.

It covers the physiological measurements that the products provide, the Measurement Server that

acquires those measurements, and the monitoring system that displays them.

Who Should Use This Guide

This guide is for biomedical engineers or technicians responsible for troubleshooting, repairing,

and maintaining Philips’ patient monitoring systems.

How to Use This Guide

This guide is divided into eight sections. Navigate through the tab le of conte nts at the left of the

screen to select the desired topic. Links to other relevant sections are also provided within the

individual topics. In addition, scrolling through the topics with the page up and page down keys

is also possible.

Abbreviations

Abbreviations used throughout this guide are:

Name Abbreviation

IntelliVue MP20/MP30 Patient Monitor the monitor

Multi-Measurement Module MMS

9

Page 10

1 Introduction Responsibility of the Manufacturer

Name Abbreviation

Measurement Link MSL

Medical Information Bus MIB

Anesthetic Gas Module AGM

Responsibility of the Manufacturer

Philips only considers itself responsible for any effects on safety, EMC, reliability and

performance of the equipment if:

- assembly operations, extensions, re-adjustments, modifications or repairs are carried out by

persons authorized by Philips, and

- the electrical installation of the relevant room complies with national standards, and

- the instrument is used in accordance with the instructions for use.

To ensure safety and EMC, use only those Philips parts and accessories specified for use with

the monitor. If non-Philips parts are used, Philips is not liable for any damage that these parts

may cause to the equipment.

This document contains proprietary information which is protected by copyright. All Rights

Reserved. Reproduction, adaptation, or translation without prior written permission is prohibited,

except as allowed under the copyright laws.

Philips Medizin Systeme Böblingen GmbH

Hewlett-Packard Str. 2

71034 Böblingen, Germany

The information contained in this document is subject to change without notice.

Philips makes no warranty of any kind with regard to this material, including, but not limited to,

the implied warranties or merchantability and fitness for a particular purpose.

Philips shall not be liable for errors contained herein or for incidental or consequential damages

in connection with the furnishing, performance, or use of this material.

10

Page 11

Passwords 1 Introduction

Passwords

In order to access different modes within the monitor a password may be required. The

passwords are listed below.

Monitoring Mode: No password required

Configuration Mode: 71034

Demo Mode: 14432

Service Mode: 1345

Consult the configuration guide before making any changes to the monitor configuration.

Warnings and Cautions

In this guide:

- A warning alerts you to a potential serious outcome, adverse event or safety hazard. Failure

to observe a warning may result in death or serious injury to the user or patient.

- A caution alerts you where special care is necessary for the safe and effecti ve use of the

product. Failure to observe a caution may result in minor or moderate personal injury or

damage to the product or other property, and possibly in a remote risk of more serious

injury.

11

Page 12

1 Introduction Warnings and Cautions

12 13

Page 13

2Theory of Operation

Monitor Theory of Operation

The IntelliVue MP20/MP20Junior/MP30 Patient Monitor:

- displays real-time data

- controls the attached measurement server

- alarms in the case of patient or equipment problems

- offers limited data storage and retrieval (trending)

2

NOTE

- interfaces to the Philips Clinical Network and other equipment

A monitor with just a single integrated measurement server can be connected to additional

building blocks to form a monitoring system with a large number of measurements, additional

interface capabilities and slave display. These elements cooperate as one single integrated

real-time measurement system.

The following descriptions may vary depending on the monitor option purchased.

Page 14

2 Theory of Operation Monitor Theory of Operation

System Boundaries

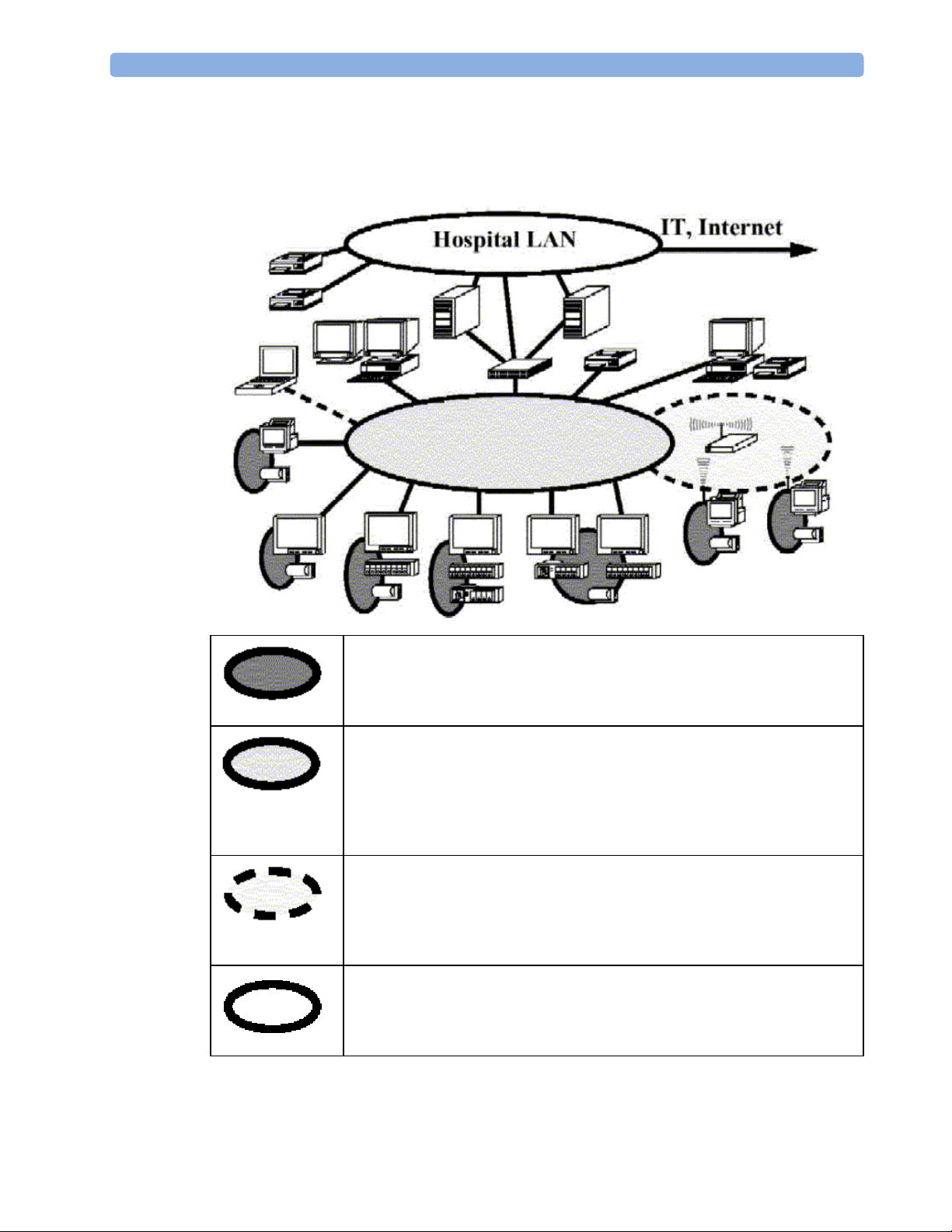

The following diagram discusses specific boundaries within the overall system with respect to

their openness and real-time requirements:

Measurement LAN

combines components of one patient monitor; real time requirements across

all interconnected elements

Philips Clinical Network (wired LAN)

connects multiple patient monitors, information centers, application servers;

closed system, only Philips qualified products (tested and with regulatory

approval) are connected, Philips is responsible for guaranteed real-time

functionality and performance

Philips Clinical Network (wireless)

