Page 1

Page 2

CPFAFFi

Automatic

93

INSTRUCTIONS

FOREWORD

Your

dream

has

come

true.

You

ore

now

the

proud

owner

of

a

Pfaff

Automatic

93,

the

sewing

machine

which

will

enable

you

to

master

all

ordinary

sewing

and

darning

lobs

that

may

come

up

in

a

home.

In

addition,

your

machine

can

sew

a

large

number

of

beautiful

decorative

designs

completely

automatically.

This

instruction

book

will

help

you

understand

the

machine

and

give

you

valuable

tips

to

make

sewing

more

fun

four

you.

Even

if

you

are

an

experienced

seamstress,

you

will

find

this

book

a

valuable

guide

to

easy

sewing.

Follow

these

simple

instructions

and

familiarize

yourself

with

the

exclusive

features

of

your

machine.

You

will

find

sewing

exciting

on

your

eosy4o-operate

Pfaff

93.

If

you

have

any

sewing

problems,

please

contact

your

Pfaff

dealer.Hewill

be

glad

to

help

you

at

any

time.

G.M.

PFAFF

AG

Karlsruhe-Durlach

Branch

Page 3

DR506

DR

508

DR

507

Qieijicn

c6

$,“i

Machiw

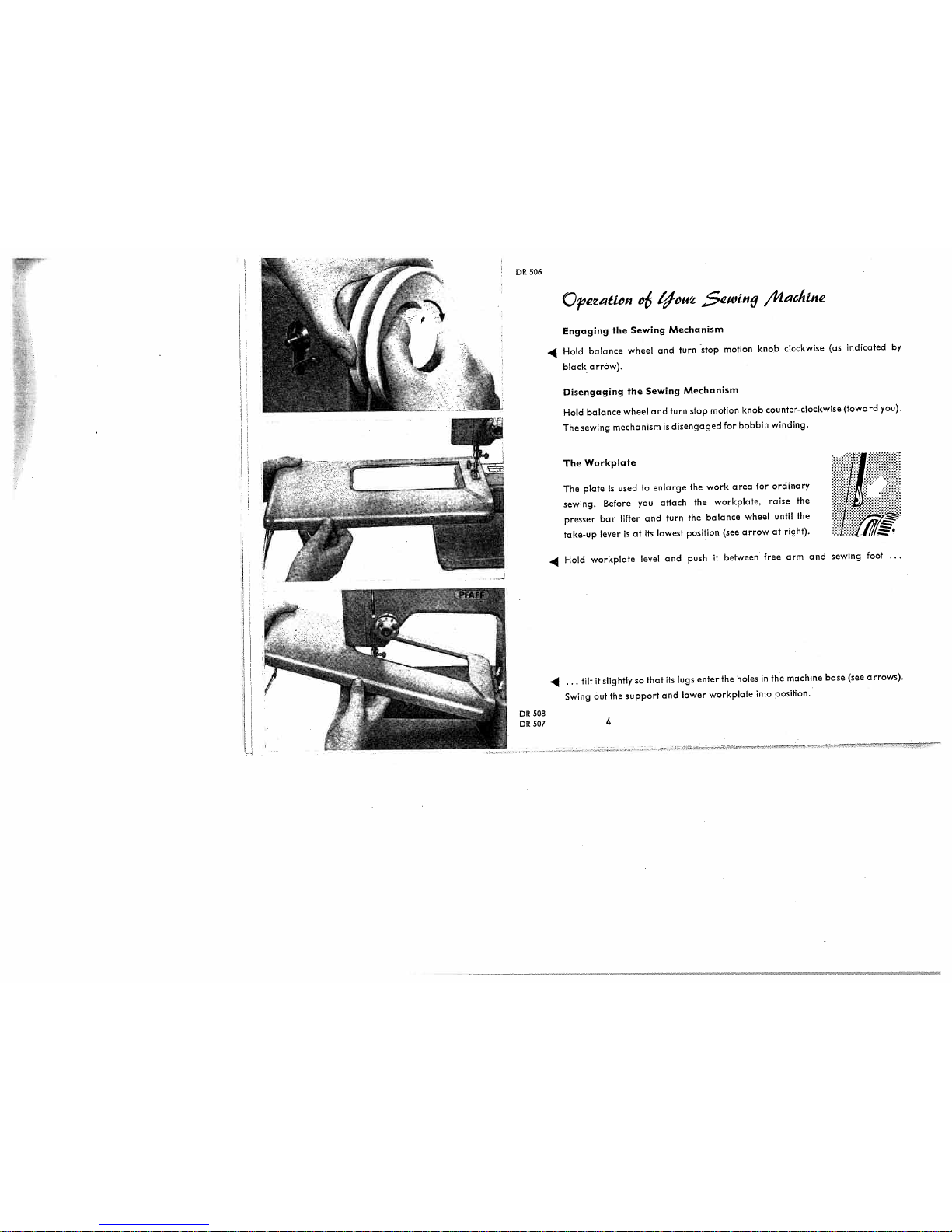

Engaging

the

Sewing

Mechanism

.4

Hold

balance

wheel

and

turn

stop

motion

knob

clockwise

(as

indicated

by

black

arrow).

Disengaging

the

Sewing

Mechanism

Hold

balance

wheel

and

turn

stop

motion

knob

counter-clockwise

(toward

you).

The

sewing

mechanism

is

disengaged

for

bobbin

winding.

The

Workplate

The

plate

is

used

to

enlarge

the

work

area

for

ordinary

sewing.

Before

you

attach

the

workplate,

raise

the

presser

bar

lifter

and

turn

the

balance

wheel

until

the

take-up

lever

is

at

its

lowest

position

(see

arrow

at

right).

.4

Hold

workplate

level

and

push

it

between

free

arm

and

sewing

foot

tiltitslightly

so

that

its

lugs

enter

the

holes

in

the

machine

bose

(see

arrows).

Swing

out

the

support

and

lower

workplate

into

position.

I.

4

Page 4

DR5

I

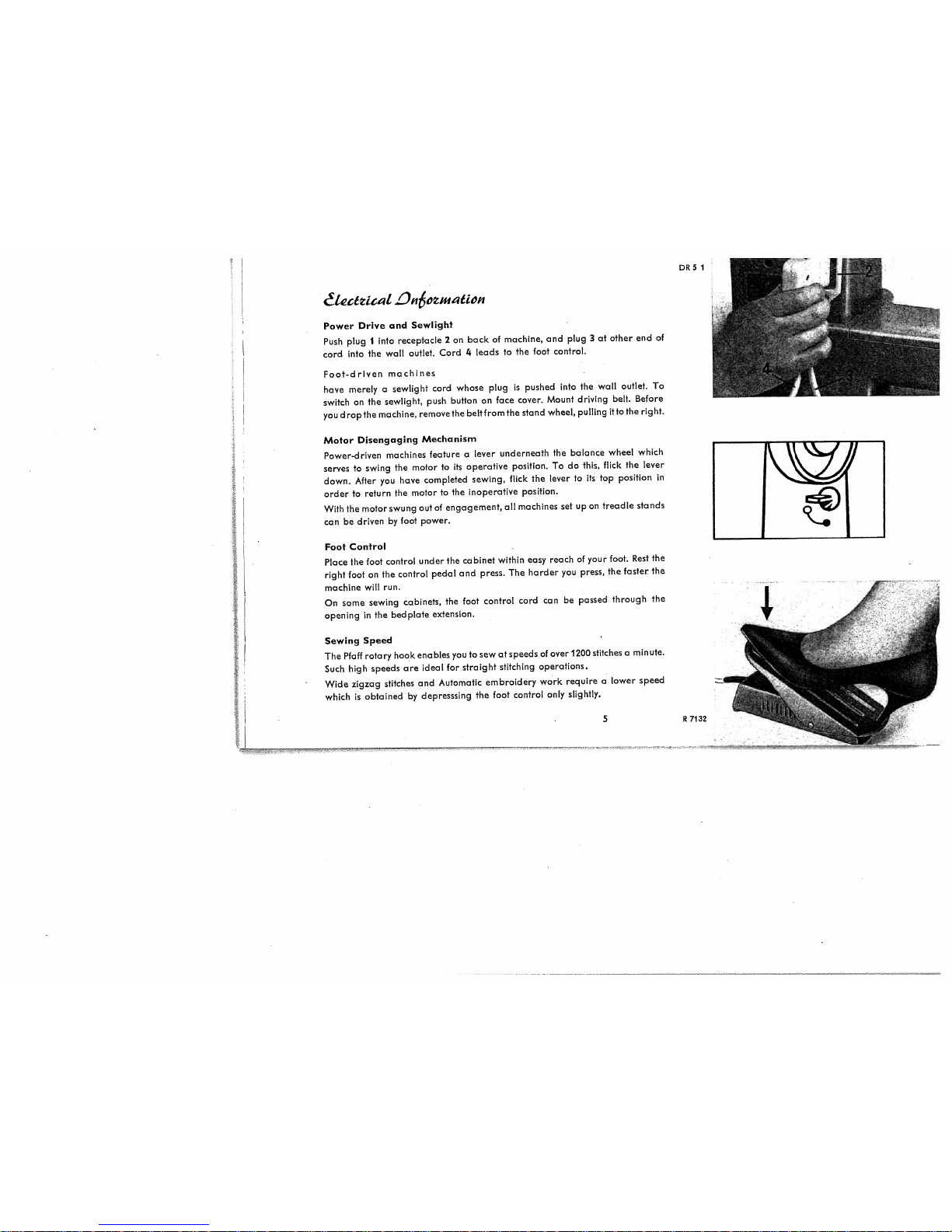

Power

Drive

and

Sewlight

Push

plug

I

into

receptacle

2

on

back

of

machine,

and

plug

3

at

other

end

of

cord

into

the

wall

outlet.

Cord

4

leads

to

the

foot

control.

Foot-driven

machines

hove

merely

a

sewlight

cord

whose

plug

is

pushed

into

the

wall

outlet.

To

switch

on

the

sewlight,

push

button

on

face

cover.

Mount

driving

belt.

Before

you

drop

the

machine,

remove

the

beltfrom

the

stand

wheel,

pulling

itto

the

right.

Motor

Disengaging

Mechanism

Power-driven

machines

feature

a

lever

underneath

the

balance

wheel

which

serves

to

swing

the

motor

to

its

operotive

position.

To

do

this,

flick

the

lever

down.

After

you

hove

completed

sewing,

flick

the

lever

to

its

top

position

in

order

to

return

the

motor

to

the

inoperative

position.

With

the

motor

swung

out

of

engagement,

oIl

machines

set

upon

treadle

stands

can

be

driven

by

foot

power.

Foot

Control

Place

the

foot

control

under

the

cabinet

within

easy

reach

of

your

foot.

Rest

the

right

foot

on

the

control

pedal

and

press.

The

harder

you

press,

the

faster

the

machine

will

run.

On

some

sewing

cabinets,

the

foot

control

cord

can

be

passed

through

the

opening

in

the

bedplate

extension.

