Philips FWC80C37 Service Manual

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

Pg. SCHEMATIC DIAGRAMS AND PC BOARDS

1. OVERALL WIRING DIAGRAM

2. FRONT BOARD SCHEMATIC DIAGRAM

3. CDC KEY SCHEMATIC DIAGRAM

4. HEADPHONE SCHEMATIC DIAGRAM

5. CONTROL SCHEMATIC DIAGRAM

6. EC05 TUNER SCHEMATIC DIAGRAM

7. CASSETTE ANALOG SCHEMATIC DIAGRAM

8. CASSETTE SERVO SCHEMATIC DIAGRAM

9. CD SCHEMATIC DIAGRAM 1

10. CD SCHEMATIC DIAGRAM 2

11. POWER SUPPLY SCHEMATIC DIAGRAM

12. L/R AMPLIFIER SCHEMATIC DIAGRAM

13. AF8 SCHEMATIC DIAGRAM 1

14. AF8 SCHEMATIC DIAGRAM 2

15. FRONT CBA (COMPONENT SIDE)

16. FRONT CBA (COPPER SIDE)

17. CDC KEY CBA (COMPONENT SIDE)

18. CDC KEY CBA (COPPER SIDE)

Manual 1970

Model no.: FWC80C37

First Publish: 08-02-00

Rev. Date: 04-05-2005

Print Date: 05.04.2005

19. HEADPHONE CBA (COMPONENT SIDE)

20. HEADPHONE CBA (COPPER SIDE)

21. CONTROL CBA (COMPONENT SIDE)

22. CONTROL CBA (COPPER SIDE)

23. CD CBA (COMPONENT SIDE)

24. CD CBA (COPPER SIDE)

25. L/R AMP AND SUPPLY CBA (COMPONENT SIDE)

26. L/R AMP AND SUPPLY CBA (COPPER SIDE)

27. AF8 CBA (COMPONENT SIDE)

28. AF8 CBA (COPPER SIDE)

29. OVERALL BLOCK DIAGRAM

30. EC05 TUNER BLOCK DIAGRAM

31. CASSETTE BLOCK DIAGRAM

32. CD BLOCK DIAGRAM

33. CASSETTE WIRING DIAGRAM 1

34. CASSETTE WIRING DIAGRAM 2

REFER TO SAFETY GUIDELINES

SAFETY NOTICE: ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation Visit our World Wide Web Site at http://www.forceonline.com

PDF created with pdfFactory trial version www.pdffactory.com

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

Manual 1970

Model no.: FWC80C37

First Publish: 08-02-00

Rev. Date: 04-05-2005

Print Date: 05.04.2005

Mechanical Assembly

REFER TO SAFETY GUIDELINES

SAFETY NOTICE: ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation Visit our World Wide Web Site at http://www.forceonline.com

PDF created with pdfFactory trial version www.pdffactory.com

DISASSEMBLY INSTRUCTIONS

Dismantling the Cassette Cover

Remove Cassette Cover

Cassette Cover

Dismantling the CDC Module and Front Panel

Note: Position (pos.) numbers below refer to the Cabinet Exploded View

1) Loosen 18 screws to remove the Cabinet Rear (pos. 259):

- 5 screws each on the left and right side of the Cassette Cover

- 8 screws on the back of the Cabinet Rear.

2) Slide out the CDC Tray as shown, using a flat head screwdriver.

CDC Tray Removal 1

CDC Tray Removal 2

3) Remove the Cover Tray CDC (pos. 106) as shown.

Cover Tray CDC Removal

4) Loosen 2 screws A and 2 screws B to remove the CDC Module (pos. 1104) as shown.

5) Remove 1 screw (pos. 305) at the bottom to separate the Front Panel Assembly from

the Plate Bottom (pos. 231).

CDC Front View

CDC Module Removal

Dismantling the Front Board

Remove Control Board

1) Remove 1 screw C as indicated to loosen the Headphone Board (pos. 1101-E).

2) Remove 5 screws D as indicated to loosen the Plate Front (pos. 254).

Front Board View

PDF created with pdfFactory trial version www.pdffactory.com

3) Remove 4 screws E as indicated to loosen the Front Board (pos. 1100-A).

4) Remove 5 screws F as indicated to loosen the Control Board (pos. 1100-B).

Dismantling the ETF Tape Module

1) Remove 6 screws G as indicated to loosen the ETF Tape Module (pos. 1103).

ETF Tape Module Removal

Dismantling the Rear Portion

AF Board Top View

Rear View

1) Remove 5 screws J as indicated to loosen the AF Board (pos. 1101).

2) Remove 4 screws K and unlatch M1 as indicated to loosen the Tuner Board (pos. 1102).

3) Remove 5 screws L and unlatch M2 as indicated to take out the Plate Rear (pos. 229).

4) Remove 4 screws P and unlatch M3 as indicated to free the Power Module (pos. 1105)

from the Bottom Plate assembly.

Repair Hints

1) The Knob Volume Rotary (pos. 149) can be removed by inserting a strong string into the

slot and pulling it out in the direction indicated. See picture 1.

Picture 1

2) The Jog Rotary (pos. 138) can be removed by inserting a strong string into the slot and

pulling it out in the direction indicated. See picture 2.

Picture 2

3) During reassembly of the Power Module, place the Bracket Mains Socket (pos. 232) behind

the Mains Socket and catch it onto the Rucksack (pos. 1105-201) of the Power Module. See

pictures 3 and 4.

Picture 3

PDF created with pdfFactory trial version www.pdffactory.com

Picture 4

4) During repair, it is possible to disconnect the Tuner Board and CDC Module completely unless the

fault is suspected to be in that area. This will not affect the performance of the rest of the set.

Note: The flex cables are very fragile; care should be taken not to damage them during repair. After

repair, be very sure that the flex cables are inserted properly into the flex sockets before encasing,

otherwise faults may occur.

5) Due to the short flex cable wires in the ETF Module, the pc board should be disconnected and

reconnected on the reverse side of the tape mechanism to keep it electrically connected during

repair. See picture 5.

Picture 5

6) Use an insulation sheet to prevent the AF Board and ETF Board from being damaged or short-

circuited to any metal parts.

Service pos. A

Service pos. B

Service pos. C

CD Drive Mechanism

Mechanism Photo

CD Servicing Hints

Replacement of CD Drive

Warning

Charged capacitors on the servo board may damage the CD drive electronics when

connecting a new CDM mechanism. That is why, in addition to safety measures such

as switching off the power supply and utilizing ESD protection, additional actions

must be taken by the repair technician.

The following steps must be done when replacing the CD drive mechanism:

PDF created with pdfFactory trial version www.pdffactory.com

1. Disconnect the CD drive flexfoil from the old CD drive.

2. Short circuit the flexfoil with a paperclip to protect the laser against ESD.

Flexfoil short-circuit

3. Remove the old CD drive.

4. Remove the short circuit from the flexfoil.

Note

The laser diode of this CD drive is protected against ESD by a solder joint which short circuits the laser

diode to ground. For proper functionality of the CD drive, this solder joint must be removed after

connection of the drive to the system.