like Philips Clinical Network (wired) LAN, however due to current wireless

technologies available it has reduced bandwidth, longer late nci es, reduced

functionality

Hospital LAN, Internet

Standard Network, not under Philips control, no guaranteed service, no

real-time requirements

14

Page 15

Monitor Theory of Operation 2 Theory of Operation

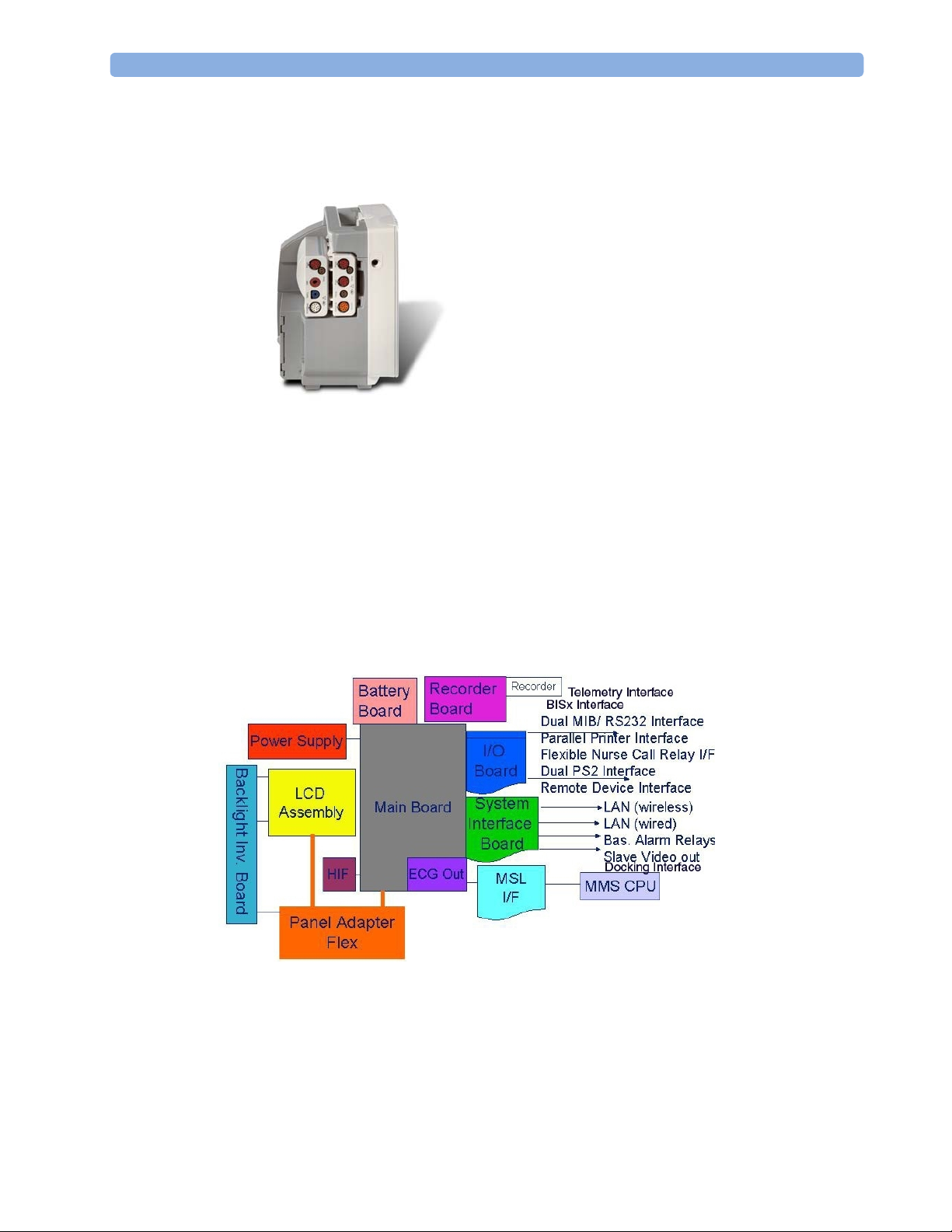

Hardware Building Blocks

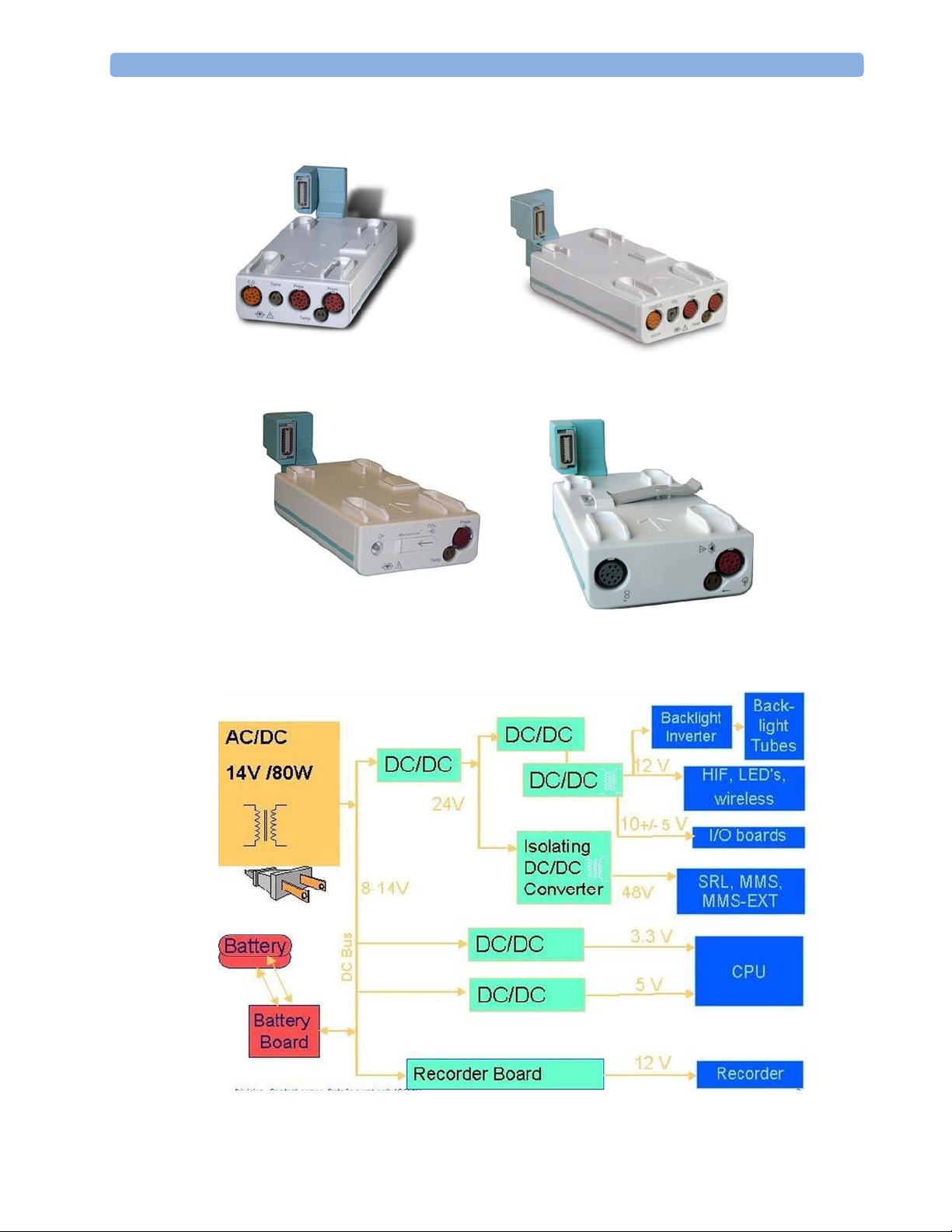

The following hardware building blocks make up the monitoring system:

IntelliVue MP20

The MP20 monitor:

- integrates the display and processing unit into a single package

- uses a 10.4” TFT SVGA color display

- uses the Philips Navigation Point as primary input device; computer devices such as mice,

- supports the MMS and MMS extensions.

Building Blocks:

trackball, and keyboard can be added optionally

15

Page 16

2 Theory of Operation Monitor Theory of Operation

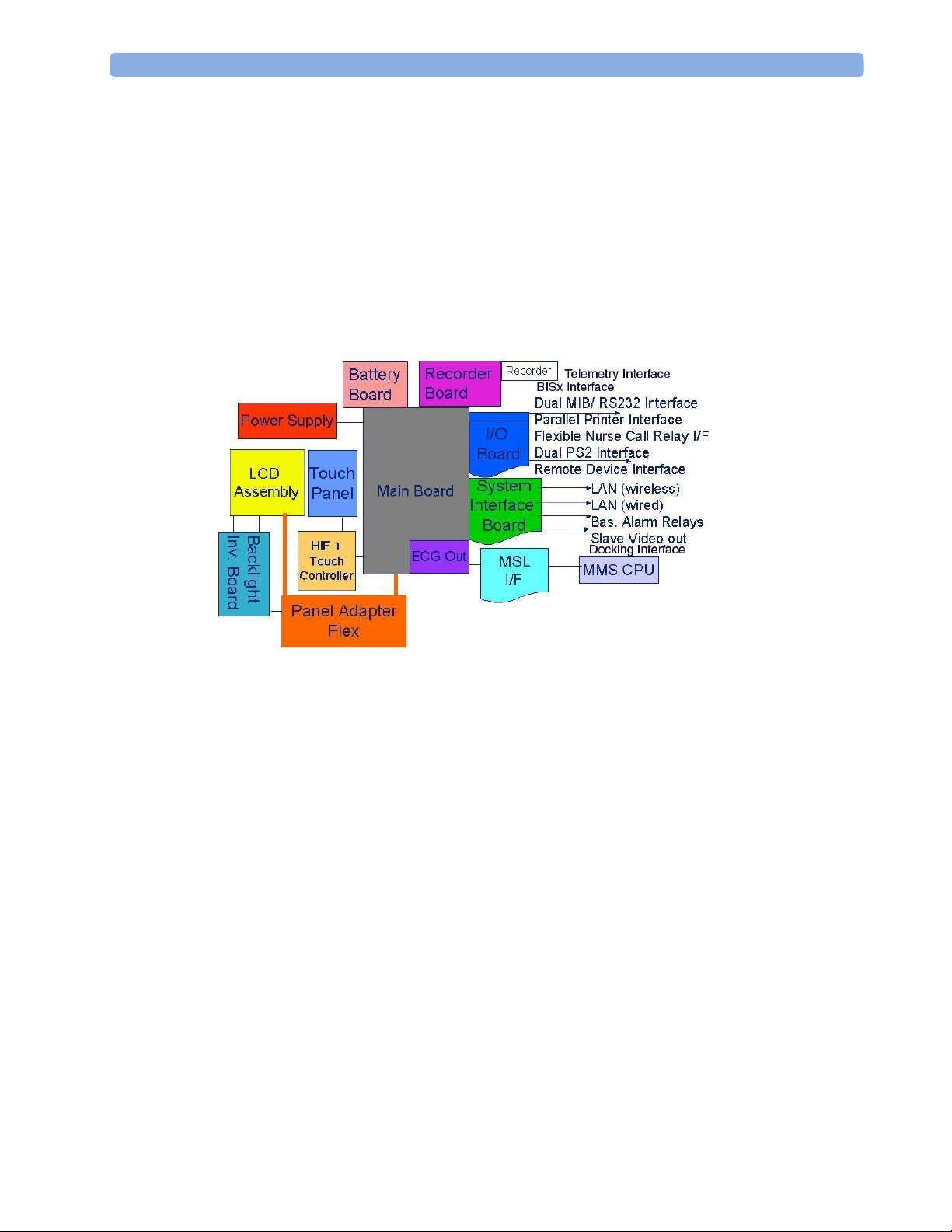

IntelliVue MP30

The MP30 monitor:

- integrates the display and processing unit into a single package

- uses a 10.4” TFT XGA color display

- uses the Touchscreen and Philips Navigation Point as primary input devices. Computer

devices such as mice, trackball, and keyboard can be added optionally.

