Page 1

a

a

Page 2

CPFAFFi

Automatic

92

INSTRUCTIONS

FOREWORD

Your

dream

has

come

true.

Your

are

now

the

proud

owner

of

a

Pfaff

Automatic

92,

the

sewing

machine

which

will

enable

you

to

master

all

ordinary

sewing

and

darning

jobs

that

may

come

up

in

a

home.

In

addition,

your

machine

can

sew

a

large

number

of

beautiful

decorative

designs

completely

automatically.

This

instruction

book

will

help

you

understand

the

machine

and

give

you

valuable

tips

to

make

sewing

mare

fun

for

you.

Even

if

you

are

an

experienced

seamstress,

you

will

find

this

book

a

valuable

guide

to

easy

sewing.

Follow

these

simple

instructions

and

familiarize

yourself

with

the

exclusive

features

of

your

machine.

You

will

find

sewing

exciting

on

your

easy-to-operate

Pfaff

92.

If

you

have

any

sewing

problems,

picce

conaci

your

Pfaff

dealer.

He

will

be

glad

to

help

you

at

any

time.

G.M.PFAFF

AG

Karisruhe-Durlach

Branch

Page 3

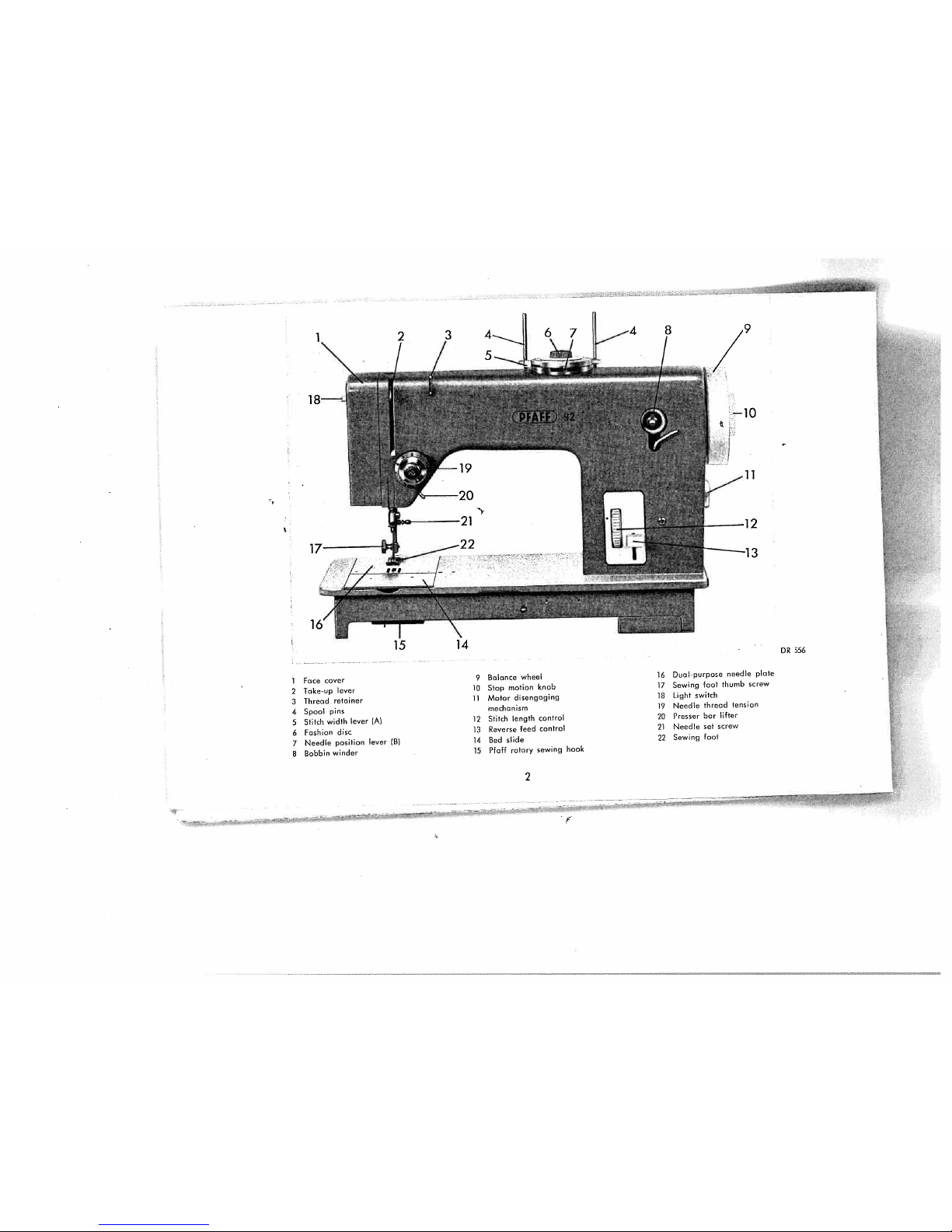

1

Face

cover

2

Take-up

lever

3

Thread

retainer

4

Spool

pins

5

Stitch

width

lever

)A)

6

Foshion

disc

7

Needle

position

lever

(B)

8

Bobbin

winder

9

Balance

wheel

to

stop

motion

knob

11

Motor

disengaging

mechanism

12

Stitch

length

control

13

Reverse

Feed

control

14

Bed

slide

15

Pfoff

rotary

sewing

hook

16

Dual-purpose

needle

plate

17

Sewing

foot

thumb

screw

18

Light

switch

19

Needle

thread

tension

20

Presser

bar

lifter

21

Needle

set

screw

22

Sewing

foot

51i

6

\

7

I

[4

21

1

7—___—22

DR

556

2

Page 4

•

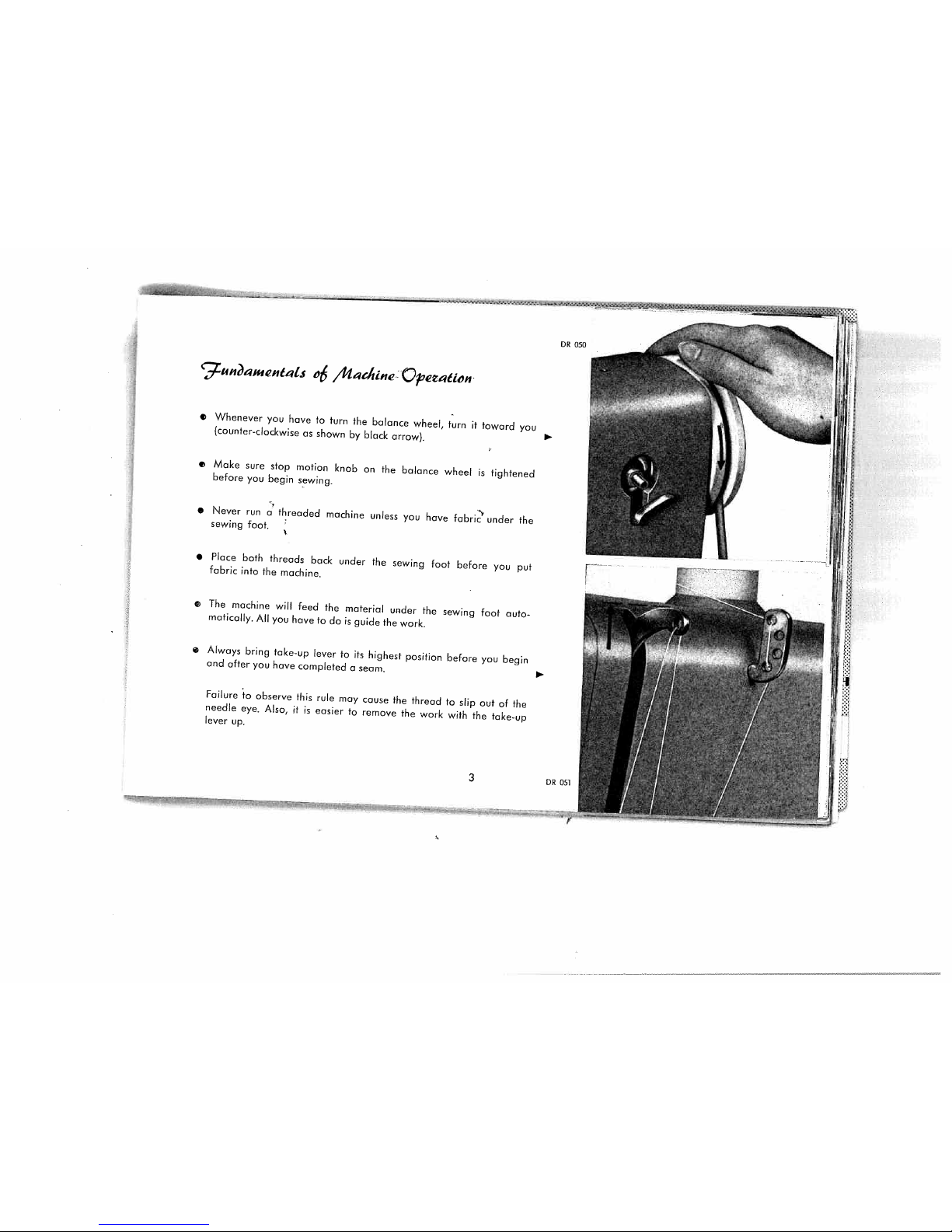

Whenever

you

have

to

turn

the

balance

wheel,

turn

it

toward

you

(counter-clockwise

as

shown

by

black

arrow).

•

Make

sure

stop

motion

knob

on

the

balance

wheel

is

tightened

before

you

begin

sewing.

•

Never

run

a

1

threaded

machine

unless

you

have

fabri

under

the

sewing

foot.

•

Place

both

threads

back

under

the

sewing

foot

before

you

put

fabric

into

the

machine.

The

machine

will

feed

the

material

under

the

sewing

foot

auto

matically.

All

you

have

to

do

is

guide

the

work.

•

Always

bring

take-up

lever

to

its

highest

position

before

you

begin

and

after

you

have

completed

a

seam.

Failure

to

observe

this

rule

may

cause

the

thread

to

slip

out

of

the

needle

eye.

