Page 1

.{•••'•3k

€

-912/01

-

912/02

Semi-automatic

Bobbin

Winder

Provisional

and

Service

Instruction

Manual

Book

'Vi

G.

M.

PFAFF

AG

K

AIS

ERS

LA

U TE RN

BRANCH

Printed in Germany

Page 2

1.

1.1

Instructions

Winding

the

First

Bobbin

1.2

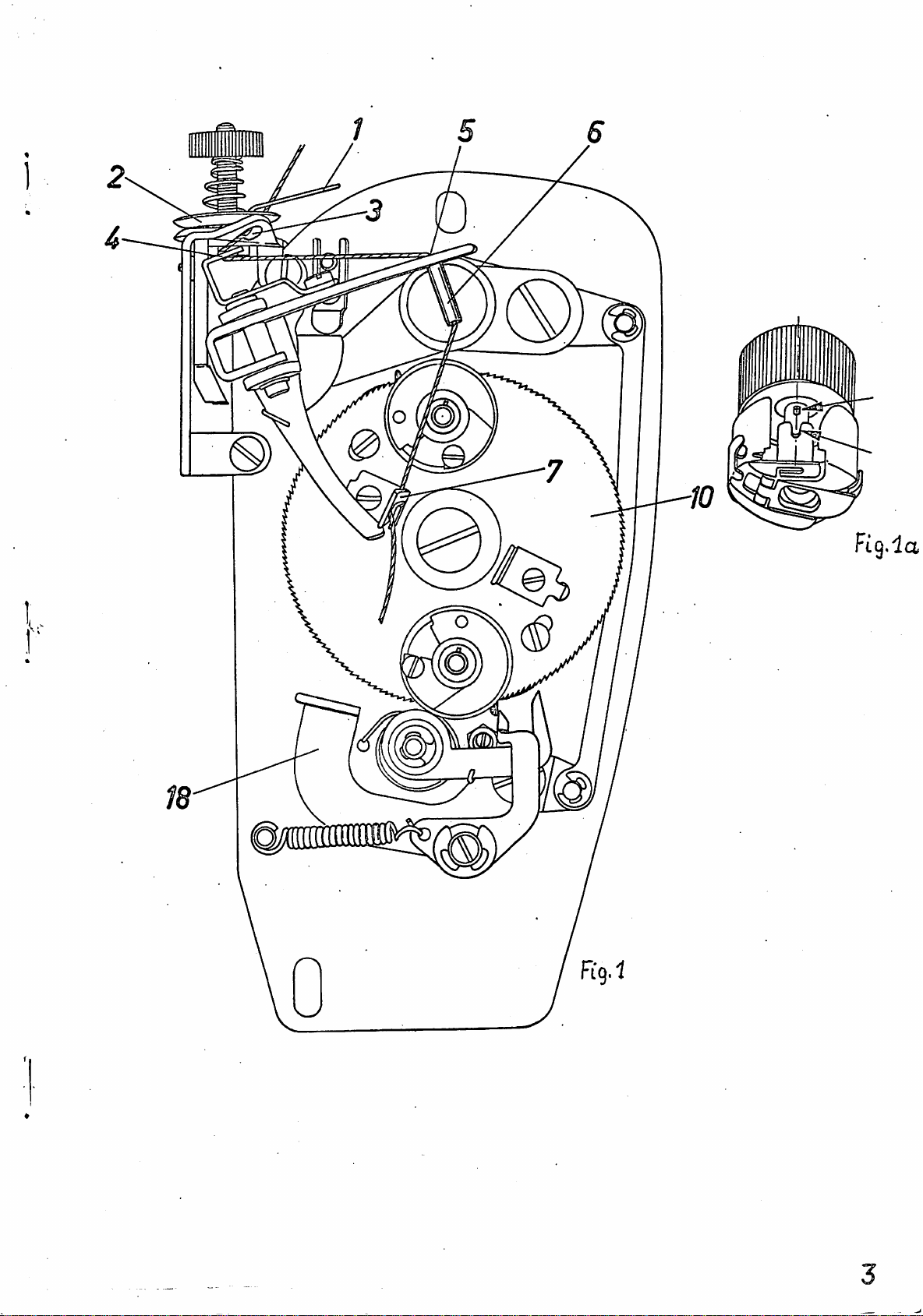

Thread

thread

the

empty

that

arrows

place

Depress

thread

out

.