- supports the MMS and MMS extensions

Building Blocks:

Optional Hardware

One slot is provided for one of three available system interface boards. If the monitor is ordered

with the wireless LAN option a wireless transmitter is required. For further details regarding the

wireless network please refer to the M3185A Philips Clinical Network documentation.

16

Page 17

Monitor Theory of Operation 2 Theory of Operation

Compatible Devices

M8045A Docking Station

M3001A Multi-Measurement Module (MMS)

M3002A IntelliVue X2

17

Page 18

2 Theory of Operation Monitor Theory of Operation

Power Supply

M3012A, M3014A, M3015A, M3016A MMS Extensions

Power Supply Architecture

18

Page 19

Monitor Theory of Operation 2 Theory of Operation

The AC/DC converter transforms the AC power coming from the power plug into 14 V/80W DC

source and isolates the monitoring system from the AC power mains.The 14V is distributed via

power bus and supplies power to all the components of the system: The 48V DC power needed

for the MMS and MMS Extension is created by an isolating DC/DC converter. The power

needed for the backlights is converted to 12V DC by the backlight DC/DC converter. The CPU

and the non-isolated I/O boards are supplied with 3.3 V and 5 V DC power. Isolated interface

boards require a power of 10V AC. The remote HIF board and the LEDs are supplied with 12V

DC power.

CPU Boards

The CPU boards have an MPC852/50 MHz processor in the patient monitor and an

MPC860/50MHz in the MMS that provides a number of on-chip, configurable interfaces. An

array of fast UARTS with configurable protocol options are implemented in an ASIC (along

with other system functions such as independent watchdogs etc.), providing interfacing

capabilities to measurement modules and System Interface and I/O boards. The serial interfaces

can easily be electrically isolated. The main board contains additional video hardware.

The CPUs provide two LAN interfaces to interconnect CPUs (via the MSL) and to connect to the

Philips Clinical Network.

The CPU capabilities are identical. Different loading options are coded on serial EEPROMs to

support the automatic configuration of the operating system at boot time.

19

Page 20

2 Theory of Operation Monitor Theory of Operation

System Interface and I/O Boards

Interfaces to the monitor are implemented via I/O boards. The location of these boards is

restricted by general rules. The I/O slot designations diagram and the I/O matrix which outline

the I/O board placement rules can be found in the Installation Instructions section.

The following is a list of Interface (I/O) boards which may be present in your monitor,

depending on your purchased configuration:

System Interface boards:

- Video for slave display

- Philips Clinical Network (LAN wired or wireless)

- Basic Alarm Relay (Nurse Call)

- Docking Interface

I/O boards:

- PS/2

- MIB/RS232

- Flexible Nurse Call

- Parallel printer

- USB

- Remote devices (Remote Alarm Device, Remote Extension Device)

- BISx Interface

- IntelliVue 802.11 Bedside Adapter

The specifications for the above listed interfaces can be found in the technical data sheet for the

monitor and in the Installation and Specifications chapter of the Instructions for Use.

20

Page 21

Monitor Theory of Operation 2 Theory of Operation

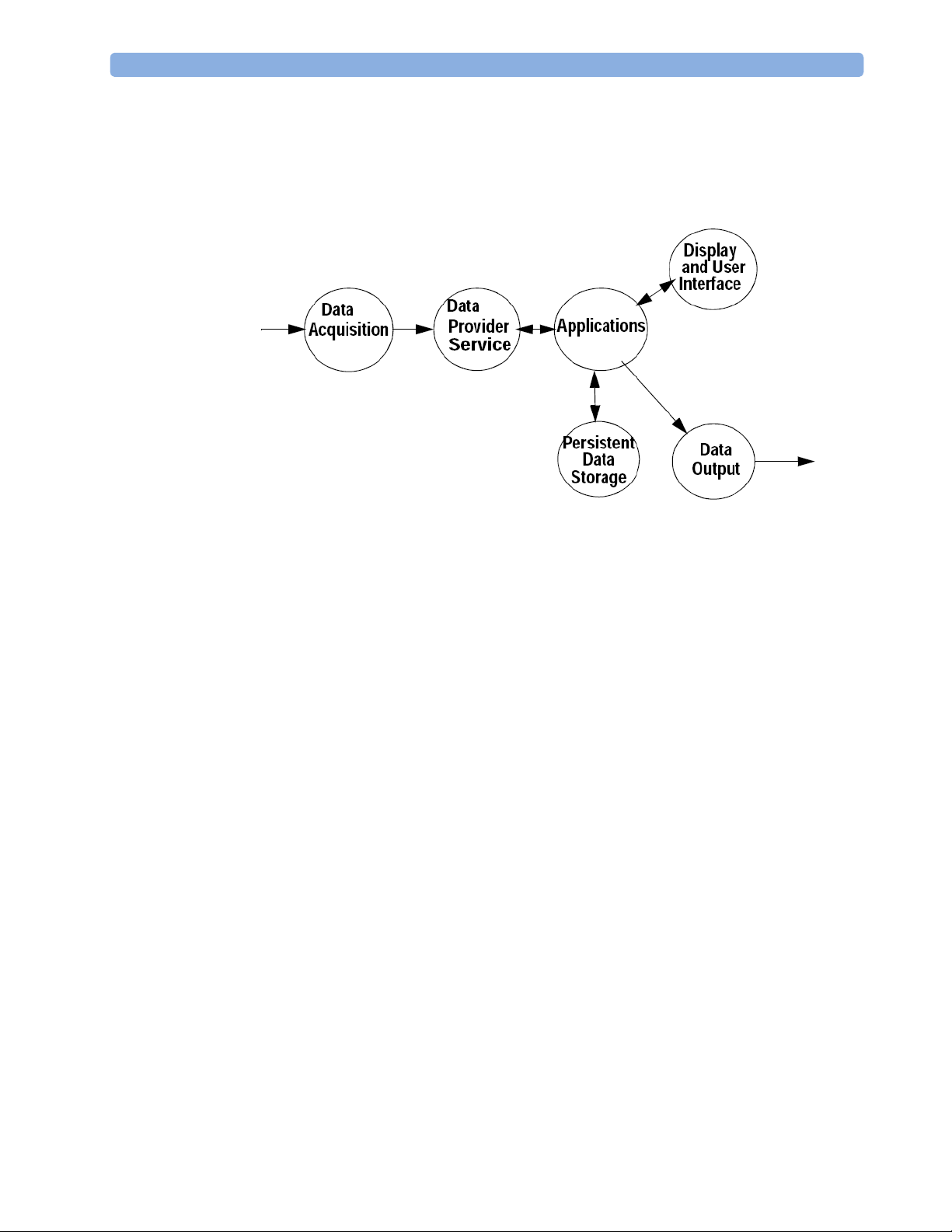

Data Flow

The following diagram shows how data is passed through the monitoring system. The individual

stages of data flow are explained below.

Data Acquisition

Monitoring data (for example patient measurement data in the form of waves, numerics and

alerts) is acquired from a variety of sources:

- Measurement Server

- External measurement devices

- Server systems on the Philips Clinical Network

The Measurement Server connected to the internal LAN convert patient signals to digital

data and applies measurement algorithms to analyze the signals.

Data can be also acquired from devices connected to interface boards of the monitor.

Software modules dedicated to such specific devices convert the data received from an

external device to the format used internally. This applies to the Anesthetic Gas Module.

To enable networked applications such as the other bed overview, data can be acquired from

server systems attached to the Philips Clinical Network, for example a Philips Information

Center

21

Page 22

2 Theory of Operation Monitor Theory of Operation

Data Provider System Service

All data that is acquired from measurement servers or external measurement devices is

temporarily stored by a dedicated data provider system service. All monitor applications use this

central service to access the data in a consistent and synchronized way rather than talking to the

interfaces directly.

This service makes the applications independent of the actual type of data acquisition device.

The amount of data stored in the data provider system service varies for the different data types.

For example several seconds of wave forms and the full set of current numerical values are

temorarily stored in RAM.

Persistent Data Storage System Service

Some applications require storage of data over longer periods of time. They can use the

persistent data storage system service. Dependent on the application requirements, this service

can store data either in battery backed-up (buffered) memory or in flash memory. The buffered

memory will lose its contents if the monitor is without power (not connected to mains) for an

extended period of time. The flash memory does not lose its contents.

