Page 1

PFAFF

335

Instruction

manual

296-12-17

Betriebsanleitung engl. 8.96

599

Page 2

This Instruction manual is validfor all models and subclasses listed in the

chapter„Specifications".

The reprinting, copying or translation of

part, is only

source.

G.M.

PFAFF

permitted

with

our

previous

PFAFF

Instruction Manuals,

permission

and

with

written

whether

referencetothe

Aktiengeselischaft

Postfach

D -

Konigstr.

D -

67653

67655

3020

Kaiserslautern

154

Kaiserslautern

Editing/Illustrations

Verlag

D-77901

-TD

Lahr

inwhole or in

Page 3

Contents

1 Safety

1.01 Directives 1

1.02 General

1.03 Safety symbols

1.04 Important points for

1.05 Operating and specialist personnel 1 - 3

1.05.01 Operating personnel 1 - 3

1.05.02 Specialist personnel 1 - 4

1.06 Danger symbols 1 - 5

2

3 Specifications

3.01

3.02

4 Disposal of

Proper

PFAFF335

Possible

notesonsafety

the

use

models

the

and

machine

user 1 - 3

subclasses

1-1

-1

1

-1

1-2

2-1

3-1

3-1

3-1

4-1

5 Transport, packaging

5.01 Transportto the customer's premises 5 -1

5.02 Transport

5.03 Disposal of the packaging 5 -1

within

and

storage

5

-1

the customer's premises 5 -1

5.04 Storage 5 -1

6 Explanation of the symbols

7 Operational controls

7.01

7.02 Pedal

7.03

7.04

On/Offswitch 7 -1

Stitch-length adjustmentlever/reverse sewing

Adjustment nutforthe top feed

8 Mountingand initial operation

8.01

Mounting

lift

6-1

7-1

7-1

7-2

7-3

8-1

8-1

8.01.01

8.01.02

8.01.03

8.01.04

PFAFF

Adjusting

Tightening

Mounting

Mounting

the

the

the

the

table

V-belt

upper

lower

height

V-belt

V-belt

guard

guard

8-1

8-2

8-3

8-3

Page 4

Contents

8.01.05

8.01.06

8.02

8.03 Switching the machineon/off

9 Preparation

9.01 Needle

9.02 Inserting the needle

9.03

Mounting

Mounting

Initial

operation

and

Winding

the sewing

lamp

the spoolholder

thread 9

the

bobbin

thread, adjusting the thread tension 9 - 2

8-4

8-4

8-4

8-4

9-1

-1

9-2

9.04 Removing the bobbincase, threading the bobbincase 9 - 3

9.05 Insertingthe bobbin case, adjusting the bobbinthread tension

9.06

Threading the needle thread

9.07 Adjusting the needle thread tension

0

0.01 Servicing intervals

Care

and

maintenance

9-3

9-4

9-4

10-1

10-1

0.02

0.03

0.04

0.05 Lubricating

0.06

Cleaning

General

Lubricating

Checking

lubrication

the

sewing

the

hook

the

air pressure

head

0.07 Emptying/ Cleaning the water container of

1

1.01

1.02 Notes on adjusting

1.03

1.04 Adjusting

1.04.01 Positioning

1.04.01.01

Adjustment

Tools, gauges and otheradjustment accessories

Abbreviations

the

basic machine

the

feed dog

Lateral positioning of

the

feed dog

1.04.01.02 Lengthwise positioning of the feed dog

1.04.02 Centering

the

needle in

the

needle hole

the

airfilter

10-1

10-2

10-3

10-3

10-4

10-4

11-1

11-1

11-1

11-1

11-2

11-2

11-2

11-3

11-4

1.04.03 Pre-adjusting

1.04.04

1.04.05 Needle rise, hook-to-needle clearance and needle height

1.04.06

Driving

Vibrating

the

needle height

motion of the top and bottom feed dogs

presserfeeding motion

1.04.07 Vibrating presser lift

11-5

11-6

11-7

11-8

11-9

PFAFF

Page 5

Contents

1.04.08

Needle

thread

tension

release

1.04.09 Thread check spring

1.04.10

1.04.11

1.05 Adjusting

1.05.01

1.05.02

Bobbin

winder

Regulatingthe pressure on the presserfoot..

the

Preadjusting

Tripping

lever height

thread

the

trimmer

control cam

-800/52

1.05.03 Feed regulator pin

1.05.04 Engagingsolenoid

1.05.05 Adjustingthe height of the feed regulator pin.

1.05.06 Thread catcher, front point of reversal

1.05.07 Lateral adjustment of

the

thread catcher

1.05.08 Control cam, finaladjustment

1.05.09

1.05.10 Triggering

1.05.11

Knife

Cutting

the

needle thread tension

test

1-10

1-11

1-12

1-13

1-14

1-14

1-15

1-16

1-17

1-18

1-18

1-20

1-21

1-22

1-23

1-24

1.05.12

Positioner

1-25

PFAFF

Page 6

Safety

Safety

1.01

1.02

Directives

This

machineisconstructedinaccordance

conformity

and

manufacturer's

declarations.

Inaddition to this Instruction Manual,

other

regulations

mental

The

other

protection

regionally valid regulations of

supervisory

General

•

This

machine

completely

•

All

Notes

before

operating

notes

read

on Safety

and

legal

requirements

regulations!

the

organisations

on

safety

may

onlybeoperatedbyadequately

and

understood

and

the

machine.

aretobe

Instruction Manuals of

with

the

observe

social

the

also all generally

-including

insurance

strictly

Instruction Manual.

adhered

European regulations

accepted,

thoseofthe

society

trained

the

motor

country

for occupational

to!

operators

manufacturer

containedinthe

statutory

and

all valid environ

accidents

and

only

after

aretobe

and

or

having

read

• This machine may onlybeused

operated

be

•

When

bobbin),

maintenance

off

• Everyday

• Repairs

or

appropriately

•

When

removed

and

• Work on electrical

without

adhered

exchanging

when

the

On/Off switch or by removing

maintenance

and

servicing or carrying

from

function

to.

threading

work,

special

trained

the

checks

its

safety

sewing

tools (e.g. needle,

the

the

machine is to be

work is only to be carried

maintenance

personnel.

compressed

carried

equipment

devices.

machine,

out

out

for

the

All

when

the

work

repairs on

air supply.

purpose

safety

separated

may

for which it is

regulations relevant to its

presser

leaving

plug from

onlybecarried

pneumatic

The

foot, needle plate,

the

machine

from

the

the

mains.

out

by appropriately trained personnel.

out

devices,

only

exceptions

intended

unattended

power

by qualified

the

machineisto

to this

and may

operation

feed

dog

and

not

are

or

during

be

supply by switching

service

are

adjustments

staff

be

to

by appropriately trained personnel.

may onlybecarried out by appropriately trained personnel.

• Work is not permitted on parts and

supply. Exceptions to this

1

-1

are

equipment

in accordance with

which

are

connectedtothe

the

regulations EN 50110.

power

PFAFF

Page 7

Safety

• Modifications and alterationsto the machine mayonlybe carriedout under observance

of all

the

relevant safety regulations.

1.03

• It is forbidden to

entire

sewing

operate

unit complies with

the

machine

head

the

regulations of

until

such

the

timeasis

EC Directives.

determined

that

• Onlyspare parts which have been approved by us are to be used for repairs! We

expressly point out that any replacement parts or accessories which are not supplied by

us have not been tested and approved by us. The installation and / or use of any such

products can lead to negative

We shall not be

Safety

In this Instruction Manual

A

symbols

Danger!

Pointstobe

liable

for any damage which may be caused by

safety

observed.

changesinthe

symbols

are

construction characteristics of

non-original

used. Their

meanings

are

the

parts!

as follows.

the

machine.

1.04

Danger of injury for operating

and

specialist personnel!

A

Important

• This Instruction Manual is a

operating personnelatall

The

• The operating and specialist personnel is to be instructed as to

the

• It is the duty of

• It is the obligation of the operator to ensure that none of the safety mechanisms are

removed

• Itis the obligation of the operator to ensure that only authorised persons operate and

work

points

Instruction Manual

machine

or

on

the

for

and

regarding

the

operator to onlyoperate the machine in perfect running order.

deactivated.

machine.

the

user

component

times.

mustberead

safe

work

part of

before

methods.

the

machine and

operating

the

mustbeavailable to

machine

for

the

safety equipment of

the

first

time.

the

Further

information

canbeobtainedatyour

PFAFF

agent.