Sewing

Speed

The

Pfaff

rotary

hook

enables

you

to

sew

ot

speeds

of

over

1200

stitches

a

minute.

Such

high

speeds

ore

ideal

for

straight

stitching

operations.

Wide

zigzag

stitches

and

Automatic

embroidery

work

require

a

lower

speed

which

is

obtained

by

depresssing

the

foot

control

only

slightly.

5

R7I32

Page 5

DR

4898

6

$&ip1e

$tIu4iq

.4

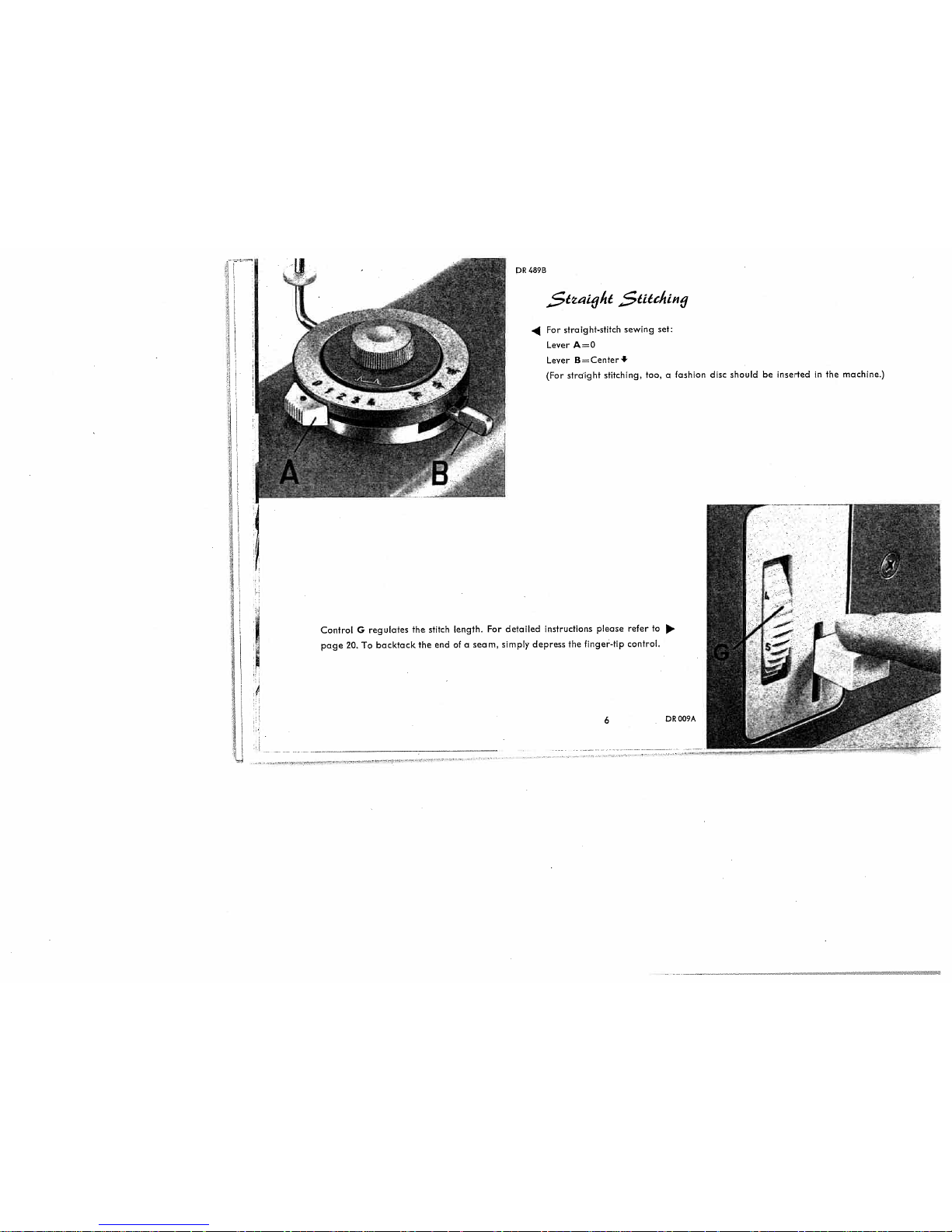

For

stroight-stitch

sewing

set:

Lever

A=O

Lever

B=Center+

(For

stroight

stitching,

too,

a

fashion

disc

should

be

inserted

in

the

machine.)

Control

G

regulates

the

stitch

length.

For

detailed

instructions

please

refer

to

page

20.

To

backtack

the

end

of

a

seam,

simply

depress

the

finger-tip

control.

6

DROO9A

Page 6

DR

489A

i92a1

$“i

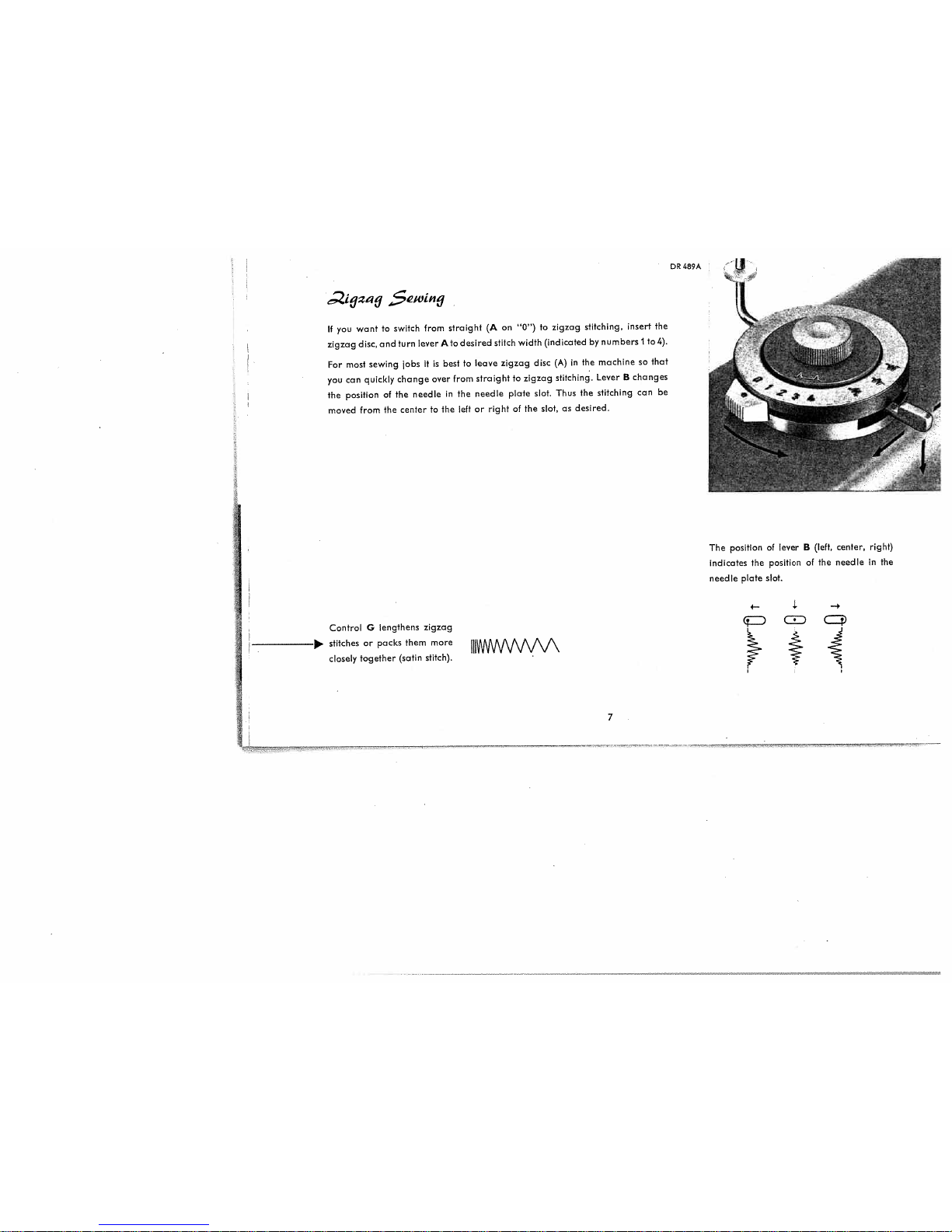

If

you

want

to

switch

from

straight

(A

on

“0”)

to

zigzag

stitching,

insert

the

zigzag

disc,

and

turn

lever

A

to

desired

stitch

width

(indicated

by

numbers

ito

4).

For

most

sewing

jobs

it

is

best

to

leave

zigzag

disc

(A)

in

the

machine

so

that

you

can

quickly

change

over

from

straight

to

zigzag

stitching.

Lever

B

changes

the

position

of

the

needle

in

the

needle

plate

slot.

Thus

the

stitching

con

be

moved

from

the

center

to

the

left

or

right

of

the

slot,

as

desired.

The

position

of

lever

B

(left,

center,

right)

indicates

the

position

of

the

needle

in

the

needle

plate

slot.

4—

.

-+

Control

G

lengthens

zigzag

stitches

or

packs

them

more

closely

together

(satin

stitch).

I

Page 7

Aiitcusati

9a.chtcn

7t.cts

Functional

Stitches

Three

exchangeable

fashion

discs

are

furnished

with

each

machine.

These

discs

are

used

to

make

the

zigzag

stitch,

the

elastic

serpentine

stitch,

and

the

blindstifch,

and

are

marked

as

follows:

Disc

A

=

zigzag

stitch

Disc

B

=

elastic

serpentine

stitch

Disc

C

=

blindstitch

Ornamental

Stitches

Fashion

discs

D,

E,

F

and

G

serve

to

produce

various

decorative

designs.

Countless

pattern

variations

are

possible

by

changing

both

the

stitch

length

and

the

stitch

width.