Cut

off

over

after

time).

bobbin.

The

bobbin

sewing.

by

half

the

bobbin

ceive

Bobbin

Take

sewing

spindle.

bobbin

winder

cally

stitches

truding

case

with

the

guides

the

in

on

guide

knife

the

The

the

Changing

the

hook

case

spindle.

cut

bobbin

bobbin

key

Fig.

the

starting

the

protruding

?.

bobbin

bobbin

is

When

a

turn

case.

next

bobbin

and

Depress

with

to

of

the

on

the

the

1-6

enters

la)

spindle.

tube

(The

wound

the

and,

bobbin

case

place

As

the

next

back

full

winder

(Fig.

on

the

the

and

lever

6_

is

thread

winder

winder

automatically

bobbin

while

The

bobbin

with

starting

the

full

3'"ou

proper

seam.

Of

bobbin

by

upper

slot

that

2^

lowered

thread

has

is

is

case.

it

on

do

length

the

leading

l).

the

(FiS-

has

been

now

full,

doing

winder

the

the

lever

bobbin

this,

Teai-

bobbin

in

Push

bobbin

in

into

end

to

ready

empty

upper

required

off

the

the

the

the

bobbin

bobbin

1)•

As

the

by

be

cut

threaded

while

gear

so,

automatically

is

bobbin

1_8

(Fig.

from

the

thread

the

and

sewing

thread

bobbin

winder

case

you

bobbin

pulling

off

for

the

wheel

now

bobbin

the

for

thread

insert

hook.

spindle

case

snaps

do

by

for

winding

machine

1Q

ready

out

winder

1)