PFAFF

Page 8

Safety

1.05

1.05.01

Operating

Operating

and

specialist

personnel

personnel

Operating personnel are persons responsible for

the

machineaswellastaking care of faults arising in

The operating personnel is obliged to

• always

never

•

machine.

•

not

•

also

around

• always immediately report to

may

observe

use

wear

ensure

the

limit its

the

Notes on Safety in

any working

loosely fitting clothing or jewellery

that

only

machine.

safety.

methods

authorised

observe

the

which could limit

the

persons

person

have

responsible

the

the

equipping, operating and cleaning of

the

sewing

following points and must:

Instruction Manual.

the

level of

suchaschains

accesstothe

any

area.

safety

in using

or rings.

potentially

changesinthe

the

dangerous

machine

area

which

1.05.02 Specialist

Specialist personnel

electronics and mechanics. They are responsible for the lubrication, maintenance, repair and

adjustmentofthe

The specialist personnel is obliged to observe

• always

• switch off the On/Offswitch before carrying out adjustments or repairs and ensure that

it cannot be switched on again unintentionally.

• never work on parts which are stillconnected to the power supply. Exceptions are

contained in

•

when

servicing or carrying

the

compressed

• replace the protective coverings and close the electrical control box after allrepairs or

maintenance

personnel

observe

the

work.

are

persons

machine.

the

Notes on Safety in

regulations EN 50110.

with a specialist education in

the

following points and must:

the

Instruction Manual.

out

repairs on pneumatic devices,

the

fields of electrics,

remove

the

air supply. The only exceptions to this are function checks.

machine from

1 - 3 PFAFF

Page 9

Safety

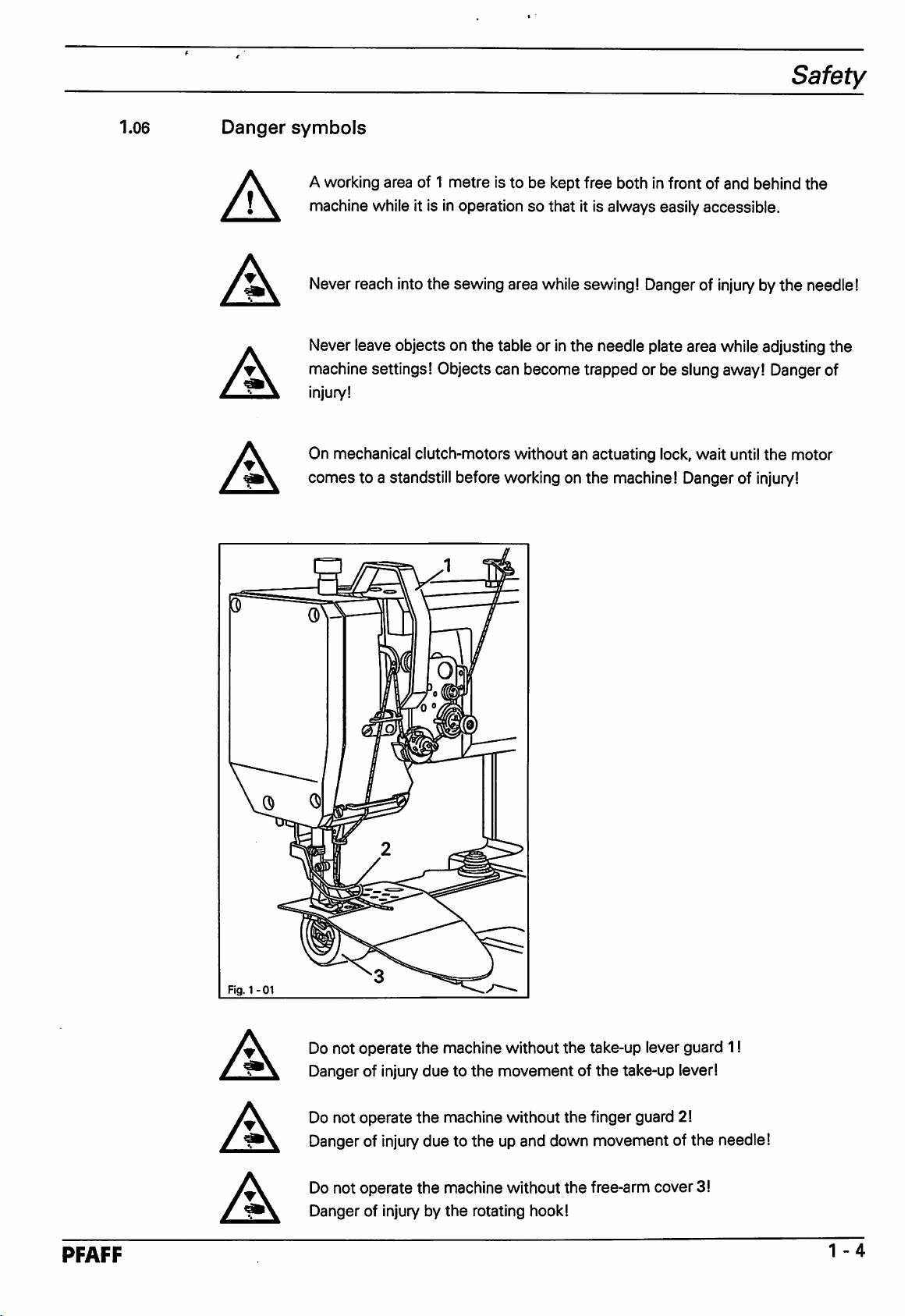

1.06

Danger

f\

A

A

•\

A

A

symbols

A working area of 1

machine

Never reach into the sewing area while sewing! Dangerof

Never leave objects on

machine settings! Objects can become trapped or be slung away! Dangerof

injury!

On mechanical clutch-motors without an actuating lock, wait until

comes

whileitisinoperationsothatitis

to a standstill before working on

metre

the

is to be kept

table or in

free

both in front of and behind

always

the

needle plate area while adjusting

the

machine! Danger of injury!

easily

accessible.

injurybythe

the

motor

the

needle!

the

Fig.

1-01

PFAFF

A

A

A

Do not

Danger of injury

Do not

Danger of injury due to

Do not operate

Danger of injury by

operate

operate

the

machine without

duetothe

the

machine without

the

the

machine without

the

rotating hook!

the

take-up lever guard 11

movementofthe

the

up and down movement of

the

take-up lever!

finger guard 2!

free-arm cover3!

the

needle!