Also,

it

is

easier

to

remove

the

work

with

the

take.up

lever

up.

t

/Uat.411W-

OR

050

L1!1

3

DR

05

F

Page 5

OR

506

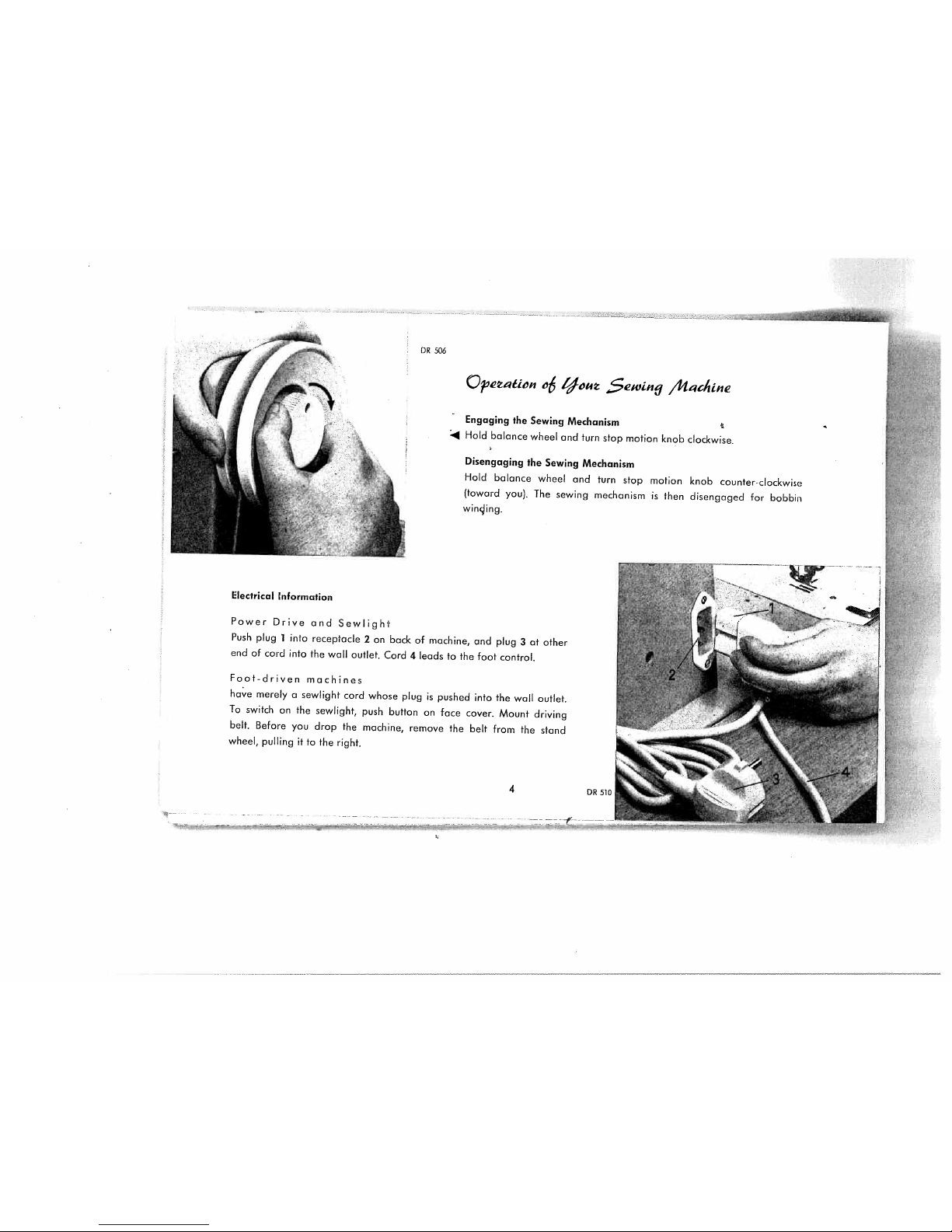

Disengaging

the

Sewing

Mechanism

Hold

balance

wheel

and

turn

stop

motion

(toward

you).

The

sewing

mechanism

is

then

wining.

Electrical

Information

Power

Drive

and

Sewlight

Push

plug

1

into

receptacle

2

on

bock

of

machine,

and

plug

3atother

end

of

card

into

the

wall

outlet.

Cord

4

leads

to

the

foot

control.

Foot-driven

machines

have

merely

a

sewlight

cord

whose

plug

is

pushed

into

the

wall

outlet.

To

switch

on

the

sewlight,

push

button

on

face

cover.

Mount

driving

belt.

Before

you

drop

the

machine,

remove

the

belt

from

the

stand

wheel,

pulling

it

to

the

right.

Qjetion

o6

icti

$winy

,Madine

Engaging

the

Sewing

Mechanism

.4

Hold

balance

wheel

and

turn

stop

motion

knob

clockwise.

knob

counter-clockwise

disengaged

for

bobbin

\

1

4

Page 6

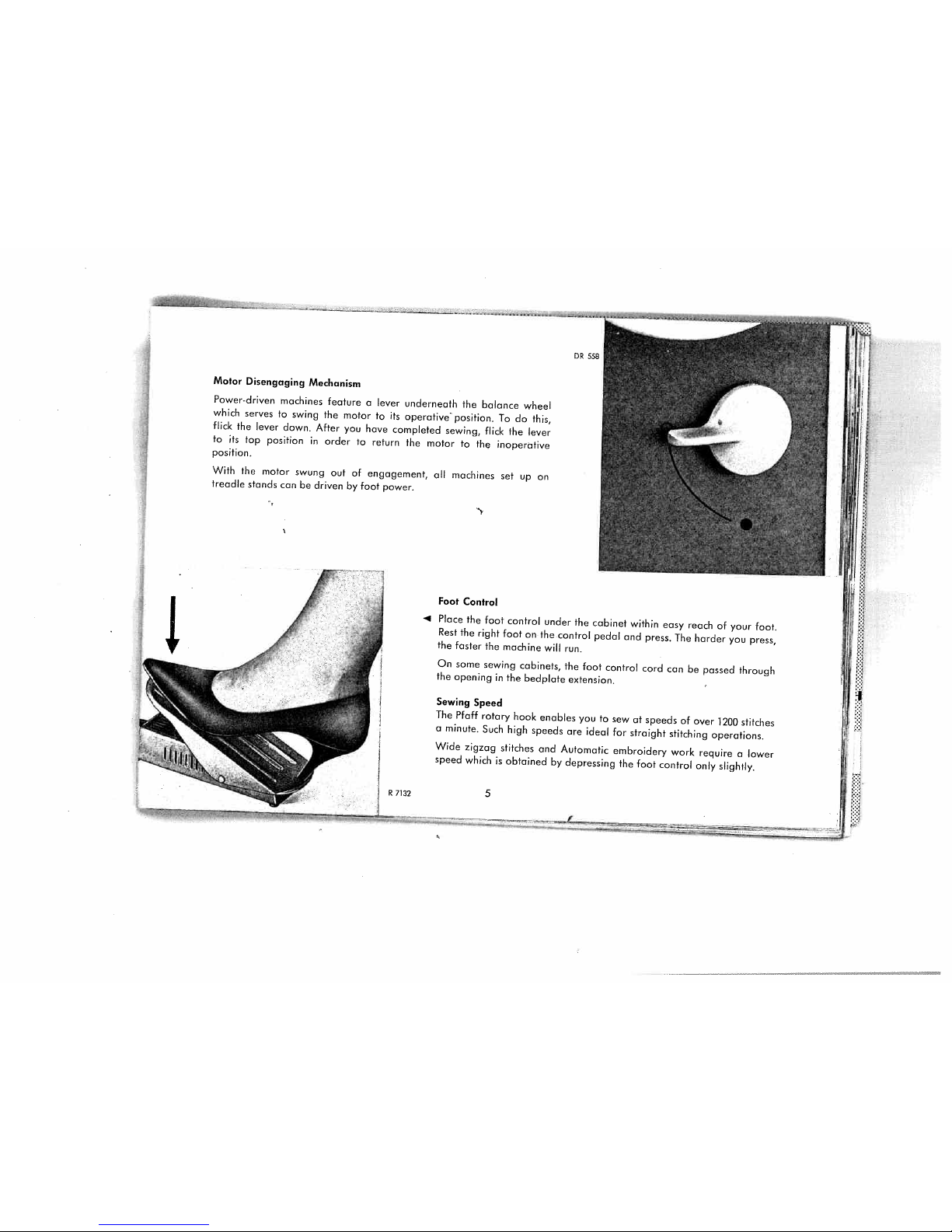

Motor

Disengaging

Mechanism

Power-driven

machines

feature

a

lever

underneath

the

balance

wheel

which

serves

to

swing

the

motor

to

its

operativ&

position.

To

do

this,

flick

the

lever

down.

After

you

have

completed

sewing,

flick

the

lever

to

its

top

position

in

order

to

return

the

motor

to

th

inoperative

position.

With

the

motor

swung

out

of

engagement,

all

machines

set

up

on

treadle

stands

can

be

driven

by

foot

power.

1j

4

Place

the

foot

control

under

the

cabinet

within

easy

reach

of

your

foot.

Rest

the

right

foot

on

the

control

pedal

and

press.

The

harder

you

press,

the

faster

the

machine

will

run.

On

some

sewing

cabinets,

the

foot

control

cord

can

be

passed

through

the

opening

in

the

bedplate

extension.

Sewing

Speed

The

Pfoff

rotary

hook

enables

you

to

sew

at

speeds

of

over

2OO

stitches

a

minute.

Such

high

speeds

are

ideal

for

straight

stitching

operations.

Wide

zigzag

stitches

and

Automatic

embroidery

work

require

o

lower

speed

which

is

obtained

by

depressing

the

foot

control

only

slightly.

f.

Foot

Control

R7132

5

I

Page 7

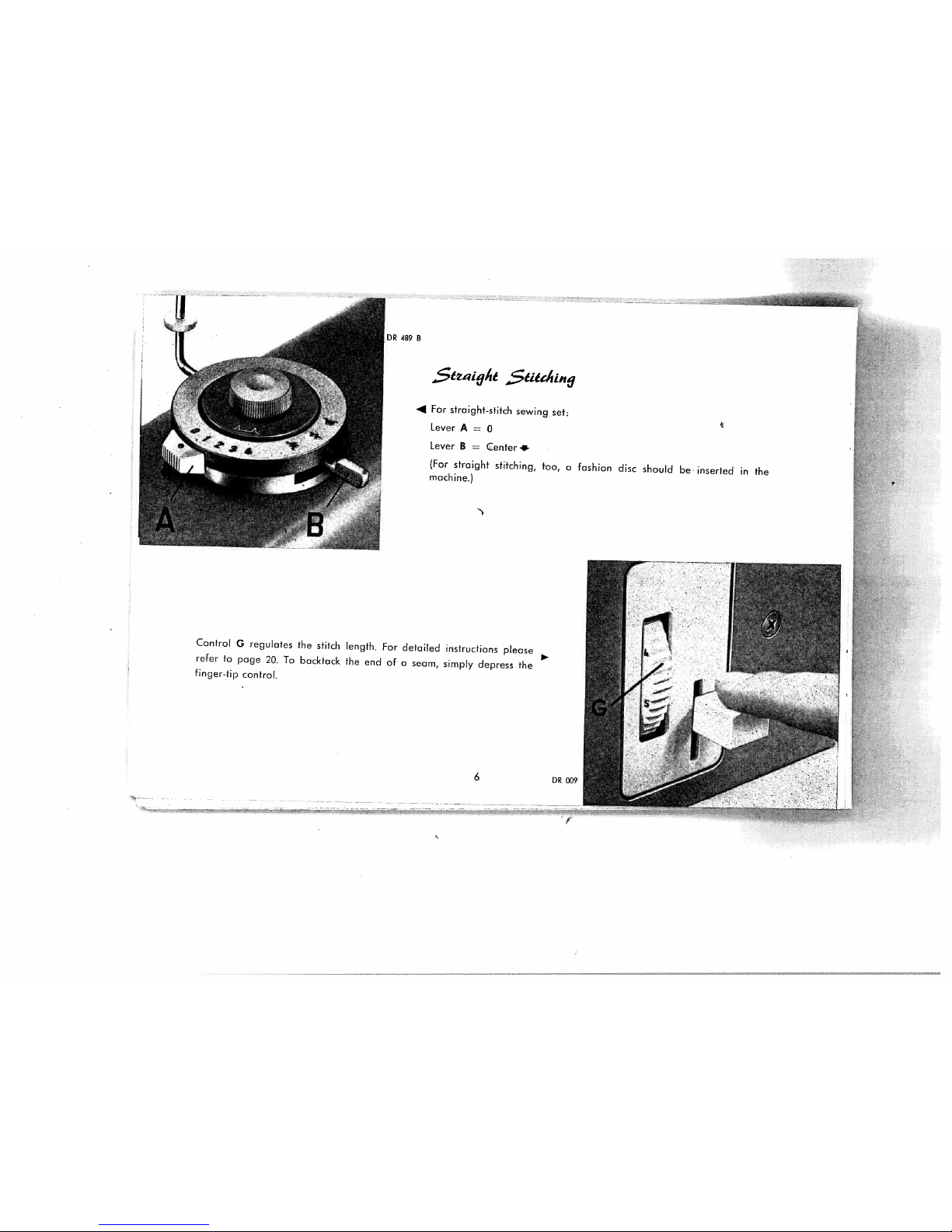

Lever

A

=

0

(For

straight

stitching,

too,

a

fashion

disc

should

be

inserted

in

the

machine.)