The trend application for example stores vital signs data in a combination of flash memory and

buffered memory, while the system configuration information (profiles) is kept purely in flash

memory.

Display and User Interface Service

Applications can use high level commands to display monitoring data or status and command

windows on the internal LCD panel. These commands are interpreted by the display manager

application. This application controls the dedicated video hardware which includes video

memory and a special ASIC.

User input is acquired from a variety of input devices, for example the Navigation Point, the

touchscreen or other standard input devices (keyboard, mouse) which may be attached to I/O

boards. The system software makes sure that the user input is directed to the application which

has the operating focus.

Data Output

The monitoring system is very flexible and customizable regarding its data output devices.

Built-in devices (for example LAN, alarm lamps, speaker, video) provide the basic output

capabilities.

These capabilities can be enhanced by adding additional I/O boards, as required in the specific

end-user setup. The additional I/O boards typically provide data to externally attached devices,

for example to printers, RS232 based data collection devices, nurse call systems etc.

The monitor can identify I/O boards by means of a serial EEPROM device that stores type and

version information. The operating system detects the I/O boards and automatically connects

them with the associated (interface driver) application. For some multi-purpose cards it is

necessary to configure the card for a particular purpose first (for example the dual MIB/RS232

card can support external touch display, data import, data export).

22

Page 23

Monitor Theory of Operation 2 Theory of Operation

Monitor Applications

The monitor applications provide additional system functionality over the basic measurement

and monitoring capabilities. This includes for example trending, report generating, event storage

or derived measurements.

In general, the monitor applications use the data provider system service to access the

measurement data. Application interfaces to the other system services allow the application to

visualize data, to store data over extended periods of time or to output data to other devices.

Internal LAN (Measurement Link)

All components of the monitoring system (including measurement servers and CPUs in the

monitor) communicate using an IEEE802.3/ Ethernet LAN in the Measurement Link (MSL).

This network is used to distribute data between the components, for example:

- Digitized patient signals including wave data, numerical data and status information

(typically from the measurement server to a display unit)

- Control data representing user interactions (typically from the display unit to a measurement

server)

- Shared data structures, for example representing patient demographical data and global

configuration items

The internal LAN allows plug and play configuration of the monitoring system. The system

automatically detects plugging or unplugging of measurement servers and configures the system

accordingly.

The components on the internal LAN are time-synchronized to keep signal data consistent in the

system. Dedicated hardware support for synchronization eliminates any latency of the network

driver software.

The integrated LAN provides deterministic bandwidth allocation/reservation mechanisms so that

the real-time characteristic of signal data and control data exchange is guaranteed. This applies

to the data flow from the measurement server to the monitor (for example measurement signal

data) and the data flow from the monitor to a measurement server (for example to feed data to a

recorder module).

Integrated communication hubs in the monitor allow flexible cabling options (star topology,

daisy chaining of servers).

23

Page 24

2 Theory of Operation Monitor Theory of Operation

Philips Clinical Network

The monitoring system may be connected to the Philips Clinical Network, for example to

provide central monitoring capabilities or other network services. This connection may be

through a normal wired connection or through a wireless connection.

The monitor supports the connection of an external wireless adapter or an internal wireless

adapter (#J35). Switching between wired and wireless networks is automatically triggered by the

plugging or unplugging of the network cable.

The Philips Clinical Network protocols function very similarly to the protocols used on the

internal LAN.

After configuration, the monitoring system sends the digitized patient signals including wave

data, numerical data and status information onto the network. Control data representing user

interactions can be exchanged between the monitoring system and a central station

bi-directionally.

Additional protocols are supported for networked applications, for example for the other bed

overview function, which allows viewing of monitoring data from other patients on the network.

For plug and play operation, the monitoring system uses the standard BootP protocol to

automatically acquire a network address.

How does the Support Tool Work with the Monitor

The support tool is a Windows application typically installed on the laptop of a customer

engineer or a biomedical engineer working in the customer’s own service department.

The purpose of the support tool is to upgrade, configure and diagnose all monitoring componen ts

(modules, measurement servers, and monitors) in the system over the network.

The service protocol developed for this purpose uses a raw access to the devices without the

need for IP addresses etc. over a standard customer network installation, so that even defective

devices can be upgraded as long as the few kBytes of initial boot code are working. The boot

code itself can also be upgraded using the same protocol.

The tool allows access to internal service information and to serial numbers. It can be remotecontrolled, for example via a dial-up connection from a response center, provided the proper

infrastructure is in place.

For details see the Instructions for Use for the Support Tool.

24

Page 25

Monitor Theory of Operation 2 Theory of Operation

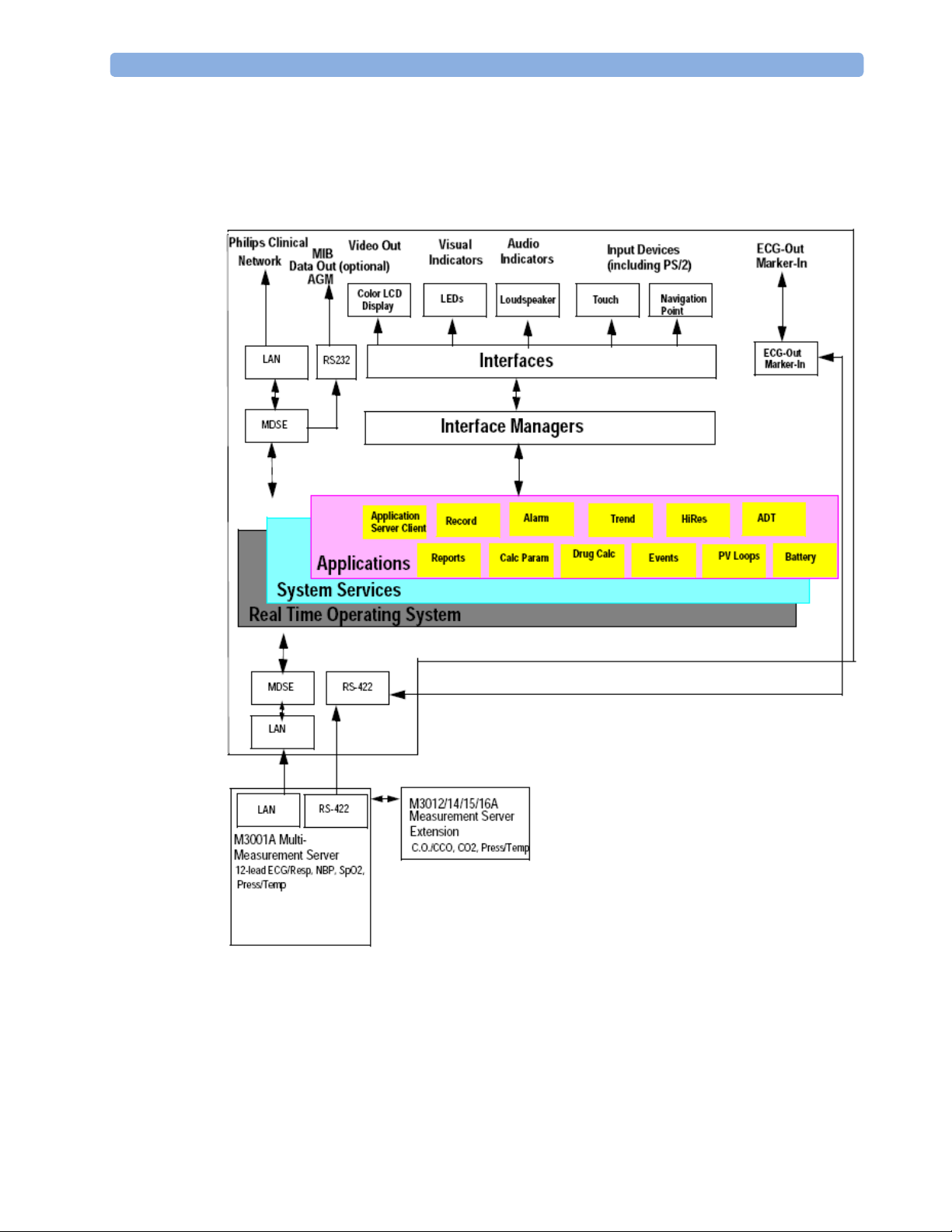

Monitor Software Block Diagram

shows the functional block diagram for the monitoring system. A legend explaining terms and

diagram elements follows. The information below varies depending on the purchased monitor

options.

IntelliVue Patient Monitoring System Functional Block Diagram

25

Page 26

2 Theory of Operation Monitor Theory of Operation

Block Diagram Legend

Functional Block Description

Services

Operating System The Operating System (OS) provides a layer of isolation between the specific

hardware implementation and the application software. The OS performs system

checks and allocates resources to ensure safe operation when the system is first

started. This includes internal self-tests on several hardware modules and

configuration checks for validity of configuration with the operating software.

During normal operation, the OS continues to run checks on system integrity. If

error conditions are detected the OS will halt monitoring operations and inform

the operator about the error condition.

System Services The System Services provide generic common system services.

