Page 1

coverlockTM 4.0

Owner’s Manual

Page 2

This household sewing machine is designed to comply with IEC/EN 60335-2-28 and UL1594

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical appliance, basic safety precautions should always be followed, including the

following:

Read all instructions before using this household sewing machine.

DANGER - To reduce the risk of electric shock:

• A sewing machine should never be left unattended when plugged in. Always unplug this sewing

machine from the electric outlet immediately after using and before cleaning.

WARNING - To reduce the risk of burns, À re,

electric shock, or injury to persons:

• This sewing machine is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the sewing machine by a person responsible for their safety.

• Children should be supervised to ensure that they do not play with the sewing machine.

• Use this sewing machine only for its intended use as described in this manual. Use only attachments

recommended by the manufacturer as contained in this manual.

• Never operate this sewing machine if it has a damaged cord or plug, if it is not working properly, if

it has been dropped or damaged, or dropped into water. Return the sewing machine to the nearest

authorized dealer or service center for examination, repair, electrical or mechanical adjustment.

• Never operate the sewing machine with any air openings blocked. Keep ventilation openings of the

sewing machine and foot controller free from the accumulation of lint, dust, and loose cloth.

• Keep À ngers away from all moving parts. Special care is required around the sewing machine needle

and blades.

• Always use the proper needle plate. The wrong plate can cause the needle to break.

• Do not use bent needles.

• Do not pull or push fabric while stitching. It may deÁ ect the needle causing it to break.

• Wear safety glasses.

• Switch the sewing machine off (“0”) when making any adjustment in the needle area, such as threading

needle, changing needle, or changing presser foot, etc.

• Always unplug sewing machine from the electrical outlet when removing covers, lubricating, or when

making any other user servicing adjustments mentioned in the instruction manual.

• Never drop or insert any object into any opening.

• Do not use outdoors.

• Do not operate where aerosol (spray) products are being used or where oxygen is being administrated.

• To disconnect, turn all controls to the off (“0”) position, then remove plug from outlet.

• Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

SAVE THESE INSTRUCTIONS

Page 3

OPERATING INSTRUCTIONS

INTRODUCTION

Parts of the machine .................................................................... 4

Accessories ....................................................................................... 5

Optional accessories from INSPIRA™ .................................... 6

PREPARATIONS

Connecting the foot control and the power supply ........ 7

Setting up the spool stand ........................................................ 7

Setting up the telescopic thread stand ................................8

Front cover ....................................................................................... 8

Open ..............................................................................................................8

Close ..............................................................................................................8

Attaching the waste tray .............................................................8

Presser foot lift ...............................................................................8

Changing the presser foot ......................................................... 9

Needle information .......................................................................9

Changing the needles ..................................................................9

Movable upper cutter ...............................................................10

Disengaging, position B ......................................................................10

Engaging, position A ............................................................................10

2-thread overlock converter ....................................................10

Engaging ...................................................................................................10

Disengaging .............................................................................................10

Upper looper .................................................................................11

Disengaging .............................................................................................11

Engaging ...................................................................................................11

Changing to coverstitch table B ............................................11

Stitch À nger lever setting .........................................................11

THREADING

General threading information ..............................................12

Threading the upper looper (red) .........................................13

Threading the lower looper (yellow) ....................................14

Threading chainstitch looper (purple) ................................15

Threading the right needle .....................................................16

Threading the left needle ........................................................17

Threading the chainstitch needle .........................................18

Threading the coverstitch needles .......................................19

Threading the right coverstitch needle ........................................19

Threading the middle coverstitch/chainstitch needle ...........20

Threading the coverstitch left needle ...........................................21

Needle threader ...........................................................................22

Changing thread ..........................................................................22

TOUCH SCREEN

Touch screen overview ..............................................................23

Select a stitch ................................................................................23

Recommendations ................................................................................23

On-screen stitch adjustments ................................................24

Thread tension .......................................................................................24

Differential feed ...................................................................................... 24

Stitch length ............................................................................................24

Sewing speed .......................................................................................... 24

Save Stitch ......................................................................................25

Personal Name .......................................................................................25

Delete personal stitch ..........................................................................25

Load Stitch .....................................................................................25

Settings menu ...............................................................................26

Display contrast .....................................................................................26

Sound .........................................................................................................26

Language ..................................................................................................26

Calibrate touch screen ........................................................................ 26

Info System ....................................................................................26

Pop-ups ...........................................................................................27

STITCHES & SEWING TECHNIQUES

Stitch overview ..............................................................................28

Start sewing ...................................................................................33

Pin Placement ........................................................................................33

Chain off ....................................................................................................33

Rolled edge sewing .....................................................................34

Coverstitch sewing ......................................................................34

Machine set up .......................................................................................34

Start sewing ............................................................................................. 34

Securing the coverstitch seam end ...............................................34

Flatlock sewing .............................................................................35

Standard Á atlock stitch ....................................................................... 35

Ornamental Á atlock stitch .................................................................35

Ladder stitch ........................................................................................... 35

Chainstitch sewing ......................................................................36

Machine set up .......................................................................................36

Start and end of sewing ..................................................................... 36

Sewing hints ..................................................................................36

Pintuck sewing .......................................................................................36

Sew in Circles .......................................................................................... 36

Securing the thread chain .................................................................36

Braiding by chaining off ..................................................................... 36

Lowering the needle(s) .......................................................................36

STITCH ADJUSTMENTS

Stitch width adjustment ...........................................................37

Width adjustment by changing needle position ...................... 37

Width adjustment with the cutting width dial ...........................37

Presser foot pressure adjustment ........................................37

Stitch length adjustment ..........................................................37

Differential feed adjustment ...................................................38

Gathered overlock (stretch, knit fabrics) .....................................38

Stretch overlock (lightweight fabrics) ...........................................38

Thread tension À ne tuning ......................................................39

MAINTENANCE

Machine maintenance ...............................................................41

Cleaning ....................................................................................................41

Cleaning the touch screen ................................................................. 41

Oiling ..........................................................................................................41

Replacing the movable upper cutter ............................................41

Storage .............................................................................................42

Servicing ..........................................................................................42

Trouble shooting ..........................................................................42

Machine speciÀ cations ..............................................................43

Intellectual Property ...................................................................43