8

Page 8

OR

544A

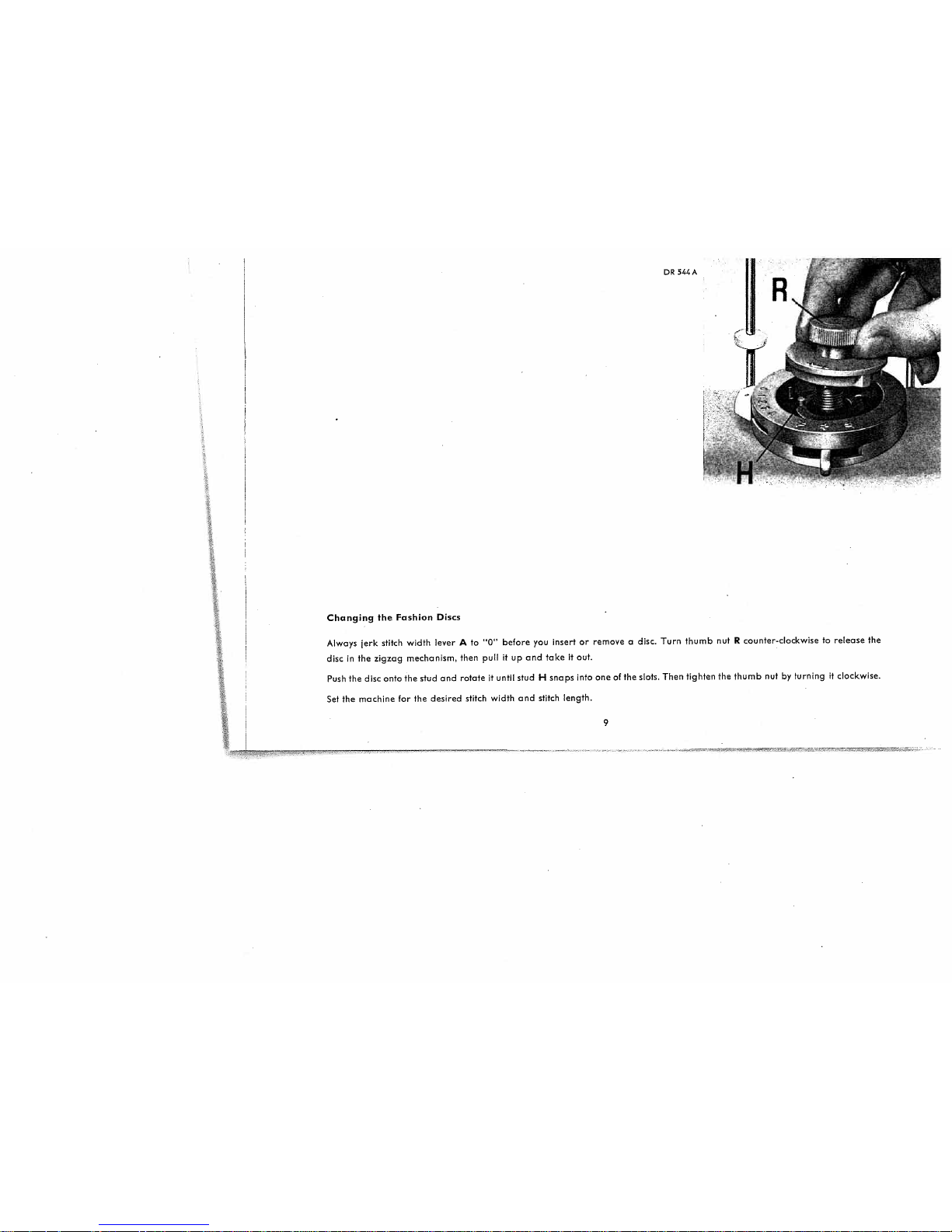

Changing

the

Fashion

Discs

Always

lerk

stitch

width

lever

A

to

“0’

before

you

insert

or

remove

a

disc.

Turn

thumb

nut

R

counter-clockwise

to

release

the

discinthe

zigzag

mechanism,

then pulliiup

and

take

it

out.

Push

the

disc

onto

the

stud

and

rototeituntil

stud

H

snaps

into

one

of

the

slots.

Then

tighten

the

thumb

nut

by

turning

it

clockwise.

Set

the

machine

for

the

desired

stitch

width

and

stitch

length.

9

Page 9

DR

614

DR

613

icoj,ig

e4

13c6

6in

Case

Raise

needle

to

its

highest

point

and

open

free

arm

cover.

Lift

latch

k

with

the

thumb

of

your

left

hand

and

pull

out

bobbin

case

with

bobbin.

When

you

release

the

latch,

the

bobbin

drops

out.

10

I

Page 10

Oni

th

73ô66in

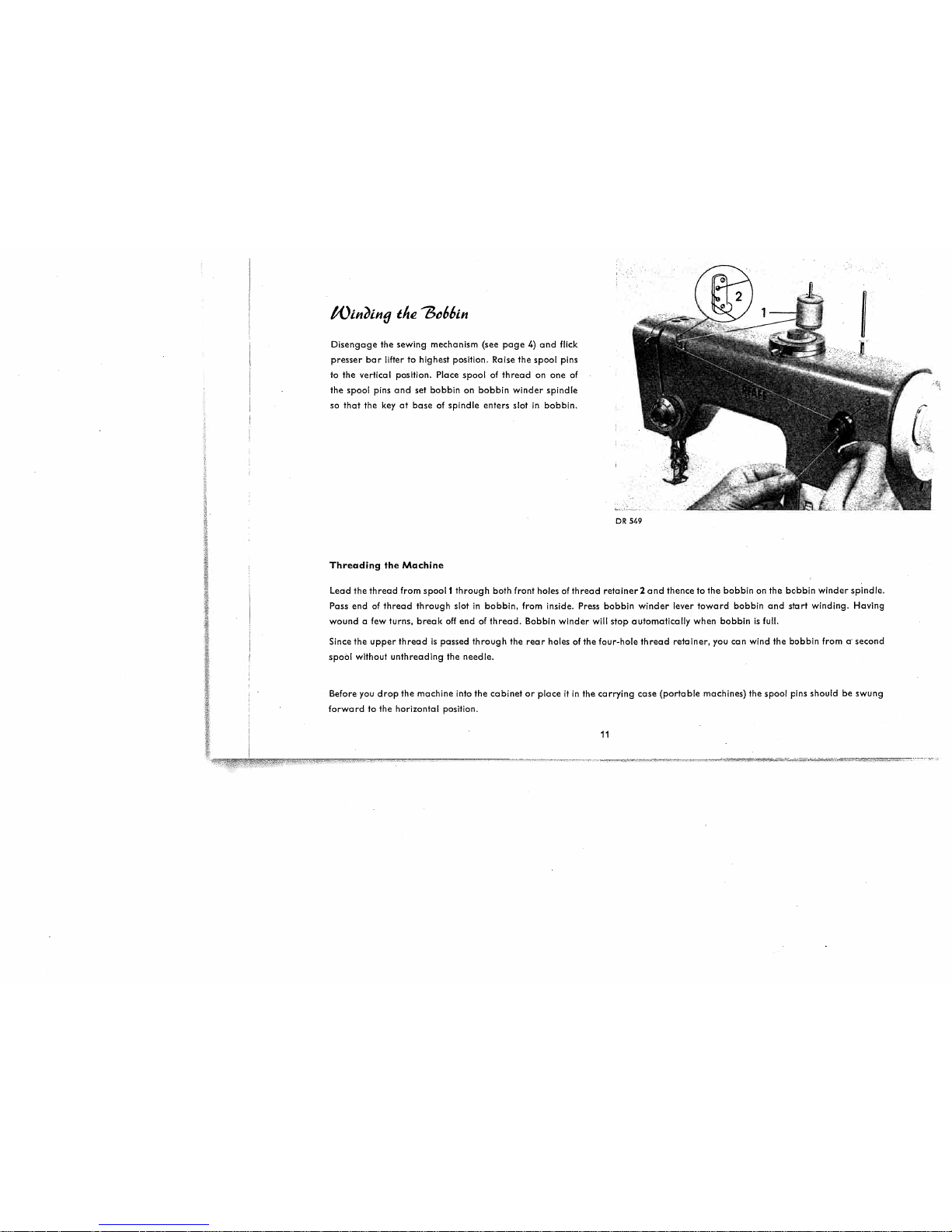

Disengage

the

sewing

mechanism

(see

page4)and

flick

presser

bar

liftertohighest

position.

Raise

the spool

pins

to

the vertical

position.

Place

spoolofthreadonone

of

the

spool

pins

and

set

bobbinonbobbin

winder

spindle

so

that

the

keyatbaseofspindle

enters

slotinbobbin,

Threading

the

Machine

Lead

the

thread

from

spoolIthrough

both

front

holes

of

thread

retainer2

and

thencetothe

bobbinonthe

bobbin

winder

spindle.

Pass

endofthread

through

slotinbobbin,

from inside.

Press

bobbin

winder

lever

toward

bobbin

and

start

winding.

Having

woundafew

turns,

break

off

endofthread.

Bobbin

winder

will

stop

automatically

when

bobbinisfull.

Since

the

upper threadispassed

through

the

rear

holes

of

the

four-hole

thread

retainer,

you

can

wind

the

bobbin

froma-second

spool

without

unthreading

the

needle.

Before

you

drop

the

machine

into

the

cabinet

or

place

it in

the

carrying case

(portable

machines)

the

spool

pins

shouldbeswung

forwardtothe

horizontal

position.

DR

549

11

Page 11

a

9t.tt

?0

661n

into

th

73c66e,,

Case

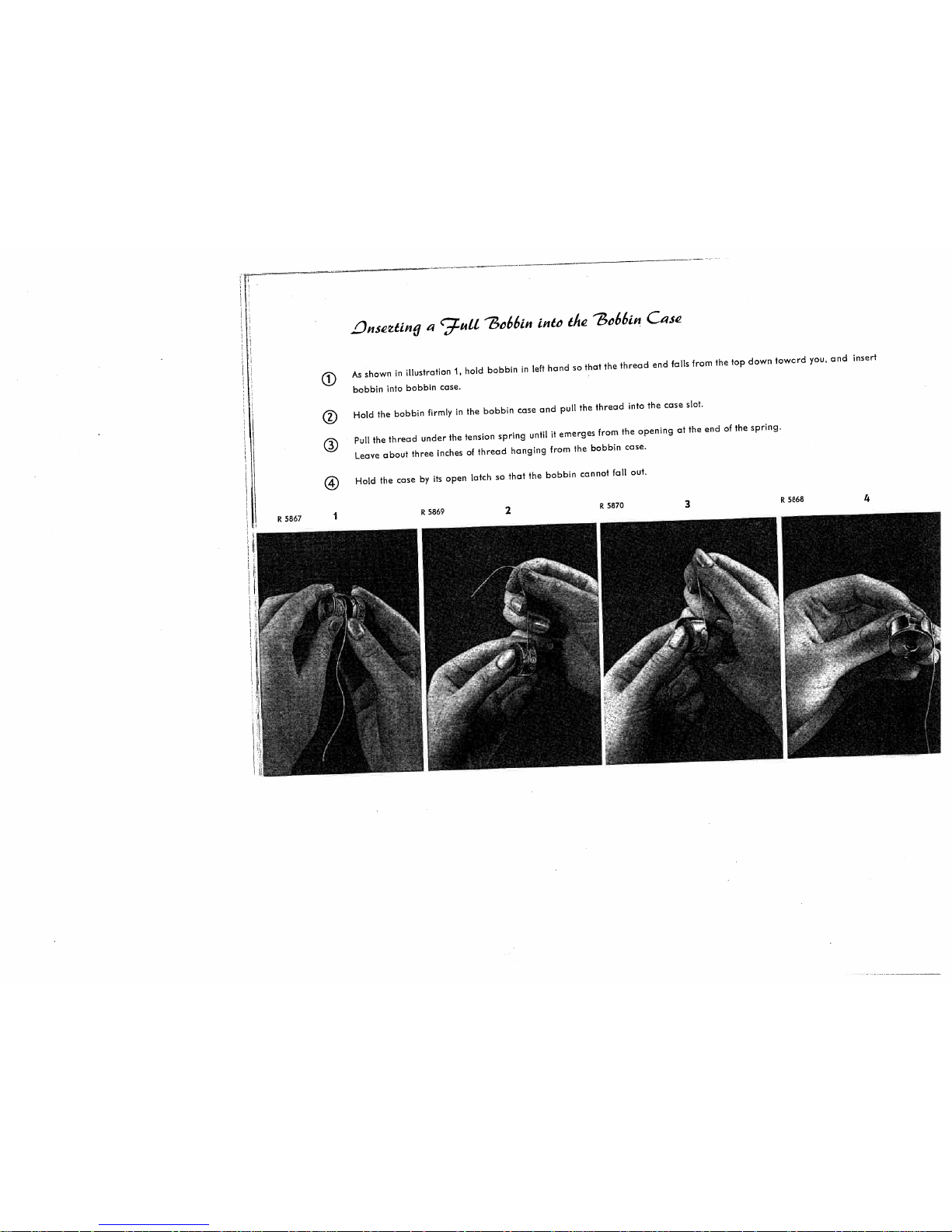

As

shown

in

illustration

1,

hold

bobbin

in

left

bond

so

that

the

thread

end

falls

from

the

top

down

toward

you,

ond

insert

bobbin

into

bobbin

case.