Control

G

regulates

the

stitch

length.

For

detailed

instructions

please

refer

to

page

20.

To

backtock

the

end

of

a

seam,

simply

depress

the

finger-tip

control.

4

For

troighi-stitch

sewing

set:

Lever

B

=

Center+

F:

F

[.

I:

F

6

F

Page 8

lJqa9

$ewIi.

-

If

you

want

to

switch

from

straight

(A

on

“0”)

to

zigzag

stitching,

insert

the

zigzag

disc,

and

turn

lever

A

to

desired

stitch

width

(indicated

by

numbers

1to4).

For

most

sewing

jobs

it

is

best

to

leave

zigzag

disc

(A)

in

the

machine

so

that

you

can

quickly

change

over

from

straight

to

zigzag

stitching.

Lever

B

chanes

the

position

of

the

needle

in

the

needle

plate

slot.

Thus

the

stitching

can

be

moved

from

the

center

to

the”4eft

or

right

of

the

slot,

as

desired.

Control

G

lengthens

zig

.

zag

stitches

or

packs

them

more

closely

together

(sa

tin

stitch).

—

DR4B9A

j

The

position

of

lever

B

(left,

center,

right)

indicates

the

position

of

the

needle

in

the

needle

plate

slot.

II—

4—

V

.1

-4

I

7

F

Page 9

Aiitcmati

9ashitn

7

jscj

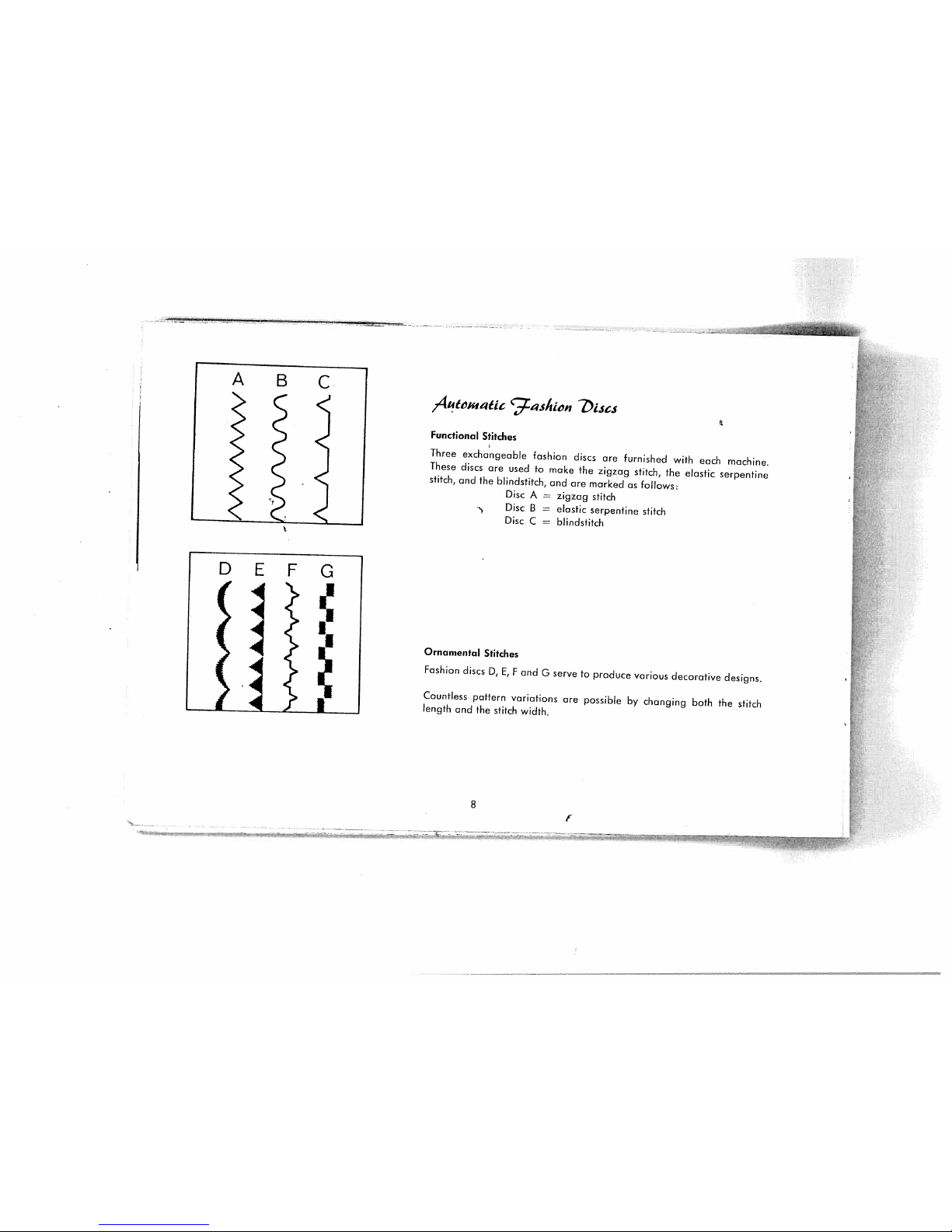

Functional

Stitches

Three

exchangeable

fashion

discs

are

furnished

with

each

machine.

These

discs

are

used

to

make

the

zigzag

stitch,

the

elastic

serpentine

stitch,

and

the

blindstitch,

and

are

marked

as

follows:

Disc

A

zigzag

stitch

Disc

B

=

elastic

serpentine

stitch

Disc

C

blindstitch

Ornamental

Stitches

Fashion

discs

D,

E,

F

and

G

serve

to

produce

various

decorative

designs.

Countless

pattern

variations

are

possible

by

changing

both

the

stitch

length

and

the

stitch

width.

8

Page 10

Changing

the

Fashion

Discs

Always

erk

stitch

width

lever

A

to

“0”

before

you

insert

or

remove

a

disc.

Turn

thumb

nut

R

counter-clockwise

to

re

lease

the

disc

in

the

zigzag

mechanism,

then

pull

it

up

and

take

it

out,

Push

the

disc

onto

the

stud

and

rotate

it

until

stud

H

snaps

into

one

of

the

slots.

Then

tighten

the

thumb

nut

by

turning

it

clockwise.

Set

the

machine

for

the

desired

stitch

width

and

stitch

length.

DR

544

A

RJ

9

Page 11

Ii

It

I

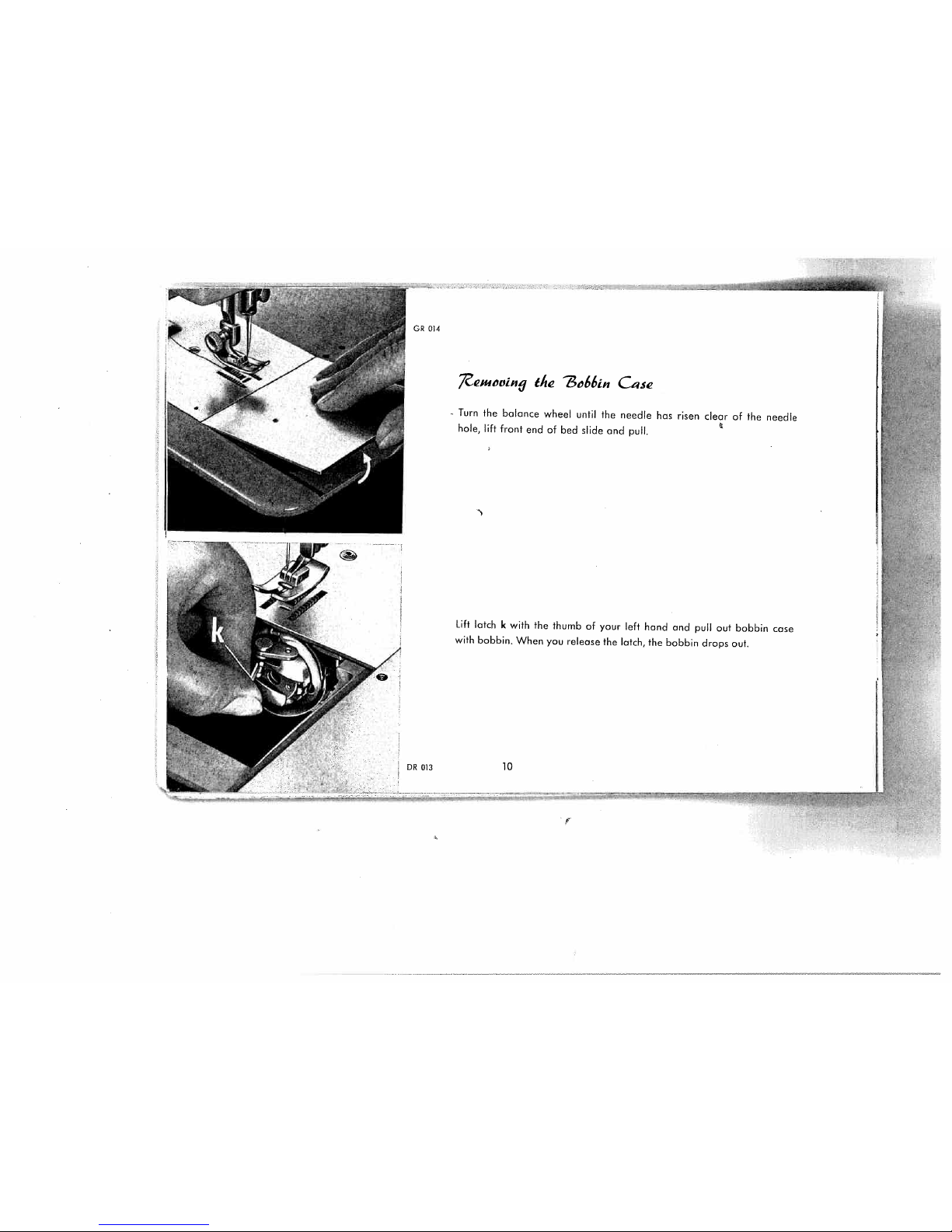

GR

014

2emiwtn

9

t4!

?3o66

in

Caie

Turn

the

balance

wheel

until

the

needle

has

risen

clear

of

the

needle

hole,

lift

front

end

of

bed

slide

and

pull.

Lift

latch

k

with

the

thumb

of

your

left

hand

and

pull

out

bobbin

case

with

bobbin.

When

you

release

the

latch,

the

bobbin

drops

out.