Page 4

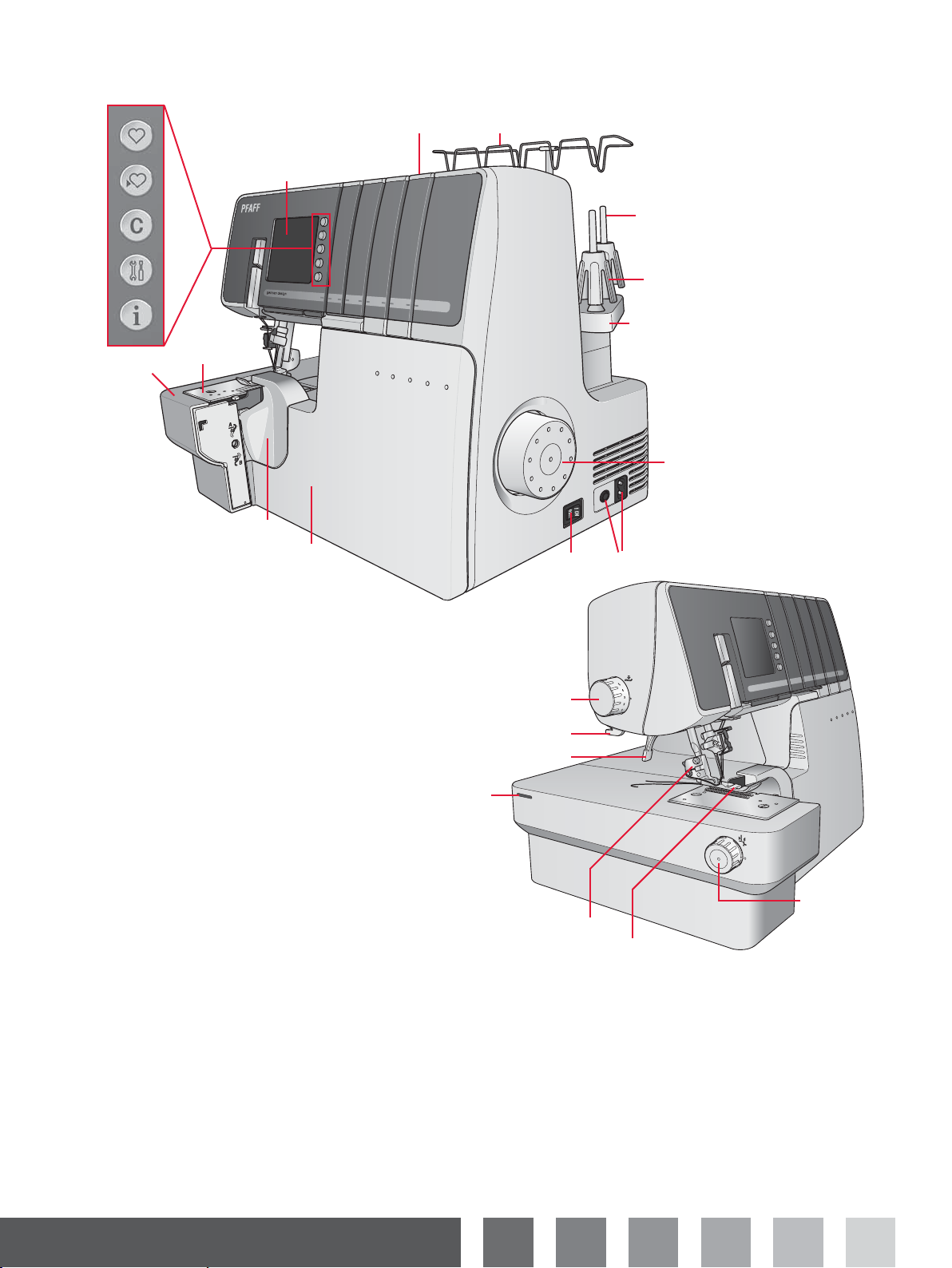

Parts of the machine

4

2

1

3

5

coverlock 4.0

6

7

8

10

9

18

17

16

15

11

12

13 14

1. Telescopic thread stand

2. Handle

3. Touch screen

4. Load stitch button

5. Save stitch button

6. Clear button

7. Settings menu button

8. Info button

9. Stitch plate

10. Flat bed extension

11. Cutter cover A

12. Front cover

13. Power & light switch

14. Foot control/electric power cord socket

15. Handwheel

16. Spool stand

17. Cone holder

18. Spool pin

PFAFF

19

20

21

22

23

24

19. Presser foot pressure adjusting dial

20. Thread cutter

21. Presser foot lift

22. Hole for extension table

23. Presser foot ankle

24. Presser foot

25. Cutting width dial

coverlock 4.0

german design

25

Introduction4

Page 5

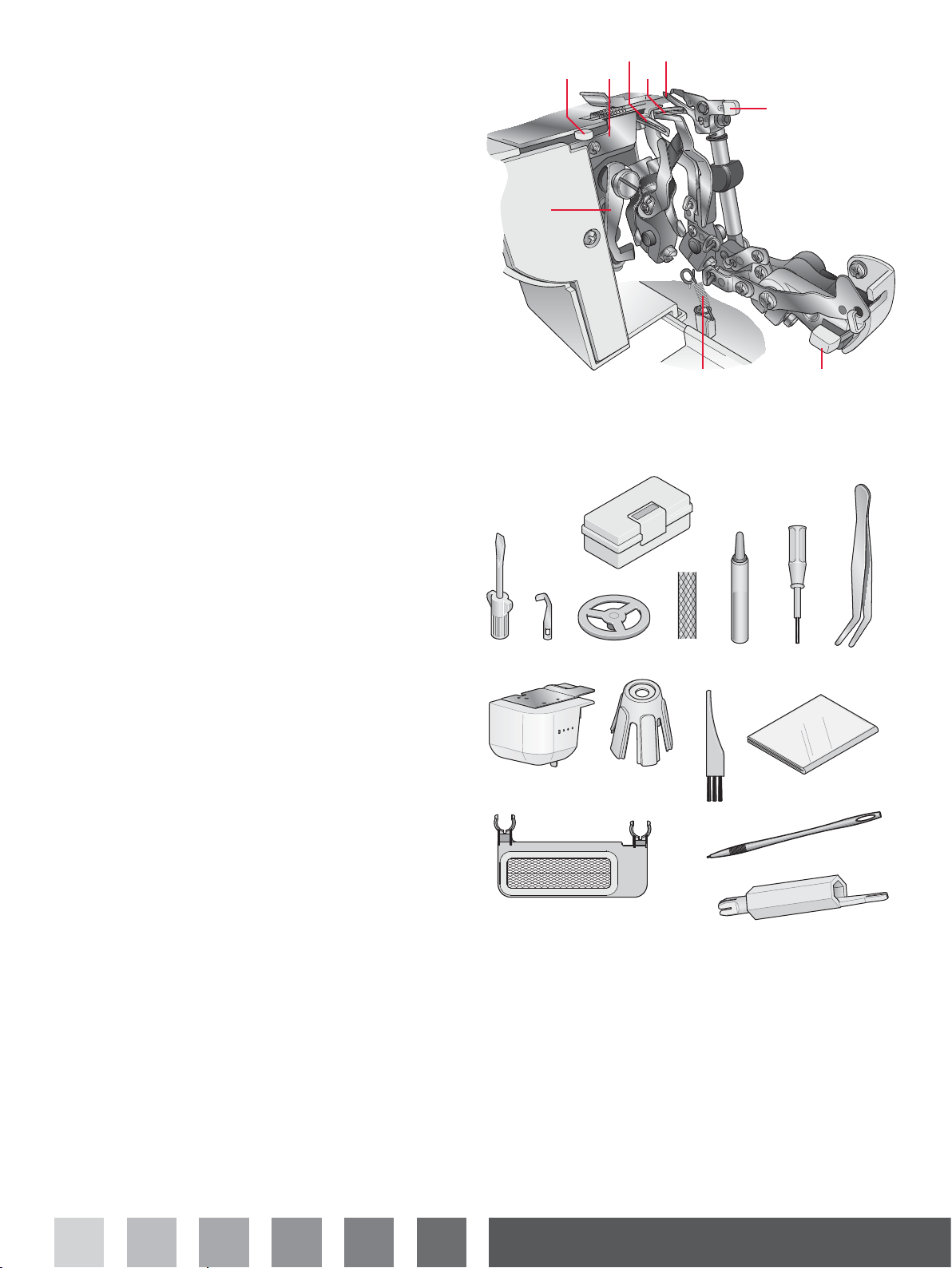

26. Moveable upper cutter

27. Stitch À nger lever

28. Stationary lower cutter

29. Chainstitch/Coverstitch looper

30. Lower looper

31. Upper looper

32. 2-thread converter

33. Upper looper clutch

33. Chain/coverstitch thread guide

26

29

2827 30

31

32

3334

Accessories

Accessories are contained in the accessory box.

1. Accessory box

2. Screwdriver

3. Knife blade (for the movable upper cutter)

4. Thread unreeling discs (5)

5. Thread spool nets (5)

6. Oiler

7. Allen key

8. Tweezers (placed on the inside of the front cover)

9. Coverstitch table B (for Cover/chainstitch)

10. Cone holders (5)

11. Lint brush

12. Dust cover

13. Waste tray

14. Stylus (placed on the inside of the front cover)

15. Needle threader

16. Extension table including four legs and push pin (not

pictured).

Assemble the extension table and legs according to the

illustrations provided with the table. The push pin is

used in the small holes in the table to hold your fabric

in place when sewing circles (see page 36).

17. Needle pack (not pictured) system ELx705 including

three needles, size #14/90 and two needles, size

#12/80. Two needles, size #14/90, are in the machine

on delivery.

1

23 4 5 6 7 8

9

13

10

11

15

12

14

Introduction

5

Page 6

Optional accessories from INSPIRA™

Optional presser feet specially prepared for this machine are available at your PFAFF® dealer.

The snap-on type presser foot used on this machine allows easy removal and replacement.

Some fabrics have a lot of excess dye which can cause

discoloration on other fabric but also on your overlock

Elastic Foot 620 08 65-96

The Elastic Foot guides and stretches narrow elastic

(¼-½”, 6-12mm) as you sew it to fabric. It is great for

sewing for active wear, lingerie and other elastic insertion

techniques.

Blindhem & Lace Foot 620 08 69-96

The Blindhem Foot is perfect for sewing invisible hems

and for applying lace. The hem is sewn, overcast and

trimmed in one step.

machine. This discoloring may be very difÀ cult or

impossible to remove.

Fleece and denim fabric, especially red and blue, often

contain a lot of excess dye.

If you suspect that your fabric/ready-to-wear garment

contains a lot of excess dye, always pre-wash it before

sewing to avoid the discoloring.

Beading Foot 620 08 66-96

The Beading Foot smoothly guides beads and pearls

through a channel on the foot for easy application on

garments or crafts.

Piping Foot 620 08 67-96

The Piping Foot is perfect for inserting packaged piping

into seams and on edges for a tailored À nish. The trim

is sewn between the two layers of fabric in one step. A

groove under the foot helps guide the piping. You can also

create your own piping for a custom À nish.

The Piping Foot makes it fast and easy to cover cording

with fabric and to insert piping into seams for a

professional look!

Taping Foot 620 08 68-96

The Taping Foot is used to apply seam tapes to seams

to prevent stretching. It is especially good for stabilizing

shoulder seams. With this foot you can reinforce and

construct seams in one step.

Introduction6

Page 7

Connecting the foot control and the

power supply

Among the accessories you will À nd the power cord and

the foot control.

Note: Before plugging in the foot control, check to ensure that it

is type ”FR5” (see underside of foot control).

1. Pull out the cord from the foot control. Connect the foot

control to the front socket on the bottom right side of

the machine (A).

2. Connect the power cord to the rear socket on the

bottom right side of the machine (B). Plug the cord into

the wall socket.

Before plugging your machine in, make sure the voltage is the

same as indicated on the plate under the machine. SpeciÀ cations

vary from country to country.

3. Press the ON/OFF switch to ON to turn on power and

light (C).

Note: When the front cover is open the safety switch is activated

and prevents the machine from sewing, even if the foot control is

pressed.

B

A

C

Note: To retract the foot control cord, unplug the foot control

from the machine (A). Pull the cord gently and release - the cord

will retract itself into the foot control.

POLARIZED PLUG INFORMATION

(FOR U.S.A. & CANADA ONLY)

This appliance has a polarized plug (one blade wider

than the other). To reduce the risk of electric shock,

this plug is intended to À t in a polarized outlet only

way. If the plug does not À t fully in the outlet, reverse

the plug. If it still does not À t, contact a qualiÀ ed

electrician to install the proper outlet. Do not modify

the plug in any way.