1-4

Page 10

Safety

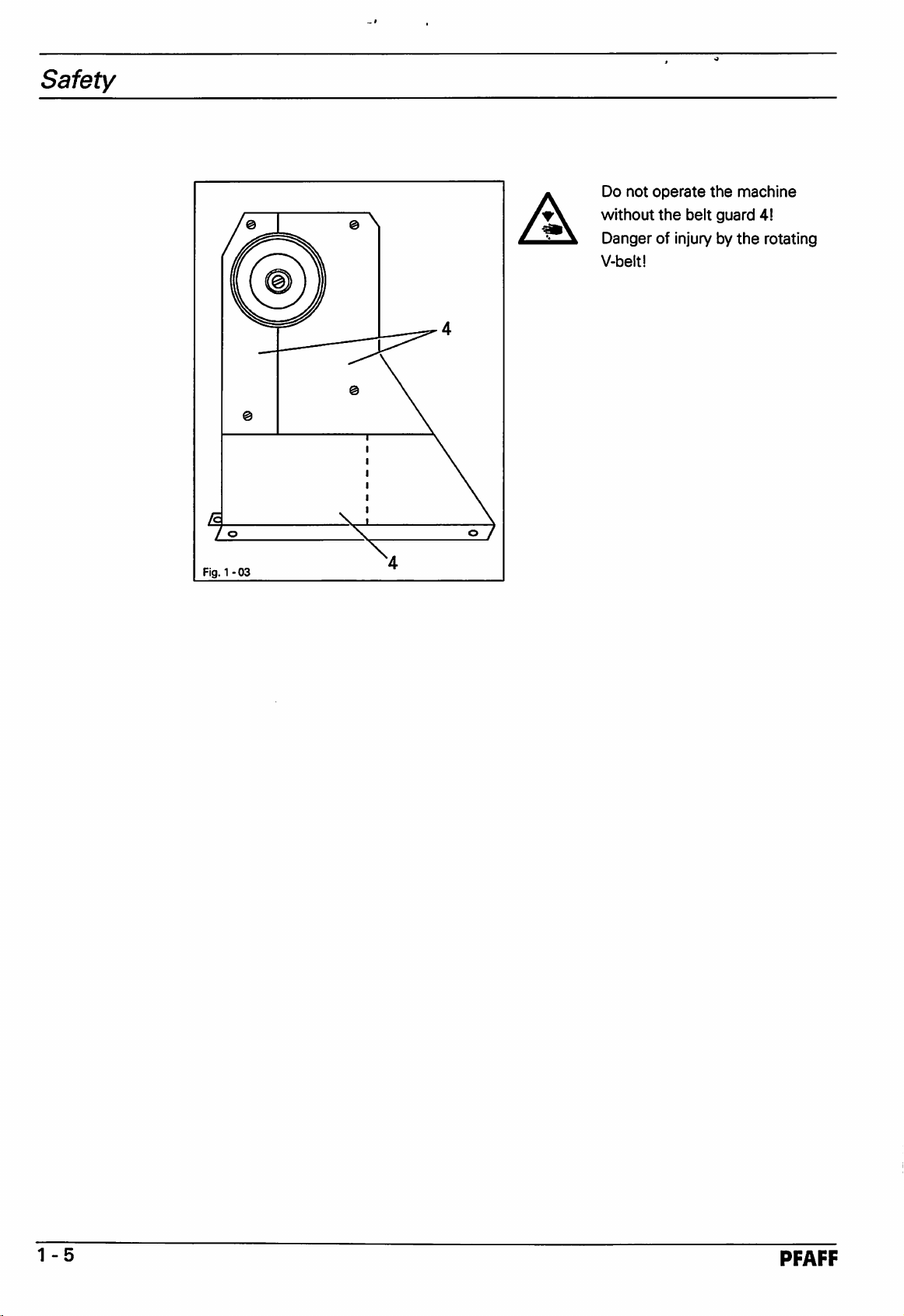

A

Do

not

operate

without

Danger of injury by

V-beltl

the

belt

the

guard

machine

4!

the

rotating

Fig. 1

-03

1-5

PFAFF

Page 11

Properuse

Proper

The

PFAFF

feeds

A

use

335 is a single needle, free-arm sewing machine with bottom, top and needle

for

sewing

lockstitch

Anyand all

manufacturer

held liable for any

The appropriate

adjustment, maintenance and repair

seams.

uses

of this machine which have not been approved of by

are

consideredtobe

damaged

useofthe

causedbythe

machine includes

inappropriate!

inappropriate

the

measures

The

manufacturer

useofthe

observance of all operational,

required by

the

manufacturer!

the

cannot

machine!

be

PFAFF

2

-1

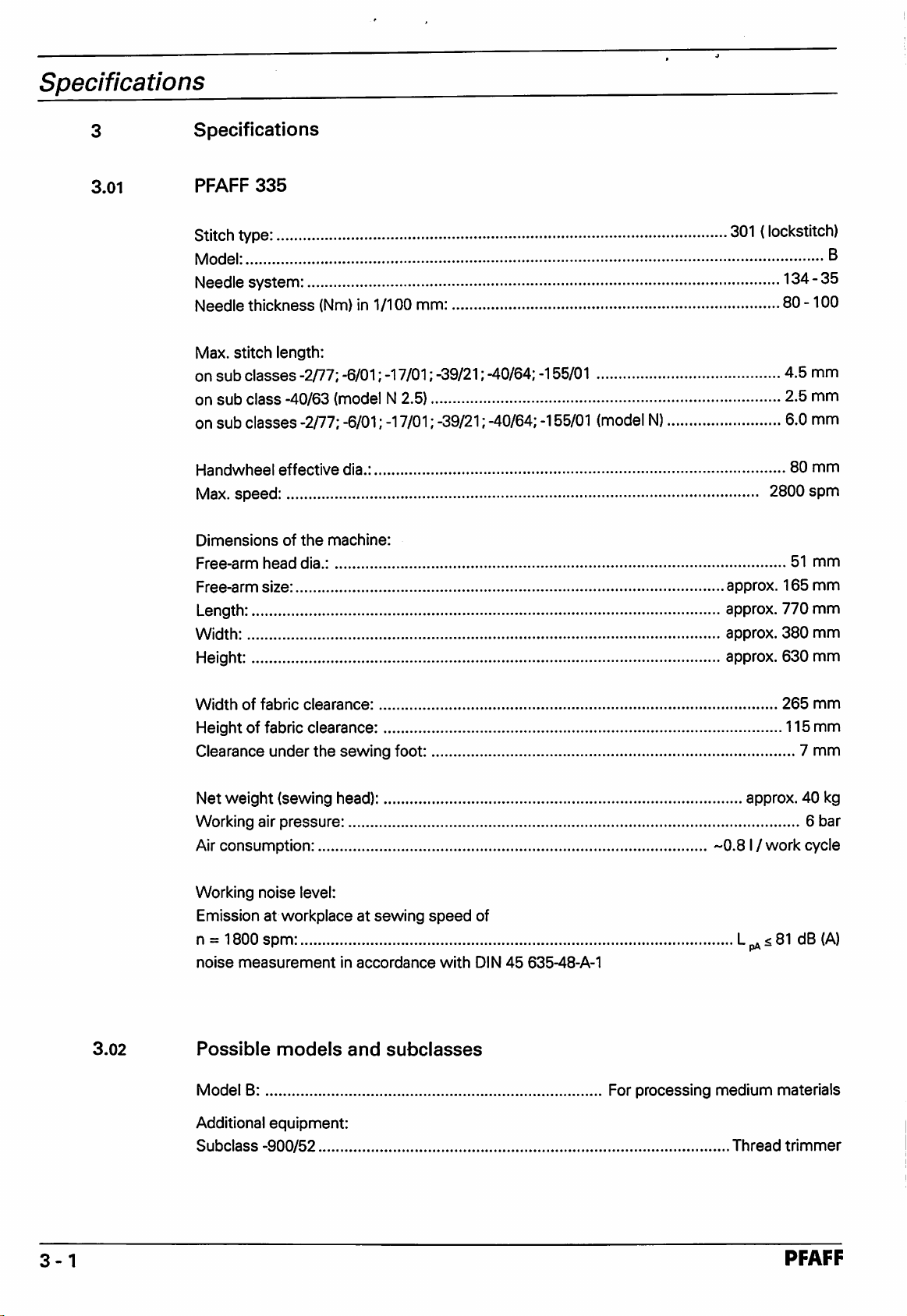

Page 12

Specifications

3

3.01

Specifications

PFAFF

Stitch

Model: 3

Needle

Needle thickness

Max.

on

on

on

Handwheel

Max.

Dimensions

Free-arm

Free-arm

Length: approx. 770 mm

Width:

Fleight: approx. 630 mm

335

type:

301

{lockstitch)

system: 134-35

(Nm)

in 1/1GOmm: 80

stitch

length:

sub

classes

sub

class -40/63 (model N 2.5) 2.5 mm

sub

classes

-2/77; -6/01; -17/01; -39/21; -40/64; -155/01 4.5 mm

-2/77; -6/01; -17/01; -39/21; -40/64; -155/01 (model

effective

dia.:

N)

6.0 mm

speed: 2800 spm

of

the

machine:

head

dia.: 51

size:

approx.

approx.