10

DR

013

Page 12

iOmn?tnj

th

73c66

tn

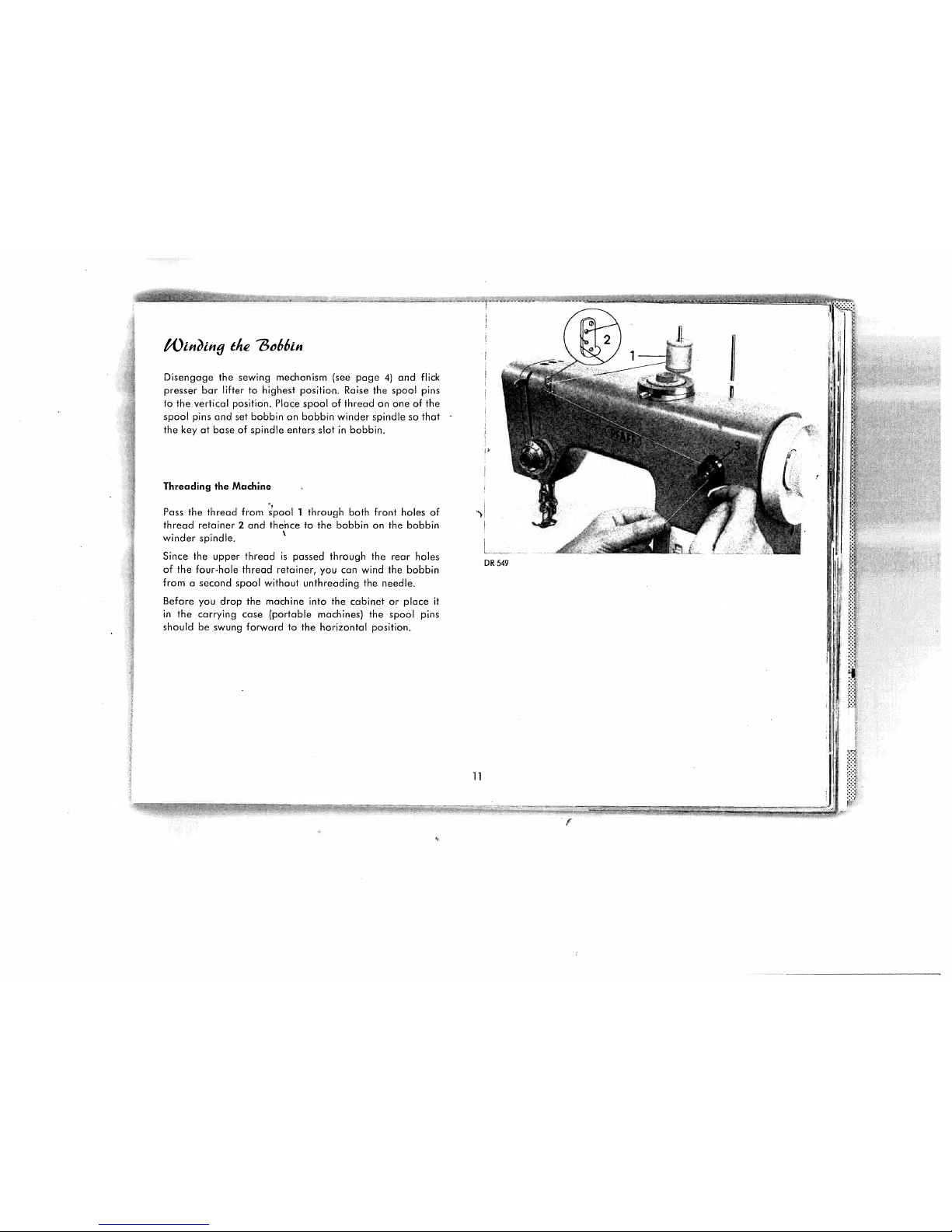

Disengage

the

sewing

mechanism

(see

page4)and

flick

presser

bar

liftertohighest

position.

Raise

the

spool

pins

to

the

vertical

position.

Place

spoolofthreadonone

of

the

spool

pins

and

set

bobbinonbobbin

winder

spindlesothat

the

key

at

base

of

spindle

enters

slot

in

bobbin.

Threading

the

Machine

Pass

the

thread

from

pool

1

through

both

front

holes

of

thread

retainer

2

and

thecetothe

bobbinonthe

bobbin

winder

spindle.

Since

the

upper

threadispassed

through

the

rear

holes

of

the

four-hole

thread

retainer,

you

can

wind

the

bobbin

from

a

second

spool

without

unthreading

the

needle.

Before

you

drop

the

machine

into

the

cabinet

or

place

it

in

the

carrying

case

(portable

machines)

the

spool

pins

should

be

swung

forwardtothe

horizontal

position.

DR

549

11

Page 13

R5868

4

1!

NV

—---..----

,,

,,,

3iseung

t.stt

t,66in

uiit’

the

?3c66j,

Ca5e

CD

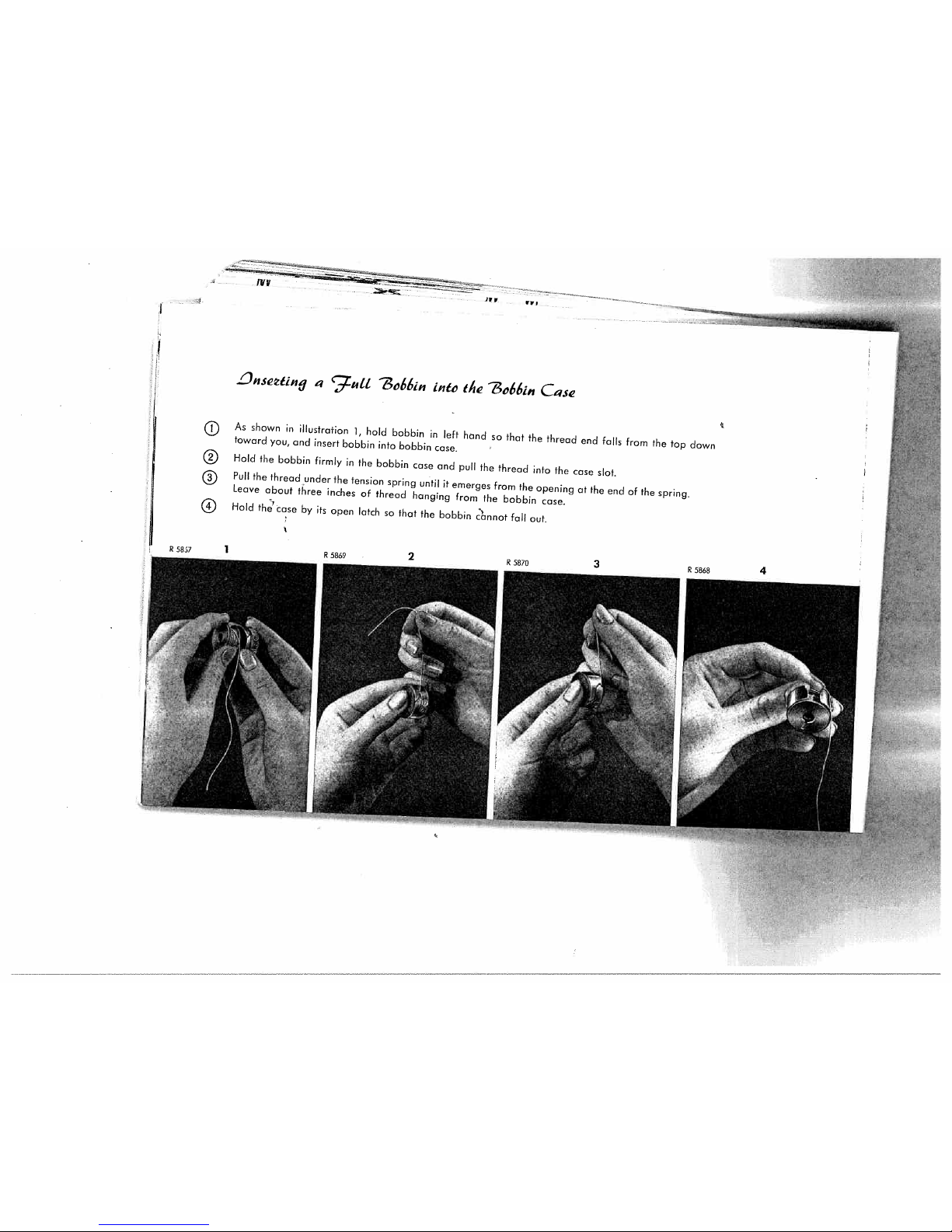

As

shown

in

illustration

1,

hold

bobbin

in

left

hand

so

that

the

thread

end

falls

from

the

top

down

toward

you,

and

insert

bobbin

into

bobbin

case.

Hold

the

bobbin

firmly

in

the

bobbin

case

and

pull

the

thread

into

the

case

slot.

Pull

the

thread

under

the

tension

spring

until

it

emerges

from

the

opening

at

the

end

of

the

spring.

Leave

about

three

inches

of

thread

hanging

from

the

bobbin

case.

Hold

the’

case

by

its

open

latch

so

that

the

bobbin

cbnnot

fall

out.

R

58S7

1

R

5869

2

R

5870

3

::

•

Page 14

.LJiiwZttflJ

th

73t,66in

Ca.c

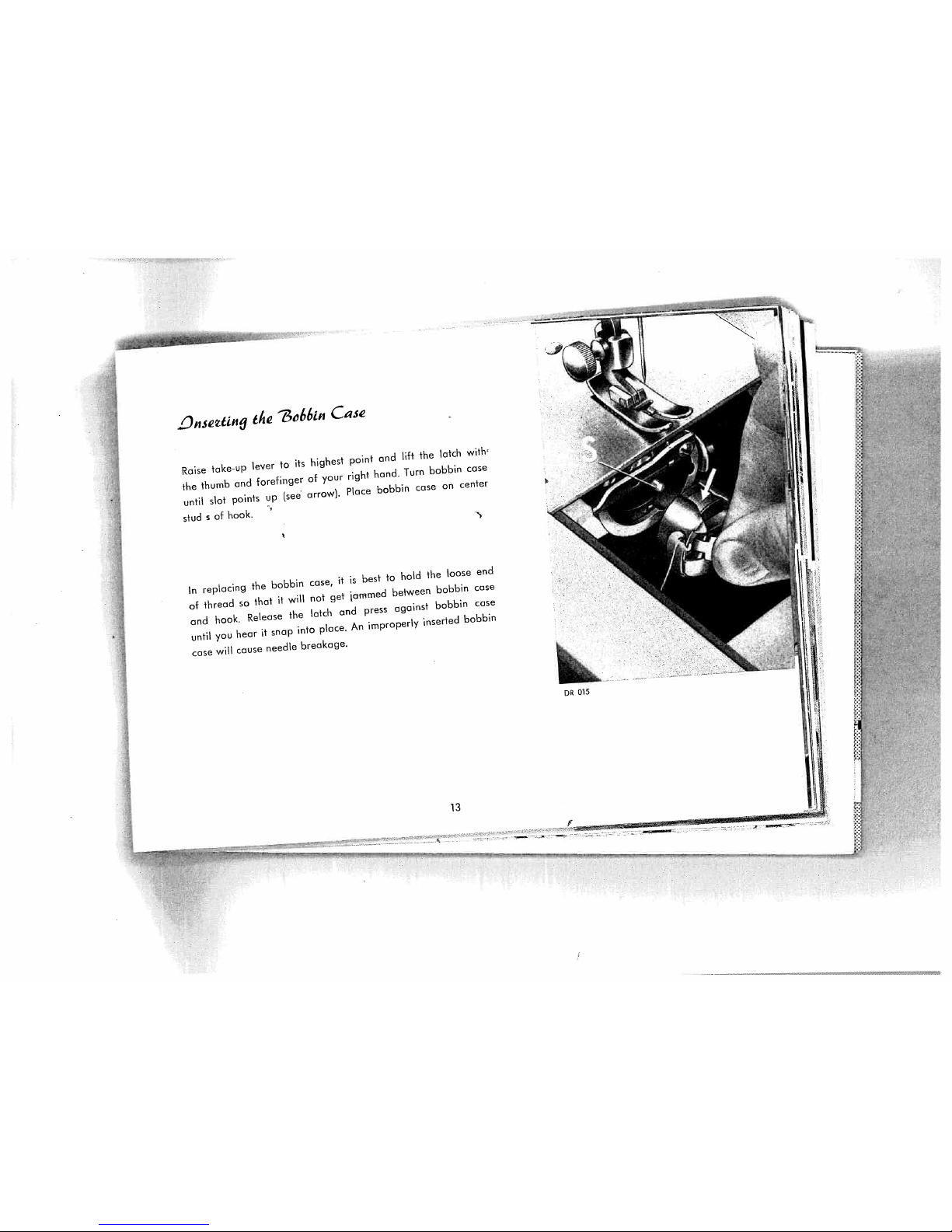

Raise

take-up

lever

to

its

highest

point

and

lift

the

latch

with’

the

thumb

and

forefinger

of

your

right

hand.