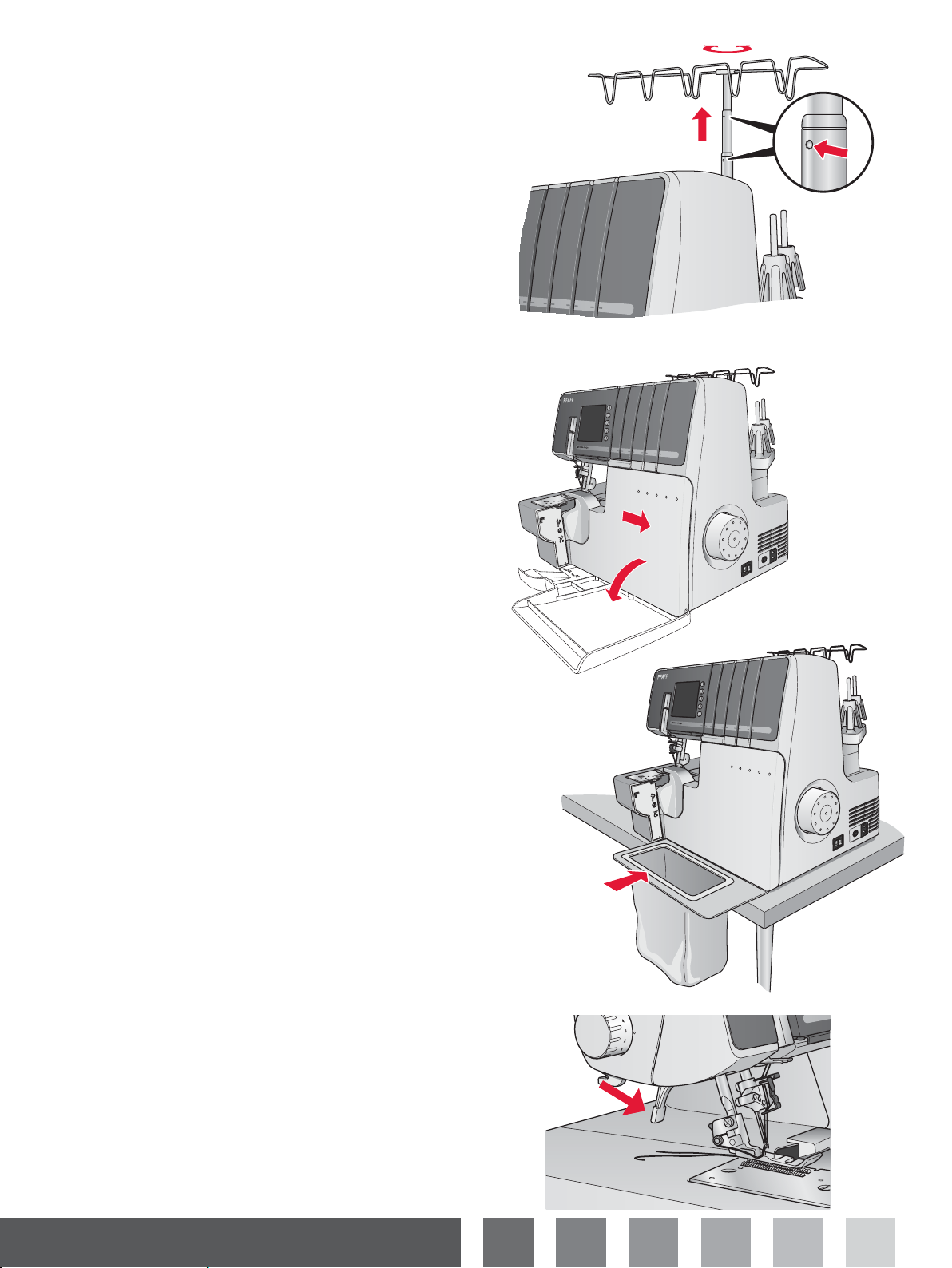

Setting up the spool stand

Insert the spool stand then push to right as illustrated.

Preparations 7

Page 8

man

design

Setting up the telescopic thread stand

Extend the telescopic thread stand to its full height, then

turn until it clicks into place. Place the thread spools over

the cone holders on the spool pin.

If the machine is already threaded, straighten the threads

to prevent tangling.

Front cover

Open

First push the cover to the right as far as it will go and

then pull it downward toward you.

Close

First pull the cover upward and then slide it to the left

until it locks.

Note: The front cover has a safety switch and the machine will

not sew if the front cover is open.

Attaching the waste tray

Position the machine so the front is nearly aligned with

the edge of the table. Insert the U-shaped hooks of the

waste tray onto the two suction cups on the underside of

the machine. Make sure the trim falls into the bag while

sewing.

coverlock 4.0

1

2

coverlock 4.0

Presser foot lift

Raise the presser foot by lowering presser foot lift at the

back of the machine.

Pressing down on the presser foot lift puts the presser foot

in the extra lift position.

Preparations8

ger

Page 9

german design

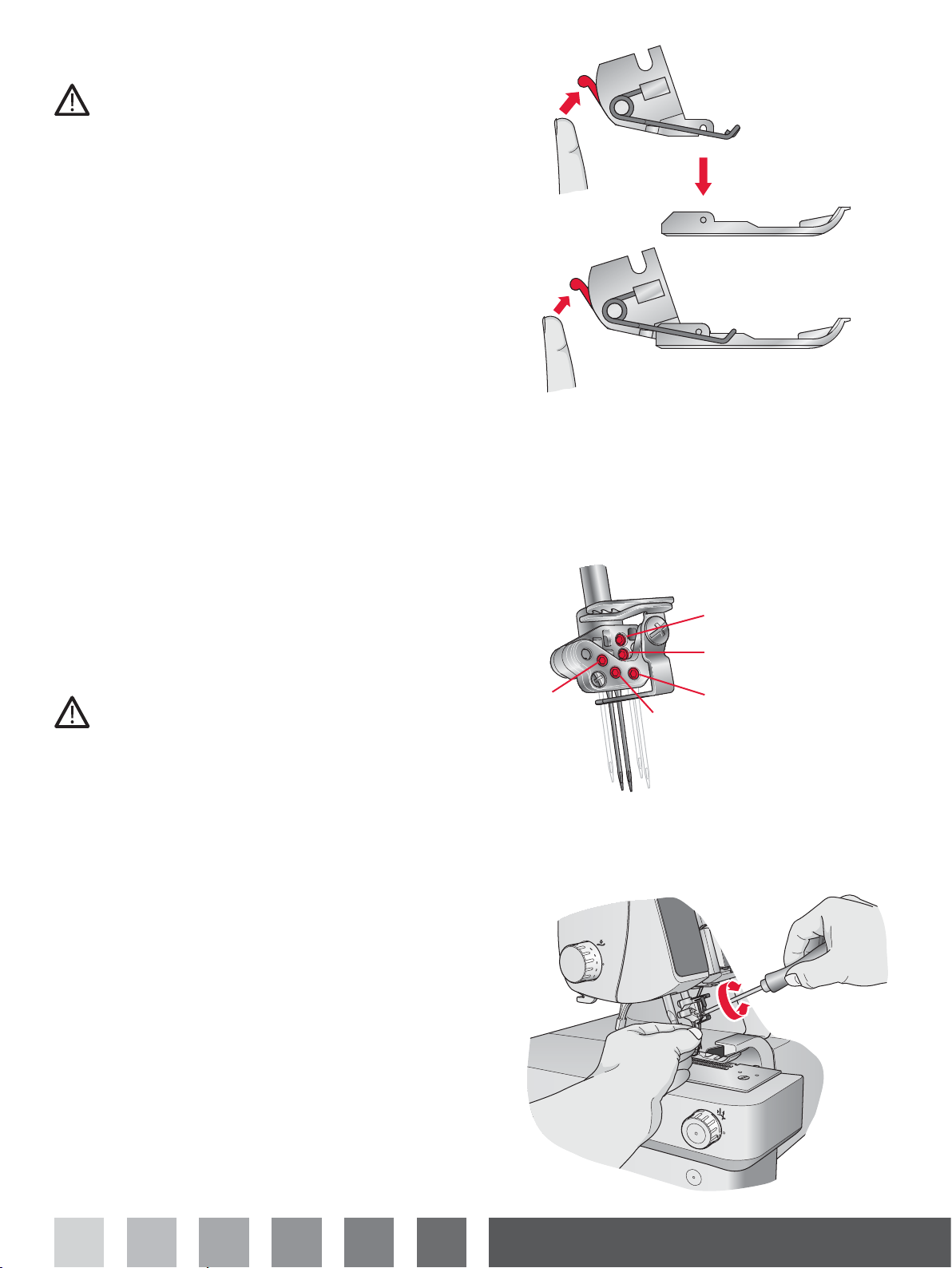

Changing the presser foot

Turn off the main power switch and unplug the machine.

• Raise the presser foot.

• Turn the handwheel toward you until the needles are at

the highest position.

• Push the red button on the back of the presser foot ankle

to release the presser foot.

• Raise the presser foot to the extra lift position and the foot

will come off.

• Place the new foot with the pin right underneath the

groove of the ankle while in the extra lift position. Lower

the presser foot. Push the red button on the back of the

presser foot ankle and the foot will snap into place.

Needle information

This overlock uses a Á at shank industrial needle that

eliminates the possibility of inserting the needle backwards.

Do not attempt to use a standard household sewing machine

needle of any size or type in this overlock.

Use INSPIRA™ needle EL x 705 sizes 14/90 and 12/80,

supplied with this machine.

Changing the needles

Turn off the main power switch and unplug the machine.

• Turn the handwheel toward you until the needles are at

the highest position.

• Place a thick piece of fabric under the presser foot. Lower

the needles halfway into the fabric.

• Loosen, but do not remove the needle clamp screw with

the allen key while you are holding the needles.

Note: When inserting needles into the A and/or B needle clamps it

is necessary to loosen the needle clamp screws for both A and B.

• Remove the selected needle.

• Hold the new needle with the Á at surface to the back.

• Insert the needle into the needle clamp as far as it will go.

• Securely tighten the needle clamp screw using the allen

key.

Note: Do not over-tighten the screw as this may cause the needle

clamp to be damaged.