165

380

80

-100

mm

mm

mm

mm

3.02

Widthoffabric

Height of fabric clearance: 115

Clearance

Net

weight

Working air

Air consumption:

Working

Emission

n =

1800

noise

measurement

Possible

Model

Additional

Subclass

B: For

under

clearance:

the

sewing

foot: 7

265

(sewing head): approx. 40 kg

pressure:

-0.81/work

noise

level:

at

workplaceatsewing

spm:

in

accordance

models

equipment:

-900/52

and

speed

with

subclasses

of

DIN45635-48-A-1

processing

L s 81 dB

medium

Thread

materials

trimmer

mm

mm

mm

6 bar

cycle

(A)

3

-1

PFAFF

Page 13

Disposal

of

the

machine

Disposal

• The proper disposal of machine

•

The

The electrical

•

The

environmental protection regulations. If

A

of

machine

materials

machine

usedonthe

equipment

waste

Special

disposed of in accordance with

waste

machines

consists

is tobedisposed

care

is tobetaken

wasteisthe

are

of plastics and copper.

of in

that

responsibility of

steel,

aluminium,

accordance

necessary

parts soiled with lubricants are separately

the

locally valid pollution control regulations!

the

customer.

brass

and

various plastics.

with

the

locally valid

a specialist is tobecommissioned.

PFAFF

4-1

Page 14

Transport,

packaging

and

storage

5

5.01

Transport,

packaging

Transporttothe

Within

Machines without table

packaged.

Germany,

completemachines

5.02 Transport within

The manufacturer carries no

Care is to be taken to transport

5.03

Disposalofthe

The packaging of the machine consists of wood, paper, cardboard and

The proper disposal of the packaging is the responsibility of the customer.

and

customer's

and

motor (machine

the

customer's

liability

packaging

storage

premises

(with

tableand

heads

motor)

only)

premises

for transport within

the

machine in an upright position.

the

aredelivered without

and

machines for export

customer's

premises.

VCE

packaging.

are

fibre.

5.04

Storage

The machine can be

protected

For longer storage the

be

protected

from

dust

against corrosion e.g. by a film of oil.

stored

and

moisture.

individual

for up to 6 months if not in use. During this time it should be

parts of the machine, especially the moving parts, should

5-1

PFAFF

Page 15

Explanation

of

the

symbols

Explanation

In

the

following

information

The symbols used have

n

of

the

section

are

accentuatedbysymbols.

Note,

information

Cleaning,

Servicing, repairing, adjustment, maintenance

(onlyto be carried

symbols

of this Instruction Manual, certain

the

following meanings:

care

out

by specialist personnel)

tasksorimportant

pieces

of

Lubrication, greasing

PFAFF

6-1

Page 16

Elements

of

operation

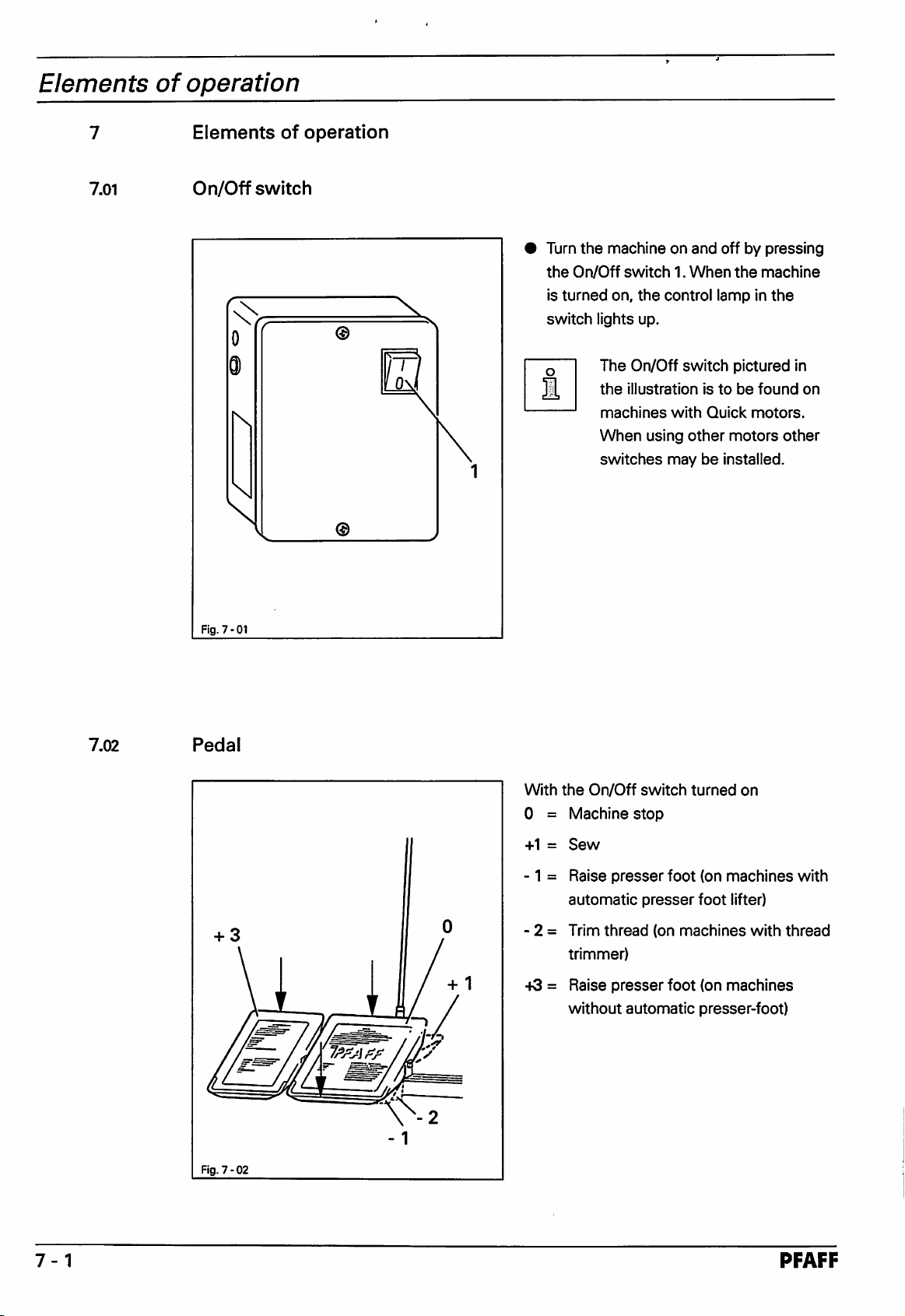

7.01

Elements

On/Off

switch

of

operation

• Turn

the

is

turned

switch

the

machineonand

On/Off

switch1.When

on,

lights up.

The

On/Off

the

illustrationistobefound

machines

When

switches

the

control lamp in

switch

with

Quick

using

other

maybeinstalled.

off by

the

pictured

motors

pressing

machine

the

in

on

motors.

other

7.02

Fig.

Pedal

7-01

With

the

On/Off

0 =

Machine

-1-1=Sew

-1

= Raise

automatic

- 2 =

Trim

trimmer)

-tS = Raise

without

stop

presser

thread

presser

automatic

switch

foot

presser

(on

foot

turned

(on

machines

foot

lifter)

machines

(on

machines

presser-foot)

on

with

with

thread

Fig.