In particular:

They use a real-time clock component to track time. They synchronize to network

time sources and verify the accuracy of the system time information. They are also

responsible for managing persistent user configurat io n data for all Measurement

Servers and IntelliVue Patient Monitoring System software modules. User

configuration data is stored in a non-volatile read/write storage device

Applications

Reports The Reports Service retrieves current and stored physiological data and status data

to format reports for printing paper documentation. The following reports are

supported:

- Vital Signs Report

- Graphical Trend Report

- Event Review Report

- Event Episode Report

- ECG Report (12 Lead/Multi-Lead)

- Cardiac Output Report

- Calculations Report (Hemodynamic/Oxygenation/Ventilation)

- Calculations Review Report

- Wedge Report

- Test Report

The Reports service generates report data which can be printed on a local or a

central printer.

26

Page 27

Monitor Theory of Operation 2 Theory of Operation

Functional Block Description

Record The Record Service retrieves current and stored physiological data and status data

to format a continuous strip recording. A recording can be triggered manually by

the operator or automatically by an alarm condition. The Record Service uses the

services of the Recorder Interface to control an M1116B Recorder. The Record

Service can also send data to a central recorder.

Alarm The Alarm Service contains logic that prioritizes alarm conditions that are

generated either by the Measurement Servers or by IntelliVue Patient Monitoring

System software modules. Visual alarm signals (messages) are displayed at the top

of the IntelliVue Patient Monitoring System display and alarm sounds are

generated by a loudspeaker. Alarm conditions may be generated when a

physiological parameter exceeds preselected alarm limits or when a physiological

parameter or any other software module reports an inoperative status (technical

alarm, for example, the ECG leads may have fallen off the patient). The Alarm

service manages the alarm inactivation states, for example suspension of alarms,

silencing of alarms, and alarm reminder. Alarm signals may also be configured as

latching (alarm signals are issued until they are acknowledged by the operator,

even when the alarm condition is no longer true). The Alarm service controls the

visual alarm signals (alarm lamps).

Trend The Trend service stores the sample values of physiological data and status data

with a resolution of 12 seconds, 1 minute or 5 minutes for a period of up to 48

hours. The data is kept in battery buffered read/write storage and flash memory

devices to be preserved across power failures. The stored data is protected via

consistency checks and checksums. When a new patient is admitted, the trend

database erases all data of the previous patient.

HiRes The OxyCRG (Oxygen CardioRespiroGram) service derives a high-resolution

trend graph from the Beat-to-Beat Heart Rate, SpO2 or tcpO2, and Respiration

physiological data. The OxyCRG is specialized for neonatal applications, allowing

the operator to identify sudden drops in Heart Rate (Bradycardia) and SpO2

(Desaturation), and supporting the operator in visualizing Apnea situations.

ADT The ADT (Admit/Discharge/Transmit) service maintains the patient demographics

information. The operator may admit a new patient, discharge the old patient and

enter or modify the patient demographics. The ADT service also supports the

transport of a patient (trend database) with the M3001A Multi-Measurement

Module. The ADT service controls the deletion of old patient data, the upload of

trend data from the M3001A and the switching back of all settings to user

defaults. It also synchronizes patient information with a central station on the

network.

Calc Param The Calc Param (Calculated Parameters) service accesses current, stored and

manually entered physiological data as input to calculation formulas. With these

formulas, derived hemodynamic, oxygenation and ventilation variables are

computed. The calculation results, including the input parameters, are stored for

later review using the Trend service.

27

Page 28

2 Theory of Operation Monitor Theory of Operation

Functional Block Description

Interface Managers

MDSE The MDSE (Medical Data Service Element) Interface Manager is responsible for

the exchange of real-time data between the IntelliVue Patient Monitoring System

display unit and the Measurement Servers and Flexible Module Rack as well as

between the IntelliVue Patient Monitoring System display unit and other devices

attached to the network. MDSE establishes and maintains a data communication

link between the devices. It provides configuration information about the remote

device to applications in the local device and it allows the exchange of

measurement data and status information between the devices.

Printer The Printer Interface Manager provides a high level interface to a printer. It

provides means to:

- establish a connection to the printer

- transfer data to the printer

- get status of the printer

- close connection to the printer

The Printer Interface Manager also supervises the connection to the printer and

whether the printer accepts data (for example paper out). The Printer Interface

Manager notifies the operator in such cases.

Display & Operator

Interface

The Display and Operator Interface Manager performs the following tasks:

- Screen presentation of real-time and stored physiological measurement data,

alarm condition data and status information received from the MDSE

interface manager, the Alarm service or other IntelliVue Patient Monitoring

System modules

- Screen presentation of operating controls (control windows)

- Processing of operating control commands received from HIF Control

interface. The module verifies and interprets the received commands and

forwards them to other software modules of the IntelliVue Patient Monitoring

System display unit, Measurement Servers or Flexible Module Rack

- Sound generation (issues audible alarm signals and generates audible

information signals, for example QRS and SpO2 tones, operator audible

feedback)

Interfaces

LAN The LAN interface implements the physical layer of IEEE 802.3. The LAN

interface performs Manchester encoding/decoding, receive clock recovery,

transmit pulse shaping, jabber, link integrity testing, reverse polarity

detection/correction, electrical isolation, and ESD protection. Electronically

separated interfaces are used for communication to the Measurement Servers or

Flexible Module Rack and to the network.

Centronics The Centronics interface implements the standard signaling method for

bi-directional parallel peripheral devices according to IEEE 1284-I. The interface

is used as a parallel interface to a standard printer with electrical isolation and

ESD protection.

28

Page 29

Monitor Theory of Operation 2 Theory of Operation

Functional Block Description

Display Controller The Display Controller Interface consists of a video controller chip, video RAM

and the controlling software. The Display Controller interface processes the high

level display commands (character and graphic generation, wave drawing) and

translates them into pixels, which are written into the video RAM where the video

controller chip generates the video synchronization signals and the pixel stream

for the Color LCD Display.

HIF Control The HIF (Human Interface Control) interface scans the Human Interface devices

for operator controls (Touch Screen, Speed Point, USB and PS/2 devices), formats

the collected data and sends it to the display and Operating Interface.

ECG-Out Marker-In The ECG Out/Marker In interface receives the ECG waveform directly from the

ECG/Resp Arrhythmia ST-Segment physiological algorithm via an RS-422 serial

interface and converts the digital ECG signal to an analog ECG signal. In addition,

the ECG Out controller receives from a connected device the marker information

and forwards this data to the ECG/Resp Arrhythmia ST-Segment physiological

algorithm. The converted analog signal is used to synchronize a con ne cted devi ce

to the patient’s ECG

RS-422 The serial link RS-422 interface communicates the ECG signal to the ECG

Output/Marker In of the IntelliVue Patient Monitoring System display unit. The

interface is a serial, differential, full-duplex link. The interface is ESD protected.

PS/2 The PS/2 interface supports the serial protocol of standard PS/2 devices (mouse).

The PS/2 serial protocol is interpreted by the HIF Control interface.

Nurse Call The Nurse Call board contains 2 connectors. A phone jack type connector and a

multi-port connector. The phone jack type connector has a single close-on-alarm

relay. The multi-port connector has three alarm relays which are configurable to

be open or closed on alarm. In addition, this interface has an audible alert

capability for loss of AC power.

MIB The MIB interface allows full-duplex, short-haul asynchronous binary

communication between the monitor and an arbitrary (medical/non-medical)

device using an eight-pin RJ45 modular connector. Switching between MIB and

RS232 protocol is possible.

Docking Interface The docking interface provides necessary connections for docking an MP20/30 or

MP40/50 monitor onto the docking station.

BISx Interface The BISx interface allows the usage of Aspect’s BISx solution with an MP20/30

monitor.

IIT Interface The IIT interface allows operation of the MP2/X2/MP5/MP20/MP30/MP40/MP50

monitors with IntelliVue Instrument Telemetry.

29

Page 30

Page 31

3Testing and Maintenance

Introduction

This chapter provides a checklist of the testing and maintenance procedures to ensure the

performance and safety of the monitor, the Multi-Measurement Module (MMS) and the MMS

Extensions.

3

These tests must be performed only by qualified personnel certified by the responsible

organization. Qualifications required are: training on the subject, knowledge, experience and

acquaintance with the relevant technologies, standards and local regulations. The personnel

assessing safety must be able to recognize possible consequences and risks arising from

non-conforming equipment.

All recurring safety and performance assurance tests must be performed under equal

environmental conditions to be comparable.

Preventive Maintenance refers specifically to the series of tests required to make sure the

measurement results are accurate. The accuracy and performance procedures are designed to be

completed as specified in the following sections or when readings are in question.

For detailed instructions on the maintenance and cleaning of the monitor and its accessories, see

Care and Cleaning, Using Batteries and Maintenance and Troubleshooting in the monitor's

Instructions for Use.

31

Page 32

3 Testing and Maintenance Terminology and Definitions

Terminology and Definitions

The following terms and definitions are used throughout this chapter and taken from the

international standards IEC 60601-1, IEC 60601-1-1 and IEC 62353.

- Medical System: a medical electrical system is a combination of at least one medical

electrical device and other electrical equipment, interconnected by functional connection or

use of a multiple portable socket-outlet.

- Patient Vicinity: any area in which intentional or unintentional contact can occur between

the patient and parts of the medical system or between the patient and other persons who

have had contact with parts of the medical system. The patient vicinity is defined anywhere

within 1.5m (5 feet) of the perimeter of the patient's bed and 2.5m (8.2 feet) from the floor.