A

B

C

D

E

A. Overlock left needle

B. Overlock right needle

C. Coverstitch left needle

D. Coverstitch middle needle

E. Coverstitch right needle

Preparations 9

Page 10

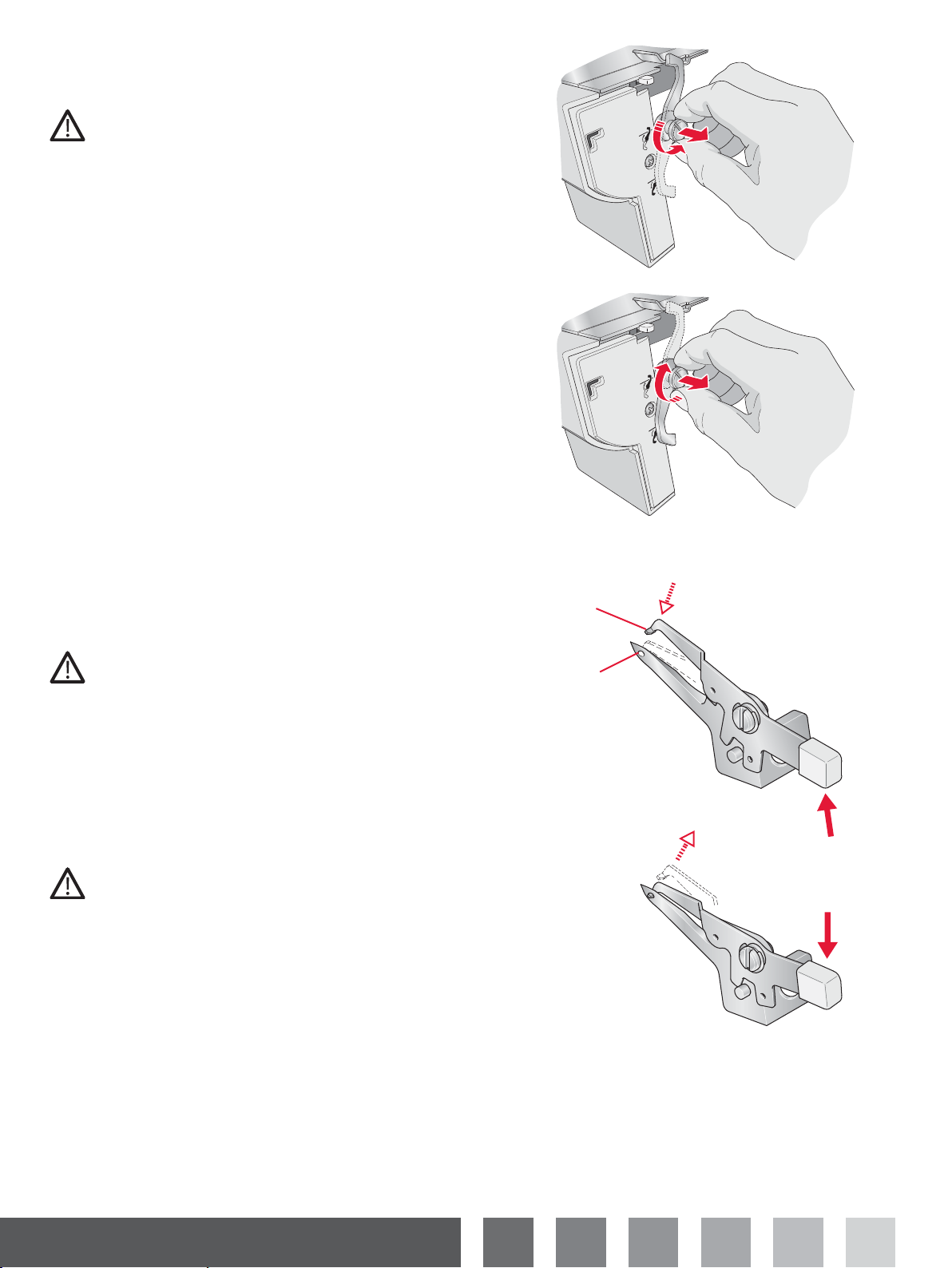

Movable upper cutter

Disengaging, position B

Turn off the main power switch and unplug the machine.

• Turn the handwheel toward you until the upper cutter

is raised to the highest position.

• Open the front cover.

• Pull the movable cutter knob to the right as far as it will

go.

• Turn the knob toward you counter clockwise until the

cutter clicks into the locked position B.

Engaging, position A

• Open the front cover and pull the movable cutter knob

to the right as far as it will go.

• Turn the knob clockwise until the cutter clicks into the

cutting position A.

A

B

B

A

B

B

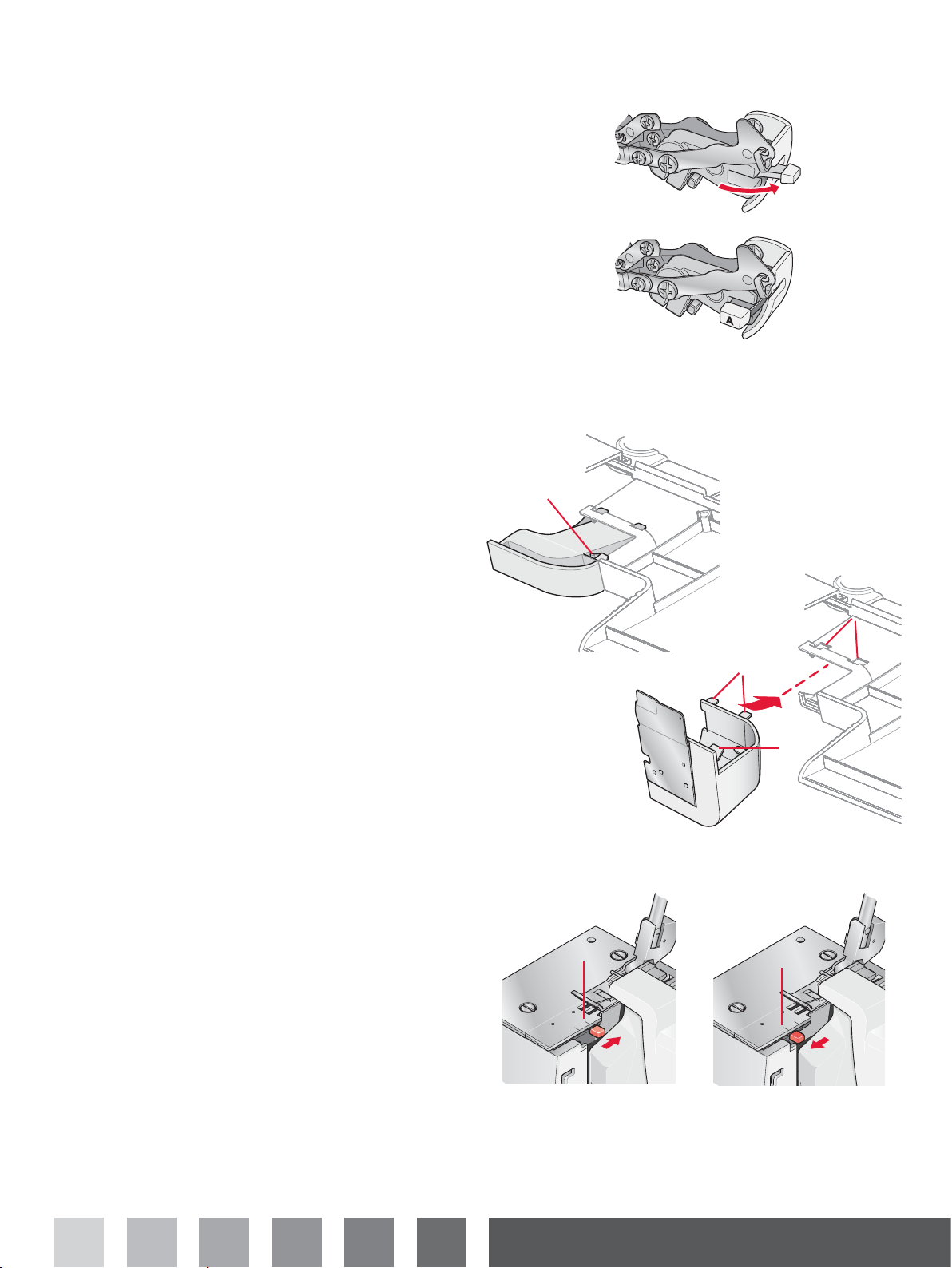

2-thread overlock converter

Engaging

Turn off the main power switch and unplug the machine.

2-thread overlock stitches are sewn using one needle

thread and the lower looper thread. Before sewing, the

2-thread converter must be attached to the upper looper.

• Open the front cover.

• Raise the white handle on the 2-thread converter to

insert the sharp edge (A) of the converter in the eye (B)

of the upper looper.

Disengaging

Turn off the main power switch and unplug the machine.

• Lower the white handle on the converter and remove

the sharp edge (A) from the eye (B) of the upper looper.

A

B

Preparations10

Page 11

B

A

Upper looper

Disengaging

For coverstitch and chaintitch sewing the upper looper

needs to be disengaged.

• Turn the handwheel until the upper looper is in its

lowest position.

• Push the clutch lever to the right and back until

position B is visible from the front.

Engaging

• Turn the handwheel until the upper looper is in its

lowest position.

• Pull the clutch lever toward you until position A is

visible from the front.

Changing to coverstitch table B

For coverstitch and chainstitch sewing the coverstitch

table B should be used.

• Lift the hook (1) to release the cutter cover A and pull it

towards you.

1

• Insert the coverstitch table B by À tting the two front

pins (2) into the holes (3) and make sure the hook (4)

clicks into place.

Stitch À nger lever setting

The stitch À nger lever should be set to N for all standard

overlock sewing. To sew rolled edge you need to retract

the stitch À nger by setting the stitch À nger lever to R.

When moving the stitch À nger lever, be sure to push the

lever as far as it will go in each direction.

3

2

4

N

N

R

R

N

R

Preparations 11

Page 12

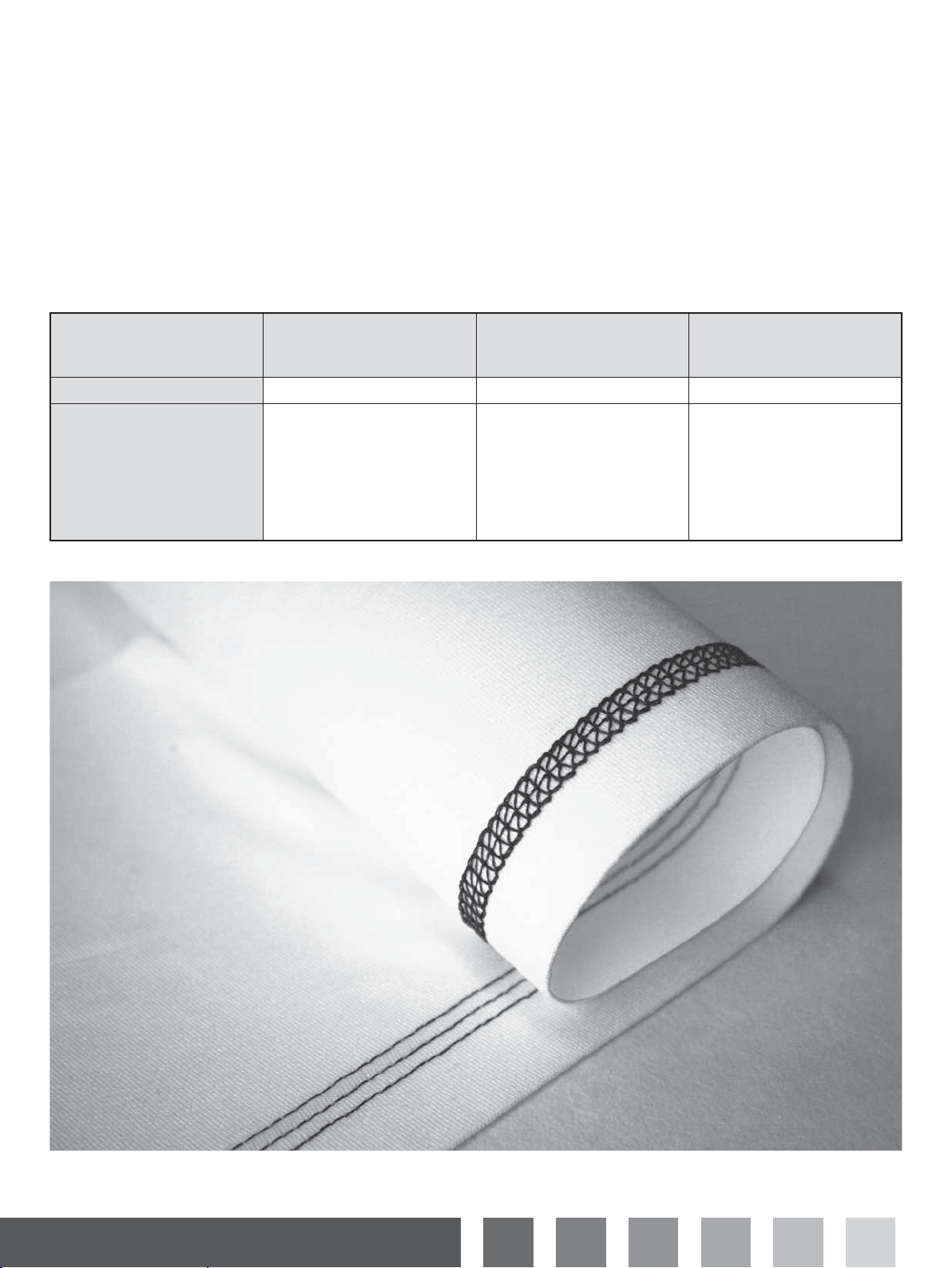

General threading information

A color coded diagram is located inside the front cover for quick reference. Always start threading the loopers and then

the needles from right to left.