7-02

7-1

PFAFF

Page 17

Elements

of

operation

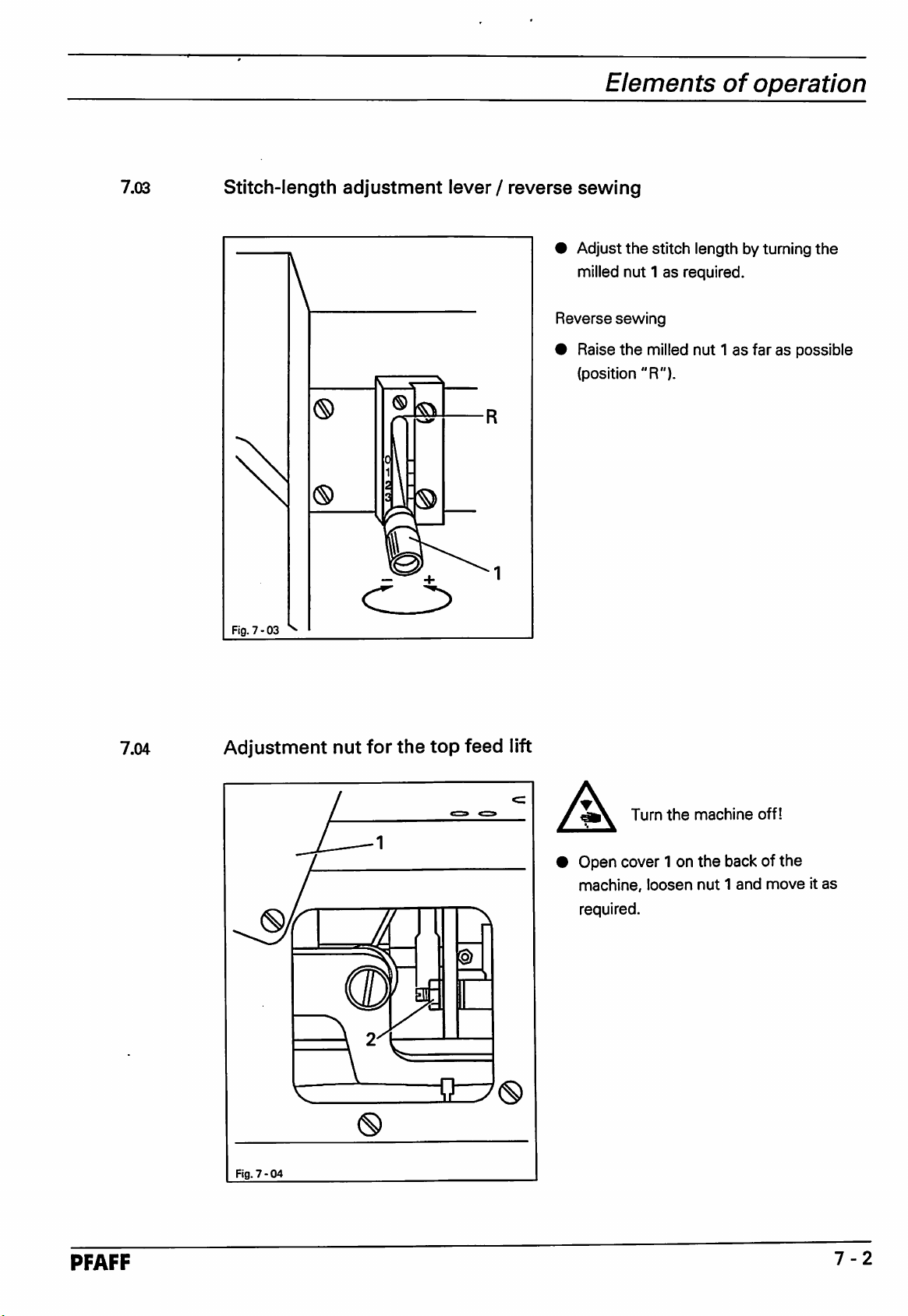

7.03

Stitch-length

Fig.

7-03

adjustment

lever /

reverse

• Adjust

Reverse

• Raise

sewing

the

stitch

length by turning

milled nut 1asrequired.

sewing

the

milled

nut1as

(position

"R").

the

faraspossible

7.04

Adjustment

Fig.

7-04

nut

m

for

the

top

feed

lift

A

Turn

Open cover 1 on

machine,

required.

the

loosen

machine

the

back of

nut1and

off!

the

moveitas

PFAFF

7-2

Page 18

Mounting

and

initial

operation

8

8.01

Mounting

I\

A

Mounting

and

initial

This machine may only be mounted and put into operation by qualified

specialists!

Connections

machine's

A solid, horizontal

Due to packaging reasons,

The

adjustmentofthe

operation

All

relevant safety regulations are to be adhered to!

for

electrical

location

{see

surface

and

compressed

chapter

table-top height is

3: Specifications).

and

adequate

the

table top is lowered for transport.

air

supplies

lighting

describedinthe

must

mustbeavailableatthe

alsobeguaranteed.

following.

8.01.01 Adjusting

Fig.

8-01

the

table

height

i

•

Loosen

Tighten

8-1

screws

screws

1 and

set

1 firmly.

the table height as desired.

PFAFF

Page 19

Mounting

and

initial

operation

8.01.02 Tightening

Fig.

8-02

the

V-belt

Loosen

Tighten

switch

Tighten

nuts

the

V-belt using

2.

nuts

1.

the

dolly

1.

Fig.

8-02 shows a Quick motor. Ifanother motor is used proceed as described

in

the

instruction

manual!

PFAFF

8-2

Page 20

Mounting

and

Initial

operation

8.01.03

Mounting

Fig.

8-03

the

upper V-belt guard

• Attach

V-beltguard 1 and 2 using

• Then

the

table

the

two

upper

screw

the

two

lower V-belt guard 3 and 4

top

with

screws

segmentsofthe

screws

lower

segments

onto

6.

5.

of

the

8.01.04 Mounting

Fig.

8-04

the

lower V-belt guard

• Align

that

run freely.

•

Tighten

the

V-belt guard 7 in

both

the

motor pulley

screws

suchaway

and

the

V-belt

8.

8-3

Fig.8-04

in

the

shows

instruction

a Quick motor. Ifanother motor is used proceedasdescribed

manual!

PFAFF

Page 21

Mounting

and

Initial

operation

8.01.05 Mounting

Screw

a

specialist.

8.01.06 Mounting

•

Mount

• Insert

8.02 initial

• Before operating the machine, check the electrical and pneumatic connections for

• Clean the machine thoroughly and then oilit (see chapter 11 Care and maintenance).

•

the

operation

possible

Have

specialist personnel checkifthe machine's motorcan be put intooperation with

the power

the

machine

the

sewing

the

sewing

the

spool holder

the

spool holder.

spool holder into

damage.

supply

available

unless

lamp

these

lamp^

onto

the

and ifthe

checks

the

hole in

table

have

top

{wood

the

table

terminal

been

screws

top

5x35)

and affix it with

boxisconnected

successfully carried

and

have it

the

properly.

out.

connected

enclosed

nuts.

Never operate

by

• The handwheel must rotate towards the operator when the machine is running.Ifthis is

not

the

case, have

• Connect the machine to

pressureofapprox.6bar.Ifnecessary,

the

air

pressure).

8.03 Switching

•

Switch

• Carry

Thesewing lampis not included inthe standard

the

outatest

the

machine altered by specialist personnel.

the

machine on/off

machineon(see

run.

the

compressed air system. The manometer must display a

chapter

adjusttothis

7.01).

value

(see

chapter

11.06

delivery.

Adjusting

PFAFF

Page 22

Preparation

Preparation

A

A

All

regulations and instructions inthis Instruction

manual

are to be observed.

Specialattention should be paidto the safety regulations!

Preparationwork is onlyto be carried out by appropriatelytrained personnel.

The machine must always be separated from the power supplybyswitchingoff

the

on/off switch or by removing

carrying

out

preparation work!

the

mains plug from

the

powersupply

when

9.01

Needle

and

thread

The choice of the correct needle depends on the machine model and the thread and material

used.

Needle

Model

B

or

Use

For

comparable

sewing

medium

thicknessesorthread

materials

types

Max.

thread

thickness

Synthetic

40/3

thickness

in

*•

1/100

80-100

(Nm)

mm

9-1

PFAFF

Page 23

Preparation

9.02

Inserting

Fig.

9-01

the

needle

A

Switch

• Loosen

• Insert

• Retighten

the

long

grooveinthe

pointingtothe

off

the

machine!

the

needle

needleasfaraspossible (The

the

needle

left).

needle

retaining

retaining

screw

must

be

screw

1.

1.

9.03

Winding

Fig.

9-02

the

bobbin

thread,

adjusting

the

thread

tension

• Place an empty bobbin onto

•

Press

the

bobbin-winder

•

The

bobbin is filled during

the

bobbin holder 1.

ratchetinthe

the

sewing

direction of

process.

the

arrow.

• The bobbinwinder stops automaticallywhen the bobbin is

• The tension of

the

thread on

the

bobbin can be adjusted with milled nut 2.

PFAFF

full.

9-2

Page 24

Preparation

9.04

Removing

Fig. 9 - 03

the

bobbin case, threading

the

bobbin

A

Removing

• Lift

Threading

•

•

of

the

case

Thread

Fig. 9-04.

The

bobbin

the

arrow

case

Switch

the

retainer1and

2.

the

the

the

bobbin

bobbin

bobbininaccordance

must

when

the

machine

case.

remove

case.

rotateinthe

thread

off!

the

bobbin

with

direction

is pulled.