- Separation Device/Transformer: a component or arrangement of components with input

parts and output parts that, for safety reasons, prevent a transfer of unwanted voltage or

current between parts of a medical system.

- Multiple Portable Socket-Outlet: a combination of two or more socket-outlets intended to

be connected to or integrated with flexible cables or cords, which can easily be moved from

one place to another while connected to the power mains.

- Functional Connection: an electrical connection for transfer of signals and/or power.

- Tests: Safety or Performance Assurance test procedures which may consist of several steps.

32

Page 33

Recommended Frequency 3 Testing and Maintenance

Recommended Frequency

Perform the procedures as indicated in the suggested testing timetable. These timetable

recommendations do not supersede local requirements.

Tests Frequency

Preventive Maintenance*

Table 1: Suggested Testing Timetable

NBP Performance Once every two years, or more often if

Microstream CO2 Calibration

(M3015A)

specified by local laws.

Once a year or after 4000 hours of

continuous use and following any

instrument repairs or the replacement of

any instrument parts.

Other Regular Tests

Performance Assurance

Tests

Safety

Tests

Visual

Electrical

Visual Inspection

Before each use.

Power On Test

ECG/Resp Performance

ECG Sync Pulse Performance

SpO2 Performance

NBP Performance

Once every two years, or if you suspect

the measurement is incorrect, except

Mainstream CO2 Accuracy Check,

Sidestream CO2 Accuracy Check and

Flow Check - required once a year.

Invasive Pressure Performance

Temperature Accuracy

M3014A Capnography Extension

Performance Tests

Microstream CO2 Performance Test

BIS Performance

Nurse Call Relay Performance

Visual Inspection After each service event.

Protective Earth

Equipment Leakage Current

Patient Leakage Current

Once every two years and after repairs

where the power supply has been

removed or replaced or the monitor has

been damaged by impact.

System Test Once every two years

*M3015A with the old hardware Rev. A (i.e. Serial No. DE020xxxxx) also require the CO2

pump/CO

scrubber replacement procedure. This is required every three years or after 15000

2

operating hours.

33

Page 34

3 Testing and Maintenance When to Perform Tests

When to Perform Tests

This table tells you when to perform specific tests.The corresponding test procedures are

described in the following sections All tests listed below must be performed on the monitor

itself, any attached MMS/X2 and FMS incl. parameter modules.

When to perform tests

Service Event

(When performing...

Installation

Installation of a monitor in combination with

a medical or non-medical device connected to

the same multiple socket outlet.

Installation of a standalone monitor with no

display connected to the video output

Installation of a monitor with a medical

display specified by Philips

Installation of a monitor with an off-the-shelf

display (non-compliant with IEC60601-1)

Installation of monitor with IntelliVue

Instrument Telemetry (IIT)

Installation of a monitor with AGM or

IntelliVue G1/G5, connected to separate

mains sockets.

Installation of a monitor with IT equipment

e.g. printer, PC connected via a functional

connection e.g. Centronics or USB.

Tests Required

...Complete these tests)

Perform Visual Inspection, Power On and

System Tests

Perform Visual Inspection and Power On Test

Perform Visual Inspection and Power On Test

Perform Visual Inspection, Power On and

System Test

Perform Visual Inspection, Power On and IIT

communication test

Perform Visual Inspection and Power On Tests

Perform Visual Inspection, Power On and

System Tests

Installation of monitor with IntelliVue

802.11 Bedside Adapter

Installation of networked monitor (LAN) Perform Visual Inspection and Power On Test

Preventive Maintenance

Preventive Maintenance*

34

Perform Visual Inspection, Power On and

IntelliVue 802.11 Bedside Adapter

Communication Test

Perform preventive maintenance tests and

procedures:

- NBP calibration

- Microstream CO2 calibration (M3015A)

Page 35

When to Perform Tests 3 Testing and Maintenance

Service Event

(When performing...

Other Regular Tests and Tasks

Visual Inspection

Power On Test

Repairs

Repairs where the monitor, MMS or X2 have

been damaged by impact, liquid ingression,

fire, short circuit or electrical surge.

Repairs where the power supply, the mains

socket or an interface board is removed or

replaced or the protective earth ground

connection is disrupted.

Repairs where the unit has been opened

(front and back separated).

Tests Required

...Complete these tests)

Perform Visual Inspection test block

Perform Power On test block

Perform Visual Inspection, Power On, all

Safety Tests and Full Performance Assurance

Tests

Perform Visual Inspection, Power On, all

Safety Tests and Basic Performance Assurance

Test

Perform Visual Inspection, Power On, all

Safety Tests and Basic Performance Assurance

Test

Repairs of IntelliVue Instrument Telemetry

(IIT) Module

Repairs of IntelliVue 802.11 Bedside

Adapter

Perform Visual Inspection, Power On Test

Block and IIT communication test

Perform Visual Inspection, Power On and

IntelliVue 802.11 Bedside Adapter

Communication Test

Repairs of the MMS or X2 (all service events

where the MMS or X2 have been opened)

Perform Visual Inspection, Power On, all

Safety Tests and Basic Performance Assurance

Test.

If a certain parameter seems suspicious,

perform Full Performance Assurance Test for

this parameter.

Repairs where the NBP pump of the MMS or

X2 has been replaced

Perform Visual Inspection, Power On, all

Safety Tests, Basic Performance Assurance

Test and NBP Performance Test and

Calibration

Repairs of the AGM or IntelliVue G1/G5 Perform Basic Performance Assurance Test.

For further testing requirements, see AGM or

IntelliVue G1/G5 Service Guide

Repairs where the MMS or X2 has been

replaced.

Perform Visual Inspection, Power On and

Basic Performance Assurance

Repairs where the printer connected via

Centronics or USB I/O board has been

Perform Visual Inspection, Power On, System

Test and Printer Test.

replaced.

35

Page 36

3 Testing and Maintenance When to Perform Tests

Service Event

(When performing...

All other IntelliVue Monitoring System

repairs (except when power supply is

Tests Required

...Complete these tests)

Perform Visual Inspection, Power On Test and

Basic Performance Assurance Test

removed)

Performance Assurance

Basic Performance Assurance Perform basic performance assurance tests for

the respective monitoring system component.

Full Performance Assurance Perform all accuracy and performance test

procedures listed in the following sections. If a

particular measurement is in question, perform

the measurement performance test only.

Upgrades

Software Upgrades Perform Visual Inspection, Power On Test and

Basic Performance Assurance Test unless

otherwise specified in the Upgrade Installation

Notes shipped with the upgrade.

Hardware Upgrades Perform Visual Inspection, Power On Test and

Basic Performance Assurance Test unless

otherwise specified in the Upgrade Installation

Notes shipped with the upgrade.

NOTE

Hardware Upgrades where IntelliVue

Instrument Telemetry (IIT) is installed

Perform Visual Inspection, Power On Test,

Basic Performance Assurance Test and IIT

communication Test

Hardware Upgrades where IntelliVue 802.11

Bedside Adapter is installed

Perform Visual Inspection, Power On Test,

Basic Performance Assurance Test and

IntelliVue 802.11 Bedside Adapter

Communication Test

Installation of Interfaces or Hardware

Upgrades where the power supply or

Perform Visual Inspection, Power On Test,

Basic Performance Tests and all Safety Tests

parameter boards need to be removed.

Combining or Exchanging System

Components

Perform the System Test for the respective

system components

*M3015A with the old hardware Rev. A (i.e. Serial No. DE020xxxxx) also require the pump and

scrubber replacement procedures.

It is the responsibility of the facility operator or their designee to obtain reference values for

recurring safety and system tests. These reference values are the results of the first test cycles

after an installation. You may also purchase this service from Philips.

36

Page 37

Testing Sequence 3 Testing and Maintenance

Testing Sequence

Summary of the recommended sequence of testing:

Start

Select the test

Visual Inspection

Safety Tests

Performance Tests

Reporting of Results

Evaluation of Results

See When to Perform Tests

See Visual Test (see "

page

38).

Before Each Use" on

See Safety Test Procedures (on page

41).

See Performance Assurance Tests (on page

81).

See Reporting of Test Results (on page

101)

See Evaluation of Test Results (on page

104)

NOTE

Check and prepare for normal use

If any single test fails, testing must be discontinued immediately and the device under test must

be repaired or labeled as defective.

37

Page 38

3 Testing and Maintenance Visual Inspection

Visual Inspection

Before Each Use

Check all exterior housings for cracks and damage. Check the condition of all external cables,

especially for splits or cracks and signs of twisting. If serious damage is evident, the cable should

be replaced immediately. Check that all mountings are correctly installed and secure. Refer to

the instructions that accompany the relevant mounting solution.

After Each Service, Maintenance or Repair Event

Ensure all fuses accessible from the outside comply with the manufacturer’s specification.

Check:

- the integrity of mechanical parts, internally and external ly .

- any damage or contamination, internally and externally

- that no loose parts or foreign bodies remain in the device after servicing or repair.

- the integrity of all relevant accessories.

Power On Test

1. Connect the monitoring system to mains and switch it on. This includes connected displays,

2. Make sure that all steps listed in the table Initial Instrument Boot Phase in the

The expected test result is pass: the monitor boots up and displays an ECG wave. The wave

might be a flat line if no simulator is attached.