See the table below for recommendations on what needles and thread to use for different fabric weights.

Tip: Your new machine is threaded to sew a standard overlock. Tie your own threads to these threads and carefully pull them

through the machine, to easily thread your new overlock machine the À rst time.

Note: If the lower looper should come unthreaded, do the following;

1. Unthread the needle(s)

2. Thread the lower looper

3. Thread the needle(s)

Fabric Light fabric

(voil, crepe, georgette, etc.)

Needles

Thread

#12 #14 #14

Polyester

(spun À lament)

Twisted thread

#60/2 - #100/3

Twisted thread

#80/3 - #100/3

Medium fabric

(cotton, chino, wool, satin

etc.)

Twisted thread

#60/2

Heavy fabric

(denim, jersey, tweed etc.)

Twisted thread

#50/2 - #60/2

Threading12

Page 13

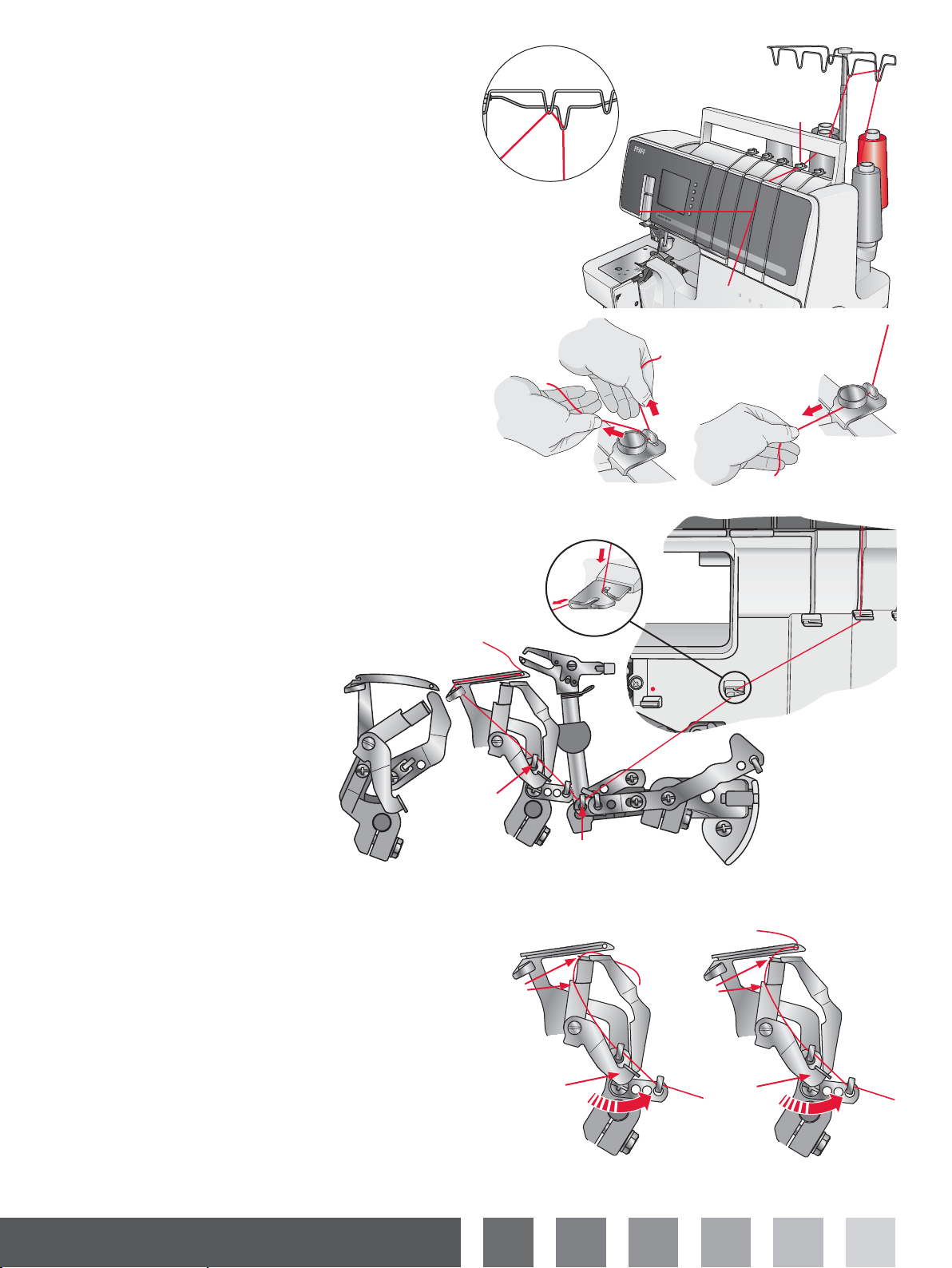

Threading the upper looper (red)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3)

1

coverlock 4.0

3

2

1

2

• Thread the looper area of the machine following the

red color coded thread guides (4-9).

• Use the tweezers to thread the hole in the upper looper

from front to back (9).

• Pull about 10 cm (4”) of thread through the looper and

place it to the back of the stitch plate.

9

8

5

6

7

9

4

Threading 13

Page 14

Threading the lower looper (yellow)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Turn the handwheel toward you until the lower looper

extends out 10 mm (3/8”) from the needle plate edge.

• Thread the looper area of the machine following the

yellow color coded thread guides (4-10).

• Place the thread through threading guide (4).

• Place the thread through the right slot of threading

guide (5).

1

1

2

coverlock 4.0

3

2

5

4

• To thread the last thread guide (9), pull about 10 cm

(4”) of thread through the guide (8).

Tip: Moving the stitch À nger lever to R makes the threading

easier. Remember to set it back to N before starting to sew.

Option 1

• Place the thread into the “V” cutouts (A) on threader

lever. Pull the threader lever (B) up into place and

back to snap the thread into thread guide 9. Thread the

looper eye (10) from front to back using the tweezers.

Option 2

• Thread the looper eye (10) from front to back using

the tweezers. Make sure the thread runs into the “V”

cutouts (A) on threader lever. Firmly hold the thread

tail with left hand and pull the threader lever (B) up

into place and back to snap the thread into thread

guide 9.

10

9

5

7

8

6

9

A

B

Option 1 Option 2

A

B

Threading14

Page 15

Threading chainstitch looper (purple)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Turn the handwheel toward you until the chainstitch

looper is at the far right.

• Thread the looper area of the machine following the

purple color coded thread guides (4-11).

• Place the thread through threading guide (4).

• Place the thread through the front slot of threading

guide (5).

1

1

2

coverlock 4.0

3

2

5

10

9

• Thread the chainstitch thread guide (8)

by holding the thread in front of the

thread guide pin and pulling the thread

backward and up, until the thread rests inside the

thread guide loop and under the spring.

• To thread the last thread guide (10), pull about 10 cm

(4”) of thread through the guide (9).

Tip: Moving the stitch À nger lever to R makes the threading

easier. Remember to set it back to N before starting to sew.

Option 1

• Place the thread into the “V” cutouts (A) on threader

lever. Pull the threader lever (B) up into place and back

to snap the thread into thread guide 10. Thread the

looper eye (11) from front to back using the tweezers.

Option 2

• Thread the looper eye (11) from front to back using the

tweezers. Make sure the thread runs into the left “V”

cutout (A) on threader lever. Firmly hold the thread tail

with left hand and pull the threader lever (B) up into

place and back to snap the thread into thread guide 10.

11

7

8

8

10

A

BB

Option 1 Option 2

4

5

6

A

Threading 15

Page 16

Threading the right needle

(green, B on needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

1

1

2

coverlock 4.0

3

4

2

• Continue to thread points (4-8).

• Slip the thread into the rear slot on the thread guide (5)

and into the slot on the take-up lever cover (6). Then

slip the thread into the right slot on the thread guides

(7) and (8).

• Before threading the eye of the needle, make sure the

thread is behind the thread guide located on the bottom

of the needle clamp.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make needle eye threading

easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading16

Page 17

Threading the left needle

(blue, A on needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Continue to thread points (4-8).

1

coverlock 4.0

3

4

2

1

2

• Slip the thread into the middle slot on the thread guide

(5) and into the slot on the take-up lever cover (6). Then

slip the thread into the middle slot on the thread guides

(7) and (8).

• Before threading the eye of the needle, make sure the

thread is behind the thread guide located on the bottom

of the needle clamp.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make needle eye threading

easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading 17

Page 18

Threading the chainstitch needle

(blue, D on needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Continue to thread points (4-8).

1

coverlock 4.0

3

4

2

1

2

• Slip the thread into the middle slot on the thread guide

(5) and into the slot on the take-up lever cover (6). Then

slip the thread into the middle slot on the thread guides

(7) and (8).

• Before threading the eye of the needle, make sure the

thread is in front of the thread guide located on the

bottom of the needle clamp.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make the threading easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading18

Page 19

Threading the coverstitch needles

Note: Thread the needles in to following order: right (E), middle

(D), left (C)

Threading the right coverstitch needle

(red, E on the needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Continue to thread points (4-8).

1

coverlock 4.0

3

4

2

1

2

• Slip the thread into the rear slot on the thread guide (5).

and into the slot on the take-up lever cover (6). Then

slip the thread into the right slot on the thread guides

(7) and (8).