Hold

the

bobbin

firmly

in

the

bobbin

case

and

pull

the

thread

into

the

case

slot.

Pull

the

thread

under

the

tension

spring

until

it

emerges

from

the

opening

at

the

end

of

the

spring.

Leave

about

three

inches

of

thread

hanging

from

the

bobbin

case.

Hold

the

case

by

its

open

latch

so

that

the

bobbin

cannot

fall

out.

R

5867

1

R

5869

2

R

5870

3

R

5868

4

Page 12

L,istin

9

tk

7

3c66in

Ca.c€

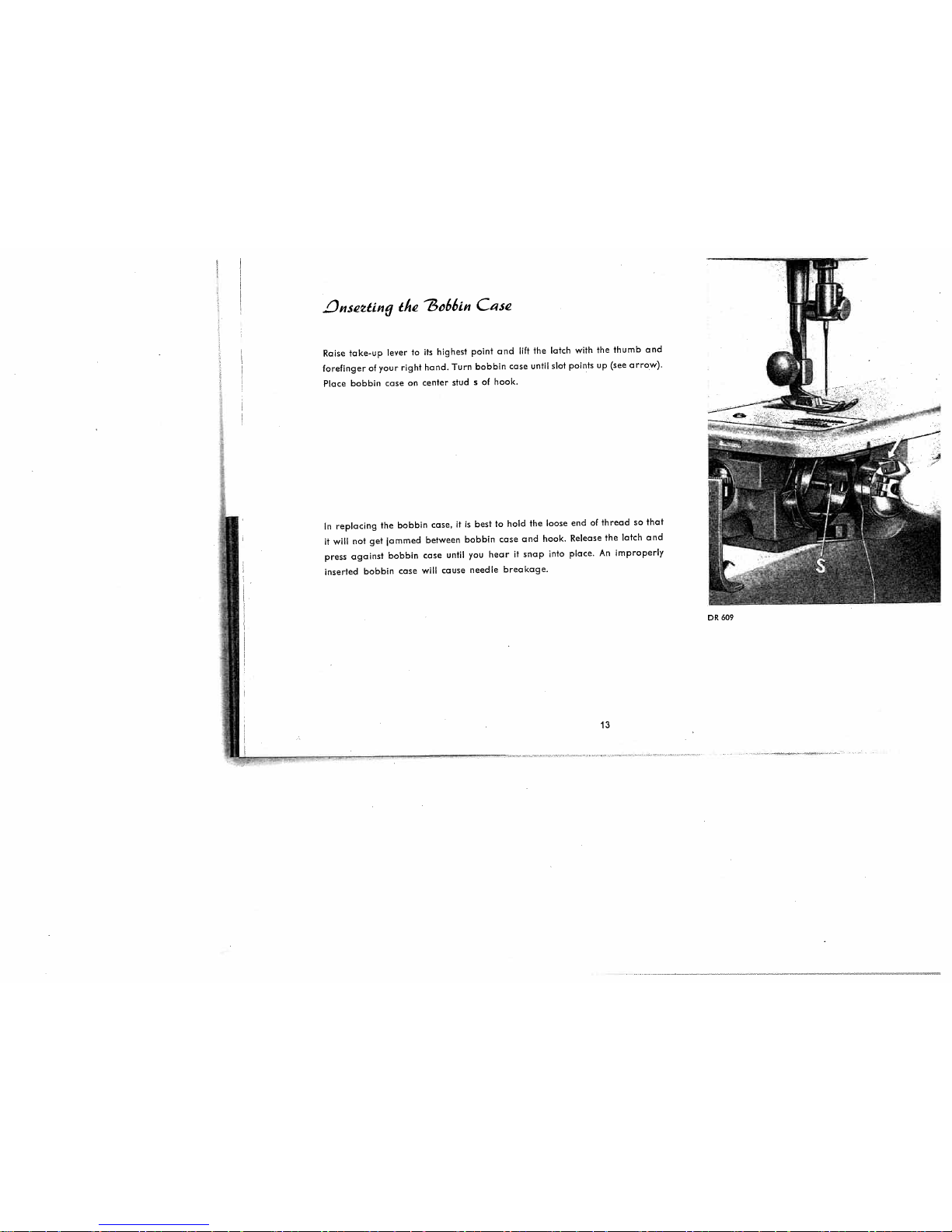

Raise

take-up

lever

to

its

highest

point

and

lift

the

latch

with

the

thumb

and

forefinger

of

your

right

hand.

Turn

bobbin

case

until

slot

points

up

(see

arrow).

Place

bobbin

case

on

center

stud

s

of

hook.

In

replacing

the

bobbin

case,

it

is

best

to

hold

the

loose

end

of

thread

so

that

it

will

not

get

jammed

between

bobbin

case

and

hook.

Release

the

latch

and

press

against

bobbin

case

until

you

hear

it

snap

into

place.

An

improperly

inserted

bobbin

case

will

cause

needle

breakage.

DR

609

13

Page 13

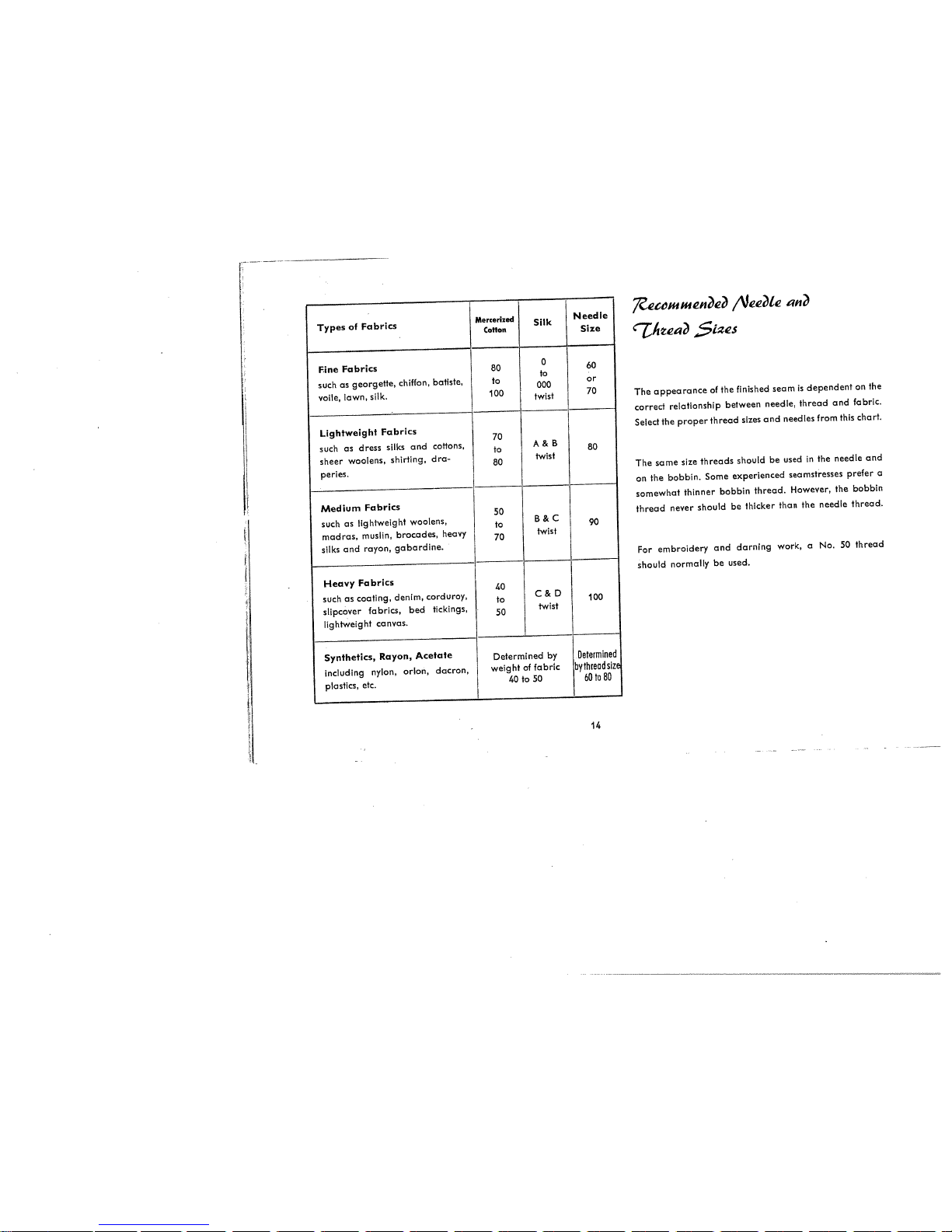

Types

of

Fabrics

Mercerized

Silk

Needle

Cotton

Size

Fine

Fabrics

80

0

60

to

such

as

georgette,

chiffon,

batiste,

to

000

or

voile,

lawn,

silk.

100

70

twist

Lightweight

Fabrics

70

such

as

dress

silks

and

cottons,

A

&

B

to

80

sheer

woolens,

shirting,

draW

80

twist

peries.

Medium

Fabrics

50

such

as

lightweight

woolens,

to

B

&

C

90

madras,

muslin,

brocades,

heavy

70

twist

silks

and

rayon,

gabardine.

Heavy

Fabrics

40

such

as

coating,

denim,

corduroy,

to

C

&

D

100

slipcover

fabrics,

bed

tickings,

50

j5t

lightweight

canvas.

Synthetics,

Rayon,

Acetate

Determined

by

Determined

including

nylon,

orIon,

dacron,

weight

of

fabric

bythreadsiz

plastics,

etc.

40

to

50

60

to

80

?&cmusn

/Vet!

an?

‘7ha

$tzc

The

appearance

of

the

finished

seam

is

dependent

on

the

correct

relationship

between

needle,

thread

and

fabric.

Select

the

proper

thread

sizes

and

needles

from

this

chart.

The

same

size

threads

should

be

used

in

the

needle

and

on

the

bobbin.