Turn

bobbin

case

until

slot

pointS

up

(se

arrow).

Place

bobbin

case

on

center

stud

s

of

hook.

In

replacing

the

bobbin

case,

it

is

best

to

hold

the

loose

end

of

thread

so

that

it

will

not

get

jammed

between

bobbin

case

and

hook.

Release

the

latch

and

press

against

bobbin

case

until

you

hear

it

snap

into

place.

An

improperly

inserted

bobbin

case

will

cause

needle

breakage.

13

—

——

w-

-_

—

DR

015

F

Page 15

mHu2n?1e

/lJee21e

an?

‘hea?

5ie.c

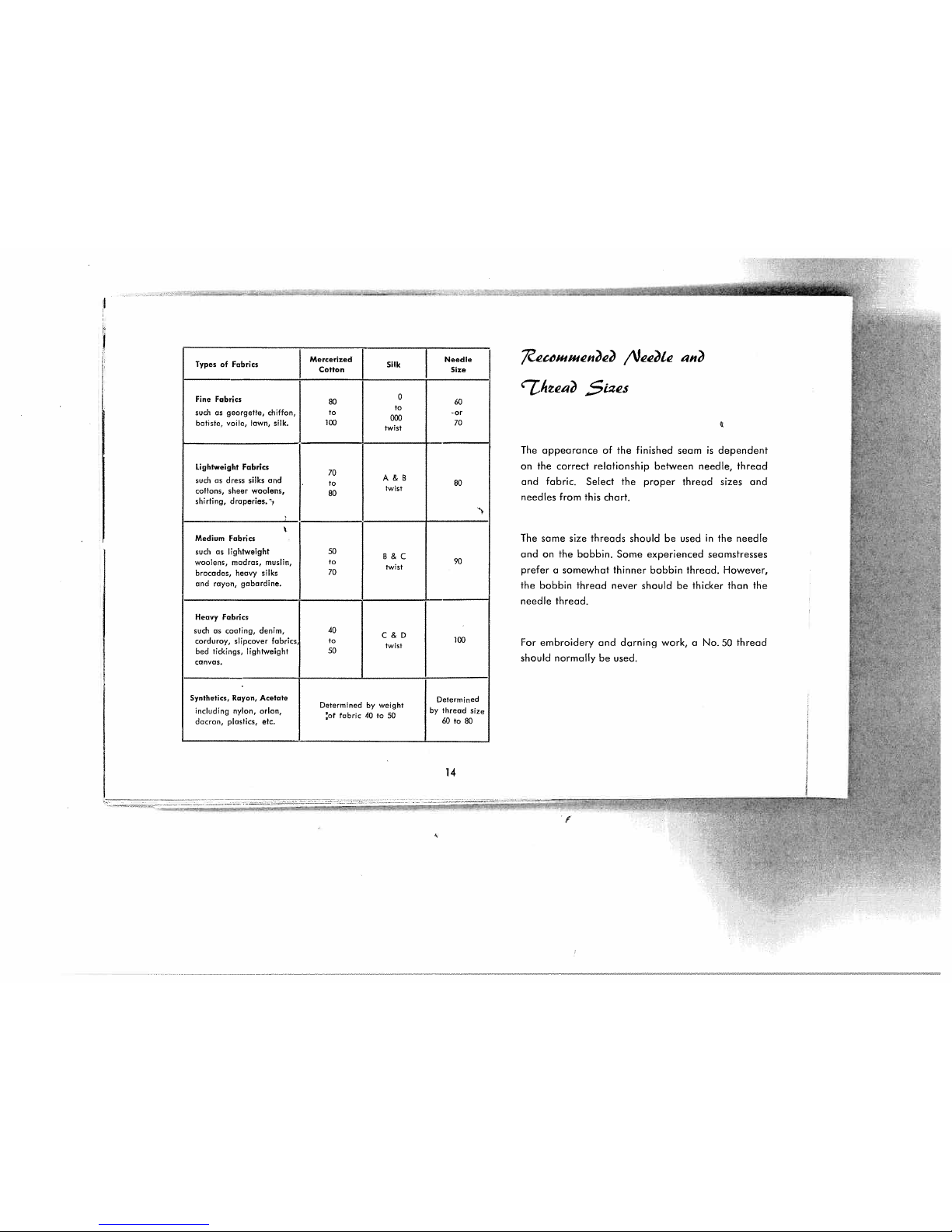

The

appearance

of

the

finished

seam

is

dependent

on

the

correct

relationship

between

needle,

thread

and

fabric. Select

the

proper

thread

sizes

and

needles

from

this

chart.

The

same

size

threads

should

be

used

in

the

needle

and

on

the

bobbin.

Some

experienced

seamstresses

prefer

a

somewhat

thinner bobbin

thread.

However,

the

bobbin

thread

never

should

be

thicker

than

the

needle

thread.

For

embroidery

and

darning

work,

a

No.

50

thread

should

normally

be

used.

Mercerized

Needle

Types

of Fabrics

Silk

Cotton

Size

Fine

Fabrics

0

such

as

georgette,

chiffon,

to

to

-or

000

batisie,

voile,

lawn,

silk.

100

70

twist

Lightweight

Fabrks

70

suchasdress

silks

and

A&B

to

80

cottons,

sheer

woolens,

80

twist

shirting,

droperies.

,

‘5

Medium

Fabrics

such

as

lightweight

50

B&C

woolens,

madras,

muslin,

to

90

twist

brocodes,

heavy

silks

70

and

rayon,

gabardine.

Heavy

Fabrics

such

as

coating,

denim,

40

C&D

corduroy,

slipcover

fabrics

to

100

twist

bed

tickings,

lightweight

50

canvas.

Synthetics,

Rayon,

Acetate

Determined

Determined

by

weight

including

nylon,

orIon,

of

fabric

40

to

50

by

thread

size

dacron,

plastics,

etc.

60

to

80

I

14

Page 16

czan

9aas

a6ciit

7Vee1s

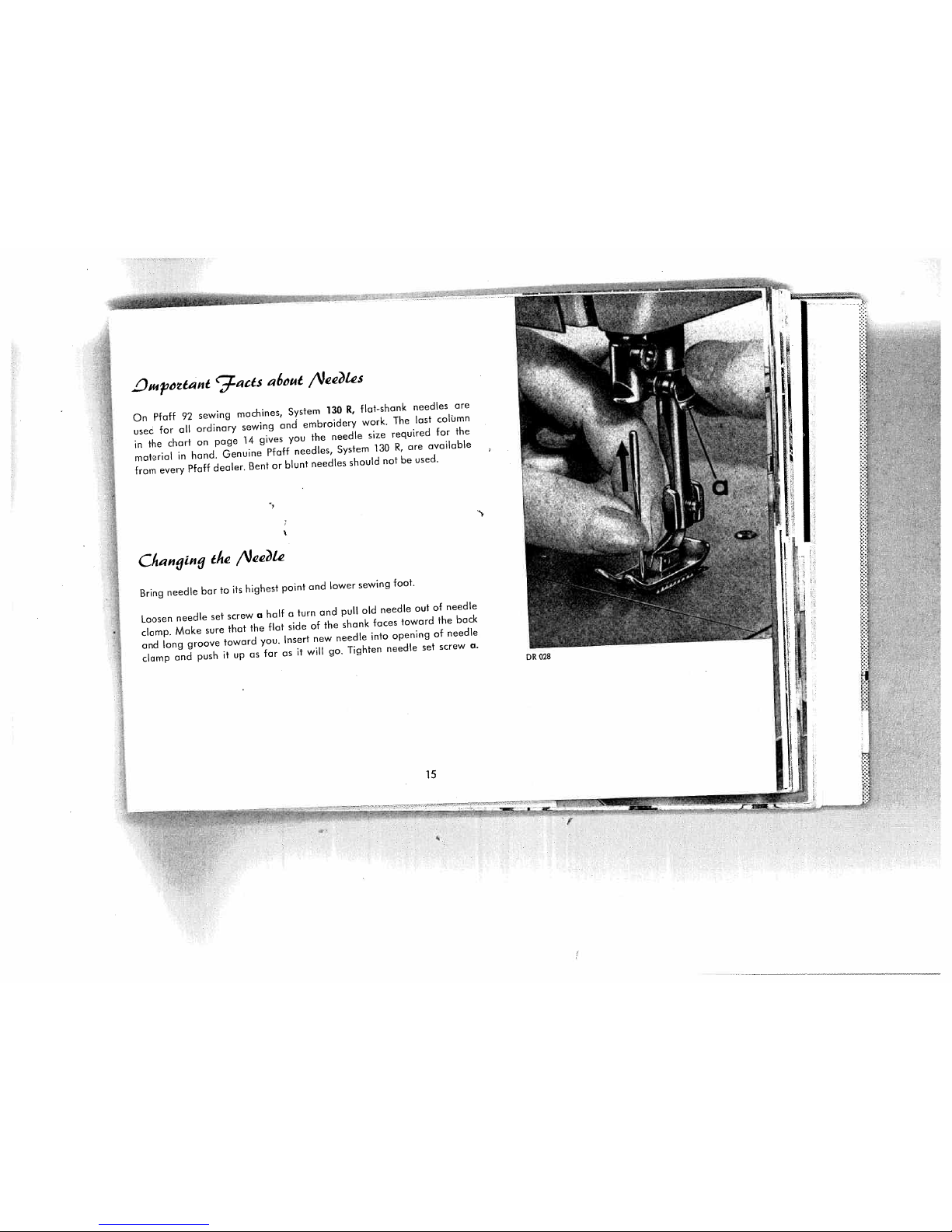

On

Pfoff

92

sewing

machines,

System

130

R,

flat-shank

needles

are

used

for

all

ordinary

sewing

and

embroidery

work.

The

last

colbmn

in

the

chart

on

page

14

gives

you

the

needle

size

required

for

the

material

in

hand.

Genuine

Pfaff

needles,

System

130

R,

are

available

from

every

Pfaff

dealer.

Bent

or

blunt

needles

should

not

be

used.

ChanjinfJ

th

/\ket&

Bring

needle

bar

to

its

highest

point

and

lower

sewing

foot.

Loosen

needle

set

screw

a

half

a

turn

and

pull

old

needle

out

of

needle

clomp.

Make

sure

that

the

flat

side

of

the

shonk

faces

toward

the

bock

and

long

groove

toward

you.

Insert

new

needle

into

opening

of

needle

clomp

ond

push

ii

up

as

far

as

it

will

go.