• Before threading the eye of the needle, make sure the

thread is in front of the thread guide located on the

bottom of the needle clamp for coverstitch.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make the threading easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading 19

Page 20

Threading the middle coverstitch/chainstitch

needle (green, D on the needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Continue to thread points (4-8).

1

1

2

coverlock 4.0

3

4

2

• Slip the thread into the middle slot on the thread guide

(5) and into the slot on the take-up lever cover (6). Then

slip the thread into the middle slot on the thread guides

(7) and (8).

• Before threading the eye of the needle, make sure the

thread is in front of the thread guide located on the

bottom of the needle clamp for coverstitch and for

chainstitch.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make the threading easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading20

Page 21

Threading the coverstitch left needle

(blue, C on the needle clamp)

• Raise the presser foot to release tension discs.

• Pass the thread from back to front through the thread

guide on the thread stand (1).

• Thread the top cover thread guide by pulling the

thread towards the left until it slips under the guide.

Then pull the thread along the right side of the button

as illustrated (2).

• Lift up the handle and bring the thread under it. While

holding the thread with both hands, pass it between

the tension discs and pull it down to make certain it is

properly placed between the tension discs (3).

• Continue to thread points (4-8).

1

1

2

coverlock 4.0

3

4

2

• Slip the thread into the front slot on the thread guide

(5) and into the slot on the take-up lever cover (6). Then

slip the thread into the left slot on the thread guides (7)

and (8).

• Before threading the eye of the needle, make sure the

thread is in front of the thread guide located on the

bottom of the needle clamp.

• Thread the eye of the needle (9). Use the needle

threader (see page 22) to make the threading easier.

• Pull about 10 cm (4”) of thread through needle eye to

hang free.

• Place the thread to the back, under the presser foot.

6

5

7

8

9

9

Threading 21

Page 22

PFAFF

coverlock 4.0

german design

PFAFF

coverlock 4.0

german design

Needle threader

To make threading the needles easier, use the needle

threader included with the accessories.

• Turn the handwheel so the needles are in their highest

position and lower the presser foot. Make sure one

of the rectangular markings of the needle threader is

pointing upwards. Place the thread from right to left in

the notch on the tip of the needle threader.

• Hold the needle threader against the needle. Move

the needle threader down to the needle eye and press

gently against the needle, causing a small metal pin

to push the thread through the needle eye and form a

thread loop.

• Use the needle threader to pull the thread loop out

behind the needle.

Changing thread

The following is an easy way to change threads:

• Cut the thread in use near the spool, behind the guides

on the telescopic thread stand.

• Remove the thread spool and place the new thread on

the spool pin.

• Tie the end of the new thread to the end of the old

thread. Cut the thread tails to 2-3 cm in length and

À rmly pull both threads to test knot security.

• Raise the presser foot to release the tension discs.

• Pull the threads through the machine one at a time

until the knots are in front of the needle. If the threads

do not pull easily, check for tangles on thread guides or

looping under thread stand.

• Cut the thread behind the knot and thread the needle.

Note: When using standard thread spools, place the thread

unreeling disc as shown to prevent the thread from getting

caught on the edge of the spool.

Threading22

Page 23

Touch screen overview

Sewing mode is the À rst view on the graphic display after

you turn on the machine. Your selected stitch will be

shown in real size in the stitch À eld. Here you will À nd

all the basic information you need to start sewing. This

is also the menu where you adjust the settings of your

stitch. When turning on the machine, the last sewn stitch

is selected.

1. Stitch selection drop down menu

2. Stitch À eld

3. Needle position recommendation

4. Cutting width recommendation

5. Presser foot pressure recommendation

6. Thread tension adjustment

7. Differential feed adjustment

8. Stitch length adjustment

9. Speed setting

10. Icons for increasing and decreasing the value of the

selected adjustment.

3

1

2

6

7

4

98

5

10

Select a stitch

• Touch the arrow to the right in the stitch selection

drop down menu to open a list of the coverlock™ 4.0

stitches.

• Use the scroll bar arrows to scroll in the list. Touch a

stitch in the list to select it.

Recommendations

Recommendations for needle position, cutting width and

presser foot pressure are always visible in the Sewing

mode view. When a stitch is selected, a pop-up with

extended recommendations is displayed. Touch the OK

icon (A) to close the pop-up.

11. Recommendation for Cutter cover A/Coverstitch table B

12. Stitch À nger lever setting recommendation

13. Upper cutter position A/B recommendation

14. Recommendation for 2-thread converter

15. Recommendation for upper looper clutch lever setting

A/B

The extended recommendations for the selected stitch can

also be found in the Info System view, see page 26.

A

11 12

13

15

14

Touch screen 23

Page 24

On-screen stitch adjustments

Your machine will set the best settings for each selected

stitch. You can make your own adjustments on the

selected stitch.

The setting changes only affect the selected stitch. Your

changed settings will be reset to default when selecting

another stitch. The changed settings are not automatically

saved when turning your machine off.

Thread tension

Touch the arrow pointing right next to the thread tension

icon to open a thread tension adjustment window where

the tension for each of the À ve threads is displayed. Touch

the value number for a thread to select it. The value

number becomes surrounded by a black frame, showing

that it is selected. Touch - or + to adjust the thread tension

for the selected thread. The value number becomes

inverted on a dark background, showing that the standard

setting has been changed.

Touch the arrow pointing left to close the thread tension

adjustment window.

See page 39 for an overview of tension adjustments for each

stitch type.

Differential feed

To adjust the differential feed, touch the differential feed

icon. It becomes surrounded by a black frame, showing

that it is selected. Touch - or + to adjust the differential

feed. The value number becomes inverted on a dark

background, showing that the standard setting has been

changed.

See page 38 for more instructions on adjusting the differential

feed.

Stitch length

To adjust the stitch length, touch the stitch length icon. It

becomes surrounded by a black frame, showing that it is

selected. Touch - or + to adjust the stitch length. The value

number becomes inverted on a dark background, showing

that the standard setting has been changed.

See page 37 for more instructions on adjusting the stitch length.

Sewing speed

To adjust the maximum sewing speed, touch the speed

icon. It becomes surrounded by a black frame, showing

that it is selected. Touch - or + to adjust the sewing speed.

The selected speed level is shown in the speed icon. Five

levels of speed are available.

Touch screen24

Page 25

Save Stitch

B

To save the adjusted stitch, touch the Save Stitch button

to open the Save Stitch view. You can save up to 30

different stitches. You can scroll through the list to À nd a

free position, using the arrows. Any box without a stitch

is a free position and can be used to save your new stitch.

Touch a free position and then OK (A) to save your stitch.

The stitch information appears in the selected position.

Touch Cancel (B) to close the saving window and return

to the Sewing mode view.

Any box with a stitch is an occupied position. You can

overwrite a previously stored stitch. Simply touch the

stitch to overwrite. A pop-up will ask you to conÀ rm that

you want to overwrite the previously stored stitch. The

stitch information appears in the selected position.

Personal Name

When a stitch is saved, it keeps the original stitch name.

To give your saved stitch a new personal name, touch the

keyboard icon (C) to open up a window for entering a

personal name.

A

C

Touch the letters on the keyboard to enter your name.

Touch the arrow (D) to delete an entered character. Touch

“Aa1” (E) to change between uppercase letters, lowercase

letters and numbers. Touch OK (A) to conÀ rm the new

name, or Cancel (B) to cancel and keep the old name.

Delete personal stitch

To delete a saved stitch, use the scroll bar arrows to step

through the list. The inverted stitch number shows which

stitch is selected. Touch the Clear button. A pop-up will

ask you to conÀ rm the deletion.

Load Stitch

To load a previously saved stitch, touch the Load button.

Use the scroll bar arrows to scroll in the list. Touch a

stitch in the list to select it, or touch Cancel (B) to return to

Sewing mode view.

B

A

DE

B

Touch screen 25

Page 26

When a stitch is selected, a pop-up message with detailed

information about the stitch appears. Touch OK (A) to

load the selected stitch or Cancel (B) to return to the Load

Stitch list.

Settings menu

Touch the Settings button to open the settings menu. Here

you can adjust the machine settings. Touch the Settings

button again to close the settings menu and save the

changes in the machine memory.

The changes in settings are saved after turning off the

machine.

Display contrast

Change the contrast on the touch screen to suit your needs

by touching - or +. The contrast value is displayed next to

the -/+ icons.

Sound

Turn the sound on and off by touching the speaker icon. A

crossed-out speaker indicates that the sound is off.

B

A

Language

Step through the available languages used on screen by

touching the arrows. The language description changes

for each touch.

Calibrate touch screen

When touching the icons on the screen, the screen might

need a calibration to adjust to your touch. Touch the

calibrate icon to open a special screen for touch screen

calibration. With your stylus, À rst touch the center of the

cross in the top left corner, then touch the center of the cross

in the bottom right corner. The calibration screen closes

automatically when you have touched the second cross.

Info System

For more information about a selected stitch, touch the Info

button. The À rst tab shows what the stitch is used for. The

second tab shows valuable hints, and the third tab shows

the types of fabric recommended for that particular stitch.

The fourth tab shows the machine setup recommendations

for the selected stitch.

See page 23 for explanation of the different recommendations.

Touch the Info button again to close.

Touch screen26

Page 27

Pop-ups

Front cover open

As a safety precaution you cannot sew with the front

cover open. The pop-up will close when the front cover is

closed.

Presser foot is up

You cannot start sewing with the presser foot up. The

pop-up will close when the presser foot is lowered.

Warning, overloaded, please wait

If you are sewing on very heavy fabric or if the machine is

blocked when sewing, the main motor can get overloaded

and the machine will stop sewing. The pop-up will close

when the main motor and power supply are secure.

Please raise the presser foot to calibrate

The presser foot must be raised when turning on the

machine. The pop-up will close when the presser foot is

raised.

Touch screen 27

Page 28

Stitch overview

The settings shown in this table are our recommendations based on normal conditions. The correct tension is set

automatically when selecting a stitch. It may be necessary to adjust the thread tension according to the stitch, type

of fabric and thread you are using. For best results make tension adjustments in small steps of no greater than half a

number at a time. Always test sew on a sample of your fabric before sewing on your garnment.

Different stitches are obtained by combining different needle positions, threading methods, and the use of the 2-thread

converter.