MMS, X2, MMS Extensions and gas analyzers.

Troubleshooting section are completed successfully and that an ECG wave appears on the

screen.

38

Page 39

Safety Tests 3 Testing and Maintenance

Safety Tests

Safety tests are comprised of the following tests performed on the monitoring system:

- protective earth resistance

- equipment leakage current

- applied part leakage current

- system test (if required)

Safety test requirements are set according to international standards, their national deviations and

specific local requirements. The safety tests detailed in this Service Guide are derived from

international standards but may not be sufficient to meet local requirements. We recommend that

you file the results of safety tests. This may help to identify a problem early particularly if the

test results deteriorate over a period of time.

Each individual piece of equipment of the monitoring system which has its own connection to

mains or which can be connected or disconnected from mains without the use of a tool must be

tested individually. The monitoring system as a whole must be tested according to the System

Test (on page

66) procedure.

Accessories of the monitoring system which can affect the safety of the equipment under test or

the results of the safety test must be included in the tests and documented.

39

Page 40

3 Testing and Maintenance Safety Tests

Warnings, Cautions, and Safety Precautions

- These tests are well established procedures of detecting abnormalities that, if undetected,

could result in danger to either the patient or the operator.

- Disconnect the device under test from the patient before performing safety tests.

- Disconnect the device under test from mains before performing safety tests. If this is not

possible, ensure that the performance of these tests does not result in danger to the safety

analyzer operator, patients or other individuals.

- Test equipment (for example, a Safety Analyzer) is required to perform the safety tests.

Please refer to Annex C of IEC/EN 62353 for exact requirements for the measurement

equipment and for measurement circuits for protective earth resistance and leakage currents.

Refer to the documentation that accompanies the test equipment. Only certified technicians

should perform safety testing.

- The consistent use of a Safety Analyzer as a routine step in closing a repair or upgrade is

emphasized as a mandatory step to maintain user and patient safety. You can also use the

Safety Analyzer as a troubleshooting tool to detect abnormalities of line voltage and

grounding plus total current loads.

- During safety testing, mains voltage and electrical currents are applied to the device under

test. Ensure that there are no open electrical conductive parts during the performance of

these tests. Avoid that users, patients or other individuals come into contact with touch

voltage.

- For Europe and Asia/Pacific, the monitor complies with:

IEC60601-1:1988 + A1:1991 + A2:1995 = EN60601-1:1990 +A1:1993 + A2:1995

IEC60601-1-1:2000

For USA, the monitor complies with:

UL60601-1

For Canada, CAN/CSA C22.2#601.1-M90

- Local regulations supersede the testing requirements listed in this chapter.

- If a non-medical electrical device is connected to a medical electrical device, the resulting

medical electrical system must comply with IEC/EN 60601-1-1.

- Perform safety tests as described on the following pages.

40

Page 41

Safety Tests 3 Testing and Maintenance

Safety Test Procedures

Use the test procedures outlined here only for verifying safe installation or service of the

product. The setups used for these tests and the acceptable ranges of values are derived from

local and international standards but may not be equivalent. These tests are not a substitute for

local safety testing where it is required for an installation or a service event. If using an approved

safety tester, perform the tests in accordance with the information provided by the manufacturer

of the tester and in accordance with your local regulations, for example IEC/EN 60601-1,

UL60601-1 (US), IEC/EN 62353, and IEC/EN 60601-1-1. The safety tester should print results

as detailed in this chapter, tog ether with other data.

Please refer to Annex C of IEC/EN 62353 for requirements for the measurement equipment and

for measurement circuits for protective earth resistance and leakage currents.

The following symbols are used in the diagrams illustrating the safety tests:

CAUTION

Supply mains

Protective earth

L, N Supply mains terminals PE Protective earth terminal

Mains part

F-type applied part

Applied part

Measuring device

Connection to accessible

conductive parts

.........

Resistance measuring

device

Optional connection

After each service, maintenance or repair event:

Ensure all fuses accessible from the outside comply with the manufacturer’s specification.

Check:

- the integrity of mechanical parts, internally and external ly .

- any damage or contamination, internally and externally.

- that no loose parts or foreign bodies remain in the device after servicing or repair.

- the integrity of all relevant accessories.

41

Page 42

3 Testing and Maintenance Safety Tests

Hints for Correct Performance of Safety Tests

- Perform a visual inspection on all detachable power cords used with the monitoring system

and include these in all safety test procedures.

- Connection lines such as data lines or functional earth conductors may appear to act like

protective earth connections. These may lead to incorrect measurements and need to be

considered during testing. If necessary, unplug these connections.

- Position all cables and cords in such a manner that they do not influence the safety tests.

- Measurement of insulation resistance is not required.

42

Page 43

Safety Tests 3 Testing and Maintenance

Guideline for Performance of Safety Tests

Connect the detachable power cord of the device under test to the safety analyzer's test mains

port. Connect the enclosure test lead of the safety analyzer to the enclosure of the device under

test, e.g. to the equipotential connector. For testing the applied part leakage current, connect all

applied parts to the safety analyzer using the appropriate patient lead or adapter cable. For the

ECG parameter all ten ECG-leads need to be connected to the safety analyzer. If necessary, use

an adapter cable to connect all ten ECG-leads. If necessary, repeat the safety test procedure until

all available applied parts have been tested. Refer to the documentation that accompanies the

safety analyzer for further details on how to set up and perform the test.

Protective Earth Resistance Test - Setup Example

Equipment Leakage Current Test - Setup Example

43

Page 44

3 Testing and Maintenance Safety Tests

Applied Part Current Test - Setup Example

NOTE

The above graphics resemble the Metron QA-90 setup and are protected by copyright. Copyright

owned by Fluke (Metron).

44

Page 45

Safety Tests 3 Testing and Maintenance

Safety Test Adapter Cable - Schematics

The following graphics provide schematics of safety test (patient lead) adapter cables which can

be used for electrical safety testing. These schematics can also be used as a guideline for making

your own safety test adapter cables. Alternatively, other methods to make safety test adapter

cables can be used, e.g. using a modified accessory cable.

NOTE

You may not need all of the cables displayed below for electrical safety testing of your

respective monitor.

ECG:

45

Page 46

3 Testing and Maintenance Safety Tests

SpO2 (MP2/X2, MP5, M3001A & M1020B #A01, #A02, #A03):

46

Page 47

Safety Tests 3 Testing and Maintenance

SpO2 (M1020A):

47

Page 48

3 Testing and Maintenance Safety Tests

Invasive Pressure:

M1006B #C01:

48

Page 49

Safety Tests 3 Testing and Maintenance

Temperature:

49

Page 50

3 Testing and Maintenance Safety Tests

CO2 (MP5, M3014A):

50

Page 51

Safety Tests 3 Testing and Maintenance

CO2 (M1016A, M3016A):

4 = all resistors 120 KOhm

51

Page 52

3 Testing and Maintenance Safety Tests

Cardiac Output:

52

Page 53

Safety Tests 3 Testing and Maintenance

BIS:

Use Clamp Adapter Cable and M1034-61650 BIS sensor simulator.

53

Page 54

3 Testing and Maintenance Safety Tests

VueLink:

4 = 220 Ohm

54

Page 55

Safety Tests 3 Testing and Maintenance

IntelliBridge:

55

Page 56

3 Testing and Maintenance Safety Tests

EEG:

56

Page 57

Safety Tests 3 Testing and Maintenance

SvO2 (M1021A):

57

Page 58

3 Testing and Maintenance Safety Tests

ScvO2 (M1011A):

58

Page 59

Safety Tests 3 Testing and Maintenance

tcpO2/tcpCO2:

59

Page 60

3 Testing and Maintenance Safety Tests

MP5 predicitive Temperature:

60

Page 61

Safety Tests 3 Testing and Maintenance

MP5 TAAP:

61

Page 62

3 Testing and Maintenance Safety Tests

S(1): Protective Earth Resistance Test

Test to perform:

Measuring circuit for the measurement of Protective Earth Resistance in medical electrical

equipment that is disconnected from the supply mains.

NOTE

This measures the impedance of the Protective Earth (PE) terminal to all exposed metal parts of

the Instrument under Test (IUT), which are for safety reasons connected to the Protective Earth

(PE).

Measurements shall be performed using a measuring device capable to deliver a current of at

least 200 mA into 500 mOhms with maximum 24V

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, UL2601-1 Ed. 2/UL60601-1:2003

and CSA 601.1-M90.

For measurement limits, refer to Safety (1) test, Test and Inspection Matrix.

Report the highest value (X1).

Test Expected test results

Protective Earth Resistance Test (with

X1 <= 300mOhms

mains cable)

- If the protective earth resistance test fails, testing must be discontinued immediately and the

device under test must be repaired or labeled as defective.

- All values for current and voltage are the root mean square (r.m.s.) values, unless otherwise

stated.

- Flex the power cord during the protective earth resistance test to evaluate its integrity. If it

does not pass the test, exchange the power cord.

62

Page 63

Safety Tests 3 Testing and Maintenance

S(2): Equipment Leakage Current Test - Normal Condition

Test to perform:

Measuring circuit for the measurement of Equipment Leakage Current - Direct method

according to IEC/EN 62353.