and

lower

is

the

the

through

case

(see

this,

case

the

hand

the

rotates

to

of

pull

bobbin

automati

starting

end

bobbin

with

so

into

cut

thread

only

fii'st

the

is

threads

re

the

the

pro

Page 3

4

s

Fig.-la

m

s

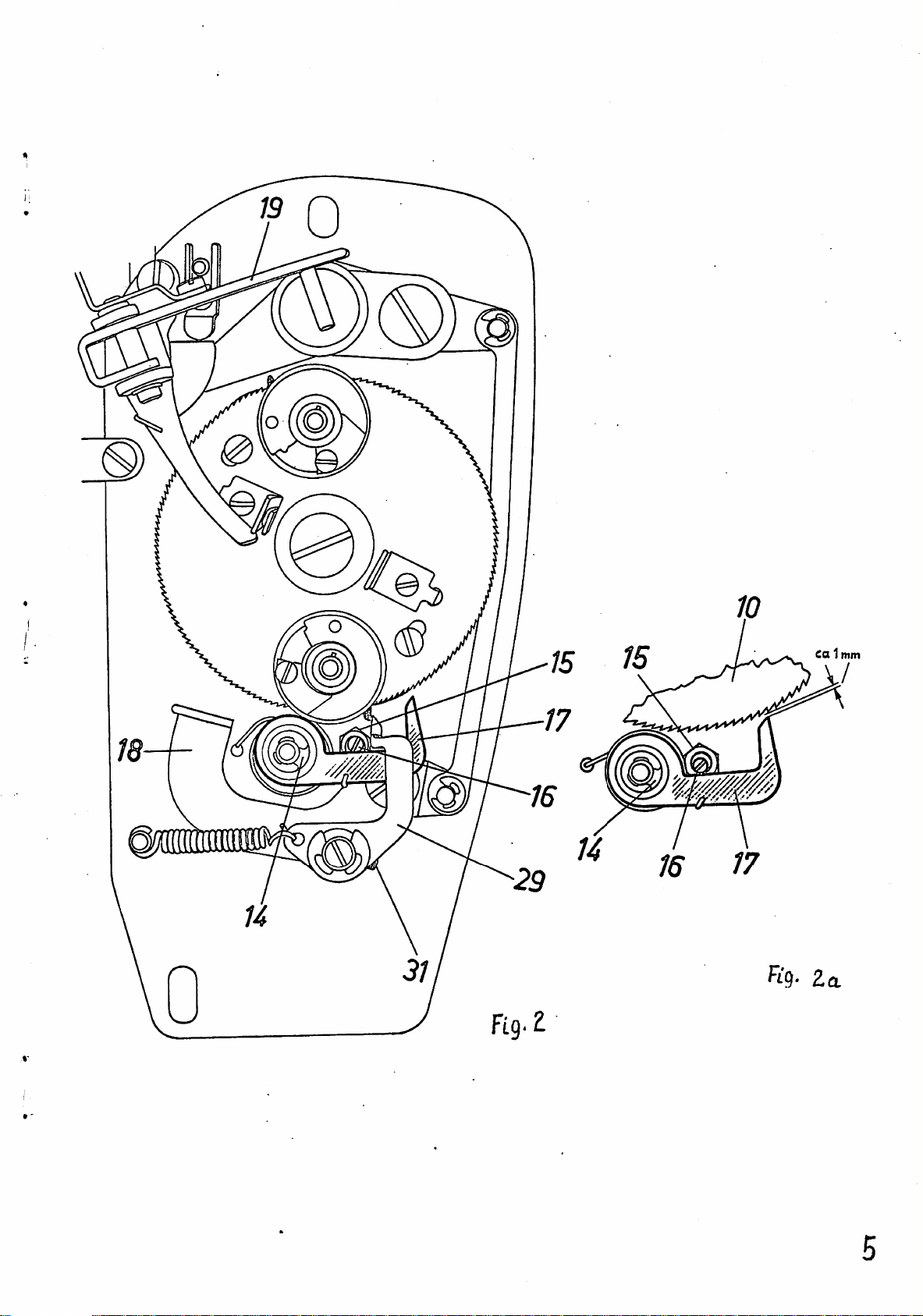

Page 4

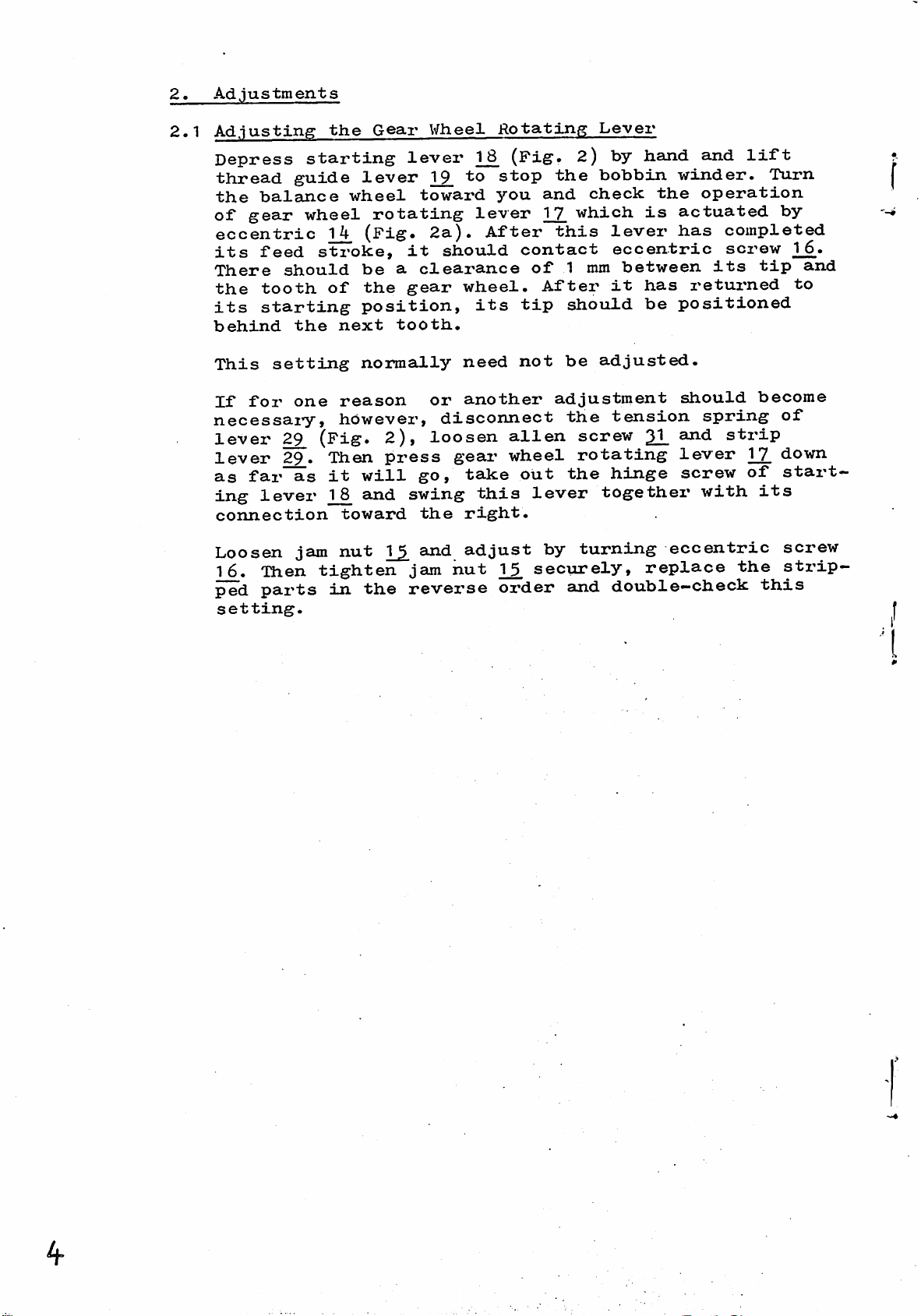

2.

2.1

Ad.lustments

Ad.justing

the

Gear

Wheel

Rotating

Lever

Depress

thread

the

of

gear

eccentric

its

There

the

its

behind

This

If

necessai-y,

level'

lever

as

ing

connection

Loosen

16.

ped

setting.

balance

feed

should

tooth

starting

setting

for

29_

29^.

far

lever

Then

parts

guide

the

one

as

jam

starting

wheel

wheel

14

stroke,

of

next

reason

however,

(Pig.

Then

it

1_8

toward

nut

tighten

in

lever

lever

towai-d

rotating

(Pig.

it

be

a

clearance

the

gear

position,

tooth.

normally

2),

press

will

and

the

go,

swing

1^

jam

revei'se

the

and

^8

1_2.

to

you

lever

2a).

After

should

wheel.

its

need

or

another

disconnect

loosen

gear

take

this

right.

adjust

nut

(Pig.

stop

contact

of

tip

not

alien

wheel

out

lever

securely,

oz'der

2)

the

and

1_7

check

which

this

1 mm

After

should

be

adjustment

the

screw

rotating

the

by

turning

and

by

hand

bobbin

is

lever

winder.

the

actuated

has

and

operation

eccentric

between

it

has

returned

be

positioned

adjusted.

should

tension

spring

2L

lever

hinge

together

screw

with

eccentric

replace

double—check

lift

Turn

completed

screw

its

tip

become

strip

1J7

of

its

the

this

by

16.

and

to

of

down

start

screw

sti'ip-

4*

Page 5

15 15

Ca 1 mm

16 17

2 a.