Same

experienced

seamstresses

prefer

a

somewhat

thinner

bobbin

thread.

However,

the

bobbin

thread

never

should

be

thicker

than

the

needle

thread.

For

embroidery

and

darning

work,

a

No.

50

thread

should

normally

be

used.

14

Page 14

£J,i,ictant

9.:acec

a6cut

1

1c

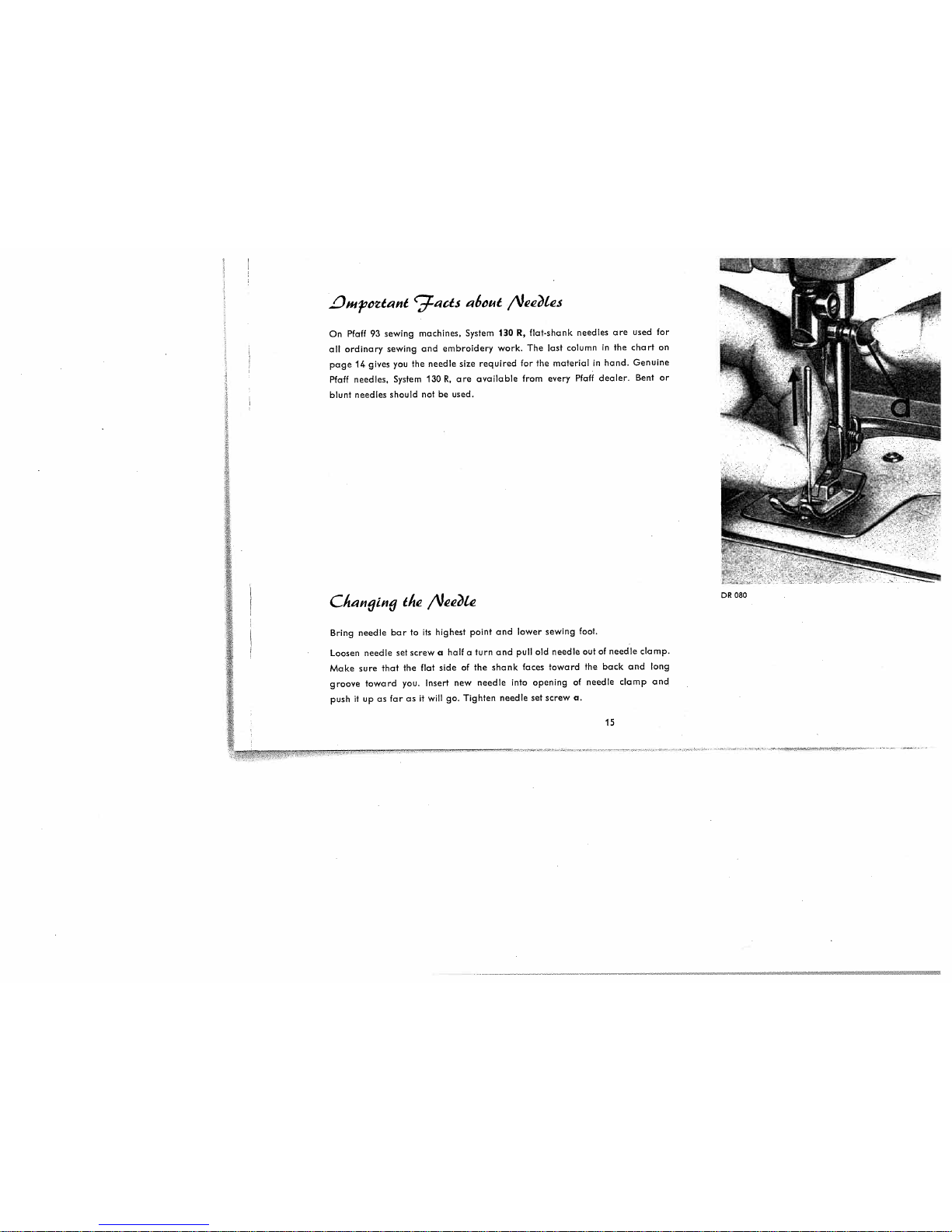

On

Pfaff

93

sewing

machines,

System

130

R,

flat-shank

needles

are

used

for

all

ordinary

sewing

and

embroidery

work.

The

lost

column

in

the

chart

on

page

16

gives

you

the

needle

size

required

for

the

material

in

hand.

Genuine

Pfaff

needles,

System

130

R,

are

available

from

every

Pfaff

dealer.

Bent

or

blunt

needles

should

not

be

used.

Chan

9ln9

he

,‘Veete

DR

080

Bring

needle

bar

to

its

highest

point

and

lower

sewing

foot.

Loosen

needle

set

screw

a

half

a

turn

and

pull

old

needle

out

of

needle

clamp.

Make

sure

that

the

flat

side

of

the

shank

faces

toward

the

back

and

long

groove

toward

you.

Insert

new

needle

into

opening

of

needle

clamp

and

push

it

up

as

far

as

it

will

go.

Tighten

needle

set

screw

a.

I

jg

15

Page 15

tij

‘ha?iny

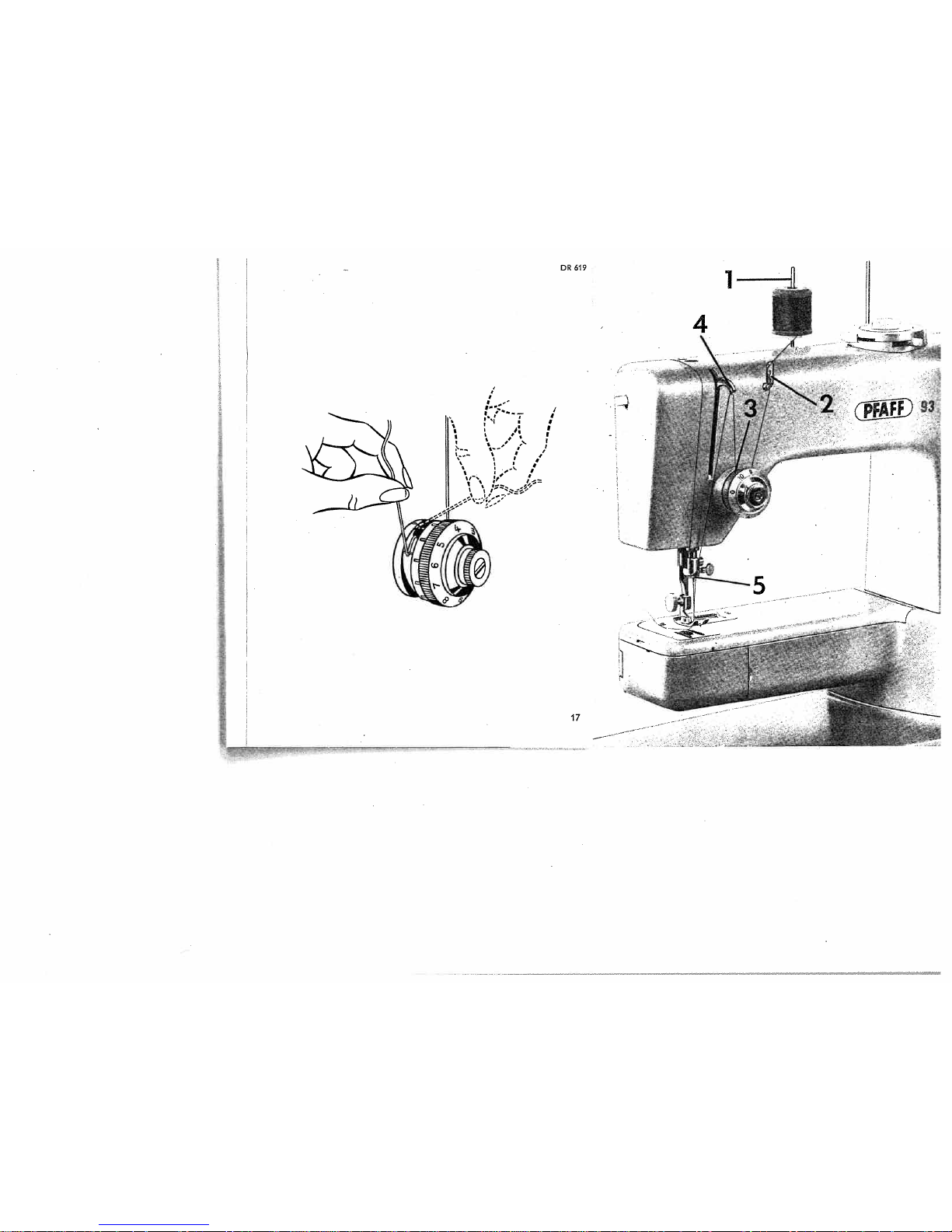

Raise

the

spool

pins

to

the

vertical

position

ond

ploce

a

spool

of

thread

on

one

of

them.

Loce

the

threod

through

the

two

rear

openings

of

threod

retoiner

2

(see

illustroiion).

Pull

threod

between

ony

two

of

tension

discs

3,

os

illustrated,

and

jerk

it

far

over

to

the

right

so

that

it

slips

properly

into

the

slot

and

under

the

thread

check

spring.

At

the

same

time,

press

the

thread

between

spool

and

tension

against

the

top

of

the

machine.

Bring

take-up

lever

4

as

high

as

it

will

go

and

pass

thread

from

right

to

left

through

the

hole

at

its

end

and

into

slot

at

left

of

thread

guide

S.

Then

thread

needle,

front

to

back.

16

Page 16

DR

619

•1

11

I

5

17

Page 17

Hold

needle

thread

lightly

in

your

left

hand.

Turn

balance

wheel

toward

you

until

the

needle

moves

once

down

and

up

again.

Lightly

pull

needle

thread

to

draw

bobbin

thread

up

through

the

needle

hole.

Place

both

threads

bock

under

the

sewing

foot.

0R615

Ccect

eutaflon

Balanced

tensions

are

essential

for

sewing.

If

your

tension

is

correct,

you

will

have

perfect

seams

as

sketched

below

(Ill).

Sketch

I

—

The

threads

interlock

on

the

underside

of

the

fabric.

Ca

use:

Upper

tension

too

loose

or

lower

tension

too

tight.

Sketch

II

—

The

threads

interlock

an

the

surface

of

the

fabric.

Cause:

Upper

tension

too

tight

or

lower

tension

too

loose.

IT

II

III

Z4winfy

i4i

t4€

73c66in

A

18

Page 18

DR

580

7yu1t?tIn7

U

iei

‘7.eiisio,i

The

bobbin

thread

tension

has

been

set

foramedium

grade

and

need

not

be

adjusted

for

all

ordinary

sewing

operations.

If

a

special

sewing

operation

should

require

a

looser

or

tighter

tension,

turn

the

small

knurled

screw

on

the

bobbin

case

with

the

tip

of

your

thumbasfollows:

Turn

it

left

gEE(

—

for

looser

tension.

Turn

it

right

>)

—

for

tighter

tension.

Determine

whether

the

bobbin

thread

tension

is

set

for

a

medium

grade

by

holding

the

thread

end

between

thumb

and

forefinger

and

letting

the

bobbin

case

hang

freely.