Icon explanation

A

B

Needle position 2-thread converter

E

CD

N/R

1

Cutting width

Stitch À nger lever setting

Stitch

5-thread safety stitch, wide

For joining with a reinforced stitch

and overcasting in one step. A

durable chainstitch seam with

overlock edge for garment sewing,

quilt piecing and other projects.

5-thread safety stitch, narrow

For joining with a reinforced stitch

and overcasting in one step. A

durable chainstitch seam with

overlock edge for garment sewing,

quilt piecing and other projects.

A/B

Setting for upper cutter, clutch lever and use of

cutter cover A or coverstitch table B

A

B

E

CD

A and

D

B and

D

N/R A/B

6.0 N No A

6.0 N No A

Threading path

BGRYP

•••••

•••••

2

3

4

4-thread overlock

For all seams where stretch or give

is needed, such as neck edges,

side seams, sleeves, etc. Specialty

techniques can be done with a

4-thread overlock seam such as

A and

B

6.0 N No A

••••

gathering, applying piping with the

optional piping foot and elastic with

the optional elastic foot.

4-thread safety stitch, wide

For joining with reinforced stitch

and overcasting in one step.

Converter required.

A and

D

6.0 N Yes A

•• ••

Stitches & sewing techniques28

Page 29

5

6

Stitch

4-thread safety stitch, narrow

For joining with reinforced stitch

and overcasting in one step.

Converter required.

3-thread overlock, wide

For sewing two layers of stretchy

fabric or overcasting a single layer of

light to medium fabric. Use heavier

threads in the loopers to create

decorative braids. (Hold your hand

behind the presser foot and gently

and slowly pull the thread chain as

you sew, trying to keep the same

tension as it has been sewn onto

fabric.)

A

B

E

CD

B and

D

A 6.0 N No A

N/R A/B

6.0 N Yes A

Threading path

BGRYP

•• ••

•••

7

8

9

3-thread overlock, narrow

For sewing two layers of stretchy

fabric or overcasting a single layer

of light fabric. Popular for creating

decorative tucks. Use decorative

threads in the loopers and regular

thread in the needle. Use different

colors in the loopers to get an

interesting effect.

3-thread narrow edge*

For edging lightweight fabrics. It

gives a nice À nish on silky scarves,

pillow rufÁ es and napkins. Thread

the looper with a decorative

lightweight thread, such as 40

weight rayon for a beautiful satin

edge. Read more on page 34.

3-thread Á atlock stitch, wide

For sewing stretchy fabrics together

with a decorative effect either

with the Á atlock side or the ladder

stitch side. Create varying effects

by threading the loopers with

decorative thread. Read more on

page 35.

B 6.0 N No A

B 6.0 R No A

A 6.0 N No A

•••

•••

•••

* Not recommended for heavyweight woven fabrics or medium to heavyweight stretch fabrics.

Stitches & sewing techniques 29

Page 30

10

11

Stitch

3-thread Á atlock stitch, narrow

For sewing stretchy fabrics together

with a decorative effect either

with the Á atlock side or the ladder

stitch side. Create varying effects

by threading the loopers with

decorative thread. Read more on

page 35.

3-thread wrapped overlock,

wide

For À nishing edges on lightweight

fabrics. Adjust the differential feed

to create a lettuce edge on À ne

fabrics.

3-thread wrapped overlock,

narrow

For À nishing edges on lightweight

fabrics. Adjust the differential feed

to create a lettuce edge on À ne

fabrics.

A

B

E

CD

B 6.0 N No A

A 6.0 N No A

B 6.0 N No A

N/R A/B

Threading path

BGRYP

•••

•••

•••

12

13

14

3-thread stretch overlock

For sewing extra stretchy fabrics.

Add additional stretch by using

a stretchy type thread in the

loopers. Change the thread tension

accordingly.

3-thread rolled edge*

For edging lightweight fabrics. It

gives a nice À nish on silky scarves,

pillow rufÁ es and napkins. For a

beautiful rolled edge, thread the

looper with decorative thread and

the needle and lower looper with

lightweight regular thread. Read

more on page 34.

A and

B

B 6.0 R No A

6.0 N Yes A

•• •

•••

* Not recommended for heavyweight woven fabrics or medium to heavyweight stretch fabrics.

Stitches & sewing techniques30

Page 31

15

16

Stitch

2-thread overlock, wide

For overcasting a single layer of

light to medium weight fabrics.

Converter required.

2-thread overlock, narrow

For overcasting a single layer of

light to medium weight fabrics.

Converter required.

2-thread narrow edge*

Use for edging lightweight fabrics.

Converter required. Read more on

page 34.

A

B

E

CD

A 6.0 N Yes A

B 6.0 N Yes A

B 6.0 R Yes A

N/R A/B

Threading path

BGRYP

••

••

••

17

18

19

20

2-thread Á atlock, wide

For sewing stretchy fabrics

together with a decorative effect

either with the Á atlock side or the

ladder stitch side. Create varying

effects by threading the loopers

with decorative thread. Converter

required. Read more on page 35.

2-thread wrapped overlock,

wide

Decorative À nish for garments and

homedec. Converter required.

2-thread wrapped overlock,

narrow

Gives a beautiful À nish to

lightweight fabrics. Use transparent

threads with this stitch to get an

almost invisible edge, this gives a

very beautiful look on À ner fabrics.

Converter required.

A 6.0 N Yes A

A 6.0 N Yes A

B 6.0 N Yes A

••

••

••

* Not recommended for heavyweight woven fabrics or medium to heavyweight stretch fabrics.

Stitches & sewing techniques 31

Page 32

21

22

Stitch

2-thread rolled edge*

For edging lightweight fabrics. It

gives a nice À nish on silky scarves,

pillow rufÁ es and napkins. Thread

the looper with a decorative

lightweight thread, such as 40

weight rayon for a beautiful satin

edge. Converter required. Read

more on page 34.

Coverstitch, triple

For hems on stretch fabrics and

for decorative effects on all kind

of fabrics. Use decorative thread

in looper for embellishment. Read

more on page 34.

Coverstitch, wide

For hems on stretch fabrics and

for decorative effects on all kind

of fabrics. Use decorative thread

in looper for embellishment. Read

more on page 34.

A

B

E

CD

B 6.0 R Yes A

C, D

and E

C and

E

N/R A/B

-R No B

-R No B

Threading path

BGRYP

••

••• •

•••

23

24

25

Coverstitch, narrow

For hems on stretch fabrics and

for decorative effects on all kind

of fabrics. Use decorative thread

in looper for embellishment. Read

more on page 34.

Chainstitch

For all types of sewing such

as construction, hemming and

piecing quilts. Baste with ease

for construction as it is an easily

unraveled stitch, and never run out

of bobbin thread. Use decorative

thread in looper for embellishment.

Read more on page 36.

C and

D

D-RNoB

-R No B

•• •

••

* Not recommended for heavyweight woven fabrics or medium to heavyweight stretch fabrics.

Stitches & sewing techniques32

Page 33

Start sewing

Pin Placement

When securing the fabric pieces using pins, insert straight

pins to the left of the presser foot. The pins will be easy to

remove and are away from the cutters.

Sewing over pins will damage and might destroy the

cutting edge of the cutters.

• When the machine is completely threaded, close the

front cover and bring all of the threads over the stitch

plate and slightly to the left under the presser foot.

• Ensure that the upper blade moves against the lower

blade correctly by turning the handwheel slowly

toward you. If the blades are not moving correctly,

check if there are any fabric or waste thread stuck

between the blades.

• Hold the threads and pull them slightly.

• Turn the handwheel toward you two to three complete

turns to start making a thread chain. Check if all

threads wind around the stitch À nger of the stitch plate.

If the threads do not wind around the À nger, make sure

each thread is threaded correctly.

• Continue holding the thread chain while pressing the

foot control. Sew until the chain is 5-8 cm (2-3”) in

length.

• Place fabric under the front of the presser foot and sew

a test sample. Guide the fabric slightly with your left

hand while sewing. Do not pull on the fabric as this

may deÁ ect the needle, causing it to break.

5-8 cm

(2-3“)

Chain off

• When you reach the end of the fabric, continue sewing

while drawing the À nished fabric gently backwards

and to the left. This is called chaining off. It prevents

the threads from coming undone and prepares for the

next sewing task.

• Cut off the thread chain 2-5 cm (1-2”) behind the

presser foot using the thread cutter on the left side of

the machine. Pull the threads around the thread cutter

from the back, then toward you.

Tip: When you have re-threaded the machine, always chain off

and test sew a sample to test thread tension.

Tip: The presser foot on this machine has marks to indicate the

needle position. Use this as a guide when sewing.

Stitches & sewing techniques 33

Page 34

Rolled edge sewing

The rolled edge stitch is appropriate for lightweight fabrics such as lawn, voil, organdy, crepe, etc. The rolled edge is

achieved by adjusting the thread tension to make the fabric edge roll under the fabric while overlocking. Adjust the

thread tension to change the degree of rolling. To sew a rolled edge you need to set the stitch À nger lever to R. (See

page 11)

Tip: For a beautiful rolled edge, thread the upper looper with a decorative thread and the needle and lower looper with lightweight

regular thread.

Note: Make a thread chain and test sew on a sample of your fabric before sewing on your garment. Hold the thread chain before

sewing to keep it from curling into the seam.

Note: The minimum overlock stitch width that can be obtained for rolled edging is approximately 1.5 mm.

Coverstitch sewing

The coverstitch can be used for covering, binding or top-stitching necklines and for hemming the bottom of T-shirts

and sweatsuits, etc. in addition to Á at joining seams (plain seaming).The coverstitch is most suitable for stretchy fabrics.

It can also be used for woven fabrics.

Machine set up

• Disengage the movable upper cutter. (See page 10)

• Set the stitch À nger lever to R. (See page 11)

• If inserted, remove needle B and needle A.

• Install needles C, D and/or E depending on desired coverstitch.

• Disengage the upper looper. (See page 11)

• Remove cutter cover A and install coverstitch table B (see page 11). The graduations on the coverstitch table indicate

the distance, in cm and inches, from coverstitch middle needle. Use it as a guide when positioning the fabric edge.

• Close front cover.

Start sewing

• Raise the presser foot by lowering presser foot lift.

• Place material under the presser foot behind the needle.

• Lower the presser foot by raising the presser foot lift.

Note: When you start to sew from the middle of the fabric, place the fabric at the desired starting point of sewing.

Securing the coverstitch seam end

Chaining off is not possible after sewing coverstitch because it causes the

seam to unravel when the looper thread is pulled out at the end of sewing.

Therefore, secure the seam end in the following manner.