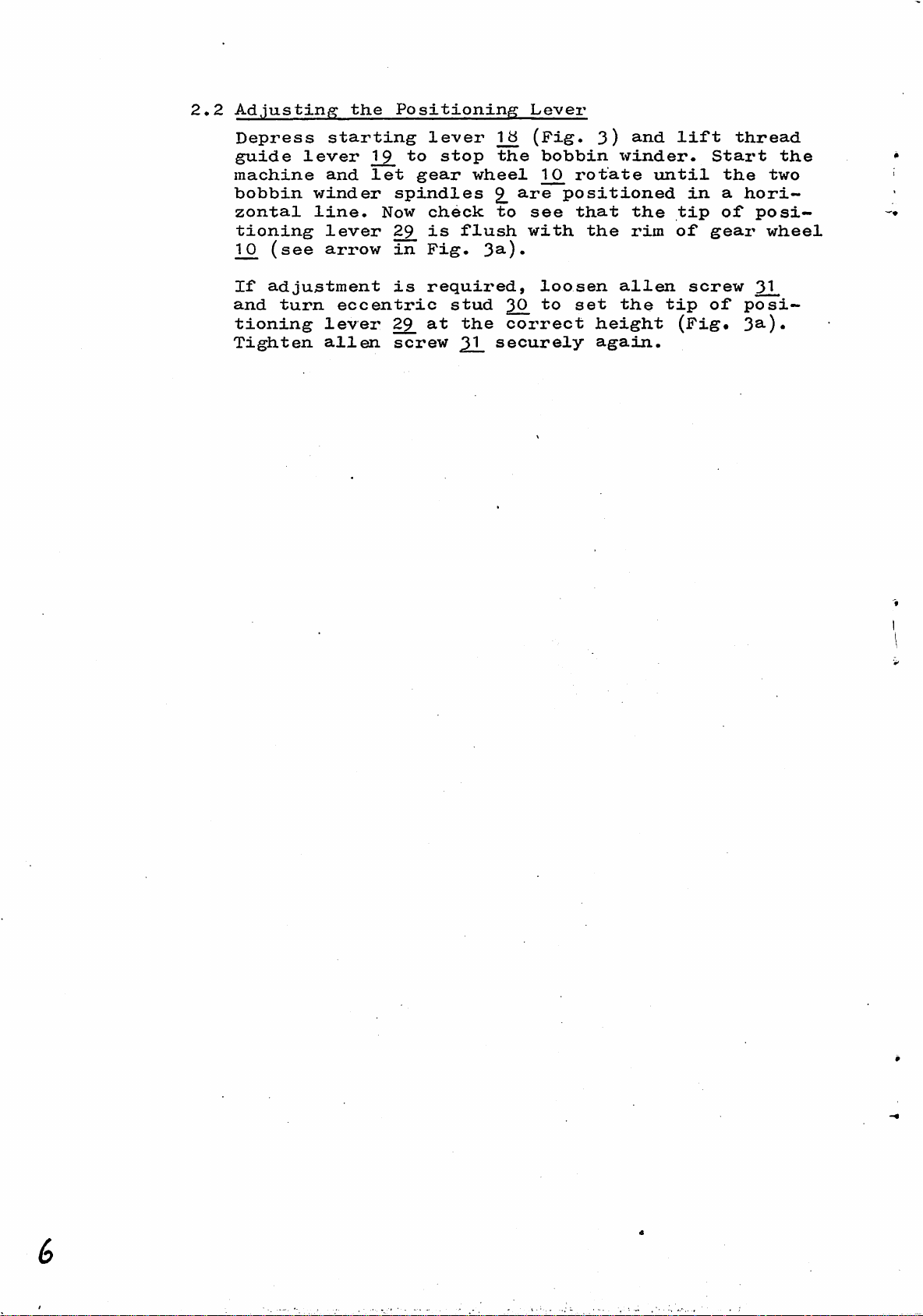

Page 6

2.2

Adjusting

tlie

Positioning

Lever

Depress

guide

machine

bobbin

zontal

tioning

10

(see

If

adjustment

and

turn

tioning

Tighten

starting

level'

and

winder

line.

lever

arrow

eccentric

lever

alien

T_2^

let

spindles

Now

29_

in

is

22_

screw

lever

stop

gear

check

is

Fig.

requii'ed,

stud

at

wheel

flush

the

21.

the

2.

to

3a).

2^

correct

securely

(Fig.

bobbin

1_0

see

with

loosen

3)

x^rinder.

rotate

positioned

that

the

rim

alien

height

again.

and

the

until

lift

in

tip

of

screw

(Fig.

Start

the

a

of

gear

thread

the

two

hori

posi

wheel

31

posi

3a).

Page 7

(D

0

GD

s

r £

-Sy

L

Page 8

2.3

Adjusting

the

Stopping

of

the

Gear

\^^t^eel

Check

protrude

.

1^.

stop

tighten

Stax't

the

tating

wheel

position

thread

stopped

tube

winder

If

move

winder

make

stop

Move

winder

too

to

see

about

To

adjust,

tripping

screws

the

bobbin

lever

10.)

of

guide

coi^rectly,

6

should

spindle

adjustment

stop

sto-jps

sure

tripping

the

tz^ipping

stops

late.

that

points

machine

winder

1_7

Depress

bobbin

tube

be

is

tripping

correctly.

you

do

point

too

the

1

mm

loosen

2&_

securely.

and

stops

no

6

in

9,»

required,

not

point

eai'ly,

two

beyond

set

as

let

longer

starting

winder

(Fig.

the

left

line

point

disturb

27.

as

stop

sci^ew

shown

gear

the

tripping

teeth

2^

in

wheel

Fig.

automatically.

engages

lever

spindle

4).