Tighten

needle

set

screw

a.

15

Page 17

t4ii

‘7ha?mnq

Raise

the

spool

pins

to

the

vertical

position

and

place

a

spool

of

thread

on

one

of

them.

Lace

the

thread

rough

the

two

rear

openings

of

thread

retainer

2

(see

illustration).

Pull

thread

between

any

two

of

tension

discs

3,

as

illustrated,

and

jerk

it

far

over

to

the

right

so

that

it

slips

properly

into

the

slot

and

under

the

thread

che&

spring.

At

the

same

time,

press

the

thread

between

spool

and

tension

against

the

top

of

the

machine.

Bring

take-up

lever

4ashigh

as

it

will

go

and

pass

thread

from

right

to

left

through

the

hole

at

its

end

and

into

slot

at

left

of

thread

guide

5.

Then

thread

needle,

front

to

back.

16

Page 18

LI

I

Page 19

I

DR

046

A

Cczect

c7ensi,n

7cyutattcn

Balanced

tensions

are

essential

for

sewing.

If

your

tension

is

correct,

you

will

hove

perfect

seams

as

sketched

below

(Ill).

Sketch

I

—

The

threads

interlock

on

the

underside

of

the

fabric.

C

a

u

s

e

:

Upper

tension

too

loose

or

lower

tension

too

tight.

Caus

Sketch

II

—

The

threads

interlock

on

the

surface

of

the

fabric.

Upper

tension

too

tight

or

lower

tension

too

loose.

Hold

needle

thread

lightly

in

your

left

hand.

Turn

balance

wheel

toward

you

until

the

needle

moves

once

down

and

up

again.

Lightly

pull

needle

thread

to

drawbobbin

thread

up

through

the

needle

hole.

Place

both

threads

back

under

the

sewing

foot.

H

III

th

3o6&

18

Page 20

jjtatin

the

‘7hea

7ensicn

The

bobbin

thread

tension

has

been

set

for

a

medium

grade

and need

not

be

adjusted

for

all

ordinary

sewing

operations.

If

a

special

sewing

operation

should

require

a

looser

or

tighter

tension,

turn

the

small

knurled

screw

on

the

bobbin

case

with

the

tip

of

your

thumb

as

follows:

Turn

it

left

for looser

tension.

-

Turn

it

right

for

tighter

tension.

Determine

whether

the

bobbin

thread

tension

is

set

for

a

medium

grade

by

holding

the

thread

end

between

thumb

and

forefinger

and

letting

the

bobbin

case

hang

freely.

The

tension

should

be

strong

enough

to

keep

the

bobbin

case

from

being

pulled

down

by

its

own

weight.

However,

as

you

jerk

your

hand

slightly,

the

bobbin

case

should

gradually

slide

down.

Do

not

turn

the

knurled,

screw

too

far

to the

left

to

keep

it

from

falling

out.

Choose

the

loweF

tension

slightly

stronger

when

doing

ornamental

stitching

to

be

sure

you

always

have

a

neat

satin

stitch

on

the

right

side

of

the

fabric.

The

upper

tension

is

so

designed

that

all

grades

of

tension

—

loose

to

tight

—

can

be

covered

with

one

complete

turn

of

the

tension

dial.

The

numbers

on

the

tension

dial

indicate

different

degrees

of

tension.

The

higher

the

number,

the

greater

the

tension.

Only

in

very

rare

cases

will

it

be

necessary

to

reset

the

tension.

For

ordinary

sewing,

the

upper

tension

should

be

set

between

3

and

5.

V

A

Your

upper

tension

has

a

third

tension

disc

for

two

needle

work.

19

Page 21

A.ernjth

ji(aticn

The

stitch

length

control

serves

to

regulate

the

stitch

length

and

to

limit

it

in

sewing

backwards.

The

numbers

on

the

control

indicate

the

stitch

length

(te

higher

the

number,

the

longer

the

stitch).

When

the

control

is

set

on

“0”,

the

machine

ceases

feeding.

To

regulate

the

stitch

length,

turn

the

control

until

the

number

indicating

the

desired

stitch

length

is

opposite

the

mark

on

the

left

edge

of

the

slot.

(The

position

of

the

mark

is

indicated

by

an

arrow

in

the

illustration).

To

sew

in

reverse,

simply

press

the

finger-tip

control

down.

When

the

control

is

released,

the

machine

resumes

forward

sewing.

This

feature

is

ideal

for

backtccking

the

beginning

or

end

of

a

seam

and

for

darning

rips.

-

-

-

-

r---;

Fi.

20

Page 22

1$

I

Ii

I,

P11!

OR

042

Chanyin9

the

$eI(in9

9cct

Lift

both

needle

and

presser

bar

to

their

highest

positions

and

turn

sewing

foot

thumb

screw

b

to

the

left.

Tilt

the

foot

sideways

and

-pull

it

down.

Reverse

procedure

to

slip

on

new

foot

and

tighten

screw

b

securely.

DR043

21

—

‘—

—

-r

Page 23

Turn

needle

plate

half

a

turn

so

that

roised

portion

is

at

the

front

(see

illustration)

and

replace.

Press

down

stud

and

replace

bed

slide.

Thread

the

needle

with

darning

wool

and

lower

presser

bar

lifter.

Now

you

can

embroider

and

darn

without

presser

foot,

moving

the

work

freely

by

hand.

22

—

-

—

t-

7!2ainq

4jcu

,41achine

Z’aniny

Remove

the

sewing

foot

and

the

bed

slide.

Lift

front

end

of

needle

plate

and

tilt

out.

Page 24

DR

047

mnj

an

m6ci?iiig

9cct

Remove

the

sewing

foot.

Attach

darning

foot

No.

93-100

154-91

from

ihe

rear.

Hold

spring

clip

c

so

that

it

is

behind

the

needle

set

screw,

and

tighten

screw

b.

At17)tit,s

$,vin

9cct

(with

Clear-View

Shoe)

All-purpose

sewing

foot

No.

93-1

00

179-00

is

attached

as

instructed

on

page

21.

The

transparency

of

its

shoe

facHitates

all

sewing

operations

where

it

is

importanttowatch

the

needle

penetrate

the

fabric.

Special

application

possibilities

are

discussedinthe

second

partofthis

book

under

the

heading

“Using

Sewing

Feet

and

Attachments”.

0R588

23

-

I

Page 25

Ca

an

/i1aIntenanc

Longevity

and

smooth

machine

performance

are

dependent

on

regular

and

proper

cleaning

and

oiling.

Use

Pfaff

sewing

machine

oil

only.

Never

lubricate

maiine

with

animal

or

vegetable

oils.

All

moving

and

rotating

parts

require

regular

lubricatioii.

Begin

under

the

bedplate.

If

you

have

a

portable

machine,

tilt

it

back,

loosen

the

large

thumb

screw

on

the

underside

Qf

the

machine

base,

and

remove

the

base.

In

replacing

the

machine

base,

tighten

thumb

screw

lightly.

DR

590

A

From

time

to

time,

lubricate

the

needle

bar

frame

bearings

in

the

sewing

head.

For

removing

the

face

cover

see

page

26.

The

principal

oiling

points

ore

marked

by

arrows

in

the

illustrationsonthese

pages.

_________

-

Page 26

To

oil

the

zigzag

mechanism,

remove

the

4

fashion

disc

and

apply

a

drop

of

oil

to the

two

marked

oiling

points

(see

arrows).

DR

589

Do

not

lubricate

the

bobbin

winder.

The

raceway

in

the

sewing

hook

is

the

most

important

oiling

point.

Put

one

drop

of

oil

into

the

raceway

each

day

you

sew

(see

picture

at

top

right).

From

time

to

time,

remove

the

needle

plate

and

clean

the

machine

feed

with

a

soft

brush.

Take

a

toothpick

and

remove

accumulations

of

packed

lint.

Take

out

the

bobbin

case

and

the

bobbin

and

clean

the

vicinity

of

the

Sewing

Hook.

Before

you

begin

to

oil

the

mechanism

under

the

bedplote

and

at

the

needlebar

end

of

the

machine,

remove

the

dirt

and

lint

which

has

accumulated

on

these

parts.

25

1;i

:

——

DR

587

Page 27

II

r

IL

i.

L.

GR024

Chaiijinq

the

biqht

73ut6

The

built-in

15-watt

sewing

light

illuminates

the

areaofstitching

perfectly.

To

change

the

light

bulb,

remove

the

face

cover,

push

the

bulb

into

its

socket,

turn

left,

and

pull

out.

When

inserting

sew

light

bulb,

be

sure

to

slide

bulb

pins

into

socket

slots.

Press

bulb

in

and

turn

right.

)

V

7Zeiucomn

9

the

9ate

Côoe

To

change

the

light

bulboroil

the

parts

at

the

needle-bar

end,

remove

the

face

coverbypullingitupwards.

eitacmny

the

‘ae

Ccae

5

Slip

tip

d

into

slot

e

and

push

face

coverupuntil

it

snaps

into

place.

0R512

26

DR505

-

Page 28

1

r

1.

Machine

Sldps

Stitches

Cause:

Remedy:

Needle

incorrectly

inseçted.

Push

needleupas

farasit

will

go

andbesure

that

the

long

groove

faces

toward

yOu,

and flat

sideofshank

away

from

you.

Wrong

needle.

Choose

the

carrect

needle

from

chart

on

page

14.

(For

ordinary

sewing,

use

System

130

R

needles.)

Needle

bent.

Insert

new

needle.

Machine

threaded

improperly.

Check

and

correct

threading

as

instructed

on

pages

16

and

17.

Needle

too

fine

or

too

thick

for

the

thread.

Use

correct

needle

and

thread

(see

chart

on

page

14).

2.

Needle

Thread

Breaks

Cause:

Remedy:

In

The

above

mentioned

may

cause

thread

See

remedies

listed

under

1.

above.

breakage.

tij

Thread

tension

too

tight.

Adjust

tensions

as

instructed.

Ij

Poor,

knotty

or rotten

thread

used.

Use

good

quality

threads

only.

¶

Hook

raceway

is

jammed

with

thread

or

Clean

and

oil

hook

raceway.

needs

oiling.

Burrs

or

sharp

edges

on

needle

plate

slot.

Polish

needle

plate

slot

with

fine

emery

cloth.

j

Page 29

3.

Needle

Breaks

Cause:

Bent

needle

strikes

point

of

sewing

hook.

Needle

too

thin

or

thread

too

heovy.

Fabric

pulls

needle

so

it

bends

and

strikes

needle

plate.

Bobbin

case

inserted

incorrectly.

4.

Faulty

Stitch

Formation

Cause:

Improper

tension.

Thread

too

heavy,

knotty

or

hard.

Bobbin

unevenly

wound.

Pieces

of

thread

between

tension

discs.

5.

Machine

Feeds

Improperly

Cause:

Machine

does

not

feed

because

stitch

lenqth

control

set

on

“0”.

Accumulations

of

lint

packed

between

feed

teeth.

Remedy:

Replace

needle

at

once

to

prevent

further

damage.

Use

correct

needle

and

thread

sizes.

Don’t

force

the

feeding

motion.

Guide

the

material

lightly.

Push

bobbin

case

until

you

hear

it

snap

into

place.

Remedy:

Adjust

tensions

as

instructed.

Use

only

first-rate

thread

—

the

correct

size

for

the

needle

and

fabric.

Don’t

run

thread

over

finger

when

winding

the

bobbin,

but

lead

it

around

needle

thread

tension.

Raise

presser

bar

lifter

and

remove

thread.