Solder Joint Photo

Service Position

CD Mechanism Wiring

PDF created with pdfFactory trial version www.pdffactory.com

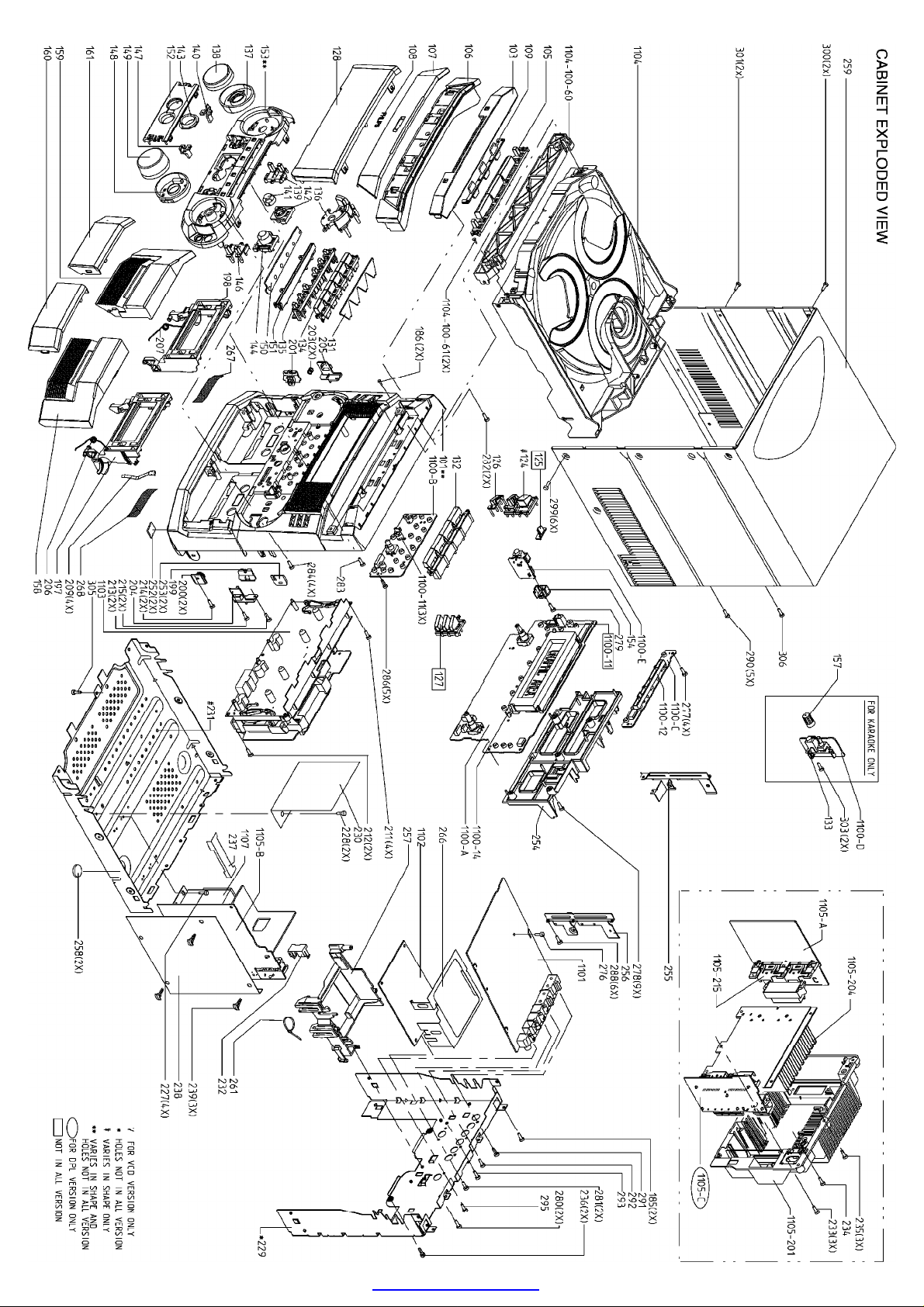

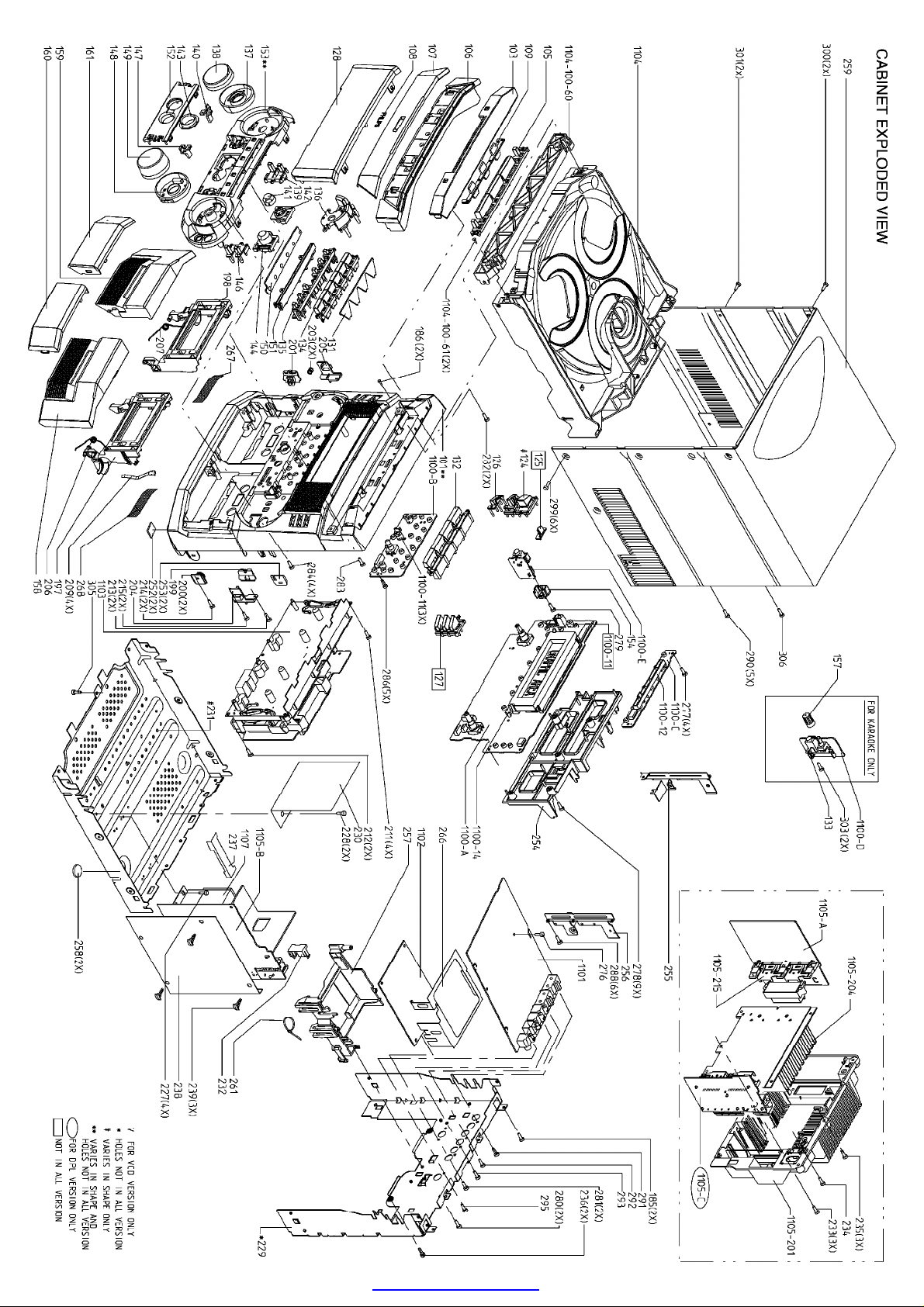

Cabinet Exploded View

PDF created with pdfFactory trial version www.pdffactory.com

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

Manual 1970

Model no.: FWC80C37

First Publish: 08-02-00

Rev. Date: 04-05-2005

Print Date: 05.04.2005

Mechanical Diagrams

REFER TO SAFETY GUIDELINES

SAFETY NOTICE: ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation Visit our World Wide Web Site at http://www.forceonline.com