9.05

Inserting

Fig.

9-04

the

bobbin

case,

adjusting

the

bobbin

A

Inserting

•

Insert

into

Adjusting

• Adjust

screw

Switch

the

the

place.

the

the

3.

thread

the

bobbin

bobbin

bobbin

bobbin

tension

machine

case.

case2so

thread

thread

off

I

thatitclicks

tension.

tension with

9-3

PFAFF

Page 25

Preparation

9.06

9.07

Fig.

9-05

Threading

the

Switch

needle

the

machine

thread

off!

A

• Thread

is

Adjusting

Adjusttension 1 so that the stitch loops are insidethe sewing material.

the

threaded

machine in accordance with Fig. 9-05, taking care to ensure

from

the

left

(see

arrow).

the

needle

thread

tension

that

the

needle

PFAFF

9-4

Page 26

Care

and

10

maintenance

Care

and

maintenance

10.01

Servicing

Cleaning

General lubrication

intervals

daily,

moreoftenifin

continuous operation

twice

weekly

Lubricating the sewing head twice weekly

Lubricating the hook daily

Checking the air pressure dailybefore starting sewing

Water

containerofthe

service

unit daily

before

starting

sewing

10.02

Cleaning

Fig.

10-01

• To

reassemble

caretoensure

the

slot

• Unscrew

•

The

replace

6.

the

hook finger 3

the

the

that

free

bobbin

the

projection on

arm

cover.

compartment,

the

and

insert

the

A

• Clean

daily,

operation.

• Raise

position

•

Remove

•

Unscrew

position-finger1.

•

Unscrew

finger 3.

• Turn

same

•

Remove

hook

carry

out

backofthe

bobbin with

Switch

the

more

the

and

the

the

screw2and

the

handwheel

heightasthe

the

race

these

steps

bobbin

the

the

machine

hook

and

hook

often

whenincontinuous

needle

bartoits

remove

bobbin

bobbin

the

and

case

until

free-arm

the

remove

hook point 5.

bobbin

with

case

petroleum.

in reverse order. Take

case

position-finger 1 is in

bobbin

case.

off!

compartment

highest

cover.

bobbin

point

and

case.

the

hook

4 isatthe

clean

the

10-1

PFAFF

Page 27

Care

and

maintenance

10.03

General

lubrication

\

©

I

Fig.

A

10-02

^

Only

use

oil

with a mean viscosity of 22.0 mmVsat 40°Cand a density of 0.865

g/cm^at15°C!

We

recommend

PFAFF

sewing

machine

oil.

Part

no.

280-1

-120

144.

A

• Oilallof

in Fig. 10-02 and 10-03 twice a week.

• To reach

Fig.10-03,

and lay

• Using both hands stand the sewing head

up so that it

• Lift

and place the sewing head in an upright

position.

Switch

the

the

sewing head slightly, pull piston 1

off

the

machine!

the

bearings which

the

oilingpoints marked in

pull

out piston 1

sewing head on its back.

rests

on piston 1.

are

(Fig.

marked

10-02)

Danger of crushing

sewing head and pedestal!

PFAFF

Fig.

A

10-03

between

10-2

Page 28

Care

and

maintenance

10.04

Lubricating

/°

mfW

Jl

Fig.

10-W

the

sewing

J

i

fflflk

^1''

jRCUJlCT

.H

head

w/

1

LW

oi

V

A

Unscrew

week

sliding

Replace

Switch

the

and

oil all of

surfaces

the

off

sewing

marked

sewing

the

the

head

machine!

head

bearings

cover

twice

and

in Fig. 10-04.

cover.

a

10.05

A

^ We

Lubricating

Only

use

oil with a

g/cm=^at15°C!

recommend

the

hook

mean

PFAFF

viscosity of 22.0 mmVsat40®C

sewing

machine

oil.

Part

Switch

no.

A

•

Remove

1to2

(Fig. 10-06) daily.

•

Re-insert

the

drops

the

bobbin

of oil into

bobbin

andadensityof0.865

280-1

-120

144.

off

the

machine!

case

and

the

hook

case.

squeeze

race

0

Fig.

10-05

10-3

Fig.

10-06

PFAFF

Page 29

Care

and

maintenance

10.06

Adjusting

Fig.

10-07

the

air

>®o

pressure

• Before using

the

air

the

pressureonthe

• The manometer

of

approx.6bar.

• If

the

reading is different, adjust the

pressuretothis

• Todoso,

manometer

lift

button2and

displays a

machine, always check

manometer

must

display a pressure

value.

turn

pressure

1.

it until

of 6

the

bar.

10.07

Emptying/Cleaning

Fig.

10-08

the

max.

water

container

A

Emptying

•

Cleaning

•

• Clean

•

of

the

air

filter

Turn

the

machine

Water

when

the

removed

the

Unscrew

the

Remove

from

the

trap 1

from

water

the

compressed-air

the

air

filter.

water

trap

1

empties

compressed-air

the

filter 2

filter

itself automatically

air

filter.

trap1and

with

compressed

with isopropyl alcohol. Part

95-665735-91.

Screw

back

filter2backinand

on.

off

I

hose

filter 2.

number

water

is

trap

hose

air or

1

PFAFF

10-4

Page 30

Adjustment

n

11.01

11.02

Adjustment

Tools,

•

• Spanners (wrenches) with jaw width from 7 to 14 mm

• Allan keys from 2 to 6

•

• Adjustment gauge, Part No. 08-880 218-00

•

• Gauge, (top

•

•

Notes

gauges

Screwdrivers

Metal

rule,

Terminal

Needles,

Sewing

screw.

system

thread

on

adjusting

and

with

other

blade

accessories

width

from2to10mm

mm

Part

No.

08-880

Part

feed

lift 7 mm). Part No. 61-111 630-14

No.

218-00

08-880

137-00

134-35

and

test

material

11.03

All

adjustmentsinthis

the

machine

not

mentioned

before

Abbreviations

tdc=top

bdc=bottom

which

making

dead

in

the

the

adjustment

center

dead

manual

havetobe

text.

The

center

are

based

removed

screws

and

tightened

and

on a

and

nuts

completely

replaced

written

again

when

assembled

for

checks

in

brackets

the

and

adjustment

aretobe

machine.

Covers

work

loosened

adjustmentiscomplete.

on

are

11-1

PFAFF

Page 31

Adjustment

11.04

11.04.01

11.04.01.01

Adjusting

Positioning

the

the

basic

feed

Lateral positioning of

Requirement

The clearances from

must

be

the the

the

same

machine

dog

the

left

and

size.

feed

dog

right of

the

bottom

feed

dog 1 to

the

needle

plate

cutout

•

a

Fig.

11-01

Movethe bottomfeed dog 1 (screws 2) inaccordance with the requirement.

PFAFF

11

-2

Page 32

Adjustment

11.04.01.02

Lengthwise positioning of

Requirement

With the stitch length

set

the

feed

dog

at its longest the clearances behind and infront of the bottom

feed dog 5 to the needle plate cutout must be the same.

Fig.

11-02

•

Set

the

11-3

•

Move

of

the

•

Loosen

•

Move

• Tighten

longest

the

rock shaft. The left

screws

the

screws

clamp

bottom

stitch

length.

piece1(screws2)as

4.

4.

feed

screw

dog

5 in

accordance

must

fartothe

stillbeon

with

leftaspossibleonthe

the

clamp surface.

the

requirement.

clamp

surface

PFAFF

3

Page 33

Adjustment

11.04.02

Centering

Requirement

With

the

middle.

the

needle

stitch length

set

in

the

at "0"

needle

the

needle

hole

must

enter

the

needle hole exactly in

the

i

PFAFF

Fig.

11-03

• Unscrew

•

Set

the

•

Insertanew

•

Bring

the needle to a

handwheel.

•

Move

the

• Tighten

•

Position

So

the

vibrating

stitch length at "0" and bringthe needle to its tdc.

needle.

needle

screws

stop 8 so that it istouching the needle barframe 7 and tighten screw 6.