Remedy:

Regulate

stitch

length,

as

desired.

Take

off

needle

plate

and

remove

lint

with

a

stiff

brush.

28

Page 30

6.

Machine

Works

Heavily

Couse:

Remedy:

Hook

raceway

locks

oil

or

is

obstructed

by

Clean

and

oil

hook

raceway.

pieces

of

thread.

Mechanism

clogged

by

inferior

oil.

Use

only

Pfoff

sewing

machine

oil

—

never

salod

oil

or

glycerine.

Bobbin

winder

working

whfle

sewing.

Stop

bobbin

winder.

7.

Machine

Fails

to

Sew

Zigkag

or

Ornamental

Stitch

Desired

4

Cause:

Remedy:

Wrong

fashion

disc

inserted

or

none

at

all.

Jerk

stitch

width

lever

to

“0”

and

insert

proper

fashion

disc.

j,..

For

straight

stitching,

too,

a

fashion

disc

should

be

inserted

in

the

machine

(see

pp.

6,

7

and

9).

8.

Motor

Idles

4

Cause:

Remedy:

Motor

disengaging

lever

raised

Flick

lever

down

(see

page

5).

tIl

Thread

Jamming

The

Pfaff

rotary

hook

will

not

normally

jam,

even

if

the

machine

should

be

handled

improperly.

If

thread

should

happen

to

jam

in

the

hook

raceway,

the

power

of

the

motor

in

most

instances

will

be

sufficient

to

overcome

hard

working

of

the

mechanism.

If

this

action

should

not

free

the

jammed

thread,

put

a

dop

of

kerosene

into

the

hook

raceway,

jerk

the

balance

wheel

back,

then

rock

it

back

and

forth.

‘

29

J

JiLl

Page 31

DR

032

(-‘LcIn

9

$Qw1n9

et

an

,,4tta4menLc

(setting

see

page

6)

Zipper

Insertion

Machine

Setting:

A

0;

B

Pin

or

baste

closed

zipper

on

wrong

side

of

fabric.

Position

of

zipper

de

pends

on

whether

or

not

you

want

the

edge

of

the

fabric

to

overlap

the

zip

per.

Turn

fobçic

to

right

side.

Run

a

straight

seam

close

to

left

edge

of

zipper;

stitch

ac1oss

end

and

up

the

other

side

in

one

continuous

operation.

Use

right

edge

of

foot

as

a

guide.

Sew

parallel

rows

of

straight

or

zigzag

stitches

at

various

distances

from

the

fabric

edge

by

using

ad

justable

seam

guide

No.

847

300

and

the

edge

stitcher

(without

qçilting

gauge).

The

seam

guide

is

fastened

to

the

machine

bed

with

the

long

thumb

screw.

For

wider

marginal

stitching,

turn

edge

guide

half

a

turn

and

use

low

end

asa

guide.

(To

sew

narrow

parallel

seams,

guide

fabric

edge

or

prece

ding

seam

along

right

edge

of

sewing

foot,

using

no

edge

guide.)

Quilting

Machine

Setting:

A

0;

B

*

Edge

stitcher

No.847600

used

with

the

quilting

gauge

sews

parallel

rows

of

stitching

at

any

distance

over

the

entire

surface

of

the

fabric.

Always

guide

the

gauge

finger

along

the

preceding

row

of

stitches.

Attractive

tea

cosies,

slippers,

seat

pads

and

covers

can

be

quilted.

J

DROO2

30

F

Edge

Stitching

84

Machine

Setting:

A

0to4;

B

—.

V

r

I

DR

003

Page 32

Second

Seam

847

541

Flat

Felled

Seams

Machine

Setting:

A

0

or

2;

B

+

4

First

Seam

Lay

pieces

together

with

the

wrong

sides

facing

and

truding

‘Is

inch.

Feed

both

pieces

into

felling

foot,

as

bottom

fabric

is

folded

over

DR

048

edge

of

top

piece

and

stitched

down.

Make

sure

that

protruding

seam

allowance

is

not

folded

Open

the

two

pieces,

place

them

under

the

needle

right

side

up,

insert

seam

ridge

into

felling

foot

opening,

and

stitch

down

to

the

left.

Make

sure

that

second

seam

is

placed

close

to

the

edge

but

not

beyond

it.

The

felling

foot

has

a

needle

slot,

rather

than

a

needle

hole,

to

permit

zigzag

felling.

-

—fl---

—-

__________

I,

q1

I

M

Flat

felled

seams

are

used

to

durably

join

two

pieces

of

fabric.

They

are

made

in

two

operations.

Flat

felled

seams

usually

are

straight-stitched.

Narrow

zigzag

stitches

are

used

for

felling

an

elasticized

fabrics

only.

the

bottom

piece

pro-

illustrated,

so

that

the

twice.

31

D49

Page 33

847

551

Hemming

Machine

Setting:

A

=

U

or

2

to

3;

B

The

hemmer

foot

is

indispensable

if

you

want

to

sew

a

uniform

hem.

You

can

hem

with

straight

or

zigzag

stitches,

depending

on

the

type

of

fabr’c

you

are

using.

Clip

off

the

corner

of

th

fabric

to

facilitate

insertion

into

the

hemmer

foot

curl.

Feed

fabric

so

that

the

raw

edge

is

in

line

with

the

left

edge

of

the

hemmer

foot.

If

you

feed

less,

the

fabric

will

not

be

folded

twice

and

the

raw

edge

will

show.

I

Avoid

ugly

ends

by

slowing

down

feeding.

To

do

this,

press

the

fabric

against

the

needle

plate

on

the

left

side

of

the

foot

before

you

come

to

the

end

of

the

hem.

OR

508

F

I

D509

32

Page 34

_838954

Stitching

Synthetic

Materials

Curtains

Machine

Setting:

A

ito

3,

depending

on

material;

B

Stitch

Length:

Minimum

Insert

fashion

disc

A.

:

To

finish

the

edge

of

syntetic

curtain

fabrics,

such

as

Diolen,

use

a

matching

synthetic

thread.

If

necessary,

ease

the

upper

and

lower

tensions

somewhat.

Both

these

hints

should

be

adhered

to

in

order

to

avoid

shrinking

of

both

the

thread

and

the

fabric

in

the

laundry.

.1•

To

butt

seam

the

various

sections

of

curtains,

proceed

as

instructed

on

page

34.

Plastic

Sheets

Machine

Setting:

A

=

0

to

2;

B

Stitch

Length:

Medium

Plastic

curtains,

as

are

used

in

kitchens

and

bathrooms,

are

sewn

with

synthetic

thread

or

cotton

and

a

fine

needle.

Place

a

piece

of

tissue

paper

under

sticky

plastic

sheets

which

can

be

easily

removed

after

the

sewing.

To

prevent

plastic

sheets

from

sticking

to

the

sewing

foot,

apply

a

drop

of

oil

to

its

sole.

33

Page 35

—

838

954

Overcasting

Edges

Machine

Setting:

A

=

2

to

4;

B

=

Overcasting

prevents

frayed

edges.

Use

a

long

wide

zigzag

stitch

and

sew

edge

with

the

needle

taking

one

stitch

into

the

fabric

and

the

other

over

its

edge

(normal

tension

setting).

You

may

overcast

edges

after

fabric

is

cut

and

before

the

pieces

are

joined.

838

954

Butt

Seaming

Machine

Setting:

A

3or4;

B

Two

similar

piecesoffabric

which

do

not

rovel

easily

may

be

butted

together

and

joined

with

zigzag

stitches.

Worn

bed

sheets

may

be

mended

this

way.

Cut

out

worn

center

strip.

Place

the

selvaged

edges

of

the

remaining

pieces

of

sheet

under

the

sewing

foot

so

that

the

abutted

edges

are

centered

under

the

needle.

Join

them

with

close,

wide

zigzag

stitches

to

obtain

a

neat

and

flat

seam.

Hem

raw

edges

of

sheet.

34

OR

037

I

F

Page 36

Triangular

Tears

Triangular

tears

are

best

darned

by

placing

the

torn

section

between

hoops

and

making

close

stitches

across

and

lengthwise.

Move

work

under

the

needle

with

both

hands.

Thin

Spots

Remember

that

“a

stitch

in

time

saves

nine”

and

reinforce

spots

that

have

worn

thin

with

short

stitches

made

lengthwise

and

across

worn

section.

This

job

can

be

donewithoutfoot,too.

Small

Holes

Darn

small

and

medium-size

holes

by

trimming

ragged

edges

with

the

fabric

grain.

First

stitch

back

and

forth

across

the

hole

from

one

side

to

the

other

with

the

machine

running

at

high

speed.

Then

turn

the

fabric

at

right

angles

and

sew

back

and

forth

35

over

preceding

work

with

short

stitches.

Make

sure

the

stitches

are

taken

right

into

the

good

material.

Long

Rips

may

be

darned

with

the

normal

sewing

foot

and

without

hoops.

Set

needle

plate

in

its

normal,

or

sewing,

position

and

use

forward-reverse

feed

control.

DR

056

DR

057

Darning

Machine

setting:

A

0,

B

=

+

Prepare

your

machine

for

darning

as

instructed

on

pages

22

and

23.

Place

fabric

into

darning

hoop,

the

damaged

area

being

in

the

center

of

the

hoop.

Hoops

may

be

obtained

from

your

Pfaff

dealer.

r

-

-

Page 37

Large

holes

can

be

patched

quickly.

The

following

method

may

be

used

for

jersey

nd

other

elastic

fabrics.

Cut

patch

so

that

its

grain

will

match

the

rest

of

the

fabric.

Place

the

patch

over

the

damaged

area.

Sew

it

down

with

an

elastic

serpentine

stitch

of

medium

length.

For

additional

strength,

stitch

over

corners

twice.

Turn

over

and

trim

close

to

seams.

Ordinary

Fabrics

Machine

Setting:

A

2;

8

Stitch

Length:

Minimum

Insert

fashion

disc

A.

Patches

are

inserted

in

ordinary

fabrics

with

short

zigzag

stitches.

Sew

over

corners

twice.

Other

than

that,

proceed

as

instructed

above.

For

added

strength,

sew

around

patch

again,

guiding

the

edge

of

the

sewing

foot along

the

first

seam.

DR582

DR

581

08566

36

r

838

954

u

Inserting

Patches

Elastic

Fabrics

Machine

Setting:

A

4;

8

=

Stitch

Length:

Medium

Insert

fashion

disc

B

(elastic

serpentine

stitch).

F:

r

1*

Page 38

31COS

BIindstitchng

Machine

Setting:

A

=

4;

B

=

Stitch

Length:

Maximum

Insert

fashion

disc

C.

Skirts,

dresses

and

ladies’

coats

of medium

and

heavy-weight

fabrics

are

hemmed

with

blind

stitches.

To

do

this,

insert

the

blindstitch

disc

andaNo.

70

needle.

Use

embroidery

thread

No.

50

or

silk

thread

that

matches

the

fabrlt

Ease

upper

tension

somewhat.

Next,

follow

this

procedure:

Turn

fabric

wrong

side

up.

Fold

finished

edge

of

woolen

fabrics

once

(Fig.

1),

other

thin

fabrics

twice

(Fig.

2).Inthis

latter

case

there

is

no

need

to

finish

the

edge.

It

is

besttopress

or

baste

the

hem.

Guide

the

work

evenly.

Set

stitch

width

lever

Asothat

needle

takes

left stitch

exactly

in

the

folded

edge

and

right

stitch

up

to

or

over

the

hem

edge.

When

hem

is

finished,

stitches

will

not

be

visible

on

top

side.