PDF created with pdfFactory trial version www.pdffactory.com

MAIN CABINET EXPLODED VIEW Page: 1 of 7

PDF created with pdfFactory trial version www.pdffactory.com

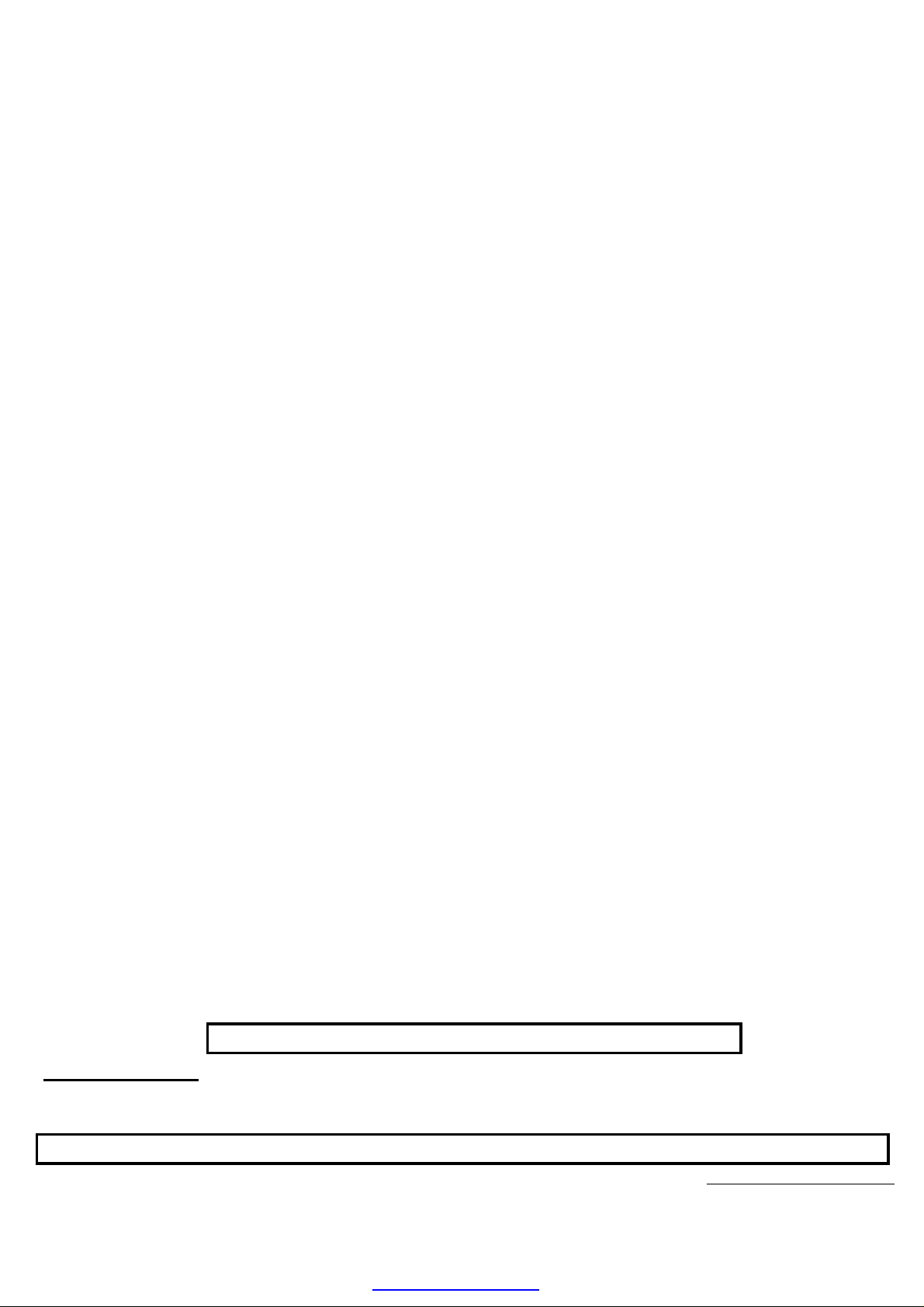

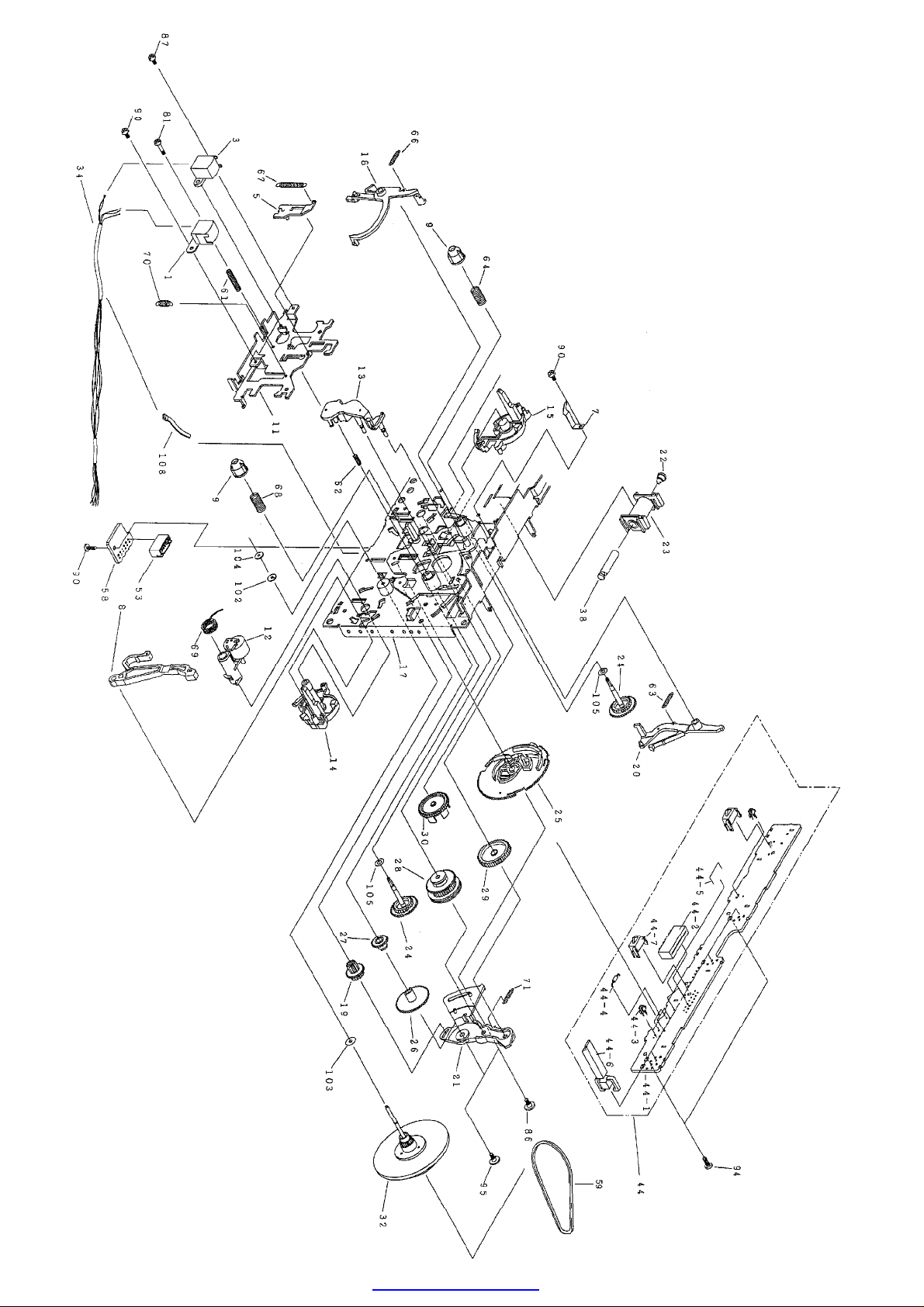

TAPE MECHANISM A EXPLODED VIEW Page: 2 of 7

PDF created with pdfFactory trial version www.pdffactory.com

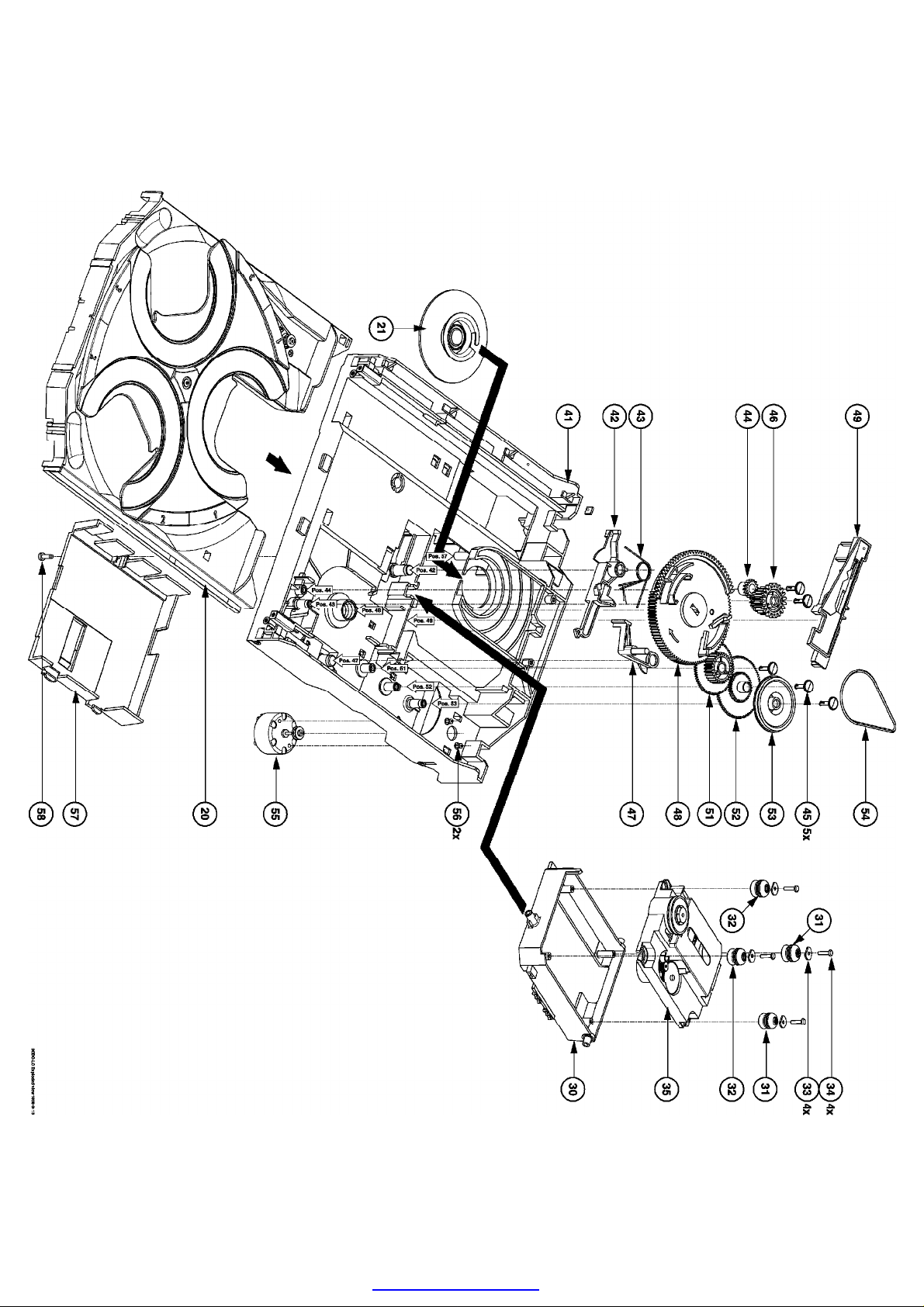

TAPE MECHANISM B EXPLODED VIEW 1 Page: 3 of 7

PDF created with pdfFactory trial version www.pdffactory.com

TAPE MECHANISM B EXPLODED VIEW 2 Page: 4 of 7