Theneedle barframe7 inguide9 andthe

move

bar

3, 4

freely.

presser

Loosen

position

frame

and

5.

foot 1 and

screws3,4, 5

directly

7 in

overthe bottom feed dog by turning the

accordance

the

presser foot 2.

and

6.

with

the

requirement.

vibrating

presser

drive

shaft must

11

-4

Page 34

Adjustment

11.04.03

Pre-adjusting

Requirement

With

the

needle

must

be

15

mm.

the

needle

baratits

bdc

height

the

distance

between

the

needle

bar

and

the

needle

plate

Fig. 11

-04

Move

the

needle

11-5

bar1(screw

2) in

accordance

with

the

requirement

without

twisting it.

PFAFF

Page 35

Adjustment

11.04.04

Driving

Requirement

With

the

dogs

should

motion

longest stitch length

not

of

move

the

when

top

the

and

set

bottom

and

the

reverse

feed

dogs

needle bar at its bdc

feed

lever is activated.

the

top

and

bottom

feed

Fig. 11

-05

•

Set

the

PFAFF

longest

• Loosen screw 1 far enough so that the feed

shaft

with

• Bring

•

• Tighten

While

it

slightly

the

keeping

screws

stitch

length.

some

difficulty.

needle to its bdc.

this

position,

movethe feed

so that the requirement is

1.

fulfilled

driving

driving

eccentric 2 can be turned on the

eccentric2 to the top and then move

whenthe reversefeed

leverisactivated.

11

-6

Page 36

Adjustment

11.04.05

Needle

Requirement

Withthe stitch length

must

be

rise,

hook-to-needle

correct:

clearance

set

at "0" (1.8 mm after the bdc of the needle bar)the following

and

needle

height

1. The hook point must be opposite the middleof the needle and the distance to the

needle

must

be

0.05-0.1

mm.

2. The top edge of the needle eye must be 0.8 mm from the hook point.

Fig.

11-06

Set

the

11

-7

stitch lengthat"0"

machine).

Bring

the

needletoits

under

the

needle bar bearing. Position

plate

and

screw

Remove

screw

Move

Rotate

Bring

the

clampistouching

the

hook on

the

the

hook

Taking care to

On machines with a thread trimmer

a

shaft

it tight.

measuring

the

hook in accordance with requirement 2 (adjust needle height if necessary).

shaft

ensure

and

the

adjustmentofthe

and

bdc

and

plate

and

the

needle

hook

shaftinaccordance

bearing 3 to

that

the

bevel

loosen

slide

the

turn

bar

restonthe

gear

screws

1.8

mm

the

screw

the

handwheel

bearing.

hook

4 is resting on

the

adjustment of

hook

shaft

1 and 2

(screw

measuring

plate

clampsothat it

in its direction of rotation until

with

requirement

and

tighten

the

bearing, tighten

the

bearing3are

2 is on

the

with

restsonthe

1.

screw

2.

axial play on

not

necessary.

its

back of

slot

directly

measuring

screws

the

the

the

1.

hook

PFAFF

Page 37

Adjustment

11.04.06

Vibrating

Requirement

With

the

point

must

at

maximum.

presser

presser

both reach

feeding

foot 3 resting on

the

needle

motion

the

needle

plate at

the

plate

same

the

time

vibrating

with

presser6and

the

vibrating

the

presser

needle

stroke

0

Fig.

11-07

•

Loosen

• Slide bolt 2 upwards in

• Allow

the

nut

presser

1.

foot 3 to rest on

the

elongated hole and tighten nut 1.

the

needle plate.

• Loosen screws 4 enough so that the feed

difficulty.

• Rotate the

• Tighten

• Carry

lifting

screws

outacheck.

4.

eccentric 5 in accordance with the requirement.

lifting

eccentric 5 can be rotated with

PFAFF

11

-8

Page 38

Adjustment

11.04.07

Vibrating

Requirement

With

the

and

vibrating

is

rotated.

presser

vibrating

lift

presser

presserfoot2 must

liftatmaximum

lift

7.0 mm

andthe stitch lengthset at "0", presser foot 1

from

the needle platewhenthe handwheel

m

7

mm

Fig.

11-08

Set

the

11

-9

vibrating

Allow

the

the

Turn

reached

Turn

crank3(screws

Carry

outacheck.

presser

handwheel

its

highest

presser

foot

lift at maximum

1 to

restonthe

in its direction of rotation until

point.

4) in

accordance

and

needle

with

the

stitch lengthat"0".

plate.

the

vibrating

the

requirement.

presser

foot 2

has

PFAFF

Page 39

Adjustment

11.04.08

Needle

Requirement

With

thread

the

tension

presser

foot lifted,

The distance of 0.5

to

more

than1mm

release

the

two

mmisthe

with

tension disks

minimum clearance. The clearance

thick

threads.

must

be at least 0.5

]

mm

apart.

can

range up

Fig. 11

-09

• Raise

•

Align

requirement.

0.5

mm

<-/

V-/

the

presser

foot

using

the

hand

lever.

the compression plate 1 behind the tension bearingboard 2 inaccordance with the

o

When

the

a

tension

is correct

the

release

pin

must

PFAFF

notbeunder

pressure.

11-10

Page 40

Adjustment

11.04.09

Thread

Requirement

check

spring

The movement of the thread check spring must be finished

the material (= approx. 7 mm spring movement).

The length of the spring movement can varya

changesinthe

sewing

parameters.

vy/hen

the needle point enters

little

upwards or downwards due to

o

7

mm

Fig.

11-10

Thread

foot

Loosen

Sew a few stitches by turning the handwheel and then raise the take-up lever to its tdc.

When continuing to turn the handwheel

spring 2

Inthis position bring stop 3 to rest on

onto

the

machine, place

the

material using

screw

should

1.

move

the

the

back

about7mm.

test

material under

hand

lever.

the

the

presser

(in

direction of rotation)

thread check spring and tighten

foot and lower

the

thread check

the

screw

presser

1.

11-11

PFAFF

Page 41

Adjustment

11.04.10

Bobbin

Requirement

1. With

2.

bobbin

wheel

The

bobbin

the

reached

winder

bobbin

winder

1.

winder

disengaged, however,

winder

a point approx. 1

must

engaged

stop

automatically

mm

the

below

winder

the

friction

the

bobbin rim.

spindle

wheel5must

when

the

mustbedriven reliably. With

not

touch

the

drive

thread

woundonthe

bobbin

the

has

1

mm

Fig.

11-11

Adjust

Placea

winder.

the

drive

bobbin

wheel 1 (screws2)inaccordance with requirement 1.

on the winder spindle,thread the bobbinand switch on the bobbin

Shiftthe regulating pin3 (screws4)inaccordancewith requirement 2.

PFAFF

11

-12

Page 42

Adjustment

11.04.11

Regulating the pressure on the presser foot

Requirement

The material must be fed perfectlyeven at top sewing speed. There must not be any

pressure marks on the material.

Fig.

11-12

Turn

screw

11-13

1 in

accordance

with

the

requirement.

PFAFF

Page 43

Adjustment

11.05

11.05.01

Adjusting

Preadjusting

Requirement

With

the

take-up

underneath

the

the

thread

the

lever

cam

control

at its

follower

trimmer

cam

bdc,

projection

5.

-900/52 (optional)

4onthe

control

cam2 must be

@1

^iTr

directly

Fig.

11-13

•

Loosen

• Bring

• Turn

• In this position,

bearing 3

•

Make

• Carry

the

two

screwsonthe

the

take-up lever to its

the

control

the

outacheck.

cam

and

below

second

2 on its

taking

it,

tighten

screwonthe

control

bdc

shaftinaccordance

caretoensure

the

accessible

cam2through

by turning

control

that

screwonthe

cam2accessible

the

handwheel.

with

the

the

the

control

assembly

requirement.

cam

control

and

PFAFF

hole

2 is touching

cam

2.

tighten

it.

1.

the

11-14

Page 44

Adjustment

11.05.02

Tripping lever height

Requirement

With the needle bar at its bdc there must be a distance of 1.0 mm between the tripping

lever3and

the

control

cam

4.

ozn.

3

I

mm

Fig.

11-14

Bring

the

needle bar to its bdc by turning

Move the carrier 1 (screws 2)of the tripping lever 3 in the elongated hole in accordance

with

the

requirement.

the

handwheel.