The

tension

should

be

strong

enough

to

keep

the

bobbin

case

from

being

pulled

downbyits

own

weight.

However,

as

you

jerk

your

hand

slightly,

the

bobbin

case

should

gradually

slide

down.

Do

not

turn

the

knurled

screw

too

far

to

the

left

to

keep

it

from

falling

out.

Choose

the

lower

tension

slightly

stronger

when

doing

ornamental

stitching

to

be

sure

you

y

always

have

a

neat

satin

stitch

on

the

right

side

of

the

fabric.

The

final

stitch

appeara

nce

can

be

regulated

by

the

upper

tension

dial,

as

follows:

Turn

left

—(E(

for

looser

tension.

Turn

right

)‘—

for

tighter

tension.

The

upper

tension

is

so

designed

that

all

grades

of

tension

—

loose

to

tight

—

con

be

covered

with

one

complete

turnofthe

tension

dial.

The

numbers

on

the

tension

dial

indicate

different

degrees

of

tension.

The

higher

the

number,

the

greater

the

tension.

Only

in

very

rare

cases

will

it

be

necessary

to

reset

the

tension.

For

ordinary

sewing,

the

upper

tension

should

be

set

between

3

and

5.

Your

upper

tension

has

a

third

tension

disc

for

two

needle

work.

A

R

8029

19

Page 19

OR

008

$titti4

p1atun

The

stitch

length

controj

serves

to

regulate

the

stitch

length

and

to

limit

it

in

sewing

backwards.

The

numbers

on

the

control

indicate

the

stitch

length

(the

higher

the

number,

the

longer

the

stitch).

When

the

control

is

set

on

“0”,

the

machine

ceases

feeding.

To

regulate

the

stitch

length,

turn

the

control

until

the

number

indicating

the

desired

stitch

length

is

opposite

the

mark

on

the

left

edge

of

the

slot.

(The

position

of

the

mark

is

indicated

by

an

arrow

in

the

illustration.)

7eos

$ewin9

To

sew

in

reverse,

simply

press

the

finger-tip

control

down.

When

the

control

in

released,

the

machine

resumes

forward

sewing.

This

feature

is

ideal

for

bcicktacking

the

beginning

or

end

of

a

seam

and

for

darning

rips.

20

OR

009

F

Page 20

DR

042

t

it

in

nber,

ding.

the

(The

Chan

9mn6

th

$wuIij

‘Etwt

Lift

both

needle

and

presser

bar

to

their

highest

positions

and

turn

sewing

foot

thumb

screw

b

to

the

left.

Tilt

the

foot

sideways

and

puli

it

down.

Reverse

procedure

to

slip

on

new

foot

and

tighten

screw

b

securely.

DR043

21

Page 21

DR

616

awij

ticu

,4lachiiw

6c

Raise

the

needle

and

remove

the

sewing

foot.

Put

the

rear

end

of

your

brush

under

the

edge

of

the

needle

plate

and

lift

until

the

press

stud

snaps

out.

Turn

needle

plate

upside

down

and

replace

so

that

raised

portionisat

front

(see

illustration).

Press

down

stud,

thread

needle

with

embroidery

thread

or

darning

wool

and

lower

presser

bar

lifter.

Now

you

can

embroider

and

darn

without

presser

foot,

moving

the

work

freely

by

hand.

22

DR

612

Page 22

anin

an?

m6ci?eg

9ôct

Remove

the

sewing

foot.

Attach

darning

foot

No.

93-100154-91

from

the

rear.

Hold

spring

clip

c

so

that

it

is

behind

the

needle

set

screw,

and

tighten

screw

b.

Ate-

7

j2cs

$eivin

9ôce

(with

Clear-View

Shoe)

All-purpose

sewing

foot

No.

93-100179-00

is

attached

as

instructed

on

page

21.

The

tronsparency

of

its

shoe

facilitates

all

sewing

operations

where

it

is

impor

tant

to

watch

the

needle

penetrate

the

fabric.

Special

application

possibilities

are

discussed

in

the

second

part

of

this

book

under

the

heading

“Using

Sewing

Feet

and

Attachments”.

I

your

brush

1

snaps

out.

0R08.3

•

DR588

•

23

Page 23

Ca

an

/i1ainhnana!

Longevity

and

smooth

machine

performance

are

dependent

on

regular

and

proper

cleaning

and

oiling.

Use

PFAFF

sewing

machine

oil

only.

Never

lubricate

machine

with

animal

or

vegetable

oils.

All

moving

and

rotating

ports

require

regular

lubrication.

DR

053

To

oil

mechanism

in

free

arm,

remove

sewing

foot,

raise

needle

and

swing

out

free

arm

cover.

Turn

thumb

nutruntil

free

arm

top

cover

is

loose.

Now

lift

the

top

cover

and

pull

it

out

lengthwise

of

the

arm.

The

principal

oiling

points

are

marked

by

arrows

in

the

illustrations

on

these

pages.

To

replace

and

secure

top

cover,

proceed

in

reverse

order.

From

time

to

time,

lubricate

the

needle

bar

frame

bearings

in

the

sewing

head.

DR

605

DR606

24

Page 24

There

are

two

openings

in

the

rim

of

the

stitch

width

dial,

one

on

the

left

and

the

other

at

the

back

(see

arrows).

These

openings

are

the

oil

holes

of

the

zigzag

mechanism.

Make

sure

you

put

only

one

drop

of

oil

into

the

oil

hole

locatedonthe

left of

the

balance

wheel,

if

there

is

suchanoil

hole

on

your

machine.

Do

not

lubricate

the

bobbin

winder.

DR053

DR557

lle

and

swing

is

loose.

Now

jincipal

oiling

The

raceway

in

the

sewing

hook

is

the

most

important

oiling

point.

Put

one

drop

of

oil

into

the

raceway

each

day

you sew

(see

picture

at

top

right).

From

time

to

time,

remove

the

needle

plate

and

clean

the

machine

feed

with

a

soft

brush.

Take

a

toothpick

and

remove

accumulations

of

packed

lint.

Take

out

the

babbin

case

and

the

bobbin

and

clean

the

vicinity

of

the

sewing

hook.

Before

you

begin

to

oil

the

mechanism

under

the

arm

top

cover

and

at

the

needle-bar

end

of

the

machine,

remove

the

dirt and

lint

which

has

accumulated

ew!ng

head.

on

these

parts.

DR611

25

DR

610

Page 25

[

DR

024

Chaqin

9

th

9

ht

?3ut6

The

built-in

15-watt

sewing

light

illuminates

the

area

of

stitching

perfectly.

To

change

the

light

bulb,

remove

the

face

cover,

push

the

bulb

into

its

socket,

turn

left,

and

pull

out.

When

inserting

sew

light

bulb,

be

suretoslide

bulb

pins

into

socket

slot.

Press

bulb

in

and

turn

right.

7uscoinfy

the

a€e

Côo

To

change

the

light

bulb

or

oil

the

parts

at

the

needle-bar

end,

remove

the

face

cover

by

pulling

it

upwards.

9ai

Cco

.4

Slip

tip

d

into

sloteand

push

face

cover

up

until

it

snaps

into

place.

DR

512

26

Page 26

C7c6te

4

5hcctinfy

2.

Needle

Thread

Breaks

Cause:

The

above

mentioned

may

cause

thread

breakage.

Thread

tension

too

tight.

Poor,

knotty

or

rotten

thread

used.

Hook

raceway

is

jammed

with

thread

or

needs

oiling.

Burrs

or

sharp

edges

on

needle

plate

slot.

Remedy:

Push

needle

up

as

far

as

it

will

go

and

be

sure

that

the

long

groove

faces

toward

you,

and

flat

side

of

shank

away

from

you.

Choose

the

correct

needle

from

chart

on

page

14.

(For

ordinary

sewing,

use

System

130R

needles.)

Insert

new

needle.

Check

and

correct

threading

as

instructed

on

pages

16

and

17.

Use

correct

needle

and

thread

(see

chart

on

page

14).

Remedy:

See

remedies

listed

under

1.

above.

Adlust

tensions

as

instructed.

Use

good

quality

threads

only.

Clean

and

oil

hook

raceway.

Polish

needle

plate

slot

with

fine

emery

cloth.

1.

Machine

Skips

Stitches

Cause:

Needle

incorrectly

inserted.

Wrong

needle.

Needle

bent.

Machine

threaded

improperly.

Needle

too

fine

or

too

thick

for

the

thread.

I

1

I

I

I

27

Page 27

iii

3.

Needle

Breaks

Cause:

Bent

needle

strikes

point

of

sewing

hook.

Needle

too

thin

or

thread

too

heavy.

Fabric

pulls

needle

so

it

bends

and

strikes

needle

plate.

Bobbin

case

inserted

incorrectly;

4.

Faulty

Stitch

Formation

Ca

use:

Improper

tension.

Thread

too

heavy,

knotty

or

hard.

Bobbin

unevenly

wound.

Pieces

of

thread

between

tension

discs.

Remedy:

Replace

needle

at

once

to

prevent

further

damage.

Use

correct

needle

and

thread

sizes.

Don’t

force

the

feeding

motion.

Guide

the

material

lightly.

Push

bobbin

case

until

you

hear

it

snap

into

place.

Remedy:

Adjust

tensions

as

instructed.

Use

only

first-rate

thread

—

the

correct

size

for

the

needle

and

fabric.

Don’t

run

thread

over

finger

when

winding

the

bobbin.

(For

instructions

see

page

11).

Raise

presser

bar

lifter

and

remove

thread.

5.

Machine

Feeds

Improperly

Cause:

Machine

does

not

feed

because

stitch

length

control

set

on

“0”.

Accumulations

of

lint

packed

between

feed

teeth.

Remedy:

Regulate

stitch

length,

as

desired.

Take

off

needle

plate

and

remove

lint

with

a

stiff

brush.

28

Page 28

6.

Machine

Works

Heavily

Cause:

Hook

raceway

tacks

oil

or

is

obstructed

by

pieces

of

thread.

Mechanism

clogged

by

inferior

oil.

Bobbin

winder

working

while

sewing.

7.

Machine

Fails

to

Sew

Zigzag

or

Ornamental

Stitch

Desired

Remedy:

Clean

and

oil

hook

raceway.

Use

only

Pfaff

sewing

machine

oil

—

never

salad

oil

or

glycerine.

Stop

bobbin

winder.

Cause:

Remedy:

Wrong

fashion

disc

inserted

or

none

at

all.

Jerk

stitch

width

lever

to

“0”

and

insert

proper

fashion

disc.

8.

Motor

Idles

For

straight

stitching,

too,

a

fashion

disc

should

be

inserted

in

the

machine

(see

pp.

6,

7

and

9).

Couse:

Remedy:

Motor

disengaging

lever

raised.

Flick

lever

down

(see

page

5).

Thread

Jamming

The

Pfaff

rotary

hook

will

not

normally

jam,

even

if

the

machine

should

be

handled

improperly.