PDF created with pdfFactory trial version www.pdffactory.com

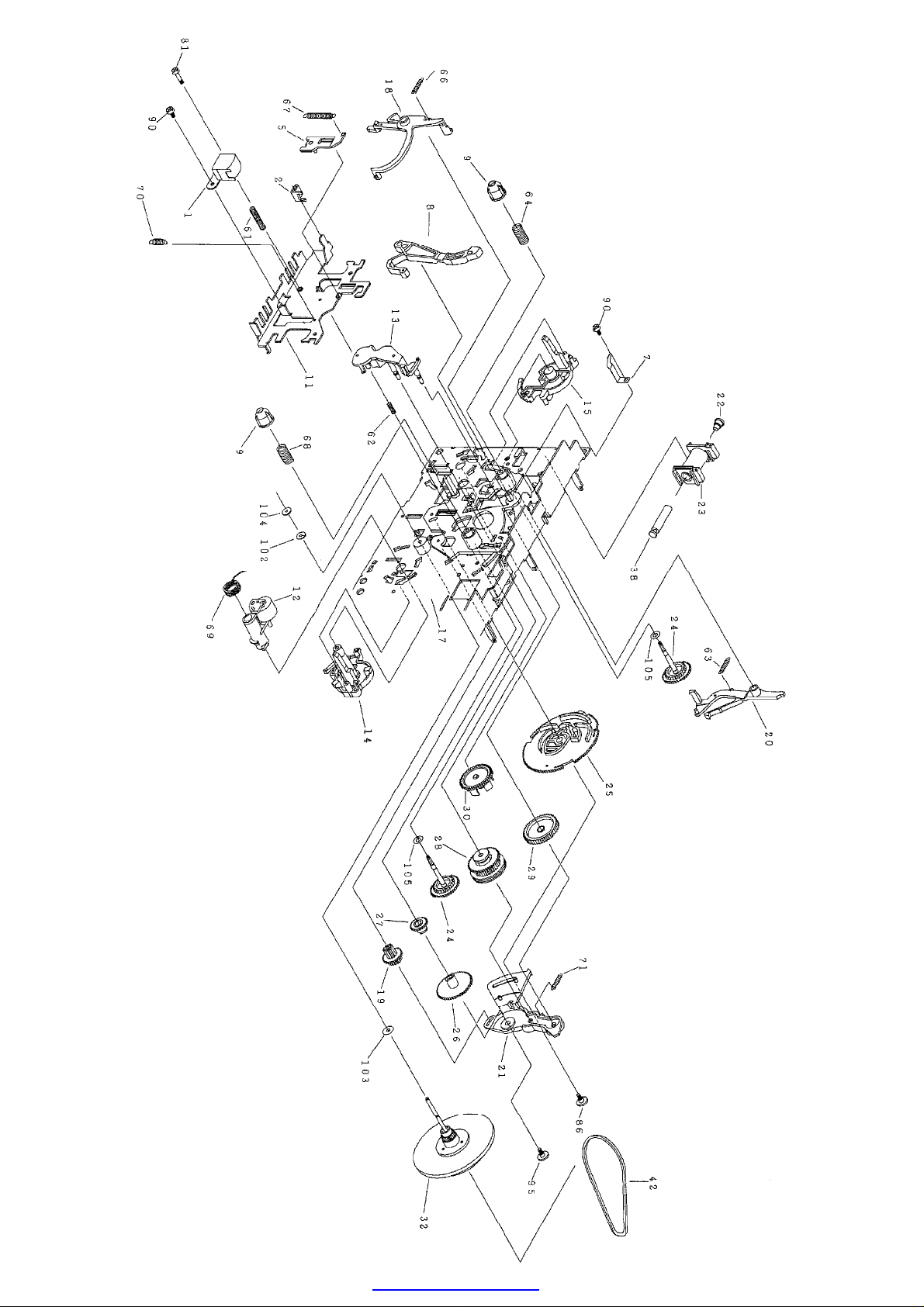

TAPE MECHANISM MOTOR EXPLODED VIEW Page: 5 of 7

PDF created with pdfFactory trial version www.pdffactory.com

CD MECHANISM EXPLODED VIEW 1 Page: 6 of 7

PDF created with pdfFactory trial version www.pdffactory.com

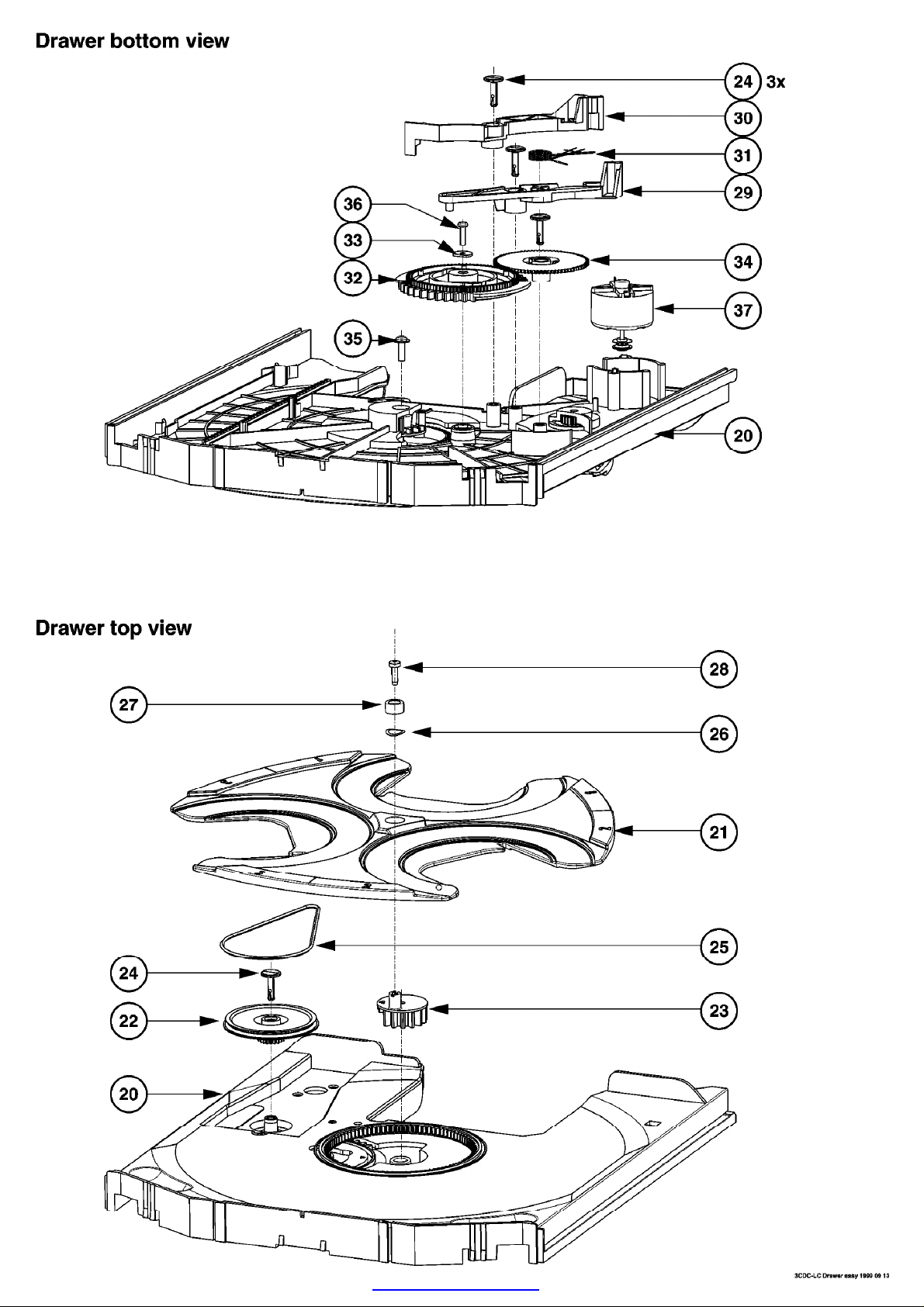

CD DRAWER MECHANISM TOP AND BOTTOM EXPLODED VIEW Page: 7 of 7

PDF created with pdfFactory trial version www.pdffactory.com

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

Manual 1970

Model no.: FWC80C37

First Publish: 08-02-00

Rev. Date: 04-05-2005

Print Date: 05.04.2005

General Information

REFER TO SAFETY GUIDELINES

SAFETY NOTICE: ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation Visit our World Wide Web Site at http://www.forceonline.com

PDF created with pdfFactory trial version www.pdffactory.com

GENERAL INFORMATION

FWC80C37 Photograph

VERSION VARIATIONS

Type /Versions: FWC80

Features and

Board used:

/22 /34 /37

Aux. Input x x x

Line Out x x x

Surround Out

Subwoofer Out x x x

Digital Out x x x

Matrix Surround

CD Text

Dolby B x

RDS x x

News x x

Dolby Prologic (DPL)