When sewing through to the edge of fabric

• Knot the needle threads (2 or 3 threads) together À rst, as shown on the

illustration.

• Tie these threads with the looper threads.

• Cut extra threads.

When sewing is stopped halfway

• Pull out the needle threads (2 or 3 threads) on the underside of the fabric

and knot the threads in the same manner as described above.

• Cut extra threads.

Note: Normally, the seams at the start of sewing do not unravel, but it is wise to

secure the seam end following the same steps as described when sewing through to the

edge of the fabric.

Stitches & sewing techniques34

Page 35

Flatlock sewing

A Á atlock stitch is made by sewing the seam and pulling the fabric apart to Á atten the seam. The Á atlock stitch

can be used both as a decorative construction stitch, sewing two pieces together (Standard Á atlock stitch), or for

embellishment on only one piece of fabric (Ornamental Á atlock stitch).

There are two ways to sew a Á atlock stitch. Either with the wrong sides of the fabric together to create a decorative

look, or with the right sides together, to create a ladder stitch.

Standard Á atlock stitch

• Use the left or the right needle.

• For 2-thread Á atlock: Engage the 2-thread converter

(see page 10). Thread the lower looper and the left (A)

or right (B) needle.

For 3-thread Á atlock: Thread the lower and upper

looper and the left (A) or right (B) needle.

• Place the wrong sides of the two pieces of fabric

together to sew a decorative stitch on the right side of

the garment.

• Sew the seam, trimming the excess fabric. The needle

thread will form a V on the underside of the fabric. The

lower looper thread will pull into a straight line at the

fabric edge.

• Unfold the fabric and pull on opposite sides of the

seam to pull the stitches Á at.

Standard Á atlock stitch Ornamental Á atlock stitch

Ornamental Á atlock stitch

• Disengage the movable upper cutter (see page 10). The

fabric should not be trimmed on this stitch.

• Follow steps 1-3 above.

• Fold the fabric piece, wrong sides together, to sew a

decorative stitch from the right side of the garment (at

the fold).

• Position the fabric so the seam is sewn with part of the

stitch extending off the fabric.

• Unfold the fabric and pull on opposite sides of the

stitch to Á atten.

Tip: The upper looper thread is the prominent thread in the

Á atlock stitch. Place a decorative thread in the upper looper and

regular threads in the lower looper and needle.

Ladder stitch

To create a ladder stitch, sew with right sides of the fabric

together. The needle thread will be the prominent thread

that creates the ladder.

3-thread ladder stitch

Stitches & sewing techniques 35

Page 36

Chainstitch sewing

The chainstitch is sewn with two threads, one needle and one looper. Normally, the machine trims the fabric edge

while the seam is being sewn. However, a chainstitch seam can be placed at a desired distance from edge of fabric by

putting the upper cutter in B position, disengaging the upper looper and installing coverstitch table B. (See page 10-11)

Turn off the main power switch and unplug the machine.

Machine set up

• Disengage the movable upper cutter. (See page 10)

• Disengage the upper looper. (See page 11)

• Remove cutter cover A and install coverstitch table B (see page 11). The graduations on the coverstitch table indicate

the distance, in cm and inches, from coverstitch middle needle. Use it as a guide when positioning the fabric edge.

Start and end of sewing

When starting to sew after threading the machine, sew 2-3 cm on a scrap fabric and chain off to make a chain. At end of

sewing, pull the fabric lightly to the rear of machine and chain off.

Sewing hints

Pintuck sewing

Sew decorative pintucks on the fabric before cutting

out the garment. Use overlock right needle and select

3-thread overlock, narrow.

Note: The rolled edge stitch can also be used for this technique.

• Disengage the movable upper cutter. (See page 10)

• Mark the fabric with the desired number of pintucks

using a water-soluble fabric marker.

• Fold the fabric with the wrong sides together and sew.

• Press the pintucks in the same direction.

Sew in Circles

(only suitable for heavy and medium weight fabrics)

The extension table has 13 holes in it, used to sew in

circles.

Sew circles with the movable upper cutter engaged (A

position, see page 10) to get a beautiful edge, or disengage

the movable upper cutter (B position, see page 10) and

sew circle embellishments.

• Mark a dot in the center of the area that will be the

circle and place stabilizer under the fabric.

• Pierce the fabric at the mark with the sharp

end of the push pin (A). Place the pin into

the selected hole on the extension table. Push

the pin and its bottom plate (B) together.

• Lower the presser foot and sew. The fabric

will feed in a circle around the push pin.

• When the circle is complete, overlap the seam for a few

centimetres (an inch). Thread the threads into a large

eyed, hand sewing needle and pull them to the wrong

side of the fabric and secure.

A

B

Securing the thread chain

Thread the chain into a large eyed, hand sewing needle.

Insert the needle into the end of the seam and pull the

chain into the seam to secure the threads.

Braiding by chaining off

1. Disengage the movable upper cutter. (See page 10)

2. Insert À ller cord such as yarn or twill tape through the

hole in the front of the foot.

3. Position the À ller cord under the foot and chain off the

desired length.

4. Chained off braids can be used individually or woven

into 3 or 4 ply braids.

Lowering the needle(s)

When you stop sewing, the machine always stops with

the needle(s) in the up position. Tap the foot control one

time to lower the needle(s) into the fabric. The needle

down position is useful to hold your fabric in place when

making adjustments or when turning the fabric to change

direction when chainstitch sewing.

Stitches & sewing techniques36

Page 37

Stitch width adjustment

The stitch width can be increased or decreased by

changing the needle position or with the cutting width

dial.

Width adjustment by changing needle position

A) When only the left needle, or when both needles are

used the stitch width is 6 mm.

B) When only the right needle is used the stitch width is 4

mm.

C) When using the chainstitch needle the stitch width is 9

mm.

Width adjustment with the cutting width dial

By À ne tuning the cutting width using the cutting width

dial further adjustments are possible within the range

shown below.

• When only the left needle is used: 5 - 7 mm

• When only the right needle is used: 3 - 5 mm

• When using the chainstitch needle: 8 - 10 mm

Turn the dial to adjust the desired seam width. For

standard setting the dial should be set to 6.0.

A) Left needle B) Right needle C) Chainstitch

6 mm 9 mm4 mm

5.5

•

6.0

6.5

needle

Presser foot pressure adjustment

The presser foot pressure for sewing based on normal

conditions should be set to 2.5. Adjustments in some

instances may be necessary. Increase or decrease the

pressure until you are satisÀ ed with the result. Always

test sew on a sample of your fabric before sewing on your

garment.

Less pressure: Decrease the pressure by turning the

adjustment dial in counter-clockwise direction to a value

between 2.5 and 1.

More pressure: Increase the pressure by turning the

adjustment dial in clockwise direction to a value between

2.5 and 5.

Back to standard setting: Turn the adjustment dial until

the mark on the knob is set to 2.5.

Stitch length adjustment

Stitch length is automatically set when selecting a stitch

but it may have to be adjusted depending on fabric

type. Adjust the stitch length to 4 mm when sewing on

heavyweight fabrics. Adjust the stitch length to 2 mm

when sewing on lightweight fabrics.

To adjust the stitch length, touch the stitch length icon. It

becomes surrounded by a black frame, showing that it is

selected. Touch - or + to adjust the stitch length.

PFAFF

Stitch adjustments 37

Page 38

Differential feed adjustment

The differential feed system consists of two sets of feed

teeth arranged one behind the other. Both feed teeth work

independently of each other to give perfect results when

sewing on speciality fabrics. When the amount of feed by

the front feed teeth is changed in relation to the feed by

the rear feed teeth it will “stretch” or “gather” the fabric.

Use the differential feed to prevent stretching of knit

fabrics and puckering of lightweight fabrics.

The differential feed is automatically set to 1.0 when

any of the coverlock™ 4.0 stitches is selected. This is the

setting for overlock stitching on normal fabric. To adjust

the differential feed, touch the differential feed icon. It

becomes surrounded by a black frame, showing that it is

selected. Touch - or + to adjust the differential feed.

Gathered overlock (stretch, knit fabrics)

When overedging stretch fabric, such as knits and jersey, adjust the differential feed to a value between 1.0 and 2.0. The

setting depends on the material being sewn as well as the desired amount of gathering. Test sew with different settings

before sewing on your garment.

Stretch overlock (lightweight fabrics)

When overedging light woven or loosely knit fabrics, such as silk and silky knitwear, adjust the differential feed to a

value between 0.6 and 1.0. When sewing, apply gentle tension to the fabric by holding the seam lightly in front and

back of the presser foot. The setting depends on the material being sewn as well as the desired amount of stretching.

Test sew with different settings before sewing on your garment.

Fabric Differential feed 1.0 Adjustment Result

Stretch fabric

1.0 - 2.0

(Knit, jersey)

Non-stretch fabric

1.0

(Chino, denim)

Lightweight fabric

0.6 - 1.0

(Silk, silky knitwear)

Stitch adjustments38

Page 39

Thread tension À ne tuning

Thread tension is automatically set when selecting a stitch but it may have to be À ne tuned depending on:

• Type and thickness of the fabric

• Needle size

• Size, type and À bre content of the thread

See page 24 for how to adjust the thread tension settings.

2-thread overlock

When the lower looper thread lies on the underside of

the fabric

When the needle thread tension is too loose Increase the needle thread tension (blue or green), or

2-thread overlock, wrap

When the lower looper thread tension is too tight or

needle thread tension is too loose

When the lower looper thread tension is too loose Increase the lower looper thread tension (yellow).

3-thread Á atlock stitch

When the lower looper thread tension is too loose Increase the lower looper thread tension (yellow), or

When the upper looper thread tension is too loose Increase the upper looper thread tension (red), or

When the needle thread tension is too loose Increase the needle thread tension (blue or green), or

Increase the looper thread tension (yellow), or decrease

the needle thread tension (blue or green).

decrease the lower looper thread tension (yellow).

Decrease the lower looper thread tension (yellow), or

increase the needle thread tension (blue or green).

decrease the needle thread tension (blue or green).

decrease the needle thread tension (blue or green).

decrease the upper looper thread tension (red).

3-thread overlock

When the upper looper thread lies on the underside of

the fabric

When the lower looper thread appears on the top of the

fabric

When the needle thread is too loose Increase the needle tension (blue or green).

Increase the upper looper thread tension (red), or

decrease the lower looper thread tension (yellow).

Increase the lower looper thread tension (yellow), or

decrease the upper looper thread tension (red).

4-thread overlock