If

thread

should

happen

to

jam

in

the

hoob

raceway,

the

power

of

the

motor

in

most

instances

will

be

sufficient

to

overcome

hard

working

of

the

mechanism.

If

this

action

should

not

free

the

jammed

thread,

put

a

dop

of

kreosene

info

hook

raceway,

jerk

the

balance

wheel

back,

then

rock

it

back

and

forth.

29

Page 29

847600

Zipper

Insertion

Pin

or

baste

closed

zipper

on

wrong

side

of

fabric.

Position

of

zipper

depends

on

whether

or

not

you

wont

the

edge

of

the

fabric

to

overlap

the

zipper.

Turn

fabric

to

right

side.

Run

a

straight

seam

close

to

left

edge

of

zipper,

stitch

across

end

and

up

the

other

side

in

one

continuous

operation.

Use

right

edge

of

foot

as

a

guide.

Quilting

Machine

Setting:

A=0;

B=+

4

Edge

stitcher

No.

847600

used

with

the

quilting

gauge

sews

parallel

rows

of

stitching

over

the

entire

surface

of

the

fabric.

Always

guide

the

gauge

finger

along

the

preceding

row

of

stitches.

Attractive

tea

cosies,

slippers,

seat

pads

and

covers

can

be

quilted.

Machine

Setting:

A=0;

B=

4

OR

002

DROO3A

30

Page 30

847551

Flat

Felled

Seams

Mochine

Setting:

A=0

or

2;

B=

‘I

Flat

felled

seams

are

used

to

durably

join

two

pieces

of

fabric.

They

ore

made

in

two

operations.

Flat

felled

seams

usually

are

straight-stitched.

Narrow

zigzag

stitches

ore

used

for

felling

on

elasticized

fabrics

only.

4

First

Seam

Lay

pieces

together

with

the

wrong

sides

facing

and

the

bottom

piece

pro

truding

‘/a

inch.

Feed

both

pieces

into

felling

foot,

as

illustrated

so

that

the

bottom

fabric

is

folded

over

edge

of

top

piece

and

stitched

down.

Make

sure

thot

protruding

seam

allowance

is

not

folded

twice.

DR

075

Second

Seam

Open

the

two

pieces,

ploce

them

under

the

needle

right

side

up,

insert

seam

ridge

into

felling

foot

opening,

and

stitch

down

to

the

left.

Moke

sure

that

second

seam

is

placed

closetothe

edge

but

not

beyond

it.

The

felling

foot

has

a

needle

slot,

rather

than

a

needle

hole,

to

permit

zigzag

felling.

31

DR

049

• •

-.•

Page 31

DR

073

4

Avoid

ugly

ends

by

slowing

down

feeding.

To

do

this,

press

the

fabric

against

the

needle

plate

on

the

left

side

of

the

foot

before

you

come

to

the

end

of

the

hem.

847551

Hemming

Machine

Setting:

A=O

or

2

to

3;

B=4

The

hemmer

foot

is

indispensable

if

you

wont

to

sew

a

uniform

hem.

You

can

hem

with

straight

or

zigzag

stitches,

depending

on

the

type

of

fabric

you

ore

using.

Clip

off

the

corner

of

the

fabric

to

facilitate

insertion

into

the

hemmer

foot

curl.

Feed

fobric

so

that

the

raw

edge

is

in

line

with

the

left

edge

of

the

hemmer

foot.

If

you

feed

less,

the

fabric

will

not

be

folded

twice

and

the

raw

edge

will

show.

DR

074

32

Page 32

838

954

Overcasting

Edges

Machine

Setting:

A=2

to

4;

B=

4

Overcasting

prevents

frayed

edges.

Use

a

long

wide

zigzag

stitch

and

sew

edge

with

the

needle

taking

one

stitch

into

the

fabric

and

the

other

over

its

edge

(normal

tension

setting).

You

may

overcast

edges

after

fabric

is

cut

and

before

the

pieces

are

joined.

DR

081

838

954

Butt

Seaming

Machine

Setting:

A=3

or

4;

B=

4

Two

similar

pieces

of

fabric

which

do

nat

ravel

easily

may

be

butted

together

and

joined

with

zigzag

stitches.

Worn

bed

sheets

may

be

mended

this

way.

Cut

out

worn

center

strip.

Place

the

selvaged

edges

of

the

remainIng

pieces

of

sheet

under

the

sewing

foot

so

that

the

abutted

edges

are

centered

under

the

needle,

Join

them

with

close,

wide

zigzag

stitches

to

obtain

a

neat

and

flat

seam.

Hem

raw

edges

of

sheet.

DR

045

33

Page 33

DR

076

Darning

without

Darning

Hoops

You

will

really

appreciate

the

free

arm

of

your

Pfaff

93

when

you

darn

tubular

clothing,

suchasunderpants,

sleeves,

socks

or

stockings

without

darning

hoops.

4

Trim

ragged

edges

of

hole

with

the

fabric

grain,

then

stitch

bock

and

forth

across

the

hale

from

one

side

to

the

other

with

the

machine

running

at

high

speed.

ii

Now

sew

back

and

forth

over

preceding

work

with

short

stitches

taken

length-

wise

of

the

arm.

This

onchors

threads

in

the

unworn

area

around

the

hole.

Always

hold

fabric

taut.

I

:1

I

—

Page 34

Triangular

Tears

Triangular

tears

are

best

darned

by

placing

the

torn

section

between

hoops

and

making

close

stitches

across

and

lengthwise.

Move

work

under

the

needle

with

both

hands.

Thin

Spots

Remember

that

‘a

stitch

in

time

saves

nine”

and

reinforce

spots

that

have

worn

thin

with

short

stitches

made

lengthwise

and

across

worn

section.

This

job

can

be

done

without

foot,

too.

Small

Holes

Darn

small

and

medium-size

holes

by

trimming

ragged

edges

with

the

fabric

grain.

First

stitch

back

and

forth

across

the

hole

from

one

side

to

the

other

with

the machine

running

at

high

speed.

Then

turn

the

fabric at

right

angles

and

sew

back

and

forth

over

preceding

work

with

short

stitches.

Make

sure

the

stitches

are

taken

right

into

the

good

material.

Long

Rips

may

be

darned

with

the

normal

sewing

foot

and

without

hoops.

Set

needle

plate

in

its

normal,

or

sewing,

position

and

use

forward-reverse

feed

control.

DR

056

Darning

Machine

setting:

A=O;

8=4

Prepare

your

machine

for

darning

as

instructed

on

pages

22

and

23.

Place

fabric

into

darning

hoop,

the

damaged

area

being

in

the

center

of

the

hoop.

Hoops

may

be

obtained

from

your

Pfaff

dealer.

DR

559

35

Page 35

DR

582

838

954

Inserting

Pakhes

Elastic

Fabrics

Insert

fashion

disc

B

(elastic

serpentine

stitch).

Machine

Setting:

A=4;

B=

Stitch

Length:

Medium

Large

holes

can

be

patched

quickly.

The

following

methad

may

be

used

for

jersey

and

other

elastic

fabrics.

Cut

patch

so

that

its

grain

will

match

the

rest

of

the

fabric.

Place

the

patch

over

the

damaged

area.

LI

Sew

ii

down

with

an

elastic

serpentine

stitch

of

medium

length.

.4

For

additional

strength,

stitch

over

corners

twice.

Turn

over

and

trim

close

to

seams.

Ordinary

Fabrics

Insert

fashion

disc

A.

Machine

Setting:

A=2;

B=

1

Stitch

Length:

Minimum

Patches

are

inserted

in

ordinary

fabrics

with

short

zigzag

stitches.

Sew

over

corners

twice.

Other

than

that,

proceed

as

instructed

above.

.4

For

added

strength,

sew

around

patch

again,

guiding

the

edge

of

the

sewing

DR

581

foot

along

the

first

seam.

36

0R566

Page 36

DR

567

stitch).

Blindsfitching

Insert

fashion

disc

C.

Machine

Setting:

A=4;

B=1

Stitch

Length:

Maximum

he

following

method

may

be

used

for

tch

so

that

its

grain

will

match

the

rest

Skirts,

dresses

and

ladies’

coats

of

medium

and

heavyweight

fabrics

ore

damaged

area,

hemmed

with

blind

stitches.

To

do

this,

insert

the

blindstitch

disc

and

a

No.

70

-

needle.

Use

embroidery

thread

No.

50

or

silk

thread

that

matches

the

fabric.

stitch

of

medium

length.

Ease

upper

tension

somewhat.

rners

twice.

Turn

over

and

trim

close

Next,

follow

this

procedure:

Turn

fabric

wrong

side

up.

Fold

finished

edge

of

woolen

fabrics

once

(Fig.

1),

other

thin

fobrics

twice

(Fig.

2).

In

this

lotter

cose

there

is

no

need

to

finish

the

cs

with

short

zigzag

stitches.

Sew

over

edge.

It

is

best

to

press

or

baste

the

hem.

Guide

the

work

evenly.

Set

stitch

ed

as

instructed

above,

width

lever

A

so

that

needle

takes

left

stitch

exactly

in

the

folded

edge

and

again,

guiding

the

edge

of

the

sewing

right

stitch

up

to

or

over

the

hem

edge.

When

hem

is

finished,

stitches

will

not

________________

be

visible

on

top

side.

37

Page 37

DR

082

Sewing

Buttonholes

Insert

fashion

disc

A.

Machine

Setting:

A=lt/s

(first

notch);

B=

Stitch

Length:

Almost

0

(for

buttonhole

seam)

Use

only

No.

50

embroidery

and

darning

threod.

Attach

buttonhole

foot

No.

847616

and

set

slide

on

buttonhole

gouge

to

button

hole

length

desired.

The

buttonhole

is

the

right

length

when

beginning

of

first

seam

reaches

red

end

of

slide

indicator

(see

arrow).

When

you

fallow

the

procedure

on

the

opposite

page,

the

bat-tacks

at

each

end

of

your

buttonhole

will

be

twice

as

wide

as

a

buttonhole

seam.

If

you

prefer

more

prominent

buttanholes,

pull

a

filler

cord

through

the

hole

in

left

toe

of

foot.

To

get

the

correct

stitch

length,

sew

on

a

piece

of

scrap

material.

in

making

buttonholes

in

soft

or

loosely

woven

fabrics,

it

is

advisable

to

place

a

piece

of

tissue

paper

under

the

material.

To

strengthen

buttonholes

in

tricot

and

knit

fabrics,

insert

a

piece

Qf

firmly

woven

cotton

material

between

the

fabric

layers.

—

s.loQI7e

Buttonholes

may

be

made

with

the

aid

of

the

oil-purpose

sewing

foot.

Place

the

filler

cord

in

the

left

groove

of

the

clear-view

shoe.

38

Page 38

Instructions

for

Buttonholing

thread.

slide

on

buttonhole

gouge

to

button-

right

length

when

beginning

of

first

see

arrow).

pposite

page,

the

bartacks

at

each

videasa

buttonhole

seam.

pull

o

filler

cord

through

the

hole

gth,

sew

on

a

piece

of

scrap

material.

oven

fabrics,

itisadvisable

to

place

I.