Incredible Surround

Karaoke Features

Voltage Selector

Lower Power Standby (Clock Display Off) x x

Tuner Board - EC05 System x x

Tuner Board - Tuner 95 x

ETF7 ND/DD/FR - Chapter 9 x x

ETF7 DB/DD/FR - Chapter 9A x

SPECIFICATIONS

PDF created with pdfFactory trial version www.pdffactory.com

GENERAL:

Mains voltage : 110-127V/220-240V Switchable for /21/21M

120V for /37

220V for /33

220-230V for /22/34

230-240V for /30

Mains frequency : 50/60Hz

Power consumption

Low power standby : < 2W

Standby : < 15W

At 1/8 rated power out : 85W

Power consumption (/37)

Standby : < 15W

At 1/8 rated power out : 75W

Clock accuracy : < 4 seconds per day

Dimensions of center unit : 265 x 310 x 390mm

TUNER:

FM

Tuning range : 87.5-108MHz

65.81-74MHz for /34

Grid : 50kHz (and 30kHz for /34)

100kHz for /37

IF frequency : 10.7MHz ± 25kHz

Aerial input : 75 ohm coaxial

300ohm click fit for /37

Sensitivity at 26dB S/N : < 7µV

Selectivity at 600kHz bandwidth : > 25dB

Image rejection : > 25dB [> 75dB]

Distortion at RF=1mV, dev. 75kHz : < 3%

-3dB Limiting point : < 8uV

Crosstalk at RF=1mV, dev. 40kHz : > 18dB

MW (AM)

Tuning range : 531-1602kHz

530-1700kHz for /21/21M/37

Grid : 9kHz

10kHz for /21/21M/37

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : < 4.0mV/M

Selectivity at 18kHz bandwidth : > 18dB

IF rejection : > 45dB

PDF created with pdfFactory trial version www.pdffactory.com

Image rejection : > 28dB

Distortion at RF=50mV, m=80% : < 5%

LW

Tuning range : 153-279kHz

Grid : 3kHz

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : [< 7.0mV/M]

Selectivity at 18kHz bandwidth : [> 24dB]

IF rejection : [> 26dB]

Image rejection : [> 35dB]

Distortion at RF=50mV, m=80% : [< 5%]

AMPLIFIER:

Output power (6 ohms, 1kHz, 10% THD)

Left/Right : 2 x 60W

Output power (6 ohms, 60Hz-12.5kHz, 10% THD) /37

Left/Right : 2 x 50W

Frequency response within ±3dB : 60Hz-16kHz

Digital Sound Control (DSC) : Optimal, Classic, Techno, Jazz, Rock, Vocal

Virtual Environment Control (VEC) : Hall, Disco, Concert, Club, Cinema, Arcade

WOOX : 1, 2, 3

Headphone output at 32 ohms : 18mW ± 1dB

Input sensitivity

Aux. in : 500mV ± 2dB, 1kHz

Microphone : 4mV ± 2dB

Output sensitivity

Line out (Left/Right) : 500mV ± 2dB at 22 kohm

Subwoofer out at max. vol. (100Hz) : 1.3V ± 2dB at 22 kohm

CASSETTE RECORDER:

Number of tracks : 2 x 2 stereo

Tape speed : 4.76 cm/sec ± 2%

Wow and flutter : < 0.4% (DIN)

Fast-wind/Rewind time C60 : 130 sec.

Bias system : 75kHz ± 10kHz

Rec./PB freq. response within 8dB : 80Hz - 12.5kHz

Signal to noise ratio (unweighted) : > 44dB

1

PDF created with pdfFactory trial version www.pdffactory.com

COMPACT DISC:

Measurement done at output conn. of the CDC module.

Set level at 6 ohms speaker loads.

Frequency response : < ± 3dB for 63Hz - 14kHz

Signal/Noise ration (unweighted) : 60dBA

Signal/Noise ratio (A-weighted) : 67dBA

THD (30Hz-16kHz) : 1.5%

Channel difference (250Hz-10kHz) : < ± 2dB

Channel separation (20Hz-20kHz) : 30dB

Channel separation (1kHz) : 40dB

[....] Values indicated are for "Tuner 95 Board" only

1)

Default setting is OFF.

SERVICE AIDS:

Service Tools:

Universal Torx driver holder 4822 395 91019

Torx bit T10 150mm 4822 395 50456

Torx driver set T6 - T20 4822 395 50145

Torx driver T10 extended 4822 395 50423

Cassette:

SBC419 Test cassette CrO2 4822 397 30069

SBC420 Test cassette Fe 4822 397 30071

MTT150 Dolby level 200nWb/M 4822 397 30271

Compact Disc:

SBC426/426A Test disc 5 + 5A 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz 4822 397 30155