NOTE

This test measures leakage current of exposed metal parts of the monitor and the functional earth

leakage current. It tests normal and reversed polarity. Perform the test with S1 closed (Normal

Condition).

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, UL2601-1 Ed. 2/UL60601-1:2003

and CSA 601.1-M90.

For measurement limits, refer to Safety (2) test, Test and Inspection Matrix.

Report the highest value (X1).

Test Expected test results

Equipment Leakage Current Test

X1 <= 100μA

(Normal Condition - with mains

cable)

All values for current and voltage are the root mean square (r.m.s.) values, unless otherwise

stated.

63

Page 64

3 Testing and Maintenance Safety Tests

S(3): Equipment Leakage Current Test - Single Fault Condition

Test to perform:

Measuring circuit for the measurement of Equipment Leakage Current - Direct method

according to IEC/EN 62353.

This test measures leakage current of exposed metal parts of the monitor and the functional earth

leakage current. It tests normal and reversed polarity. Perform the test with S1 open (Single Fault

Condition).

NOTE

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, UL2601-1 Ed. 2/UL60601-1:2003

and CSA 601.1-M90.

For measurement limits, refer to Safety (3) test, Test and Inspection Matrix.

Report the highest value (X2).

Test Expected test results

Equipment Leakage Current Test

X2 <= 300μA

(Single Fault Condition - with mains

cable)

All values for current and voltage are the root mean square (r.m.s.) values, unless otherwise

stated.

64

Page 65

Safety Tests 3 Testing and Maintenance

S(4): Applied Part Leakage Current - Mains on Applied Part

NOTE

During measurement of the Applied Part Leakage Current it is possible that the measured current

can exceed the allowed limit (per IEC/EN 60601-1 or IEC/EN 62353).

This can occur when the safety tester is connected to the invasive blood pressure and

temperature connectors at the same time during the applied leakage current measurement.

The connectors for the invasive blood pressure and temperature are independently functioning

connectors.

Although there are individual connectors on the front end, internally those parameters use the

same electrical insulation interface and are hardwired to each other. This results in an electrical

short of those connectors during measurement if a test current is applied simultaneously .

Therefore this should be avoided.

Due to the combined insulation interface, it is sufficient to connect to only one parameter

interface (that is, Invasive Blood Pressure or Temperature) of the invas ive bl ood

pressure/temperature measurement block. This avoids a short and the potential of exceeding the

limit for the current.

Test to perform:

65

Page 66

3 Testing and Maintenance System Test

Measuring circuit for the measurement of Applied Part Leakage Current - Direct method

according to IEC/EN 62353.

This test measures applied part leakage current from applied part to earth caused by external

main voltage on the applied part. Each polarity combination possible shall be tested. This test is

applicable for ECG measurement inputs.

There are no parts of the equipment that are not protectively earthed.

This safety test is based on IEC/EN 60601-1, IEC/EN 62353, UL2601-1 Ed. 2/UL60601-1:2003

and CSA 601.1-M90.

For measurement limits and test voltage, refer to Safety (4) test, Test and Inspection Matrix.

Report the highest value. (X1).

Test Expected test results

Applied Part Leakage Current Test

S4 <= 50μA

(Single Fault Condition - mains on

applied part)

NOTE

All values for current and voltage are the root mean square (r.m.s.) values, unless otherwise

stated.

System Test

After mounting and setting up a system, perform system safety tests according to IEC/EN

60601-1-1.

What is a Medical Electrical System?

A medical electrical system is a combination of at least one medical electrical piece of

equipment and other electrical equipment, interconnected by functional connection or use of a

multiple portable socket-outlet.

- Devices forming a medical electrical system must comply with IEC/EN 60601-1-1.

- Any electrical device such as IT equipment that is connected to the medical electrical

equipment must comply with IEC/EN 60601-1-1 and be tested accordingly.

66

Page 67

System Test 3 Testing and Maintenance

General Requirements for a System

After installation or subsequent modification, a system must comply with the requirements of the

system standard IEC/EN 60601-1-1. Compliance is checked by inspection, testing or analysis, as

specified in the IEC/EN 60601-1-1 or in this book.

Medical electrical equipment must comply with the requirements of the general standard IEC/EN

60601-1, its relevant particular standards and specific national deviations. Non-medical electrical

equipment shall comply with IEC safety standards that are relevant to that equipment.

Relevant standards for some non-medical electrical equipment may have limits for equipment

leakage currents higher than required by the standard IEC/EN 60601-1-1. These higher limits are

acceptable only outside the patient environment. It is essential to reduce equipment leakage

currents to values specified in IEC 60601-1 when non-medical electrical equipment is to be used

within the patient environment.

System Example

This illustration shows a system where both the medical electrical equipment and the

non-medical electrical equipment are situated at the patient’s bedside.

67

Page 68

3 Testing and Maintenance System Test

WARNING

- Do not use additional AC mains extension cords or multiple portable socket-outlets. If a

multiple portable socket-outlet is used, the resulting system must be compliant with IEC/EN

60601-1-1. Do not place multiple socket-outlets on the floor. Do not exceed the maximum

permitted load for multiple socket-outlets used with the system. Do not plug additional

multiple socket outlets or extension cords into multiple socket outlets or extension cords

used within the medical electrical system.

- Do not connect any devices that are not supported as part of a system.

- Do not use a device in the patient vicinity if it does not comply with IEC/EN 60601-1. The

whole installation, including devices outside of the patient vicinity, must comply with

IEC/EN 60601-1-1. Any non-medical device placed and operated in the patient’s vicinity

must be powered via a separating transformer (compliant with IEC/EN 60601-1-1) that

ensures mechanical fixing of the power cords and covering of any unused power outlets.

68

Page 69

System Test 3 Testing and Maintenance

System Installation Requirements

- Ensure that the the medical electrical system is installed in a way that the user achieves

optimal use.

- Make sure the user is informed about the required cleaning, adjustment, sterilization and

disinfection procedures listed in the Instructions for Use.

- The medical electrical system must be installed in such a way that the user is able to carry

out the necessary cleaning, adjustment, sterilization and disinfection procedures listed in the

Instructions for Use.

- Ensure that the medical electrical system is installed in a way that an interruption and

restoration of power to any part of the medical electrical system does not result in a safety

hazard.

- We recommend using fixed mains socket outlets to power the medical system or parts

thereof. Avoid using multiple portable socket-outlets.

- Any multiple portable socket outlets used must be compliant with IEC 60884-1 and IEC

60601-1-1.

- Ensure that any part of the system connected to multiple portable socket-outlets is only

removable with a tool, i.e. the multiple portable socket-outlet provides a locking mechanism

to prevent power cords from being plugged or unplugged unintentionally. Otherwise, the

multiple portable socket-outlet must be connected to a separation device. Multiple Socket

Outlets used within the medical electrical system must only be used for powering medical

electrical equipment which is part of the system.

- Ensure that any functional connections between parts of the medical electrical system are

isolated by a separation device according to IEC 60601-1-1 to limit increased equipment

leakage currents caused by current flow through the signal connections. This only works if

the equipment leakage current of the respective medical electrical system parts is not

exceeded under normal conditions.

- Avoid increase of equipment leakage currents when non-medical electrical equipment within

the medical electrical system is used. This only works if the equipment leakage current of

the respective medical electrical system parts is not exceeded under normal conditions. Use

additional protective earth connection, separation device or additional non-conductive

enclosures.

- Within the patient environment it is important to limit electrical potential differences

between different parts of a system. If necessary, use potential equalization equipment

(equipotential cable) or additional protective earth connections.

- Medical electrical equipment used in medical rooms must be connected to potential

equalization equipment (equipotential cable) to avoid electrical potential differences. Check

your local requirements for details.

69

Page 70

3 Testing and Maintenance System Test

Required Protective Measures at System Installation

For any IT equipment (IEC60950) operated in patient vicinity ensure that the equipment leakage

current does not exceed the limits described in IEC 60601-1. Use a separation device to ensure

compliance. After installation of IT equipment in patient vicinity, an enclosure leakage current

test is required.

70

Page 71

System Test 3 Testing and Maintenance

Case 1: Medical Device Combined with Medical Device

If you combine a medical device with another medical device (incl. Philips specified displays) to

form a medical electrical system according to IEC60601-1-1, no additional protective measures

are required. The medical electrical devices may be located in or outside the patient vicinity in a

medically used room. This is valid as long as the medical devices are connected to separate

mains outlets. No system test is required.

71

Page 72

3 Testing and Maintenance System Test

If the combined medical devices are connected to the same multiple portable socket outlet an

enclosure leakage current test of the entire device combination on the multiple portable socket

outlet is required to ensure that the resulting protect ive earth leakage current and equipment

leakage current does not exceed the limits of IEC 60601-1-1. Avoid using multiple portable

socket outlets. The medical electrical devices may be located in or outside the patient vicinity in

a medically used room. If the limits are exceeded, additional protective measures are required,

e.g. a separation device or the connection of each device to separate mains.

72

Page 73

System Test 3 Testing and Maintenance

Case 2: Medical Device Combined with a Non-Medical Device

If you combine a medical device with a non-medical device to form a medical electrical system

according to IEC60601-1-1, additional protective measures are required, e.g. usage of a

separation device. The medical electrical devices or the IT equipment may be located in or

outside the patient vicinity in a medically used room. After system installation incl. protective