If

edge

with

of

the

loosen

27.

sideways

As

you

make

the

to

or

shown

the

to

in

left

the

and

the

1^

9,

in-

the

bobbin

thread

center

set

until

this

vertical

Fig.

if

i-ight,

of

adjust

4a.

1_0_

(Gear

teeth

and

relation

screw

the

points

gear

wheel

Then

rotate

wheel

of

check

winder

guide

of

bobbin

2^

the

adjustment,

setting

4a.

bobbin

if

it

27

the

until

ro

gear

the

to

has

and

bobbin

of

stops

Check

in

the

the

same

position

manner

of

and

the

adjust,

other

bobbin

if

winder

necessai'y.

spindle

5

Page 9

iT

6^

d

Page 10

2,4

Ad

.jus

ting

the

Bobbin

i/inder

Spindles

\\rhen

bobbin

at

the

line

If

adjustment

the

upper

key

enters

Fig.

thread

gear

5a)

of

easily

Loosen

bobbin

winder

the

bobbin

spindle

depx'ess

19.

Let

be

tightened

make

does

the

bobbin

winder

top

(dash-dot

bobbin

la.

Depress

guide

wheel

pinion

accessible.

both

winder

until

is

starting

gear

sure

not

that

exceed

and

the

H)

alien

case

at

spindle

slightly

line

is

slot

lever

rotate

3^

spindle

the

the

wheel

again.

the

winder

i^equired,

winder

starting

1_2.

on

screws

bobbin

until

position

lever

10

end

0.1

in

in

until

the

As

mm.

has

(Fig.

Fig.

the

"to

can

case

the

1_8

turn

you

play

stopped,

to

the

place

spindle,

bobbin

lever

stop

both

back

2^

be

key

indicated

and

until

tighten

5)

5)«

of

jast

turned.

is

of

should

right

1_8_

the

alien

gear

at

on

lift

the

key

a

bobbin

making

case,

(Fig.

bobbin

lightly

the

the

thread

both

the

bobbin

be

of

the

sure

as

sci'ews

wheel

Run

top.

bobbin

above.

screws

two

on

the

positioned

vertical

case

5)

on

that

shown

and

winder.

3^

1_0

are

so

that

the

bobbin

When

winder

Again

guide

3^

alien

winder

the

in

lift

Let

(Fig.

the

rotate

lever

oan

screws,

spindle

To

guide

wheel

press

that

cutout.

Check

and,

check,

lever

turn

down

thread

the

if

depress

1_2,

until

starting

guide

other

necessary,

to

bobbin

starting

stop

the

lever

tube

auijust.

the

bobbin

^

windez'

lever

bobbin

is

case

is

and

centered

spindle

1_8

and

winder.

at

check

in

in

the

to

lift

the

the

Let

top.

make

bobbin

thi'ead

the

Then

sure

same

gear

case

manner

-10

Page 11

9

s

Page 12

2.5

Ad.justing

the

Amount

of

Thread

on

the

Bobbin

Place

bin

6)

Check

Thread

when

,

positioned

case

To

thread

bin.

21

wrench

Turn

thr

Tighten

tighten

and

a

winder

and

to

the

(Fig.

adjust,

Loosen

upwards

this

ead.

this

bobbin

slowly

see

guide

lower

guide

(see

segment

the

them

might

case

spindle.

lift

when

lever

about

6).

again

lever

the

or

downwai'ds

arrow

alien

too

cause

this

end

1

depress

lower

in

up

screws,

much

with

Depress

thread

J[_9,

should

of

mm

inside

1_9,

down

alien

Fig.

for

as

heavy

an

guide

lever

thread

starting

with

6).

more

but

they

empty

starting

stops

stop

guide

cutout

onto

screw

a

hexagon

thread,

make

press

working.

bobbin

lever

the

lever

the

2^

levei'

1_2_byhand.

the

bobbin

bobbin

tube

2^

of

core

and

socket

or

sure

on

you

a

hollow

on

^

the

and

of

turn

down

the

18

is

the

do

bob

(Pig,

winder.

winder

still

bobbin

push

bob

segment

screw

for

not

shaft

less

(g

Fig.