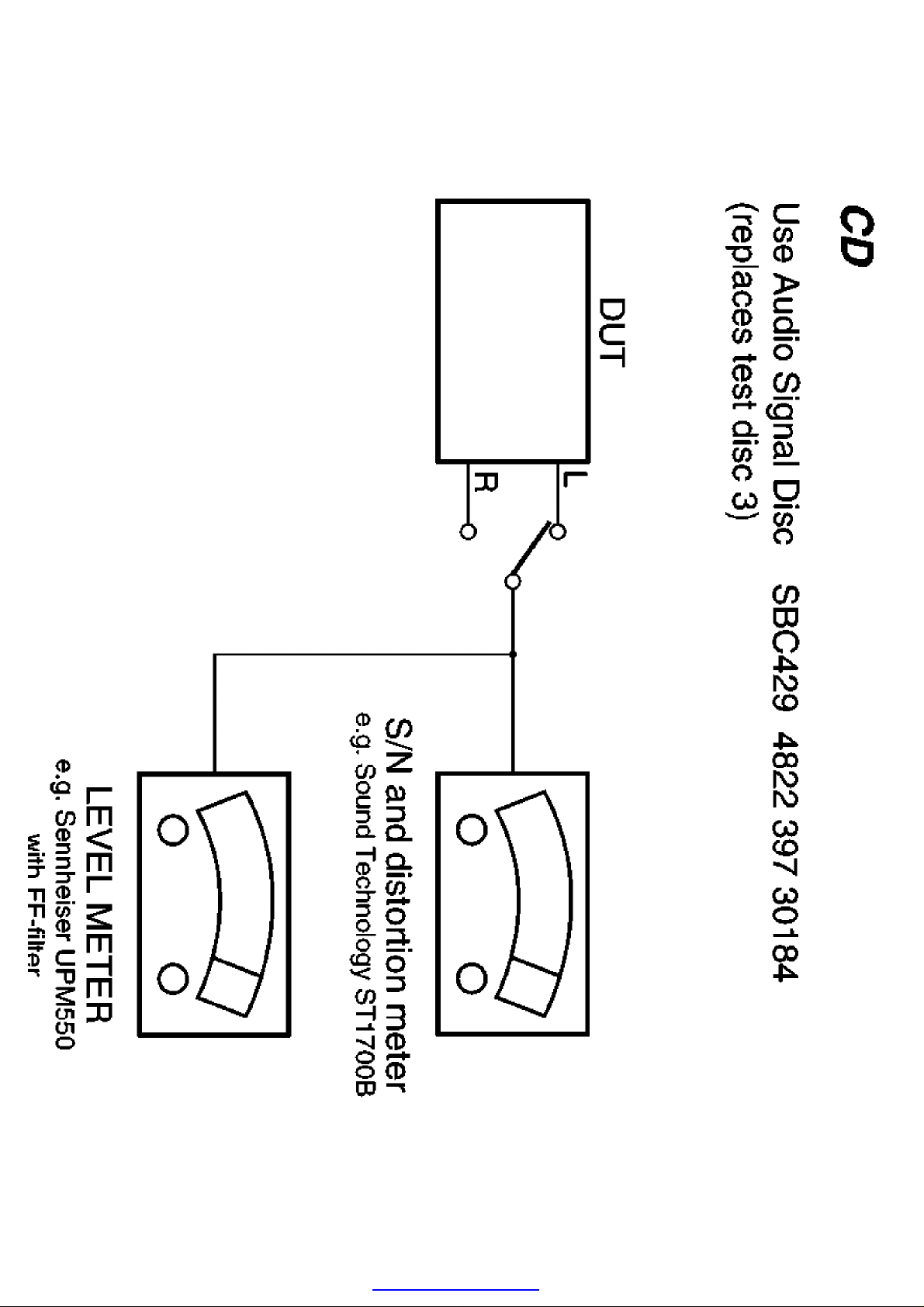

SBC429 Audio Signals disc 4822 397 30184

Dolby Pro-logic Test Disc 4822 395 10216

ESD Equipment:

Anti-static table mat - large 1200x650x1.25mm 4822 466 10953

Anti-static table mat - small 600x650x1.25mm 4822 466 10958

Anti-static wristband 4822 395 10223

Connector box (1Mý) 4822 320 11307

Extension cable

(to connect wristband to conn. box) 4822 320 11305

Connecting cable

(to connect table mat to conn. box) 4822 320 11306

Earth cable (to connect product to mat or box) 4822 320 11308

Complete kit ESD3

(combining all above products) 4822 320 10671

Wristband tester 4822 344 13999

PDF created with pdfFactory trial version www.pdffactory.com

WARNING

with the same potential as the mass of the set via a wrist wrap with resistance. Keep components and

All ICs and many other semiconductors are susceptible to electrostatic discharges (ESD). Careless

handling during repair can reduce life drastically. When repairing, make sure that you are connected

tools also at this potential.

Safety regulations require that the set be restored to its original condition and that parts which are

identical with those specified be used.

Warning !

Invisible laser radiation when open. Avoid direct exposure to beam.

"After servicing and before returning set to customer perform a leakage current measurement test

from all exposed metal parts to earth ground to assure no shock hazard exist. The leakage current

must not exceed 0.5mA."

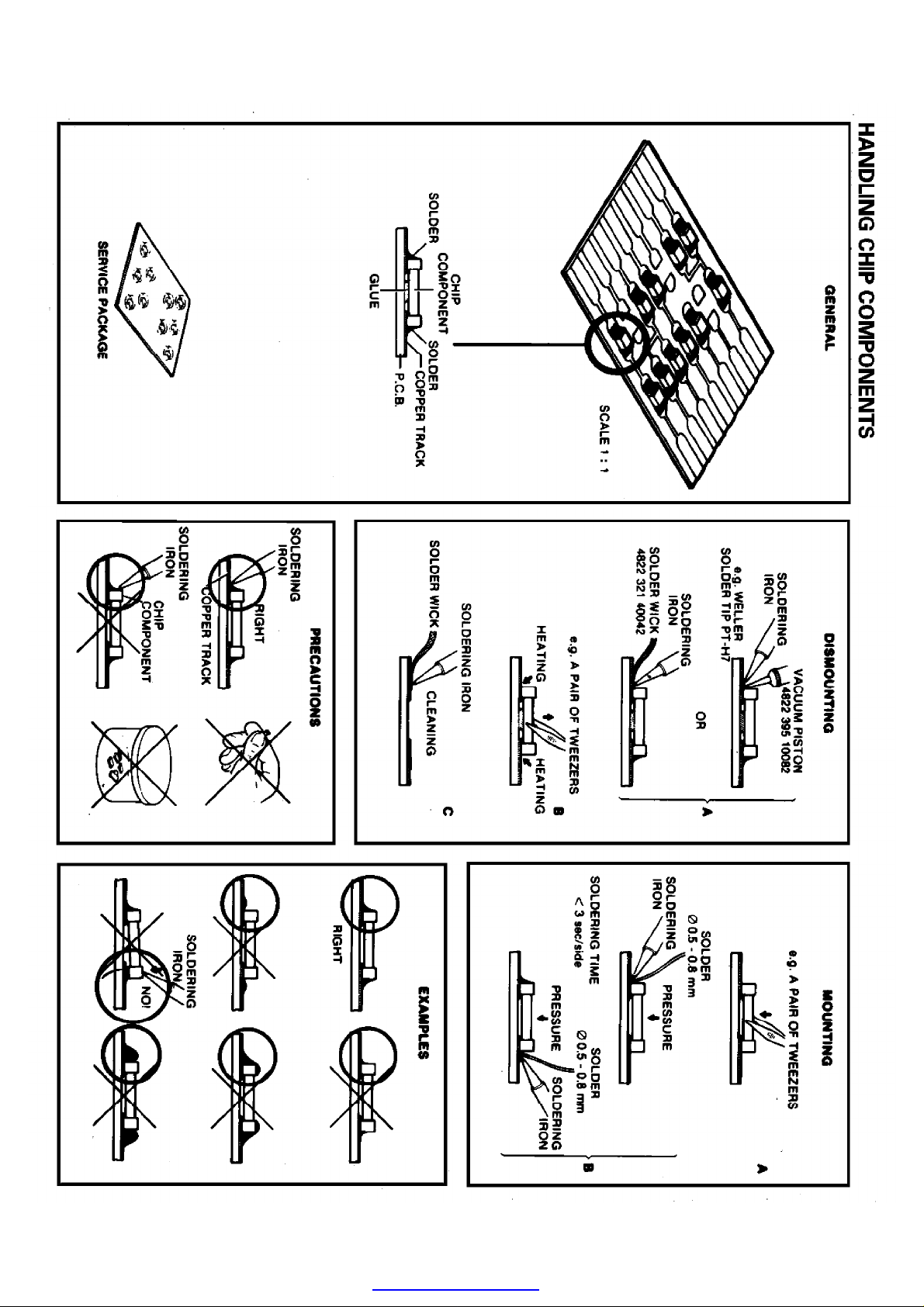

Handling Chip Components

PDF created with pdfFactory trial version www.pdffactory.com

Handling Chip Components

PDF created with pdfFactory trial version www.pdffactory.com

Philips Consumer Electronics

Technical Service Data

Service and Quality

Service Publications Dept.

One Philips Drive

P.O. Box 14810

Knoxville, TN 37914

Manual 1970

Model no.: FWC80C37

First Publish: 08-02-00

Rev. Date: 04-05-2005

Print Date: 05.04.2005

Electrical Adjustments

REFER TO SAFETY GUIDELINES

SAFETY NOTICE: ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE

HIMSELF WITH THE CHASSIS AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS

TO BE USED WHEN SERVICING ELECTRONIC EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING

© Philips Electronics North America Corporation Visit our World Wide Web Site at http://www.forceonline.com

PDF created with pdfFactory trial version www.pdffactory.com

Adjustments

Safety Instructions:

WARNING

All ICs and many other semiconductors are susceptible to electrostatic discharges

(ESD). Careless handling during repair can reduce life drastically. When repairing,

make sure that you are connected with the same potential as the mass of the set via

a wrist wrap with resistance. Keep components and tools also at this potential.