To

strengthen

buttonholes

in

tricot

woven

cotton

material

between

the

‘ith

the

aid

of

the

all-purpose

sewing

he

left

groove

of

the

clear-view

shoe.

4

Change

dial

A

to

“1h/”.

Trim

filler

cord

at

end

of

first

stitch

row.

Sew

second

row

and

stop

about

4

to

6

stitches

(h/ton)

from

end

of

first

row.

5

Turn

dial

A

to

second

notch

position

(or

“4”).

Make

second

tack,

as

instructed

above

(under

3).

6

Turn

dial

A

to

“0”,

and

make

3

or

4

fastening

stitches.

4

7

Trim

both

the

sewing

and

filler

threads.

Open

the

buttonhole

with

your

seam

ripper.

Be

careful

not

to

injure

the

bartacks.

I

Sew

first

side

over

a

filler

cord.

When

beginning

of

seam

reaches

red

end

of

slide

indicator

on

buttonhole

gauge,

it

is

the

right

length.

Leave

needle

in

fabric

on

right

side

of

its

throw.

2

Lift

foot,

turn

fabric

around

clockwise,

using

needle

as

a

pivot.

Lower

foot,

take

one

stitch

to

the

left,

pull

filter

cord

taut

and

toy

it

parallel

to

completed

line

of

stitching.

3

Turn

dial

A

until

it

is

caught

in

second

notch

(or

stops

at

4).

Make

4

to

6

bartack

stitches,

slightly

holding

the

material

to

reduce

length

of

bar.

C

0

1

39

Page 39

—

g-lCO79

Button

Sewing

Insert

fashion

disc

A.

Machine

Setting:

A=0;

B=

Don’t

be

afraid

to

sew

on

buttons

or

rings

with

your

Pfaff.

The

needle

won’t

break

and

the

threads

will

not

get

loose

either.

The

latter

may

happen

only

with

ready-mode

clothing

sewn

with

a

chain

stitch,

It

won’t

be

worthwile

to

take

the

machine

out

for

sewing

on

o

single

button,

but

you

will

appreciate

this

feature

when

sewing

lines

of

buttons

on

pillow

and

bed

covers,

on

shirts

or

dresses,

or

when

fastening

rings

on

curtains,

etc.

There

your

machine

will

come

in

very

handy.

Attach

all-purpose

sewing

foot

No.

93-100179-00

and

set

the

stitch

length

control

on

0.

Hooks

and

eyes

ore

sewn

on

with

the

aid

of

a

special

button

sewing

foot,

No.

847608,

which

can

be

obioiried

from

your

Pfoff

dealer.

Turn

the

needle

plate

half

a

turn

so

that

the

raised

portion

is

at

the

front

(see

picture

at

the

bottom

of

page

22).

The

raised

portion

of

the

needle

plale

feotures

on

elongated

needle

hole.

Place

button

under

button

sewing

foot

and

align

so

that

needle

will

enter

left

hole.

Let

needle

stitch

through

hole

and

make

one

or

two

tying

stitches.

Raise

needle.

Turn

dial

A

counter-clockwise,

usually

to

3,

until

needle

on

the

right

of

its

throw

is

centered

over

right

hole,

Start

machine

and

sew

as

many

zigzag

stitches

as

you

deem

necessary

to

fasten,

button

securely.

Return

dial

A

to

0

and

make

two

or

three

tying

stitches.

When

sewing

on

four-hole

buttons,

reposition

button

ond

repeat

the

above

process,

stitching

through

the

second

pair

of

holes.

DR

583

40

Page 40

DR

044

gs

with

your

Pfaff.

The

needle

won’t

•

either.

The

latter

may

happen

only

ham

stitch.

It

won’t

be

worthwile

to

ngle

button,

but

you

will

appreciate

on

pillow

and

bed

covers,

on

shirts

urtains,

etc.

There

your

machine

will

sewing

foot

No.

931OO179-OQ

and

uid

of

a

special

button

sewing

foot,

n

your

Pfaff

dealer.

Turn

the

needle

ion

is

at

the

front

(see

picture

at

the

he

needle

plate

features

an

elongated

lie

stitch

through

hole

and

make

one

on

the

right

of

its

throw

is

centered

fasten

buffon

securely.

Return

dial

A

ng

through

the

second

pair

of

holes.

836954

Attaching

Lace

Machine

Setting:

A=2;

B=

You

can

attach

lace

edging

in

one

simple

operation.

Fold

the

edge

of

the

fabric

about

/e”

over

to

the

wrong

side,

following

the

texture,

and

preferably

iron

it

down.

Place

the

straight

edge

of

the

lace

on

the

fold

of

the

fabric

and

sew

it

down

with

narrow

zigzag

stitches,

taking

one

stitch

into

lace

and

fabric

and

the

other

into

lace

only.

Cut

off

excessive

cloth

on

the

wrong

side

of

the

material

close

to

the

seam.

Shell-Edging

Made

with

Blindstitch

Disc

Machine

Setting:

A=4;

B=

+

Stitch

Length:

Medium

Insert

foshion

disc

C,

and

tighten

upper

and

lower

thread

tensions.

Shell

edging

is

an

effective

fashion

trim

on

blouses

(particularly

those

made

of

delicate,

soft

fabrics).

Fold

fabric

along

desired

line.

Guide

work

so

that

needle

takes

one

stitch

in

the

fabric,

and

the

other

over

its

edge.

(As

the

thread

interlock

outside

the

material,

its

edge

is

drawn

back,

producing

the

desired

shell

edging.)

Shell

edging

makes

a

nice

trimming

on

handkerchiefs,

too.

41

DR

564

Page 41

DR

033

838

954

Applique

Work

Insert

fashion

disc

A.

Machine

Setting:

A=lt/

2

to2;B=

+

Applique

is

easy

and

modern.

Trace

design

on

wrong

sideoffabric

ond baste

a

piece

of

contrasting

material

to

right

side.

Outline

design

on

wrong

side

withanarrow

zigzag

stitch—and

the

motif

will

appear

on

right

side.

Trim

excess

material

closetothe

seam

and

sew

over

edges

of

applique

with

a

medium-wide

satin

stitch.

If

you

want

to

give

the

design

a

plastic

effect,

use

buttonhole

foot

Nr.

847616

or

all-pur

pose

sewing

foot,

flick

leverBto

the

left

and

satin-stitch

over

a

filler

thread

(see

also

page

38).

Appliqueisvery

effective on

buster

suits,

pinafores,

bibs,

frocks,

covers,

wall

hang

ings,orwherever

a

gay

note

is

desired.

Fill

out

small,

but

essential

sections

of

design

with

granite

stitches.

V

42

R

7220

Page 42

DR

038

lique

is

very

effective

on

buster

suits,

3fores,

bibs,

frocks,

covers,

wall

hang

or

wherever

o

gay

note

is

desired.

out

small,

but

essential

sections

of

ign

with

granite

stitches.

V

Monogram

Embroidery

Insert

fashion

disc

A.

Machine

Setting:

A=3

to

4;

B=

4

Prepare

machine

as

for

darning.

Script

letters

are

best

for

monogram

embroi

dery

without

a

sewing

foot.

It

requires

a

little

pratice.

You

will

soon

enjoy

creative

embroidery

once

you

have

learned

to

move

the

material

at

a

uniform

rate.

The

fabric

should

be

held

tout

in

the

hoops

and

the

presser

bar

lifter

lowered,

Let

the

needle

stitch

into

the

fabric

at

the

beginning

of

your

design

and

draw

bobbin

threadupthrough

the

fabric.

Hold

both

thread

ends

and

sew

over

outline,

moving

hoops

slowly

and

evenly.

To

give

your

monogram

dimensional

quality,

embroider

outline

twice.

Be

sure

stitches

are

closely

spaced.

L

535

954

—

ü

chi€fti:.A2’/2to3;

The

procedure

below

is

primarily

used

for

block

letters.

Set

needle

plate

so

that

feed

dog

feeds

the

material.

Attach

all-purpose

sewing

foot

and

set

machine

for

satin

stitch.

Sew

outlines

of

monogram

making

sure

that

seams

do

not

overlap

at

joints

of

letters.

43

DR

031

i

Page 43

838

954

Straight-Stitch

Hemstitching

Infert

fashion

disc

A.

Machine

Setting:

A=0;

B=

Stitch

length:

Medium

to

maximum.

Insert

twin

hemstitching

needle,

System

130

Zwi-Ho,

as

instructed

on

page

15.

Turn

out

needle

set

screw

a

little

further

than

for

ordinary

needles.

The

thread

size,

threading

procedure

and

thread

tension

are

the

same

as

for

cording

work

(see

page

45).

Beautiful

hemstitching

effects

on

blouses,

dresses,

handkerchiefs,

doilies

and

so

forth,

con

be

obtained

with

Pfaff’s

System

130

twin

needle.

The

harder

the

fabric

yarn,

the

more

pronounced

the

hemstitching

will

be.

For

this

reason,

batiste,

organdy,

georgette,

etc.

ore

best

suited

to

hemstitching.

while

woolly

fabrics

are

not

recommended.

DROOl

Procedure

Fold

fabric

to

mark

seamline

or

trace

seamline

on

fabric.

Sew

first

row.

Guide

fabric

so

that

wing

needle

stitches

along

traced

line.

At

the

end

of

the

seam,

turn

fabric

half

a

turn

and

sew

second

row.

Guide

fabric

in

such

a

way

that

wing

needle

penetrates

the

needle

holes

it

has

made

and

enlarged

pre

viously.

Imitation

hemstitching

thus

requires

at

least

two

operations.

If

desired,

addi

tional

straight

or

curved

ornamental

seams

may

be

stitched

paralleltothe

first

one.

Exciting

decorative

effects

may

be

obtained

by

using

van-colored

embroidery

and

darning

threads.

4

Zigzag

Hemstitching

Insert

fashion

disc

A.

Machine

Setting:

A=Up

to

11/2;

B=

4

Same

as

above,

except

that

the

wing

needle

should

penetrate

the

traced

line

only

when

it

is

on

the

left

of

its

throw.

R

8427

44

Page 44

Cording

Machine

Setting:

A=0;

B=#

To

cord

on

your

Pfaff

93,

useacording

foot

and

a

twin

needle.

Twin

needles

are

available

for

needle

distances

of

1.2

(3/oa”),

1.6

(h/l6),

1.8,

2.0

(/o4”),

2.5

(3/),

3.0,

and

4.0

(5/)

millimeters.

Cording

feet

are

available

in

three

varieties,

as

follows:

Pin

tucks

are

made

with

cording

foot

No.

847680

(7

grooves,

/64”

wide

each)

and

a

1.2-mm

twin

needle.

For

narrow

cording

use

cording

foot

No.

847675

(5

grooves,

l/ia’

wide

each;

see

ill.)

and

a

1.6-mm

twin

needle.

Wider

cording

is

made

with

cording

foot

No.

847671

(3

grooves,

5/6a

wide

each)

and

a

twin

needle

with

a

needle

distance

of

2,0

or

2.5

millimeters.