11-15

PFAFF

Page 45

Adjustment

11.05.03

Feed

regulator pin

Requirement

Withthe needle barat its bdc, the feed regulatorpin 6 must be able to

path of

the

control

cam7when

the

engaging solenoid 6 is activated.

«

fall

lightly

intothe

I

Fig.

11-15

• Bring

• Activate

• Tighten lockingscrew 2 (nut 3) far enough so that it just touches

• Loosen

• Carry

is in

the

needle

the

magnet

locking

accordance

outacheck.

bar to its

screw 2 approx. 1/2 a turn

with

bdc

core

1 manually.

the

requirement.

by turning

the

handwheel.

until

the movement of the feed regulator pin 5

o

the

tripping lever 4.

PFAFF

11

-16

Page 46

Adjustment

11.05.04

Engaging solenoid

Requirement

With

the

needle

clearance of approx. 0.5

bar at its bdc and with

the

magnet

mm

between the pawl 7 and the retainingcollar6.

core 1 fully activated,

there

must

be a

11-17

Fig.

n-16

Bring

Push

Loosen

Move

In

this

Carry

the

needle

the

magnet

screws

the

magnet

position,

outacheck.

If

the

magnet housing 4 touches lever 4, move lever 4 (screw 5) a little to

left.

bar

to its

bdc

core

1 inasfarasit will go

2.

housing 3 axially in

tighten

screws

by turning

accordance

2.

the

handwheel.

and

leave it in this position.

with

the

requirement.

\

the

PFAFF

Page 47

Adjustment

11.05.05 Adjusting

Requirement

With

the

a

clearanceof0.3

regulator pin.

the

heightofthe

thread

trimmer

mm

feed

in resting position

between

the

highest

regulator pin

and

the

point of

pawl 4 clicked in place

the

control

cam5and

there

the

must

feed

be

PFAFF

Fig.

11-17

Bring

Activate

Allow

Carry

O

the needle bar to its tdc byturningthe handwheel.

the

magnet

the

retaining

With

the

requirement

outacheck.

0.3

mm

core

1.

collar2(screws

pawl4clicked

(see

large circle).

into

3)to

place,

lightly

touch

pawl

thisadjustmentprocedure

4 (see

arrowinsmall

fulfills

the

circle).

11

-18

Page 48

Adjustment

11.05.06

Thread catcher, front point of reversal

Requirement

With the thread catcher 3 at its front point of reversal, the rear edge of the thread catcher

cutout

must

still be 1

mm

over

the

front

edgeofthe

bobbin

case

position-finger 6.

11-19

1

mm

Fig.

11-18

Bring

the

needle bar to its bdc by turning

the

handwheel.

Activatethe magnet core 1 allowingthe feed regulator pin 2 to

cam.

Bring

the

thread catcher 3 to its front point of reversal by turning the handwheel in its

direction

Loosen

Adjust

catcher

Tighten

of

rotation.

screws

the

carrier

screws

4.

thread catcher 3 in accordance with

5.

4.

the

requirement by turning

J

'ysLjJr

fall

into the path of the

the

thread

PFAFF

Page 49

Adjustment

11.05.07

Lateral

Requirement

With

middleofthe

adjustmentofthe

the

needle

needle.

baratits bdc,

thread

the

tip of

catcher

the

thread

S 9

catcher3must

point exactlyatthe

Fig.

11-19

Remove

Bring

Align

Activate

tdc.

thread bobbin case position-finger 6 duringits course of movement.

Screw

PFAFF

knife 1

the needle barto its bdcby

the

thread

the

Take

care to ensure that the thread catcher 3 does notcome intocontact with the

on

(screws

2).

turning

the handwheel.

catcher3(screws4)laterallyinaccordance

magnet

knife1(screws

core

manually

2).

and

turn

the

handwheel

with

until

the

requirement.

the

needle

barisatits

11-20

Page 50

Adjustment

11.05.08 Control

Requirement

Withthe end of the thread guard 2 mm behindthe

finger

be approx. 4 mm as viewed inthe direction of feed.

cam,

final

adjustment

3,the clearance between the threadcatcher

^3

middle

point

ofthe

4andthe thread

bobbin

case position-

guard

2 must

11-21

2

mm

Fig.

11-20

Bring

the

Activate

needle bar to its bdc by turning

the

magnet1core

manually.

the

handwheel.

Continueturningthe handwheel (direction of rotation)

4

mm

until

the end of the thread guard 2

is 2 mm behind the middleof the bobbin case position-finger3 as viewed in the direction

of

feed.

Inthis position

requirement.

Ifnecessary, adjust

the

positionof the thread catcher point 4 must be in accordance with the

the

control

cam

accordingly

(see

page 11-14).

PFAFF

Page 51

Adjustment

11.05.09

Knife

Requirement

With

the

edge

knife

left

edgeofthe

must

thread catcher notch 1

be flush with

the

edgeofthe

mm

infront of

thread catcher (see arrow in circle).

the

knife edge,

the

left

Fig.

11-21

•

PFAFF

Loosen

•

Bring

•

Turn

the

•

Laterally

• Tighten

•

By

the

screws2on

the

needle

knife

bartoits

1.

bdcbyturning

the handwheelinits direction of rotation

same

align

screws

turning

knife

levelasthe

knife1in

the

handwheel,

blade.

knife

2.

Re-adjust

blade.

accordance

check

the

thread

with

that

the

catcher 4ifnecessary (see page

the

handwheel

until

and

the pointof the thread catcher 4 is at

the requirement (see

backofthe

thread

activate

arrow).

catcher

the

magnet

does

11-20).

not

core

catch

11

3.

on

-22

Page 52

Adjustment

11.05.10

Triggering

Requirement

the

needle

thread

tension

With the tip of the release lever 5 at the highest point of

tension

disks

mustbeat

0 ~n O

least5mm

apart.

the

tension release cam 4,

the

Fig.

11-22

11

• Bring

• Bring

•

• Adjust

• Finish

-23

the

the

Turn

the

handwheel

front

pointofreversal.

the

sewing

needle

foot to

bartoits

in

heightofthe

restonthe

bdc

by turning

its

direction

transmission

tension disks is in accordance with

the

thread trimming

to its

tdc.

In this position

Finally, apply a light

release

lever

5.

coatofgreasetothe

process

the

needle

needle

of

the

rotation

plate using

handwheel

until

bar2(screws3)so

the

requirement.

by turning

thread

the

tension

surfaceofthe

the

hand lever.

and

activate

the

thread

catcher

that

handwheel

and

mustbefully activated.

release

the

distance

bring

cam4and

the

has

magnet

reached

the

between

take

up lever

the

tip of

PFAFF

core

its

1.

the

the

Page 53

Adjustment

11.05.11

Cutting

Requirement

Both

test

threads

r

mustbetrimmed

0

perfectly.

Q ©

Fig.

11-23

Bring

PFAFF

the needle bar to its bdc byturning

Turn

the

handwheelinits

point of reversal.

Takeone thread doubled and pullit into

cutting

If

the

test

by continuing to turn

one of the threads is not cut properly, adjust the relationshipof

knife

(11-20).

directionofrotation

the

the

handwheel and activate the magnet core 1.

until

the

cutout of

handwheel.

the

thread

the

thread catcher 2. Carry out a

catcher

the

2 isatits

thread catcher to

front

11-24

Page 54

Adjustment

11.05.12

Positioner

Requirement

When interrupting the sewing procedure the machinemust position itselfat 4 mm after

the bdc of the needle bar. After trimming

the

tdcofthe

Carry

take-up

lever.

out the adjustment in accordance with the instruction manualof the motor.

the

thread, the machine must position itself at

11-25

PFAFF

Page 55

Notei

PFAFF

11

-2(

Page 56

PFAFF

G.M.

PFAFF

Aktiengesellschaft

Postfach

D-67653

Konigstr.

D-67655

Telefon:(0631)

Telefax;

Telex:

Geclrijcltiinder

Pfinied in Gefmany

ImpnmeenR.F.A.

Impresoenla R.F.A.

Stampaio

OTneyaiaMo

3020

Kaiserslautern

154

Kaiserslautern

(0631)

45753

BRD

in R.F.G.

®Pr

200-0

172

PFAFF

02

D

Loading...

Loading...