Safety regulations require that the set be restored to its original condition and that

parts which are identical with those specified be used.

Invisible laser radiation when open. Avoid direct exposure to beam.

After servicing and before returning the unit to the customer, perform a leakage

current measurement test from all exposed metal parts to earth ground to assure no

shock hazards exist. The leakage current must not exceed 0.5mA.

Schematic Notes:

1. All resistor values are in ohms, and the value multiplier is often

used to indicate decimal point location (e.g., 2K2 indicates 2.2K).

2. Resistor values with no multiplier may be indicated with either an

“E“ or ”R“ (e.g., 220E or 220R indicates 220 ohms).

3. All capacitor values are expressed in Microfarads (e.g., u = x10-6),

nanofarads (e.g., n = x10-9), or picofarads (e.g., x10

-12

).

4. Capacitor values may also use the value multiplier as the decimal

point indication (e.g., 2p2 indicates 2.2pF.).

5. Voltages listed on schematics often use a comma to indicate the

decimal point location as it is perceived as being ”more visible.“

Refer to individual schematic diagrams for all other component indications.

PDF created with pdfFactory trial version www.pdffactory.com

SERVICE AIDS:

Service Tools:

Universal Torx driver holder 4822 395 91019

Torx bit T10 150mm 4822 395 50456

Torx driver set T6 - T20 4822 395 50145

Torx driver T10 extended 4822 395 50423

Cassette:

SBC419 Test cassette CrO2 4822 397 30069

SBC420 Test cassette Fe 4822 397 30071

MTT150 Dolby level 200nWb/M 4822 397 30271

Compact Disc:

SBC426/426A Test disc 5 + 5A 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz 4822 397 30155

SBC429 Audio Signals disc 4822 397 30184

Dolby Pro-logic Test Disc 4822 395 10216

ESD Equipment:

Anti-static table mat - large 1200x650x1.25mm 4822 466 10953

Anti-static table mat - small 600x650x1.25mm 4822 466 10958

Anti-static wristband 4822 395 10223

Connector box (1Mohm) 4822 320 11307

Extension cable

(to connect wristband to conn. box) 4822 320 11305

Connecting cable

(to connect table mat to conn. box) 4822 320 11306

Earth cable (to connect product to mat or box) 4822 320 11308

Complete kit ESD3

(combining all above products) 4822 320 10671

Wristband tester 4822 344 13999

PC Board Location

Display Location of PC Boards

MEASUREMENT SETUPS

Display FM Tuner Measurement Setup

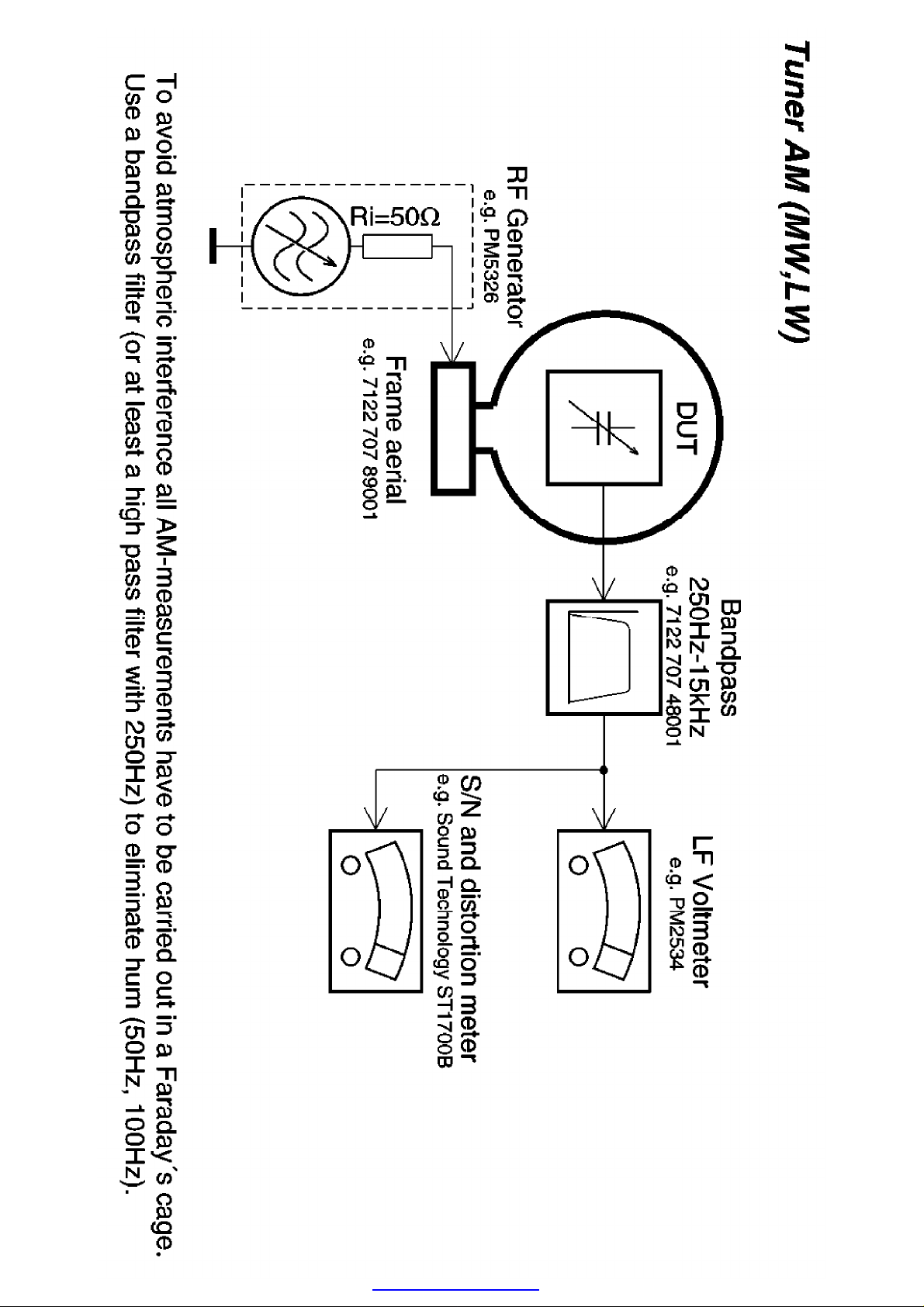

Display AM Tuner Measurement Setup

Display CD Measurement Setup

Display Tape Deck Recorder Measurement Setup

PDF created with pdfFactory trial version www.pdffactory.com

Service Test Program

Display Service Test Program

ADJUSTMENT TABLES

Display Tuner Adjustments - ECO5

Display Tuner CBA Top View

Display Tuner CBA Bottom View

Display Tape Mechanism Adjustment Table

Display Tape CBA Top View

Display Tape CBA Bottom View

PDF created with pdfFactory trial version www.pdffactory.com

Display Location of PC Boards

PDF created with pdfFactory trial version www.pdffactory.com

Display FM Tuner Measurement Setup

PDF created with pdfFactory trial version www.pdffactory.com

Display AM Tuner Measurement Setup

PDF created with pdfFactory trial version www.pdffactory.com

Display CD Measurement Setup

PDF created with pdfFactory trial version www.pdffactory.com

Loading...

Loading...