6

Page 13

2.6

Inopei'ative

Position

of

Thread

Guide

Lever

When

be

thread

(Pig.

To

the

this

the

a

clearance

guide

7).

adjust,

latter

adjustment,

bobbin

loosen

higher

tube

winder

of

4-5

6

and

the

or

tighten

is

mm

set

lower,

inoperative,

between

the

screw

the

rim

as

appropriate.

set

the

of

of

screw

the

stop

there

lower

gear

securely.

2^

end

wheel

and

After

should

of

set

Fig.

mm

7

-15

Page 14

2.7

Ad.justinff

When

should

and

If

the

adjustment

spring

as

may

clearance.

thread

be

left

suspension

be

Lever

guide

a

clearance

knife

required

Tighten

is

12

levei'

7.

required,

screw

to

both

19_

of

2^

obtain

screws

1-2

is

inopei'ative,

mm

8)*

loosen

and

the

between

stop

tui^n

securely.

the

above-mentioned

lever

screw

set

there

26

collar

12

and

Note

bound

that

to

screws

cause

which

heavy

0

are

working.

tightened

too

much

are

Page 15

2.8

Setting

the

Thread

Guide

Lever

to

the

Bobbin

\\nierL

inclined

this

flush

in

Fig.

If

it

adjust

inaJcing

the

left

thread

toward

position,

with

9a-)*

is

not,

the

sure

side

guide

the

the

rear

loosen

position

that

of

base

the

fork

lever

rear

wall

of

plate

set

thread,

prong

32*

1_9.

edge

of

screw

i%

inoperative,

13*

of

the

guide

of

bracket

i^Tith

tube

bobbin

^3.

lever

^

(Fig.

lever

should

(see

9)»

3iL

it

1_2,

in

arrow

s^nd

29.

while

contacts

is

be

Fig.

Fig.

9

9a

Page 16

2.9

Adjusting

Remove

ing

lever

(Fig.

about

winder

bobbin

10)

5 mm

spindle

the

1_8

by

hand

between

Leaf

case

(Fig.

9.*

Spi'ing

with

5).

until

thread

bobbin

Lift

there

thread

guide

is

and

a

tube

depress

guide

clearance

6

and

start

lever

bobbin

]_2.

of

When

not

at

wider

press

To

from

flat

set

in

be

its

than

thread

adjust,

the

spring

screw

this

engaged

forward

5 mm,

loosen

inside

38

position,

by

point

guide

37

to

securely.

of

leaf

leaf

set

the

of

lever

the

thread

spring

revei'sal.

spring

^2.

screw

tension

correct

guide

37,

27.

2^

position.

i.e.

If

should

rear.

which

bracket

lever

the

can

is

start

aind

Then

1_2.

should

gap

be

must

be

grows

to

reached

swing

tighten

Fig.

i

10

^6

Page 17

Final

Inspection

of

Bobbin

Winder

Start

it

(Fig.

guide

of

If

ed

second

Thread

and

upper

l8

bobbin

chine

If

adjust

check

winder

Now

stops

the

it

in

place

and

the

the

the

machine

automatically.

5)

and

tube

is

par.

bobbin

not,

bobbin

the

6^

2.3

bobbin

a

bobbin

bobbin

start

and

stop.

speed

bobbin

the

the

cover.

bobbin

shortly

segment

following

check

is

positioned

winder

readjust

above.

winder

winder

the

is

winder

and

let

whether

spindle.

Make

spindle.

winder

case

spindle.

machine.

It

is

before

either

as

instructed

adjustments

is

the

bobbin

Depress

the

exactly

the

bobbin

the

as

instructed

with

recommended

too

an

Depi'ess

Watch

the

full

ready

starting

left

winder

same

anpty

the

bobbin

or

in

and

for

winder

edge

above

check

in

bobbin

starting

machine

to

reduce

is

not

par.

replace

operation.

lever

of

the

as

full.

full

2.5»

run

thread

center

insti'uc.t-

for

par.

on

wind

the

enough,

the

until

T_8

the

1.1

the

lever

the

ma

Double-

bobbin

^7

Loading...

Loading...