37

DR

567

_

Page 39

Sewing

Buttonholes

Machine

Setting

A

=

1V

2

(first

notch);

B

Stitch

Length:

Almost

0

(for

buttonhole

seam)

Insert

fashion

disc

A.

Use

only

No.

50

embroidery

and

darning

thread.

Attach

buttonhole

foot

No.

847616

and

set

slide

cn

buttonhole

gauge

to

buttonhole

length

desired.

The

buttonhole

is

the

right

length

when

beginning

of

first

seam

reaches

red

end

of

slide

indicator

(see

arrow).

When

you

follow

the

procedure

on

the

opposite

page,

the

bartacks

at

each

end

of

your

buttonhole

will

be

twice

as

wide

as

a

buttonhole

seam.

If

you

prefer

more

prominent

buttonholes,

pull

a

filler

cord

through

the

hole

in

left

toe

of

foot.

To

get

the

correct

stitch

length,

sew

on

a

piece

of

scrap

material.

In

making

buttonholes

in

soft

or

loosely

woven

fabrics,

it

is

advisable

to

place

a

piece

of

tissue

paper

under

the

material.

To

strengthen

buttonholes

in

tricot

and

knit

fabrics,

insert

a

piece

of

firmly

woven

cotton

material

between

the

fabric

layers.

9’IOO79

.

.

I

Buttonholes

may

be

made

with

the

aid

of

the

all-

purpose

sewing

foot.

Place

the

filler

cord

in

the

left

groove

of

the

clear-view

shoe.

38

Page 40

Instructions

for

Buttonholing

Sew

first

side

overafiller

cord.

When

beginning

of

seam

reaches

red

end

of

slide

indicator

on

buttonhole

gauge,

it

is

the

right

length.

Leave

needle

in

fabric

on

right

side

of

its

throw.

2

Lift

foot,

turn

fabric

around

clockwise,

using

needle

as

a

pivot.

Lower

foot,

take

one

stitch

to

the

left,

pull

filler

cord

taut

and

lay

it

parallel

to

completed

line

of

stitching.

3

Turn

dial

A

untilitis

couht

in

second

notch

(or

stopsat4).

Make4to

6

bortock

stitches,

slightly

holding

the

material

to

reduce

length

of

bar.

4

4

Change

dialAto

“11/2’.

Trim

filler

cordatend

of

first

stitch

row.

Sew

second

row

and

stop

about4to6stitches

(/io”)

from

end

of

first

row.

5

Turn

dialAto

second

notch

position

(or

“4”).

Make

second

tack,

as

instructed

above

(under

3).

6

Turn

dialAto

“0”

and

make3or

4

fastening

stitches.

7

Trim

both

the

sewing

and

filler

threads.

Open

the

buttonhole

with

your

seam

ripper.

Be

careful

not

to

injure

the

bartocks.

E)

39

Page 41

.

r

Button

Sewing

Dorc’t

be

afraid

to

sew

on

buttons

or

rings

with

your

Pfoff.

The

needle

won’t

breok

and

the

threads

will

not

get

loose

either.

Thetlatter

may

happen

only

with

ready-made

clothing

sewn

with

a

chain

stitch.

It

wont

be

worthwiie

to

take

the

machine

out

for

sewing

on

a

single

button,

but

you

will

appreciate

this

feature

when

sewing

lines

of

buttons

on

pillow

and

bed

covers,

on

shirts

or

dresses,

or

when

fastening

rings

on

curtains

etc.

There

your

machine

will

come

in

very

handy.

Attach

all-purpose

sewing

foot

No.

93-100

179-00.

Hooks

aO)d

eyes

are

sewn

on

with

the

aid

of

a

special

button

sewing

r

foot,

No.

847

608,

which

can

be

obtained

from

your

Pfoff

dealer.

Turn

the

needle

plate

half

a

turn

so

thot

the

raised

portion

is

at

the

front

(see

picture

at

the

bottom

of

page

22).

The

raised

portion

of

the

needle

plate

features

an

elongated

needle

hole.

I

t.

Place

button

under

button

sewing

foot

and

align

so

that

needle

will

enter

left

hole.

Let

needle

stitch

through

hole

and

make

one

or

two

tying

stitches.

Raise

needle.

Turn

dial

A

counter-clockwise,

usually

to

3,

until

needle

on

the

right

of

its

throw

is

centered

over

right

hole.

Start

machine

and

sew

as

many

zigzag

stitches

as

you

deem

neces

sary

to

fasten

button

securely.

Return

dial

A

to

0

and

make

two

or

three

tying

stitches.

When

sewing

on

four-hole

buttons,

reposition

button

and

repeat

the

above

process,

stitching

through

the

second

pair

of

holes.

g

40

DR

583

Page 42

838

954

Attaching

Lace

Machine

Setting:

A

=

2;

B

=

You

can

attach

lace

edging

in

one

simple

operation.

Fold

the

edge

of

the

fabric

about

%“

over

to

the

wrong

side,

following

the

texture,

and

preferably

iron

it

down.

Place

the

straight

edge

of

the

lace

onthe

fold

of

the

fabric

and

sew

it

down

with

narrow

zigzag

stitches,

taking

one

stitch

into

lace

and

fabric

and

the

other

into

lace

only.

Cut

off

excessive

cloth

on

the

wrong

side

of

the

material

close

to

the

seam.

Shell-Edging

Made

with

Blindstitch

Disc

Machine

Setting:

A

4;

B

=

+

Stitch

Length:

Medium

Insert

fashion

disc

C,

and

tighten

upper

and

lower

thread

tensions.

Shell

edging

is

an

effective

fashion

trim

an

blouses

(particularly

those

made

of

delicate,

soft

fabrics).

Fold

fabric

along

desired

line.

Guide

work

so

that

needle

takes

one

stitch

in

the

fabric,

and

the

other

over

its

edge.

(As

the

threads

interlock

outside

the

material,

its

edge

is

drawn

back,

producing

the

desired

shell

edging).

Shell

edging

makes

a

nice

trimming

on

handkerchiefs,

too.

OR

044

41

0R564

Page 43

DR

033

838

954

Applique

Work

Machine

Setting:

A

1/2

to

2;

B

Insert

fashion

disc

A.

Applique

is

easy

and

modern.

Trace

design

an

wrong

side

of

fabric

and

baste

a

piece

of

contrasting

material

to

right

side.

Outline

design

on

wrong

side

with

a

narrow

zigzag

stitch

—

and

th

motive

will

appear

on

right

side.

R

7167

42

R

7220

Applique

is

very

effective

on

buster

suits,

pinafores,

bibs,

frocks,

covers,

wall

hangings,

or

wherever

a

gay

note

is

desired.

Fill

out

small,

but

essential

sections

of

design

with

granite

stitches.

V

Trim

excess

material

close

to

the

seam

and

sew

over

edges

of

applique

with

a

medium

wide

satin

stitch.

If

you

want

to

give

the

design

a

plastic

effect,

use

buttonhole

foot

Nr.

847

66

or

all-purpose

sewing

foot,

flick

lever

B

to

the

left

and

satin-stitch

over

a

filler

thread

(see

also

page

38).

Page 44

Machine

Setting:

A

=

3

to

4;

B

=

Insert

fashion

disc

A.

4

Prepare

machine

ts

for

darning.

Script

letters

are

best

for

monogram

embroidery

without

a

sewing

foot.

It

requires

a

little

practice.

You

will

soon

enjoy

creative

embroidery

once

you

have

learned

to

move

the

material

at

a

uniform

rate.

The

fabric

should

be

held

taut

in

the

hoops

and

the

presser

bar

lifter

lowered.

Let

the

needle

stitch

into

the

fabric

at

the

beginnin’

of

your

design

and

draw

bobbin

thread

up

through

the

fabric.

Hold

both

thread

ends

and

sew

over

outline,

moving

hoops

slowly

and

evenly.

To

give

your

monogram

dimensional

quality,

em

broider

outline

twice.

Be

sure

stitches

are

closely

spaced.

DR

038

Monogram

Embroidery

838

954

ü

Sewing

Monograms

Machine

Setting:

A

21/2

to

3;

B

4

The

procedure

below

is

primarily

used

for

block

letters.

Set

needle

plate

so

that

feed

dog

feeds

the

material.

Attach

all-purpose

sewing

foot

and

set

machine

for

satin

stitch.

Sew

outlines

of

monogram,

making

sure

that

seams

do

not

overlap

at

joints

of

letters.

43

DRO31

Page 45

838

954

Straight-Stitch

Hemstitching

Machine’Setting:A0.

B

=

+

Stitch

length:

Medium

to

maximum.

Insert

twin

hemstitching

needle,

System

130

Zwi-Ho,

as

instructed

on

page

15.

Turn

out

needle

set

screw-a

little

further

than

for

ordinary

needles.

The

thread

size,

threading

procedure

and

thread

tension

are

the

same

as

for

cording

work

(see

page

45).

Beautiful

hemstitching

effects

on

blouses,

dresses,

handkerchiefs,

doilies

andsoforth,

can

be

obtained

with

Pfaffs

System

130

twin

needle.

The

harder

the

fabric

yarn,

the

more

pronounced

the

hemstitching

will

be.

For

this

reason,

batiste,

organdy,

georgette,

etc.

are

best

suited

to

hemstitching,

while

woolly

fabrics

are

not

recommended.

Fold

fabric

to mark

seamline

or

trace

seamline

on

fabric.

Sew

first

row.

Guide

fabric

so

that

wing

needle

stitches

along

traced

line.

At

the

end

of

the

seam,

turn

fabric

half

a

turn

and

sew

second

row.

Guide

fabric

in

such

a

way

that

wing

needle

penetrates

the

needle

holes

it

has

made

and

enlarged

previously.

Imitation

hemstitching

thus

requires

at

least

two

operations.

If

desired,

additional

straight

or

curved

ornamental

seams

may

be

stitched

parallel

to

the

first

one.

Exciting

decorative

effects

may

be

obtained

by

using

van-colored

embroidery

and

darning

threads.

Zigzag

Hemstitching

Machine

Setting:

A

Up

to

1/2;

B

+

Insert

fashion

disc

A

Same

as

above,

except

that

the

wing

needle

should

penetrate

the

traced

line

only

when

itison

the

left

of

its

throw.

-

,r

Infert

fashion

disc

A.

Procedure

DR

001

R

8427

44

Page 46

Cording

Machine

Setting:

A0;B

To

cordonyour

Pfaff

92,

useacording

foot andatwin

needle.

Twin

needles

are

available

for

needle

distances

of

1.2

(3/64”),

1.6

(1/16”),

1.8,

2.0 (5/64”),

2.5

(3132),

3.0,

and

4.0

(5/32”)

millimeters.

Cording feet

are

availableinthree

varieties,asfollows:

Pin

tucks

are

made

with

cording

foot

No.

847680(7grooves,

3/64”

wide

each)

and

a

1.2-mm

twin

needle.

For

narrow

cording

use

cording

foot

No.

847675

(5

grooves,

1/16”

wide

each;

see

ill.)

anda1.6-mm

twin

needle.

Wider

cordingismade

with

cording foot

No.

847

671

(3

grooves,

5/64”

wide

each)

and

a twin

needle

withaneedle

distance

of

2.0or2.5

millimeters.

Cording

feet

and

twin

needles,

System

130,

ore

suppliedonspecial

request

and at

extra

cost.

Changing

the

Needle

and

the Sewing

Foot

Bring

take-up

levertohighest

point,

loosen

needle

set screwa,and

pull

ordinary

needle

out